Patents

Literature

15045 results about "Small hole" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

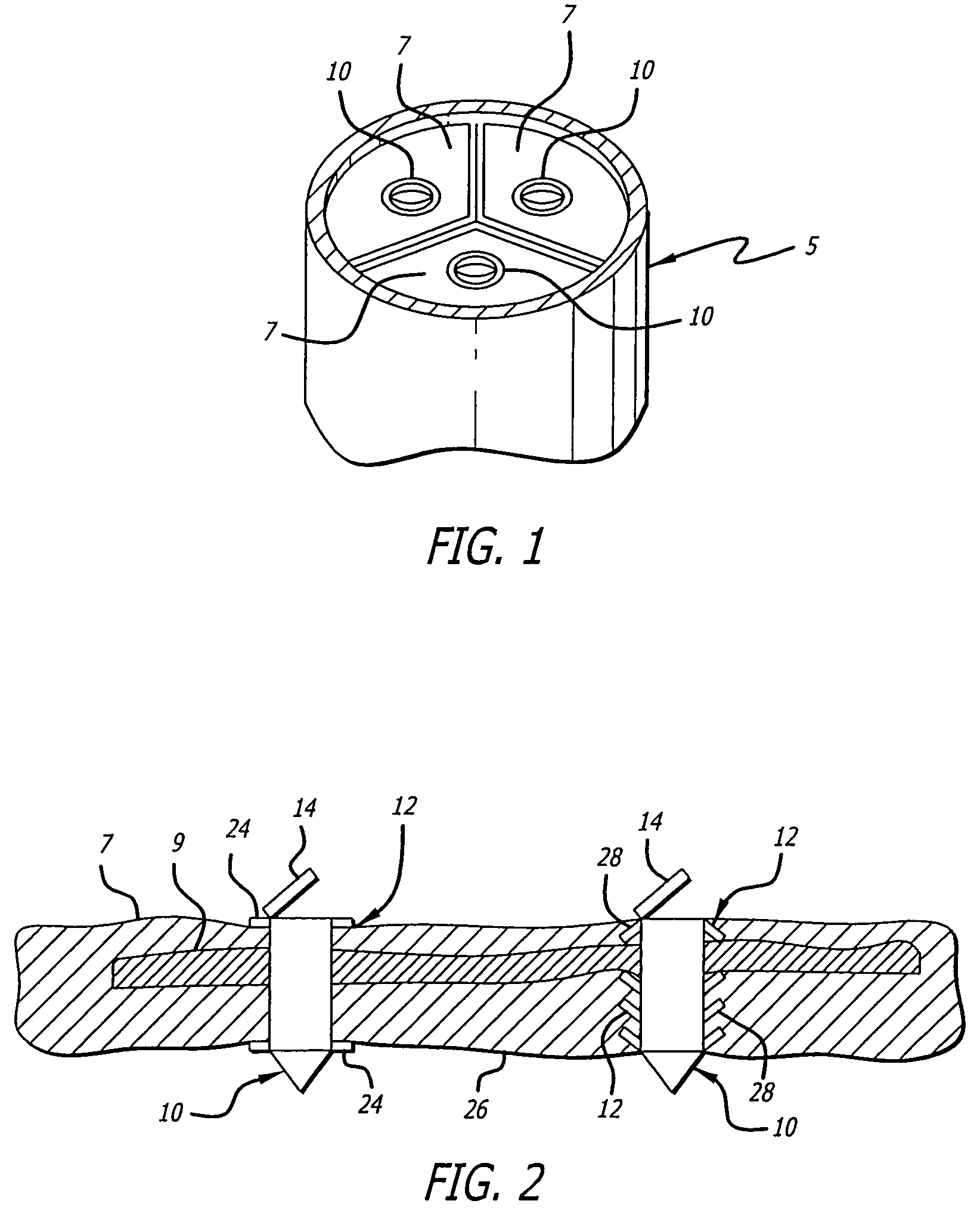

Material delivery system

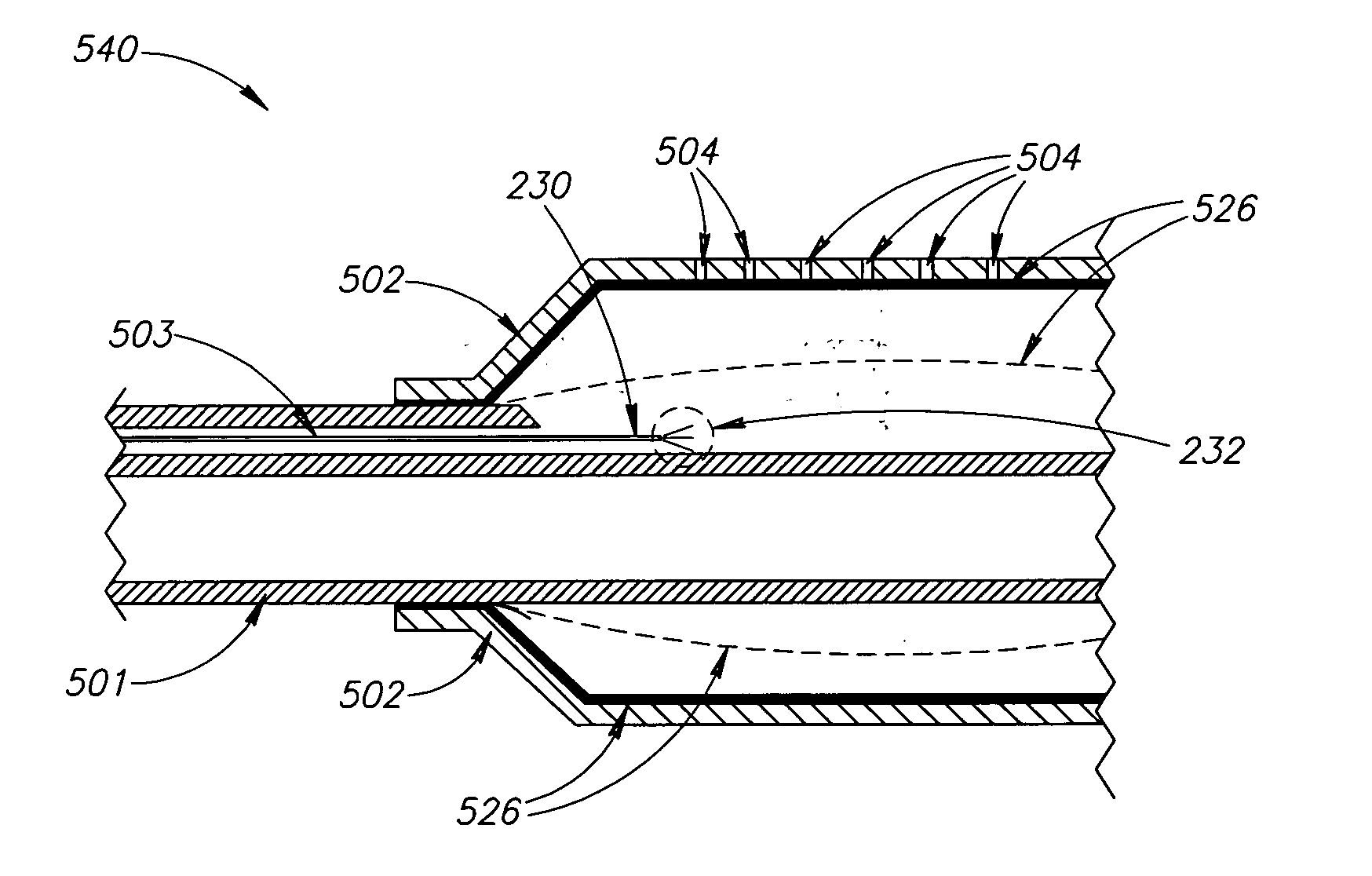

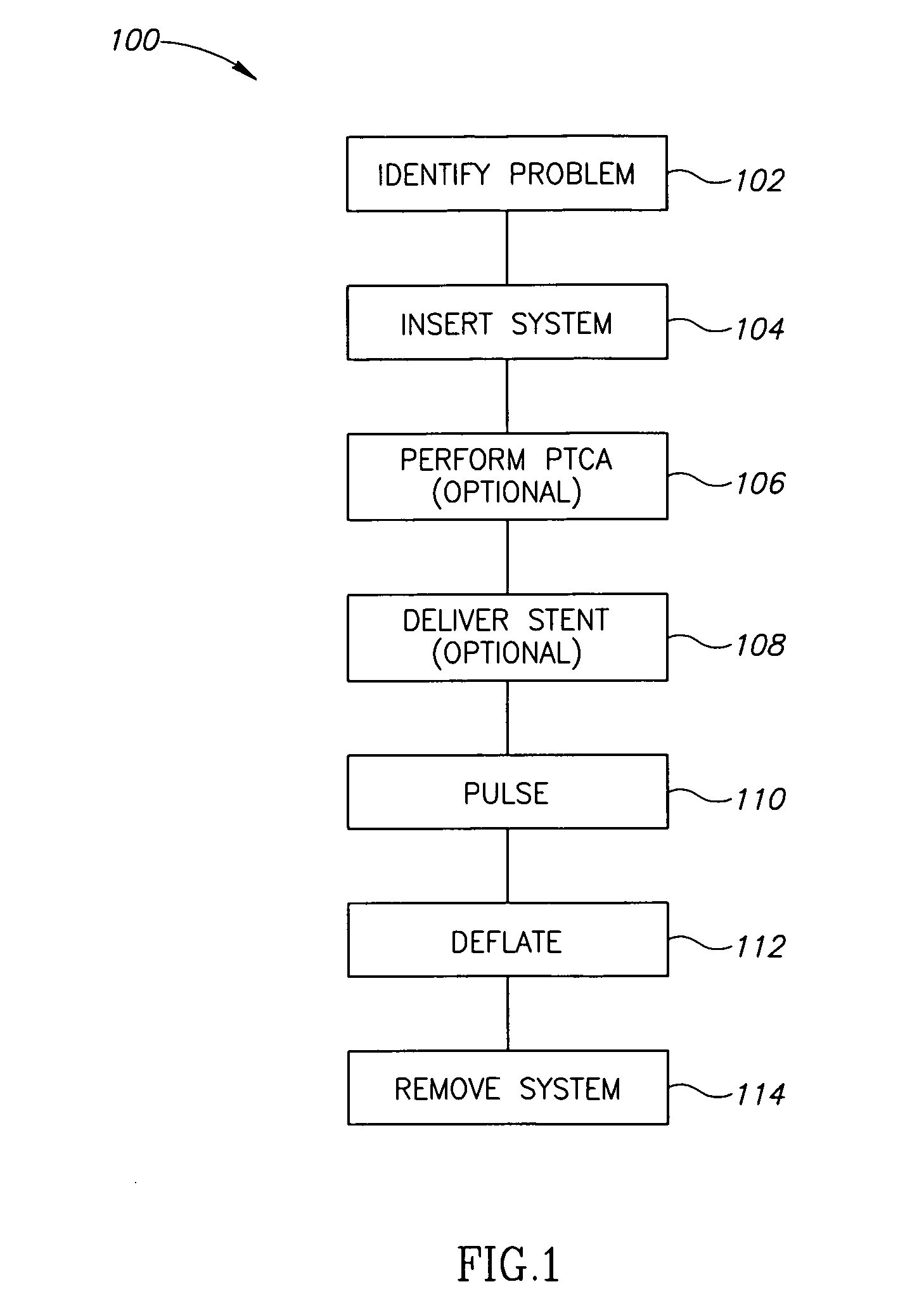

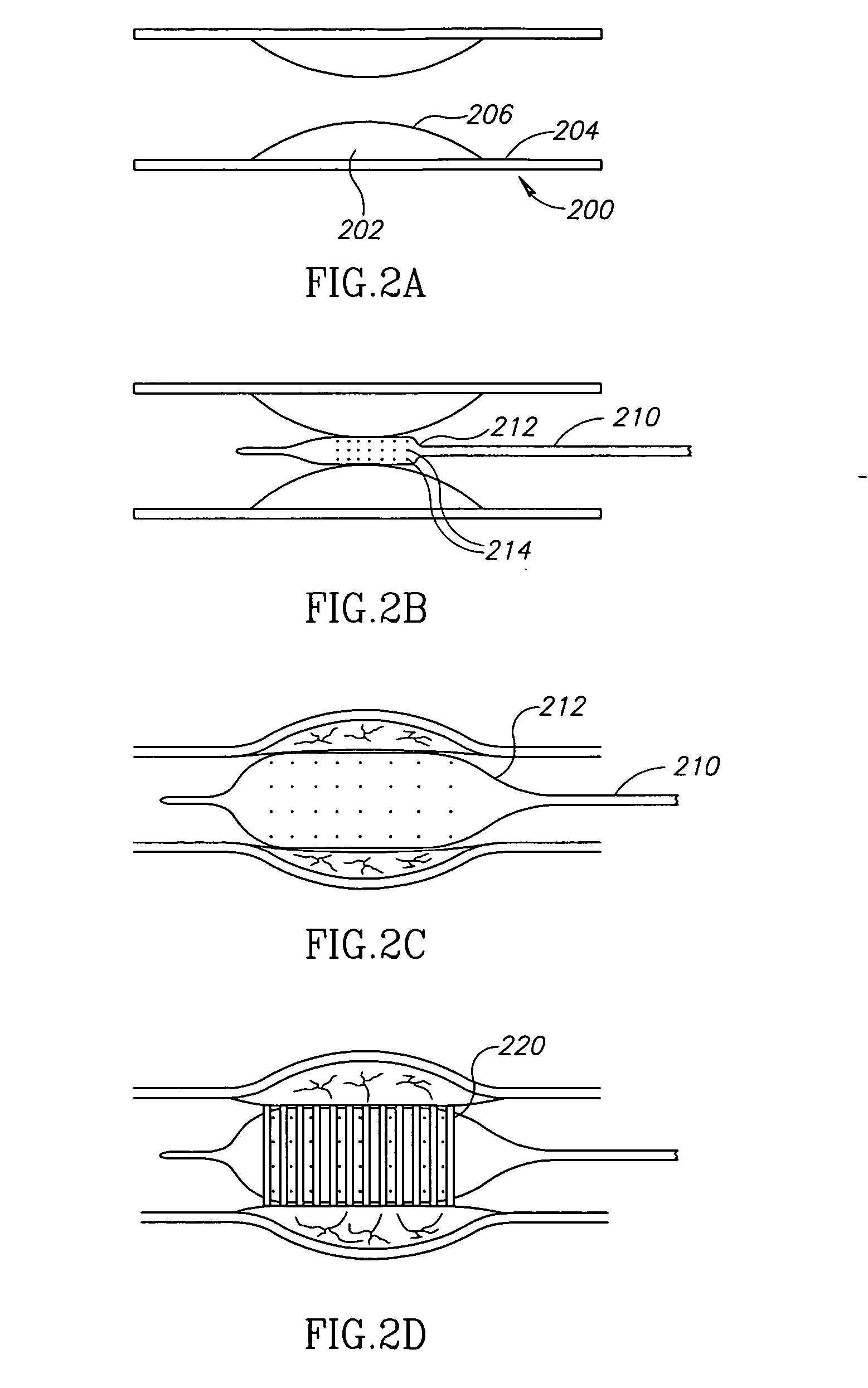

InactiveUS20060190022A1Relief from rhinitisAvoid transmissionStentsBalloon catheterSurgeryTarget tissue

A method for injecting a therapeutic agent into a target tissue, the method comprising: (a) providing an expandable member; (b) positioning said expandable member in proximity to the target tissue; (c) Introducing the therapeutic agent into the expandable member until a desired pressure is achieved; and (d) creating a plurality of small apertures in the expandable member.

Owner:BY PASS

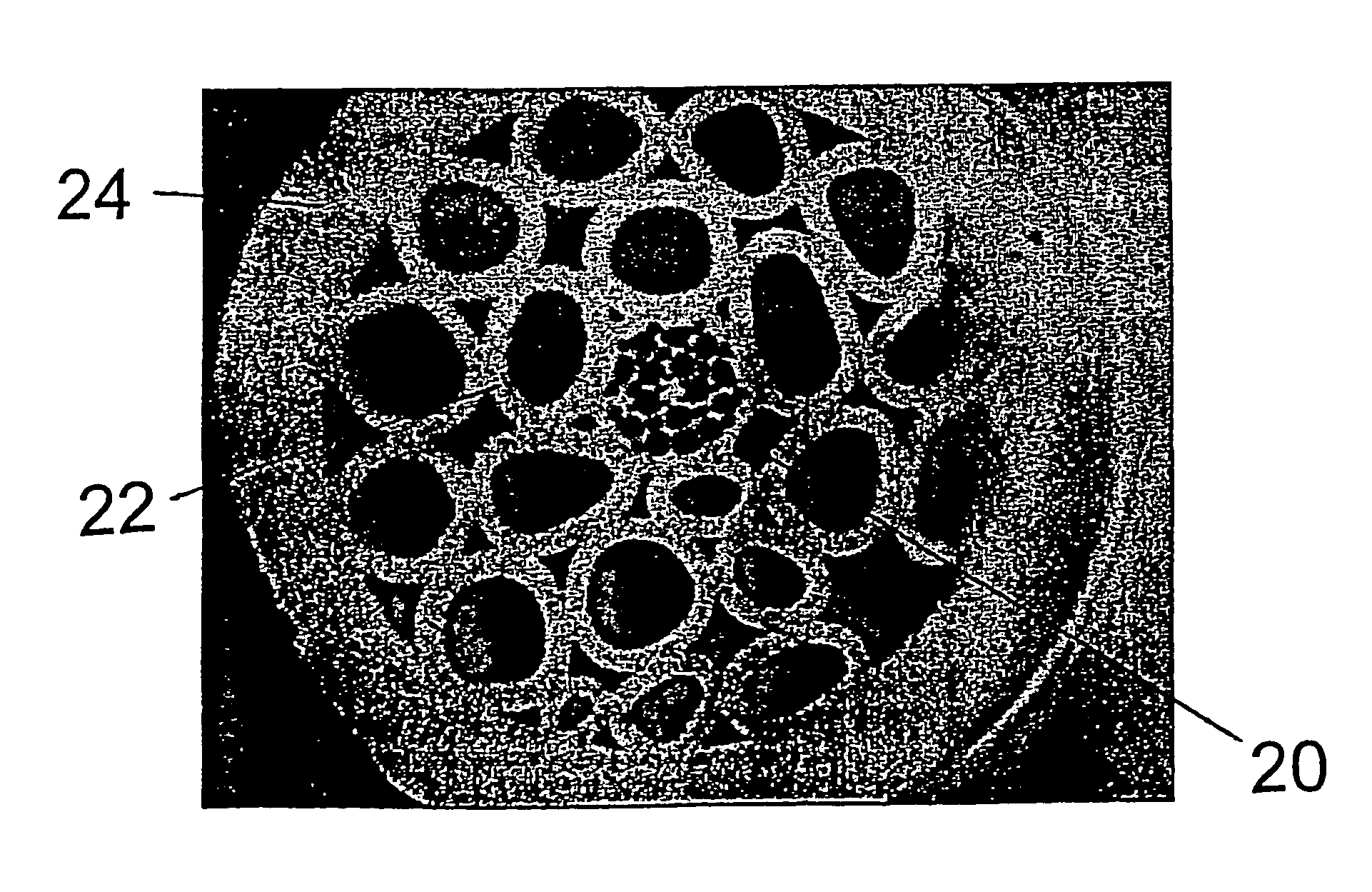

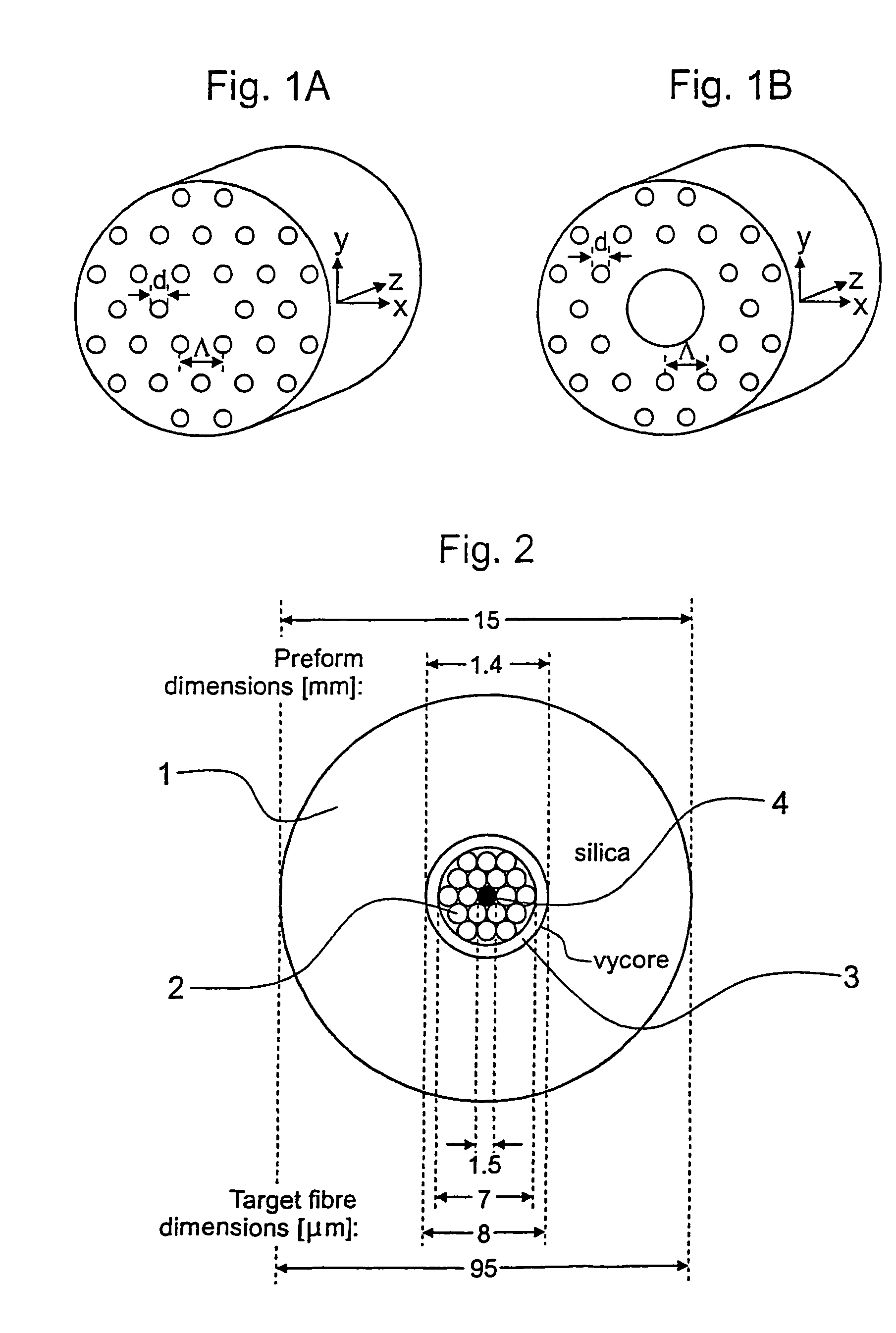

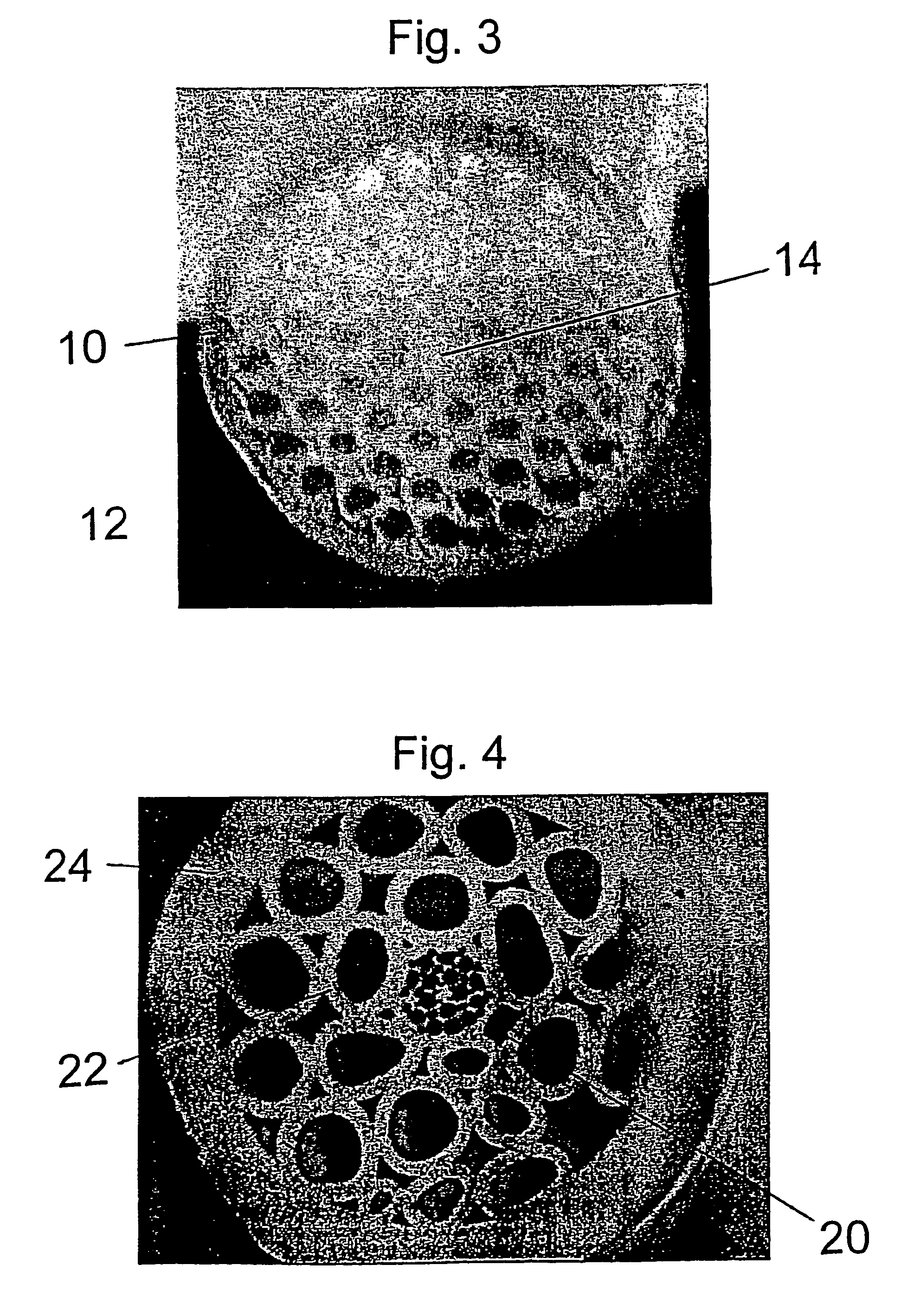

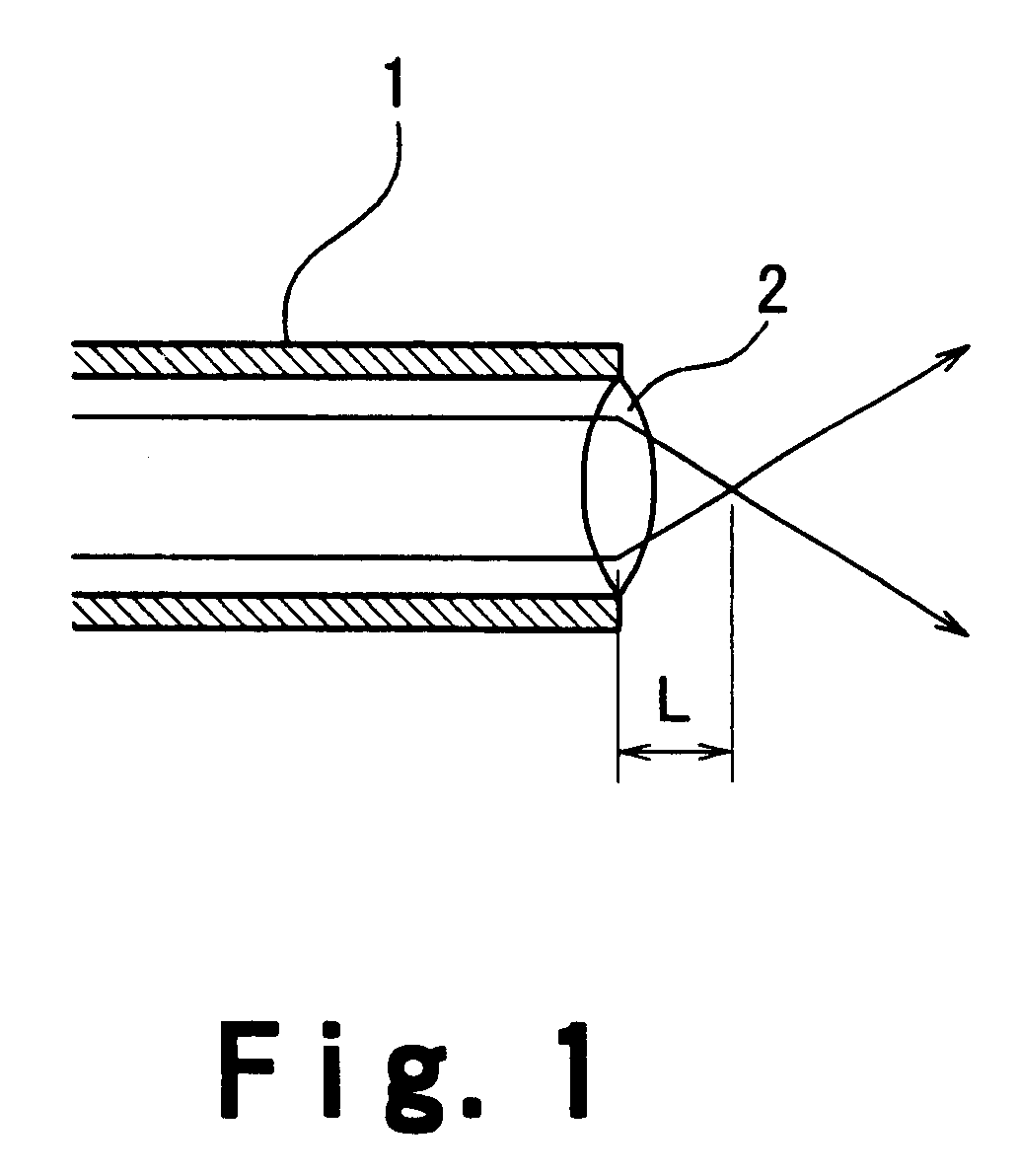

Holey optical fibres

An optical fiber structure having a holey fiber arranged in a holey outer support structure made up of holey tubes encased in a thin walled outer jacket. The holey fiber may have a solid core surrounded by a holey cladding having a plurality of rings of holes. With the invention it is possible to produce robust, coated and jacketed fibers with microstructured core features of micrometer size relatively easily using existing fiber fabrication technology. This improvement is a result of the outer holey structure which reduces the thermal mass of the supporting structure and makes it possible to reliably and controllably retain small hole features during the fiber fabrication process.

Owner:UNIV OF SOUTHAMPTON

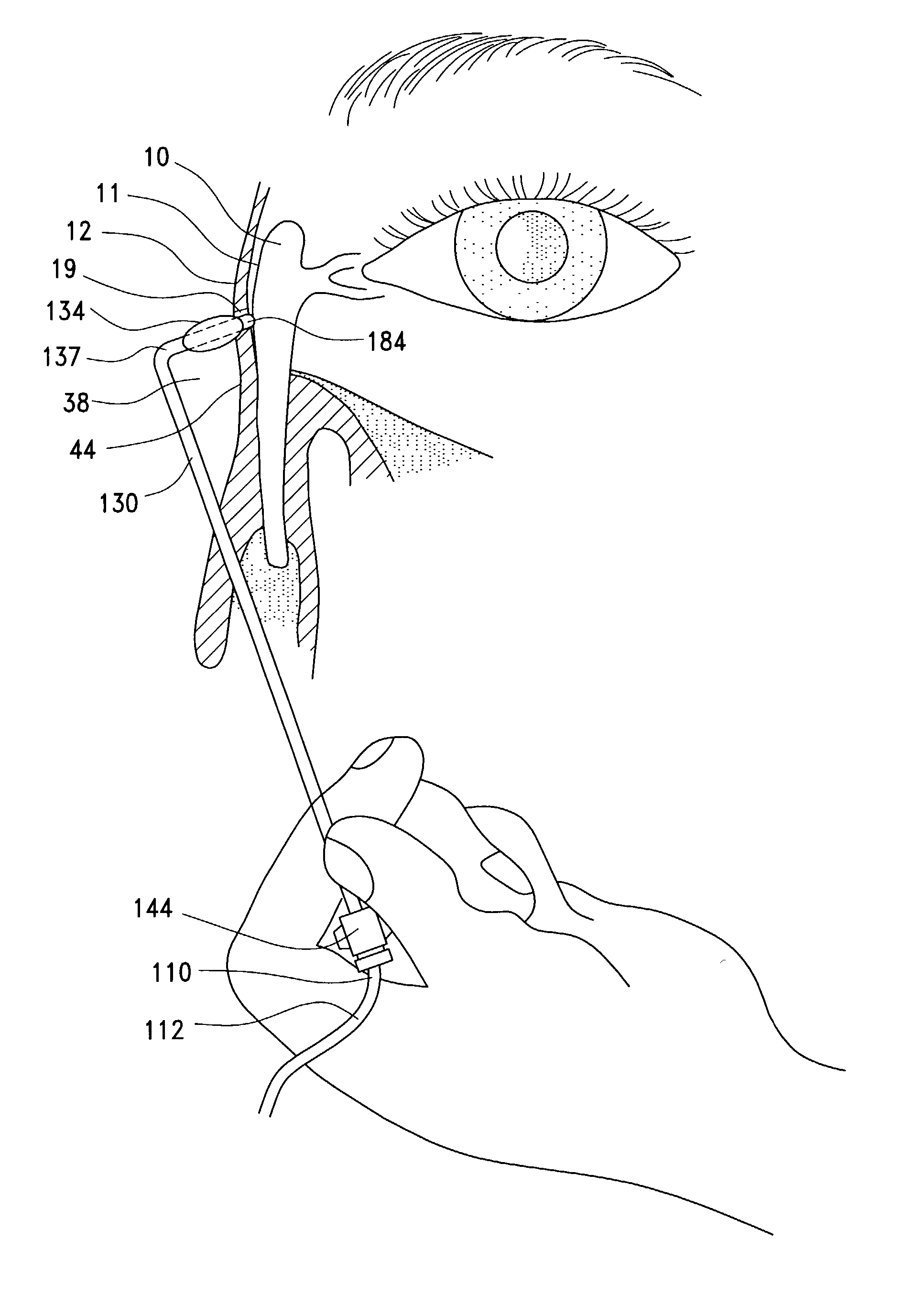

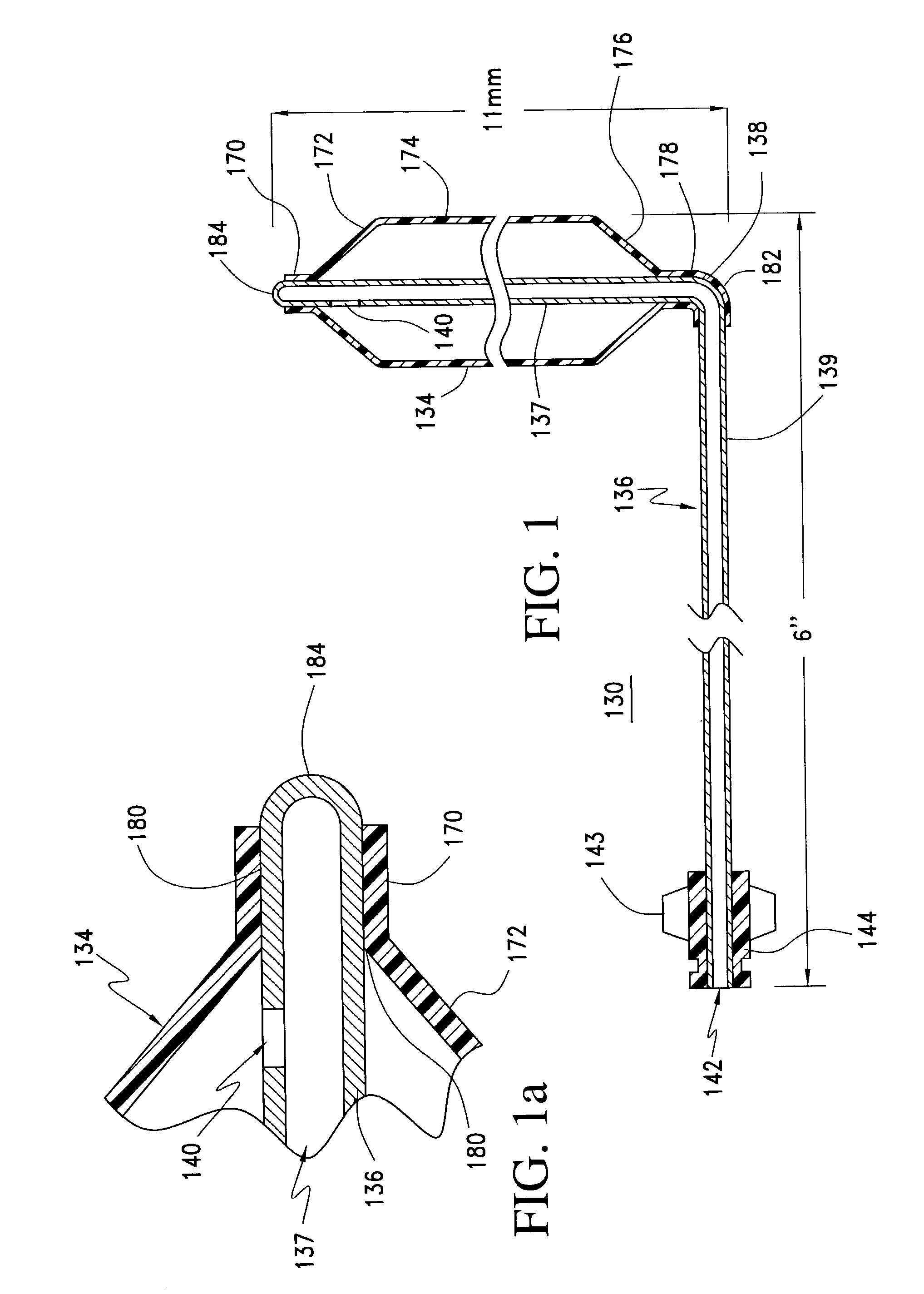

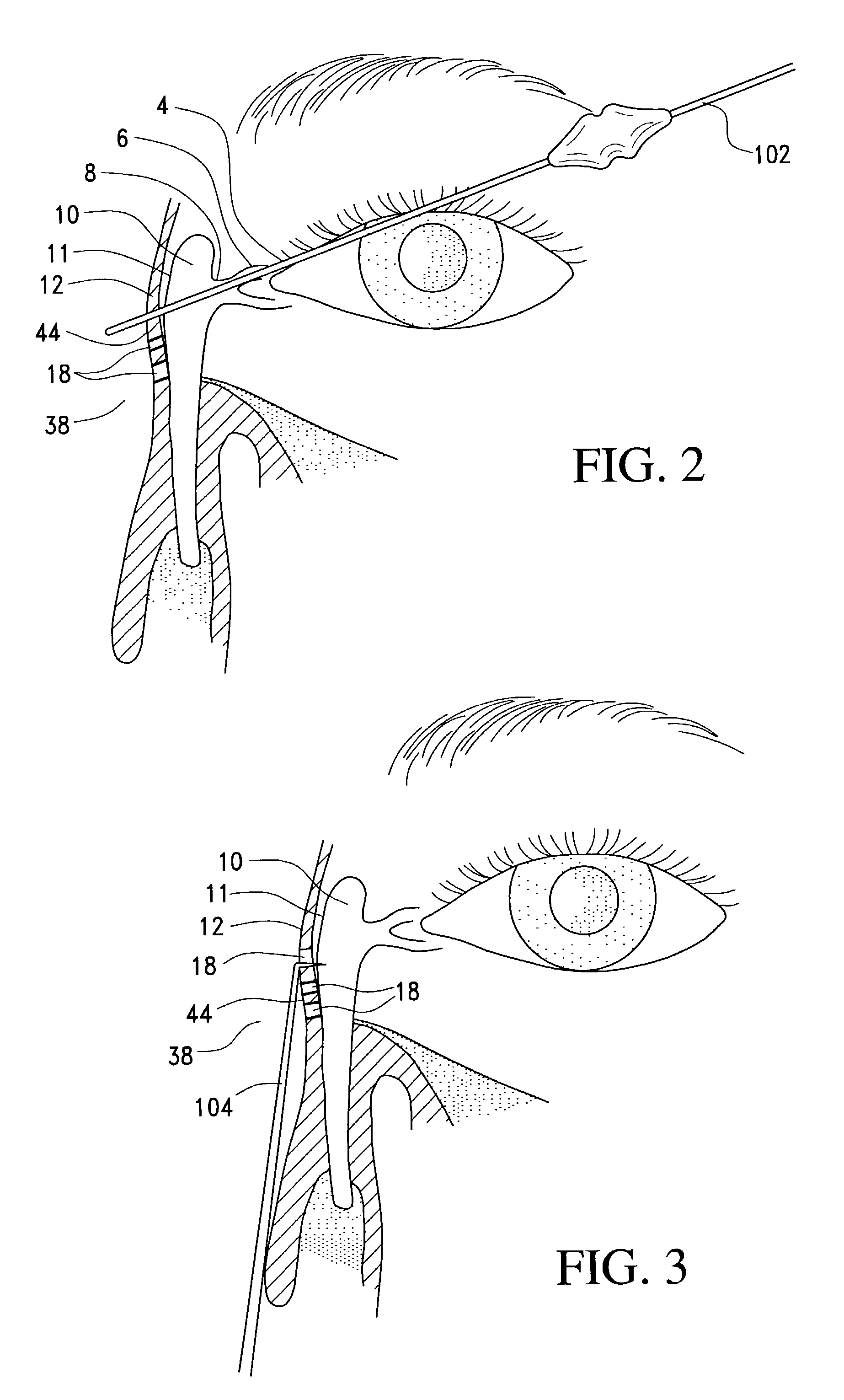

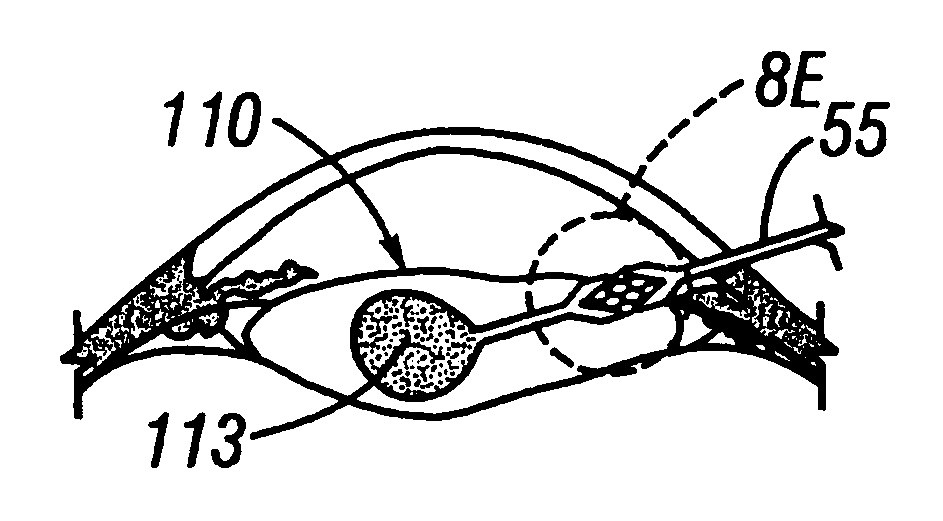

Transnasal method and catheter for lacrimal system

A balloon catheter for treatment of a patient's lacrimal system is applied transnasally without the use of a guide wire or a curve retention member. The catheter uses a stainless steel hypotube of sufficient stiffness and column strength to be pushed from the patent's nasal cavity through an opening-formed through the lateral nasal wall and lacrimal fossa, into the lacrimal sac. The catheter has an inflatable member mounted about a rigid bent distal segment. The opening is first formed by pushing small holes through the medial sac, lacrimal fossa, and lateral nasal wall with an instrument and coalescing the holes. The catheter is then introduced into the nasal cavity and pushed laterally through the opening by manipulating its proximal end. Pressurized fluid is then applied to the catheter to inflate the inflatable member and dilate the opening.

Owner:BECKER BRUCE

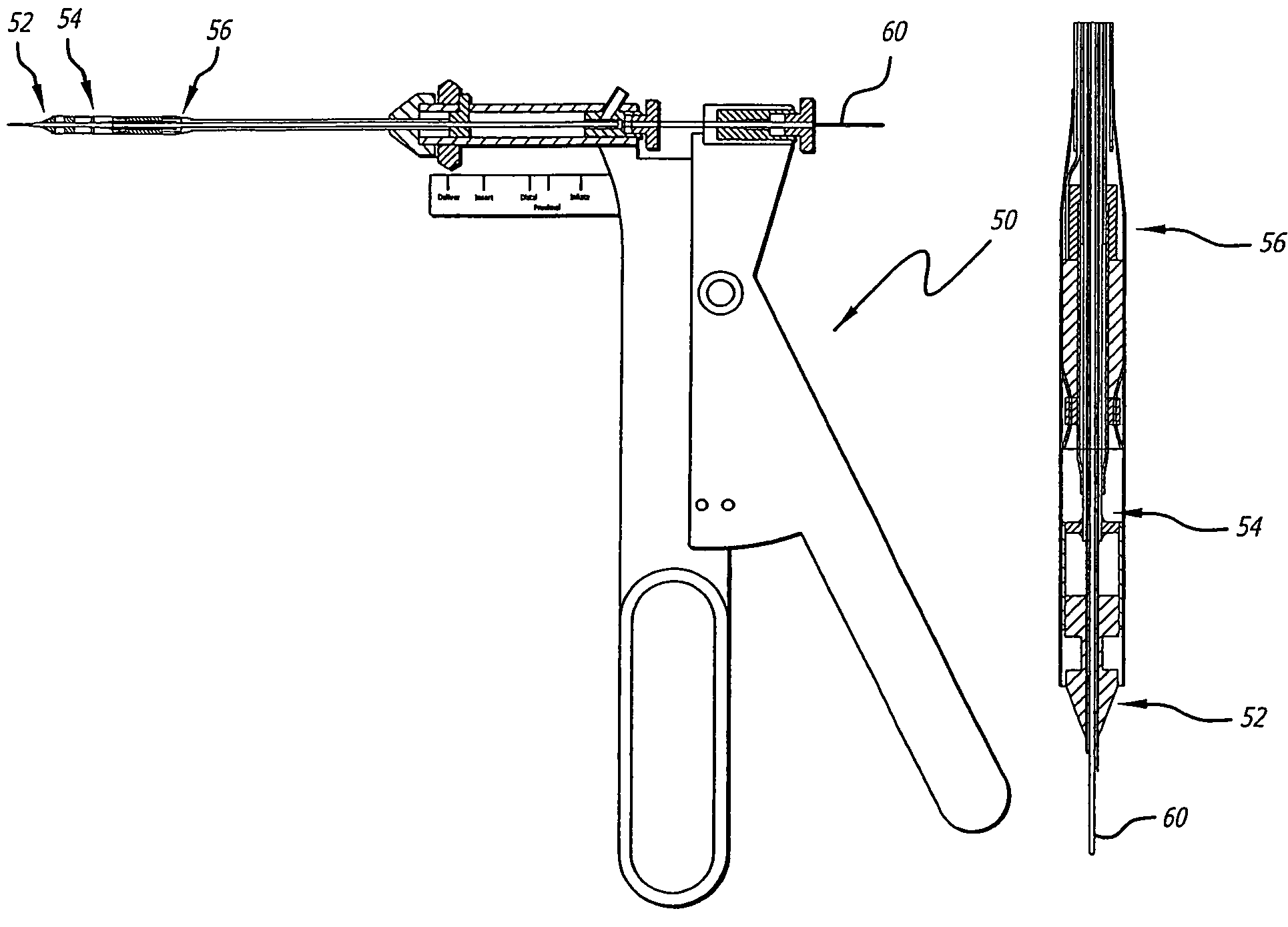

Delivery device for leaflet valve

InactiveUS7335218B2Reduce riskHeart valvesSurgical needlesAttachment siteAortocoronary bypass surgery

Owner:HLT INC

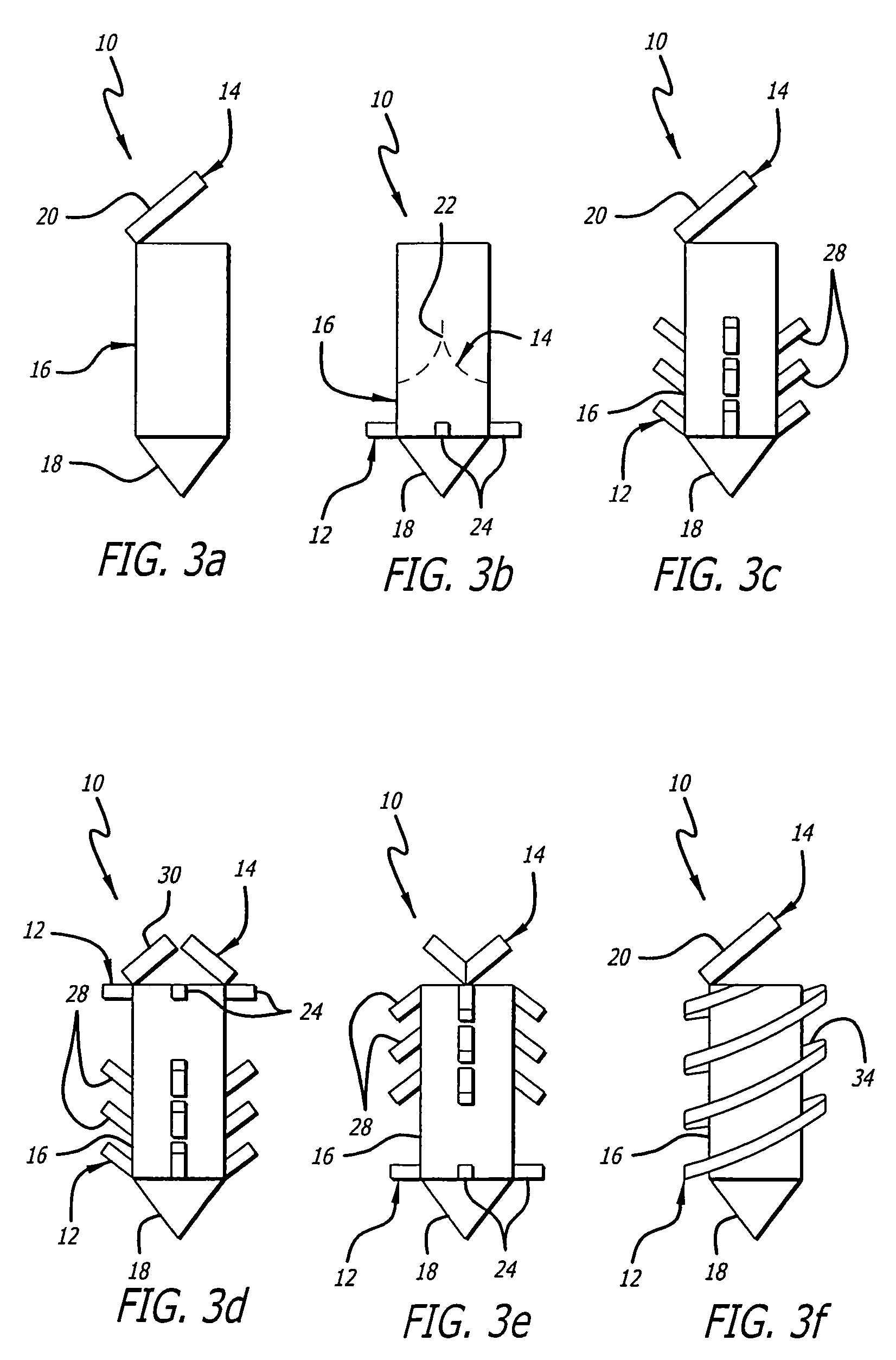

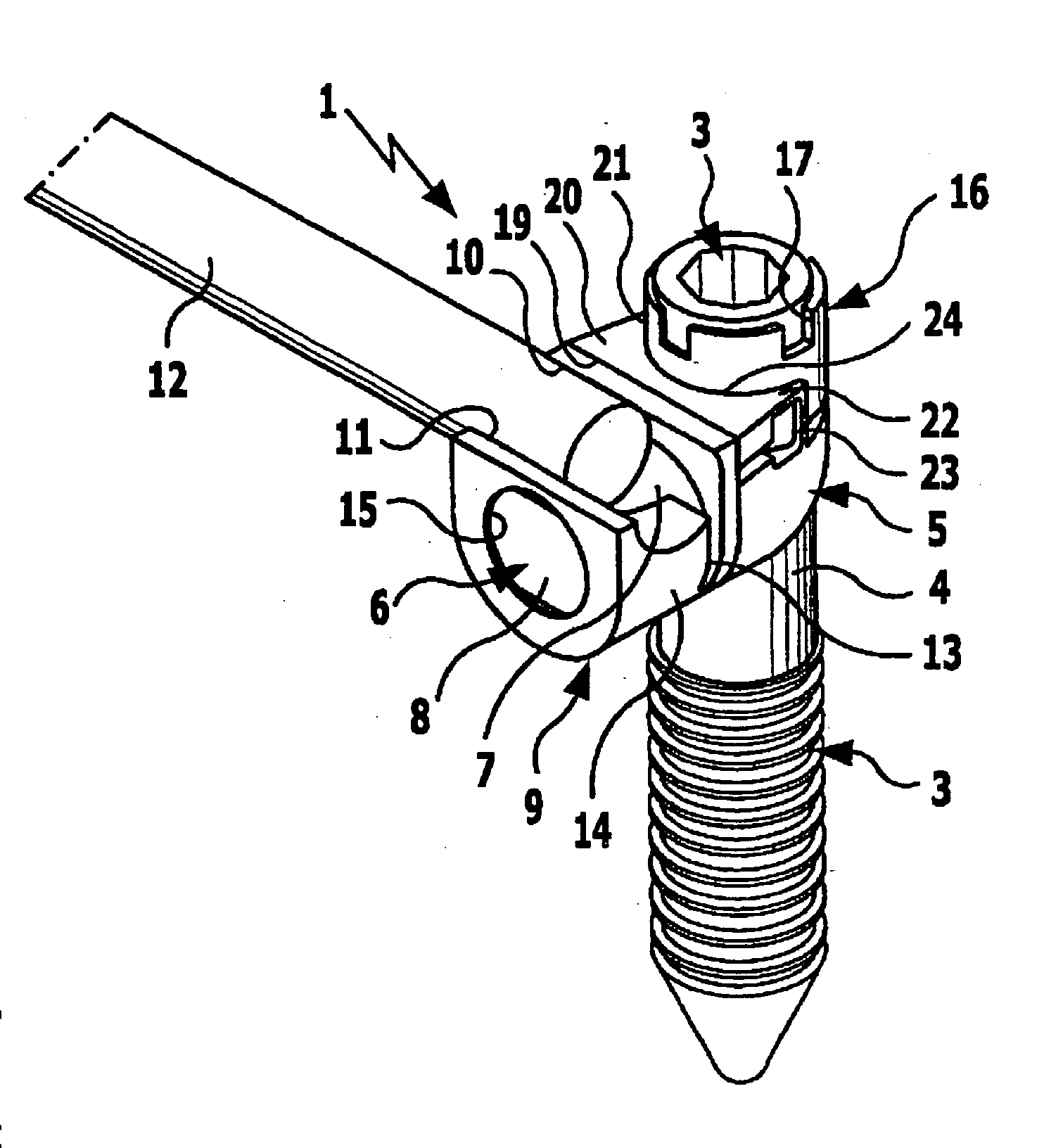

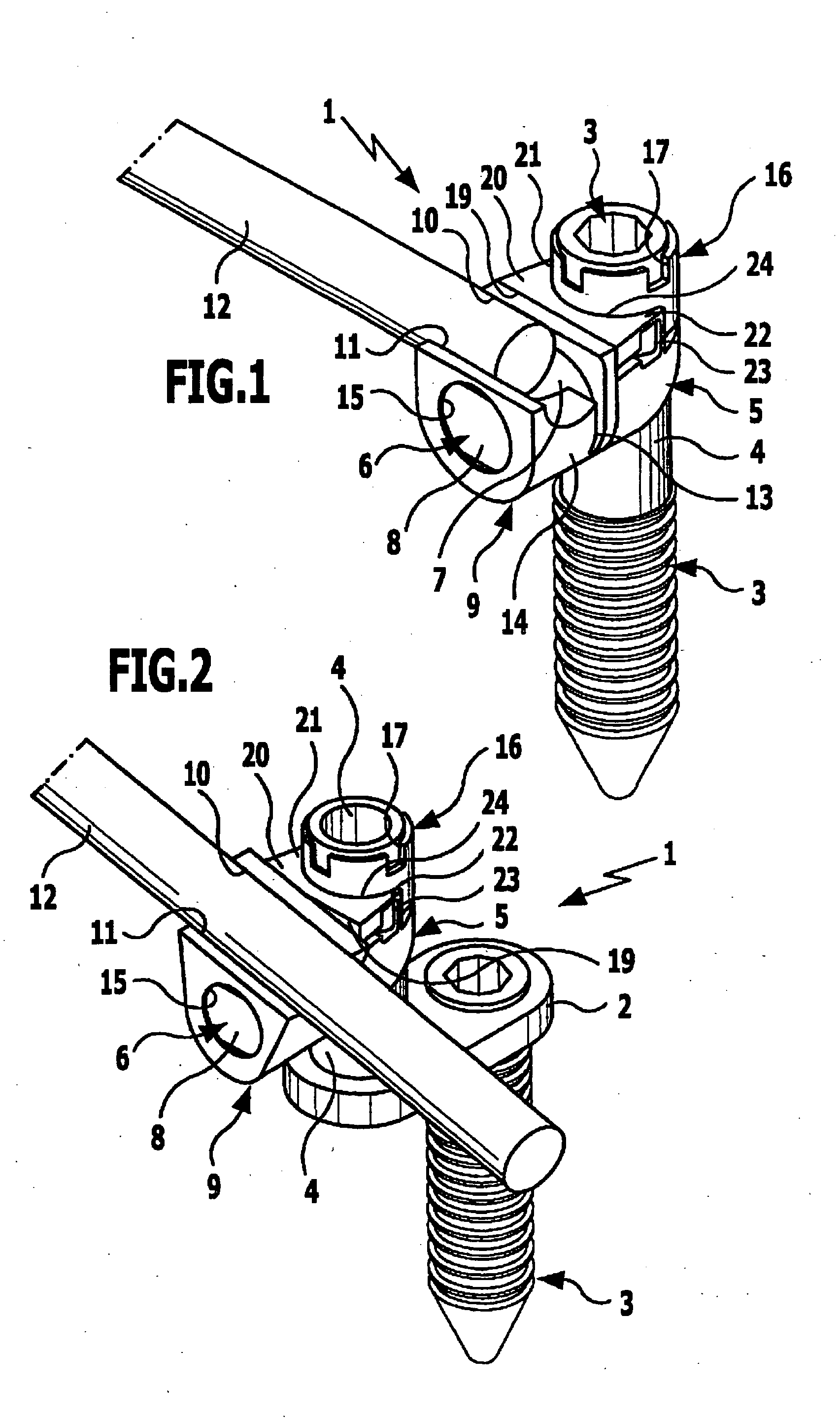

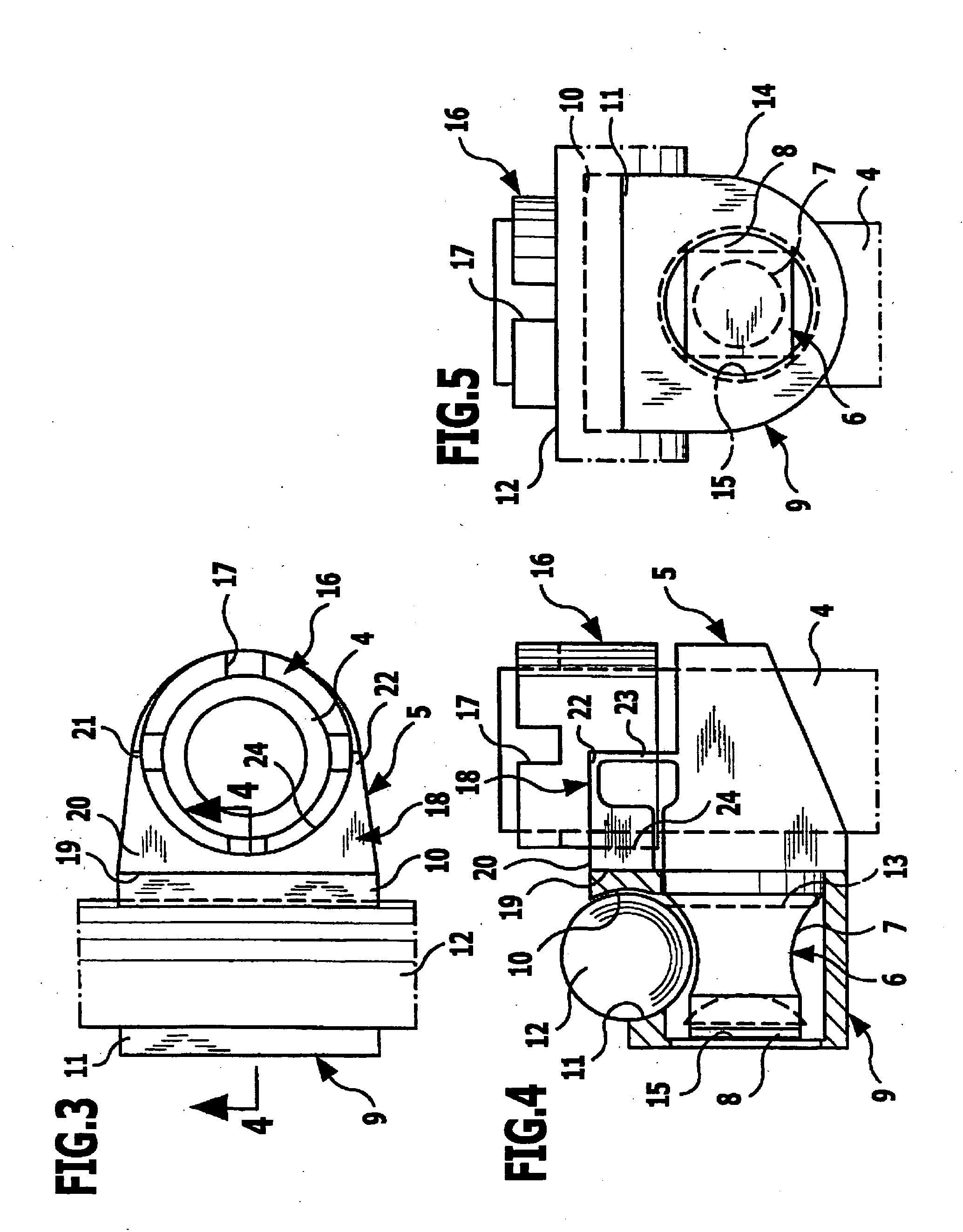

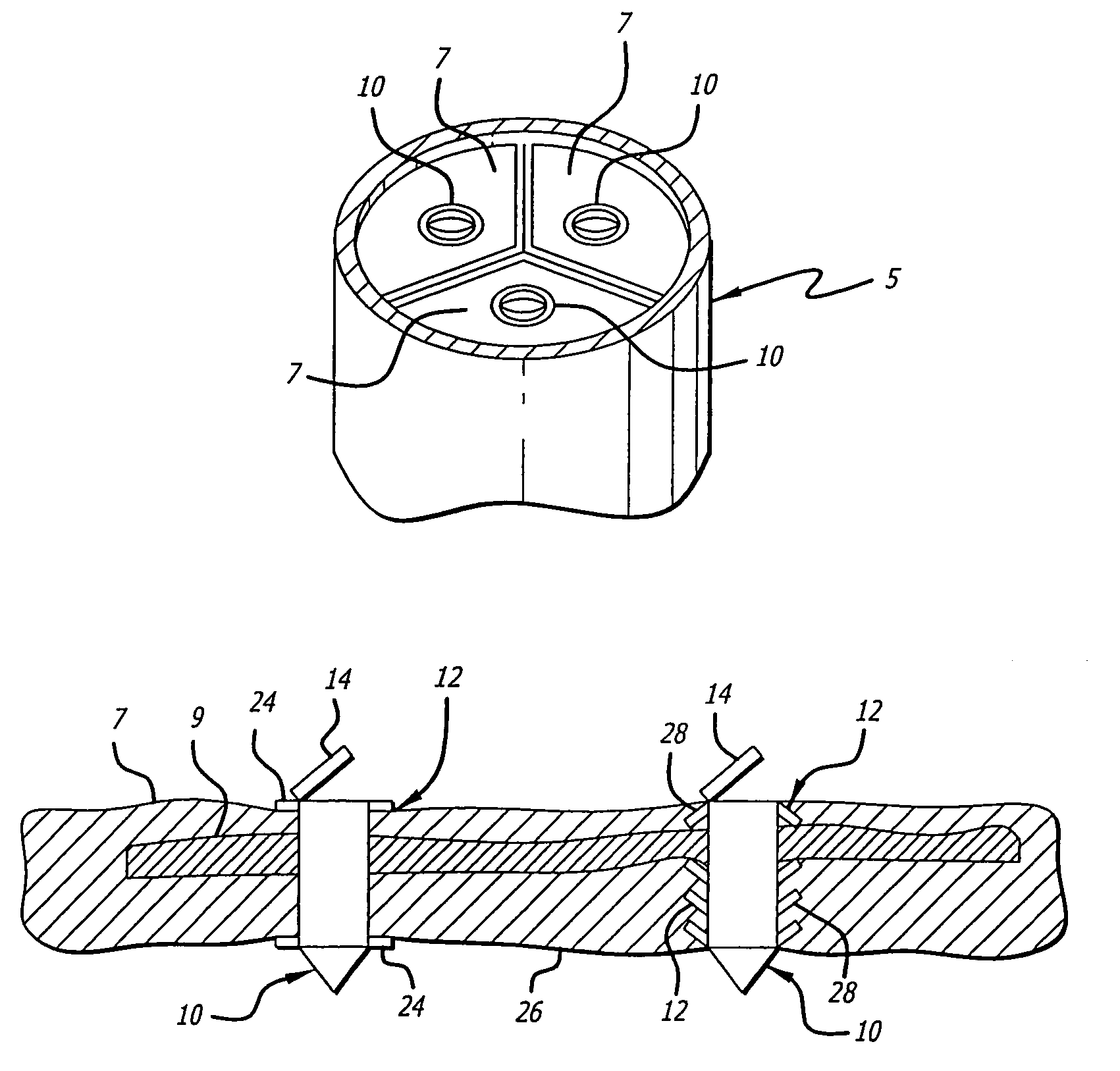

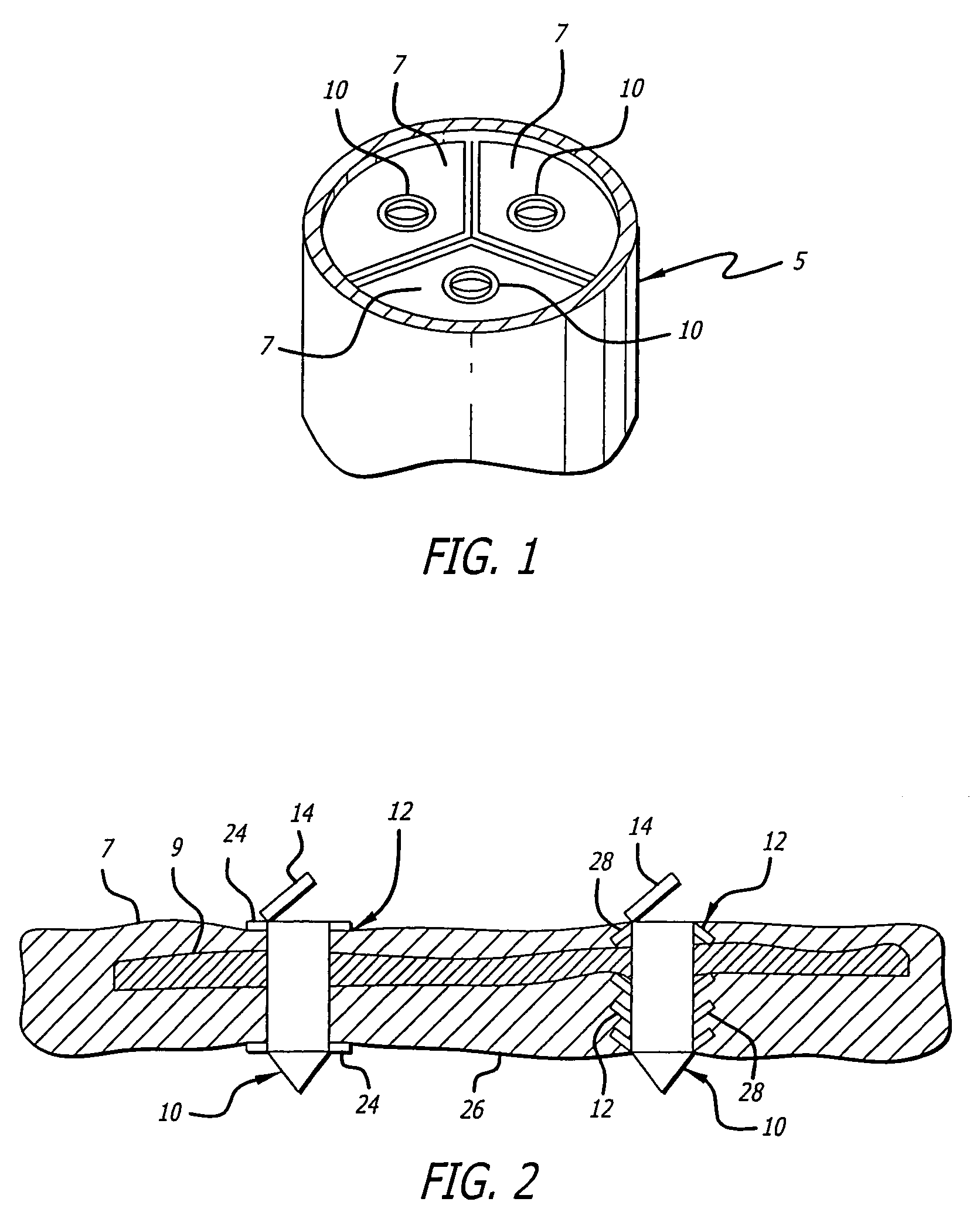

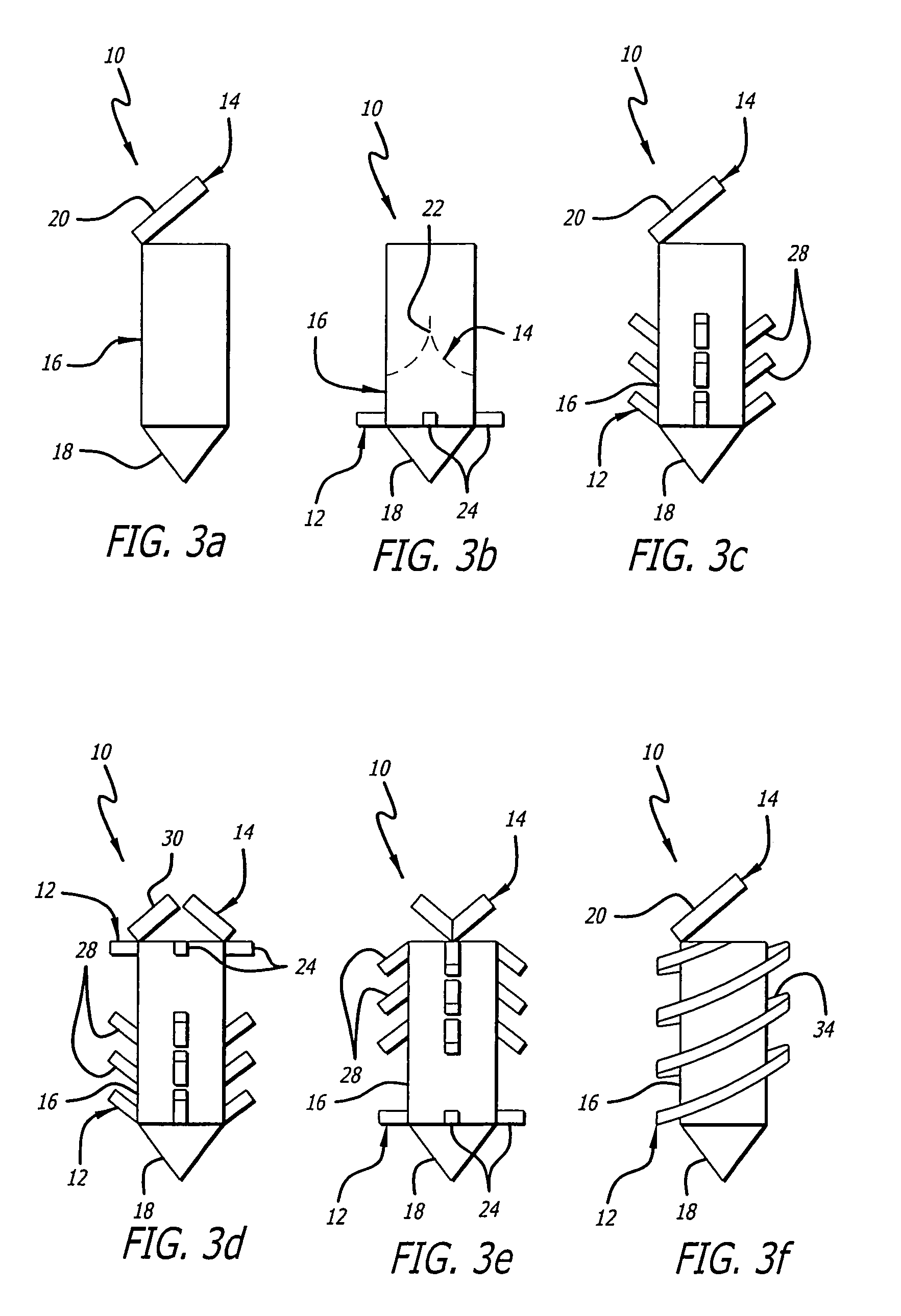

Orthopedic fixation device

InactiveUS20060004360A1Easy to operateLimited rotatabilitySuture equipmentsInternal osteosythesisOrthopedic fixation devicesPlastic surgery

The invention relates to an orthopedic fixation device for securing a rod-like fixation element, with two clamping jaws which can be moved relative to one another and which, when brought together, clamp the fixation element between them. In order to permit space-saving configurations of a fixation device that can be introduced and operated through small orifices in the body, a cam body is provided which is mounted on the fixation device so as to be able to rotate next to the clamping jaws in the direction of tightening and which, when rotated, pushes one clamping jaw toward the other.

Owner:AESCULAP AG

Leveler compounds

ActiveUS7128822B2No suppressed local platingOverplating is reduced or substantially eliminatedOrganic chemistrySpray nozzlesCopper platingMetal

Compounds that function to provide level or uniform metal deposits are provided. These compounds are particularly useful in providing level copper deposits. Copper plating baths and methods of copper plating using these compounds are also provided. These baths and methods are useful for providing a planarized layer of copper on a substrate having small apertures. The compositions and methods provide complete fill of small apertures with reduced void formation.

Owner:SHIPLEY CO LLC

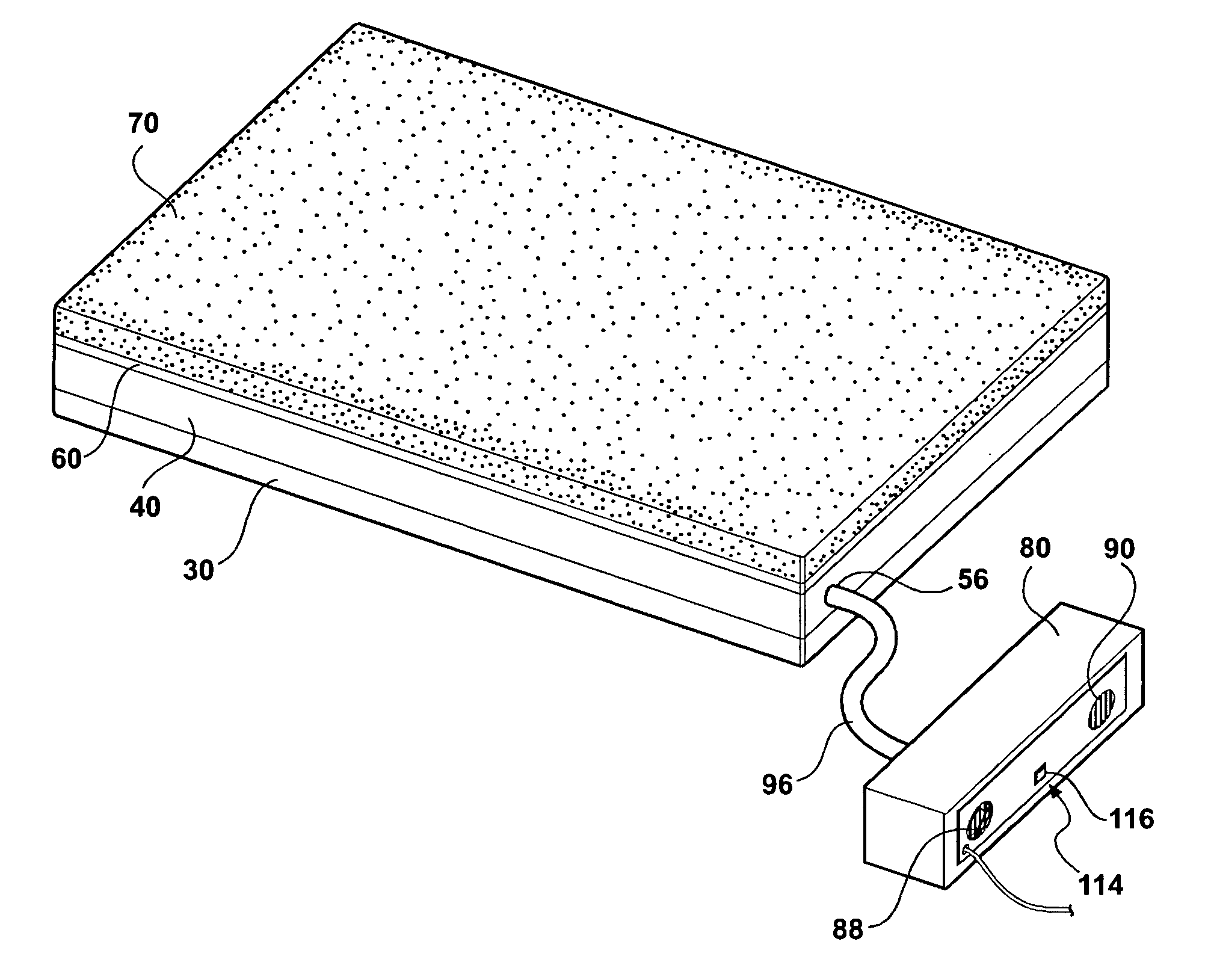

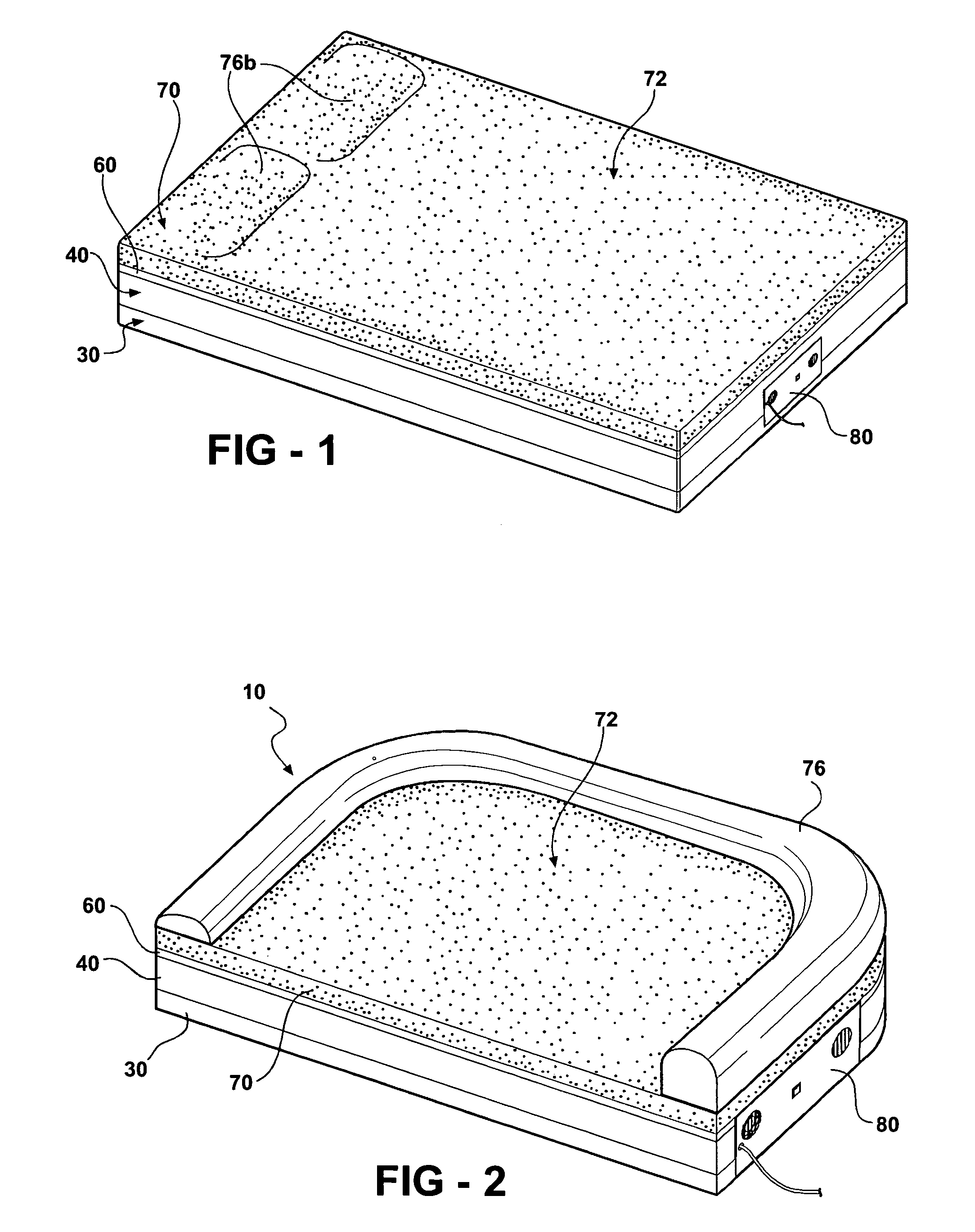

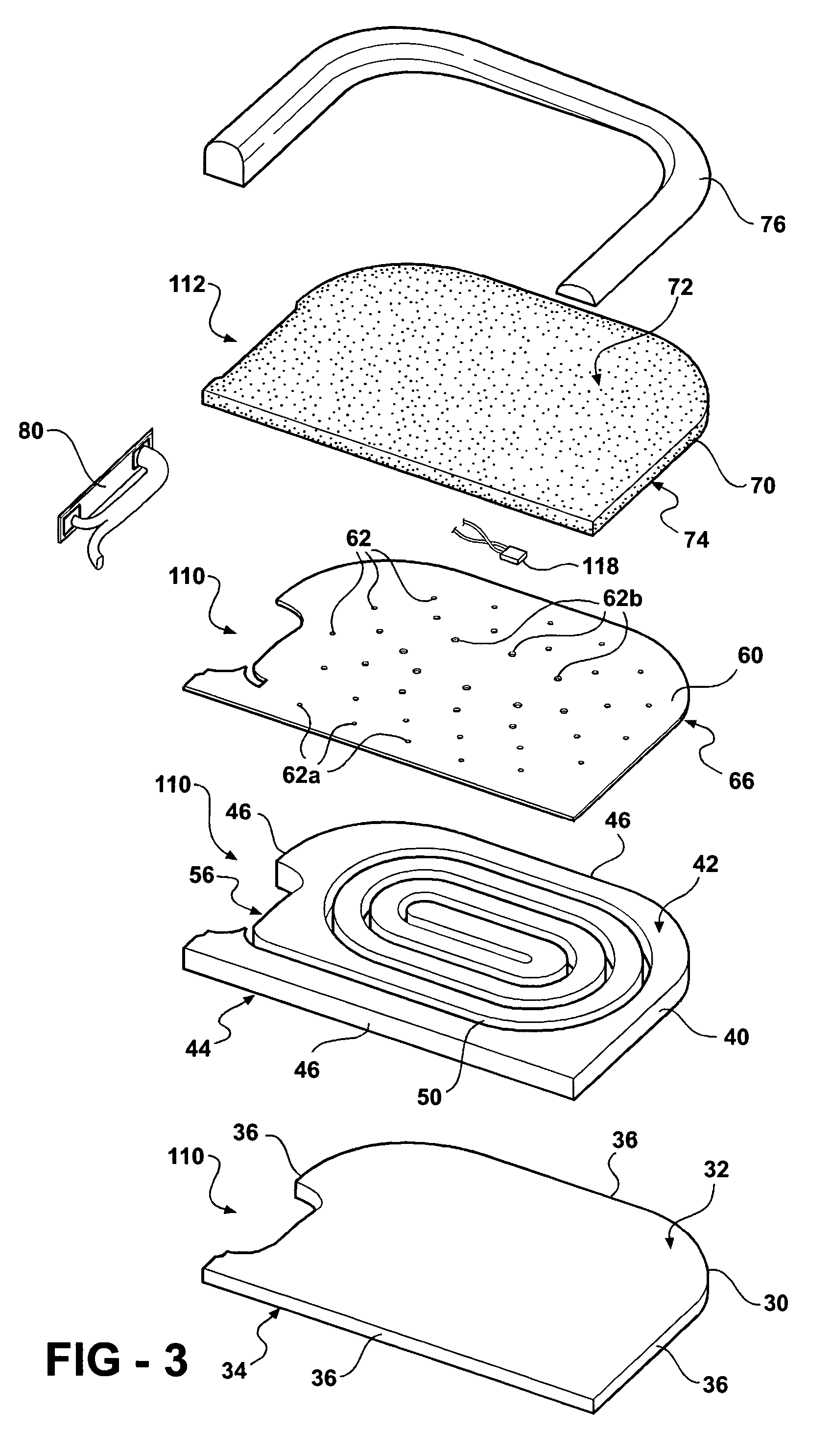

Comfort product

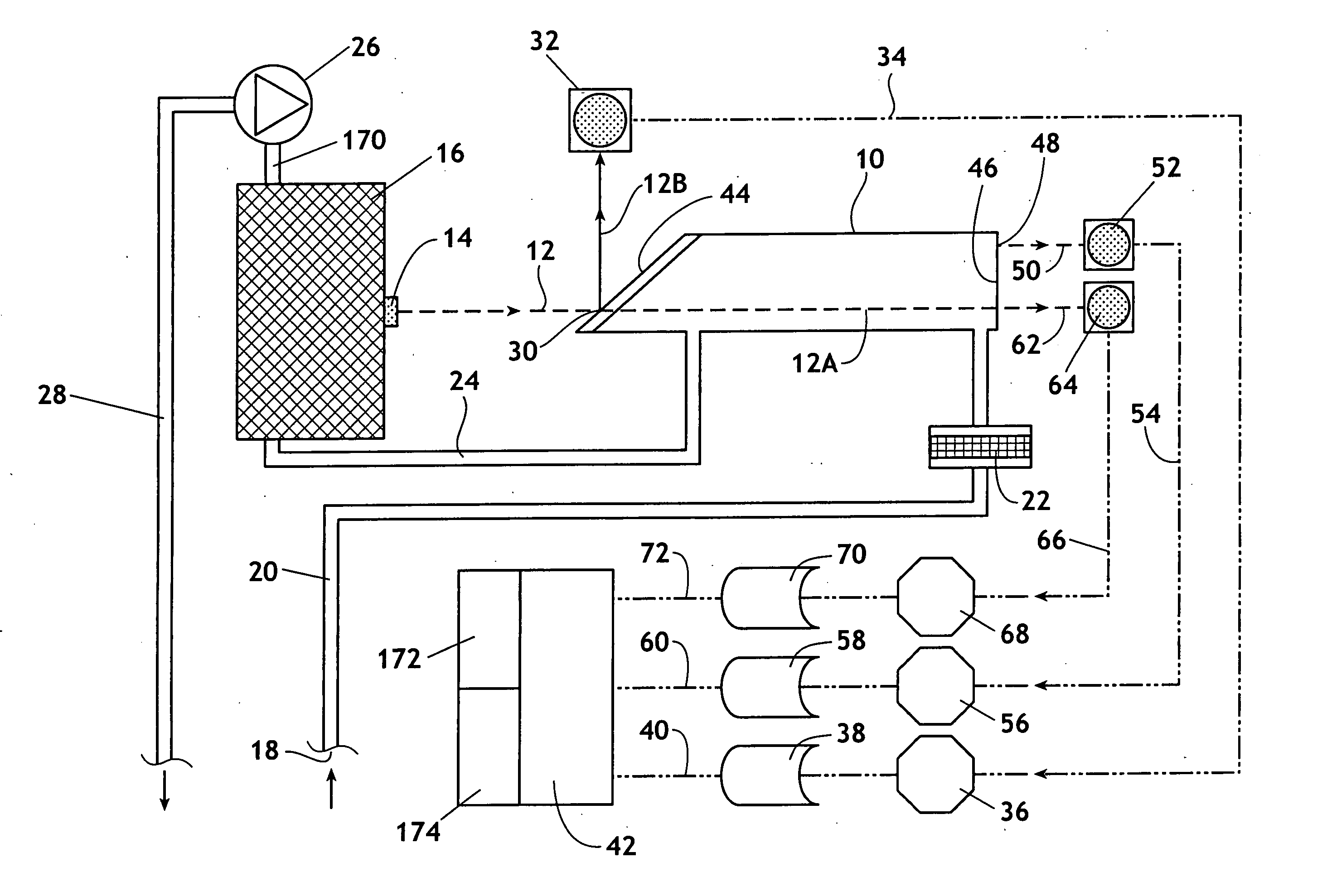

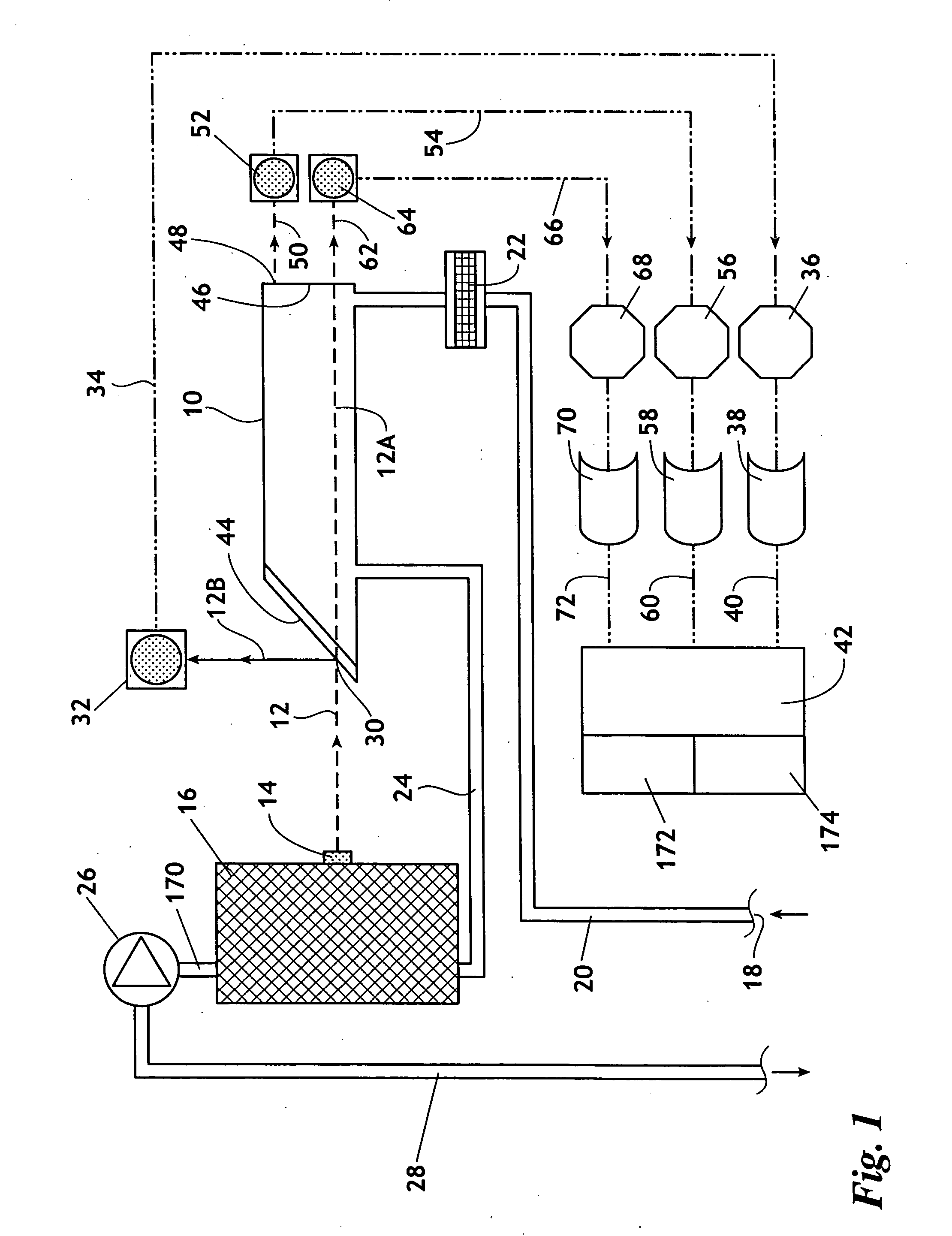

An improved comfort product that uses an airflow through a heat exchanger and into the comfort product to selectively heat or cool an occupant has a support layer contacting and supporting a channel layer. The channel layer has at least one channel with an opening to accept air. The channel layer contacts and supports an engineered distribution layer that has numerous small holes making it air permeable. The engineered distribution layer contacts and supports an air permeable comfort layer that is of such size and shape to support an occupant of the comfort product. The comfort product also has a heat exchanger assembly for supplying heated or cooled air to the opening in the channel. The heat exchanger assembly includes an air intake having an intake fan, an exhaust outlet and a heat exchanger for selectively heating or cooling air flowing through the heat exchanger resulting in selectively heated or cooled supply air and exhaust air. The intake fan forces air through the heat exchanger where some of the air is selectively heated or cooled to be supplied to the comfort product and some air is used as exhaust air (to remove the unwanted heat if the supplied air is cooled or to warm the exhaust side of the heat exchanger if the supply air is warmed.). The selectively heated or cooled supply air then moves through the channels in the channel layer and the exhaust air exits through the exhaust vent. The selectively heated or cooled supply air then moves through the engineered distribution layer where the numerous small holes diffuse the air and then the selectively heated or cooled air then moves through the comfort layer where the air is further diffused and where the selectively heated or cooled air can selectively heat or cool an occupant of the comfort product.

Owner:RIVERPARK INC A IN THE STATE OF INDIANA

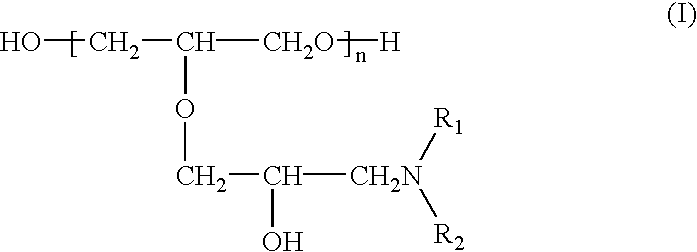

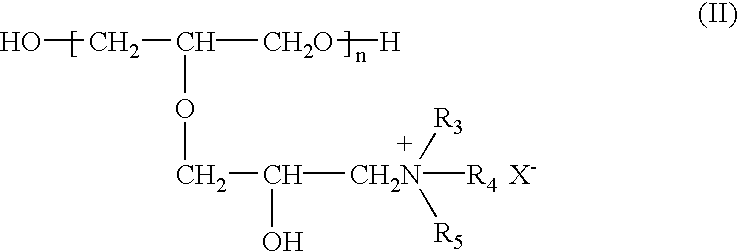

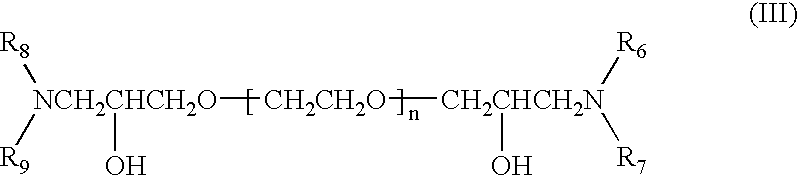

Copper plating bath and plating method for substrate using the copper plating bath

InactiveUS6800188B2Excellent characteristic and uniformityImprove reliabilityAnti-corrosive paintsLiquid/solution decomposition chemical coatingCopper platingGlycidyl ethers

A copper plating bath comprising a reaction condensate of an amine compound and glycidyl ether and / or a quaternary ammonium derivative of this reaction condensate, and a plating method using this copper plating bath are disclosed. A copper plating bath capable of providing highly reliable copper plating on a substrate such as a silicone wafer semiconductor substrate or printed board having minute circuit patterns and small holes such as blind via-holes, through-holes, and the like, and a method of copper plating using the copper plating bath can be provided.

Owner:EBARA-UDYLITE CO LTD

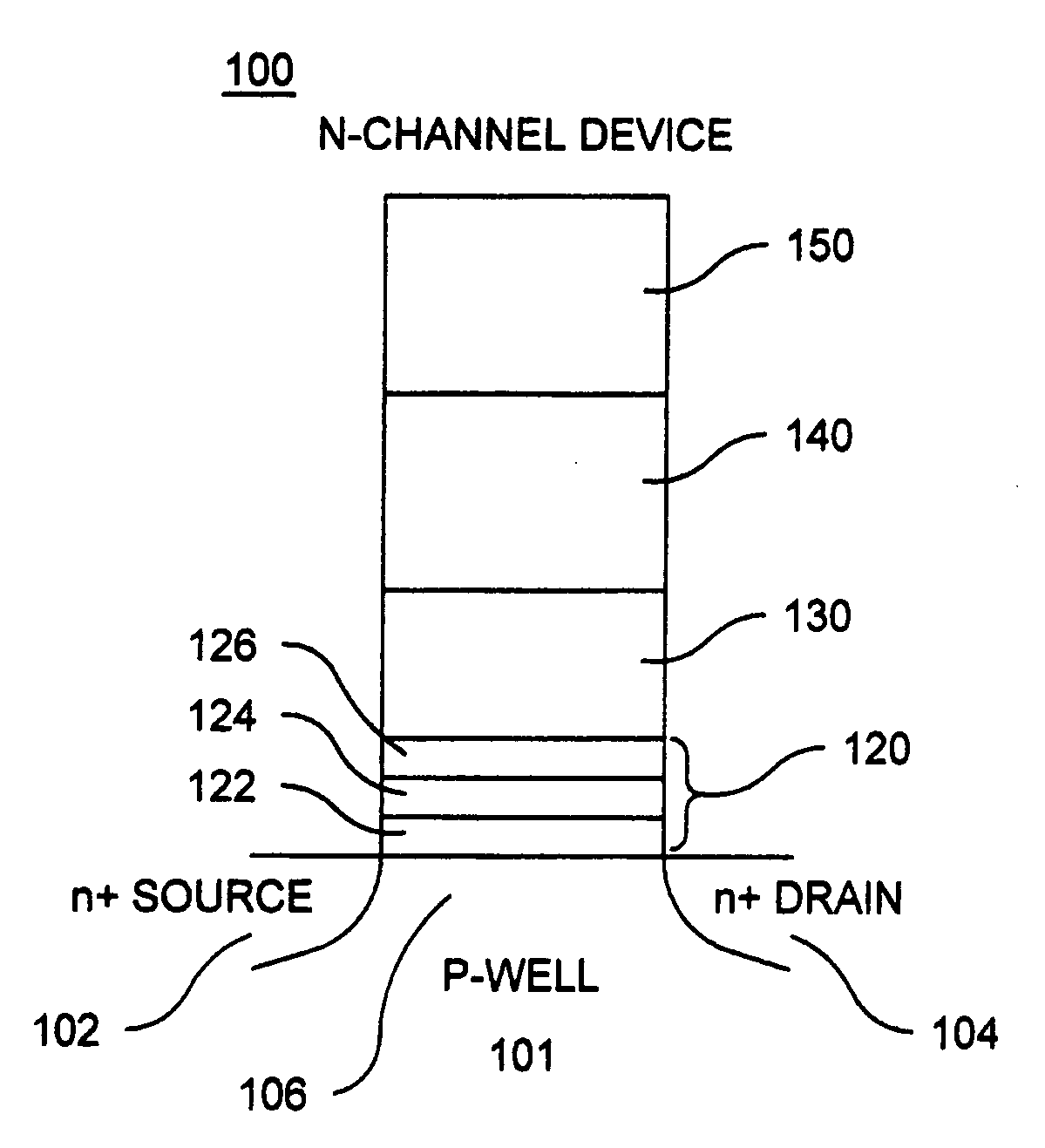

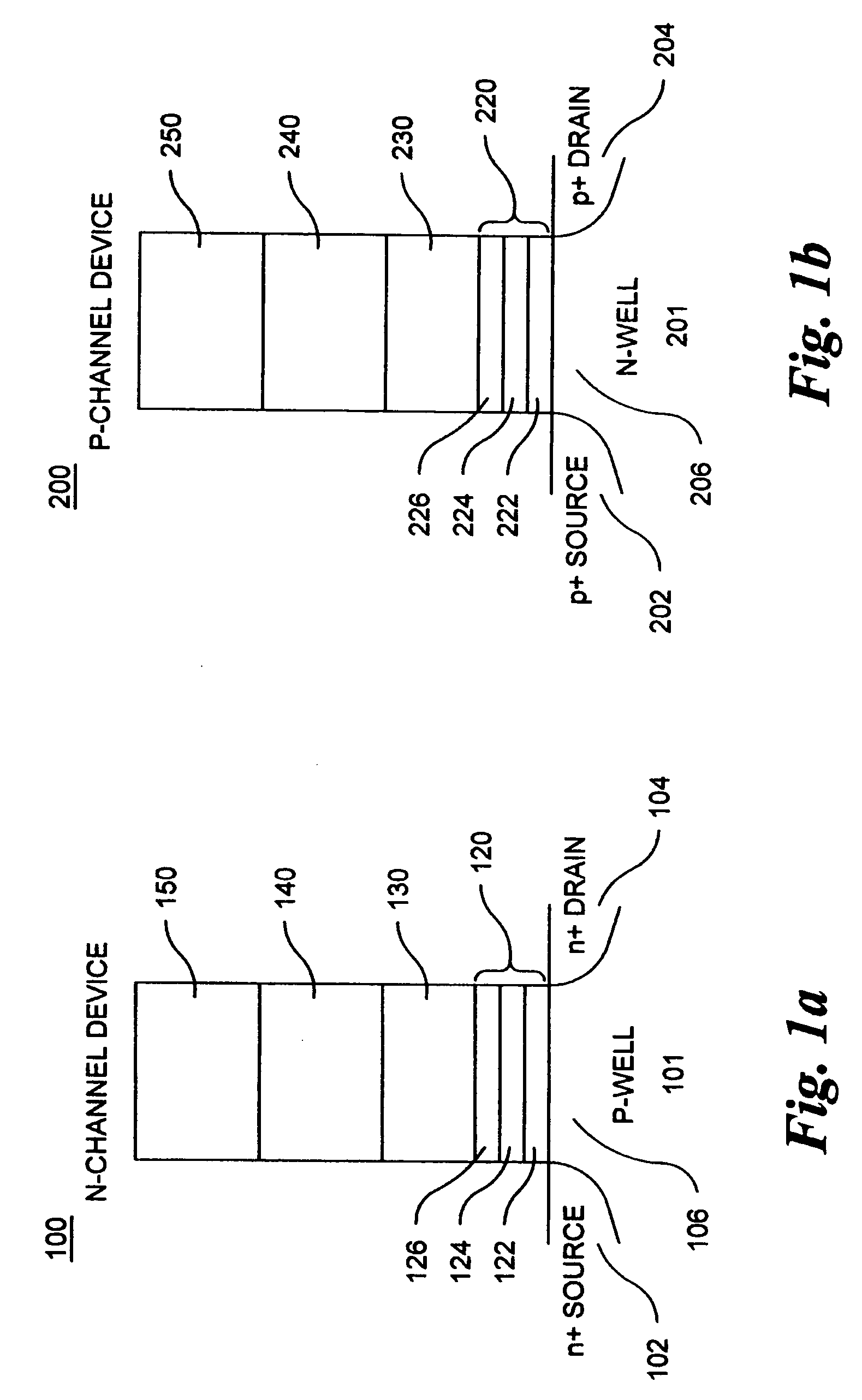

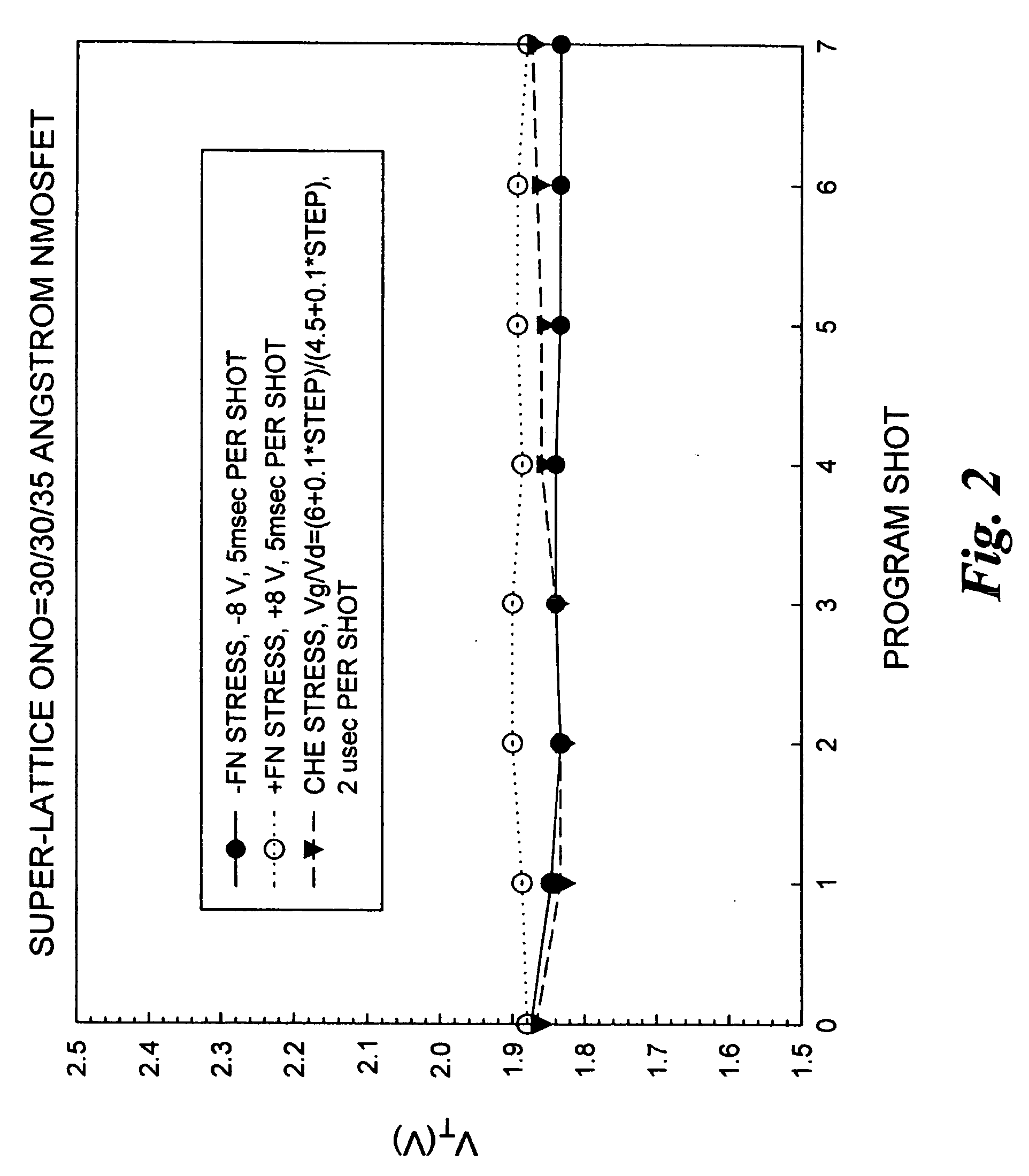

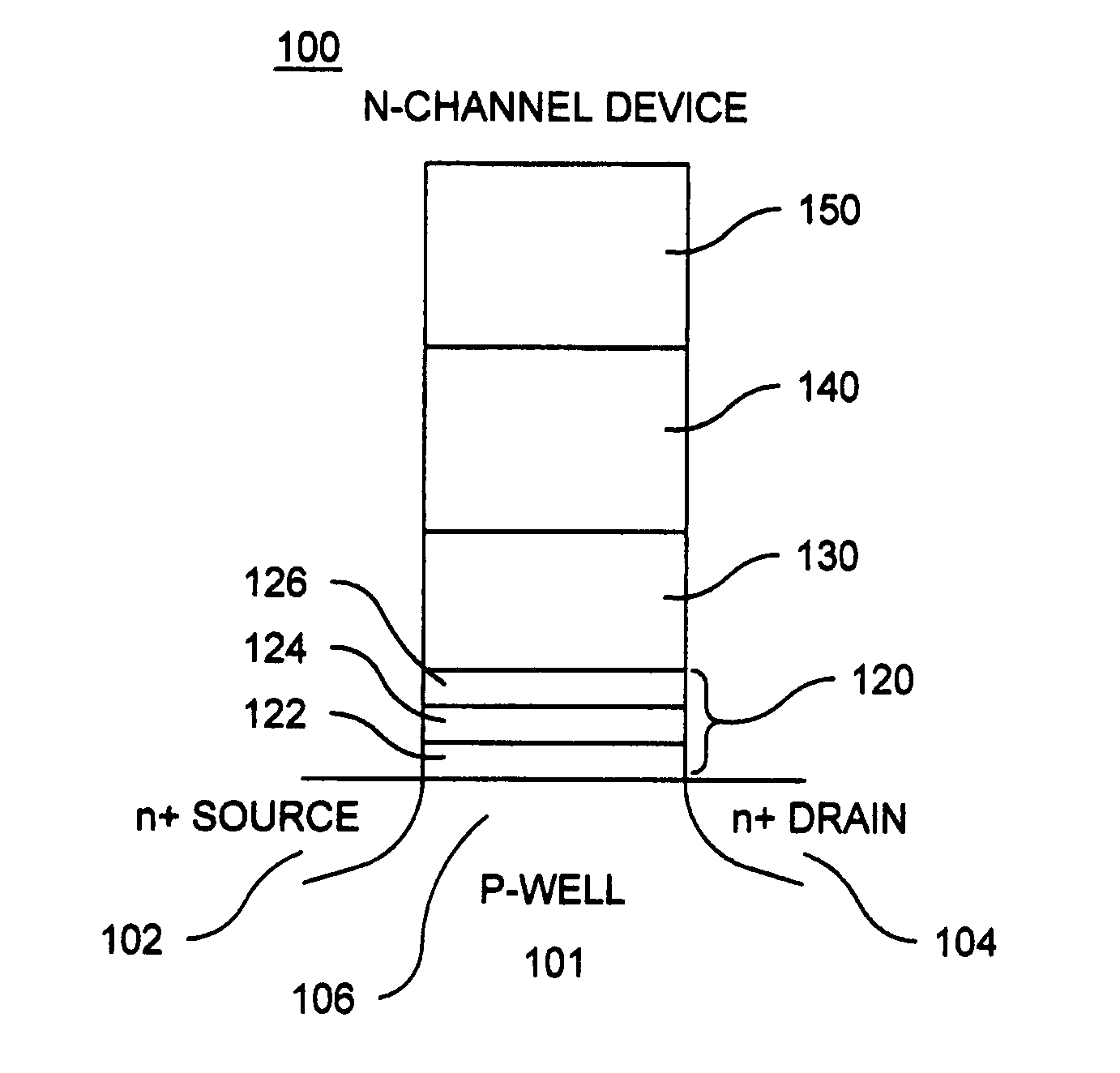

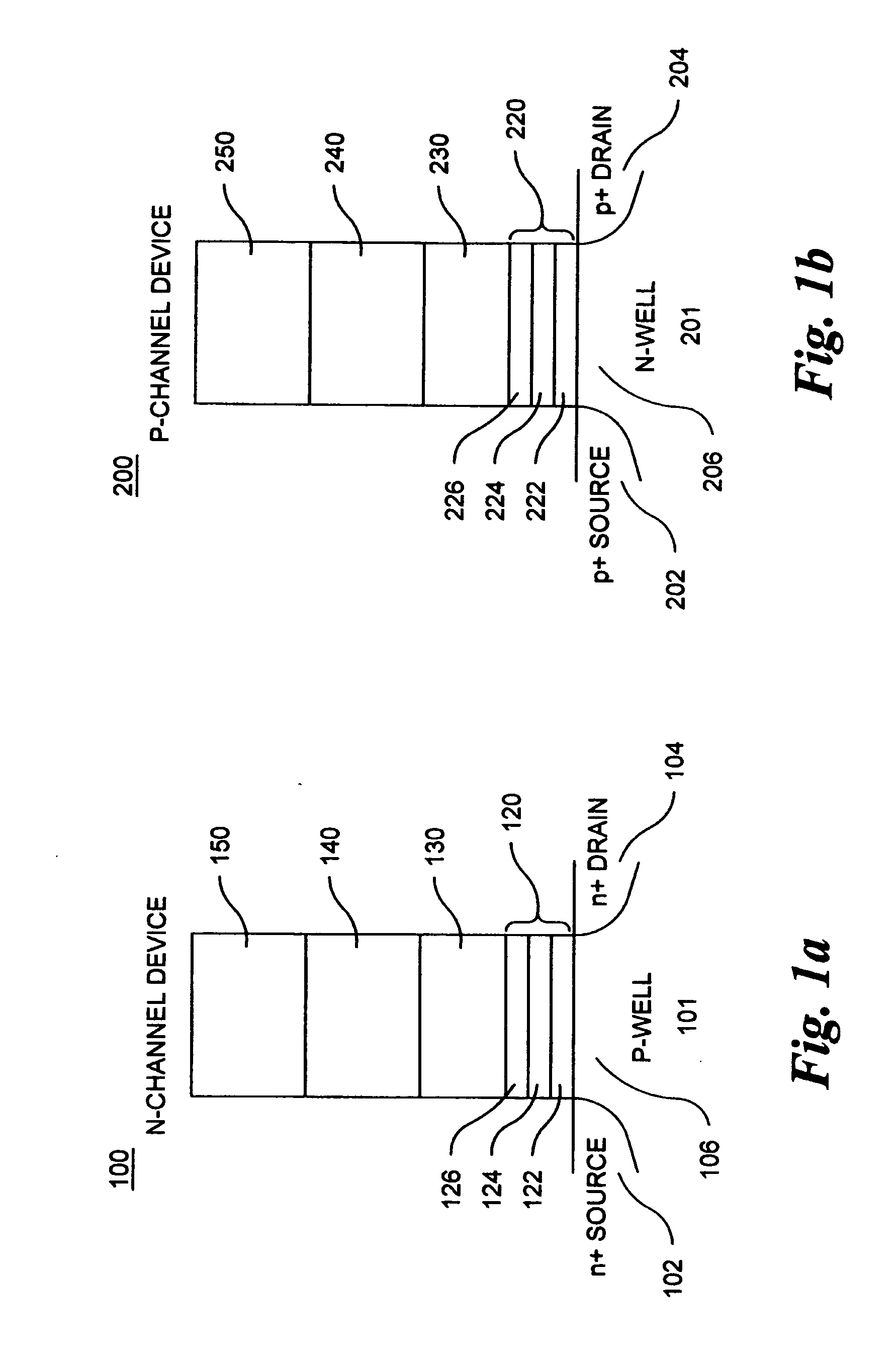

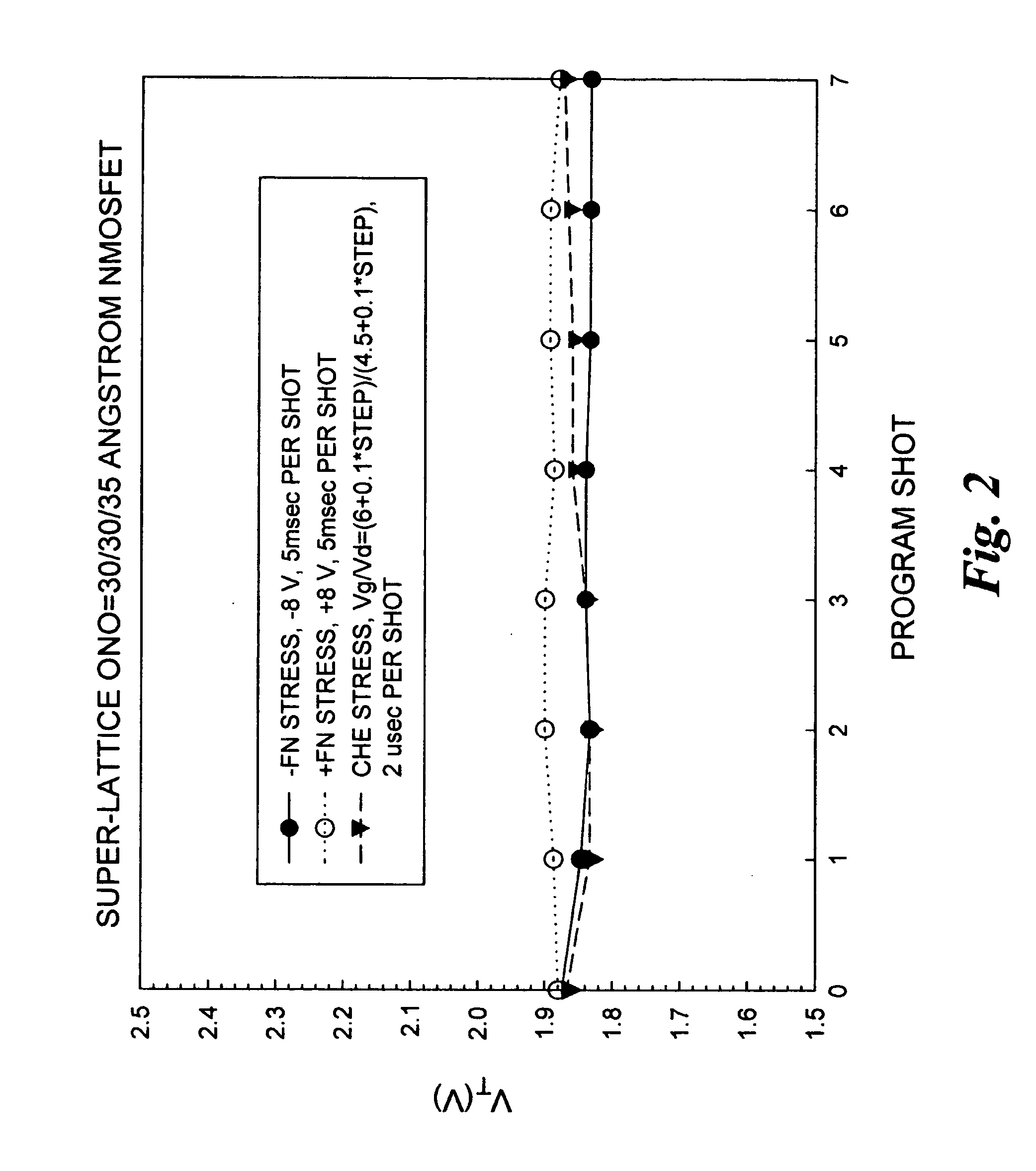

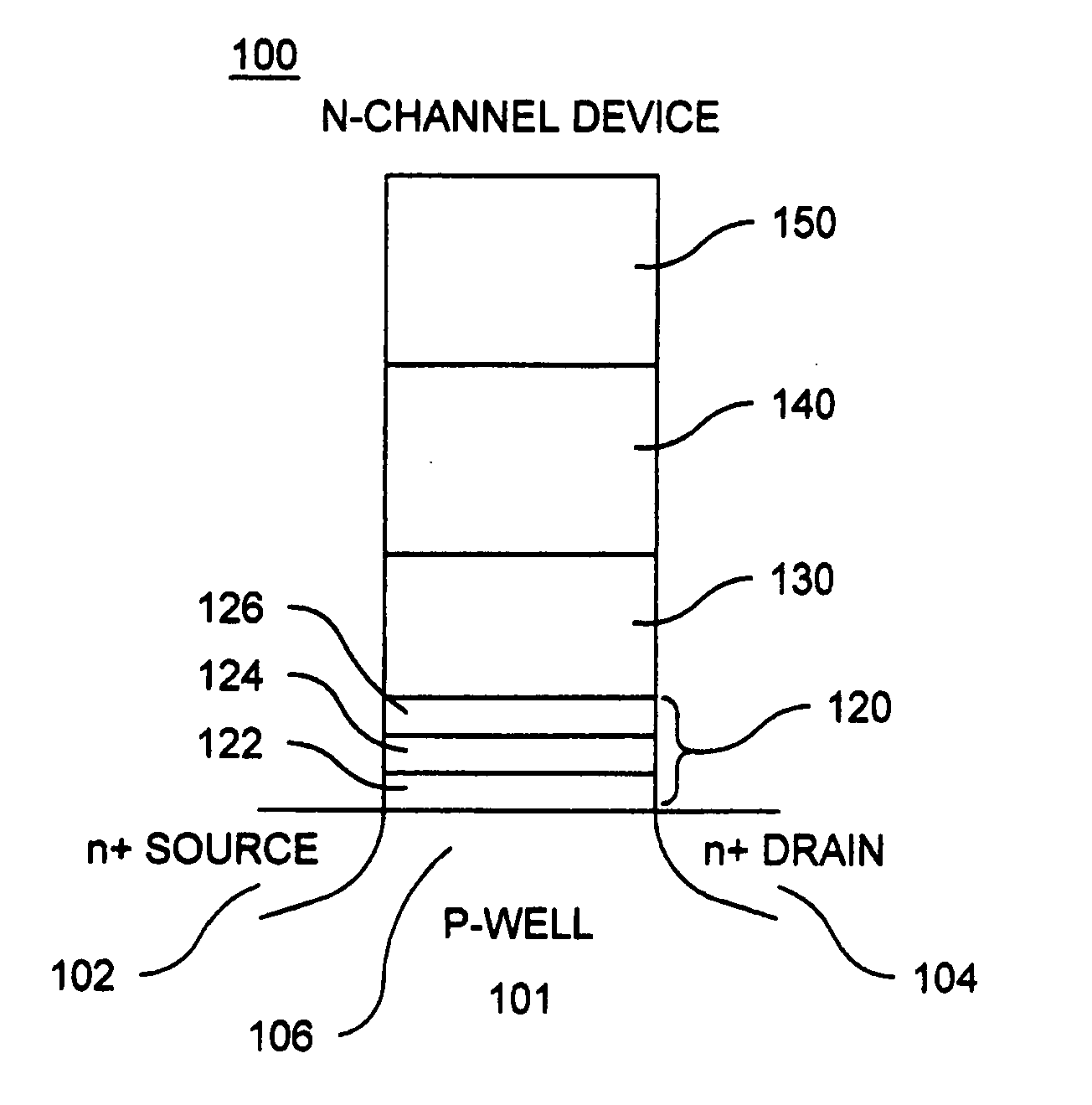

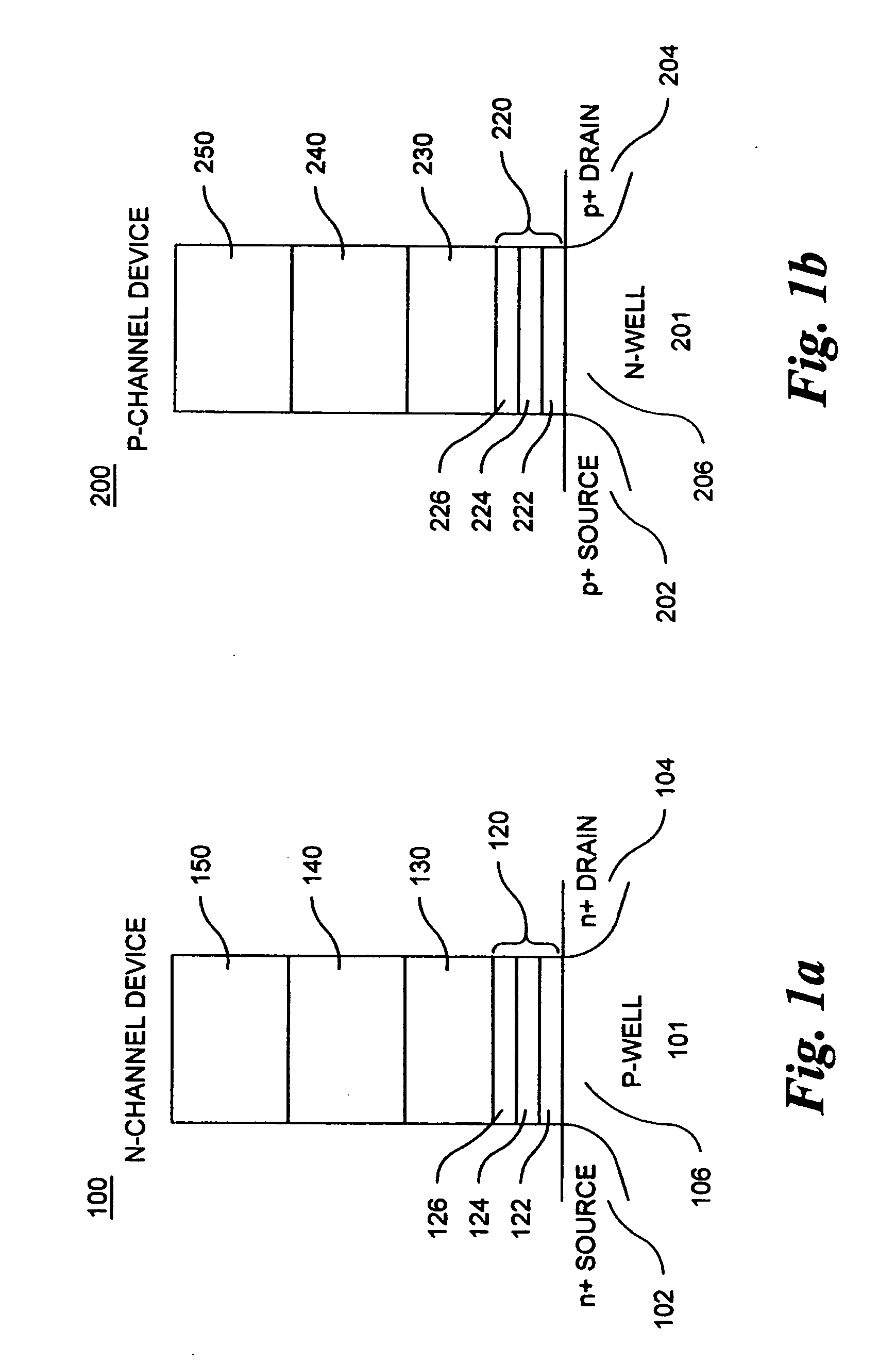

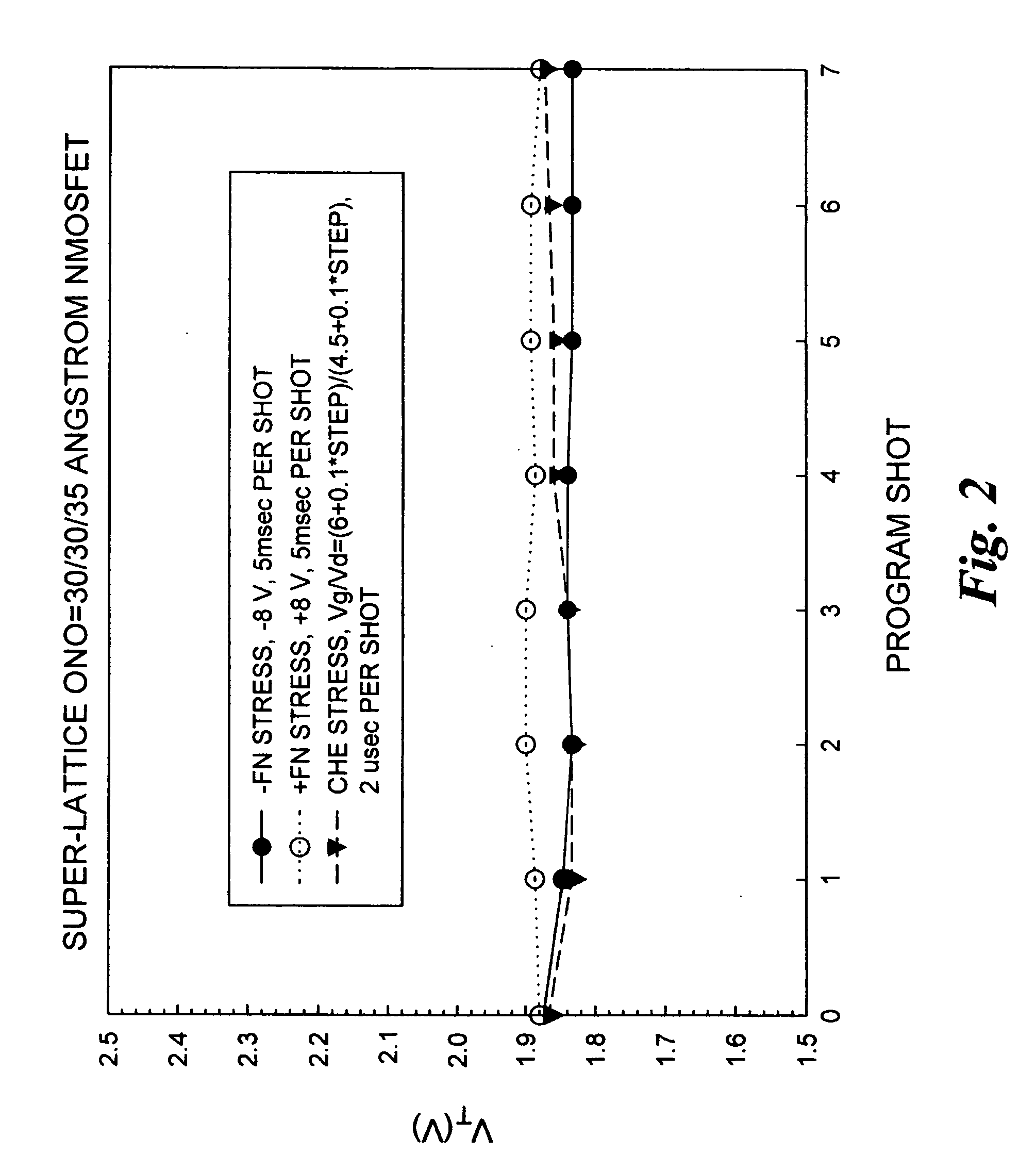

Non-volatile memory cells, memory arrays including the same and methods of operating cells and arrays

ActiveUS20060202261A1Easy to eraseLarge operating windowSolid-state devicesRead-only memoriesEngineeringDielectric structure

Memory cells comprising: a semiconductor substrate having a source region and a drain region disposed below a surface of the substrate and separated by a channel region; a tunnel dielectric structure disposed above the channel region, the tunnel dielectric structure comprising at least one layer having a small hole-tunneling-barrier height; a charge storage layer disposed above the tunnel dielectric structure; an insulating layer disposed above the charge storage layer; and a gate electrode disposed above the insulating layer are described along with arrays thereof and methods of operation.

Owner:MACRONIX INT CO LTD

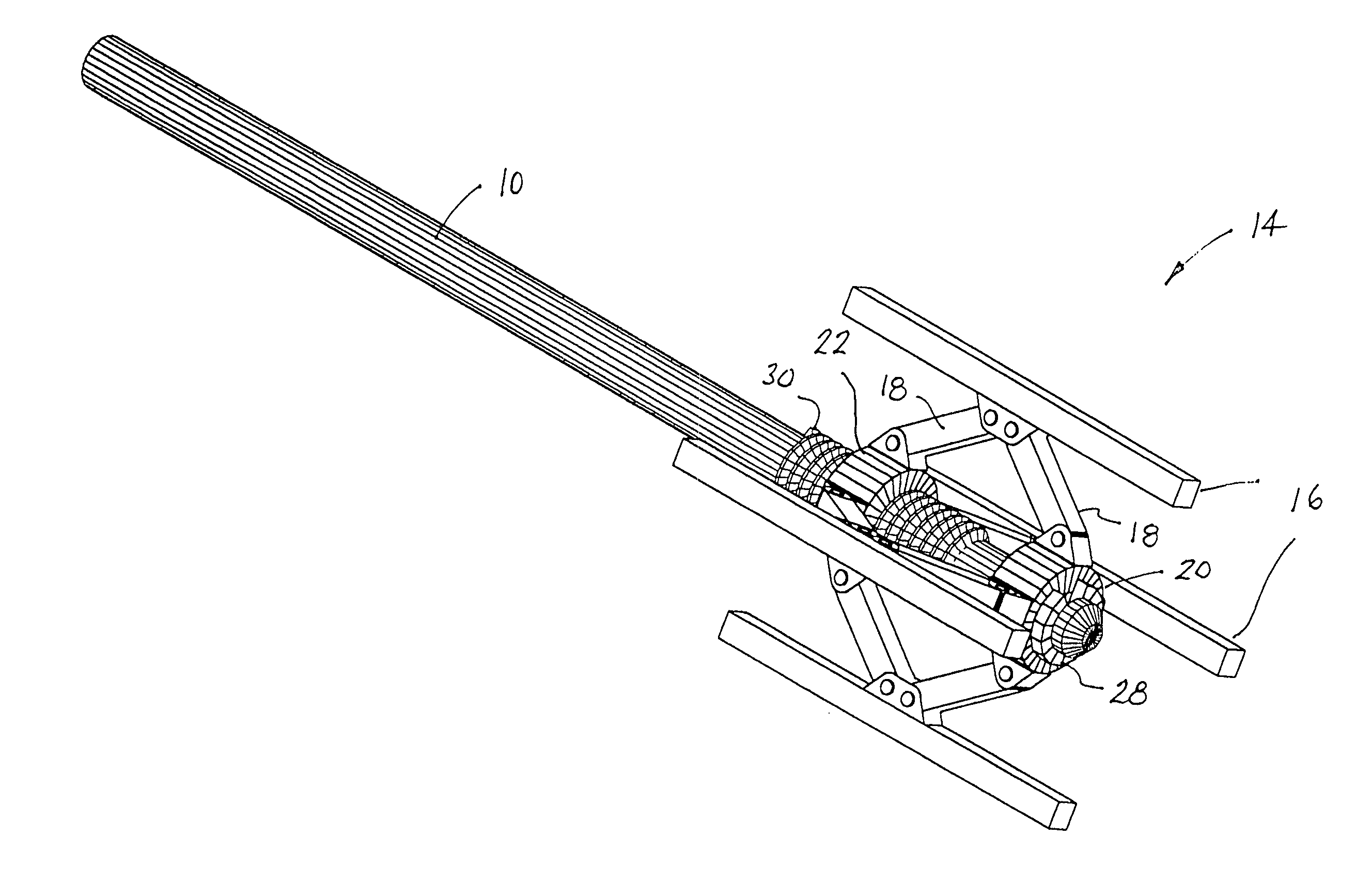

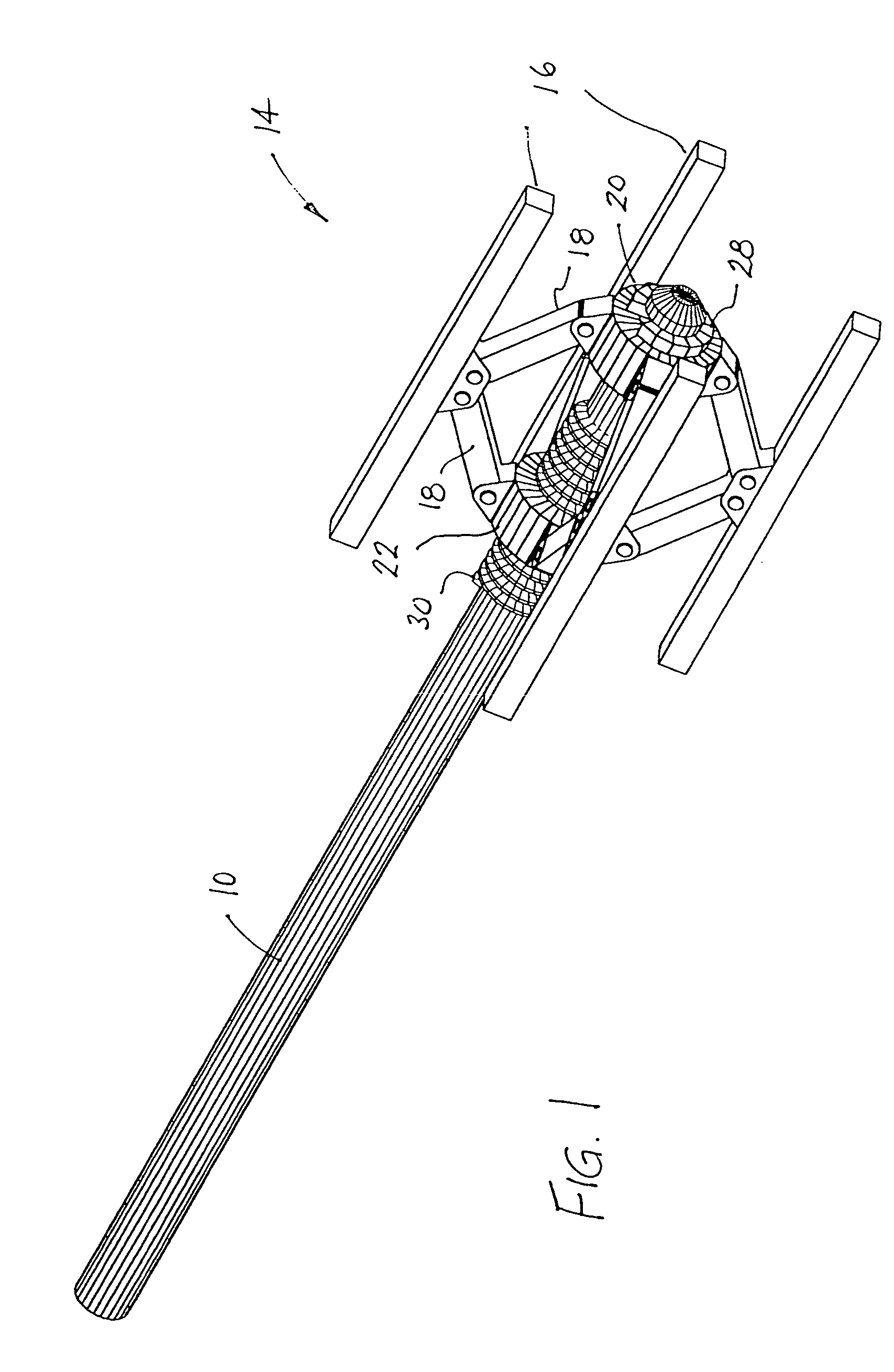

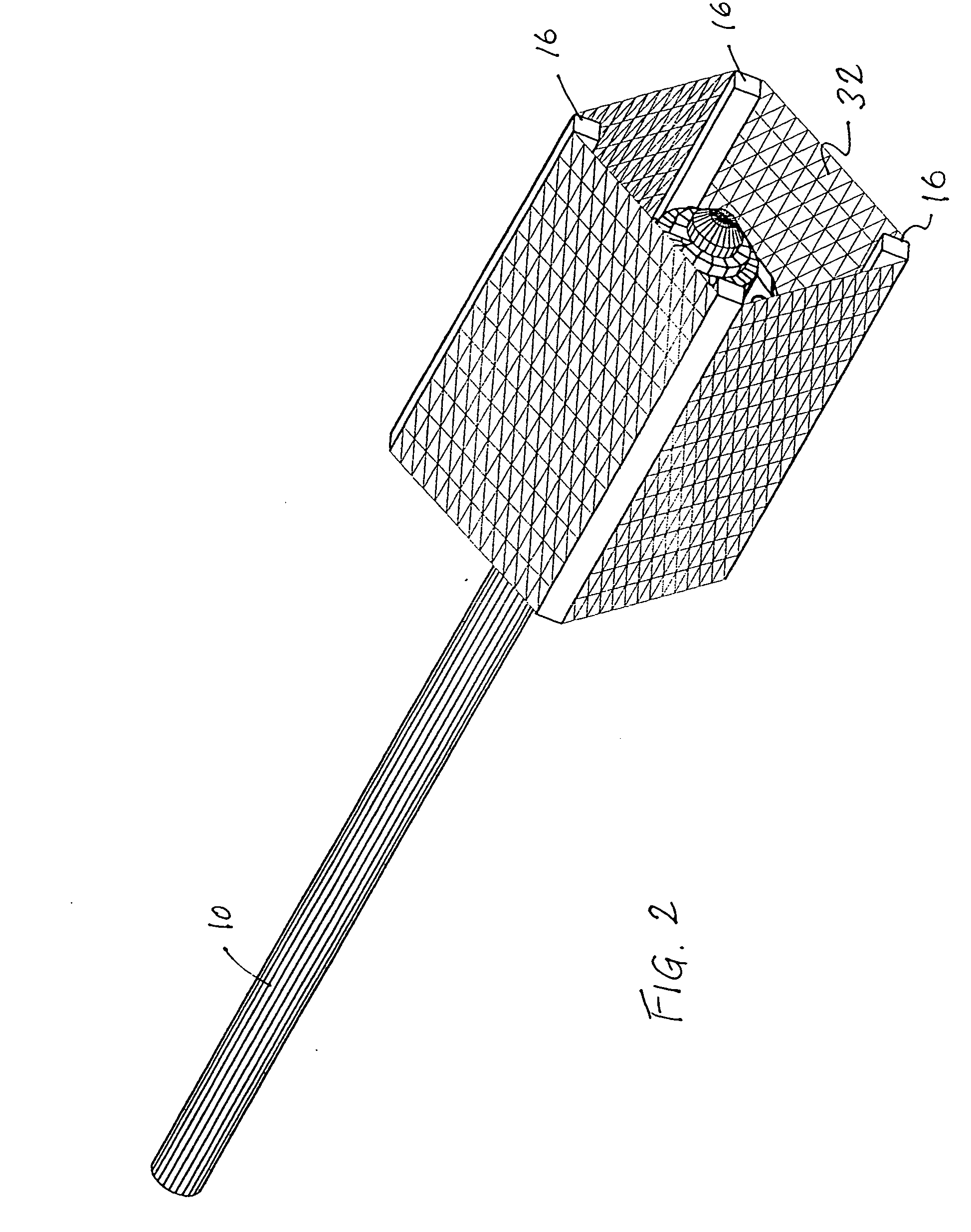

Mechanical bone tamping device for repair of osteoporotic bone fractures

InactiveUS20050124989A1Risk minimizationHighly inaccurate and uncontrollable cavity formationInternal osteosythesisDilatorsOsteoporotic boneBiomedical engineering

A mechanical bone tamping device for osteoporotic repair include a pair of arms mounted on a spreading mechanism such as a screw jack. The mechanism is introduced into a small hole in a vertebra through a cannula, and is then operated to spread the arms apart, forming a cavity which may be filled with cement to fortify the vertebra.

Owner:SUDDABY LOUBERT

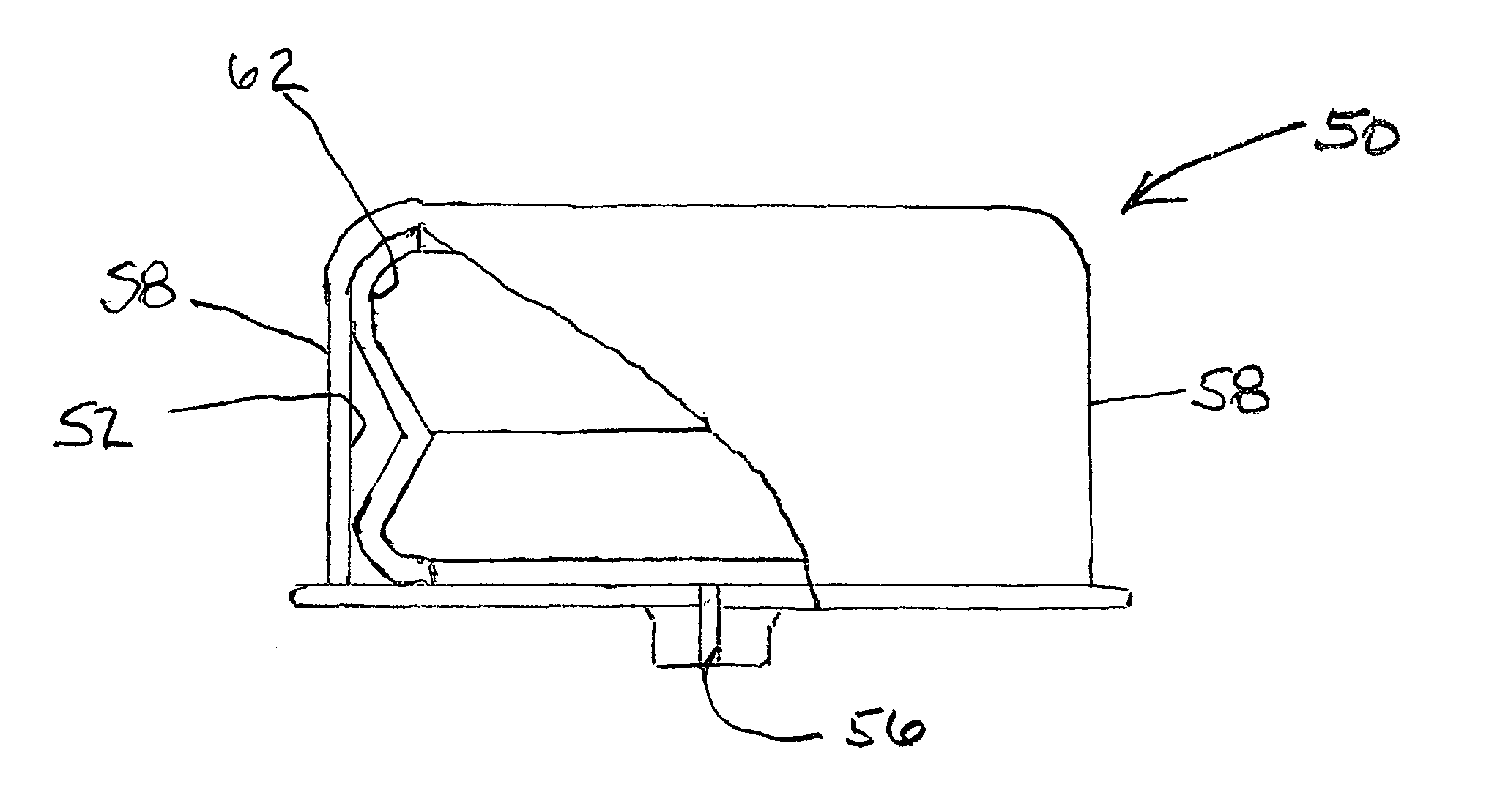

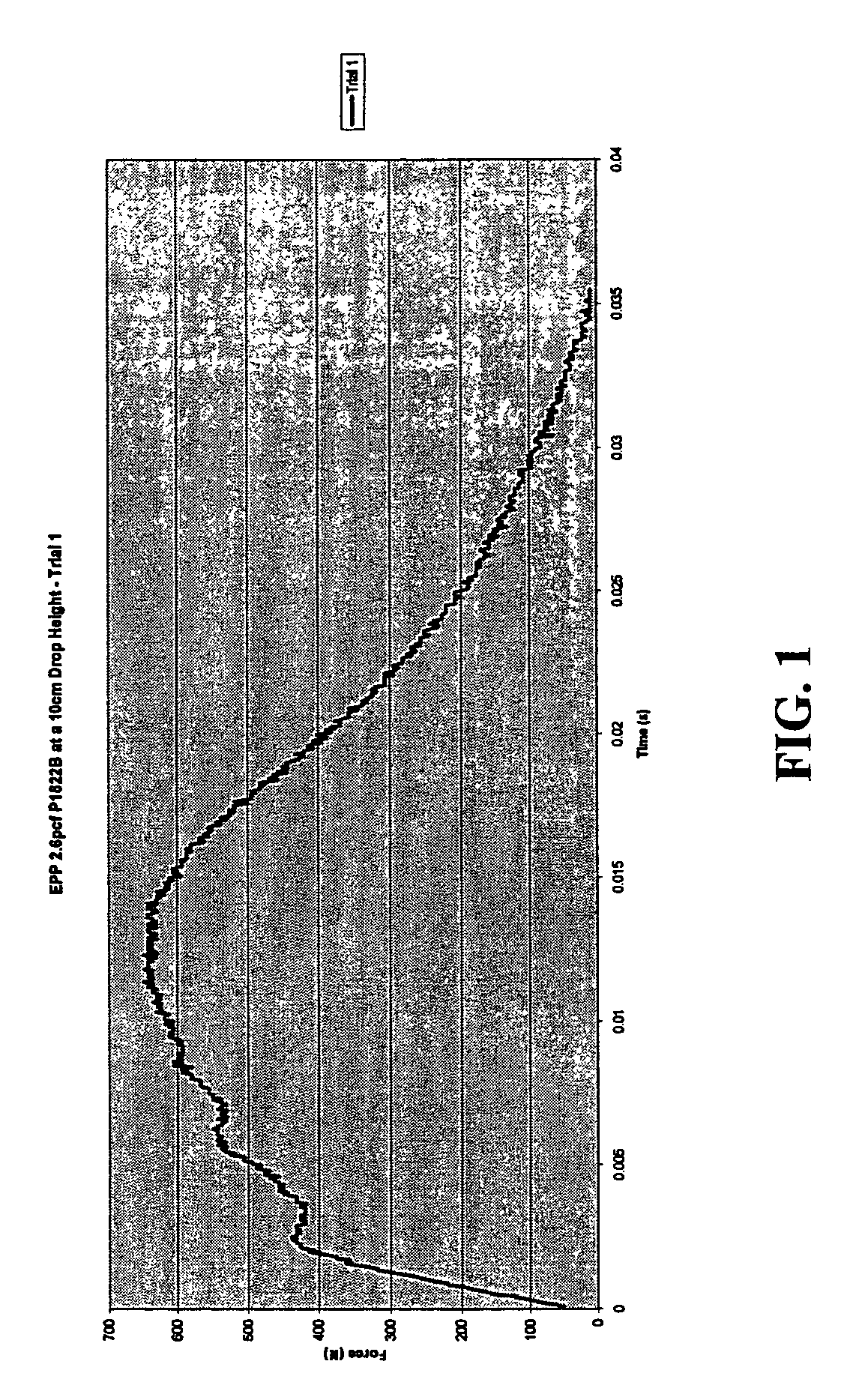

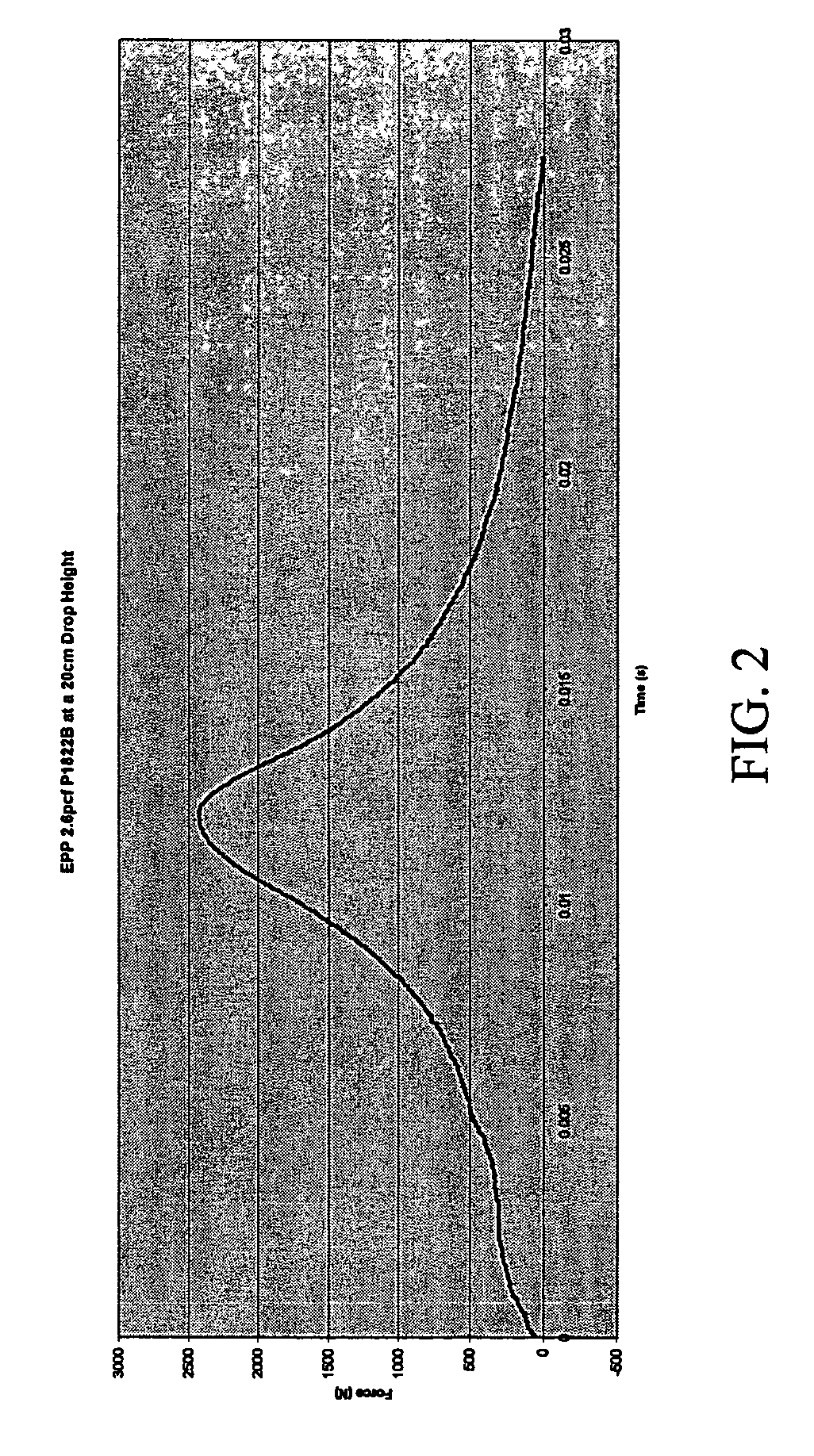

Impact energy management method and system

ActiveUS7774866B2Little strengthExtension of timeChemical protectionHeat protectionElectrical resistance and conductanceEngineering

An impact-absorbing protective structure comprises one or more compressible cells. Each cell is in the form of a thin-walled plastic enclosure defining an inner, fluid-filled chamber with at least one small orifice through which fluid resistively flows. Each cell includes an initially resistive mechanism that resists collapse during an initial phase of an impact and that then yields to allow the remainder of the impact to be managed by the venting of fluid through the orifice. The initially resistive mechanism may be implemented by providing the cell with semi-vertical side walls of an appropriate thickness or by combining a resiliently collapsible ring with the cell. After the initially resistive mechanism yields to the impact, the remainder of the impact is managed by the fluid venting through the orifice. The cell properties can be readily engineered to optimize the impact-absorbing response of the cell to a wide range of impact energies.

Owner:XENITH

Non-volatile memory cells, memory arrays including the same and methods of operating cells and arrays

ActiveUS20060198190A1Easy to optimizeEasy to eraseSolid-state devicesRead-only memoriesDielectric structureCondensed matter physics

Memory cells comprising: a semiconductor substrate having a source region and a drain region disposed below a surface of the substrate and separated by a channel region; a tunnel dielectric structure disposed above the channel region, the tunnel dielectric structure comprising at least one layer having a small hole-tunneling-barrier height; a charge storage layer disposed above the tunnel dielectric structure; an insulating layer disposed above the charge storage layer; and a gate electrode disposed above the insulating layer are described along with arrays thereof and methods of operation.

Owner:MACRONIX INT CO LTD

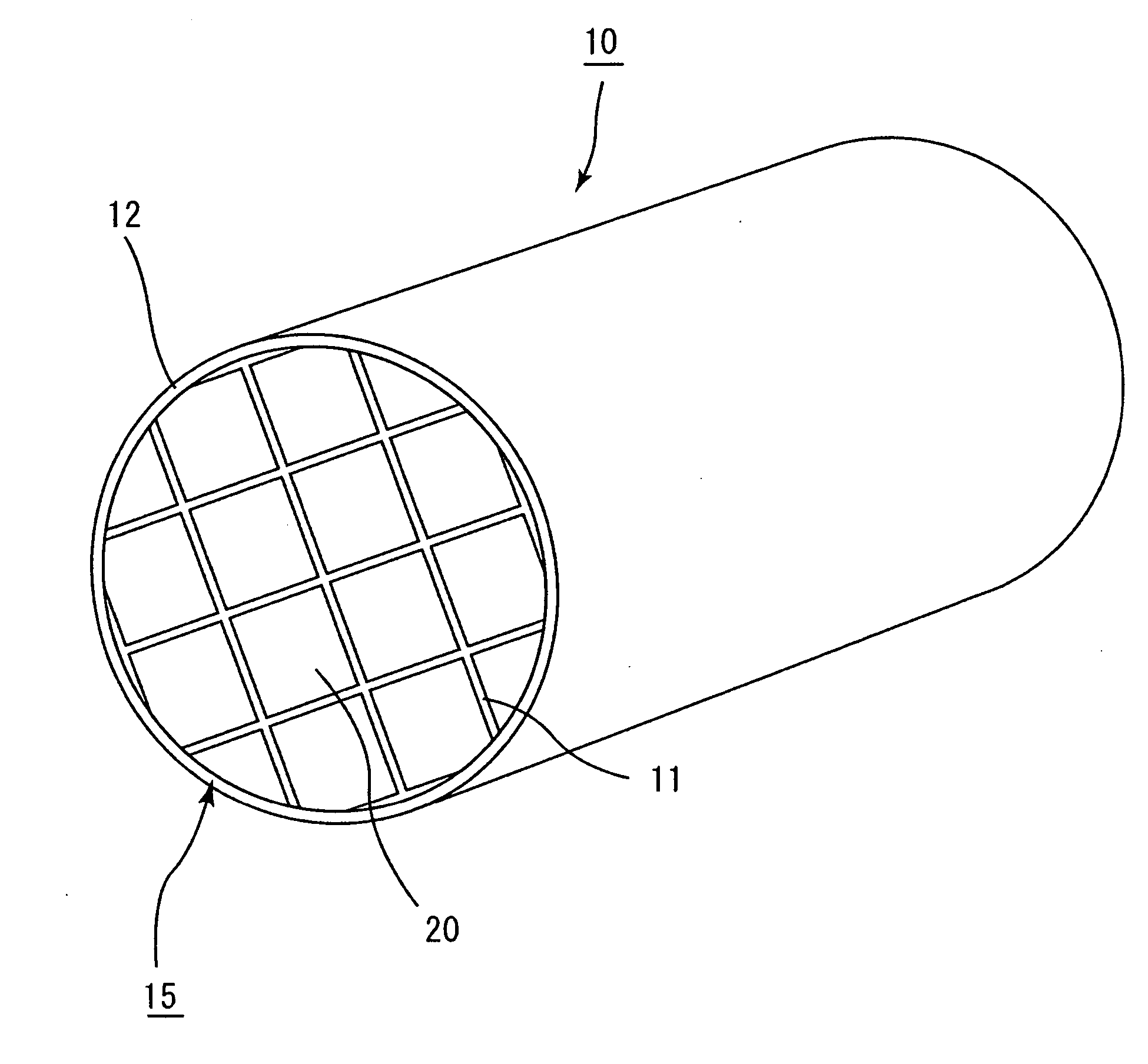

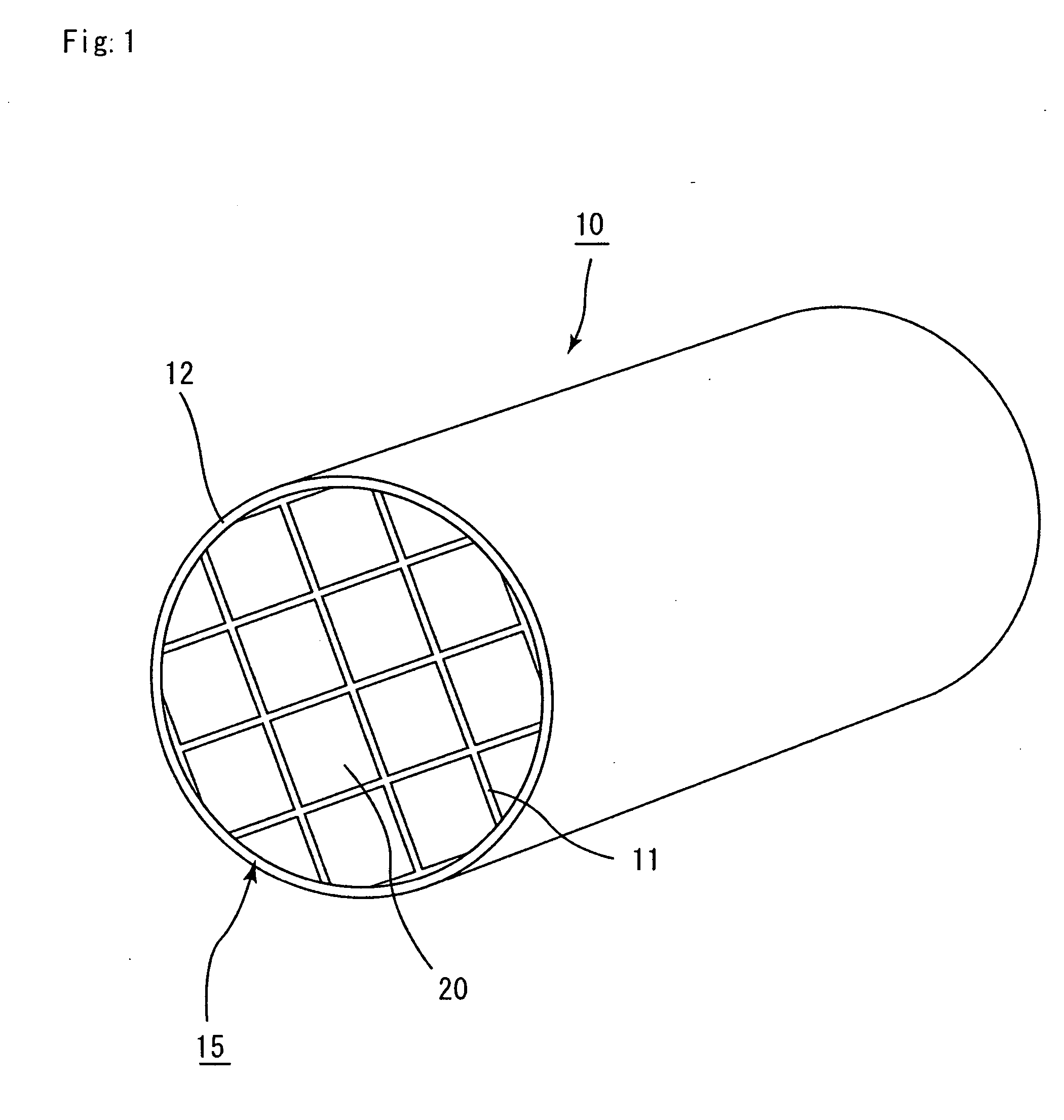

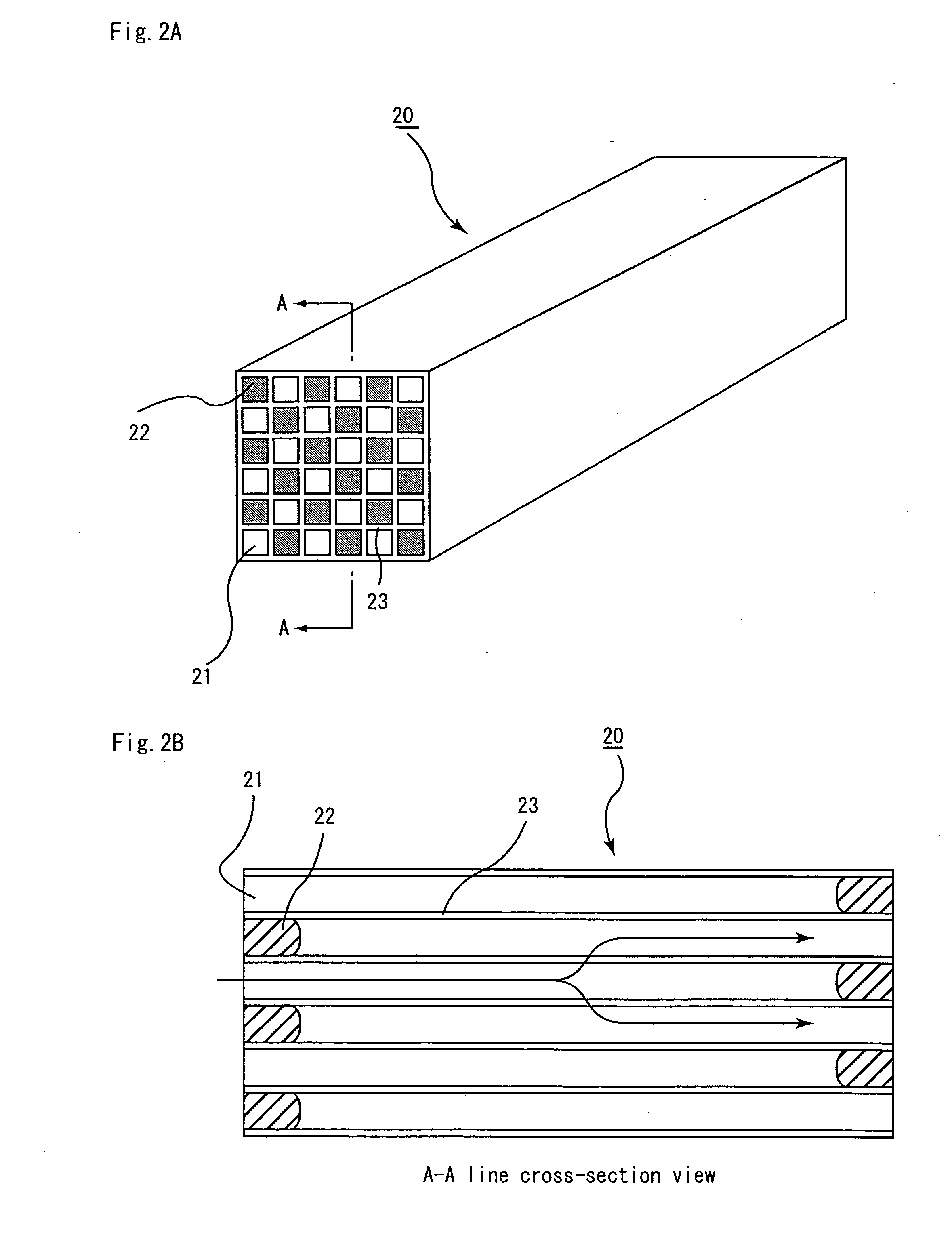

Honeycomb structured body

Owner:IBIDEN CO LTD

Non-volatile memory cells, memory arrays including the same and methods of operating cells and arrays

InactiveUS20060198189A1Easy to eraseLarge operating windowRead-only memoriesDigital storageDielectric structureCondensed matter physics

Memory cells comprising: a semiconductor substrate having a source region and a drain region disposed below a surface of the substrate and separated by a channel region; a tunnel dielectric structure disposed above the channel region, the tunnel dielectric structure comprising at least one layer having a small hole-tunneling-barrier height; a charge storage layer disposed above the tunnel dielectric structure; an insulating layer disposed above the charge storage layer; and a gate electrode disposed above the insulating layer are described along with arrays thereof and methods of operation.

Owner:MACRONIX INT CO LTD

Method of treating diseased valve

A device and method for improving flow through a native blood vessel valve, such as the aortic valve, are provided. The present invention allows a miniature valve to be implanted into affected leaflets percutaneously, obviating the need for coronary bypass surgery. The method includes the cutting of small holes, on the order of 4 mm, in the leaflets of a targeted valve, thereby allowing blood to flow through the newly formed holes. The holes are used as attachment sites for the miniature valves of the present invention.

Owner:HLT INC

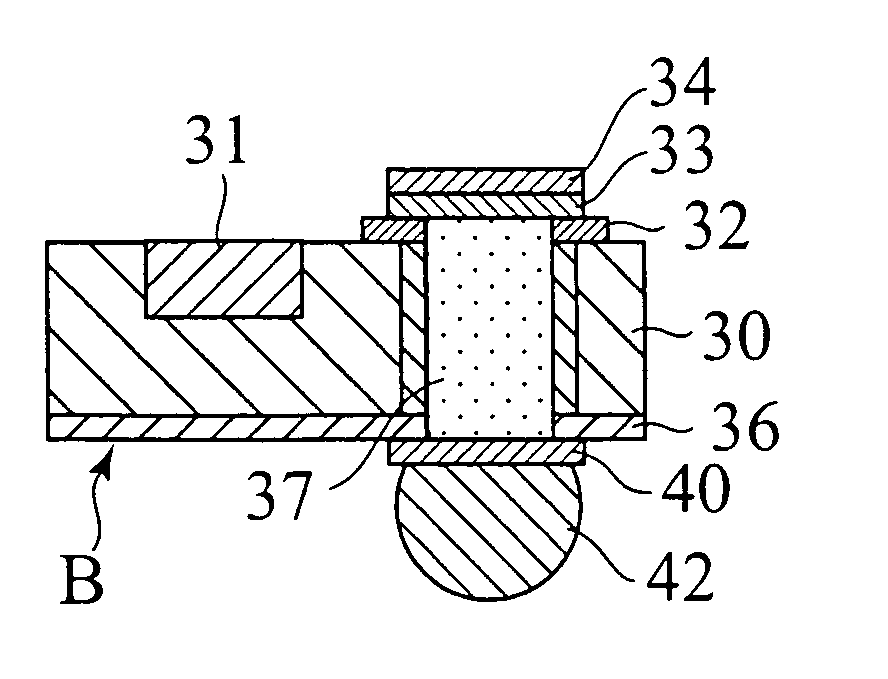

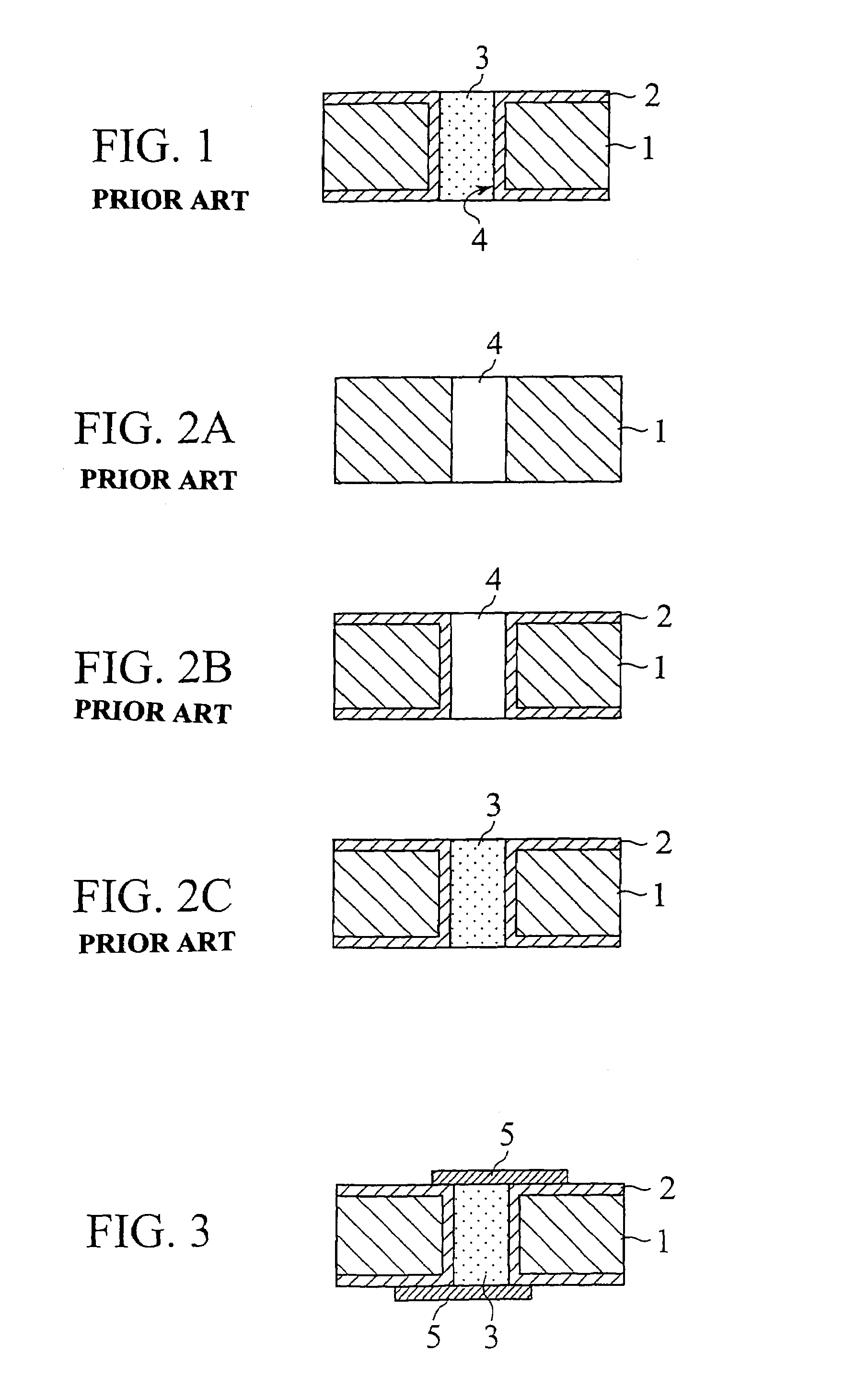

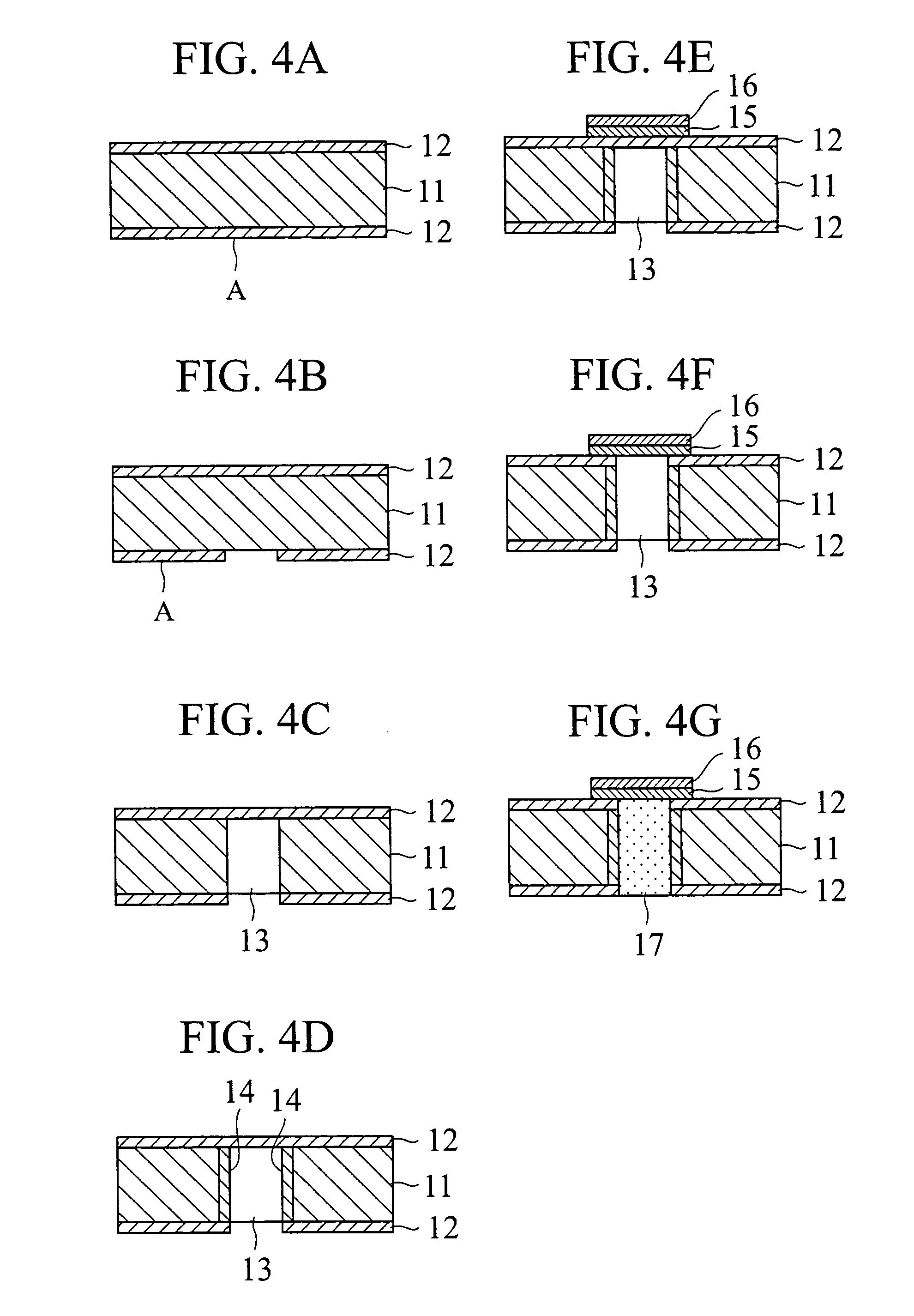

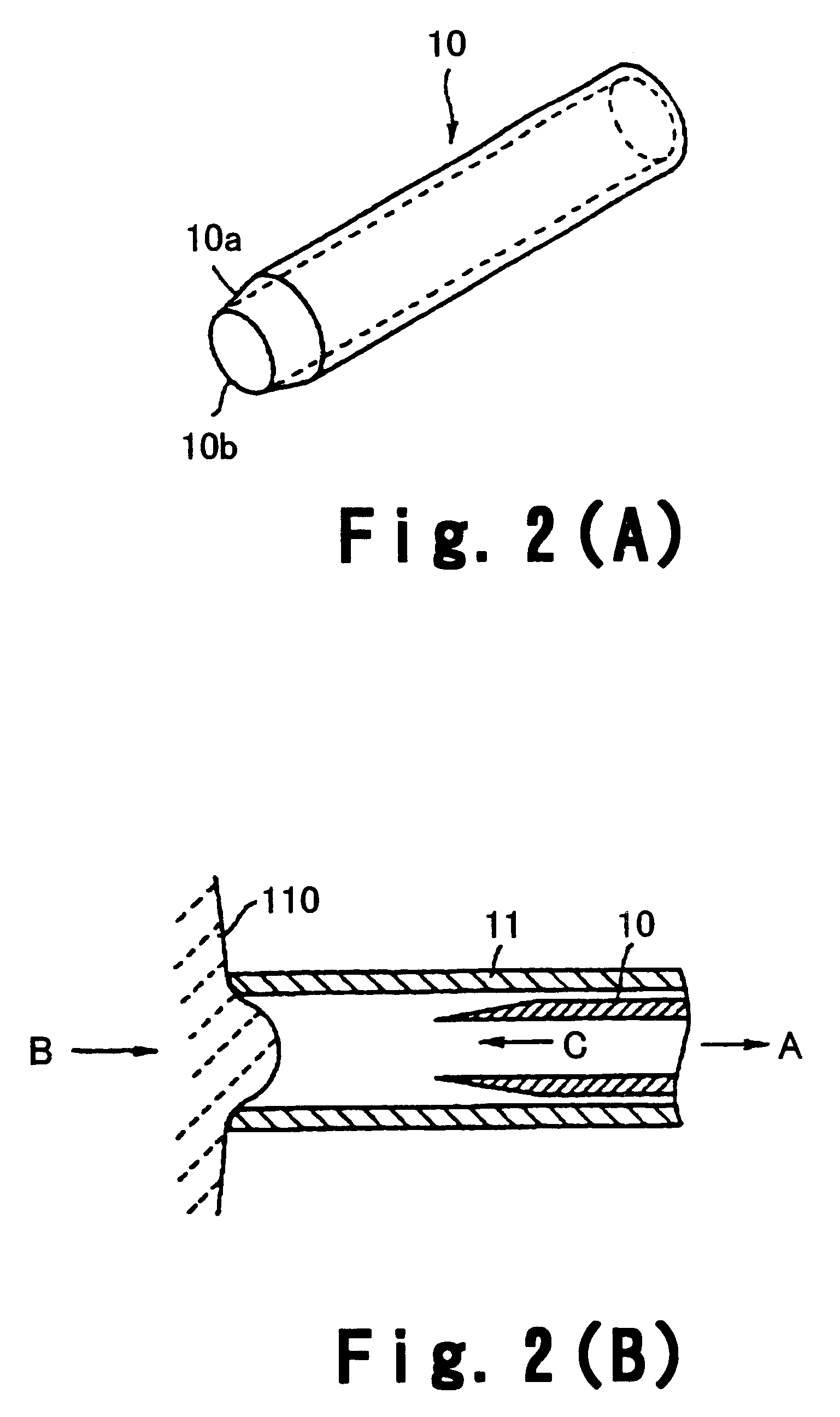

Manufacturing method of a semiconductor substrate provided with a through hole electrode

ActiveUS7022609B2Semiconductor/solid-state device detailsSolid-state devicesThin metalConductive materials

A manufacturing method of a semiconductor substrate provided with a through hole electrode is proposed. In accordance with the methods, it is possible to effectively form a through hole electrode in a semiconductor substrate in which a device and a wiring pattern have been already fabricated. This manufacturing method includes the steps of forming a first silicon oxide film 12 on a principal surface of the semiconductor substrate 11, forming a small hole 13 through the semiconductor substrate 11 from the opposite the step to reach to the first silicon oxide film 12, covering the inside of the small hole 13 with the second silicon oxide film 14, forming a first thin metal film 15 and a second thin metal film 16 on the first silicon oxide film 12, partially removing the first silicon oxide film 12 corresponding to the end of the small hole 13, and filling the small hole 13 with the conductive material to form a through hole electrode 17.

Owner:FUJIKURA LTD +1

Method of crystalline lens replacement

InactiveUS6413262B2Easy injectionSuitable refractive powerEye surgerySurgical instrument detailsLens crystallineLens substance

A method of crystalline lens replacement for eyes comprises the steps of forming a small hole that penetrates through the lens capsule, removing a part of the crystalline lens substance through the hole, refilling the lens capsule by injecting a composition comprising a hydrophilic polymer directly into the lens capsule, and closing the hole. The method of crystalline lens replacement may be performed on animals or humans. Furthermore, the method of crystalline lens replacement may be performed on a patient suffering from cataract, where the opaque crystalline lens substance in the lens capsule is removed.

Owner:SAISHIN MOTOTSUGU +3

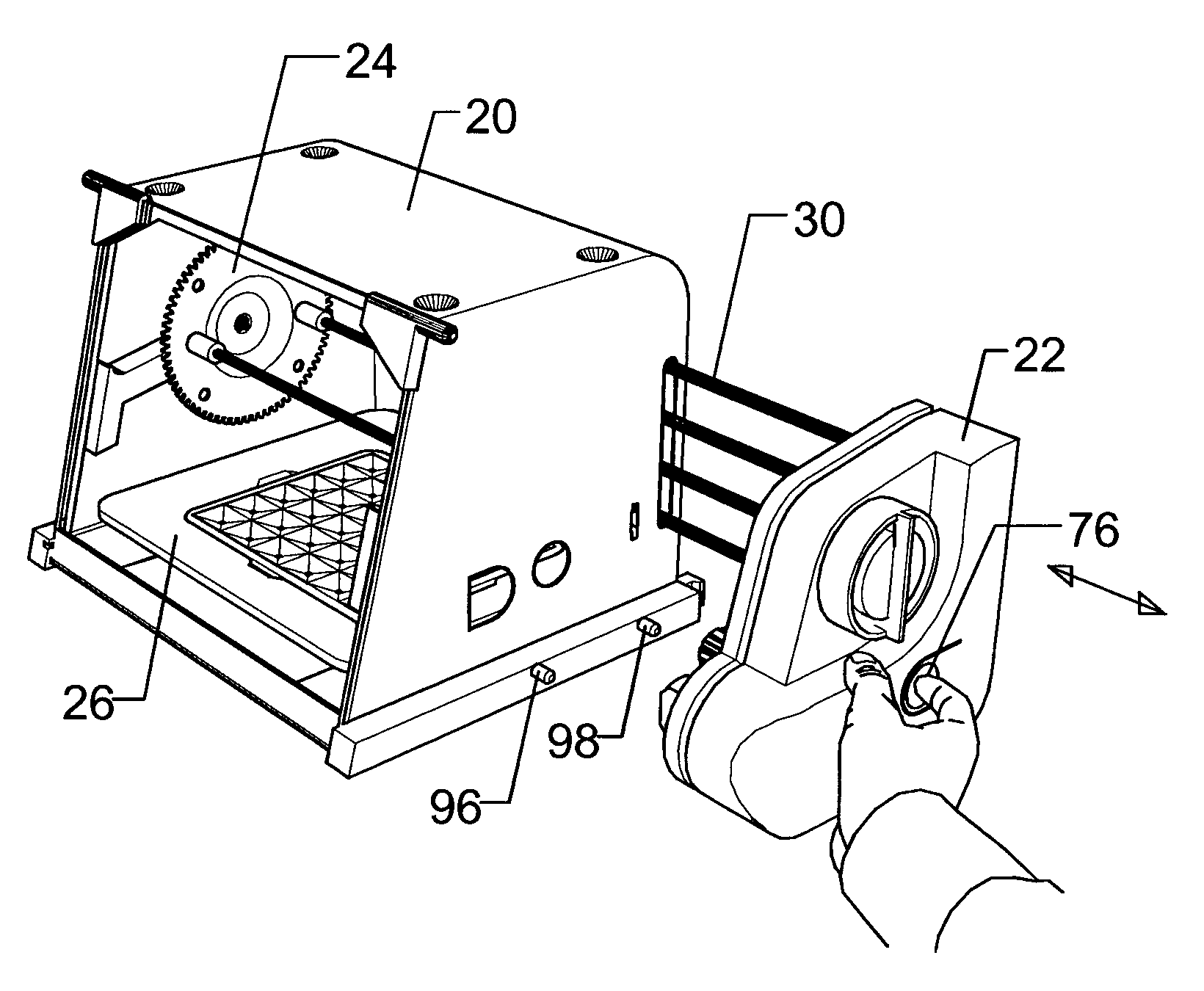

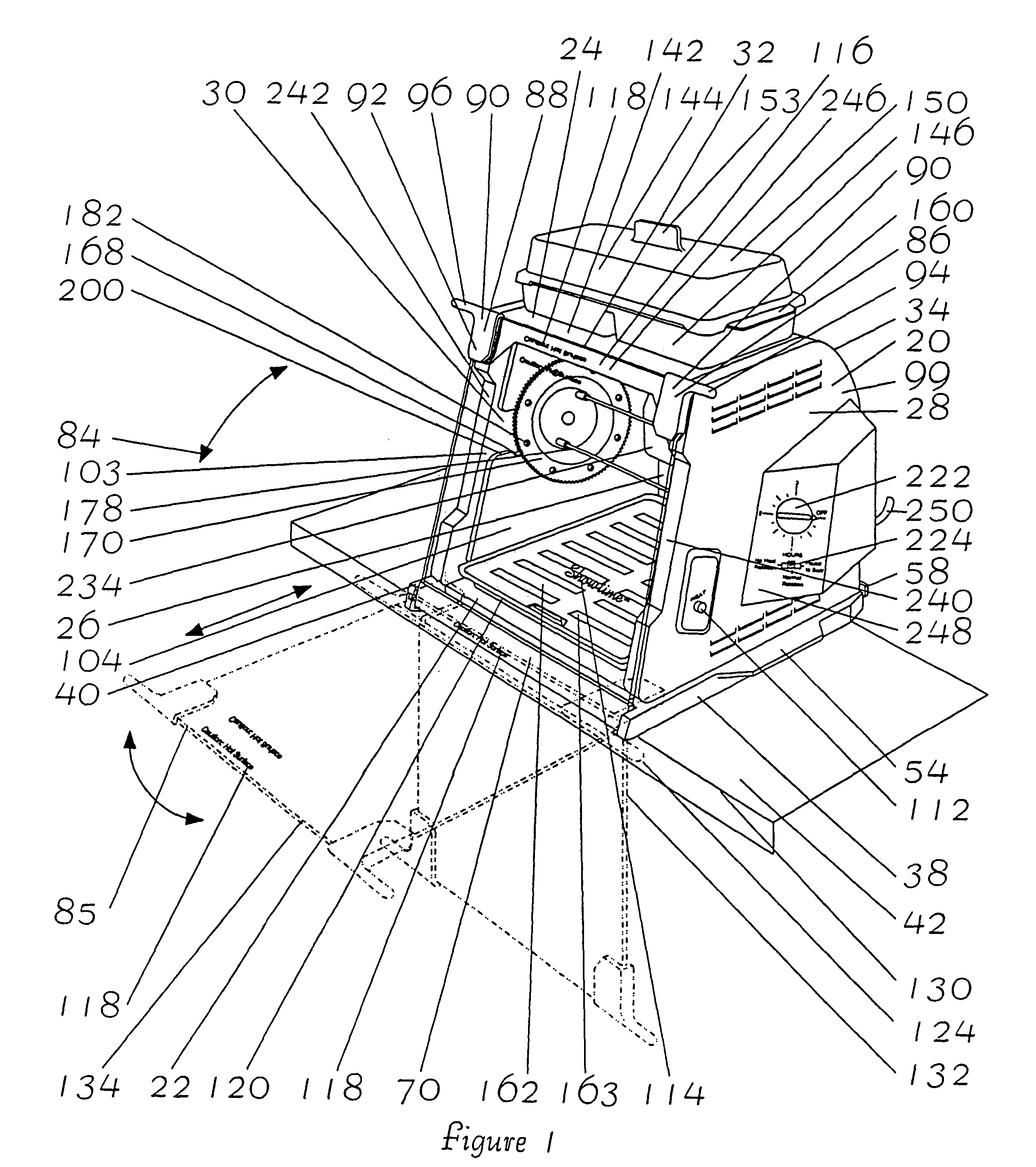

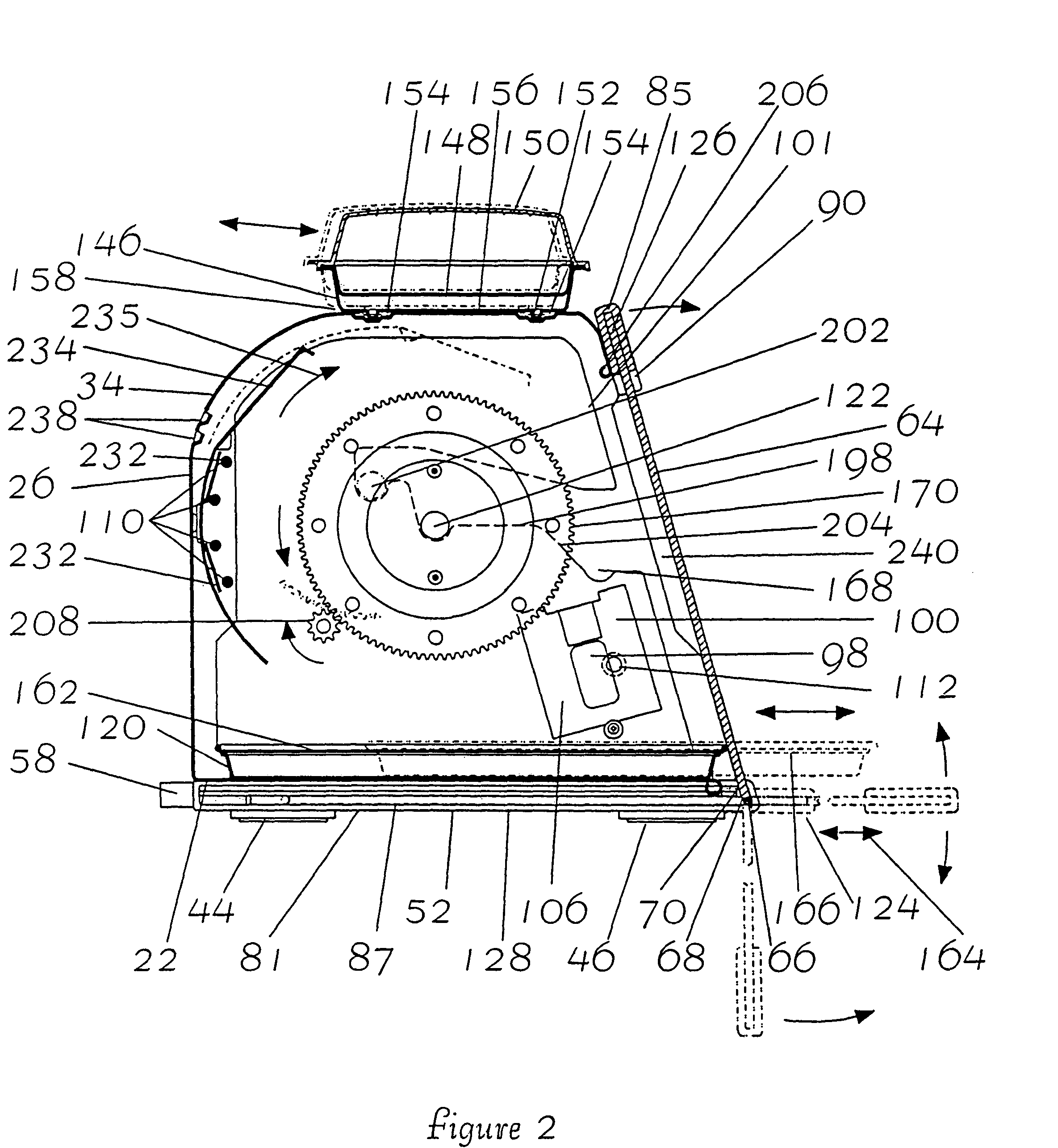

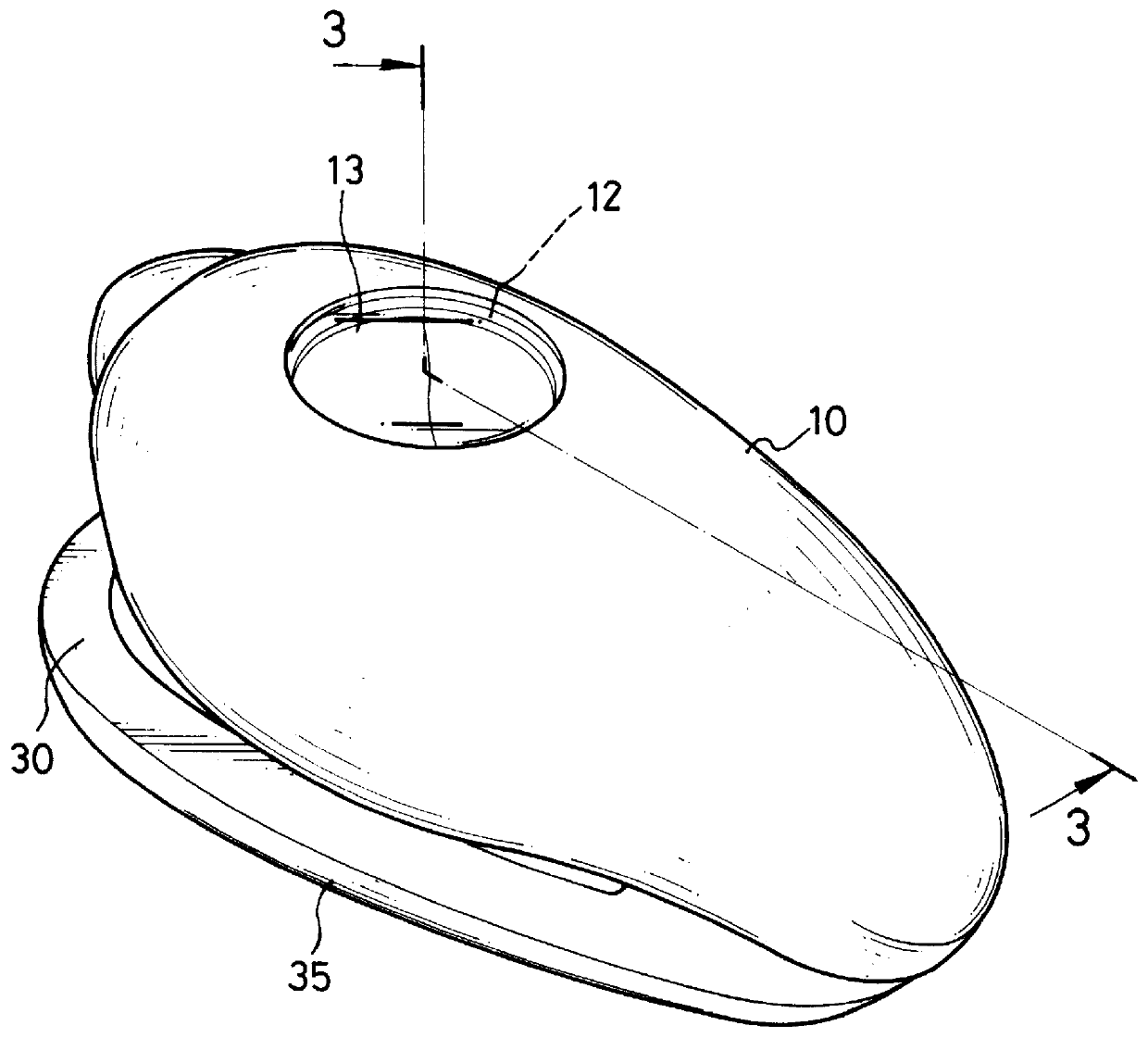

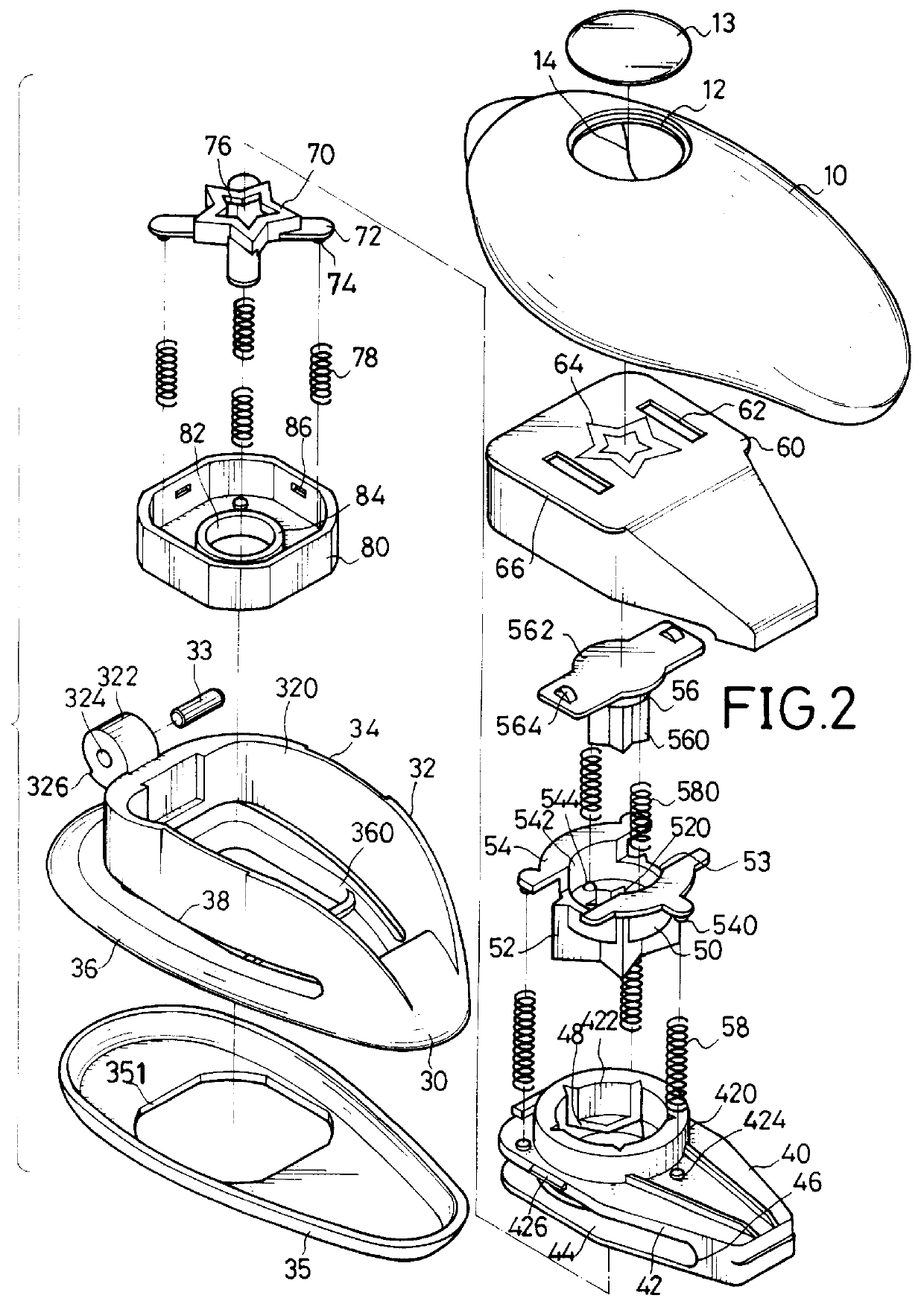

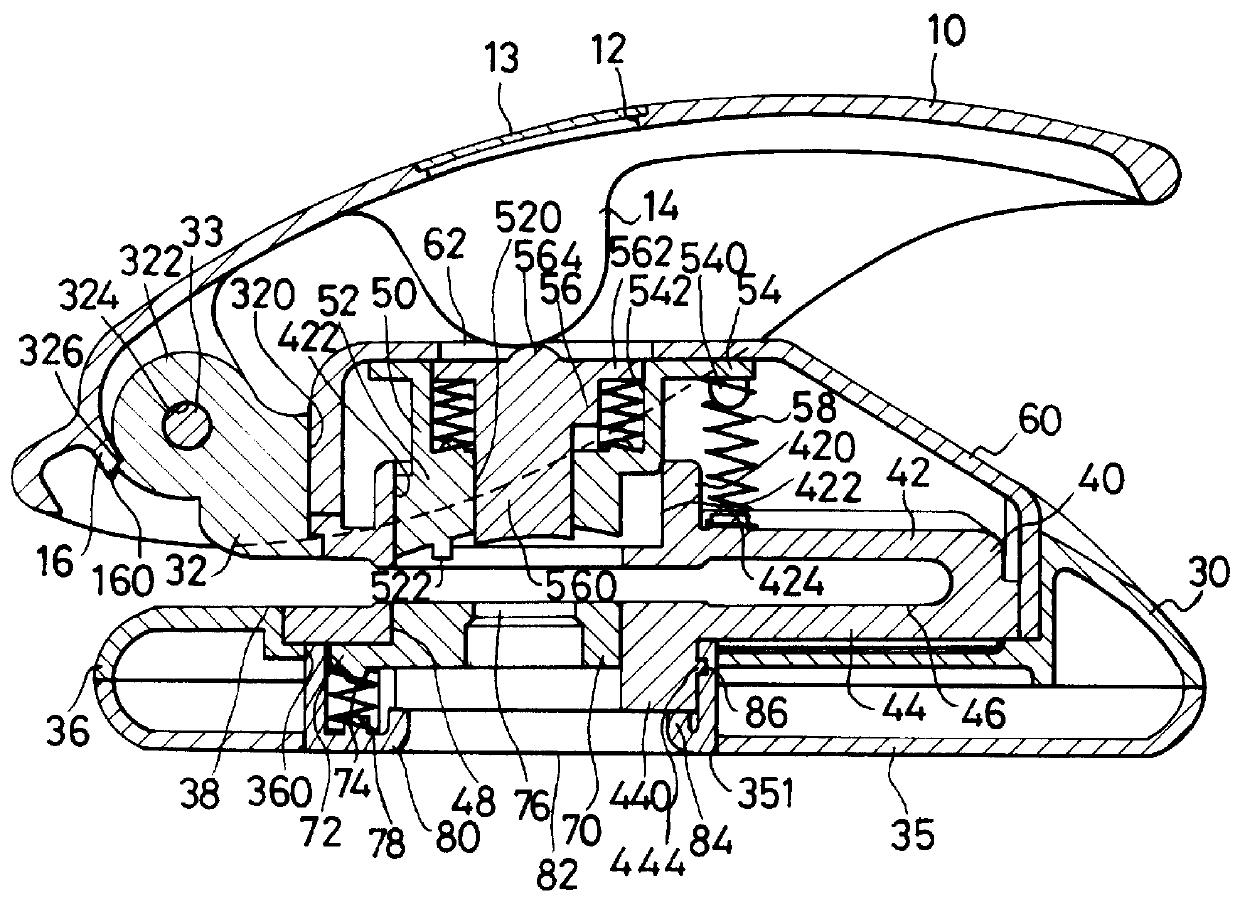

Enclosed rotisserie with detachable electronic components

InactiveUS7021204B2Easy to insertEasy to removeRoasting apparatusRoasters/grillsEngineeringElectronic component

The present invention is directed toward an improved rotisserie oven, having the following features: a removable side mounted control box; single wall oven cabinet construction; single wall oven cabinet construction with tabs protruding from the lower side edges of the oven cabinet which mount feet to support the cabinet; a rigid heat coil structurally connected to the removable control box; a heat coil, supported by a bracket within the oven cabinet which both allows the heat coil to be slid in and out of the oven cabinet and allows for expansion of the heat coil when the coil is energized; a light bulb integrated with the removable control box so that the bulb's globe protrudes into the interior of the oven cabinet when the control box is mounted on the oven cabinet; a drive mechanism integrated into the removable control box which allows the control box to be easily removed from the oven cabinet; a drip pan located below the spit, which has its liquid catching reservoir recessed in from the pan's perimeter; a drip pan cover with an array of small holes recessed into its surface; a spit assembly, whose axis of rotation is located closer to a glass view port located on the oven cabinet's exterior than to the heater located within the oven cabinet; and a spit assembly, whose axis of rotation is located closer to the oven cabinet's loading door than to the top, bottom, back and heat coil within the oven cabinet, using the rotisserie in combination with specific foods and eating schedule, to help people lose weight.

Owner:RONCO HLDG

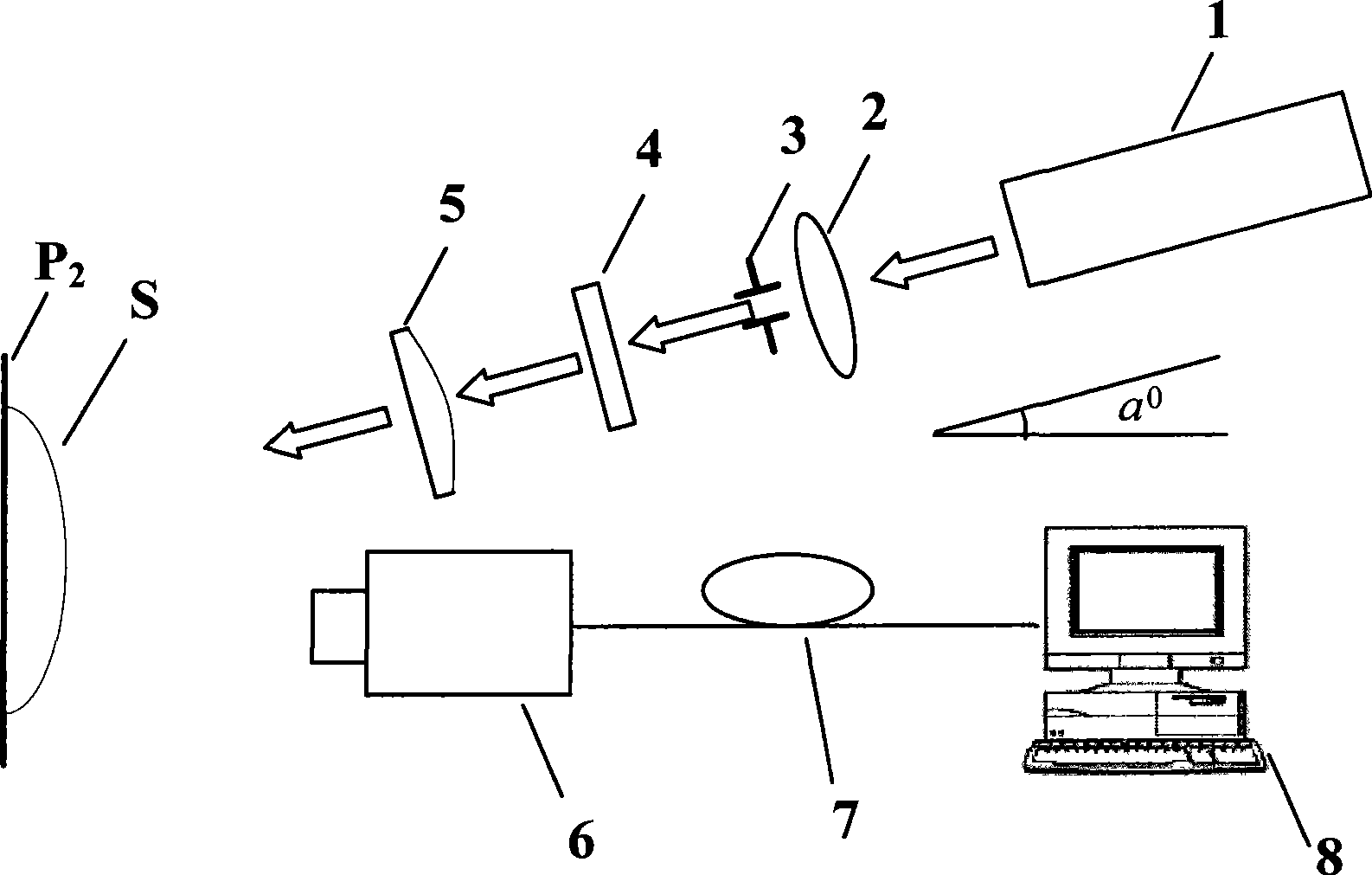

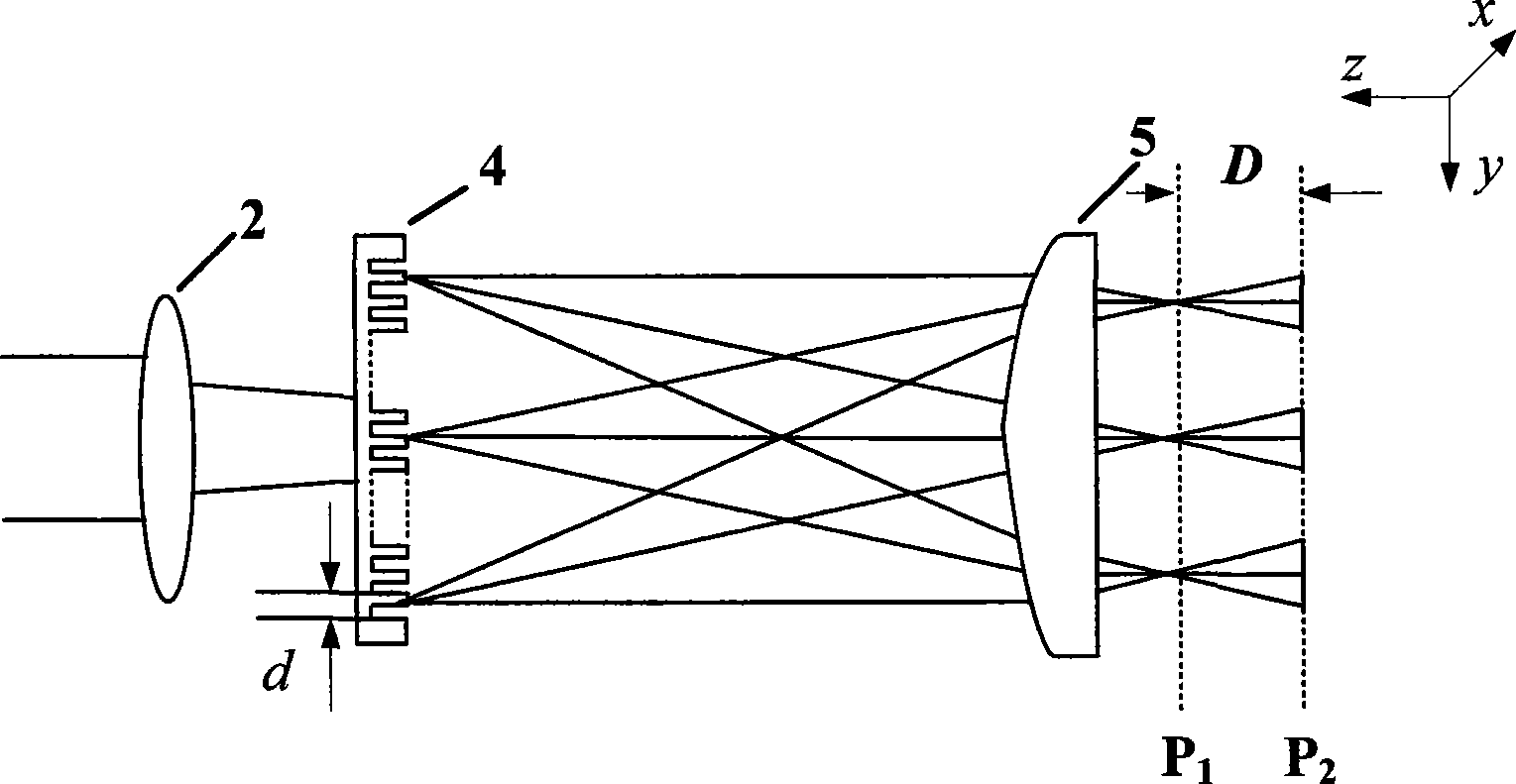

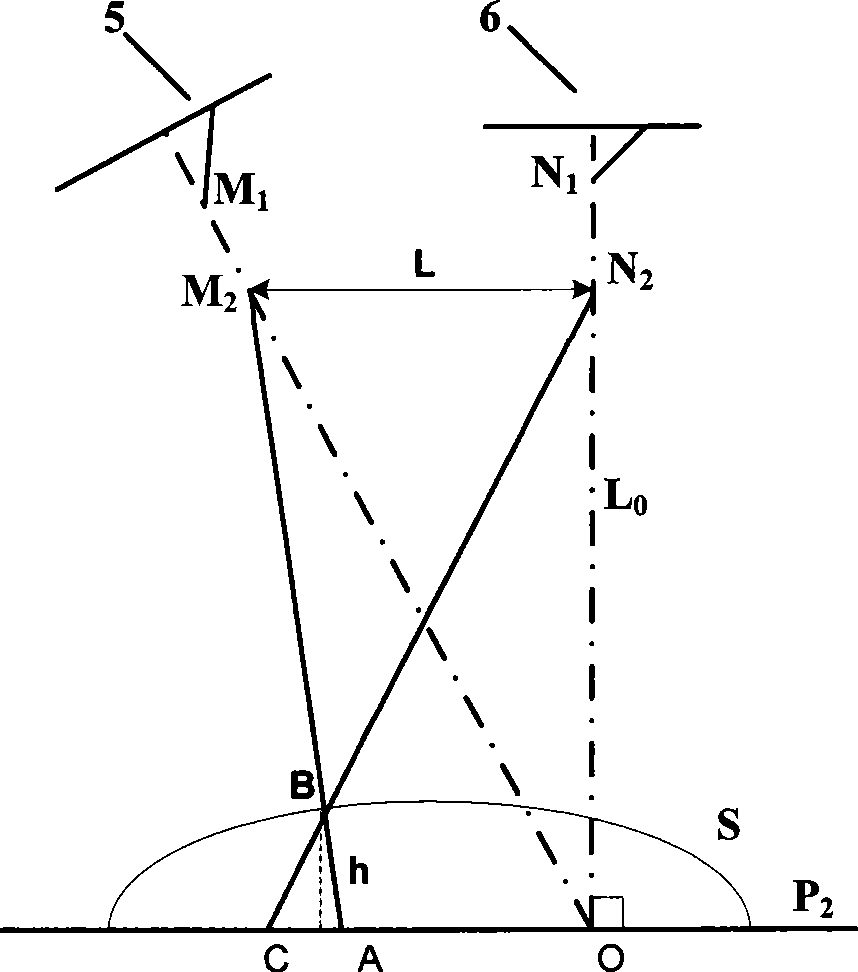

Object three-dimensional contour outline measuring set and measuring method

ActiveCN101451826AUniform light intensity at the spectral pointImprove energy utilizationUsing optical meansInformation processingMeasurement device

An object three-dimensional outline measurement device and a measurement method are disclosed, the device is composed of a laser diode, a lens, an aperture diaphragm, a two-dimensional Dammam grating, a cylindrical mirror and an area array CCD camera, a transmission line and a computer, the connection relationship therebetween is as below: a beam emitted by the laser diode passes through the lens, the aperture diaphragm, the two-dimensional Dammam grating, and the cylindrical mirror sequentially to form one-dimensional projection array stripes, which illuminates the surface of an objective to be measured, the area array CCD camera collects the grating projection strips modulated by three-dimensional digital shape on the surface of the measured objective and outputs the strips to the computer via the transmission line, the computer includes an image collecting interface, image collecting software and three-dimensional measurement information reconstruction algorithm software. The invention has, by utilizing the Fourier transform three-dimensional outline measurement structure, the advantages of high energy utilization rate, simple measurement structure, high measurement precision, convenient computer reconstruction information processing and great easiness for operation.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

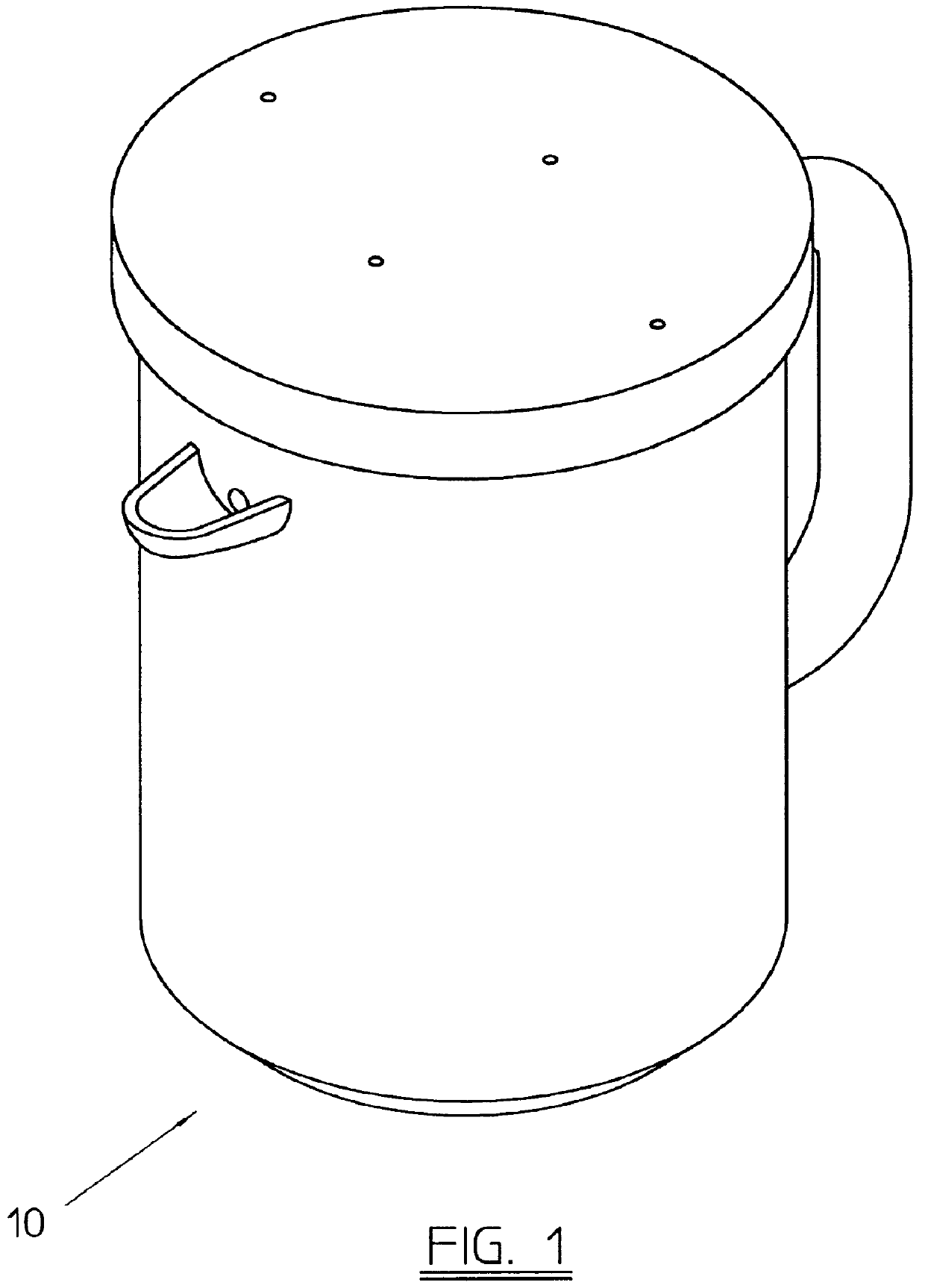

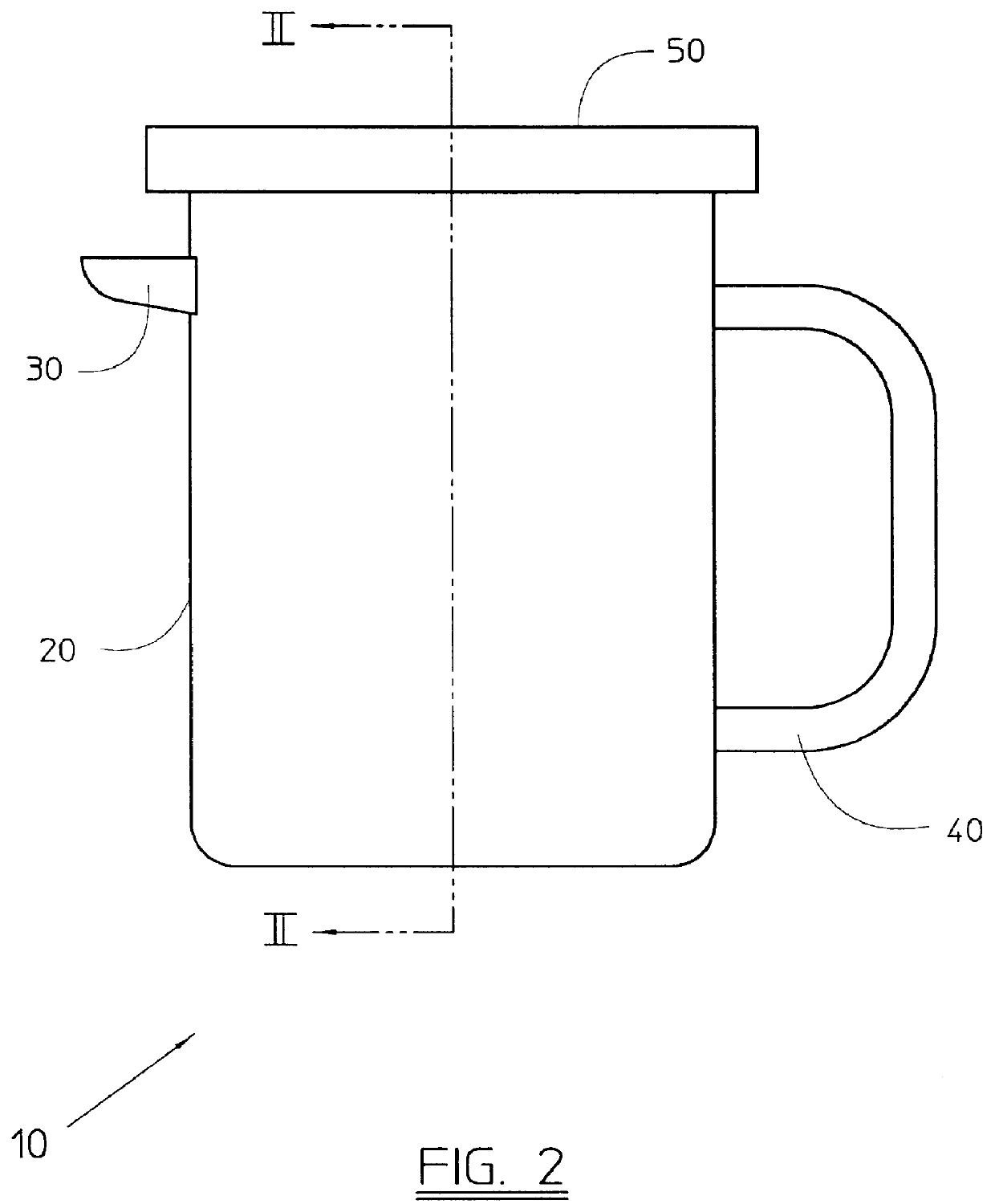

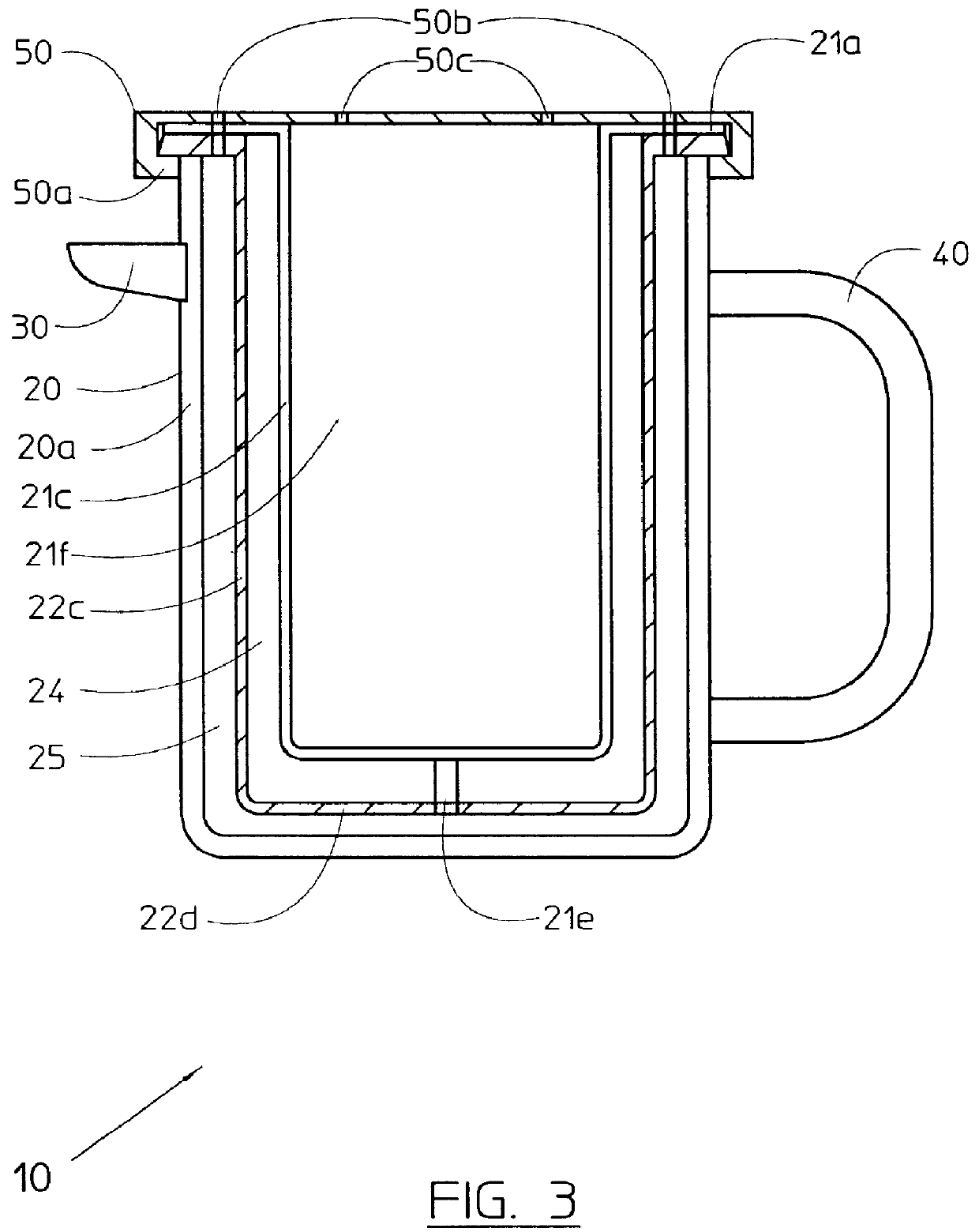

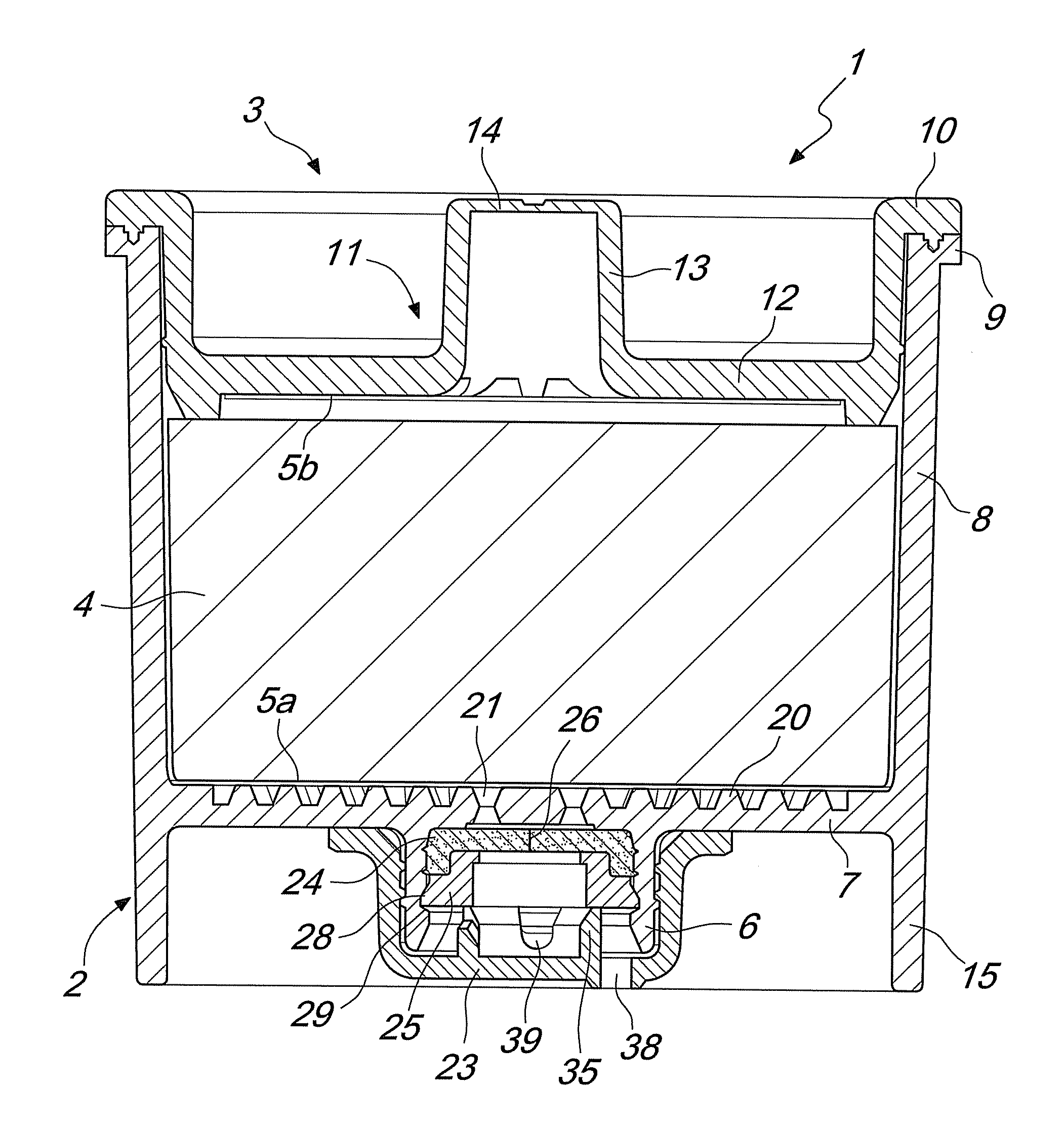

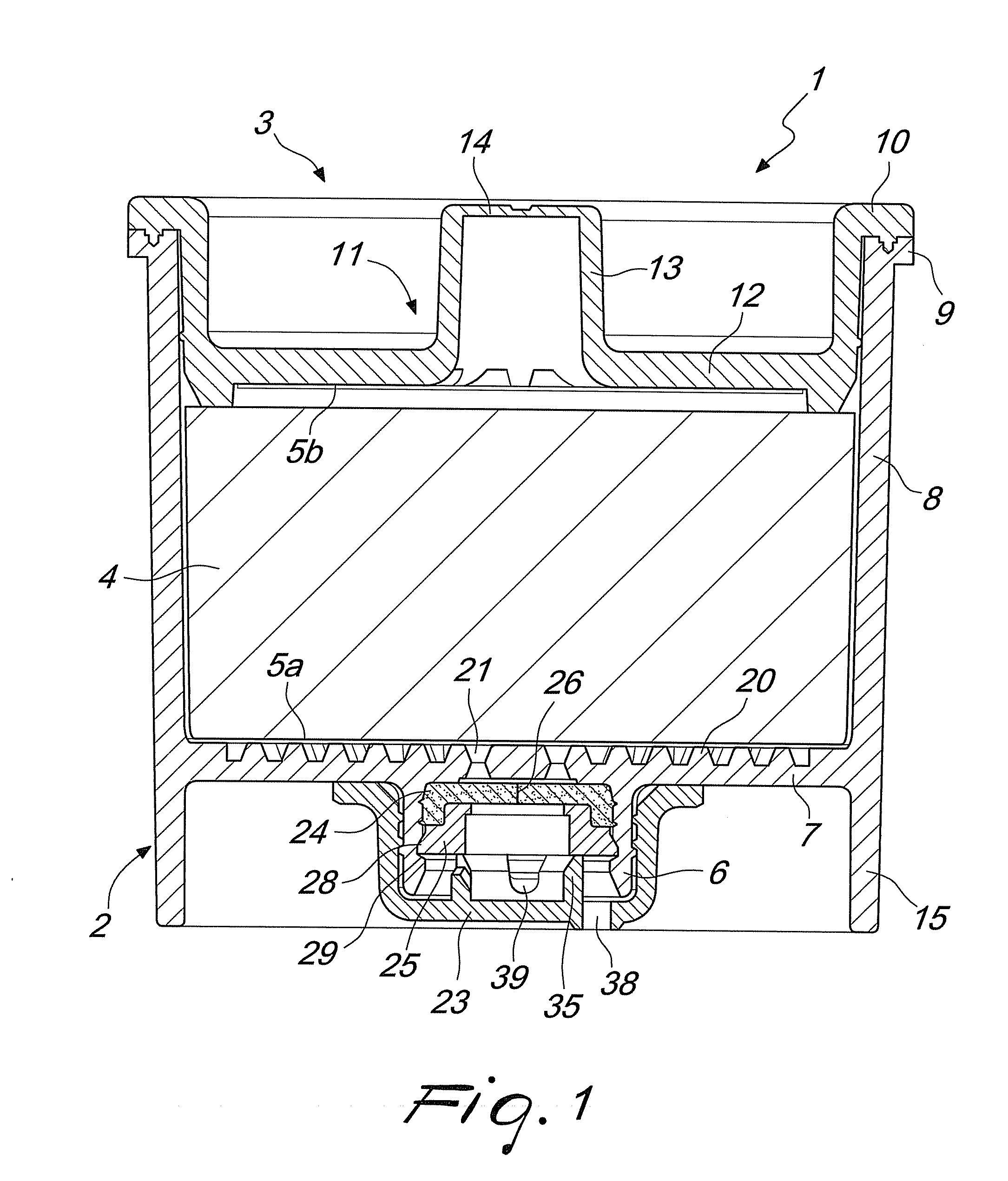

Constant temperature beverage cup

InactiveUS6161720AKeep warmSmooth temperatureDomestic cooling apparatusLighting and heating apparatusRespiratorEngineering

The invention is a drinking vessel that keeps coffee or other hot beverages hot, yet readily drinkable. The basic design of the invention is an inner beverage vessel and an outer beverage chamber with an insulator chamber of air between them. There is a small hole in the bottom of the inner beverage vessel which allows the contents to flow into the outer beverage chamber. When the drinker tips the cup to drink, beverage flows from the inner beverage vessel to the outer beverage surrounding the cup and pours out of a mouthpiece. The amount of liquid that fills the outer beverage chamber quickly cools enough to drink, but still remains warm. The insulator chamber keeps the beverage in the inner beverage vessel hot for a longer period of time. The lid for the cup is sealed to keep the contents warm but has a small pinhole to eliminate the build-up of a vacuum.

Owner:CASTLE BENEDICT P

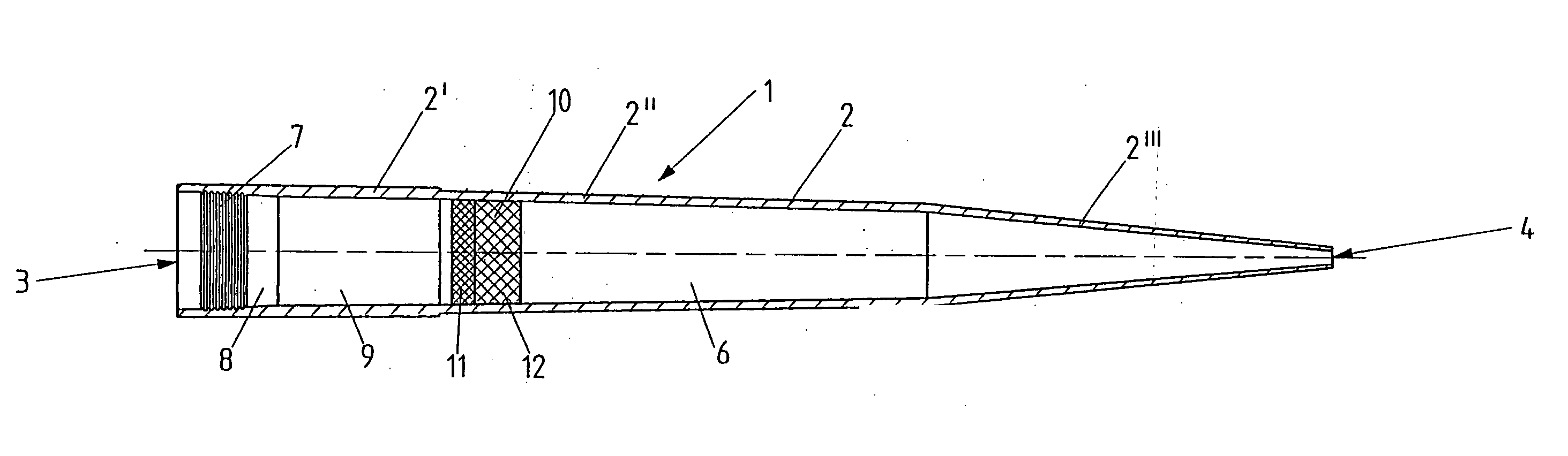

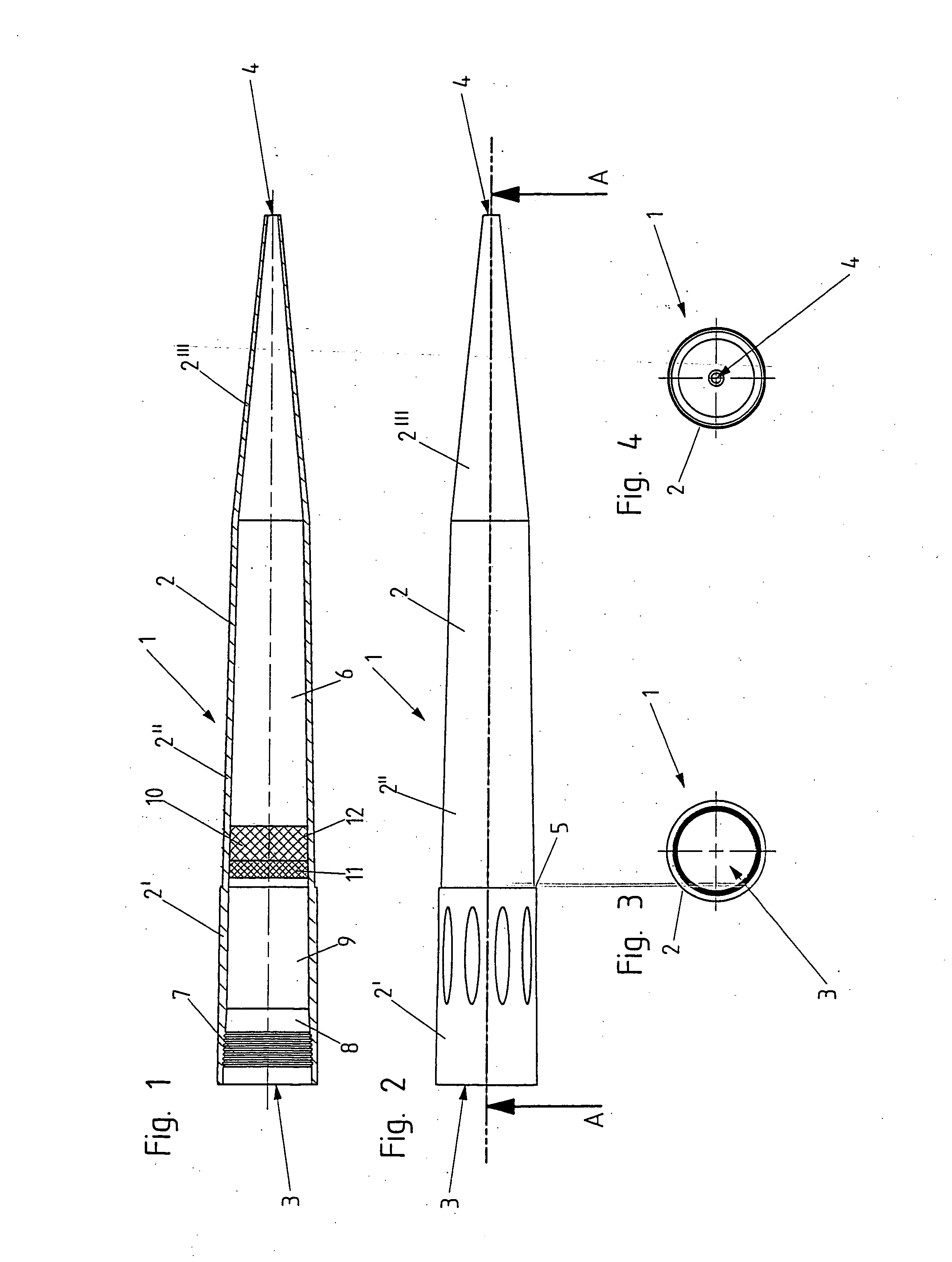

Filter pipette tip

ActiveUS20060177352A1Metering accuracy is not impairedImprove filtering effectAnalysis using chemical indicatorsAnalysis by subjecting material to chemical reactionPipettePore diameter

Filter pipette tip with a small tube with a relatively large aperture at one end for attaching to a pipette, a relatively small aperture at the other end for the passage of liquid and a through-channel between the large aperture and the small aperture and a porous filter arranged in the through-channel, filling up a portion of the through-channel and comprising at least two layers arranged in series in the direction of the through-channel of which a fine-pore layer has a pore size of a maximum of approximately 20 μm and a coarse-pore layer a pore size of approximately 20 to 50 μm, the two layers having different pore sizes.

Owner:EPPENDORF SE

Paper punch

A paper punch has an inner punch and an outer punch movably received with respect to each other. The outer punch has a first contour punch so as to be able to punch a hole in a piece of paper with the same contour as that of the first contour punch, and the inner punch has a second contour punch so as to punch a small hole in a piece of paper with the same contour as that of the second contour punch. Because the second contour punch moves first and the first and the second contour punches are placed concentrically, a piece of paper is then able to be punched twice by the first and the second contour punches to have an attractive shape.

Owner:LEE CHENG HO

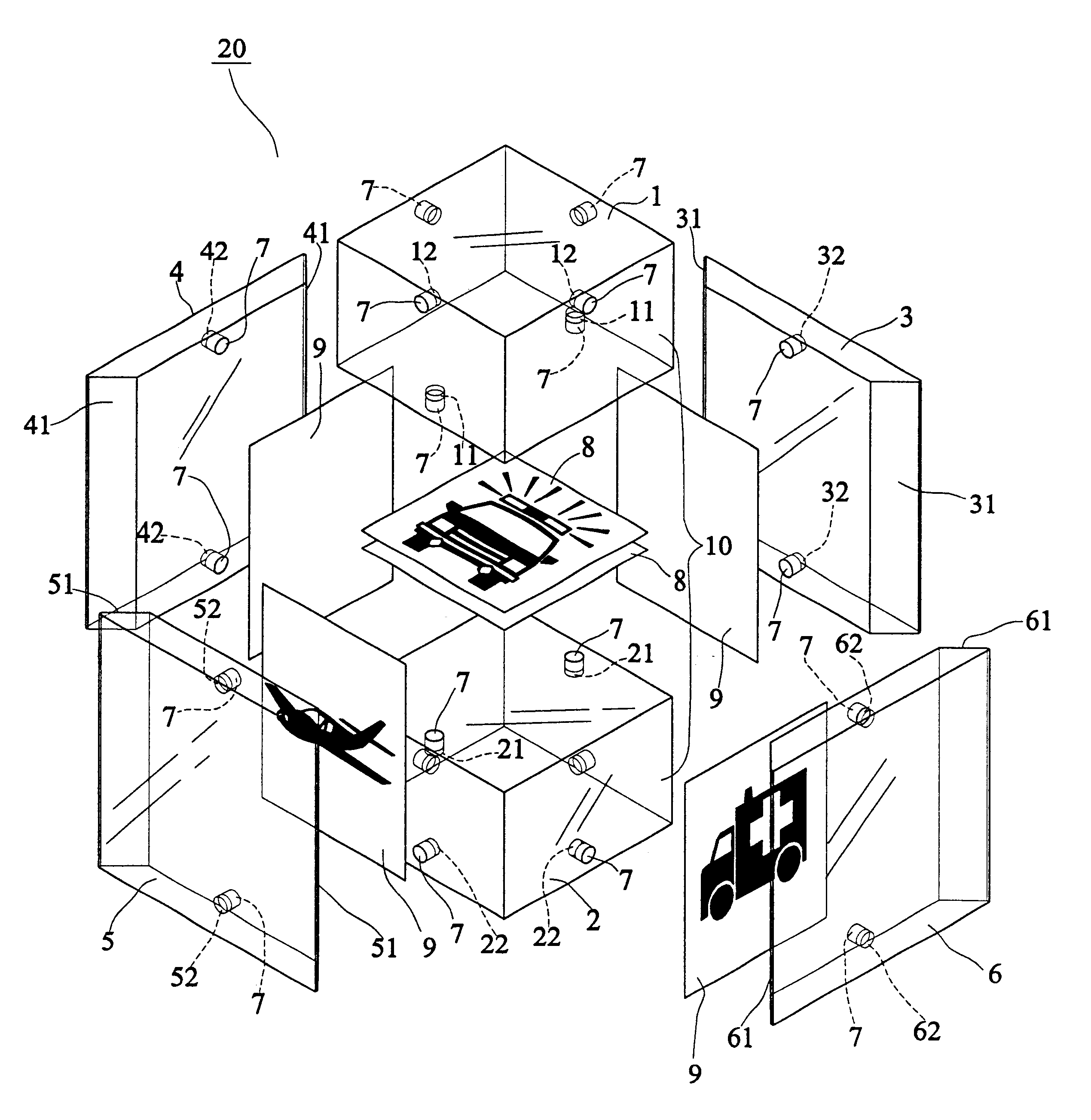

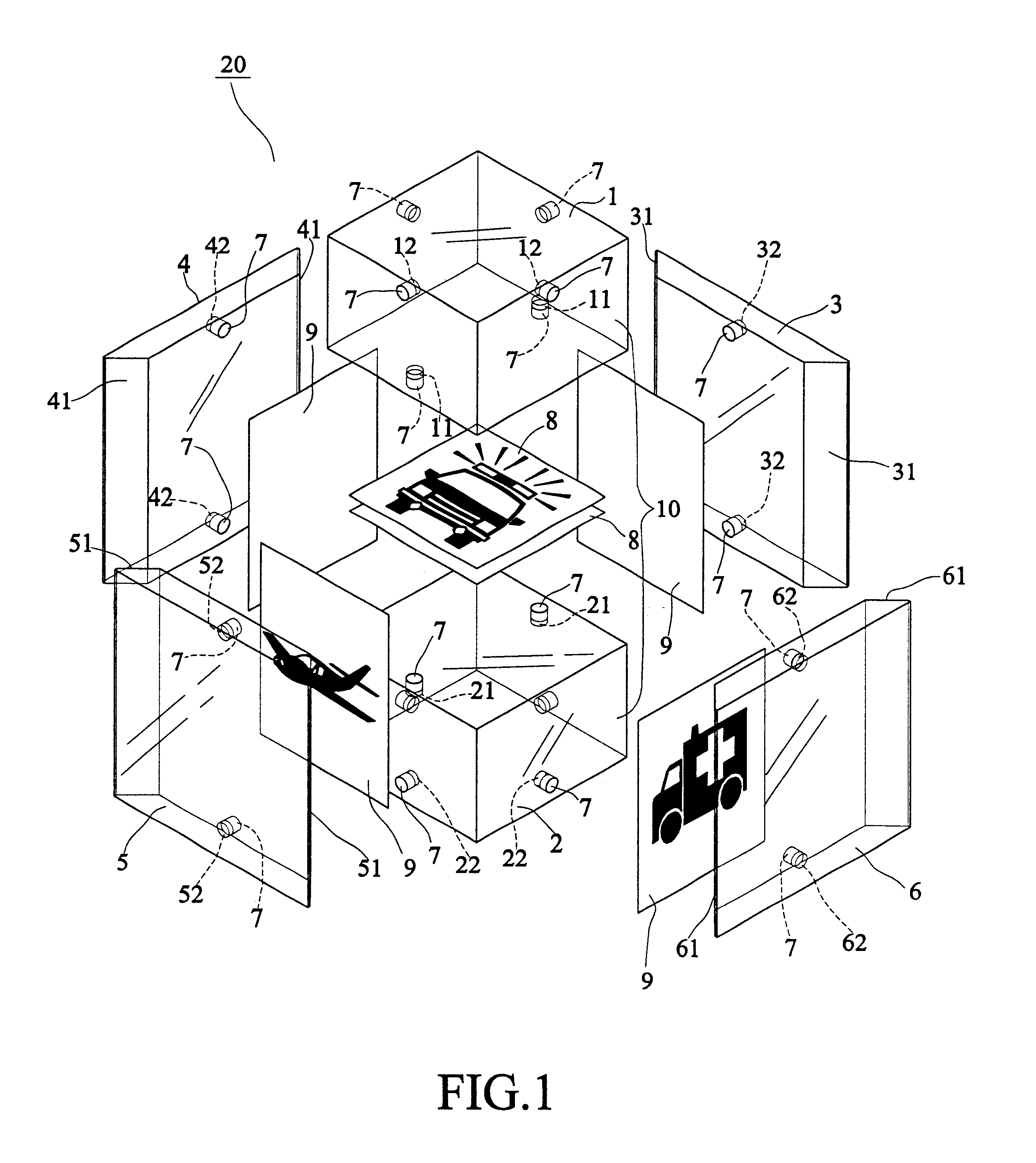

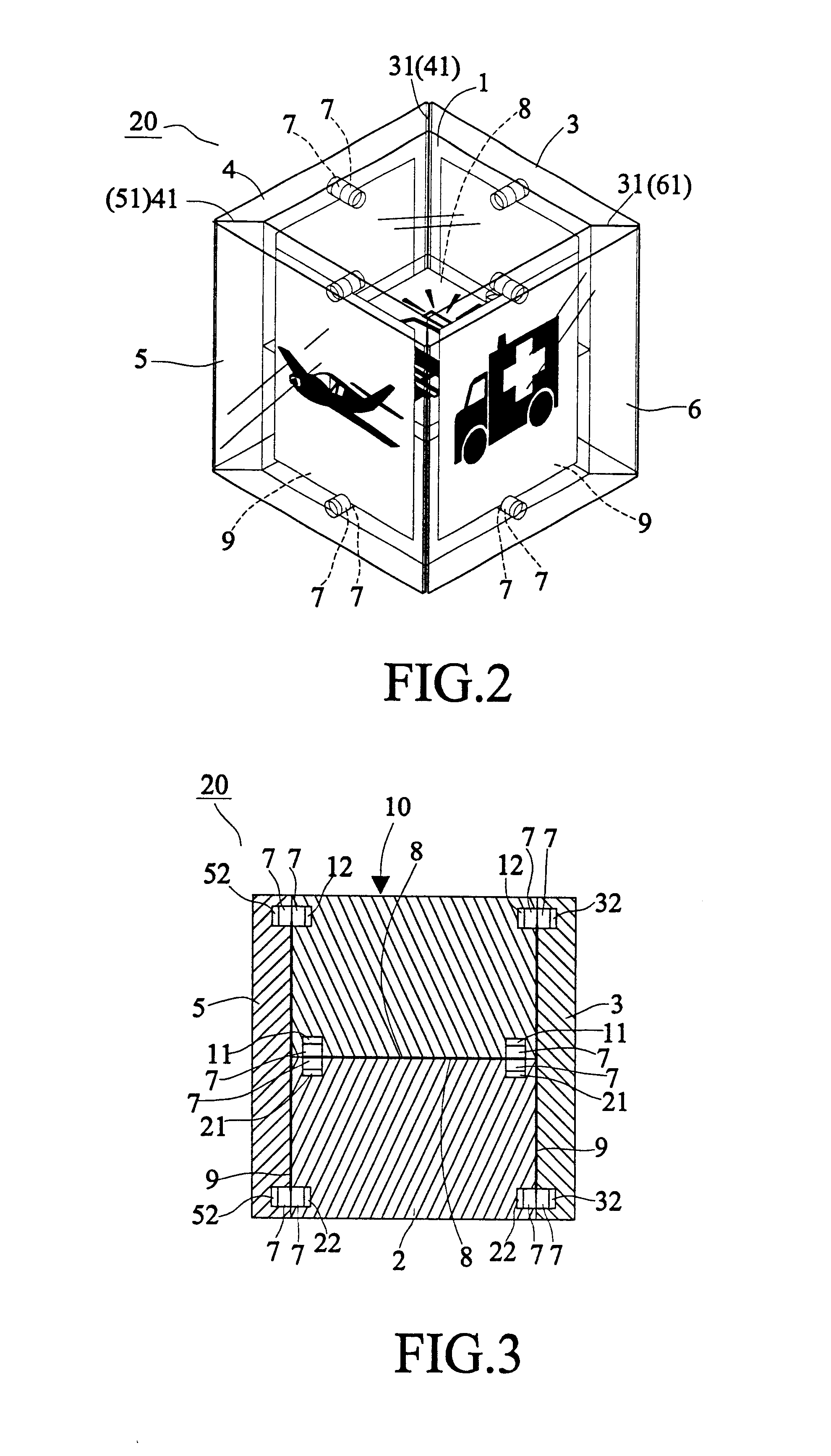

Transparent cube having picture displaying function

A transparent cube with picture displaying function comprising a transparent body and a plurality of transparent boards surrounded the transparent body, characterized in that the four side walls of the transparent body are provided with at least two small holes containing small magnet therein, and the inner side wall of the four transparent boards are provided with at least two small holes corresponding to the small holes of the transparent body and also containing a small magnet therein; when the transparent body contacts with the four transparent boards face to face, the transparent body is firmly secured together with the four transparent boards as a result of attraction force between the small magnets, and a picture (or photograph) is inserted in between the contact face of the transparent body and the four transparent boards such that the transparent cube can provides four displayed pictures for appreciation.

Owner:YEH SY YING

Method and device for detecting gases by absorption spectroscopy

ActiveUS20060119851A1Increase the itineraryImprove portabilityTransmissivity measurementsWavelengthAbsorption spectroscopy

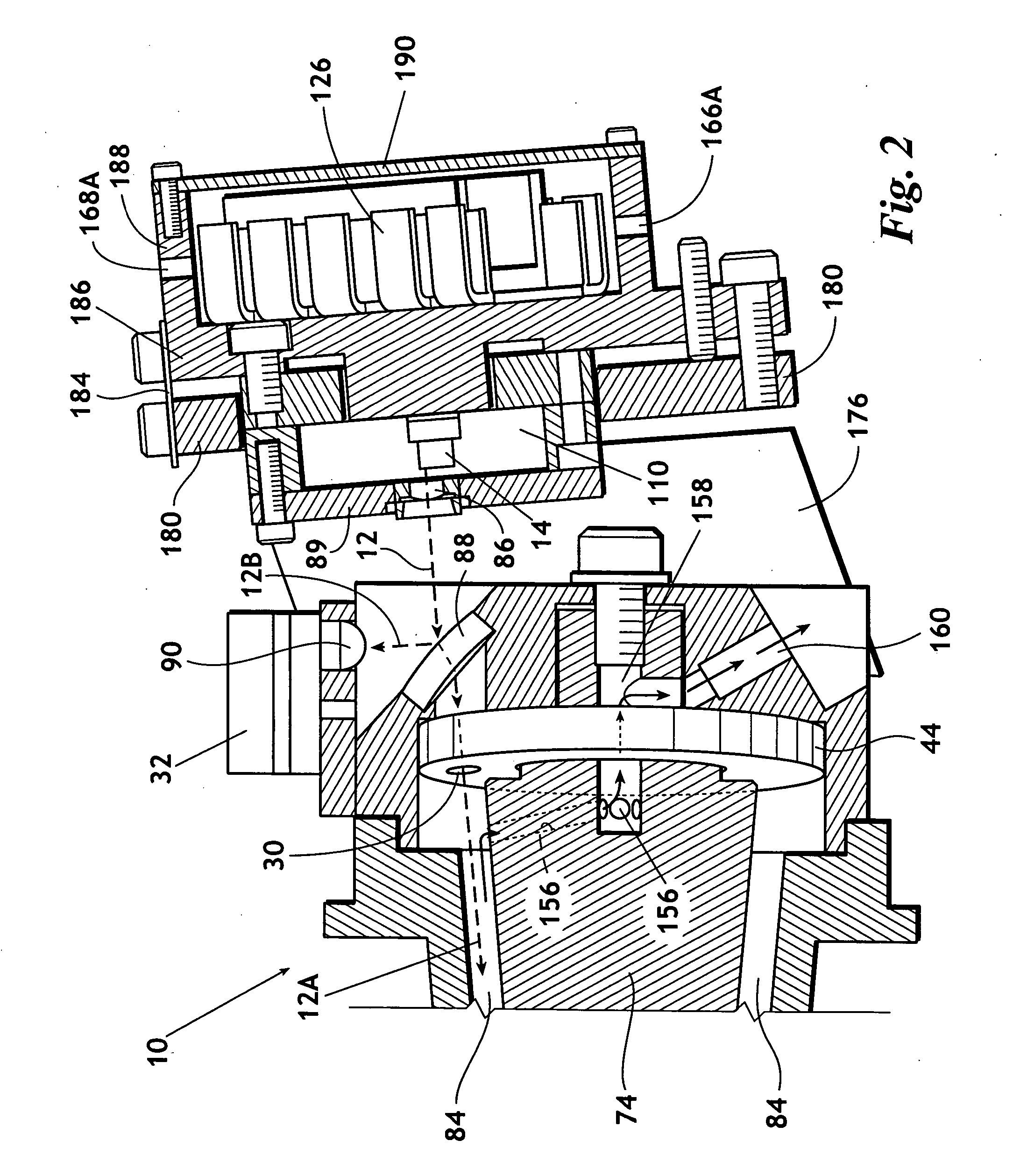

A method and device for measuring a concentration of a preselected gas in a gas sample are disclosed. The device comprises a Herriott type multipass cell (10) having a center axle (74) and a housing (80A, 80B) surrounding and spaced from the axle to provide a tubular sample cavity (84). The gas sample is pumped through the sample cavity via apertures (154, 156) provided in opposed ends of the axle. A first mirror (44) and a second mirror (46) are supported at opposed ends of the axle. A light source, e.g. a laser or LED, is provided for emitting a light beam into the sample cavity via an entry aperture (30) in the first mirror, the light beam having a wave length at which the preselected gas strongly absorbs. The beam is reflected between the mirrors for a number of times before exiting the cell via an exit aperture (48) in the second mirror and impinging on a detector (52). The device further comprises a reference detector (32) for monitoring the intensity of the unattenuated light beam and a detector for detecting the intensity of light transmitted through the second mirror after a single pass through the cell. The light source is operatively connected to a heat control assembly having a heat sink and the gas sample is passed said heat sink to augment temperature control of the light source.

Owner:ECOTEC INT HLDG LLC

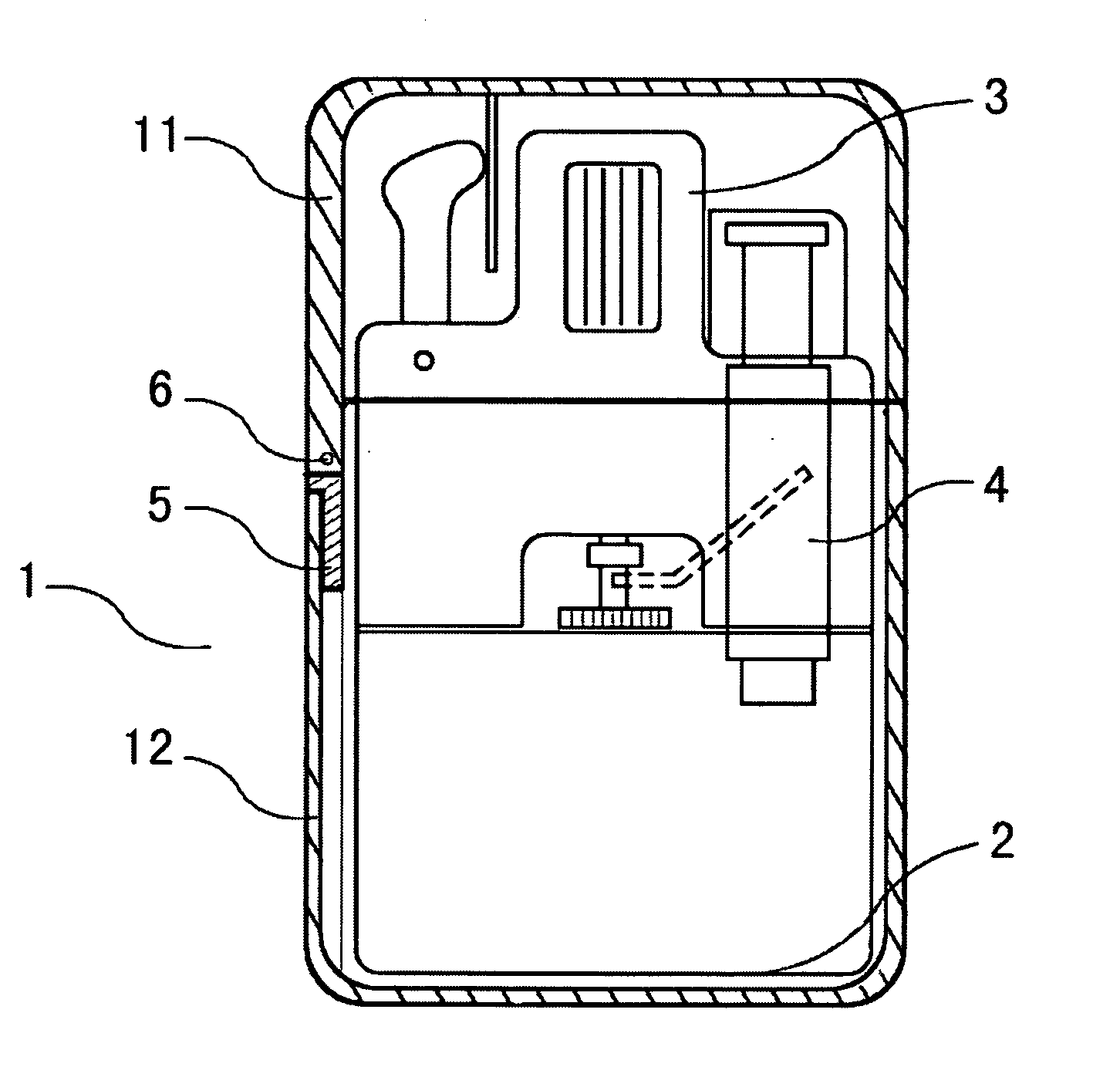

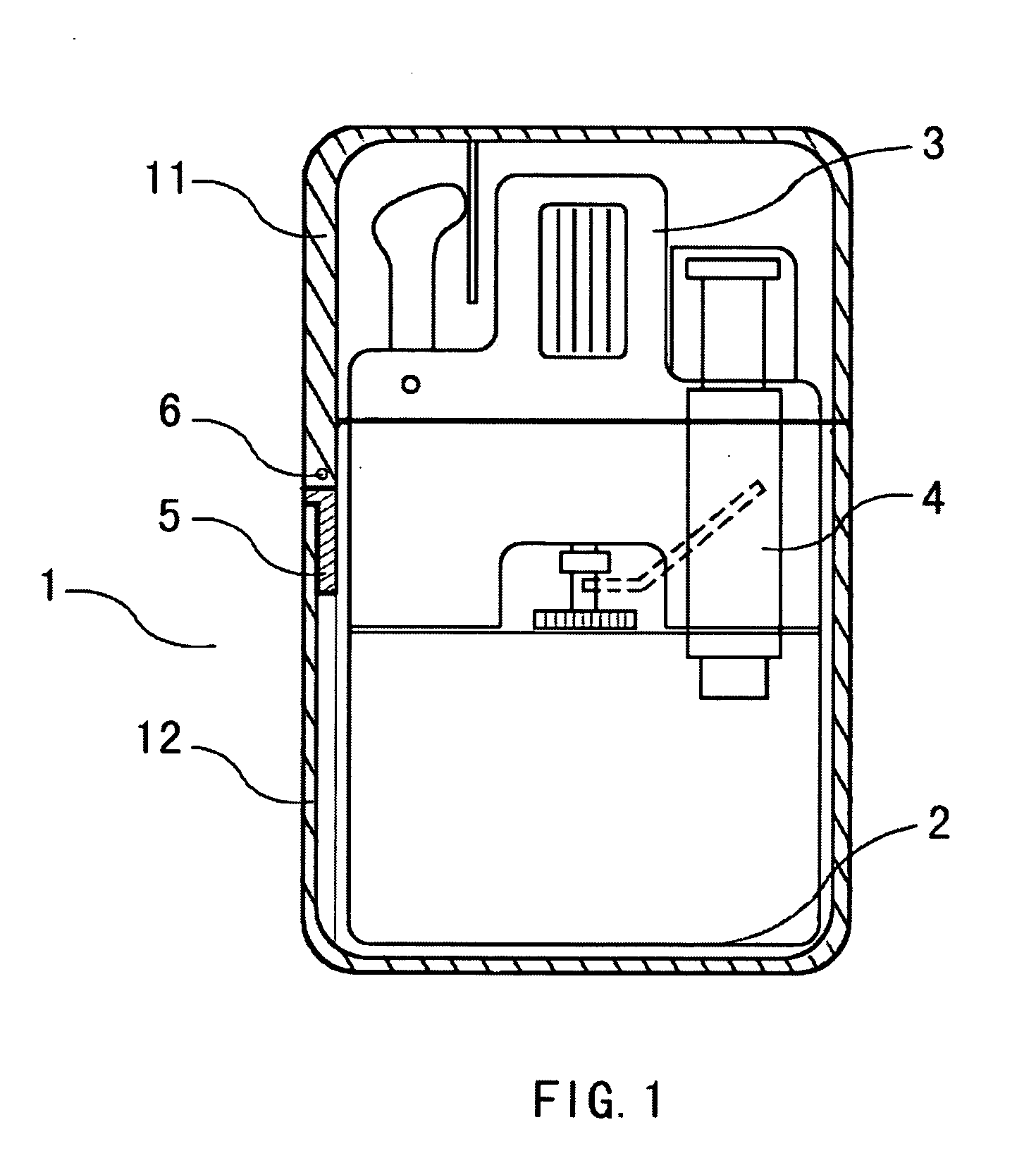

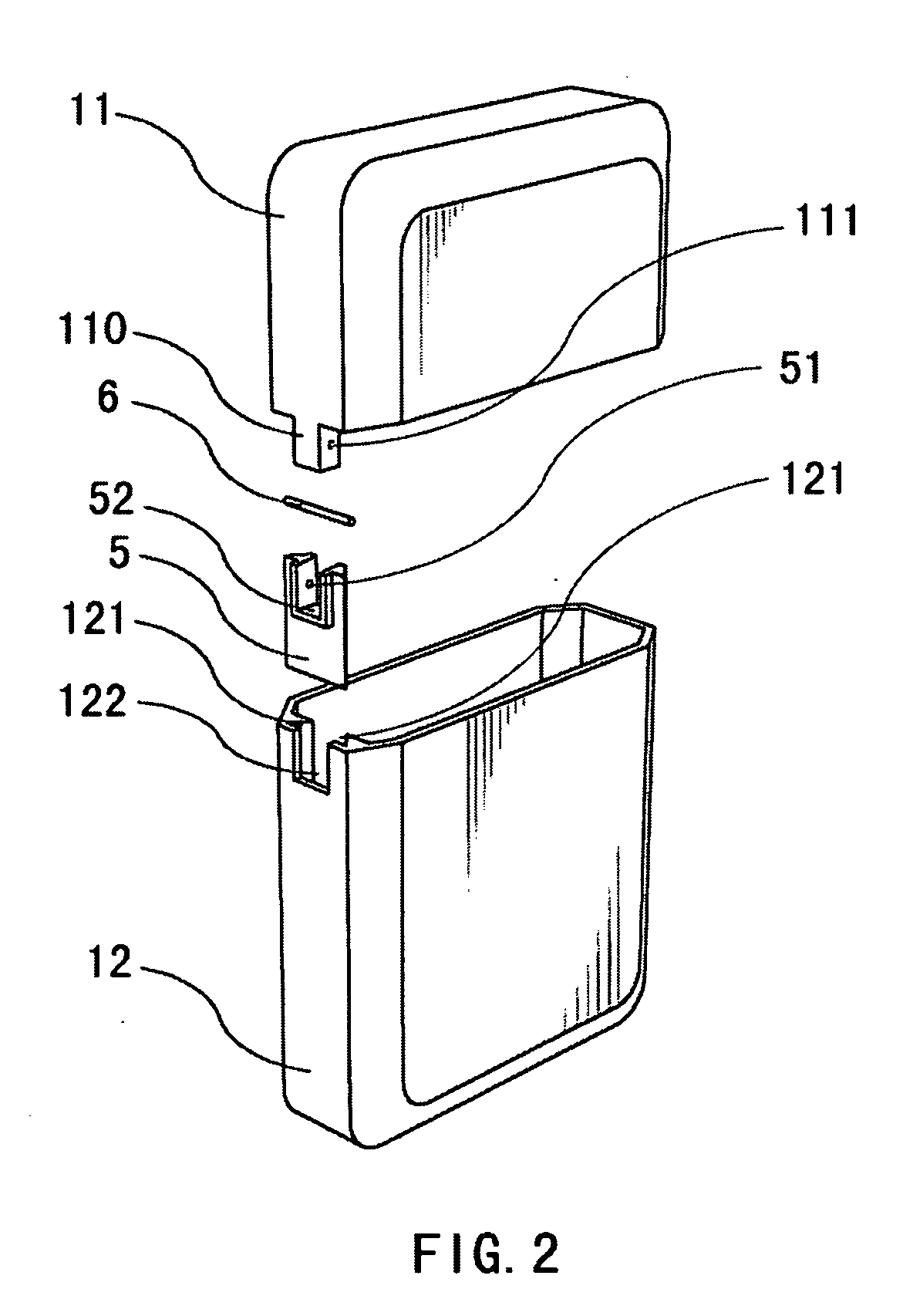

Lighter

InactiveUS20050118545A1Simple structureEasy to assembleFuel lightersExtinguishing-devicesCombustionEngineering

A lighter comprises a lighter housing, a gas container for storing liquid inflammable gas, a combustion device connected to the gas container, and an igniter for igniting inflammable gas in the combustion device. The housing includes an upper cover and a case, wherein one side of the upper cover includes a protuberance forming a small hole thereon; a connector disposed below the protuberance of the upper cover for connecting the upper cover and the case, wherein the connector includes a recess portion coupling with the protuberance and having transverse holes on both sides of the recess portion; and a bolt for rotationally connecting the protuberance and the recess portion; wherein the case has at its edge port a longitudinal groove connected to the connector and having an opening at the edge port of the groove to couple with the protuberance of the upper cover.

Owner:WONG CHI LAM

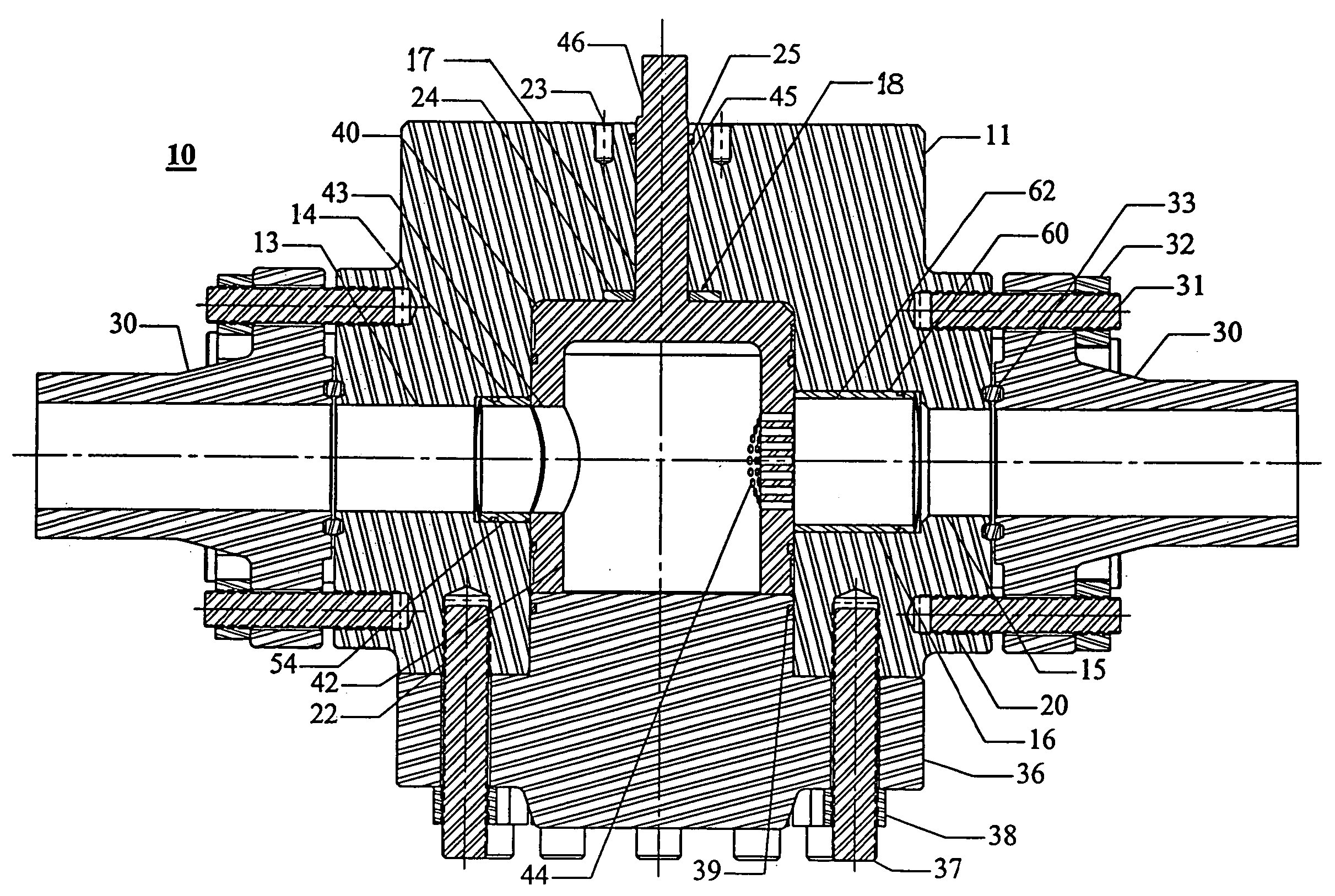

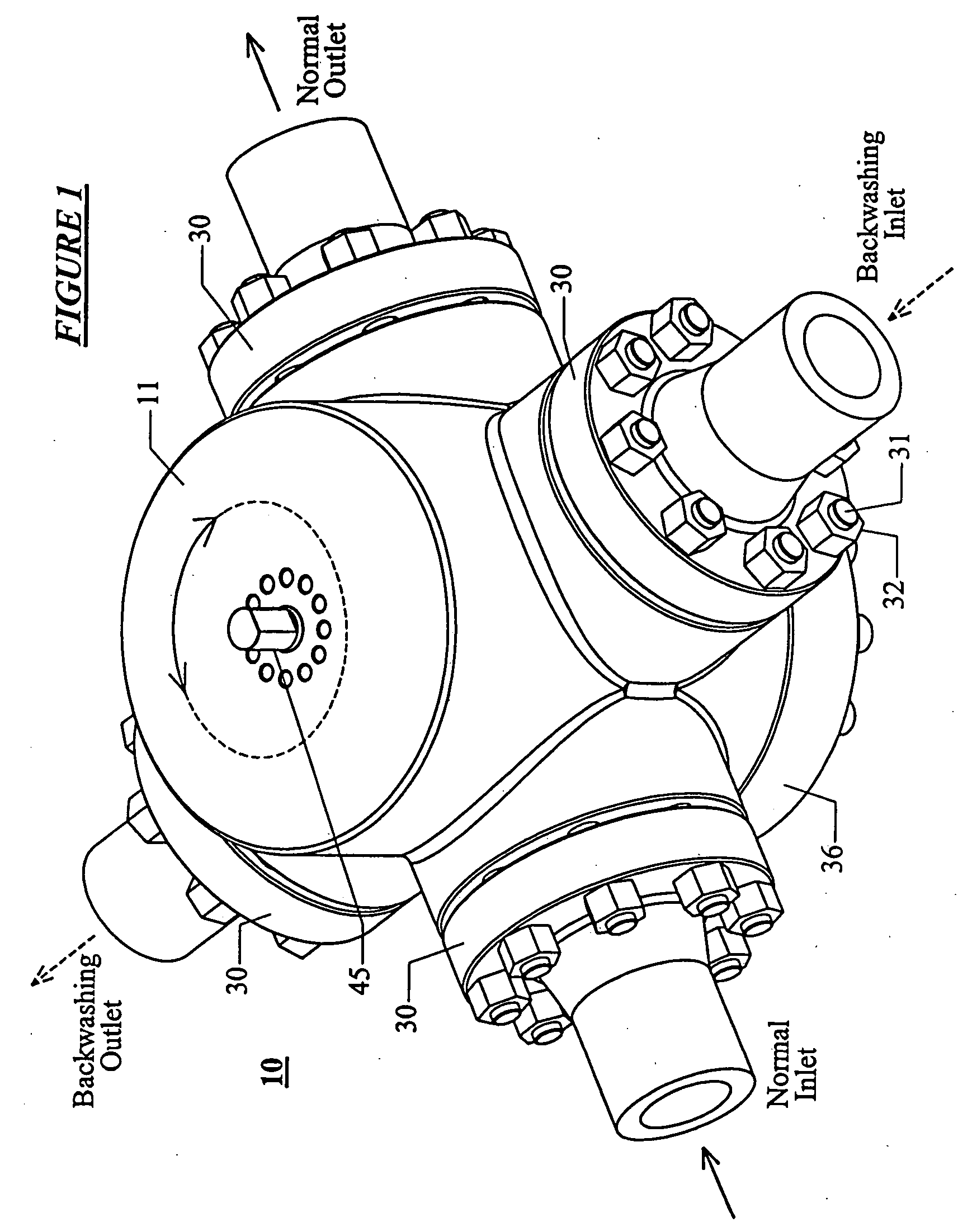

Solids strainer system for a hydraulic choke

InactiveUS20050006150A1Improve liquidityDrilling rodsValve members for absorbing fluid energyTransverse planeEngineering

The invention contemplates a strainer based upon a four-way, two-position rotary cylindrical plug valve having a hollow plug. The normal entry port for the sealing plug of the plug valve is a circular radial hole passing from the exterior of the plug into the interior cavity of the plug. The normal exit port for the sealing plug is a regular array of small holes across from and coaxial with the normal entry hole. The ports for the valve body are in two pairs positioned at 90° from each other, with the axes of the ports lying in the same transverse plane as the ports of the valve plug.

Owner:EXPRO AMERICAS

Method for extracting espresso coffee particularly from a cartridge with crema generating septum, and beverage obtainable from the method

A method for extracting an espresso coffee beverage by means of an espresso coffee machine, comprising:a) providing an extraction chamber, which comprises a dose of roasted and ground espresso coffee and a normally-closed septum which is arranged downstream of the coffee dose;b) injecting hot water into the chamber, outward dispensing of the beverage being prevented through the normally-closed septum;c) when the water pressure reaches a preset value, the partition is opened in order to force the beverage to pass through a small orifice before it is dispensed into the cup, the size of the orifice being such as to keep the dose of coffee contained in the extraction chamber at a substantially uniform pressure along the direction of the flow of water, so that the espresso coffee beverage extracted through the orifice comprises crema.

Owner:ILLYCAFFE SPA

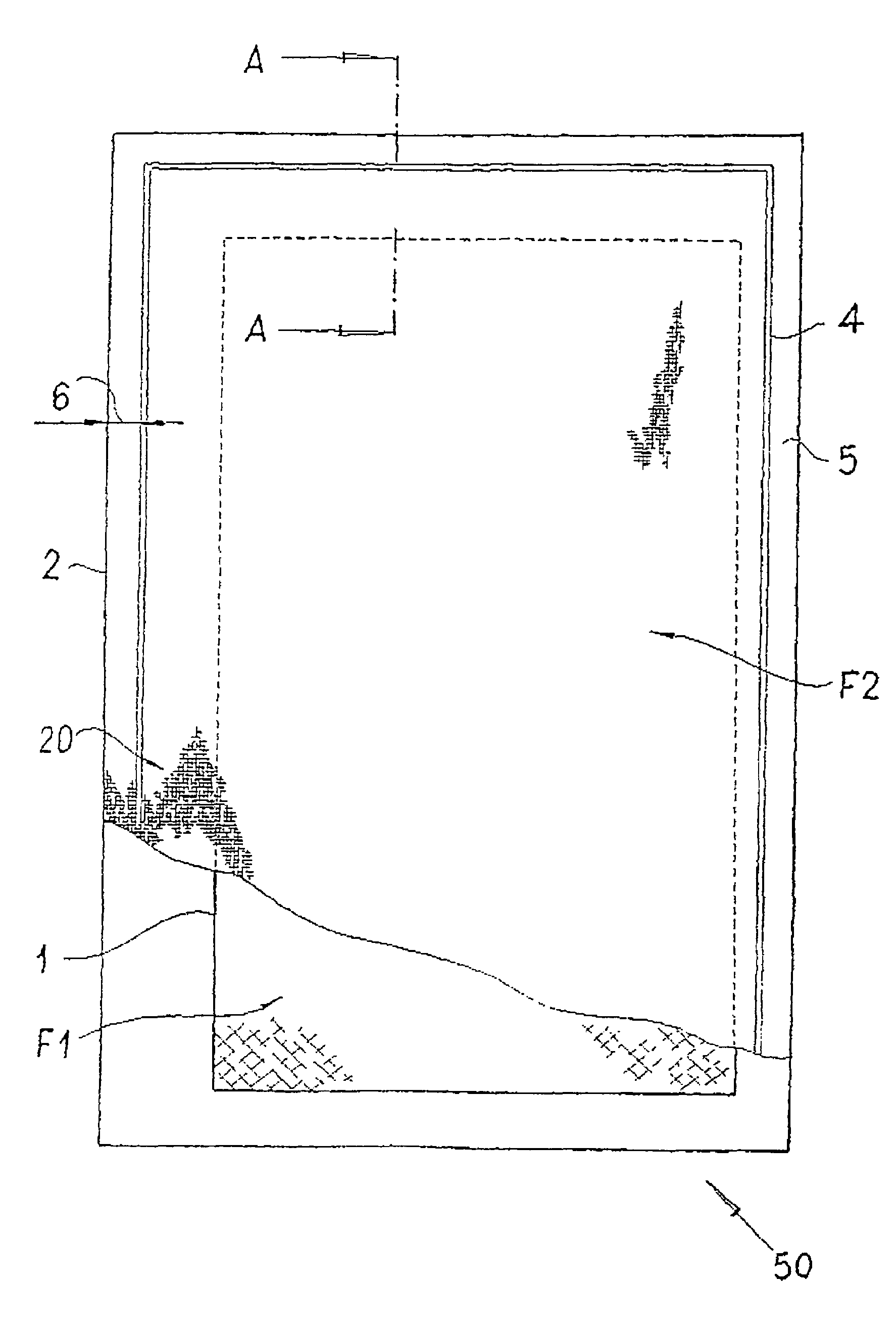

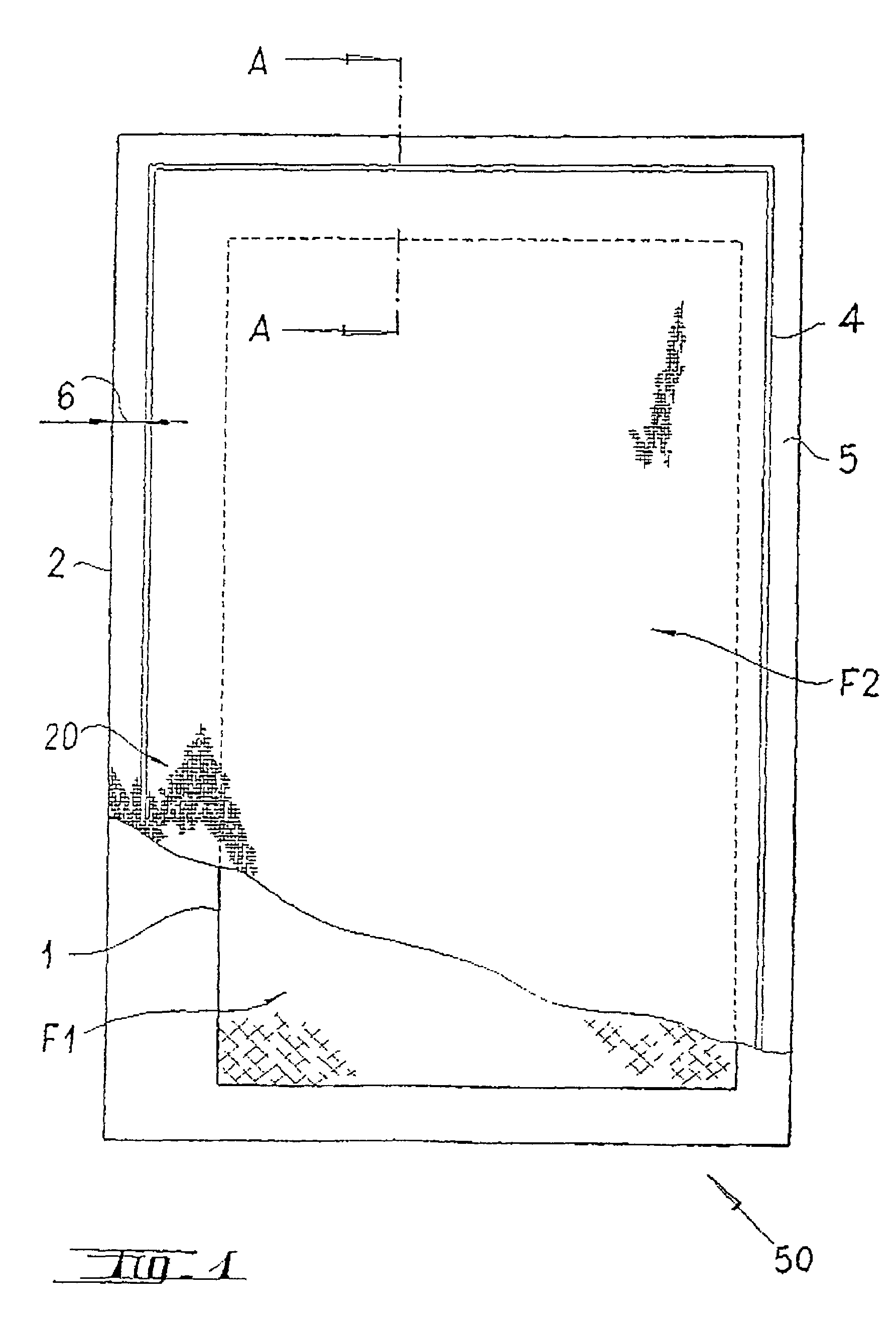

Absorption body for attachment to the human body

An absorptive body (50) for attachment to the human body, especially for absorbing fluids coming out of parts of the human body such as wounds, has a substantially flat material section made of an absorbing material (1), which consists of an absorbing non-woven having super-absorber particles spread therein, and a fluid-permeable shell (2) that surrounds the material section, forms a barrier against solid excretions and enables the passage of other excreted substances into the material section made of absorbing material (1) that is arranged inside the shell (2). The shell is made of a small-pored material, whose pores are smaller than the unwetted super-absorber particles.

Owner:BSN MEDICAL GMBH & CO KG

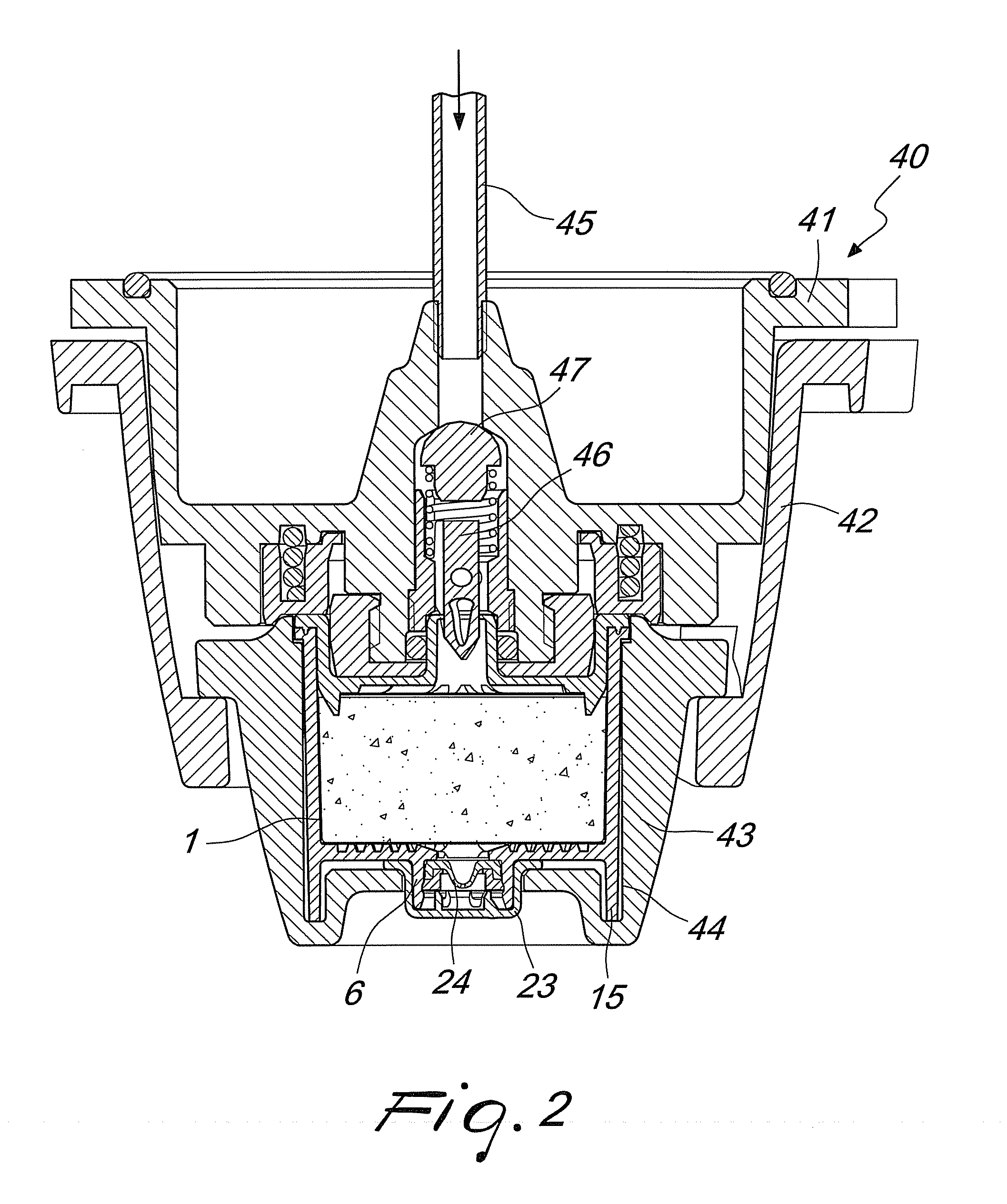

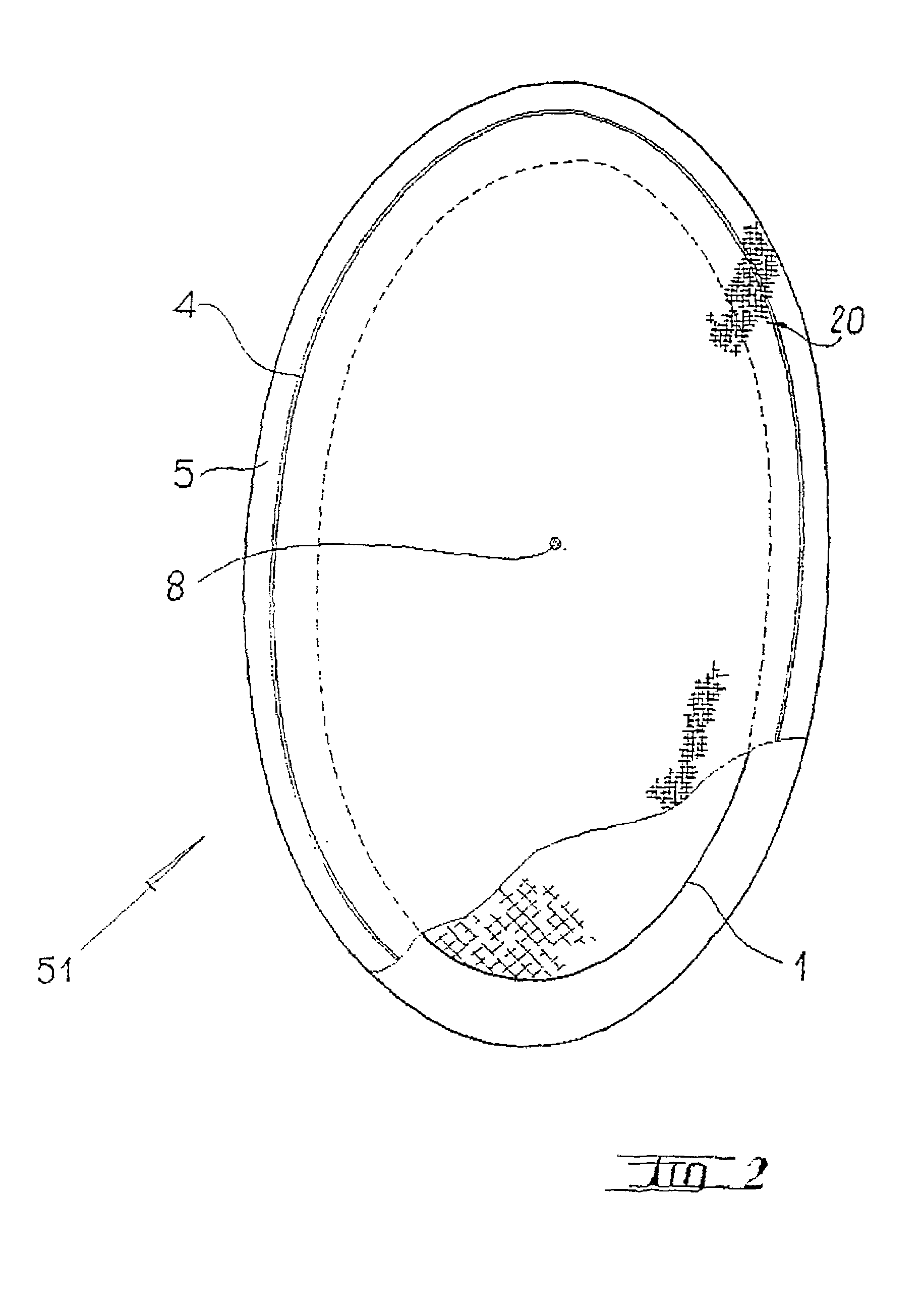

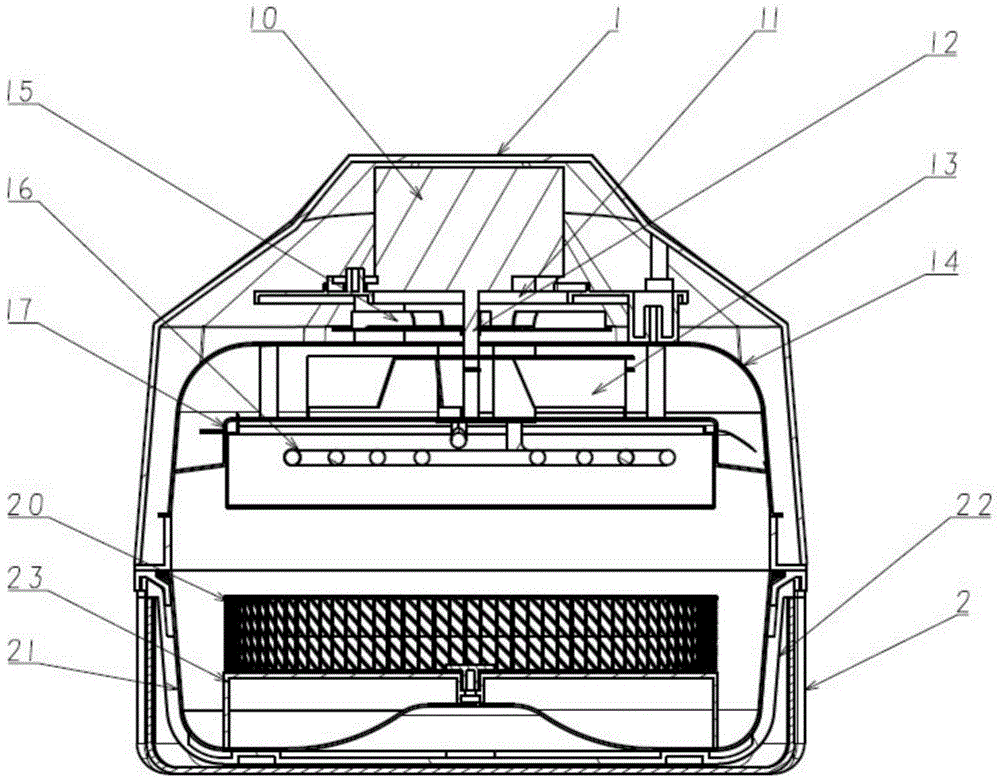

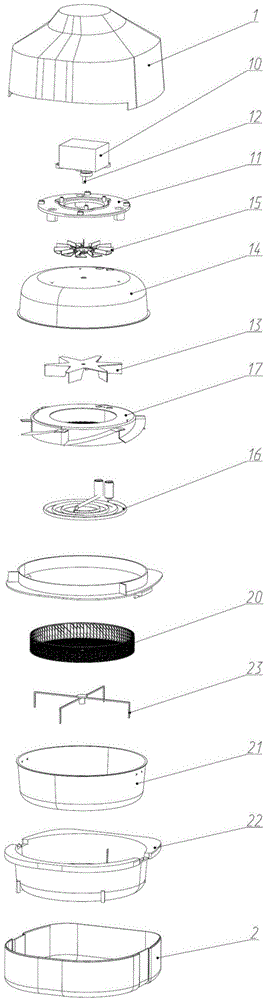

Air fryer capable of forming thermal cycle heating through cyclone

The invention discloses an air fryer capable of forming thermal cycle heating through cyclone. The air fryer comprises a windshield cover, a motor assembly, an extractor fan and a rotating air duct unit, wherein the lower part of the windshield cover is opened, and a small hole is formed in the center of the upper part of the windshield cover; the motor assembly is arranged at the upper part of the windshield cover and comprises a motor transmission shaft, and the motor transmission shaft penetrates through the small hole in the center of the upper part of the windshield cover; the extractor fan is arranged in the windshield cover and is connected with the motor transmission shaft; the rotating air duct unit is arranged in the windshield cover, is positioned under the extractor fan and is fixedly connected with the windshield cover through a connecting post, a ventilating opening is formed in the upper part of the rotating air duct unit, and the lower part of the rotating air duct unit is opened; the rotating air duct unit can enable air flowing downwards under the combined action of the extractor fan and the windshield cover to flow downwards rotationally along a certain angle to form the cyclone. According to the air fryer disclosed by the invention, the thermal cycle heating is formed through the cyclone, and thus food can be more uniformly baked by hot air.

Owner:KINGCLEAN ELECTRIC GREEN TECH SUZHOU

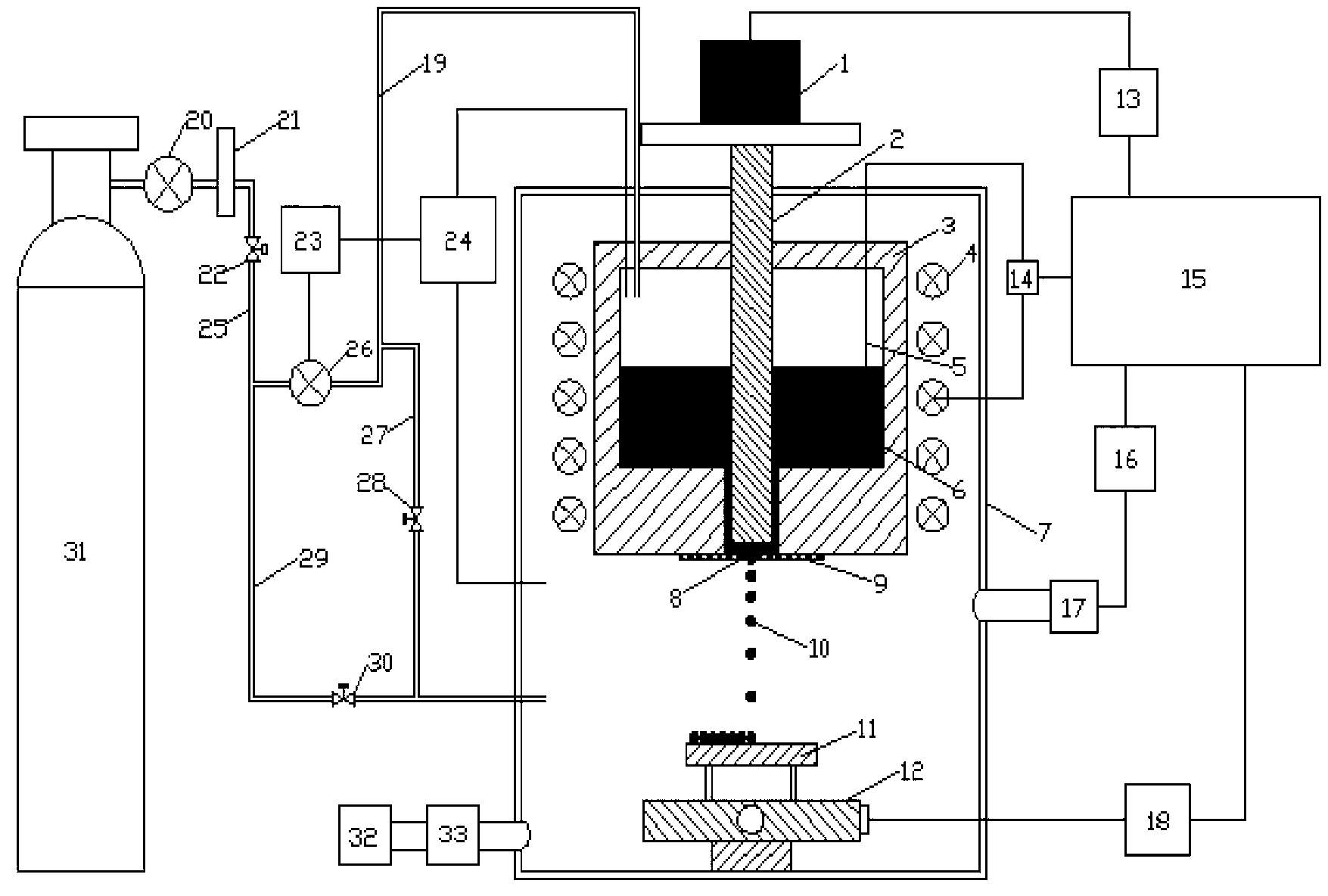

Three-dimensional rapid prototyping method and device based on pulse small hole droplet injection

The invention relates to a three-dimensional rapid prototyping method and device based on pulse small hole droplet injection and belongs to the technical field of three-dimensional rapid prototyping. The three-dimensional rapid prototyping method is characterized in that a heater is used for heating a crucible until the metals in the crucible are in the molten state, a positive differential pressure value is set between the interior of the crucible and a vacuum chamber, simultaneously a piezoelectric ceramic driver applies certain pulse signals to piezoelectric ceramics to lead the piezoelectric ceramics to drive a transmission bar to generate longitudinal infinitesimal displacement, the infinitesimal displacement acts on the metal melt at the bottom of the crucible, tiny droplets are injected from small holes arranged at the bottom of the crucible, one droplet can be formed at the position of the small holes once the piezoelectric ceramics move for one time, size data of the droplets are timely analyzed through a photograph system, further the optimum parameter is obtained through adjustment; and the droplets fall to a moving three-dimensional motion platform to be deposited, and accordingly needed metal parts are formed through depositing. The three-dimensional rapid prototyping method and device based on pulse small hole droplet injection have the advantages that the pulse small holes inject to generate the metal droplets with uniform and controllable sizes, prototyped products are fine and uniform in microstructure, the prototyping process is strong in controllability, and the formed parts are high in accuracy.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com