Heat load test method and device for split type dewar at different refrigeration temperatures

A test device and separate technology, which is applied in the field of engineering Dewar thermal load testing, achieves the effects of simple device and implementation method, low cost and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] Below in conjunction with accompanying drawing, the specific embodiment of this patent is described in further detail:

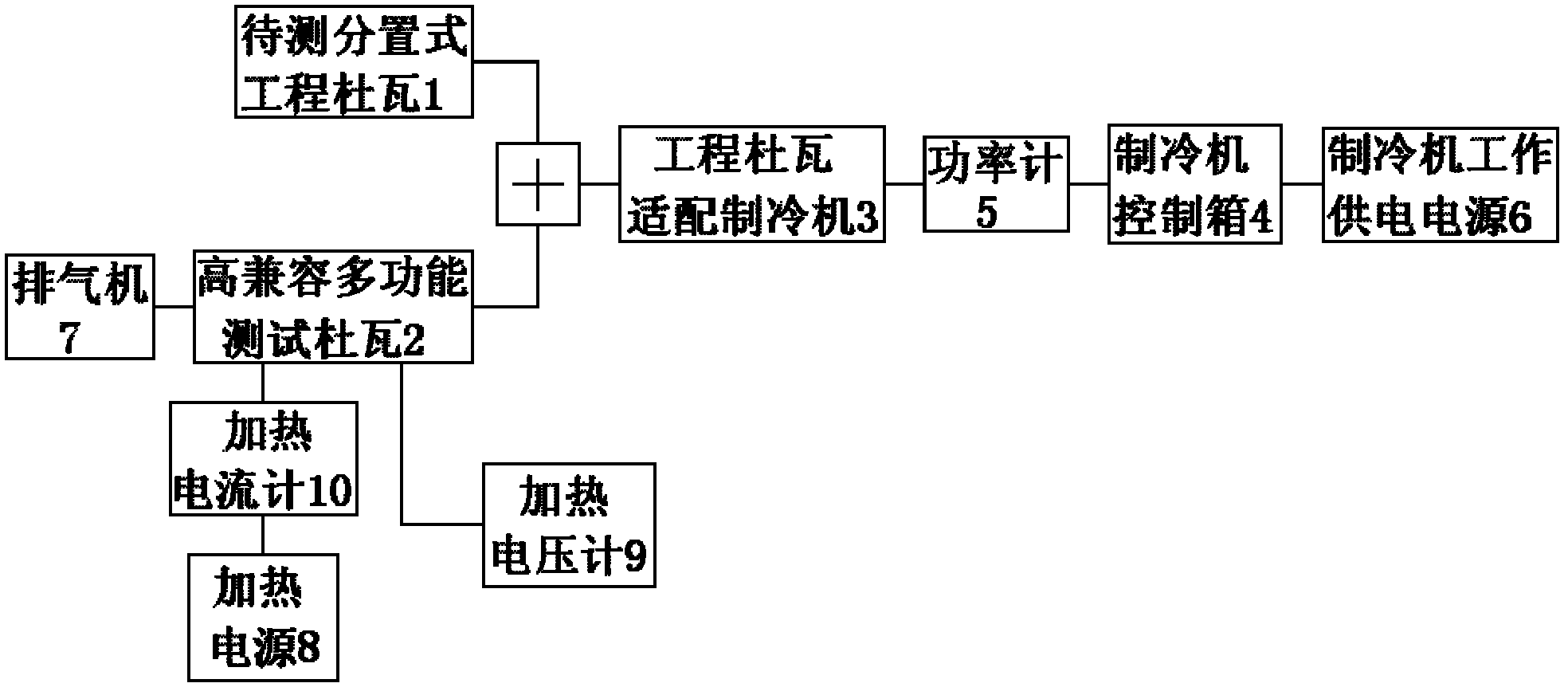

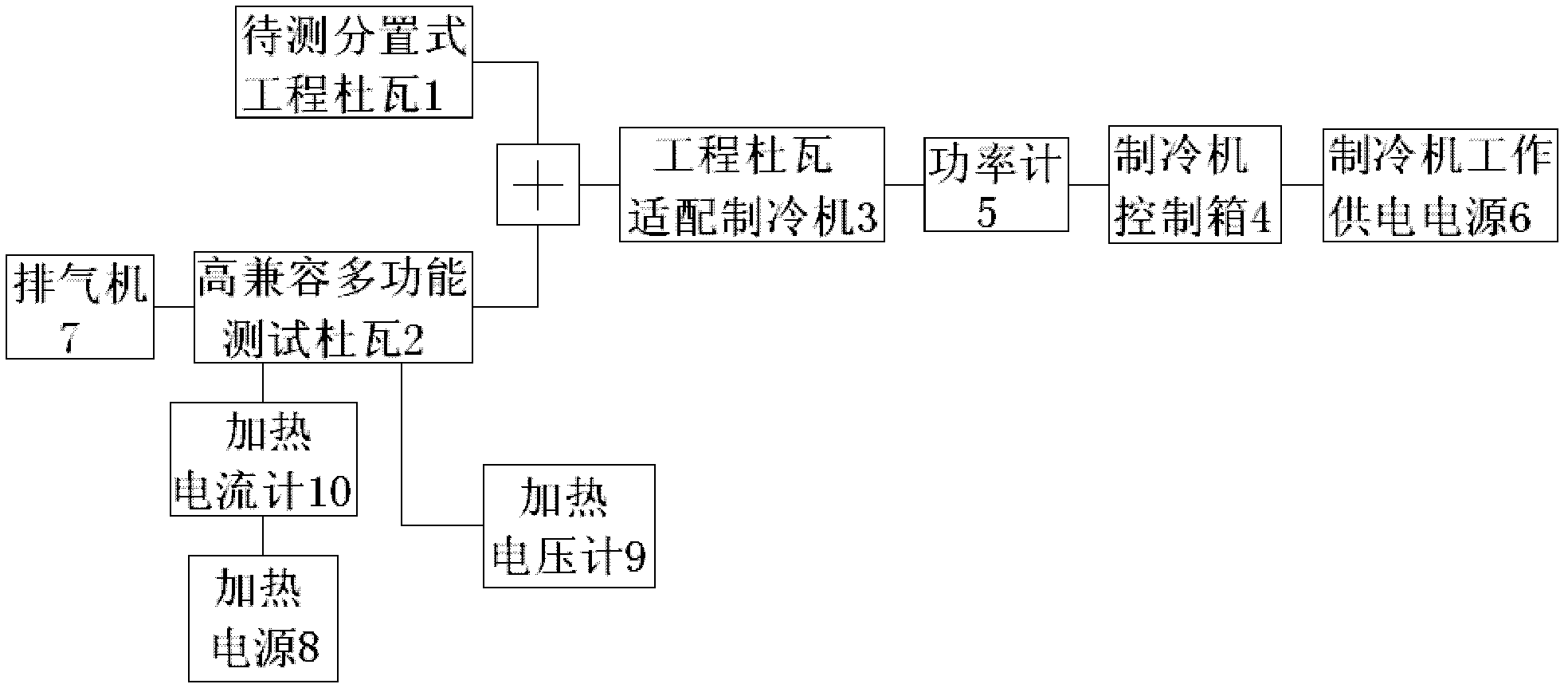

[0073] Embodiment is the thermal load test of a certain large thermal load (according to estimation thermal load value is greater than 1.5 watts) infrared detector focal plane Dewar assembly, as attached figure 1 As shown, its main implementation method is as follows:

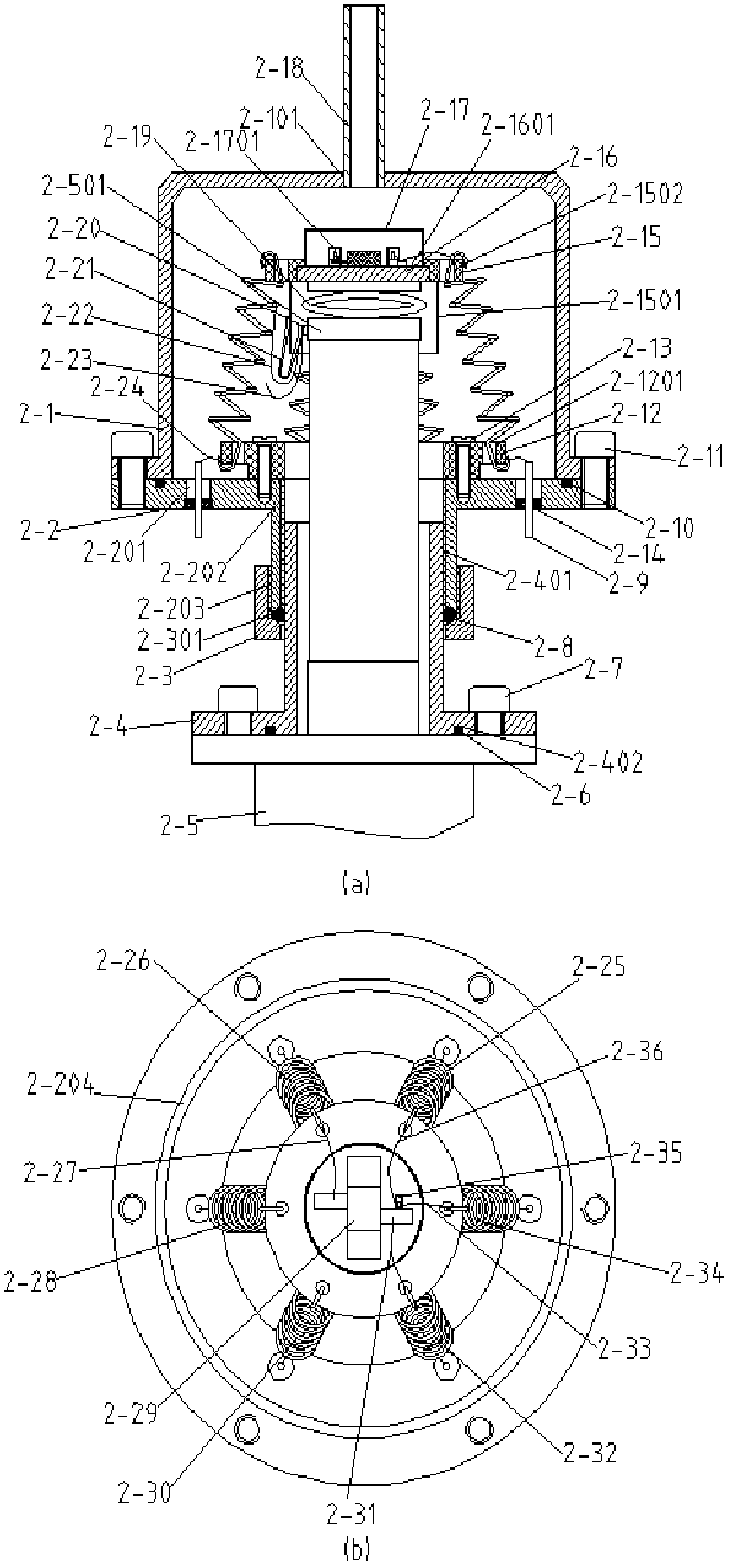

[0074] 1. The preparation method and assembly sequence of each component of the highly compatible and multifunctional testing Dewar in this patent are as follows:

[0075] a) The cavity cap 2-1 is made of stainless steel 304L, and the exhaust pipe 2-18 is an oxygen-free copper tube with an outer diameter of 6mm and an inner diameter of 4mm and a length of 60mm. The exhaust pipe 2-18 is brazed to the cavity cap 2- with a brazing furnace. At the opening 2-101 of the exhaust pipe of 1, use a leak detector to check the weld, and the leak rate reaches 1.0×10 -11 torr·l / s level, meet the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com