Optical fiber sensor of plasma resonance microstructure

A plasmonic resonance, microstructure fiber technology, applied in instruments, scientific instruments, material analysis by optical means, etc., can solve the problems of bulky, difficult real-time detection, etc., achieve small size, compact structure, strong anti-interference ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

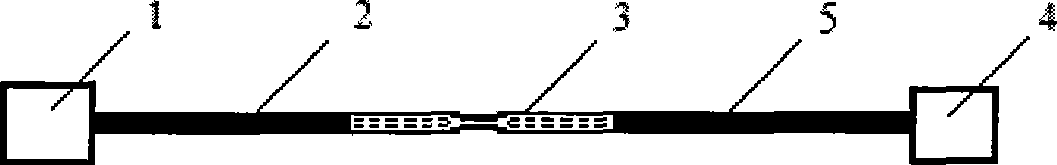

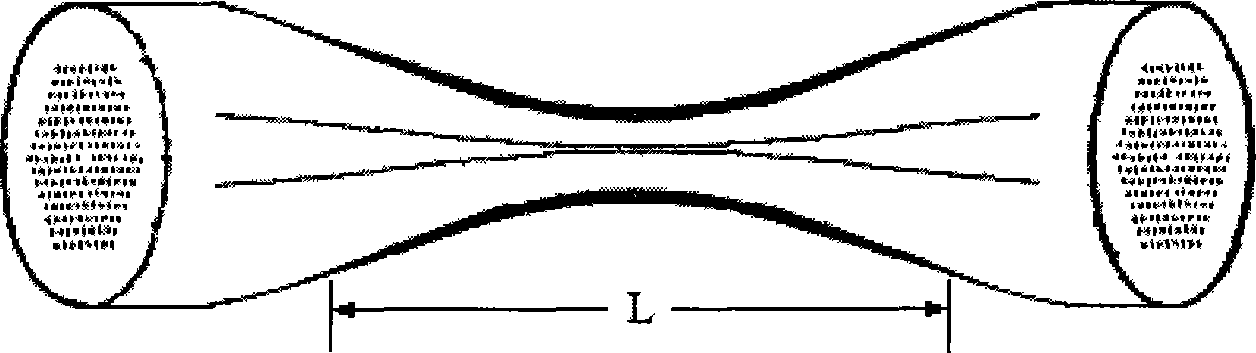

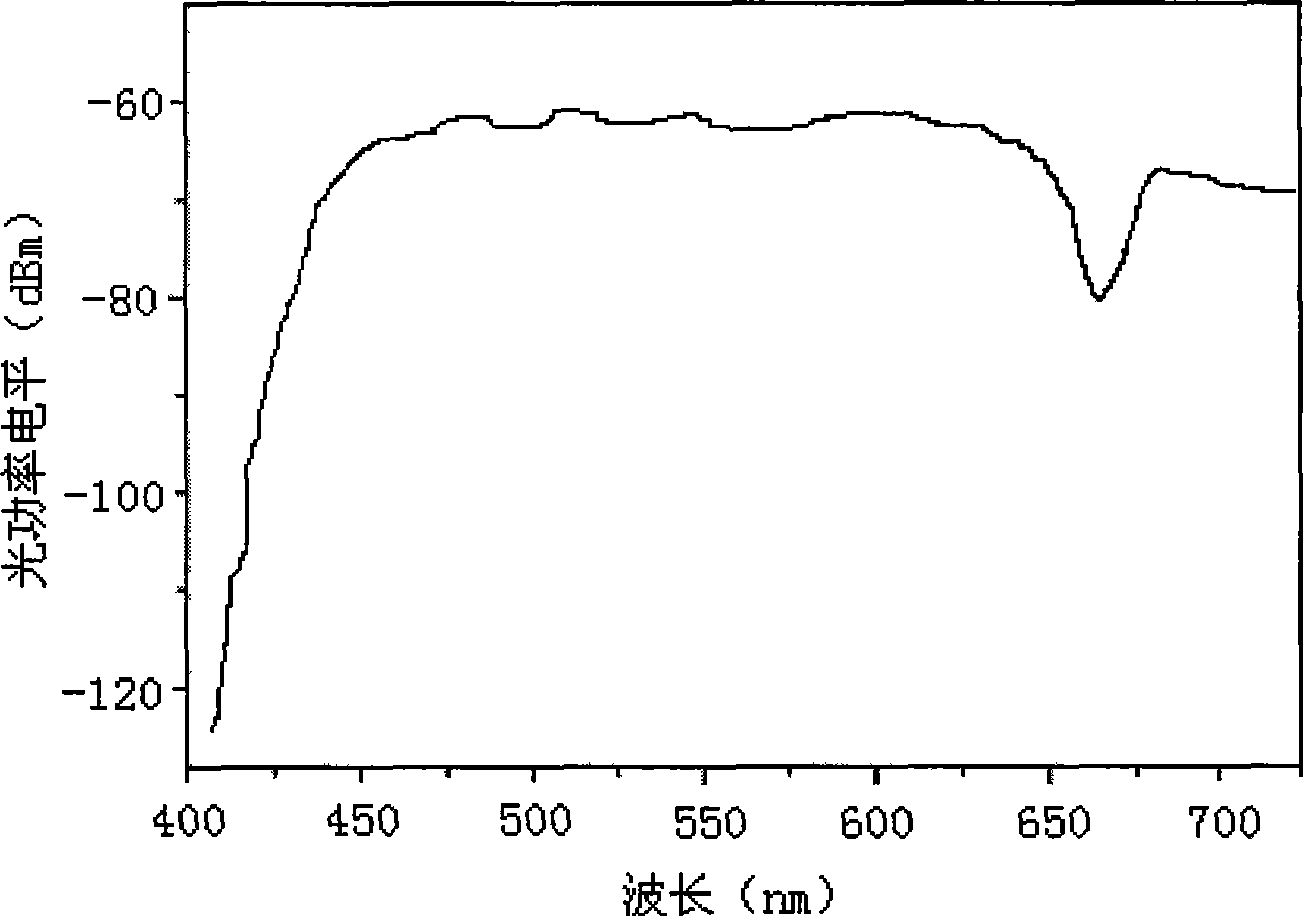

[0020] refer to figure 1 , figure 2 , the plasmon resonance microstructure optical fiber sensor of the present invention comprises: a light source 1, two common single-mode optical fibers 2, 5, a microstructured optical fiber 3 and a photodetector 4, one end of the first common single-mode optical fiber 2 and the light source 1 connection, the other end of the first common single-mode fiber 2 is connected to one end of the microstructured fiber 3, the other end of the microstructured fiber 3 is connected to one end of the second common single-mode fiber 5, and the second common single-mode fiber 5 The other end is connected with the photodetection system 4. The micro-structured optical fiber is formed by tapering a photonic crystal fiber with a parallelepipedic cross-section and a two-dimensional periodic structure. The surface of the tapered segment L is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com