Patents

Literature

2455 results about "Metal membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

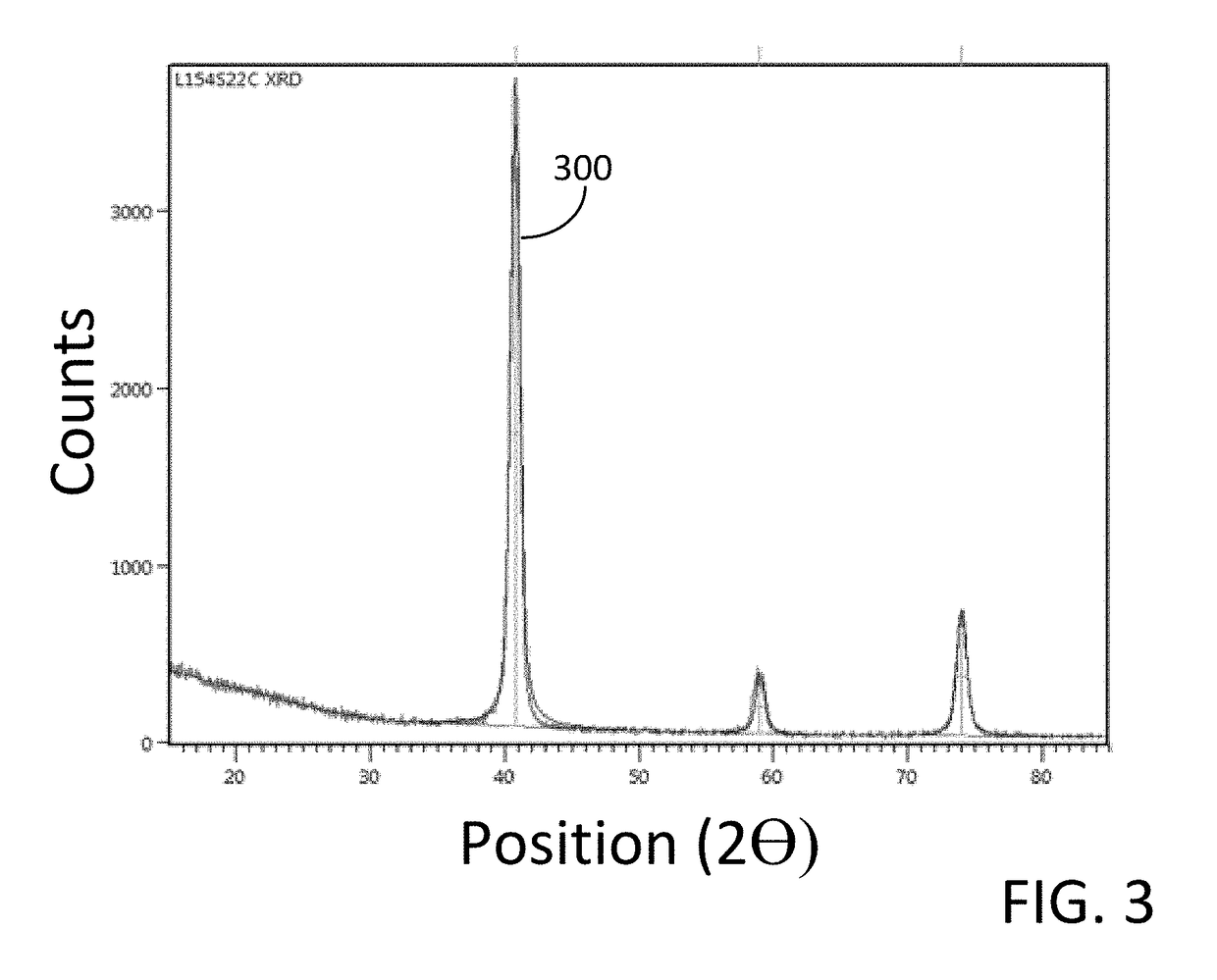

Process for Preparing Graphene on a SiC Substrate Based on Metal Film-Assisted Annealing

ActiveUS20140367642A1Simply and energy-efficientFlat surfaceMaterial nanotechnologyVacuum evaporation coatingCarbon filmElectron beam deposition

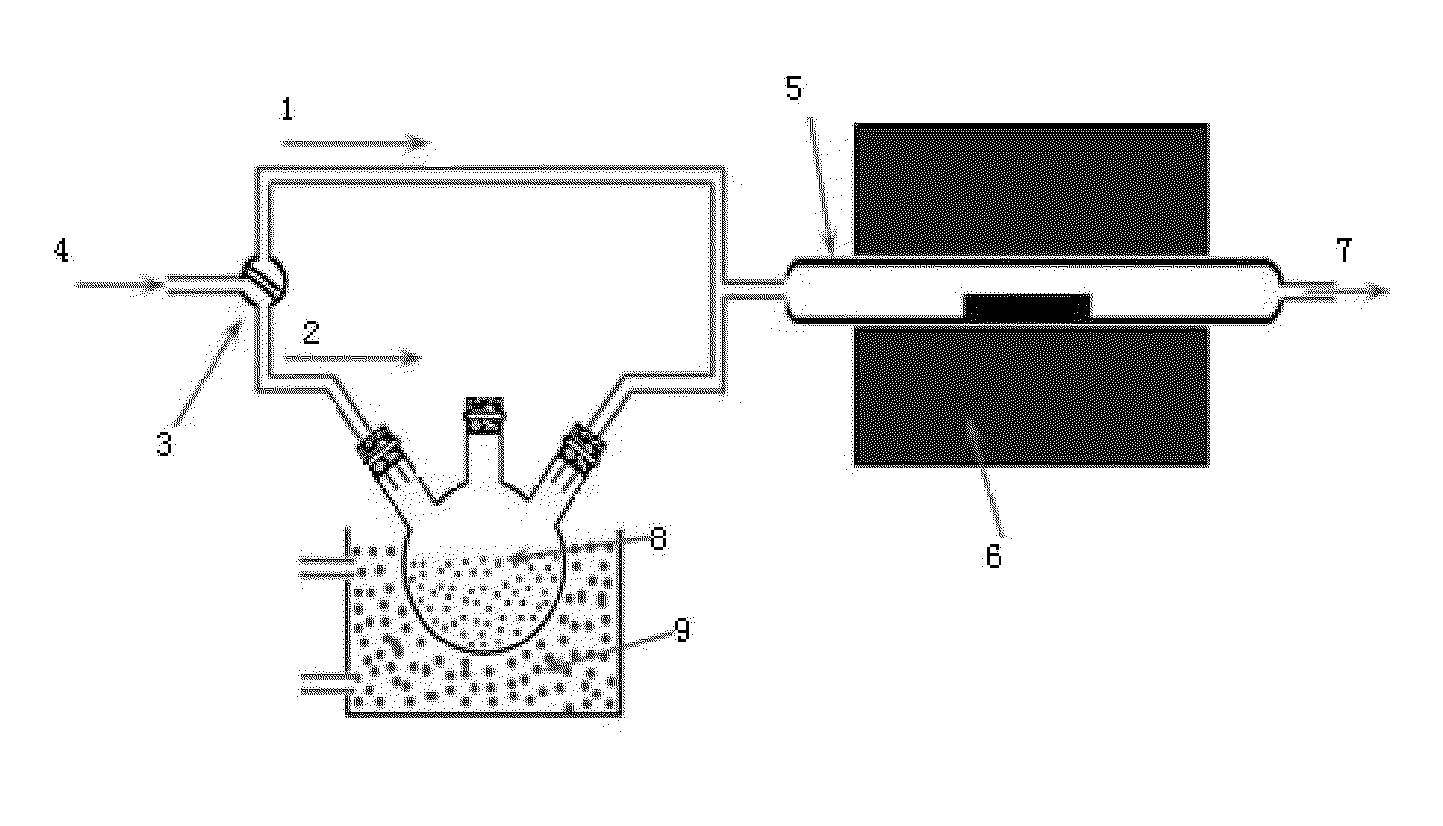

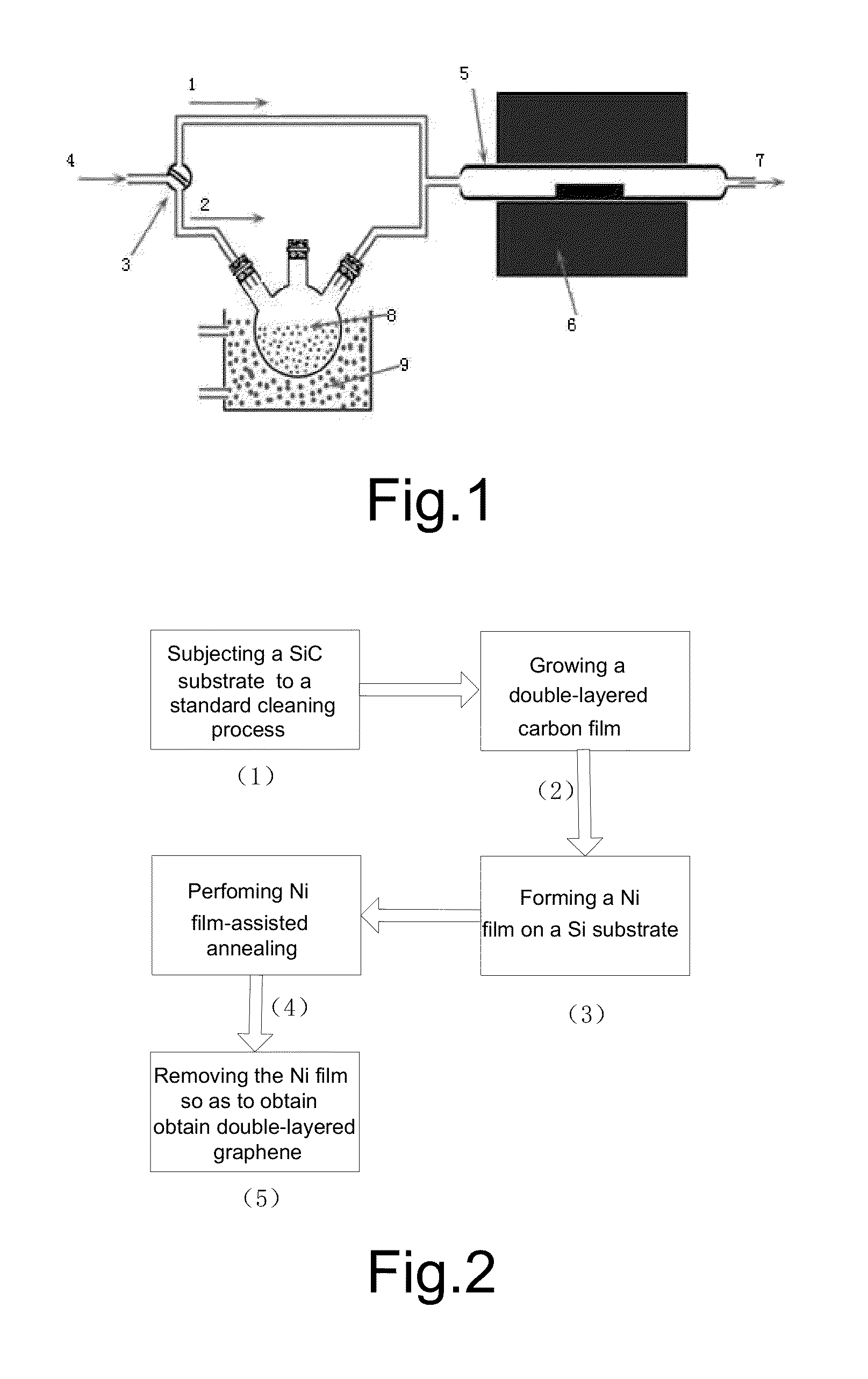

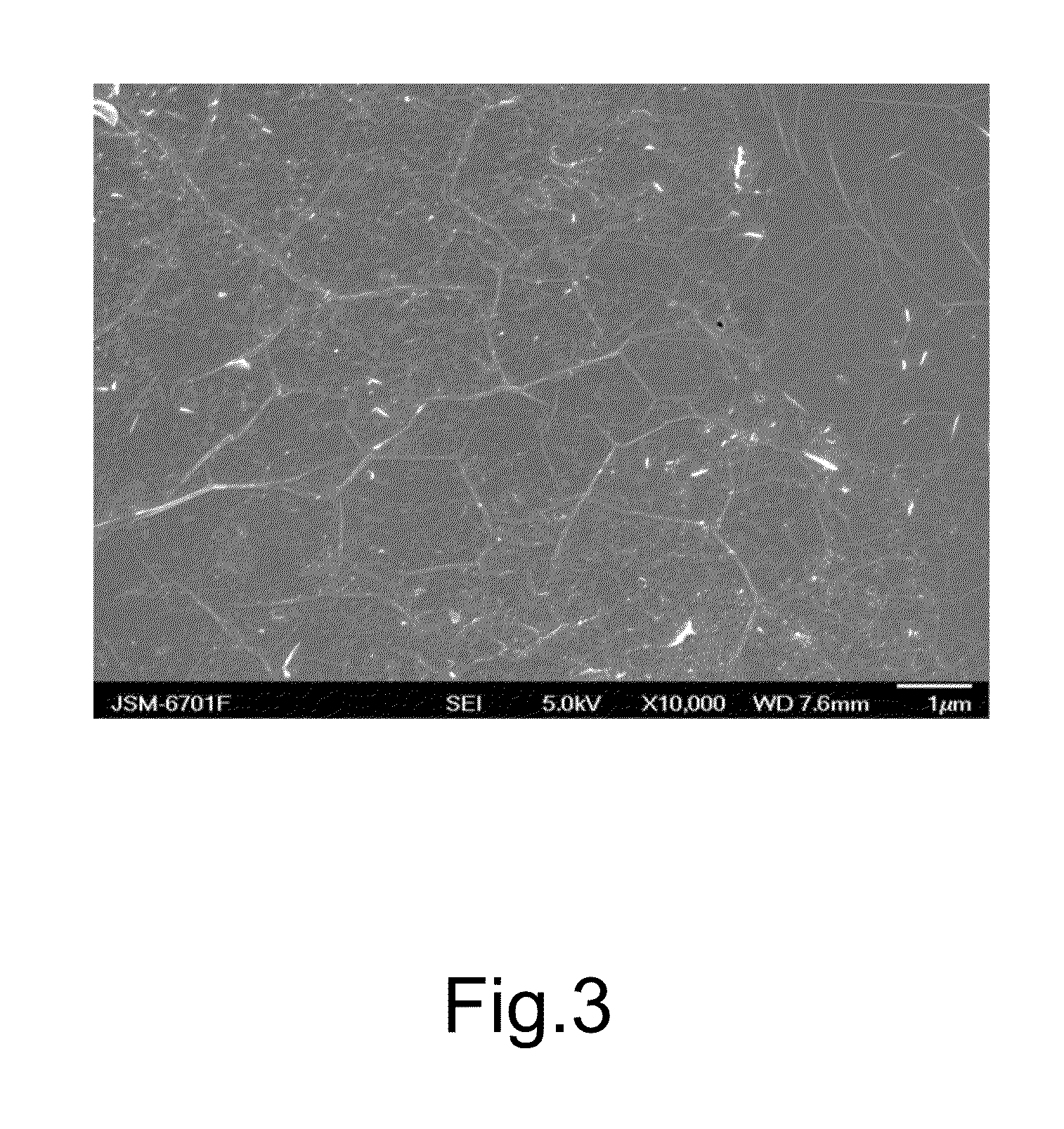

Provided is a process for preparing graphene on a SiC substrate, based on metal film-assisted annealing, comprising the following steps: subjecting a SiC substrate to a standard cleaning process; placing the cleaned SiC substrate into a quartz tube and heating the quartz tube up to a temperature of 750 to 1150° C.; introducing CCl4vapor into the quartz tube to react with SiC for a period of 20 to 100 minutes so as to generate a double-layered carbon film, wherein the CCl4 vapor is carried by Ar gas; forming a metal film with a thickness of 350 to 600 nm on a Si substrate by electron beam deposition; placing the obtained double-layered carbon film sample onto the metal film; subsequently annealing them in an Ar atmosphere at a temperature of 900 to 1100° C. for 10-30 minutes so as to reconstitute the double-layered carbon film into double-layered graphene; and removing the metal film from the double-layered graphene, thereby obtaining double-layered graphene. Also provided is double-layered graphene prepared by said process.

Owner:XIDIAN UNIV

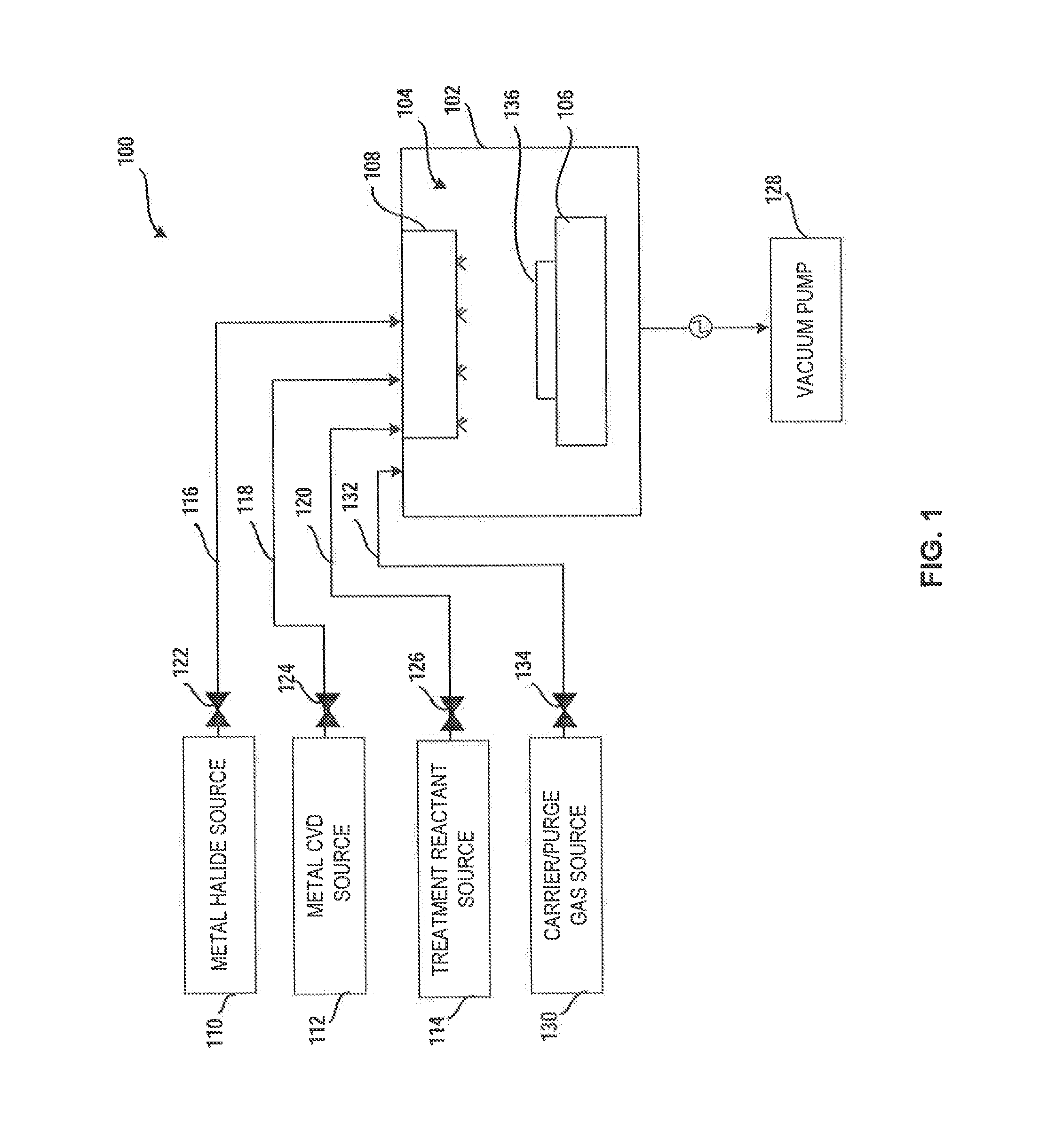

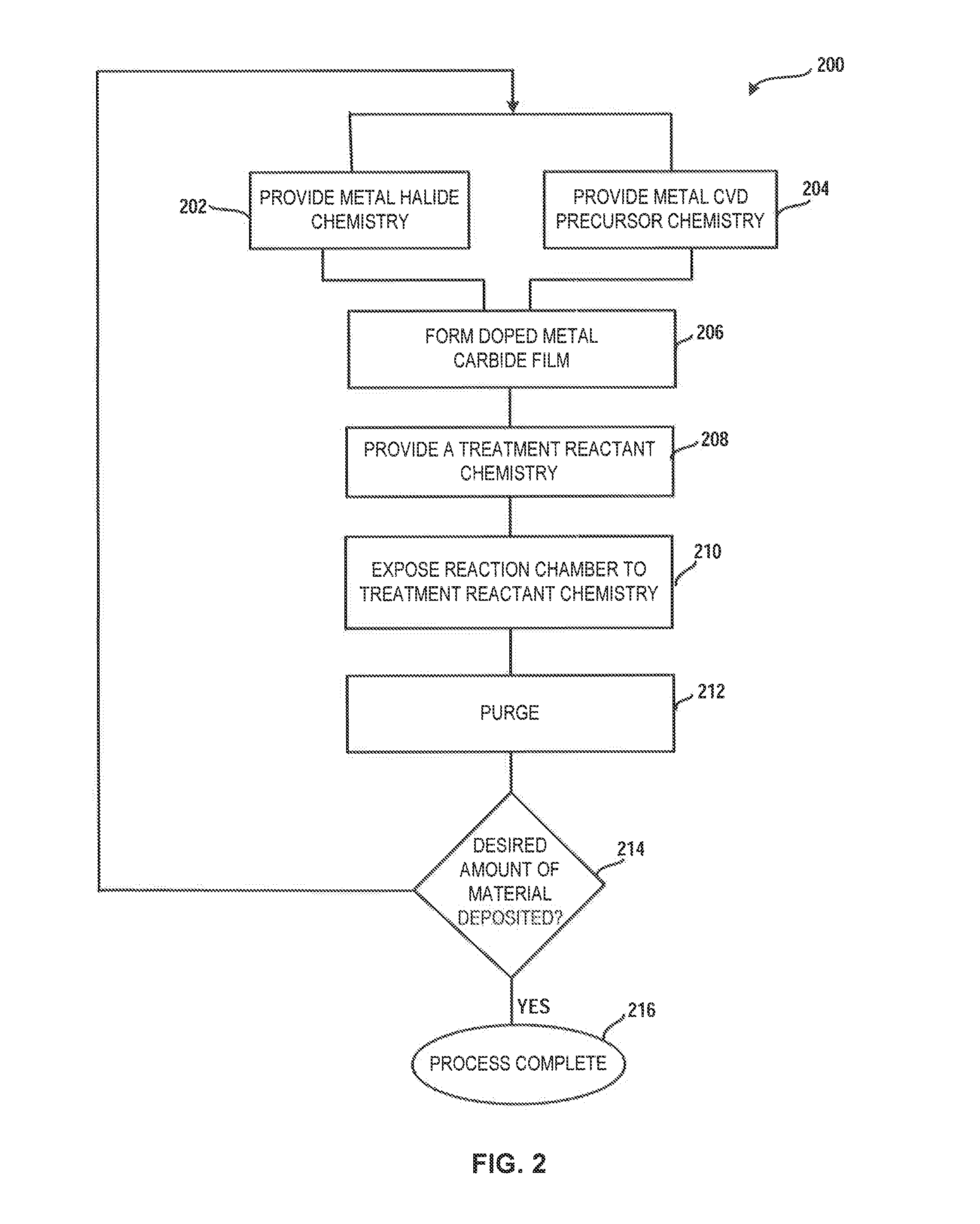

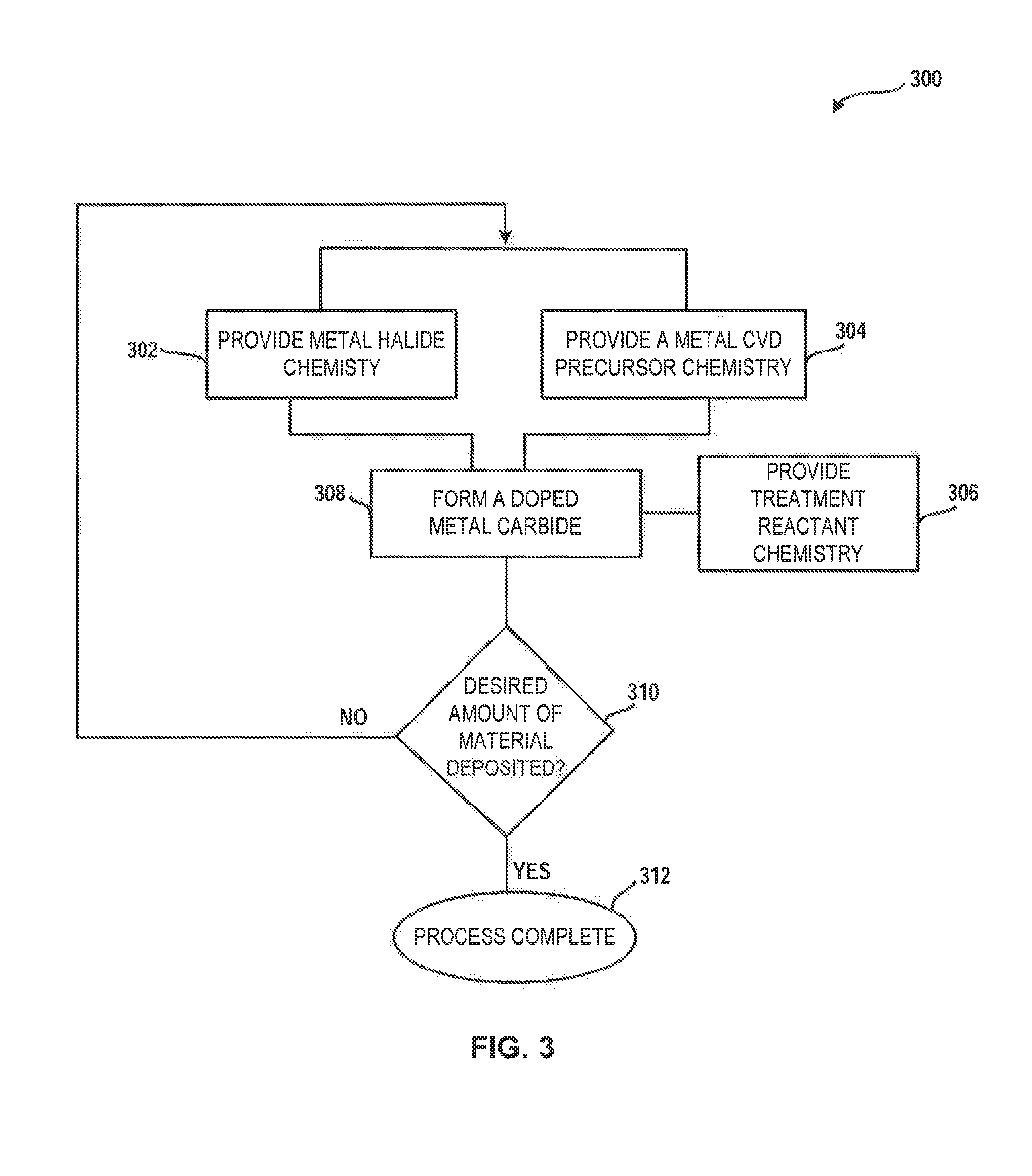

Method and system for treatment of deposition reactor

ActiveUS20140220247A1Substrate throughput can be increasedReduce operating costsSemiconductor/solid-state device manufacturingChemical vapor deposition coatingTitanium carbideMetal membrane

A system and method for treating a deposition reactor are disclosed. The system and method remove or mitigate formation of residue in a gas-phase reactor used to deposit doped metal films, such as aluminum-doped titanium carbide films or aluminum-doped tantalum carbide films. The method includes a step of exposing a reaction chamber to a treatment reactant that mitigates formation of species that lead to residue formation.

Owner:ASM IP HLDG BV

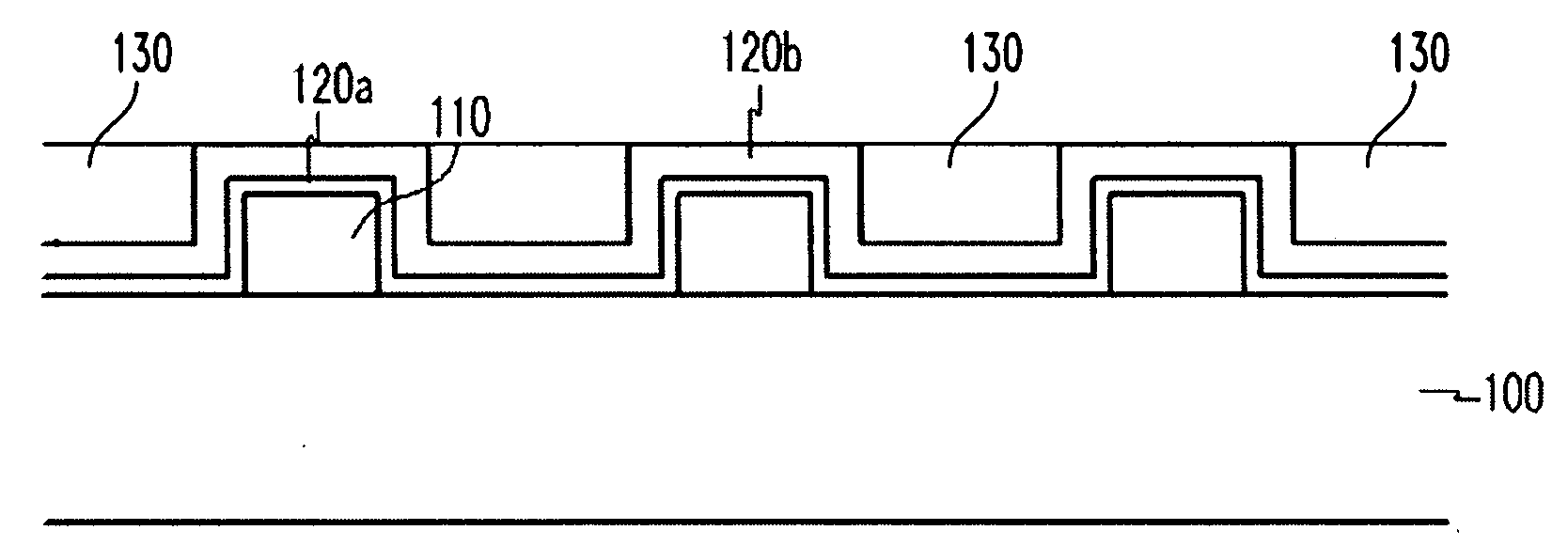

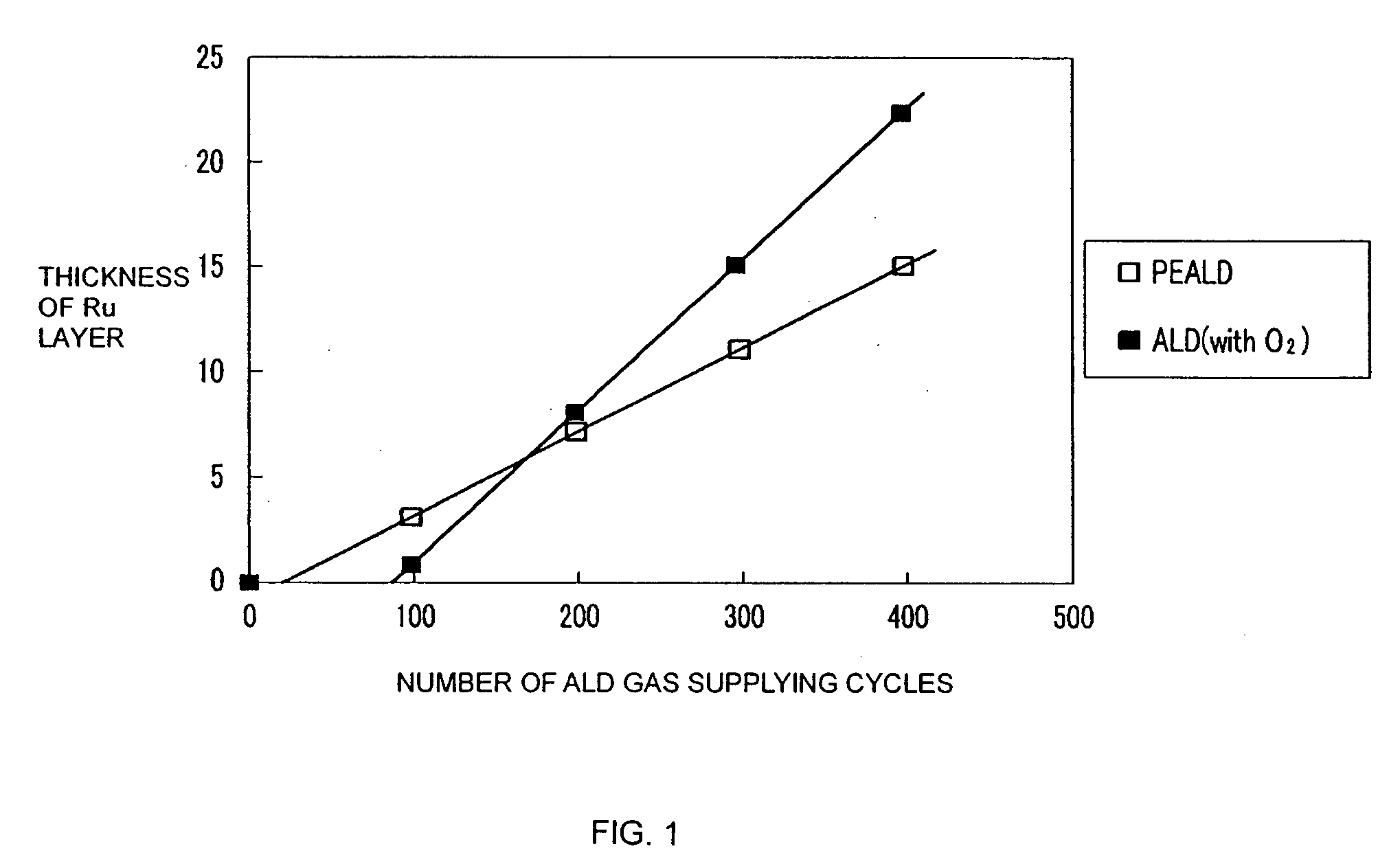

Method of depositing Ru films having high density

ActiveUS20070190782A1Good step coverageHigh densityData processing applicationsSemiconductor/solid-state device detailsHigh densityRuthenium

A ruthenium film deposition method is disclosed. In one embodiment of the method, a first ruthenium film is deposited by using a PEALD process until a substrate is substantially entirely covered with the first ruthenium film. Then, a second ruthenium film is deposited on the first ruthenium film by using a thermal ALD process having a higher deposition speed than that of the PEALD process. In the method, a ruthenium metal film having a high density is formed in a short time by combining a PEALD process of depositing a ruthenium film at a low deposition speed and a deposition process of depositing a ruthenium film at a higher deposition speed. Accordingly, it is possible to form a ruthenium film having high density, a smooth surface, good adhesiveness, and a short incubation period. Therefore, according to the embodiment, in comparison to cases of using only a PEALD process or an ALD process that has a long incubation period, it is possible to obtain a ruthenium film having a large thickness and a high density in the same time interval. As a result, the ruthenium film formed by the ruthenium film deposition method according to the embodiment is more suitable for electrode structures of semiconductor devices than the ruthenium films formed by using conventional methods.

Owner:ASM KOREA LTD

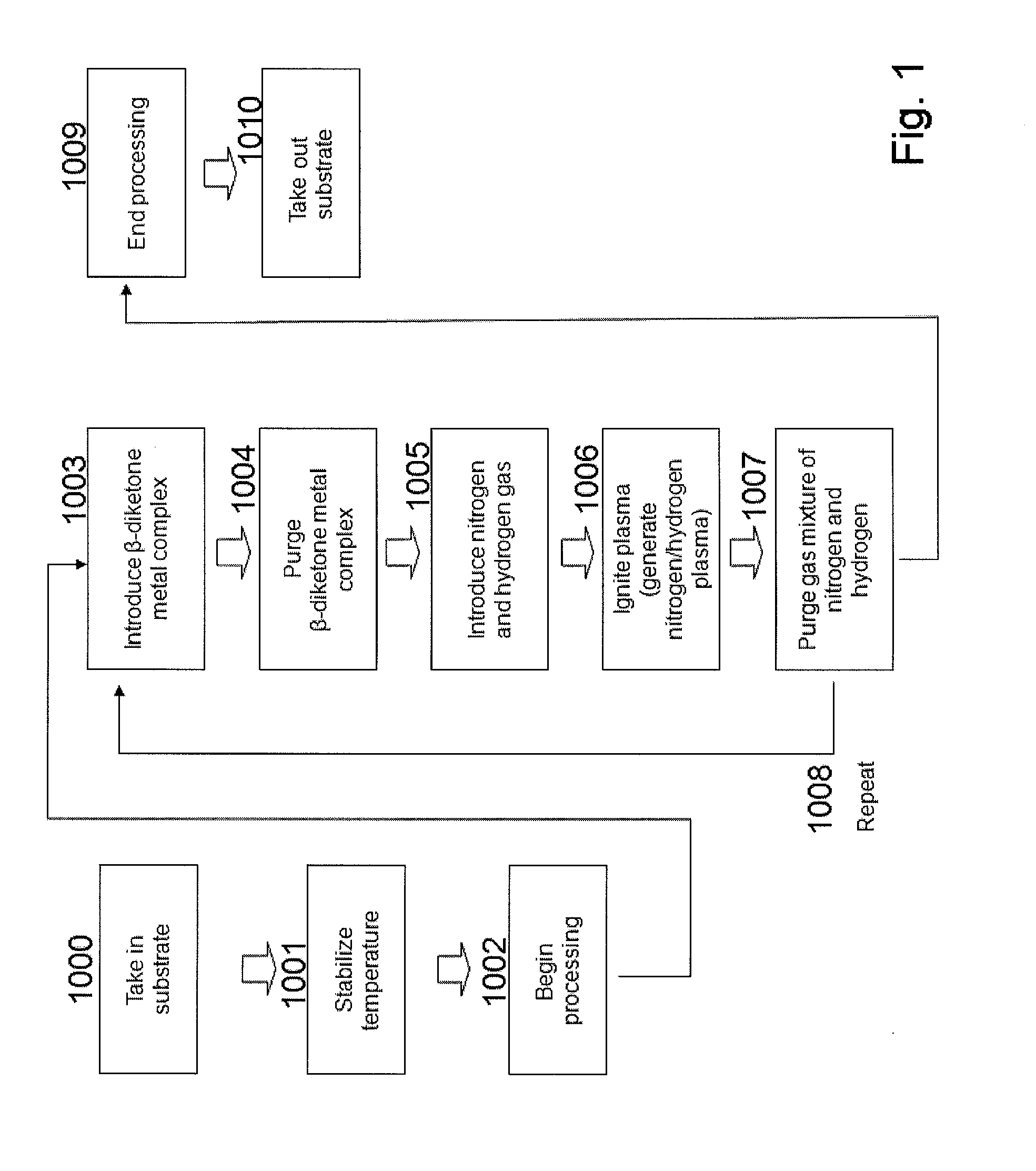

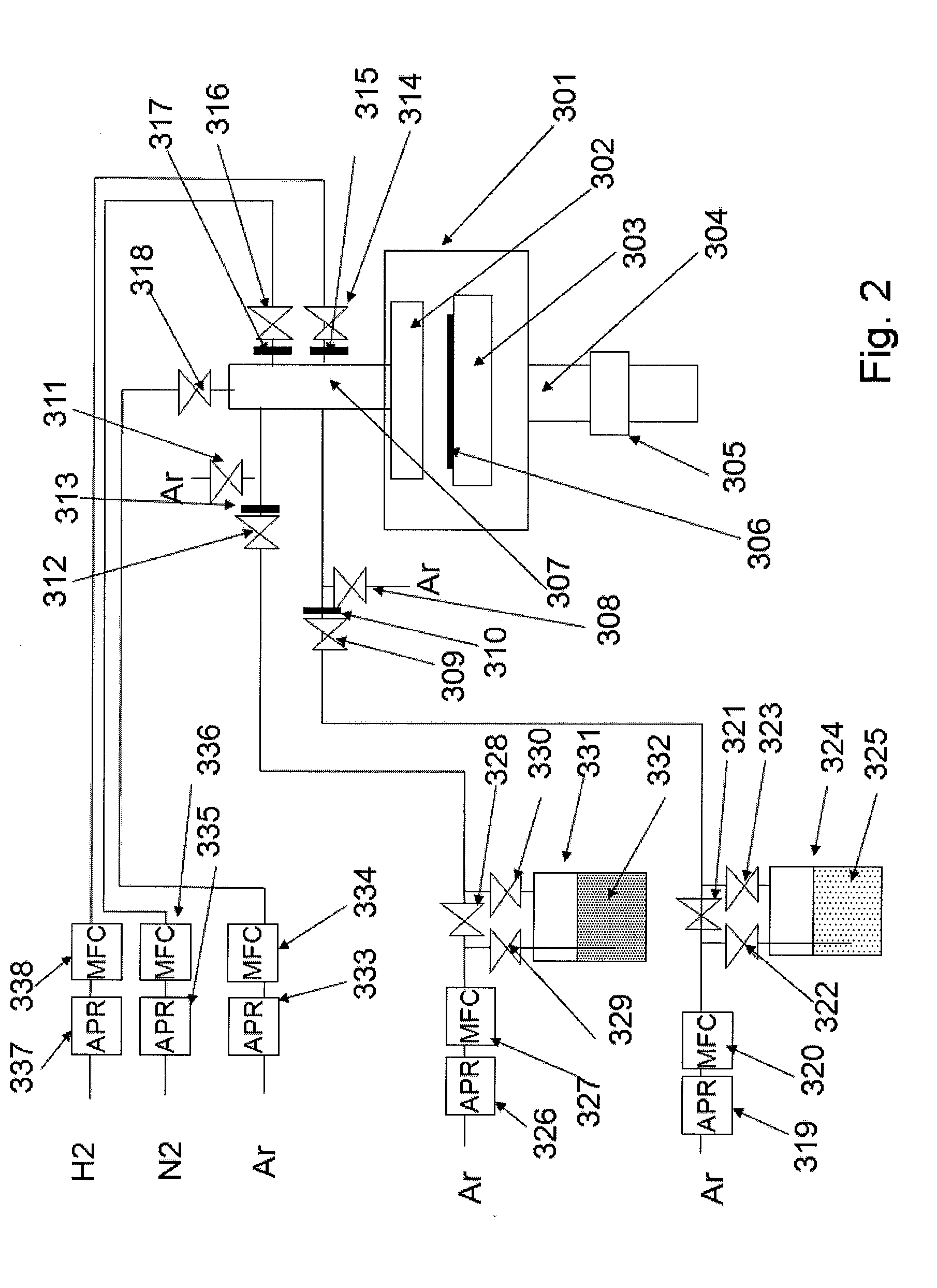

Method for forming metal film by ald using beta-diketone metal complex

ActiveUS20100092696A1Improve shielding effectRapid and reliable mannerVacuum evaporation coatingPretreated surfacesDiketoneHydrogen

A method of forming a single-metal film on a substrate by plasma ALD includes: contacting a surface of a substrate with a β-diketone metal complex in a gas phase; exposing molecule-attached surface to a nitrogen-hydrogen mixed plasma; and repeating the above steps, thereby accumulating atomic layers to form a single-metal film on the substrate.

Owner:ASM JAPAN

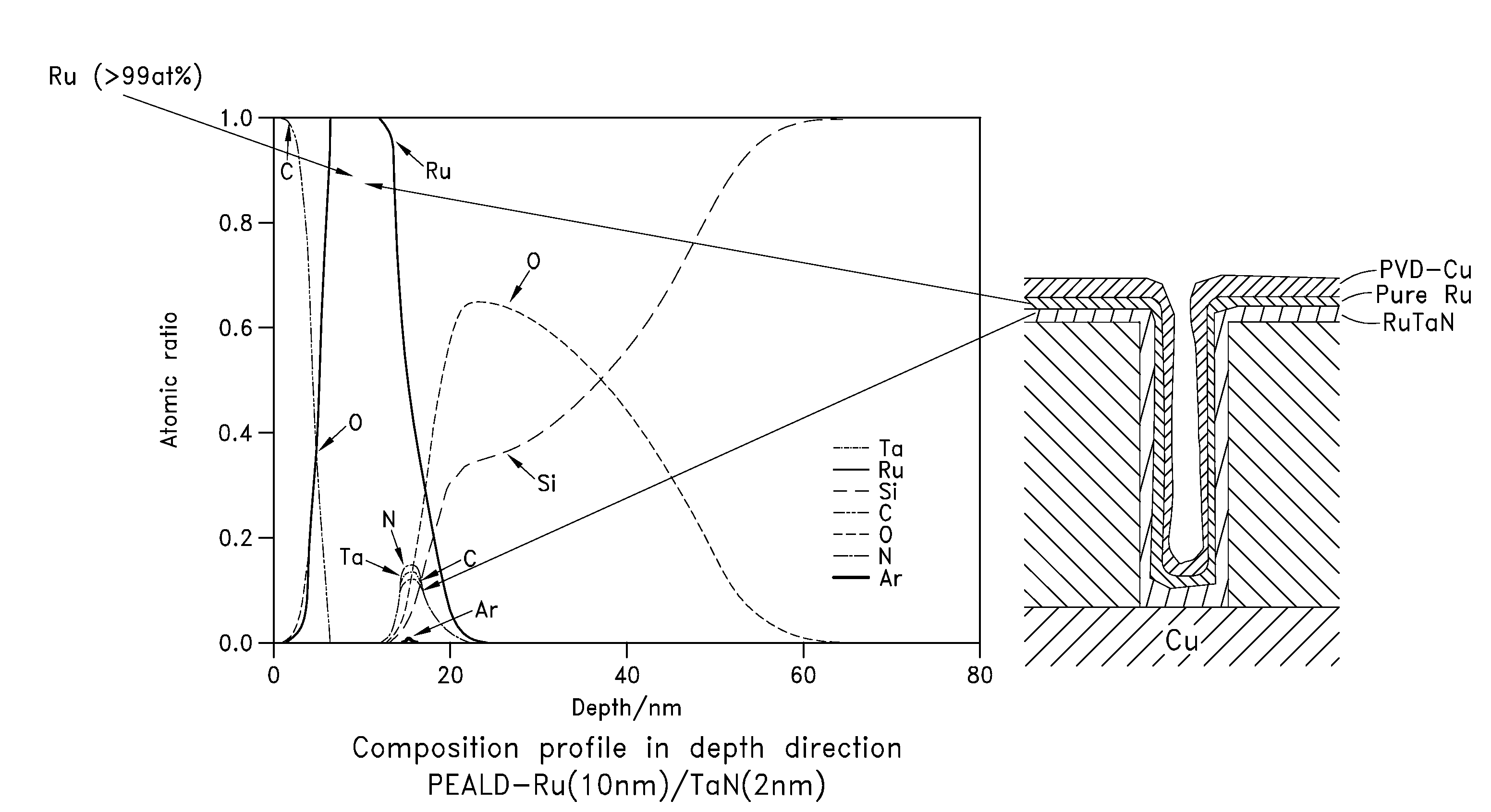

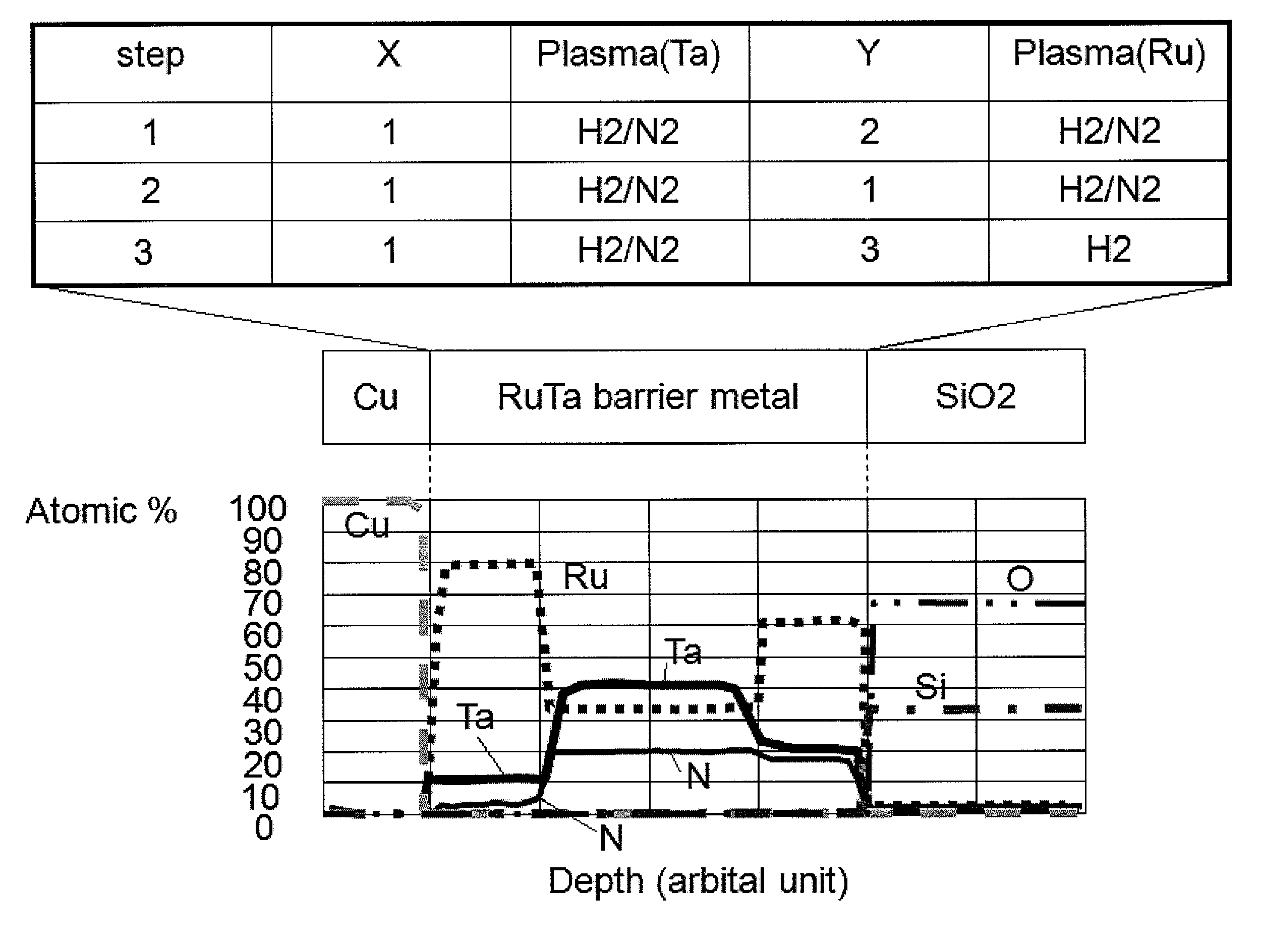

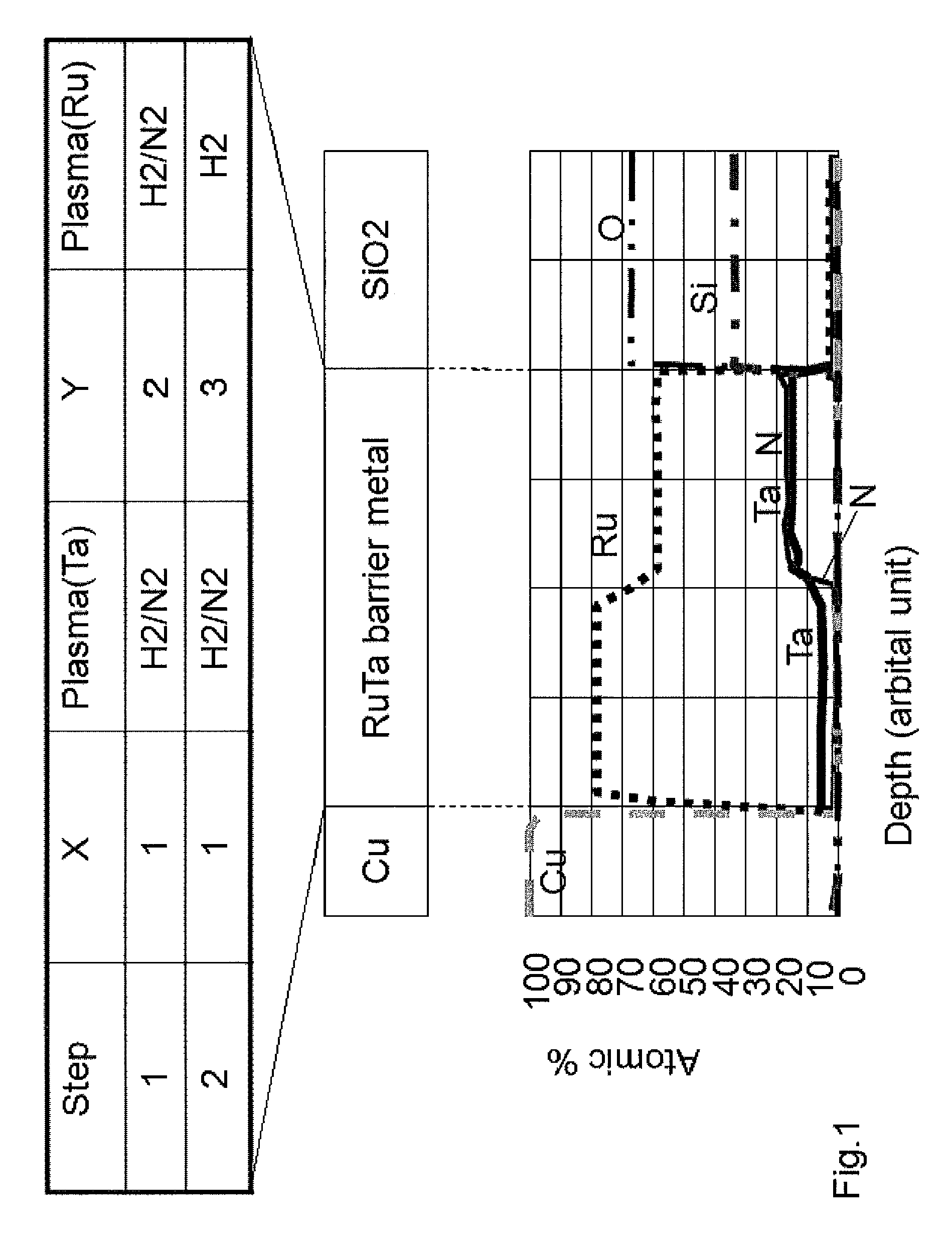

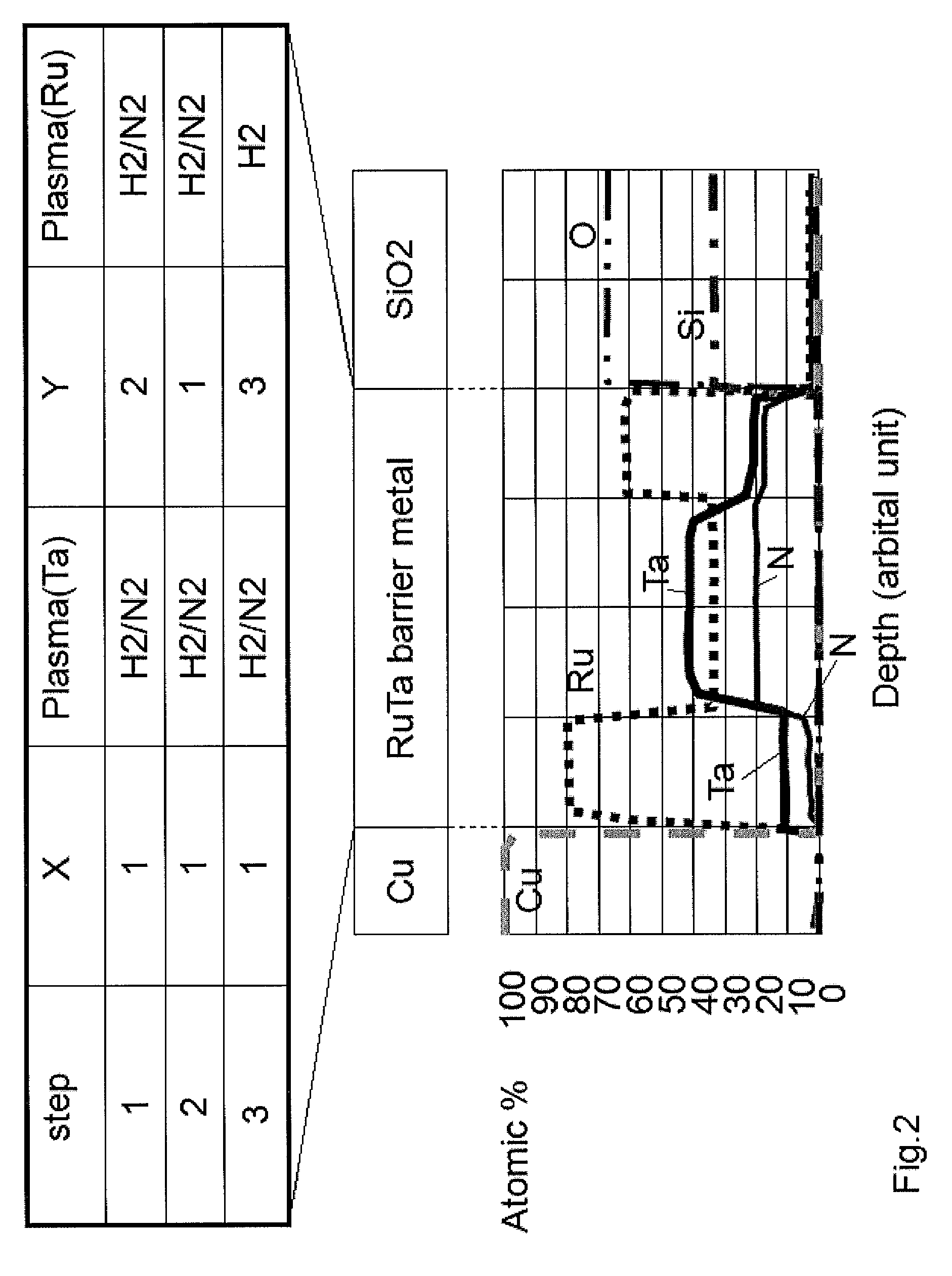

Atomic composition controlled ruthenium alloy film formed by plasma-enhanced atomic layer deposition

ActiveUS8084104B2Reduce resistanceLow densitySemiconductor/solid-state device detailsSynthetic resin layered productsRutheniumAlloy

A metal film composed of multiple atomic layers continuously formed by atomic layer deposition of Ru and Ta or Ti includes at least a top section and a bottom section, wherein an atomic composition of Ru, Ta or Ti, and N varies in a thickness direction of the metal film. The atomic composition of Ru, Ta or Ti, and N in the top section is represented as Ru(x1)Ta / Ti(y1)N(z1) wherein an atomic ratio of Ru(x1) / (Ta / Ti(y1)) is no less than 15, and z1 is 0.05 or less. The atomic composition of Ru, Ta or Ti, and N in the bottom section is represented as Ru(x2)Ta / Ti(y2)N(z2) wherein an atomic ratio of Ru(x2) / (Ta / Ti(y2)) is more than zero but less than 15, and z2 is 0.10 or greater.

Owner:ASM JAPAN

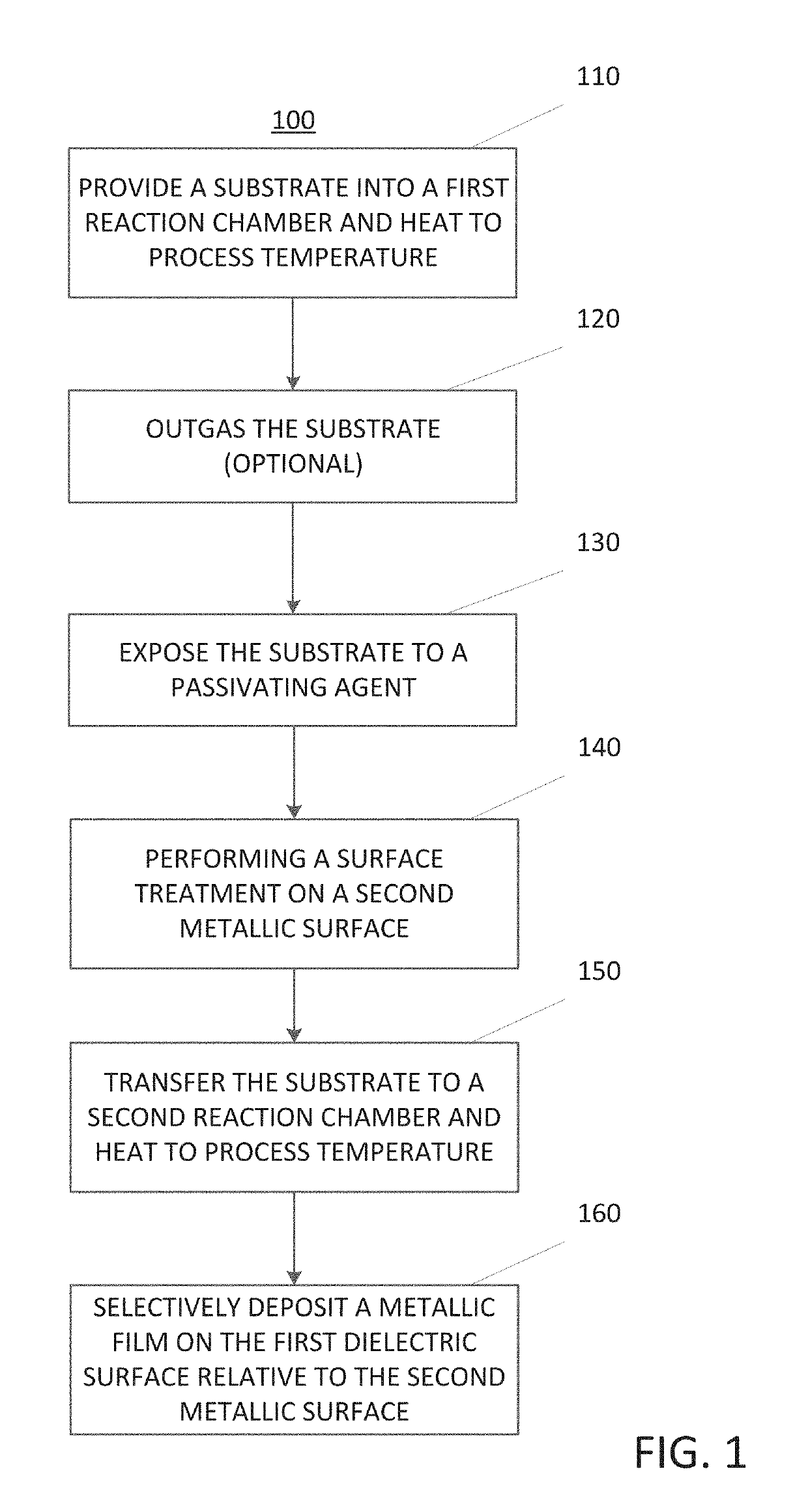

Method for selectively depositing a metallic film on a substrate

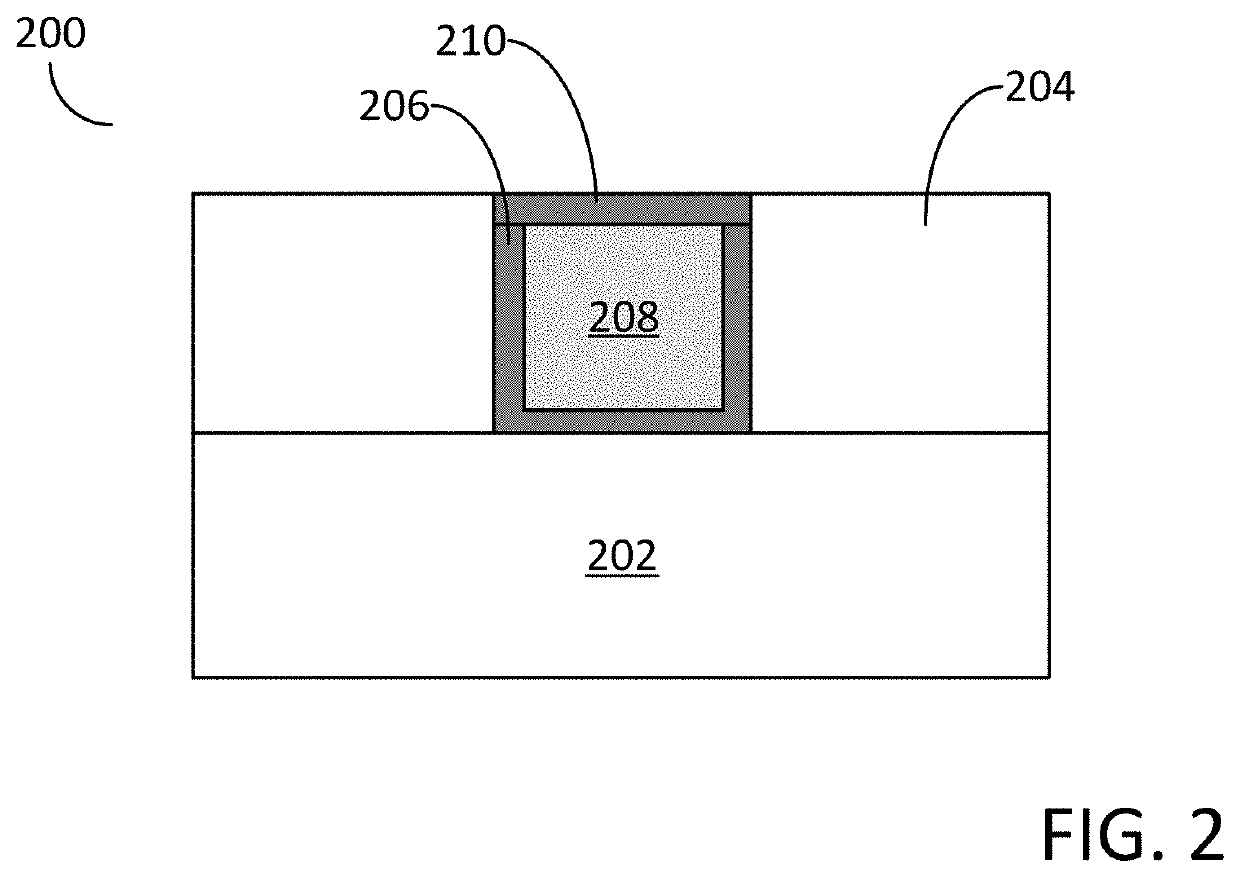

ActiveUS20190109009A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectric surfaceSelective deposition

A method for selectively depositing a metallic film on a substrate comprising a first dielectric surface and a second metallic surface is disclosed. The method may include, exposing the substrate to a passivating agent, performing a surface treatment on the second metallic surface, and selectively depositing the metallic film on the first dielectric surface relative to the second metallic surface. Semiconductor device structures including a metallic film selectively deposited by the methods of the disclosure are also disclosed.

Owner:ASM IP HLDG BV

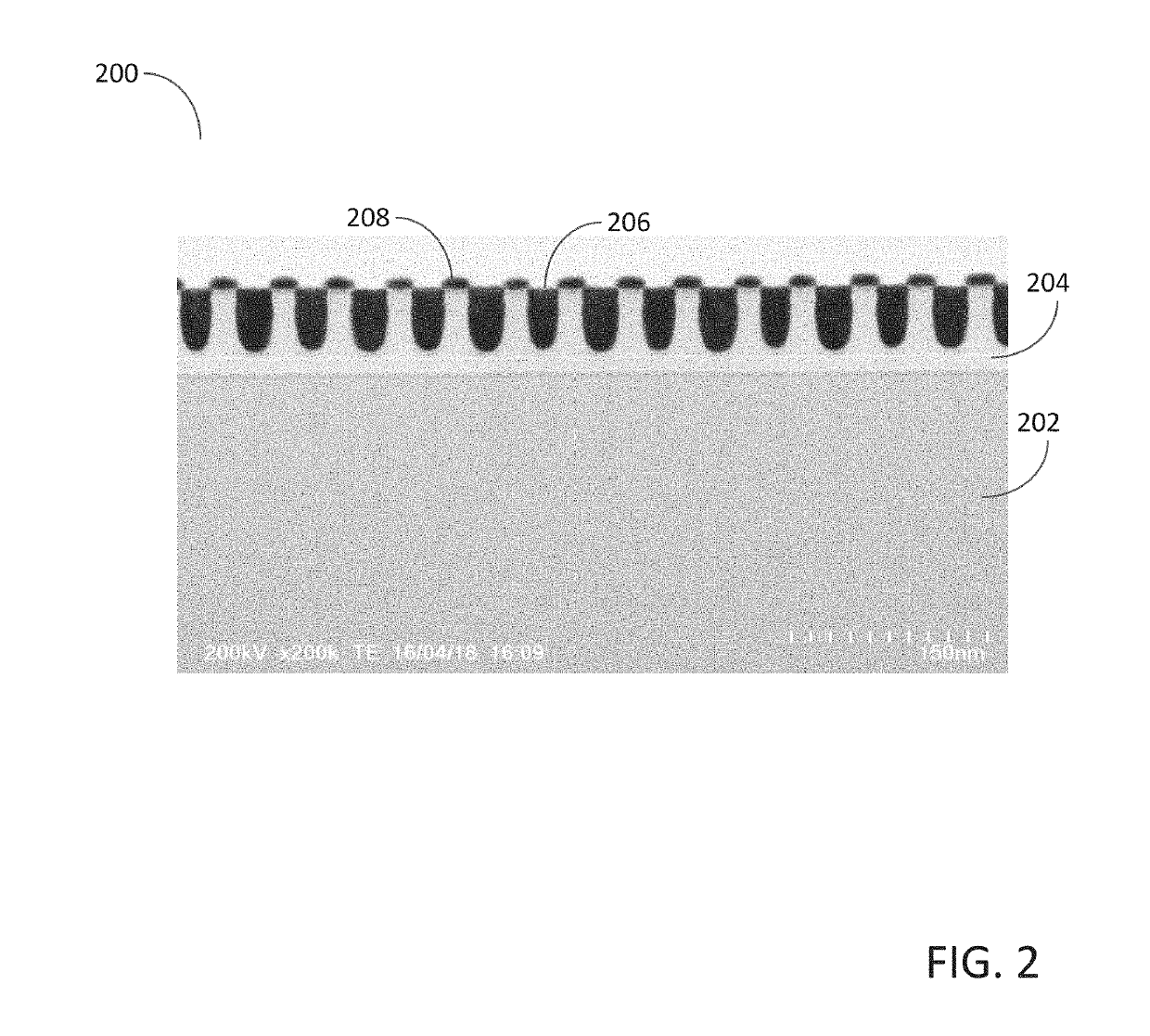

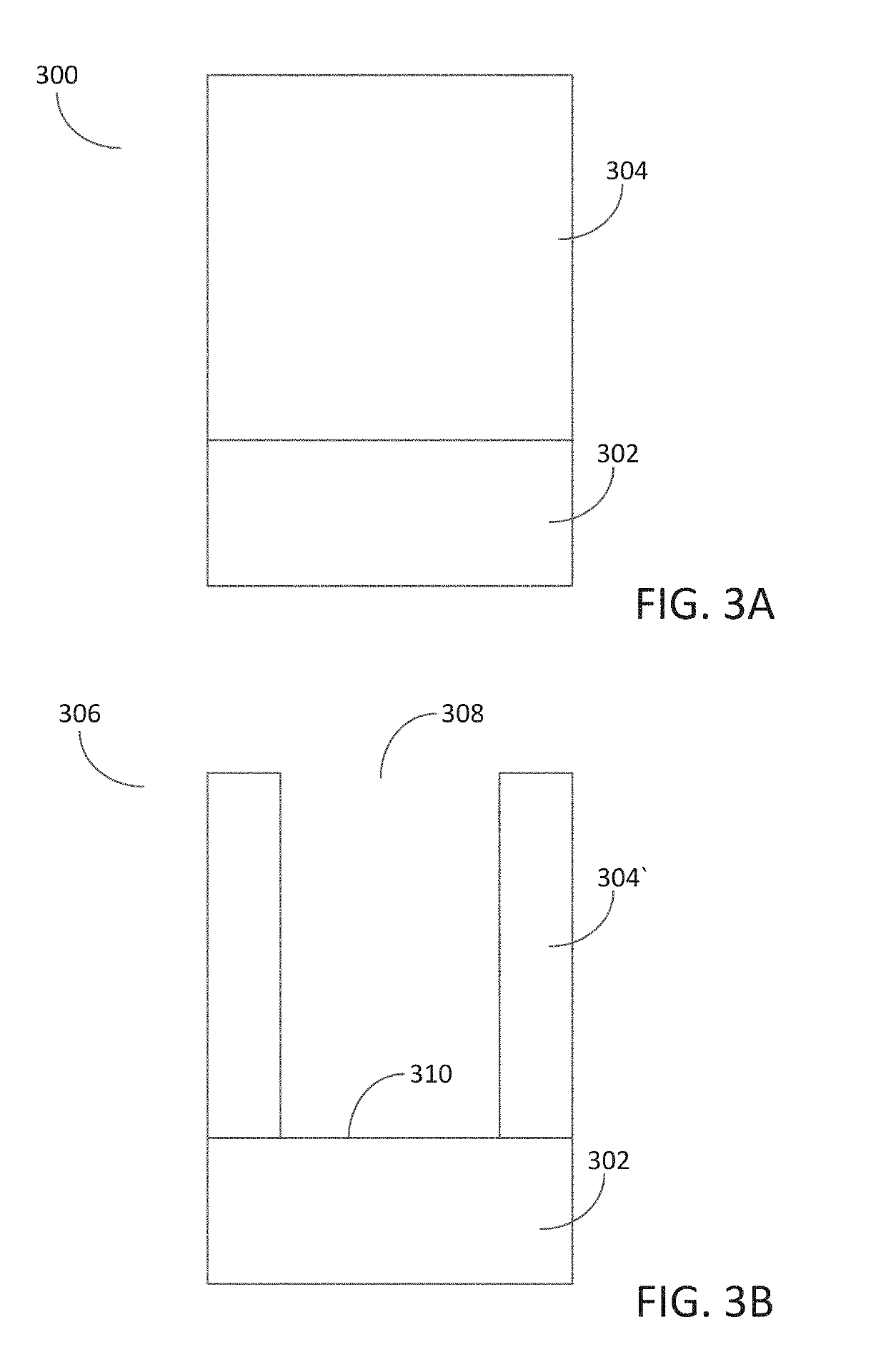

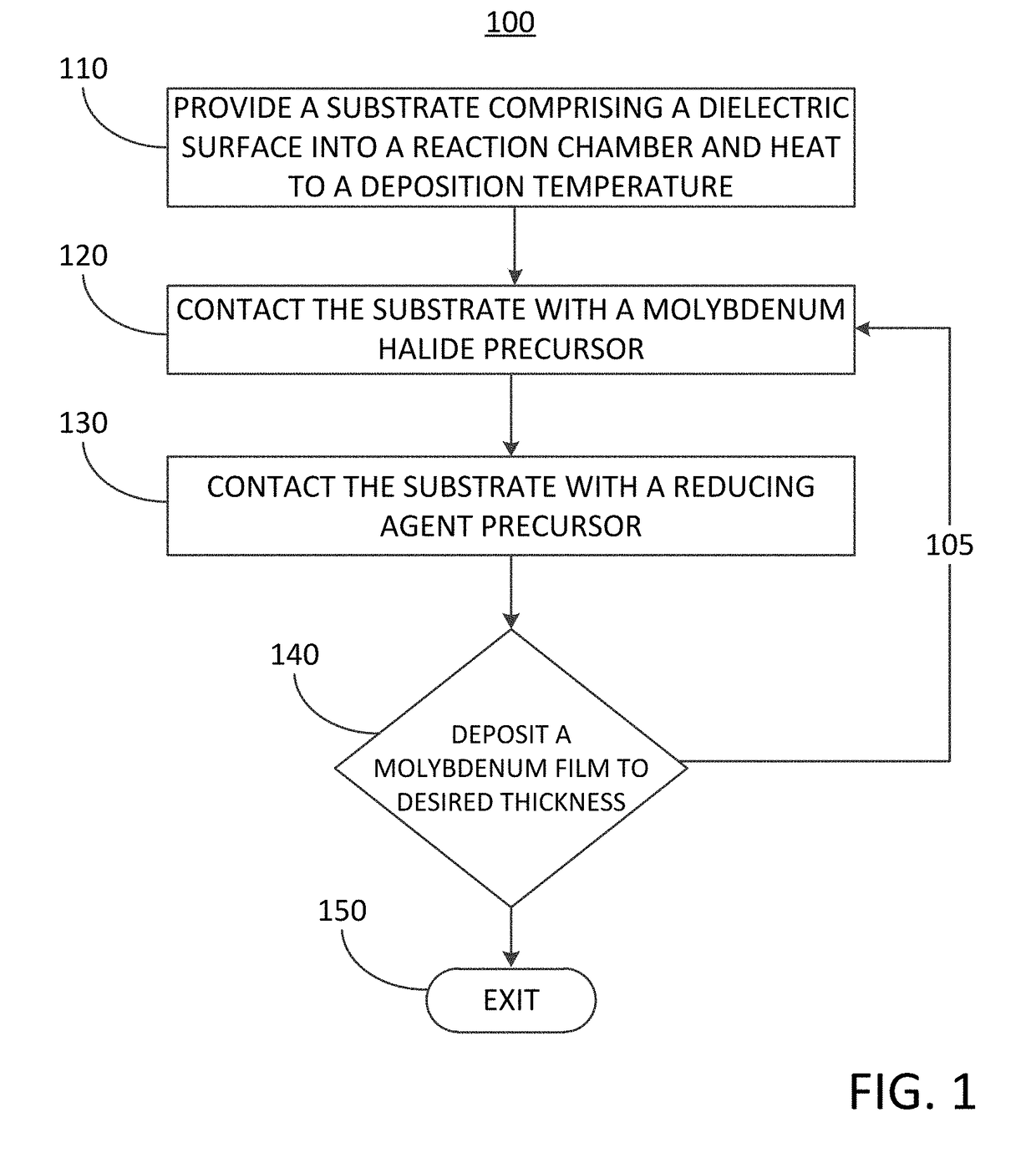

Methods for depositing a molybdenum metal film on a dielectric surface of a substrate and related semiconductor device structures

PendingUS20190067003A1Semiconductor/solid-state device detailsSolid-state devicesGas phaseDielectric surface

Methods for depositing a molybdenum metal film directly on a dielectric material surface of a substrate by a cyclical deposition process are disclosed. The methods may include: providing a substrate comprising a dielectric surface into a reaction chamber; and depositing a molybdenum metal film directly on the dielectric surface, wherein depositing comprises: contacting the substrate with a first vapor phase reactant comprising a molybdenum halide precursor; and contacting the substrate with a second vapor phase reactant comprising a reducing agent precursor. Semiconductor device structures including a molybdenum metal film disposed directly on a surface of a dielectric material deposited by the methods of the disclosure are also disclosed.

Owner:ASM IP HLDG BV

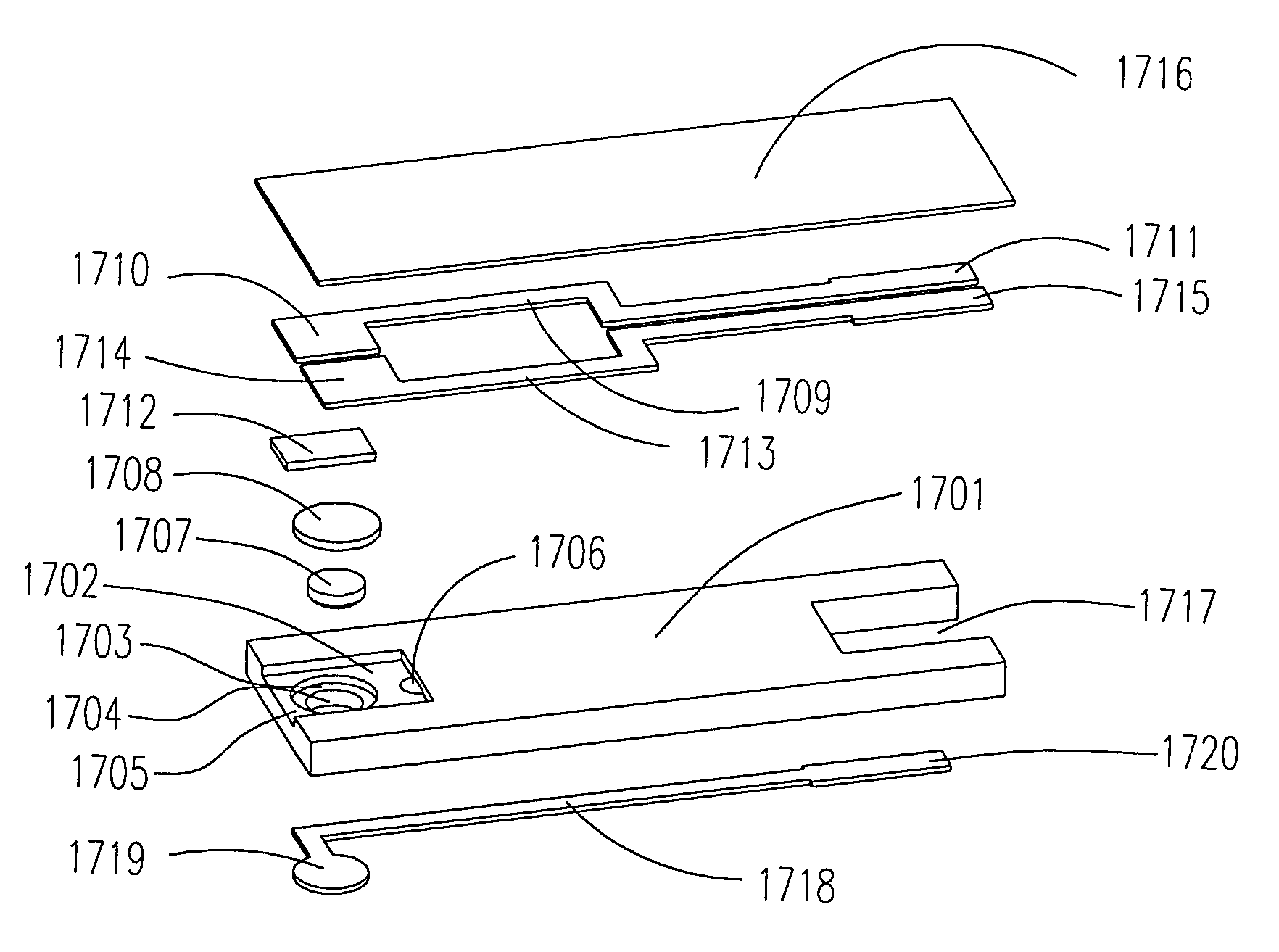

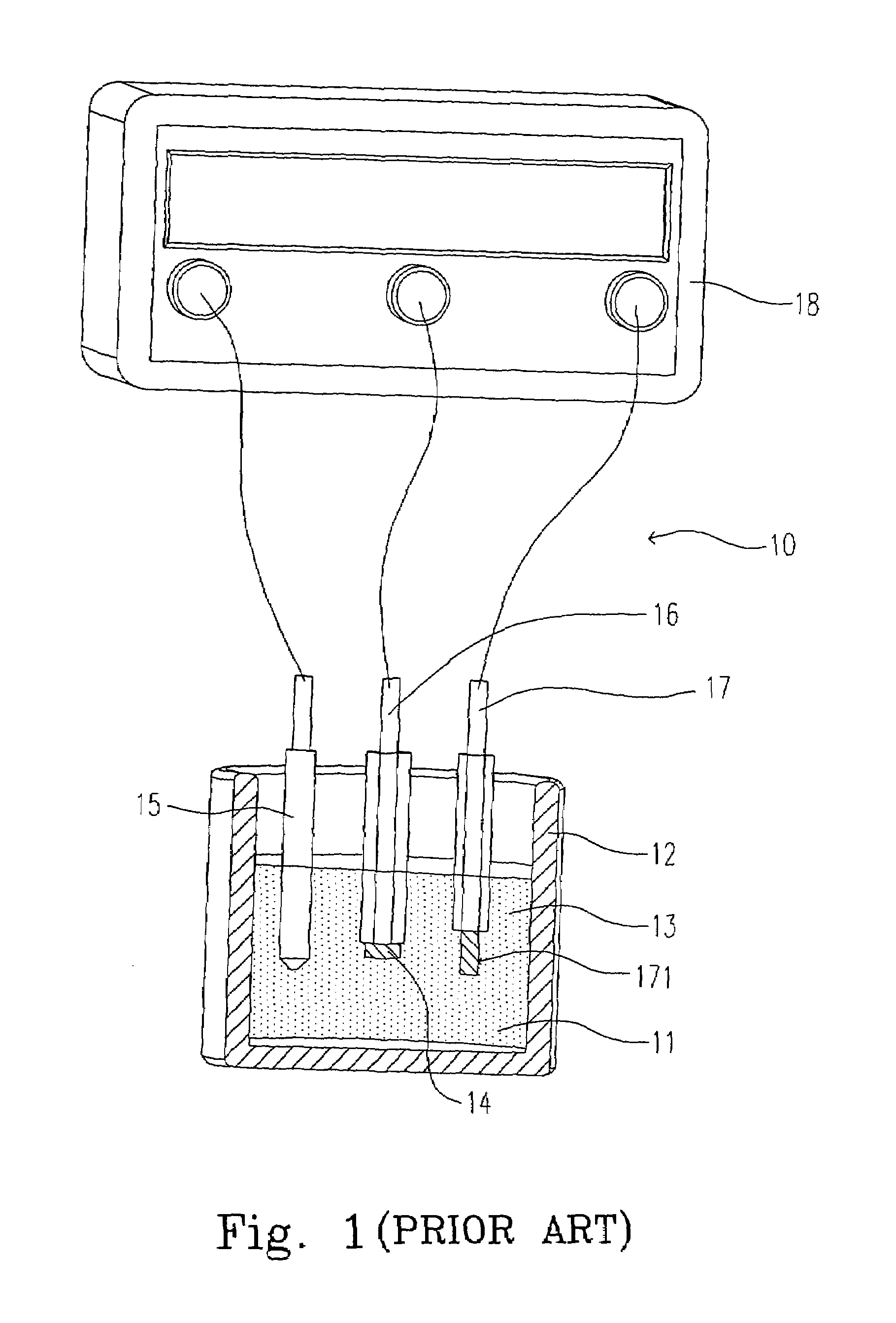

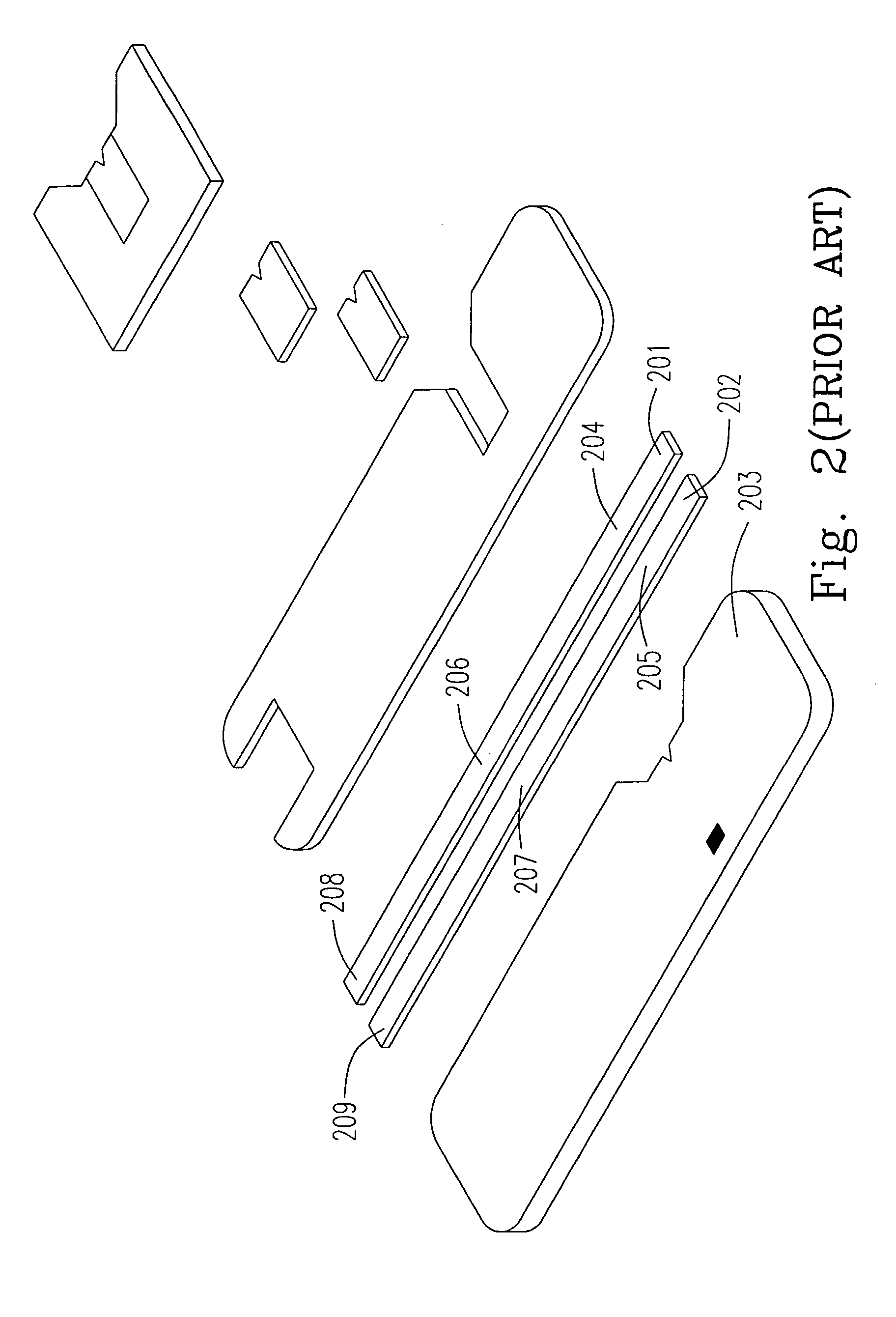

Structure and manufacturing method of disposable electrochemical sensor strip

ActiveUS7063776B2Reduce the amount requiredShorten production timeImmobilised enzymesBioreactor/fermenter combinationsMetalElectrical and Electronics engineering

A disposable electrochemical sensor strip is provided. The sensor strip includes an isolating sheet having at least a through hole, at least a conductive raw material mounted in the through hole, a metal film covered on the conductive raw material to form an electrode which comprises an electrode working surface for processing an electrode action, and an electrode connecting surface, at least a printed conductive film mounted on the isolating sheet and having a connecting terminal for being electrically connected to the electrode connecting surface, and a signal output terminal for outputting a measured signal produced by the electrode action.

Owner:HUANG CHUN MU

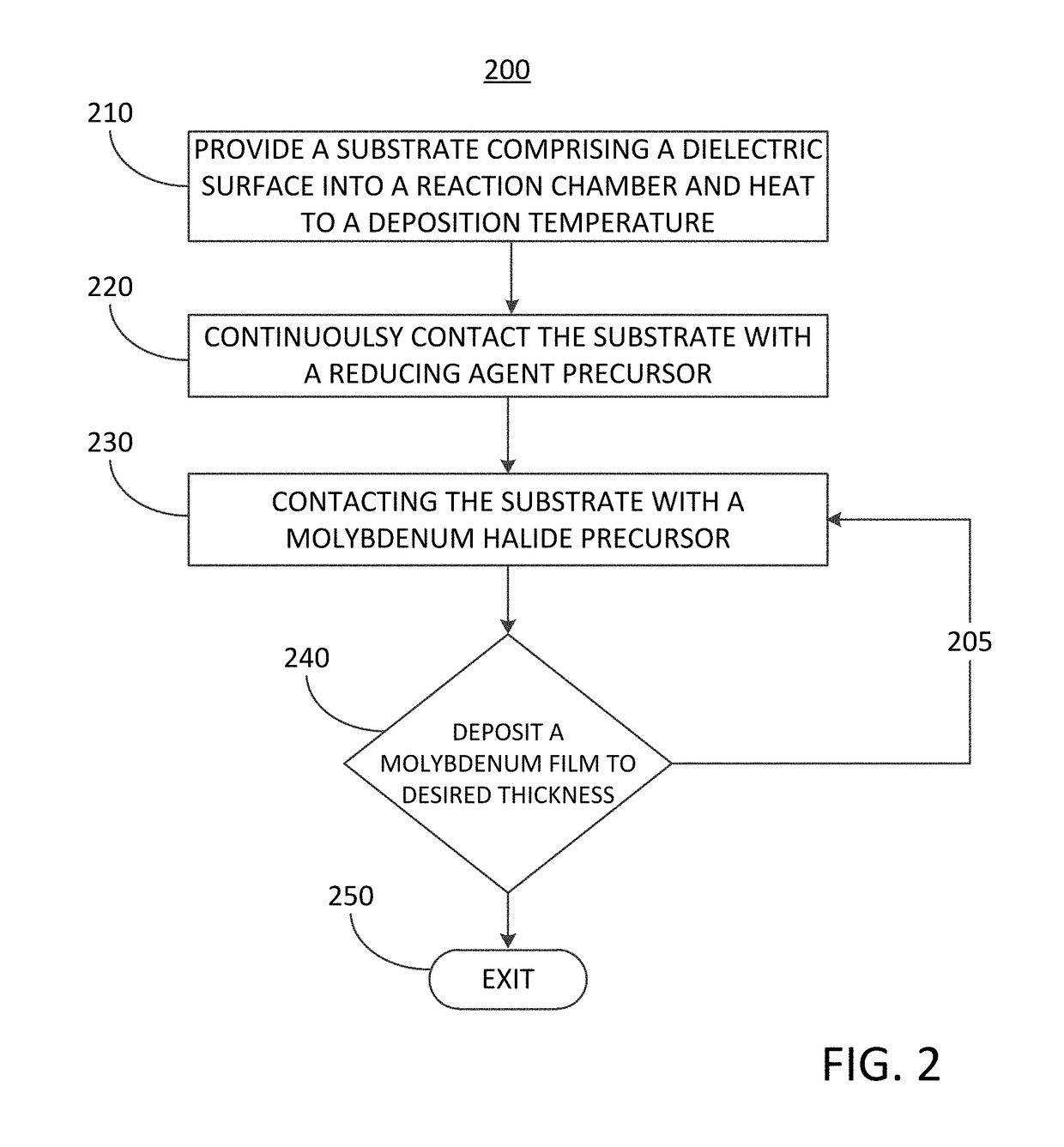

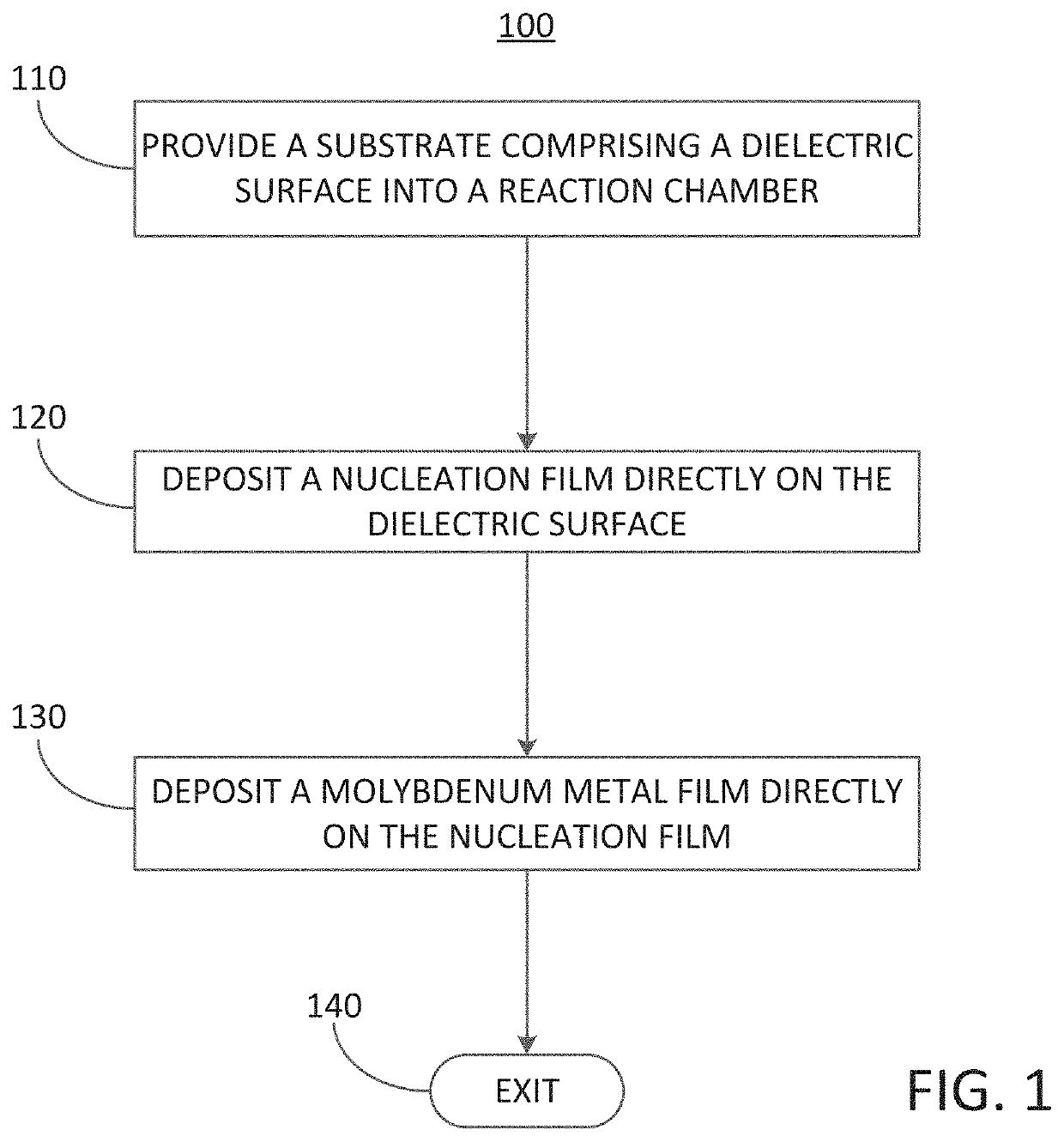

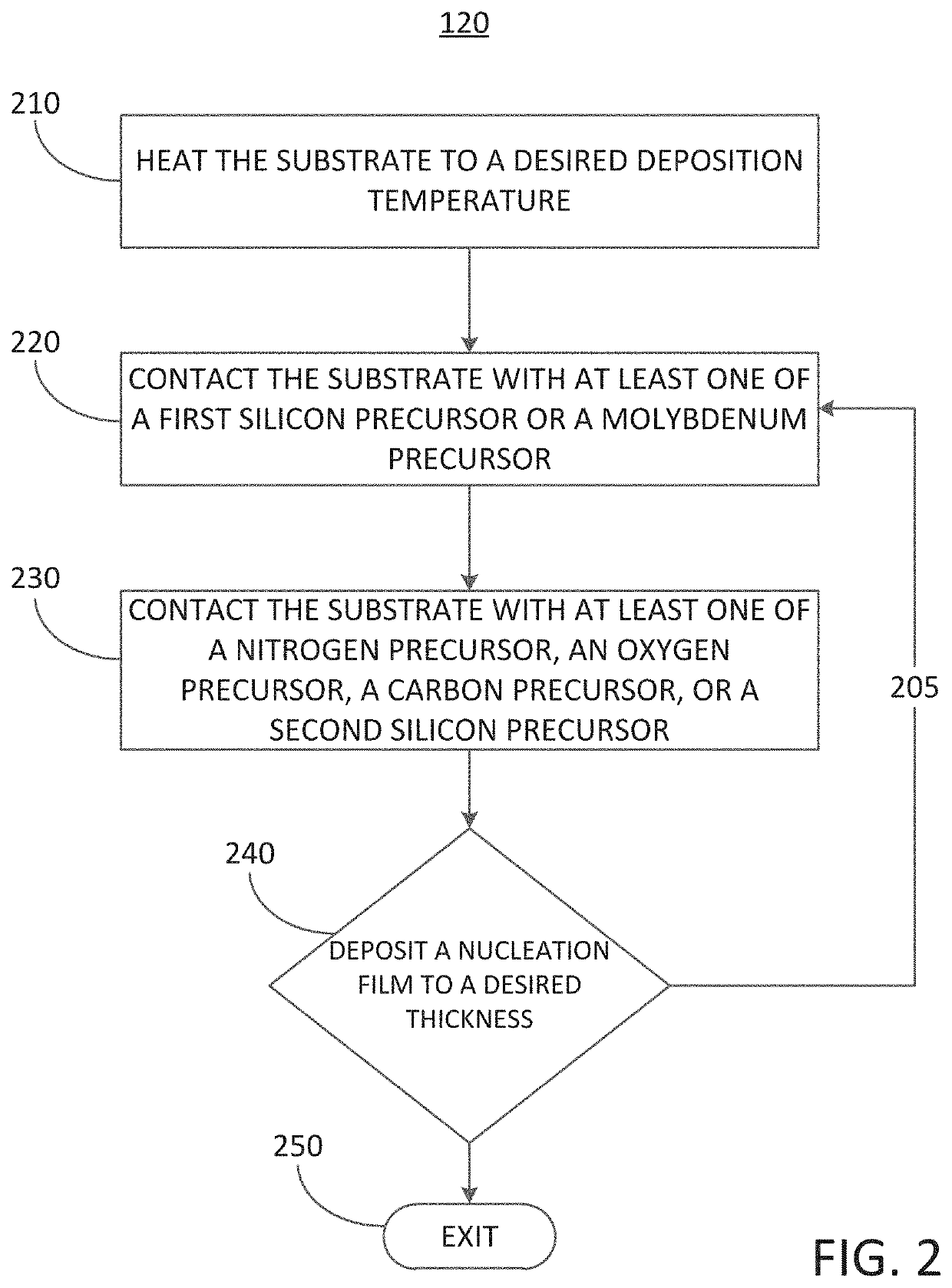

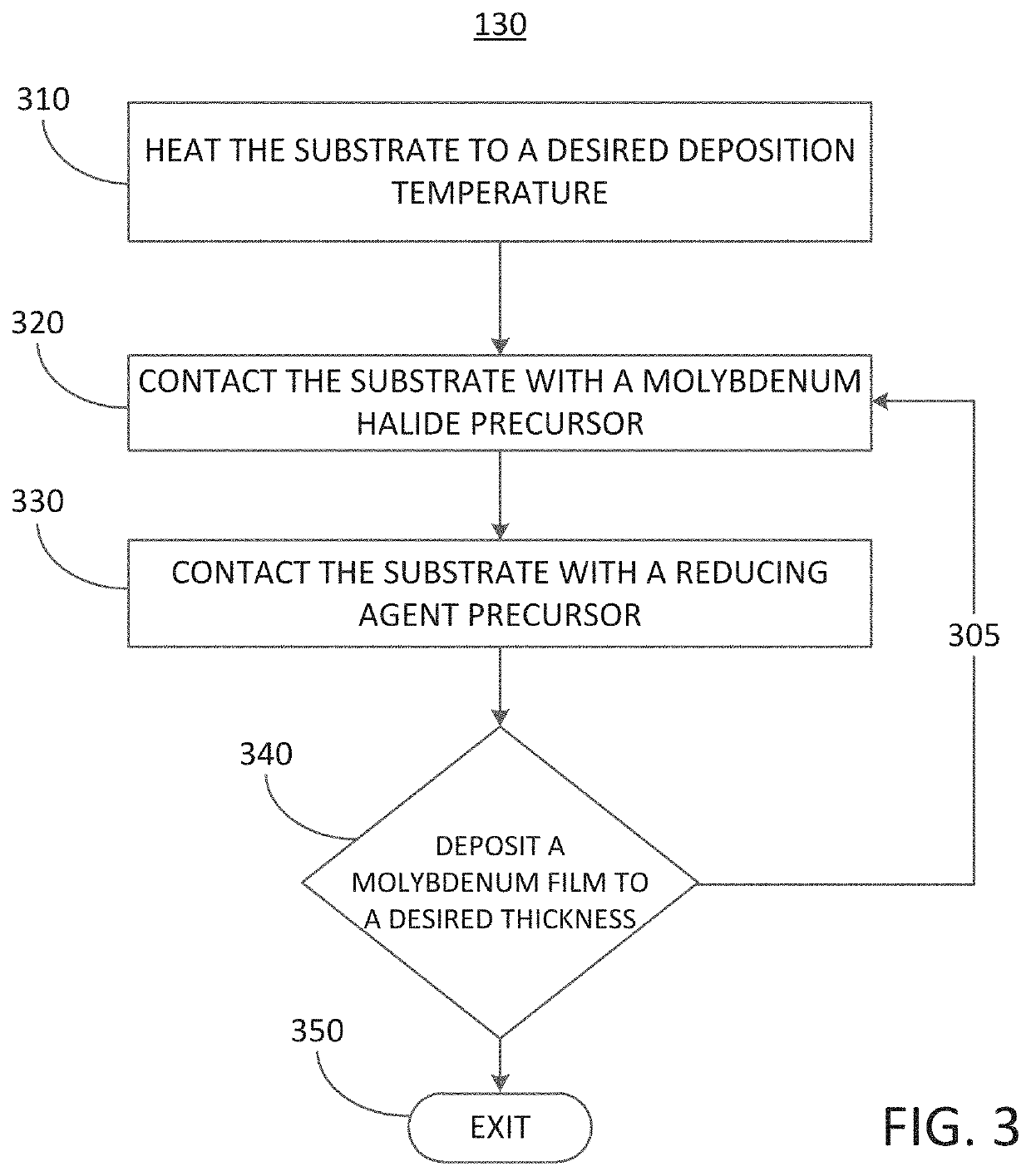

Methods for depositing a molybdenum metal film over a dielectric surface of a substrate by a cyclical deposition process and related semiconductor device structures

ActiveUS20210151352A1Semiconductor/solid-state device detailsSolid-state devicesDevice materialPhysical chemistry

Methods for depositing a molybdenum metal film over a dielectric surface of a substrate by a cyclical deposition process are disclosed. The methods may include: providing a substrate comprising a dielectric surface into a reaction chamber; depositing a nucleation film directly on the dielectric surface; and depositing a molybdenum metal film directly on the nucleation film, wherein depositing the molybdenum metal film includes: contacting the substrate with a first vapor phase reactant comprising a molybdenum halide precursor; and contacting the substrate with a second vapor phase reactant comprising a reducing agent precursor. Semiconductor device structures including a molybdenum metal film disposed over a surface of a dielectric material with an intermediate nucleation film are also disclosed.

Owner:ASM IP HLDG BV

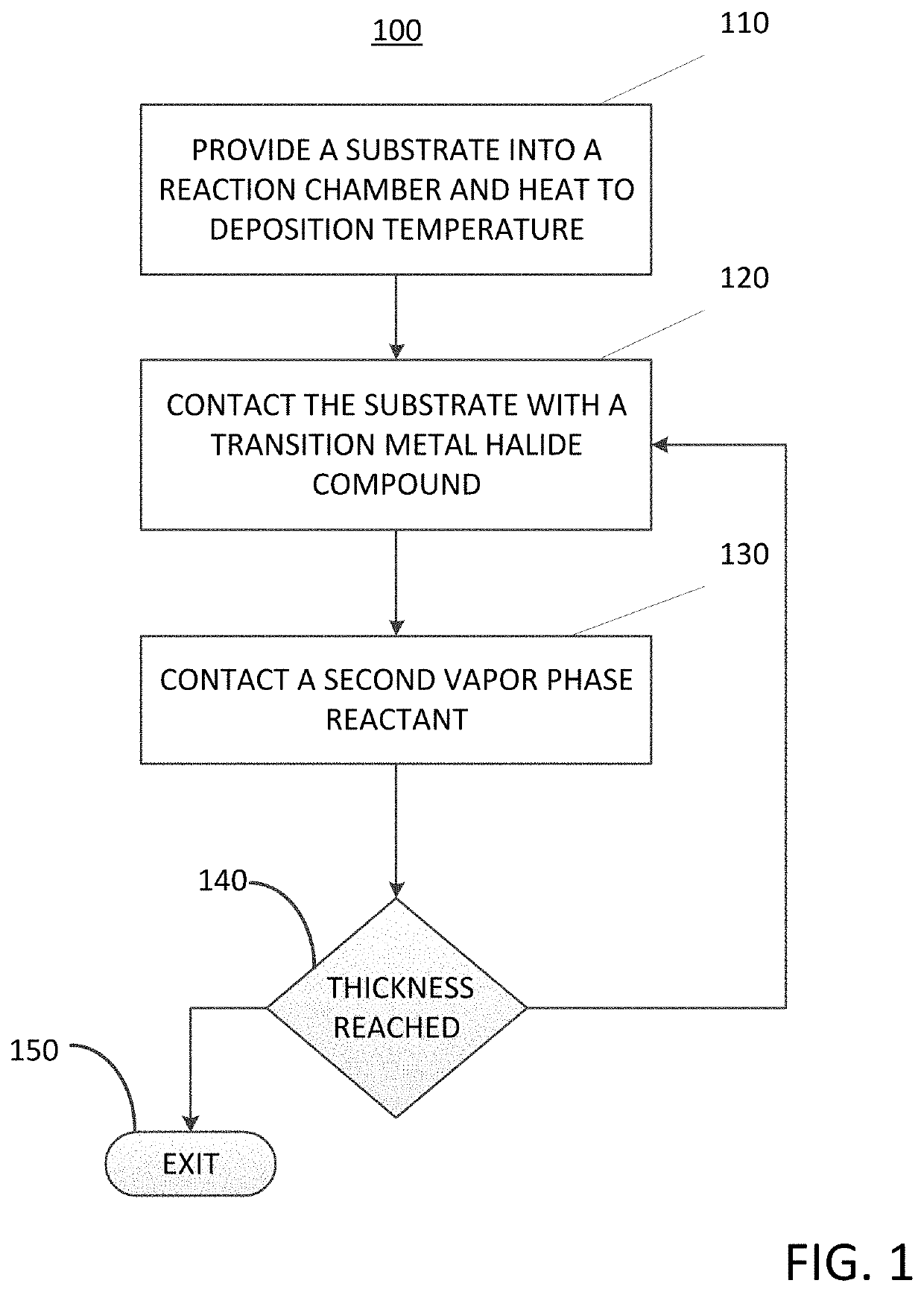

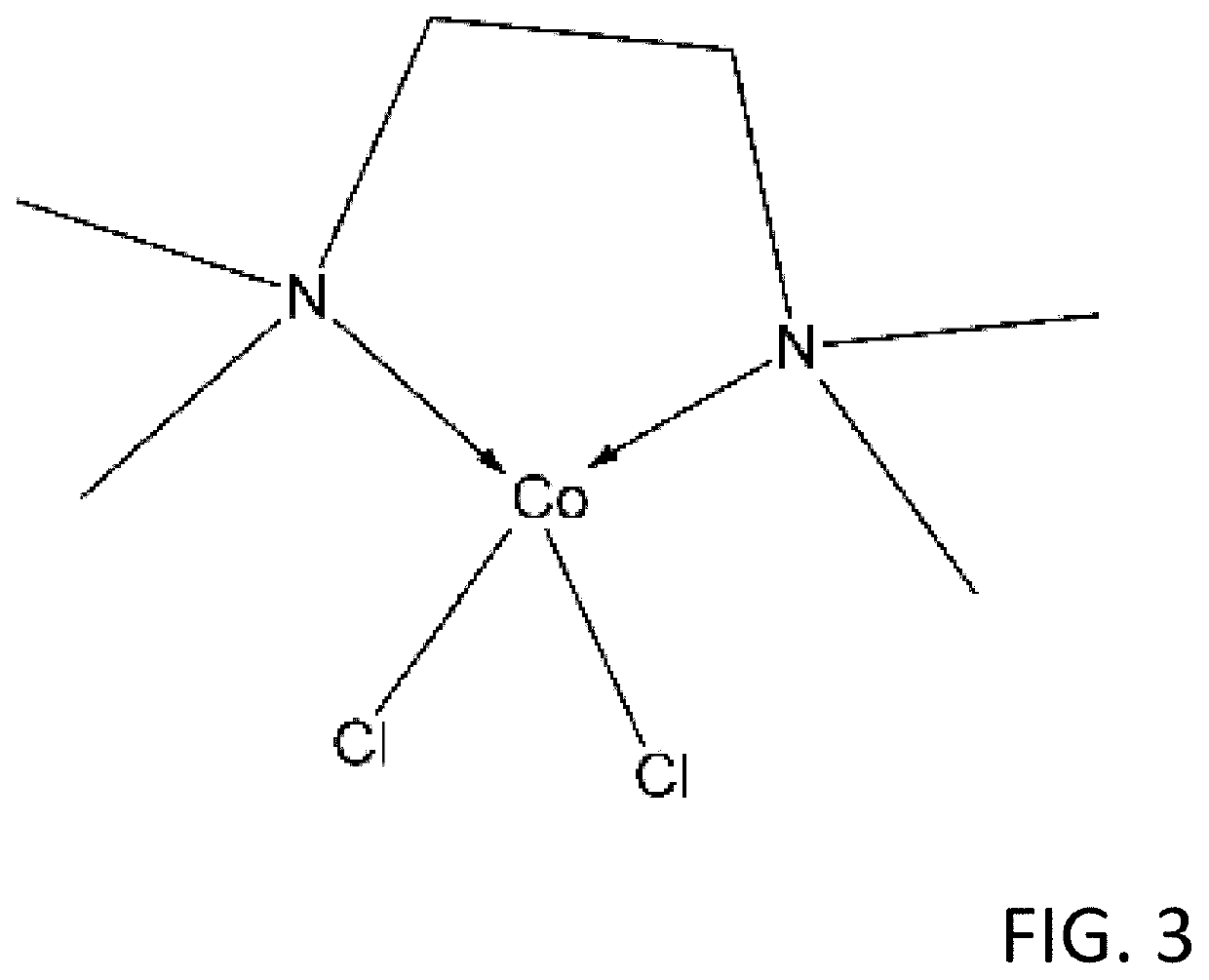

Method of forming a transition metal containing film on a substrate by a cyclical deposition process, a method for supplying a transition metal halide compound to a reaction chamber, and related vapor deposition apparatus

ActiveUS10731249B2Semiconductor/solid-state device detailsSolid-state devicesPhysical chemistryDeposition process

A method of forming a transition metal containing films on a substrate by a cyclical deposition process is disclosed. The method may include: contacting the substrate with a first vapor phase reactant comprising a transition metal halide compound comprising a bidentate nitrogen containing adduct ligand; and contacting the substrate with a second vapor phase reactant. A method for supplying a transition metal halide compound comprising a bidentate nitrogen containing ligand to a reaction chamber is disclosed, along with related vapor deposition apparatus.

Owner:ASM IP HLDG BV

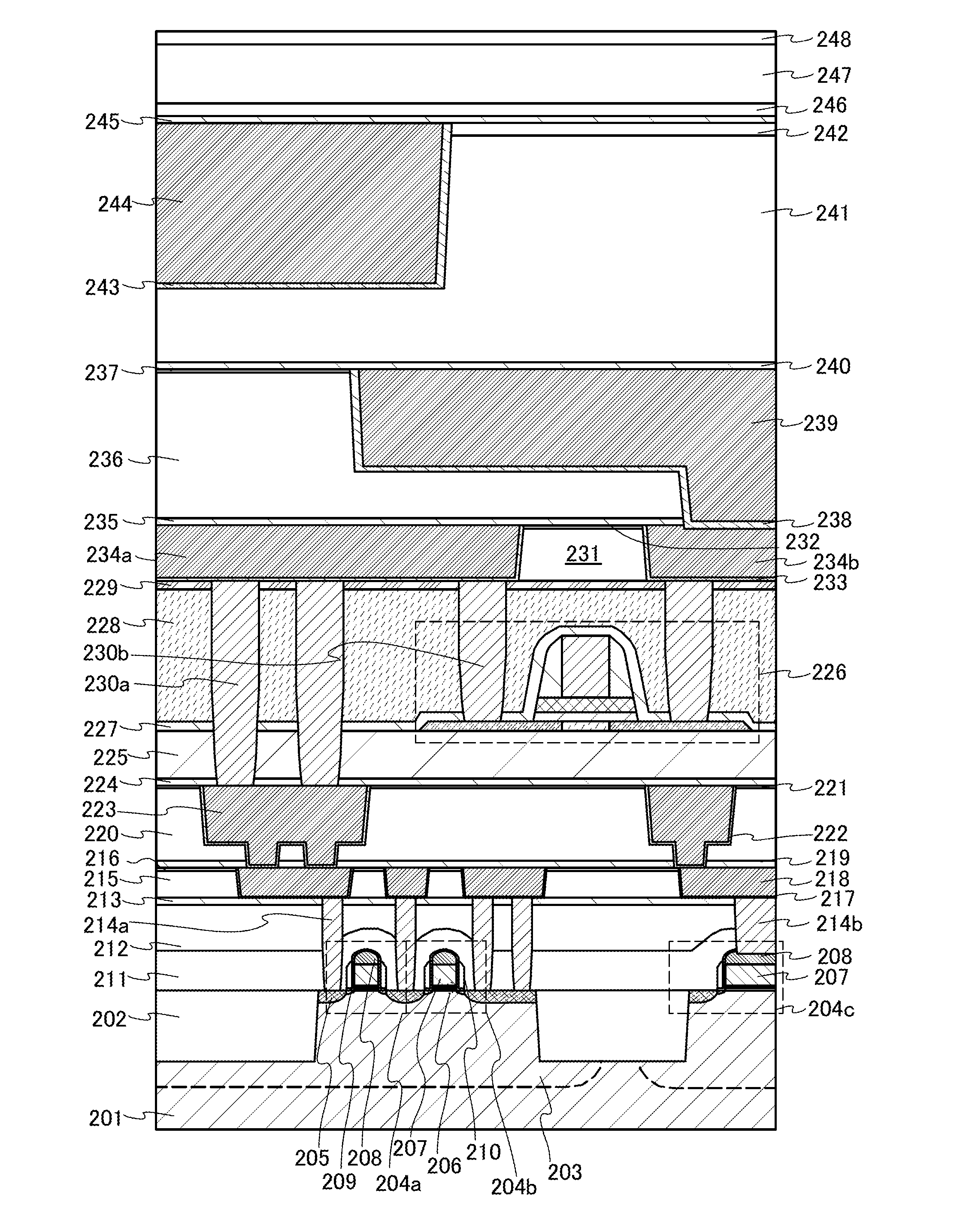

Method for manufacturing semiconductor device

InactiveUS20130203214A1Effective diffusionTotal current dropTransistorSolid-state devicesDevice materialPhysical chemistry

To improve productivity of a transistor that includes an oxide semiconductor and has good electrical characteristics. In a top-gate transistor including a gate insulating film and a gate electrode over an oxide semiconductor film, a metal film is formed over the oxide semiconductor film, oxygen is added to the metal film to form a metal oxide film, and the metal oxide film is used as a gate insulating film. After an oxide insulating film is formed over the oxide semiconductor film, a metal film may be formed over the oxide insulating film. Oxygen is added to the metal film to form a metal oxide film and added also to the oxide semiconductor film or the oxide insulating film.

Owner:SEMICON ENERGY LAB CO LTD

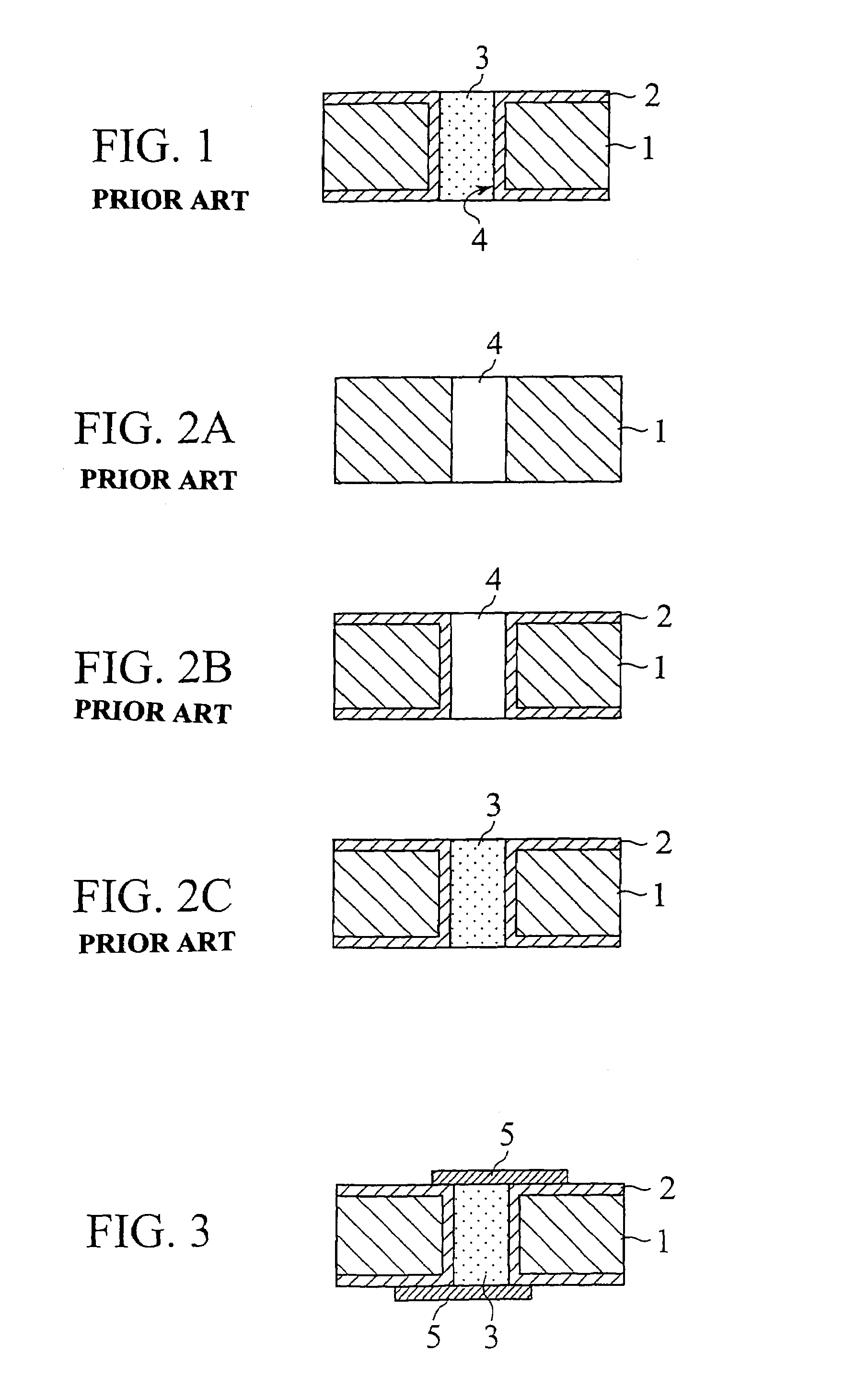

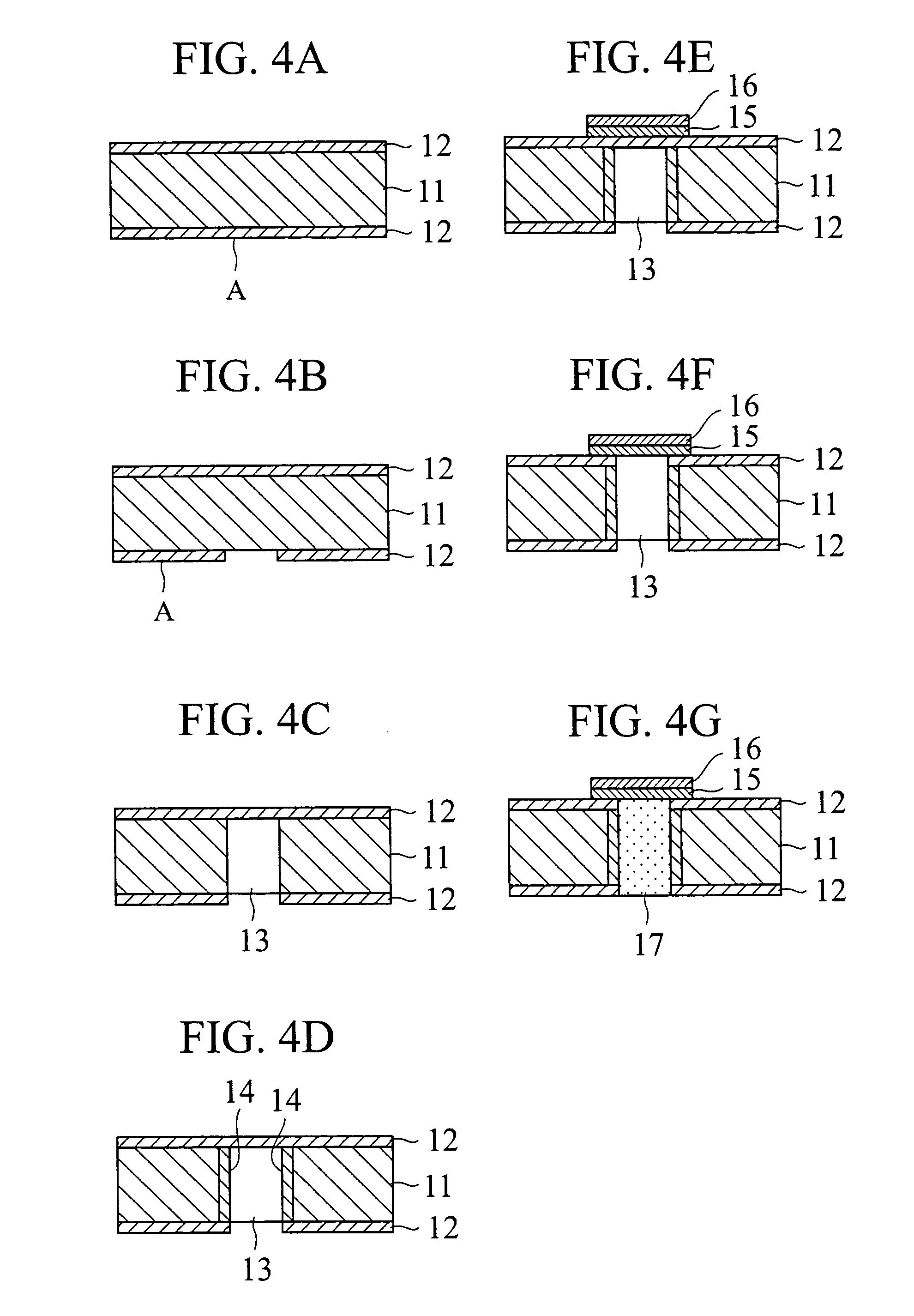

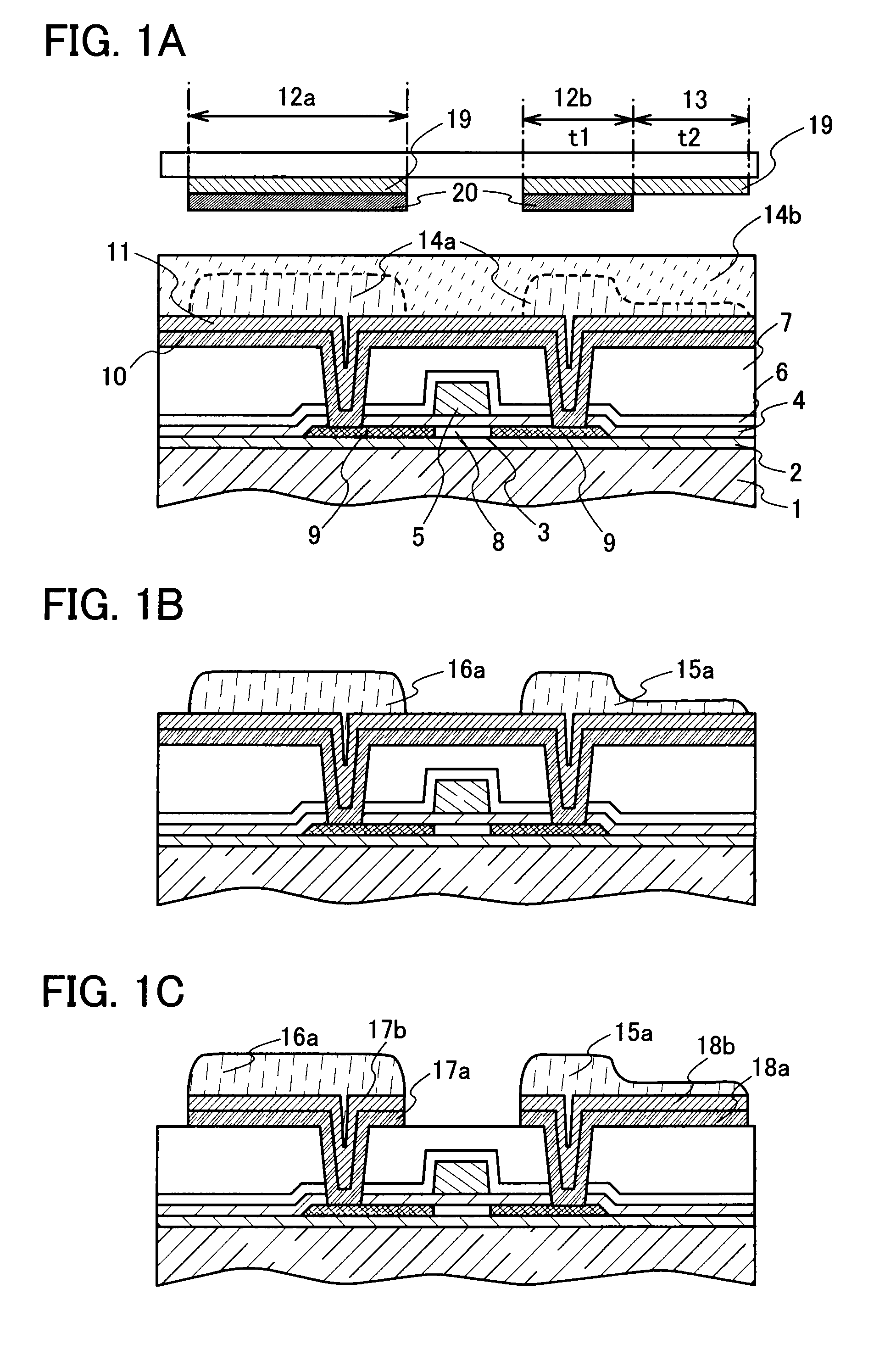

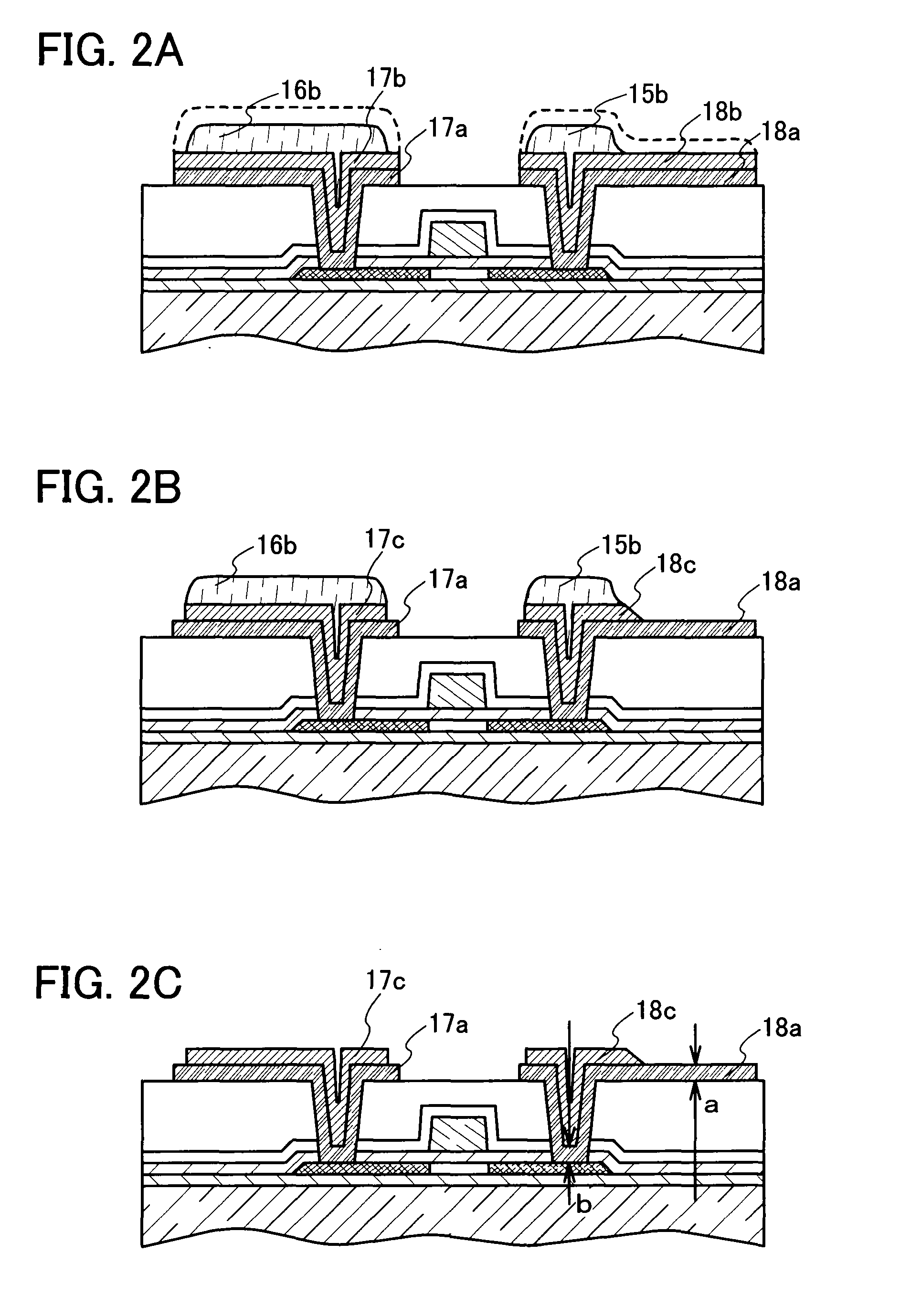

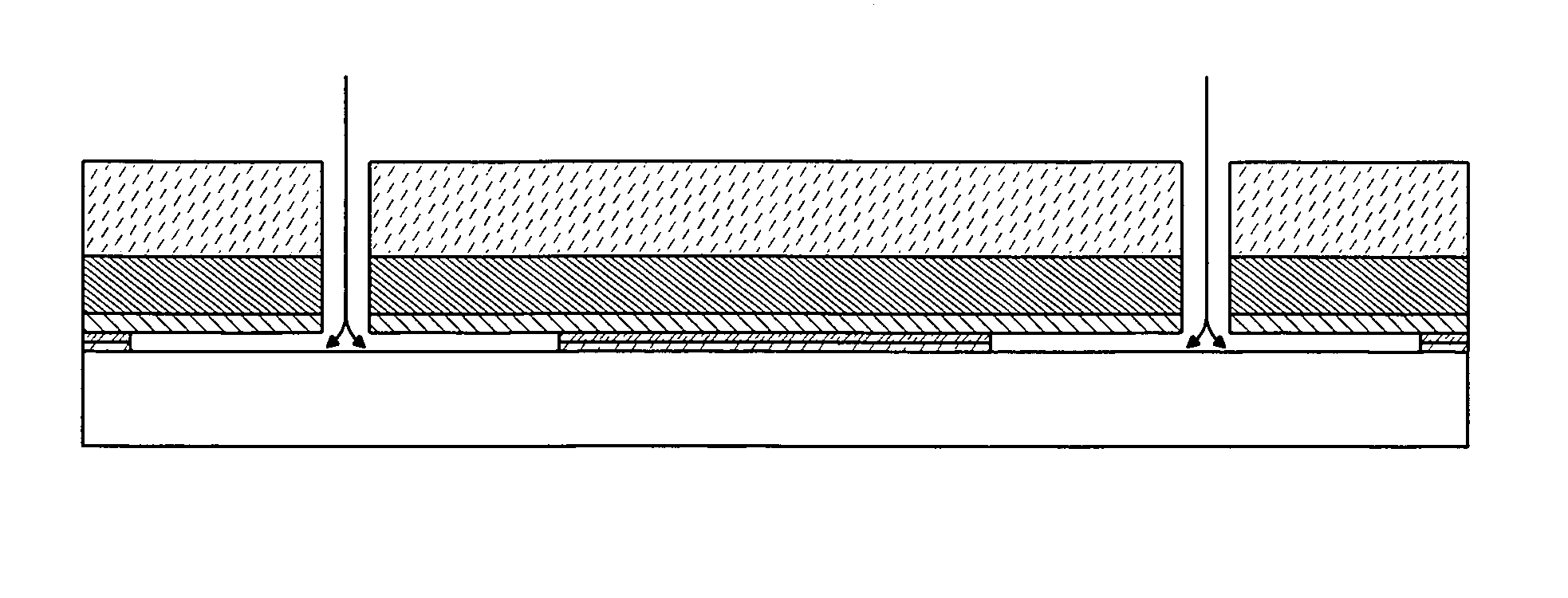

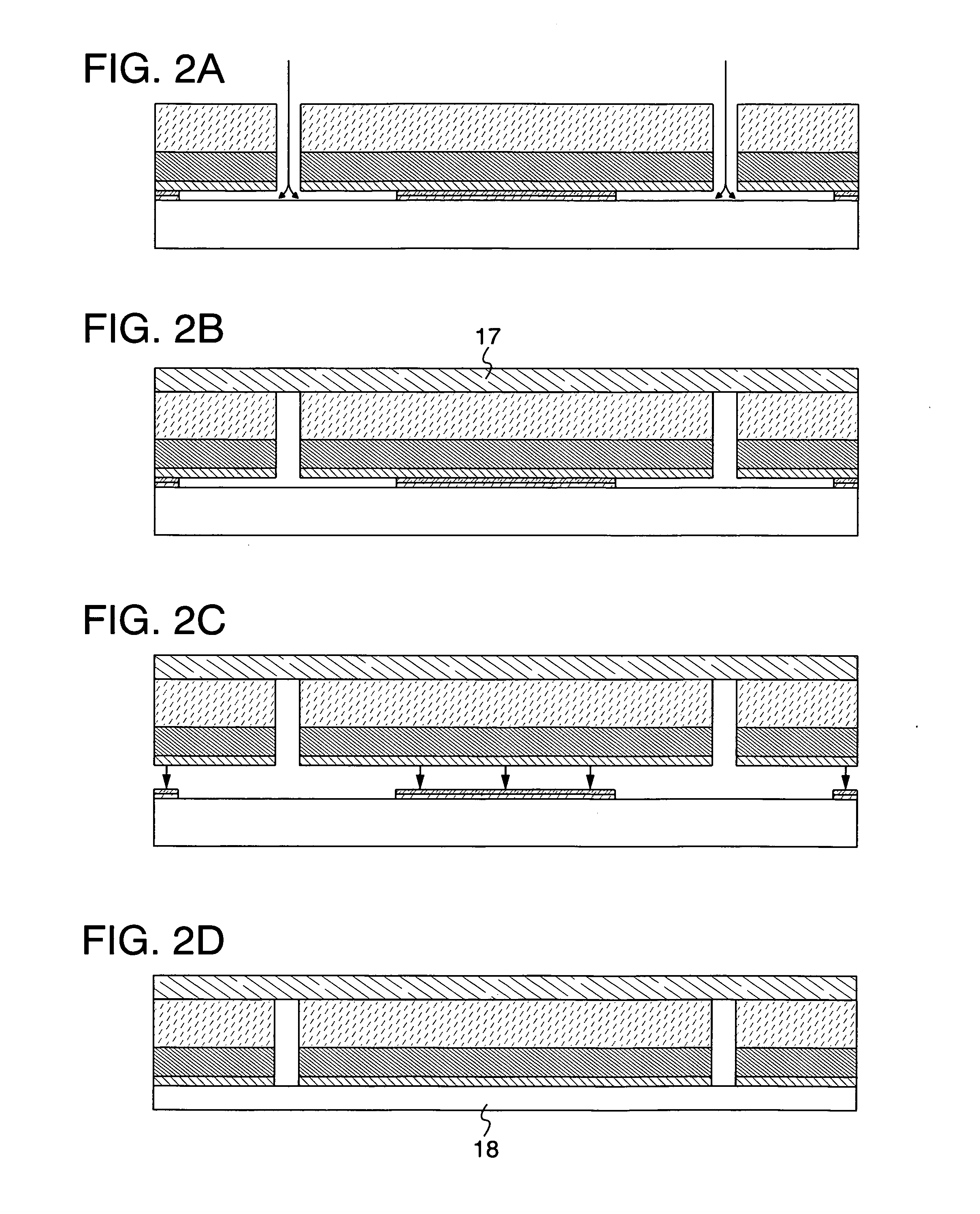

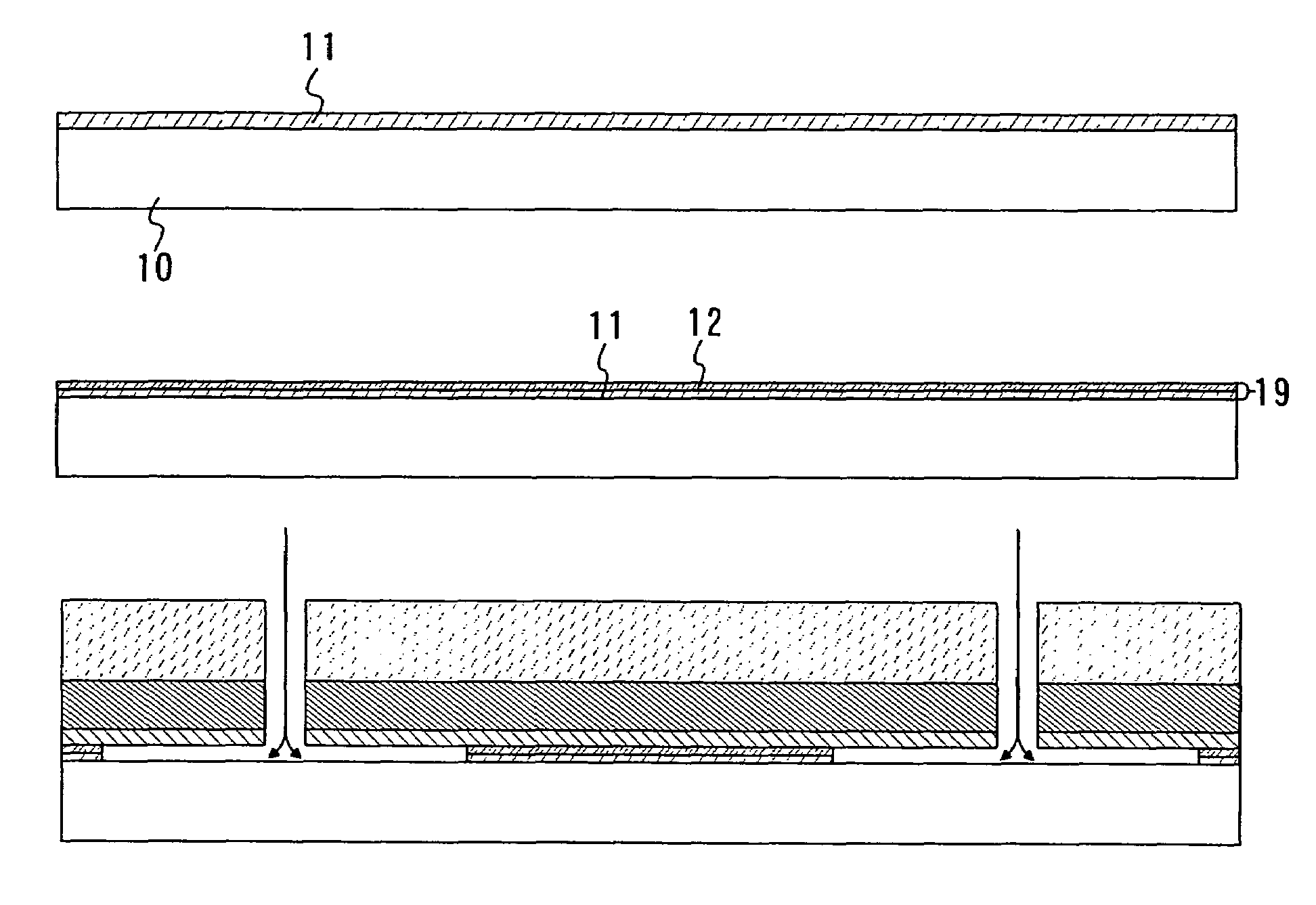

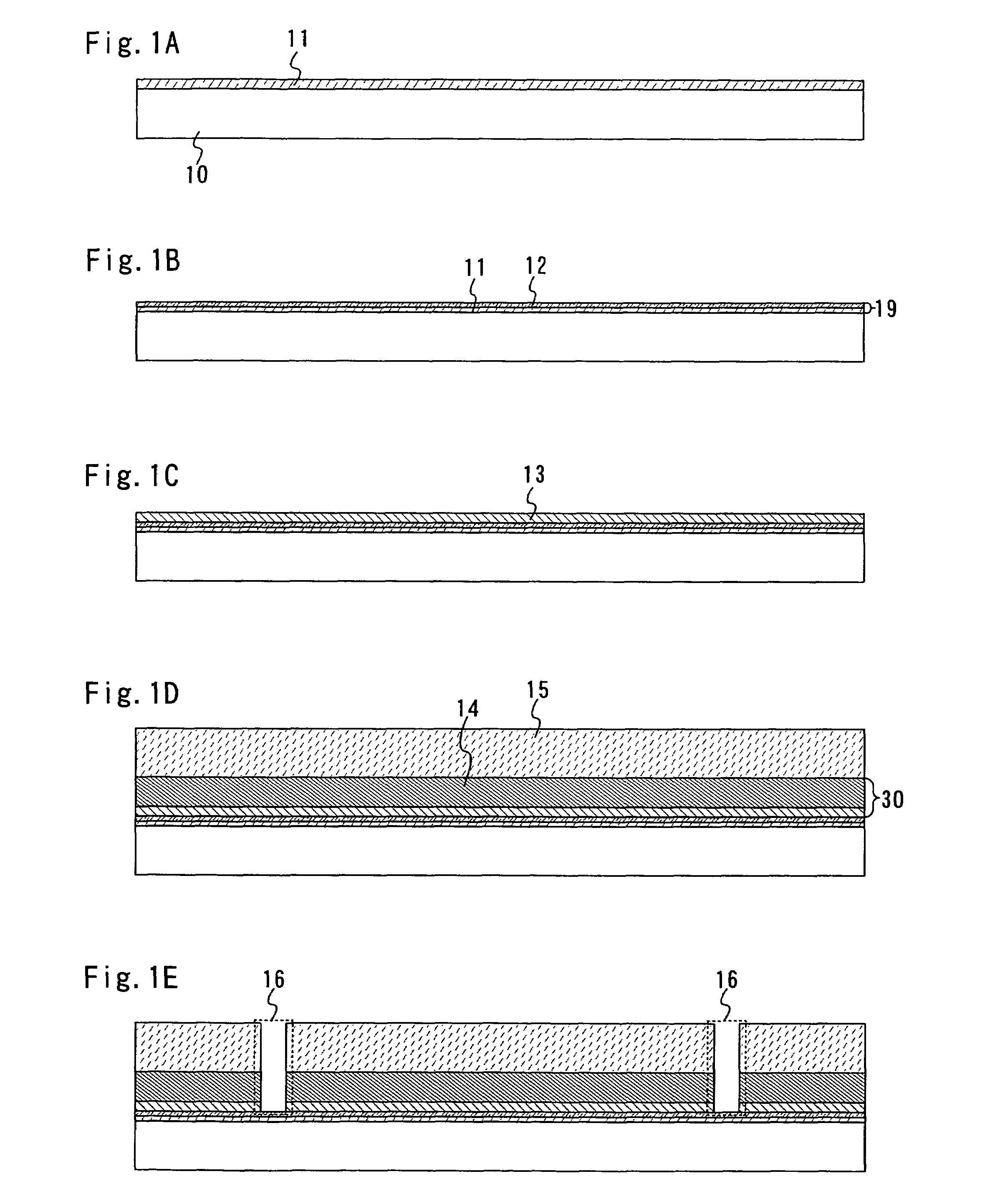

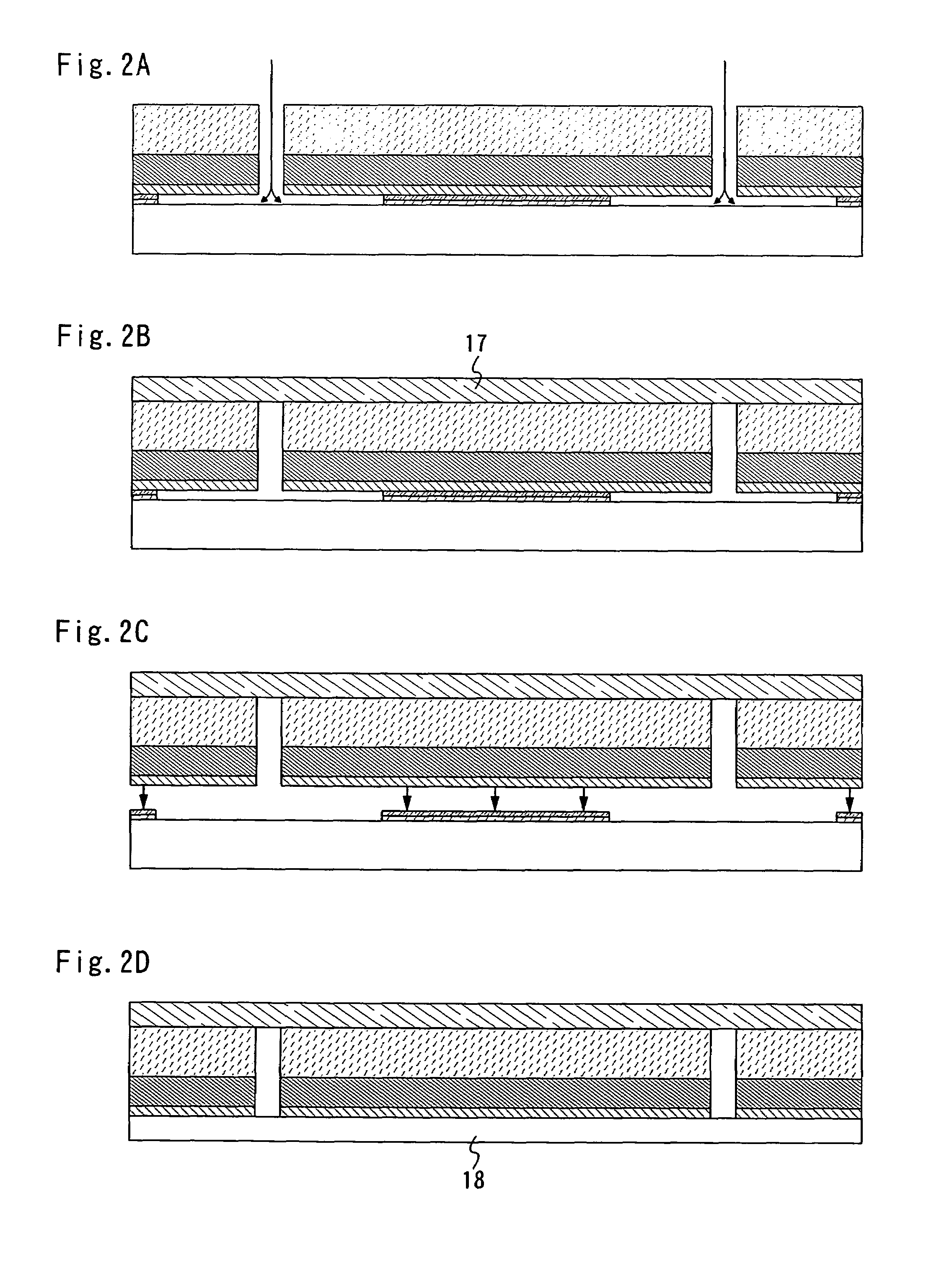

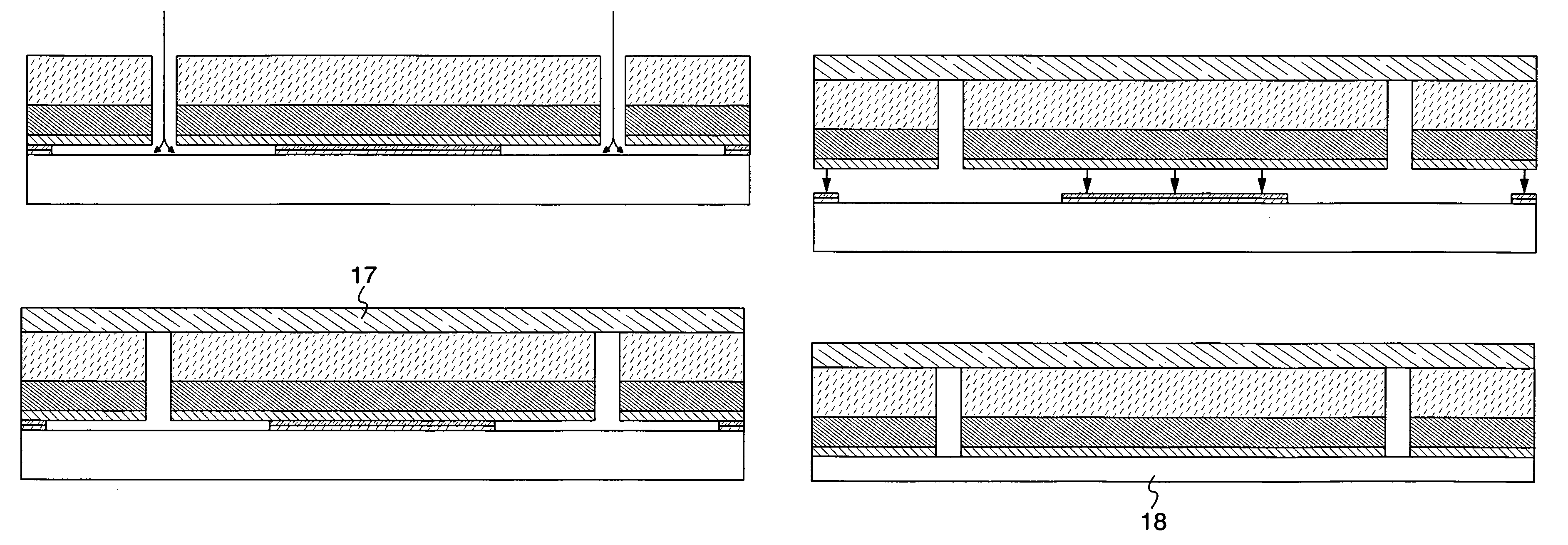

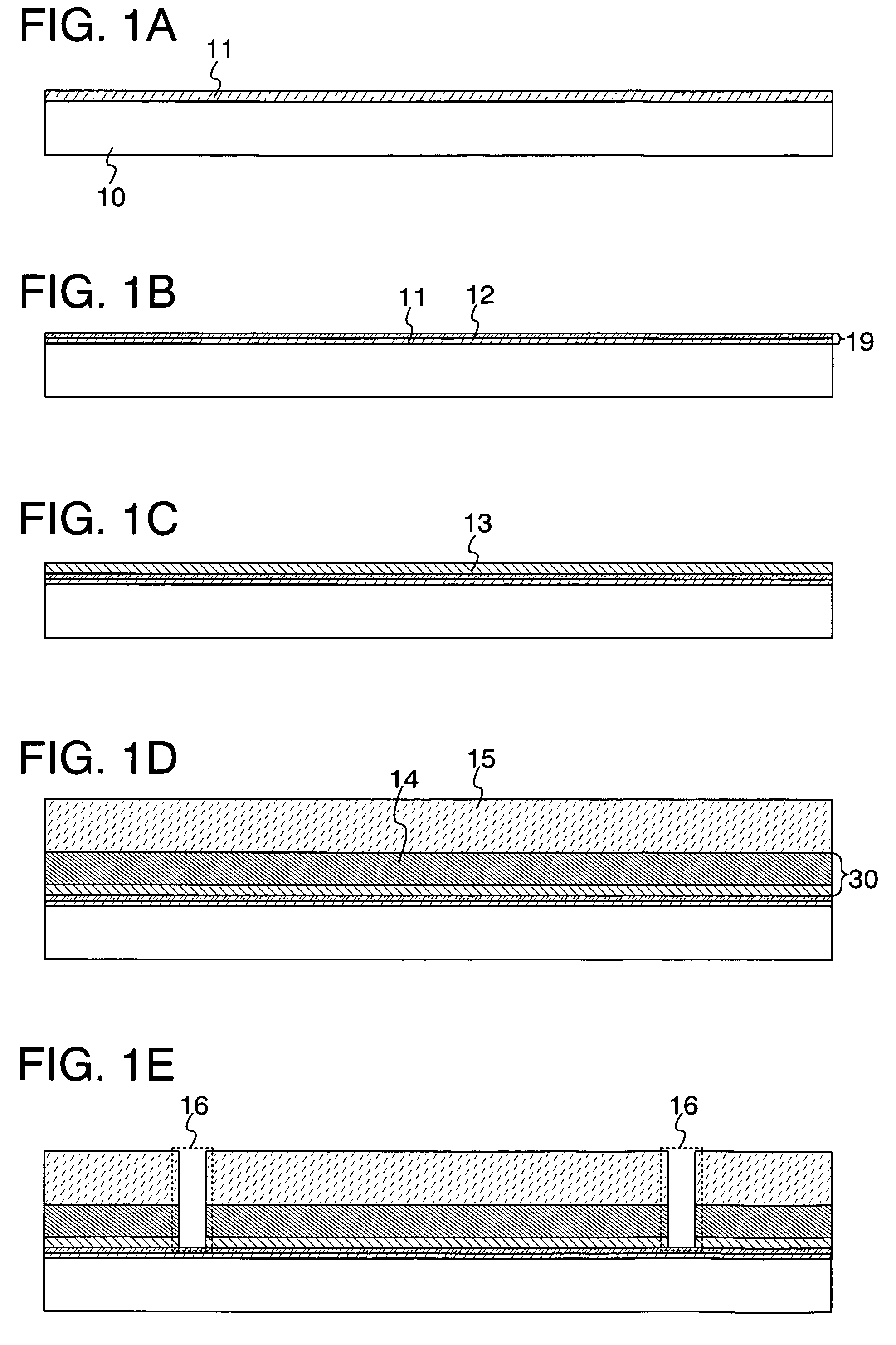

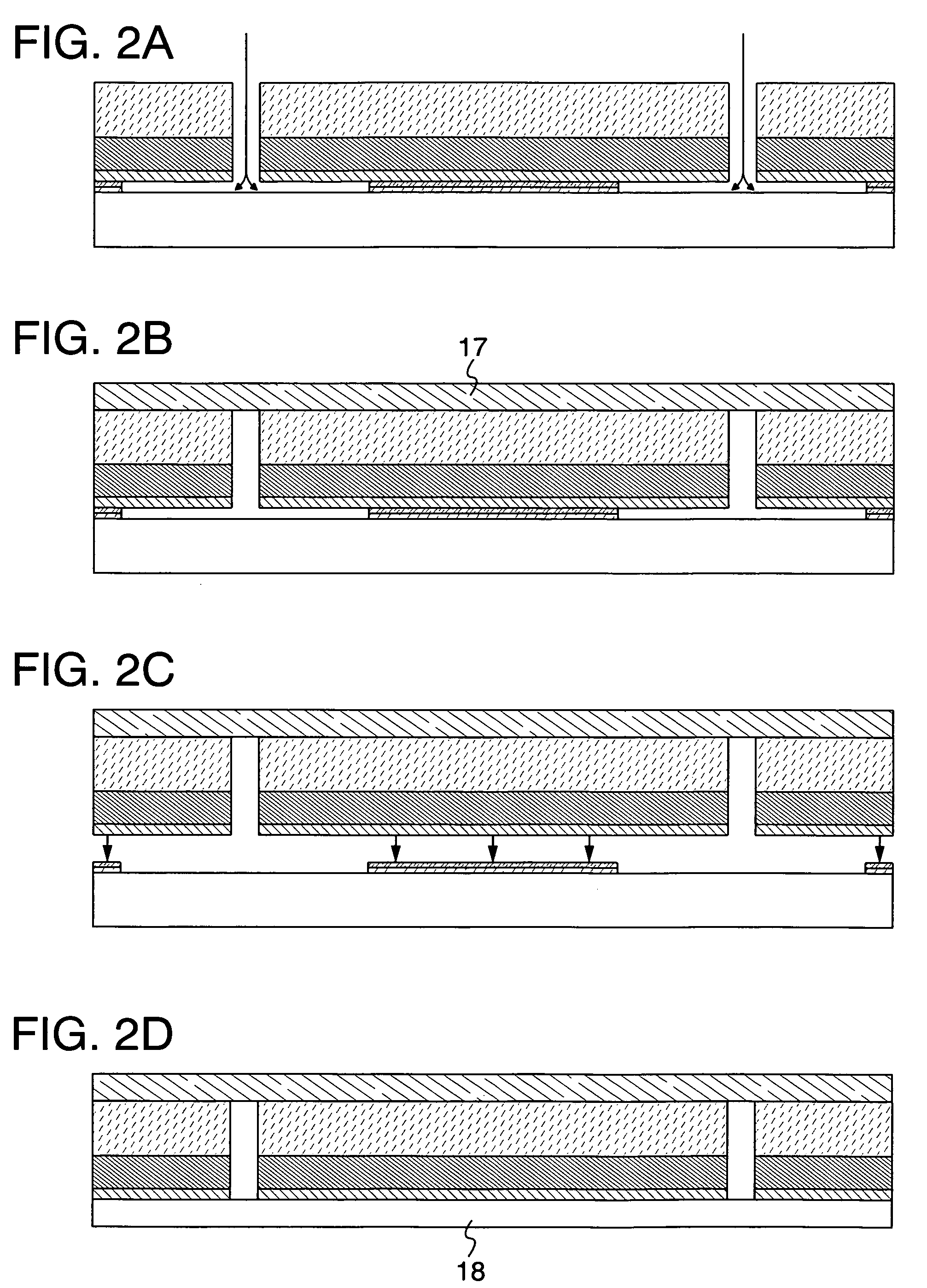

Manufacturing method of a semiconductor substrate provided with a through hole electrode

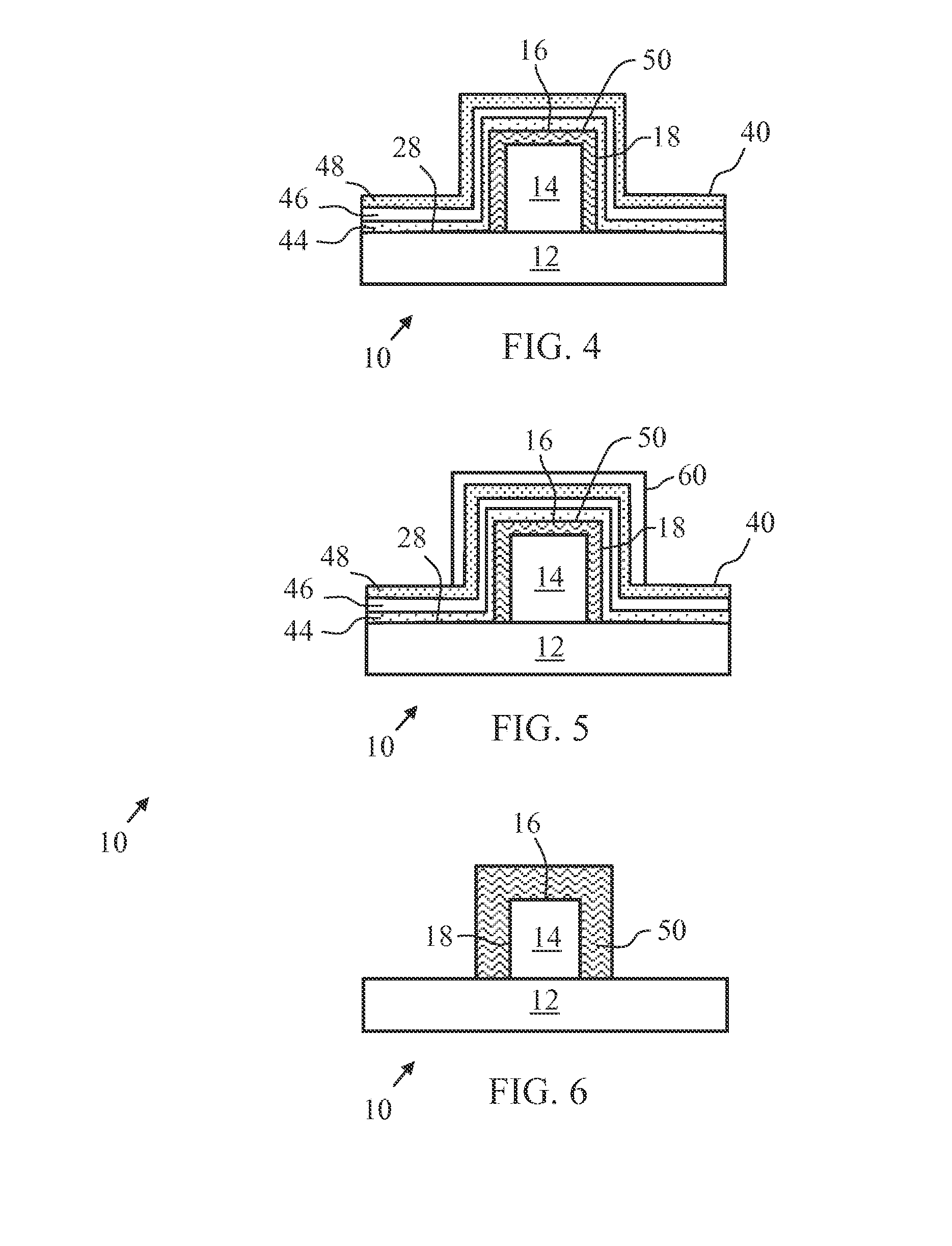

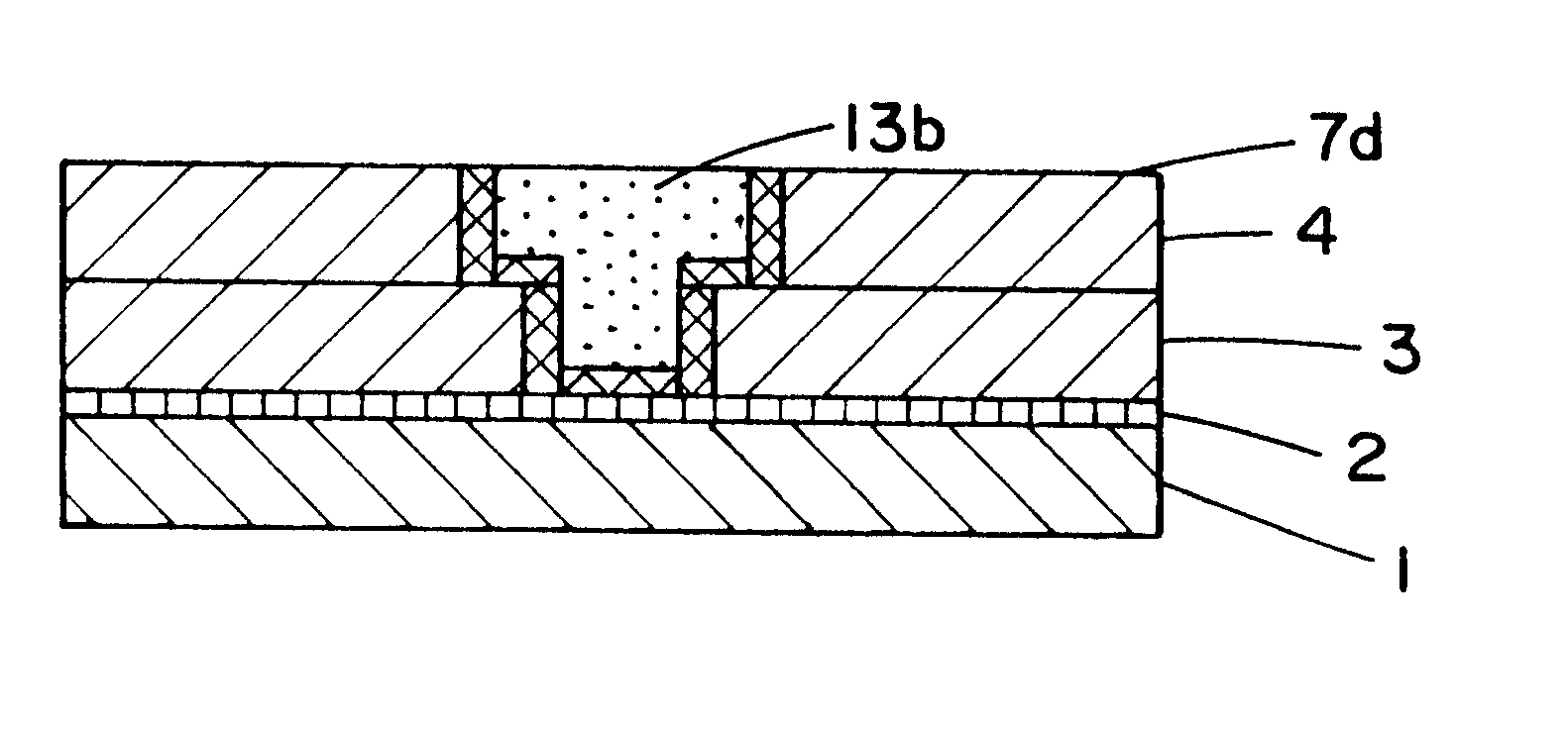

ActiveUS7022609B2Semiconductor/solid-state device detailsSolid-state devicesThin metalConductive materials

A manufacturing method of a semiconductor substrate provided with a through hole electrode is proposed. In accordance with the methods, it is possible to effectively form a through hole electrode in a semiconductor substrate in which a device and a wiring pattern have been already fabricated. This manufacturing method includes the steps of forming a first silicon oxide film 12 on a principal surface of the semiconductor substrate 11, forming a small hole 13 through the semiconductor substrate 11 from the opposite the step to reach to the first silicon oxide film 12, covering the inside of the small hole 13 with the second silicon oxide film 14, forming a first thin metal film 15 and a second thin metal film 16 on the first silicon oxide film 12, partially removing the first silicon oxide film 12 corresponding to the end of the small hole 13, and filling the small hole 13 with the conductive material to form a through hole electrode 17.

Owner:FUJIKURA LTD +1

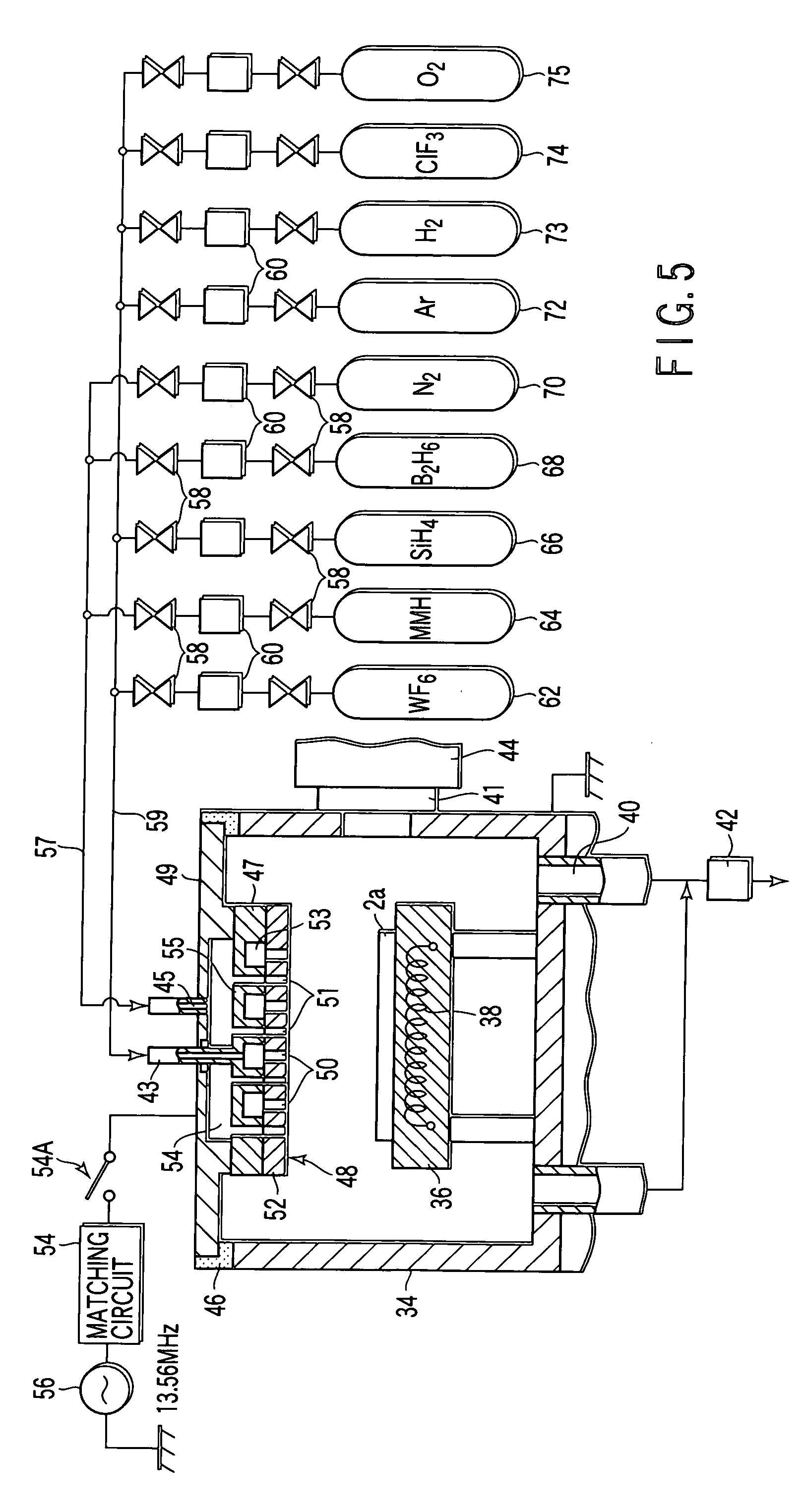

Method of forming a metal film for electrode

InactiveUS20050191803A1Semiconductor/solid-state device detailsSolid-state devicesGroup elementProcess engineering

A method of forming a refractory metal film doped with III or V group elements. The first process gas is supplied from a first gas source through a first gas introducing member to and through a gas supply mechanism toward a substrate within a processing vessel. The second process gas is supplied from a second gas source through a second gas introducing member to and through the gas supply mechanism toward the substrate within the processing vessel. The processing vessel is purged by evacuating the processing vessel by an evacuating mechanism, while supplying the inert gas from a third source through a third gas introducing member to and through the gas supply mechanism into the processing vessel. The supplying the first process gas and the supplying the second process gas are repeated with the supplying the purging gas being carried out between supplying the first and second gases performed so that residual gas present in the processing vessel after performing the supplying of the first and second process gases is reduced to a level of 1 to 30% based on the entire capacity of the processing vessel.

Owner:TOKYO ELECTRON LTD

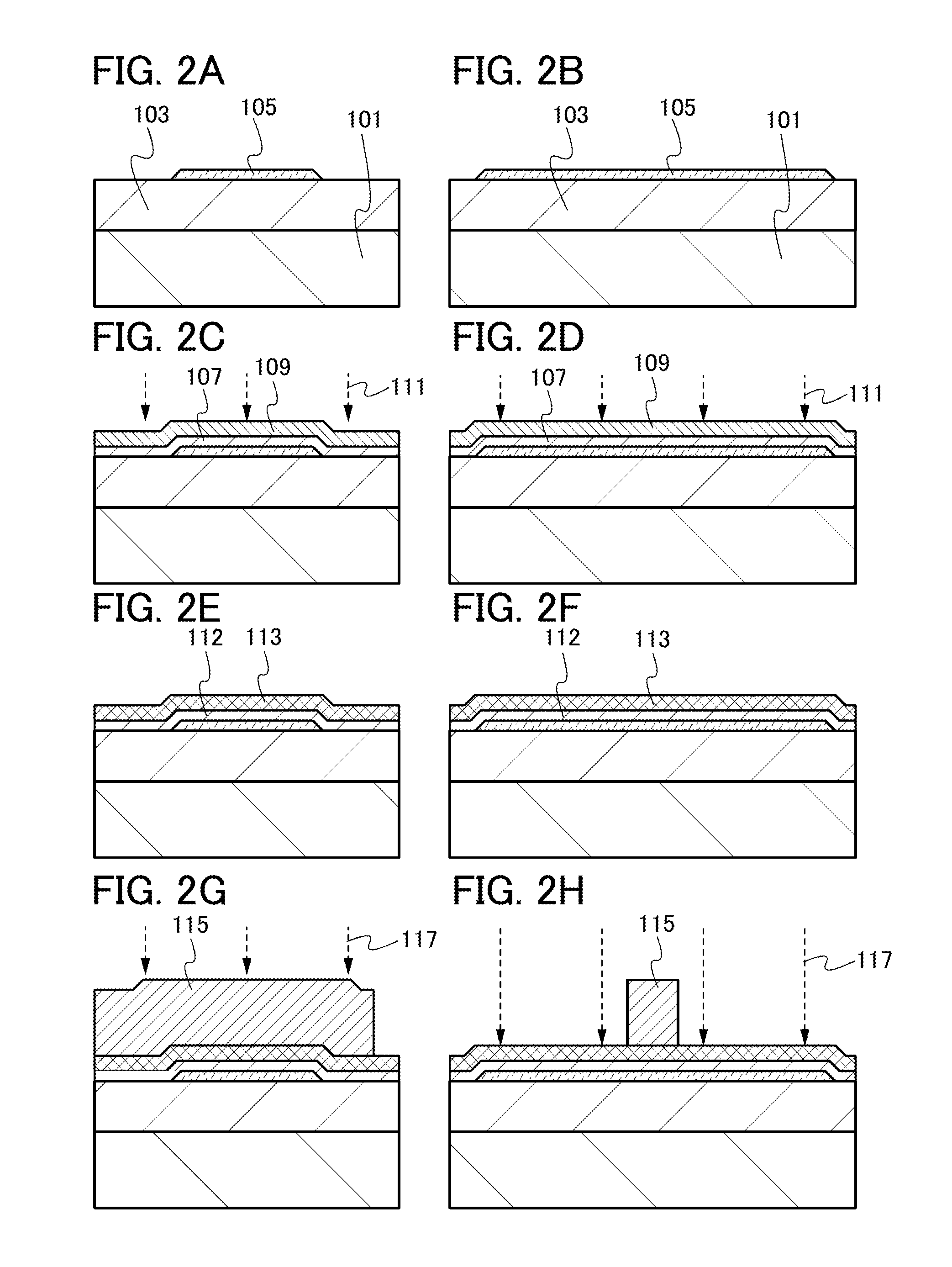

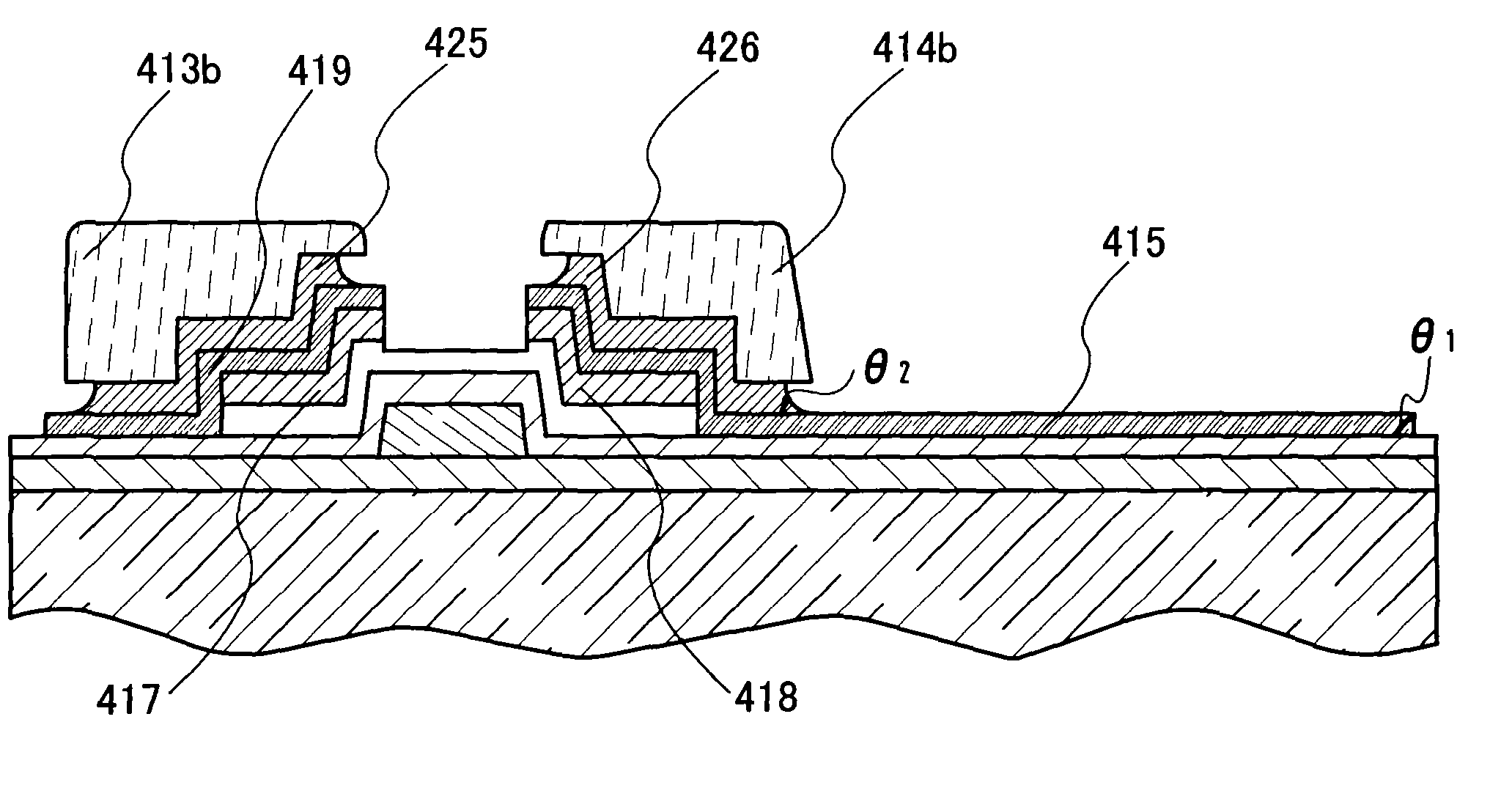

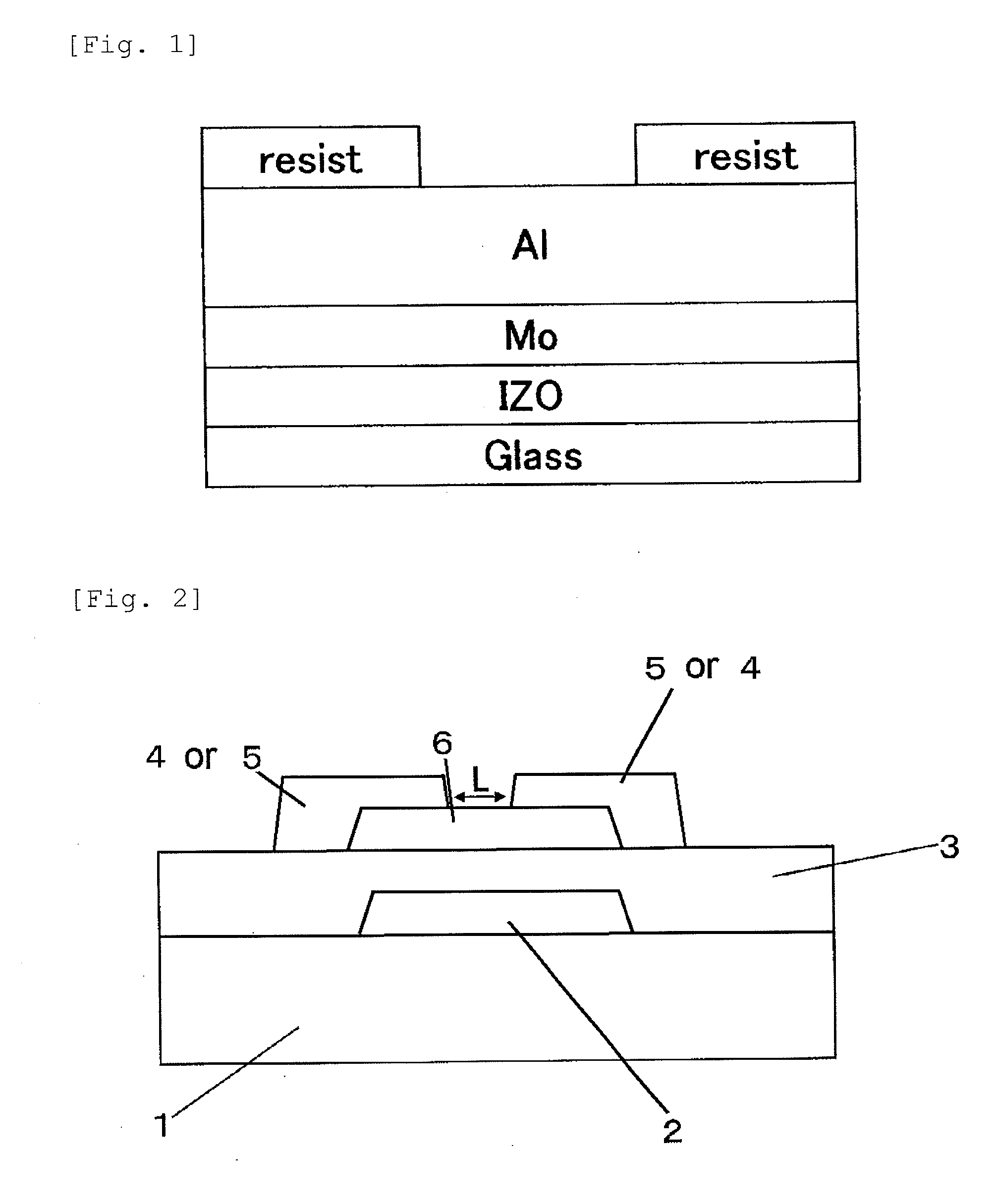

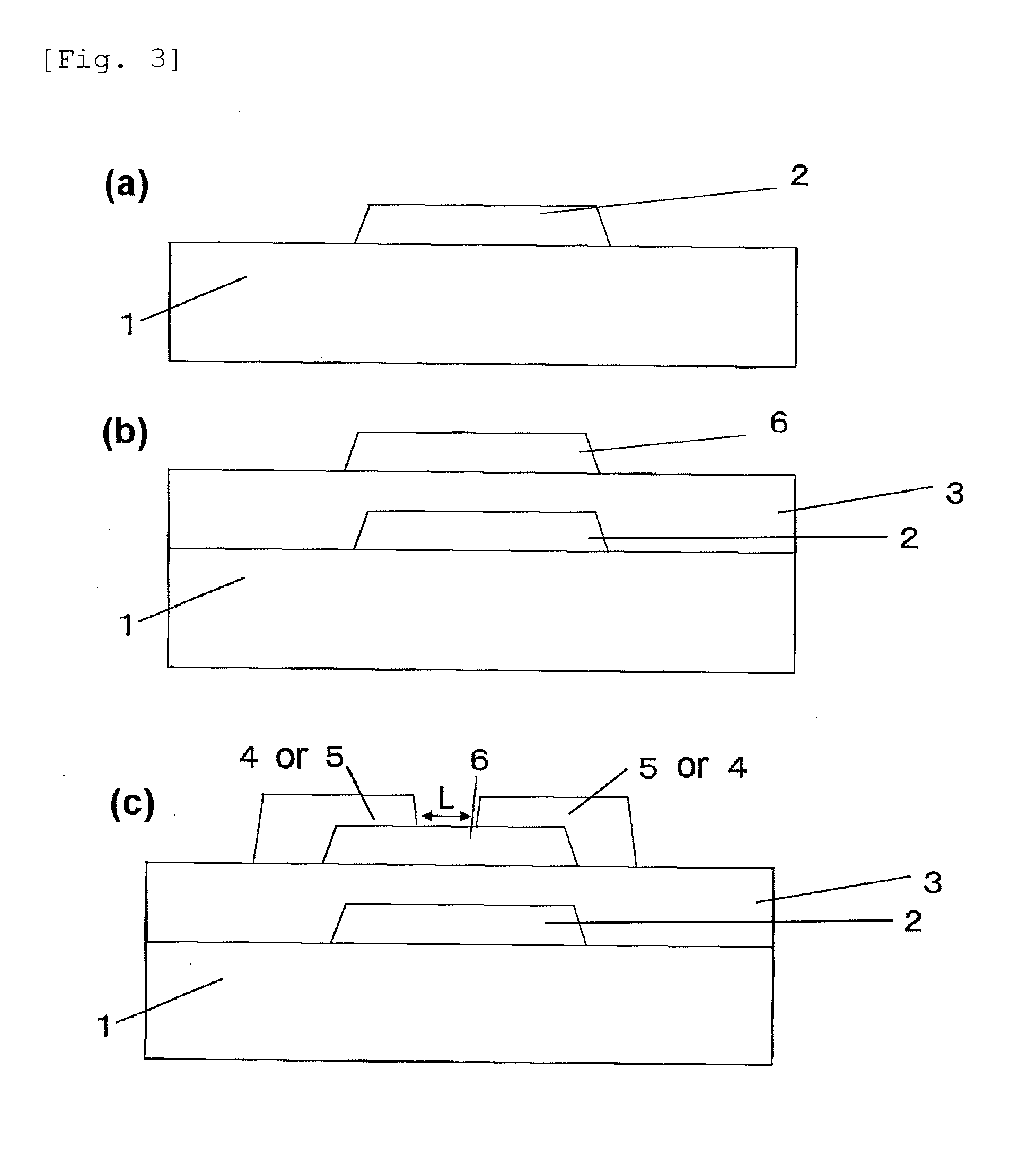

Display device and manufacturing method thereof

ActiveUS20070139571A1Reduce production processAvoid disconnectionElectroluminescent light sourcesSolid-state devicesDisplay deviceMetal membrane

It is an object of the present invention to form a pixel electrode and a metal film using one resist mask in manufacturing a stacked structure by forming the metal film over the pixel electrode. A conductive film to be a pixel electrode and a metal film are stacked. A resist pattern having a thick region and a region thinner than the thick region is formed over the metal film using an exposure mask having a semi light-transmitting portion. The pixel electrode, and the metal film formed over part of the pixel electrode to be in contact therewith are formed using the resist pattern. Accordingly, a pixel electrode and a metal film can be formed using one resist mask.

Owner:SEMICON ENERGY LAB CO LTD

Manufacturing method of semiconductor device

InactiveUS20060121694A1Low costImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsSemiconductor

A manufacturing method of a semiconductor device at low cost with high reliability, wherein a semiconductor device is manufactured by peeling an element forming layer having a thin film transistor and the like provided over a substrate from the substrate. A metal film is formed on a substrate, plasma treatment is applied thereto to form a metal oxide film on the metal film, an element forming layer is formed on the metal oxide film, an insulating film is formed to cover the element forming layer, an opening is formed in the insulating film and the element forming layer, an etchant is injected through the opening to remove the insulating film and the element forming layer, and the element forming layer is peeled off the substrate. The peeling may be performed by removing the metal film and the metal oxide film partially and then employing a physical means.

Owner:SEMICON ENERGY LAB CO LTD

Manufacturing method of semiconductor device

InactiveUS7465674B2Low costImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingDevice materialMetal membrane

An object of the present invention is to provide a method for manufacturing a semiconductor device with high reliability, at low cost, in which an element forming layer having a thin film transistor and the like provided over a substrate is peeled from the substrate, so that a semiconductor device is manufactured. According to the invention, a metal film is formed over a substrate, a plasma treatment is performed to the metal film in a dinitrogen monoxide atmosphere to form a metal oxide film over the metal film, a first insulating film is formed continuously without being exposed to the air, an element forming layer is formed over the first insulating film, and the element forming layer is peeled from the substrate, so that a semiconductor device is manufactured.

Owner:SEMICON ENERGY LAB CO LTD

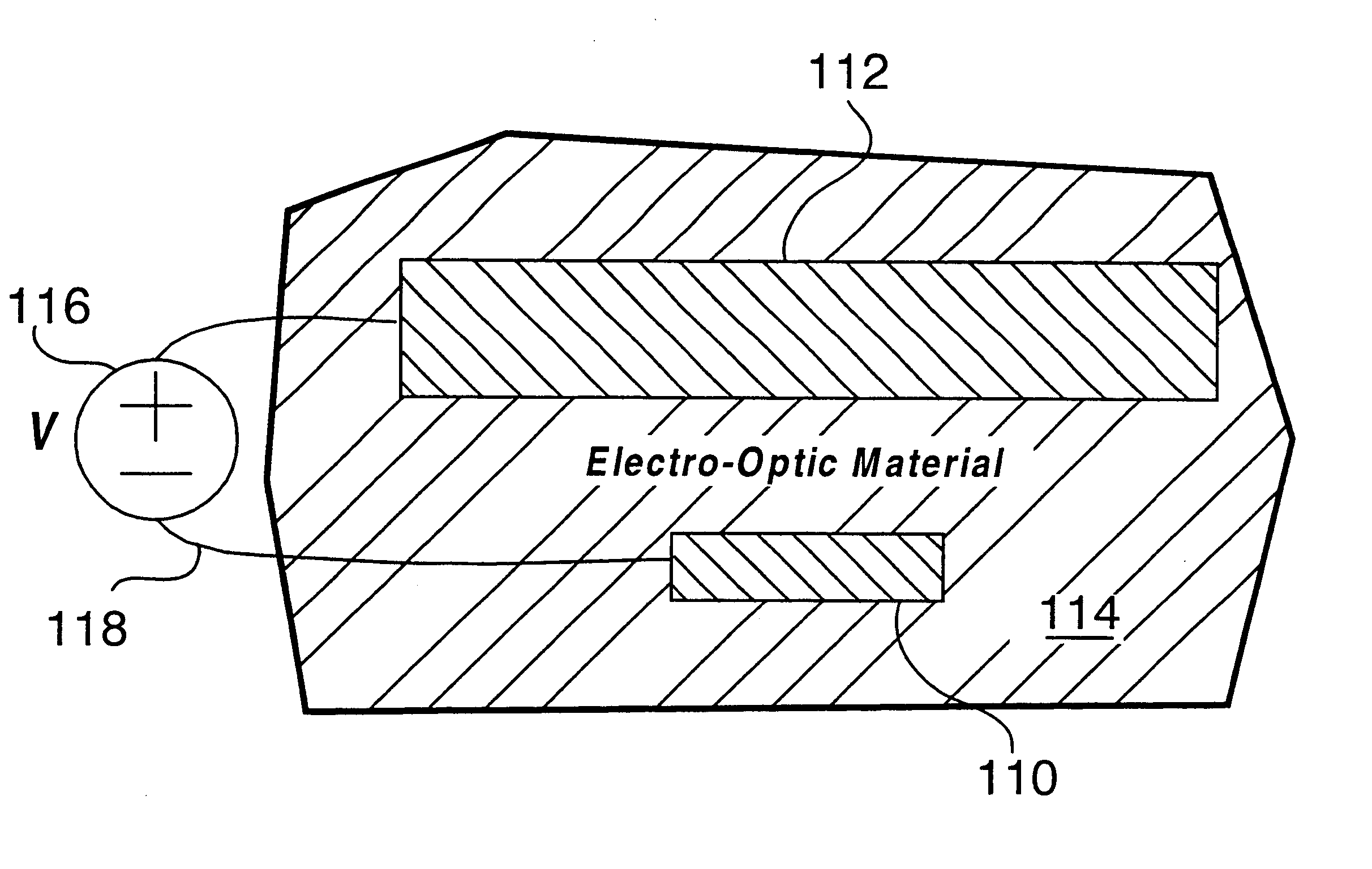

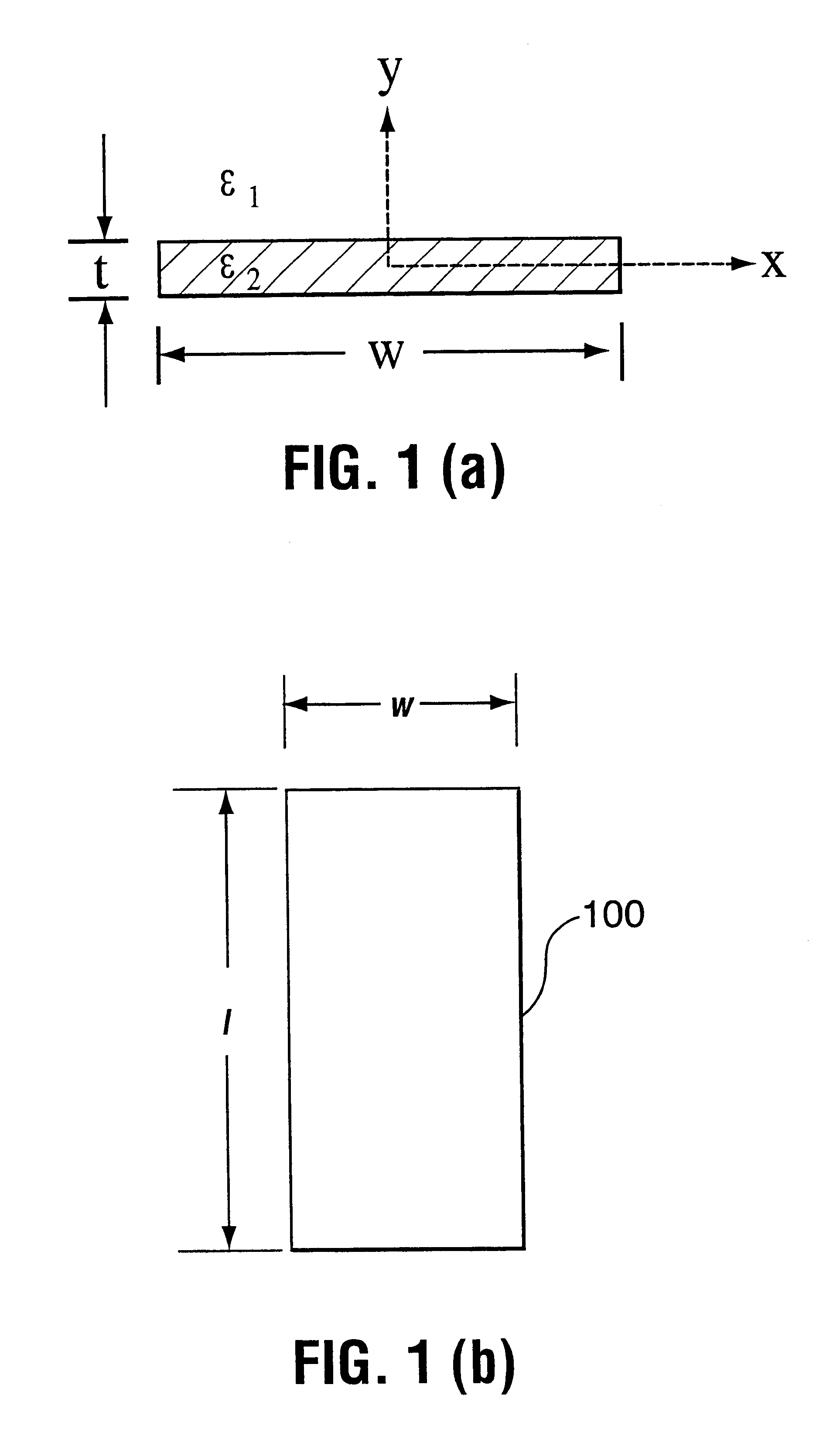

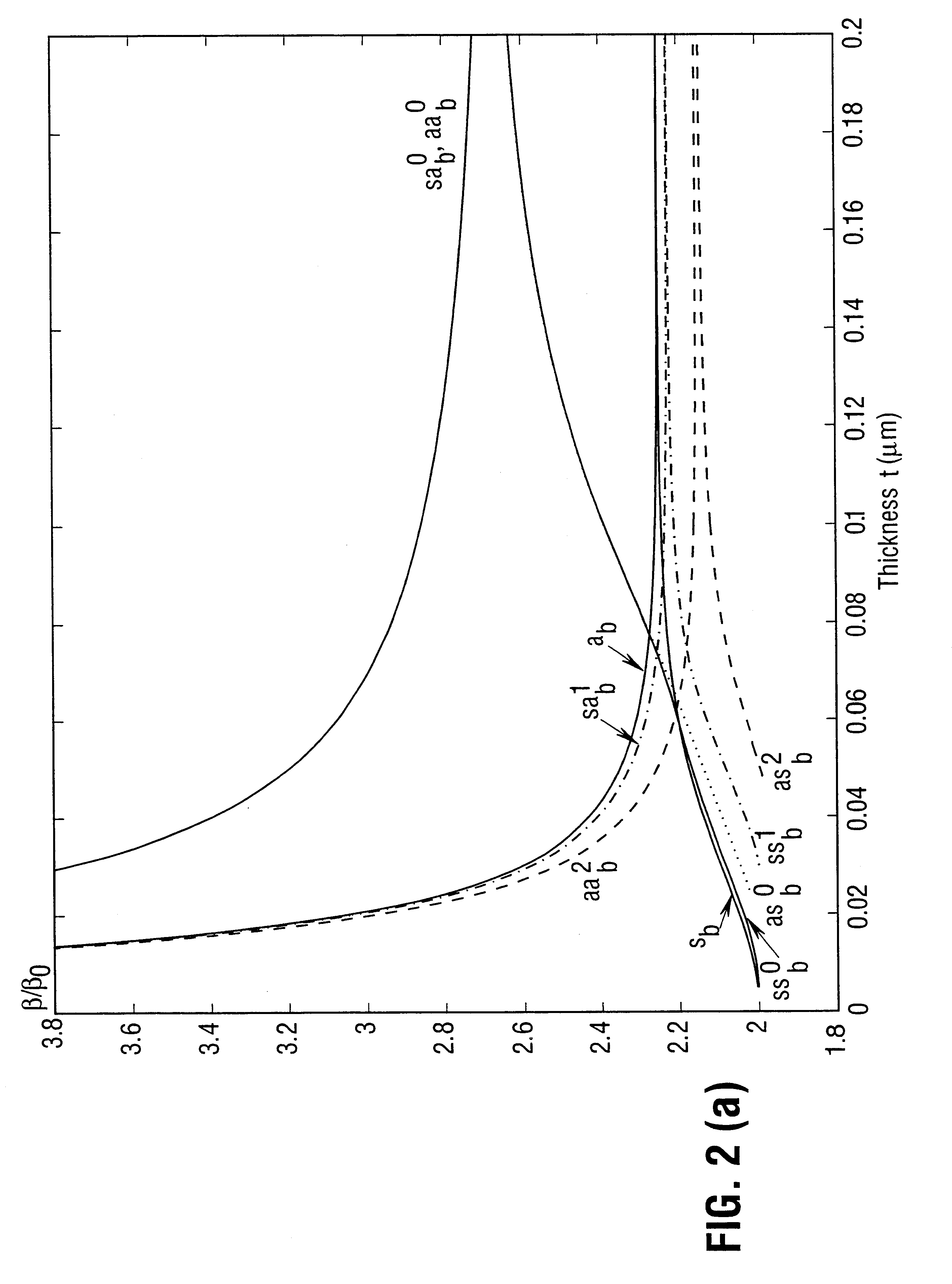

Optical waveguide structures

InactiveUS6614960B2Optical resonator shape and constructionRecord information storageUltrasound attenuationElectricity

Waveguide structures comprising a thin lossy metal film of finite width embedded in an infinite homogeneous dielectric support purely bound electromagnetic modes of propagation low mode power attenuation in the neighbourhood of 10 to 0.1 dB / cm is achievable at optical communications wavelengths, with even lower values being possible. Carefully selecting the film's thickness and width can make this mode the only long-ranging one supported. In addition, the mode can have a field distribution that renders it excitable using an end-fire approach. The finite-width metal film waveguide may be used for applications requiring short propagation distances and 2-D field confinement in the transverse plane, enabling various devices to be constructed, such as couplers, splitters, modulators, interferometers, switches and periodic structures. Under certain conditions, an asymmetric structure can support a long-ranging mode having a field distribution that is suitable to excitation using an end-fire technique.

Owner:UNIVERSITY OF OTTAWA

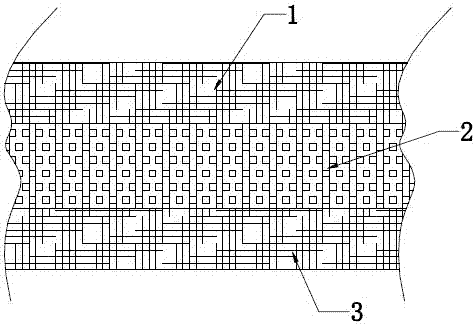

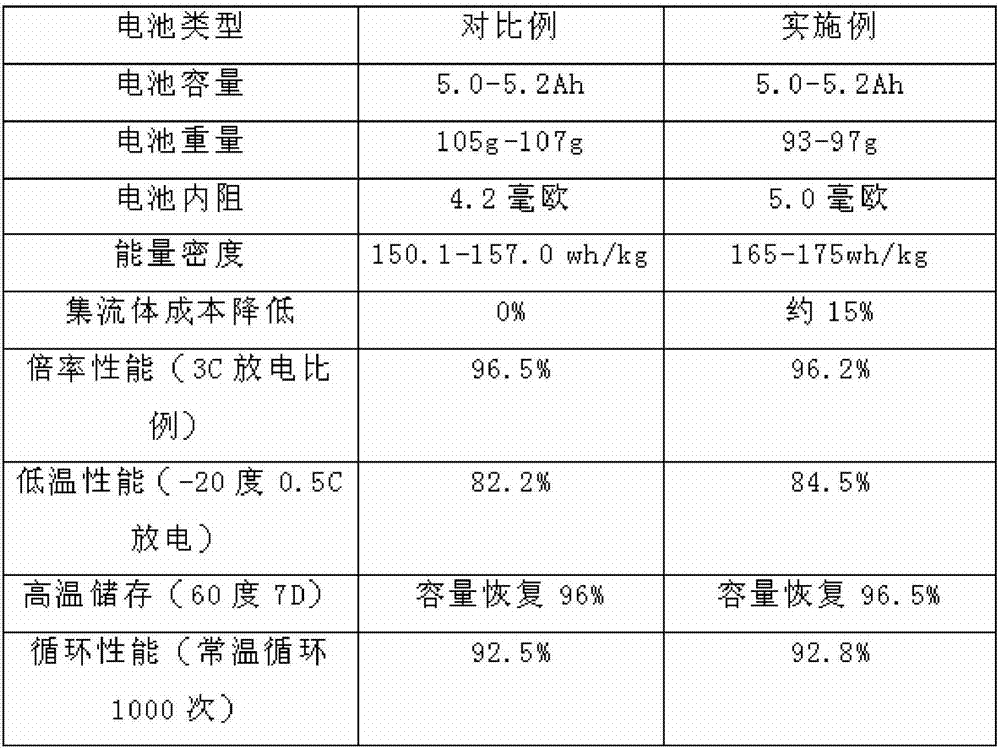

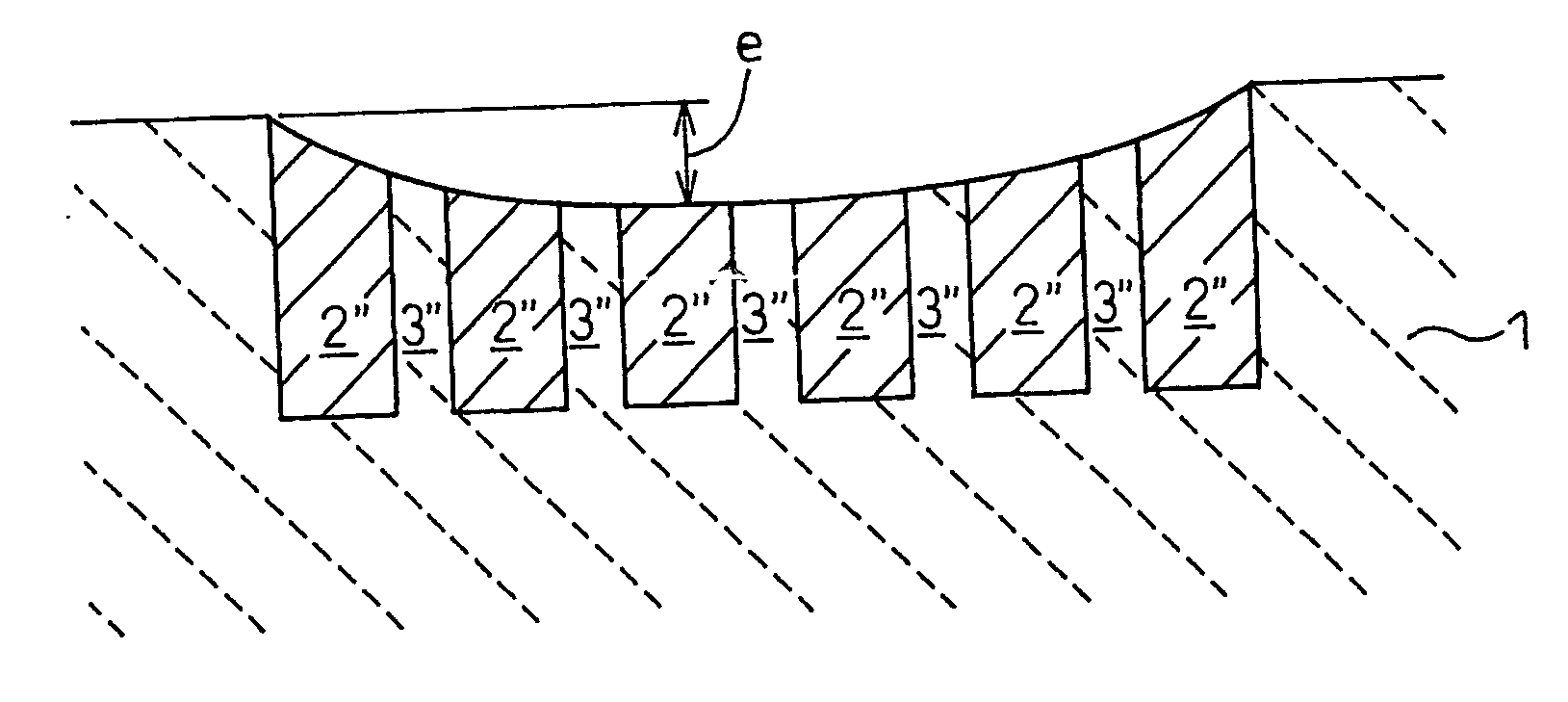

Composite current collector, and lithium ion secondary battery applying current collector

InactiveCN107221676AReduce weightHigh tensile strengthElectrode carriers/collectorsElectrolysisLithium-ion battery

The invention discloses a current collector, and an application of the current collector in a lithium ion battery, and concretely relates to a composite current collector, and a lithium ion secondary battery applying the current collector. The composite current collector comprises an upper metal layer, a lower metal layer and a nonmetal layer arranged between the upper metal layer and the lower metal layer, vacuum electroplating, electrolytic electroplating or composite bonding compounding is carried out between the upper metal layer and the nonmetal layer and between the nonmetal layer and the lower metal layer, and the thickness of the nonmetal layer is controlled to be 2-20 [mu]m; and the thickness of each of the upper metal layer and the lower metal layer is controlled to be 1-10 [mu]m. The above structure reduces the weight of the current collector and guarantees that the composite current collector have excellent tensile strength and excellent flexibility; the outer layer of the current collector is the metal layer, and has a conductive effect; and the above reasonable structure design substantially improves the mass energy density of the produced lithium ion secondary battery and effectively prolongs the cycle life of the battery.

Owner:JIANGSU DAOYING TECH CO LTD

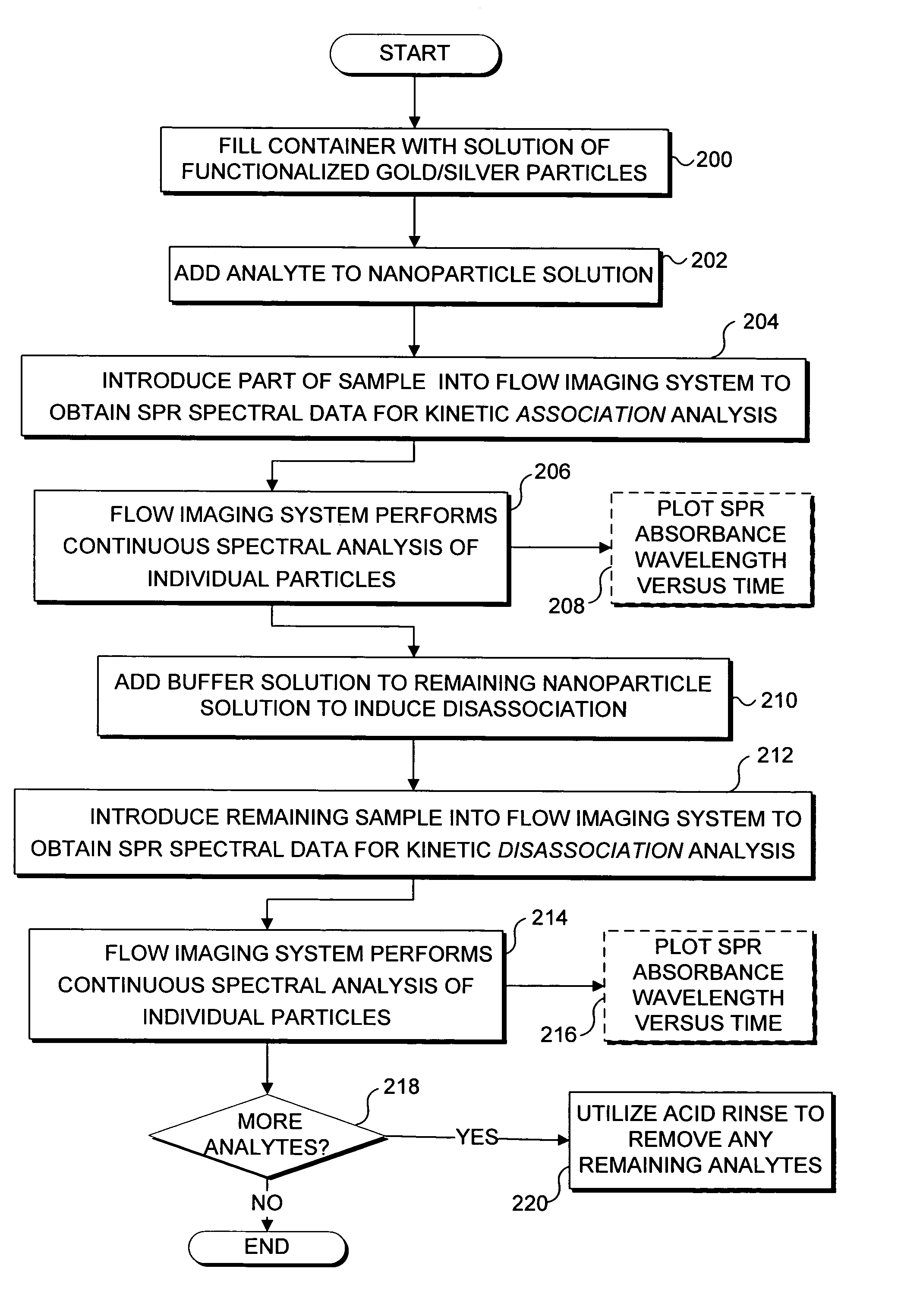

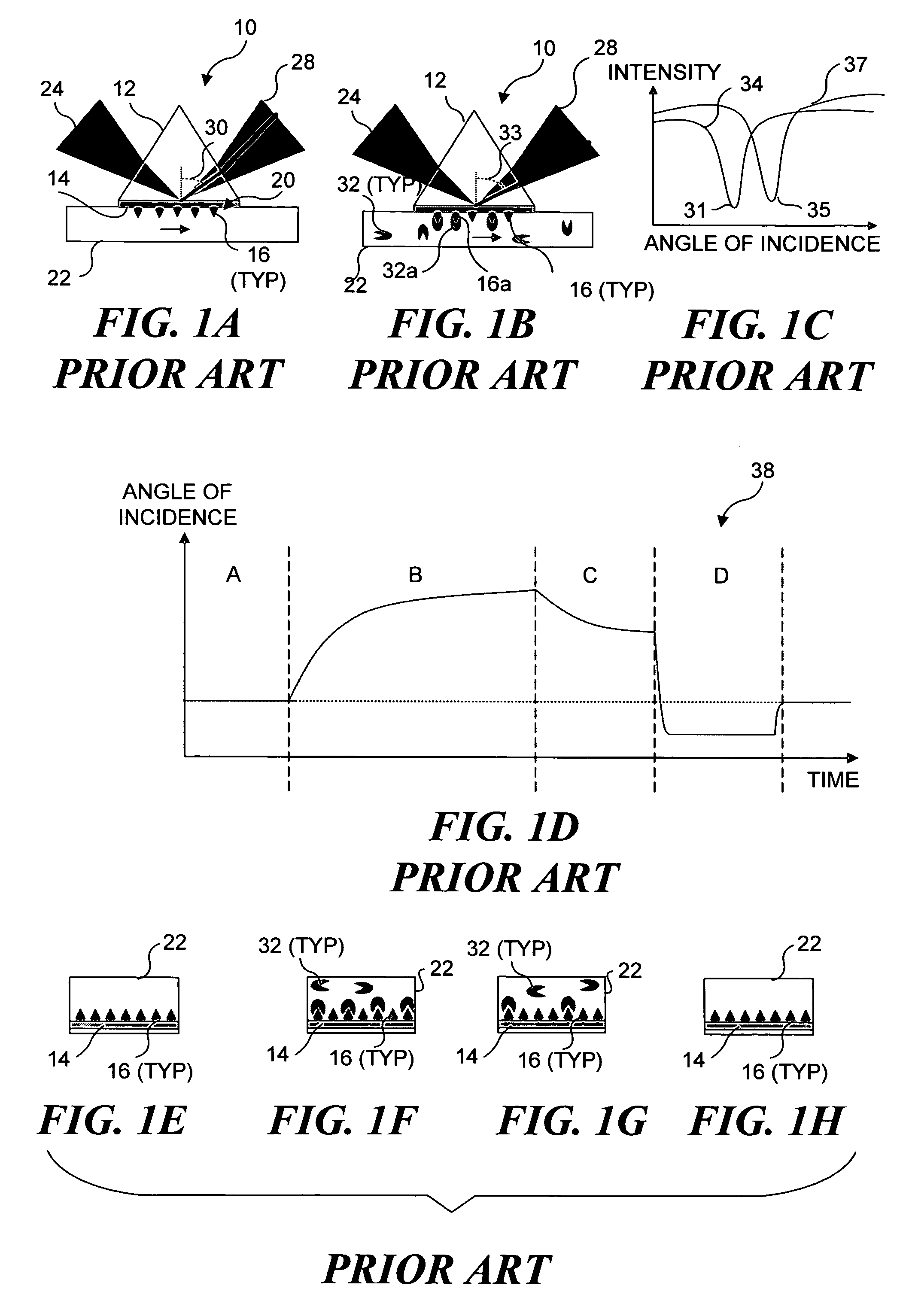

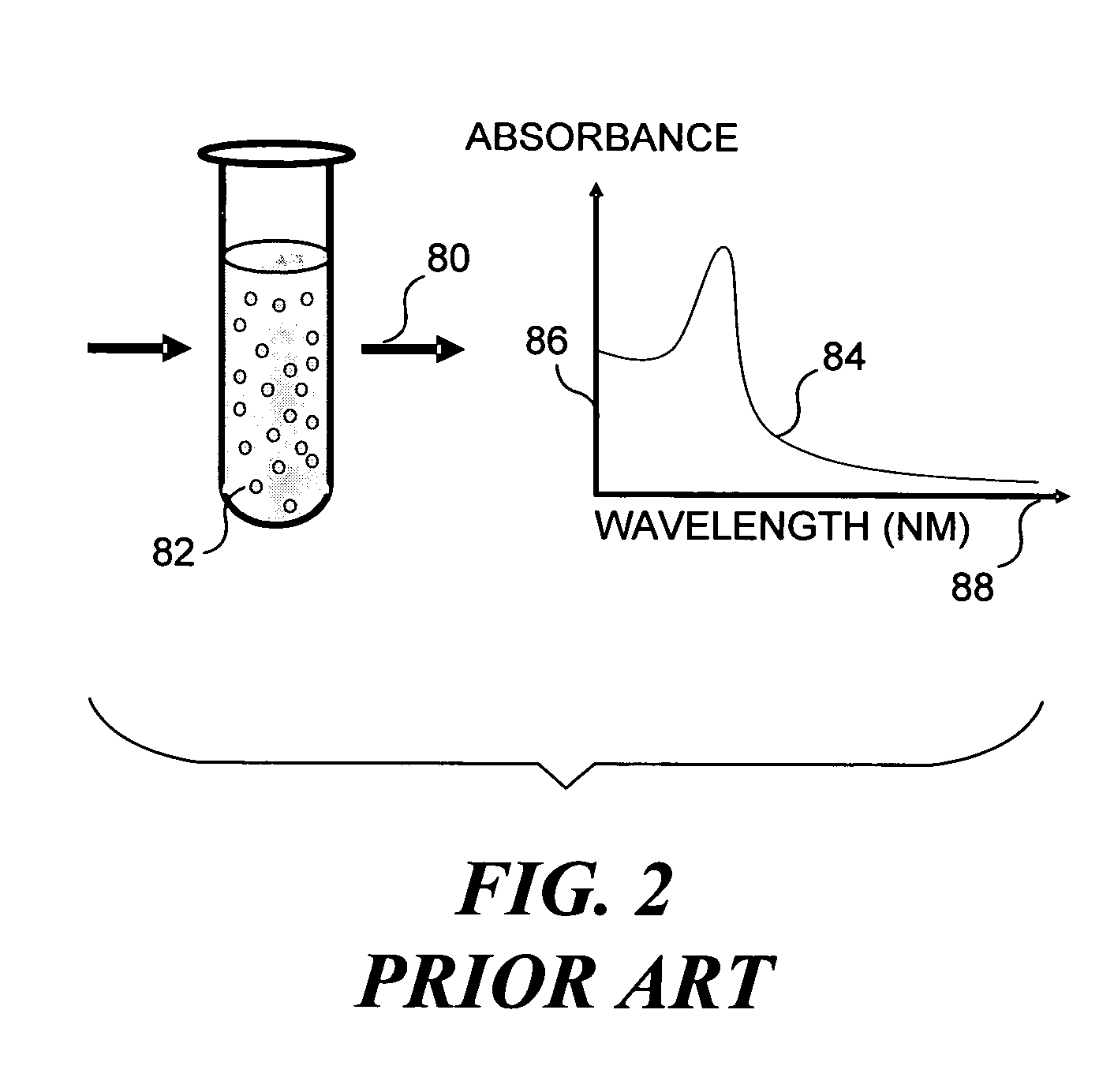

Imaging platform for nanoparticle detection applied to SPR biomolecular interaction analysis

InactiveUS7057732B2Increase curve 's linearityAccurate CalibrationSpectrum investigationInvestigating moving fluids/granular solidsSurface plasmonic resonanceAnalyte molecule

A flow imaging system is used to implement surface plasmon resonance (SPR) detection to study bio-molecular interactions. The flow imaging system is used to capture SPR absorption spectra of large numbers of objects, where each object includes both a metal film capable of exhibiting SPR, and detecting molecules. Analyte molecules are added to a solution of such objects, and the result is introduced into the flow imaging system which collects full SPR spectral data from individual objects. The objects can be nanoparticles or larger particles that support metal island films. The SPR spectral data can be used to determine specificity, kinetics, affinity, and concentration with respect to the interactions between the detecting molecules and the analyte molecules.

Owner:CYTEK BIOSCI

Process for atomic layer deposition of metal films

InactiveUS6869876B2Satisfies needSemiconductor/solid-state device manufacturingSolid state diffusion coatingHalogenMetal halides

In the present invention, a metal halide film is grown which is then reduced to the metal film rather than growing the metal film directly on the substrate surface. In certain embodiments, a metal halide film is grown from at least two precursors: a halogen-containing precursor and a metal-containing precursor. The metal halide film is then exposed to a reducing agent to form the metal film. In certain preferred embodiments, the metal halide film is exposed to the reducing agent prior to the completion of the growing step.

Owner:AIR PROD & CHEM INC

Manufacturing method of semiconductor device

InactiveUS7482248B2Low costImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingDevice materialThin membrane

A manufacturing method of a semiconductor device at low cost with high reliability, wherein a semiconductor device is manufactured by peeling an element forming layer having a thin film transistor and the like provided over a substrate from the substrate. A metal film is formed on a substrate, plasma treatment is applied thereto to form a metal oxide film on the metal film, an element forming layer is formed on the metal oxide film, an insulating film is formed to cover the element forming layer, an opening is formed in the insulating film and the element forming layer, an etchant is injected through the opening to remove the insulating film and the element forming layer, and the element forming layer is peeled off the substrate. The peeling may be performed by removing the metal film and the metal oxide film partially and then employing a physical means.

Owner:SEMICON ENERGY LAB CO LTD

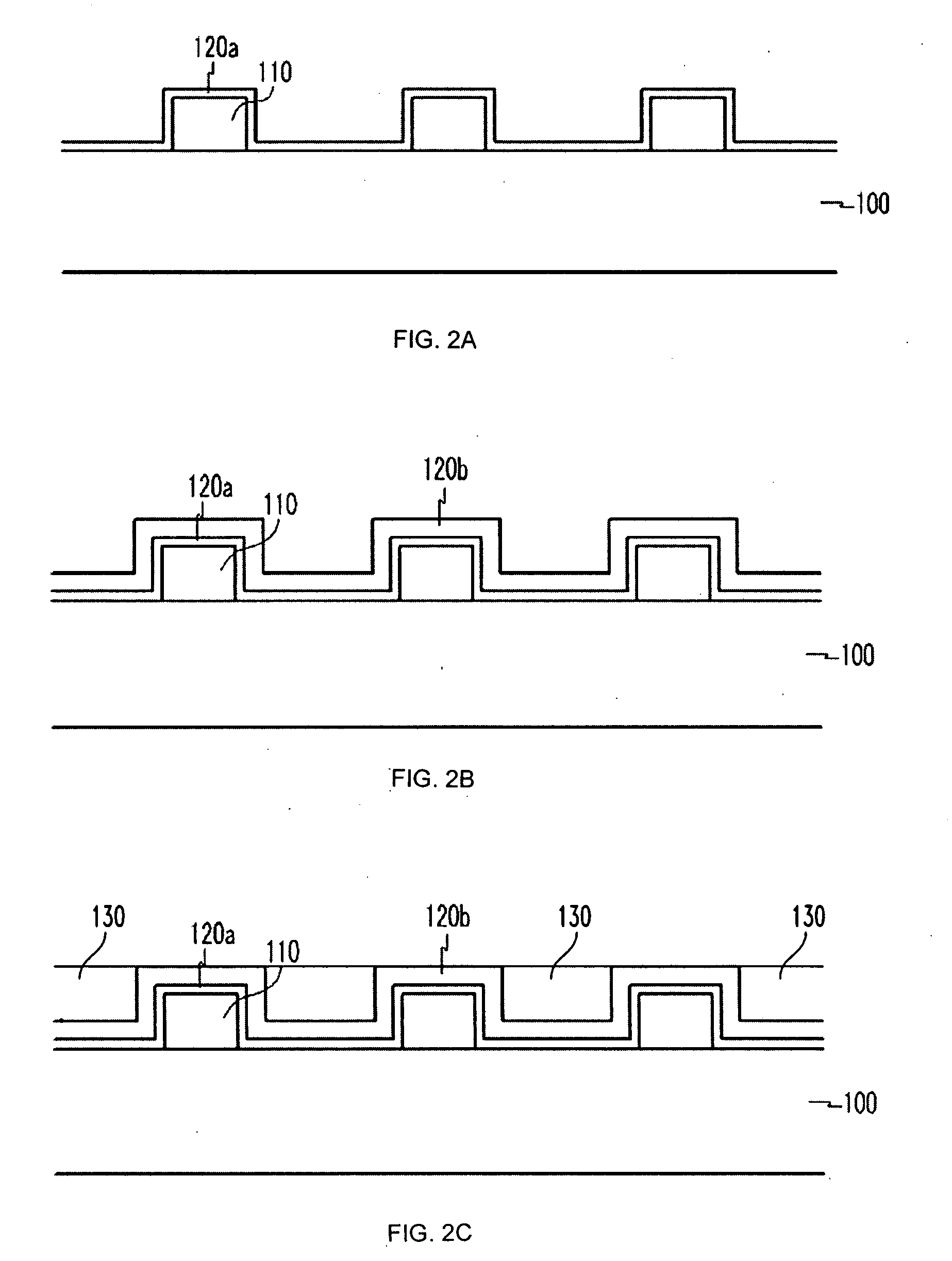

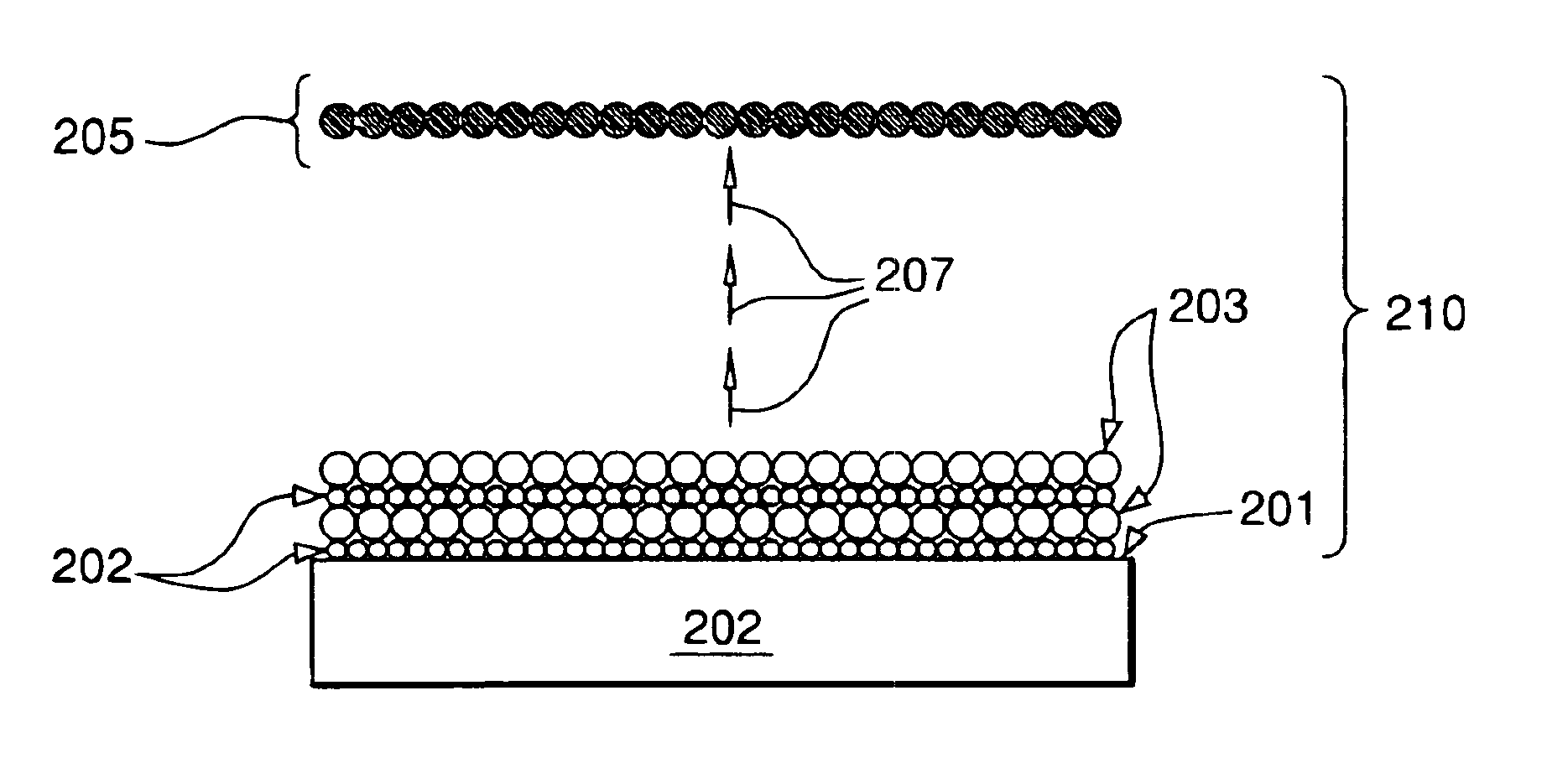

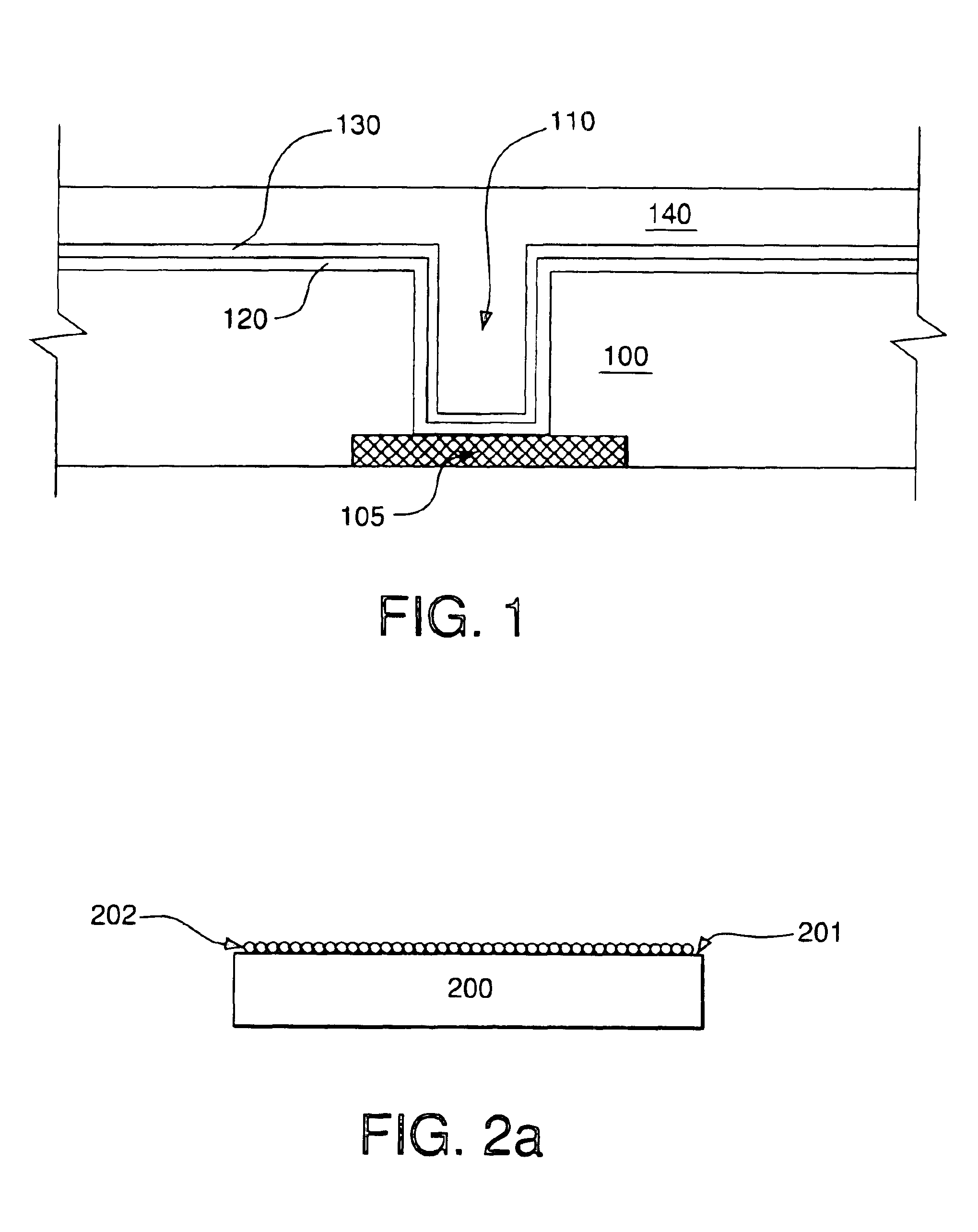

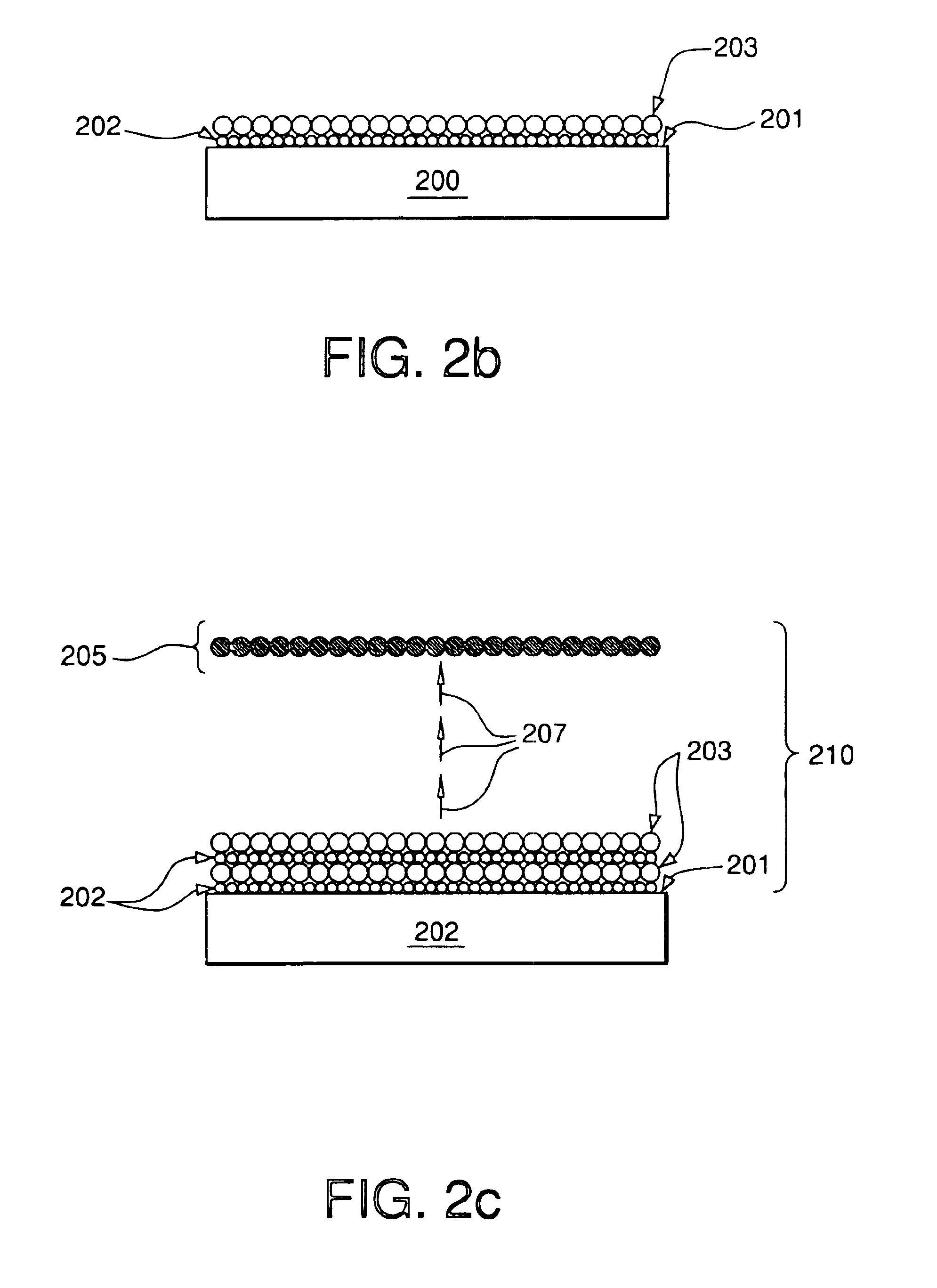

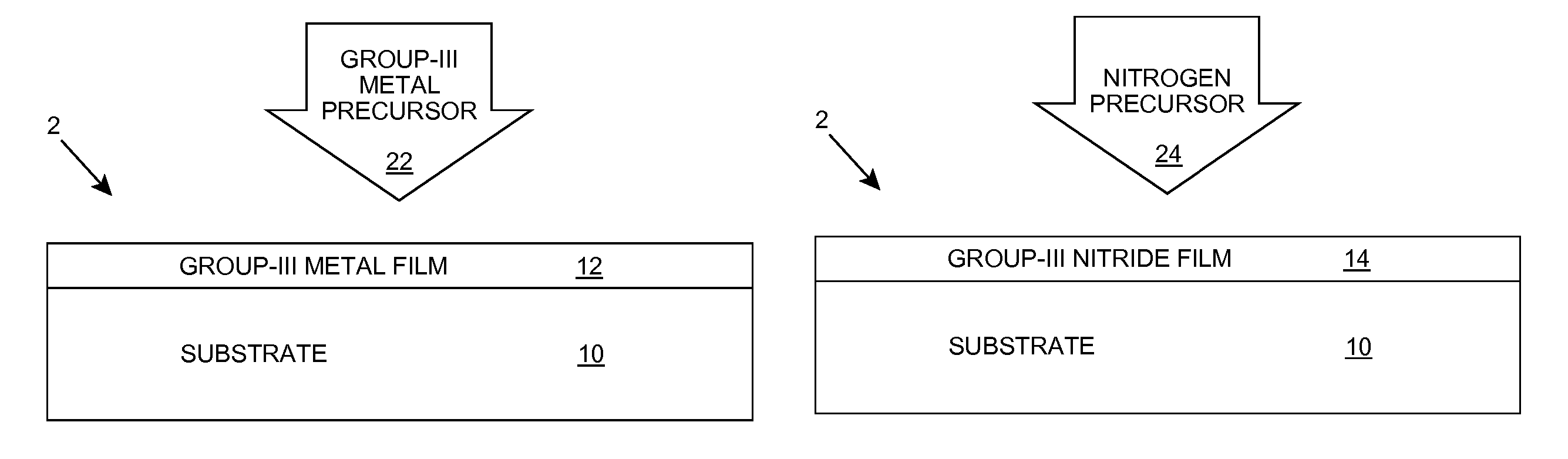

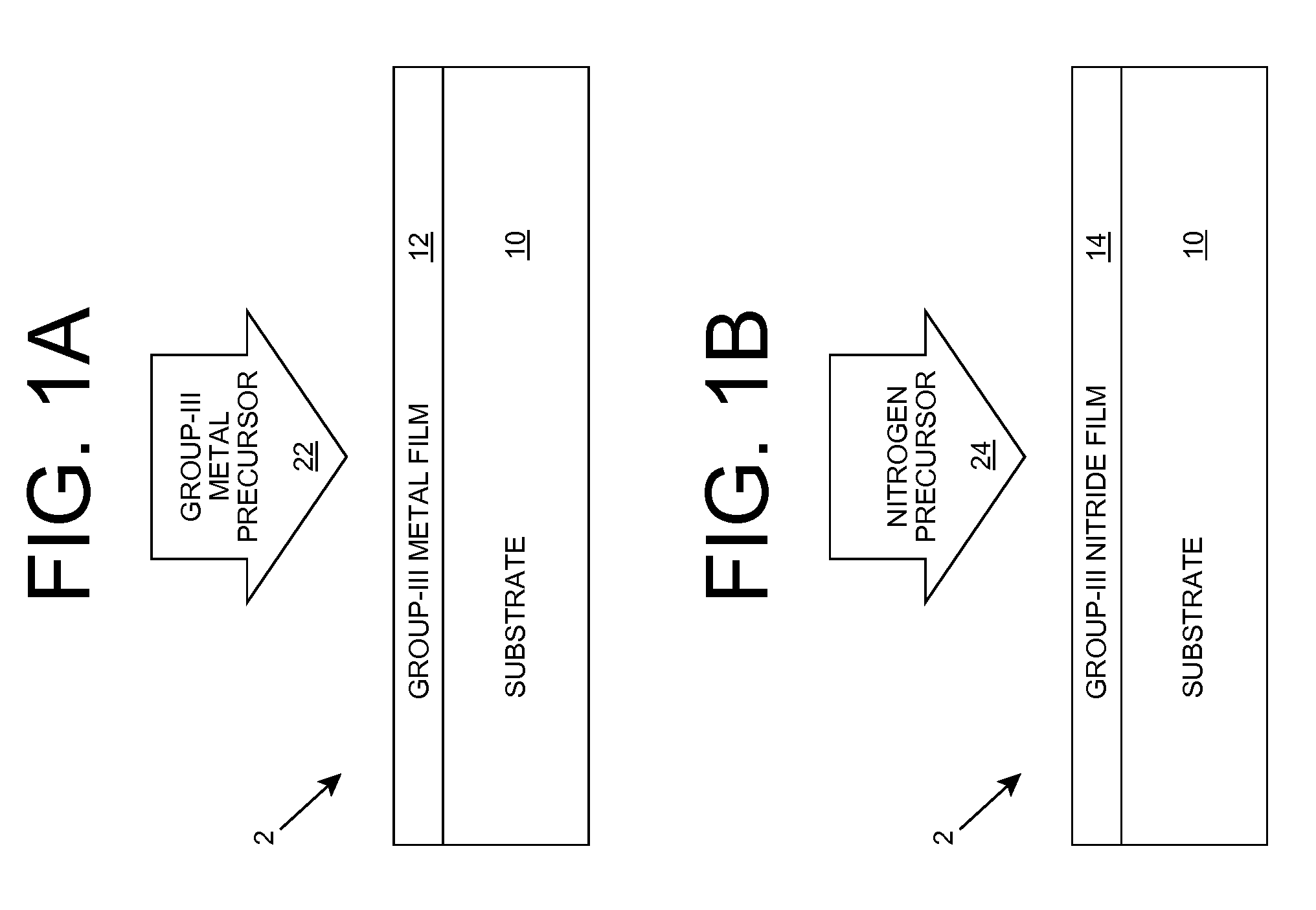

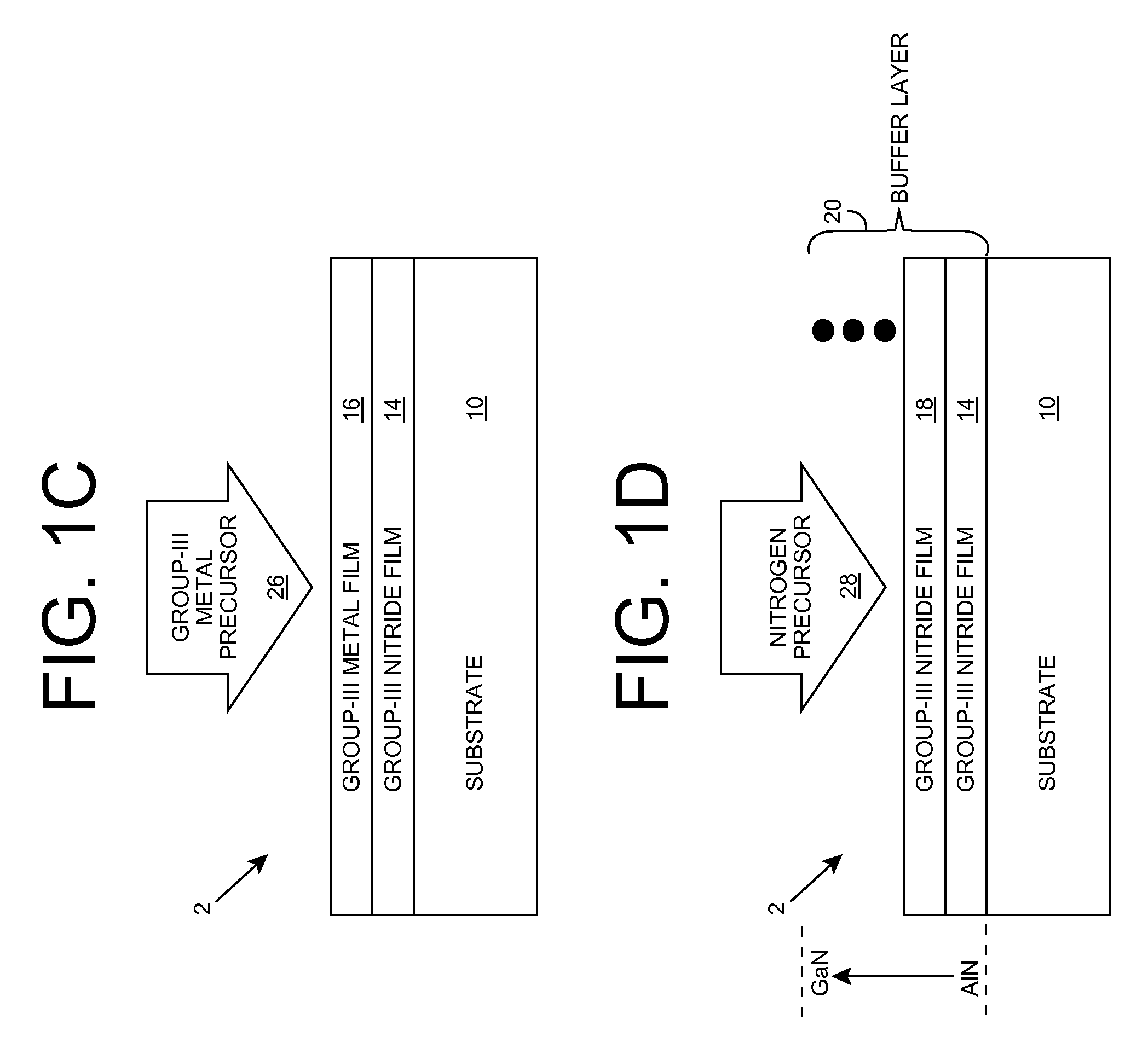

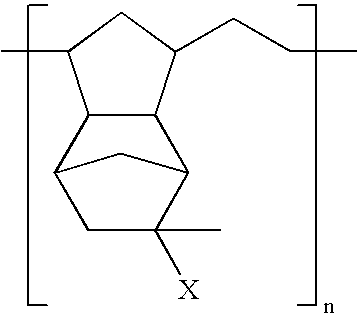

Layer Growth Using Metal Film and/or Islands

ActiveUS20060286782A1Polycrystalline material growthSemiconductor/solid-state device manufacturingHeterojunctionMetal membrane

A solution for manufacturing a nitride-based heterostructure, semiconductor, device, or the like, by growing one or more layers using a metal film and / or nitride islands is provided. In an embodiment of the invention, a group-III nitride film is grown on a surface of a lower layer. The nitride film is grown by first epitaxially growing a group-III metal film on the surface in a substantially nitrogen-free atmosphere. The group-III metal film is grown such that it covers substantially an entire area of the surface. Next, the group-III metal film is nitridated to form a group-III nitride film. This process can be repeated one or more times to form the layer. In another embodiment of the invention, islands are formed on a surface of a lower layer from a group-III nitride film. The islands can be used to subsequent group-III nitride growth to form the group-III nitride layer. The invention provides an improved solution for growing a layer that can be used to generate heterostructures / semiconductors / devices having improved characteristics.

Owner:SENSOR ELECTRONICS TECH

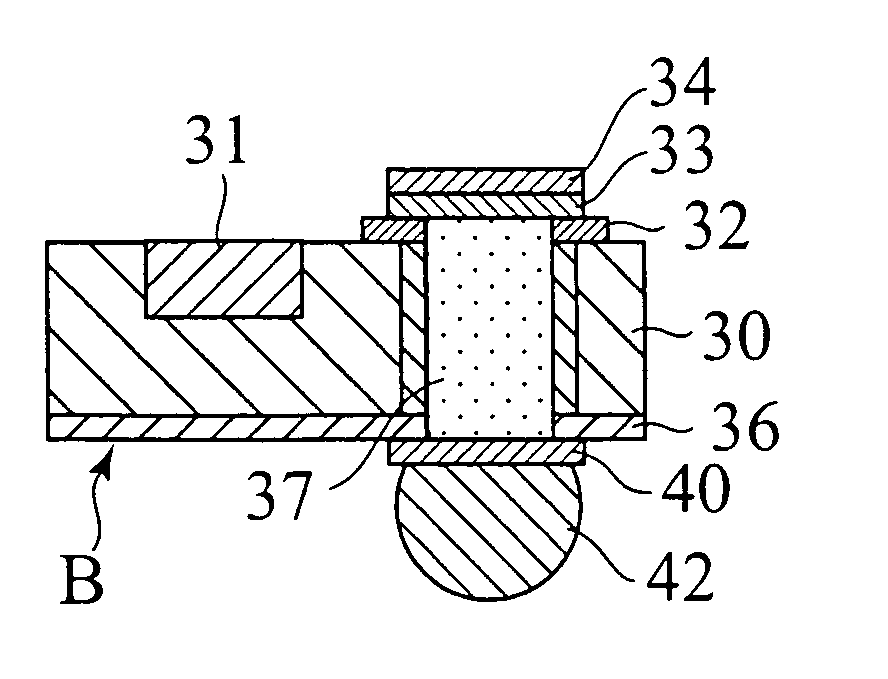

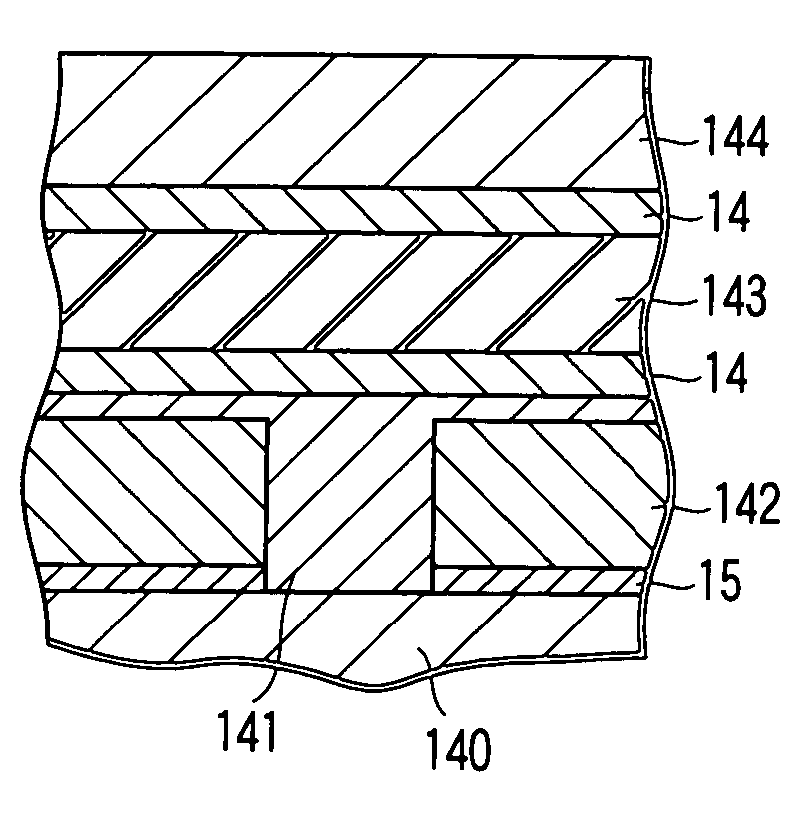

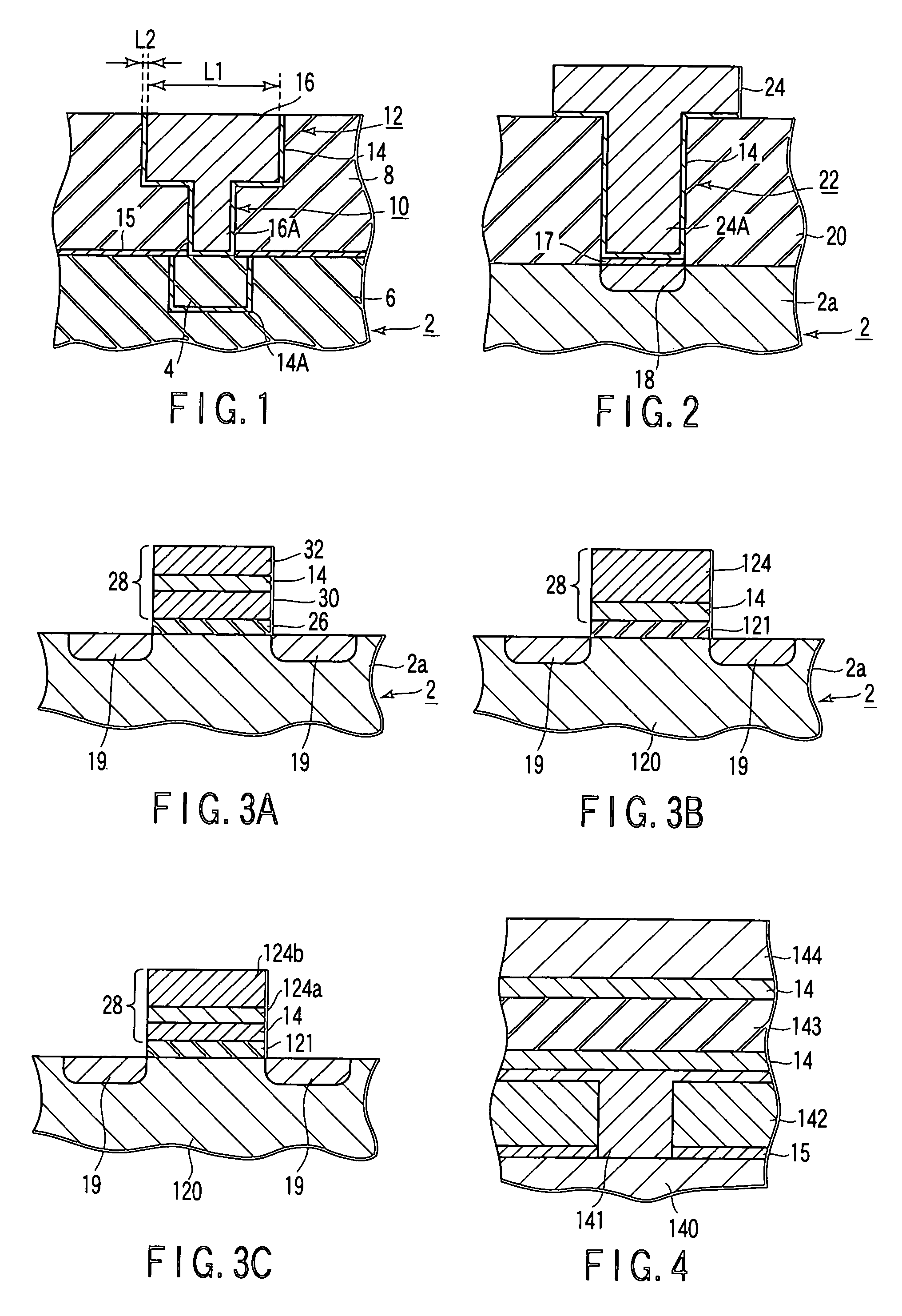

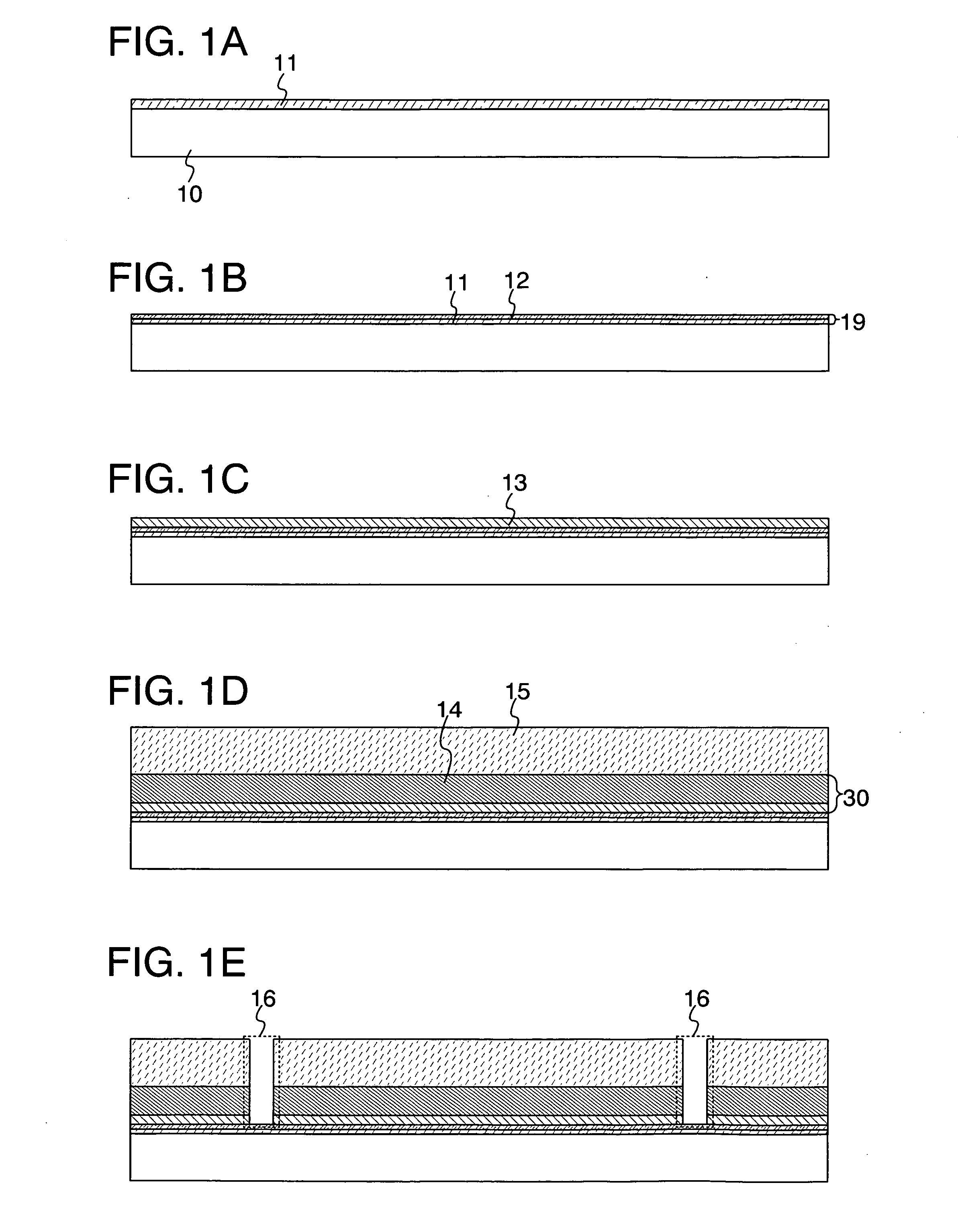

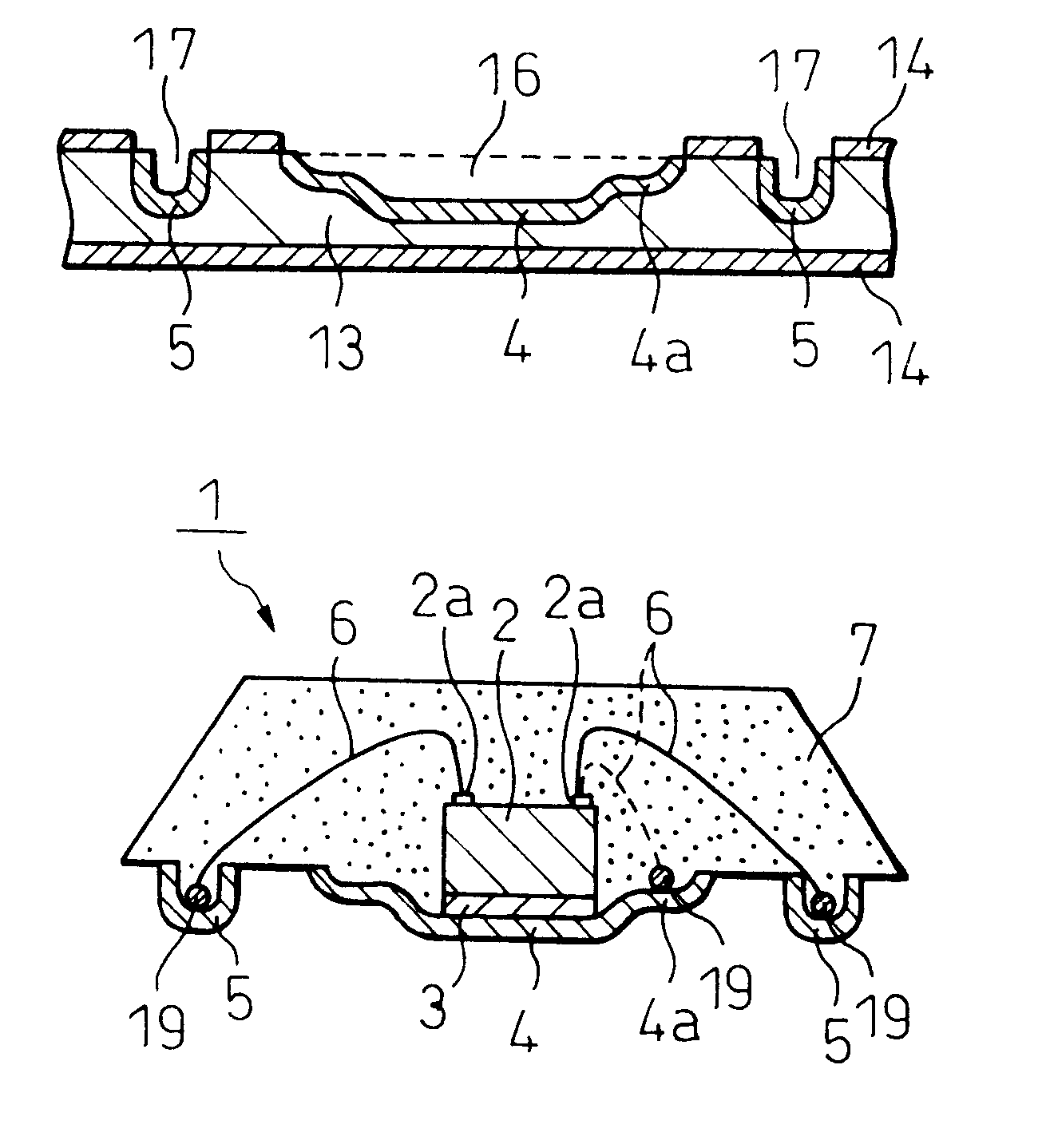

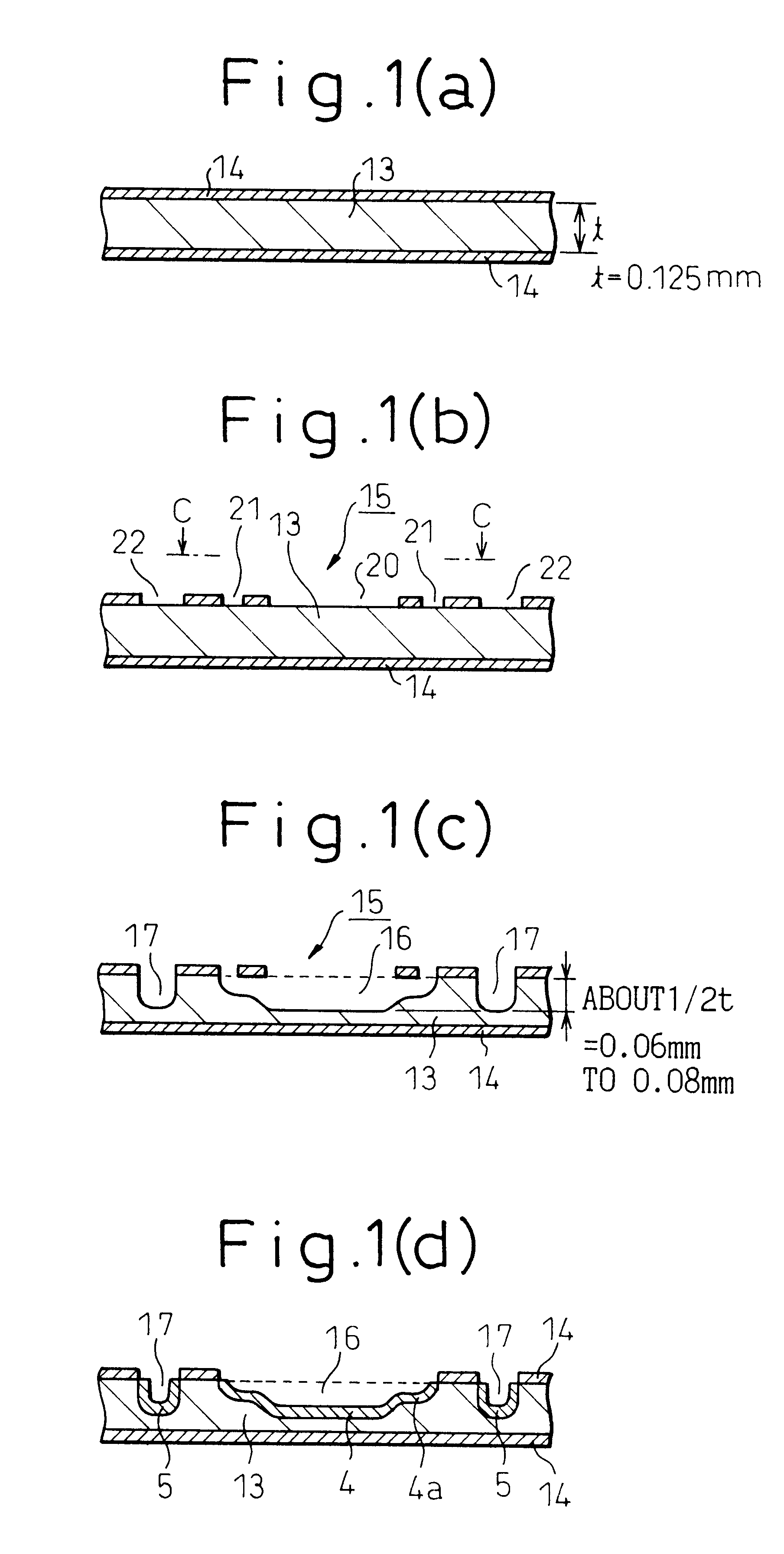

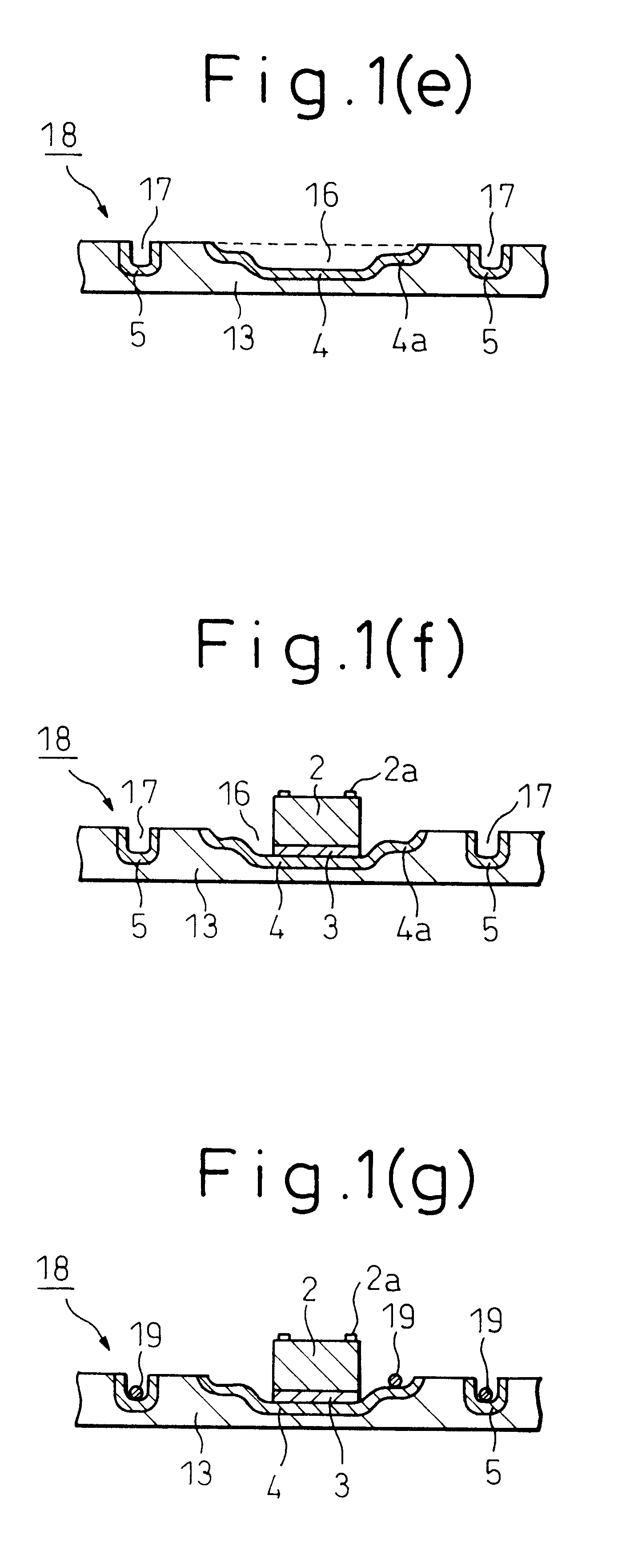

Process of making carrier substrate and semiconductor device

A semiconductor device comprises a semiconductor element having a signal electrode and a ground electrode. A mounting part metallic film has a bottom area on which the semiconductor element is mounted and a stepped area located at a periphery of the bottom area and being higher in horizontal level than the bottom area. A connector part metallic film is spaced from the mounting part metallic film and arranged at a peripheral region thereof. The signal electrode of the semiconductor element is electrically connected to the connector part metallic film and the ground electrode of the semiconductor element is electrically connected to the stepped area of the mounting part metallic film. The semiconductor element is shielded with resin together with mounting / connecting sides of the mounting part metallic film and the connector part metallic film.

Owner:SHINKO ELECTRIC IND CO LTD

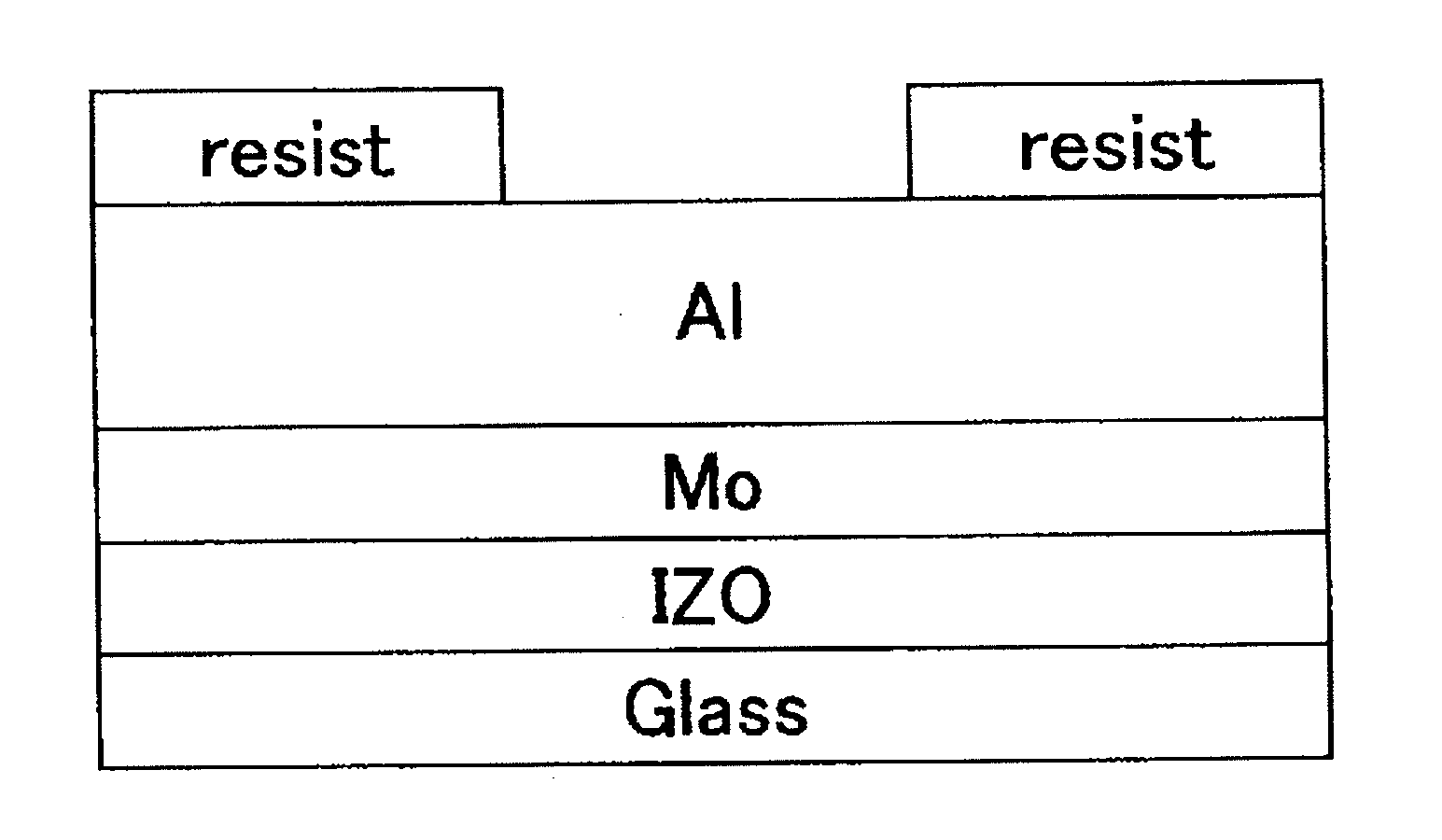

Etching solution composition

InactiveUS20100320457A1High selectivityImprove uniformity and stabilitySemiconductor/solid-state device manufacturingNon-linear opticsMetallurgyAlloy

Provided is an etching solution composition for selectively etching a metal film, which is composed of Al, Al alloy or the like and is arranged on an amorphous oxide film, from a laminated film including the metal film and an amorphous oxide film of various types. The etching solution composition is used for selectively etching the metal film from the laminated film which includes the amorphous oxide film and the metal film composed of Al, Al alloy, Cu, Cu alloy, Ag or Ag alloy, and is composed of an aqueous solution containing an alkali.

Owner:IDEMITSU KOSAN CO LTD +1

Polishing composition and polishing method

InactiveUS20070128872A1Other chemical processesSemiconductor/solid-state device manufacturingPhosphoric Acid EstersPhosphate

As a polishing composition which allows high-speed polishing while dishing and erosion are prevented and the flatness of metal film is maintained, there is provided a polishing composition for polishing a metal film provided on a substrate having trenches such that the metal film fills the trenches, so as to provide a planarized surface, wherein the composition comprises water, a phosphate ester having a C≧6 carbon atom alkyl group in its molecule, and an etchant for the metal, and has a pH of 5 to 11.

Owner:SHOWA DENKO KK

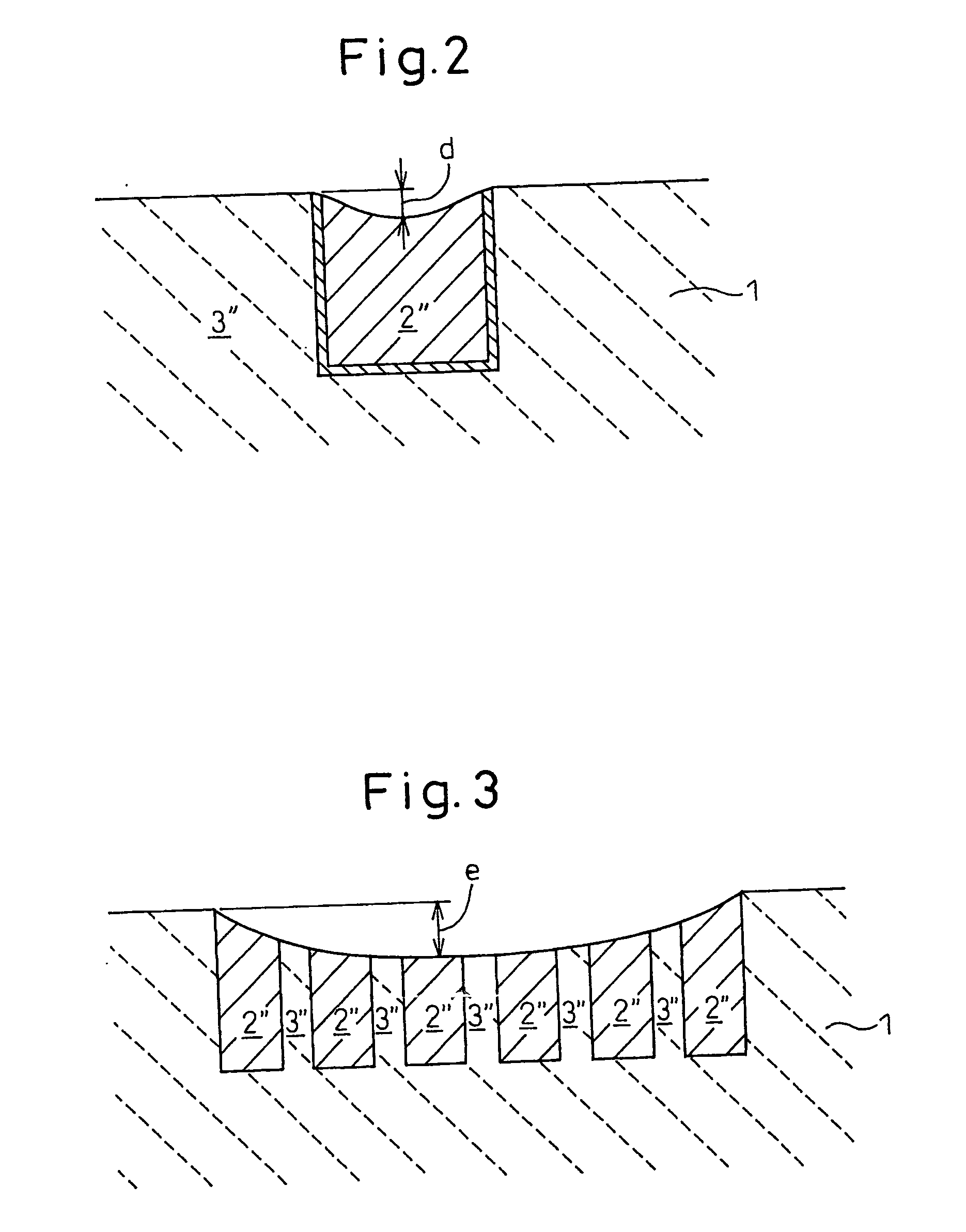

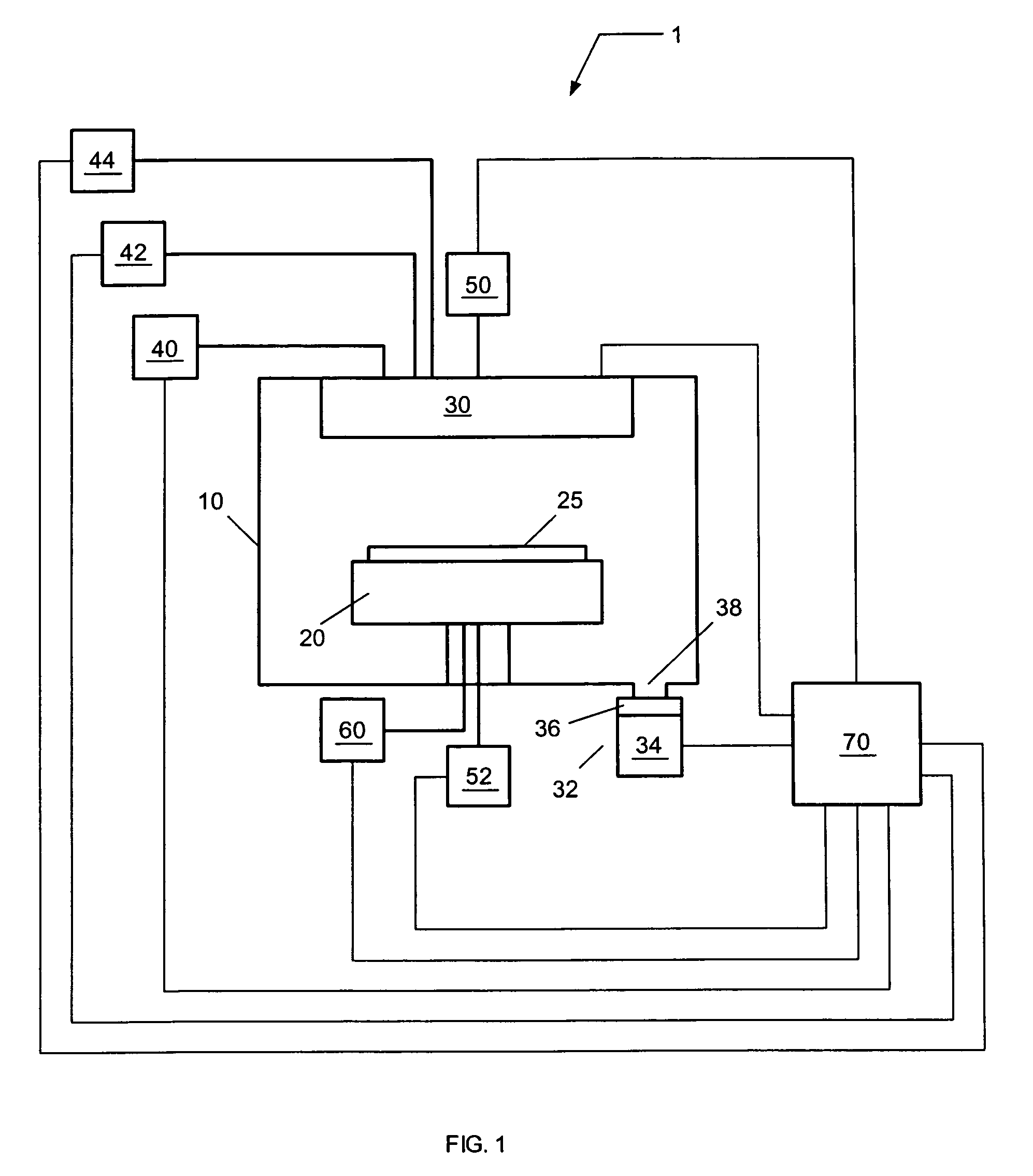

Method of integrating PEALD Ta-containing films into Cu metallization

InactiveUS7959985B2Improving property and integration of Ta-containingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenMetallurgy

A method for forming a modified TaC or TaCN film that may be utilized as a barrier film for Cu metallization. The method includes disposing a substrate in a process chamber of a plasma enhanced atomic layer deposition (PEALD) system configured to perform a PEALD process, depositing a TaC or TaCN film on the substrate using the PEALD process, and modifying the deposited TaC or TaCN film by exposing the deposited TaC or TaCN film to plasma excited hydrogen or atomic hydrogen or a combination thereof in order to remove carbon from at least the plasma exposed portion of the deposited TaCN film. The method further includes forming a metal film on the modified TaCN film, where the modified TaCN film provides stronger adhesion to the metal film than the deposited TaCN film. According to one embodiment, a TaCN film is deposited from alternating exposures of TAIMATA and plasma excited hydrogen.

Owner:TOKYO ELECTRON LTD

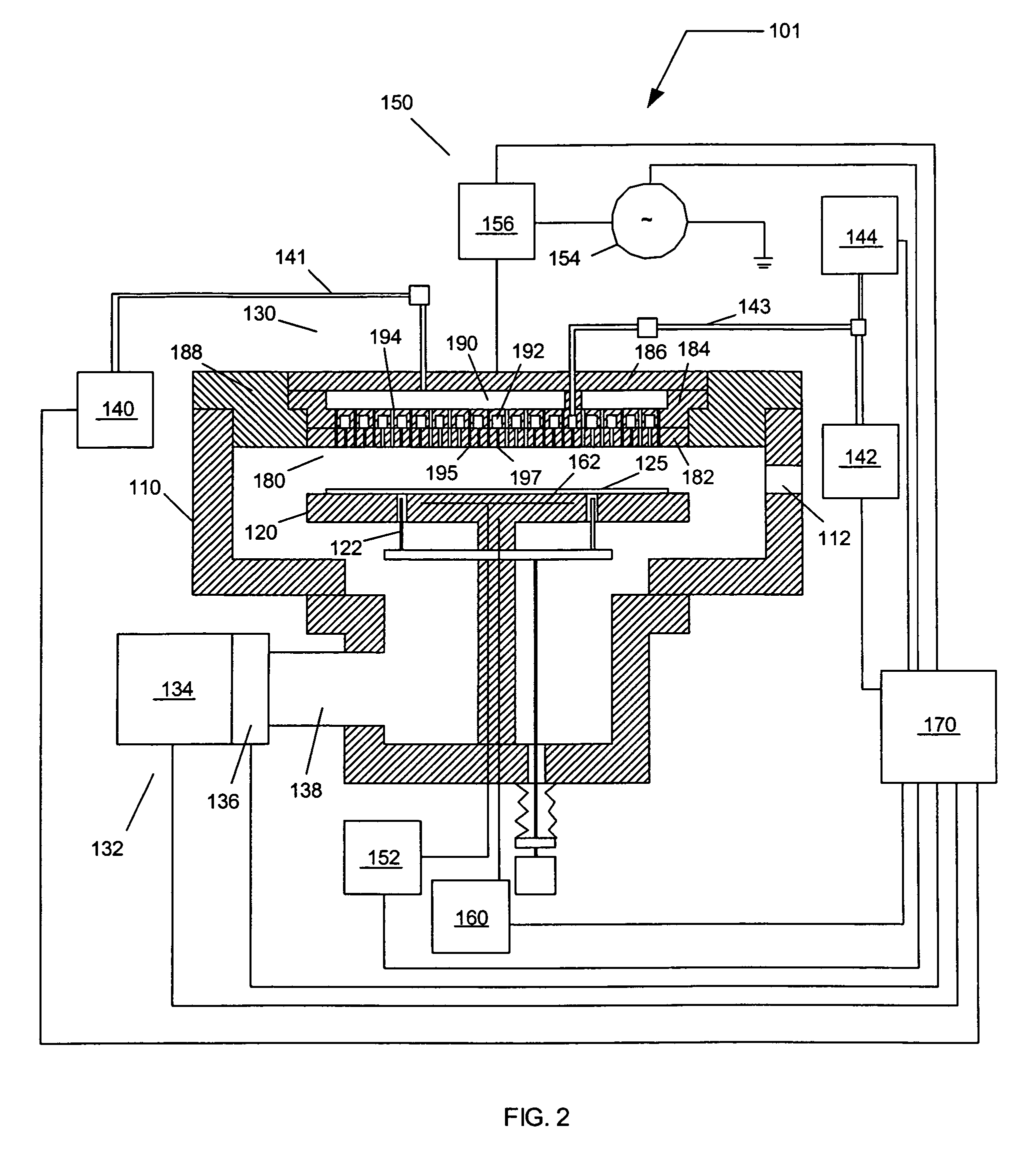

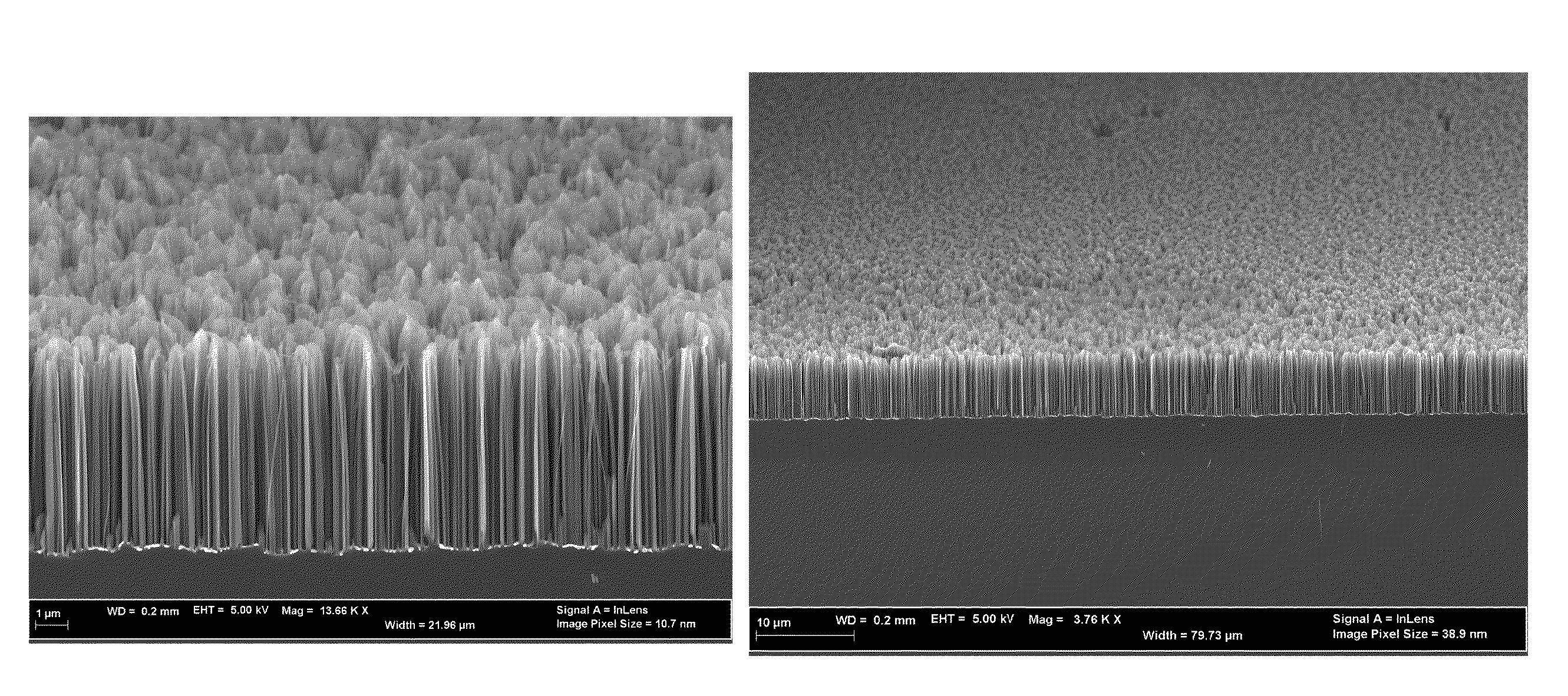

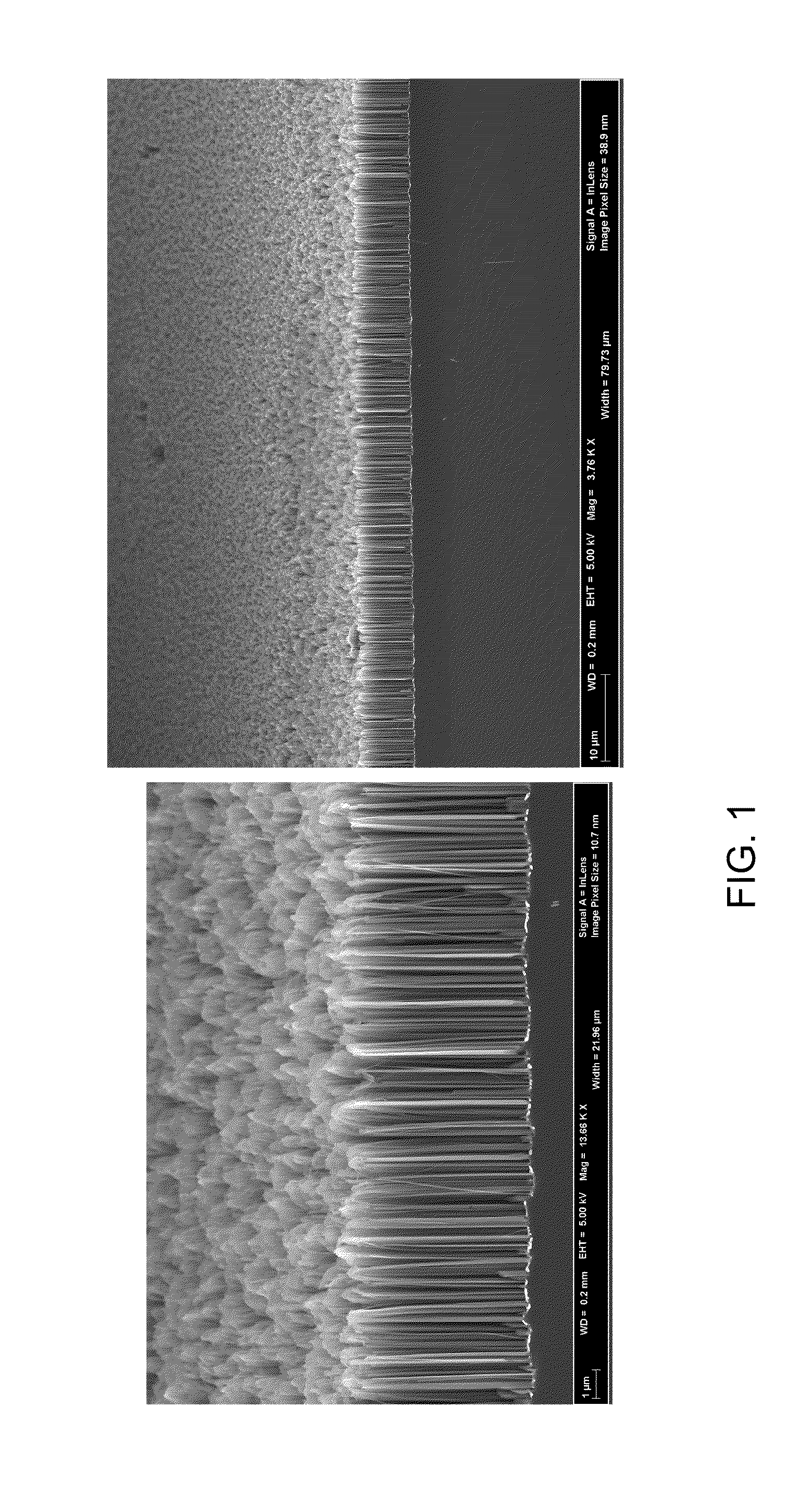

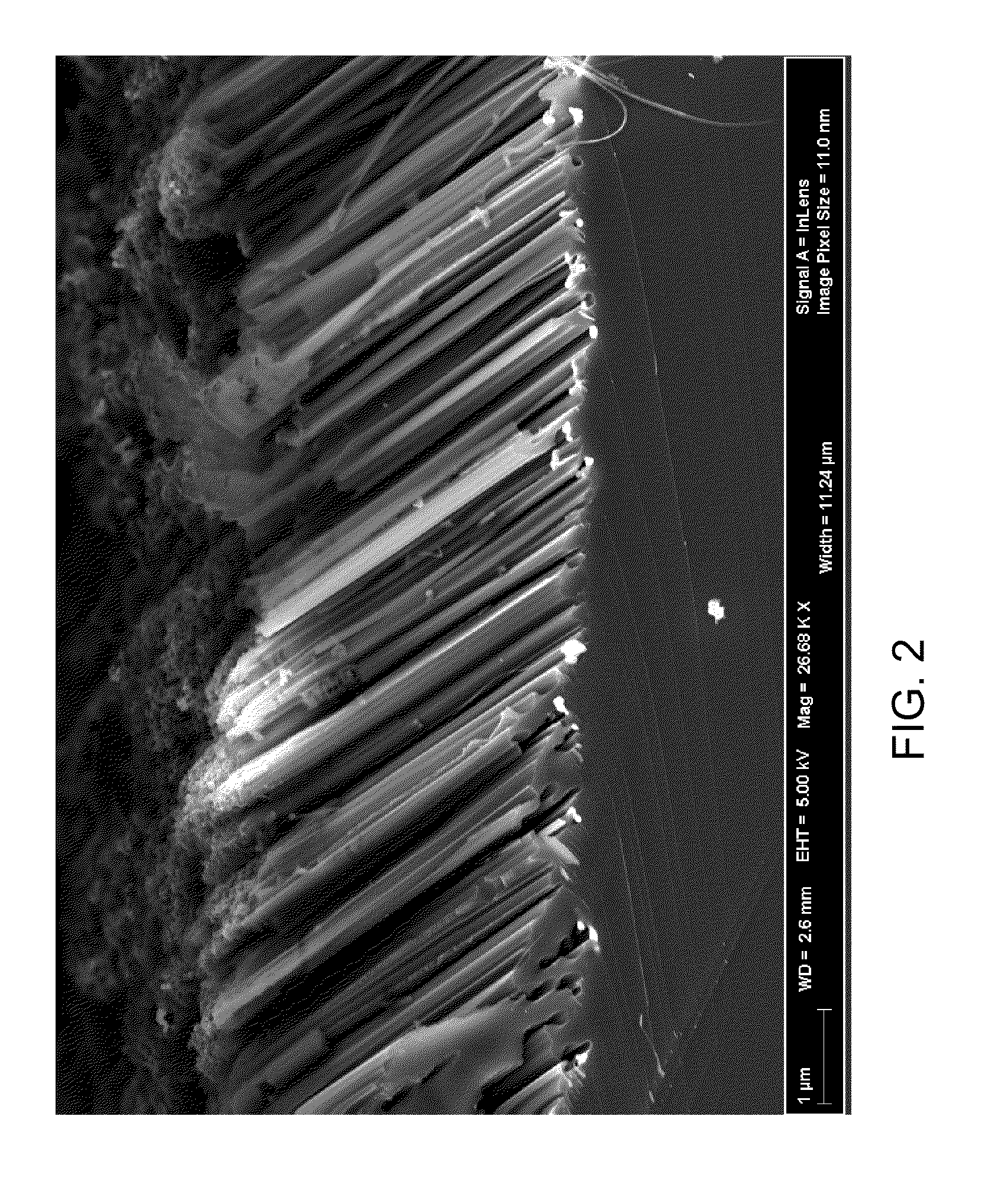

Process for Fabricating Nanowire Arrays

ActiveUS20090256134A1Sufficient adhesionMaterial nanotechnologyOther chemical processesNanoparticleNanowire array

A process is provided for etching a silicon-containing substrate to form nanowire arrays. In this process, one deposits nanoparticles and a metal film onto the substrate in such a way that the metal is present and touches silicon where etching is desired and is blocked from touching silicon or not present elsewhere. One submerges the metallized substrate into an etchant aqueous solution comprising HF and an oxidizing agent. In this way arrays of nanowires with controlled diameter and length are produced.

Owner:ADVANCED SILICON GRP TECH LLC

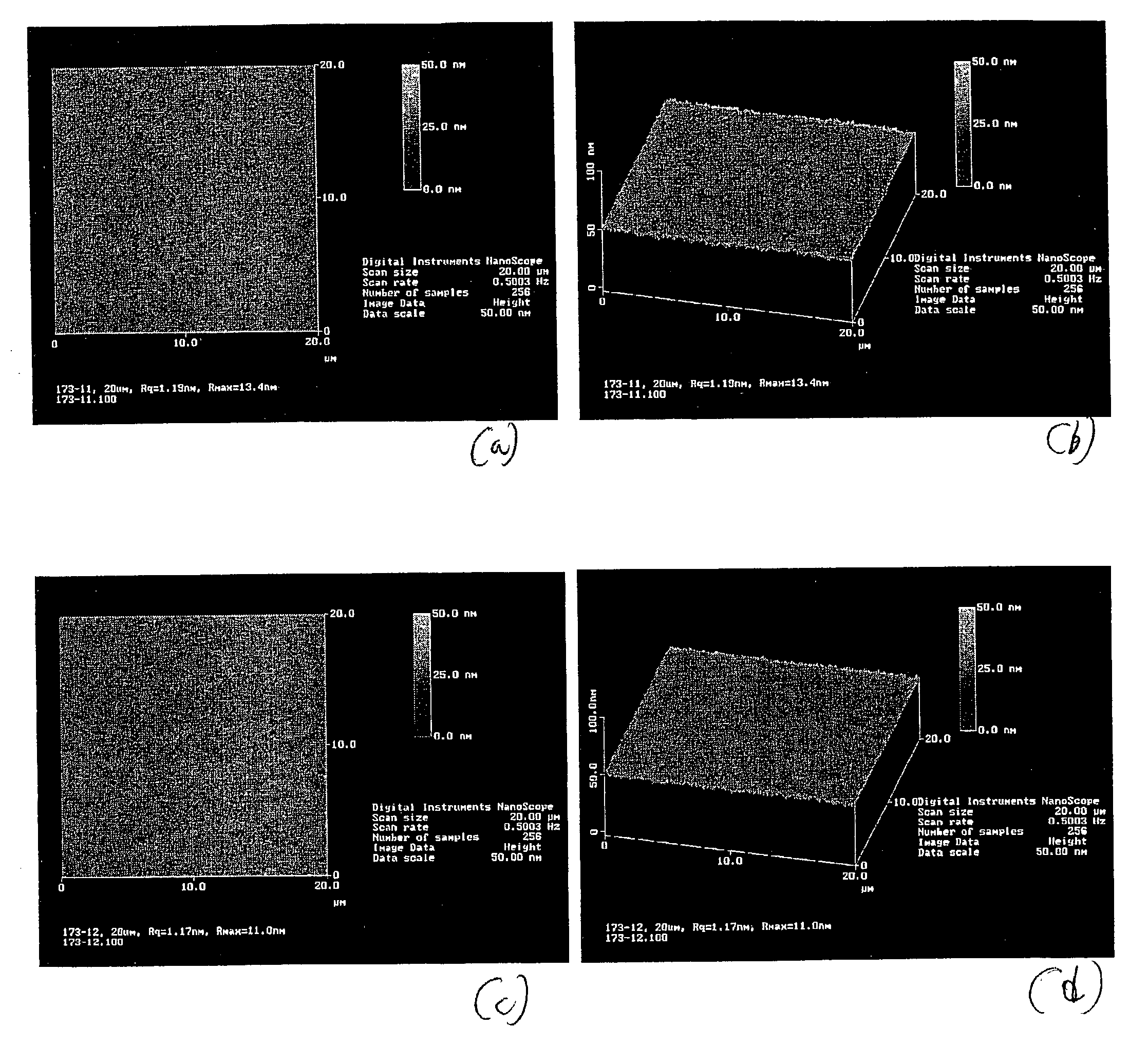

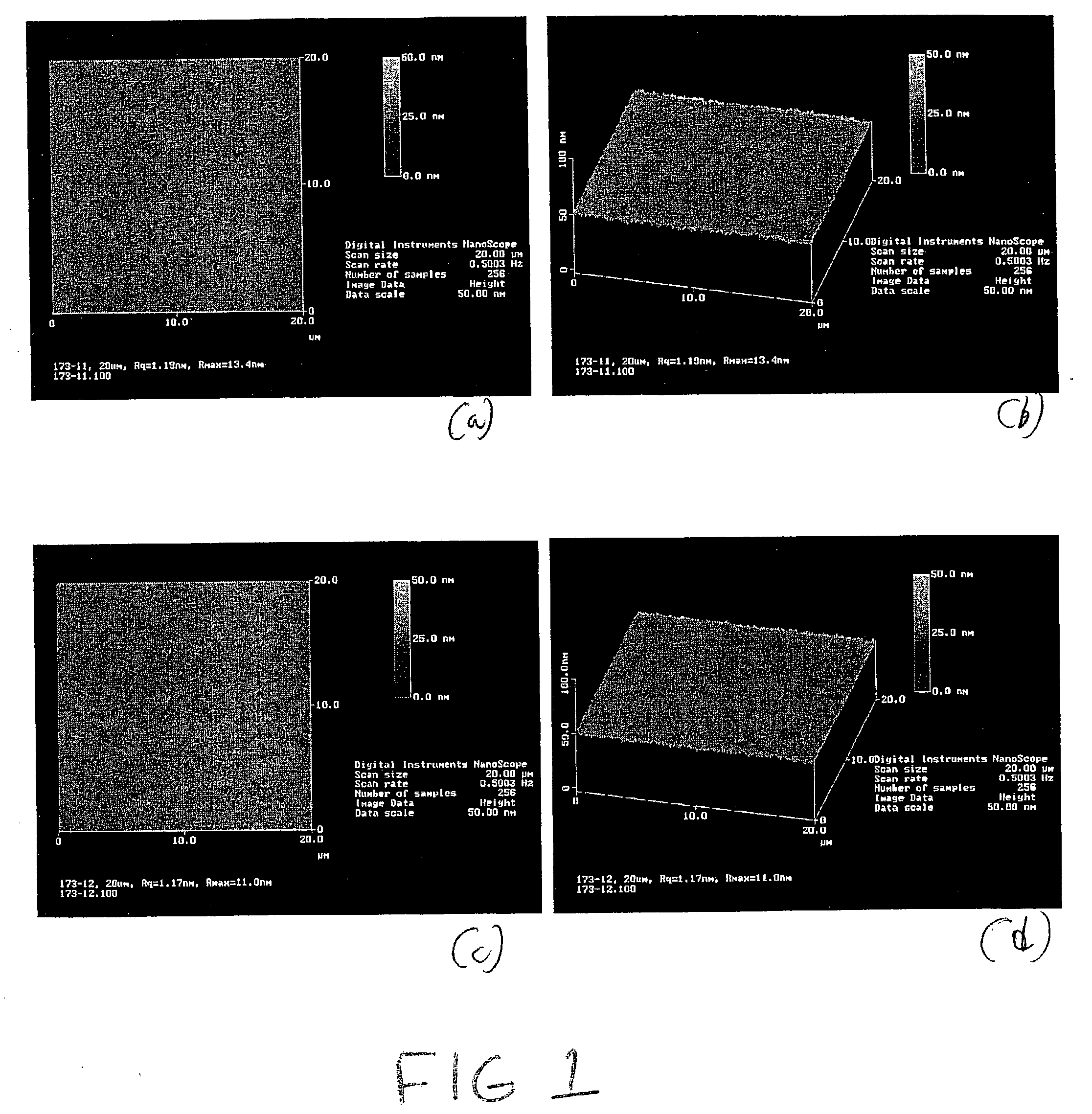

Transparent conductive film for flat panel displays

ActiveUS20040086717A1High transmittanceLow electric resistanceSolid-state devicesVacuum evaporation coatingTransmittanceIndium

Transparent conductive films for flat panel displays and methods for producing them are disclosed. In general, a method according to the present invention comprises: (1) providing a flexible plastic substrate; (2) depositing a multi-layered conductive metallic film on the flexible plastic substrate by a thin-film deposition technique to form a composite film, the multi-layered conductive metallic film comprising two layers of an alloy selected from the group consisting of indium cerium oxide (InCeO) and indium tin oxide (ITO) surrounding a layer of an alloy of silver, palladium, and copper (Ag / Pd / Cu); and (3) collecting the composite film in continuous rolls. Typically, the thin-film deposition technique is DC magnetron sputtering. Another aspect of the invention is a composite film produced by a method according to the present invention. Still another aspect of the invention is a composite film comprising a multilayered film as described above formed on a flexible plastic substrate, wherein the composite film has a combination of properties including: transmittance of at least 80% throughout the visible region; an electrical resistance of no greater than about 10 Omega / square; a root-mean-square roughness of no greater than about 2.5 nm; and an interlayer adhesion between the multi-layered metallic film and the remainder of the composite film that is sufficiently great to survive a 180° peel adhesion test.

Owner:XYLON LLC

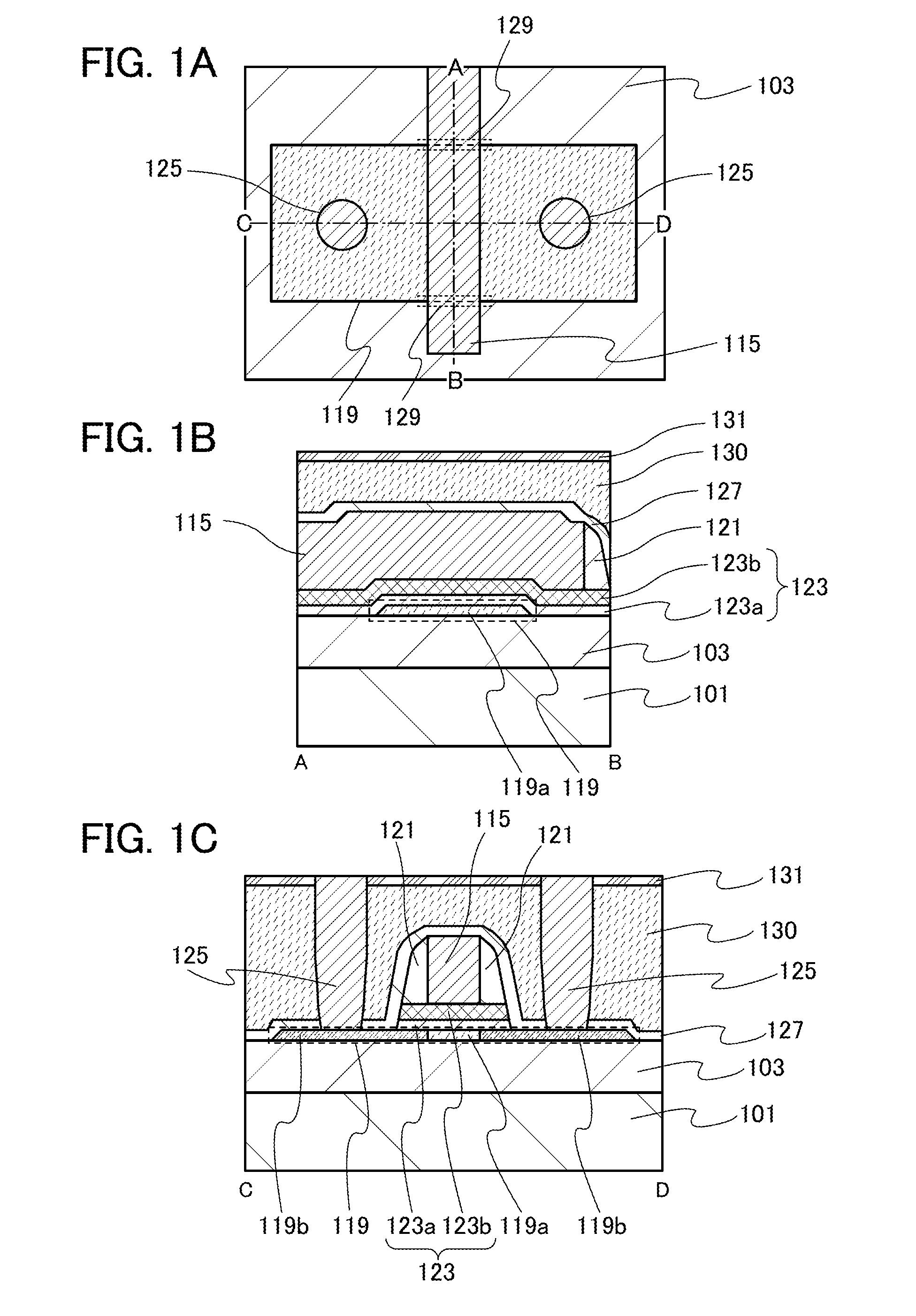

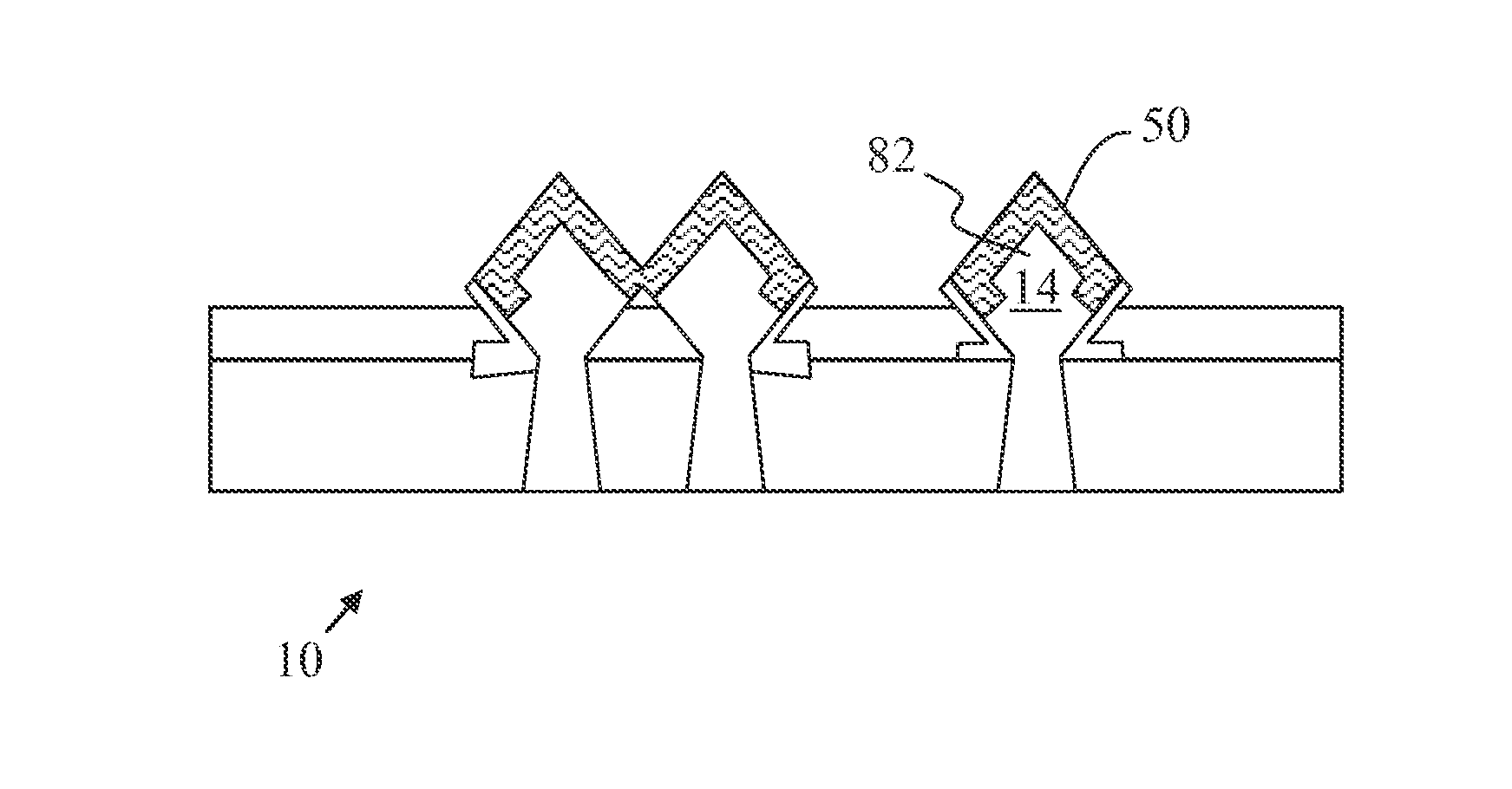

Integrated circuits and methods for fabricating integrated circuits with silicide contacts on non-planar structures

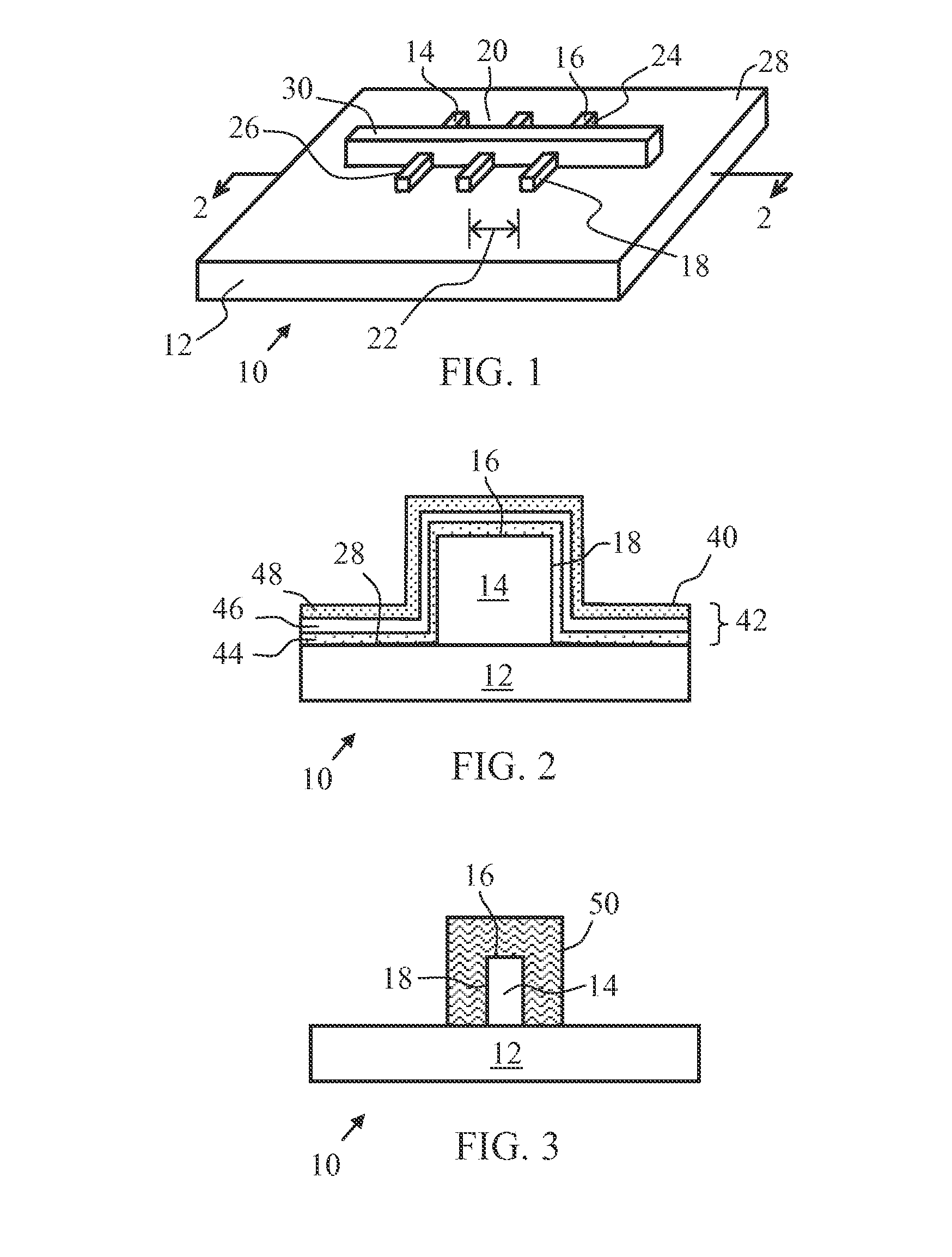

ActiveUS20140167264A1Semiconductor/solid-state device detailsSolid-state devicesMetal silicideMetal membrane

Integrated circuits and methods for fabricating integrated circuits are provided. In an embodiment, a method for fabricating an integrated circuit includes providing a semiconductor substrate and forming fins over the semiconductor substrate. Each fin is formed with sidewalls. The method further includes conformally depositing a metal film stack on the sidewalls of each fin. In the method, the metal film stack is annealed to form a metal silicide film over the sidewalls of each fin.

Owner:GLOBALFOUNDRIES US INC

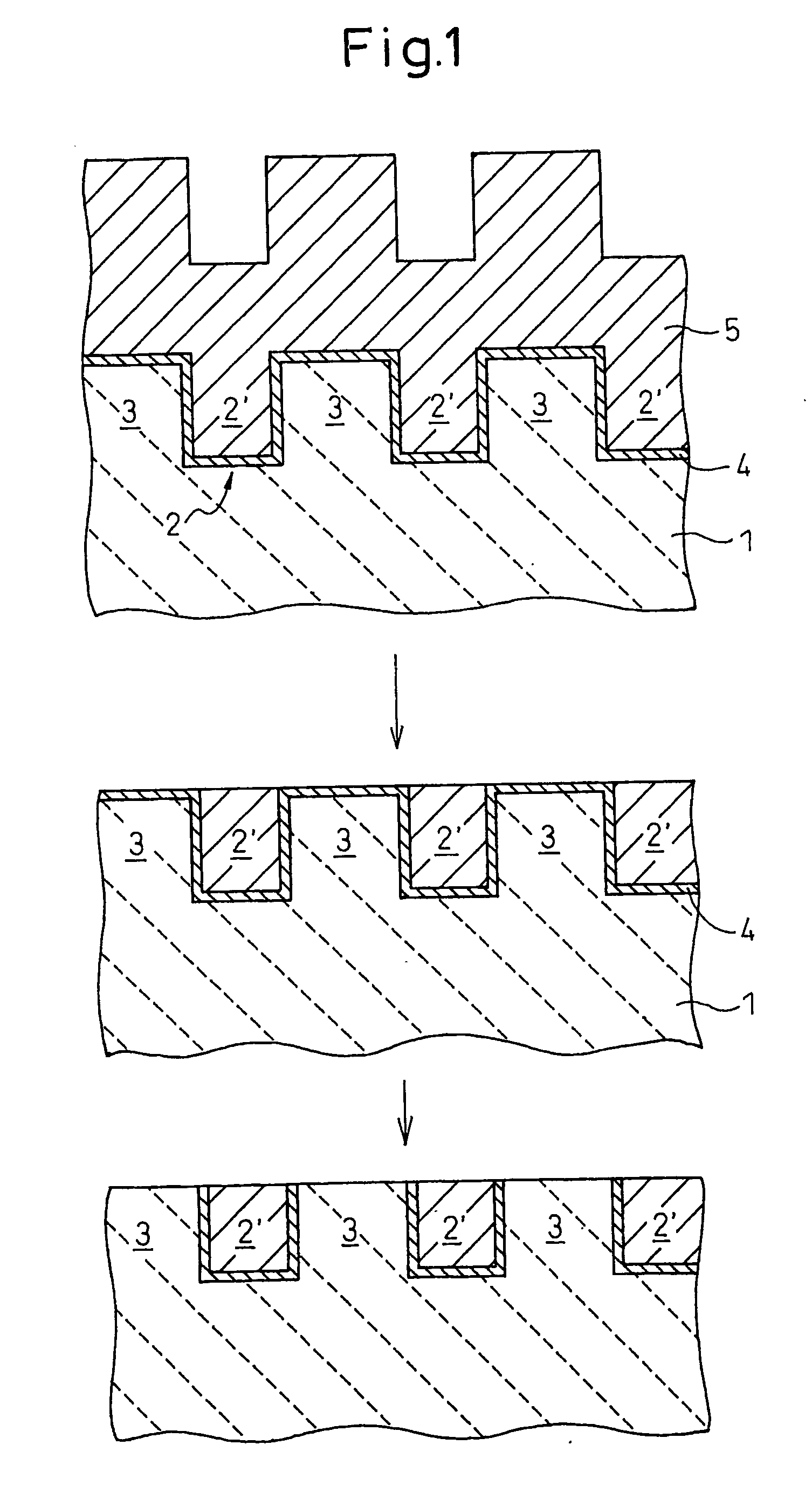

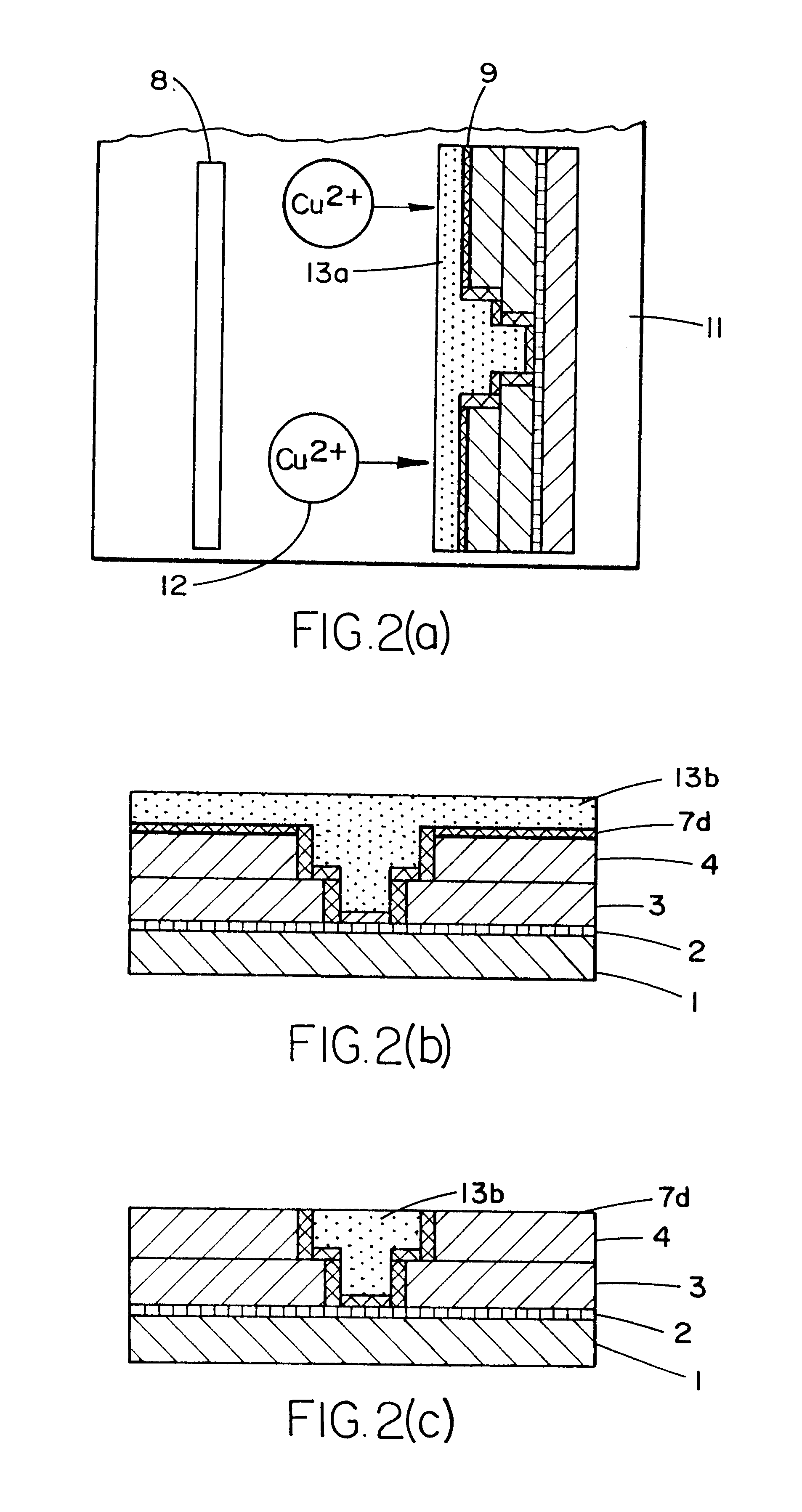

Process for forming fine wiring

InactiveUS6294467B1Quality improvementLower resistanceSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingHydrogenSilicon oxide

The present invention is directed to a process for manufacturing a semiconductor device. It includes a step for forming a fine wiring, and provides a process for uniformly and positively forming a film of a barrier metal, such as tantalum, for preventing the metal, such as copper, which becomes the first material for the wiring, from diffusing into a silicon oxide film. The process involves depositing an oxide of a barrier metal on a substrate which is formed with a via hole by a process such as CVD process. A high quality barrier metal film is formed by reducing the oxide by applying a negative potential to the oxide in a solution in which hydrogen ions are present. Subsequently an embedded wiring is formed by embedding the main metal by a plating process and the like and polishing to remove unnecessary portions.

Owner:RENESAS ELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com