Patents

Literature

30results about How to "Occurrence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

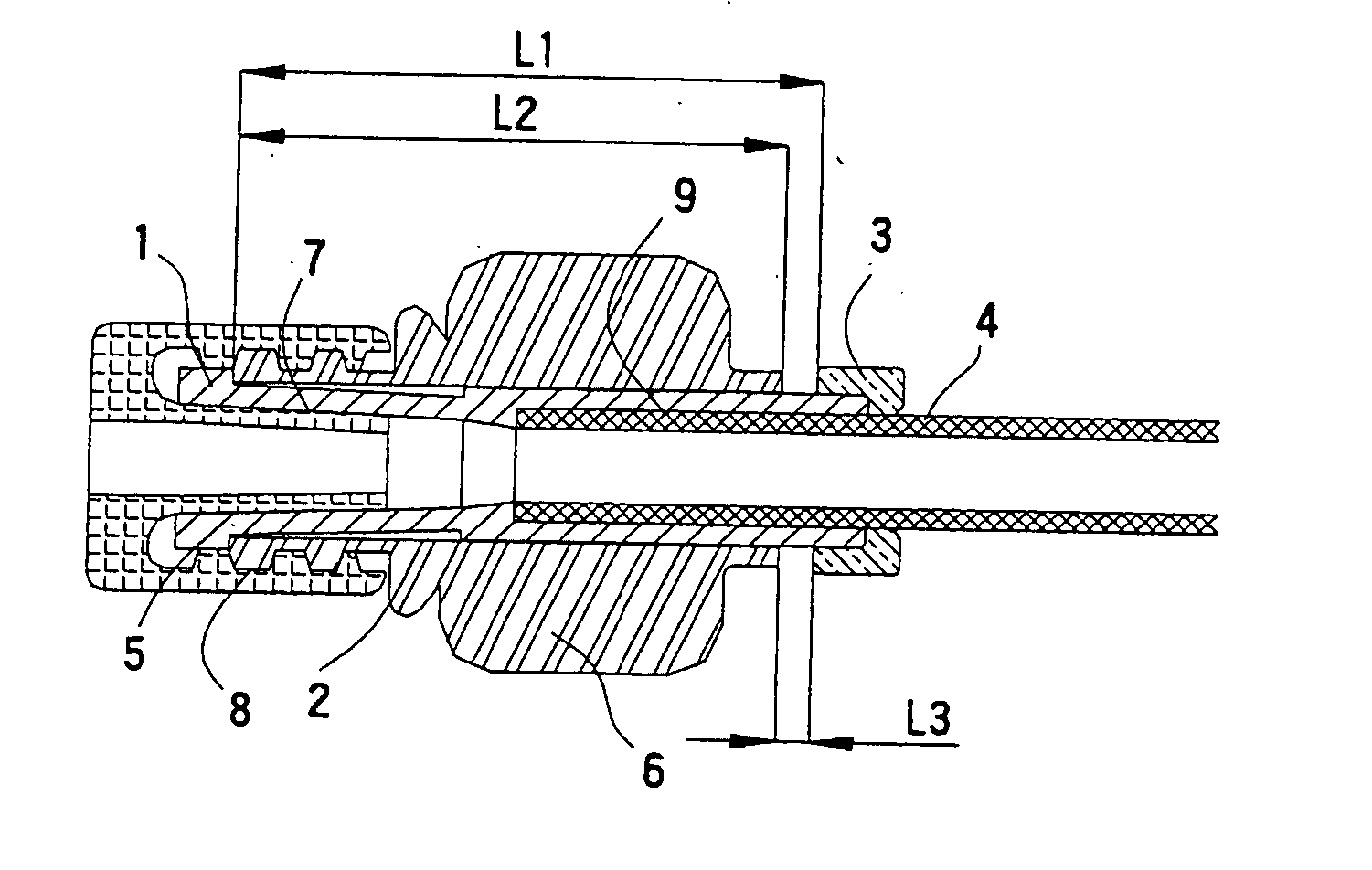

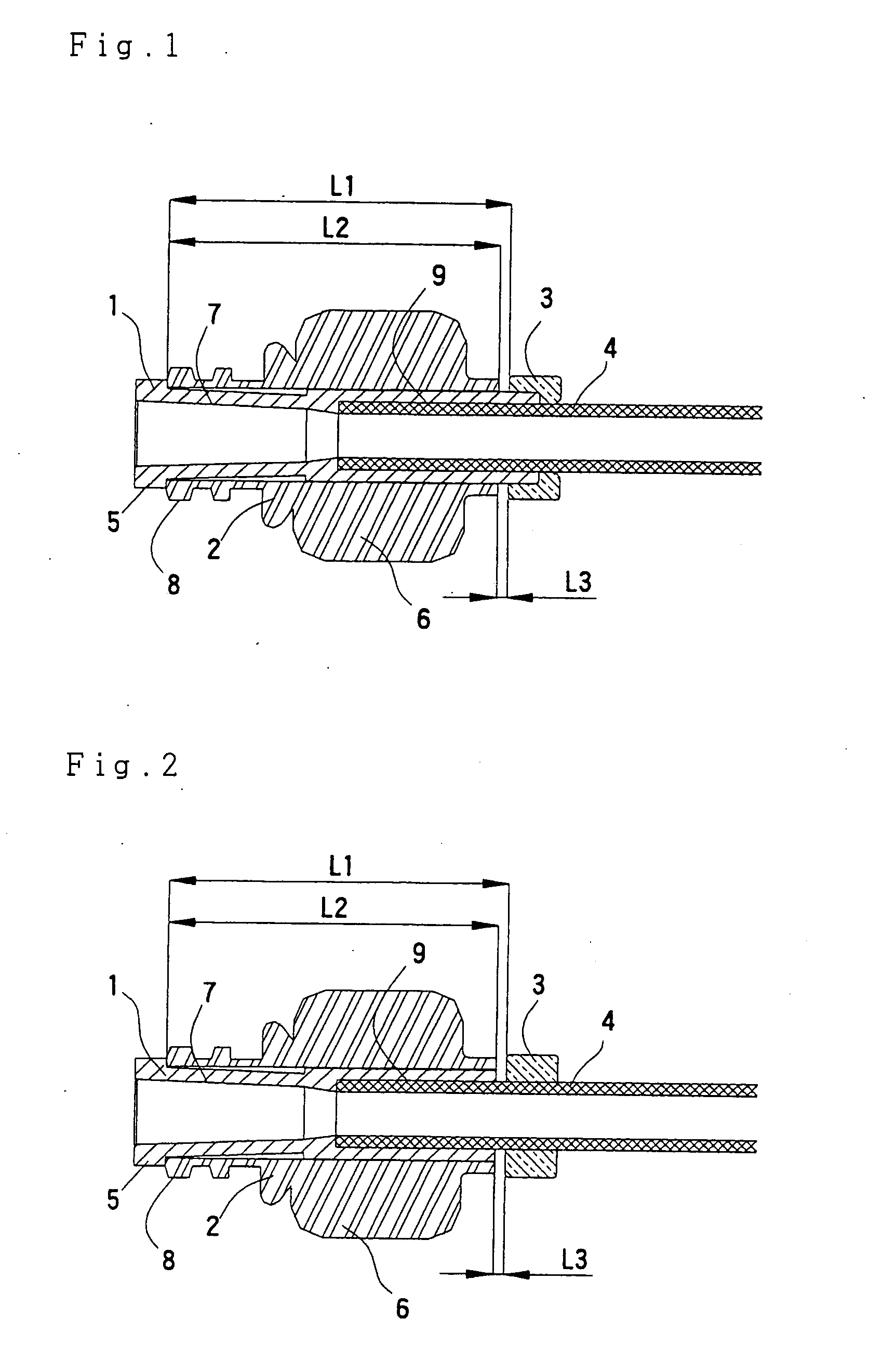

Female connector

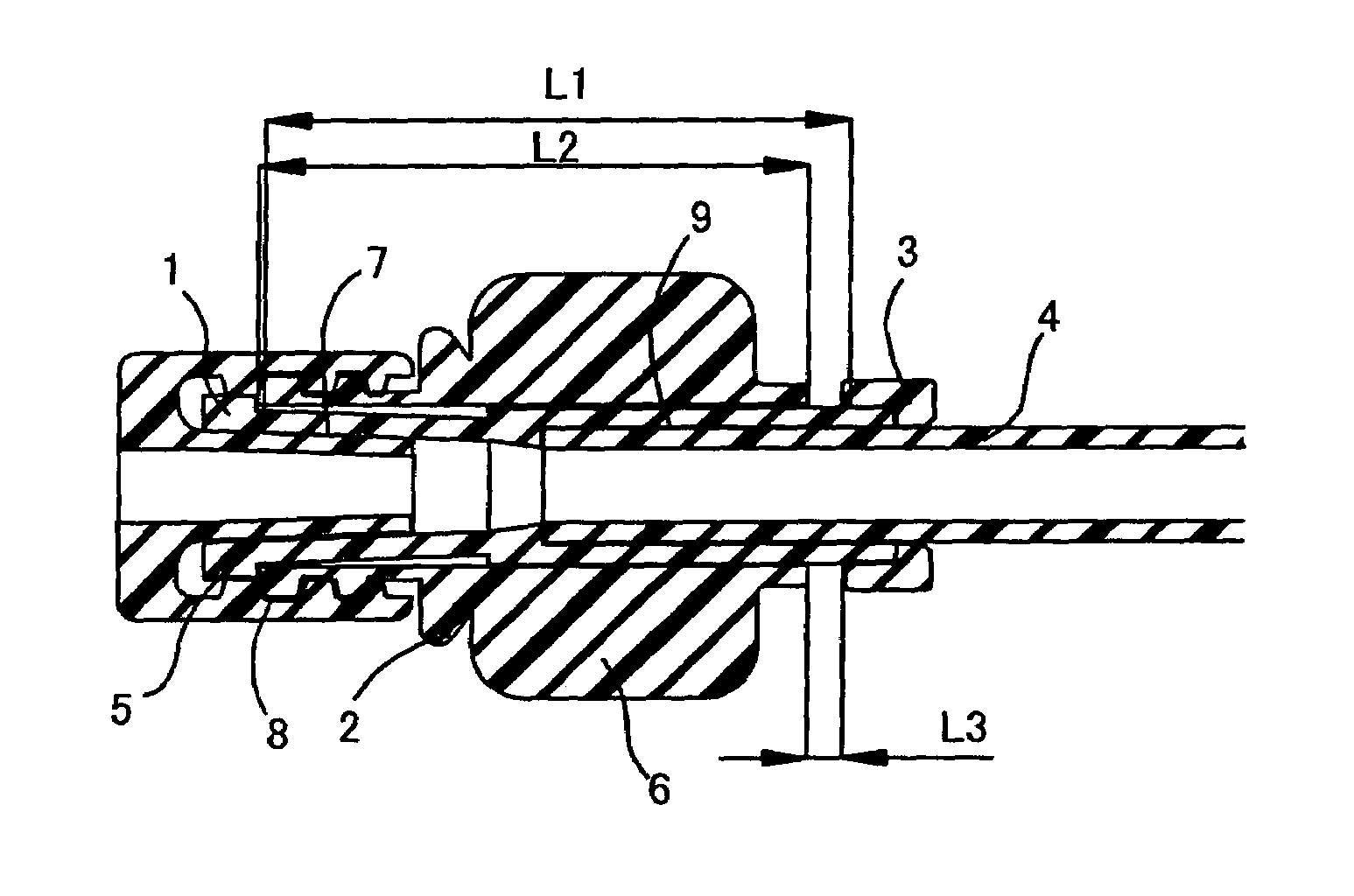

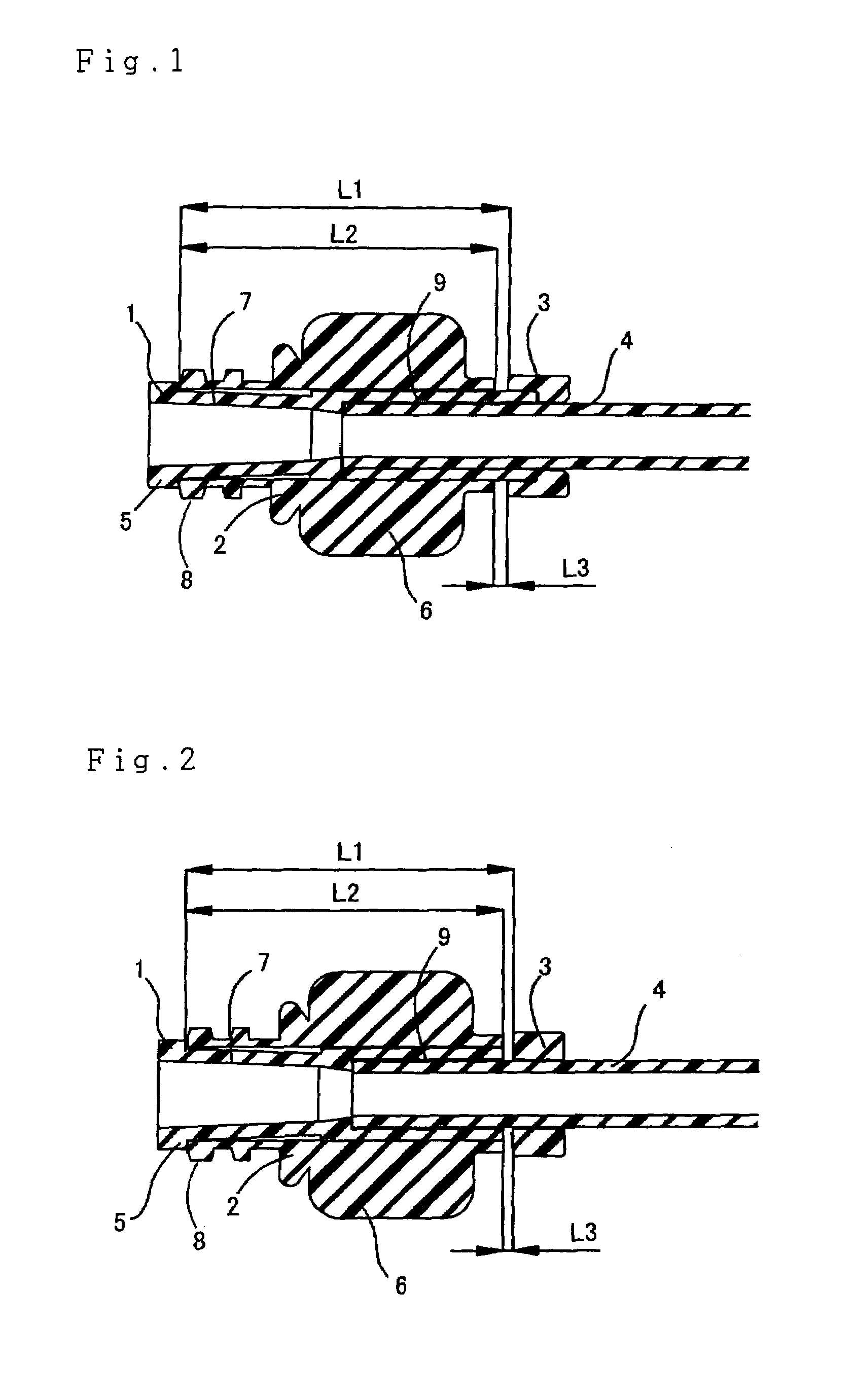

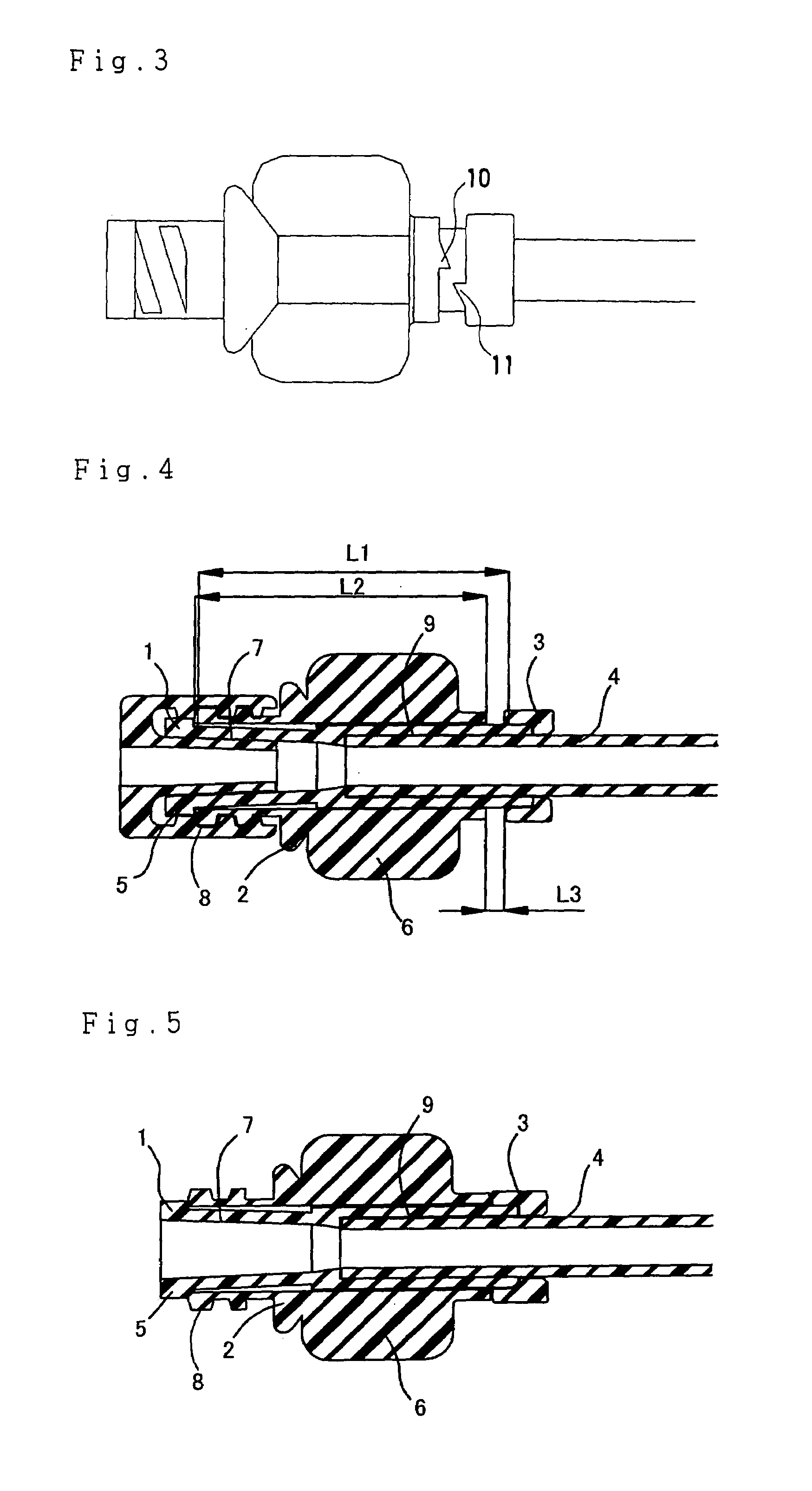

A female connector including: a cylindrical core member having a luer taper on a distal inner surface thereof and a tube bonding portion formed on a proximal end inner surface and being formed with a flange at a distal extremity thereof; a cylindrical housing having a male screw formed on an outer surface thereof and mounted to an outer periphery of the core member without being fixed, and a stopper fixed at a position apart from the flange of the core member, wherein the distance (L1) between the flange and the stopper is larger than the length (L2) of the housing in the axial direction when a male connector is connected to the female connector.

Owner:NIPRO CORP

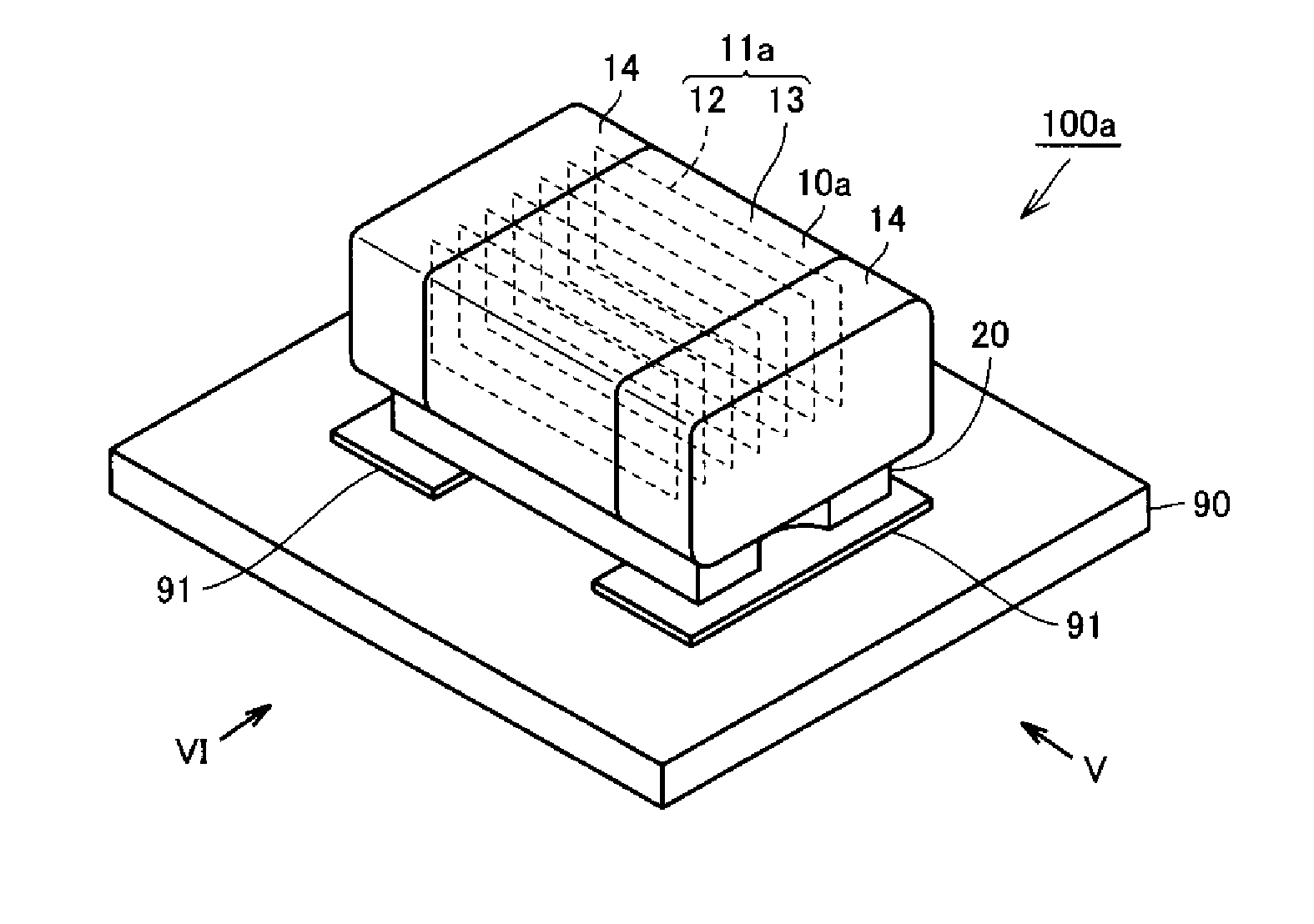

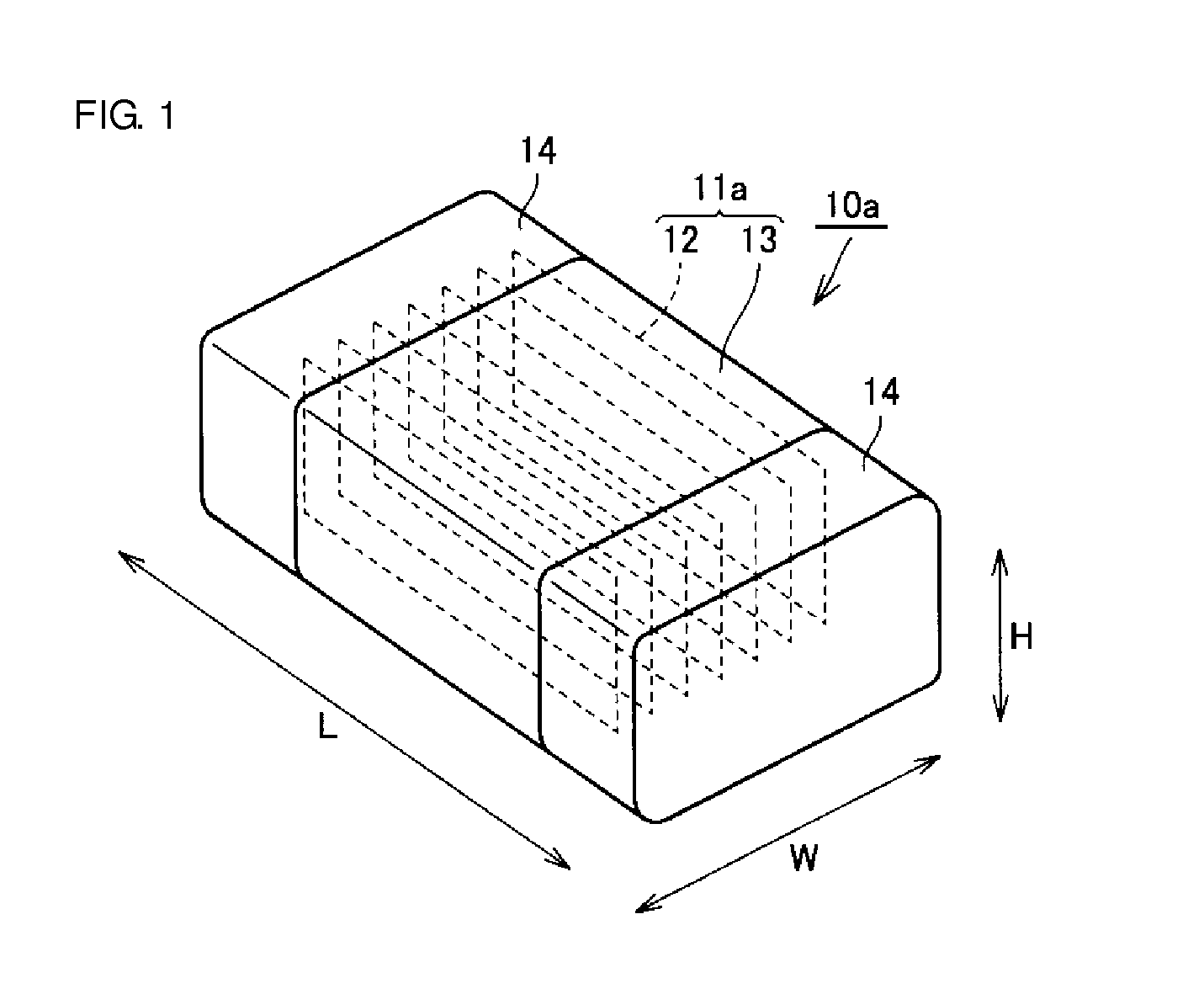

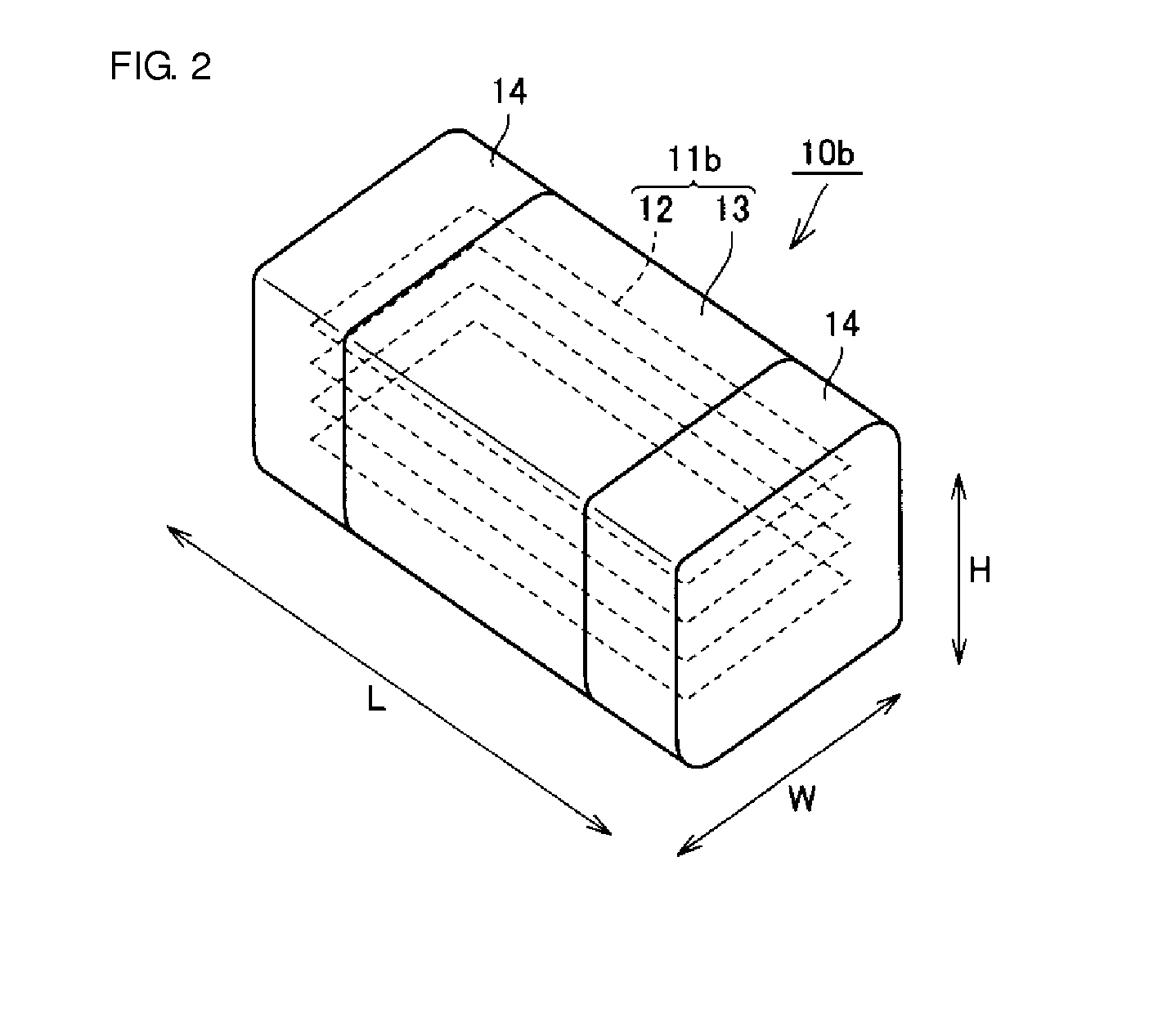

Electronic component

ActiveUS20150270068A1OccurrenceAvoid glitchesResistor terminals/electrodesFixed capacitor dielectricEngineeringElectronic component

An electronic component includes an electronic element including external electrodes on a surface and a substrate terminal on which the electronic element is mounted. The substrate terminal includes a first main surface, a second main surface opposite the first main surface, and a peripheral surface joining the first main surface and the second main surface. The substrate terminal includes mounting electrodes provided on the second main surface and electrically connected to the external electrodes of the electronic element, and connection electrodes provided on the first main surface and electrically connected to lands of a circuit substrate. A maximum width of the connection electrodes is greater than a maximum width of the mounting electrodes.

Owner:MURATA MFG CO LTD

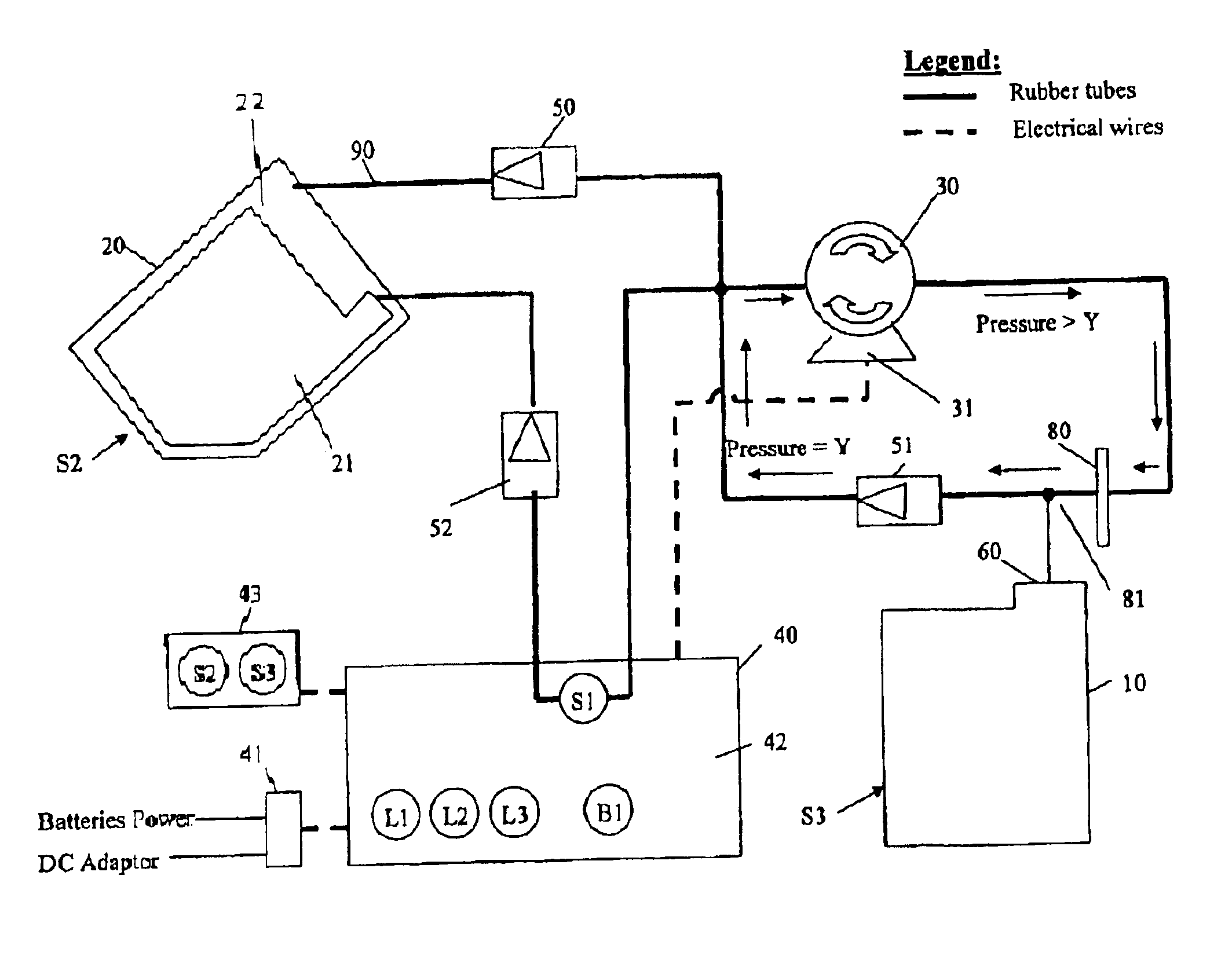

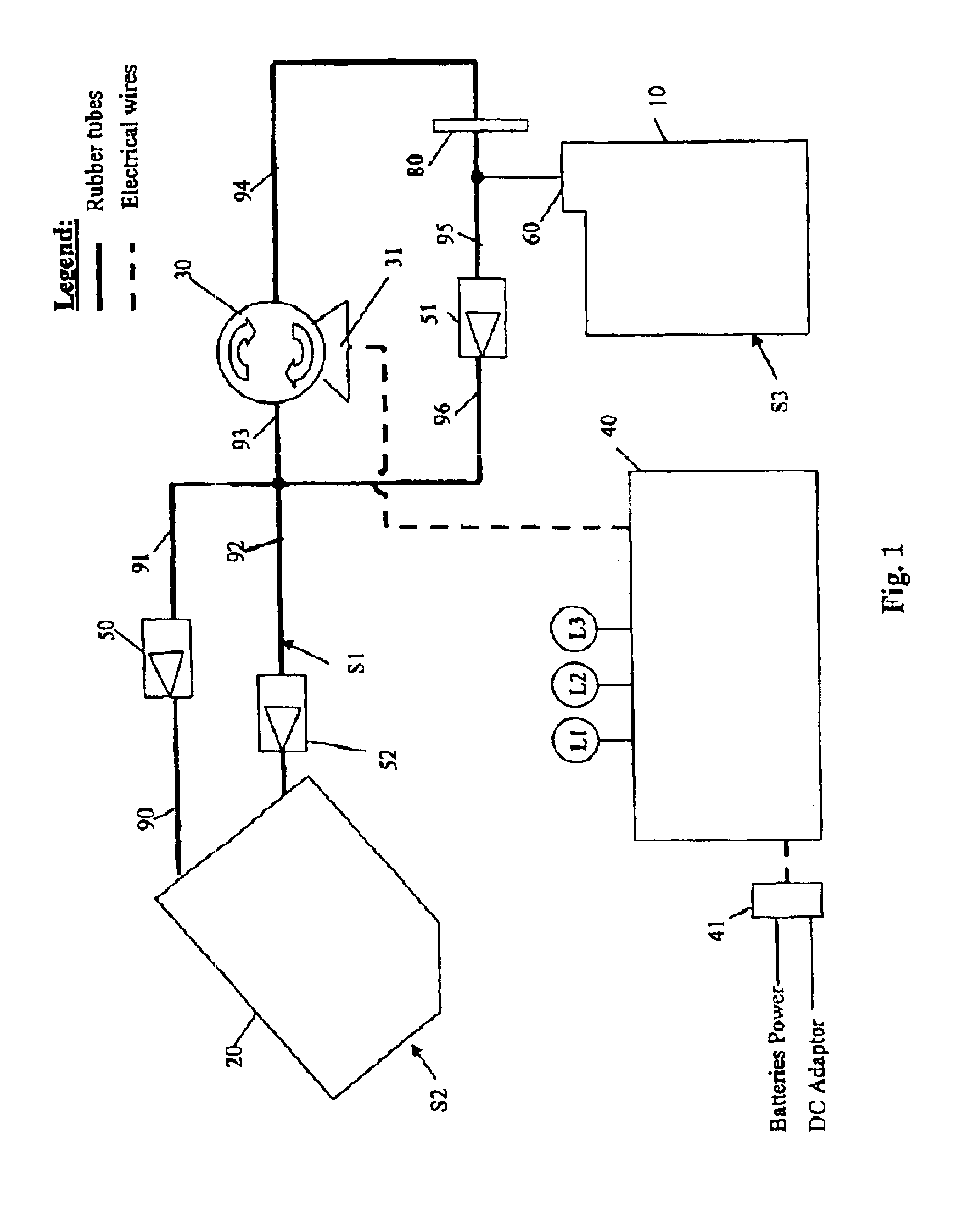

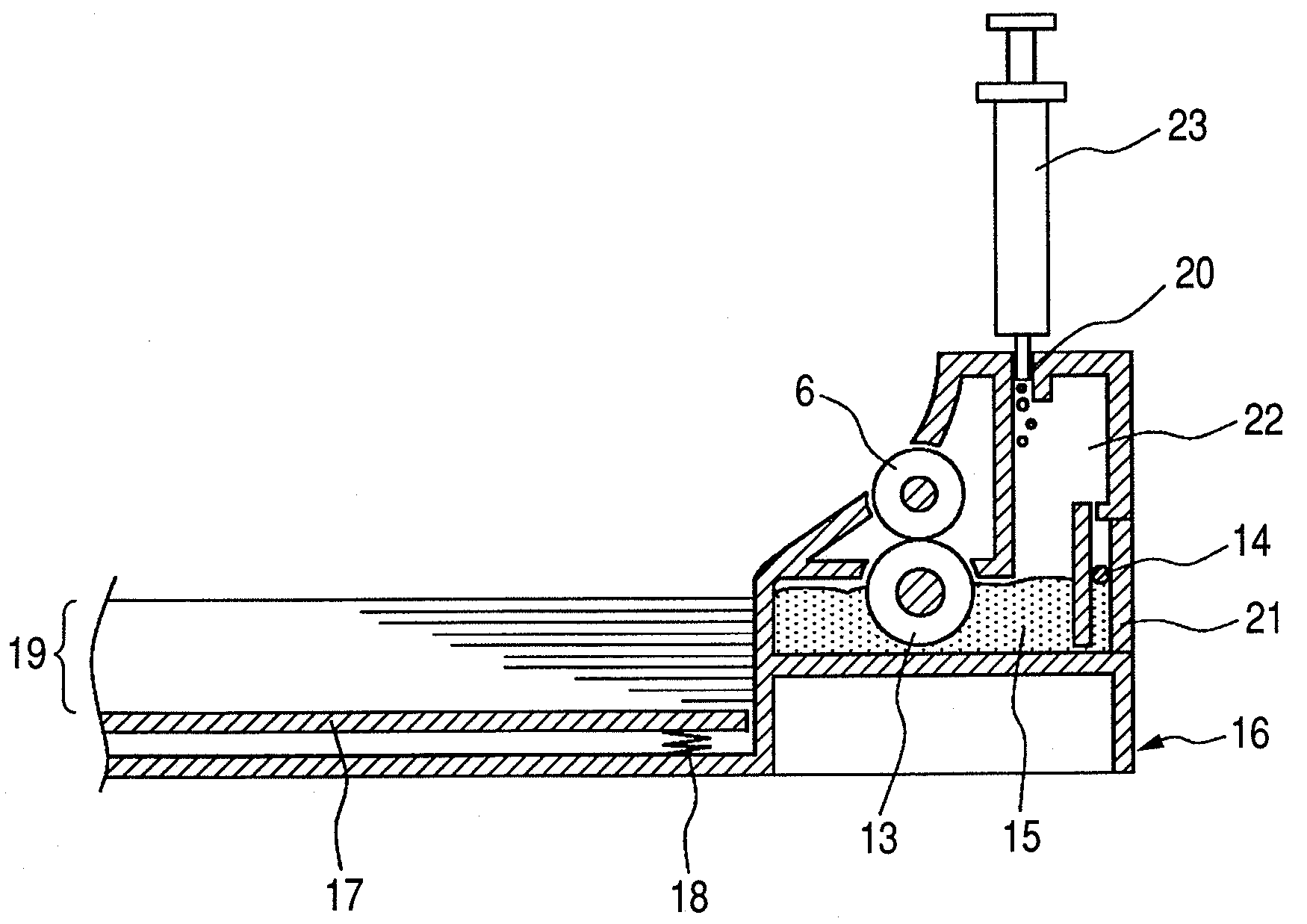

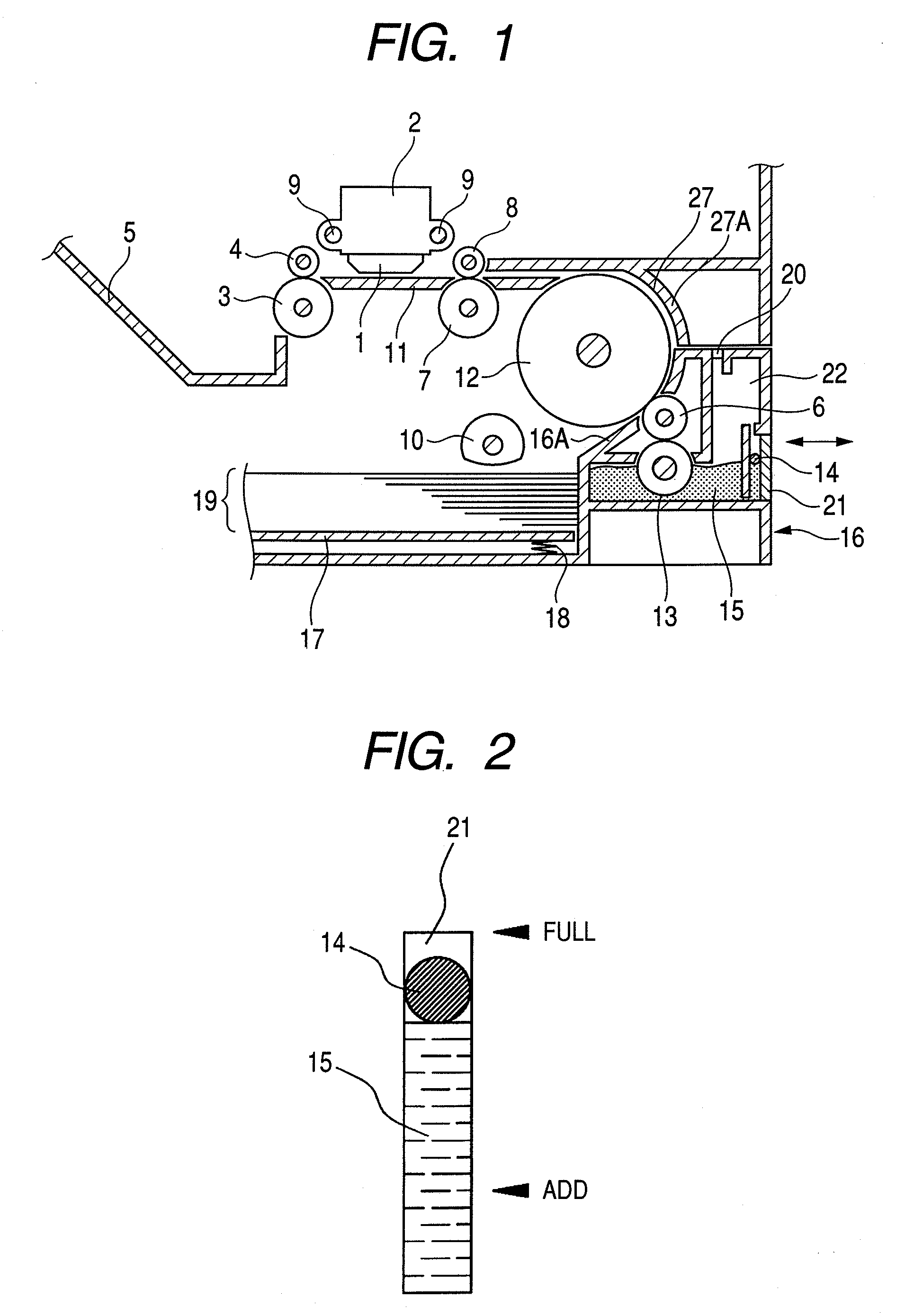

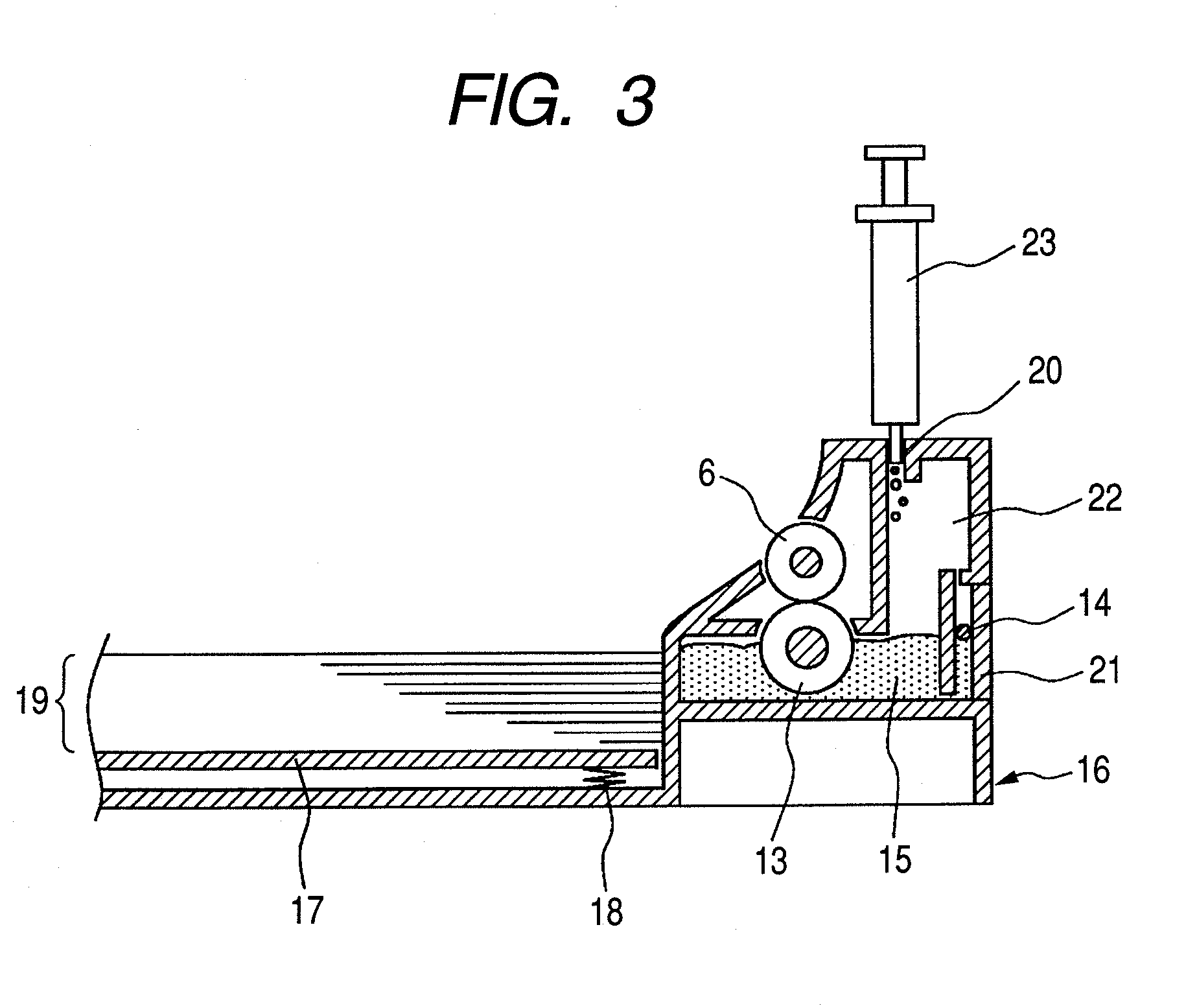

Refill station

A refill station adapted to dock an ink replenishment cartridge and a printer cartridge to have its ink replenished using a flow system whereby cannula or needle interconnection with the system of the cartridges allows electronic monitoring and sequencing of the operations. The flow system has threshold valving, at least one damped route, at least one by pass route and a pump whereby ink can be cleared from the printer cartridge and be replaced by more ink from the replenishment cartridge. Pressure relief and ink quality maintenance procedures are embodied in flow system.

Owner:INKE PTE LTD (SG)

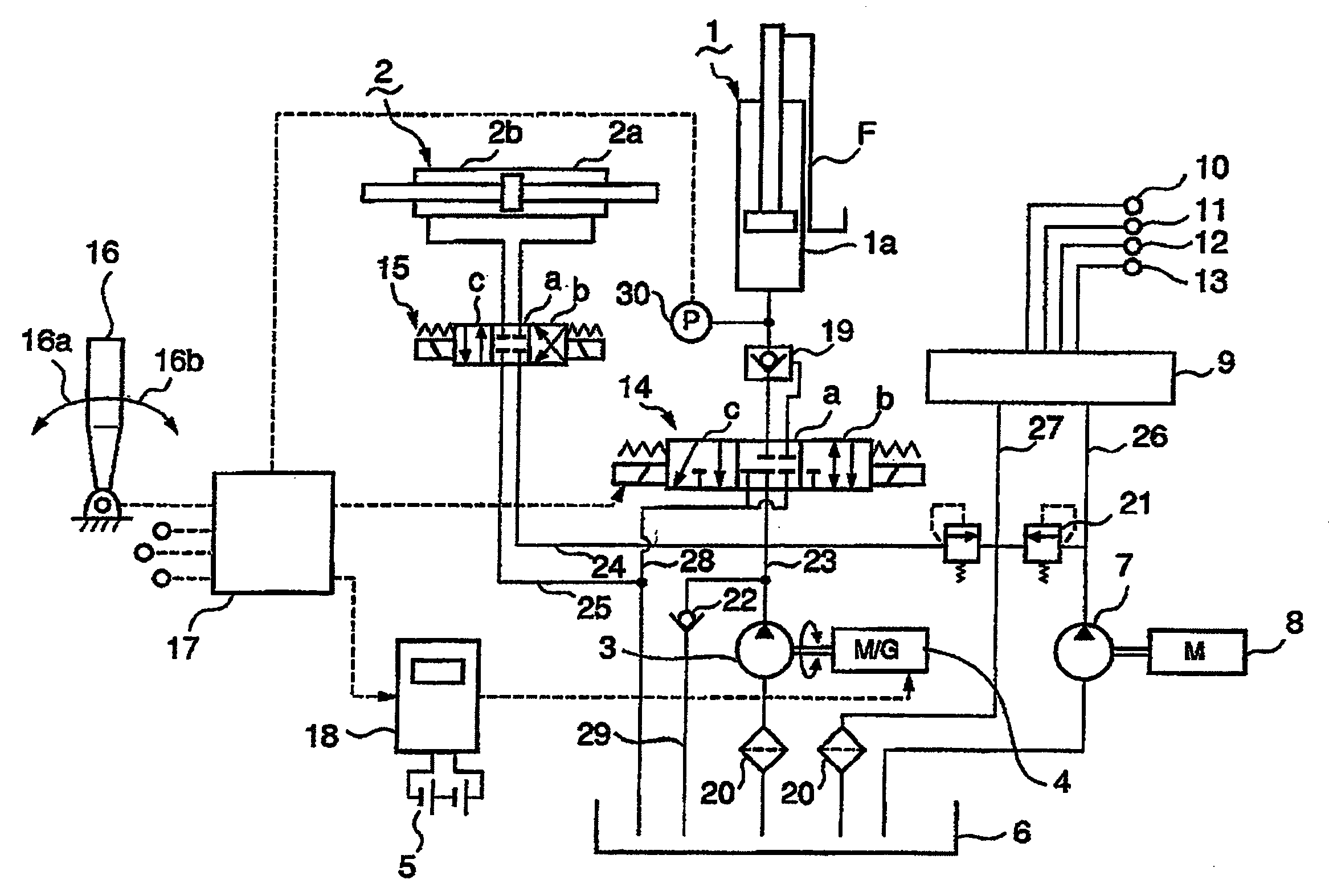

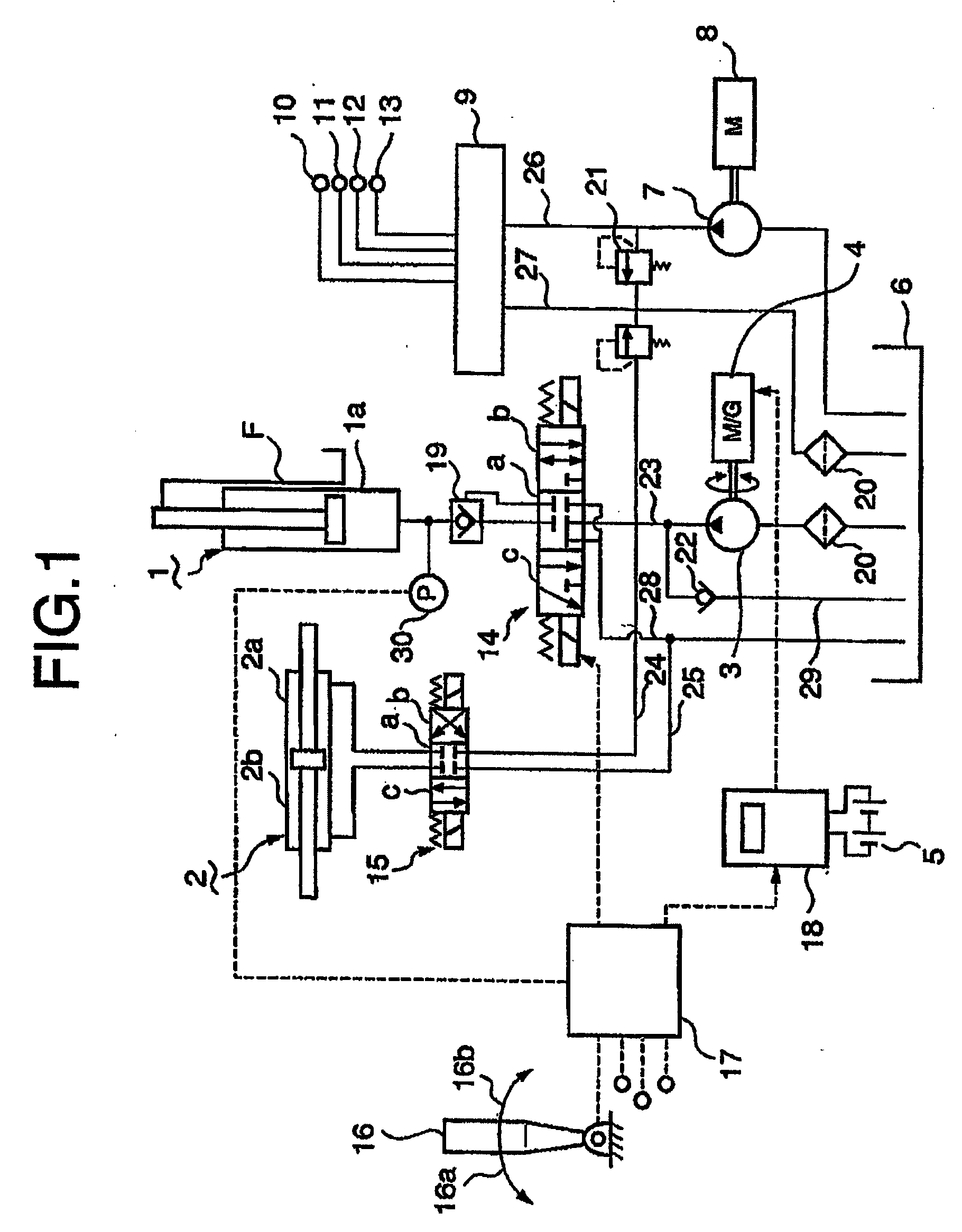

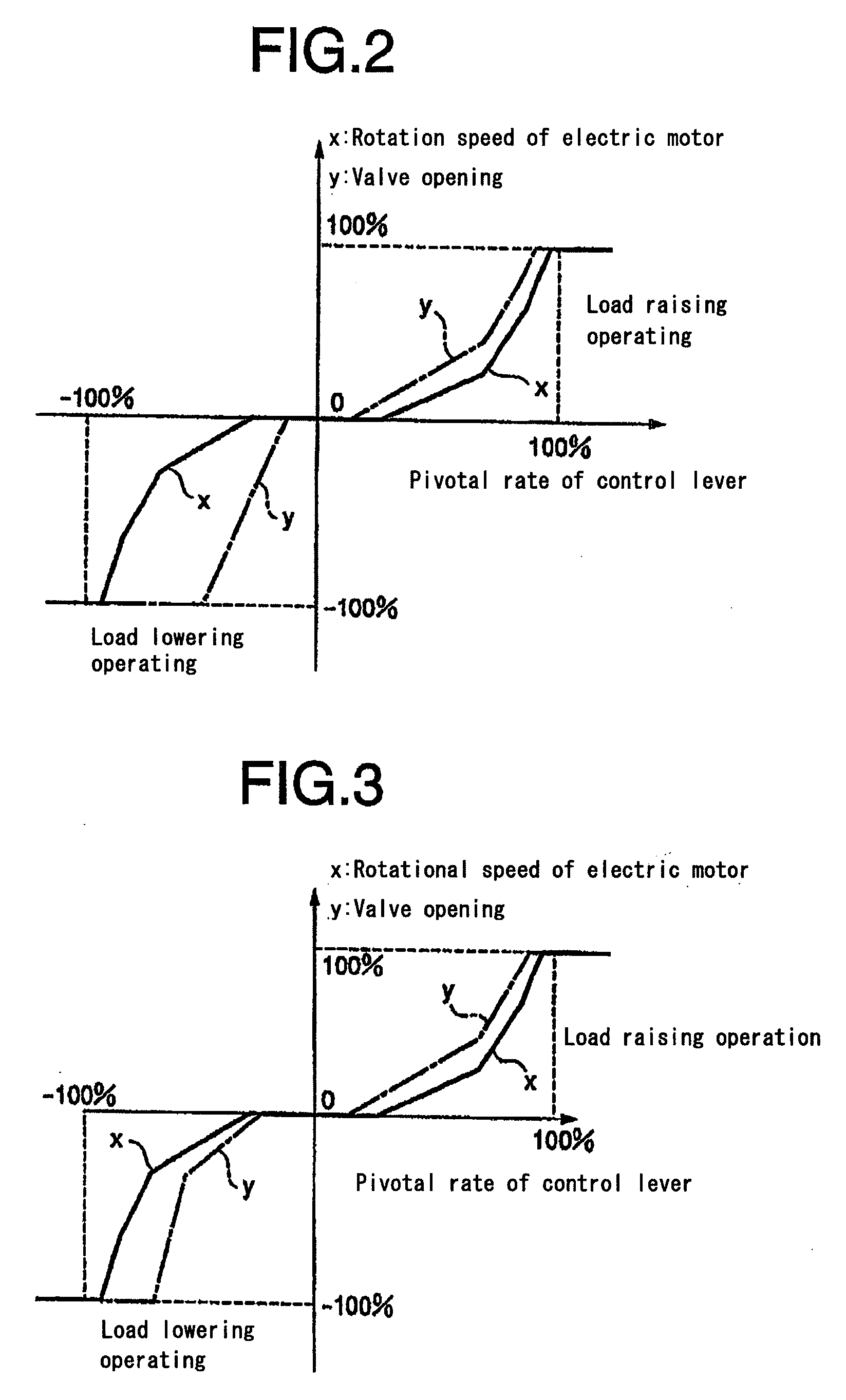

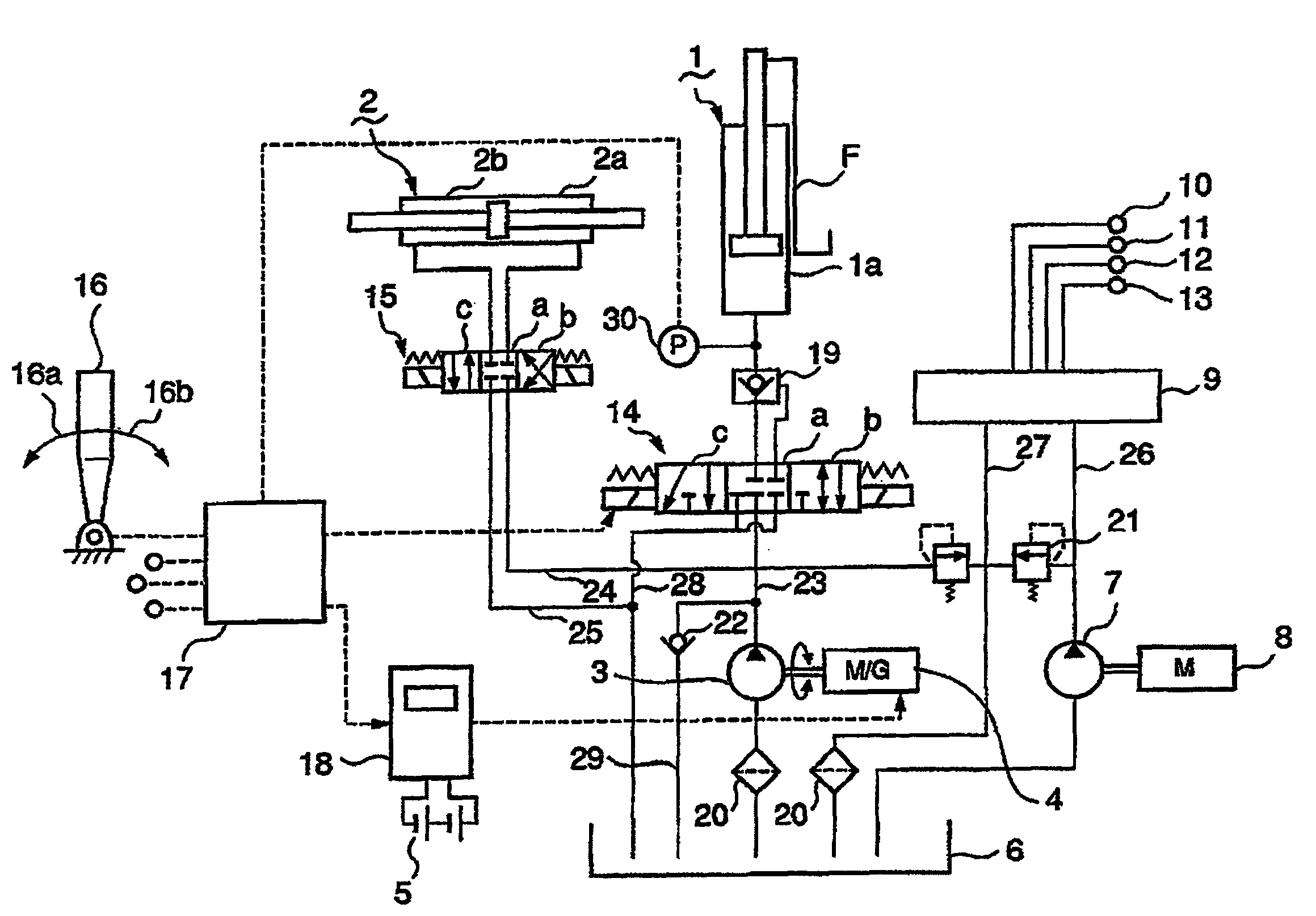

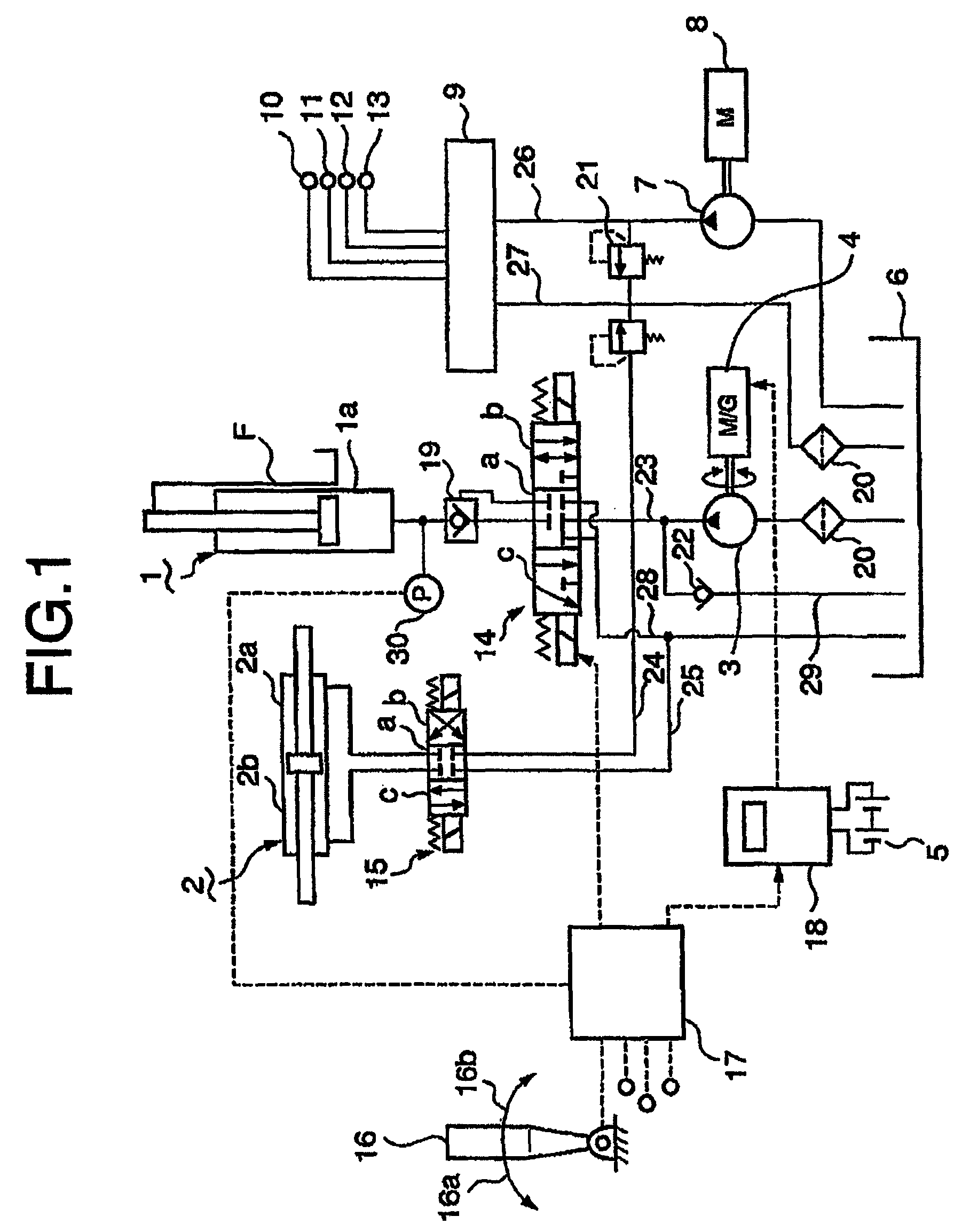

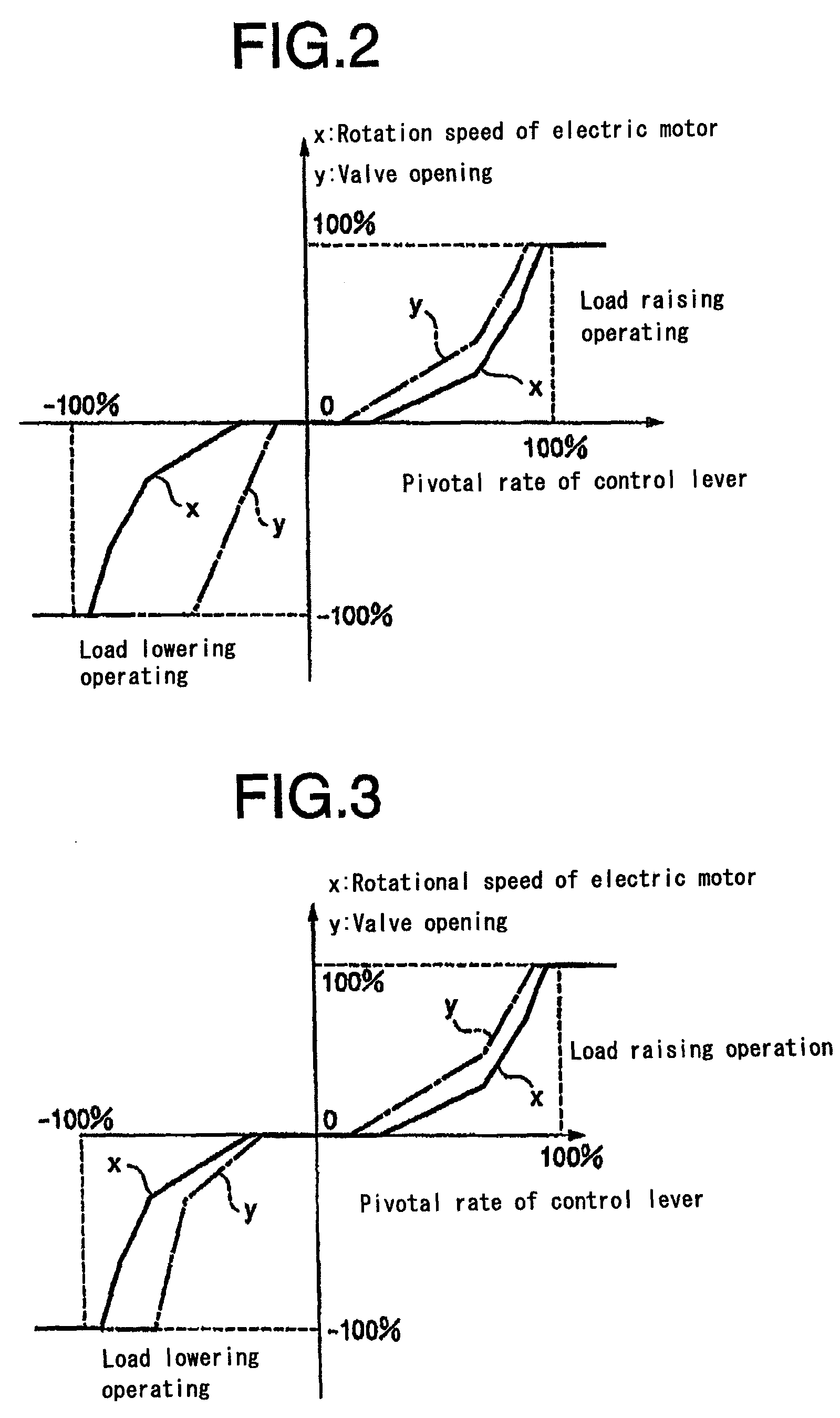

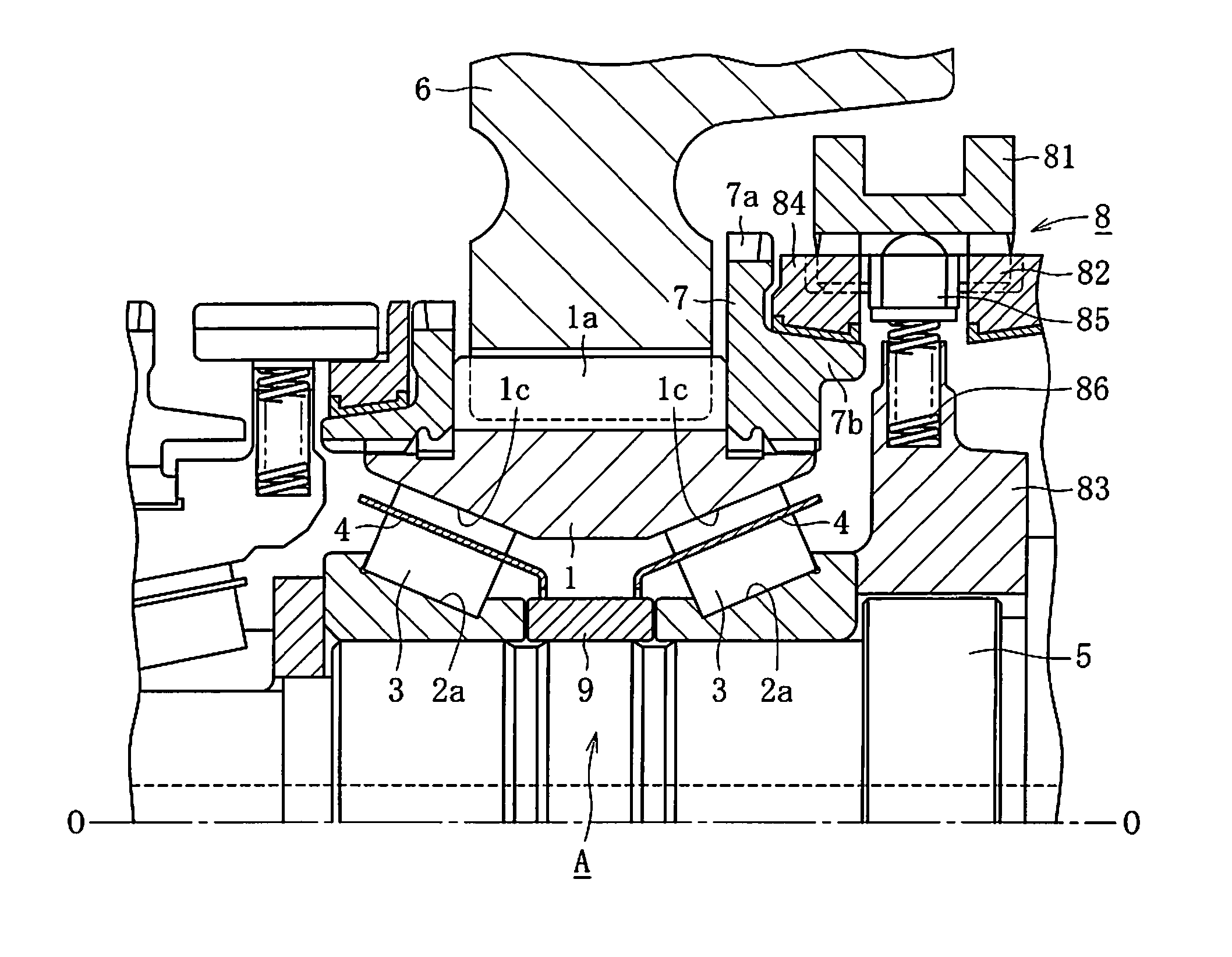

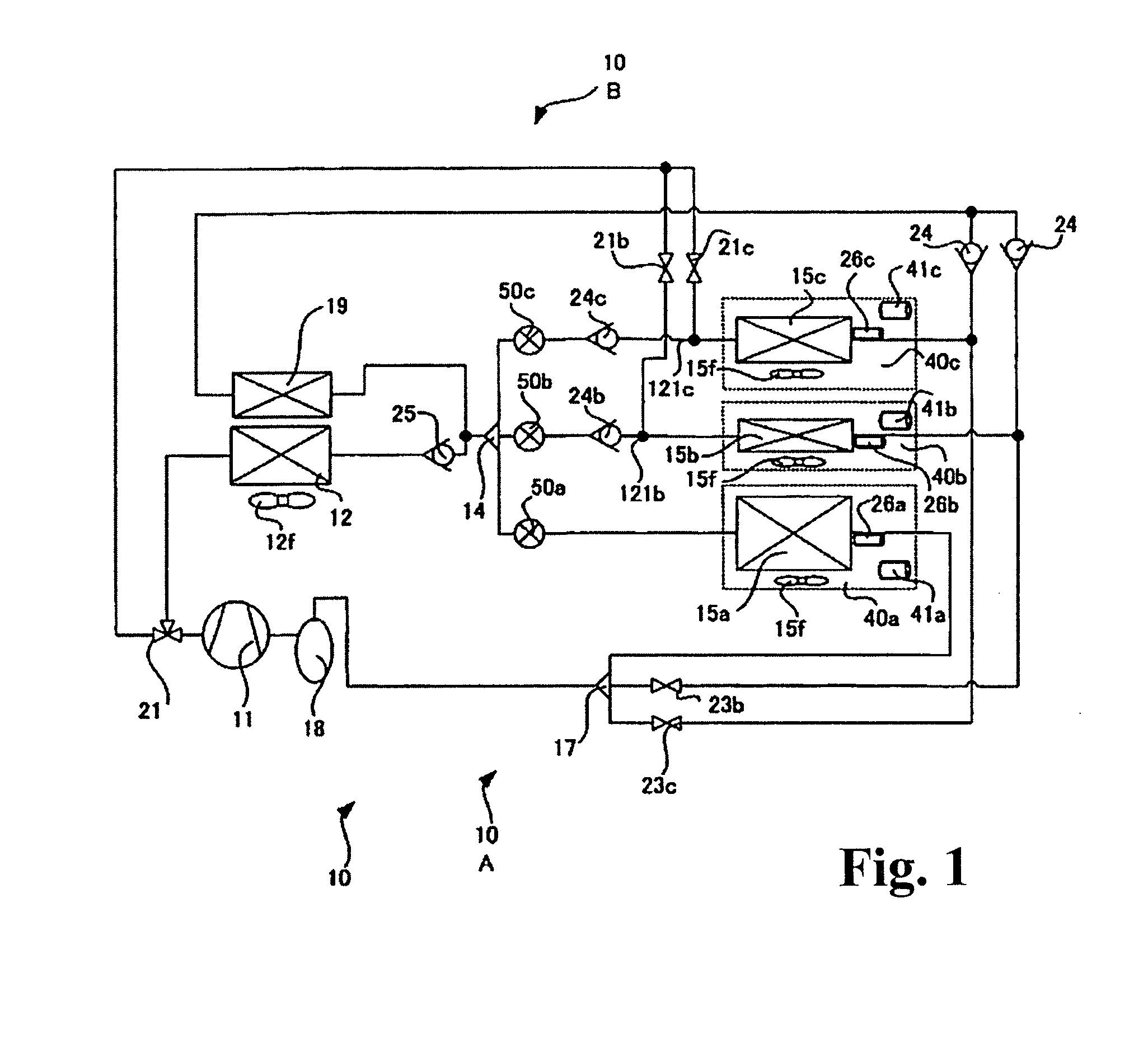

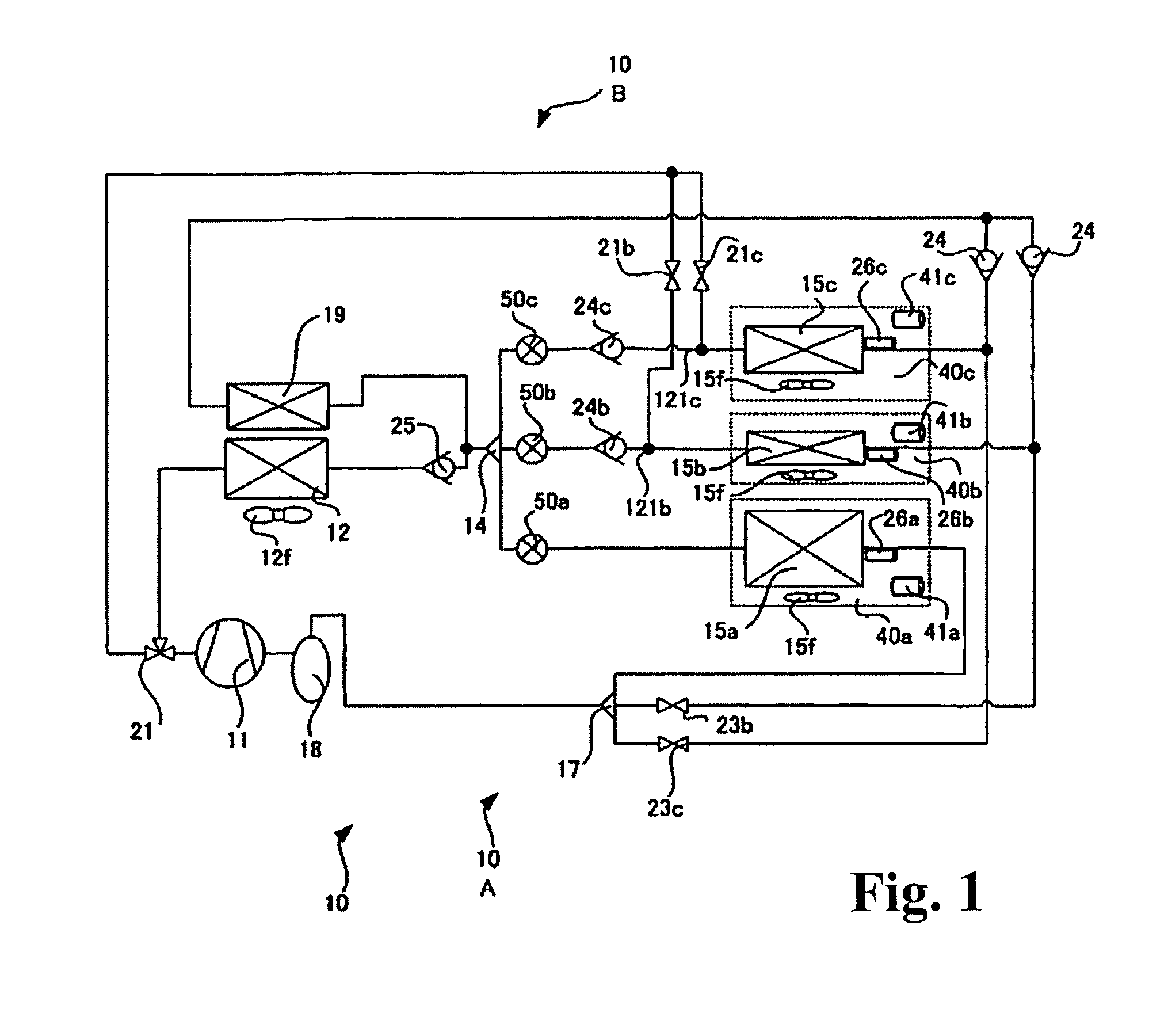

Energy Recovering Method and System in Hydraulic Lift Device of Battery Operated Industrial Trucks

An energy recovering system in a hydraulic lift device of a battery operated industrial truck. With the system, working oil can be supplied to other hydraulic actuators while energy recovering operation is performed by the hydraulic lift device, occurrence of pressure pulsation in the working oil can be prevented, and energy recovering efficiency is increased. The hydraulic lift device comprises a lift cylinder (1) for lifting a fork F, an electric motor (4) rotated by power supply from a battery (5), a hydraulic pump (3) for supplying pressurized oil to the lift cylinder (1), a control valve (14) disposed in a pressurized oil supply path (23), and a controller (17). The controller (17) controls the opening of the control valve (14) and rotation speed of the electric motor (4) which functions as an electric generator driven by the hydraulic pump (3) rotated by the action of the pressurized oil returning from the lift cylinder (1) when a load is lowered so that the generated electricity charges the battery (5) to recover the potential energy of the load.

Owner:NIPPON YUSOKI

Energy recovering method and system in hydraulic lift device of battery operated industrial trucks

An energy recovering system in a hydraulic lift device of a battery operated industrial truck. With the system, working oil can be supplied to other hydraulic actuators while energy recovering operation is performed by the hydraulic lift device, occurrence of pressure pulsation in the working oil can be prevented, and energy recovering efficiency is increased. The hydraulic lift device comprises a lift cylinder (1) for lifting a fork F, an electric motor (4) rotated by power supply from a battery (5), a hydraulic pump (3) for supplying pressurized oil to the lift cylinder (1), a control valve (14) disposed in a pressurized oil supply path (23), and a controller (17). The controller (17) controls the opening of the control valve (14) and rotation speed of the electric motor (4) which functions as an electric generator driven by the hydraulic pump (3) rotated by the action of the pressurized oil returning from the lift cylinder (1) when a load is lowered so that the generated electricity charges the battery (5) to recover the potential energy of the load.

Owner:NIPPON YUSOKI

Process for Producing Poly(Arylene Sulfide), and Poly(Arylene Sulfide)

ActiveUS20130065054A1OccurrenceReduce odorSynthetic resin layered productsCellulosic plastic layered productsSolventSeparating agent

Disclosed is a process for producing poly(arylene sulfide) which includes: a polymerization step of polymerizing a dihalogenated aromatic compound and at least one sulfur source selected from the group consisting of alkali metal sulfides and alkali metal hydrogen sulfides in an organic amide solvent, preferably in the presence of a phase separating agent; a separation step of separating a polymer from a reaction liquid containing a produced polymer after the polymerization step; a washing step of washing the polymer with a washing liquid that consists of water and / or an organic solvent; and a separated liquid treatment step of bringing both a separated liquid that has been recovered after the separation of the polymer in the separation step and a separated liquid containing a wash waste liquid that has been recovered after the separation of the polymer in the washing step into contact with an alkaline compound. Also disclosed is poly(arylene sulfide).

Owner:KUREHA KAGAKU KOGYO KK

Female connector

ActiveUS20050146136A1Avoid disconnectionOccurrenceCatheterPipe-jointsMechanical engineeringGeneral surgery

A female connector including: a cylindrical core member having a luer taper on a distal inner surface thereof and a tube bonding portion formed on a proximal end inner surface and being formed with a flange at a distal extremity thereof; a cylindrical housing having a male screw formed on an outer surface thereof and mounted to an outer periphery of the core member without being fixed, and a stopper fixed at a position apart from the flange of the core member, wherein the distance (L1) between the flange and the stopper is larger than the length (L2) of the housing in the axial direction when a male connector is connected to the female connector.

Owner:NIPRO CORP

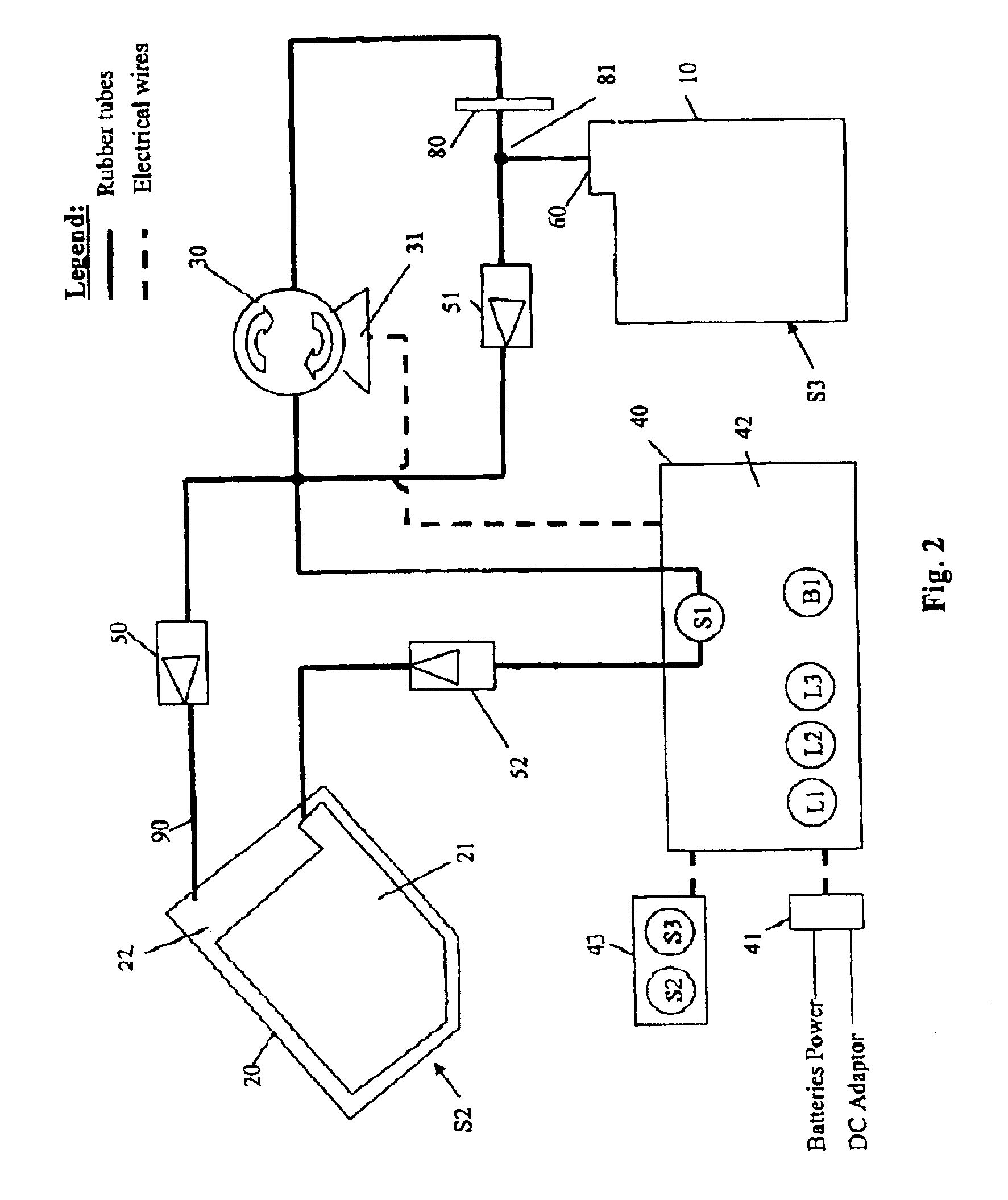

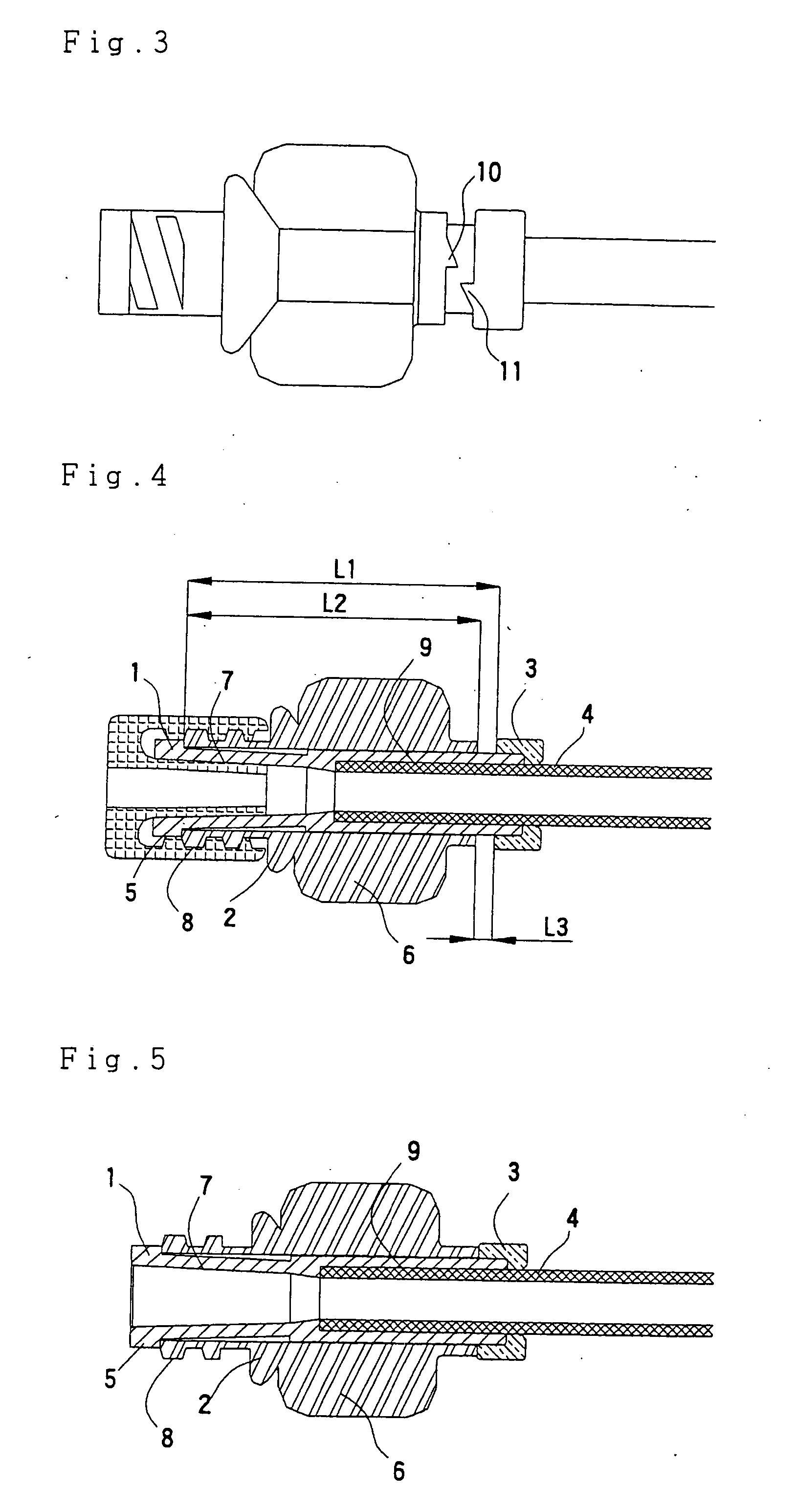

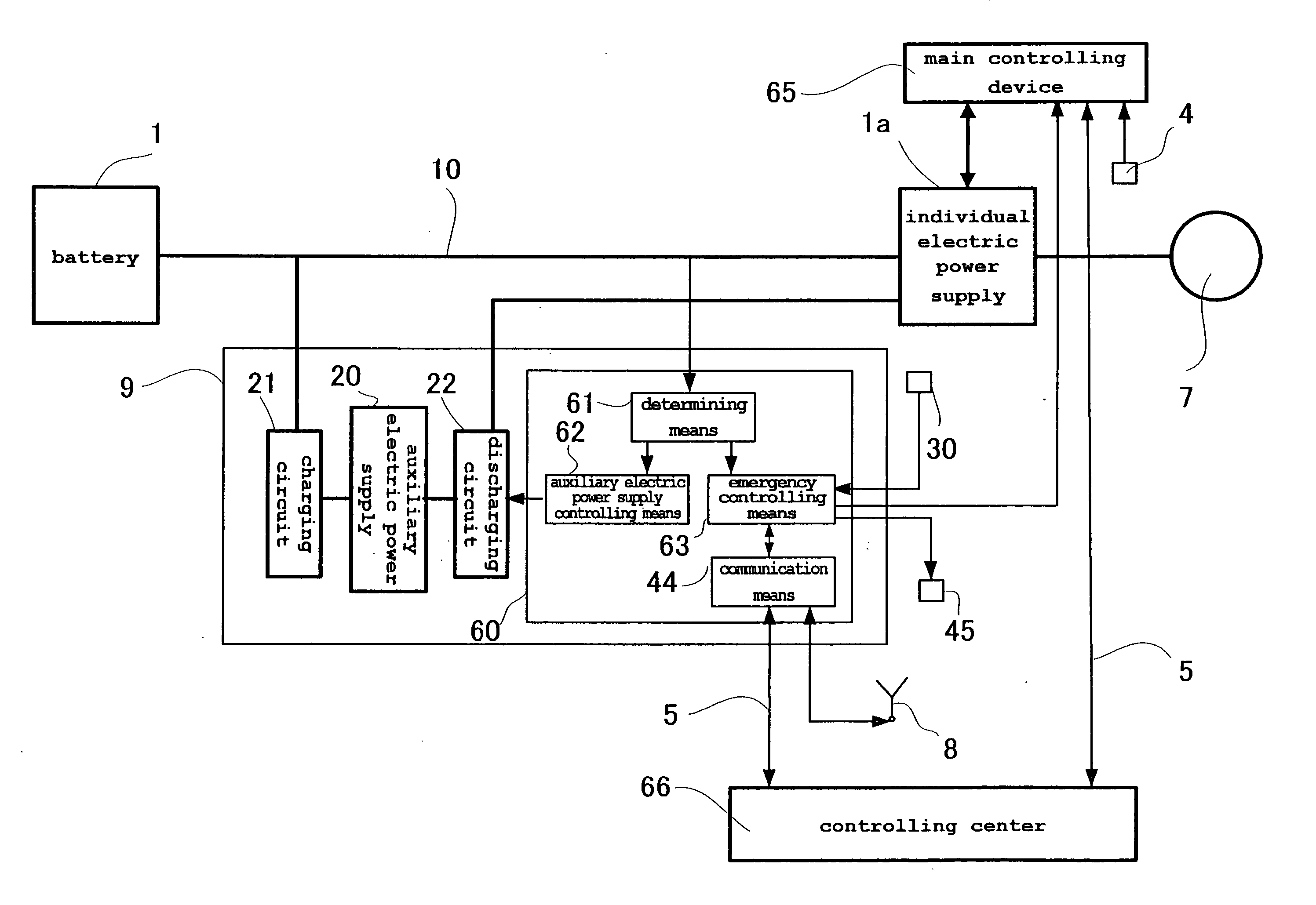

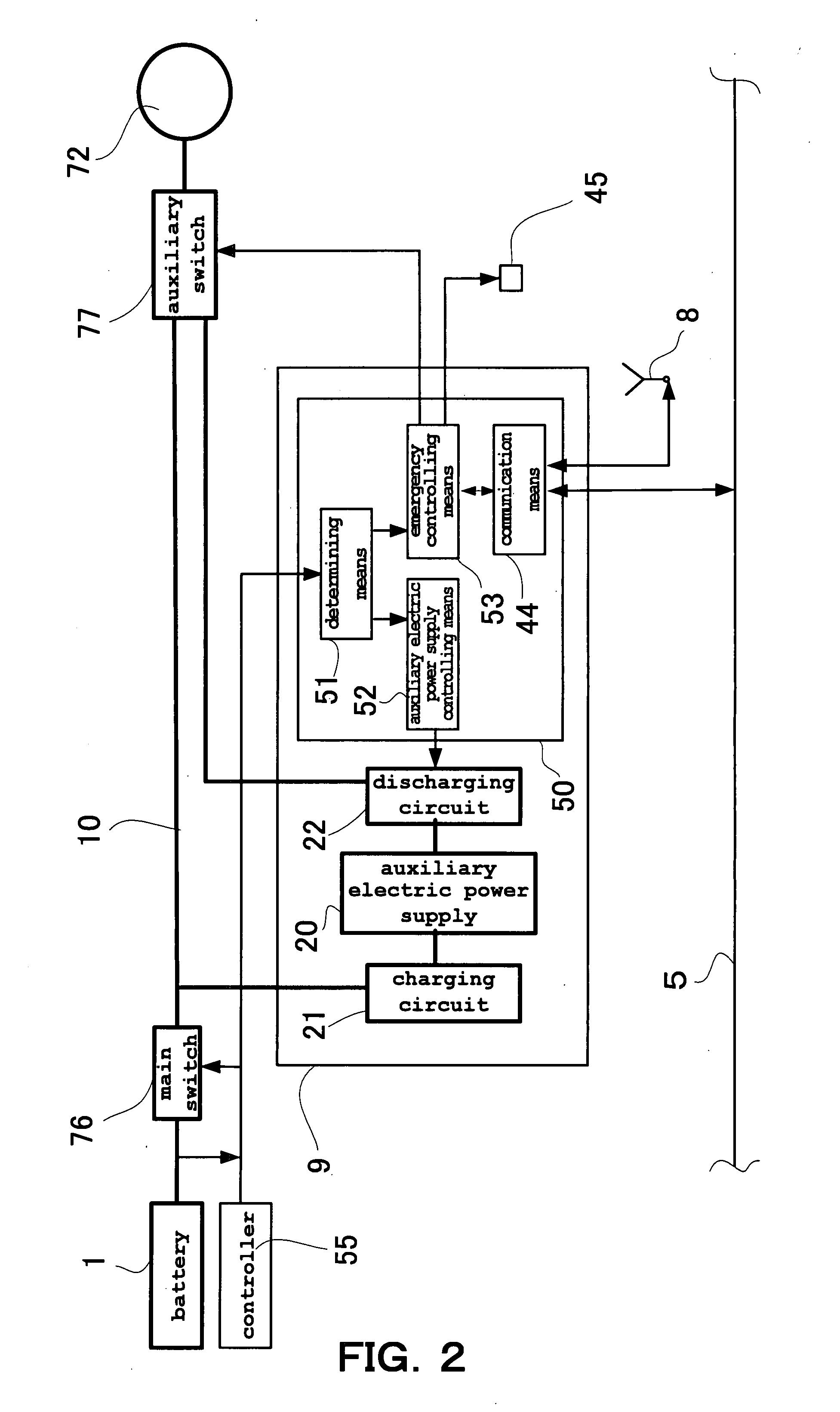

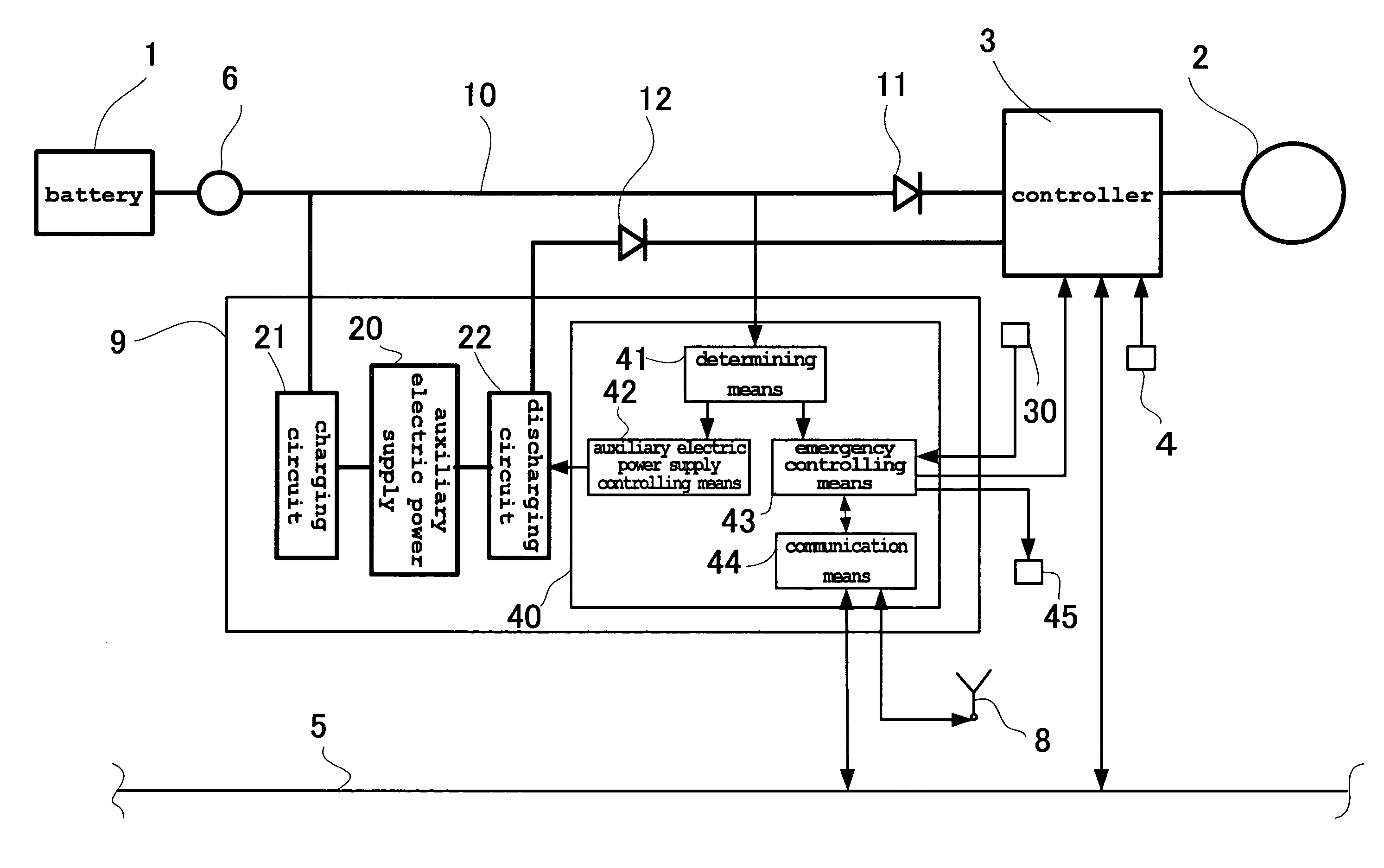

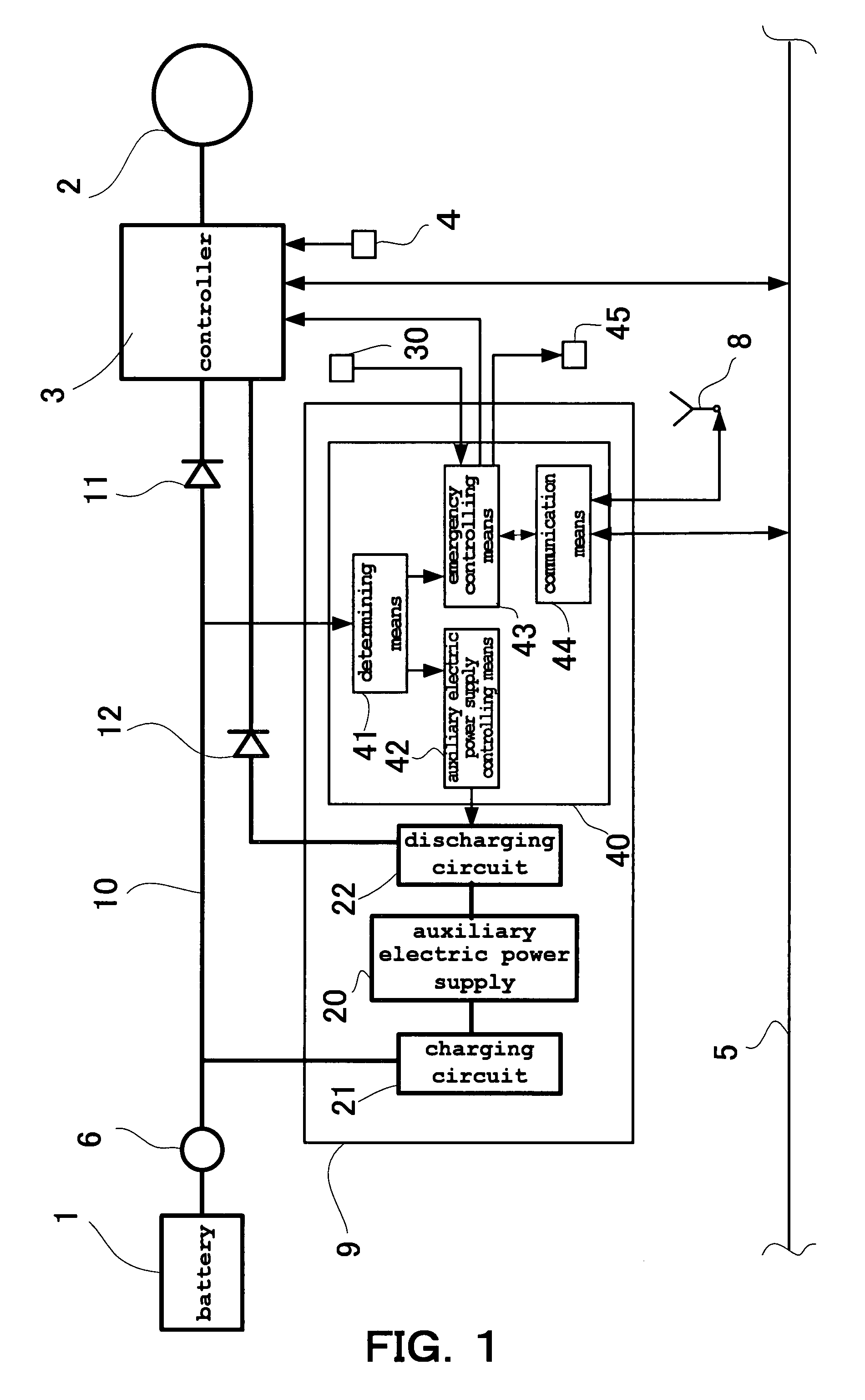

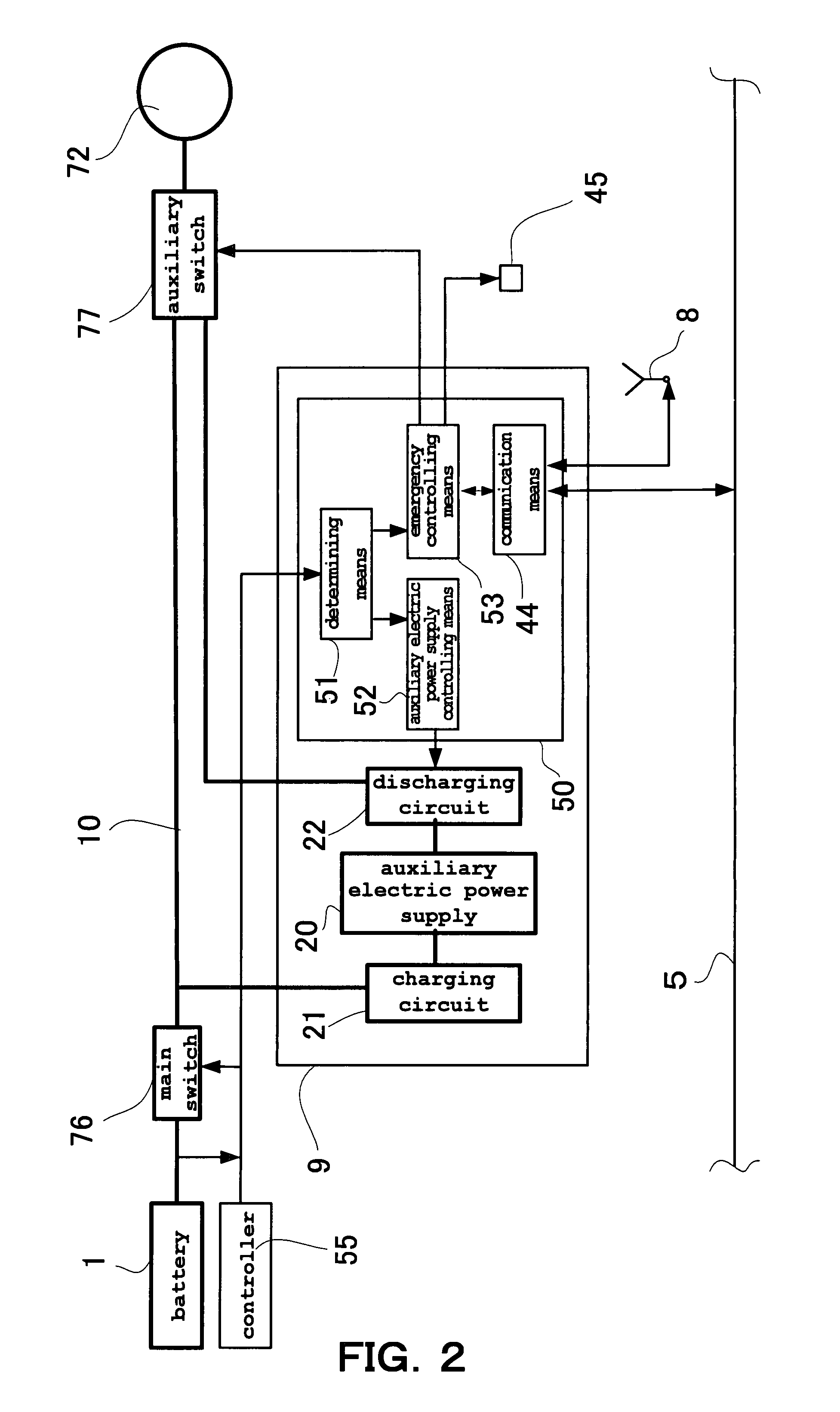

Emergency Electric Power Supply Unit

InactiveUS20070262649A1OccurrenceBatteries circuit arrangementsOptical signallingElectric powerEmergency control

An emergency electric power supply unit (9) for backing up the main electric power supply system (1, 10) at the time of the malfunction of the main electric power supply system (1, 10) which includes an industrial apparatus operated by cooperatively controlling an auxiliary machinery (2) operated by the electric power supplied from the main electric power supply system (1, 10), an auxiliary electric power supply (20) for storing the electric power, a charging circuit (21) for charging the electric power supplied from the main electric power supply (1) in the auxiliary electric power supply (20), a discharging circuit (22) for supplying the electric power charged in the auxiliary electric power supply (20) to the auxiliary machinery (2), and an emergency controlling circuit (40) for controlling the discharging circuit (22) so that the electric power from the auxiliary electric power supply (20) is supplied to the auxiliary machinery (2) at the time of the malfunction of the main electric power supply system (1, 10) and for controlling the operation of the auxiliary machinery (2) in response to the operational state of the industrial apparatus at the time of the malfunction of the main electric power supply system (1, 10).

Owner:ASHITATE ELECTRIC +1

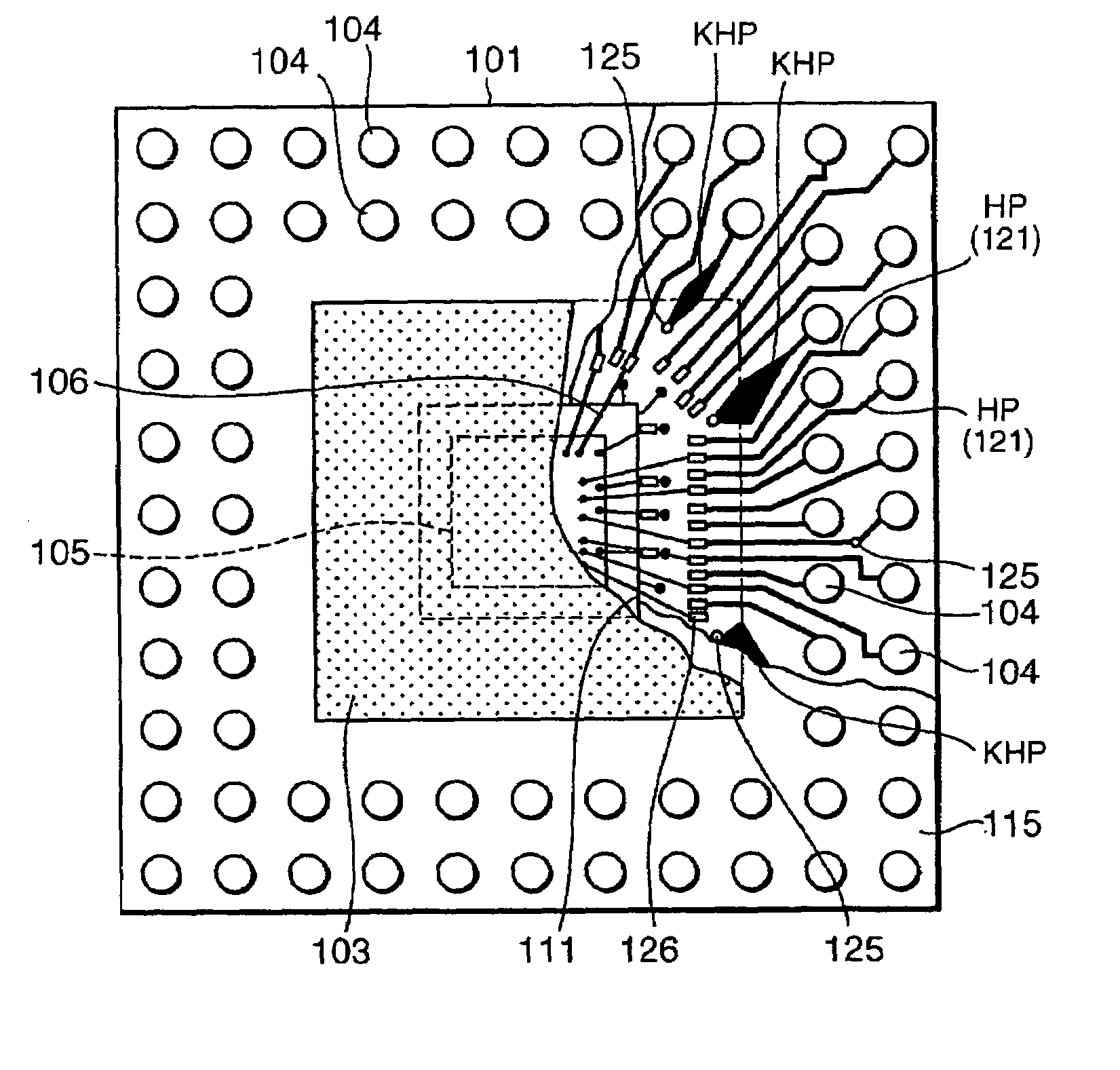

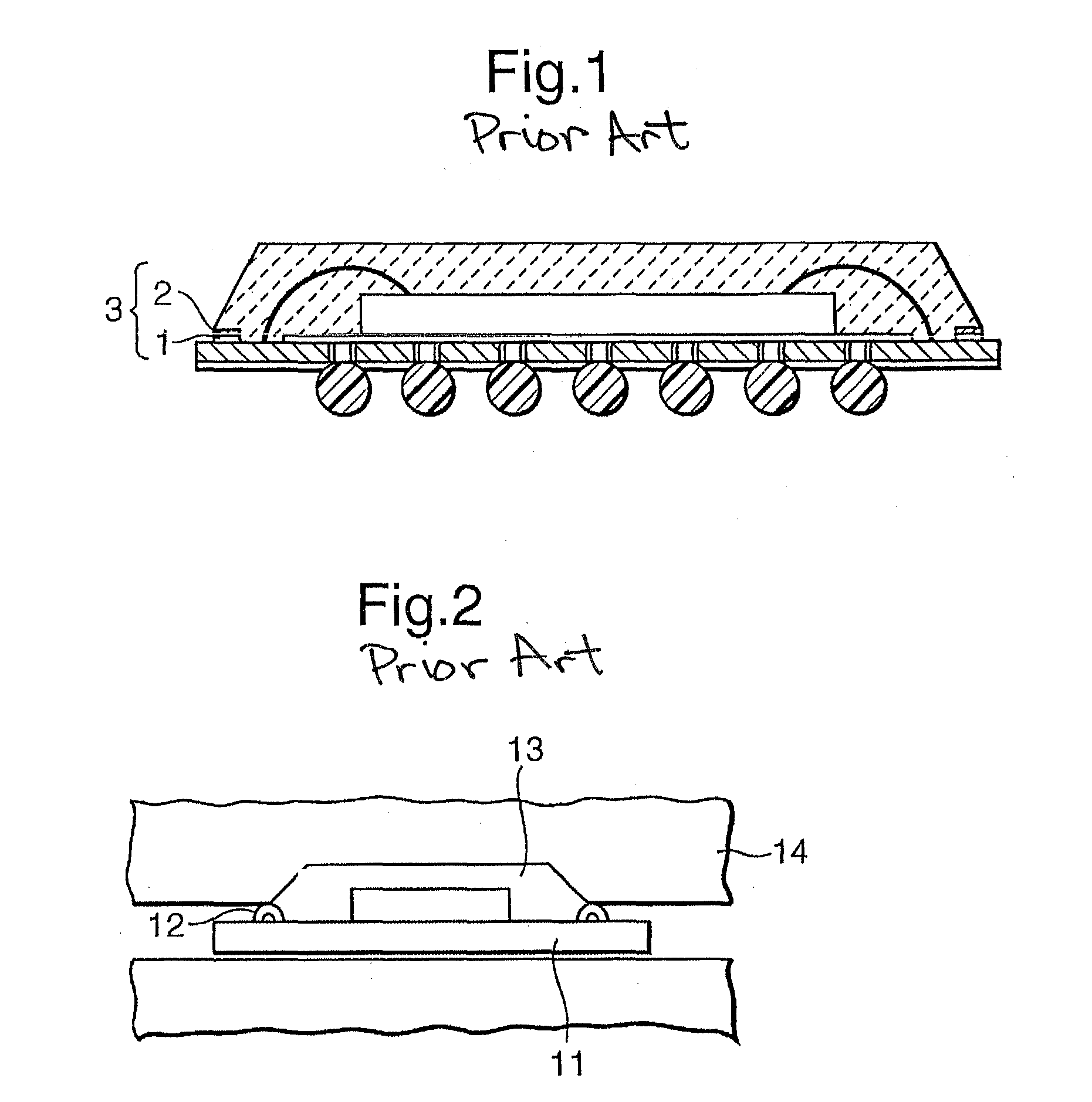

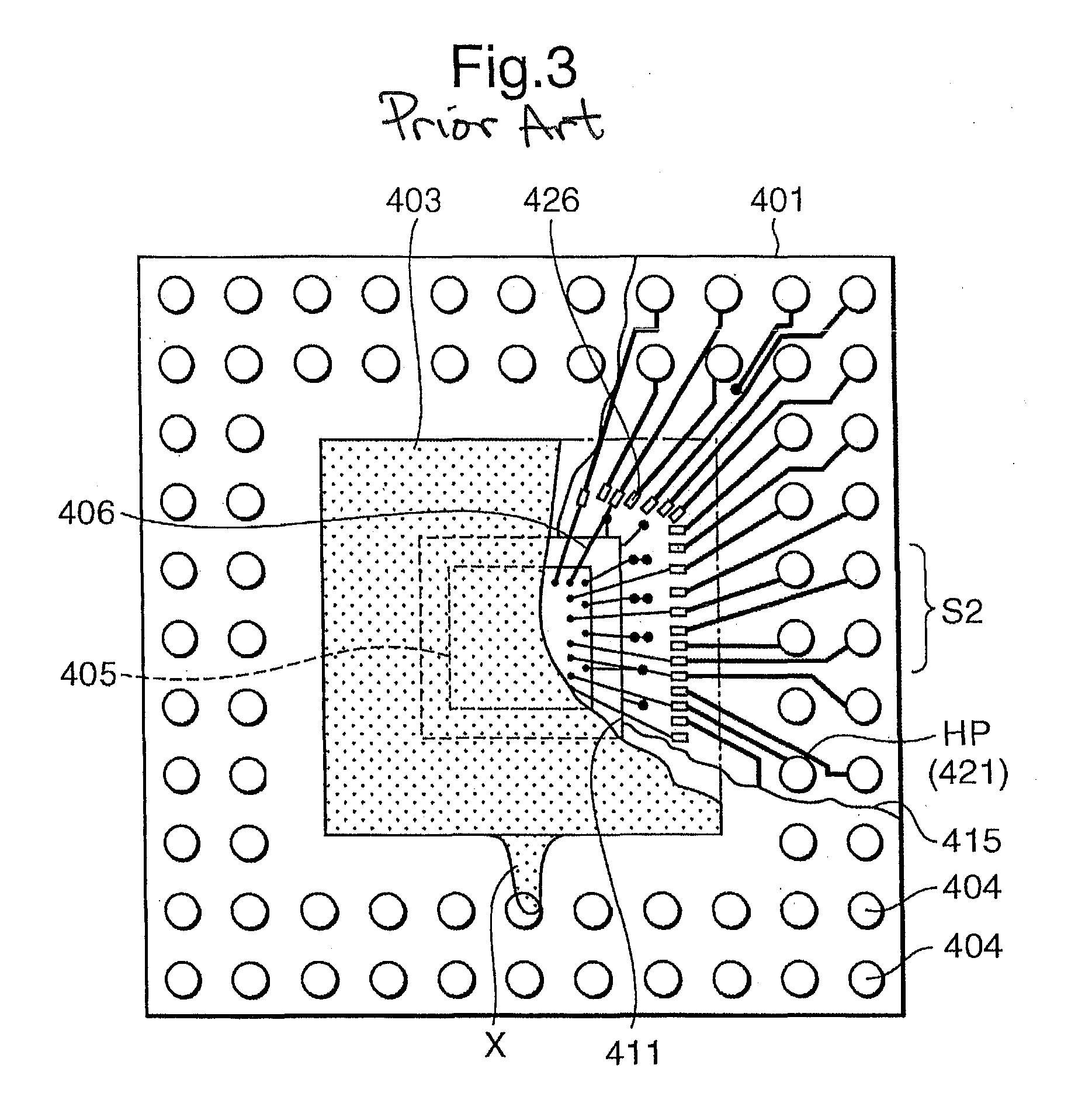

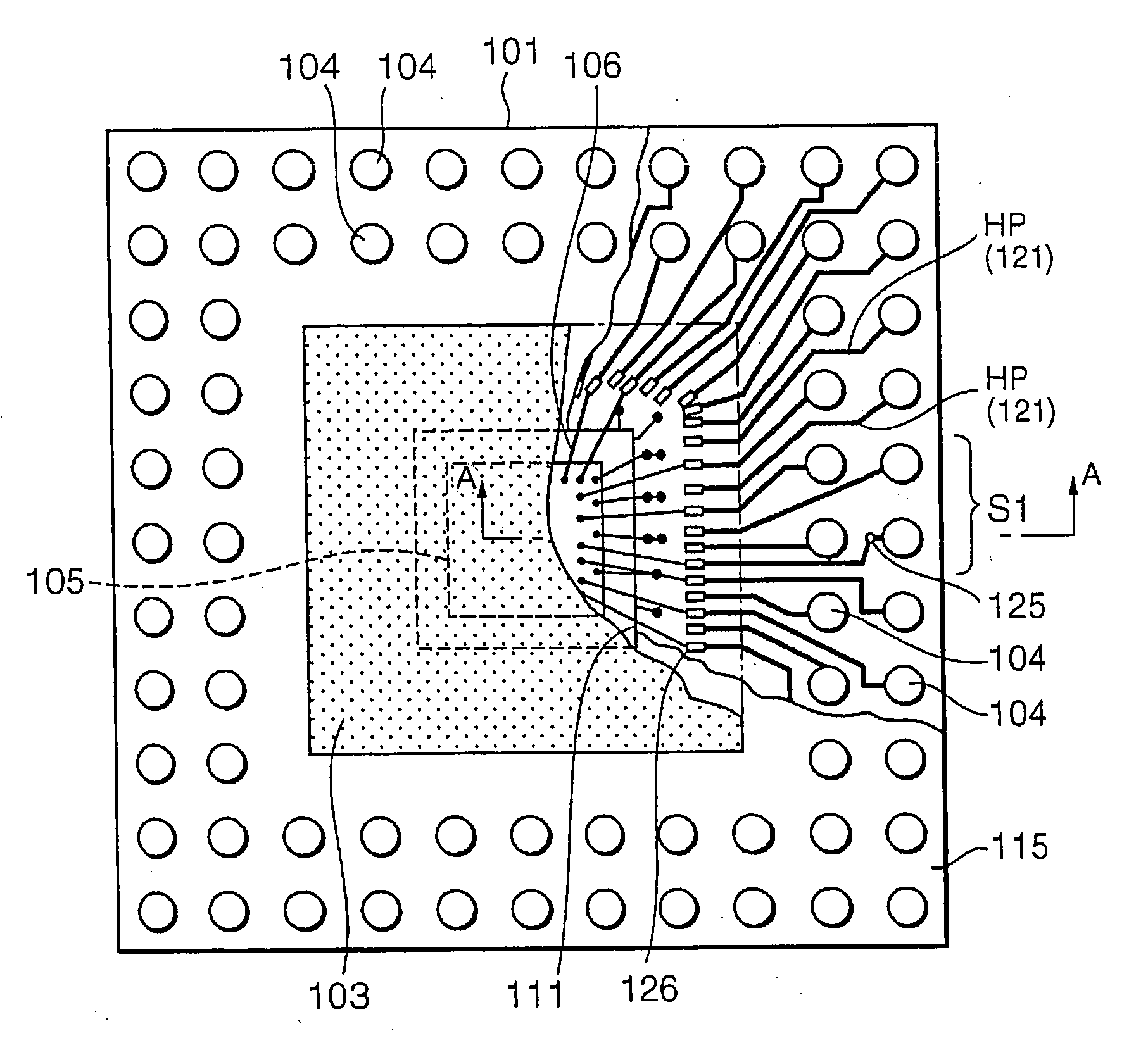

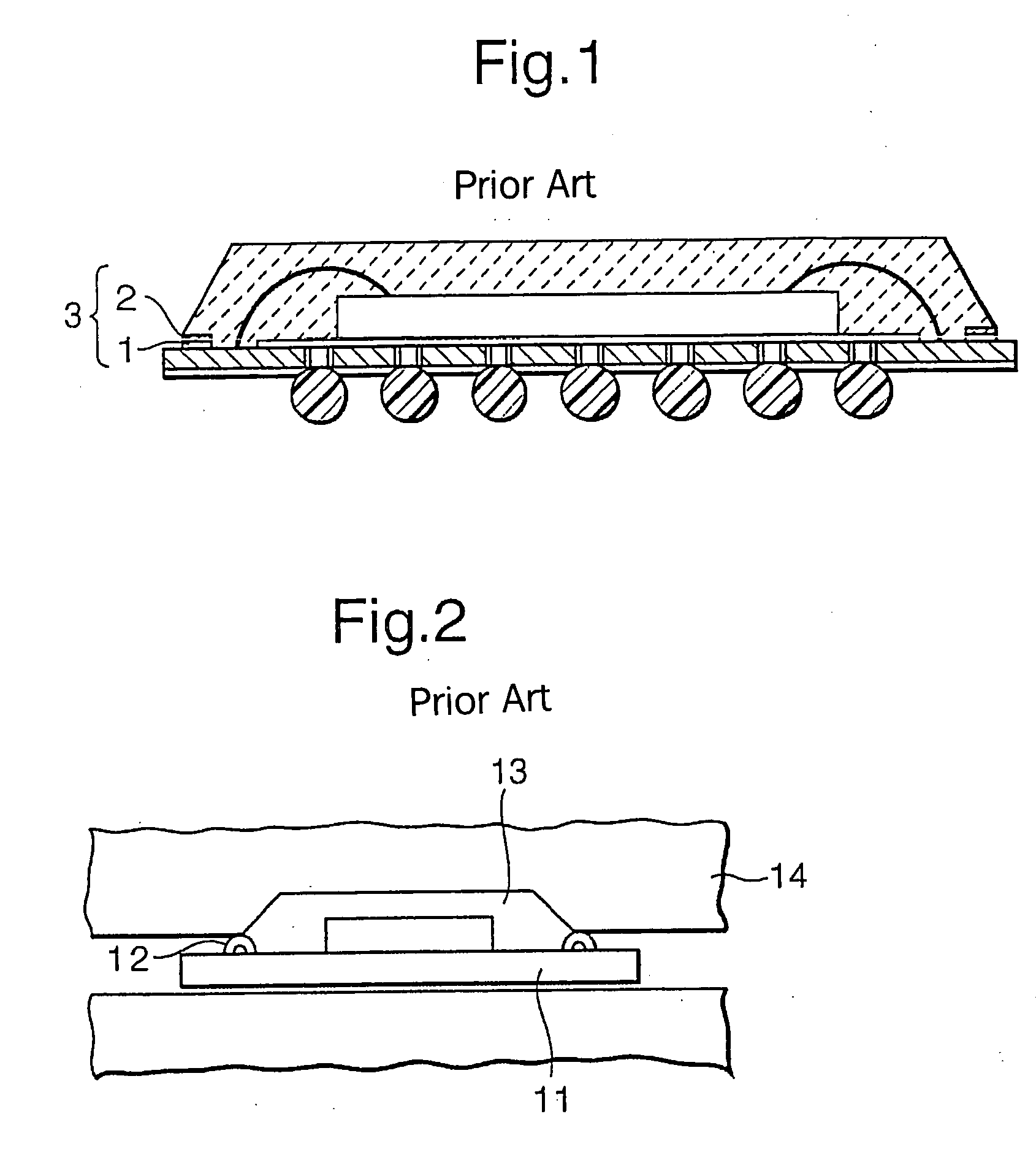

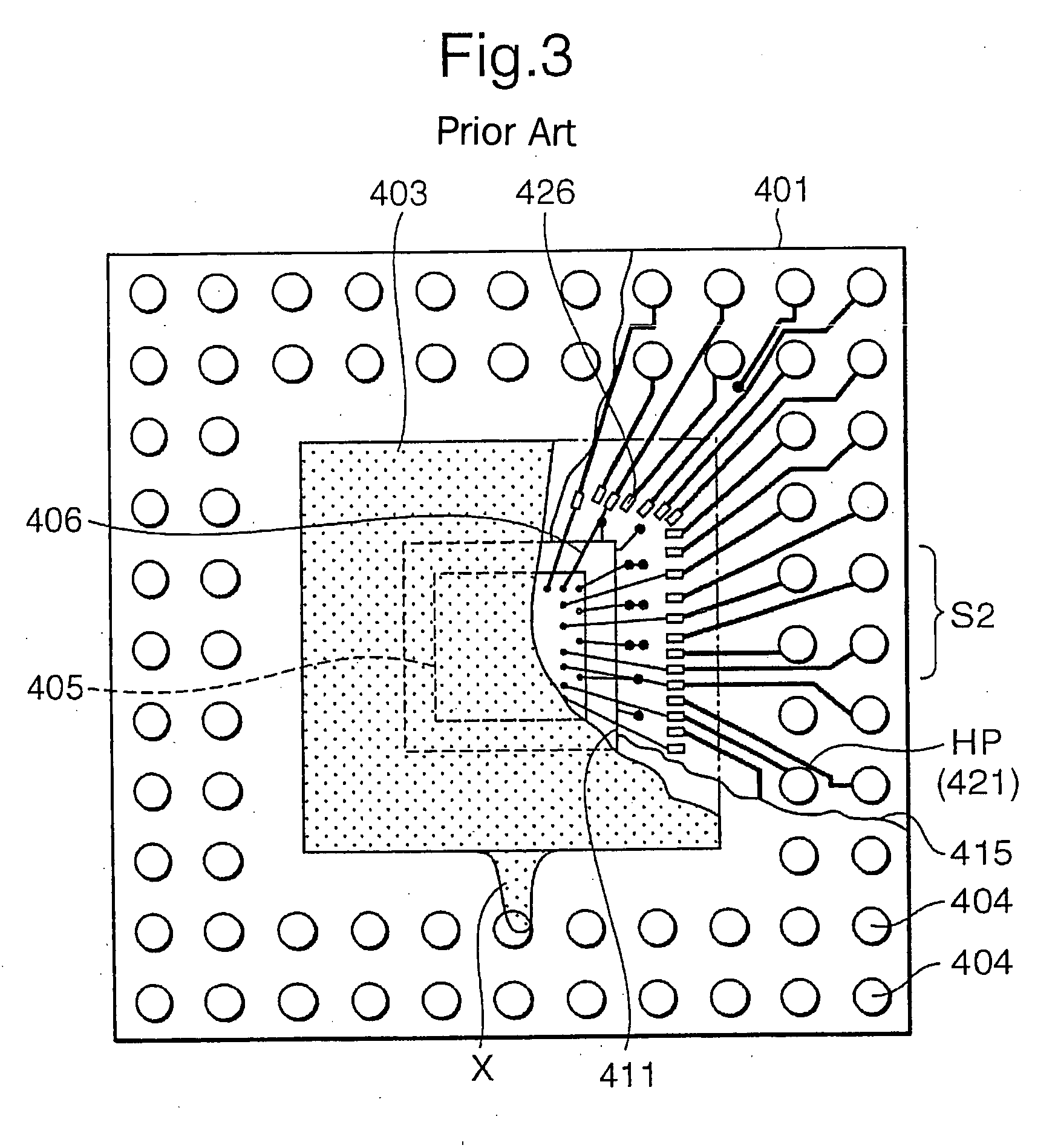

Semiconductor device having resin-sealed area on circuit board thereof

InactiveUS7084511B2Avoid it happening againEvenly dispersedSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsResistShell molding

A semiconductor device having a molded sealing resin for sealing a semiconductor chip on a circuit board thereof reduces resin burrs resulting from the leakage of the sealing resin, and also restrains the occurrence of disconnection caused by a wiring layer being crushed. In the semiconductor device, the sealing resin for sealing the semiconductor chip is molded on the circuit board that has a plurality of wiring patterns and a solder resist for insulatively covering the wiring patterns formed on the front surface thereof, the interval of the wiring patterns is set to range from 50% to 200% of its adjacent interval in a molding line area of the sealing resin.

Owner:RENESAS ELECTRONICS CORP

Reaction liquid, set of ink and reaction liquid, ink jet recording apparatus and image recording method

InactiveUS20090185019A1InhibitionImprove image qualityMeasurement apparatus componentsDuplicating/marking methodsPolyethylene glycolImage recording

A reaction liquid destabilizing the dissolved state or dispersed state of a coloring material by being in contact with an ink containing the coloring material on a recording medium, wherein the reaction liquid contains at least calcium ions, glycerin and polyethylene glycols, and wherein the content and ratio of these components are specified.

Owner:CANON KK

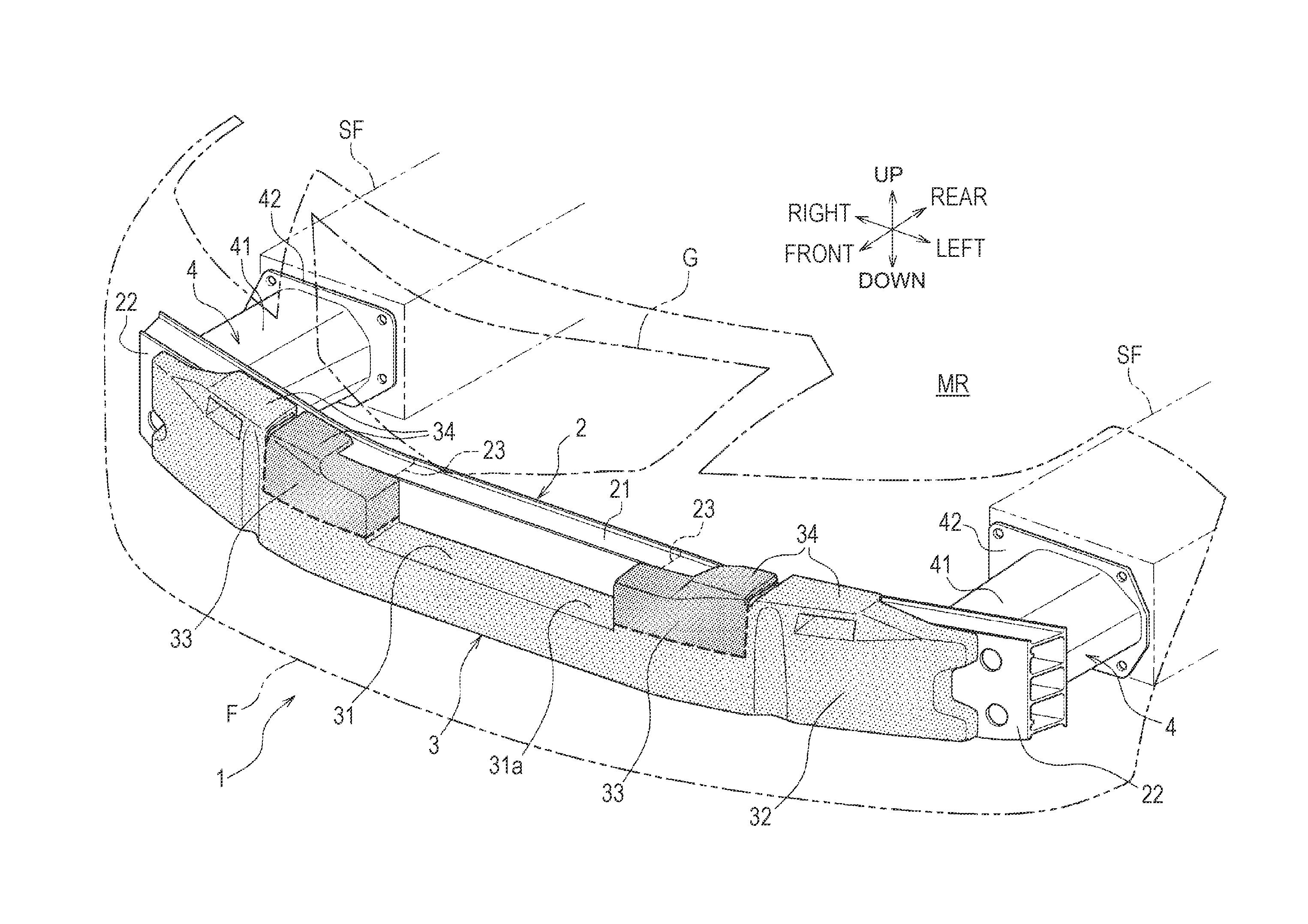

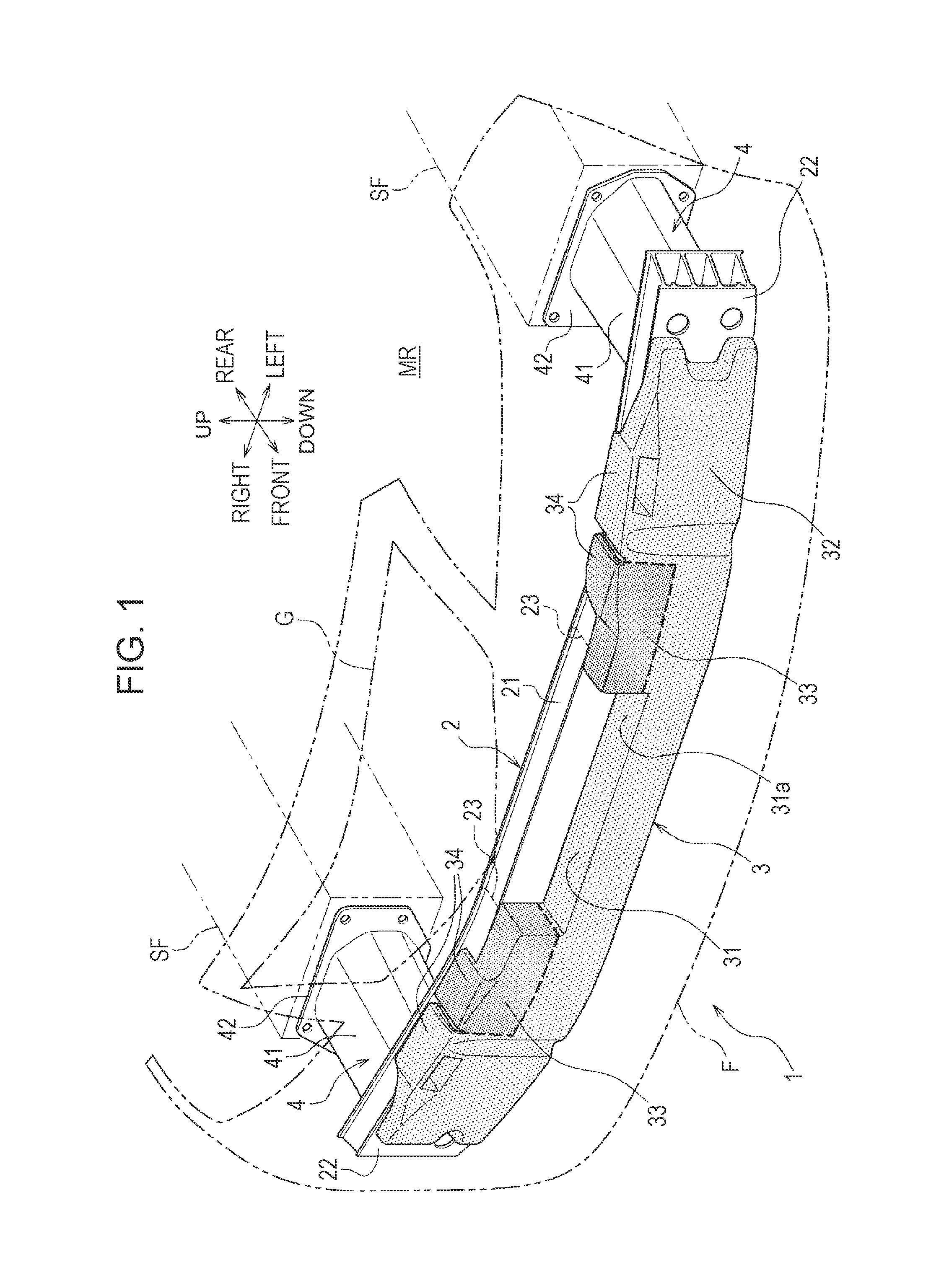

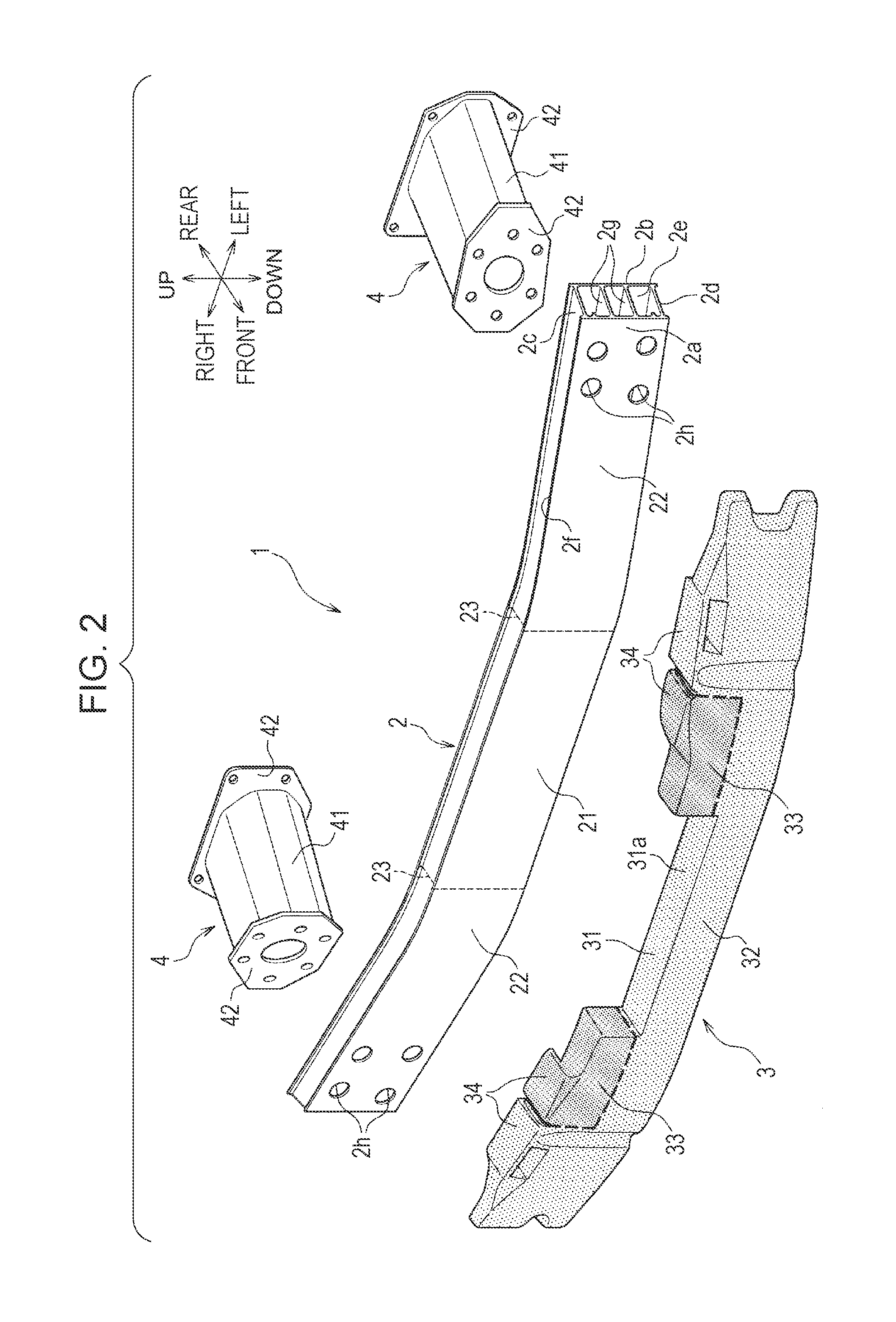

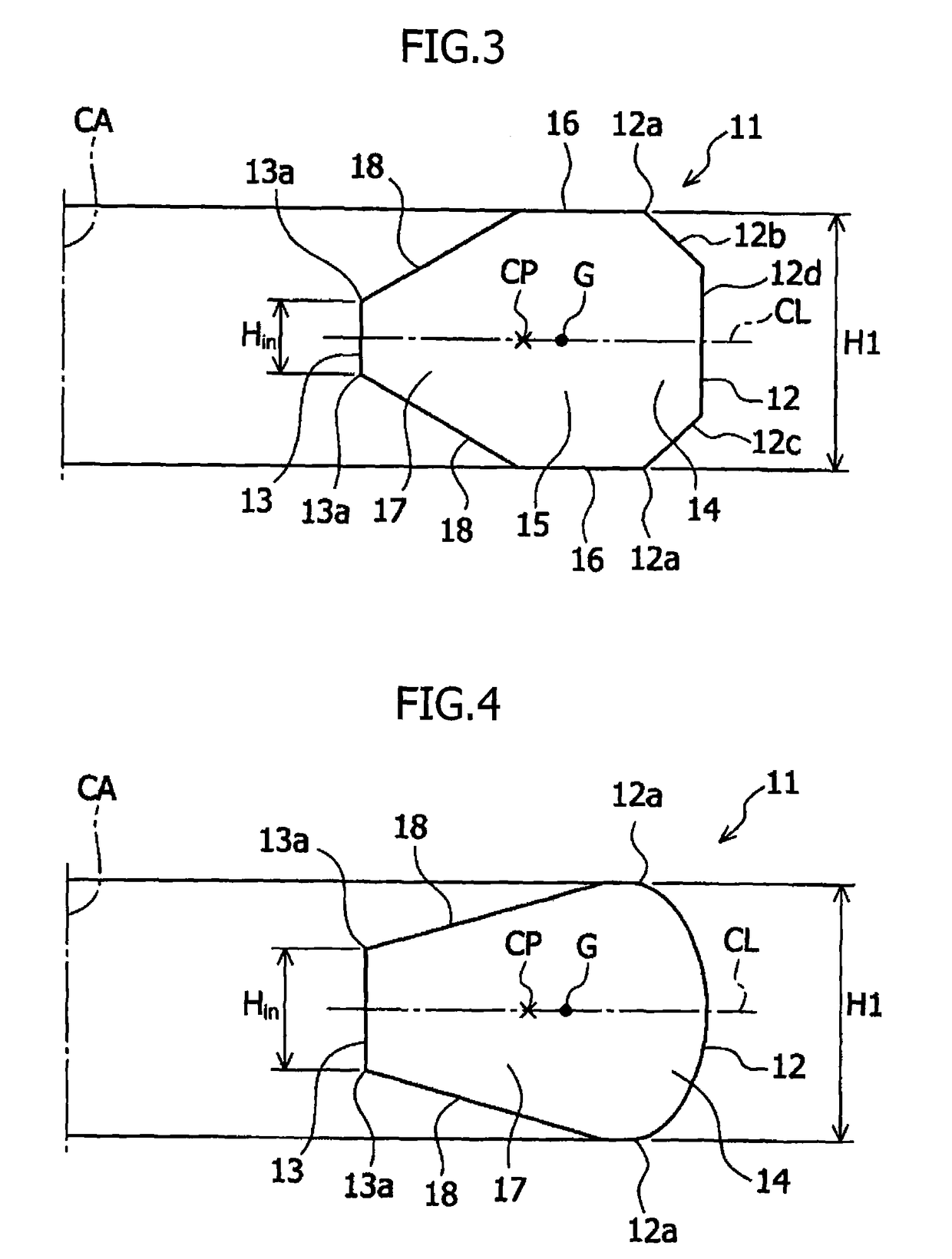

Bumper structure

Owner:HONDA MOTOR CO LTD

Process for producing poly(arylene sulfide), and poly(arylene sulfide) comprising contacting a wash liquid with an alkaline compound

ActiveUS9068047B2OccurrenceReduce odorSynthetic resin layered productsCellulosic plastic layered productsHydrogenOrganic solvent

Disclosed is a process for producing poly(arylene sulfide) which includes: a polymerization step of polymerizing a dihalogenated aromatic compound and at least one sulfur source selected from the group consisting of alkali metal sulfides and alkali metal hydrogen sulfides in an organic amide solvent, preferably in the presence of a phase separating agent; a separation step of separating a polymer from a reaction liquid containing a produced polymer after the polymerization step; a washing step of washing the polymer with a washing liquid that consists of water and / or an organic solvent; and a separated liquid treatment step of bringing both a separated liquid that has been recovered after the separation of the polymer in the separation step and a separated liquid containing a wash waste liquid that has been recovered after the separation of the polymer in the washing step into contact with an alkaline compound. Also disclosed is poly(arylene sulfide).

Owner:KUREHA KAGAKU KOGYO KK

Semiconductor device having resin-sealed area on circuit board thereof

InactiveUS20060231936A1Easy to manufactureOccurrenceSemiconductor/solid-state device detailsSolid-state devicesResistShell molding

A semiconductor device having a molded sealing resin for sealing a semiconductor chip on a circuit board thereof reduces resin burrs resulting from the leakage of the sealing resin, and also restrains the occurrence of disconnection caused by a wiring layer being crushed. In the semiconductor device, the sealing resin for sealing the semiconductor chip is molded on the circuit board that has a plurality of wiring patterns and a solder resist for insulatively covering the wiring patterns formed on the front surface thereof, the interval of the wiring patterns is set to range from 50% to 200% of its adjacent interval in a molding line area of the sealing resin.

Owner:RENESAS ELECTRONICS CORP

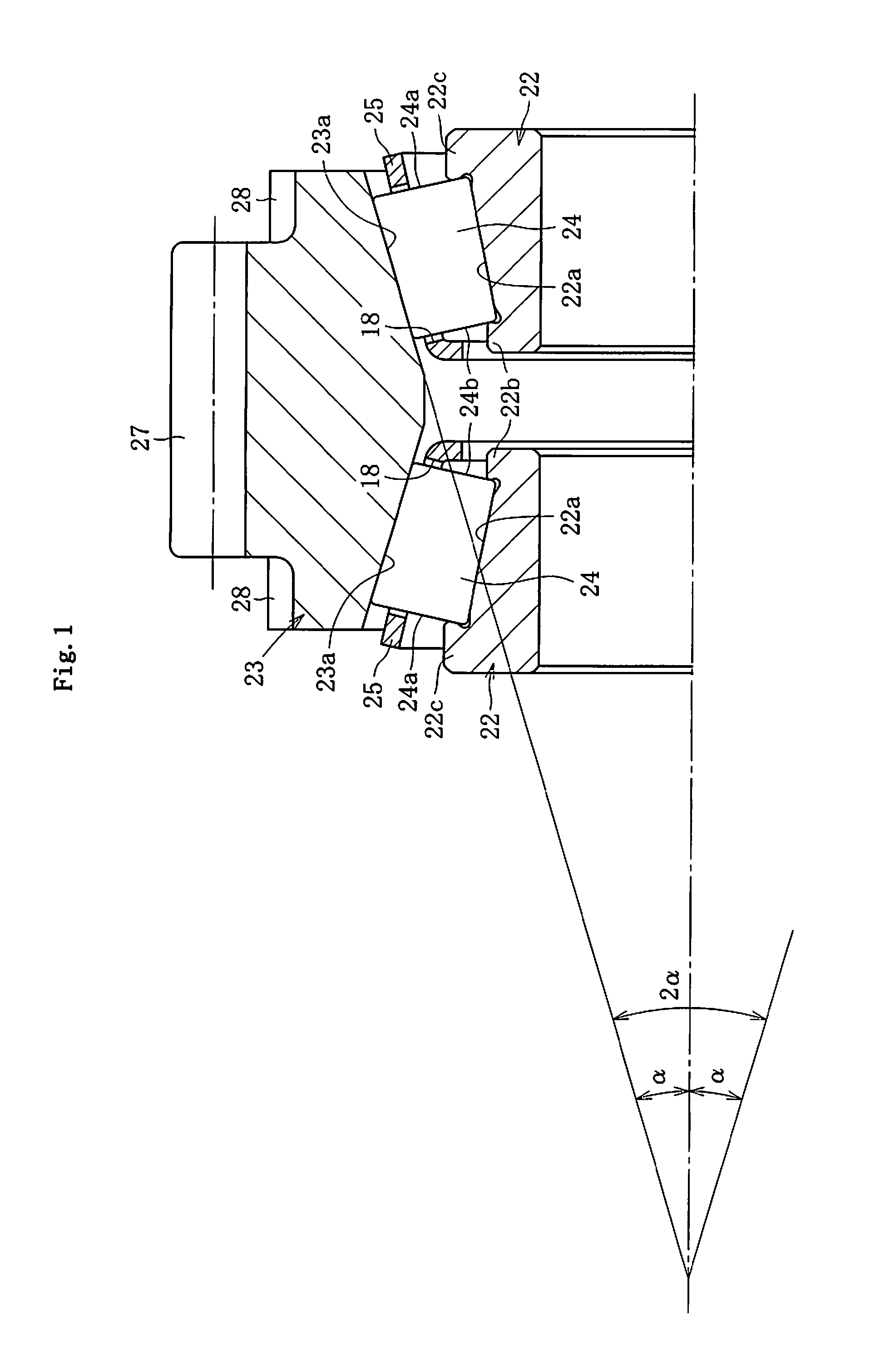

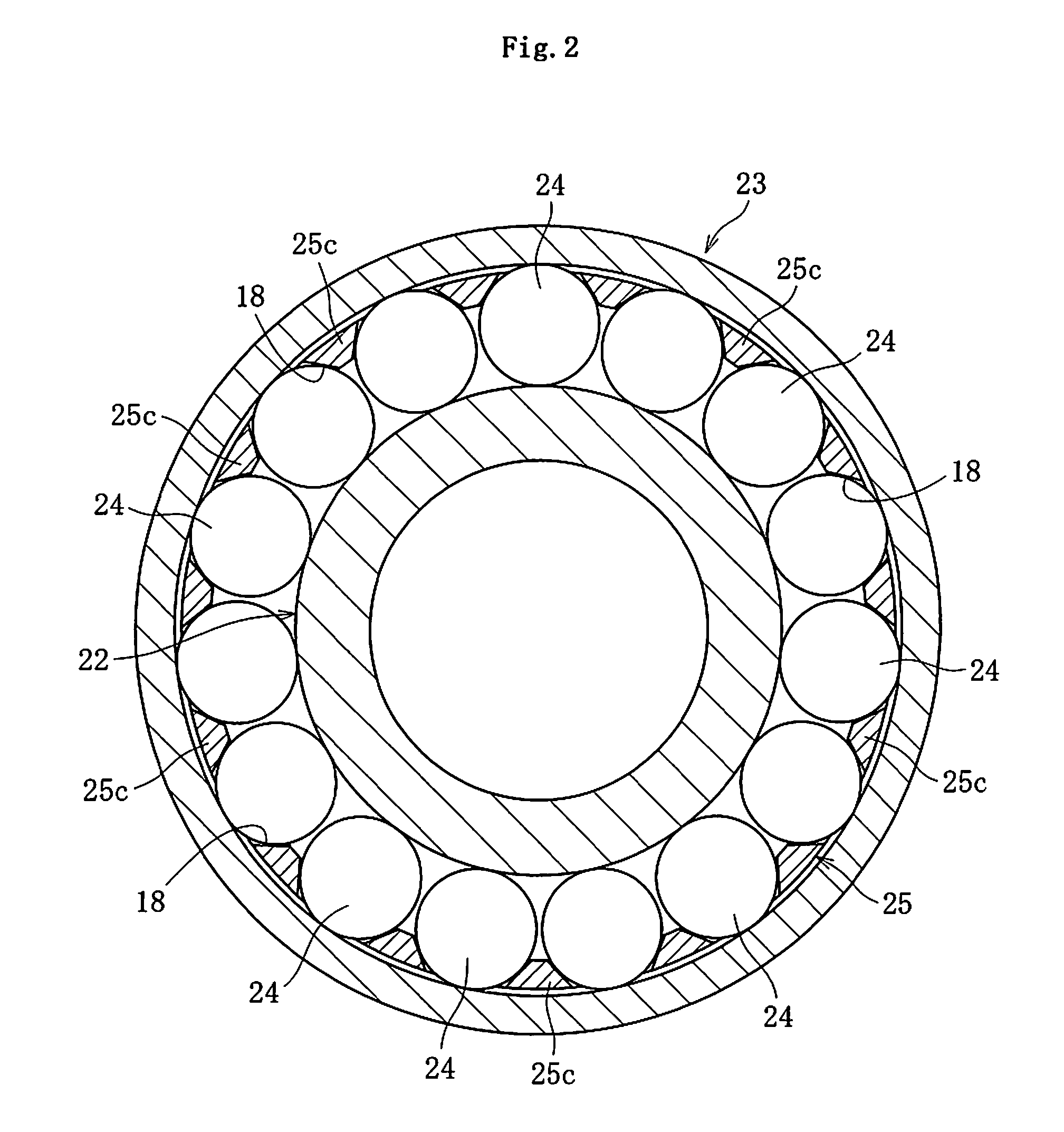

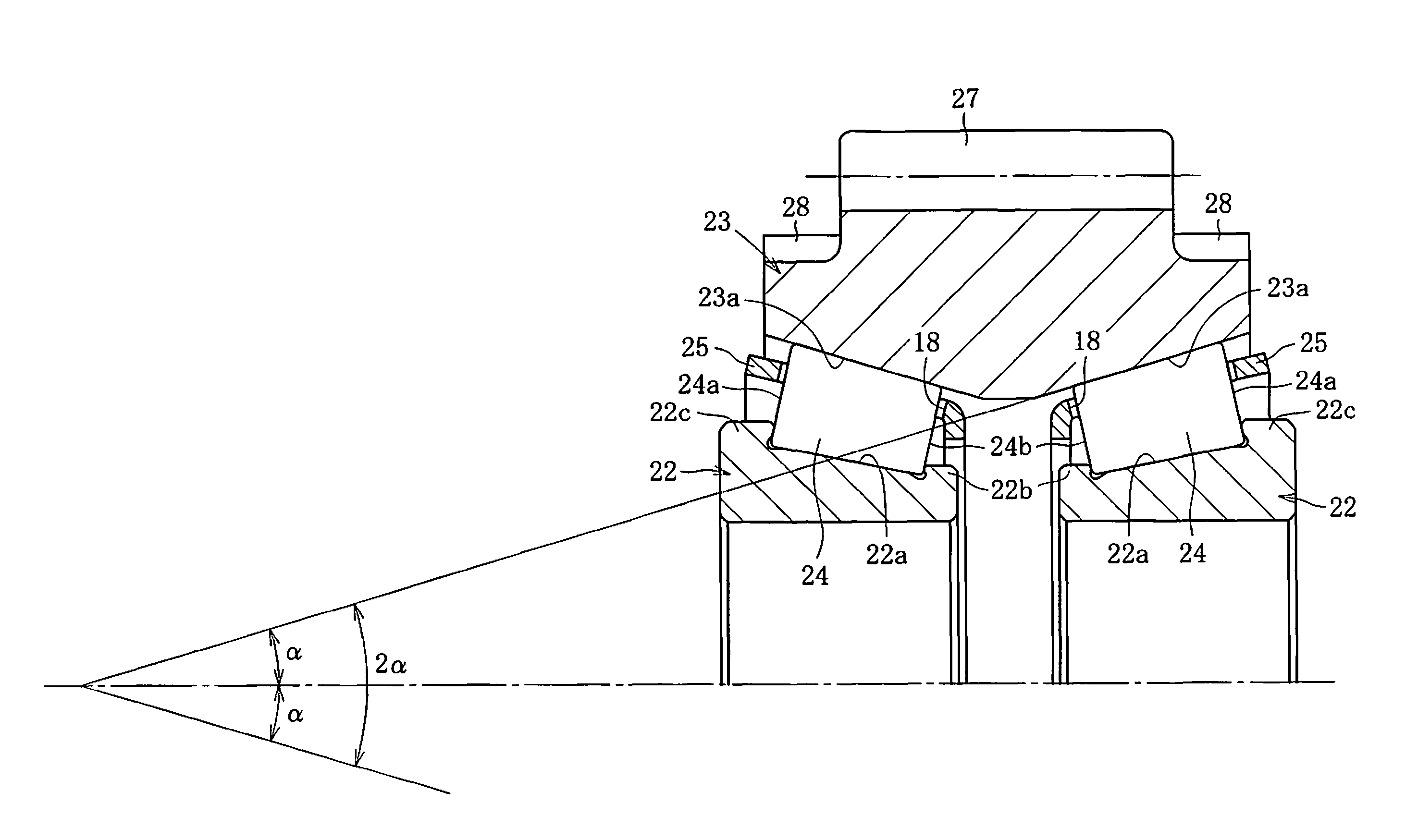

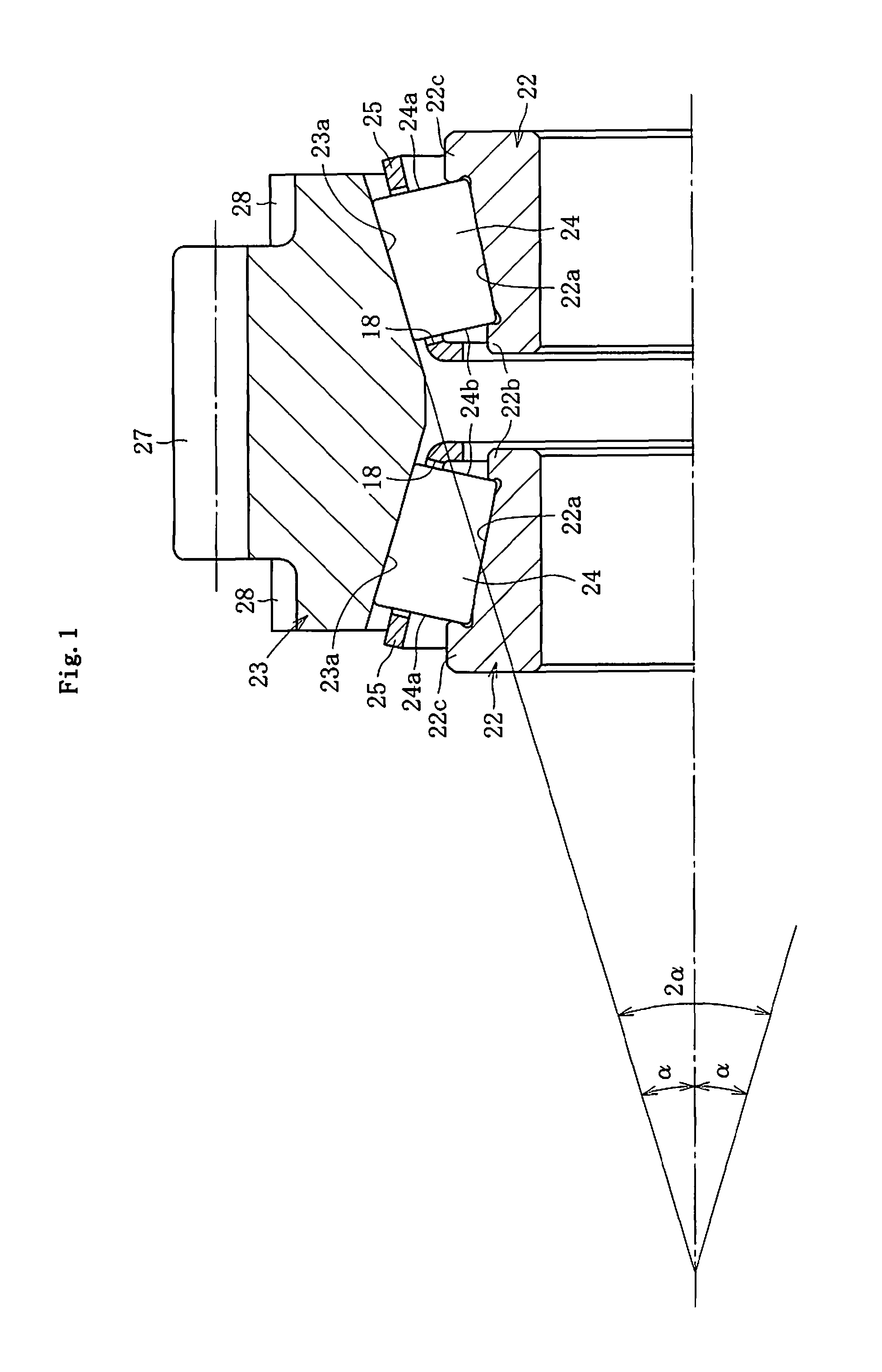

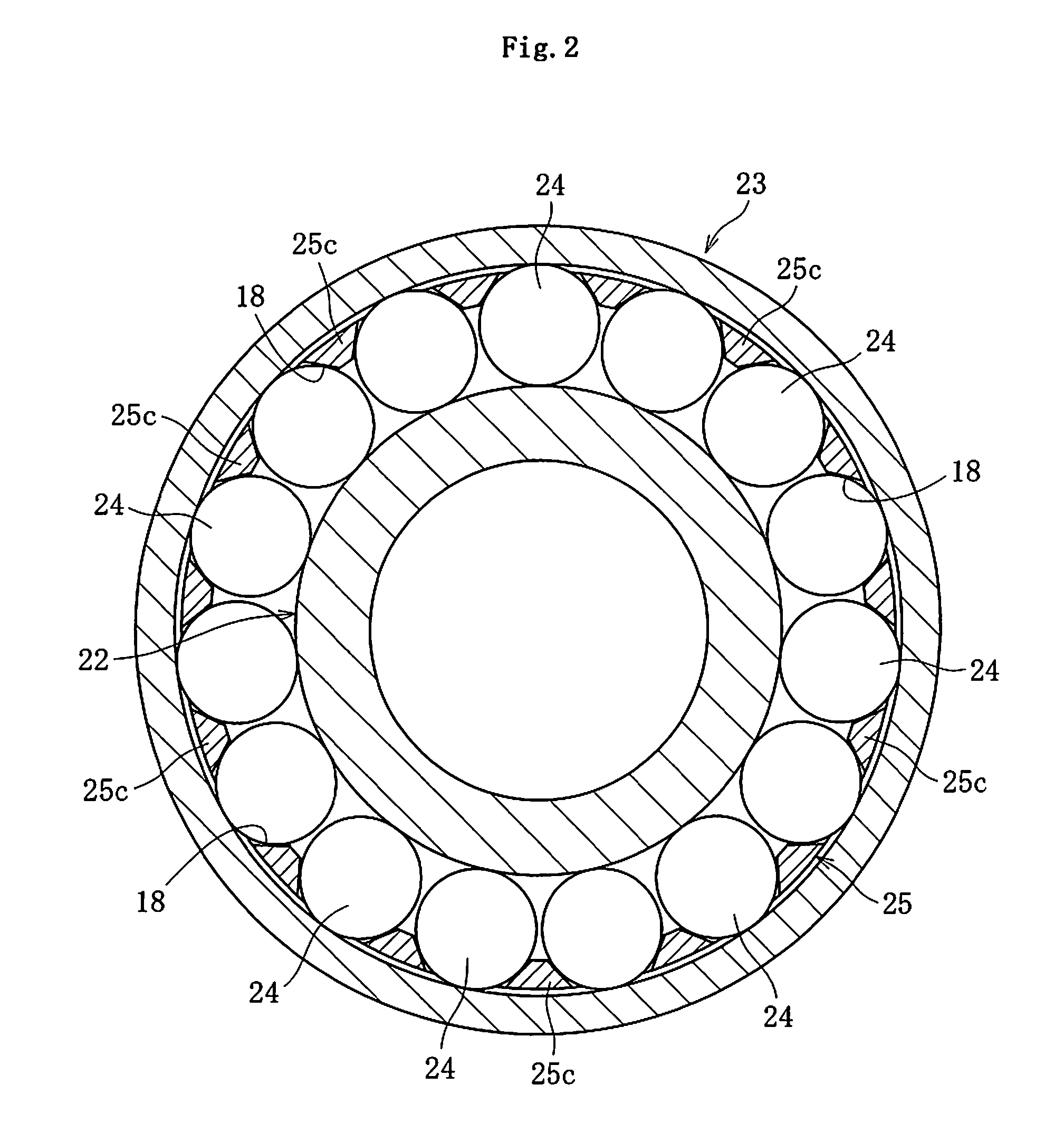

Tapered roller bearing

ActiveUS20100322547A1Occurrence can be suppressedReduce pressureRoller bearingsShaftsEngineeringMechanical engineering

A tapered roller bearing includes an outer ring 23, an inner ring 22, a tapered roller 24 interposed between the outer ring 23 and the inner ring 22, and a cage 25 holding the tapered roller 24. The tapered roller bearing is used in an idler portion of an automobile transmission that switches between an idle state in which the outer ring 23 rotates freely in relation to the inner ring 22 and a shift state in which the outer ring 23 rotates synchronously with the inner ring 22. The tapered roller bearing includes a fretting suppressing means configured by a ratio of dynamic load rating Cr to static load rating Cor being set to Cor / Cr≧1.4.

Owner:NTN CORP

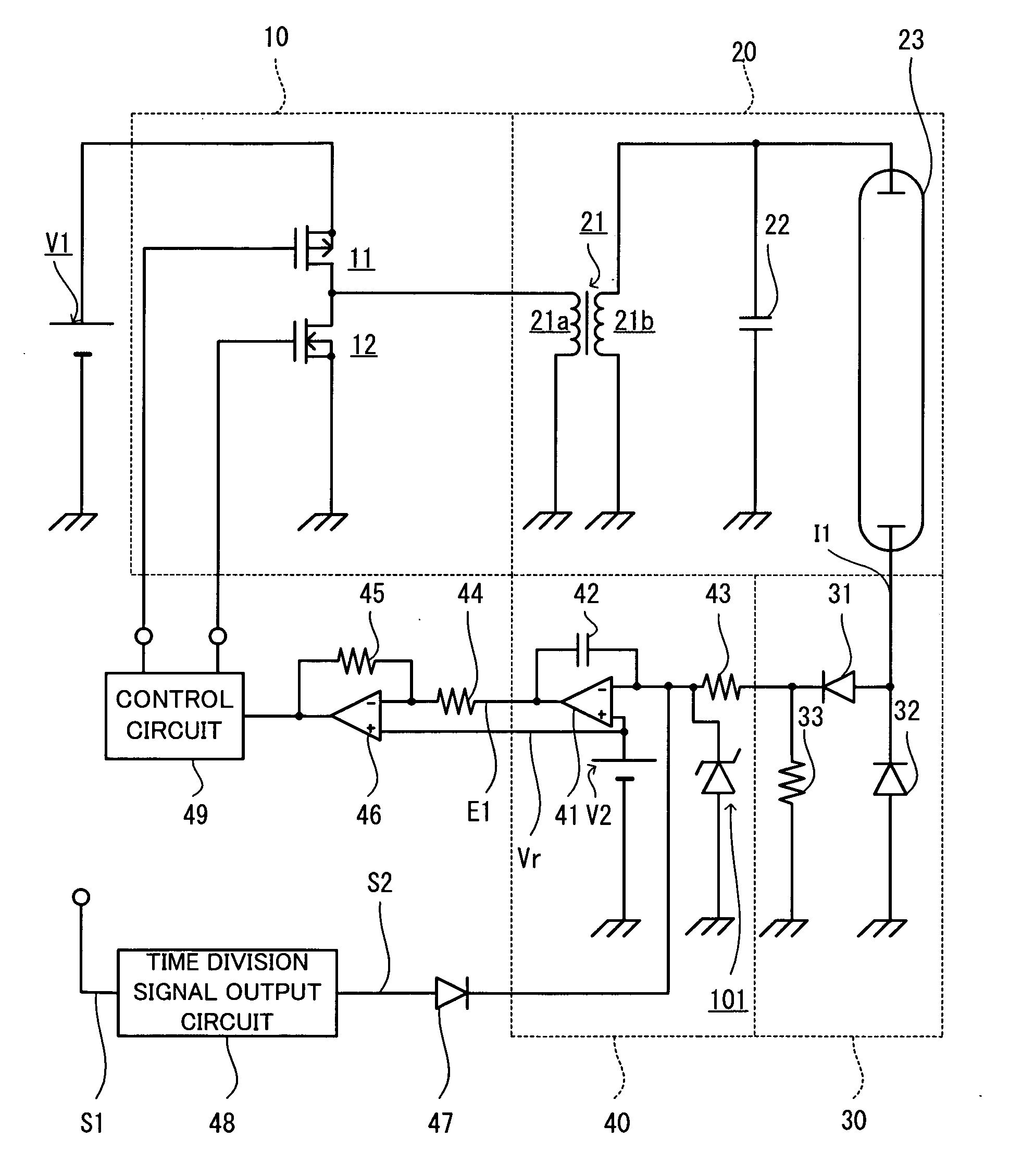

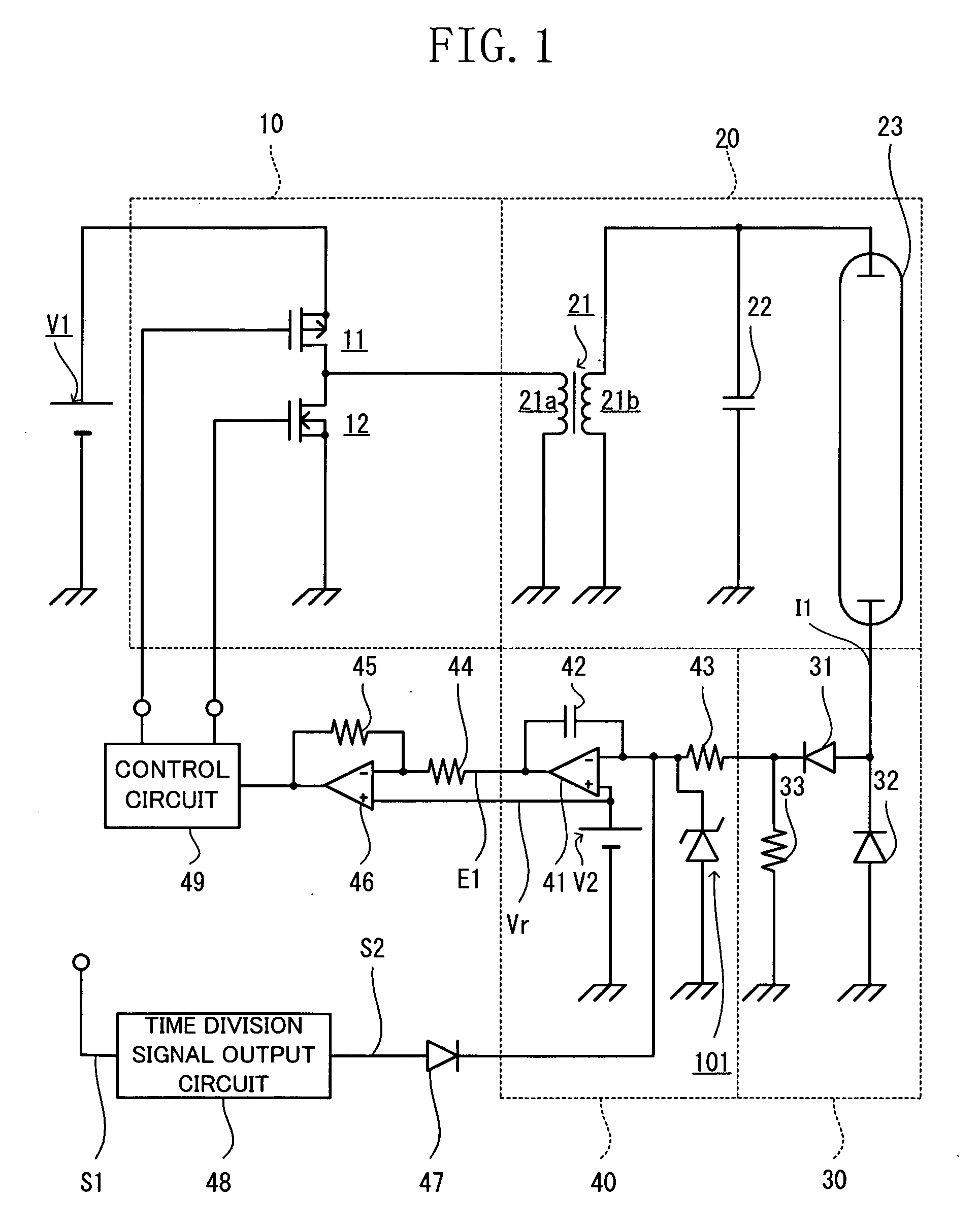

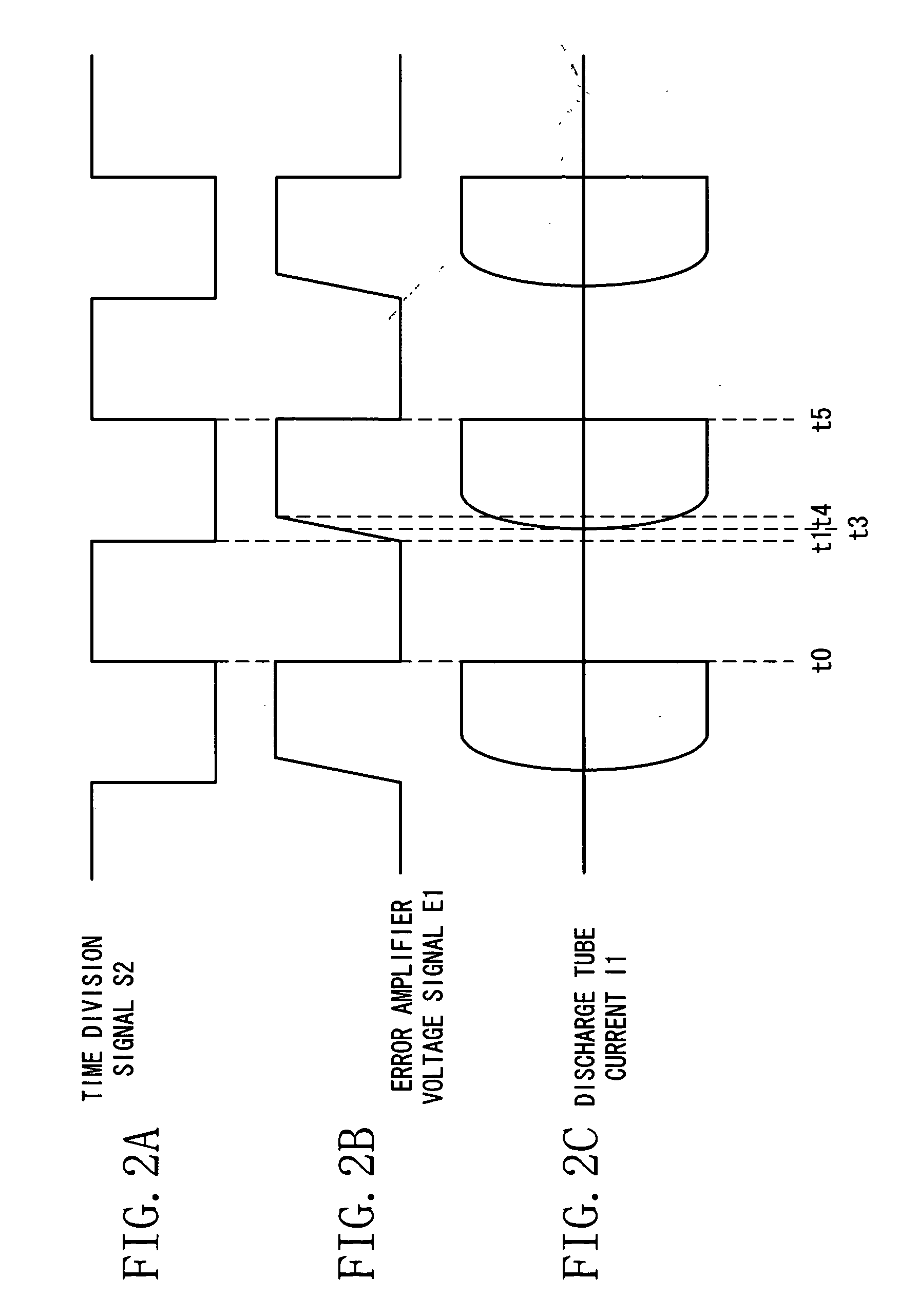

Discharge tube operation device

InactiveUS20060214606A1InhibitionDesired illuminanceElectric light circuit arrangementElectric discharge lampsCharge and dischargeControl circuit

A time division signal (S2) for instructing a lit period and an unlit period of a discharge tube (23) is input to an error amplifier (41) of an integration circuit (40). The integration circuit (40) charges and discharges a capacitor (42) in accordance with the time division signal (S2). By utilizing this operation, a control circuit (49) adjusts a current flowing through the discharge tube (23) to light and extinguish the discharge tube (23).

Owner:SANKEN ELECTRIC CO LTD

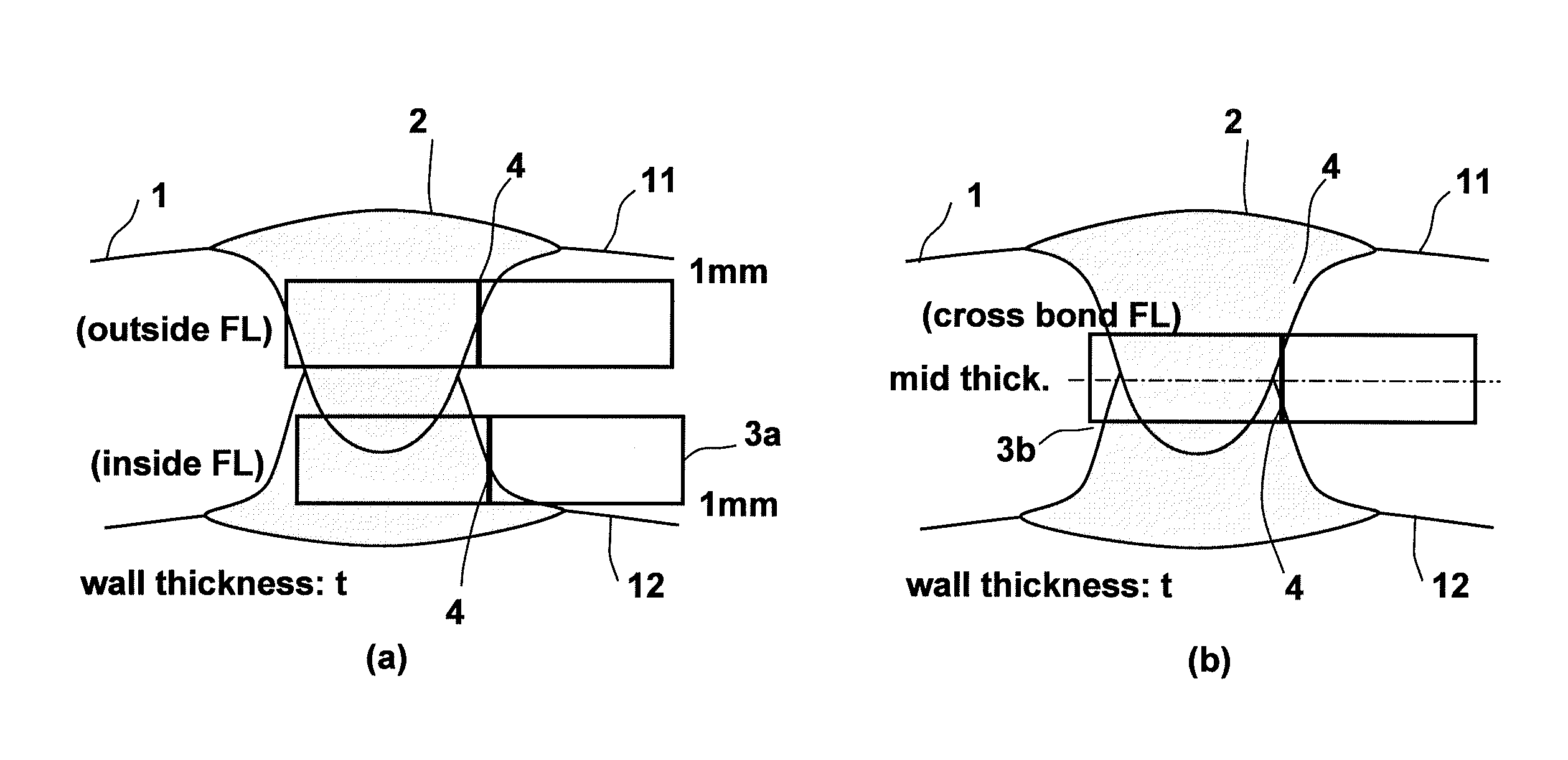

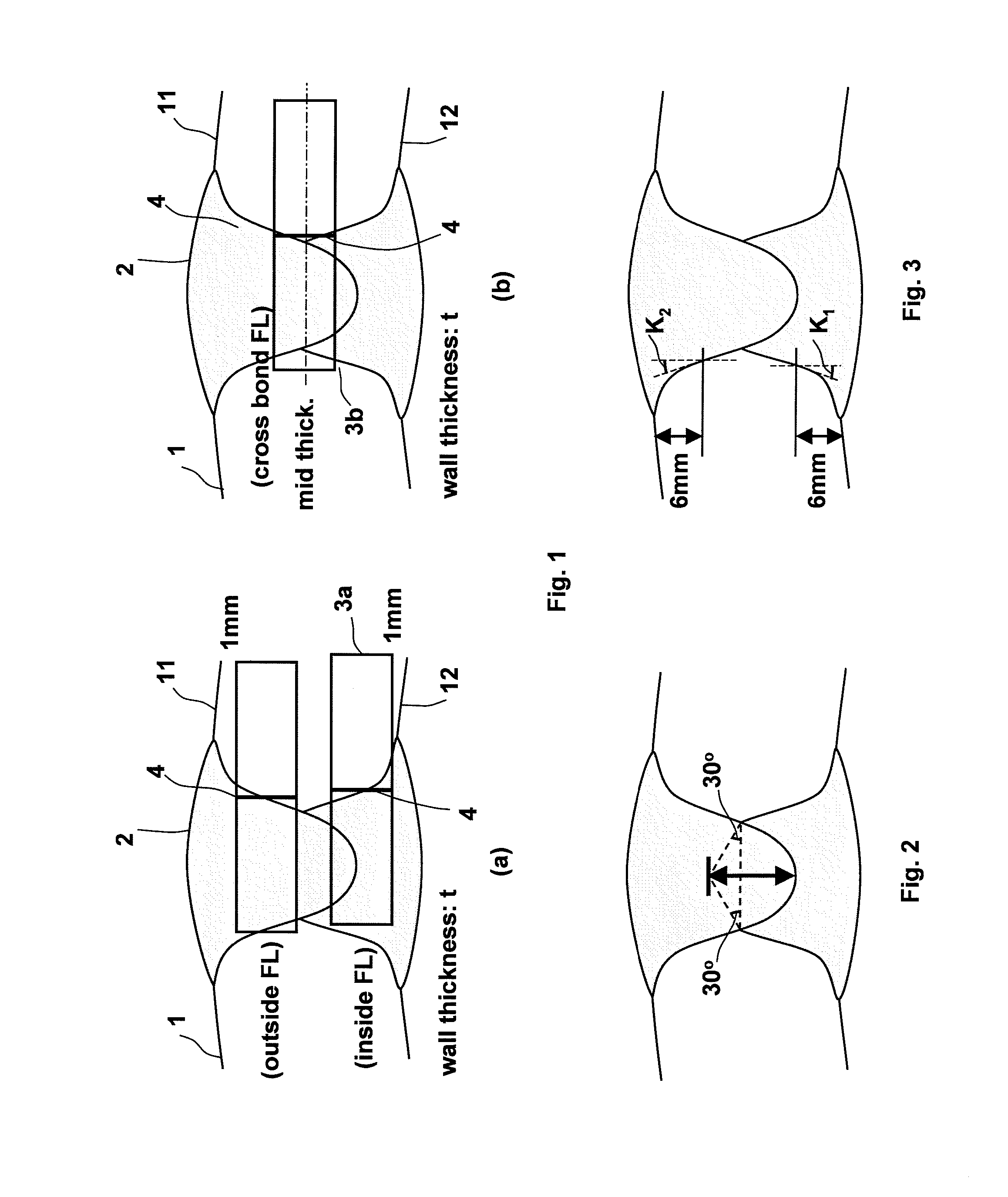

Welded steel pipe with excellent welded heat-affected zone toughness and process for producing same

InactiveUS20140227549A1Improve productivityLow costArc welding apparatusFurnace typesButt weldingAustenite grain

A welded steel pipe with excellent welded heat-affected zone toughness includes a butt weld formed by prior welding either an inner surface or an outer surface with a single layer for each of the inner and outer surfaces, wherein in the metallographic structure of a welded heat-affected zone, the martensite-austenite constituent (MA) area fraction is 4% or less, the average prior-austenite grain size is 400 μm or less, and the following items are taken into account: the average prior-austenite grain size of a welded heat-affected zone formed by prior welding, the average prior-austenite grain size of a welded heat-affected zone formed by subsequent welding, the bead width determined at a position 5 mm apart from the tip of a weld bead formed by subsequent welding, the fusion line tilt angle of a weld bead of prior welding, and the fusion line tilt angle of a weld bead of subsequent welding.

Owner:JFE STEEL CORP

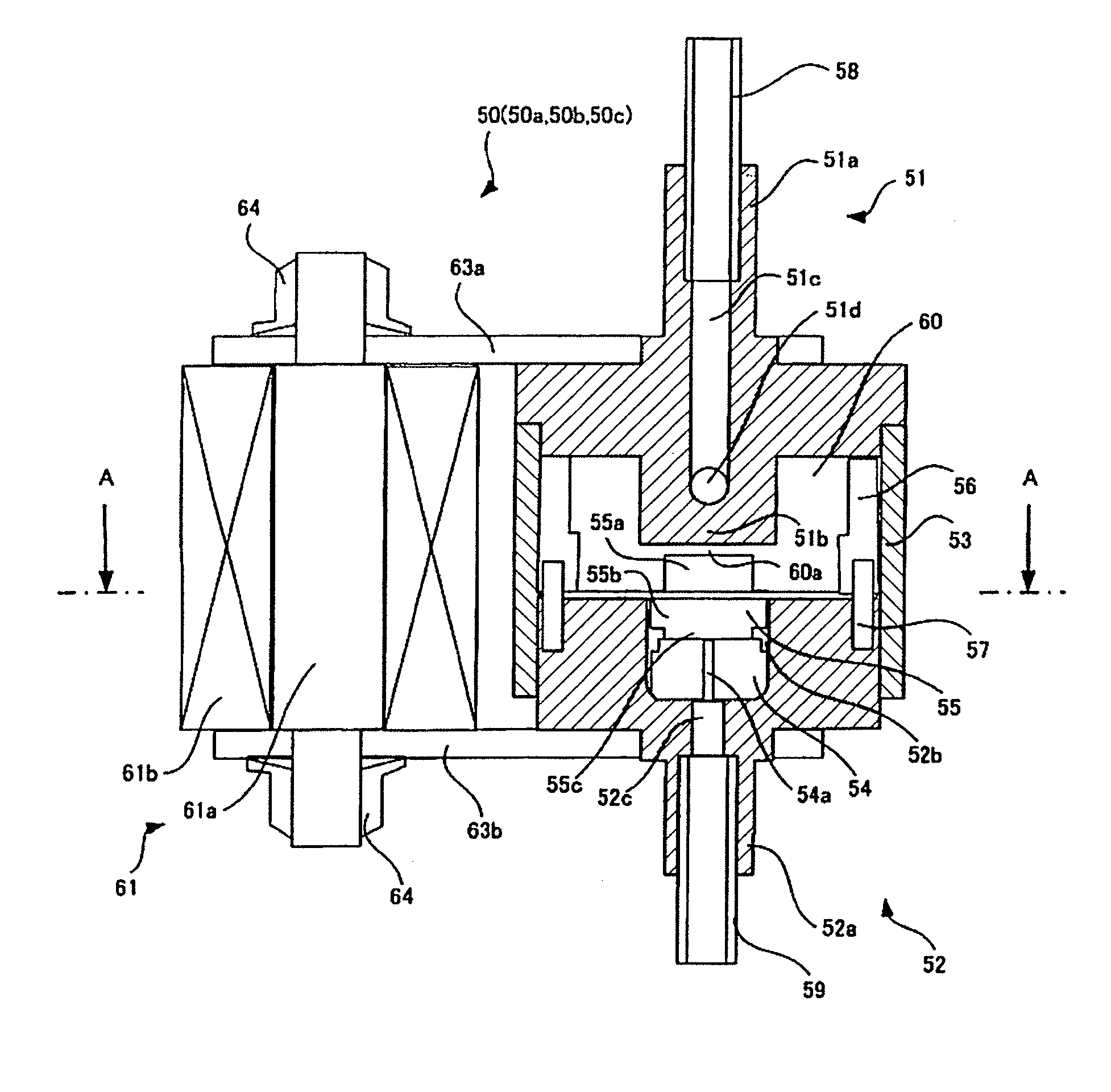

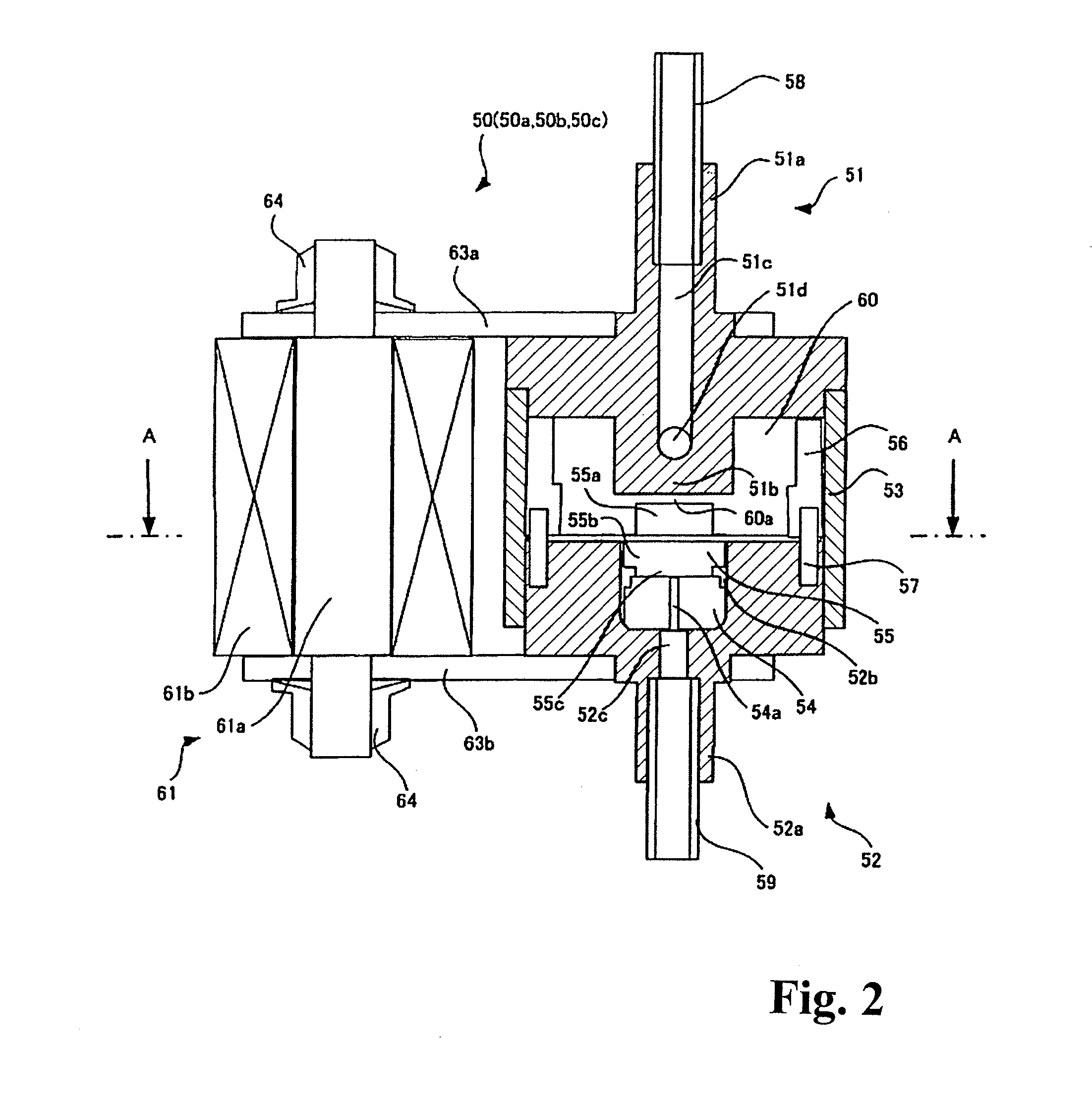

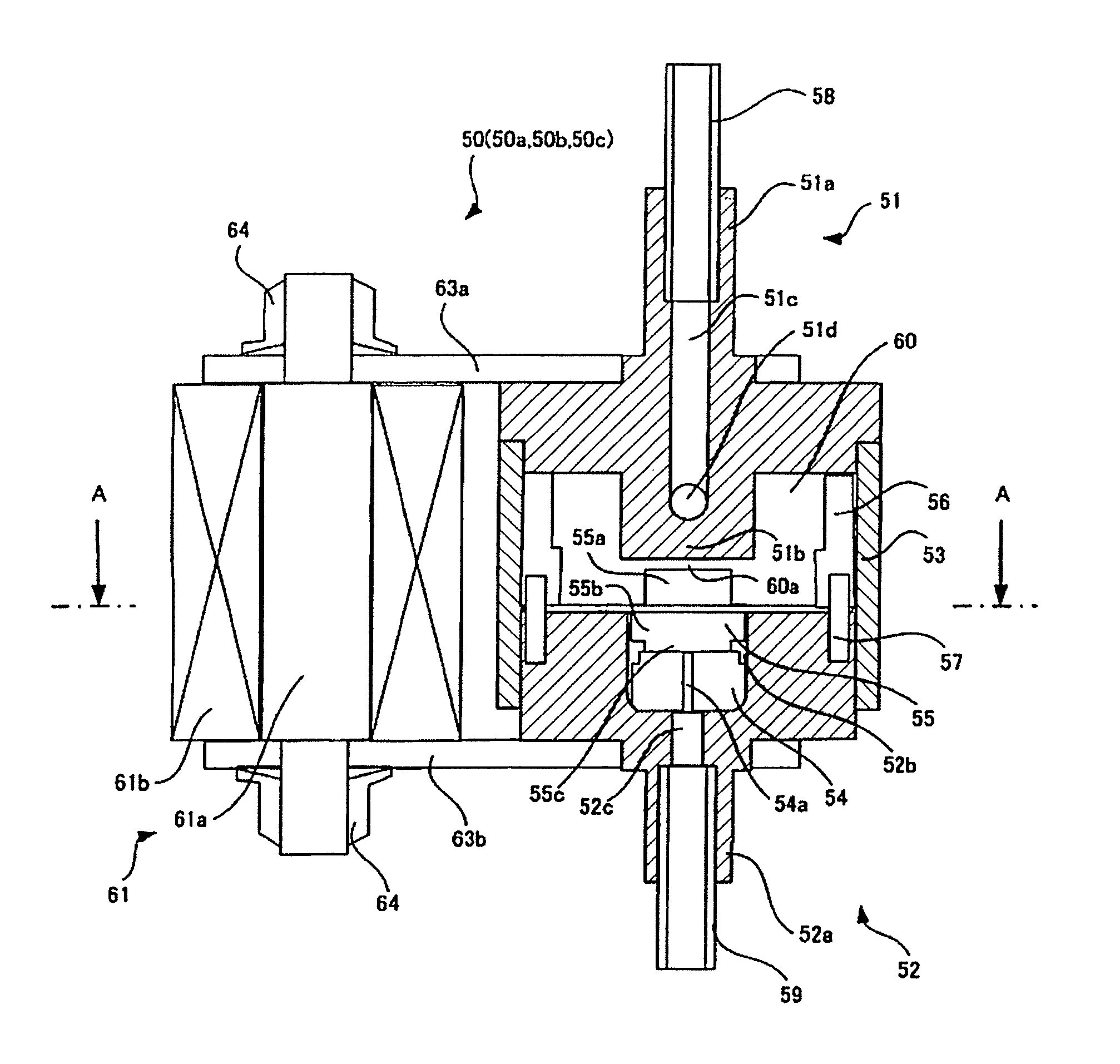

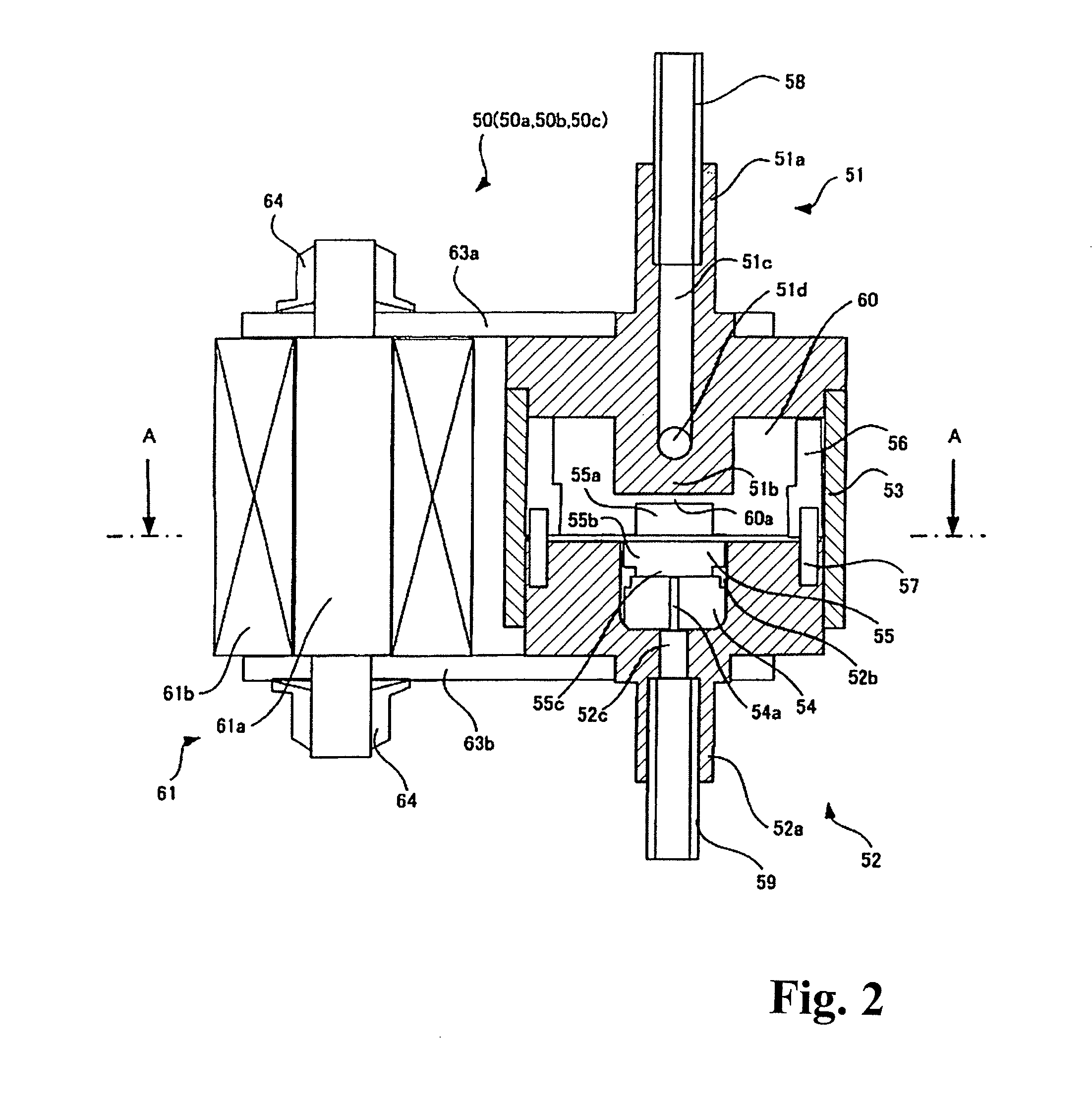

Electronic expansion valve

ActiveUS20120326064A1Low costOccurrenceOperating means/releasing devices for valvesEfficient regulation technologiesSludgeElectronic expansion valve

An electronic expansion valve (50) includes a small hole (54a) that expands a refrigerant, a valve body (55c) that opens and closes the small hole, an elastic member (70) that urges the valve body to close the small hole, and a solenoid (61) that suctions the valve body to open the small hole, and expands the refrigerant by opening and closing the valve body. The elastic member is a disc spring in which a plurality of slits (73) formed in a spiral form is provided at mutually equal pitches on the perimeter. Therefore, there is no need for a guide, the occurrence of sludge due to sliding is suppressed, and the electronic expansion valve operates stably over a long period.

Owner:FUJI ELECTRIC CO LTD

Emergency electric power supply unit

InactiveUS7511389B2OccurrenceBatteries circuit arrangementsElectric devicesEngineeringElectric power

An emergency electric power supply unit (9) for backing up the main electric power supply system (1, 10) at the time of the malfunction of the main electric power supply system (1, 10) which includes an industrial apparatus operated by cooperatively controlling an auxiliary machinery (2) operated by the electric power supplied from the main electric power supply system (1, 10), an auxiliary electric power supply (20) for storing the electric power, a charging circuit (21) for charging the electric power supplied from the main electric power supply (1) in the auxiliary electric power supply (20), a discharging circuit (22) for supplying the electric power charged in the auxiliary electric power supply (20) to the auxiliary machinery (2), and an emergency controlling circuit (40) for controlling the discharging circuit (22) so that the electric power from the auxiliary electric power supply (20) is supplied to the auxiliary machinery (2) at the time of the malfunction of the main electric power supply system (1, 10) and for controlling the operation of the auxiliary machinery (2) in response to the operational state of the industrial apparatus at the time of the malfunction of the main electric power supply system (1, 10).

Owner:ASHITATE ELECTRIC +1

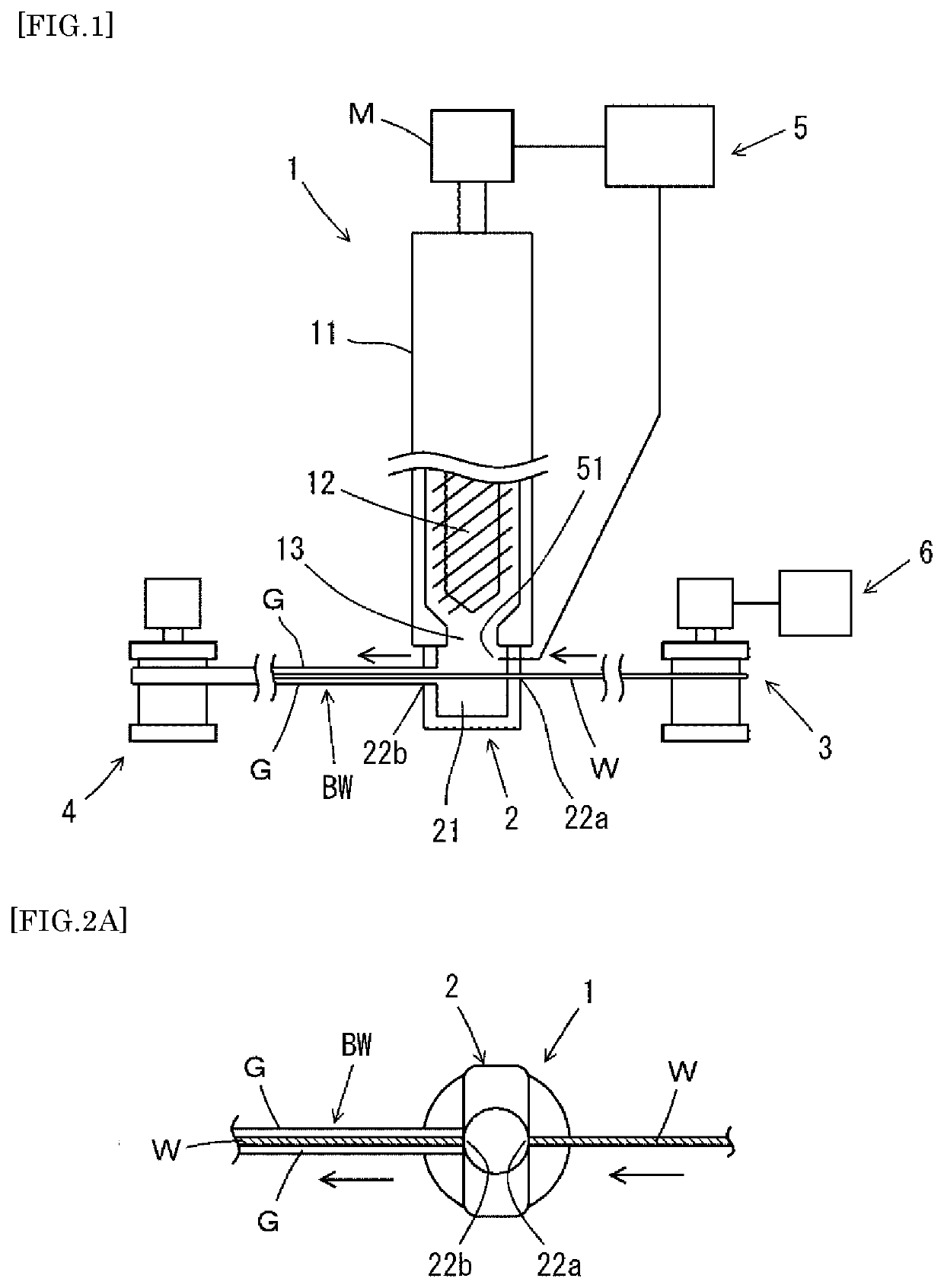

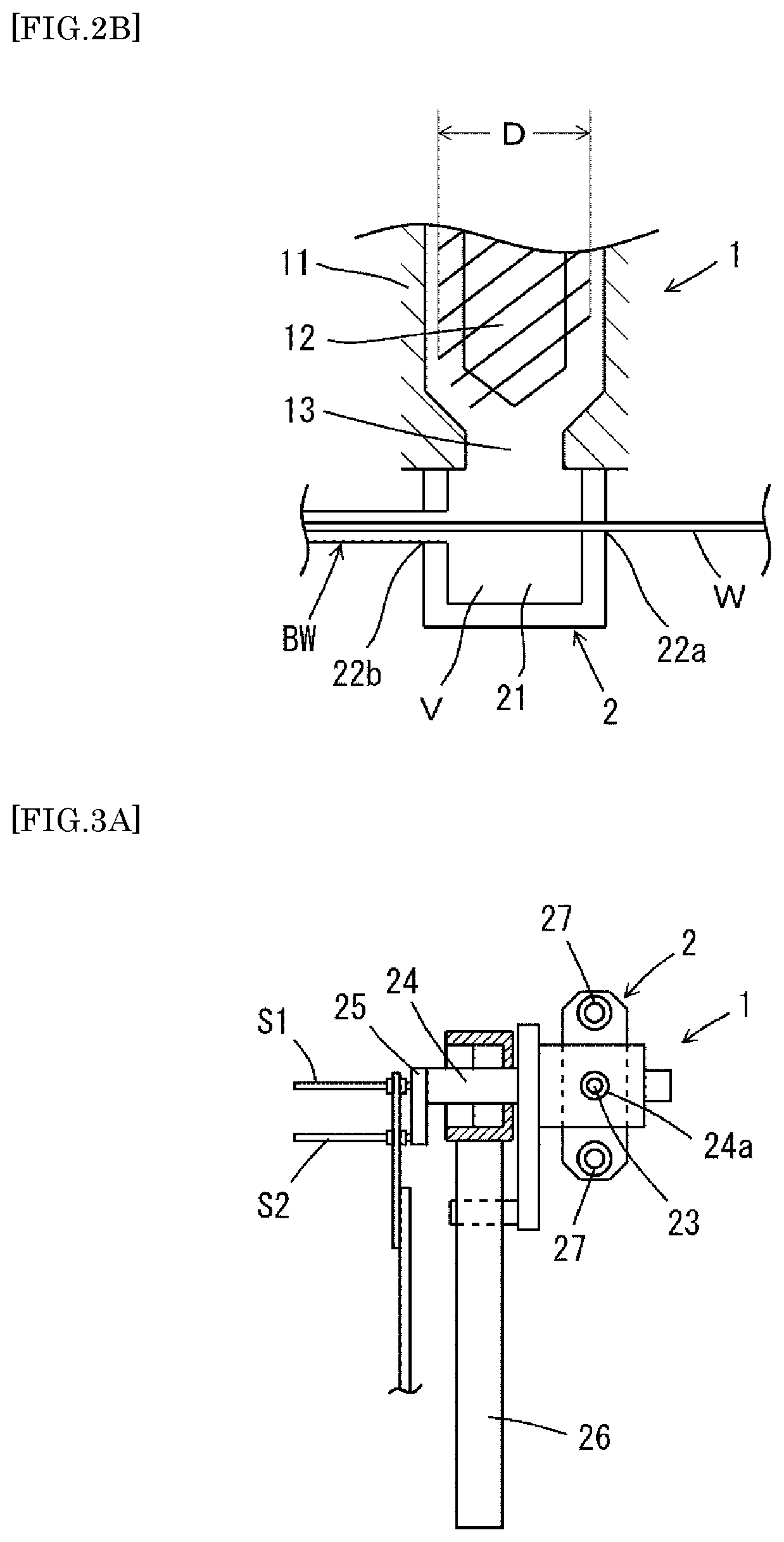

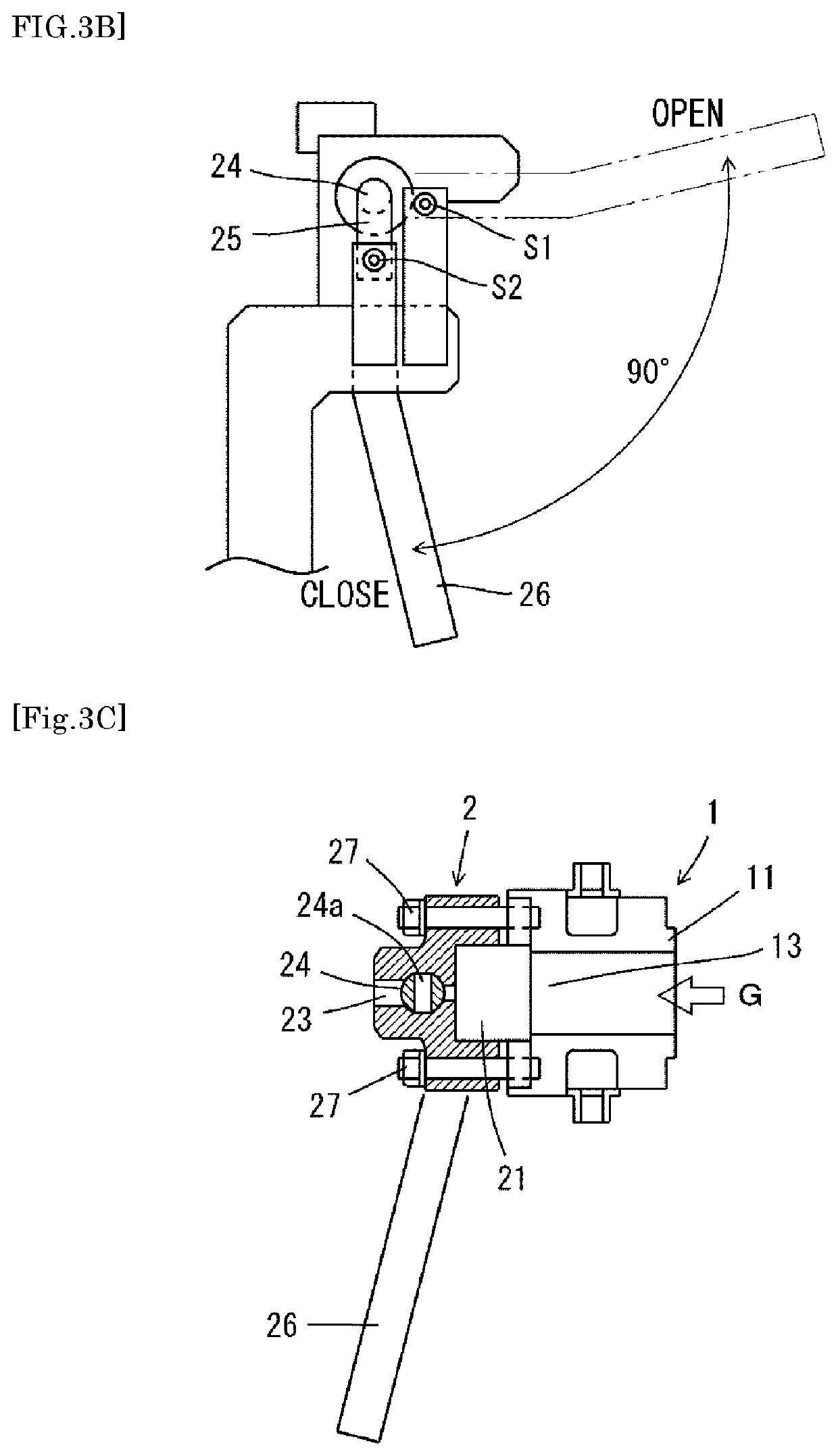

Rubber-coated cord manufacturing device and rubber-coated cord manufacturing method

InactiveUS20210008782A1Avoid it happening againReduce the burden onFibre treatmentPlastic recyclingPolymer scienceEngineering

Provided is a rubber-coated cord manufacturing technique with which the occurring of rubber spew can be prevented and waste in the form of scrap can be reduced during a rubber-coated cord manufacturing step, and with which the burden on an operator can be reduced and a high-quality rubber-coated cord can be stably produced. This rubber-coated cord manufacturing device comprises: an extrusion head that coats rubber on the surface of a cord, the extrusion head including a screw rotation type extruder which extrudes rubber, an insertion port into which the cord is inserted, and a flow path of rubber which has been extruded from the extruder; a cord supply device that supplies the cord to the extrusion head; a rubber-coated cord winding device that winds a rubber-coated cord which has been coated with rubber by the extrusion head; and a head pressure controller that controls the head pressure of the extrusion head. The head pressure controller performs control to maintain the head pressure at a prescribed level by feeding back to the extruder the monitoring results of the head pressure while the cord is coated with the rubber, and adjusting the rotation speed of the screw.

Owner:SUMITOMO RUBBER IND LTD

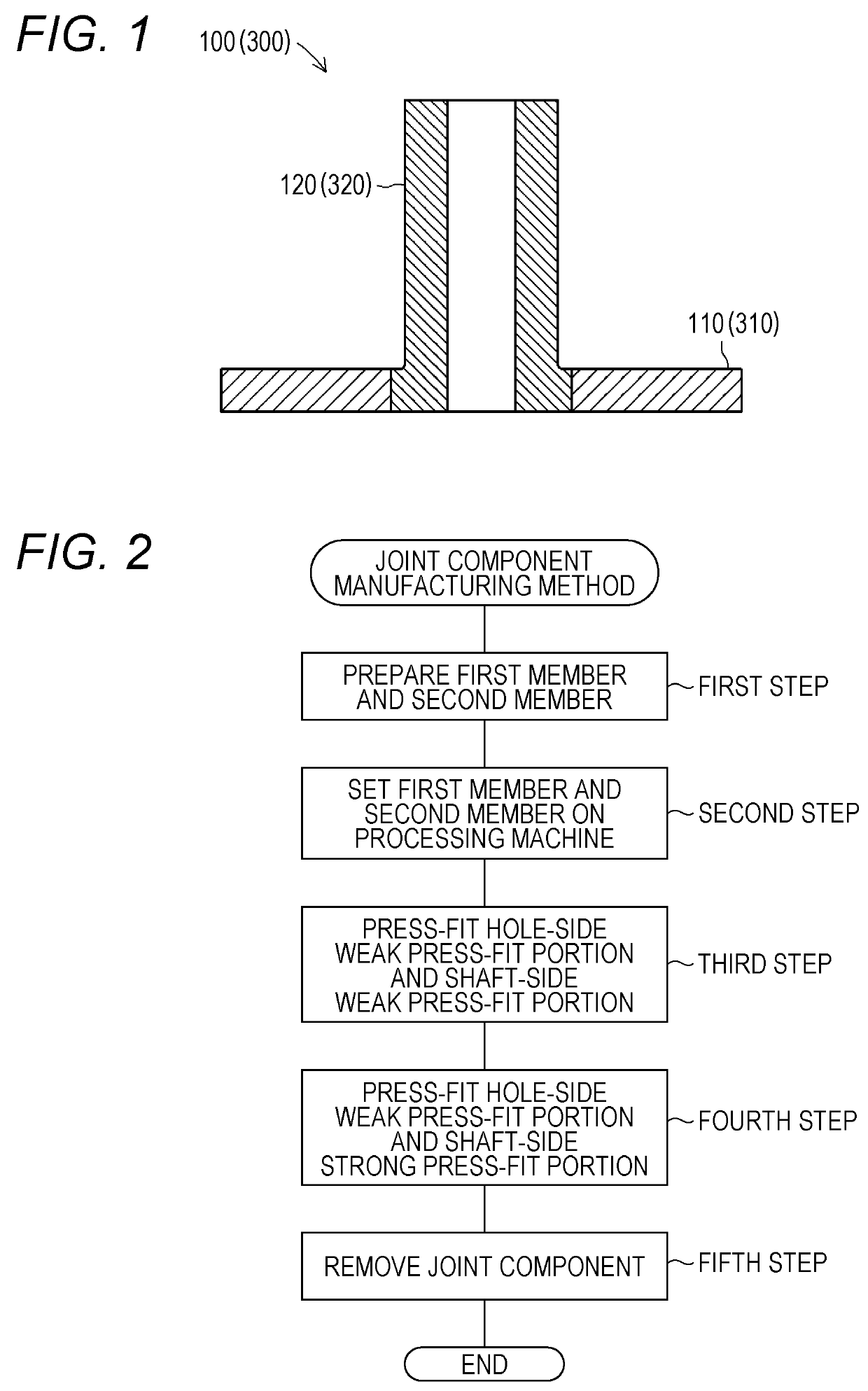

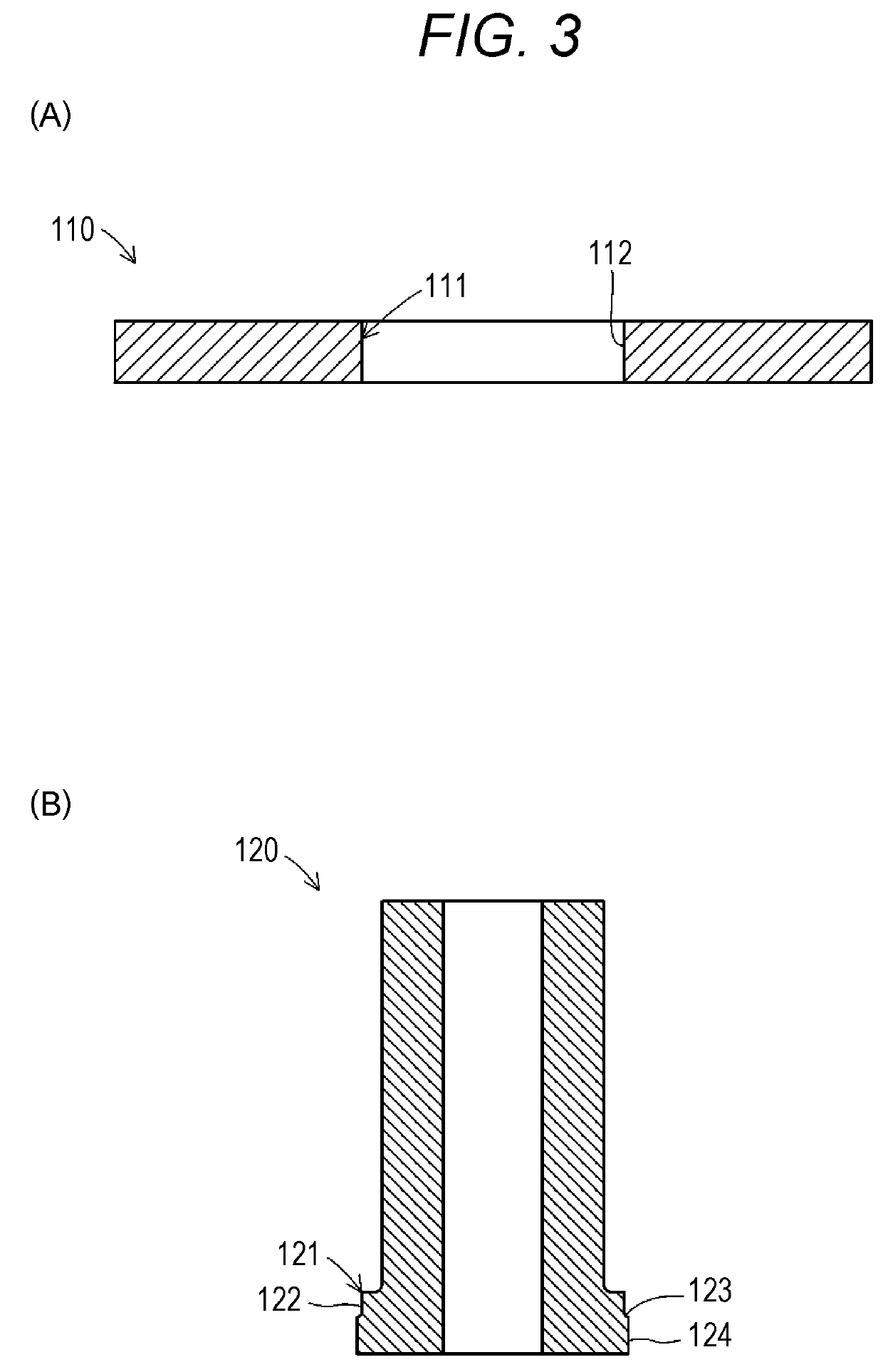

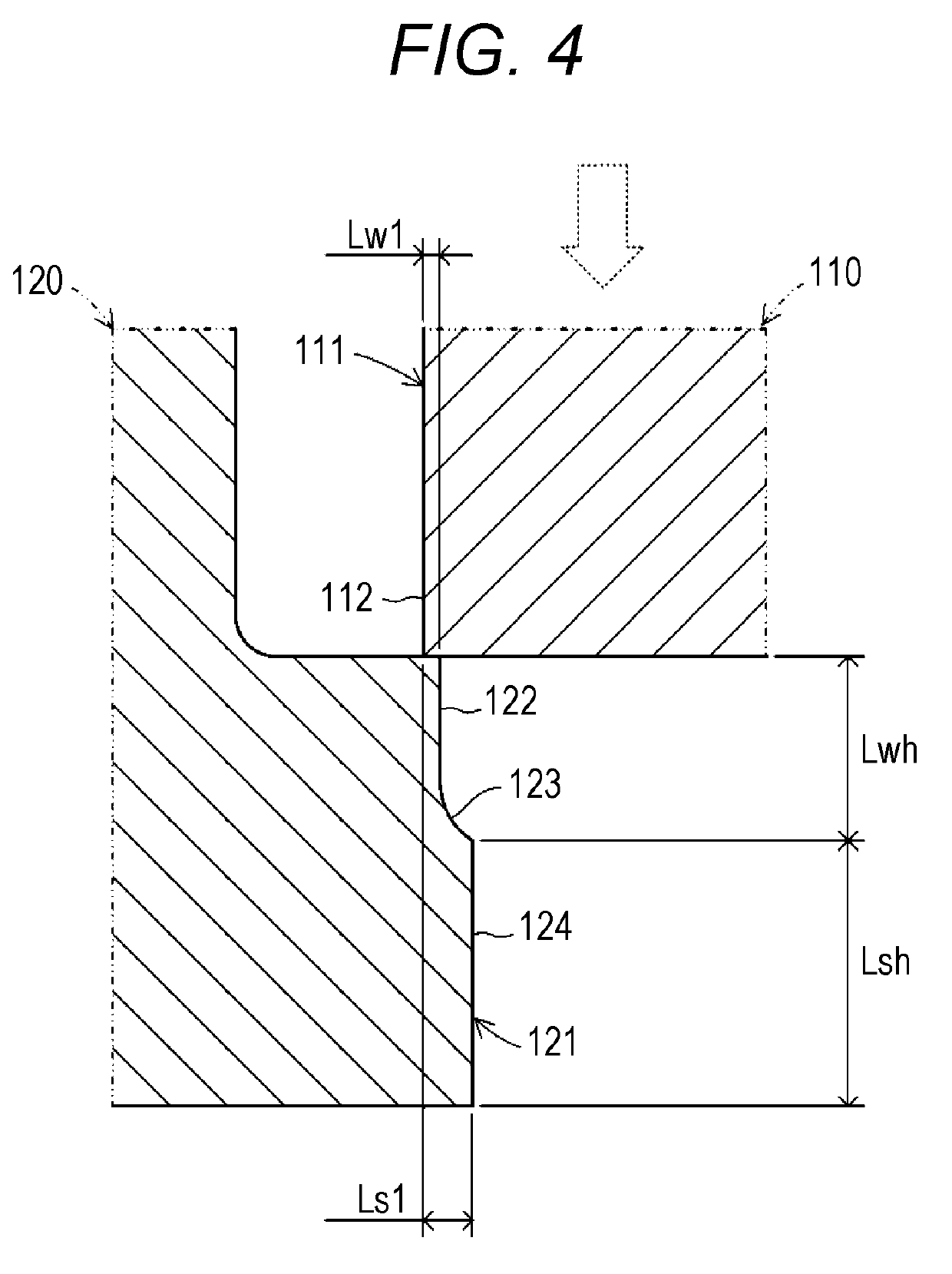

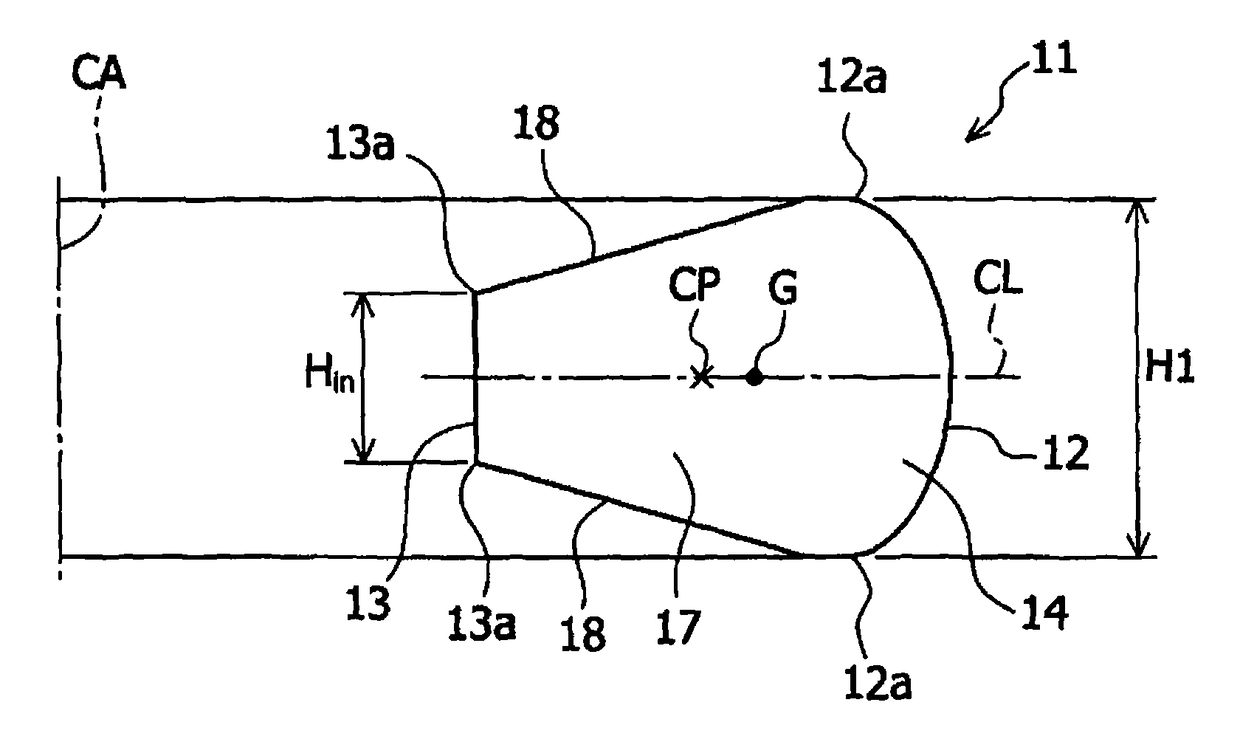

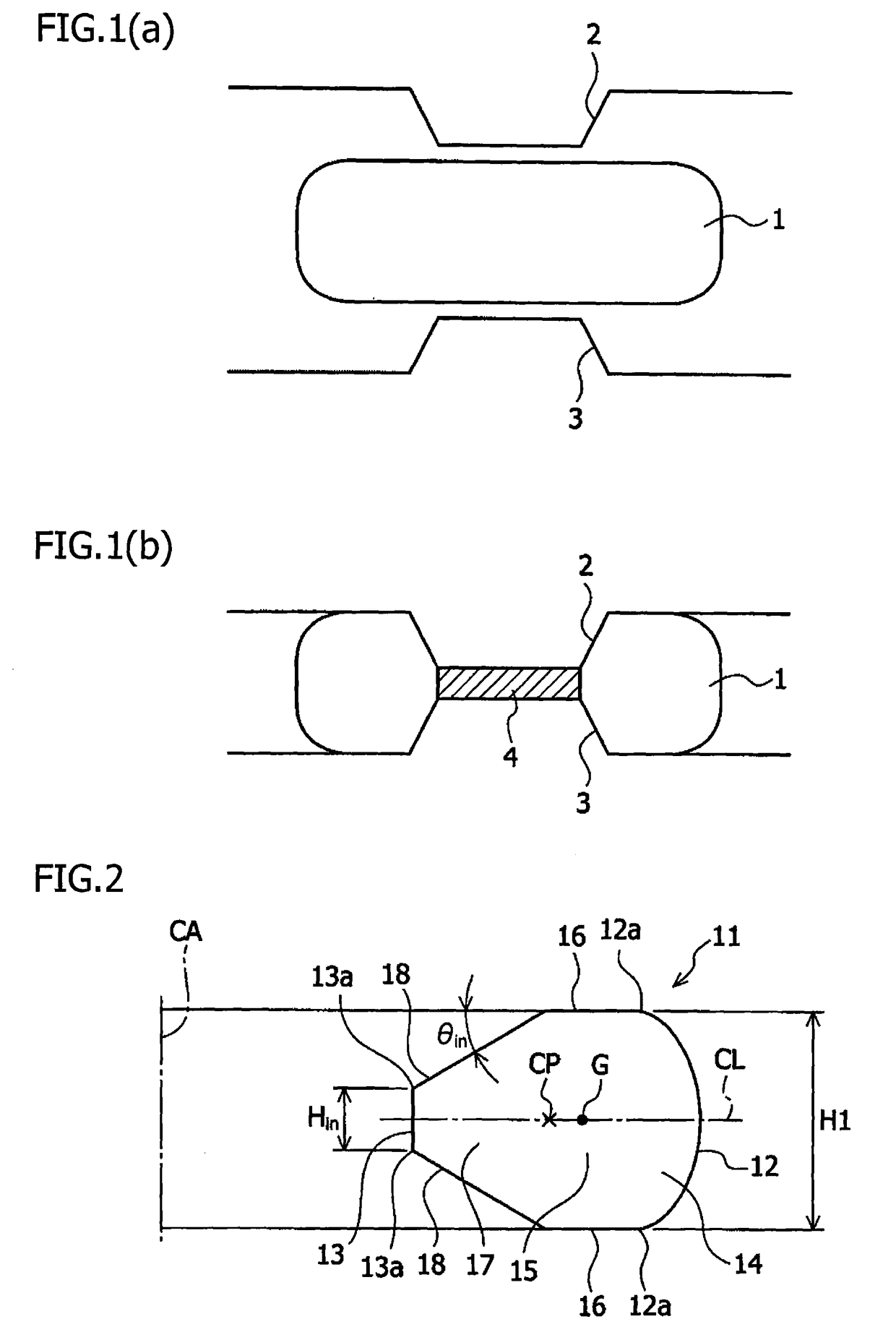

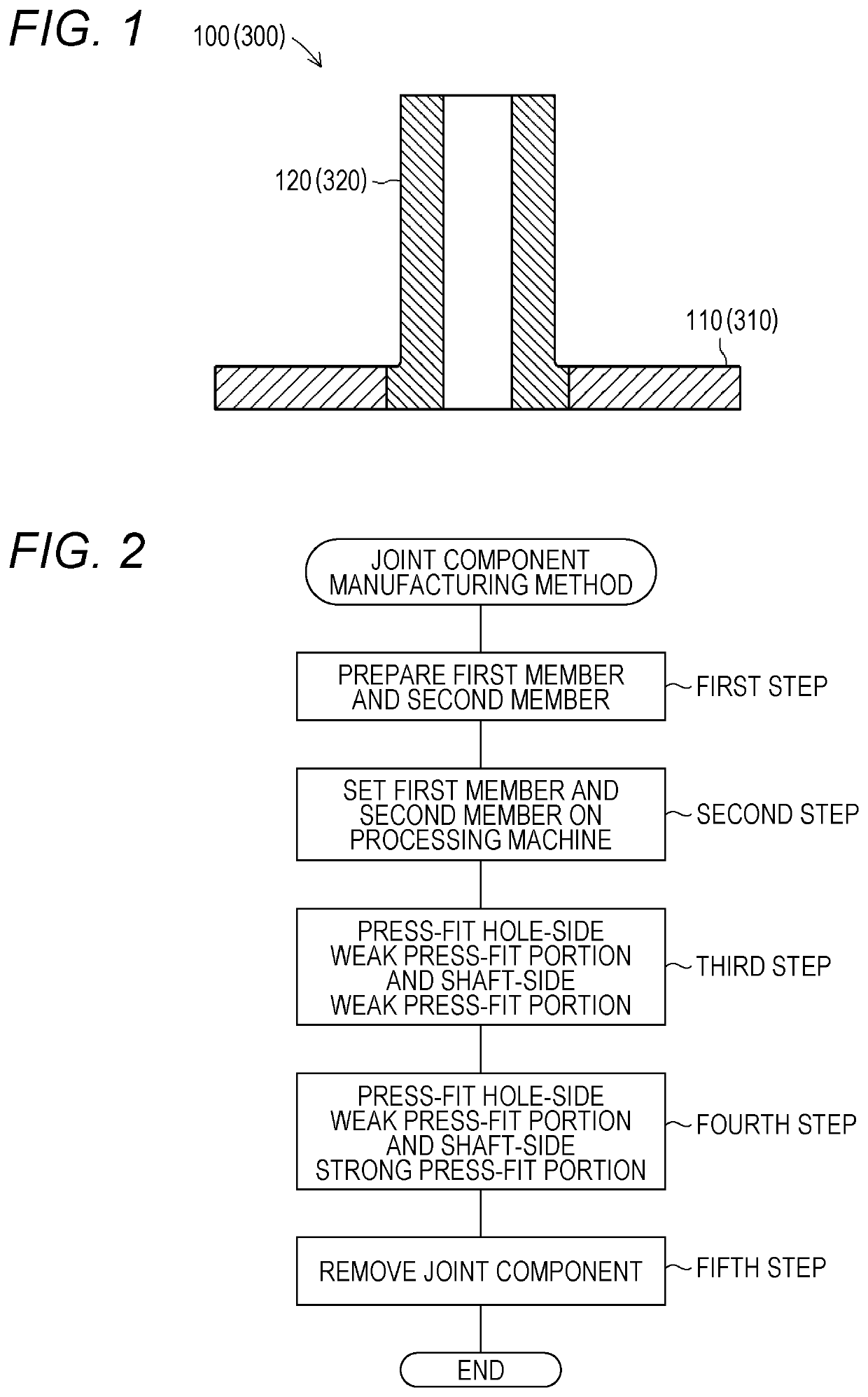

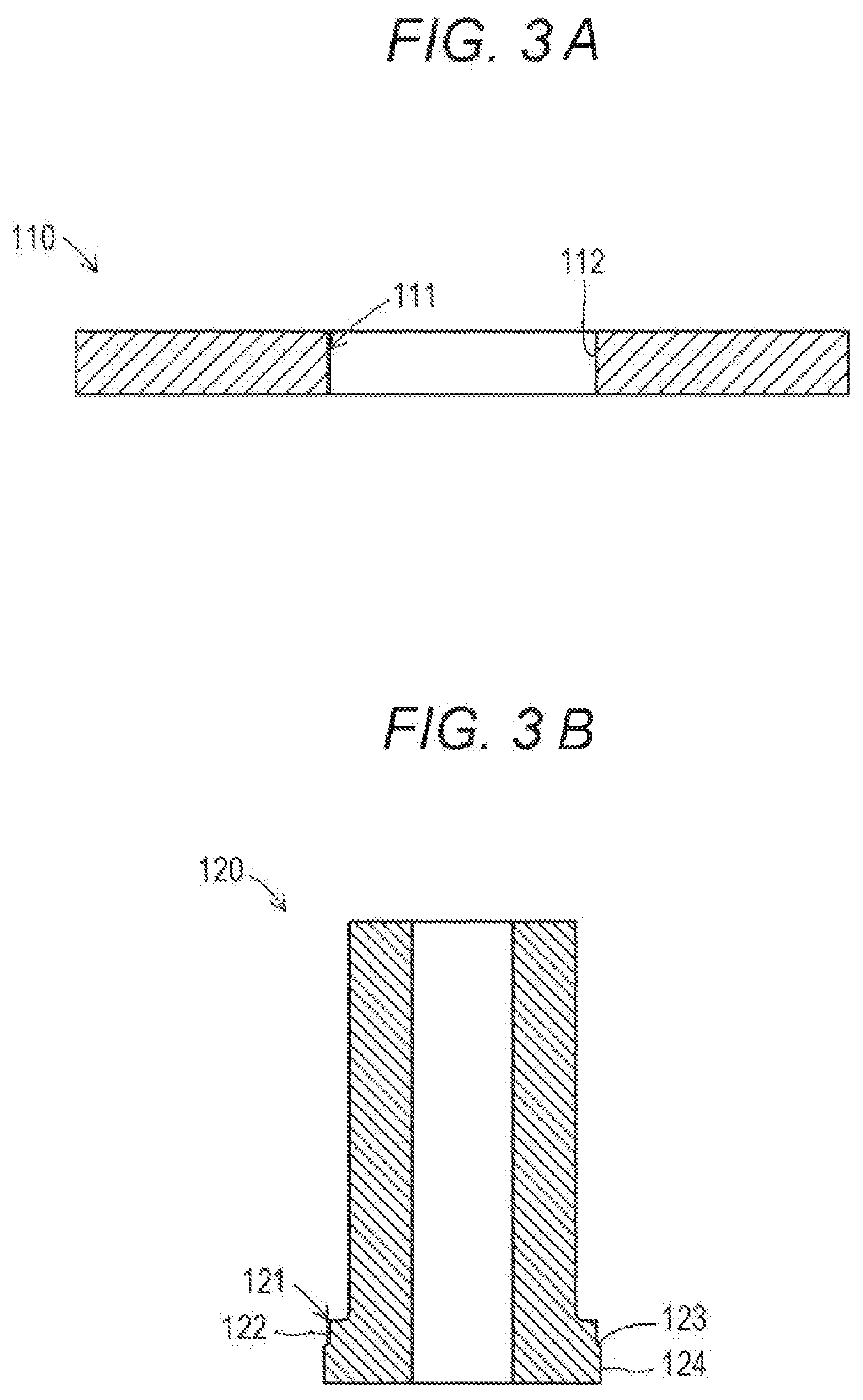

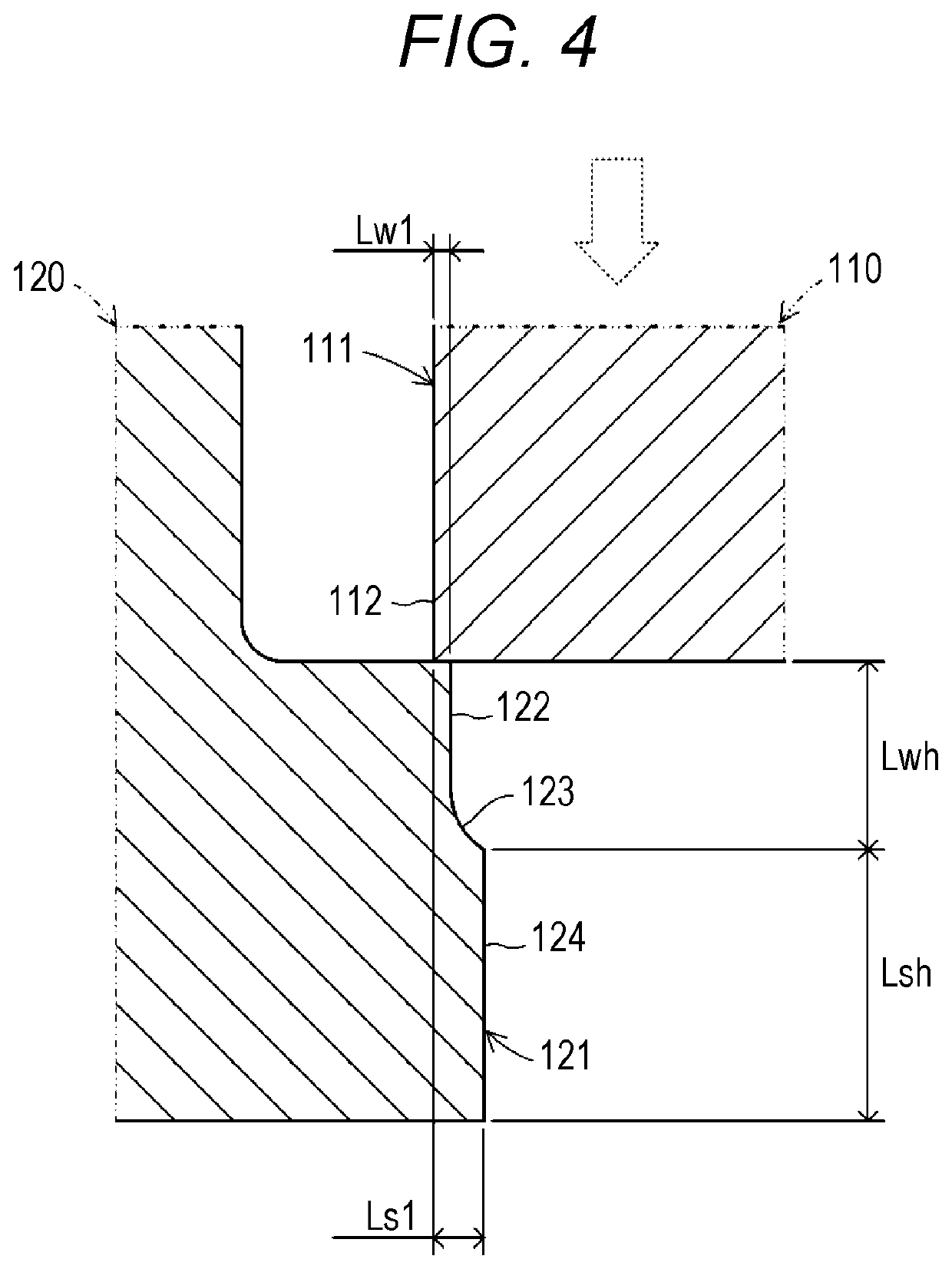

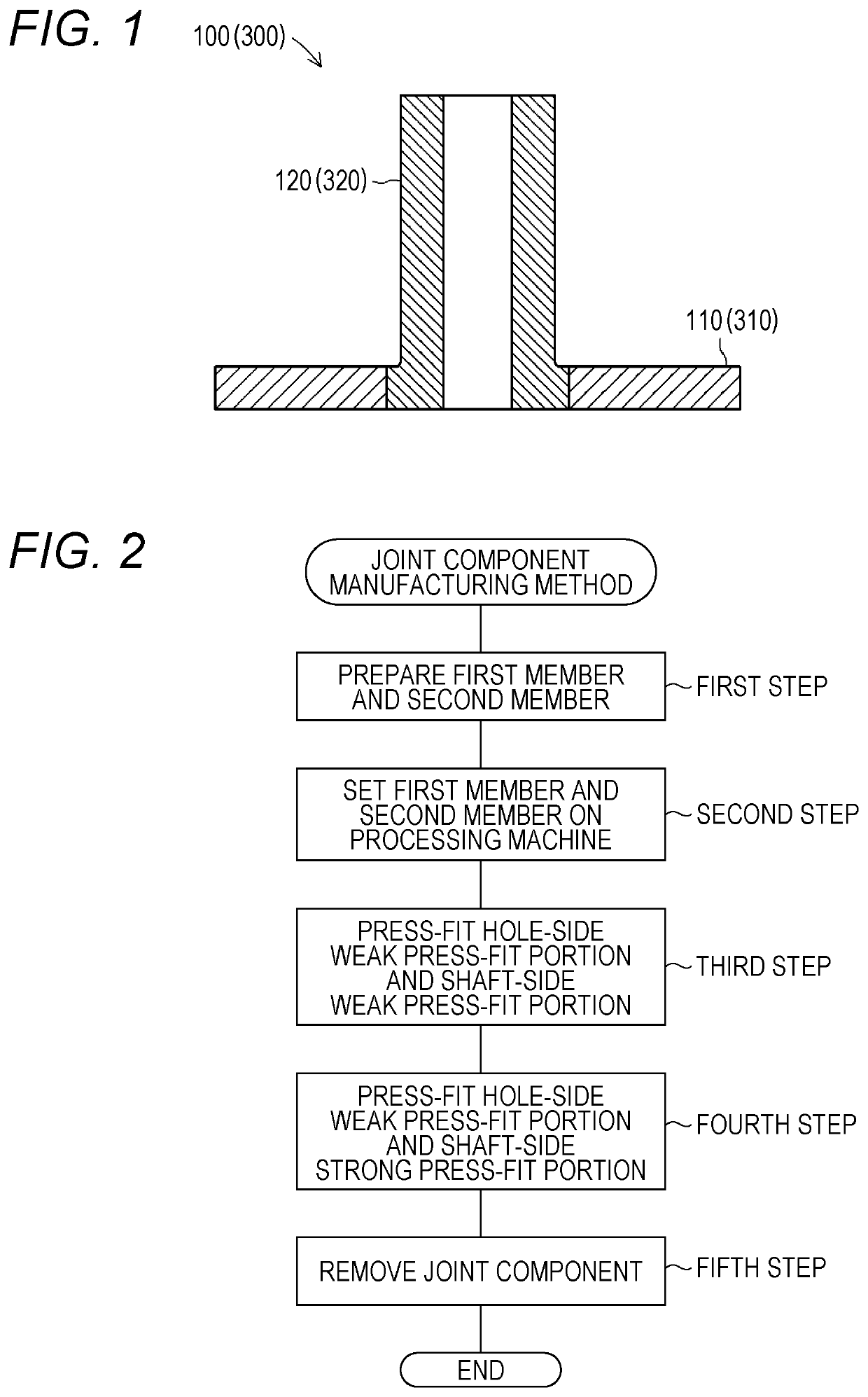

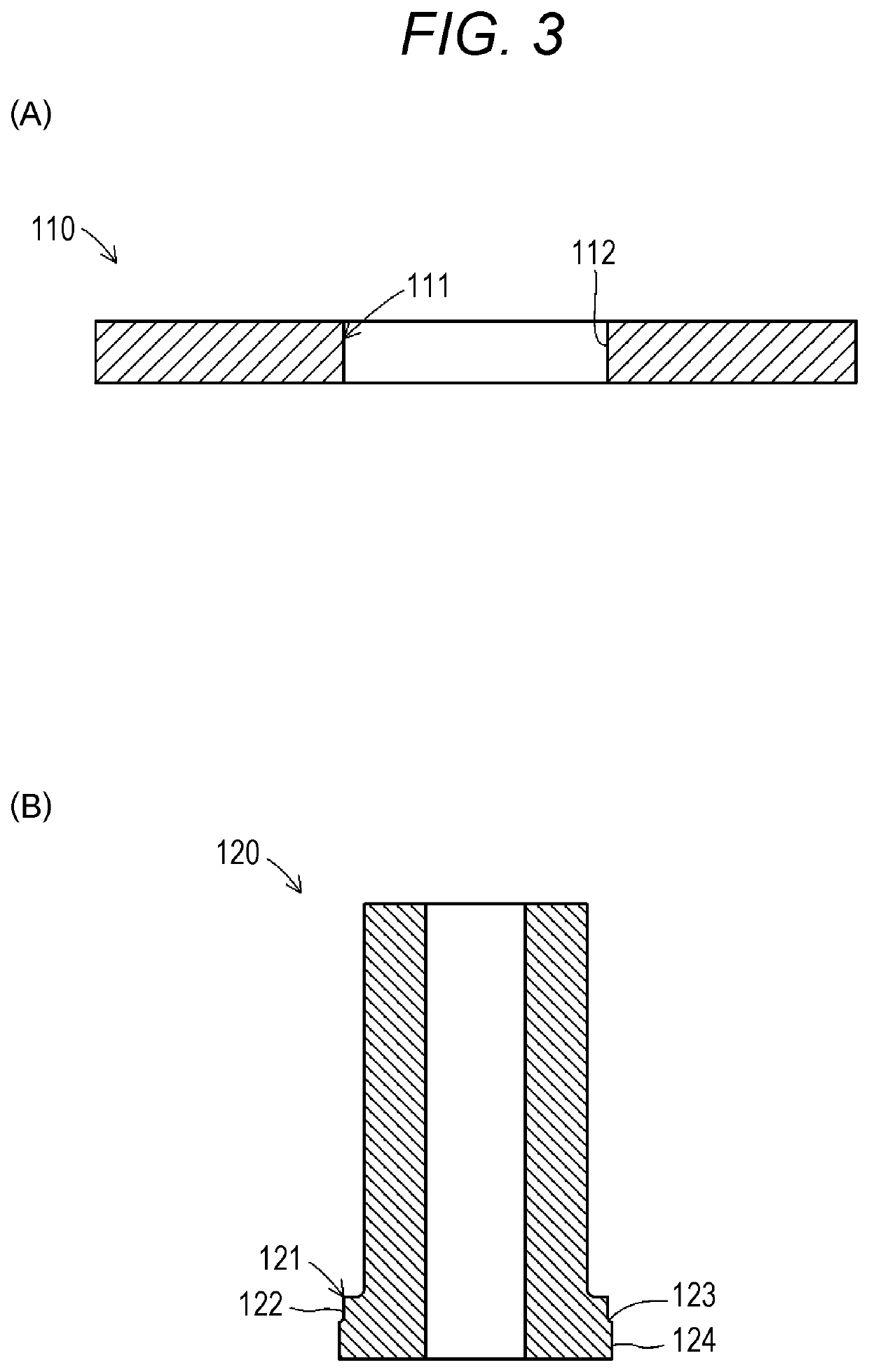

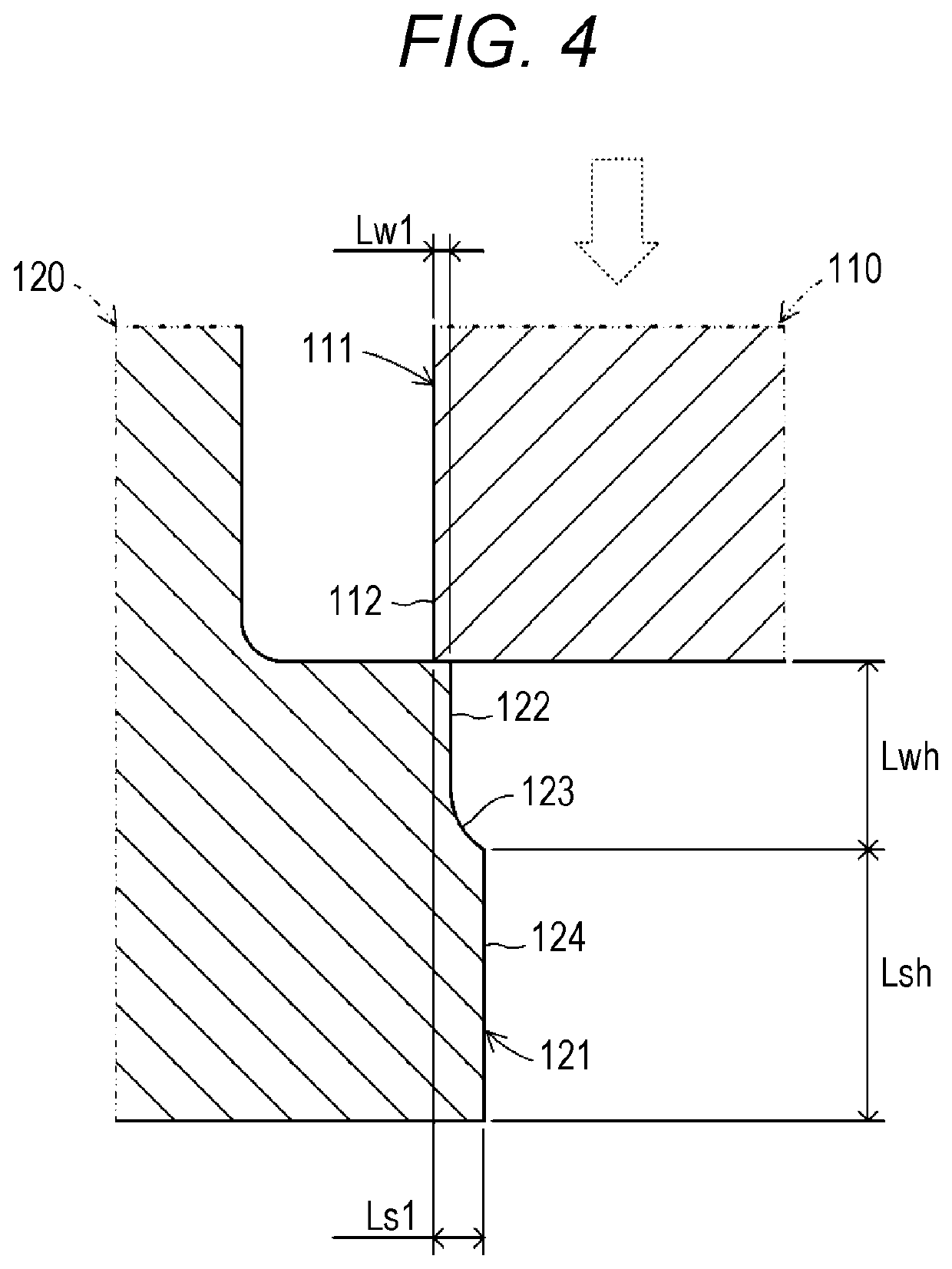

Joint component manufacturing method

ActiveUS20190247909A1Easy to installReduce generationShrinkage connectionsRod connectionsJoint componentEngineering

Provided is a joint component manufacturing method for reducing occurrence of burrs upon bonding between a first member having a hole and a second member having a shaft portion and firmly bonding both members. In the method for manufacturing a joint component 100, a hole-side weak press-fit portion 112 is formed at a hole 111 of a flat plate ring-shaped first member 110. Moreover, each of a shaft-side weak press-fit portion 122 and a shaft-side strong press-fit portion 124 is formed at a shaft portion 121 of a cylindrical second member 120. The hole-side weak press-fit portion 112 and the shaft-side weak press-fit portion 122 are defined by a first weak press-fit interference Lw1 formed thinner than a first strong press-fit interference Ls1. The shaft-side strong press-fit portion 124 is defined by a first strong press-fit interference Ls1 as the minimum necessary press-fit interference for electric resistance welding upon electric resistance welding between the hole 111 and the shaft portion 121.

Owner:FCC KK

Tapered roller bearing

ActiveUS8439574B2Occurrence can be suppressedReduce pressureRoller bearingsShaftsFree rotationEngineering

A tapered roller bearing includes an outer ring, an inner ring, a tapered roller interposed between the outer ring and the inner ring, and a cage holding the tapered roller. The tapered roller bearing is for being used in an idler portion of an automobile transmission that switches between an idle state in which the outer ring rotates freely in relation to the inner ring and a shift state in which the outer ring rotates synchronously with the inner ring. In one embodiment, the tapered roller bearing has a ratio of roller dynamic load rating Cr to static load rating Cor of Cor / Cr≧1.4. In an alternative embodiment, MoS2 processing is performed on a surface of the tapered roller and the tapered roller bearing has a ratio of roller dynamic load rating Cr to static load rating Cor of Cor / Cr≧1.3.

Owner:NTN CORP

Manufacturing method for material for ring rolling

ActiveUS9719369B2Easy to manufactureAccurate shapeBlade accessoriesMachines/enginesHot workingMaterials science

A manufacturing method provides a high-quality material for ring rolling. The manufacturing method of the material for ring rolling includes a step of heating a disk-shaped material for hot forging to a hot working temperature, a step of arranging the material for hot forging onto a lower die having a convex portion with a truncated conical shape, a step of forming a thin portion by pressing a center portion of the material for hot forging by using an upper die having a convex portion with a truncated conical shape, and a step of manufacturing a material for ring rolling by removing the thin portion wherein a center of gravity on a half section of the material for ring rolling is located so as to be closer to an outer peripheral surface of the half section than a center of the half section in a thickness direction of the half section.

Owner:HITACHI METALS LTD

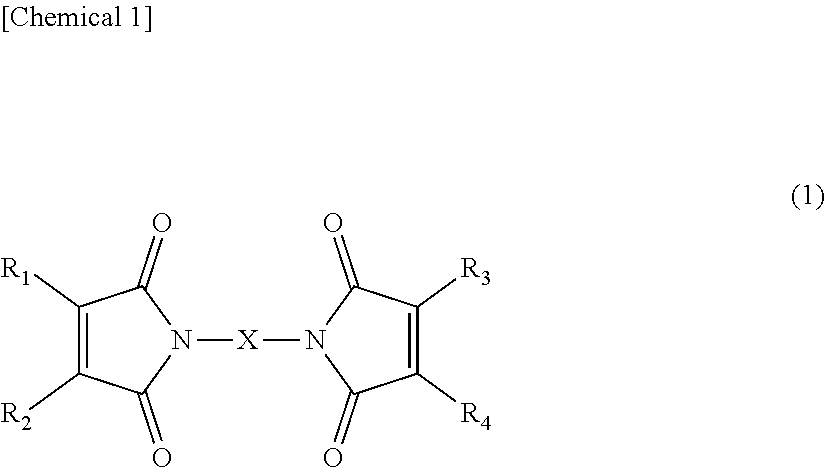

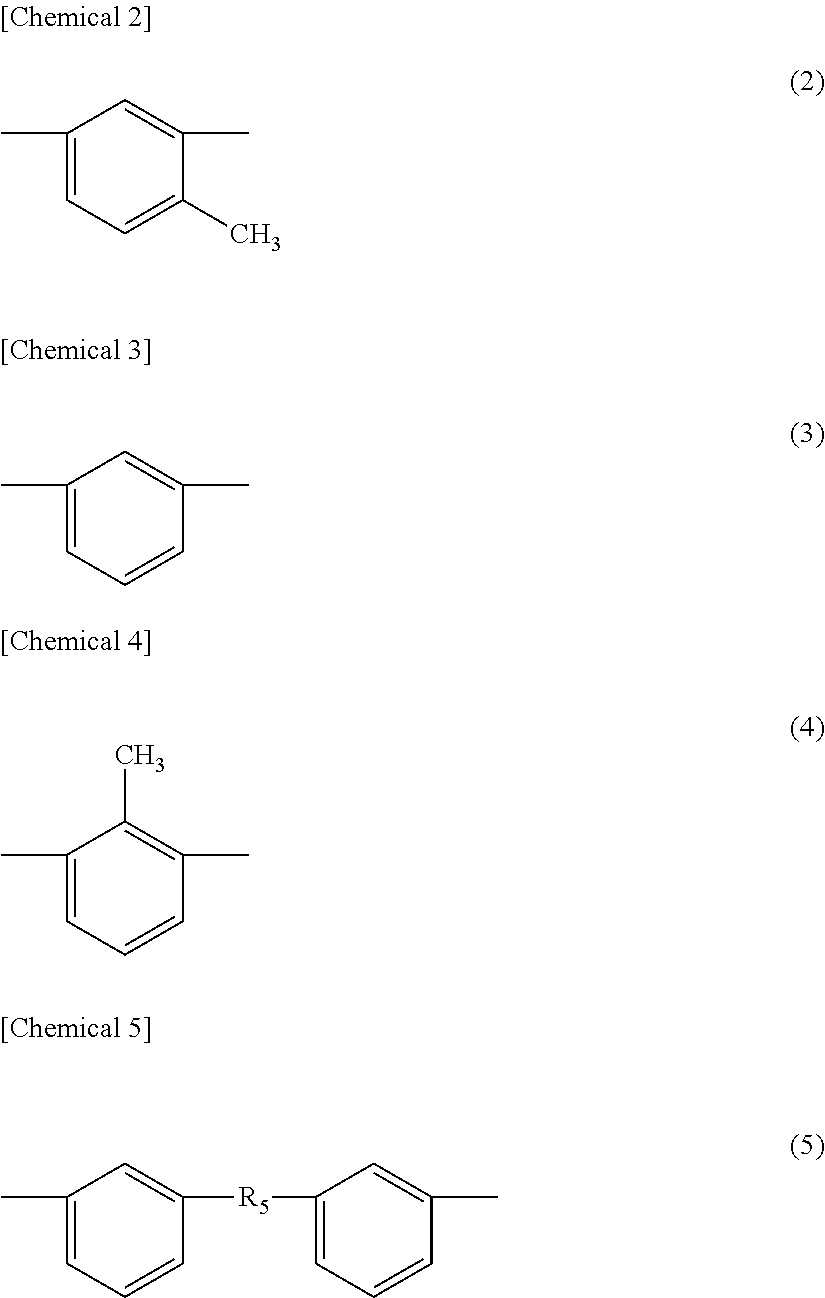

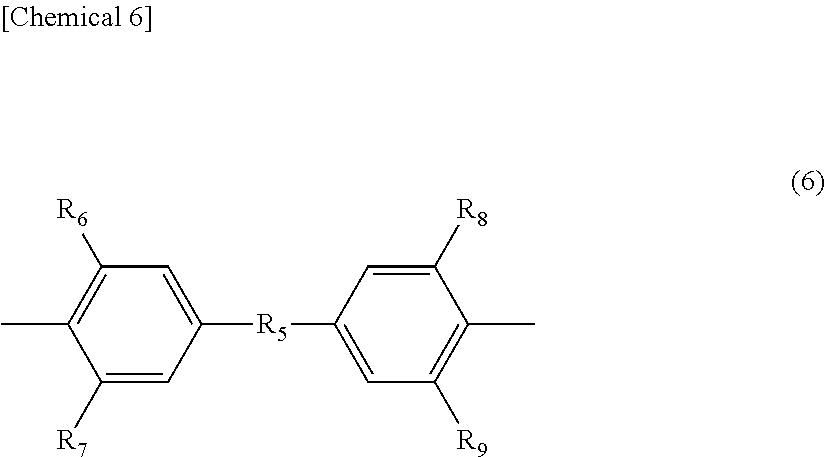

Method for producing composite material

A prepreg consisting cf a fiber reinforcement material and a resin composition containing a bismaleimide resin is molded through a first heating step in which the prepreg is held at a temperature (T1) equal to or higher than a temperature at which the resin composition exhibits a viscosity of 100 (Pa·s) and equal to or lower than a temperature at which the resin composition exhibits the minimum viscosity for 30 minutes or more, followed by being held at a temperature equal to or higher than a curing temperature of the bismaleimide resin.

Owner:TEIJIN LTD

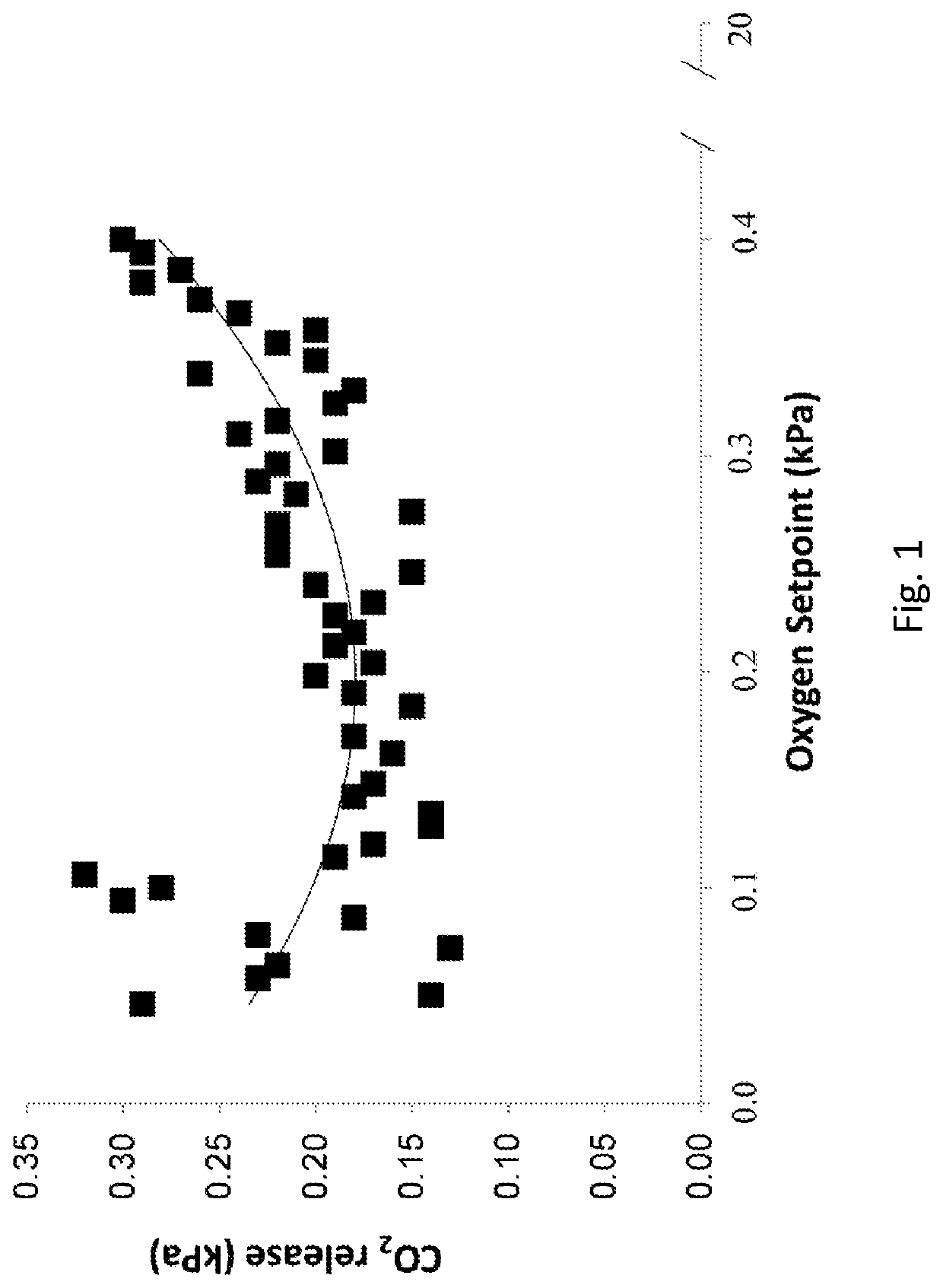

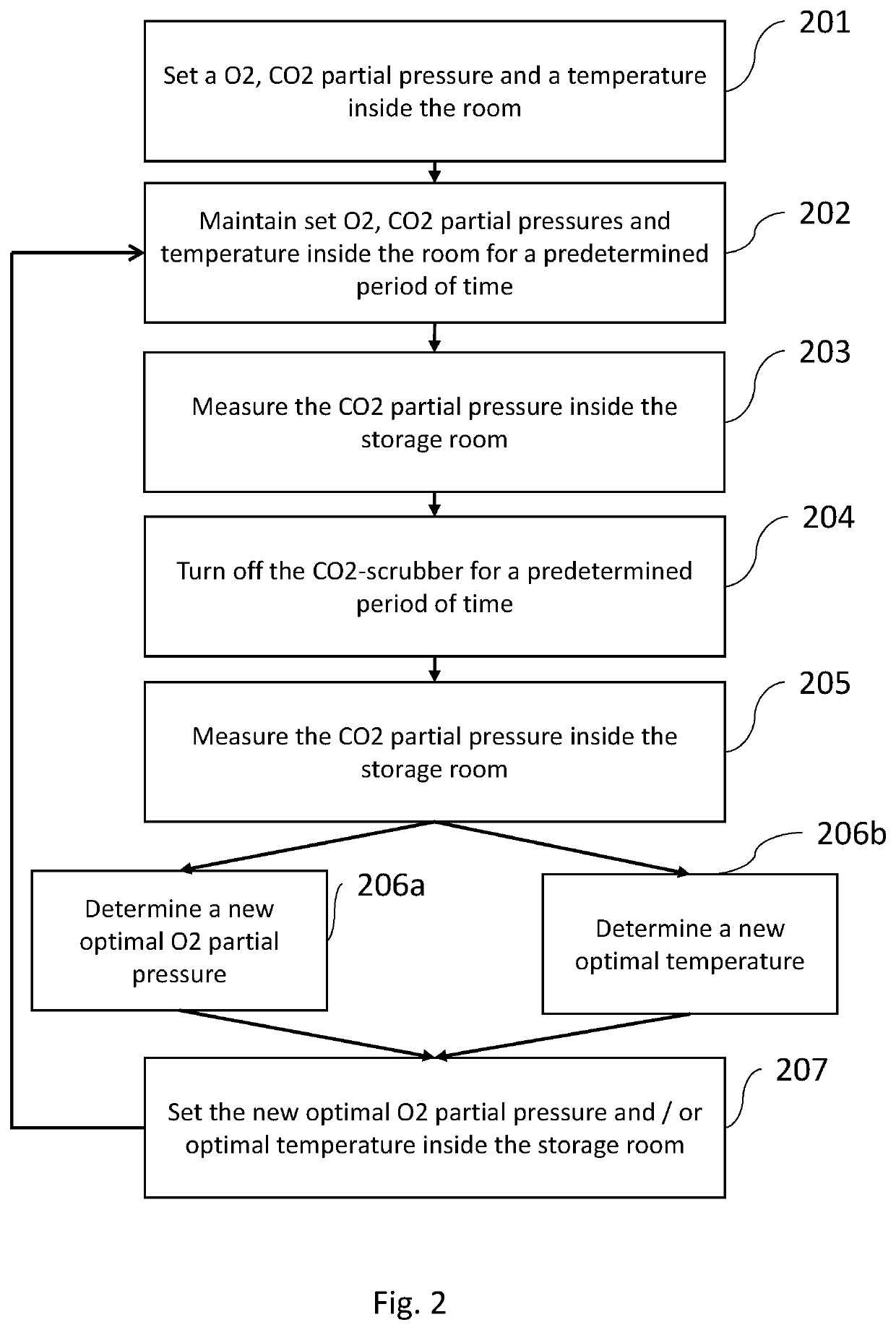

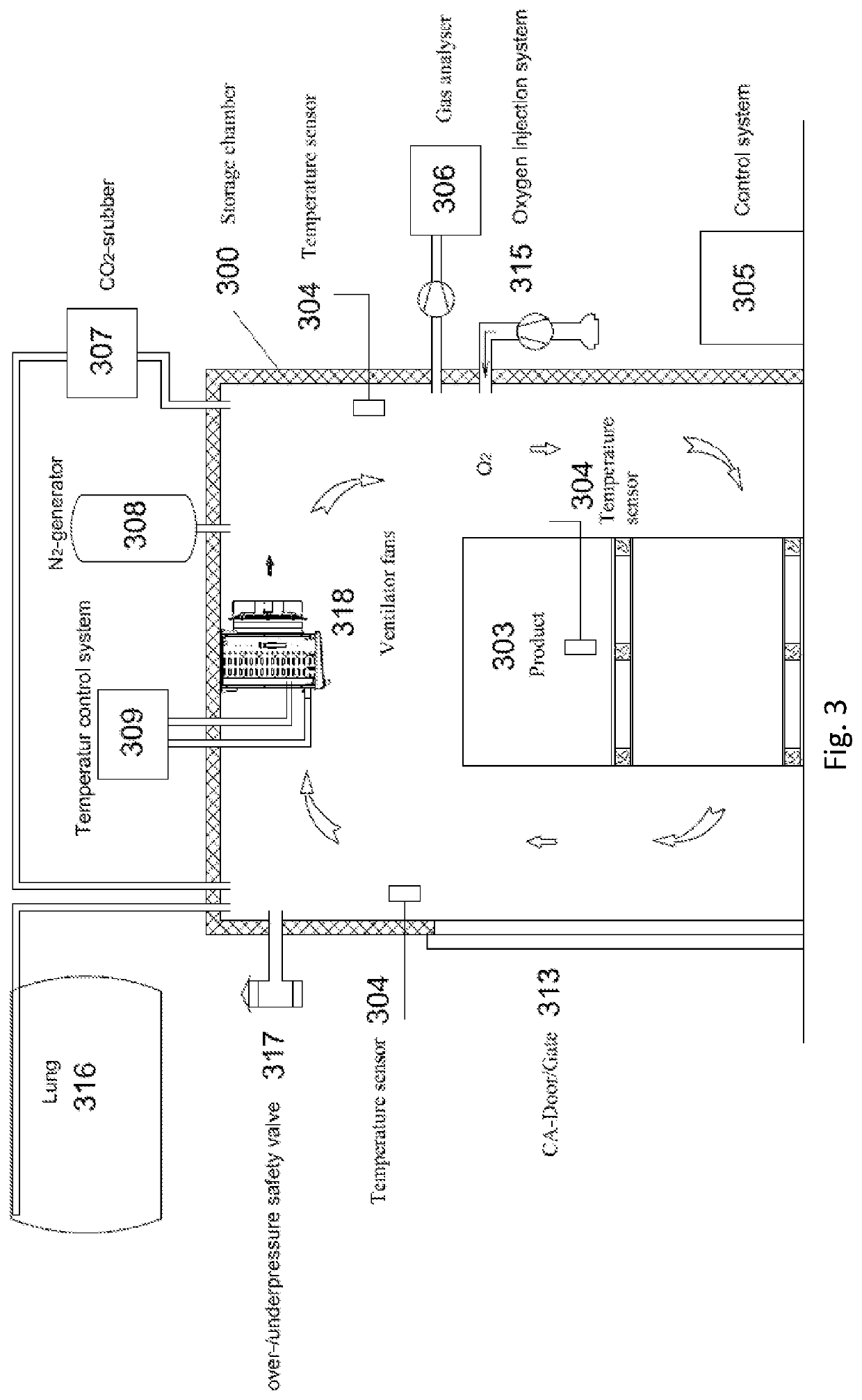

Dynamic controlled atmosphere method and apparatus

PendingUS20220282883A1Good oxygenReduce lossesProgramme controlMechanical apparatusThermodynamicsProcess engineering

The present invention relates to a method and an apparatus for controlling the atmosphere in a space. In particular, the present invention relates to a method and apparatus for controlling the atmosphere in a closable space at least partially filled with agricultural or horticultural products.In the method according to the invention an optimal oxygen partial pressure and / or an optimal temperature for storing produce is determined based on measurements of solely a carbon dioxide partial pressure.

Owner:UNIVERSIDADE FEDERAL DE SANTA MARIA

Joint component manufacturing method

ActiveUS20190381557A1OccurrenceReduce generationShrinkage connectionsRod connectionsJoint componentElectric resistance welding

Provided is a joint component manufacturing method for reducing occurrence of burrs upon bonding between a first member having a hole and a second member having a shaft portion and firmly bonding both members. In the method for manufacturing a joint component 100, a hole-side weak press-fit portion 112 is formed at a hole 111 of a flat plate ring-shaped first member 110. Moreover, each of a shaft-side weak press-fit portion 122 and a shaft-side strong press-fit portion 124 is formed at a shaft portion 121 of a cylindrical second member 120. The hole-side weak press-fit portion 112 and the shaft-side weak press-fit portion 122 are defined by a first weak press-fit interference Lw1 formed thinner than a first strong press-fit interference Ls1. The shaft-side strong press-fit portion 124 is defined by a first strong press-fit interference Ls1 as the minimum necessary press-fit interference for electric resistance welding upon electric resistance welding between the hole 111 and the shaft portion 121.

Owner:FCC KK

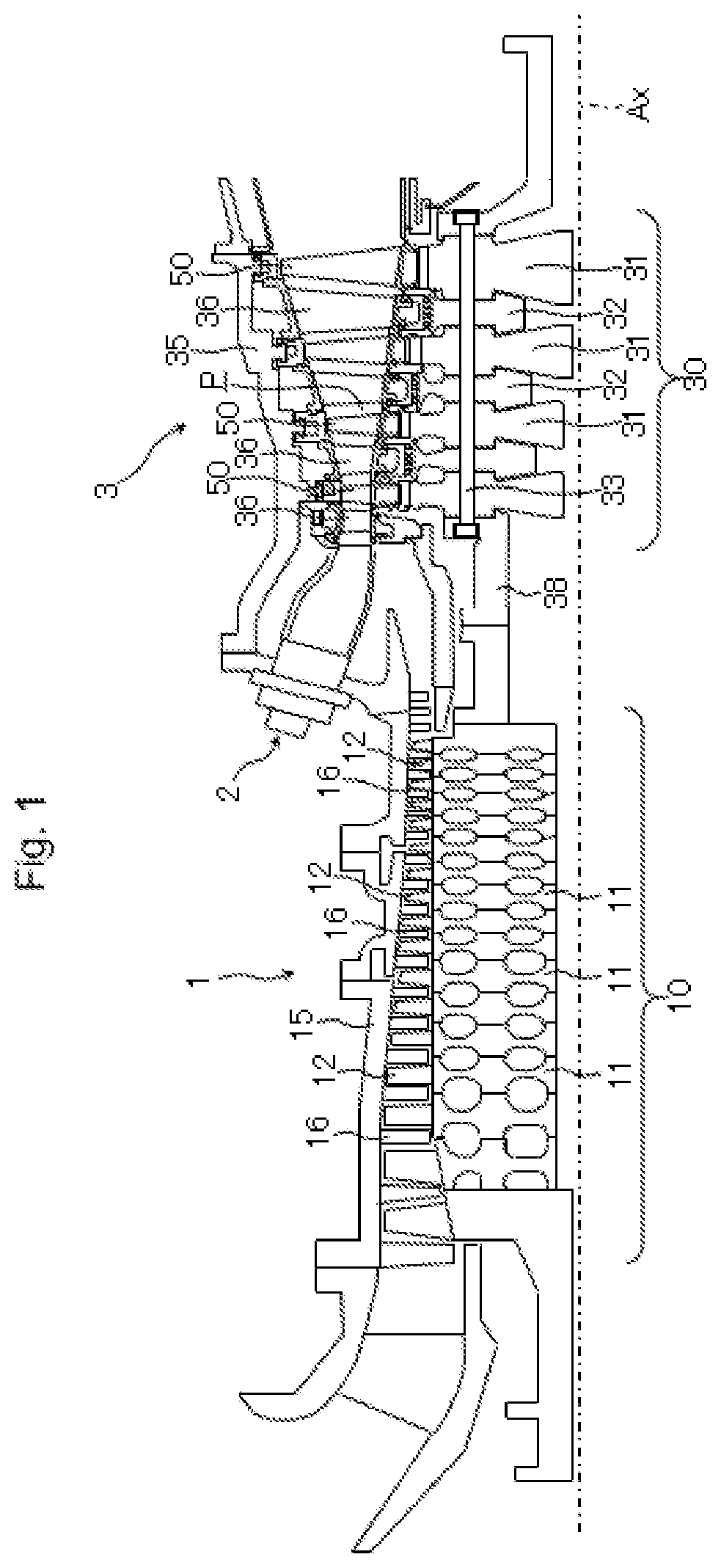

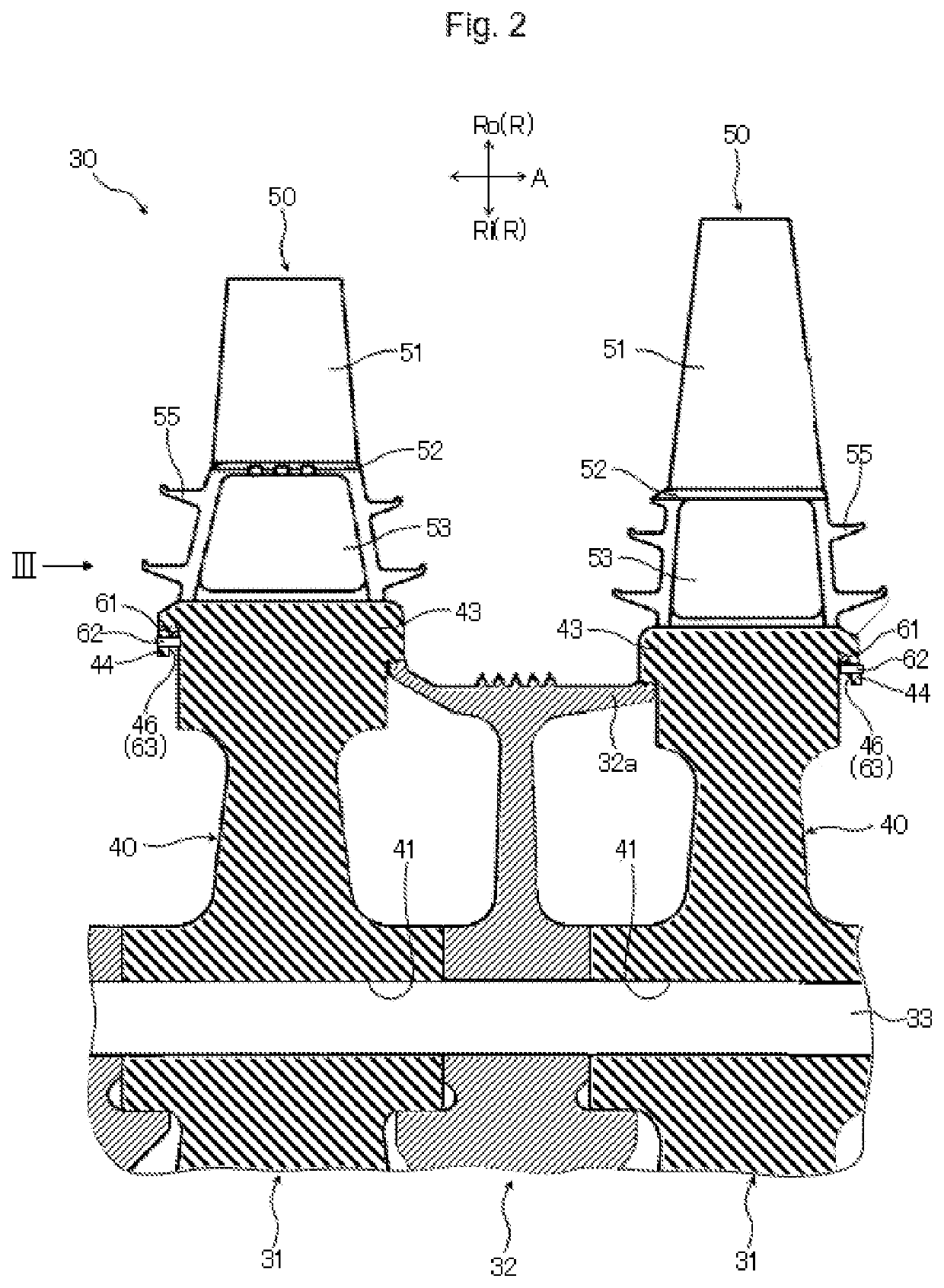

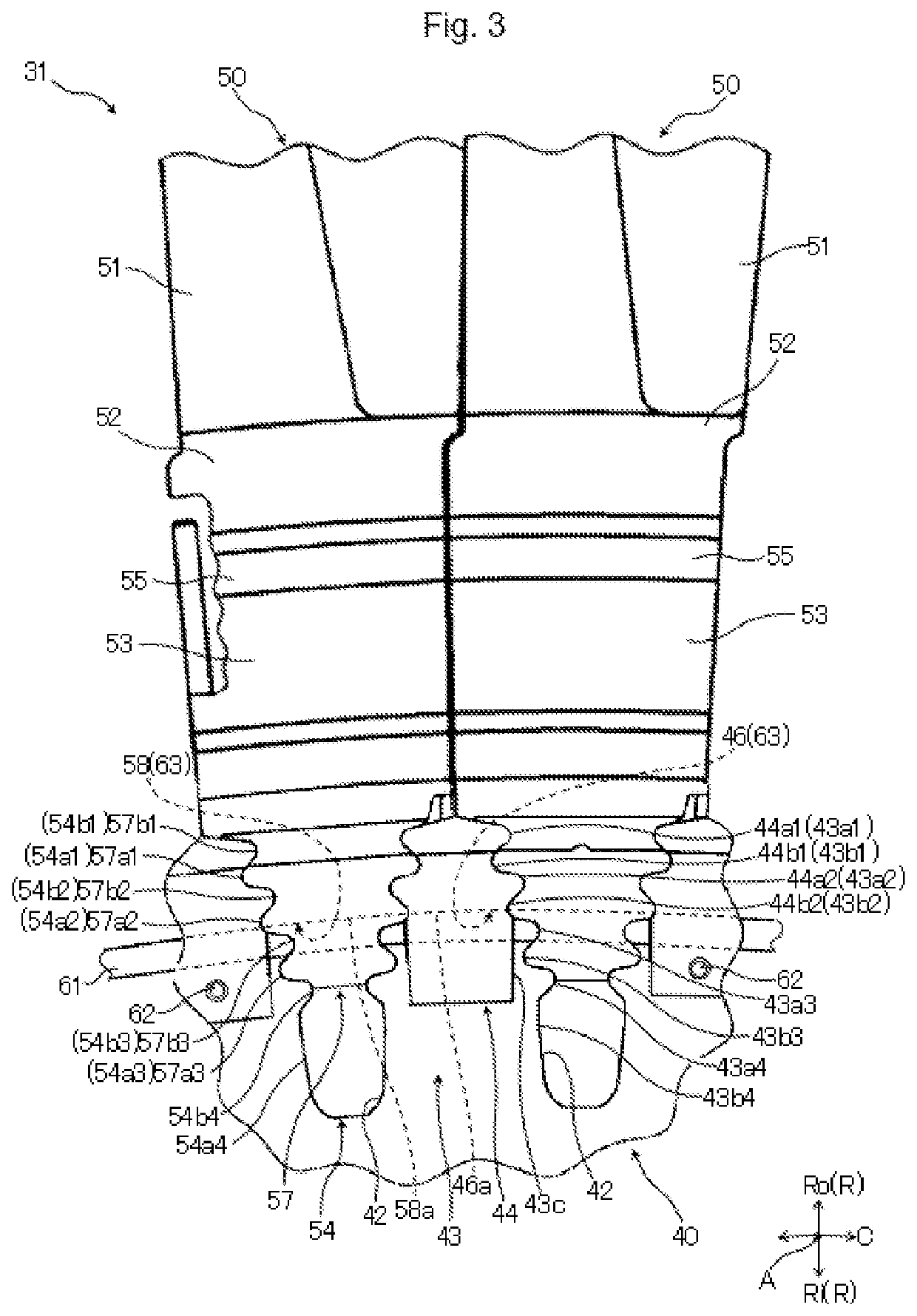

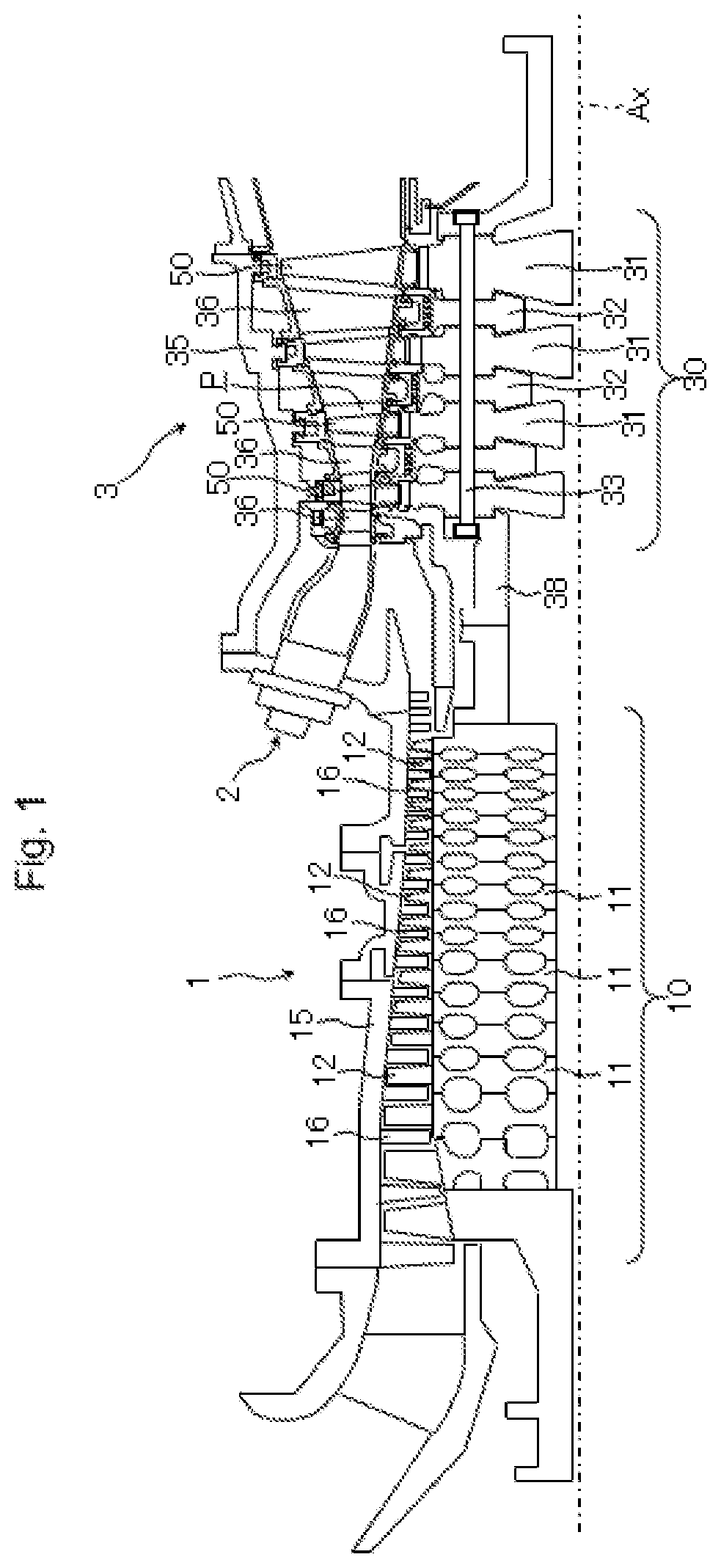

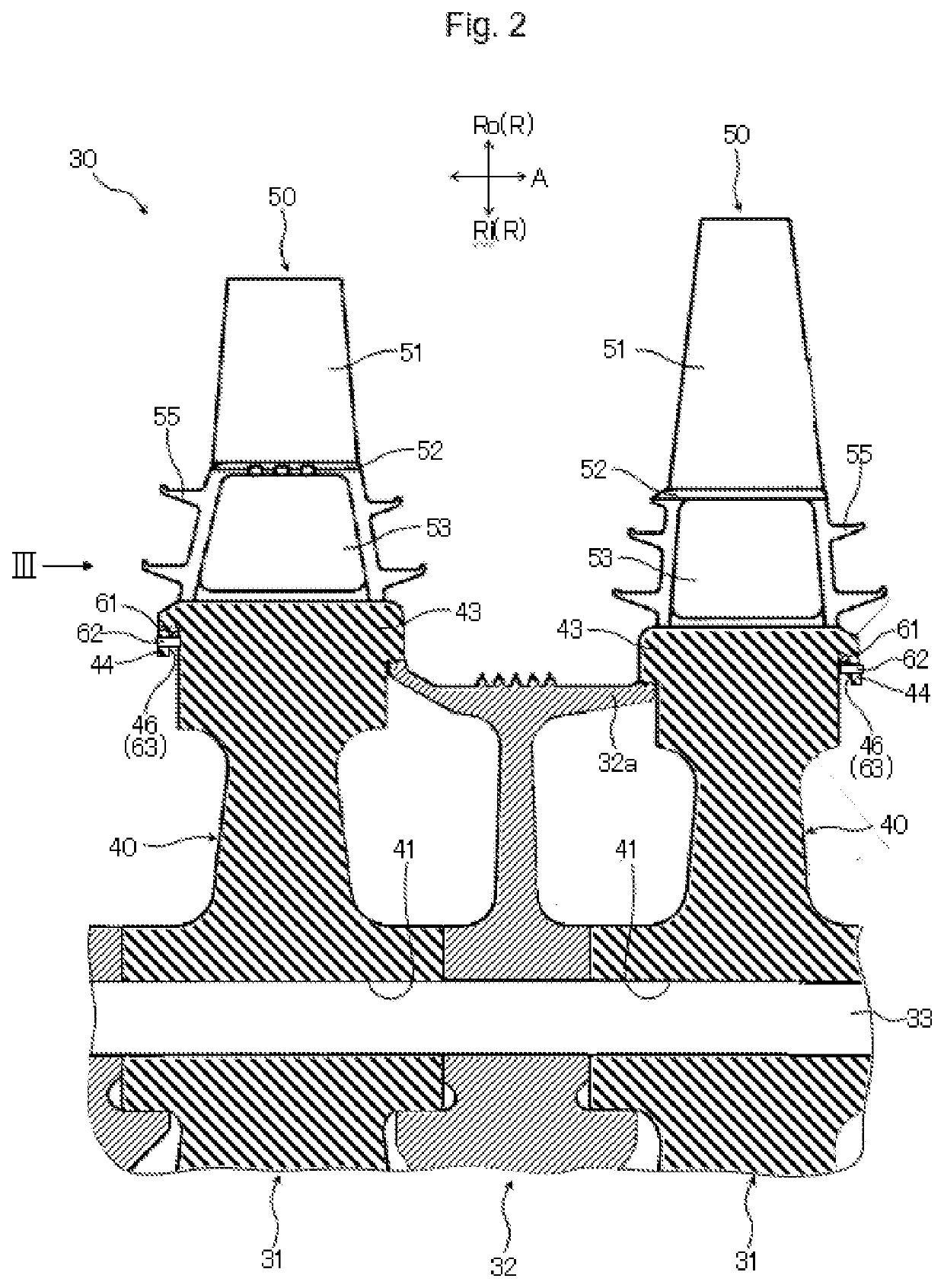

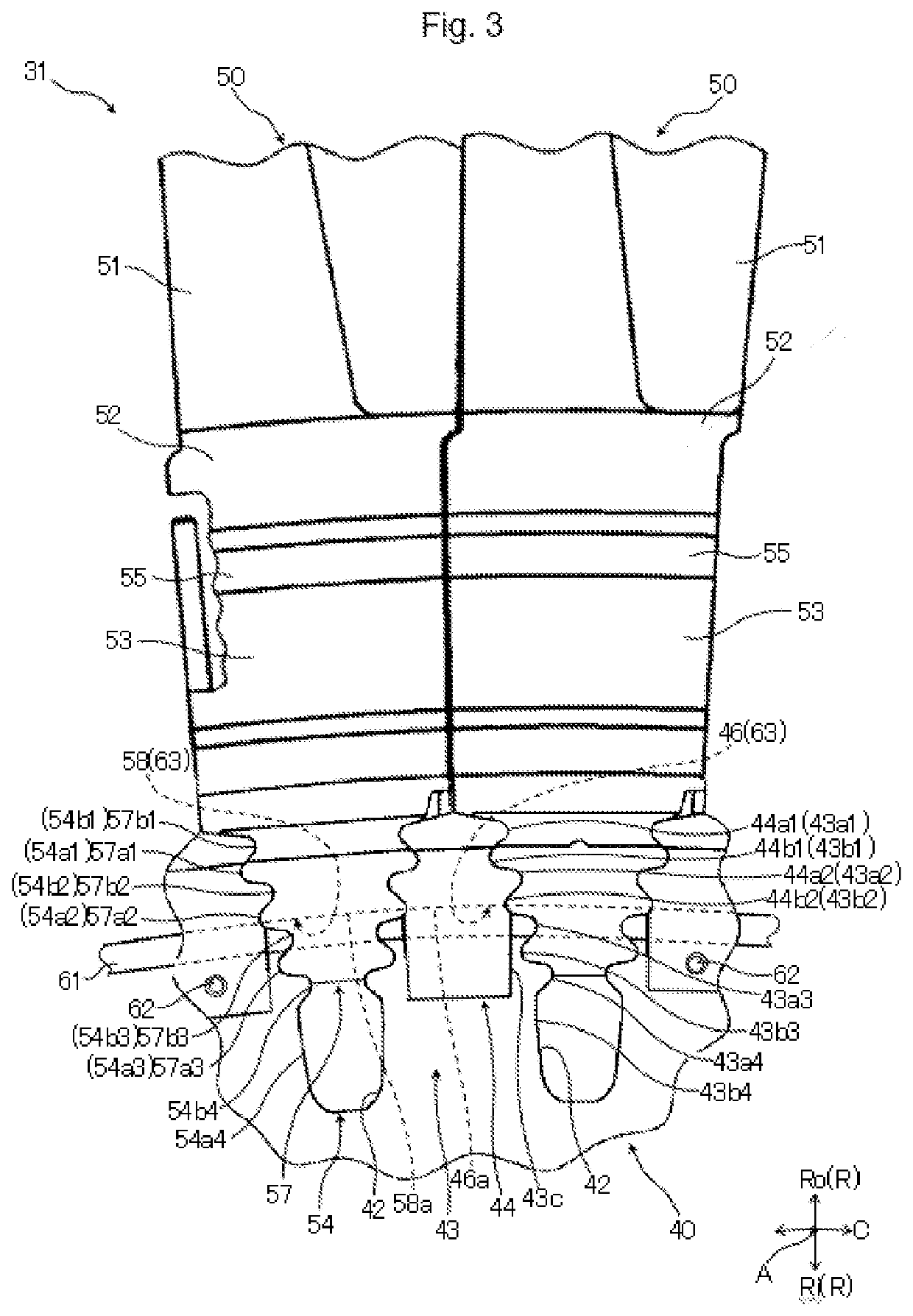

Turbine wheel

ActiveUS11377968B2Prevent local occurrence of excessive stressOccurrenceEngine manufactureBlade accessoriesImpellerTurbine wheel

Each wheel-side tab section of a turbine wheel is formed such that a bottom surface of a second groove are continuous with bottom surfaces of first grooves that are adjacent thereto. The outline shape of each wheel-side tab section when seen in an axial direction is a shape in which a portion of a particular shape is replaced with straight portions along predetermined straight lines. The particular shape includes a predetermined range of an outline shape of an attachment section as seen in the axial direction. The portion is at least on the radially inward side of the bottom surface of the second groove and is on an outer side, in the circumferential direction, of the predetermined straight lines. The predetermined straight lines pass through a central axis and points within a range along the particular shape from intersections with the bottom surface of the second groove to peaks of wheel-side hook portions adjacent, on the radially inward side, to the bottom surface of the second groove.

Owner:MITSUBISHI HEAVY IND LTD

Turbine Wheel

ActiveUS20210246801A1Prevent local occurrence of excessive stressOccurrenceEngine manufactureBlade accessoriesImpellerTurbine wheel

Each wheel-side tab section of a turbine wheel is formed such that a bottom surface of a second groove are continuous with bottom surfaces of first grooves that are adjacent thereto. The outline shape of each wheel-side tab section when seen in an axial direction is a shape in which a portion of a particular shape is replaced with straight portions along predetermined straight lines. The particular shape includes a predetermined range of an outline shape of an attachment section as seen in the axial direction. The portion is at least on the radially inward side of the bottom surface of the second groove and is on an outer side, in the circumferential direction, of the predetermined straight lines. The predetermined straight lines pass through a central axis and points within a range along the particular shape from intersections with the bottom surface of the second groove to peaks of wheel-side hook portions adjacent, on the radially inward side, to the bottom surface of the second groove.

Owner:MITSUBISHI HEAVY IND LTD

Electronic expansion valve

ActiveUS8857788B2Low costGuaranteed uptimeOperating means/releasing devices for valvesEfficient regulation technologiesSludgeEngineering

An electronic expansion valve (50) includes a small hole (54a) that expands a refrigerant, a valve body (55c) that opens and closes the small hole, an elastic member (70) that urges the valve body to close the small hole, and a solenoid (61) that suctions the valve body to open the small hole, and expands the refrigerant by opening and closing the valve body. The elastic member is a disc spring in which a plurality of slits (73) formed in a spiral form is provided at mutually equal pitches on the perimeter. Therefore, there is no need for a guide, the occurrence of sludge due to sliding is suppressed, and the electronic expansion valve operates stably over a long period.

Owner:FUJI ELECTRIC CO LTD

Joint component manufacturing method

ActiveUS10632516B2OccurrenceReduce generationShrinkage connectionsRod connectionsJoint componentElectrical resistance and conductance

Provided is a joint component manufacturing method for reducing occurrence of burrs upon bonding between a first member having a hole and a second member having a shaft portion and firmly bonding both members. In the method for manufacturing a joint component 100, a hole-side weak press-fit portion 112 is formed at a hole 111 of a flat plate ring-shaped first member 110. Moreover, each of a shaft-side weak press-fit portion 122 and a shaft-side strong press-fit portion 124 is formed at a shaft portion 121 of a cylindrical second member 120. The hole-side weak press-fit portion 112 and the shaft-side weak press-fit portion 122 are defined by a first weak press-fit interference Lw1 formed thinner than a first strong press-fit interference Ls1. The shaft-side strong press-fit portion 124 is defined by a first strong press-fit interference Ls1 as the minimum necessary press-fit interference for electric resistance welding upon electric resistance welding between the hole 111 and the shaft portion 121.

Owner:FCC KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com