Treatment process for absorbed condensate waste gas

A technology for waste gas treatment and waste gas, which is applied in the field of adsorption condensation waste gas treatment process, can solve the problems of secondary pollution, long desorption time, and inability to obtain recycled products, and achieves the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

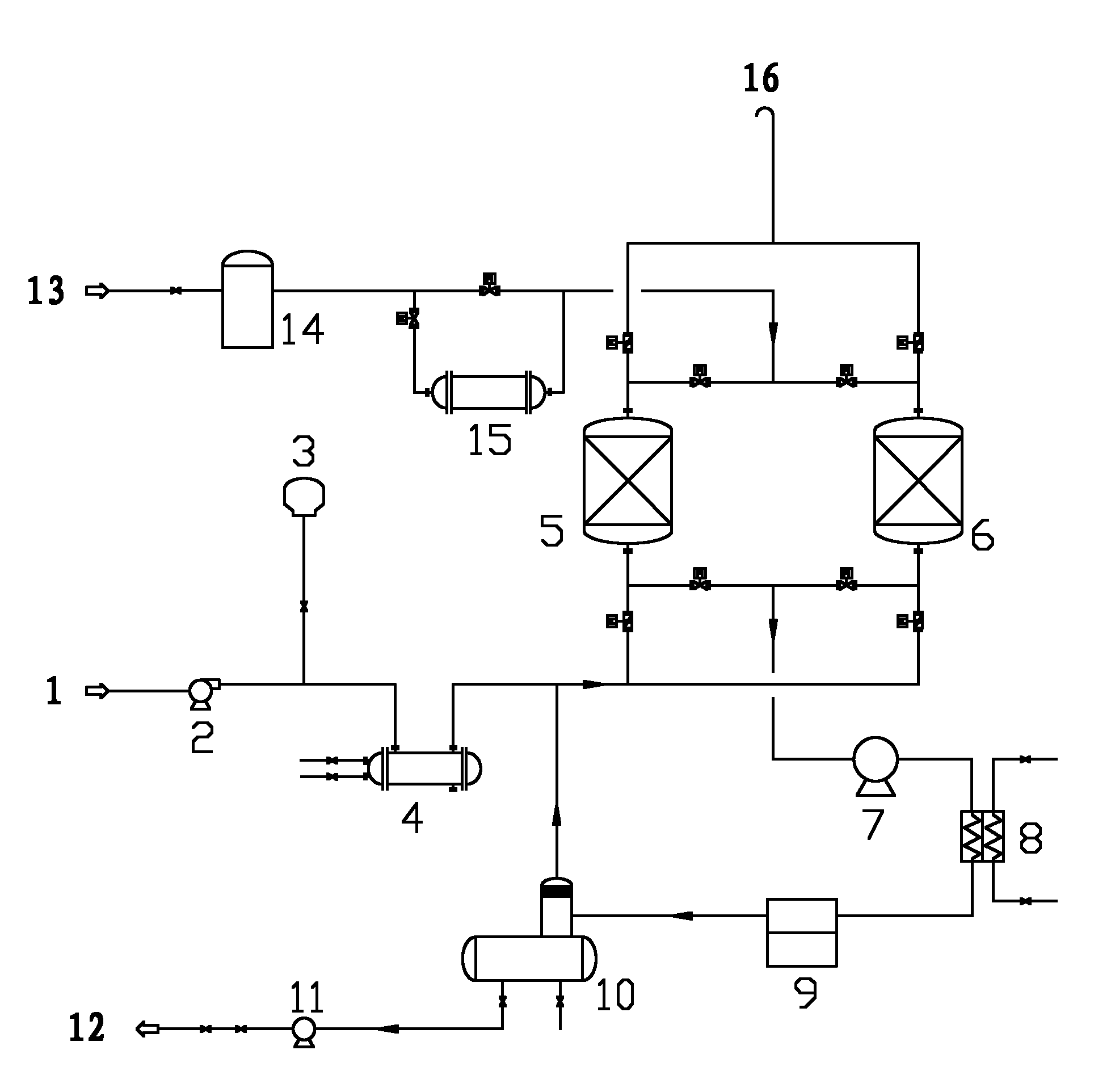

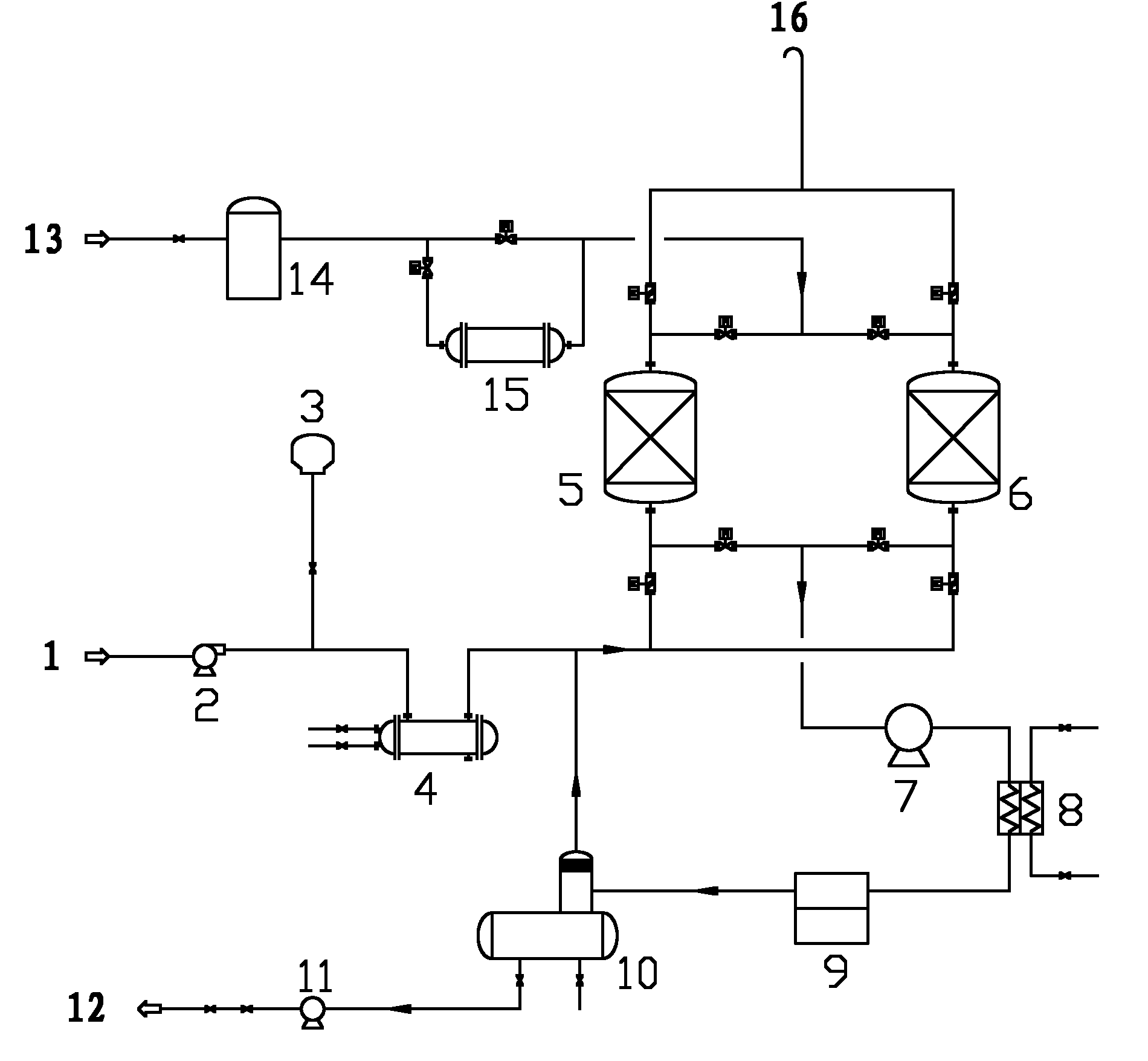

[0013] The adsorption condensation waste gas treatment process of the present invention adopts the technological method of activated carbon adsorption concentration + low temperature condensation to treat the waste gas. The adsorption tank adopts two tanks, one of which absorbs and the other regenerates, working alternately. The regeneration of the carbon bed adopts the vacuum desorption method.

[0014] The adsorption and condensation waste gas treatment process of the present invention is divided into two steps, that is, "gas phase separation + gas phase into liquid phase", specifically: 1. First, use activated carbon to adsorb and concentrate, so that the recyclable components or toxic and harmful components in the waste gas The components are adsorbed in the activated carbon, while the useless components (air or nitrogen) are not adsorbed and are directly discharged through the carbon layer, and then the components adsorbed in the pores of the activated carbon are desorbed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com