Patents

Literature

1329results about How to "Reduce Cooldown" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Minimum contact area wafer clamping with gas flow for rapid wafer cooling

ActiveUS20110318142A1Reduce CooldownSemiconductor/solid-state device manufacturingConveyor partsNitrogenEngineering

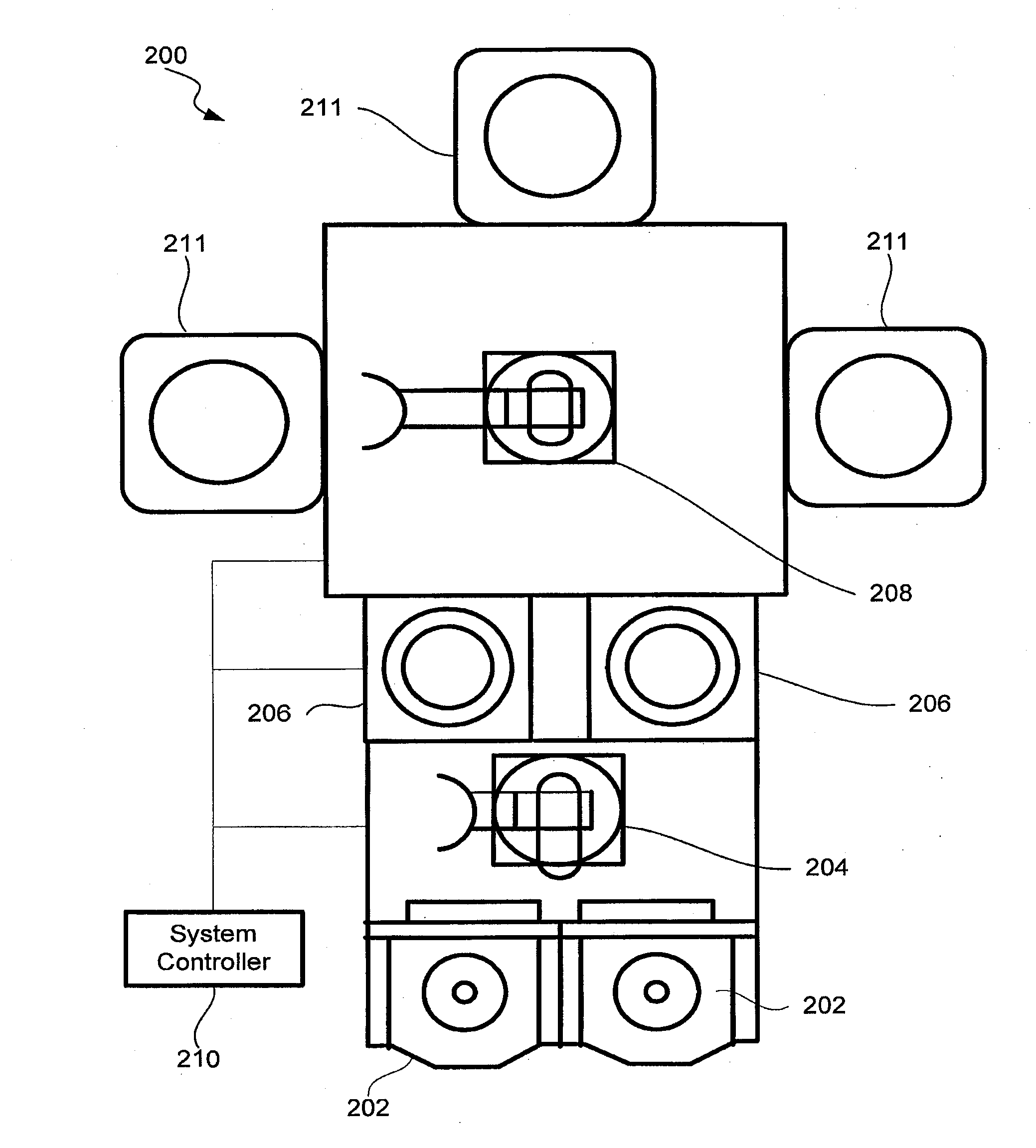

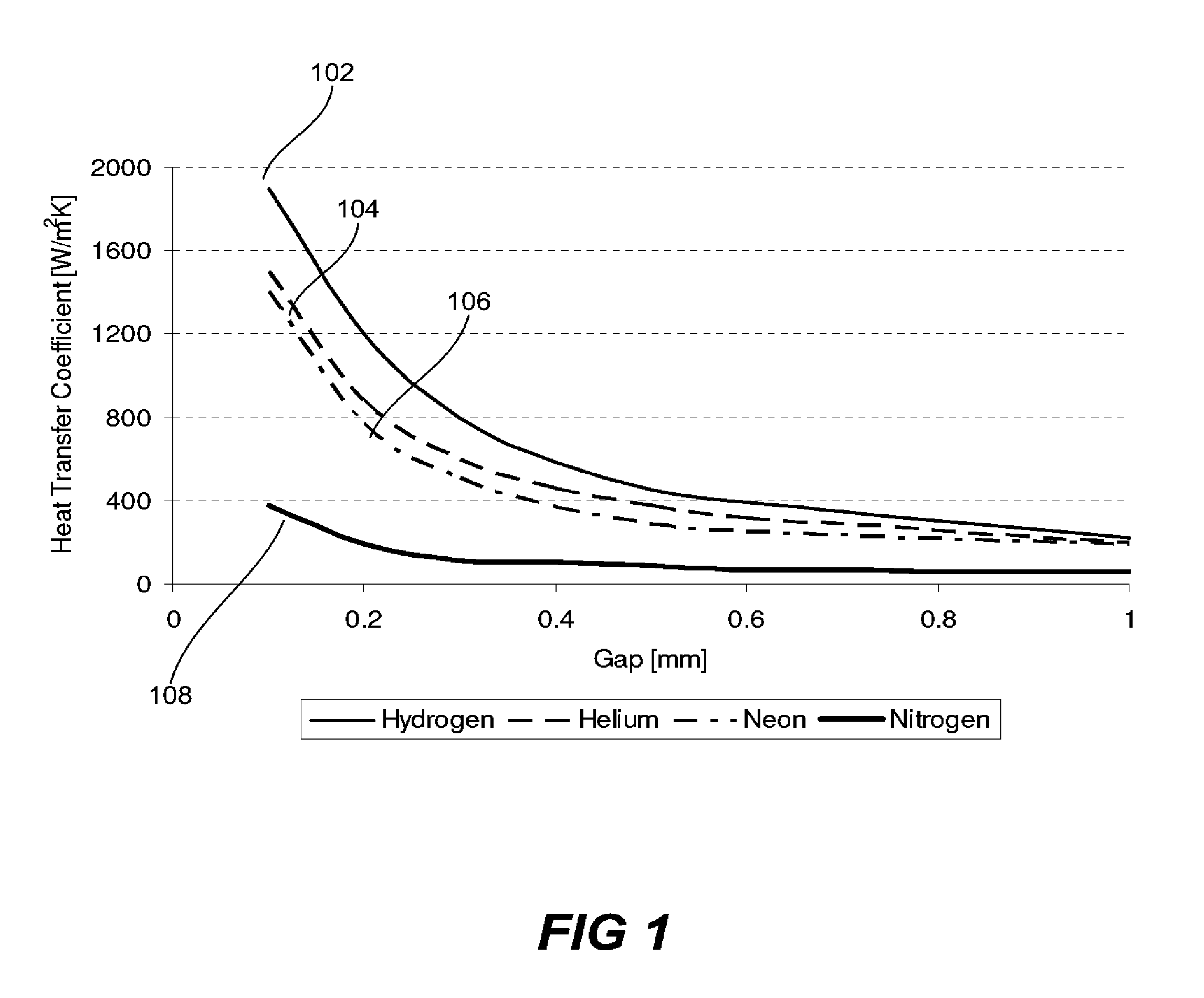

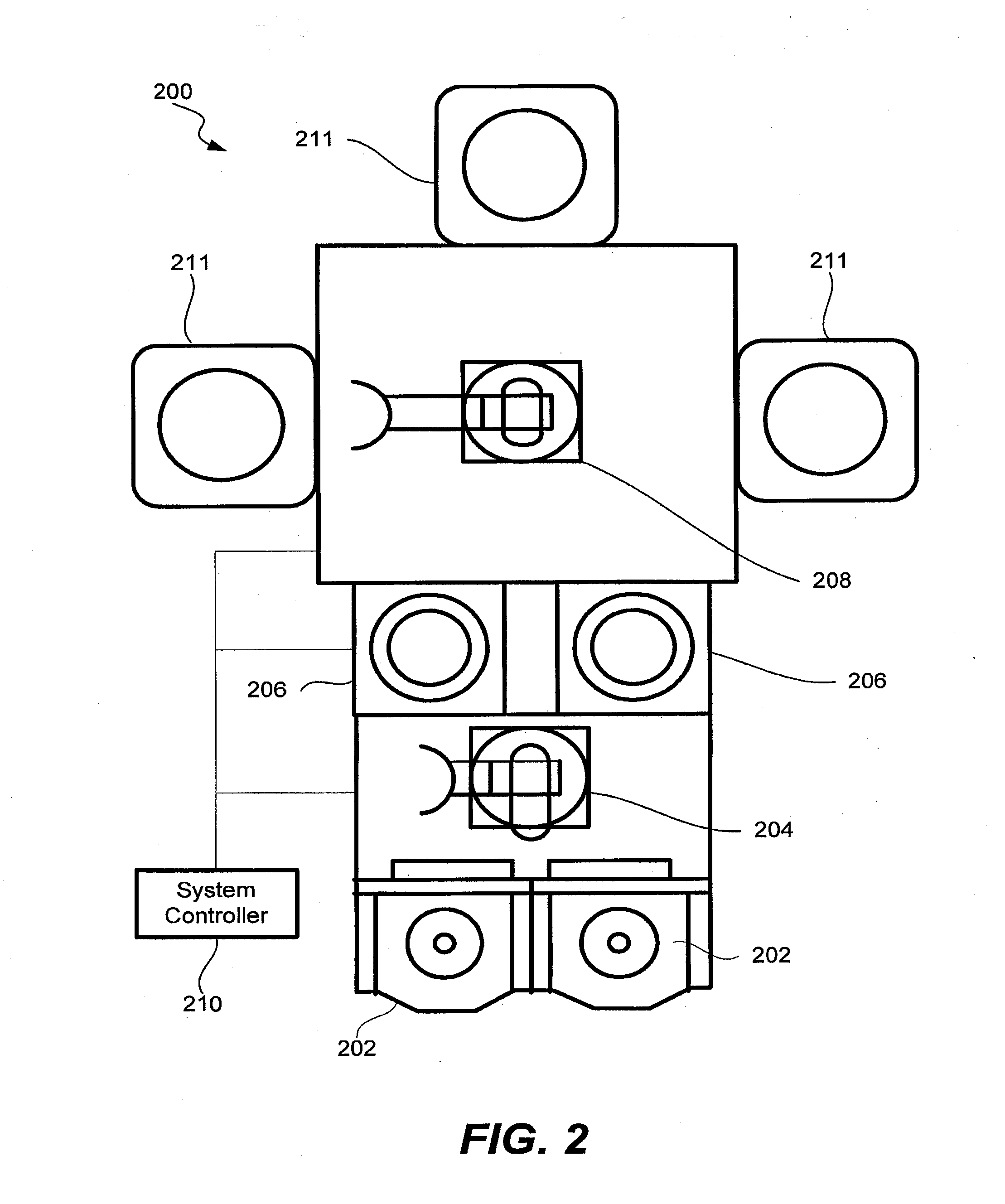

Apparatuses and methods for cooling and transferring wafers from low pressure environment to high pressure environment are provided. An apparatus may include a cooling pedestal and a set of supports for holding the wafer above the cooling pedestal. The average gap between the wafer and the cooling pedestal may be no greater than about 0.010 inches. Venting gases may be used to increase the pressure inside the apparatus during the transfer. In certain embodiment, venting gases comprise nitrogen.

Owner:NOVELLUS SYSTEMS

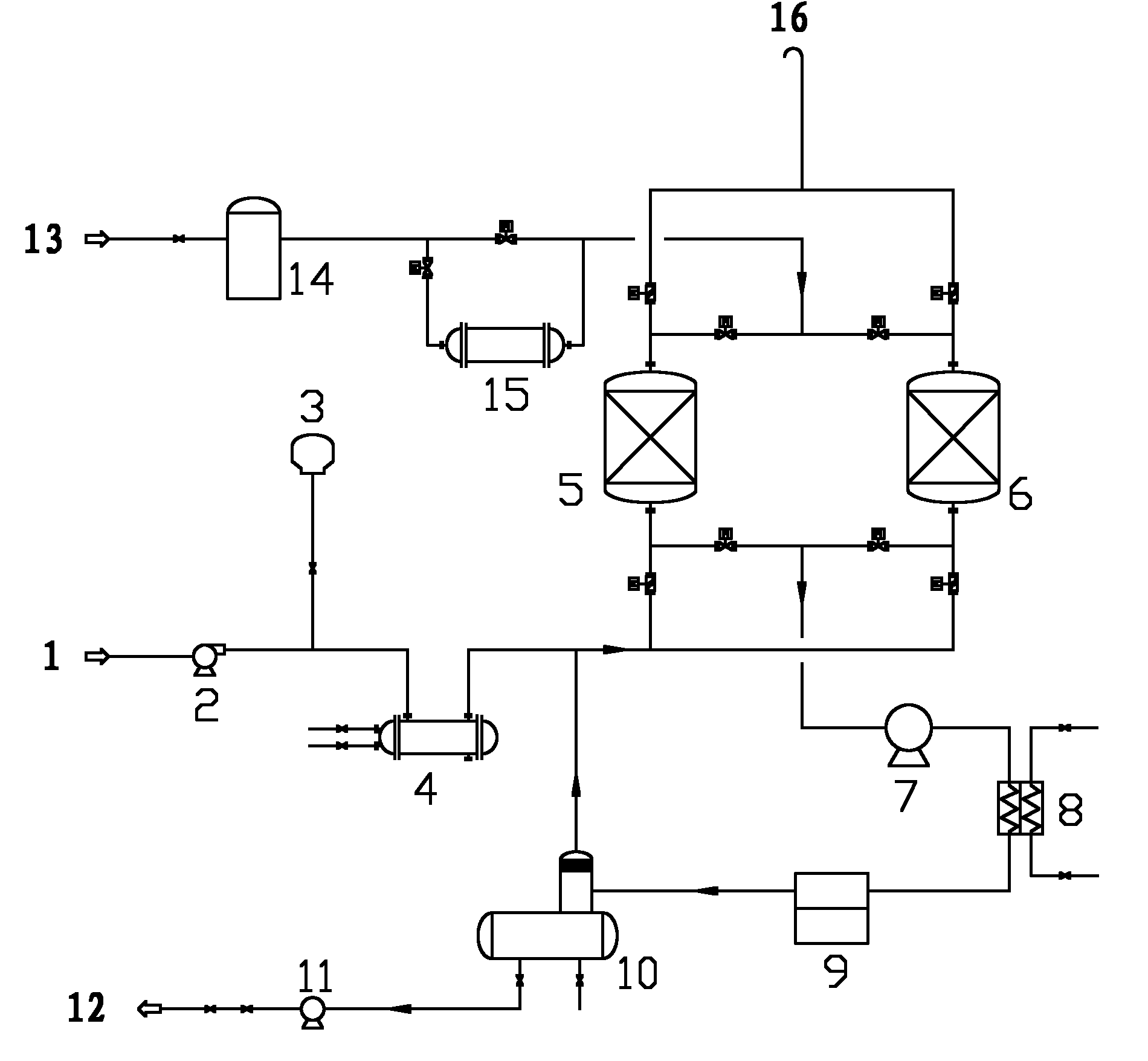

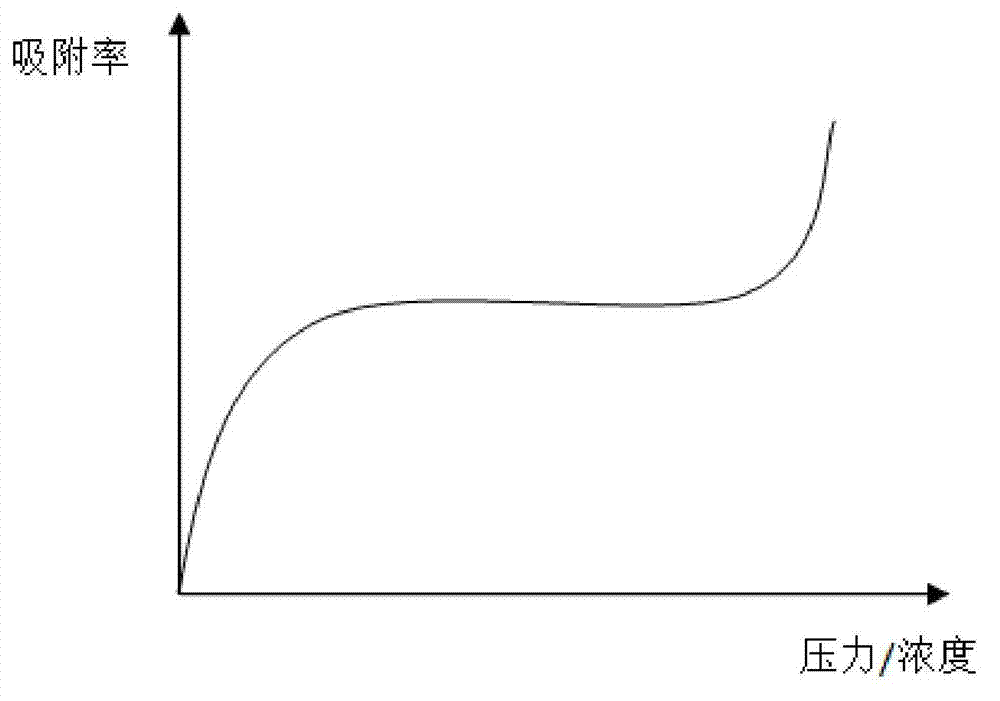

Treatment process for absorbed condensate waste gas

ActiveCN102179129ASo as not to damageShorten heating timeDispersed particle separationVapor condensationNitrogenEnvironmental engineering

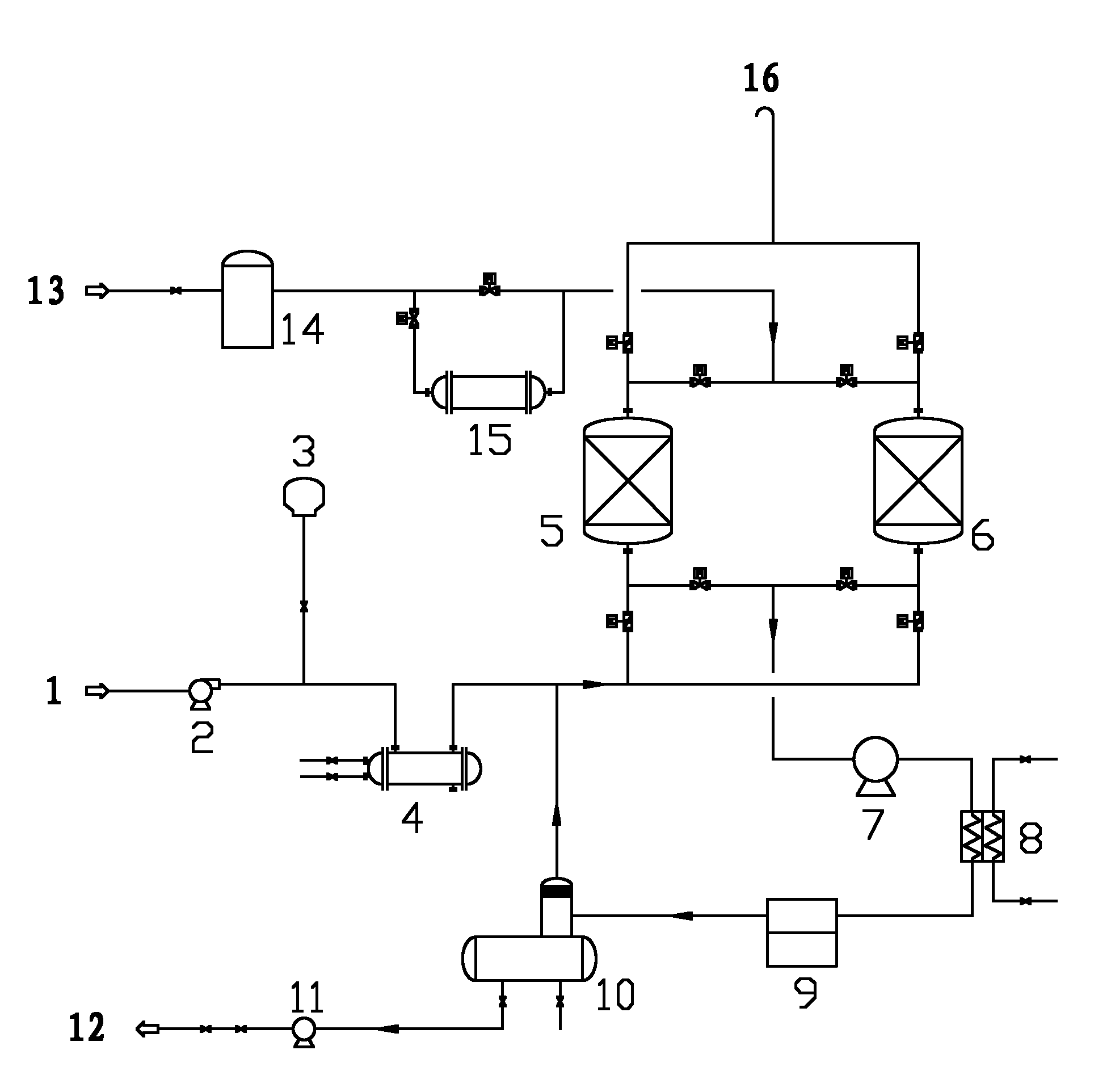

The invention provides a treatment process for absorbed condensate waste gas, wherein two active carbon absorbing tanks alternately absorb waste gas; when one active carbon absorbing tank carries out waste gas absorption work, the other active carbon absorbing tank carries out carbon bed reproduction work, wherein the absorbed waste gas in waste gas absorption work is cooled; the carbon bed reproduction work comprises a step of vacuum de-sorption and a step of nitrogen de-sorption in sequence; the step of nitrogen de-sorption comprises flowing heated nitrogen at the temperature of 60-80 DEG Cthrough the carbon bed from top to bottom so that the carbon bed is deeply desorbed, and finally cooling the carbon bed by using unheated cold nitrogen so as to recover adsorptive capacity. The process is simple without providing absorbent on the spot; and the treatment process has high treatment efficiency, and can obtain pure recovery product without causing secondary pollution.

Owner:BAY ENVIRONMENTAL TECH BEIJING

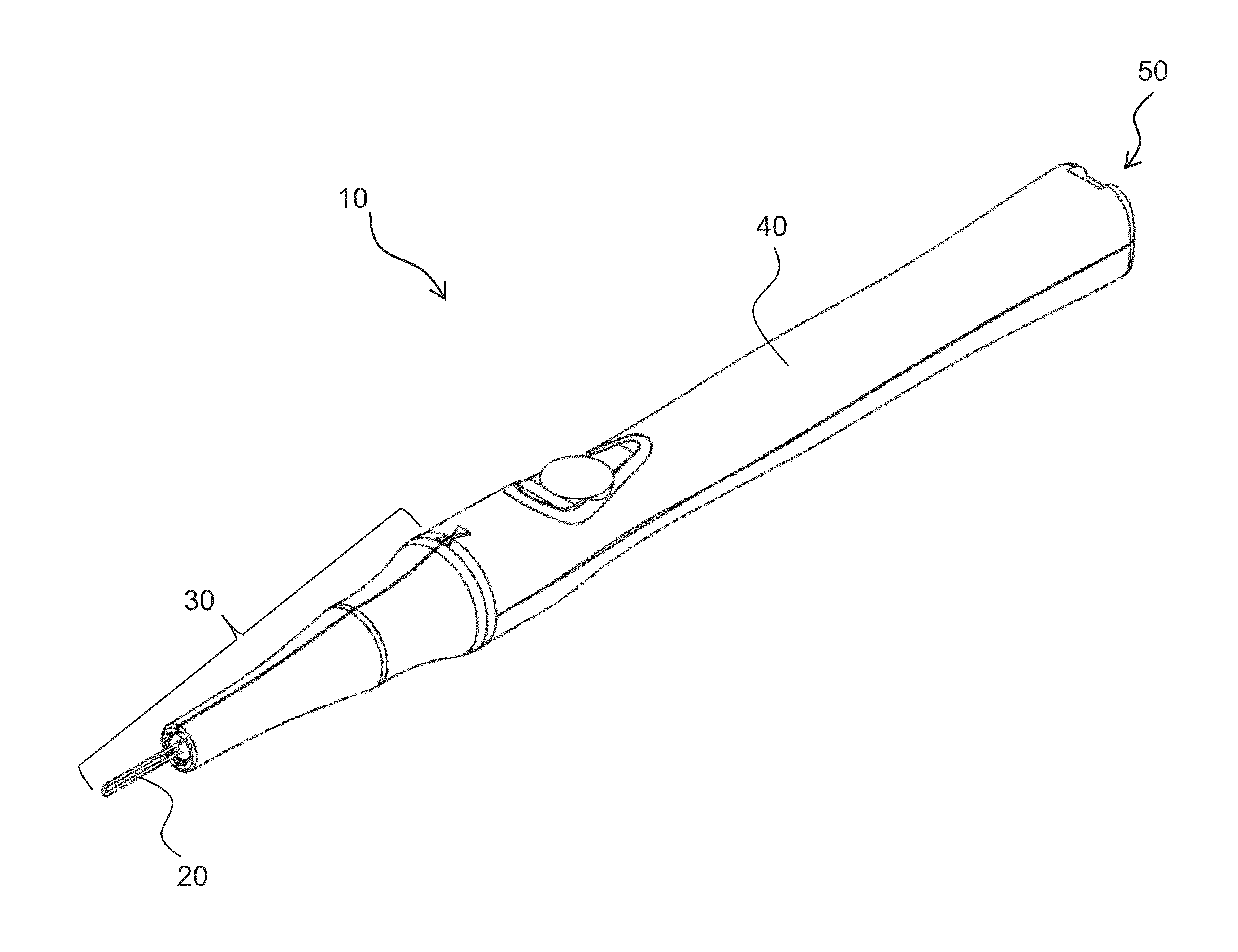

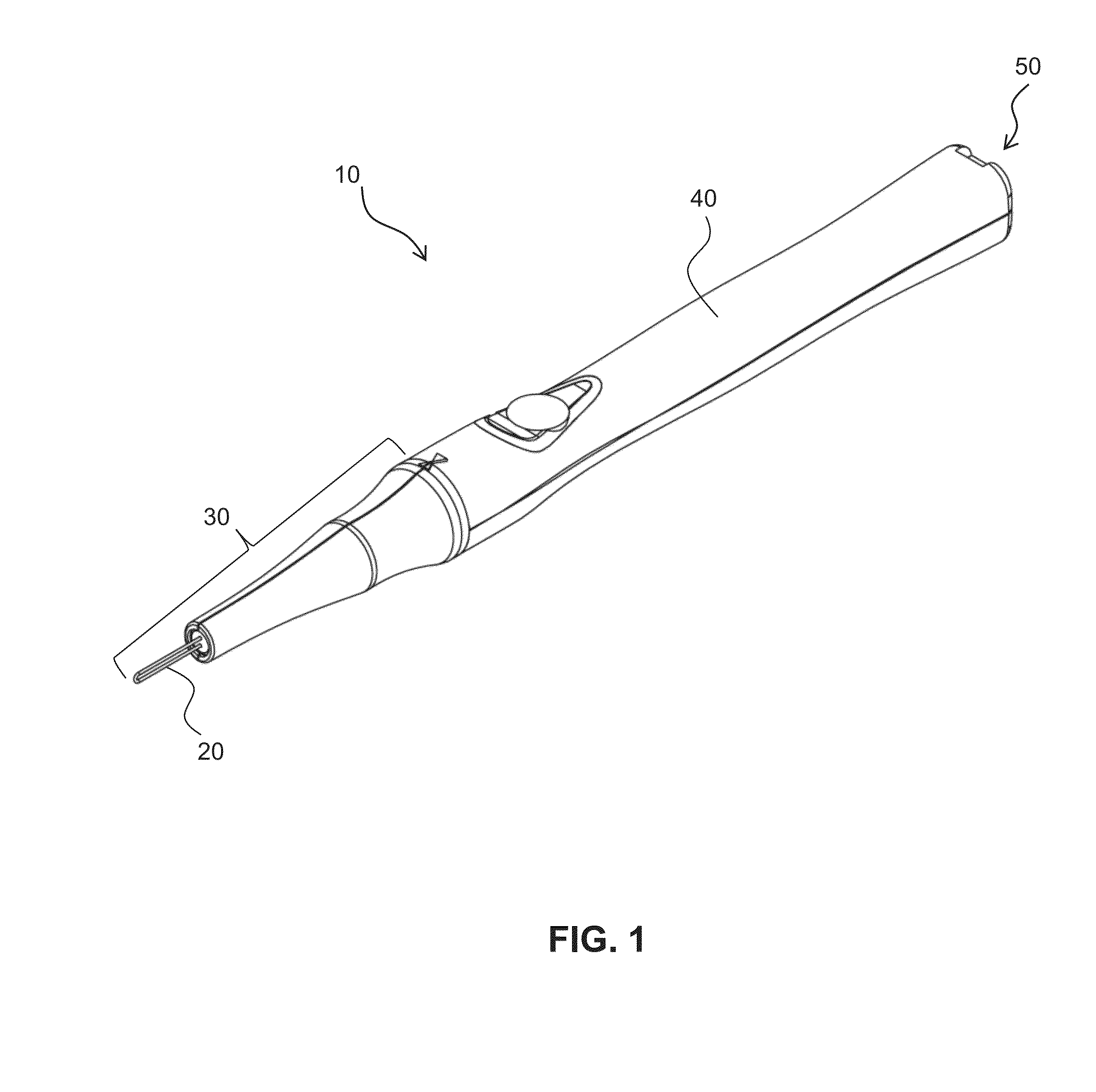

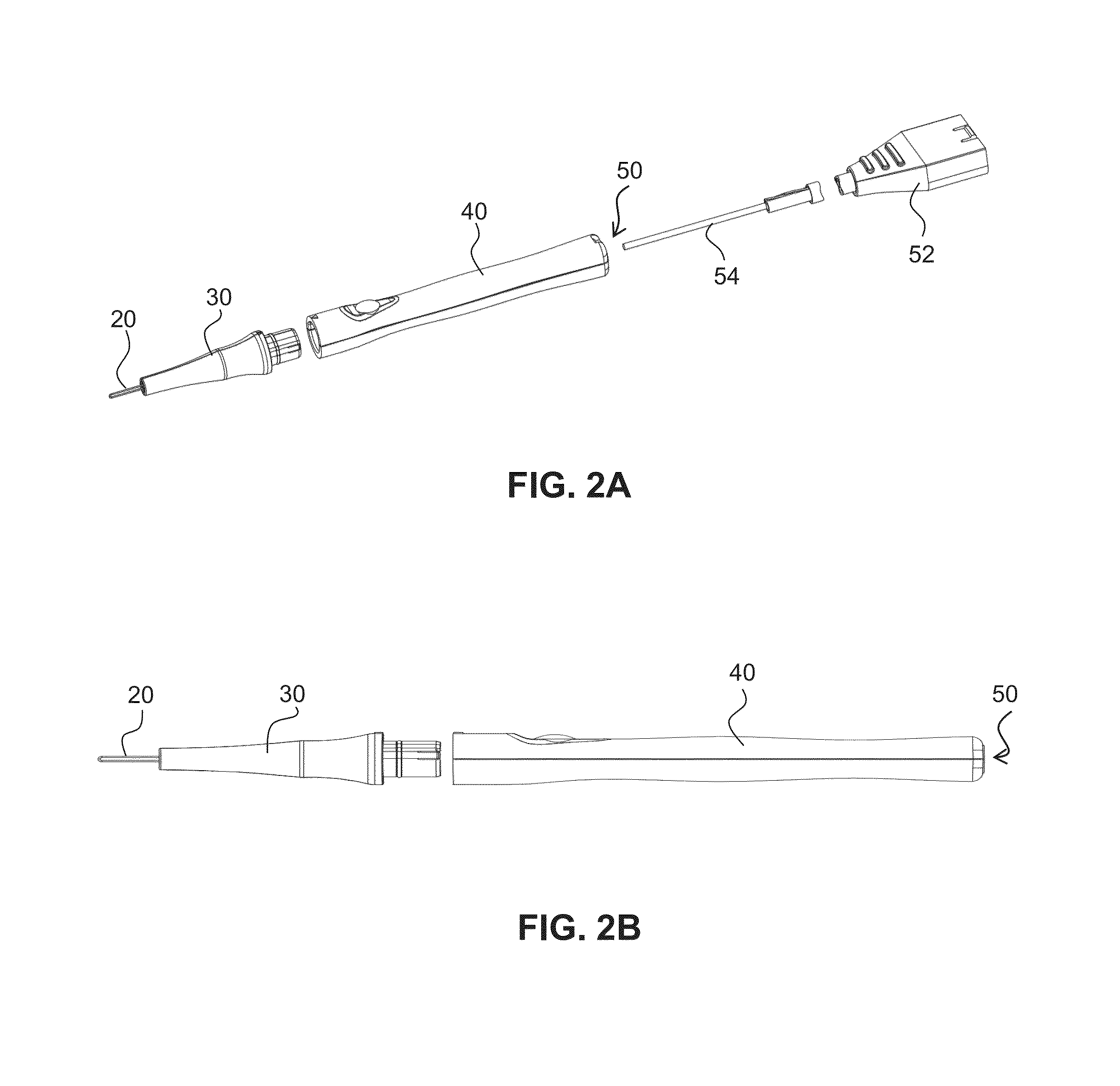

System and method for cooling of a heated surgical instrument and/or surgical site and treating tissue

ActiveUS20130023866A1Reduce temperatureReduce cooling timeSurgical furnitureDiagnosticsBlood serumSurgical instrument

A cooling system for a surgical handpiece may provide fluid flow to the surgical tip and to the internal electronic components to prevent temperatures that may damage or make the patient or surgeon uncomfortable. Tip directed gas further controls the tip-tissue interface by displacing blood or serum from the incision point, increasing precision and diminishing coagulum build-up. In the alternative, cooling fluid may be used to quench tissue being treated.

Owner:DOMAIN SURGICAL

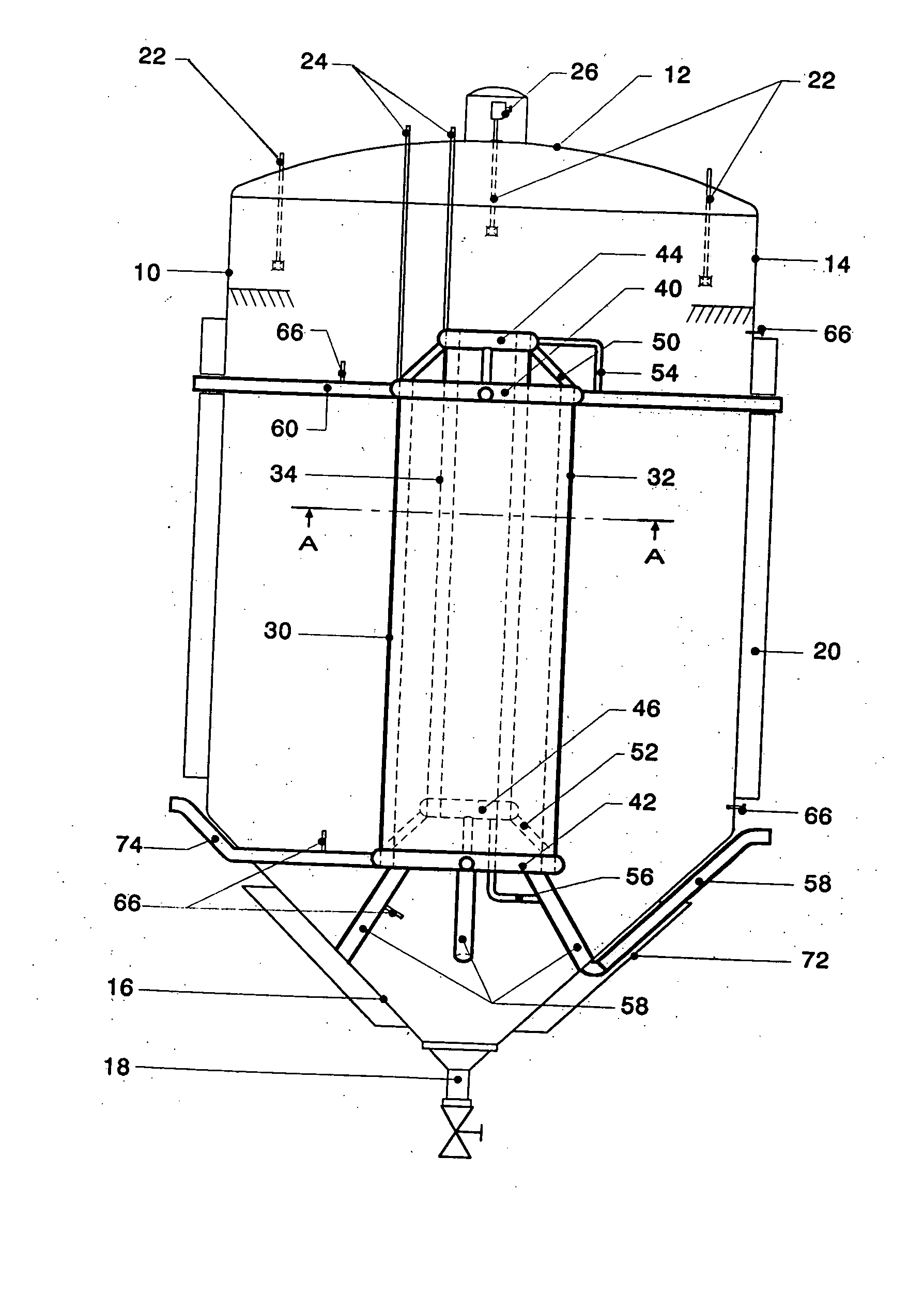

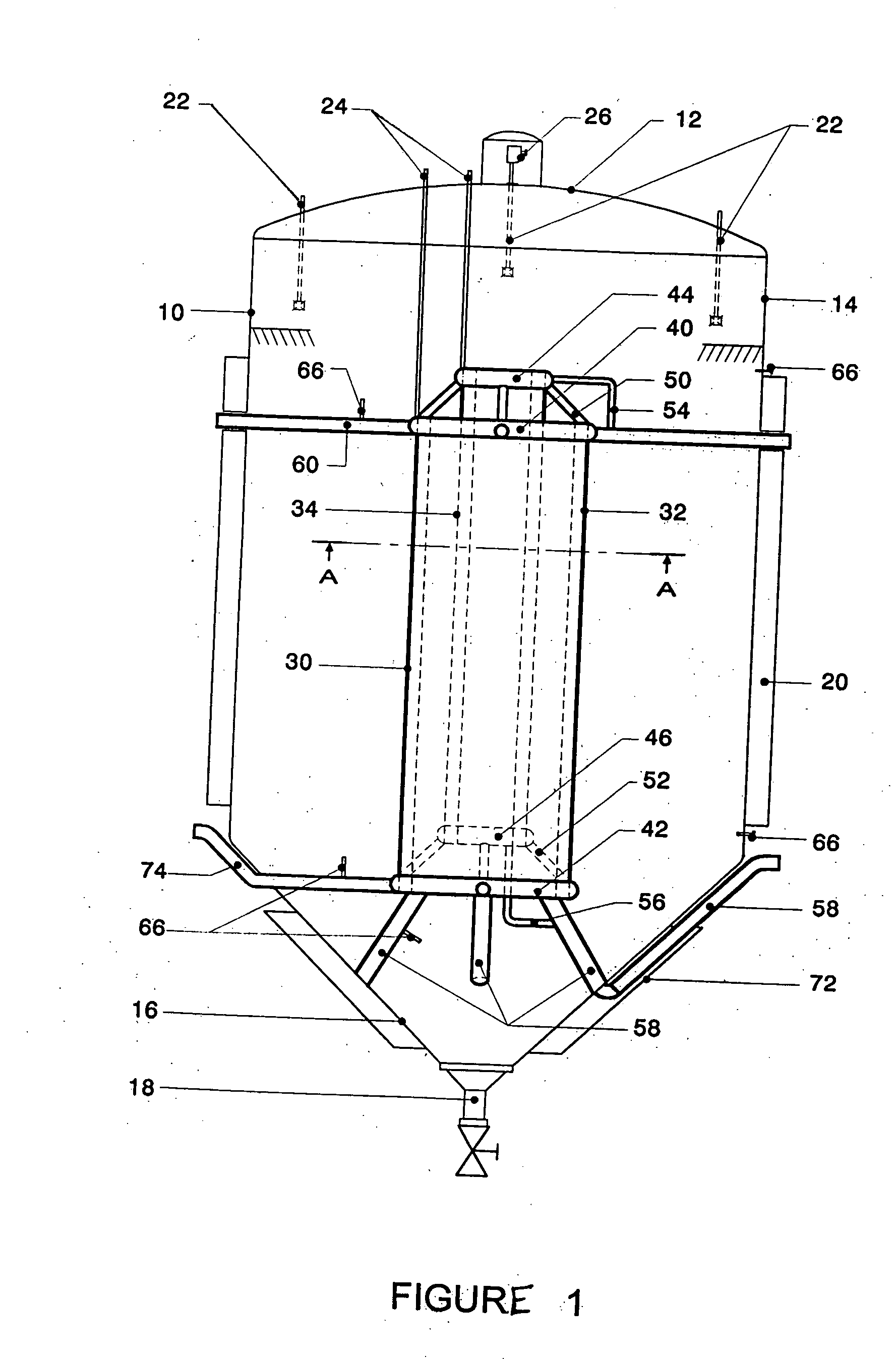

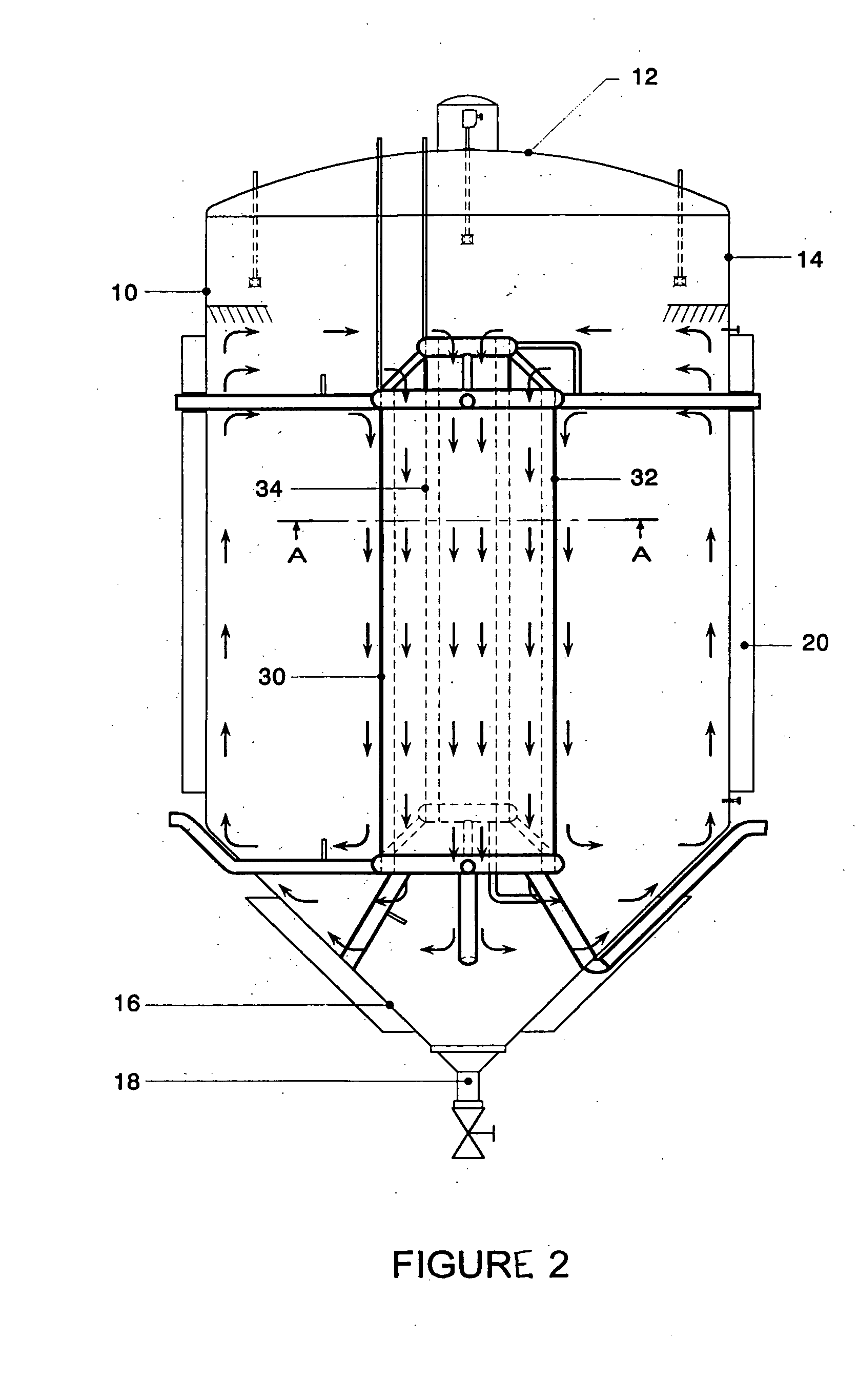

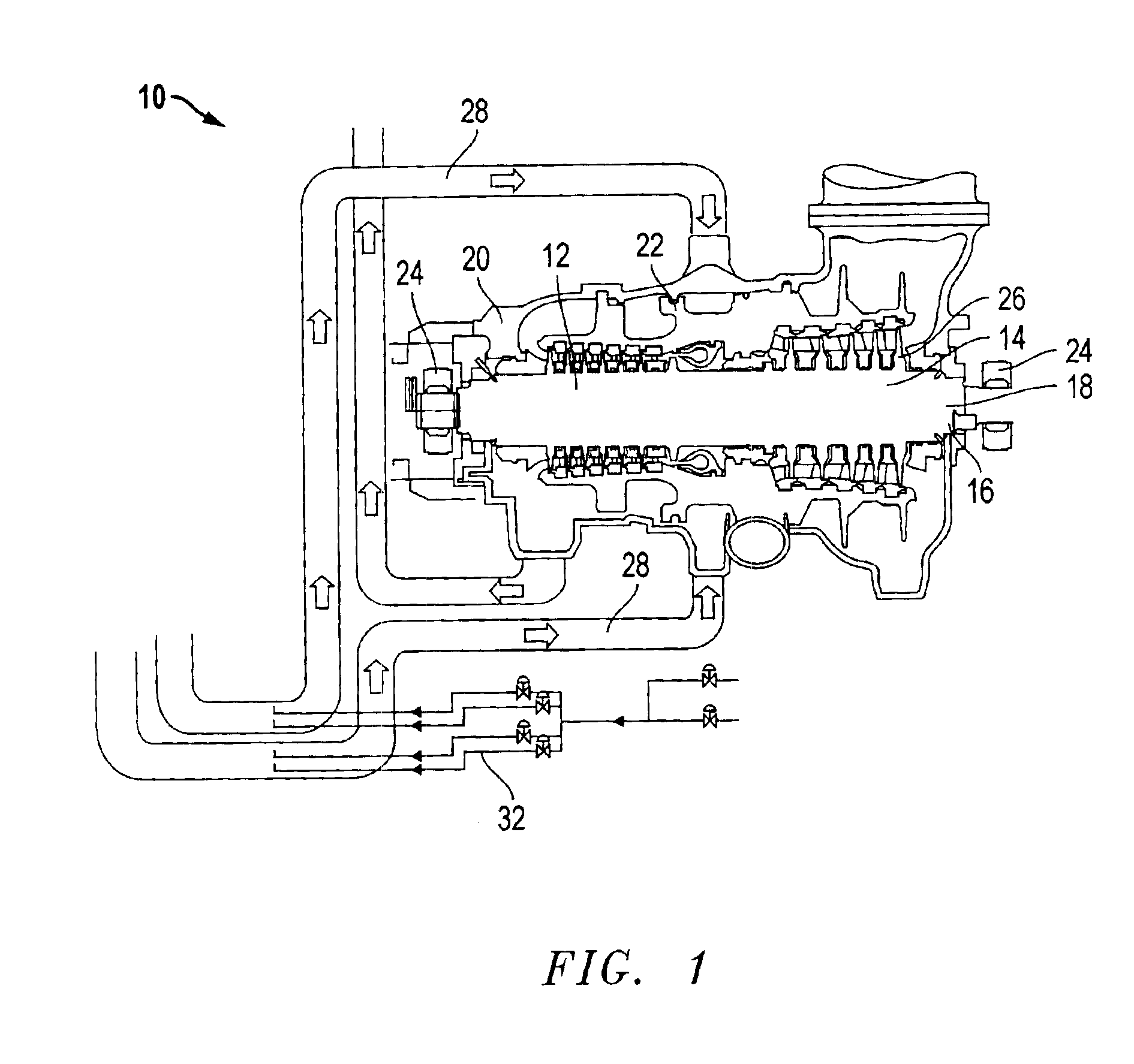

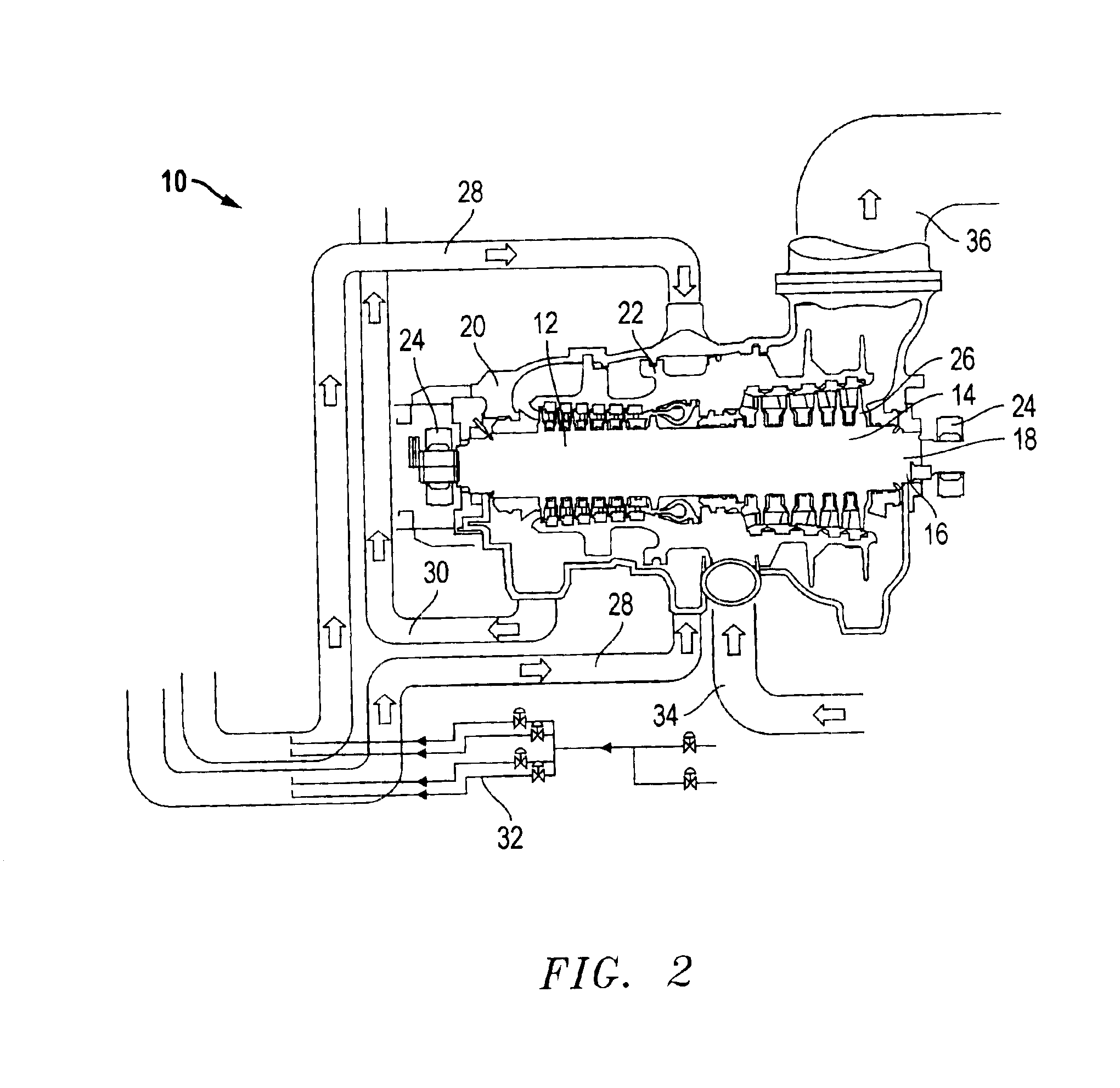

Heat exchanger for fermentation tank

InactiveUS20050077029A1Quality improvementReduce CooldownBeer fermentationWine preparationCoolant flowDouble wall

A device which is used to cool fermentation tanks and which can be used essentially in beer production, cooling and maturation, includes a vertical heat exchanger, which comprises single- or double-wall concentric cylinders and is positioned internally at the center of a tank. The length and capacity of the cylinders differ depending on the size and shape of the tank. A coolant flows through the cylinders in order to cool and to maintain a suitable temperature range. In addition, the double-wall cylinders which form the heat exchanger are interconnected by means of coolant flow and support tubes. Meanwhile, the exchanger is supported by the cone and the walls of the tank by means of tubes which are used for the passage of the coolant and the passage of signals. Moreover, the outer wall and the cone can be provided with a cooling jacket.

Owner:MORALES CERVANTES JOSE +1

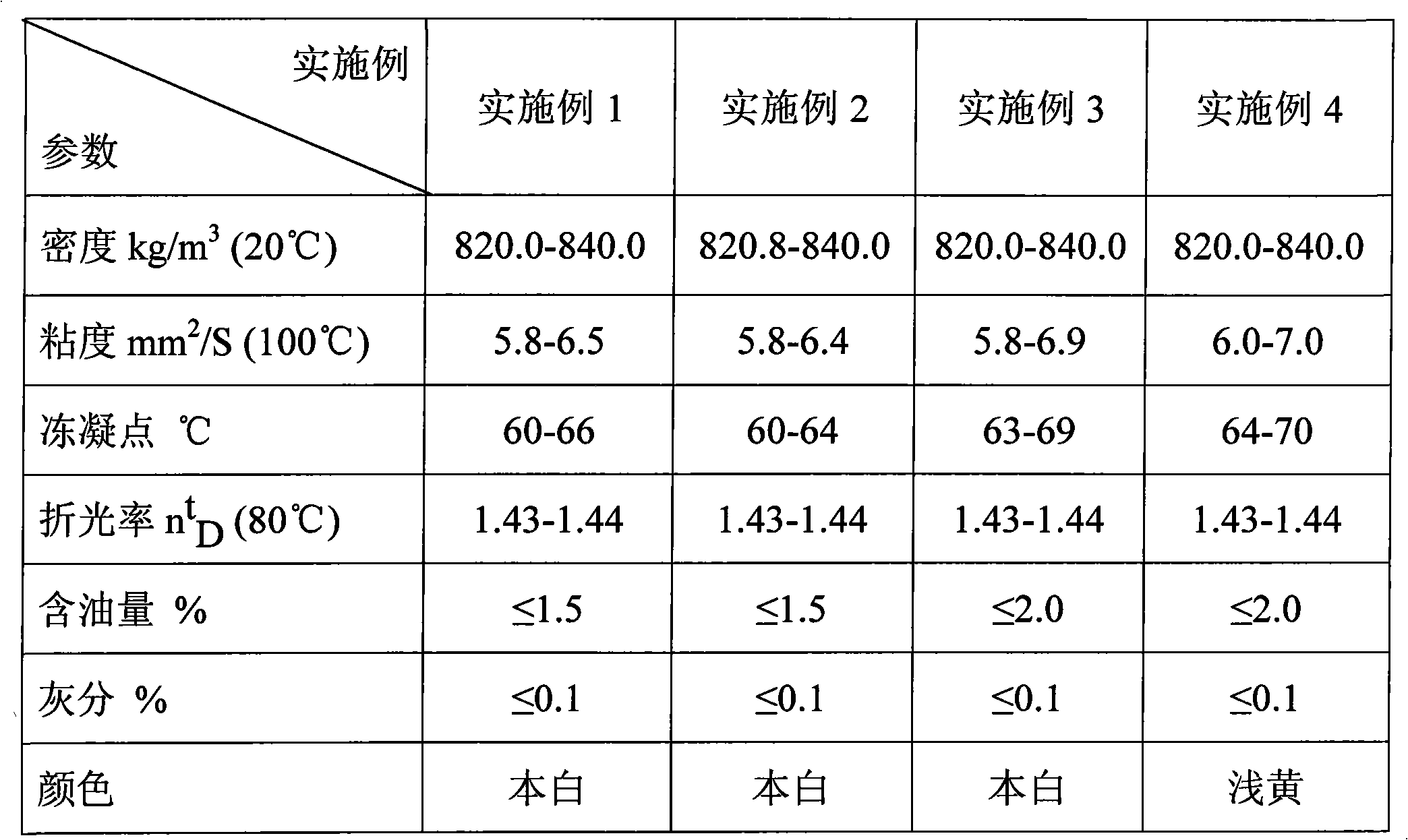

Novel rubber protective wax

The invention discloses a novel rubber protective wax which comprises the following components in percentage by weight: 14-20 percent of paraffin, 55-60 percent of mixed crystal wax, 24-30 percent ofmicrocrystalline wax and 1-2 percent of polyethylene wax. The invention has favorable seal performance and can reinforce the ozone and ageing resistance of a rubber product and prolong the service life of the rubber product.

Owner:上海绿菱特种蜡制品厂

Molding device of glass molding articles

ActiveCN104556644AReduce CooldownReduce molding cycle timeGlass reforming apparatusVacuum pressureMaterials science

The invention relates to a molding device of glass molding articles. More specifically, the molding device of the glass molding articles comprises a pre-heating mechanism contacted with a mold body in a non-load state for pre-heating, a discharge cooling line provided with a cooling water line is formed at an outlet side of a molding chamber, the cooling time in the molding chamber is shortened, the whole molding period time of glass with a curved surface portion is further shortened, a plurality of suction holes into which vacuum pressure flows are formed at the bottom of a lower mold of the mold body, vacuum pressure absorption materials flowing into the suction holes are employed during molding motions, the glass with the excellent curved surface portion is molded, an inlet side of the molding chamber is provided with a vacuum mechanism for vacuum treatment of the mold body, and the molding device can be applied to the molding of infrared glass optical lenses.

Owner:DAEHO TECH CO LTD

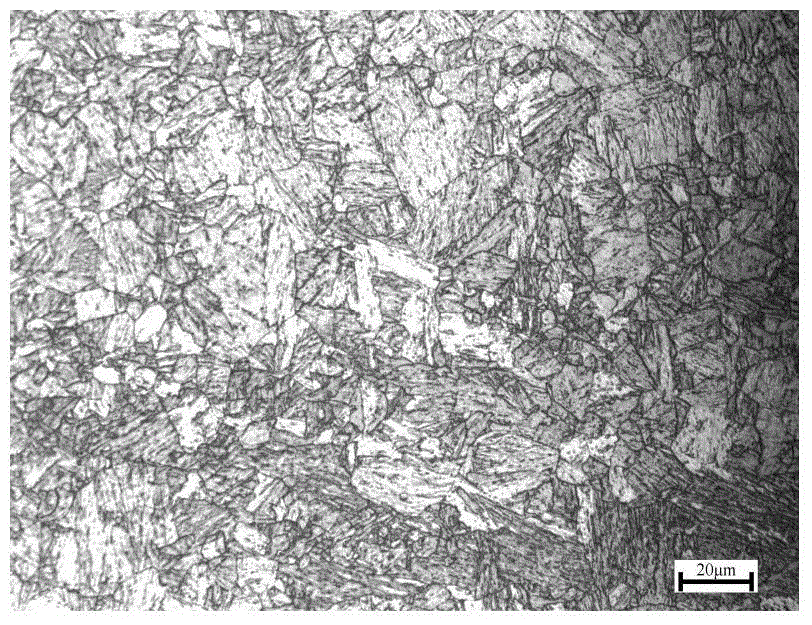

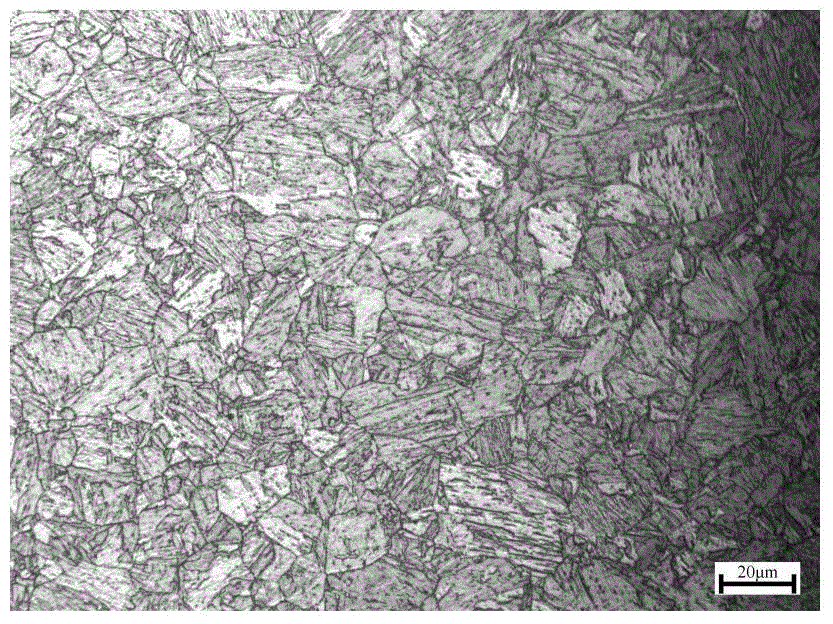

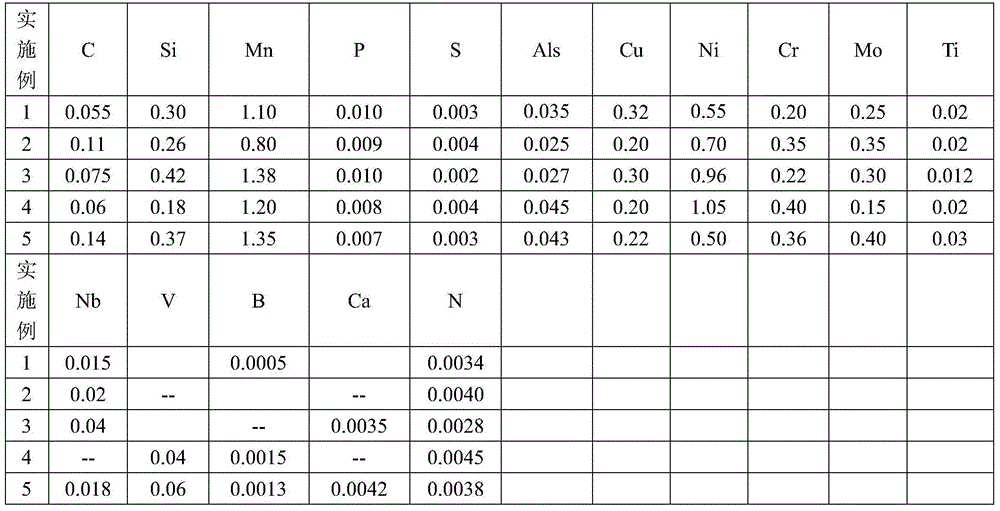

Low compression ratio 690MPa grade extra thick steel plate and production method thereof

The invention discloses a low compression ratio 690MPa grade extra thick steel plate and a production method thereof, and the low compression ratio 690MPa grade extra thick steel plate comprises the following components by weight: 0.05%-0.14% of C, 0.12%-0.45% of Si, 0.70%-1.40% of Mn, < = 0.010% of P, < = 0.005% of S, 0.025%-0.065% of Als, < = 0.005% of N, 0.10%-0.50% of Cu, 0.50%-1.00% of Ni, 0.10%-0.40% of Cr, 0.10%-0.45% of Mo, also comprises one or more than two components selected from the following chemical components: 0.03%-0.08% of V, 0.005%-0.04% of Nb, 0.005%-0.03% of Ti, 0.0008-0.004% of B and 0.002%-0.006% of Ca, and also comprises balance of Fe and inevitable impurities, wherein the total ratio of precious and strengthening elements of Cr, Mo, Ni and Cu is less than or equal to 1.5%.

Owner:ANGANG STEEL CO LTD

High-density polyethylene glued board producing method

InactiveCN101284384AReduce CooldownSave energyWood veneer joiningLow-density polyethyleneWeather resistance

A method for manufacturing a HDPE wood plywood mainly includes: rolling dense pin holes on the cementing surface of a veneer; replacing urea formaldehyde, phenolic aldehyde and other adhesives with HDPE plastic film; laying up in the common conventional plywood lay-up method and only laying the HDPE film instead of the adhesives; heating and pressuring the lay-up on a hot press machine and then pressuring and cooling on a cold press machine. The problems that the HDPE is immiscible with the wood, and can not be taken for the adhesive of the wood are solved by applying the principle of mechanical locking; The heat loss and the time consumption of the hot press machine can be avoided when the lay-up is cooled, for pressing is carried out on the hot press machine and the cold press machine respectively. The plywood product has formaldehyde-pollution-free production, high strength, durability, weather resistance, acid and alkali resistance, high water resistance, good appearance and low price. The manufacturing process has no pollution, and is environment-friendly, energy-saving, efficient and simple.

Owner:林群祥

Apparatus for producing reflective membrane with microprism array structure

ActiveCN101672939AImprove work efficiencyImprove performanceOptical elementsUV curingHeat resistance

The invention relates to an apparatus for producing a reflective membrane with a microprism array structure and solves the defects in the prior art that the hardness, scratch resistance, heat resistance and solvent resistance of microprisms are disappointing, the product consistency is poorer, the production speed is lower, the work efficiency is not high, and the like. The apparatus comprises anannular strip-shaped mould, a heating membrane pressing device and a cooling device, wherein the annular strip-shaped mould is provided with an inner surface and an outer surface which is provided with a convex continuous precise microprism array structure. The apparatus also comprises a coating device, a drying device and a UV curing device. By adding the coating device, the drying device and theUV curing device, the microprism structure is formed after the UV curing of photosensitive resin, the hardness, scratch resistance, heat resistance and solvent resistance of microprism of the microprism structure are greatly improved, and the product consistency is fine. In addition, the apparatus can also obviously improve the production speed and the work efficiency.

Owner:ZHEJIANG DAOMING OPTOELECTRONICS TECH

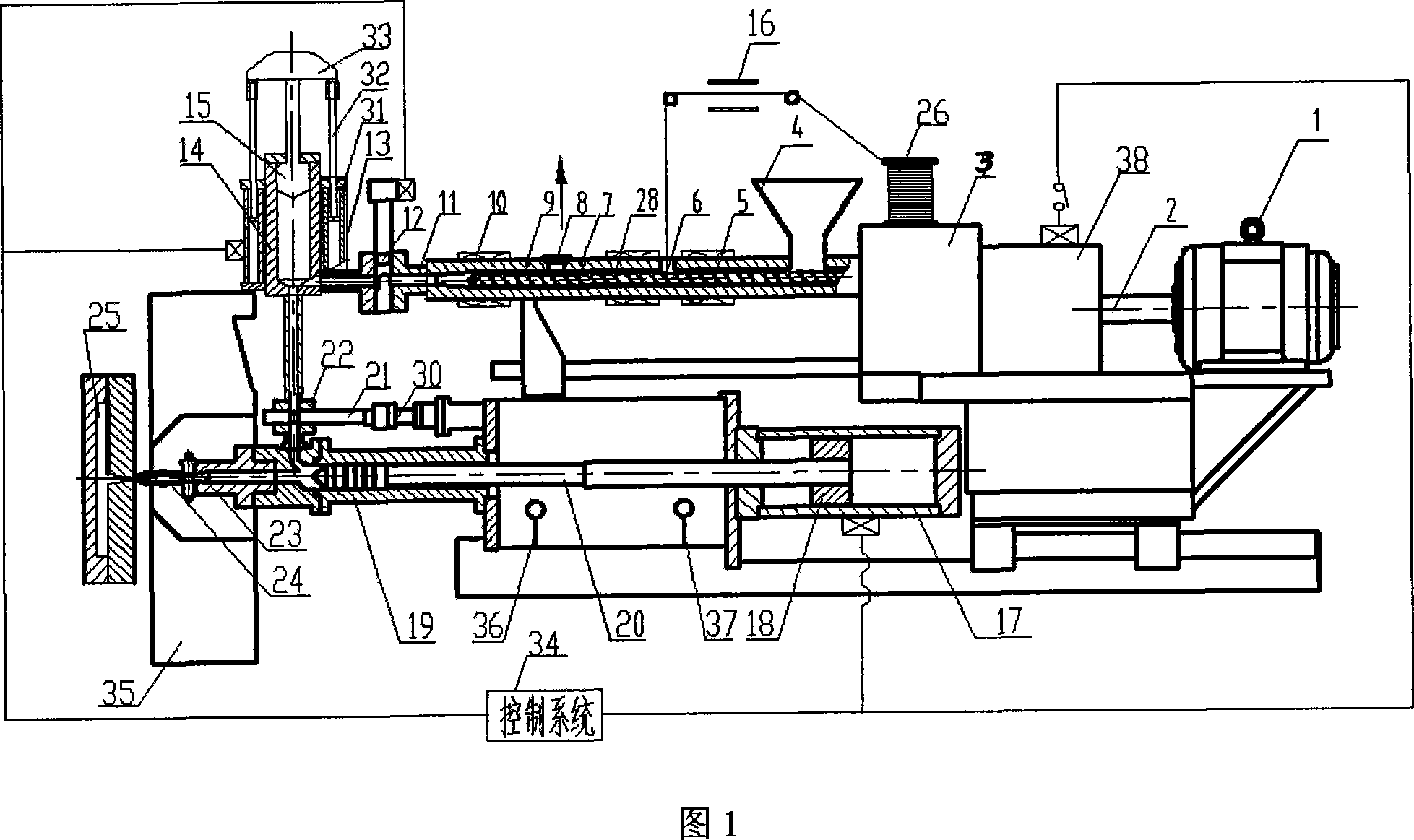

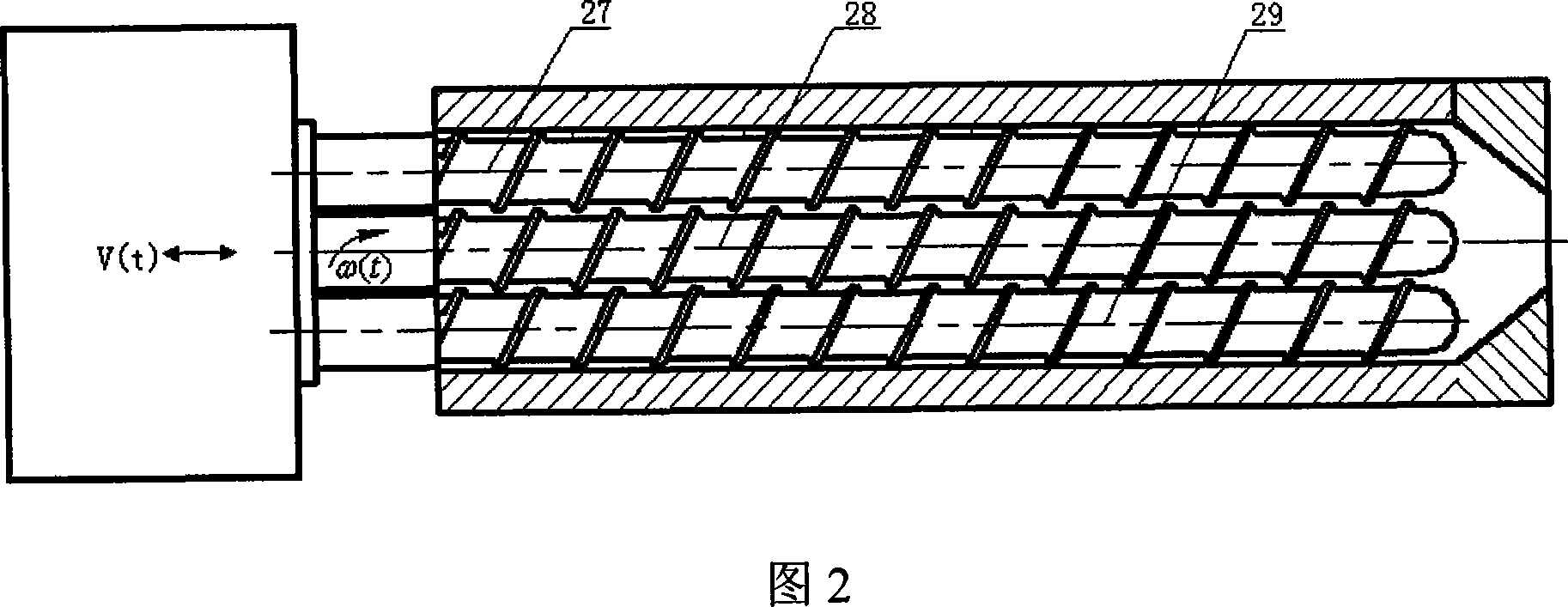

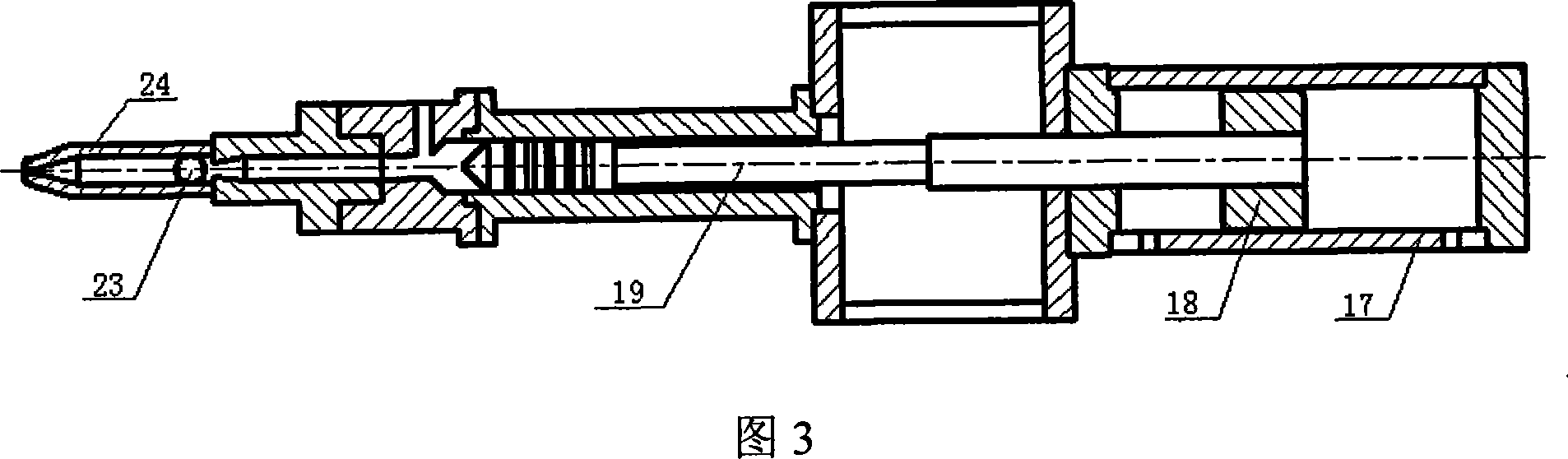

Pulse type shock processing on-line compound injection molding method and its equipment

InactiveCN101077611AIncrease fill ratioImprove interface compatibilityEngineeringFiber-reinforced composite

The present invention discloses pulse type shock reinforced in-line mixing and injecting forming method and apparatus. Pulse type shock is introduced into the whole in-line mixing and injecting forming process of producing fiber reinforced composite polymer material. The apparatus includes one plasticizing extruder with three screws arranged in one line and including one main screw capable of generating periodical axial pulse shock, one buffering storing device, and one pulse type shock pressure reinforcing plunger injecting device. The present invention can lower melt viscosity, raise mixing and homogenizing effect, raise the compatibility between fiber and polymer, lower the processing power consumption and raise product quality.

Owner:SOUTH CHINA UNIV OF TECH

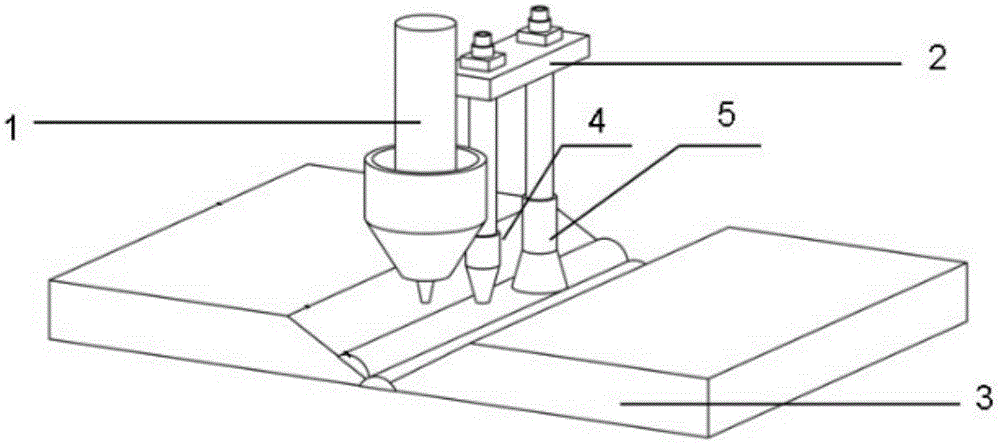

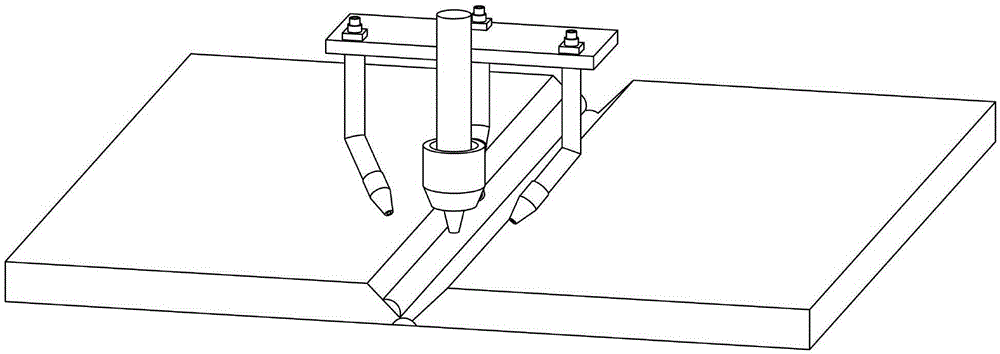

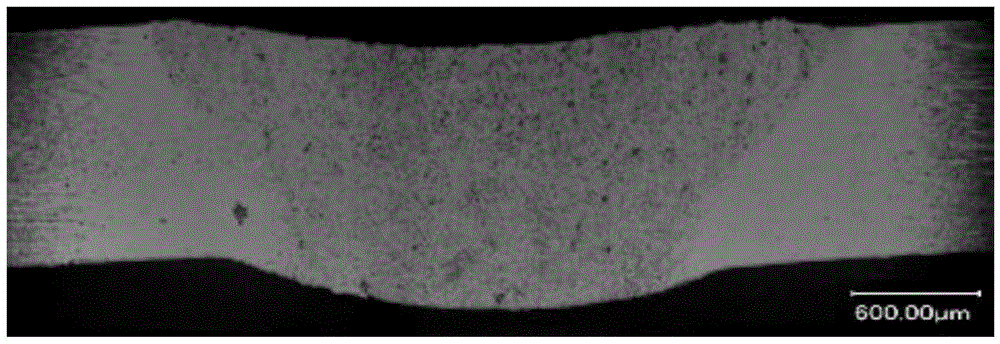

Simultaneous cooling assisted connection method based on laser additive manufacturing

InactiveCN105414746AGrain refinementImprove welding efficiencyLaser beam welding apparatusMetallurgyMartensitic stainless steel

The invention relates to a simultaneous cooling assisted connection method based on laser additive manufacturing, and aims to solve the problems of an increase in the crystal grain size, a decrease in the connector performance, and the like caused by the fact that heat cannot be effectively dissipated when titanium alloy, carbon stainless steel, martensitic stainless steel and other materials being relatively low in heat conductivity are involved in connection processes based on a laser additive manufacturing method. According to the method, a cooling device is arranged for being combined with a laser welding machine and a welding powder feeder, so as to achieving a cooling process; heat accumulated in the welding process can be effectively dissipated, so as to refine crystal grains; the welding efficiency and the connector performance are improved; in order to solve the problem that an oxidation phenomenon is likely to occur in the welding process, the cooling process is performed according to a cooling method adopting liquid nitrogen, inert gas or the like, so that connector oxidation can be effectively avoided when a cooling effect is exerted.

Owner:HARBIN INST OF TECH

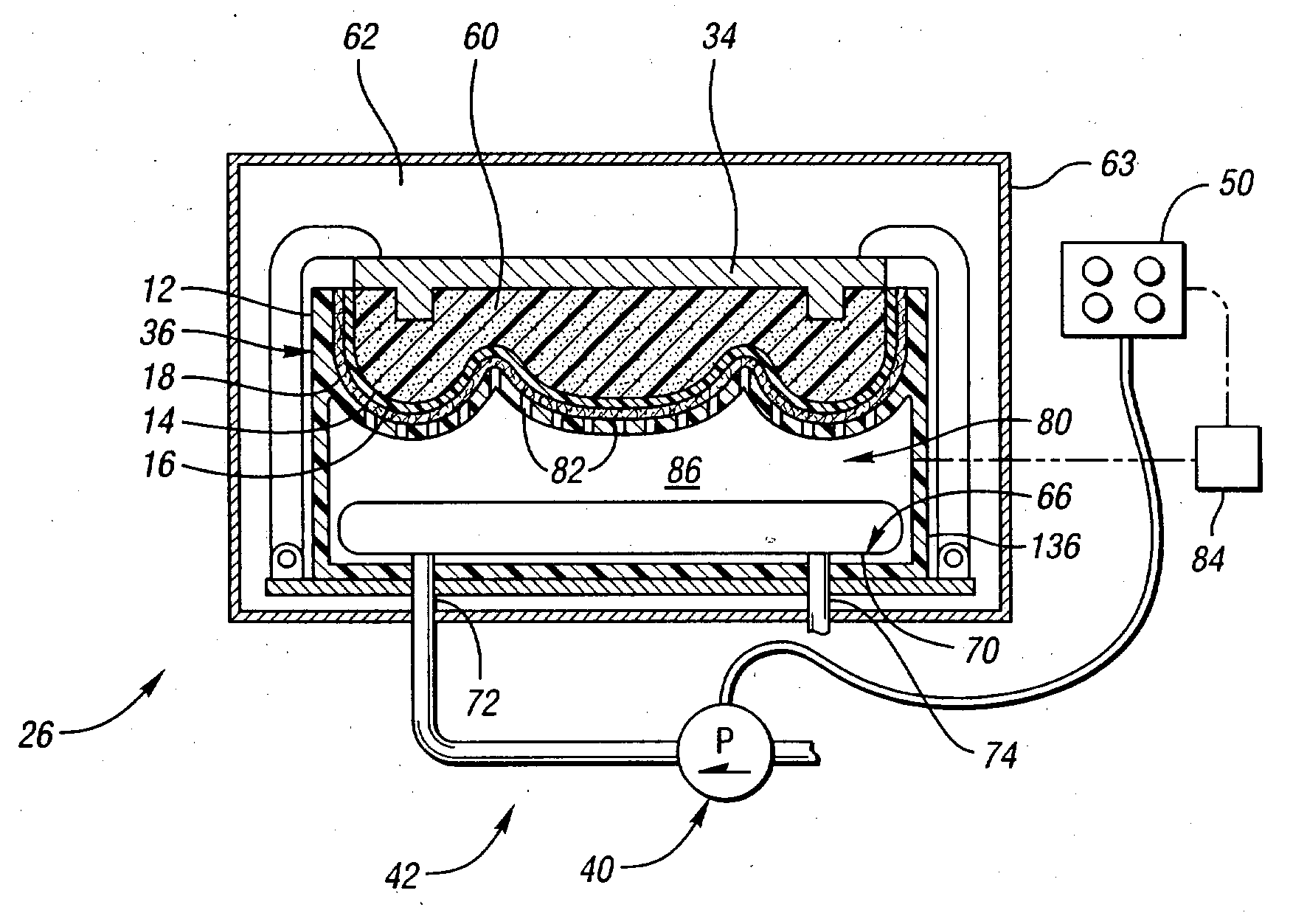

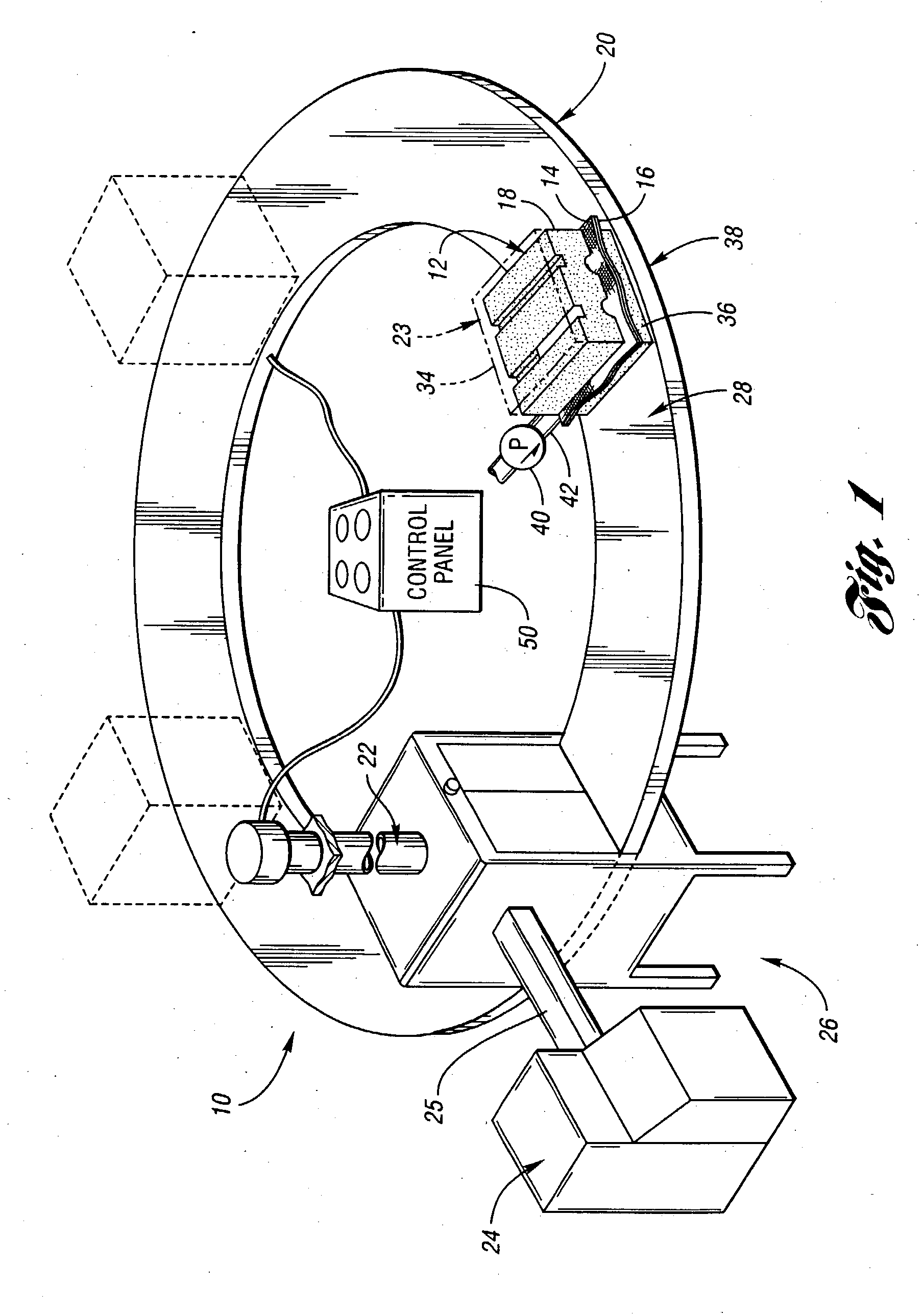

Method and apparatus for bonding a cover to a substrate using high frequency microwaves

InactiveUS20040226648A1Higher "coGood energy dissipationUpholstery manufactureLamination ancillary operationsAdhesiveEngineering

A method for adhesively bonding a covering to a support using a dry heat-sensitive adhesive to produce an assembly for an automotive interior. The method positions the layers to form an assembly of material layers in tooling that concentrates microwave radiation energy conversion to the adhesive layer above its melting temperature. The method for fabricating an assembly in accordance with the subject invention, particularly when the tooling is transparent to the radiation, controls the radiation reflection, which is generated at a frequency exceeding 30 GHz.

Owner:INT AUTOMOTIVE COMPONENTS GRP NA INC

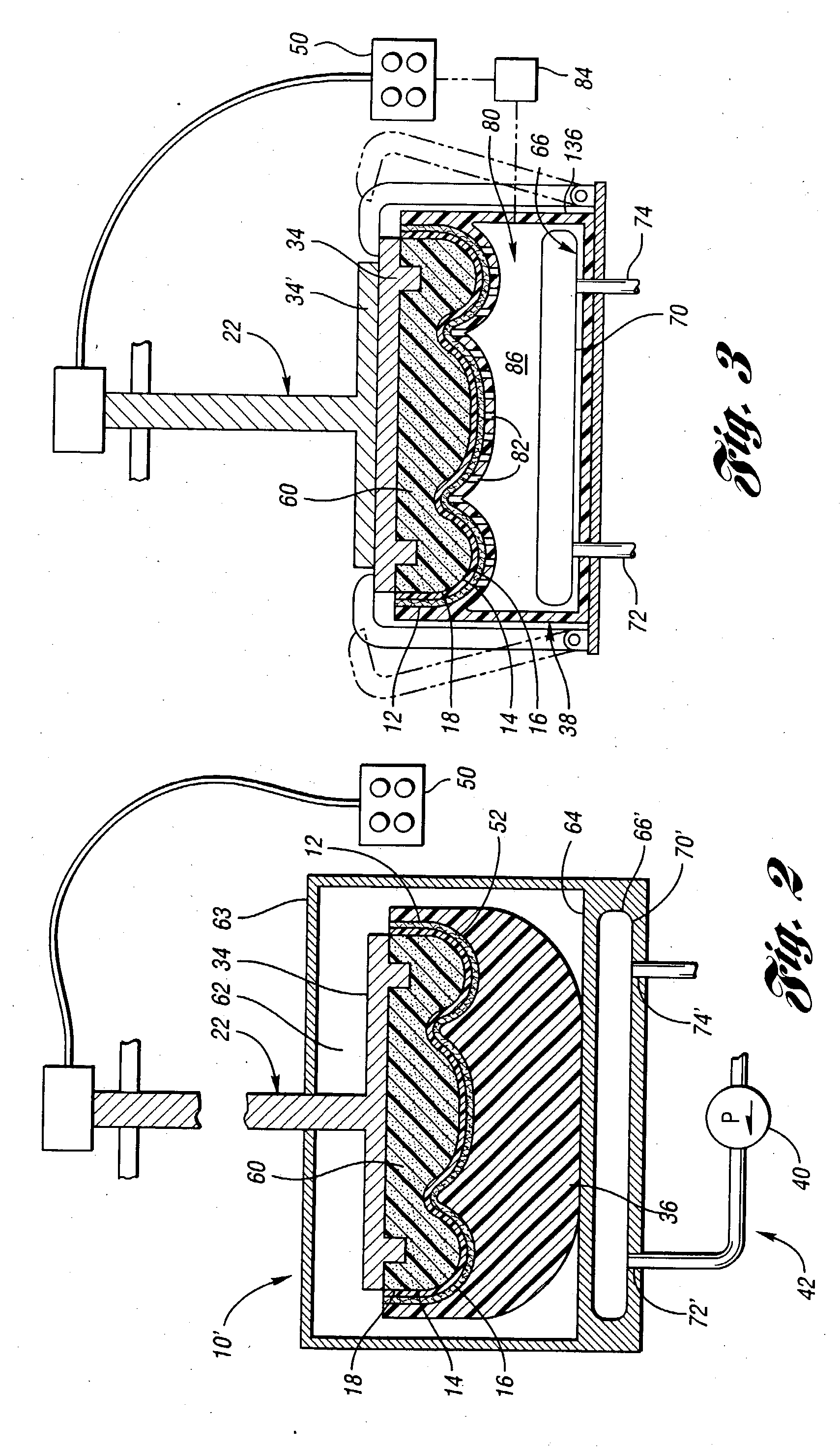

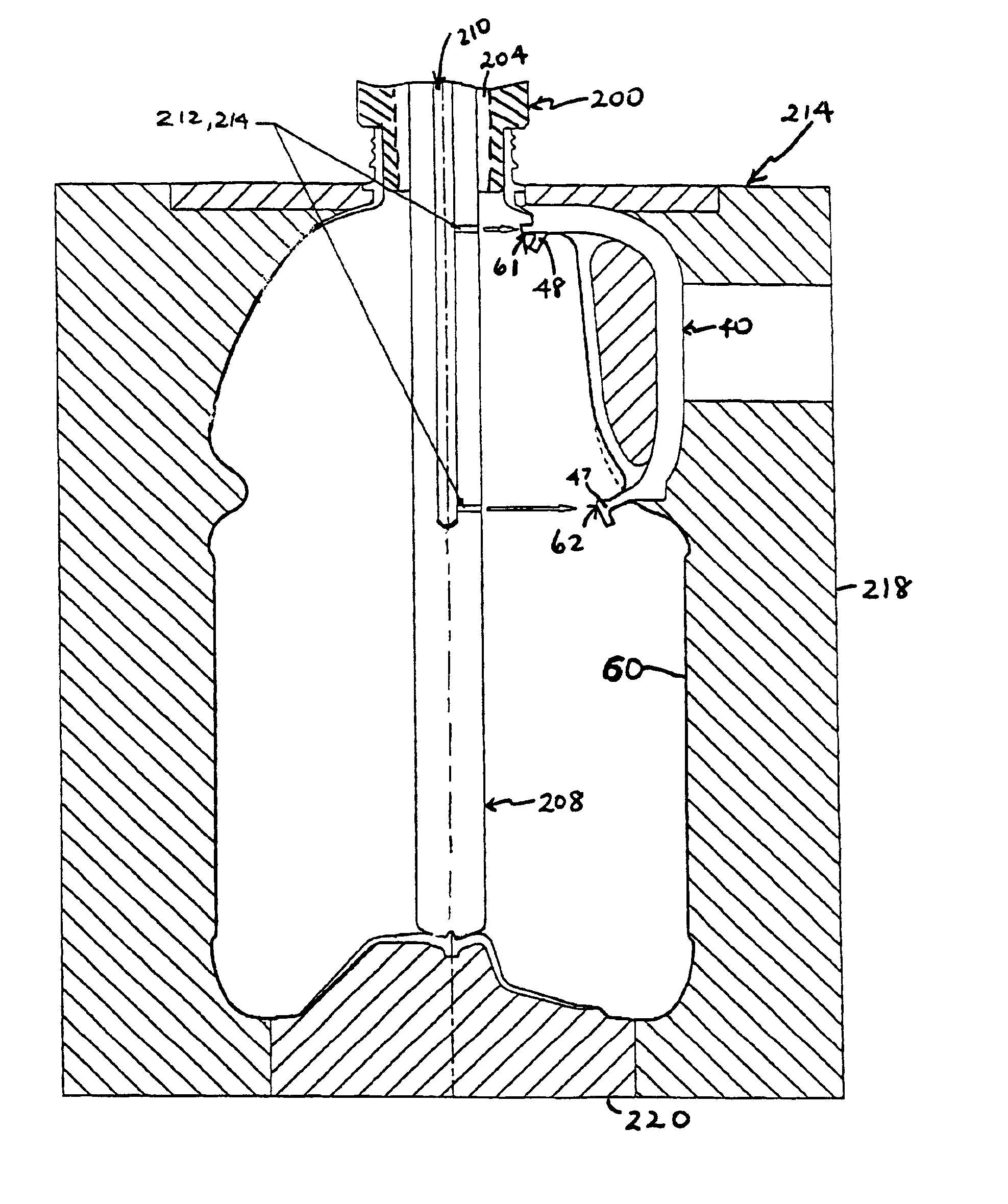

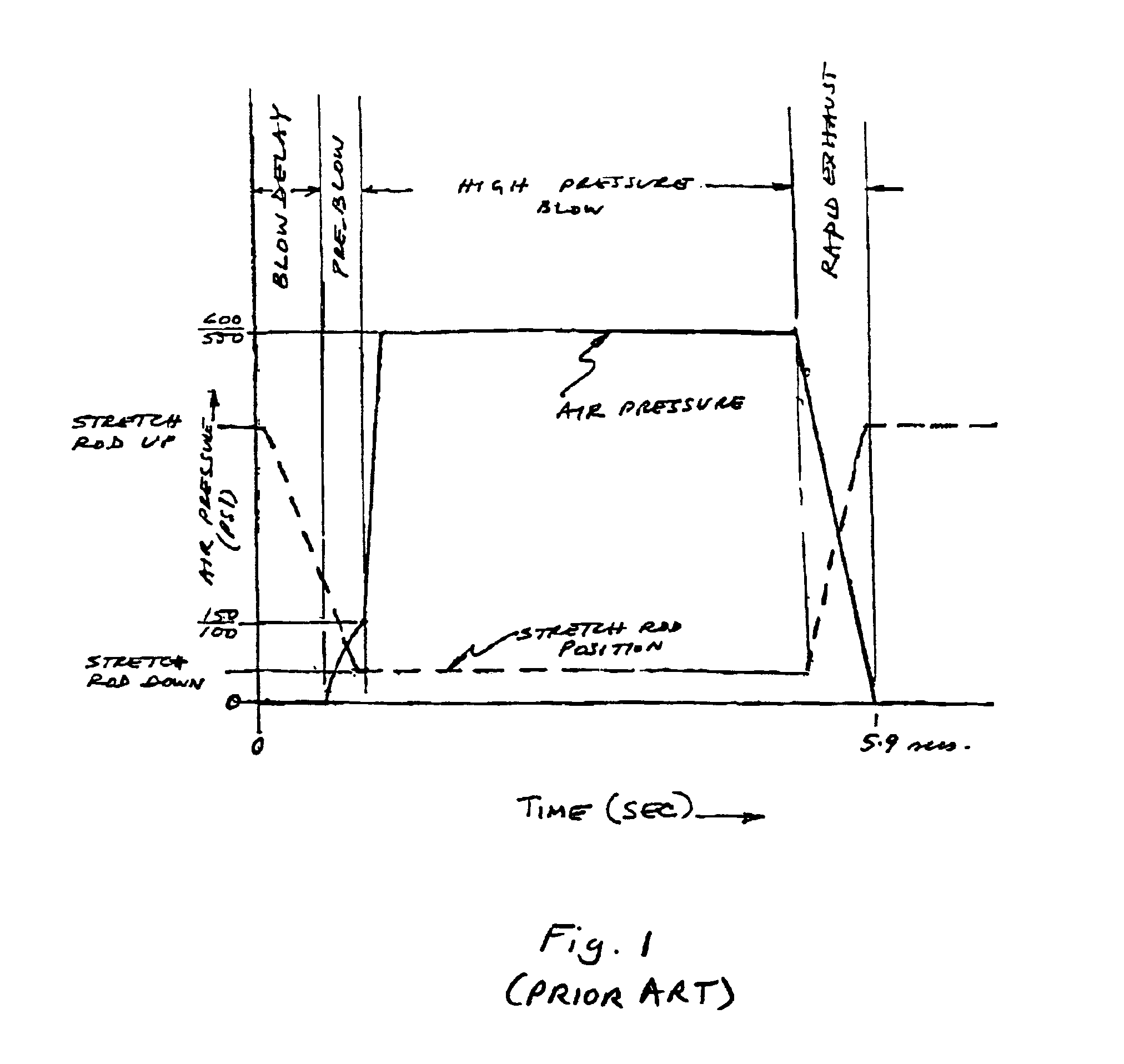

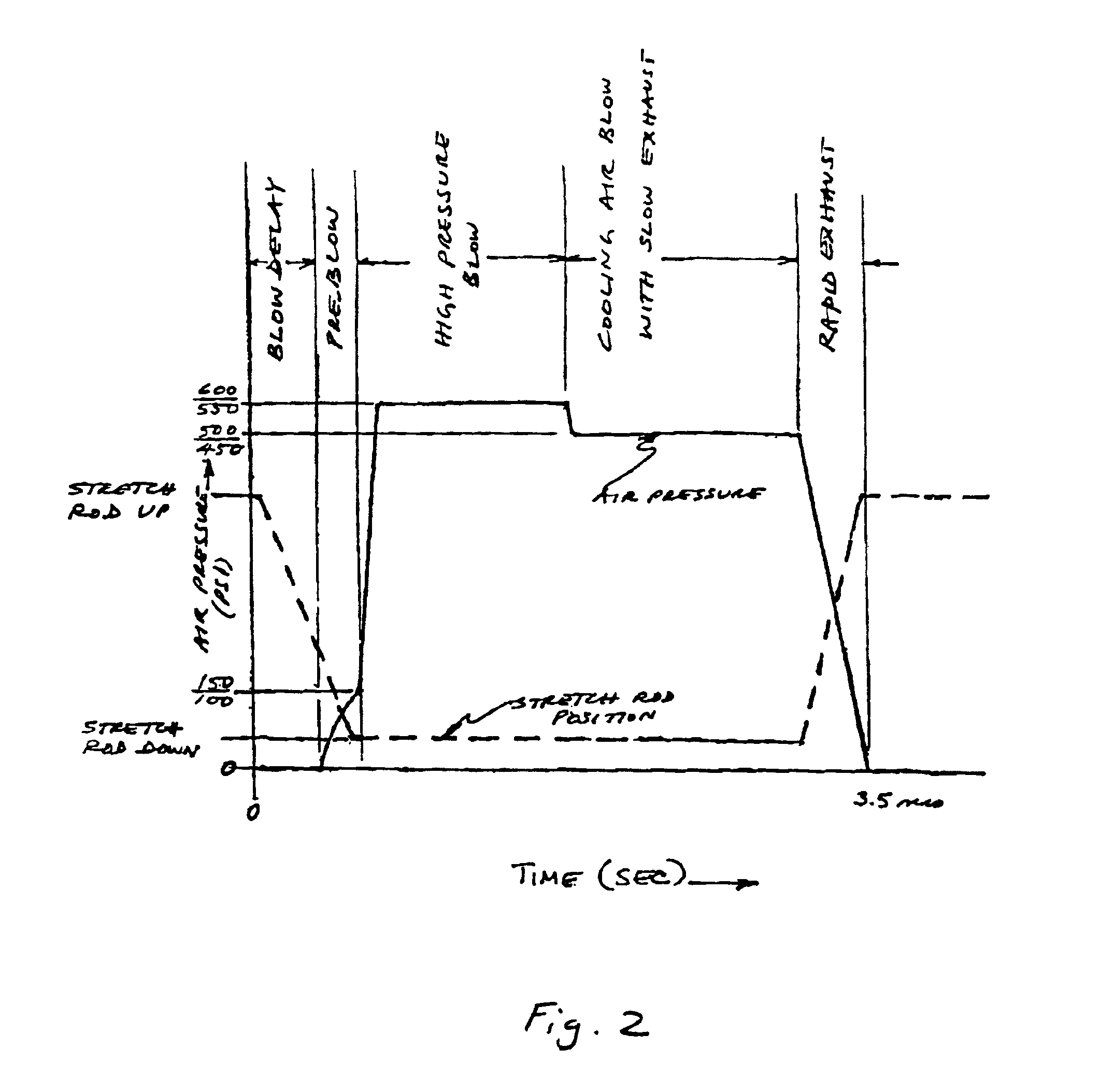

Method and apparatus for cooling during in-mold handle attachment

InactiveUS6855289B2Enhanced in-mold coolingShorten the timeDomestic articlesHollow articlesBlow moldingEngineering

Method and apparatus for in-mold handle attachment, wherein a portion of a blow-molded container is formed about a retaining member on a handle during blow molding. After forming the container portion about the retaining member, a cooling medium is directed at the location of the container portion in order to accelerate the cooling rate at the container portion. There is achieved at least one of an improvement in the security of the attachment of the handle to the container, and a reduction in the blow-mold processing time.

Owner:GRAHAM PACKAGING PET TECH

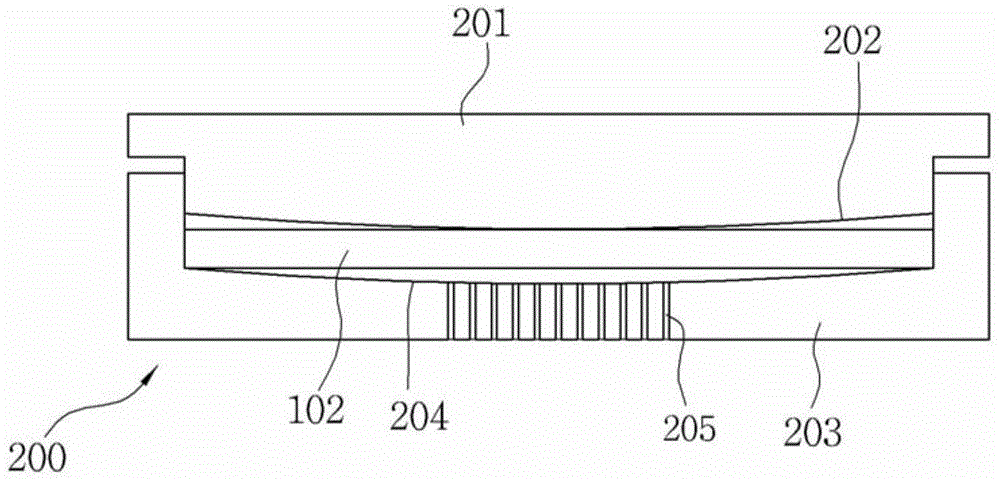

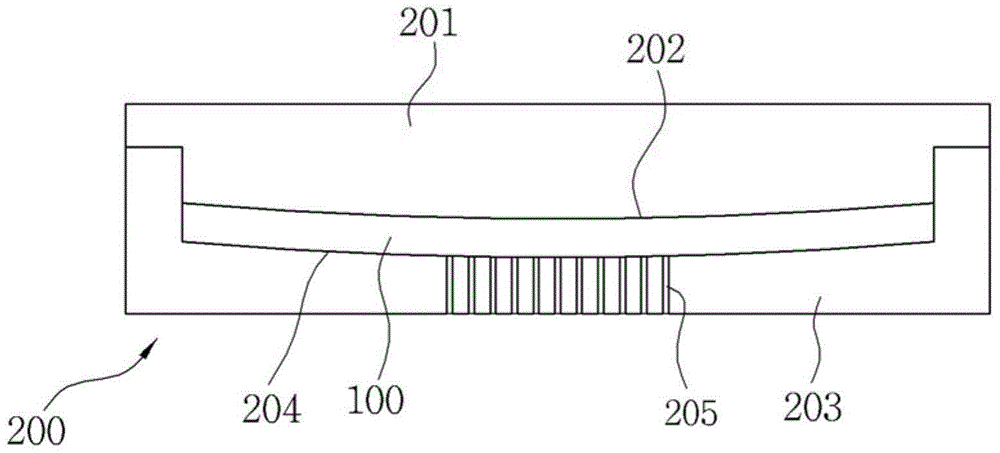

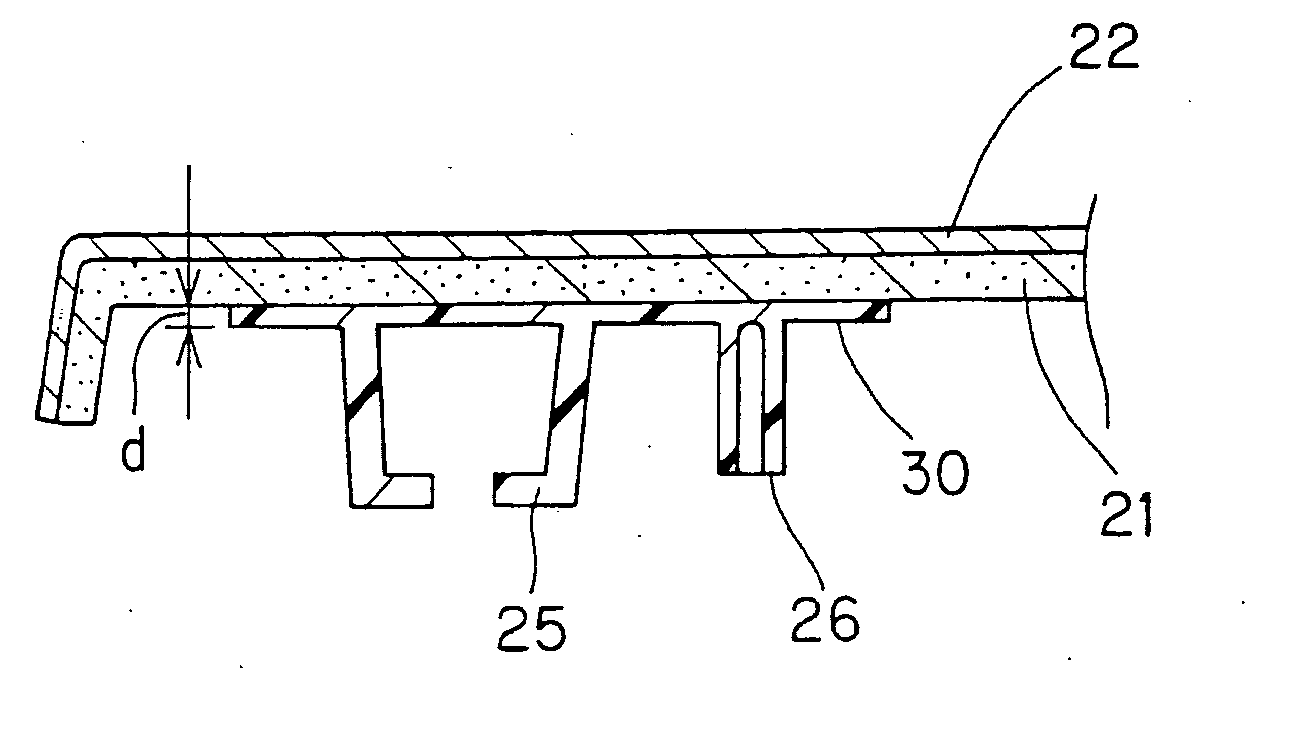

Display device

InactiveCN101842826AImprove rigidityImprove retentionNon-linear opticsIdentification meansDisplay deviceMechanical engineering

Owner:SHARP KK

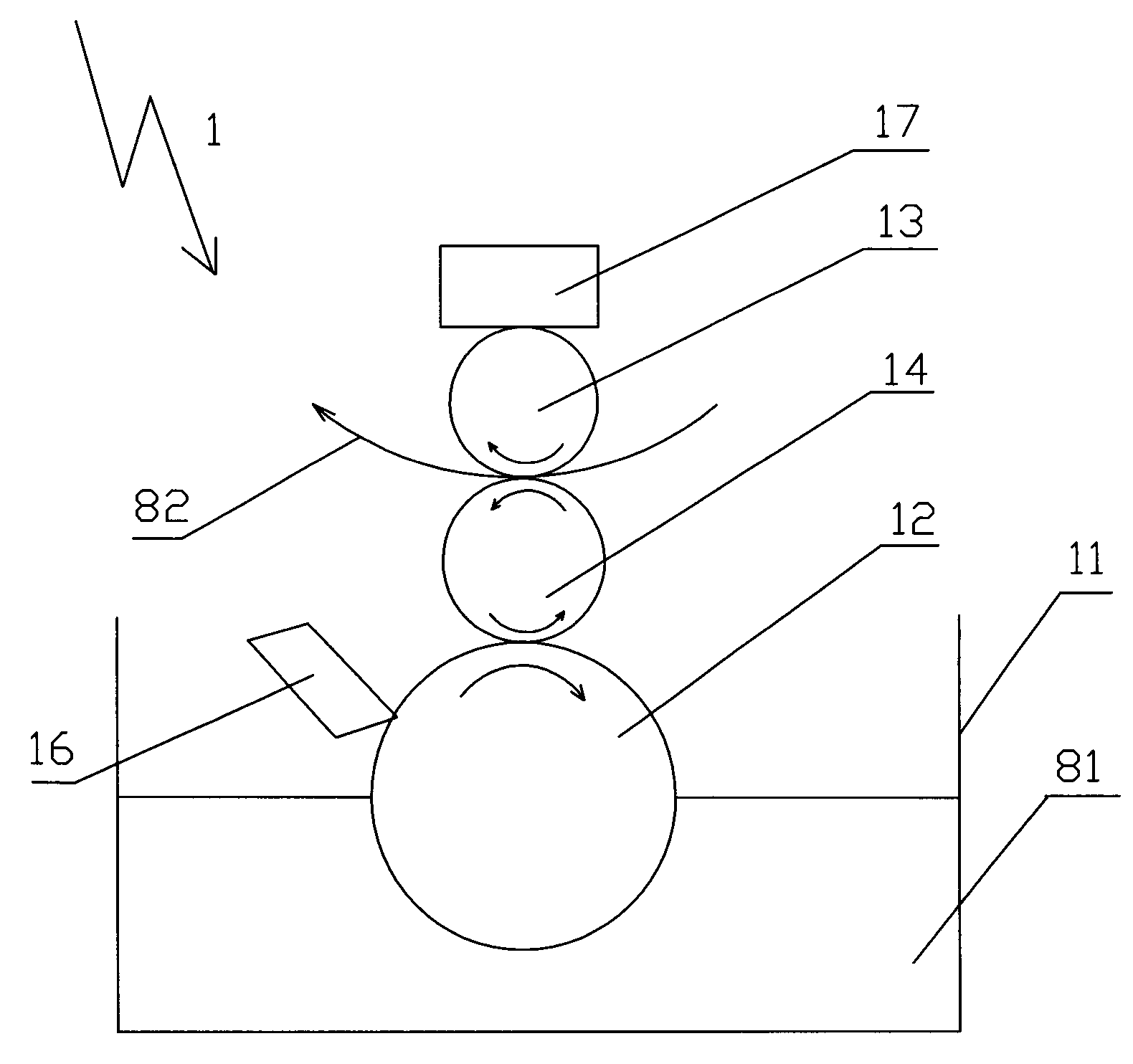

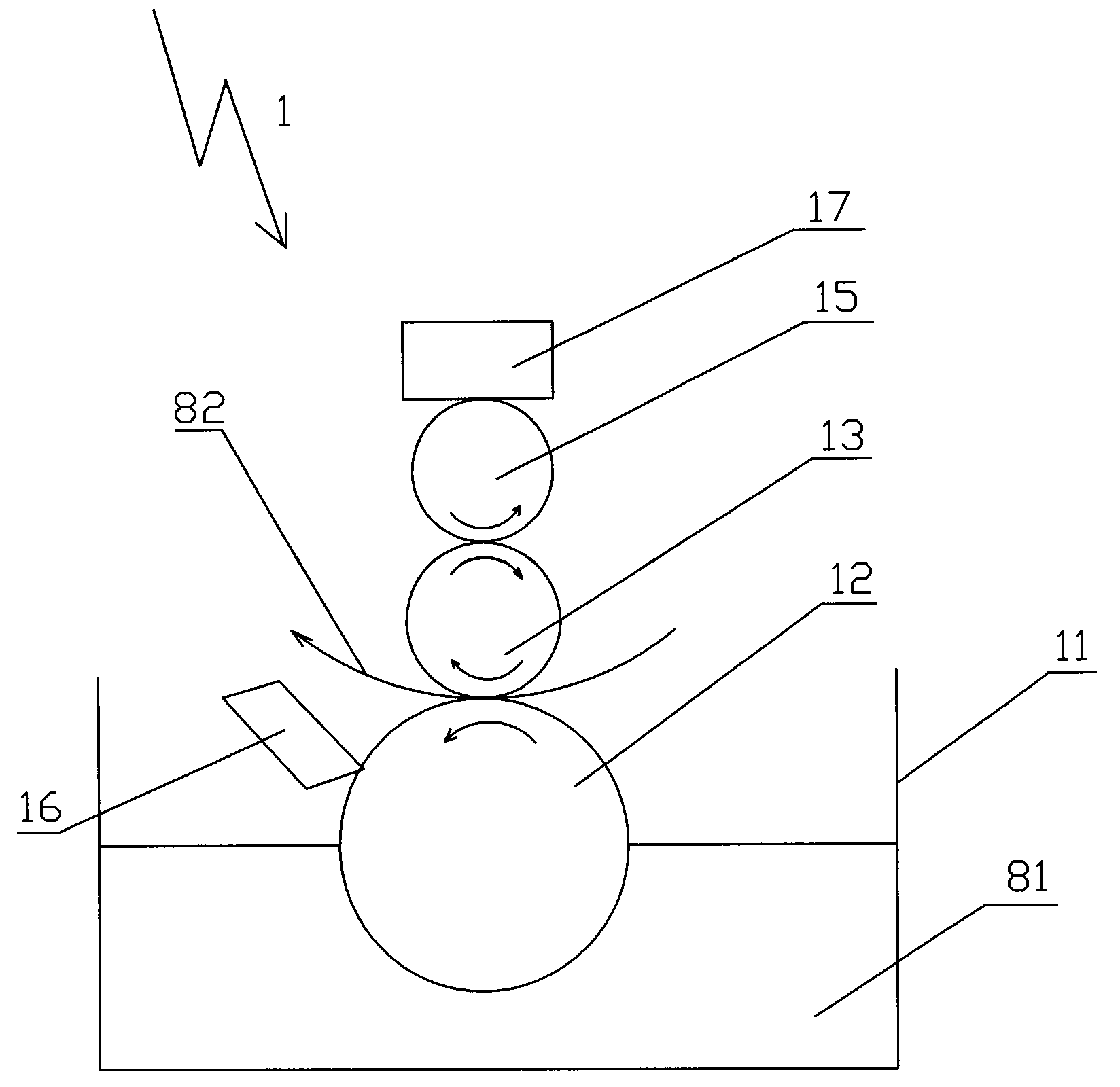

Steel plate ingot casting device and method for producing ultra-thick steel plate cast ingot with same

The invention discloses a steel plate ingot casting device, which comprises a pedestal, a fixed framework and an ingot mold, wherein the fixed framework is fixedly connected with the pedestal; the ingot mold is positioned in the fixed framework and consists of two pairs of side templates, i.e., front, rear, left and right side templates, and a bottom template; the outer sides of the side templates and the bottom template are respectively provided with a cooling water box; the side templates are provided with squeezing mechanisms; the bottom template is provided with a lifting mechanism; the side templates and the bottom template are all copper plate products; and the bottom template is provided with a runner port. According to the steel plate ingot casting device, deformation under cold and hot intensity stress can be avoided, and a shrinkage hole is avoided; since the solidification time is greatly shortened, the segregation in a steel ingot can be obviously relieved, thereby greatly improving the internal quality and the performance of a produced ultra-thick plate; and meanwhile, the steel plate ingot casting device has the advantages of freely adjustable ingot mold size, long service life of the ingot mold and the like.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

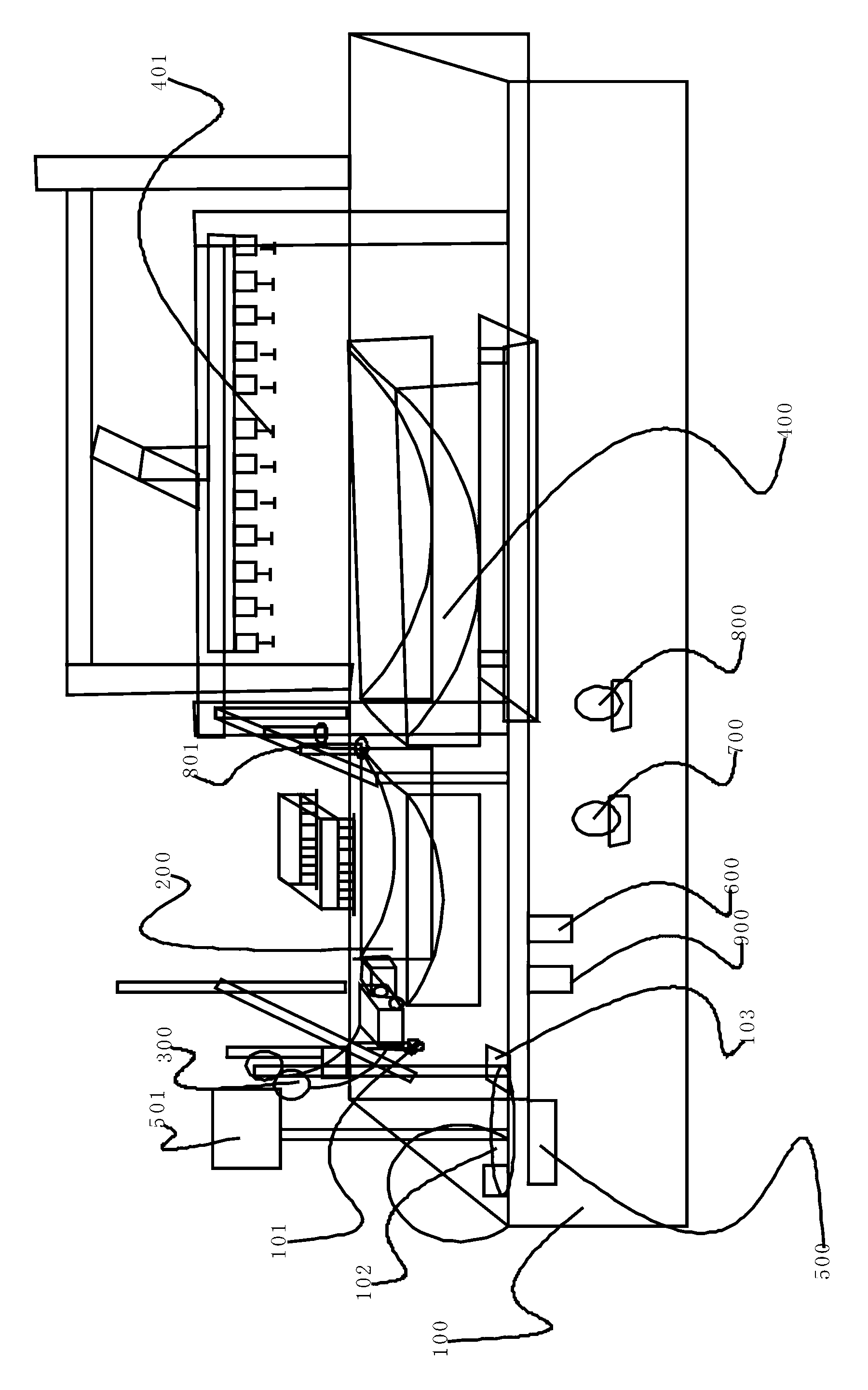

Single welding and series welding integrity device of solar cell slices

ActiveCN102699587AReduce wasteLow costFinal product manufactureWelding/cutting auxillary devicesFailure rateTemperature control

The invention discloses a single welding and series welding integrity device of solar cell slices. The provided single welding and series welding integrity device of the solar cell slices is good in positioning accuracy and compatible in the solar cell slices with different specifications, and can improve the single welding and series welding production efficiency of the solar cell slices. The device comprises a device rack, the device rack is provided with a feed mechanism, a transmission and positioning mechanism, a welding and temperature control mechanism, a blanking mechanism, a control mechanism and a power supply and control mechanism. According to the single welding and series welding integrity device of the solar cell slices, a full manual welding mode is replaced by a full automatic mechanical welding mode, the production efficiency is remarkably increased, the cell slice failure rate during a welding process is reduced, and the device is suitable for cell slice welding of the solar cells.

Owner:沈园众

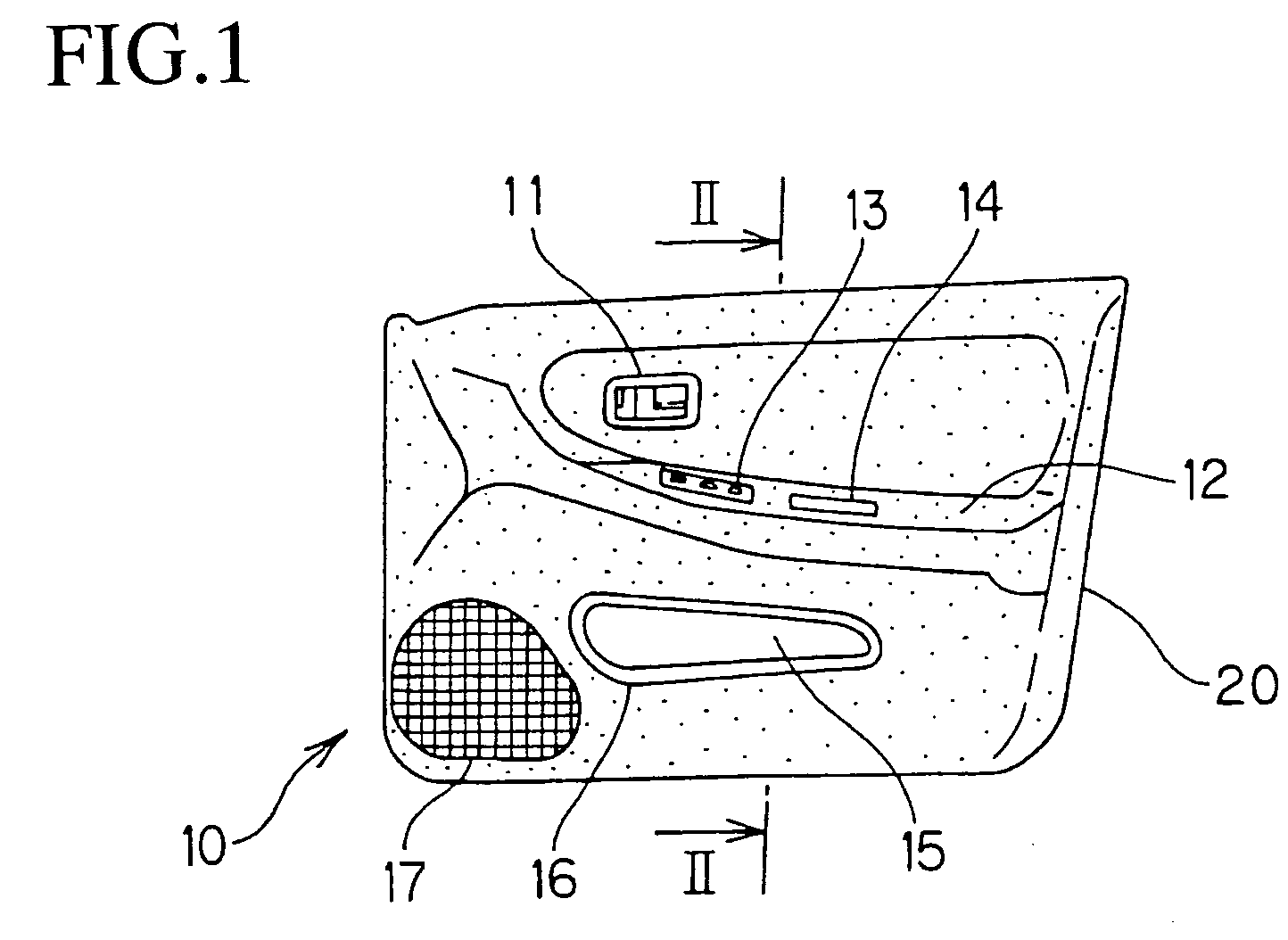

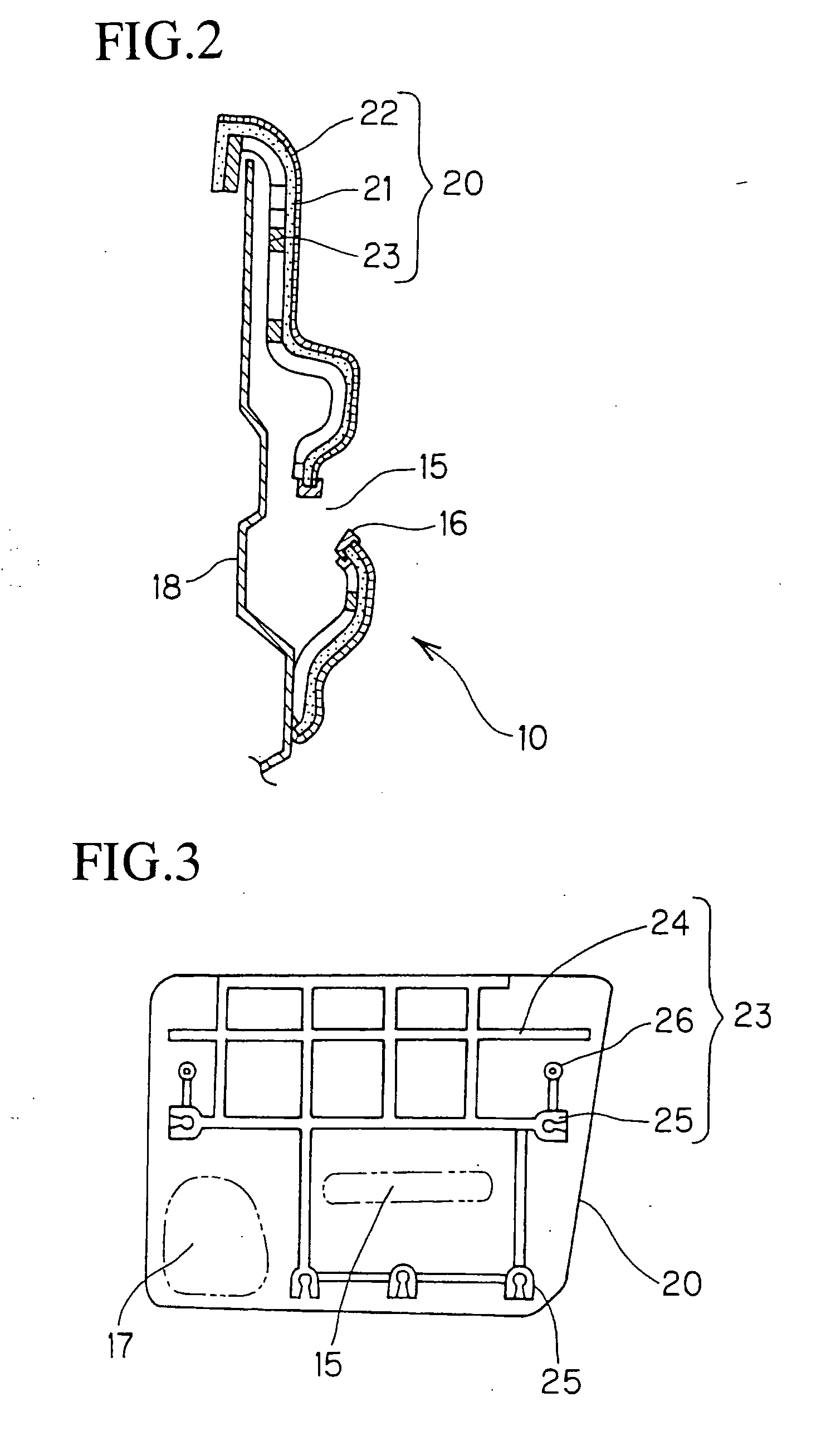

Automotive interior component and method for manufacturing the same

InactiveUS20060222841A1Reduce molded loadReduce in quantitySynthetic resin layered productsVehicle componentsDecrease weightMechanical engineering

Owner:KASAKI IND

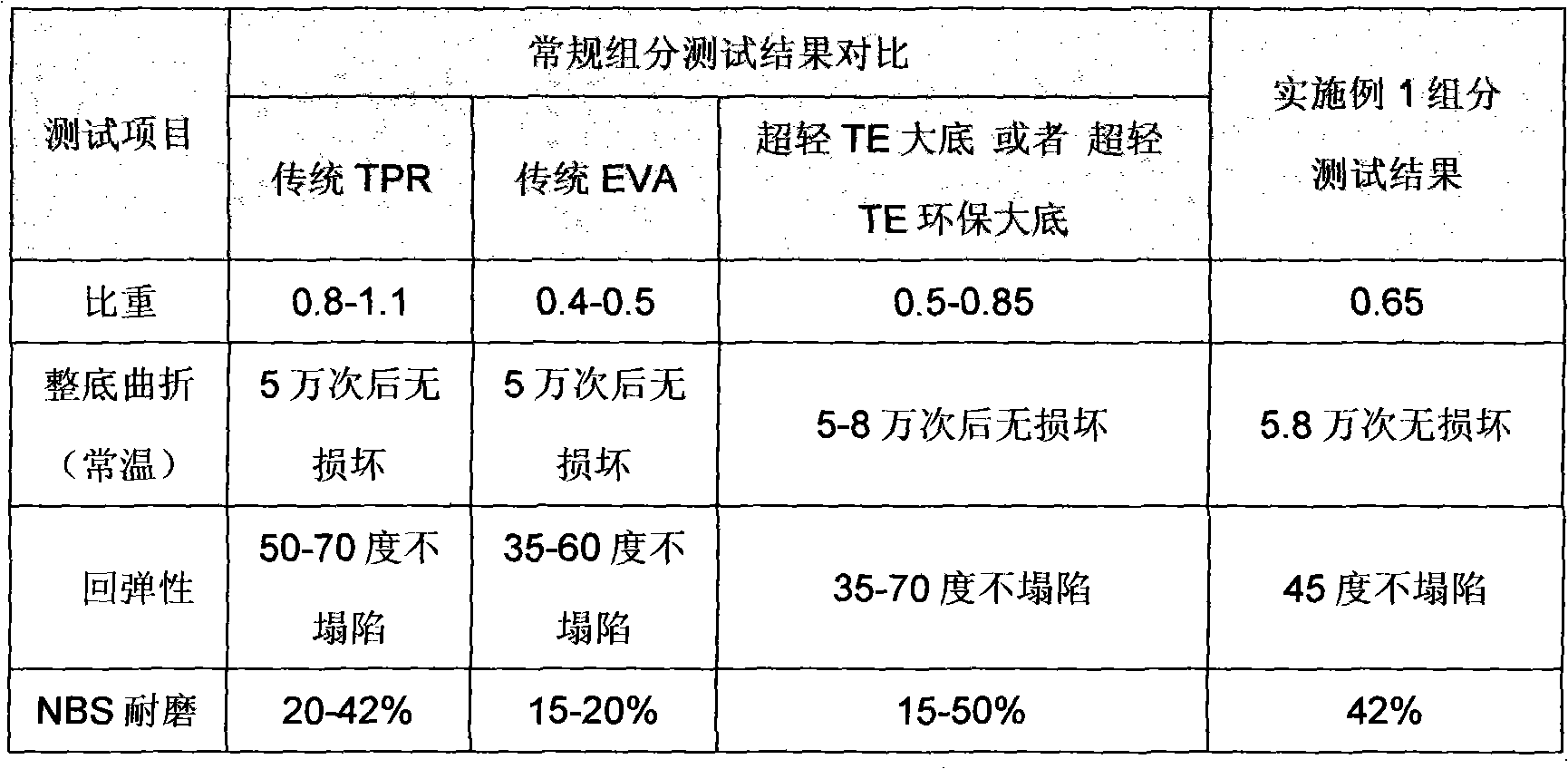

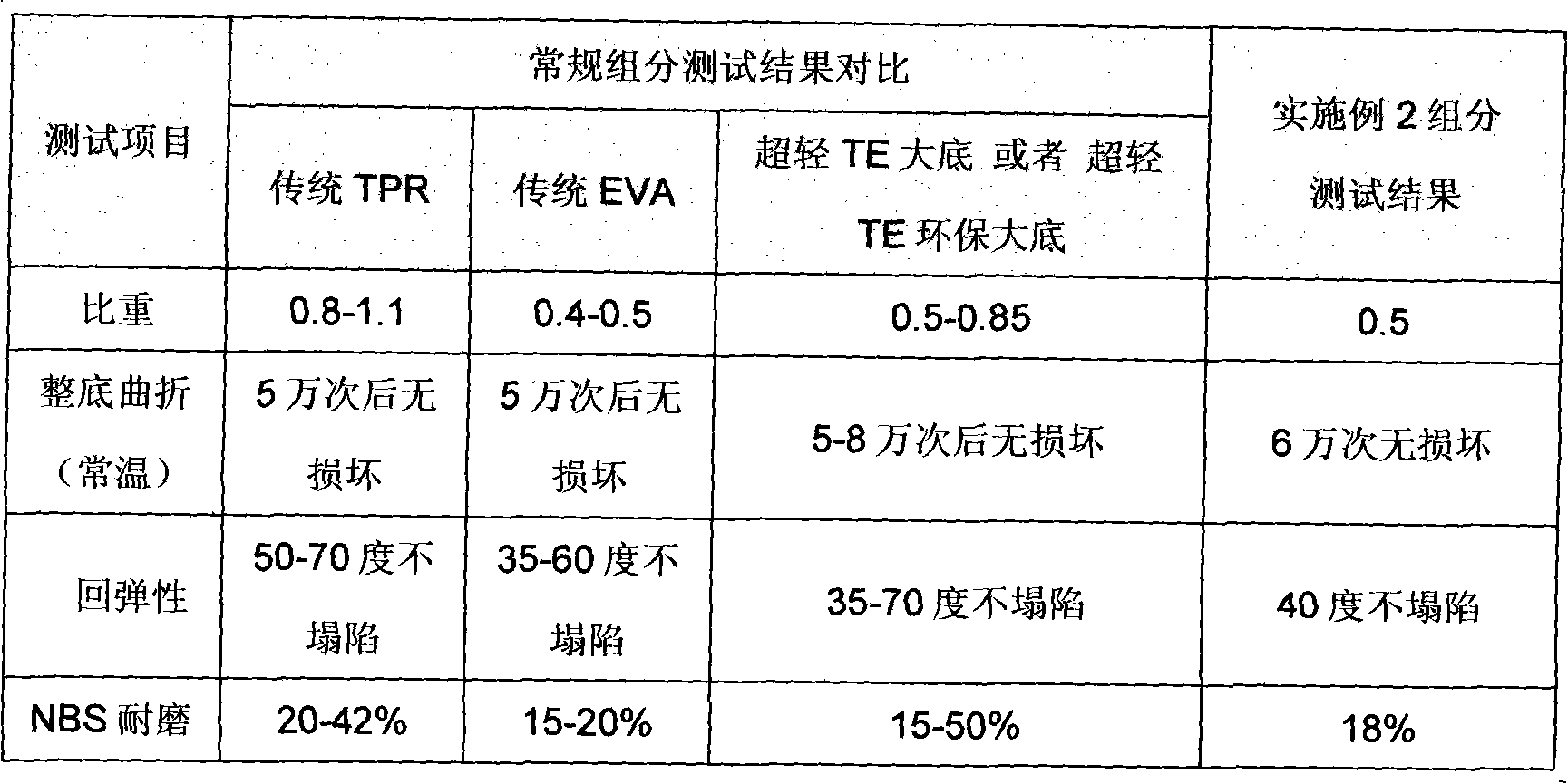

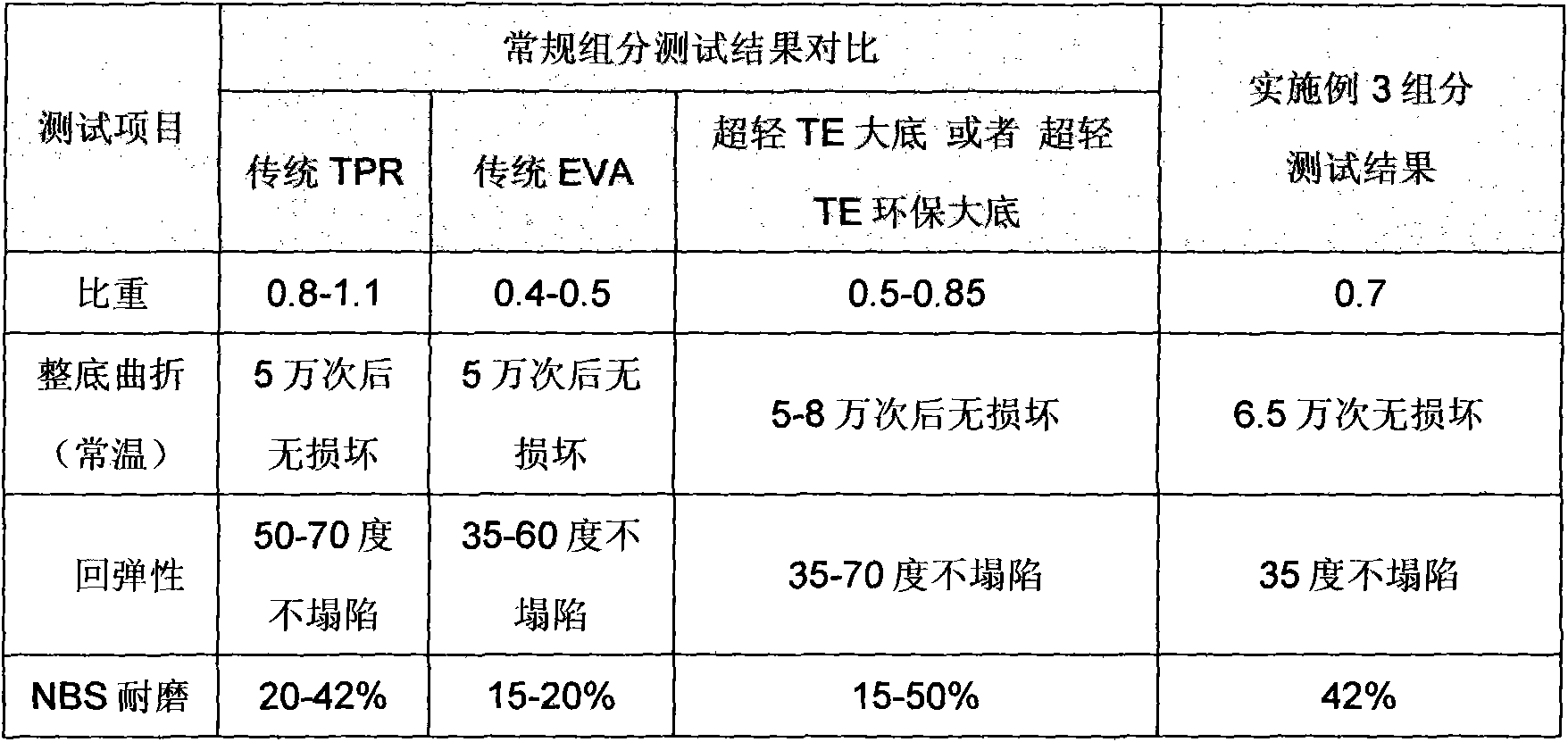

Ultra-light modified thermoplastic rubber TE material

InactiveCN102031010AProperty retentionImprove bending performanceSolesRubber materialEcological environment

The invention discloses an ultra-light modified thermoplastic rubber TE material, relating to thermoplastic rubber materials. The ultra-light modified thermoplastic rubber TE material comprises the following components in percentage by weight: 15-30% of thermoplastic elastomer (TPE), 5-10% of hydrogenated styrene-butadiene-styrene (SEBS) block copolymer, 20-40% of ethylene (E) and vinyl acetate (VA) EVA, 5-15% of ethylene octylene copolymer (POE), 15-25% of thermoplastic butadiene styrene rubber styrene-butadiene-styrene (SBS), 1-5% of poly-alpha-methyl styrene resin (ATL), 1-15% of softened oil, 1-5% of zinc oxide (ZnO), 1-3% of ultraviolet resistant agent (UV), 1-3% of antioxidant, 1-3% of titanium white, 1-3% of ultralight foaming powder, 1-3% of low-temperature expanding agent, and 1-3% of white foam which are mixed and injection-molded. In another formula, environment-friendly filling materials are used for replacing the ethylene octylene copolymer (POE) and the zinc oxide (ZnO) filling materials, the ultraviolet resistant agent, the antioxidant and the titanium white, and the purposes of protecting the ecological environment and effectively utilizing waste resources are achieved. The ultra-light modified thermoplastic rubber TE material has the advantages that the flexibility and rebound elasticity are better in large sole, the weight is lighter and the cost is low. The energy productivity is higher than that of the traditional thermoplastic rubber (TPR) by 20%-30% and is 3-4 times that of the traditional EVA.

Owner:FUZHOU ANJIANGZHIYUAN INT TRADE

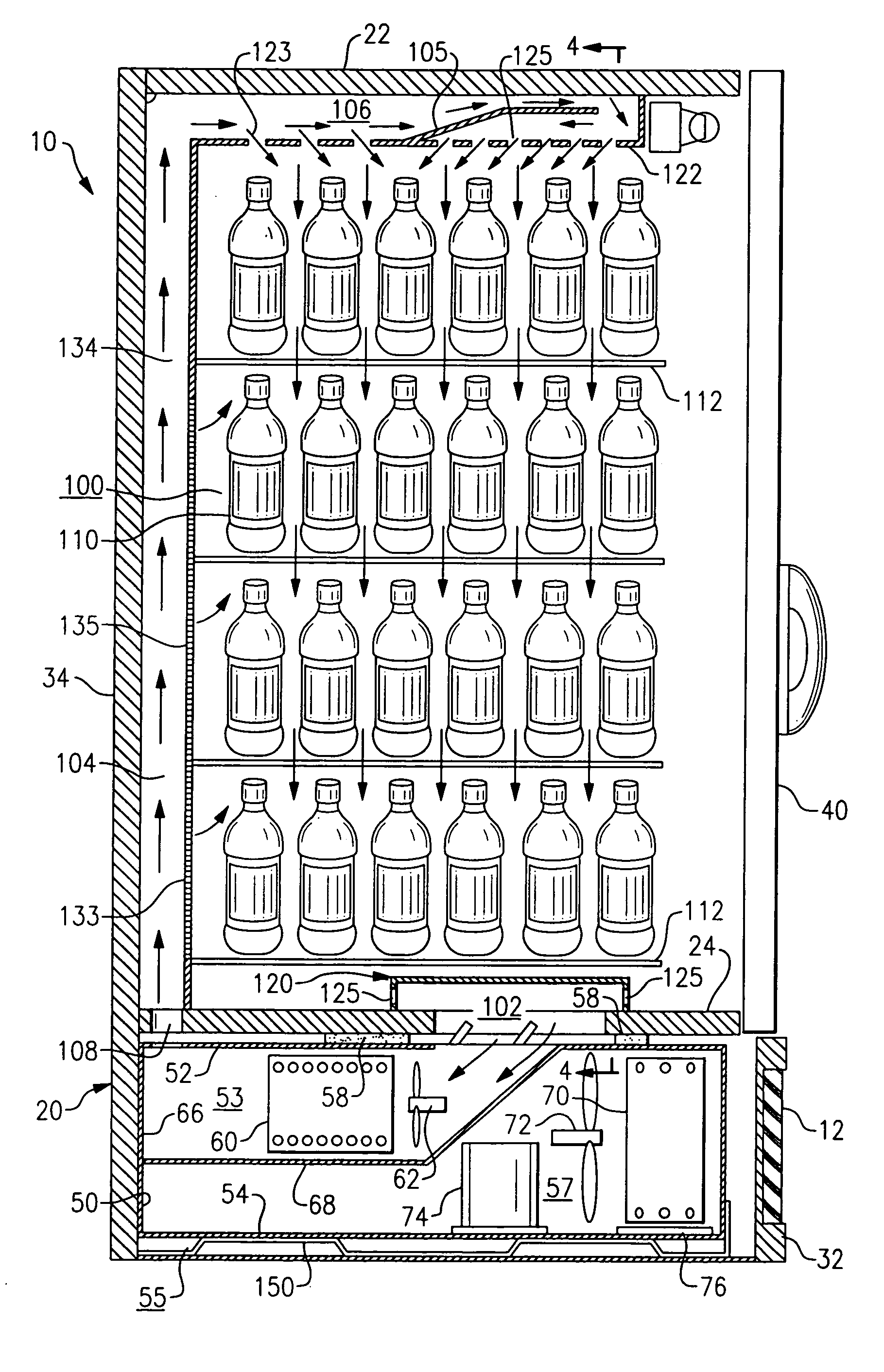

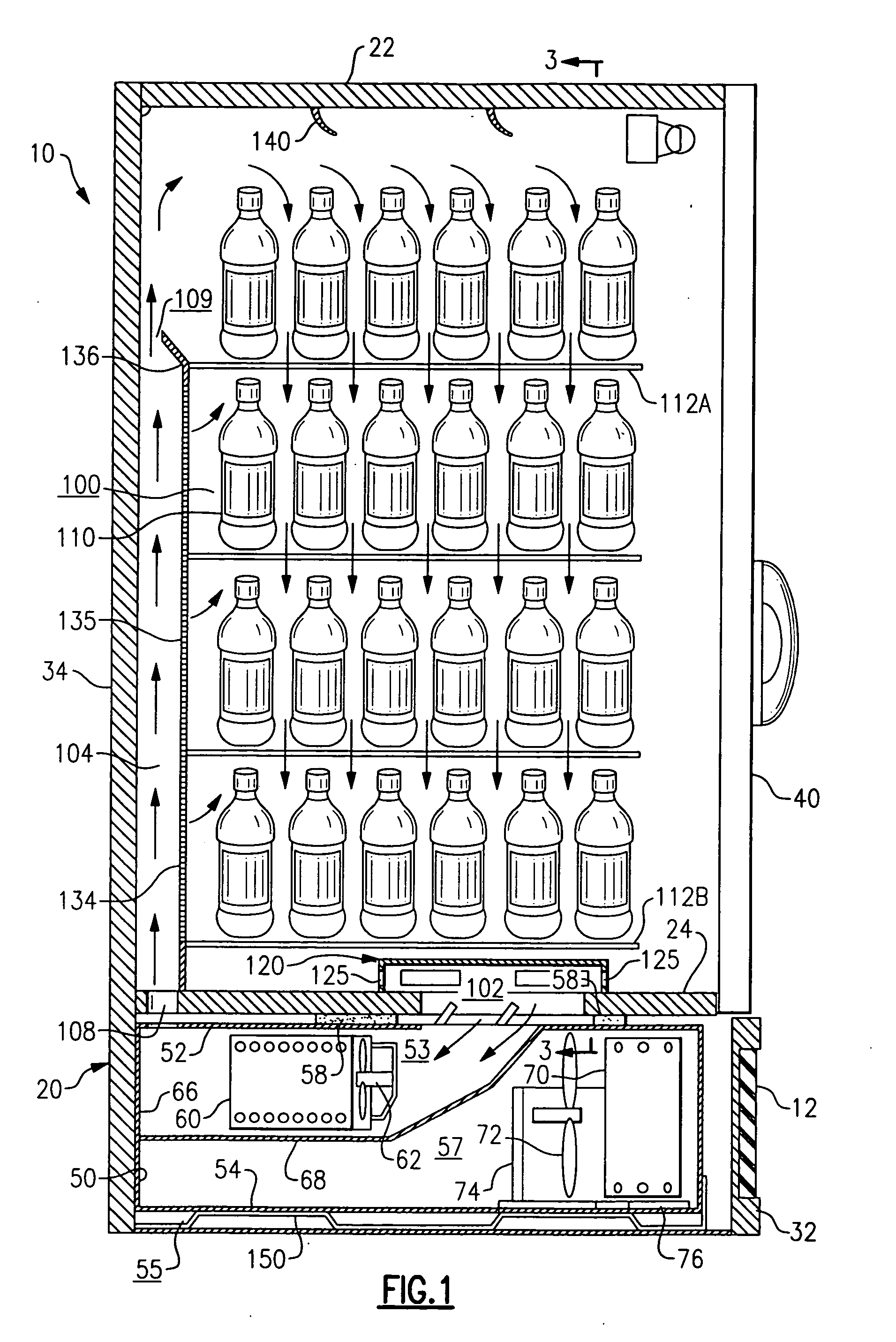

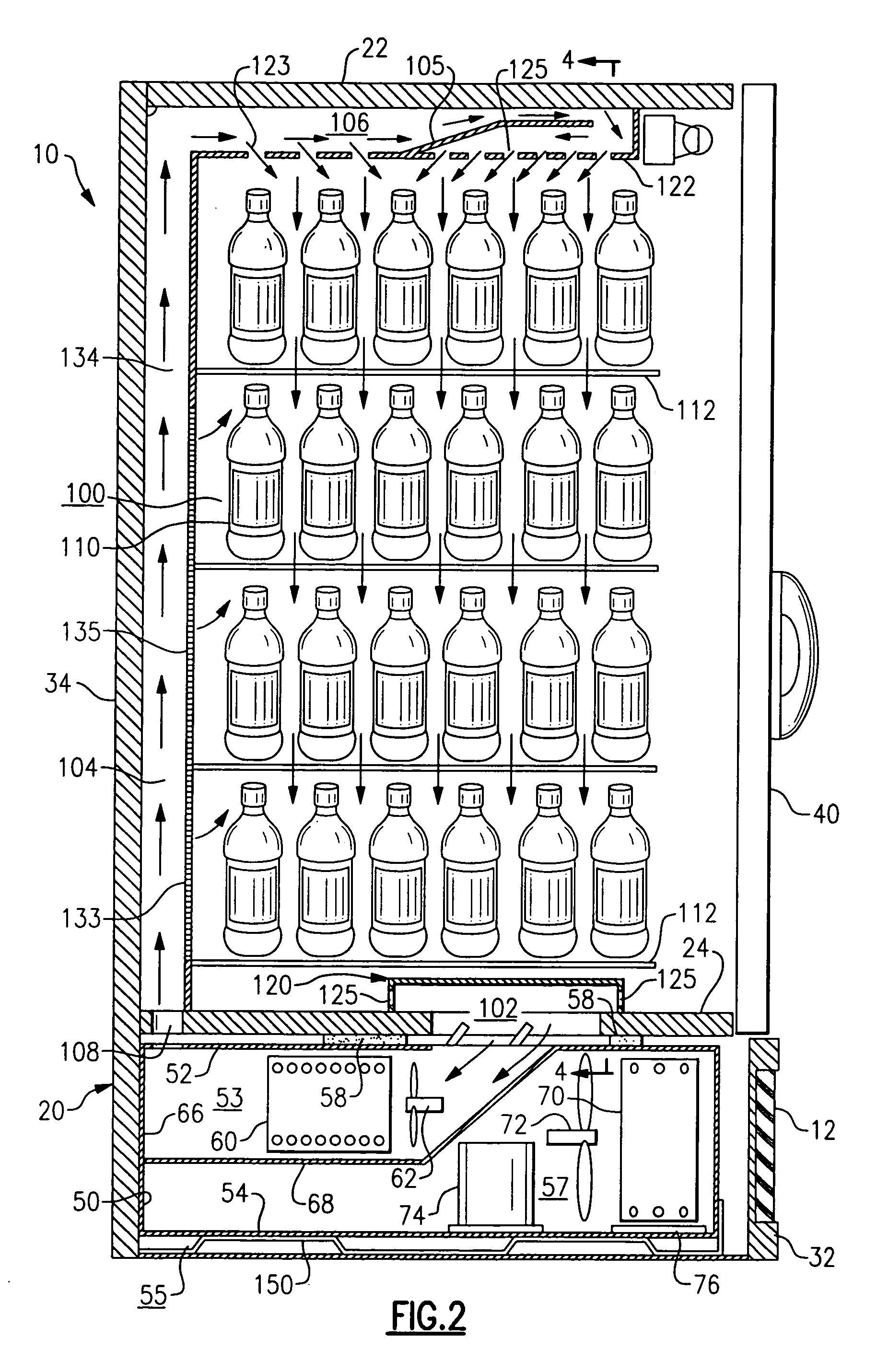

Refrigerated merchandiser

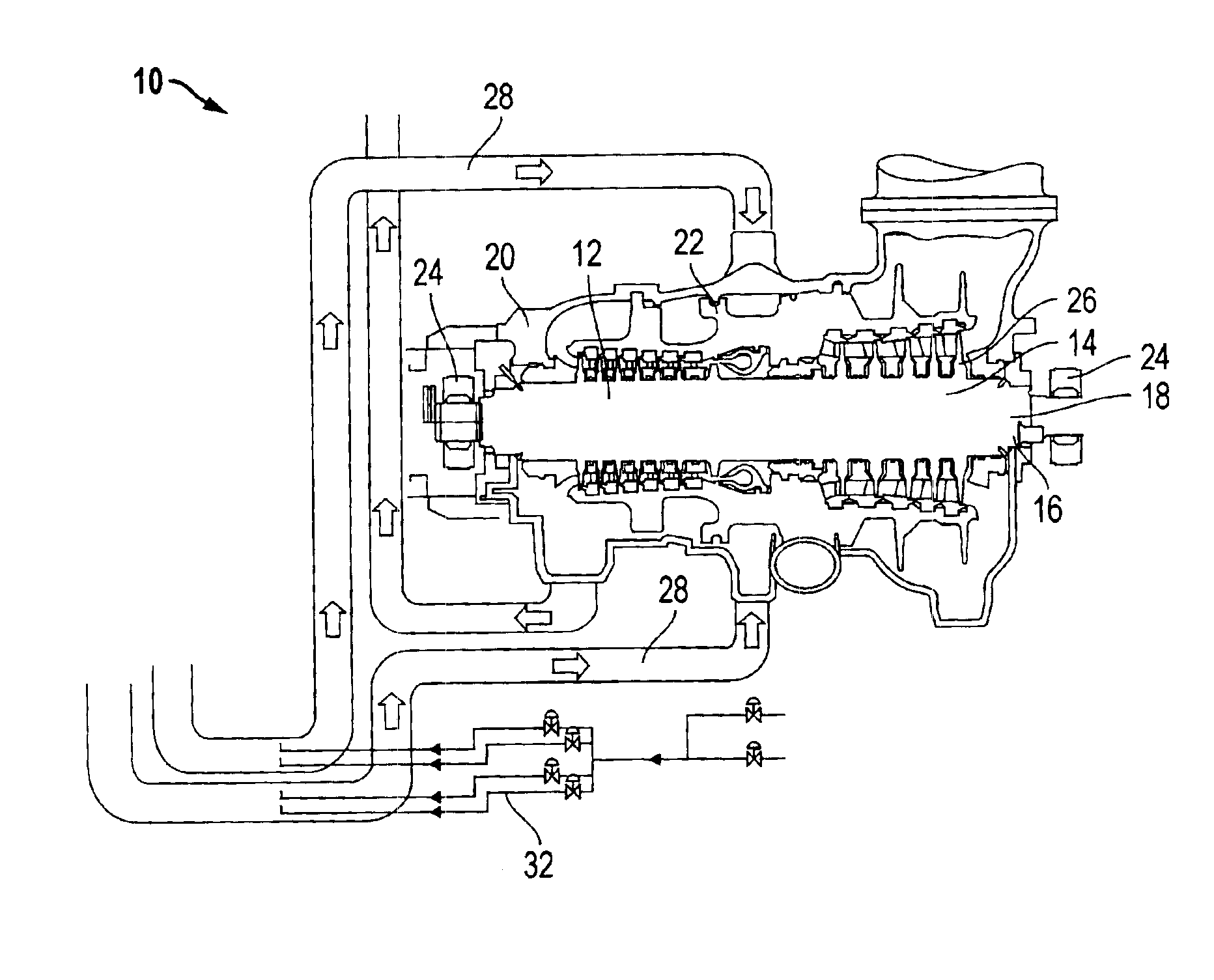

InactiveUS20060207279A1Reduce CooldownReduce variationShow cabinetsLighting and heating apparatusInterior spaceEngineering

A refrigerated merchandiser has a cabinet defining an interior product display space. A generally vertically extending air supply duct at the rear of the cabinet has an inlet for receiving the refrigerated air and an outlet at its upper end for passing the refrigerated air from the air supply duct into an upper region of the interior space along the top wall of cabinet. An evaporator fan in a compartment beneath the interior space draws air flow downwardly through the product display space and through a return air inlet in the lower wall separating the compartment from the interior space. A flow baffle may be disposed in the upper region of the interior space for directing the air downwardly into the interior space to pass through the product displayed therein and out the air return outlet in the lower wall.

Owner:CARRIER CORP

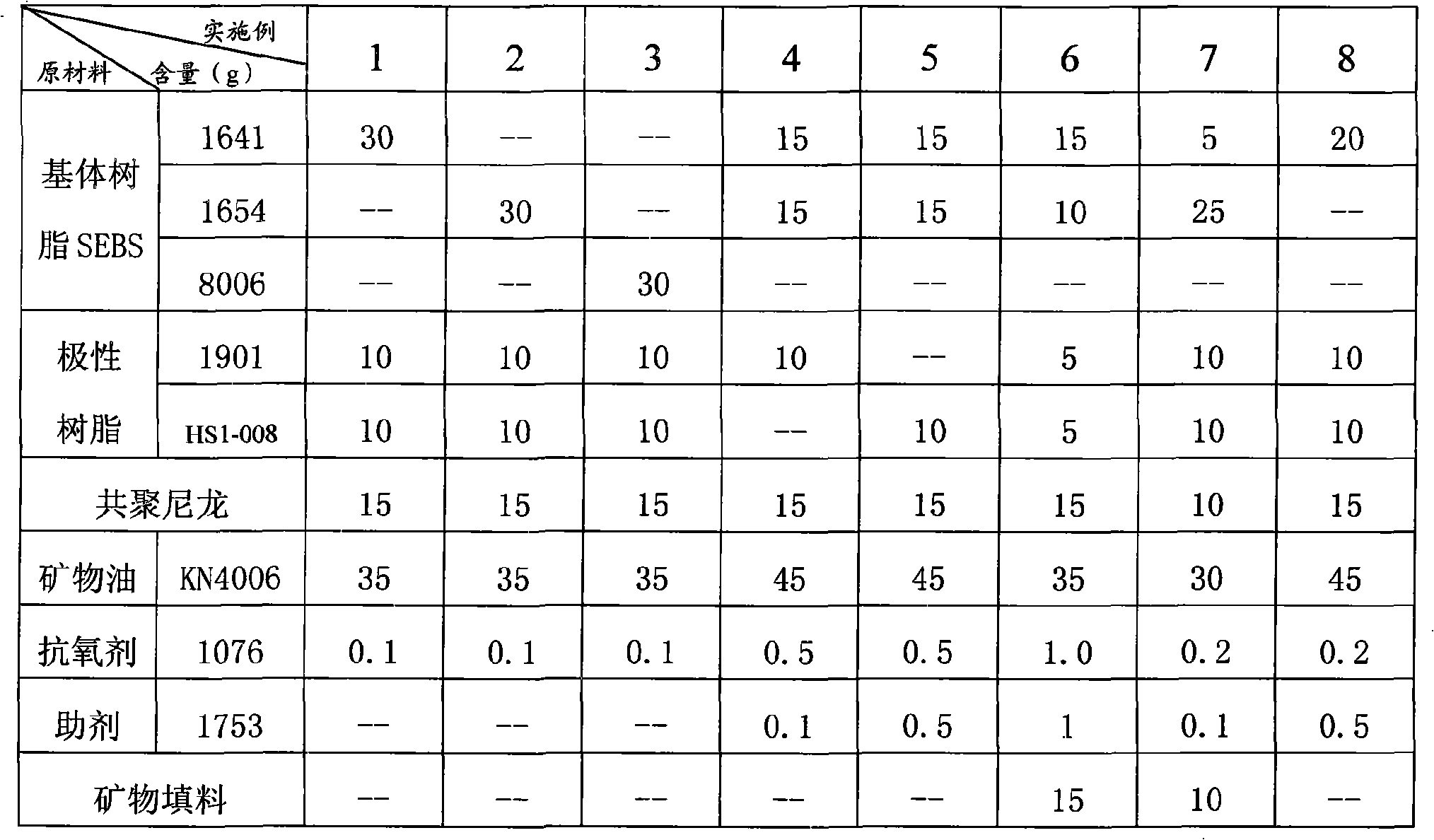

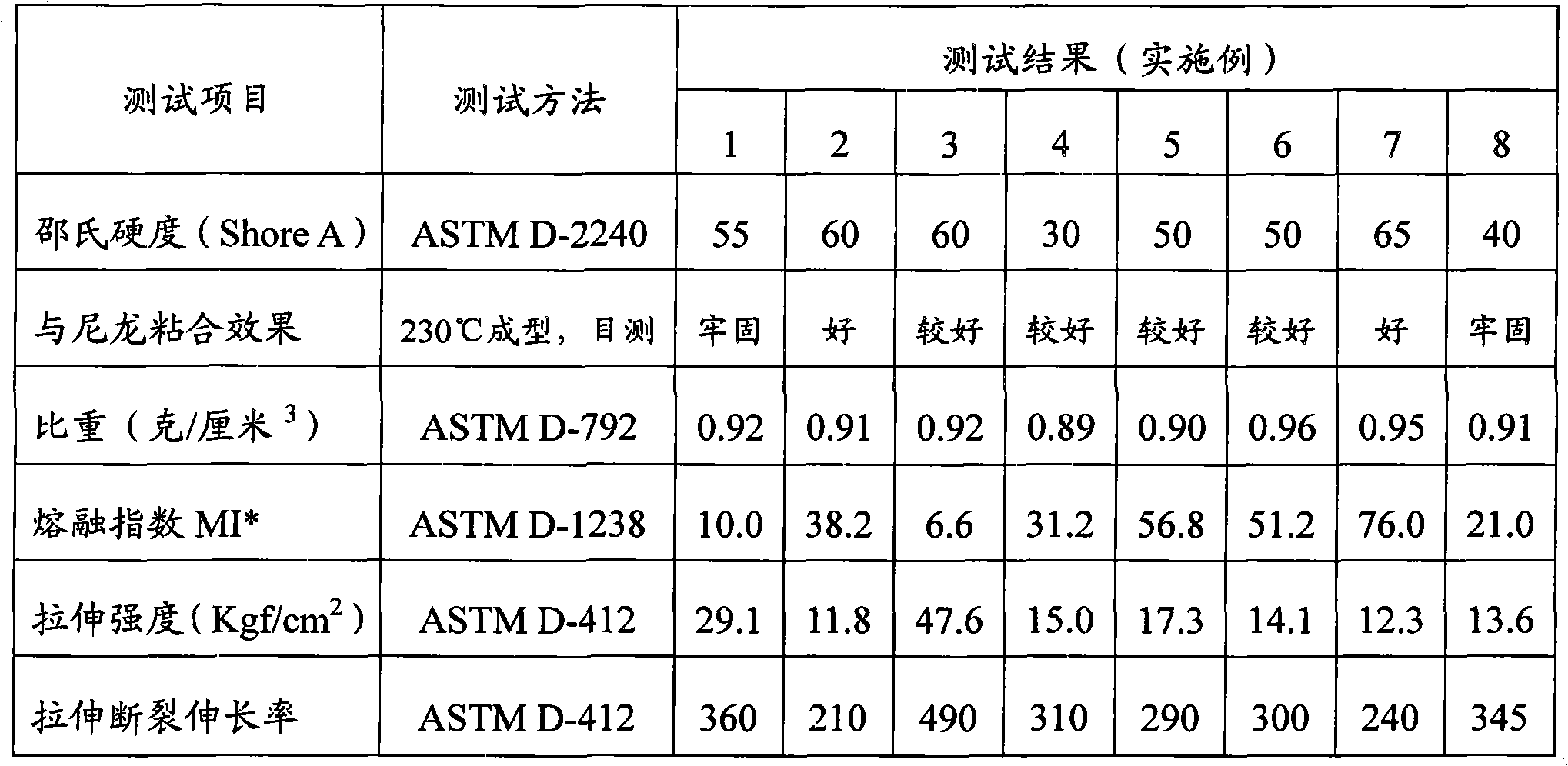

Thermoplastic elastomer for nylon material secondary injection adhering

ActiveCN101255263AEasy to adjust hardnessReduce compounding componentsNylon materialProcedure Agents

The invention relates to a thermoplastic elastomer for second encapsulating nylon, comprising: 20-30 portions of matrix resin SEBS, 10-20 portions of polarity resin, 10-15 portions of mineral oil, 0.1-1 portions of antioxidant and selectively adding 10-15 portions of mineral filler and 0.1-1 portions of processing agents. The raw material of the thermoplastic elastomer does not contains coupling agent and the injection moulding temperature is low during second encapsulating nylon composites and the cooling time of the forming is reduced and the production efficiency is increased. The second encapsulation between the obtained end product and nylon is firm and the shaping is good, with better hand feeling compared to the present product with lower hardness.

Owner:SUNGALLON PLASTICS SHENZHEN CO LTD

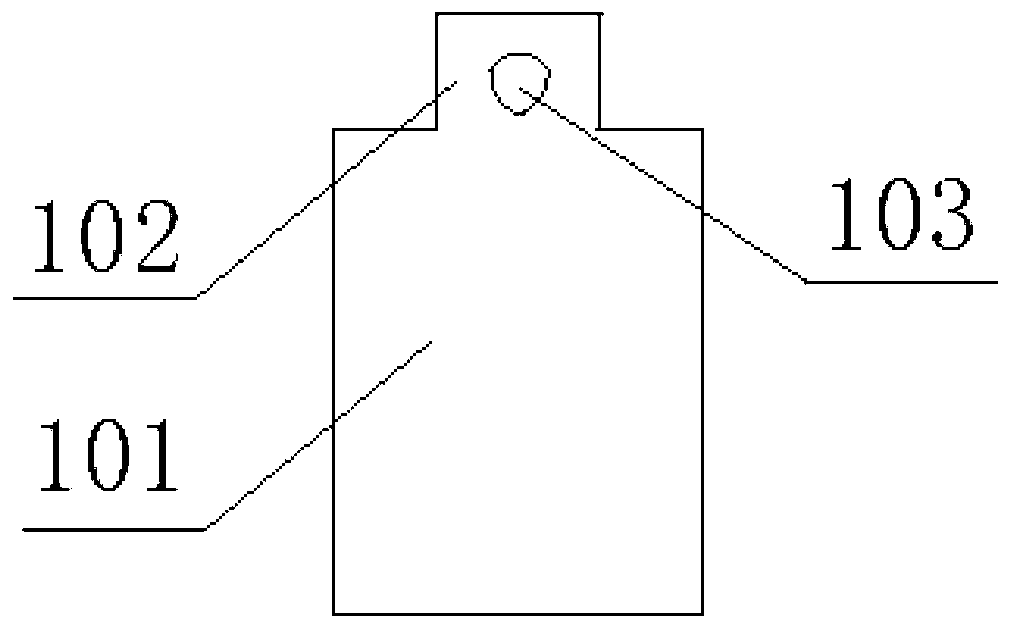

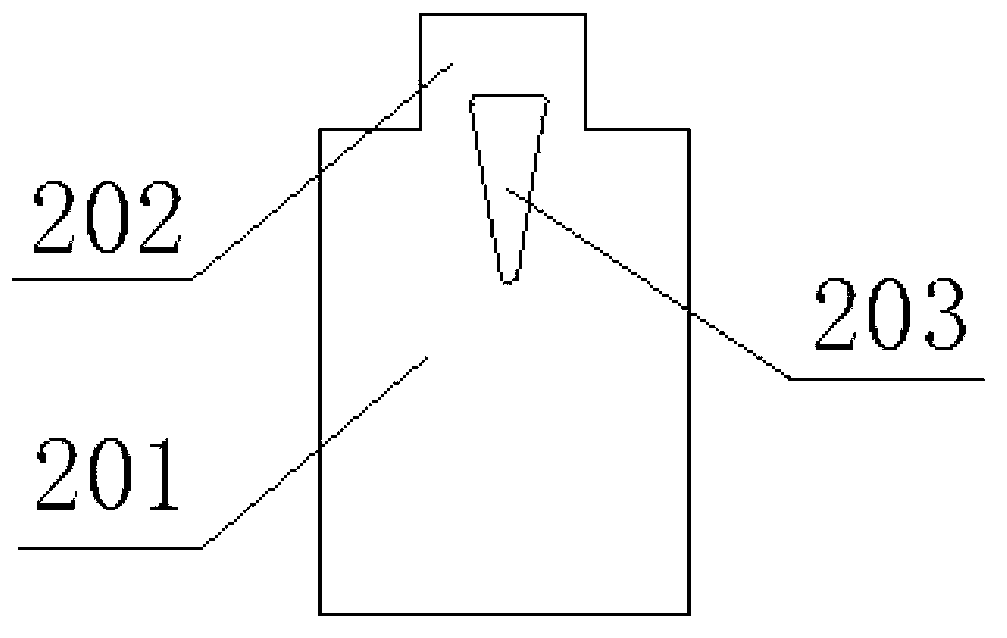

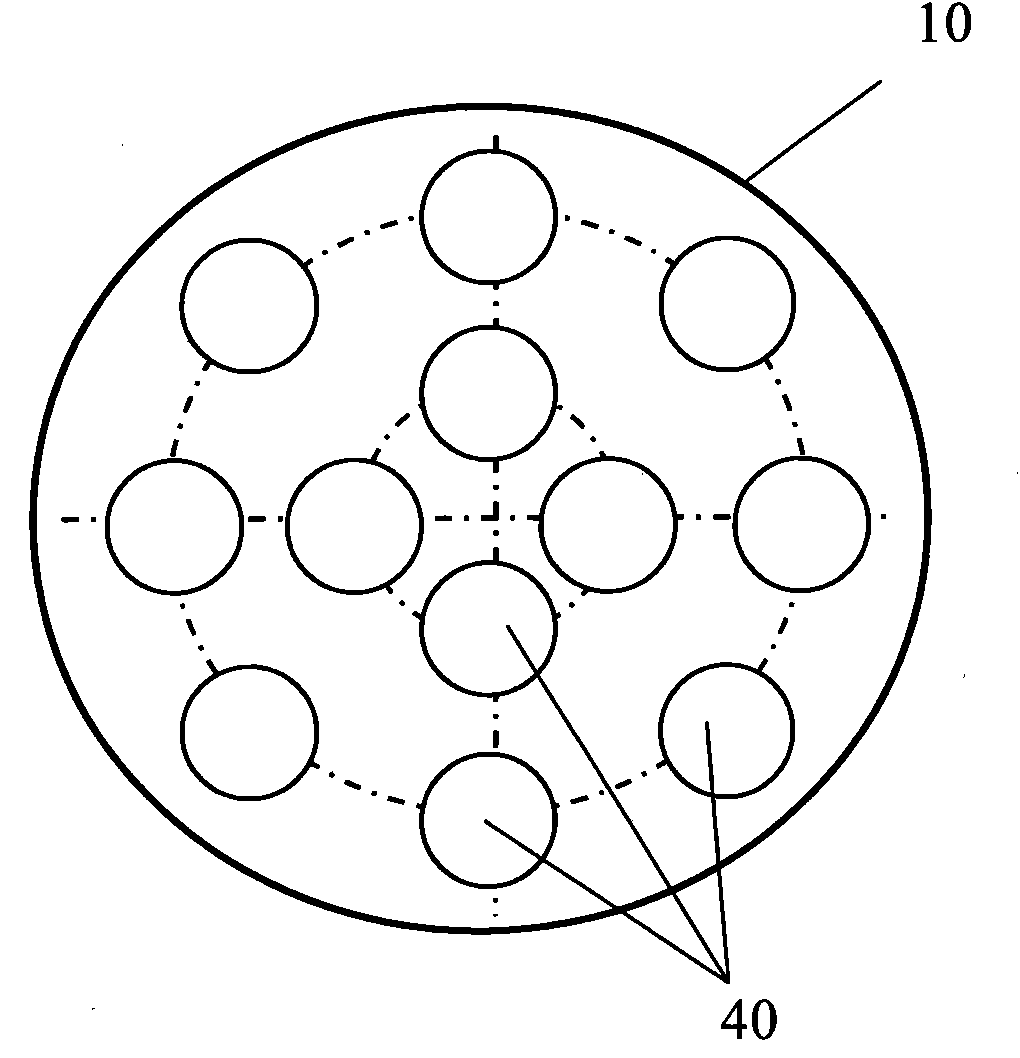

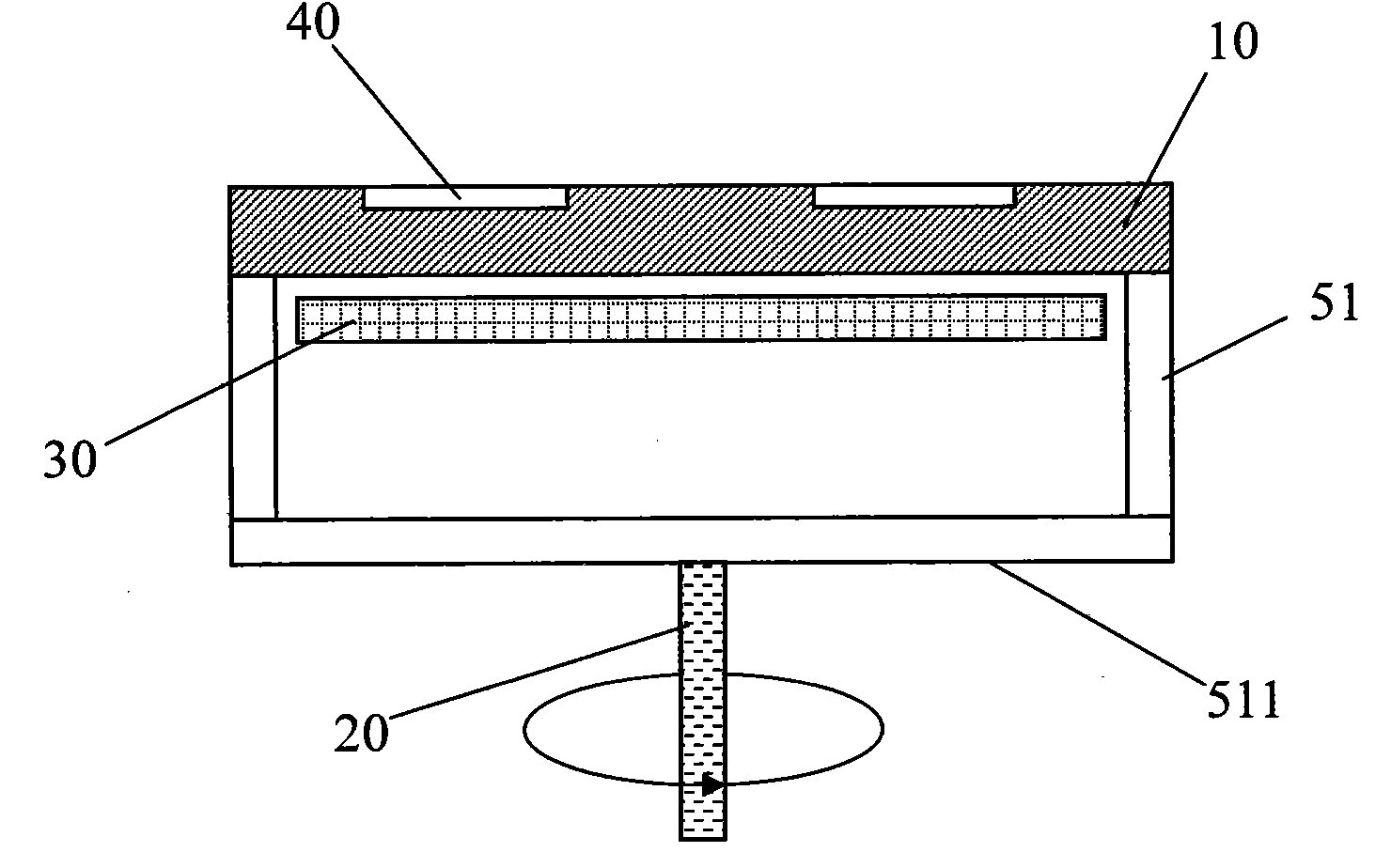

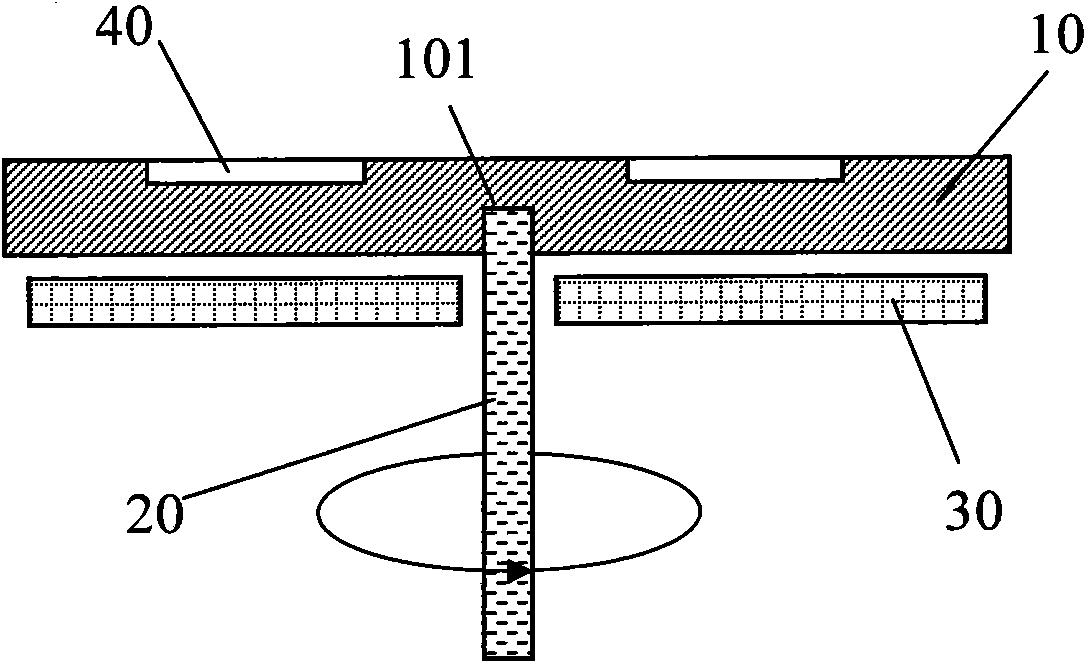

Epitaxial wafer tray and support and rotation connecting device matched with same

ActiveCN101922042AUniform gas concentrationReduce replacementSemiconductor/solid-state device manufacturingFrom chemically reactive gasesDrive shaftEngineering

The invention relates to an epitaxial wafer tray for an MOCVD (Metal Organic Chemical Vapor Deposition) reaction cavity and a support and rotation connecting device matched with same. When the tray is mechanically loaded and unloaded, and a rotating shaft projecting outward from the center of the bottom of the tray is inserted into a counter bore on the top of a drive shaft perpendicular to the rotating shaft. Respectively arranged contact surfaces parallel to the surface of the tray or contact surfaces on the corresponding side face are used for supporting the tray, and the friction transmission between the contact surfaces is used for driving the tray to rotate when the drive shaft rotates. The friction transmission is changed into contact transmission by arranging an axial locating slot and a locating key, the rotation of the tray is ensured to be consistent with that of the drive shaft, and the security of the tray under middle-high speed long-term rotation is improved. The projecting tray rotating shaft is easy to process the surfaces contacted by friction, the entire thickness of the tray is not increased under the condition of ensuring the mechanical strength of the corresponding part on the tray, and the heat capacity of the tray is reduced. Thus, the time required by heating and cooling the tray is shortened, and the production efficiency is improved, which is beneficial to quick temperature adjustment and control required by epitaxial reactions.

Owner:JIANGSU ZHONGSHENG SEMICON EQUIP

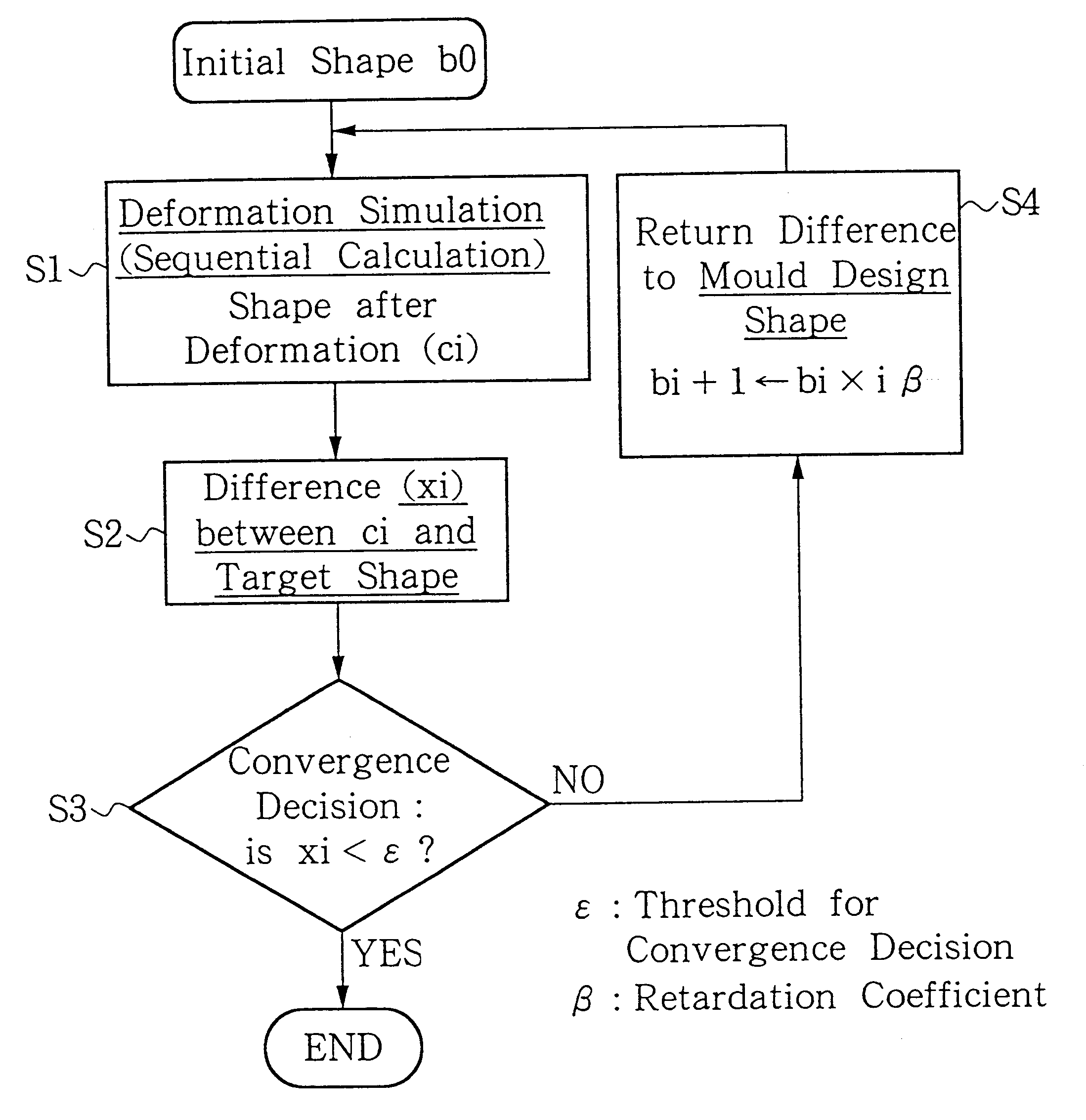

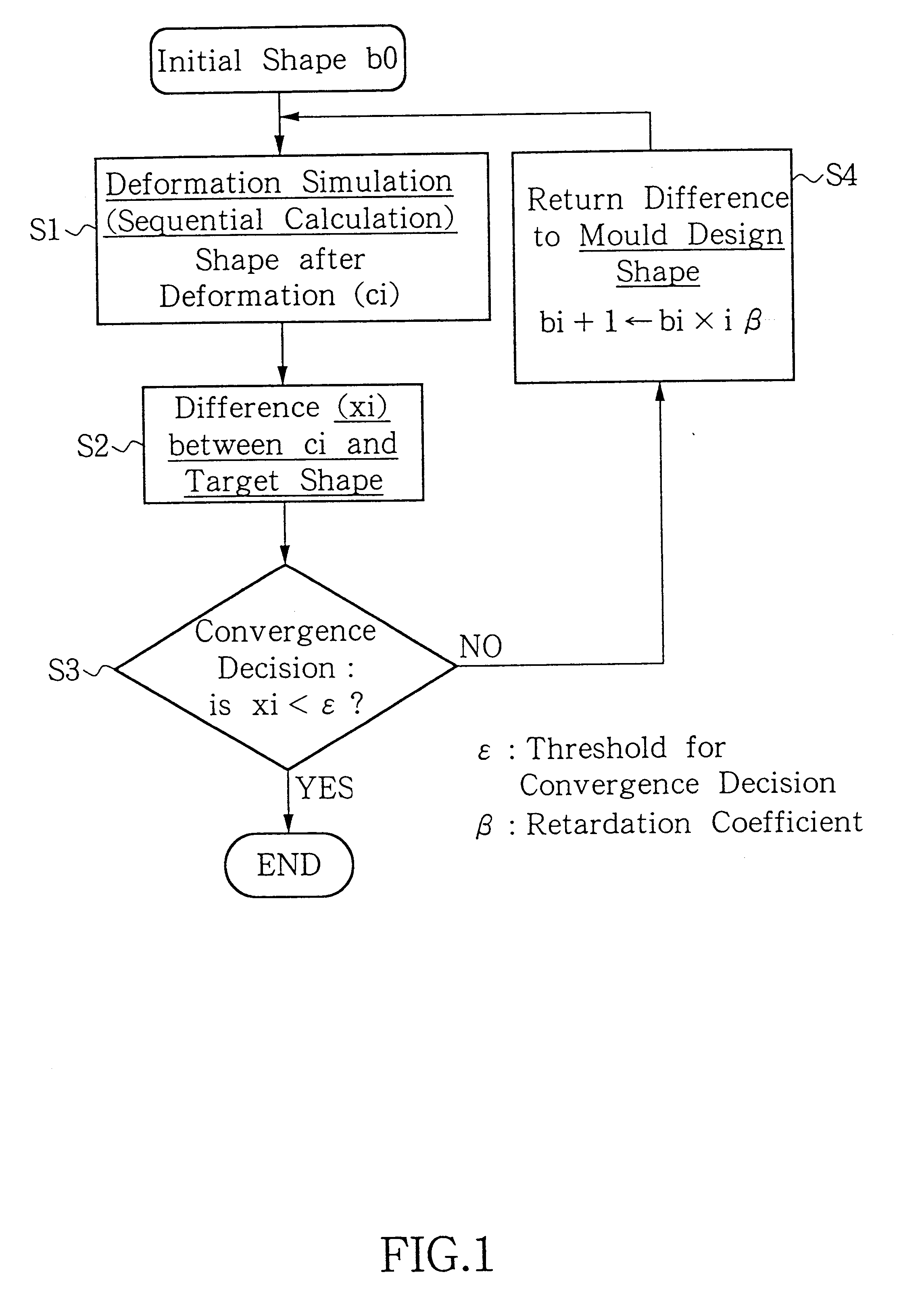

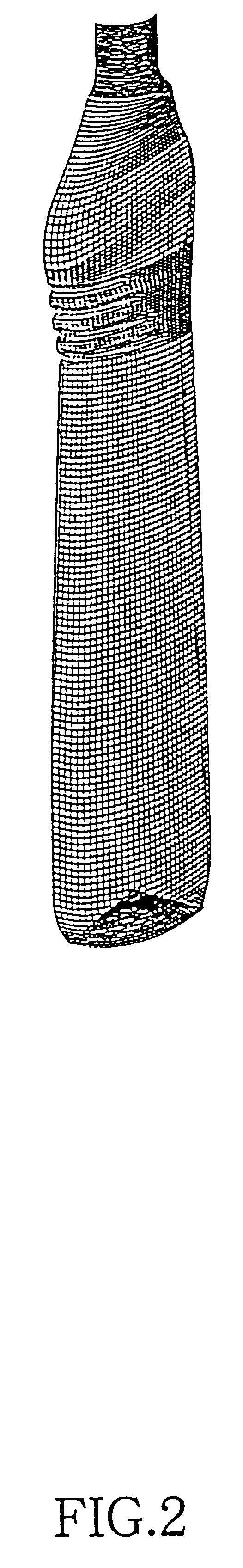

Method for designing a metal mold

InactiveUS6304794B1Reduce in quantityReduce CooldownMoulding machinesAnalogue processes for specific applicationsFinite element methodHydrostatic pressure

When a molten plastic is molded using a metal mold, sufficient cooling time has to elapse before the metal mold is opened, but this cooling time restricts the production per unit time. If a metal mold is opened without sufficient cooling, the plastic undergoes significant deformation by thermal shrink. If this deformation can be estimated and the metal mold designed so as to make allowance for the anticipated deformation, it will be possible to produce a molding with a shape that is equal to the design dimensions, despite shortening the cooling time. The finite element method is used to obtain the deformation. Mold design can also be performed taking account of the deformation due to the hydrostatic pressure that is produced when the molding is filled with its liquid contents. In addition, as for a portion of an in-mold labelled container which include lamination construction, the deformation due to thermal shrink is not estimated as a container which an in-mold label is not being applied. On this case, we have a method which is simulating deformation after adding parameters relating to the material of this label, said parameters including at least its thermal conductivity and coefficient of linear expansion. The thermal conductivity deformation simulation is by the finite element method. Production per unit time can be increased and metal mold design can be carried out independently of experience.

Owner:KAO CORP

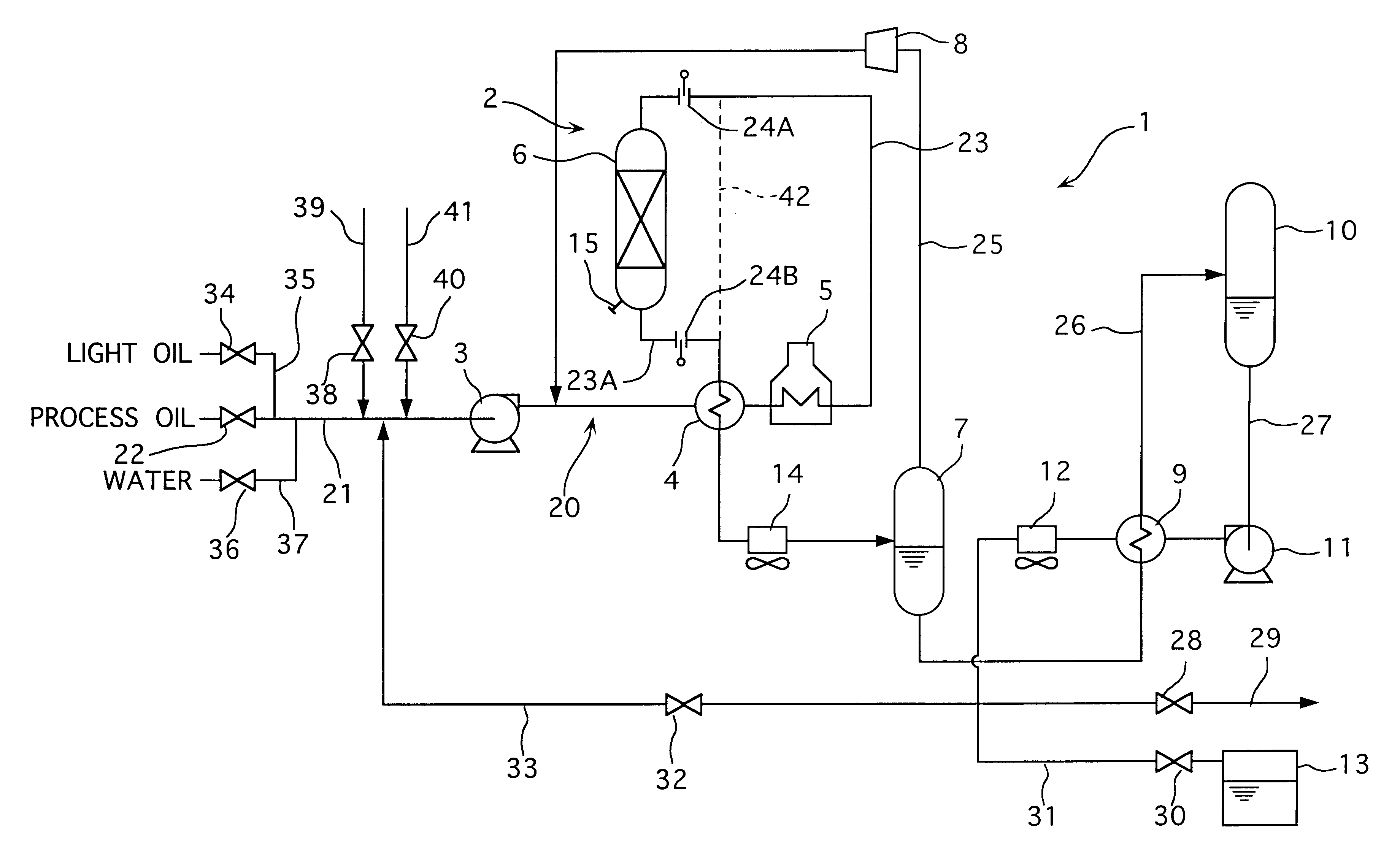

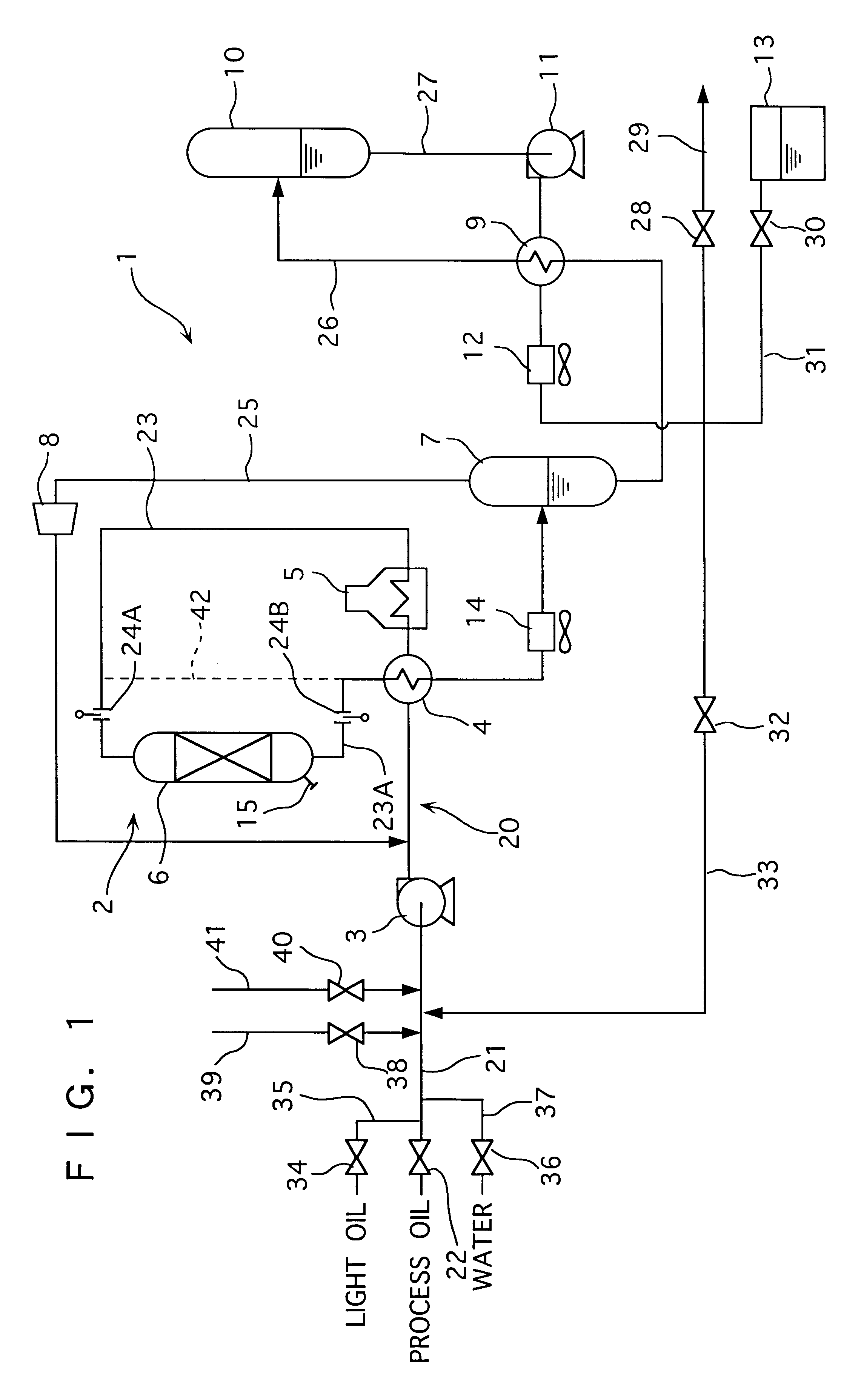

Method of cleaning and maintaining petroleum refining plants

InactiveUS6273102B1Reducing maintenance termEfficient and effectiveCatalyst protectionOther chemical processesProcess equipmentPolythionic acid

A repairing method of a petroleum refining plant for efficiently conducting cleaning process of process equipment and pipings, unloading process of agglomerated catalyst, rinsing work of the process equipment and the pipings, thereby reducing plant shutdown time, preventing stress-corrosion cracking by polythionic acid, improving production efficiency, ensuring work safety and reducing production cost, is provided. For the object, the repairing method of the petroleum refining plant of the present invention has a first step of cleaning the process equipment and the pipings and softening agglomerated catalyst inside the process equipment, second step of rinsing the process equipment and the pipings and coating a surface of the softened catalyst by a coating agent, and third step of dumping the coated catalyst from the process equipment and re-rinsing the process equipment and the pipings. Accordingly, respective work can be efficiently conducted, the plant shutdown time can be reduced, the stress-corrosion cracking by the polythionic acid can be prevented, and work safety, reduction of maintenance cost and improvement of production efficiency can be ensured.

Owner:NICCA CHEM COMPANY

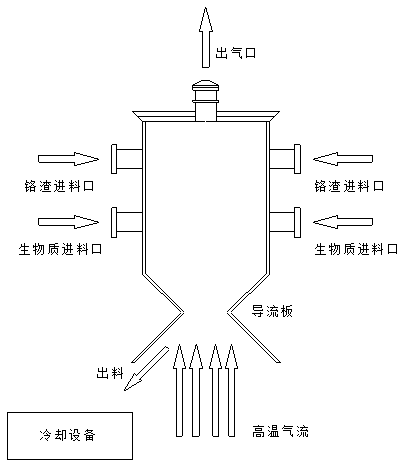

Fluidized bed type of harmless chromium slag pyrolysis process

The invention relates to a fluidized bed type of harmless chromium slag pyrolysis process. The process is characterized in that biomass and chromium slag into are respectively added into a high temperature fluidized bed pyrolysis furnace, wherein the biomass rapid melts and pyrolyses to release a lot of pyrolysis gas in the process, so as to reduce Cr (VI); at the same time pyrolysis carbon residue attaches to fluidization process the chromium slag surface to protect the reduced Cr (III) reduction in chromium residue from secondary oxidation, and the chromium slag conducts effectively catalytic cracking on be produced pyrolysis gas to avoid generation of a lot of high-pollution tar gas. Compared with the traditional pyrolysis technology, the technology greatly shortens the residence time, at the same time produces energy tail gas with high heat value, and avoids the disposal of the exhaust.

Owner:光大理工环境技术研究院(青岛)有限公司

Temperature Control Method for an Electrochemical Energy Store in a Vehicle

InactiveUS20140012445A1Easy to wearReduce storage efficiencyDigital data processing detailsSecondary cellsStored energyTemperature control

A temperature control method for an electrochemical energy storage device having a cooling device for cooling the storage device in a vehicle. An actual temperature value of the storage device is determined, and a desired temperature value of the storage device is set by a two-point control system, which activates the cooling device at an upper temperature limit of the storage device and deactivates the cooling device at a lower temperature limit. The upper temperature limit and / or the lower temperature limit are defined as a function of time during operation of the storage device or during activation of the cooling device. The upper temperature limit and / or the lower temperature limit are defined as a function of the energy storage device data and / or the vehicle operating data.

Owner:BAYERISCHE MOTOREN WERKE AG

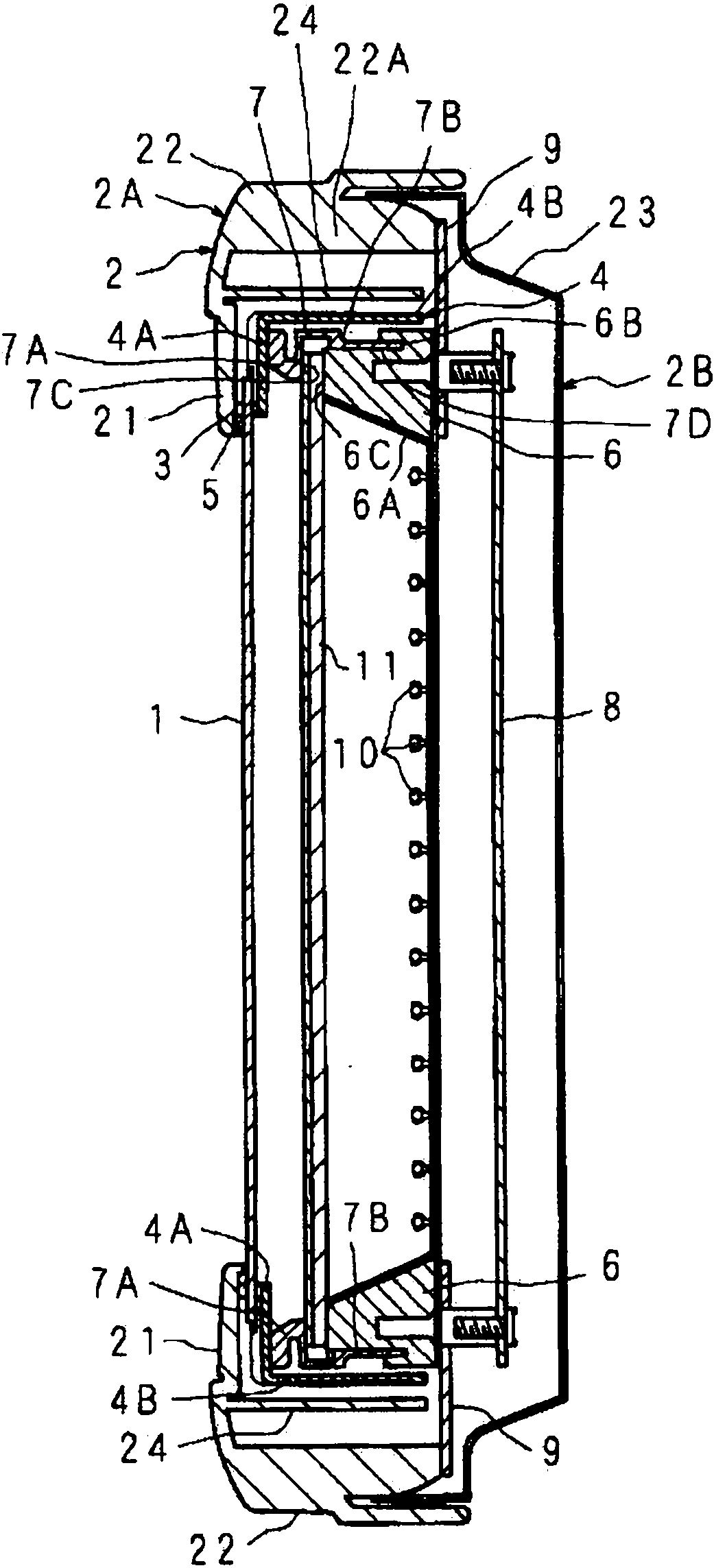

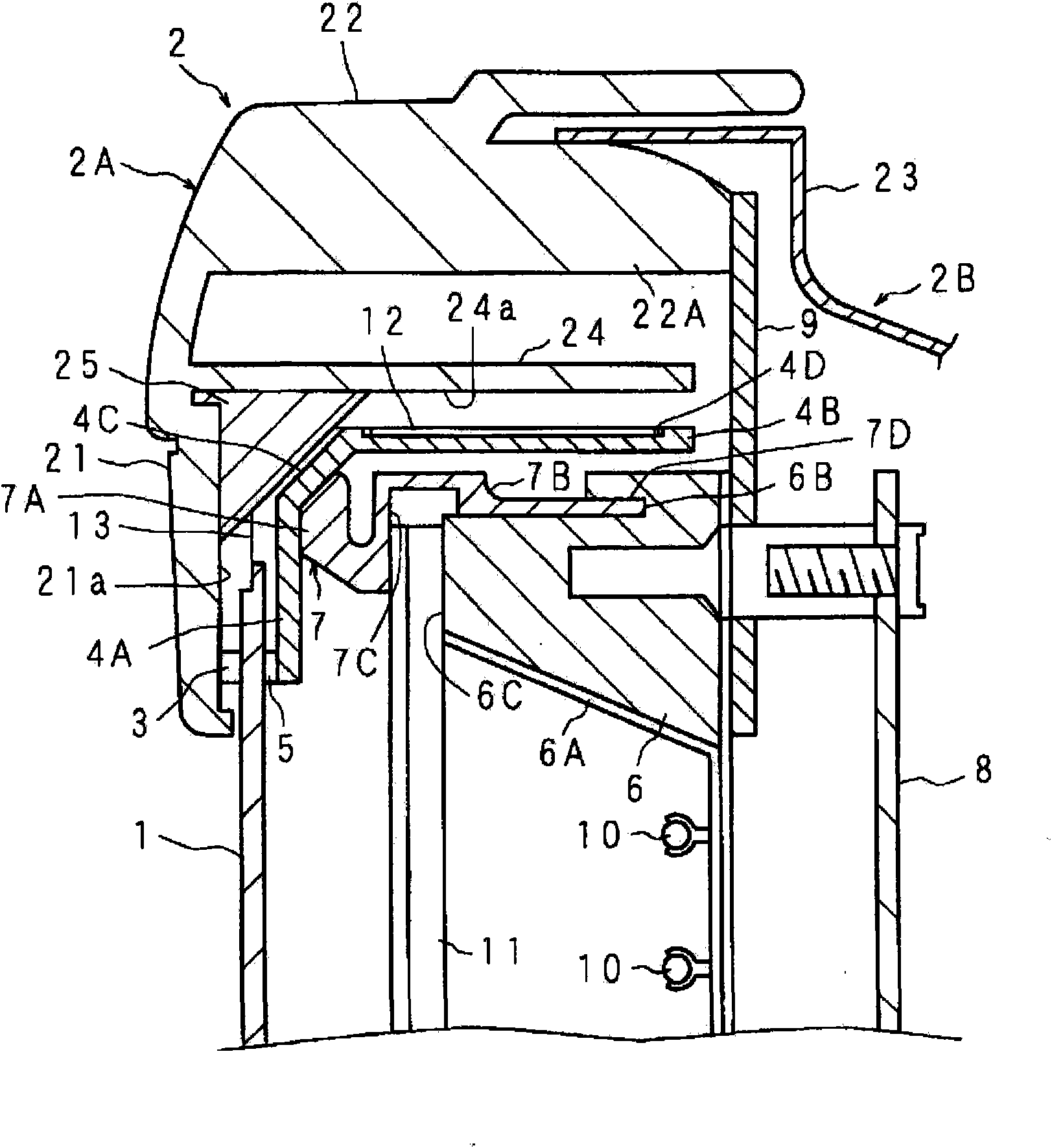

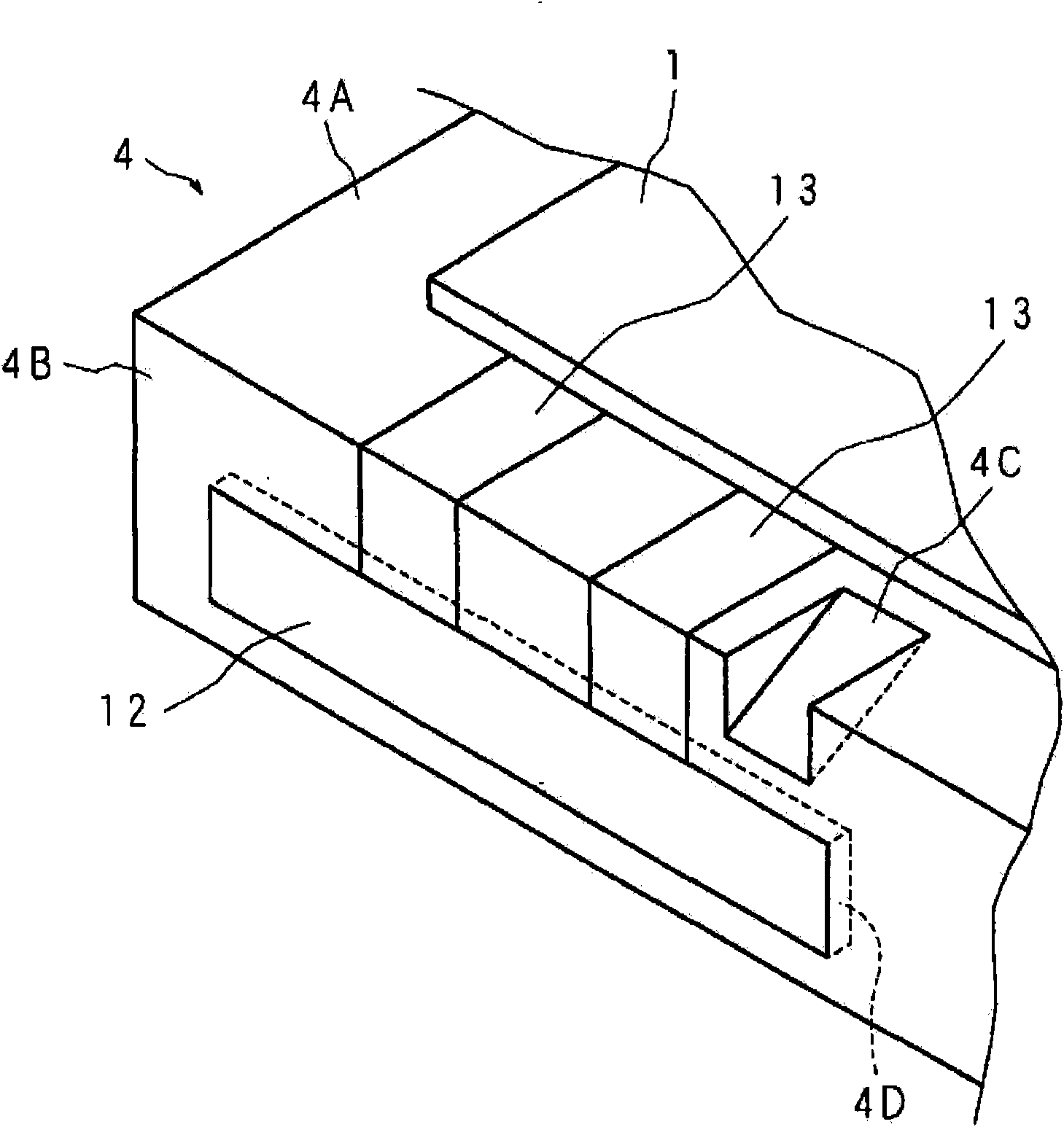

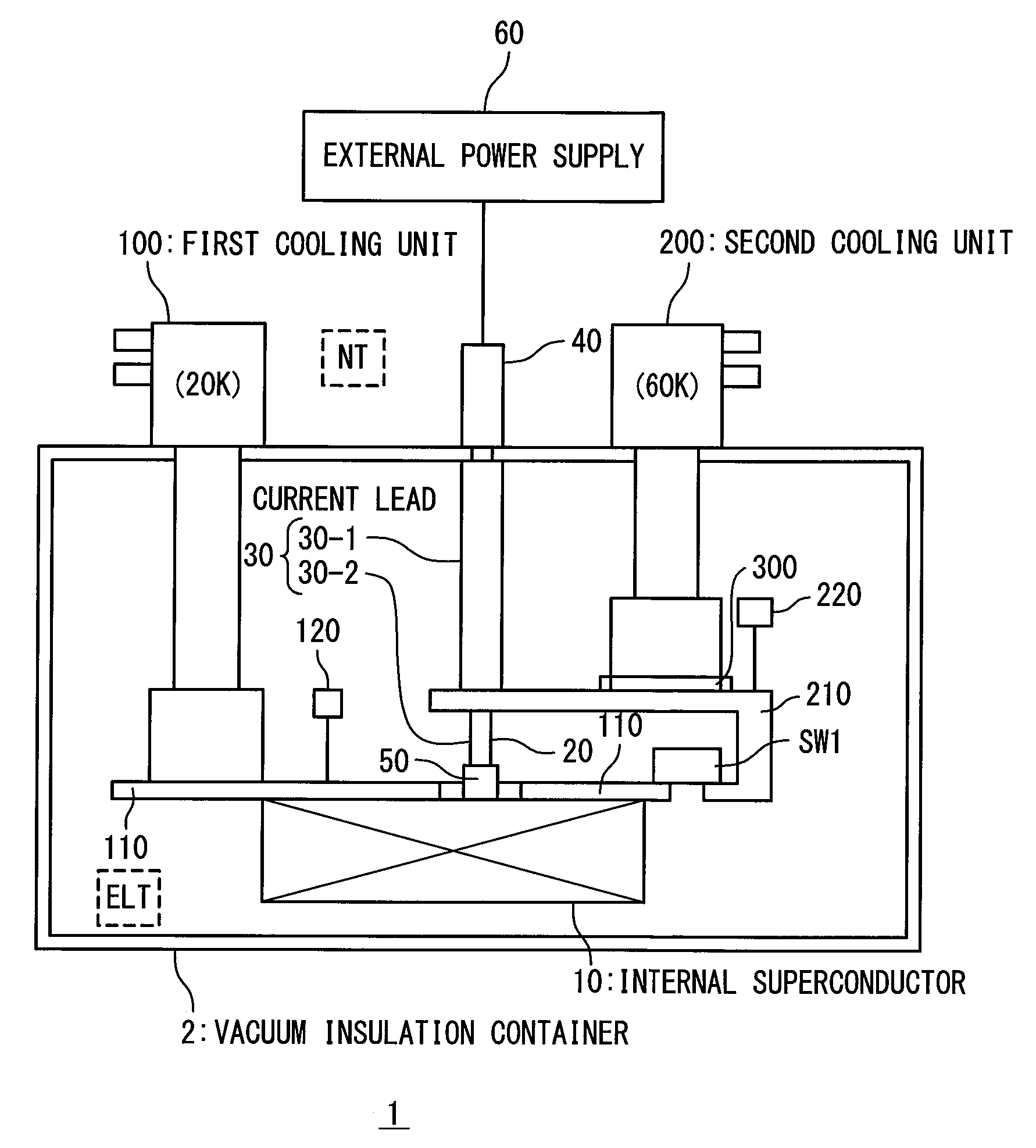

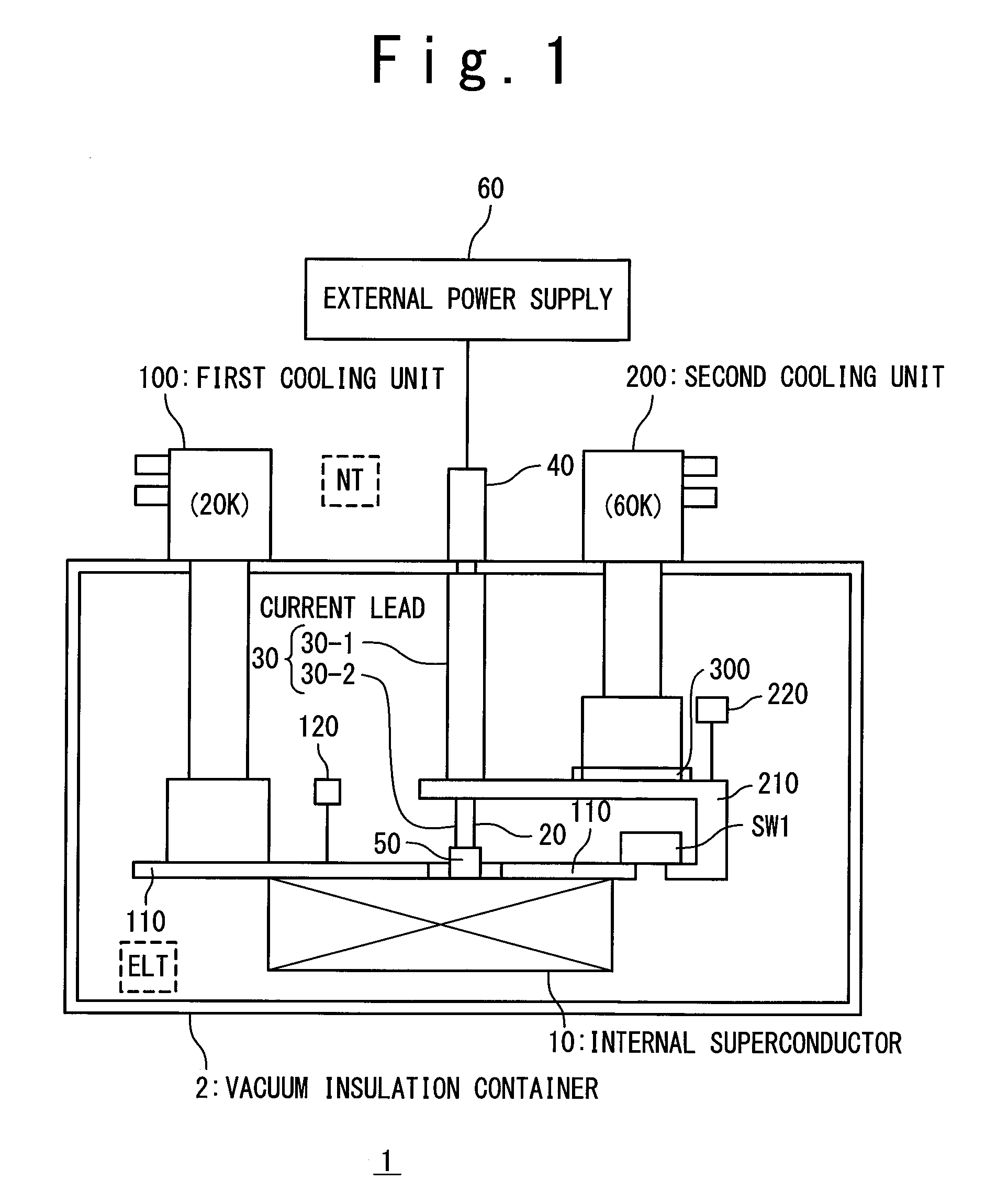

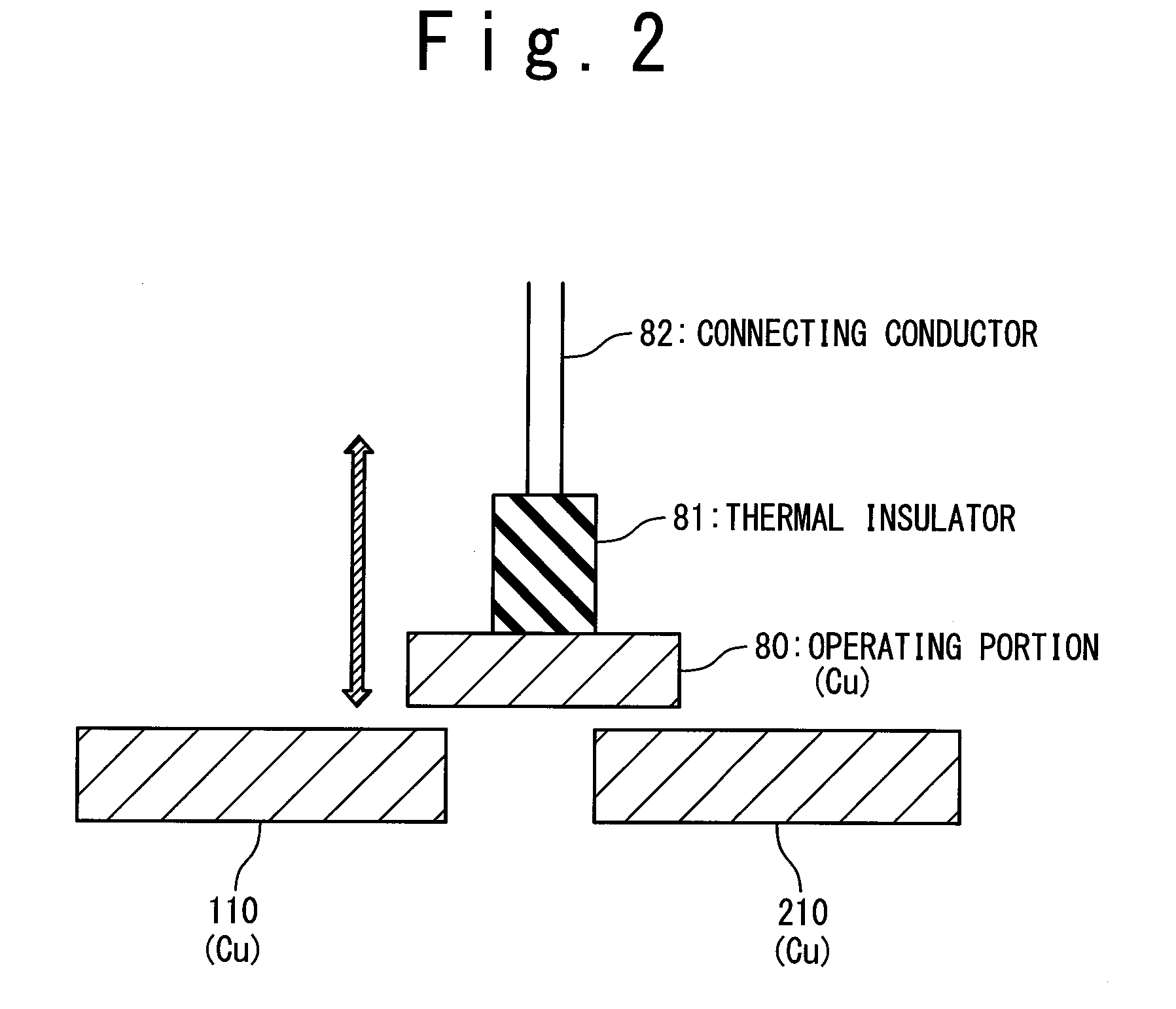

Superconductor cooling system and superconductor cooling method

ActiveUS20100113282A1Reduce CooldownSuperconductors/hyperconductorsCompression machinesElectrical conductorEngineering

A superconductor cooling system has: a first superconductor; a first cooling conductor used for cooling the first superconductor; a first cooling unit configured to cool the first cooling conductor to a first temperature; and a current lead configured to supply a current to the first superconductor. Here, a part of a path of the current is formed of a second superconductor. The superconductor cooling system further has: a second cooling conductor used for cooling the second superconductor; a second cooling unit configured to cool the second cooling conductor to a second temperature; and a first thermal conduction switch connected between the first cooling conductor and the second cooling conductor to ON and OFF heat transfer between the first cooling conductor and the second cooling conductor.

Owner:MITSUBISHI HEAVY IND LTD

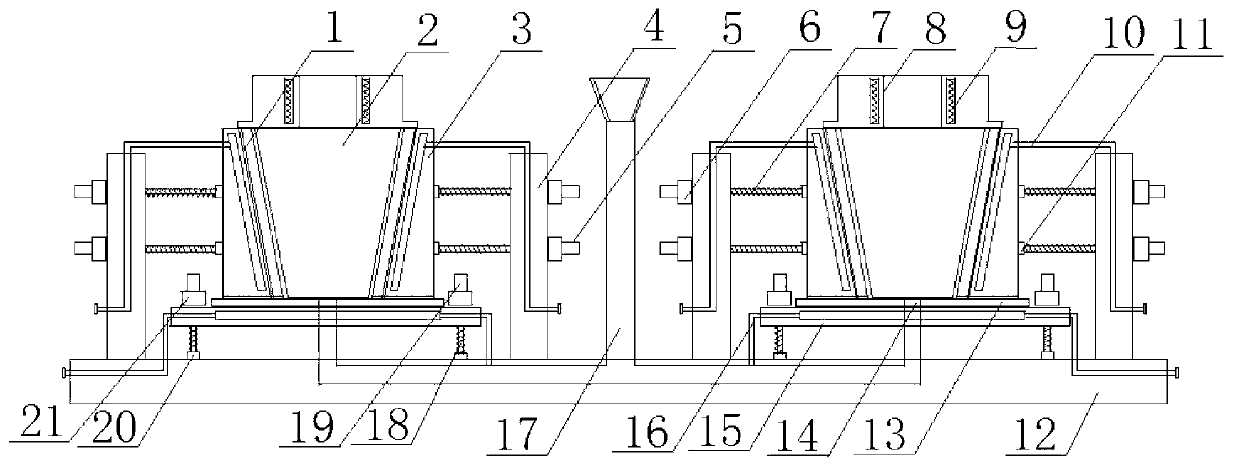

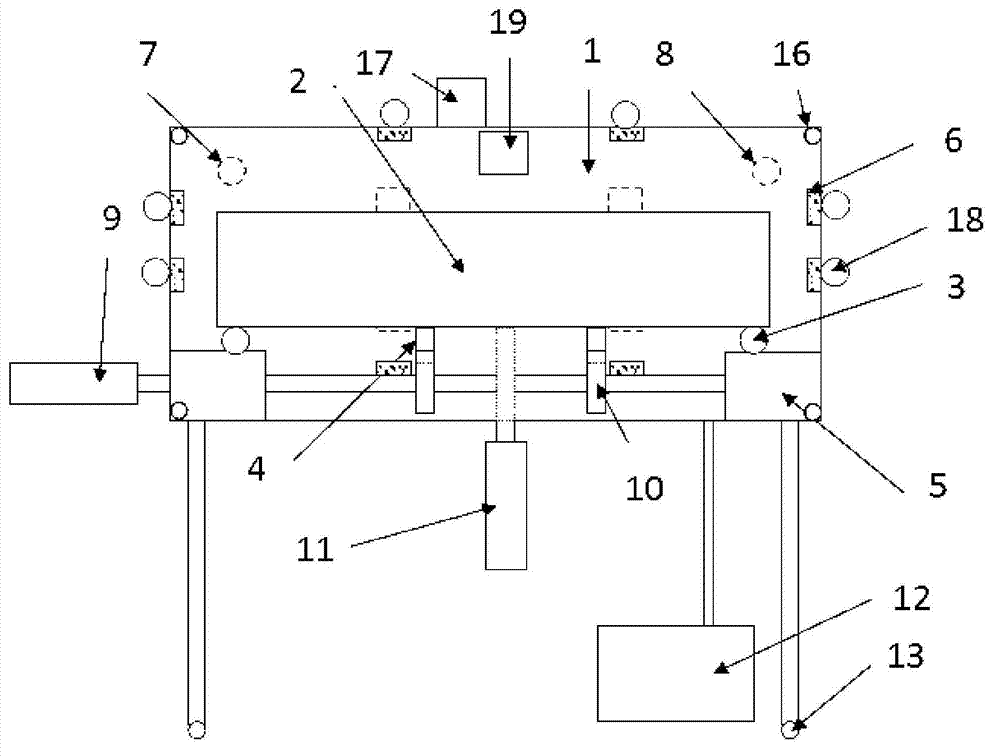

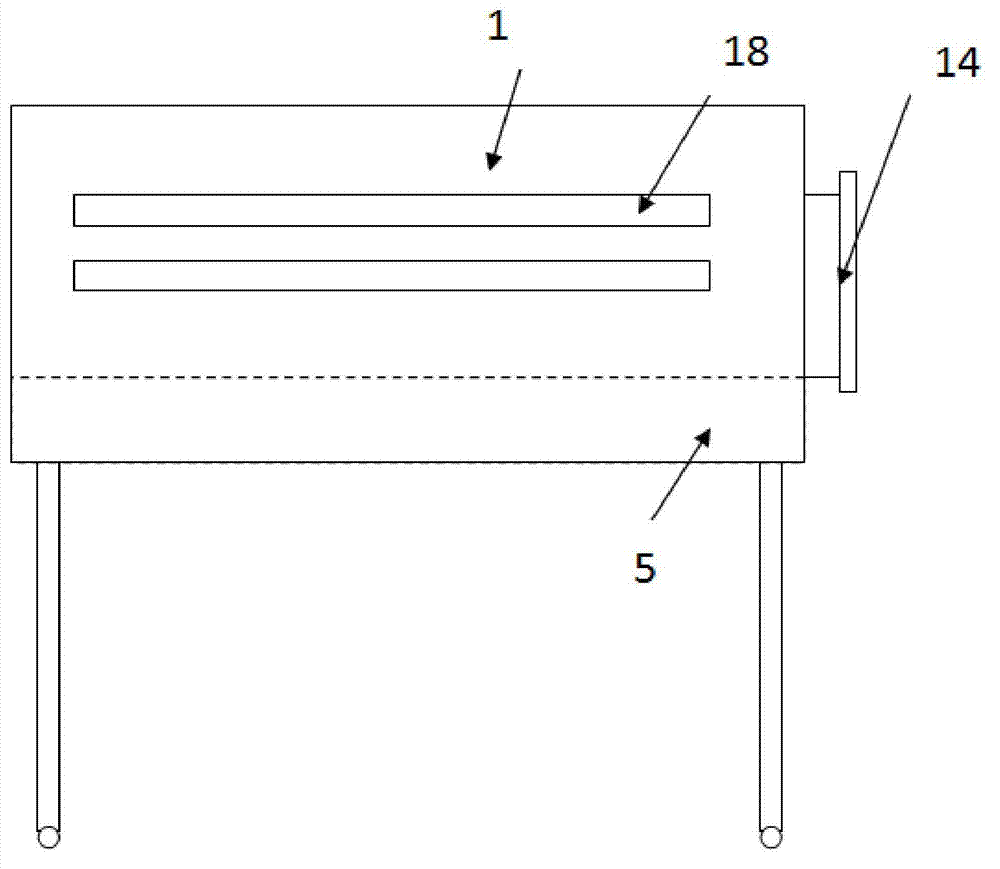

Electrode core drying device and method

ActiveCN103206838AFast heatingImprove uniformityDrying using combination processesDrying gas arrangementsAutomatic controlEngineering

The invention discloses an electrode core drying device. The electrode core drying device is characterized by comprising a drying oven, a heating device, a cooling device, a tray, a tray horizontal-moving device and a tray lifting and rotating device. An electrode core drying method includes multiple times of vacuum / inert gas-filled circulating, rotary heating, forceful cooling, exposure-free air butting and the like. By the electrode core drying device and method, inert gas is filled as heat conductive medium during heating, and heating speed is high; electrode cores are rotationally heated and subjected to forced convection, temperature uniformity is improved, and more reliable data are provided for heating temperature calculation. By the aid of vacuum and gas replenishing, water overflow is better facilitated, drying temperature of the electrode cores is lowered, and product quality is improved. During cooling of the electrode cores, cooling by inert gas and forced water cooling of a heating plate are realized, cooling time is greatly shortened, drying program is automatically controlled, the drying system is movable, a flange connector is directly abutted to a liquid injection tank through the drying oven, and secondary water absorption of the electrode cores is avoided.

Owner:GMCC ELECTRONICS TECH WUXI CO LTD

Energy-saving high-efficiency foaming molding mold

InactiveCN101474843ASmall heat capacitySuppression of cooling temperature dropInsulation layerHeat energy

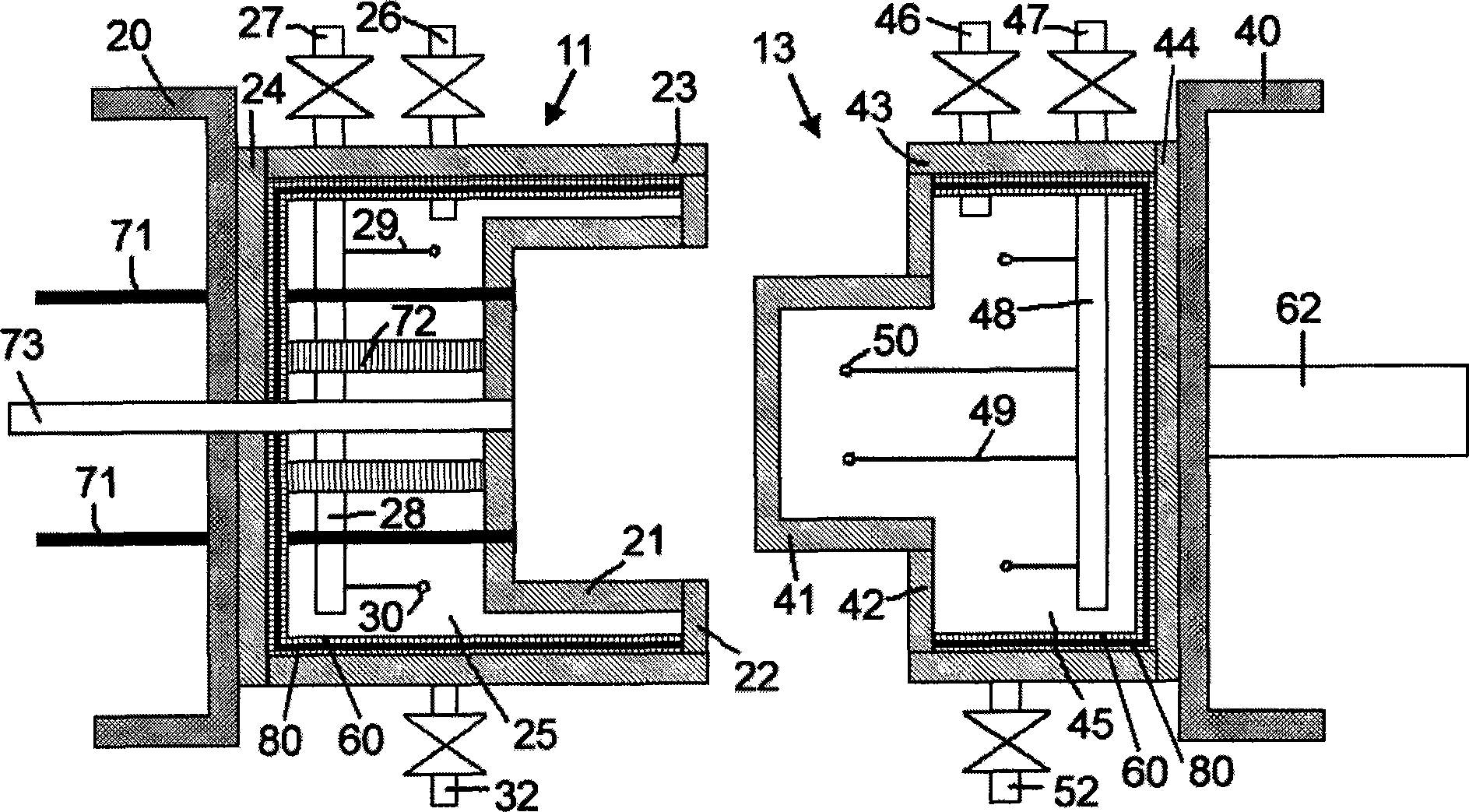

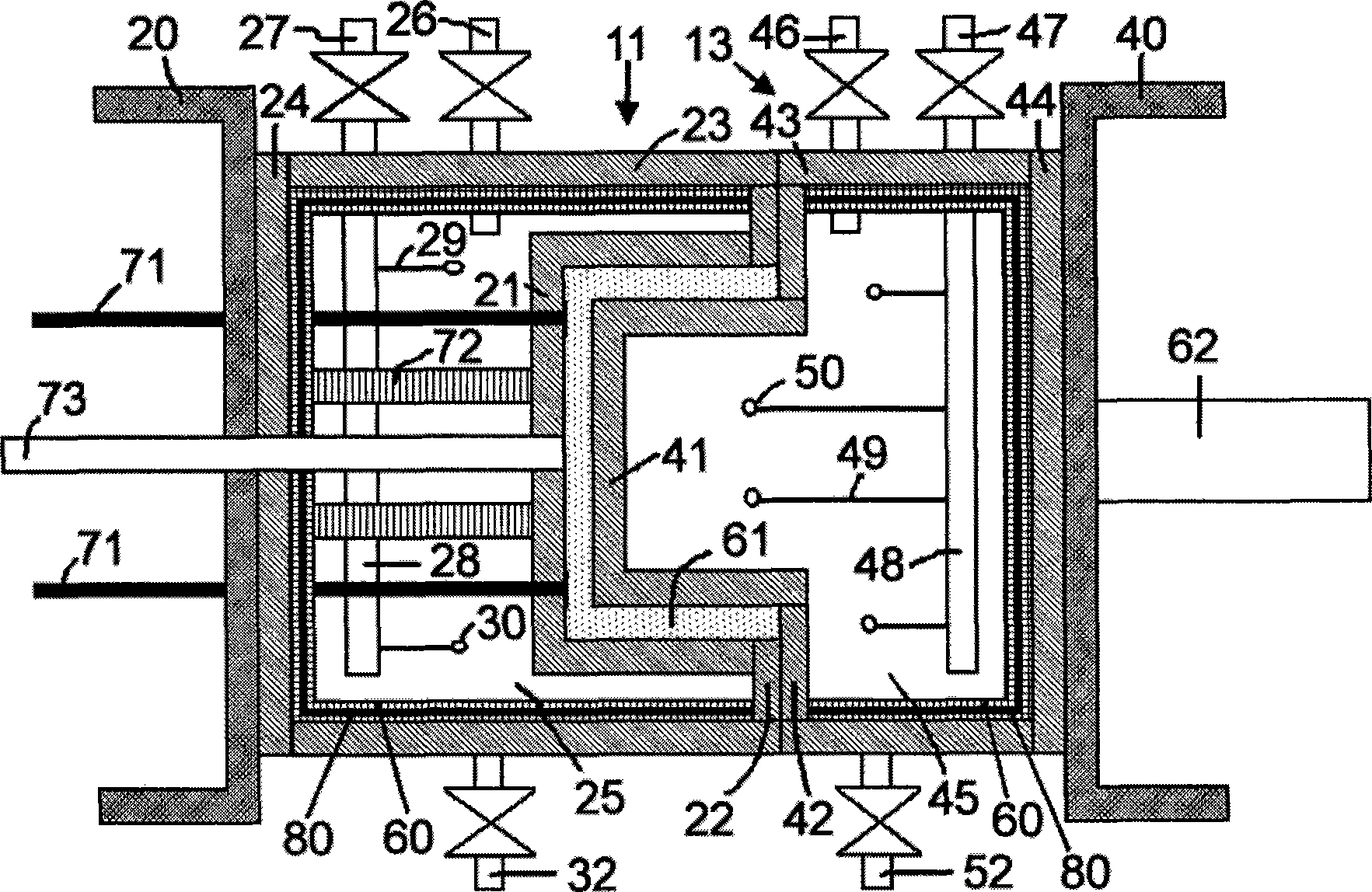

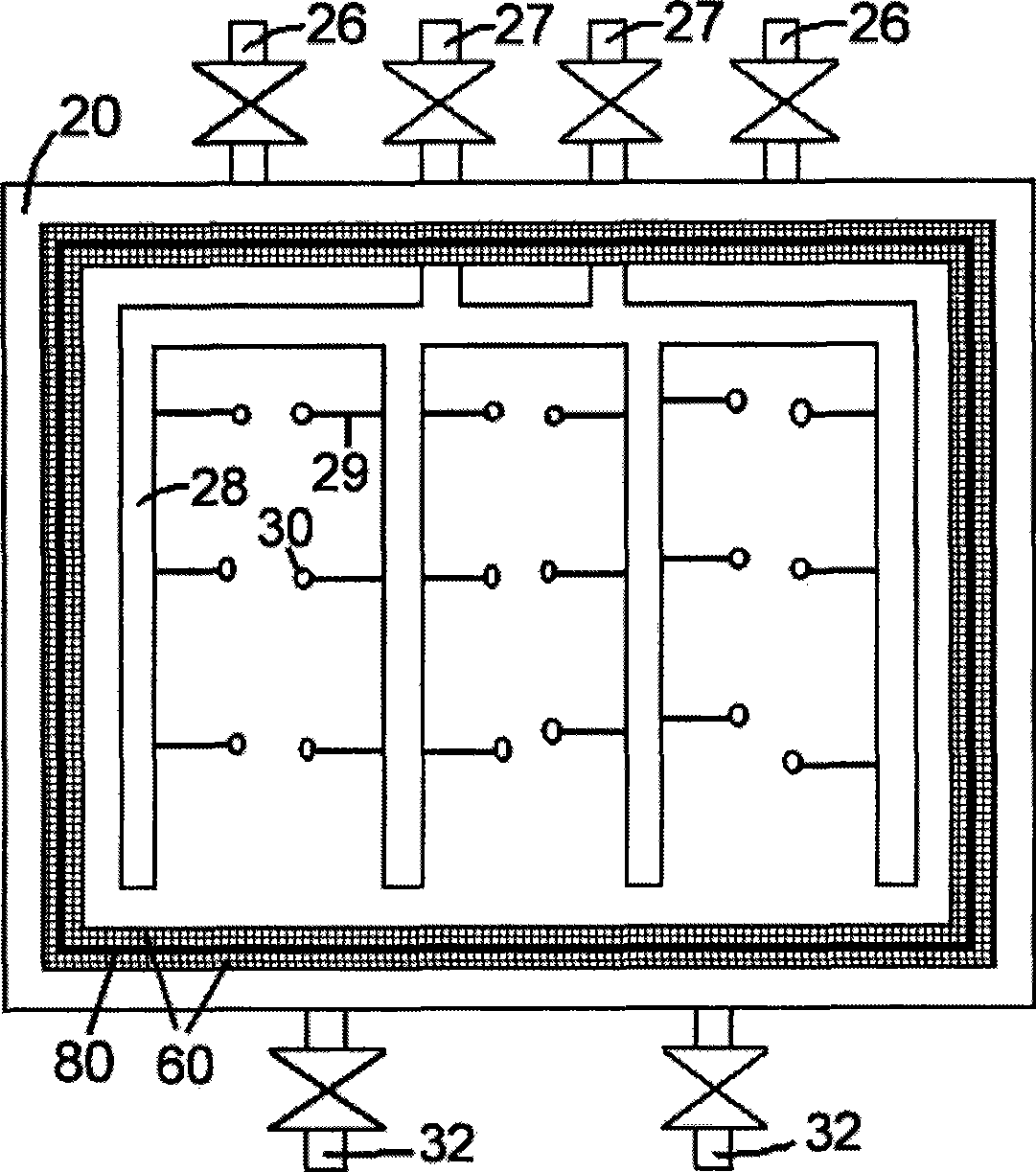

The present invention discloses a foaming shaping mold which has the advantages of energy saving and high efficiency. The foaming shaping mold comprises a cavity die (11) and a terrace die (13). The inner part of the cavity die (11) and terrace die (13) are respectively installed with steam chambers (25, 45) which are respectively composed by the enclosing of cores (21, 41), mold frames (23, 43), installation plates (22, 42) and backboards (24, 44). At least one part or total part of mold frames (23, 43) of cavity die (11) and terrace die (13), the installation plates (22, 42) and the backboards (24, 44) at the surface facing the steam chambers (25, 45) are installed with tortoise shell net (80). A heat insulation layer (60) is coated outside the tortoise shell net (80). The foaming shaping mold of the invention has the advantages of simple structure, convenient construction and low cost. The accessory heat insulation layer has the advantages of no easy break-off, long service lifetime, and stable and reliable capability. The foaming shaping mold of the invention also has the advantages of effectively reduced steam consumption rate, saved heat energy of steam, increased production efficiency of product, and suitability for generalization.

Owner:苏州雅安节能科技有限公司

System and method of cooling steam turbines

InactiveUS6898935B2Improve efficiencyReduce CooldownLiquid degasificationPump componentsPower stationDowntime

A system and method of cooling a steam turbine having internal moving components to a predetermined temperature by controlling a flow of nitrogen through the turbine, thus decreasing the downtime associated with maintaining the turbine. This provides a more efficient and cost effective method of operating a power plant.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com