Patents

Literature

296results about How to "Avoid glitches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

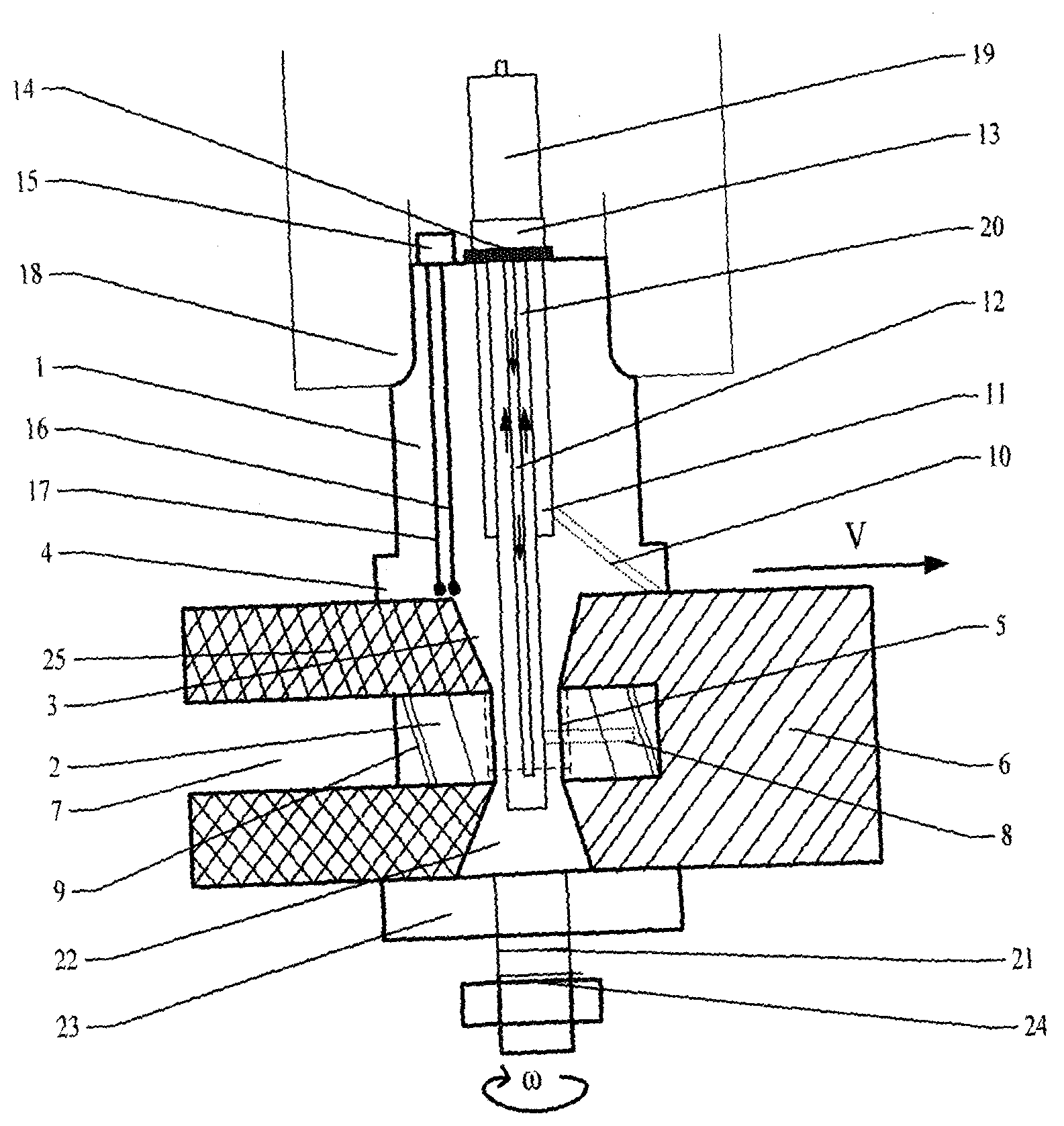

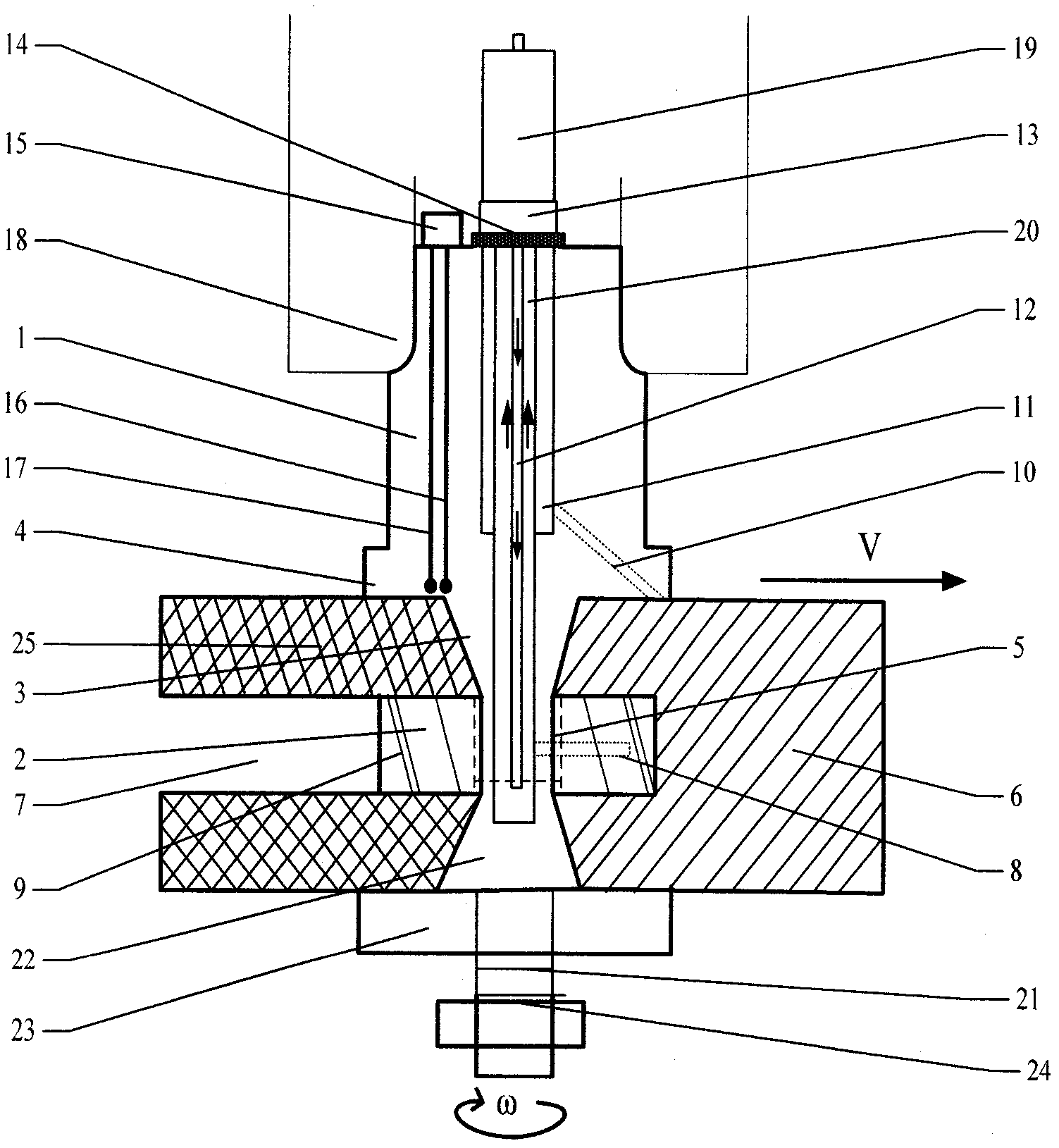

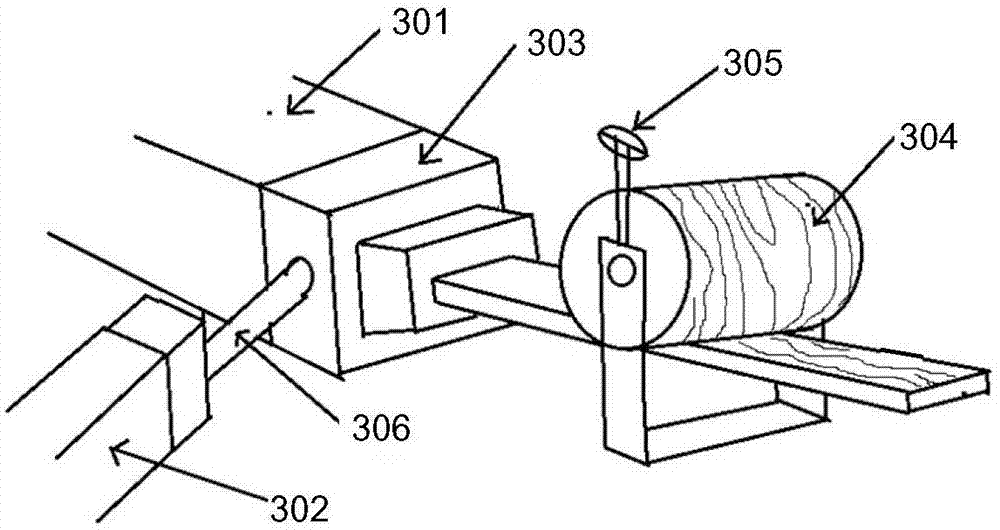

Cutting-stirring friction welding composite processing device for floating double-shaft-shoulder double-stirring needle and manufacture method thereof

InactiveCN102490018AEfficient coolingAvoid glitchesOther manufacturing equipments/toolsNon-electric welding apparatusInduction systemTemperature sensing

The invention discloses a cutting-stirring friction welding composite processing device for a floating double-shaft-shoulder double-stirring needle and a manufacture method thereof, and particularly relates to a combined or composite processing device capable of simultaneously carrying out milling or cutting processing and stirring friction welding processing and a method thereof. The cutting-stirring friction welding composite processing device for the floating double-shaft-shoulder double-stirring needle integrates a cutting system or a milling system, a stirring friction welding system, a forced cooling system, a gas protection system, a temperature sensing system, a pressure induction system, a milling liquid supply system and a sensing-free system. The cutting-stirring friction welding composite processing device has functions of temperature control, gas protection, pressure detection, cooling liquid protection, milling head replacing and floating double-shaft-shoulder self-supporting stirring friction welding. The method for carrying out cutting-stirring friction welding composite processing on workpieces can meet strength requirements of mechanical processing of ferrous light metal materials, carbon steel materials and alloy steel materials. The cutting-stirring friction welding composite processing device for a floating double-shaft-shoulder double-stirring needle and the manufacture method of the cutting-stirring friction welding composite processing device reduce manufacture procedures, save processing cost, have the advantages of being high in efficiency, excellent in quality, high in stability and saving in energy, break through limitation of conventional machining technology, form a new method and a new thought for machinery processing, and have wide application prospects in industries of heating, air conditioners, ice manufacture, freshness keeping, medicine preparation, construction, aquatic products and foods.

Owner:CHONGQING UNIV

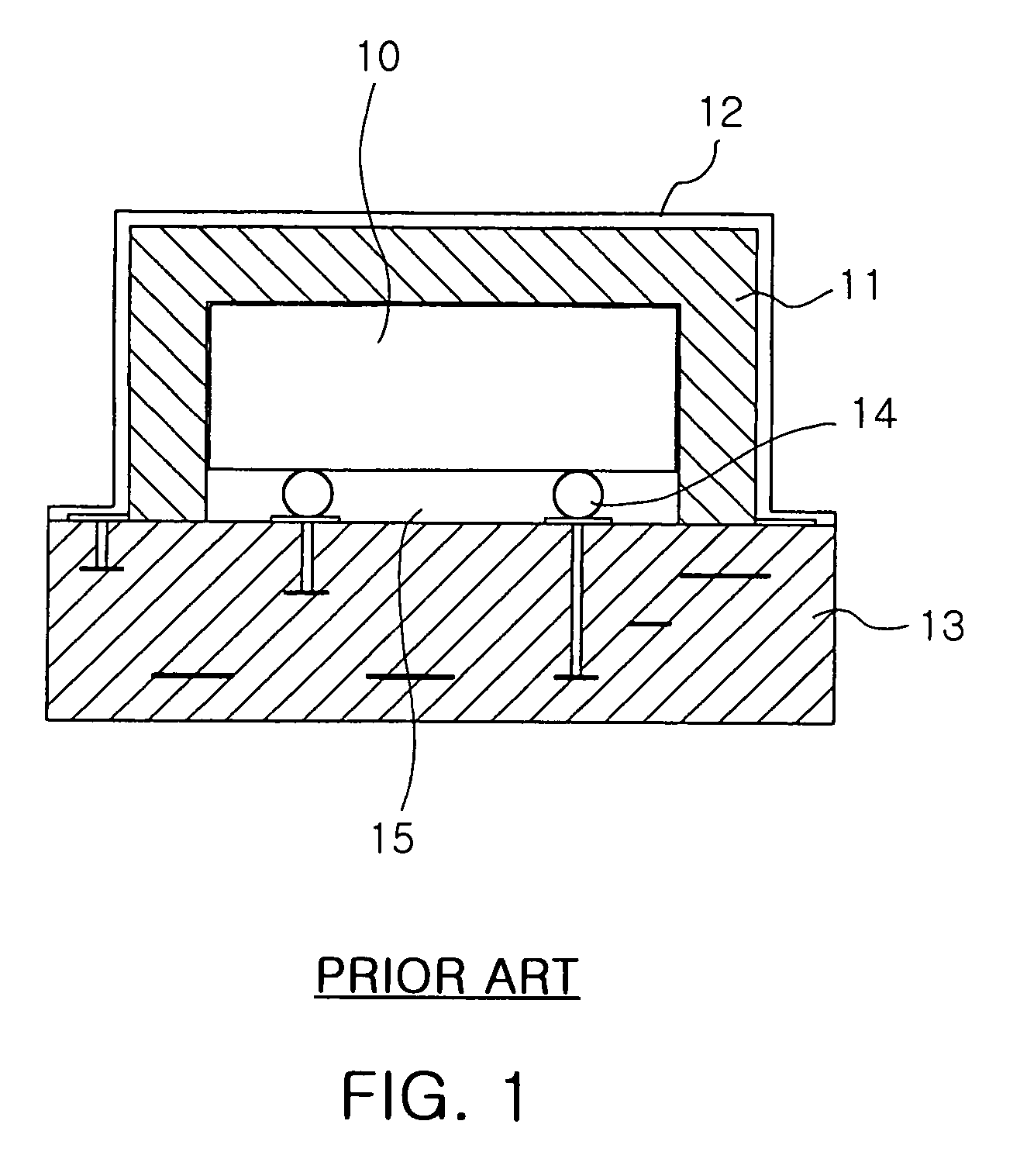

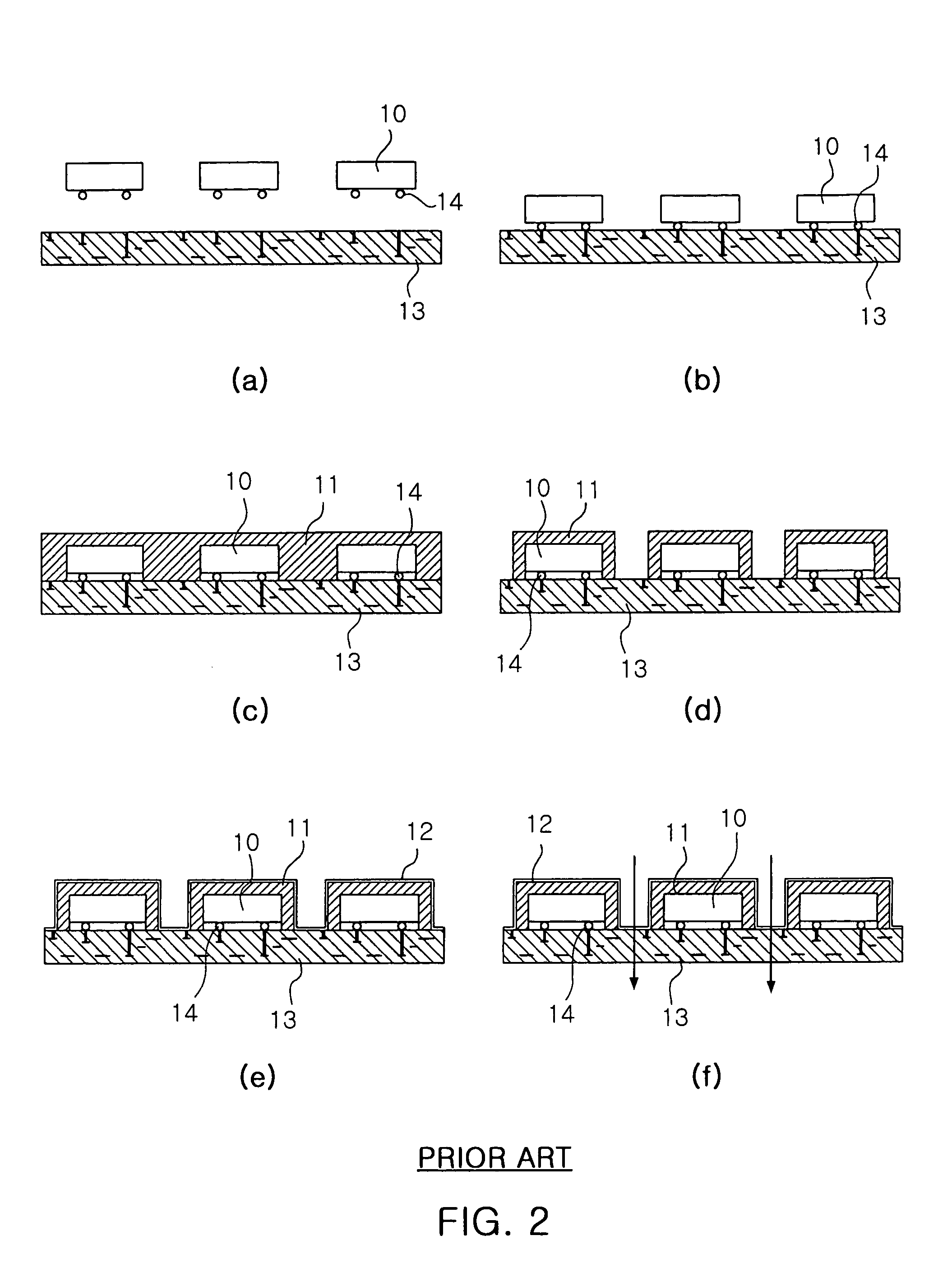

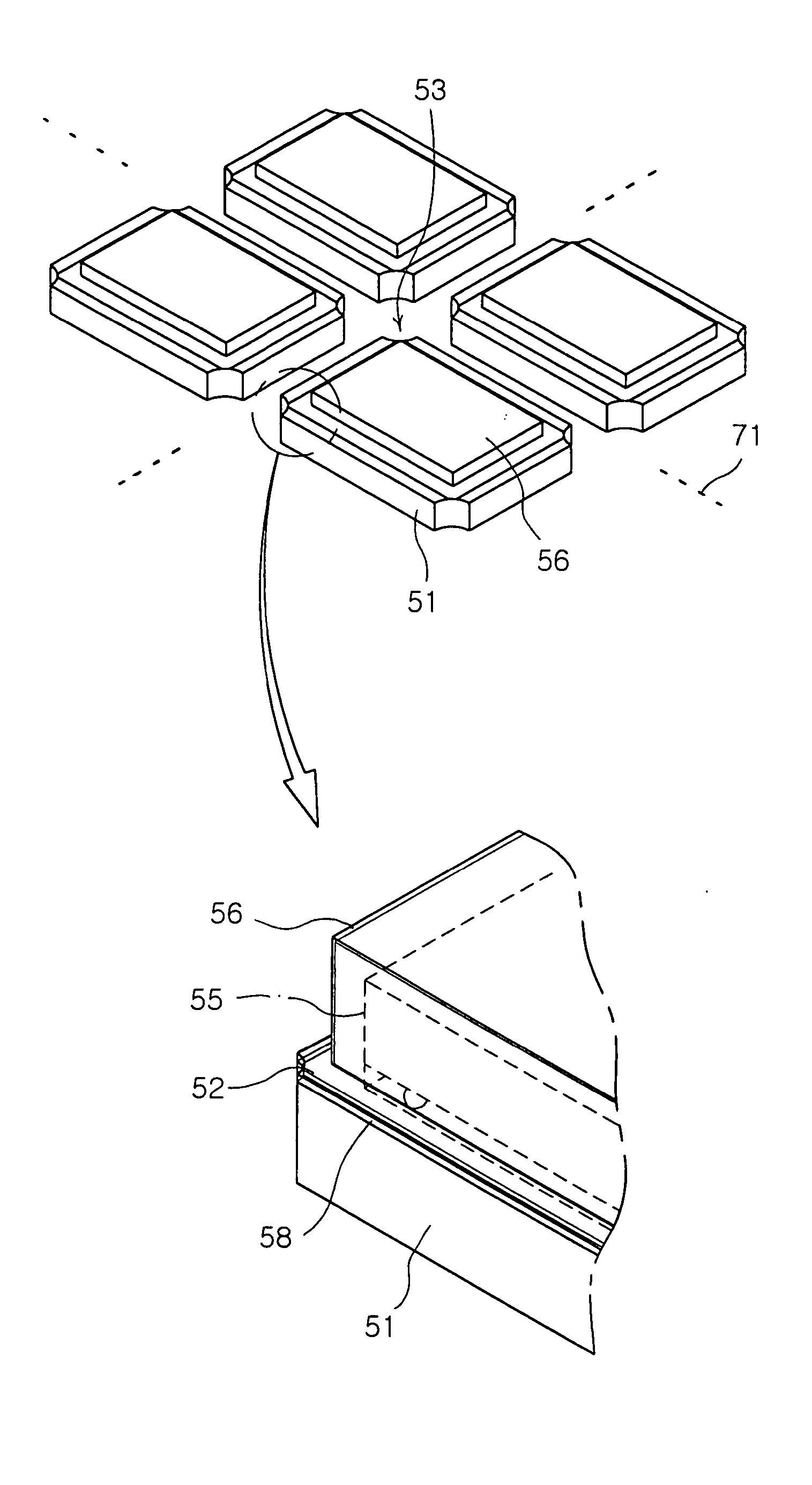

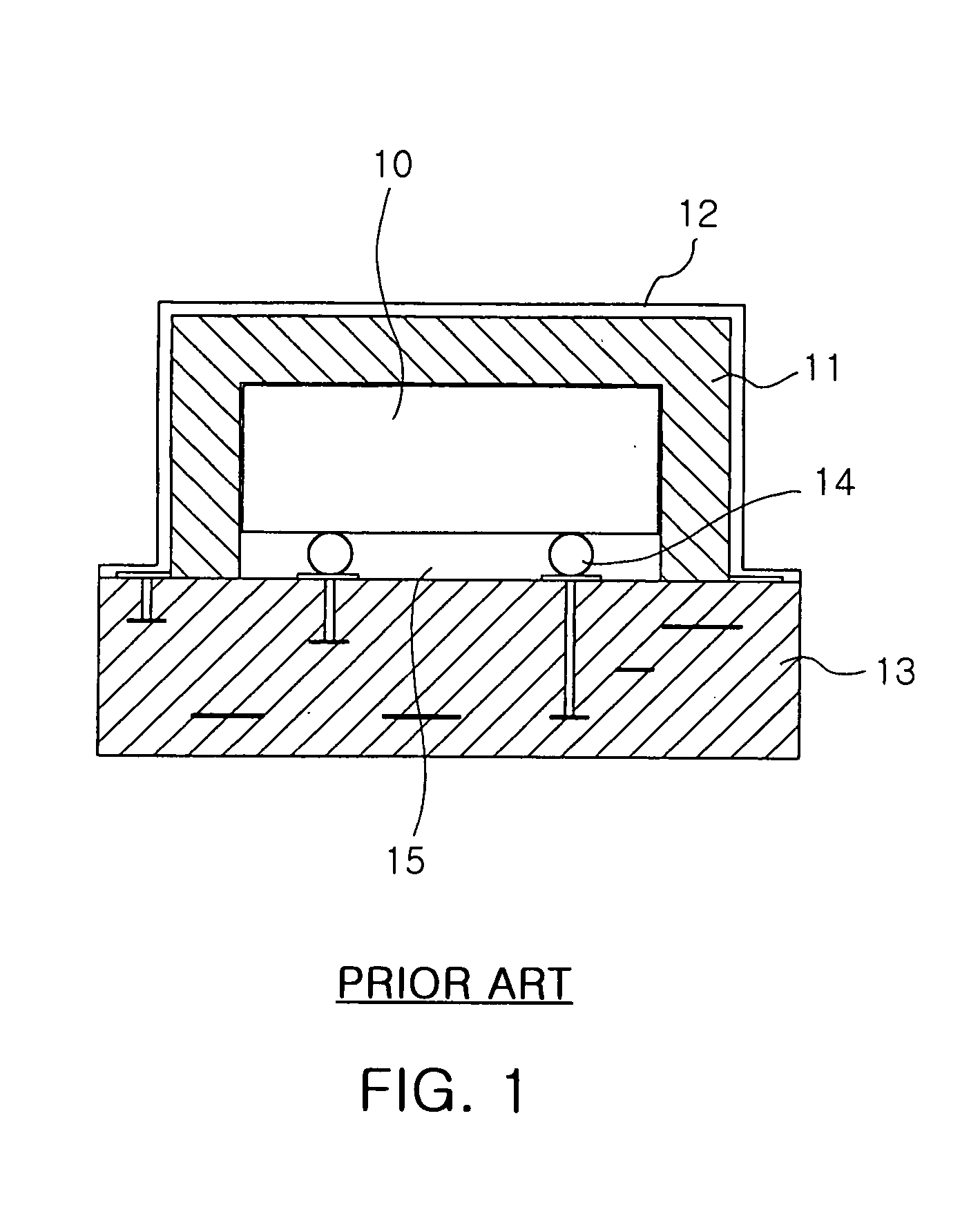

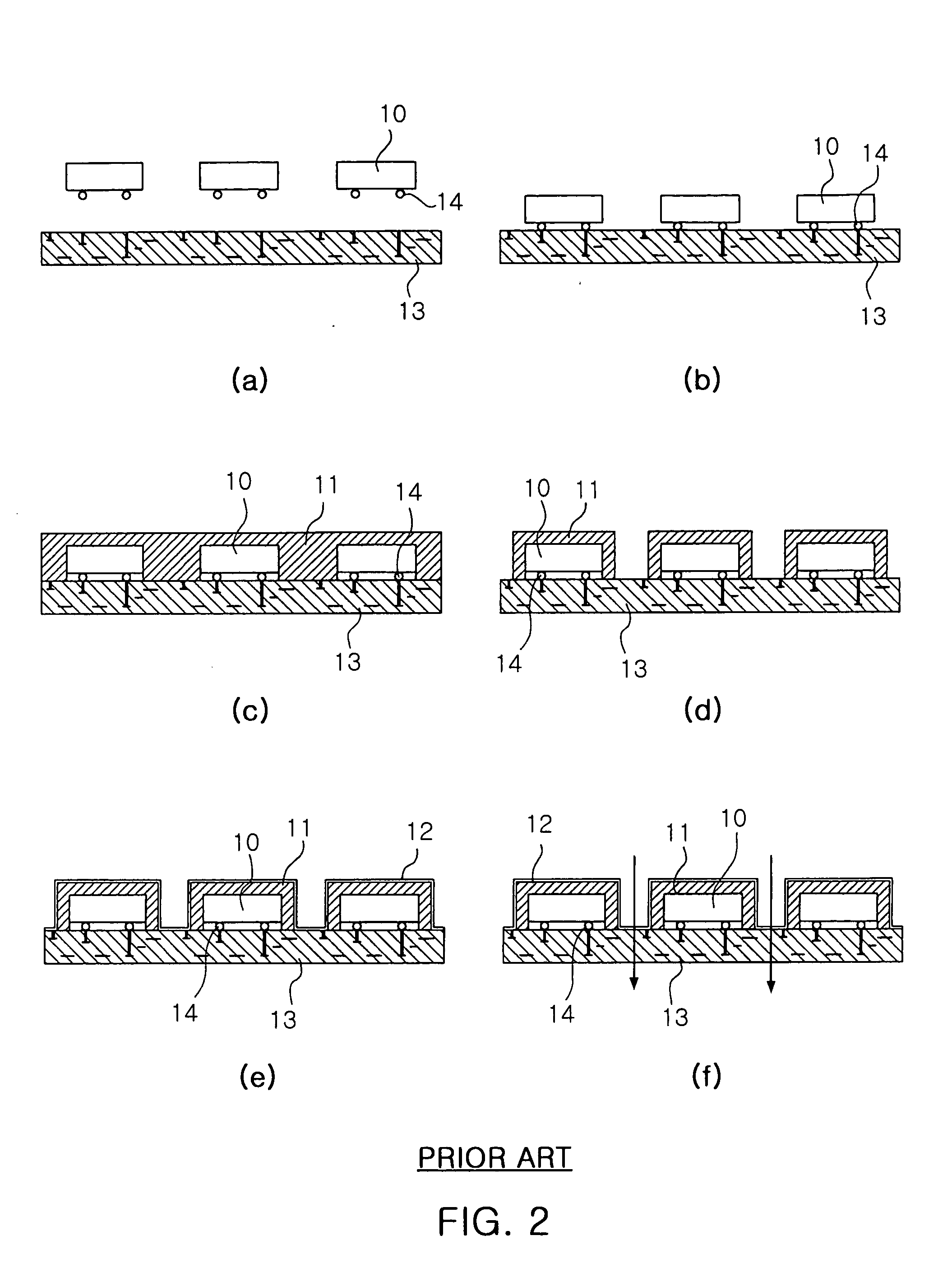

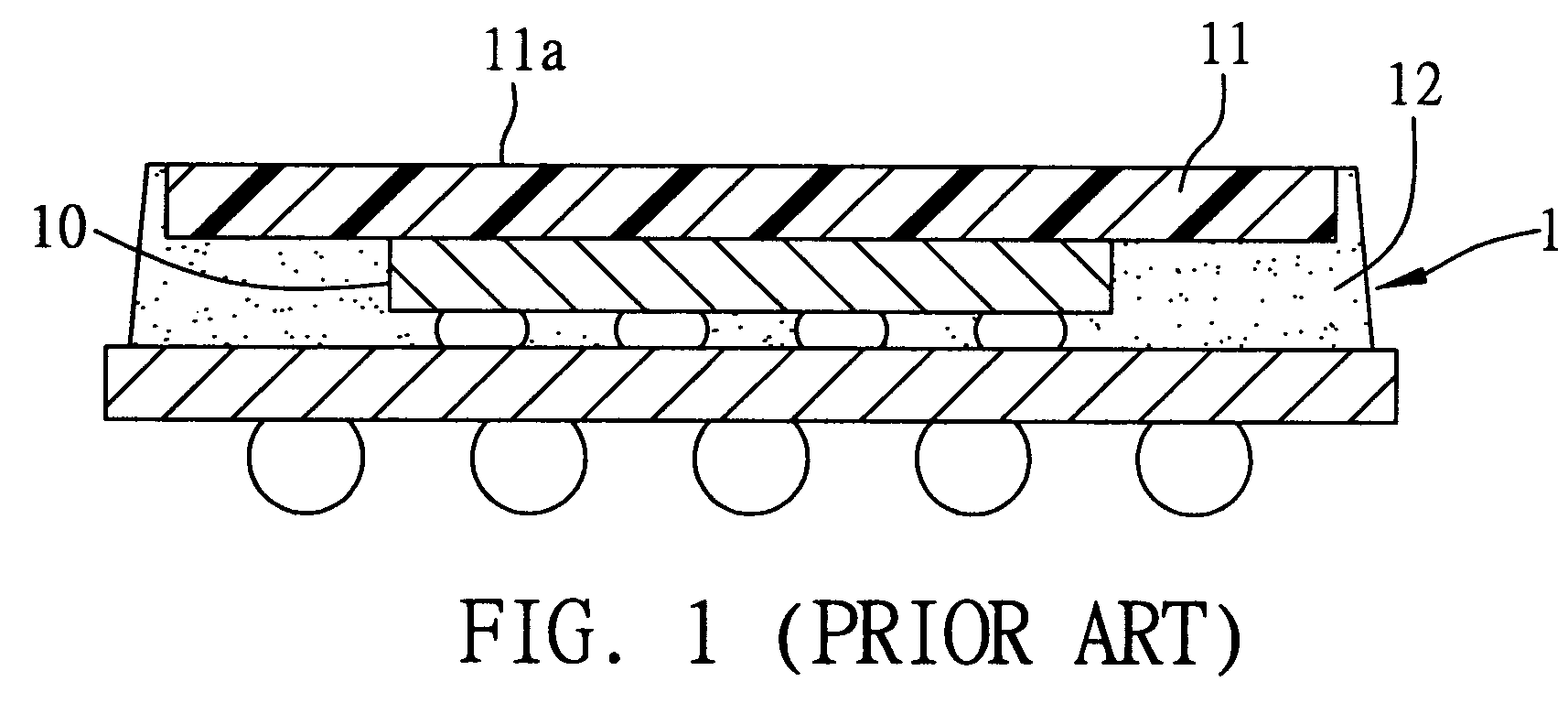

Method for fabricating surface acoustic wave filter packages and package sheet used therein

InactiveUS7045385B2Improve product reliabilityAvoid defectsImpedence networksSemiconductor/solid-state device detailsAcoustic waveSurface acoustic wave

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

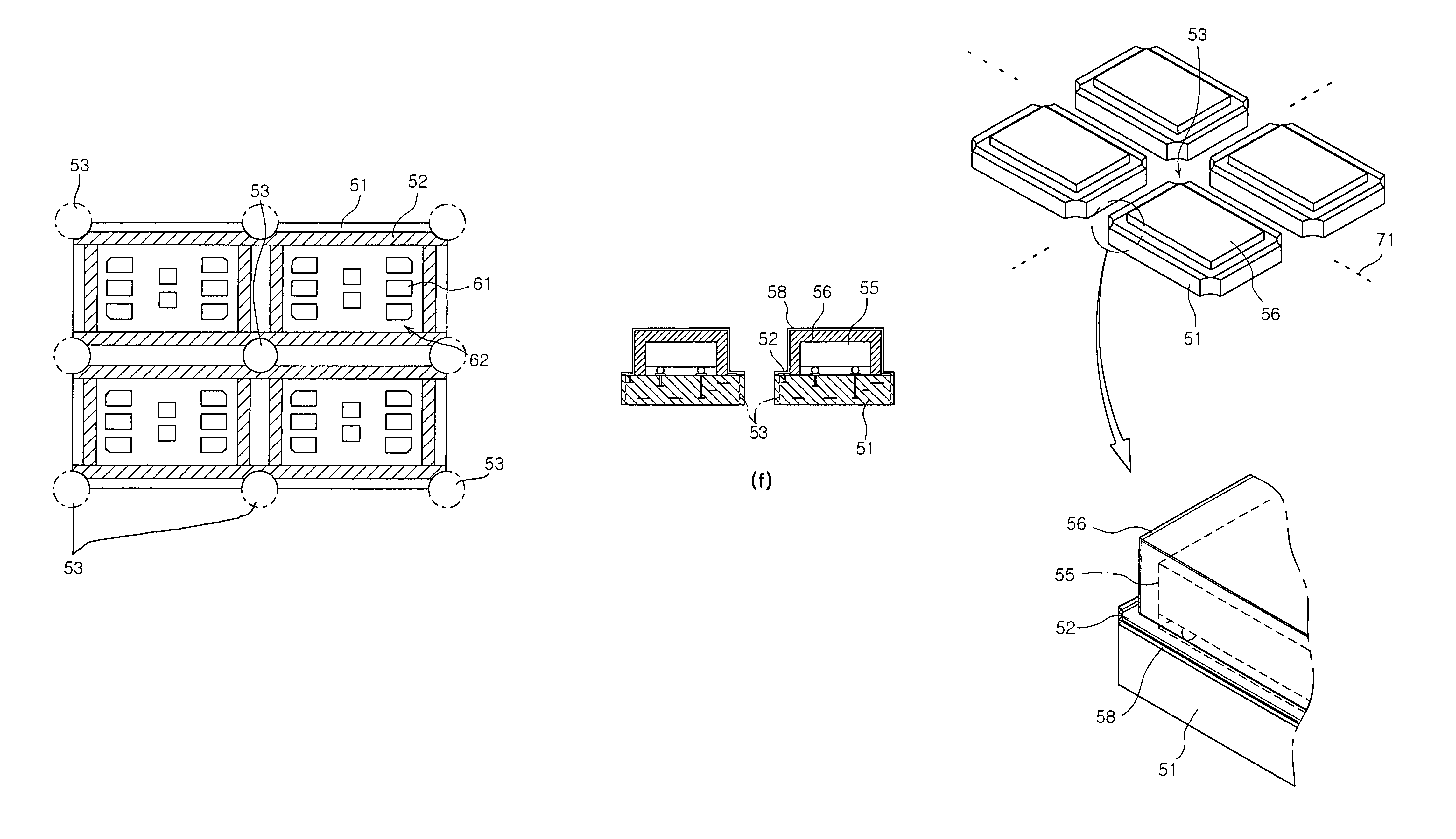

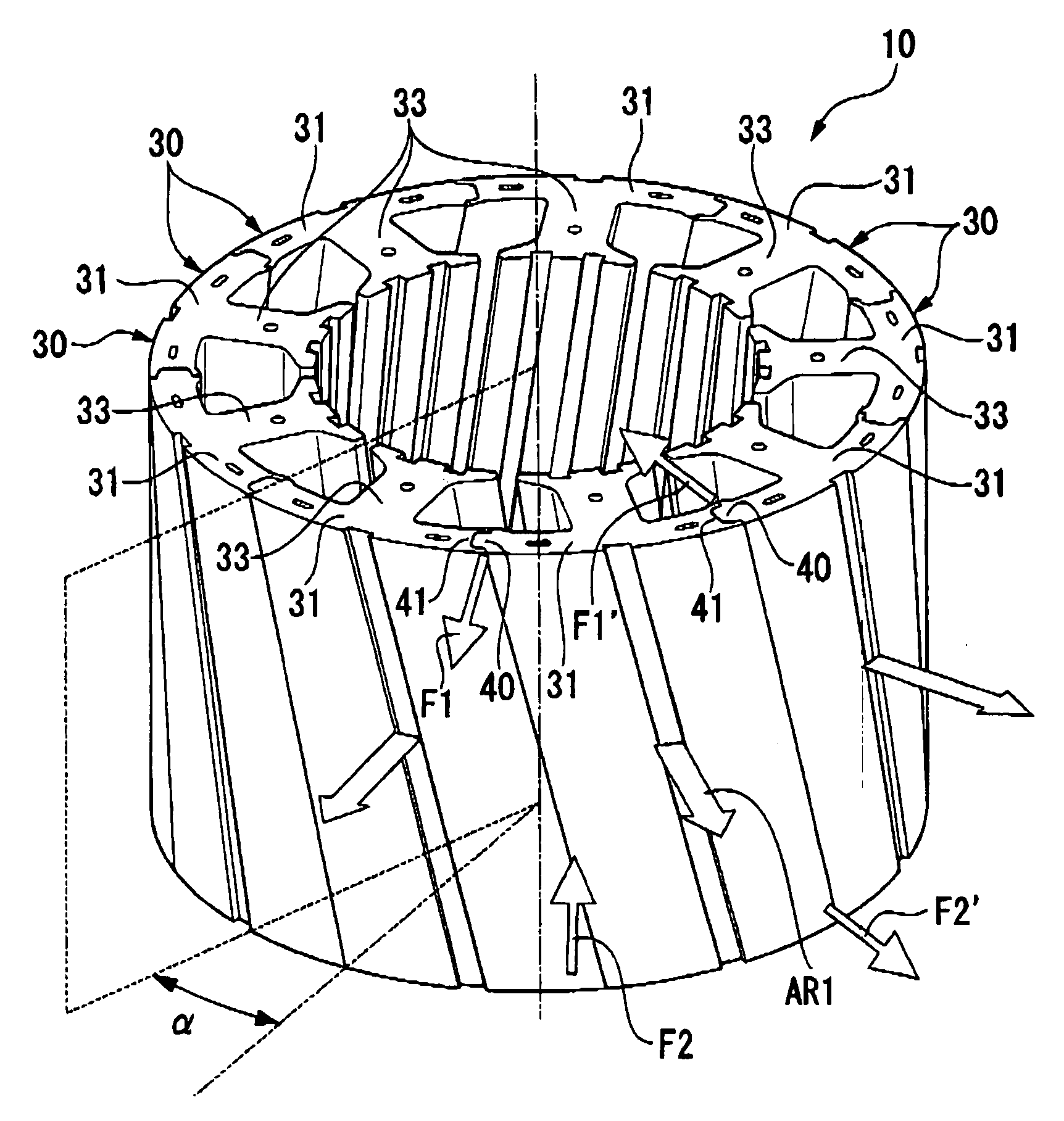

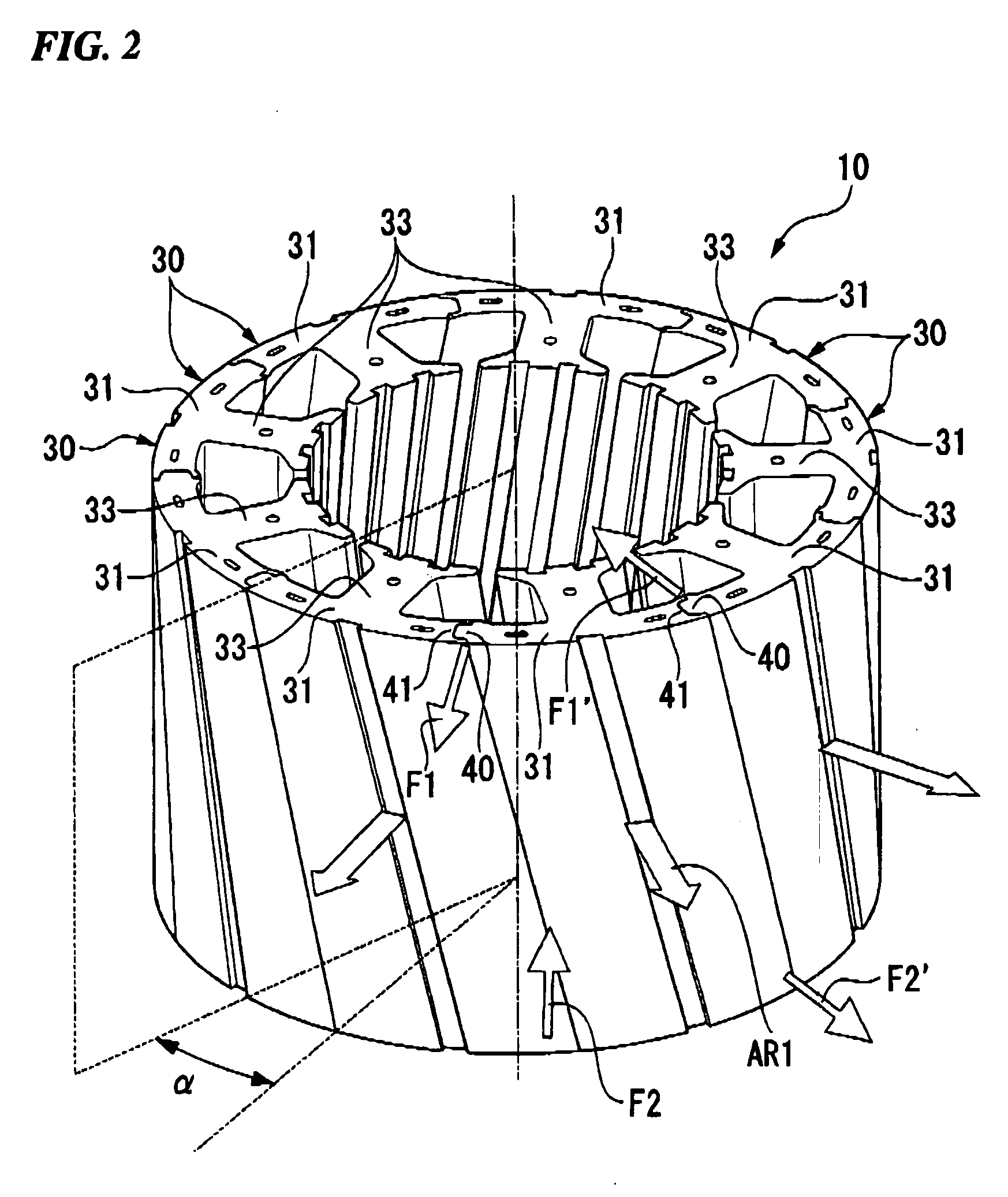

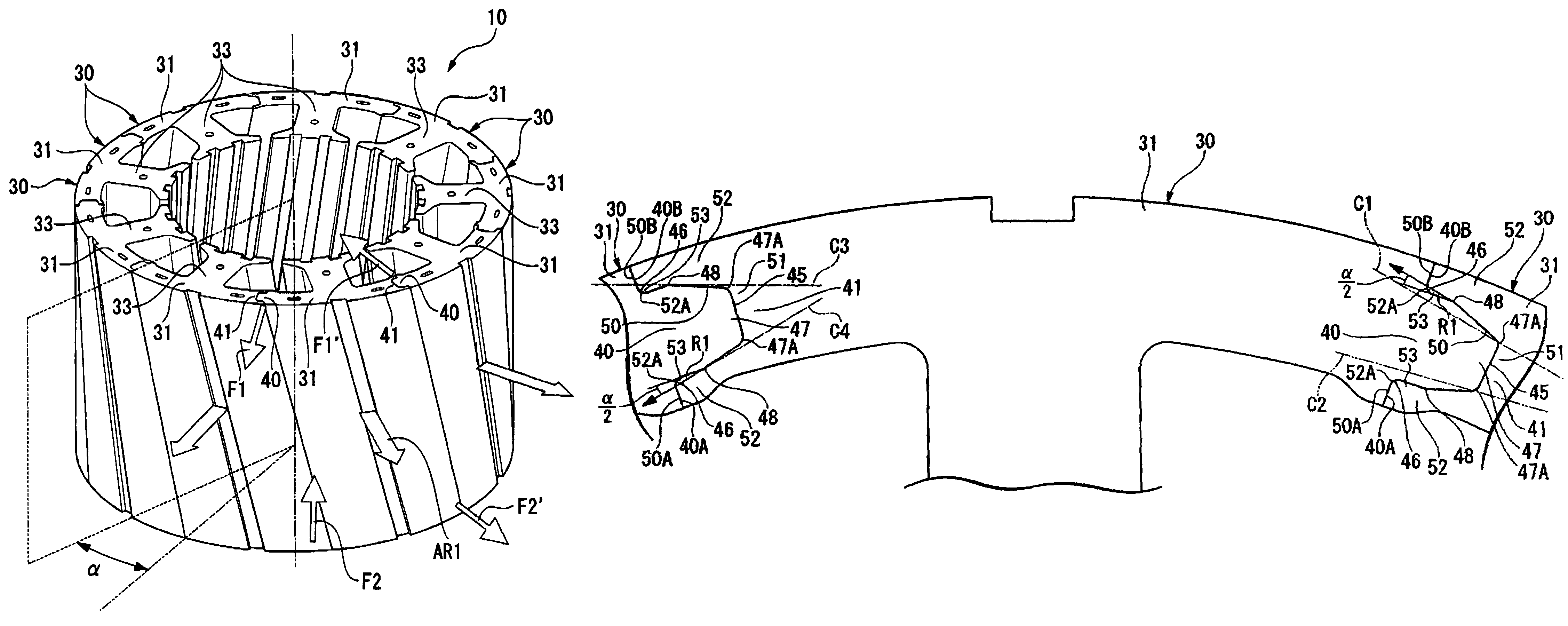

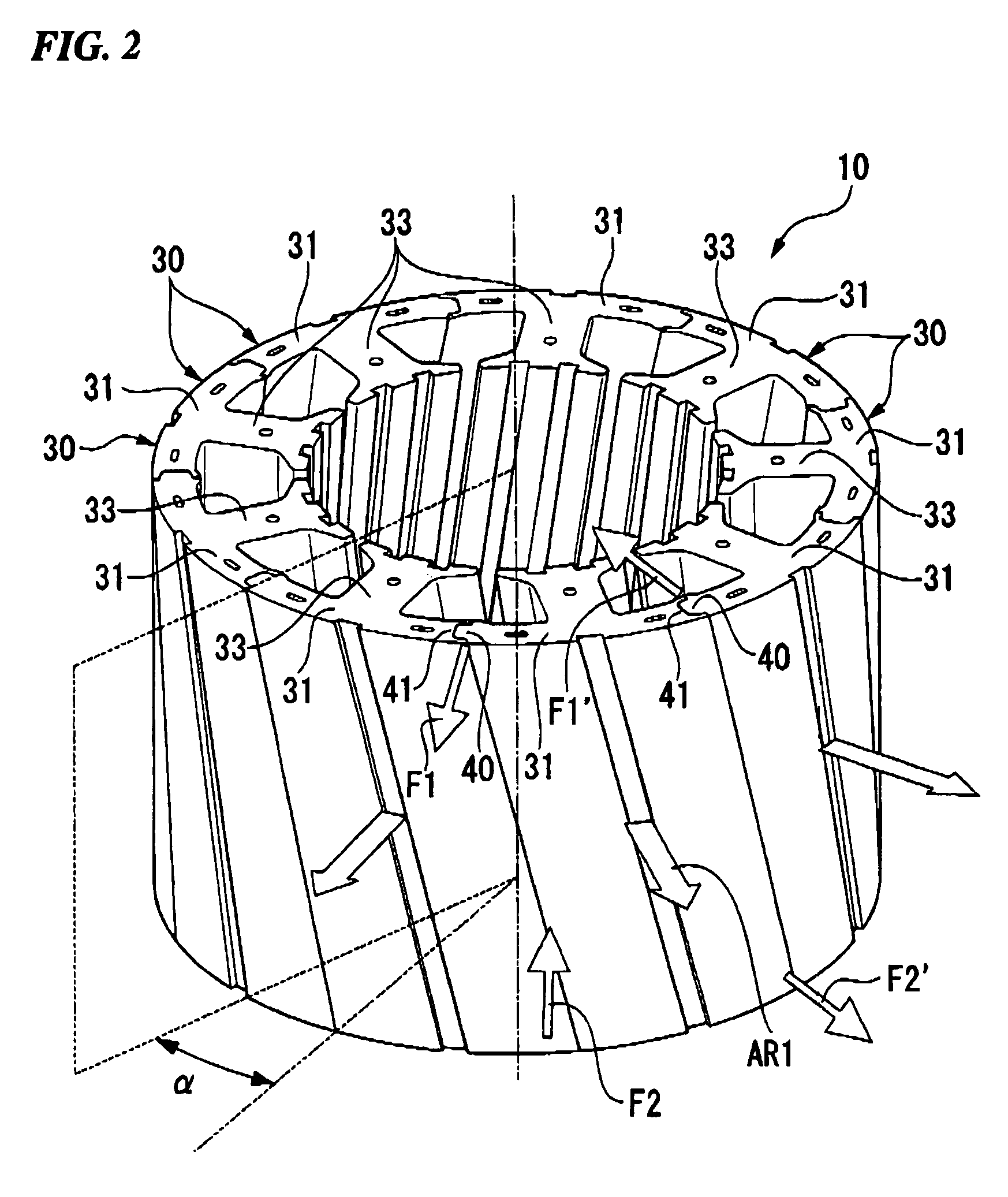

Motor, rotary electric machine and its stator, and method for manufacturing the stator

ActiveUS20090066183A1Easy to operateOptimize connection structureElectrical transducersRecord information storageElectric machineEngineering

A laminated core segment 30 into which a stator core is split has a core main body 31 that extends in an arc shape. On one end section of the core main body 31 there is formed a connecting section 40, and on the other end section there is formed a connecting section 41. The connecting section 40 is able to connect with the connecting section 41 of another laminated segment 30. In the connecting section 40 there is provided a protruding protrusion section 48, and the protrusion section 48 interferes with an interference section 53 on the connecting section 41 side when the stator core 30 is forced towards the direction in which the stator core is split. As a result, an assembly operation of the stator core becomes easier, and a magnetically excellent connecting structure can be obtained.

Owner:MITSUBA CORP

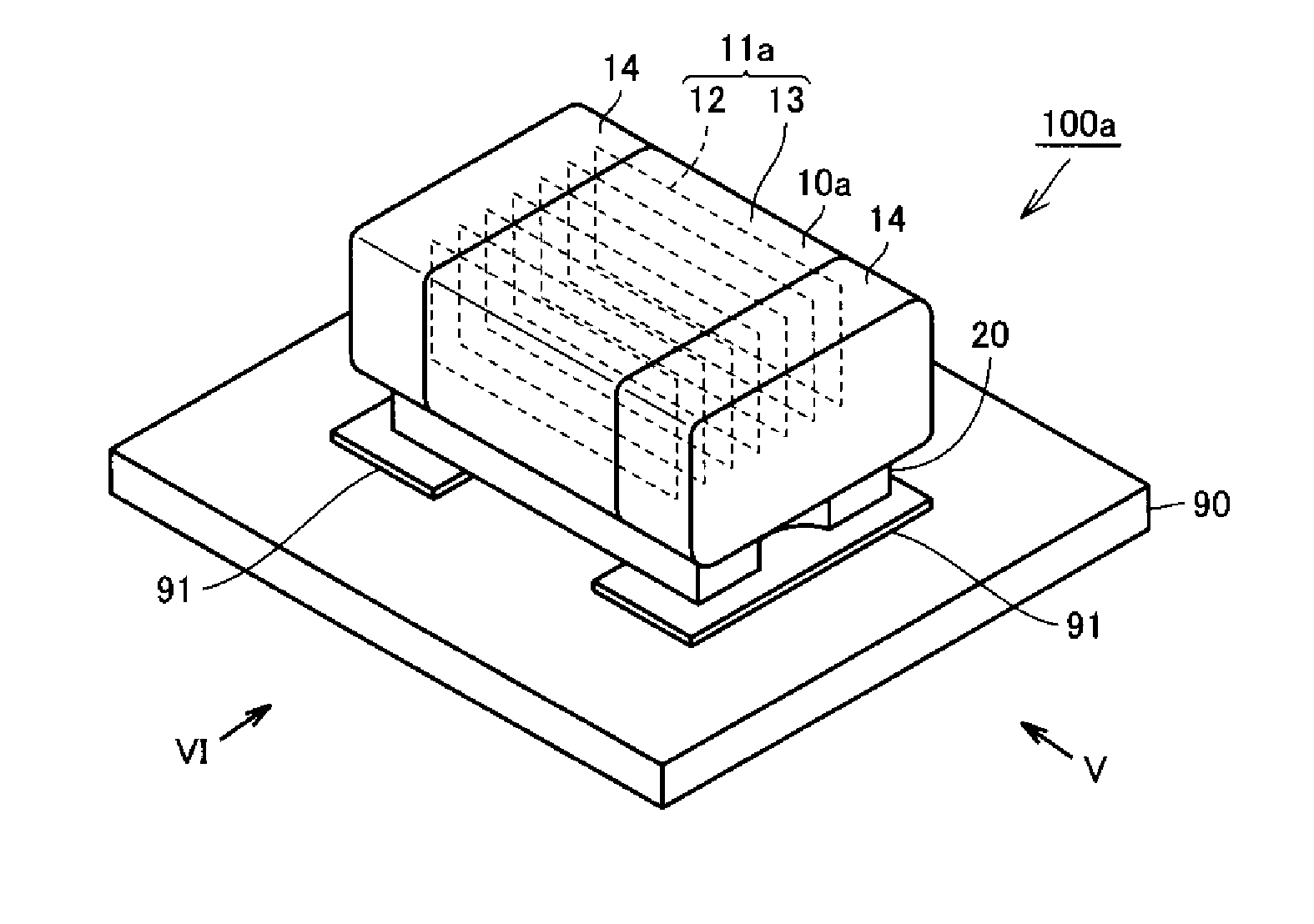

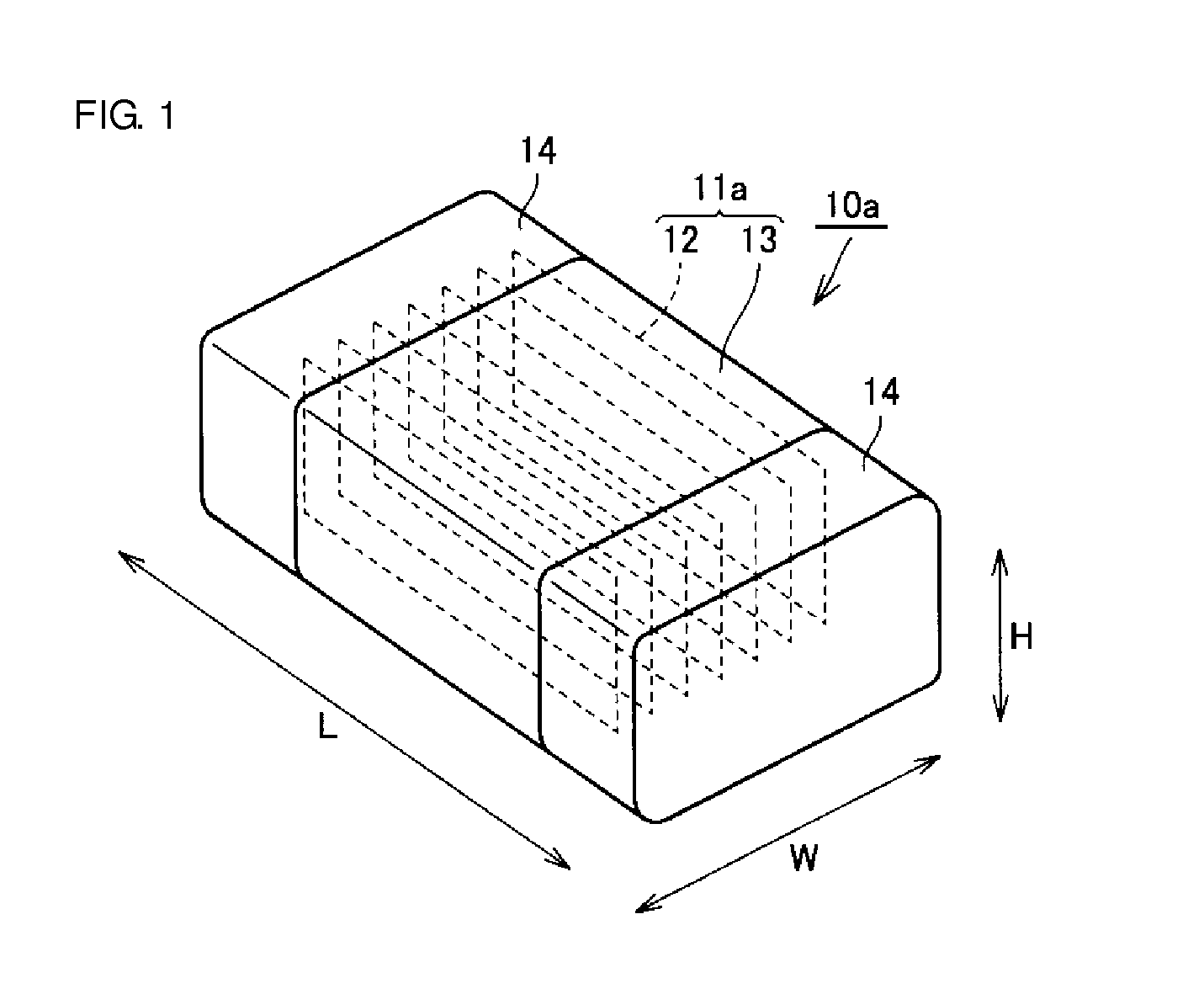

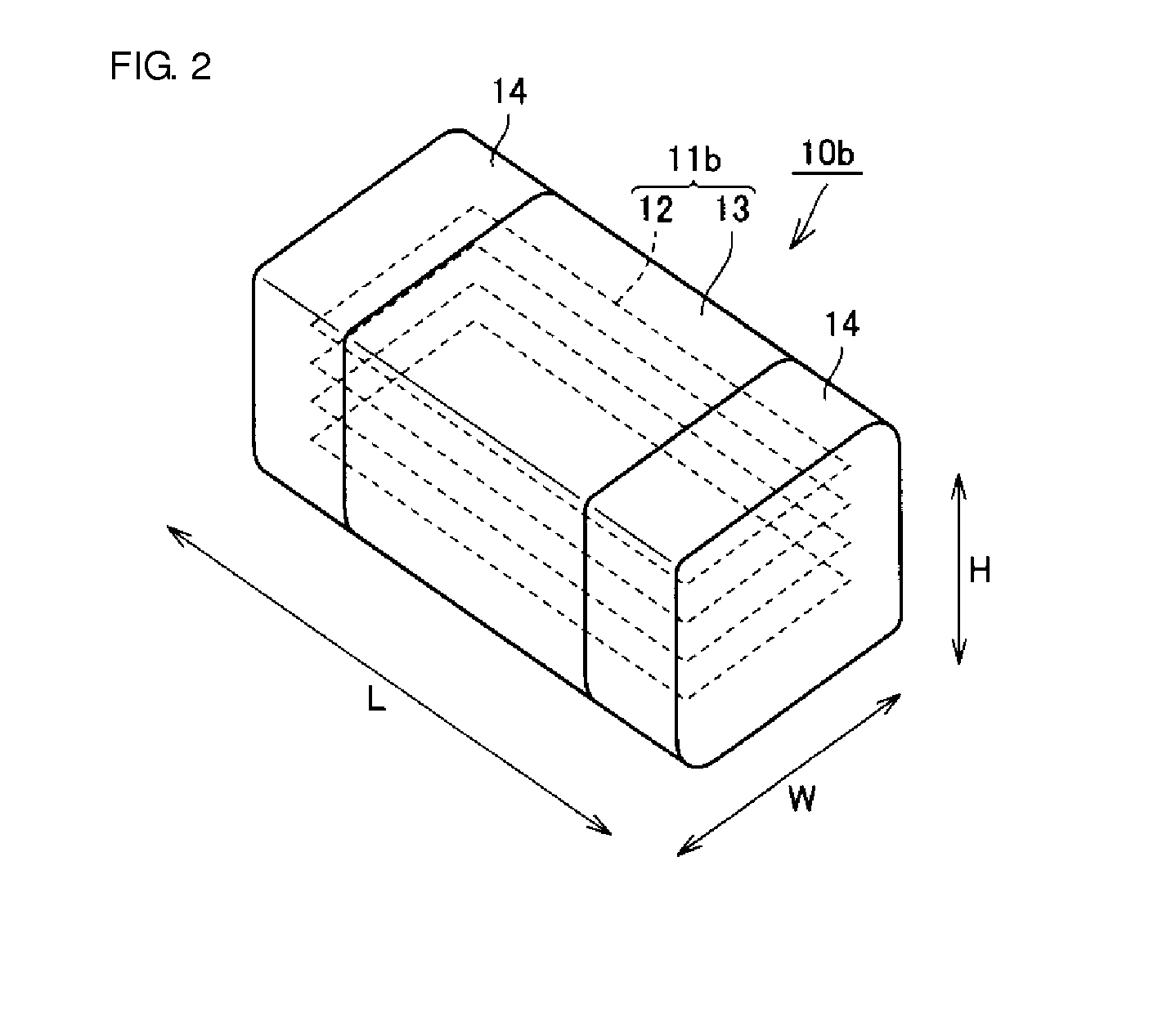

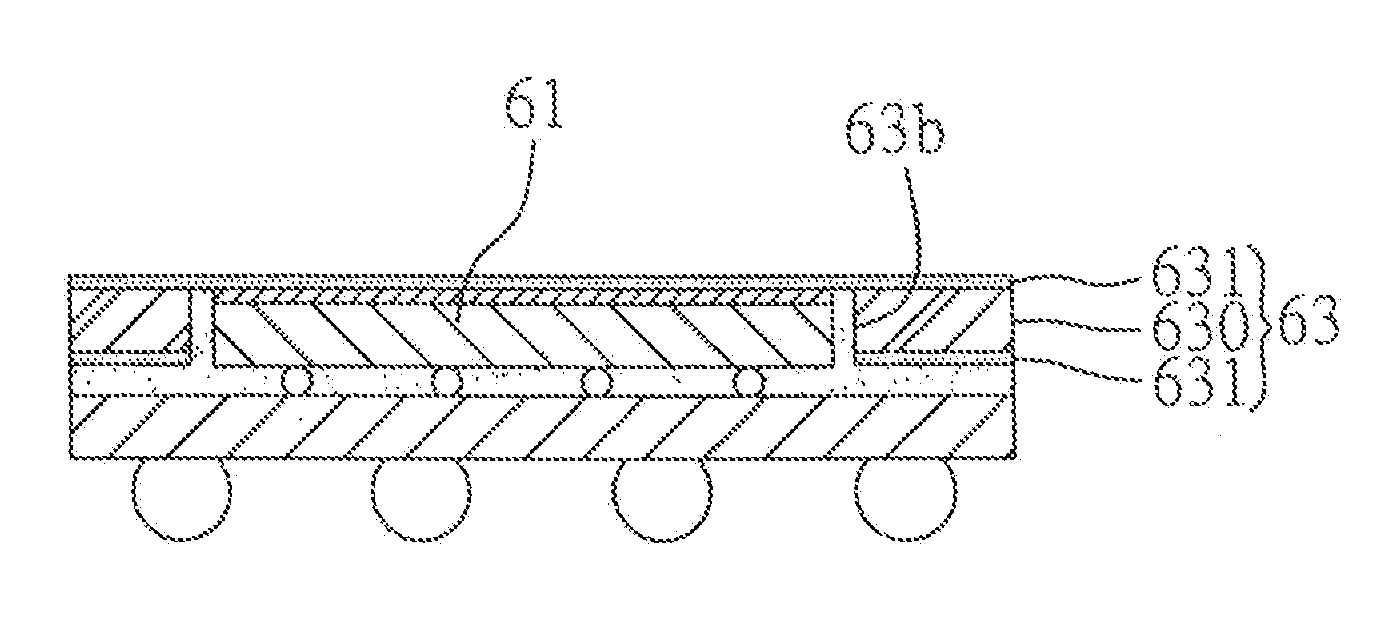

Electronic component

ActiveUS20150270068A1OccurrenceAvoid glitchesResistor terminals/electrodesFixed capacitor dielectricEngineeringElectronic component

An electronic component includes an electronic element including external electrodes on a surface and a substrate terminal on which the electronic element is mounted. The substrate terminal includes a first main surface, a second main surface opposite the first main surface, and a peripheral surface joining the first main surface and the second main surface. The substrate terminal includes mounting electrodes provided on the second main surface and electrically connected to the external electrodes of the electronic element, and connection electrodes provided on the first main surface and electrically connected to lands of a circuit substrate. A maximum width of the connection electrodes is greater than a maximum width of the mounting electrodes.

Owner:MURATA MFG CO LTD

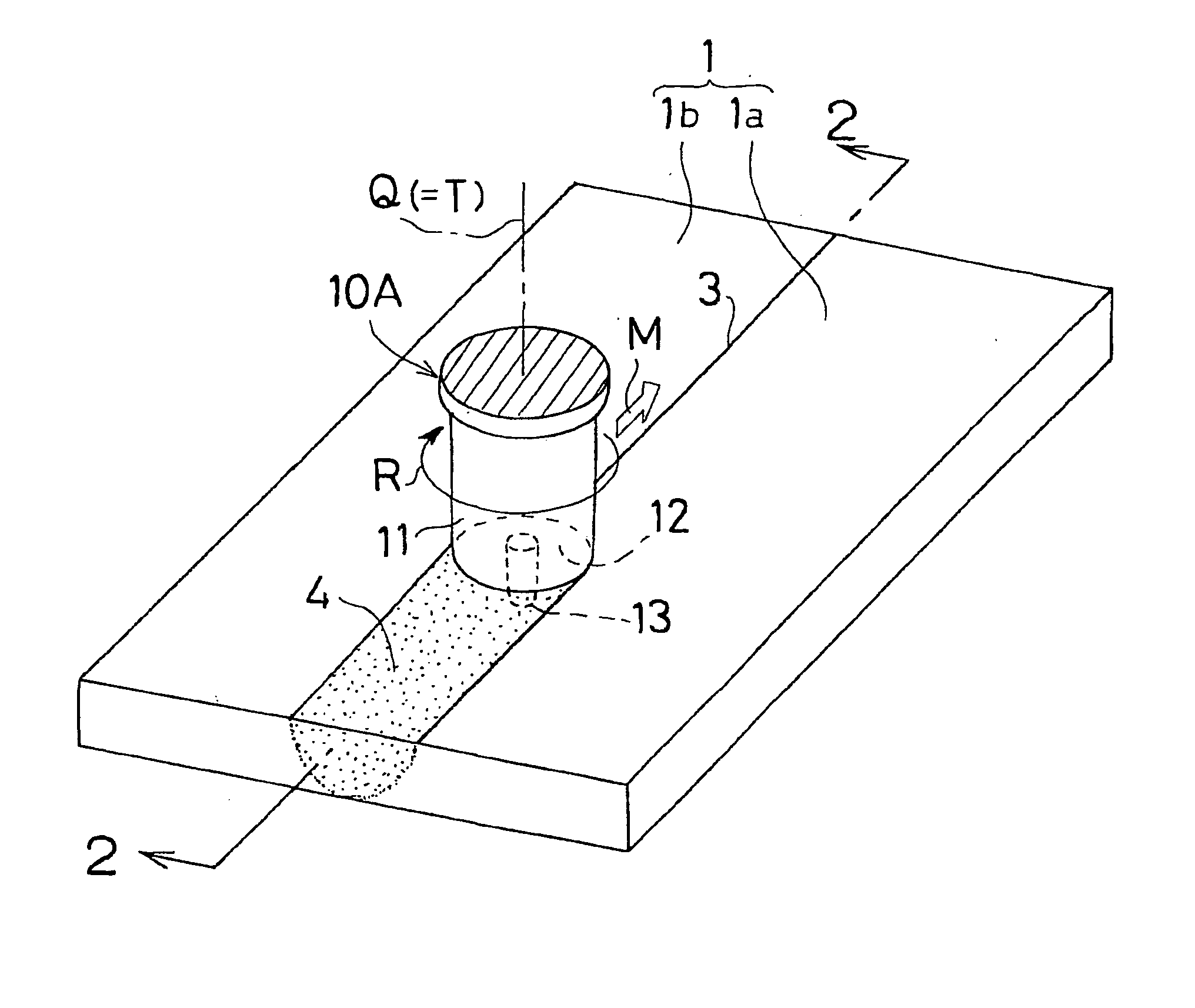

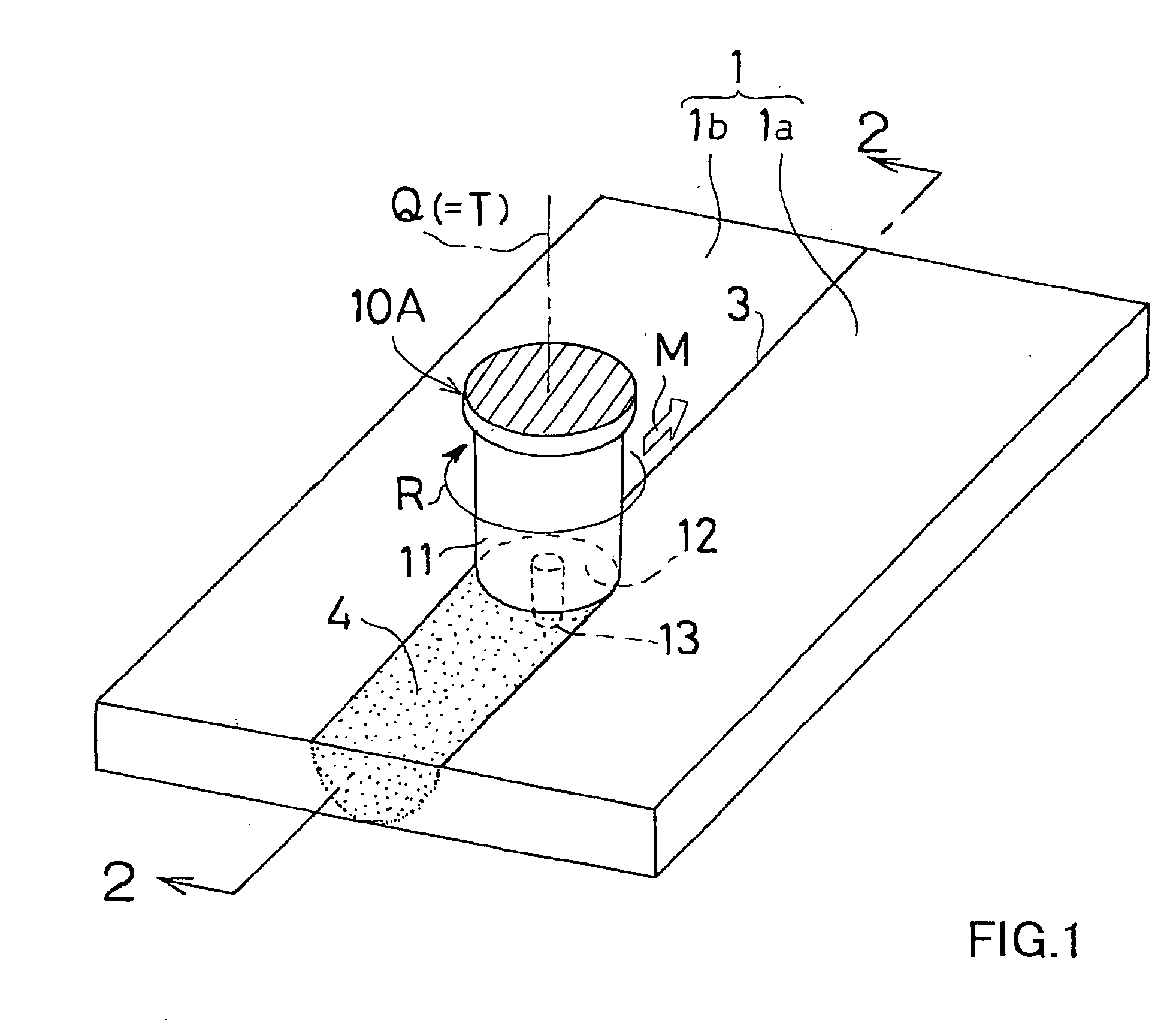

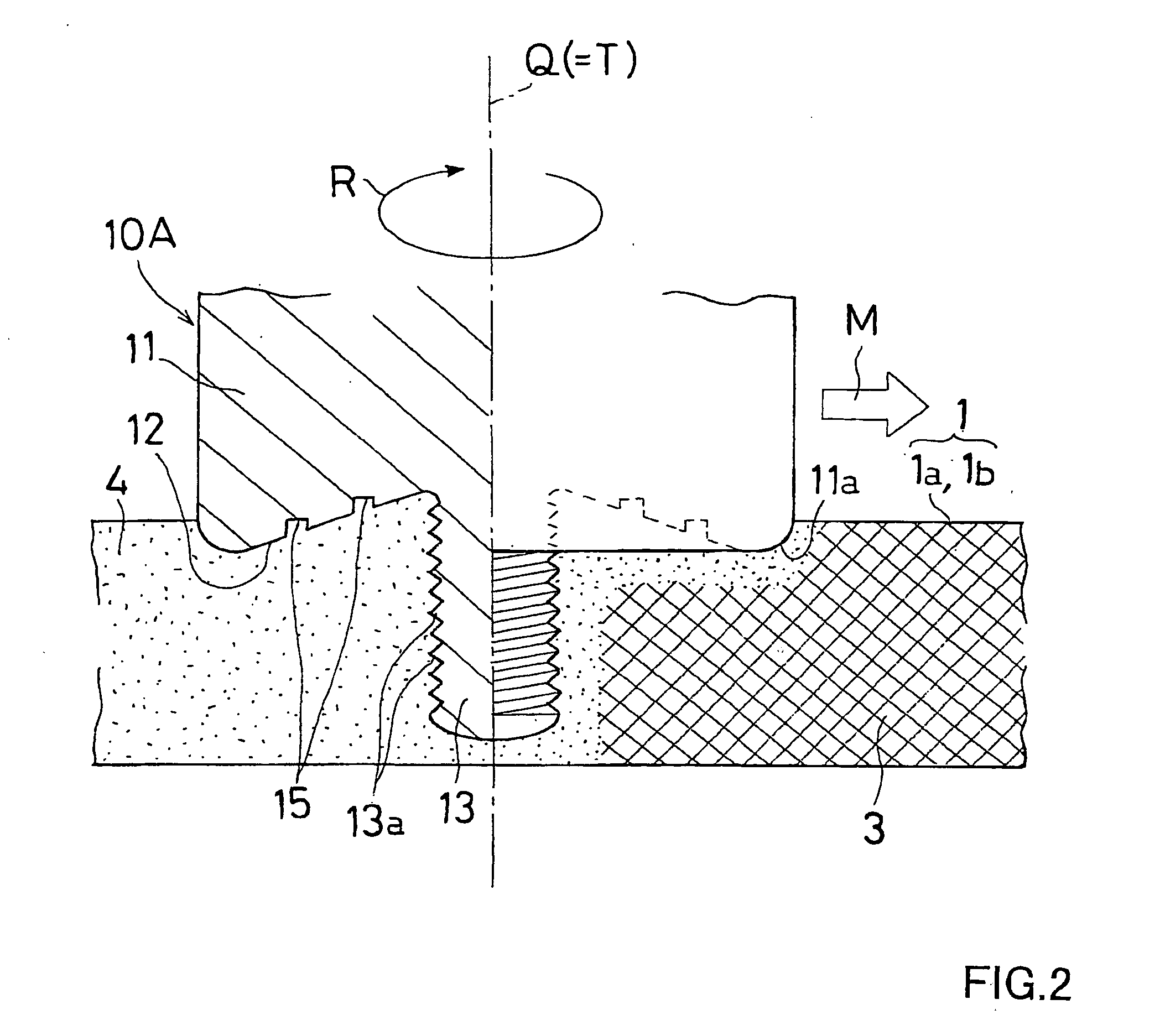

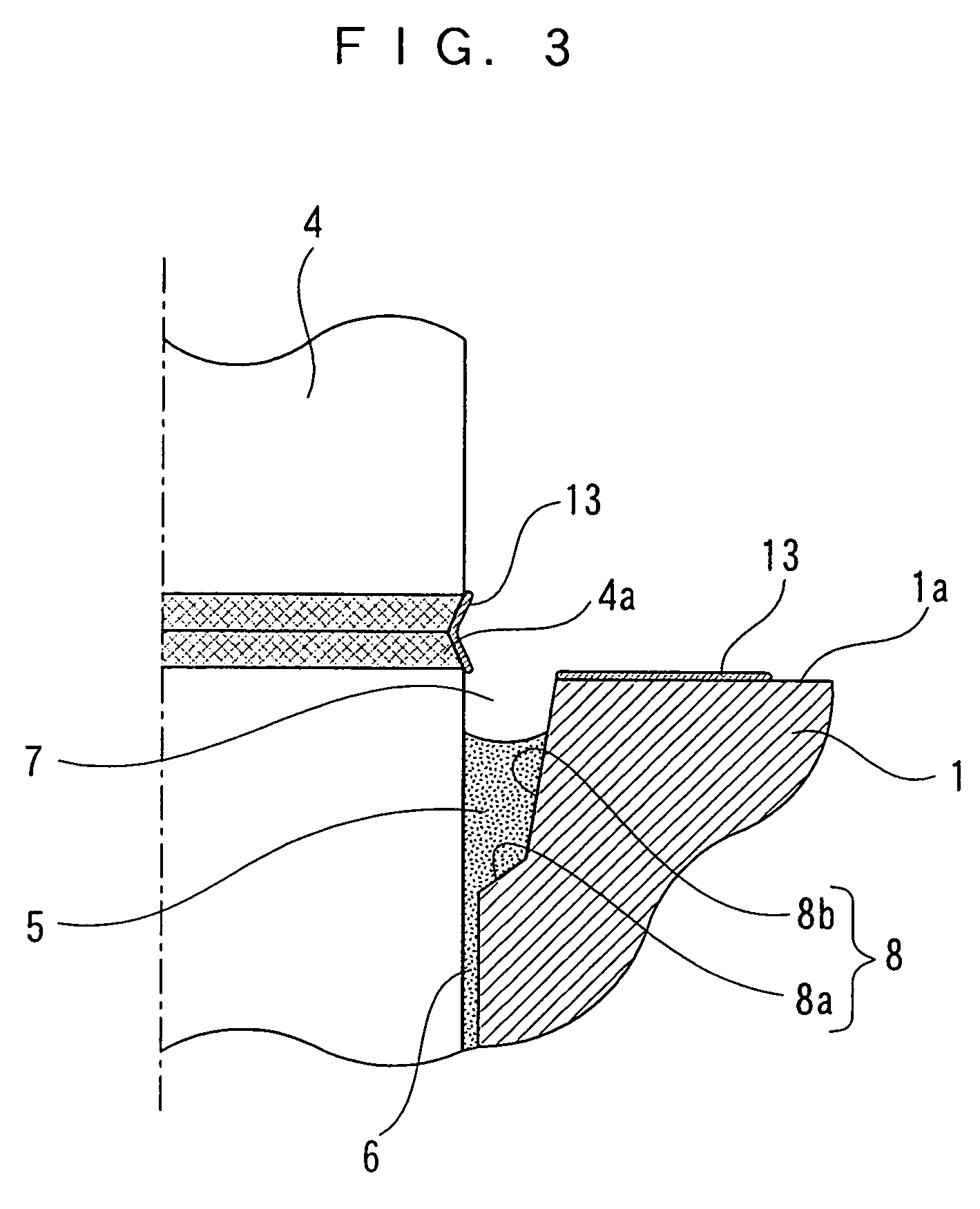

Friction agitation joining tool, friction agitation joining method and joined member manufacturing method

InactiveUS20040108359A1Prevent escapeHold steadyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

A friction agitation joining tool (10A, 10B) includes a rotor (11) having an end portion to be pressed onto at least one of surfaces of joining members (11a, 1b) and a probe (13) to be inserted into a joining portion (3) of the joining-members (1a, 1b), wherein the probe (13) has a diameter smaller than a diameter of the rotor (11). An end face (12) of the end portion of the rotor (11) is formed into a concave surface dented from a periphery of the end face (12) toward a rotational center of the end face (12). The probe (13) is protruded from the rotational center of the end face (12). The end face (12) is provided with a spiral groove (15) or an annular groove (16) surrounding the probe (13). By performing the joining operation with the joining tool (10A, 10B), a joined member with a good joint can be obtained.

Owner:SHOWA DENKO KK

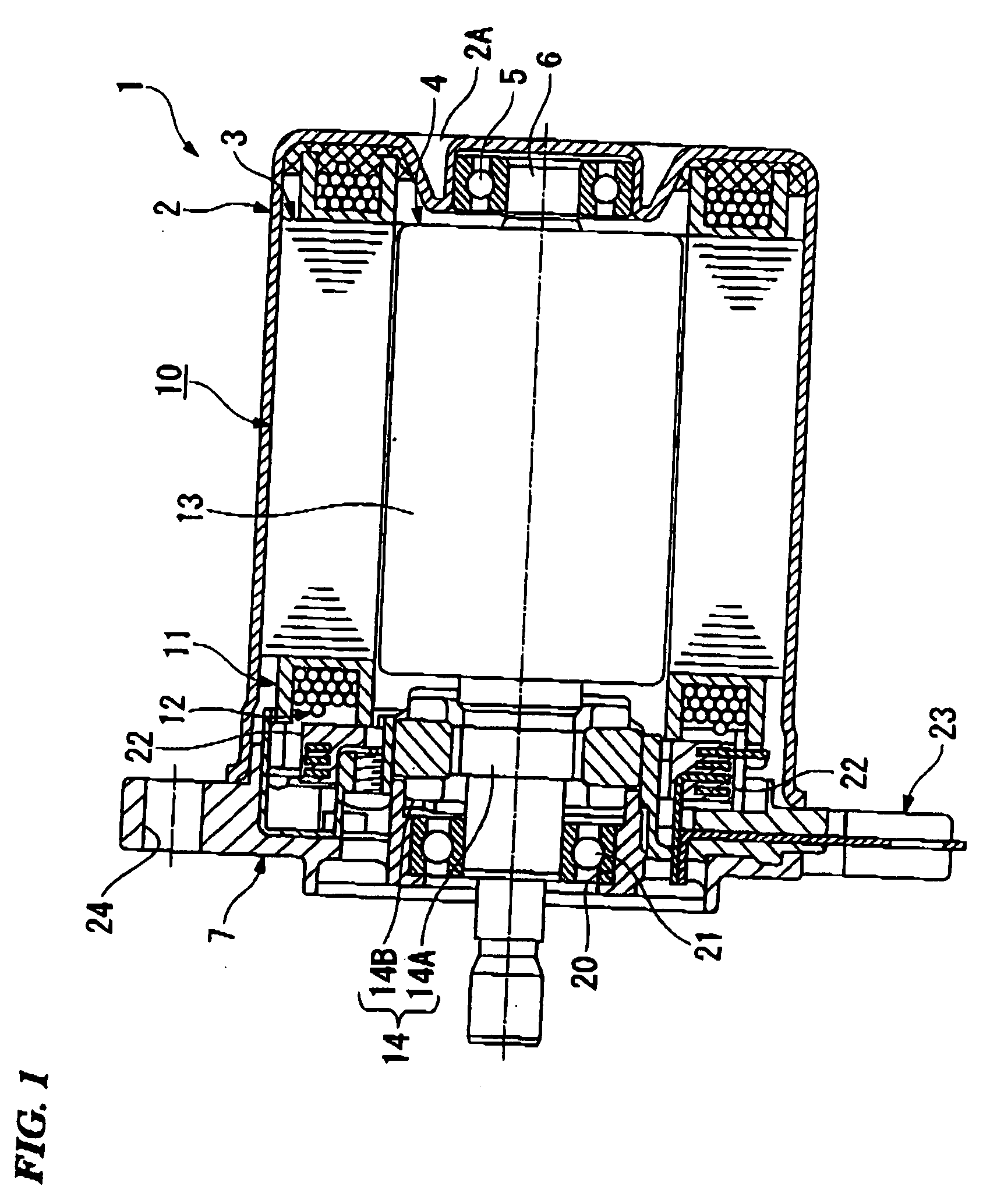

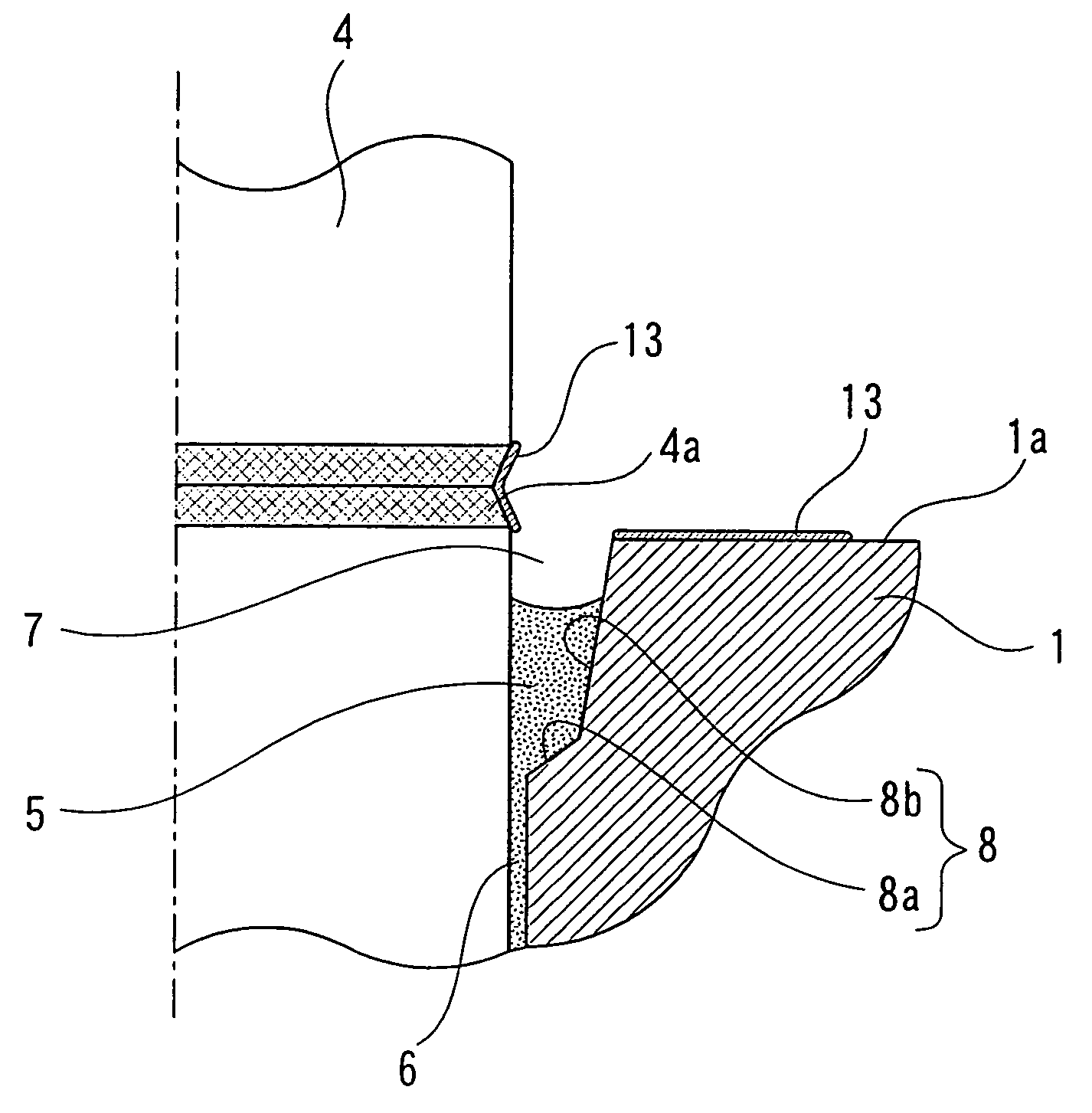

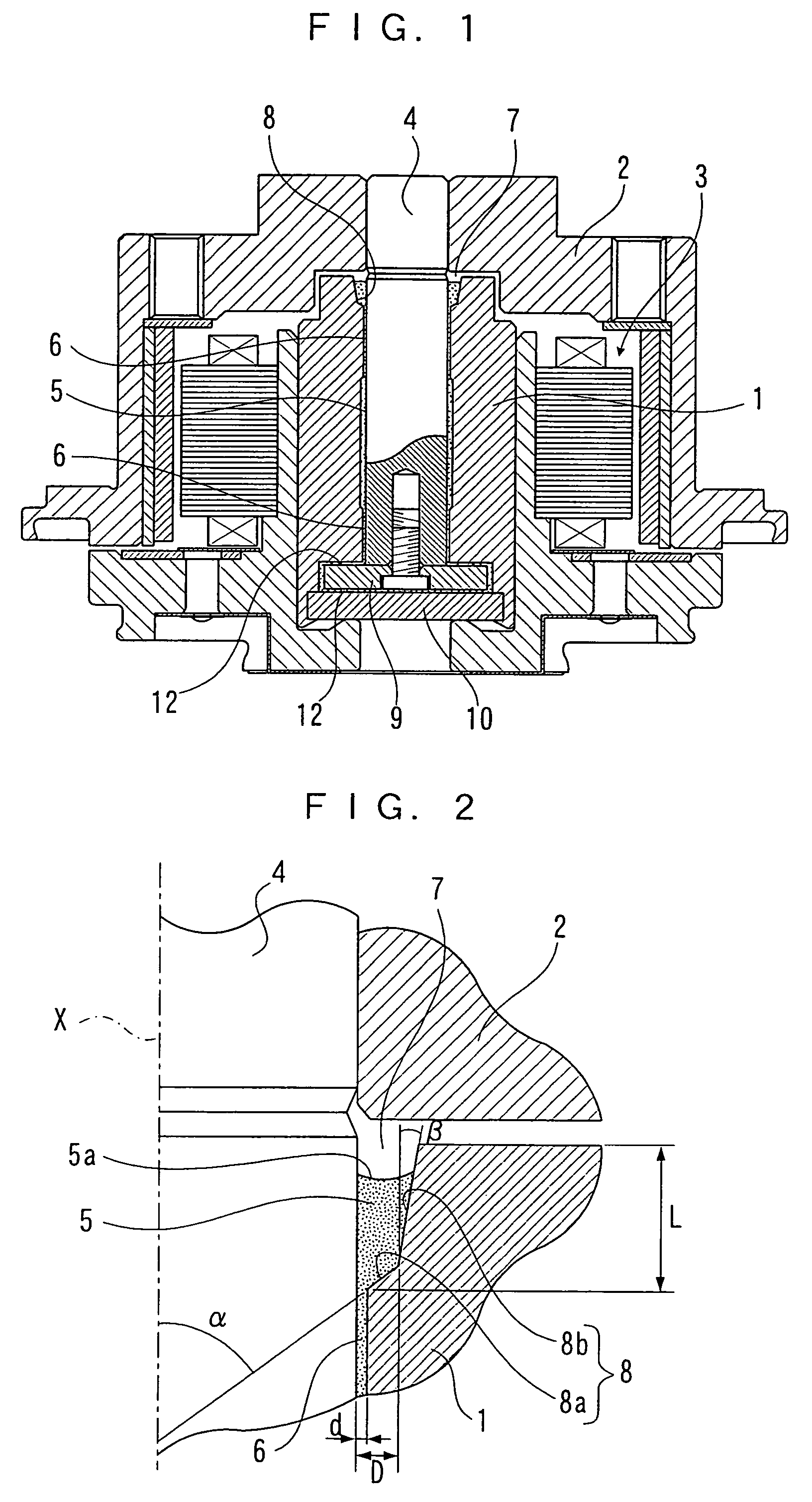

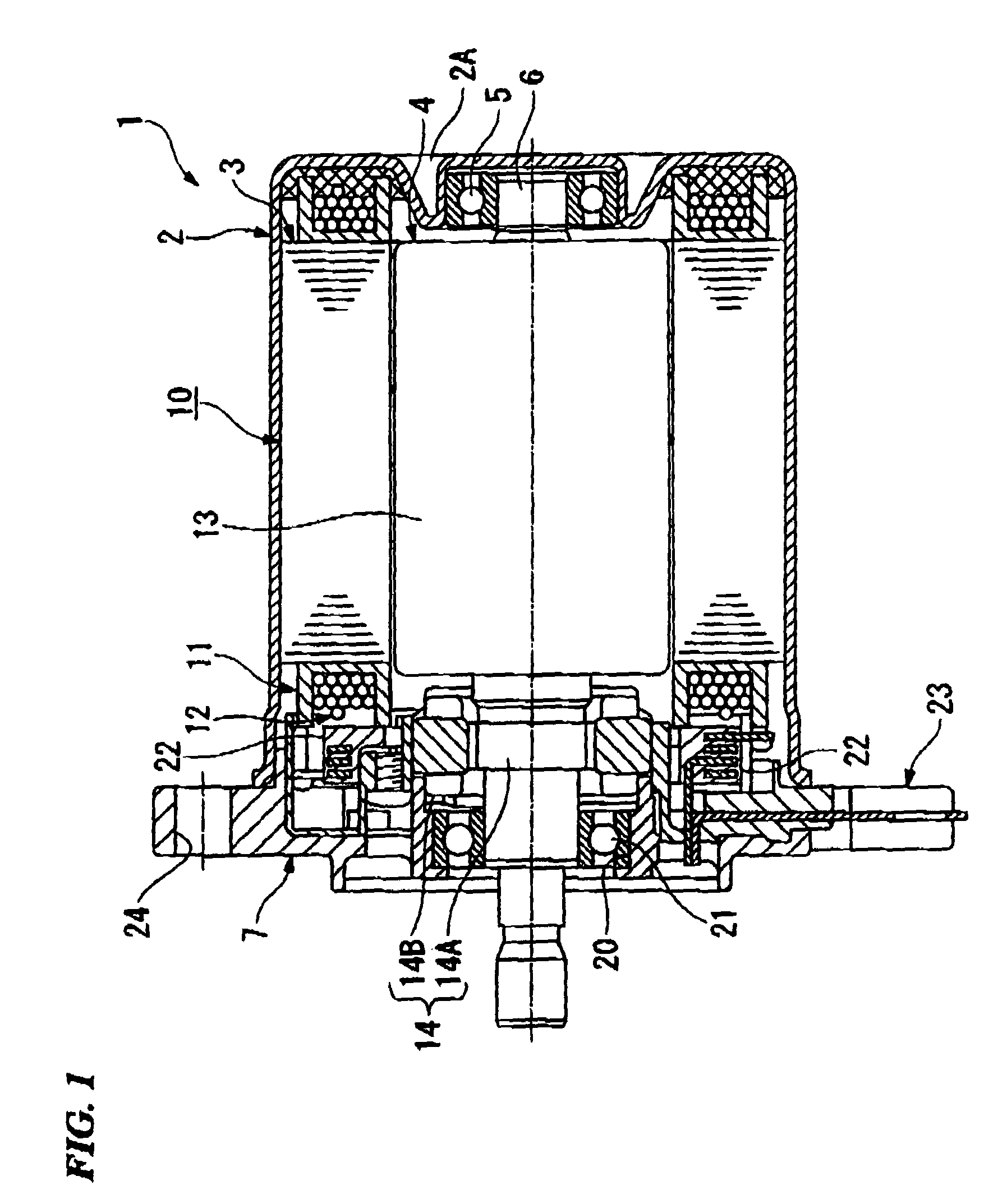

Fluid bearing device

ActiveUS7201516B2Small depthSufficient length dimensionShaftsRecord information storageEngineeringFluid bearing

A fluid bearing device capable of preventing a lubricant from scattering outward even during rotation thereof, while holding a relatively large amount of lubricant at a seal surface portion. A lubricant is filled between a sleeve and a shaft, a seal surface portion is formed on the sleeve in a location facing an open end thereof, the seal surface portion has a sectional shape defined by a plurality of inclined surfaces, and an inclination angle α of the inclined surface of the seal surface portion adjacent a radial bearing portion with respect to a shaft axis is formed to be larger than an inclination angle β of the inclined surface of the seal surface portion distant away from the radial bearing portion with respect to the shaft axis.

Owner:PHC HLDG CORP

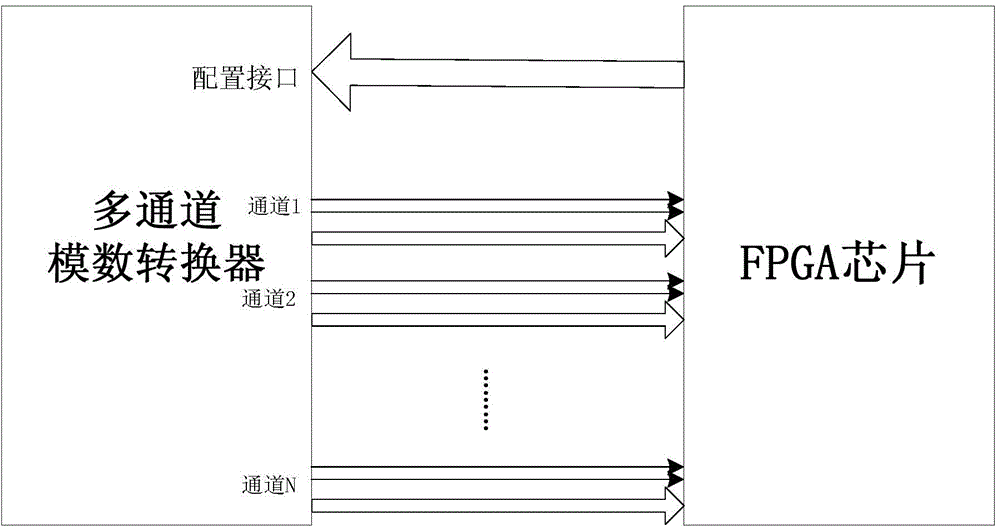

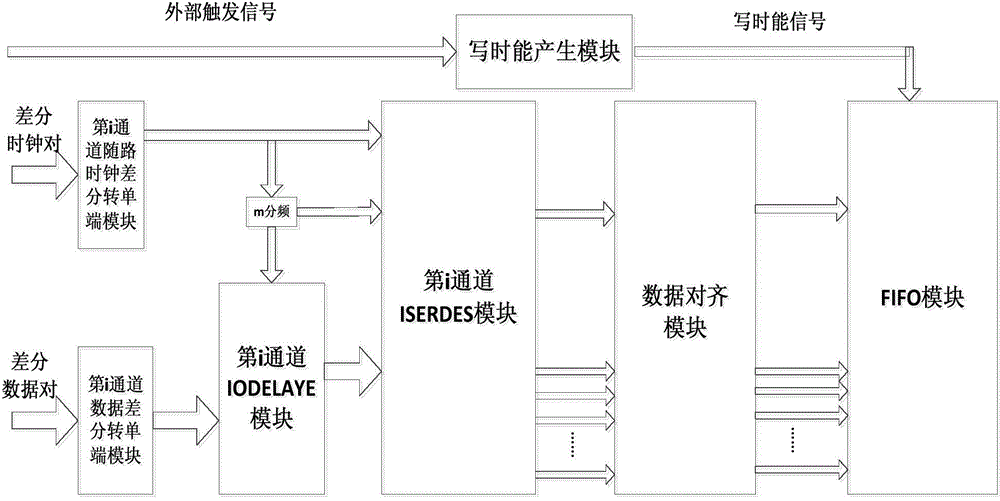

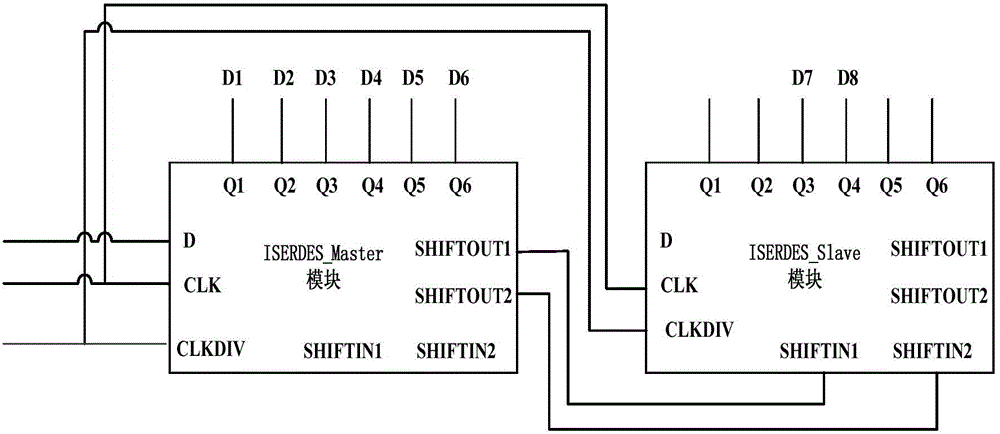

Method for achieving synchronization of multichannel analog-digital converter

ActiveCN104378114AImpact on imaging resultsAvoid glitchesAnalogue-digital convertersDigital down converterRadar

The invention belongs to the technical field of radar radio-frequency signal collecting technologies and discloses a method for achieving synchronization of a multichannel analog-digital converter. The method comprises the following steps that the multichannel analog-digital converter is configured to work in a multichannel testing mode; the multichannel analog-digital converter generates data differential pairs and channel associated clock differential pairs, and the data differential pair and the channel associated clock differential pair of each channel are sent to an FPGA chip; the FPGA chip obtains corresponding single-ended clock signals and corresponding single-ended data signals; a corresponding delay value is configured to each data bit of the single-ended data signal of each channel, according to the correspondingly delay value configured to each data bit of the singled-ended data signal of each channel, delaying processing is conducted on the signal of each data bit of the singled-ended data signal of each channel; deserializing is conducted on the delayed singled-ended data signal of each channel, and corresponding parallel data are obtained; according to the phase relationship between the parallel data of each channel, phase alignment of the parallel data of each channel is conducted.

Owner:XIDIAN UNIV

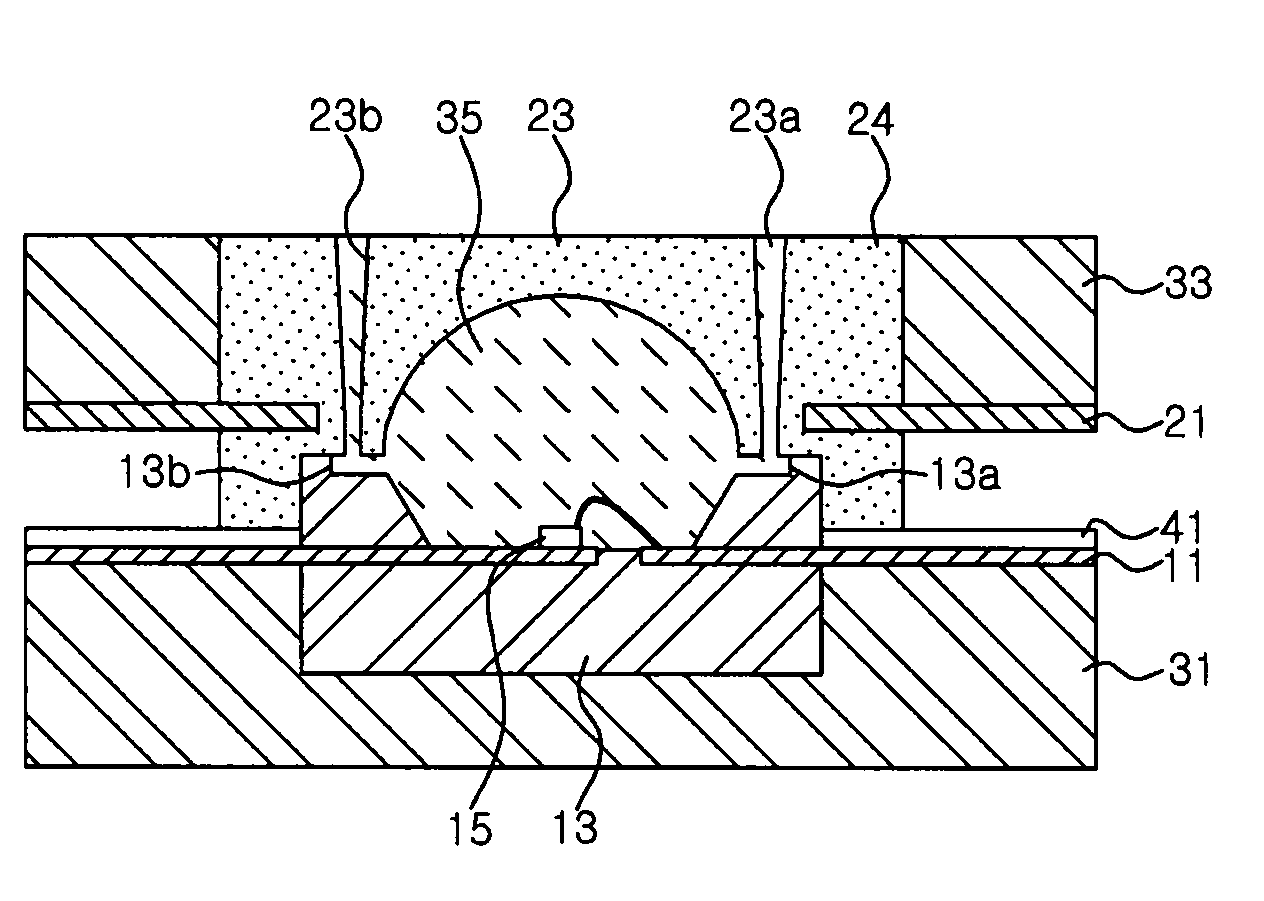

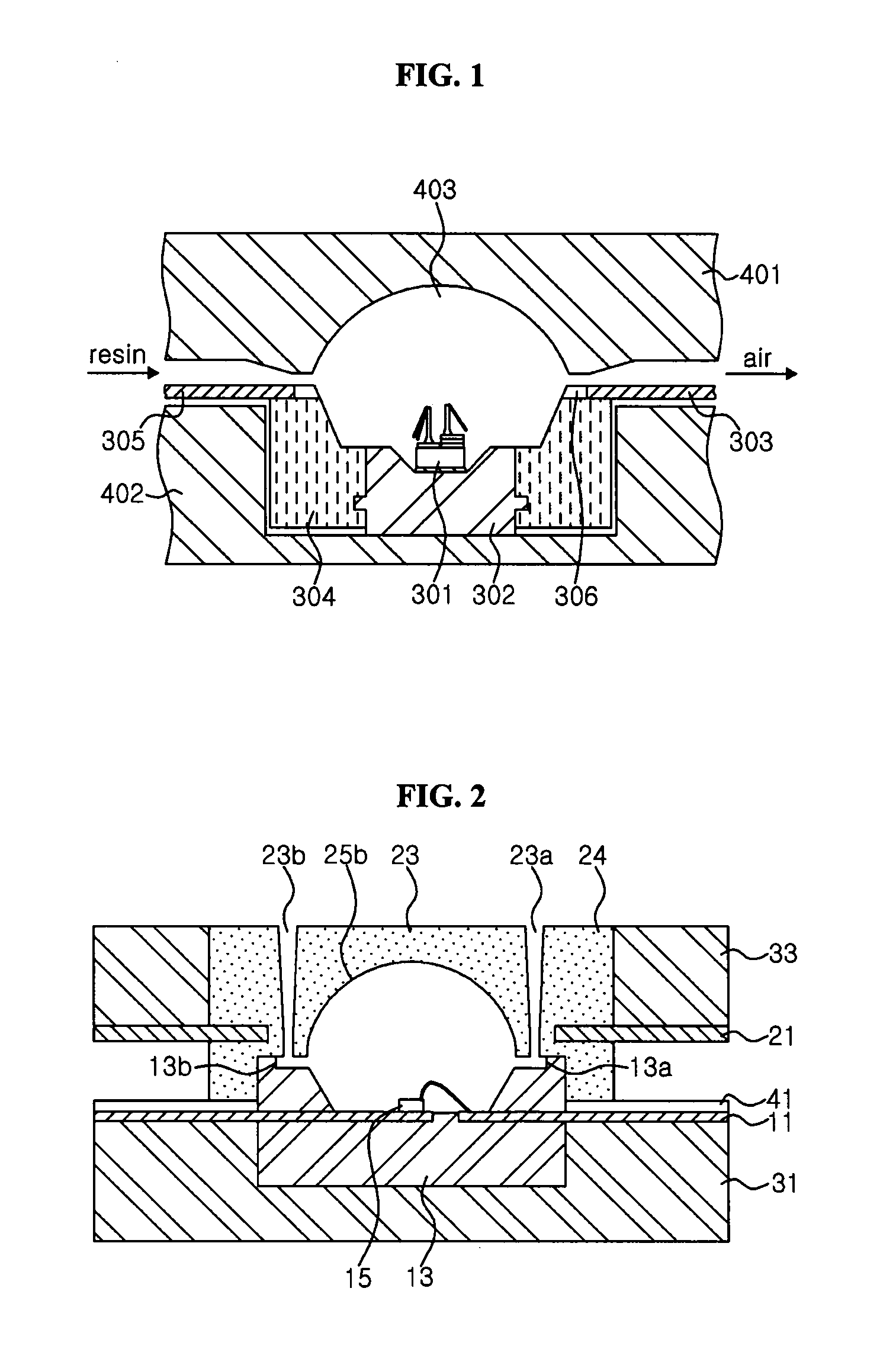

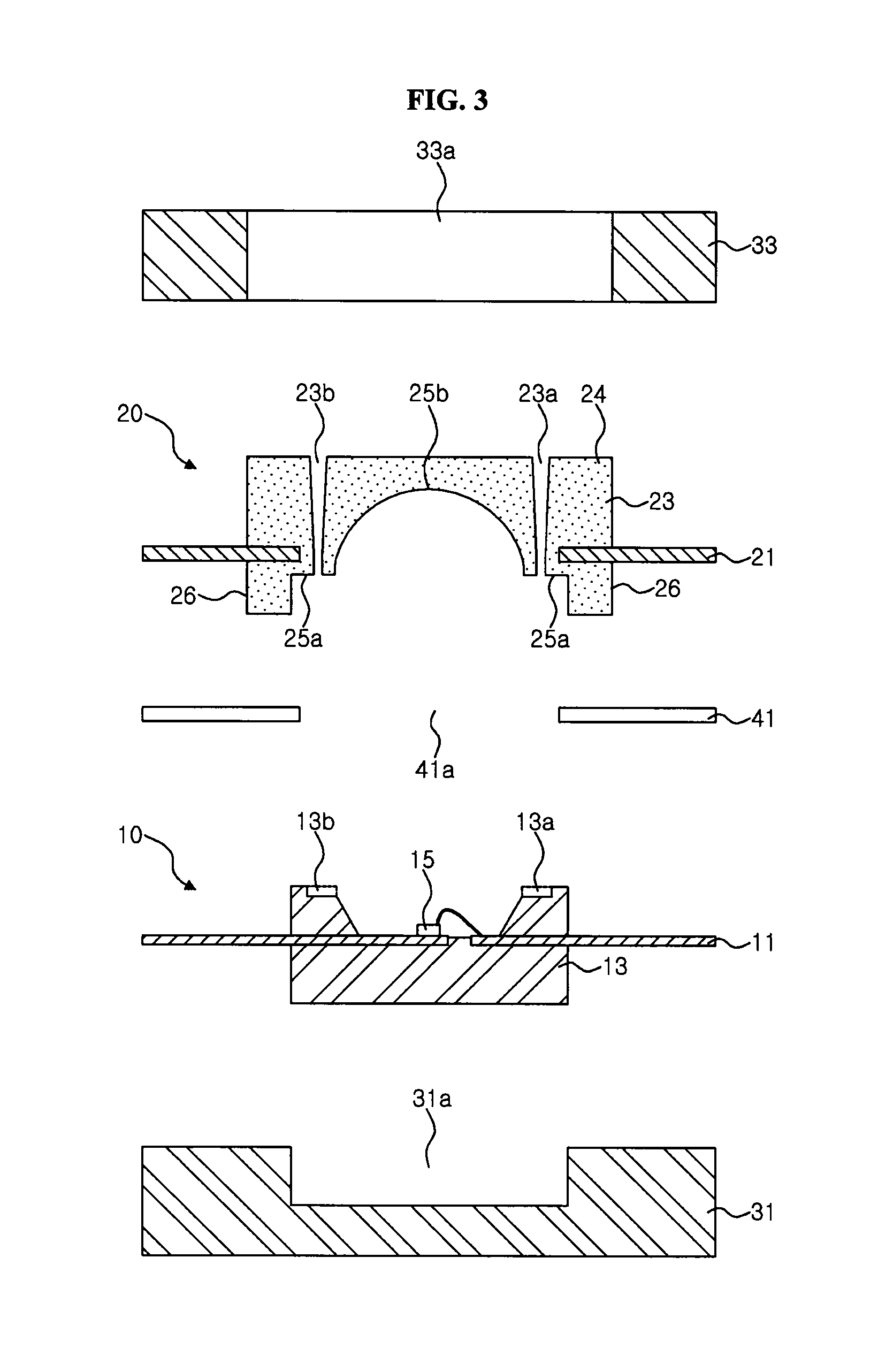

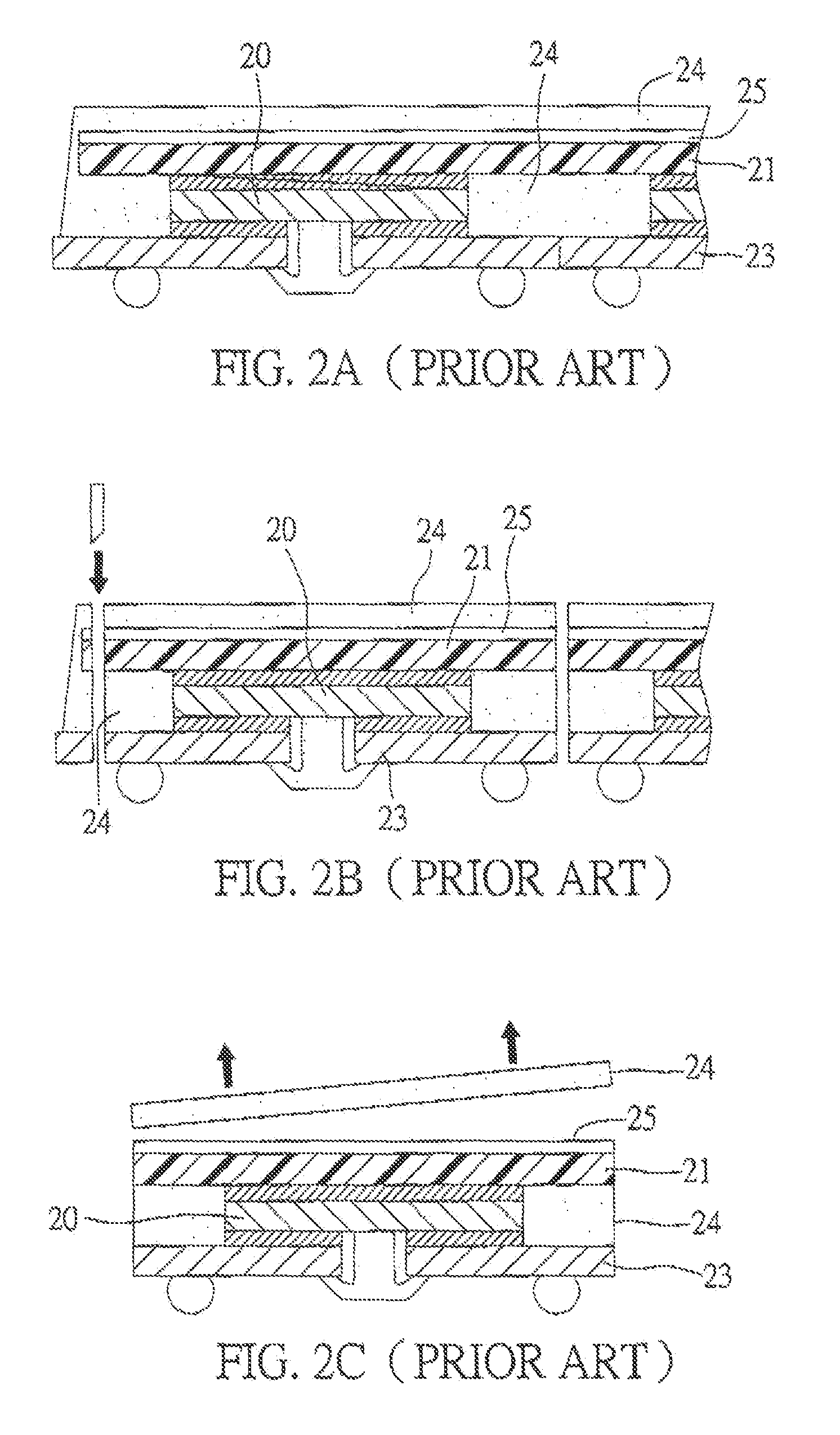

Mold for Forming a Molding Member and Method of Fabricating a Molding Member Using the Same

InactiveUS20080268559A1Avoid glitchesMold growthMould separation apparatusSemiconductor/solid-state device detailsMaterials scienceAir bubble

There are provided a mold for forming a molding member and a method for forming a molding member using the same. The mold includes an upper surface, and a lower surface having an outer peripheral surface and a concave surface surrounded by the outer circumference. Injection and discharge holes extend from the upper surface to the lower surface. Accordingly, after the mold and the package are coupled so that the discharge hole is directed upward, a molding member can be formed on the package by injecting the molding material through the injection hole, whereby it is possible to prevent air bubbles from being captured in the molding member.

Owner:SEOUL SEMICONDUCTOR

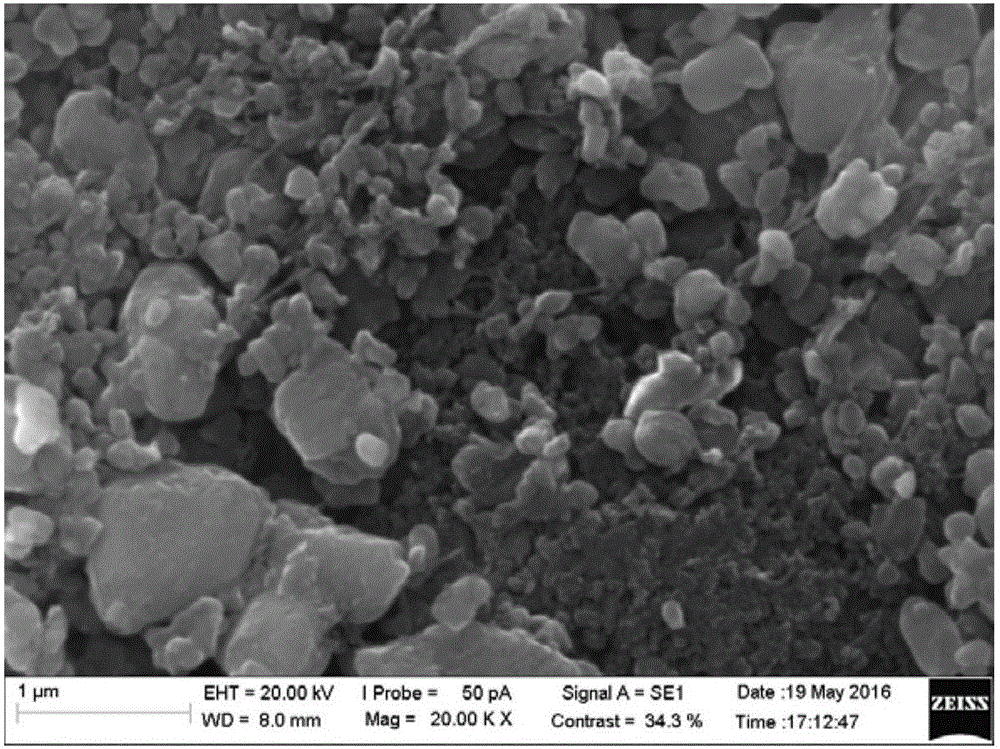

Conductive substrate, electrode, energy storing device and preparation method thereof

InactiveCN104868126AImprove flexibilityIncreased bendabilityElectrode carriers/collectorsPorosityMicrometer

The invention provides conductive substrate, an electrode, an energy storing device and a preparation method thereof. The conductive substrate comprises a non-conductive substrate layer and a conductive layer which is arranged on the non-conductive substrate layer; the non-conductive substrate layer is plastic or rubber state polymer film layer or composite polymer film layer with the thickness of 0.1 to 100 micrometer, the porosity being 40% to 60%, good flexibility, has self-supporting property and is high temperature and corrosion resistant; the particle diameter of the conductive layer is a nanoscale conductive material layer; the thickness of the conductive layer is 1 to 300 micrometers. The conductive substrate comprises a flexible non-conductive substrate layer and the conductive layer and a purpose of improving the electrode flexibility is achieved by increasing the substrate flexibility due to covering of the conductive layer on the flexible non-conductive substrate layer.

Owner:刘强

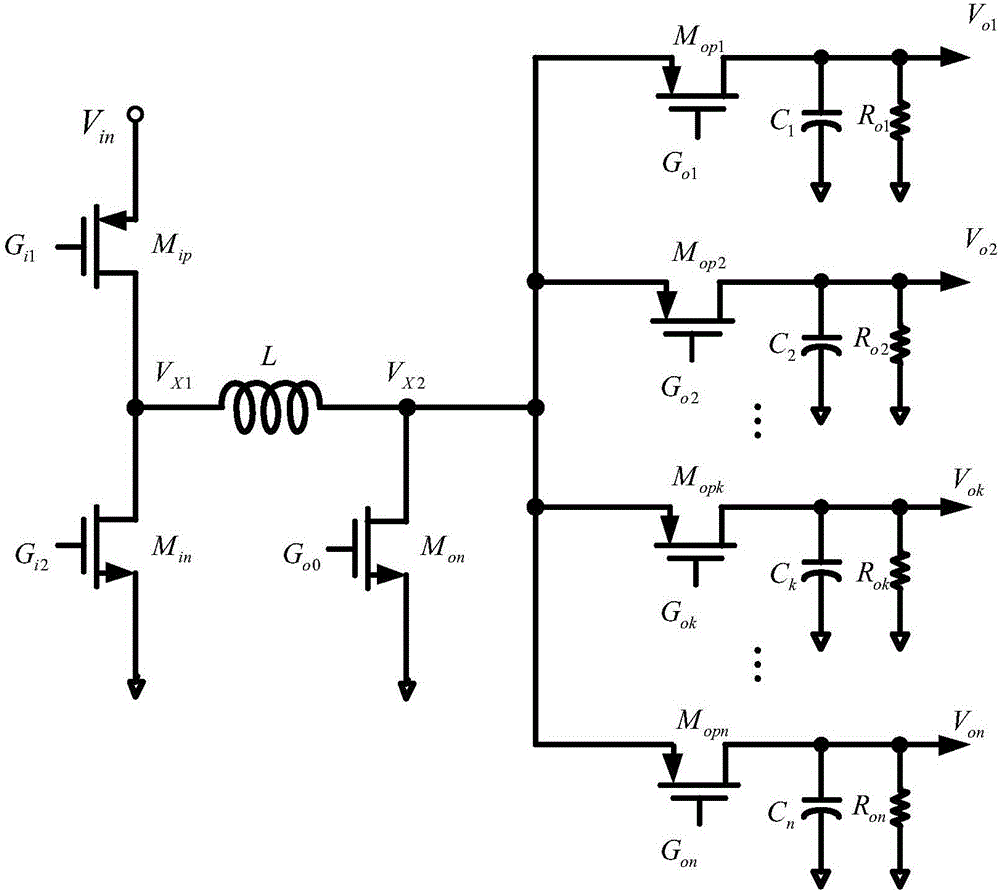

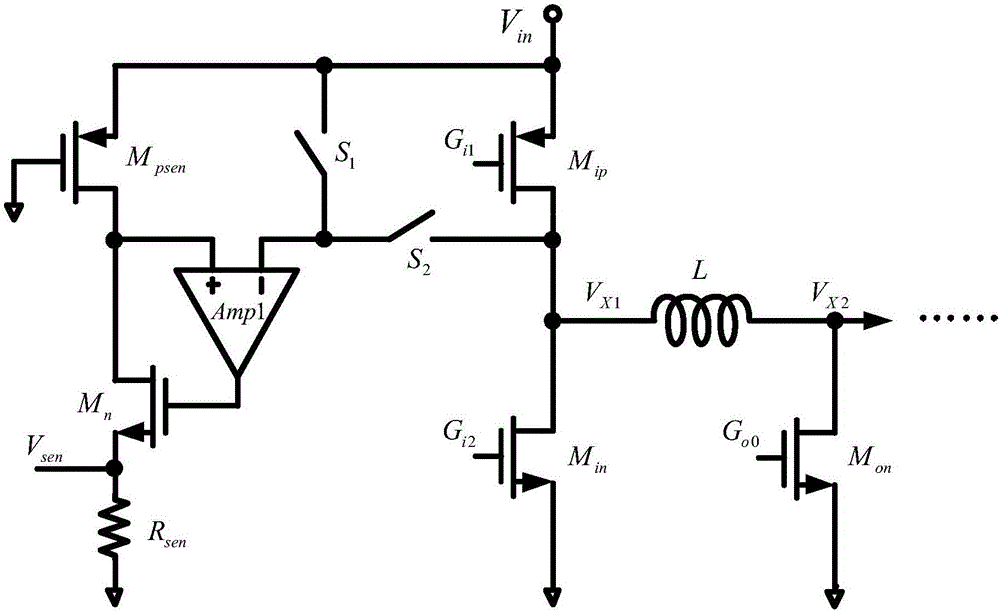

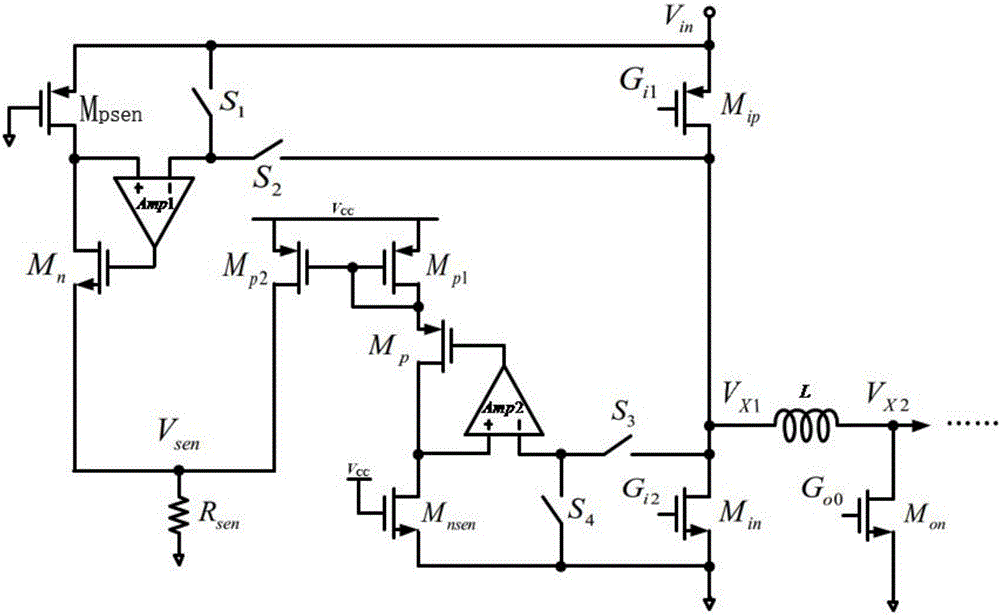

Full wave inductance current sampling circuit

ActiveCN105763047AAccurate samplingSampling signal continuousCurrent/voltage measurementDc-dc conversionFull waveEngineering

The invention discloses a full wave inductance current sampling circuit, comprising a system power level circuit, a proportion MOS tube current sampling circuit, a voltage-current and current summation circuit, and a sampling direct current correction and sampling integration circuit. The first output terminal of the system power level circuit is connected to the first input terminal of the sampling direct current correction and sampling integration circuit through the proportion MOS tube current sampling circuit, and the second output terminal of the system power level circuit is in connection with the second input terminal of the sampling direct current correction and sampling integration circuit through the voltage-current and current summation circuit. The full wave inductance current sampling circuit can realize accurate full wave inductance current sampling through the system power level circuit, the proportion MOS tube current sampling circuit, the voltage-current and current summation circuit, and the sampling direct current correction and sampling integration circuit, obtain continuous sampling signals, effectively avoid burrs, and be widely applied to the electronic circuit field.

Owner:拓尔微电子股份有限公司

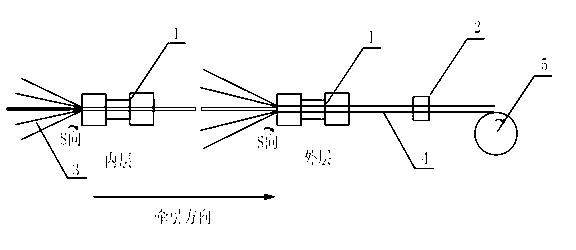

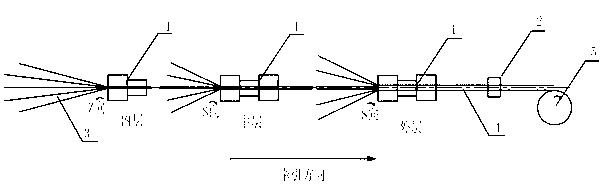

Aluminum or aluminum alloy conductor twisting and compressing process for cables

ActiveCN102800437AReduce resistanceReduce frictional resistanceCable/conductor manufactureSocial benefitsElectrical conductor

The invention provides an aluminum or aluminum alloy conductor twisting and compressing process for cables. The aluminum or aluminum alloy conductor twisting and compressing process comprises the following steps of: twisting aluminum or aluminum alloy single wires along the traction direction of the aluminum or aluminum alloy single wires; and compressing the twisted aluminum or aluminum alloy single wires by a compression roller, wherein a layer of twisting layer is formed after the aluminum or aluminum alloy single wires are twisted once and compressed by means of the compression roller, the subsequent twisting layer is twisted on the basis of the fore twisting layer, and the twisting direction of the last twisting layer is the same as that of the second last twisting layer. According to the aluminum or aluminum alloy conductor twisting and compressing process, the twisting directions of the outermost two layers of twisting layers are the same, the compression roller is combined with a nano diamond composite coating compression die, the phenomena of surface burrs of compressed round aluminum conductors, more aluminum scraps and wire fracture are prevented, the influence of alcohol which is continuously dripped for lubricating and cooling on the residual water inside or on the surface of the conductors is eliminated, the volume resistivity of the twisted and compressed cables is reduced by 0.5 to 2.0 percent, the production cost is saved, and the social benefit is higher.

Owner:SICHUAN MINGXING CABLE

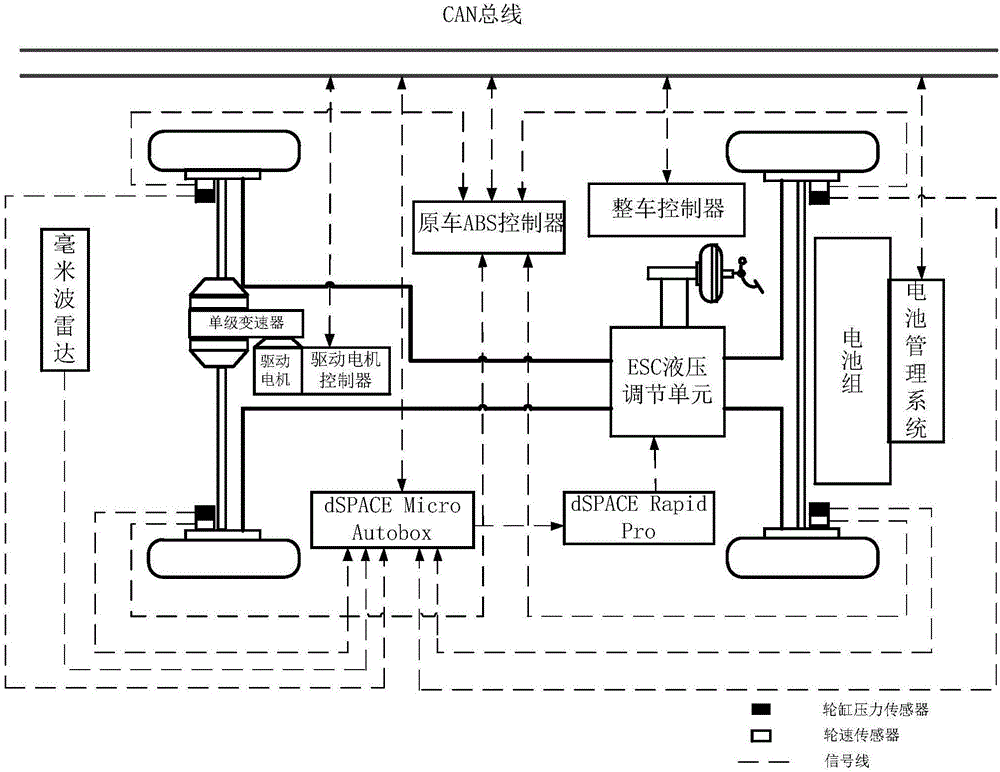

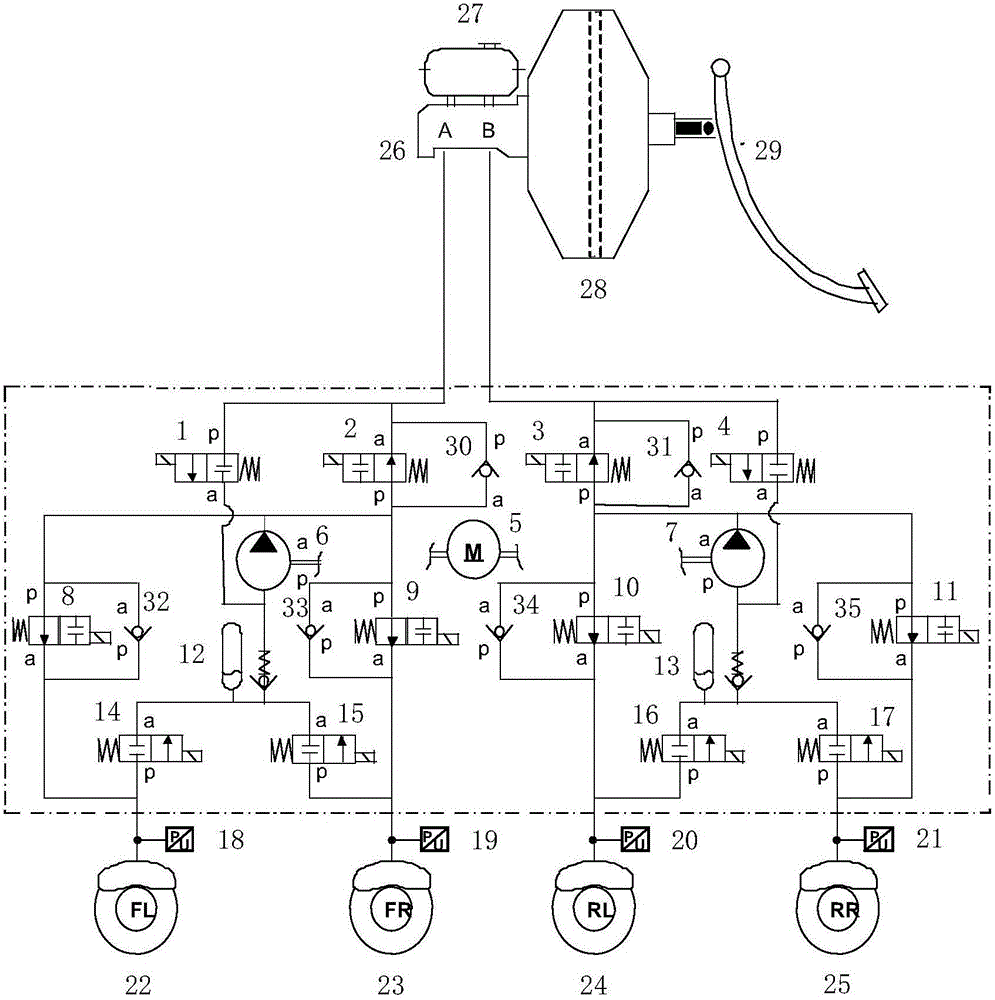

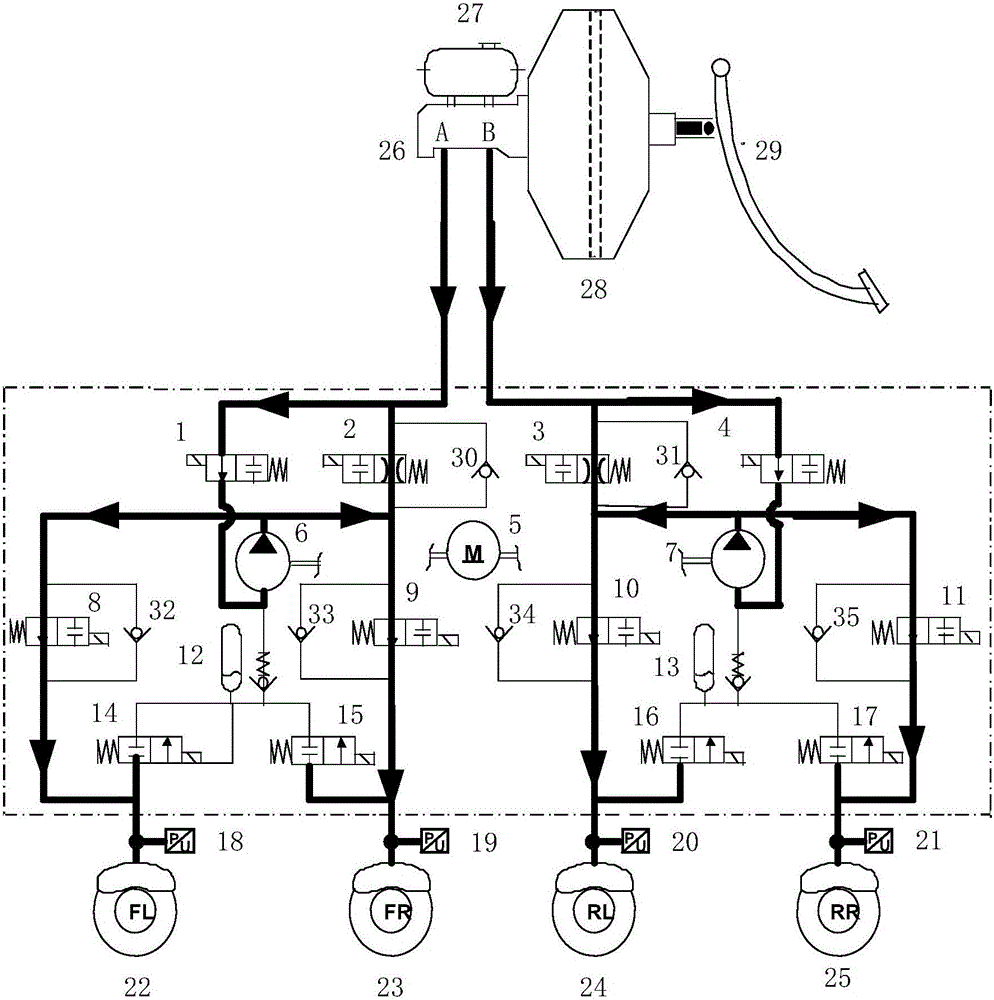

Self-adaptive cruising system and control method

InactiveCN106042978ARapid Control PrototypingStable operationSpeed controllerOperating modesWheel speed sensorWheel cylinder

The invention belongs to the field of automobile driving assistance and relates to a self-adaptive cruising system and a control method. The self-adaptive cruising system comprises a whole automobile controller, a drive motor controller, a drive motor, a battery management system, a battery pack, an original automobile ABS controller, wheel speed sensors, millimeter-wave radar fixed to a whole automobile front bumper, wheel cylinder pressure sensors installed on brake pipelines in front of braking wheel cylinders, an ESC hydraulic adjusting unit, a dSPACE Micro Autobox controller and a dSPACE Rapid pro driver. Whether a whole automobile enters a self-adaptive cruising system active braking control state or not is judged according to the whole automobile traveling state; then, under the self-adaptive cruising system active braking control, the duty ratio of conversion valves is controlled to conduct wheel cylinder pressure control, and a response to the whole automobile target braking intensity is made; and the ESC hydraulic adjusting unit conducts initialized pressure reduction control. By the adoption of the self-adaptive cruising system and the control method, the quick prototype development technology is used, and earlier stage design and an active braking function of the self-adaptive cruising system of a blade electric vehicle are achieved.

Owner:JILIN UNIV

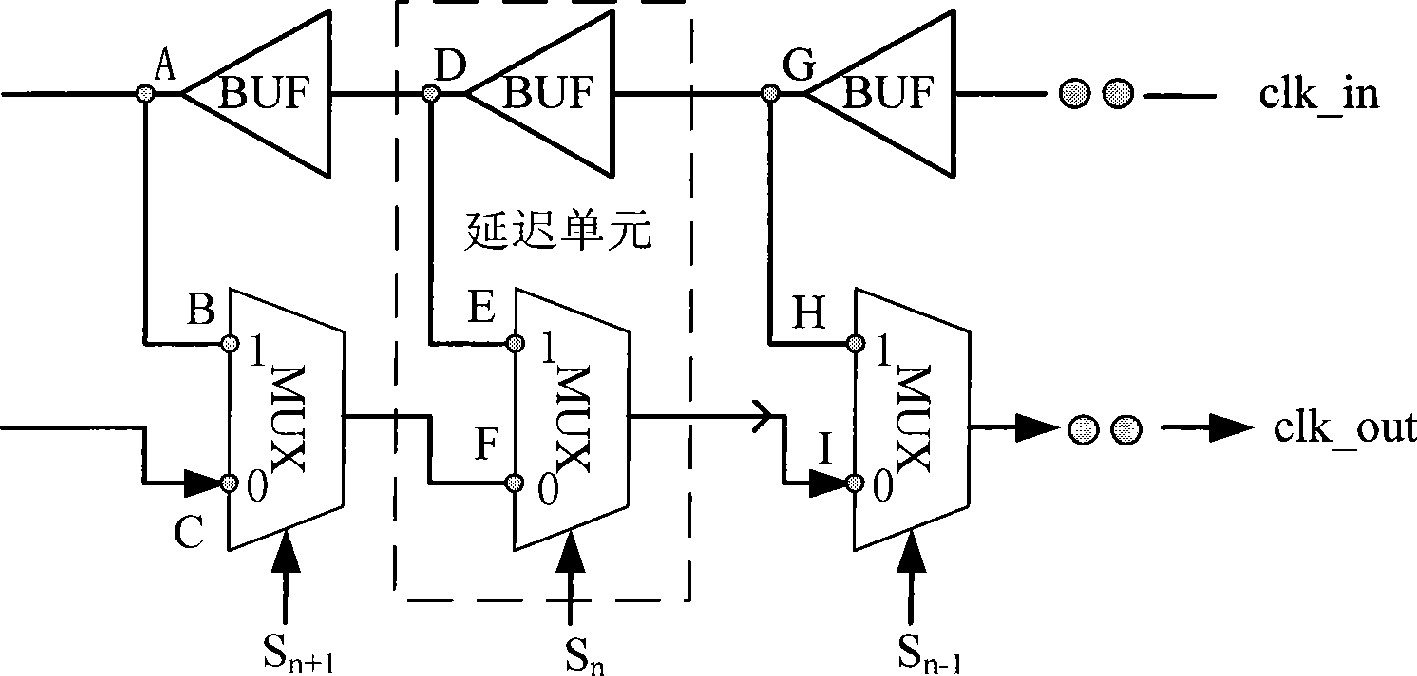

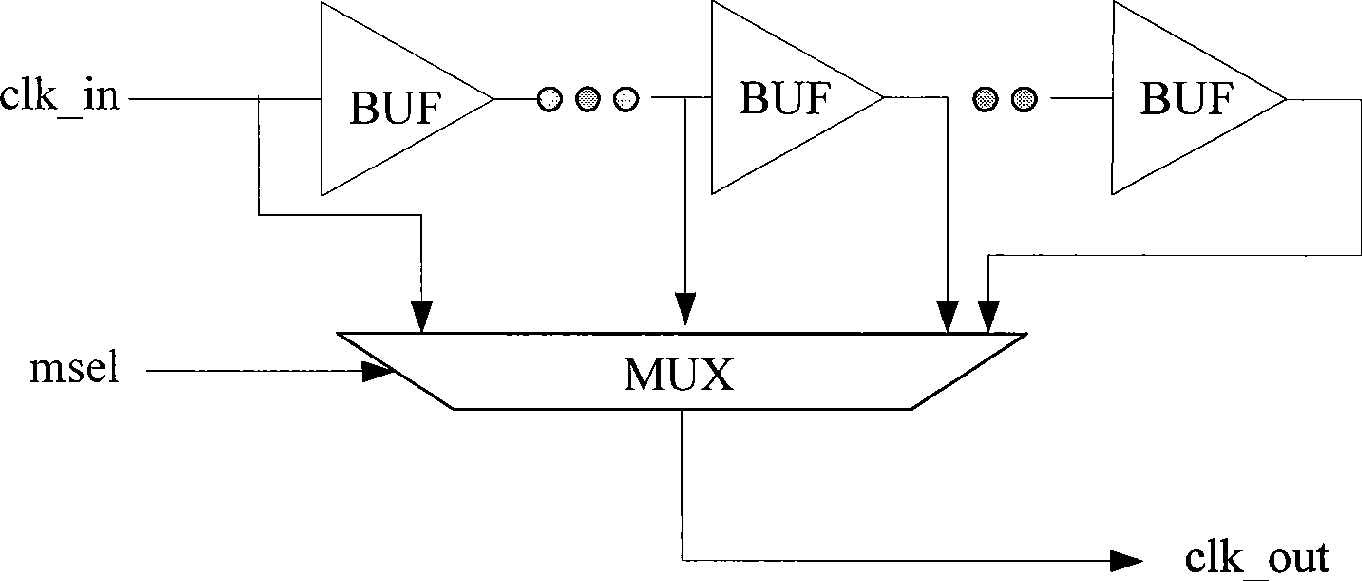

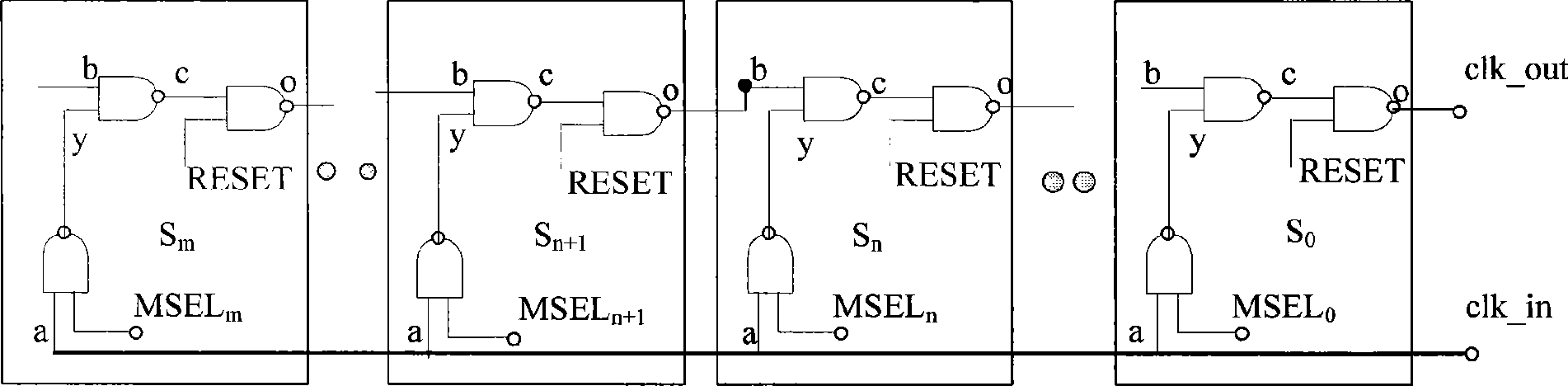

Method for digital phase-locked loop and burr elimination

ActiveCN101369814AAvoid glitchesPulse automatic controlSingle output arrangementsPhase-locked loopClock signal

The invention discloses a digital phase-locked loop and a method for eliminating spike, belonging to electronic technology field. The digital phase-locked loop includes a trigger and delay lines. the method includes the steps that the trigger receives a delayed clock signal outputted by the delay line from a triggering end, and receives signals of a first delay unit selection end in the delay line from an input end, wherein the selection end of the first delay unit is on a state 1 before triggering the trigger; the trigger samples the signal of the first delay unit selection end using delayed clock signal, and outputs signal after sampling to the selection end of a second delay unit in the delay line, wherein the selection end of the second delay unit is on the state 1 after triggering the trigger. By means of sampling the signal of the selection end of the first delay unit using delayed clock signal by the trigger and using the sampling signal as the signal of the selection end of the second delay unit, the invention avoids the spike caused by jump variation while updating delay module on the clock edge.

Owner:HUAWEI TECH CO LTD

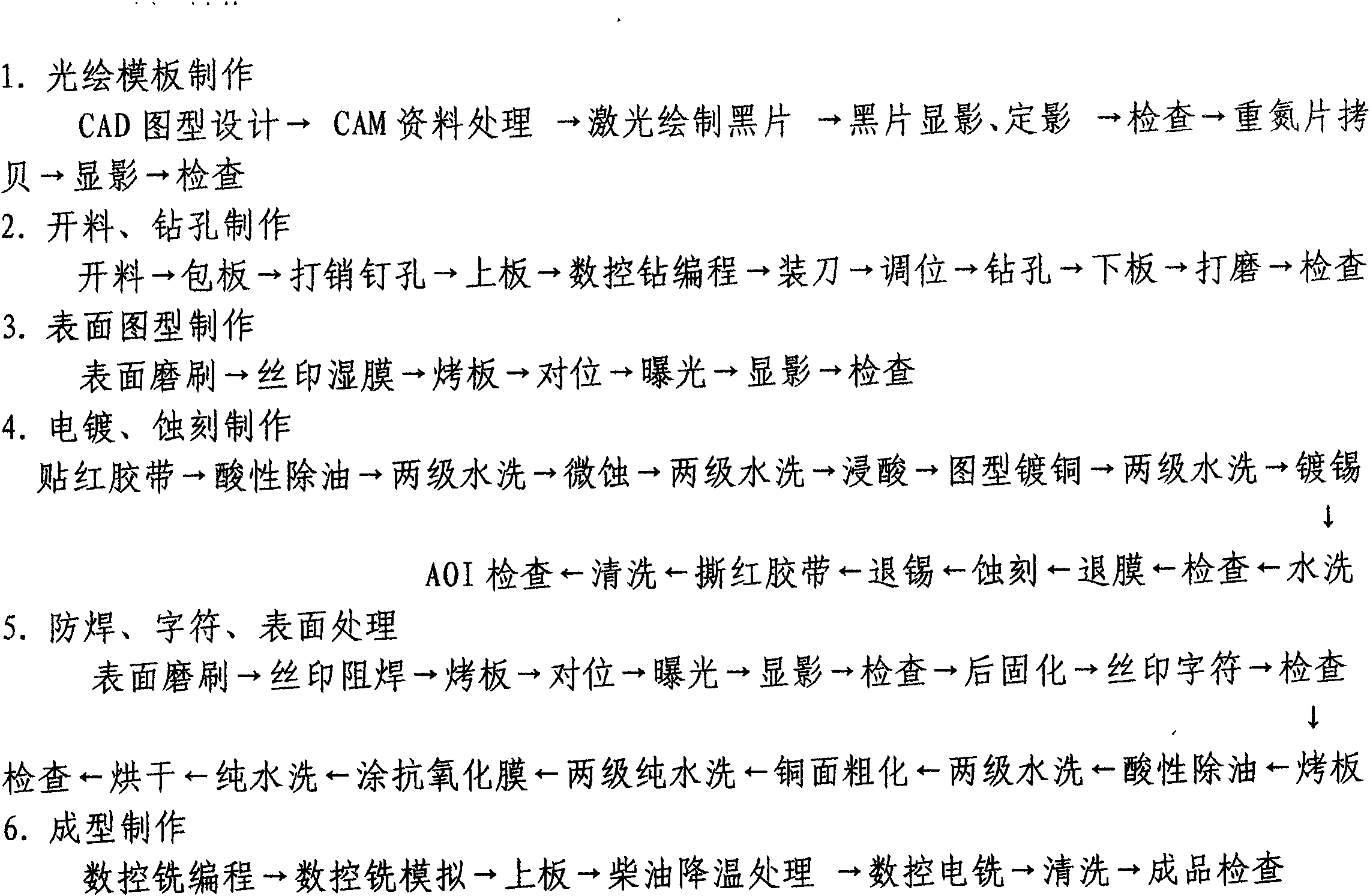

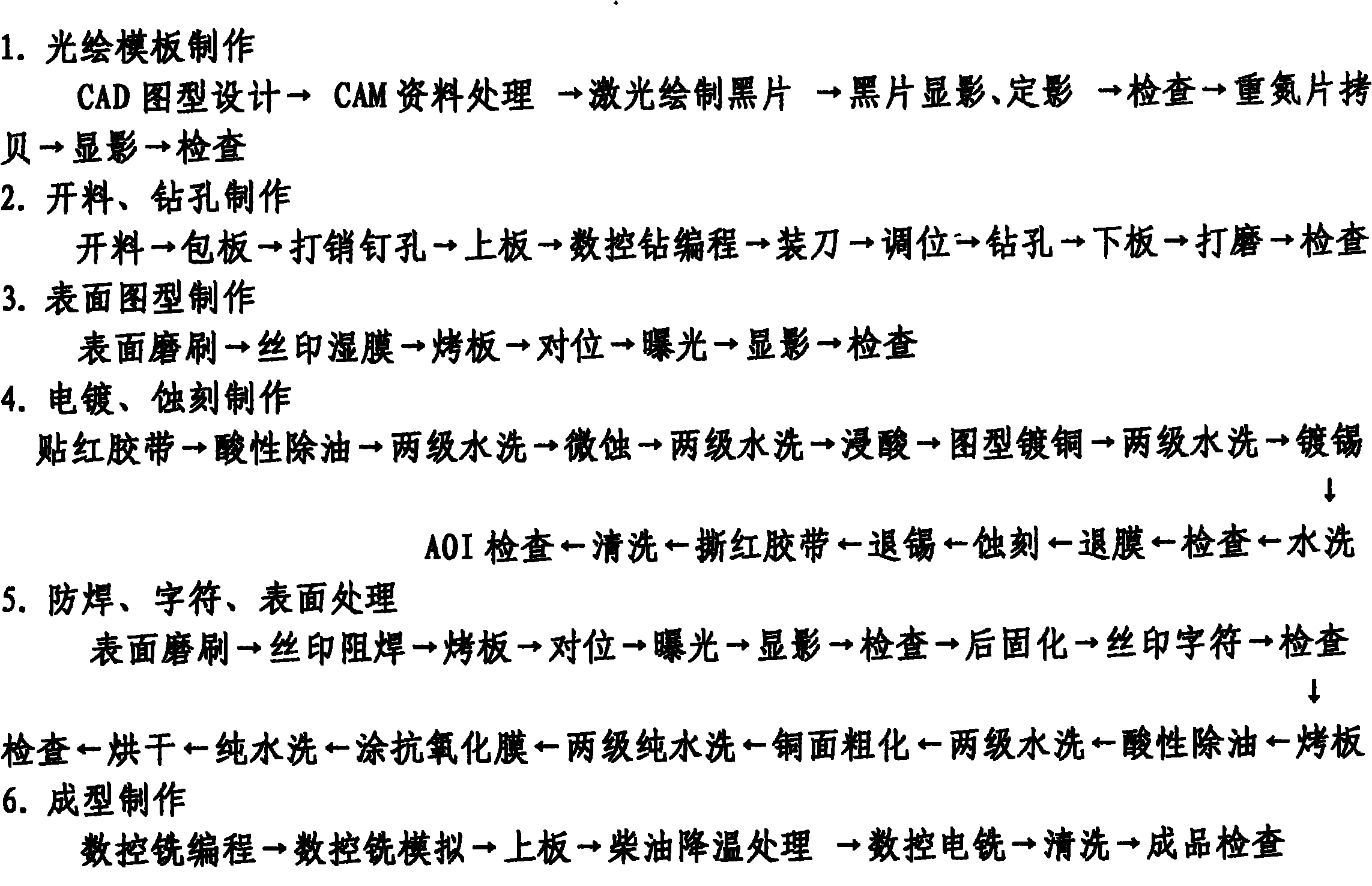

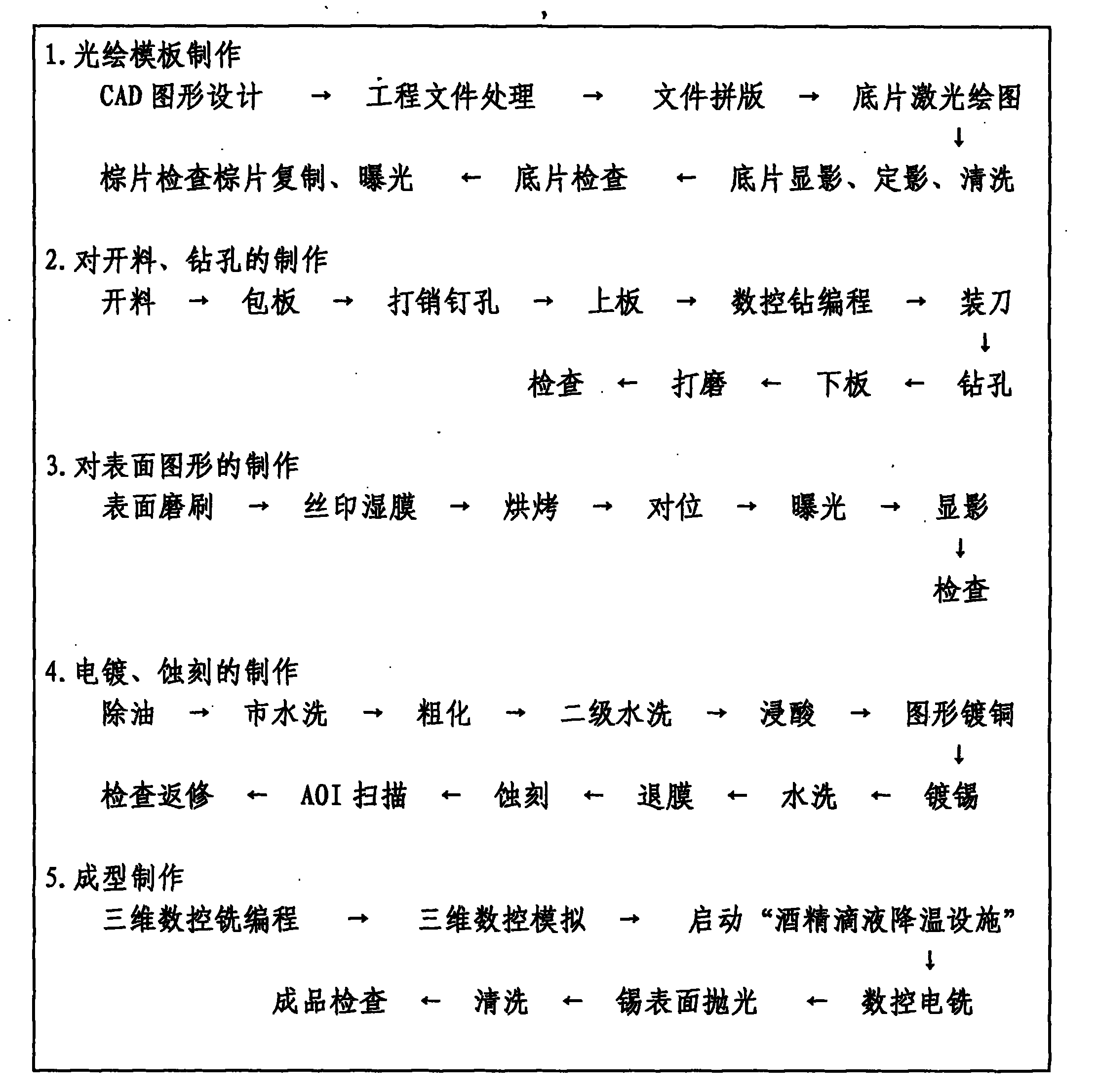

Method for making high-frequency aluminium-based circuit board

ActiveCN102159029AAvoid glitchesImprove performancePrinted circuit manufactureCircuit susbtrate materialsSurface patternElectrical and Electronics engineering

The invention discloses a method for making a high-frequency aluminium-based circuit board. The method comprises the following steps of: 1, making a photo-plotted template; 2, cutting and drilling holes; 3, making surface patterns; 4, electroplating and etching; 5, carrying out welding preventing and character and surface weldable processing; and 6, molding to make the high-frequency aluminium-based circuit board. The making accuracy of the method is high, the product quality and the work efficiency are effectively improved, and the performance of the made high-frequency aluminium-based circuit board is stable.

Owner:TAIZHOU JINDING ELECTRONICS

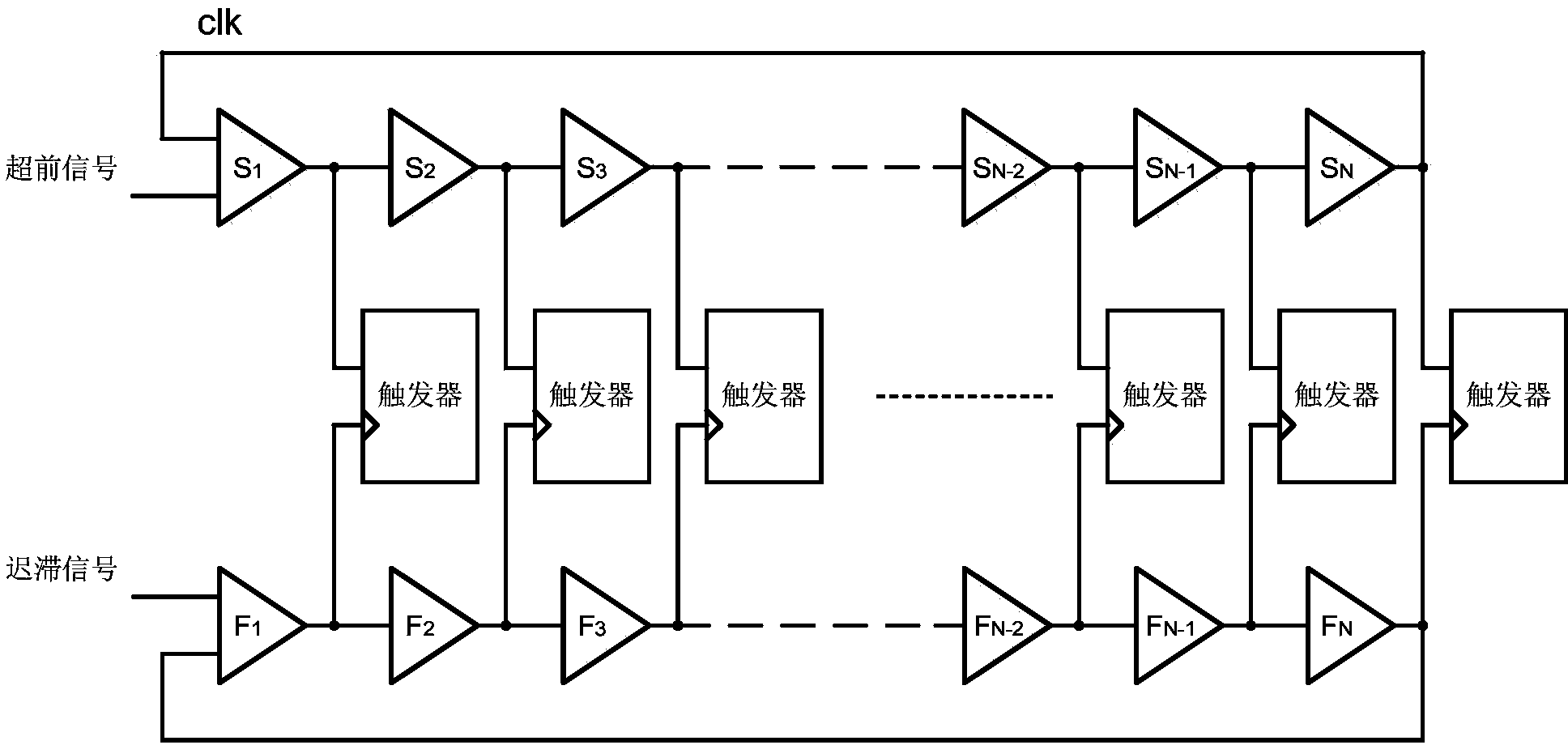

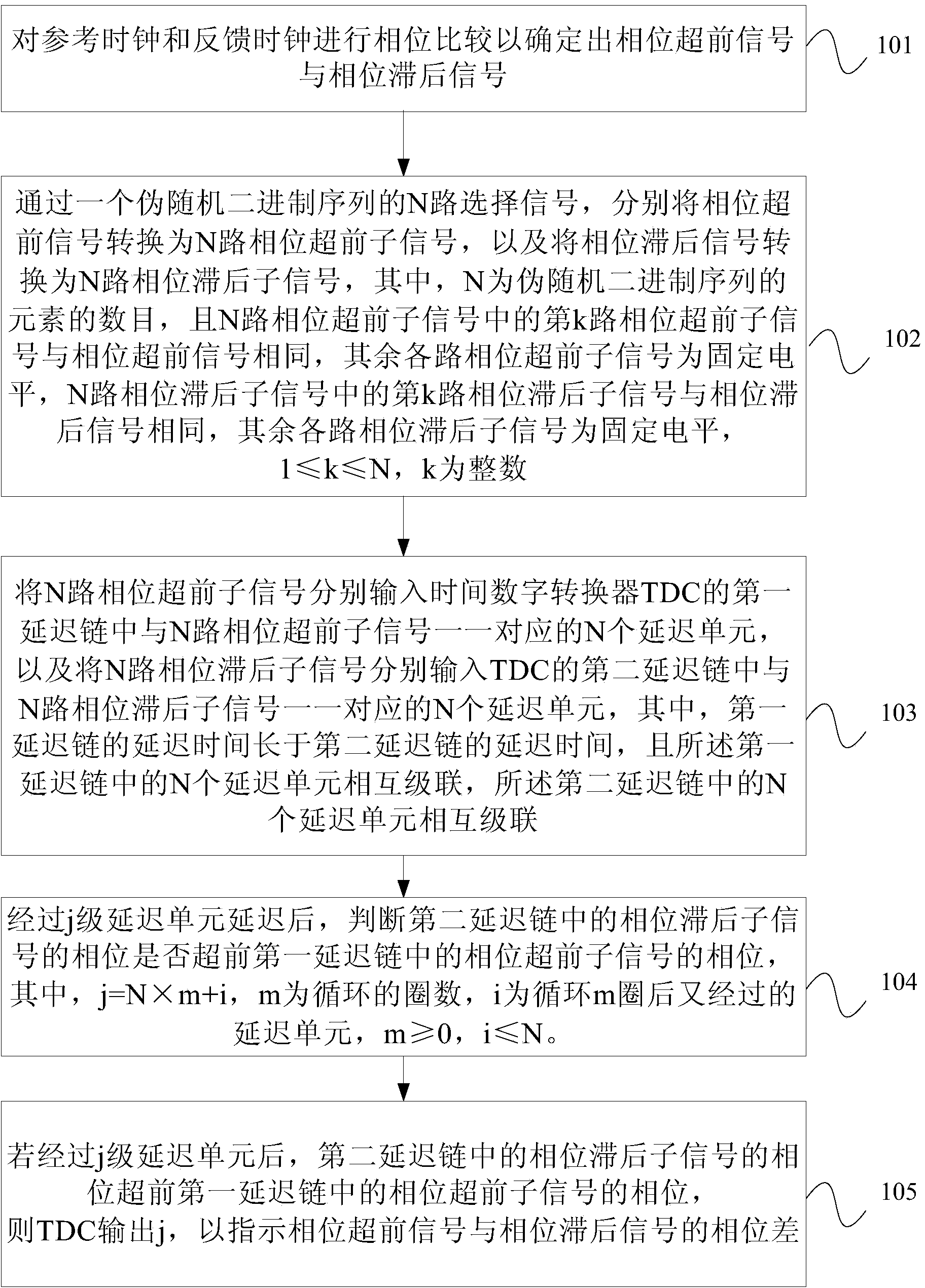

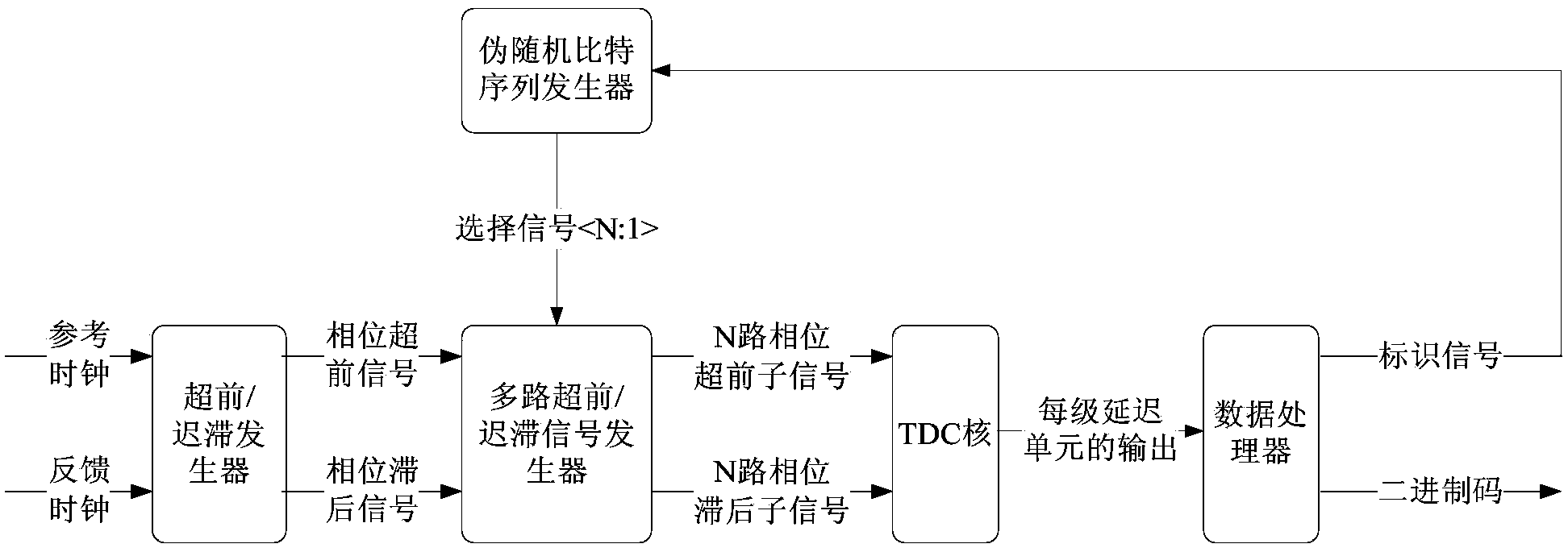

Time digital conversion method and time digital converter

The embodiment of the invention provides a time digital conversion method and a time digital converter. The method comprises the following steps that a phase lead signal and a phase lag signal are determined; through N selection signals, the phase lead signal is converted into N phase lead sub-signals, and the phase lag signal is converted into N phase lag sub-signals; the N phase lead sub-signals are input into N delay units, corresponding to the N phase lead sub-signals one to one, of a first delay chain respectively, and the N phase lag sub-signals are input into N delay units, corresponding to the N phase lag sub-signals one to one, of a second delay chain respectively; in each measurement period, the delay units of the phase lag sub-signals ahead of the phase lead sub-signals are determined, a phase difference between a reference clock and a feedback clock is converted into the stage number j of the delay units which are passed previously and then the stage number j is output; the extent of variation of the TDC gain is reduced, and the problems of linearity reduction and burrs caused by adaptation among the delay units are solved.

Owner:HUAWEI TECH CO LTD

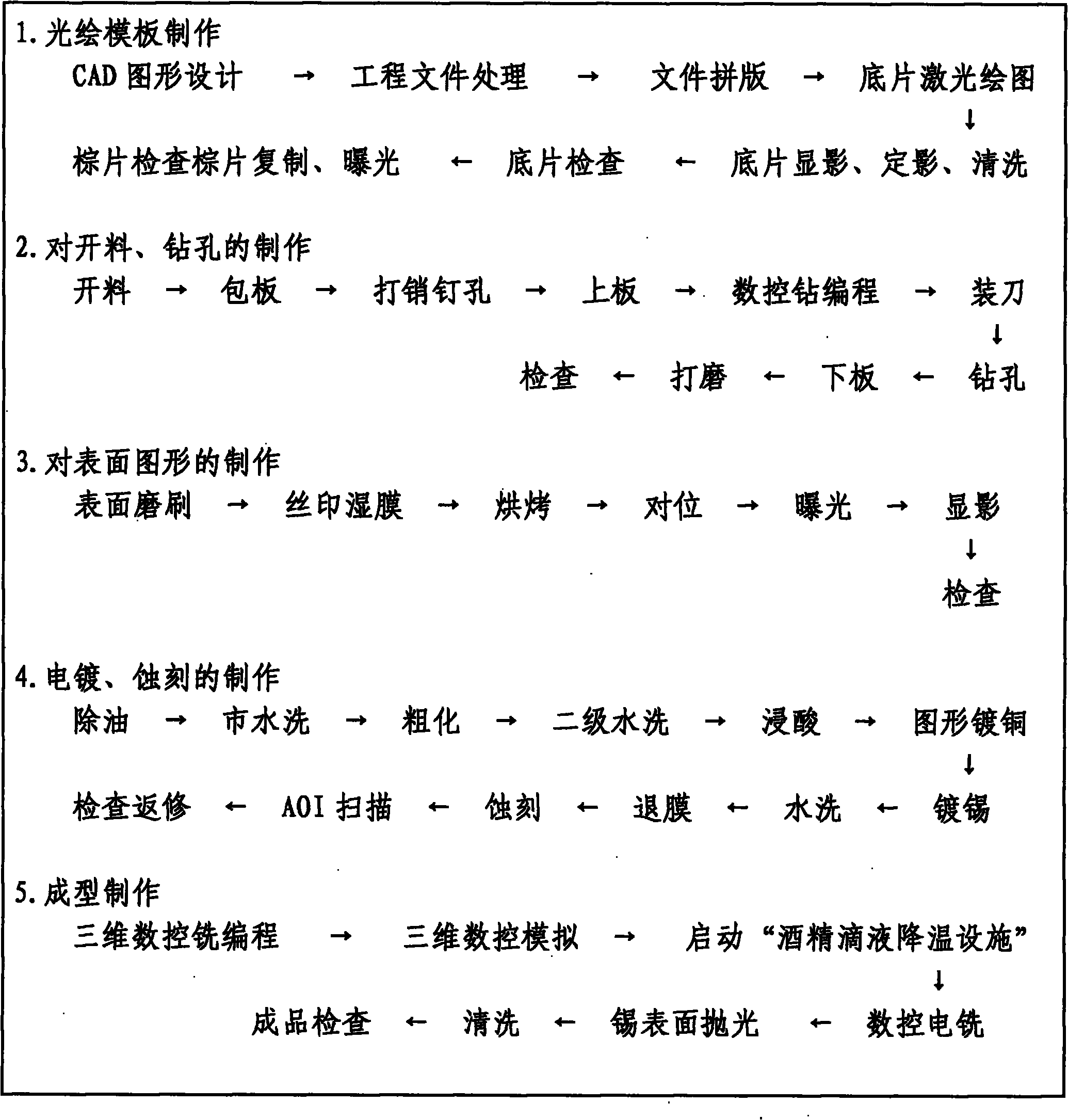

Manufacturing method for microwave high frequency metal base circuit board

InactiveCN101784162ASolve the blackeningSolve the roughness of the hole wallDrilling/boring measurement devicesTransportation and packagingMicrowaveCopper

The invention discloses a manufacturing method for a microwave high frequency metal base circuit board, which comprises the following steps: step one, manufacturing an optical drawing template; step two, manufacturing a split material and a bore hole; step three, manufacturing the surface graph of a composition board of a metal base copper-clad plate; step four, electroplating and etching; and step five, molding. Not only the manufacturing method has high manufacturing precision and effectively increases the product quality and working efficiency, but also the manufactured microwave high frequency metal base circuit board has stable performance.

Owner:施吉连

Motor, rotary electric machine and its stator, and method for manufacturing the stator

ActiveUS7595578B2Easy to assembleOptimize connection structureElectrical transducersMagnetic circuit stationary partsElectric machineEngineering

Owner:MITSUBA CORP

Method for fabricating surface acoustic wave filter packages and package sheet used therein

InactiveUS20050042804A1Enhance reliabilityPrevent defectImpedence networksSemiconductor/solid-state device detailsEngineeringAcoustic wave

Disclosed is a method for fabricating Surface Acoustic Wave filter packages using a package sheet having an outline pattern and anti-bur holes and a package sheet used therein. In the package sheet for a Surface Acoustic Wave filter package, an outline pattern is formed along outer peripheries of predetermined areas to be mounted with a plurality of SAW filter chips. The outline pattern is contacted with a metal shield layer formed on the SAW filter chips and a predetermined region of the package sheet. Circular anti-bur holes cover the corners of the areas to be mounted with the SAW filter chips and are intersected by cutting lines functioning as reference lines for cutting the sheet into a plurality of SAW filter packages.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

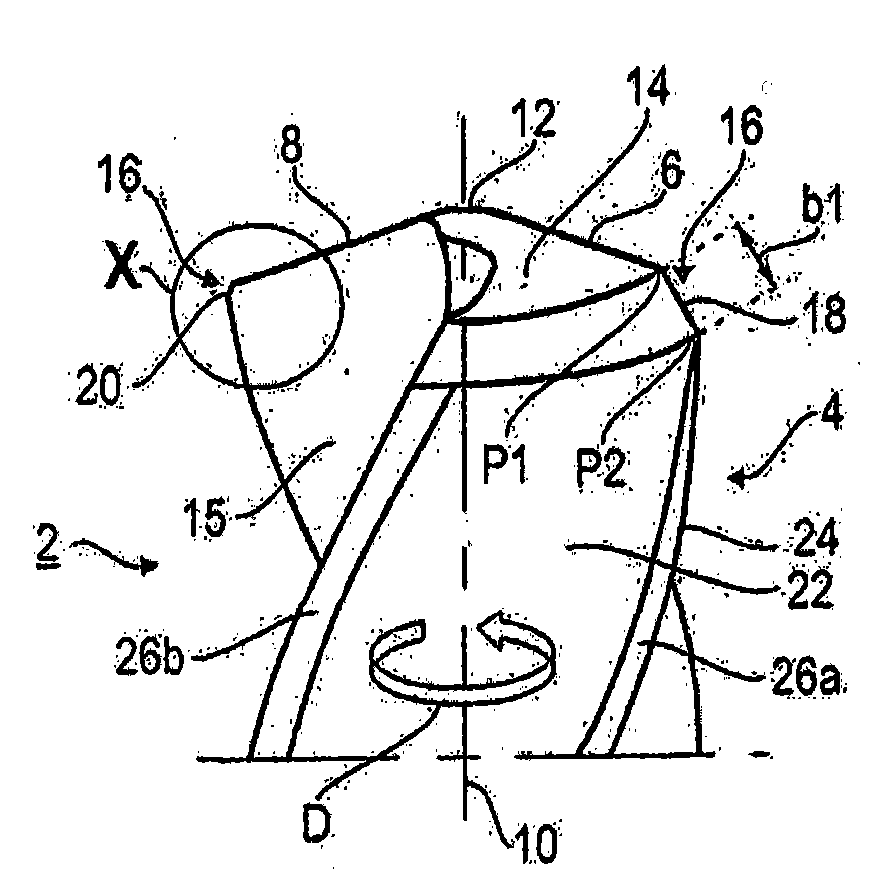

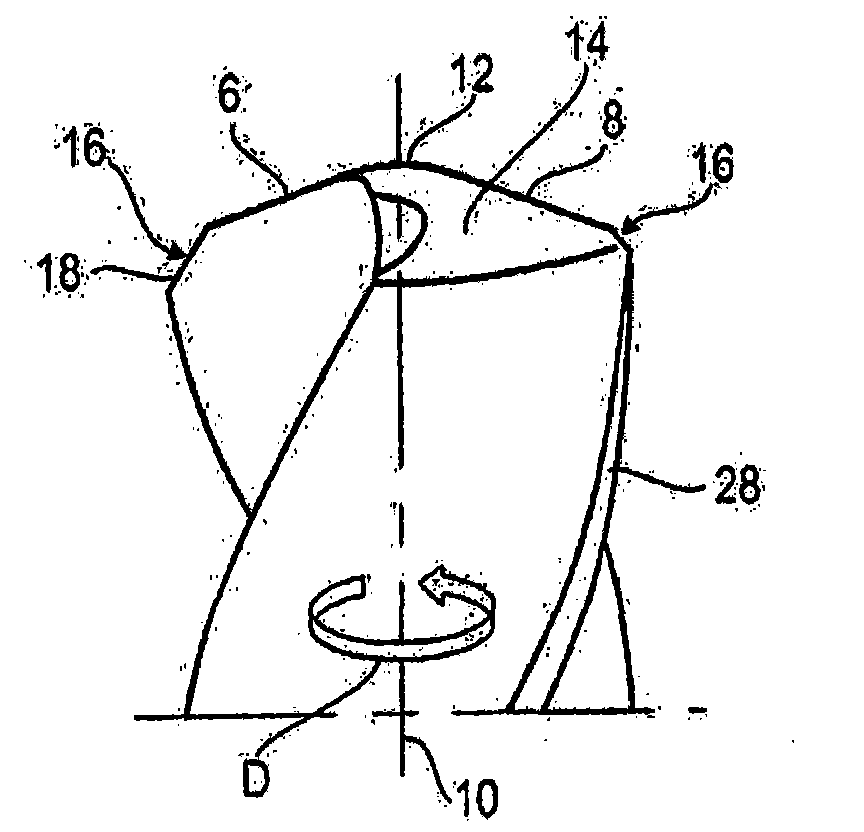

Rotary tool, in particular drill

In order to provide a rotary tool, in particular a drill (2), with a long service life together with high-quality drill holes, particularly in the case of through bores, the invention provides a cutting head (4) which extends along a rotational axis (10) and has a plurality of main cutting edges (6, 8) which extend radially outwards and each end at a cutting corner (16) having a corner bevel, wherein the corner bevels are of differing designs, specifically in the form of a roughing bevel (18) and in the form of a finishing bevel (20).

Owner:KENNAMETAL INC

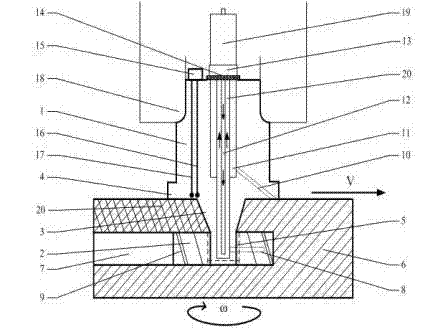

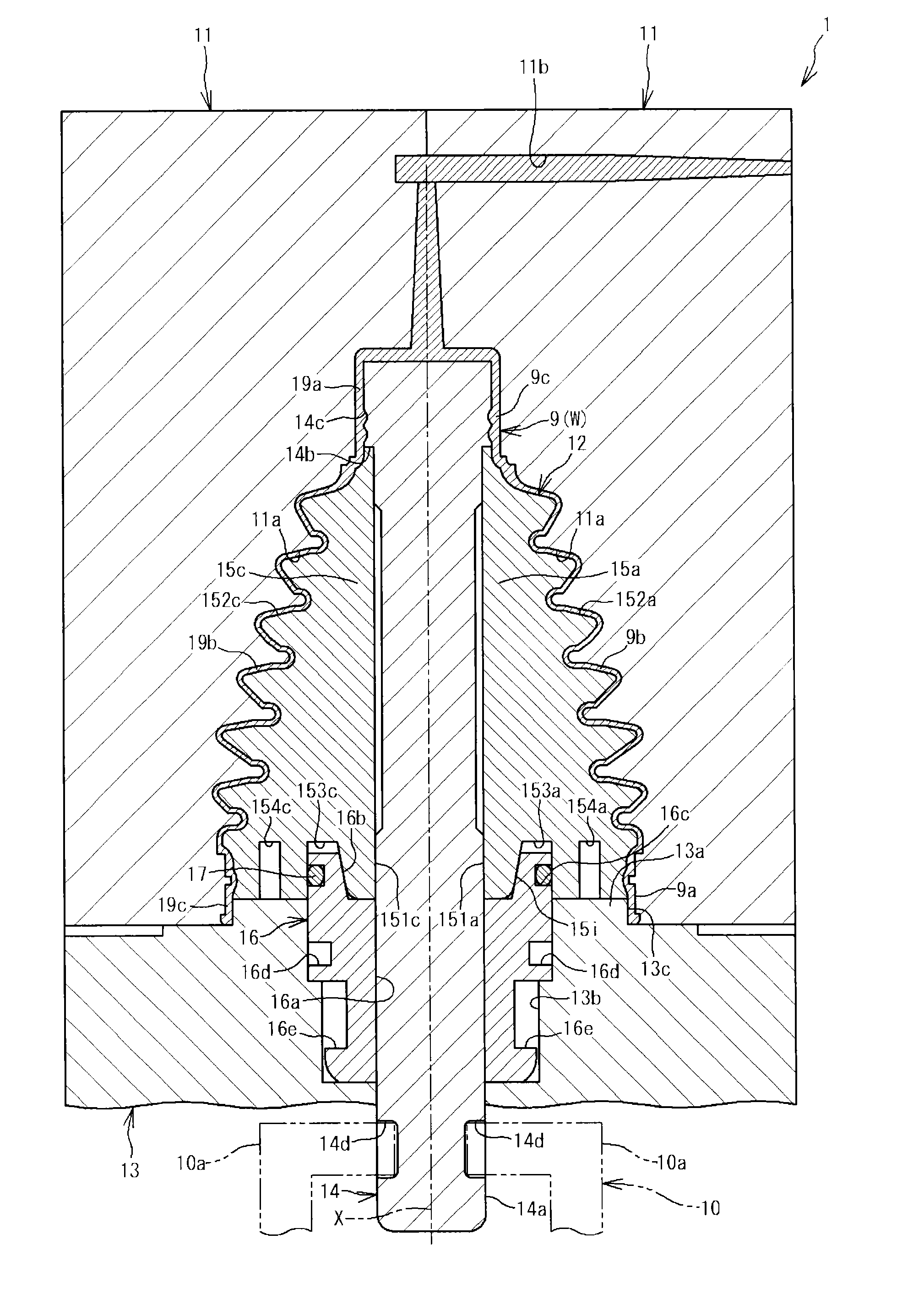

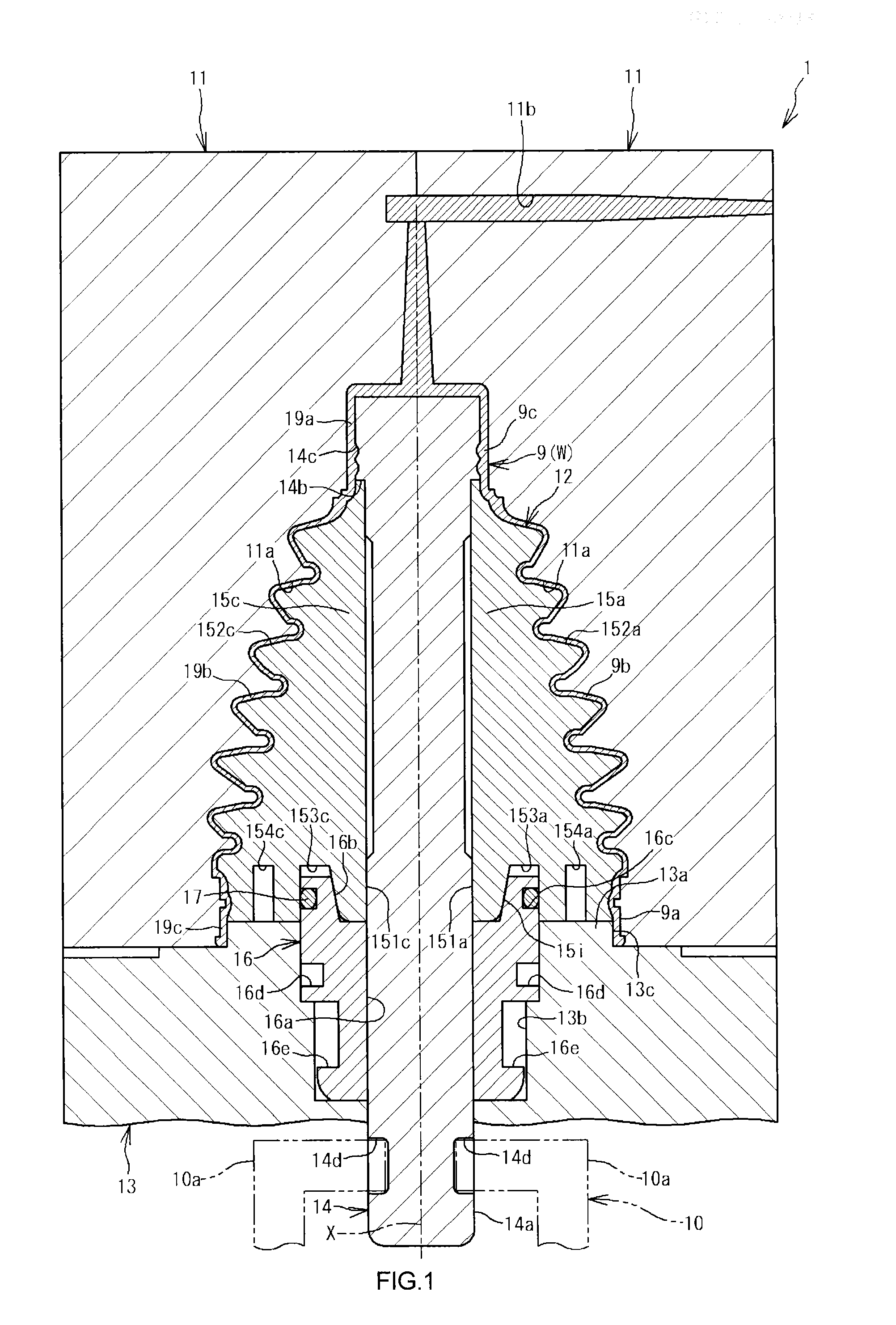

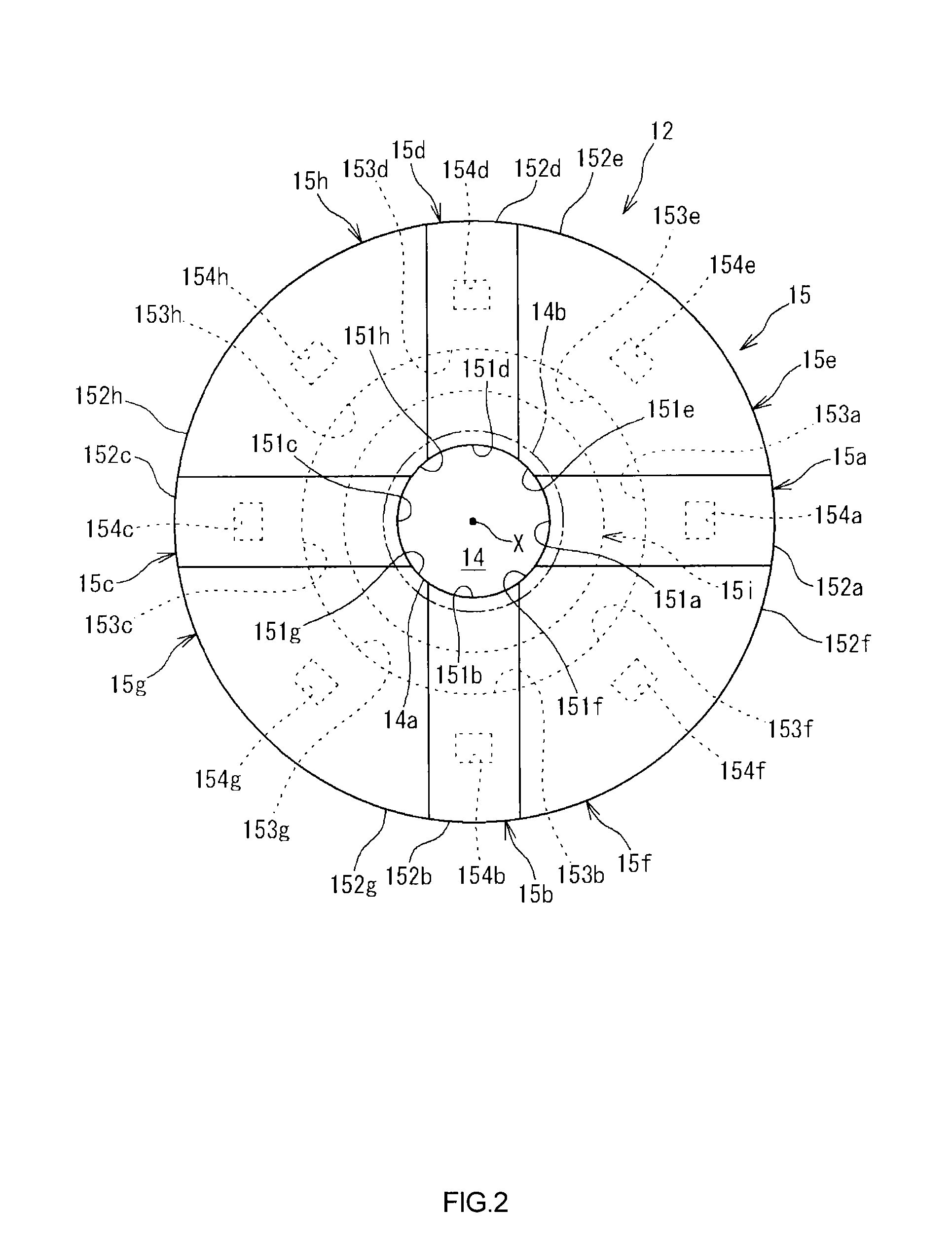

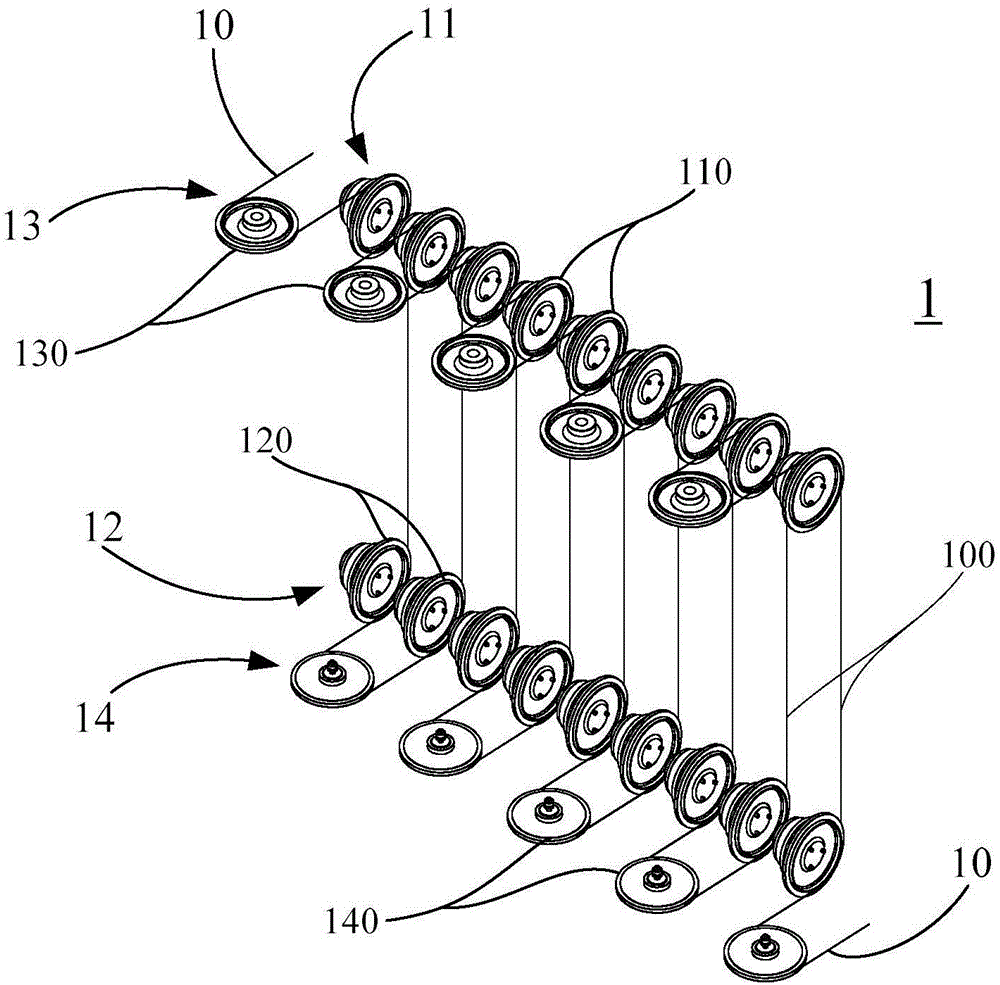

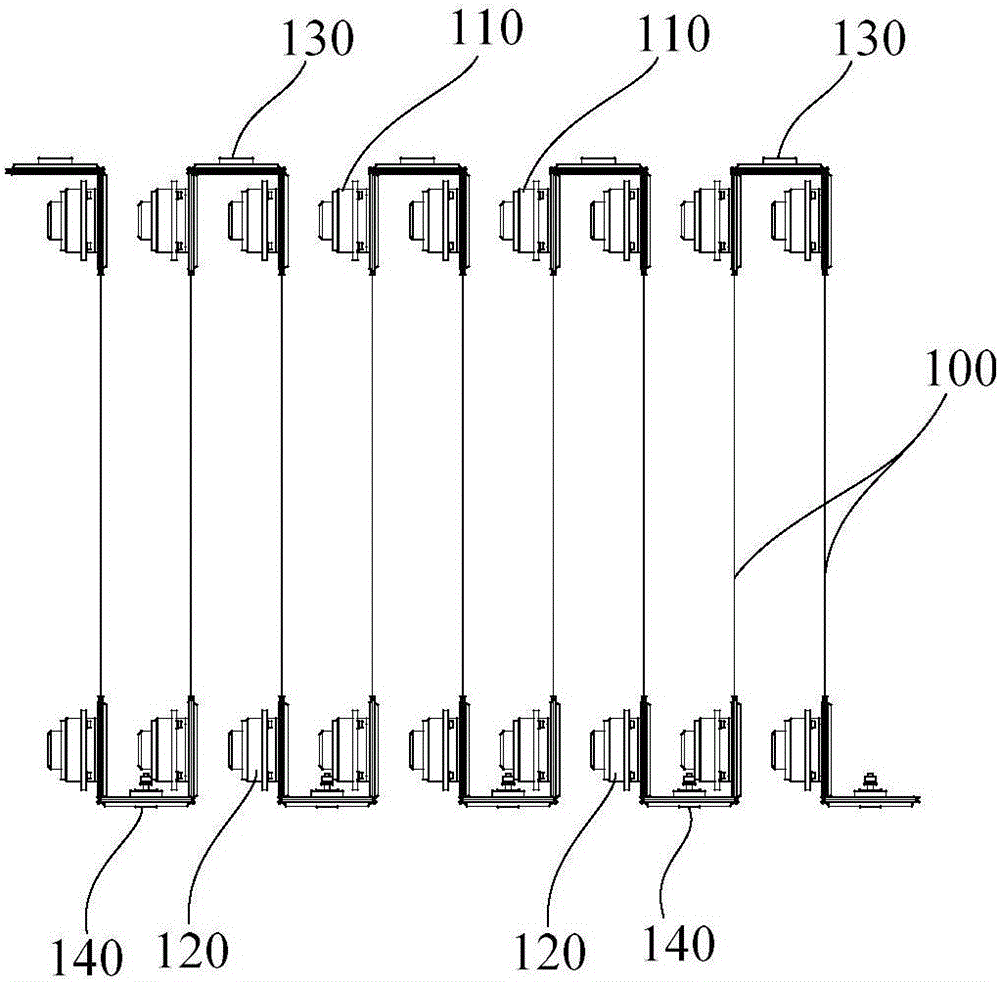

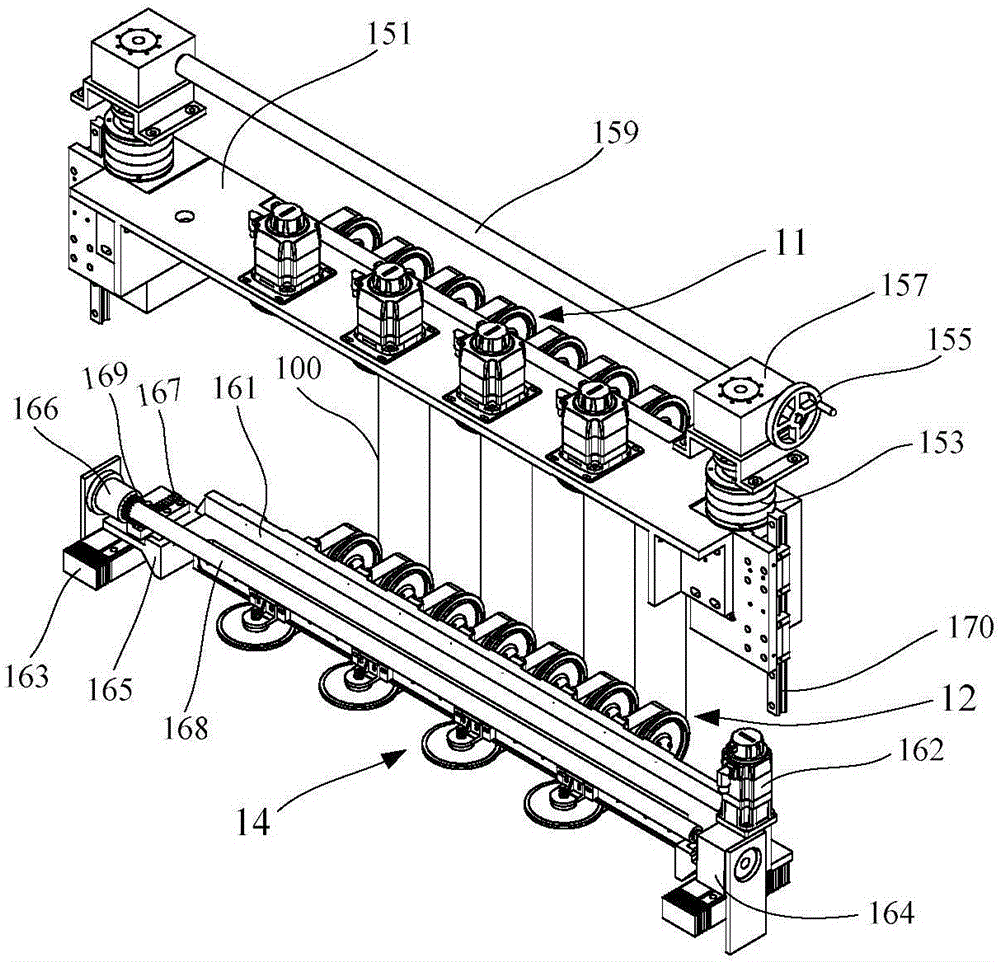

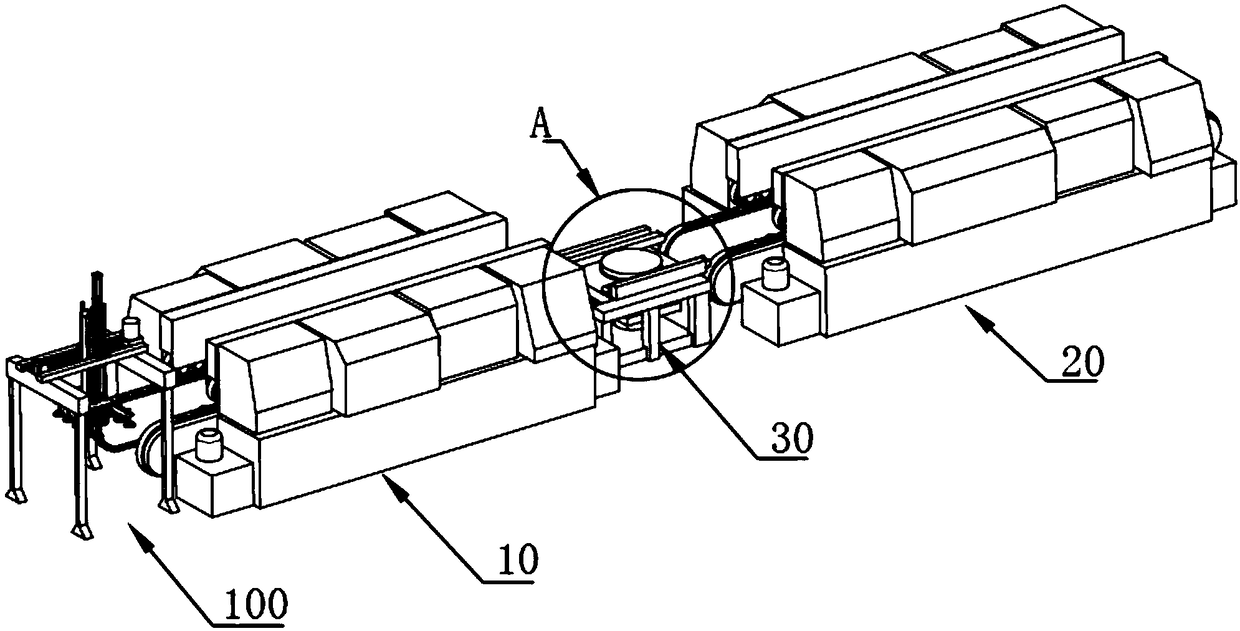

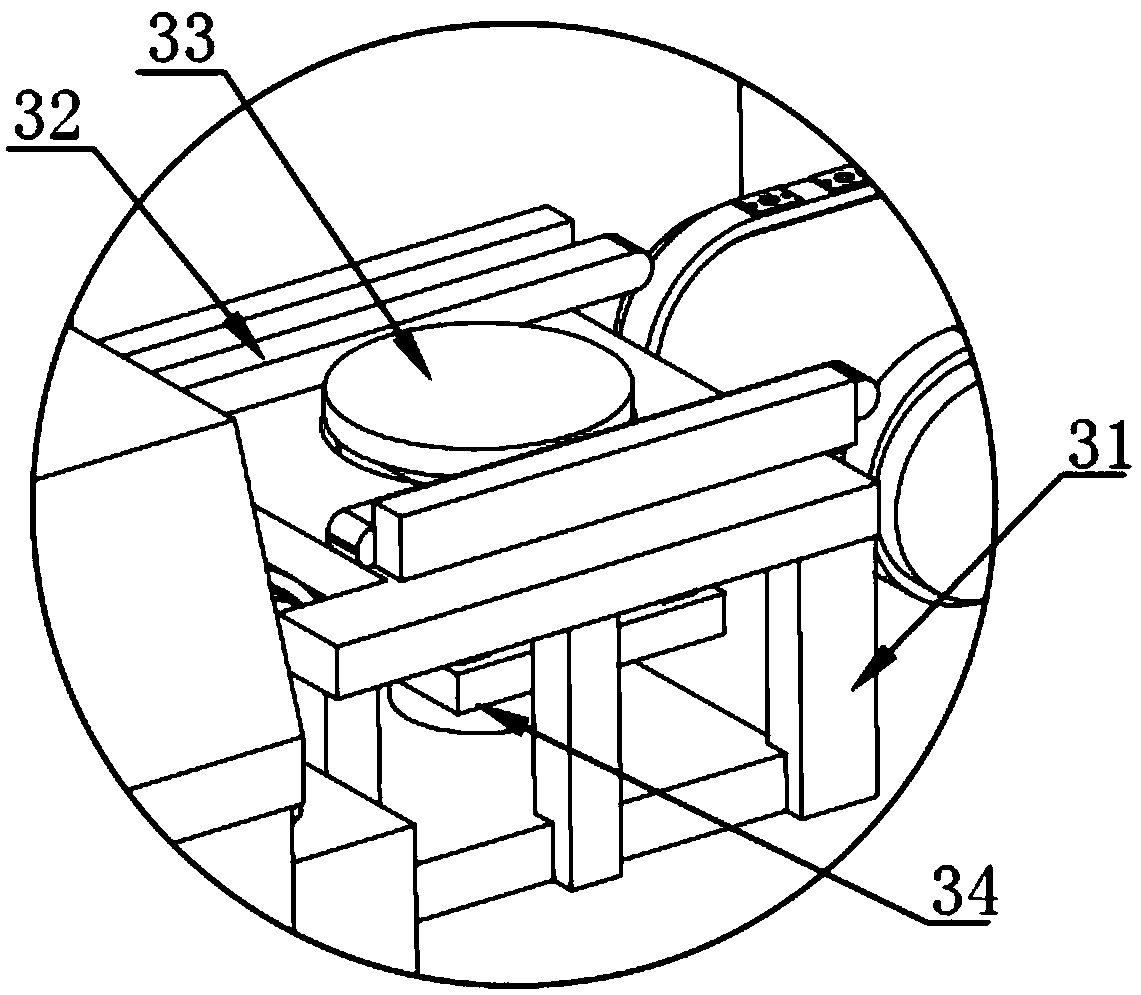

Cutting-stirring friction-welding combined machining equipment and manufacturing method thereof

ActiveCN102501074AEfficient coolingAvoid glitchesOther manufacturing equipments/toolsMaintainance and safety accessoriesTemperature sensingSensing system

The invention discloses cutting-stirring friction-welding combined machining equipment and a manufacturing method thereof. The cutting-stirring friction-welding combined machining equipment integrates a milling system or a cutting system, a stirring friction-welding system, a forced cooling system, a gas protection system, a temperature sensing system, a pressure sensing system, a milling liquid supply system and a non-sensing system. The invention provides a united or combined machining device which can carry out milling or cutting and stirring friction-welding in parallel simultaneously and a method thereof. The cutting-stirring friction-welding combined machining equipment has the functions of temperature control, gas protection, pressure detection, cooling liquid production, milling head replacement and dual-shaft shoulder self-supporting. According to the manufacturing method of the cutting-stirring friction-welding combined machining equipment, the manufacturing processes are reduced and the machining cost is saved. The limitation of the conventional mechanical machining technology is broken through, and a new method and a new idea about the mechanical manufacturing and machining are formed. The cutting-stirring friction-welding combined machining equipment and the manufacturing method in the invention have wide engineering applications to the heating industry, the air conditioning industry, the ice making industry, the freshness retaining industry, the pharmacy industry, the construction industry, the aquatic product industry and the food industry.

Owner:罗键

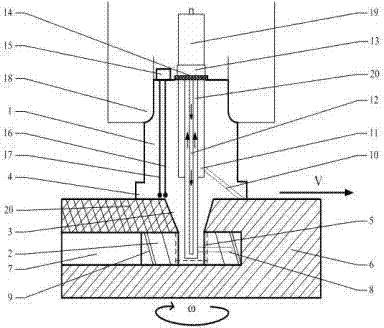

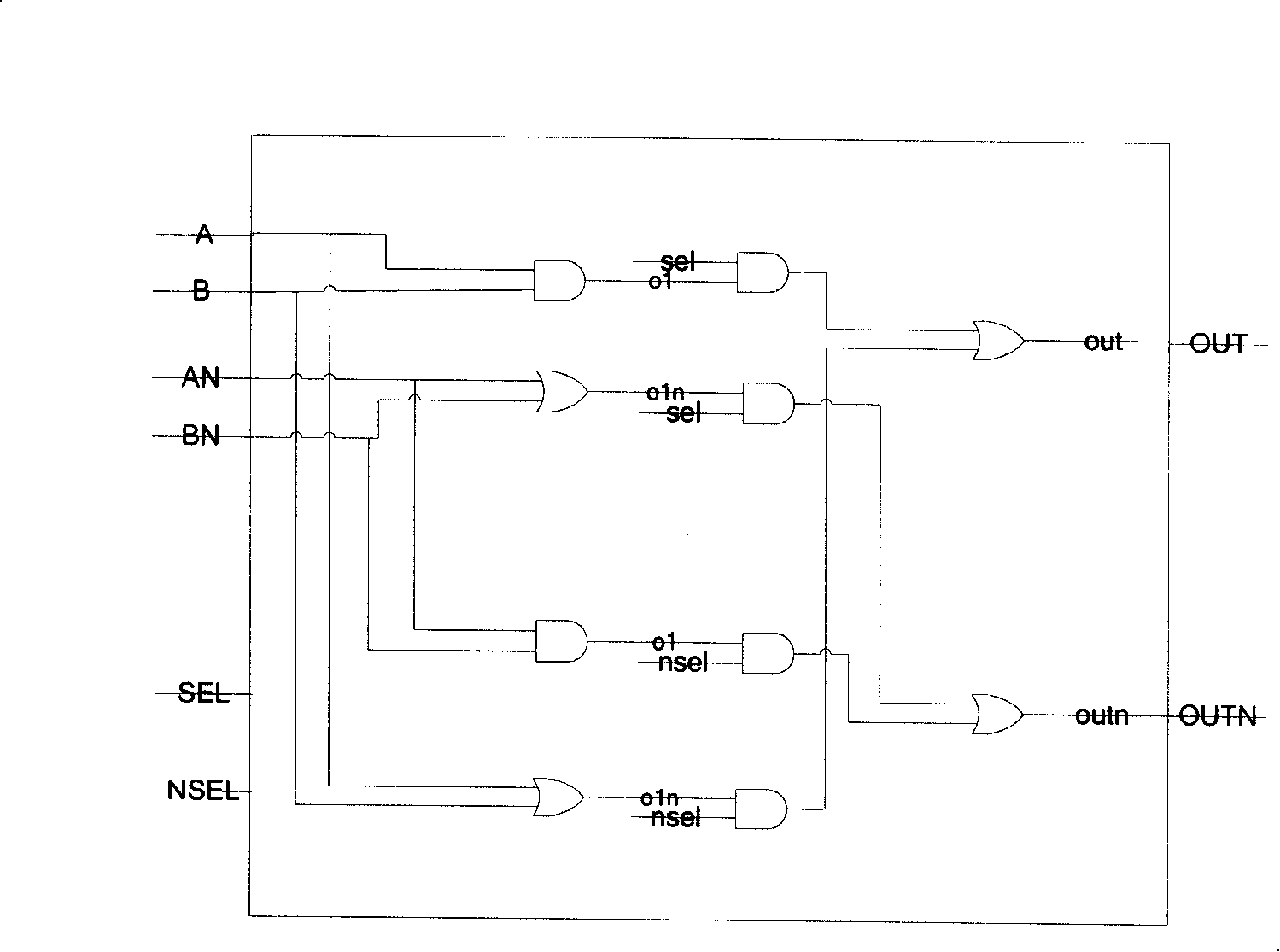

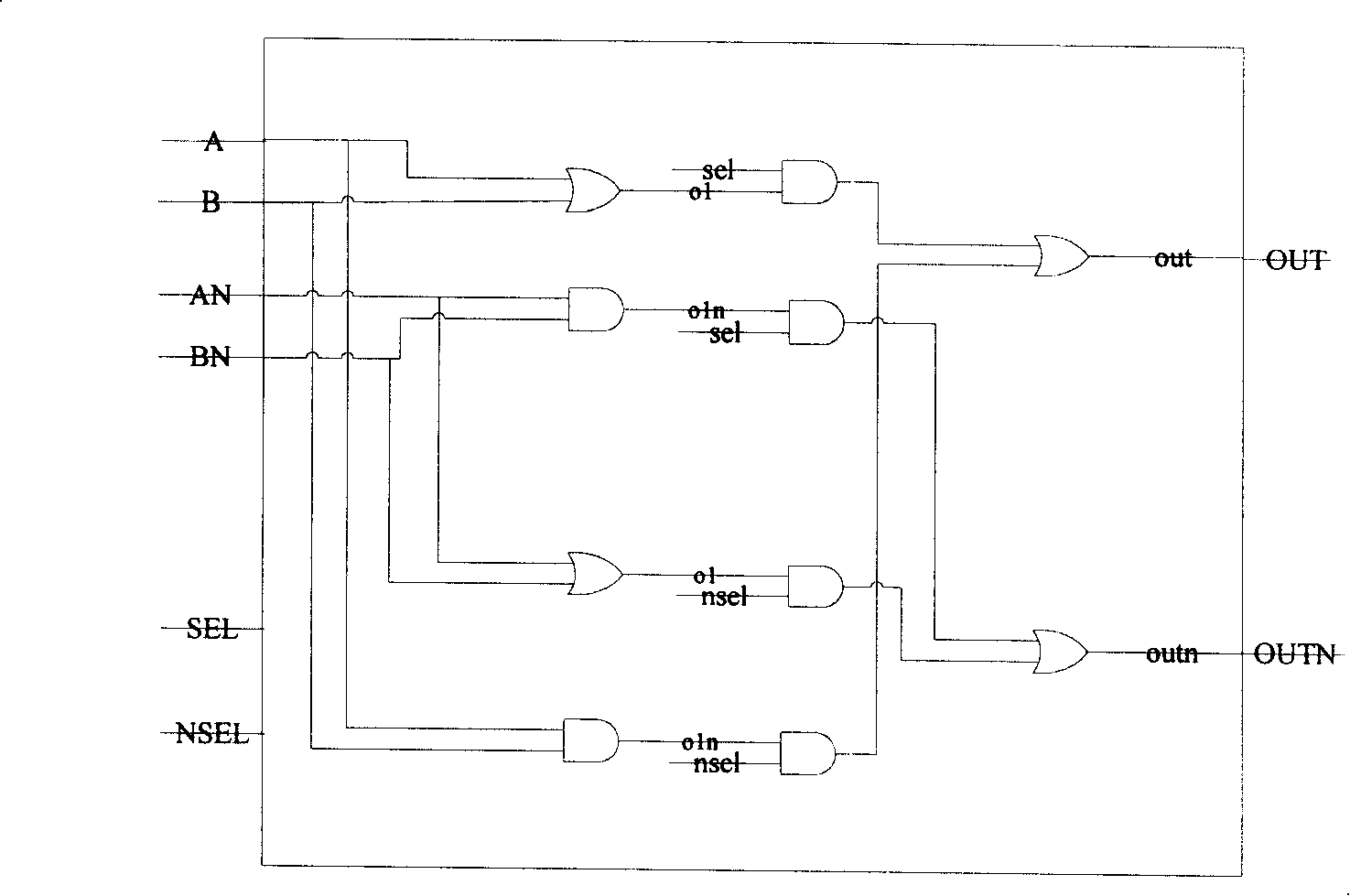

A logic unit for oppositional differential power consumption analysis

ActiveCN101187963AAchieving power balanceAvoid glitchesInternal/peripheral component protectionPower analysisConstant power

A logic unit confronting differential power analysis relates to the technical field of IC card safety and special device encryption. One output end with 01 output of a first power balance module of the invention and a random signal sel are connected to the input end of a first AND gate, and the other output end with 01n output of the first power balance module and the random signal sel are connected to the input end of a second AND gate; one output end with 01 output of a second power balance module and a random signal nsel are connected to the input end of a third AND gate, and the other output end with 01n output of the second power balance module and the random signal nsel are connected to the input end of a fourth AND gate. The output ends of the first and the fourth AND gates are connected to one outport OUT of the logic unit via a first OR gate, and the output ends of the second and the third AND gate are connected to the other output port OUTN of the logic unit. The two power balance modules and the four AND gates have constant power consumption, and the output ports of the logic unit has statistically balanced power consumption. Compared with the prior art, the invention realizes the power balance of the unit interior and the output and effectively avoids burrs.

Owner:BEIJING TONGFANG MICROELECTRONICS

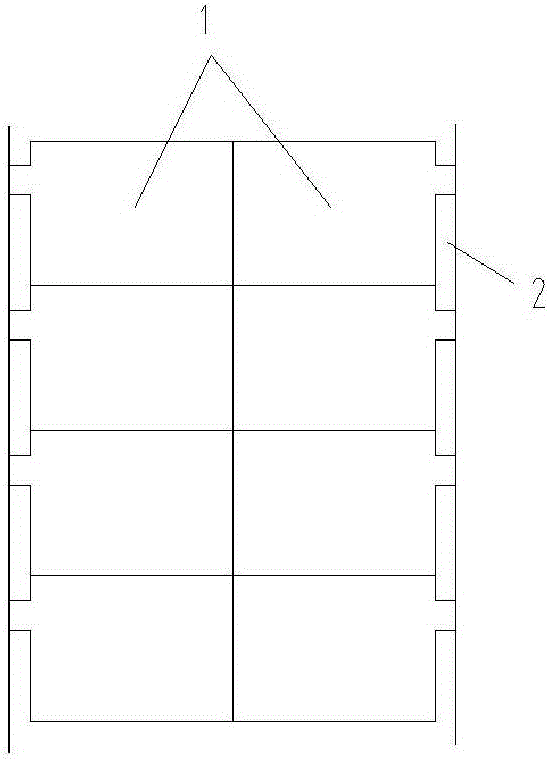

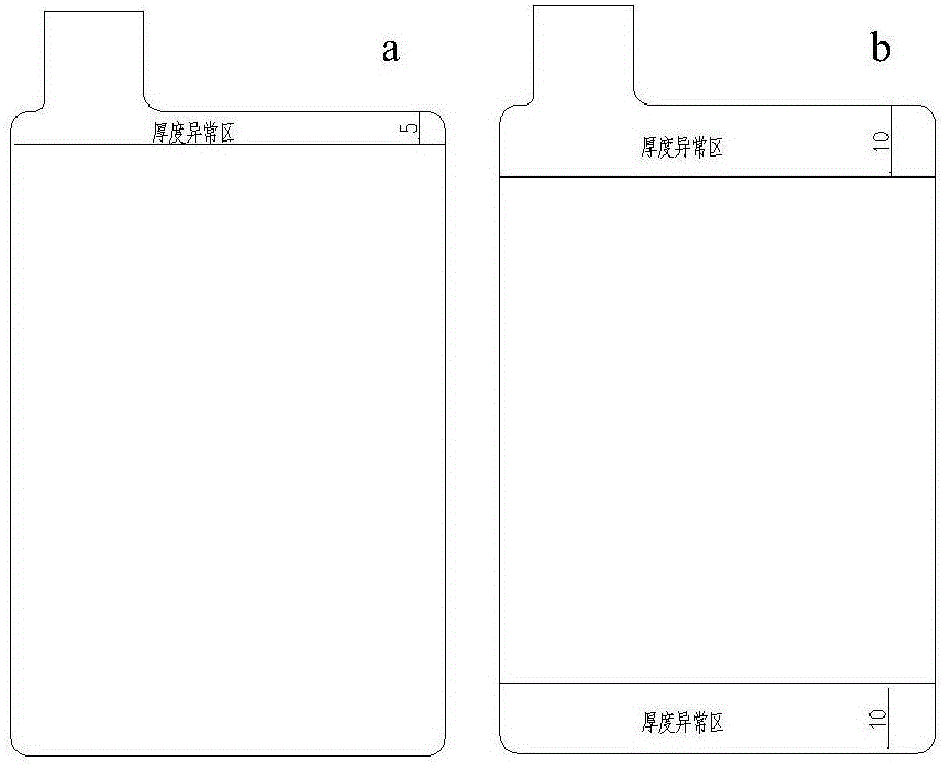

Preparation method of water system laminated type lithium-ion battery pole piece

ActiveCN106129326AQuality assuranceConsistent densityElectrode rolling/calenderingElectrode collector coatingMeasuring instrumentEngineering

The invention discloses a preparation method of a water system laminated type lithium-ion battery pole piece and belongs to the technical field of production of lithium-ion batteries. The method has the following advantages that (1) continuous coating is realized, the coating efficiency is improved, the range of a coating thickness abnormal region is reduced and the coating thickness is monitored online; (2) continuous roll pressing is realized, the roll pressing efficiency is improved, a roll pressing thickness is monitored online and frequent vibration loss of a roll pressing machine is alleviated; (3) the thicknesses of cut regions are the same in a cutting process, the cutting defects are small and the stability is good; (4) the slicing efficiency can be improved by utilizing high-speed slicing equipment, surface defects of the pole piece can be monitored online by utilizing a CCD (Charge Coupled Device) image measuring instrument and NG pole pieces are eliminated; and (5) the waste of raw material left overs is reduced and the utilization rate of positive and negative electrode foils and positive and negative electrode materials is improved.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

Fire monitoring terminal and fire safety system

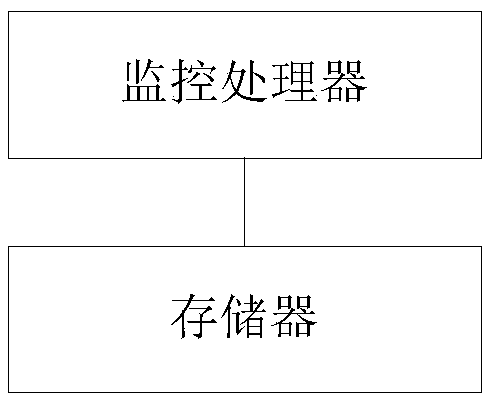

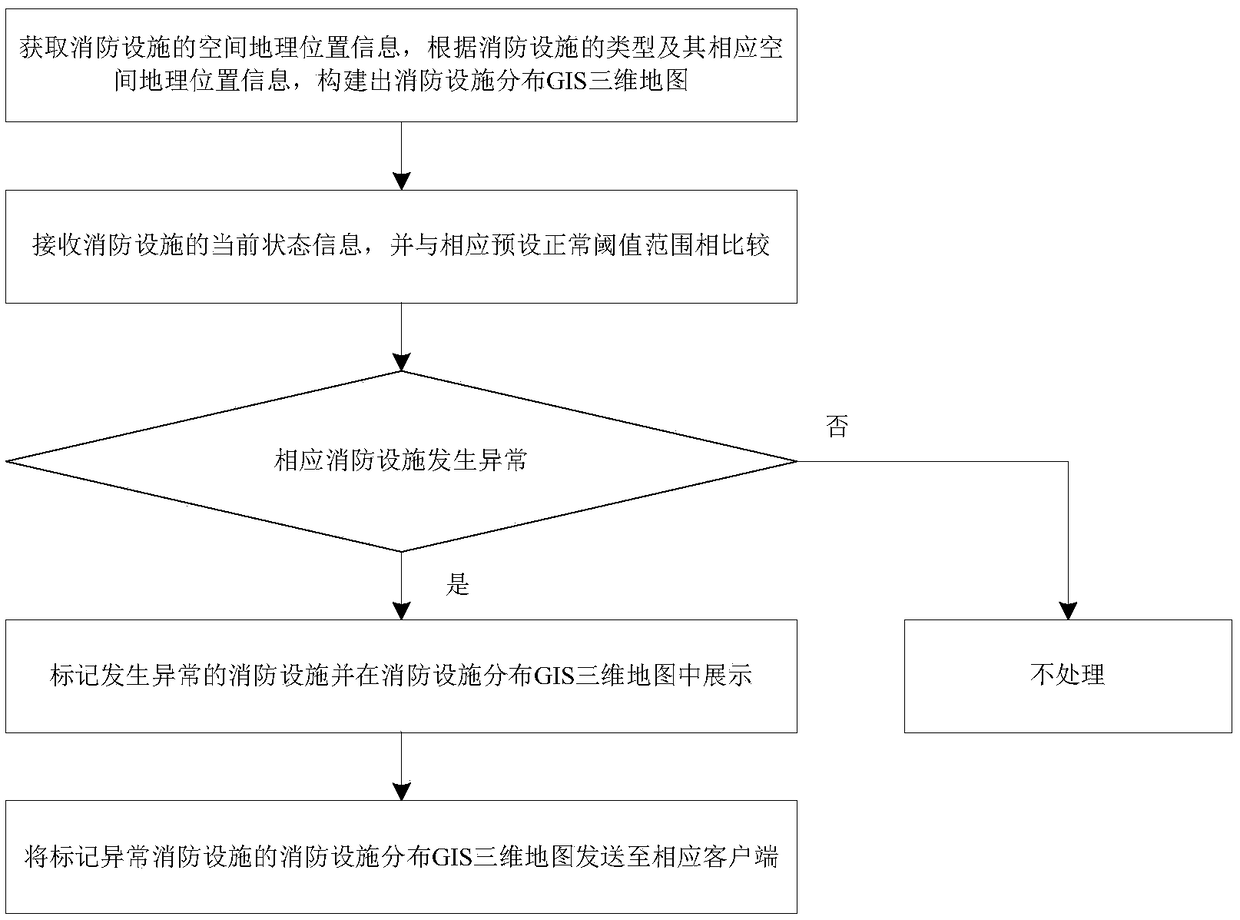

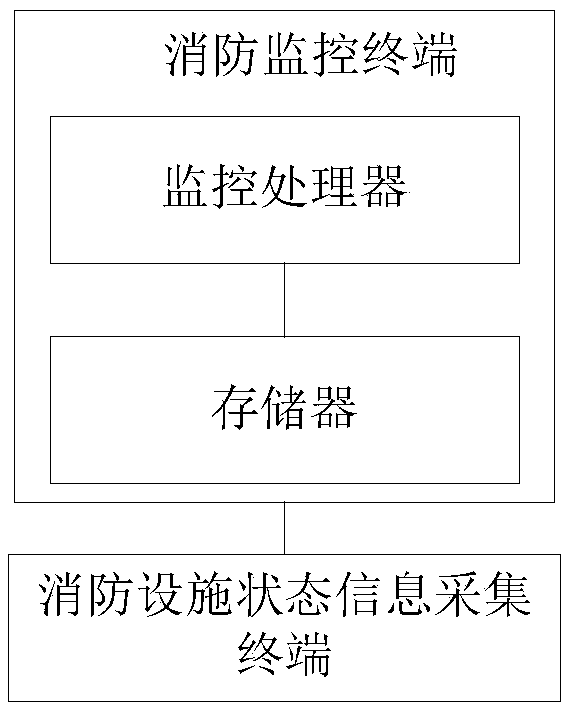

The invention discloses a fire monitoring terminal and a fire safety system. The fire monitoring terminal comprises a monitoring processor and a memory. The monitoring processing is allocated to execute the following steps: acquiring geo-spatial location information of fire control facilities, and constructing a fire control facility distribution GIS three-dimensional map according to the types and corresponding geo-spatial location information of the fire control facilities; receiving current status information of the fire control facilities, comparing the current status information and corresponding preset normal threshold range to judge whether the corresponding fire control facilities are abnormal, and marking abnormal fire control facilities if yes and displaying in the fire control facility distribution GIS three-dimensional map; and sending the fire control facility distribution GIS three-dimensional map with the marked fire control facilities to corresponding clients. Accordingto the invention, location information of the fault fire control facilities can be searched timely and accurately, the case that the fire control facilities break down when the fire happens is avoided, and smooth fire extinguishing work can be guaranteed.

Owner:山东润一智能科技有限公司

Heat dissipating semiconductor package and fabrication method thereof

InactiveUS7508066B2Avoid excessive wearLess heat sinkPrinted circuit assemblingSemiconductor/solid-state device detailsSemiconductor packageSemiconductor chip

A heat dissipating semiconductor package and a fabrication method thereof are provided. A semiconductor chip is mounted on a chip carrier. A heat sink is mounted on the chip, and includes an insulating core layer, a thin metallic layer formed on each of an upper surface and a lower surface of the insulating core layer and a thermal via hole formed in the insulating core layer. A molding process is performed to encapsulate the chip and the heat sink with an encapsulant to form a package unit. A singulation process is performed to peripherally cut the package unit. A part of the encapsulant above the thin metallic layer on the upper surface of the heat sink is removed, such that the thin metallic layer on the upper surface of the heat sink is exposed, and heat generated by the chip can be dissipated through the heat sink.

Owner:SILICONWARE PRECISION IND CO LTD

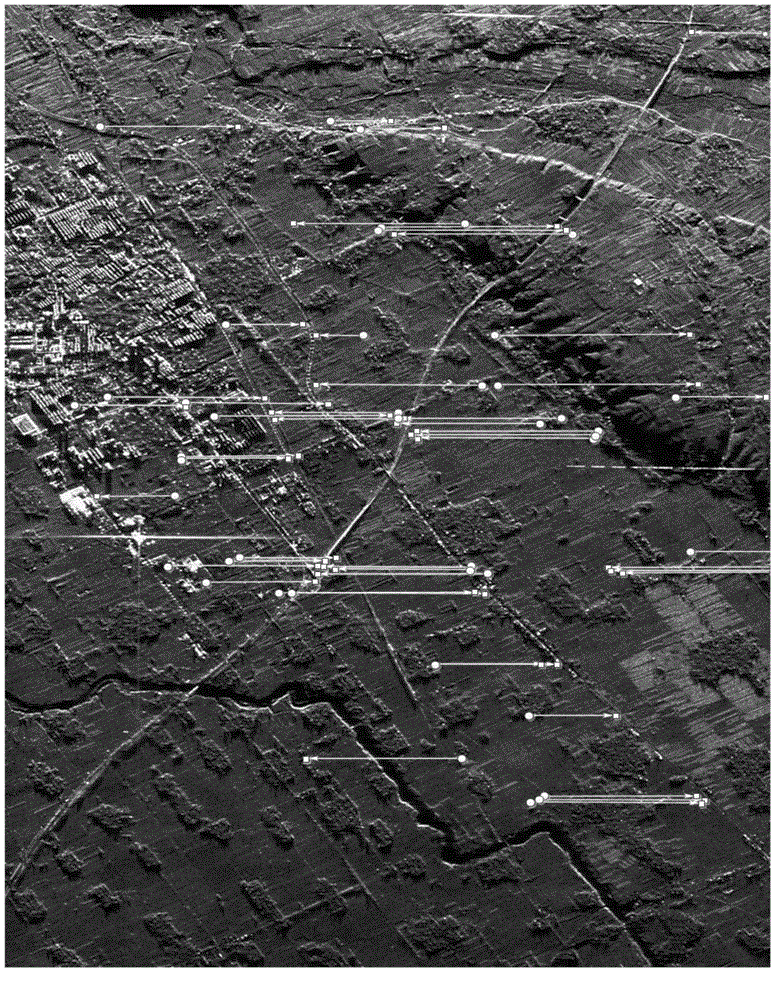

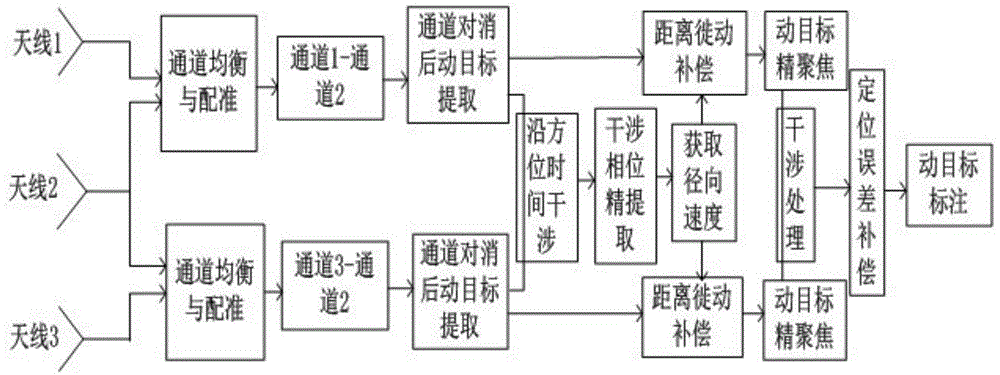

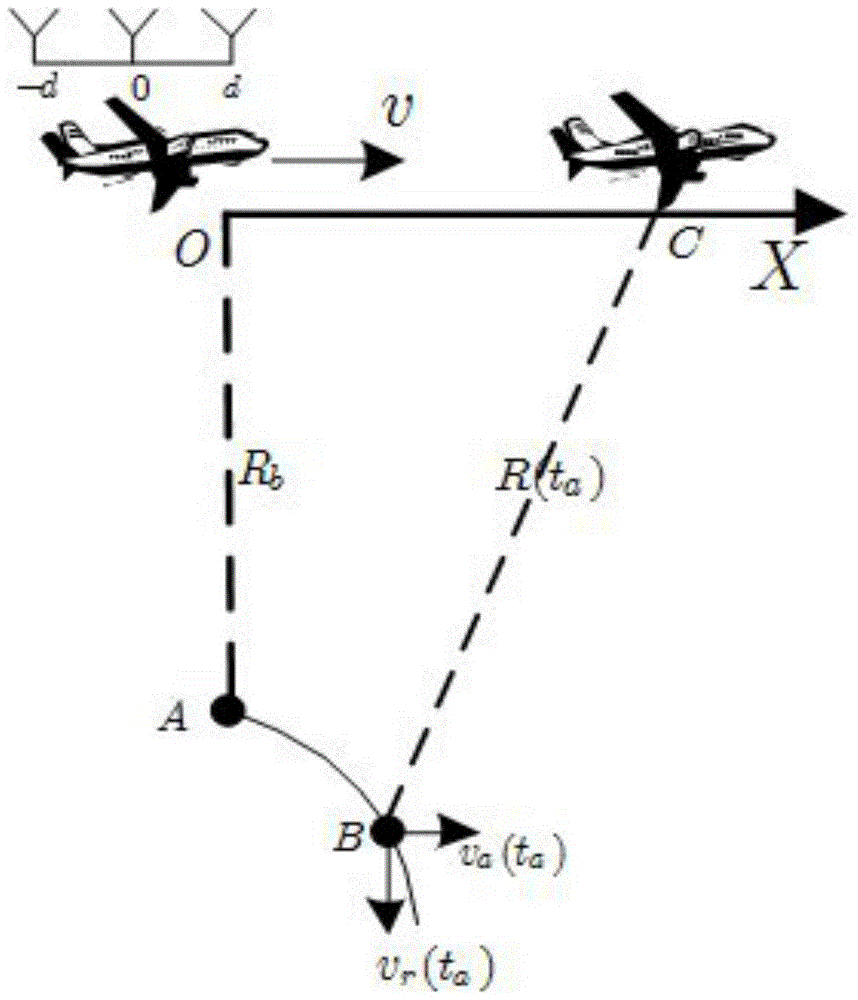

Accurate locating method for onboard tri-channel SAR-GMTI (Synthetic Aperture Radar-Ground Moving Target Indication)

ActiveCN104950307AAchieve precise positioningPrevent jumpingRadio wave reradiation/reflectionSynthetic aperture sonarTarget signal

The invention discloses an accurate locating method for onboard tri-channel SAR-GMTI (Synthetic Aperture Radar-Ground Moving Target Indication). The accurate locating method has the main ideas of sequentially carrying out range pulse compression processing, conventional motion error compensation and channel equilibrium processing on an echo signal of an original moving target received by a channel of an onboard tri-channel SAR at first; then, carrying out time-shifting rectification on all channels which are sequentially subjected to the range pulse compression processing, the conventional motion error compensation and the channel equilibrium processing according to DPCA (Displaced Phase Center Antenna) technology; respectively carrying out cancellation on every two channel signals of all channel signals which are subjected to the time-shifting rectification, and obtaining a first moving target signal and a second moving target signal; respectively carrying out phase compensation and range migration compensation on the first moving target signal and the second moving target signal; then, respectively carrying out interference processing on the first moving target signal and the second moving target signal, and obtaining an accurate focusing and imaging position of the original moving target; marking the accurate focusing and imaging position of the original moving target in a scene.

Owner:XIDIAN UNIV

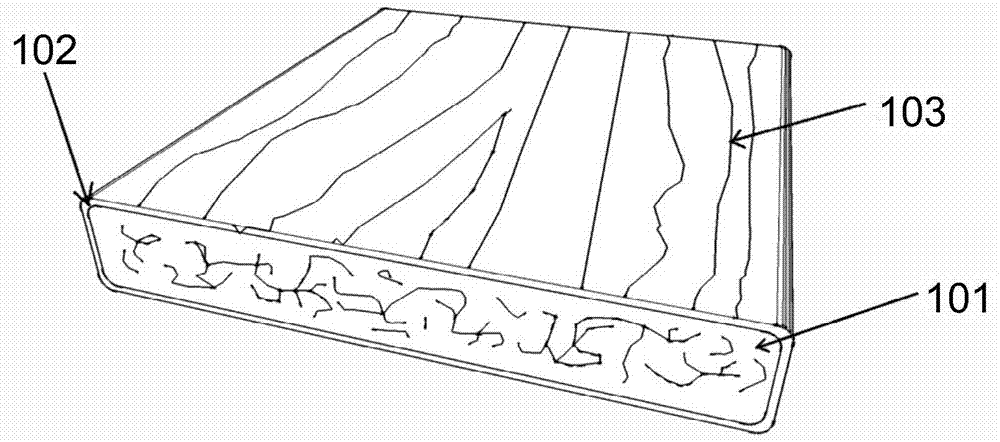

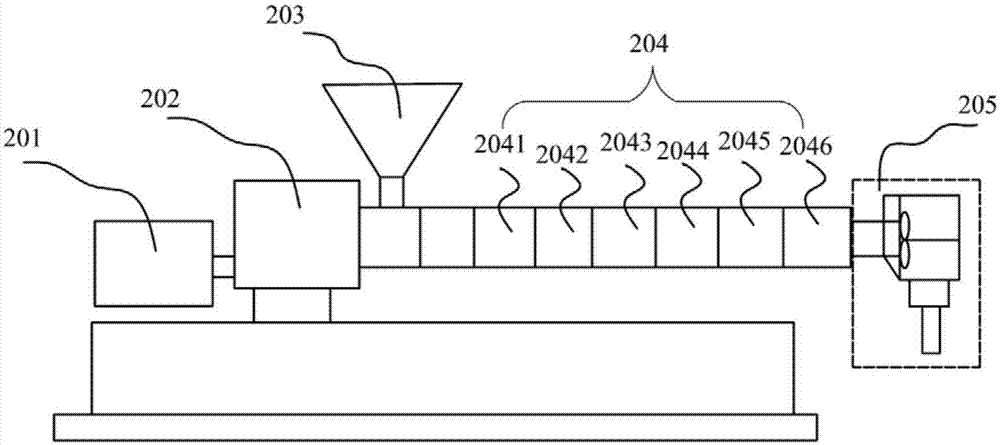

Wood-grain-imitated co-extruded plastic-wood profile and preparation method thereof

ActiveCN104723635AImprove anti-corrosion performanceImprove aging resistanceSynthetic resin layered productsSurface layerAging resistance

The invention provides a wood-grain-imitated co-extruded plastic-wood profile. The wood-grain-imitated co-extruded plastic-wood profile comprises a surface layer and a base material, wherein the adding amounts of plastic and a functional aid in the surface layer are more than the adding amounts of the plastic and the functional aid in the base material, so that the cost is favorable to be reduced; the surface layer is subjected to color adjustment by virtue of a main color and a secondary color (a third color can be increased according to requirements), so that the effects of the color shade and the layer variability of the surface layer can be well achieved. The invention further provides a preparation method of the wood-grain-imitated co-extruded plastic-wood profile. The preparation method comprises the processes of granulation, synchronous extrusion and surface treatment. According to the preparation method, surface layer particles including main color particles and secondary color particles are respectively granulated and are uniformly mixed for co-extruding the surface layer, and the surface layer is subjected to surface treatment in a 'hot plate and cold roller' manner. The co-extruded plastic-wood profile prepared by virtue of the preparation method is low in cost, excellent in water resistance, corrosion resistance and aging resistance and durable, further has the grains, color gradation and texture of imitated and natural wood, so that the user experience is improved.

Owner:湖南格林美资源利用有限公司 +2

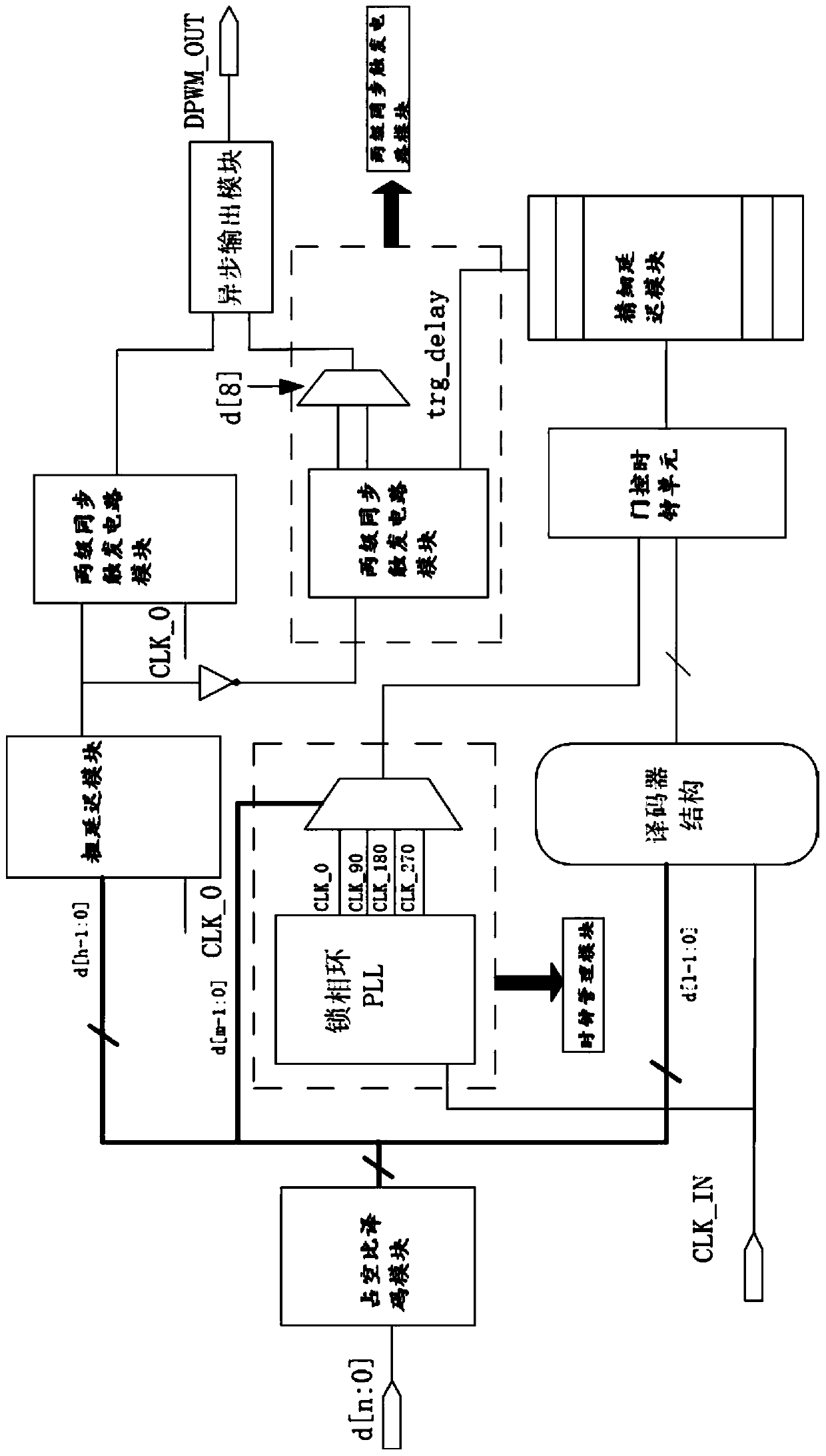

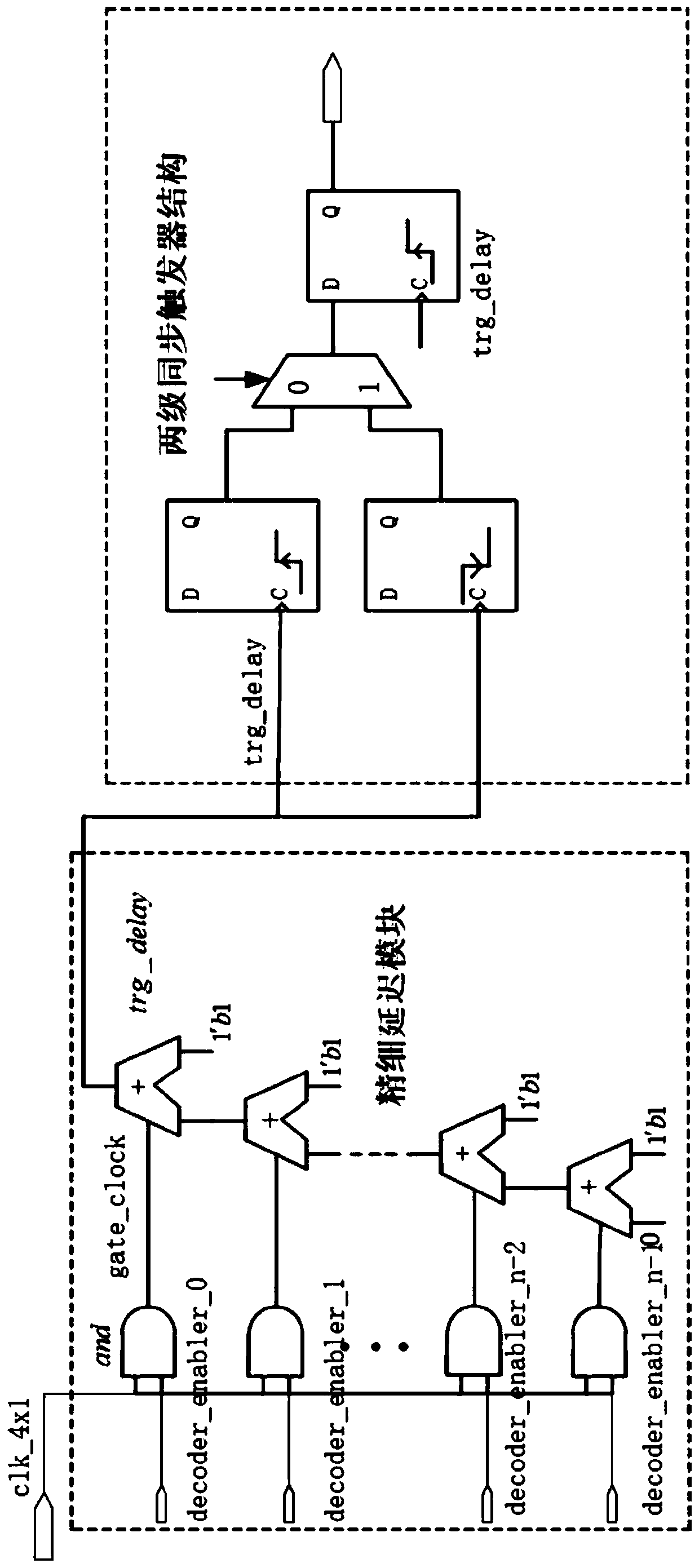

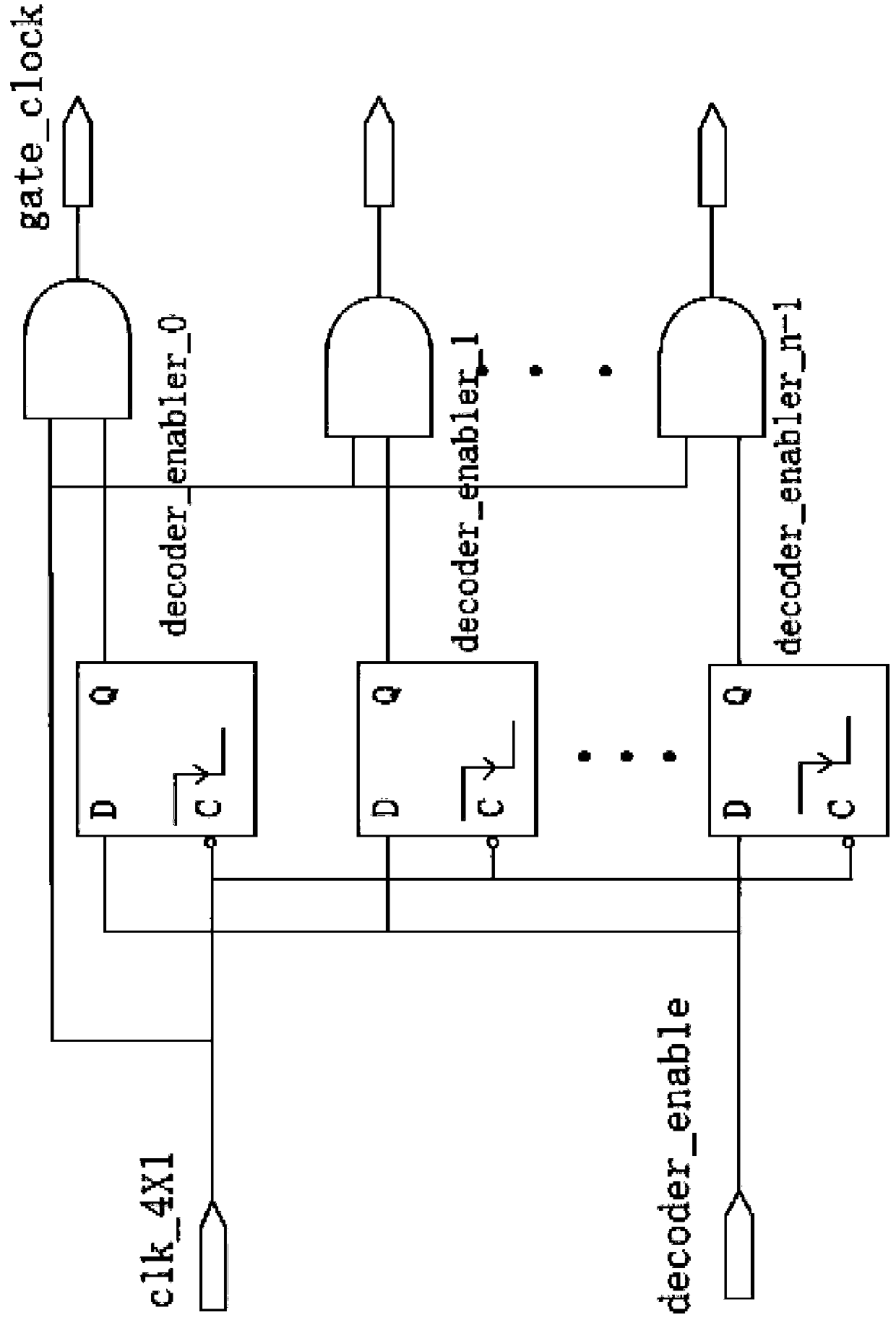

Digital pulse width modulation circuit and working method

ActiveCN110661513AHigh-resolutionReduce usagePulse duration/width modulationPower conversion systemsHemt circuitsFlip-flop

The invention relates to the technical field of power supply management chips, in particular to a digital pulse width modulation circuit, which comprises a coarse delay module based on a counter, a clock management module based on a phase-locked loop, a two-stage synchronous trigger circuit module, a fine delay module based on a carry chain unit, a duty ratio decoding module and a gated clock unit. The invention has the beneficial effects that two-stage synchronous triggers are used on two main paths of high-level output triggering and asynchronous fine phase shift clock signals. Delay of different paths is balanced. Meanwhile, the rising edge of the input clock is prevented from being very close to the rising edge of the fine phase shift clock trigger signal. The clock management module is used for obtaining four paths of signals with the phase difference of 90 degrees, and after the four paths of phase shift clock signals pass through the gating clock unit and the fine delay module,the response speed of digital switch converter voltage regulation and control is increased.

Owner:HEFEI UNIV OF TECH

Molding die for molding boot for constant velocity joint

An inner die of a molding die includes a core shaft, split dies radially arranged along an outer peripheral surface of the core shaft around an axis of the core shaft, which serves as a center, and a cylindrical set ring arranged below the split dies, the core shaft being inserted through the set ring. An annular engaging surface, which is a tapered surface whose diameter is gradually reduced downward, is formed in an inner peripheral side of an upper end portion of the set ring, and lower end portions of the respective split dies are introduced into, and engaged with the engaging surface. The molding die includes a pressing portion that presses downward upper end portions of the respective split dies introduced into the set ring, so as to move the lower end portions of the respective split dies toward the axis along the engaging surface.

Owner:JTEKT CORP

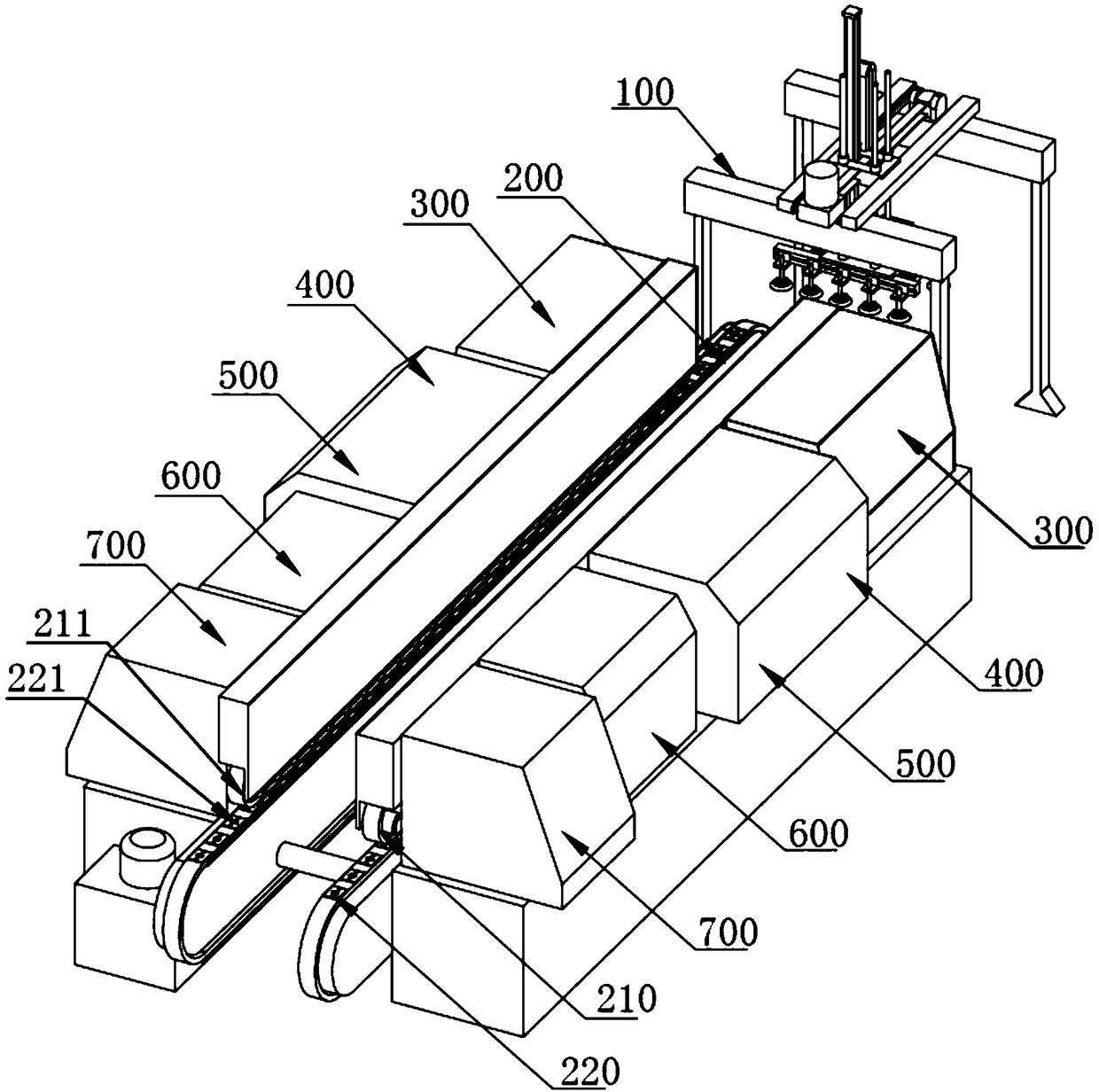

Workpiece cutting mechanism, workpiece cutting device and workpiece cutting method

ActiveCN106273013AGuaranteed stabilityGuaranteed smoothWorking accessoriesFine working devicesMechanical engineeringLine length

The invention discloses a workpiece cutting mechanism, a workpiece cutting device and a workpiece cutting method. The workpiece cutting mechanism comprises a first cutting wheel set, a second cutting wheel set, a first transition guide wheel set, a second transition guide wheel set and cutting lines; wherein the first cutting wheel set and the second cutting wheel set are oppositely arranged, the first cutting wheel set is provided with a plurality of first cutting wheels arranged side by side, and the second cutting wheel set is provided with a plurality of second cutting wheels arranged side by side; the first transition guide wheel set and the second are oppositely arranged, the first transition guide wheel set is arranged adjacent to the first cutting wheel set and provided with a plurality of first transition guide wheels side by side, and the second transition guide wheel set is arranged adjacent to the second cutting wheel set and provided with a plurality of second transition guide wheels side by side; the cutting lines are sequentially wound around the first transition guide wheels, the first cutting wheels, the second cutting wheels and the second transition guide wheels, and cutting line meshes are formed between the first cutting wheels and the second cutting wheels which are arranged in a one-to-one correspondence manner; and in this way, the stability of all cutting lines in the cutting line meshes and the stability of line lengths of the cutting lines between the first cutting wheels and the second wheels and the line distances between two adjacent cutting lines can be guaranteed.

Owner:海宁市日进科技有限公司

Full-automatic four-edge banding equipment and method for plate

PendingCN109227873AHigh degree of automationSave manpower and material resourcesPolishing machinesBelt grinding machinesMaterial resourcesEngineering

The invention relates to the technical field of plate processing equipment, in particular to full-automatic four-edge banding equipment and method for a plate. The equipment comprises a loading deviceused for taking and loading the plate, a first banding mechanism and a second banding mechanism, wherein a turntable mechanism is connected between the first banding mechanism and the second bandingmechanism, the first banding mechanism comprises a conveying device used for conveying the plate taken by the loading device, a cutting device used for cutting the plate during conveying, a banding device used for banding the cut plate, a trimming device used for trimming the banded plate, a polishing device used for polishing the trimmed plate and a sanding device used for sanding the polished plate. The full-automatic four-edge banding equipment and method for the plate have the advantages that the plate is full-automatically loaded, conveyed, cut, gummed, banded, compressed, cut off, trimmed, polished and sanded, and then repeatedly performs the above process on the plate to achieve four-edge banding, thereby solving the problem that the plate is cut and banded through manpower or half-automatic equipment in the prior art, the degree of automation is high, and the manpower and material resources are saved.

Owner:东莞市春旭机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com