Patents

Literature

35results about How to "Improve emission reduction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Atmospheric pollution source grading method based on pollutant source identification technology

ActiveCN102628852AReduce air quality concentrationImprove emission reduction efficiencyMaterial analysisTemporal resolutionCoupling system

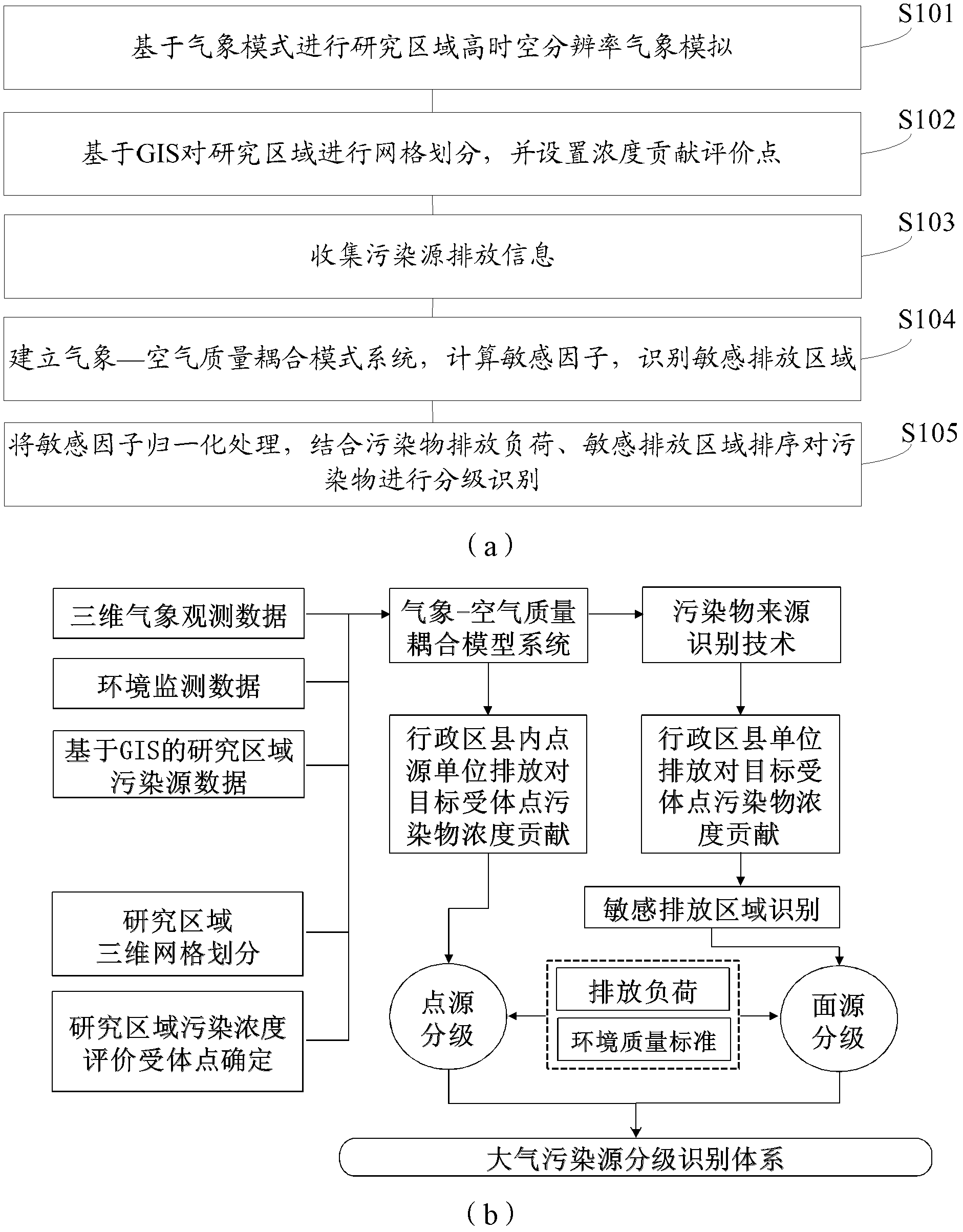

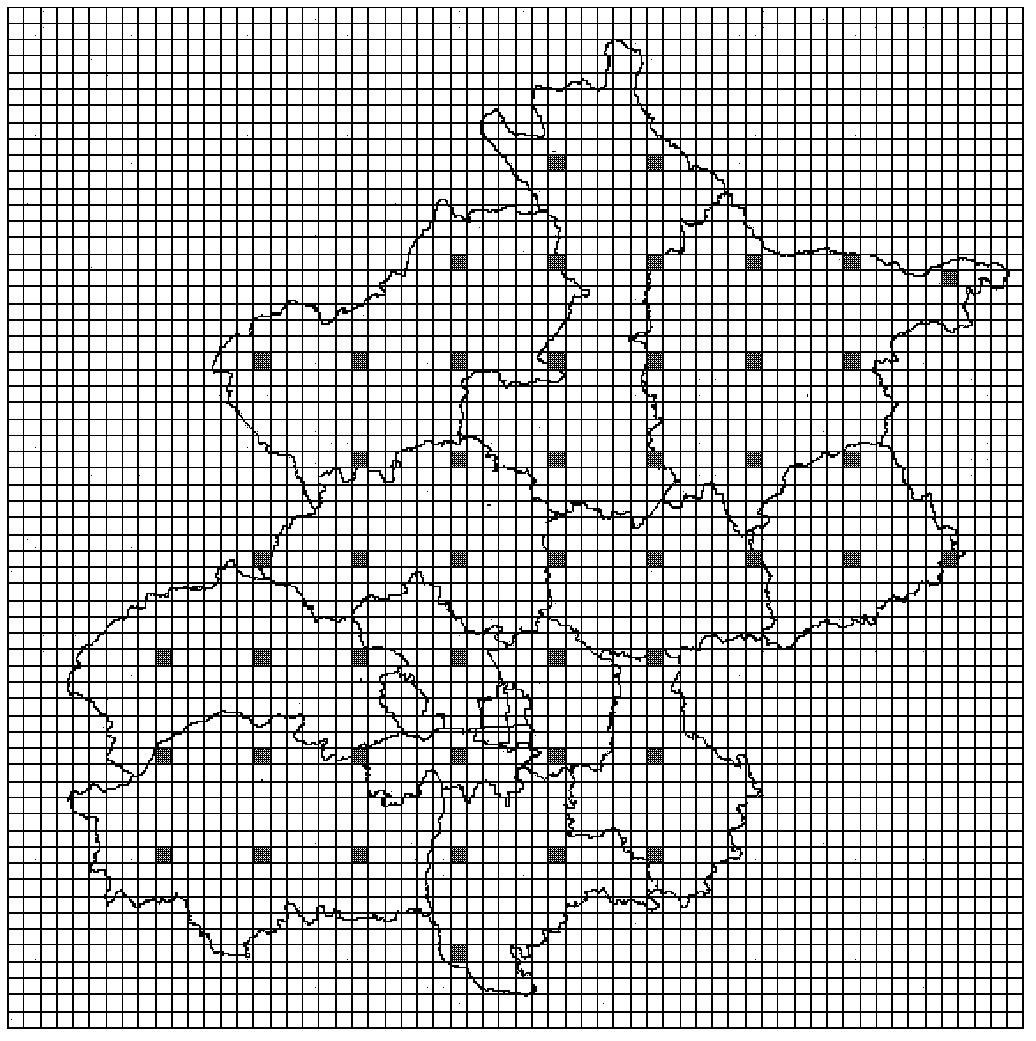

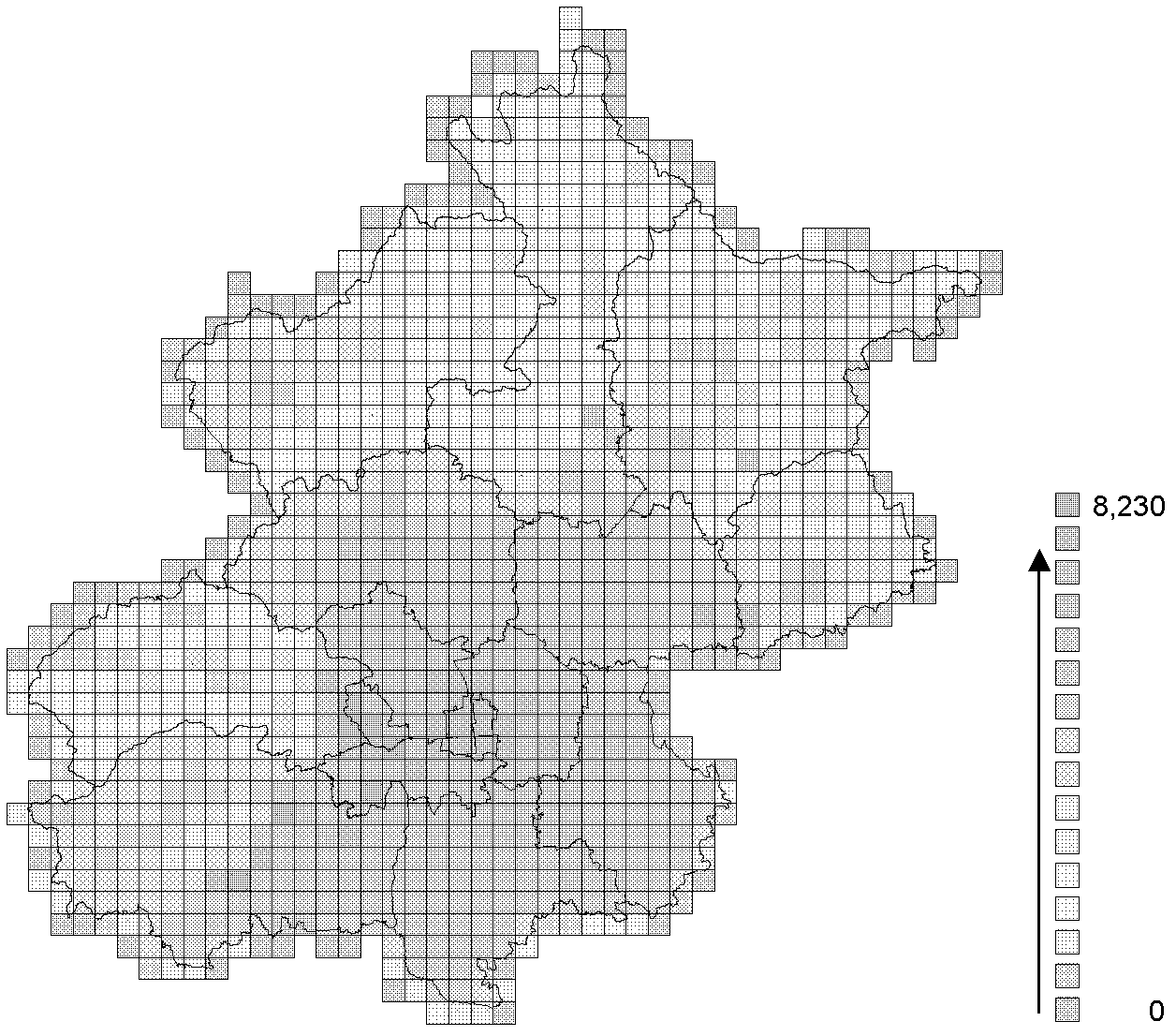

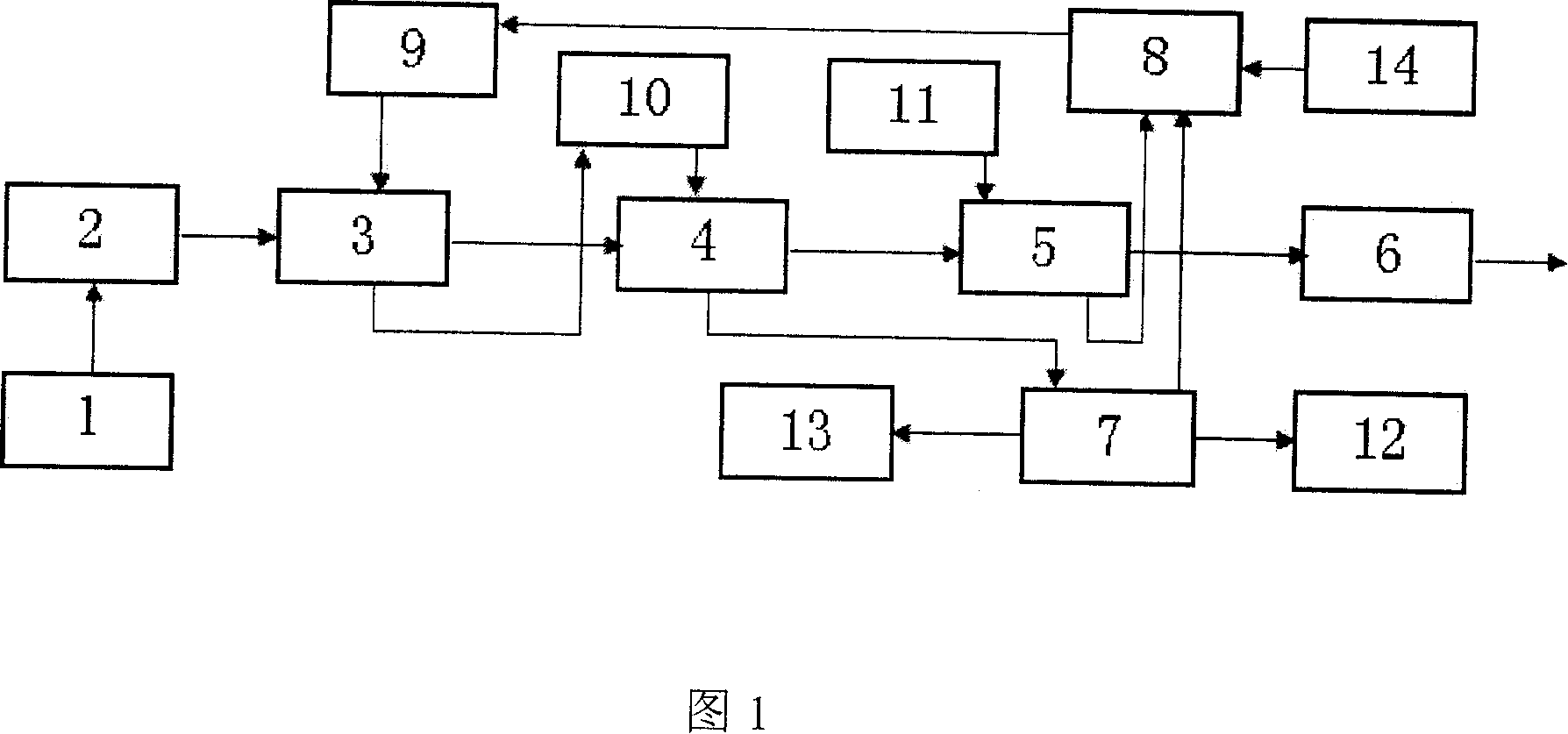

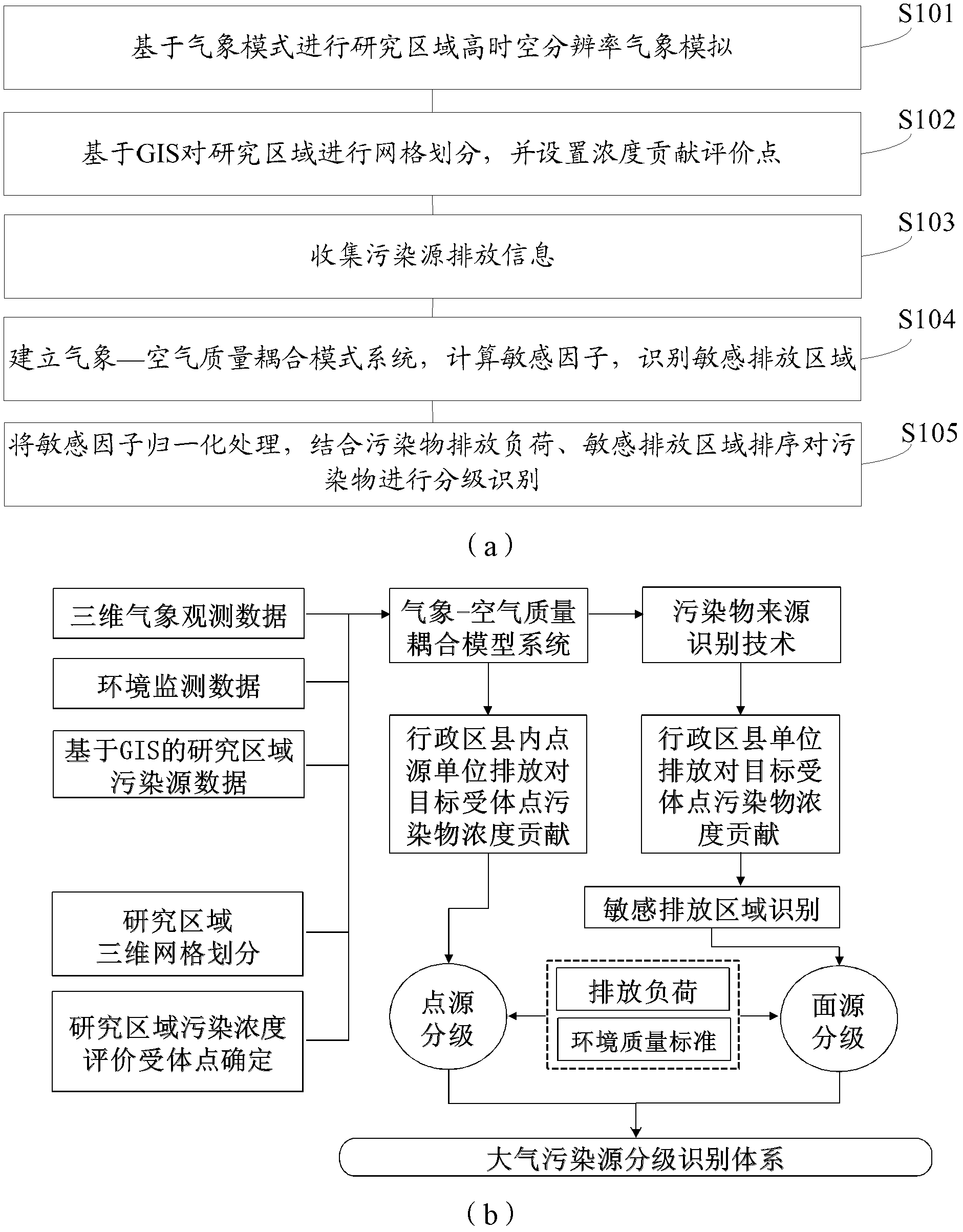

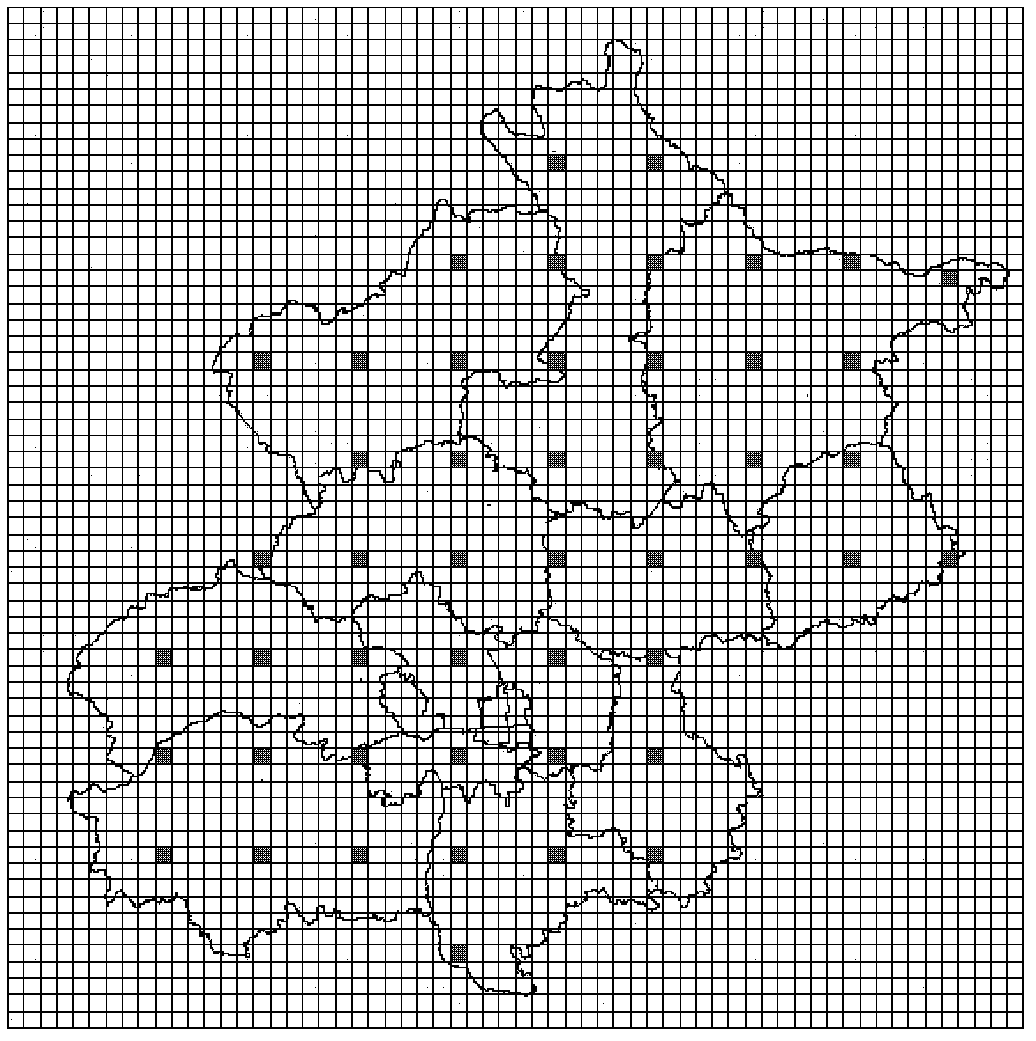

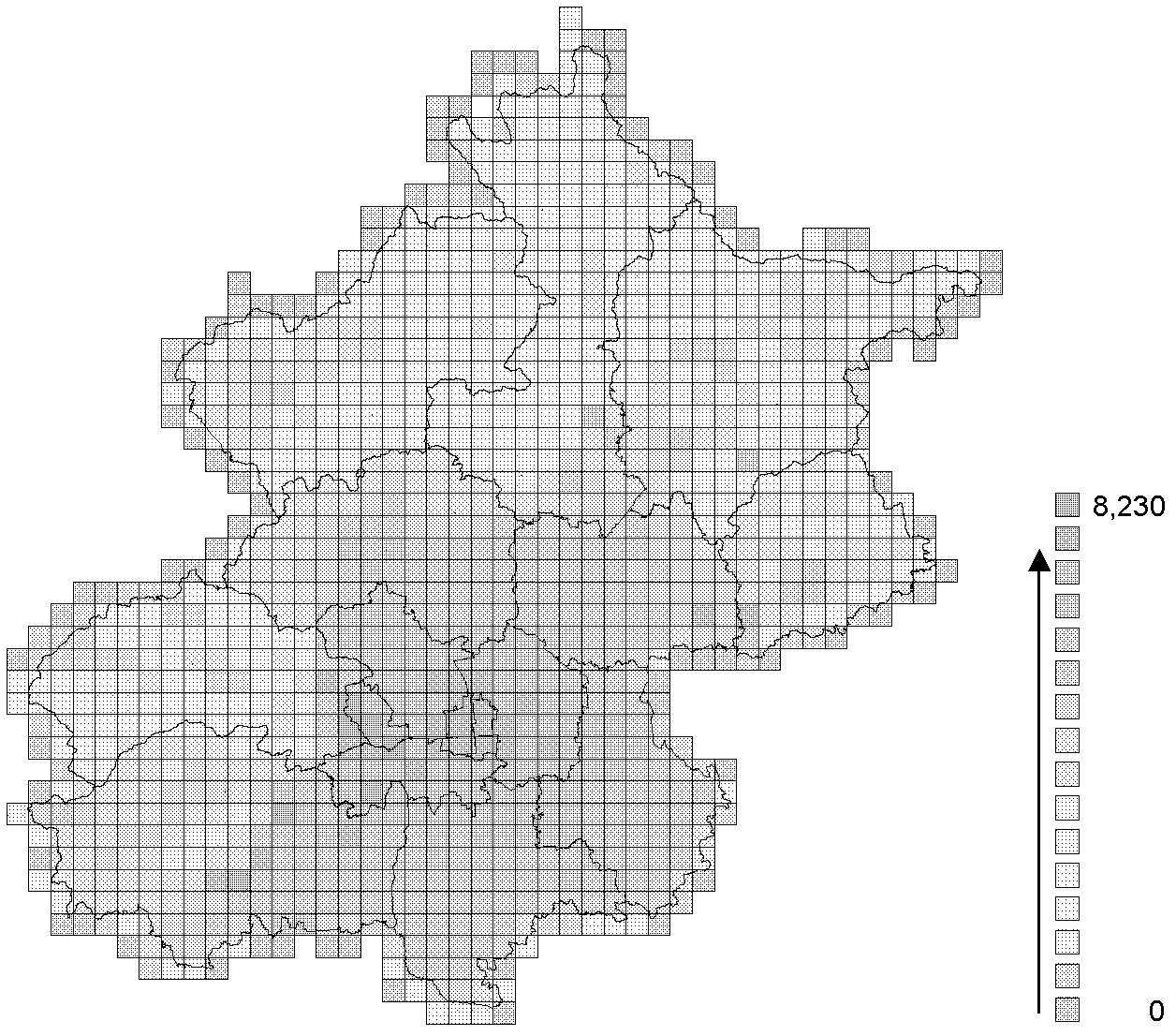

The invention provides an atmospheric pollution source grading method based on a pollutant source identification technology. The atmospheric pollution source grading method based on a pollutant source identification technology belongs to the technical field of atmospheric environment planning management, and prevention and control of pollution. The atmospheric pollution source grading method based on a pollutant source identification technology comprises the following steps of carrying out high spatio-temporal resolution meteorological simulation of a researched area based on a meteorological model, carrying out grid division of the researched area based on the geographic information system (GIS), arranging concentration contribution evaluation points, collecting pollution source discharge information, building a weather-air quality model coupled system, computing a sensitive factor, identifying sensitive discharge areas, carrying out unitization processing of the sensitive factor, and carrying out grading identification of pollution sources according to pollutant discharge loads and the order of the sensitive discharge areas. The invention aims at providing the atmospheric pollution source grading method based on a pollutant source identification technology so that the evaluation and quantitative grading of sensibility of atmospheric pollution sources are realized and an effective technical support for scientific pollutant-discharge reduction is provided.

Owner:BEIJING UNIV OF TECH

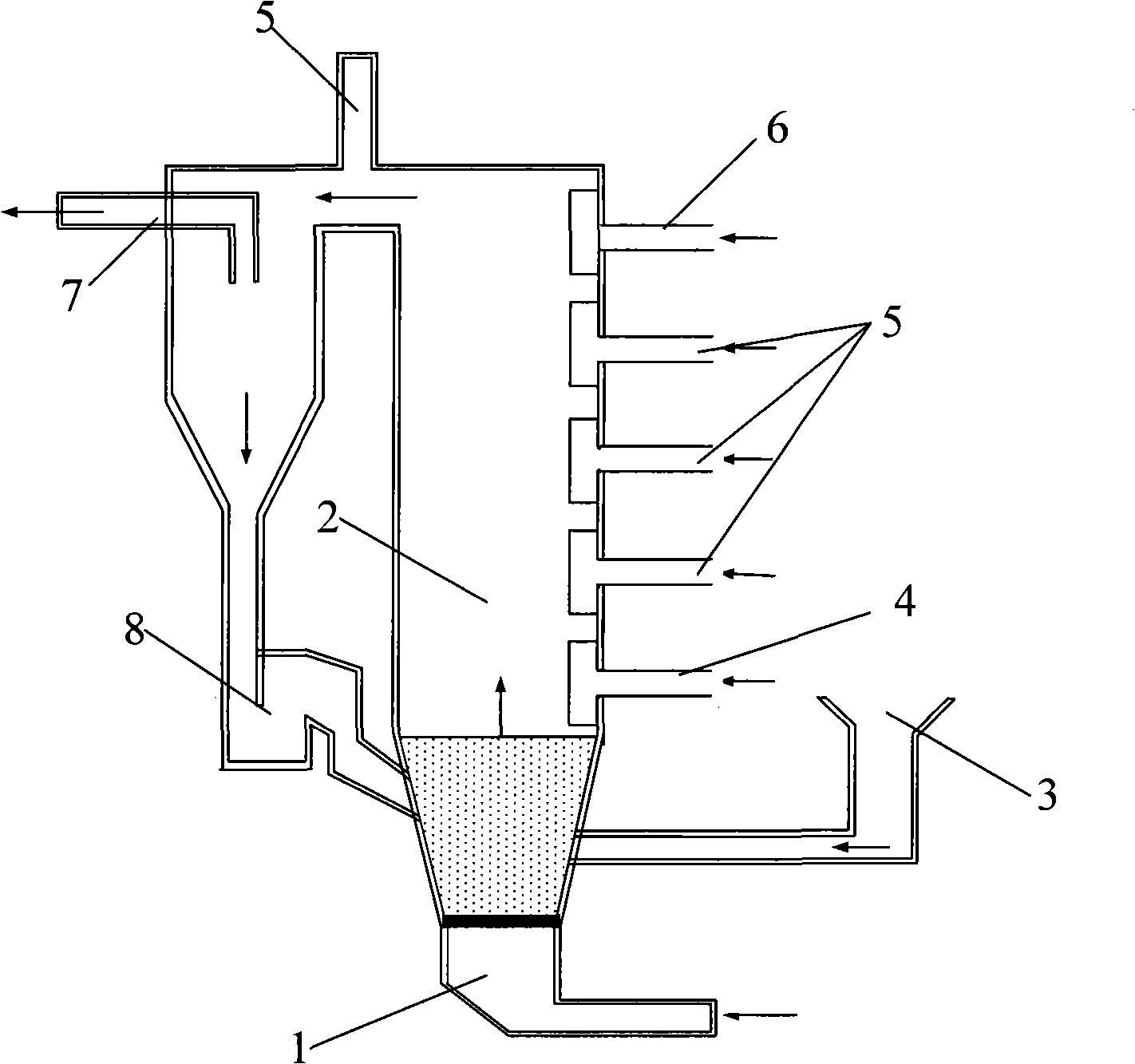

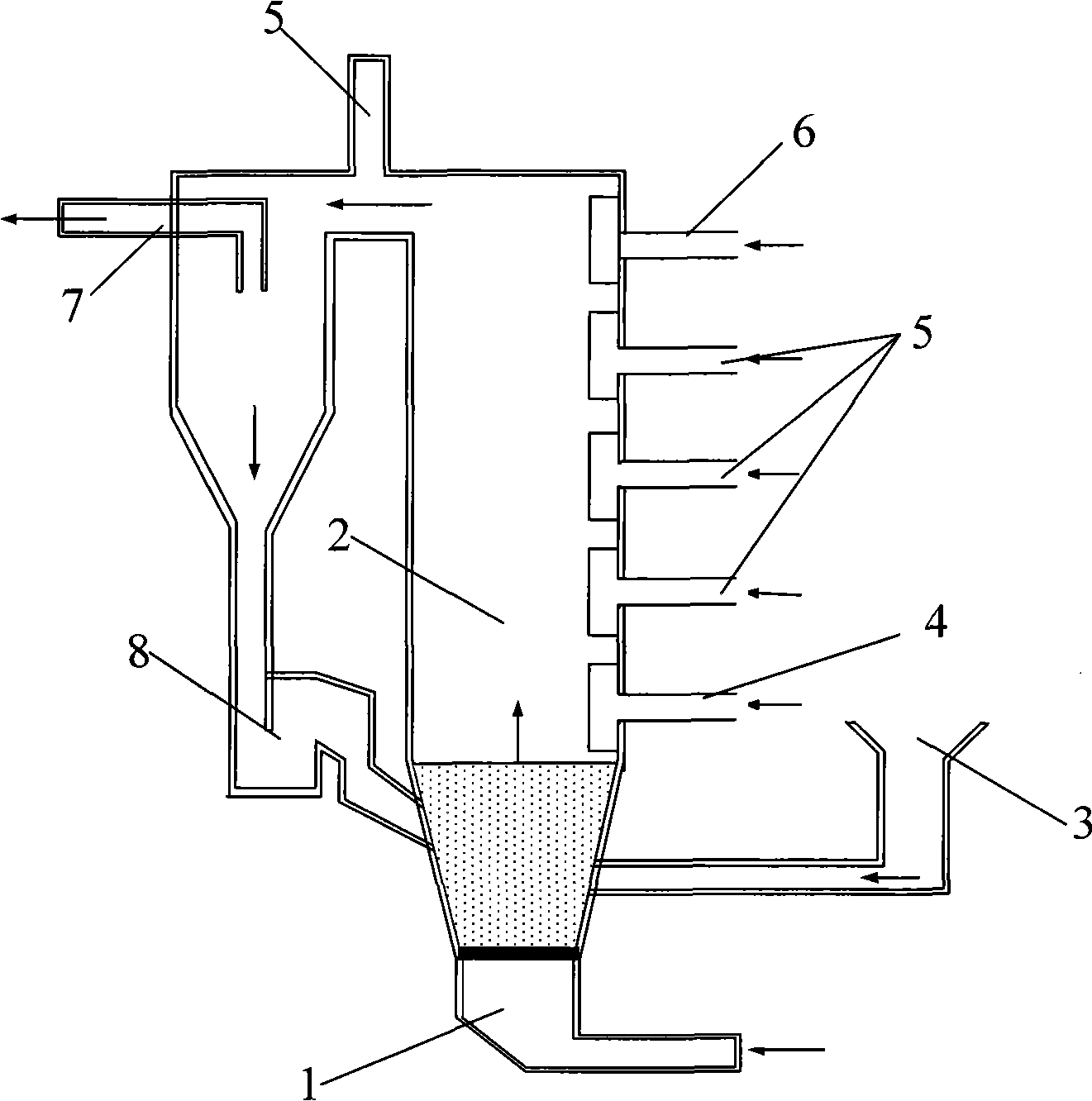

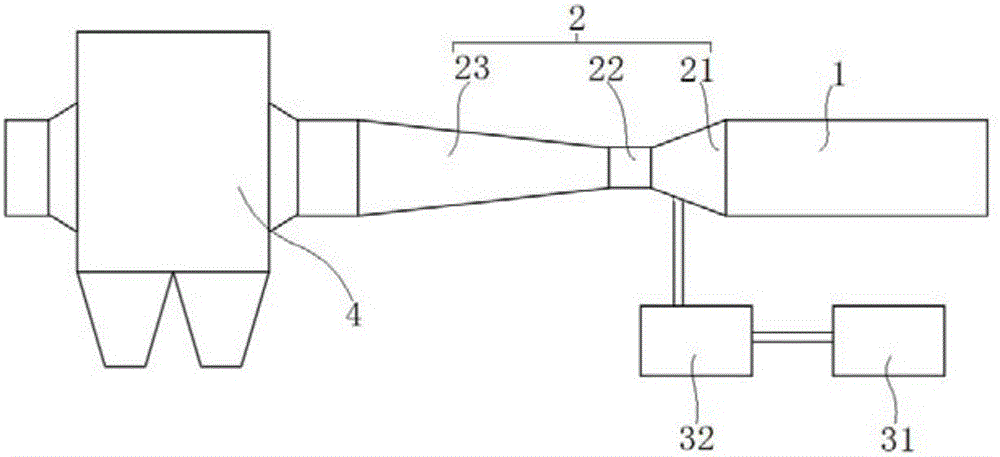

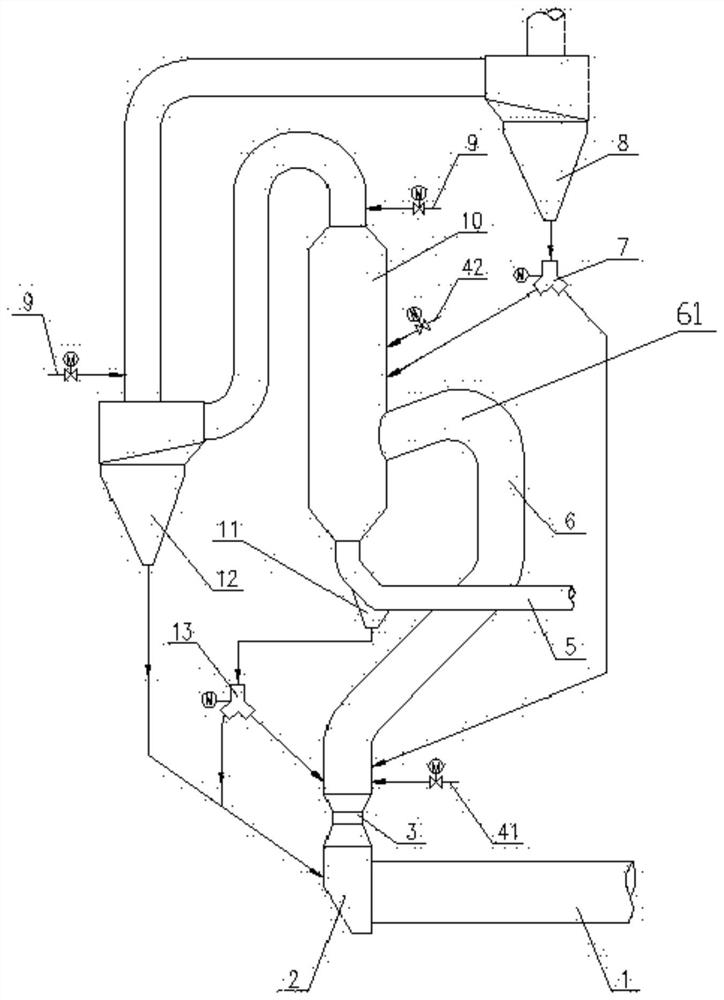

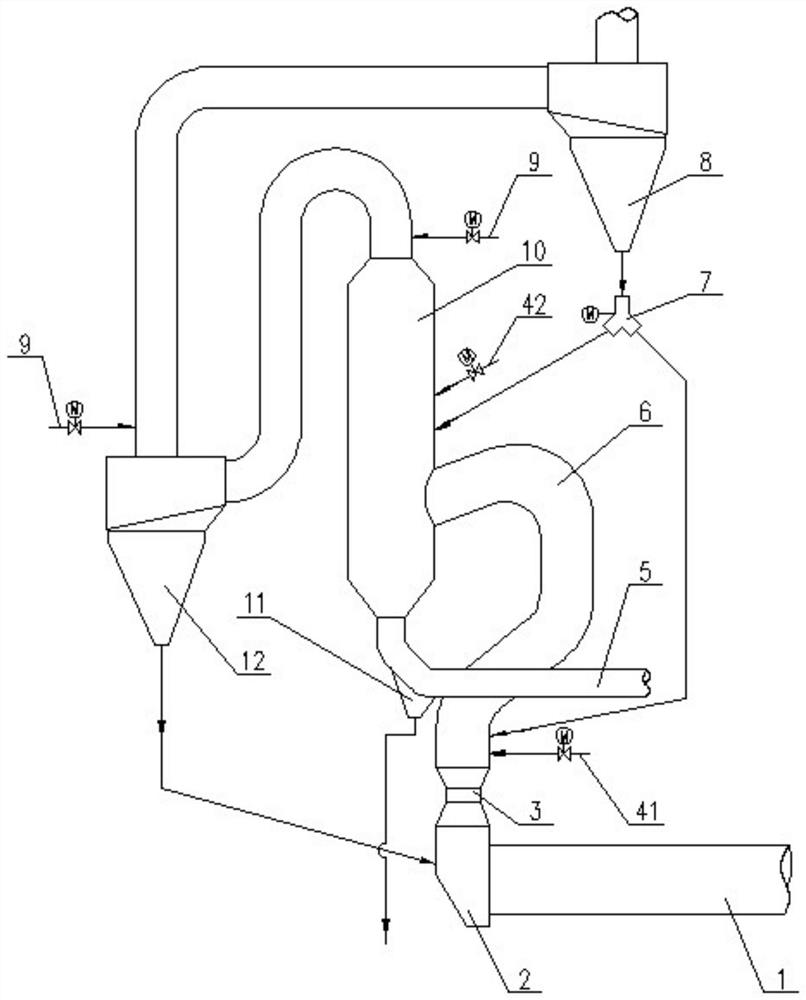

Biomass gasified gas re-burning mode and system for coal-fired fluidized bed

InactiveCN101915419AImprove combustion efficiencyImprove emission reduction efficiencyFluidized bed combustionApparatus for fluidised bed combustionSlagCoal dust

The invention belongs to the technical field of N2O emission reduction in a coal-fired fluidized bed, and particularly relates to a biomass gasified gas re-burning mode and a biomass gasified gas re-burning system for a coal-fired fluidized bed. The wall of a fluidized bed boiler is provided with a plurality of biomass gasified gas nozzles, biomass gasified gas is introduced into a hearth of the fluidized bed boiler, and the biomass gasified gas is reacted with N2O-containing smoke generated by burning of coal dust in the hearth to realize multi-stage re-burning so as to improve the burning efficiency of the whole fluidized bed and reduce the emission of N2O. Compared with pyrolysis and direct burning, the biomass gas rich in combustible substances such as H2, CH4, CO and the like has low ash content and extremely low sulfur content, has no sulfur removal problem, is ideal re-burning fuel and can effectively reduce the emission of nitrogen oxides by using mixed burning of the biomass gasified gas and the coal dust; and because of low alkali metal and chlorine content in the gasified gas, problems of slag formation and corrosion can be avoided, utilization of the coal dust is not affected and efficient clean utilization of the biomass can be realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

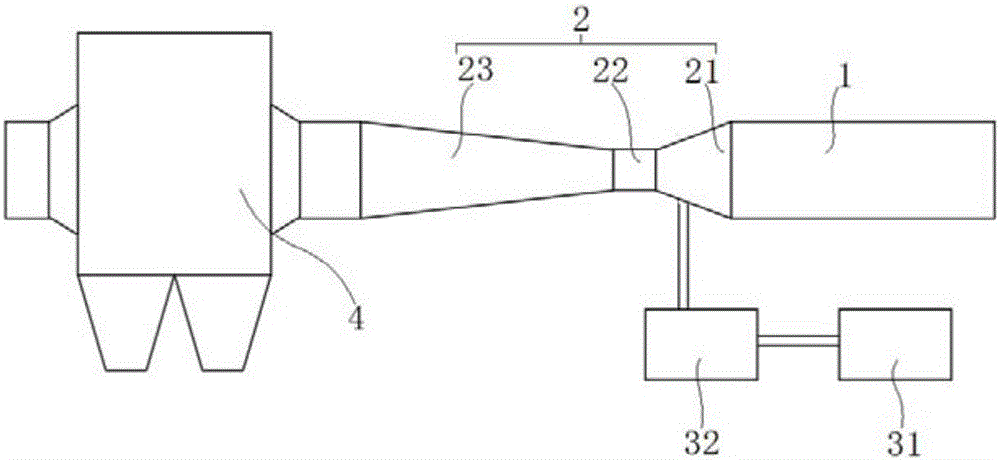

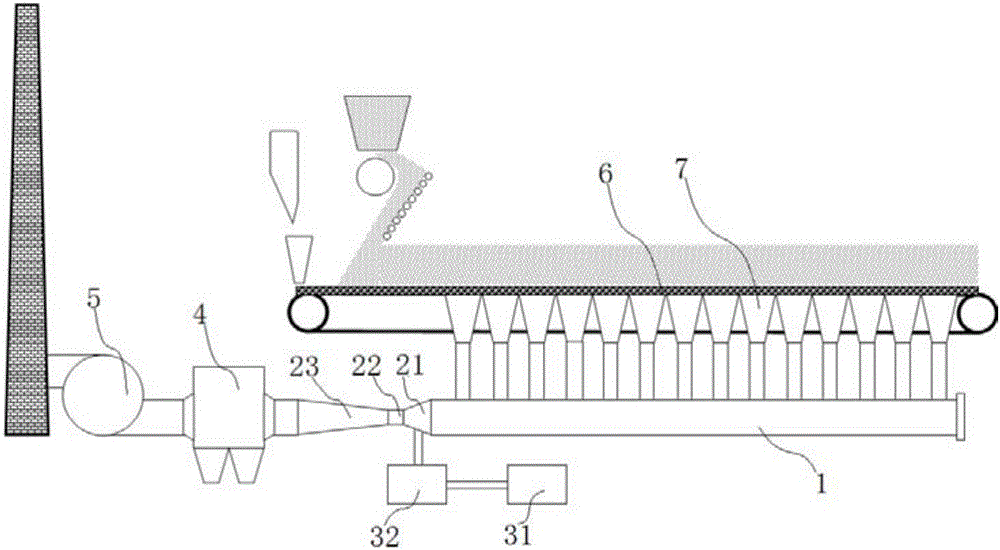

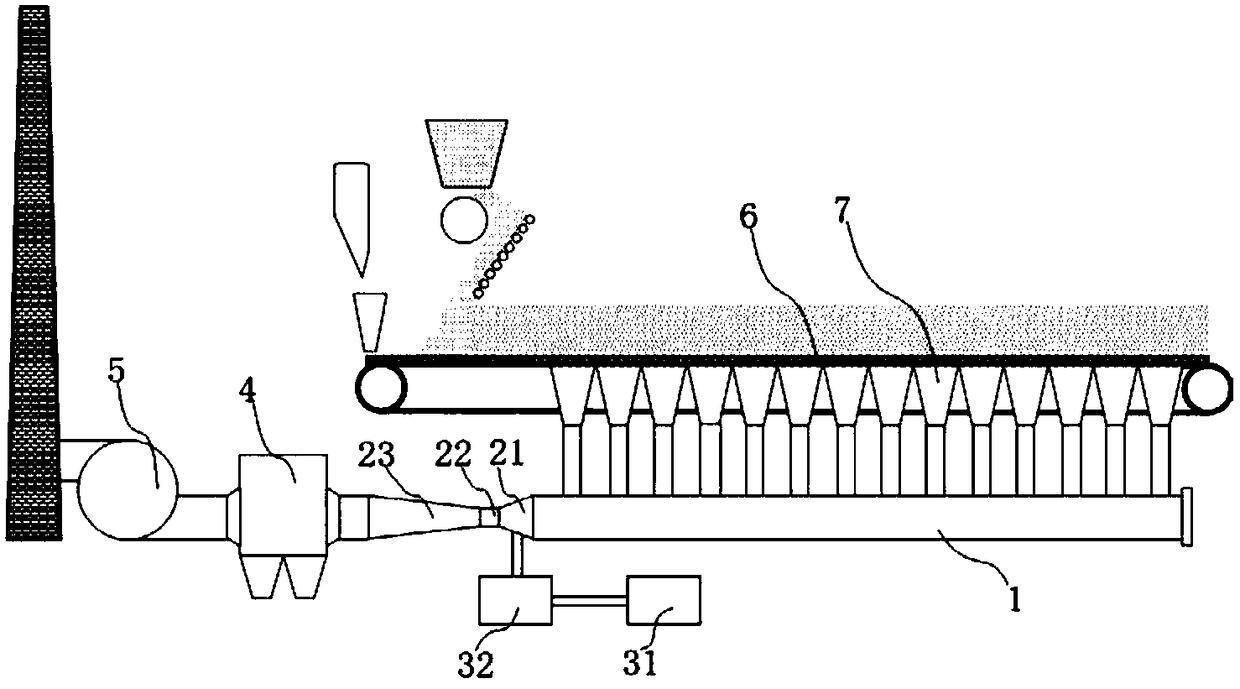

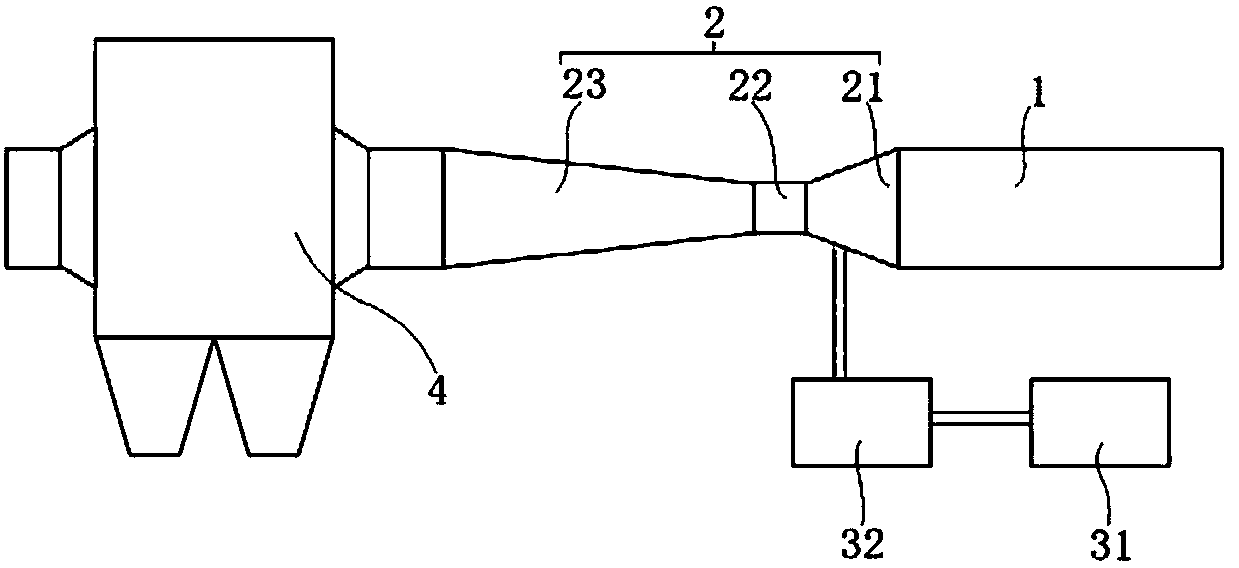

Iron ore sintering flue gas PM10 and PM2.5 emission reduction method

ActiveCN105727662AImprove reunion efficiencySpeed up the reunionCombination devicesGas treatmentIron ore sinteringPollutant

The invention discloses an iron ore sintering flue gas PM10 and PM2.5 emission reduction method, belonging to the technical field of reduction of emission of pollutants in an iron ore sintering process. According to the method, in an iron ore sintering process, an agglomeration solution is sprayed in a sintering flue gas channel, and fine particulate matter in sintering flue gas is agglomerated and grows up under the action of the agglomeration solution, and then is removed by a dedusting device; the agglomeration agent comprises polymeric aluminium chloride, sodium carboxymethylcellulose, polyacrylamide and a solid additive. According to the iron ore sintering flue gas PM10 and PM2.5 emission reduction method, the droplets of the agglomeration solution adsorbing fine particulate matter are nucleated and collided and grow up under low pressure to form large particle agglomerates, the agglomerated and grown fine particulate matter is removed by the dedusting device, and high-efficiency emission reduction of the fine particulate matter is realized. Therefore, the method can provide a brand-new means for reduction of emission of fine particulate matter in an iron ore sintering process.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

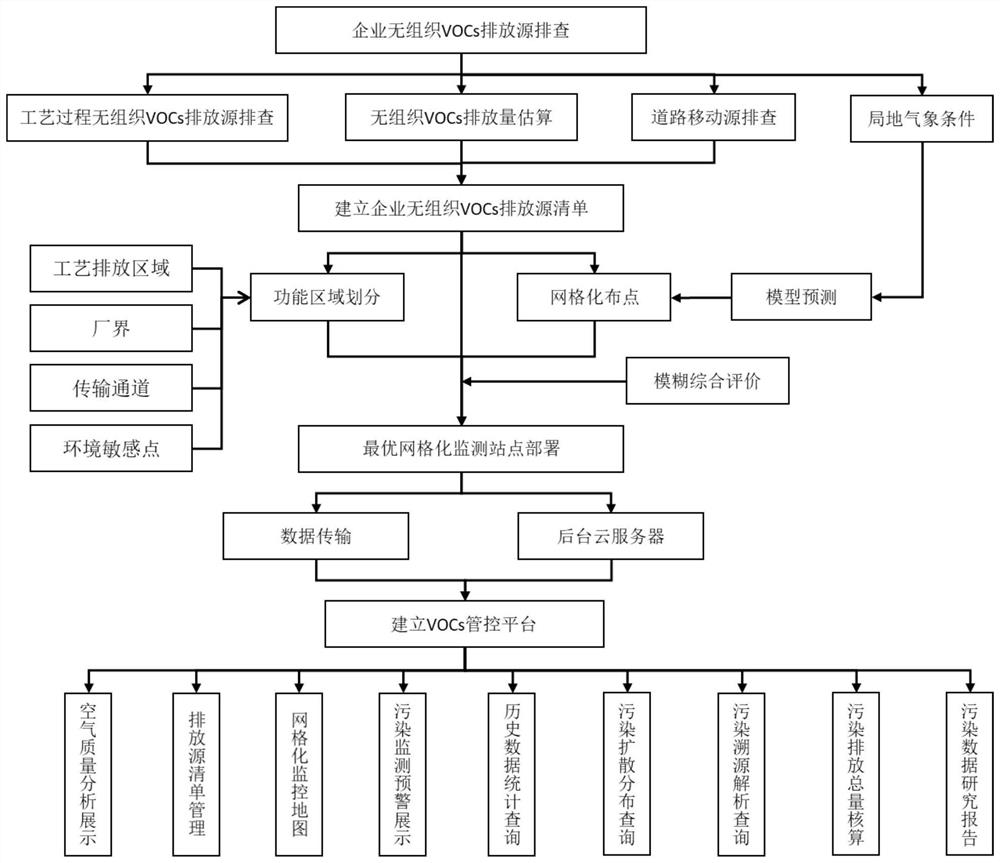

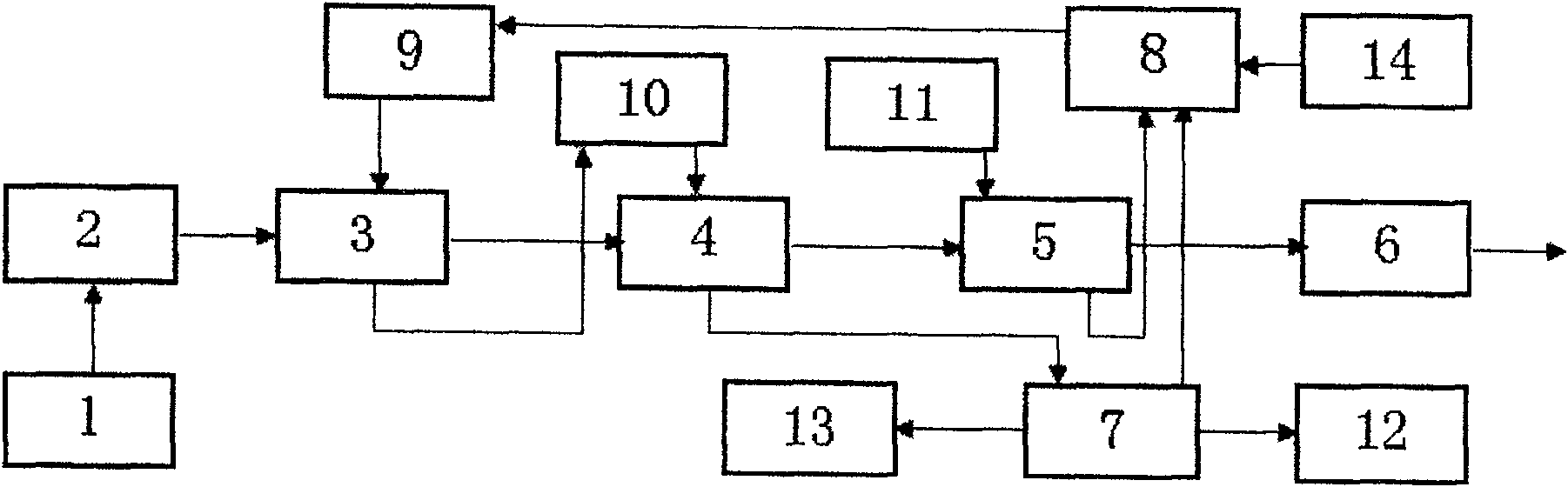

Industrial enterprise unorganized VOCs gridding monitoring, diffusion early warning and tracing method

ActiveCN114371260AReduce the influence of human subjective factorsThe monitoring result is close to the true valueParticle suspension analysisAir quality improvementEnvironmental resource managementBusiness enterprise

The invention relates to a gridding monitoring, diffusion early warning and tracing method for unorganized VOCs of an industrial enterprise. The method comprises the following steps: establishing a VOCs unorganized emission source list of the industrial enterprise; vOCs gridding monitoring stations are screened and arranged on the basis of a VOCs unorganized emission source list and local perennial meteorological conditions through a comprehensive rating method of functional region division and gridding point distribution; creating a VOCs management and control platform, displaying the grid VOCs emission level, time change trend and characteristics of the whole plant, and analyzing the total VOCs emission amount, high concentration value and occurrence time of the pollution map; through the optimized gas diffusion model and in combination with VOCs monitoring data of the whole plant, diffusion early warning analysis of VOCs pollution in the whole enterprise plant area is realized. And traceability analysis of VOCs pollution is realized through a source analysis technology. According to the invention, an integrated fine supervision mode of source combing, process monitoring and system management and control early warning of unorganized VOCs pollution of industrial enterprises is realized.

Owner:SHANGHAI LANKE PETROCHEM ENG & TECH

Method for inhibiting emission of fine particles in process of iron-ore sintering by agglomeration process

ActiveCN105797531AImprove reunion efficiencySpeed up the reunionAuxillary pretreatmentIron ore sinteringPollutant

The invention discloses a method for inhibiting emission of fine particles in the process of iron-ore sintering by an agglomeration process and belongs to the technical field of emission reduction of pollutants in the process of iron-ore sintering. The method comprises the following steps: (1) preparing agglomeration liquid, namely uniformly mixing components such as sodium carboxymethyl cellulose, polyacrylamide and an additive to obtain an agglomeration agent, and mixing the agglomeration agent and water to obtain the agglomeration liquid; (2) agglomerating fine particles, namely spraying the agglomeration liquid into flue gas to cause fine particles in the sintering flue gas to be agglomerated to grow larger under the action of the agglomeration liquid; and (3) trapping by a dust removing device, namely trapping and removing the fine particles agglomerated to grow larger by the dust removing device. The method disclosed by the invention has the advantages that agglomeration liquid droplets adsorbing the fine particles are nucleated and collide with each other and grow to form large-particle agglomerates under the condition of low pressure, and a dust-removing device is adopted to remove the fine particles agglomerated to be larger, so that an all-new emission-reducing path is provided for reducing the emission of fine particles in the process of iron-ore sintering.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for reducing emission of flue gas carbonic anhydride of fire coal electric power plant and recycle, and special system thereof

InactiveCN101130151AImprove emission reduction efficiencyAdapt to a wide temperature rangeProductsReagentsPower stationCo2 absorption

The invention discloses a discharge reducing and resourcing method of coal-burning power station flue gas carbon dioxide, which is characterized by the following: adopting amino material as adsorbent; injecting amino material solution as ammonium salt pattern into the flue gas of carbon dioxide adsorbing system after pre-dedusting the tail part of coal-burning stove to reduce 20-95% carbon dioxide in the flue gas; separating and purifying to obtain high-purity carbon oxide; fitting for industrial, chemical, food manufacturing, oil extracting oil displacement and so on; making the escape rate of ammonium in the clean gas discharged by defroster not more than 15mg / Nm3. The invention simplifies the flow path technique with obvious kind and quantity of manufacturing equipment, which has more widely using prospect.

Owner:DONGDIAN COMBUSTION TECH RES CENT +2

Gas recovery system to improve the efficiency of abatementand/or implement reuse/reclamation

InactiveUS20040187683A1Improve emission reduction efficiencyIsotope separationSorbentProcess engineering

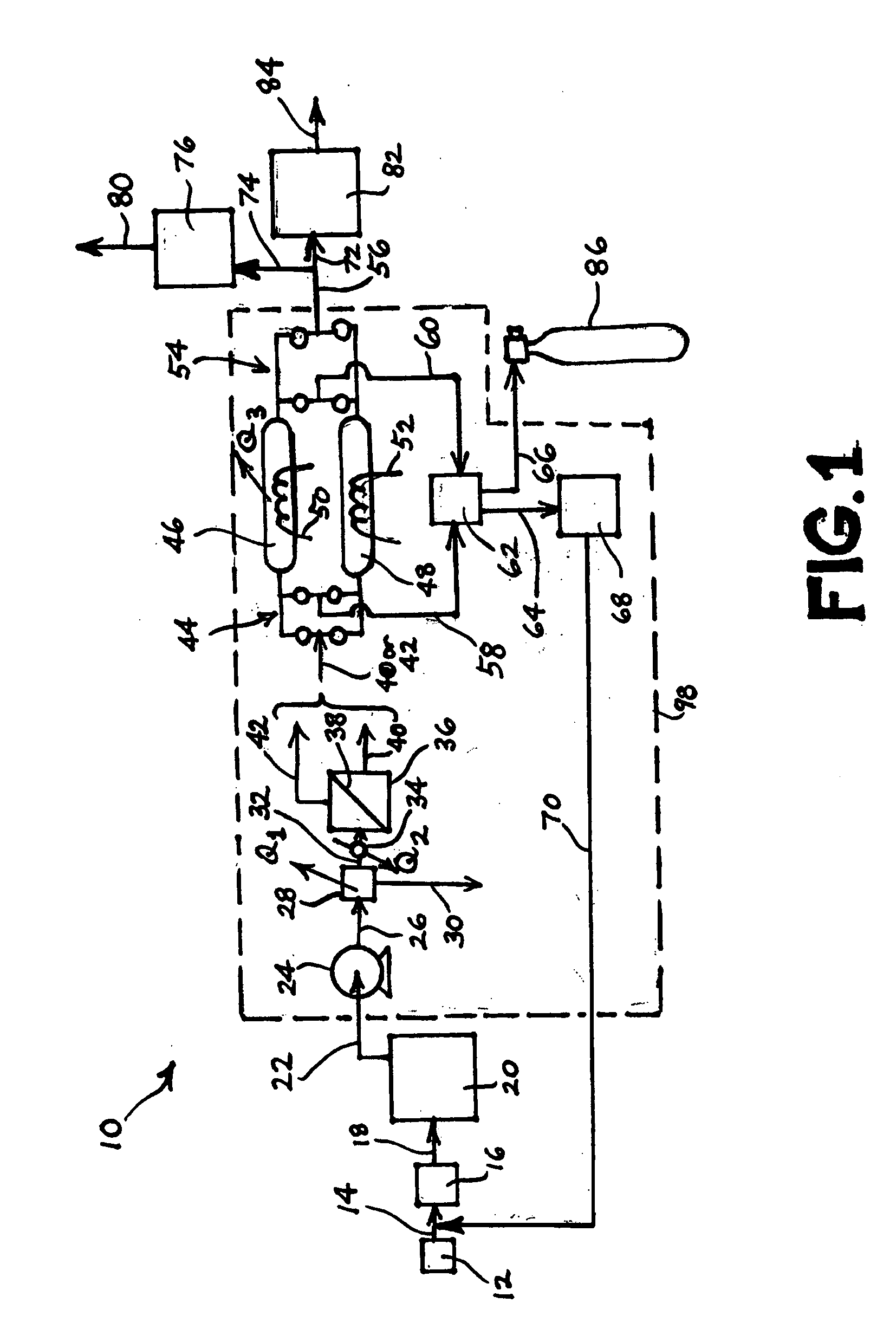

A gas recovery system for improving the efficiency of abatement and / or implementing reclamation and reuse of unused feed materials in effluent of a semiconductor manufacturing facility, especially in instances in which substantial portions of feed material are unused. The effluent is treated to reversibly capture the unused feed material, e.g., at a capture locus such as a physical adsorbent, cold finger, cryotrap, heat exchanger / condenser, membrane separation unit, filter, etc., and the captured unused feed material then is released from the capture locus and processed for such abatement and / or reclamation and reuse.

Owner:APPLIED MATERIALS INC

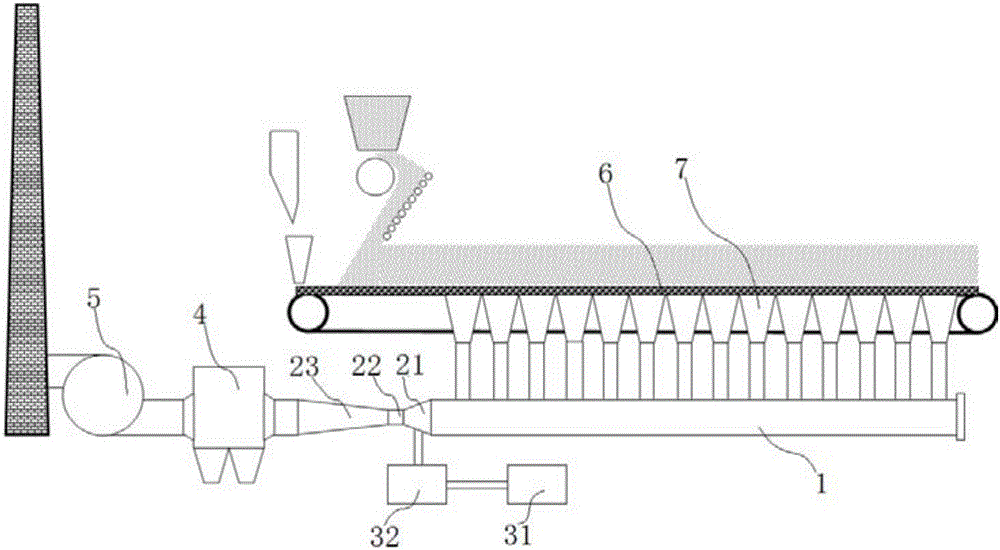

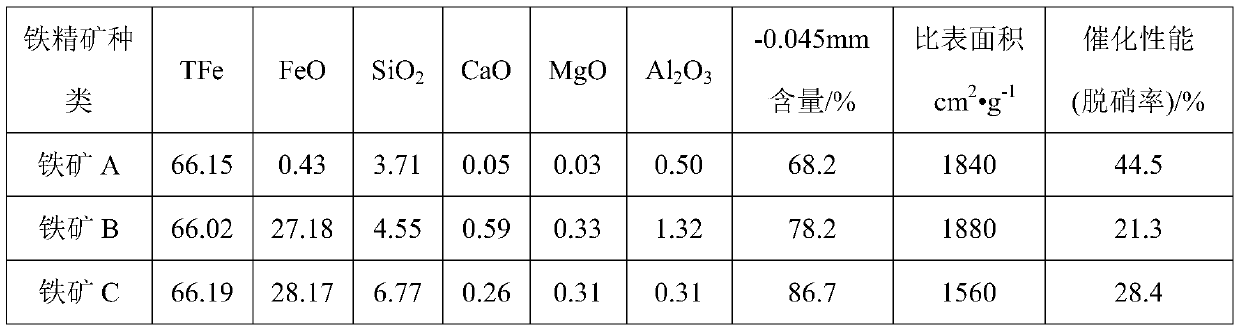

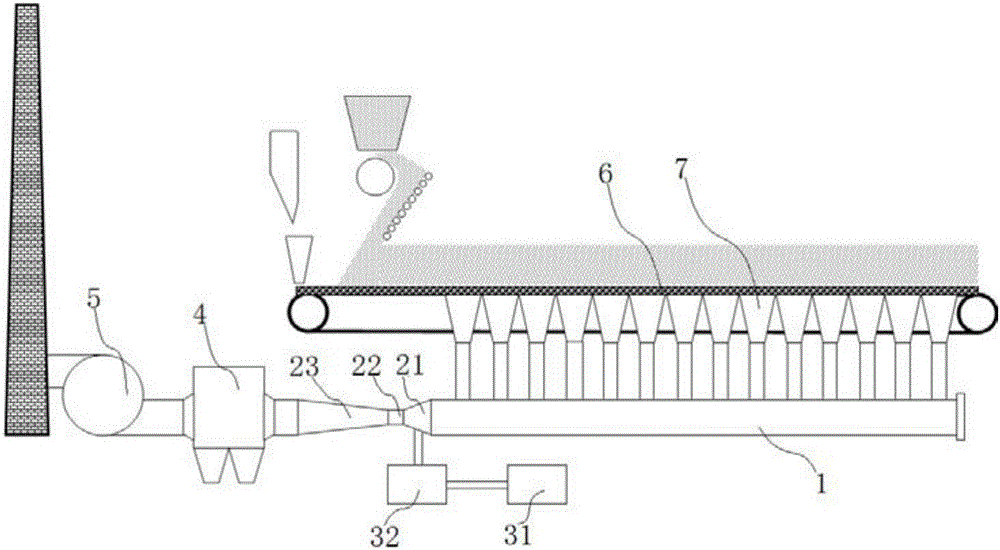

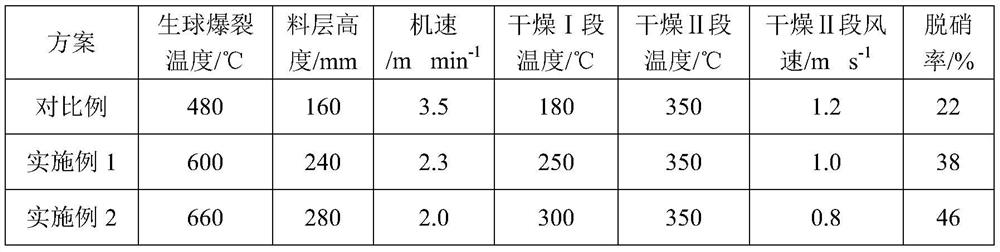

Strengthened ammonia injection denitration method based on surface catalytic performance of iron ore pellets

ActiveCN110904332AImprove denitrification effectRapid responseRotary drum furnacesPhysical chemistryRaw material

The invention relates to a strengthened ammonia injection denitration method based on surface catalytic performance of iron ore pellets. The method comprises the following steps of preparing green pellets by ingredients, drying and preheating a chain grate machine, and configuring ammonia injection denitration operation at an air draft drying section of the chain grate machine. The method is characterized by 1) determining pellet raw materials and a basic binder; 2) preparing a composite binder; 3) preparing green pellets with strong catalytic surfaces containing the composite binder; and 4) strengthening ammonia injection denitration on a pellet surface layer, decomposing and volatilizing the composite binder in a drying process to form rich pores in the pellet surface layer, increasing adsorption of NH3 and NOx on the pellet surface layer, accelerating a denitration reaction speed of the strong catalytic surface layer, and realizing strengthened ammonia injection denitration of thepellet surface layer. The method has advantages that a denitration rate is improved by more than 15 percent points compared with that of an existing ammonia spraying denitration technology; a pelletizing process does not need to be greatly changed, and only some improvements need to be made in the process of preparing the green pellets from the ingredients; and implementation and popularization are easy.

Owner:ANSTEEL GRP MINING CO LTD

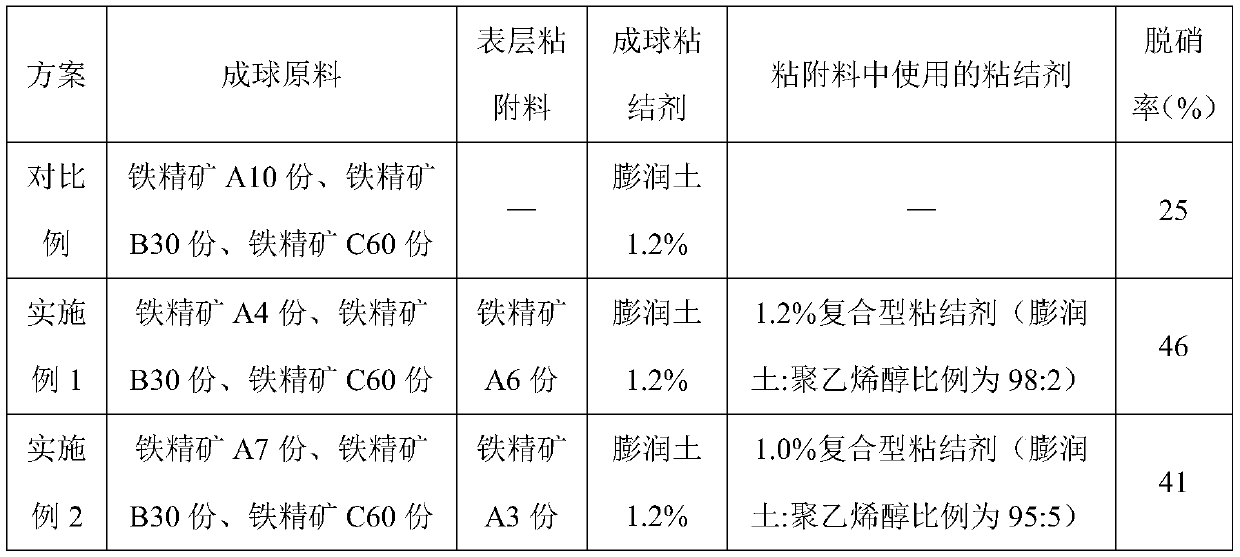

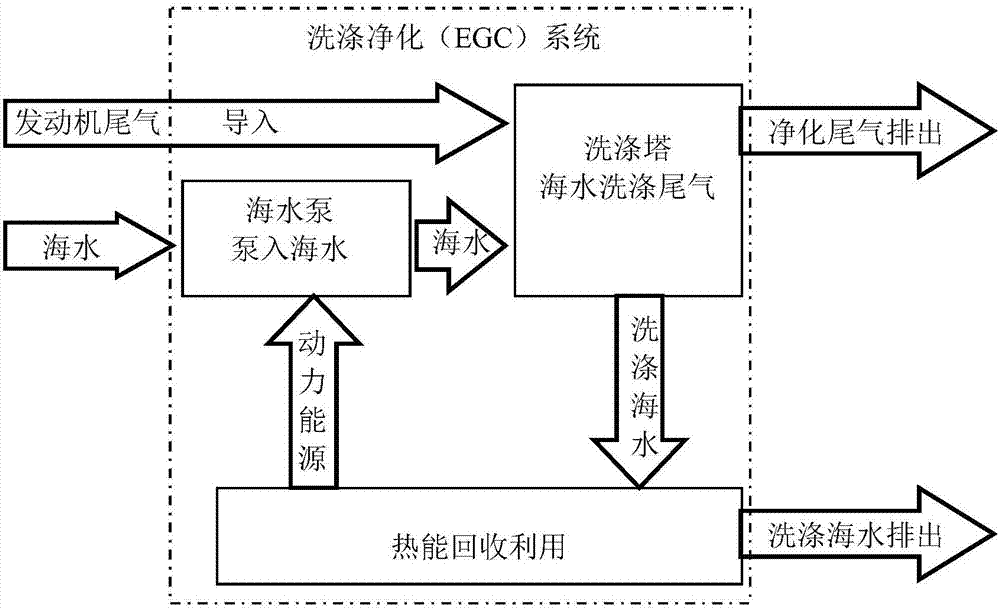

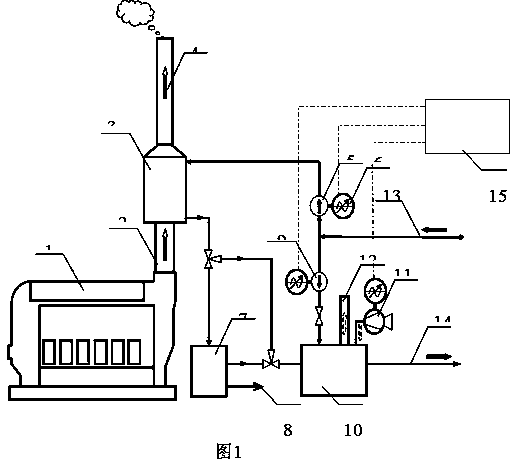

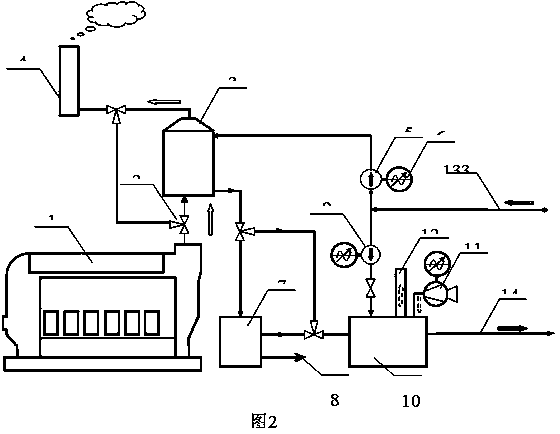

Zero-energy-consumption seawater washing and purifying method and device for marine engineering engine tail gas

InactiveCN107313842AImprove emission reduction efficiencyImprove energy efficiency indicatorsInternal combustion piston enginesExhaust apparatusSulfurProcess engineering

The invention relates to a zero-energy-consumption seawater washing and purifying method and device for marine engineering engine tail gas. The method comprises the steps that washing seawater is subjected to heat energy recycling before being drained out of a washing and purifying system, and in the step of heat energy recycling, waste heat energy of the washing seawater is recycled and used as power energy of a seawater pump. According to the zero-energy-consumption seawater washing and purifying method and device for the marine engineering engine tail gas, the engine tail gas waste heat is recycled by the adoption of a gas-liquid-solid heat transfer manner, so that the heat recycling efficiency is higher; a proper low-temperature heat source utilization manner is adopted; the emission reduction efficiency is extremely high and the energy consumption is extremely low by the adoption of a seawater washing process; in this way, by the adoption of the zero-energy-consumption seawater washing and purifying method and device for the marine engineering engine tail gas, washing and purifying and waste heat energy recycling can be conducted on the engine tail gas at the same time, and the energy consumption of the seawater washing EGC system is equivalent to near-zero even a negative, so that a low-sulfur law is implemented by the adoption of a low-carbon manner for marine ships, and the ship energy efficiency index is not reduced or even can be increased.

Owner:彭斯干

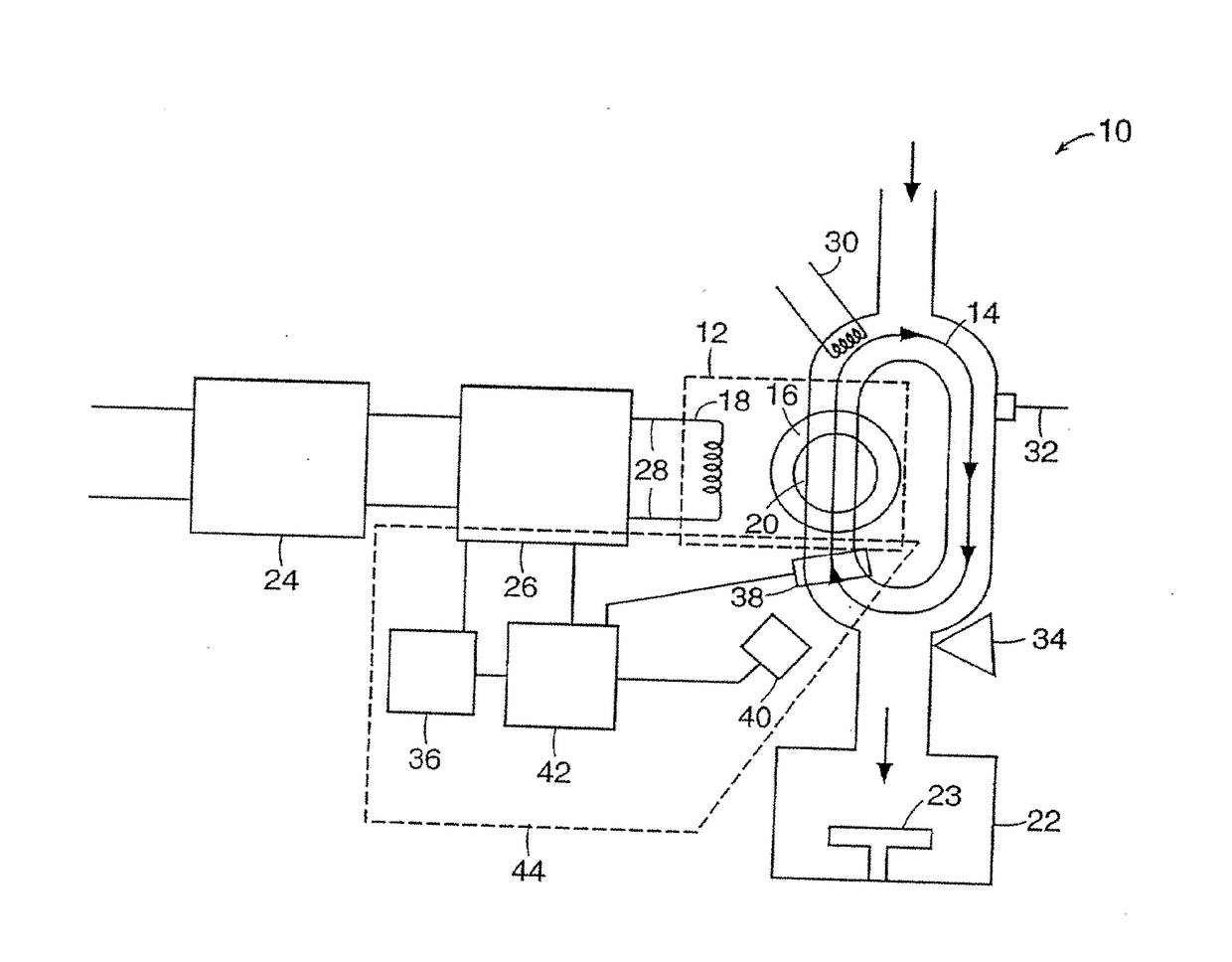

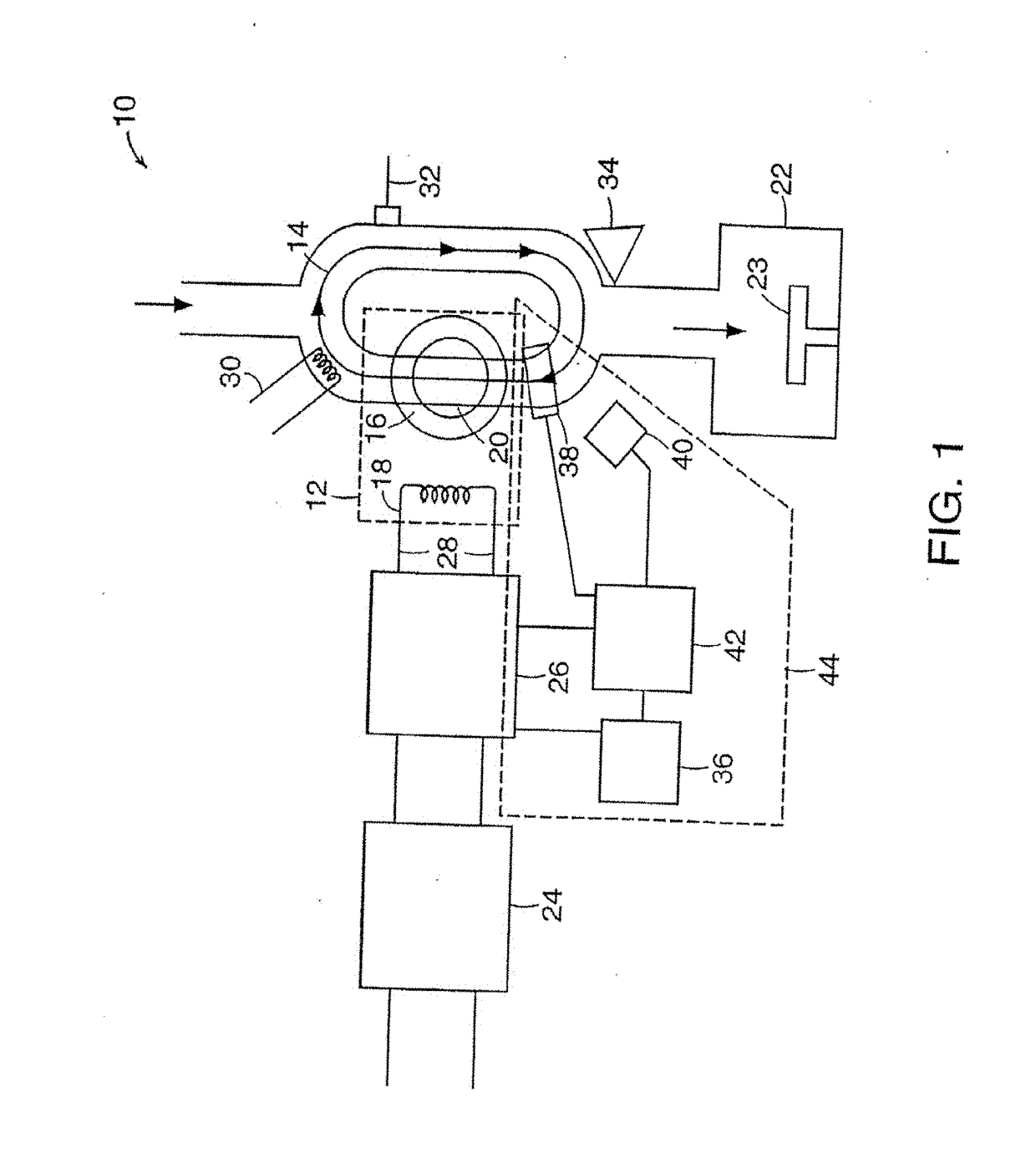

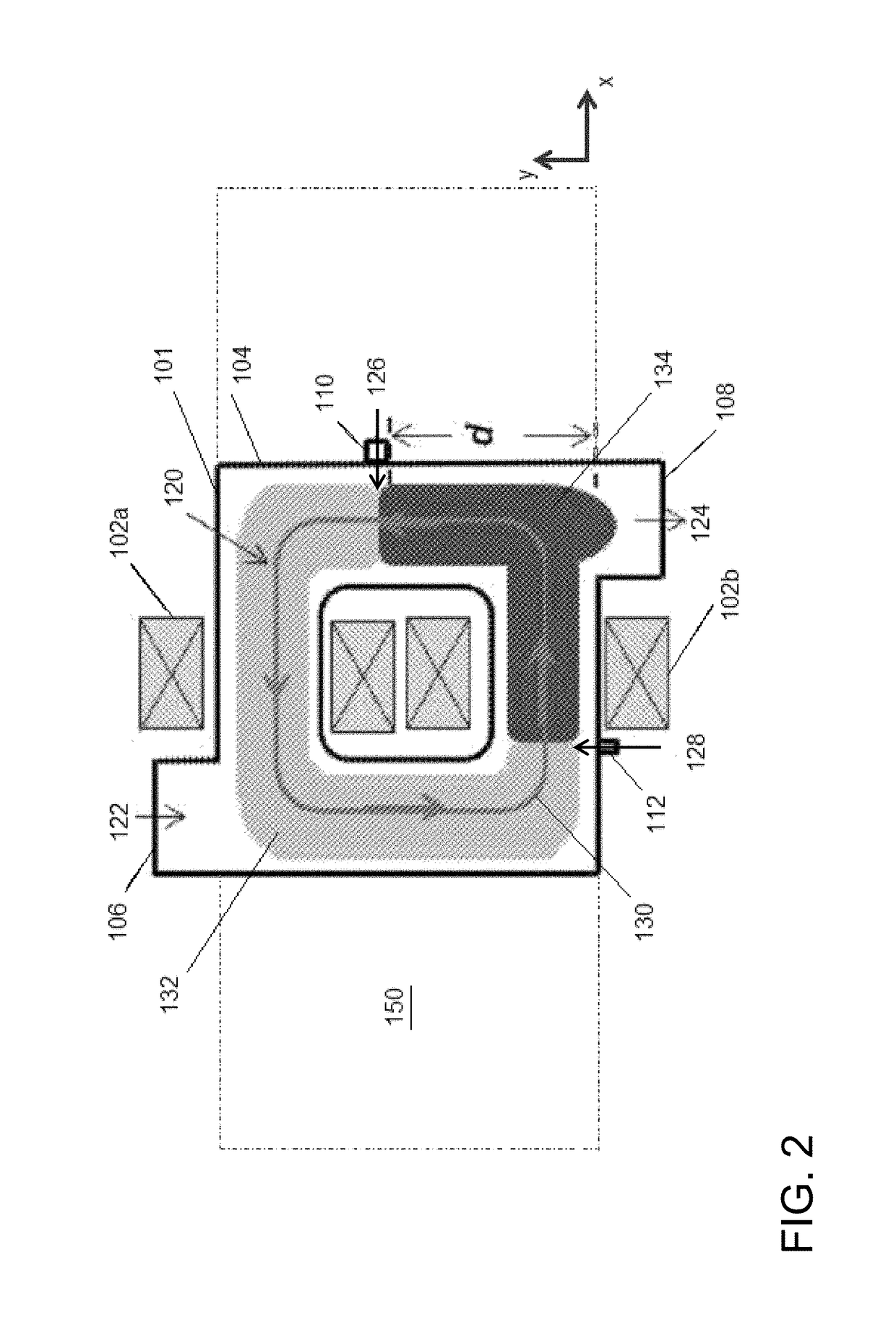

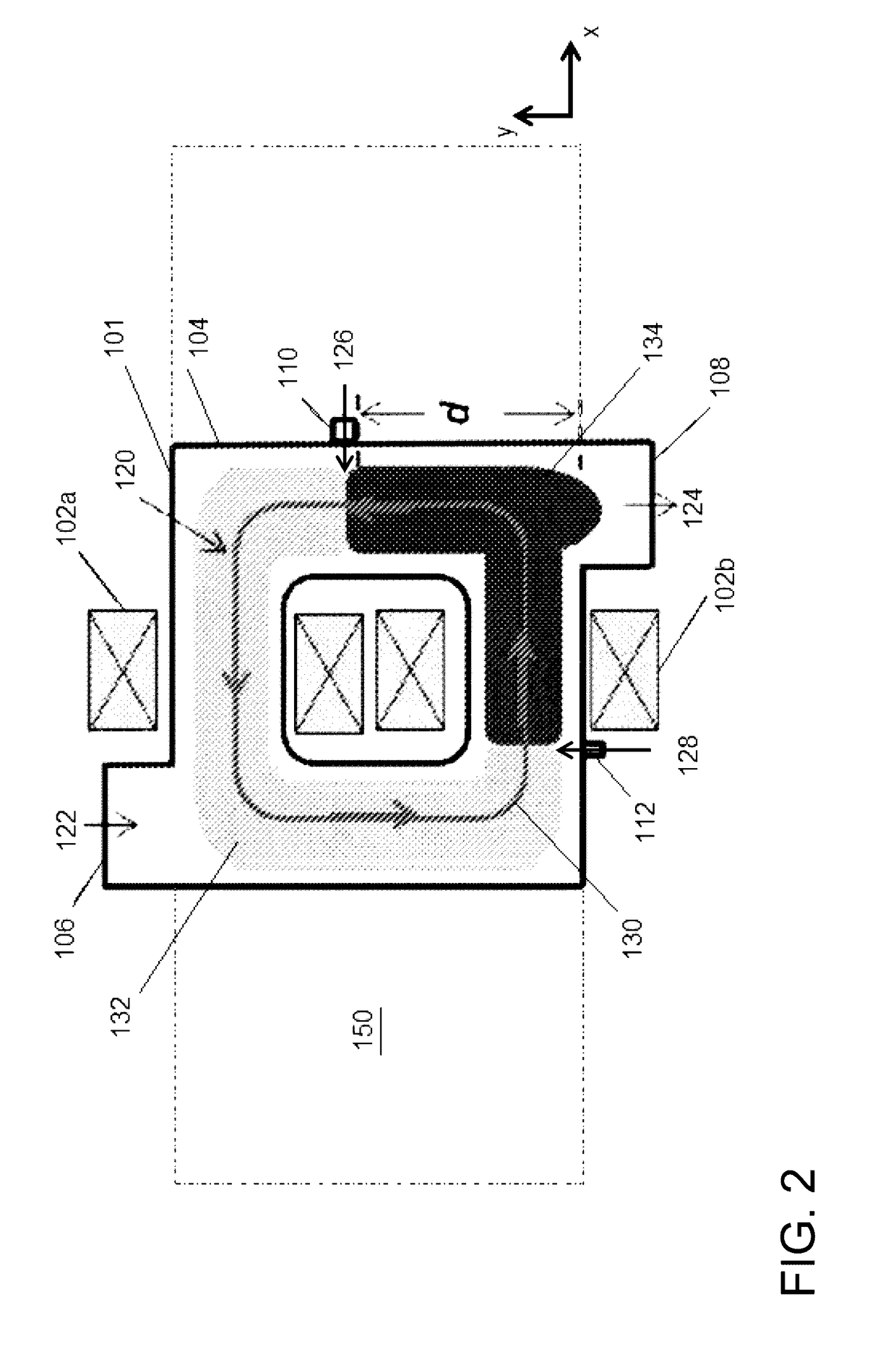

Toroidal plasma abatement apparatus and method

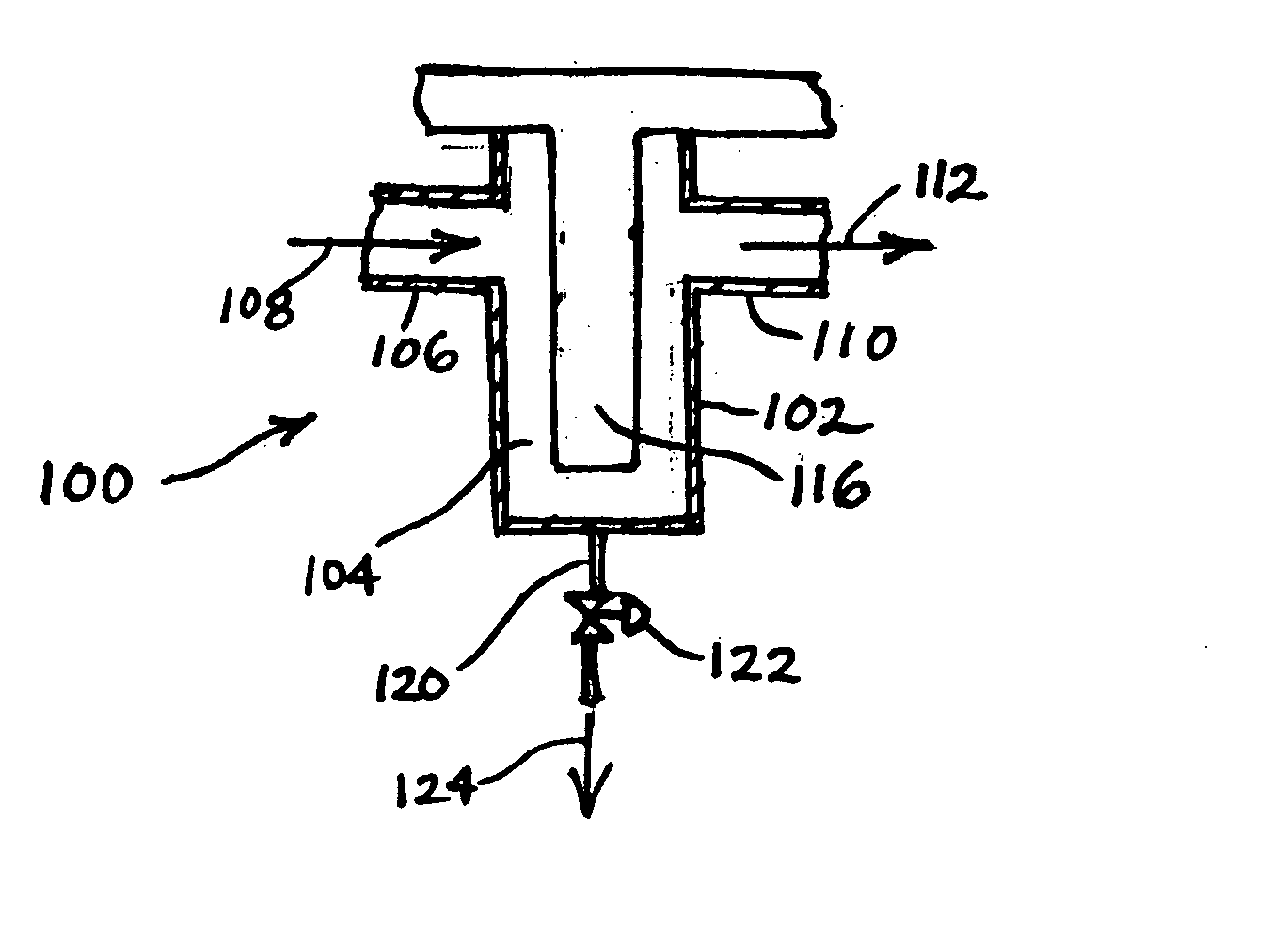

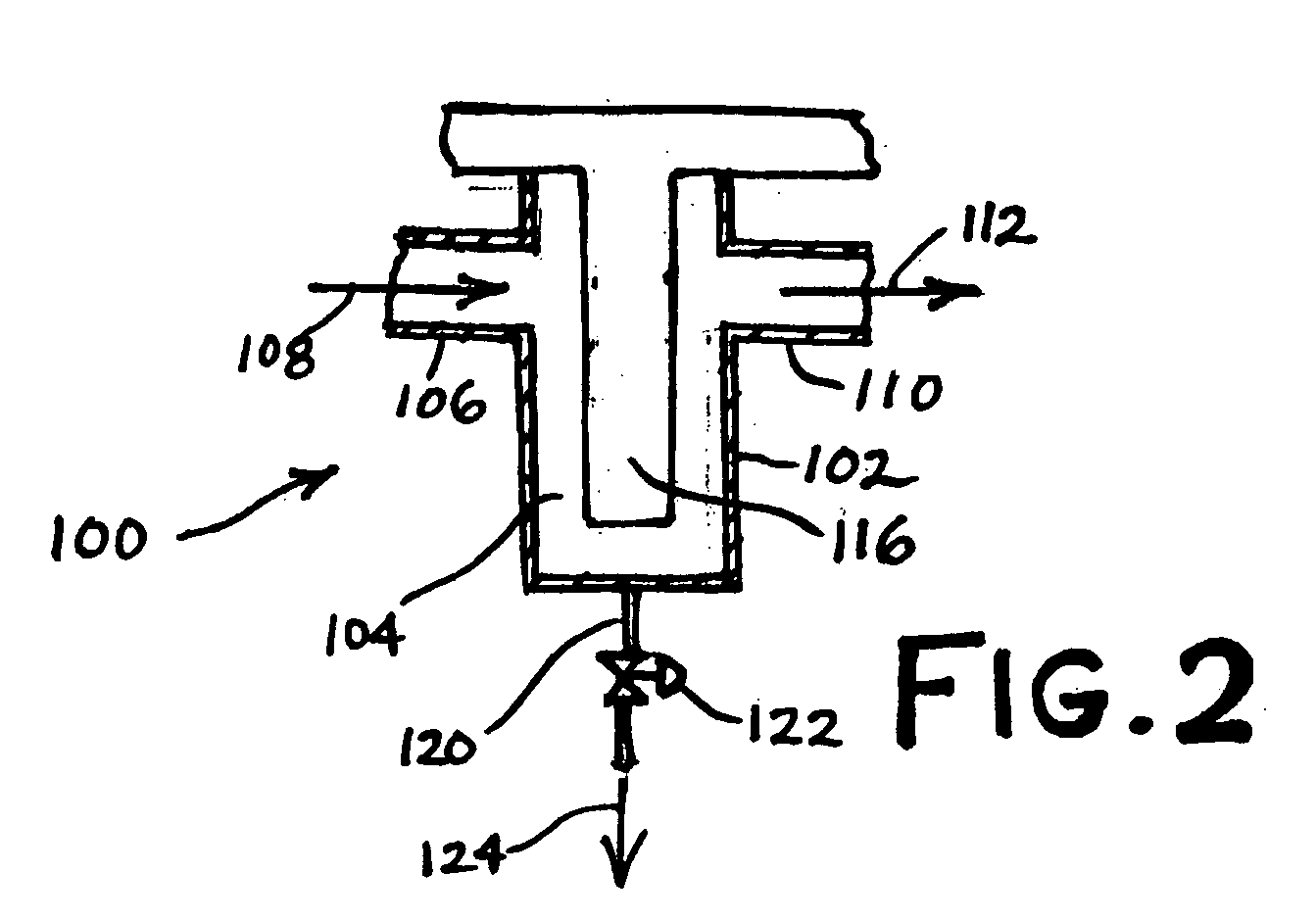

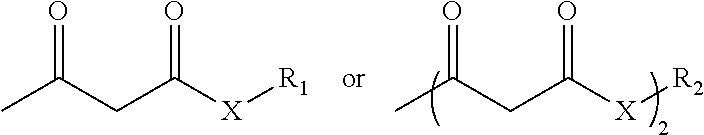

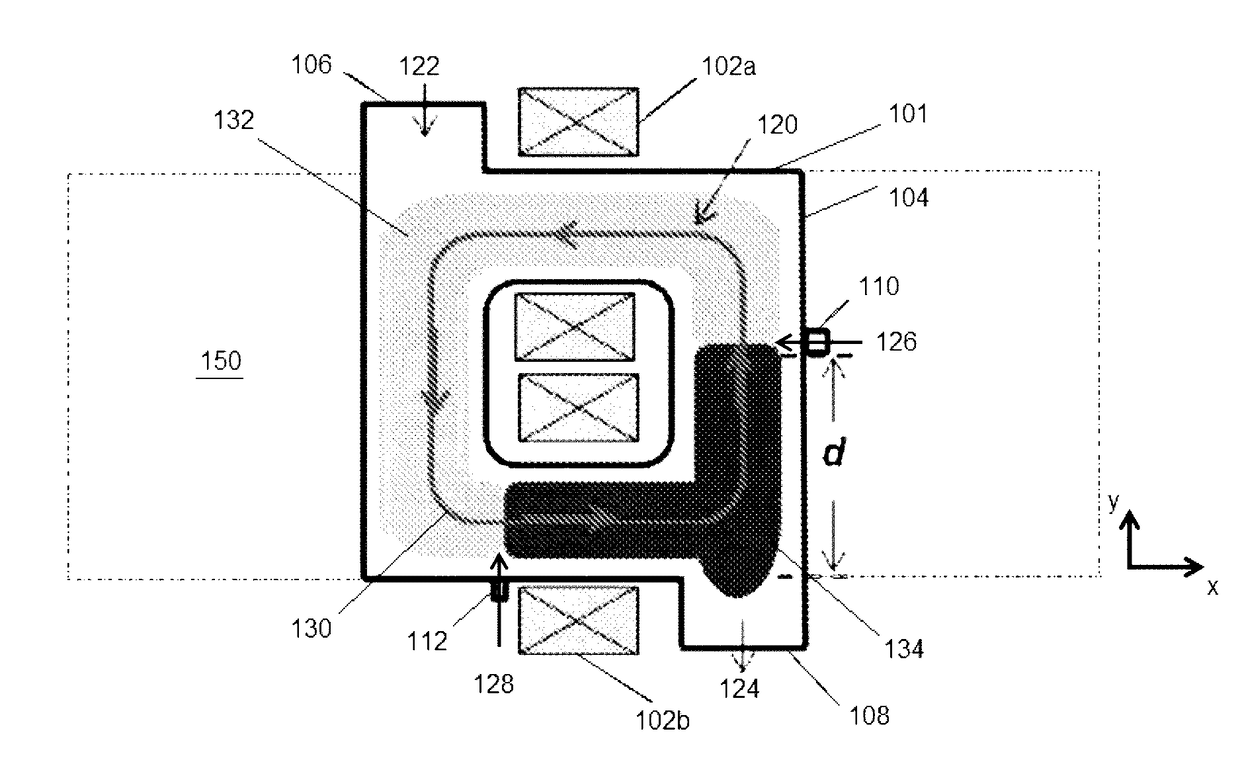

ActiveUS20170213704A1Increase conductanceEasy to integrateGas treatmentElectric discharge tubesEngineeringProduct gas

An apparatus for abatement of gases is provided. The apparatus includes a toroidal plasma chamber having a plurality of inlets and an outlet, and at least one chamber wall. One or more magnetic cores are disposed relative to the toroidal plasma chamber. The plasma chamber confines a toroidal plasma. A second gas inlet is positioned on the toroidal plasma chamber between a first gas inlet and the gas outlet at a distance d from the gas outlet, such that a toroidal plasma channel volume between the first gas inlet and the second gas inlet in the is substantially filled by the inert gas, the distance d based on a desired residence time of the gas to be abated.

Owner:MKS INSTR INC

Method for preparing agglomeration liquid for restraining iron mine sintering flue gas fine particle emissions

ActiveCN105833655AImprove reunion efficiencySpeed up the reunionAuxillary pretreatmentMass ratioFlue gas

The invention discloses a method for preparing agglomeration liquid for restraining iron mine sintering flue gas fine particle emissions, and belongs to the technical field of iron mine sintering process pollutant emission reduction .The method comprises the specific steps that A, 20-40 parts of polyacrylamide, 0-20 parts of aluminium polychlorid, 20-40 parts of sodium carboxymethylcellulose and 20-40 parts of polyacrylamide are mixed to be uniform, and a mixture A is obtained; B, 2-5 parts by mass of additive is weighed and added into the mixture A, the mixture is mixed to be uniform, and a compound agglomeration agent is obtained; C, the compound agglomeration agent in the step B is mixed with water, the mass ratio of the compound agglomeration agent to the water is 1:(2,000-10,000), and the agglomeration liquid is prepared .Agglomeration liquid mist drops on which fine particles are adsorbed are nucleated, collide and grow under the low pressure condition, large particle agglomerate is formed, agglomerated and grown fine particles are removed through a dust removal device, therefore, emissions of pollutants are restrained, and a brand-new emission reducing path is provided for emission reduction of the fine particles in the iron mine sintering process.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

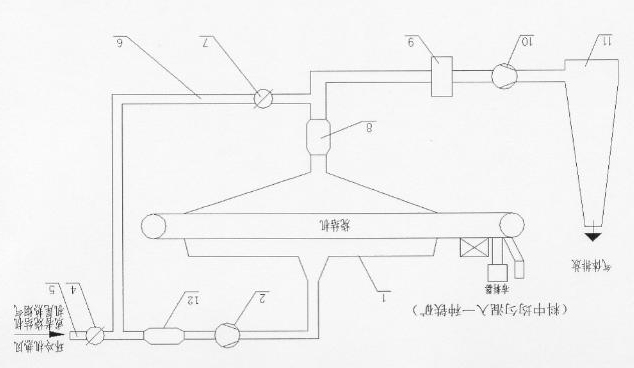

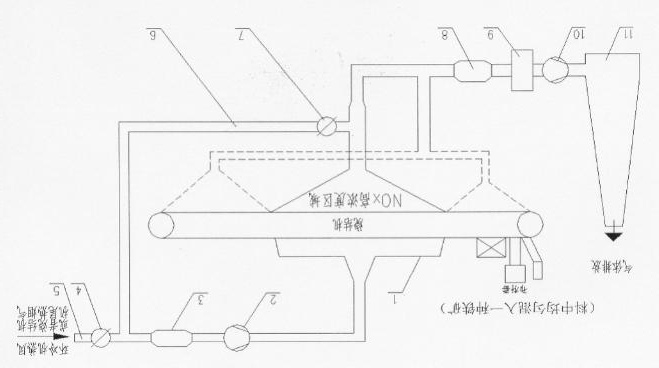

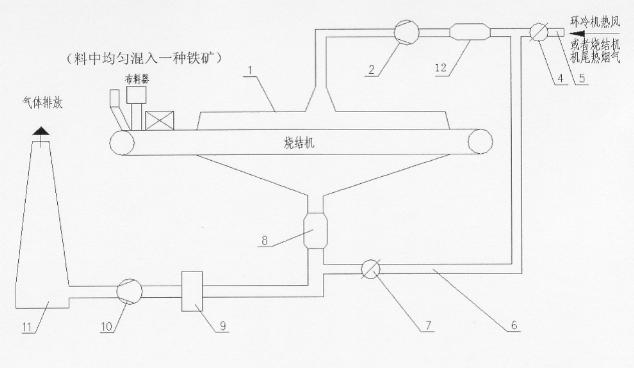

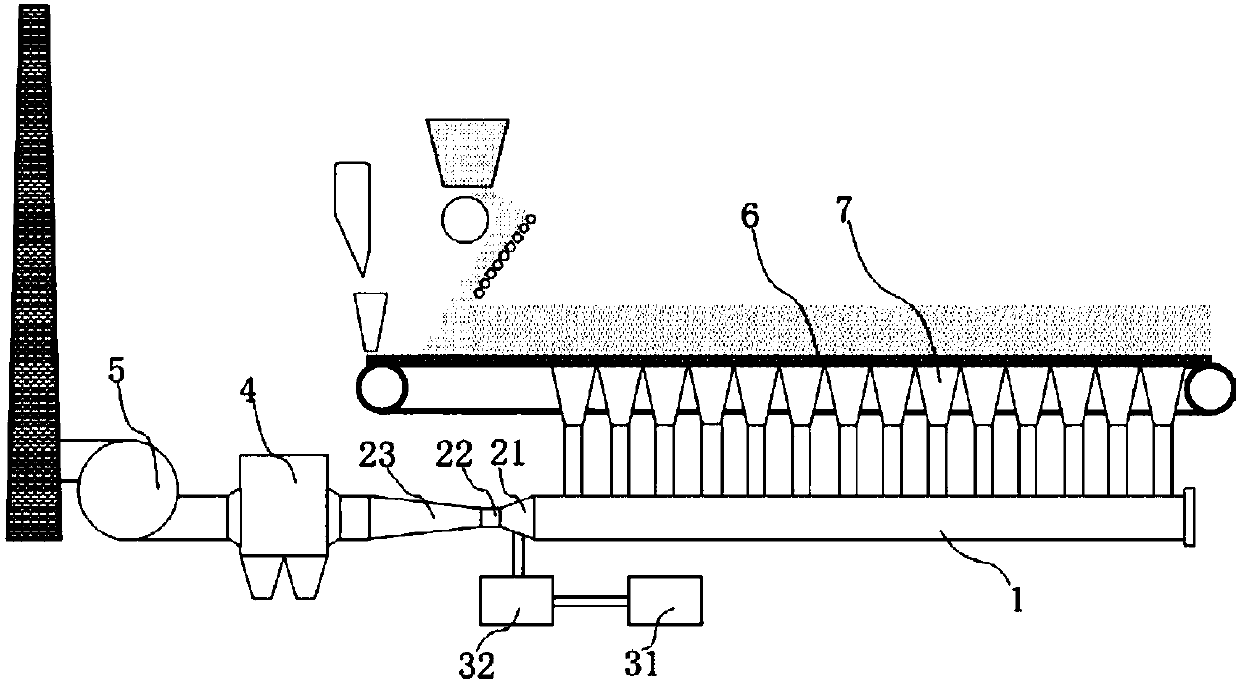

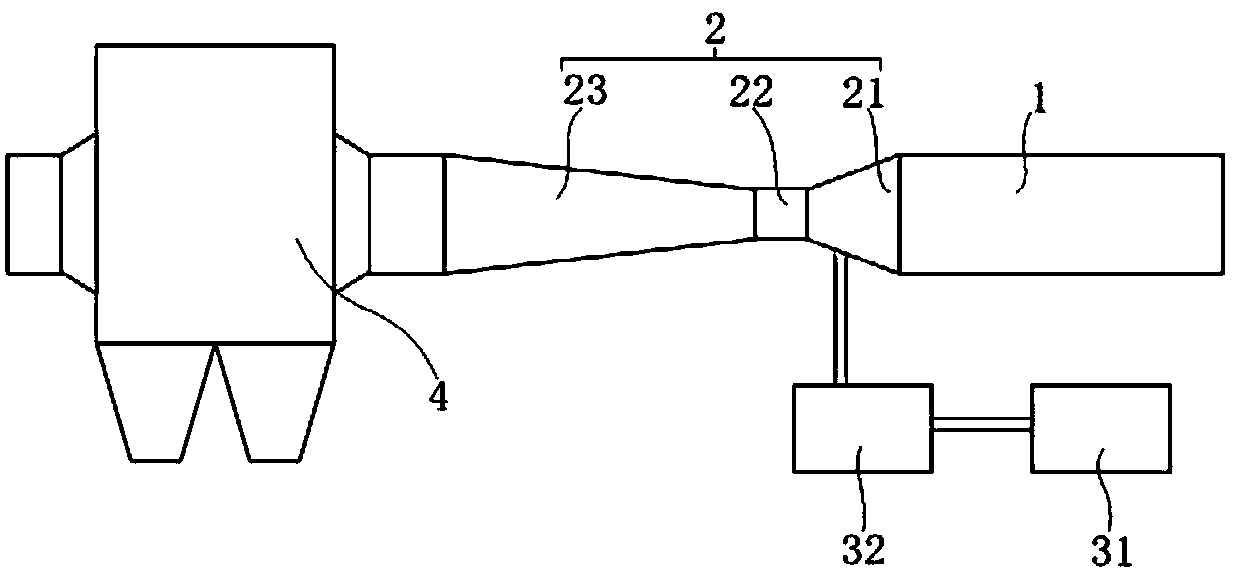

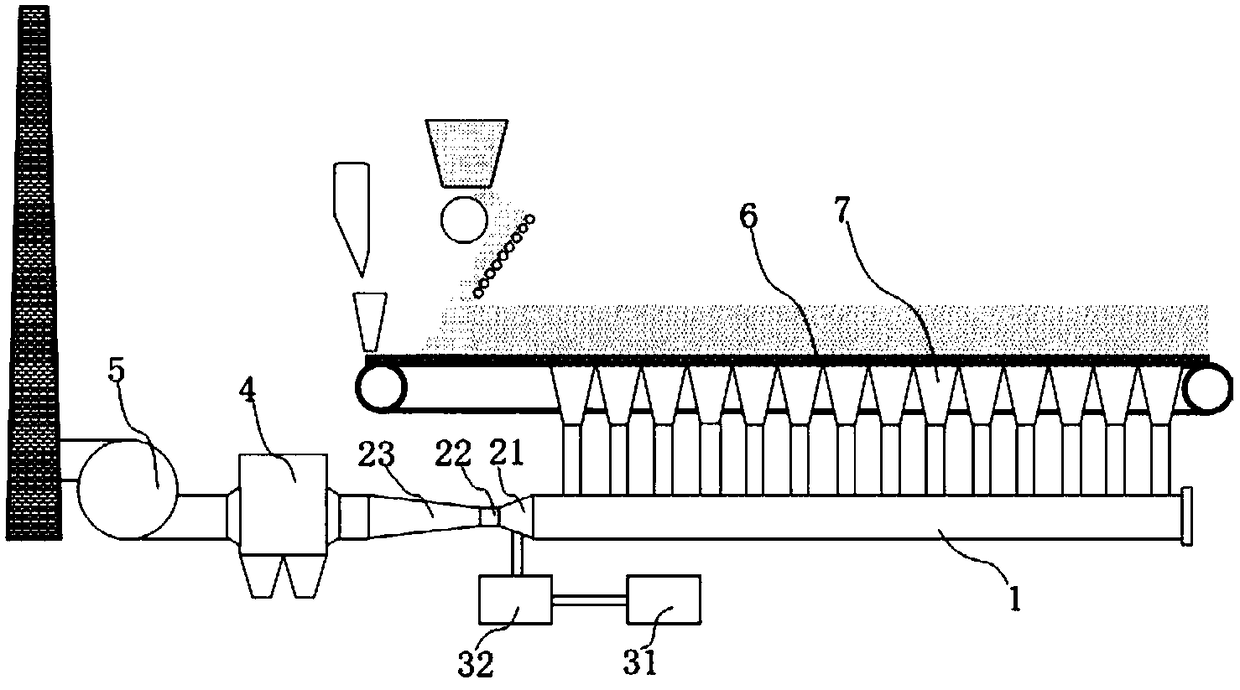

Low-carbon method for improving emission reduction efficiency of oxynitride in circulated flue gas from sintering machine

InactiveCN102188905AImprove catalytic emission reduction efficiencyNo need for additional facilitiesDispersed particle separationFurnace typesFlue gasOxygen

The invention relates to a low-carbon method for improving the emission reduction efficiency of oxynitride in circulated flue gas from a sintering machine, and the method comprises the following steps: (1) taking the flue gas in the middle of the total flue gas from a main flue, circulating the taken flue gas, wherein the flue gas is specifically taken from the area 20-70% from the head of the sintering machine to the bottom of the sintering machine, and the content of the oxygen in the flue gas in the upper circulating hood of a sintering pallet is no less than 18%; and (2) uniformly allocating an iron ore into sintering auxiliaries to serve as a catalyst. The invention provides a technical method for improving the circular denitration for the flue gas from the sintering machine with lowcost and low energy consumption. The technical method is characterized in that the iron ore is uniformly added into the sintering auxiliaries based on the flue gas circulation of the sintering machine, so as to improve the efficiency for denitration of the oxynitride. The technology provided by the invention is implemented based on the flue gas circulation of the sintering machine, the efficiencyfor denitrating the oxynitride from the circulated flue gas can be increased to 80-90% on the premise of not increasing the investment on equipment and construction, and the cost for energy consumption and operation.

Owner:BAOSTEEL ENG & TECH GRP

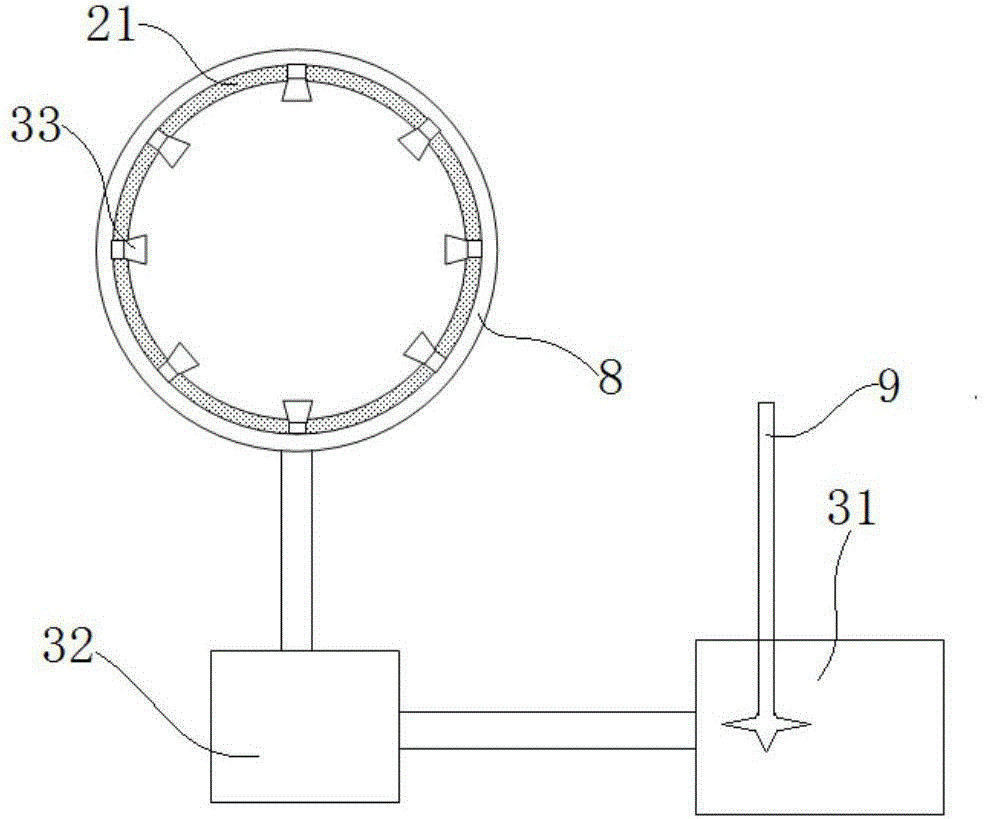

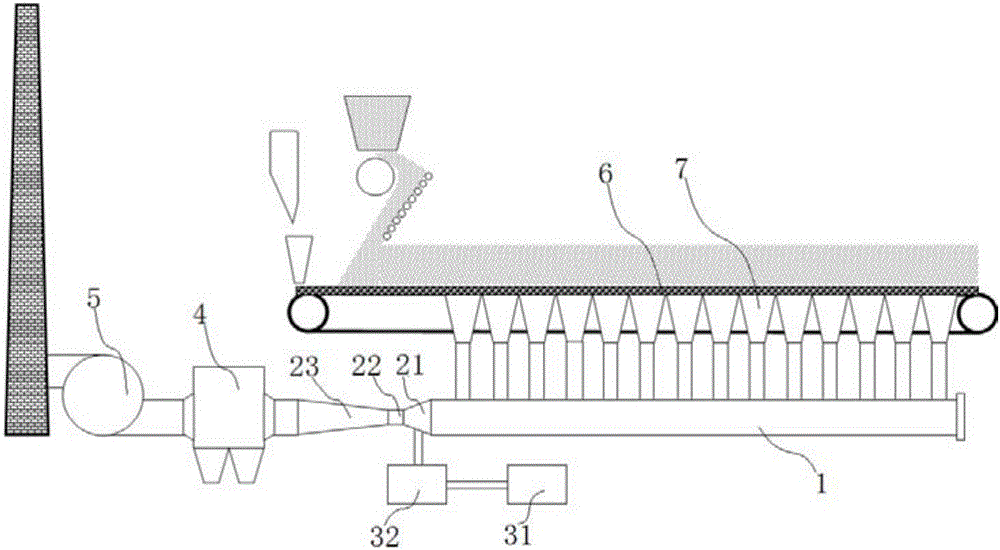

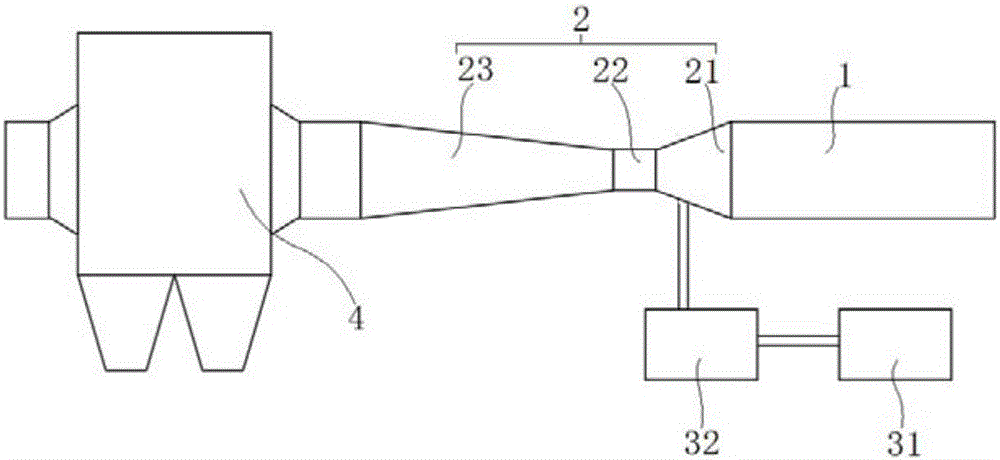

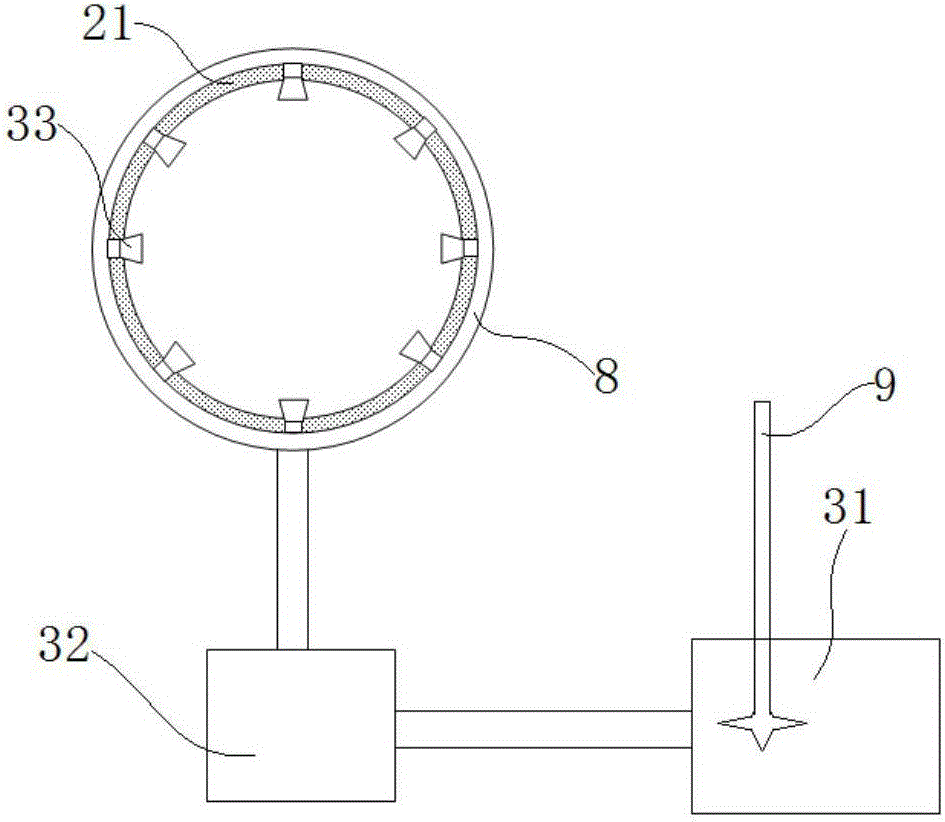

Circulating spouting type NOx emission reduction system and working method thereof

PendingCN112058064AAvoid local high temperatureAvoid or reduceGas treatmentDispersed particle separationEnvironmental engineeringMechanical engineering

The invention relates to a circulating spouting type NOx emission reduction system and a working method thereof. The circulating spouting type NOx emission reduction system comprises a rotary kiln, asmoke chamber, a spouting ring, a fuel system, a tertiary air pipe, a reactor, a first material distribution valve, a first cyclone cylinder, a denitration system, a decomposing furnace, a hopper anda second cyclone cylinder. An air inlet of the smoke chamber is connected with an air outlet of the rotary kiln, an air outlet of the reactor is connected to one side of the decomposing furnace and communicated with the interior of the decomposing furnace, and an air inlet of the reactor is connected with an air outlet of the smoke chamber through the spouting ring. An air outlet of the tertiary air pipe is connected to the bottom of the decomposing furnace, a feeding port of the hopper is connected to the lower portion of the air outlet of the tertiary air pipe, and an air inlet of the secondcyclone is connected with an air outlet of the decomposing furnace; The formation of NOX is effectively avoided or reduced so that the emission reduction efficiency of NOX is improved, and the ammonia water consumption of the denitration system is greatly reduced to save the production cost; meanwhile, the problem of serious material accumulation at the bottom of the decomposing furnace is solved, and secondary pollution can be avoided.

Owner:NANJING KISEN INT ENG

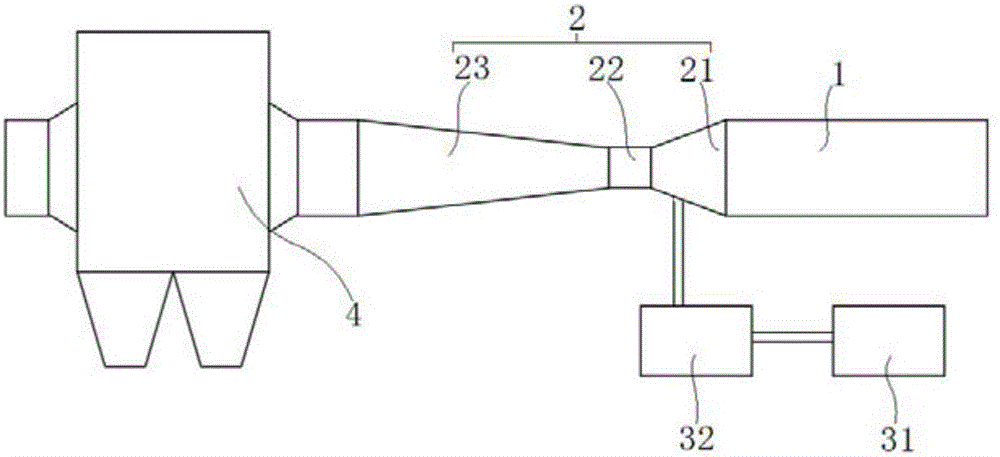

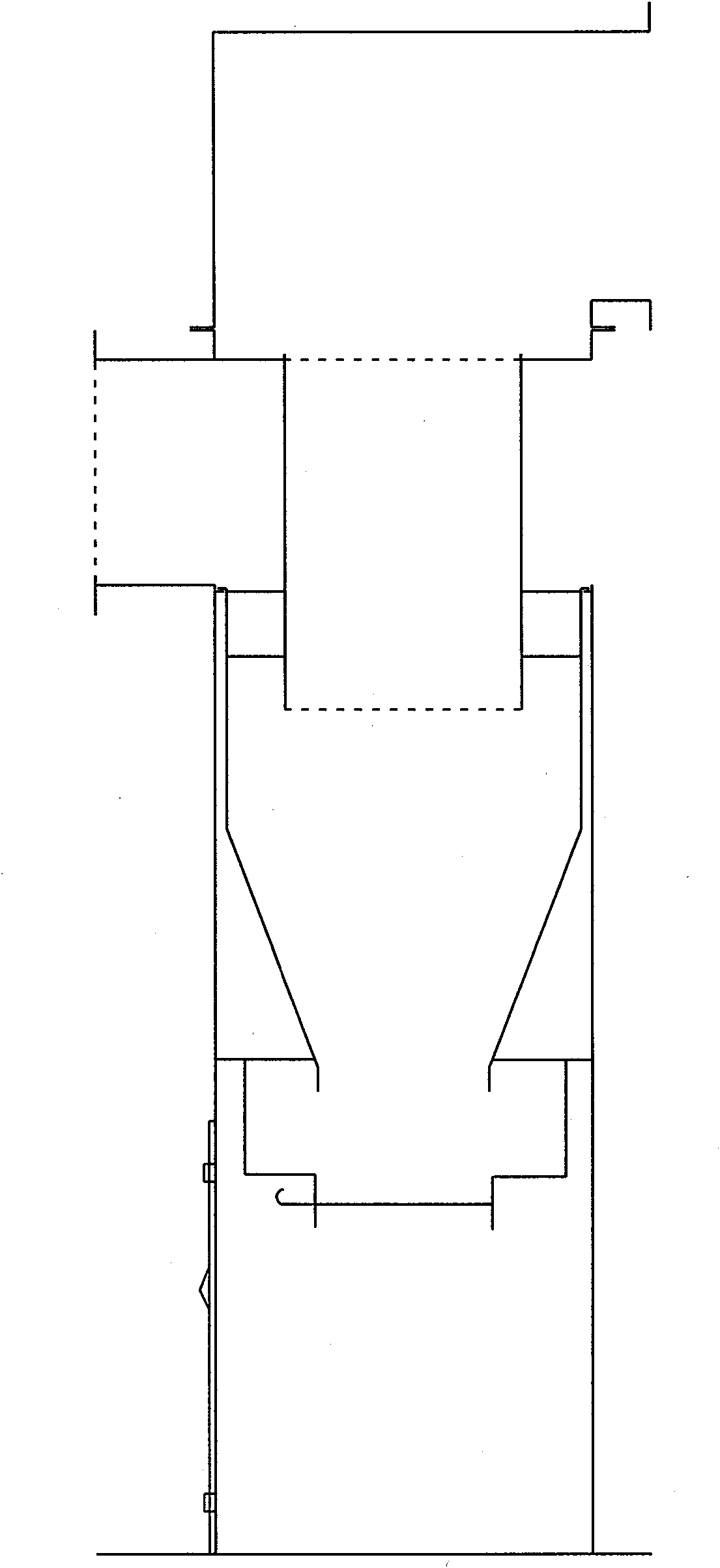

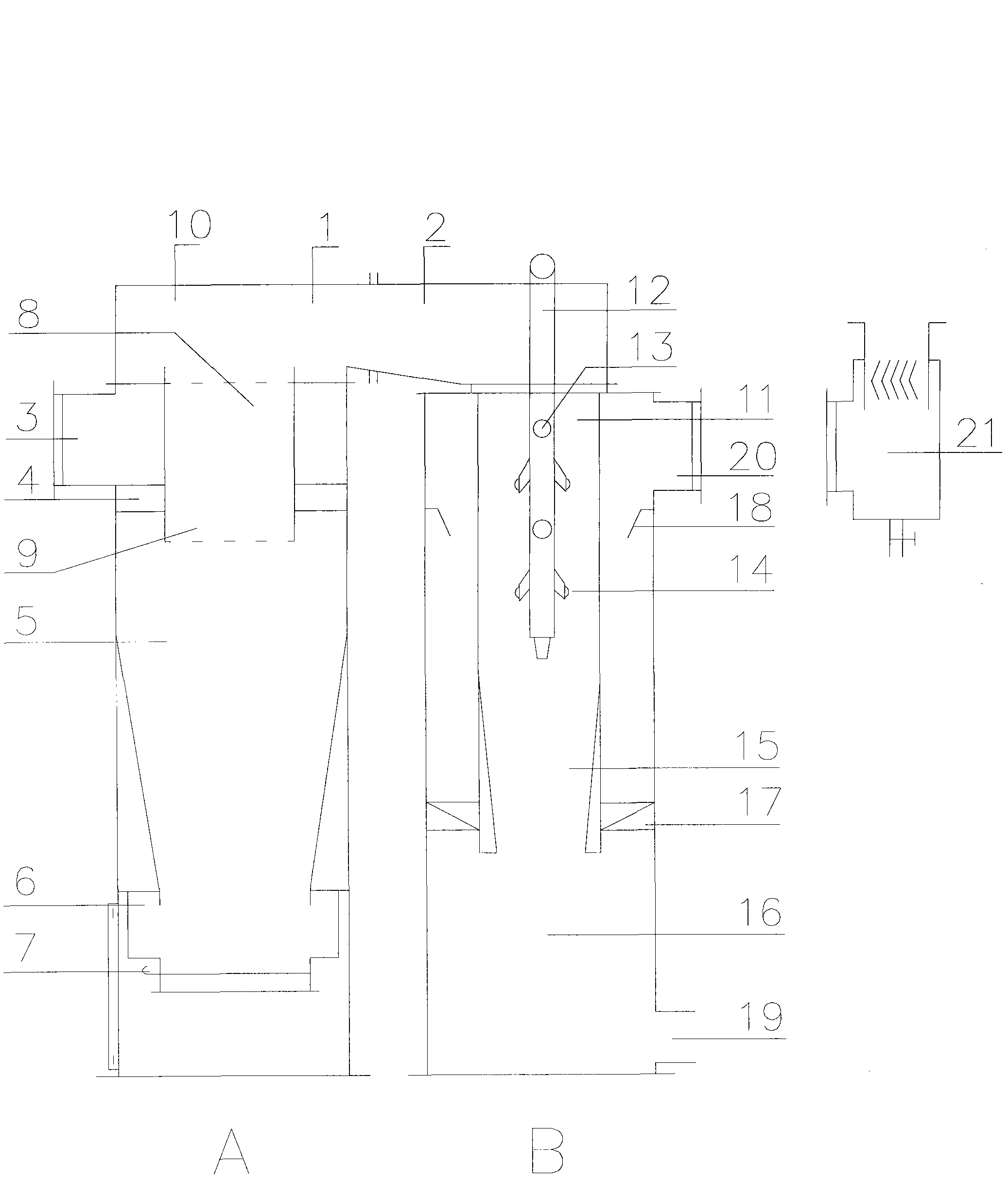

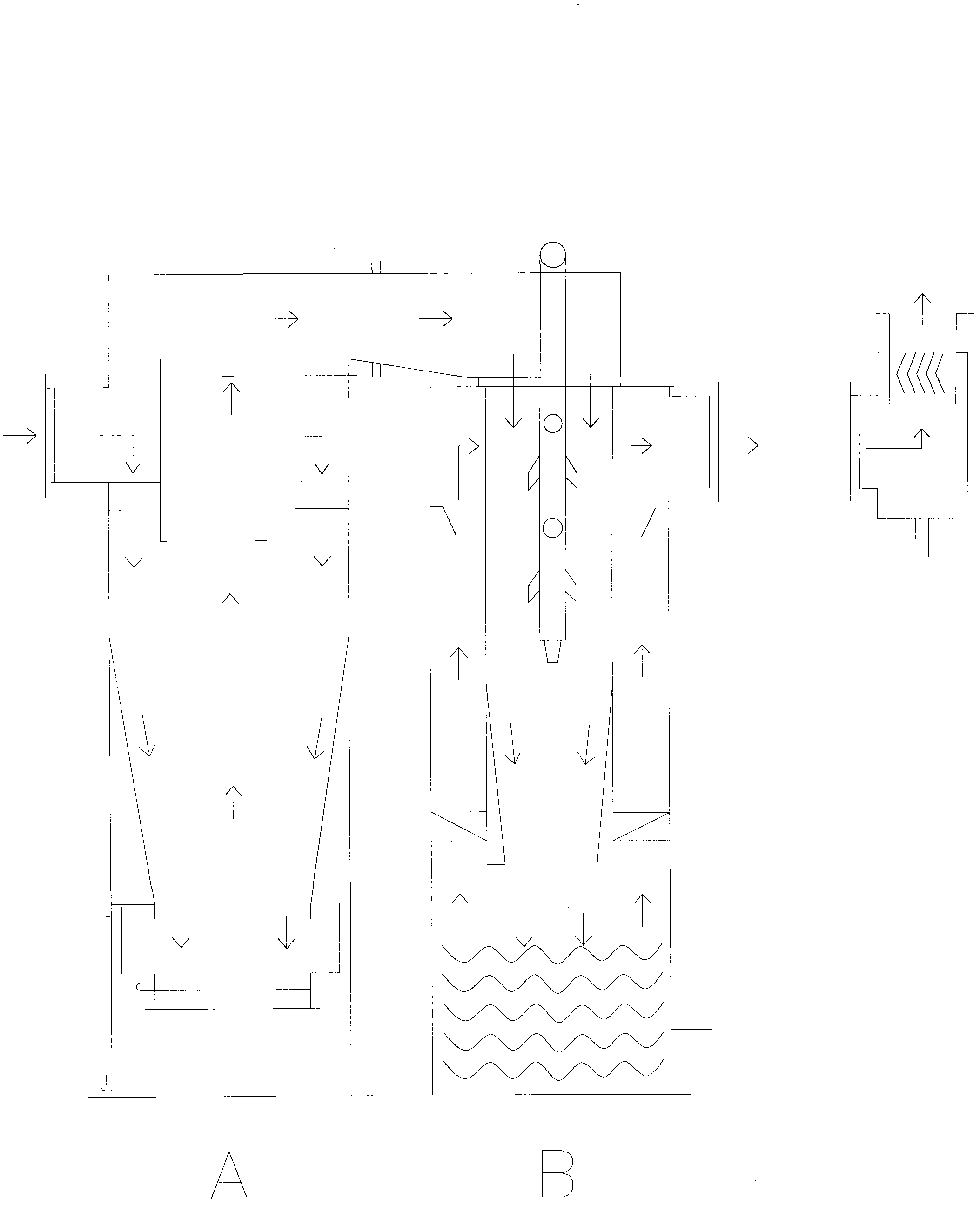

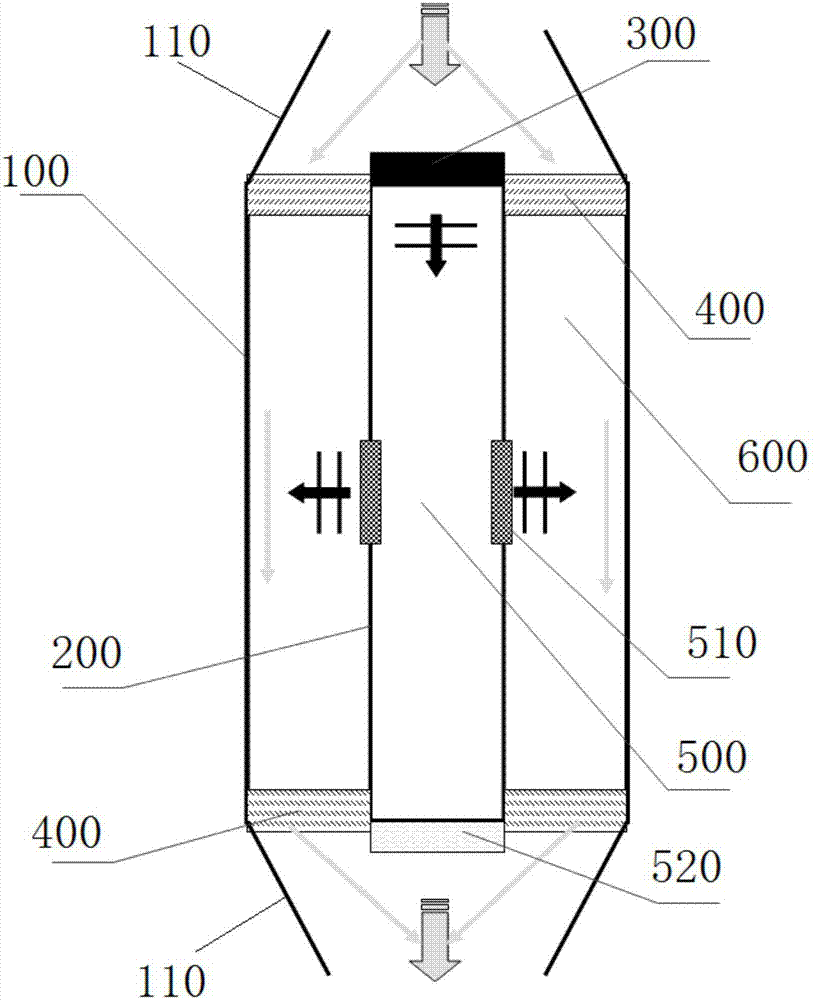

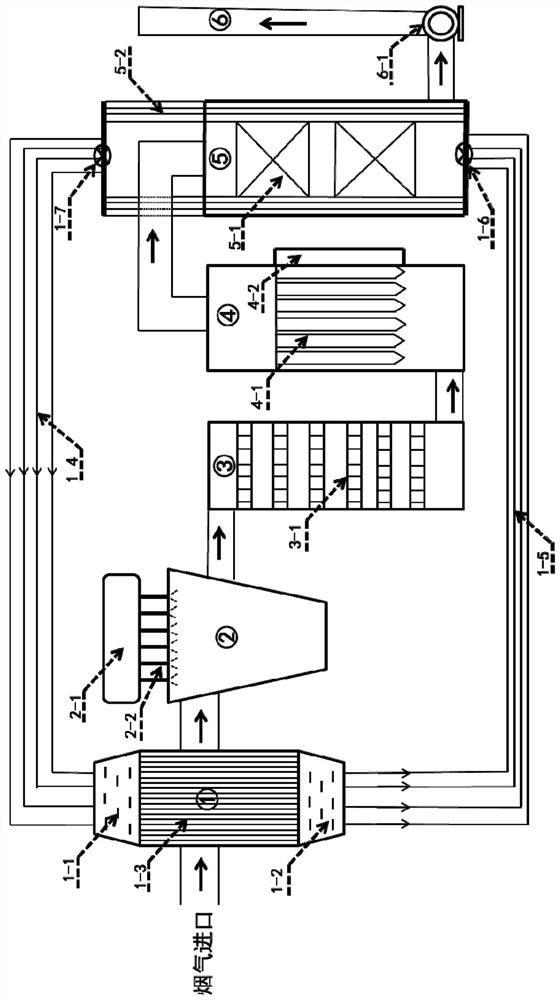

Dry dust removal and wet desulphurization integral efficient smoke gas purification device

InactiveCN102649026ASolve the problem of non-desulfurizationSolve the problem of blockage affecting desulfurization effectCombination devicesDust controlKiln

The invention provides a dry dust removal and wet desulphurization integral efficient smoke gas purification device and relates to the relevant fields of dust removal and desulphurization, smoke gas purification and energy saving and emission reduction industries. The dust removal and desulphurization device produced in China at present has the defects that the structure is simple, the performance is single, or the dust removal function is realized while the desulphurization function is not realized, or the desulphurization function is realized while the dust removal function is not realized, and the dust removal function and the desulphurization function are not perfectly combined. The dry dust removal and wet desulphurization integral efficient smoke gas purification device consists of an advanced cyclone dry dust remover and a Venturi wet desulfurization tower with highest efficiency and is characterized in that the integral efficient smoke gas purification device is formed by combined by an A tube dry dust removal structure and a B tube wet desulphurization structure, a smoke gas outlet of the dry dust remover and a smoke inlet of the wet desulphurization tower are connected into a smoke gas passage, and meanwhile, the dust removal and the desulphurization are respectively completed in each tube body. The dry dust removal and wet desulphurization integral efficient smoke gas purification device is applicable to smoke gas dust removal and desulphurization of various boilers, industrial kilns and high-emission enterprises such as cement plants, chemical plants, steel plants and power plants.

Owner:何狮强

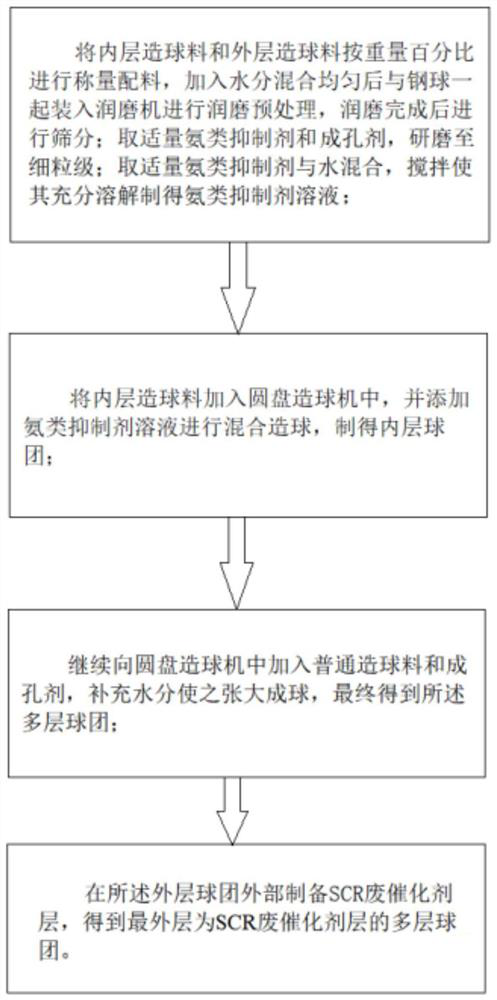

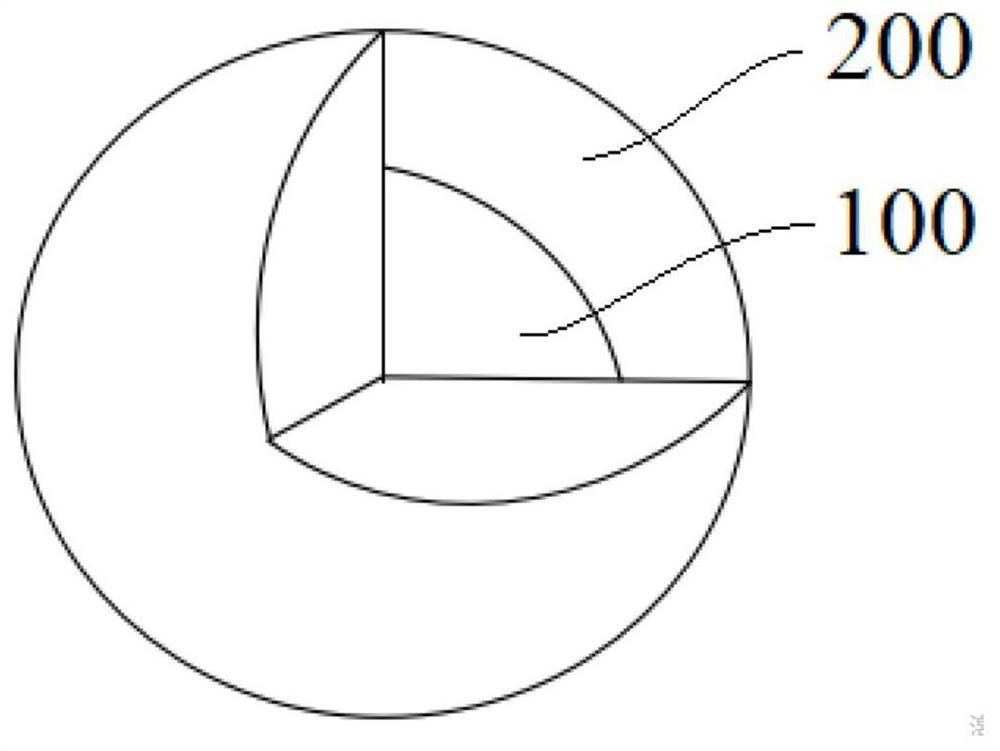

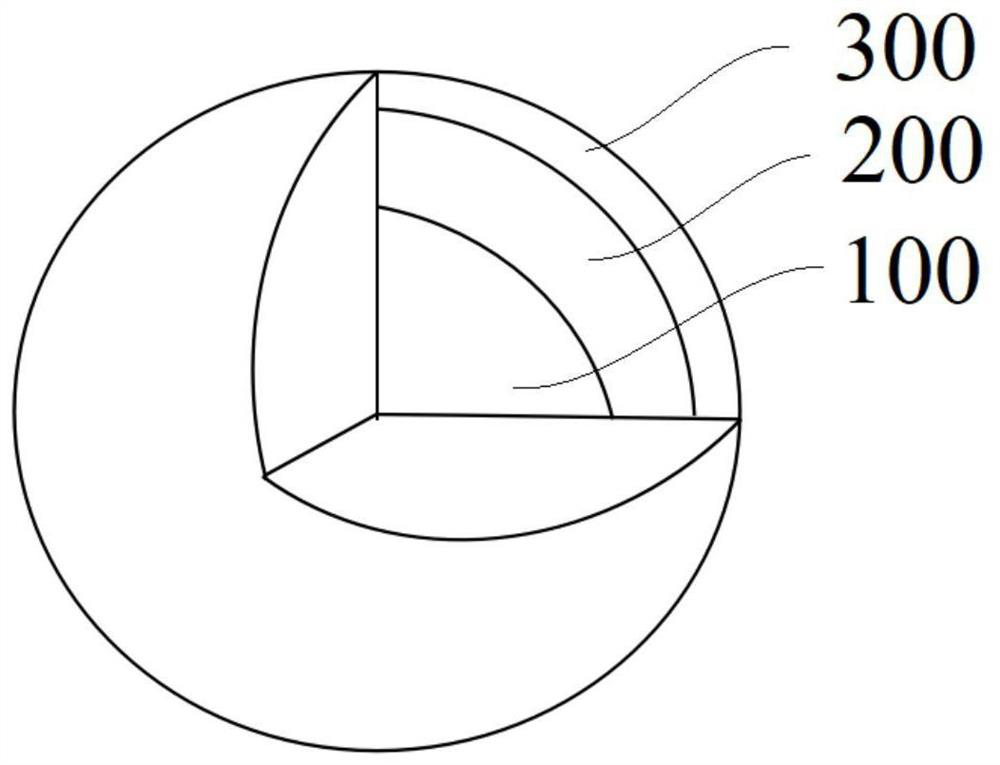

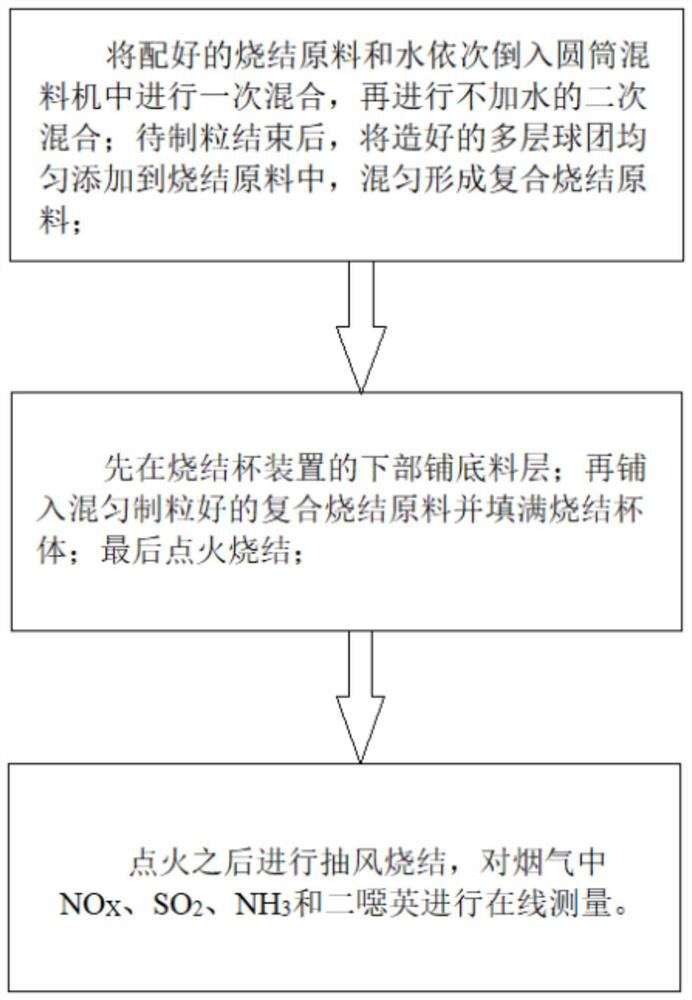

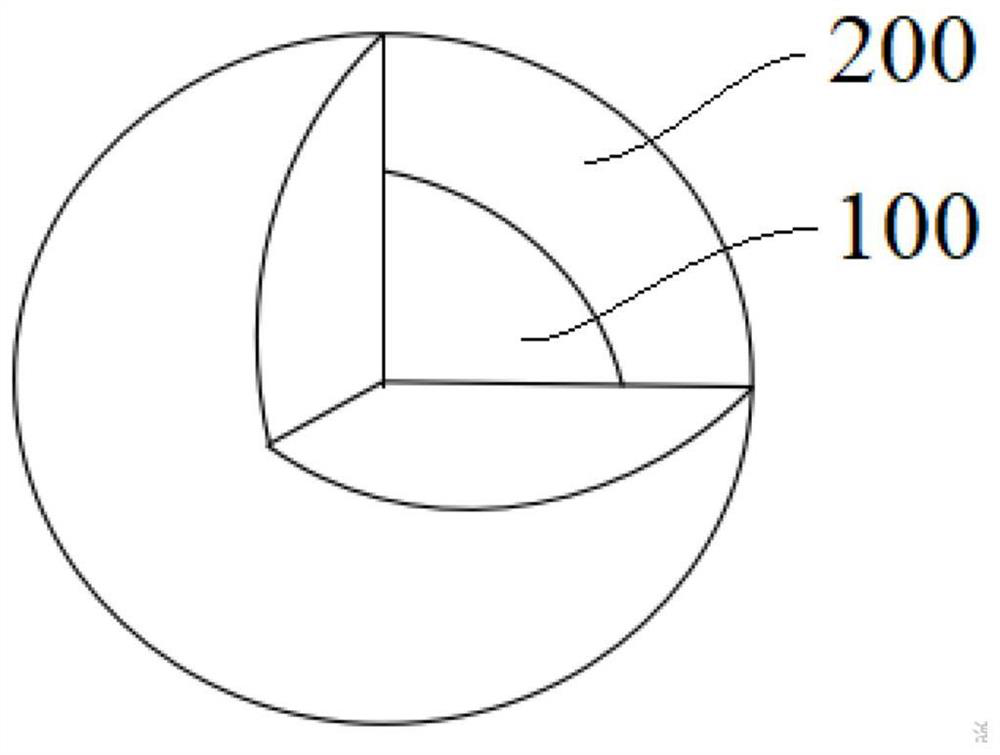

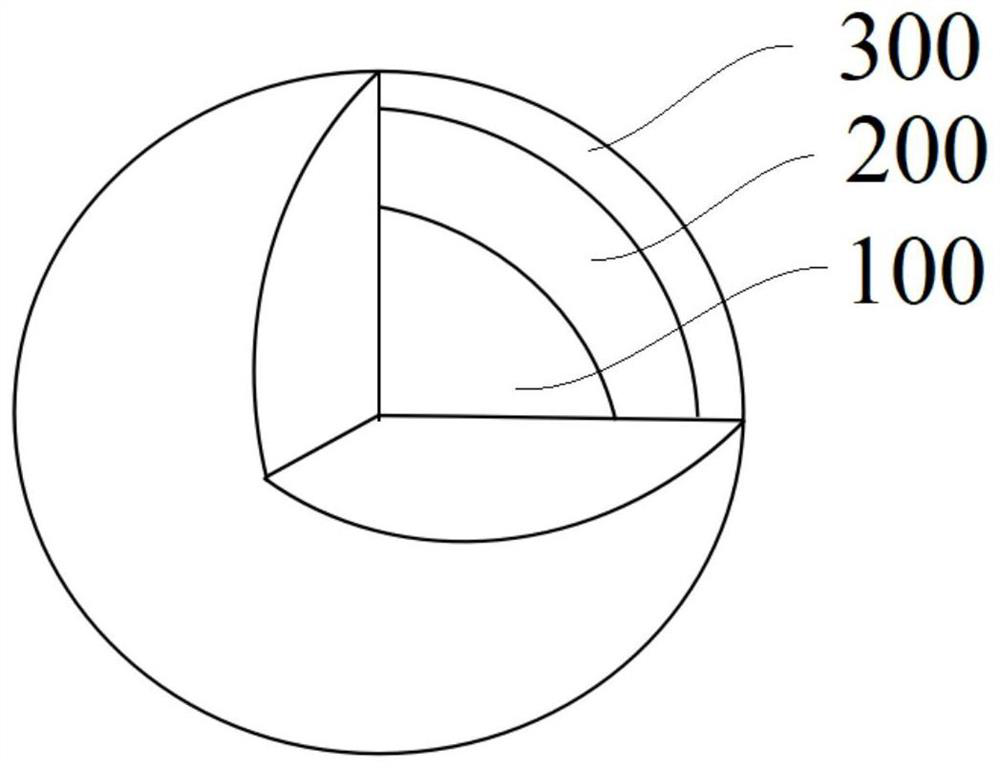

Preparation method of pellets containing SCR waste catalysts

The invention discloses a preparation method of pellets containing SCR waste catalysts, and belongs to the technical field of pollutant emission reduction in the sintering process. The preparation method comprises the following steps that firstly, inner-layer pellets are prepared, then continuous pelletizing is performed outside the inner-layer pellets to grow the pellets to obtain outer-layer pellets, catalyst layers are prepared outside the outer-layer pellets, and multi-layer pellets are finally prepared; ammonia inhibitors and inner-layer pelletizing materials are added into the inner-layer pellets, and the ammonia inhibitors can release ammonia gas after being heated and decomposed; pore-forming agents and outer-layer pelletizing materials are added into the outer-layer pellets or part of the outer-layer pellets, and pores are formed in the outer-layer pellets in the sintering process through the pore-forming agents. The pore-forming agents such as ammonium bicarbonate in the multi-layer pellets are heated and decomposed to generate the pores, so that decomposition of the ammonia inhibitors such as urea and release of NH3 are delayed, the emission window period of the ammonia inhibitors and the emission window period of NOX are consistent, NOX emission is reduced, and synergistic emission reduction of SO2, NOX and dioxin is achieved in a breakthrough mode under the action of the catalysts.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method and device for desulfurization of smoke discharged from ship

InactiveCN102112210BStrong solubility and absorption capacitySmall sizeGas treatmentInternal combustion piston enginesEnvironmental engineeringExhaust pipe

Owner:WUHAN SAFE ENVIRONMENTAL PROJECT TECH INC

Atmospheric pollution source grading method based on pollutant source identification technology

ActiveCN102628852BReduce air quality concentrationImprove emission reduction efficiencyMaterial analysisTemporal resolutionCoupling system

The invention provides an atmospheric pollution source grading method based on a pollutant source identification technology. The atmospheric pollution source grading method based on a pollutant source identification technology belongs to the technical field of atmospheric environment planning management, and prevention and control of pollution. The atmospheric pollution source grading method based on a pollutant source identification technology comprises the following steps of carrying out high spatio-temporal resolution meteorological simulation of a researched area based on a meteorological model, carrying out grid division of the researched area based on the geographic information system (GIS), arranging concentration contribution evaluation points, collecting pollution source discharge information, building a weather-air quality model coupled system, computing a sensitive factor, identifying sensitive discharge areas, carrying out unitization processing of the sensitive factor, and carrying out grading identification of pollution sources according to pollutant discharge loads and the order of the sensitive discharge areas. The invention aims at providing the atmospheric pollution source grading method based on a pollutant source identification technology so that the evaluation and quantitative grading of sensibility of atmospheric pollution sources are realized and an effective technical support for scientific pollutant-discharge reduction is provided.

Owner:BEIJING UNIV OF TECH

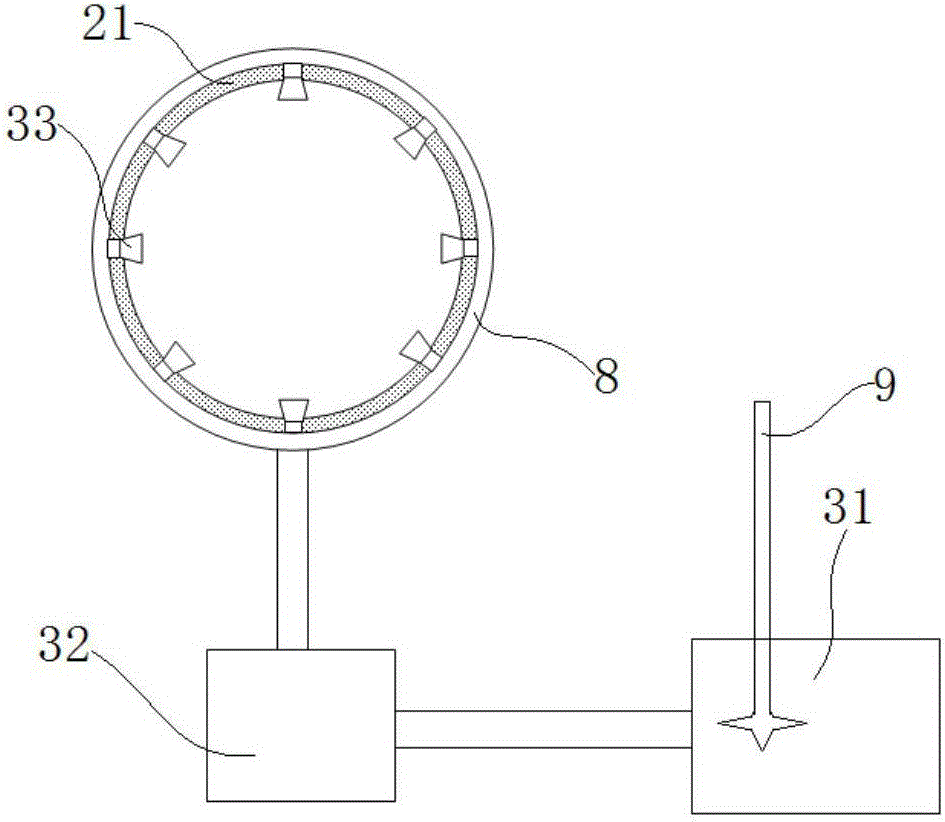

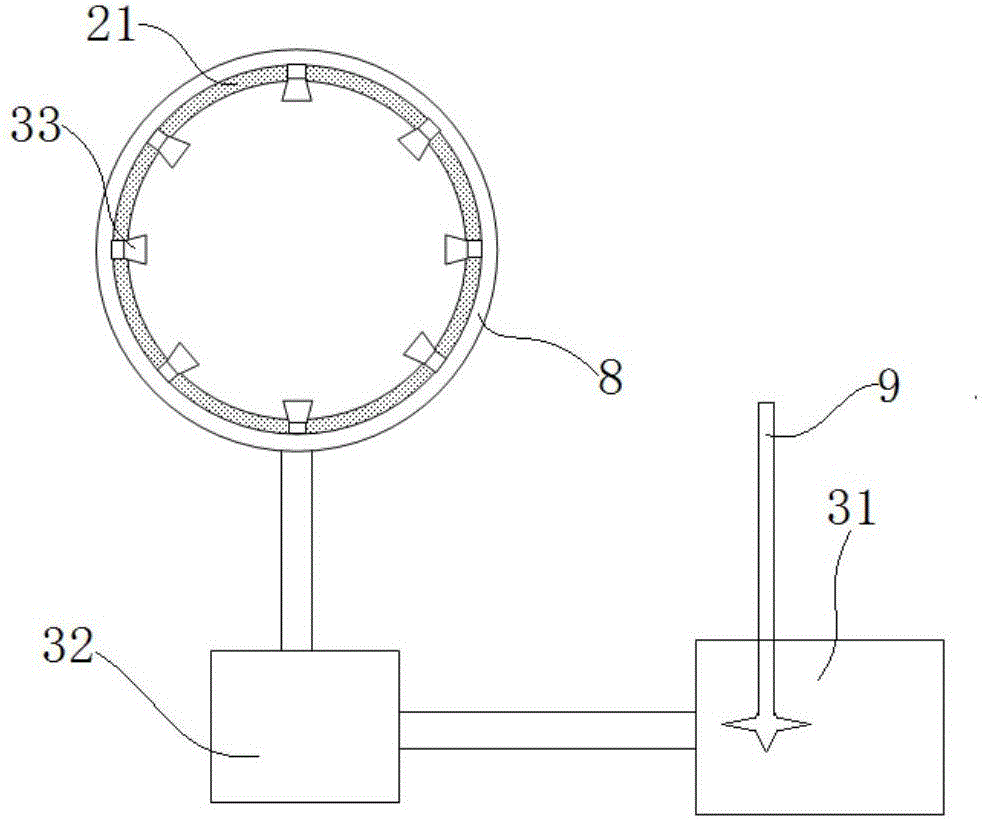

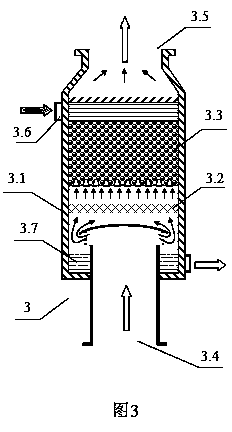

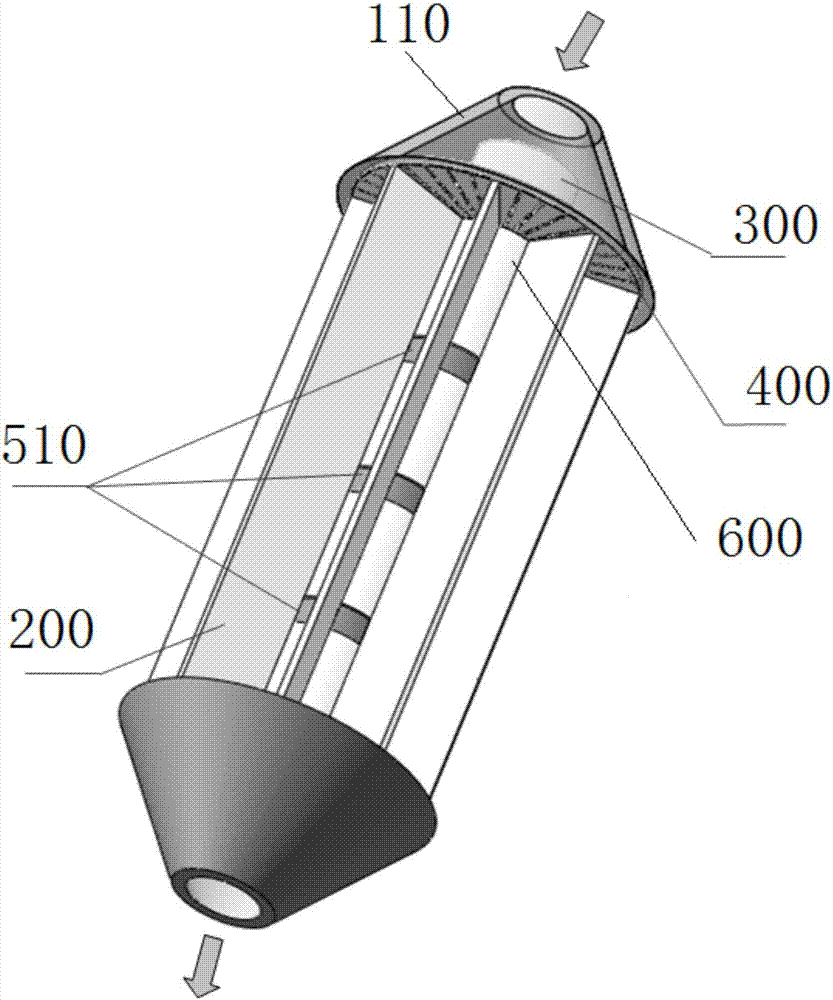

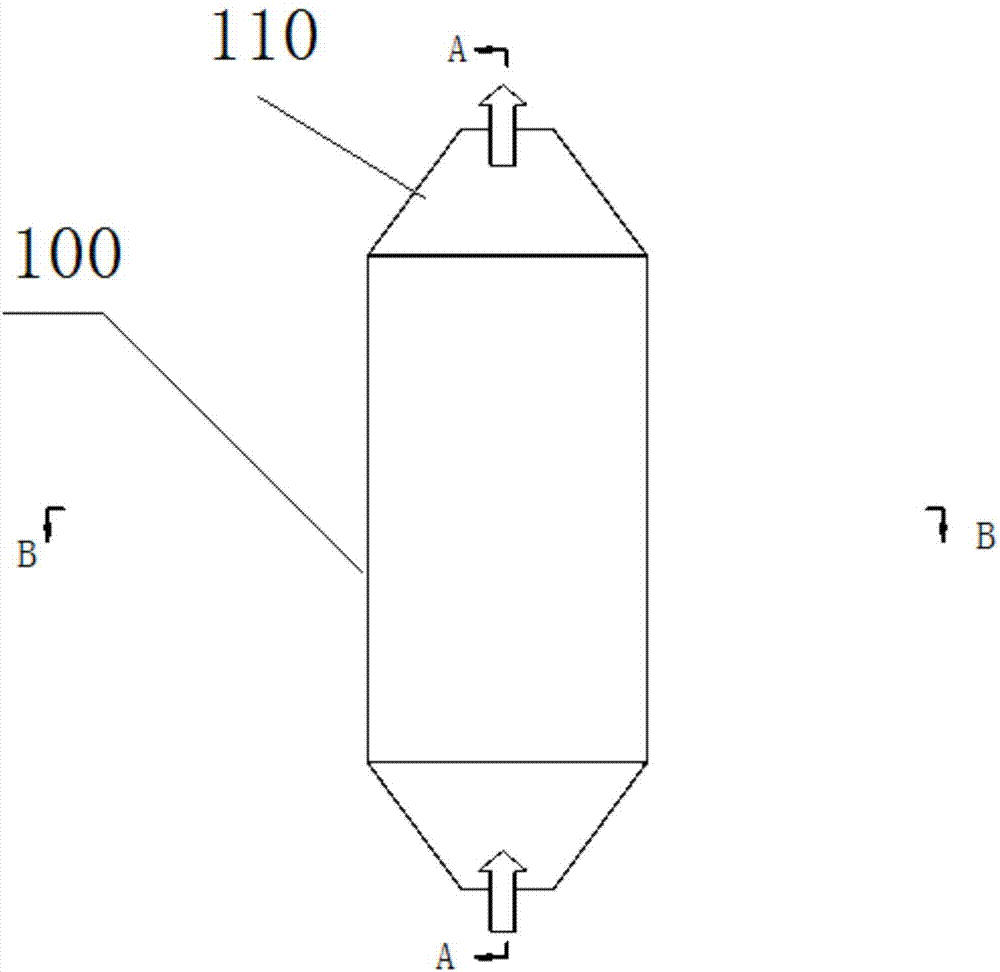

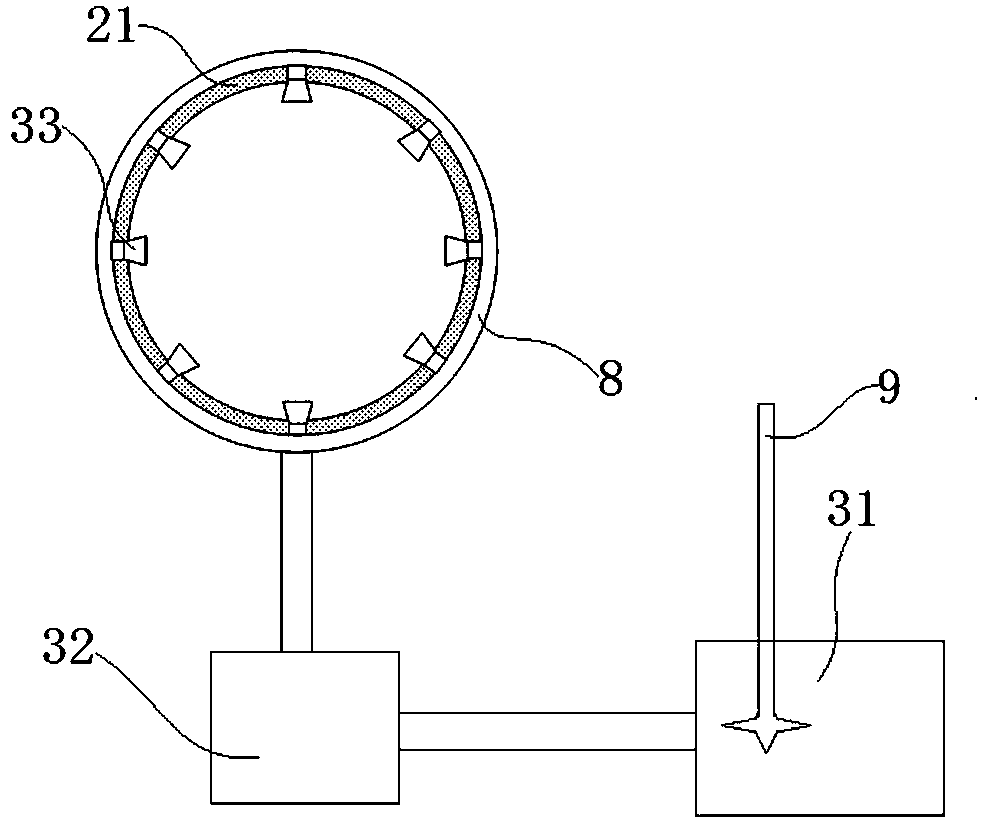

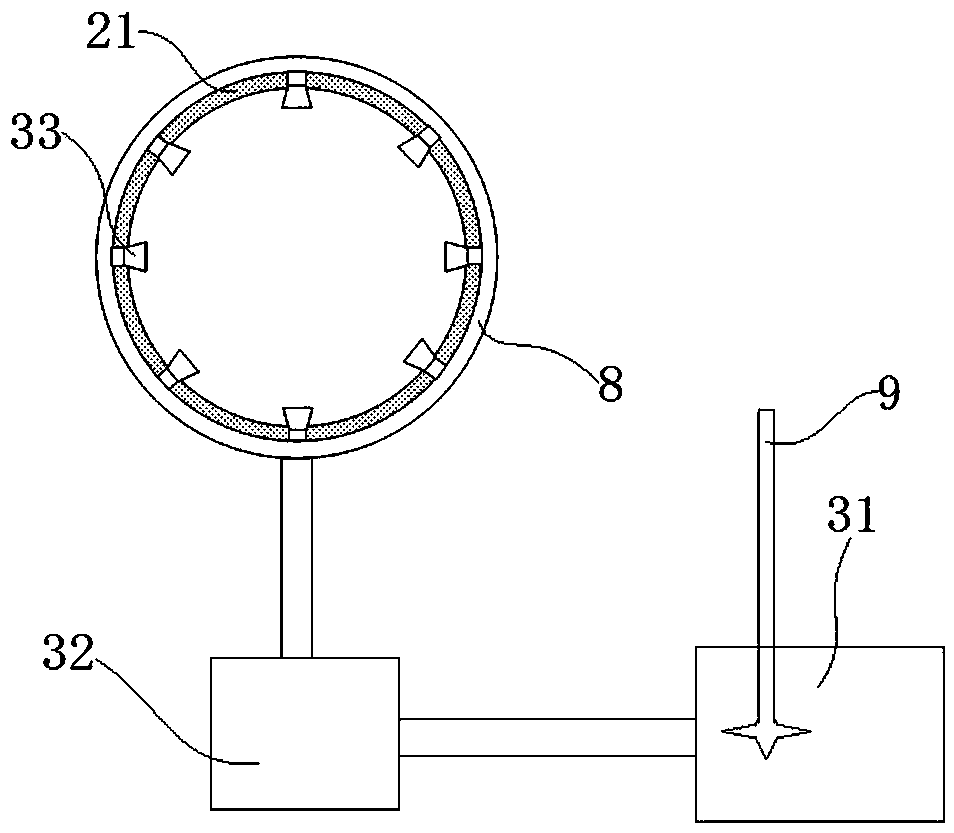

Acoustic wave agglomeration chamber for PM2.5 particulate matters in industrial flue gas and emission reducing device thereof

ActiveCN107029509AEfficient removalCompact structureHuman health protectionCombination devicesAcoustic transmissionFlue gas

The invention provides an acoustic wave emission reducing device for PM2.5 particulate matters in industrial flue gas. Cross section of an acoustic wave agglomeration chamber is partitioned to form clustered flue gas pipelines in annular arrangement through radial central partitions. Through acoustic conduction structure between the central partitions and the inner wall of the acoustic wave agglomeration chamber, one or multiple strong acoustic wave excitation is applied in the middle of each clustered flue gas pipeline, and excitation direction is perpendicular to flowing direction of the flue gas in the corresponding pipeline. By adding smoke-incoming acoustic blocking structure and gas-blocking acoustic penetrating structure at inlets, outlets and acoustic transmission positions of the clustered flue gas pipelines and matching with axial size of the flue gas pipelines in integer multiples of half wavelength, sufficient action of high-intensity acoustic waves at specific frequency and particulate matters in the flue gas is completed in each pipeline. The acoustic wave emission reducing device is compact in structure and realizes acoustic wave agglomeration of fine particulate matters for emission reducing with high efficiency and low energy consumption.

Owner:湖南赛能环测科技有限公司

Composite agglomeration agent for reducing emission of fine particles in flue gas from iron-ore sintering and agglomeration

ActiveCN105797532AImprove reunion efficiencySpeed up the reunionAuxillary pretreatmentAluminium chlorideCarboxymethyl cellulose

The invention discloses a composite agglomeration agent for reducing emission of fine particles in flue gas from iron-ore sintering and agglomeration and belongs to the technical field of emission reduction of pollutants in the process of iron-ore sintering. The composite agglomeration agent comprises the following components in parts by mass: 0-20 parts of polymeric aluminium chloride, 20-40 parts of sodium carboxymethyl cellulose, 20-40 parts of polyacrylamide and 2-5 parts of an additive. Agglomeration liquid is sprayed into a flue-gas channel of sintering flue gas, fine particles in the sintering flue gas are agglomerated to be larger under the action of the agglomeration liquid, and a dust-removing device is adopted to remove the fine particles agglomerated to be larger. The composite agglomeration agent disclosed by the invention has the advantages that agglomeration liquid droplets adsorbing the fine particles are nucleated and collide with each other and grow to form large-particle agglomerates under the condition of low pressure, and the dust-removing device is adopted to remove the fine particles agglomerated to be larger, so that an all-new emission reducing path is provided for reducing the emission of the fine particles in the process of iron-ore sintering.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

An intensified method for denitrification by ammonia spraying in the production process of iron ore pellets

ActiveCN111004914BProlong the action timeReduce difficultyGas treatmentDispersed particle separationPtru catalystAir velocity

The invention discloses an intensified method for denitrification by ammonia injection in the production process of iron ore pellets. The method is to prepare pellets with high bursting temperature and good thermal stability by adding anti-burst additives to the pellet binder bentonite. In this way, the thickness of the material layer in the heat treatment process of the pellets is increased by 1.5 to 1.75 times, the machine speed is reduced to 4 / 7 to 2 / 3, and the exhaust wind speed in the second drying section is reduced to 0.8 to 1.0m / s. Ammonia water is evenly sprayed into the air stream for denitrification. The advantages of the present invention are: due to the operation of the thick material layer and the reduction of the airflow velocity, the time for the airflow to pass through the pellet material layer is prolonged, and the concentration of iron-containing minerals and NOx, NH in the denitrification catalyst is improved. 3 The action time is longer, thereby enhancing the efficiency of ammonia spray denitrification in the drying section, and the NOx removal rate is increased by 15% to 30%.

Owner:ANSTEEL GRP MINING CO LTD

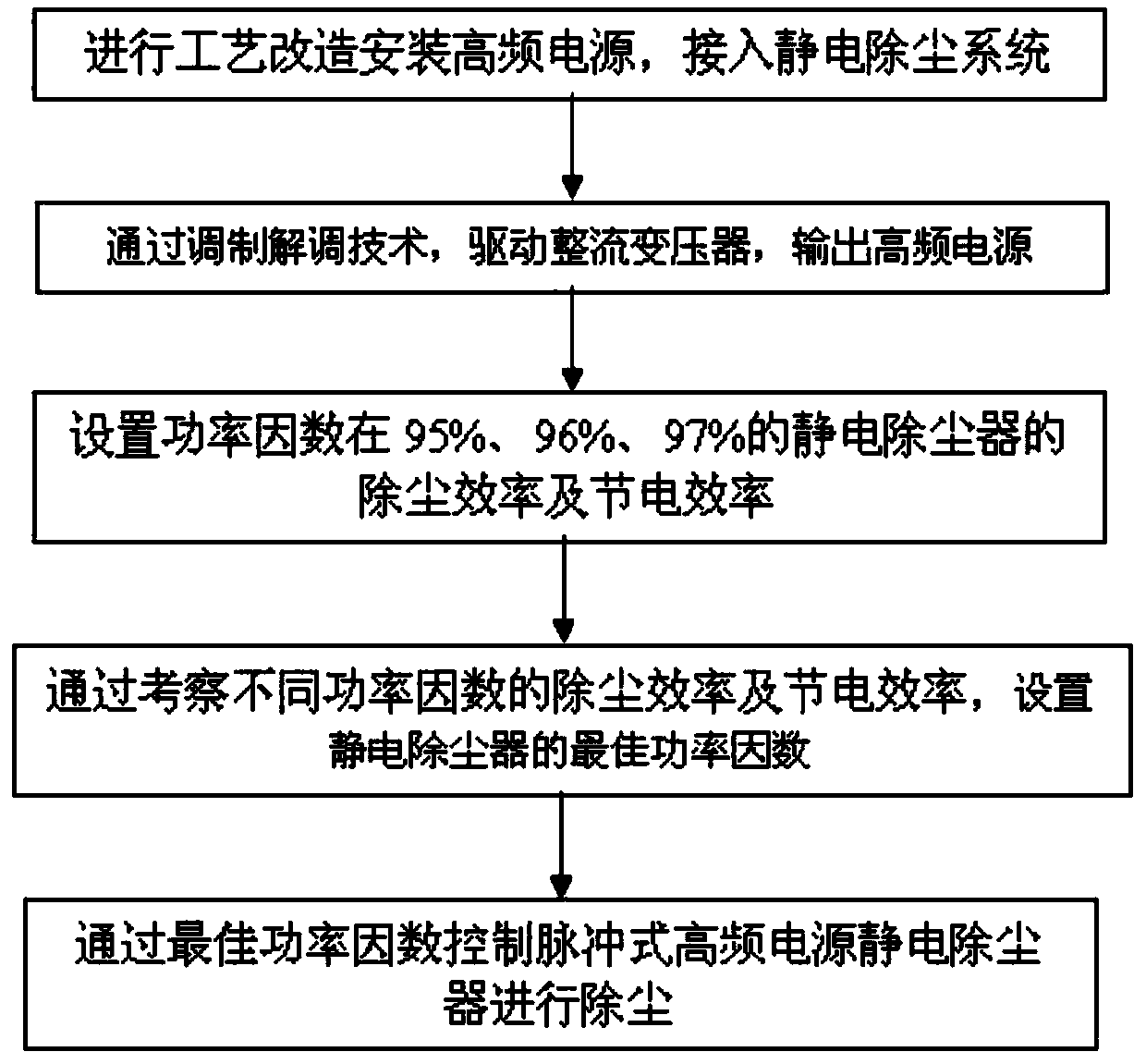

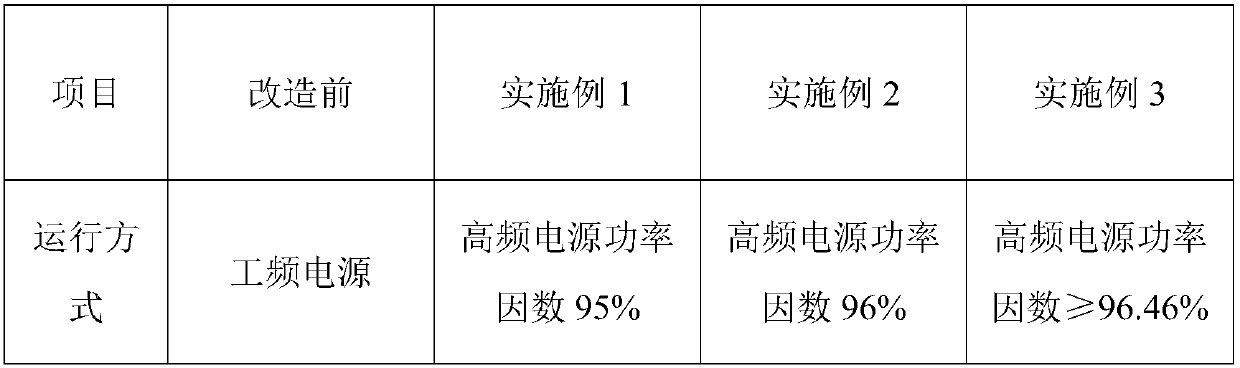

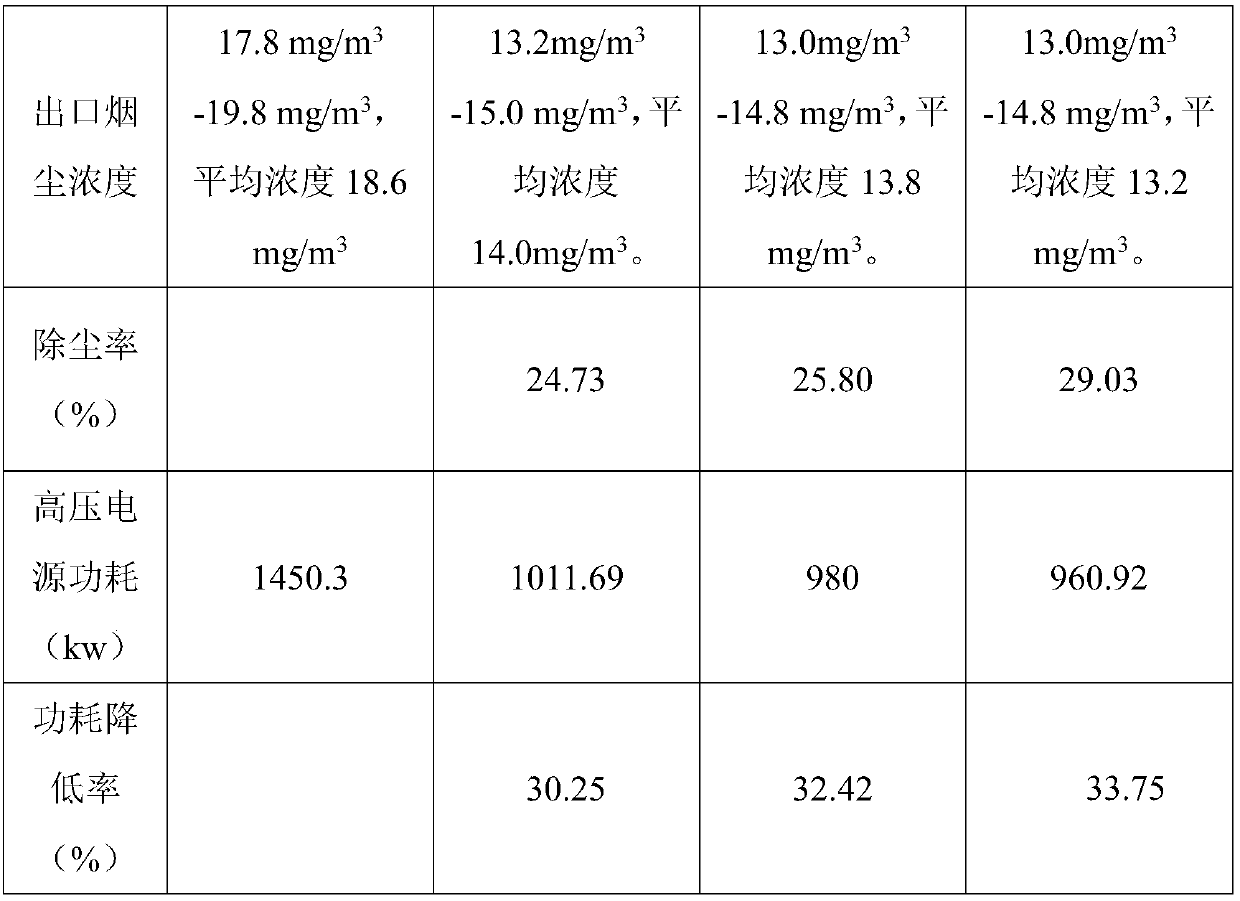

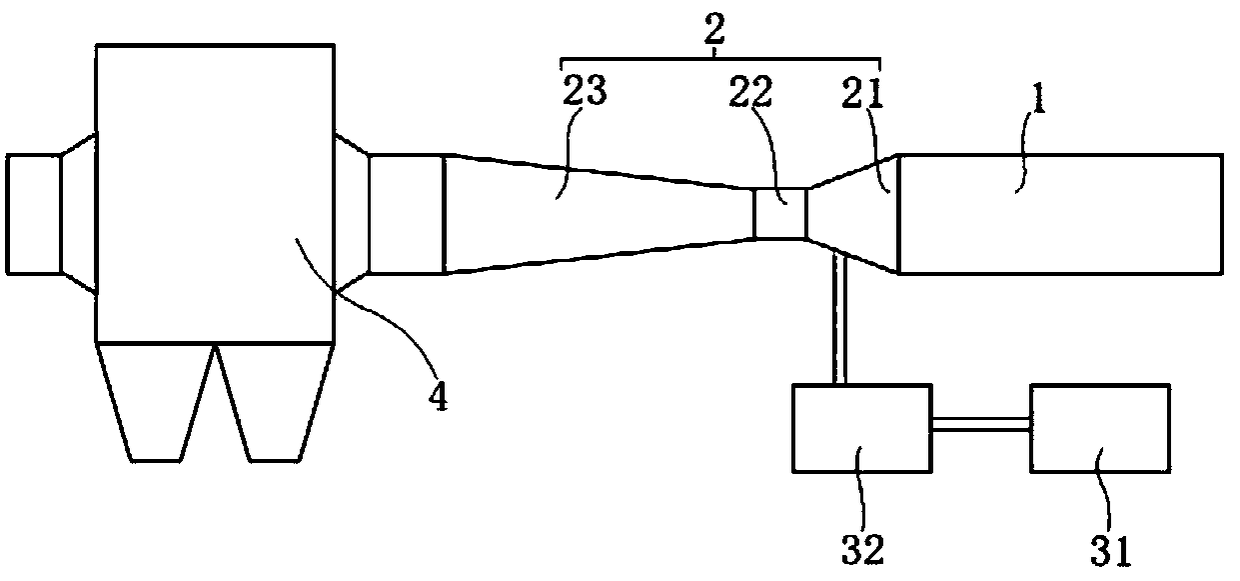

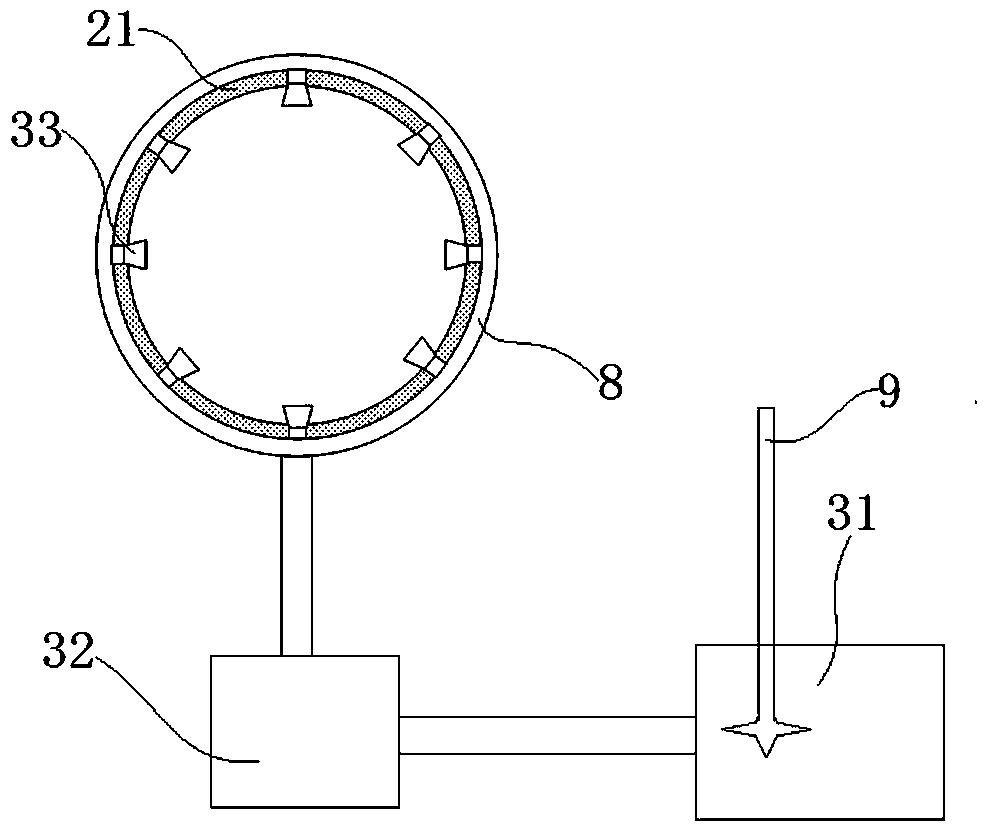

Dust removal method of pulse type high-frequency power supply

InactiveCN109604061AImprove the efficiency of electrostatic precipitatorBest application technology for dust removalExternal electric electrostatic seperatorElectricityHigh frequency power

The invention discloses a dust removal method of a pulse type high-frequency power supply. The dust removal method comprises the following steps that (1) a high-frequency power supply is installed through process improvement, and an electrostatic dust removal system is connected; (2) a modulation and demodulation technology is adopted, a rectifier transformer is driven, and a high-frequency powersupply is output; (3) the dust removal efficiency and the electricity-saving efficiency of an electrostatic dust remover with the power factors of 95%, 96% and 97% are set; (4) the optimal power factor of the electrostatic dust remover is set by investigating the dust removal efficiency and the electricity-saving efficiency of different power factors; and (5) and the pulse type high-frequency power supply electrostatic dust remover is controlled through the optimal power factor to perform dust removal. According to the method, the technical modification measures are adopted, the process is improved, and the voltage is modulated and demodulated in different degrees, so that the dust removal efficiency of the electric field is improved.

Owner:FUJIAN QINGSHAN PAPER INDUSTRY CO LTD

A method of agglomeration to suppress the emission of fine particles in the iron ore sintering process

ActiveCN105797531BImprove reunion efficiencySpeed up the reunionAuxillary pretreatmentCelluloseCarboxymethyl cellulose

The invention discloses an agglomeration method for suppressing the emission of fine particles in the iron ore sintering process, and belongs to the technical field of pollutant emission reduction in the iron ore sintering process. The steps of the present invention are as follows: step 1: preparing the agglomeration liquid, mixing components such as sodium carboxymethyl cellulose, polyacrylamide and additives uniformly to prepare an agglomerating agent, and mixing the agglomerating agent with water to prepare an agglomerating liquid; step two : The fine particles are agglomerated, the agglomeration liquid is sprayed into the flue gas, and the fine particles in the sintering flue gas are agglomerated and grow up under the action of the agglomeration liquid; Step 3: The dust removal device captures, and the dust removal device captures and removes the agglomerated fine particles . The present invention enables the agglomerated liquid mist adsorbed with fine particles to nucleate, collide, and grow up under low pressure to form large particle agglomerates, and uses a dust removal device to remove the agglomerated and grown fine particles, which is a fine particle for the iron ore sintering process. The reduction of particulate matter provides a new way to reduce emissions.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

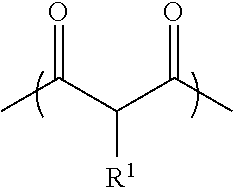

Process for preparing an acetoacetyl functional polymer

ActiveUS11130830B2Reducing aldehydeImprove emission reduction efficiencyCoatingsPolymer sciencePolymer

Owner:ROHM & HAAS CO +1

Toroidal plasma abatement apparatus and method

ActiveUS9630142B2Increase conductanceEasy to integrateGas treatmentElectric discharge tubesEngineeringPlasma channel

An apparatus for abatement of gases is provided. The apparatus includes a toroidal plasma chamber having a plurality of inlets and an outlet, and at least one chamber wall. One or more magnetic cores are disposed relative to the toroidal plasma chamber. The plasma chamber confines a toroidal plasma. A second gas inlet is positioned on the toroidal plasma chamber between a first gas inlet and the gas outlet at a distance d from the gas outlet, such that a toroidal plasma channel volume between the first gas inlet and the second gas inlet in the is substantially filled by the inert gas, the distance d based on a desired residence time of the gas to be abated.

Owner:MKS INSTR INC

Method for reducing emission of sintering flue gas pollutants by utilizing SCR-containing waste catalyst pellets

The invention discloses a method for reducing emission of sintering flue gas pollutants by utilizing SCR-containing waste catalyst pellets, and belongs to the technical field of pollutant emission reduction in the sintering process. In the preparation process of a sintering raw material, a sintering pellet is added, and the sintering pellet is sequentially provided with an inner-layer pellet, an outer-layer pellet and a catalyst layer from inside to outside. An ammonia inhibitor is included in the inner-layer pellet, and the ammonia inhibitor can release ammonia gas after being heated and decomposed. A pore-forming agent is included in the outer-layer pellet, and the pore-forming agent enables pores to be formed in the outer-layer pellet in the sintering process. The catalyst layer comprises an SCR catalyst and vanadium-titanium blast furnace slag. The pore-forming agent in the sintering pellet is heated and decomposed to generate pores, and therefore decomposition of the ammonia inhibitor such as urea and release of NH3 are delayed, the ammonia inhibitor is consistent with the NOX emission window period, NOX emission is reduced, and cooperative emission reduction of SO2, NOX and dioxin is realized in a breakthrough manner under the action of the catalyst.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A full-process low-temperature dry advanced treatment system for waste heat treatment flue gas

ActiveCN111495136BGovernance functions are closely linkedMeet the requirements of ultra-low emission standardsGas treatmentDispersed particle filtrationParticulatesTreatment system

The invention discloses a low-temperature dry deep treatment system for the whole process of waste heat treatment flue gas. The system is designed according to the characteristics of waste heat treatment flue gas. unit, low temperature vulcanization-catalytic tower and other units. In the process of treatment, energy is recycled, pollutants are treated with waste, and the treatment functions are interlocking. At low temperature (250-280°C), the particulate matter, NOx, CO, and SO in the flue gas are deeply purified. 2 , VOCs, HCl, heavy metals and dioxins, with a purification rate of over 95%, meeting the requirements of ultra-low emission standards. The system has the advantages of no waste water, low energy consumption, low investment cost, stable and reliable operation, high emission reduction efficiency, simple and easy-to-control process, etc. It is suitable for advanced treatment of heat treatment flue gas such as waste incineration, pyrolysis, and gasification.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

Method for emission reduction and recycle of flue gas carbonic anhydride of fire coal electric power plant, and special system thereof

InactiveCN100577264CImprove emission reduction efficiencyAdapt to a wide temperature rangeProductsReagentsPower stationCo2 absorption

The invention discloses a discharge reducing and resourcing method of coal-burning power station flue gas carbon dioxide, which is characterized by the following: adopting amino material as adsorbent; injecting amino material solution as ammonium salt pattern into the flue gas of carbon dioxide adsorbing system after pre-dedusting the tail part of coal-burning stove to reduce 20-95% carbon dioxide in the flue gas; separating and purifying to obtain high-purity carbon oxide; fitting for industrial, chemical, food manufacturing, oil extracting oil displacement and so on; making the escape rate of ammonium in the clean gas discharged by defroster not more than 15mg / Nm3. The invention simplifies the flow path technique with obvious kind and quantity of manufacturing equipment, which has more widely using prospect.

Owner:DONGDIAN COMBUSTION TECH RES CENT +2

A preparation method of agglomeration liquid for suppressing emission of fine particles in iron ore sintering flue gas

ActiveCN105833655BImprove reunion efficiencySpeed up the reunionAuxillary pretreatmentMass ratioFlue gas

The invention discloses a method for preparing agglomeration liquid for restraining iron mine sintering flue gas fine particle emissions, and belongs to the technical field of iron mine sintering process pollutant emission reduction .The method comprises the specific steps that A, 20-40 parts of polyacrylamide, 0-20 parts of aluminium polychlorid, 20-40 parts of sodium carboxymethylcellulose and 20-40 parts of polyacrylamide are mixed to be uniform, and a mixture A is obtained; B, 2-5 parts by mass of additive is weighed and added into the mixture A, the mixture is mixed to be uniform, and a compound agglomeration agent is obtained; C, the compound agglomeration agent in the step B is mixed with water, the mass ratio of the compound agglomeration agent to the water is 1:(2,000-10,000), and the agglomeration liquid is prepared .Agglomeration liquid mist drops on which fine particles are adsorbed are nucleated, collide and grow under the low pressure condition, large particle agglomerate is formed, agglomerated and grown fine particles are removed through a dust removal device, therefore, emissions of pollutants are restrained, and a brand-new emission reducing path is provided for emission reduction of the fine particles in the iron mine sintering process.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A composite agglomerating agent for emission reduction of fine particulate matter in flue gas from iron ore sintering agglomeration

ActiveCN105797532BImprove reunion efficiencySpeed up the reunionAuxillary pretreatmentAluminium chlorideCarboxymethyl cellulose

The invention discloses a composite agglomeration agent for reducing emission of fine particles in flue gas from iron-ore sintering and agglomeration and belongs to the technical field of emission reduction of pollutants in the process of iron-ore sintering. The composite agglomeration agent comprises the following components in parts by mass: 0-20 parts of polymeric aluminium chloride, 20-40 parts of sodium carboxymethyl cellulose, 20-40 parts of polyacrylamide and 2-5 parts of an additive. Agglomeration liquid is sprayed into a flue-gas channel of sintering flue gas, fine particles in the sintering flue gas are agglomerated to be larger under the action of the agglomeration liquid, and a dust-removing device is adopted to remove the fine particles agglomerated to be larger. The composite agglomeration agent disclosed by the invention has the advantages that agglomeration liquid droplets adsorbing the fine particles are nucleated and collide with each other and grow to form large-particle agglomerates under the condition of low pressure, and the dust-removing device is adopted to remove the fine particles agglomerated to be larger, so that an all-new emission reducing path is provided for reducing the emission of the fine particles in the process of iron-ore sintering.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Low-carbon method for improving emission reduction efficiency of oxynitride in circulated flue gas from sintering machine

InactiveCN102188905BImprove catalytic emission reduction efficiencyImprove emission reduction efficiencyDispersed particle separationFurnace typesFlue gasOxygen

The invention relates to a low-carbon method for improving the emission reduction efficiency of oxynitride in circulated flue gas from a sintering machine, and the method comprises the following steps: (1) taking the flue gas in the middle of the total flue gas from a main flue, circulating the taken flue gas, wherein the flue gas is specifically taken from the area 20-70% from the head of the sintering machine to the bottom of the sintering machine, and the content of the oxygen in the flue gas in the upper circulating hood of a sintering pallet is no less than 18%; and (2) uniformly allocating an iron ore into sintering auxiliaries to serve as a catalyst. The invention provides a technical method for improving the circular denitration for the flue gas from the sintering machine with lowcost and low energy consumption. The technical method is characterized in that the iron ore is uniformly added into the sintering auxiliaries based on the flue gas circulation of the sintering machine, so as to improve the efficiency for denitration of the oxynitride. The technology provided by the invention is implemented based on the flue gas circulation of the sintering machine, the efficiencyfor denitrating the oxynitride from the circulated flue gas can be increased to 80-90% on the premise of not increasing the investment on equipment and construction, and the cost for energy consumption and operation.

Owner:BAOSTEEL ENG & TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com