Solids strainer system for a hydraulic choke

a strainer system and choke technology, applied in the direction of sealing/packing, transportation and packaging, borehole/well accessories, etc., can solve the problems of clogging the screen itself, affecting the flow control of the choke, and causing problems such as particulate matter,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

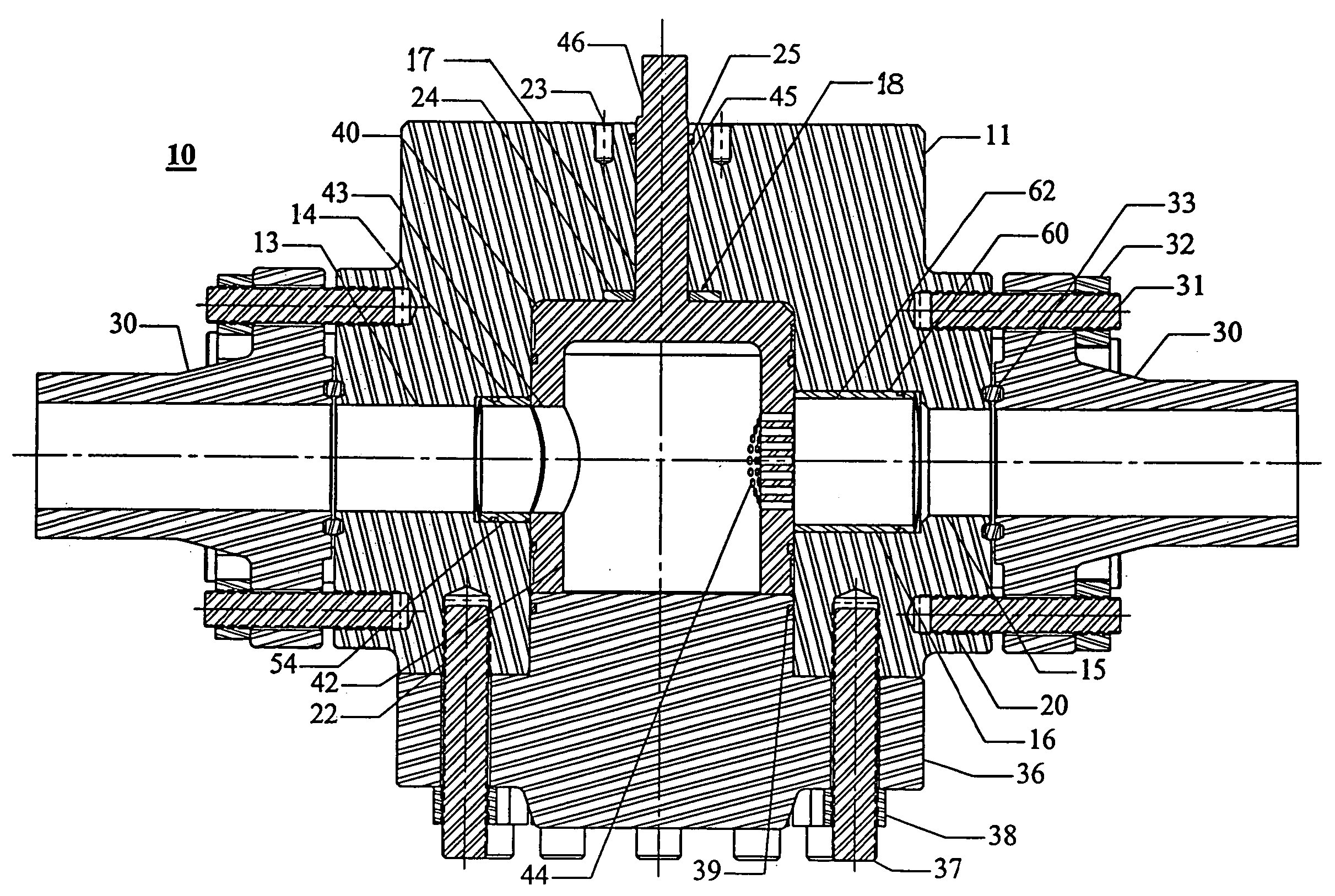

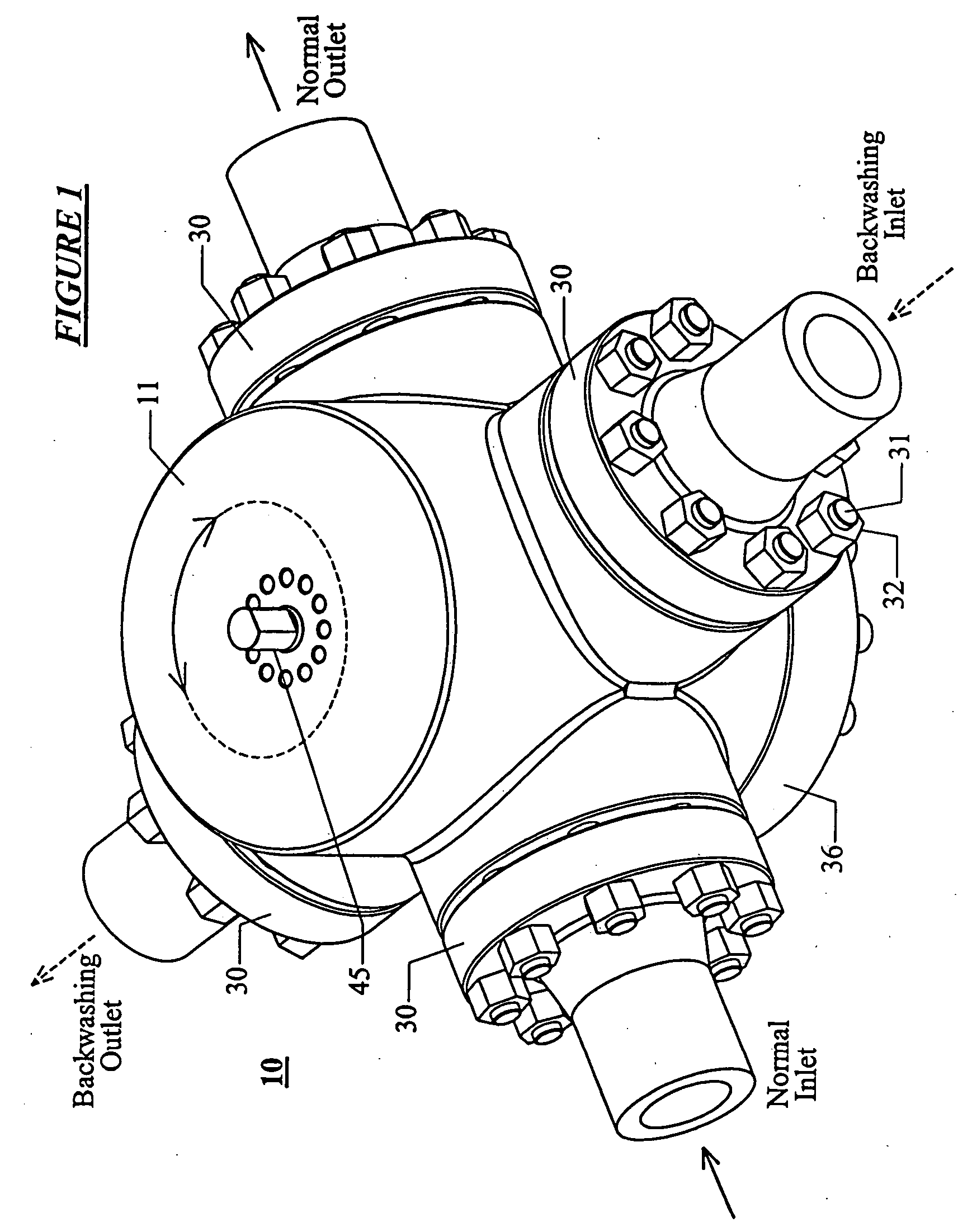

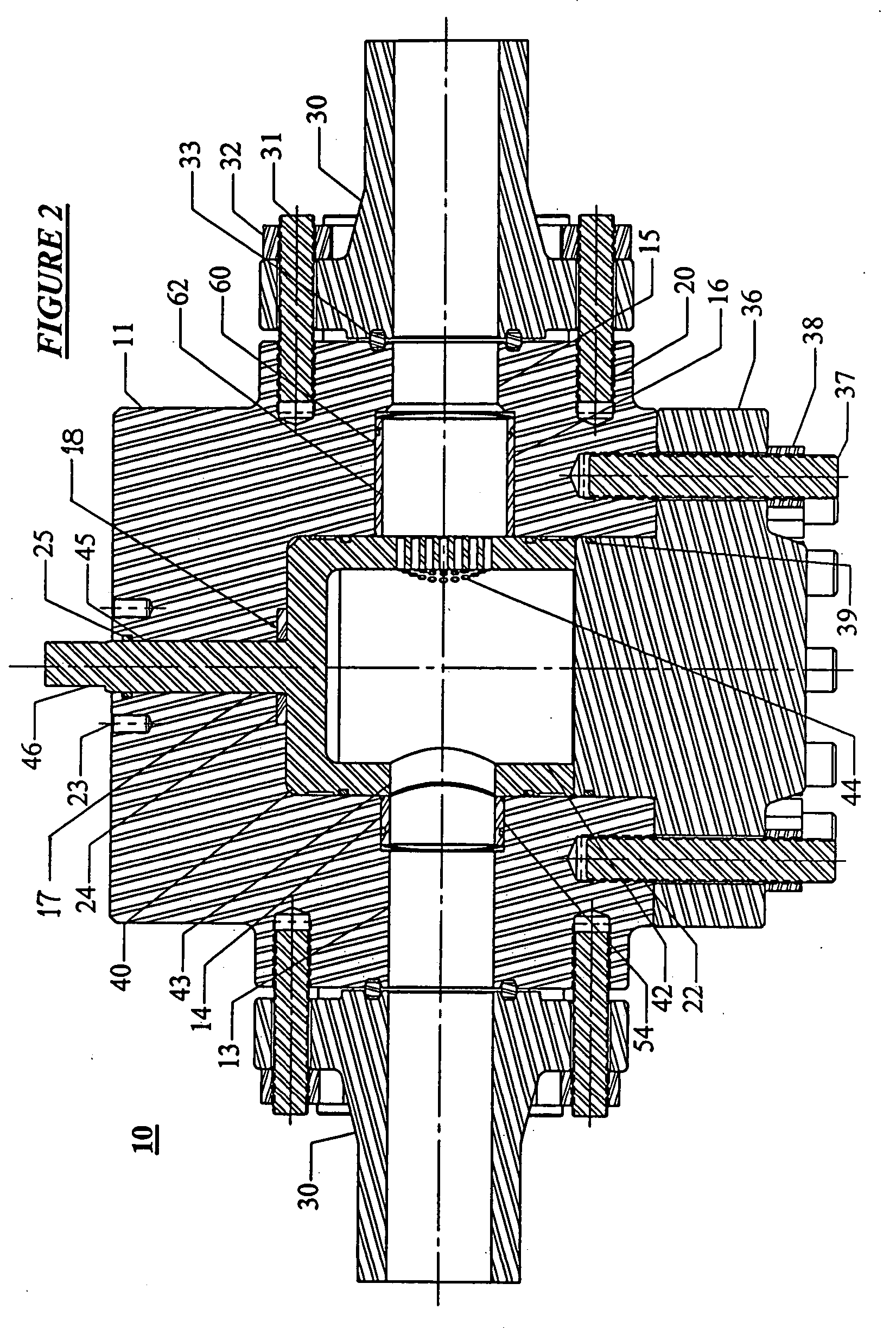

[0035] Referring to FIGS. 1 to 3, the basic strainer assembly 10 is shown in, respectively, oblique, vertical axial cross-sectional, and horizontal cross-sectional views. The major components of the strainer assembly include body 1, valve plug assembly 40, upstream and downstream seals 54 and 60 respectively, and bottom blind flange 36. The components of the strainer assembly 10 are typically made of hardened high strength low alloy steel.

[0036] The strainer basically is a two position, four way cylindrical plug valve with a modified valve plug that provides a straining function. The body 11 of strainer assembly 10 is a right circular cylindrical forging, machined component, or fabrication that has a coaxial right circular cylindrical internal valve cavity 12 and four radial branches positioned at 90° spacings. Each of the radial branches has a right circular cylindrical projected profile and an internal through bore which intersects the cavity 12. Each through flow pair of coaxial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com