Patents

Literature

92 results about "Holey fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A photonic crystal fiber (also called holey fiber, hole-assisted fiber, microstructure fiber, or microstructured fiber) is an optical fiber which obtains its waveguide properties not from a spatially varying glass composition but from an arrangement of very tiny and closely spaced air holes which go through the whole length of fiber.

Holey optical fibres

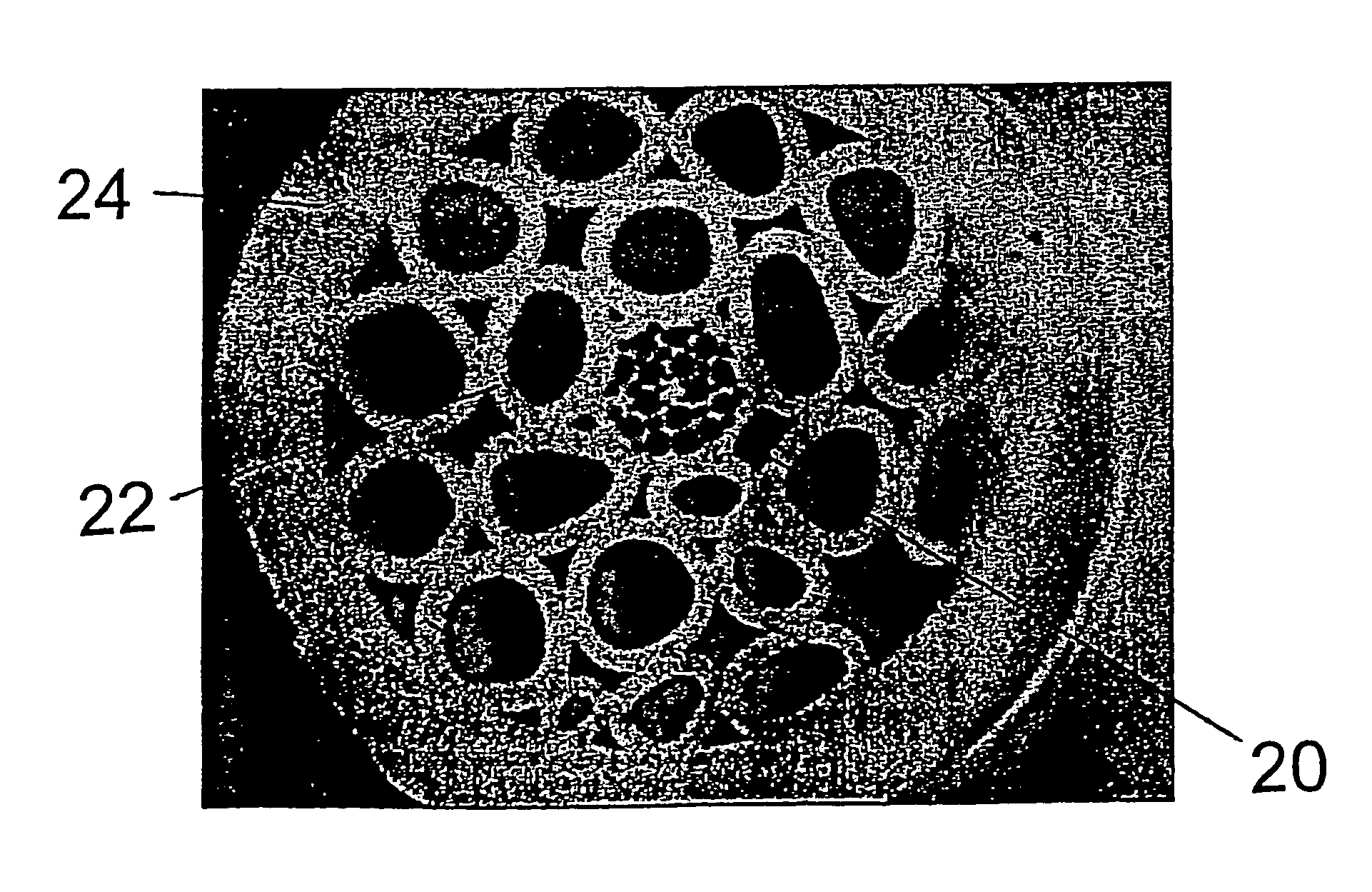

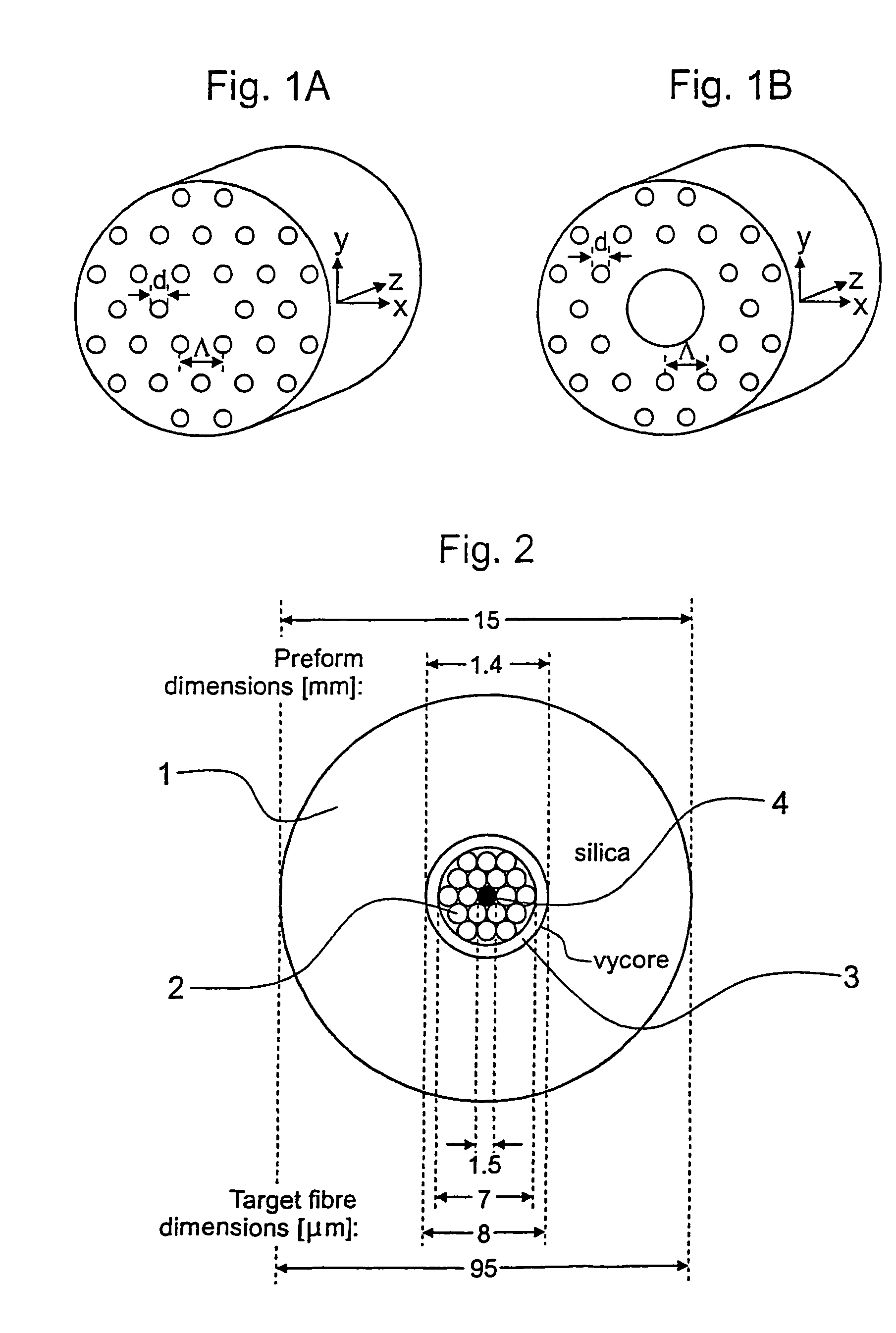

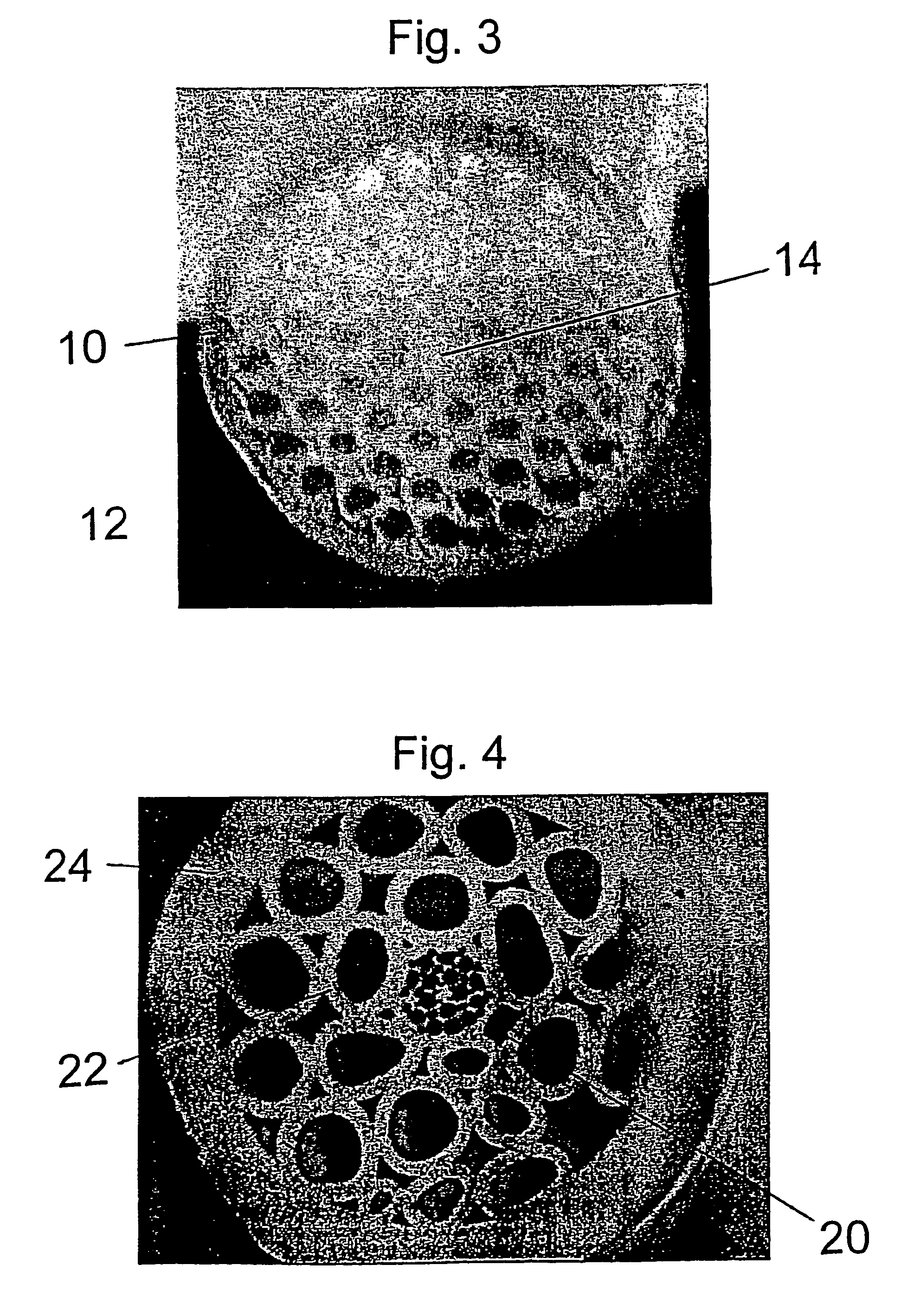

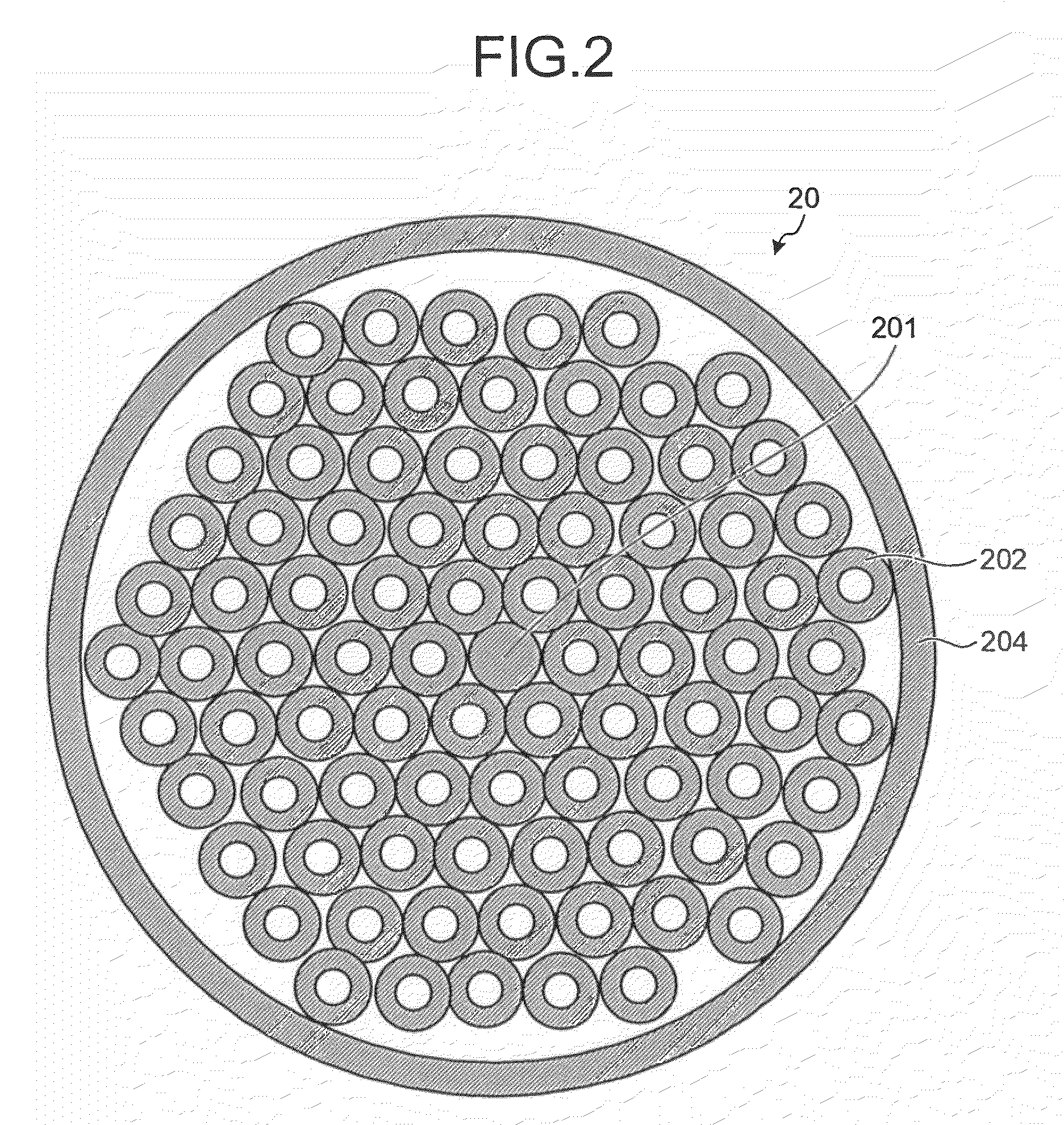

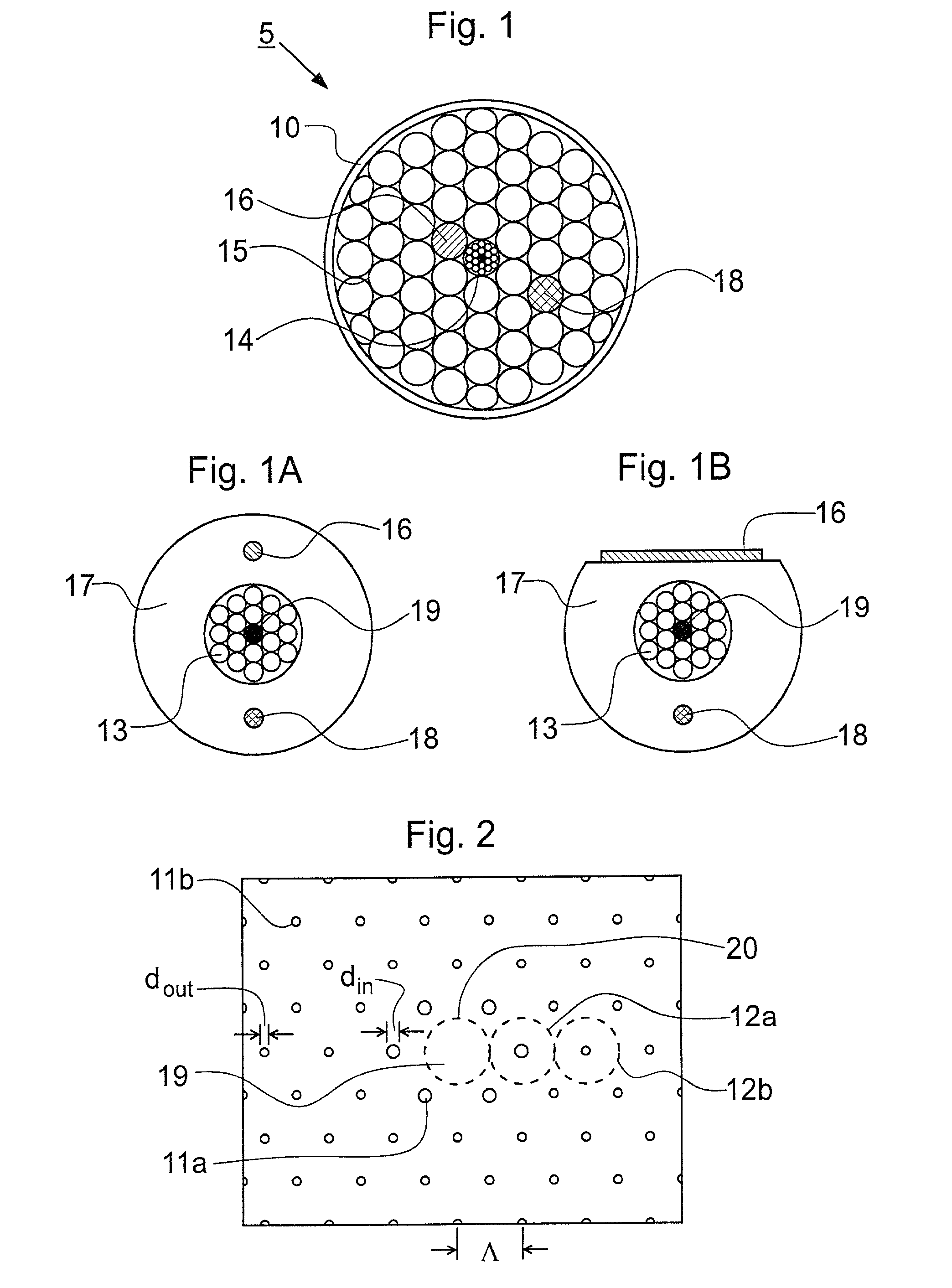

An optical fiber structure having a holey fiber arranged in a holey outer support structure made up of holey tubes encased in a thin walled outer jacket. The holey fiber may have a solid core surrounded by a holey cladding having a plurality of rings of holes. With the invention it is possible to produce robust, coated and jacketed fibers with microstructured core features of micrometer size relatively easily using existing fiber fabrication technology. This improvement is a result of the outer holey structure which reduces the thermal mass of the supporting structure and makes it possible to reliably and controllably retain small hole features during the fiber fabrication process.

Owner:UNIV OF SOUTHAMPTON

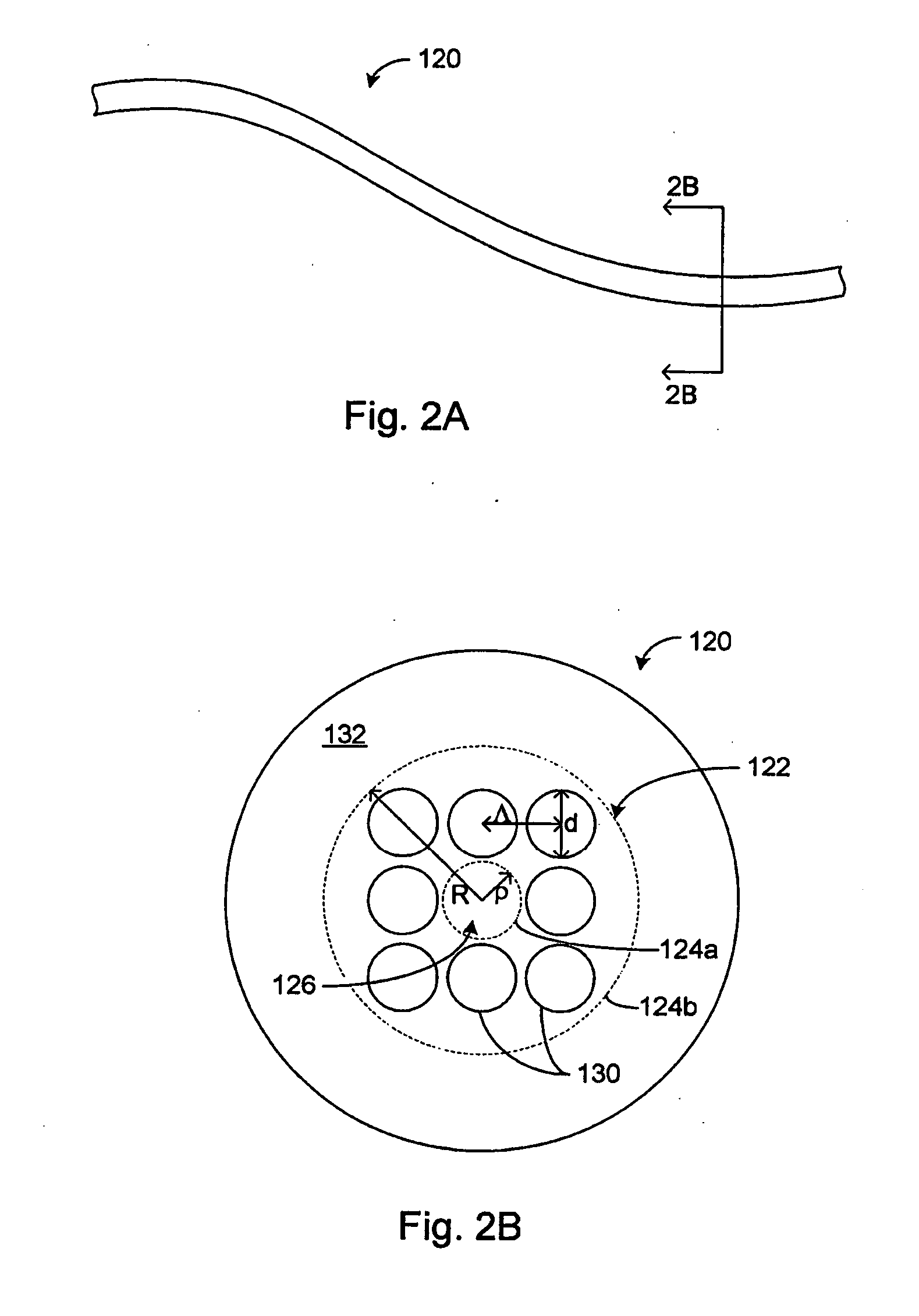

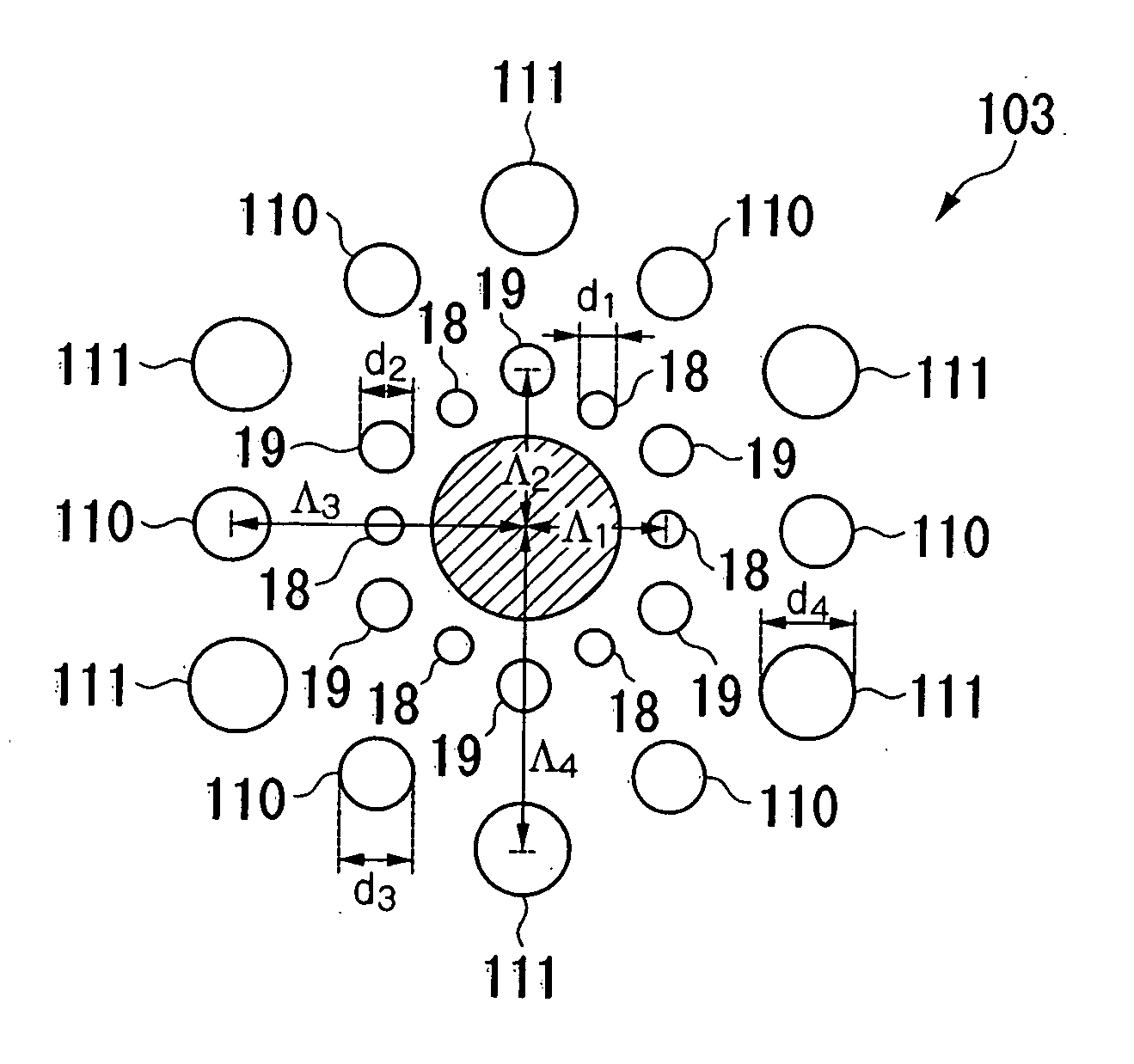

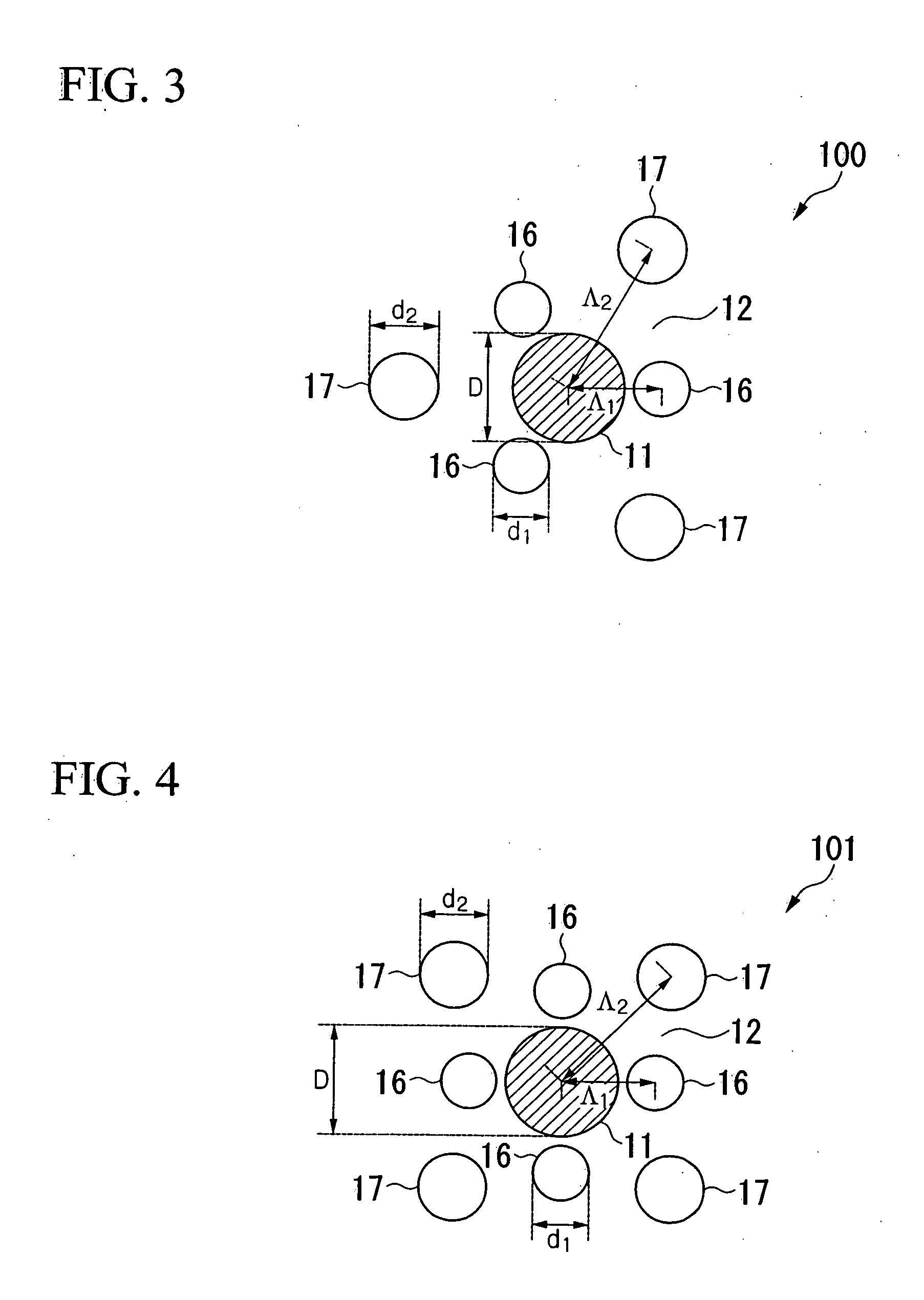

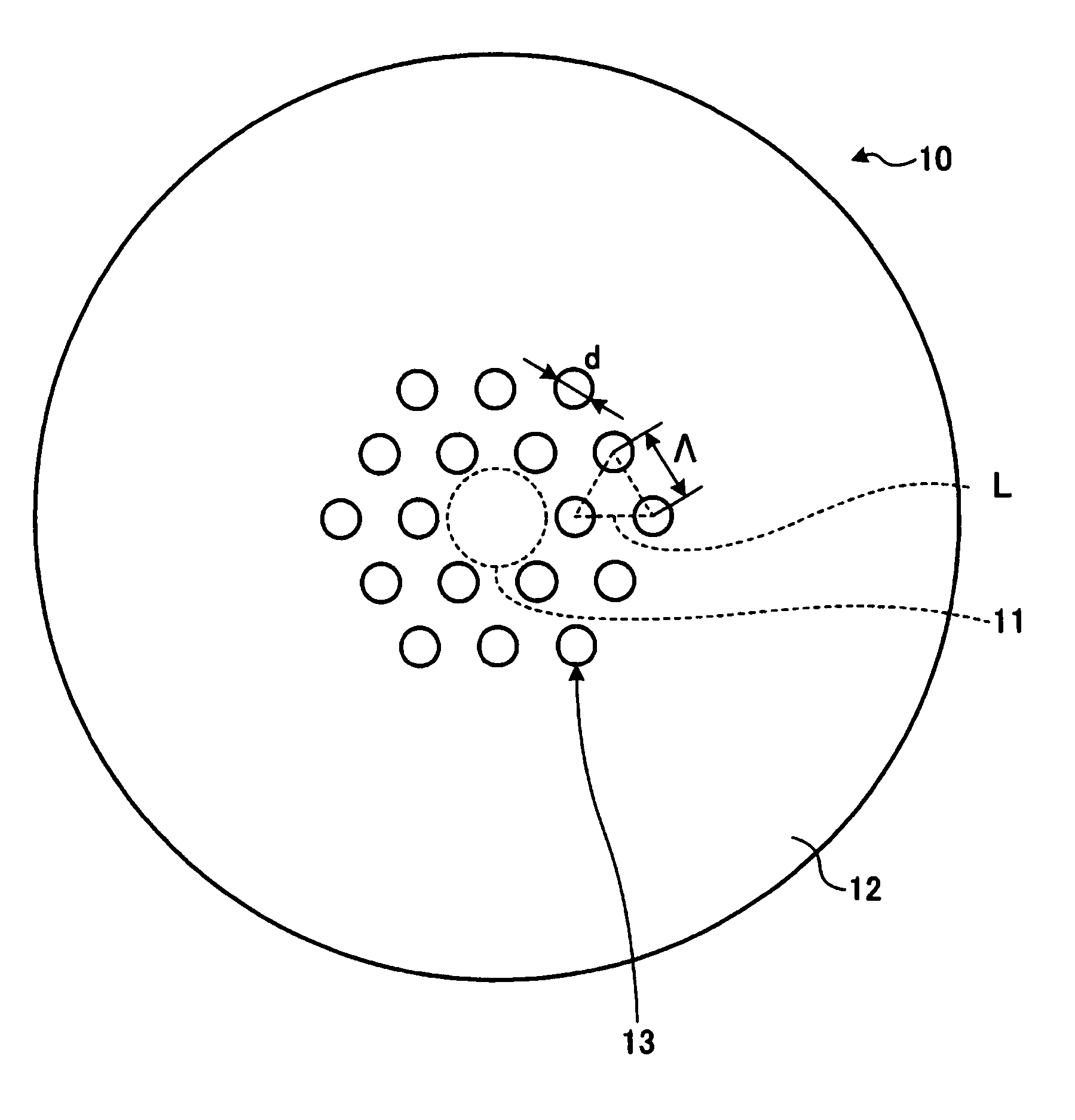

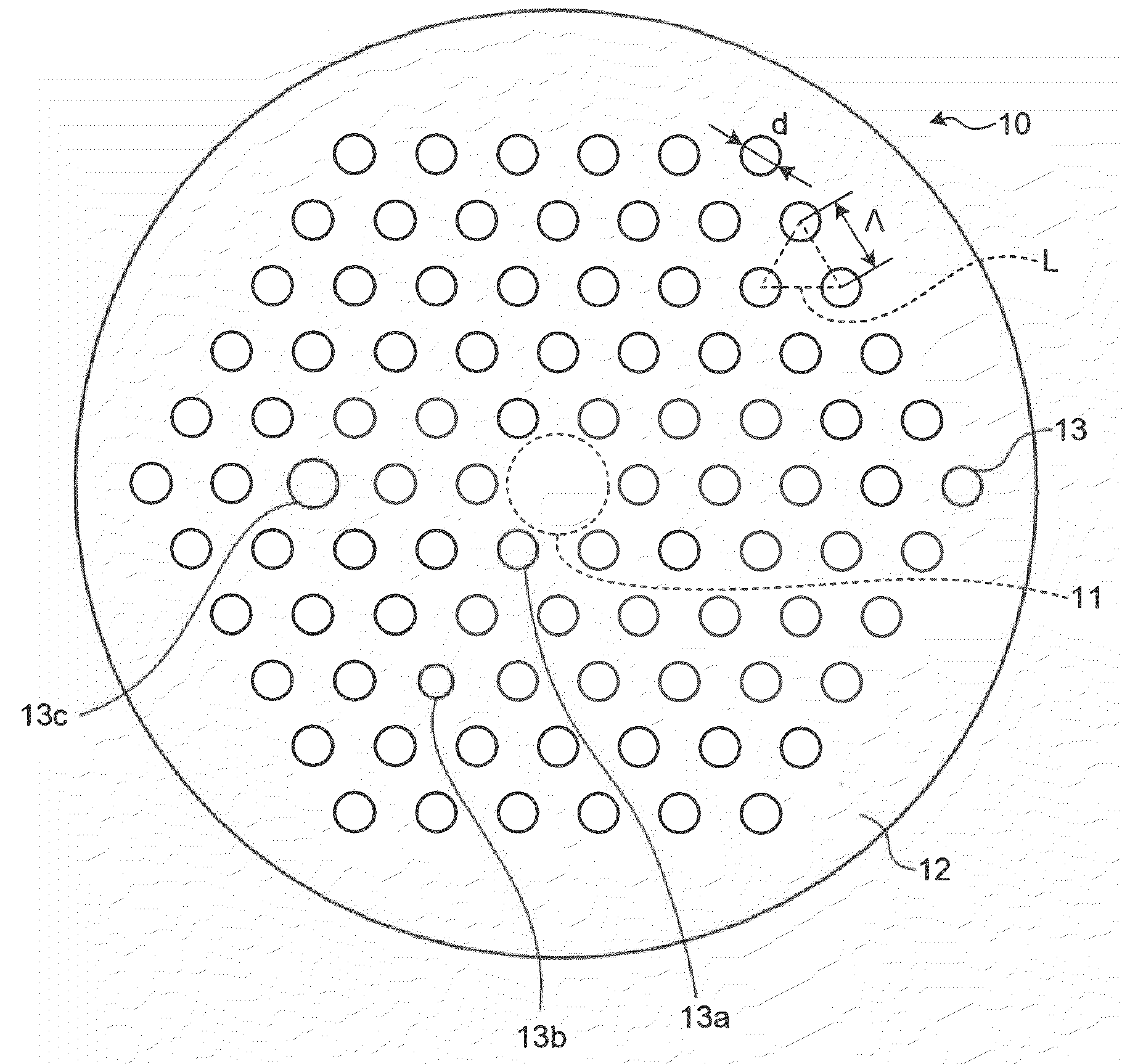

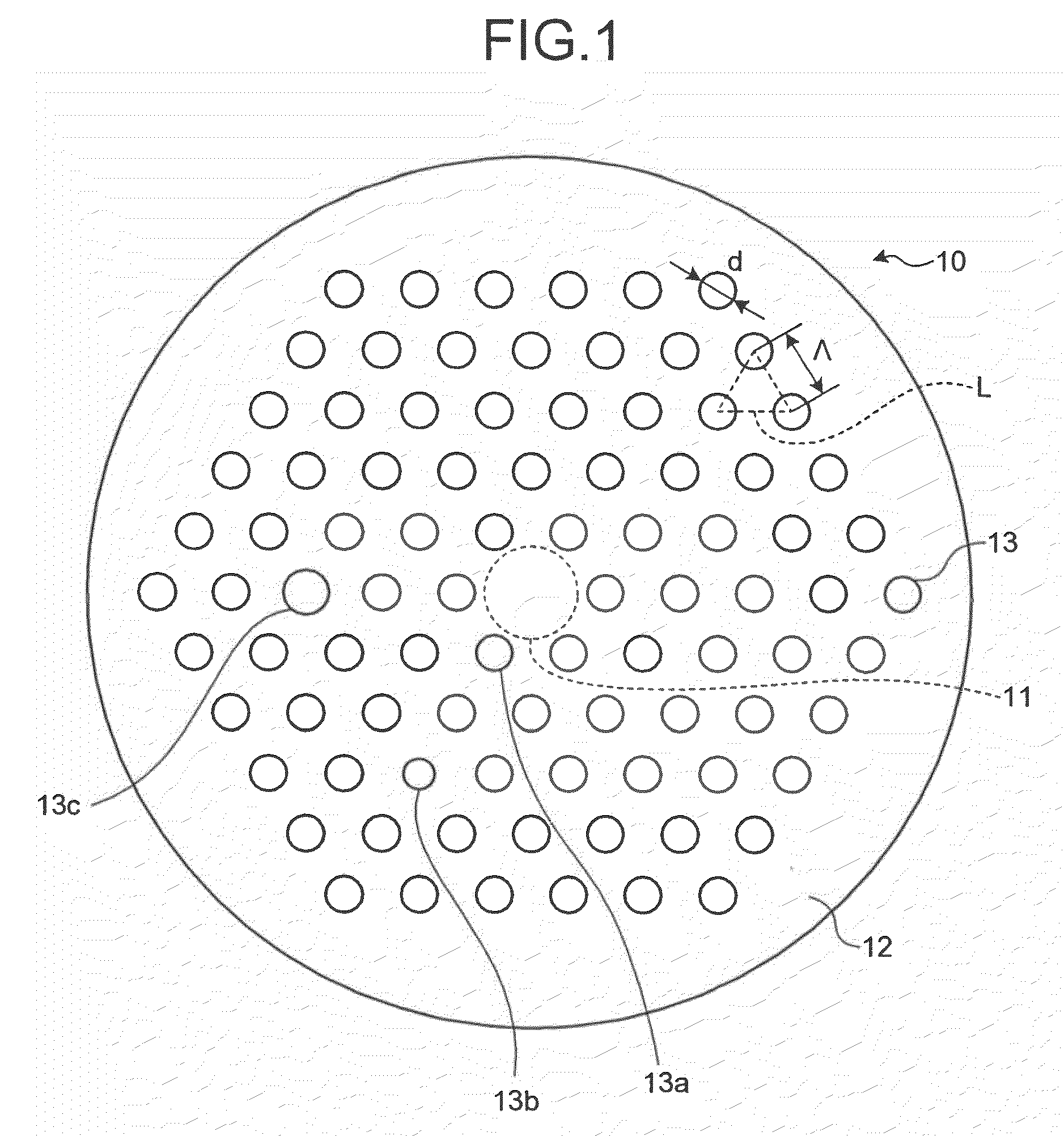

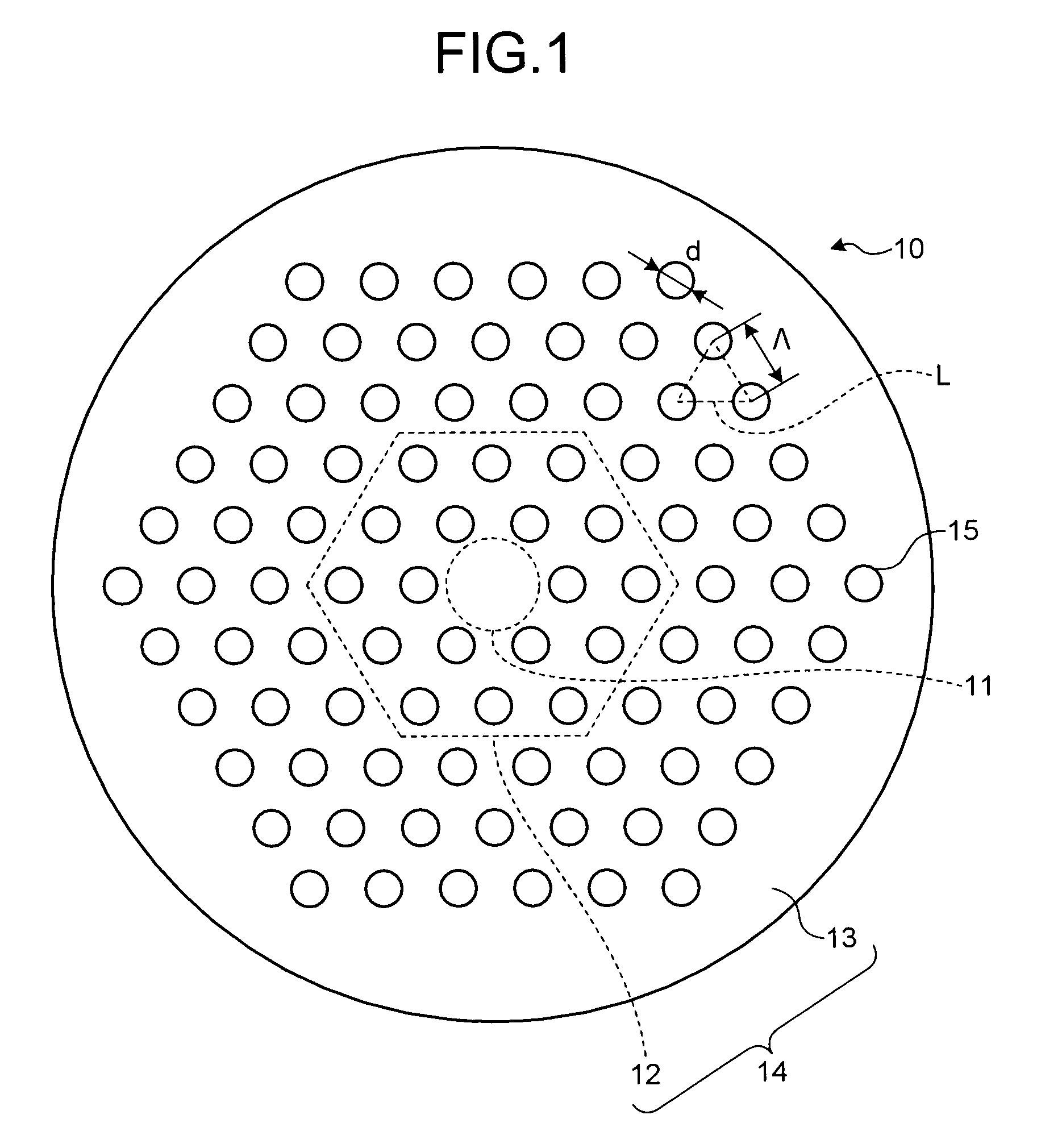

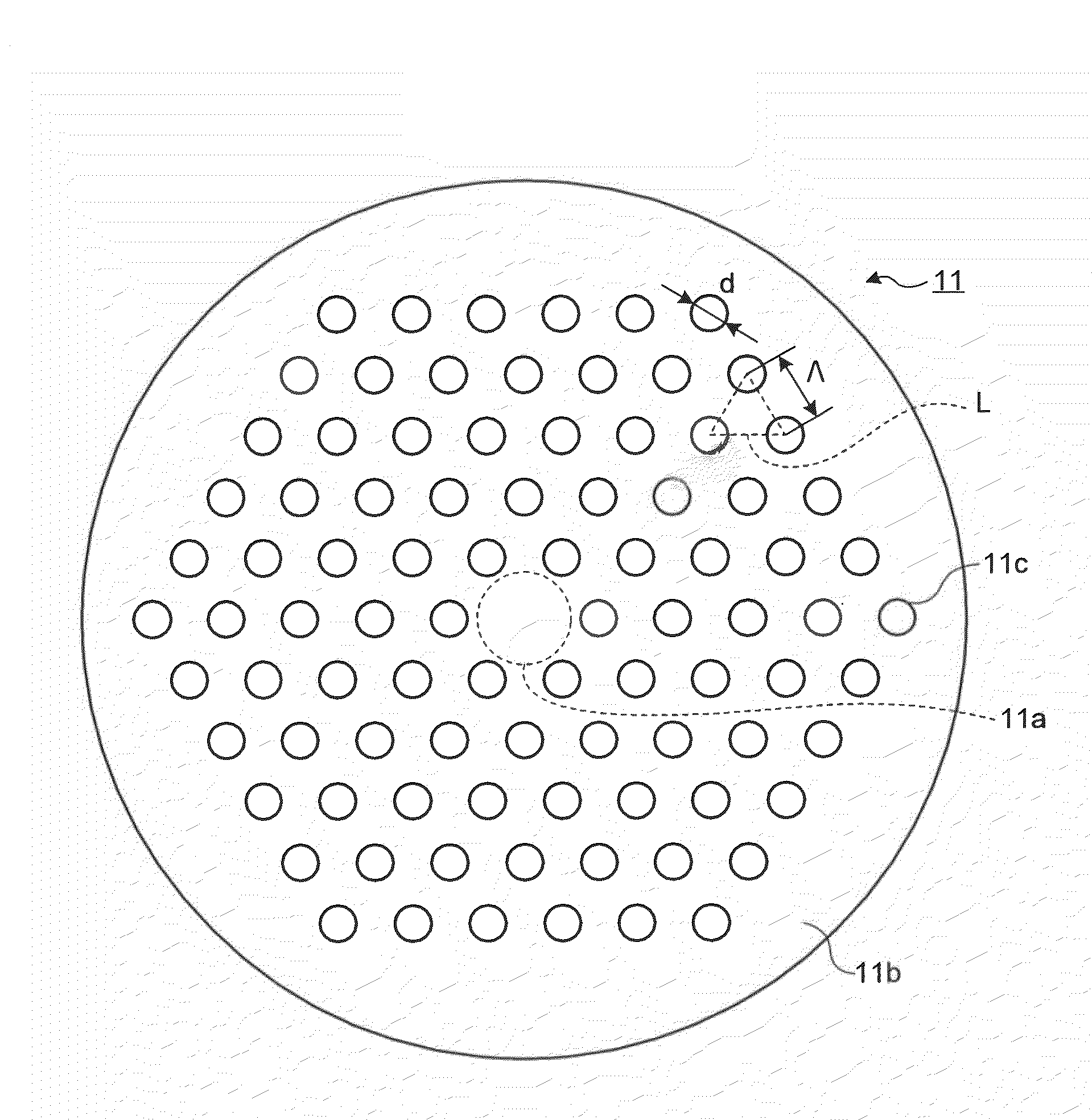

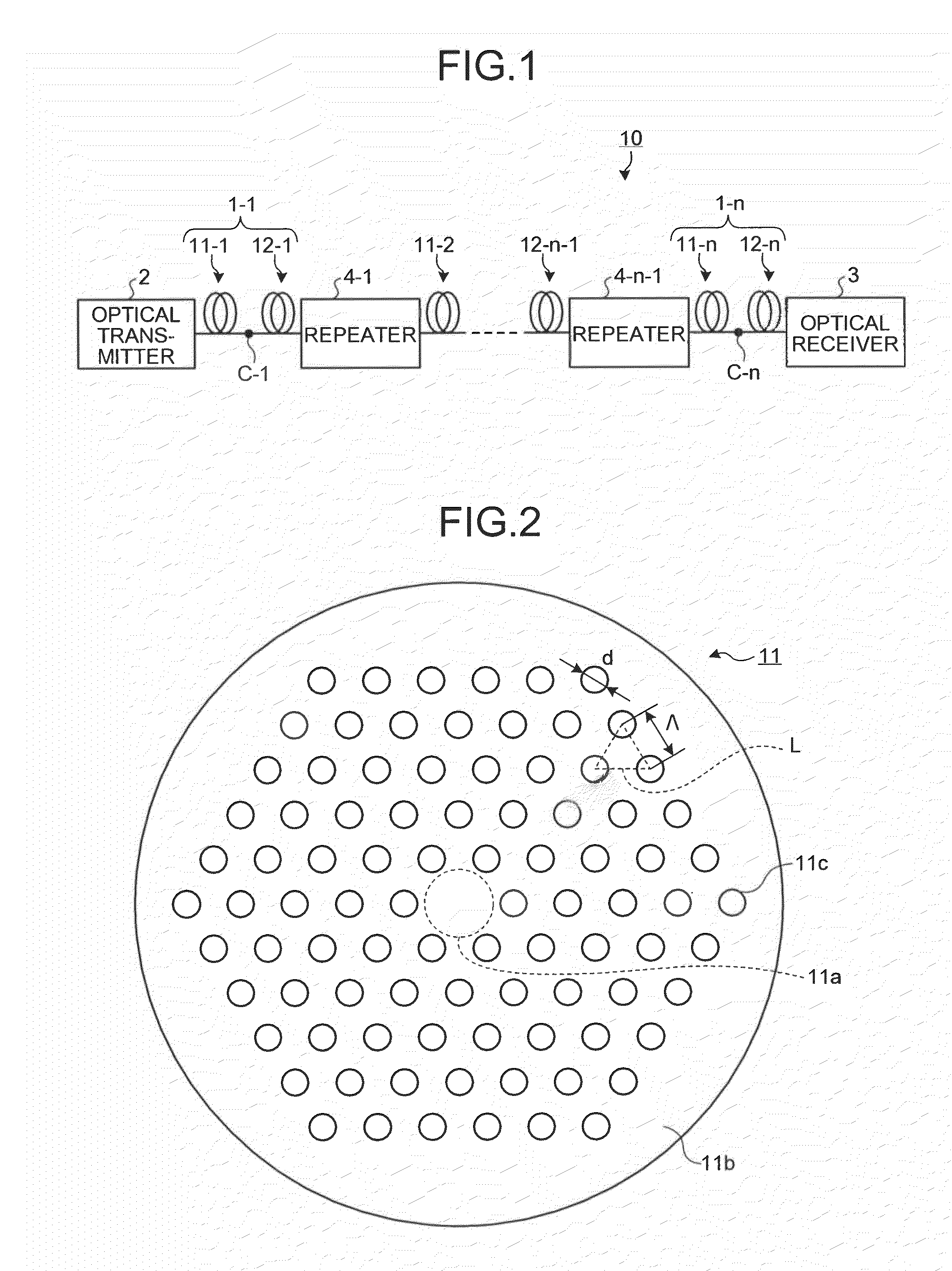

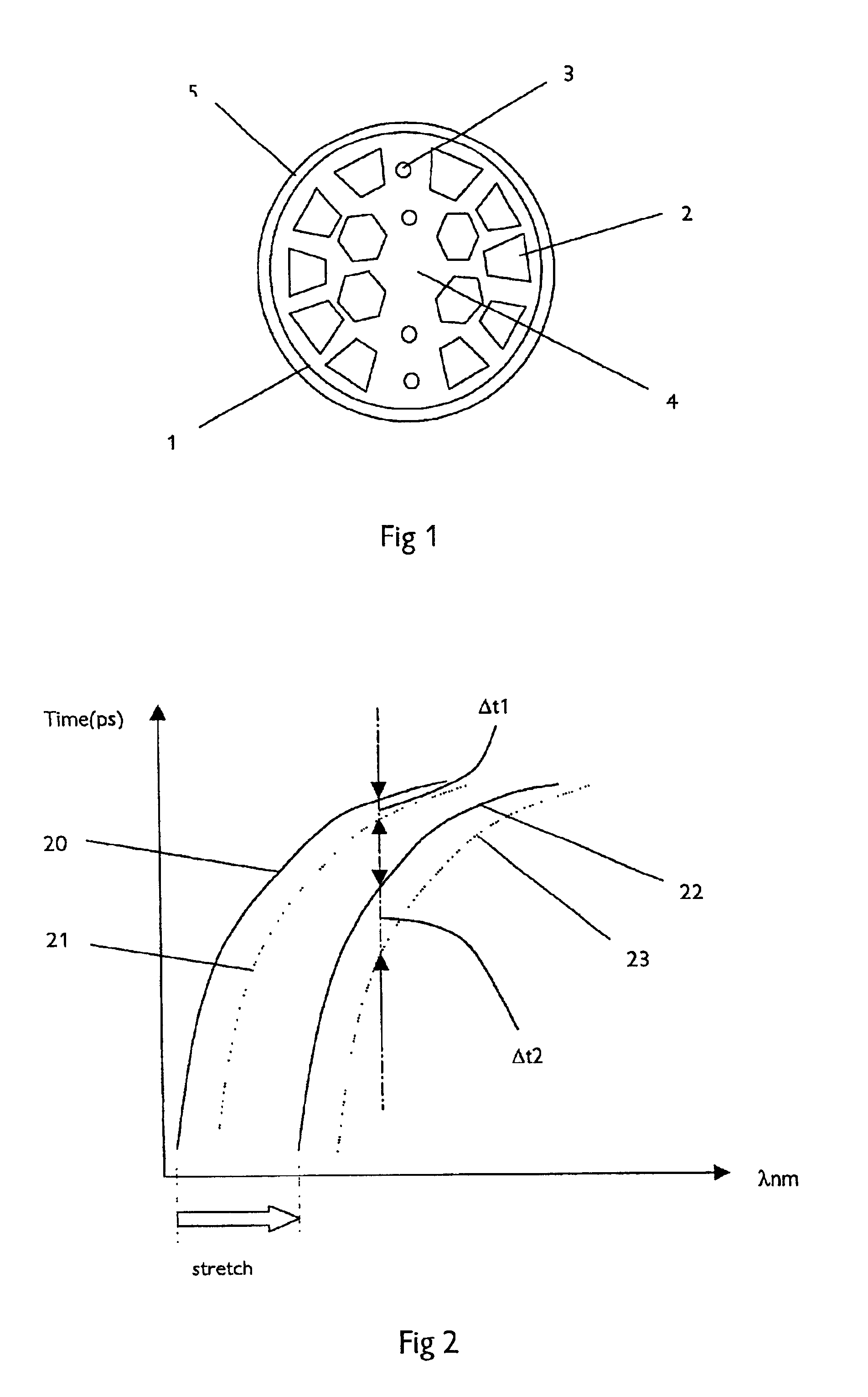

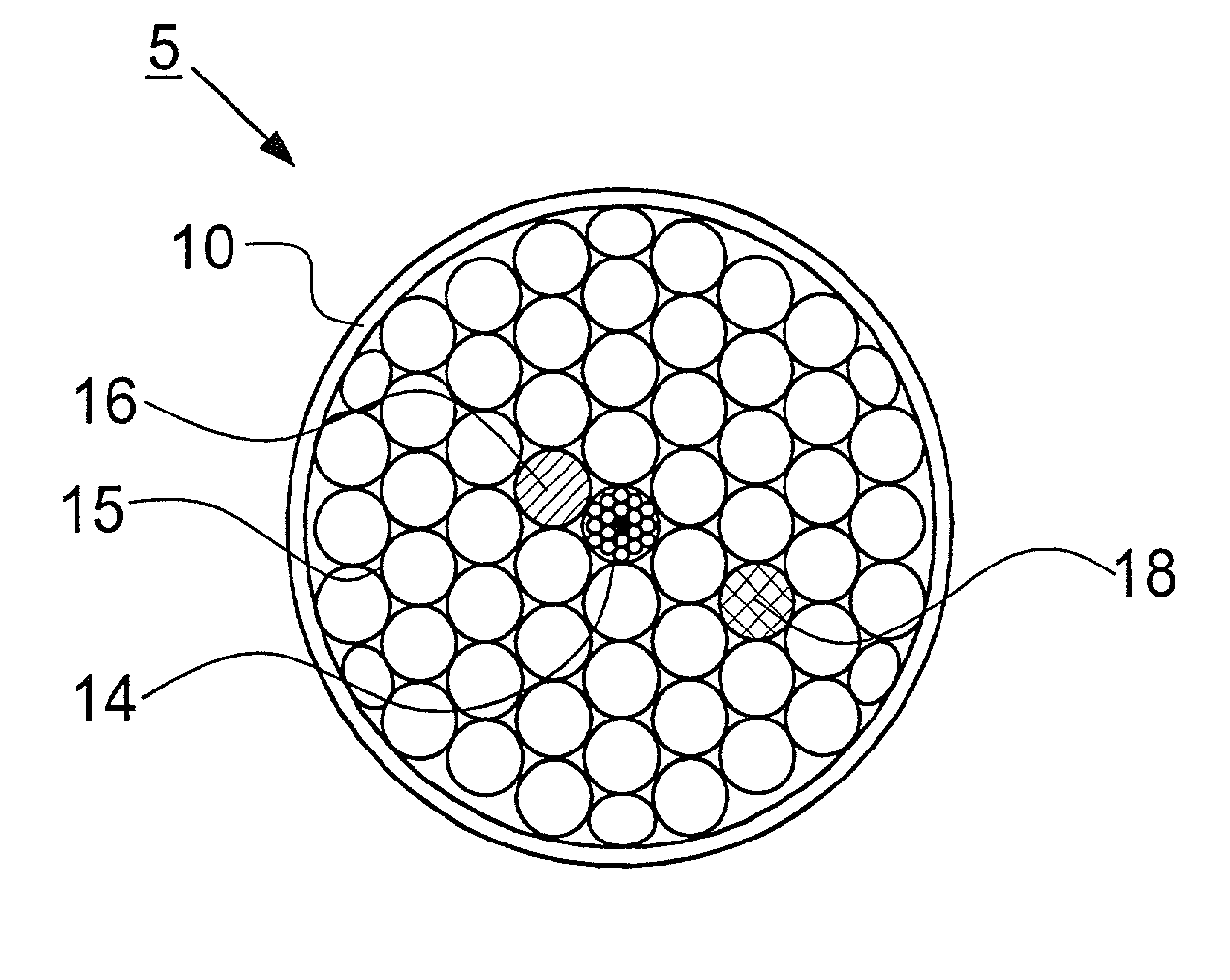

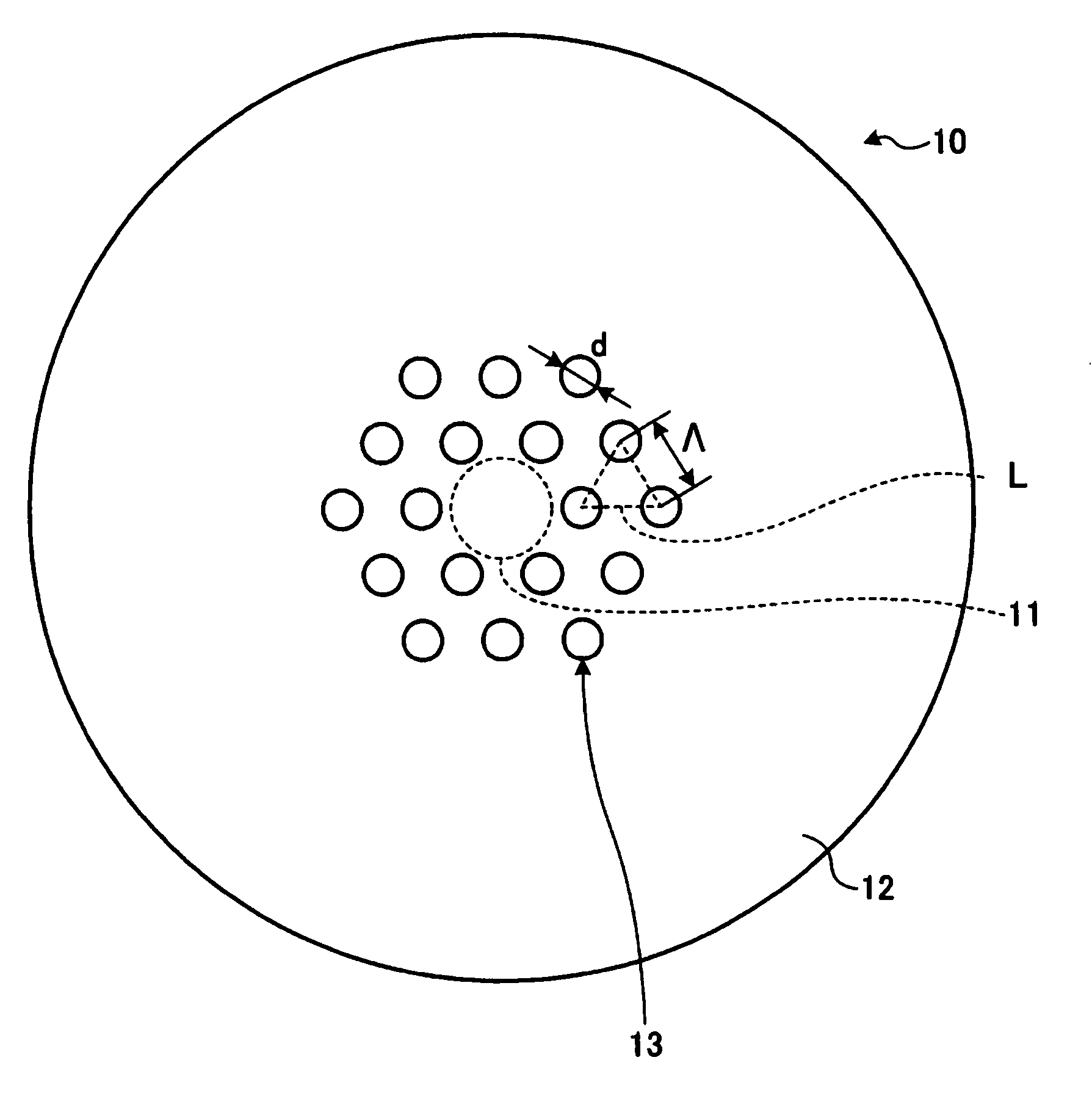

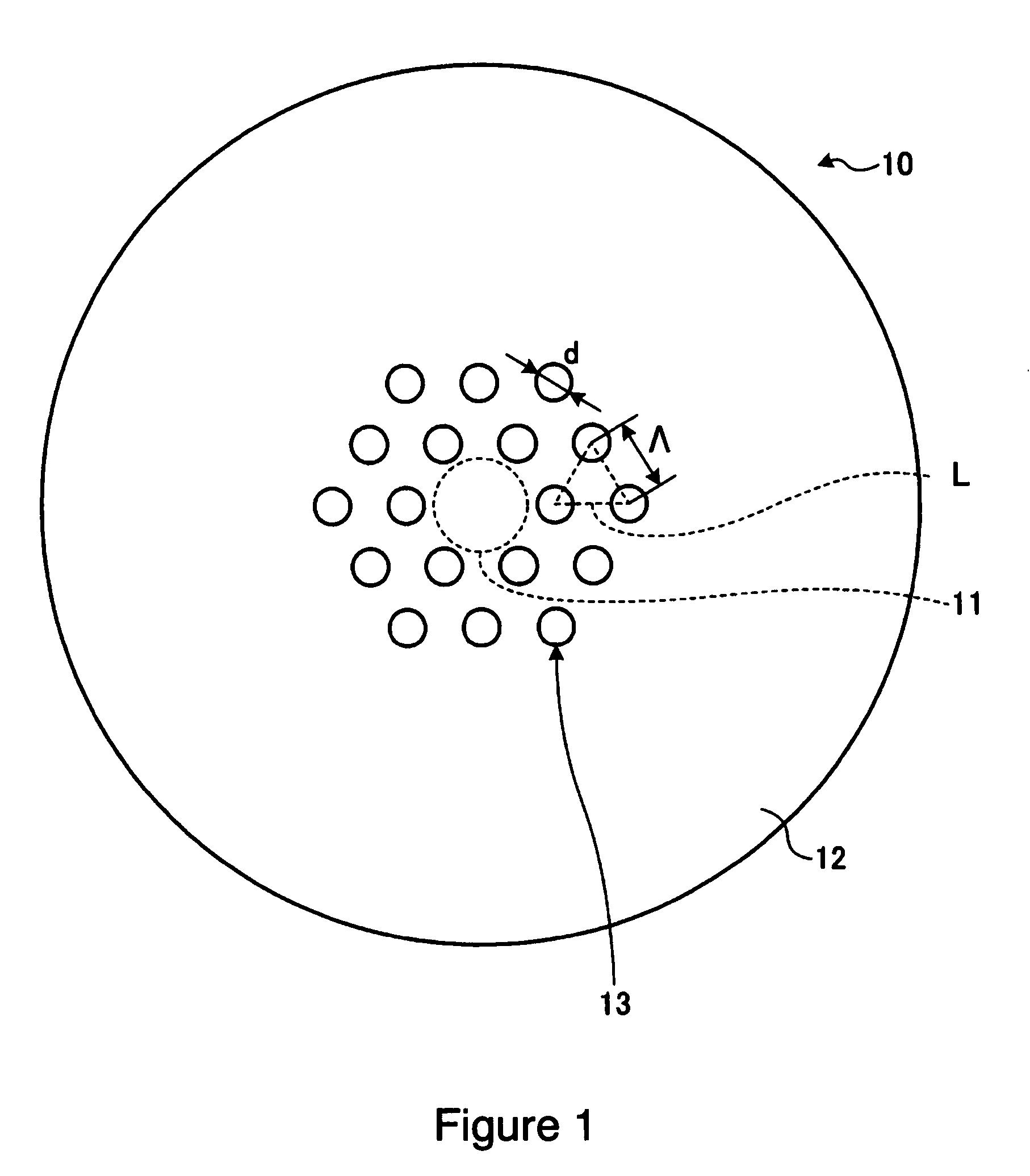

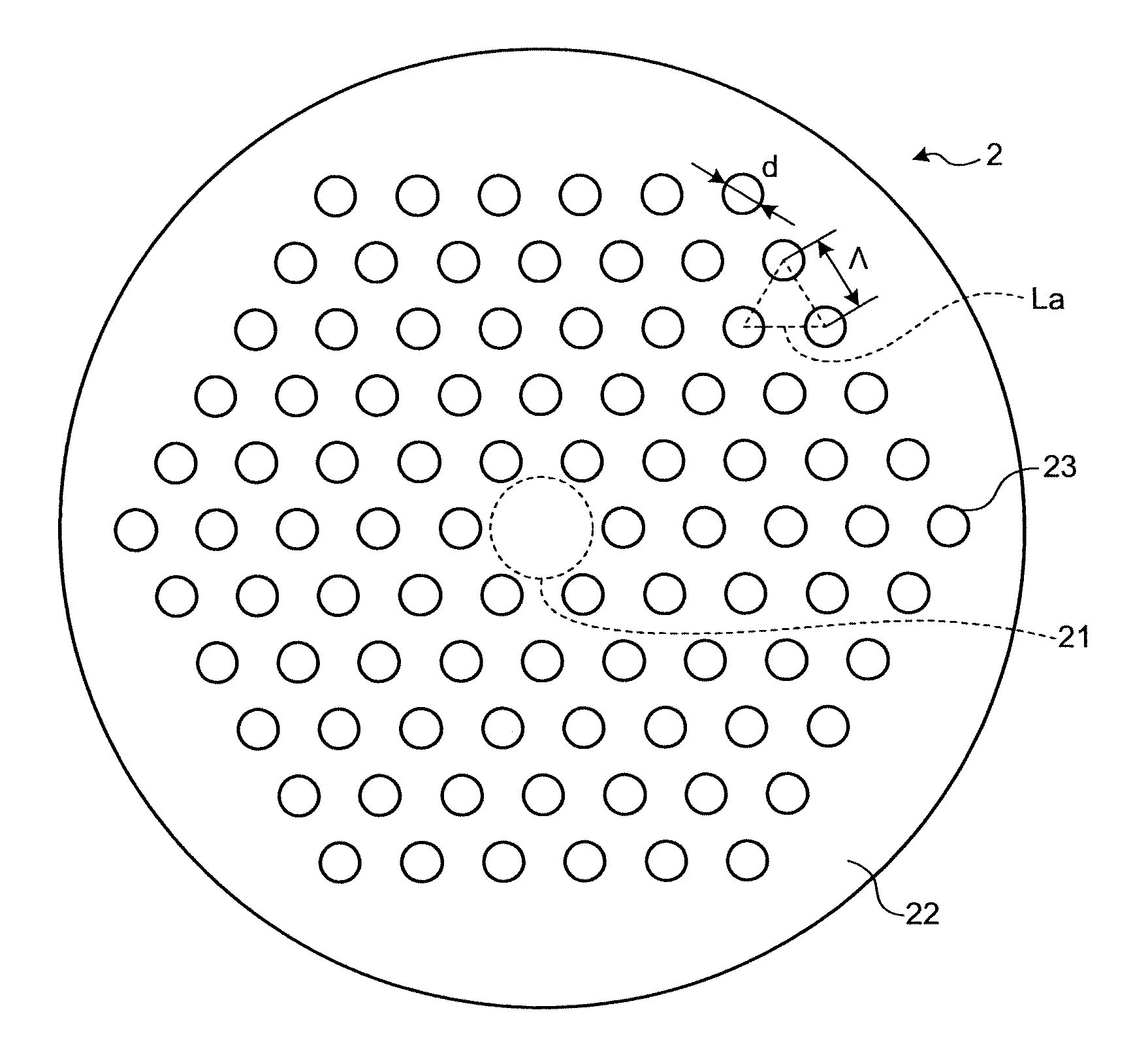

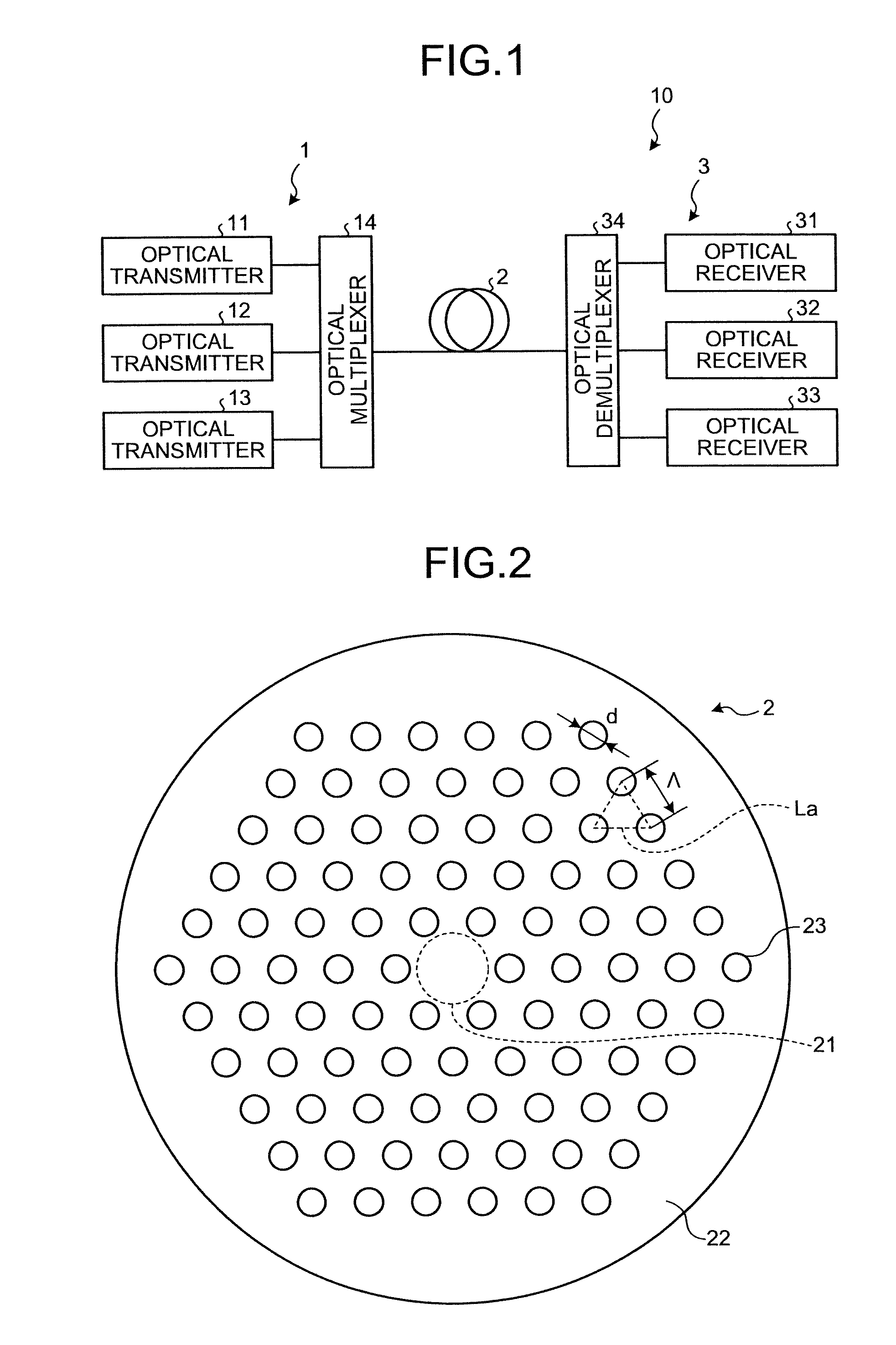

Multi-core holey fiber and optical transmission system

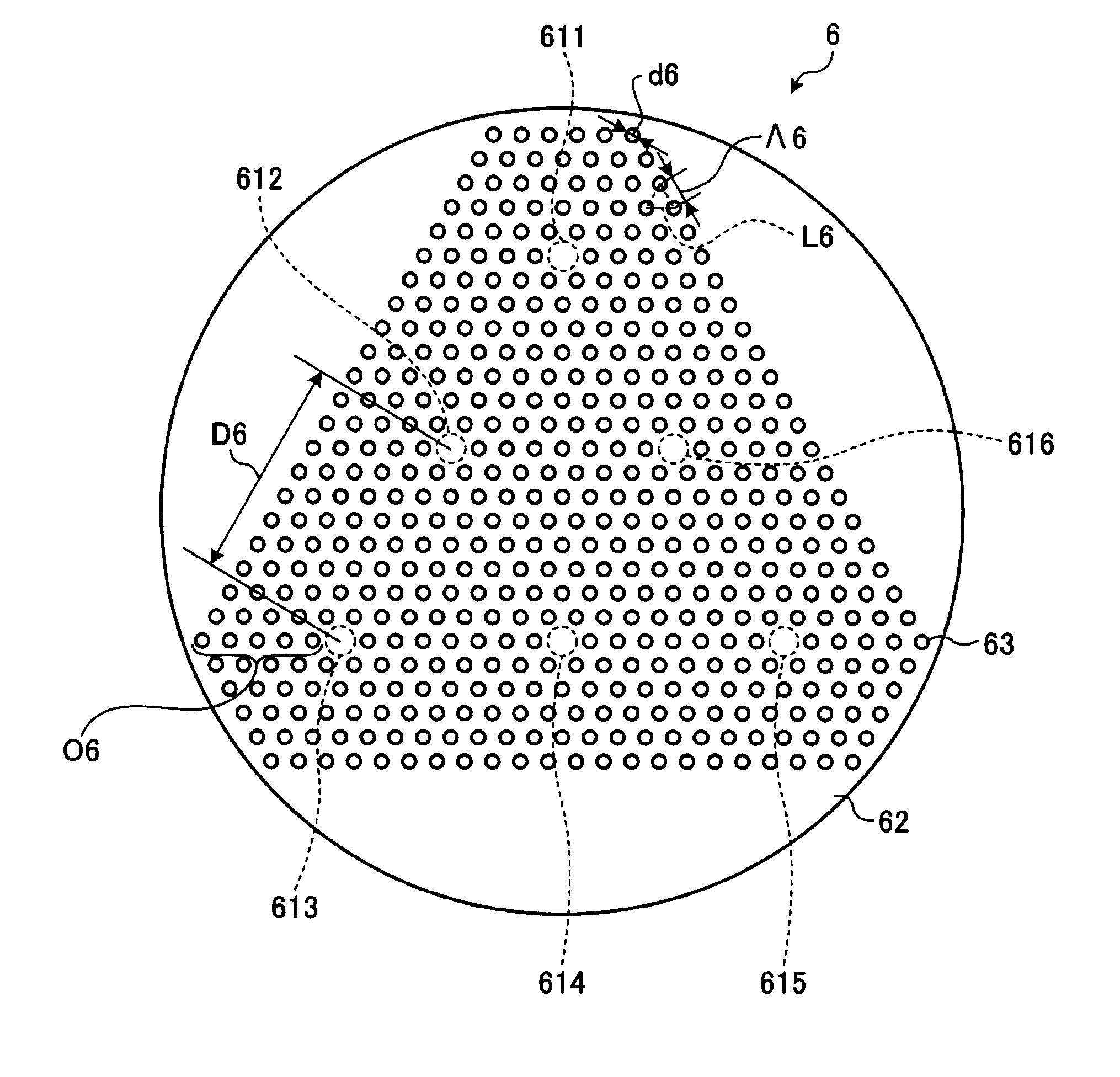

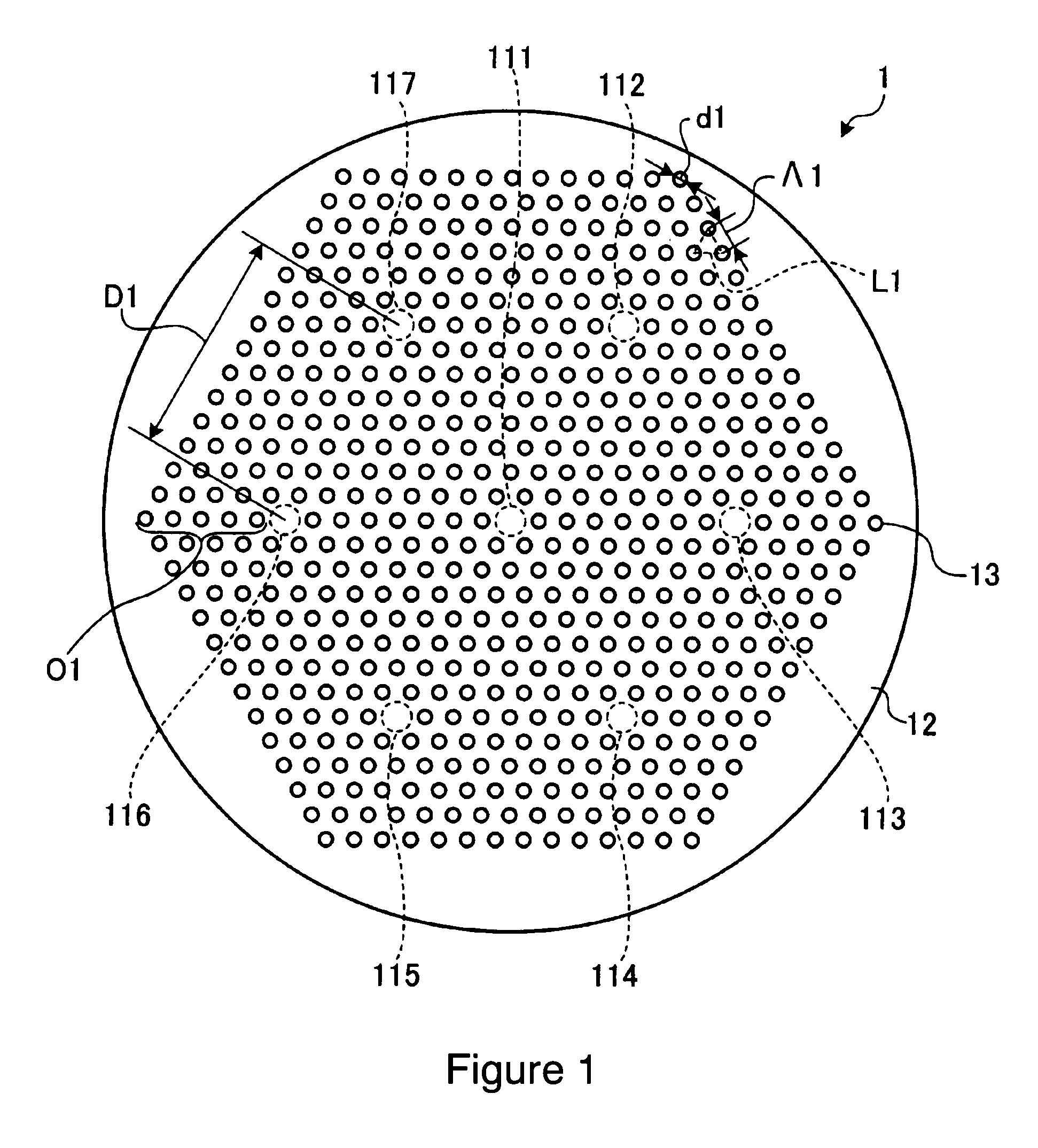

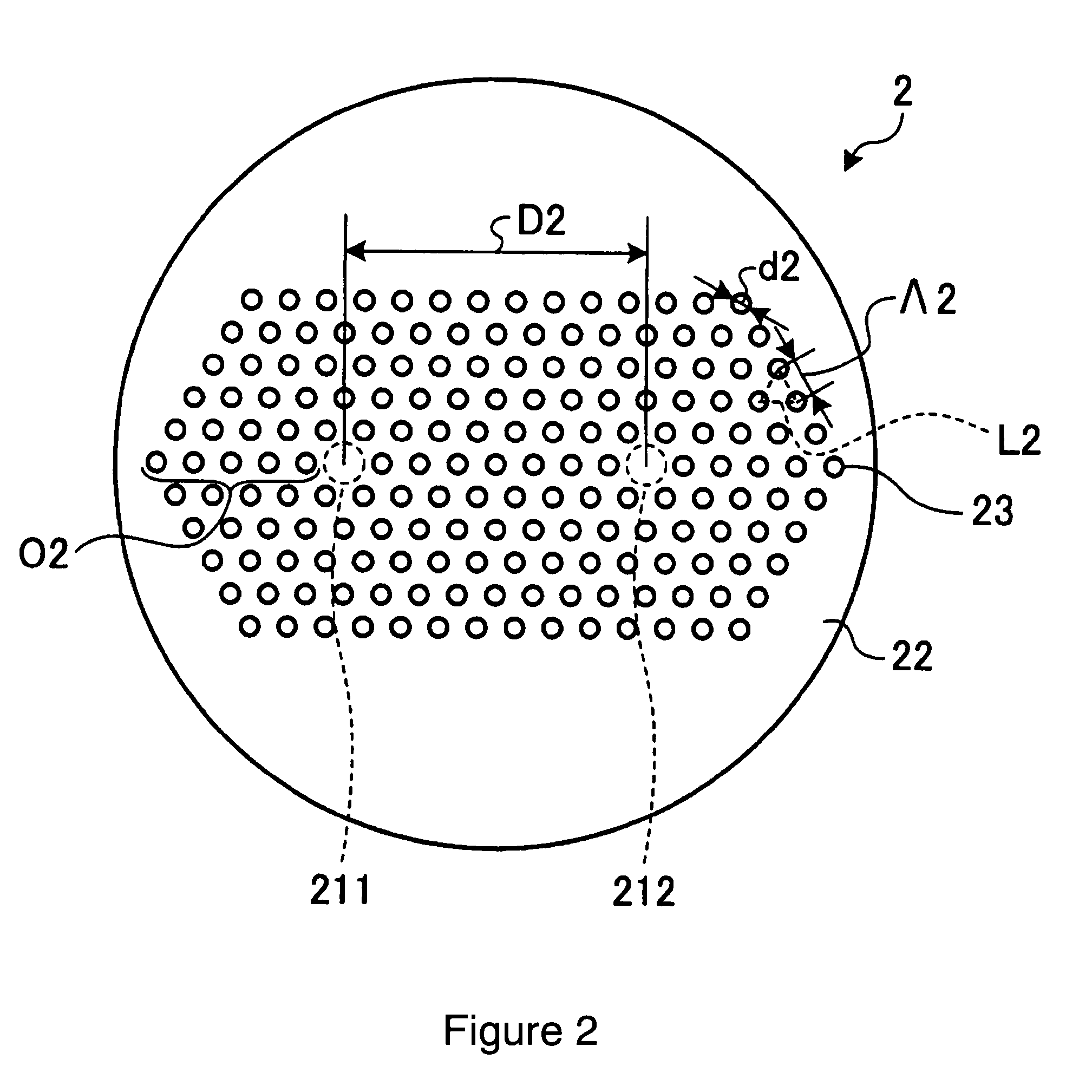

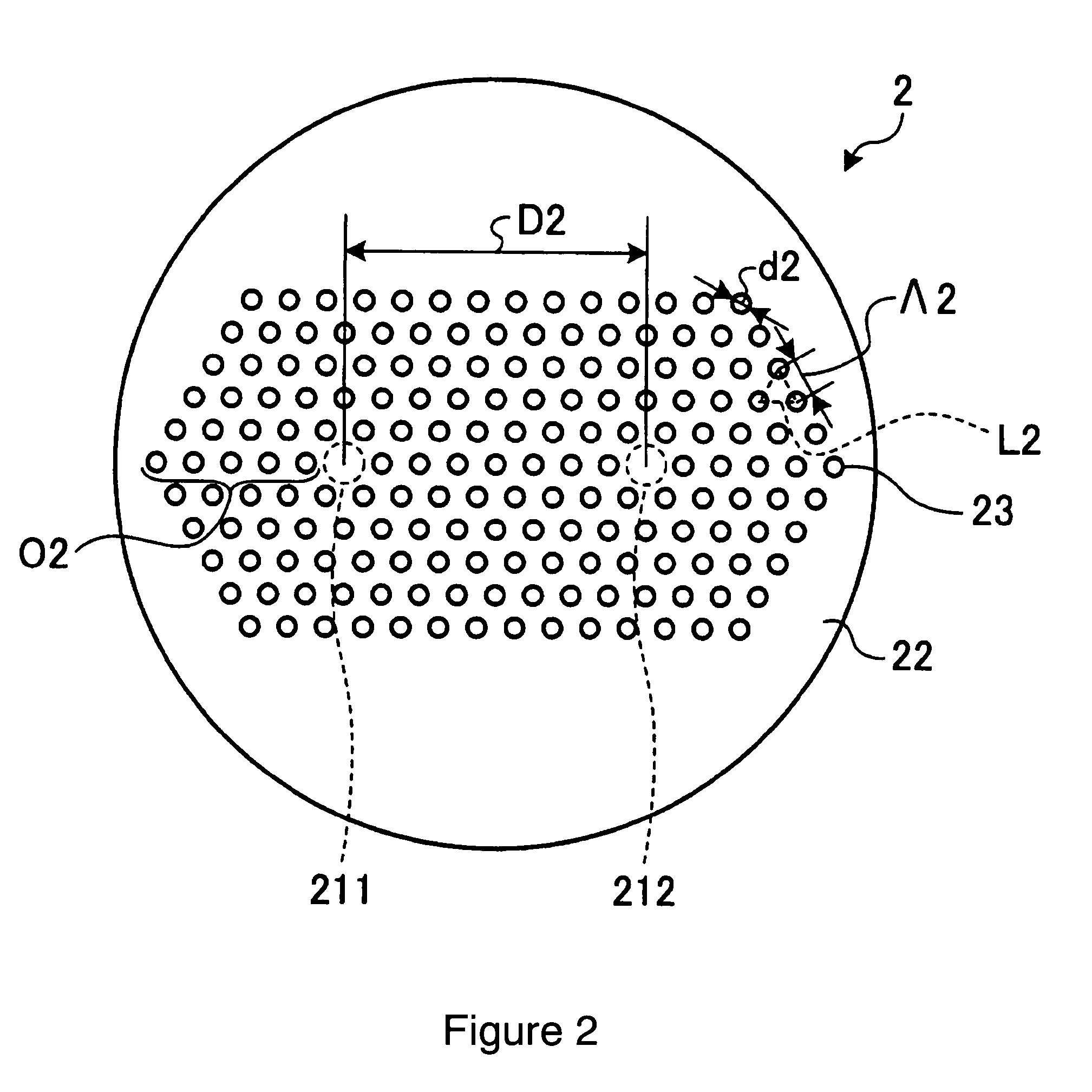

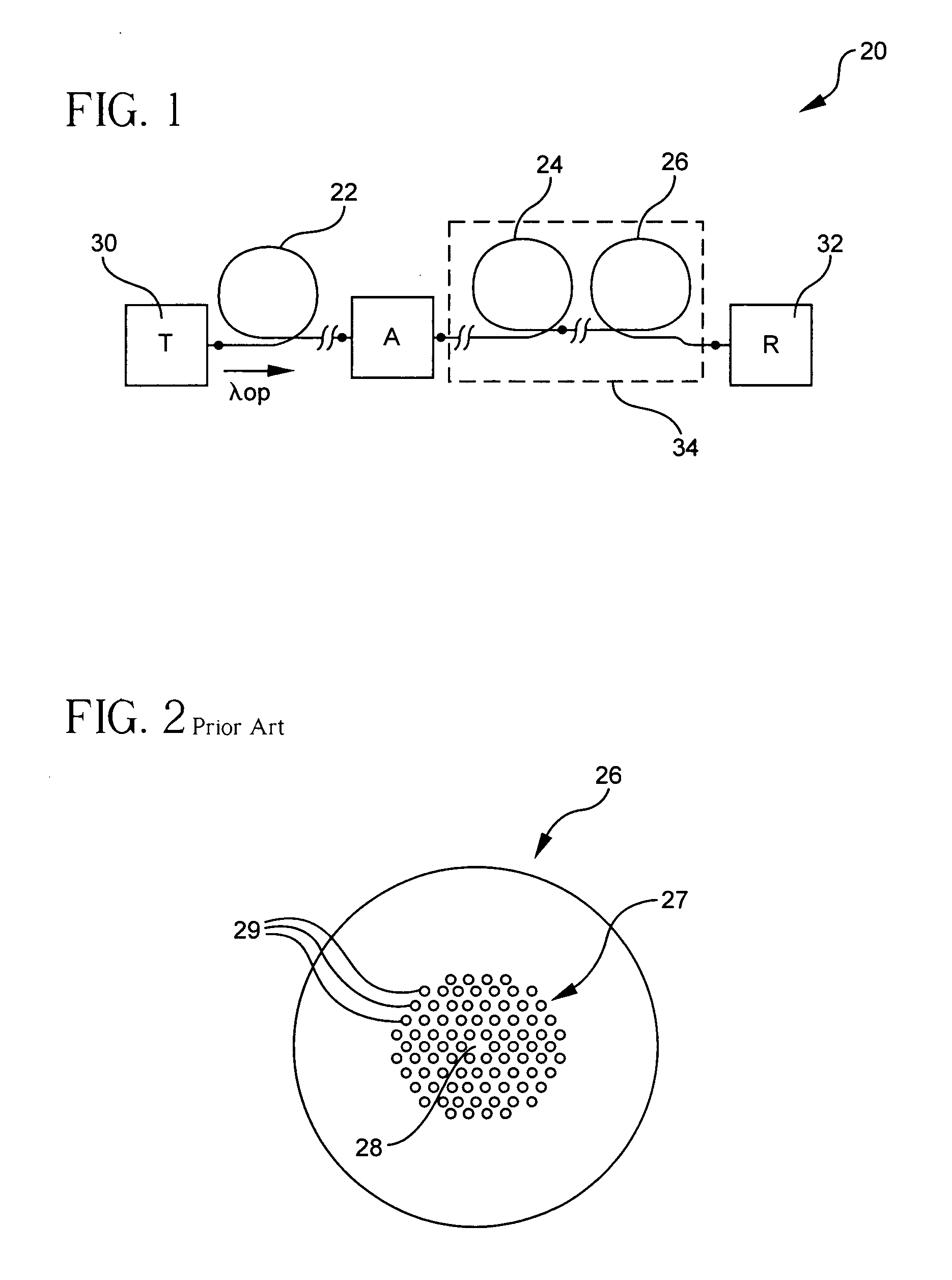

A multi-core holey fiber with suppression of crosstalk deterioration among transmitted optical signals in a plurality of cores, and an optical transmission system using the fiber are disclosed. The multi-core holey fiber comprises a plurality of cores arranged separately from each other, and a cladding surrounding the plurality of cores wherein the cladding has plurality of holes arranged in a triangular lattice shape to create hole layers around the plurality of cores. Additionally, d / Λ is not more than 0.5, where Λ [μm] is lattice constant of the triangular lattice, d [μm] is diameter of each of the holes; a distance between adjacent cores is equivalent to not less than six hole layers; the cores arranged farthest from the center of the multi-core holey fiber is surrounded by not less three hole layers; and the sum of the coupling coefficients between the adjacent cores is not more than 1.6×10−5 / m.

Owner:FURUKAWA ELECTRIC CO LTD

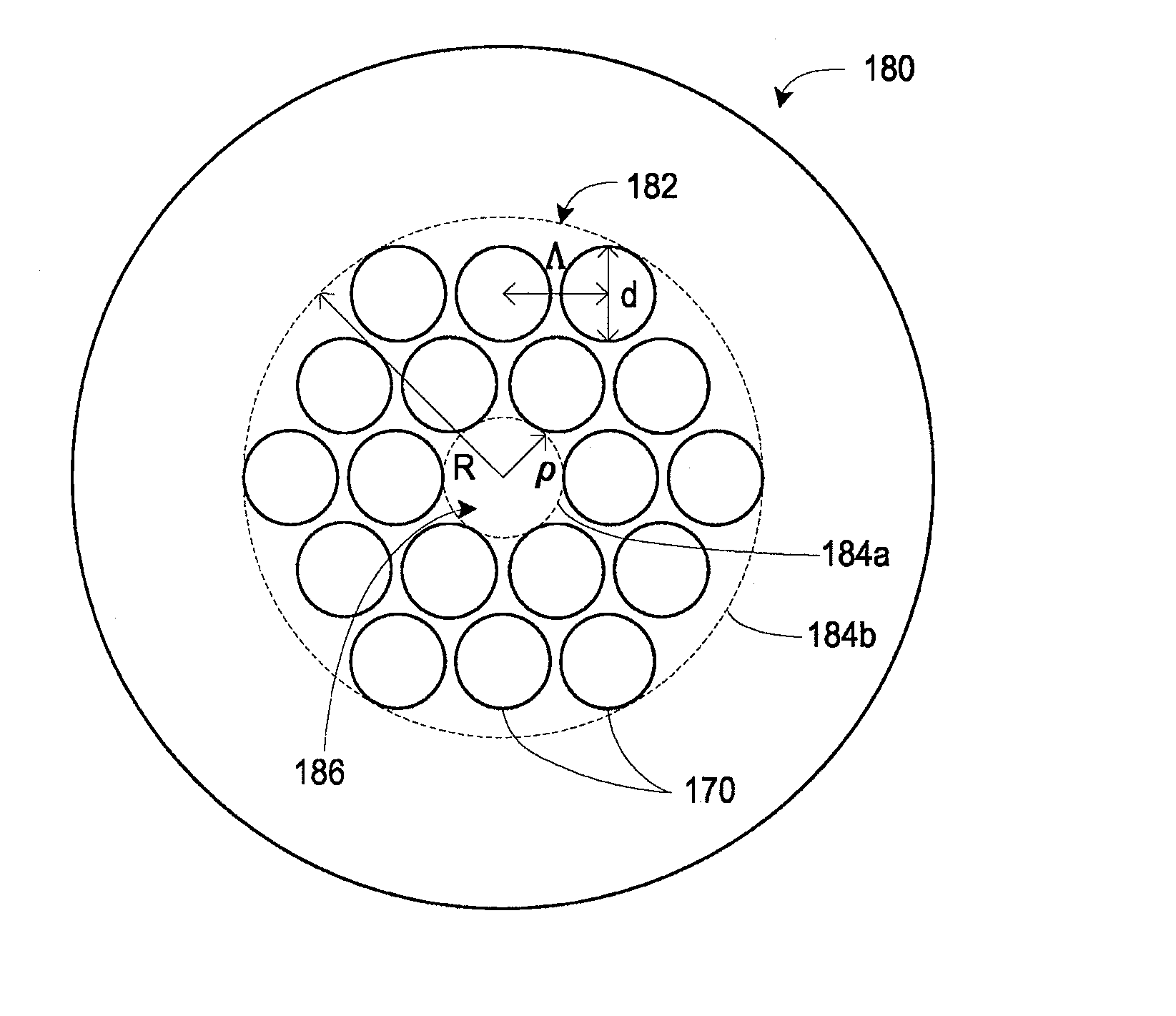

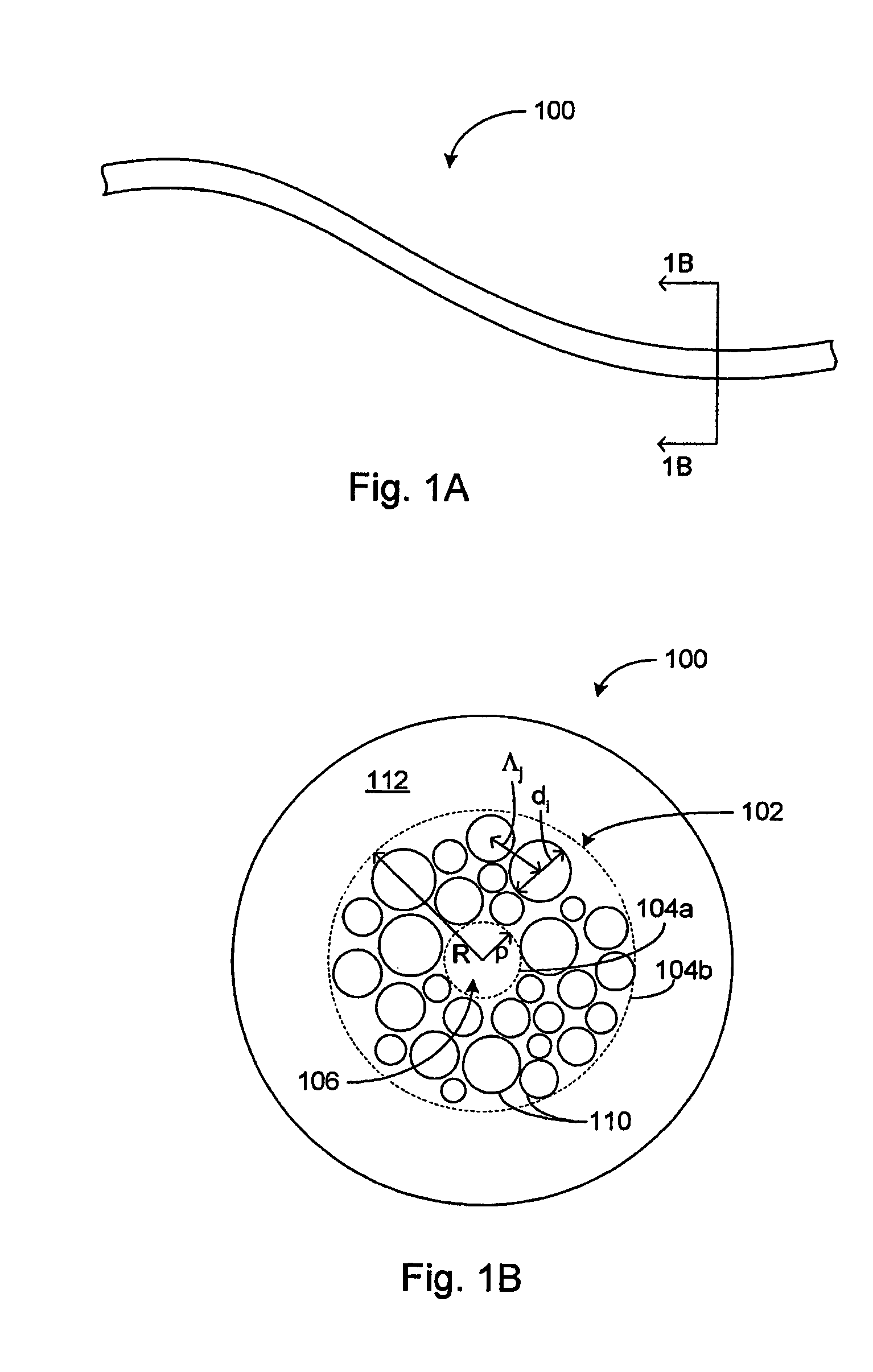

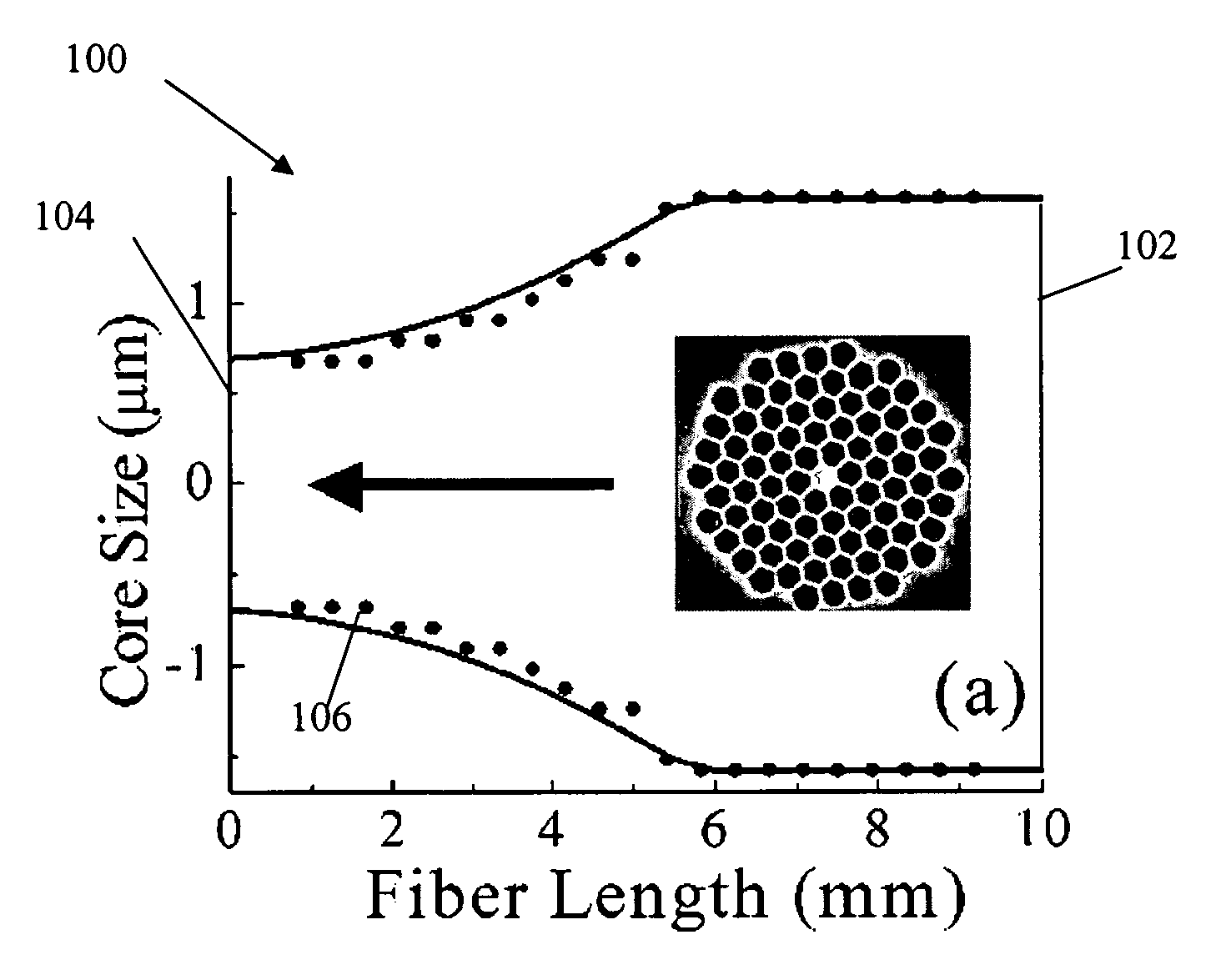

Large core holey fibers

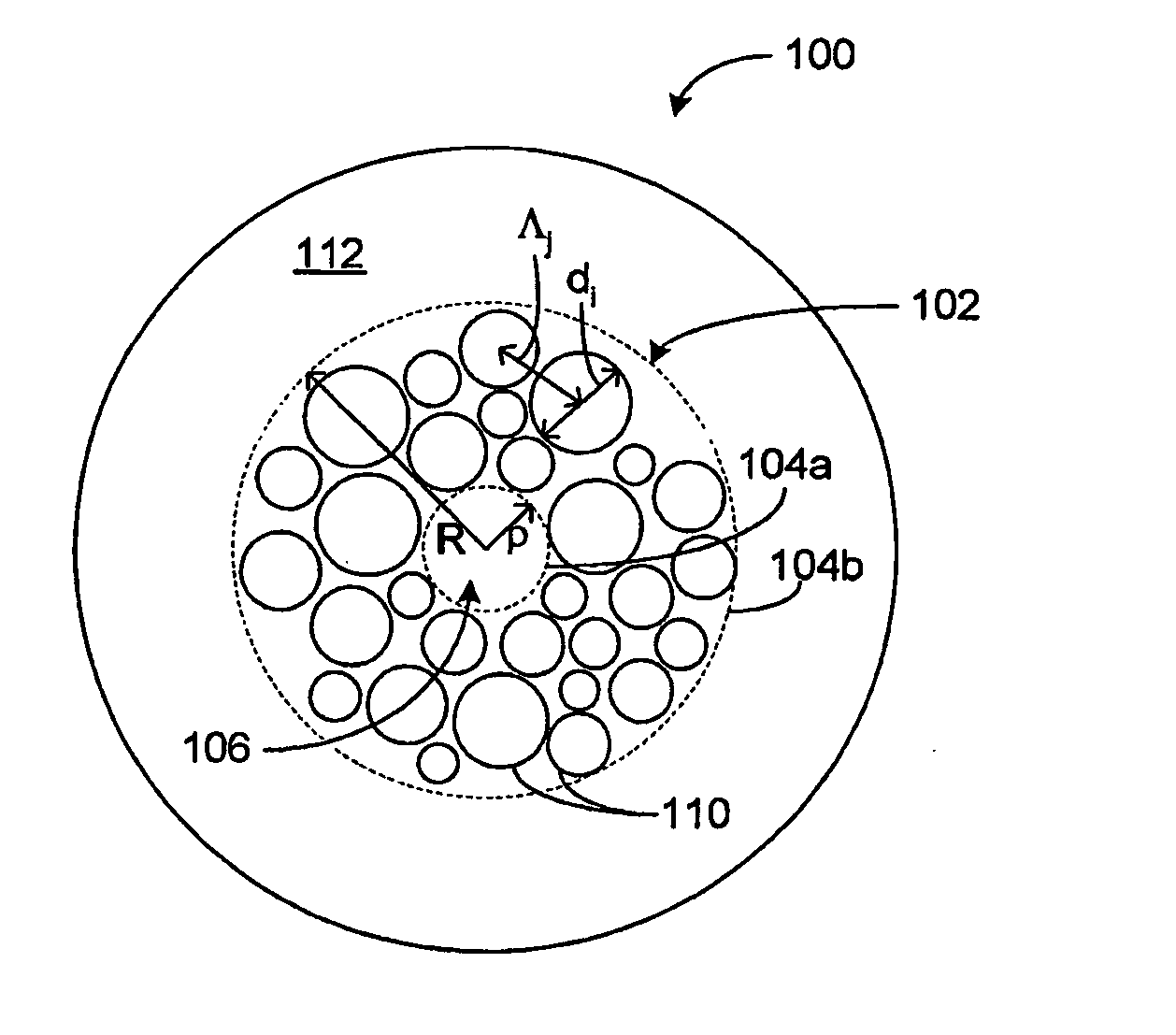

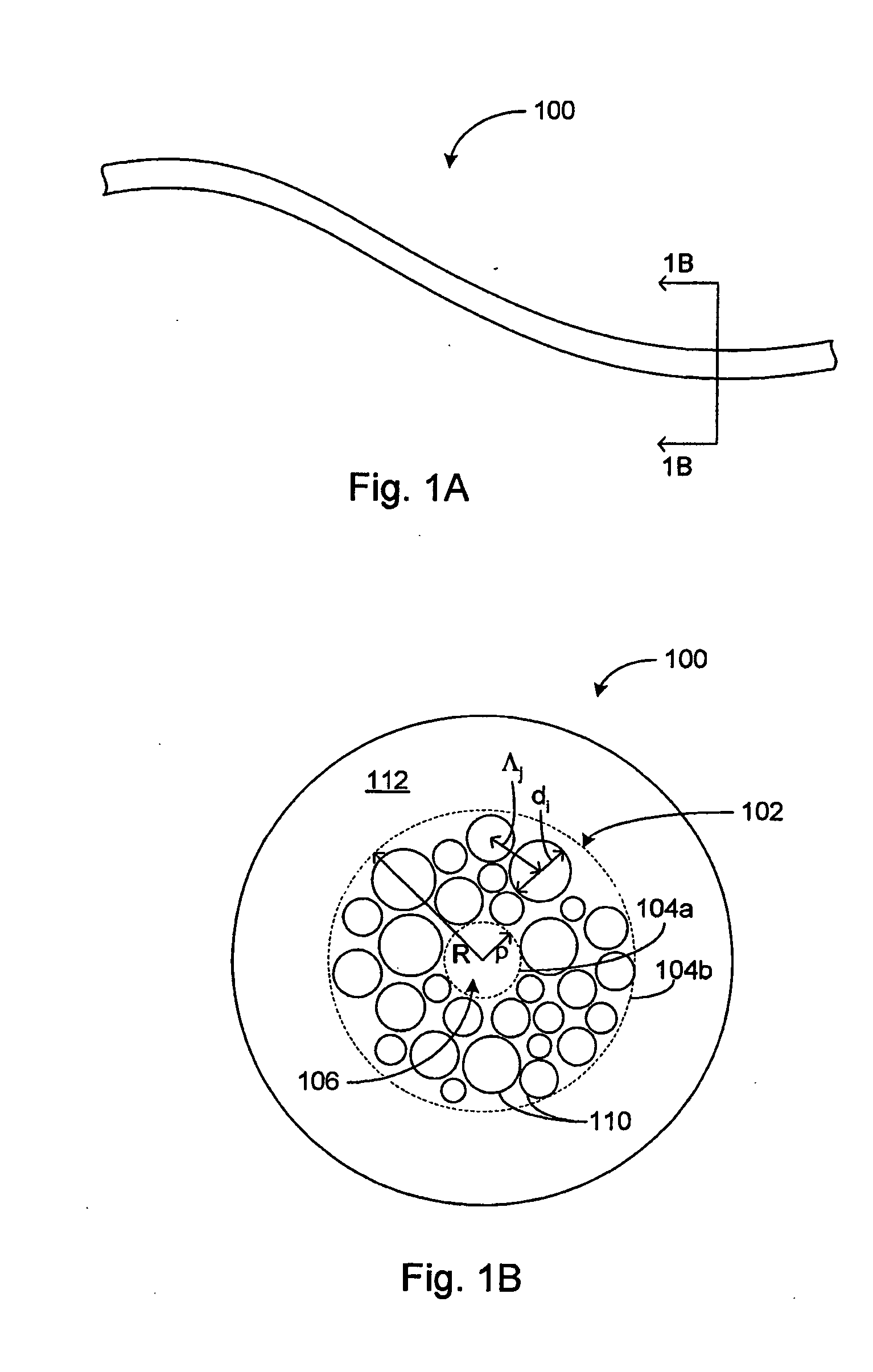

Various types of holey fiber provide optical propagation. In various embodiments, for example, a large core holey fiber comprises a cladding region formed by large holes arranged in few layers. The number of layers or rows of holes about the large core can be used to coarse tune the leakage losses of the fundamental and higher modes of a signal, thereby allowing the non-fundamental modes to be substantially eliminated by leakage over a given length of fiber. Fine tuning of leakage losses can be performed by adjusting the hole dimension and / or the hole spacing to yield a desired operation with a desired leakage loss of the fundamental mode. Resulting holely fibers have a large hole dimension and spacing, and thus a large core, when compared to traditional fibers and conventional fibers that propagate a single mode. Other loss mechanisms, such as bend loss and modal spacing can be utilized for selected modes of operation of holey fibers. Other embodiments are also provided.

Owner:IMRA AMERICA

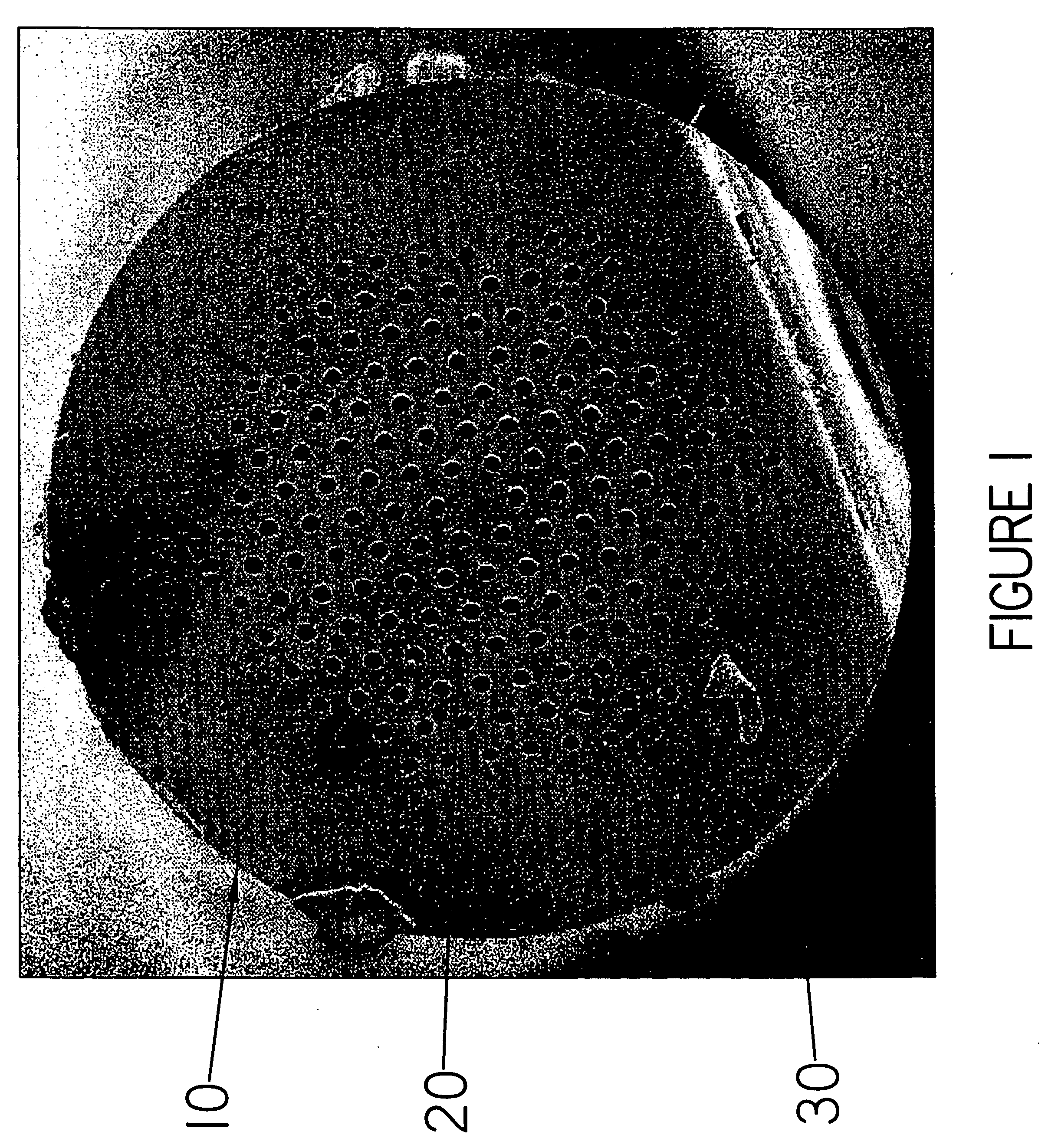

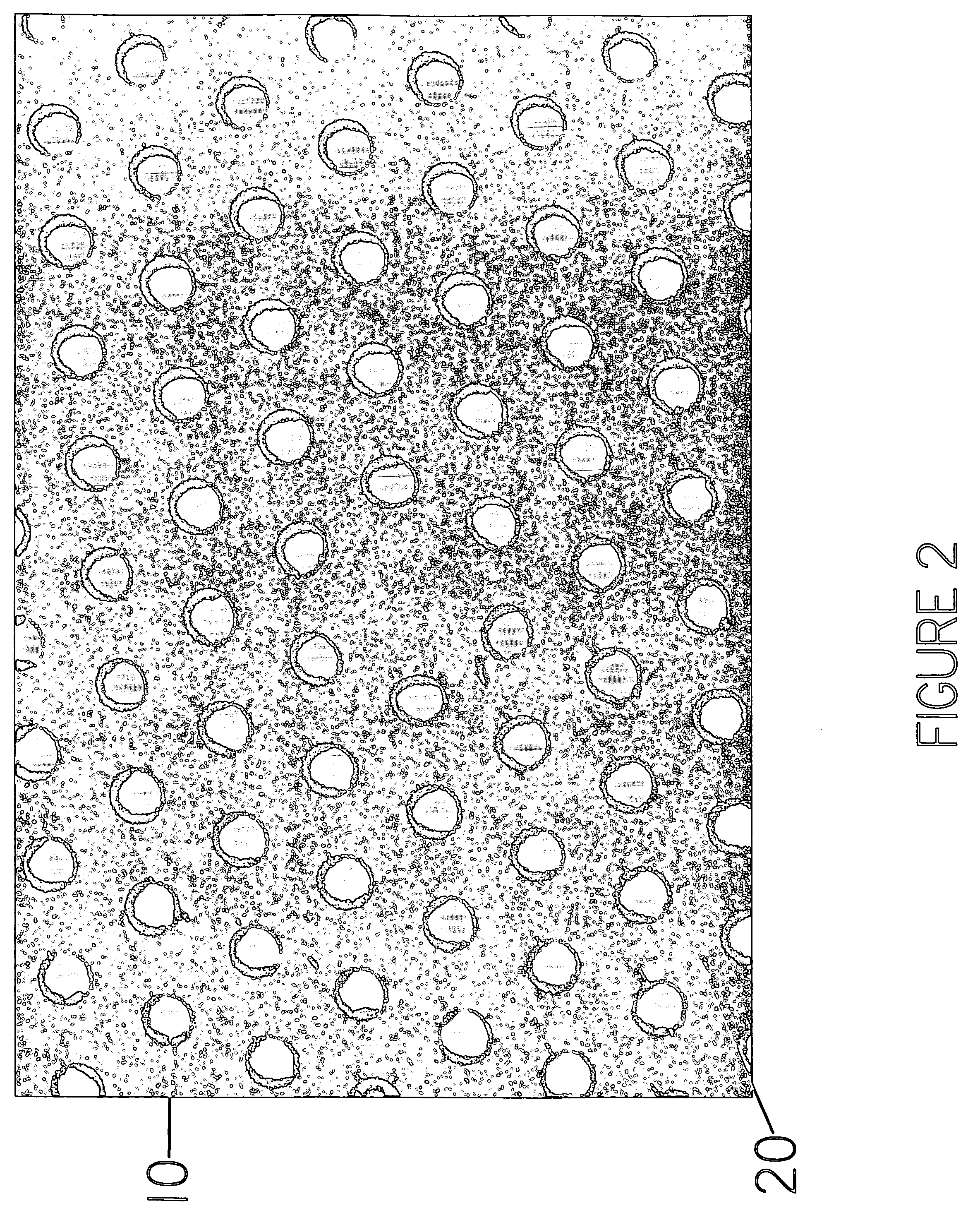

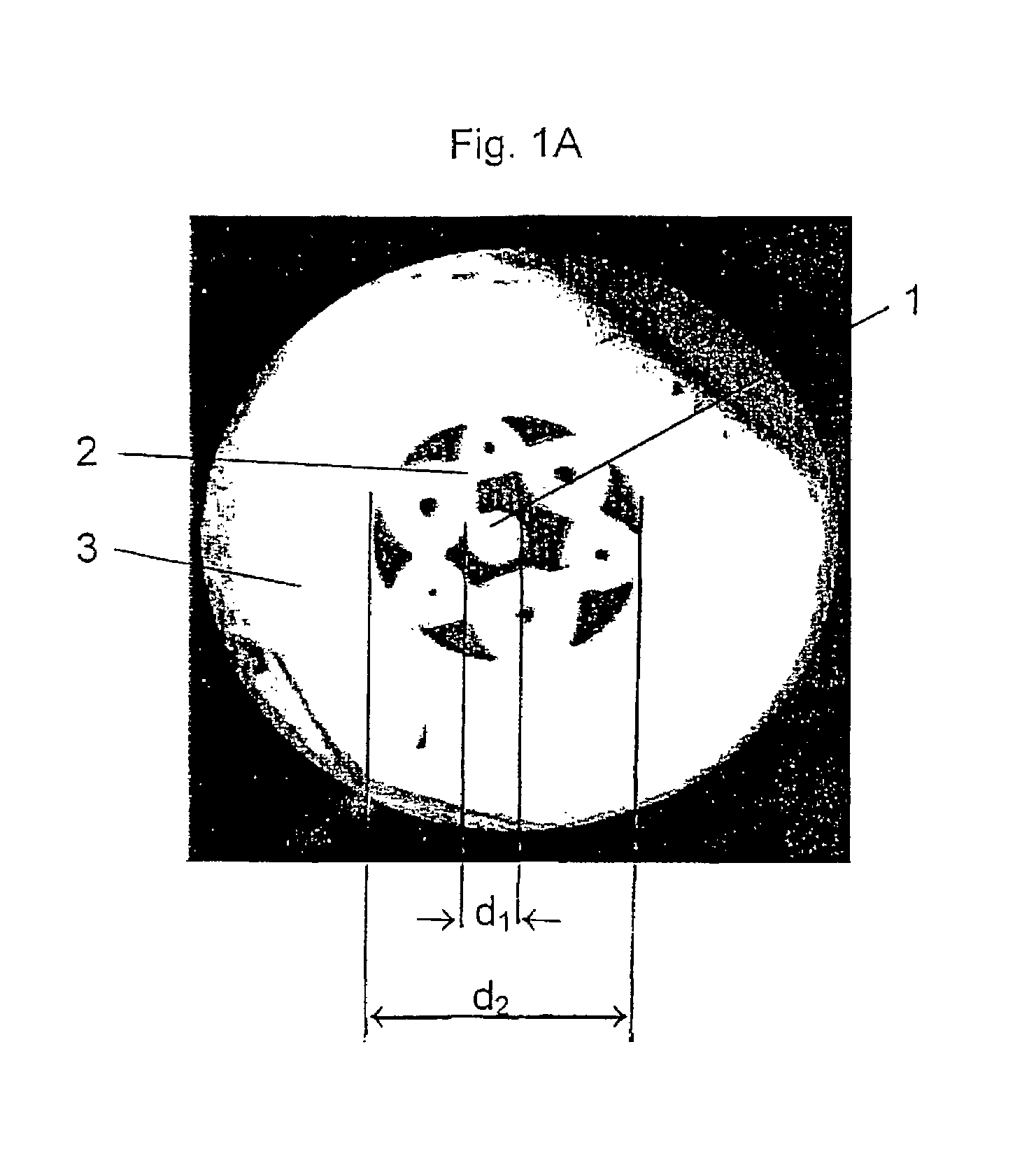

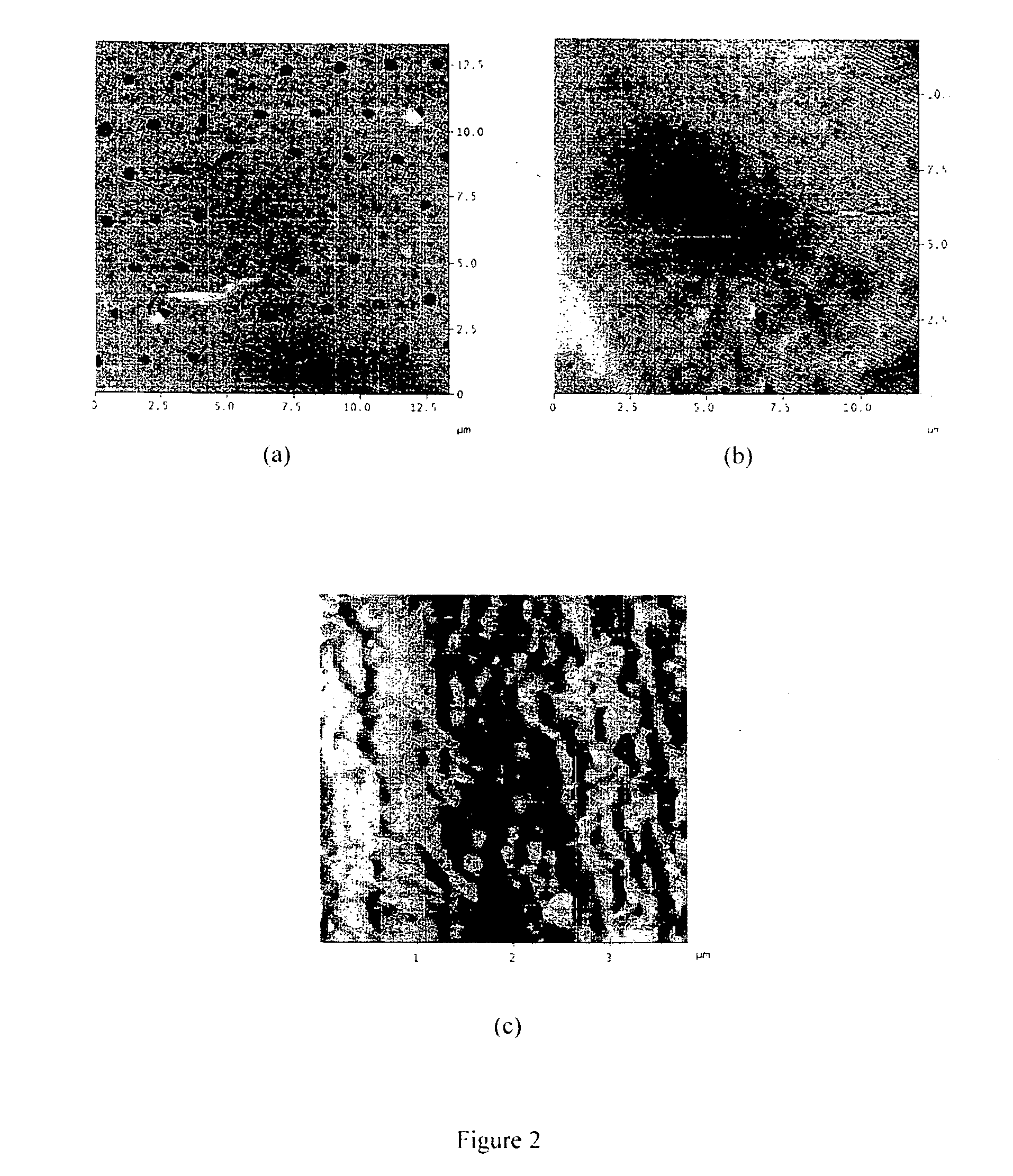

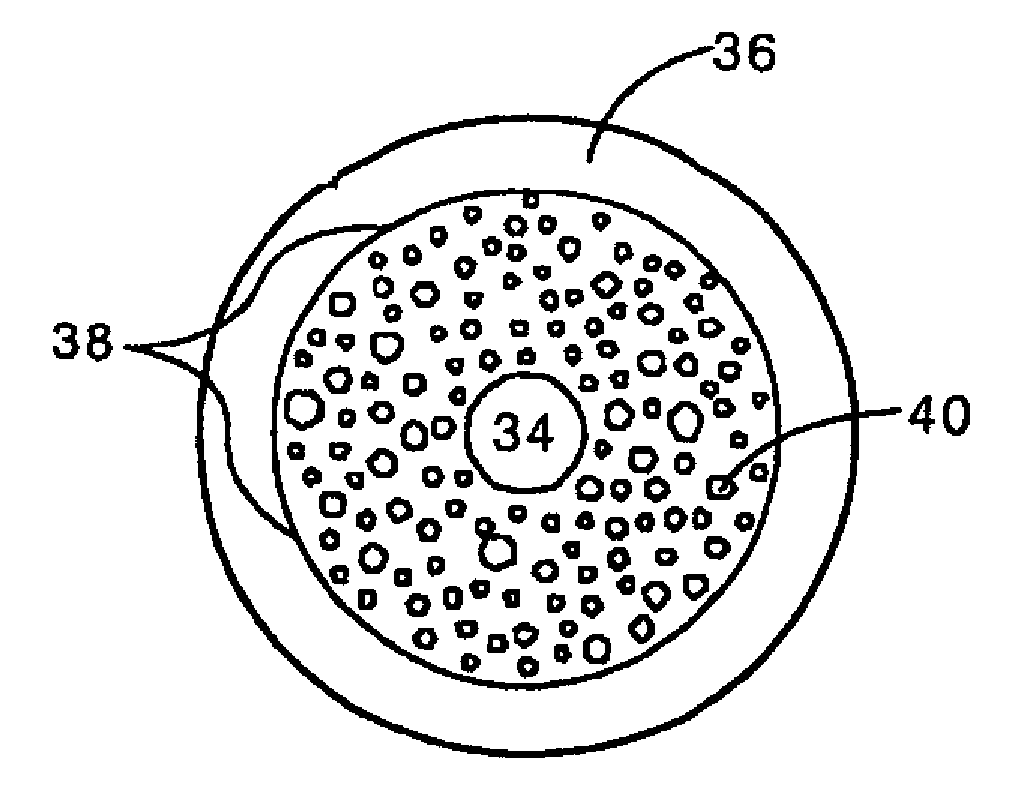

Holey optical fiber with random pattern of holes and method for making same

ActiveUS20050094954A1Glass making apparatusOptical fibre with multilayer core/claddingSilicon dioxideAir bubble

A random array of holes is created in an optical fiber by gas generated during fiber drawing. The gas forms bubbles which are drawn into long, microscopic holes. The gas is created by a gas generating material such as silicon nitride. Silicon nitride oxidizes to produce nitrogen oxides when heated. The gas generating material can alternatively be silicon carbide or other nitrides or carbides. The random holes can provide cladding for optical confinement when located around a fiber core. The random holes can also be present in the fiber core. The fibers can be made of silica. The present random hole fibers are particularly useful as pressure sensors since they experience a large wavelength dependant increase in optical loss when pressure or force is applied.

Owner:VIRGINIA TECH INTPROP INC

Large core holey fibers

Various types of holey fiber provide optical propagation. In various embodiments, for example, a large core holey fiber comprises a cladding region formed by large holes arranged in few layers. The number of layers or rows of holes about the large core can be used to coarse tune the leakage losses of the fundamental and higher modes of a signal, thereby allowing the non-fundamental modes to be substantially eliminated by leakage over a given length of fiber. Fine tuning of leakage losses can be performed by adjusting the hole dimension and / or the hole spacing to yield a desired operation with a desired leakage loss of the fundamental mode. Resulting holey fibers have a large hole dimension and spacing, and thus a large core, when compared to traditional fibers and conventional fibers that propagate a single mode. Other loss mechanisms, such as bend loss and modal spacing can be utilized for selected modes of operation of holey fibers. Other embodiments are also provided.

Owner:IMRA AMERICA

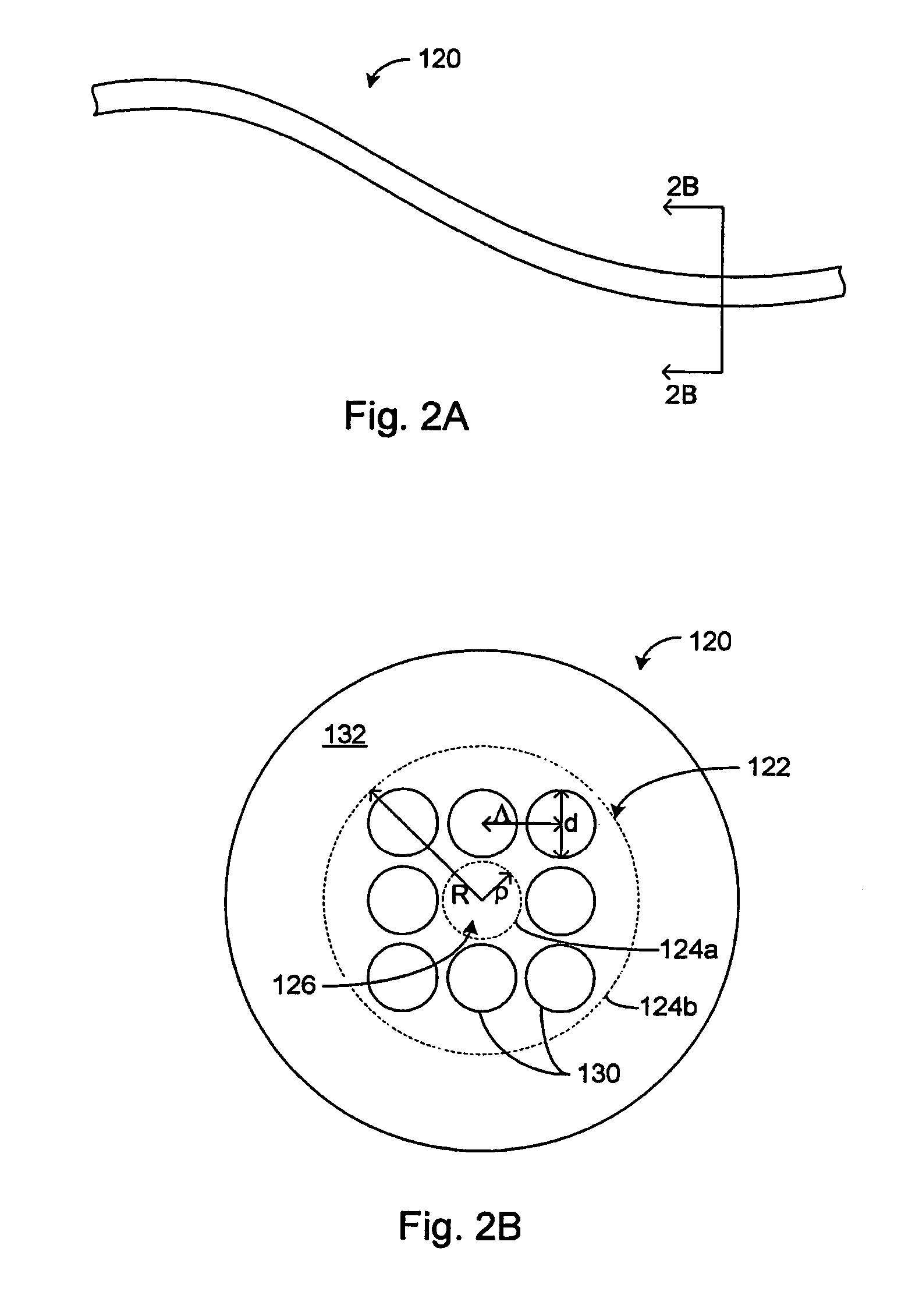

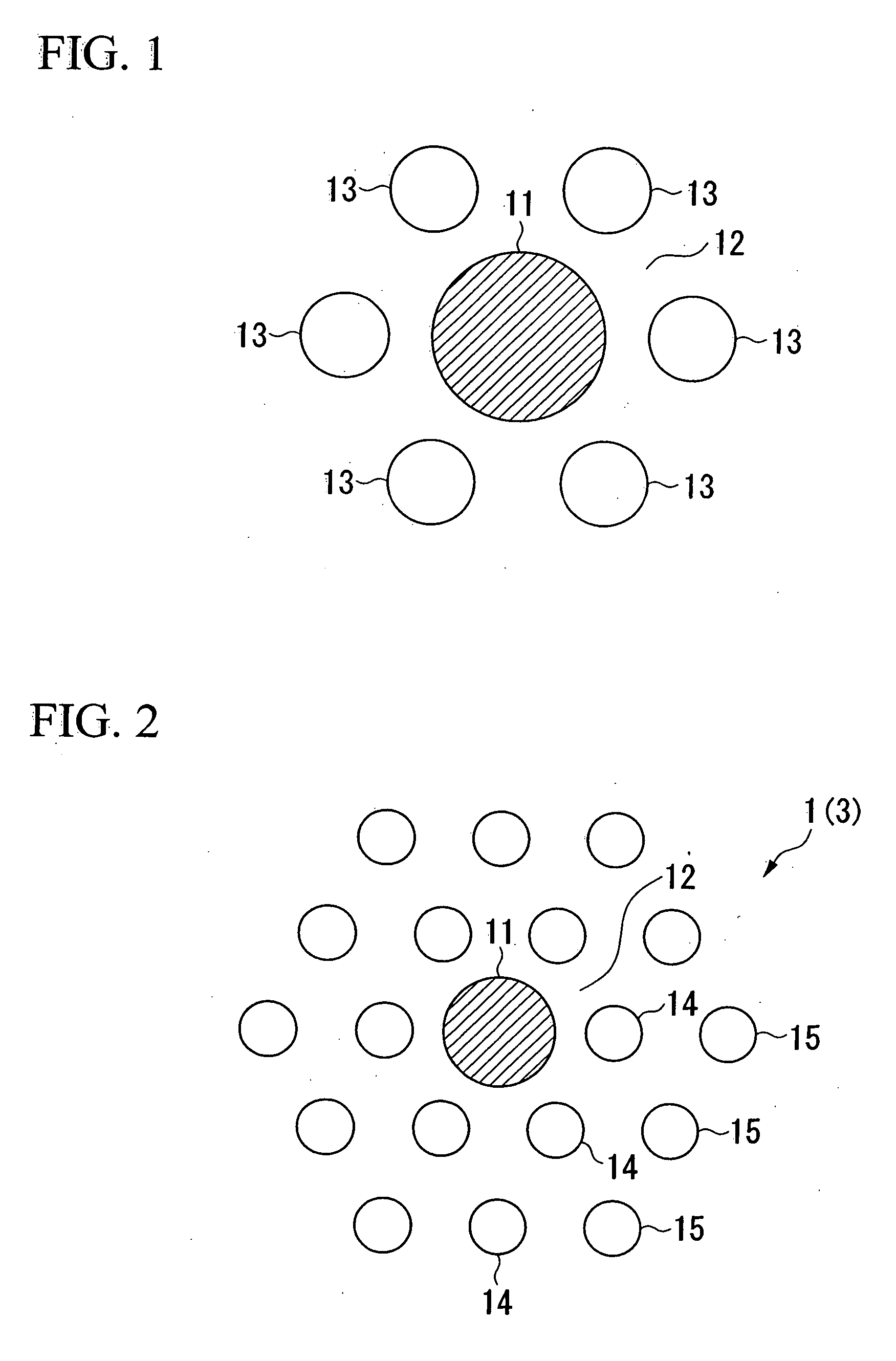

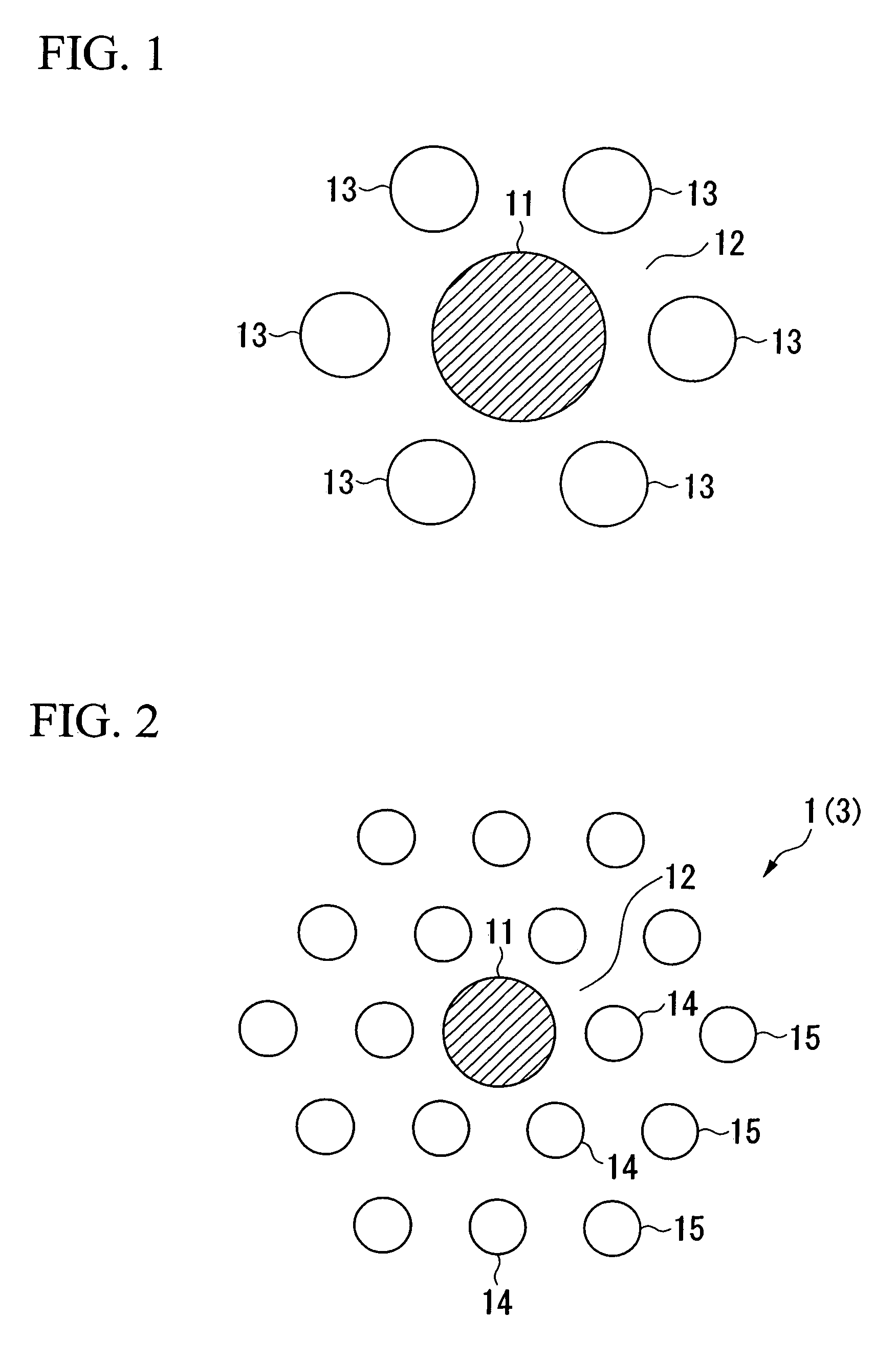

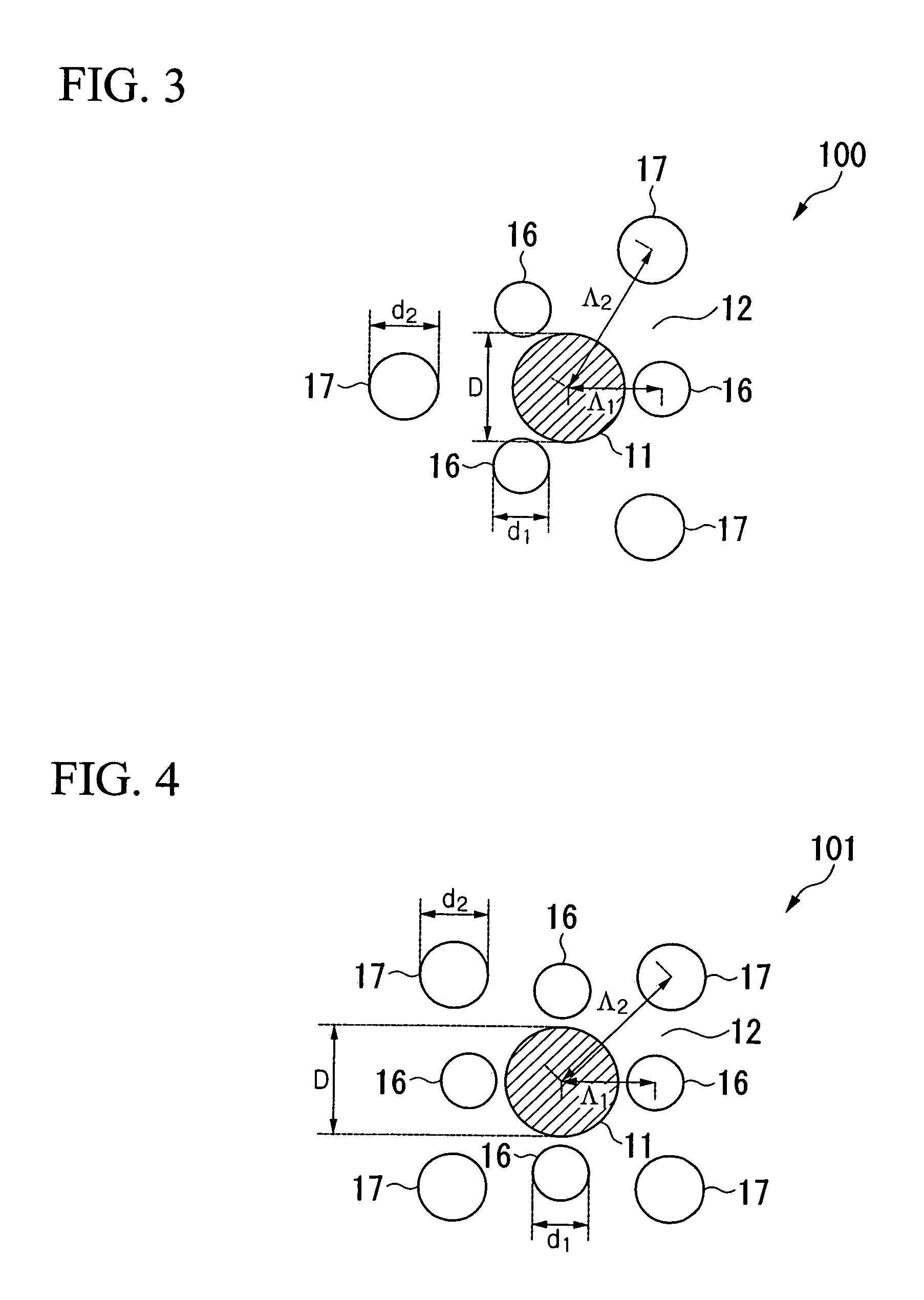

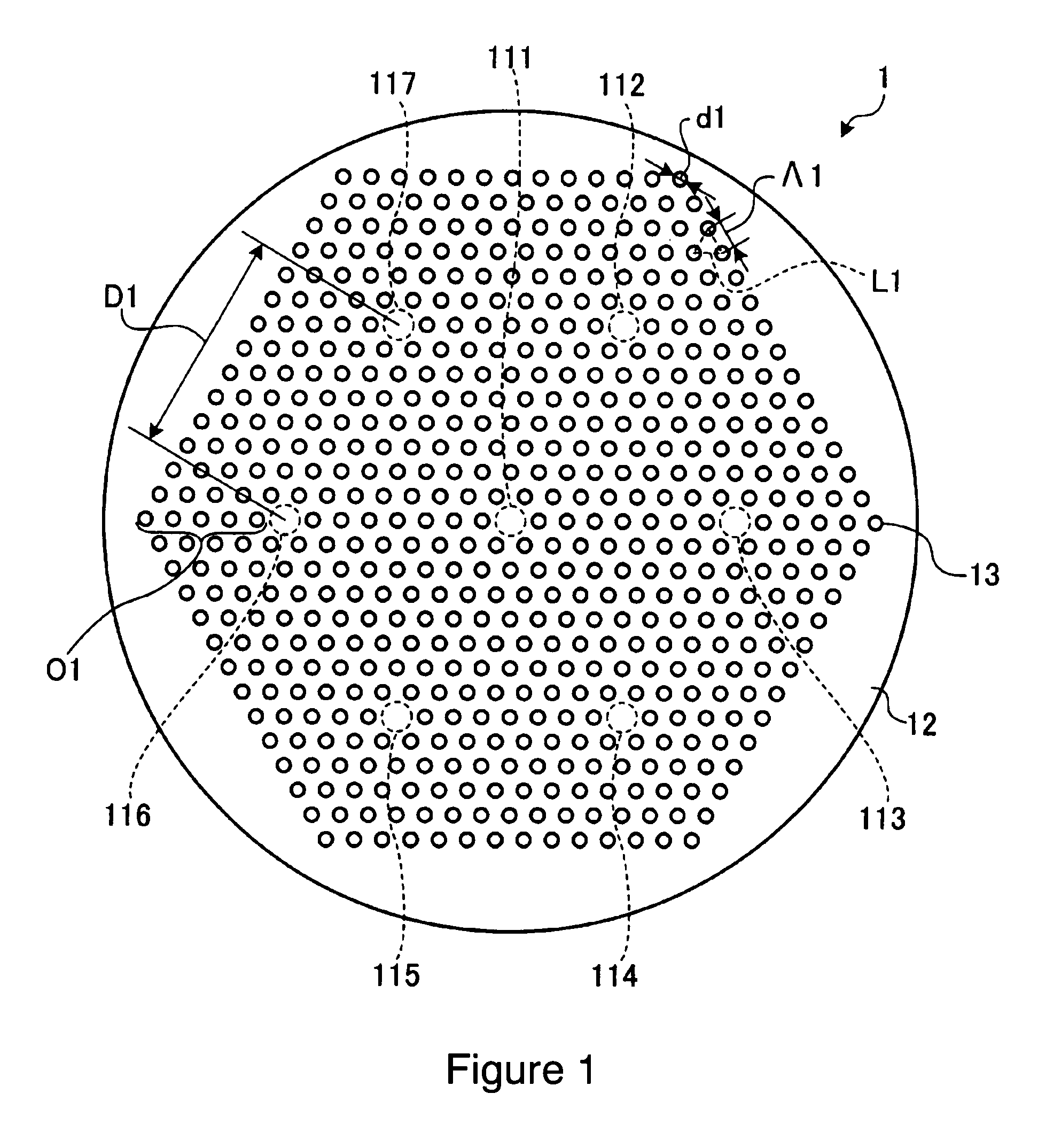

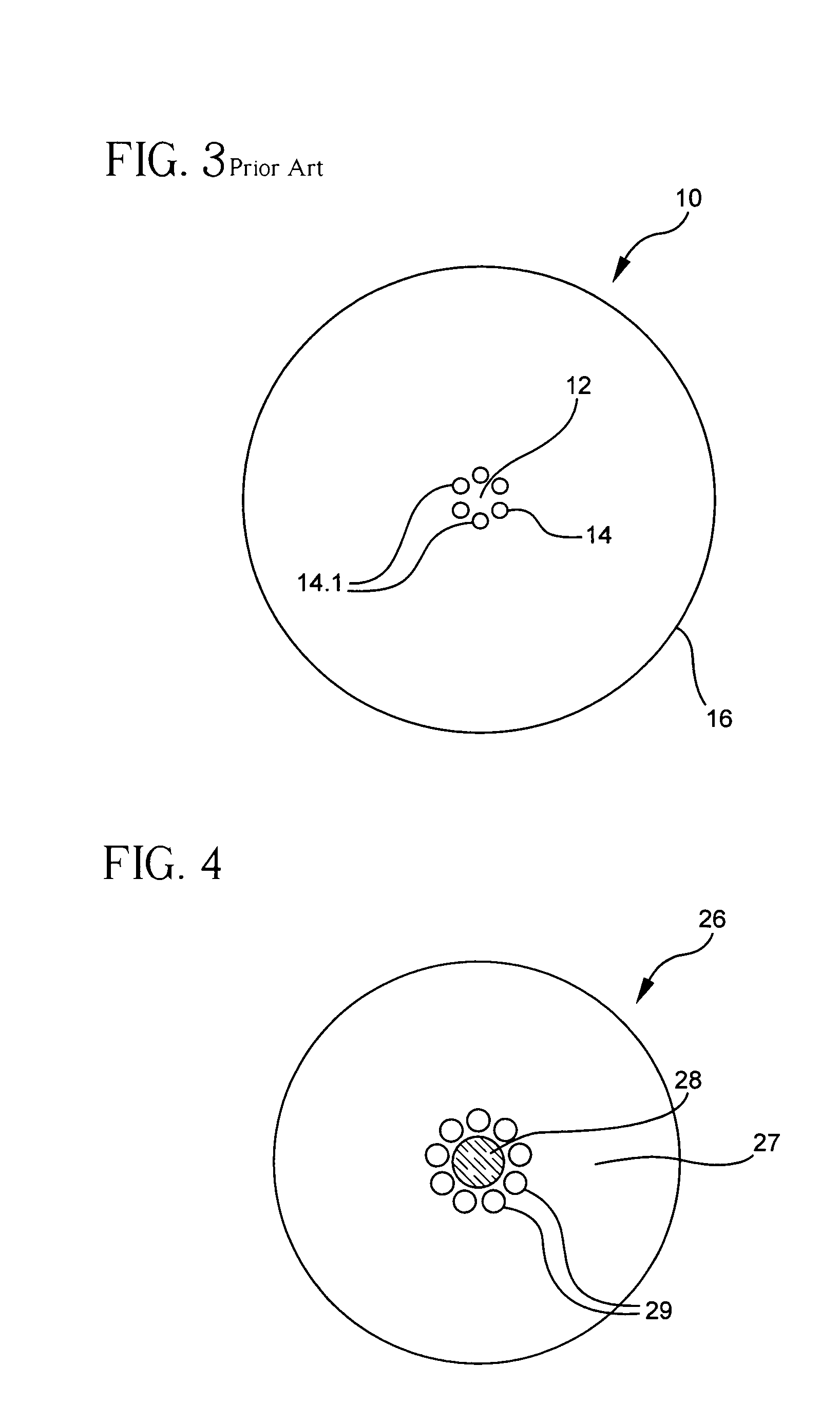

Hole-assisted holey fiber and low bending loss multimode holey fiber

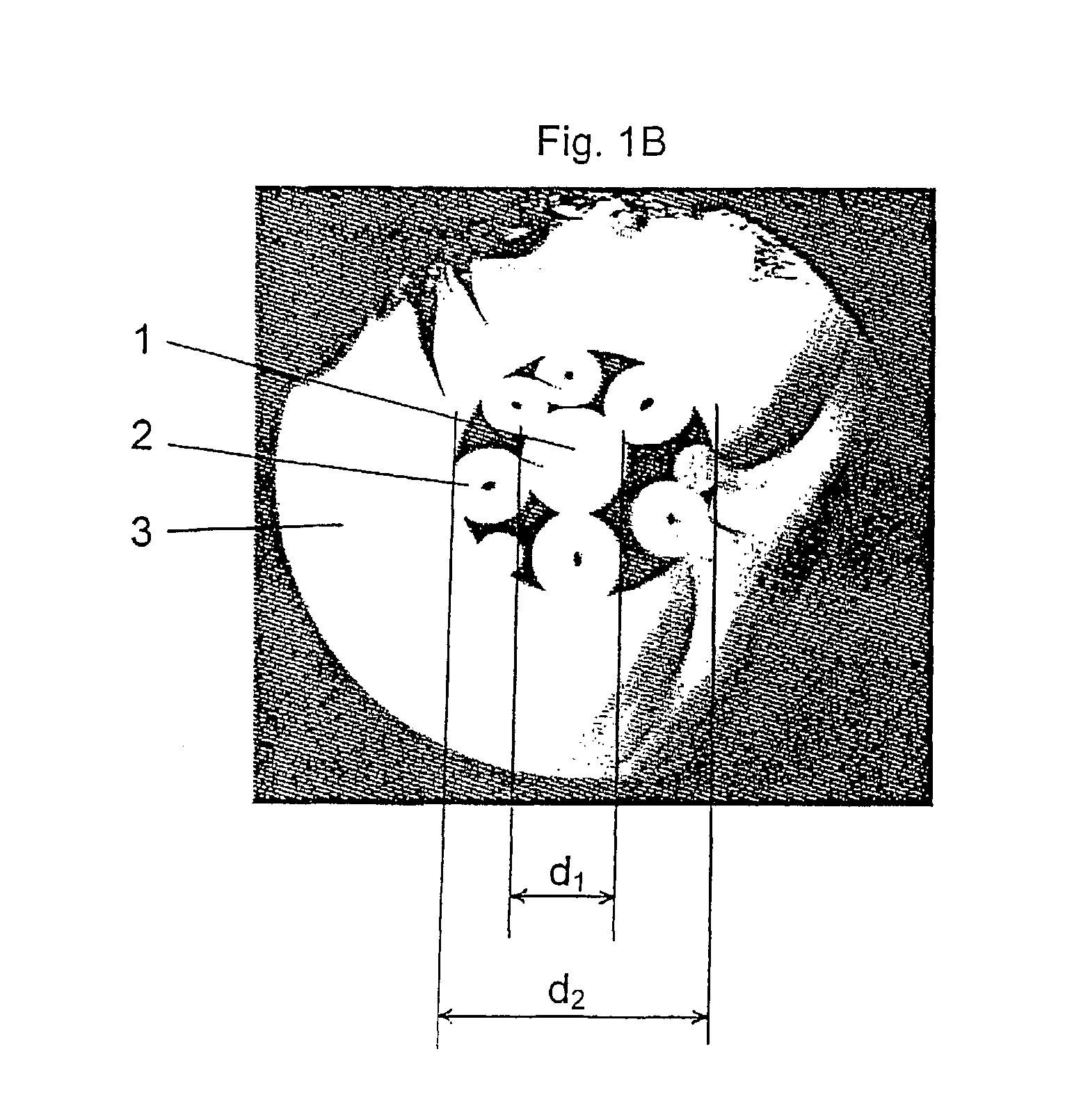

A hole-assisted holey fiber is provided. The holey fiber includes a core region; a cladding region around the core region, and a plurality of holes in the cladding region around the core region. The core region has a higher refractive index than that of the cladding region. The holes form an inner hole layer and an outer hole layer, and the inner hole layer has the same number of holes as the number of the holes in the outer hole layer. The outer layer holes are provided in locations in which inner holes are absent when viewed from the center of the core region, and holes defining the same layer have the same diameter. A distance Λ1 from a center of the core region to a center of an inner hole and a distance Λ2 from the center of the core region to a center of an outer hole satisfy the relationship Λ1<Λ2, and a diameter d1 of an inner hole and a diameter d2 of an outer hole satisfy the relationship d1≦d2.

Owner:THE FUJIKURA CABLE WORKS LTD

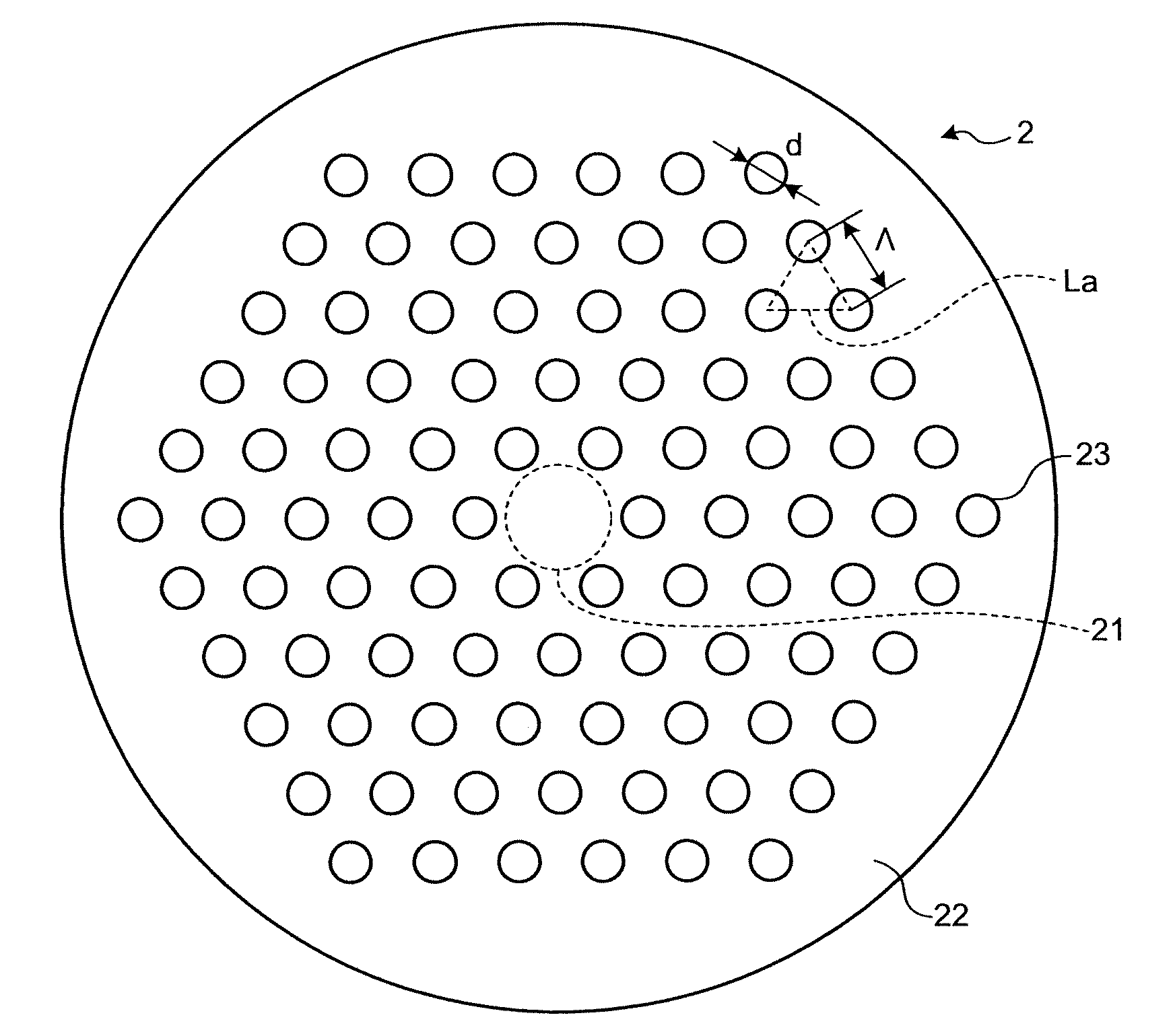

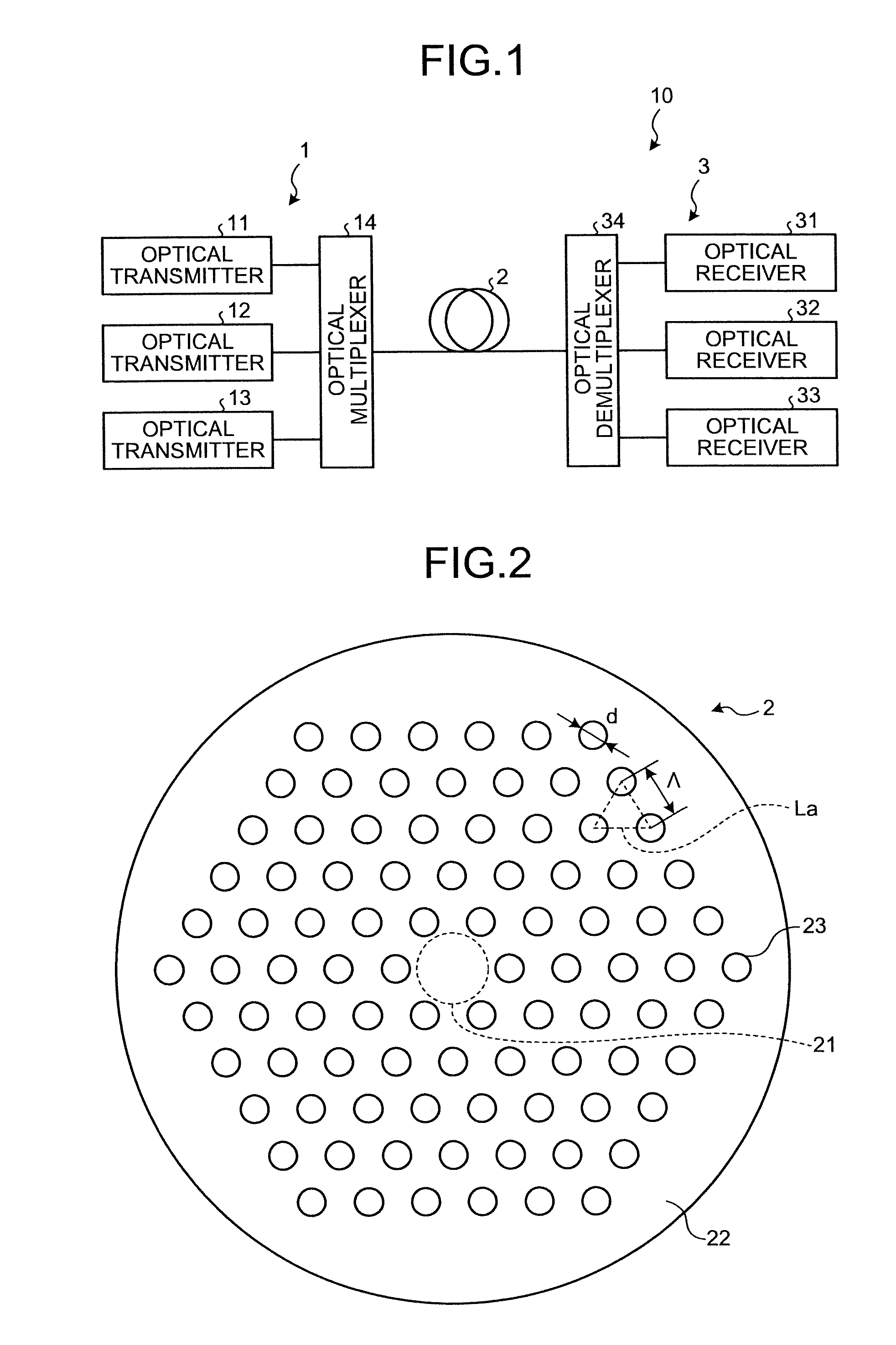

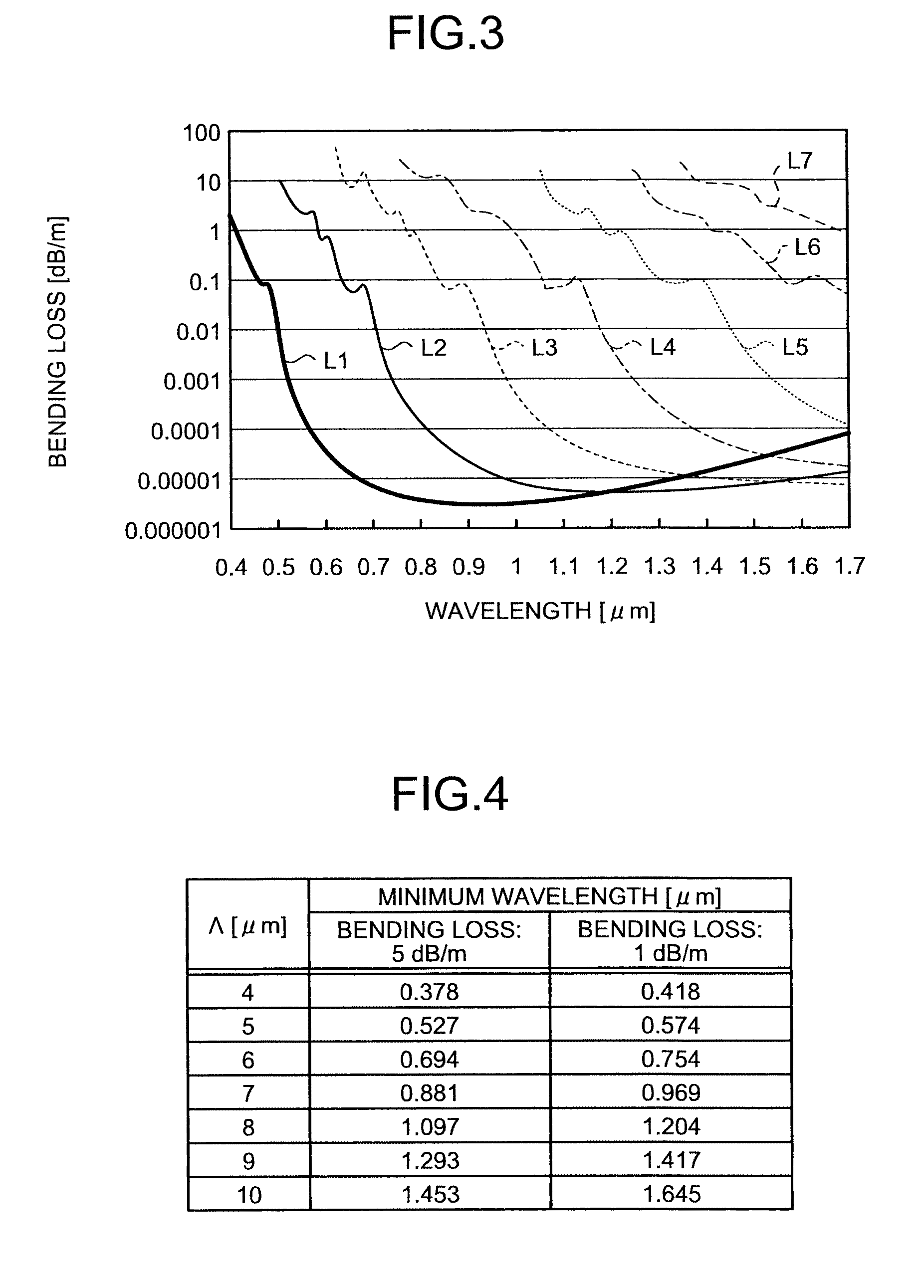

Optical transmission system and multi-core optical fiber

ActiveUS20090324242A1Solve problemsOptical fibre with multilayer core/claddingMulticore optical fibreLength waveHoley fiber

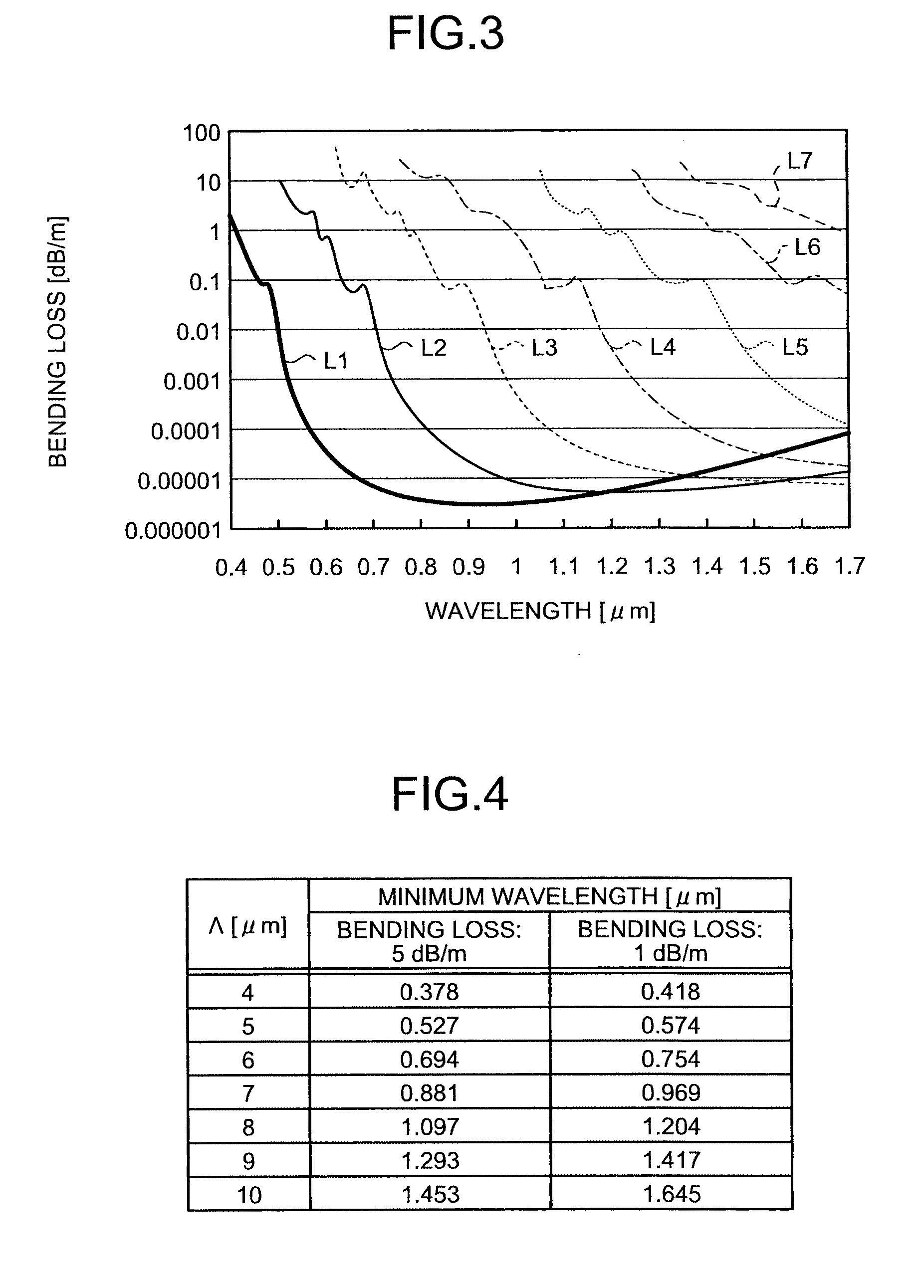

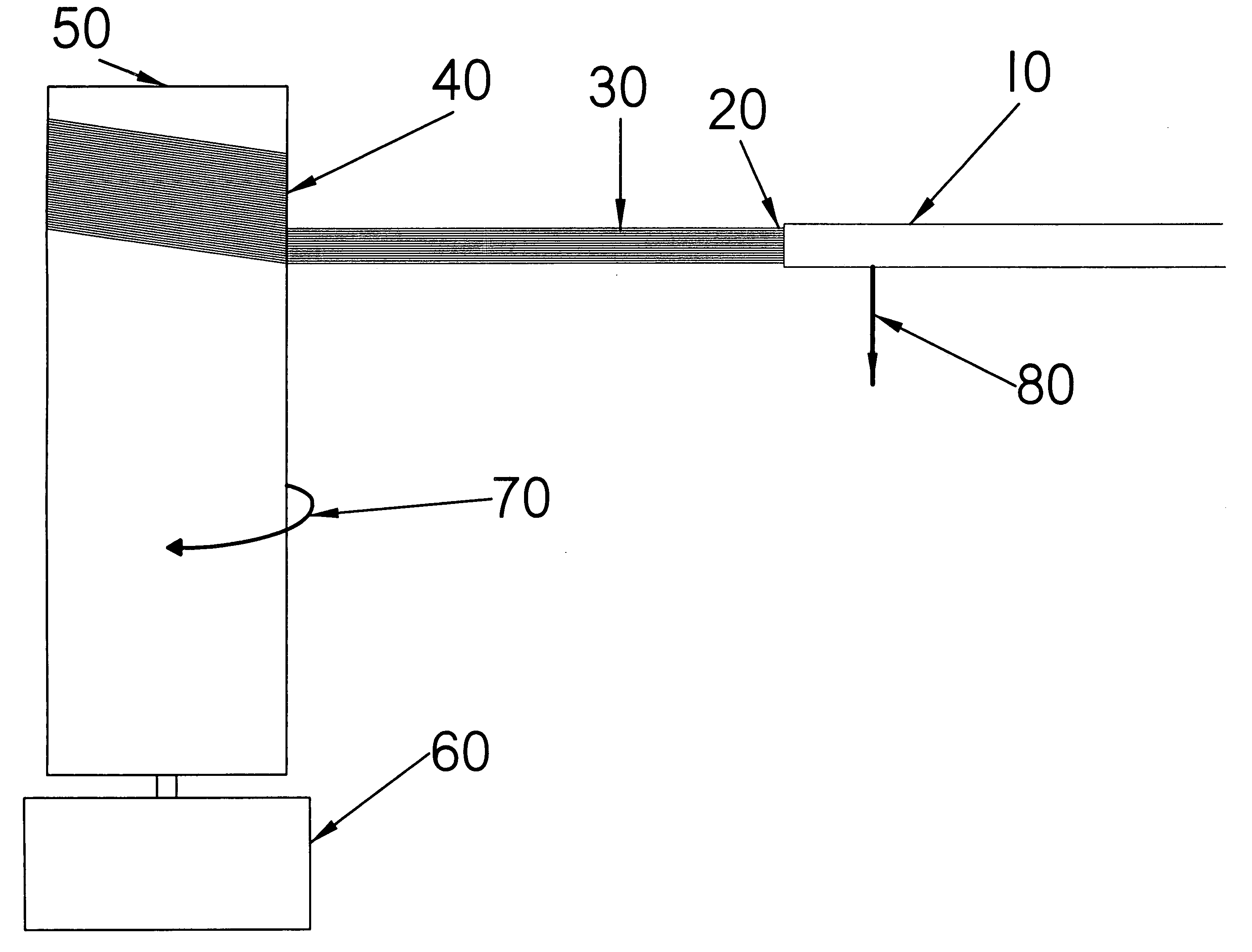

An optical transmission system includes an optical transmitting unit that outputs at least one optical signal having a wavelength included in an operation wavelength band and a holey fiber that is connected to the optical transmitting unit. The holey fiber includes a core and a cladding formed around the core. The cladding includes a plurality of holes formed around the core in a triangular lattice shape. The holey fiber transmits the optical signal in a single mode. A bending loss of the holey fiber is equal to or less than 5 dB / m at a wavelength within the operation wavelength band when the holey fiber is wound at a diameter of 20 millimeters.

Owner:FURUKAWA ELECTRIC CO LTD

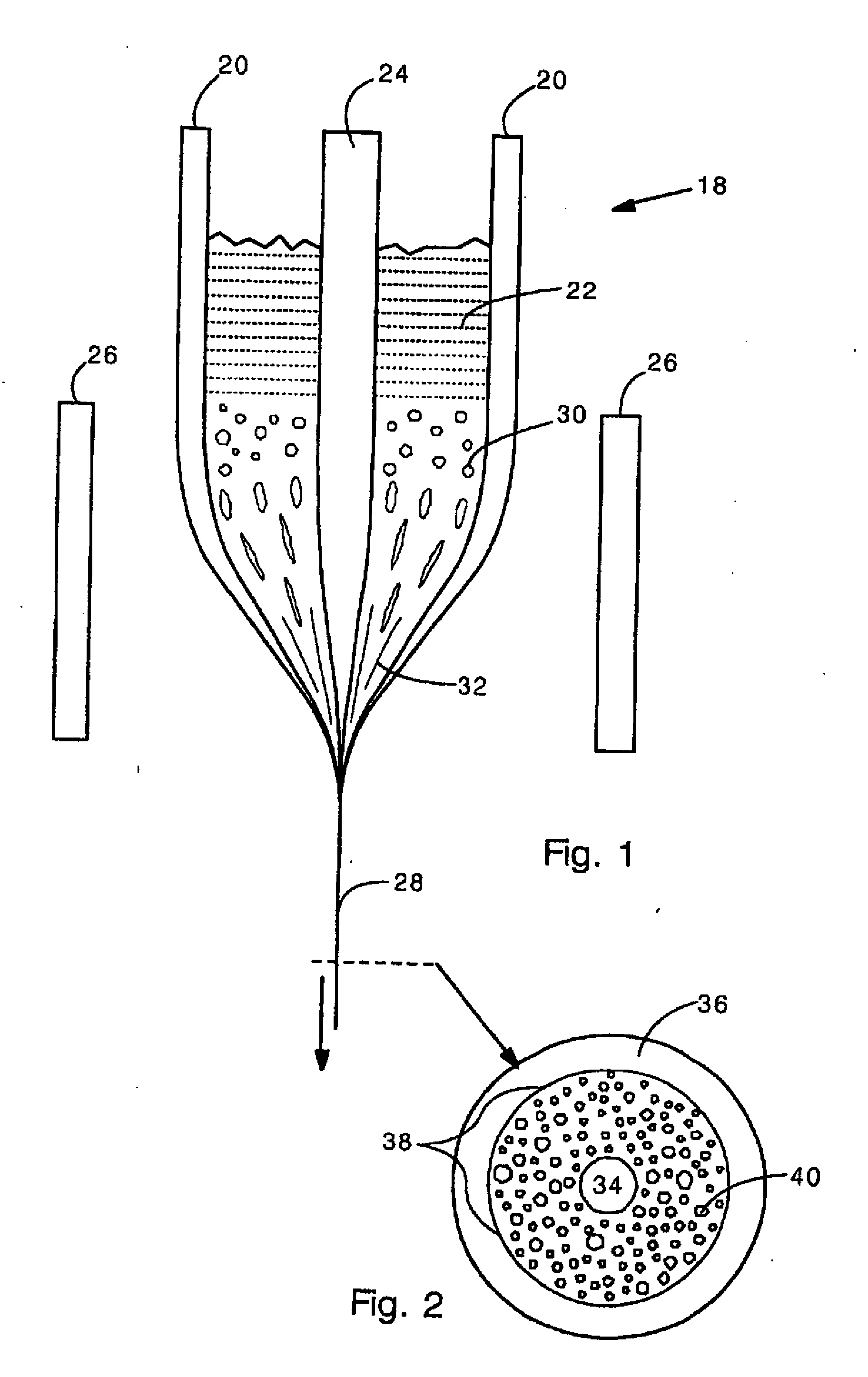

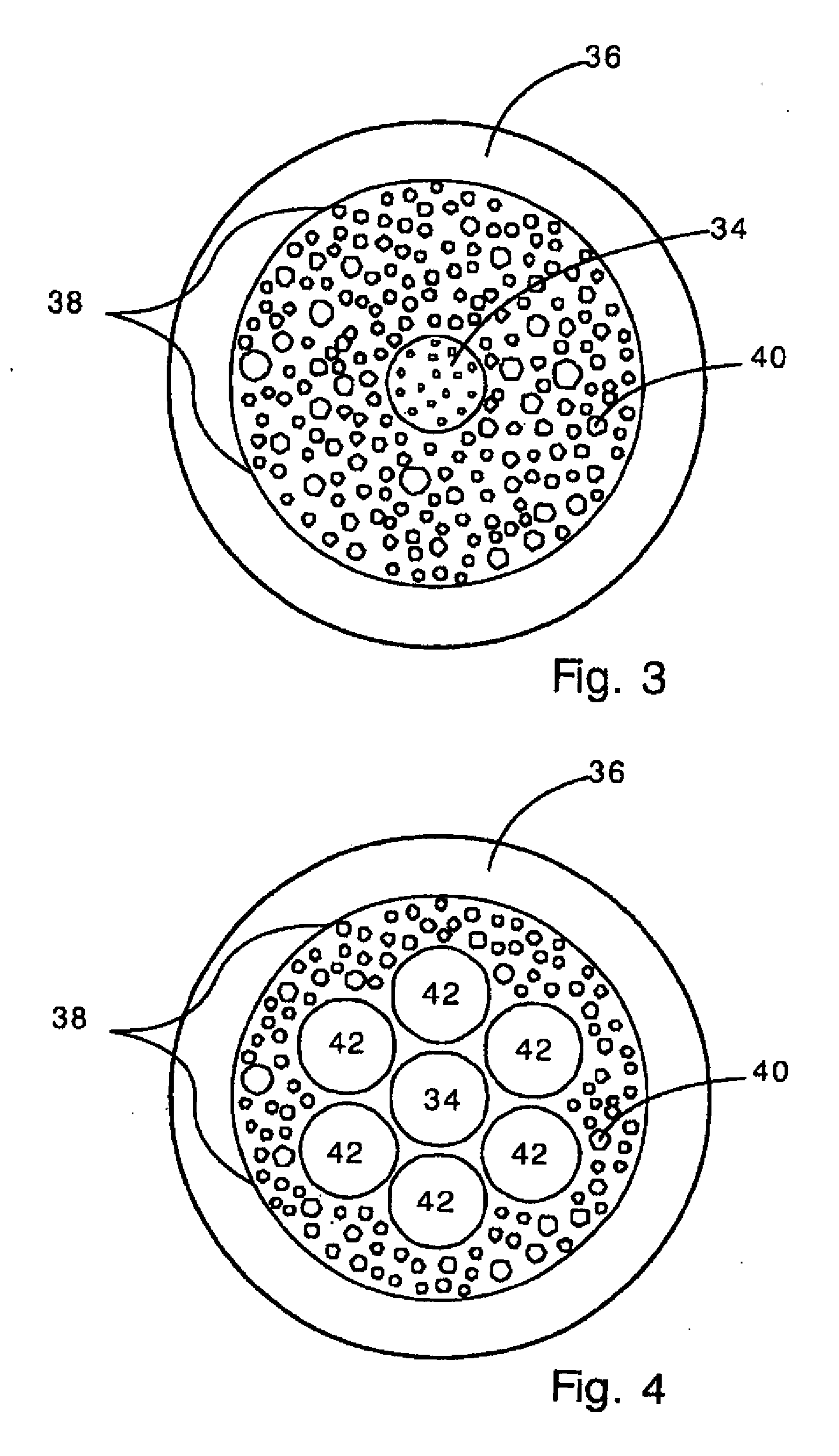

Method of synthesis and delivery of complex pharmaceuticals, chemical substances and polymers through the process of electrospraying, electrospinning or extrusion utilizing holey fibers

A method of synthesizing complex, multi-part pharmaceuticals, chemical substances and engineered polymers through the process of electrospraying, electrospinning or extrusion utilizing tiny glass fiber known as “Holey” Fibers. The “holey” fibers have a unique property associated with them as they contain various combinations of micron sized holes running the length of the glass fiber. The holes can be made homogenous, i.e. all the same diameter, or of varying dimensions in concentric rings, enabling several chemicals to be combined together at synthesis. The advantage of using a glass holey fiber is that it is made from a chemically inert glass, that will not affect to chemicals involved with the exception of certain fluorine substances.

Owner:DZIEKAN MICHAEL E +2

Hole-assisted holey fiber and low bending loss multimode holey fiber

A hole-assisted holey fiber is provided. The holey fiber includes a core region; a cladding region around the core region, and a plurality of holes in the cladding region around the core region. The core region has a higher refractive index than that of the cladding region. The holes form an inner hole layer and an outer hole layer, and the inner hole layer has the same number of holes as the number of the holes in the outer hole layer. The outer layer holes are provided in locations in which inner holes are absent when viewed from the center of the core region, and holes defining the same layer have the same diameter. A distance Λ1 from a center of the core region to a center of an inner hole and a distance Λ2 from the center of the core region to a center of an outer hole satisfy the relationship Λ1<Λ2, and a diameter d1 of an inner hole and a diameter d2 of an outer hole satisfy the relationship d1≧d2.

Owner:THE FUJIKURA CABLE WORKS LTD

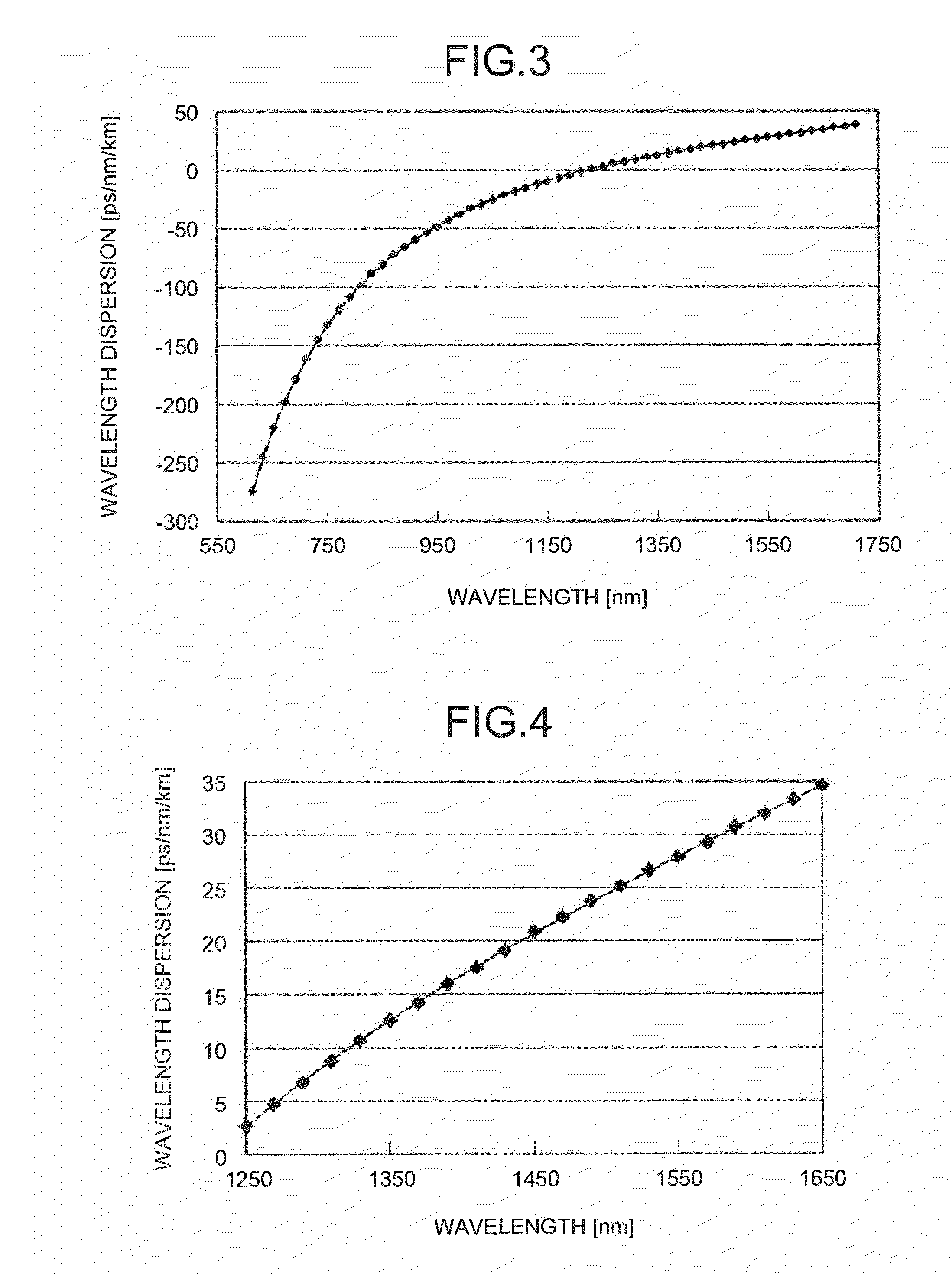

Holey fiber

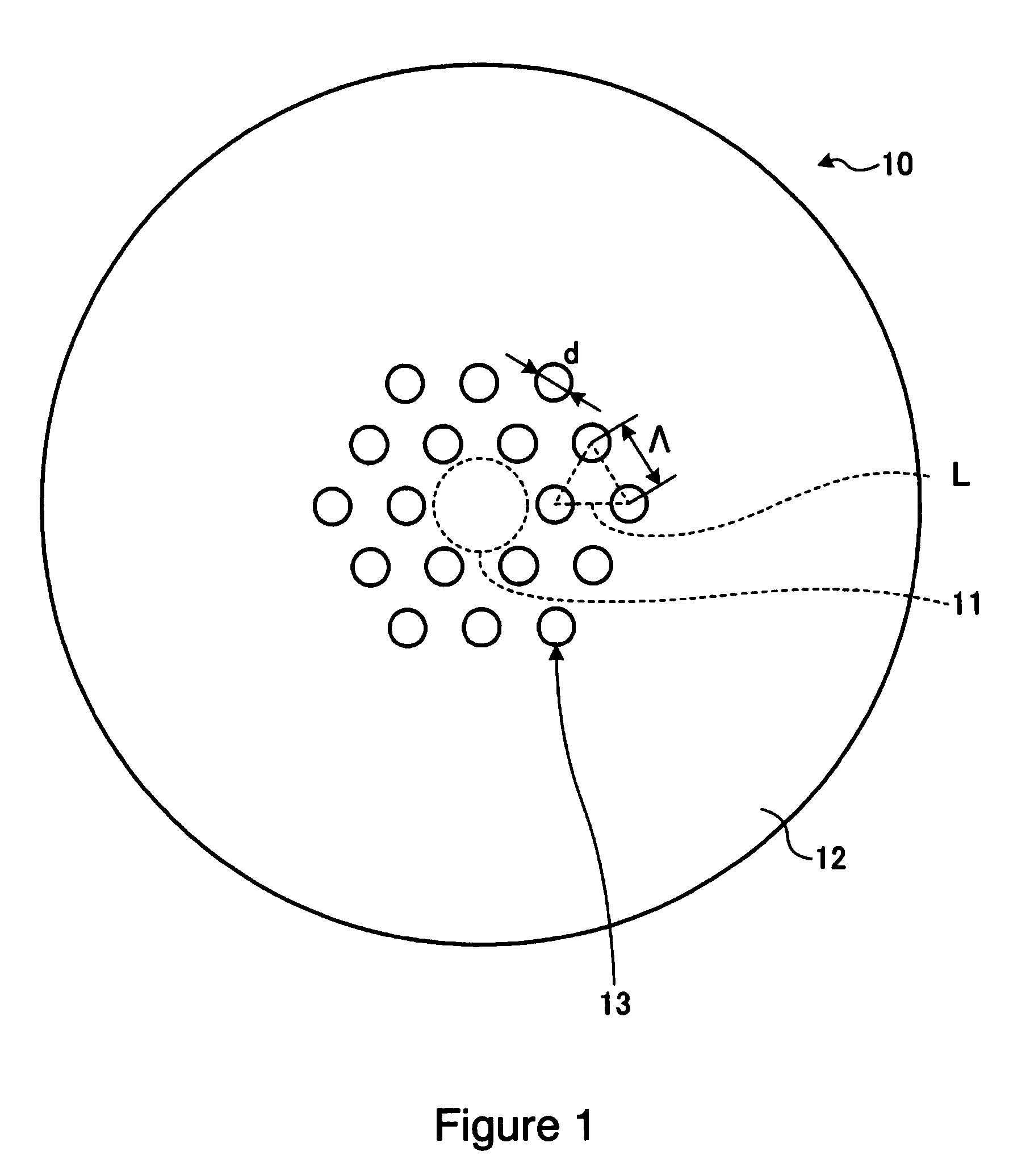

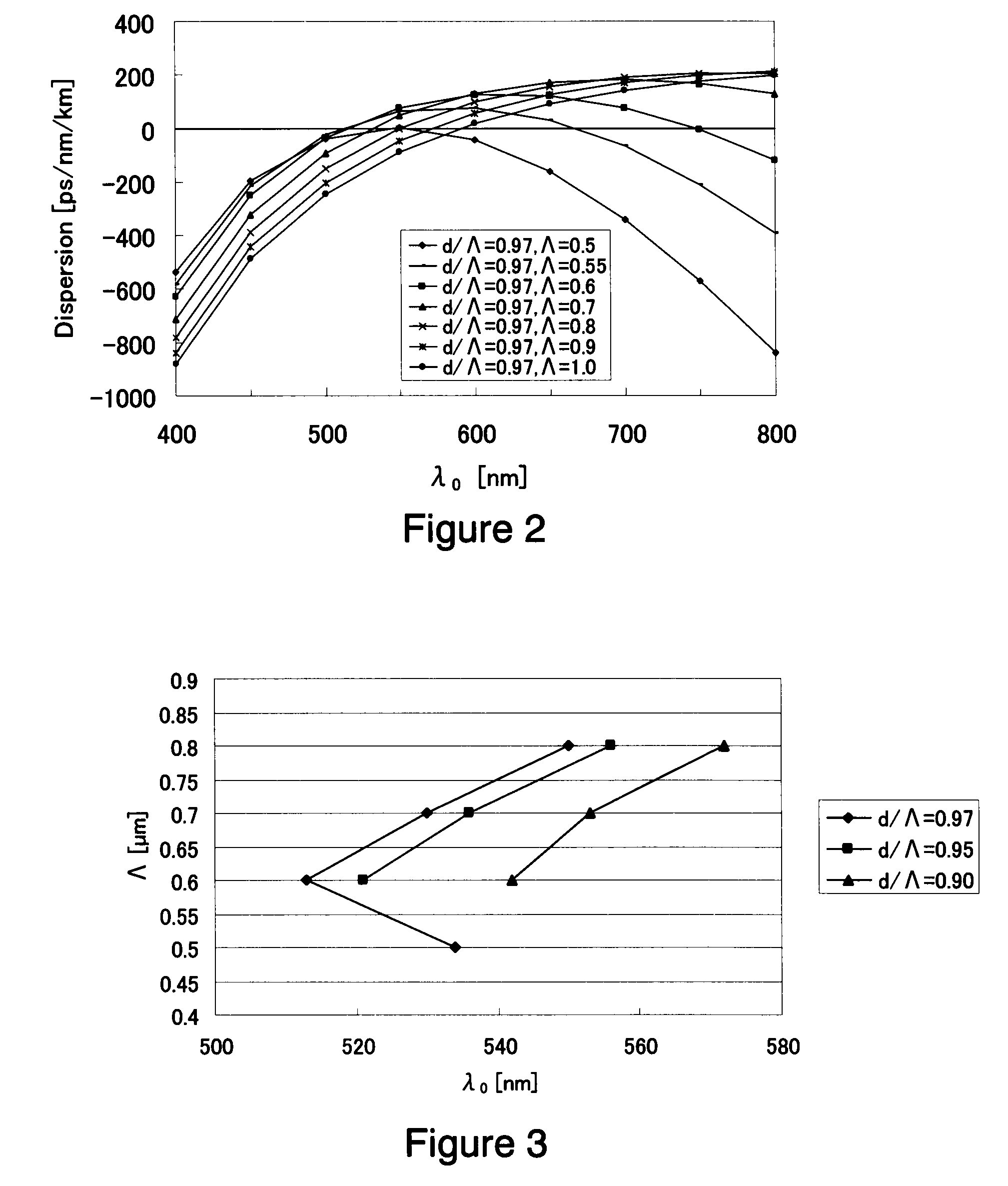

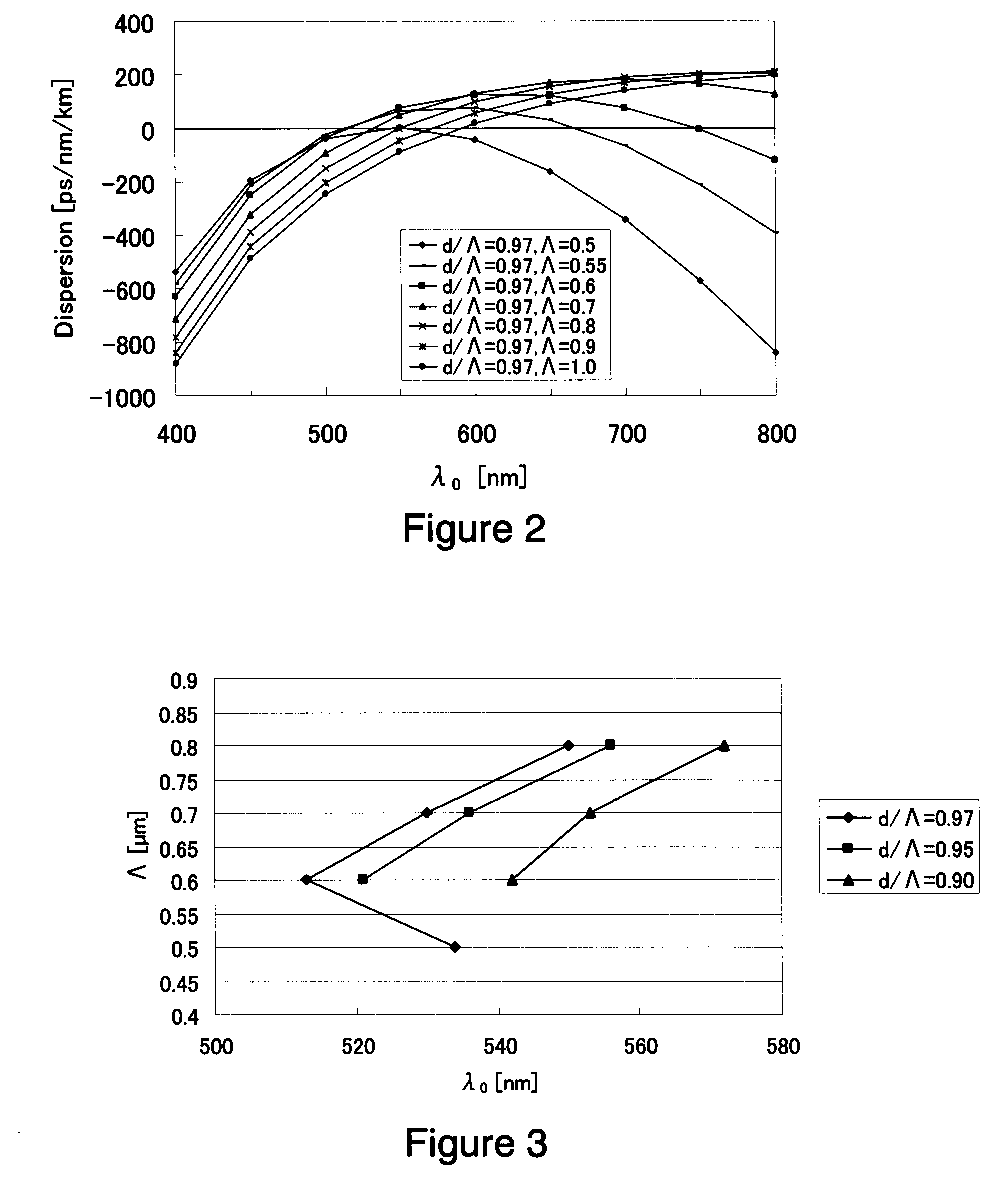

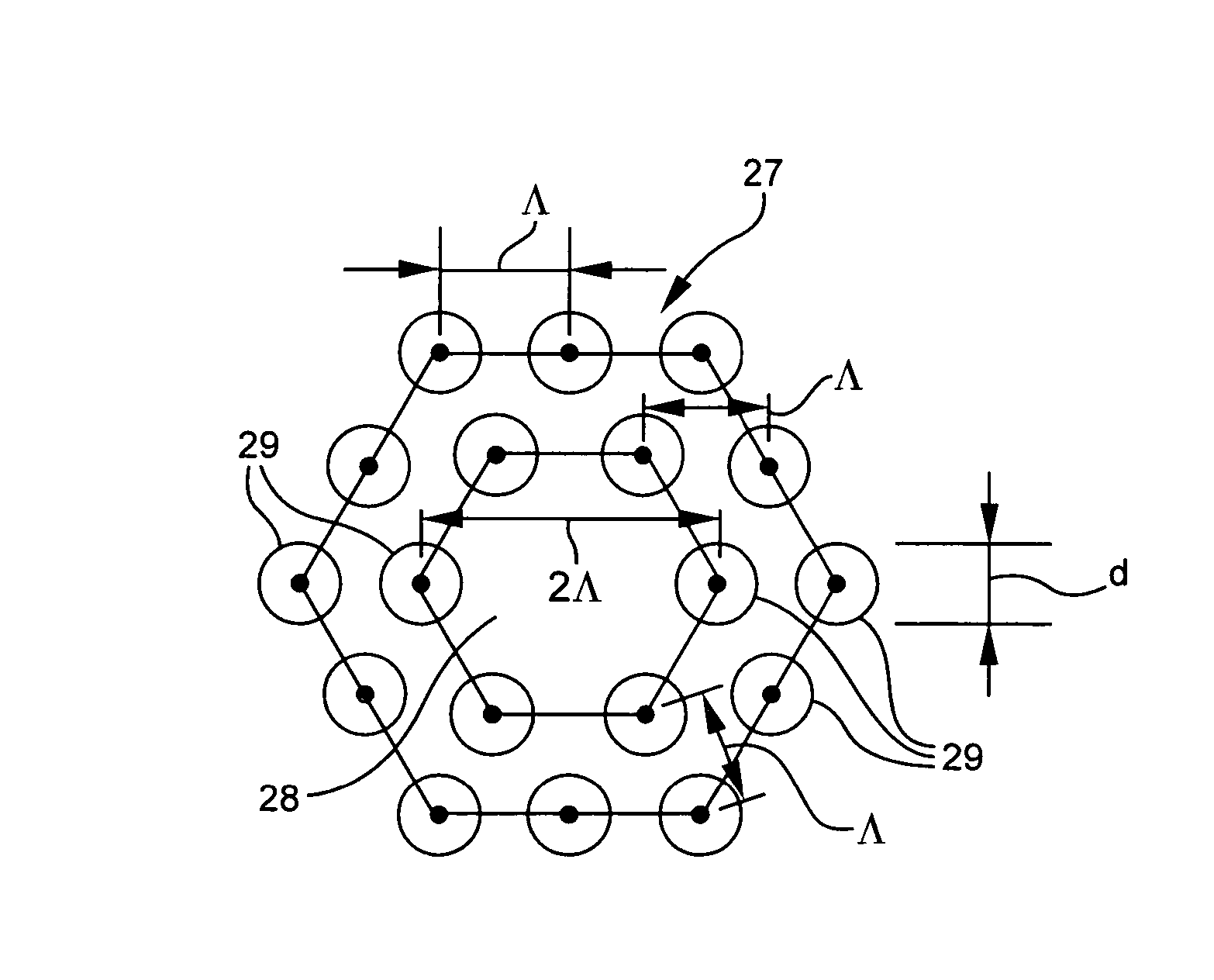

InactiveUS7693379B2Cladded optical fibreOptical waveguide light guideFiberZero-dispersion wavelength

A holey fiber, which has a zero-dispersion wavelength of less than 700 nm and operates as single mode under its zero-dispersion wavelength, is provided. The holey fiber according to the present invention comprises a core region that is formed at a center of the holey fiber; and a cladding region, formed at the circumference of the core region, which has a plurality of holes distributed as triangle lattice around the core region; wherein the holey fiber has a fundamental mode of less than 700 nm, a higher order mode, and the fundamental mode and the higher order mode confinement losses of less than 0.1 dB / m and more than 10 dB / m, respectively, at the zero-dispersion wavelength.

Owner:FURUKAWA ELECTRIC CO LTD

Holey fiber and method of manufacturing the same

A method of manufacturing a holey fiber includes forming a preform and drawing the preform. The forming includes arranging a core rod at a center of a jacket tube and arranging capillary tubes having hollows around the core rod inside the jacket tube. The drawing includes heat melting the preform in a heating furnace while controlling at least one of a gas pressure to be applied to insides of the hollows of the capillary tubes, a temperature of the heating furnace, and a drawing speed, based on a structure of air holes to be formed in a first layer from the core region.

Owner:FURUKAWA ELECTRIC CO LTD

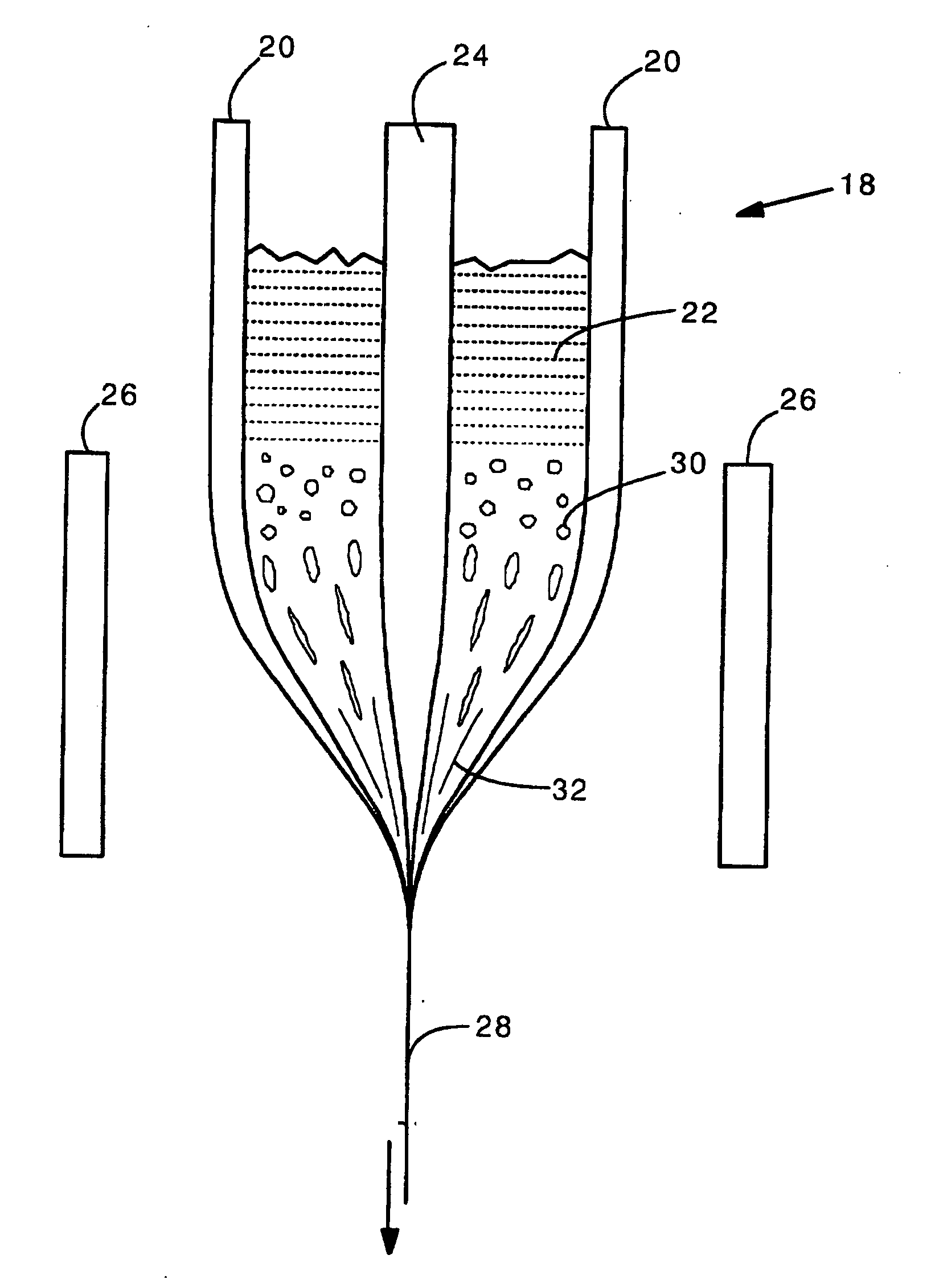

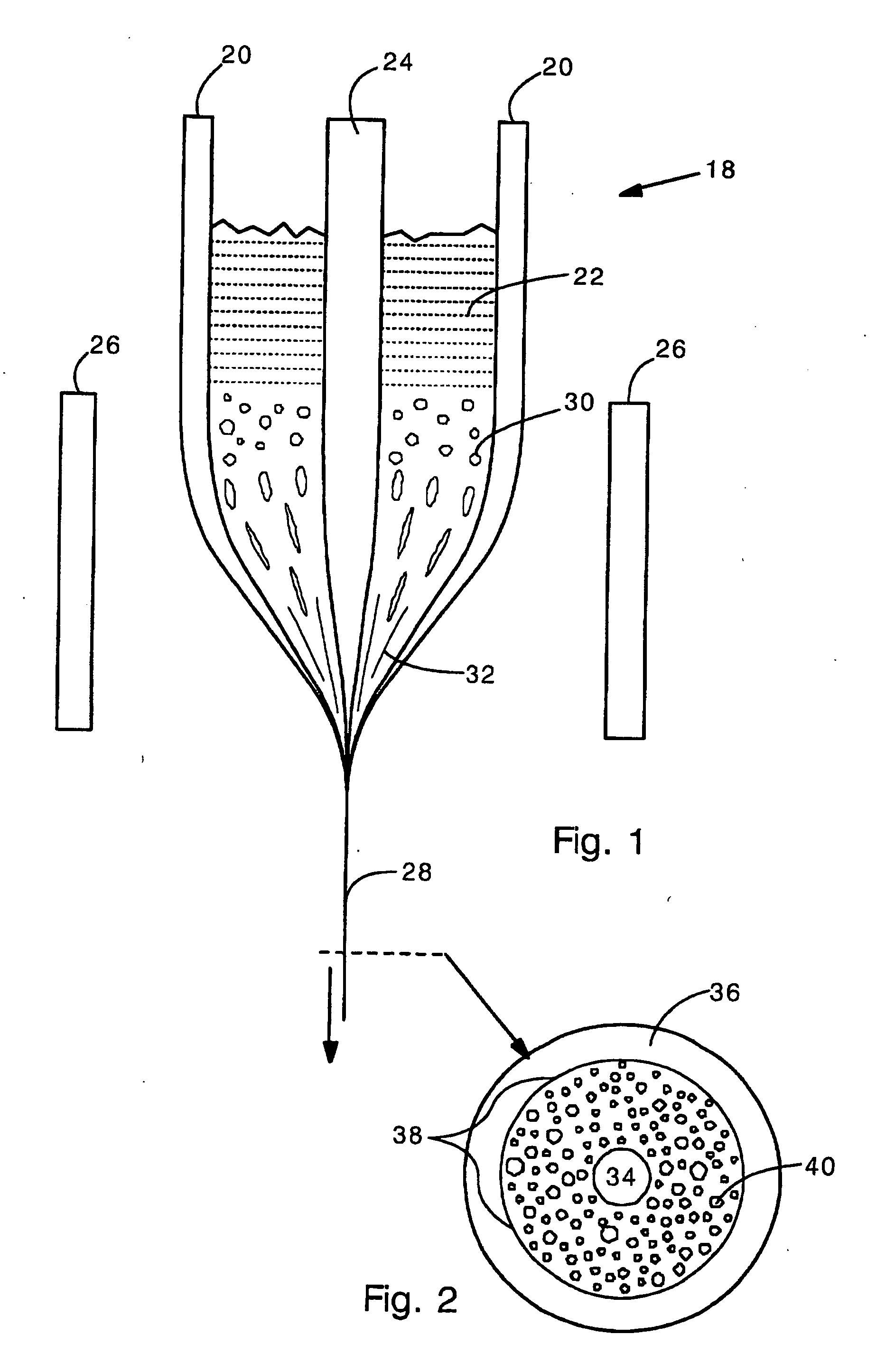

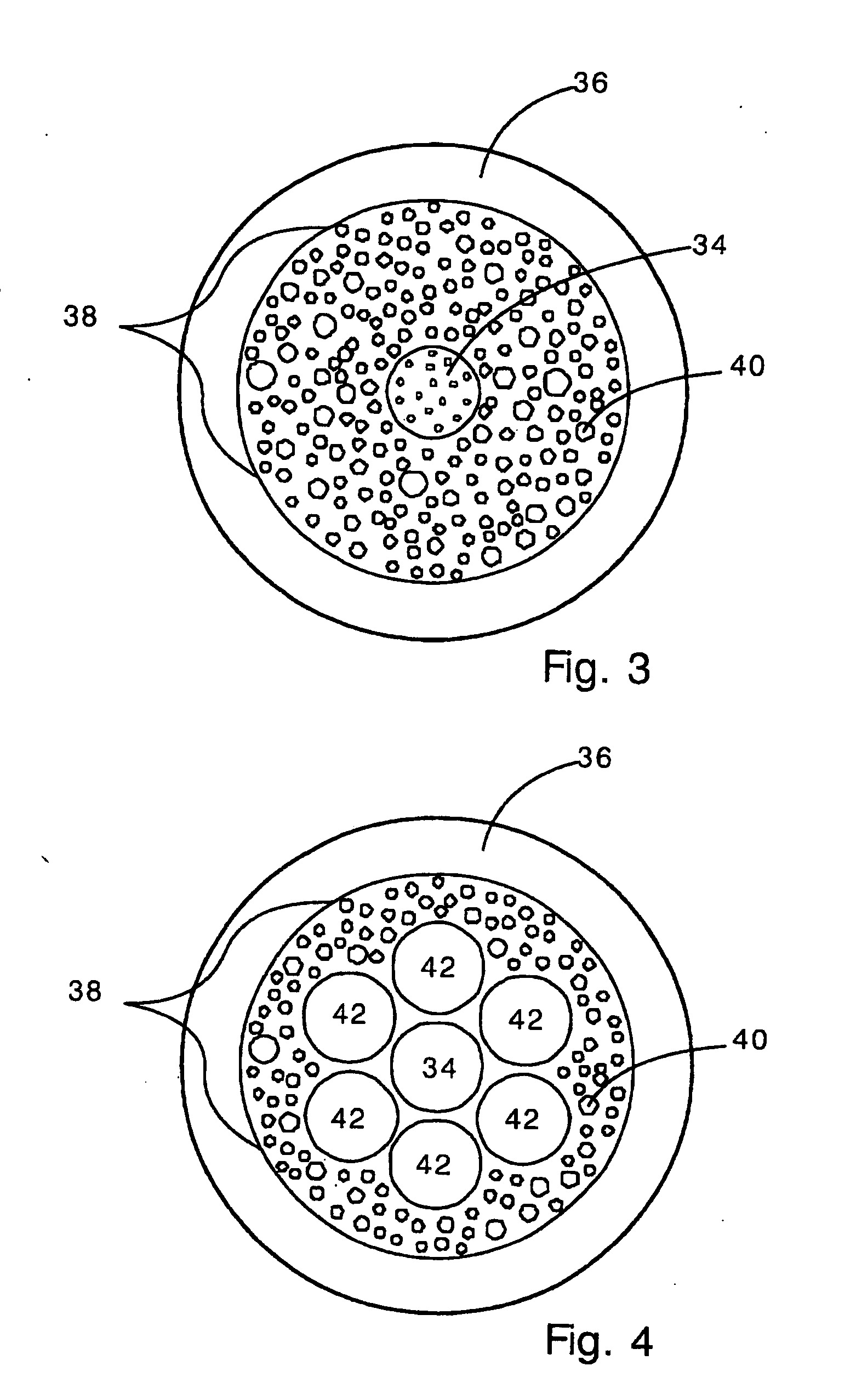

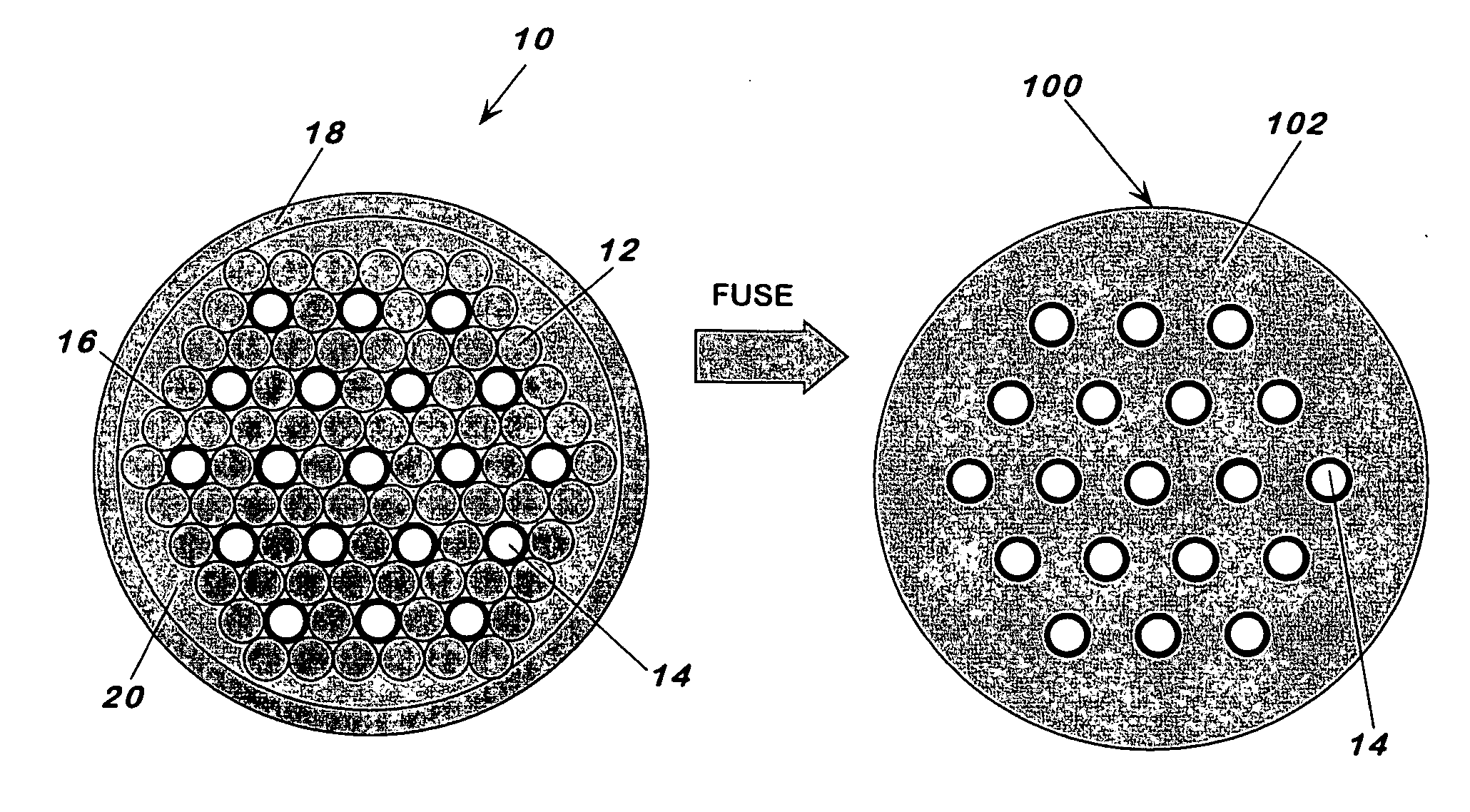

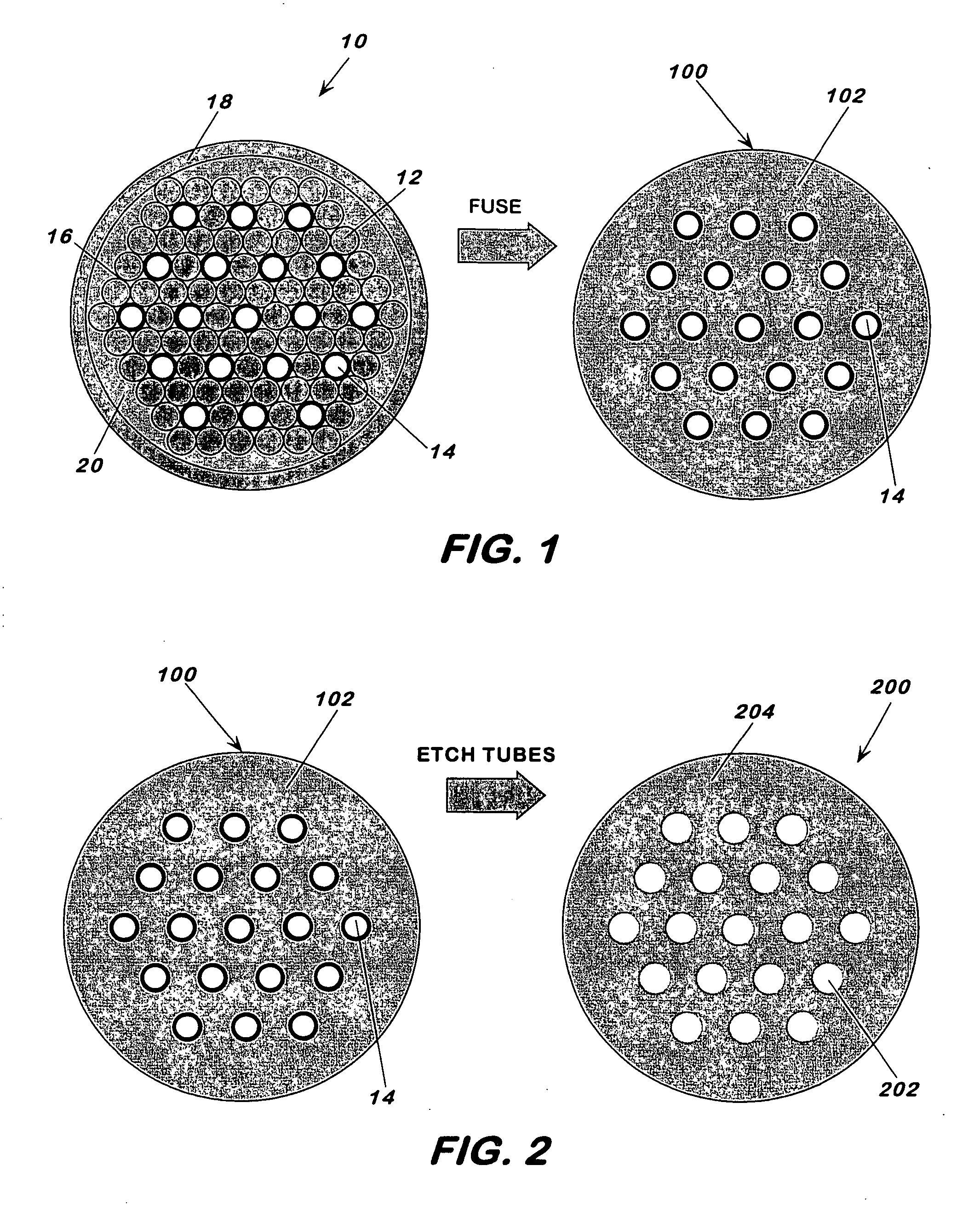

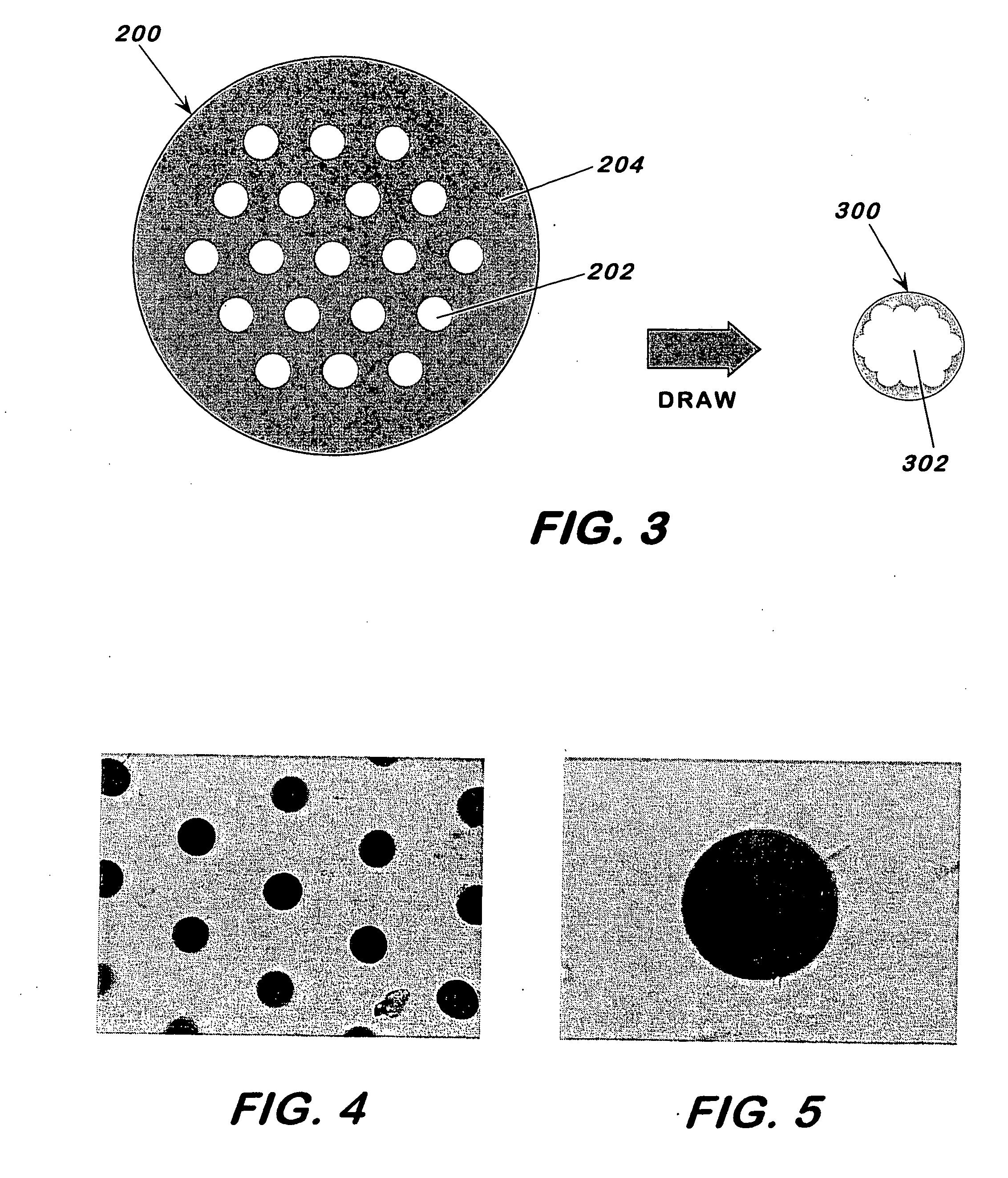

Fused array preform fabrication of holey optical fibers

InactiveUS20060153512A1Zero optical lossReduce light scatterGlass making apparatusCladded optical fibreFiberTotal internal reflection

This invention pertains to a holey fiber and to a fabrication method for making the fiber. The holey fiber can transmit light by total internal reflection or by Bragg diffraction, can be single mode or multimode and can have solid core or a hollow core. The holey fiber has outside diameter typically of 20 microns to 5 mm, a hollow core of a diameter typically of 0.2 micron to 150 microns and longitudinal channels therethrough of a diameter typically of 0.1 micron to 150 microns. The channels are disposed in a desired arrangement with center-to-center distance variation of less than about 2% along the length of the fiber and the cross-section thereof is round that varies less than about 2%. The method includes the steps of stacking structures of at least two different materials of lower and higher softening points in a desired arrangement to form a bundle containing interstices between the structures; heating the bundle to a fusion temperature which is below the softening point of the higher softening point material to form a fused element whereby the lower softening point material softens and flows around the higher softening point material and closes the interstices; removing the structures of the higher softening point material from the fused element to form a preform, thus forming openings in the fused element; and drawing the preform at a draw temperature which is below the softening point of the lower softening point material to form the holey fiber.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

Holey fiber and method of manufacturing the same

A holey fiber includes a core region and a cladding region surrounding the core region and having air holes arranged around the core region. The cladding region includes an inner cladding layer surrounding the core region and an outer cladding layer surrounding the inner cladding layer. Furthermore, viscosities of the core region and the inner cladding layer are set lower than a viscosity of the outer cladding layer.

Owner:FURUKAWA ELECTRIC CO LTD

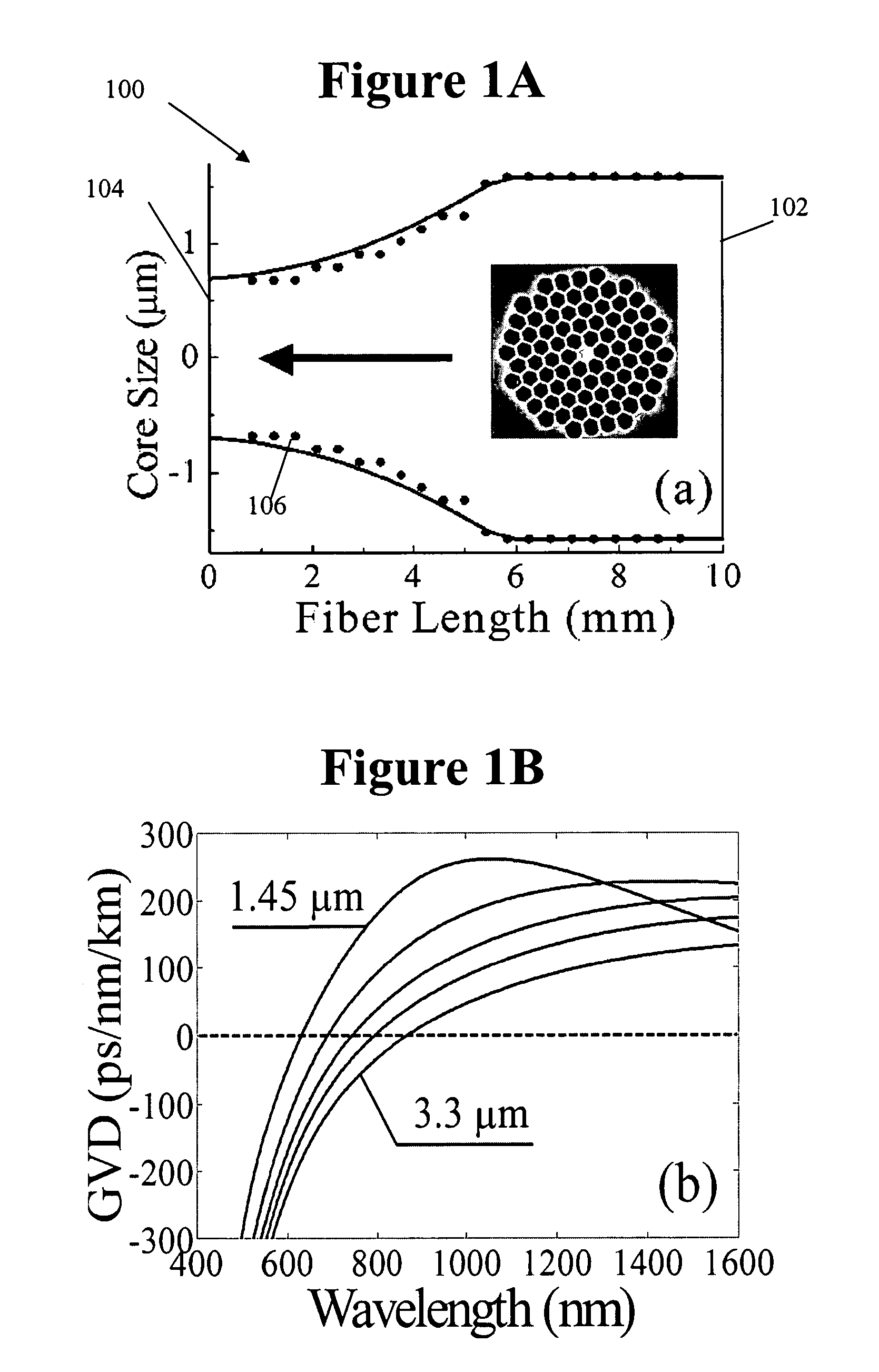

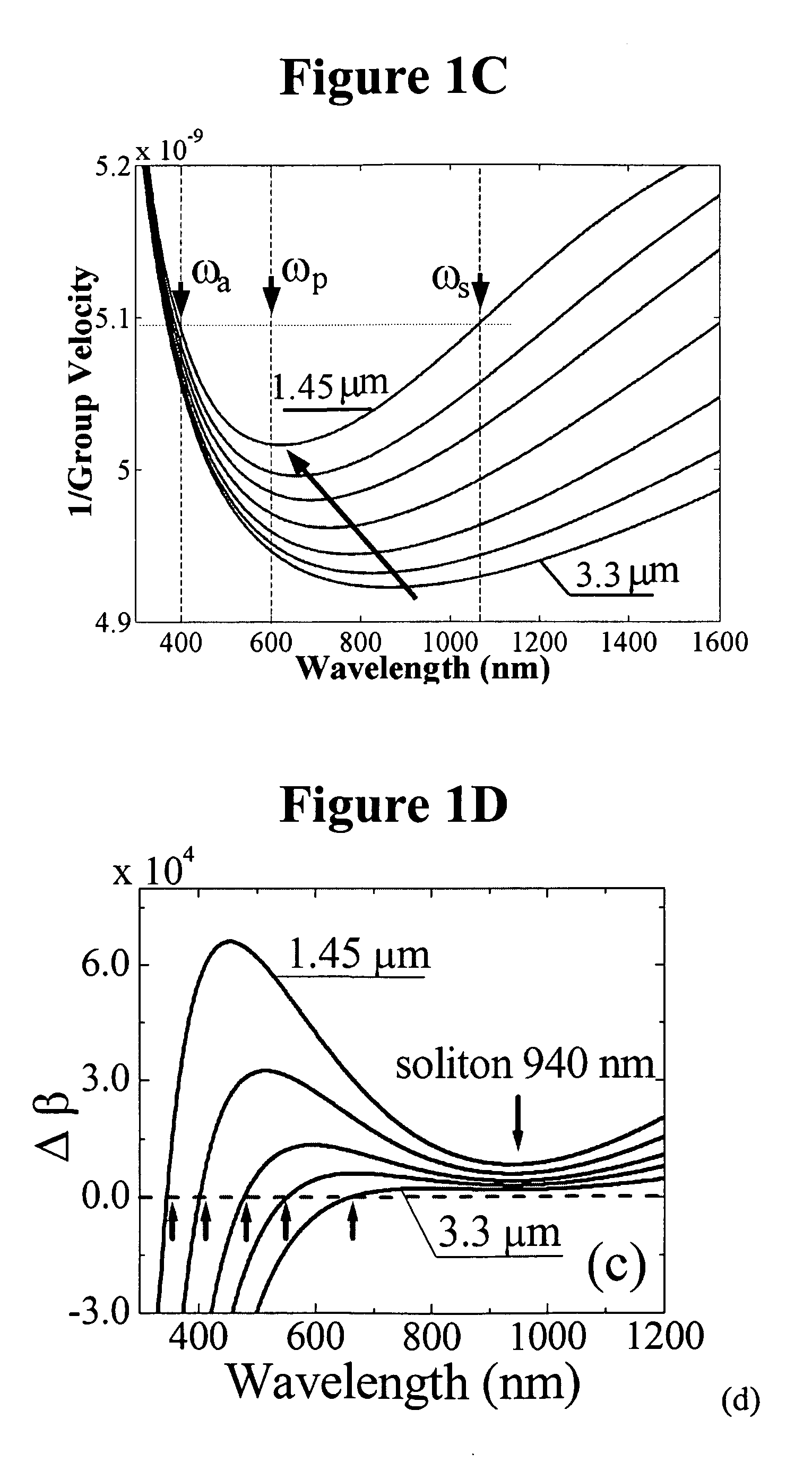

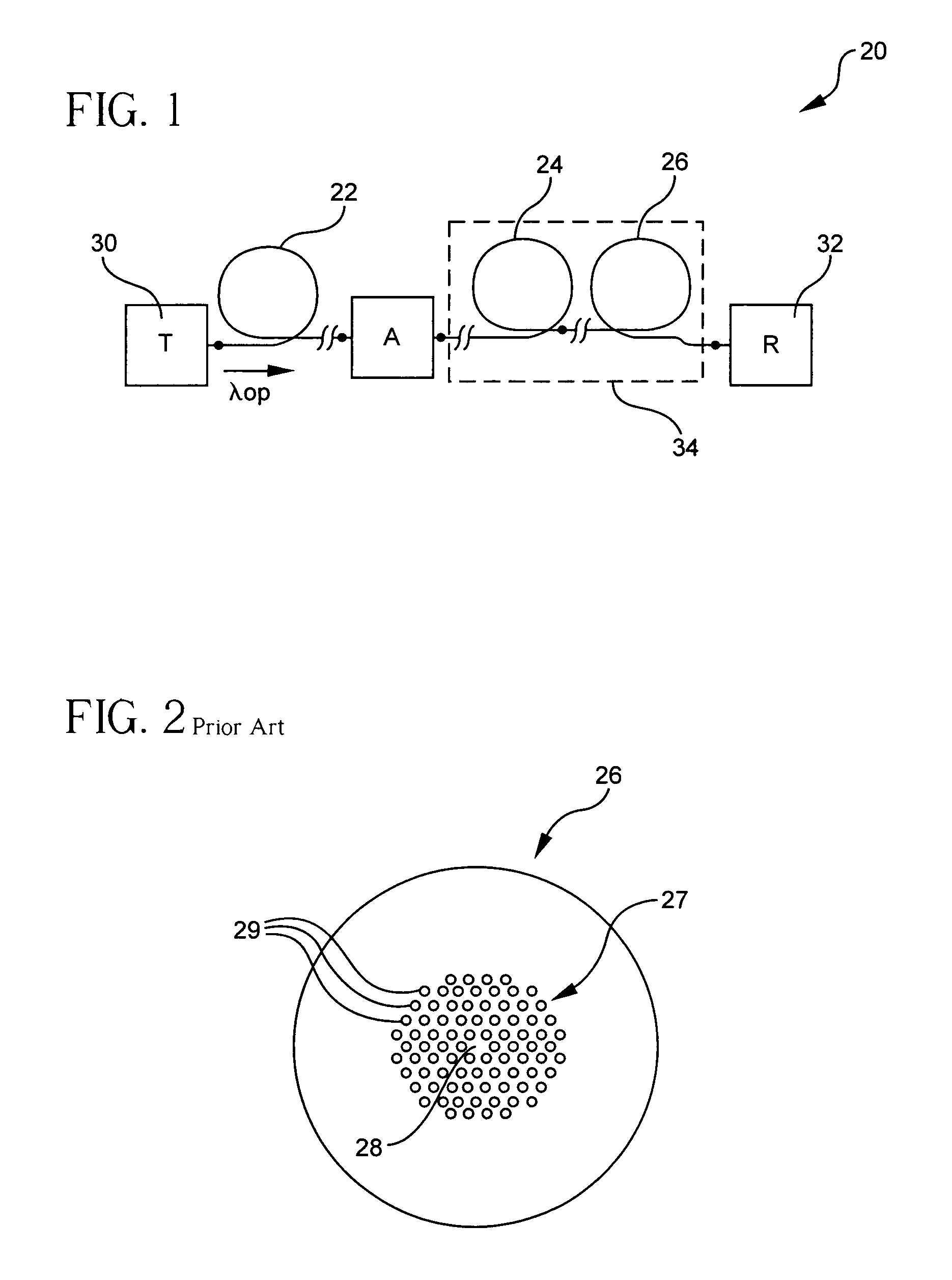

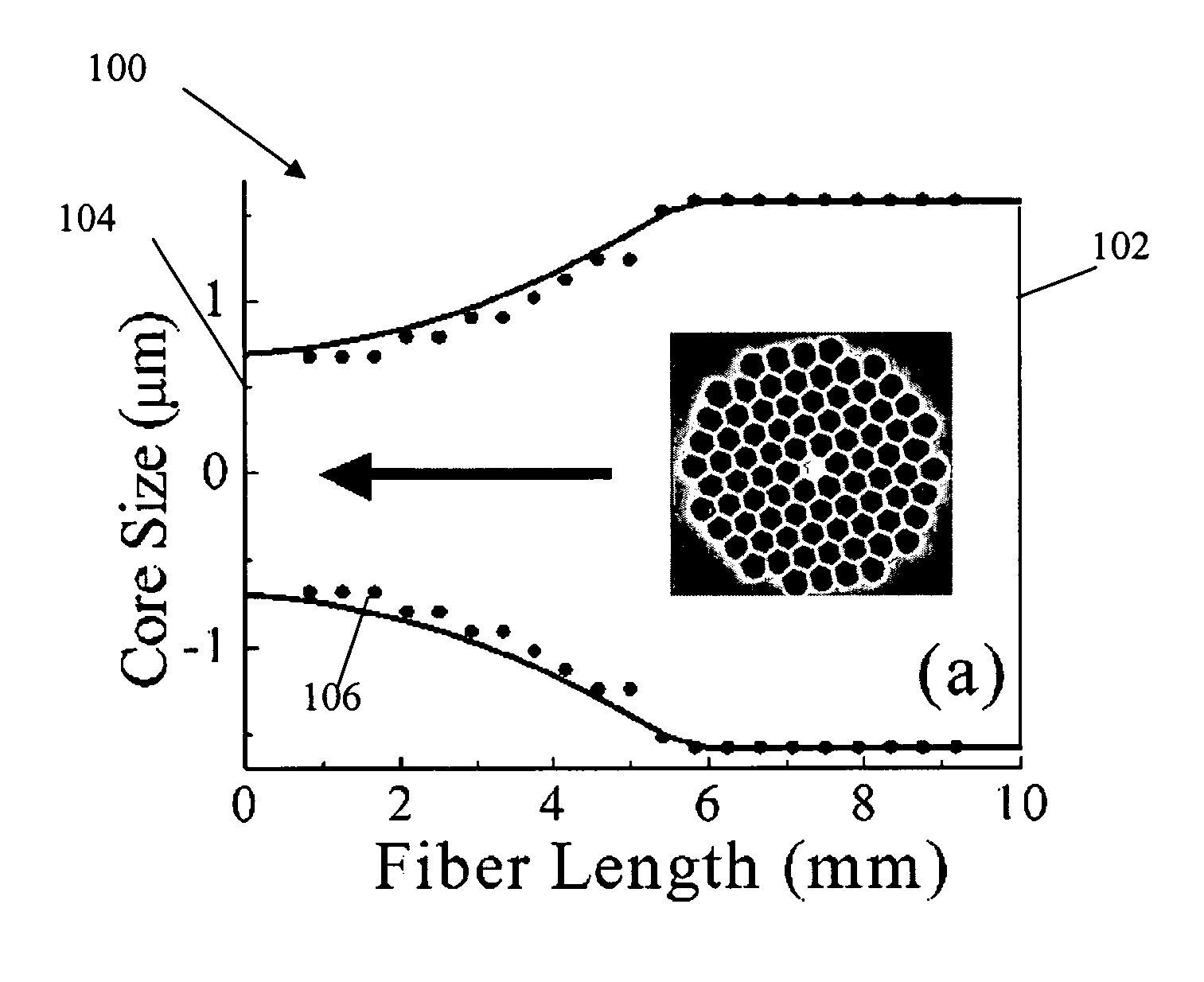

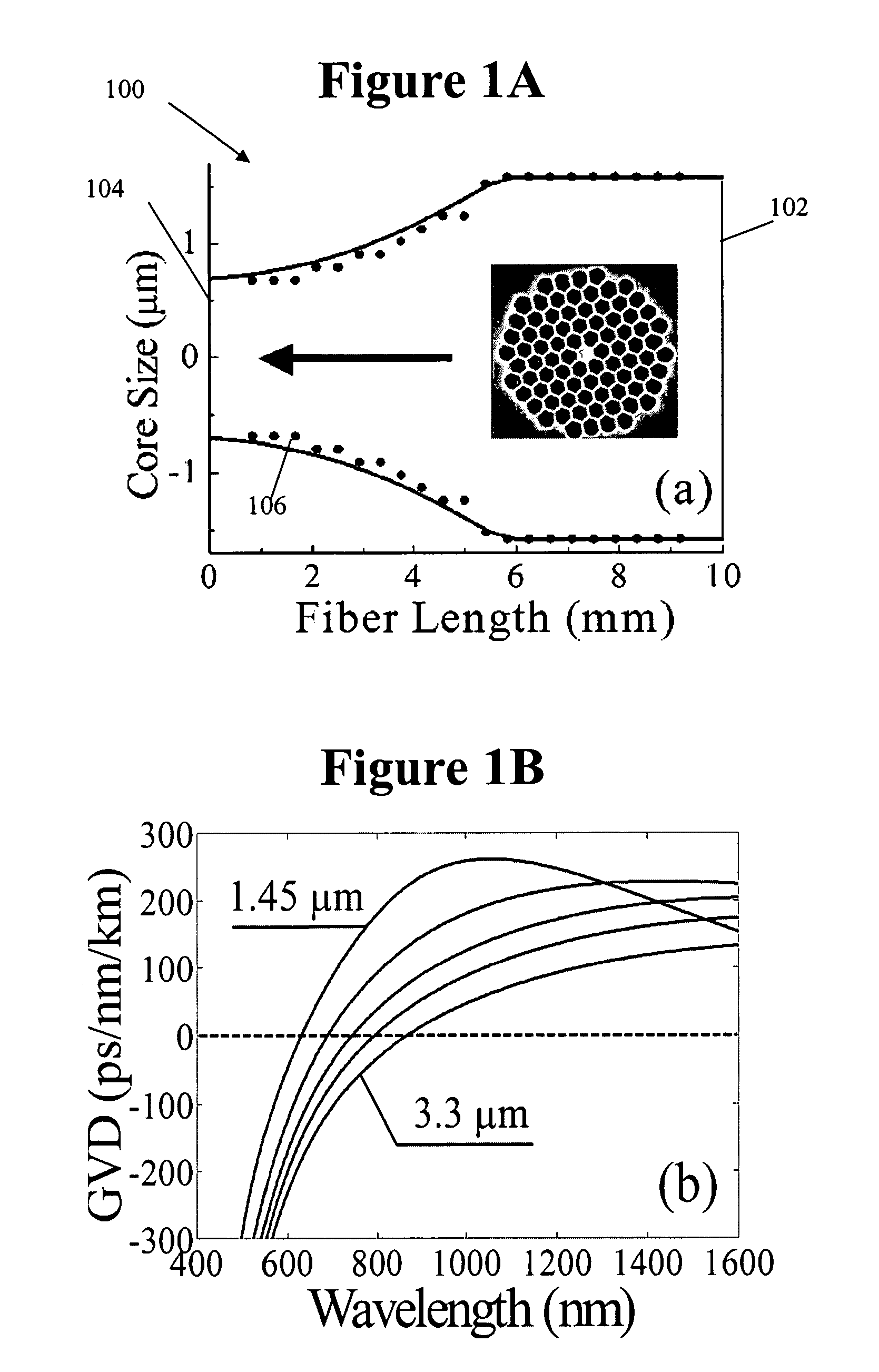

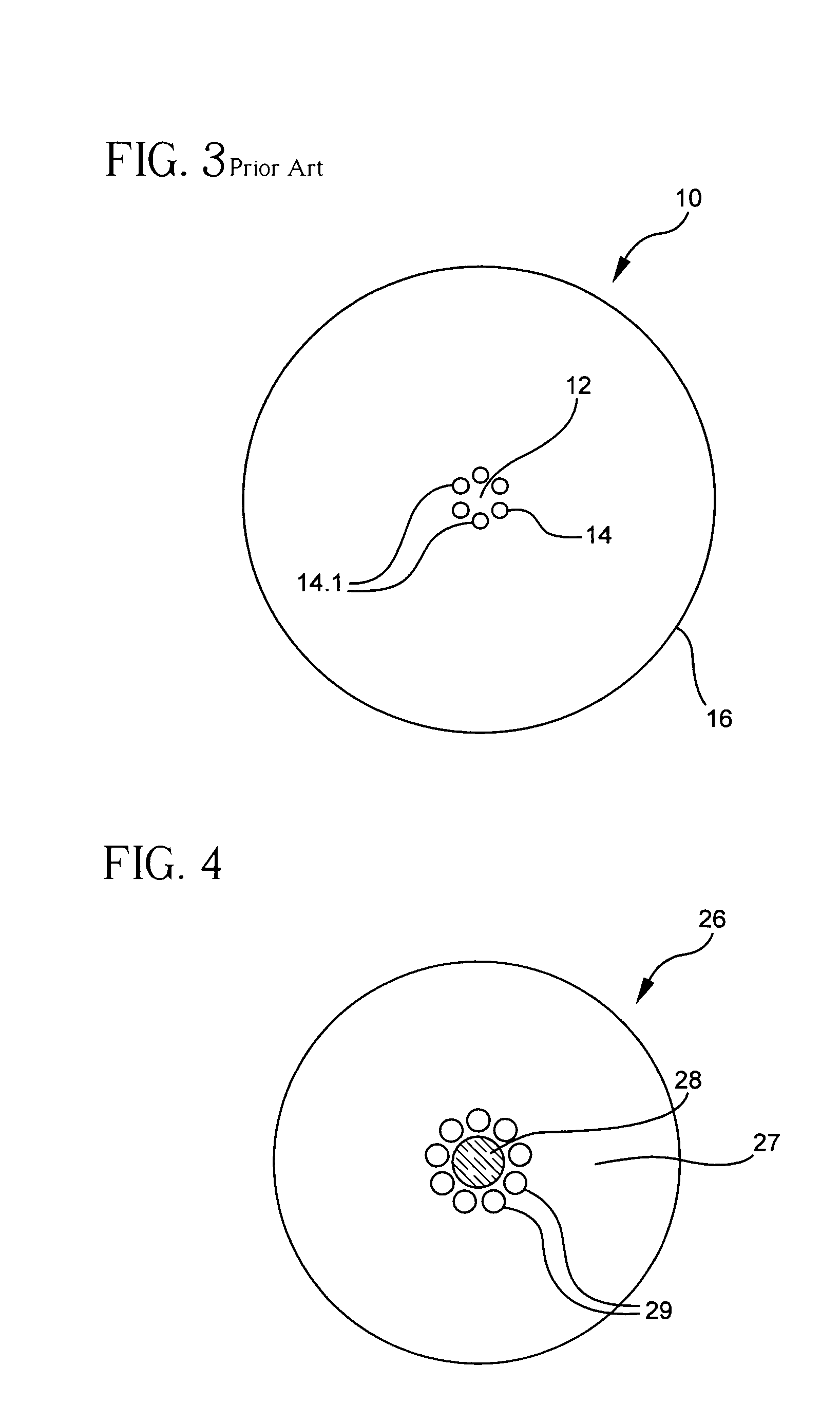

Method and optical fiber device for production of low noise continuum

InactiveUS20060159398A1New design degreeCladded optical fibreCoupling light guidesLow noisePolarization-maintaining optical fiber

Owner:UNIVERSITY OF ROCHESTER

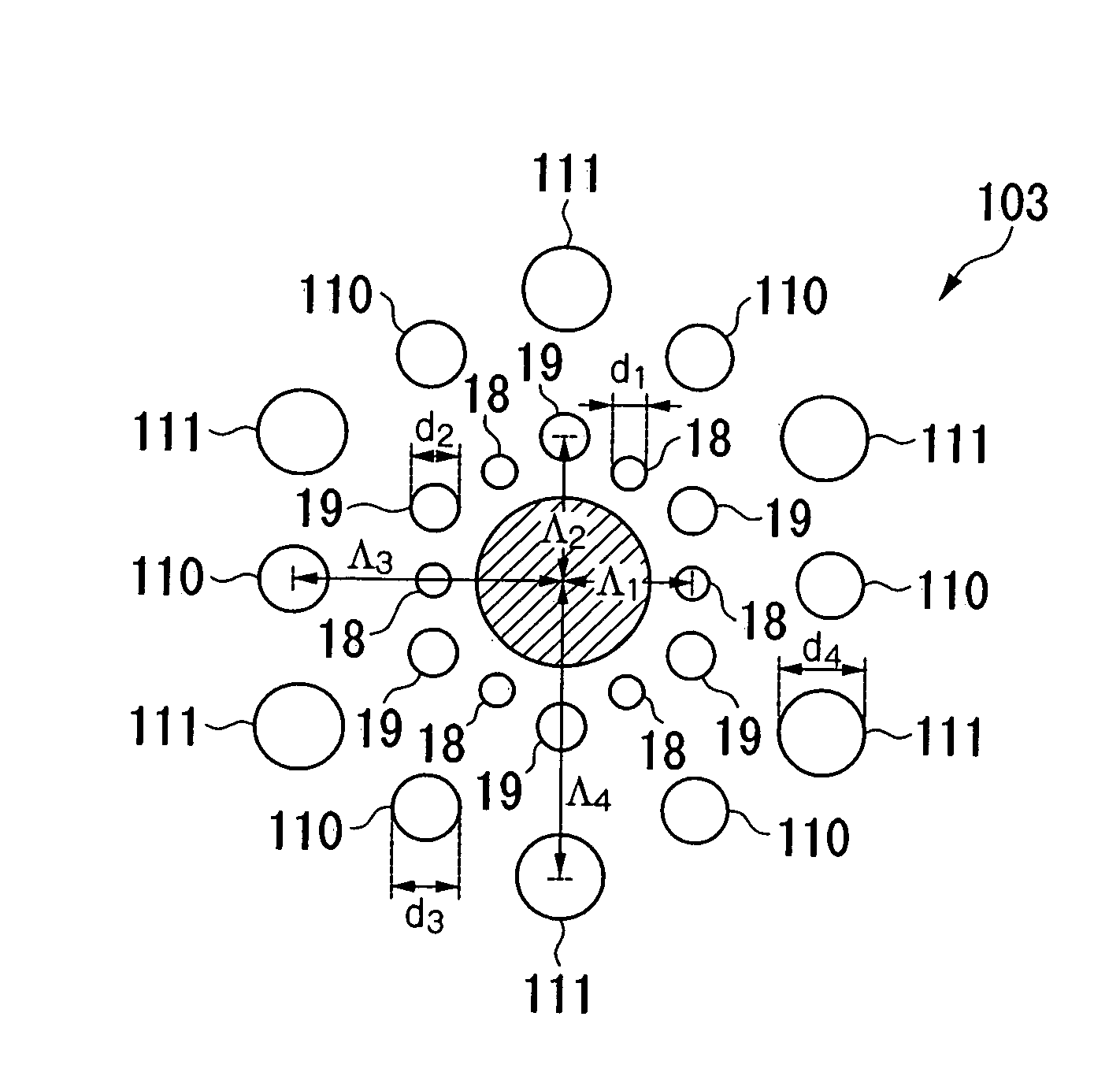

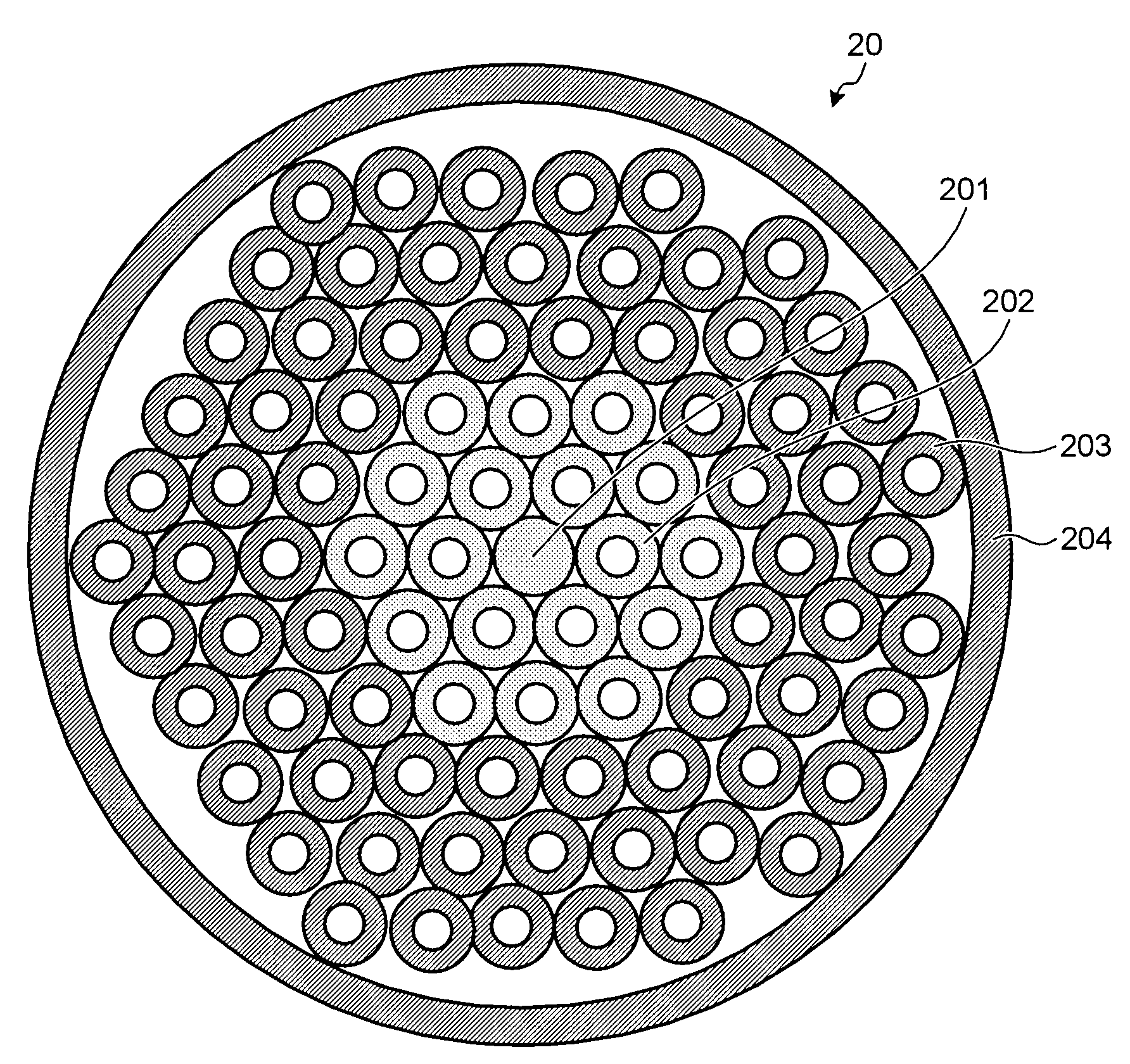

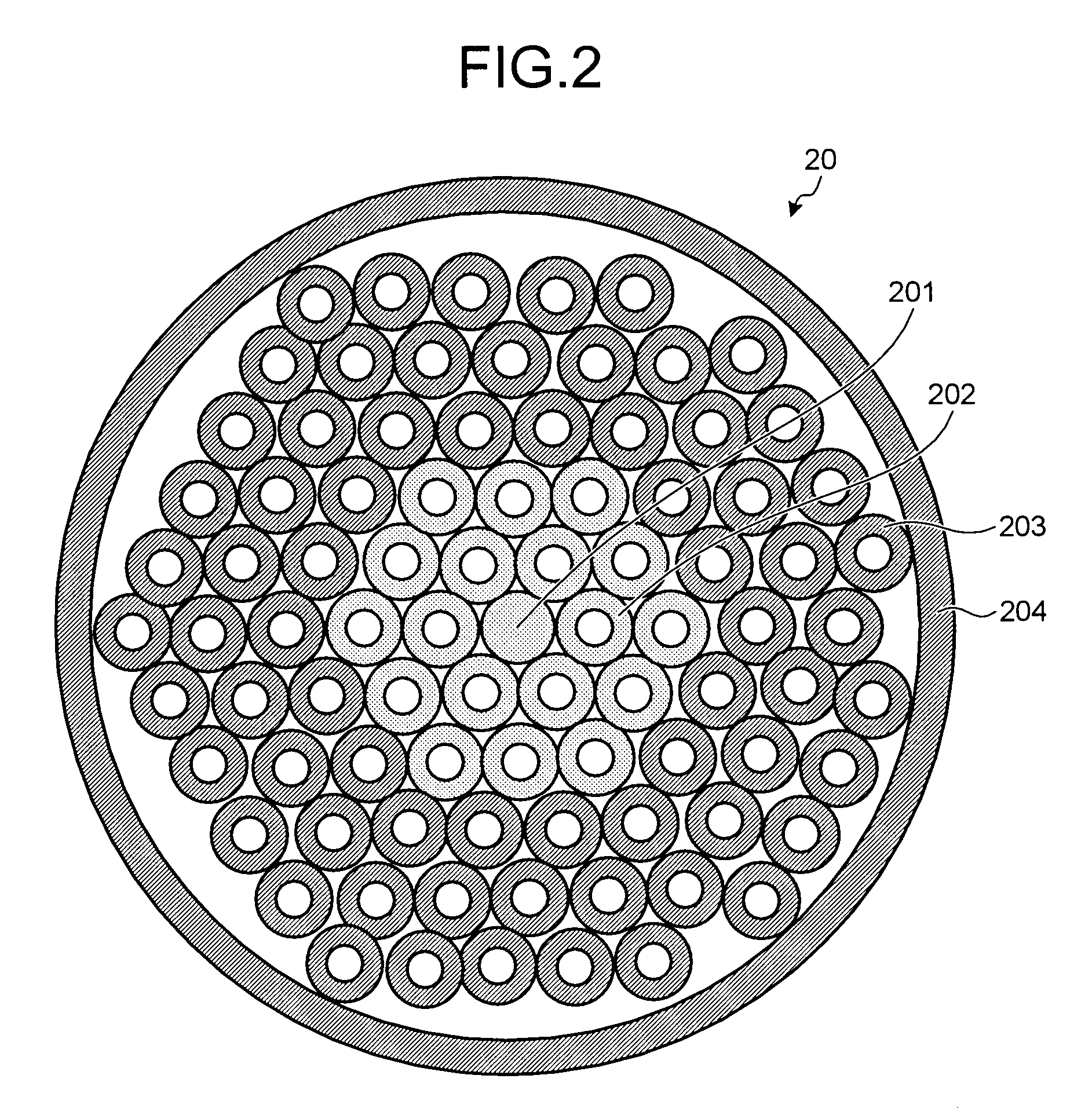

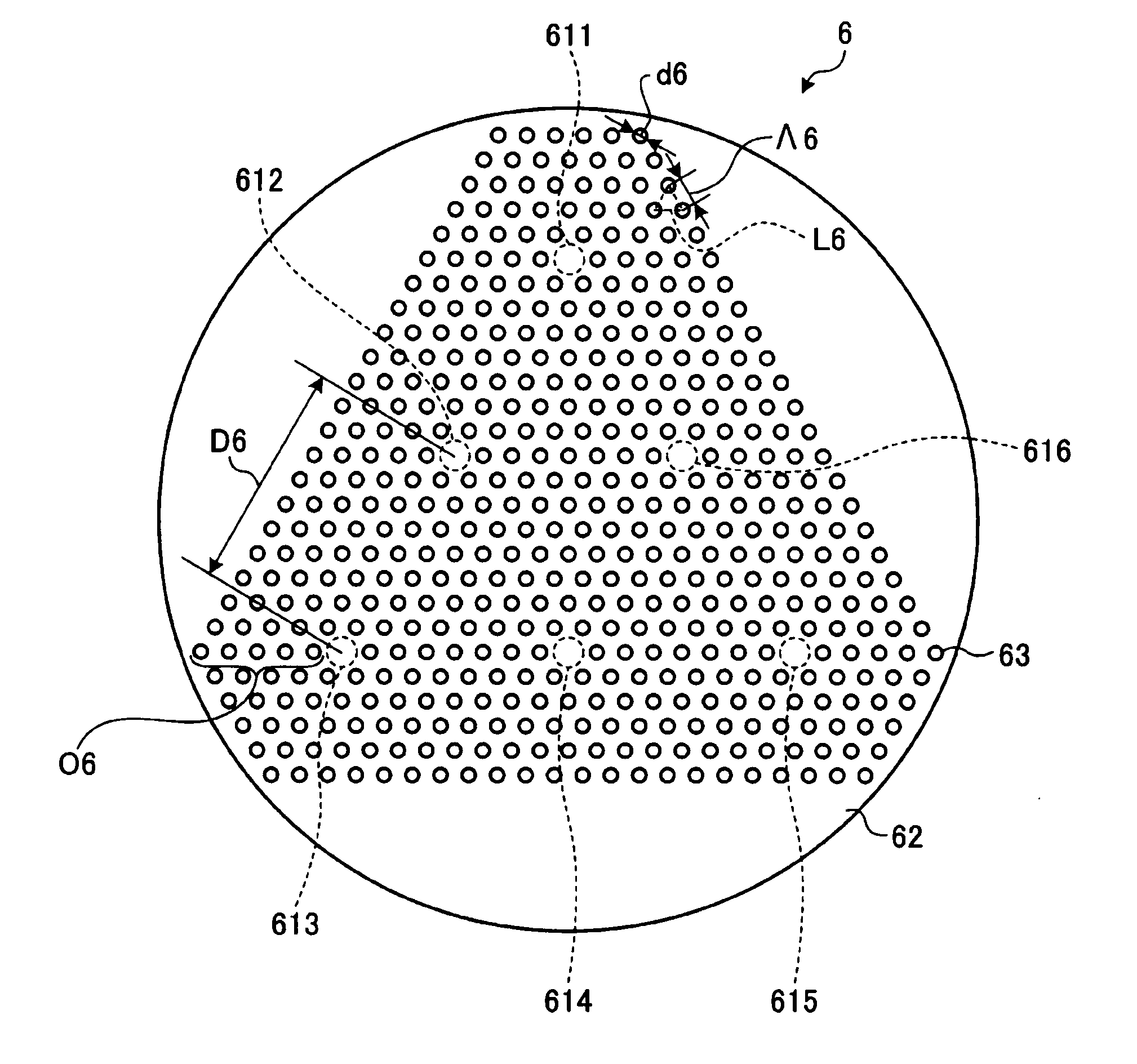

Multi-core holey fiber and optical transmission system

ActiveUS20100054742A1Solve problemsOptical fibre with multilayer core/claddingWavelength-division multiplex systemsFiberEngineering

A multi-core holey fiber with suppression of crosstalk deterioration among transmitted optical signals in a plurality of cores, and an optical transmission system using the fiber are disclosed. The multi-core holey fiber comprises a plurality of cores arranged separately from each other, and a cladding surrounding the plurality of cores wherein the cladding has plurality of holes arranged in a triangular lattice shape to create hole layers around the plurality of cores. Additionally, d / Λ is not more than 0.5, where Λ [μm] is lattice constant of the triangular lattice, d [μm] is diameter of each of the holes; a distance between adjacent cores is equivalent to not less than six hole layers; the cores arranged farthest from the center of the multi-core holey fiber is surrounded by not less three hole layers; and the sum of the coupling coefficients between the adjacent cores is not more than 1.6×10−5 / m.

Owner:FURUKAWA ELECTRIC CO LTD

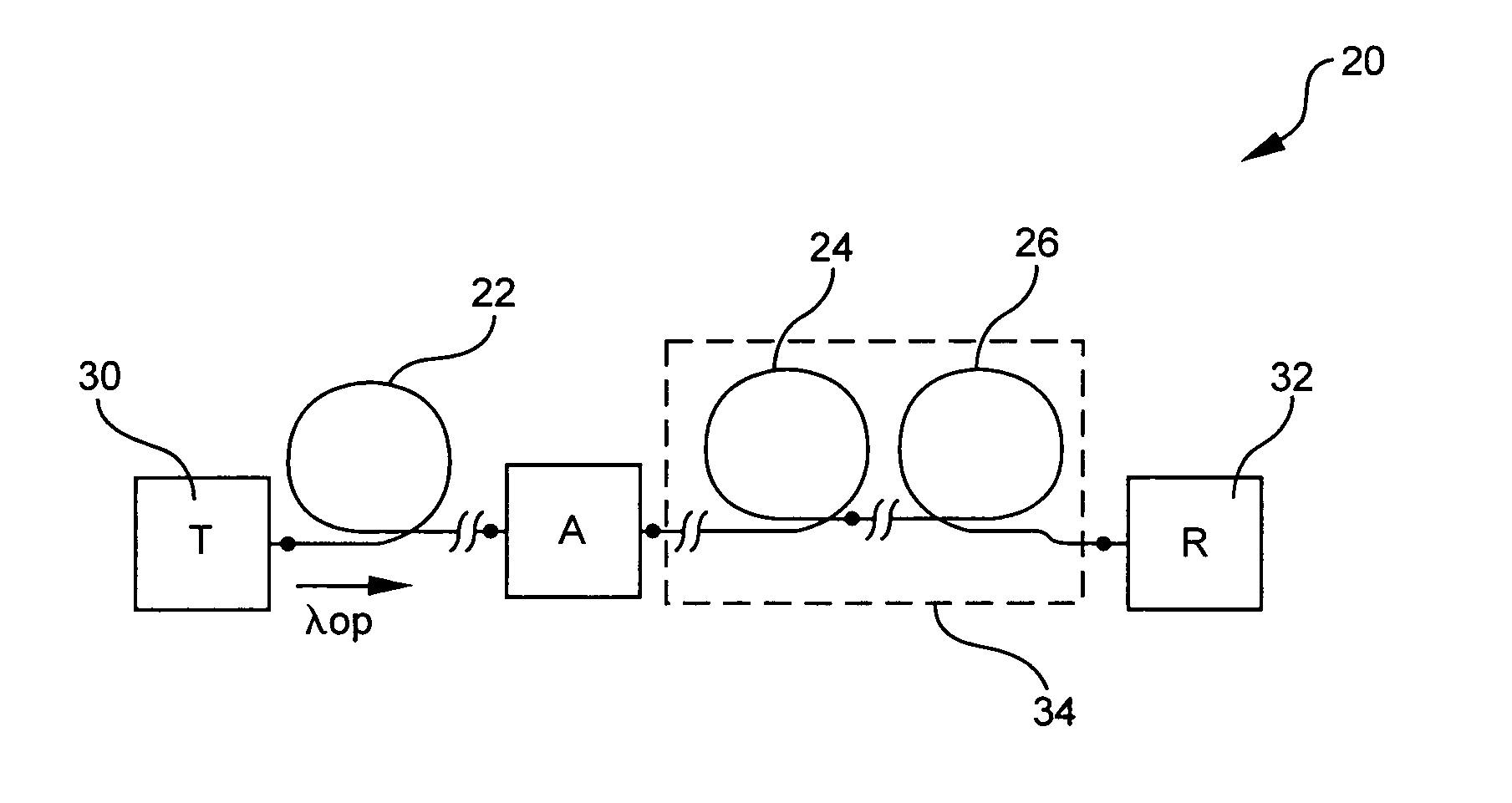

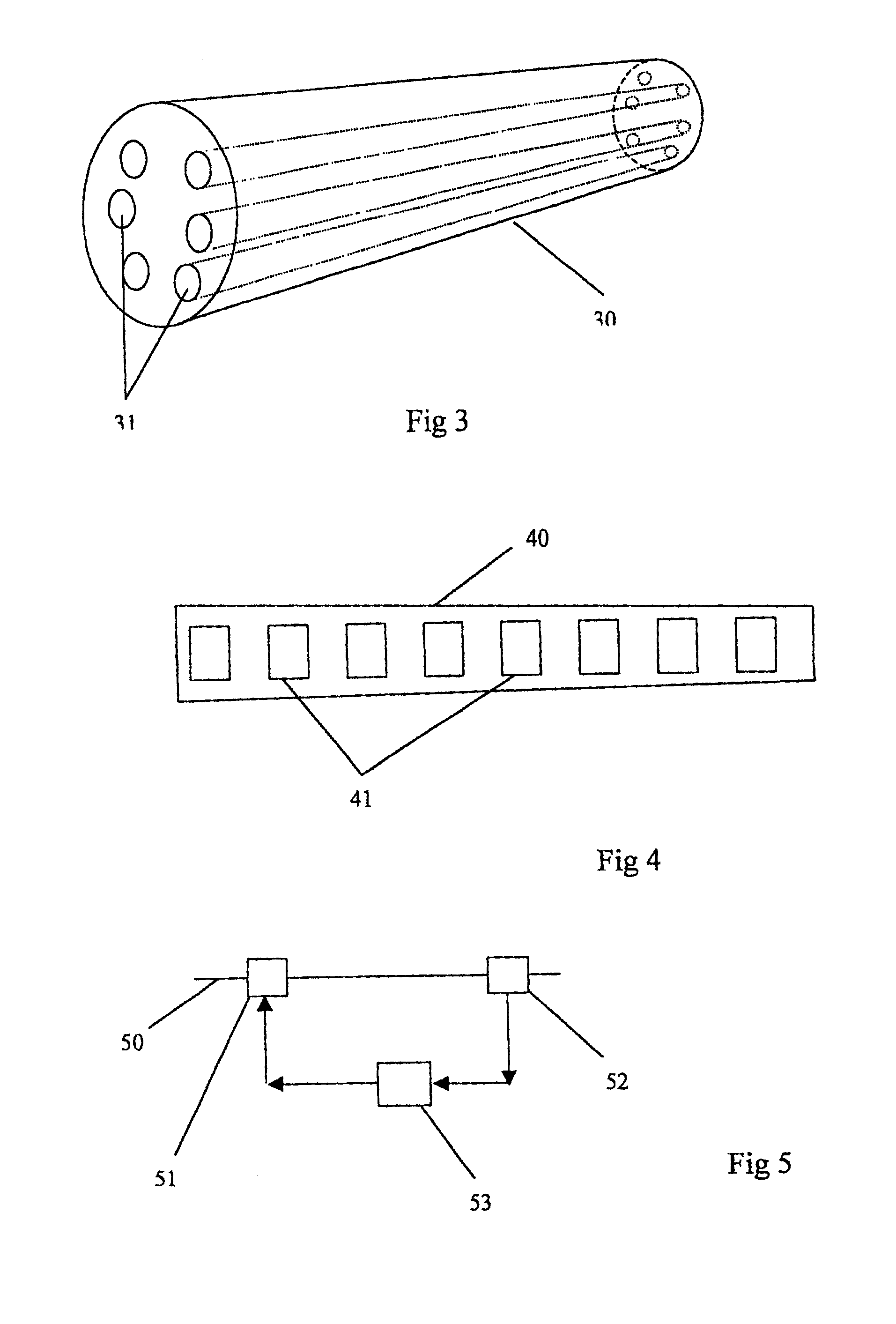

Dispersion compensated optical fiber transmission system and module including micro-structured optical fiber

InactiveUS6993228B2Optical fibre with multilayer core/claddingCoupling light guidesEngineeringOptical fiber transmission

Disclosed is an optical transmission system and module which includes a negative dispersion, dispersion compensating optical fiber coupled to a micro-structured optical fiber (such as band gap fiber, photonic crystal fiber or holey fiber) for compensating for the accumulated dispersion in a transmission fiber. The optical transmission system and module in accordance with the invention provides substantially equal compensation of total dispersion over an operating wavelength band, reduced overall system length, and lower insertion loss.

Owner:CORNING INC

Method and optical fiber device for production of low noise continuum

InactiveUS7403688B2Reduce noiseCladded optical fibreCoupling light guidesLow noisePolarization-maintaining optical fiber

Owner:UNIVERSITY OF ROCHESTER

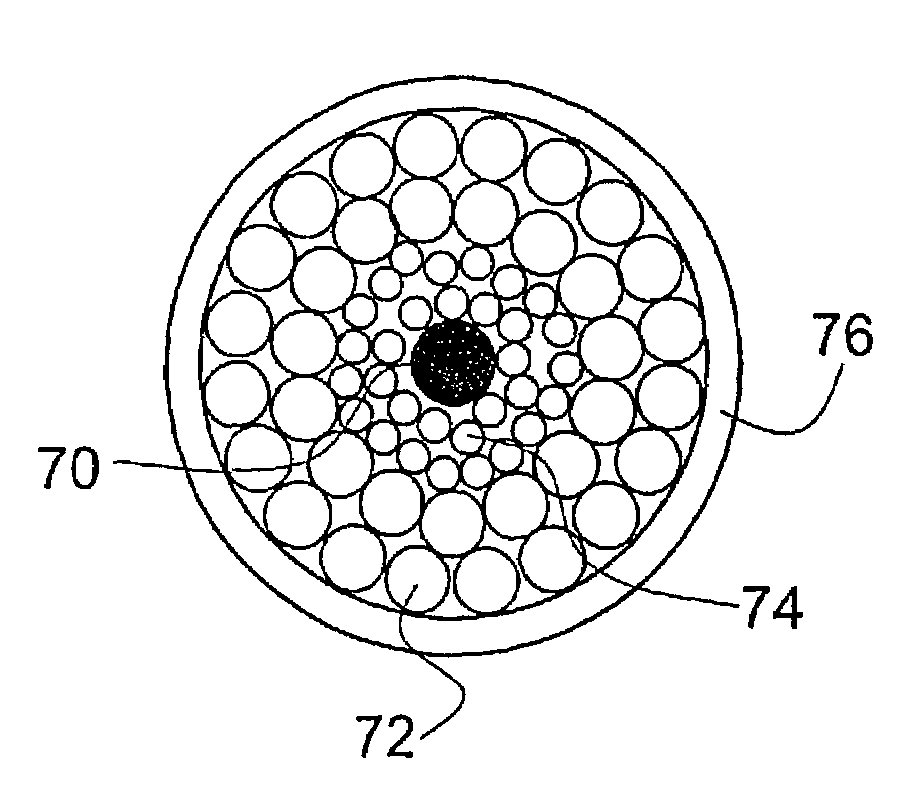

Optical transmission system and dispersion-compensating optical fiber

InactiveUS20090046984A1Solve problemsCladded optical fibreOptical waveguide light guideLength waveOptical fiber transmission

An optical transmission system employs an optical fiber as an optical transmission path that includes a holey fiber and a dispersion-compensating optical fiber. The holey fiber includes a core region that is formed at a center of the holey fiber and a cladding region having a plurality of holes around the core region at regular intervals. The dispersion-compensating optical fiber is connected close to the holey fiber and that collectively compensates wavelength dispersion of the holey fiber at an operation wavelength in at least two wavelength bands out of O band, E band, S band, C band, and L band within a predetermined range depending on a transmission rate.

Owner:FURUKAWA ELECTRIC CO LTD

Holey optical fibres of non-silica based glass

InactiveUS7155099B2Mismatch problemMinimal numberGlass making apparatusOptical fibre with multilayer core/claddingFibre typeRare earth

To overcome problems of fabricating conventional core-clad optical fibre from non-silica based (compound) glass, it is proposed to fabricate non-silica based (compound) glass optical fibre as holey fibre i.e. one contining Longitudinal holes in the cladding. This removes the conventional problems associated with mismatch of the physical properties of the core and clad compound glasses, since a holey fibre can be made of a single glass composition. With a holey fibre, it is not necessary to have different glasses for the core and cladding, since the necessary refractive index modulation between core and cladding is provided by the microstructure of the clad, i.e. its holes, rather than by a difference in materials properties between the clad and core glasses. Specifically, the conventional thermal mismatch problems between core and clad are circumvented. A variety of fibre types can be fabricated from non-silica based (compounds) glasses, for example: single-mode fibre; photonic band gap fibre; highly non-linear fibre; fibre with photosensitivity written gratings and other refractive index profile structures; and rare-earth doped fibres (e.g. Er, Nd, Pr) to provide gain media for fibre amplifiers and lasers.

Owner:UNIV OF SOUTHAMPTON

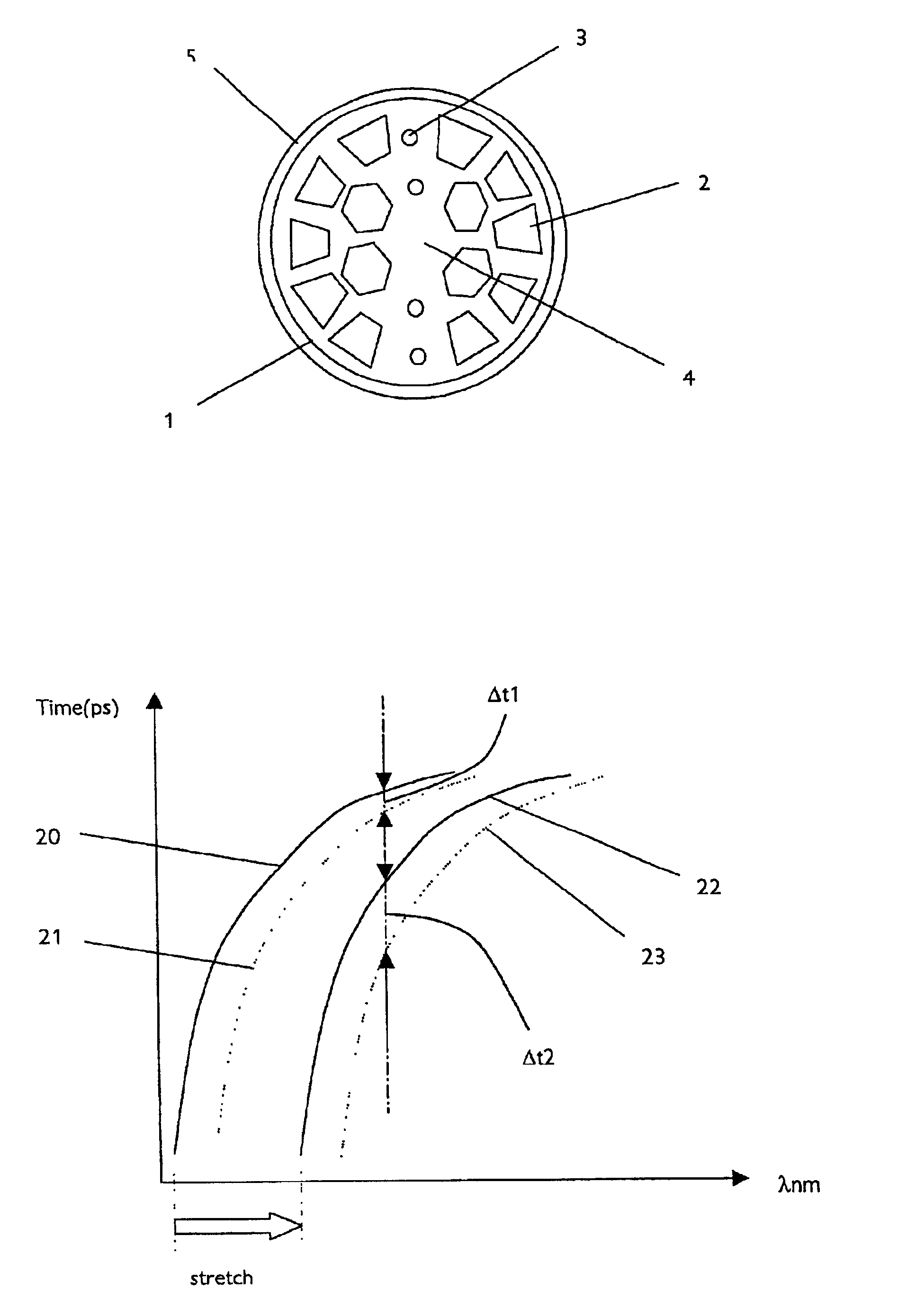

Compensating for polarisation mode dispersion in optical transmission fibers

InactiveUS6707957B1Easy to controlWavelength-division multiplex systemsCoupling light guidesGratingPhotonic crystal

Compensating for polarization mode dispersion in a birefringent optical transmission fibre is achieved by controlling the birefringence of the fibre. The difference in group velocity of the orthogonal polarization states of an optical signal transmitted over the fibre is monitored to generate an error signal representing the difference. The birefringence of the fibre is adjusted accordingly to minimize the difference and thereby provide dynamic compensation. Birefringence control may be achieved by a non-linear fibre grating written into the fibre to impose a differential time delay. The fibre may be a side hole fibre (SHF), a holey fibre (HF), a photonic crystal fibre (PCF), or any other suitable microstructure fibre. The fibre may have stressing rods, may be tapered along its length and may be controlled electrically, mechanically, acoustically or thermally by spaced heating elements.

Owner:RPX CLEARINGHOUSE

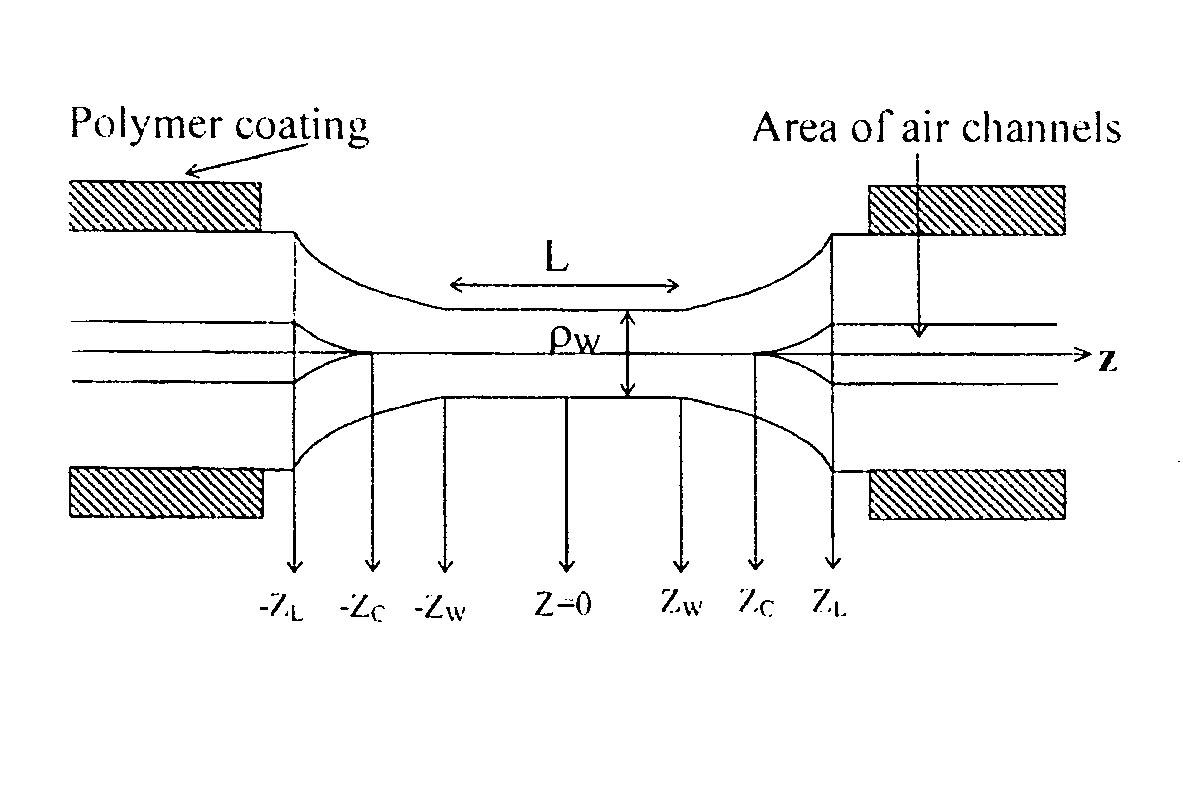

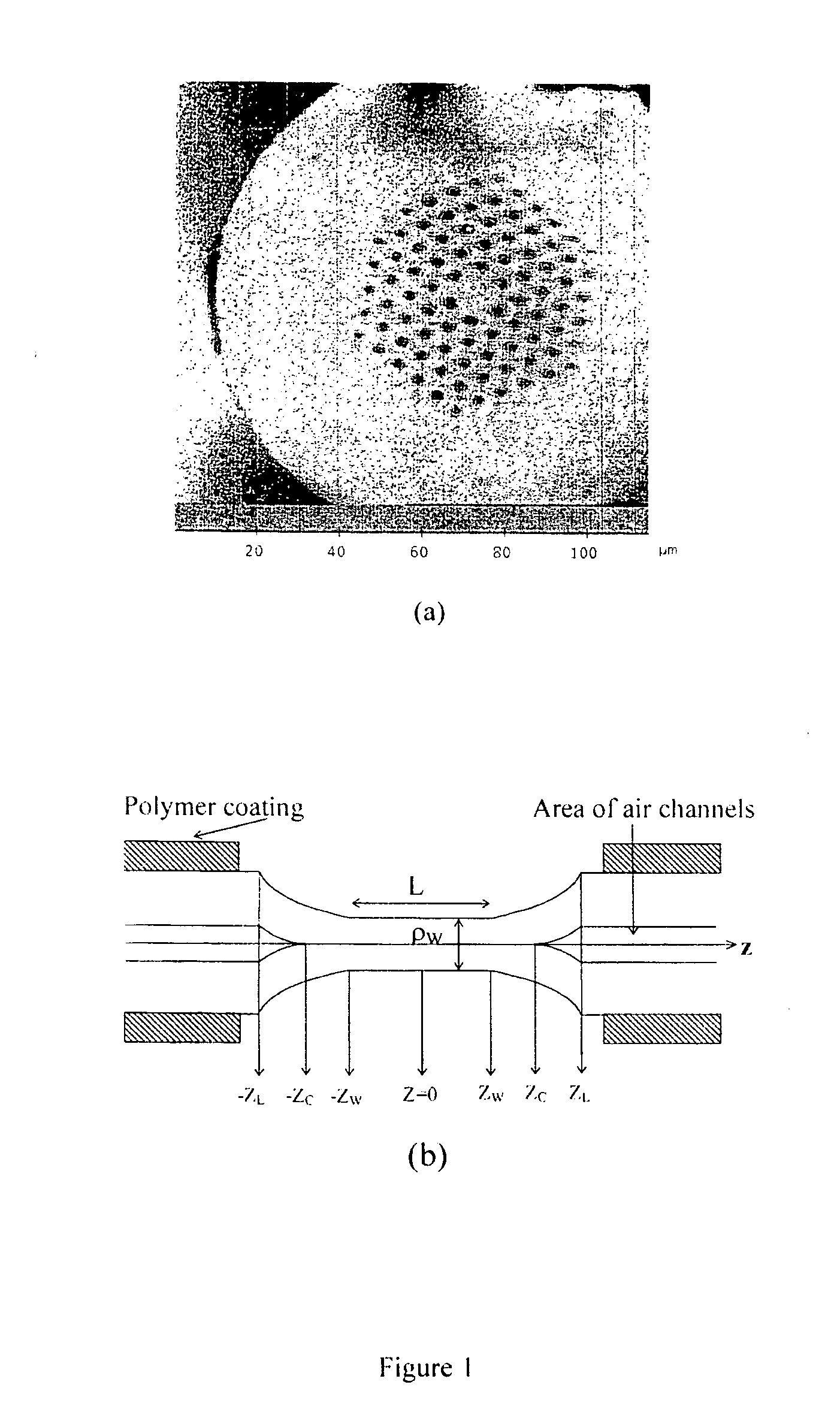

Holey fiber taper with selective transmission for fiber optic sensors and method for manufacturing the same

InactiveUS20090052852A1Reduce the overall diameterIncrease the lengthGlass making apparatusCladded optical fibreRefractive indexEngineering

Large-mode-area single material holey fiber tapers with collapsed by nonadiabatic process air holes in the waist for fiber optic sensors and a method for manufacturing these tapers are claimed. The gradual collapsing of the holes is achieved by tapering the fibers with a “slow-and-hot” method. This nonadiabatic process makes the fundamental mode of the holey fiber to couple to multiple modes of the solid taper waist. Owing to the beating between the modes, the transmission spectra of the tapered single material holey fibers exhibit several interference peaks. That means the all-fiber Mach-Zehnder type interferometer is formed in a holey fiber such a way. The multiple peaks, combined with a fitting algorithm, allow high-accuracy refractometric measurements, temperature-independent strain measurements, measurements of high temperature and may be used for measuring many others parameters.

Owner:MINKOVICH VLADIMIR PETROVICH +2

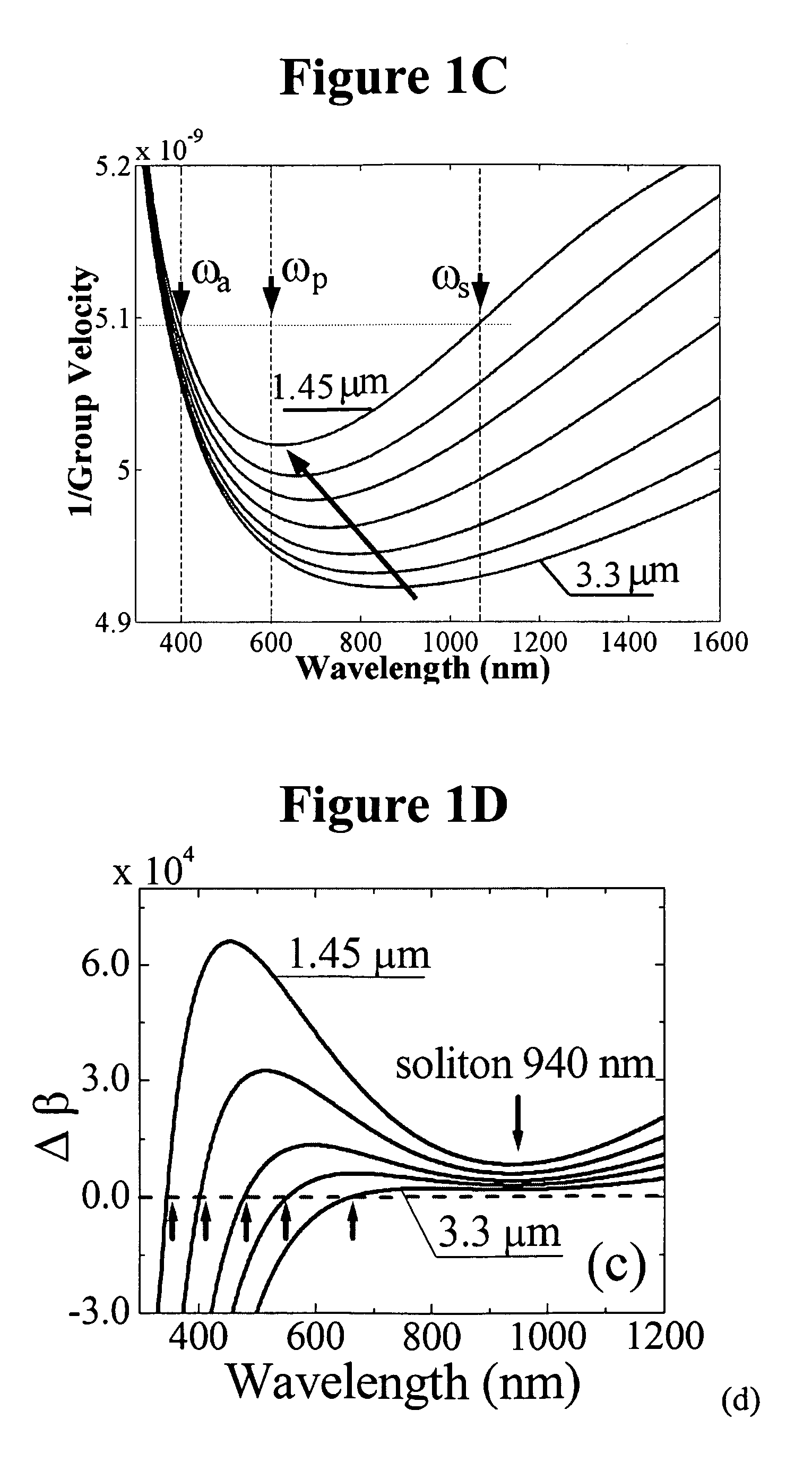

Optical parametric devices and methods for making same

InactiveUS20020126370A1Improve efficiencyBandwidth-length productLight demodulationOptical waveguide light guideOmegaWide band

An optical parametric device for broadband parametric processes involving first and second frequencies .omega..sub.1 and .omega..sub.2. The device comprises an optical fiber comprising a core and a cladding, the cladding being microstructured with holes for providing waveguiding confinement of at least one optical mode in the core. The optical fiber is poled lengthwise with a non-linearity profile having a period that satisfies a quasi phase matching (QPM) condition including the first and second frequencies. Through the use of a poled holey fiber of suitable hole structure, it is possible to increase the second harmonic (SH) efficiency in comparison with poled conventional (non-holey) fiber. This is achieved by a combination of a low mode overlap area between the fundamental and SH waves, a low absolute value of the mode area, and a large SH bandwidth per unit length of the fiber, all of which can be provided together in a poled holey fiber.

Owner:UNIV OF SOUTHAMPTON

Holey fiber

InactiveUS20090097810A1Cladded optical fibreOptical waveguide light guideFiberZero-dispersion wavelength

A holey fiber, which has a zero-dispersion wavelength of less than 700 nm and operates as single mode under its zero-dispersion wavelength, is provided. The holey fiber according to the present invention comprises a core region that is formed at a center of the holey fiber; and a cladding region, formed at the circumference of the core region, which has a plurality of holes distributed as triangle lattice around the core region; wherein the holey fiber has a fundamental mode of less than 700 nm, a higher order mode, and the fundamental mode and the higher order mode confinement losses of less than 0.1 dB / m and more than 10 dB / m, respectively, at the zero-dispersion wavelength.

Owner:FURUKAWA ELECTRIC CO LTD

Dispersion compensated optical fiber transmission system and module including micro-structured optical fiber

InactiveUS20050036752A1Optical fibre with multilayer core/claddingCoupling light guidesEngineeringHoley fiber

Disclosed is an optical transmission system and module which includes a negative dispersion, dispersion compensating optical fiber coupled to a micro-structured optical fiber (such as band gap fiber, photonic crystal fiber or holey fiber) for compensating for the accumulated dispersion in a transmission fiber. The optical transmission system and module in accordance with the invention provides substantially equal compensation of total dispersion over an operating wavelength band, reduced overall system length, and lower insertion loss.

Owner:CORNING INC

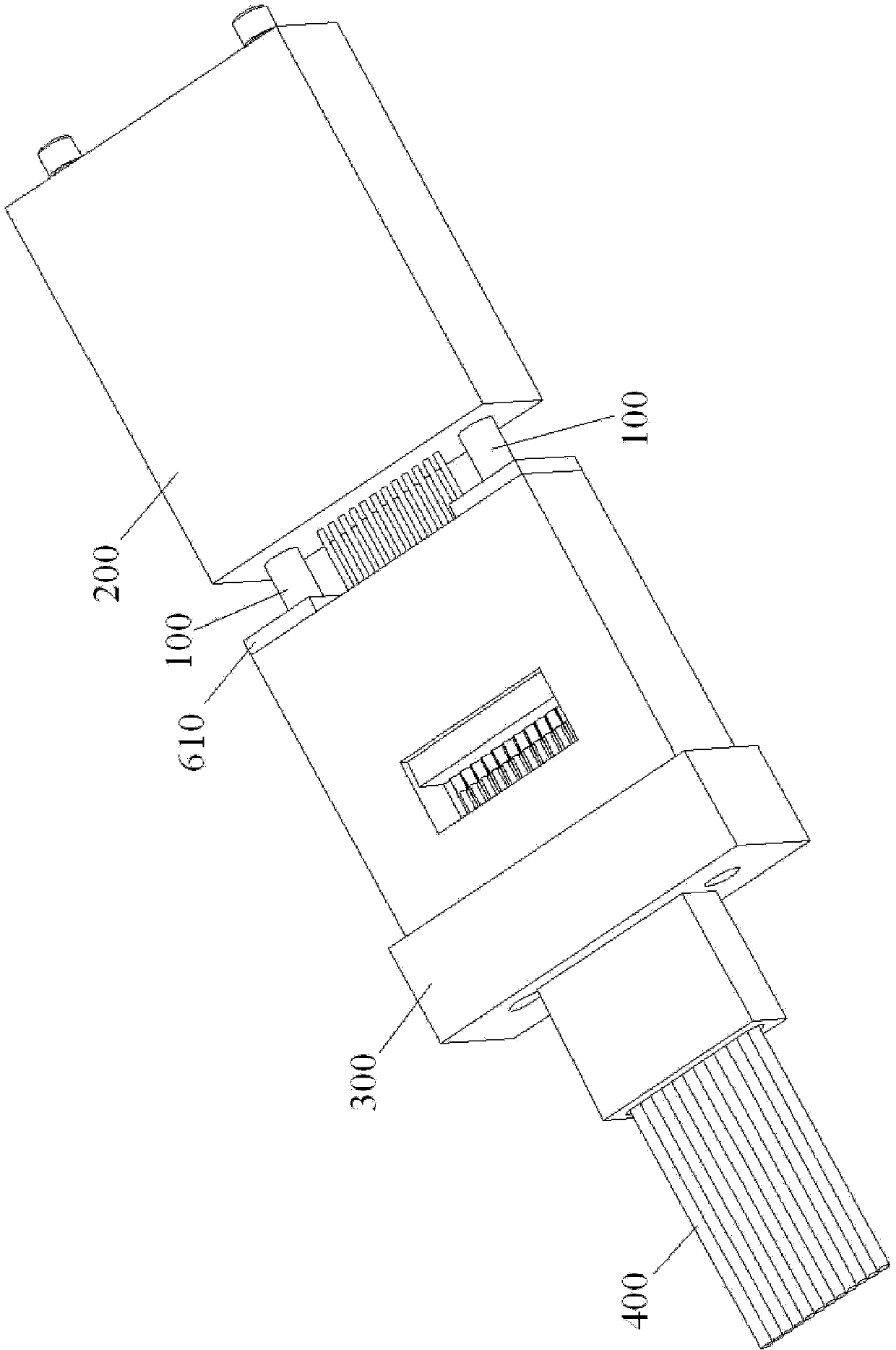

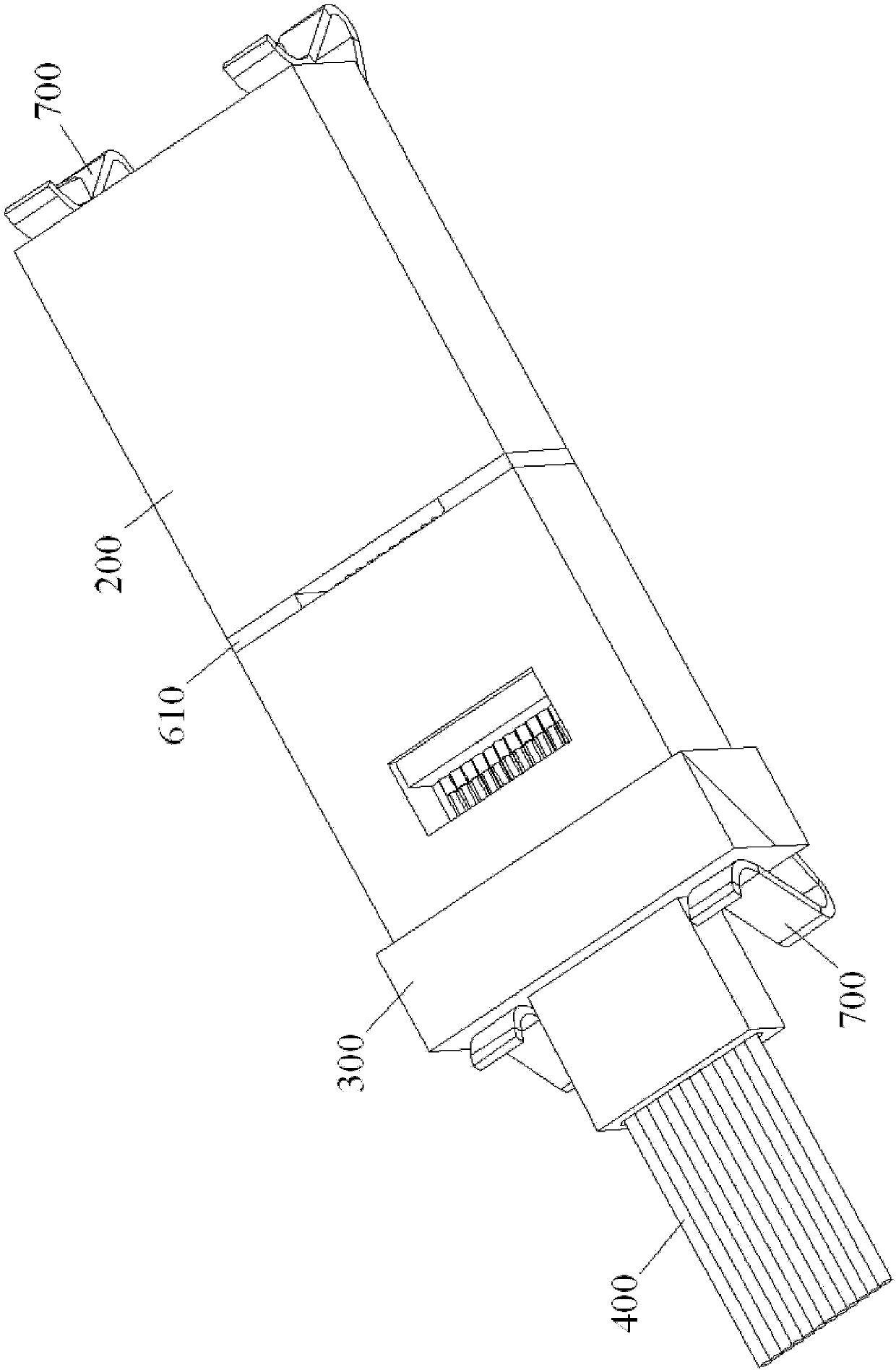

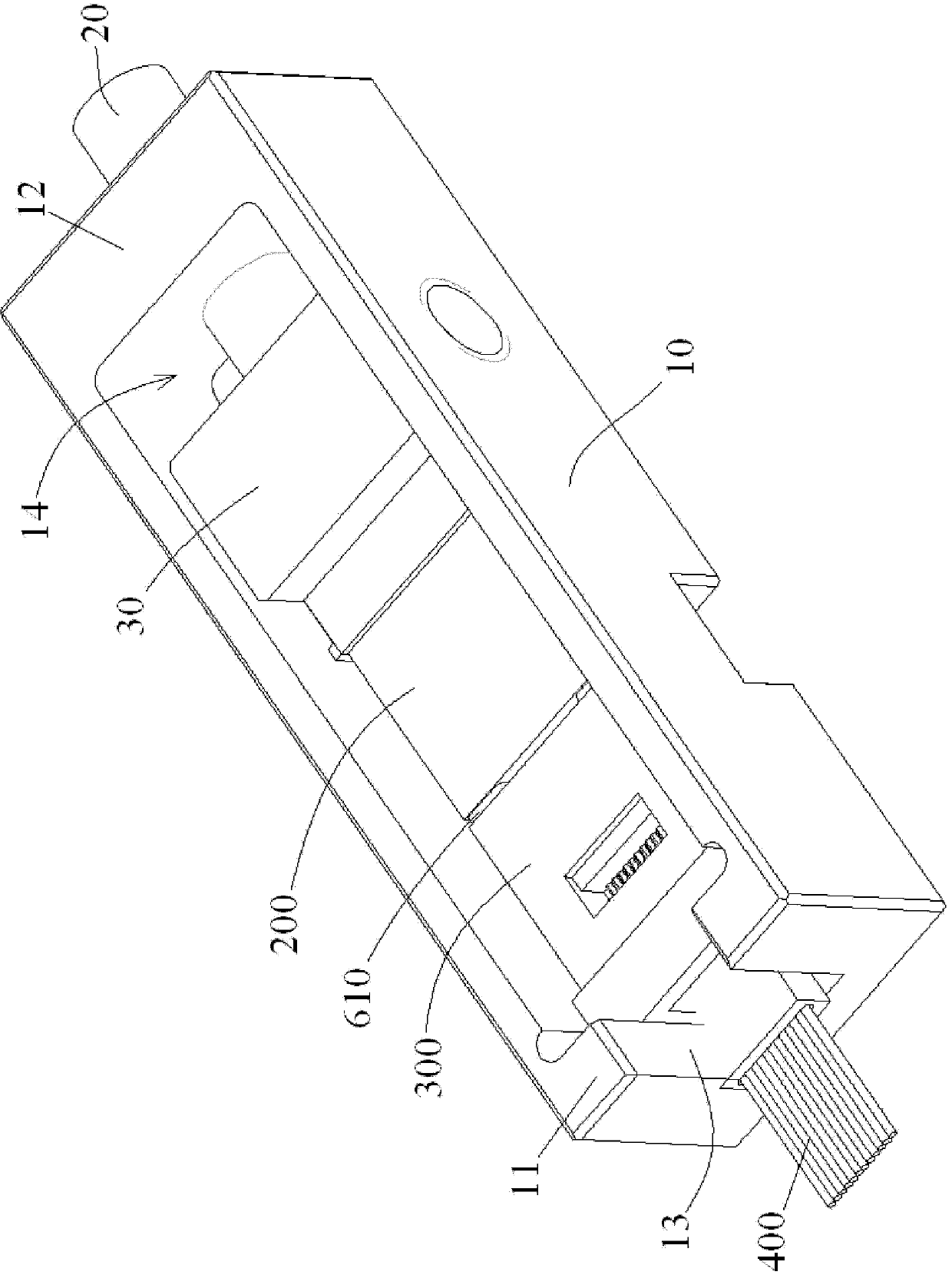

Aligning tool, aligning method, fiber inserting core assembly, and fiber connector

The invention discloses an aligning tool used for calibrating the positions of fibers in fiber through holes of a multi-hole fiber inserting core. The aligning tool comprises a high-precision alignment guiding element and a high-precision fiber position aligning element. The fiber inserting core is butted with the aligning tool through the high-precision alignment guiding element. Multiple fibers pass through the multiple fiber through holes of the fiber inserting core and are inserted into the multiple calibrating holes of the high-precision fiber position aligning element in order that the positional precision of the fibers in the fiber through holes of the fiber inserting core reaches the positional precision of the fibers in the calibrating holes of the high-precision fiber position aligning element. Therefore, a high-precision fiber connector is produced by a low-precision fiber inserting core and production cost is reduced. The invention also discloses an aligning method and a high-precision fiber connector produced by using the aligning tool and the aligning method and provided with precision equal to or more than that of a single-mode fiber connector.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD

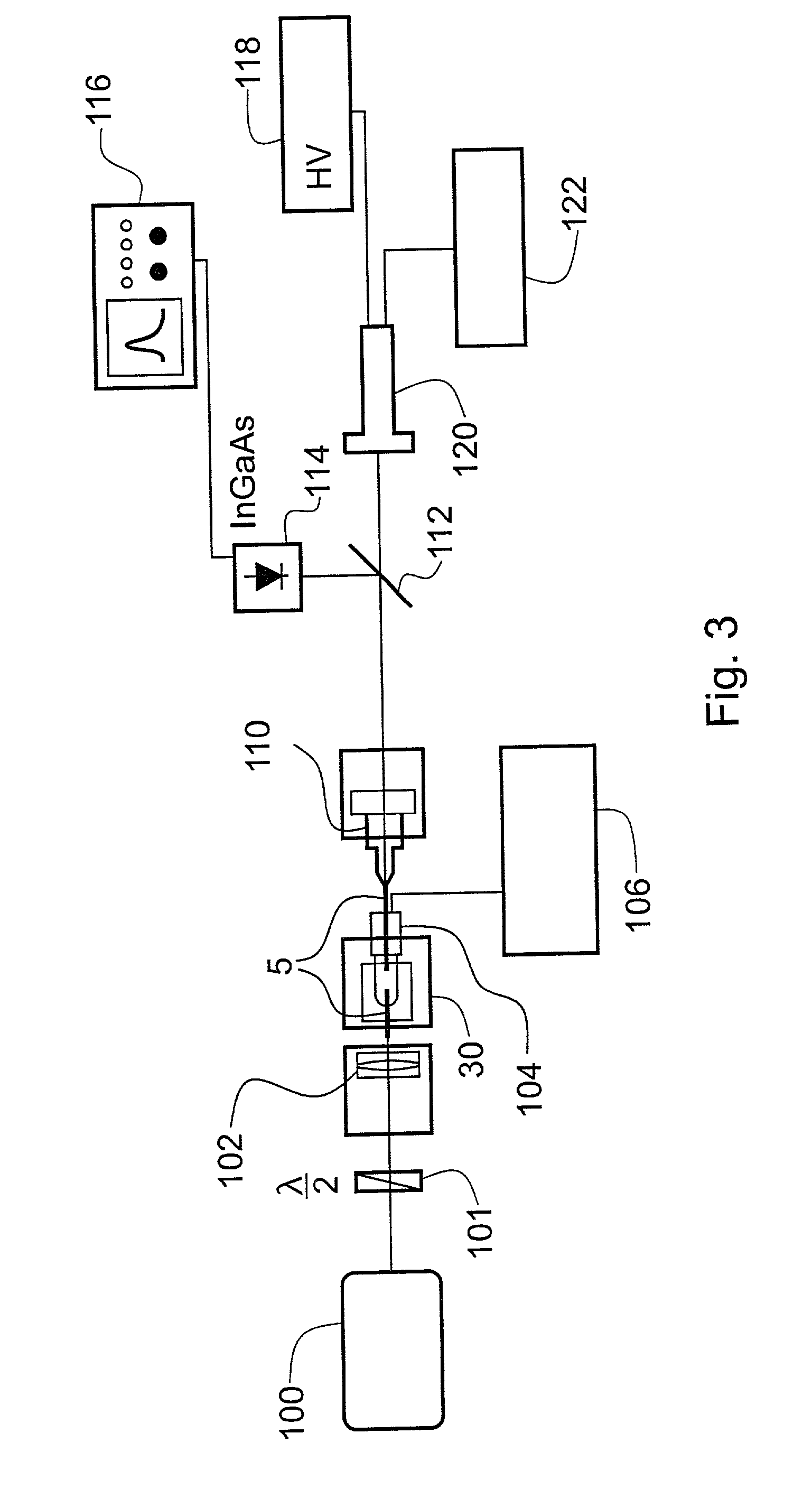

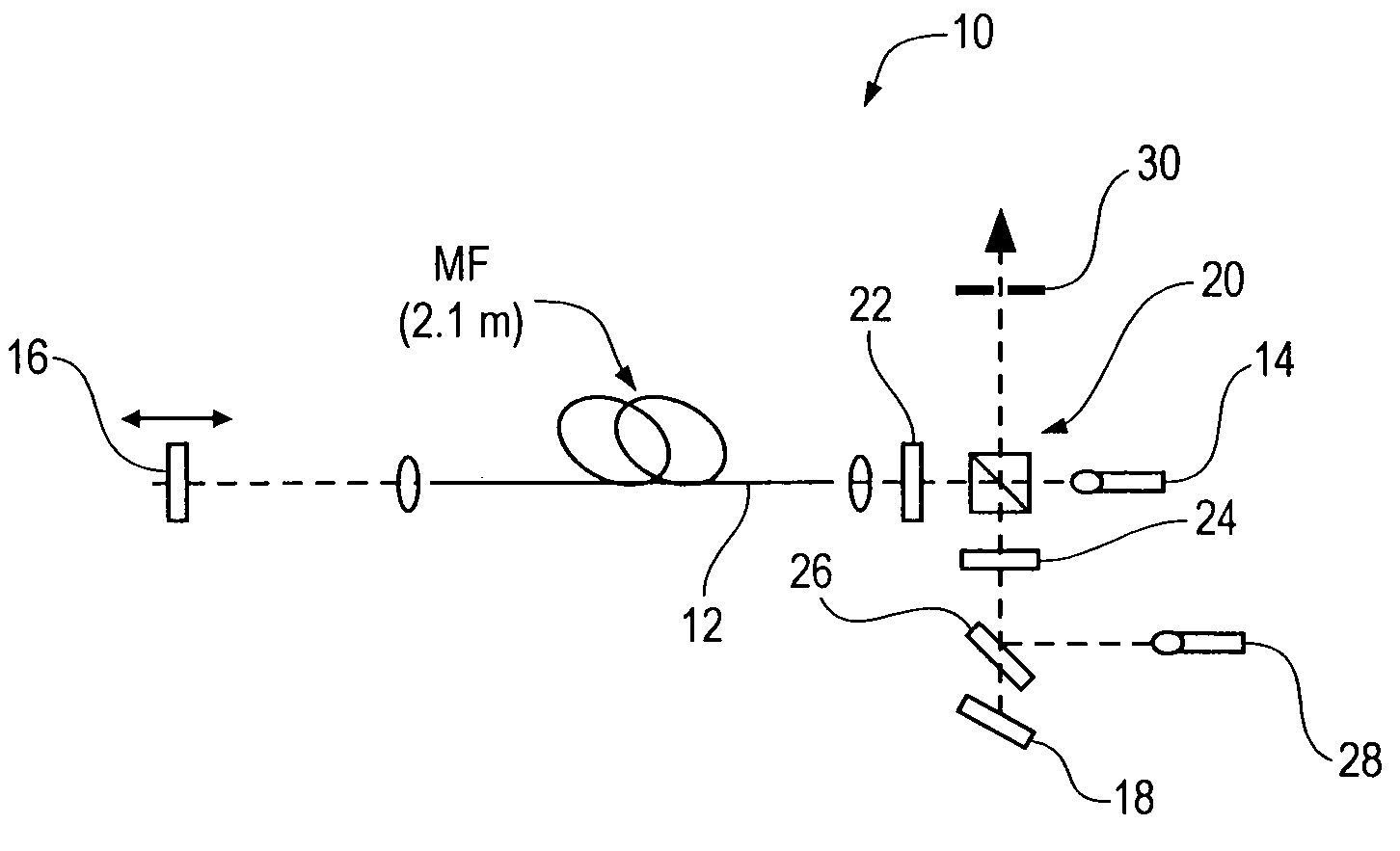

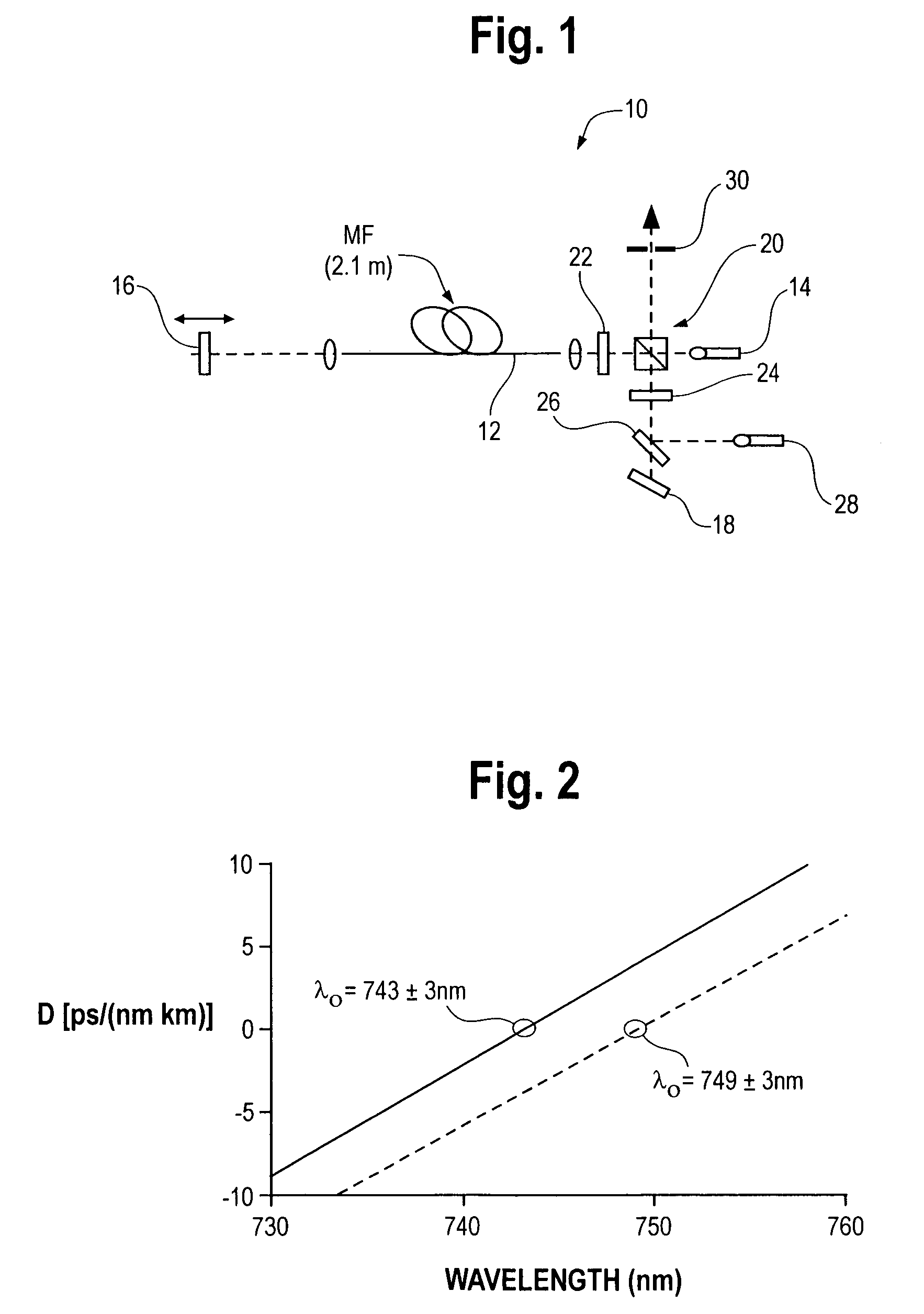

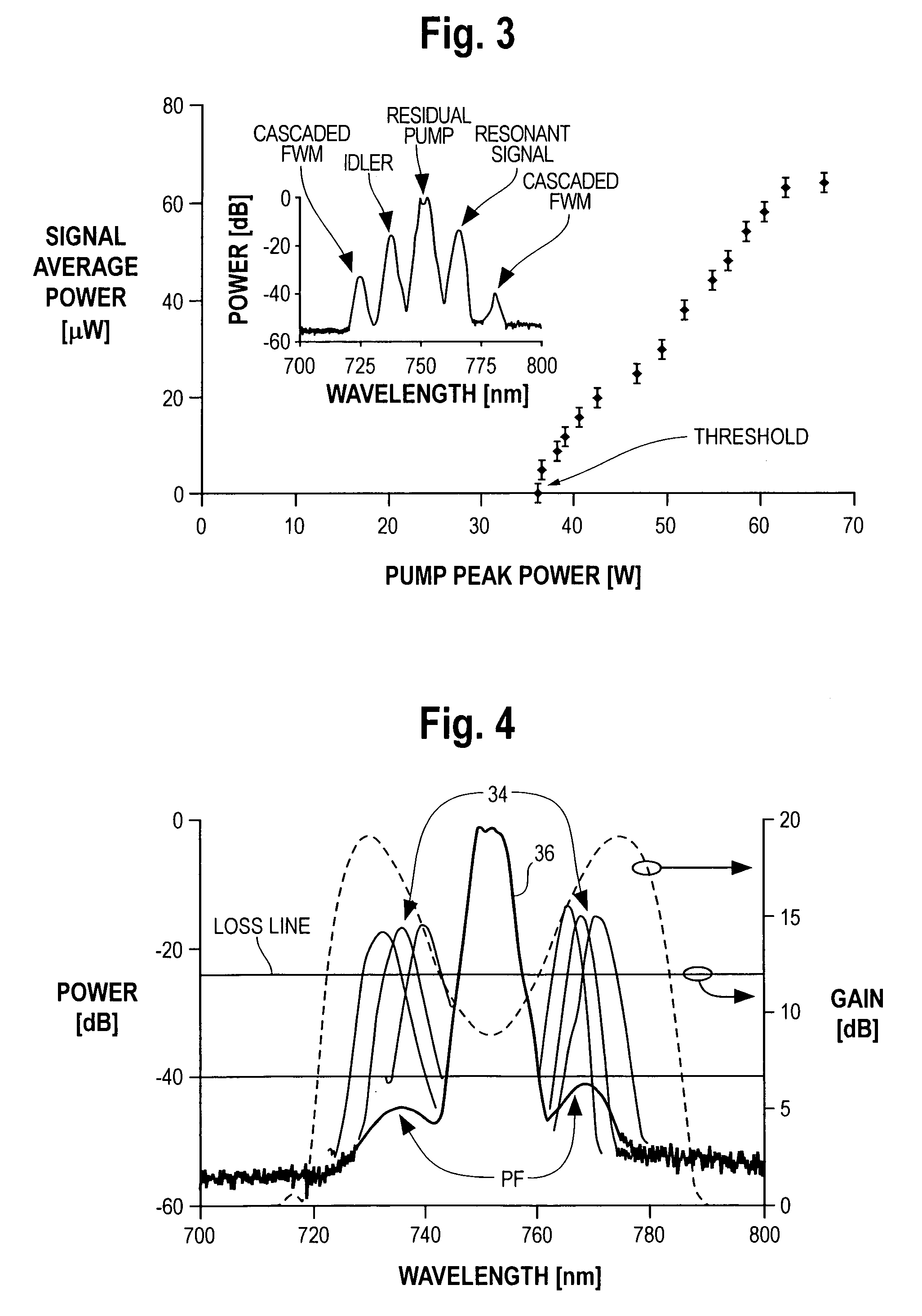

Microstructure fiber optical parametric oscillator

InactiveUS6958855B2Reduction in bending lossOvercome disadvantagesCladded optical fibreLight demodulationSignal wavePhotonic crystal

A fiber optical parametric oscillator is formed using photonic crystal fibers, also known as microstructure fibers or holey fibers. The optical parametric oscillator includes only a few meters of microstructure fiber. In one embodiment, the microstructure fiber is disposed between a highly reflective mirror and a diffraction grating in a simple Fabry-Perot configuration wherein the diffraction grating is tuned to reflect a particular wavelength of the signal wave back to the microstructure fiber. In another embodiment, the microstructure fiber is disposed in a ring cavity and the parametric oscillator is synchronously pumped. The parametric oscillator may be implemented with free space optics or use all fiber optic components.

Owner:NORTHWESTERN UNIV

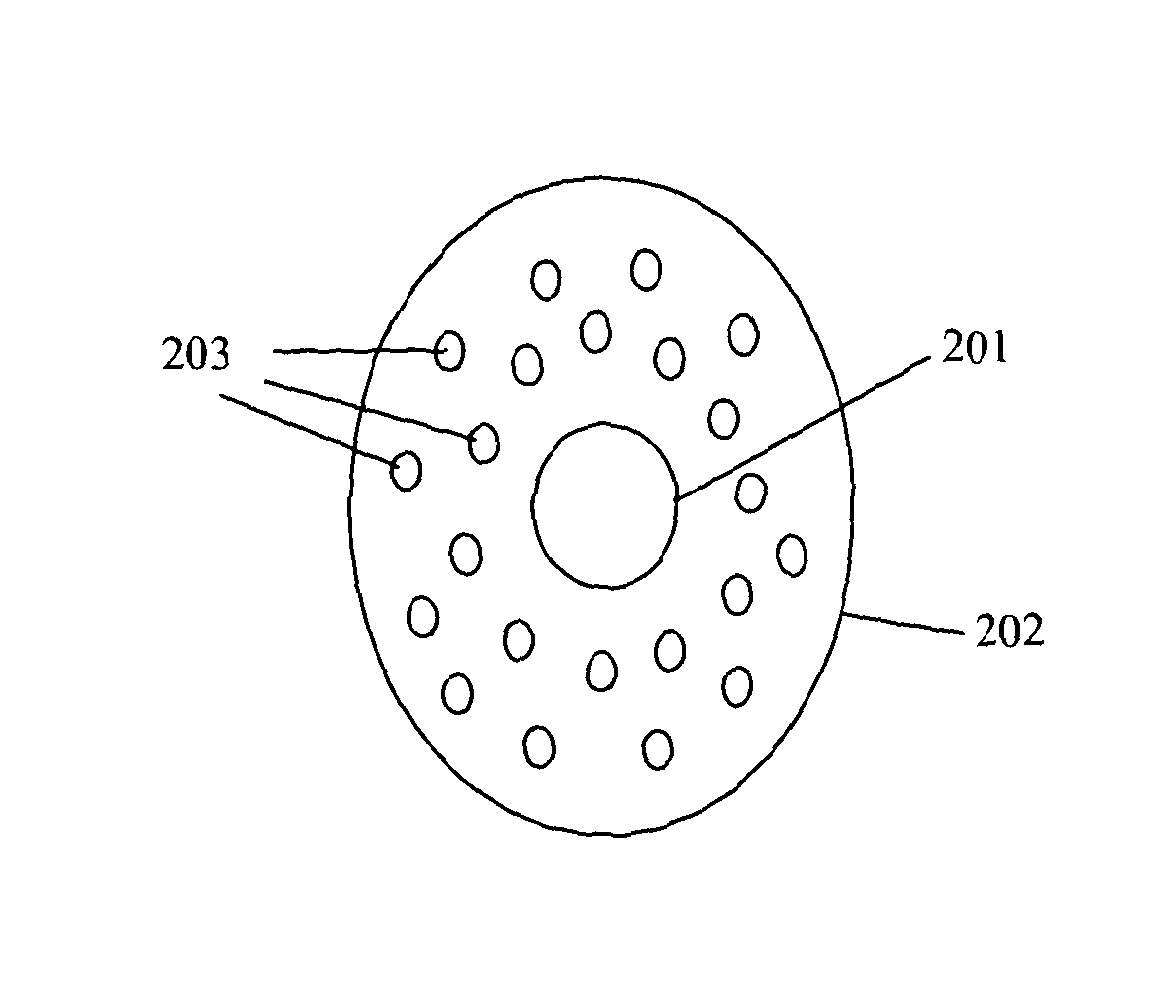

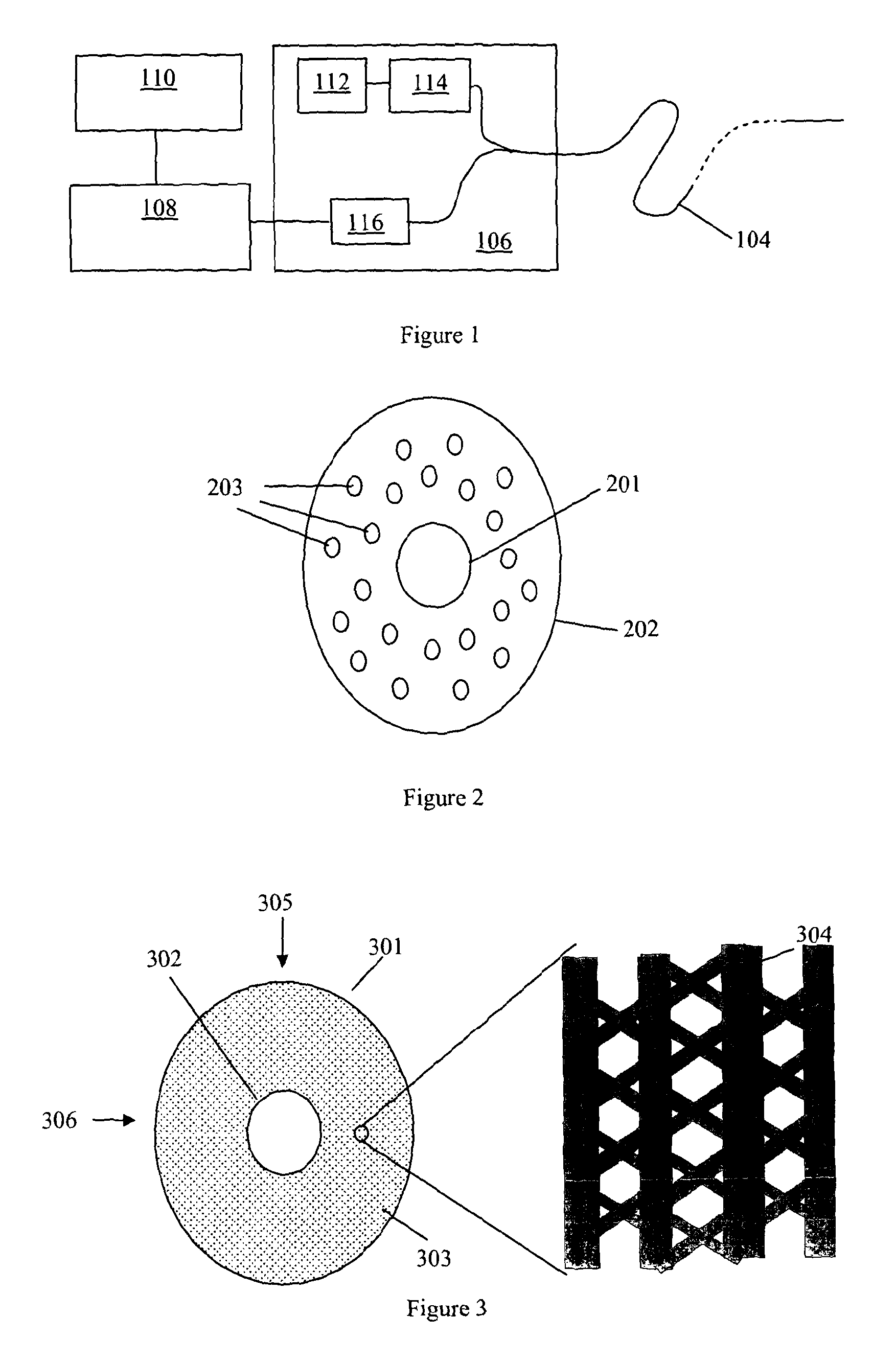

Fibre optic distributed sensing

ActiveUS9243949B2Enhance non-linear optical power thresholdGreat optical powerVibration measurement in solidsCladded optical fibreDistributed acoustic sensingMicrostructure fiber

This application describes methods and apparatus for fiber optic distributed acoustic sensing (DAS) where microstructured fiber (202), such as holey fiber or photonic crystal fiber is used as the sensing fiber (104). The microstructured fiber is configured so to provide at least one of enhanced sensitivity to a given incident acoustic signal; an enhanced non-linear optical power threshold and directional sensitivity. By configuring the microstructured fiber to be more compliant than an equivalent solid fiber and / or provide a large refractive index variation in response to applied strain, the response to a given acoustic stimulus may be larger than for the equivalent fiber, Providing a hollow core may allow higher optical powers and by providing a directionality to microstructured (304) allows the fiber to be used in a DAS system with a directional response.

Owner:OPTASENSE HLDG LTD

Holey optical fiber with random pattern of holes and method for making same

A random array of holes is created in an optical fiber by gas generated during fiber drawing. The gas forms bubbles which are drawn into long, microscopic holes. The gas is created by a gas generating material such as silicon nitride. Silicon nitride oxidizes to produce nitrogen oxides when heated. The gas generating material can alternatively be silicon carbide or other nitrides or carbides. The random holes can provide cladding for optical confinement when located around a fiber core. The random holes can also be present in the fiber core. The fibers can be made of silica. The present random hole fibers are particularly useful as pressure sensors since they experience a large wavelength dependant increase in optical loss when pressure or force is applied.

Owner:VIRGINIA TECH INTPROP INC

Optical transmission system and multi-core optical fiber

ActiveUS8335421B2Optical fibre with multilayer core/claddingMulticore optical fibreLength waveHoley fiber

An optical transmission system includes an optical transmitting unit that outputs at least one optical signal having a wavelength included in an operation wavelength band and a holey fiber that is connected to the optical transmitting unit. The holey fiber includes a core and a cladding formed around the core. The cladding includes a plurality of holes formed around the core in a triangular lattice shape. The holey fiber transmits the optical signal in a single mode. A bending loss of the holey fiber is equal to or less than 5 dB / m at a wavelength within the operation wavelength band when the holey fiber is wound at a diameter of 20 millimeters.

Owner:FURUKAWA ELECTRIC CO LTD

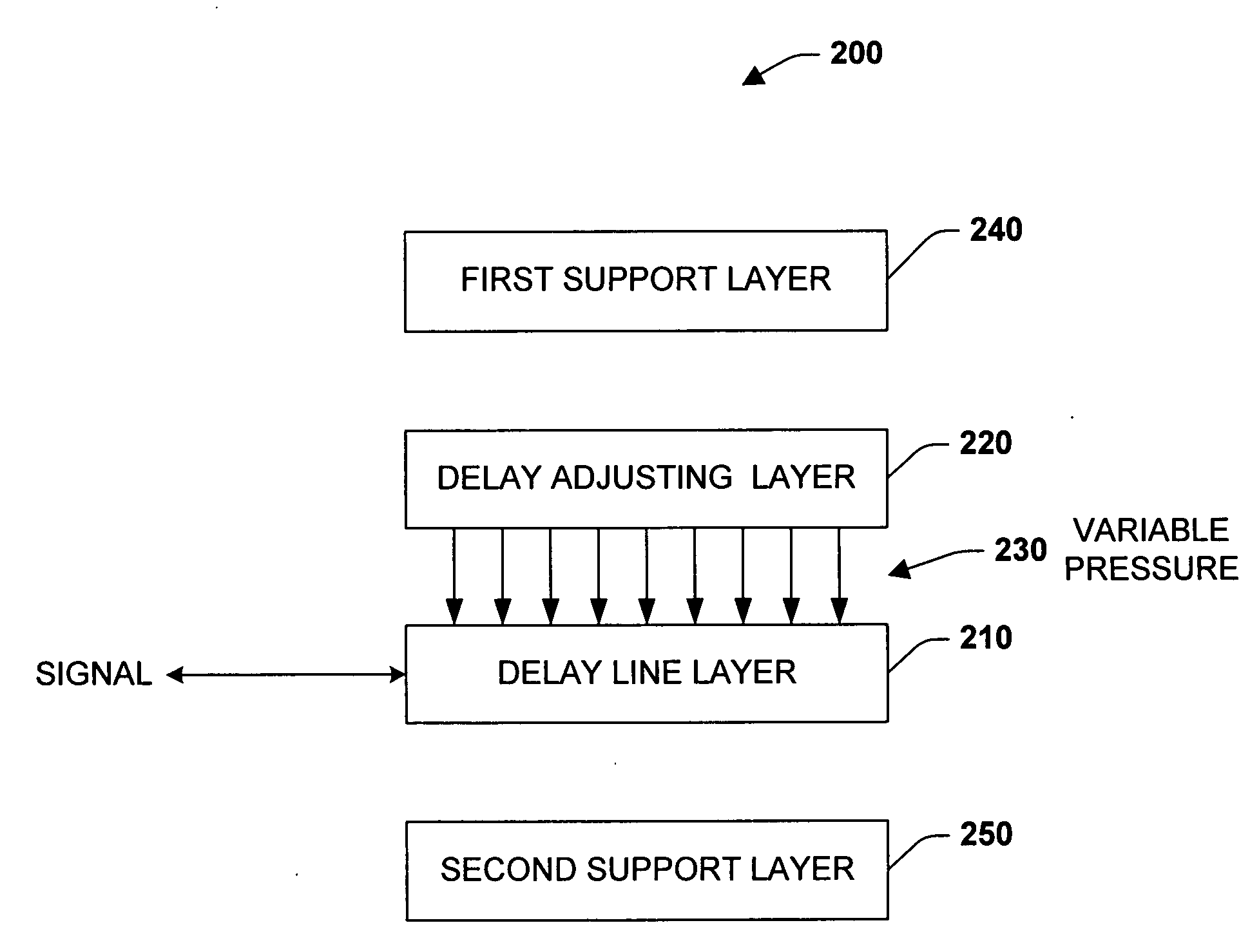

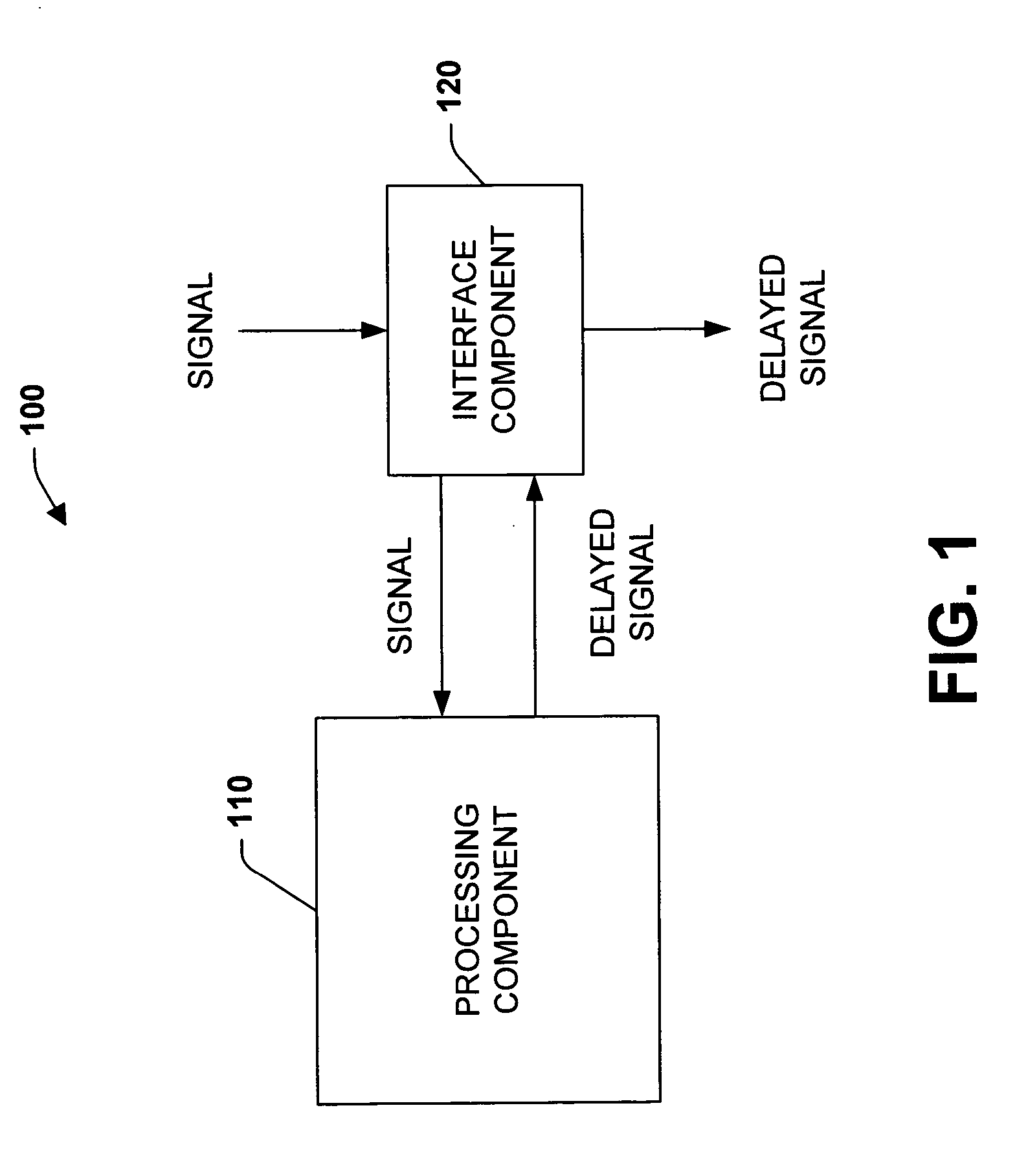

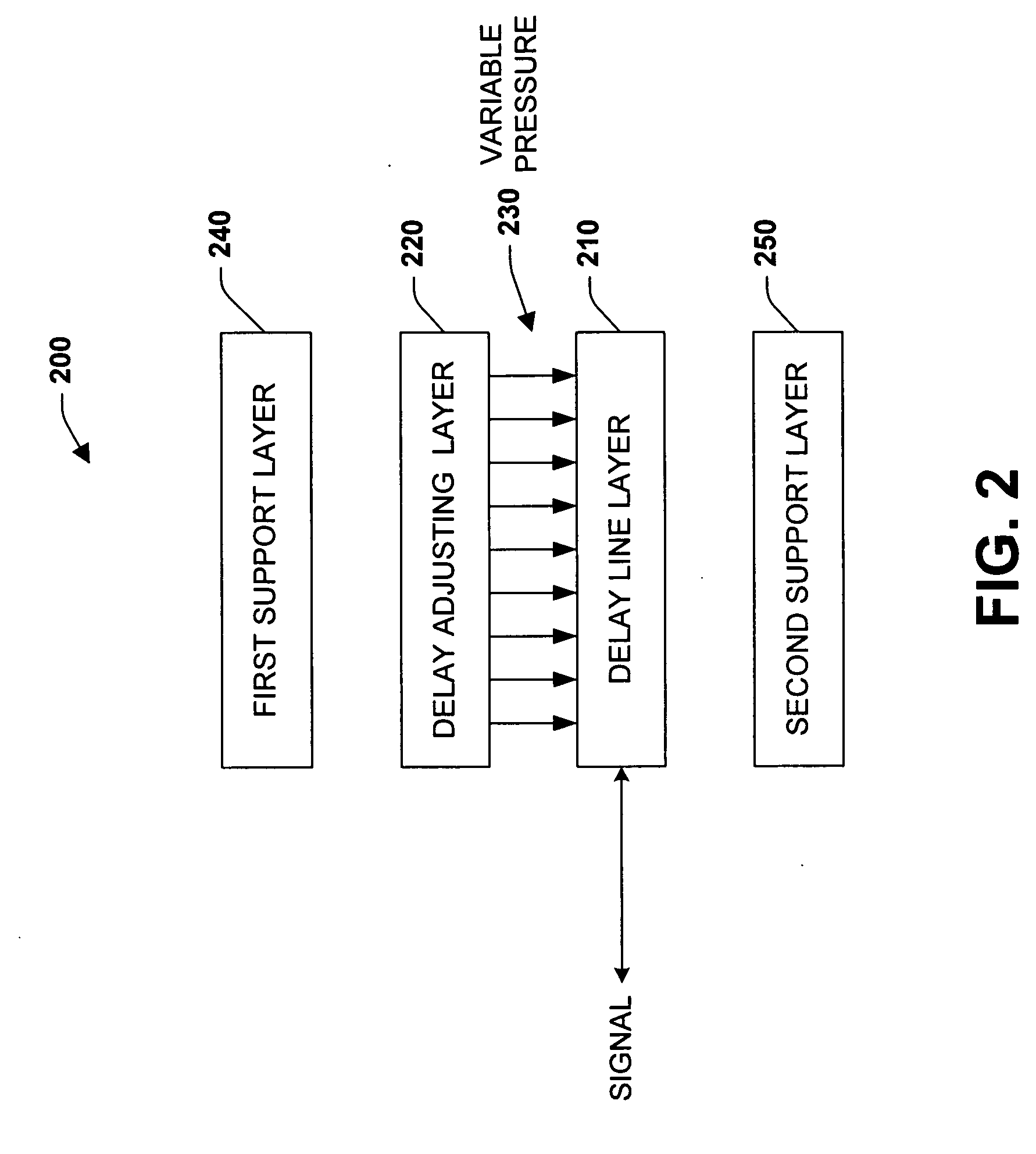

Systems and methods for a continuously variable optical delay line

InactiveUS20060140564A1Facilitate manifestation of true time delayHigh and tunable time-bandwidthCladded optical fibreCoupling light guidesFiberAngle of incidence

Owner:NORTHROP GRUMMAN SYST CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com