Patents

Literature

228 results about "Cold finger" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cold finger is a piece of laboratory equipment that is used to generate a localized cold surface. It is named for its resemblance to a finger and is a type of cold trap. The device usually consists of a chamber that a coolant fluid (cold tap water, or perhaps something colder) can enter and leave. Another version involves filling the device with a cold material (examples: ice, dry ice or a mixture such as dry ice/acetone or ice/water).

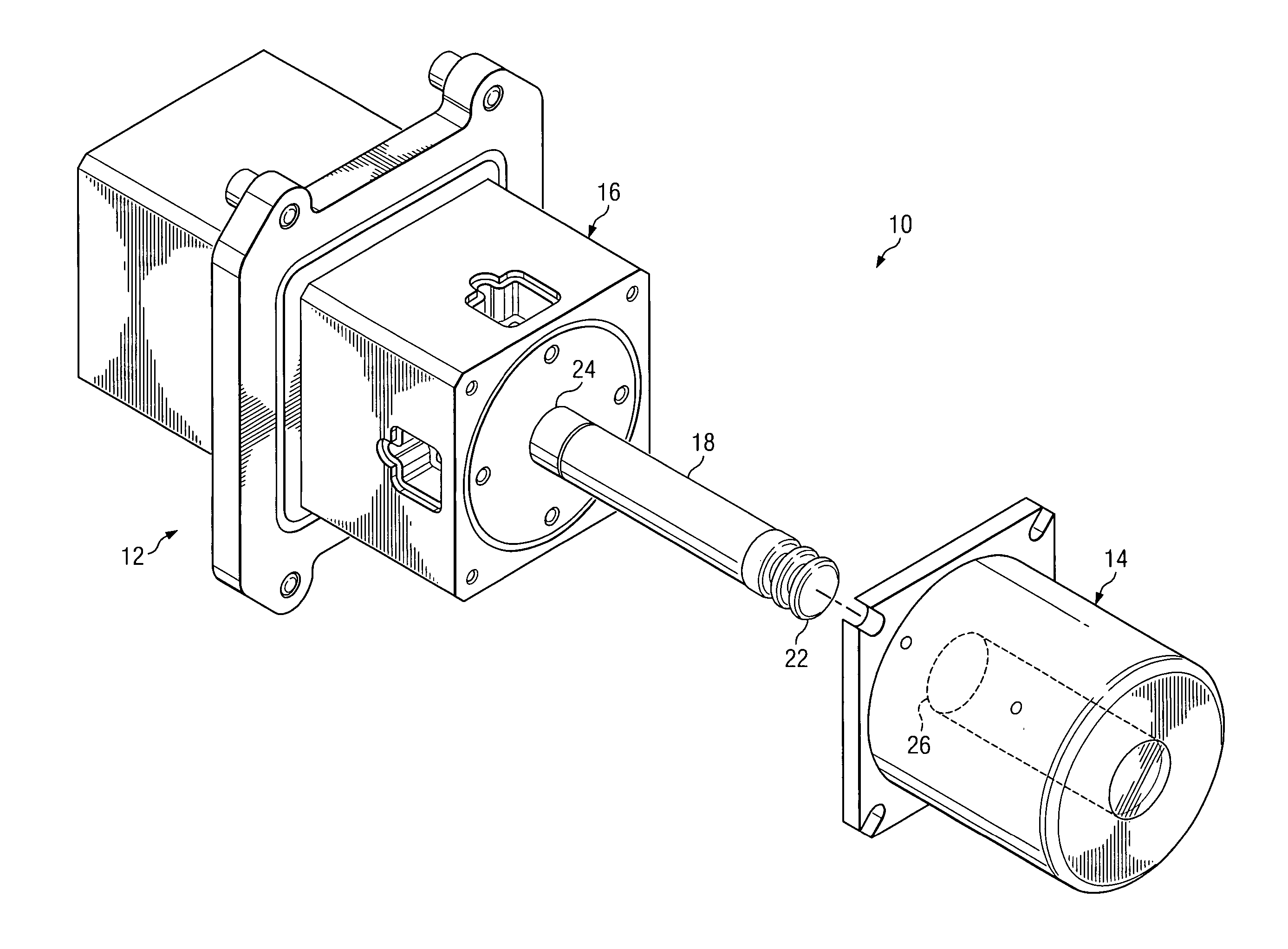

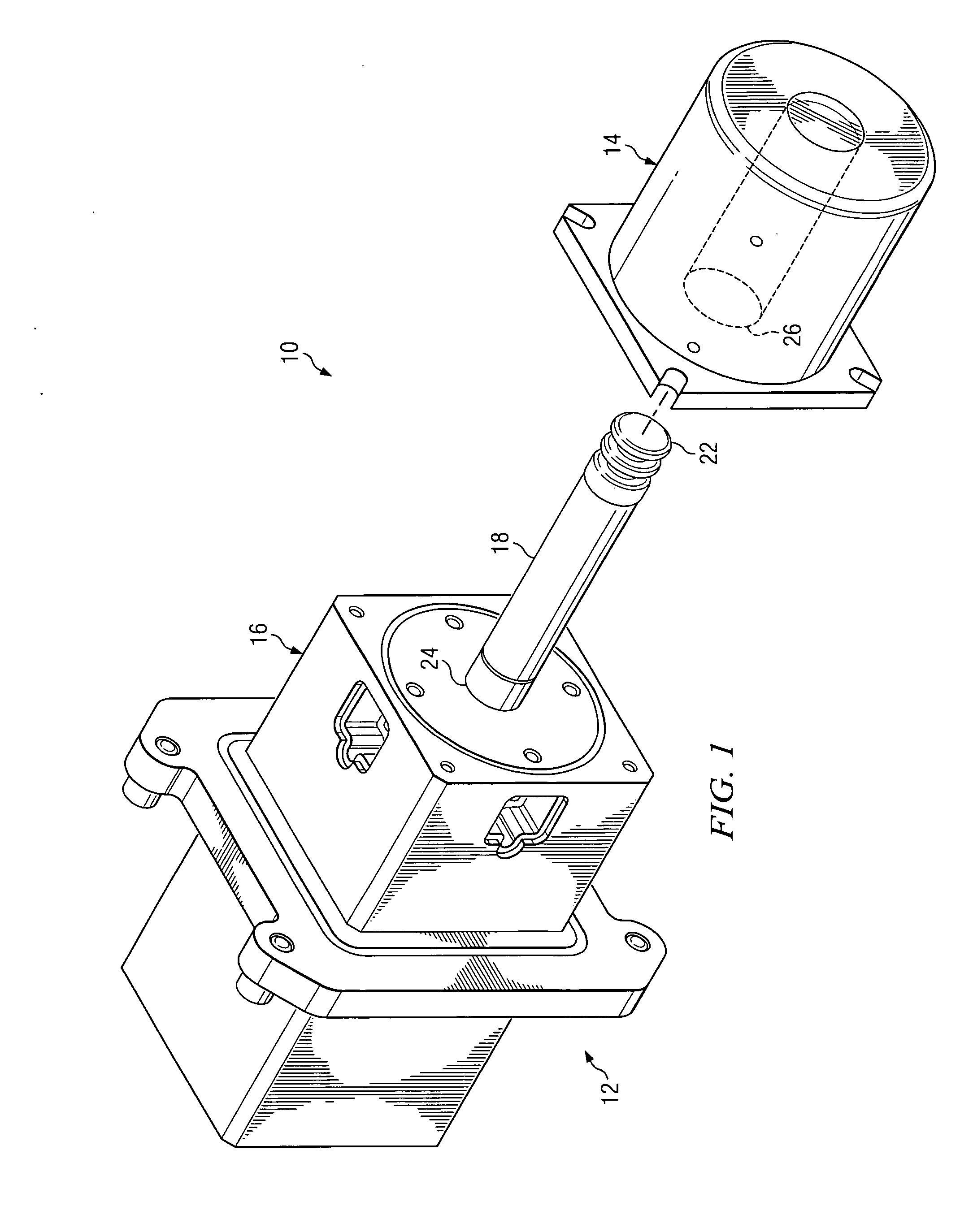

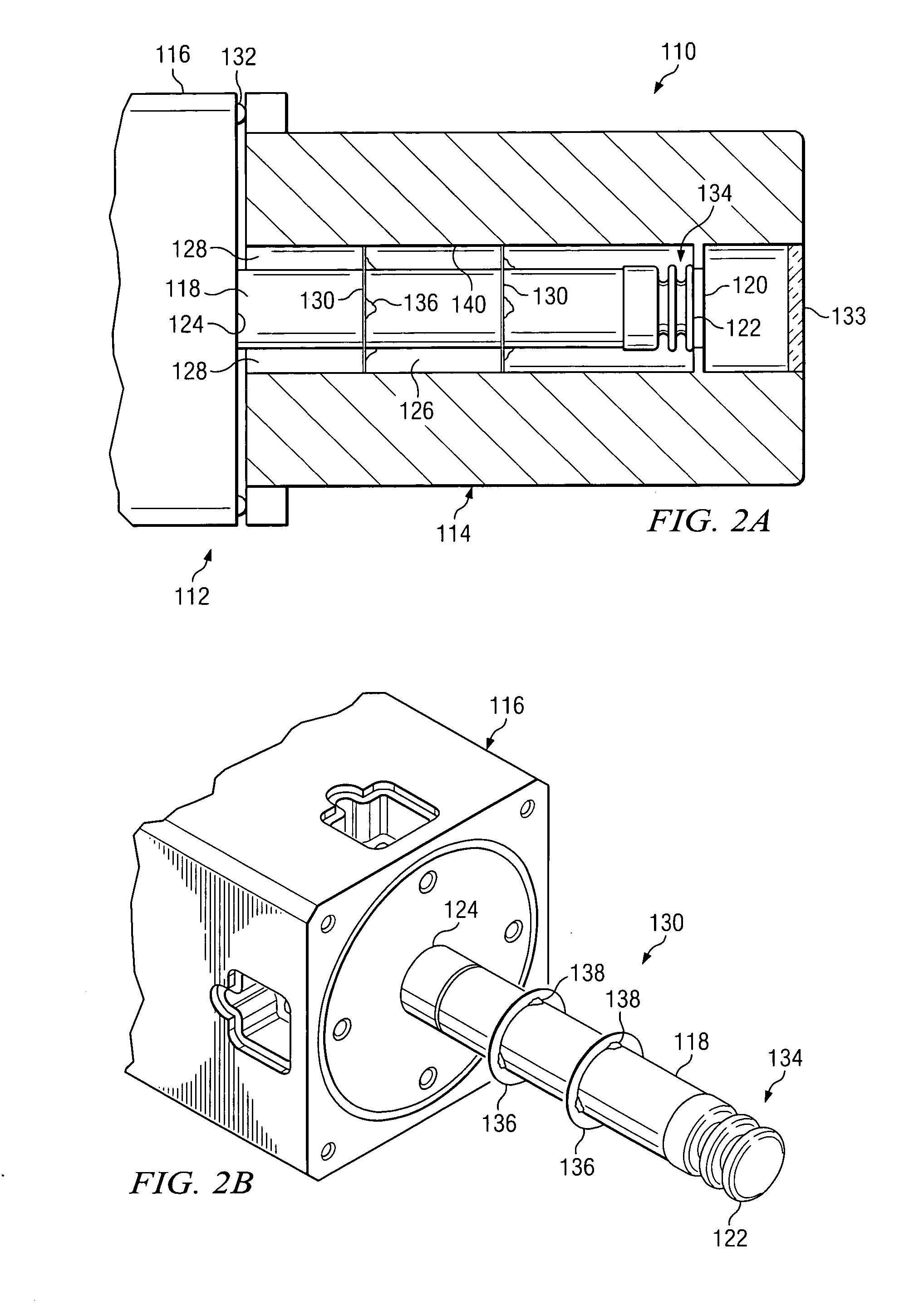

Cryogenic cooler with mechanically-flexible thermal interface

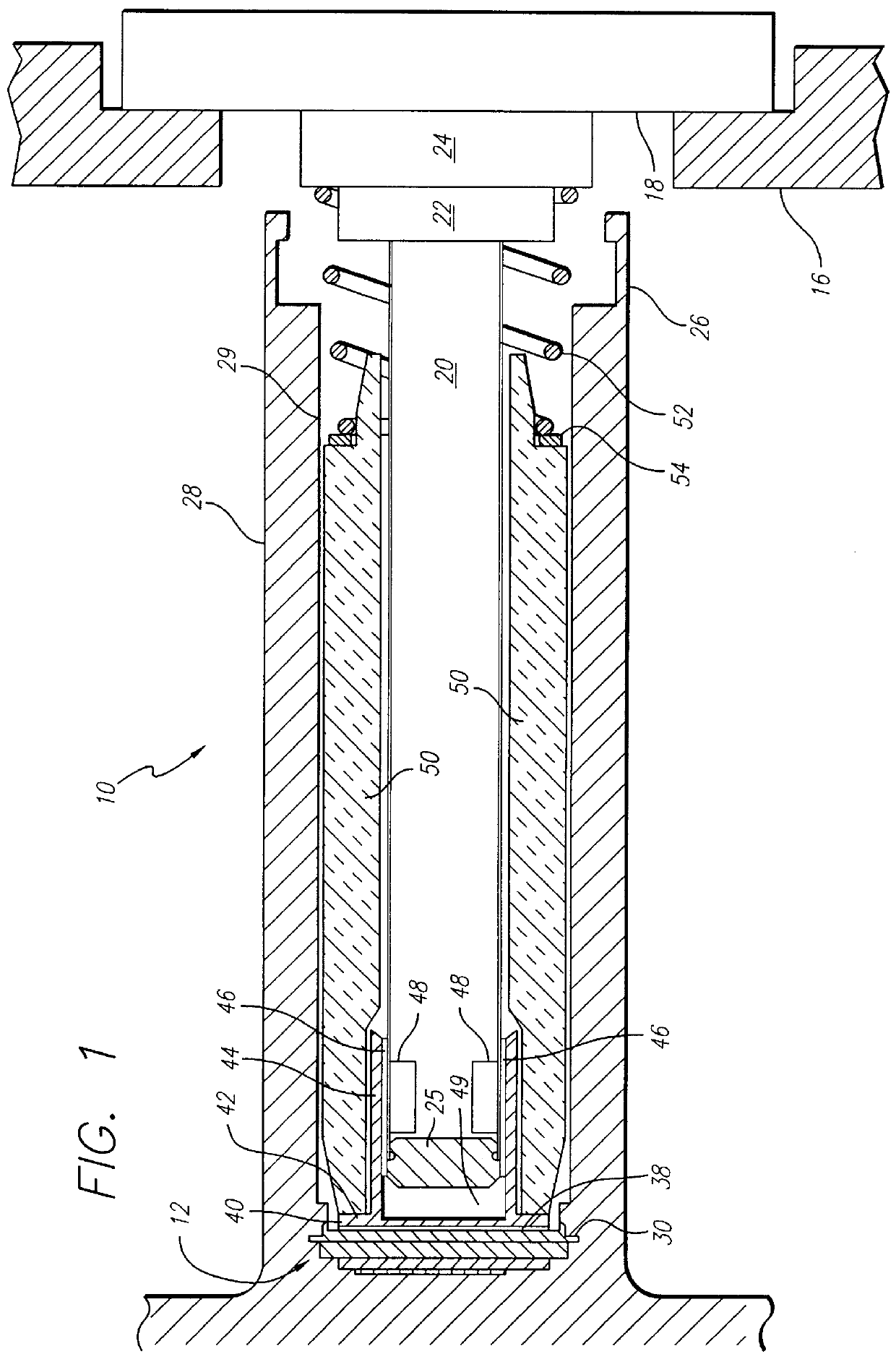

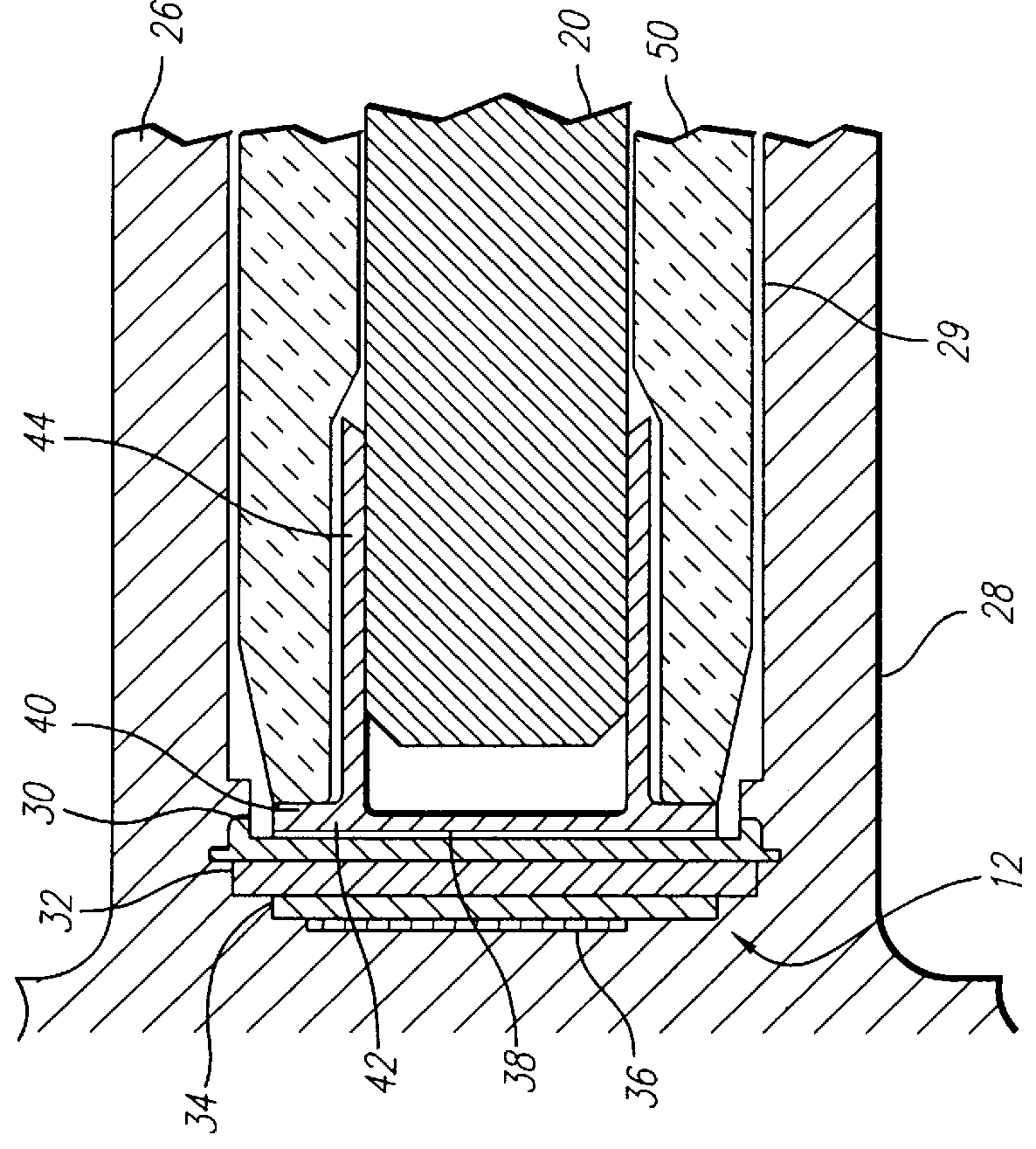

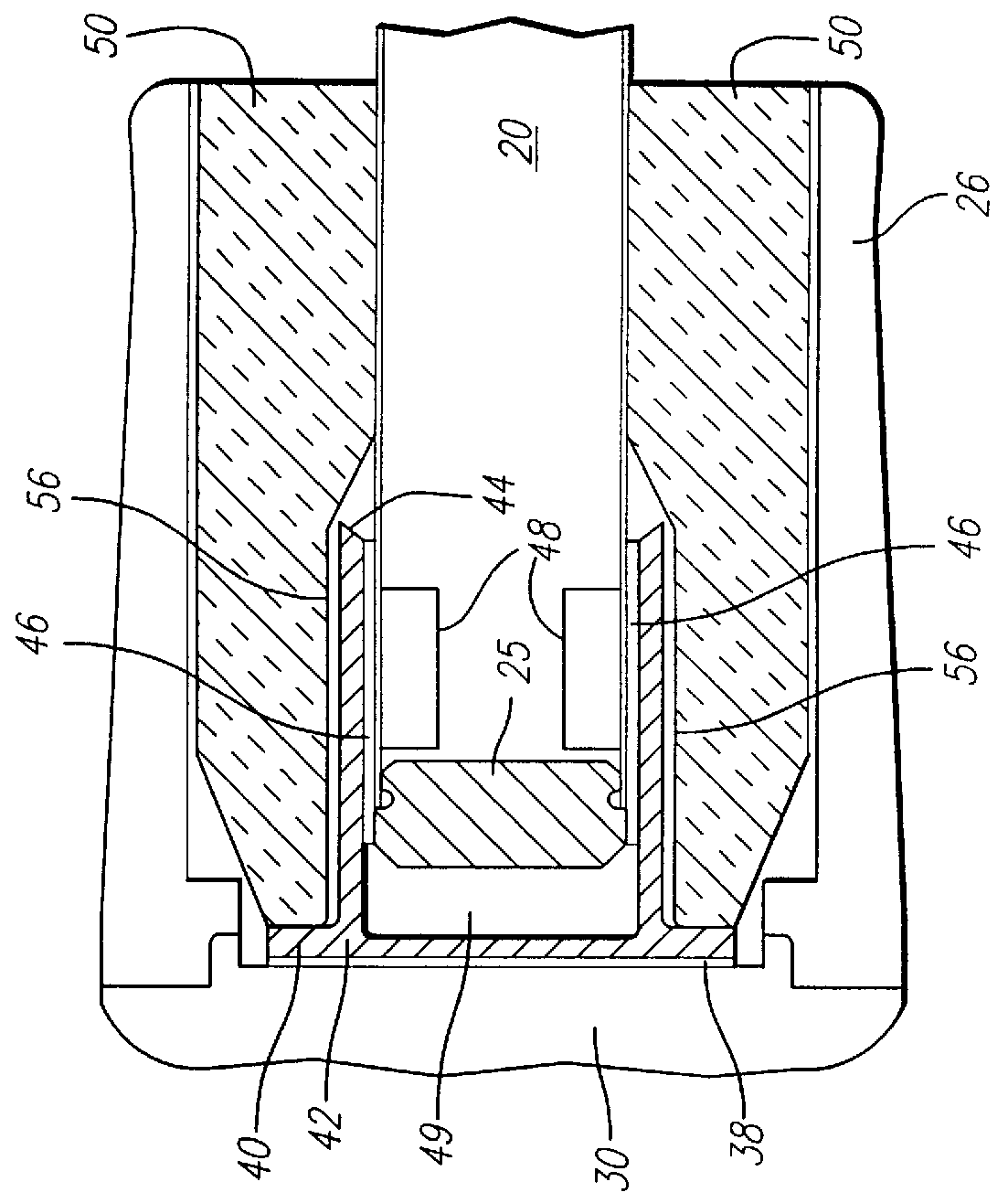

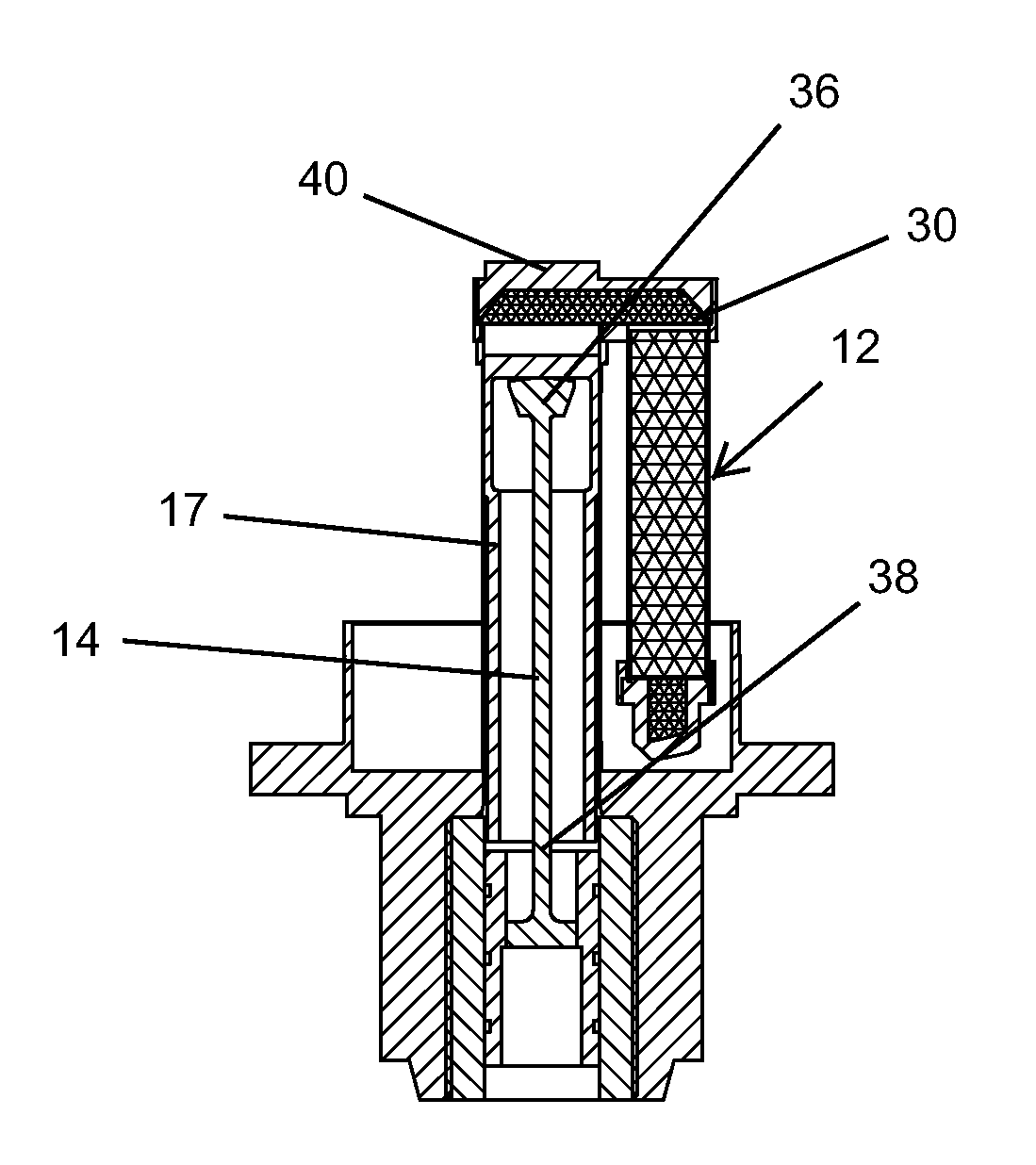

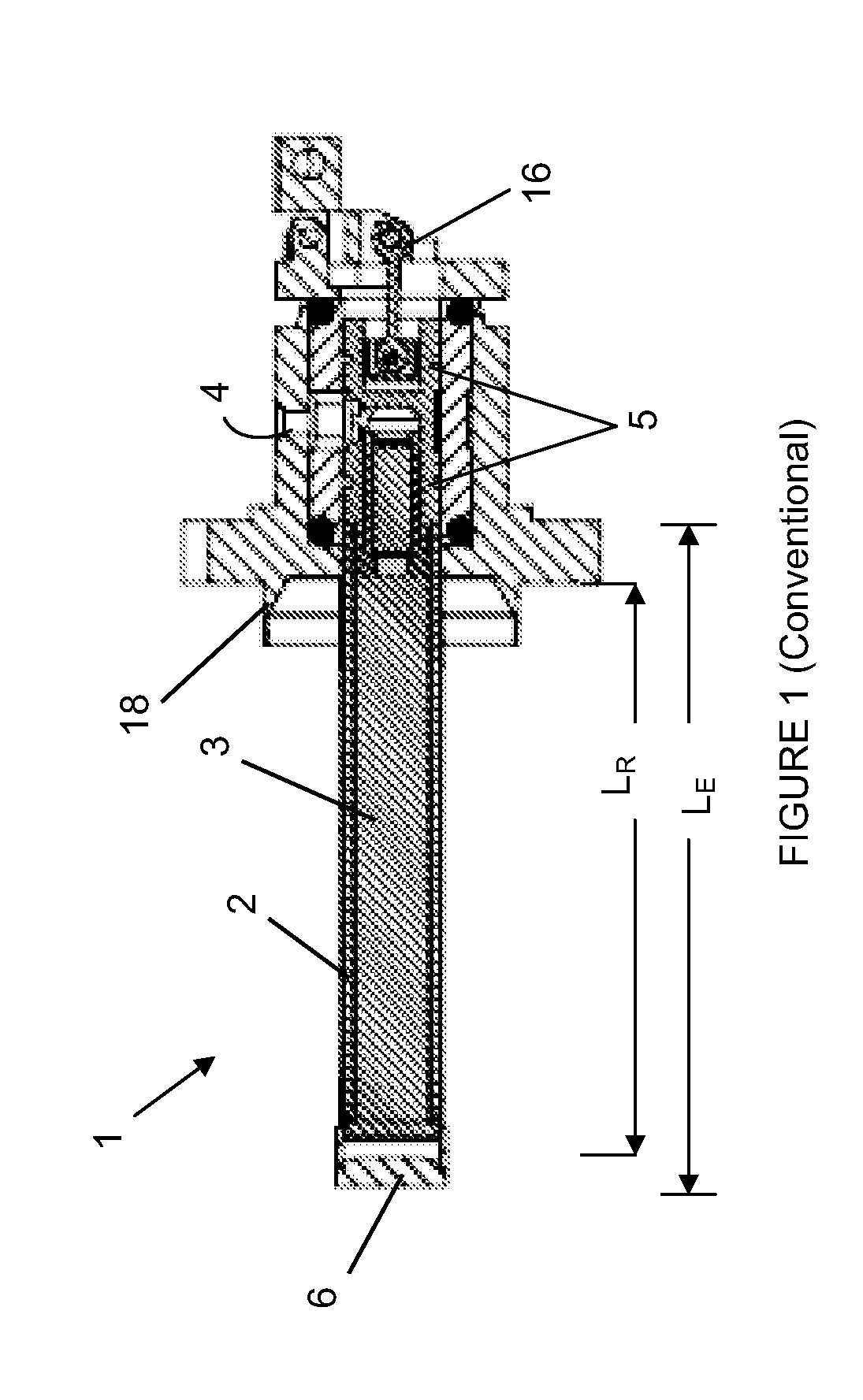

A cryogenic cooler and a dewar assembly including a cooled surface; a cooling surface for removing thermal energy from said cooled surface; and an adapter disposed between said cooling surface and the cooled surface for conducting thermal energy therebetween. A first fluid is disposed between the cooled surface and the adapter for conducting thermal energy from the cooled surface to the adapter. A second fluid is disposed between the cooling surface and the adapter for conducting thermal energy from the adapter to the cooling surface whereby the cooling surface remains free to move axially relative to the adapter at a temperature of the cooling surface at which the first fluid is susceptible to freezing. This allows for movement of the cold finger relative to the dewar and adapter, due to differential thermal coefficients of expansion or support structure motion, without adversely affecting the communication of thermal energy from the load. In the illustrative embodiment, the cooler is a Stirling cycle cooler, the first fluid is thermal grease and the second fluid is nitrogen. The cooling surface is a cylindrical cold finger of the Stirling cycle cooler and the cooled surface is an inner wall of a dewar assembly. The dewar is in thermal contact with a load. The adapter is disposed between the inner wall of the dewar and the cold finger. The adapter has an end cap and a cylindrical housing extending therefrom. The housing extends at least partially along a longitudinal axis of the cold finger. An insulator is disposed about the cold finger and the adapter housing. A spring is disposed between a proximal end of the insulator and a base of the cold finger to maintain a distal end of the insulator in contact with the adapter and the adapter in contact with the dewar.

Owner:RAYTHEON CO

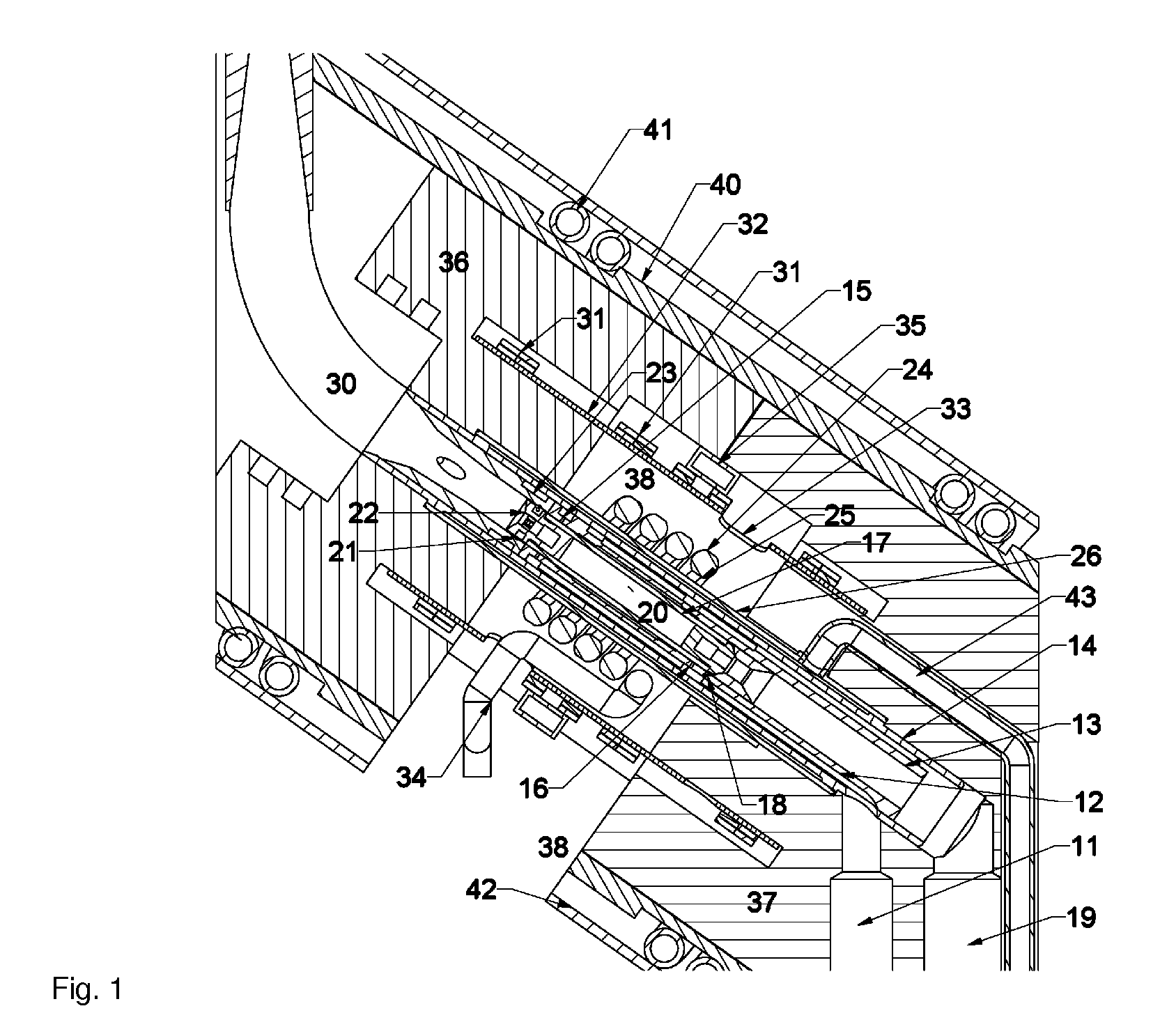

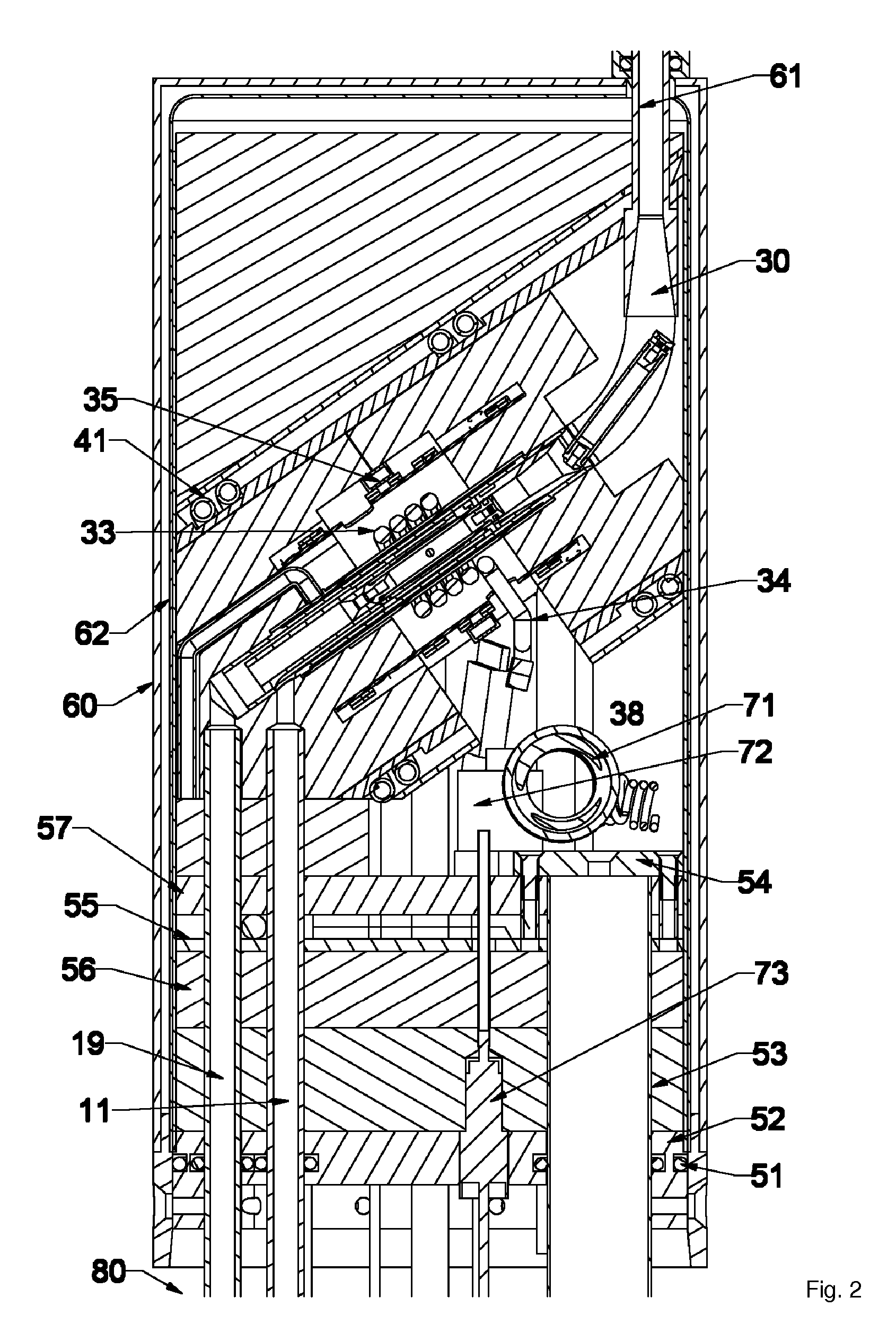

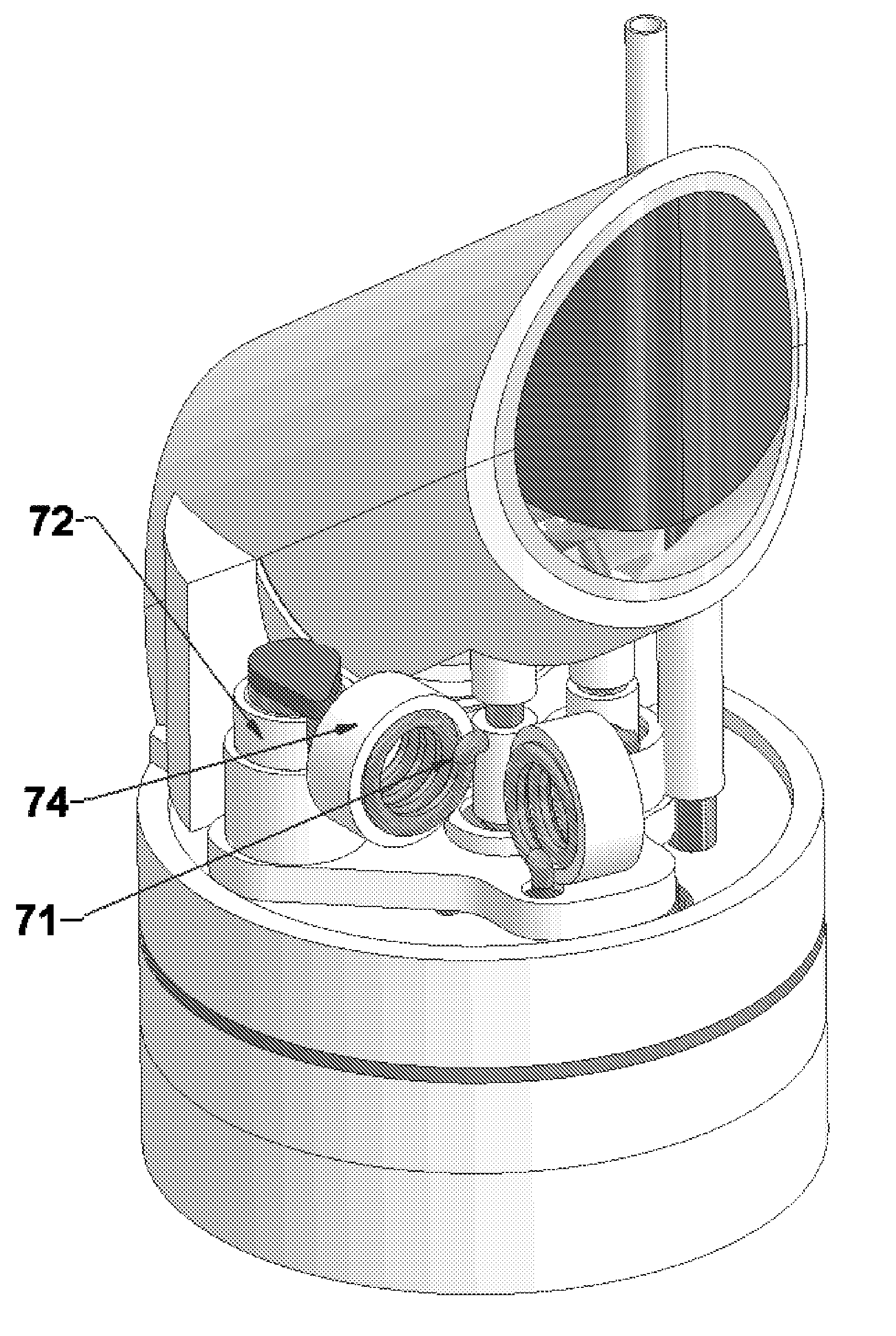

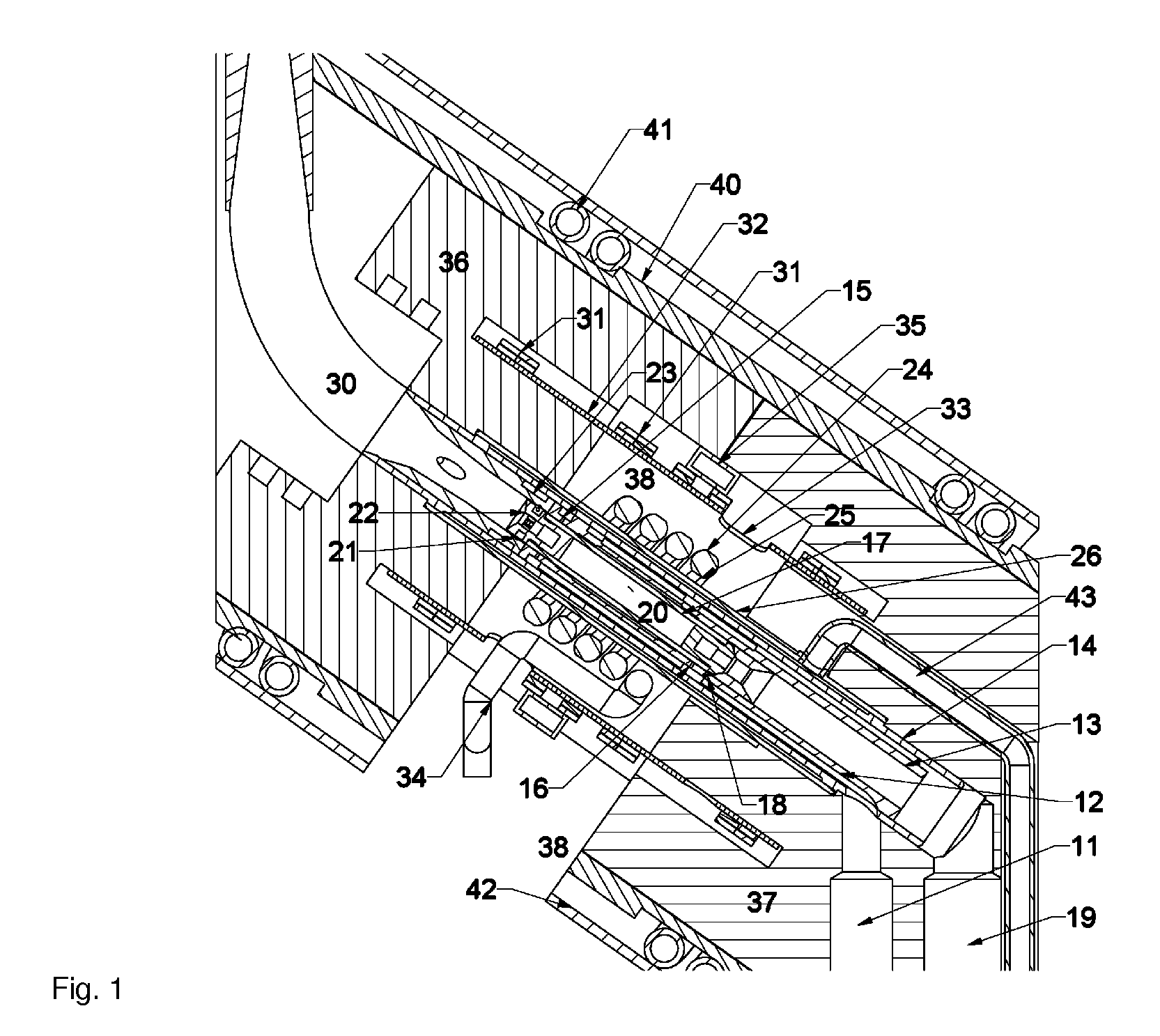

NMR CryoMAS probe for high-field wide-bore magnets

InactiveUS7282919B2Reduce riskAvoid flowElectric/magnetic detectionMeasurements using magnetic resonanceMagic angle spinningNitrogen gas

Owner:DOTY SCI

NMR CryoMAS Probe for High-field Wide-bore Magnets

InactiveUS20060176056A1Reduce riskImprovement factorElectric/magnetic detectionMeasurements using magnetic resonancePartial solutionNitrogen gas

An MAS probe is disclosed for obtaining a substantial improvement in signal to noise (S / N) in triple-resonance high-resolution (HR) magic-angle-spinning (MAS) NMR of samples near room temperature (RT) in high-field magnets where the magnet's RT shim bore is greater than 60 mm. All critical circuit components, including the sample coils, are located along with the spinner assembly in a thermally insulated cold zone pressurized with helium gas. The spinner assembly attaches to a sealed, curved, rotor-loading tube to permit automatic sample change, and it is surrounded by a partially insulated jacket cooled with a cryogenic fluid, generally nitrogen gas. The MAS probe is also compatible with magic angle gradients, variable temperature operation, field locking, and commonly available closed-cycle cold fingers. One major challenge in implementing CryoMAS is solving the problem of gas leakage from the spinner bearing, drive, and exhaust nitrogen into the cold zone, as some components will necessarily be ceramic, some plastic, and some metal. It is not desirable to use helium for the spinner bearing and drive gases for cost reasons and to prevent risk of degradation of o-ring-sealed magnet cryostats. A pressurized helium atmosphere in the cold zone may be utilized to prevent nitrogen flow from the spinner exhaust streams or atmosphere into the cold zone. The drawback to a pressurized cold zone is that the heat transfer coefficient in dense helium at low temperatures is very high, making it challenging to cool the sample coils and all the large, critical, circuit components in a practical manner. Part of the solution here is to use a first-stage cooling-jacket around the major heat leaks near the spinner exhaust flows. The critical components may be insulated with fine glass wool or teflon foam and conduction cooled without cooling much of the cold zone below the temperature of the first-stage cooling. The use of coaxial sapphire capacitors allows the noise contributions from the most critical capacitors to be reduced to a minor fraction of the total.

Owner:DOTY SCI

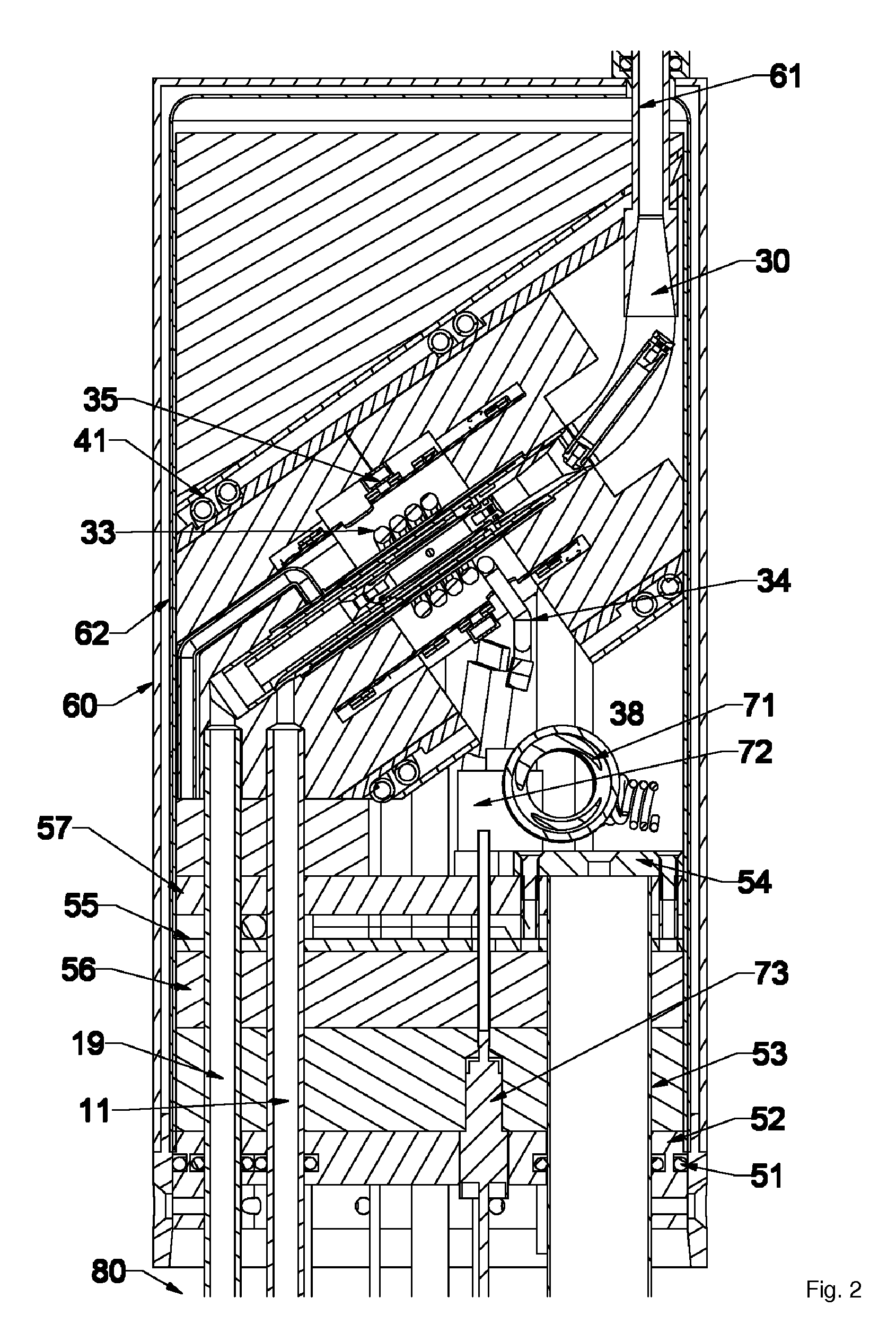

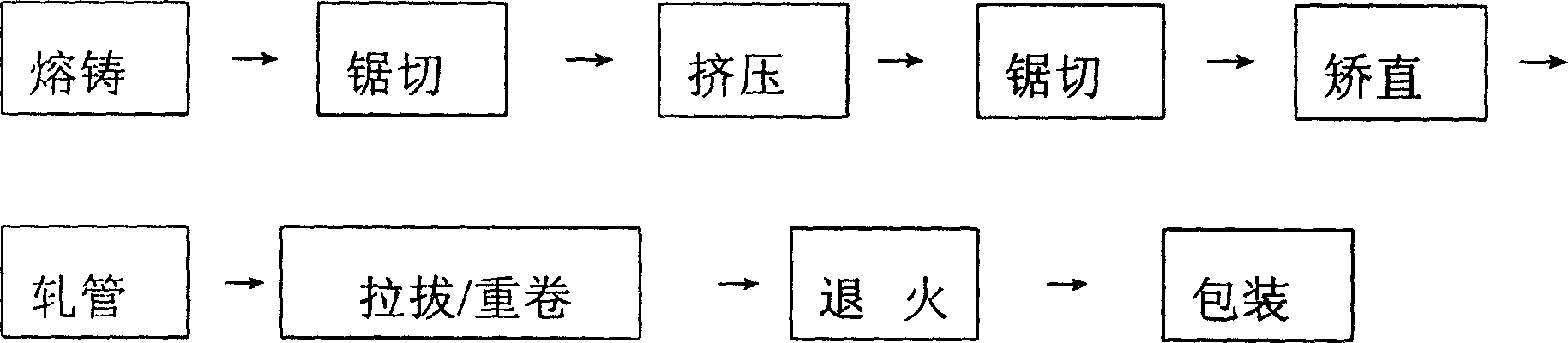

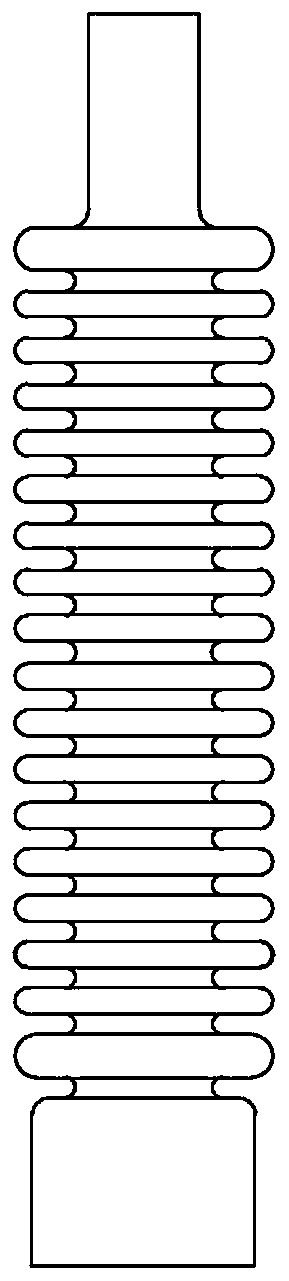

Cupronickel condensation tube production process using disk stretch

InactiveCN1754649AAchieve continuous stretchingMeet the length requirementCircular discProduction rate

This invention provides one process method by use of disc for ambrose alloy cold-finger, which comprises the following steps: melting to cutting to crushing to cutting to correction to grinding or rolling again to annealing to packing, wherein, the pulling process adopts multiple channel disc with pulling parameters in 1.30-1.45 and in and out mode oil moving viscosity of 400-900mm2 / s(40 DEG C) m wherein, Pulling mode angle of 9 degree-12 degree; motive core tamper degree of 6 degree -9 degree; pulling mode and motive core angle difference of 1 degree-3 degree.This invention adopts disc pulling process method to realize the continuous pulling to improve production rate to satisfy the market length need.

Owner:LUOYANG COPPER PROCESSING GROUP

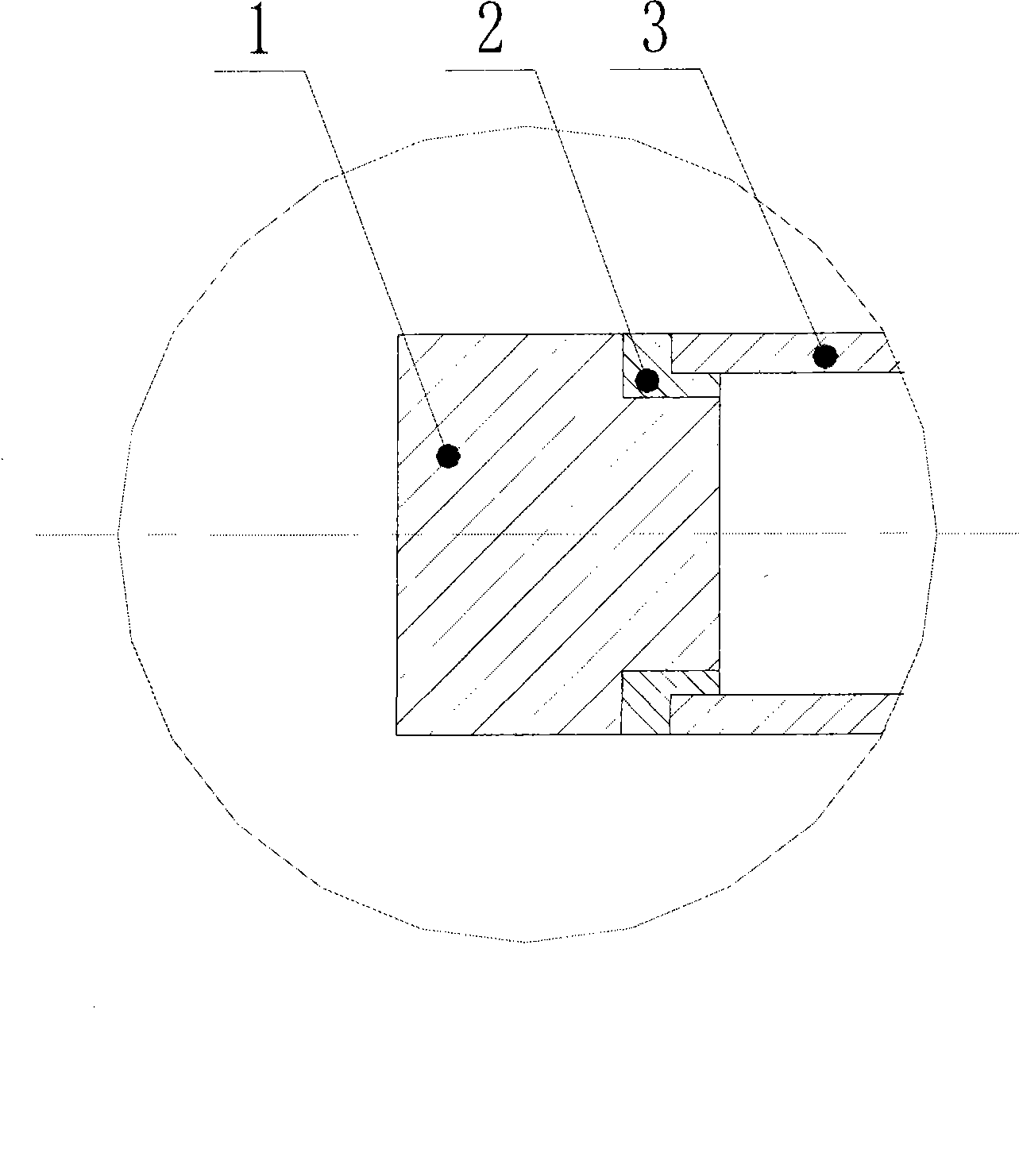

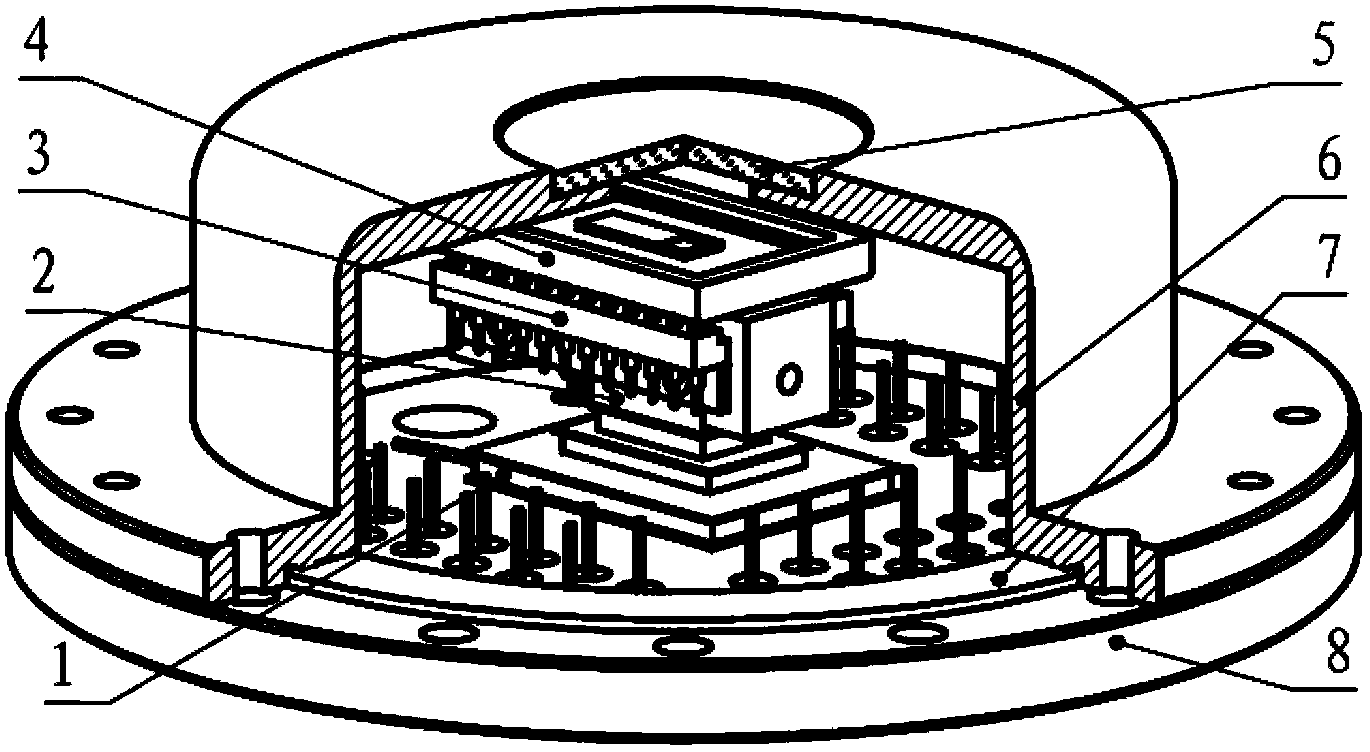

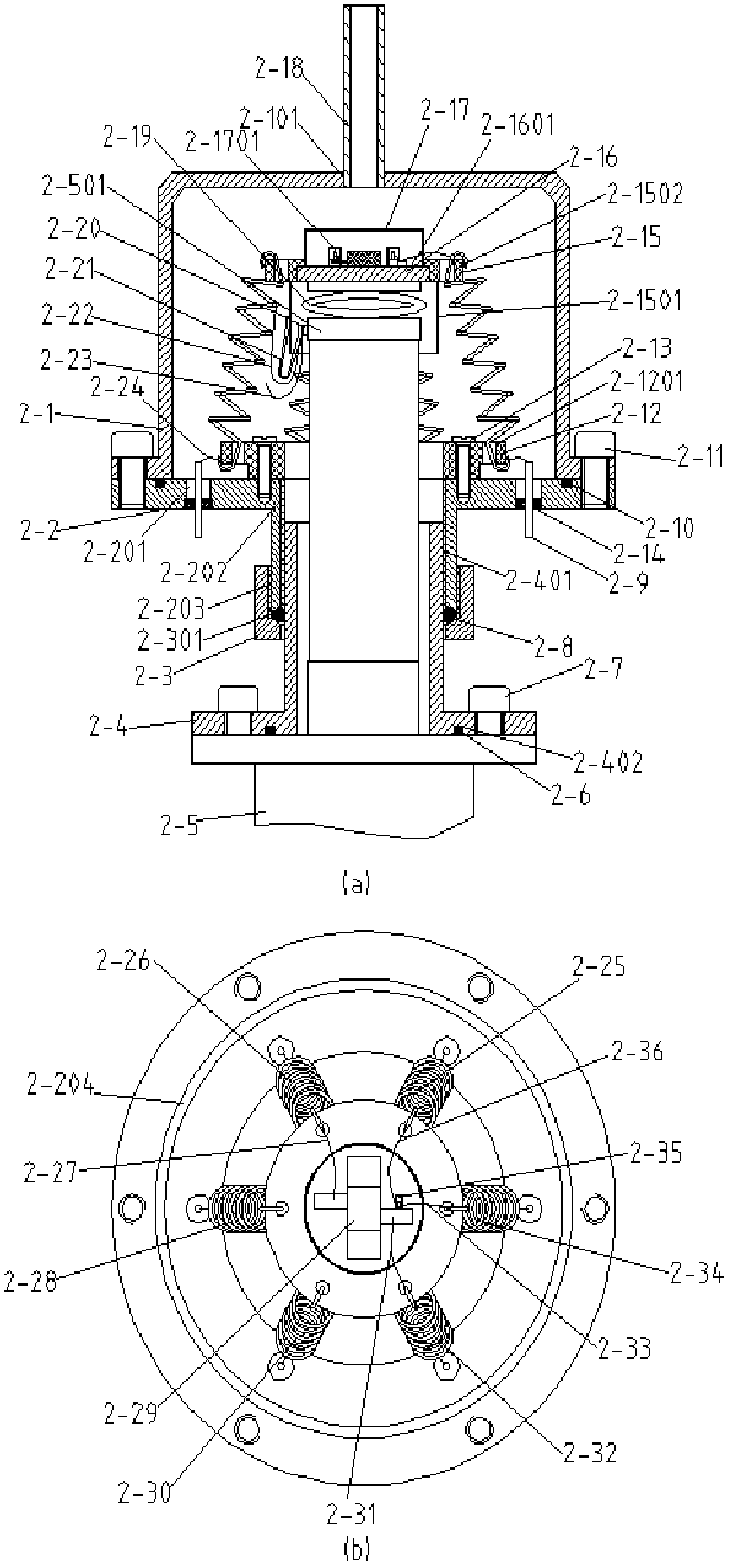

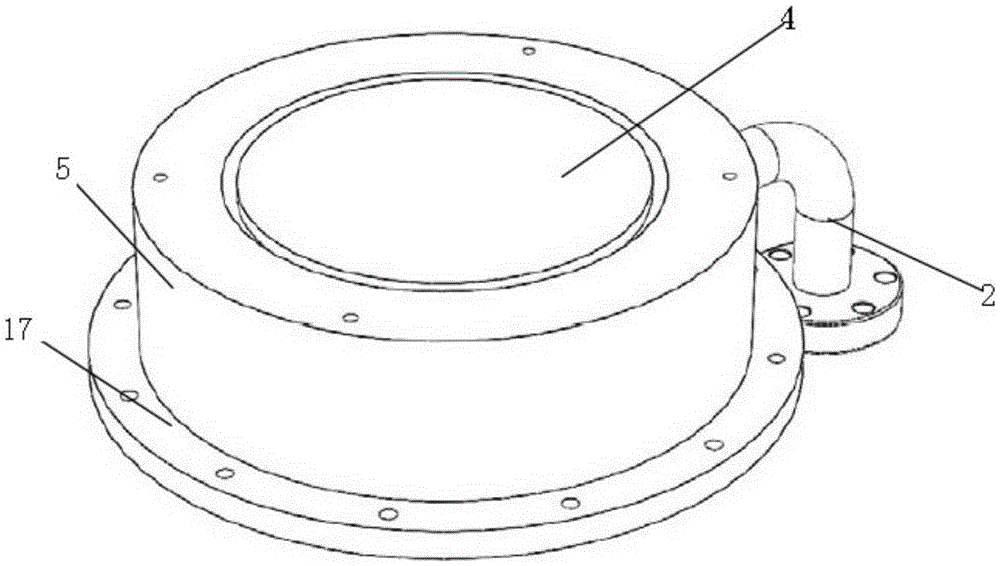

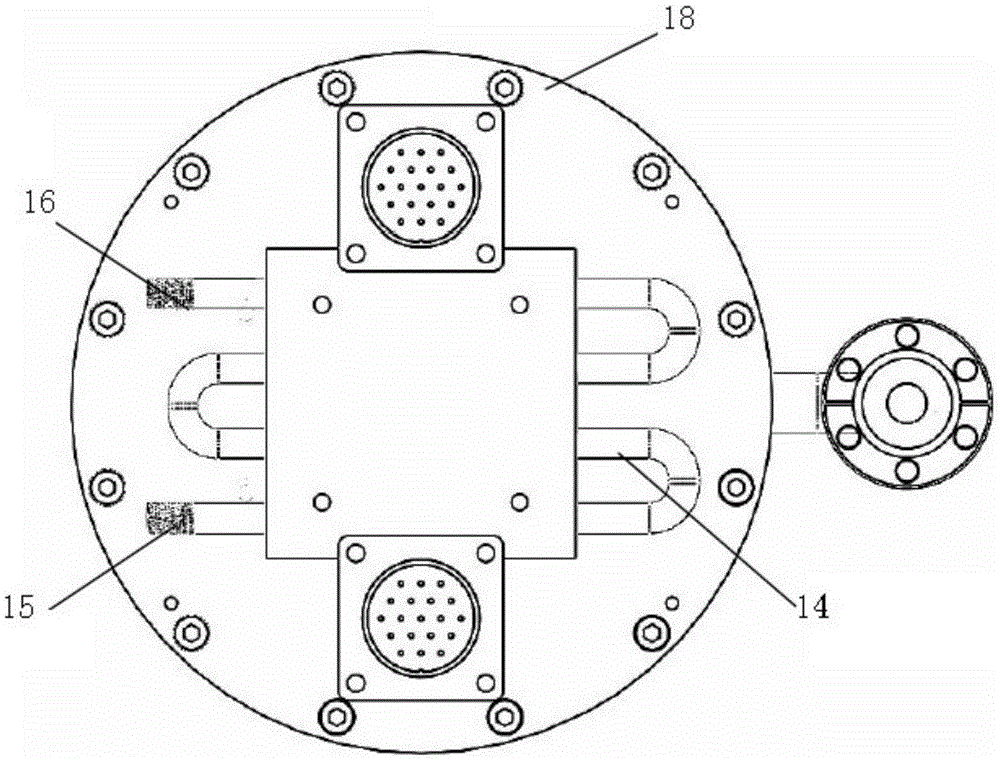

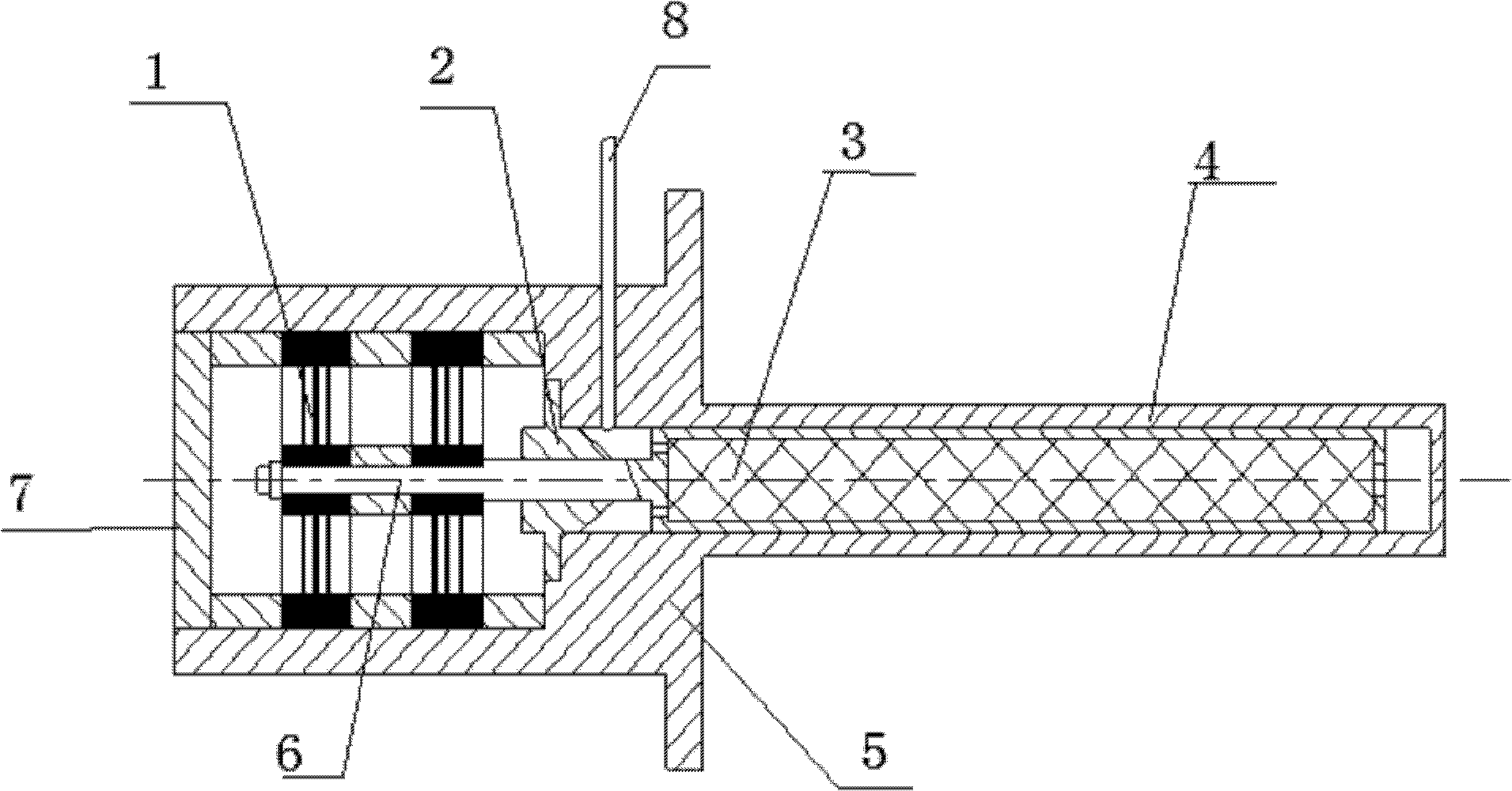

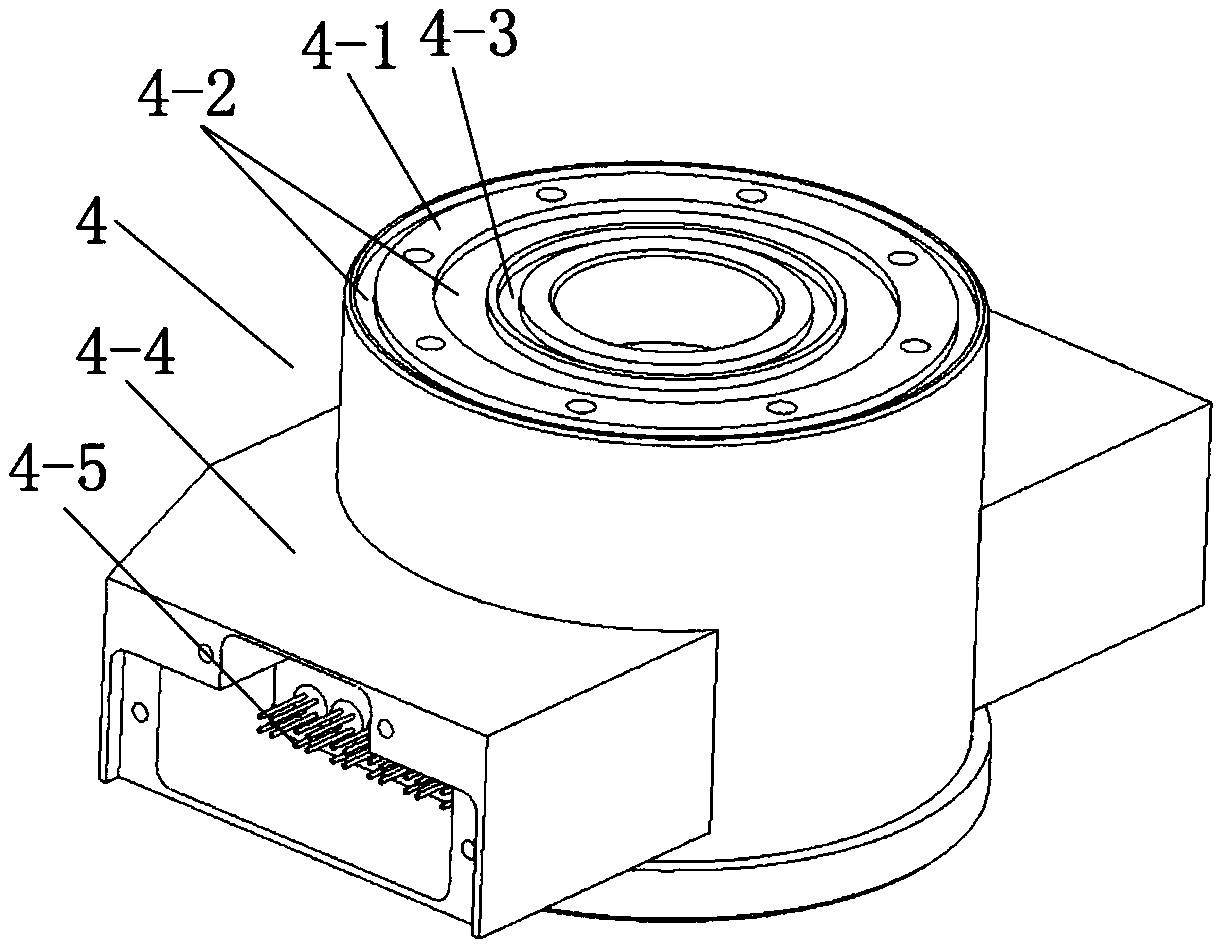

High-compatibility multi-functional test Duvel for separate Dewar hot load test

The invention discloses a high-compatibility multi-functional test Duvel for separate Duvel hot load test, which is suitable for hot load test of a separate high-hot-load engineering Duvel and test of the refrigerator coupling effect. The high-compatibility multi-functional test Duvel for the separate Duvel hot load test comprises a cavity cap, a lead disc, a sealing snap ring, a flange seat and the like. A special structure is introduced into the high-compatibility multi-functional test Duvel, and accurate test the static hot load of the separate engineering Duvel is realized through assembly replacing and thermal equivalent methods. A device and an implementing method disclosed by the invention are simple, and have high measuring accuracy, high universality and low cost. The Duvel is suitable for testing the refrigerating amounts of an engineering refrigerator at different refrigerating temperatures and testing the temperature gradients of an elastic cold chain on a cold finger of the engineering refrigerator or carbon paper or other coupling media at different refrigerating temperatures and different transmission cold amounts.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

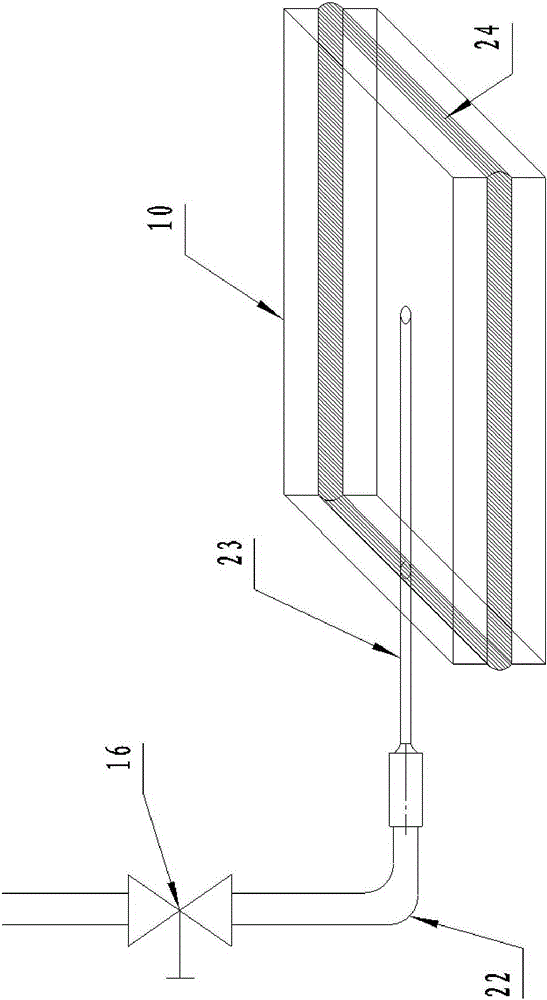

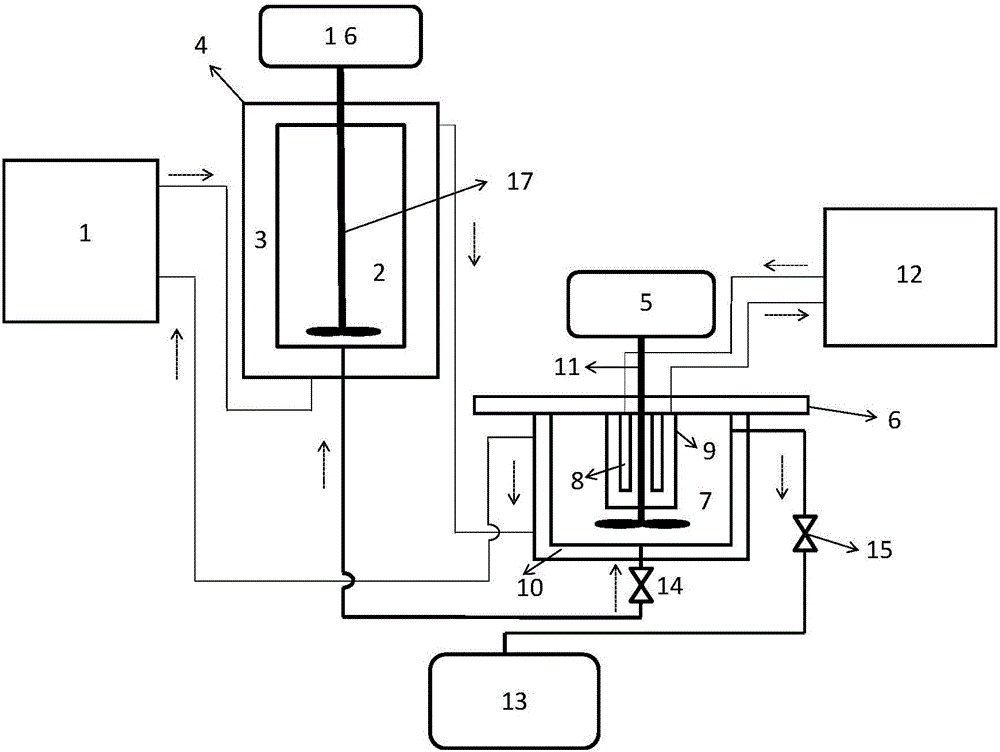

Wax deposition experimental device and method

InactiveCN105334145APromote precipitationChange the degree of blendingFlow propertiesTemperature controlExperimental methods

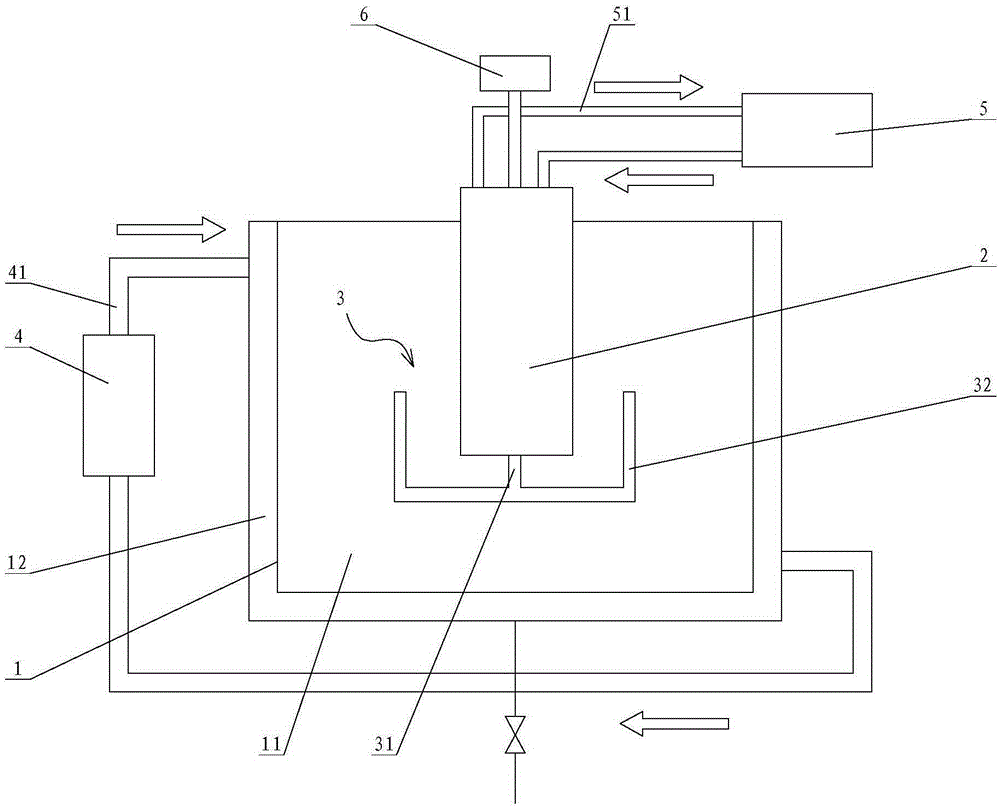

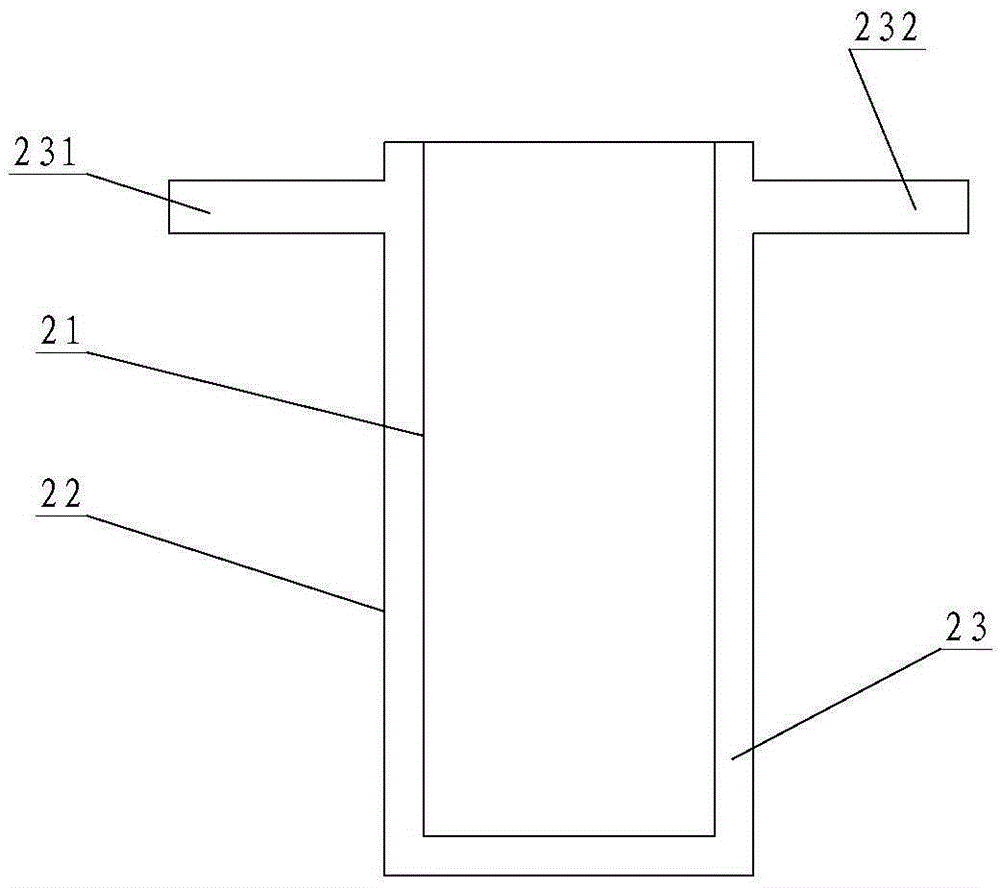

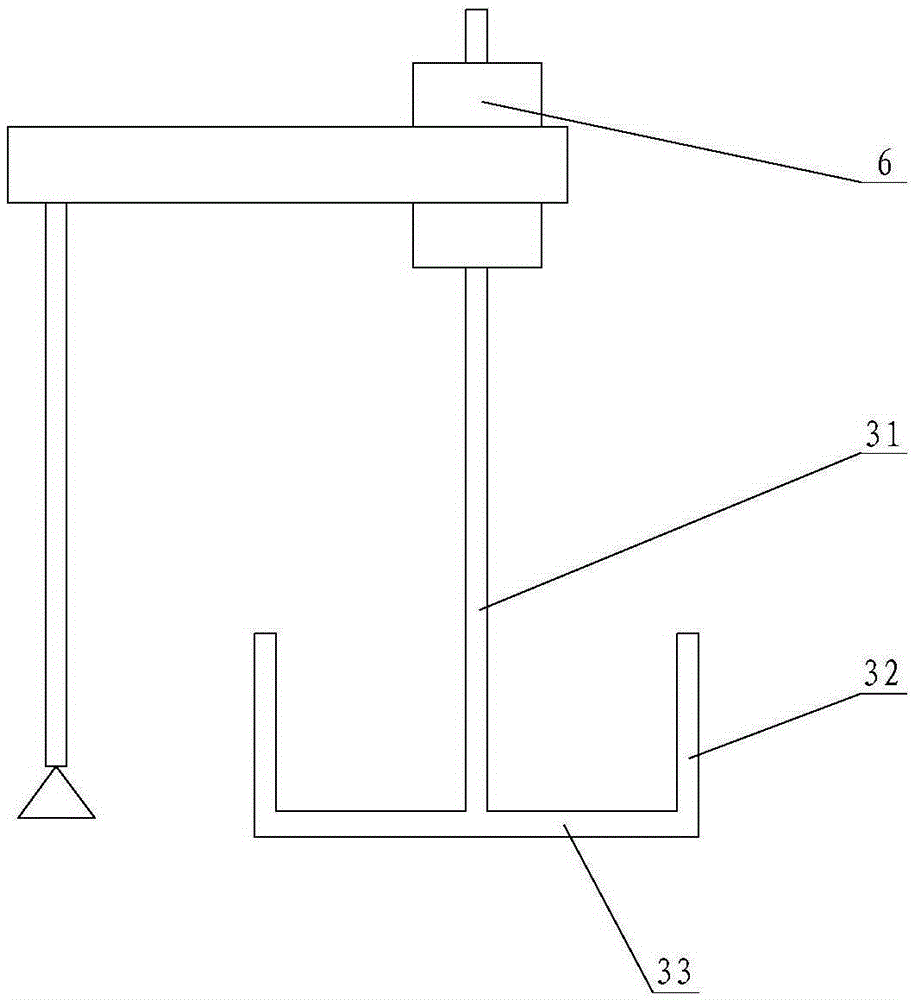

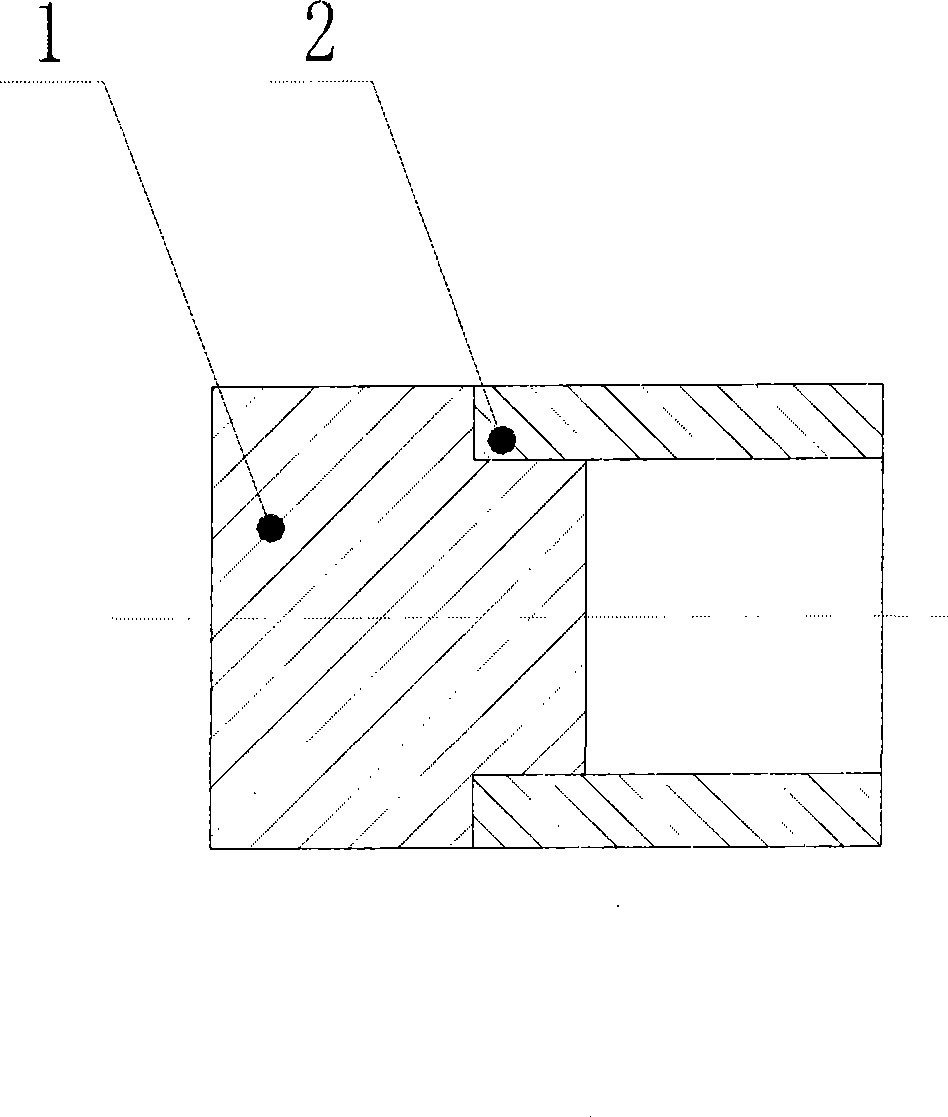

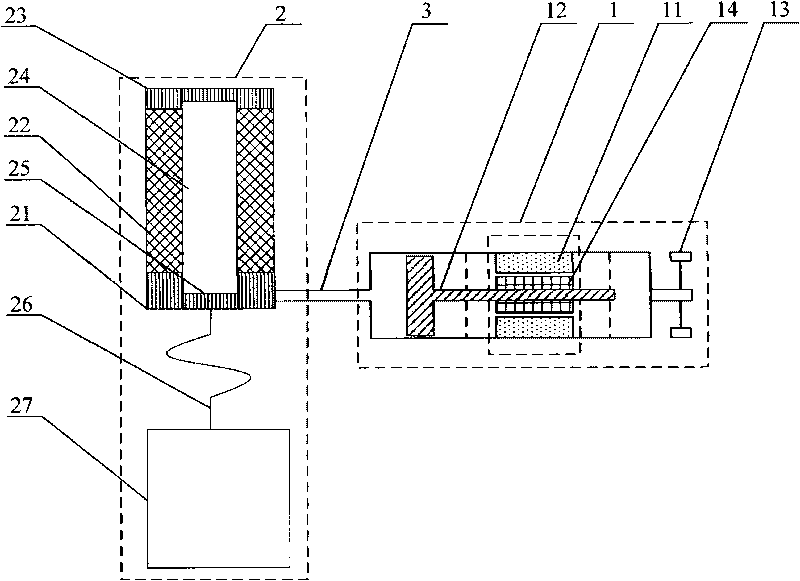

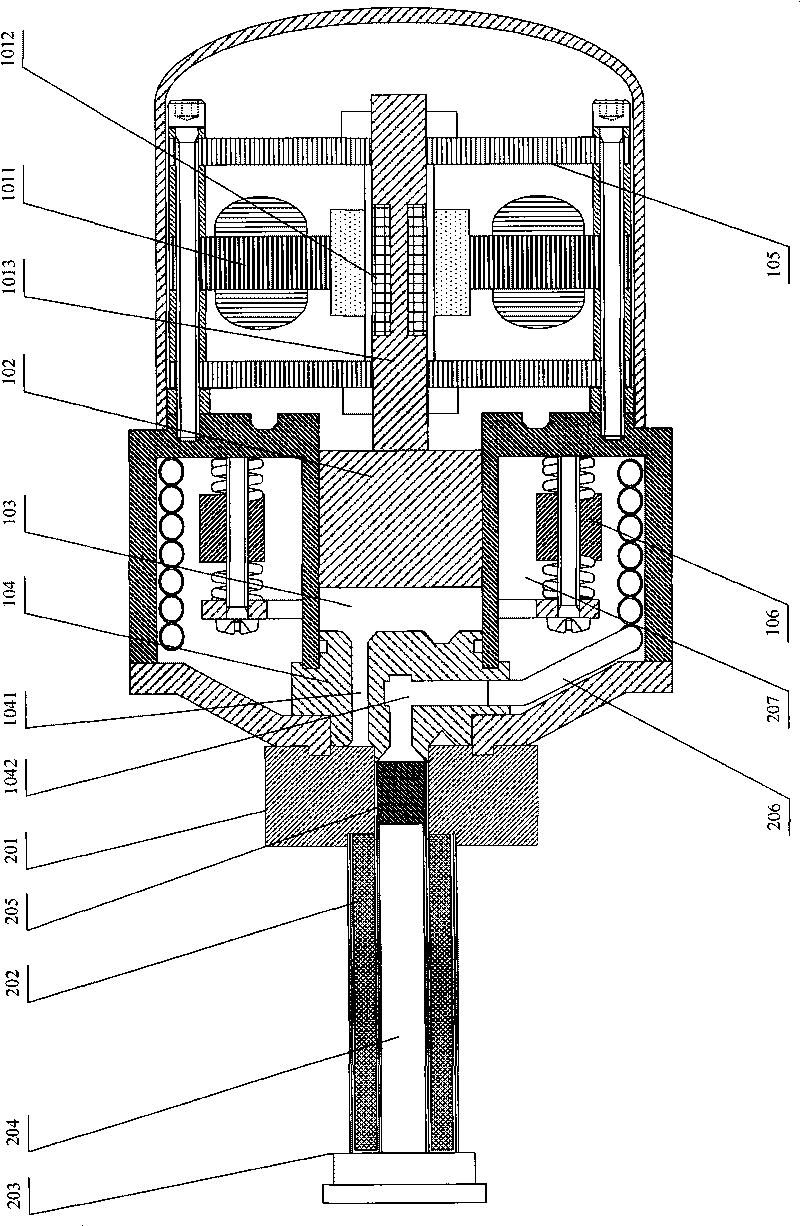

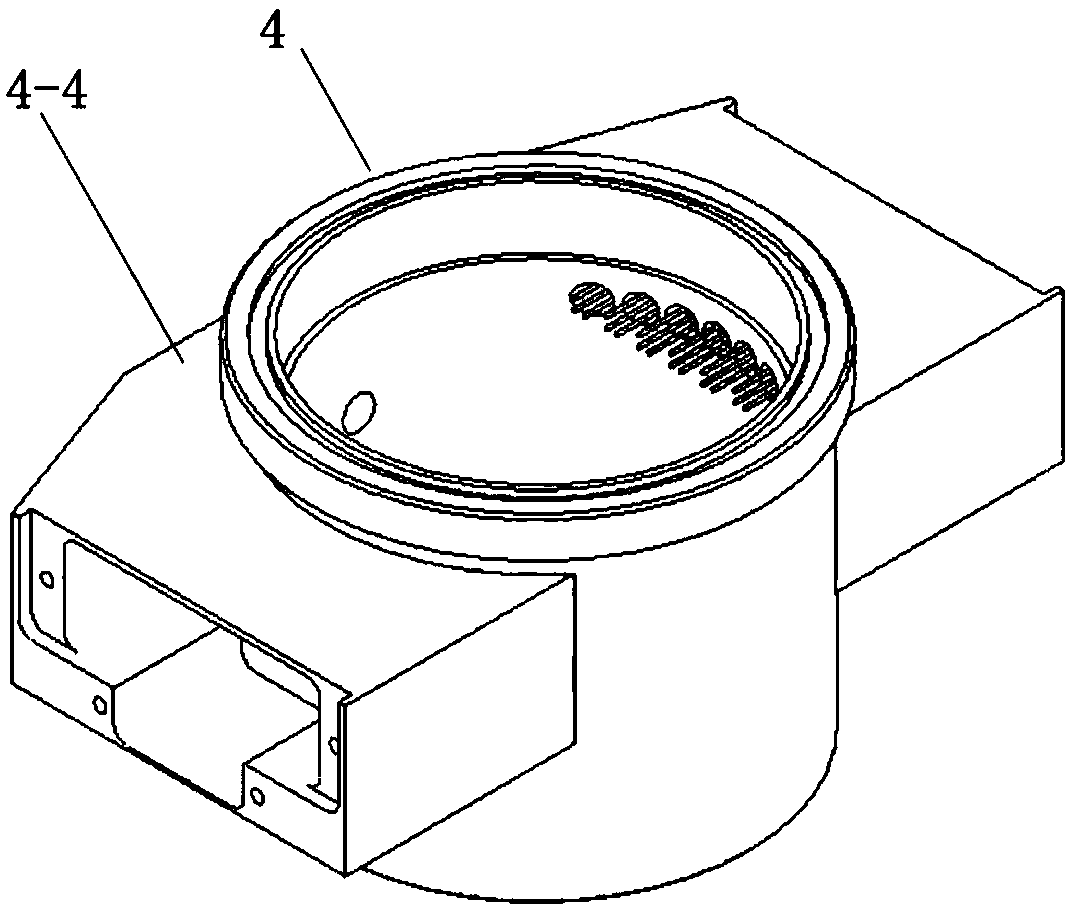

The invention provides a wax deposition experimental device and method. The wax deposition experimental device comprises an oil storage tank, a cold finger and a stirrer. The oil storage tank is provided with an oil storage cavity and sleeved with a water jacket interlayer, and the water jacket interlayer is connected with a first temperature control device. The cold finger is arranged in the oil storage cavity and is provided with an inner cylinder and an outer cylinder which is arranged outside the inner cylinder in a sleeving mode, an annular cavity is formed between the inner cylinder and the outer cylinder, and the annular cavity is connected with a second temperature control device. The stirrer is provided with a rotating shaft penetrating in the inner cylinder, and the end, penetrating out of the inner cylinder, of the rotating shaft is connected with a plurality of stirring paddles. The stirring paddles are located between the outer peripheral wall of the cold finger and the inner peripheral wall of the oil storage tank. According to the wax deposition experimental device and method, the wax deposition laws of crude oil and an oil-water mixture under the flowing condition can be determined, and it is of great significance to pipeline safety and economic operation.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Composite welding scheme between dissimilar metal materials

InactiveCN101468431AElectron beam welding apparatusWelding/soldering/cutting articlesWeld seamLaser beams

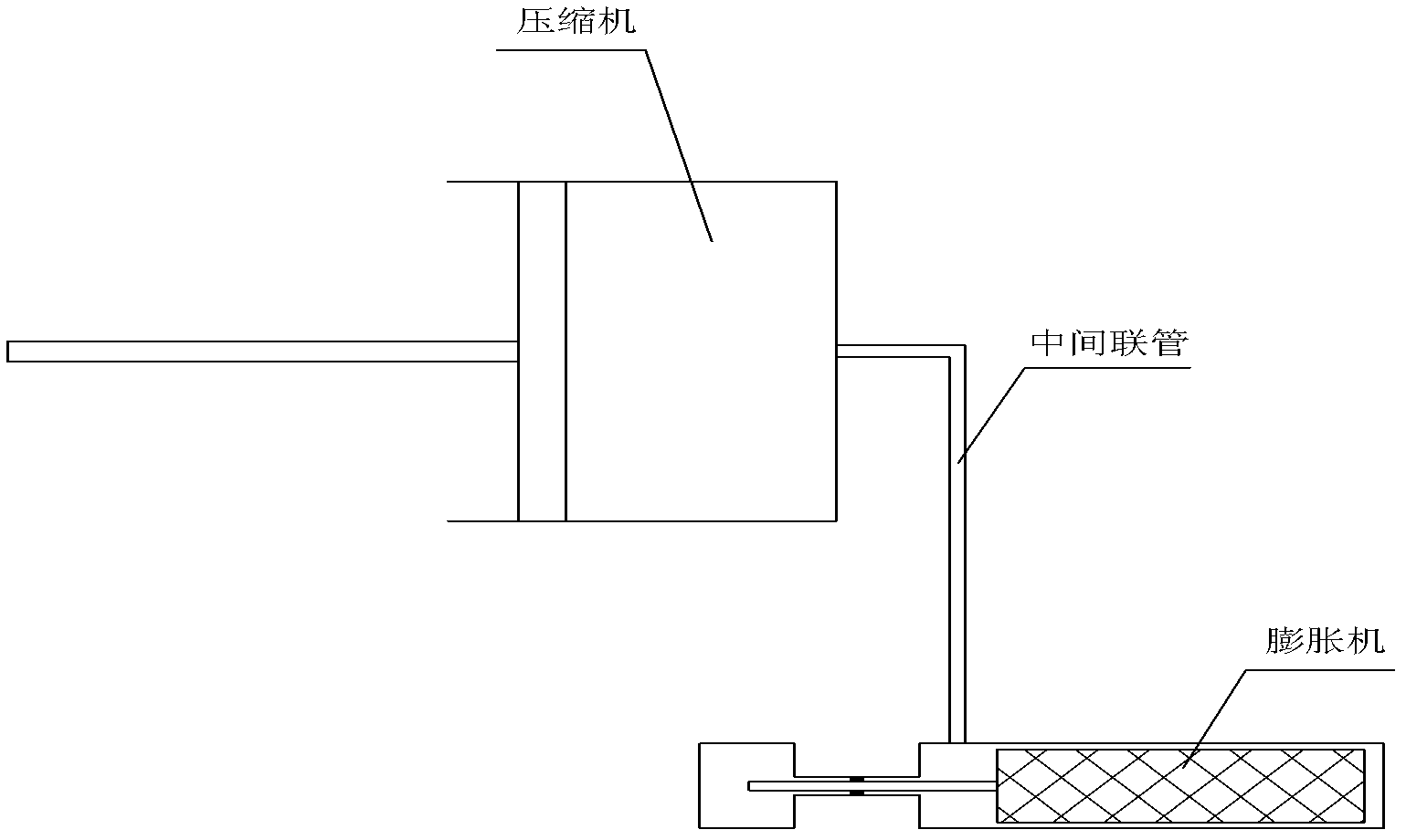

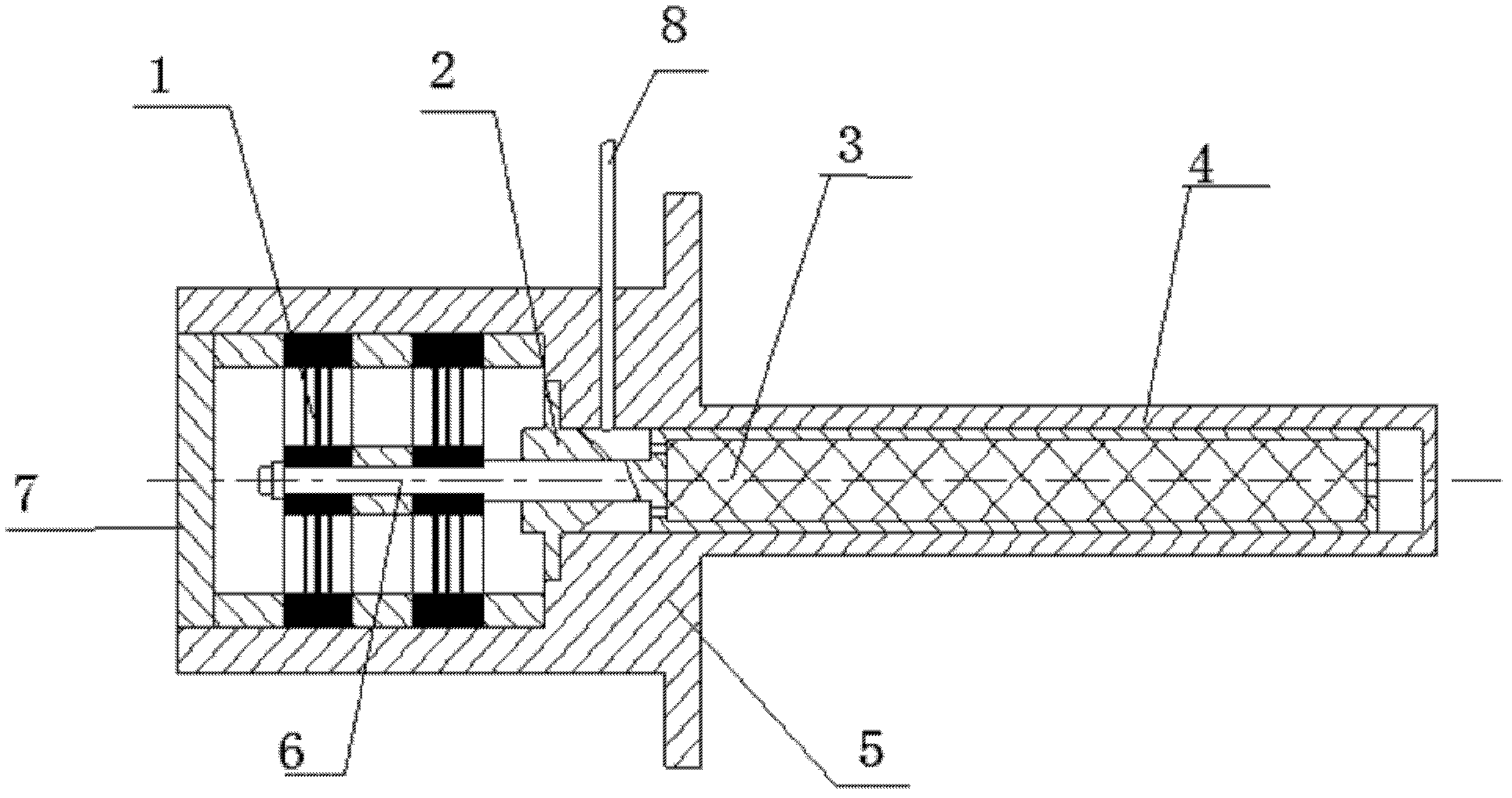

The invention relates to a composite welding proposal for different materials, in particular to composite welding for different materials between a cold finger of an expansion machine and a cold cap in a Stirling refrigerator, which belongs to the field of machinery. The welding proposal is realized by combining electron beam welding with laser welding. The oxygen-free copper cold cap is firstly connected with a transitional material into a whole by utilizing an electron beam welding mode, and then the laser welding is utilized to weld the cold cap with a thin-walled tube of the cold finger of the expansion machine after finish processing. The invention solves the difficult problem of welding different materials between the cold cap and the cold finger of the expansion machine and has the advantages of small deformation of welding seams, low structural leak rate and prolonged service life of the refrigerator. Likewise, the welding proposal can be applied to other similar occasions in the industry.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

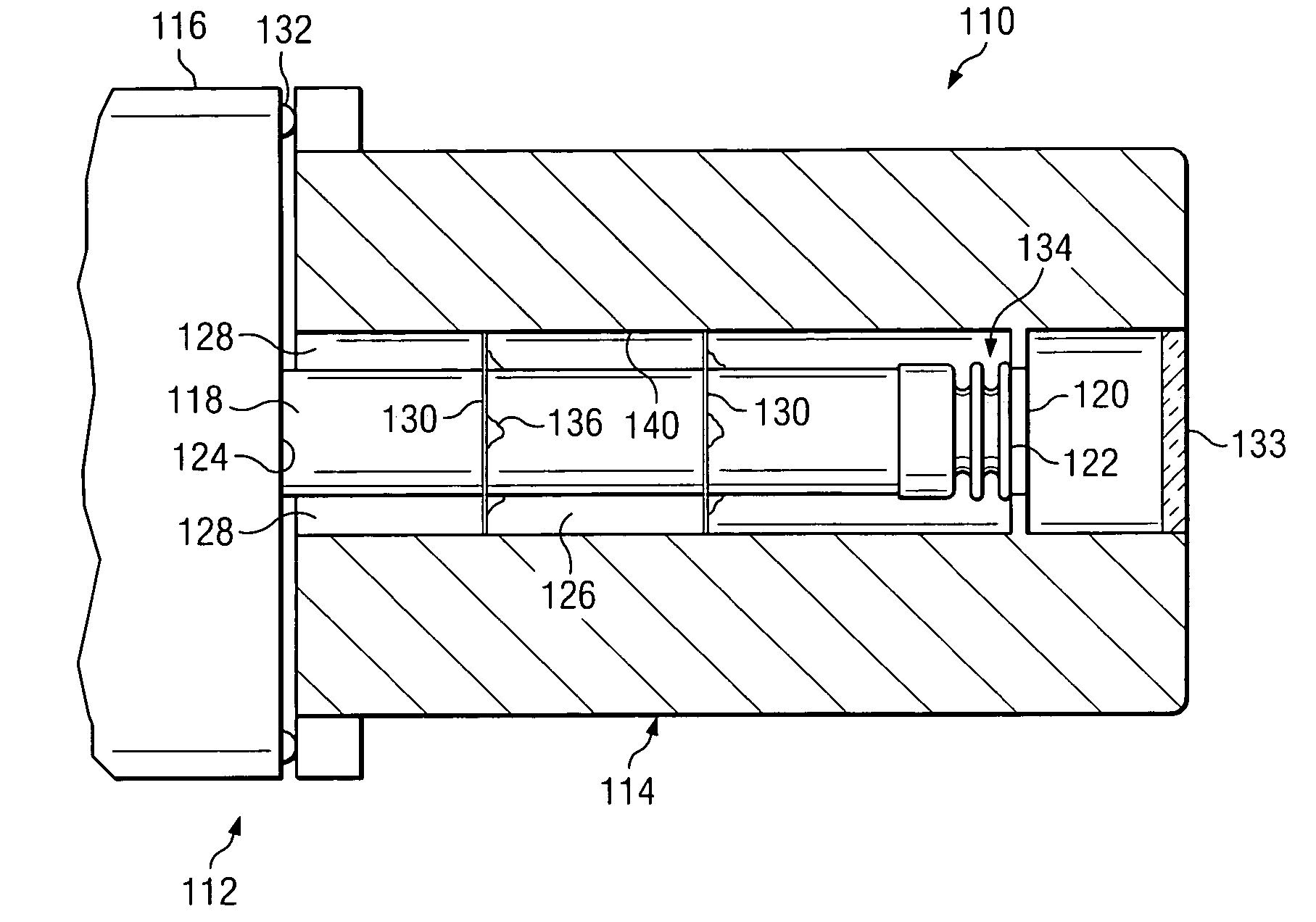

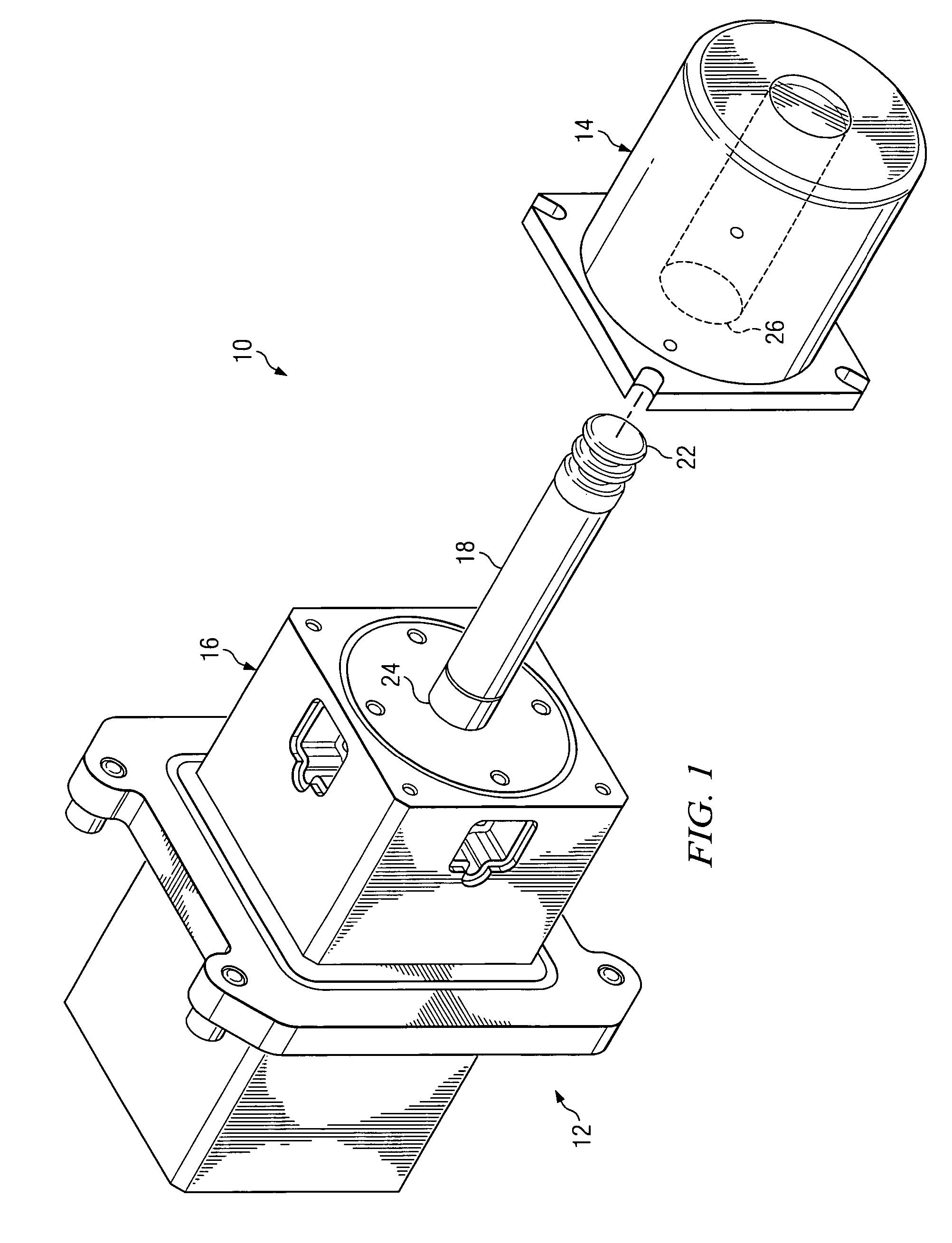

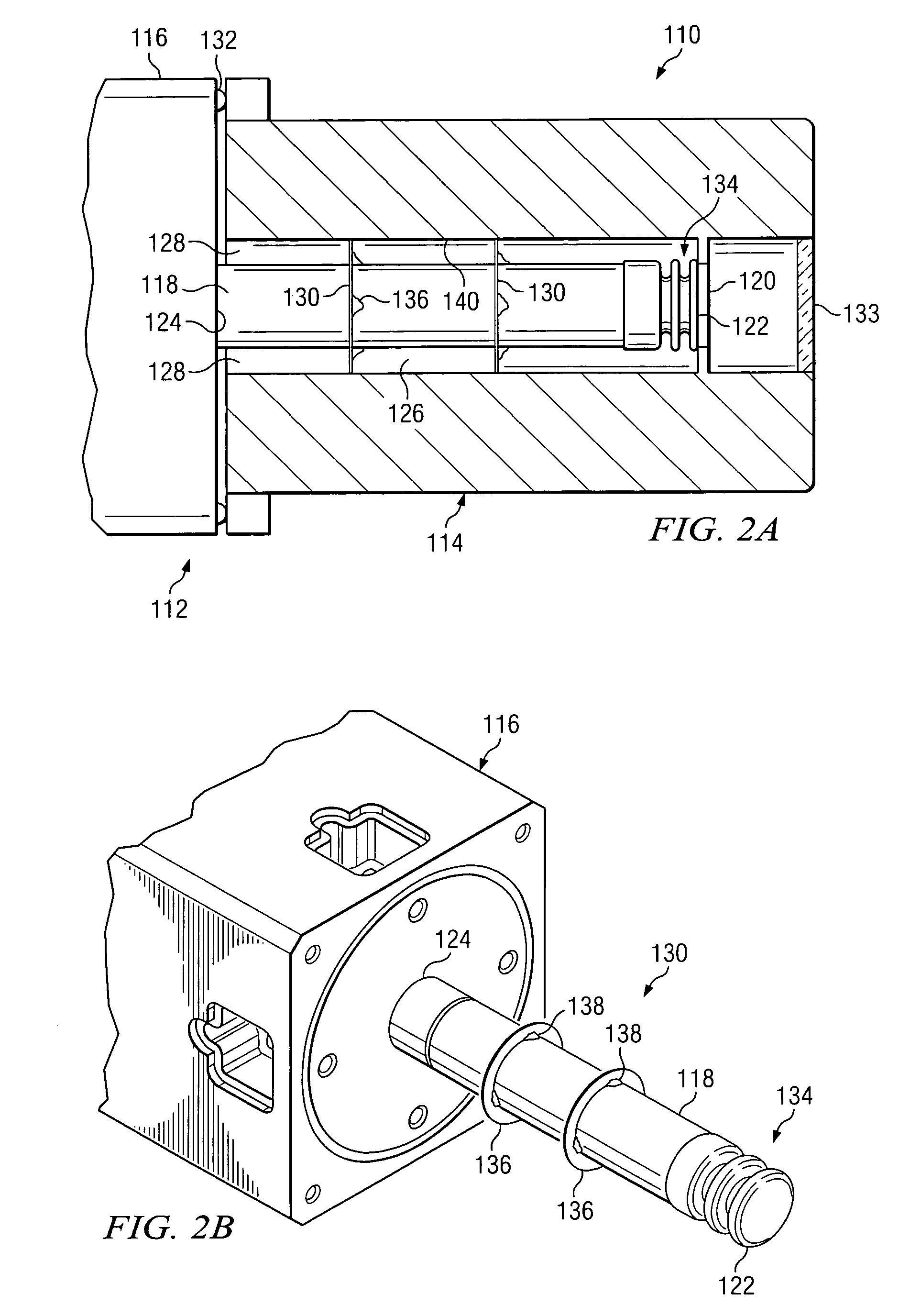

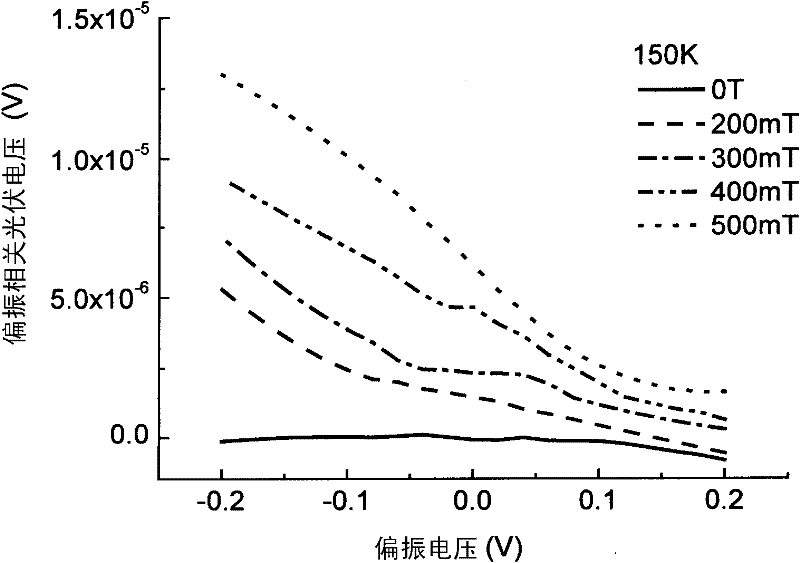

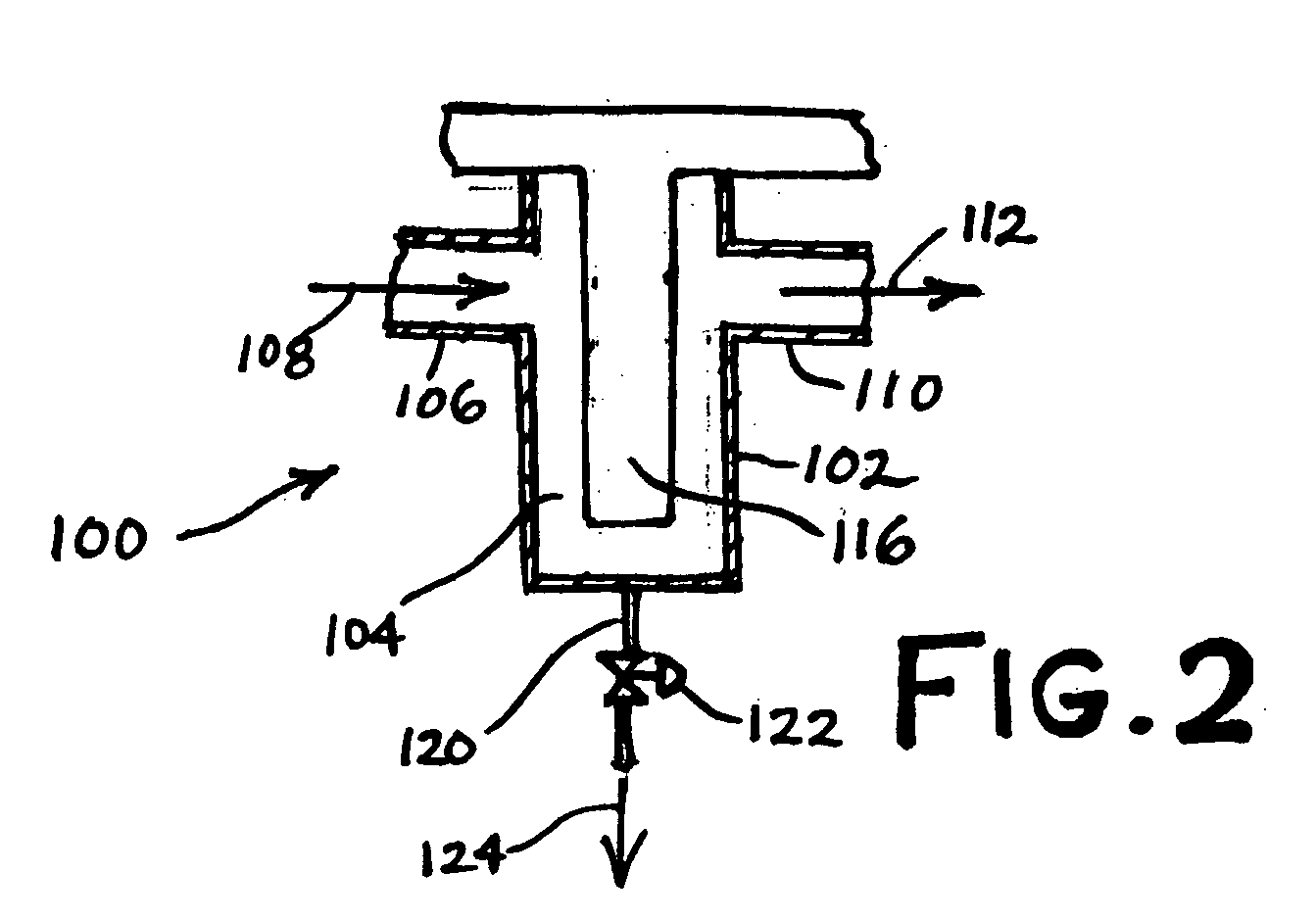

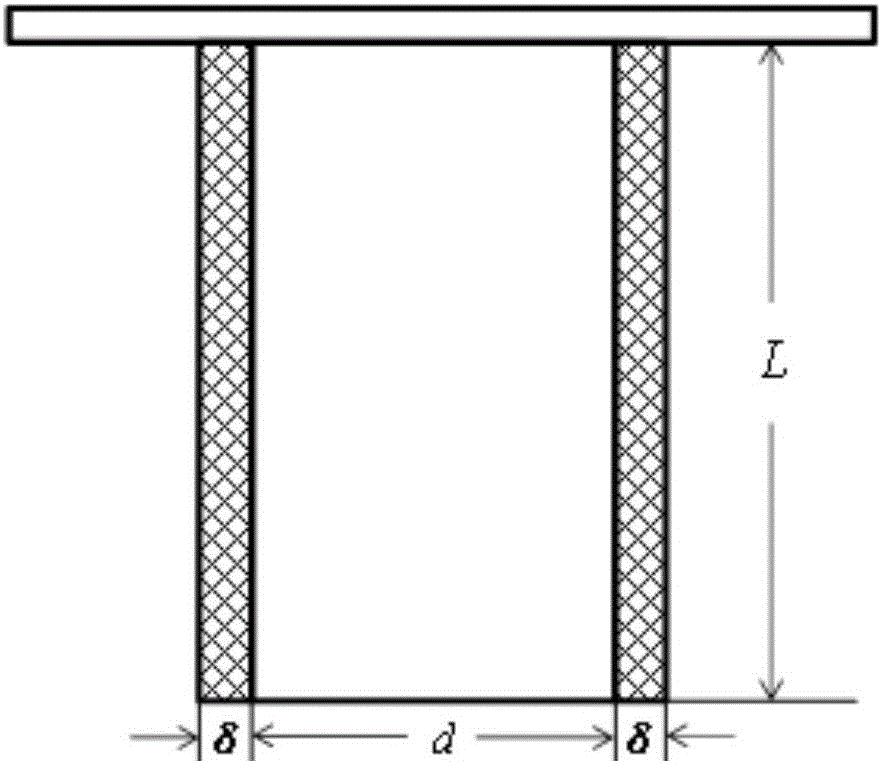

Method and system for cryogenic cooling

ActiveUS7415830B2Reduce CooldownExtend effective lifeRadiation pyrometryCompression machinesEngineeringCooling fluid

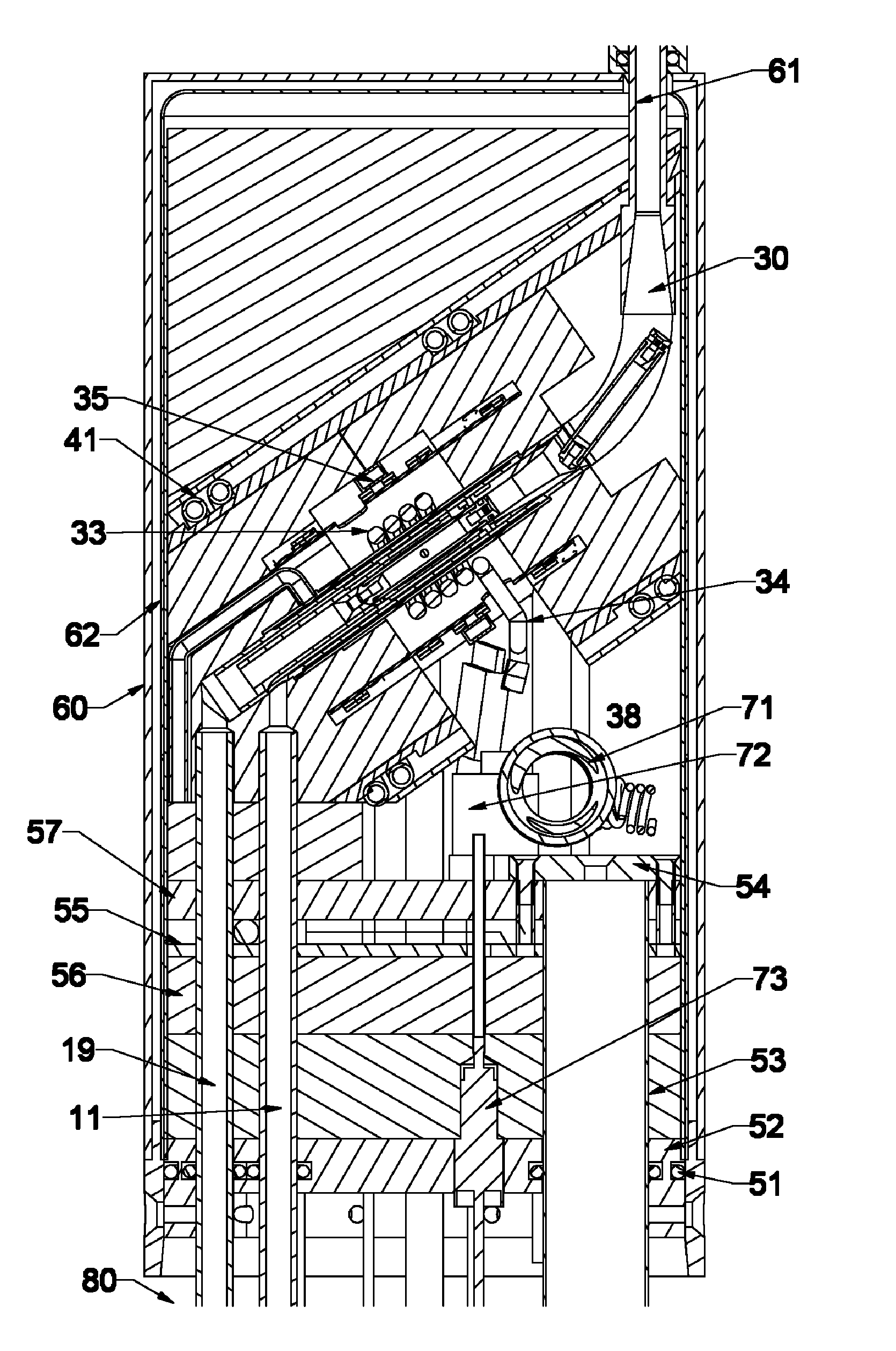

According to one embodiment, a method for improving heat transfer between a cold finger of a cryogenic cooler and a Dewar includes forming an annulus between the cold finger of the cryogenic cooler and the Dewar by inserting the cold finger into the Dewar. The cold finger has a first end and a second end. The method also includes inhibiting the formation of convective currents within the annulus in a direction between the first end and the second end. According to another embodiment of the invention, the cooling system includes a cryogenic cooler that includes a cooling section operable to generate cooling fluid and a cold finger operable to receive the cooling fluid. The cooling system also includes a Dewar formed with a void region coupled to an infrared detector. The cold finger is positioned within the void region of the Dewar creating an annulus. The cooling system also includes at least one obstruction disposed within the annulus and operable to inhibit the formation of convective currents in a direction along a length of the cold finger.

Owner:RAYTHEON CO

Expander for Stirling Engines and Cryogenic Coolers

InactiveUS20120017607A1Minimize heat conduction lossLow thermal conductivityCompression machinesGas cycle refrigeration machinesEngineeringPiston

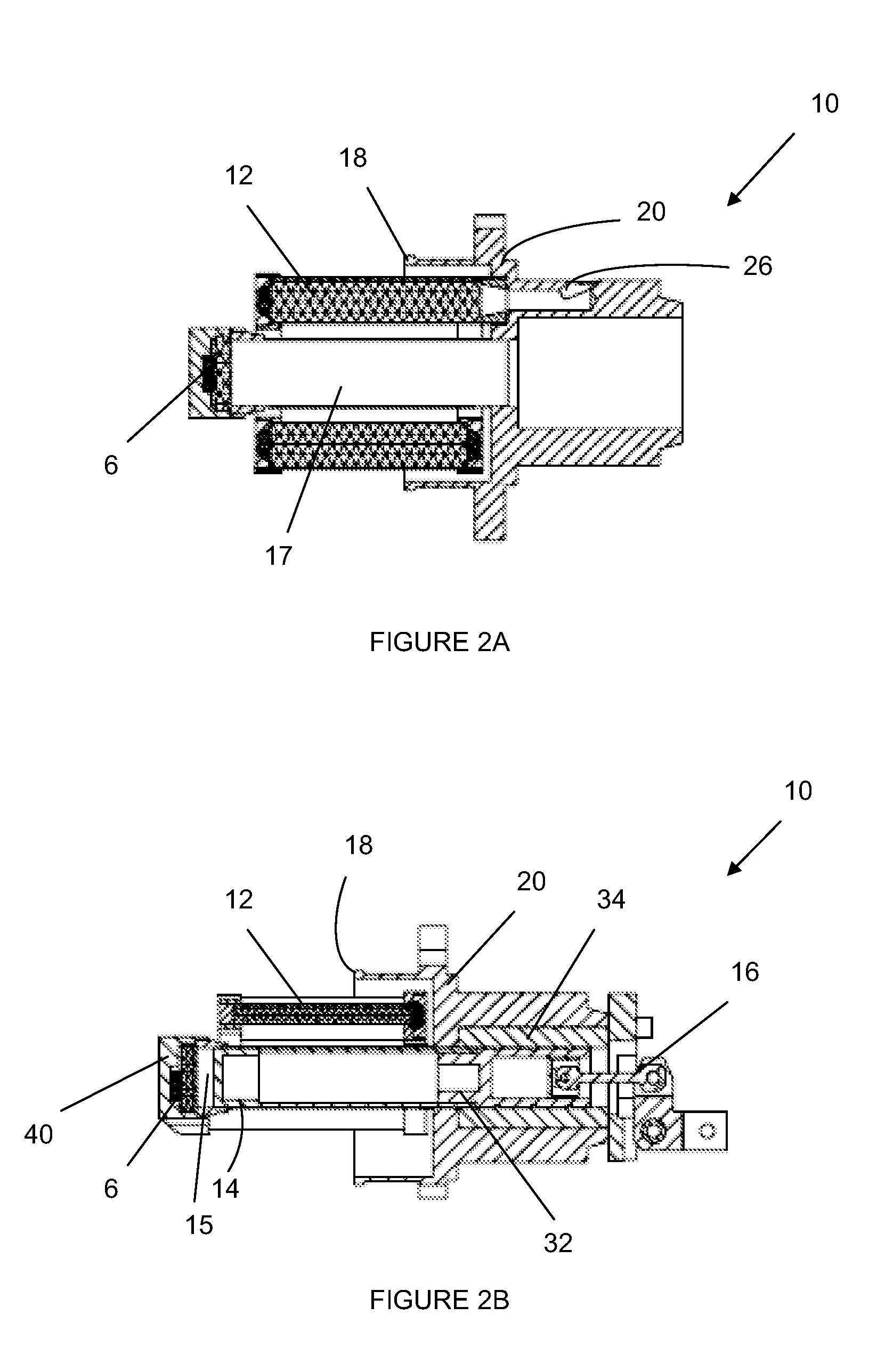

The invention is directed to an improved cryogenic cooler with an expander where the regenerator matrix is decoupled from the displacer or piston, thereby allowing the design of each to be optimized substantially independently. The regenerator matrix is preferably positioned spaced apart from the displacer and can be designed to enhance thermal exchanges and flow rates of the working gas. In one embodiment, the regenerator matrix has a serpentine shape or U-shape disposed around the displacer and the cold finger. Preferably, the regenerator matrix is static. The thermal lengths of the cold finger and / or the displacer can be extended by minimizing their geometrical lengths. Additionally, the structural integrity or stiffness of the cold finger and / or displacer can be strengthened.

Owner:TELEDYNE FLIR LLC

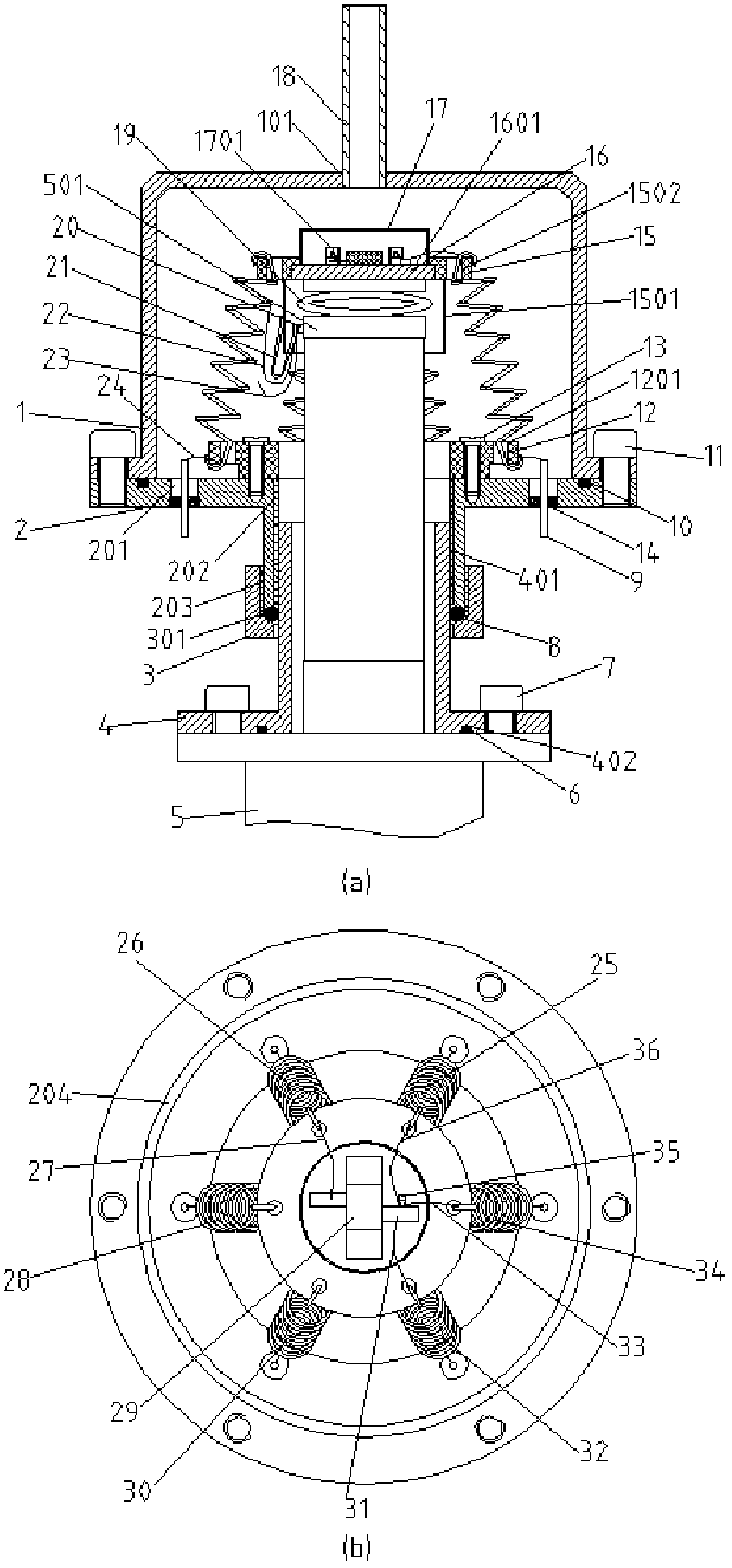

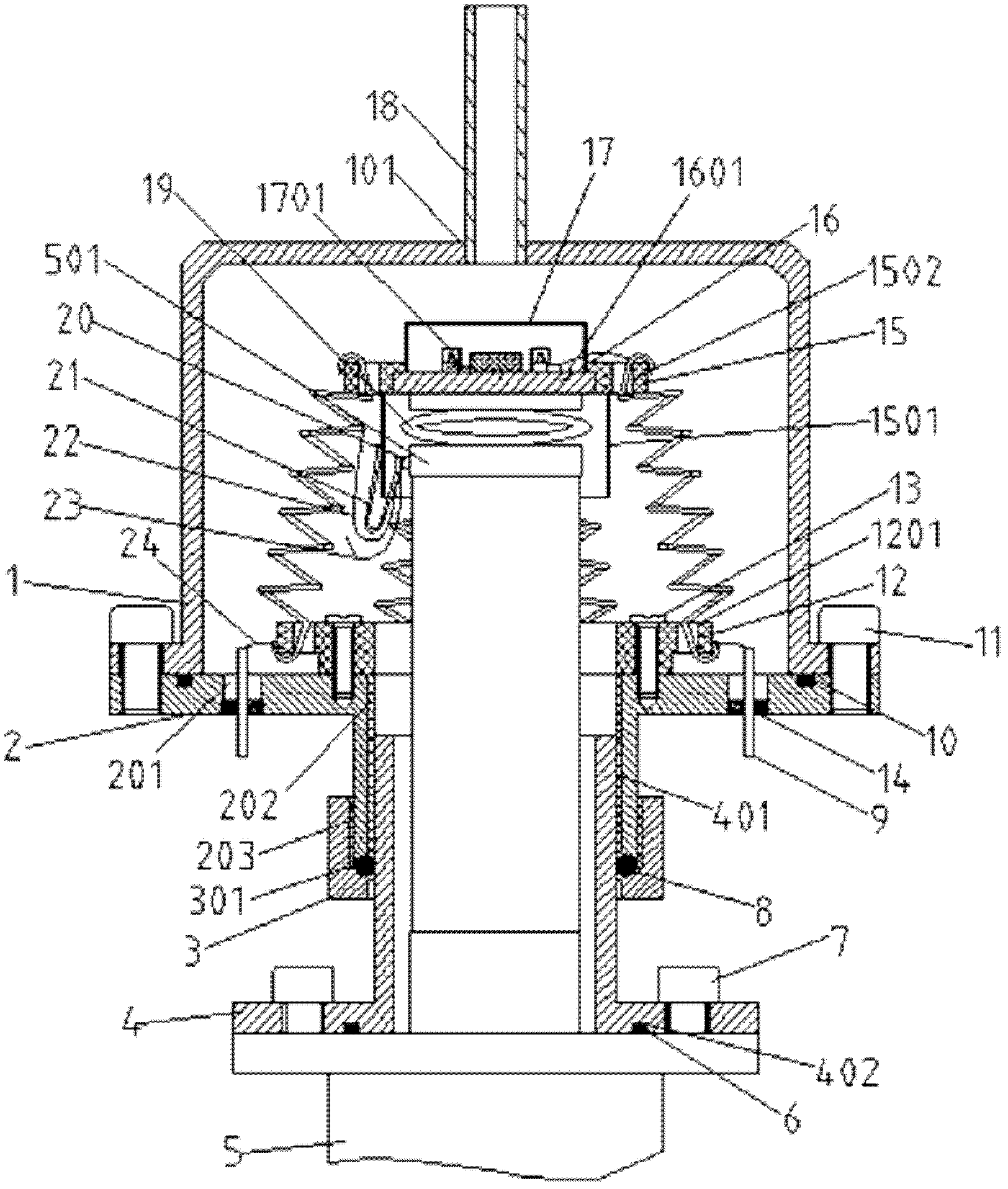

Low-temperature thermoacoustic refrigerator

InactiveCN101726131ACompact structureImprove practicalityCompression machinesThermoacousticsReciprocating motion

The invention discloses a low-temperature thermoacoustic refrigerator which comprises an oscillation wave generating part and a refrigerating part, wherein the oscillation wave generating part comprises a rotor, a stator, a piston, a passive oscillator and a cylinder; the refrigerating part comprises a first radiator, a heat regenerator, a cold finger, a heat buffer tube, a second radiator, an inertia tube and a gas reservoir which are sequentially communicated; the gas reservoir is surrounded outside the cylinder, and the inertia tube is wound on the inner wall of the gas reservoir; the end part of the cylinder is provided with a connecting piece connected with the first radiator and the second radiator, and a first gas hole and a second gas hole are arranged on the connecting piece; the first radiator is communicated with the cylinder through the first gas hole, and the second radiator is connected with the inertia tube through the second gas hole; when the oscillation wave generating part works, the piston reciprocates and generates oscillation waves under the drive of the rotor; and the oscillation waves enter the heat regenerator through the first gas hole and the first radiator. The embodiment has compact structure and small size and occupied area and improves the practicability of low-temperature thermoacoustic refrigerators.

Owner:LIHAN CRYOGENICS

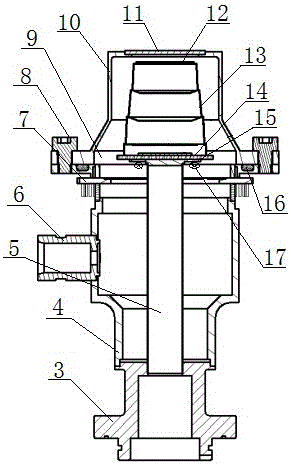

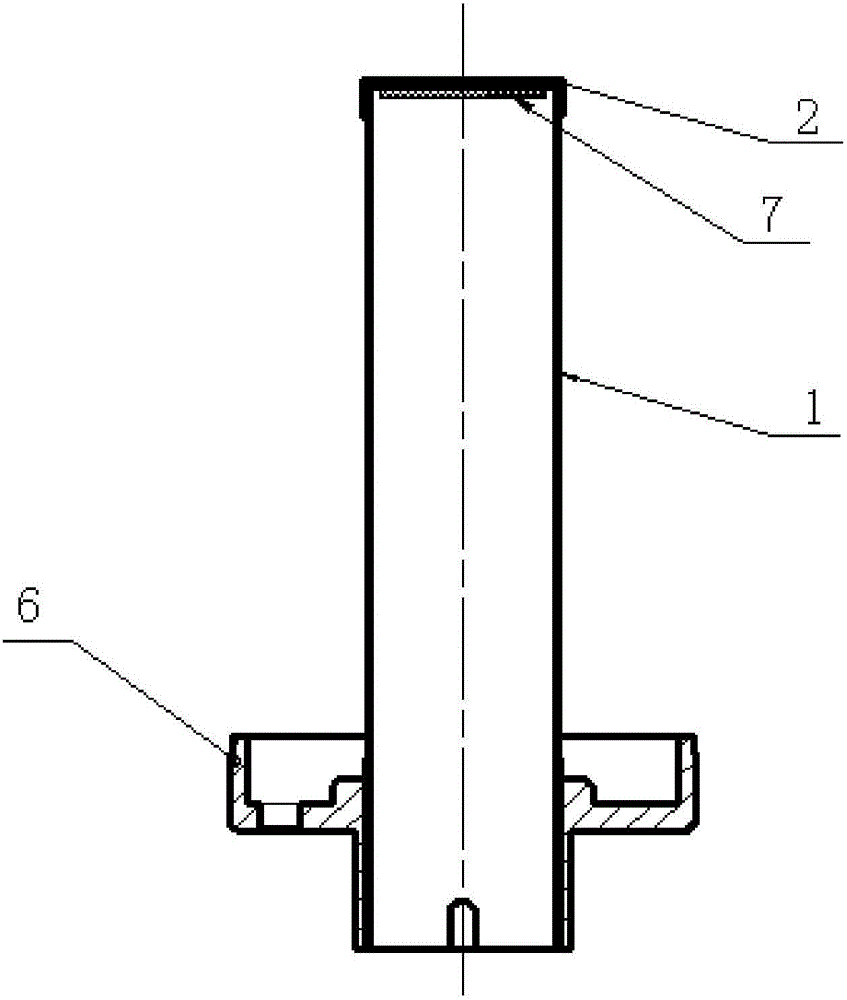

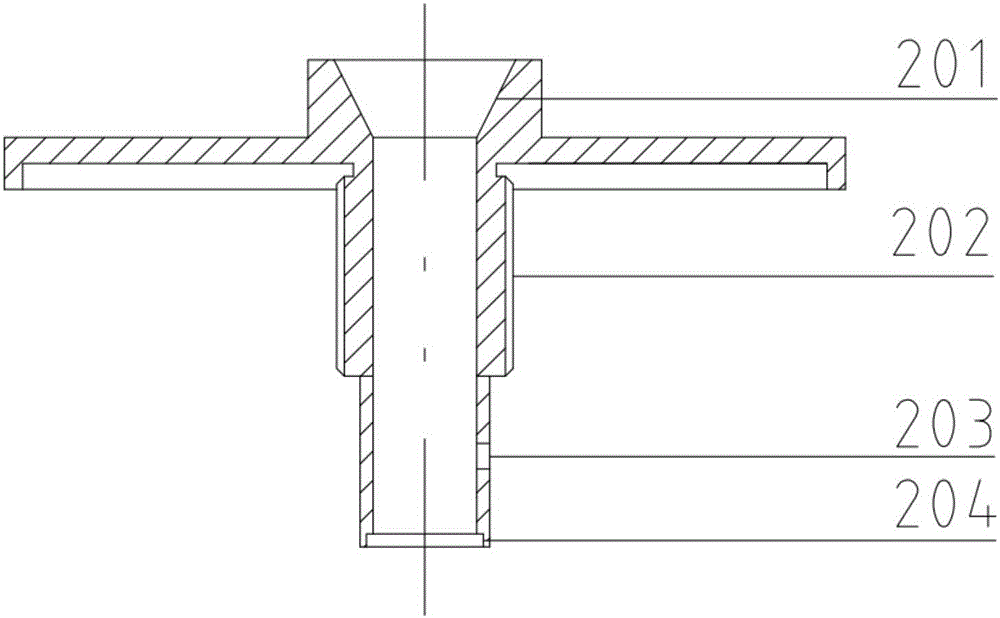

Detachable integrated temperature changing testing Dewar and assembly thereof

InactiveCN106441401AEasy to installEasy to disassembleRefrigeration safety arrangementInstrumentsThermodynamicsCold plate

The invention provides a detachable integrated temperature changing testing Dewar including a temperature changing Dewar main body, the temperature changing Dewar main body includes a cold finger base, a housing, a cold finger cylinder, a cold plate and a performance test assembly, the lower end of the housing is connected with the cold finger base, the housing includes an upper part and a lower part that are detachably connected to form an enclosed space, the cold finger cylinder, the cold plate, and the performance test assembly are successively connected in the enclosed space from the bottom to the top, a vacuum valve is arranged on the housing, and meanwhile, the invention provides a detachable integrated temperature changing testing Dewar assembly. The detachable integrated temperature changing testing Dewar is in a live-vacuum and detachable integrated structure, chip installation and detachment are convenient, the structure is compact and small, and the testing efficiency is high; and moreover, the detachable integrated temperature changing testing Dewar assembly can meet the temperature testing requirements of an infrared detector chip and other low-temperature materials in the 55K-130K temperature range.

Owner:WUHAN GAOXIN TECH

Full metal sealed EMCCD camera refrigeration dewar

InactiveCN103456757AReduce leak rateGuaranteed vacuumDomestic cooling apparatusLighting and heating apparatusElectron multiplicationEngineering

A full metal sealed EMCCD(Electron Multiplication Charge Coupled Device) camera refrigeration dewar comprises a thermoelectric cooler(TEC), a cold finger, a CCD socket, an EMCCD, a window, an outer shell, a copper seal ring and a base. A full metal sealed vacuum cavity is formed by the window, the outer shell and the base, the window and the outer shell are welded through anode welding, the outer shell and the base are sealed through knife edge flanges, the TEC, the cold finger, the EMCCD and the like are placed in the vacuum cavity, and the TEC serves as a cold source of a system. The interior of the vacuum cavity is vacuated, heat exchange between the EMCCD and the external environment is reduced to the minimum though the vacuum environment in the cavity, and thus the refrigeration effect is guaranteed. The system is suitable for the field of EMCCD camera refrigeration.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

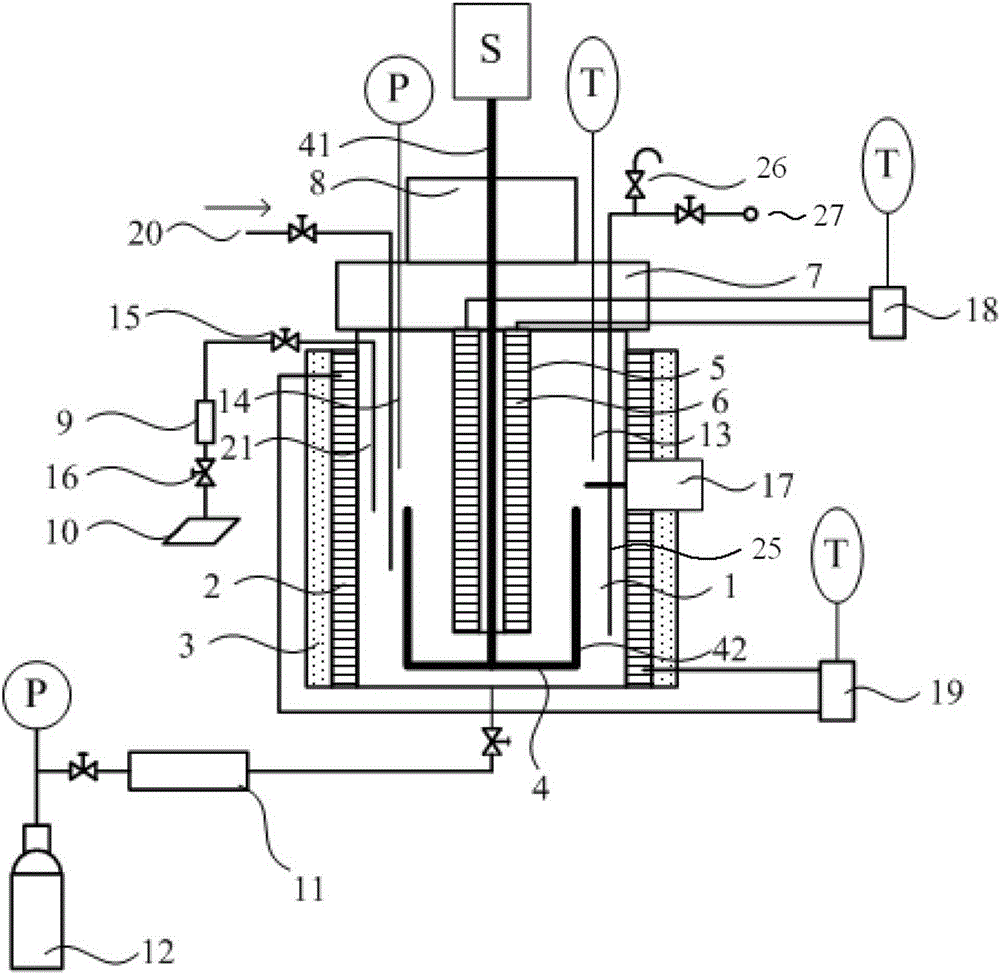

High-pressure wax deposition simulation device and method

ActiveCN105223227AGuaranteed stabilityDeposition experiment went wellInvestigating phase/state changeTemperature controlControl system

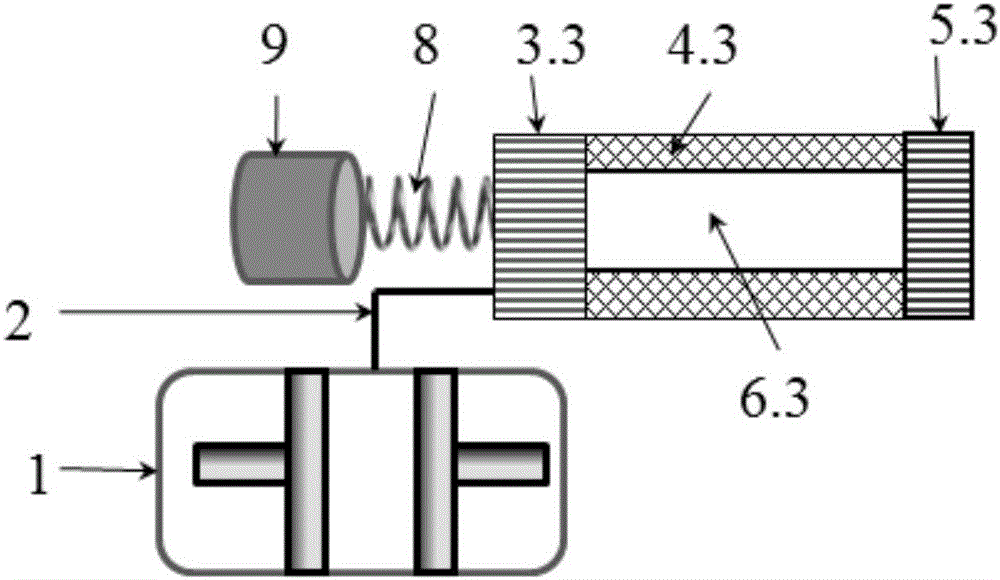

The invention provides a high-pressure wax deposition simulation device and method. The high-pressure wax deposition simulation device comprises a high-pressure kettle (1), wherein the high-pressure kettle (1) is internally provided with a cold finger (5) used for wax deposition; the temprature of the cold finger (5) is controlled by a first temperature control system (18); the temperature in the high-pressure kettle (1) is controlled by a second temperature system (19); the high-pressure wax deposition simulation device further comprises a sampling pipe (9), a sampling device (21) and a visible window (10), which can be used for sampling and observing under a high-pressure environment in the high-pressure kettle (1); and the high-pressure wax deposition simulation device further comprises a viscosity detection device (17). The high-pressure wax deposition simulation device and method provided by the invention can realize wax deposition simulation experiment, viscosity online detection and visualization processes under the high-pressure environment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Heat load test method and device for split type dewar at different refrigeration temperatures

ActiveCN102507012AEasy to installEasy to implementRadiation pyrometryCold chainRefrigeration temperature

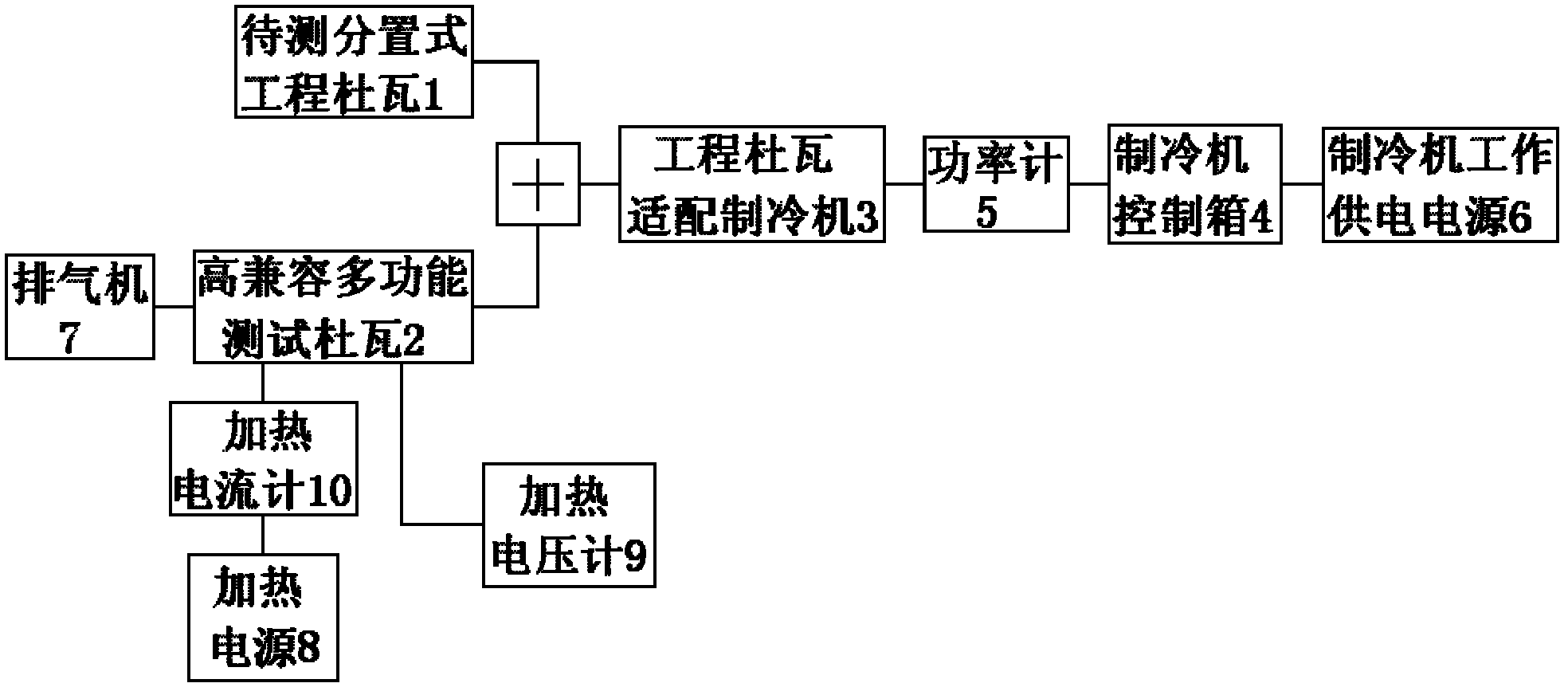

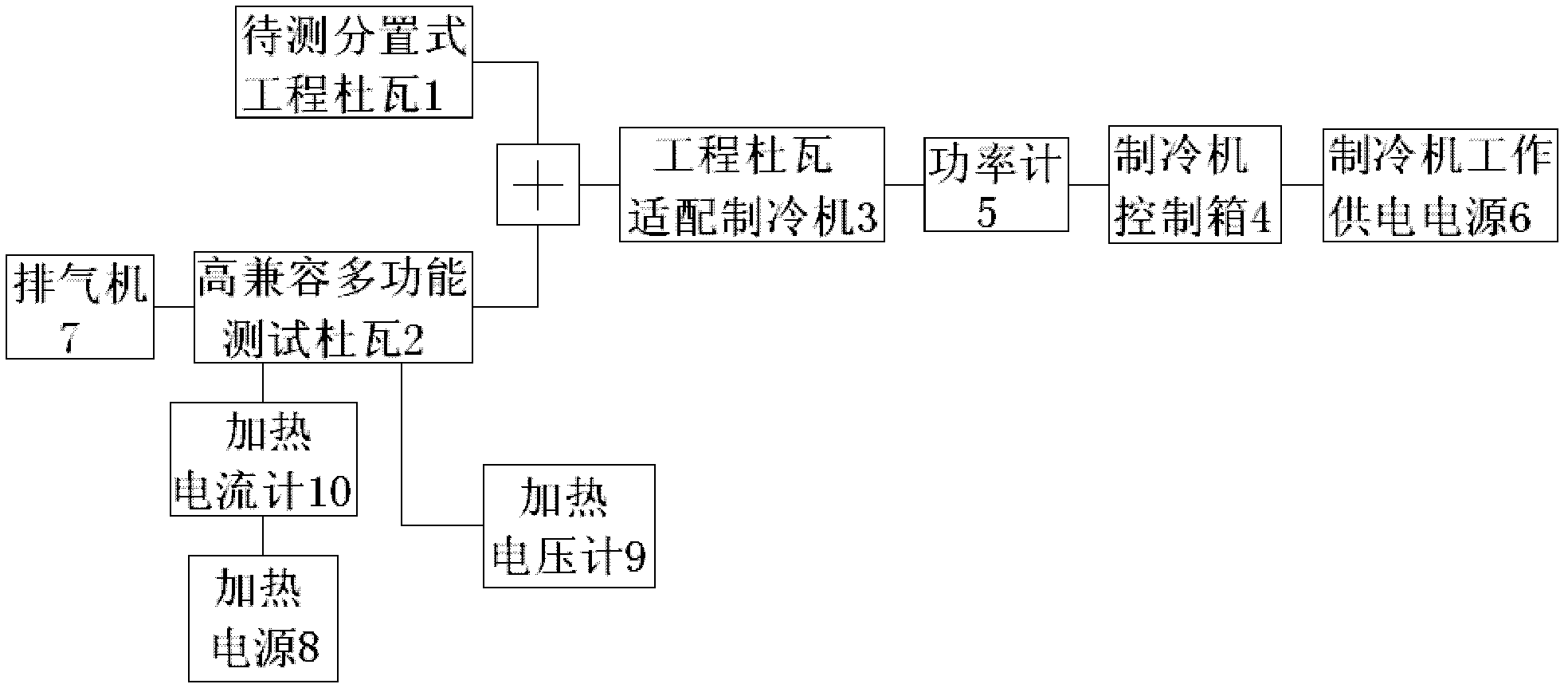

The invention discloses a heat load test method and device for split type dewar at different refrigeration temperatures. The heat load test device for the split type dewar at different refrigeration temperatures comprises a to-be-detected split type engineering dewar, a high-compatible multifunctional test dewar, an engineering dewar adapted refrigerator, a refrigerator control box, a power meter, a refrigerator working power supply, an air exhauster, a heating power supply, a heating voltmeter and a heating galvanometer. According to the heat load test method and device for the split type dewar at different refrigeration temperatures, disclosed by the invention, a special structure is introduced in the aspect of the high-compatible multifunctional test dewar, so that the static heat loadprecise detection for the split type engineering dewar is realized through an assembly replacement method and a heat equalization method. The device and implementation method thereof, disclosed by the invention, have the advantages of simpleness, high test precision, strong generality and low cost. The method and device disclosed by the invention are same suitable for testing a refrigeration capacity of an engineering refrigerator at different refrigeration temperatures. The method and device disclosed by the invention are also suitable for testing the temperature gradient of elastic cold chains or carbon paper or other coupling mediums on the cold fingers of the engineering refrigerator at different refrigeration temperatures and under different transfer refrigeration capacities.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

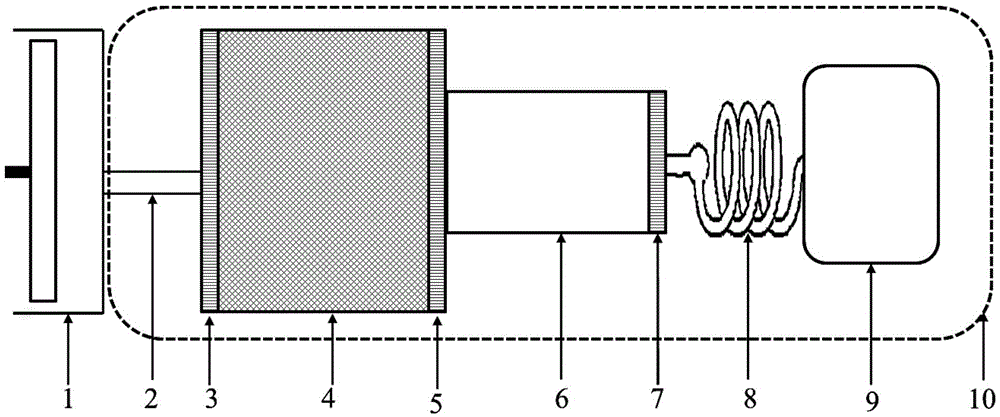

Linear compressor-driven travelling wave loop pulse tube refrigerator

InactiveCN102748891AGuaranteed cooling effectSmall pressure fluctuationsCompression machinesLinear compressorPulse tube refrigerator

The invention discloses a linear compressor-driven travelling wave loop pulse tube refrigerator, which comprises a cold finger and a linear compressor, wherein the cold finger consists of a travelling wave loop pulse tube refrigerator and an inertia tube; a piston is used for partitioning the internal space of the linear compressor into a front cavity and a back cavity; a mover, a stator and a plate spring are positioned in the back cavity; the front cavity is communicated with a primary radiator, a heat regenerator, a cold head, a pulse tube and a secondary radiator in the travelling wave loop pulse tube refrigerator in sequence; and one end of the inertia tube is connected with the secondary radiator, and the other end of the inertia tube is communicated with the back cavity. According to the characteristics of large back cavity size and small pressure fluctuation of the linear compressor, the conventional air reservoir is removed, a travelling wave loop is formed by directly communicating the inertia tube with the back cavity, and the back cavity of the compressor plays a role in replacing the air reservoir; meanwhile, direct current flow can be suppressed, an elastic membrane for partitioning the back cavity into a front cavity front part and a back cavity back part can be arranged in the back cavity, and the inertia tube is communicated with the back part of the back cavity; a direct current channel is blocked, and the refrigerating performance of the refrigerator is kept; and the structure is more compact, and practical application is more facilitated.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

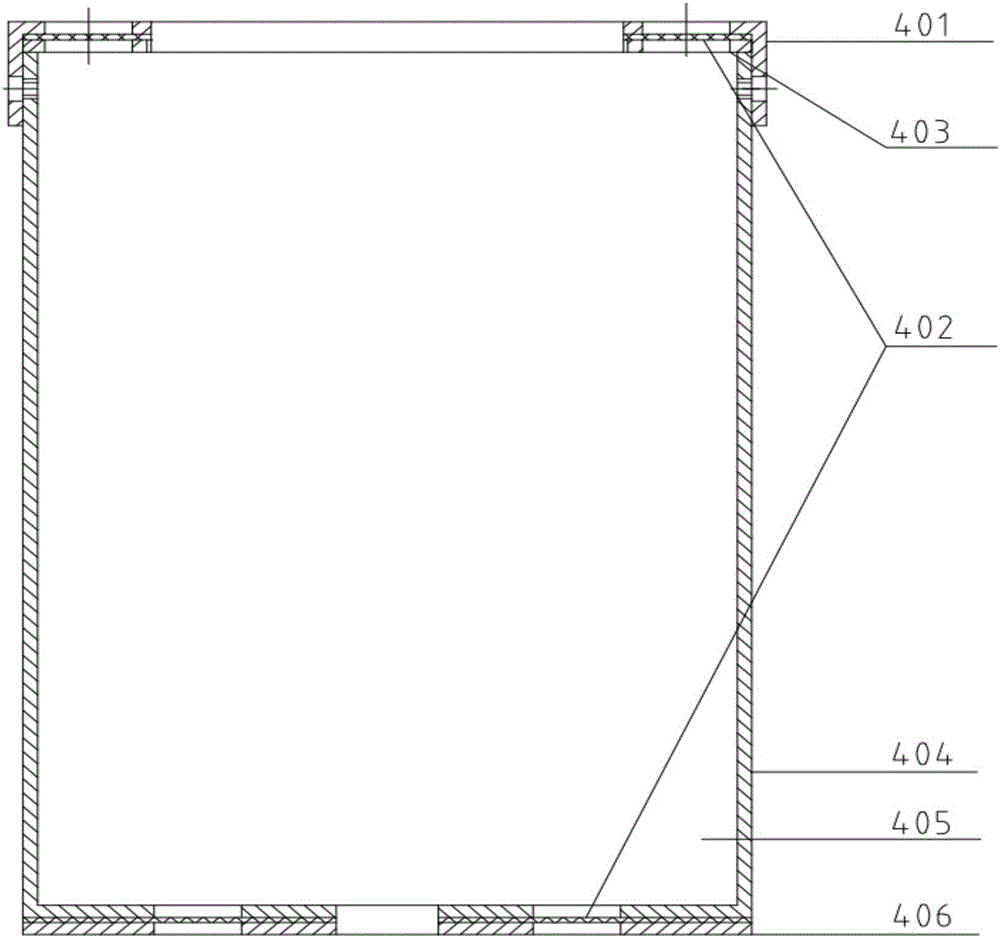

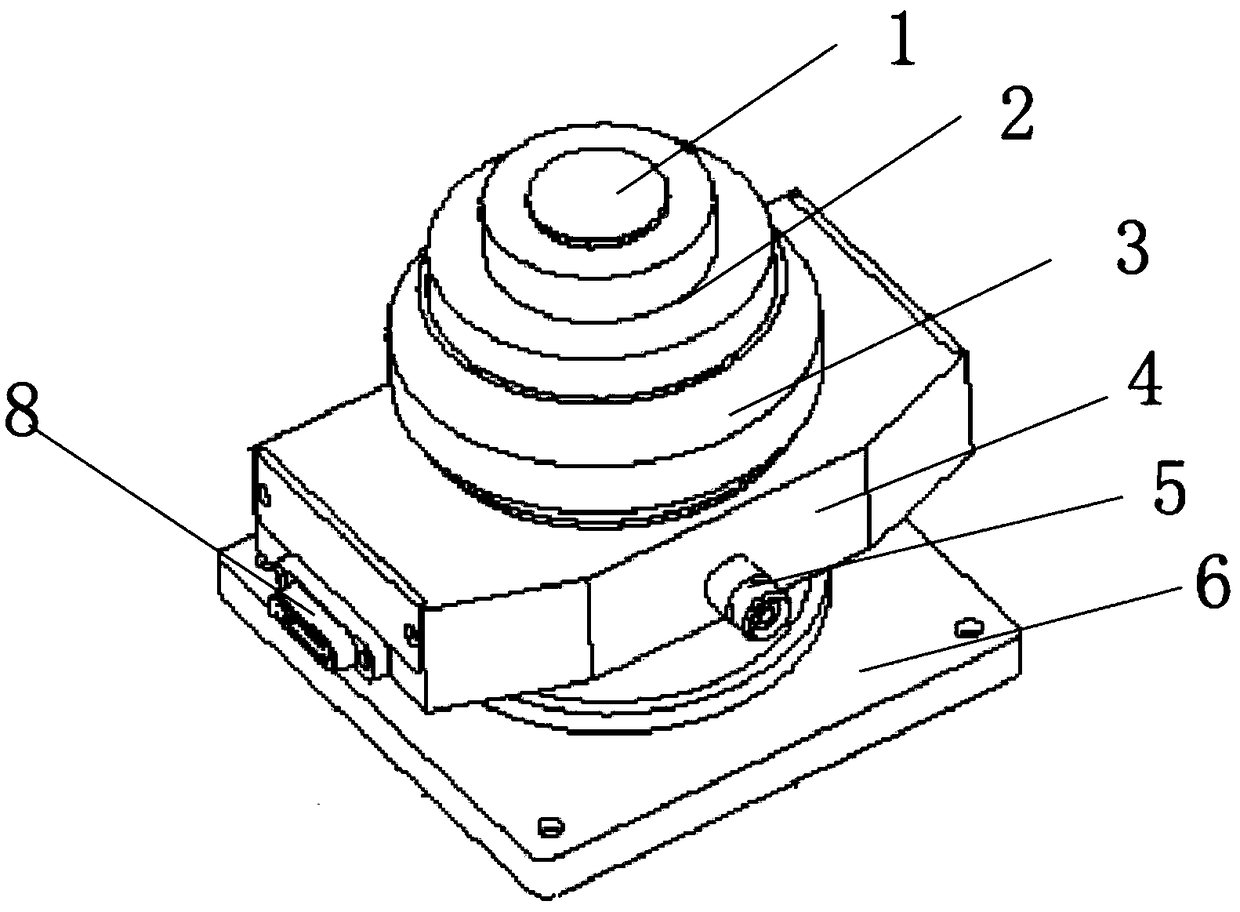

Monopole coaxial pulse tube refrigeration device of annular pulse tube structure and design method thereof

ActiveCN105115182ACompact designShorten the processing cycleCompression machinesGas cycle refrigeration machinesEngineeringRefrigeration

The invention discloses a monopole coaxial pulse tube refrigeration device of an annular pulse tube structure and a design method thereof. The device comprises a hot-end heat exchanger, a cold-end heat exchanger, an annular pulse tube arranged at the outside, a cylindrical heat regenerator internally coaxial with the pulse tube and the like. According to the device, the annular pulse tube structure is adopted, through the slit structure, the phenomenon that the pulse tube performance is deteriorated due to circulation of working gas alternating in the pulse tube and other reasons is reduced, and the performance of the pulse tube and even the performance of a complete machine are improved; a cold finger can be designed into an annular groove structure or a boss structure, coupling with equipment needing to be refrigerated is more facilitated, the refrigeration time is shortened, and the refrigeration efficiency is improved; the manufacturing process difficulty of the complete machine equipment is lowered, the production efficiency is improved, and the design and machining cost is reduced.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

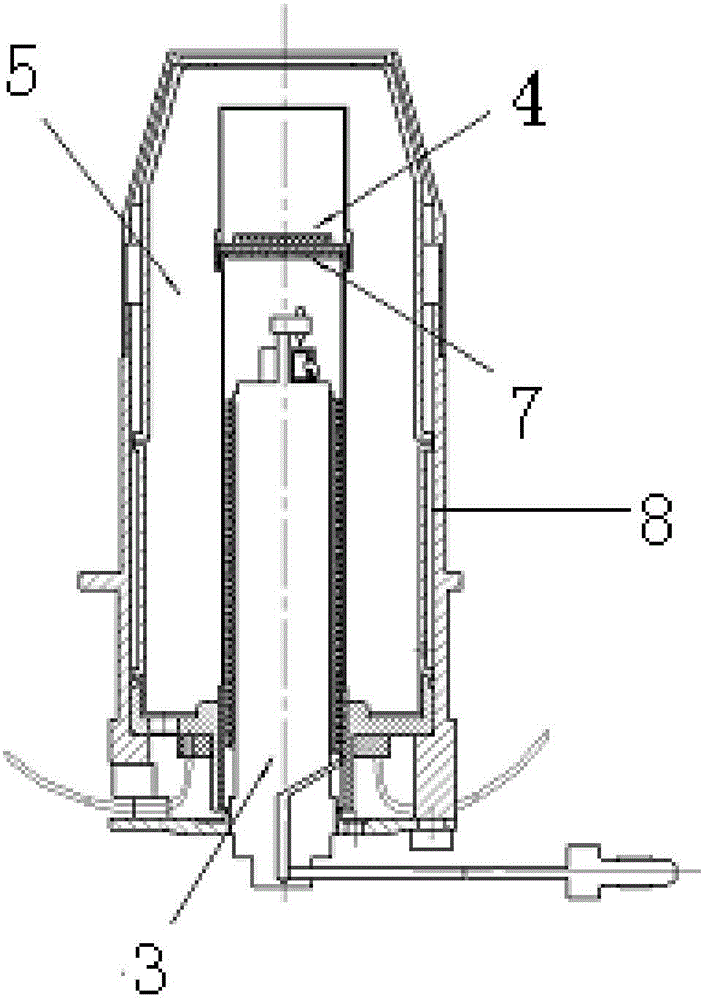

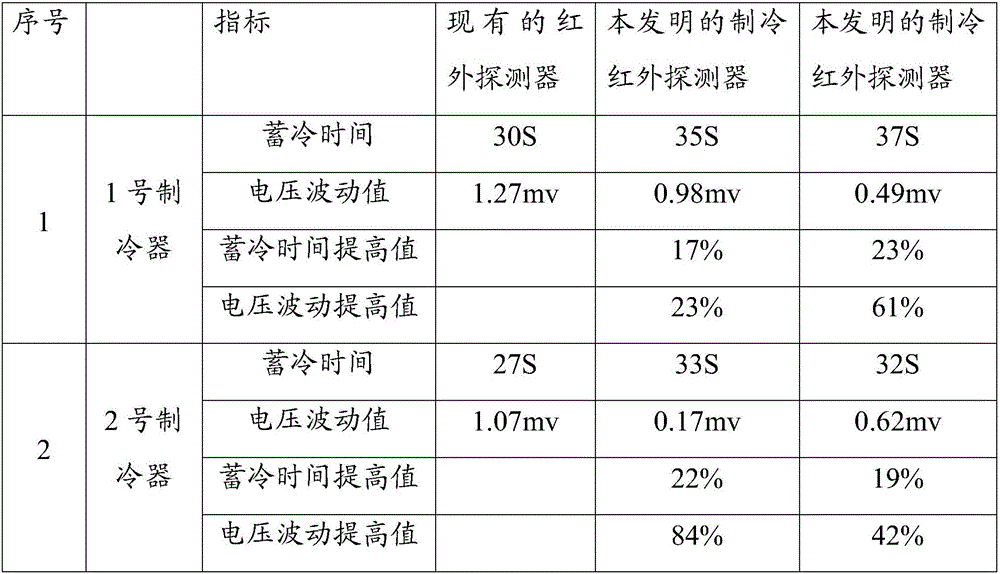

Refrigeration infrared detector

ActiveCN106706136ANo increase in gas consumptionExtend cold storage timeRadiation pyrometryTemperature controlEngineering

The invention discloses a refrigeration infrared detector. The refrigeration infrared detector comprises a dewar, a dewar cold finger, a refrigerator and a detector chip, wherein the refrigerator is positioned in the dewar cold finger; the detector chip is arranged in the dewar and is positioned on a cold head of the dewar cold finger; a cold storage device is arranged at the side, opposite to the cold head, of the bottom of the dewar cold finger. After the technical scheme is adopted, not only is cold storage time of the infrared detector prolonged while the gas consumption of the refrigerator is not increased, but the temperature control stability of the infrared detector is also improved to a certain extent.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

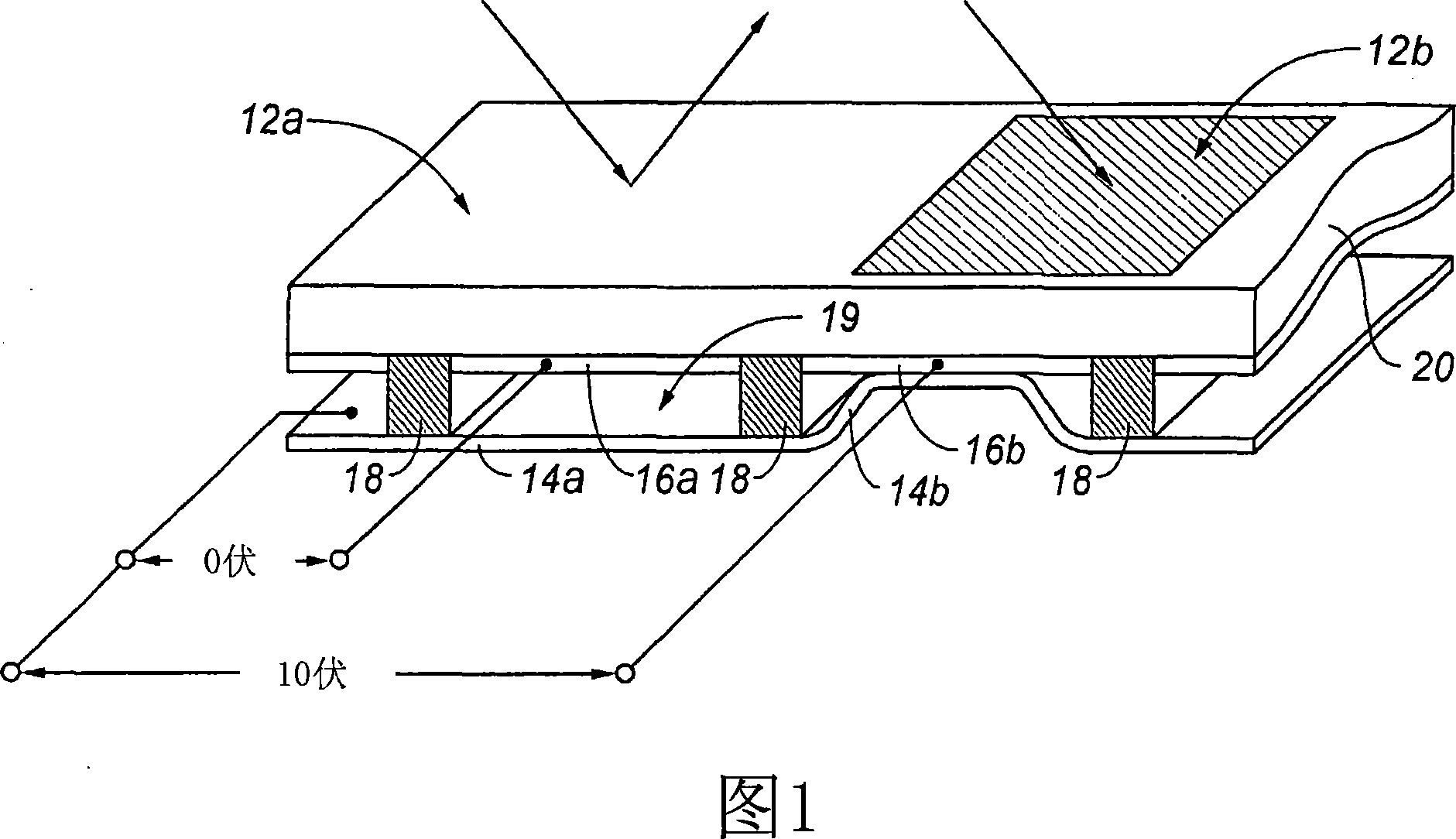

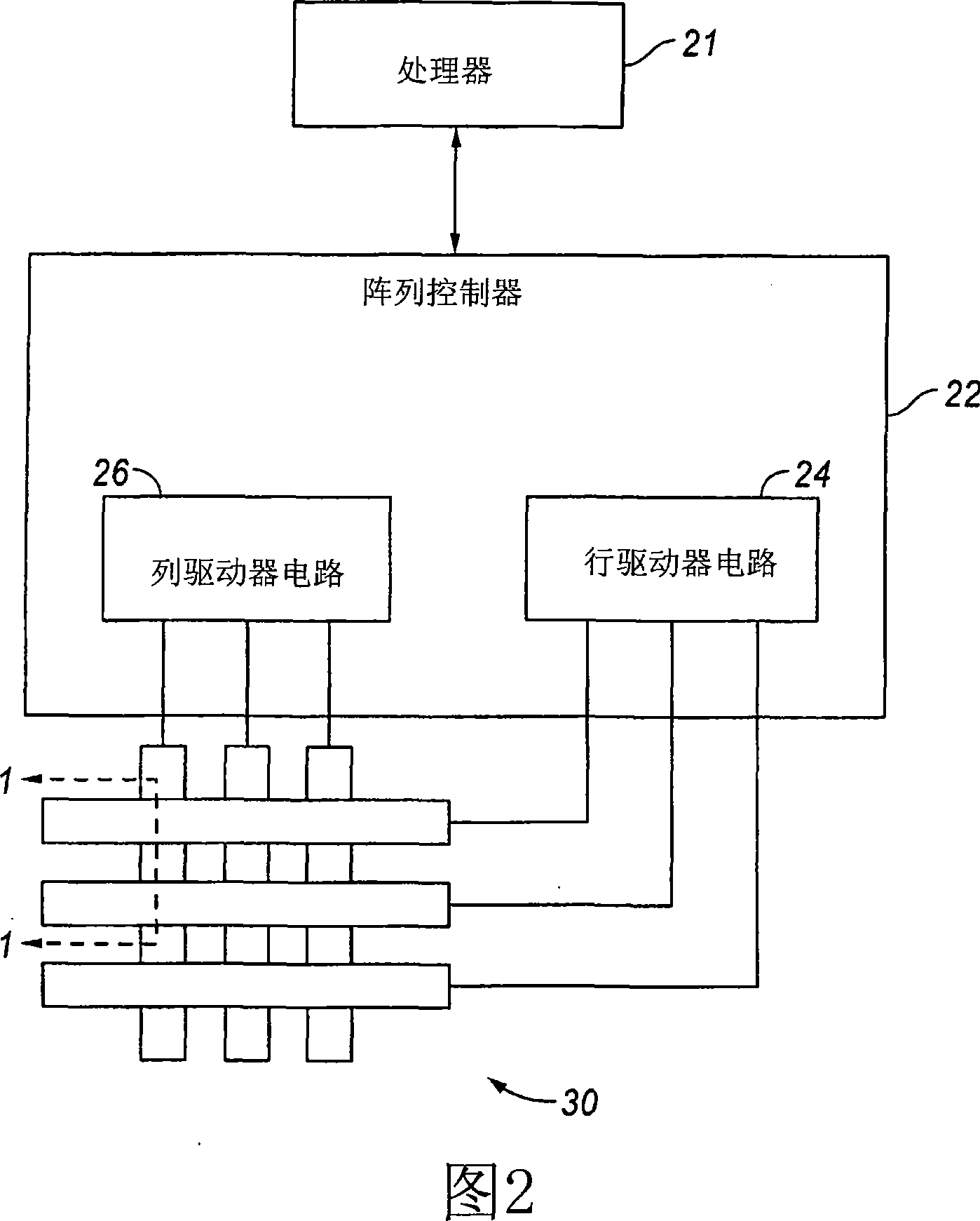

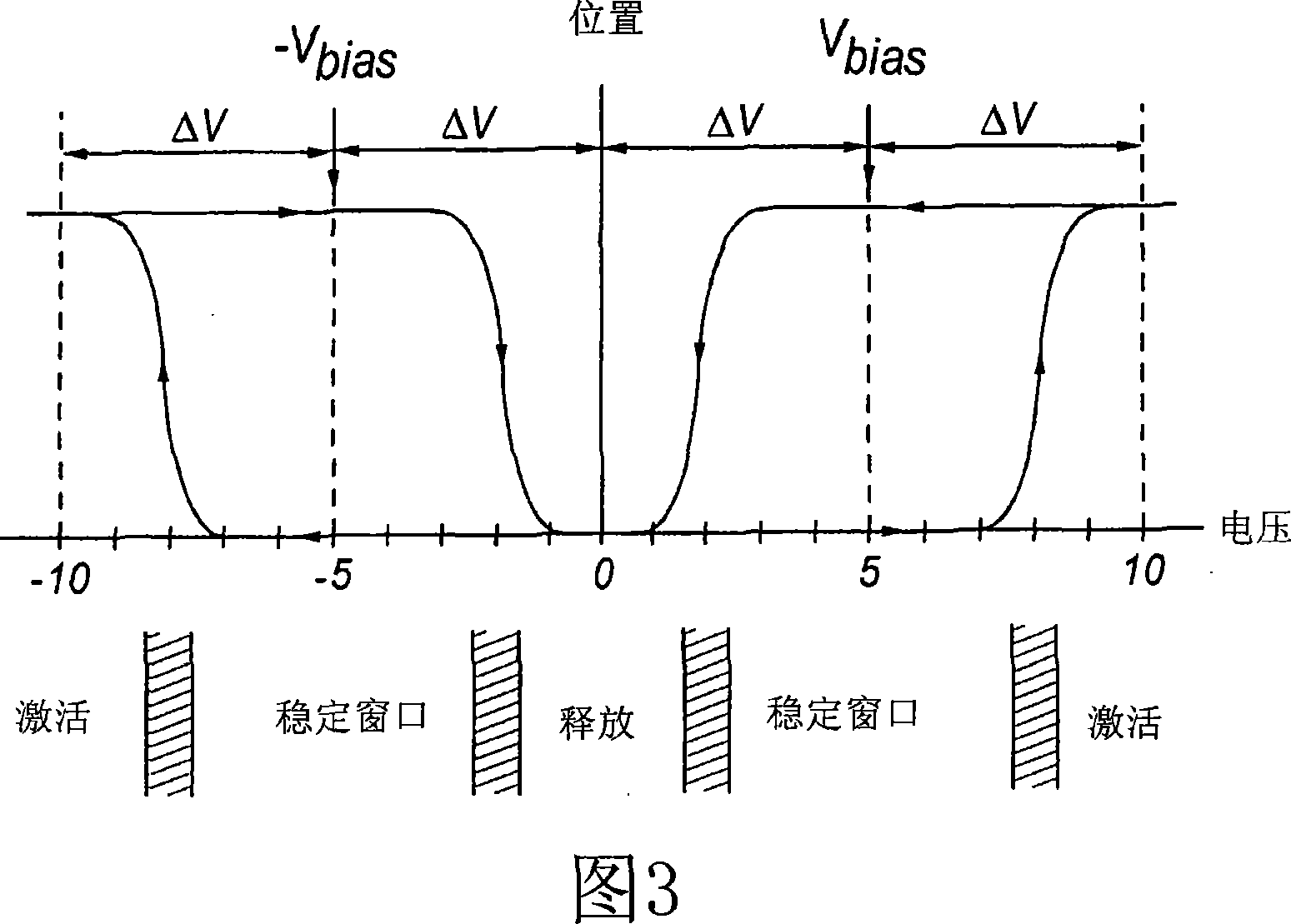

System and method of testing humidity in a sealed mems device

One embodiment provides a method of testing humidity, comprising: determining a property of a device which encloses a plurality of interferometric modulators; and determining a relative humidity value or a degree of the relative humidity inside the device based at least in part upon the determined property. In one embodiment, the property of the device includes one of the following: i) a weight of the device, ii) a color change of a desiccant enclosed in the device, iii) a resistance inside the device, iv) whether frost formed in an inside area of the device which is contacted by a cold finger device, v) whether a desiccant enclosed in the device, when water vapor is provided into the device, is working properly, and vi) combination of at lest two of i)-v).

Owner:IDC LLC

Thermoelectric refrigeration device for water cooling heat dissipating and air cooling heat dissipating

InactiveCN105352217AMeet cooling needsSimple designMachines using electric/magnetic effectsVacuum pumpingWater cycling

The invention discloses a thermoelectric refrigeration device for water cooling heat dissipating and air cooling heat dissipating. The device comprises a vacuum chamber which is surrounded by a base and an upper cover, wherein hermetic window glass is arranged on the top wall of the upper cover; a vacuum air exhaust port is formed in the sidewall of the upper cover; a TEC (semiconductor thermoelectricity cooling) refrigerating plate, a CCD (Charge Coupled Device) chip, a cold finger, a temperature sensor, an electrical plug and a vacuum absorbent are arranged in the vacuum chamber; a water circulating system is arranged in the base; a finned heat dissipator is arranged at the lower part of the base. The device is simple in design structure, and is applicable to vacuum dewar flasks in an air cooling heat dissipating manner and a water cooling heat dissipating manner, so that a thermoelectric refrigeration dewar is applicable to various situations, and the heat dissipation manner can be flexibly used.

Owner:UNIV OF SCI & TECH OF CHINA

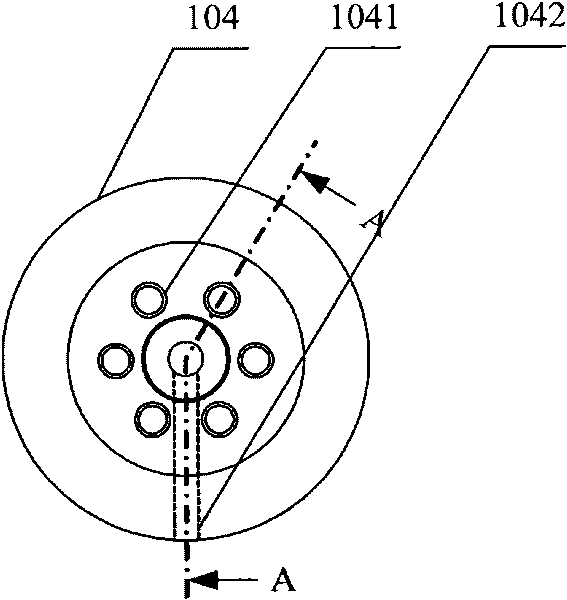

Free piston expander

ActiveCN102519178AReduce position eccentricityReduce wearCompressorFluid circulation arrangementDrive motorEngineering

The invention relates to a free piston expander and belongs to the field of low temperature refrigeration. The expander comprises a plate spring, a clearance sealing seat, a heat regenerator, a cold finger, a cold cylinder, a driving rod, an end cover, a tube connector and external equipment compressor. The cold cylinder and the cold finger are of an integrated structure. One or more plate springs are arranged in the cold cylinder. The center of the plate spring is provided with a hole. Both ends of the plate spring are fixed on the cold cylinder. The heat regenerator is positioned in the cold finger. A metal wire braided square hole net is filled in the heat regenerator. The driving rod is arranged at the front end of the heat regenerator. The driving rod extends into the cold cylinder, passes through the center of the plate spring and is fixedly connected with the center of the plate spring. The clearance sealing seat is positioned at the junction of the cold cylinder and an inner cavity of the cold finger. The application of the plate spring takes a rigid supporting effect. A driving motor is arranged in the cold cylinder, so that the energy consumption is reduced.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

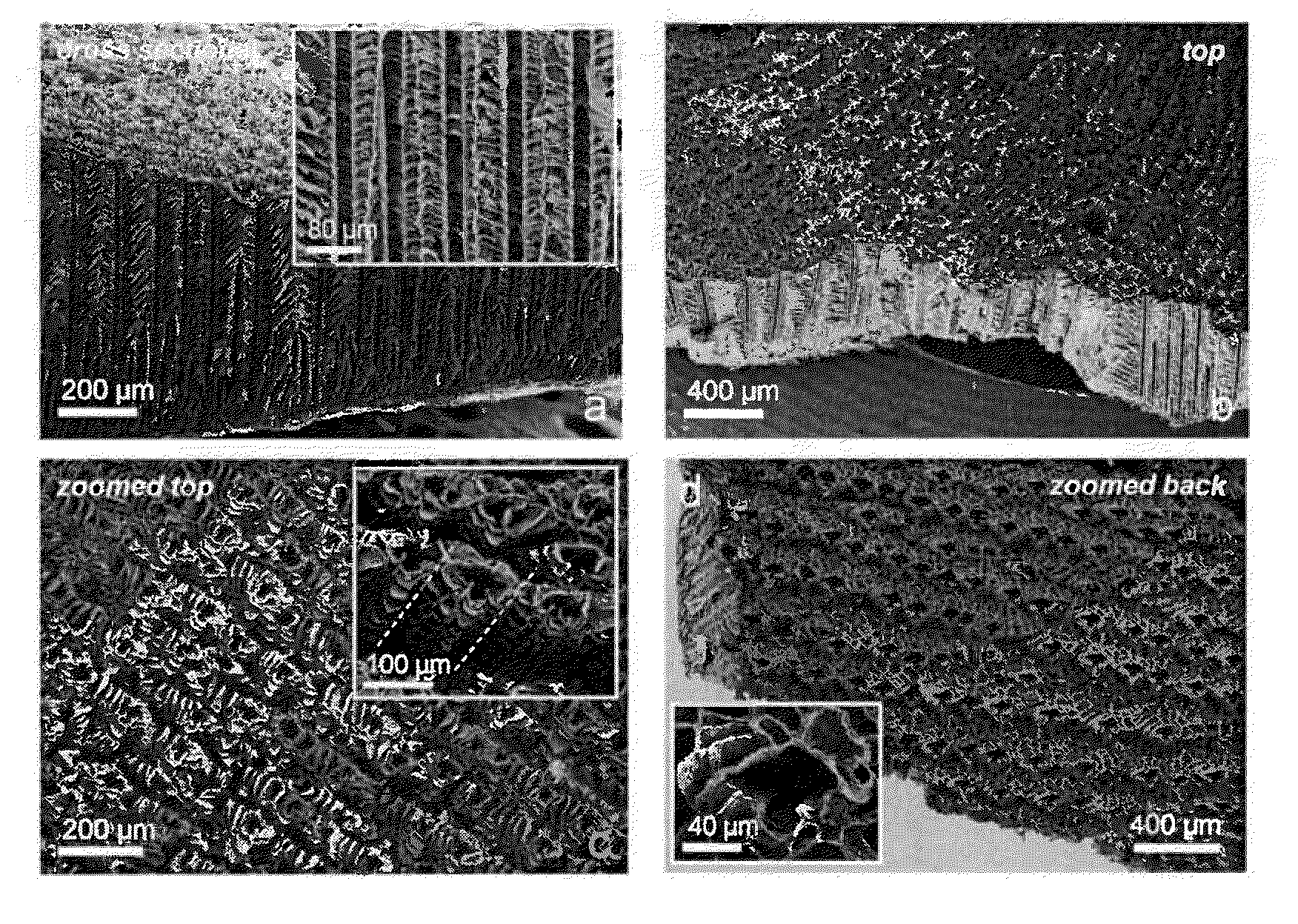

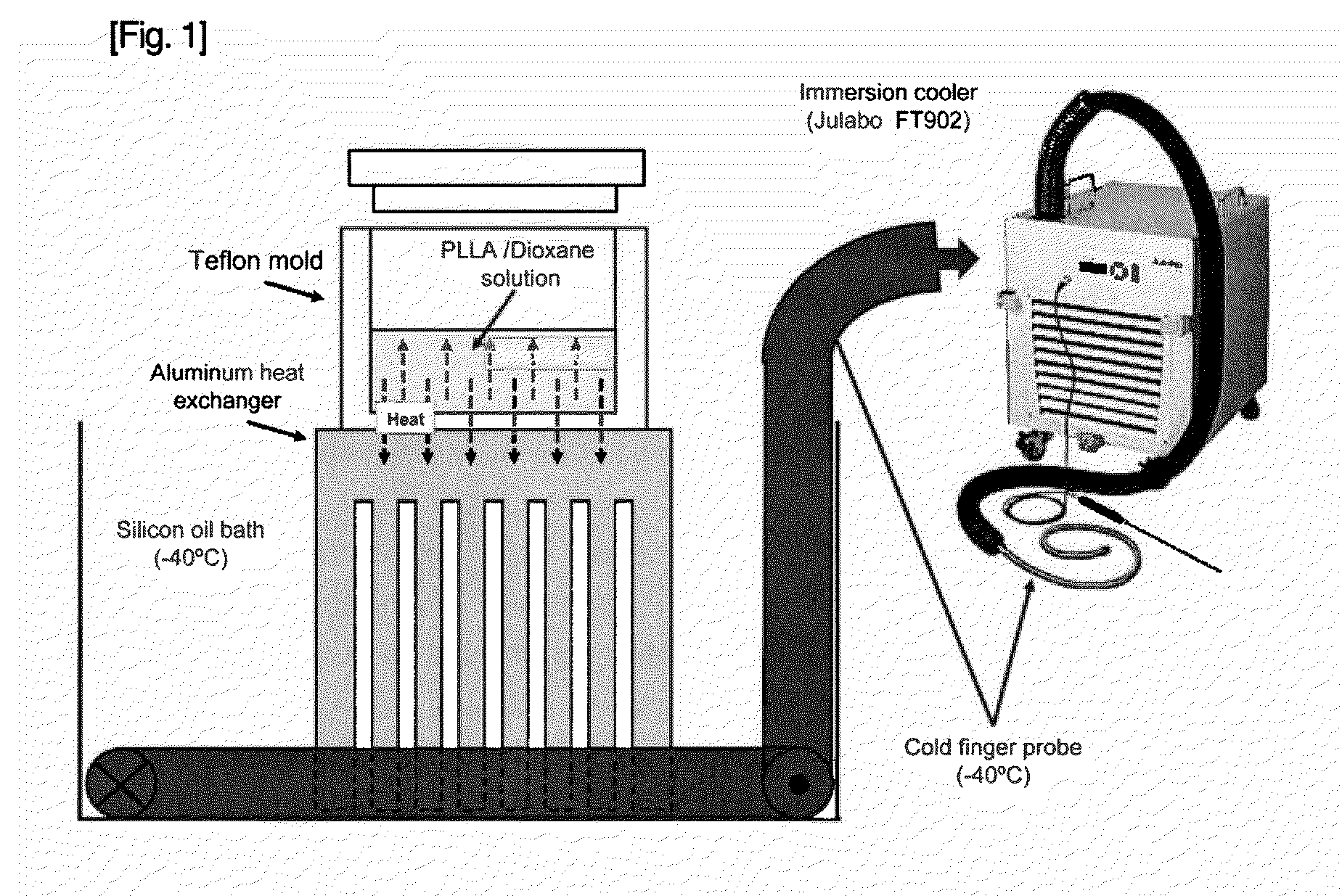

Highly porous solid material made of biodegradable polymer and method of fabricating, processing, and cell-seeding the same

InactiveUS20110171732A1Animal cellsLighting and heating apparatusTissue reconstructionAqueous solution

[Problems] A purpose of the invention is to provide highly porous 3D scaffolds made of biodegradable polymer such as poly-lactic acid, which can be preferably used for cell culture.Another purpose of this invention is to provide a method for seeding cells homogeneously inside the above mentioned 3D highly porous scaffolds.Another purpose of this invention is to provide a top-down processing method for obtaining planar porous 2D scaffolds starting the above mentioned highly porous scaffolds to be used as building blocks for thick tissue reconstruction.[Solution] Highly porous scaffolds made of biodegradable polymer such as poly-lactic acid can be fabricated by following steps:(i) biodegradable polymer is dissolved in dioxane at the defined concentration;(ii) a vessel containing the solution is mounted on a metal plate thermally driven by a cold finger to a defined temperature below 10° C., and then the vessel is kept on the plate, until the solution undergoes complete phase separation; and(iii) the obtained solids are immersed into an alcoholic aqueous solution to leach out the dioxane.

Owner:NAT INST FOR MATERIALS SCI

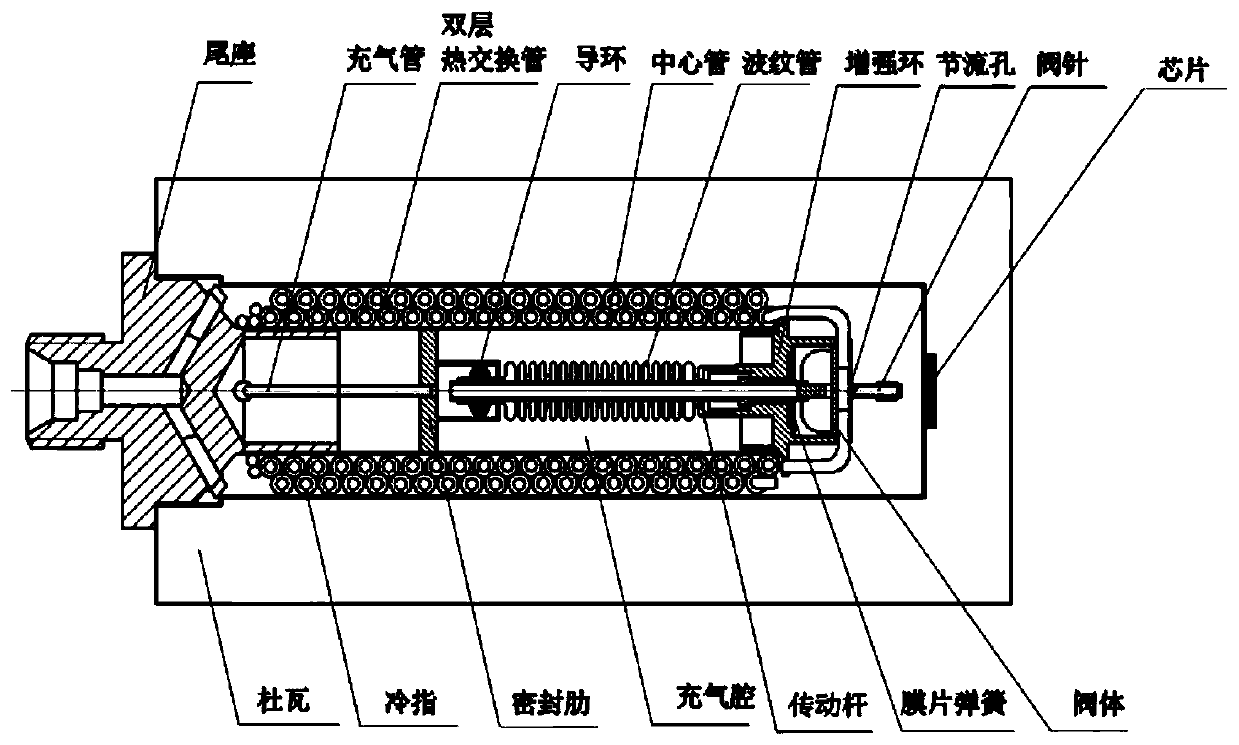

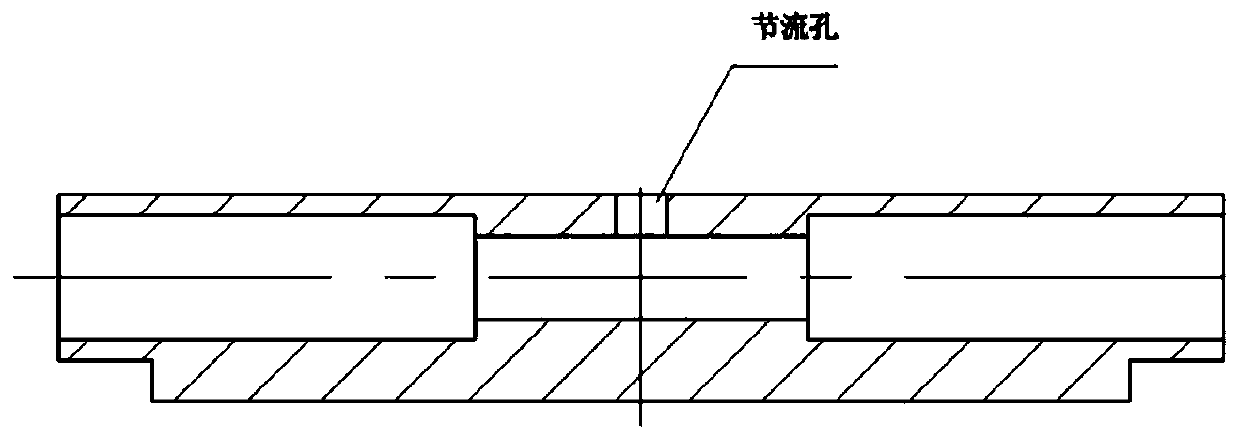

Corrugated pipe type self-adjusting J-T refrigerator

InactiveCN110274404AImprove heat transfer efficiencySmall thermal massCompression machinesEngineeringHigh pressure

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

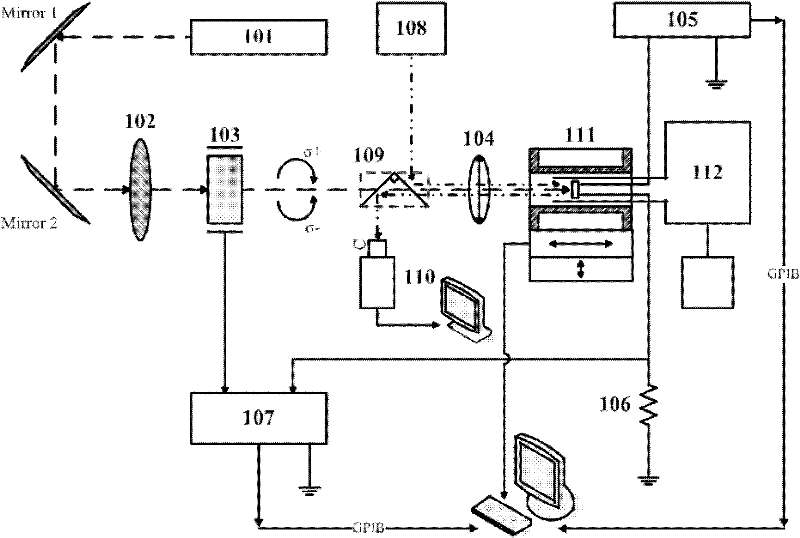

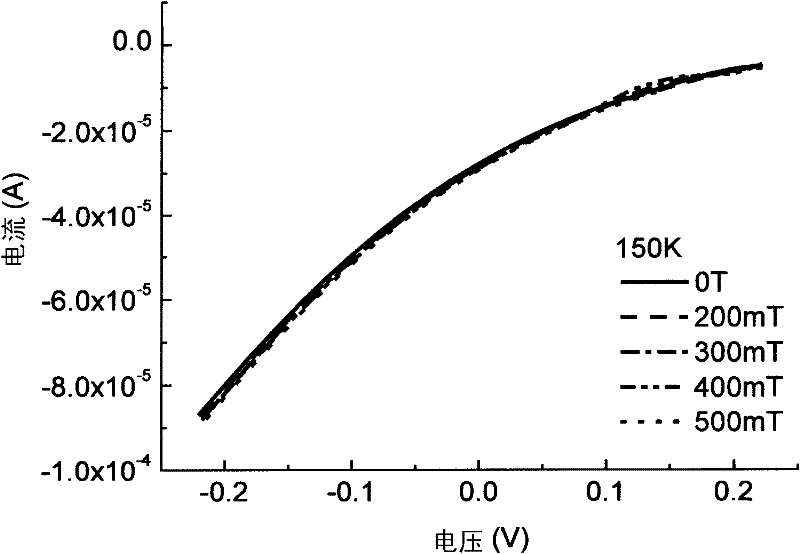

Variable temperature microscopic measurement system for measuring related electron-spin transportation

InactiveCN102253323AAccurate measurementAccurate Spin InjectionRate of change measurementMagnetic property measurementsDisplay devicePrism

The invention discloses a variable temperature microscopic measurement system for measuring related electron-spin transportation, which comprises an HeNe laser, a Grand taylor prism, a photoelastic modulator, a micro objective, a variable temperature liquid nitrogen Dewar sample holder, a digital voltage current source meter, a sampling resistance, a phase locked amplifier, a half-reflecting and half-transmitting lens group, a white light source, a camera, a display and a neodymium iron boron ring-shaped permanent magnet, wherein, the laser sent out by the HeNe laser is converted into linearly polarized light by the Grand taylor prism; the micro objective is used for focusing the incident lasers onto the platform surface of a sample; the variable temperature liquid nitrogen Dewar sample holder comprises a temperature control meter and a red copper cold finger which is used for fixing the sample to be detected on the top of the red copper cold finger; the control end of the digital voltage current source is connected with a computer through a general purpose interface bus (GPIB); the sampling resistance is used for extracting an alternating current voltage signal of the sample to be detected; the control end of the phase locked amplifier is connected with the computer through the GPIB; the half-reflecting and half-transmitting lens group is positioned on a main optical path; the white light source is used for observing the position on the platform surface of the sample to be detected; the camera and the display are used for displaying and outputting a platform surface image of the sample to be detected and the laser light spot position; and the neodymium iron boron ring-shaped permanent magnet is coaxially sheathed outside the red copper cold finger of the variable temperature liquid nitrogen Dewar sample holder.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

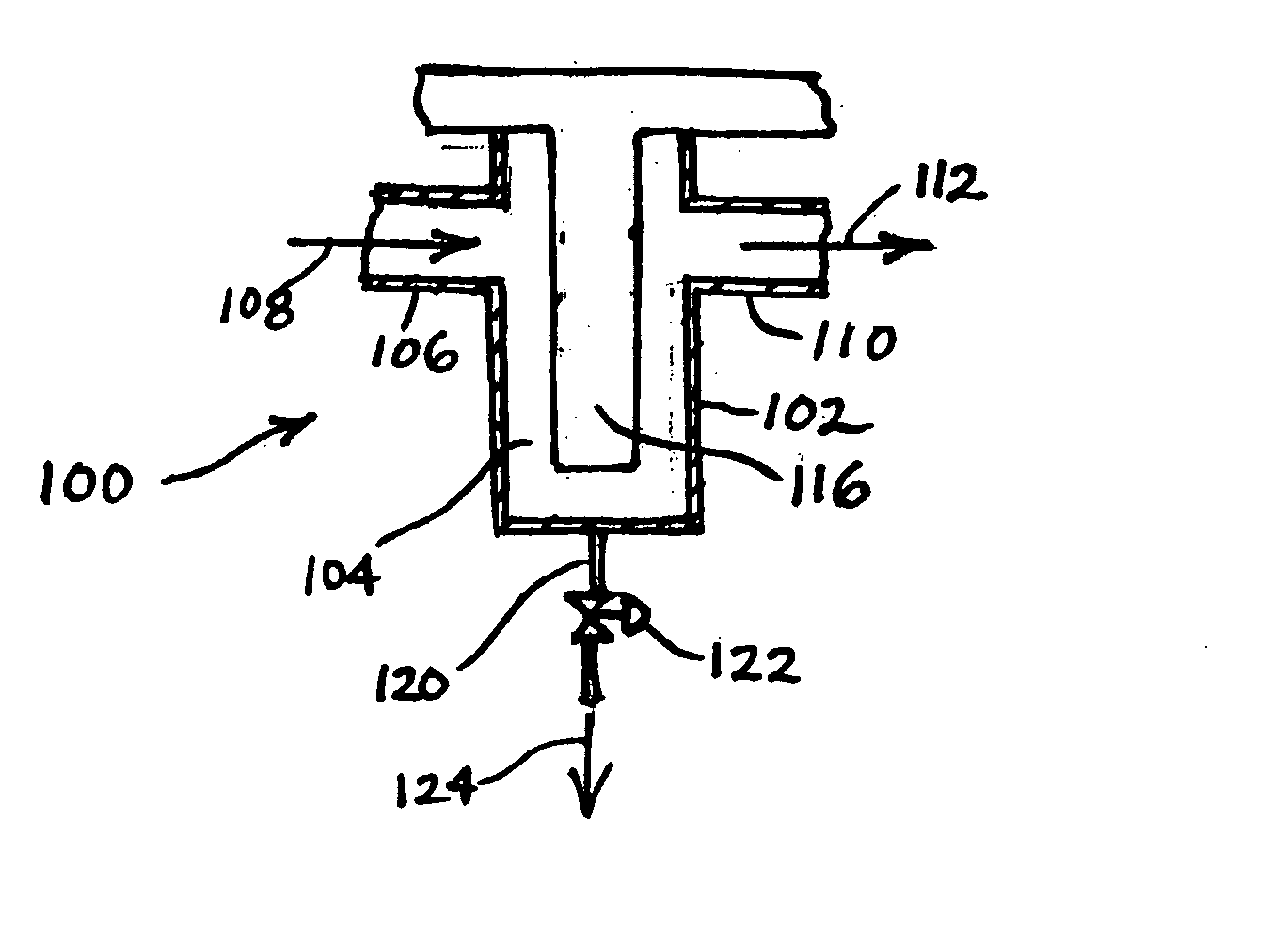

Gas recovery system to improve the efficiency of abatementand/or implement reuse/reclamation

InactiveUS20040187683A1Improve emission reduction efficiencyIsotope separationSorbentProcess engineering

A gas recovery system for improving the efficiency of abatement and / or implementing reclamation and reuse of unused feed materials in effluent of a semiconductor manufacturing facility, especially in instances in which substantial portions of feed material are unused. The effluent is treated to reversibly capture the unused feed material, e.g., at a capture locus such as a physical adsorbent, cold finger, cryotrap, heat exchanger / condenser, membrane separation unit, filter, etc., and the captured unused feed material then is released from the capture locus and processed for such abatement and / or reclamation and reuse.

Owner:APPLIED MATERIALS INC

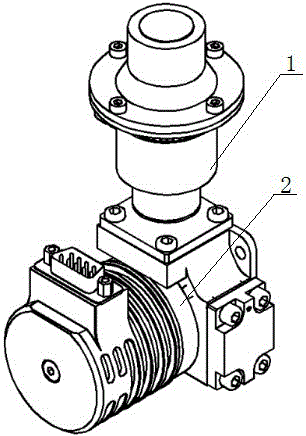

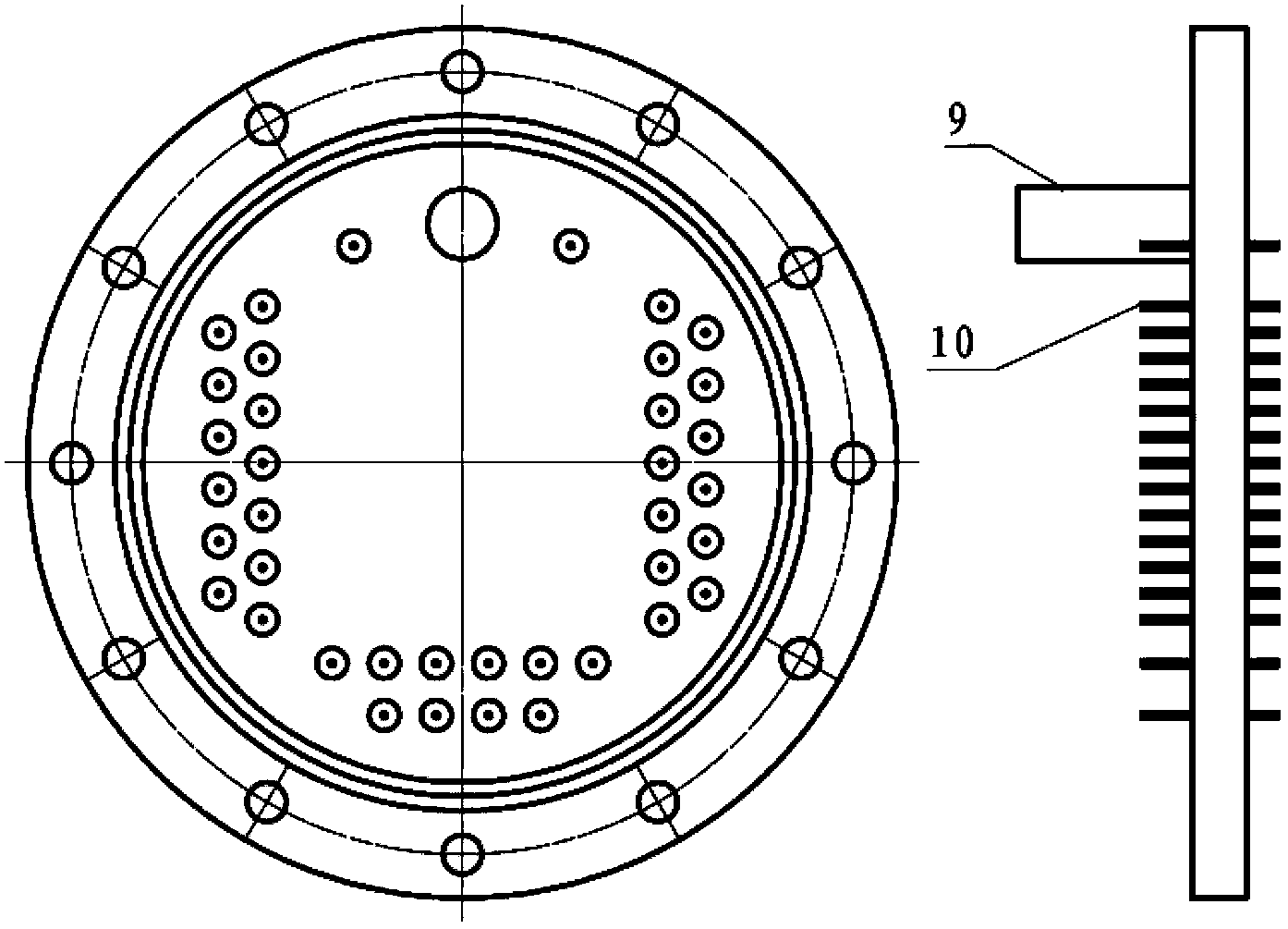

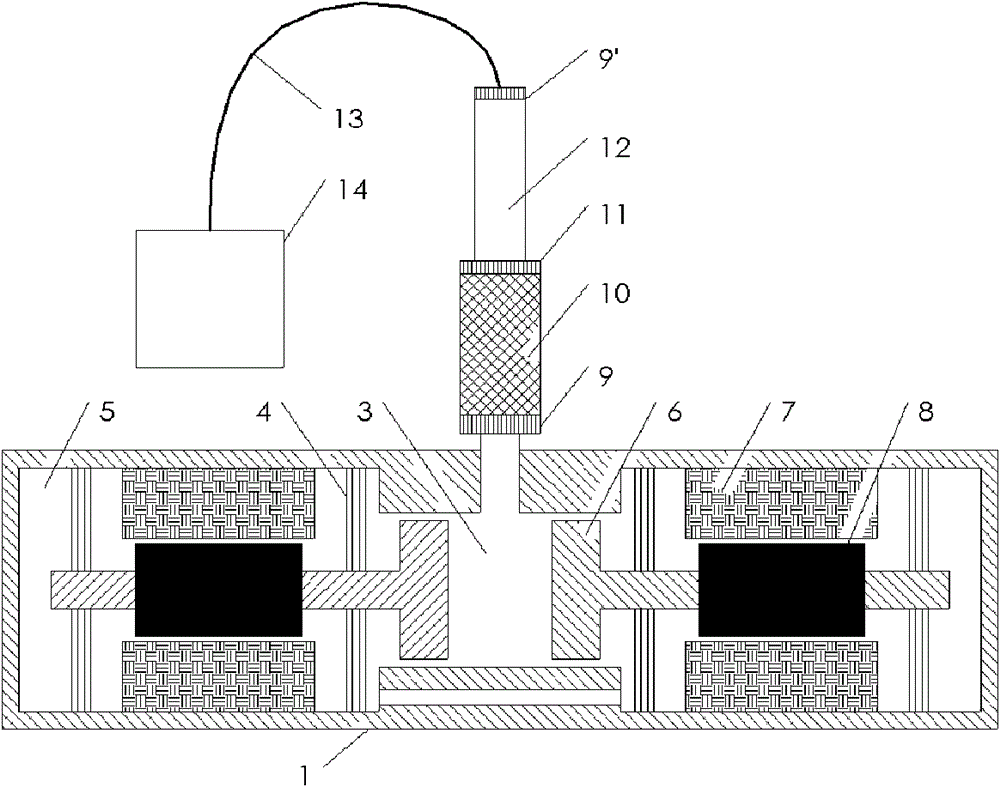

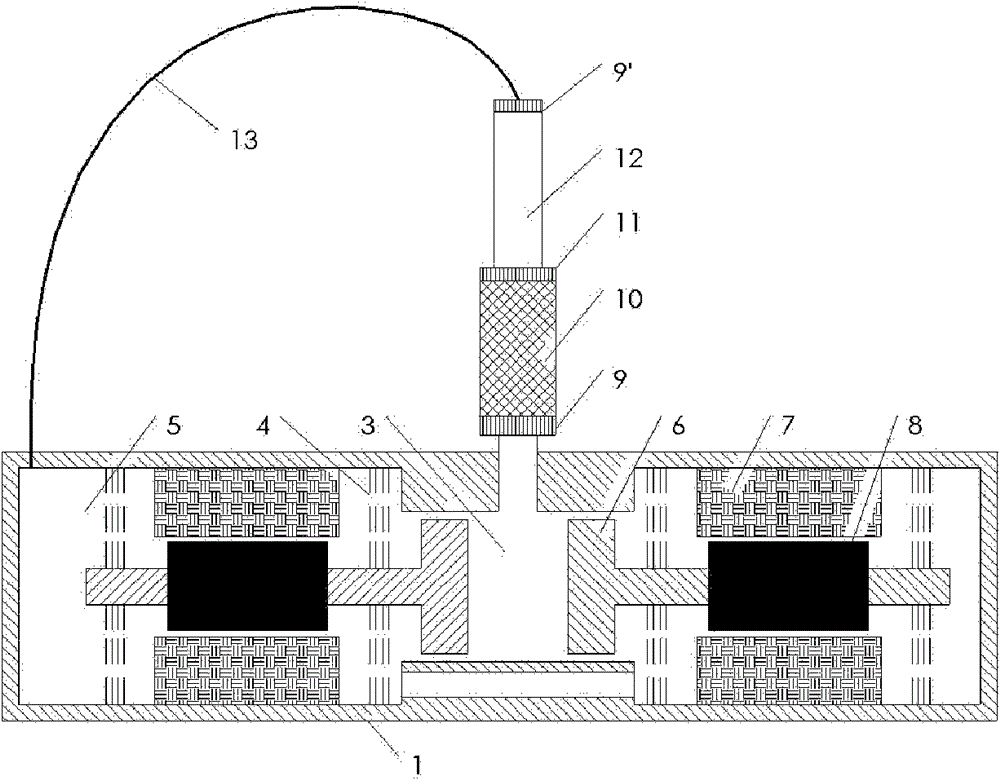

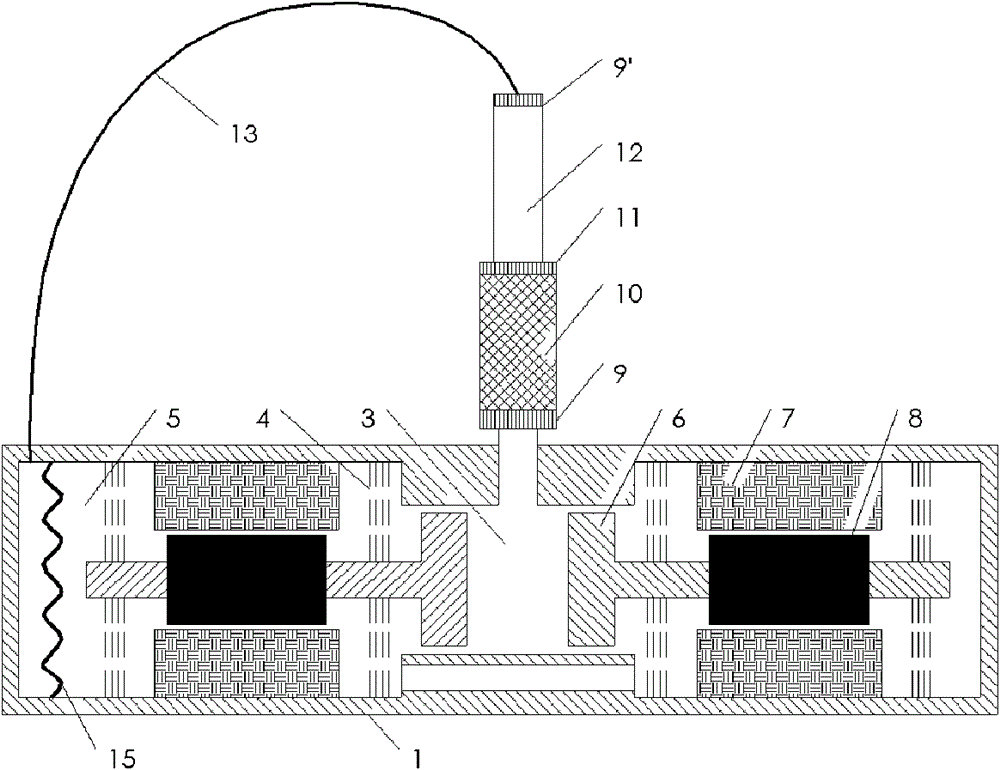

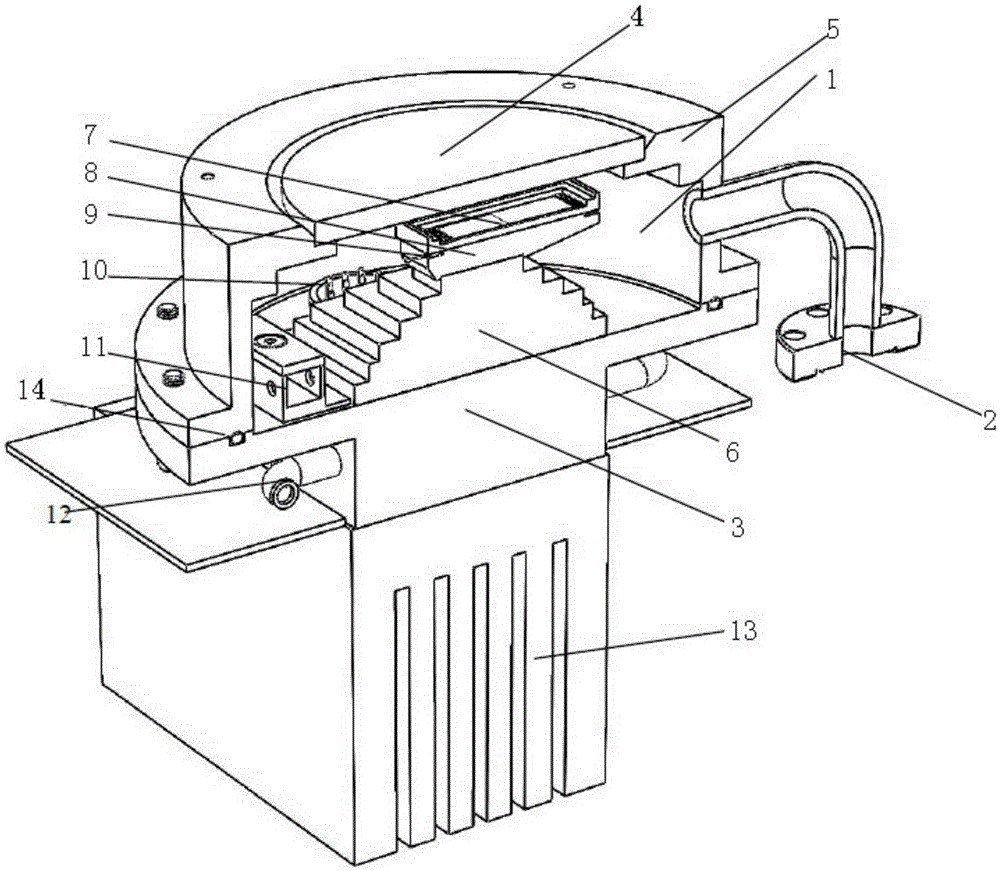

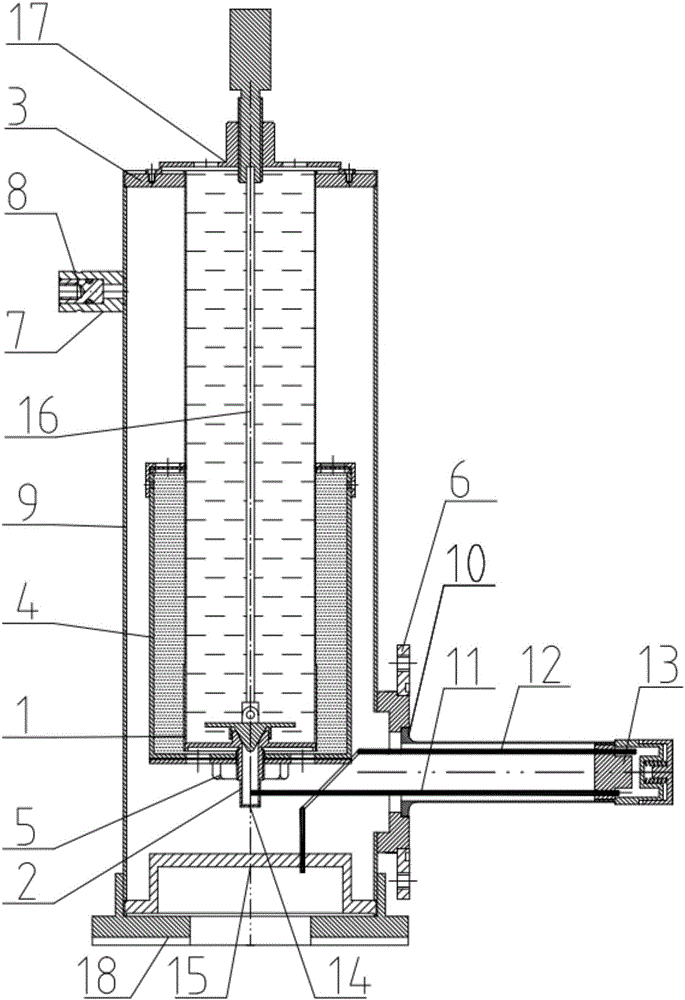

Liquid nitrogen horizontal refrigeration device for testing infrared detector Dewar assembly and design method thereof

The invention discloses a liquid nitrogen horizontal refrigeration device for testing an infrared detector Dewar assembly and a design method thereof. The device is fit for process performance test of a split type infrared detector Dewar assembly or an integrated type infrared detector Dewar assembly. The device is mainly formed by a liquid nitrogen cavity body wall (1), a liquid nitrogen cavity base (2), an upper cover (3), a vacuum keeping cover (4), a compression nut (5), a Dewar assembly installing flange (6), an extraction valve seat (7), an extraction valve plug (8), a housing (9), a cold finger (10), a transfusion pipe (11), an exhaust gas pipe (12) and a heat coupler (13). In this way, a stable adjusting value of liquid nitrogen flow can be obtained via a given computational formula and a liquid nitrogen flow adjusting rod (16) can be adjusted according to the adjusting value, thereby achieving an objective to control the liquid nitrogen flow. Thus, a problem is solved that liquid nitrogen is required for carrying out refrigeration during spectrum test, electric performance test and optical calibration of systems of a horizontally-arranged infrared detector Dewar assembly.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

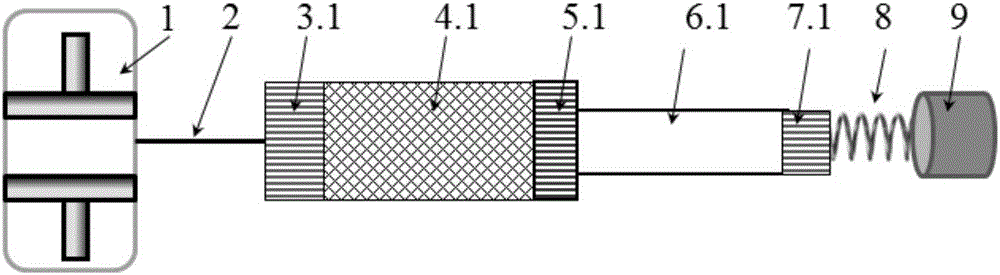

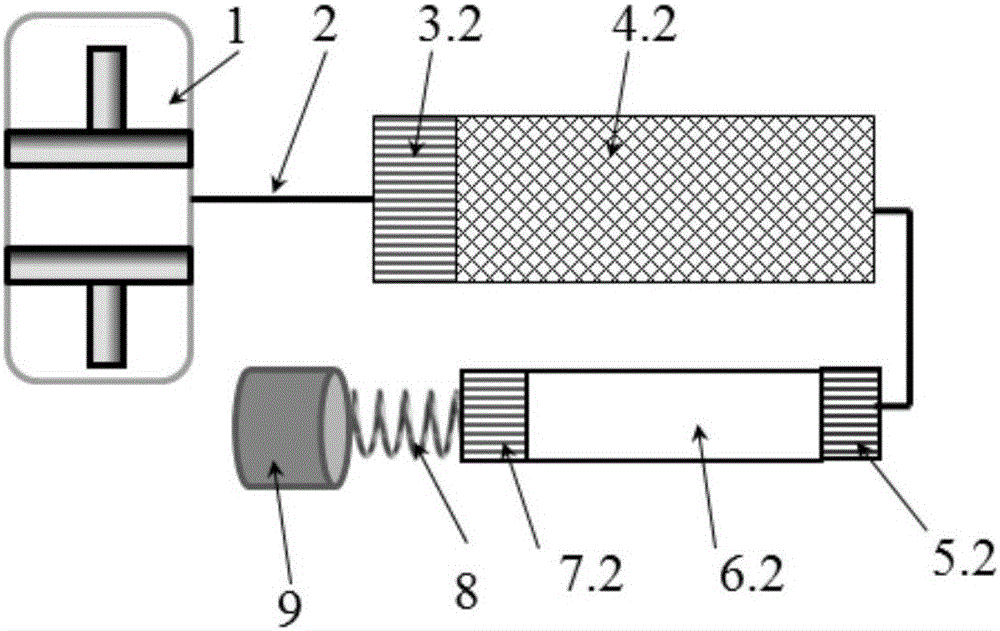

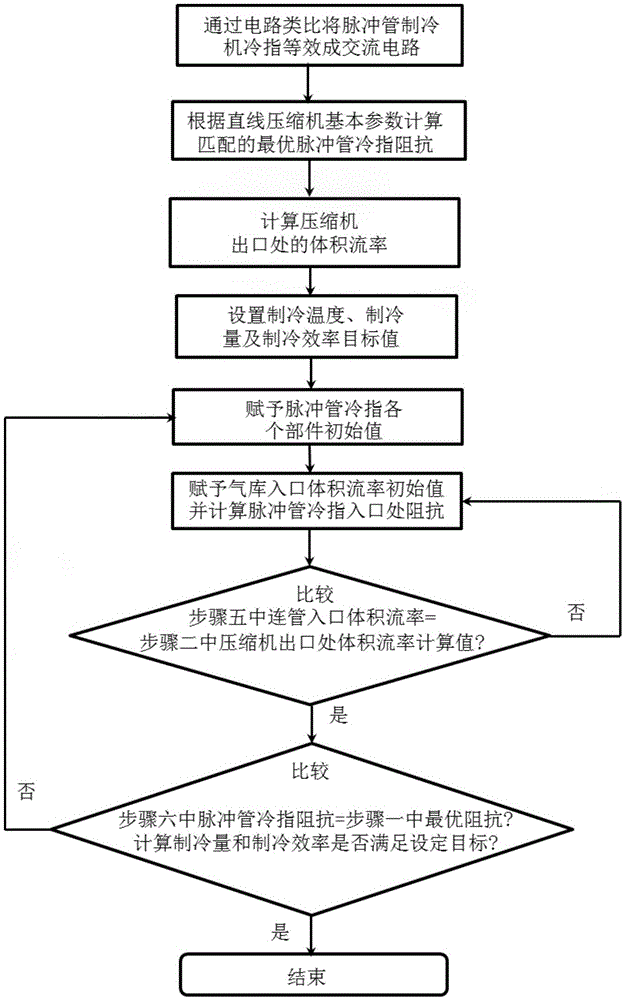

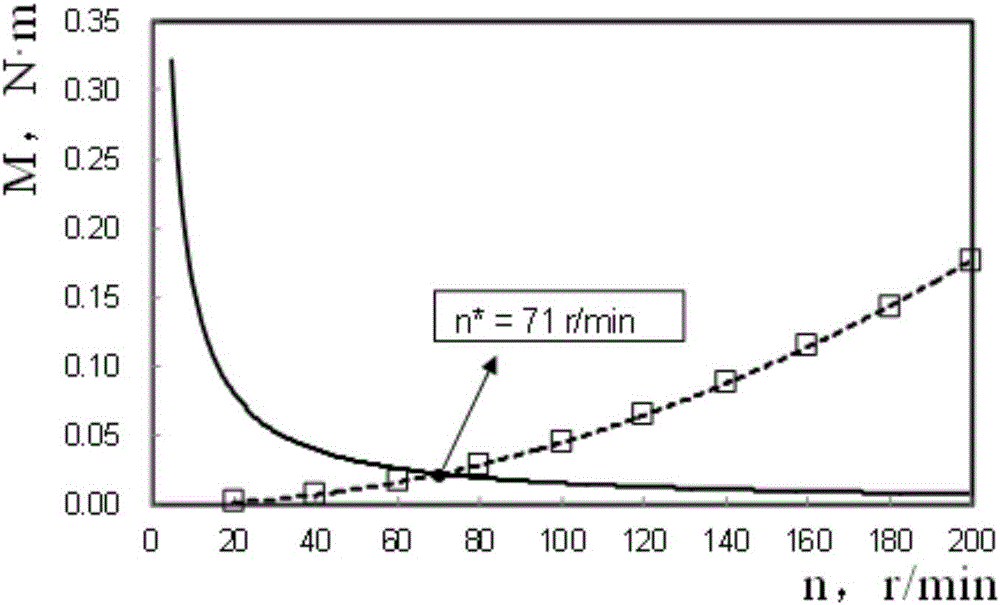

Design method for inertia pipe type pulse pipe cold finger optimally matched with linear compressor

ActiveCN105485954ASimplify the analysis processImprove cooling efficiencyCompression machinesGas cycle refrigeration machinesLinear compressorPulse tube refrigerator

The invention discloses a design method for an inertia pipe type pulse pipe cold finger optimally matched with a linear compressor. The method comprises the eight steps that firstly, the inertia pipe type pulse pipe refrigerator cold finger is equivalent into an alternating current circuit; secondly, the pulse pipe cold finger impedance under optimal matching is calculated according to compressor parameters; thirdly, the volume flow rate of a compressor outlet is calculated; fourthly, the reasonable refrigerating temperature, the reasonable refrigerating capacity and the reasonable refrigerating efficiency target are set; fifthly, all components of the pulse pipe cold finger are endowed with initial values; sixthly, the impedance value of a connecting pipe inlet is calculated; seventhly, the refrigerating capacity and the refrigerating efficiency are calculated; and eighthly, whether the calculated impedance value, the calculated refrigerating capacity and the calculated refrigerating efficiency are equal to the theoretical optimal values or not is judged through comparison, if yes, the design is finished, and if not, the fifth step is repeated to adjust the initial parameters, and the sixth step, the seventh step and the eighth step are repeated. According to the design method, very positive significance is achieved for practical development of an efficient inertia pipe type pulse pipe refrigerator.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Variable-temperature middle-measurement dewar and dewar component for chip testing

InactiveCN109084902ASolve the working requirements that cannot meet some special test temperaturesEasy assembly and testingRadiation pyrometryEngineeringRefrigerated temperature

The invention discloses a variable-temperature middle-measurement dewar and dewar component for chip testing. The variable-temperature middle-measurement dewar comprises a casing, a first cold finger,a cold head, a window component, a connector and a gas discharge nozzle, the first cold finger and the cold head are disposed in the casing, the window component and the connector are disposed outside the casing, the gas discharge nozzle is disposed on the casing, the bottom of the casing is provided with a flange for connecting to a refrigerator, the first cold finger in the casing comprises a plurality of layers of hollow support tubes, and the inner cavities of the support tubes are used to sleeve a second cold finger of the refrigerator. The variable-temperature middle-measurement dewar can realize the testing of a low temperature chip.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

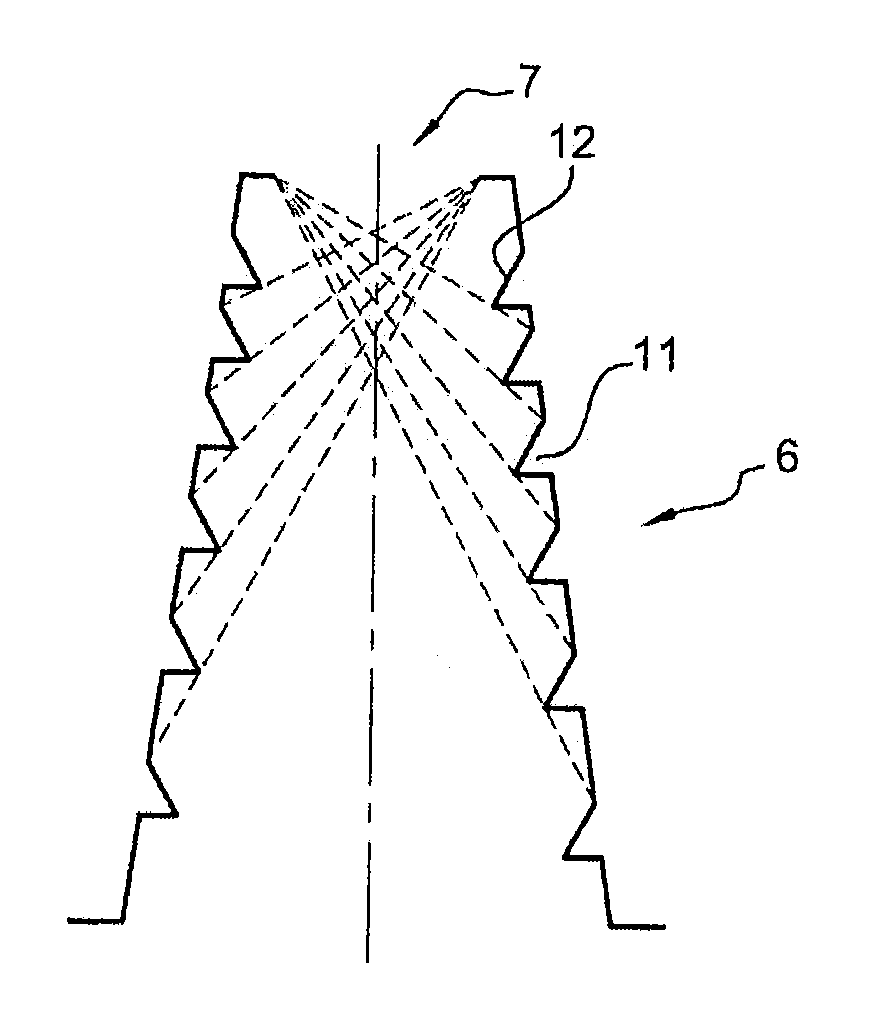

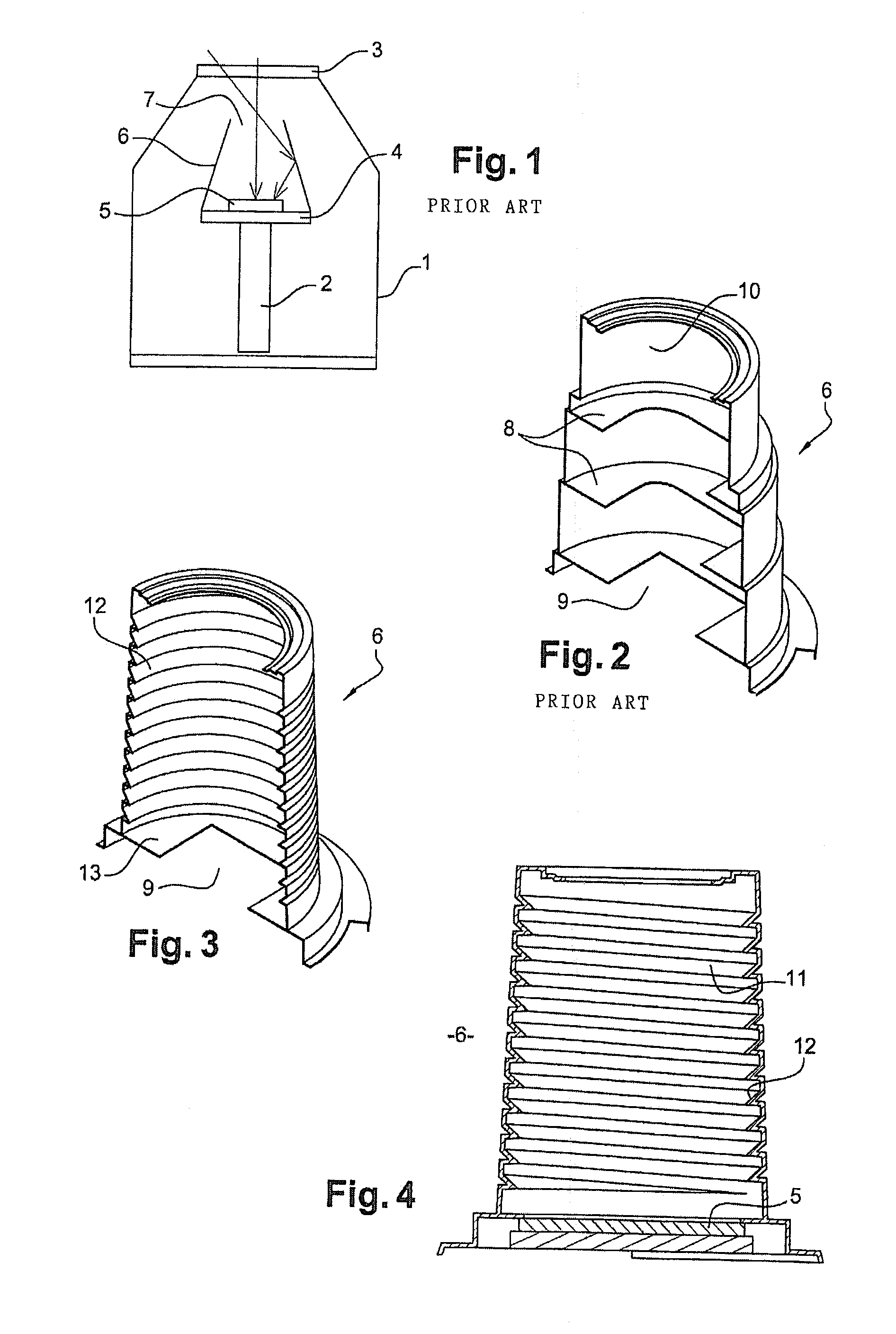

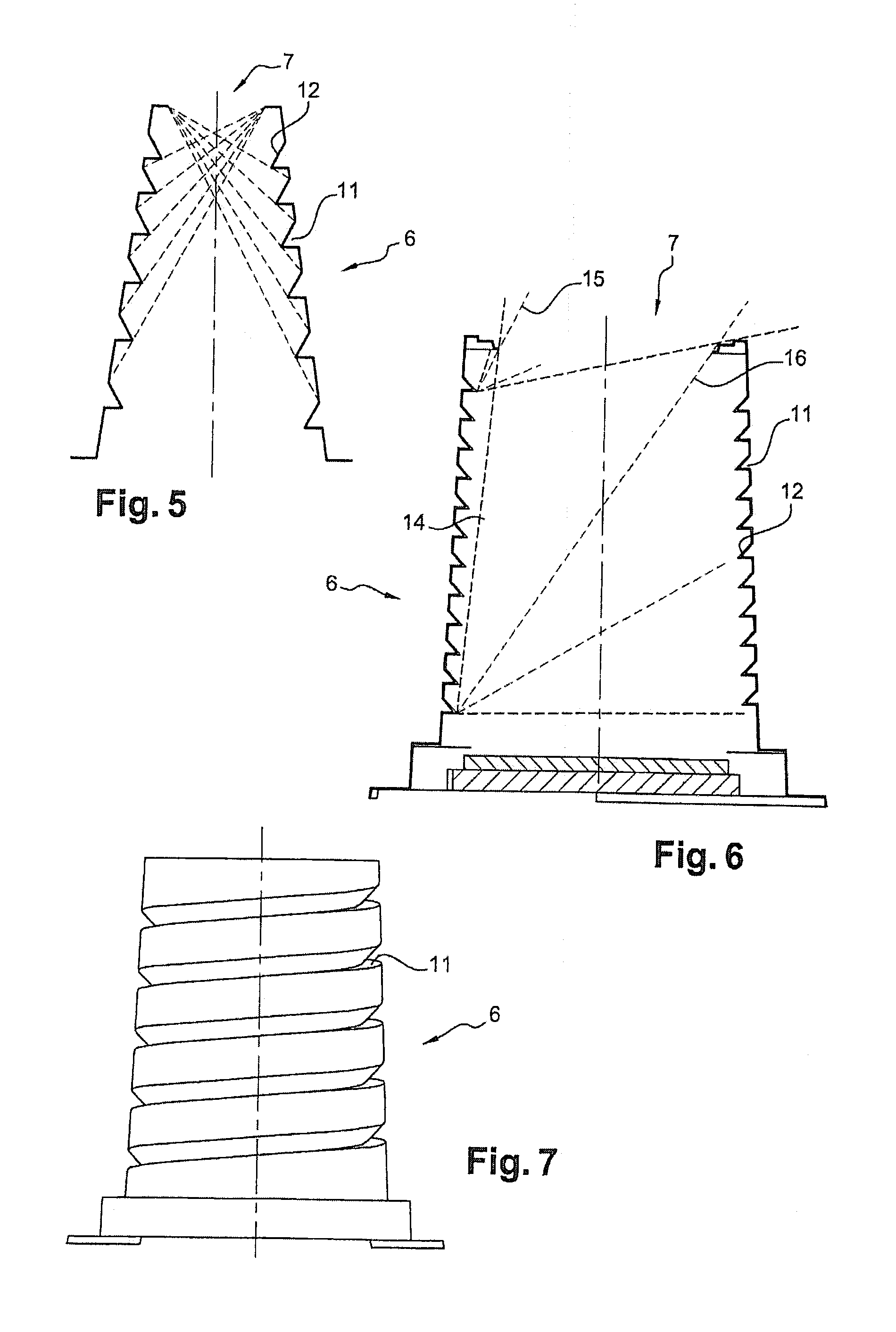

Infrared radiation detector

ActiveUS20120138802A1Reduce in quantityEliminate stray radiationRadiation pyrometryMaterial analysis by optical meansDetector circuitsThermodynamics

An infrared radiation detector includes: a cryostat having a cold finger ensuring heat exchange with a cold source and a window transparent to infrared radiation to be detected; a mechanically fixed cold plane in heat exchange with the cold finger; a detector unit comprising at least a detector circuit sensitive to the infrared wavelength range to be detected, and in direct or indirect heat exchange with the cold plane; and a mechanically fixed cold shield in heat exchange with the cold plane and limiting stray radiation. The cold shield is rotationally symmetrical. An inside wall of the cold shield has a succession of reliefs distributed in at least one helical pattern. A definition axis of the helical pattern coincides with the axis of revolution of the cold shield.

Owner:DE DETECTEURS INFRAROUGES - SOFRADIR

Detection method and system for simulating wax deposition in crude oil pipeline conveying process

InactiveCN105699415AImprove the mixing effectRealize continuous updateInvestigating phase/state changeWeighing by absorbing componentWater bathsTemperature control

The invention provides a detection method and system for simulating wax deposition in a crude oil pipeline conveying process. The method comprises the steps that a high level storage tank, an oil sample container and a low level storage tank are installed in a sequentially lowered mode; a first water bath, a temperature control interlayer of the high level storage tank and a temperature control interlayer of the oil sample container form a first closed loop; a second water bath and a hollow interlayer of a cold finger form a second closed loop; a stirrer is arranged in a hollow part of the cold finger, the stirring rate of the stirrer is changed, and the stirring rate corresponding to the shear rate under the simulated pipeline conveying condition is obtained; stirring is maintained, sediment is stripped away from the surface of the cold finger after an experiment is over, and weighing and calculating are conducted to obtain the increase rate of a wax deposition layer. The system at least comprises the high level storage tank, the oil sample container, the low level storage tank, the cold finger, the temperature control water baths and a connecting pipe. By constructing an oil sample passageway and establishing a wax deposition temperature field, continuous update of oil samples in the sample container is realized, pipe flow shear is simulated quantitatively in a stirring mode, and the wax deposition detection process is more approximate to the actual pipeline conveying condition.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Method and system for cryogenic cooling

ActiveUS20070044486A1Reduce CooldownExtend effective lifeRadiation pyrometryCompression machinesEngineeringCryocooler

According to one embodiment, a method for improving heat transfer between a cold finger of a cryogenic cooler and a Dewar includes forming an annulus between the cold finger of the cryogenic cooler and the Dewar by inserting the cold finger into the Dewar. The cold finger has a first end and a second end. The method also includes inhibiting the formation of convective currents within the annulus in a direction between the first end and the second end. According to another embodiment of the invention, the cooling system includes a cryogenic cooler that includes a cooling section operable to generate cooling fluid and a cold finger operable to receive the cooling fluid. The cooling system also includes a Dewar formed with a void region coupled to an infrared detector. The cold finger is positioned within the void region of the Dewar creating an annulus. The cooling system also includes at least one obstruction disposed within the annulus and operable to inhibit the formation of convective currents in a direction along a length of the cold finger.

Owner:RAYTHEON CO

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com