Production process for manufacturing food-level polyester bottle flakes utilizing polyester recovered bottles

A production process, technology of polyester bottle flakes, applied in the field of polyester bottle flakes production technology, can solve the problems of trace chemical substance residues, achieve high added value, reduce investment costs, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

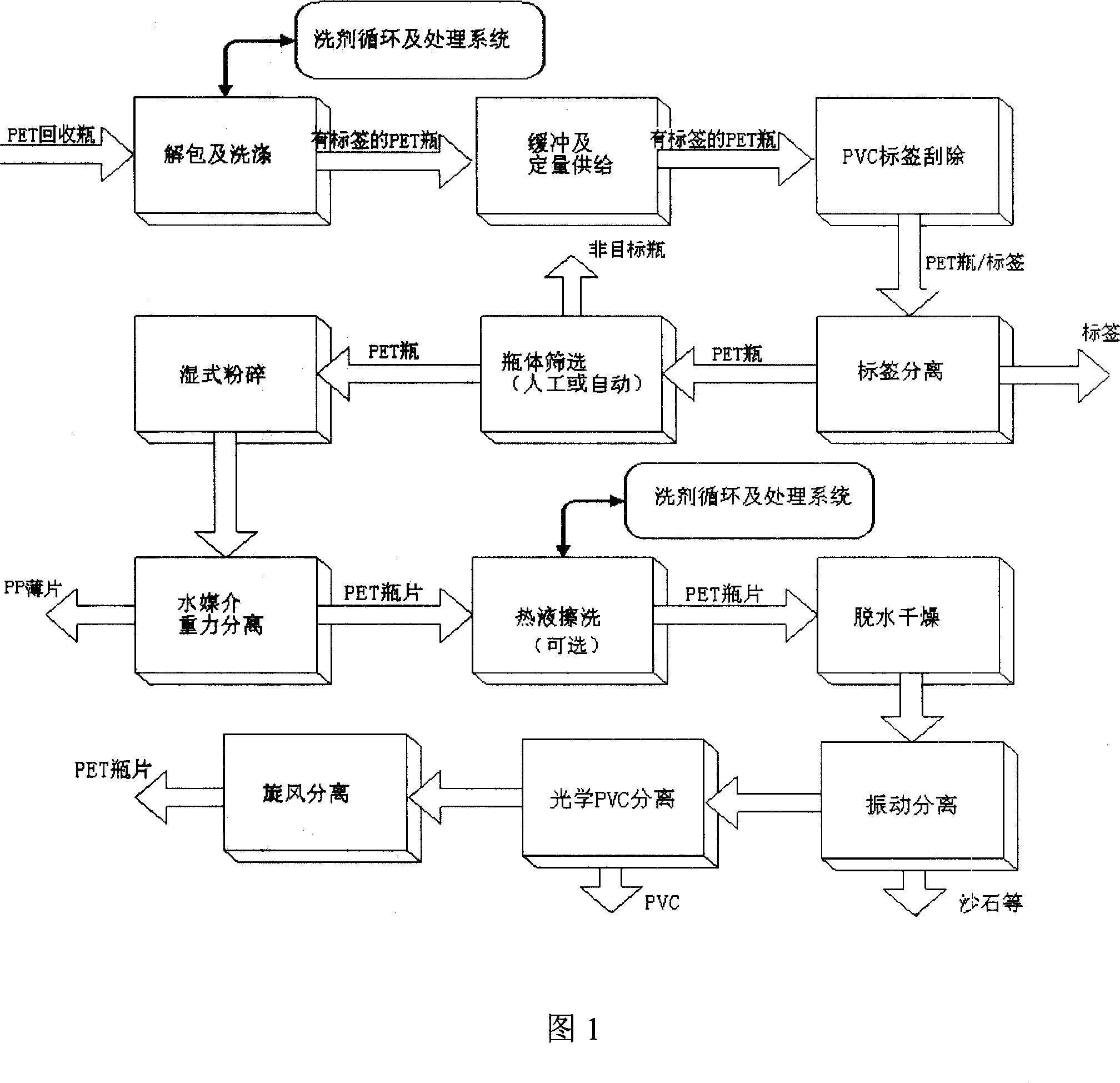

[0042] Recycling polyester (PET) bottle of the present invention produces the production technology of food polyester (PET) bottle level chip, mainly comprises:

[0043] 1. For the cleaning process of recycled polyester (PET) bottles, please refer to Figure 1.

[0044] 1. Unpacking and washing unit

[0045] Under the strong stirring force, the bottle washing machine has the function of unpacking machine, which makes the process more simple and economical. Under the action of mechanical force, chemical force of detergent and heat, the separation and removal rate of impurities contained in PET recycling bottles (referring to environmental pollutants and labels, etc., but excluding PVC heat shrinkable labels) reaches 9%. More than ten. Under this condition, the subsequent process equipment is also quite protected due to the purification of the bottle body, especially in the environment of the pulverizer, to avoid unnecessary wear and tear due to excessive pollutants.

[0046] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com