PCB (printed circuit board) defect mass detection system and method

A PCB circuit board, batch detection technology, applied in the field of detection system, to achieve the effect of saving manpower and time, good directivity, and a wide range of fault detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below with reference to the specific drawings and embodiments.

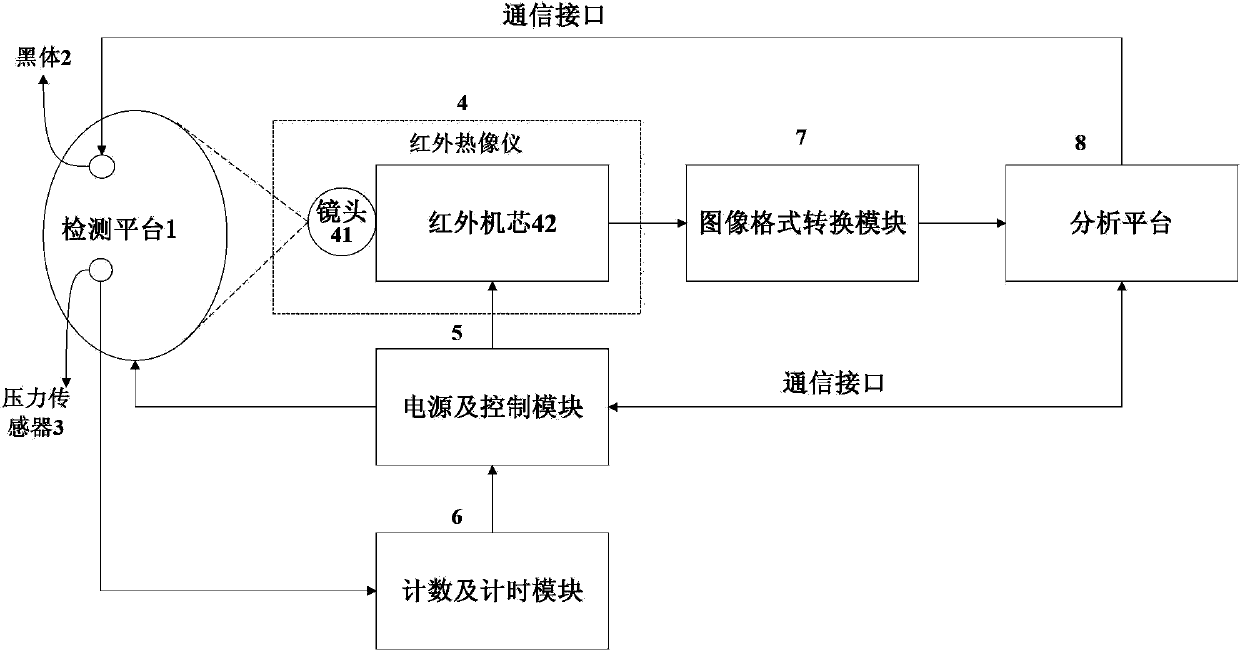

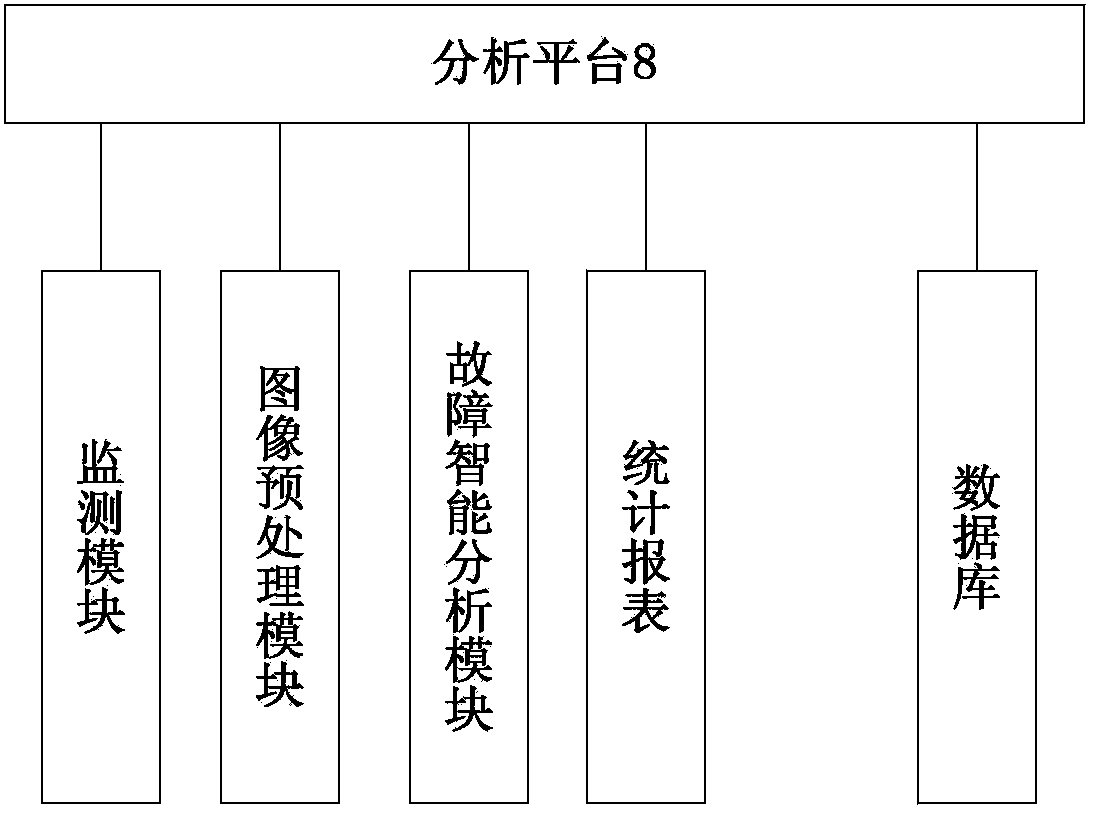

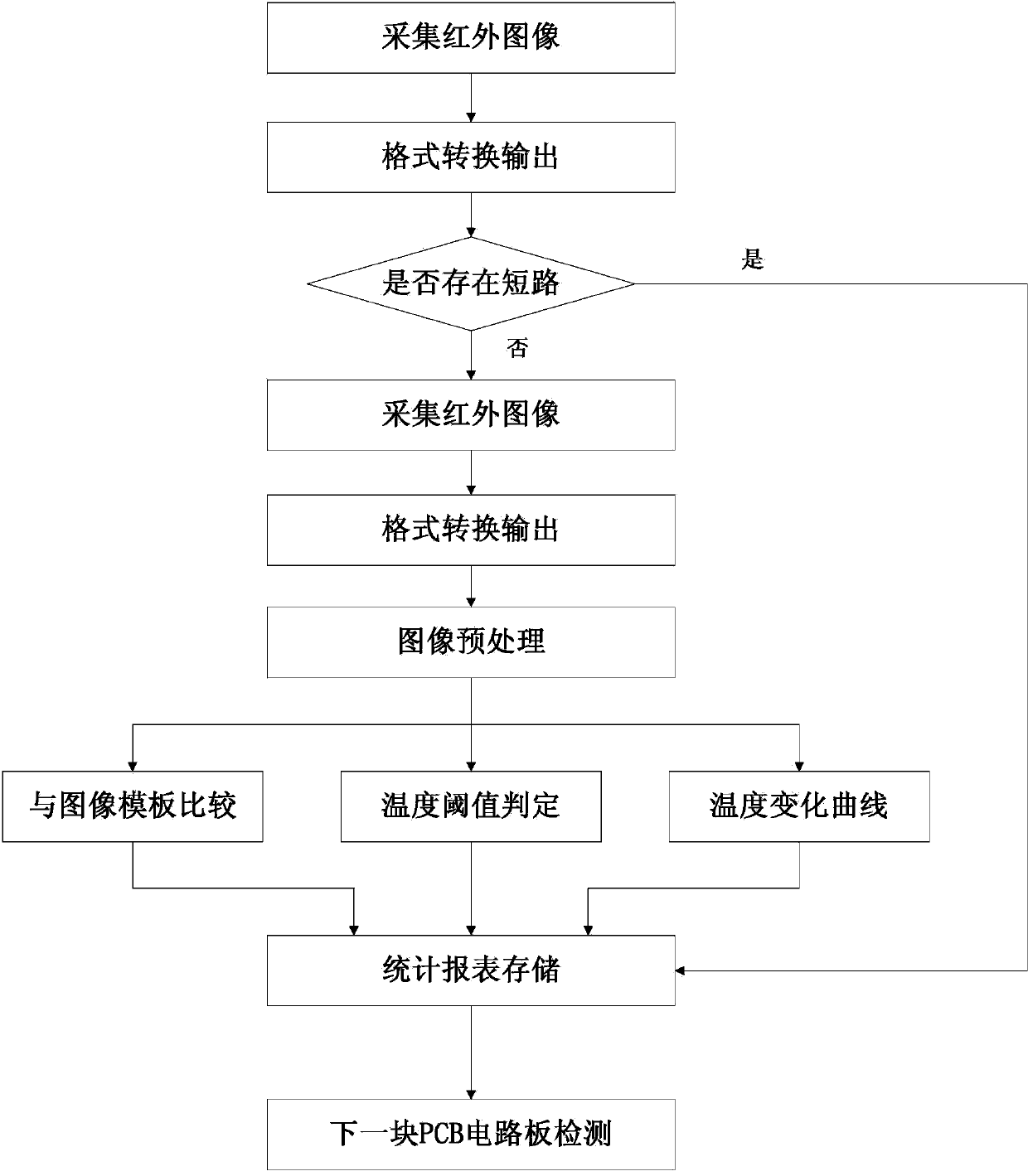

[0044] like figure 1 As shown, a batch detection system for PCB circuit board defects includes:

[0045]The infrared thermal imager 4 includes an infrared lens 41 and an infrared core 42. The infrared radiation energy of the detected PCB circuit board is collected by the infrared lens 41, and the optical path adjustment is sensed by the sensor of the infrared core 42, and the infrared core 42 converts the light signal. into electrical signals and output infrared images in analog video format;

[0046] The black body 2 is set on the detection platform 1 to provide a reference for the target temperature measurement. The PC can set the radiation temperature of its temperature cooling surface through the communication interface, and its temperature cooling surface is set in the imaging field of the infrared thermal imager 4; PCB circuit The temperature under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com