Soil remediation fertilizer prepared from kitchen waste as well as preparation method and application thereof

A kitchen waste and soil remediation technology, which is applied in the field of soil improvement, can solve problems such as soil pollution, achieve the effects of regulating soil compaction, realizing harmlessness and resource utilization, and improving the quality of compost substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

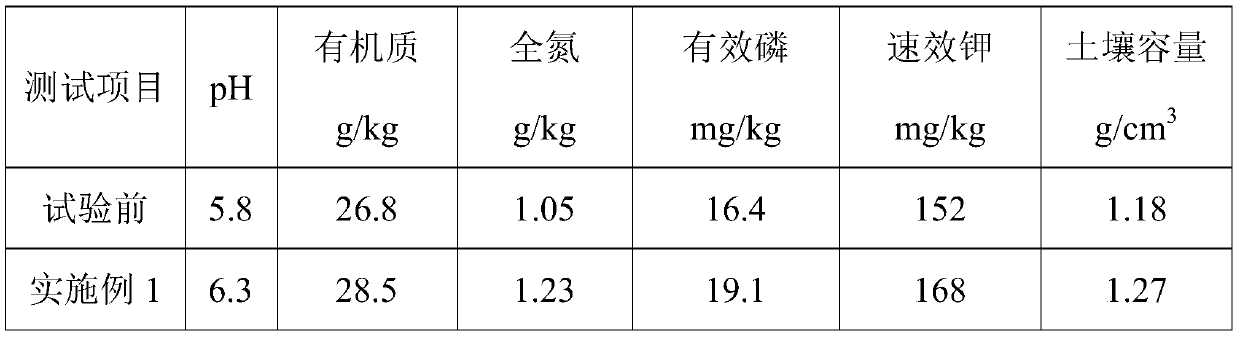

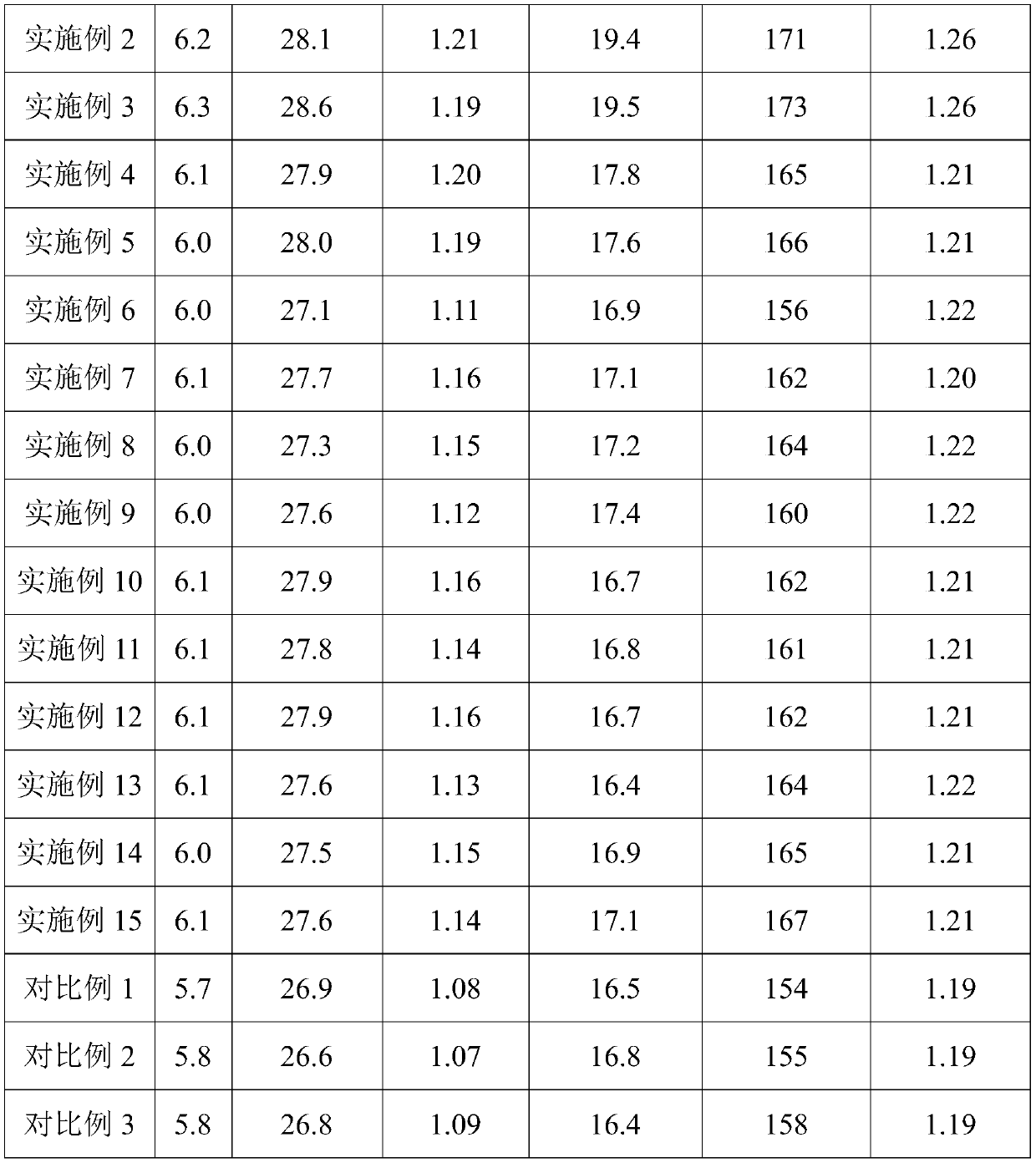

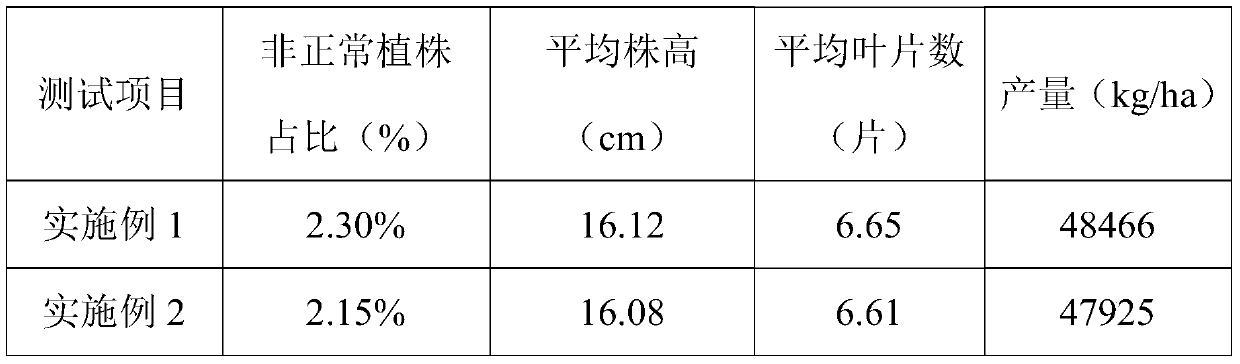

Examples

preparation example 1

[0060] This preparation example provides a kind of kitchen waste after anaerobic heat treatment, and the anaerobic heat treatment includes the following steps:

[0061] (1) Salt washing: After soaking the kitchen waste in water, dehydration and desalination are carried out by pressing to obtain Na + Desalted kitchen waste with a mass concentration of 0.11%;

[0062] (2) drying: drying the desalted kitchen waste obtained in step (1) at 125°C for 2 hours to obtain dry kitchen waste with a water content of 30%;

[0063] (3) Anaerobic heat treatment: the dried kitchen waste obtained in step (2) was subjected to anaerobic heat treatment at 350° C. for 2.5 hours to obtain the anaerobic heat-treated kitchen waste.

[0064] (4) Cooling: the anaerobic heat-treated kitchen waste obtained in step (3) is condensed through a condensing pipeline at 20°C.

preparation example 2

[0066] This preparation example provides a kind of kitchen waste after anaerobic heat treatment, and the anaerobic heat treatment includes the following steps:

[0067] (1) Salt washing: After soaking the kitchen waste in water, dehydration and desalination are carried out by pressure centrifugation to obtain Na + Desalted kitchen waste with a mass concentration of 0.3%;

[0068] (2) Drying: drying the desalted kitchen waste obtained in step (1) at 130°C for 1 hour to obtain dry kitchen waste with a water content of 37%;

[0069] (3) Anaerobic heat treatment: the dry kitchen waste obtained in step (2) was subjected to anaerobic heat treatment at 425° C. for 2 hours to obtain the anaerobic heat-treated kitchen waste.

[0070] (4) Cooling: the anaerobic heat-treated kitchen waste obtained in step (3) is condensed through a condensing pipeline at 10°C.

preparation example 3

[0072] This preparation example provides a kind of kitchen waste after anaerobic heat treatment, and the anaerobic heat treatment includes the following steps:

[0073] (1) Salt washing: After soaking the kitchen waste in water, first use centrifugation, and then use pressing to dehydrate and desalinate to obtain Na + Desalted kitchen waste with a mass concentration of 0.1%;

[0074] (2) drying: drying the desalted kitchen waste obtained in step (1) at 130°C for 2 hours to obtain dry kitchen waste with a water content of 20%;

[0075] (3) Anaerobic heat treatment: the dried kitchen waste obtained in step (2) was subjected to anaerobic heat treatment at 250° C. for 3 hours to obtain the anaerobic heat-treated kitchen waste.

[0076] (4) Cooling: the anaerobic heat-treated kitchen waste obtained in step (3) is condensed through a condensing pipeline at 30°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com