Patents

Literature

140 results about "Microstructure fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for high power optical amplification in the infrared wavelength range (0.7-20 mum)

InactiveUS20050271094A1Laser detailsNon-linear opticsAcousto-optic programmable dispersive filterAdemetionine

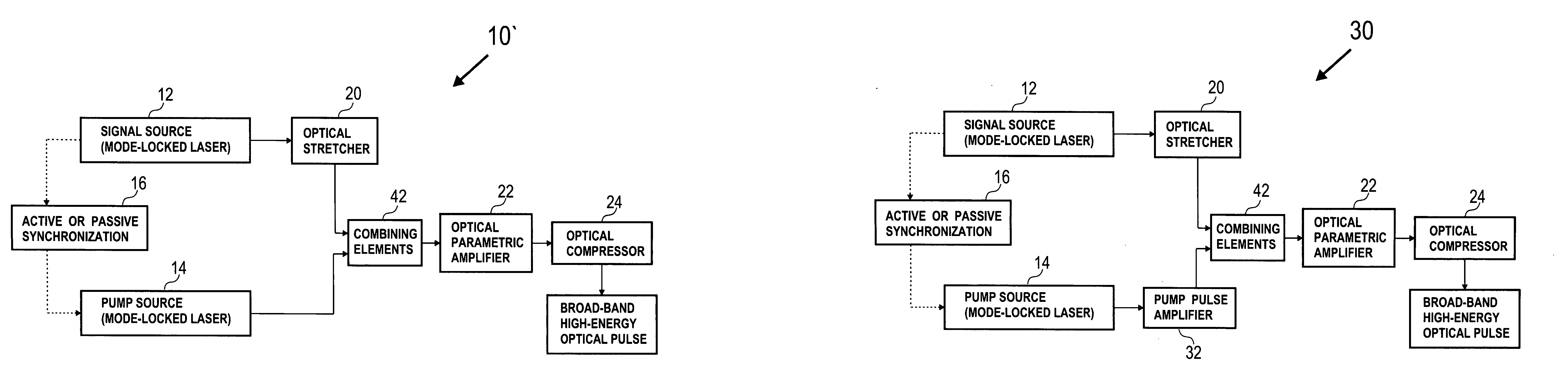

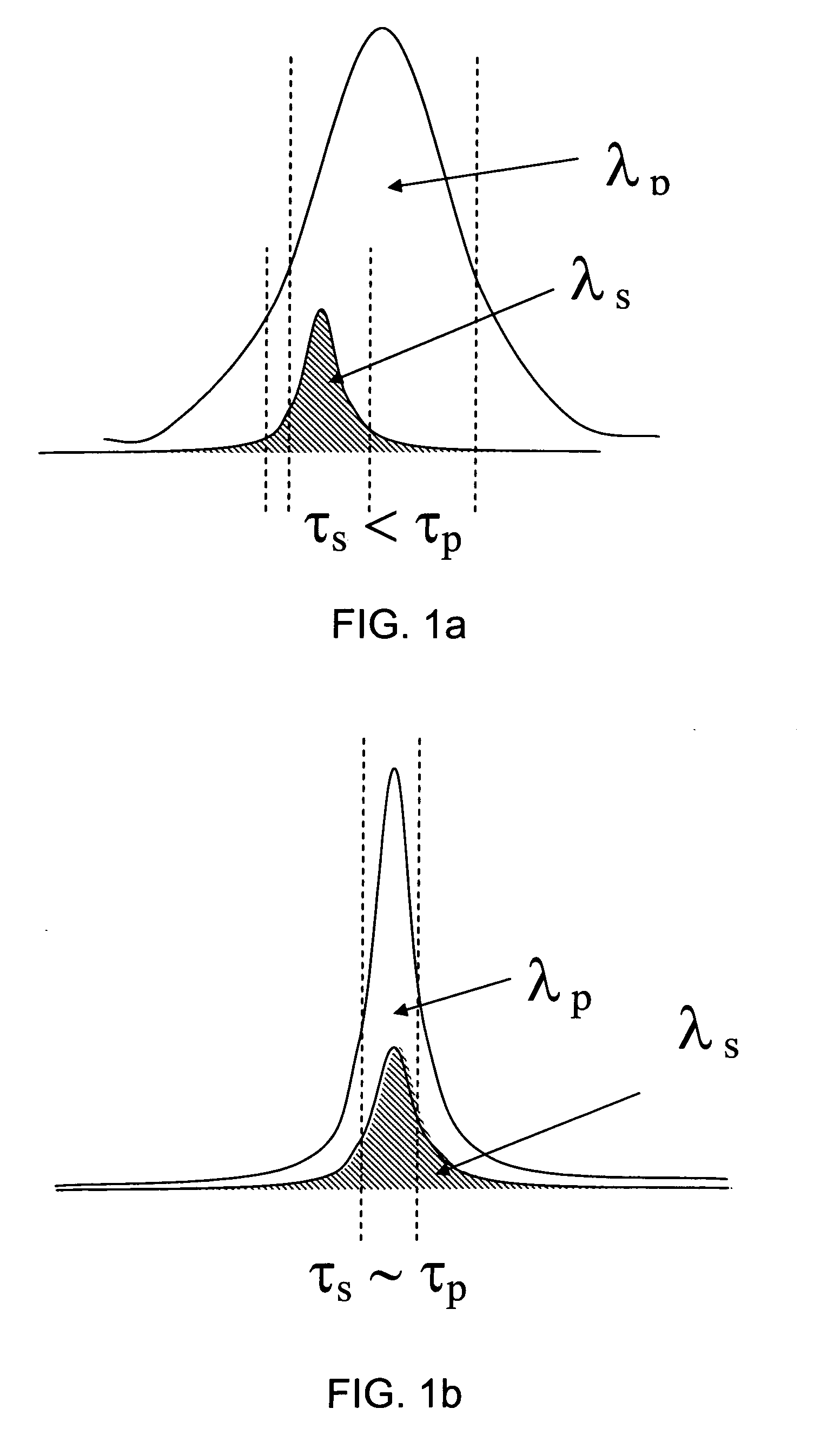

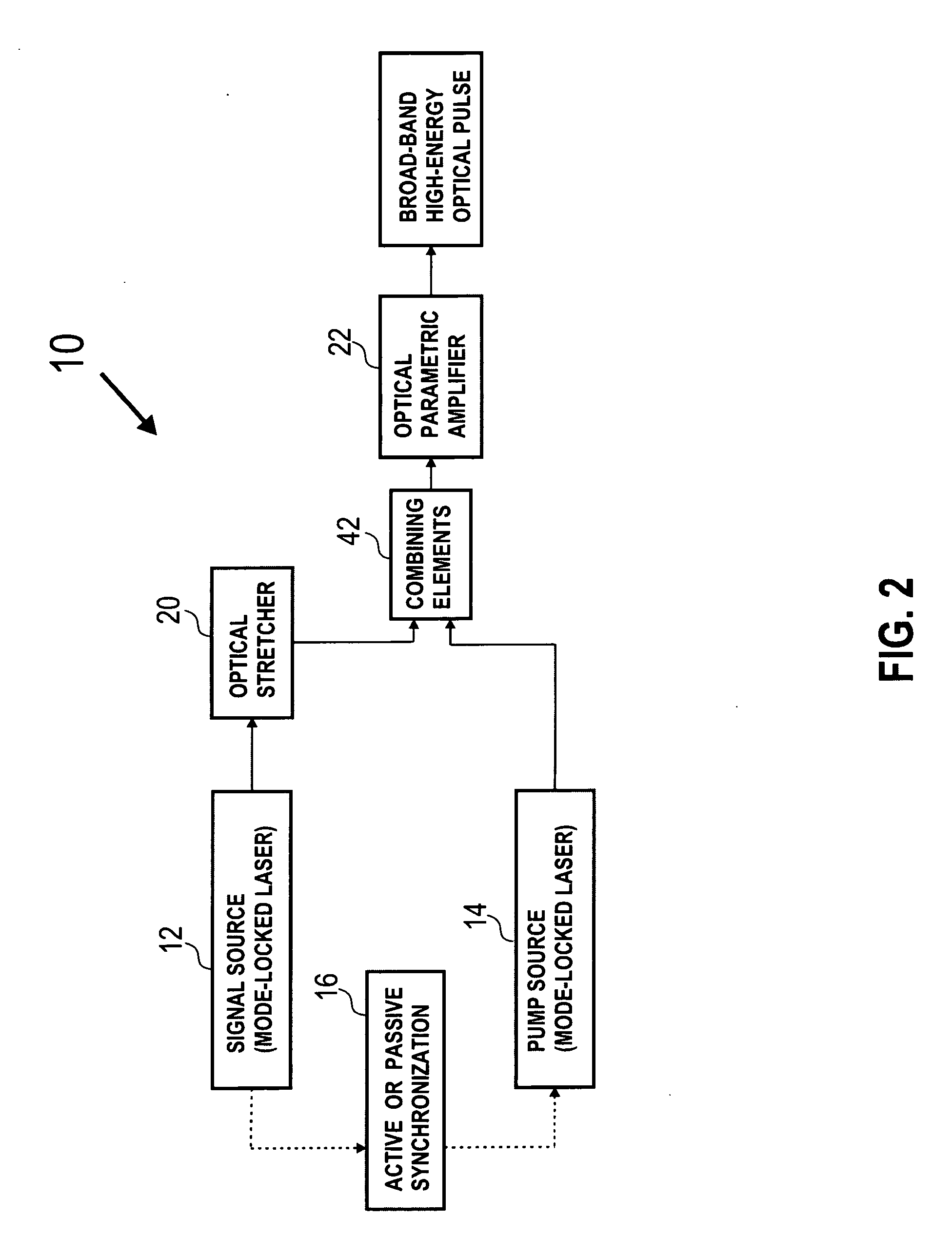

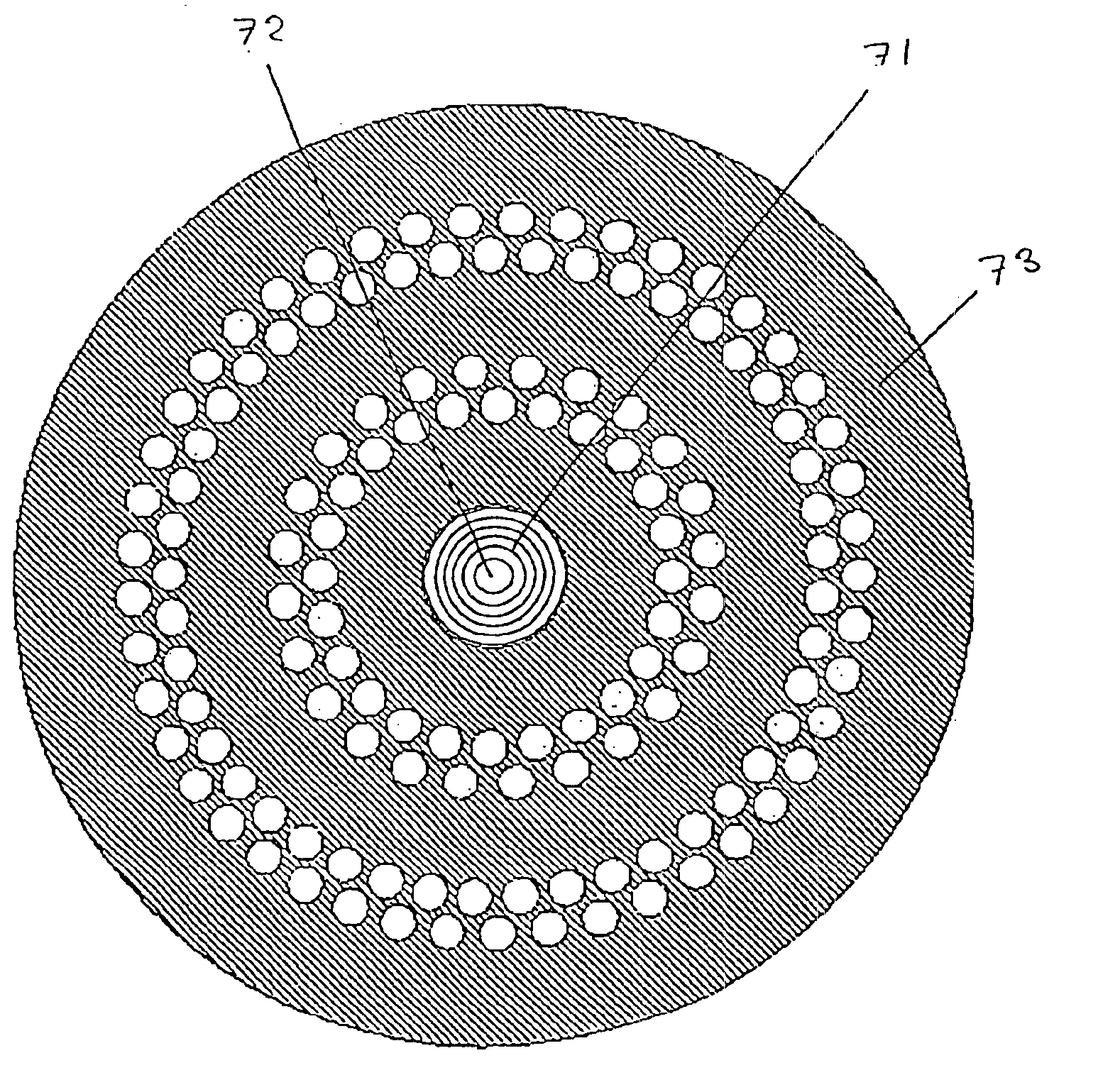

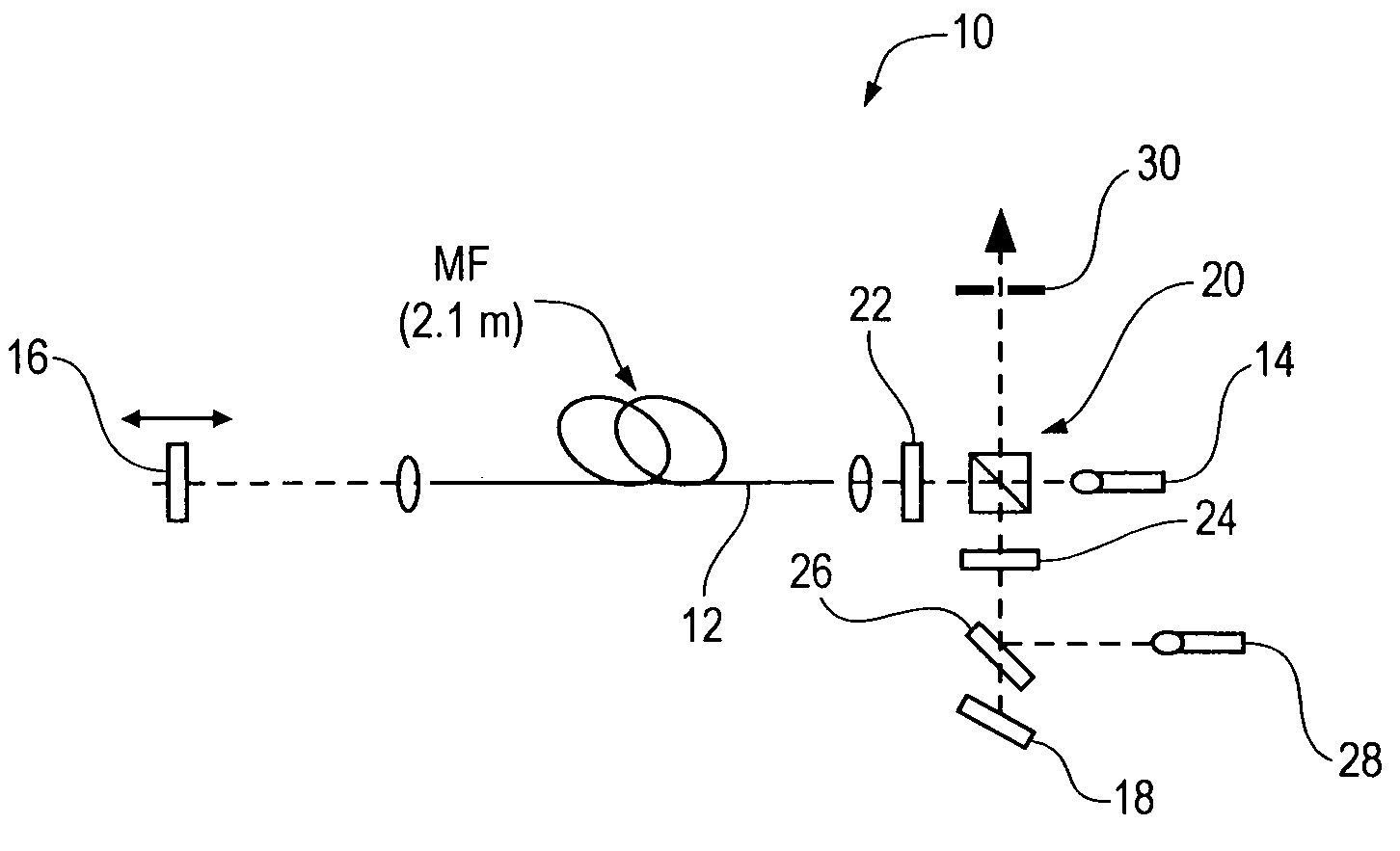

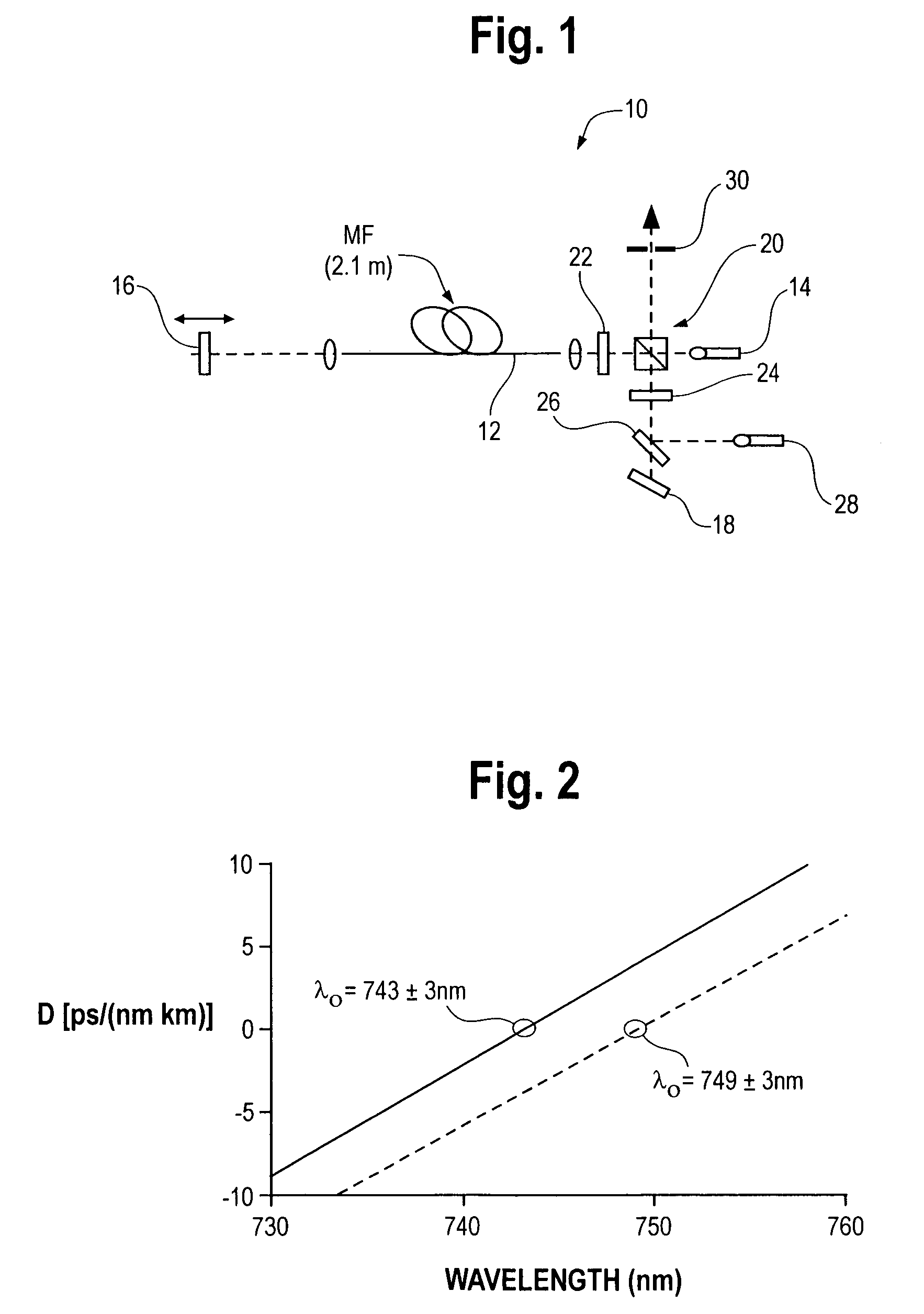

A novel method for high power optical amplification of ultrashort pulses in IR wavelength range (0.7-20 Ãm) is disclosed. The method is based on the optical parametric chirp pulse amplification (OPCPA) technique where a picosecond or nanosecond mode locked laser system synchronized to a signal laser oscillator is used as a pump source or alternatively the pump pulse is created from the signal pulse by using certain types of optical nonlinear processes described later in the document. This significantly increases stability, extraction efficiency and bandwidth of the amplified signal pulse. Further, we disclose five new practical methods of shaping the temporal and spatial profiles of the signal and pump pulses in the OPCPA interaction which significantly increases its efficiency. In the first, passive preshaping of the pump pulses has been made by a three wave mixing process separate from the one occurring in the OPCPA. In the second, passive pre-shaping of the pump pulses has been made by spectral filtering in the pump mode-locked laser or in its amplifier. In the third, the temporal shape of the signal pulse optimized for OPCPA interaction has been actively processed by using an acousto-optic programmable dispersive filter (Dazzler) or liquid crystal light modulators. In the fourth alternative method, the signal pulse intensity envelope is optimized by using passive spectral filtering. Finally, we disclose a method of using pump pulses which interact with the seed pulses with different time delays and different angular orientations allowing the amplification bandwidth to be increased. In addition we describe a new technique for high power IR optical beam delivery systems based on the microstructure fibres made of silica, fluoride or chalcogenide glasses as well as ceramics. Also we disclose a new optical system for achieving phase matching geometries in the optical parametric interactions based on diffractive optics. All novel methods of the ultrashort optical pulse amplification described in this disclosure can be easily generalized to other wavelength ranges.

Owner:MILLER ROBERT JOHN DWAYNE +3

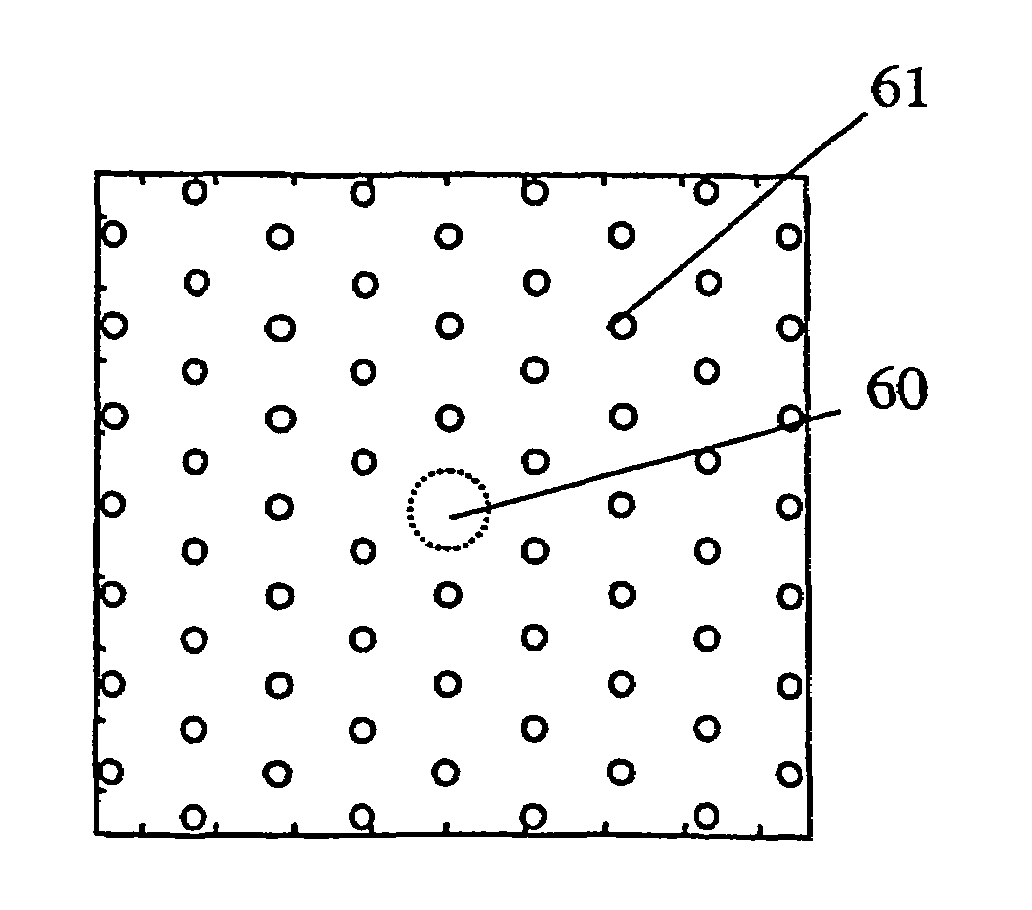

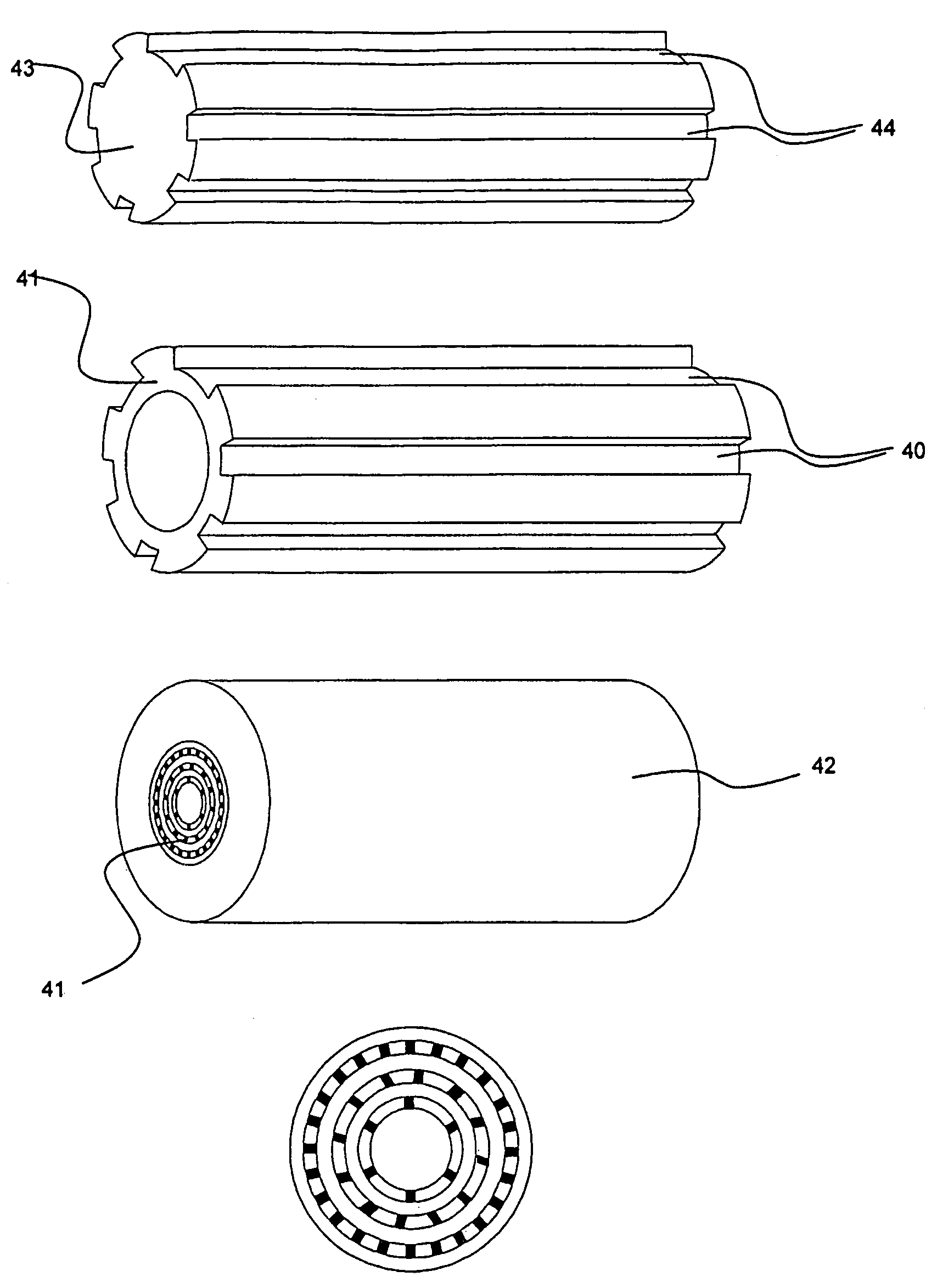

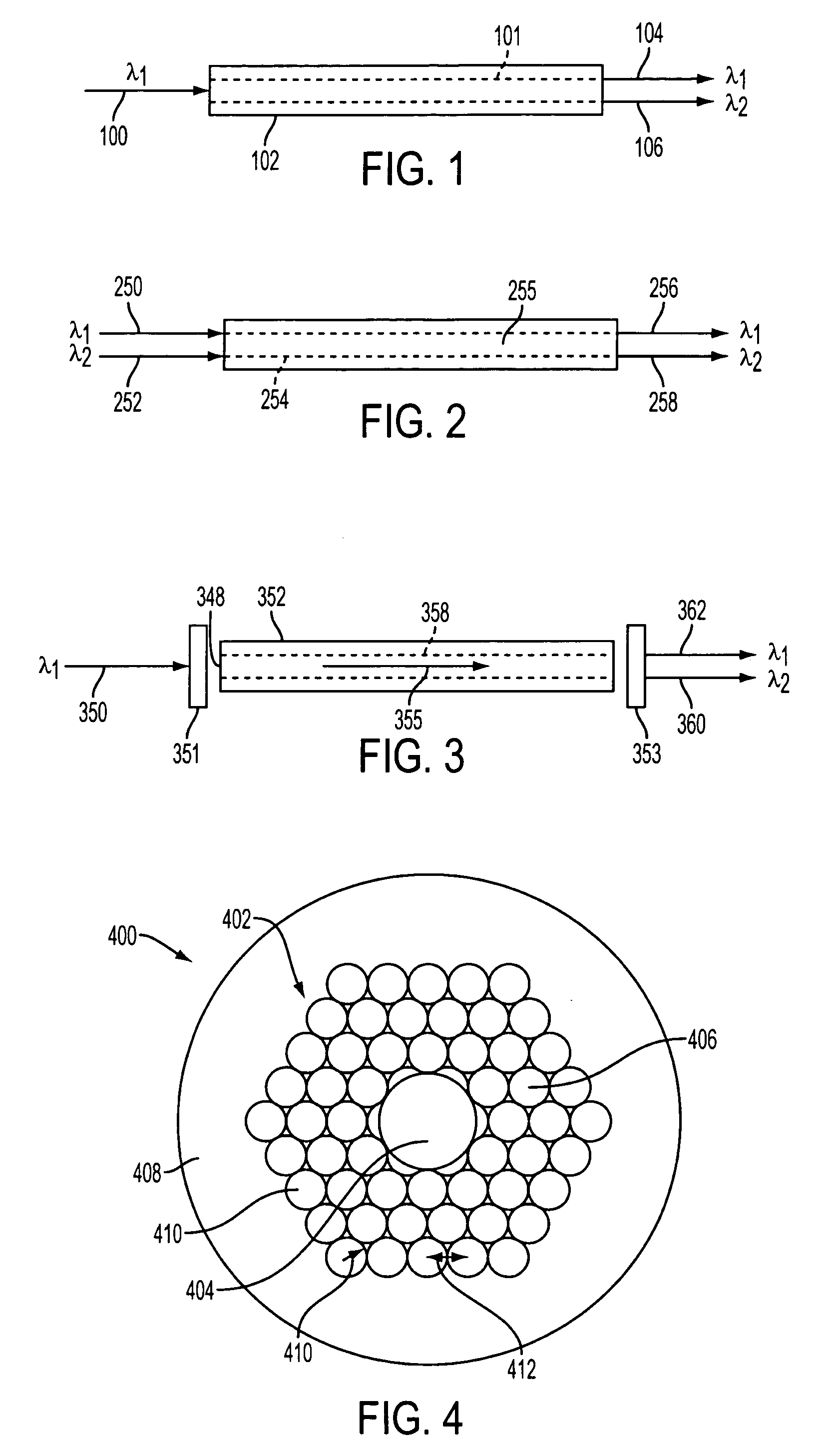

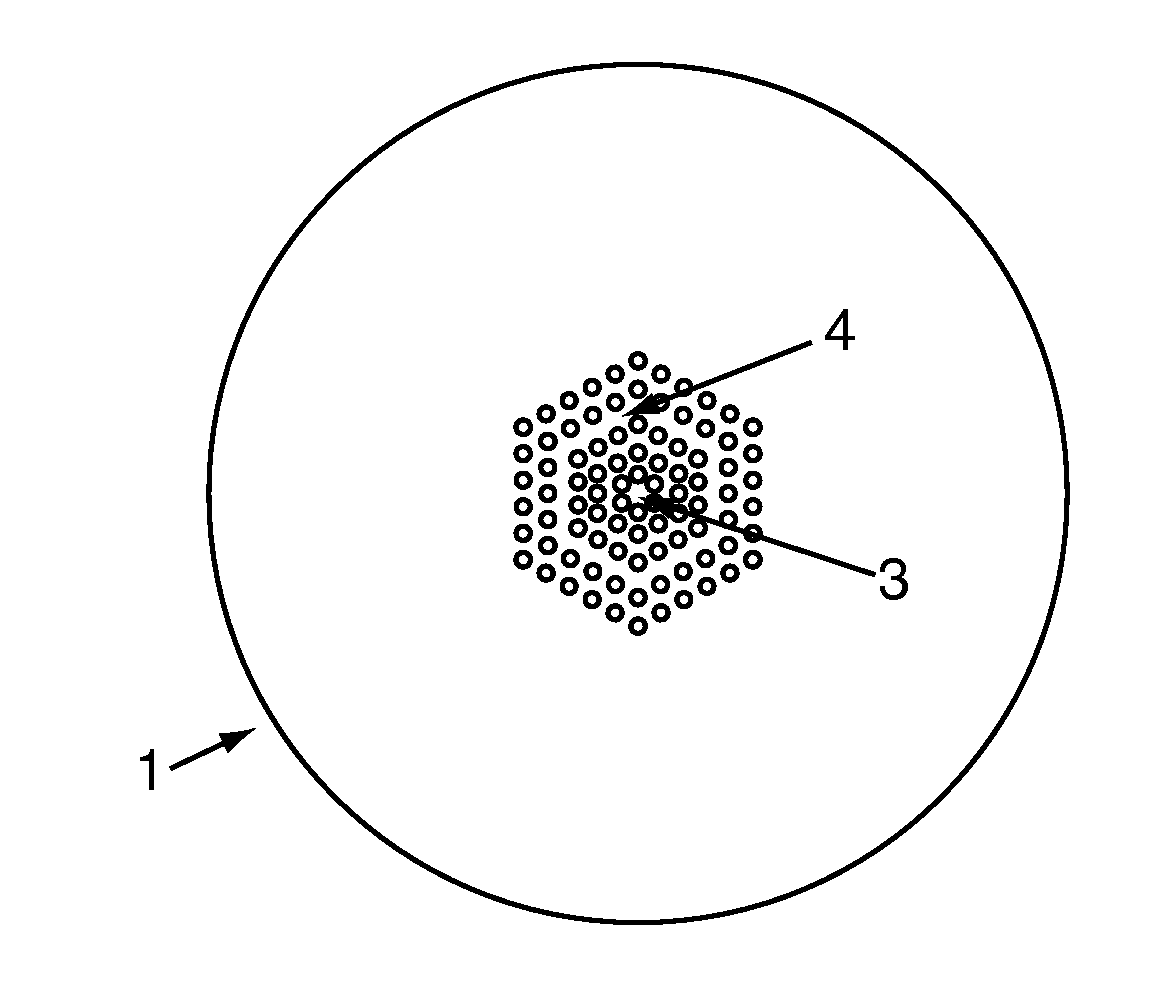

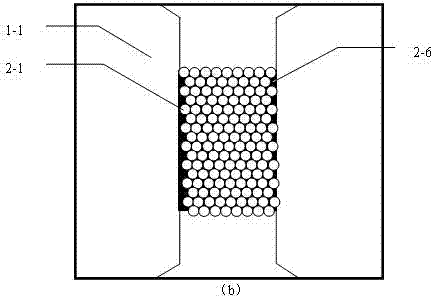

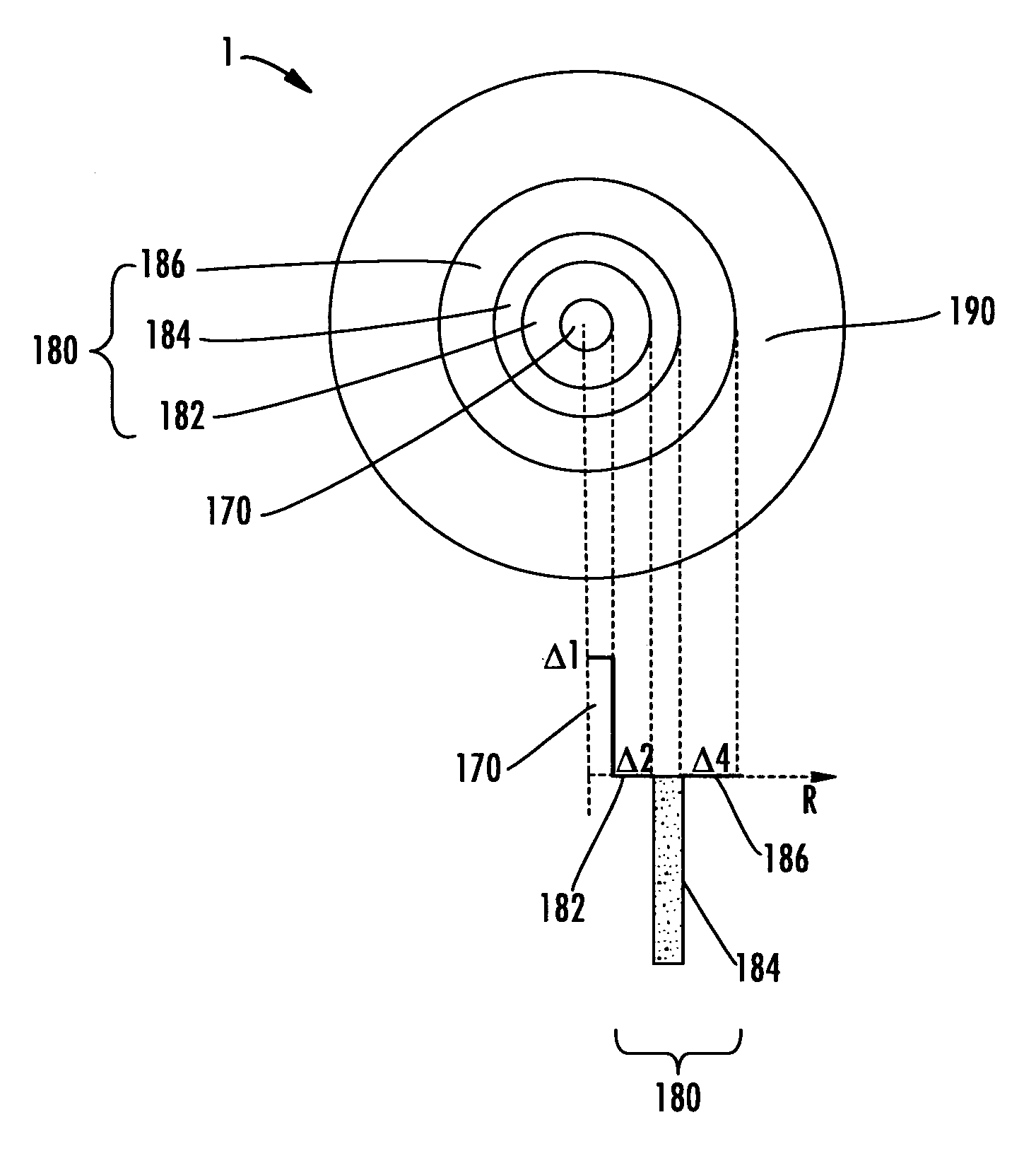

Micro-structured optical fiber

InactiveUS6892018B2Reduce coupling lossGood dispersionOptical fibre with multilayer core/claddingGlass fibre drawing apparatusPhotonic bandgapLight guide

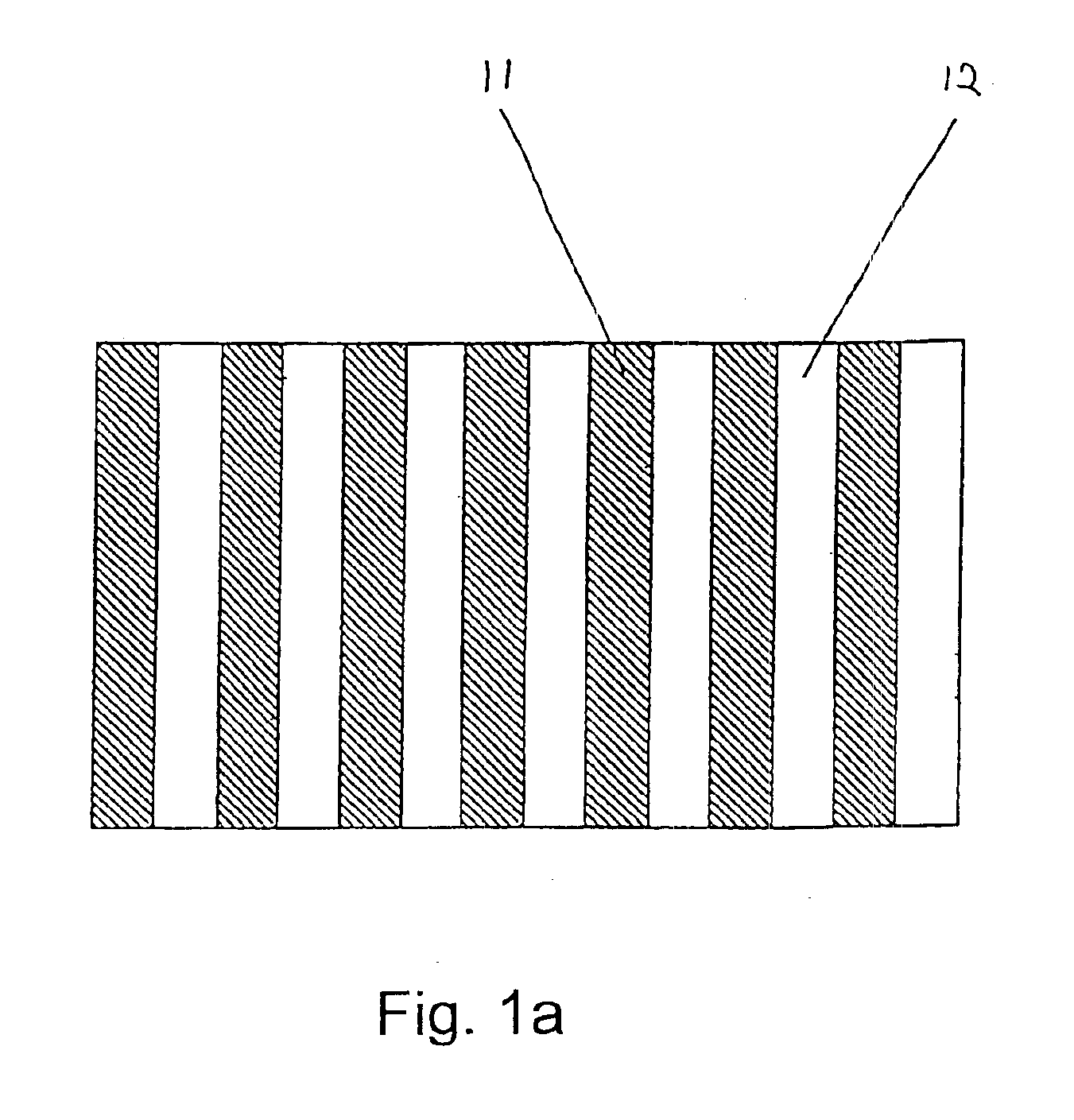

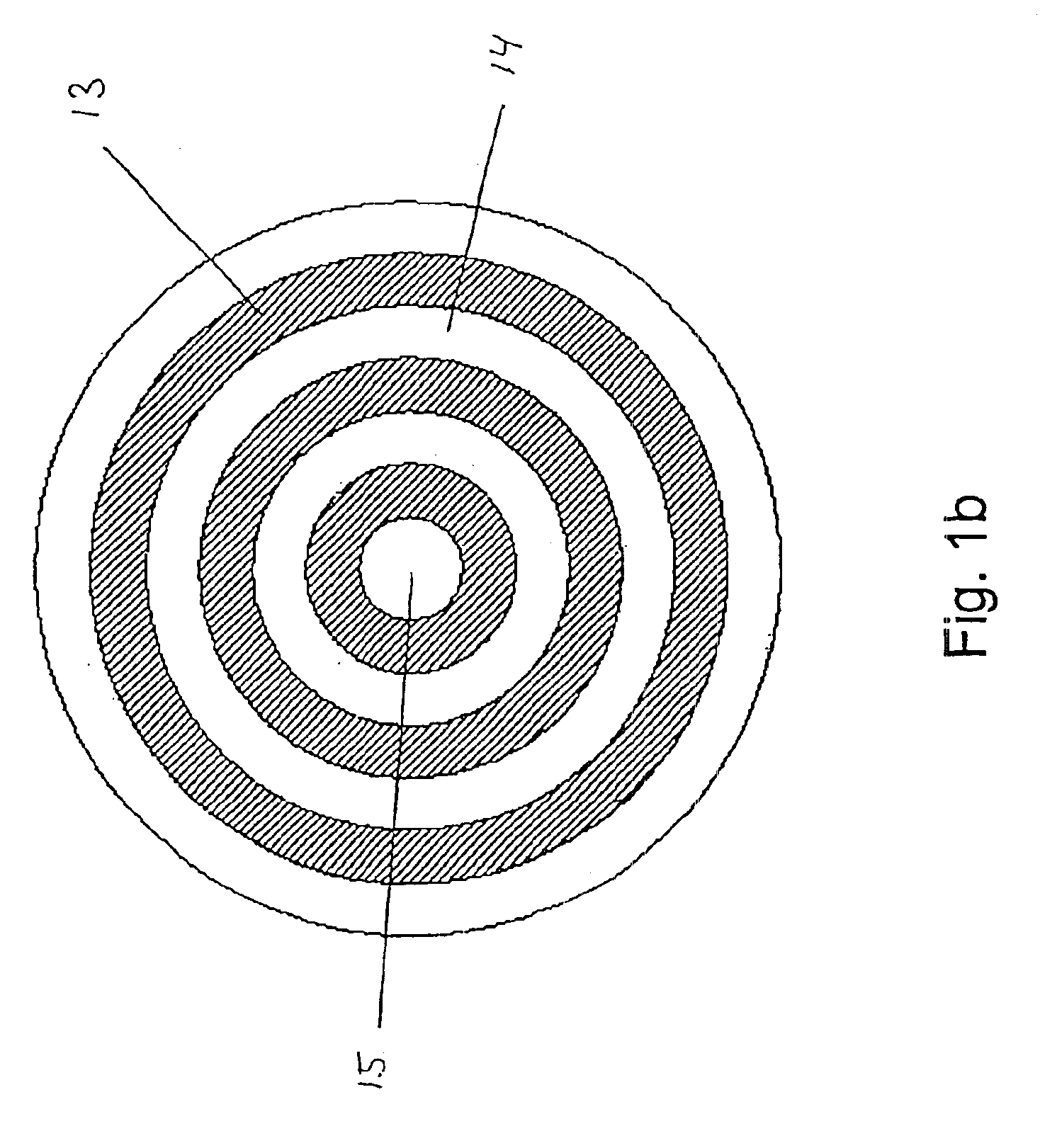

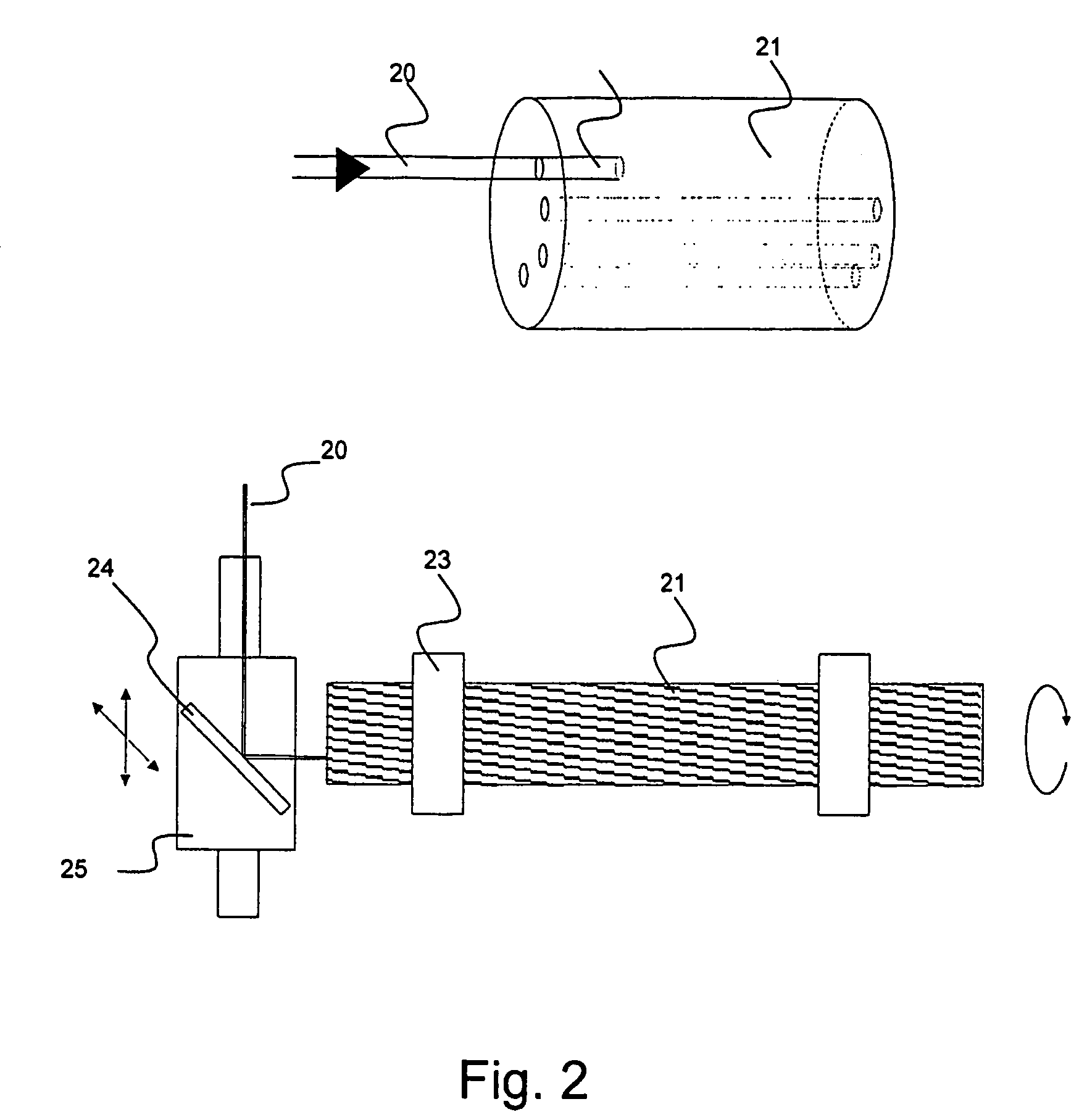

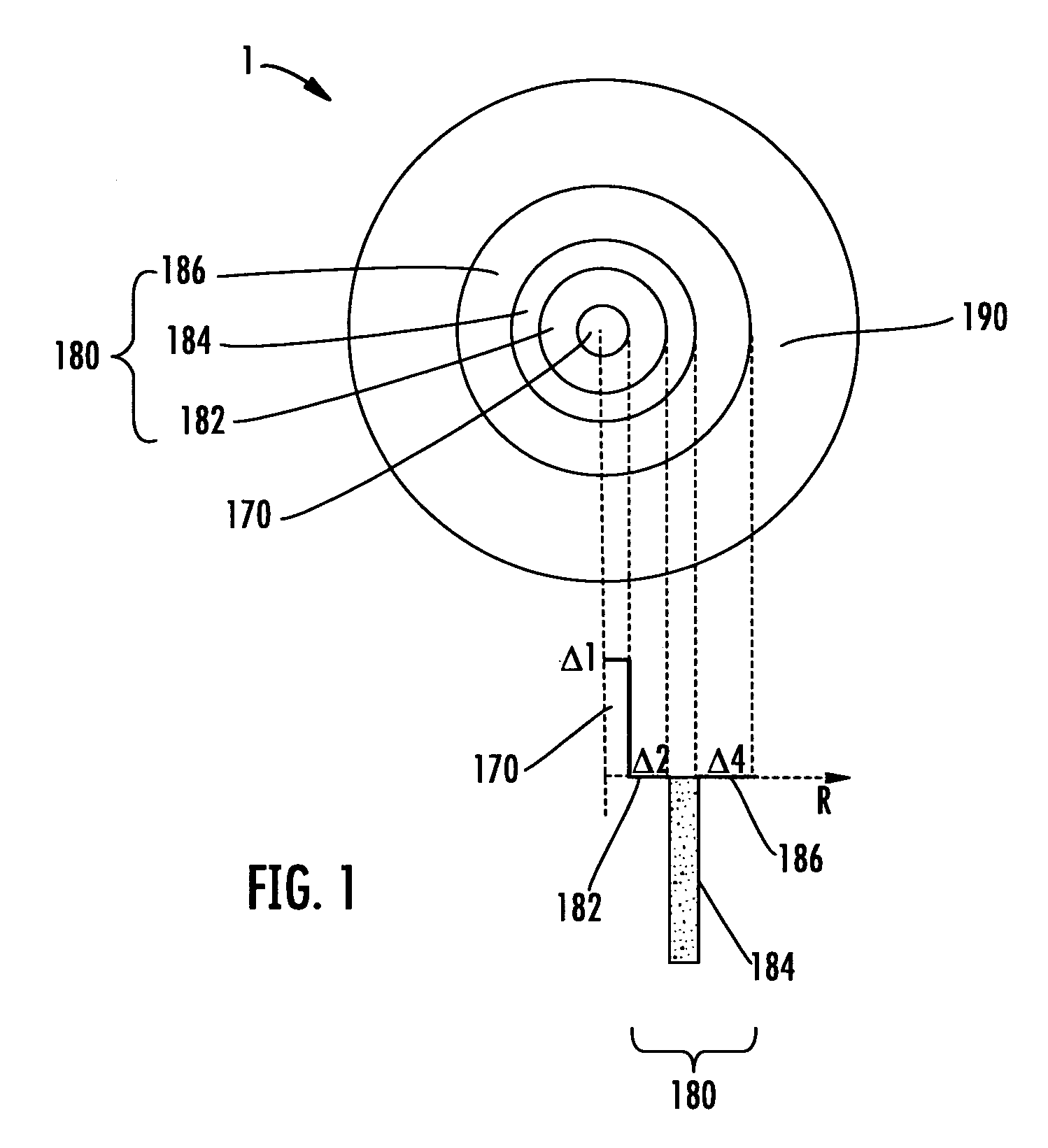

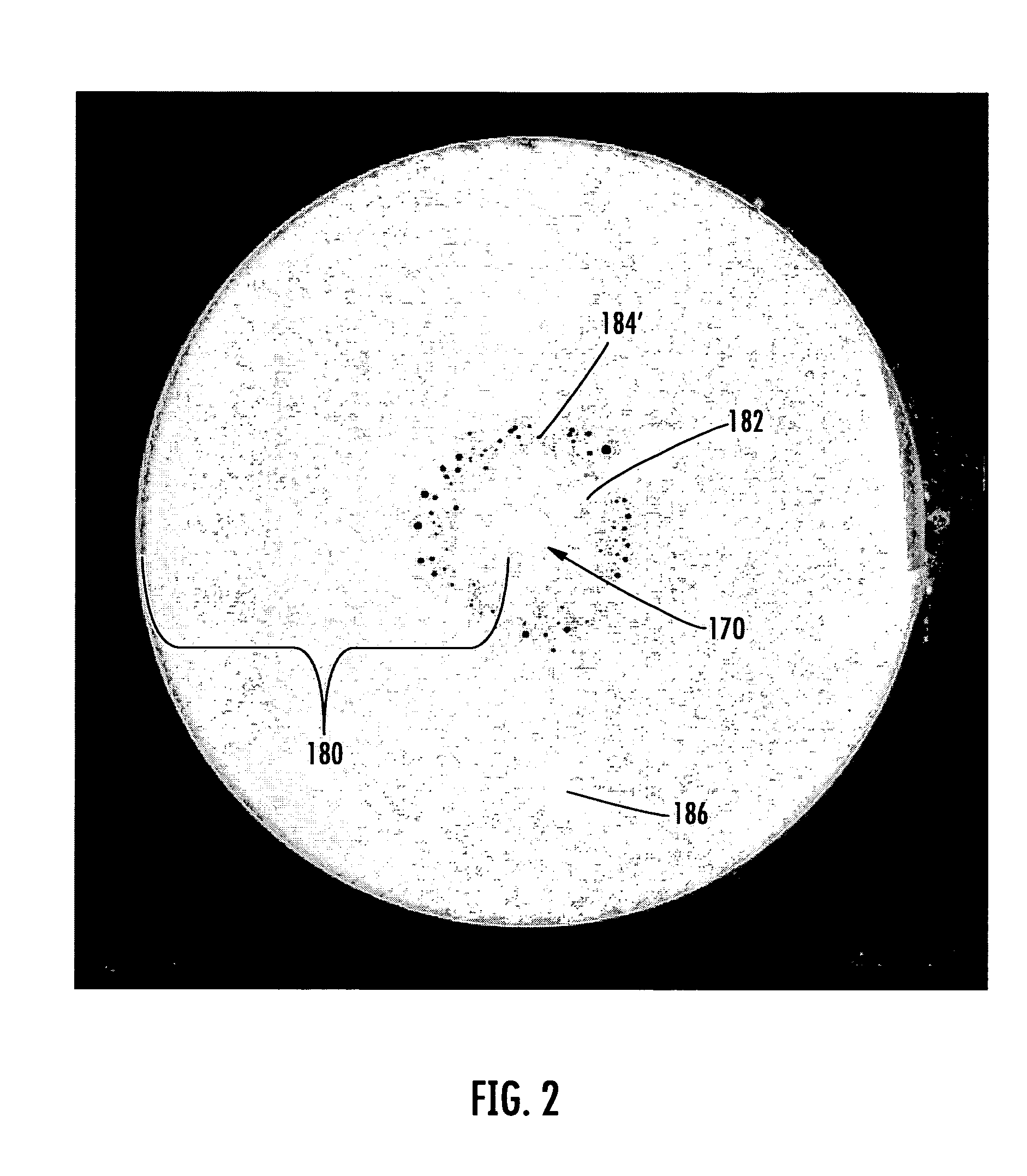

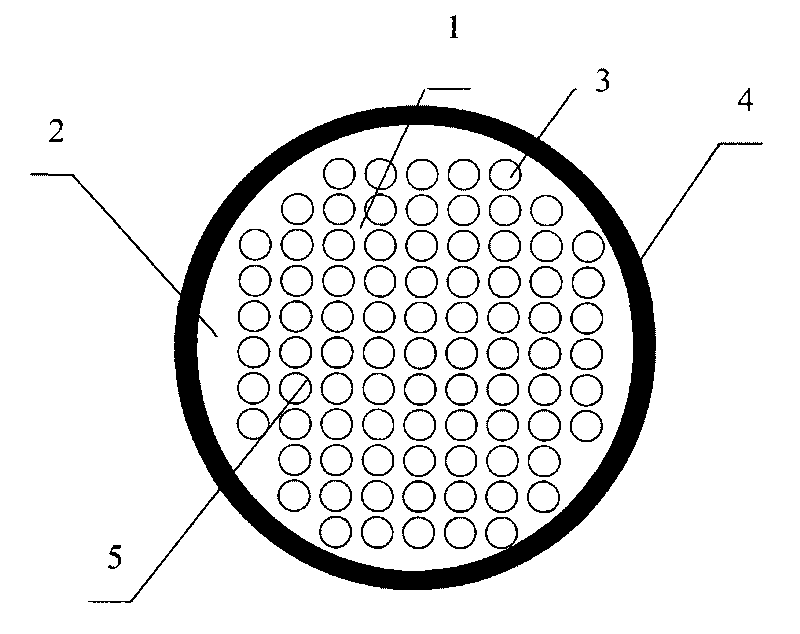

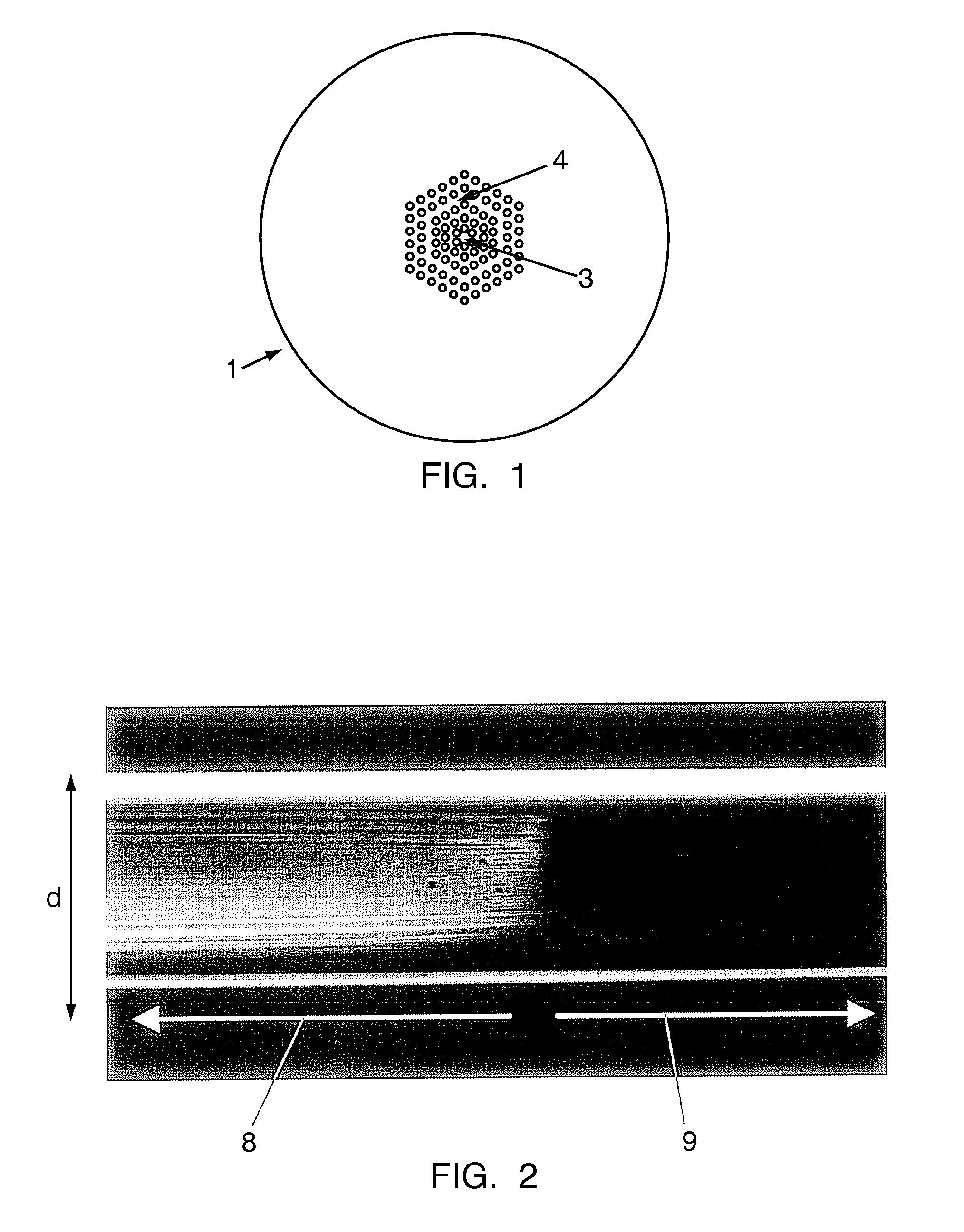

A microstructured fiber having a cladding comprising a number of elongated features that are arranged to provide concentric circular or polygonial regions surrounding the fiber core. The cladding comprises a plurality of concentric cladding regions, at least some of which comprising cladding features. Cladding regions comprising cladding features of a relatively low index type are arranged alternatingly with cladding regions of a relatively high index type. The cladding features are arranged in a non-periodic manner when viewed in a cross section of the fiber. The cladding enables waveguidance by photonic bandgap effects in the fiber core. An optical fiber of this type may be used for light guidance in hollow core fibers for high power transmission. The special cladding structure may also provide strong positive or negative dispersion of light guided through the fiber-making the fiber useful for telecommunication applications.

Owner:CRYSTAL FIBRE AS

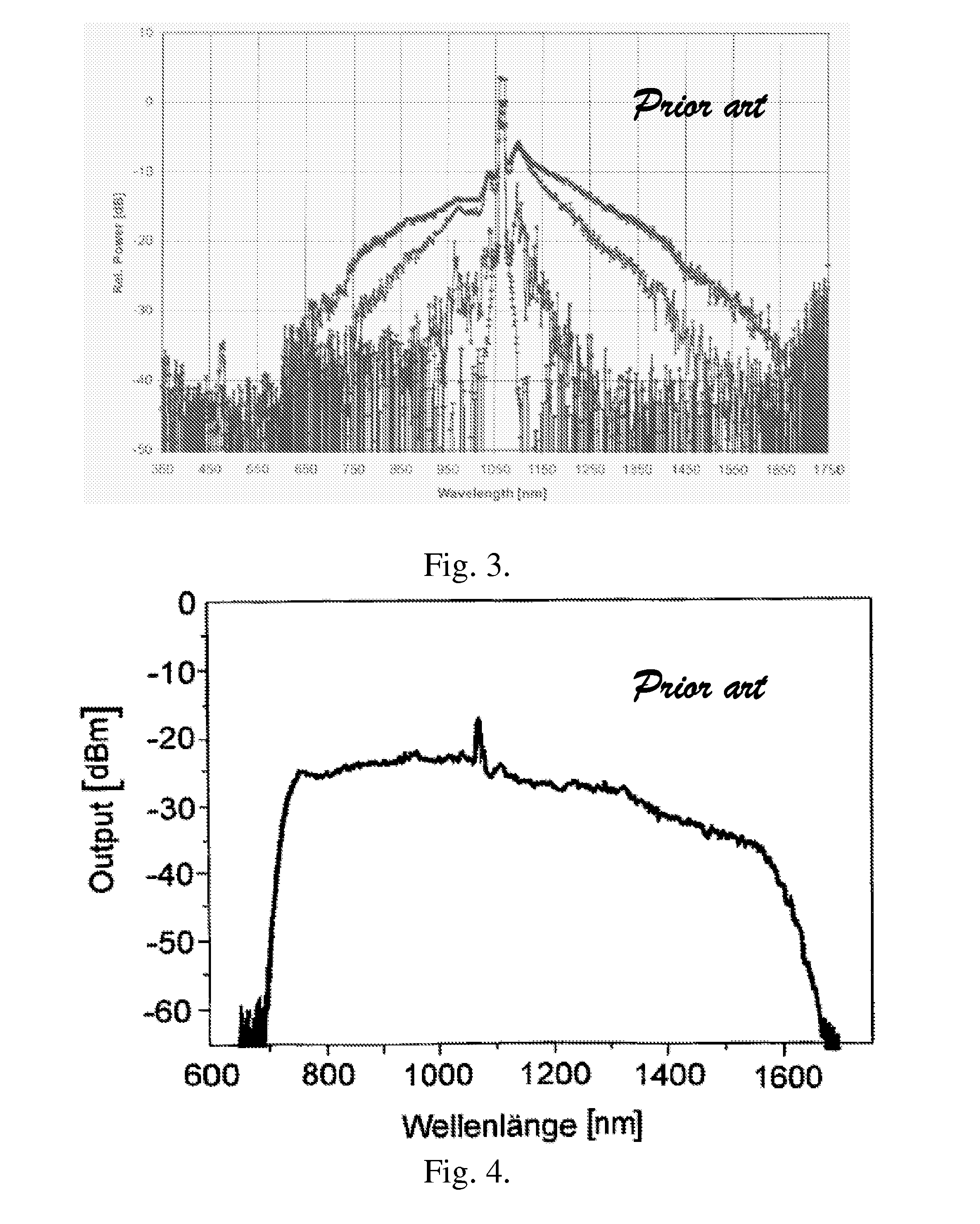

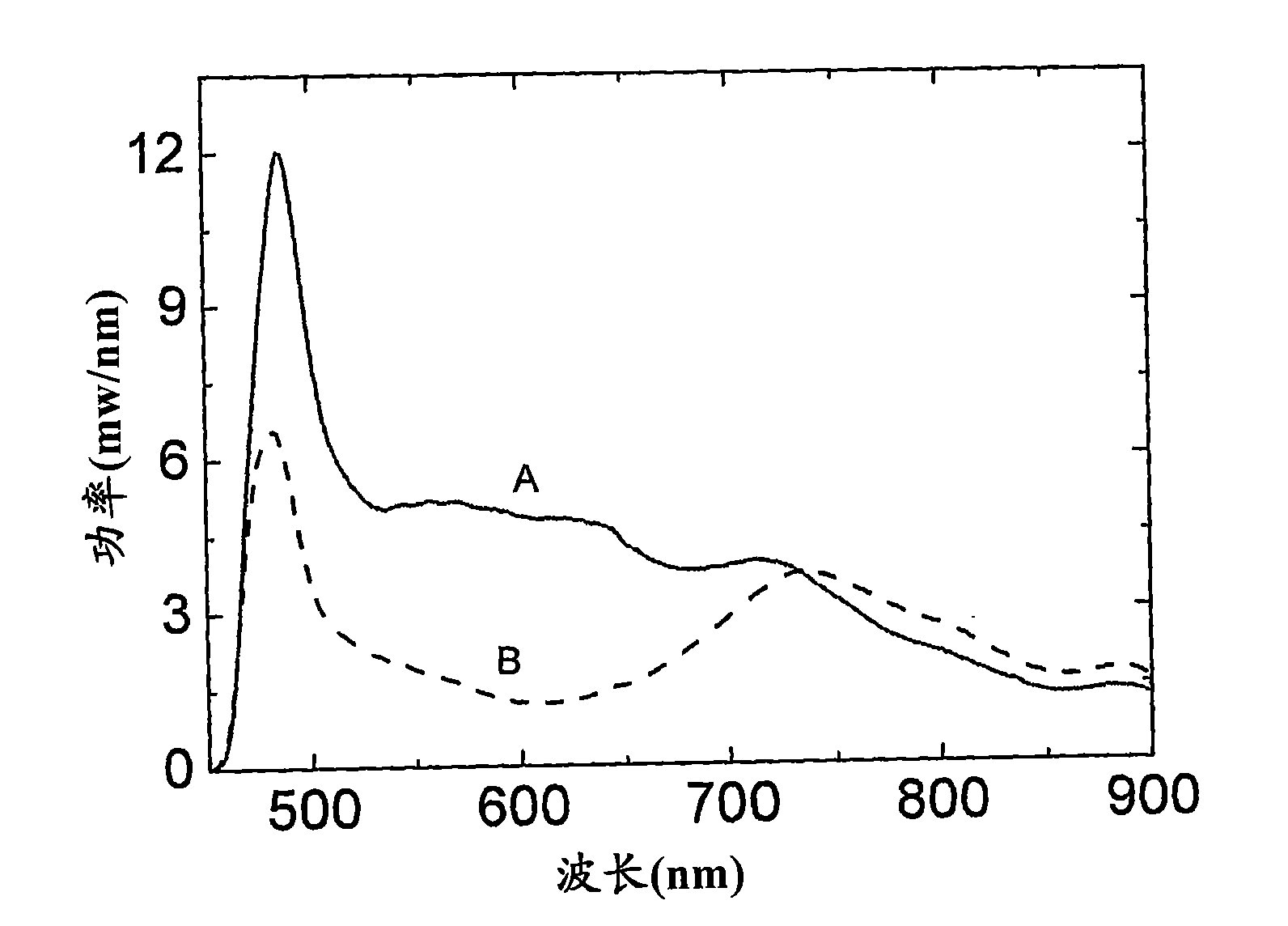

Blue extended super continuum light source

InactiveUS7800818B2Increase powerLaser using scattering effectsSemiconductor/solid-state device manufacturingInstabilityRefractive index

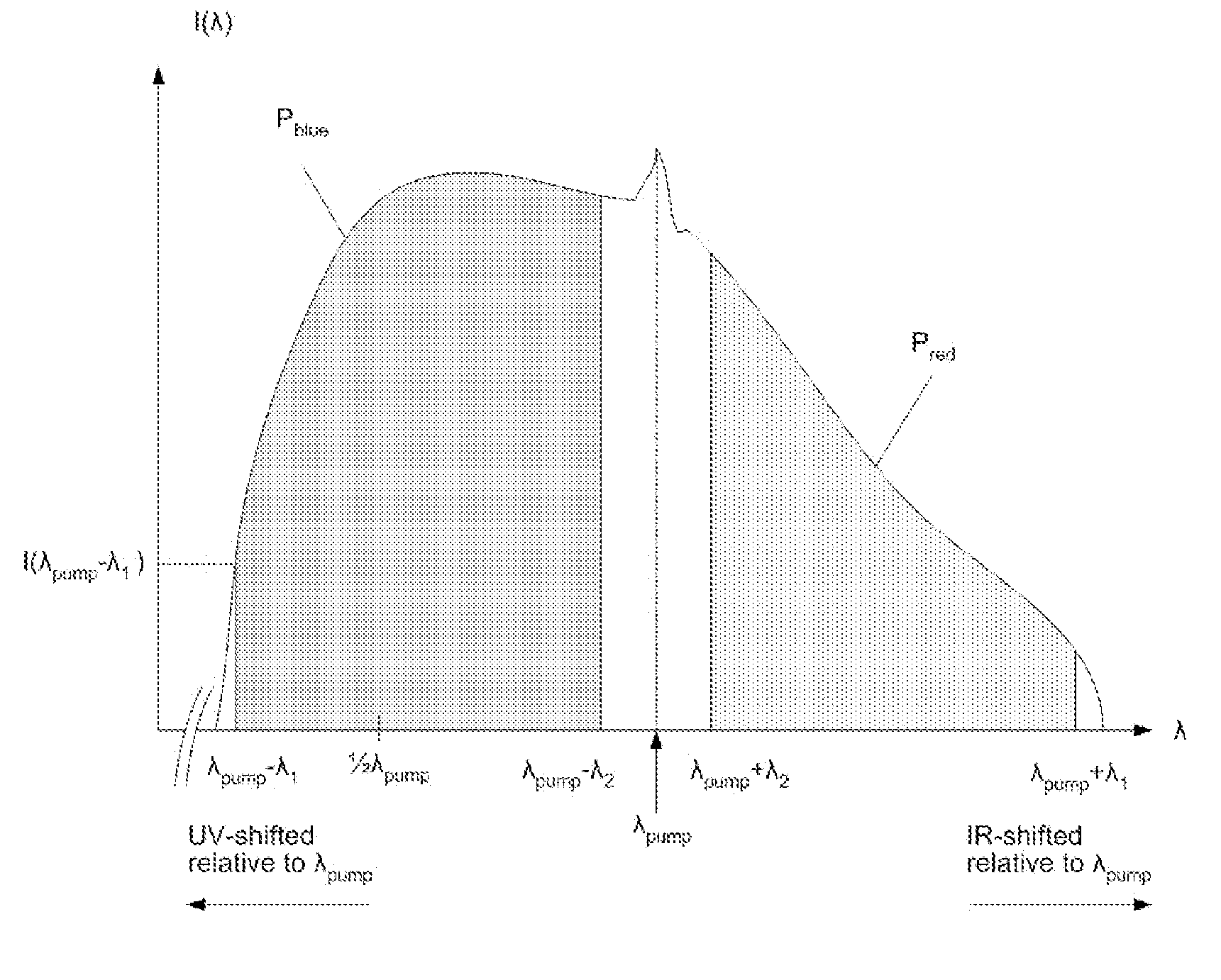

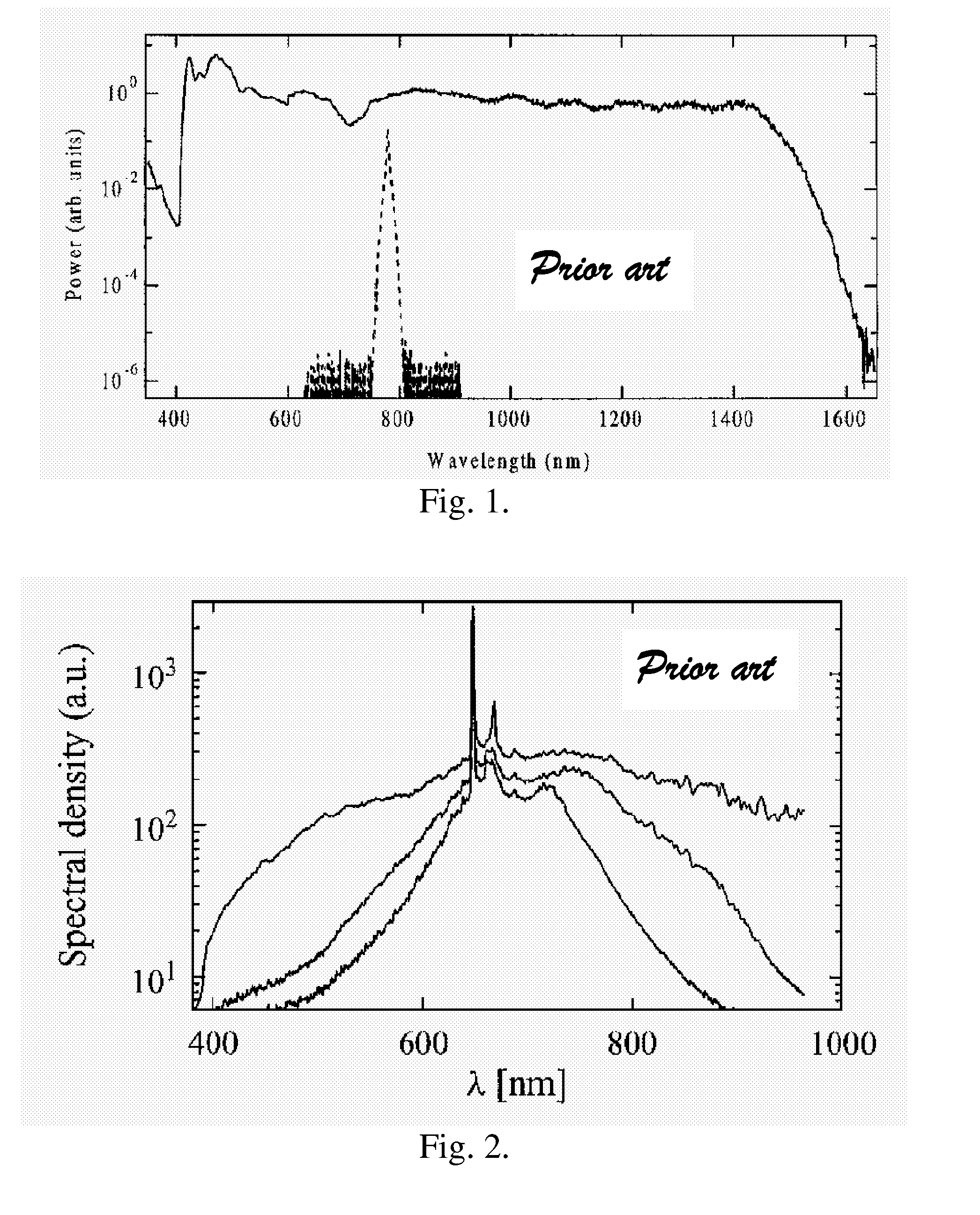

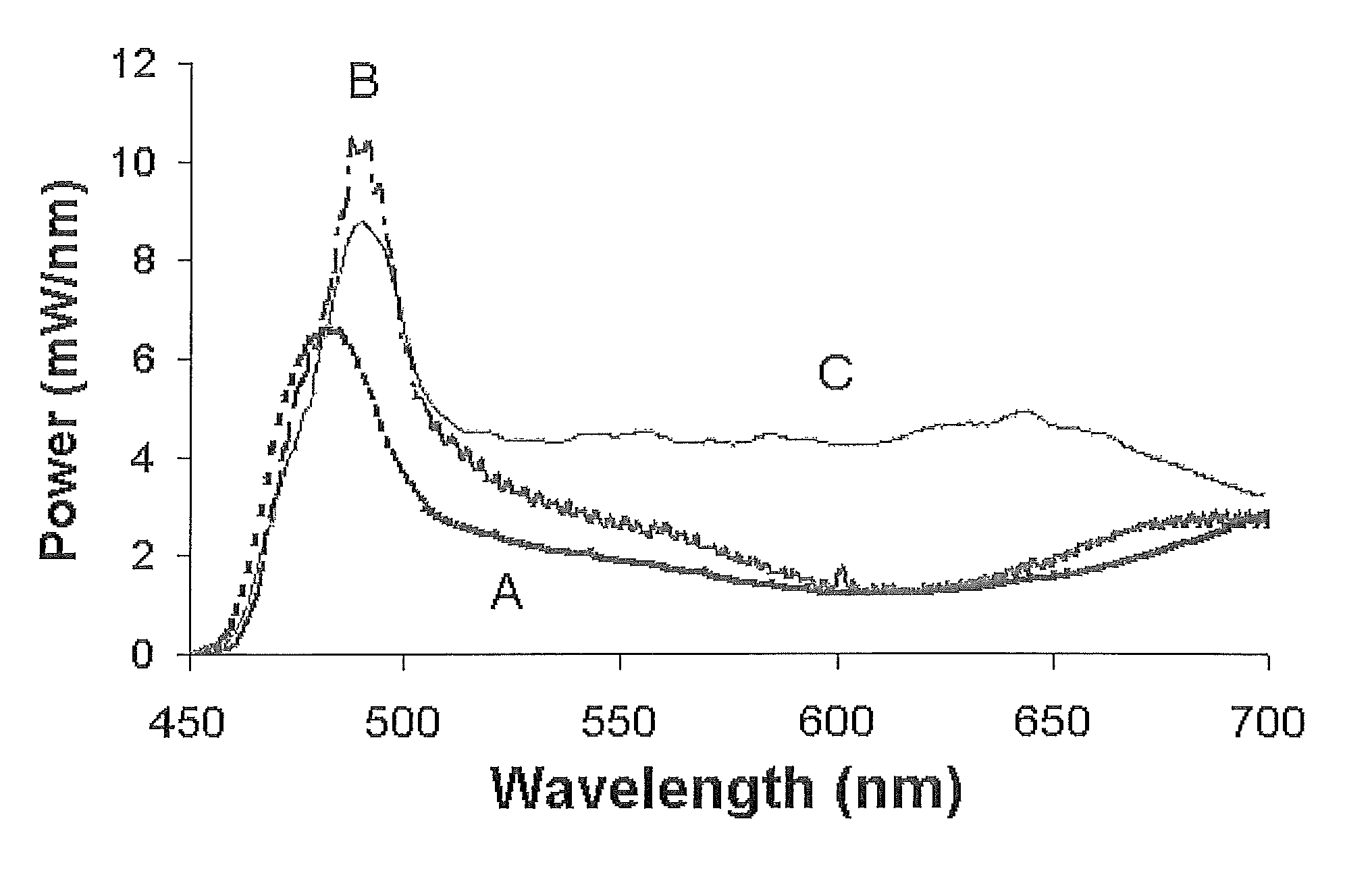

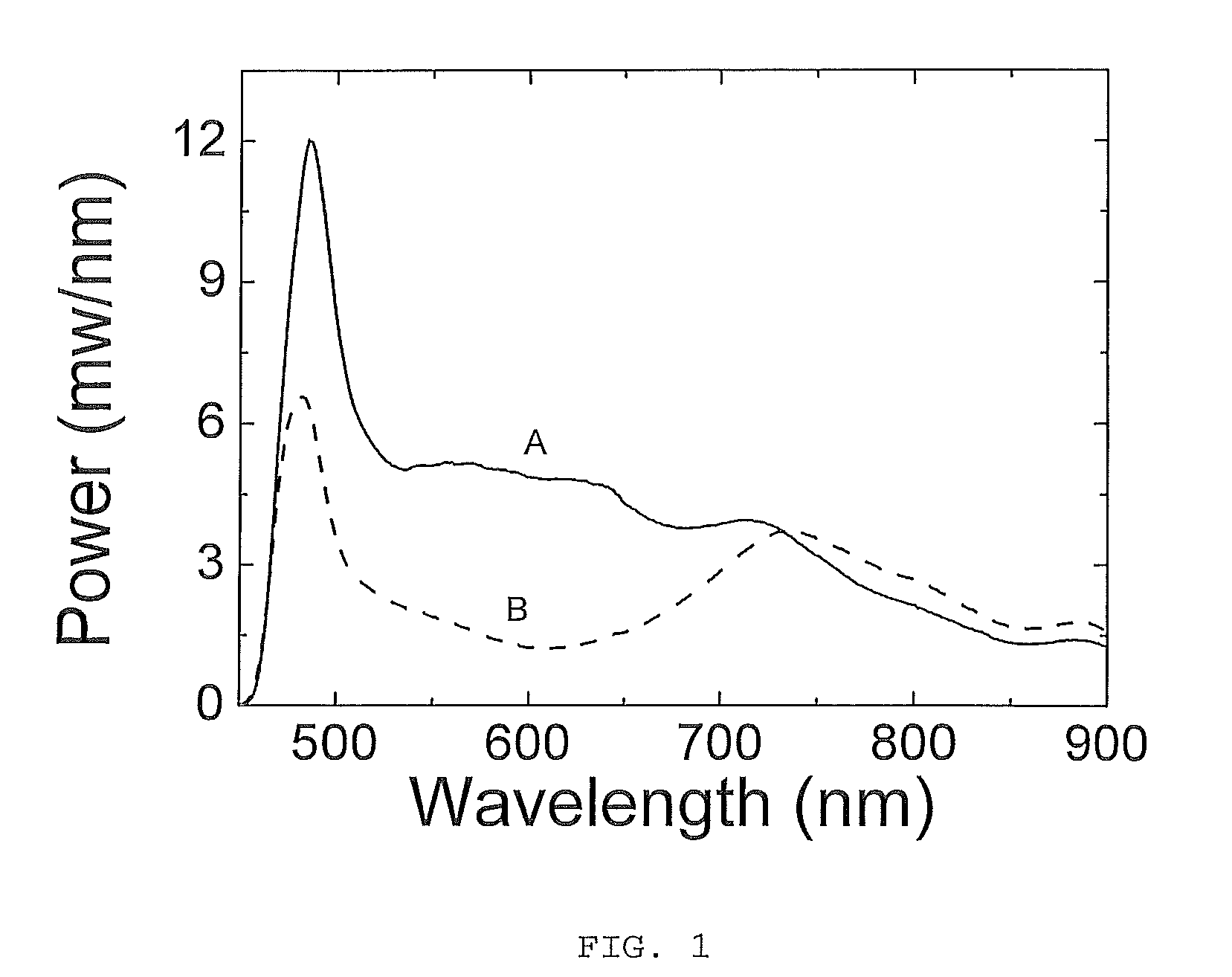

In a blue extended super continuum light source, when pulses of partly coherent monochromatic “pump” radiation of essentially constant amplitude are propagating through a microstructure fiber medium within a region of anomalous dispersion of the medium, then, provided the medium has a finite nonlinear coefficient of the index of refraction, the pump pulse is subject to a modulation instability. This results in formation of a train of narrow pulses with Tera Hertz repetition rate. Phase match between red shifted Raman solitons generated by the pump pulse and energy shed by the pump pulse at all frequencies with a group velocity below the pump pulse group velocity may lead to the formation of Cherenkov radiation. The solitons may seed Cherenkov radiation at different wavelengths depending on the actual fiber parameters. This allows extension of generated super continuum light beyond the four wave mixing limit when applying picosecond or nanosecond pump pulses.

Owner:NKT PHOTONICS

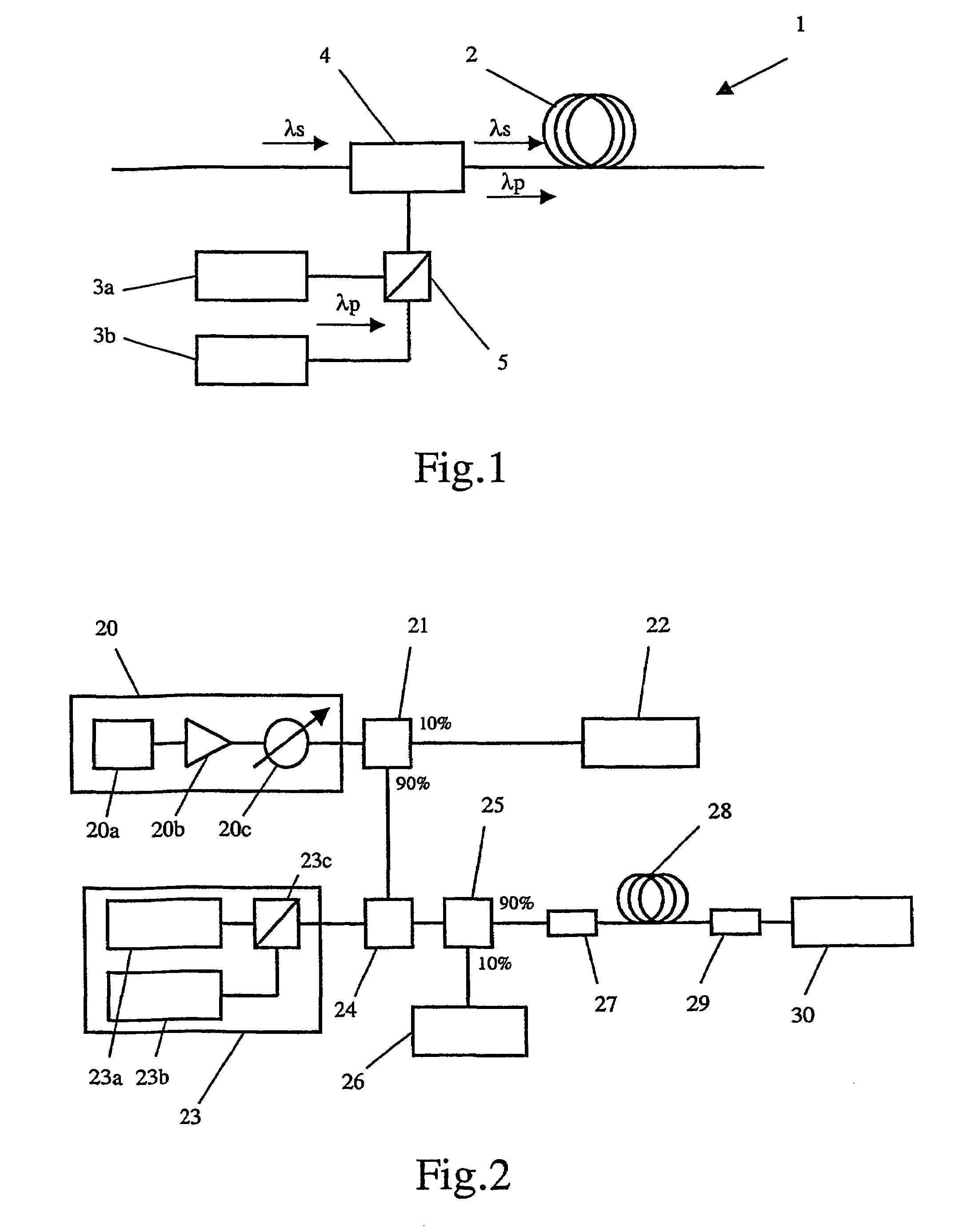

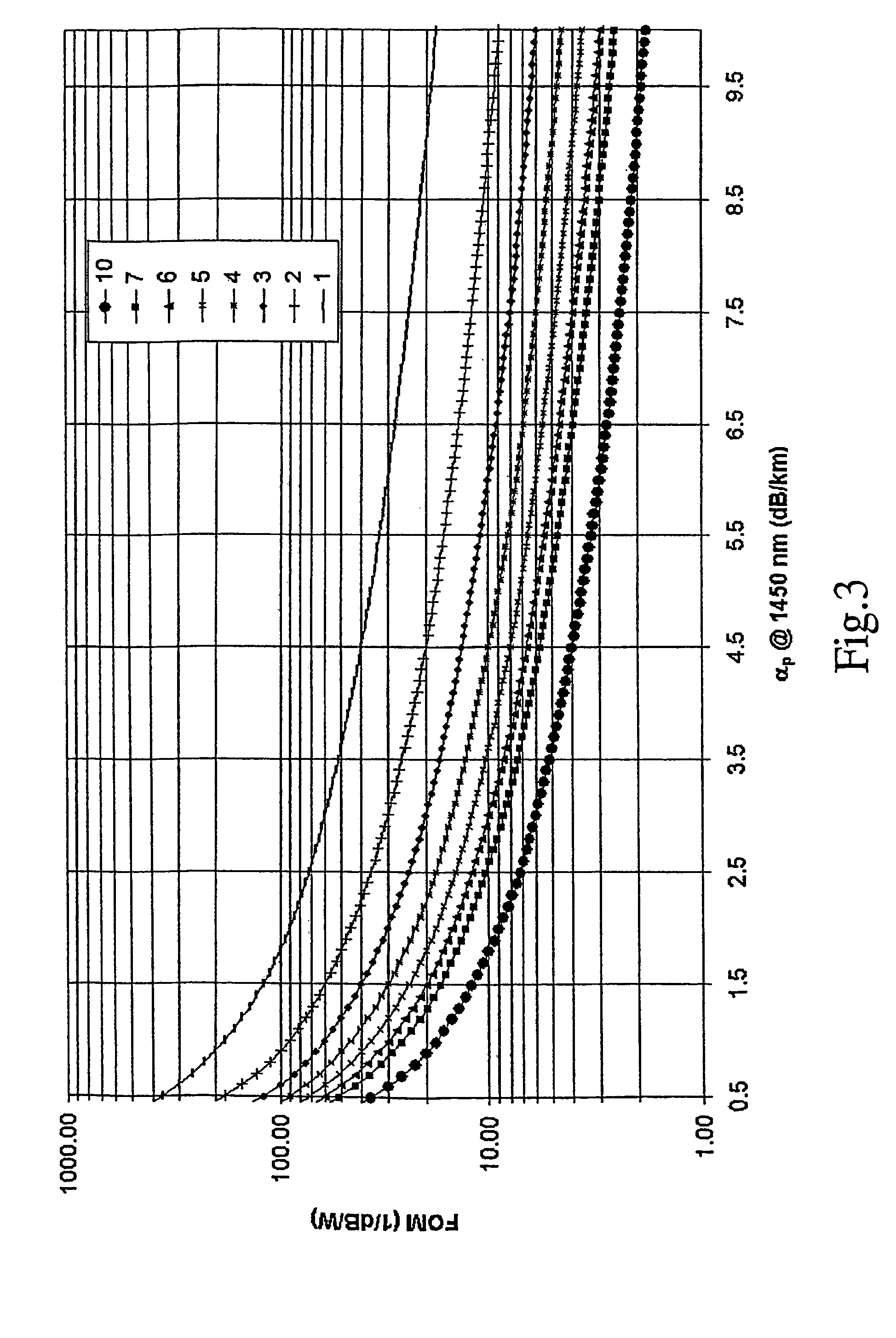

Raman amplification using a microstructured fiber

InactiveUS7116469B2Reduce decreaseEnhanced Raman effectLaser using scattering effectsFibre transmissionDopantMicrostructure fiber

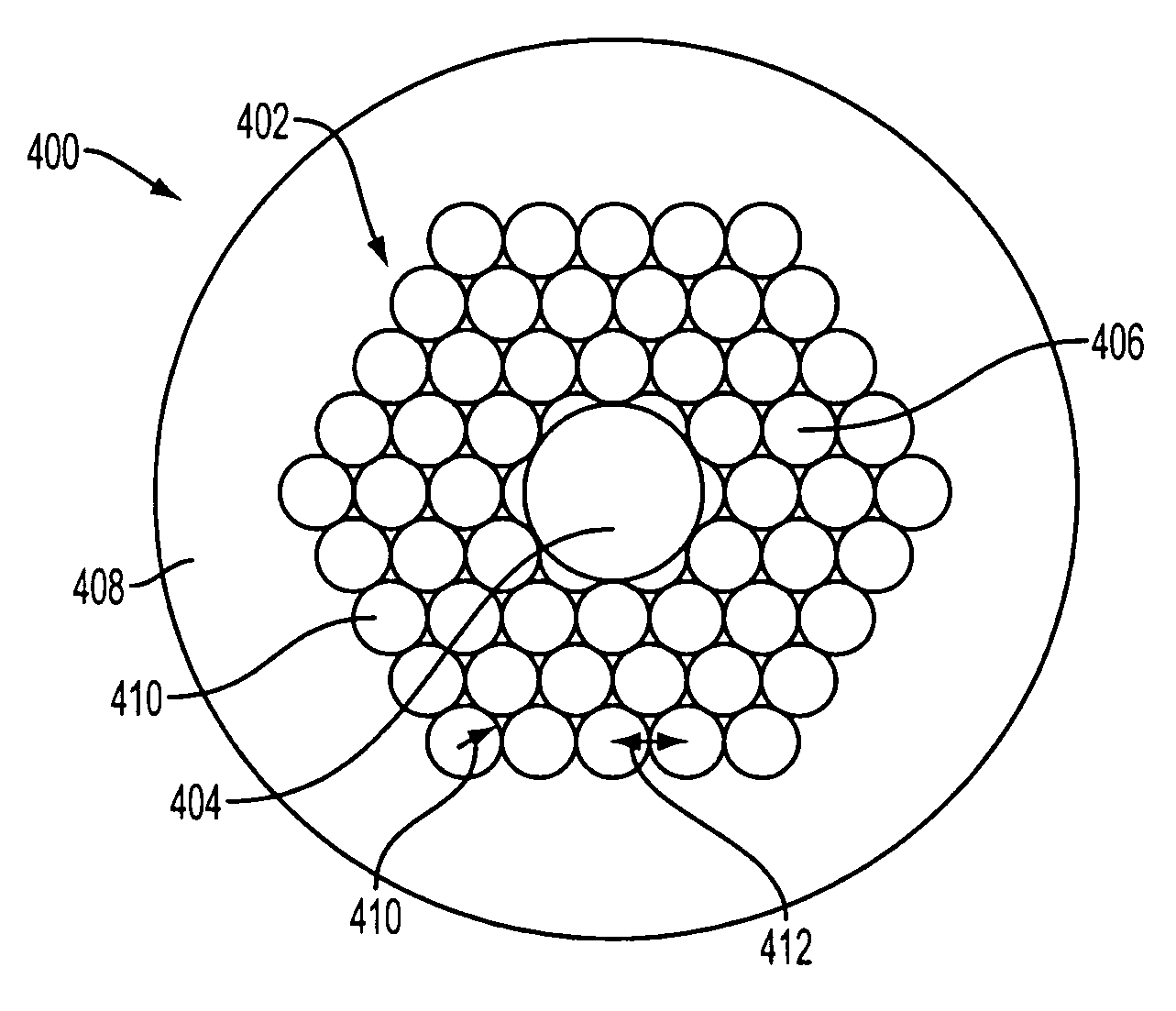

A Raman amplifier having a microstructured fiber and at least one pump laser, optically connected to one end of the microstructured fiber. The pump laser is adapted for emitting a pump radiation at a wavelength λp, and the microstructured fiber has a silica-based core surrounded by a plurality of capillary voids extending in the axial direction of the fiber. The core of microstructured fiber has at least one dopant added to silica, the dopant being suitable for enhancing Raman effect.

Owner:GOOGLE LLC

Method of inducing refractive index structures in a micro-structured fiber, a micro-structured fiber and an article

InactiveUS7792408B2Inhibition formationPrevents in-diffusion of waterLaser using scattering effectsOptical fibre with graded refractive index core/claddingGratingRefractive index

Refractive index modifications such as e.g. Fiber Bragg gratings in micro-structured Fiber are according to an aspect of the invention fabricated by first filling and / or purging the holes of the micro-structured fiber with inert gas or by evacuation and, optionally subsequently scaling the ends. Alternatively, the ends of the micro-structured fiber may be sealed without a preceding purging or evacuation of the holes. In this way hydrogen or deuterium present in the holes after photosensitizing loading will not react with atmospheric oxygen to form water. Water formed this way would otherwise seriously impair the grating formation process. Bragg gratings and other refractive index structures can thus be fabricated with high quality and predictable specifications in micro-structured fiber. Sealing the fiber ends also prevents in-diffusion of moisture. The invention may e.g. find application in connection with fiber optical sensors, high-power fiber lasers, etc.

Owner:NKT PHOTONICS

Fabrication of microstructured fibres

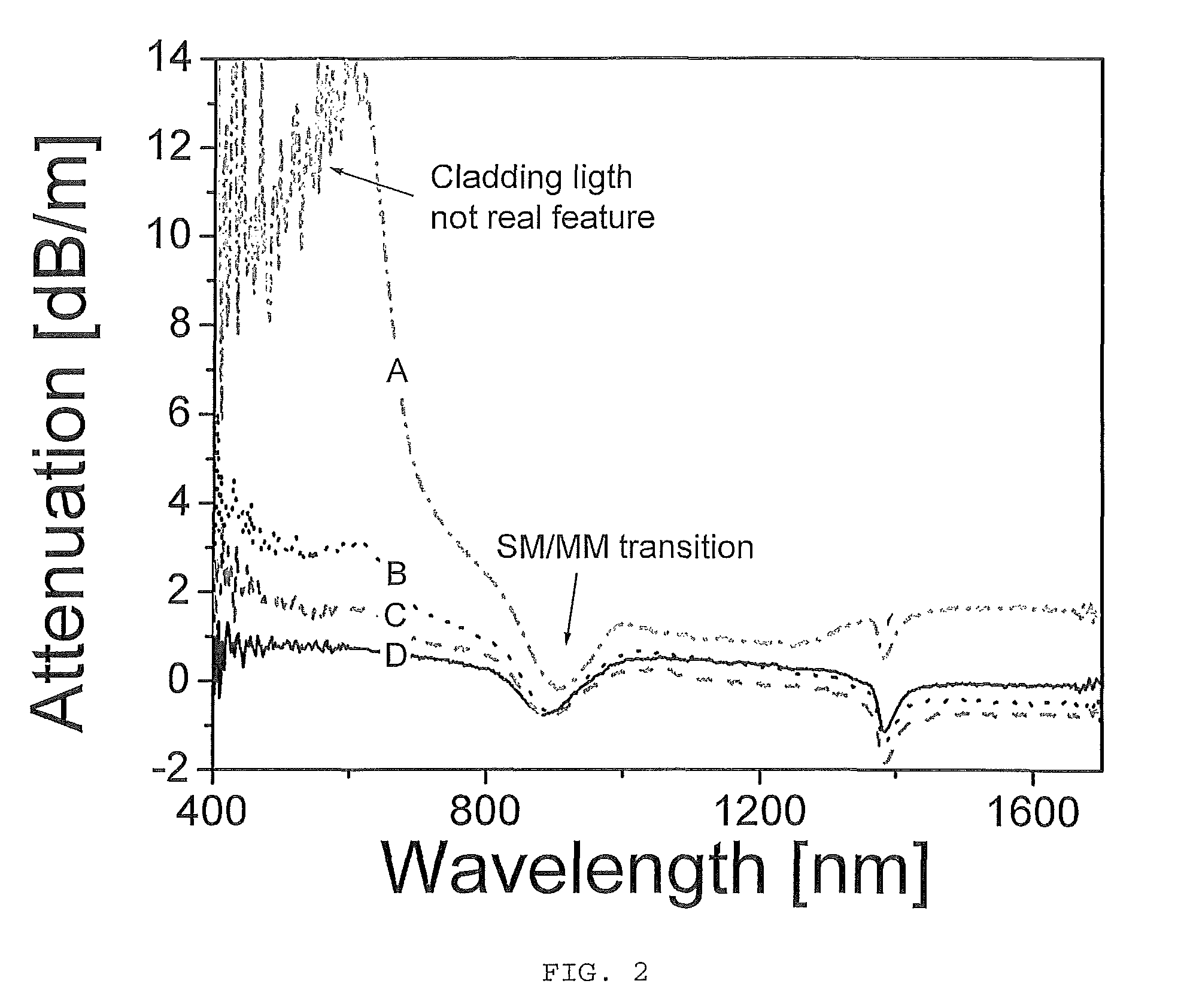

InactiveUS7155097B2Reducing splicing lossReduce uniformityGlass making apparatusOptical fibre with multilayer core/claddingMicrostructure fiberEngineering

Owner:CRYSTAL FIBRE AS

Lifetime extending and performance improvements of micro-structured fibers via high temperature loading

The disclosure relates to an optical fiber including a core and a cladding having a core material and a cladding material, respectively, wherein the fiber is a non-linear microstructured optical fiber, the microstructured optical fiber being obtainable by a method including loading the core material and optionally the cladding material with hydrogen and / or deuterium whereby the lifetime of the fiber may be extended in high pulse applications.

Owner:NKT PHOTONICS

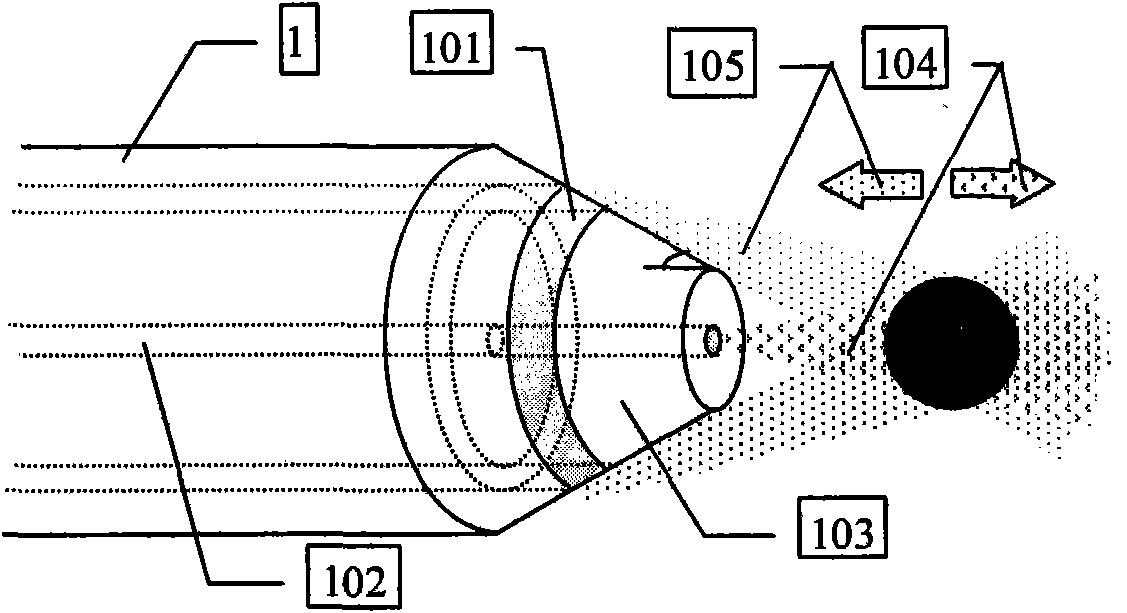

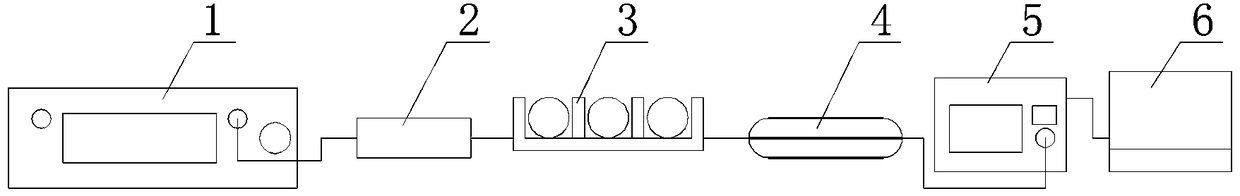

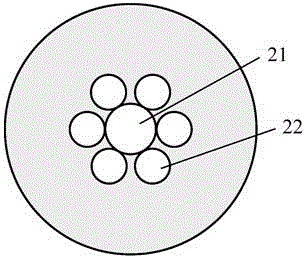

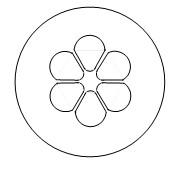

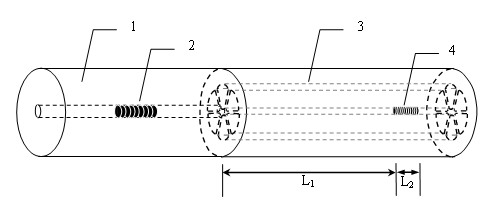

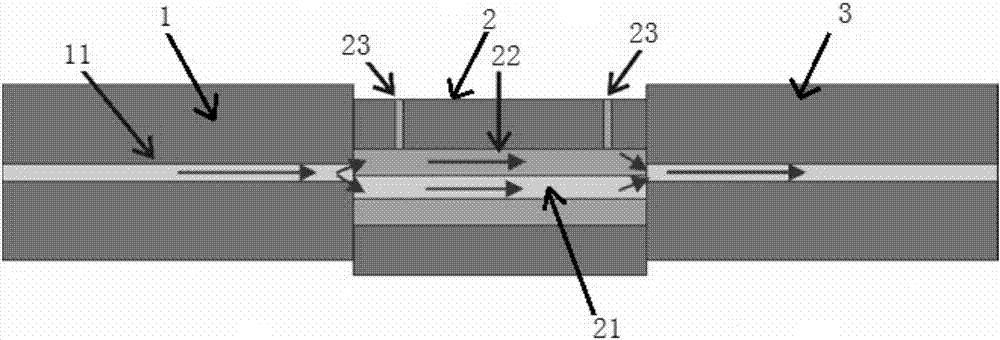

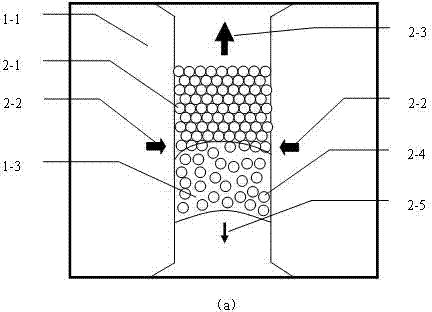

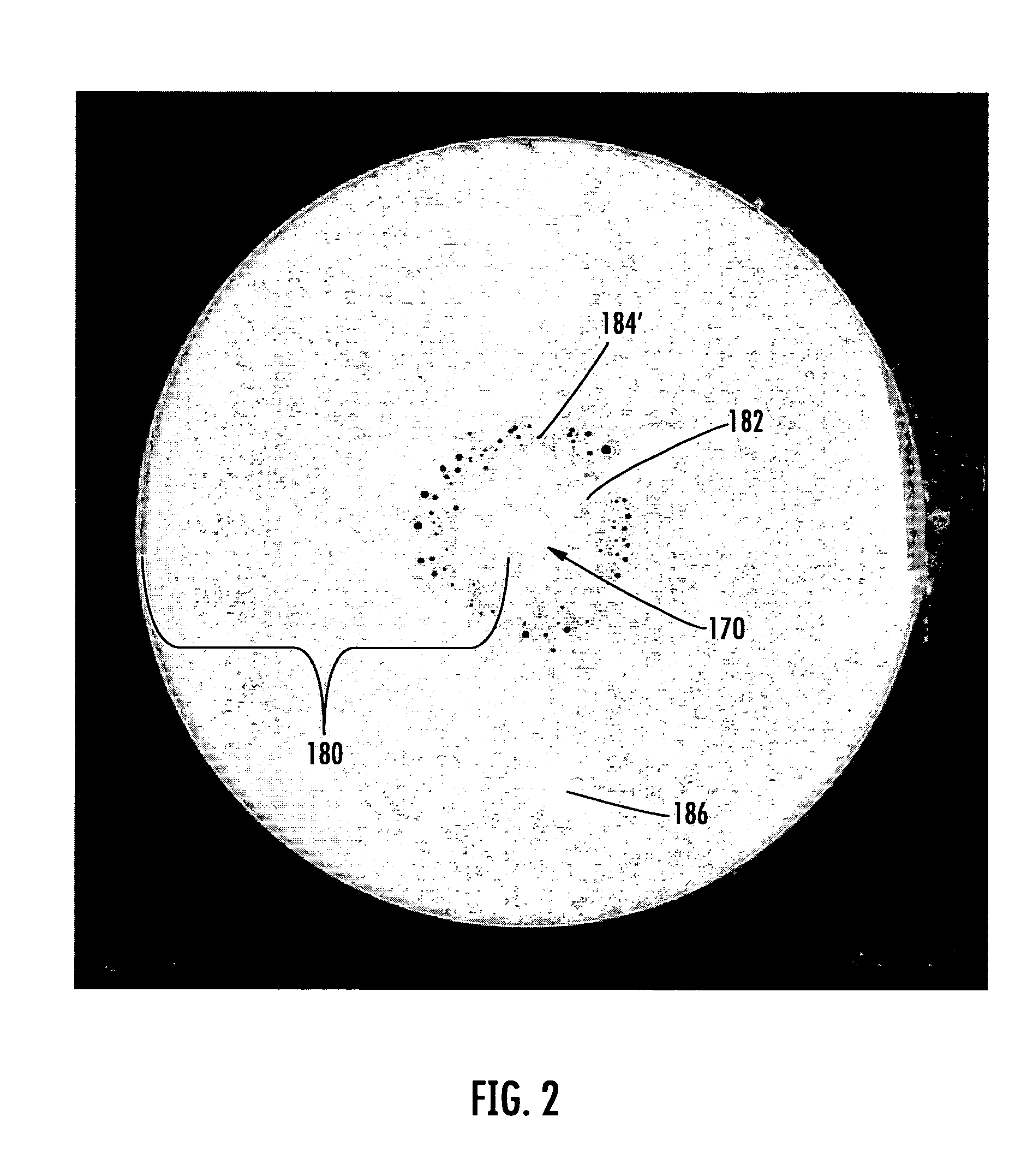

Throughput type fiber optical tweezers based on coaxial dual-waveguide structure and preparation method

InactiveCN101907743AStable captureCapture flexibleRadiation/particle handlingOptical fibre with multilayer core/claddingCoaxial cableMicrostructure fiber

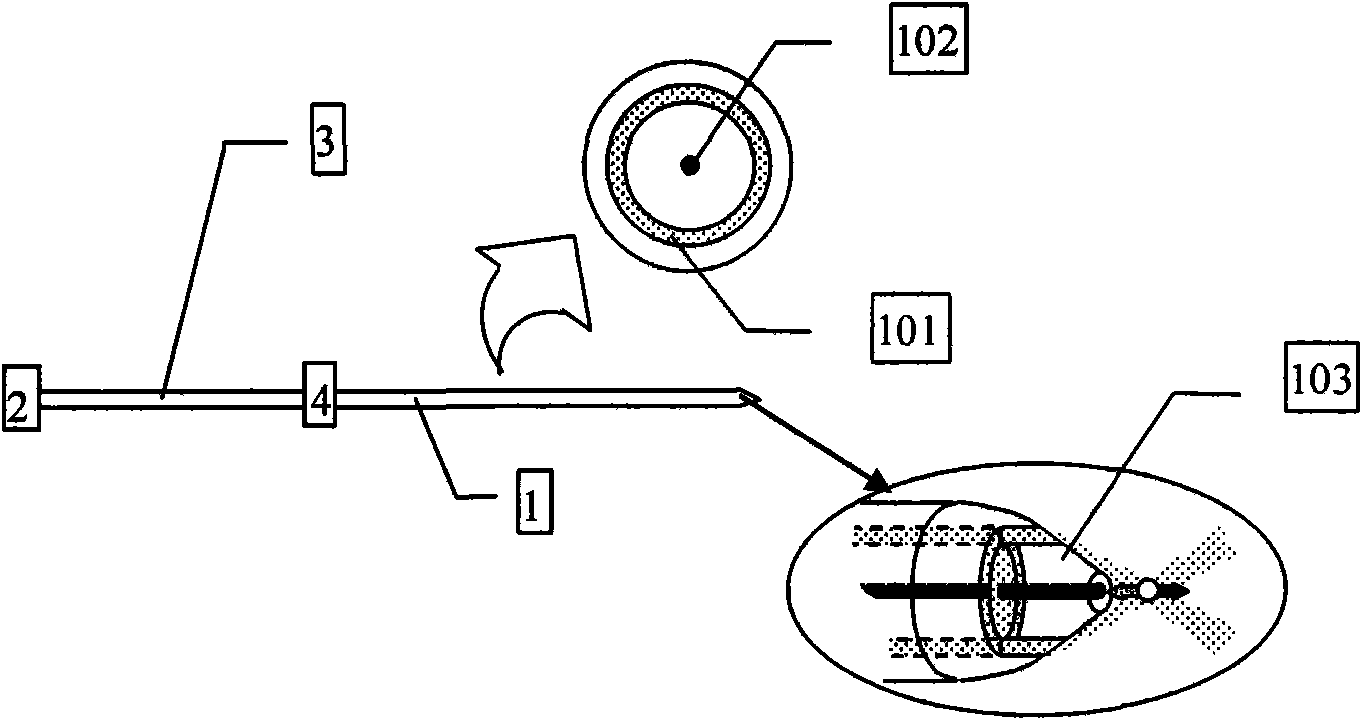

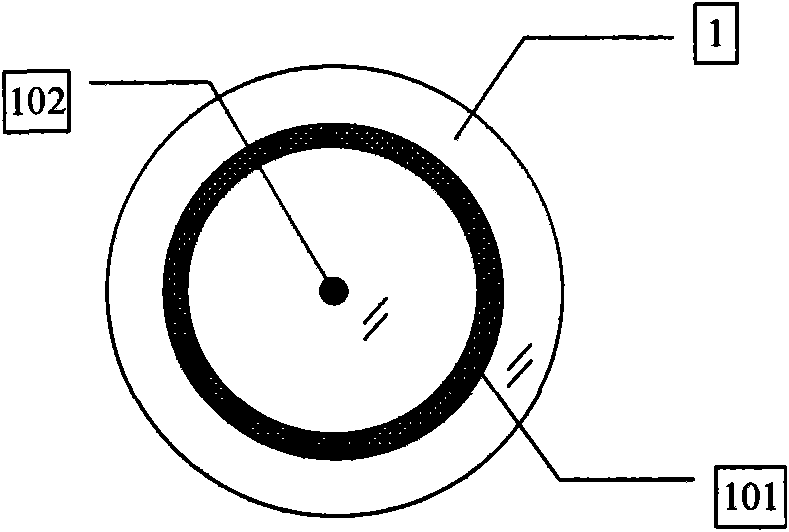

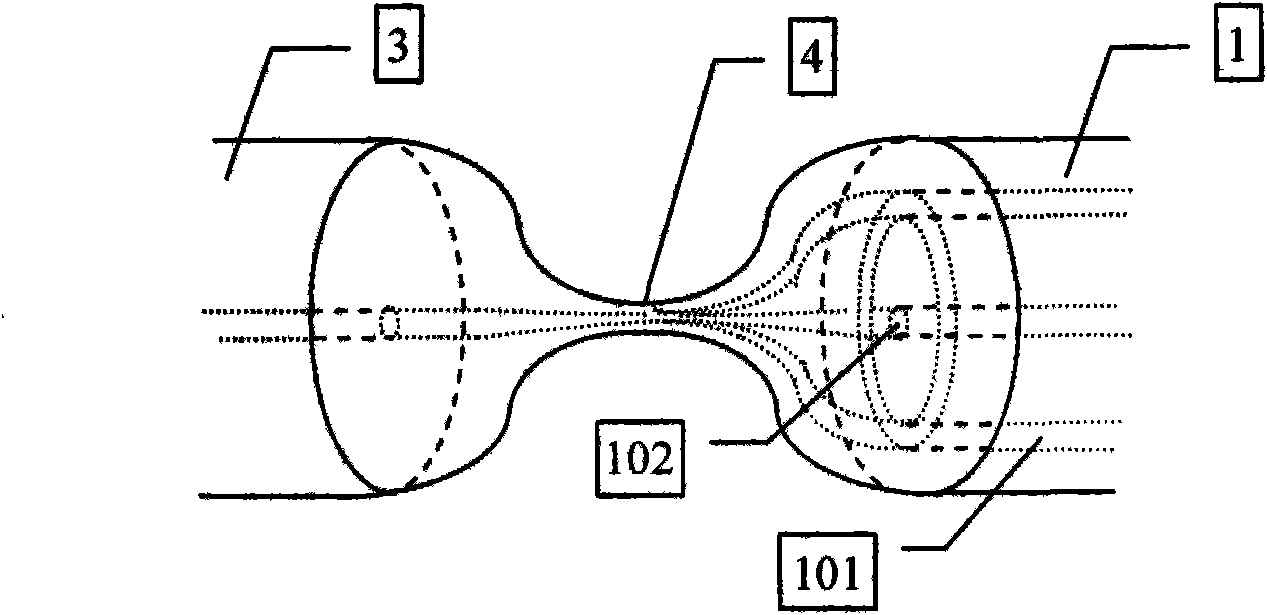

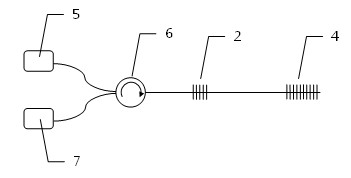

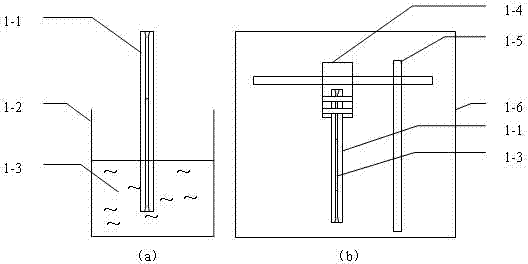

The invention provides throughput type fiber optical tweezers based on a coaxial dual-waveguide structure and a preparation method. The throughput type fiber optical tweezers mainly comprise a coaxial double-waveguide microstructure fiber [1], an LD light source with the output wavelength of lambda 1, an LD light source [3] with the output wavelength of lambda 2, a wavelength division multiplexing device [4] and a standard single-mode fiber [5]),wherein the output ends of the light source [2] and the light source [3] are connected with the two input ends of the wavelength division multiplexing device [4]; the output end of the wavelength division multiplexing device [4] is coupled with the coaxial double-waveguide fiber [1]; and the other end of the coaxial double-waveguide fiber [1] is finely ground to obtain the cone structure. The invention controls the particles by utilizing the coaxial double-waveguide fiber, changes the luminous power of the light source by adjustment, and can realize throughput, transmission and resorption of stable trapped particles; and meanwhile, the invention can trap the particles in a more flexible and accurate way, has adjustability, and greatly enhances the practicality of the fiber optical tweezers.

Owner:HARBIN ENG UNIV

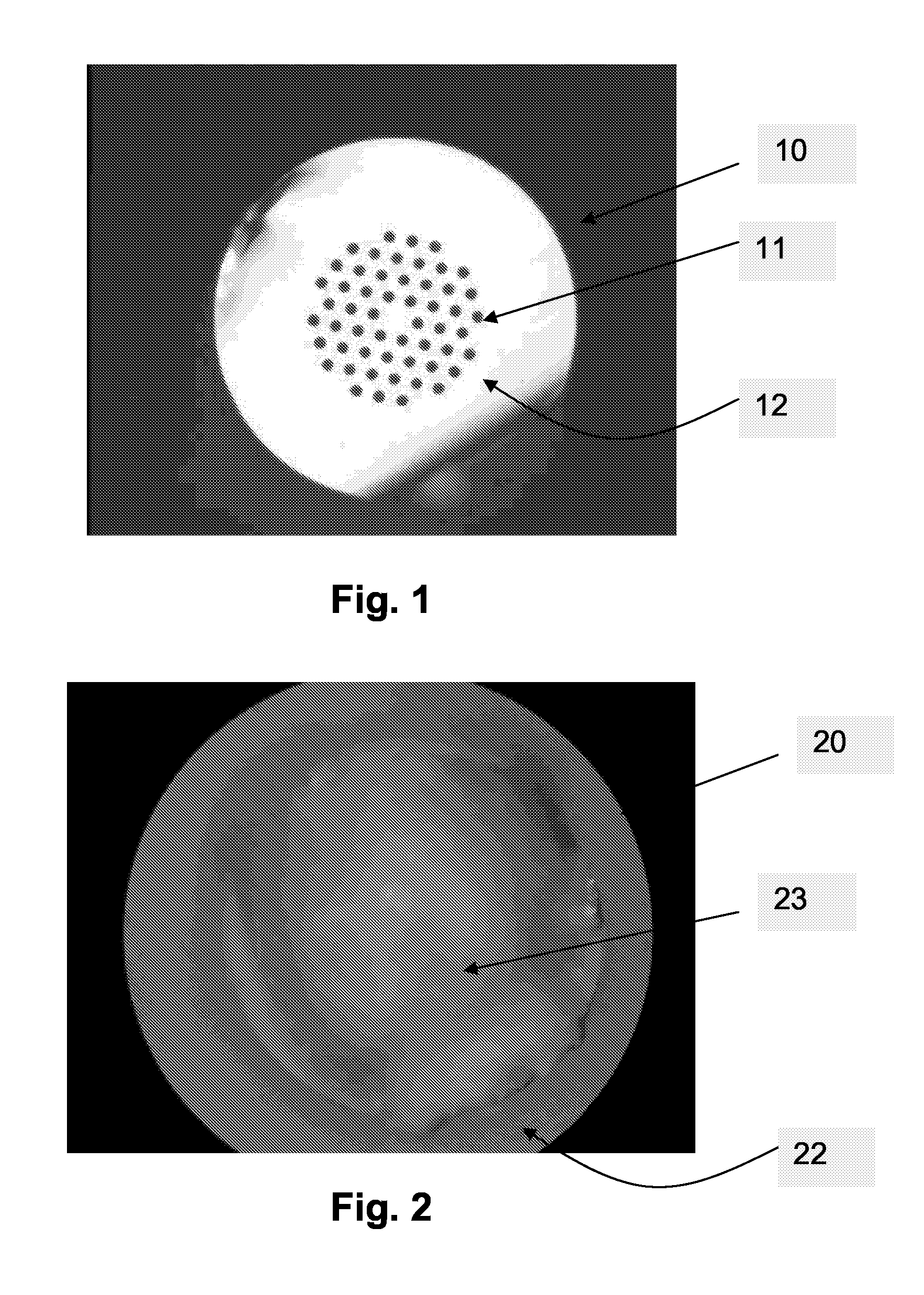

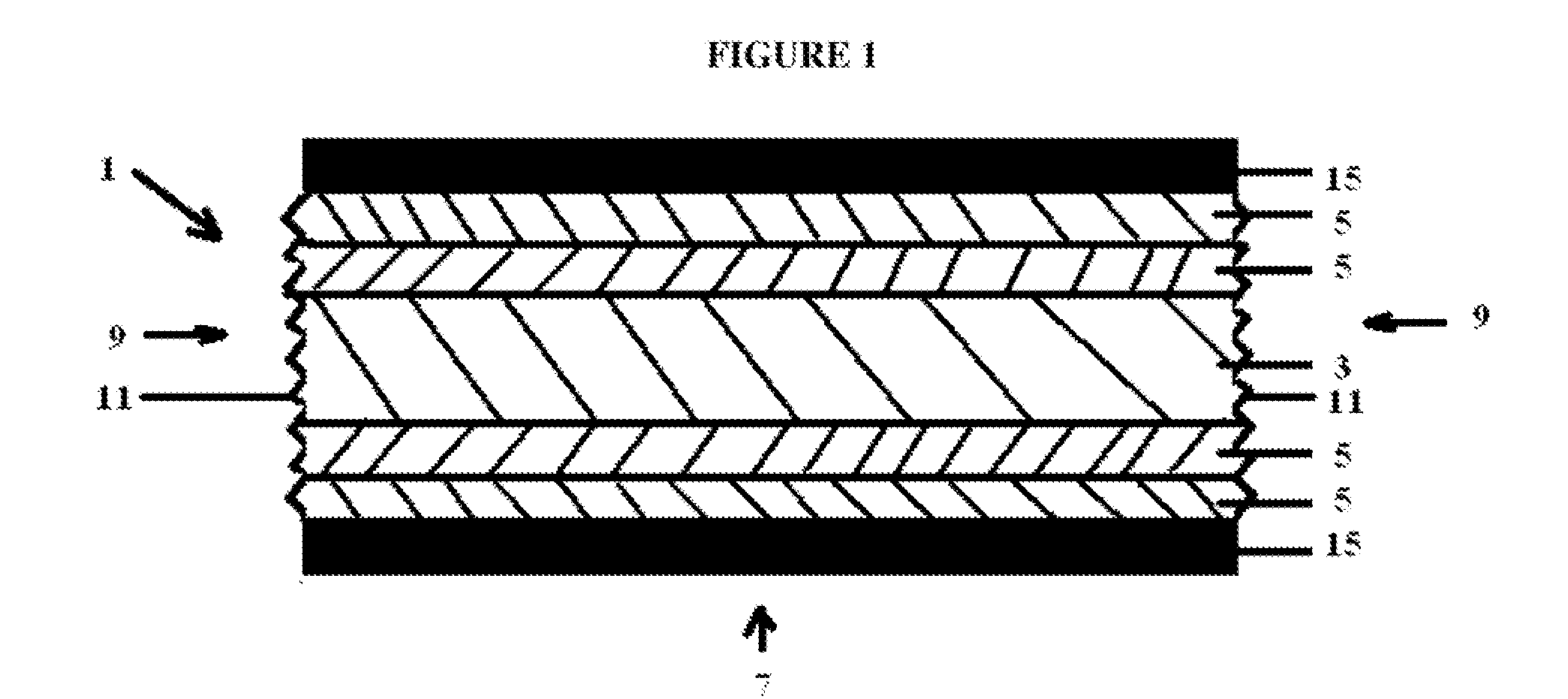

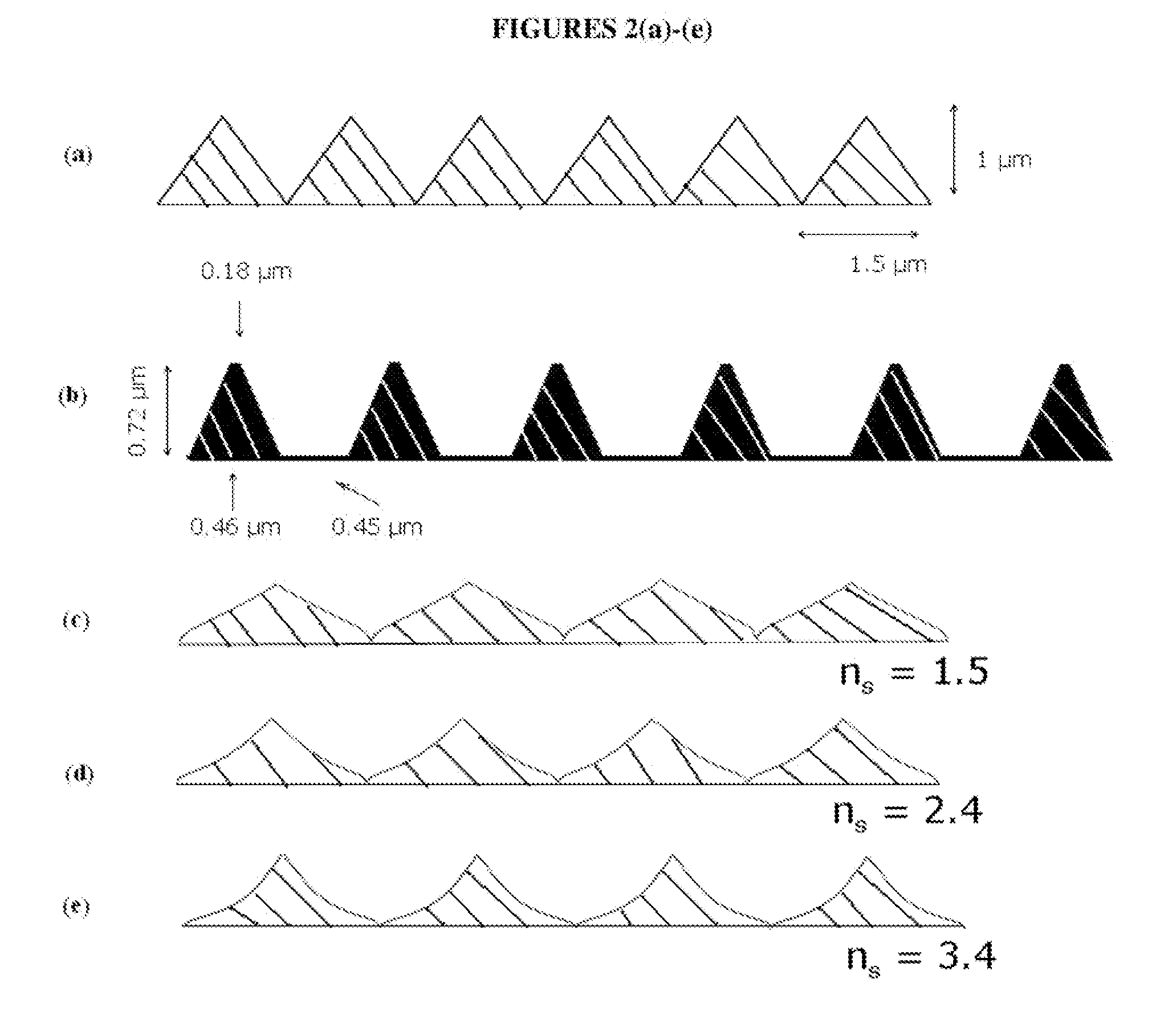

Microstructured Fiber End

InactiveUS20110033156A1High light transmittanceOptical articlesCoupling light guidesMicrostructure fiberRefractive index

An optical fiber having microstructured terminal end suitable for reducing Fresnel losses. In an exemplary embodiment, the microstructured surface includes a plurality of protrusions, recesses or combinations thereof that effectively and incrementally change the refractive index of the terminal end of the optical fiber such that the refractive index is gradually drawn closer to the refractive index value of the surrounding environmental medium.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Gas filled hollow core chalcogenide photonic bandgap fiber raman device and method

ActiveUS20060251369A1Improve efficiencyHigh average power sourceLaser detailsCladded optical fibreSolid regionPhotonic bandgap

This invention pertains to a glass fiber, a Raman device and a method. The fiber is a hollow core photonic bandgap chalcogenide glass fiber that includes a hollow core for passing light therethrough, a Raman active gas disposed in said core, a microstructured region disposed around said core, and a solid region disposed around said microstructured region for providing structural integrity to said microstructured region. The device includes a coupler for introducing at least one light signal into a hollow core of a chalcogenide photonic bandgap fiber; a hollow core chalcogenide photonic bandgap glass fiber; a microstructured fiber region disposed around said core; a solid fiber region disposed around said microstructured region for providing structural integrity to said microstructured region; and a Raman active gas disposed in the hollow core. The method includes the steps of introducing a light beam into a hollow core chalcogenide photonic bandgap glass fiber filled with a Raman active gas disposed in the core, conveying the beam through the core while it interacts with the gas to form a Stokes beam of a typically higher wavelength, and removing the Stokes beam from the core of the fiber.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

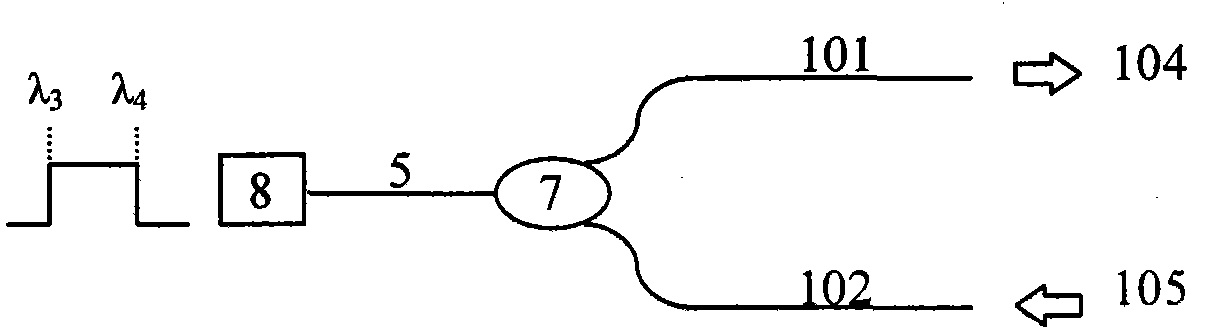

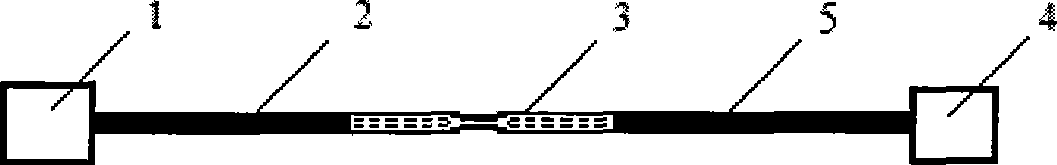

Throughput type fiber optical tweezers based on coaxial dual-waveguide structure and dynamic control method

InactiveCN101950049ACapture flexibleAccurate captureRadiation/particle handlingOptical fibre with multilayer core/claddingCoaxial cableMicrostructure fiber

The invention provides throughput type fiber optical tweezers based on a coaxial dual-waveguide structure and a dynamic control method. The tweezers mainly comprise a coaxial double-waveguide microstructure fiber (1), a wavelength-adjustable LD light source (2) and a standard single-mode single-core fiber (3), and are characterized in that the coaxial double-waveguide microstructure fiber (1) is coupled with the standard single-mode single-core fiber (3) in a fused-tapered mode; the other side of the standard single-mode single-core fiber (3) is connected with the wavelength-adjustable LD light source (2); and the other end of the coaxial double-waveguide microstructure fiber (1) is finely ground into a cone shape (103). Coaxial double-waveguide fiber is utilized to control particles, the throughput, emission and even resorption of the particles can be stably captured; and meanwhile, the throughput type fiber optical tweezers based on the coaxial dual-waveguide structure can capture the particles more flexibly and accurately and has adjustability, thereby greatly improving the practicability of the technology of the fiber optical tweezers.

Owner:HARBIN ENG UNIV

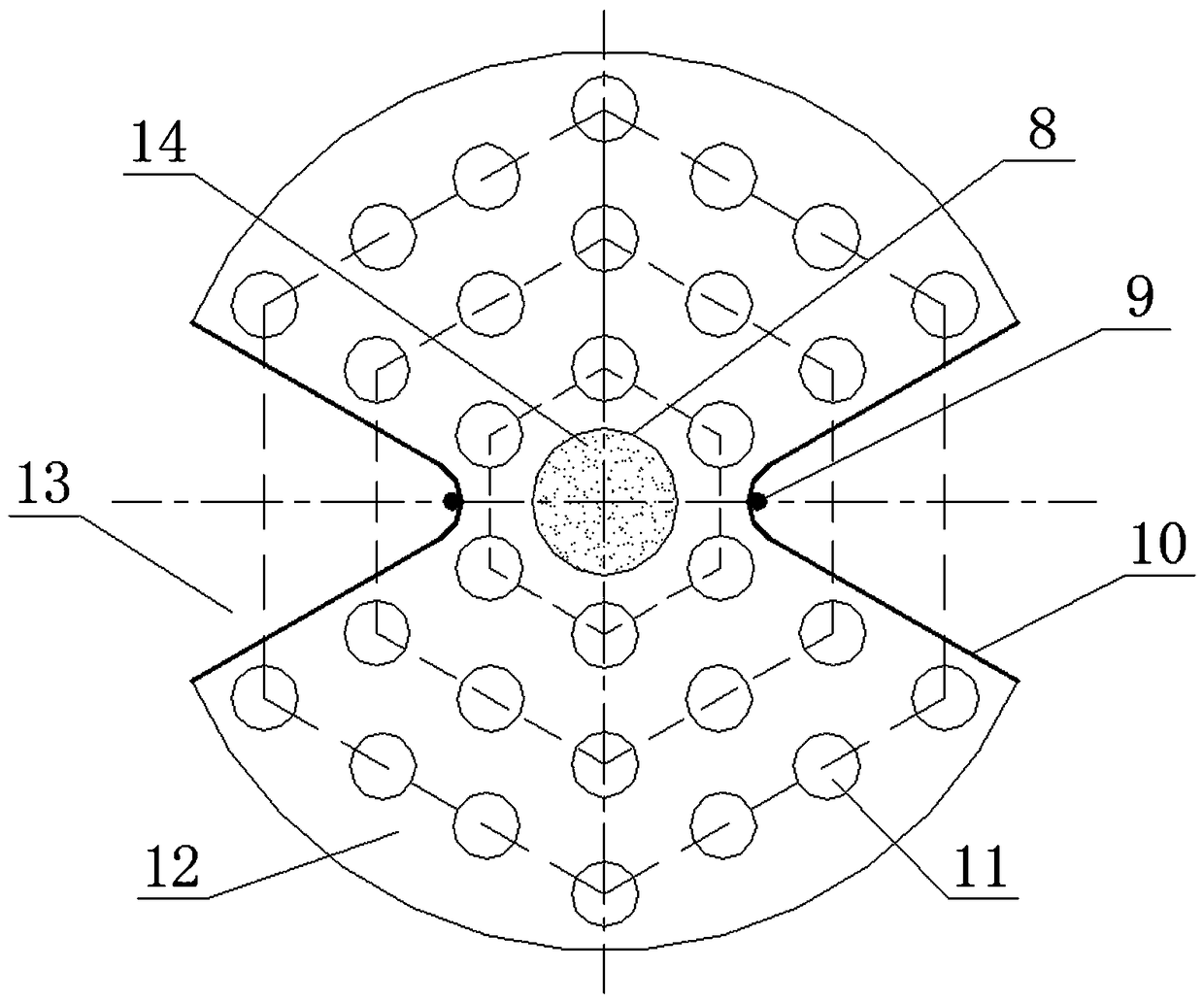

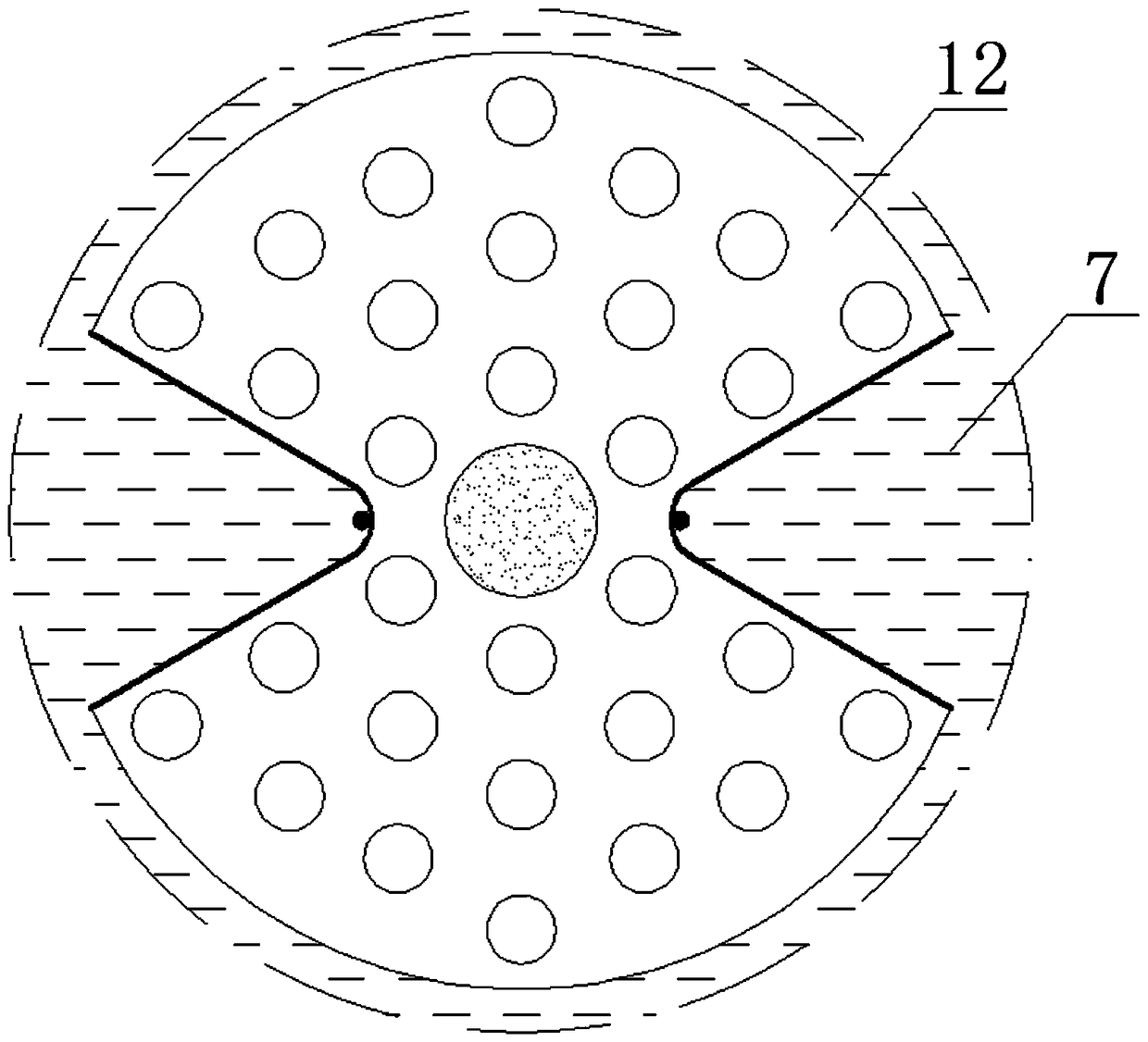

Multifunctional sensor with microstructure fiber surface plasma resonance and preparation method thereof

ActiveCN109358038AReduce volumeReasonable workmanshipAnalysis by thermal excitationRefractive indexGold film

The invention relates to a fiber sensor, particularly relates to a multifunctional sensor with microstructure fiber surface plasma resonance and a preparation method thereof. The two sides of the photonic crystal fiber substrate of the fiber are provided with fan-shaped openings that surface of which are plated with gold films. Tips of the bottom ends of the fan-shaped openings are provided with silver nanowires. The core of the photonic crystal fiber substrate is provided with a magnetic fluid, and the outer side of the core is provided with a cladding air hole. The preparation method comprises the steps of: polishing the fan-shaped openings on the photonic crystal fiber; filling the silver nanowires; uniformly plating the gold films on the surface of the fan-shaped openings; pressing themagnetic fluid into the photonic crystal fiber from a small tube; and coupling and splicing the two ends of the common single mode fiber and the photonic crystal fiber through the self-calibrating function of the a fiber fusion splicer. The sensor of the invention can achieve the analysis and detection of the external magnetic field intensity, the refractive index of the to-be-measured liquid andthe external temperature in one time, therefore, the technical defects that the conventional detection technology is complex in operation, low in detection sensitivity and non-real time online detection are overcome.

Owner:南通畅衡智能装备有限公司

Optical fiber sensor of plasma resonance microstructure

InactiveCN101413891AImprove coupling efficiencySimple processPhase-affecting property measurementsScattering properties measurementsSurface plasmonic resonanceMetal membrane

The invention discloses a plasma resonance microstructure fiber sensor which comprises a light source, two ordinary single mode fibers, a microstructure fiber and a photoelectric detector, wherein, the light source, the first ordinary single mode fiber, the microstructure fiber, the second ordinary single mode fiber and the photoelectric detector are connected sequentially; the microstructure fiber is formed by photonic crystal fiber taper which has paralleled hexagon cross section and two-dimensional periodic structure; a metal membrane and a protein polymer membrane are coated on the surface of the tapered section from inside to outside sequentially; and the periodic structure consists of a background medium and dielectric rods which are distributed and arranged in the background medium periodically. As the usage of a microstructure fiber cladding light guiding mechanism, the fiber sensor can not only educe a guided mode without peeling cladding, but also realize high coupling efficiency of optical power of incident wave entering surface plasma resonance wave without a buffer layer. The invention has the advantages of simple process, compact structure, high measuring accuracy, strong anti-interference ability, being capable of being operated in harsh environment, and the like.

Owner:ZHEJIANG UNIV

Temperature sensor based on microstructure fibers, manufacturing method of temperature sensor, and temperature measuring device

ActiveCN103954377AAdjustable fluorescence intensityHigh fluorescence intensityThermometers using physical/chemical changesMicrostructure fiberQuantum dot

The invention belongs to the technical field of temperature sensors and provides a temperature sensor based on microstructure fibers, the manufacturing method of the temperature sensor, and a temperature measuring device. The temperature sensor comprises at least two microstructure fibers, wherein every two adjacent microstructure fibers are connected in series through a multimode fiber. For a fiber core and a cladding of each microstructure fiber, air holes distributed in the axial direction are formed in the cladding at least. Quantum dot materials are arranged in the air holes. The wavelength of fluorescent light emitted by the quantum dot materials in a microstructure fiber is different from the wavelength of fluorescent light emitted by the quantum dot materials in another microstructure fiber. Compared with ordinary fluorescent materials, the quantum dots have the advantages of being large in excitation wavelength, adjustable in fluorescent wavelength, stable in fluorescent intensity and the like. By adding quantum dots in different types and sizes into the microstructure fibers, the microstructure fibers can be distinguished in a wavelength domain according to the fluorescent wavelengths, and quasi-distributed sensing is realized.

Owner:SHENZHEN UNIV

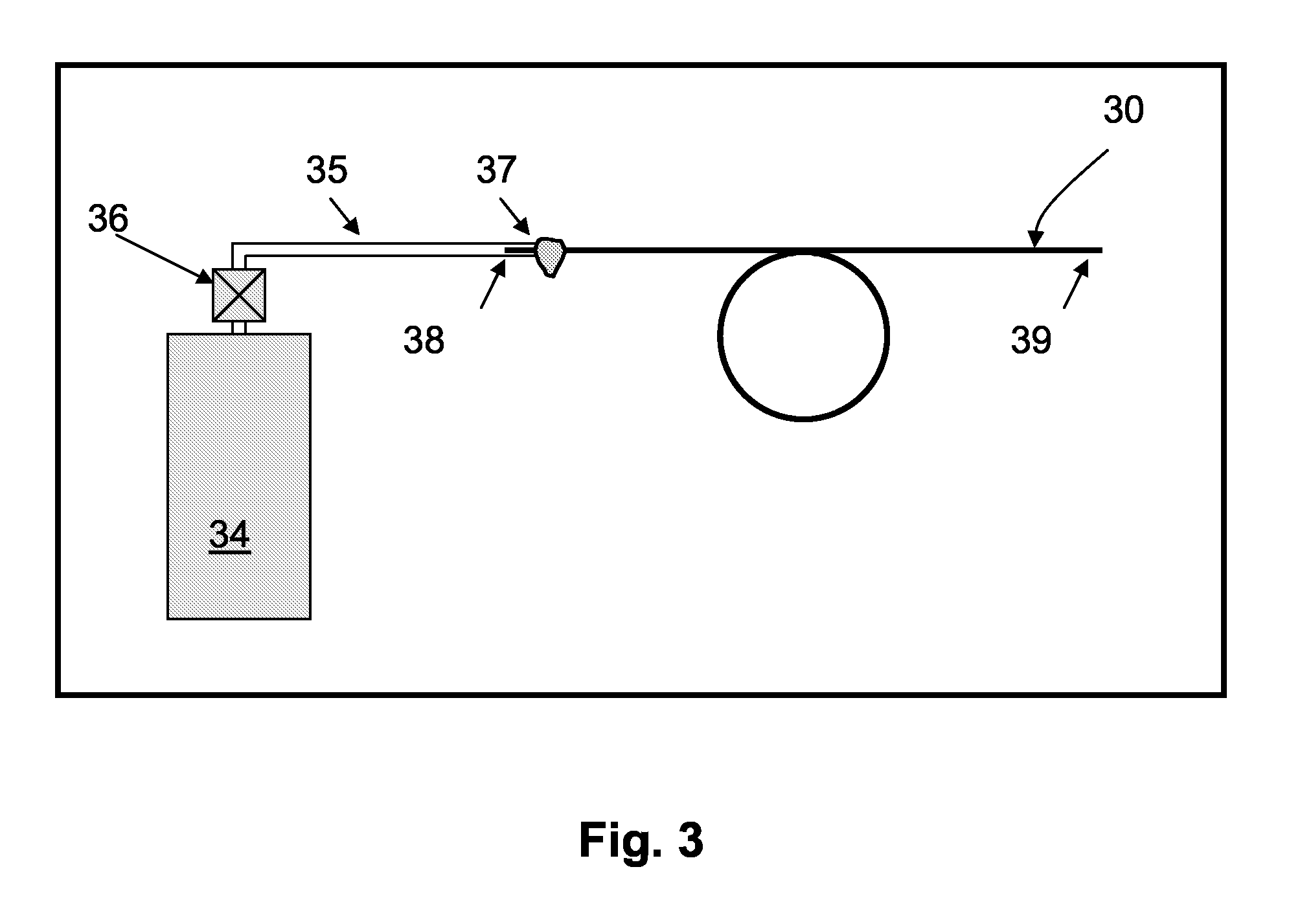

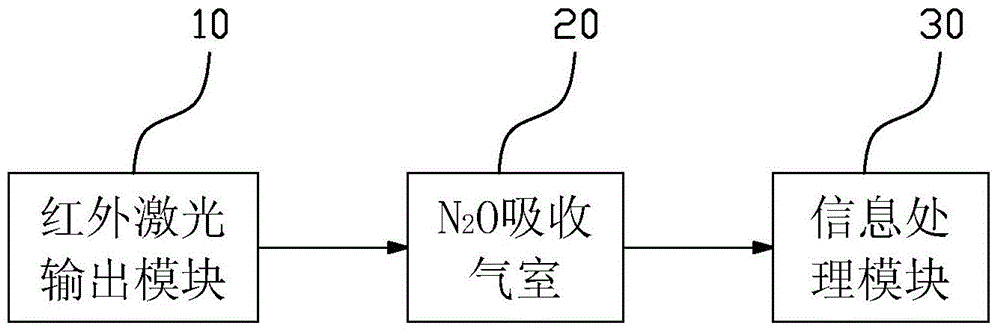

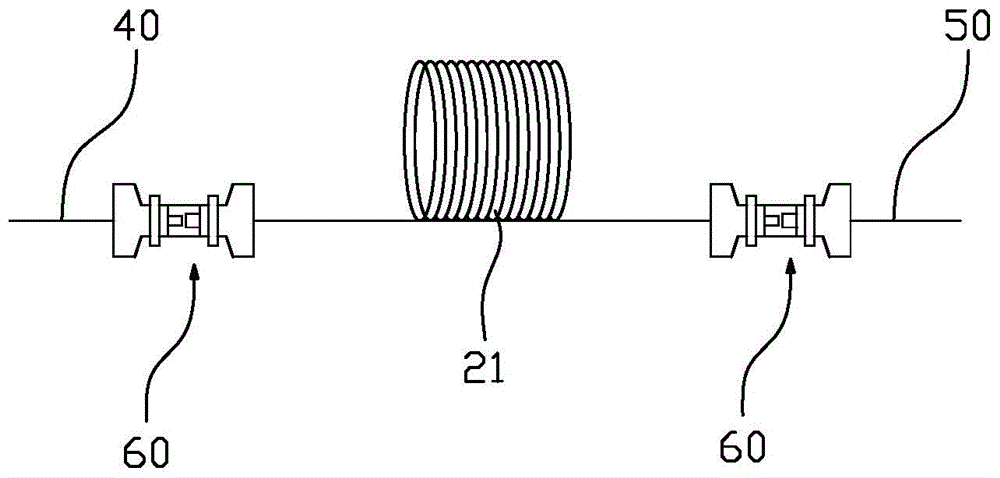

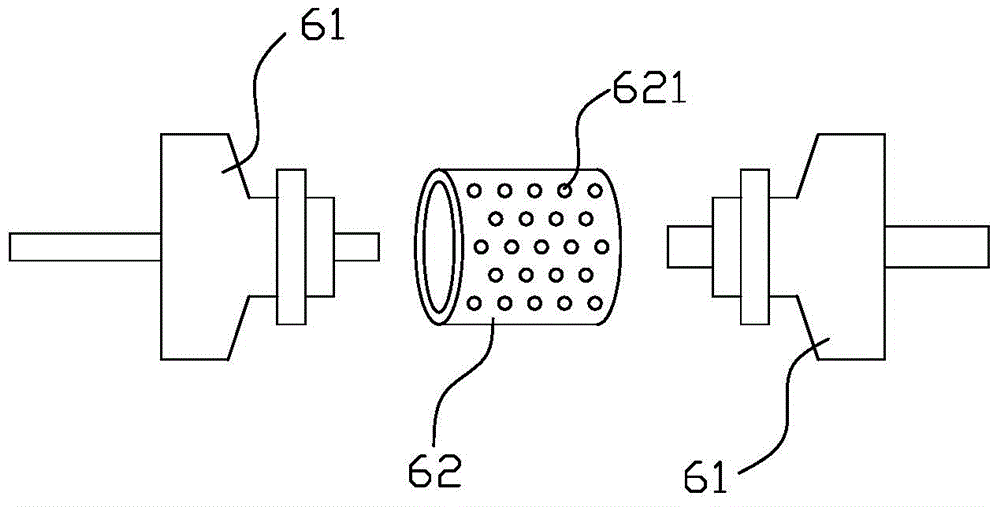

Trace nitrous oxide gas detection device

InactiveCN104390937AHigh precisionReduce lossColor/spectral properties measurementsMicrostructure fiberNitrous oxide gas

The invention relates to the technical field of low-concentration gas detection and in particular relates to a trace nitrous oxide gas detection device. The device comprises an infrared laser output module, an N2O absorption gas chamber and a signal processing module, wherein the central wavelength of laser output by the infrared laser output module is matched with the position of an N2O gas absorption peak; the N2O absorption gas chamber comprises a hollow microstructure fiber; micro pores are formed in the peripheral wall of the hollow microstructure fiber along the radial direction; the laser output by the infrared laser output module is transmitted to one end of the hollow microstructure fiber by virtue of a single mode fiber; laser subjected to N2O gas absorption in the hollow microstructure fiber is output to the signal processing module from the other end of the hollow microstructure fiber by virtue of a multimode fiber; and the N2O gas content is calculated by the signal processing module according to the laser loss. The problem that the light path is short is fundamentally solved when the gas concentration is detected by a tunable laser spectral absorption method; and moreover, the transmission loss is avoided, and the accuracy and reliability of the measurement result are improved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

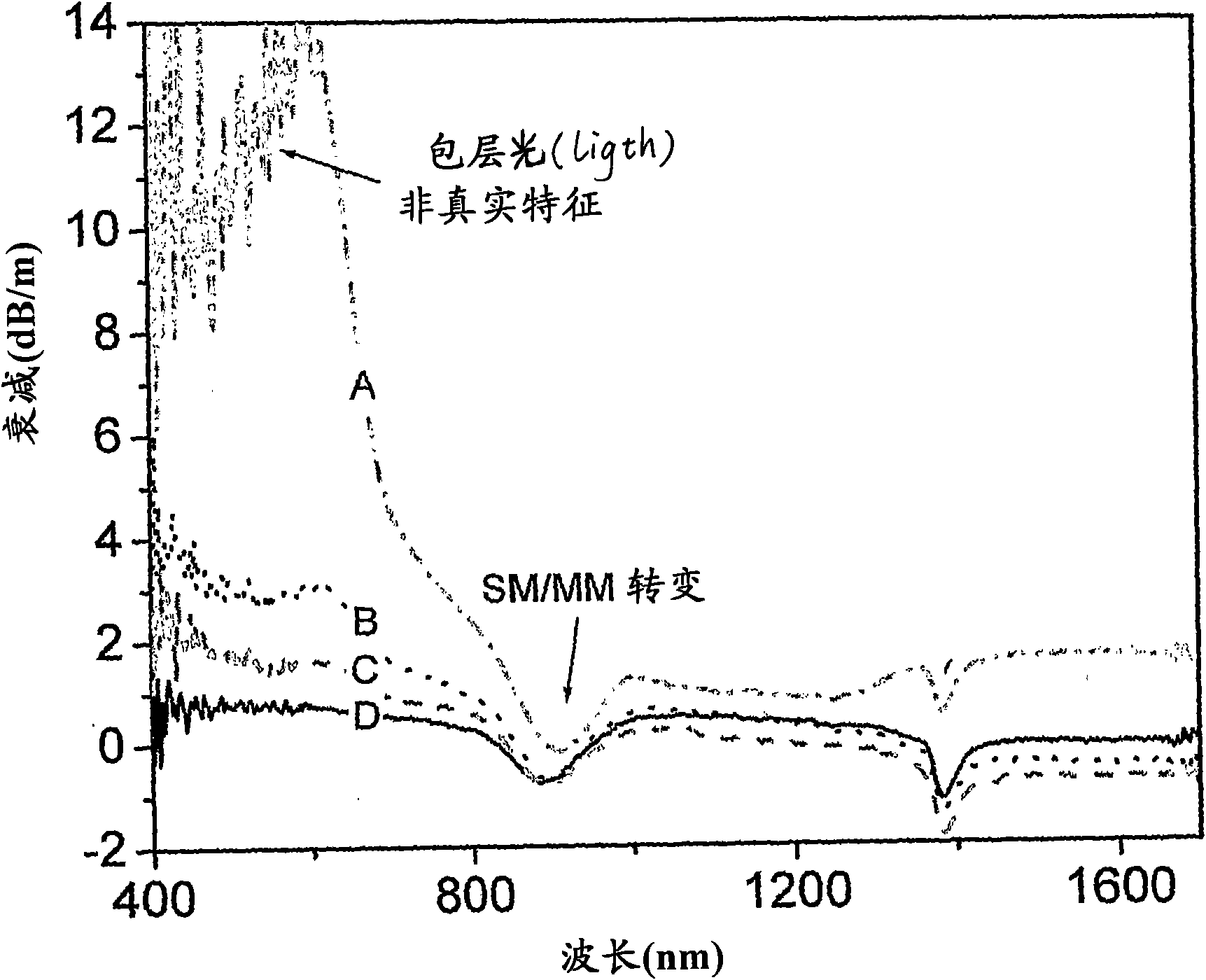

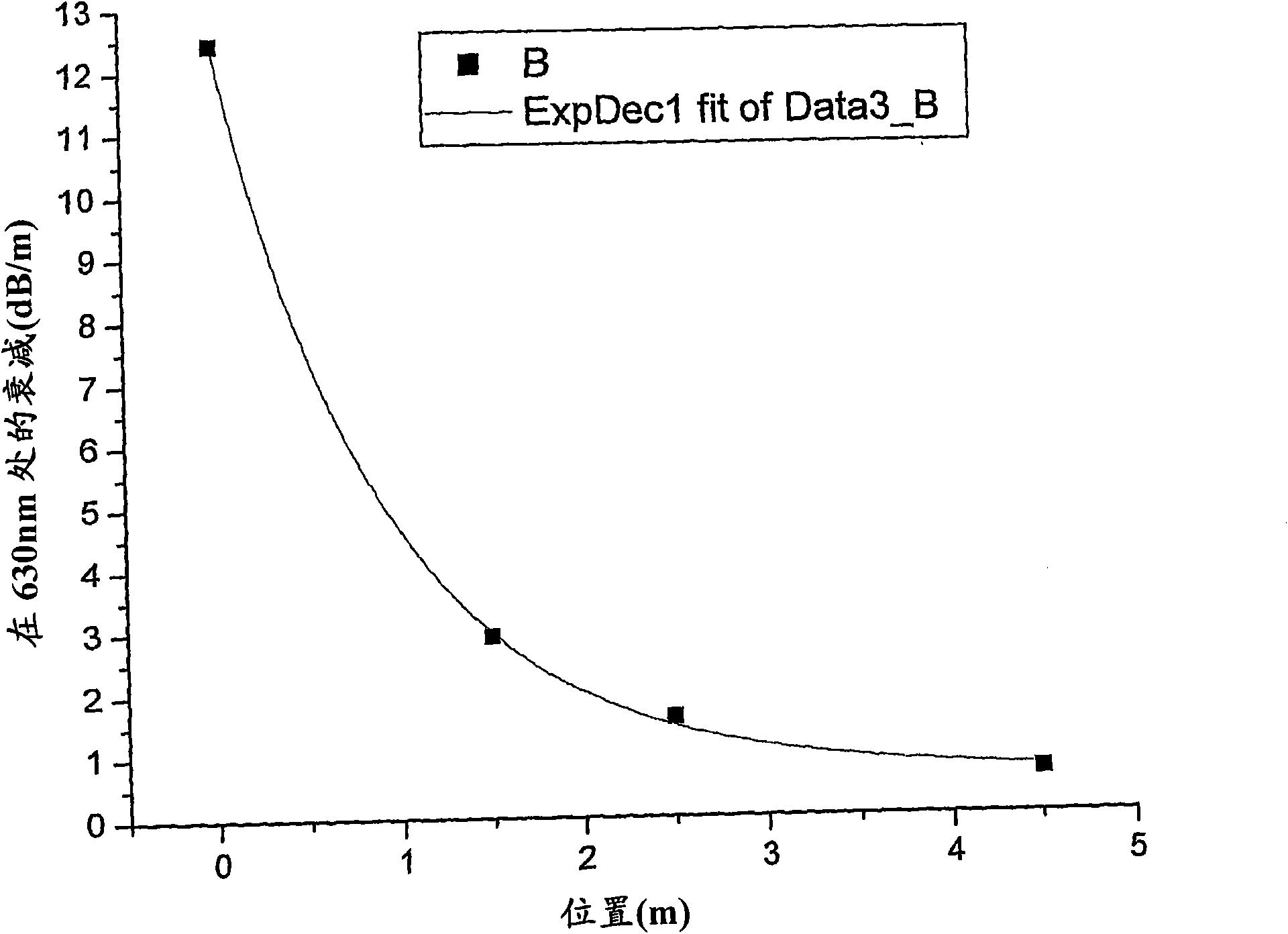

Fiber optic cables and assemblies and the performance thereof

InactiveUS20080298758A1Small component sizeTight toleranceOptical fibre with multilayer core/claddingOptical waveguide light guideUltrasound attenuationMicrostructure fiber

A fiber optic jumper assembly comprising at least one bend performance optical fiber comprising a core region and a cladding region surrounding the core region, the cladding region comprising an annular hole-containing region comprised of non-periodically disposed holes, a protective covering positioned over the at least one bend performance optical fiber, and at least one connector mounted upon each end of the at least one bend performance optical fiber. A preconnectorized fiber optic jumper assembly comprising a microstructured fiber having a delta attenuation of 0.00 dB at 5 wraps about a 6 mm diameter at a reference wavelength of 1625 nm.

Owner:CORNING OPTICAL COMM LLC

Gas filled hollow core chalcogenide photonic bandgap fiber Raman device and method

ActiveUS7283712B2Higher Stokes shift of a gasImprove efficiencyLaser detailsCladded optical fibreGlass fiberSolid region

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

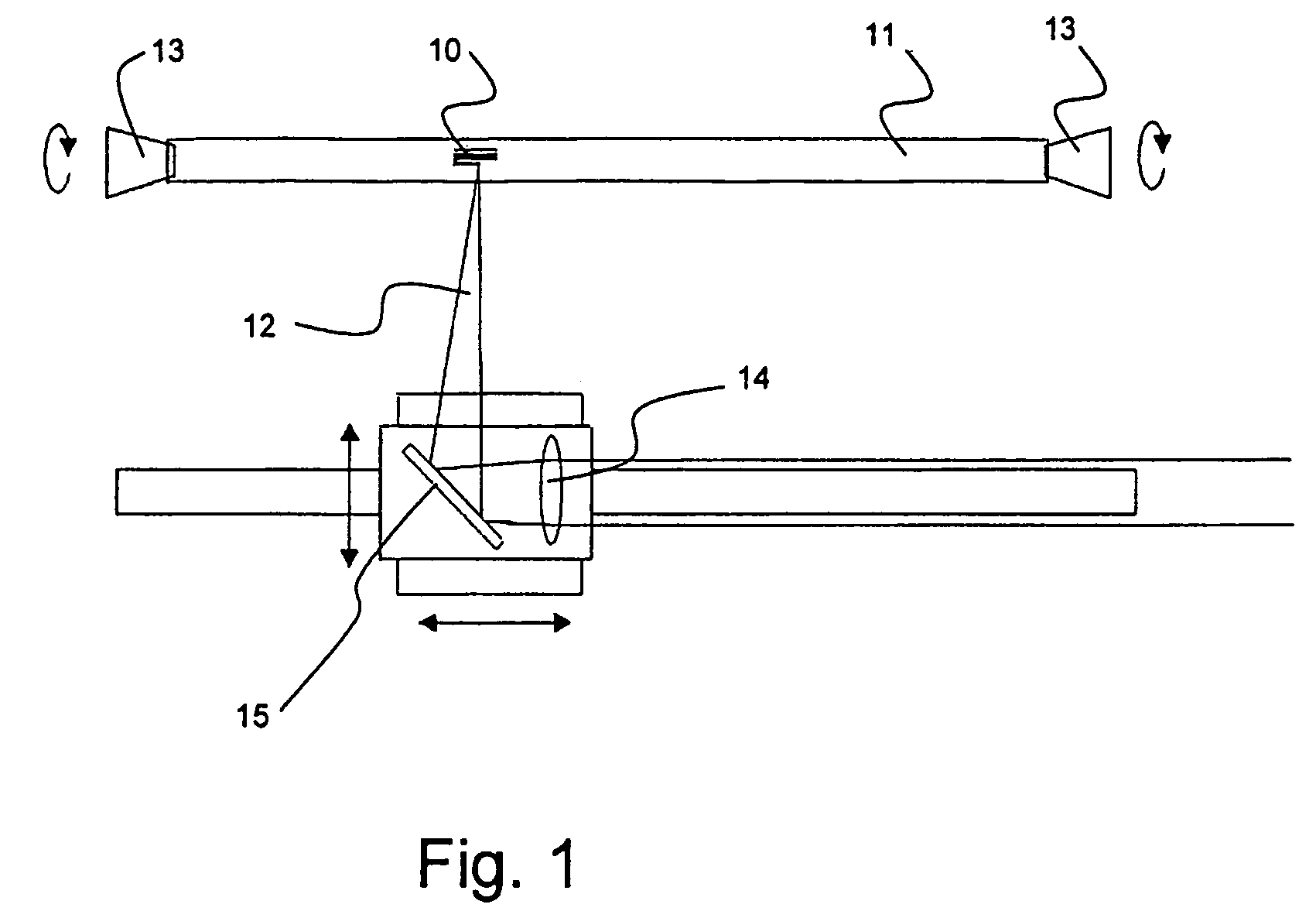

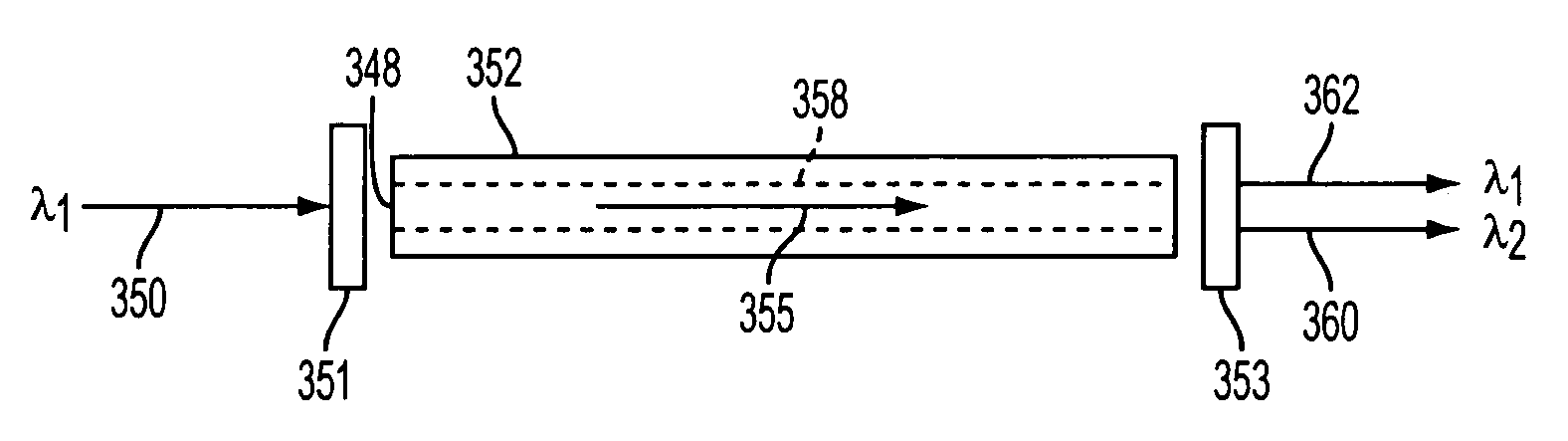

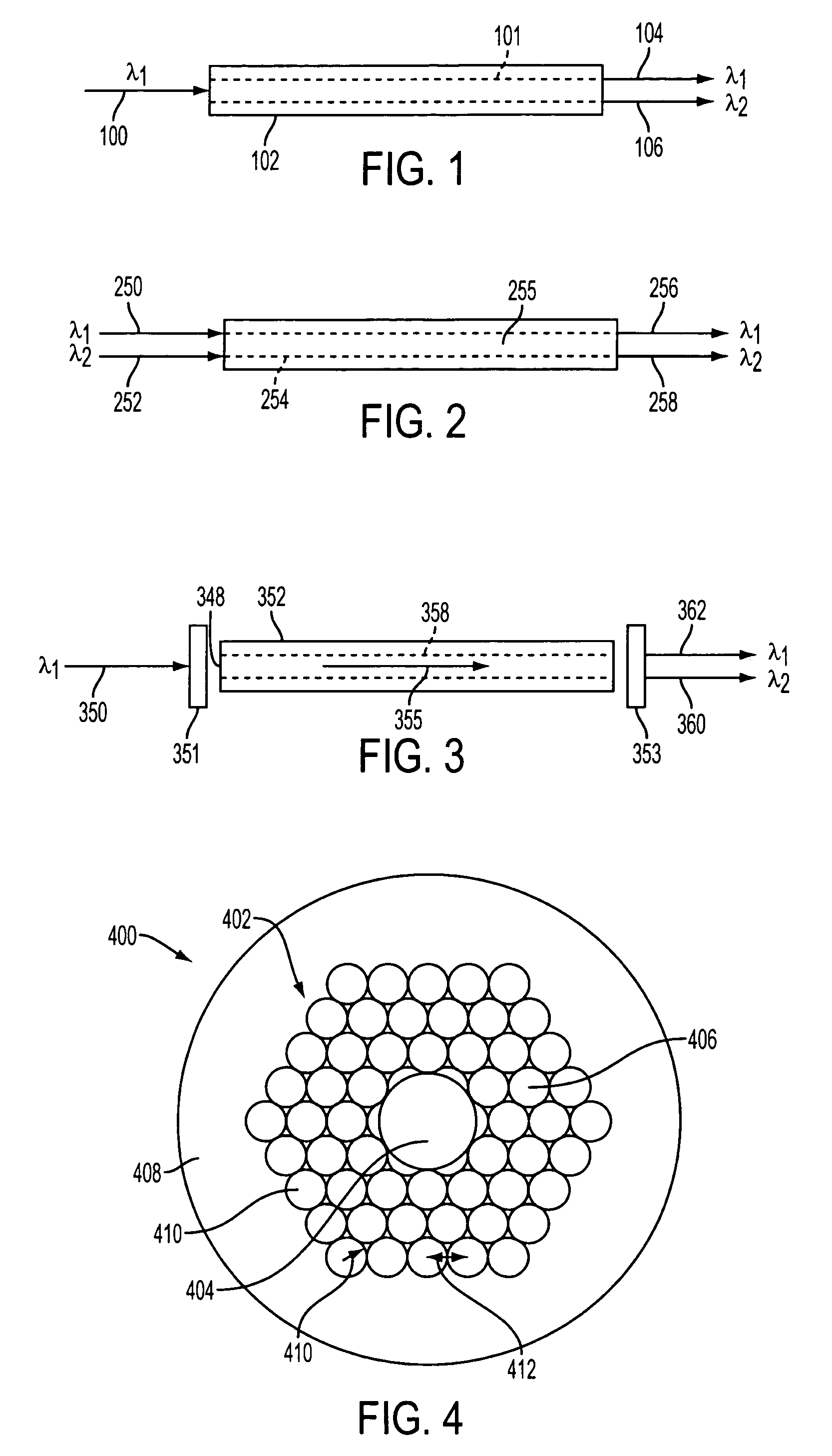

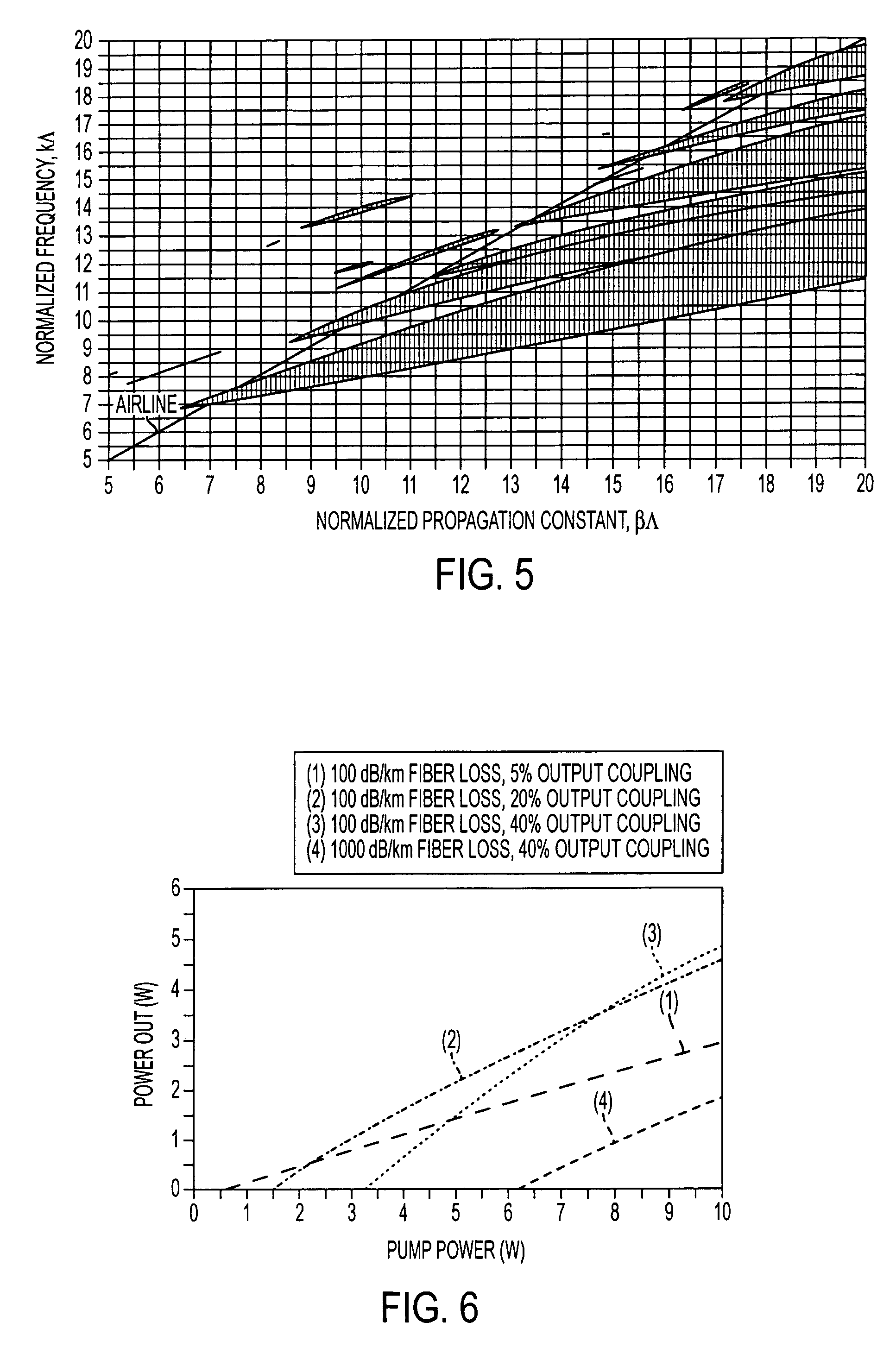

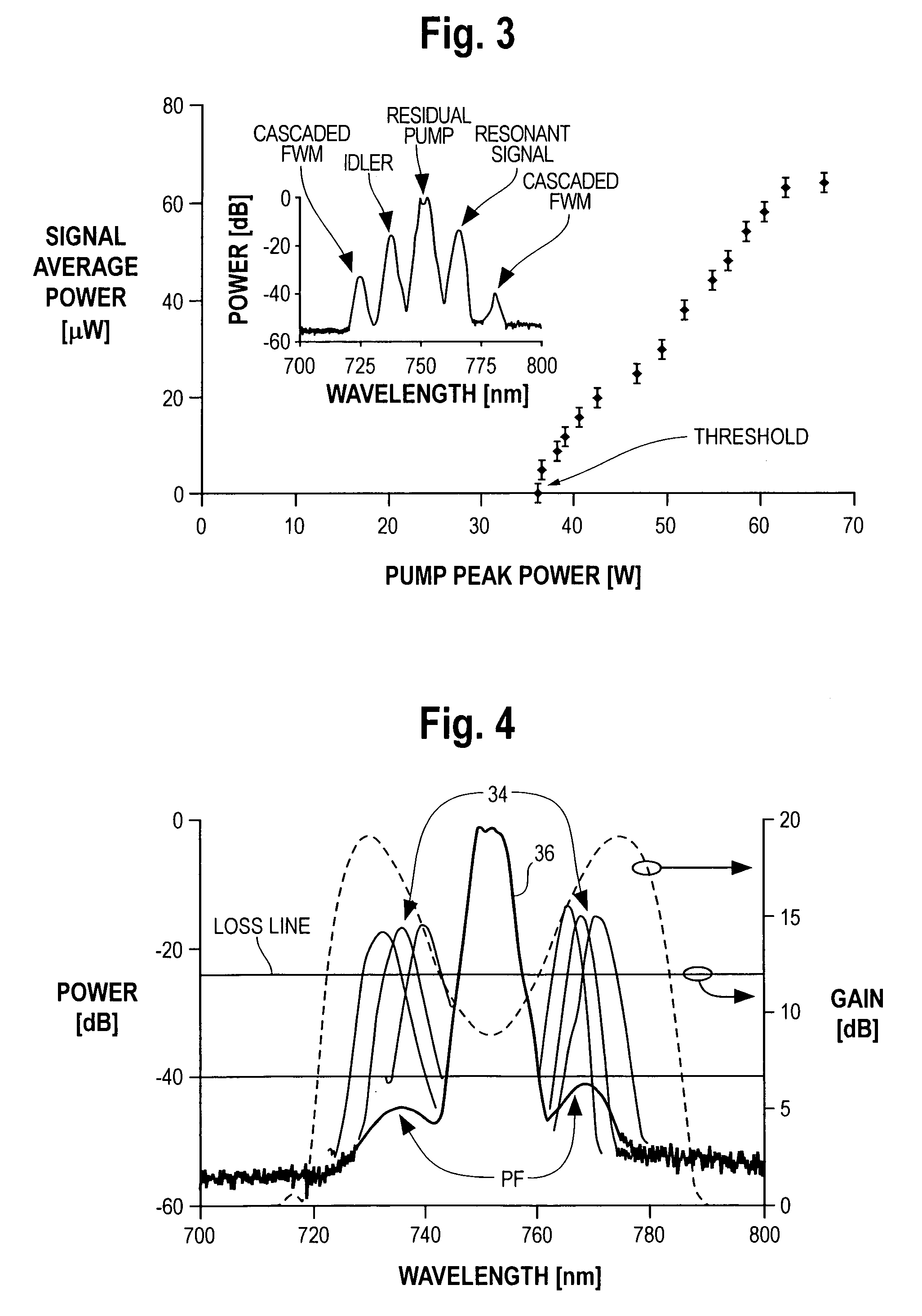

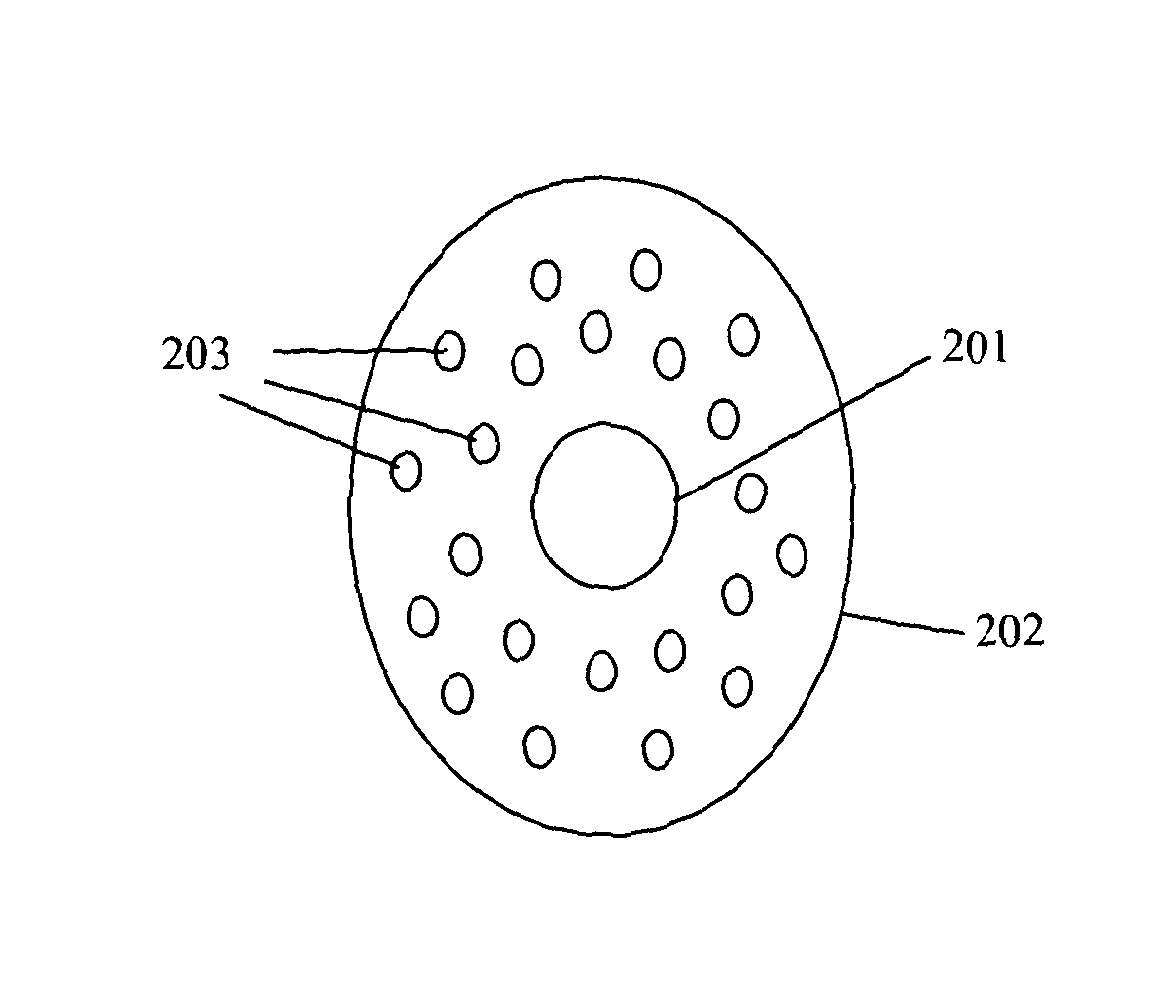

Microstructure fiber optical parametric oscillator

InactiveUS6958855B2Reduction in bending lossOvercome disadvantagesCladded optical fibreLight demodulationSignal wavePhotonic crystal

A fiber optical parametric oscillator is formed using photonic crystal fibers, also known as microstructure fibers or holey fibers. The optical parametric oscillator includes only a few meters of microstructure fiber. In one embodiment, the microstructure fiber is disposed between a highly reflective mirror and a diffraction grating in a simple Fabry-Perot configuration wherein the diffraction grating is tuned to reflect a particular wavelength of the signal wave back to the microstructure fiber. In another embodiment, the microstructure fiber is disposed in a ring cavity and the parametric oscillator is synchronously pumped. The parametric oscillator may be implemented with free space optics or use all fiber optic components.

Owner:NORTHWESTERN UNIV

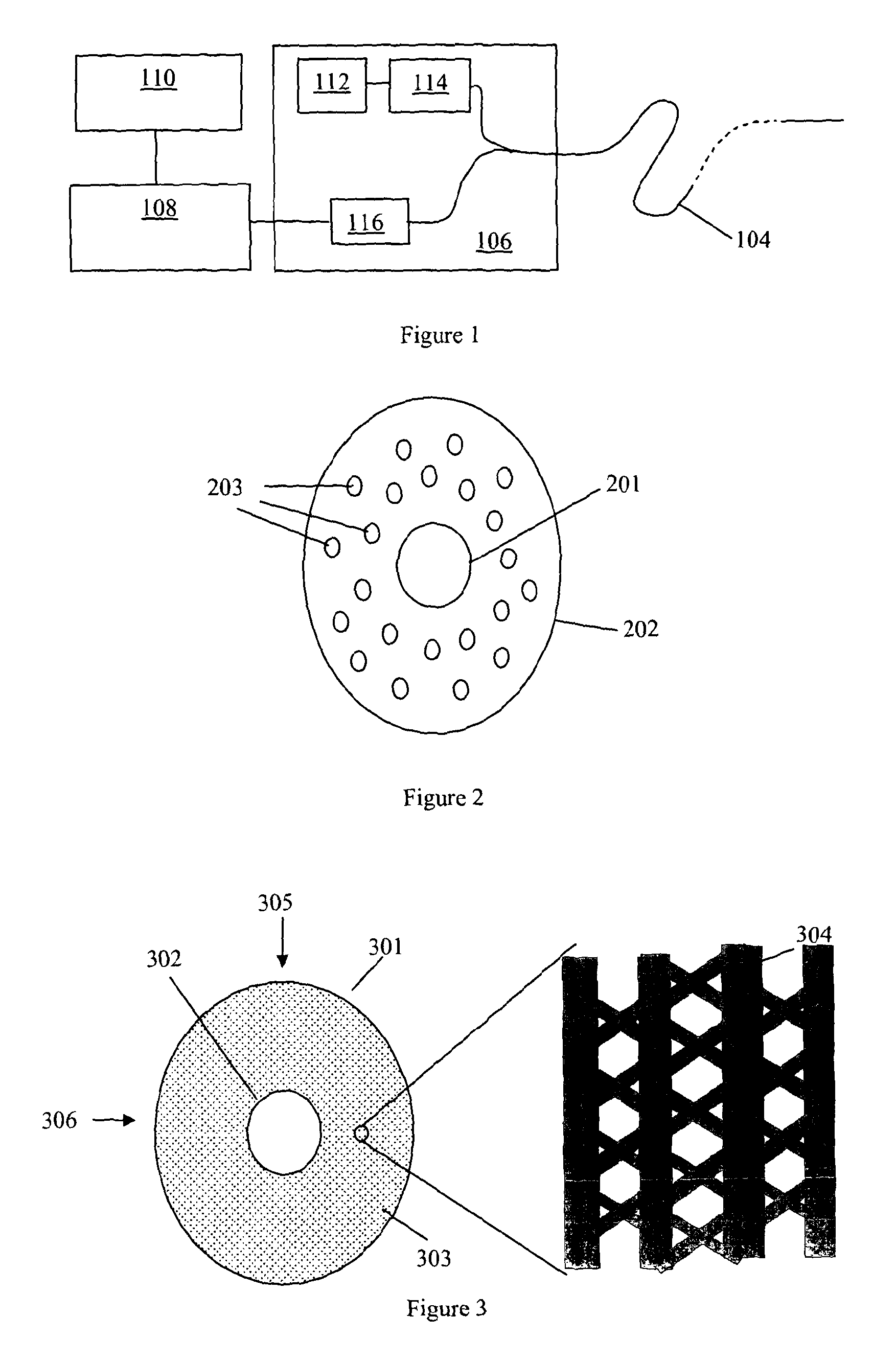

Fibre optic distributed sensing

ActiveUS9243949B2Enhance non-linear optical power thresholdGreat optical powerVibration measurement in solidsCladded optical fibreDistributed acoustic sensingMicrostructure fiber

This application describes methods and apparatus for fiber optic distributed acoustic sensing (DAS) where microstructured fiber (202), such as holey fiber or photonic crystal fiber is used as the sensing fiber (104). The microstructured fiber is configured so to provide at least one of enhanced sensitivity to a given incident acoustic signal; an enhanced non-linear optical power threshold and directional sensitivity. By configuring the microstructured fiber to be more compliant than an equivalent solid fiber and / or provide a large refractive index variation in response to applied strain, the response to a given acoustic stimulus may be larger than for the equivalent fiber, Providing a hollow core may allow higher optical powers and by providing a directionality to microstructured (304) allows the fiber to be used in a DAS system with a directional response.

Owner:OPTASENSE HLDG LTD

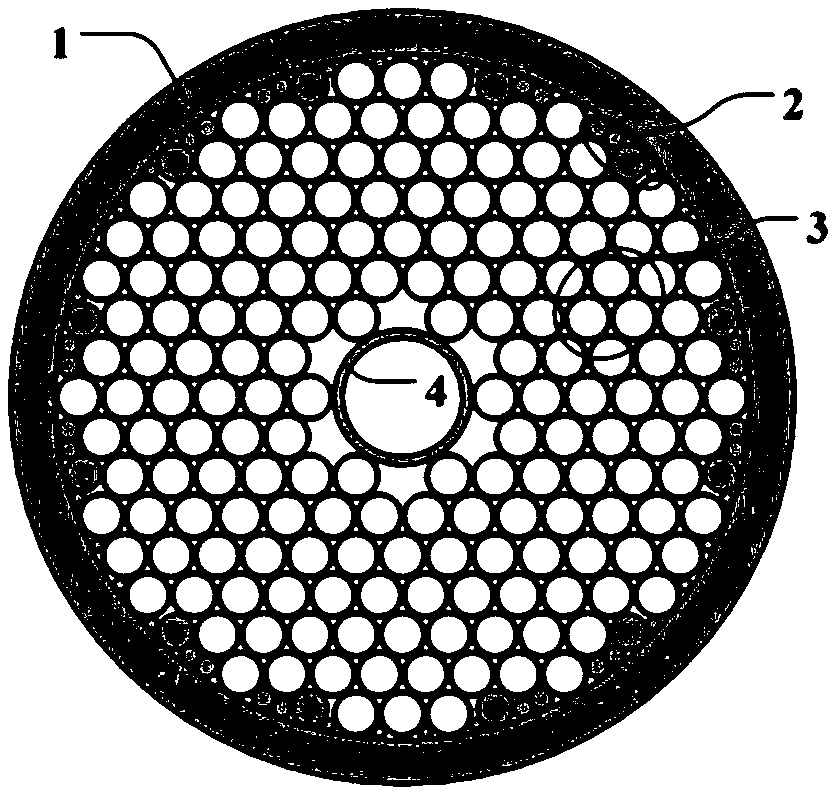

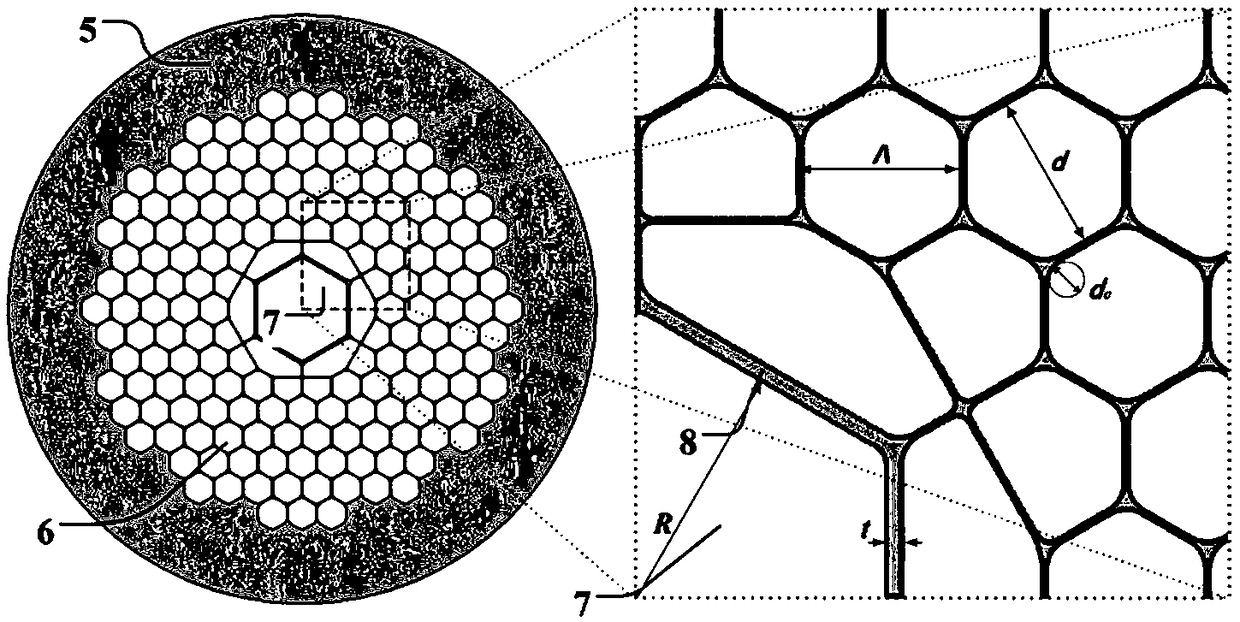

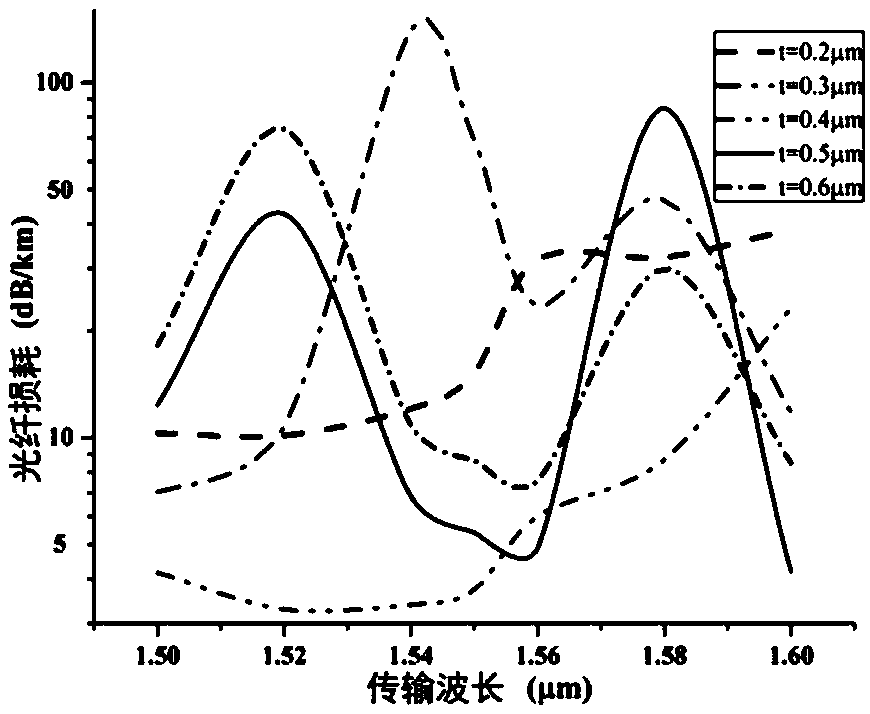

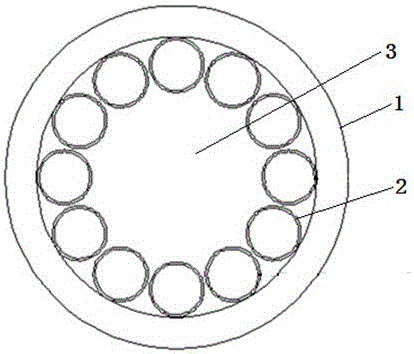

Hollow-core photonic band-gap fiber based on isolated anti-resonance layers

ActiveCN108919417AStrengthen restrictionsSuppress couplingGlass optical fibreOptical waveguide light guideMicrostructure fiberResonance

The invention discloses a hollow-core photonic band-gap fiber based on isolated anti-resonance layers and belongs to the technical field of microstructure fibers. A preparation method of the hollow-core photon band-gap fiber specifically comprises the steps that a complete stacked structure is formed through stacking of capillary tubes; after the capillary tube at the center of the stacked structure is removed, a fiber core glass tube is inserted; the periphery of the complete stacked structure is sleeved with a quartz sleeve to form a fiber preform rod; and the fiber perform rod is drawn through an existing hollow-core photonic band-gap fiber drawing method, a structure with the independent isolated anti-resonance layers is formed at the periphery of a fiber core, and thus the hollow-corephotonic band-gap fiber based on the isolated anti-resonance layers is formed. According to the hollow-core photonic band-gap fiber based on the isolated anti-resonance layers, the fiber core wall atthe fiber core is constituted by the isolated anti-resonance layers, limitation to light is enhanced, the scattering loss is reduced, and coupling between the hollow-core photonic band-gap fiber anda common single-mode fiber is facilitated.

Owner:BEIHANG UNIV

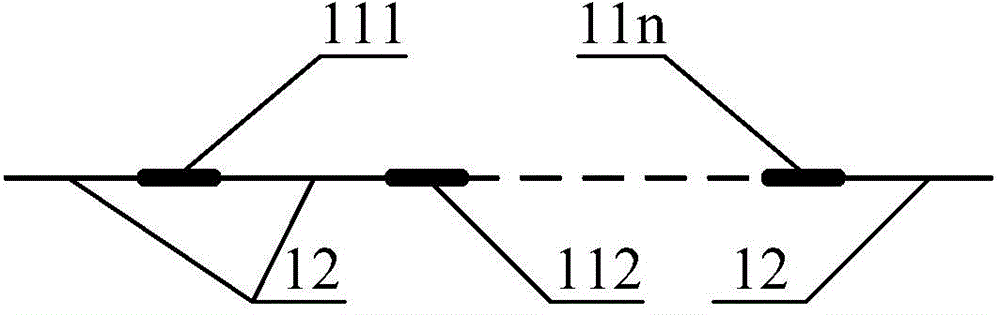

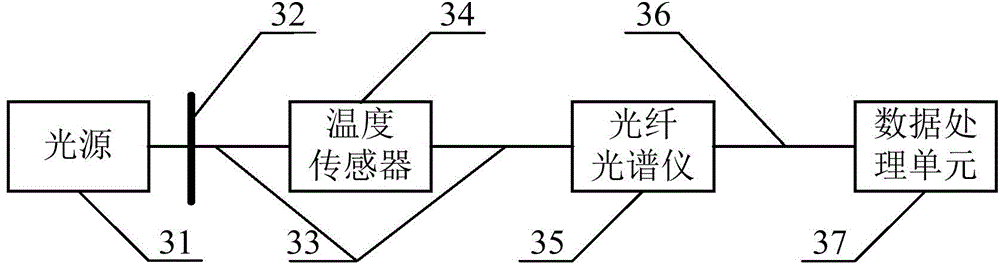

A microstructure fiber Bragg grating gas sensor and its detection device

The invention relates to a microstructure fiber Bragg grating gas sensor and a detection device. The conventional sensing schemes are all based on the analysis of transmission spectra, no specificity selection is required for the detected gas, and device structures are incompact. The gas sensor provided by the invention is composed of a segment of a single mode fiber and a segment of a microstructure fiber, the Bragg grating is respectively etched on the two segments, and the detection device using the sensor comprises an optical circulator, a broadband light source and a spectrograph, wherein the light emitted by the broadband light source is input into the sensor through the optical circulator, and the sensor reflects the light into the spectrograph for analysis, so that, the concentration of the gas to be detected can be obtained. The sensor and the device have the advantages of being simple and practical in structures, specific in gas identification, excellent in anti-interferenceperformance, adaptive to complex conditions, suitable for remote distributed sensing, and the like.

Owner:ZHEJIANG UNIV

Phase change temperature control fiber, yarn and fabric and application thereof

ActiveCN111826965AGood temperature control effectIncrease filling capacityLiquid repellent fibresMonocomponent polyolefin artificial filamentYarnMicrostructure fiber

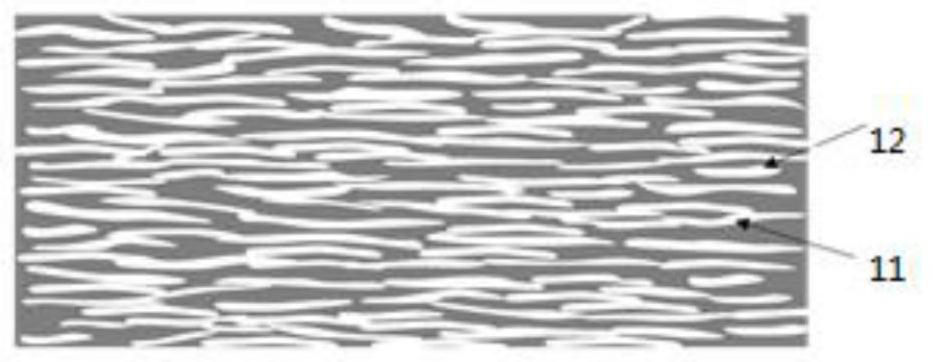

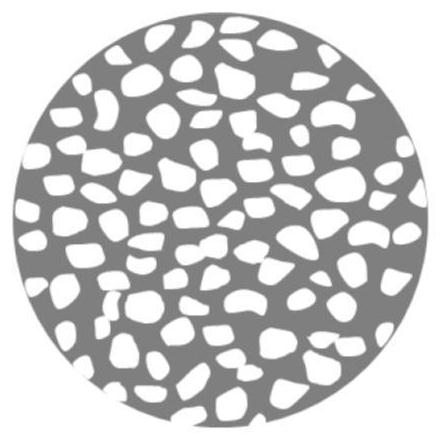

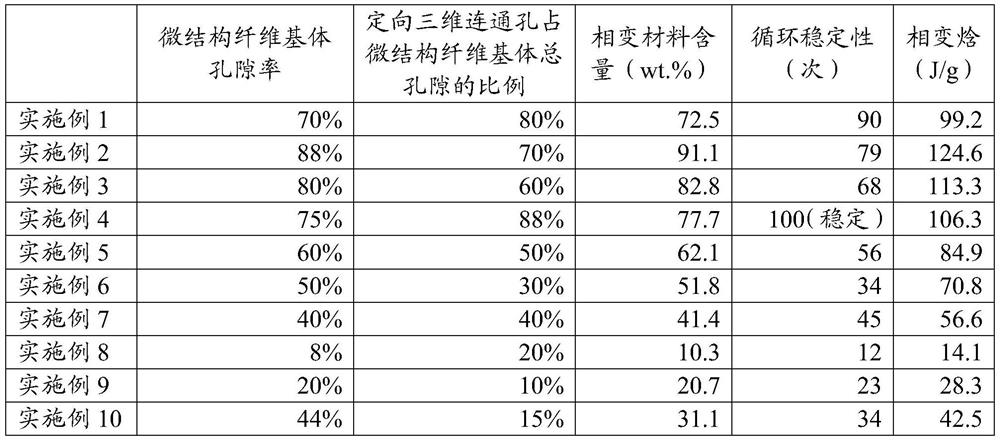

The invention provides a phase change temperature control fiber. The phase change temperature control fiber is characterized by comprising a microstructure fiber matrix and a phase change material, wherein the microstructure fiber matrix comprises three-dimensional communication holes, the phase change material fills the three-dimensional communication holes, and each three-dimensional communication hole is of a three-dimensional structure with two or more holes communicating with each other. Compared with the prior art, the phase change temperature control fiber has the following advantages:first, the filling loading capacity and cycling stability of the phase change material are improved through the fiber structure design; second, through fiber surface treatment and fiber internal doping technology, good water resistance and mechanical properties of the fiber are realized; finally, the phase change composite hydrophobic temperature control fiber provided by the invention has the functions of keeping warm and cooling in the aspect of temperature regulation and control; in the aspect of material selection, the universality is achieved, most of commercial fiber materials can be adopted, then the fiber is suitable for industrial amplification application, and meanwhile, different materials can be designed according to actual needs; and in the aspect of fabric forming, a phase change temperature control fabric can be directly woven by the phase-change fiber, and also can be woven after yarns are prepared.

Owner:武汉新润兴材料科技有限公司

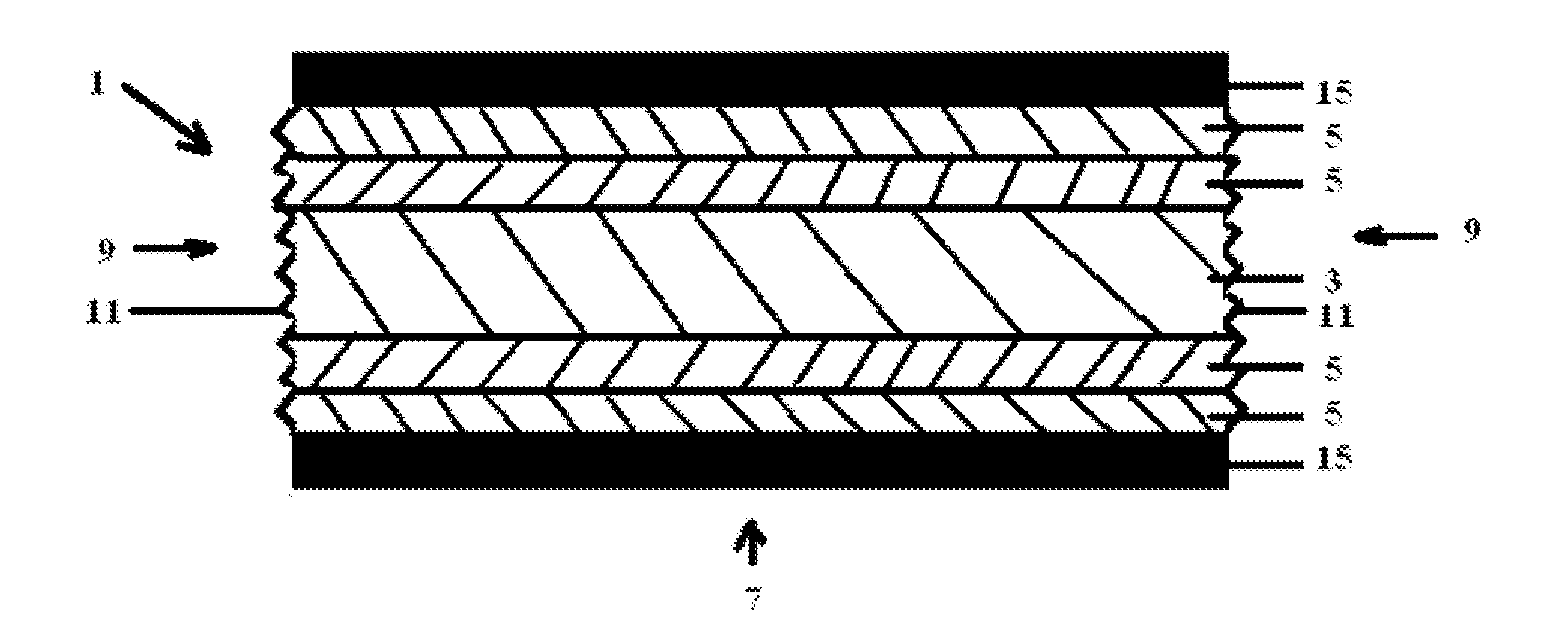

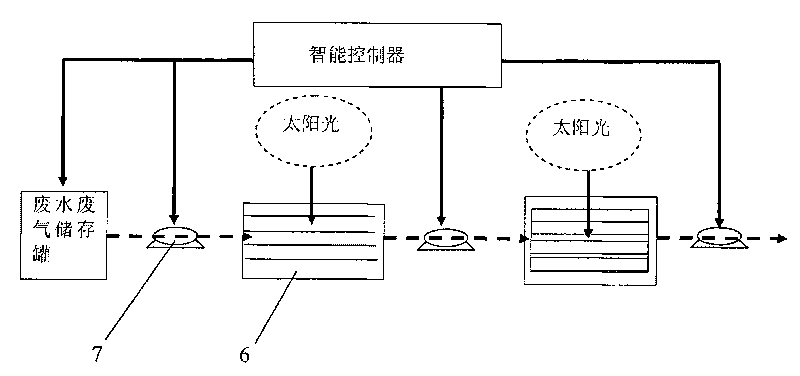

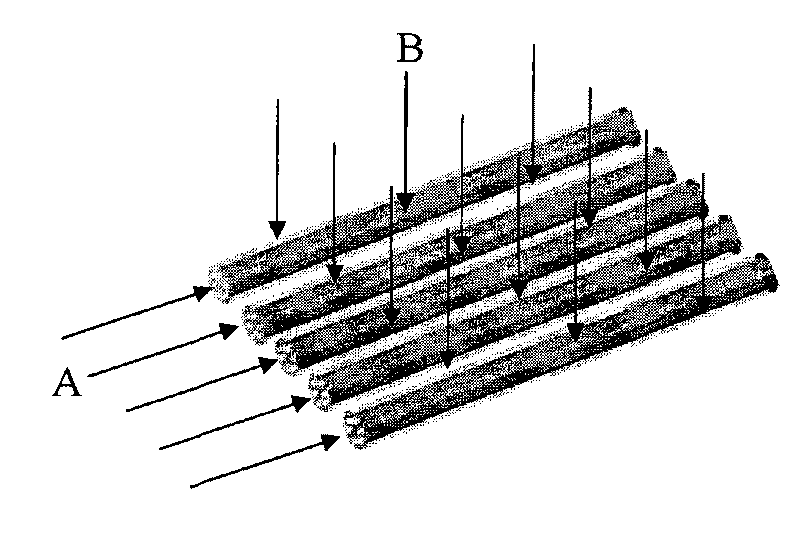

A waste water and waste gas photodegradation apparatus and system thereof

InactiveCN101746845AIncrease load rateInfinite scaleWater/sewage treatment by irradiationEnergy based wastewater treatmentMicrostructure fiberUltraviolet lights

The invention relates to a waste water and waste gas photodegradation apparatus. The apparatus comprises a microstructure fiber monomer; the microstructure fiber monomer comprises a fiber substrate, air pore channels and a cladding; the fiber substrate is arranged in the cladding; air pore channels are formed in the fiber substrate; and titanium dioxide nano-particles are arranged on the interior surfaces of the air pore channels. The apparatus greatly improves the loading rate of the titanium dioxide photocatalyst, and greatly enlarges the light receiving area so that the treatment system scale can be infinite and the apparatus lays the foundation for constructing one set of microstructure dispersion fiber load-based nano titanium dioxide photocatalysis waste water and waste gas treatment system; and a permeable ultraviolet light dispersion microstructure polymer fiber load titanium dioxide enables the apparatus to efficiently absorb ultraviolet light on long-distance side, further enlarge the light receiving area and improve the photocatalysis efficiency.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

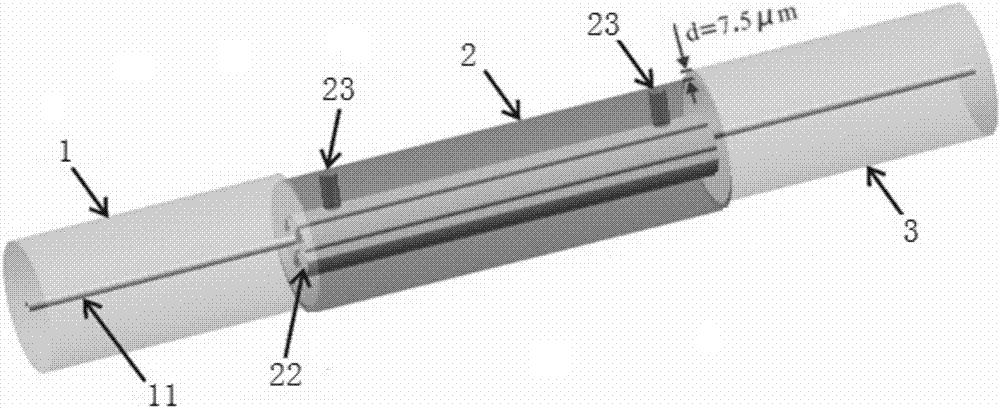

High sensitivity compact M-Z interference temperature sensor and manufacturing method thereof

InactiveCN106959172AHigh sensitivityObvious double beam interference effectThermometers using physical/chemical changesMicrostructure fiberOptoelectronics

The invention provides a high sensitivity compact M-Z interference temperature sensor and a manufacturing method thereof; the sensor comprises an input single-mode fiber, a microstructure fiber and an output single-mode fiber connected in sequence; the microstructure fiber is placed under a tested environment; the fiber core of the input single-mode fiber is respectively connected with the microstructure fiber core and an air hole filled with a high heat optical coefficient medium, thus using the microstructure fiber core to transmit partial the input single-mode fiber output light to the output single-mode fiber, and using the microstructure fiber air hole filled with the high heat optical coefficient medium to transmit the residual light to the output single-mode fiber; the output single-mode fiber transmits the received light to a spectral analyzer for spectral analysis, thus determining the temperature of the tested environment according to the spectral analysis result. The high heat optical coefficient medium is filled in the microstructure fiber, thus providing the high sensitivity super compact structure M-Z temperature sensor.

Owner:CHONGQING UNIV

Hollow-core microstructure fiber with high damage threshold

InactiveCN106814421AHigh damage thresholdOptical fibre with multilayer core/claddingOptical waveguide light guideGuiding PrinciplesHigh energy

The invention relates to a hollow-core microstructure fiber with high damage threshold, which can transmit high-energy and high-power pulse laser. An inner cladding composed of 11 to 15 quartz micro capillaries arranged at intervals is arranged around the inner wall of a quartz glass tube of an outer cladding; the parts of the 11 to 15 quartz micro capillaries, in contact with the inner wall of the quartz glass tube, are fixed on the inner wall of the quartz glass tube in a welding manner; the middle parts of the 11 to 15 quartz micro capillaries, namely the innermost layers, are a fiber core area with low refractive index; and the fiber core area with low refractive index is filled with inert gas or air or vacuum. The hollow-core microstructure fiber has the beneficial effects that the inner cladding is composed of 11 to 15 mutually separated quartz micro capillaries, namely hollow-core microstructure fibers; and light is transmitted in a hollow-core fiber core by using an anti-resonance guide principle in the structure, so that most of the transmitted light energy exists in the fiber core with low refractive index, the damage threshold of the fiber is improved, and the foundation is laid for laser transmission with high energy and high power.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

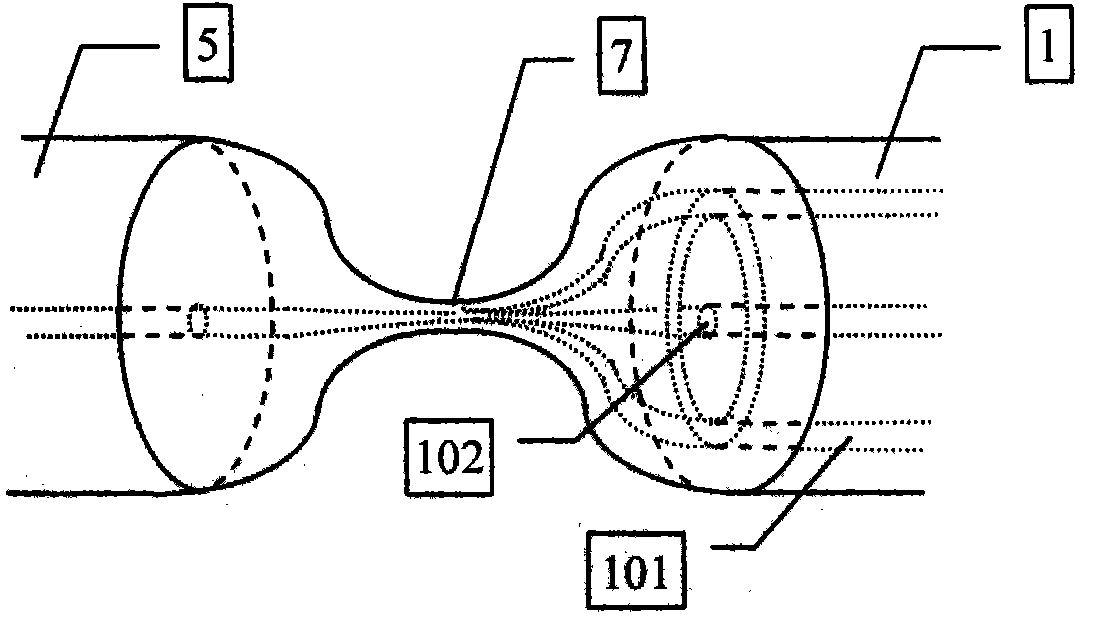

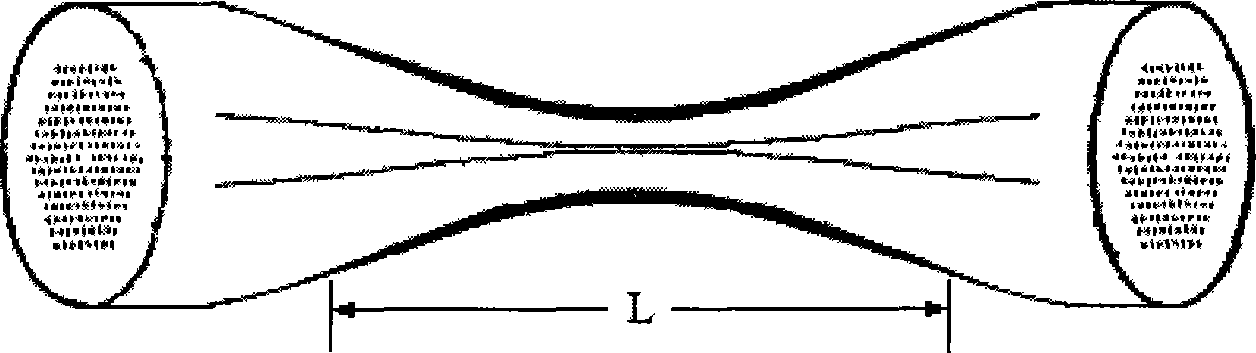

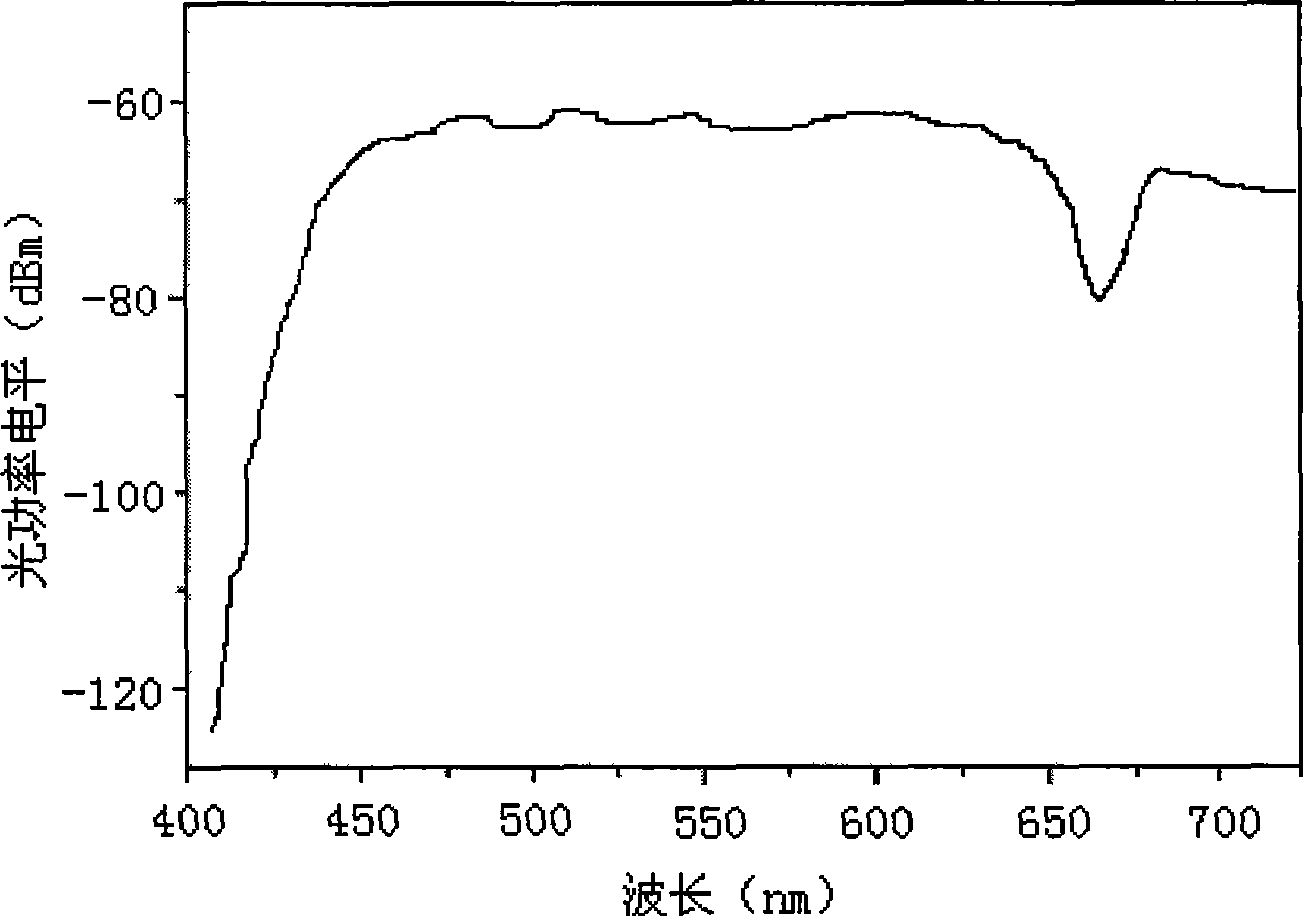

All-optical fiber interferometer

InactiveUS20100265514A1Introduce minimal lossesSimplifies their connectorizationCladded optical fibreUsing optical meansVisibilityFrequency spectrum

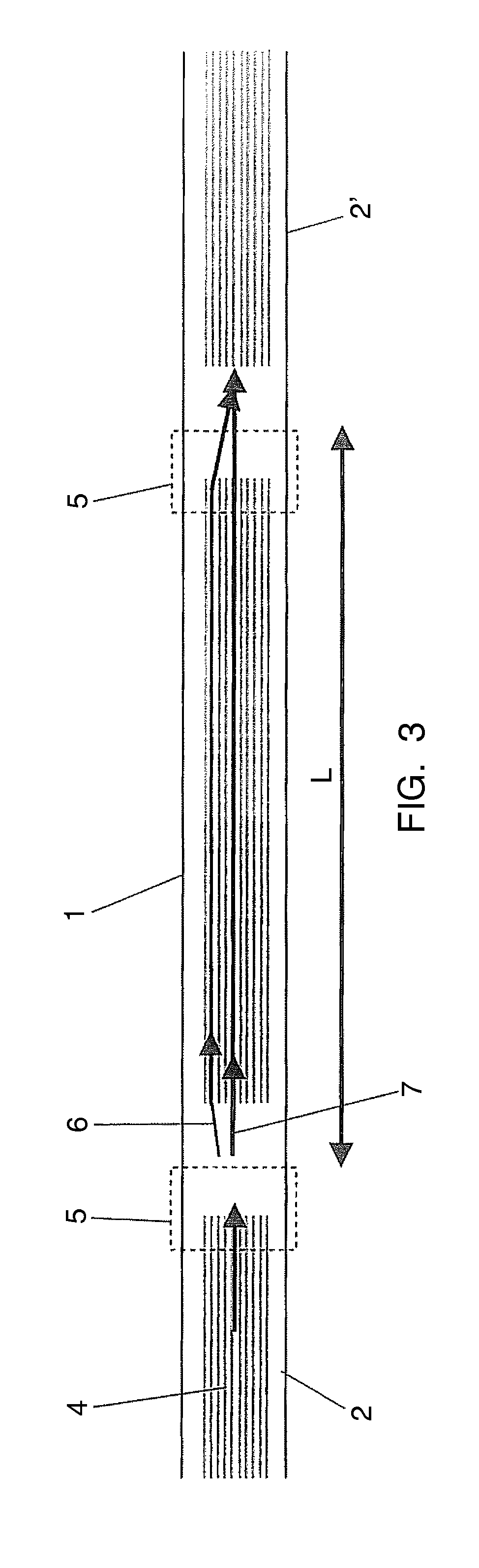

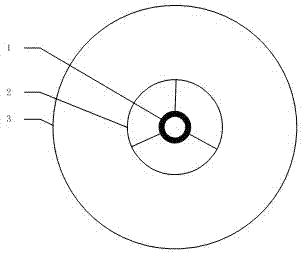

A compact and stable interferometer is easily built only with fusion splices. The air-holes of a microstructured fiber are intentionally collapsed in the vicinity of the splices and this broadens the propagating optical mode, allowing coupling from core to cladding modes. The transmission spectrum is sinusoidal and of single frequency, indicating predominant interference between the fundamental core mode (7) and a cladding mode (6). A regular interference spectrum can be observed from 650 nm to 1600 nm with fringe visibility reaching 80%. The fringe spacing is inversely proportional to the distance between the splices. This behaviour has a significant impact in optical sensing and communications and so the interferometer can be applied for strain sensing. The device comprises two splices (5) of a microstructured optical fiber (1), said splices (5) determining two regions in which the air-holes (4) are collapsed, separated a length (L) along which said two modes are excited.

Owner:INST DE CIENCIAS FOTONICAS +1

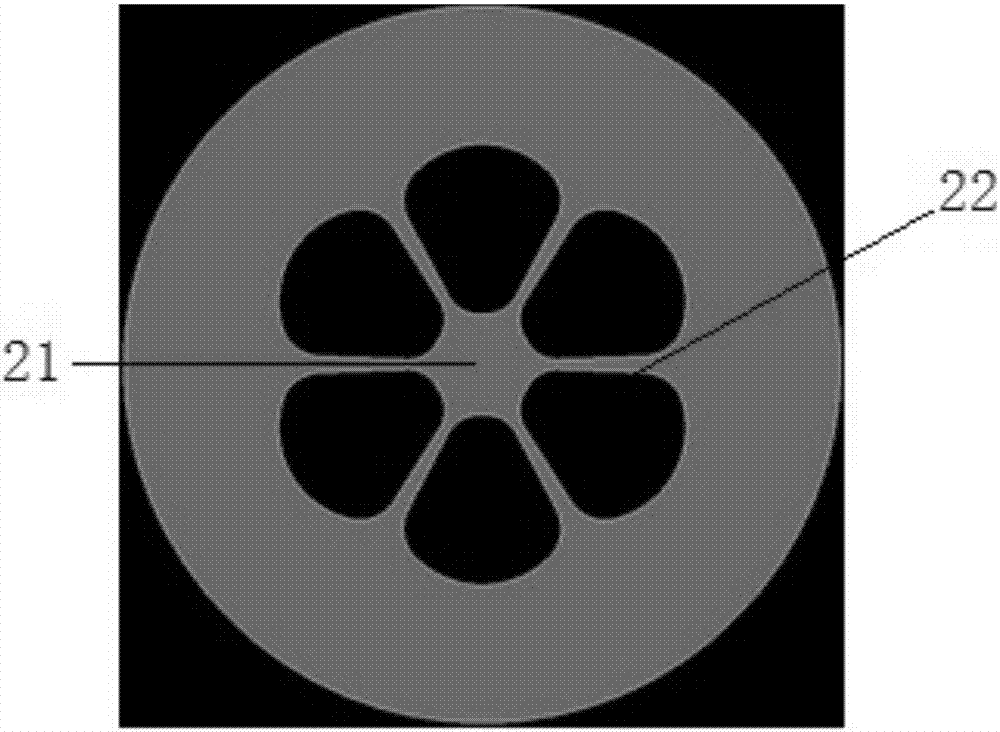

Sensing head of fluorescent fiber sensor and preparation method of sensing head

InactiveCN103616362AImprove stabilityHigh fluorescence intensityFluorescence/phosphorescenceMicrostructure fiberMethacrylate methyl

The invention relates to a sensing head of a fluorescent fiber sensor. The sensing head of the fluorescent fiber sensor is of a wheel-shaped microstructure and comprises a fiber core, a coating layer and an air hole, wherein the fiber core and the coating layer are connected through tiepieces; and the inner wall of the air hole is coated with one layer of nanogold / methyl methacrylate with the thickness of 20 nm. A preparation method of the sensing head of the fluorescent fiber sensor comprises the following steps: preparing the nanogold / methyl methacrylate; coating the nanogold / methyl methacrylate on the inner wall of the air hole of the wheel-shaped microstructure fiber; and after coating is finished, roasting for 6 hours by controlling the temperature to be 50 DEG C so as to volatilize a dichloromethane solvent to obtain the sensing head of the fluorescent fiber sensor. Compared with the like products, the sensing head of the fluorescent fiber sensor has the advantages that the lower limit and the sensitivity of fluorescent detection of the sensing head can be increased by 20 times; the required sample amount is at nL amount order.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Microstructure fiber with fiber core modified by inverse opal and preparation method thereof

InactiveCN102226847AWith blocking filter effectAchieve any frequency selectionFrom gel statePolycrystalline material growthMicrosphereMicrostructure fiber

The invention discloses a microstructure fiber with fiber core modified by inverse opal (3DOM three dimensional ordered macroporous material). The method mainly comprises the following steps: preparing a PS or PMMA colloid microballoon solution, and adding a predecessor solution (TEOS or TiBALDH) into the colloid microballoon solution in a certain proportion; growing a segment of colloid crystal in a capillary with a Sol-gel cooperation self assembly method, forming predecessor gel when colloid crystal gap moisture is reduced, and sintering the capillary at high temperature in a box-type furnace and removing the colloid crystal to form an inverse opal composition; vertically cutting two common standard fibers after part coating is removed, inserting the two fibers into the capillary from two ends of the capillary to the inverse opal composition, fixing the fibers with glue, and fixing and packaging the capillary and fibers with a thermoplastic cannula. The microstructure fiber prepared in the invention can be used as a fiber filter and a biomedical sensing member. By using a common standard fiber in preparation, the microstructure fiber can connects a present fibre-optical communication network to facilitate the realization of all-optical sensing network. The microstructure fiber has the advantages of simple preparation, reliability and strong versatility.

Owner:NANJING NORMAL UNIVERSITY

Fiber optic cables and assemblies and the performance thereof

InactiveUS7680380B2Small component sizeTight toleranceOptical fibre with multilayer core/claddingOptical waveguide light guideUltrasound attenuationMicrostructure fiber

A fiber optic jumper assembly comprising at least one bend performance optical fiber comprising a core region and a cladding region surrounding the core region, the cladding region comprising an annular hole-containing region comprised of non-periodically disposed holes, a protective covering positioned over the at least one bend performance optical fiber, and at least one connector mounted upon each end of the at least one bend performance optical fiber. A preconnectorized fiber optic jumper assembly comprising a microstructured fiber having a delta attenuation of 0.00 dB at 5 wraps about a 6 mm diameter at a reference wavelength of 1625 nm.

Owner:CORNING OPTICAL COMM LLC

Lifetime extending and performance improvements of micro-structured fibres via high temperature loading

InactiveCN101681079AExtend your lifePromote absorptionNon-linear opticsMicrostructured optical fibreMicrostructure fiberChemistry

The invention relates to an optical fibre comprising a core and a cladding comprising a core material and a cladding material, respectively, wherein said fibre is a non-linear microstructured opticalfibre, said microstructured optical fibre being obtainable by a method comprising loading said core material and optionally said cladding material with hydrogen and / or deuterium whereby the lifetime of the fibre may be extended in high pulse applications.

Owner:KOHERAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com