Patents

Literature

352 results about "Recycled products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Recycling apparatus, recycling method, and recycled product

InactiveUS6842596B2Solid waste disposalElectrographic process apparatusRecovery methodIndustrial engineering

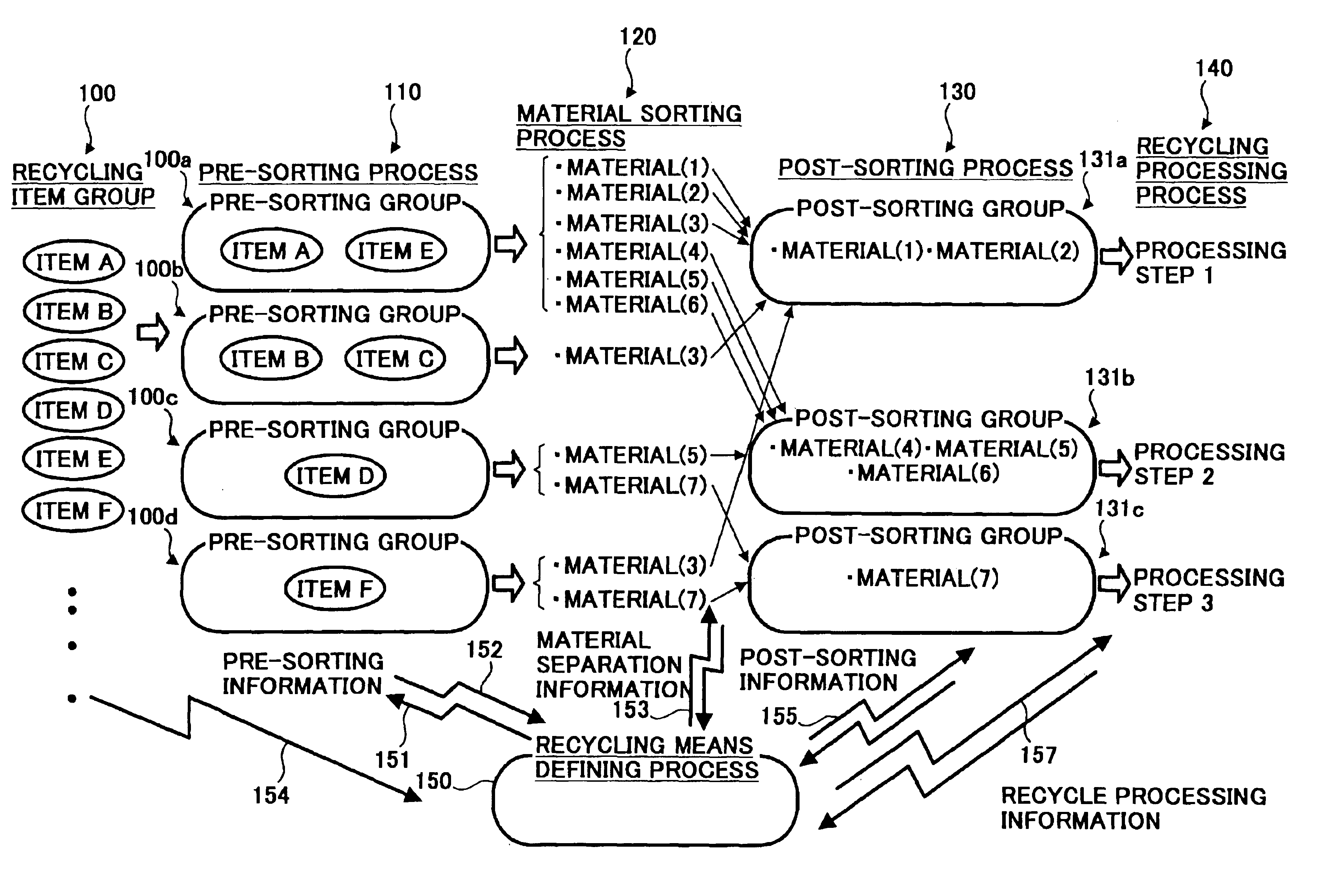

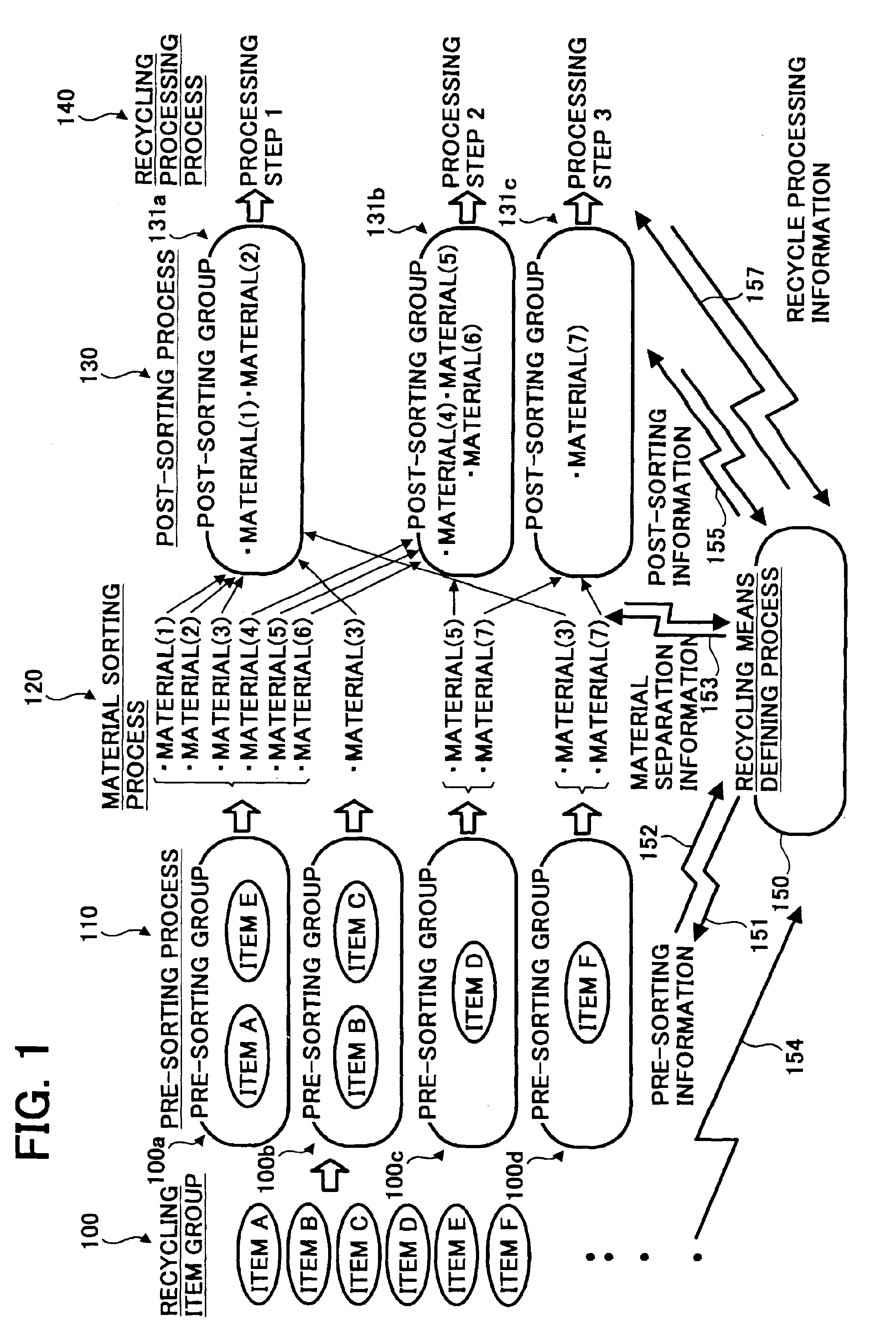

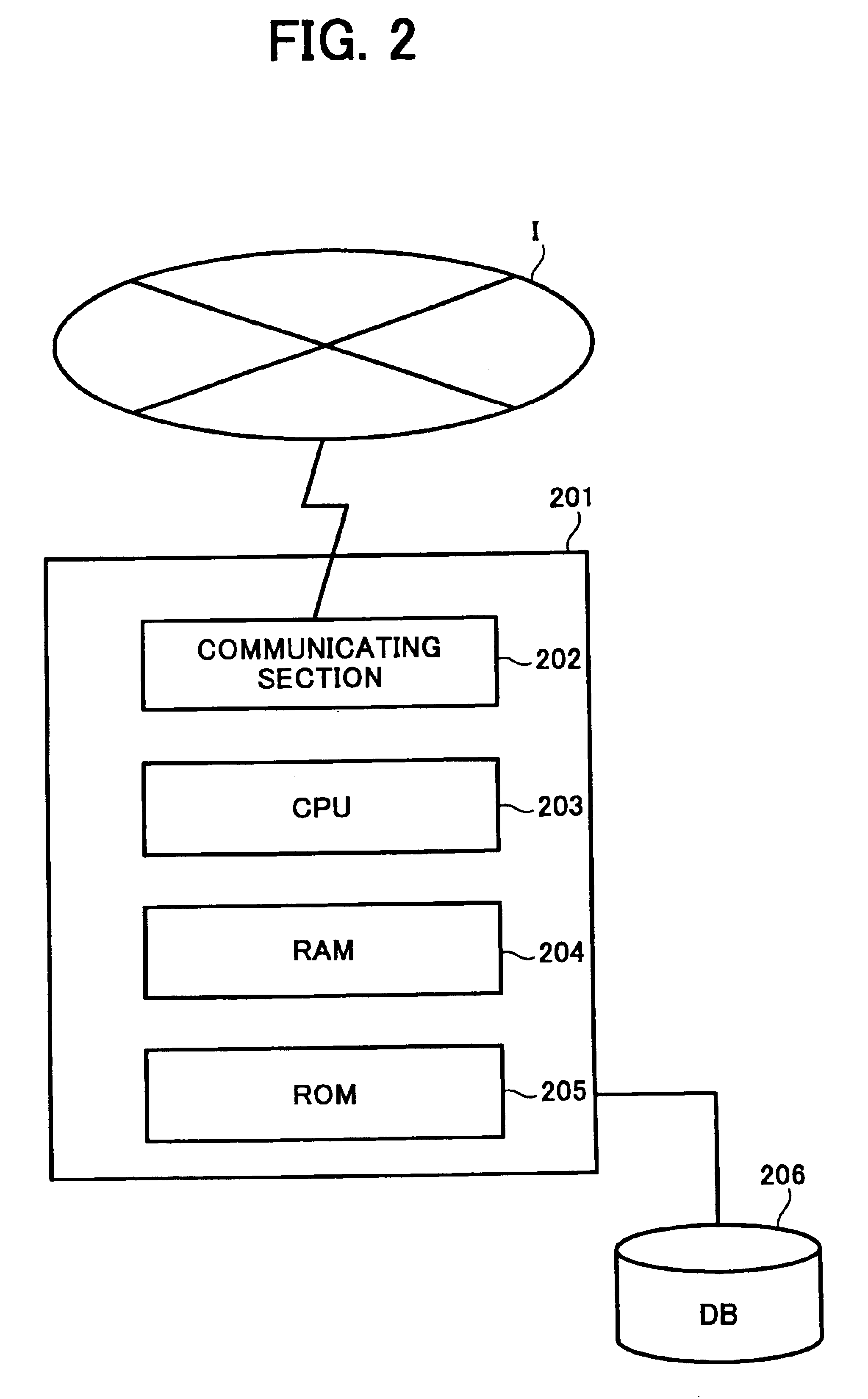

Information about a recycling item is input, a first sorting condition is prepared so as to sort the recycling item into one of a plurality of groups corresponding to conditions for decomposing the recycling item, a second sorting condition is prepared so as to sort recycling parts, which are obtained by decomposing the recycling item sorted out according to the first sorting condition, into at least one of a plurality of material groups corresponding to material of each of the recycling parts; a third sorting condition is prepared so as to sort the recycling parts sorted out according to the second sorting condition, into at least one of a plurality of processing groups corresponding to types of recycling processing to be carried out. Finally, the first, second, and the third sorting conditions are transmitted to respective fields where the recycling item and the recycling parts are sorted.

Owner:RICOH KK

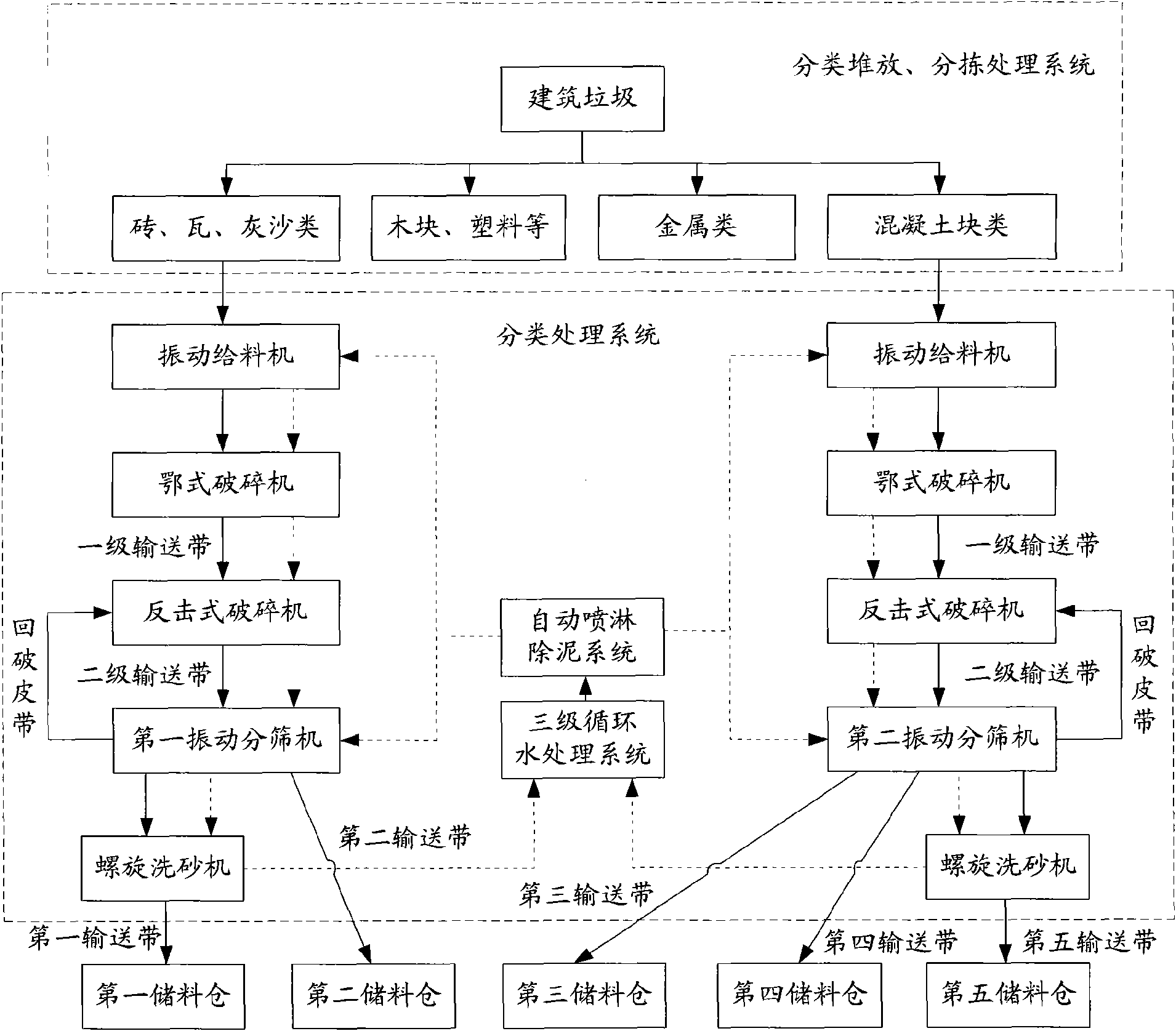

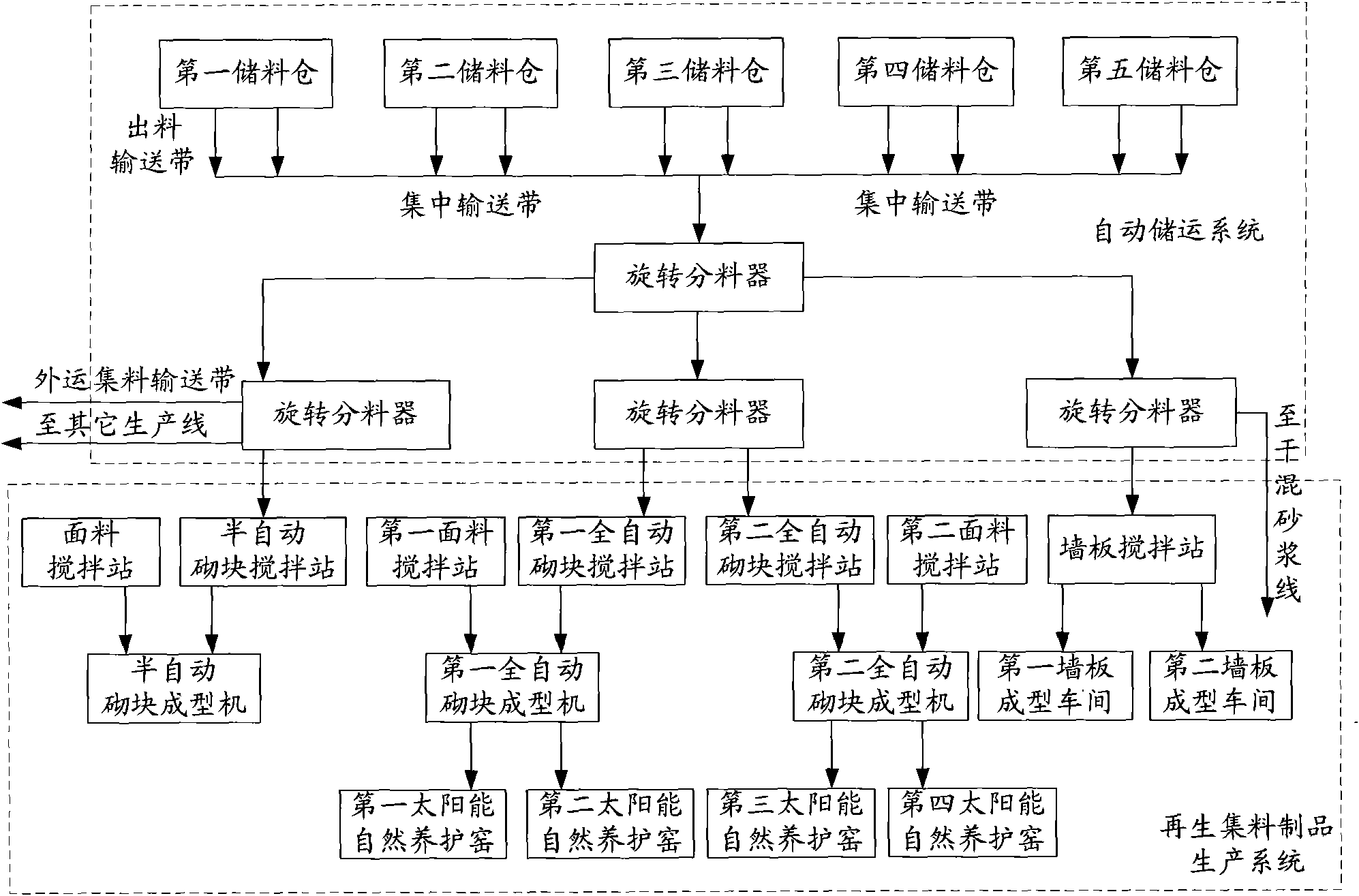

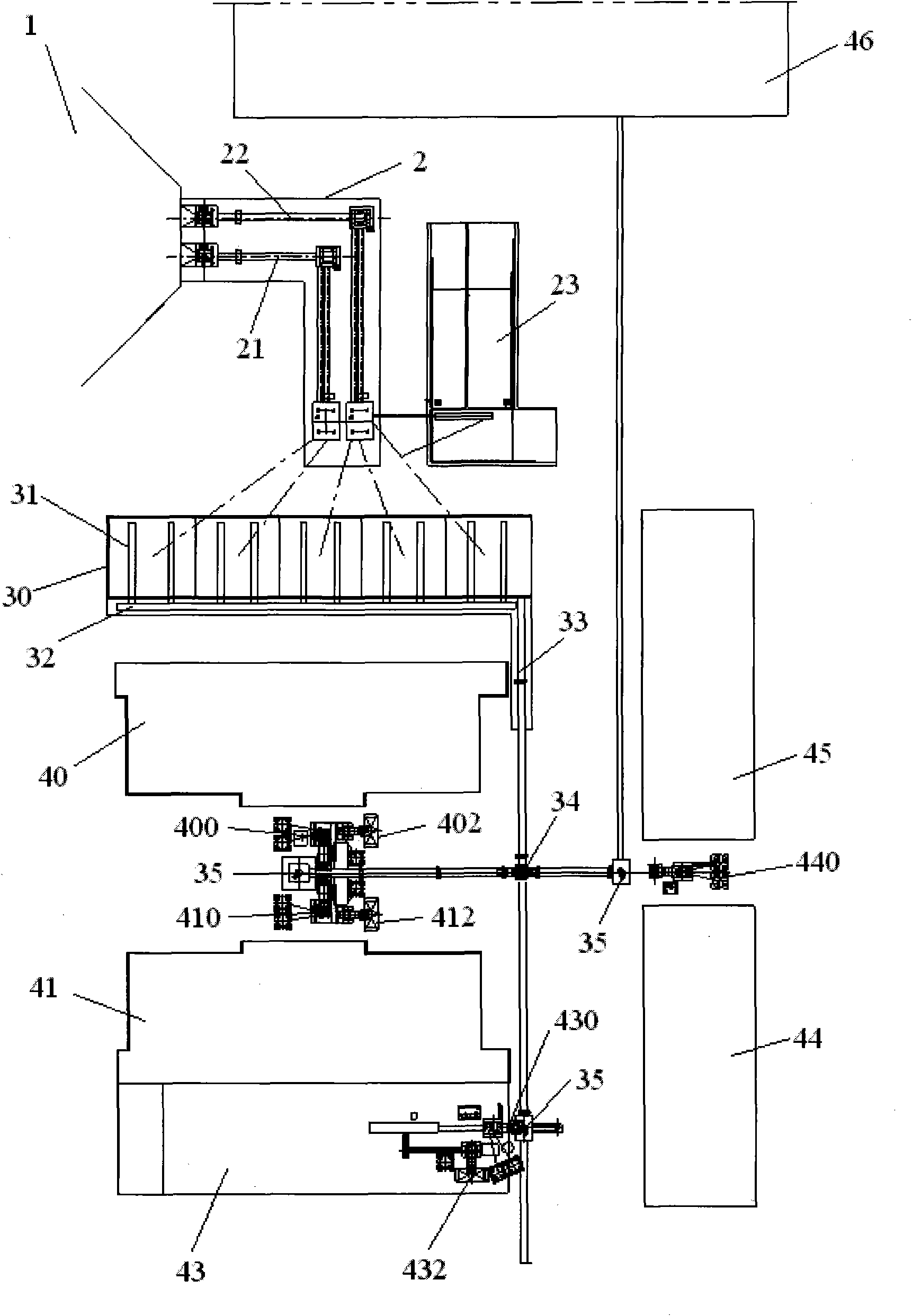

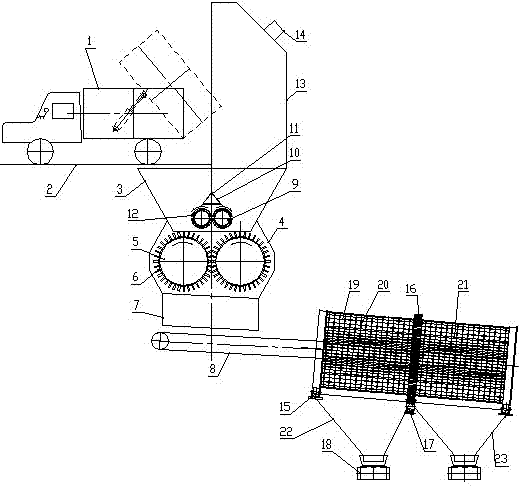

Building refuse treatment regeneration system

The embodiment of the invention discloses a building refuse treatment regeneration system, including a classification stacking, sorting processing system, a classification processing system and a plurality of storage bins, wherein, the classification processing system includes at least two parallel crushing screening process production lines and water circulating systems, each crushing screening process production line includes a feeder, crusher, as well as a screening machine connected in series in sequence, and a plurality of outlets of the screening machine are respectively connected to the plurality of storage bins through conveyor belts. By adoption of the building refuse treatment regeneration system of the embodiment of the invention, bricks, tiles, dust and sand and concrete blocks and the like in the building refuse can be divided into at least two production lines for parallel processing, which greatly enhancing the production efficiency and the purity of recycled aggregates, so that the recycled aggregates can be applied to a variety of uses, reproduced into a variety of high-quality recycled products, reducing the waste of resources and minimizing pollution that will be probably caused to the environment.

Owner:深圳市绿发鹏程环保科技有限公司

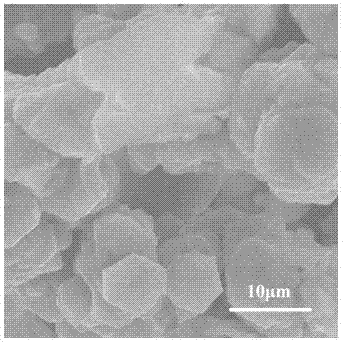

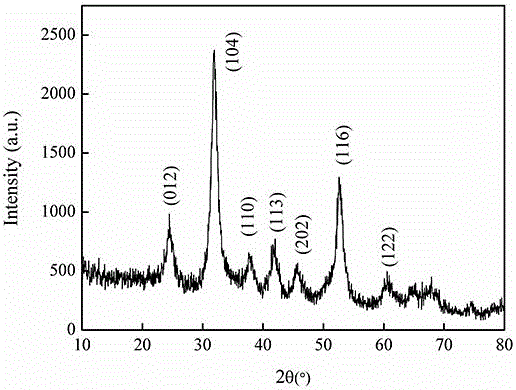

Process for reversely recycling and preparing lithium nickel manganese oxide by taking waste lithium battery as raw material

ActiveCN103199230ARealize resource utilizationGood for regulating propertiesCell electrodesWaste accumulators reclaimingElectrolysisManganese oxide

The invention discloses a process for reversely recycling and preparing lithium nickel manganese oxide by taking waste lithium batteries as raw materials. The process is characterized by comprising the following steps of: (1) preprocessing a positive battery plate of a waste lithium battery to obtain anode power; (2) dissolving the anode power in inorganic acid, and eliminating impurities to obtain mixed acid liquor containing nickel and manganese; (3) adding a nickel source or a manganese source into the mixed solution; (4) adding an acetate complexing agent, and regulating the ratio of the acetate concentration to the total metal ion concentration; (5) putting the mixed solution into an electrolytic bath to be electrolyzed, and depositing nickel manganese oxide on a titanium plate; (6) stopping the conduction of a direct current, taking the titanium plate out, separating the nickel manganese oxide on the titanium plate, and drying the nickel manganese oxide to obtain nickel manganese oxide powder; (7) and uniformly mixing the nickel manganese oxide powder and a lithium source, and then calcining the mixture to obtain lithium nickel manganese oxide. According to the process, a regenerated product having the performance the same with the performance of the original product can be obtained by the waste battery through a reverse recycling process, so that the resource utilization can be realized.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

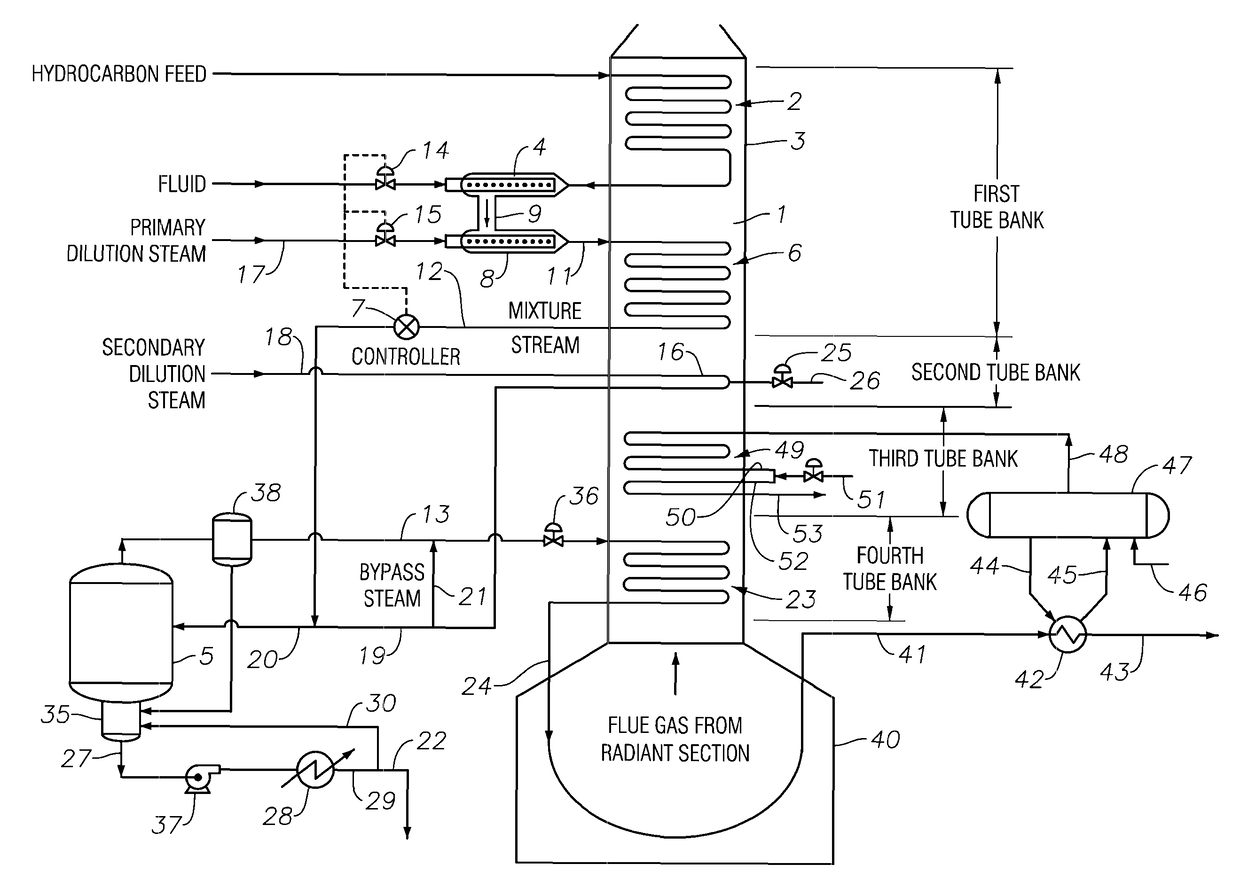

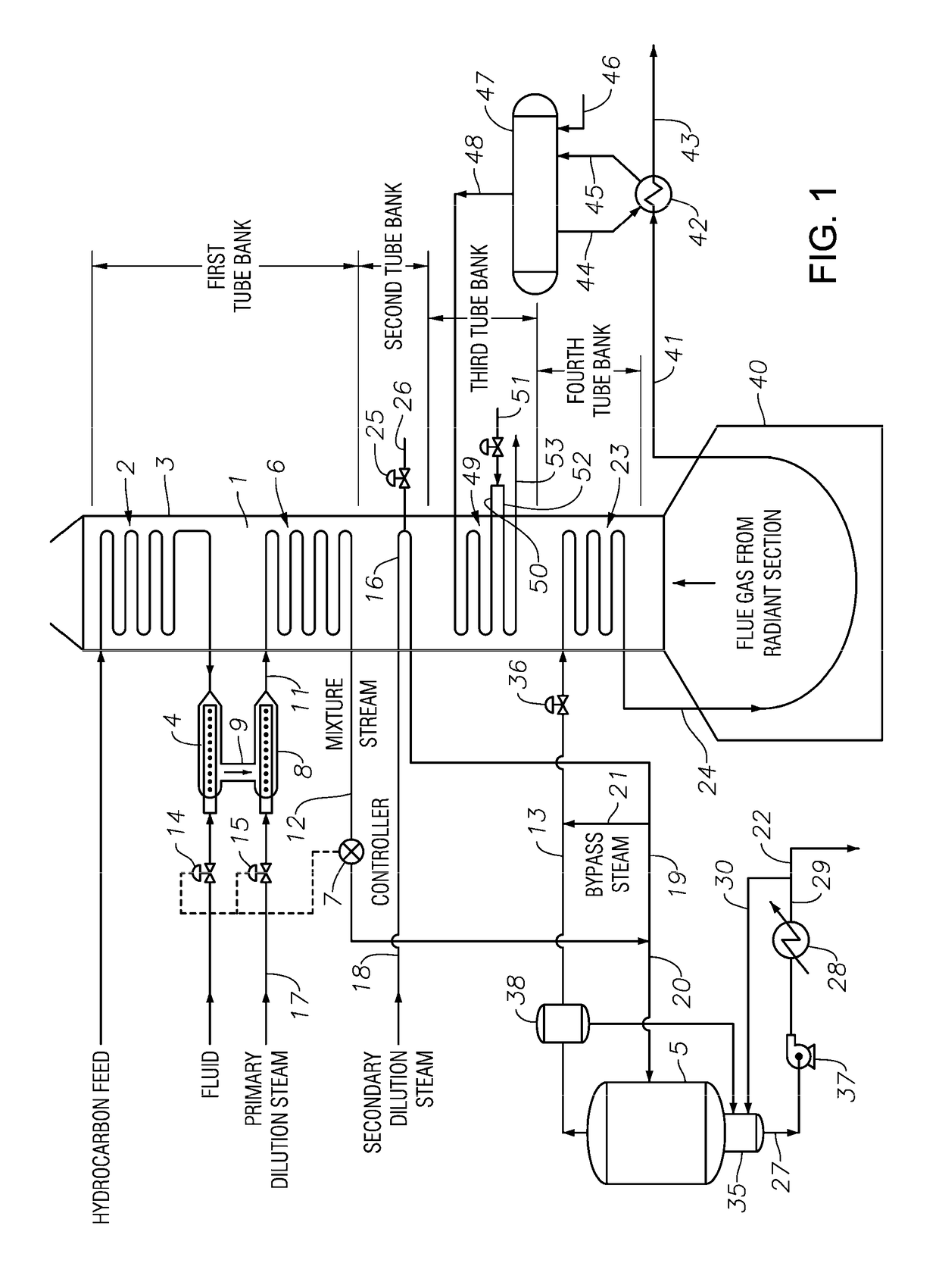

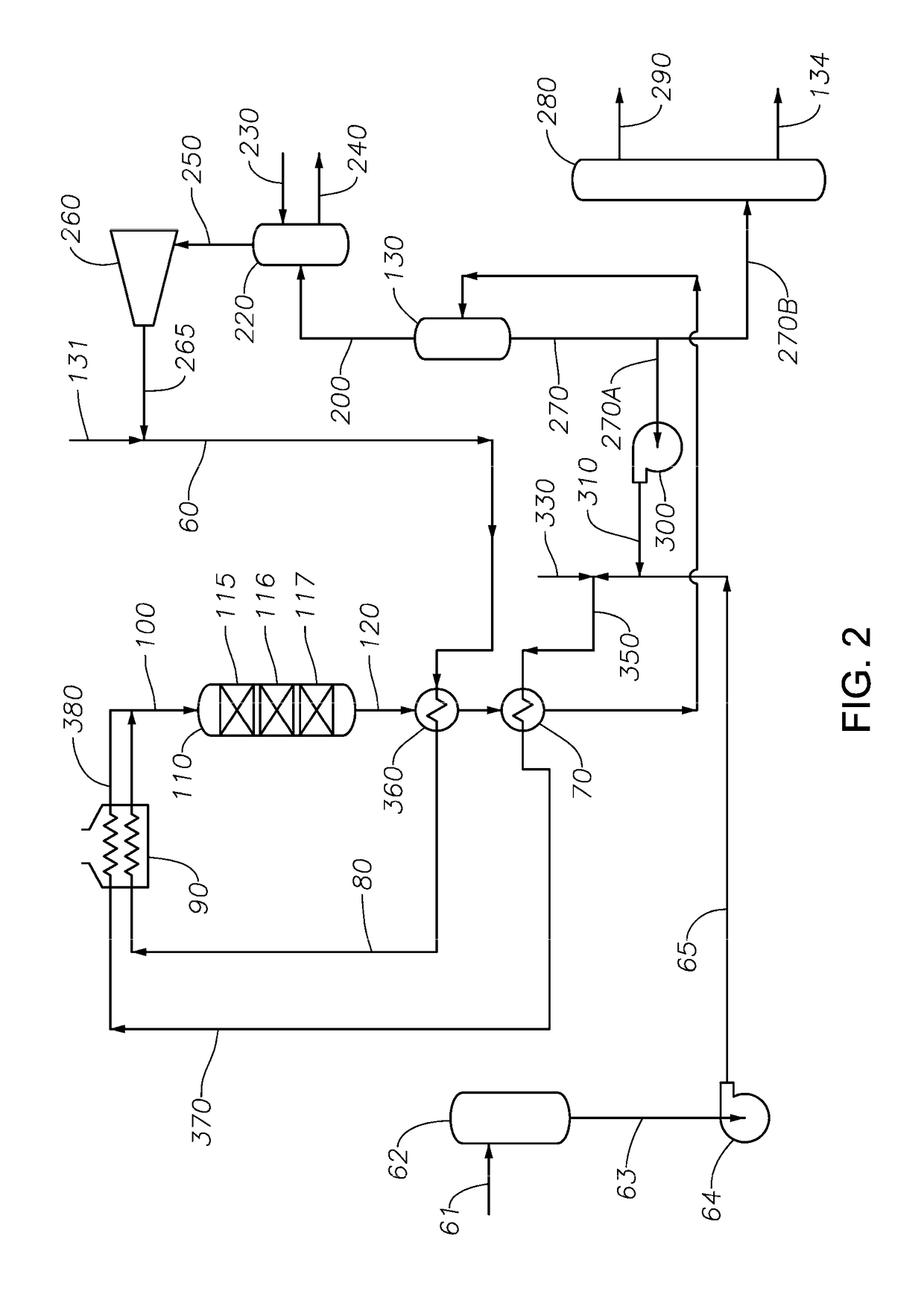

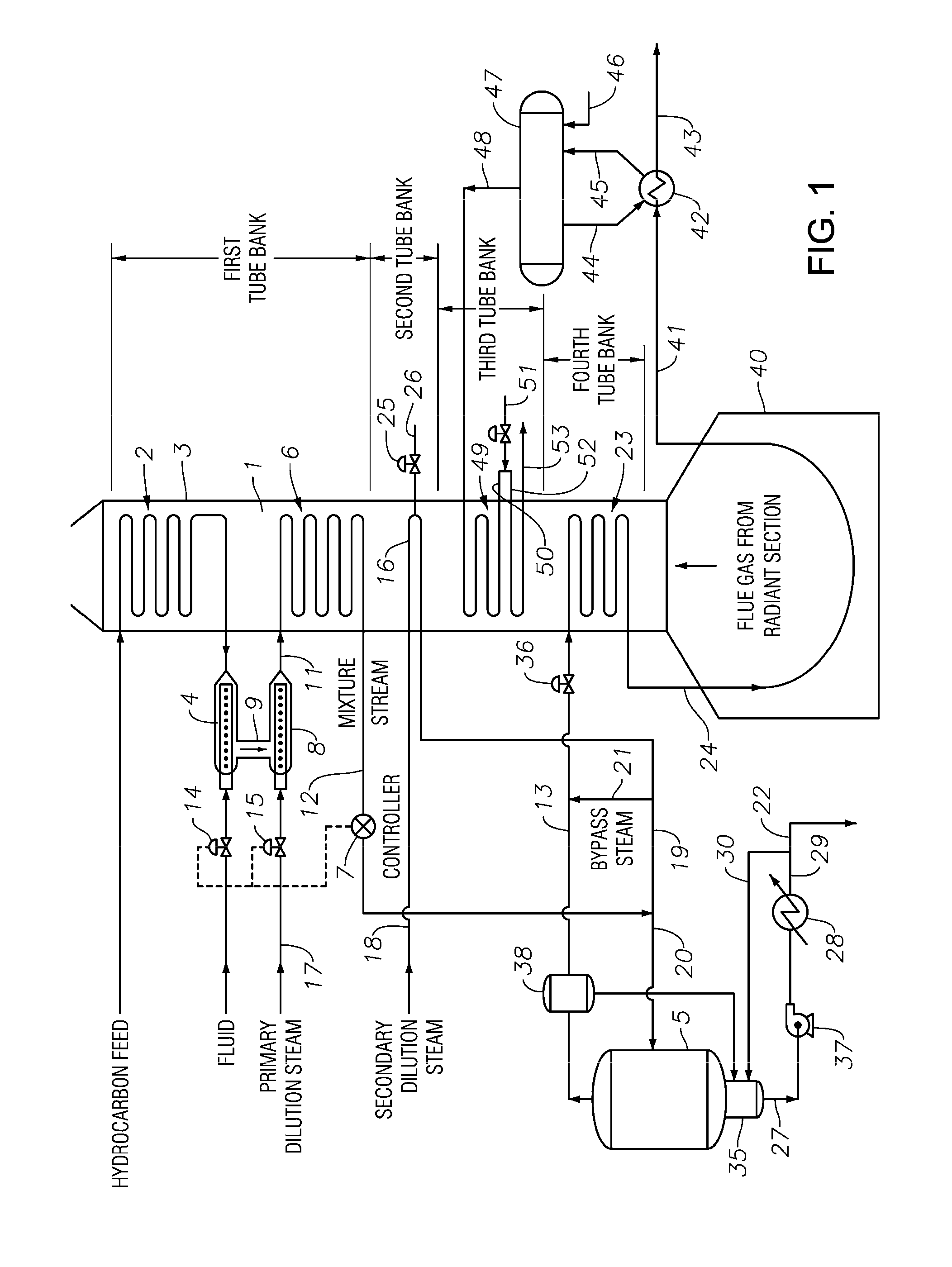

Pyrolysis tar upgrading using recycled product

ActiveUS9657239B2Pyrolysis tar hydroprocessing is improvedLesser rateHydrotreatment operations starting-upRefining to change hydrocarbon structural skeletonProcess engineeringFuel oil

The invention relates to a process for upgrading pyrolysis tar in the presence of a utility fluid. The utility fluid contains 1-ring and / or 2-ring aromatics and has a final boiling point ≦430° C. The invention also relates to the upgraded pyrolysis tar, and to the use of the upgraded pyrolysis tar, e.g., for fuel oil blending.

Owner:EXXONMOBIL CHEM PAT INC

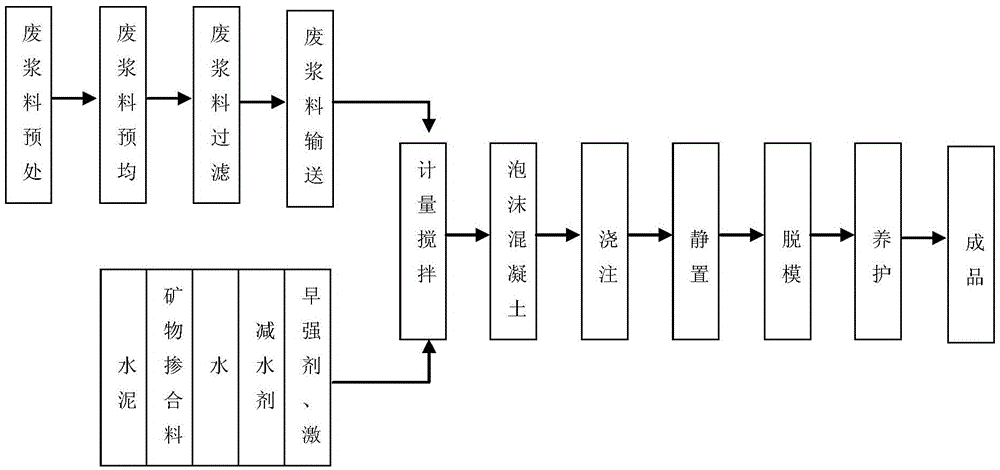

Waste slurry recycling and reusing technology of concrete mixing station

InactiveCN105645800AIncrease profitRealize comprehensive recyclingSolid waste managementCeramicwarePre treatmentLand resources

The invention discloses a waste slurry recycling and reusing technology of a concrete mixing station. The waste slurry recycling and reusing technology of the concrete mixing station comprises the following steps: firstly pre-treating waste slurry of the concrete mixing station, and maintaining the activity of a cementing material in the waste slurry; then conveying the waste slurry from a settling pond to a pre-homogenizing pond, adding water and stirring for carrying out waste slurry pre-homogenization; filtering the obtained homogenous waste slurry through a filter screen, and conveying the homogenous waste slurry to a burdening and stirring tank; metering and stirring cement, a mineral admixture, water, a water reducing agent, an early strength agent and an exciting agent according to a proportion to prepare concrete slurry, conveying the obtained concrete slurry to a foaming machine to prepare foam concrete, pouring the foam concrete in a mold, standing, demoulding, and maintaining, thus obtaining a regenerated foam concrete product with the dry density level of 600 to 800 kg / m<3>. According to the waste slurry recycling and reusing technology disclosed by the invention, the problems of waste of land resources, environment pollution and increment of running cost of the concrete mixing station due to backfilling of the waste slurry of the concrete mixing station can be solved, qualified regenerative products can be generated, and the waste slurry recycling and reusing technology is suitable for being popularized and applied.

Owner:中建西部建设西南有限公司

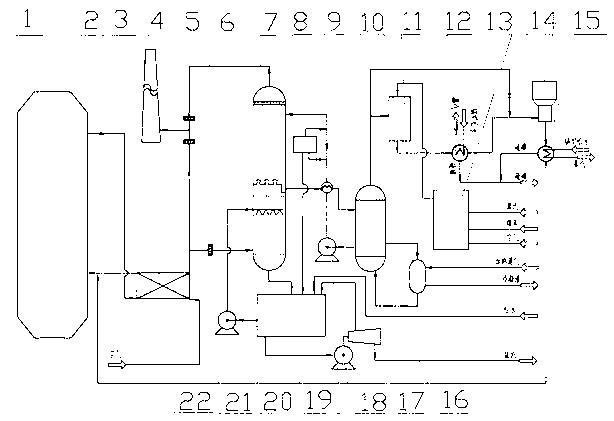

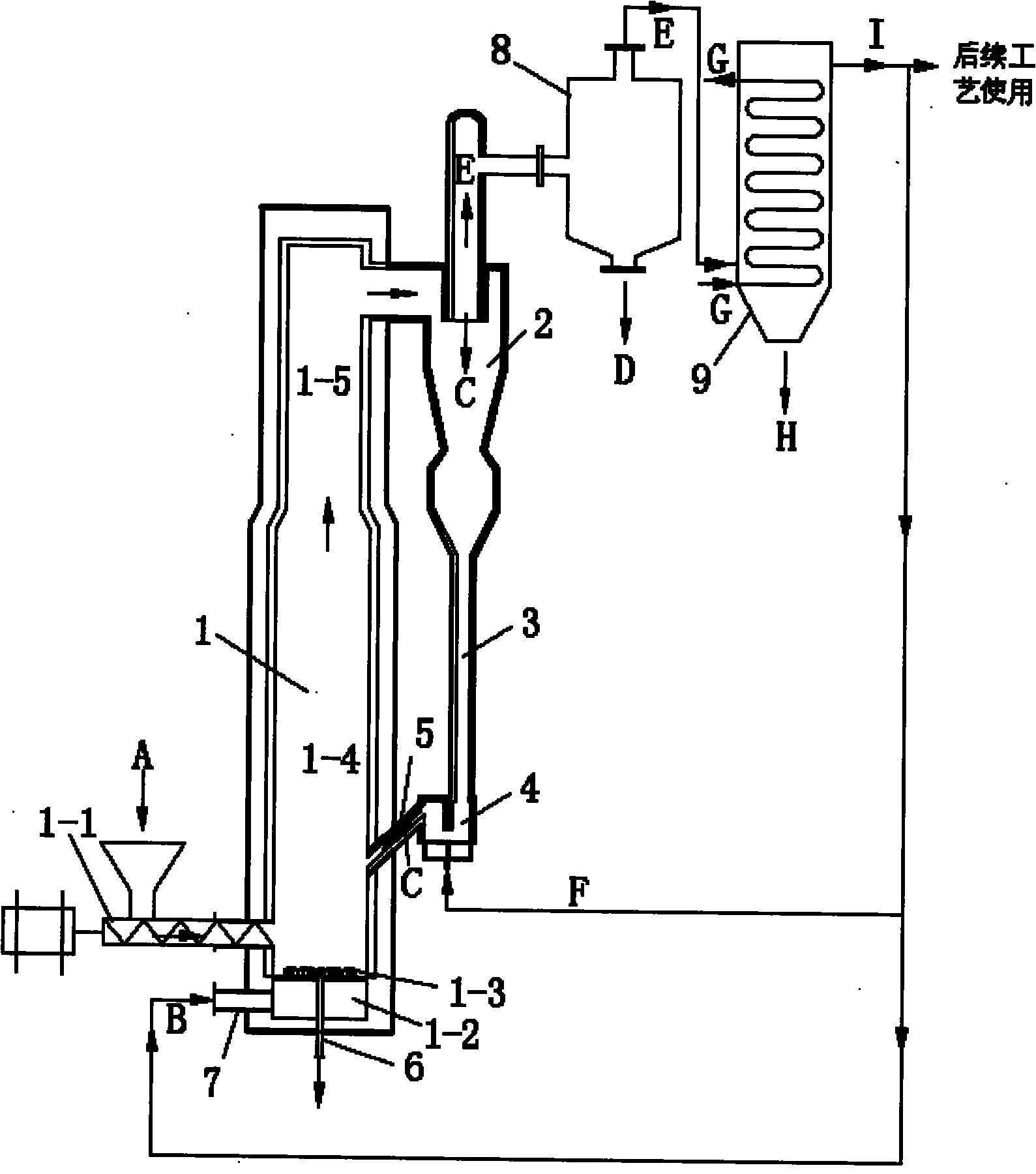

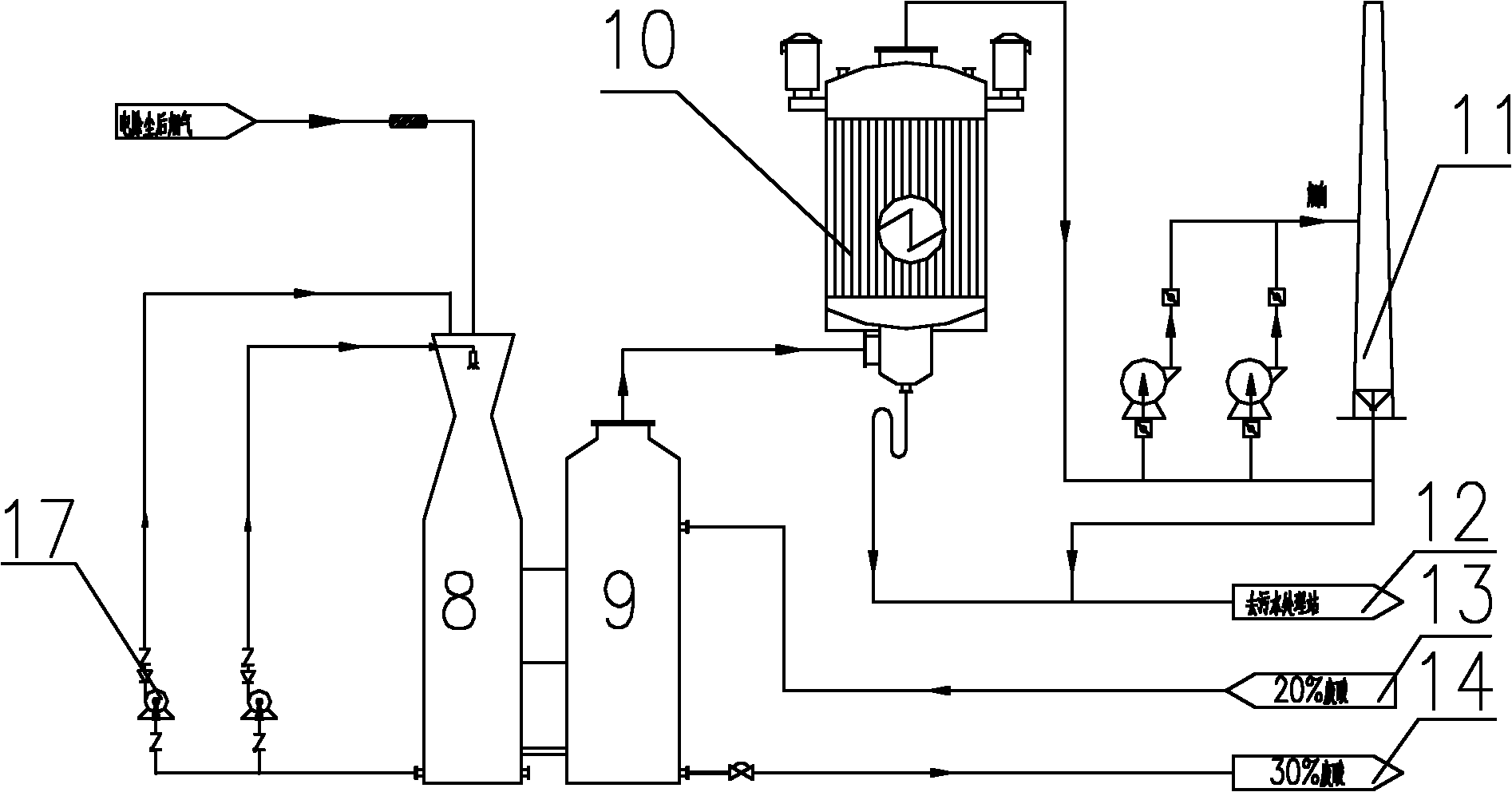

System device and method for recycling sulfur dioxide from fume to prepare sulfur

InactiveCN103303872AEmission reductionImprove performanceEnergy inputSulfur preparation/purificationCooling towerSulfur product

The invention discloses a system device and a method for recycling sulfur dioxide from fume to prepare sulfur. The device comprises three units of an absorption and pyrolysis unit, a reduction unit and a krauss unit, wherein the absorption and pyrolysis unit mainly consists of a cooling tower, an absorbing tower, a purifier, a circulation pump, a regeneration pyrolysis tank and a rich and lean liquid heat exchanger; the reduction unit mainly consists of a mixed gas generation system, a reduction reactor and a sulfur condenser; the krauss unit mainly consists of a krauss reactor and a sulfur condenser. The method comprises the steps that the absorption and pyrolysis unit absorbs and pyrolyzes the fume so as to obtain a pure sulfur dioxide gas, and the reduction unit converts the sulfur dioxide into elementary sulfur through catalysis reaction, wherein the conversion per pass is not less than 95%, and the total conversion is greater than 99.5%. The sulfur dioxide content that the fume is completely discharged is not greater than 50 milligrams per normal cubic meter. The sulfur dioxide is converted into national best grade sulfur products which are stable in property and convenient to store and transport, with high efficiency and low cost, the desulfuration operation cost is lower than the value of a recycled product, and the products can be widely applied to chemistry and thermal power industry.

Owner:陕西华锐迪橡胶科技有限公司

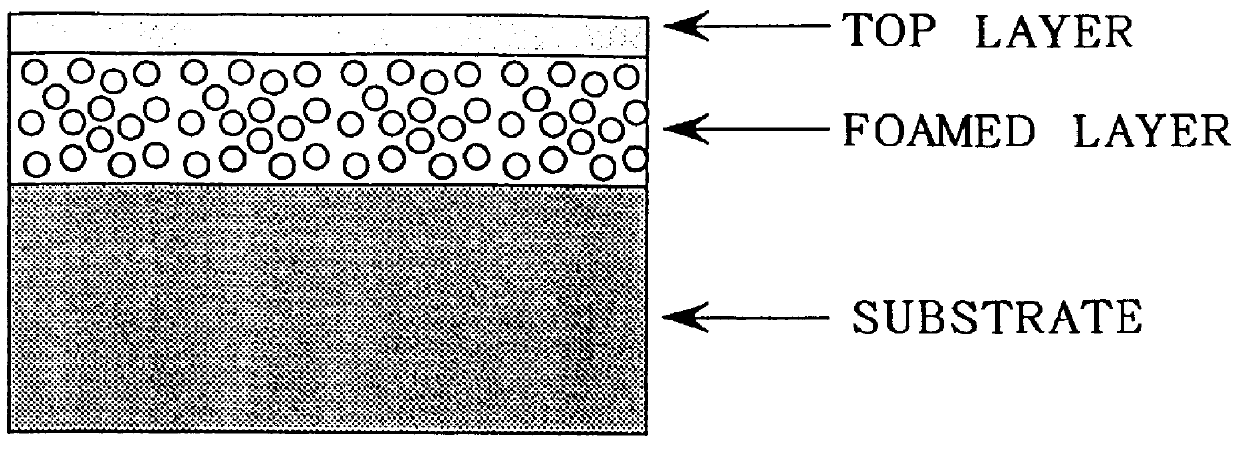

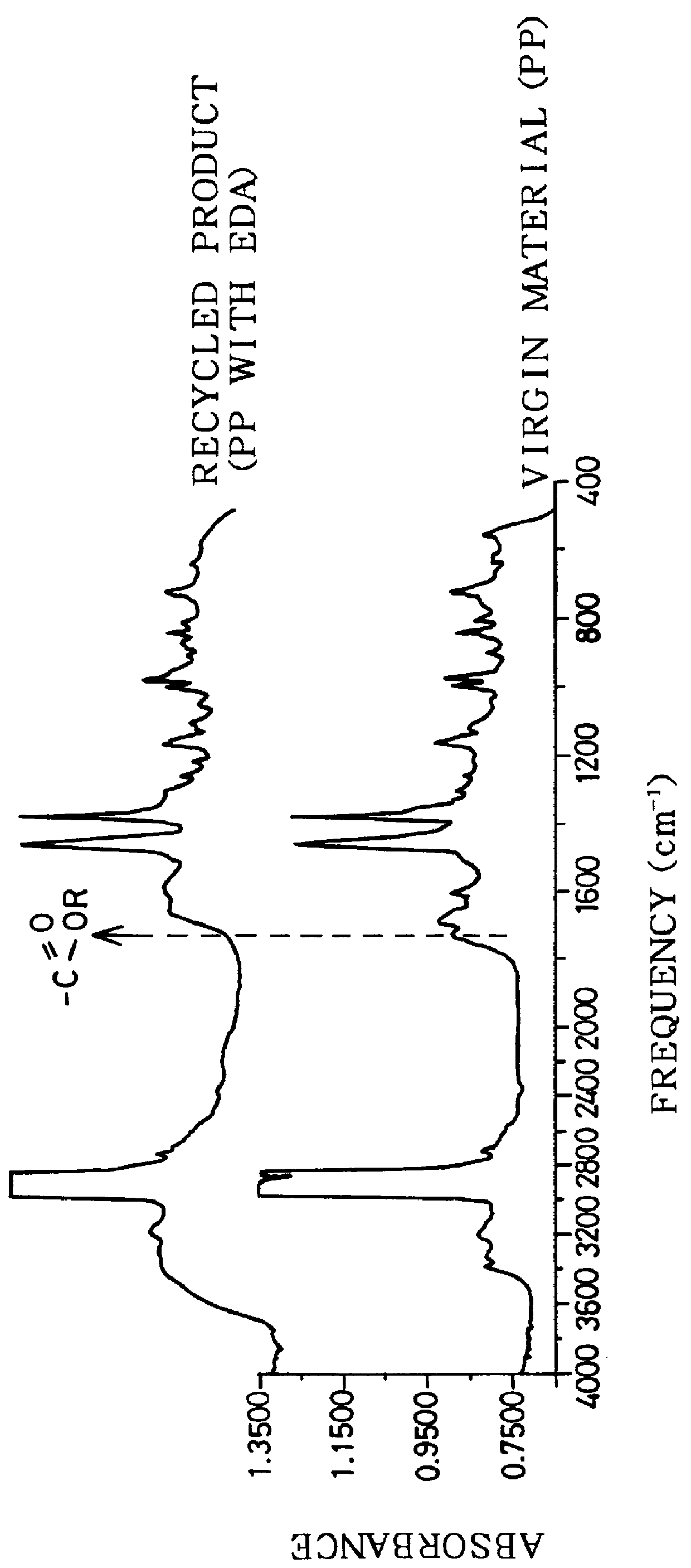

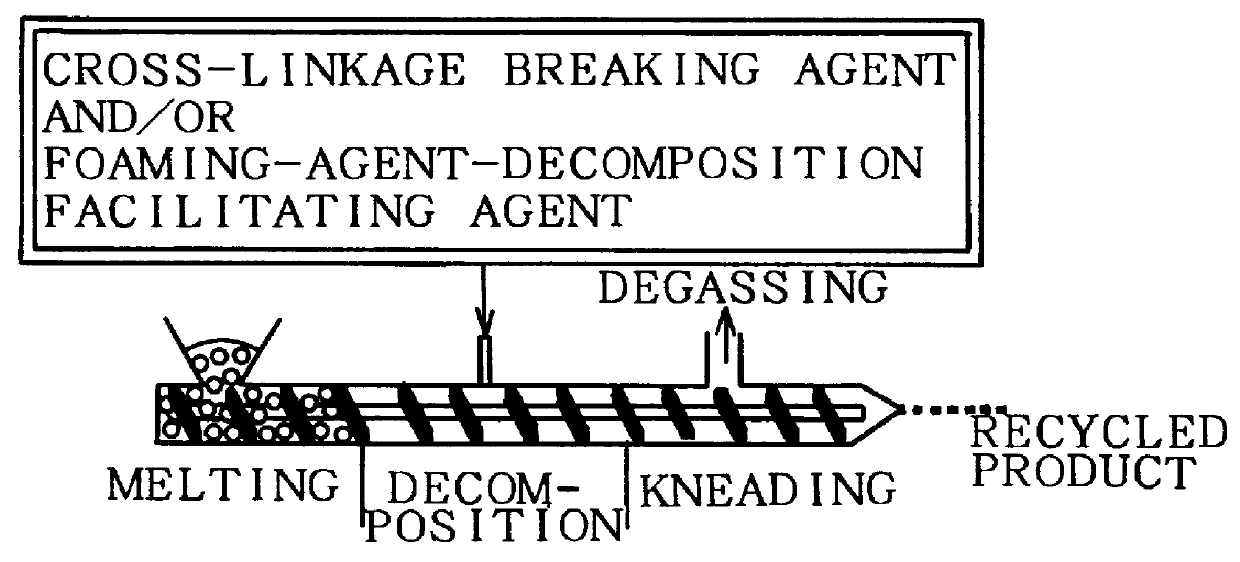

Process for recycling polyolefin cross-linked substance or polyolefin foamed substance

InactiveUS6090862AHigh elongationGood moldabilityPlastic recyclingPeptide preparation methodsCross-linkPolymer science

A process is developed for recycling a polyolefin cross-linked substance having a cross-linkage, a polyolefin foamed substance free from a cross-linkage or a polyolefin foamed substance having a cross-linkage. The process includes the step of heating the polyolefin cross-linked substance together with a cross-linkage breaking agent, whereby breaking the cross-linkage to recycle the polyolefin cross-linked substance into a moldable thermoplastic resin. Further, the process includes the step of adding a foaming-agent-decomposition facilitating agent to the polyolefin foamed substance in the course of thermally melting the polyolefin foamed substance, whereby decomposing a residual foaming agent remaining in the polyolefin foamed substance. Furthermore, the process includes the step of adding a foaming-agent-decomposition facilitating agent to the polyolefin foamed substance in the course of heating the polyolefin foamed substance to break the cross-linkage, whereby decomposing a residual foaming agent remaining in the polyolefin foamed substance. The resulting recycled product is improved in terms of moldability, strength, elongation and superficial appearance.

Owner:TOYOTA JIDOSHA KK +1

Method for recovering electrolyte of waste lithium ion battery

InactiveCN104600392AEasy to handleSimple processWaste accumulators reclaimingBattery recyclingRecovery methodOrganic solvent

The invention discloses a method for recovering electrolyte of a waste lithium ion battery. The method comprises the following steps: (1) dissecting the waste lithium ion battery, taking out a battery cell, and separating the battery cell in a centrifugal machine to obtain the waste electrolyte; (2) filtering, decoloring and dehydrating the waste electrolyte; (3) carrying out component analysis on the dehydrated waste electrolyte, supplementing electrolyte and organic solvent, adjusting the electrolyte to the component proportion of the electrolyte for the lithium ion battery, and thus producing an electrolyte product. By adopting the method, the recycling of the electrolyte of the waste lithium ion battery can be realized, the environmental pollution caused by the electrolyte can be avoided, and high efficiency and environmental protection can be realized. The recycled product can be used as the electrolyte to be returned to the lithium battery industry, so that the resource is saved, and the pollution is reduced.

Owner:HUNAN ZHENGYUAN ENERGY STORAGE MATERIALS & DEVICE INST

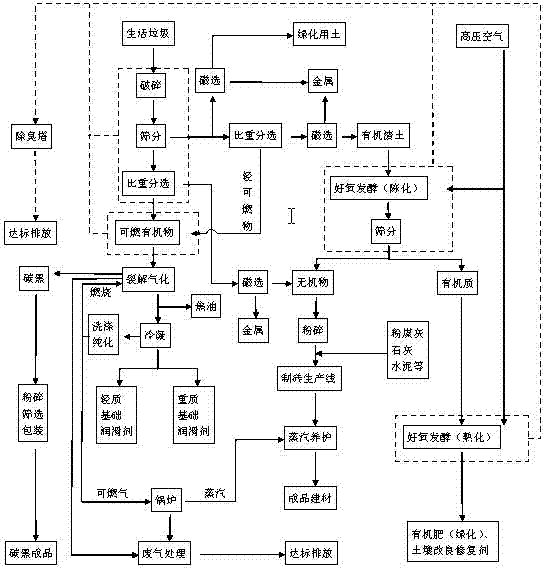

Comprehensive household garbage treatment process

InactiveCN103878167AAvoid pollutionHarmlessSolid waste disposalReduction treatmentResource utilization

The invention discloses a comprehensive household garbage treatment process which comprises the following steps: crushing household garbage; screening, and respectively performing gravity separation and magnetic separation after screening, wherein combustible organic matters and light combustibles are separated in the gravity separation process, and soil and metals for greening are separated in the magnetic separation process; performing magnetic separation on materials subjected to gravity separation, wherein organic soil residues, inorganic matters and metals are separated in the magnetic separation process; performing a first treatment step on the organic soil residues; and performing a second treatment step on the combustible organic matters and light combustibles. The process is advanced, reasonable, high in degree of automation and high in treatment capacity, more recycled products with high quality are realized, treatment cost is low, aerobic fermentation treatment processes such as aging and curing and a relative odor concentration process are performed in a closed mode, the waste gas is treated in a centralized mode and is emitted on standard, the further environmental pollution in the household garbage treatment process is avoided, the household garbage is changed into valuable materials, and the recycled products with high market values are produced, so that household garbage harmlessness, reduction treatment and comprehensive resource utilization are realized.

Owner:张共敏 +3

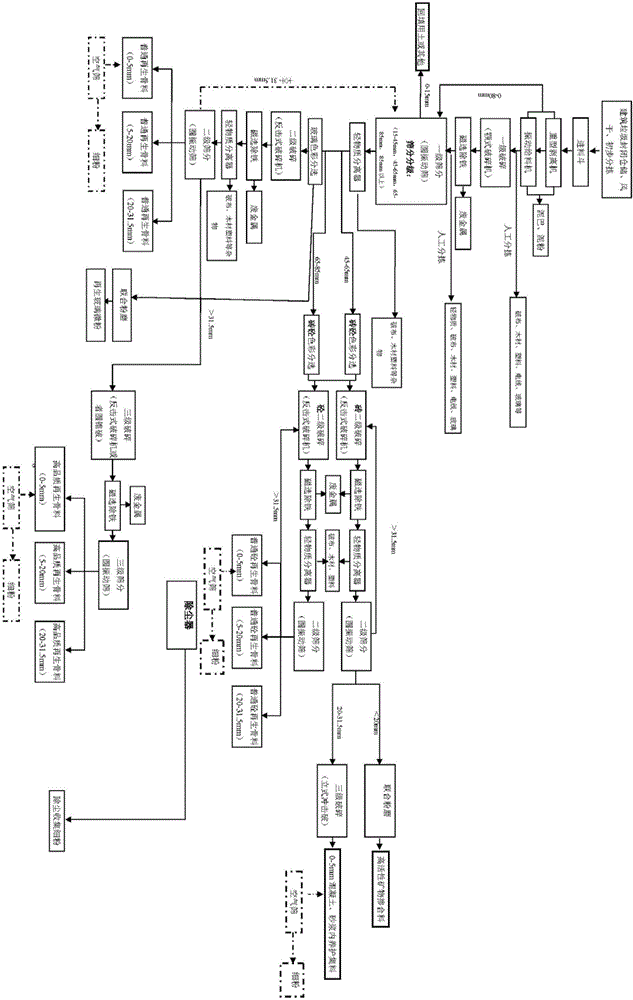

Fine treatment process for building solid waste

ActiveCN106830728ARealize refined classificationRealize resource utilizationConstruction waste recoverySolid waste disposalThree stageResource utilization

The invention discloses a fine treatment process for building solid waste, mainly comprising the following steps: pretreatment in a storage yard of building solid waste, including airing and manual sorting; stripping of mud powder and mud blocks, three-stage crushing, three-stage screening, manual sorting, air separation, magnetic separation, color separation, screening of different-hardness solid waste by different sorting techniques and combined grinding and dry type sand washing techniques, thereby preparing 2 kinds of novel green mineral aggregate, namely common recycled aggregate with particle sizes of 0-5mm, 5-20mm and 20-31.5mm, and high-strength high-quality recycled aggregate with particle sizes of 0-5mm, 5-20mm and 20-31.5mm, 5 types of high-quality, high-added value recycled products such as mortar and concrete curing aggregate, inertia micropowder and other sorted products. The fine treatment process for building solid waste realizes fine, high-added value treatment of building solid waste, achieves 100% resource utilization, and makes a great breakthrough in fine treatment in the resource utilization industry of building solid waste.

Owner:中建西部建设西南有限公司 +1

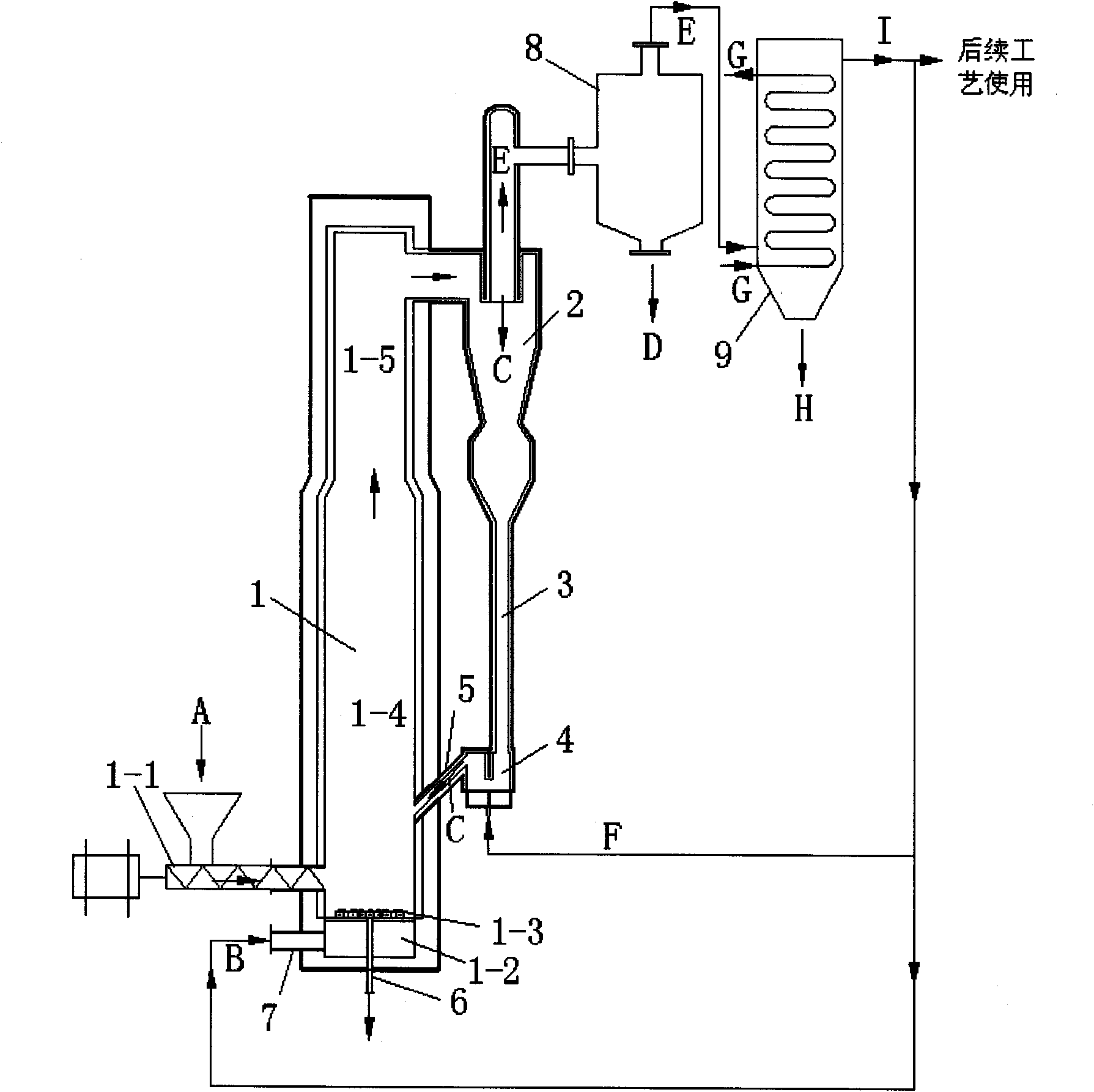

Method for pyrolyzing municipal sludge and preparing biological oil and active carbon simultaneously

InactiveCN101845311AShort stayIncrease productionSludge treatment by pyrolysisDirect heating destructive distillationActivated carbonSludge

The invention discloses a method for pyrolyzing municipal sludge and preparing biological oil and active carbon simultaneously, which can obtain high-quality biological oil and active carbon simultaneously and solves the problem that the conventional sludge pyrolysis method only can obtain a single recycled product. In the method, sludge (A) enters a pyrolysis reactor (1) through a vane feeder (1-1); fluidized wind (B) enters the pyrolysis reactor (1) through a wind chamber (1-2) and a wind distribution plate (1-3); a cyclone separator (2) catches and collects fallen pyrolytic carbon (C) and returns the pyrolytic carbon (C) to the pyrolysis reactor (1) for circulation through a blank pipe (3), a material feedback device (4) and a material returning pipe (5); the pyrolytic carbon (C) becomes active carbon (D) after repeated circulation; and then, the active carbon (D), together with pyrolytic gas (E), enters a ceramic filter (8) and is caught and collected by the ceramic filter (8); the pyrolytic gas (E) discharged by the ceramic filter (8) enters a condenser (9); and the lower part of the condenser recovers biologic oil (H) and discharges noncondensing gas (I).

Owner:JIANGSU ZHONGRONG ELECTRIC +1

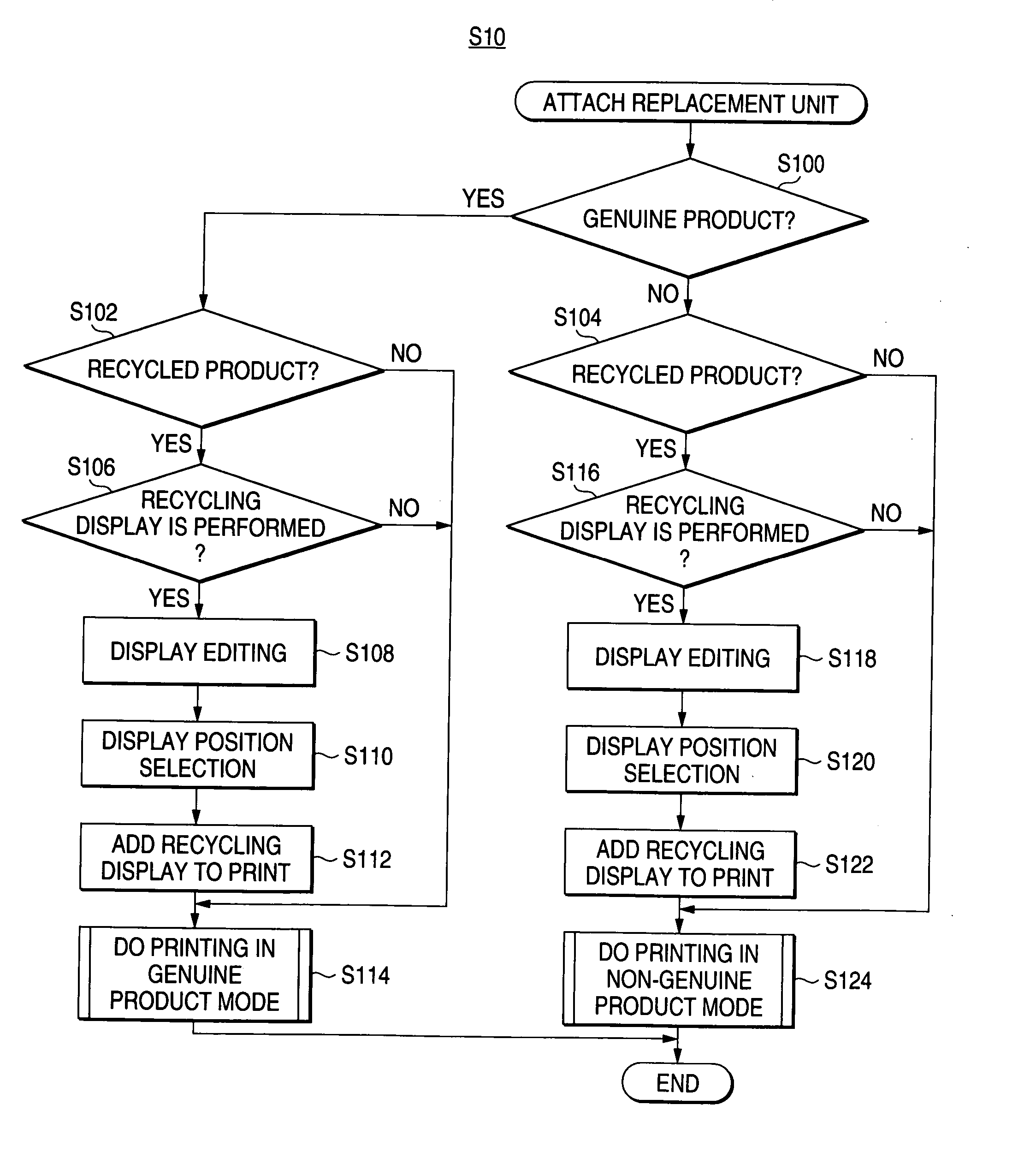

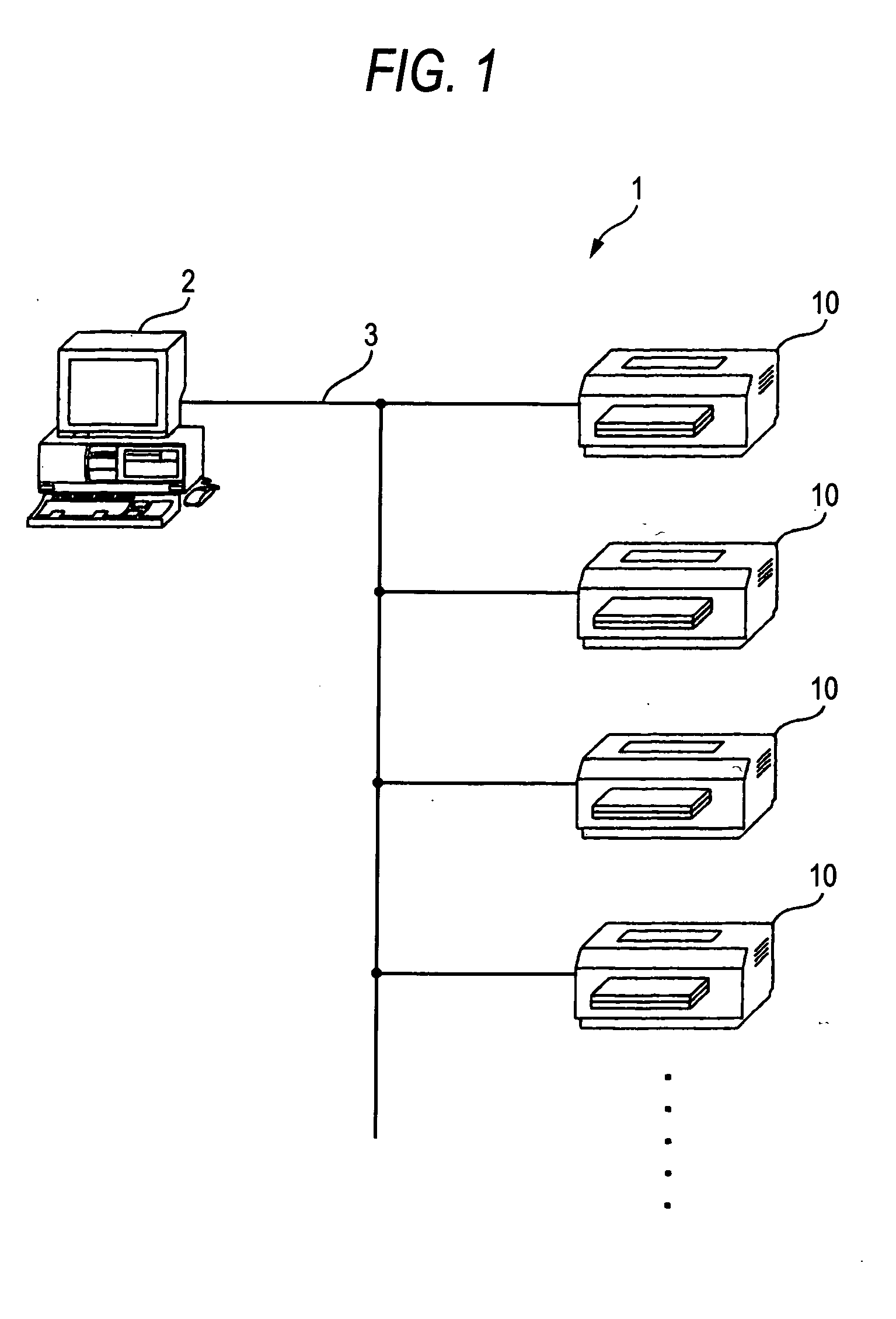

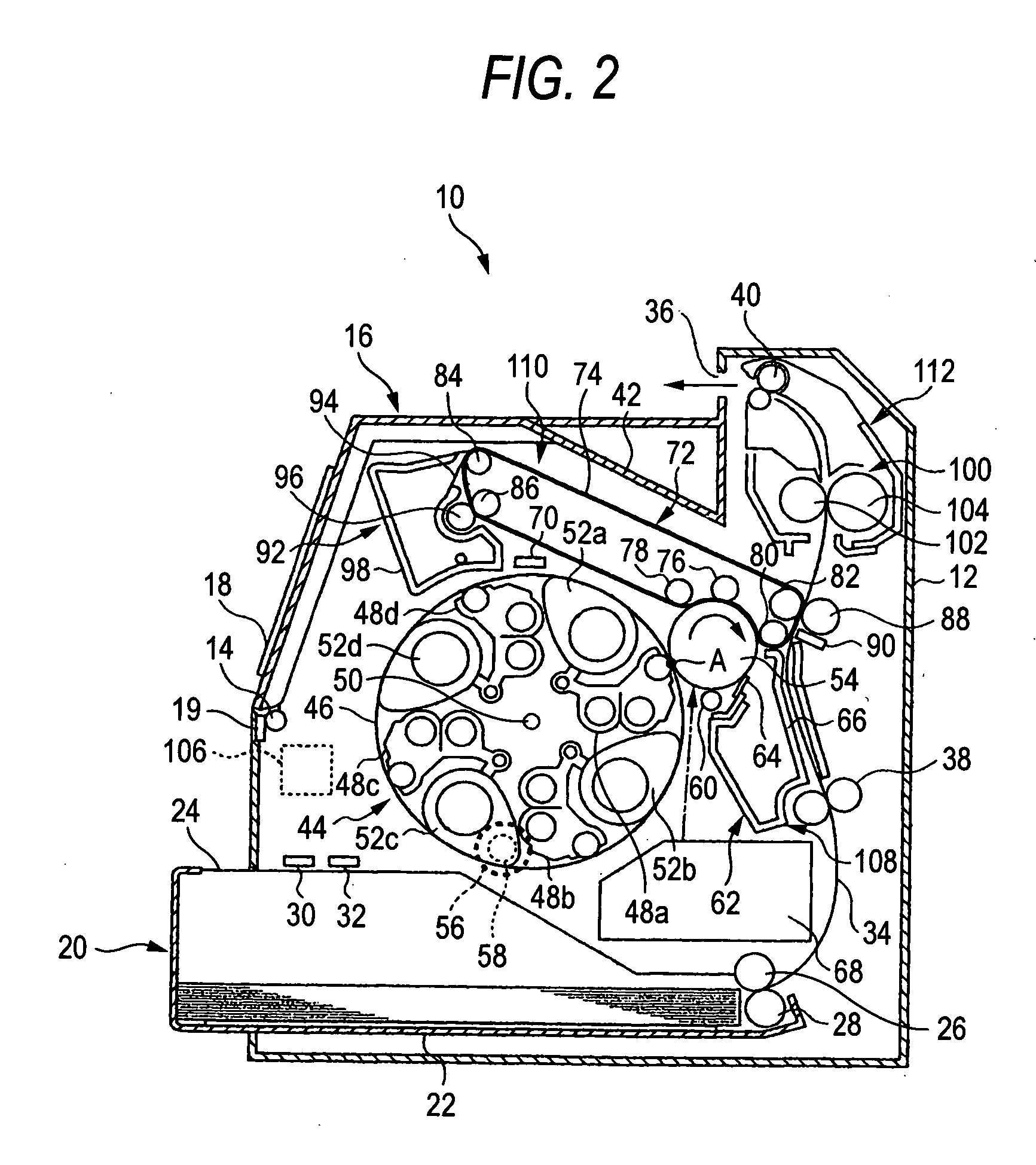

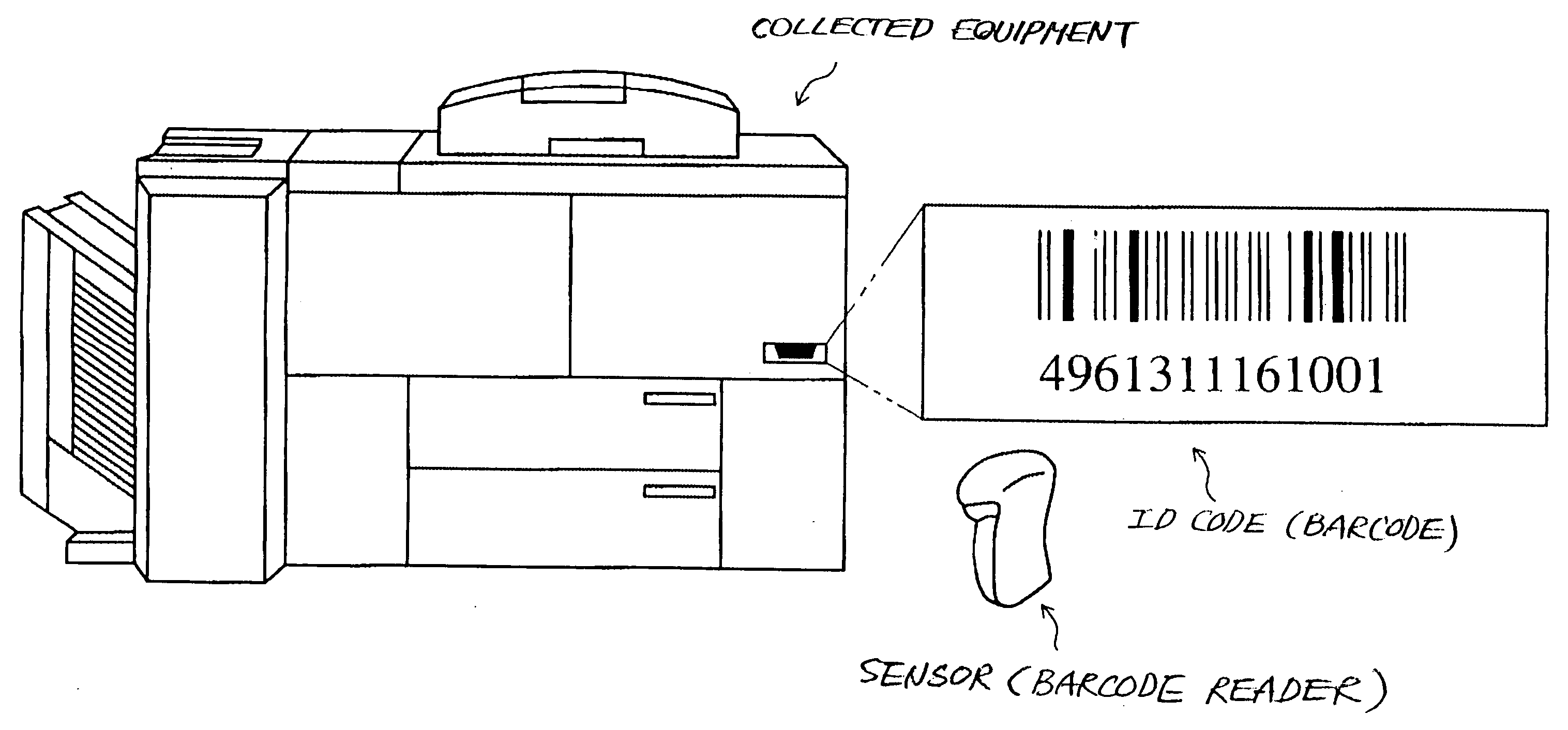

Image formation apparatus to which replacement unit is attached and image formation system

An image formation apparatus is determined whether a replacement unit attached to the image formation apparatus is a genuine product or a product other than the genuine product, and the image formation apparatus is determined whether the replacement unit is a recycled product or not. When the image formation apparatus is the recycled product and the image formation apparatus is determined that recycling display is performed, the recycling display is added to a print. The image formation apparatus is controlled in a genuine product mode when the replacement unit is the genuine product, and is controlled in a non-genuine product mode when the replacement unit is the product other than the genuine product.

Owner:FUJIFILM BUSINESS INNOVATION CORP

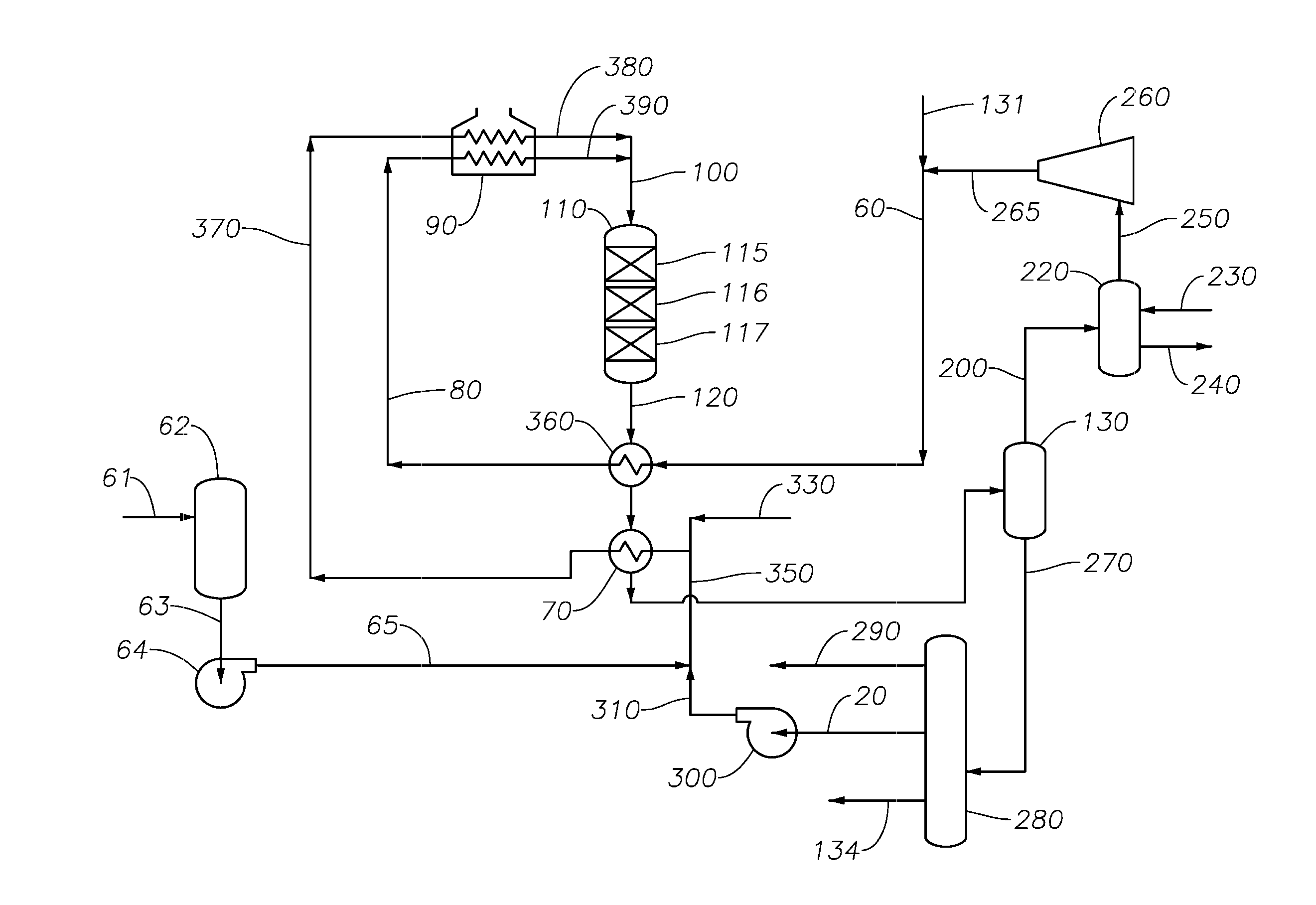

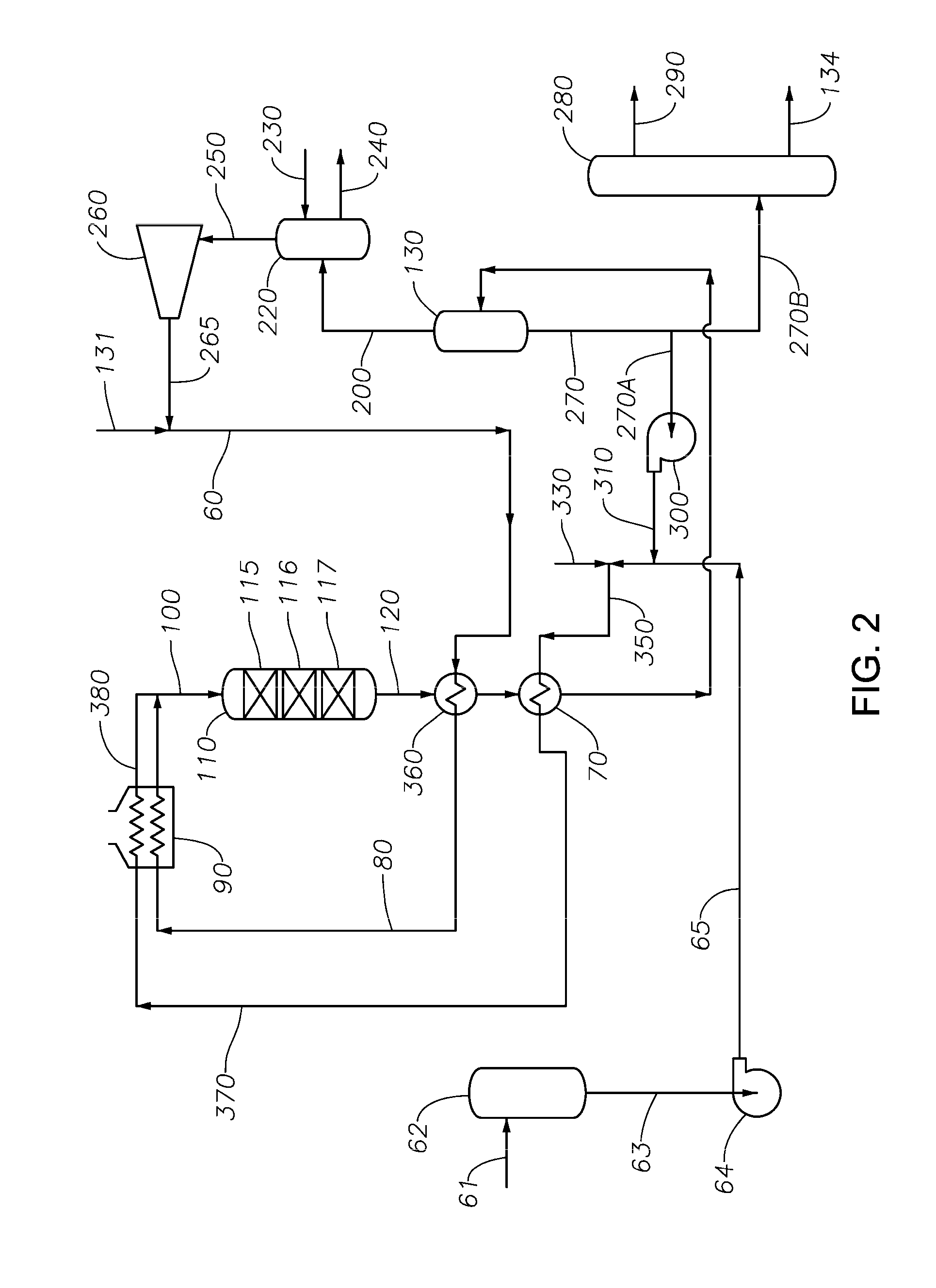

Pyrolysis Tar Upgrading Using Recycled Product

ActiveUS20150368570A1Pyrolysis tar hydroprocessing is improvedLesser rateRefining to change hydrocarbon structural skeletonTreatment with plural serial stages onlyBoiling pointTar

The invention relates to a process for upgrading pyrolysis tar in the presence of a utility fluid. The utility fluid contains 1-ring and / or 2-ring aromatics and has a final boiling point ≦430° C. The invention also relates to the upgraded pyrolysis tar, and to the use of the upgraded pyrolysis tar, e.g., for fuel oil blending.

Owner:EXXONMOBIL CHEM PAT INC

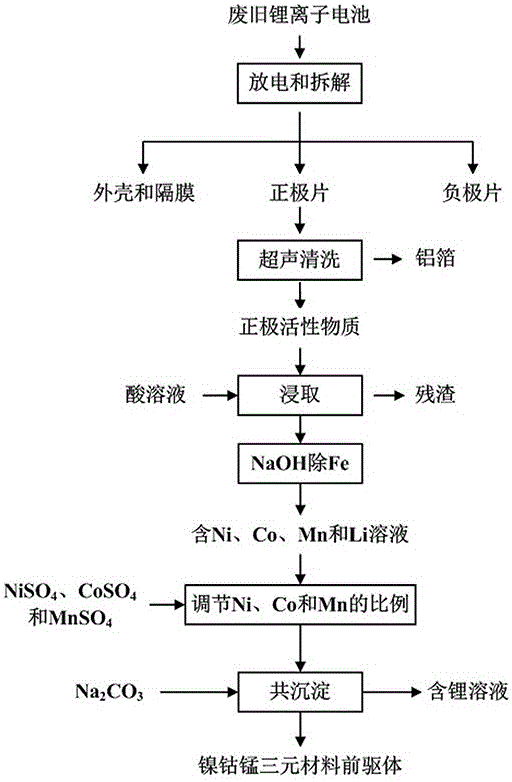

Method for preparing nickel-cobalt-manganese ternary material precursor from waste lithium ion battery

InactiveCN105789726AAvoid cross contaminationSimplify the subsequent impurity removal processWaste accumulators reclaimingBattery recyclingNickel saltFiltration

The invention discloses a method for preparing a nickel-cobalt-manganese ternary material precursor from a waste lithium ion battery. The method comprises the following steps: (1) physically disassembling the waste lithium ion battery which is fully discharged, and taking out a positive plate; (2) putting the separated positive plate into an ultrasonic cleaning machine for ultrasonic cleaning to let a positive active material fall off from a current collector aluminum foil, and directly recycling the aluminum foil after the aluminum foil is dried; (3) dissolving the positive active material obtained in the step (2) into acid, and adding sodium hydroxide to remove ferric; (4) measuring the concentration of metal ions in a leaching solution subjected to ferric removal, adding soluble nickel salt, cobalt salt and manganese salt to adjust the mole ratio of nickel, cobalt and manganese in the solution to be (1-3):(0.5-1):1; (5) adding a sodium carbonate precipitator to enable the three metal elements of nickel, cobalt and manganese to be precipitated at the same time, and performing filtration and drying to obtain the nickel-cobalt-manganese ternary material precursor. The process of the method is simple and flexible; the method is low in recycling cost, and recycled products have great value.

Owner:SUZHOU JUZHI TONGCHUANG ENVIRONMENTAL PROTECTION TECH

Elastic putty and preparation method thereof

The invention relates to elastic putty and a preparation method thereof. The elastic putty is made from the following raw materials in parts by weight: 20-25 parts of cement, 10-15 parts of fly ash or steel slag, 2-6 parts of white lime, 30-40 parts of calcium carbonate, 20-30 parts of quartz sand, 0.1-1 part of cellulose ether, 0.1-0.5 part of lignocellulose, 0.01-0.04 part of starch ether, 0.1-0.4 part of powdery water repellent and 4-15 parts of dispersible gelatine powder. The preparation method comprises the steps of adding all raw materials in a dispersion machine in proportion, and stirring the raw materials for 45 min to obtain the elastic putty. The elastic putty has good bonding strength with various materials, and has higher compressive strength, bending strength, tensile strength, permeability resistance and waterproof performance; the putty has flexibility after curing, strong protection properties, easy construction and good durability, is easy to foundry mill at early period while having high intensity at later period, is innoxious, flavourless and non-inflammable, and belongs to recycled product of industrial waste residues.

Owner:上海基成达申防水材料有限公司

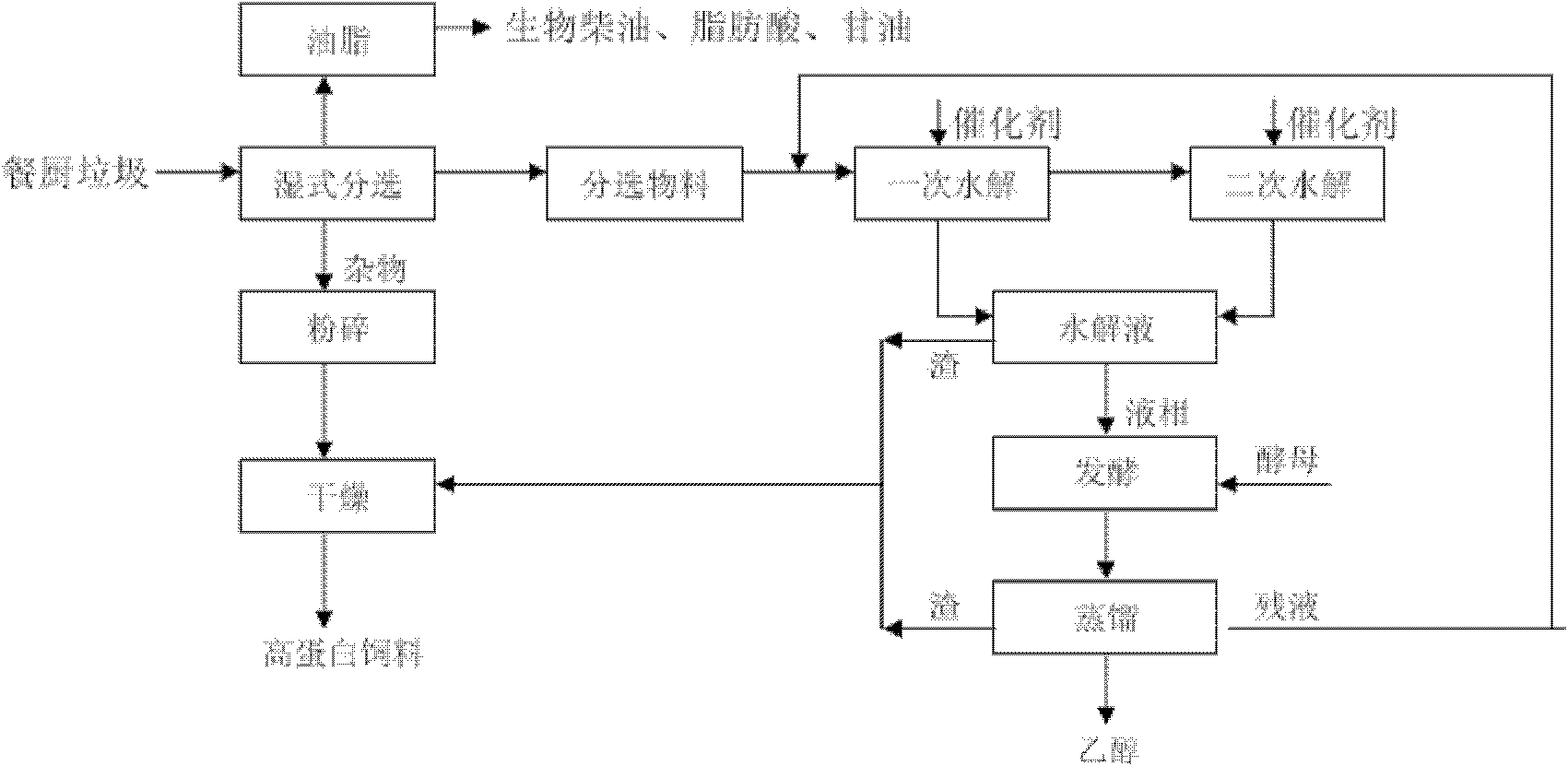

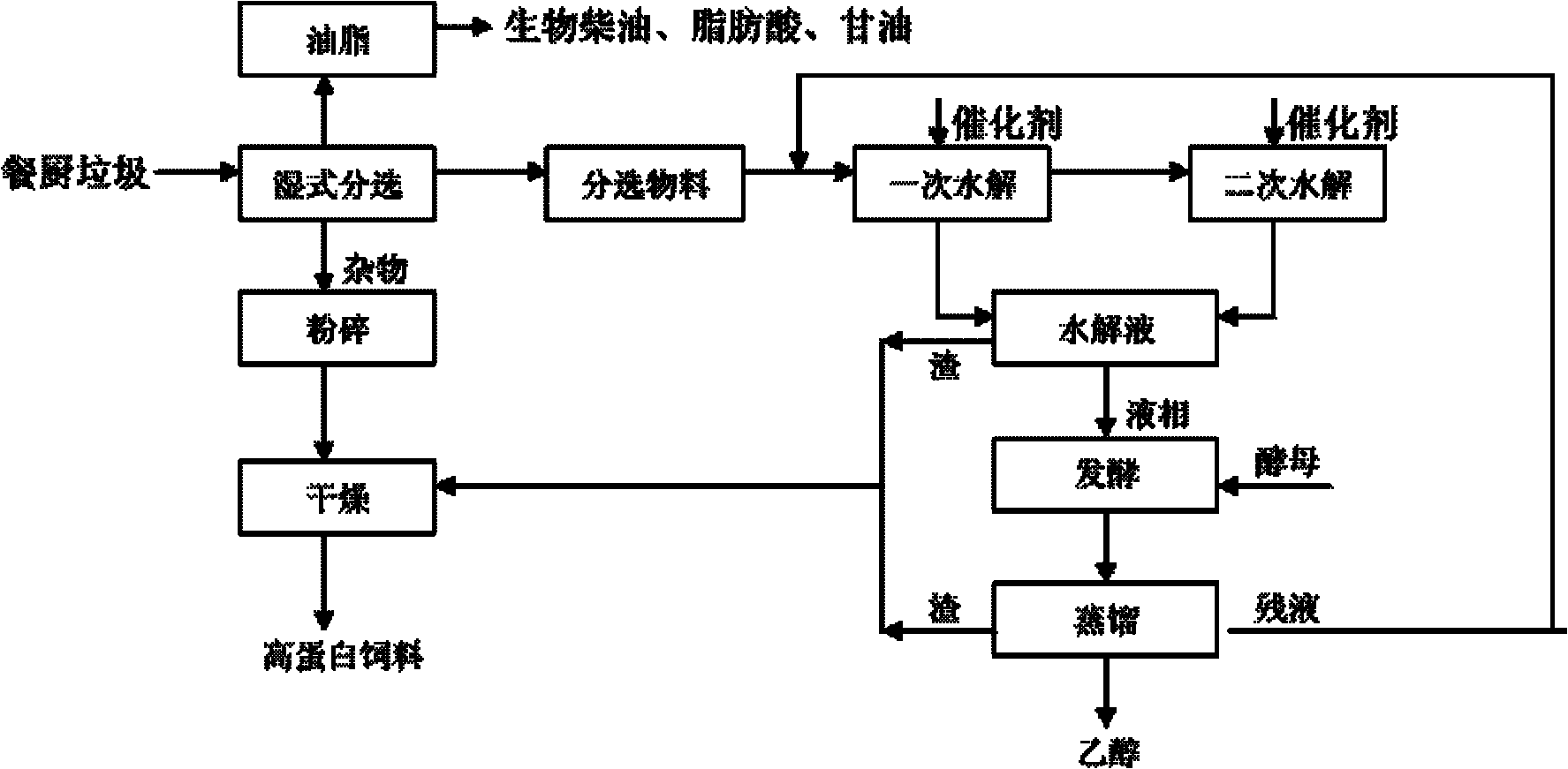

Recycling method for cleaning and processing kitchen waste

InactiveCN101890423AIncrease the degree of hydrolysisCompletely hydrolyzedFatty oils/acids recovery from wasteSolid waste disposalOil and greaseOperational costs

The invention relates to a waste processing method, in particular to relate to a recycling method for cleaning and processing kitchen waste and comprising the following steps: sorting, separating and recovering grease, performing secondary hydrolysis on materials after grease separation and recovery, further fermenting hydrolysis liquid and preparing solid residue obtained by sorting, hydrolysis and fermentation into feed. The invention has the following beneficial effects: economic and reasonable technologies suitable for industrialized application are adopted, thus greatly lowering processing cost; regenerative recycled products can be prepared with wide application and high additional value; and the production process is clean and environment-friendly, closed cycle of materials can be realized, secondary pollutants are prevented, and the recycled products have wide application, low operation cost and high economic benefit.

Owner:武汉市金书环保科技股份有限公司

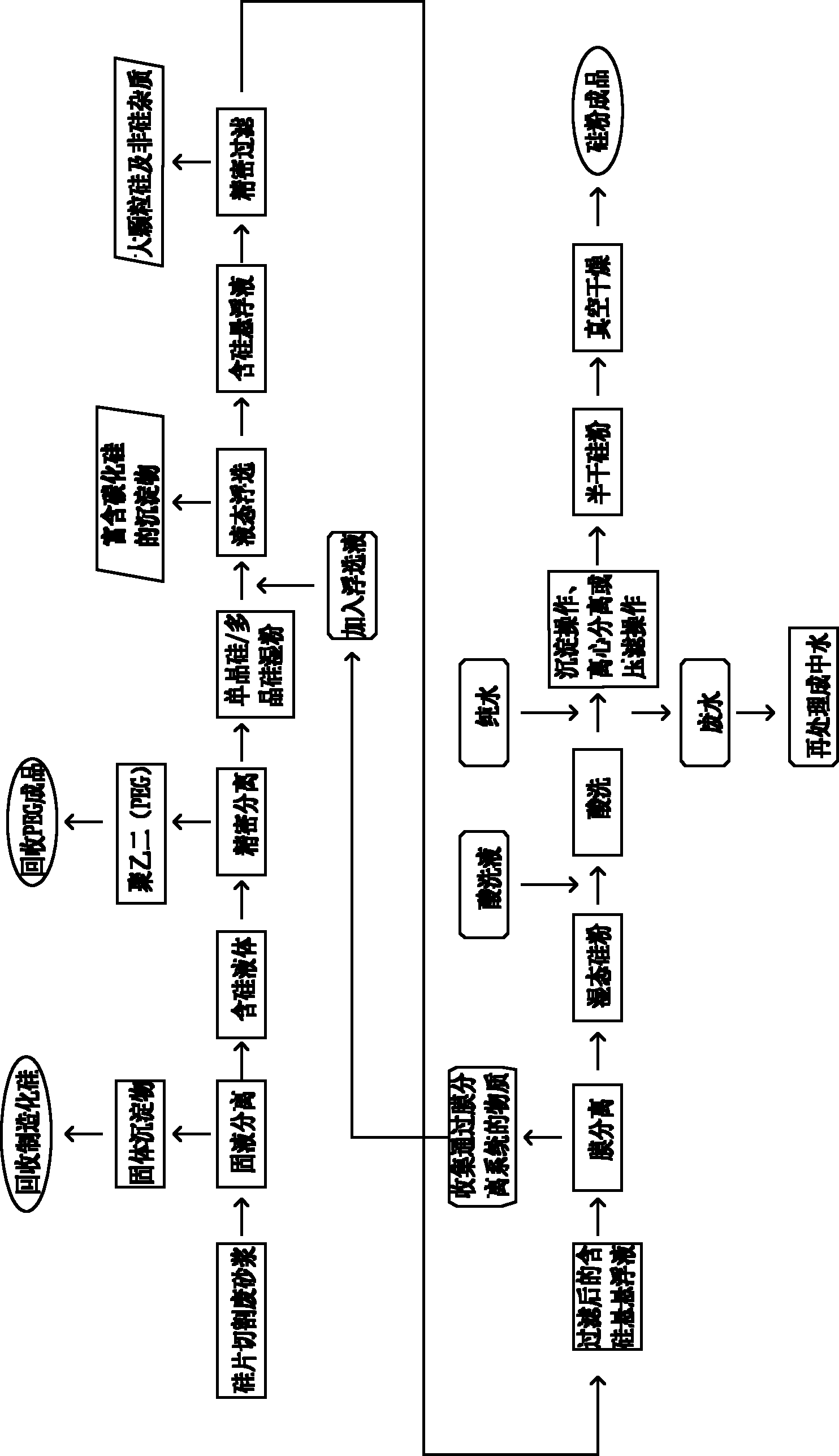

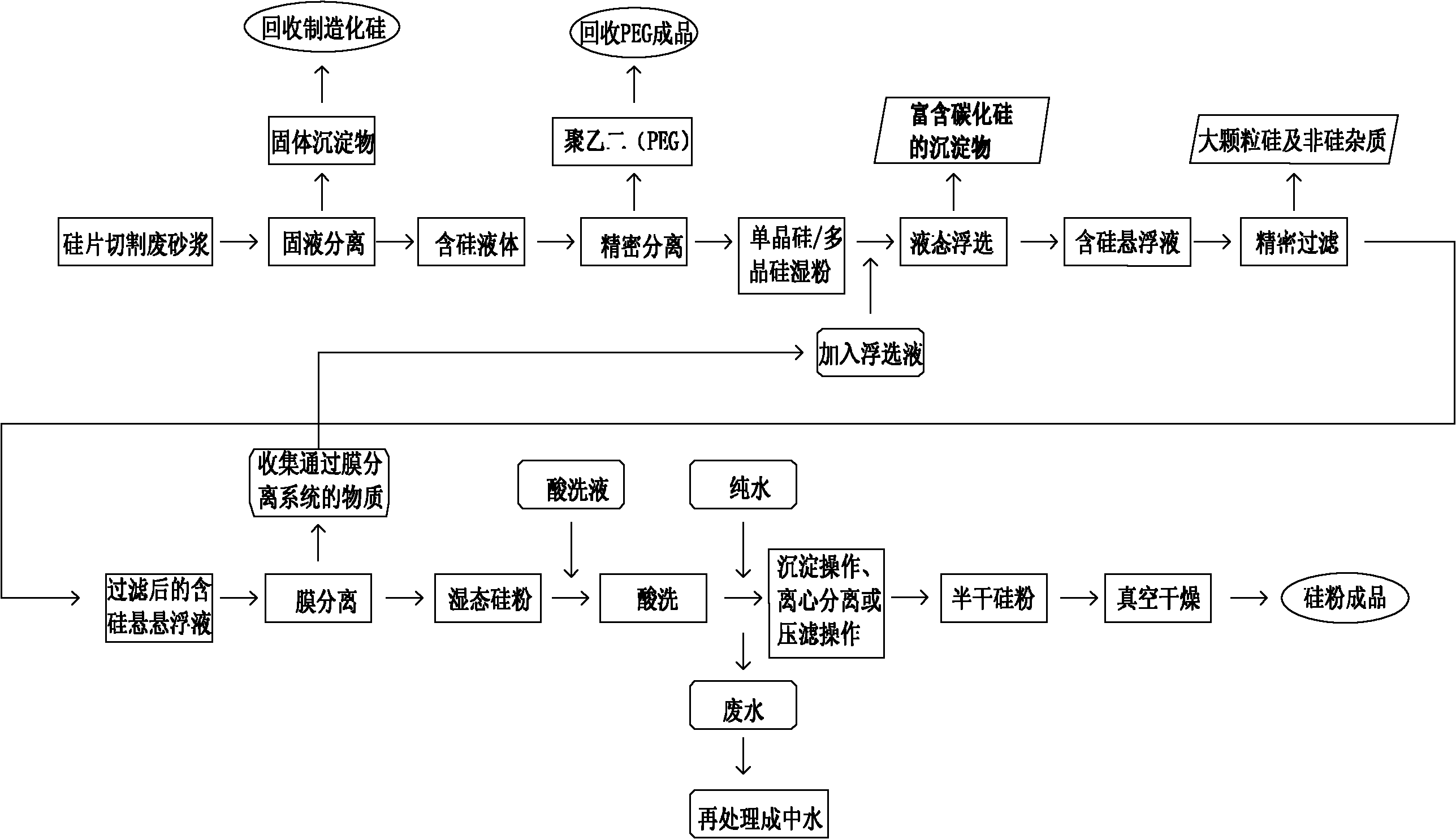

Method for recycling silicon powder from silicon slice cut waste mortar

InactiveCN102173419AAchieve recyclingImprove applicabilitySiliconLubricant compositionPolyethylene glycolSilicon chip

The invention relates to a method for recycling silicon powder from silicon slice cut waste mortar. The invention comprises seven procedural steps of solid-liquid separation of silicon slice cut waste mortar, precision separation of silicon-contained liquid, liquid flotation, precision filtering, film separation, pickling and vacuum drying. The method in the invention is used to produce silicon powder with a purity of 99.5-99.9% and solve the problems existing in the existing silicon slice cut waste mortar recycling industry, such as difficult separation between solid and liquid, low purity of recycled products, poor recycling rate, incomplete recycling process and the like. In the invention, the polyethylene glycol and carborundum can be recycled and the recycling of polycrystalline silicon and monocrystalline silicon can be realized, which improves the material recycling ratio of the solar equipment industry and come up to the cleanness standards.

Owner:常州广正知识产权代理有限公司

Recycling system and disassembling and classifying method

InactiveUS20060180518A1Accurately identifying informationImprove efficiencyData processing applicationsDigital data processing detailsUltravioletClassification methods

In a recycling system of the present invention for collecting a subject of recycling, which contains plastics, from the market and reprocessing the plastics to thereby produce a recycled product, the plastics contains a line spectrum radiation that radiates light when receiving ultraviolet rays or an electromagnetic wave. Recycle information particular to the subject of recycling is identified on the basis of the wavelengths of light radiated from the line spectrum radiation.

Owner:RICOH KK

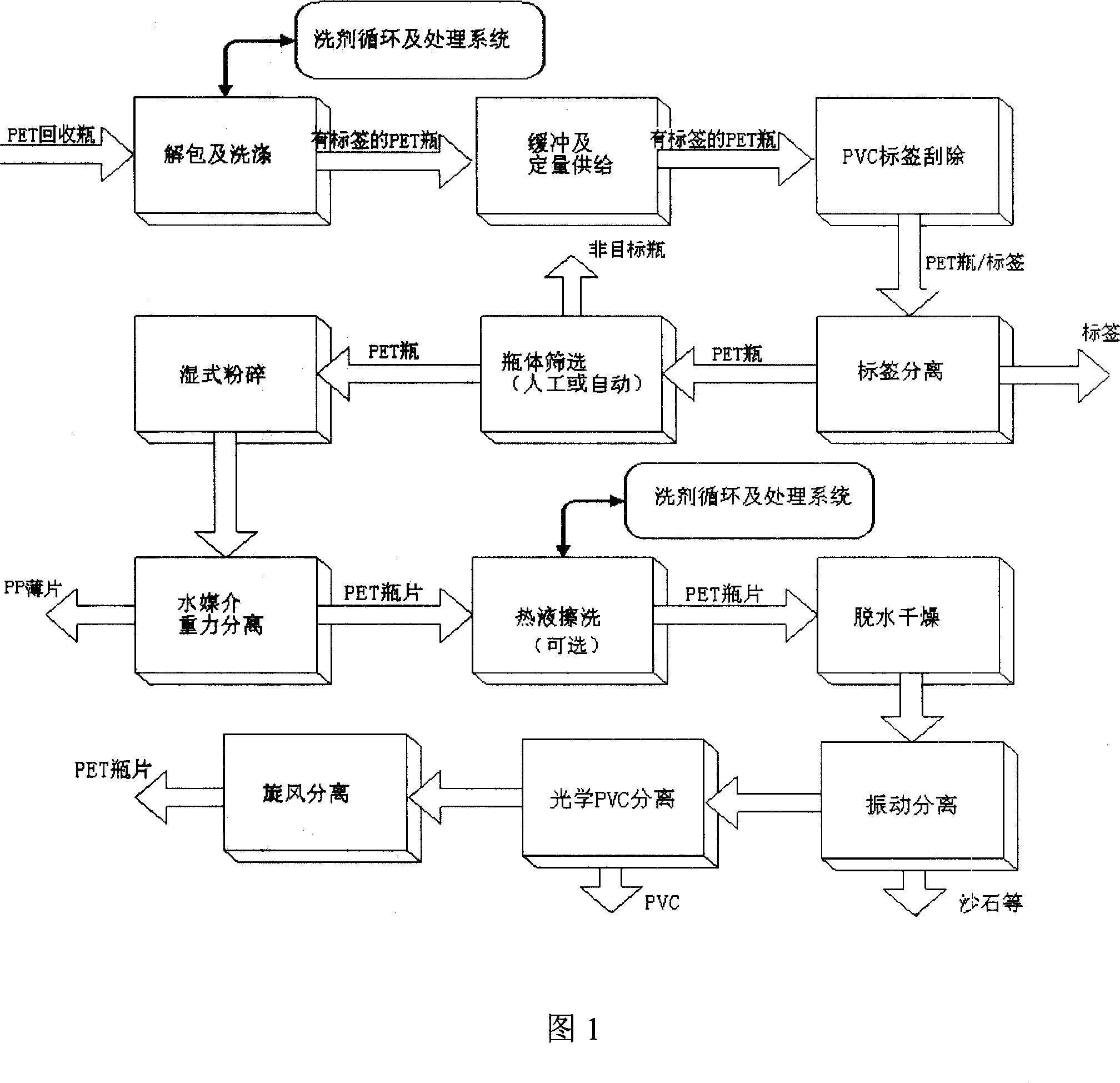

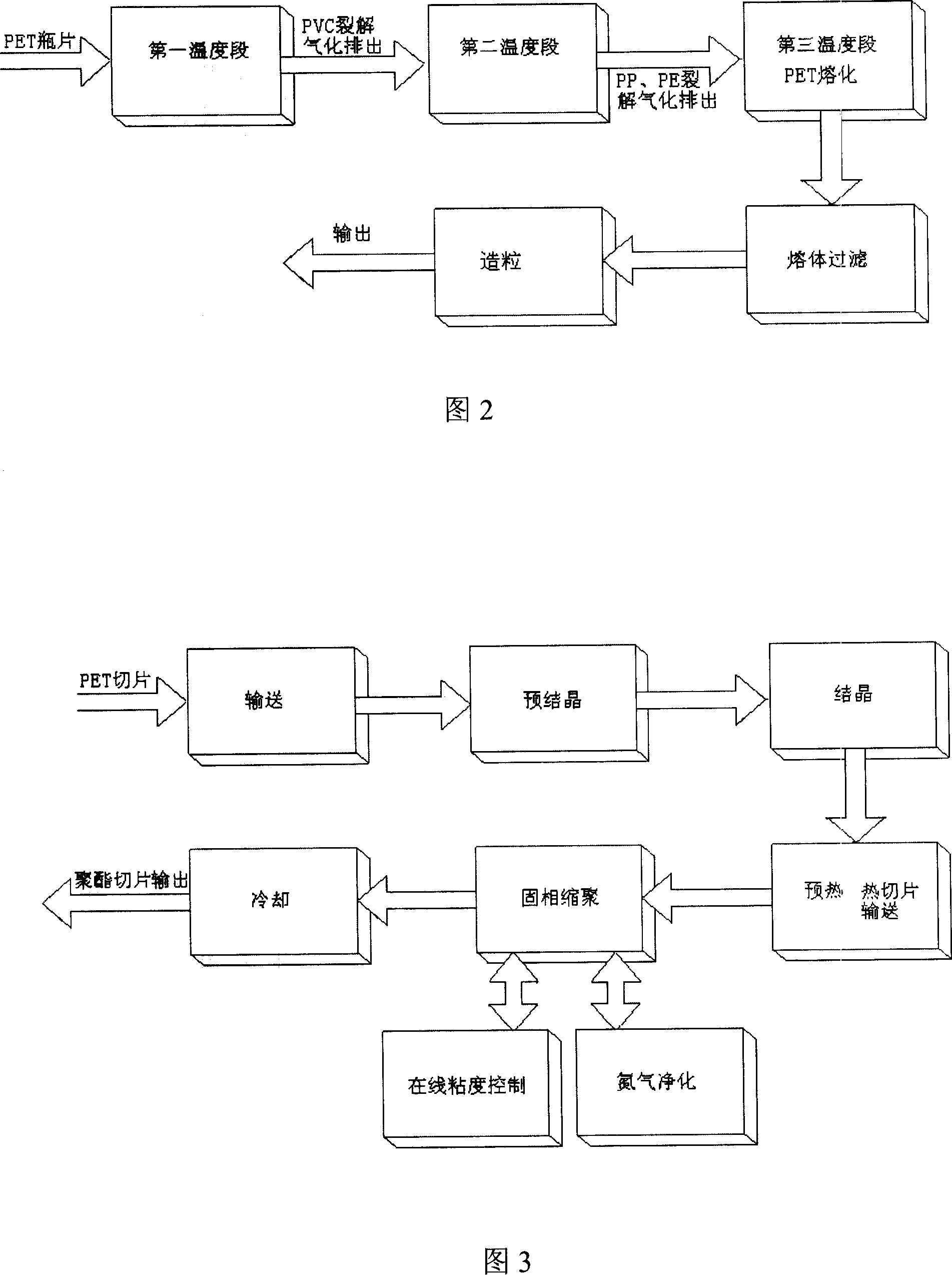

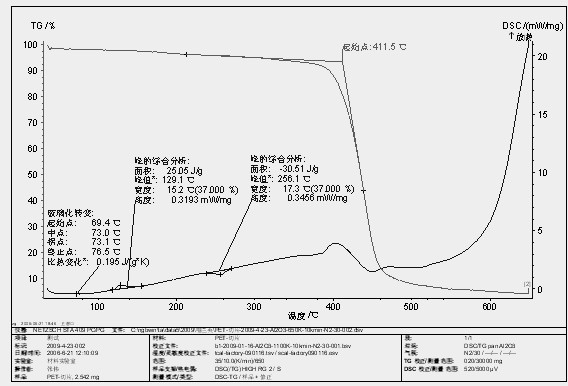

Production process for manufacturing food-level polyester bottle flakes utilizing polyester recovered bottles

This invention discloses a production technology for producing the food-grade polyester bottle slices by utilizing the restored polyester bottles. According the characteristics of restored PET bottle, the restored polyester bottles were washed firstly and pulverized to slices, then the PVC bottle bodies, the volume labels, the impurities and the foreign materials were wiped off. Secondly, according the species of the residuum, the removing technology of the corresponding trace impurity was used. So the trace impurities of PVC, PP, PE and the other mechanical impurities can be removed again. The residuum of the restored PET bottle can be cut down greatly. Finally, the solid phases were condensed together so as to obtain the food-grade polyester bottle slices. Because of using the restored polyester bottles, the production cost is low, and the production technology meet the circulating economical development idea which advocated by the country nearly. The quality of the reproduction accords with the national standards of the food-grade PET bottle. The foreign exchange of the production technology is high and the economic effects as well as the social effects are obvious.

Owner:谭亦武 +1

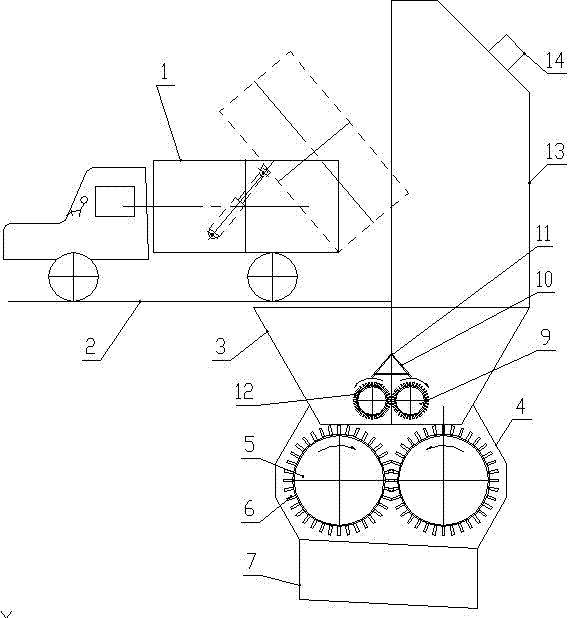

Construction waste crushing and screening line method

InactiveCN105198257ASolving Recycling ProblemsSimple processSolid waste managementProduction lineSocial benefits

Owner:北京鼎创环保有限公司

Method for recycling polyester waste by normal-pressure alcoholysis

InactiveCN101906218ALower requirementReduce recycling costsOrganic compound preparationCarboxylic acid esters preparationPolyesterEthylic acid

The invention discloses a method for recycling polyester waste by normal-pressure alcoholysis, which comprises the following steps: 1) preparing polyester waste, glycol and zinc acetate; 2) adding the prepared materials into a reactor, introducing inertia gas for protection, heating to 180 to 197.5 DEG C with stirring, and keeping the temperature for 5 to 9 hours; 3) after keeping the temperature, cooling to 90 to 105 DEG C, and filtering the hot materials under vacuum to remove non-degraded polyester waste; 4) refrigerating the filtrate at 5 DEG C for 5 to 10 hours to allow the degradation products to precipitate in form of crystals, and filtering under vacuum; and 5) drying the crystallization product under vacuum to obtain a recycled product. The method shortens flow, reduces production cost, protects environment, realizes chemical recycling, changes waste into valuable material and saves resources. The method has the advantages of simple reaction conditions, easy implementation, normal-pressure operation, low equipment requirements and low recycling cost.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

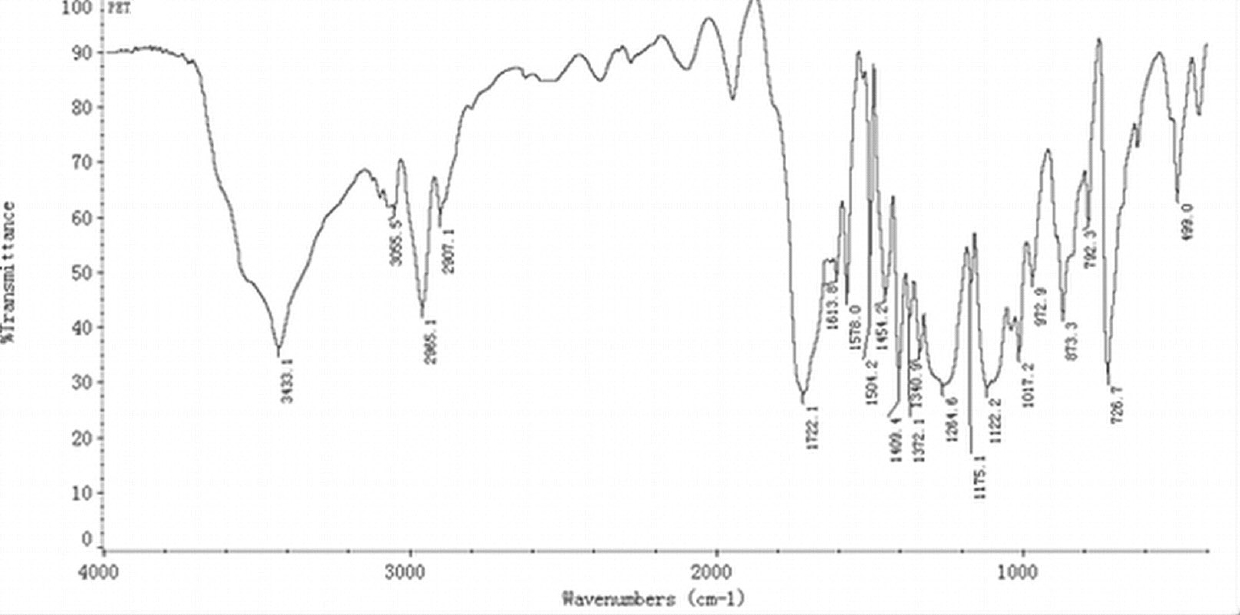

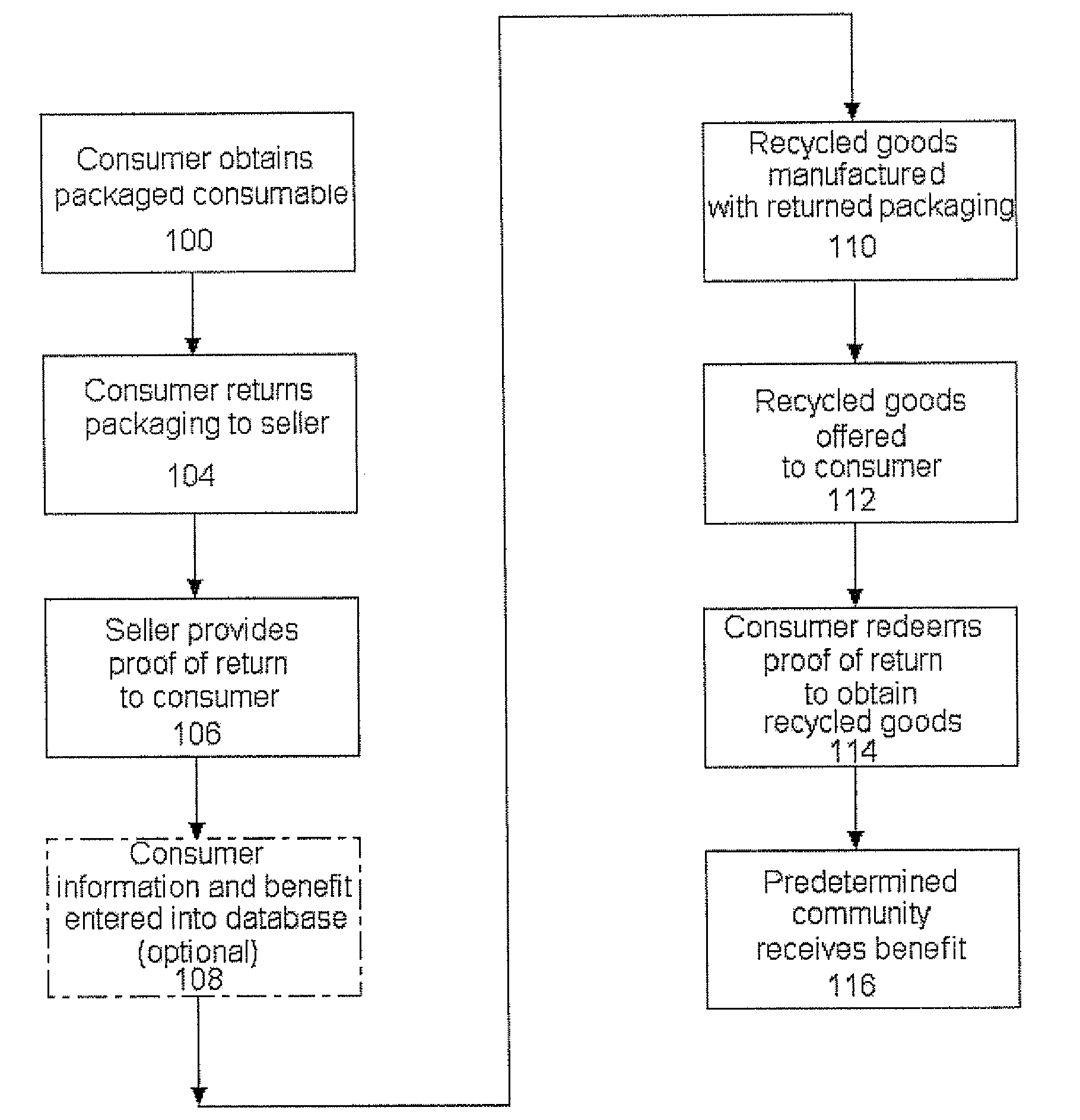

Method for recycling consumer goods

InactiveUS20080306813A1Reduce solid wasteIncrease salesDiscounts/incentivesEngineeringRecycled products

A method to encourage consumers to return reusable or recyclable containers to the origin of purchase provides to the consumer a coupon or other proof of return to be redeemed for a discount on items made with or incorporating the recycled products returned by other consumers. The returned container may then be used by the seller or the seller's affiliate or agent as material to create more recycled consumer goods.

Owner:CLOUDVIEW

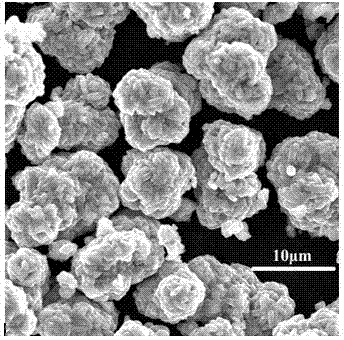

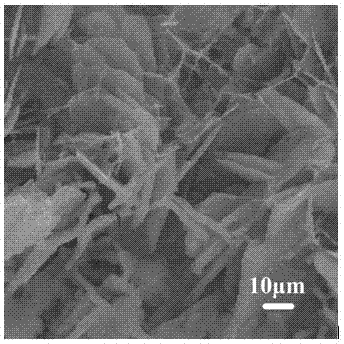

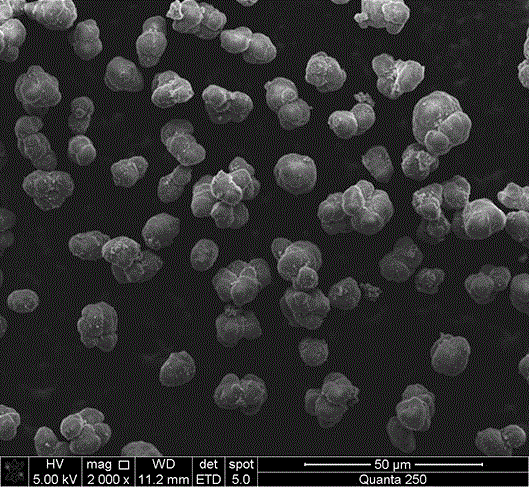

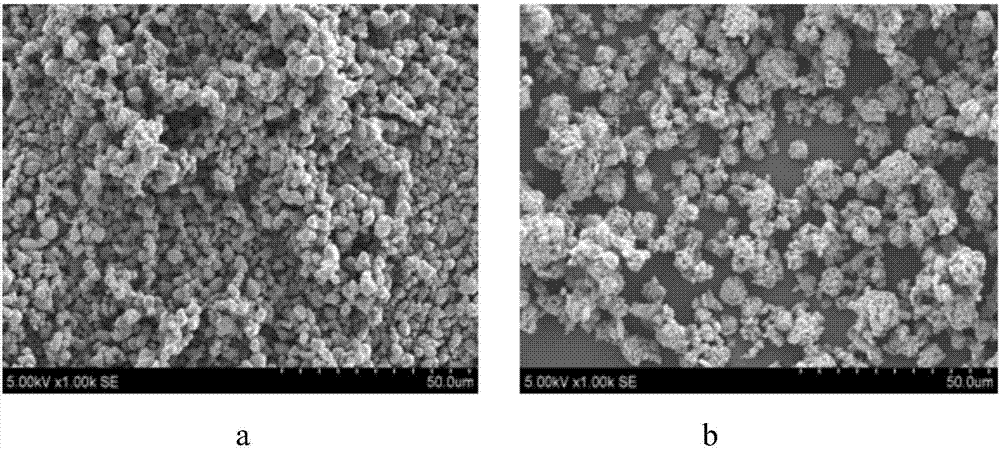

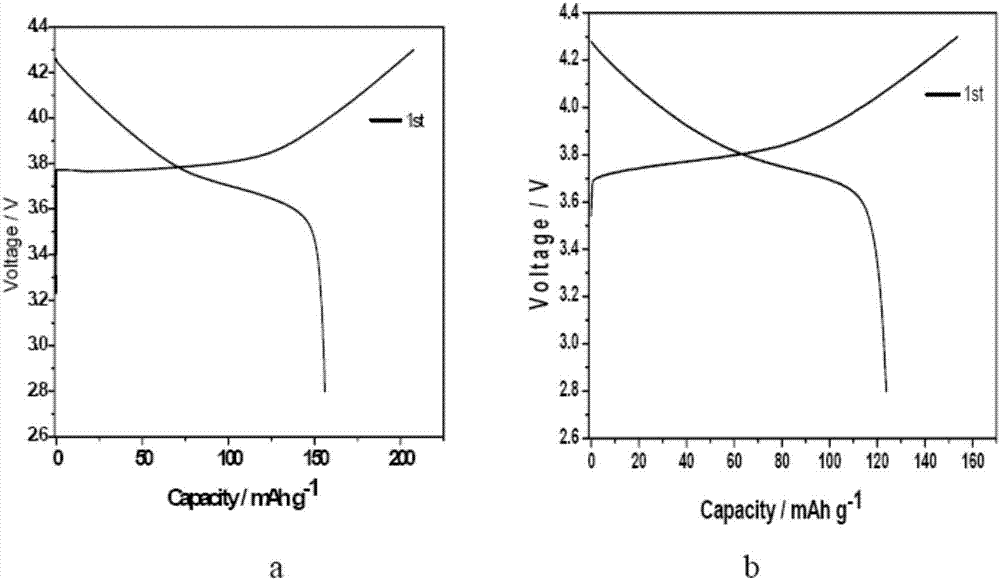

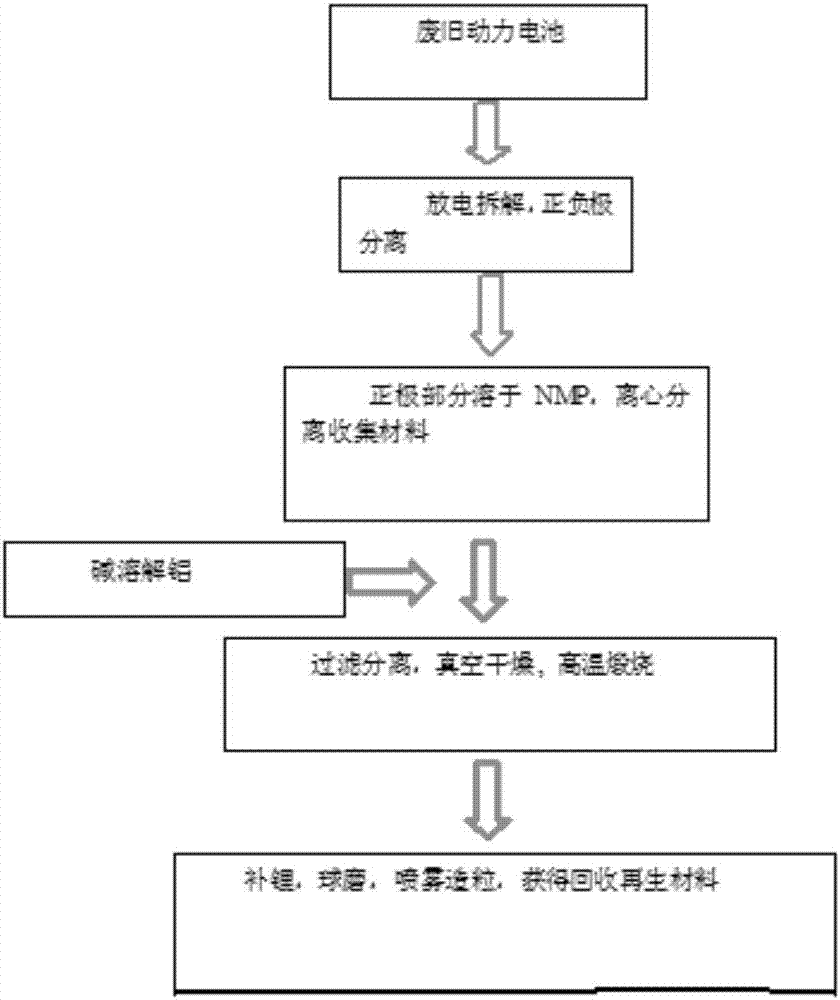

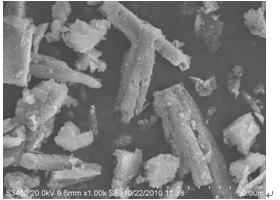

Recycling and regeneration process method for waste automobile power battery anode material

InactiveCN107994286AAchieve sustainable useThe process steps are simpleWaste accumulators reclaimingBattery recyclingMicro nanoResource utilization

The invention discloses a recycling and regeneration process method for a waste automobile power battery anode material and relates to the field of lithium ion battery anode materials. According to the process, a physical method is adopted as a main method, a chemical method is adopted as an auxiliary method, recombination is implemented together with spray granulation, and thus spherical or sphere-like granules. A battery of a waste power battery is adopted as a raw material, lithium is replenished into a recycled waste ternary material, in addition homogenate is prepared, the waste ternary material is regenerated through spray pelletization, and thus an anode material is regenerated and applied to lithium batteries. By adopting the process, submicron-granules of porous micro nano structures are recombined and regenerated by using a spray pelletization method, the specific surface area is effectively reduced, lithium ion exchange is effectively improved through the porous micro nano structures, regeneration repairing of waste materials can be promoted, and power charge and discharge properties are recovered. The process has the advantages of being high in production efficiency, simple and feasible in operation, low in cost, and the like, meanwhile the environment is protected, regenerated products are prepared, resource utilization of waste power battery materials is achieved,and relatively great economic benefits and social benefits can be made.

Owner:BEIJING UNIV OF TECH

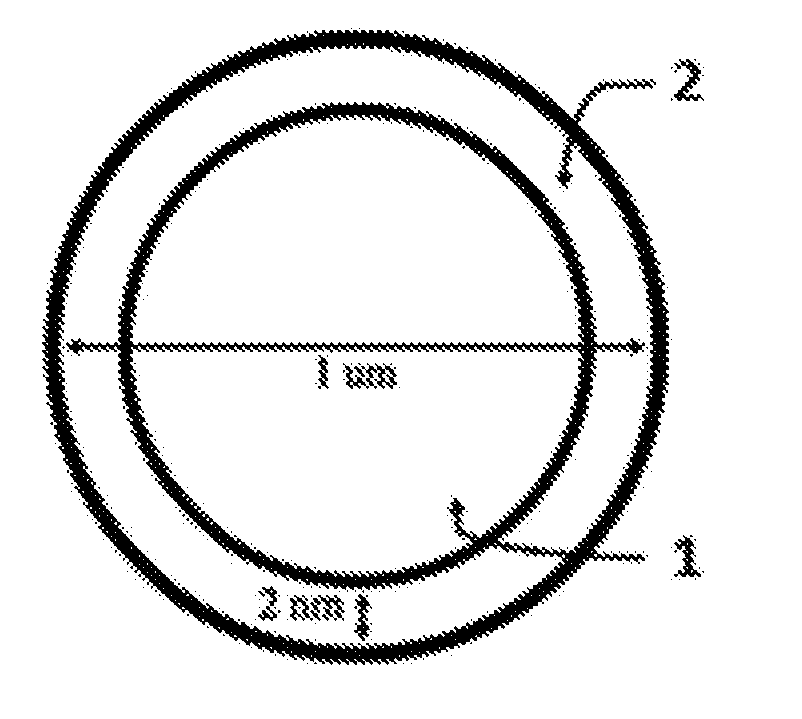

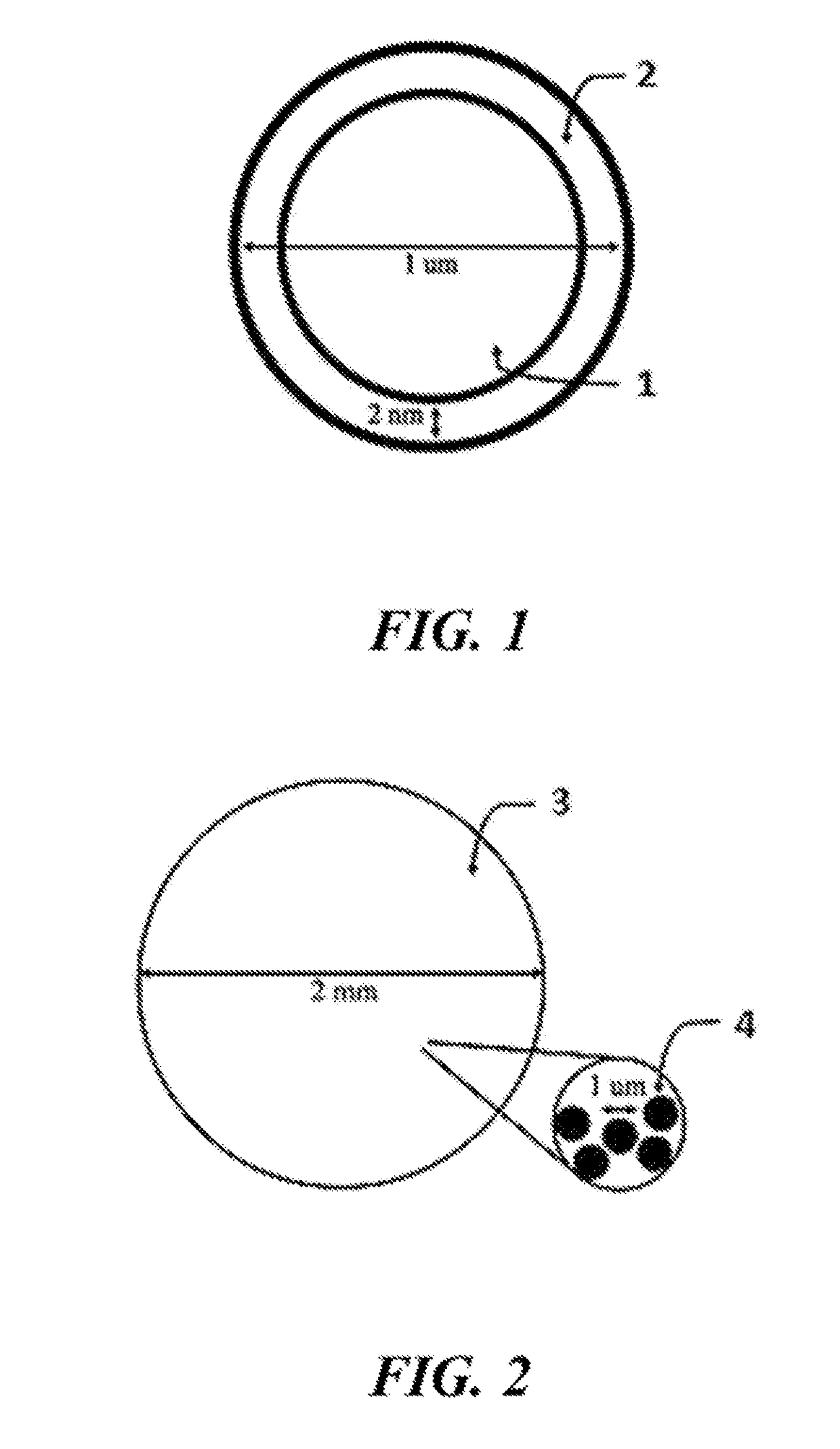

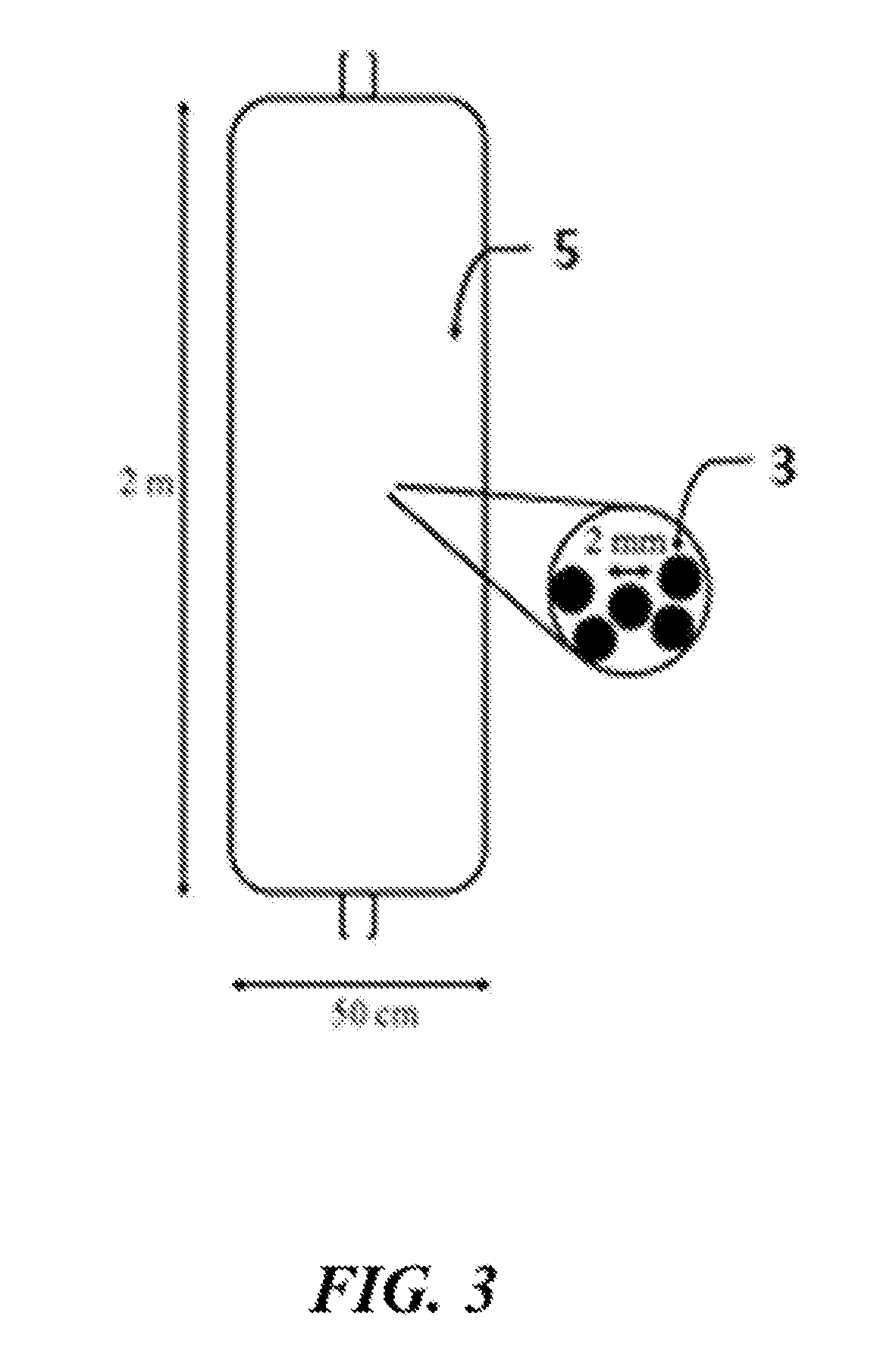

Method for recovering phosphorus in crystallization way from semiconductor industrial waste water

InactiveCN102139975ACompact structureLarge grain diameterMultistage water/sewage treatmentPhosphorus compoundsIndustrial waste waterMagnesium salt

The invention discloses a method for recovering phosphorus in a crystallization way from semiconductor industrial waste water. Main operation steps of the method are as follows: adding magnesium source to semiconductor industrial waste water; supplementing nitrogen source if necessary; controlling pH value of waste liquid; adjusting the molar ratio of magnesium salt: ammonia nitrogen: phosphate salt, blending the mixture for a certain time in a mechanical blending mode; continuously heating waste liquid in the initial phase of stirring; and keeping temperature constant after waste liquid reaches a certain temperature till the blending is over. After blending, waste liquid is statically placed and settled for a certain time; after static settling, liquid supernatant and crystallized precipitates are separated; and the crystallized precipitates can be recycled after being dried. By the process treatment, more than 90% of phosphorus in the semiconductor industrial waste water can be effectively recycled; the recycled product is dense and plump; the technology has the advantages of short response time, high product purity, simple process, simple and convenient operation, low cost and the like and has obvious environmental, economic and social benefits.

Owner:NANJING UNIV

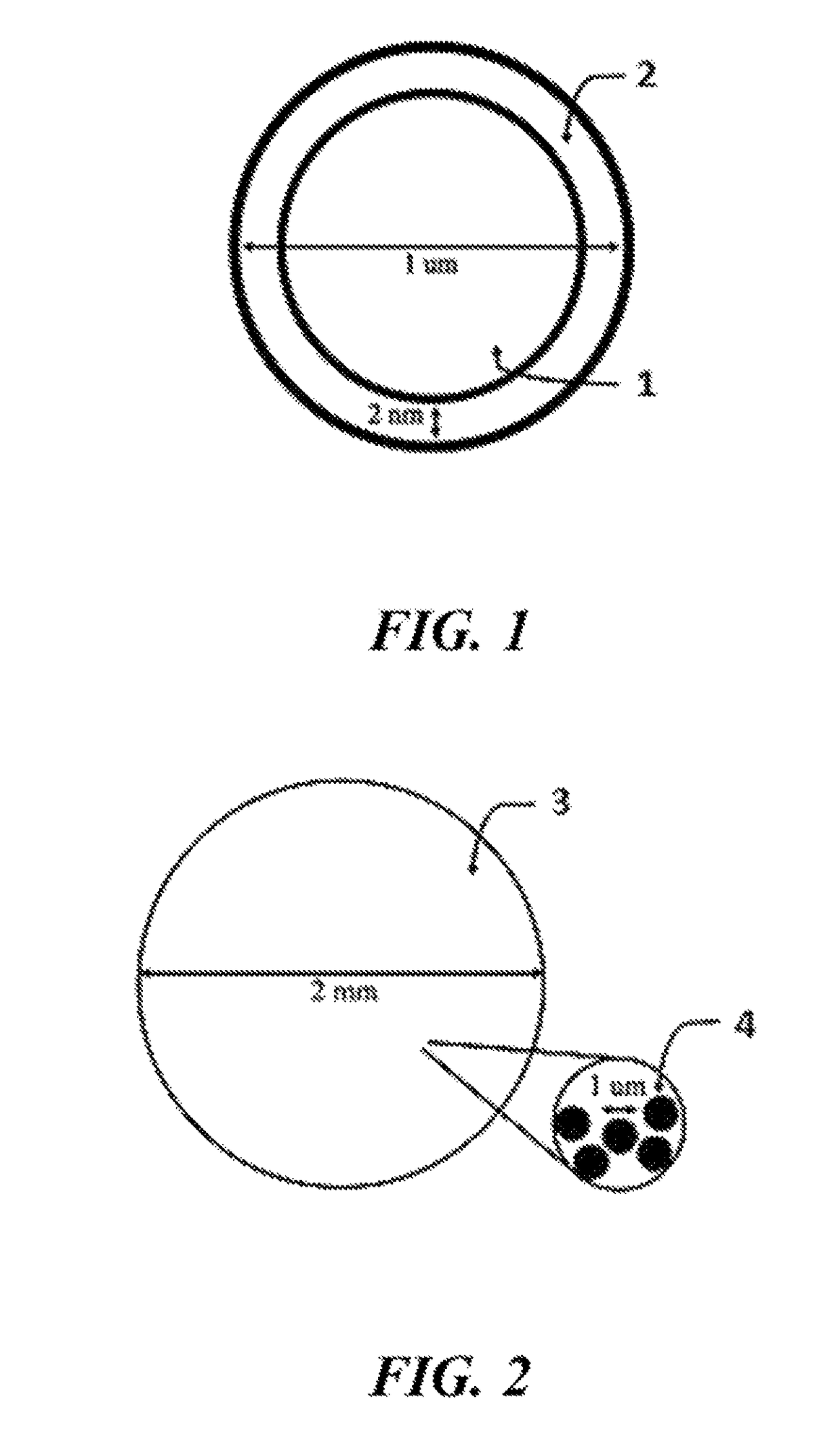

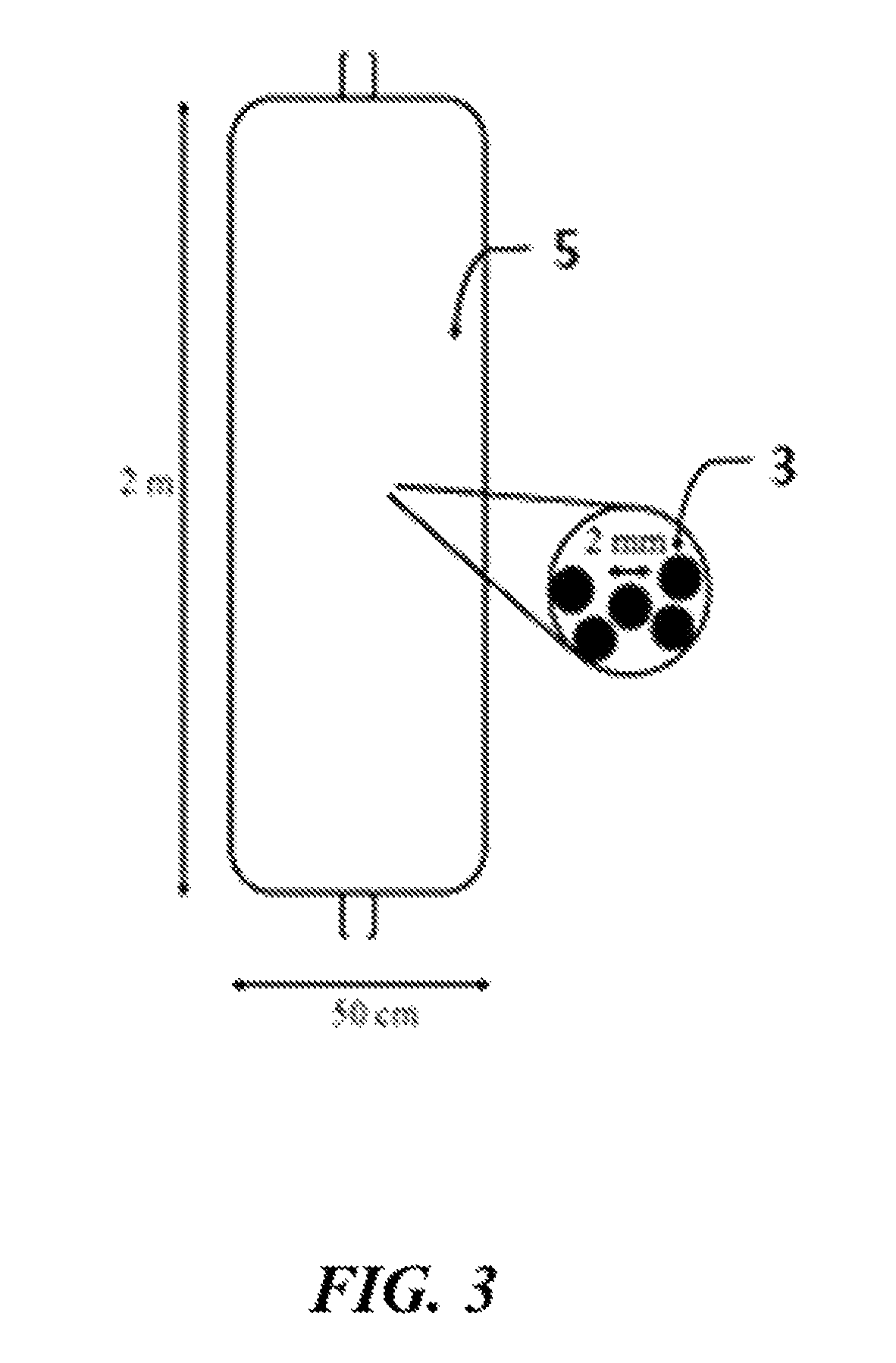

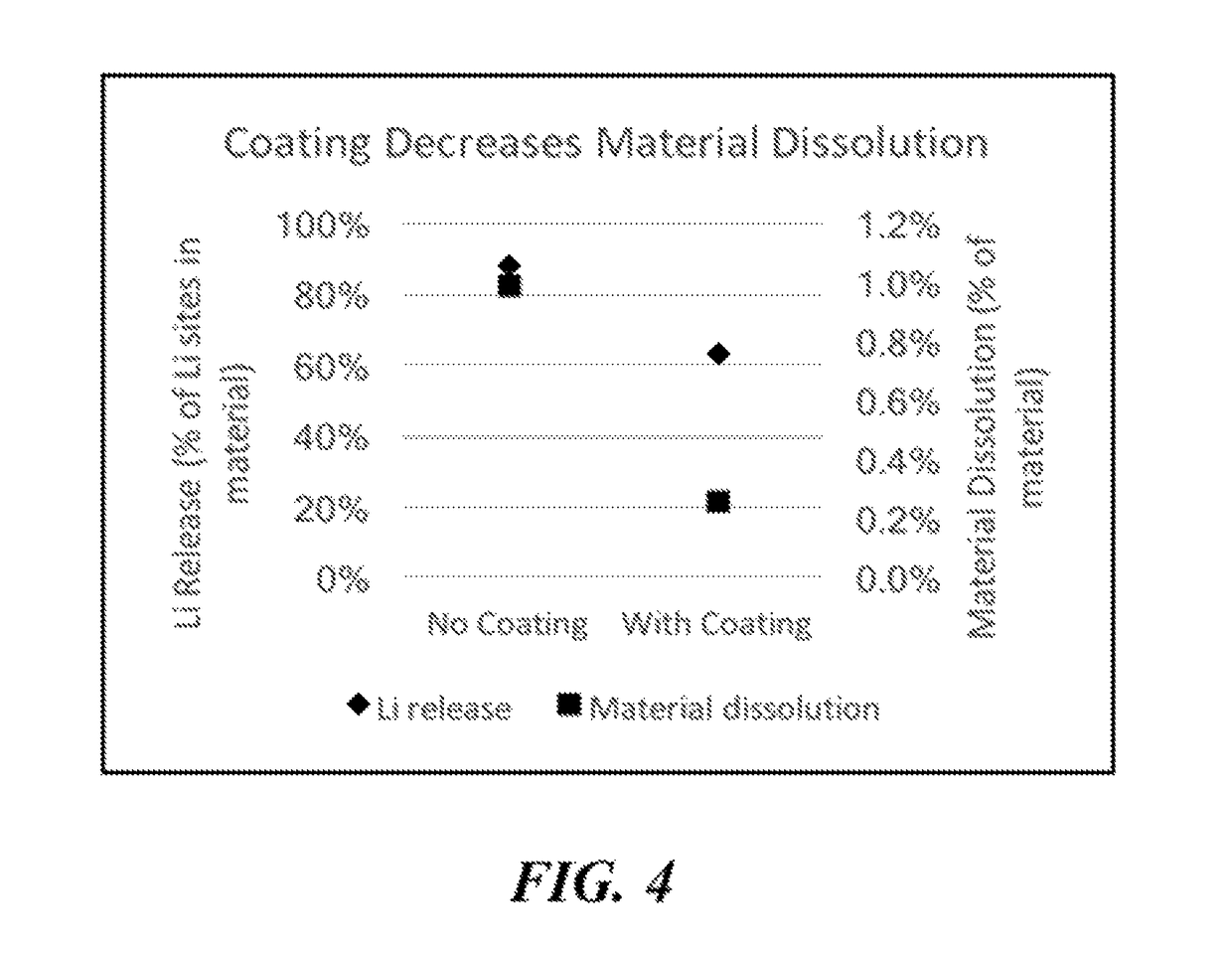

Lithium extraction with coated ion exchange particles

ActiveUS20180133619A1Inhibition of dissolutionPenetrate fastCation exchanger materialsOrganic anion exchangersLithiumIon exchange

The present invention relates to the extraction of lithium from liquid resources such as natural and synthetic brines, leachate solutions from minerals, and recycled products.

Owner:LILAC SOLUTIONS INC

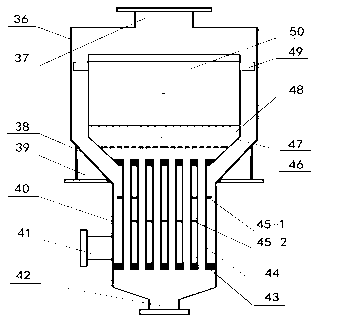

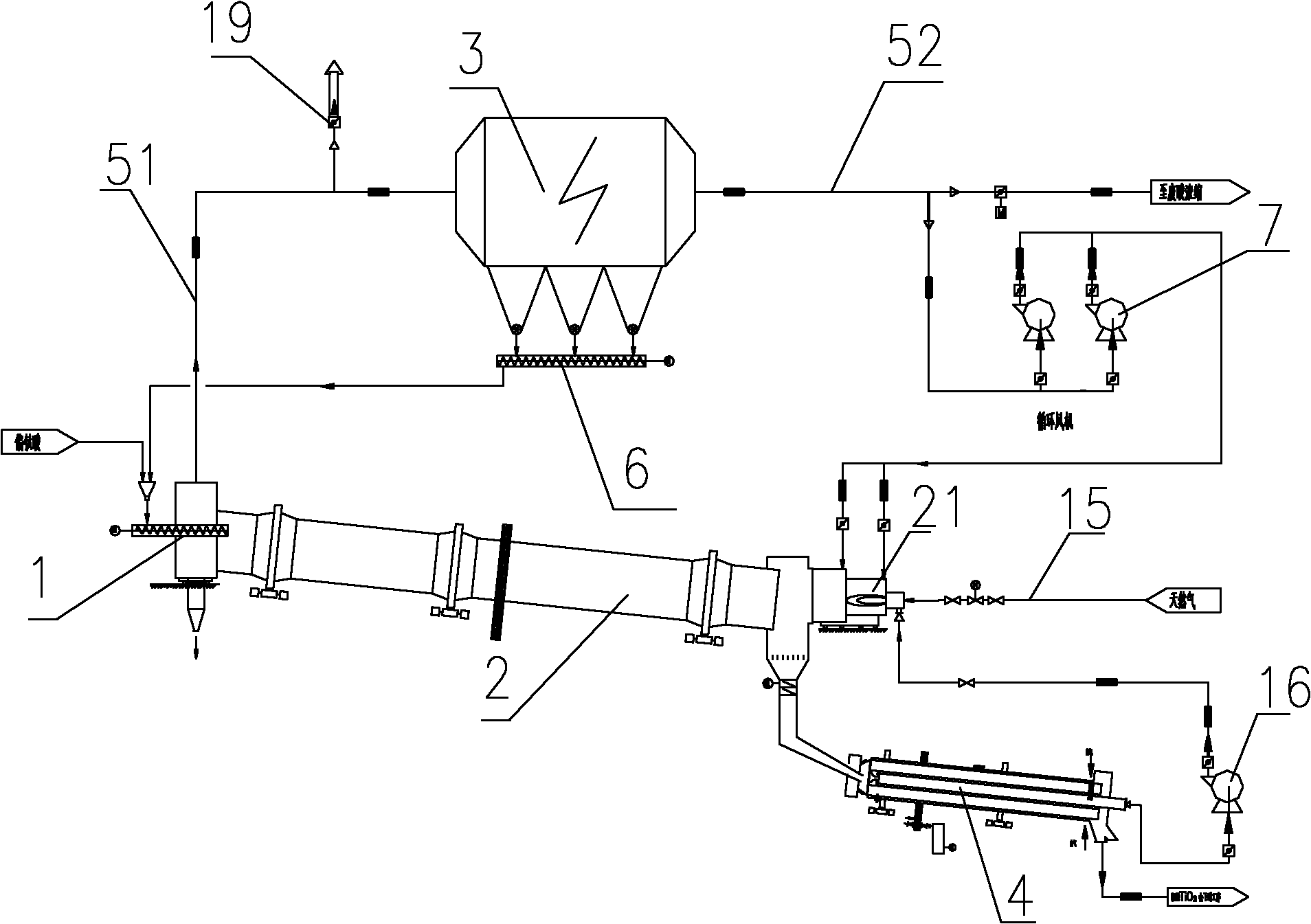

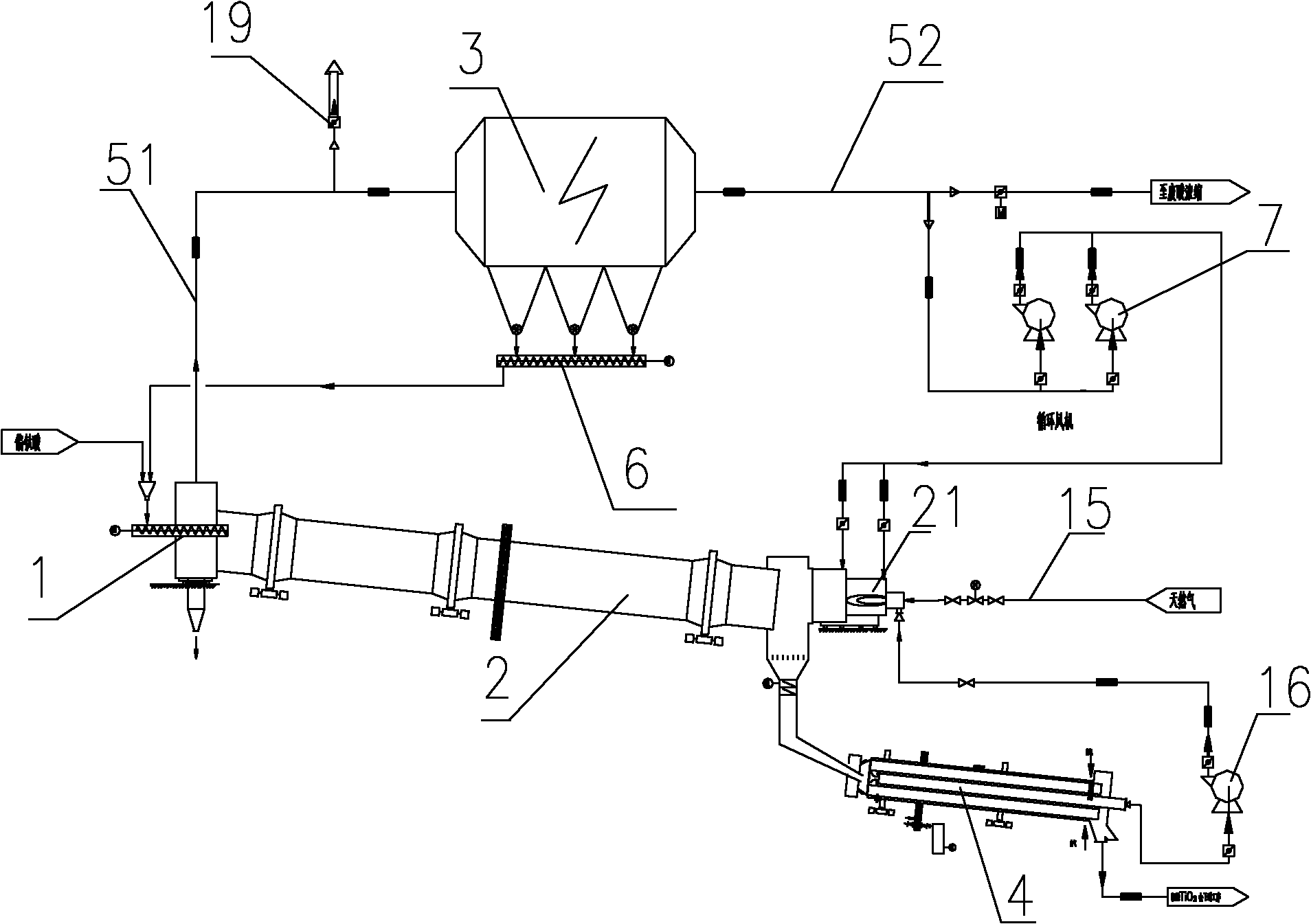

Method and device for utilizing heat energy of flue gas produced by calcining in rotary kiln in process of producing titanium dioxide by sulfuric acid method

ActiveCN102080928AHigh yieldGood energy saving and emission reduction effectRotary drum furnacesIncreasing energy efficiencyMoisturePrecipitation

The invention relates to a method for utilizing heat energy of flue gas produced by calcining in a rotary kiln in the process of producing titanium dioxide by a sulfuric acid method, which comprises the following three aspects of: (1) performing electric precipitation to purify high-temperature flue gas produced in a rotary calcining kiln, collecting dust by a dry method, and returning a recycled product to the rotary kiln for calcining again; (2) spraying 20 percent waste acid produced in the production process to one part of the purified high-temperature flue gas, performing mass transfer and heat transfer, evaporating moisture in the waste acid to improve the concentration of the waste acid to 30 percent, purifying 70 to 80 DEG C low-temperature tail gas produced by concentrating the waste acid by using an electric demisting system, and discharging the tail gas when the tail gas reaches the standard; and (3) returning the other part of the purified high-temperature flue gas to the rotary calcining kiln for recycling, supplementing heat, and adjusting temperature gradient in the kiln. Materials in the flue gas are recycled by the dry method, and the yield of a product is improved by about 0.6 percent; and a large amount of flue gas waste heat is comprehensively utilized, and the effects of saving energy and reducing emission are obvious. Meanwhile, the invention discloses a set of device for utilizing the heat energy of the flue gas produced by calcining in the rotary kiln, which is designed according to the method.

Owner:潜江方圆钛白有限公司

Fireproof thermal insulation material

The invention discloses a fireproof thermal insulation material which comprises the following components by mass ratio: 40-50% of white floating bead, 3-5% of oyster powder, 10-15% of centrifugal glass fiber, 15-20% of ceramic wool, 15-20% of bentonite, 3-5% of polyacrylamide, 5% of a penetrant, 0.1-0.3% of a rare earth additive, 5-10% of pearl fly ash and 5% of rock wool. Due to addition of the oyster powder, the fireproof thermal insulation material can be used for absorbing the toxic and harmful substances in the air; the white floating bead used in the fireproof thermal insulation material is a waste recycled product which has high fireproof degree; the ceramic wool used by the fireproof thermal insulation material has excellent thermal insulation and fireproof effects.

Owner:QINGDAO DEGU BUILDING MATERIAL

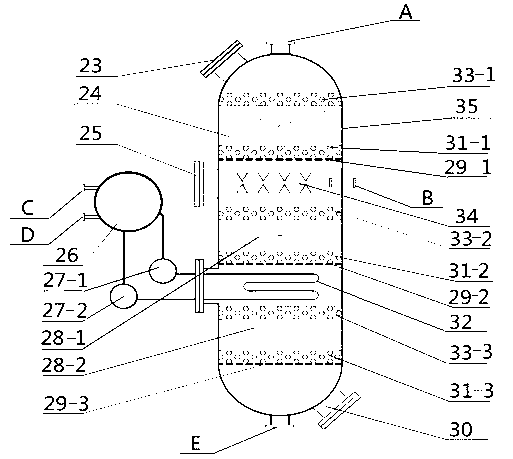

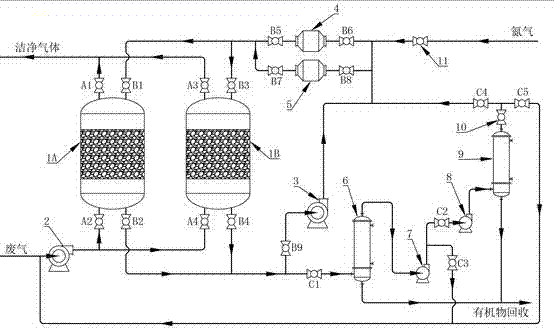

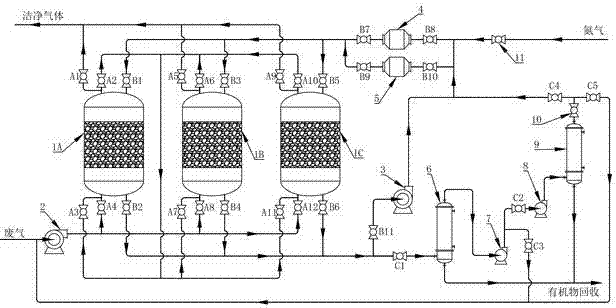

Organic waste gas adsorption-desorption recycling technology and device

InactiveCN107376590AReduce dosageReduce energy lossGas treatmentDispersed particle separationSocial benefitsNitrogen

The invention relates to an organic waste gas adsorption-desorption recycling technology and device, and belongs to the field of organic waste gas treatment. The organic waste gas adsorption-desorption recycling technology is characterized in that nitrogen is used as a medium, an organic matter is recycled via vacuum circulating adsorption and compression condensing, then the exhaust of organic waste gas can reach standards, and the secondary pollution is avoided because of recycling of the organic matter; by adopting vacuum oxygen suction and circular heating and cooling adsorbers, the usage amount of nitrogen is greatly reduced, and a whole desorption cycle is shortened; by adopting compression condensing to recycle the organic matter, the condensing temperature is increased, the requirement on a condensing system is decreased, and the energy consumption in the running of the low-temperature condensing system is decreased. The organic waste gas adsorption-desorption recycling technology has the characteristics that the applicability is wide, the investment is saved, the energy consumption is low, the quality of a recycled product is good, and the secondary pollution is avoided; the investment running cost of an enterprise is greatly reduced, and the double earning of social benefits and economic benefits is realized.

Owner:李国峰

Lithium extraction with coated ion exchange particles

ActiveUS10150056B2Penetrate fastInhibition of dissolutionCation exchanger materialsOrganic anion exchangersPregnant leach solutionLithium

The present invention relates to the extraction of lithium from liquid resources such as natural and synthetic brines, leachate solutions from minerals, and recycled products.

Owner:LILAC SOLUTIONS INC

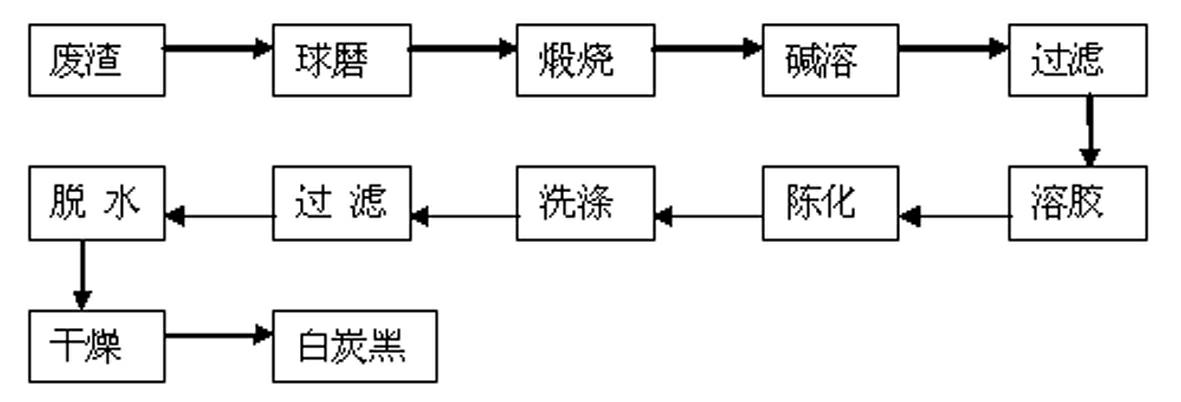

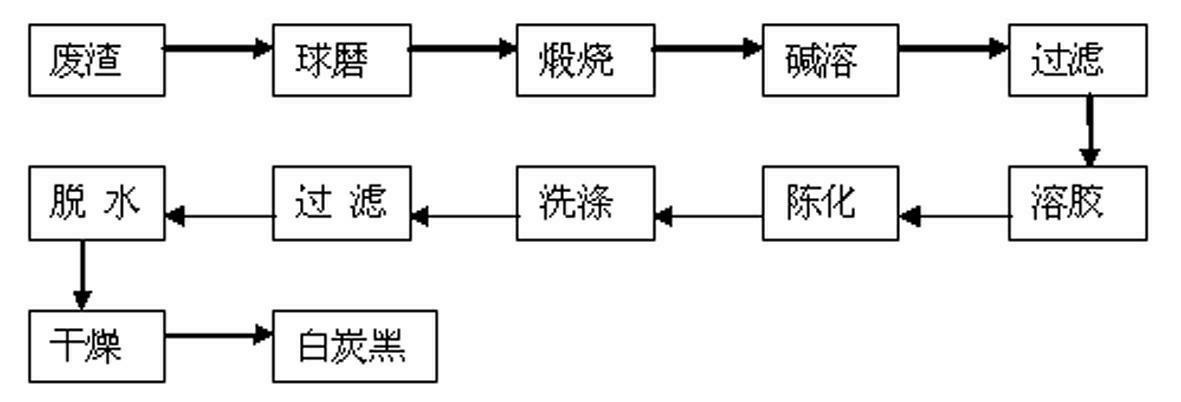

Method for preparing white carbon black by utilizing waste silicon rubber cracked residues

InactiveCN102491348AAvoid secondary pollutionHigh whitenessSilicaHazardous substanceSODIUM SILICATE SOLN

The invention relates to a method for preparing white carbon black by utilizing waste silicon rubber cracked residues. The method comprises the following steps of: crushing cracked residues, and calcining at high temperature; adding calcined ash residues, a certain amount of solid sodium hydroxide and water into a alkali-soluble reactor for reacting, and filtering to an obtain sodium silicate solution serving as filtrate; adding deionized water and a surfactant into a sol-gel reactor, and dripping an aqueous solution of sodium silicate and hydrochloric acid to obtain white carbon black, and washing, filtering, performing azeotropic dehydration with n-butyl alcohol and drying to obtain the white carbon black. According to the method, organic wastes in the residues are calcined at the high temperature to perform aerobic degradation reaction, so that toxic and harmful substances in the wastes are oxidized and pyrolyzed at the high temperature to be damaged; the superfine white carbon black is prepared from the calcined substances by the sol-gel technology; and the white carbon black has the advantages of high whiteness, small partical sizes, narrow particle size distribution, high flowability and the like, and the application range of the recycled products is broadened.

Owner:江山市华顺有机硅有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com