Patents

Literature

301 results about "Amorphous oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Amorphous oxide semiconductor (AOS)-based Schottky diodes have been utilized for selectors in crossbar array memories to improve cell-to-cell uniformity with a low-temperature process.

Amorphous Oxide And Thin Film Transistor

InactiveUS20070194379A1High ionicityGeneration of oxygen defects is less frequentTransistorVacuum evaporation coatingCharge carrierElectron

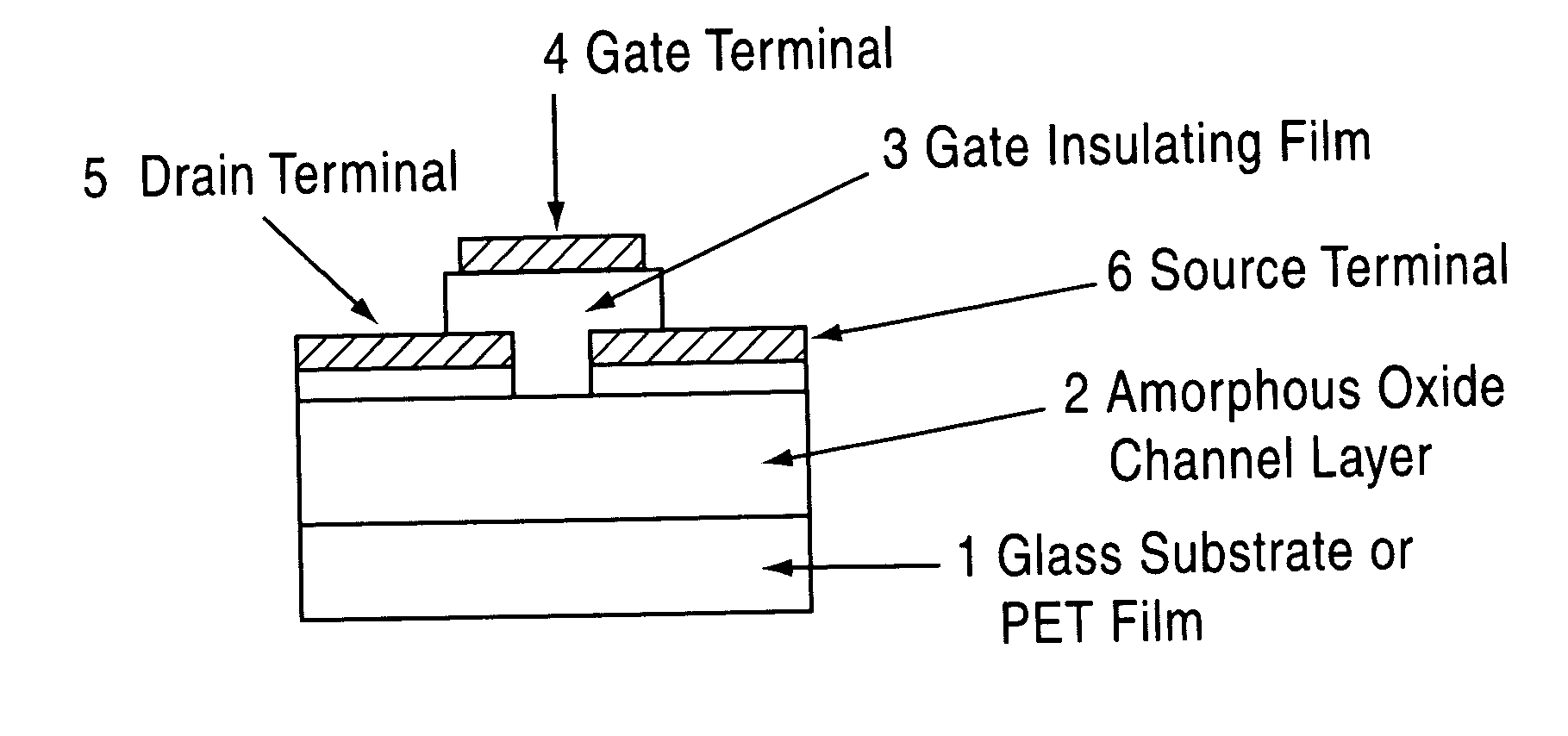

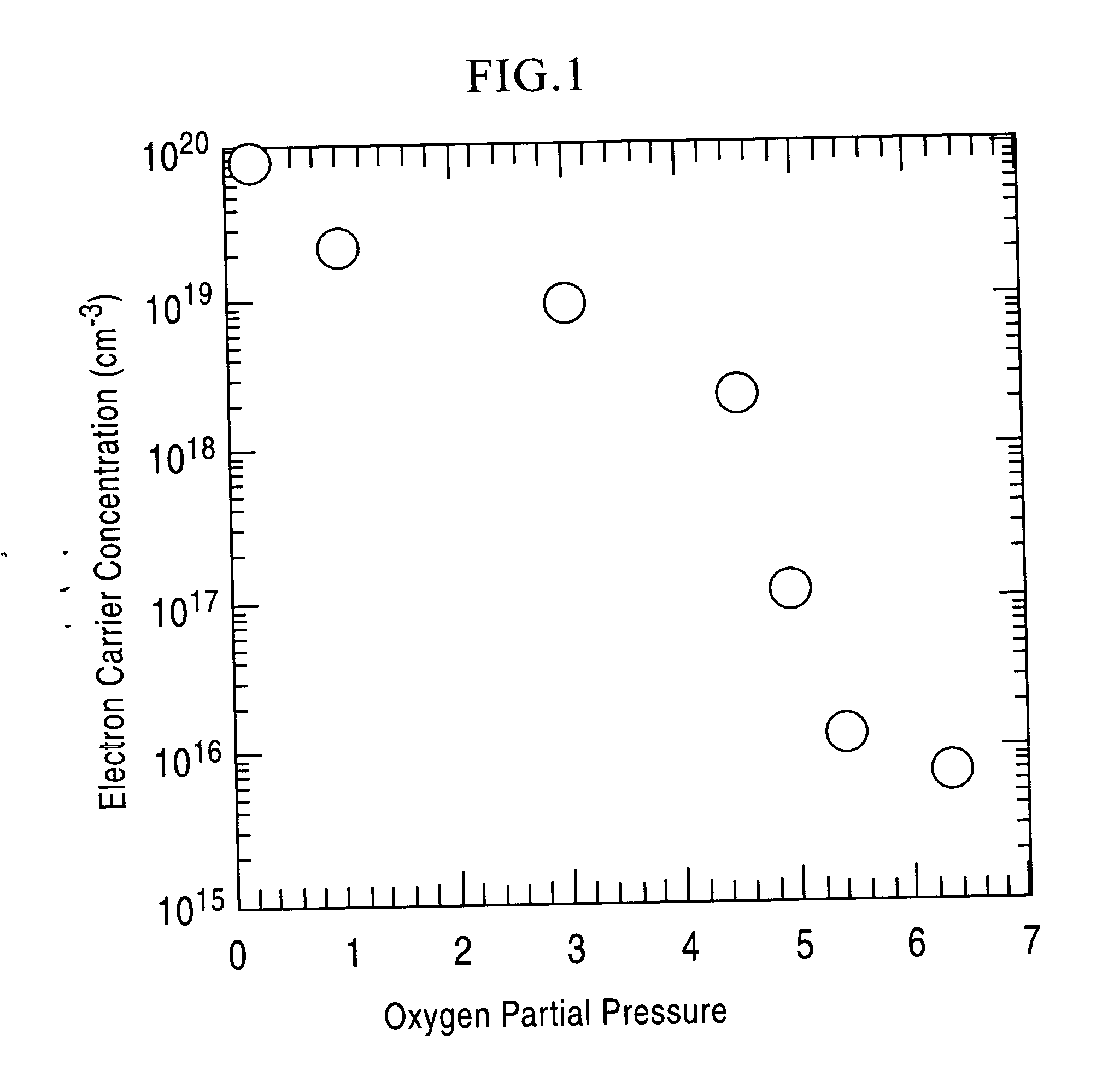

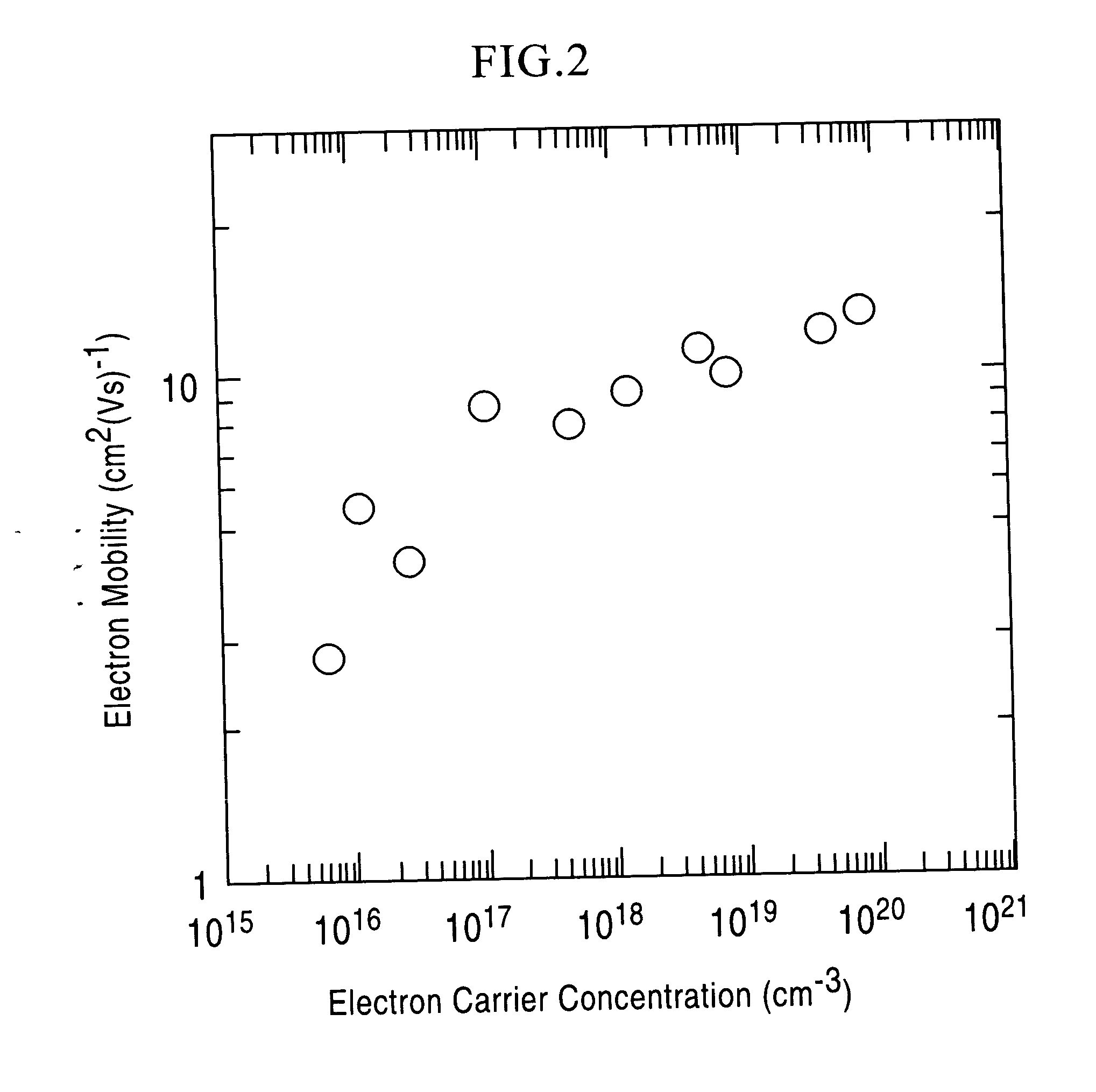

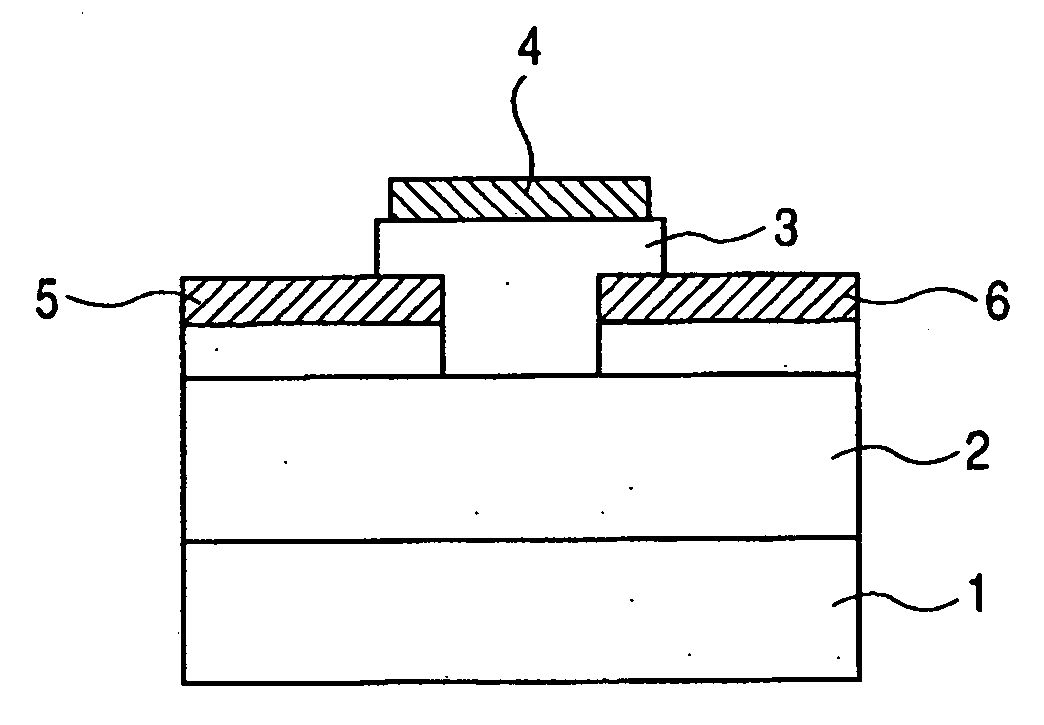

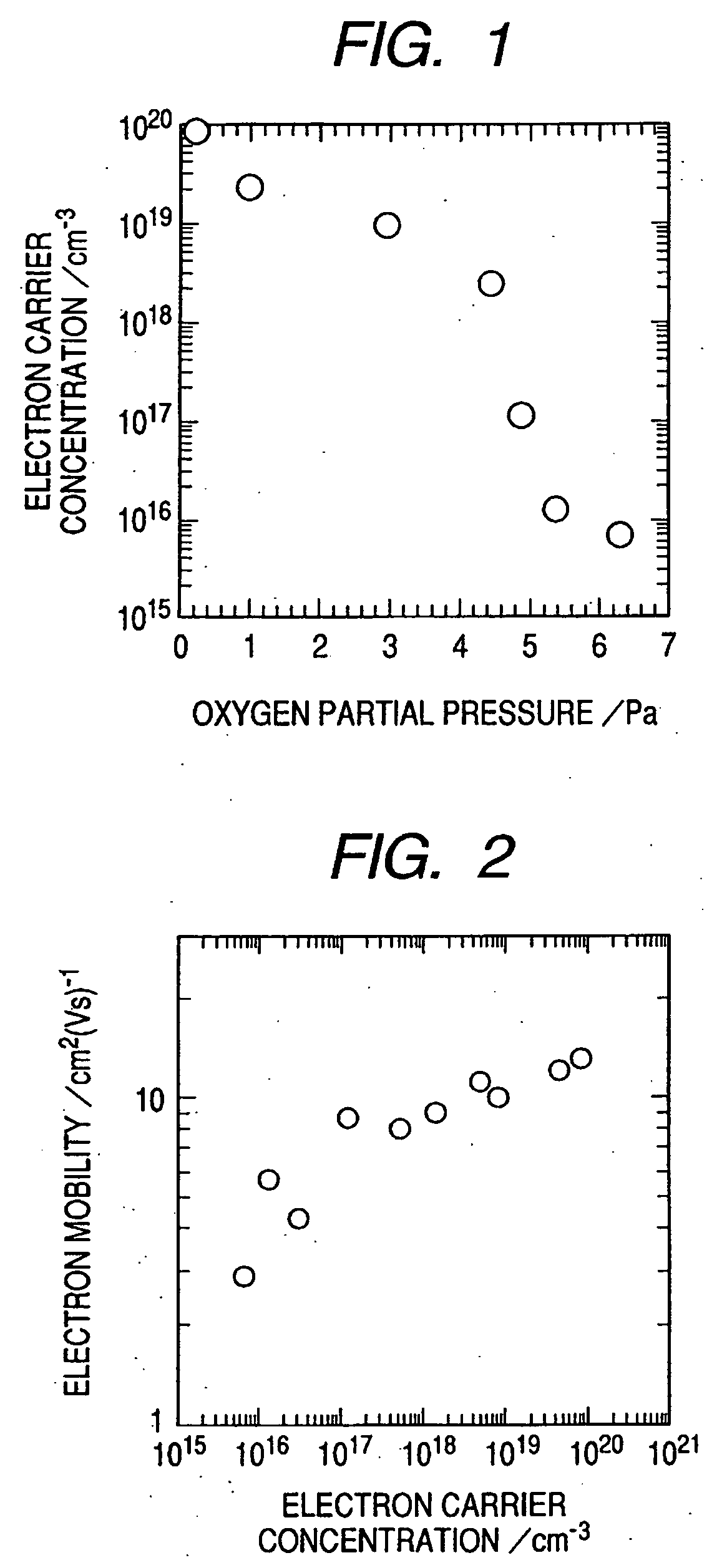

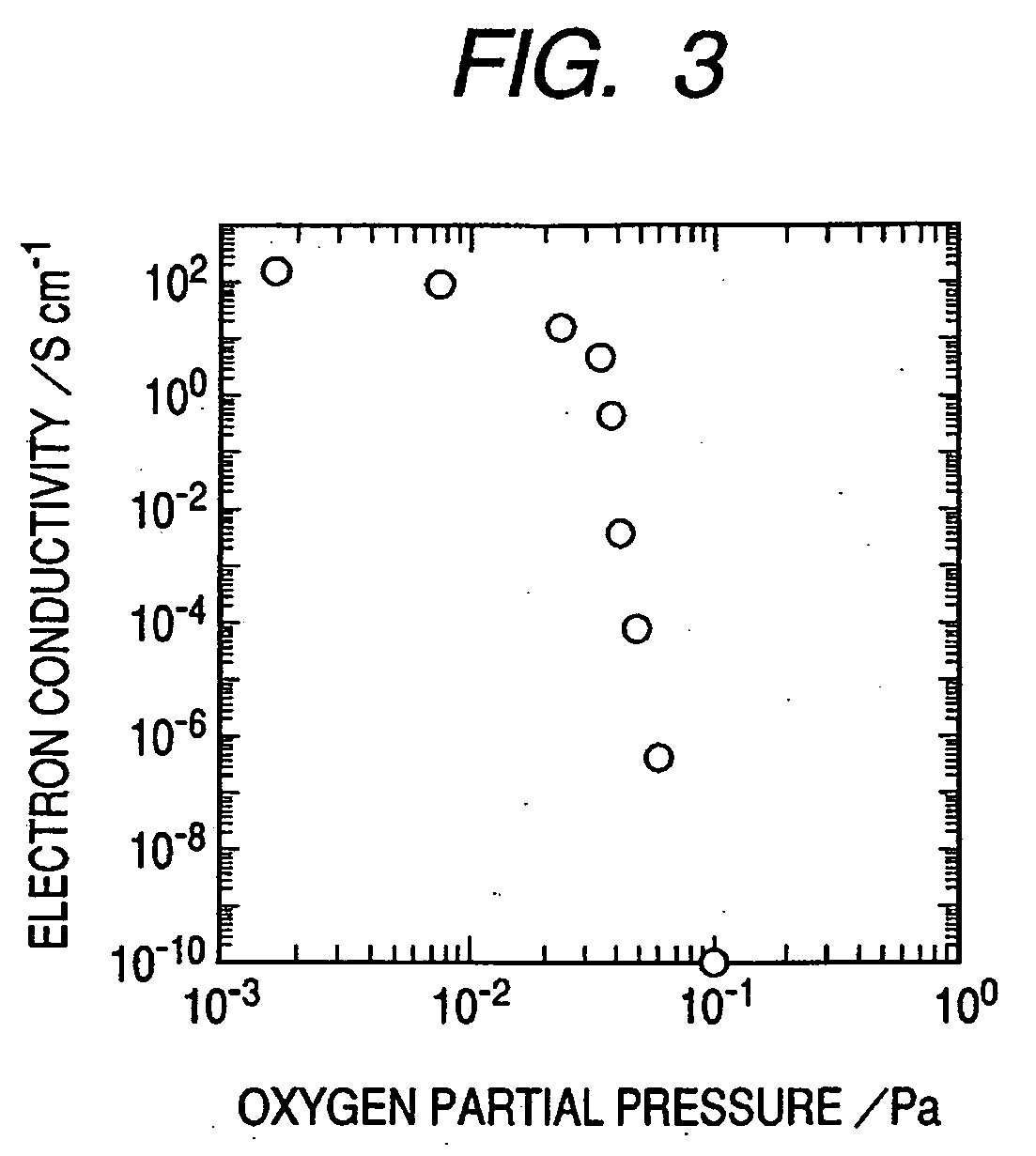

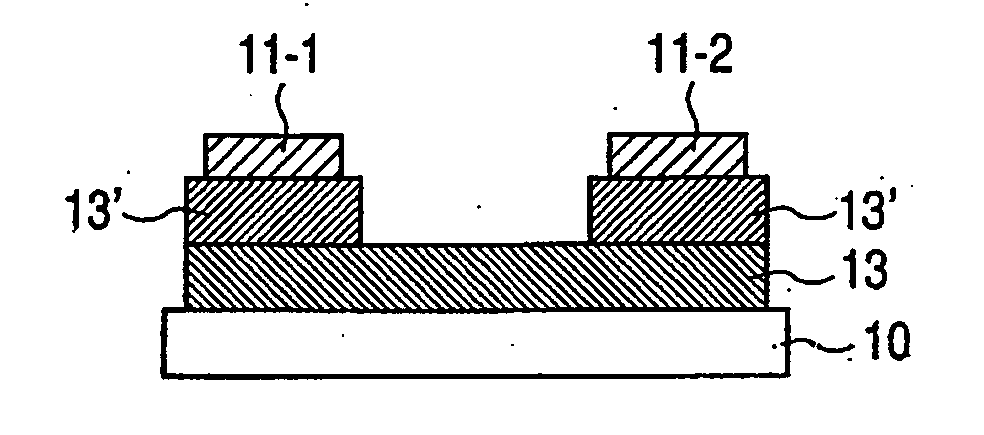

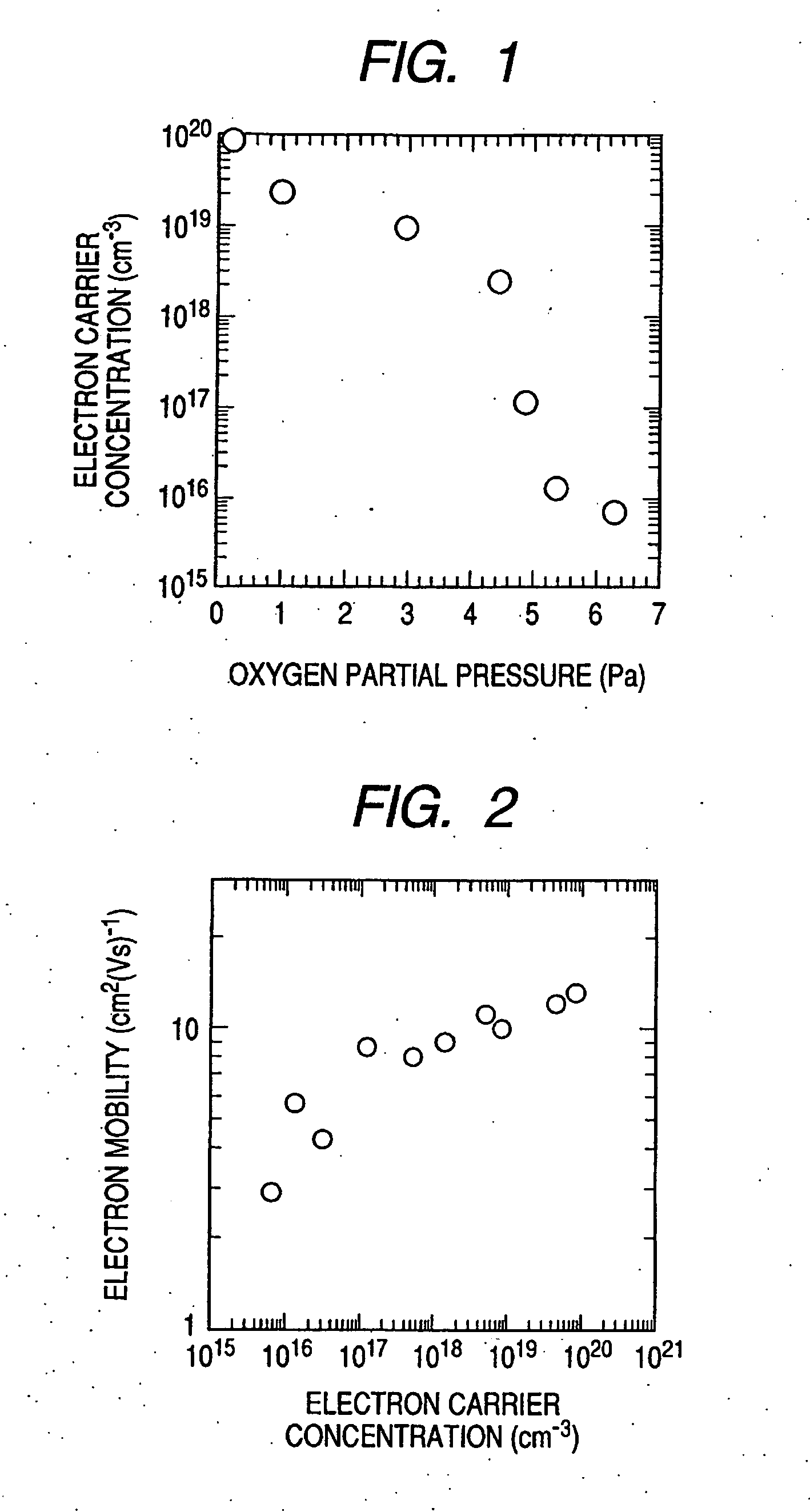

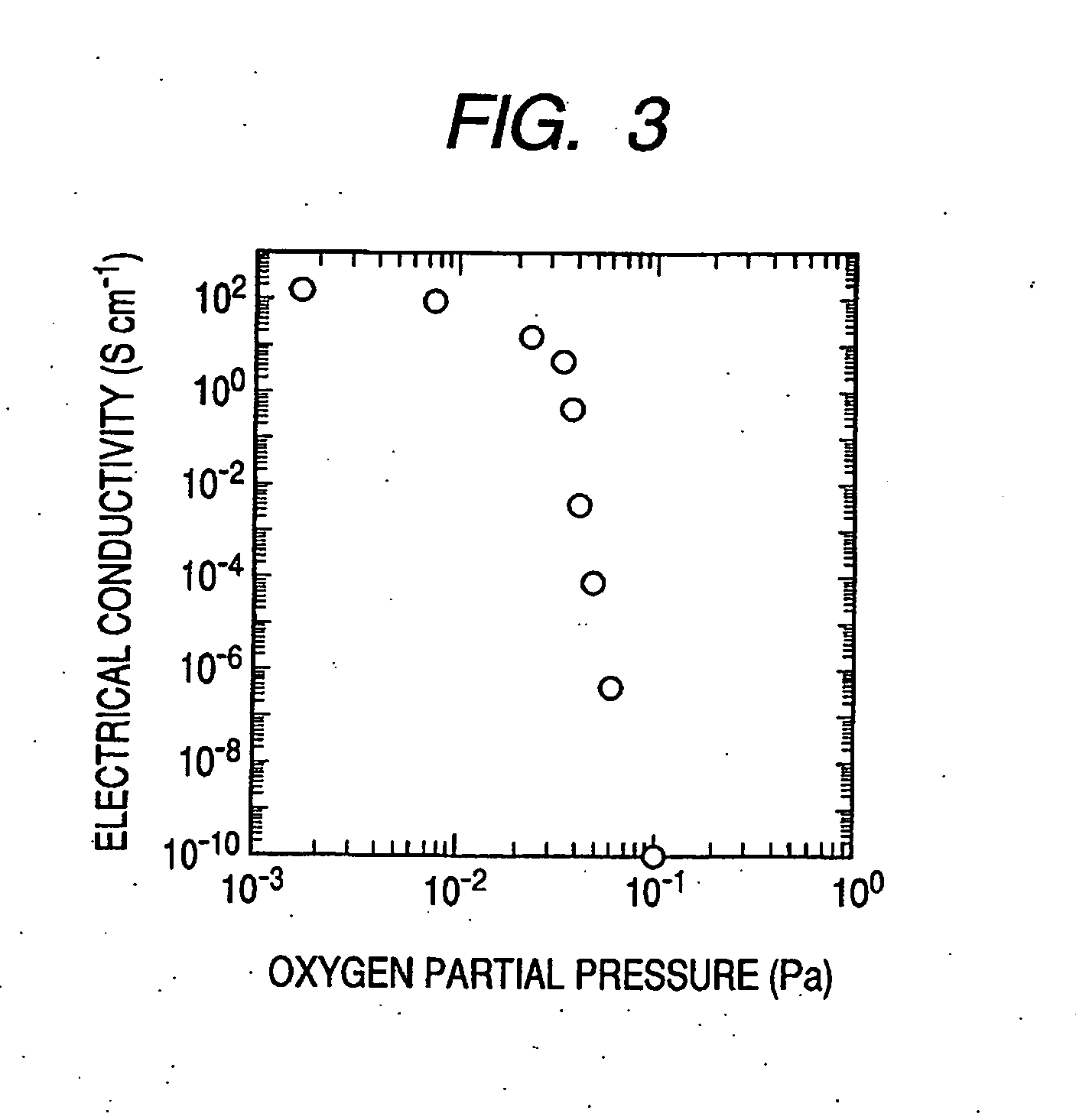

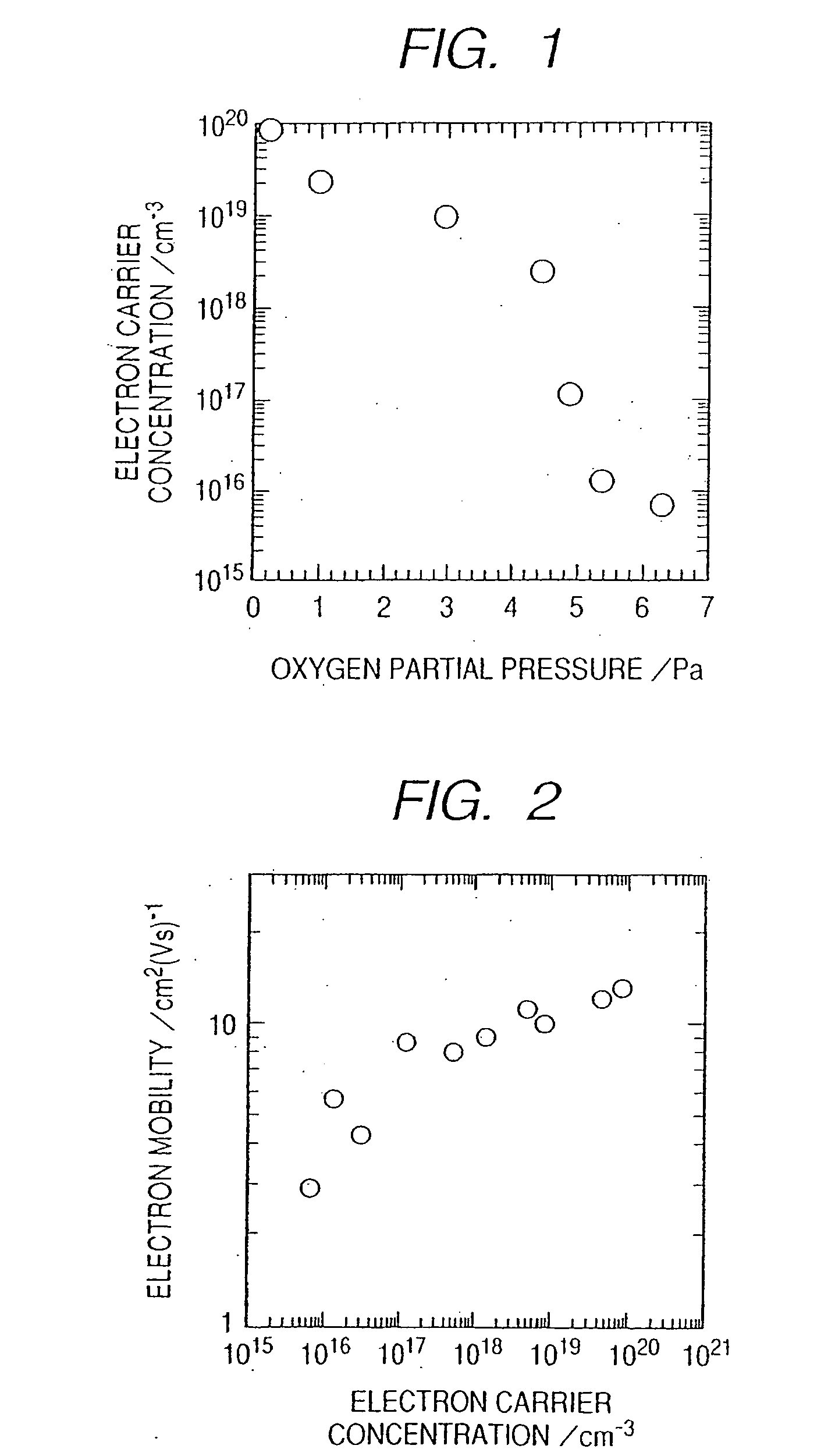

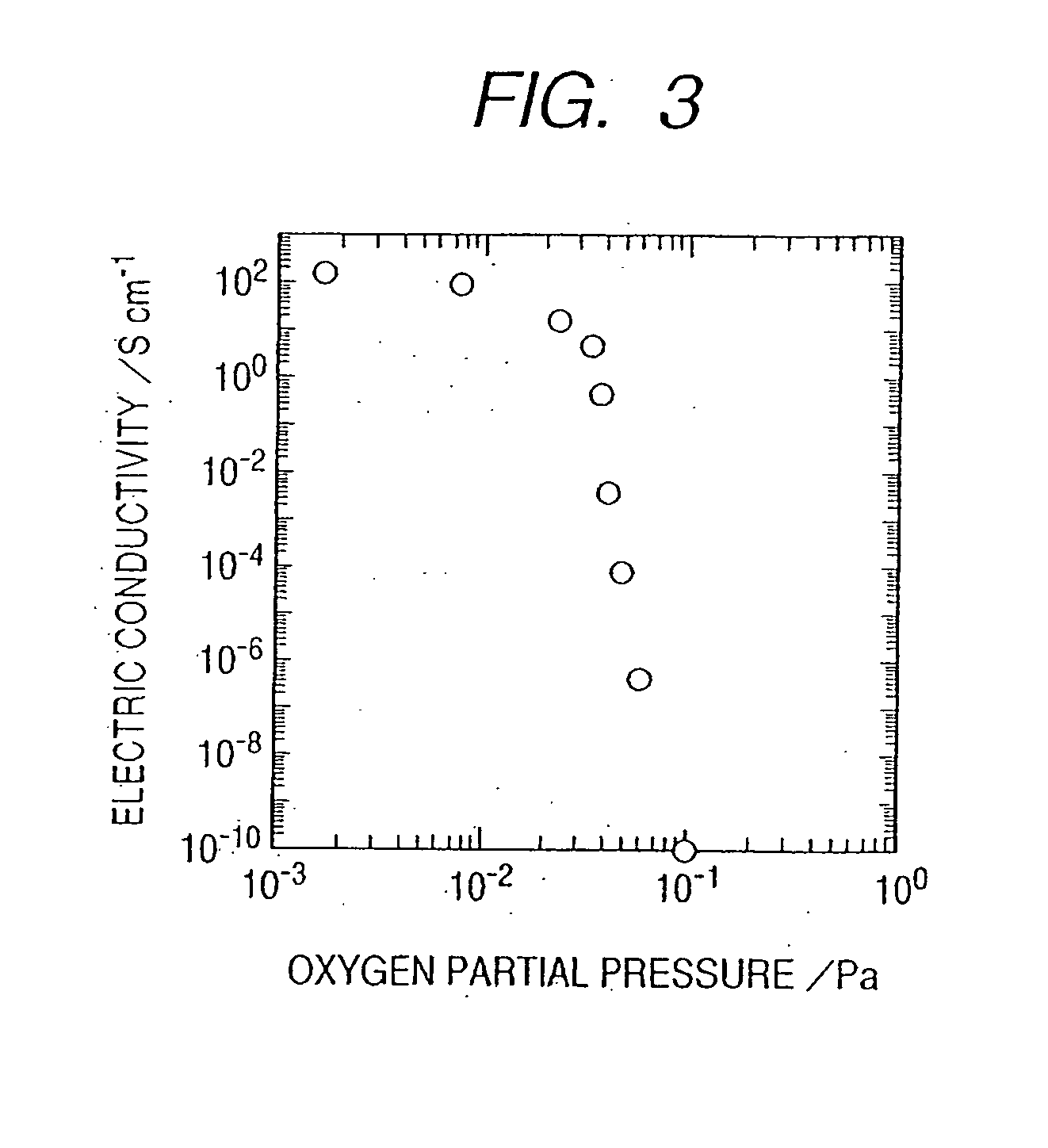

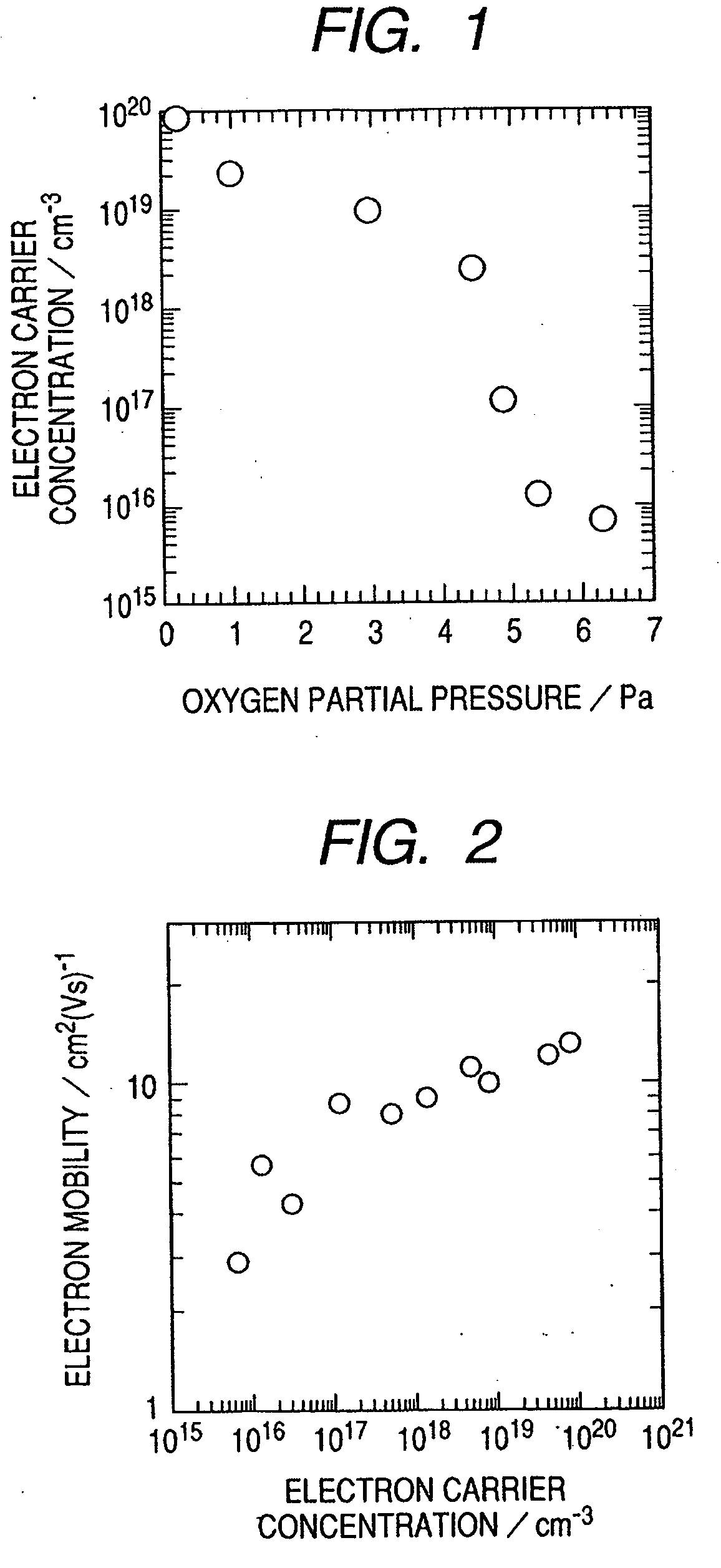

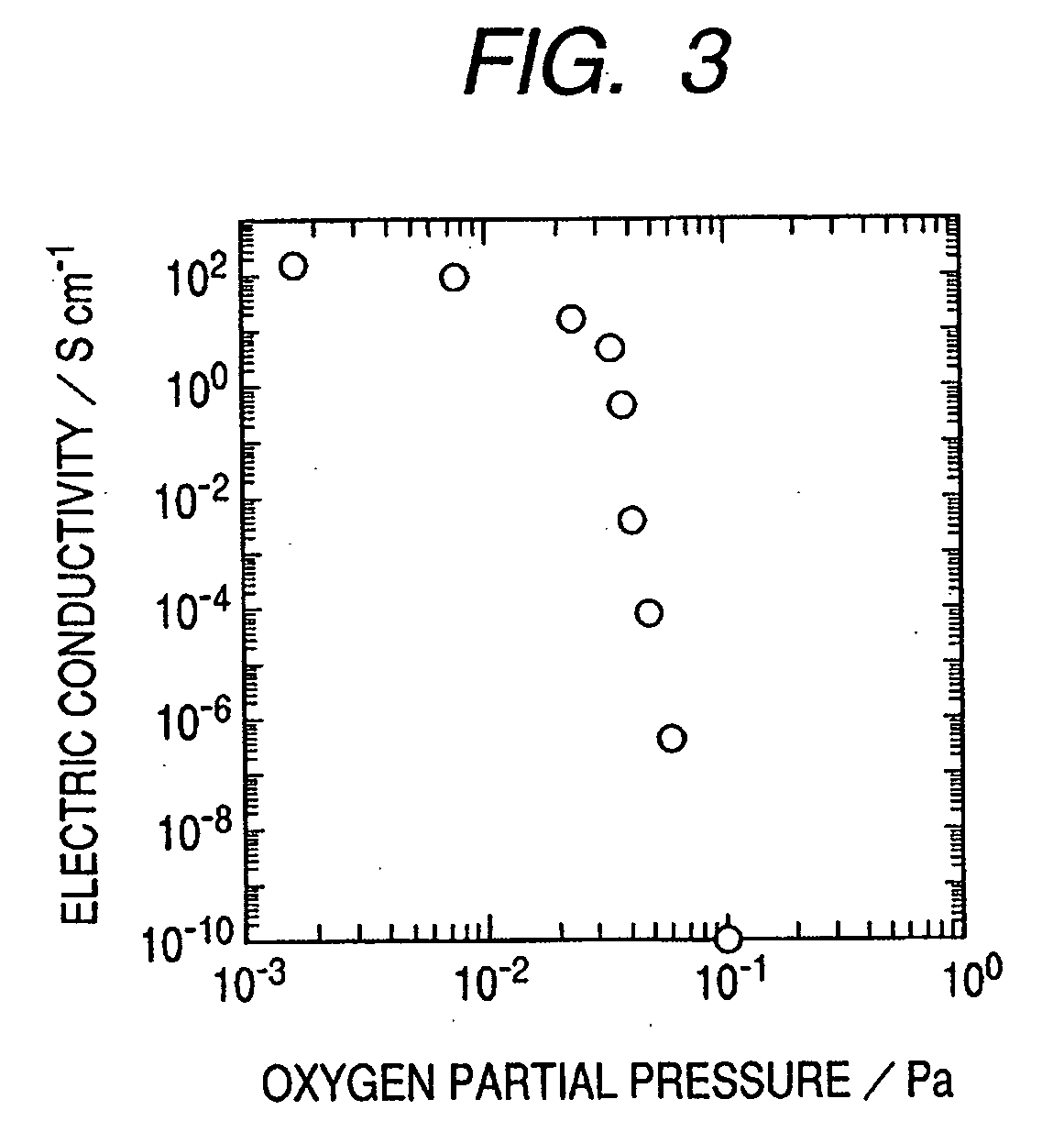

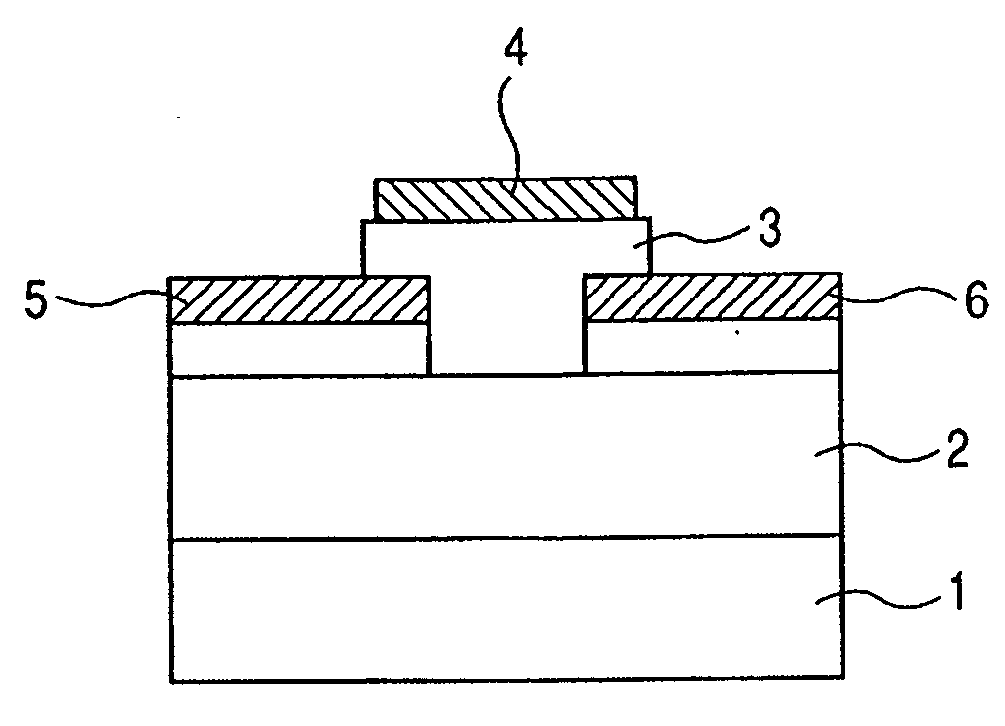

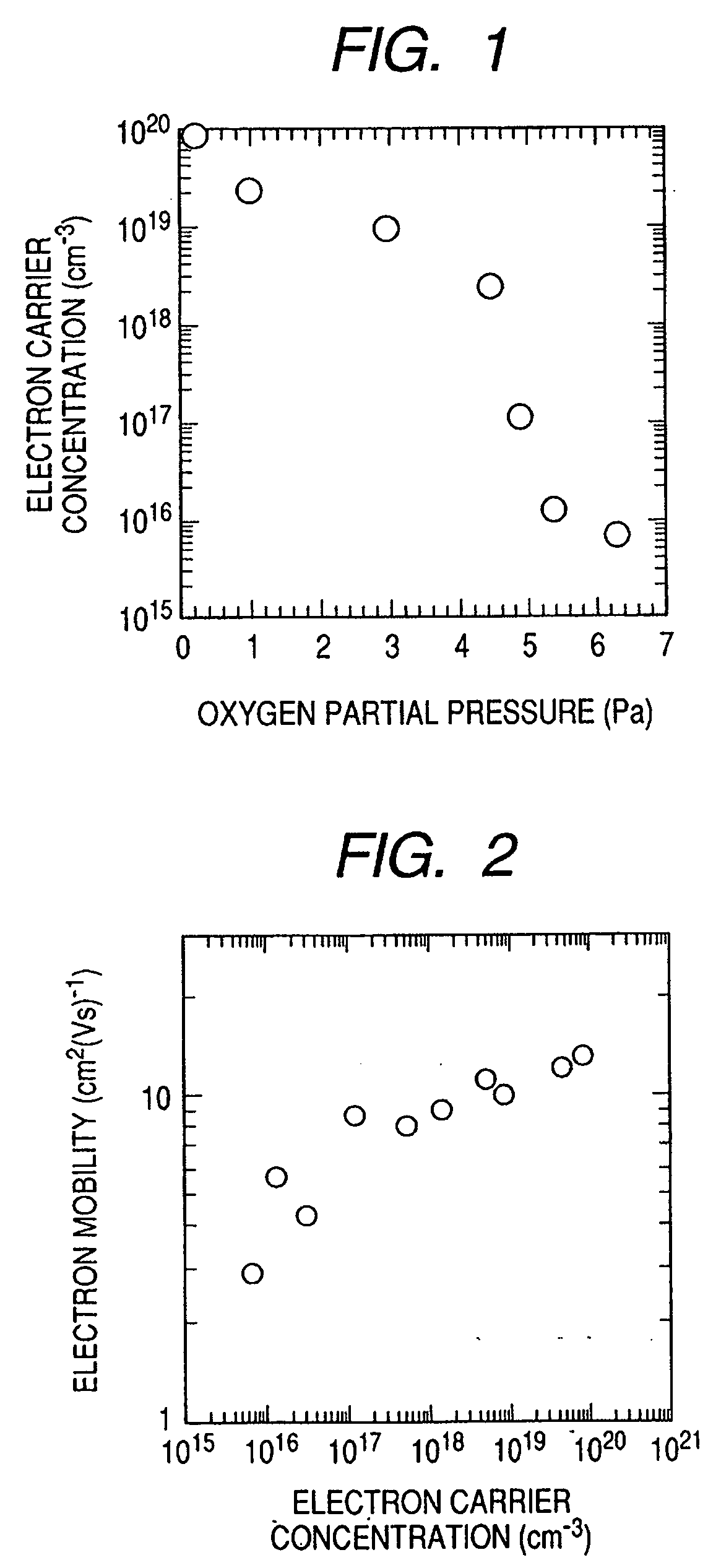

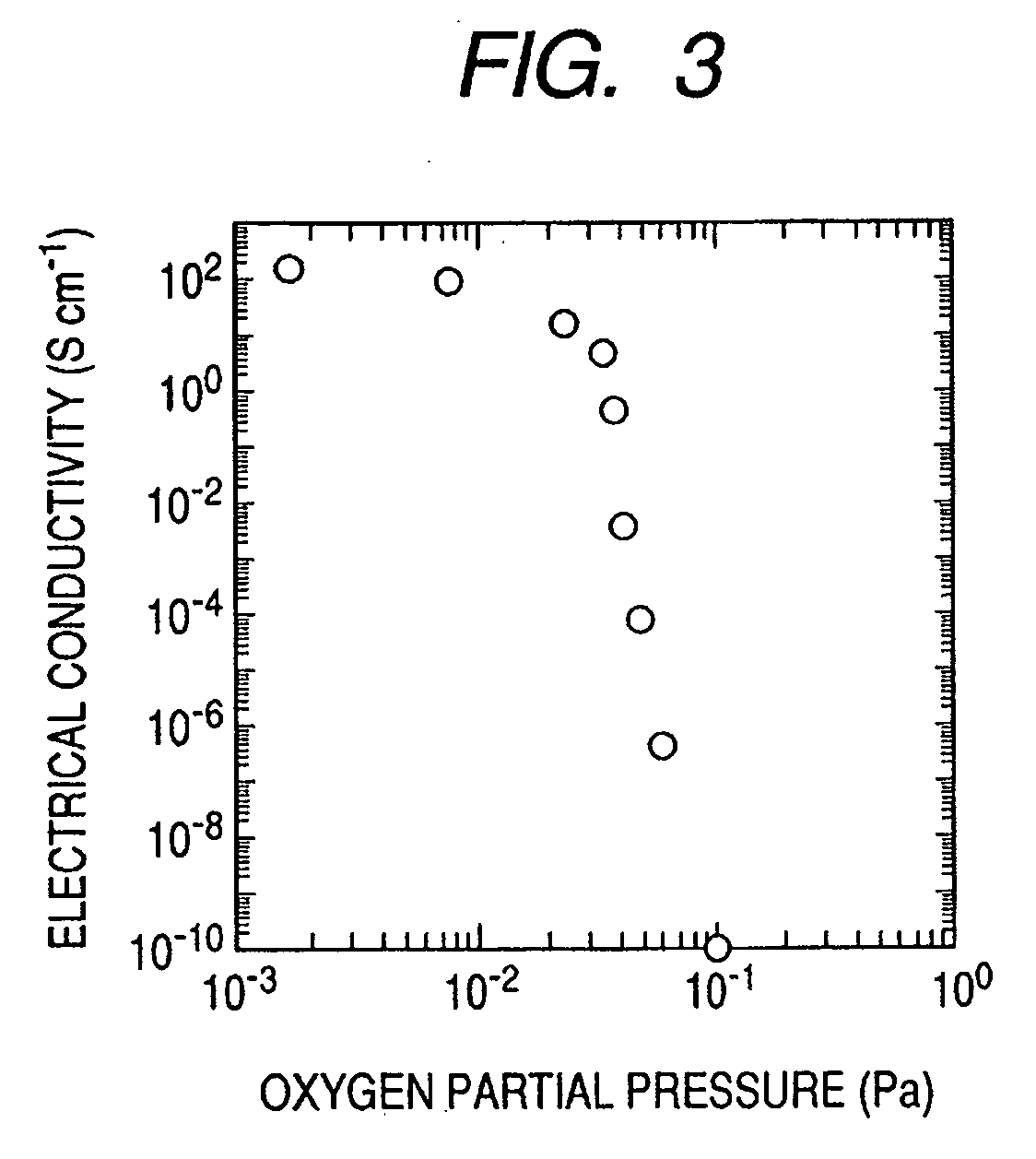

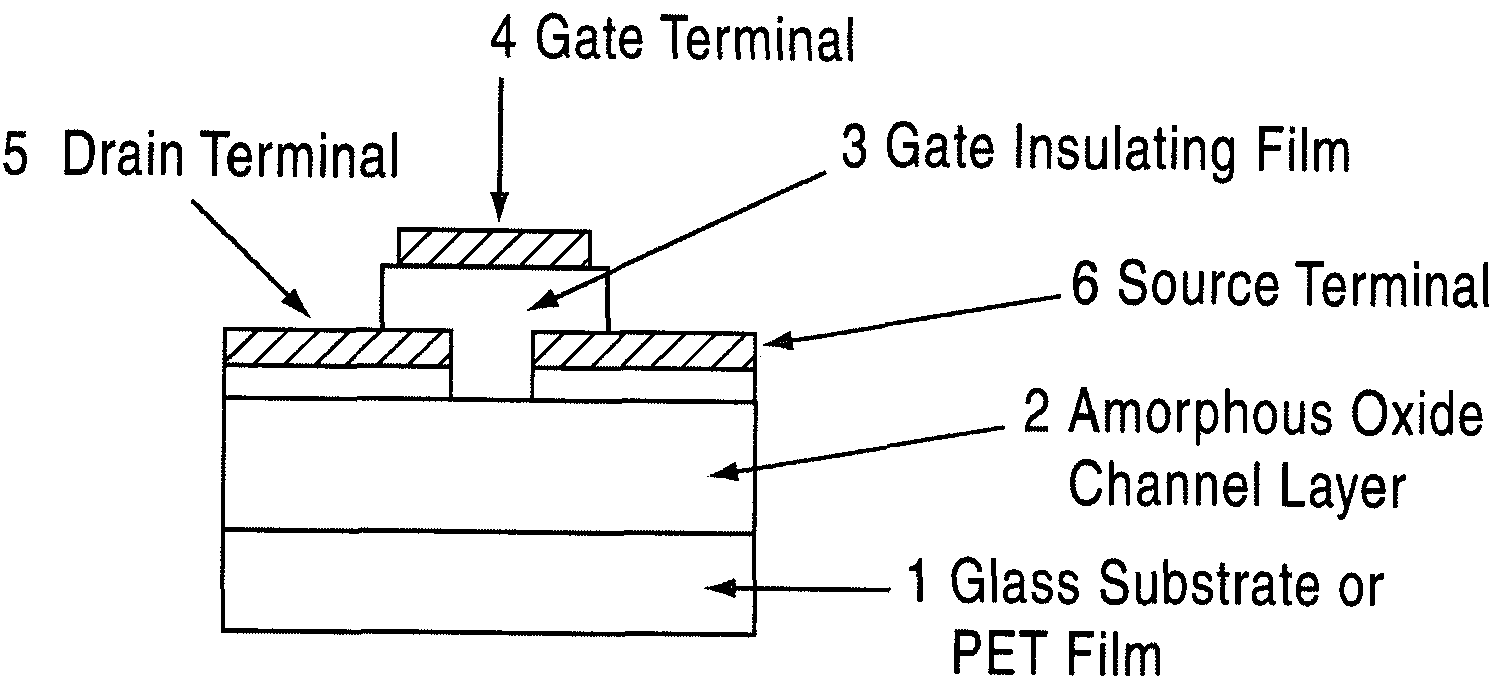

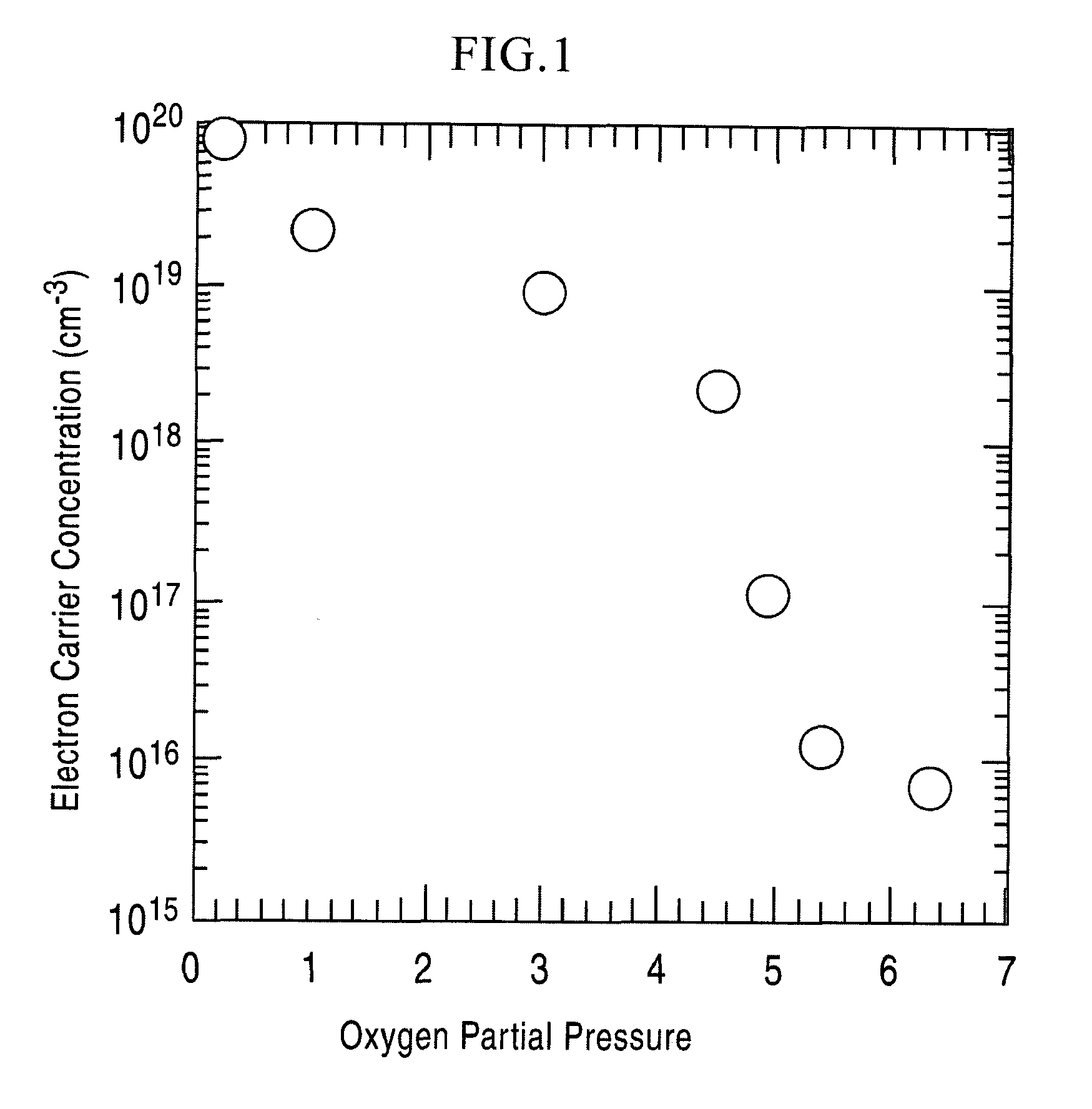

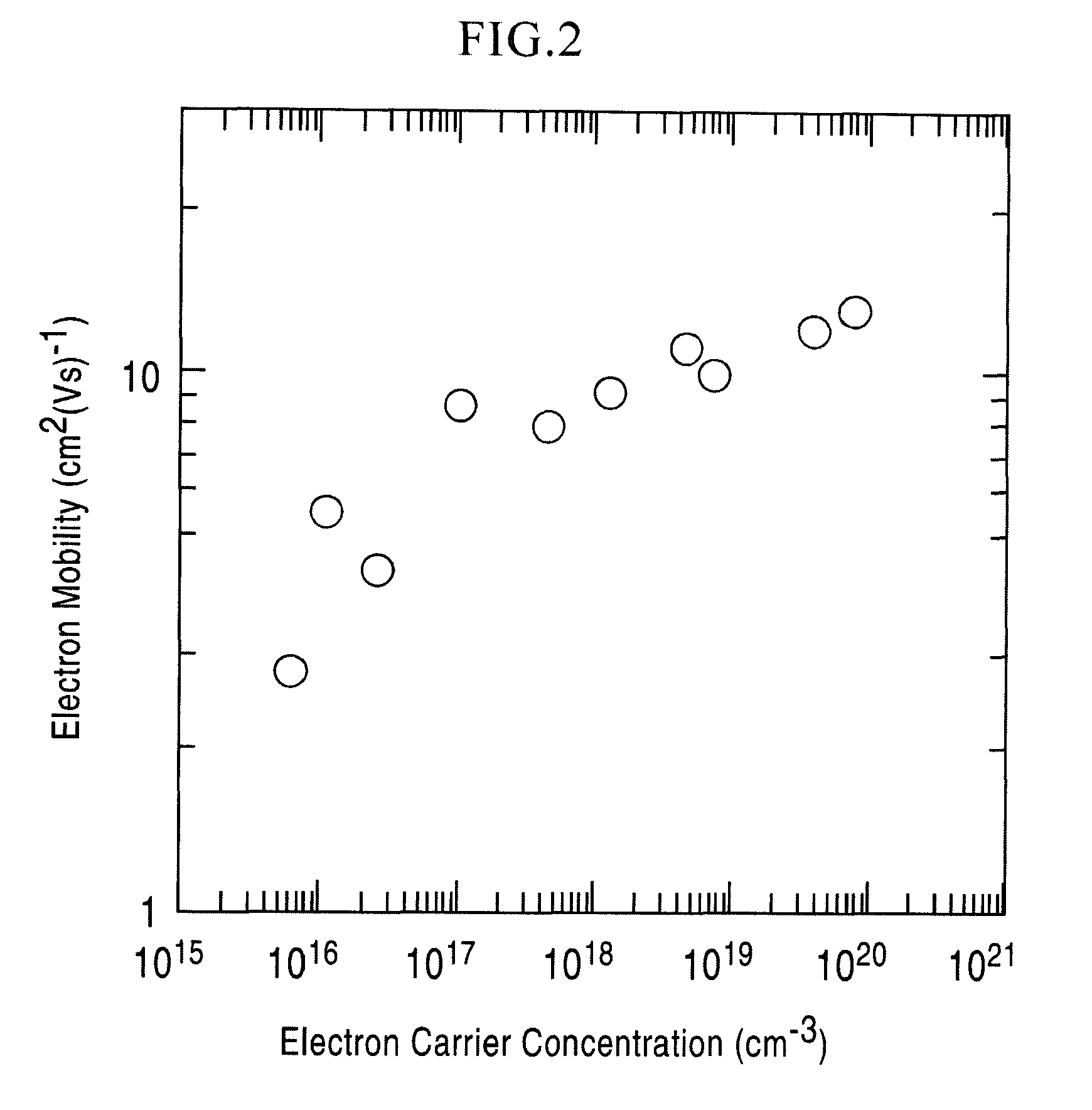

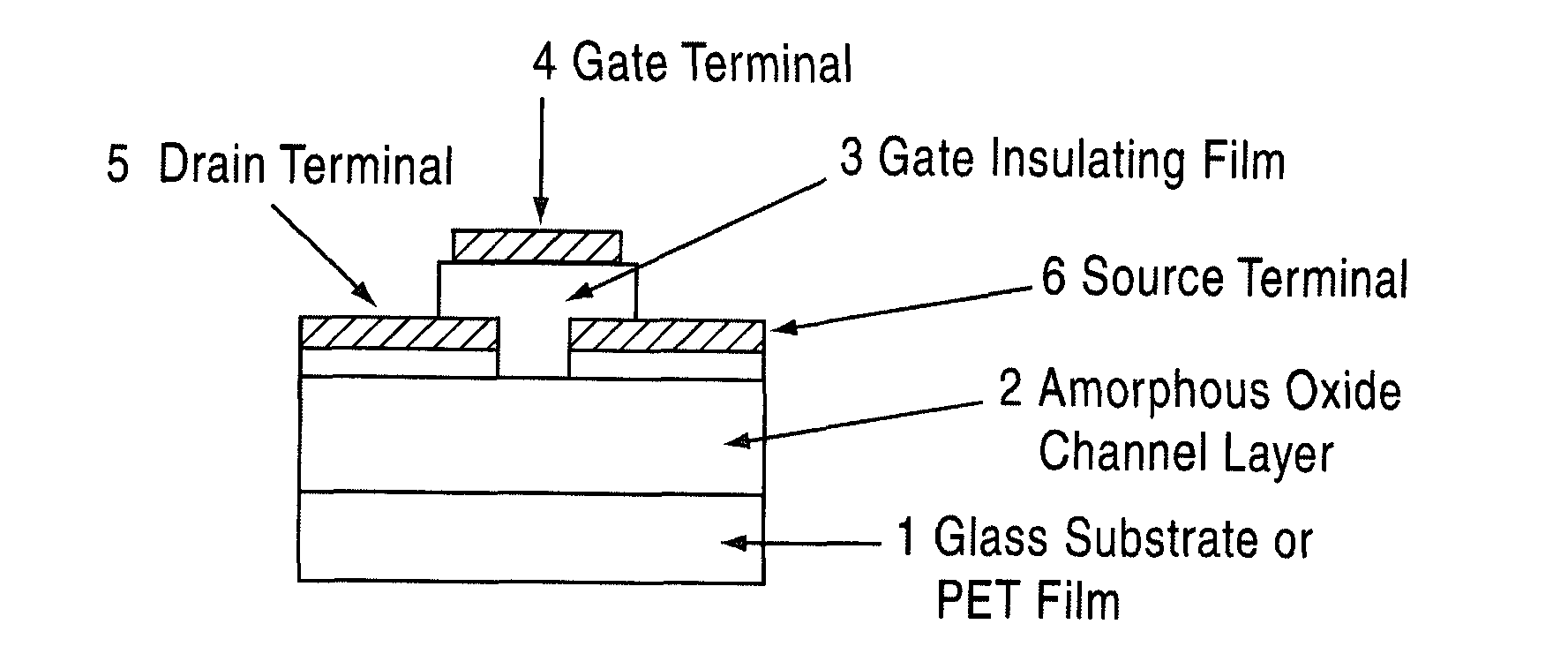

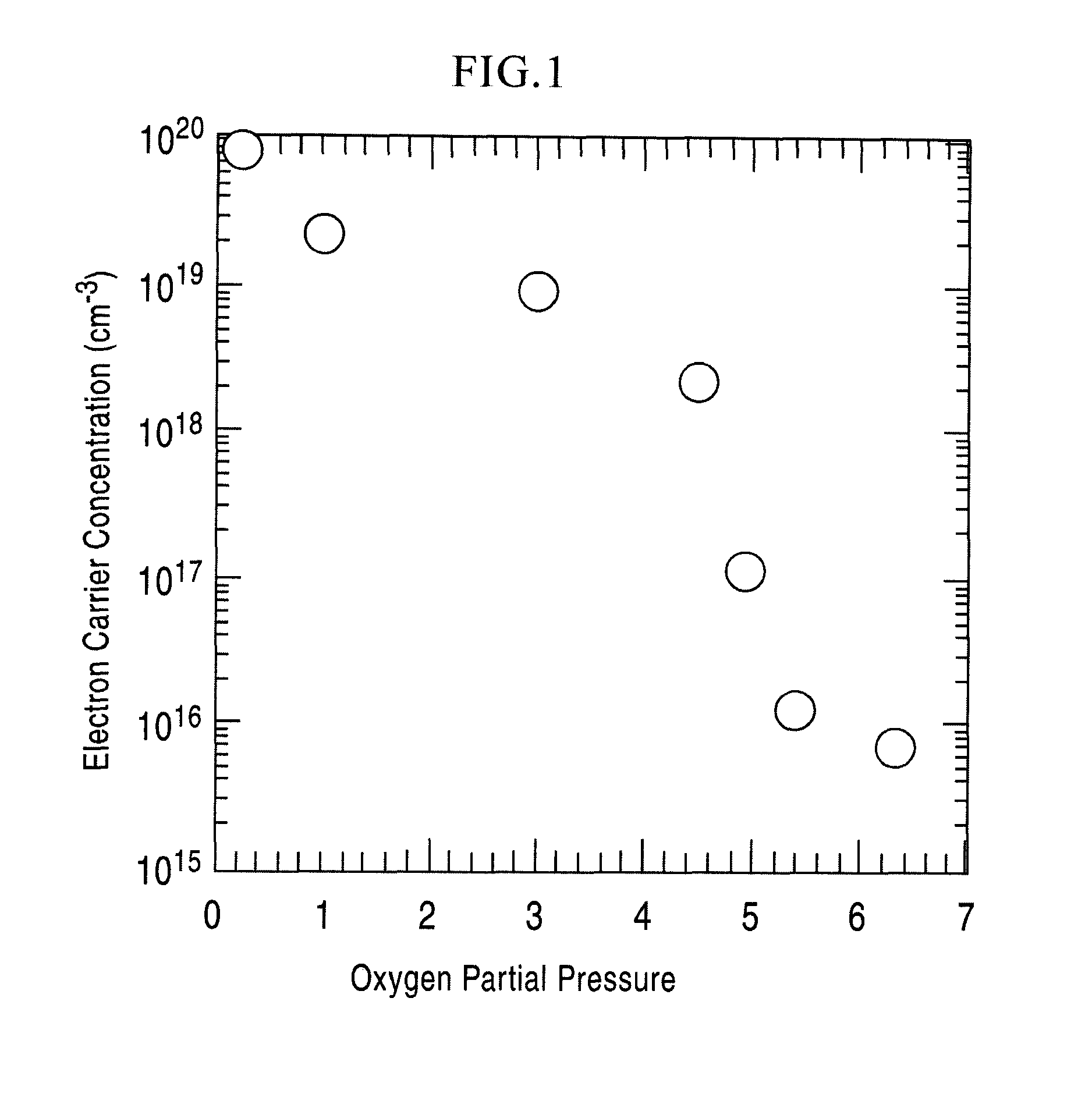

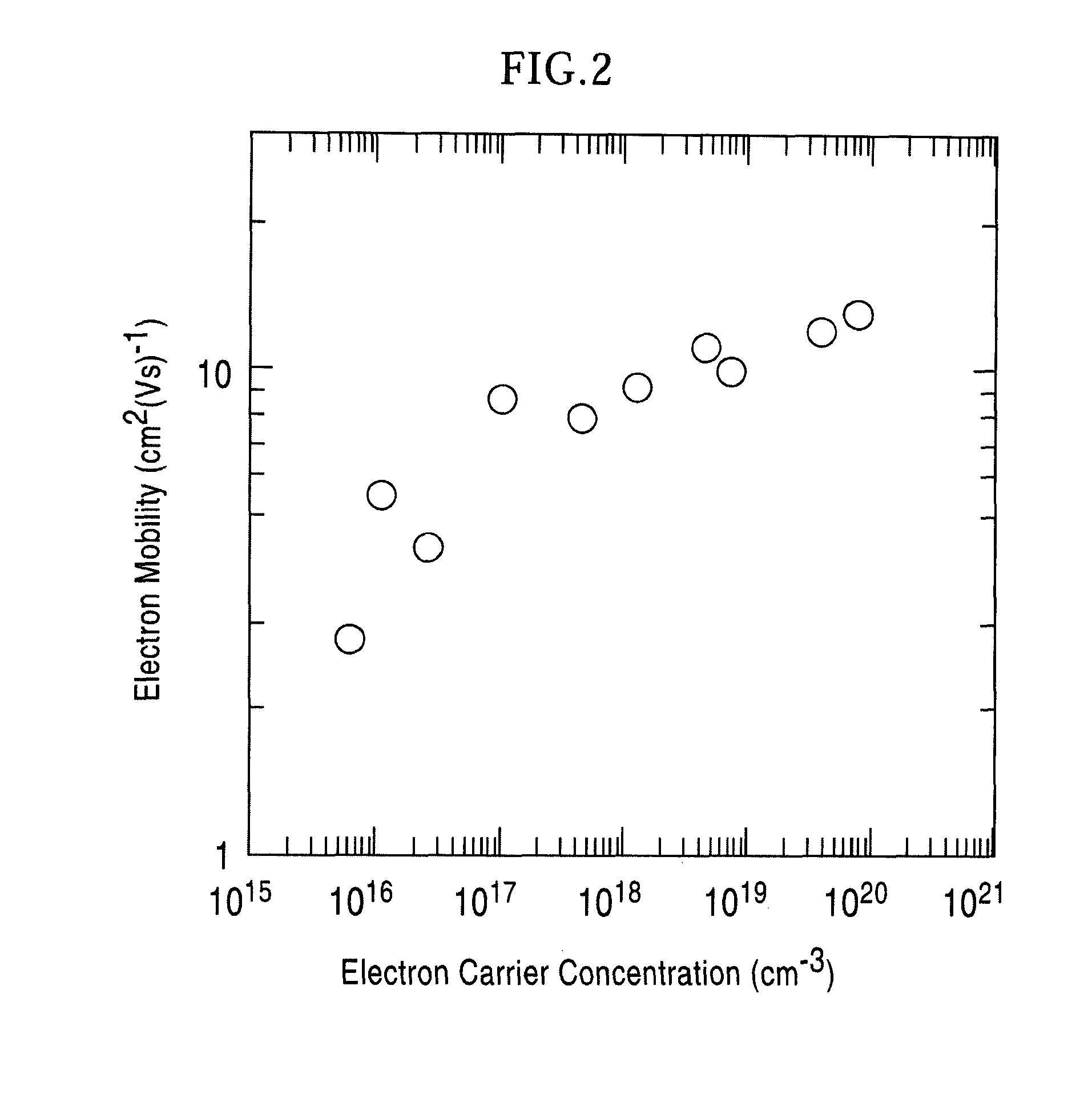

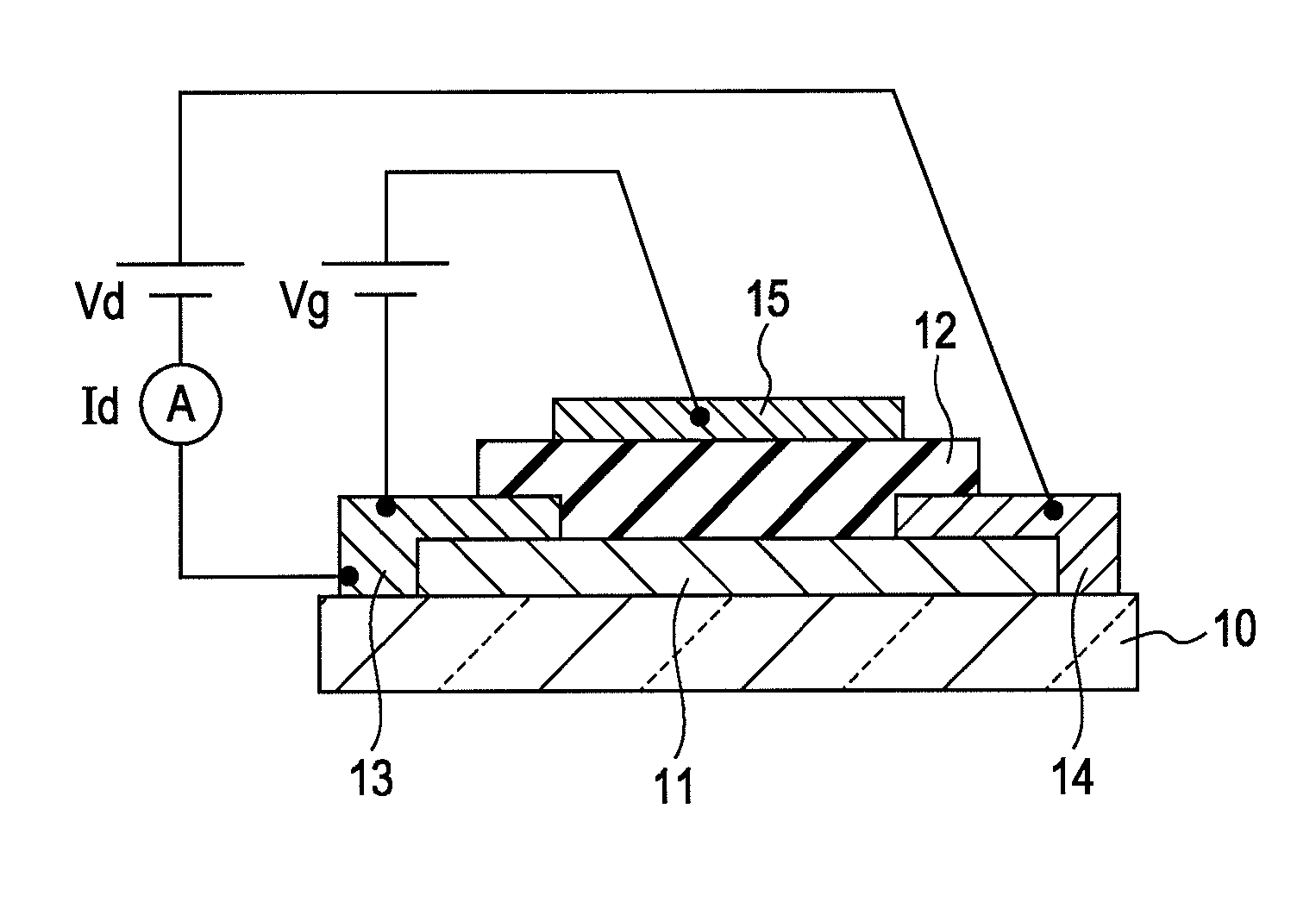

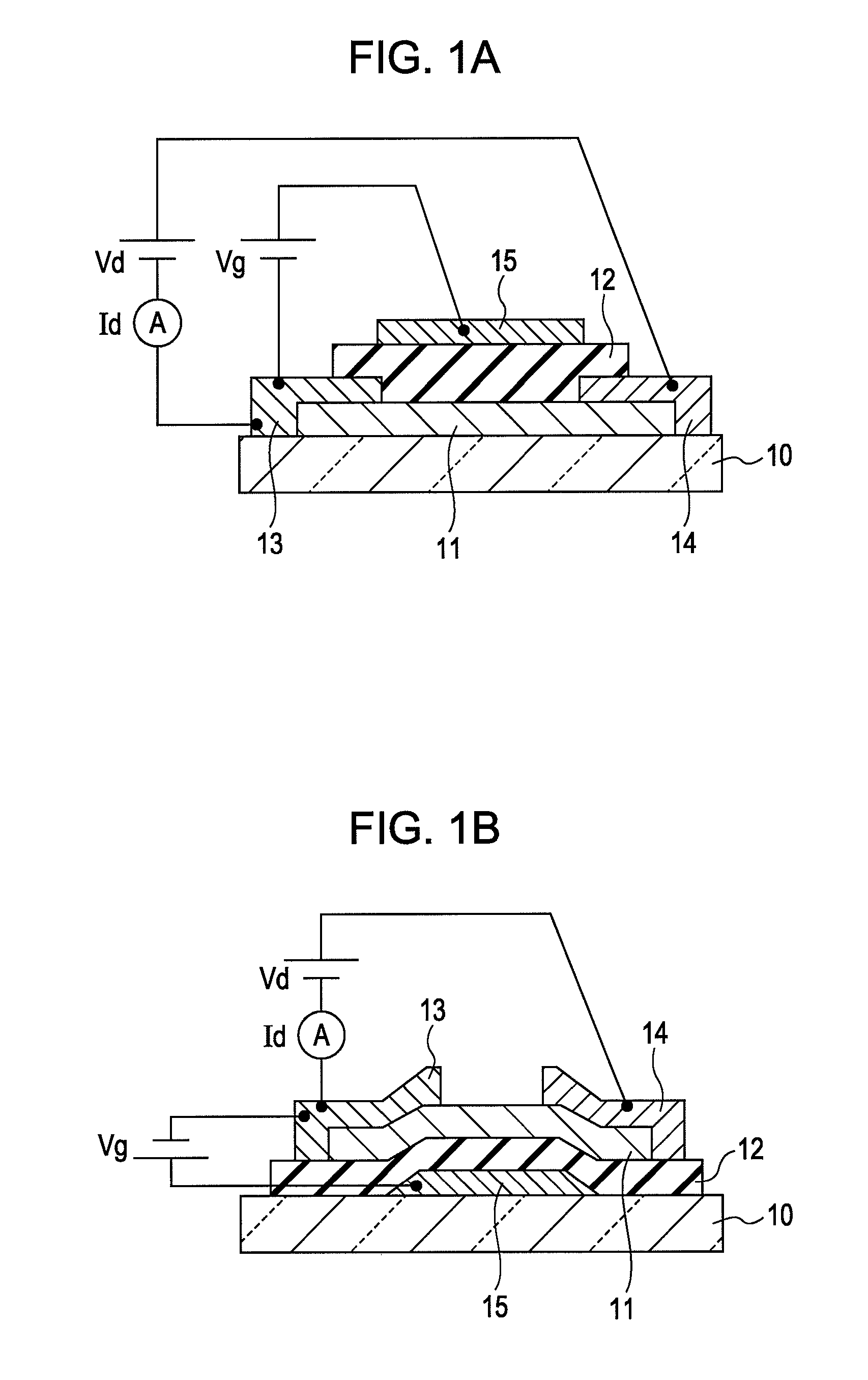

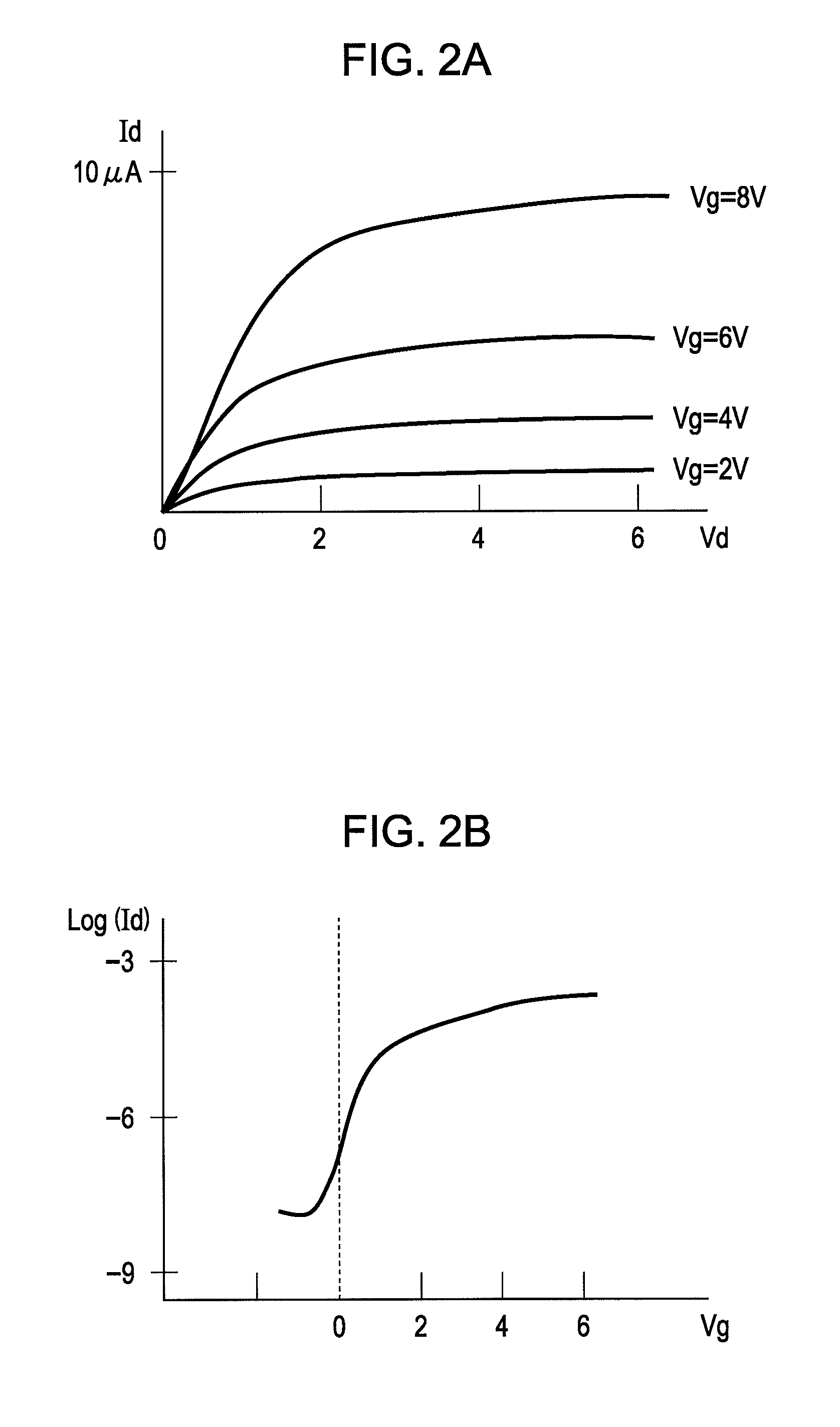

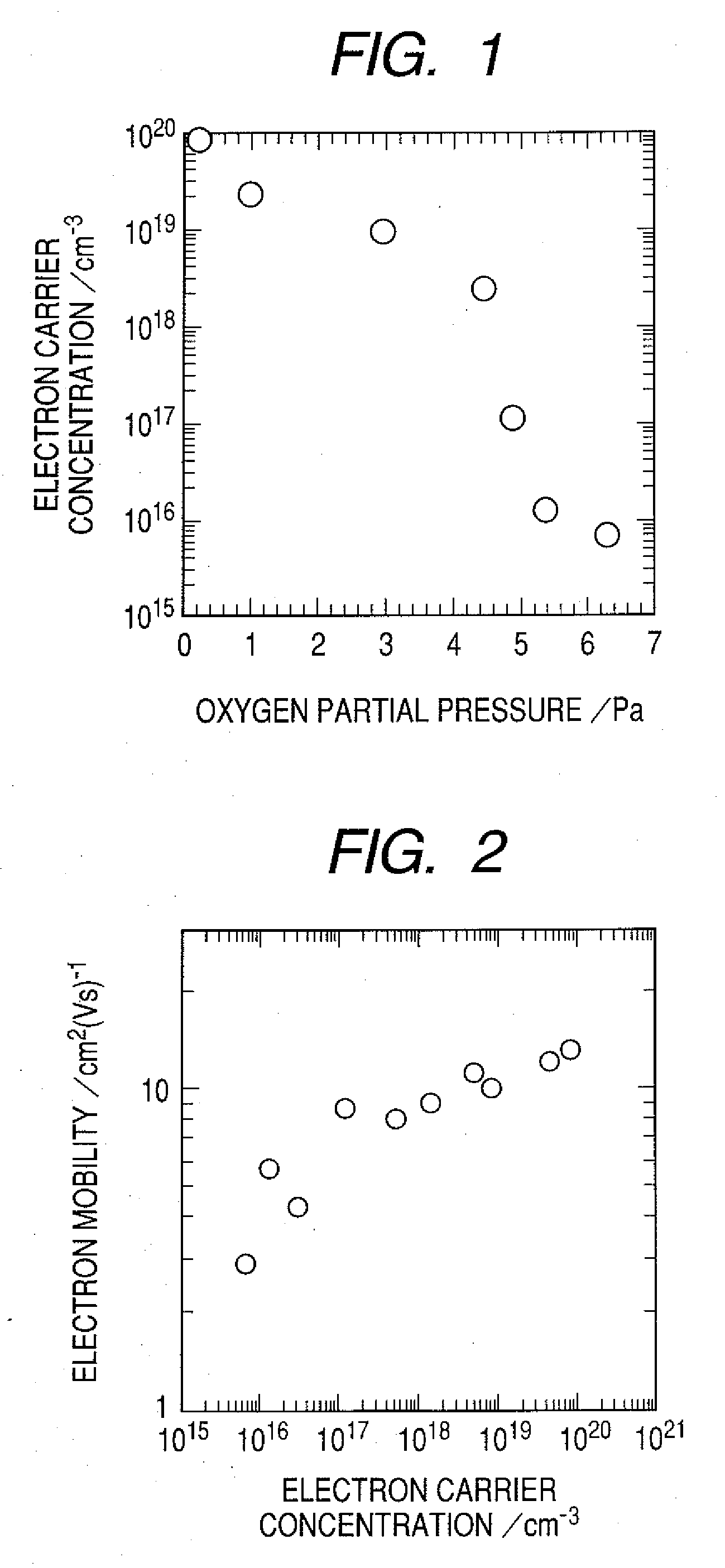

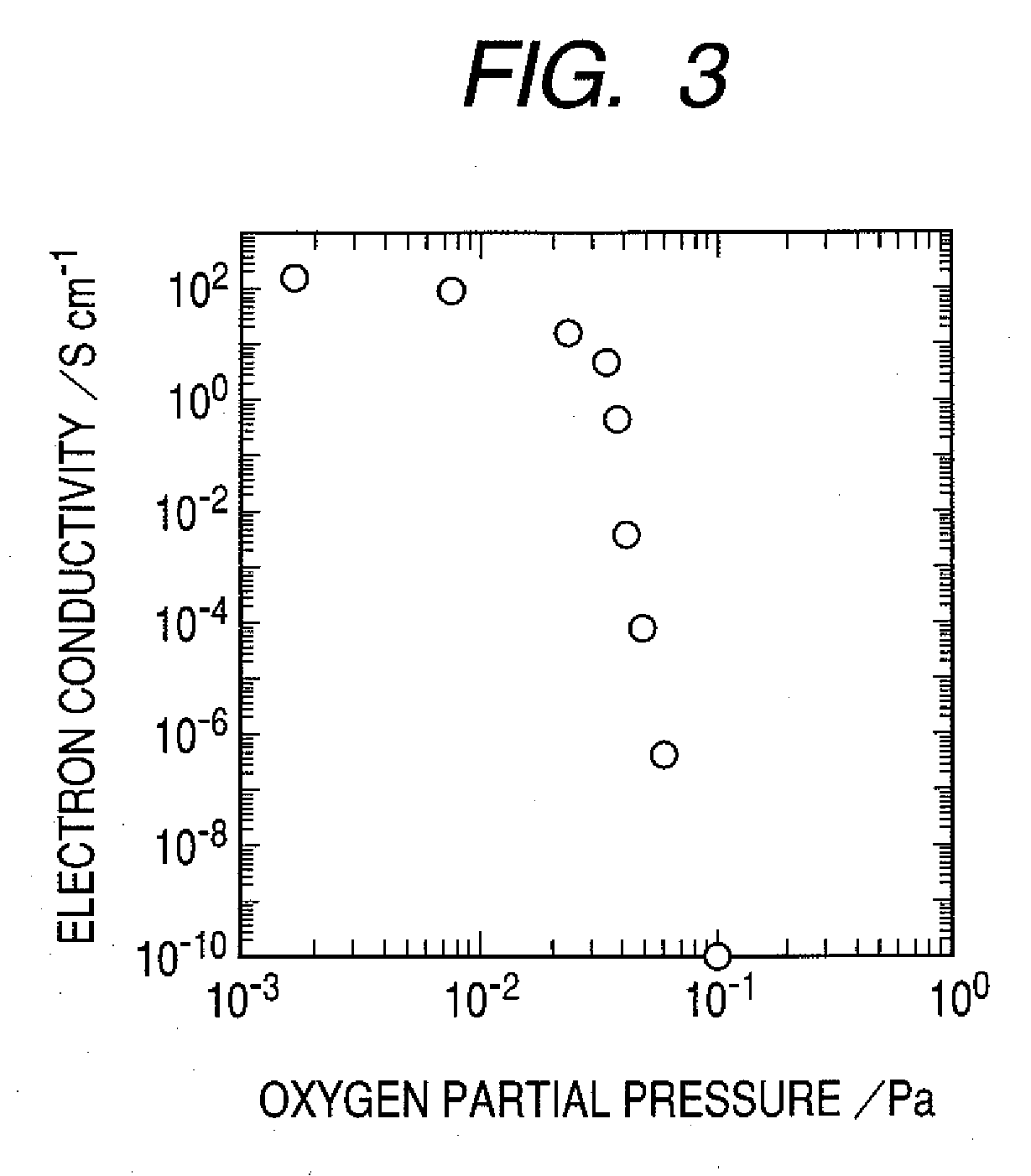

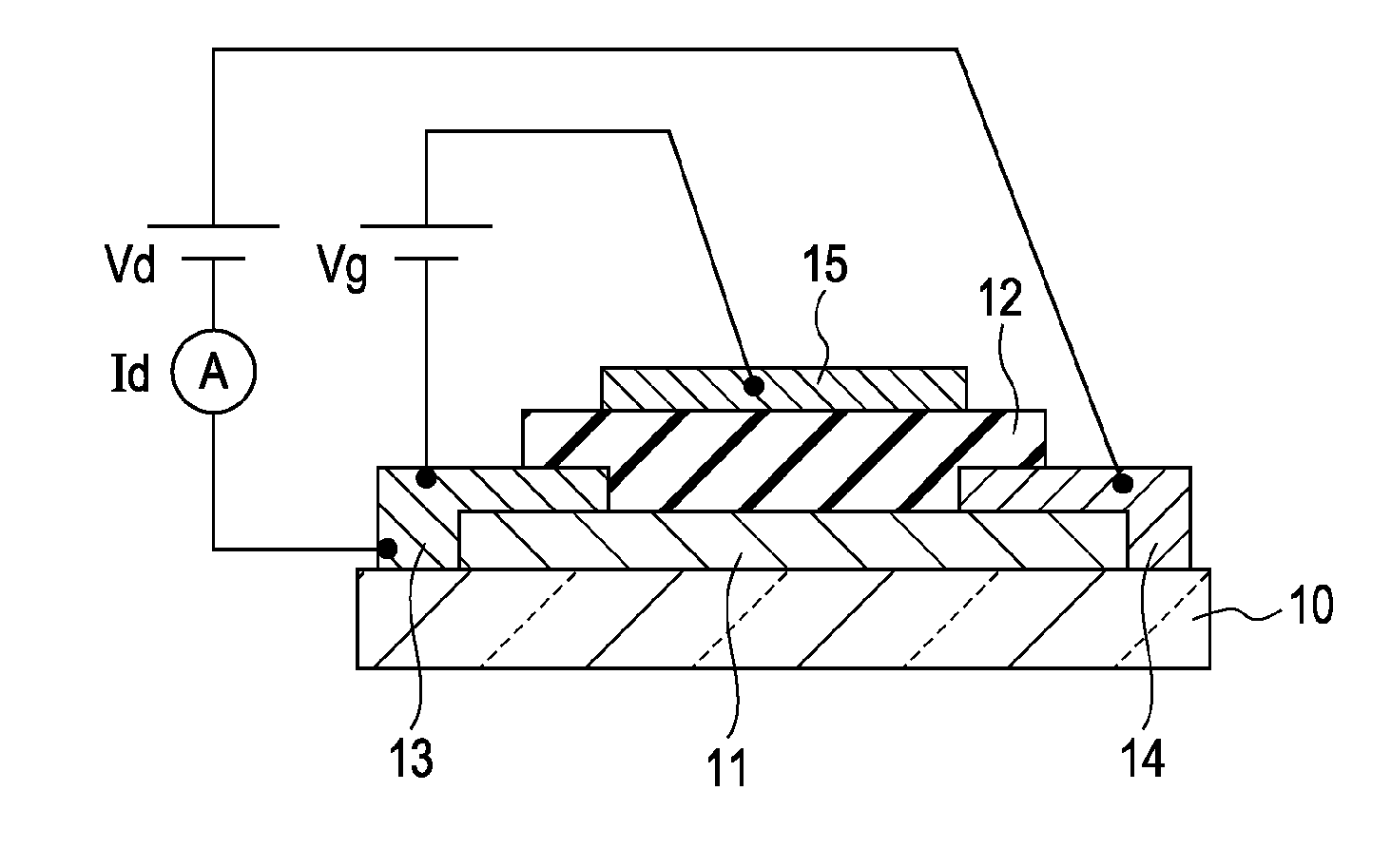

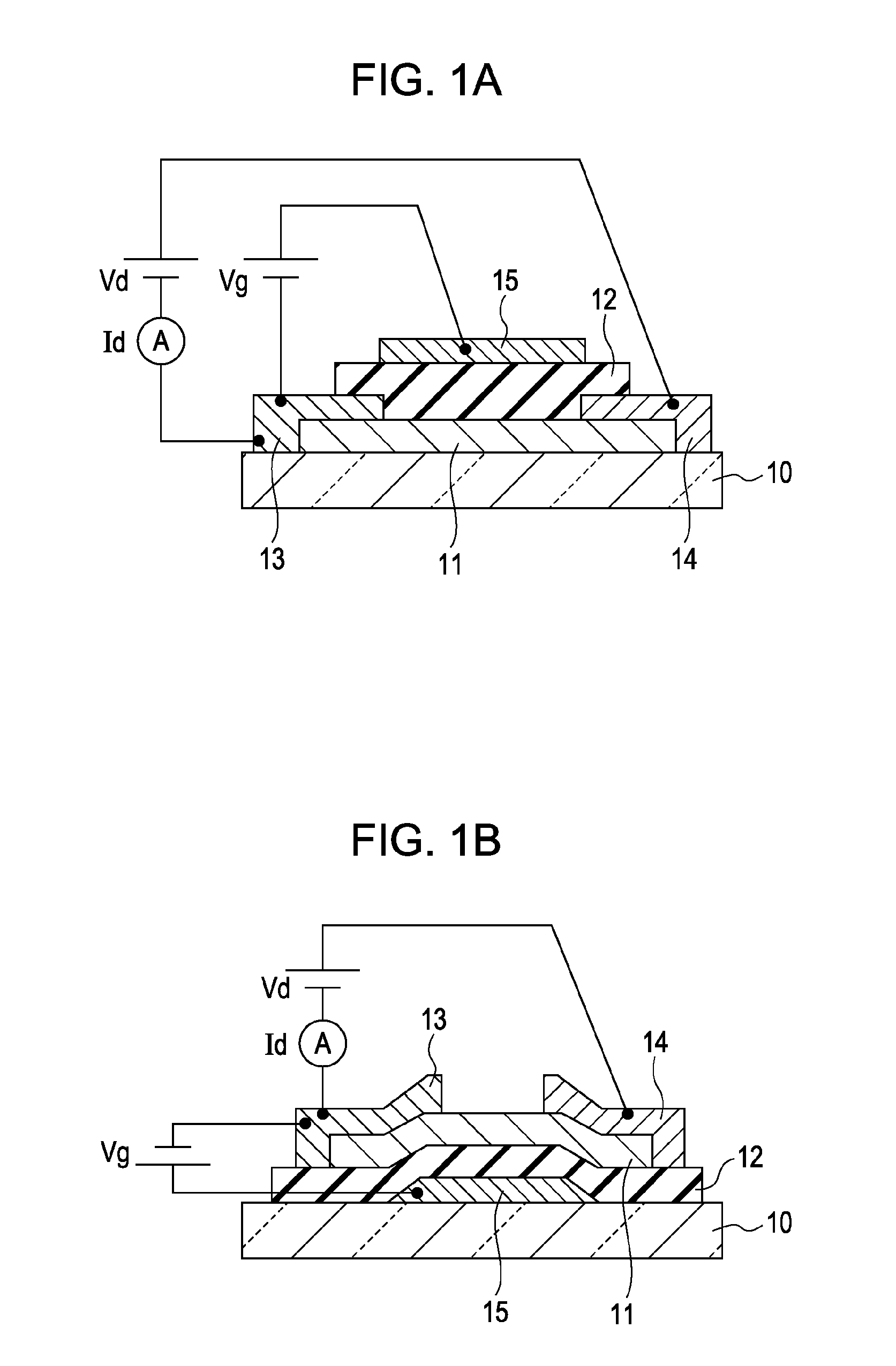

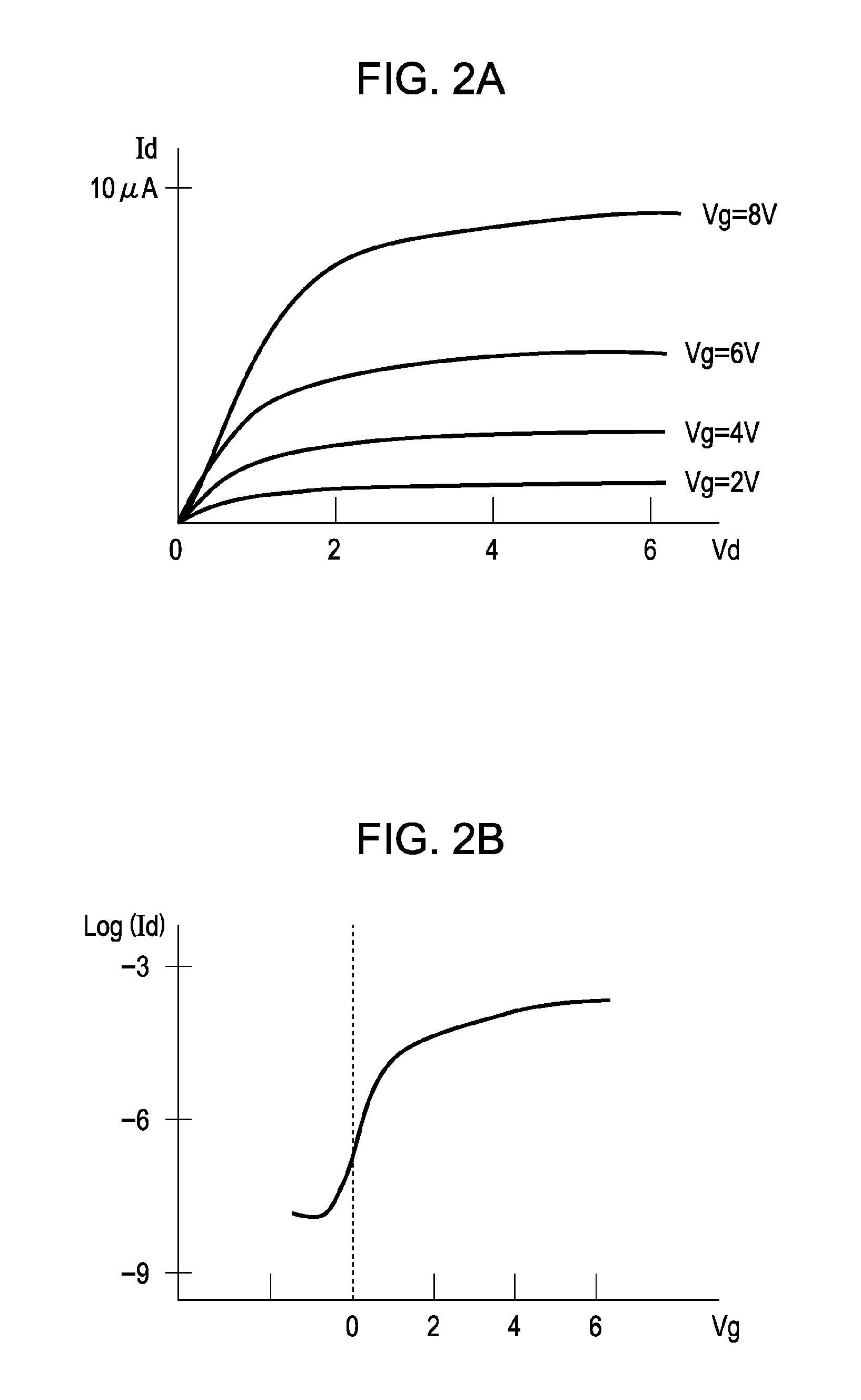

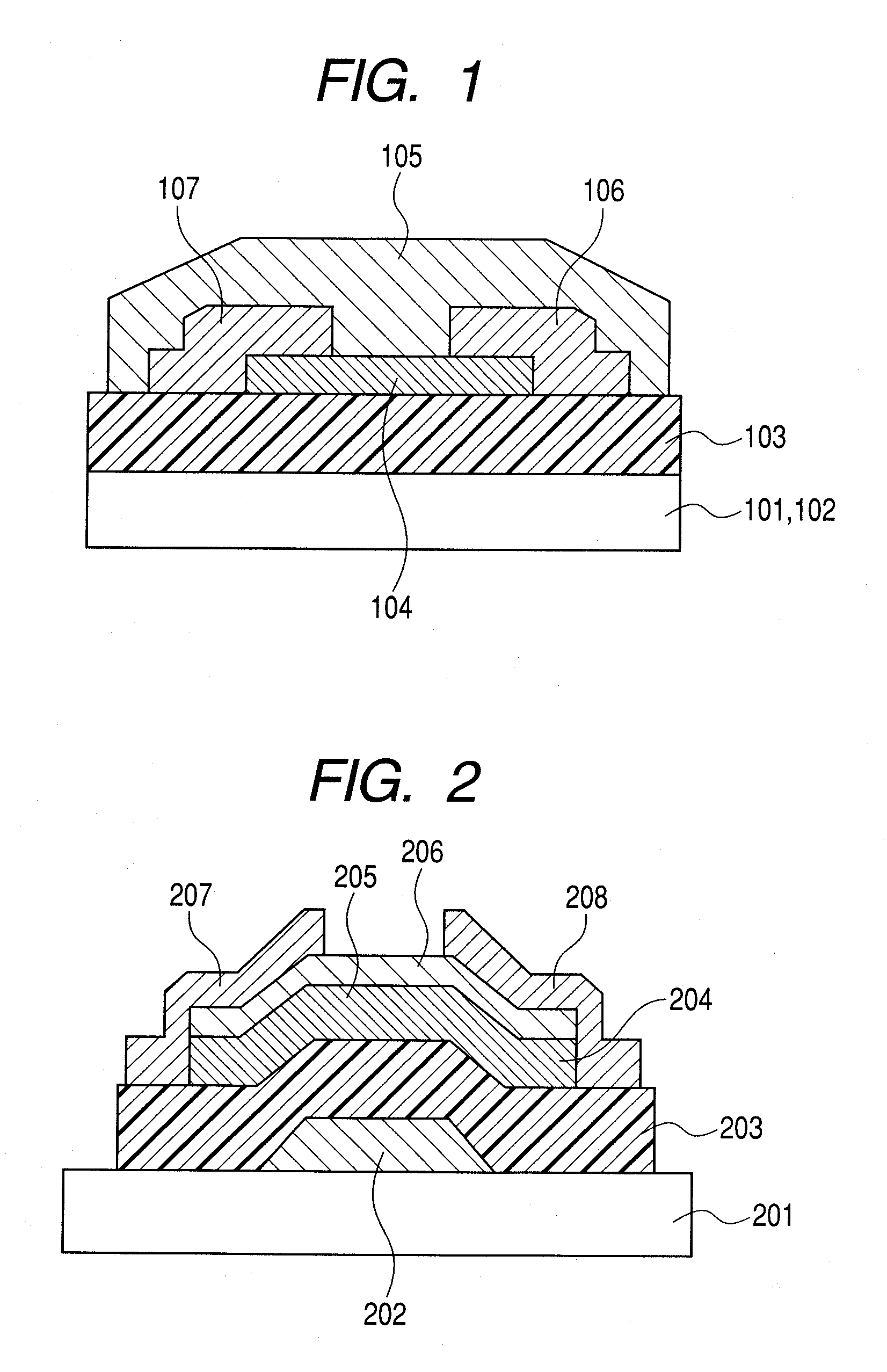

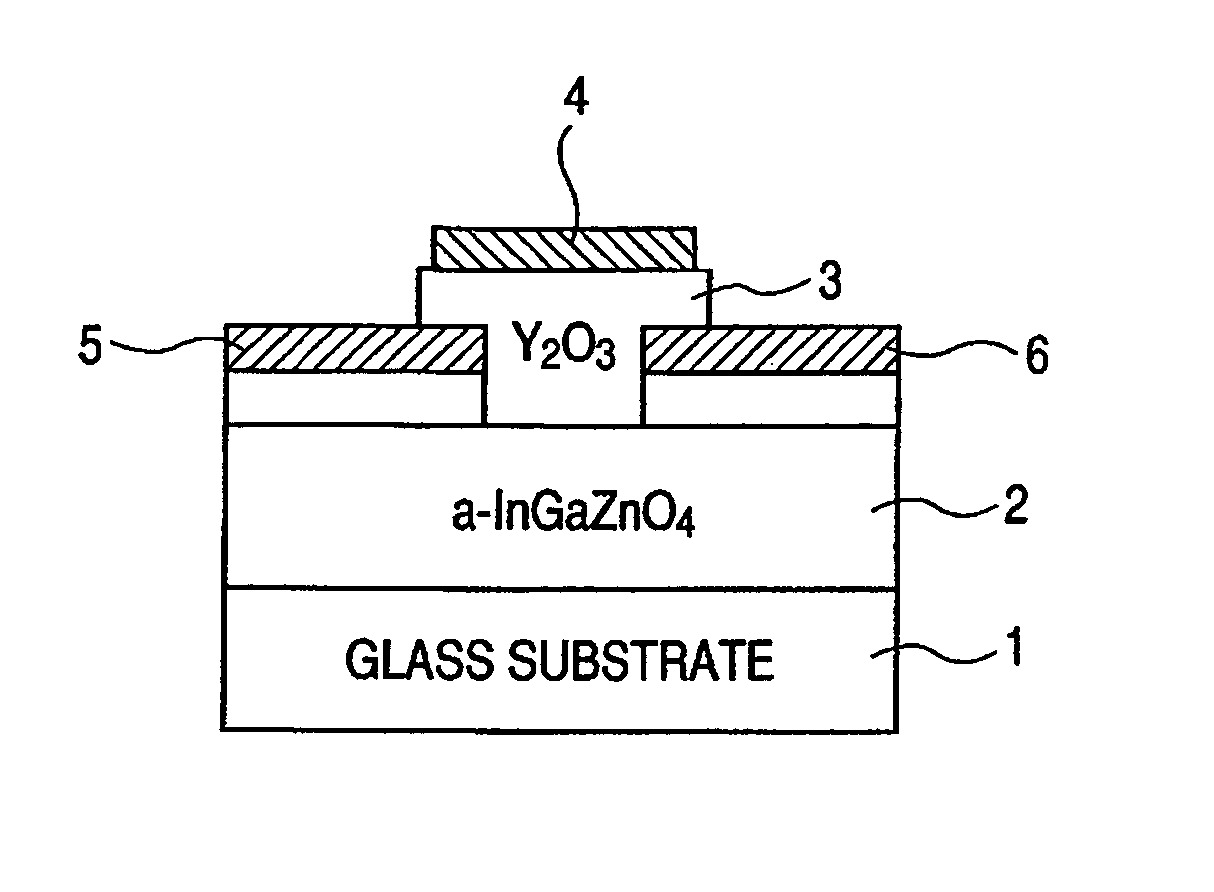

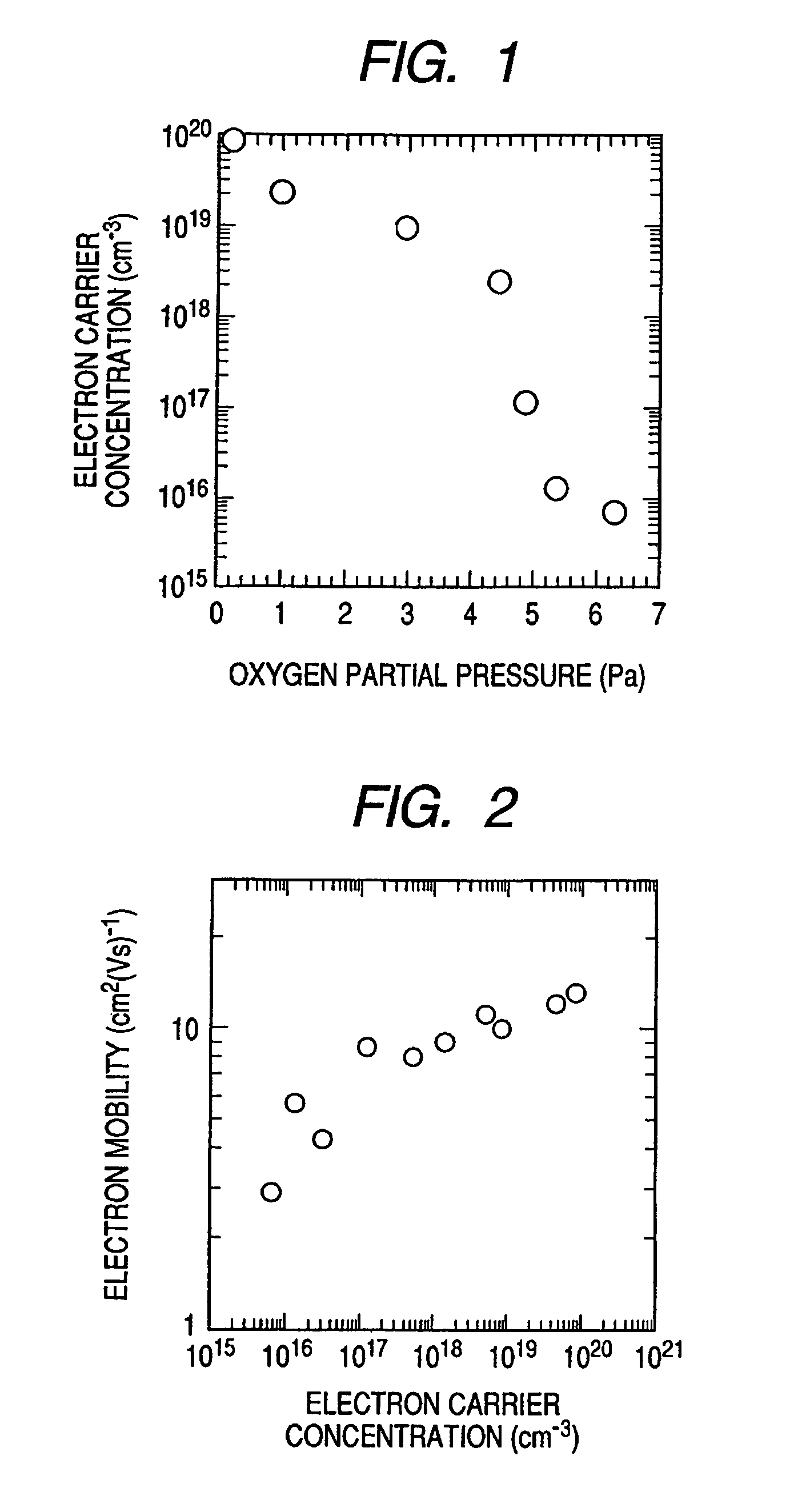

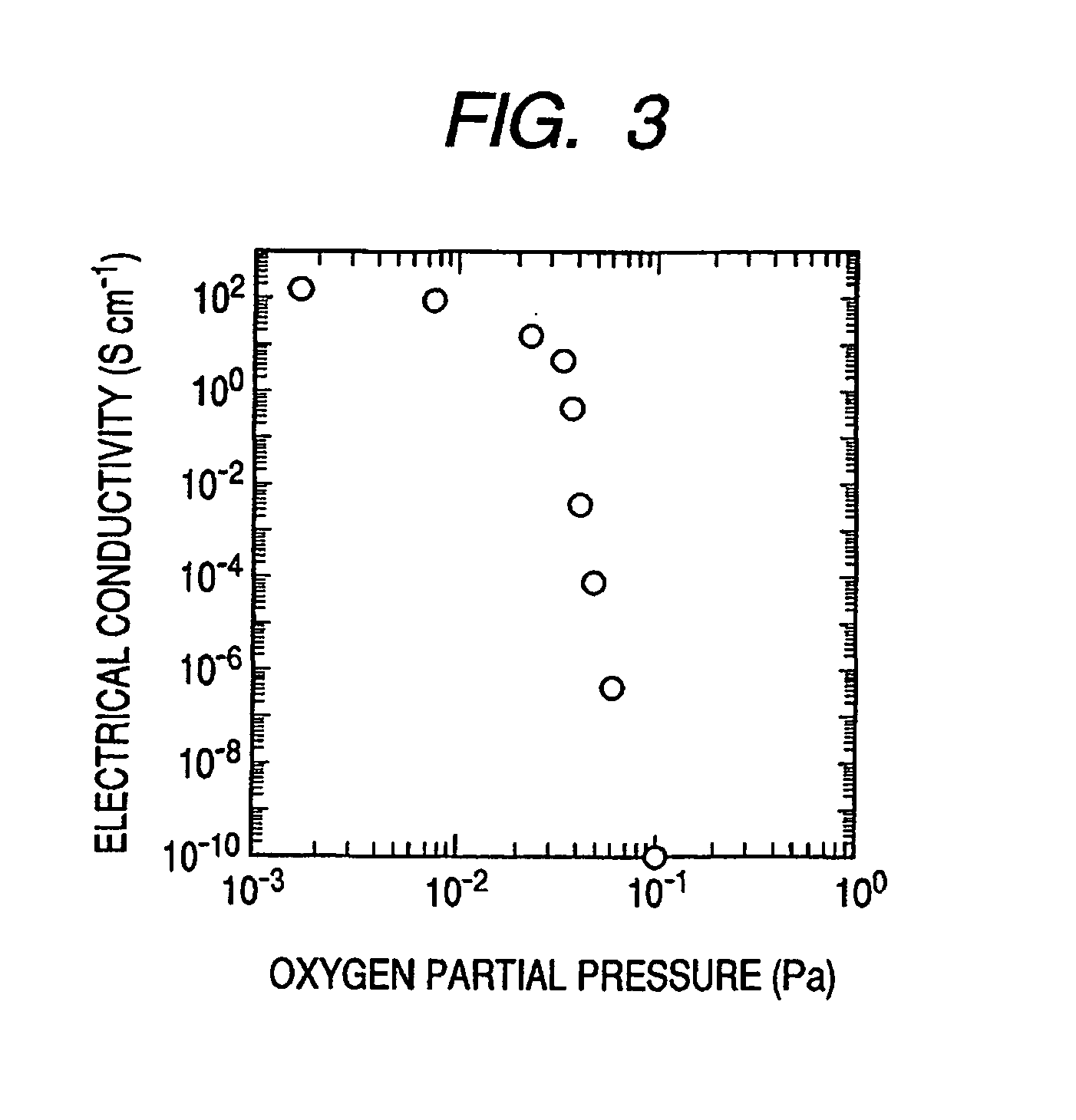

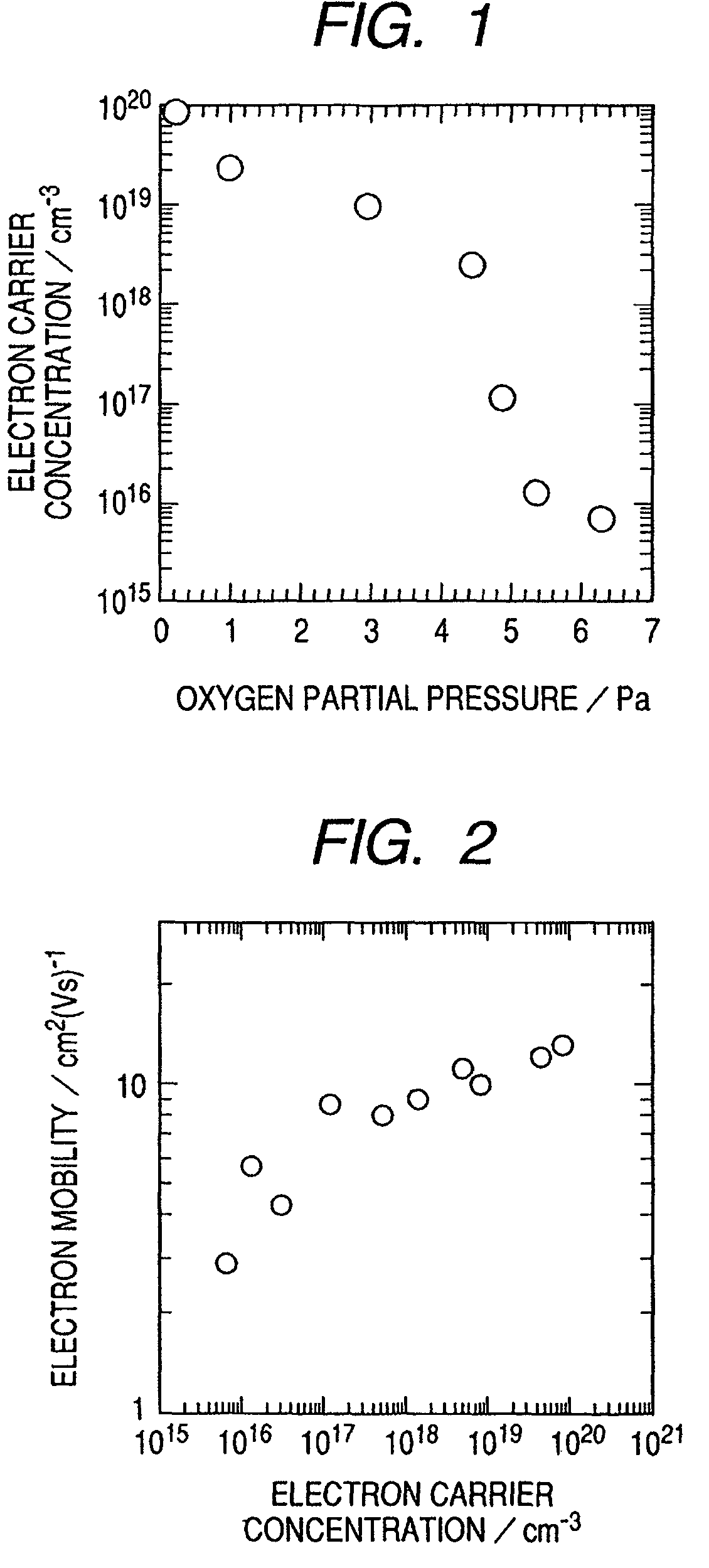

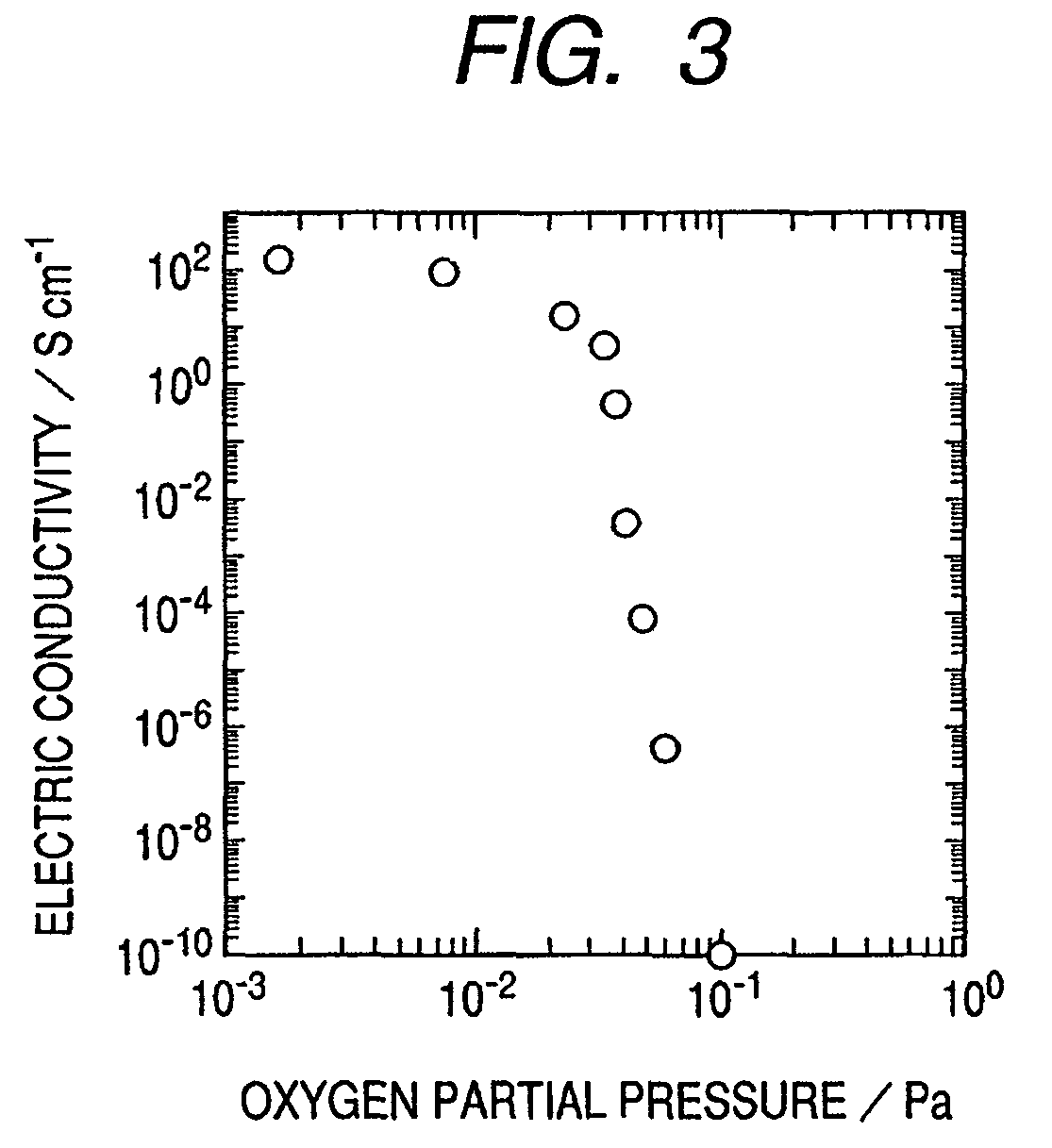

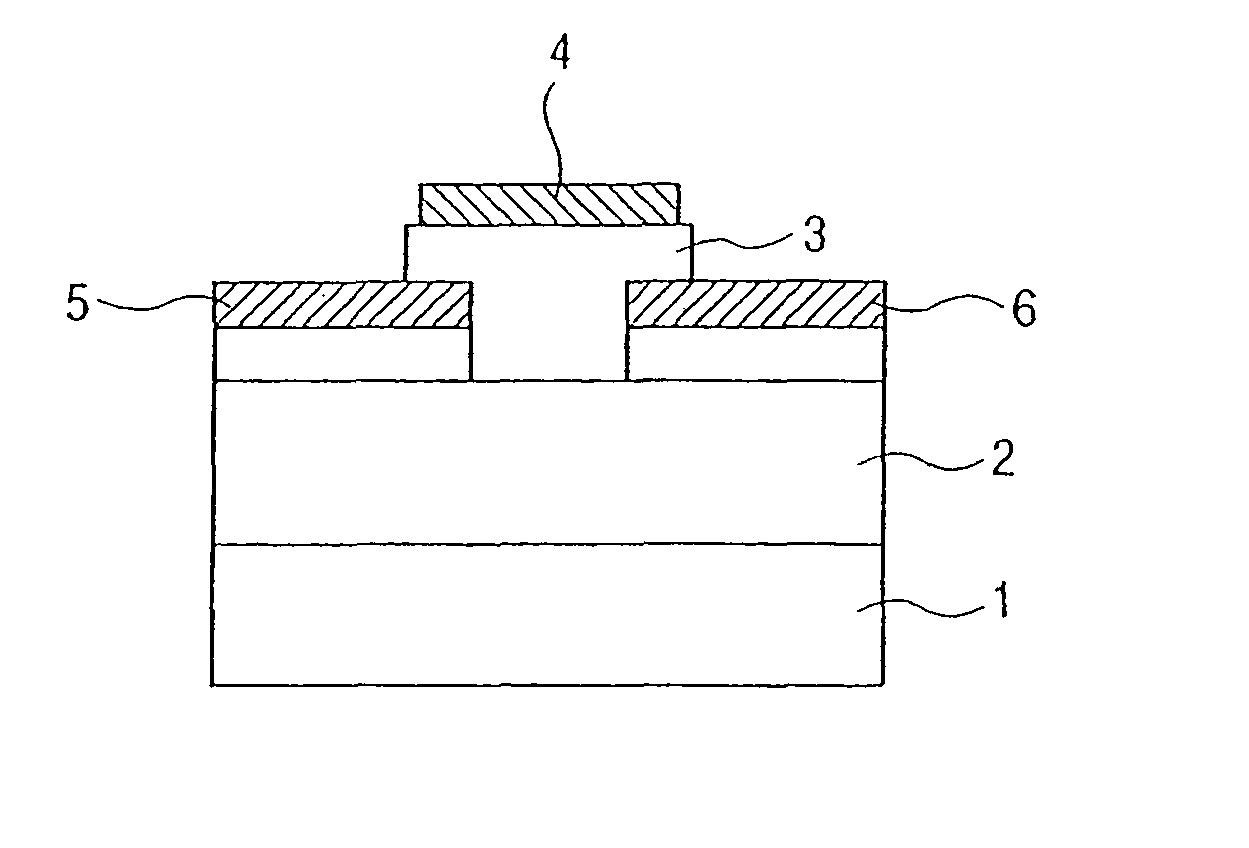

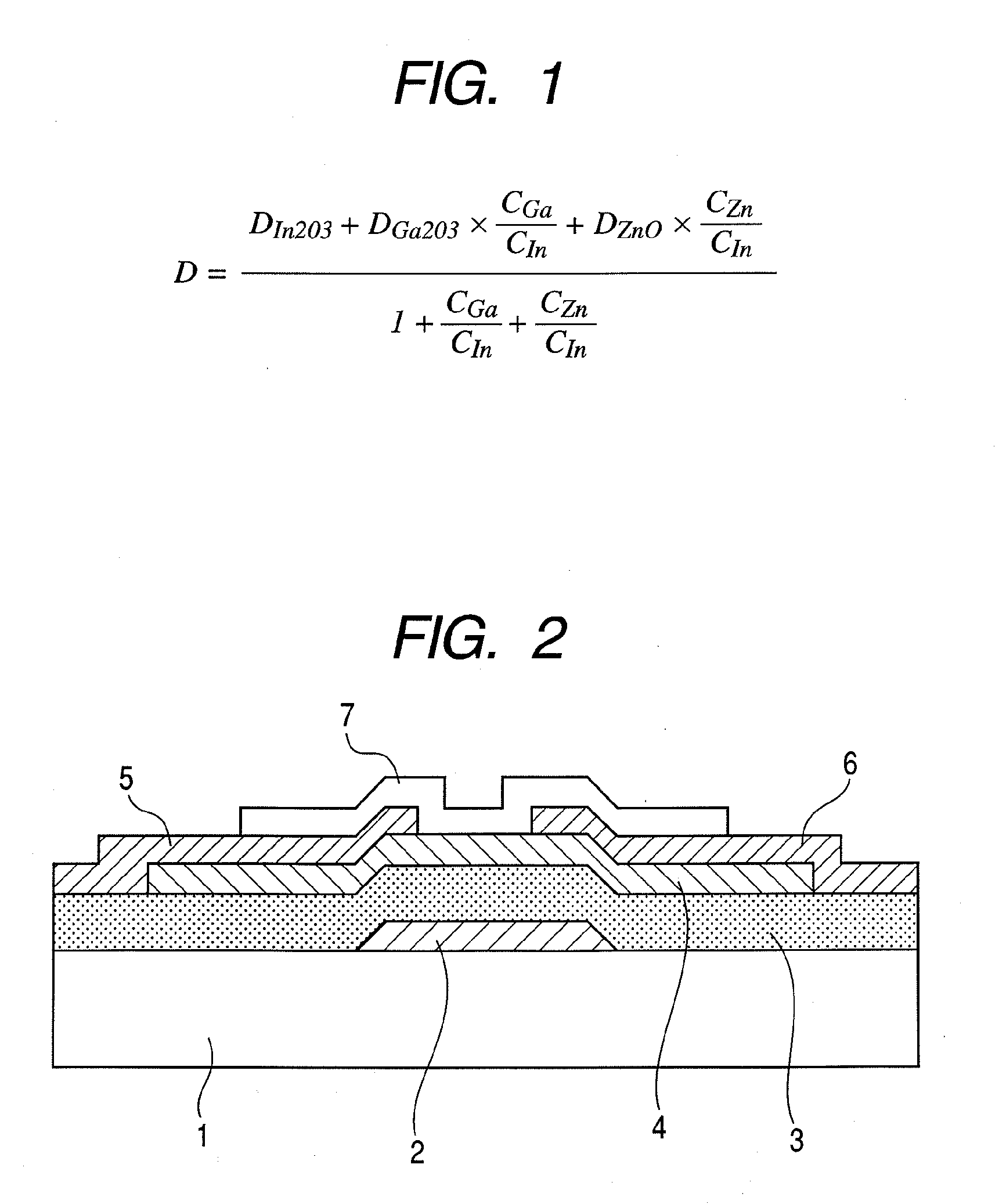

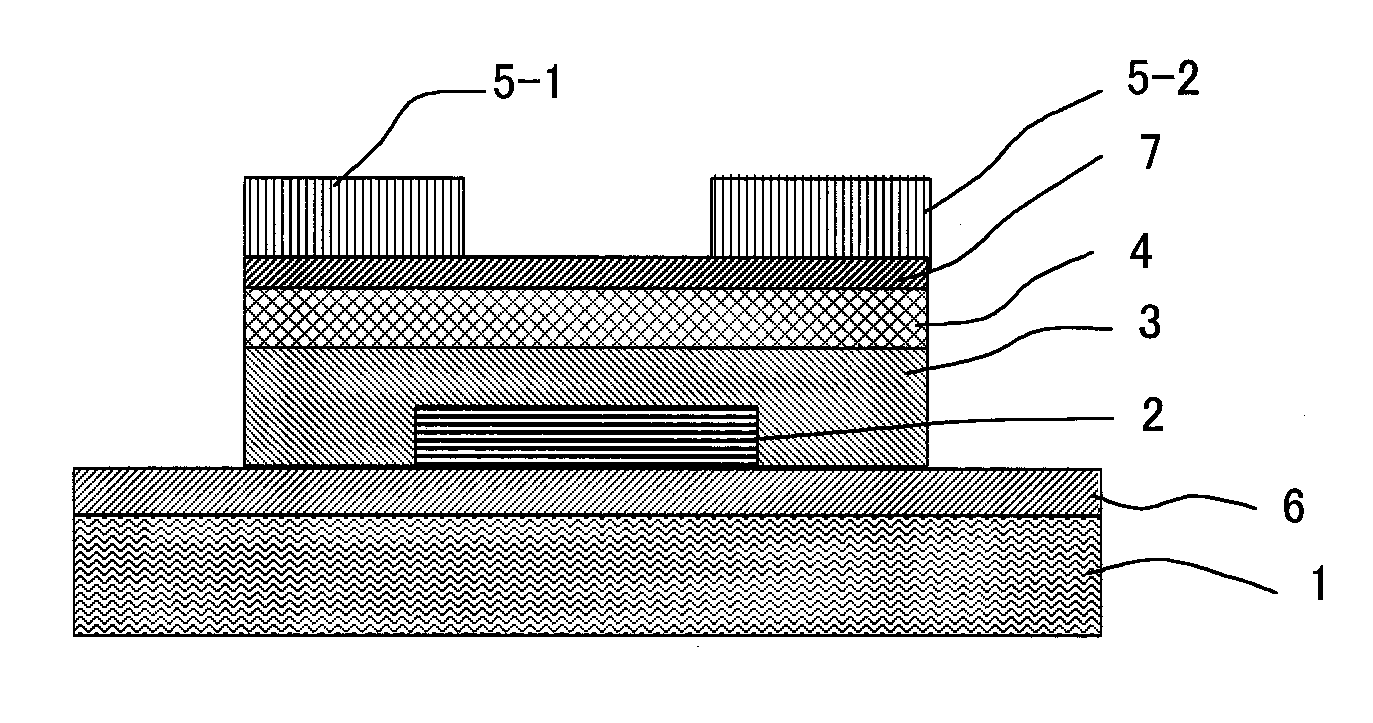

The present invention relates to an amorphous oxide and a thin film transistor using the amorphous oxide. In particular, the present invention provides an amorphous oxide having an electron carrier concentration less than 1018 / cm3, and a thin film transistor using such an amorphous oxide. In a thin film transistor having a source electrode 6, a drain electrode 5, a gate electrode 4, a gate insulating film 3, and a channel layer 2, an amorphous oxide having an electron carrier concentration less than 1018 / cm3 is used in the channel layer 2.

Owner:JAPAN SCI & TECH CORP

Amorphous oxide and field effect transistor

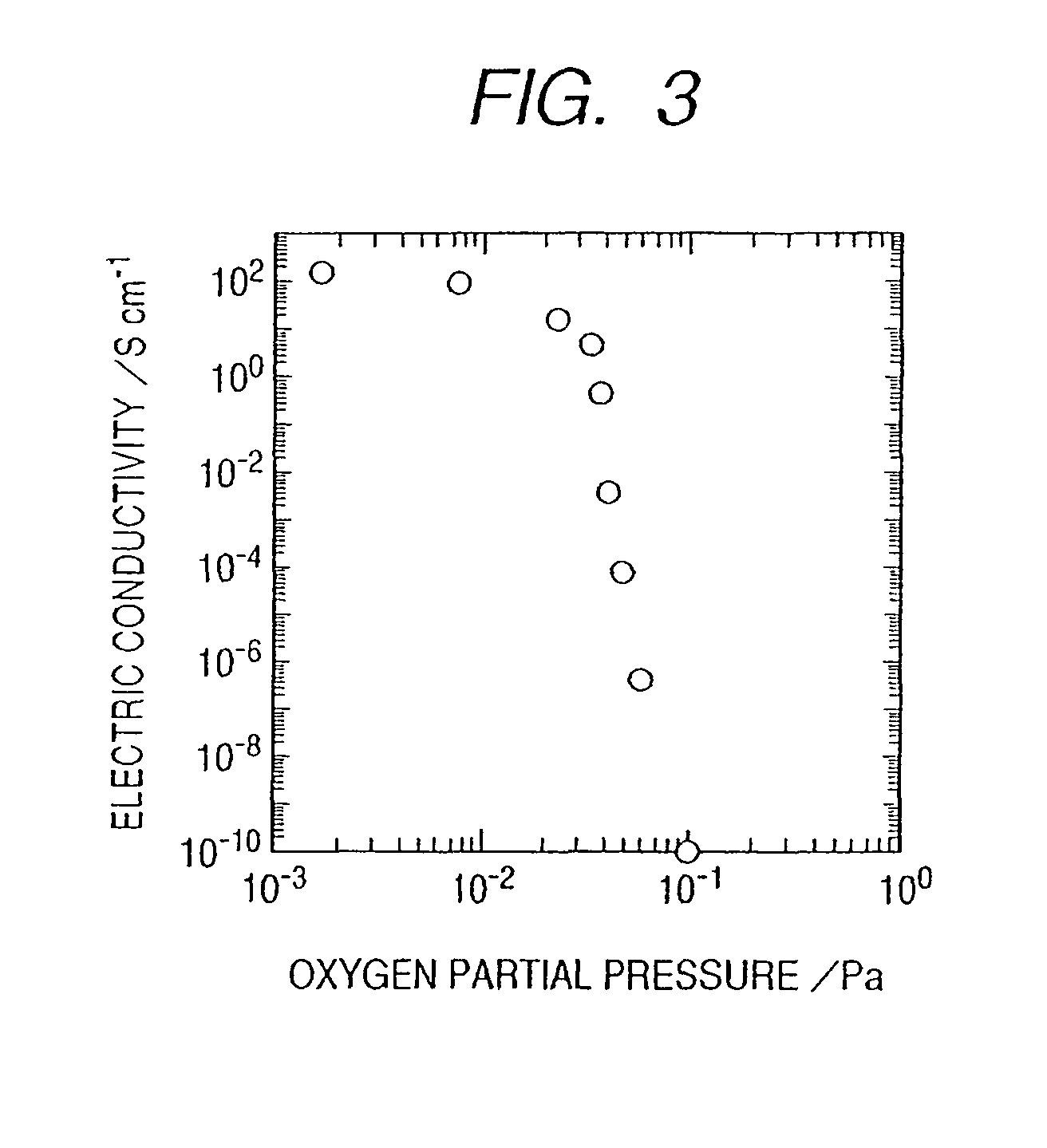

ActiveUS20060108636A1Reduced electron mobilityLow conductivitySolid-state devicesSemiconductor/solid-state device manufacturingField-effect transistorActive layer

A novel amorphous oxide applicable, for example, to an active layer of a TFT is provided. The amorphous oxide comprises microcrystals.

Owner:CANON KK +2

Electric elements and circuits utilizing amorphous oxides

Semiconductor devices and circuits with use of transparent oxide film are provided. The semiconductor device having a P-type region and an N-type region, wherein amorphous oxides with electron carrier concentration less than 1018 / cm3 is used for the N-type region.

Owner:CANON KK +2

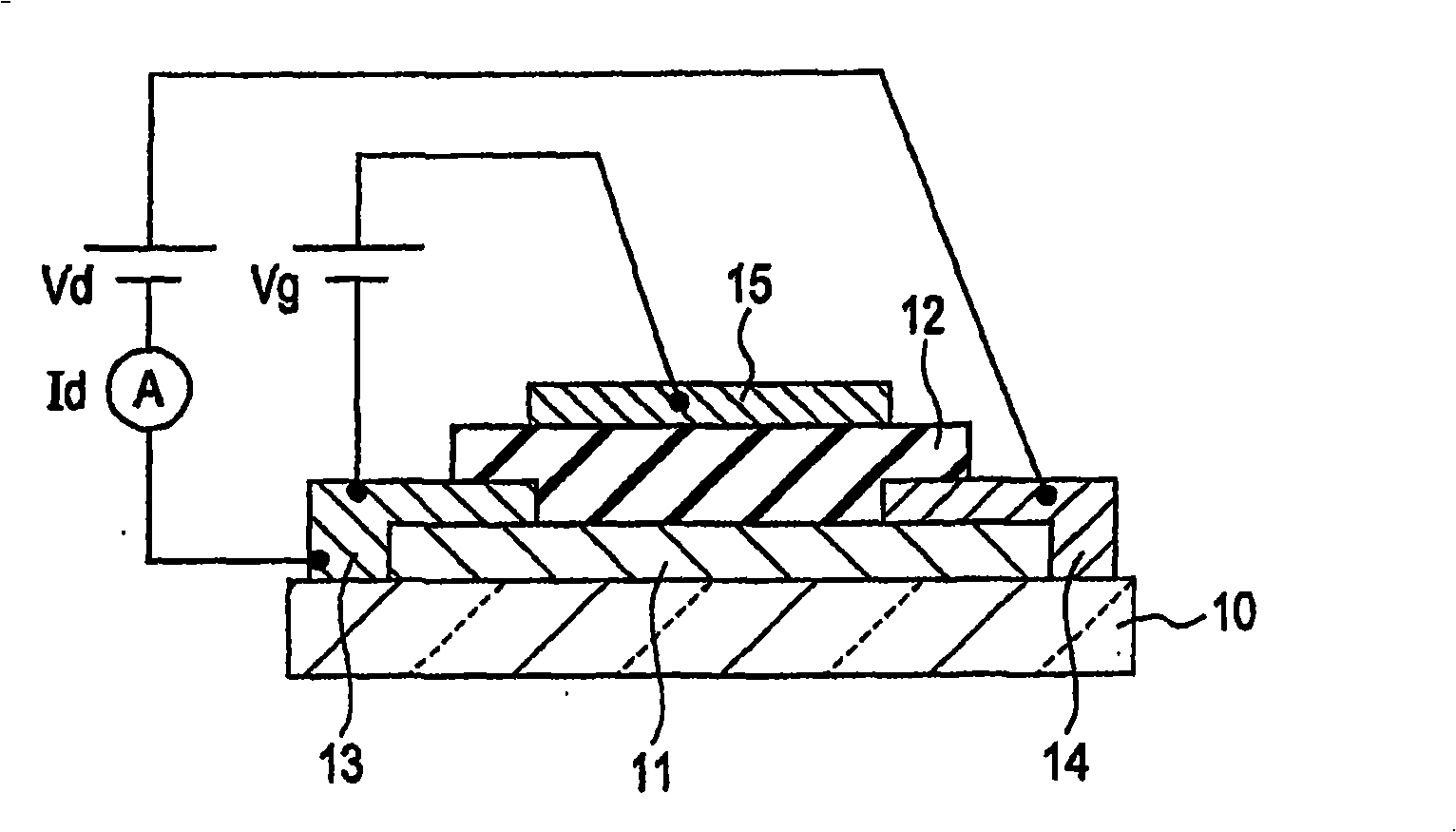

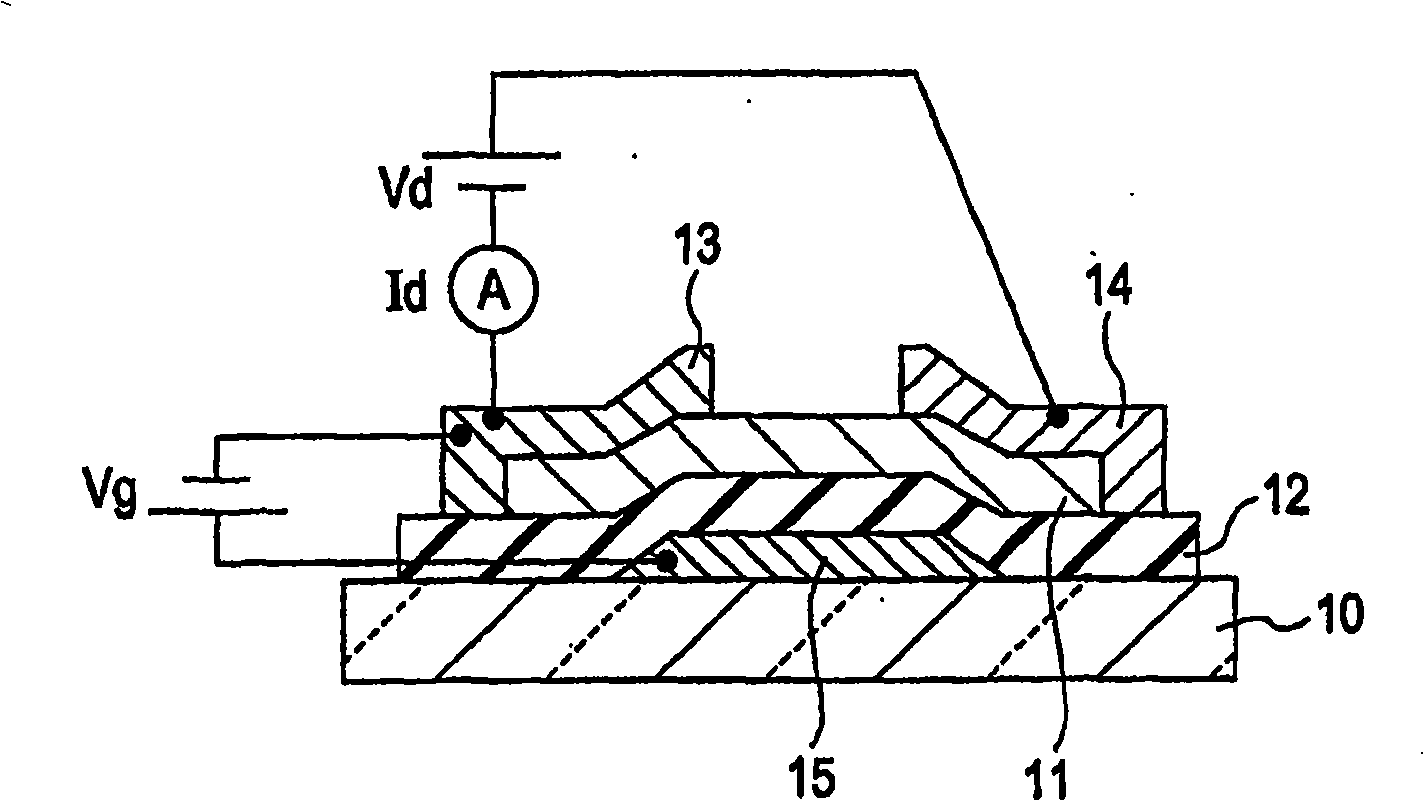

Field effect transistor

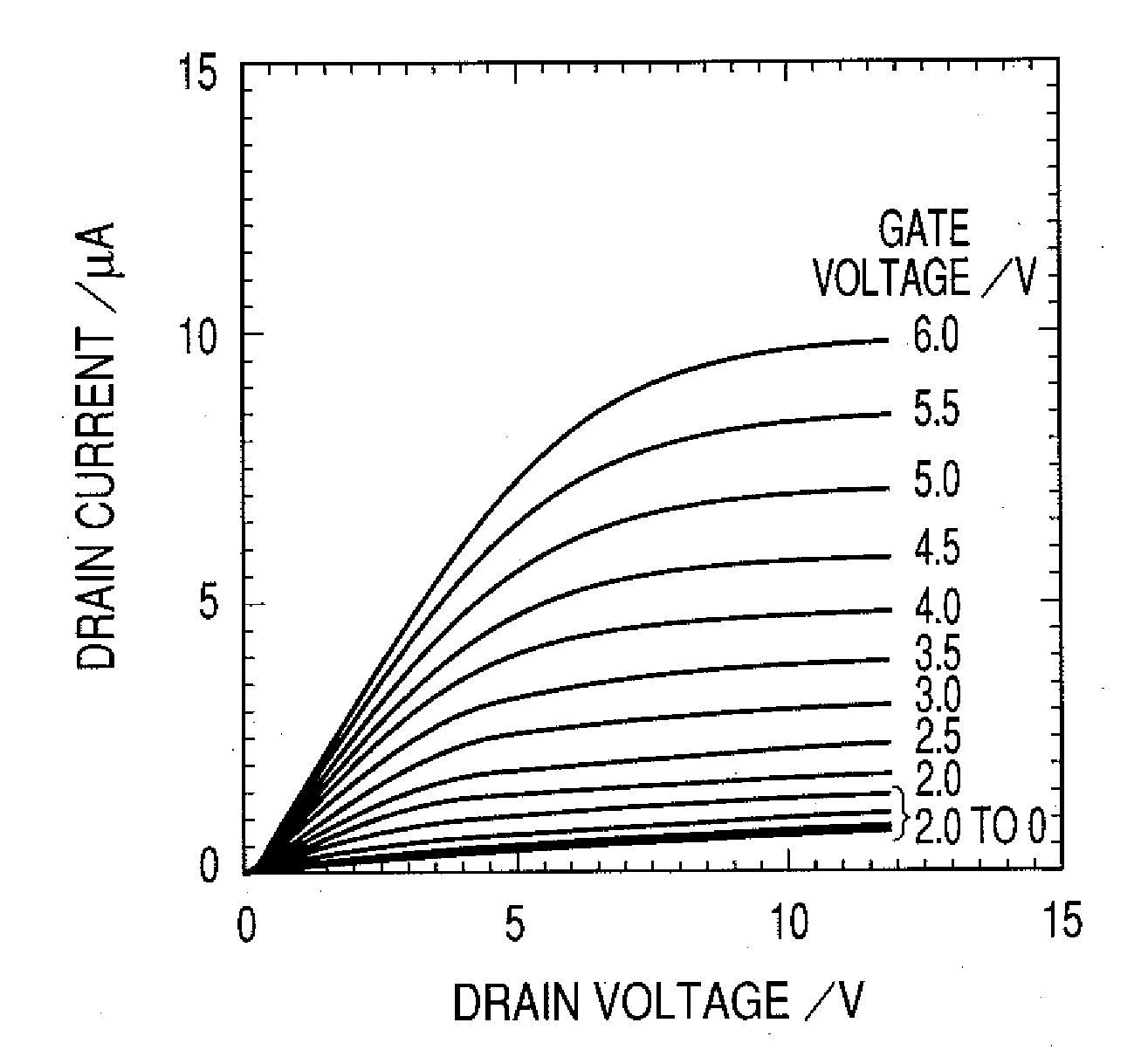

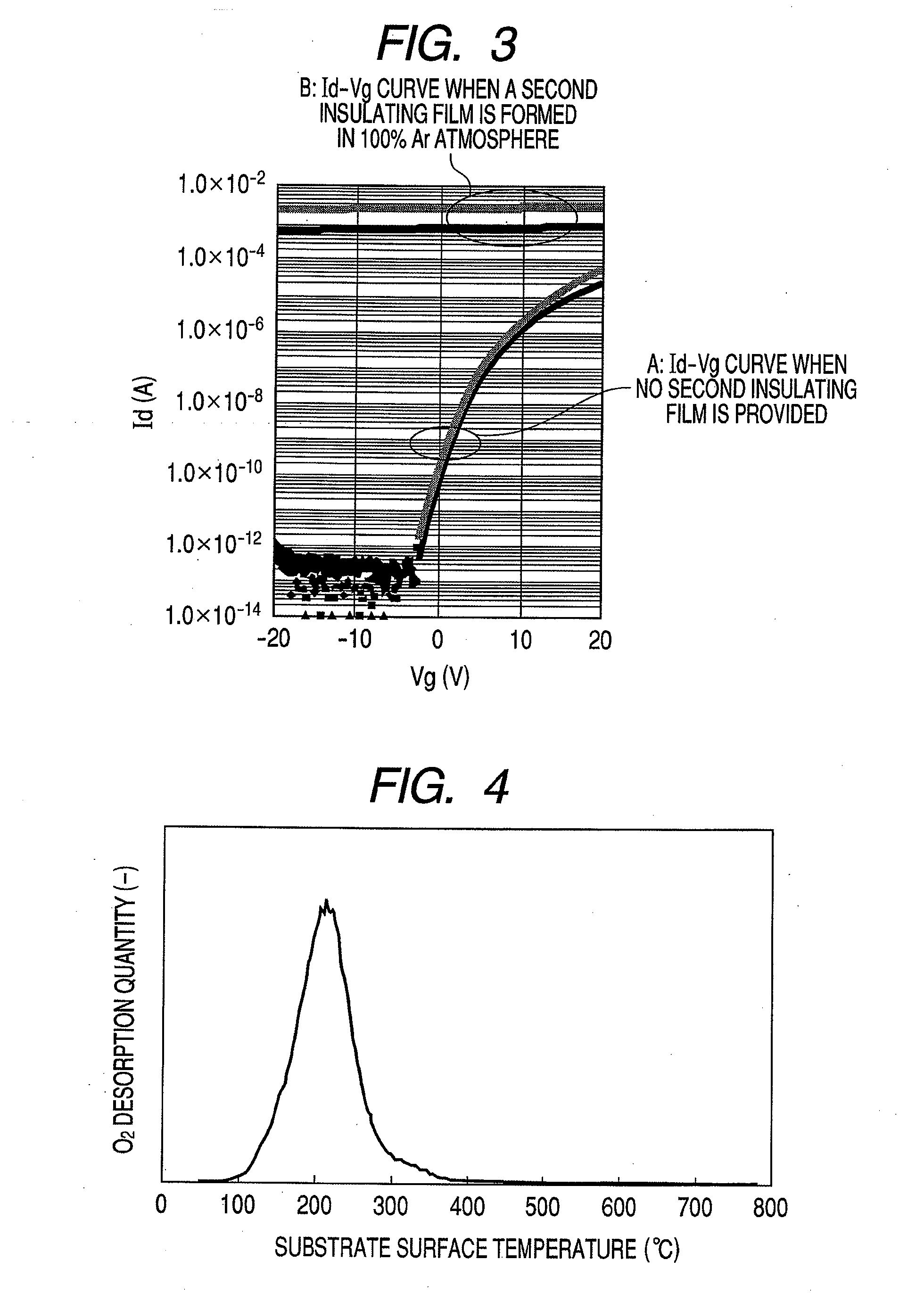

ActiveUS20060113539A1Inhibit currentMaintain good propertiesSolid-state devicesSemiconductor/solid-state device manufacturingField-effect transistorElectron

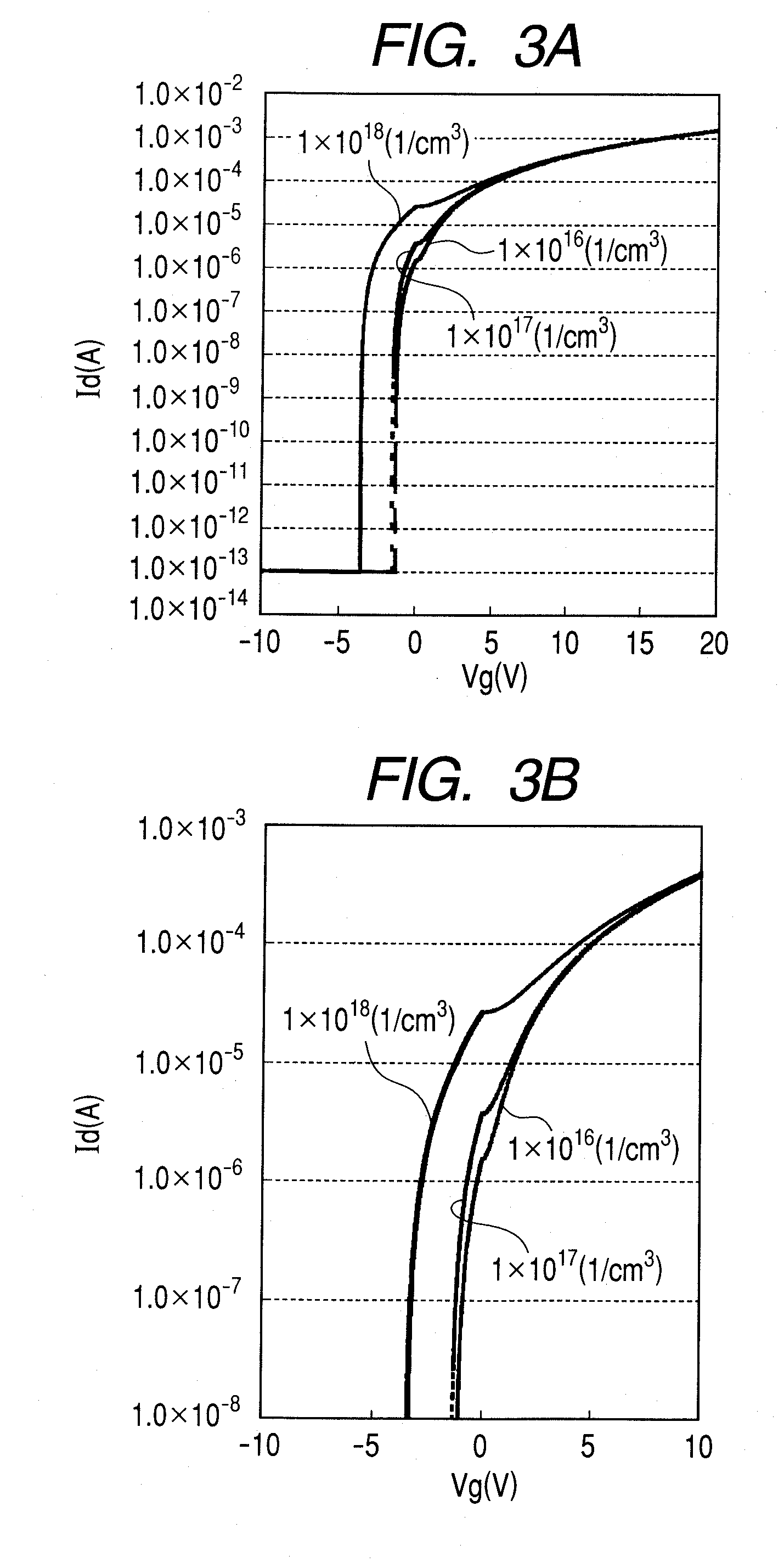

A novel field-effect transistor is provided which employs an amorphous oxide. In an embodiment of the present invention, the transistor comprises an amorphous oxide layer containing electron carrier at a concentration less than 1×10−18 / cm3, and the gate-insulating layer is comprised of a first layer being in contact with the amorphous oxide and a second layer different from the first layer.

Owner:CANON KK +2

Semiconductor apparatus and method of manufacturing the same

InactiveUS20080073653A1Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

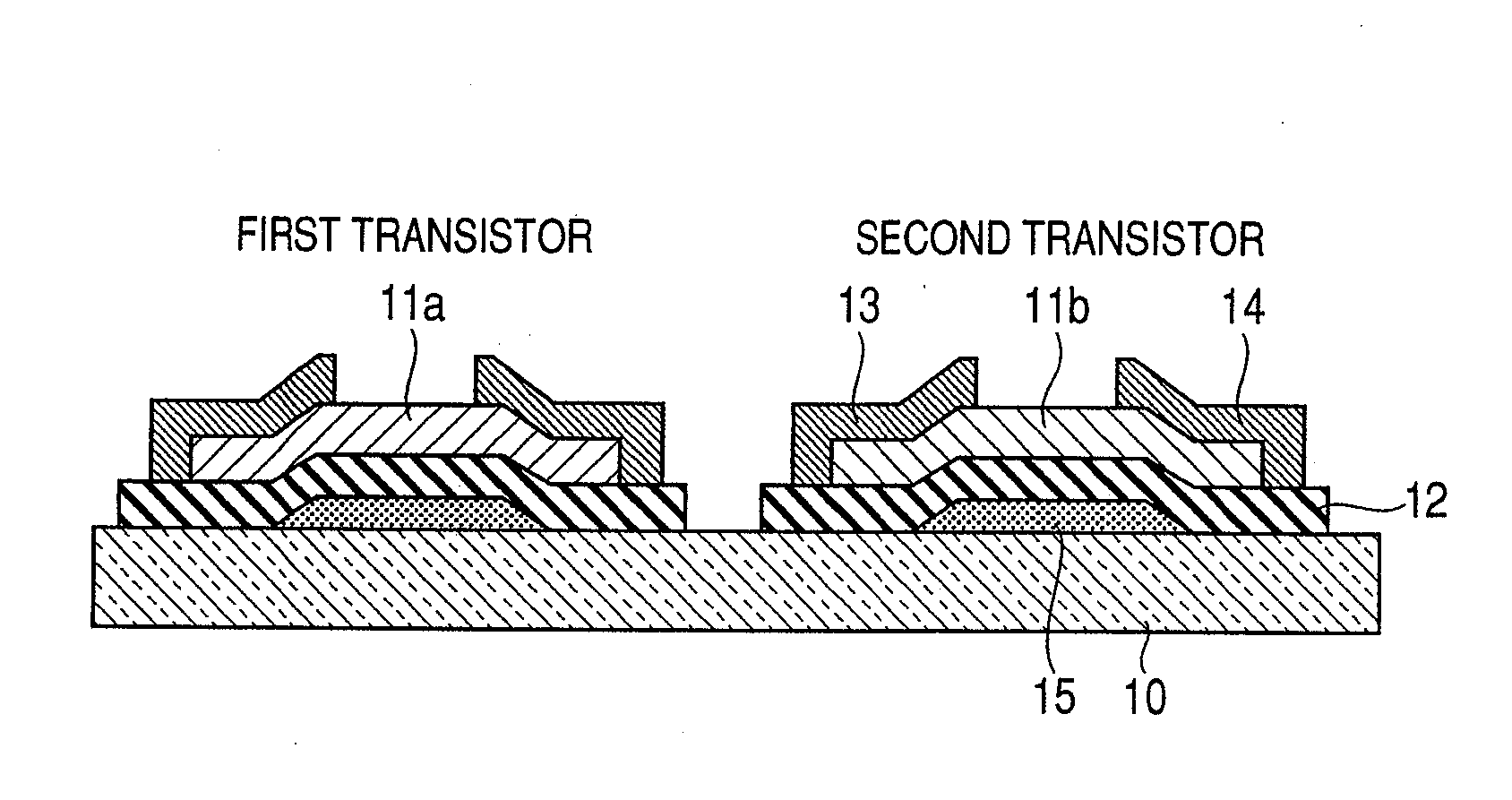

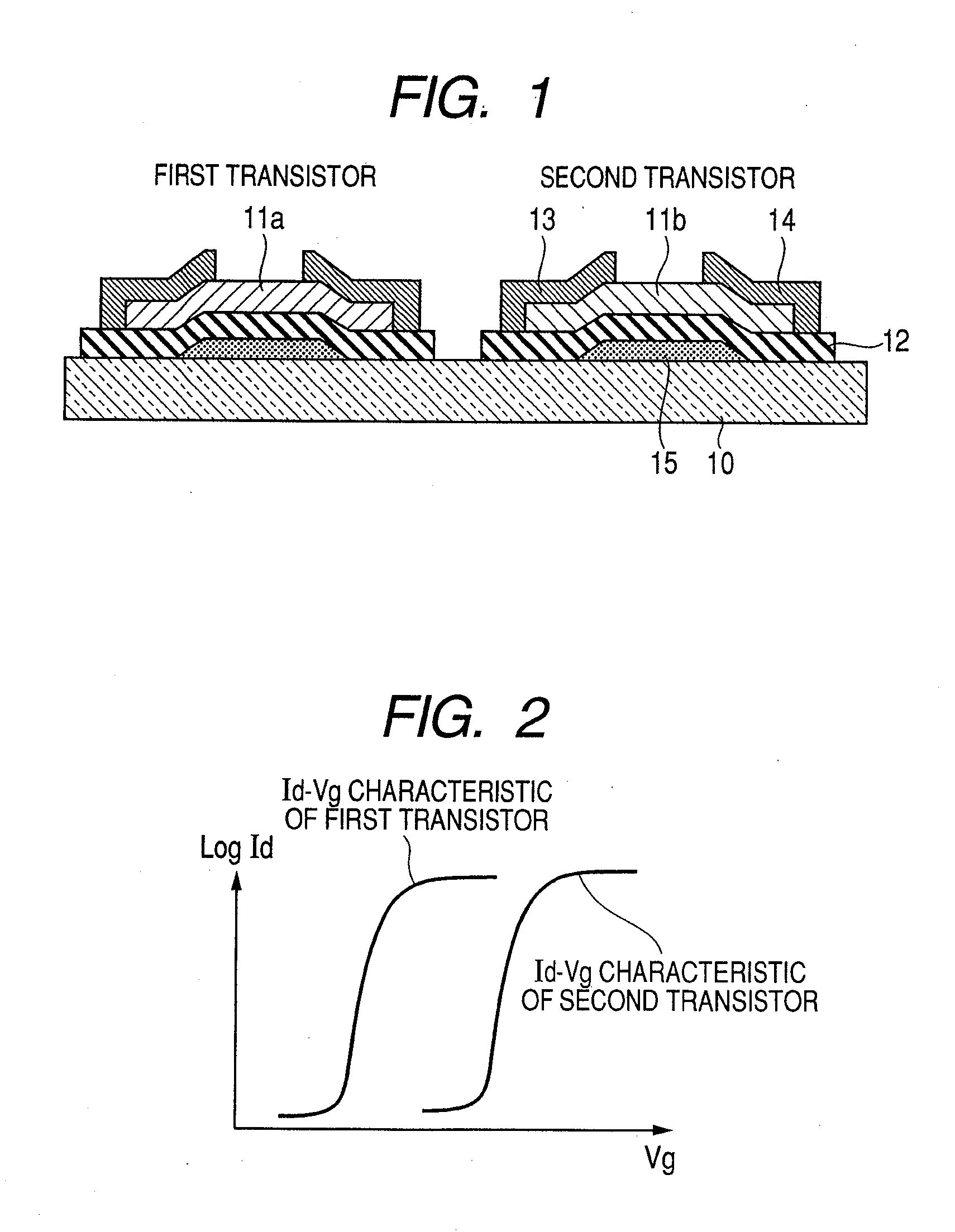

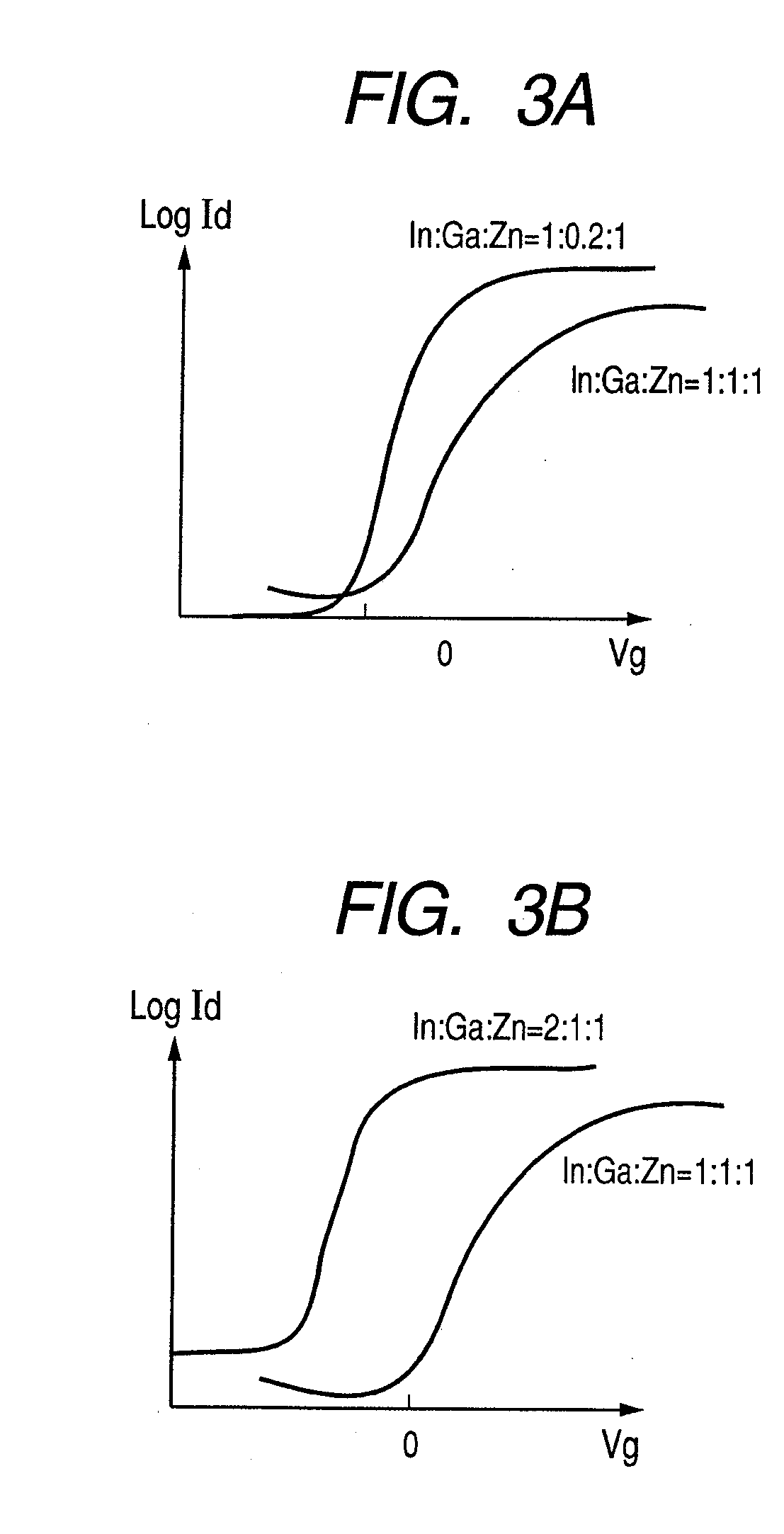

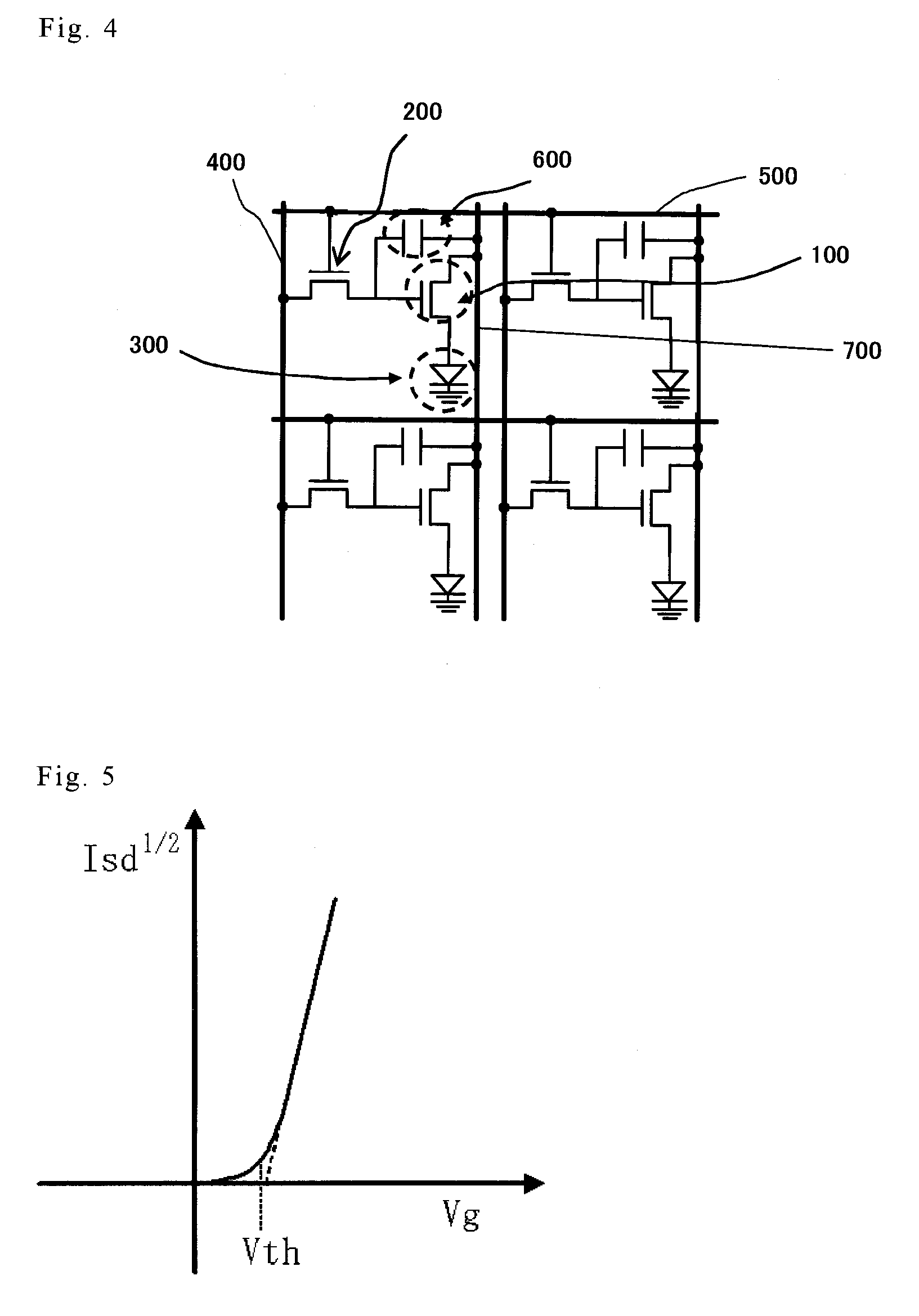

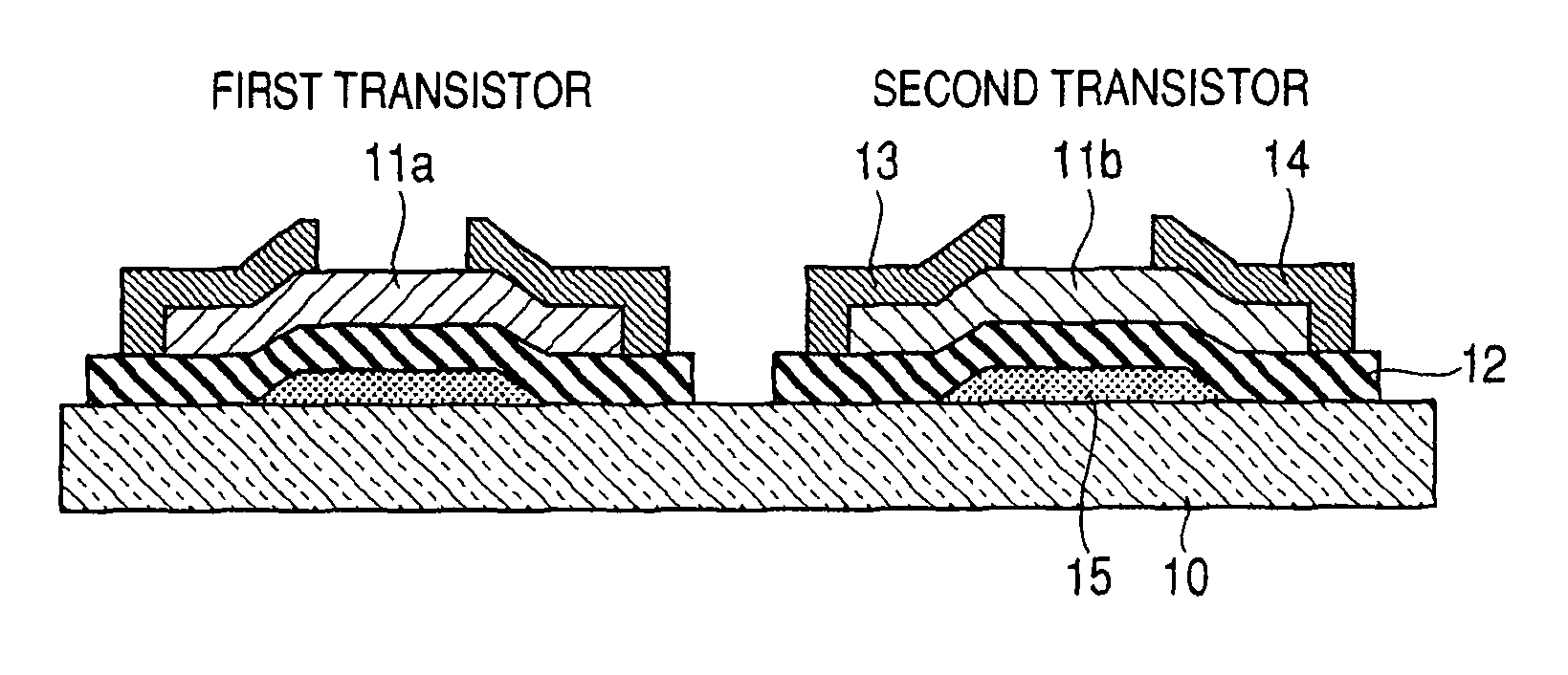

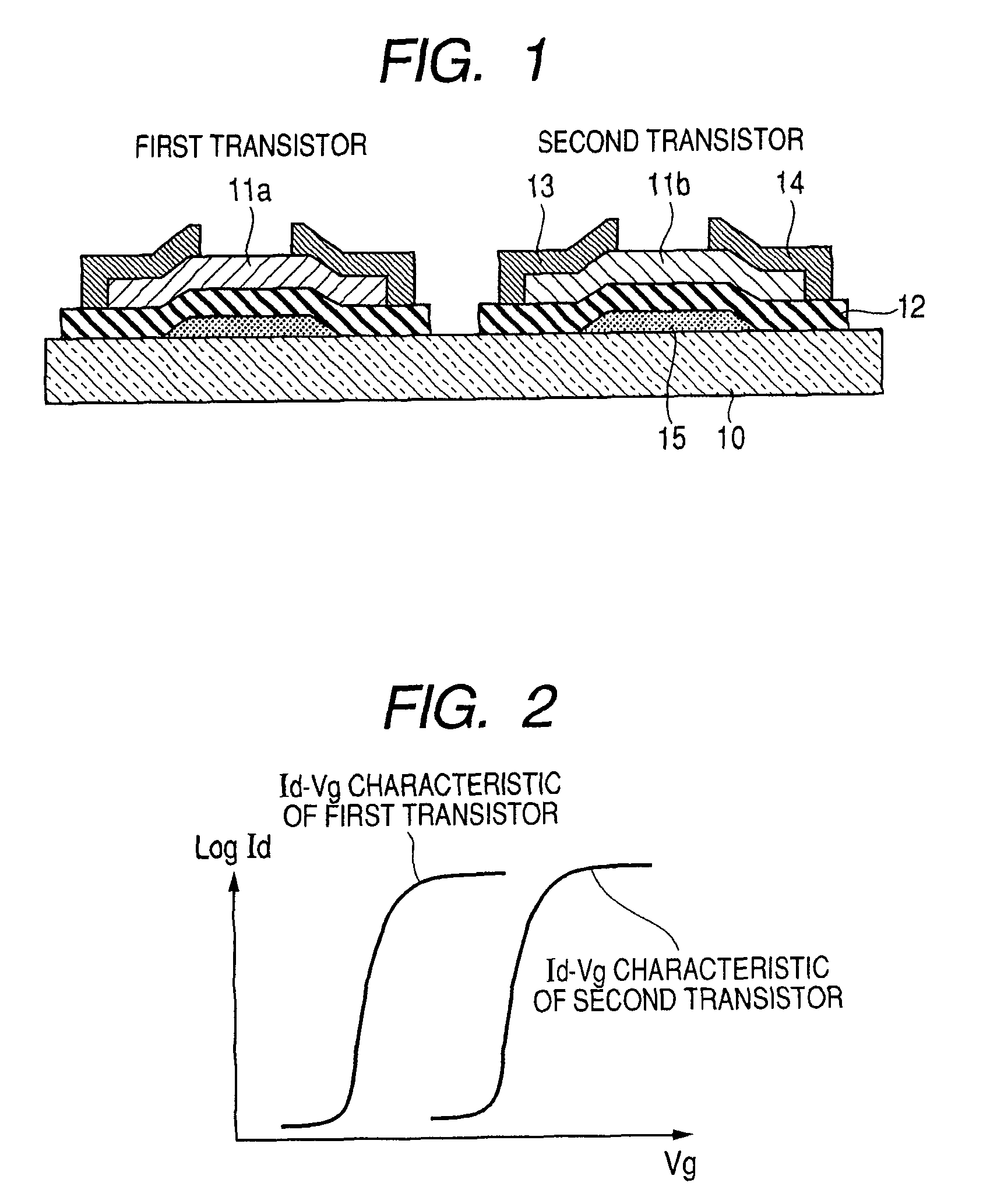

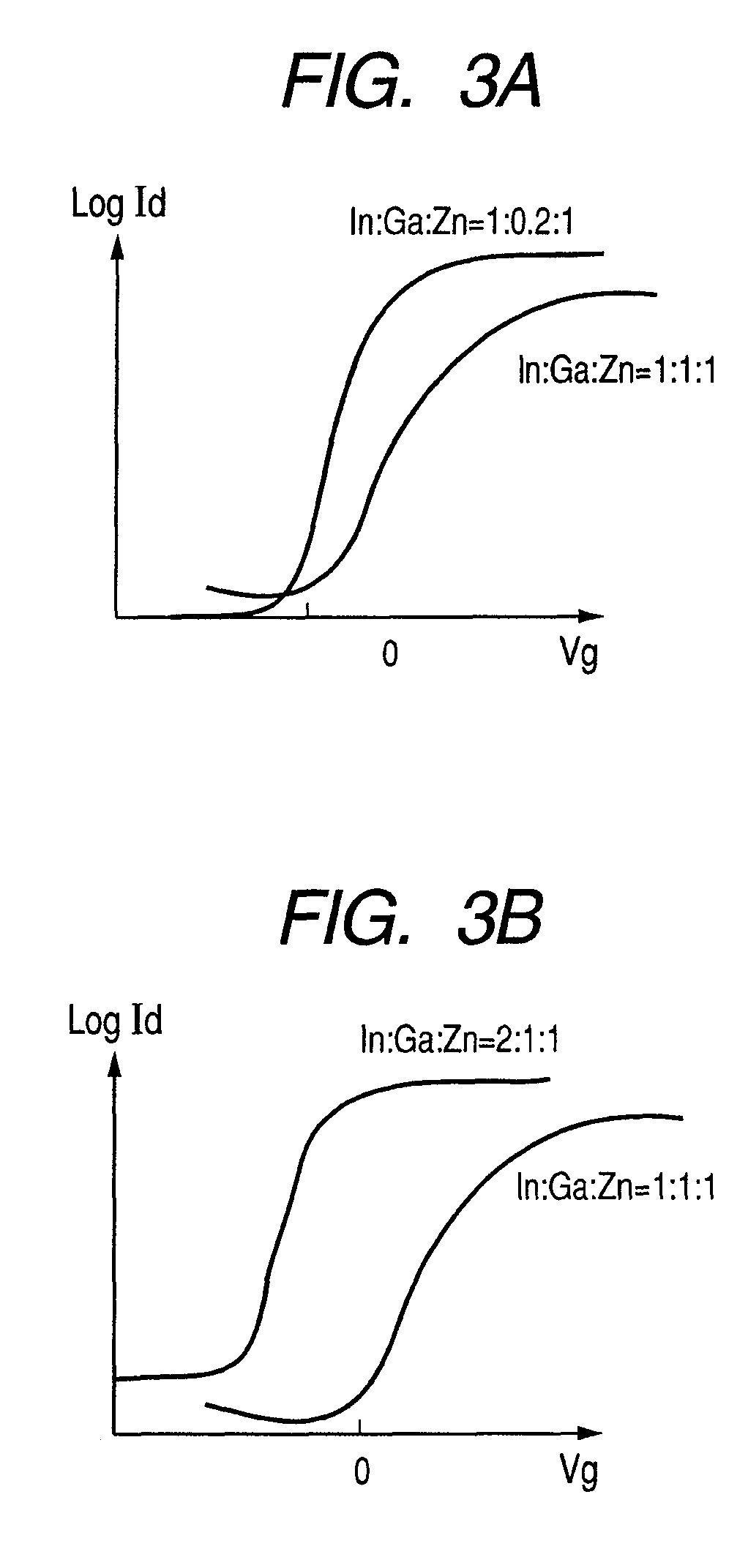

It is an object of the present invention to provide a technology of controlling a threshold voltage of a thin film transistor in which an amorphous oxide film is applied to a channel layer. There is provided a semiconductor apparatus including a plurality of kinds of transistors, each of the plurality of kinds of transistors including a channel layer made of an amorphous oxide containing a plurality of kinds of metal elements; and threshold voltages of the plurality of kinds of transistors are different from one another by changing an element ratio of the amorphous oxide.

Owner:CANON KK

Light-emitting device

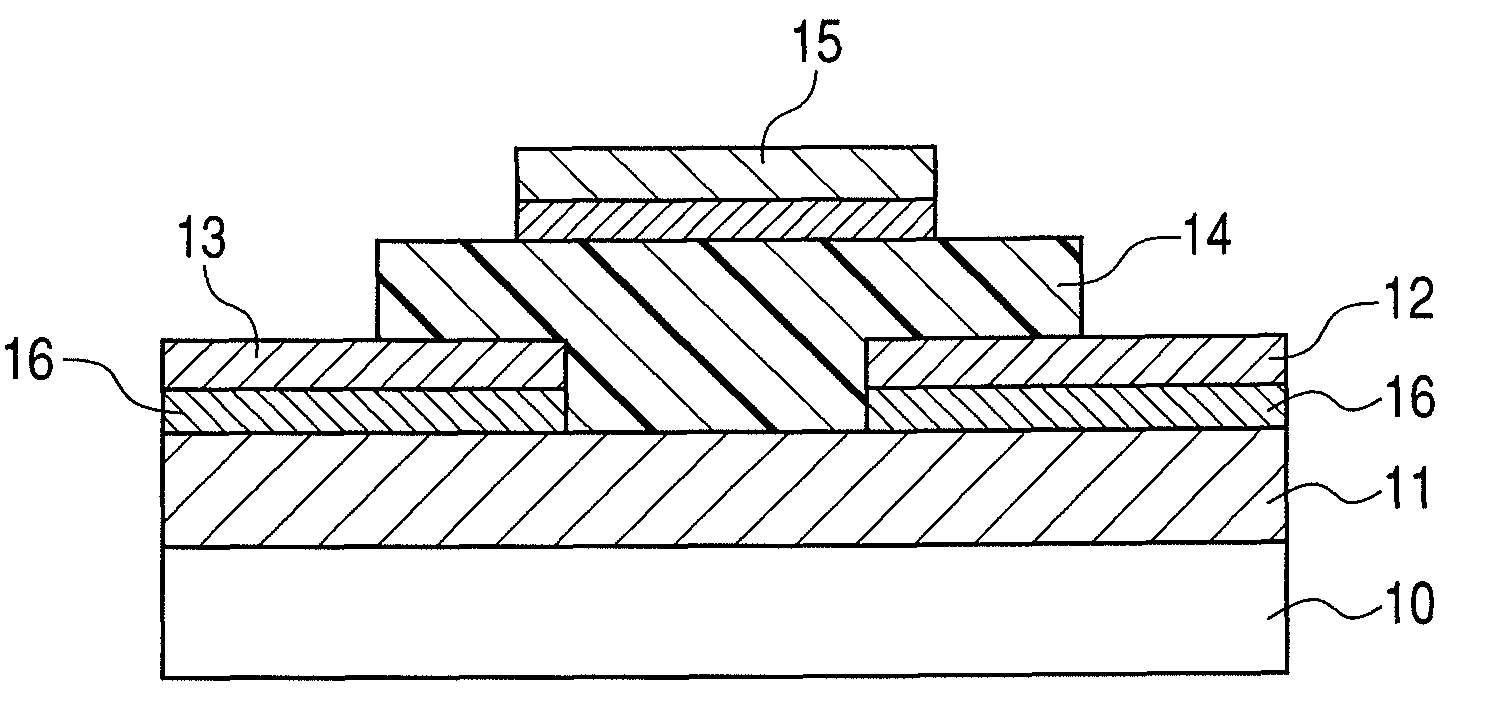

ActiveUS20060113549A1Desired characteristicTransistorElectroluminescent light sourcesField-effect transistorActive layer

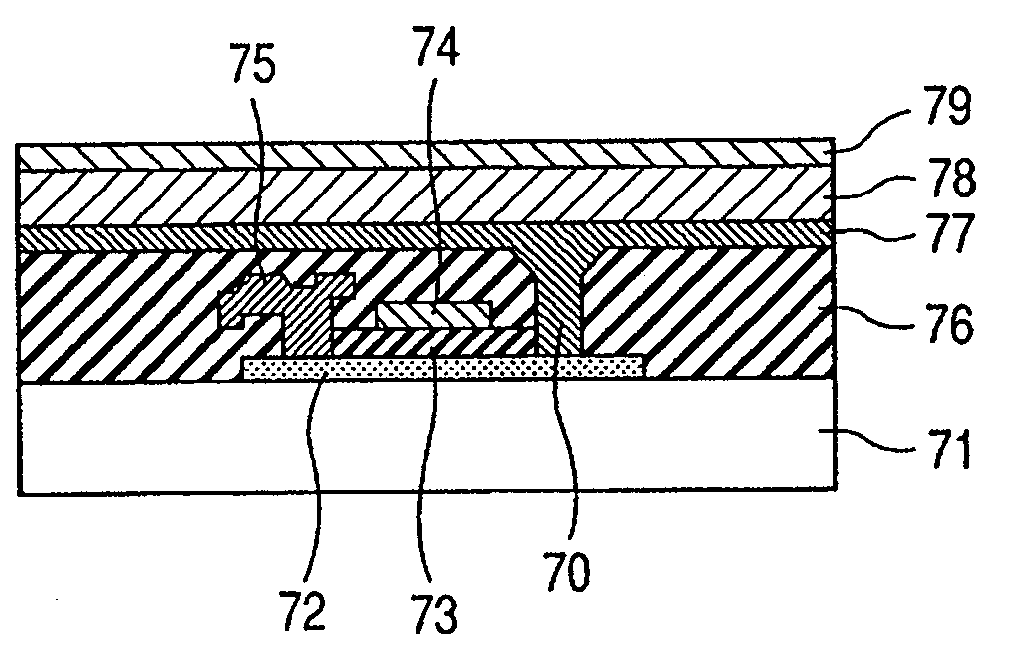

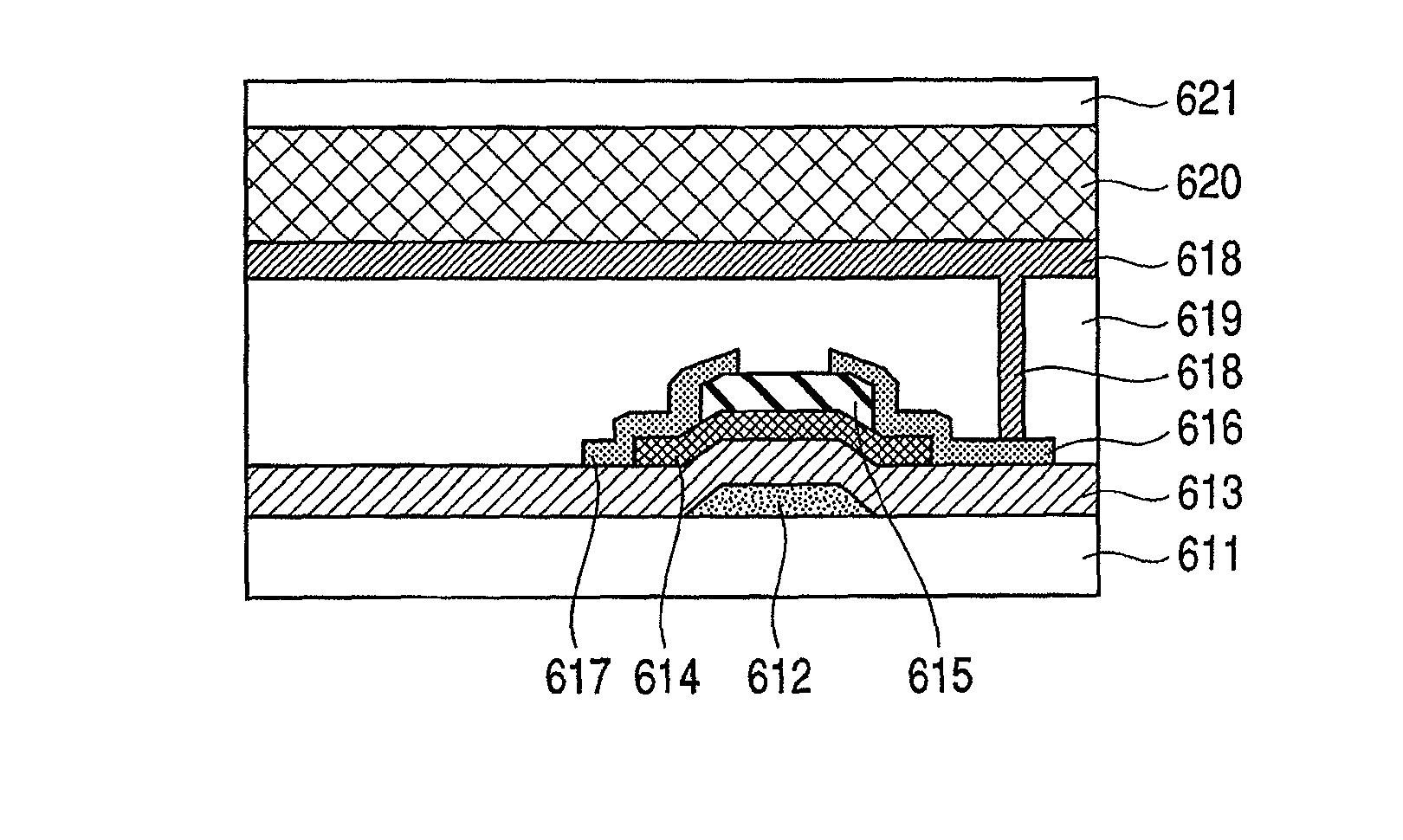

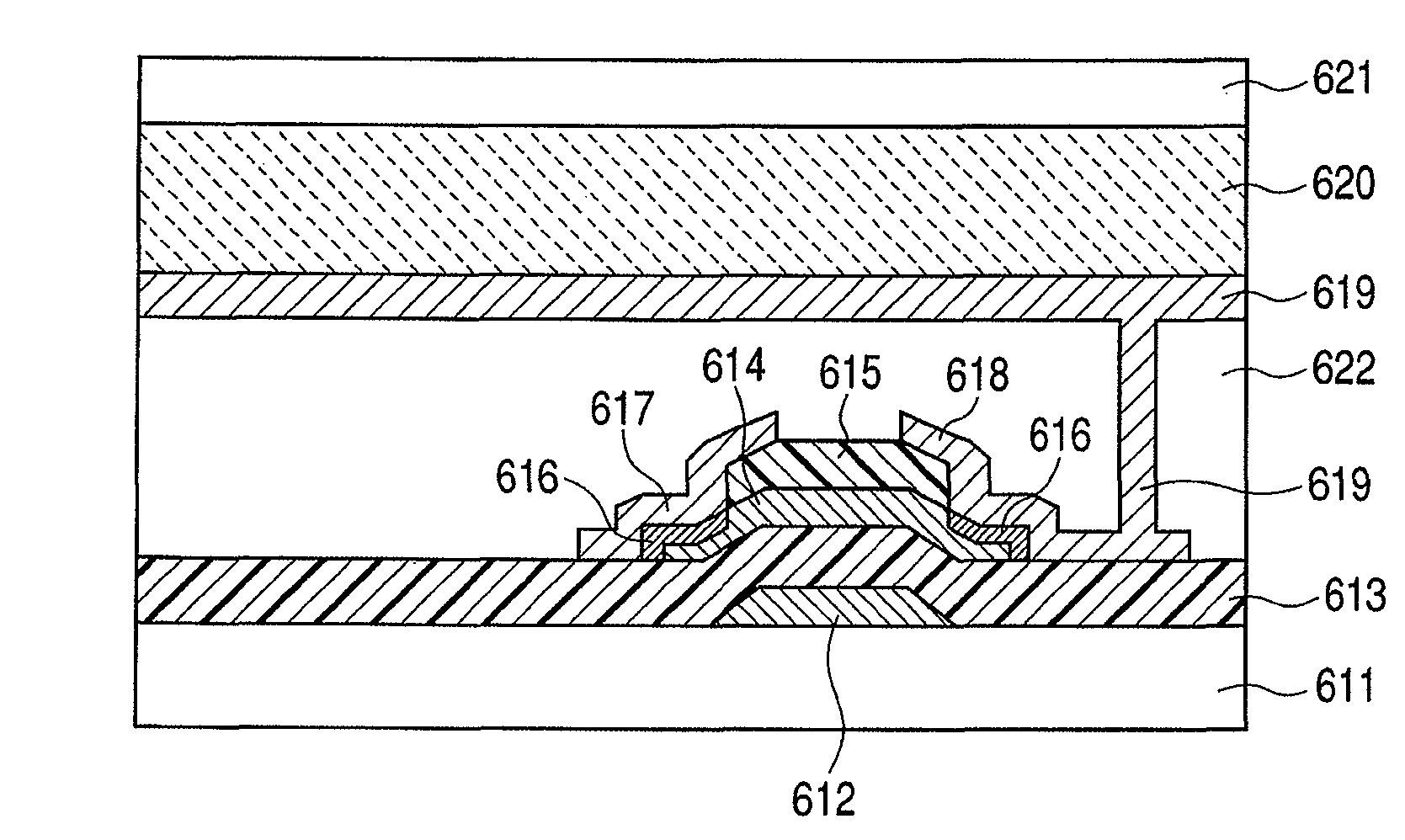

An object of the present invention is to provide a new light-emitting device with the use of an amorphous oxide. The light-emitting device has a light-emitting layer existing between first and second electrodes and a field effect transistor, of which the active layer is an amorphous.

Owner:CANON KK +2

Sensor and image pickup device

ActiveUS20060108529A1Reduce distortion problemsLessen the burden on the bodySolid-state devicesSemiconductor/solid-state device manufacturingPhysicsAmorphous oxide

A sensor for detecting a received electromagnetic wave comprising a first electrode, a second electrode and an amorphous oxide layer interposed between the first electrode and the second electrode.

Owner:CANON KK +2

Amorphous oxide and thin film transistor

The present invention relates to an amorphous oxide and a thin film transistor using the amorphous oxide. In particular, the present invention provides an amorphous oxide having an electron carrier concentration less than 1018 / cm3, and a thin film transistor using such an amorphous oxide. In a thin film transistor having a source electrode 6, a drain electrode 5, a gate electrode 4, a gate insulating film 3, and a channel layer 2, an amorphous oxide having an electron carrier concentration less than 1018 / cm3 is used in the channel layer 2.

Owner:JAPAN SCI & TECH CORP

Amorphous oxide and thin film transistor

The present invention relates to an amorphous oxide and a thin film transistor using the amorphous oxide. In particular, the present invention provides an amorphous oxide having an electron carrier concentration less than 1018 / cm3, and a thin film transistor using such an amorphous oxide. In a thin film transistor having a source electrode 6, a drain electrode 5, a gate electrode 4, a gate insulating film 3, and a channel layer 2, an amorphous oxide having an electron carrier concentration less than 1018 / cm3 is used in the channel layer 2.

Owner:JAPAN SCI & TECH CORP +2

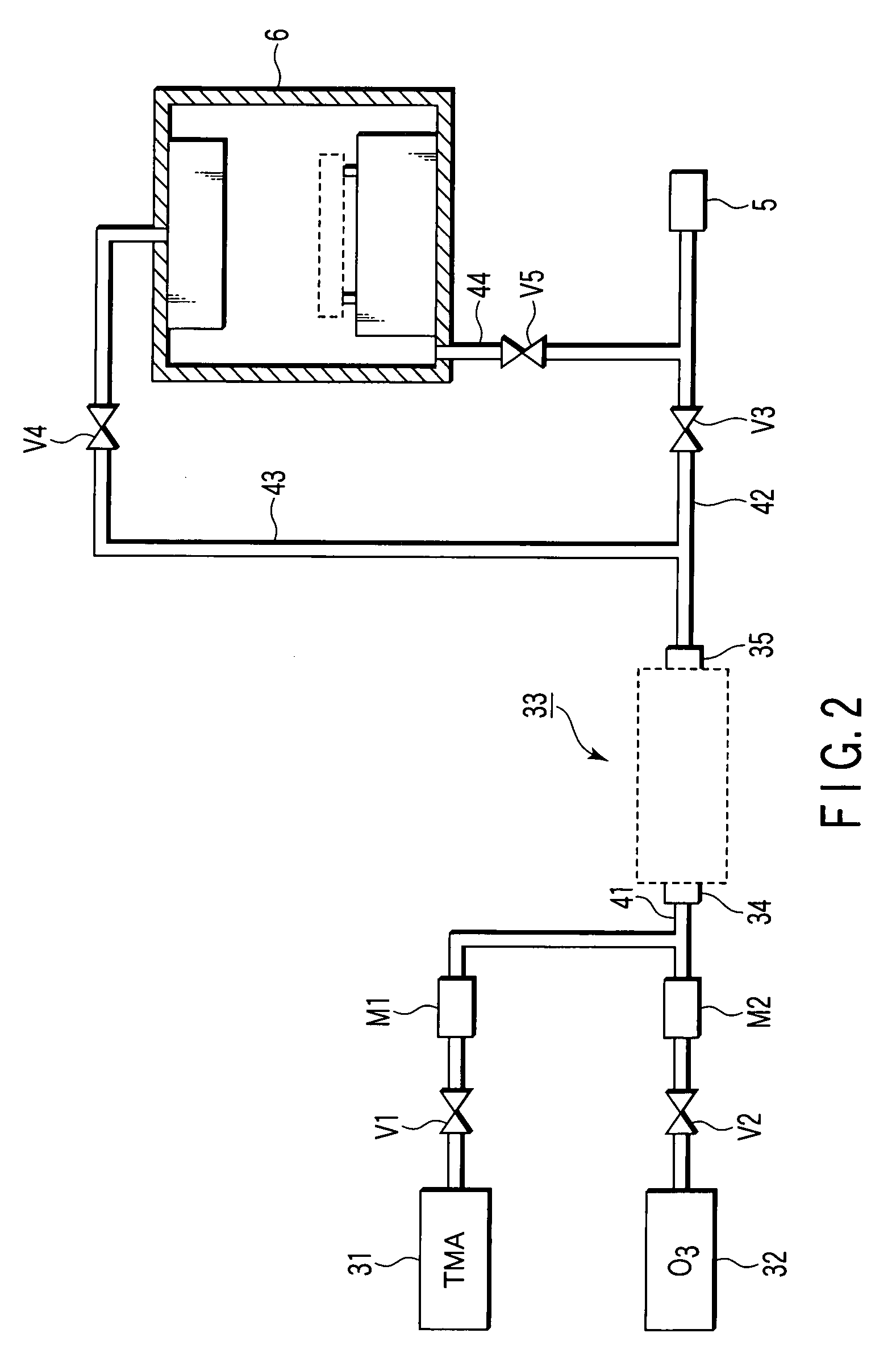

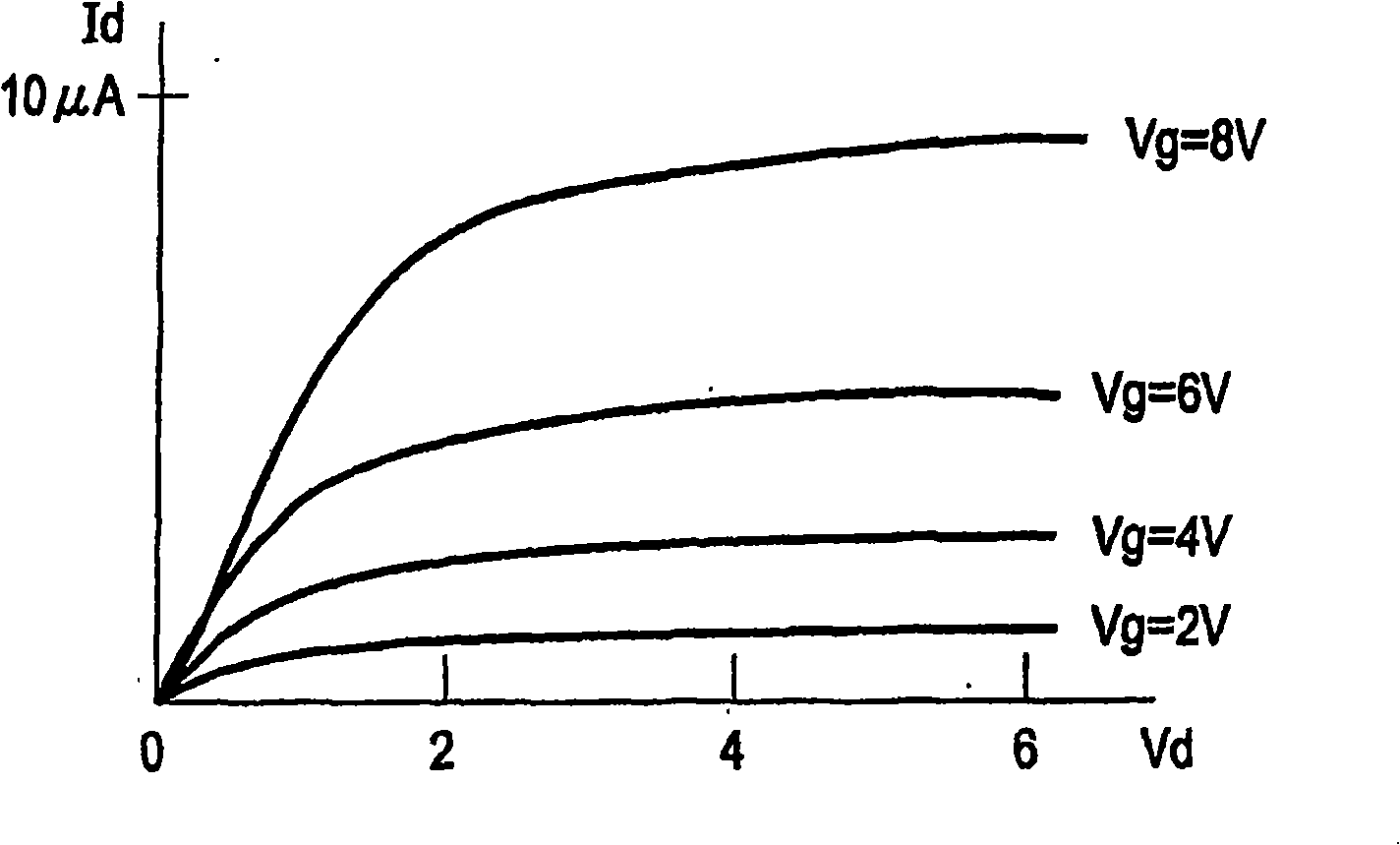

Field effect transistor using amorphous oxide film as channel layer, manufacturing method of field effect transistor using amorphous oxide film as channel layer, and manufacturing method of amorphous oxide film

InactiveUS7791074B2Easy to controlSolid-state devicesSemiconductor/solid-state device manufacturingHysteresisHydrogen

An amorphous oxide containing hydrogen (or deuterium) is applied to a channel layer of a transistor. Accordingly, a thin film transistor having superior TFT properties can be realized, the superior TFT properties including a small hysteresis, normally OFF operation, a high ON / OFF ratio, a high saturated current, and the like. Furthermore, as a method for manufacturing a channel layer made of an amorphous oxide, film formation is performed in an atmosphere containing a hydrogen gas and an oxygen gas, so that the carrier concentration of the amorphous oxide can be controlled.

Owner:CANON KK

Thin film field effect transistor and display

ActiveUS8188480B2High concentrationElectroluminescent light sourcesSolid-state devicesDisplay deviceField-effect transistor

A TFT is provided which includes, on a substrate, at least a gate electrode, a gate insulating layer, an active layer containing an amorphous oxide semiconductor, a source electrode and a drain electrode, wherein a resistance layer containing an amorphous oxide and having a thickness of more than 3 nm is disposed between the active layer and at least one of the source electrode or the drain electrode, and a band gap of the active layer is smaller than a band gap of the resistance layer. Also, a display using the TFT is provided.

Owner:SAMSUNG DISPLAY CO LTD

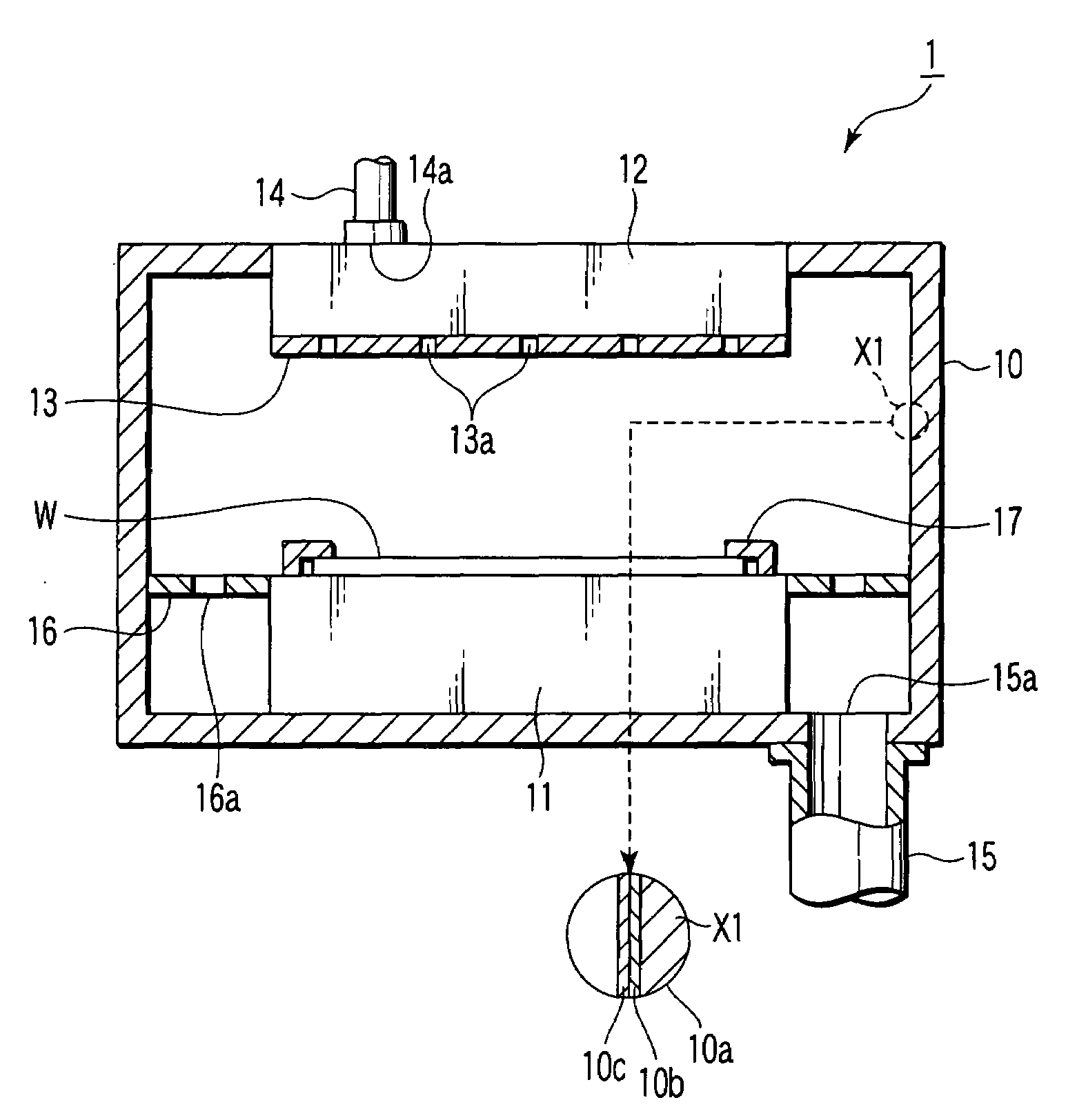

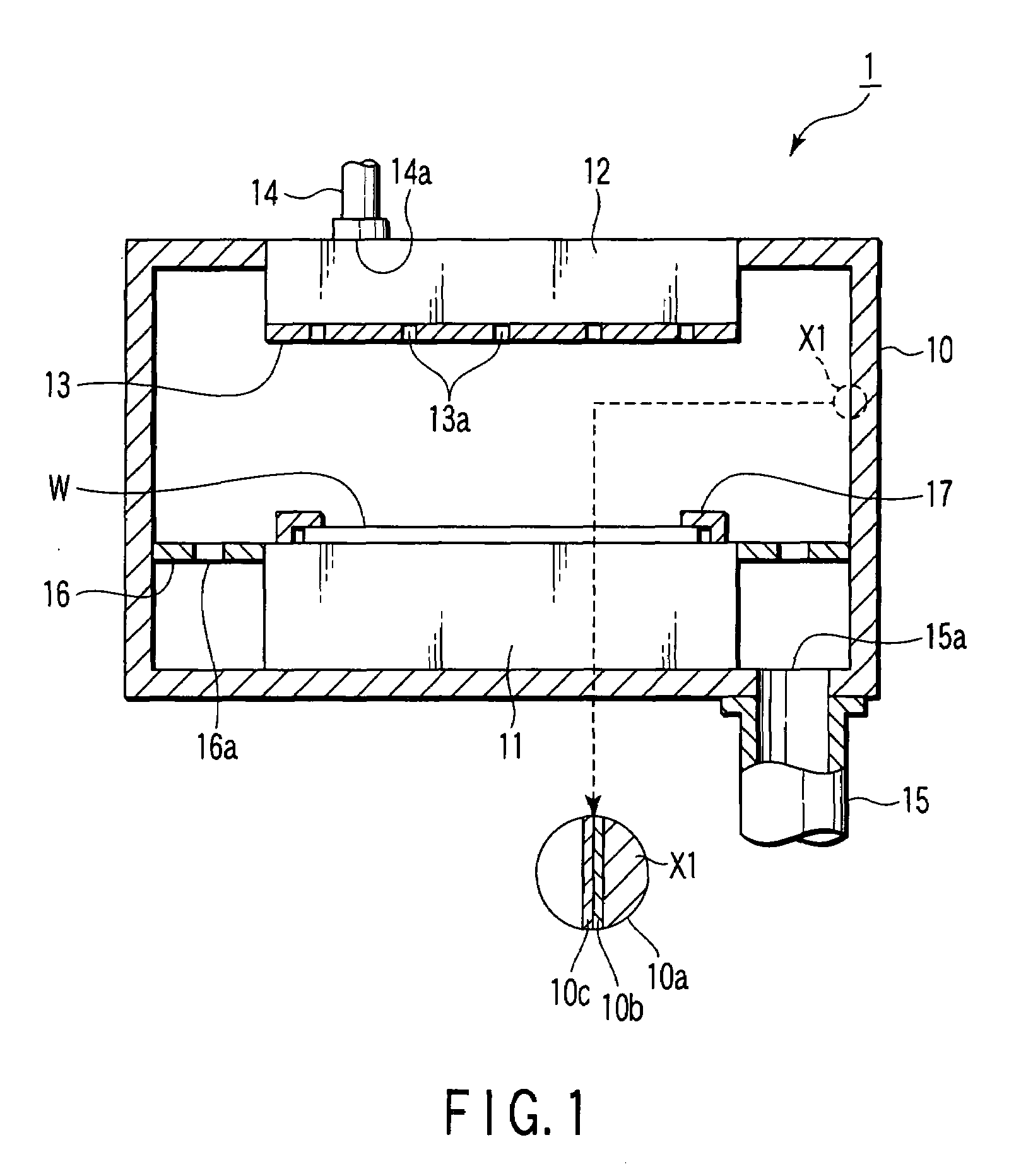

Component for semicondutor processing apparatus and manufacturing method thereof

InactiveUS20090194233A1Increased durabilityLiquid surface applicatorsSemiconductor/solid-state device manufacturingTectorial membranePorosity

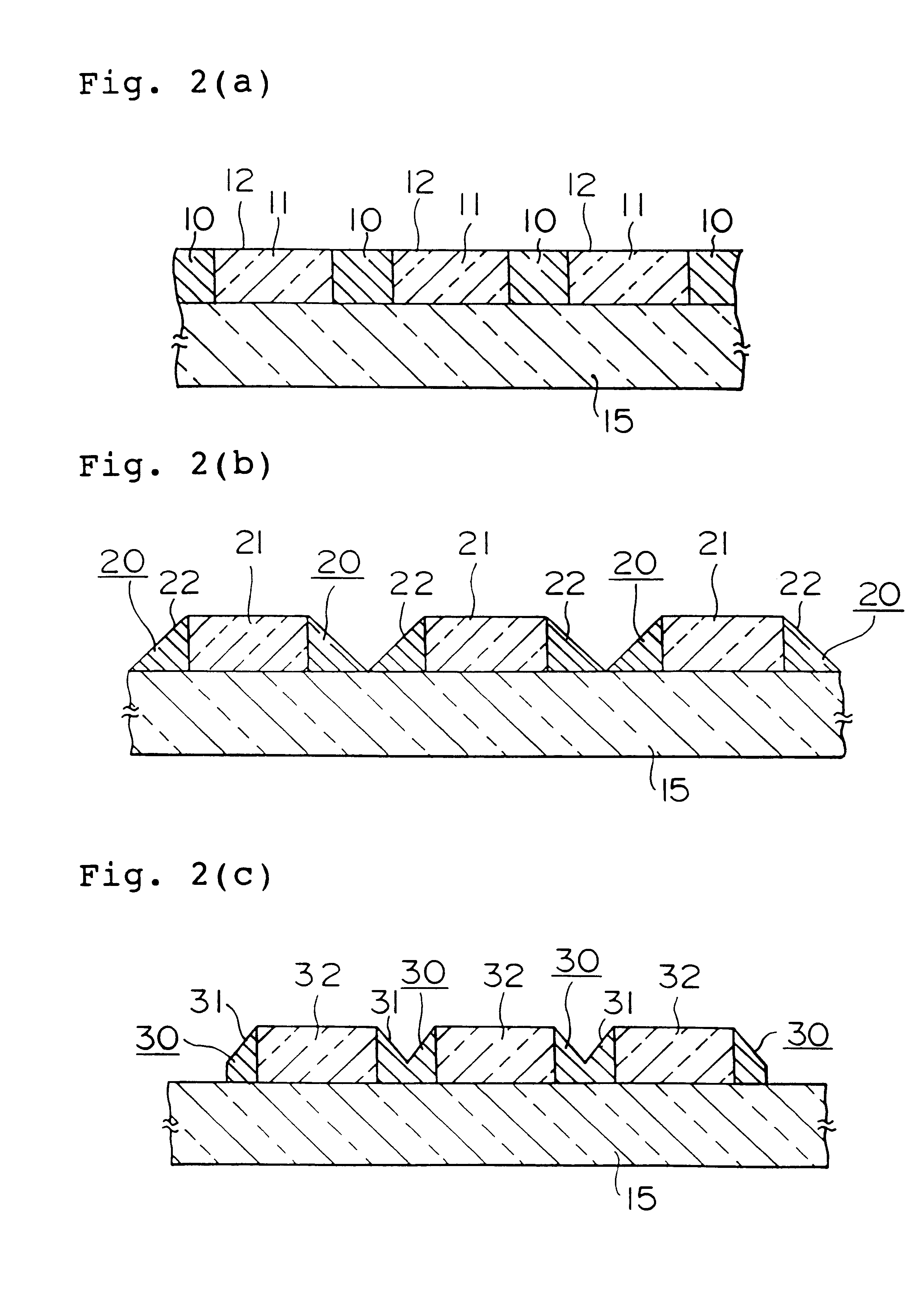

A component (10) for a semiconductor processing apparatus includes a matrix (10a) defining a shape of the component, and a protection film (10c) covering a predetermined surface of the matrix. The protection film (10c) consists essentially of an amorphous oxide of a first element selected from the group consisting of aluminum, silicon, hafnium, zirconium, and yttrium. The protection film (10c) has a porosity of less than 1% and a thickness of 1 nm to 10 μm.

Owner:TOKYO ELECTRON LTD

Field effect transistor with amorphous oxide layer containing microcrystals

InactiveUS20090179199A1Reduced electron mobilityLow conductivitySolid-state devicesSemiconductor/solid-state device manufacturingField-effect transistorActive layer

A novel amorphous oxide applicable, for example, to an active layer of a TFT is provided. The amorphous oxide comprises microcrystals.

Owner:CANON KK +1

Field effect transistor using amorphous oxide film as channel layer, manufacturing method of field effect transistor using amorphous oxide film as channel layer, and manufacturing method of amorphous oxide film

An amorphous oxide containing hydrogen (or deuterium) is applied to a channel layer of a transistor. Accordingly, a thin film transistor having superior TFT properties can be realized, the superior TFT properties including a small hysteresis, normally OFF operation, a high ON / OFF ratio, a high saturated current, and the like. Furthermore, as a method for manufacturing a channel layer made of an amorphous oxide, film formation is performed in an atmosphere containing a hydrogen gas and an oxygen gas, so that the carrier concentration of the amorphous oxide can be controlled.

Owner:CANON KK

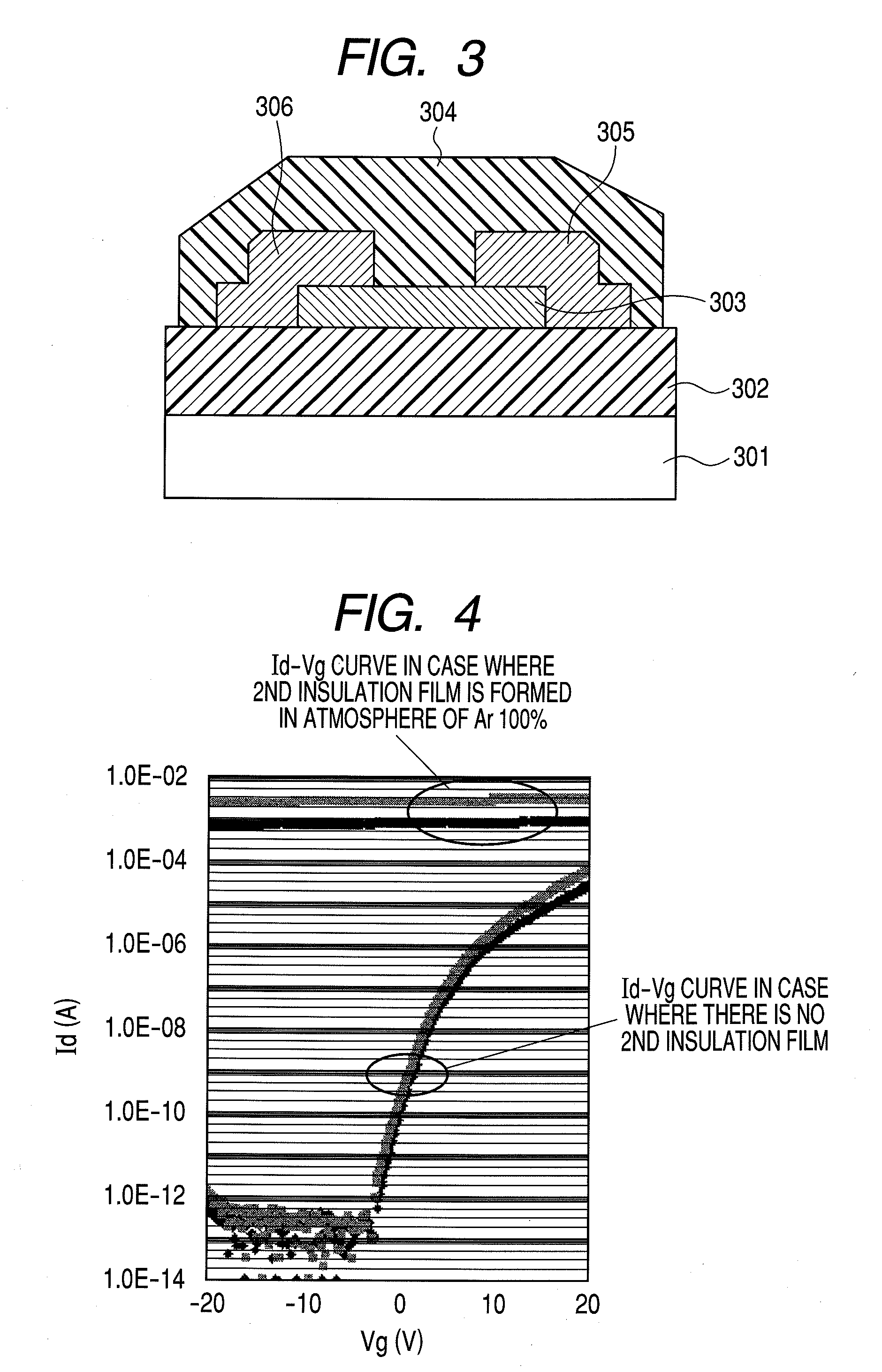

Bottom gate type thin film transistor, method of manufacturing the same, and display apparatus

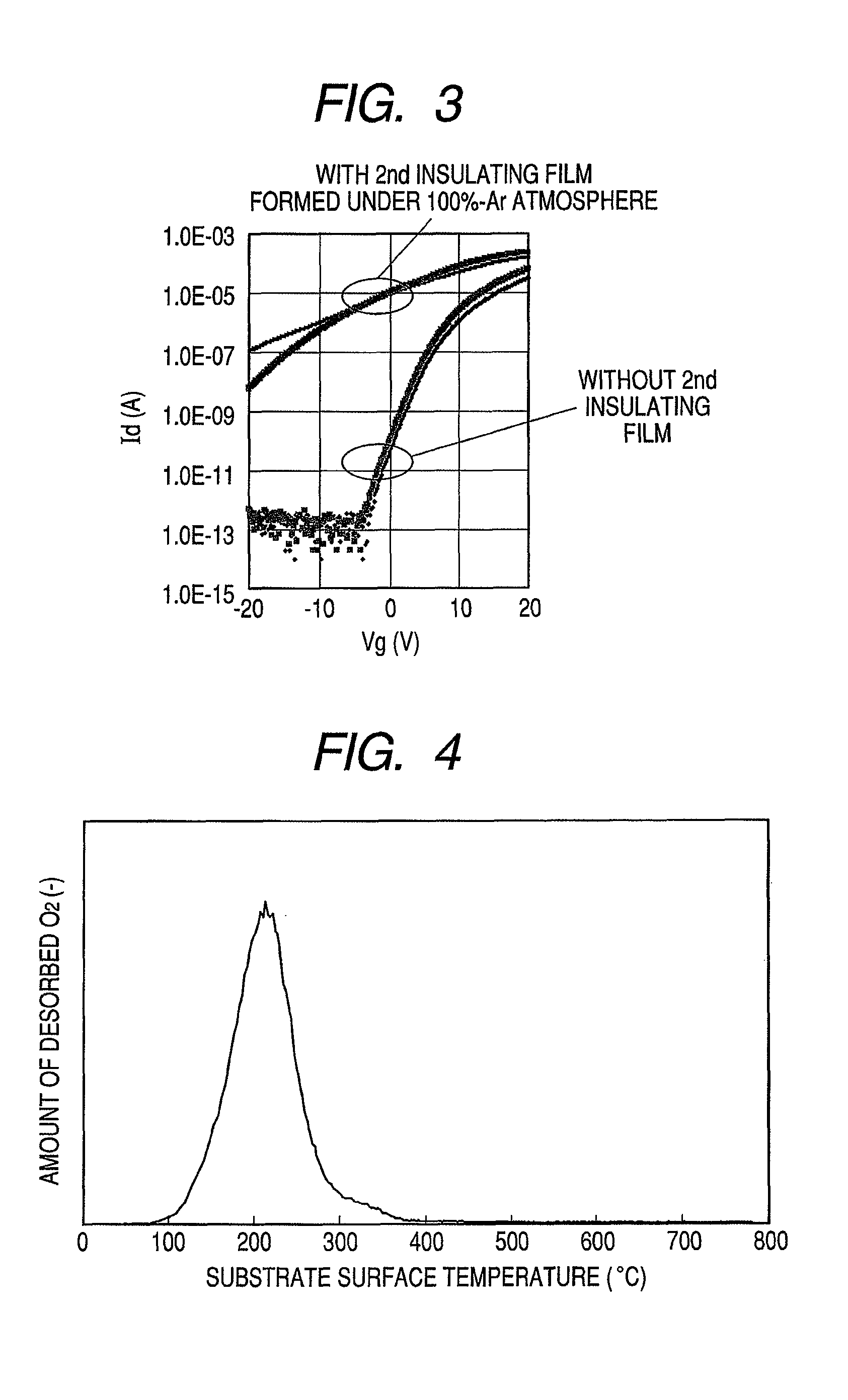

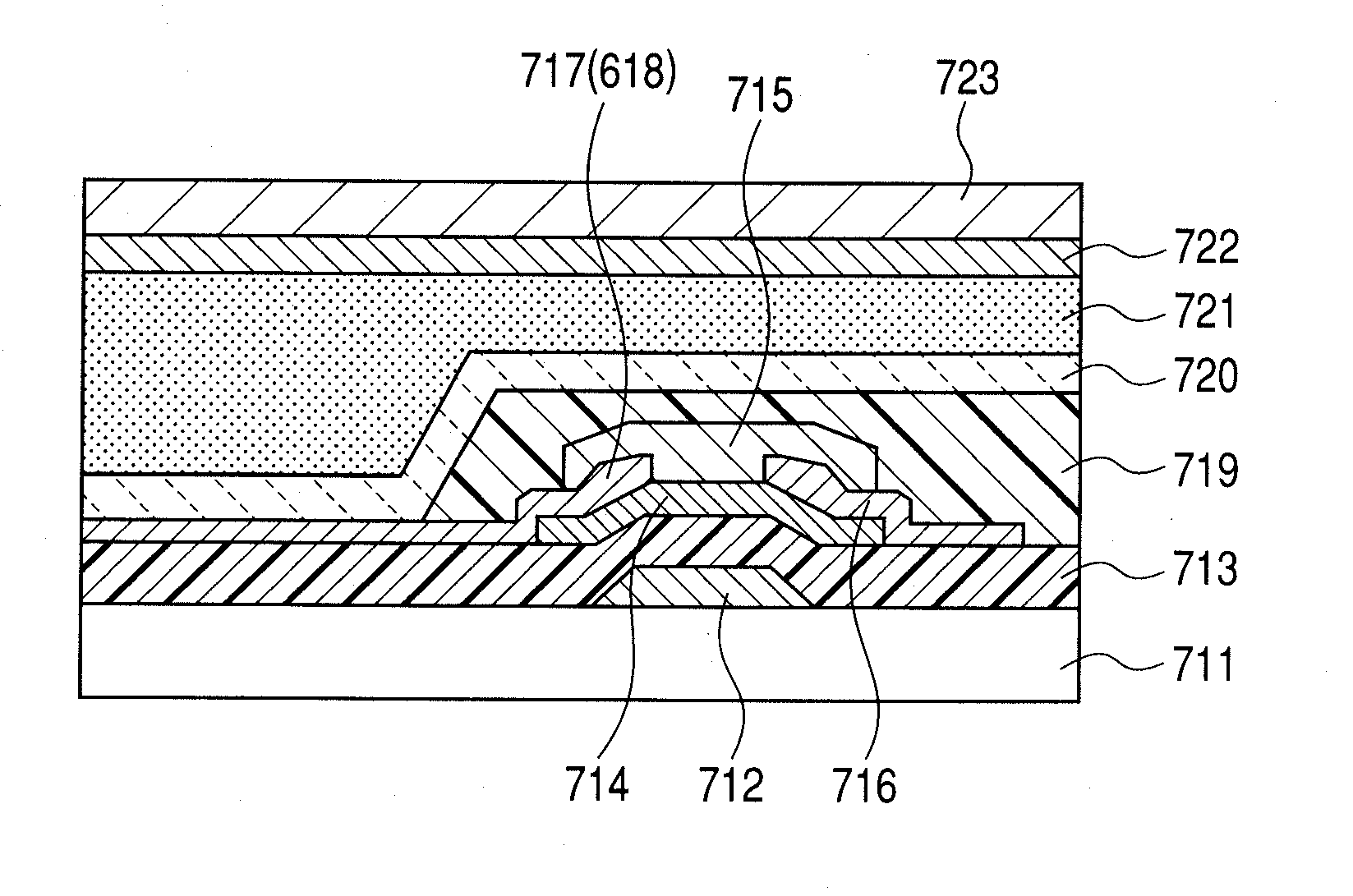

InactiveUS8148721B2Optimise total massImprove batch productivityTransistorElectroluminescent light sourcesDesorptionBottom gate

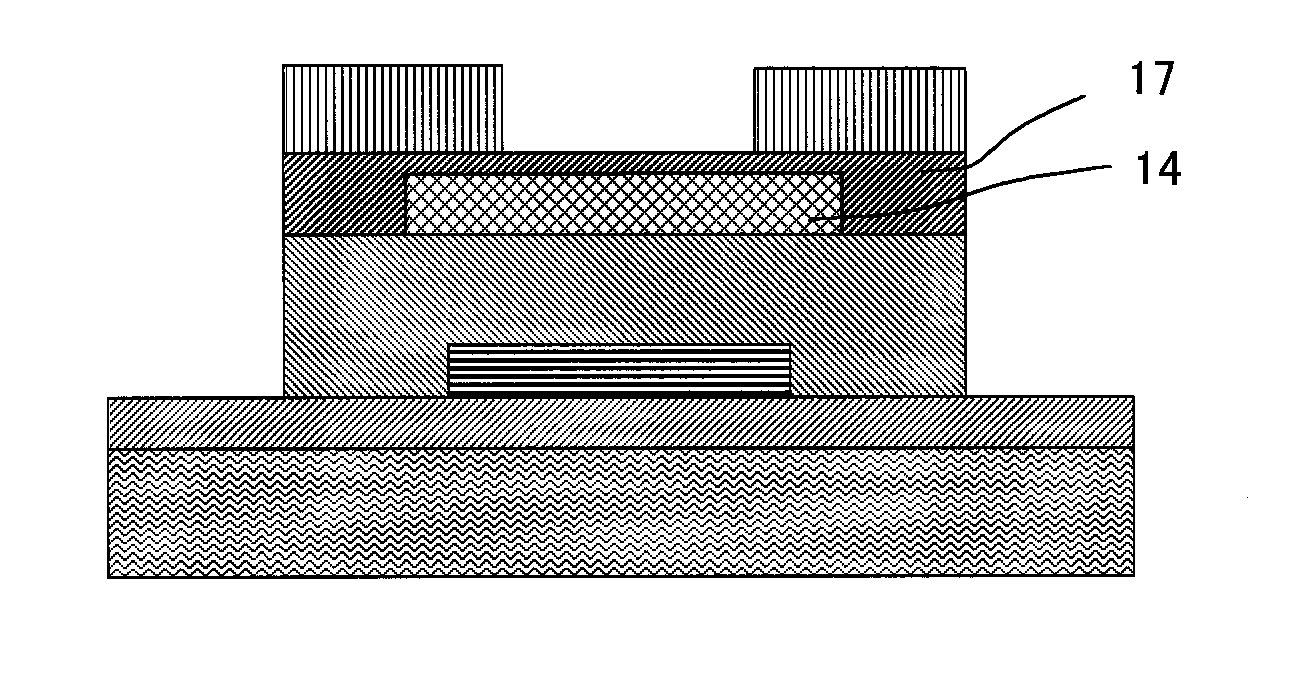

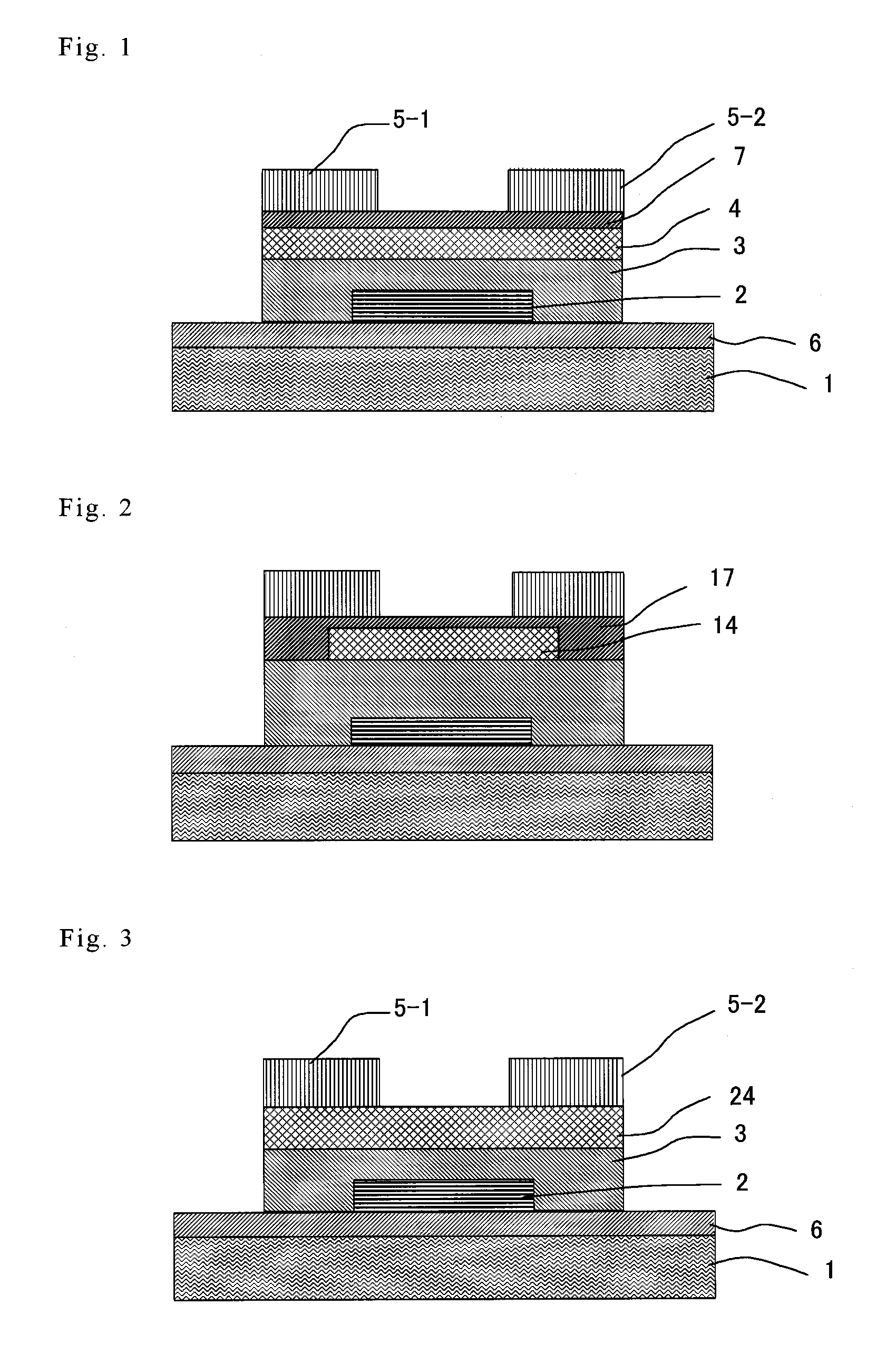

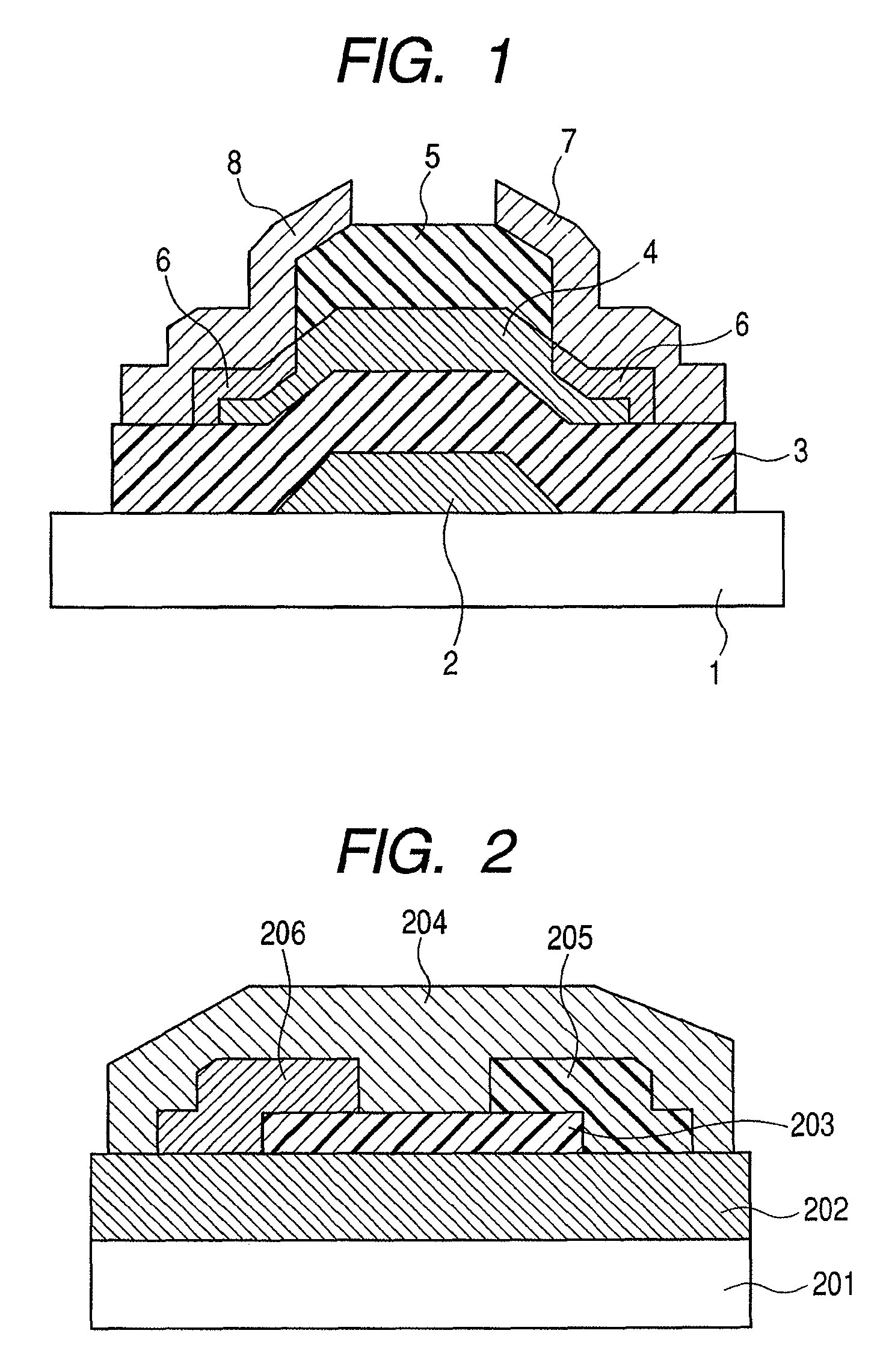

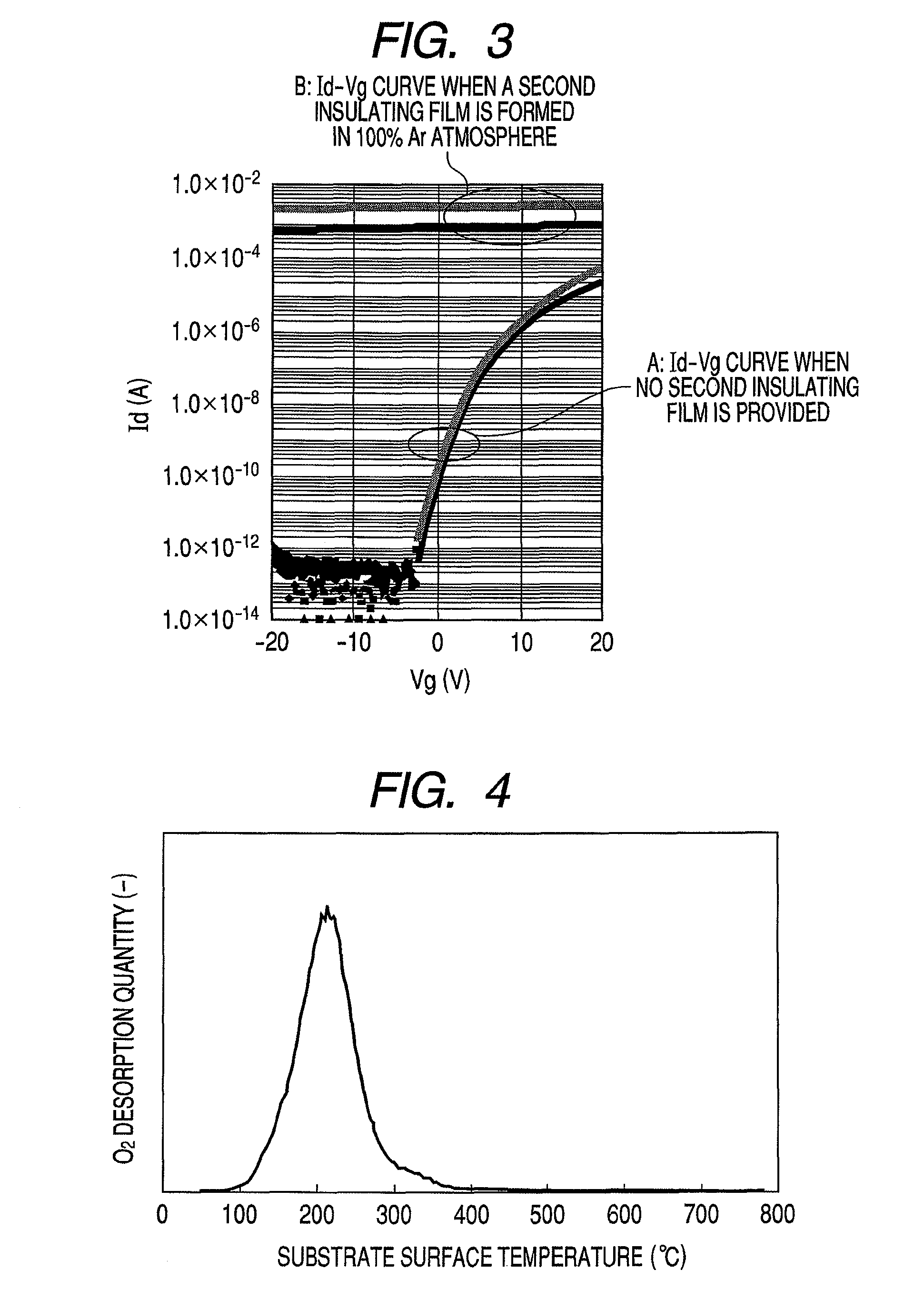

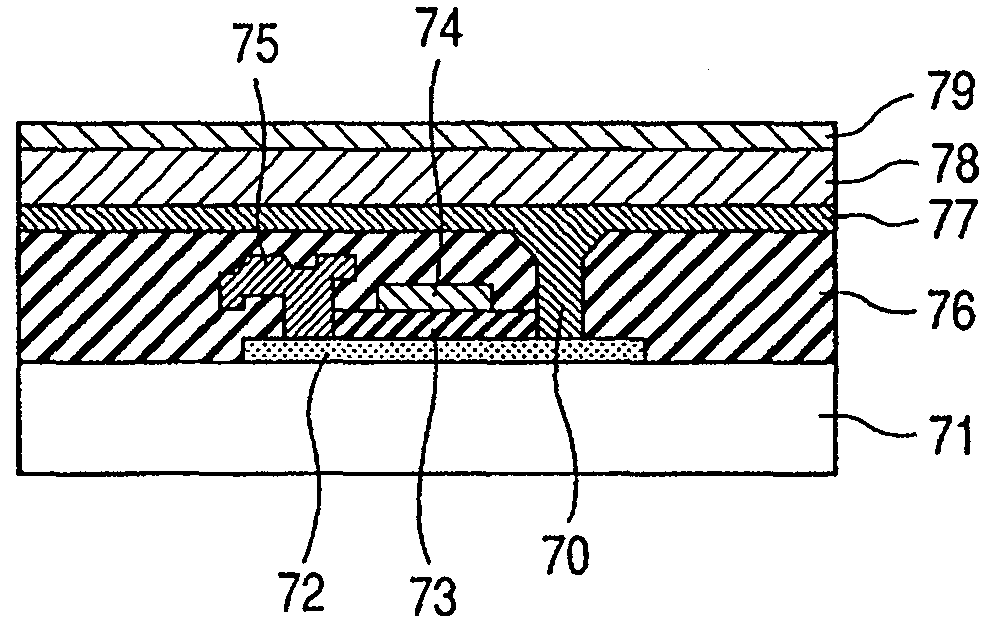

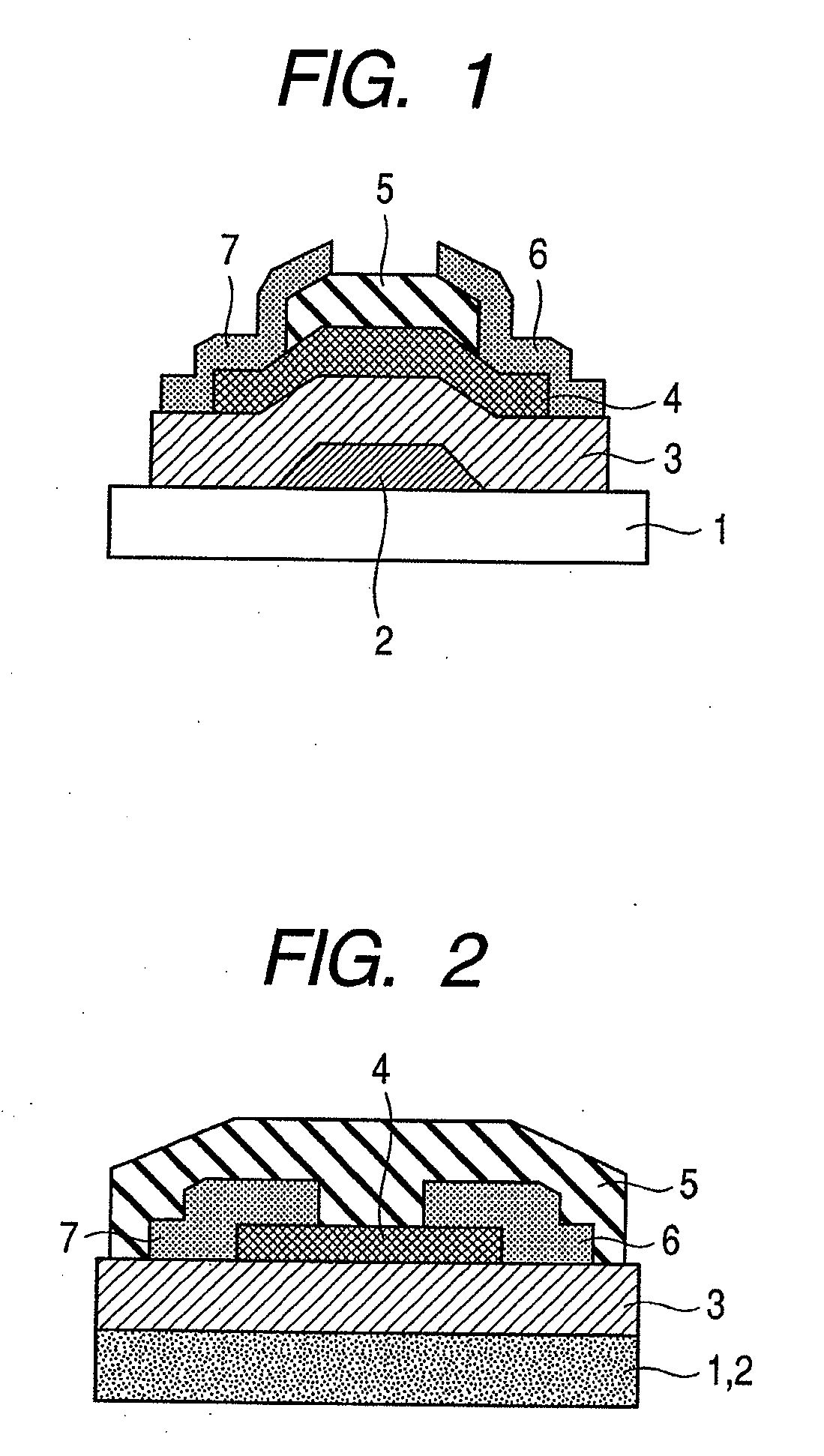

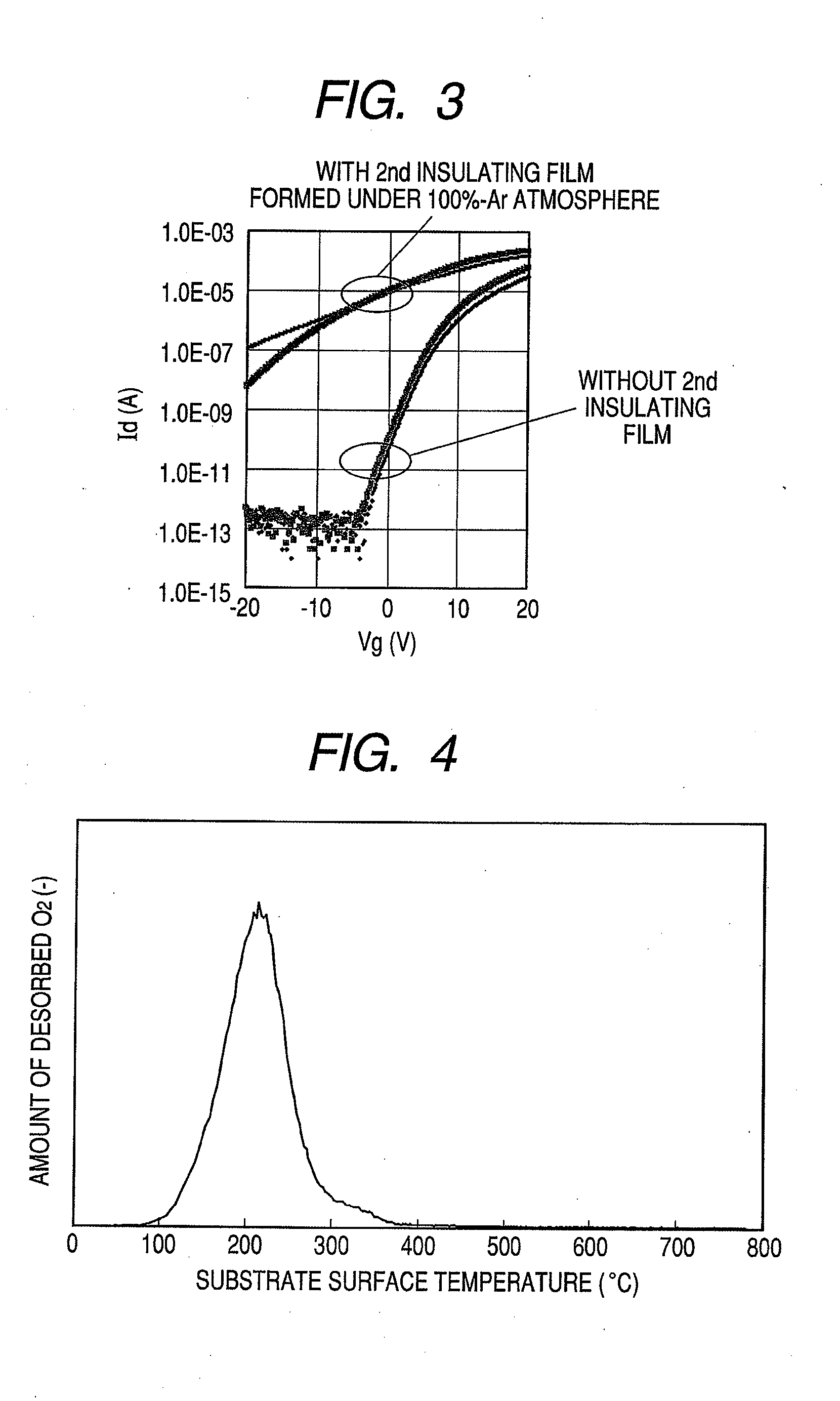

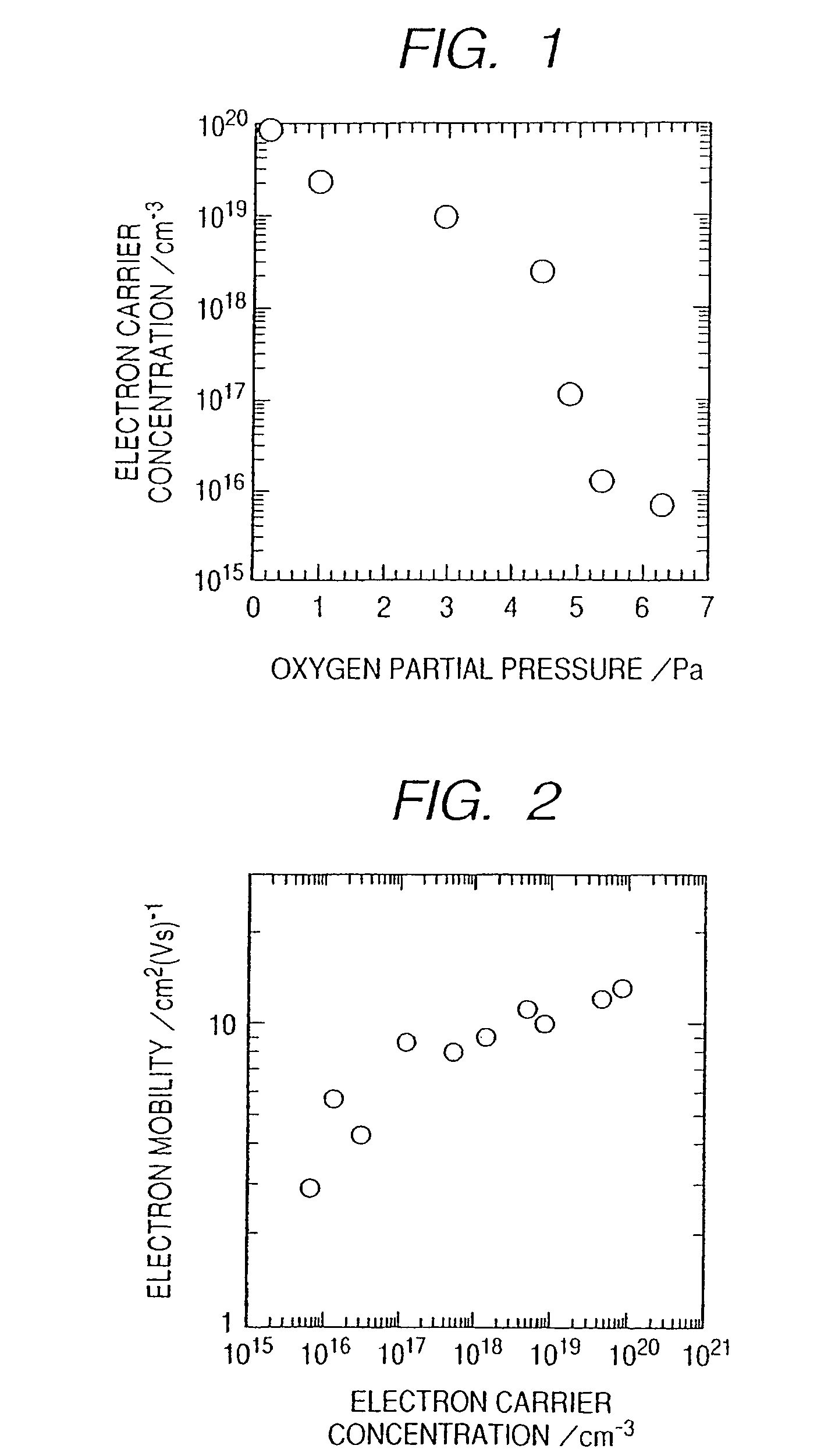

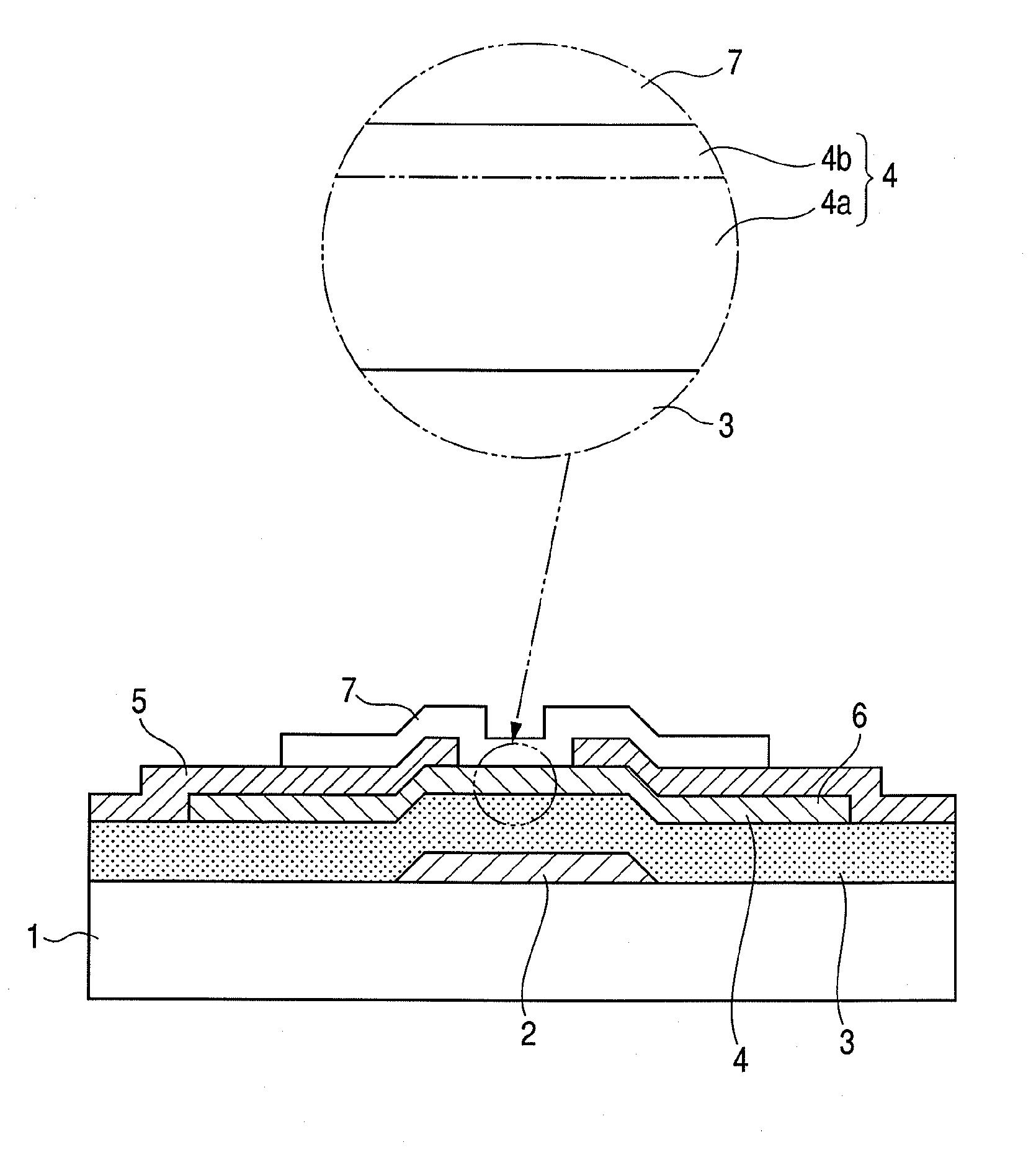

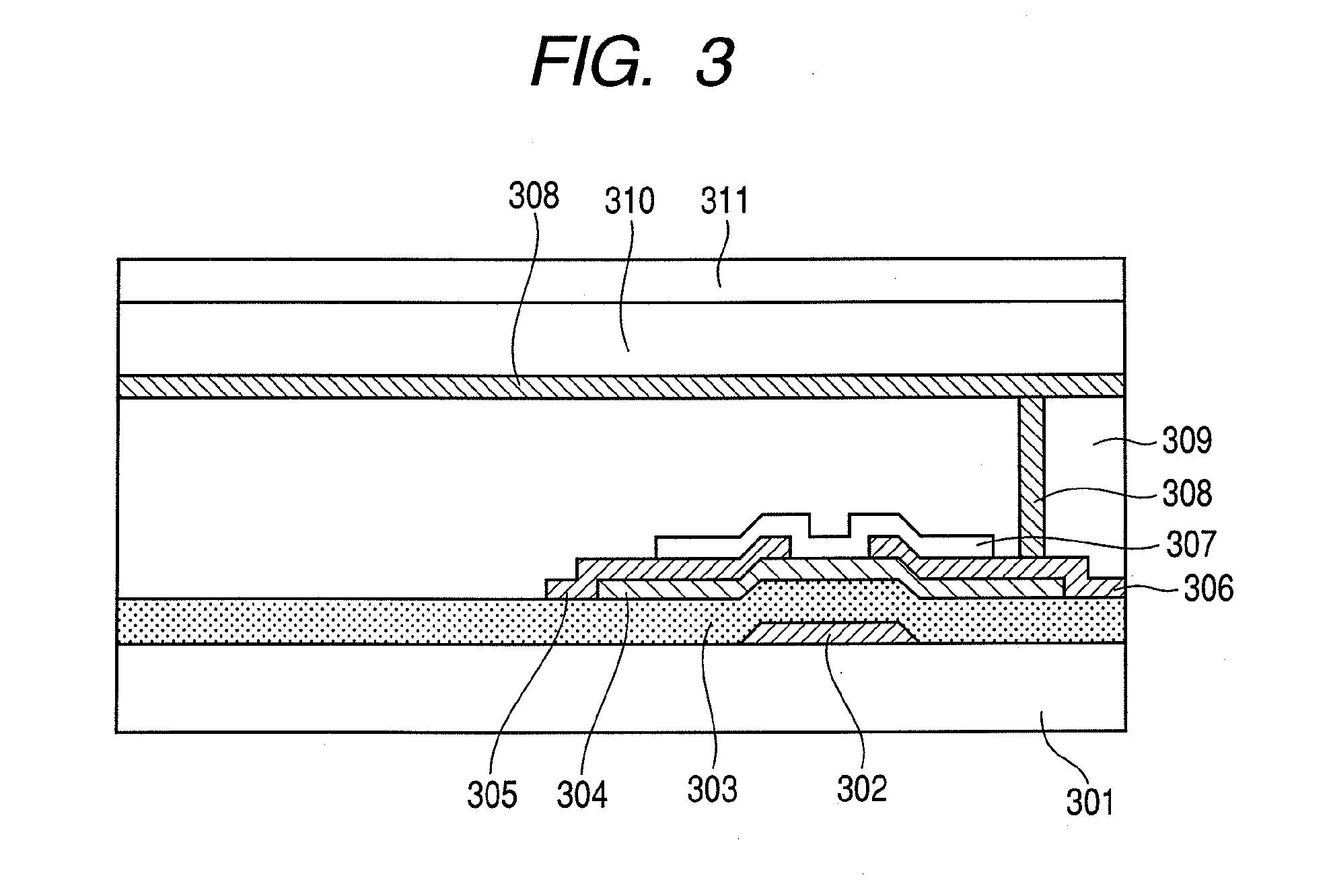

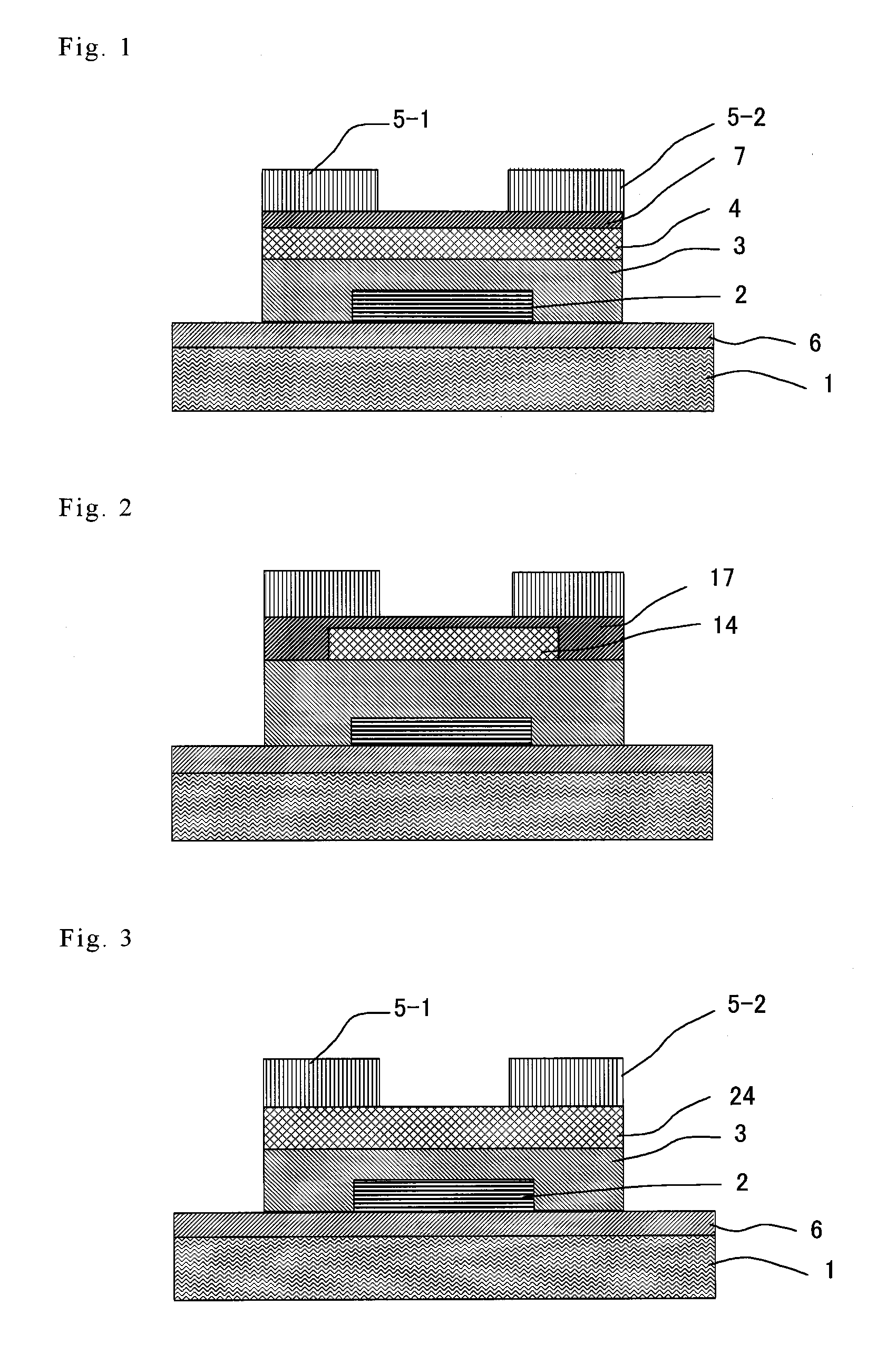

Provided is a bottom gate type thin film transistor including on a substrate (1) a gate electrode (2), a first insulating film (3) as a gate insulating film, an oxide semiconductor layer (4) as a channel layer, a second insulating film (5) as a protective layer, a source electrode (6), and a drain electrode (7), in which the oxide semiconductor layer (4) includes an oxide including at least one selected from the group consisting of In, Zn, and Sn, and the second insulating film (5) includes an amorphous oxide insulator formed so as to be in contact with the oxide semiconductor layer (4) and contains therein 3.8×1019 molecules / cm3 or more of a desorbed gas observed as oxygen by temperature programmed desorption mass spectrometry.

Owner:CANON KK

Thin-film transistor and method of manufacturing same

There is provided a thin-film transistor including at least a substrate, a gate electrode, a gate insulating layer, an oxide semiconductor layer, a source electrode, a drain electrode and a protective layer, wherein the oxide semiconductor layer is an amorphous oxide containing at least one of the elements In, Ga and Zn, the gate electrode-side carrier density of the oxide semiconductor layer is higher than the protective layer-side carrier density thereof, and the film thickness of the oxide semiconductor layer is 30 nm±15 nm.

Owner:CANON KK

Integrated circuits utilizing amorphous oxides

Owner:CANON KK +2

Method for manufacturing thin film transistor using oxide semiconductor and display apparatus

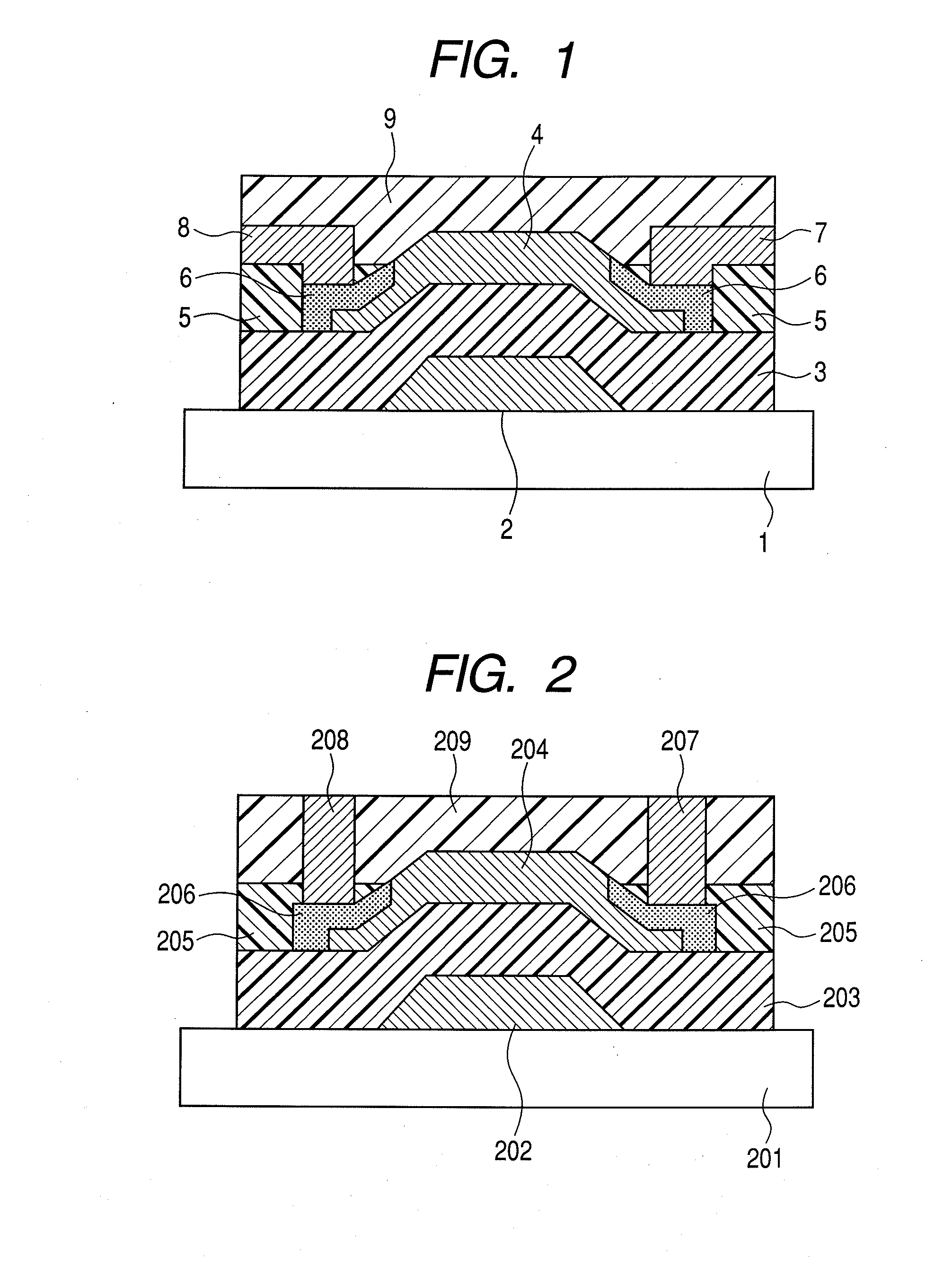

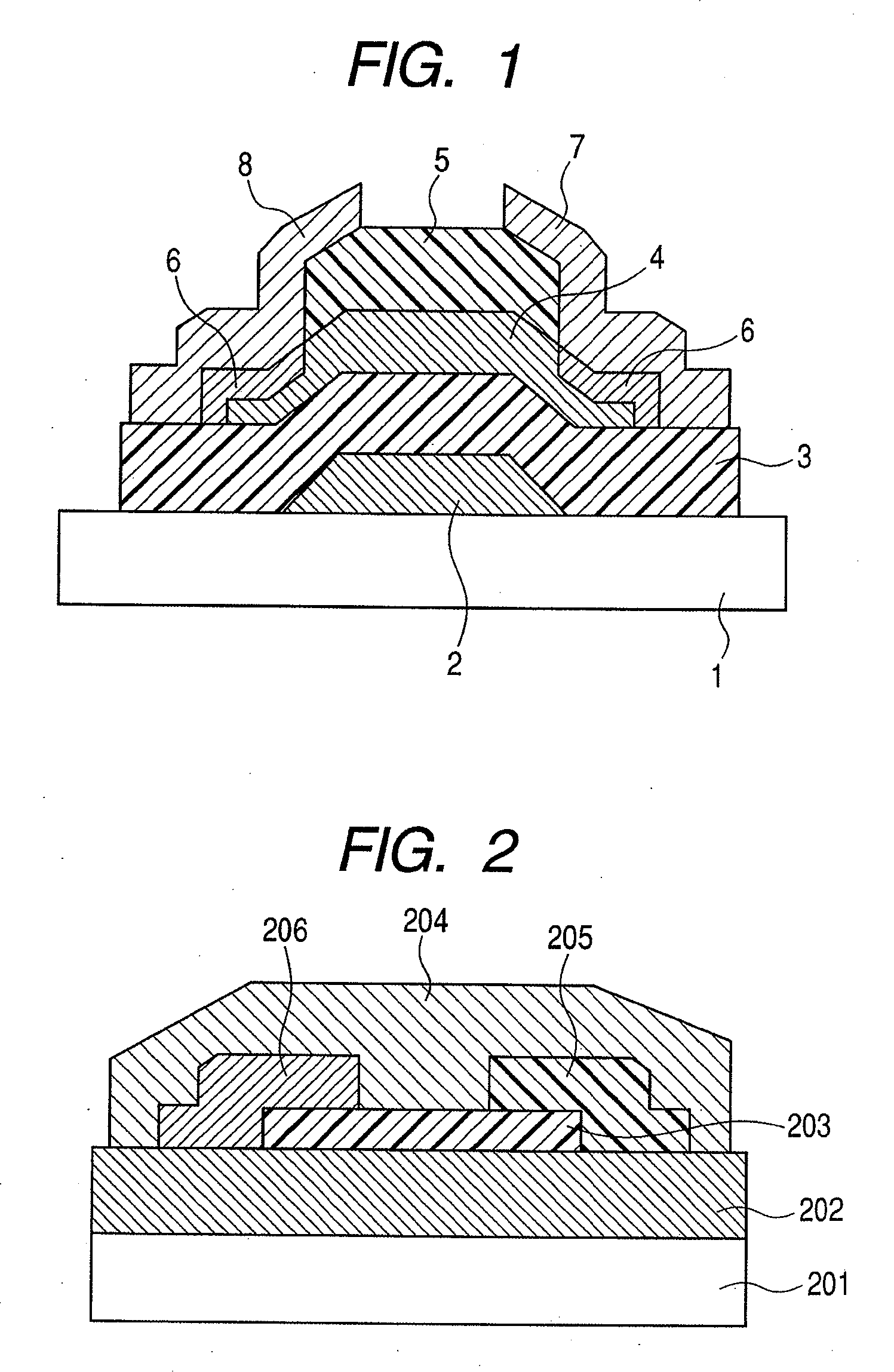

ActiveUS8143115B2Lower resistanceImprove transistor characteristicsTransistorSolid-state devicesSemiconductorAtmosphere

A thin film transistor is manufactured by forming a gate electrode on a substrate, forming a first insulating film on the gate electrode, forming an oxide semiconductor layer on the first insulating film with an amorphous oxide, patterning the first insulating film, patterning the oxide semiconductor layer, forming a second insulating film on the oxide semiconductor layer in an oxidative-gas-containing atmosphere, patterning the second insulating film to expose a pair of contact regions, forming an electrode layer on the pair of contact regions, and patterning the electrode layer to for a source electrode and a drain electrode.

Owner:CANON KK

Manufacturing method of thin film transistor using oxide semiconductor

InactiveUS8193045B2Improve transistor characteristicsReduced contact areaSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

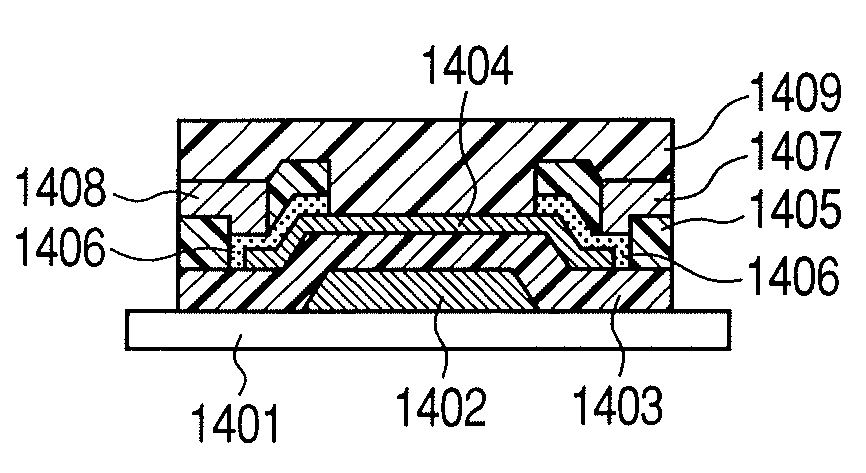

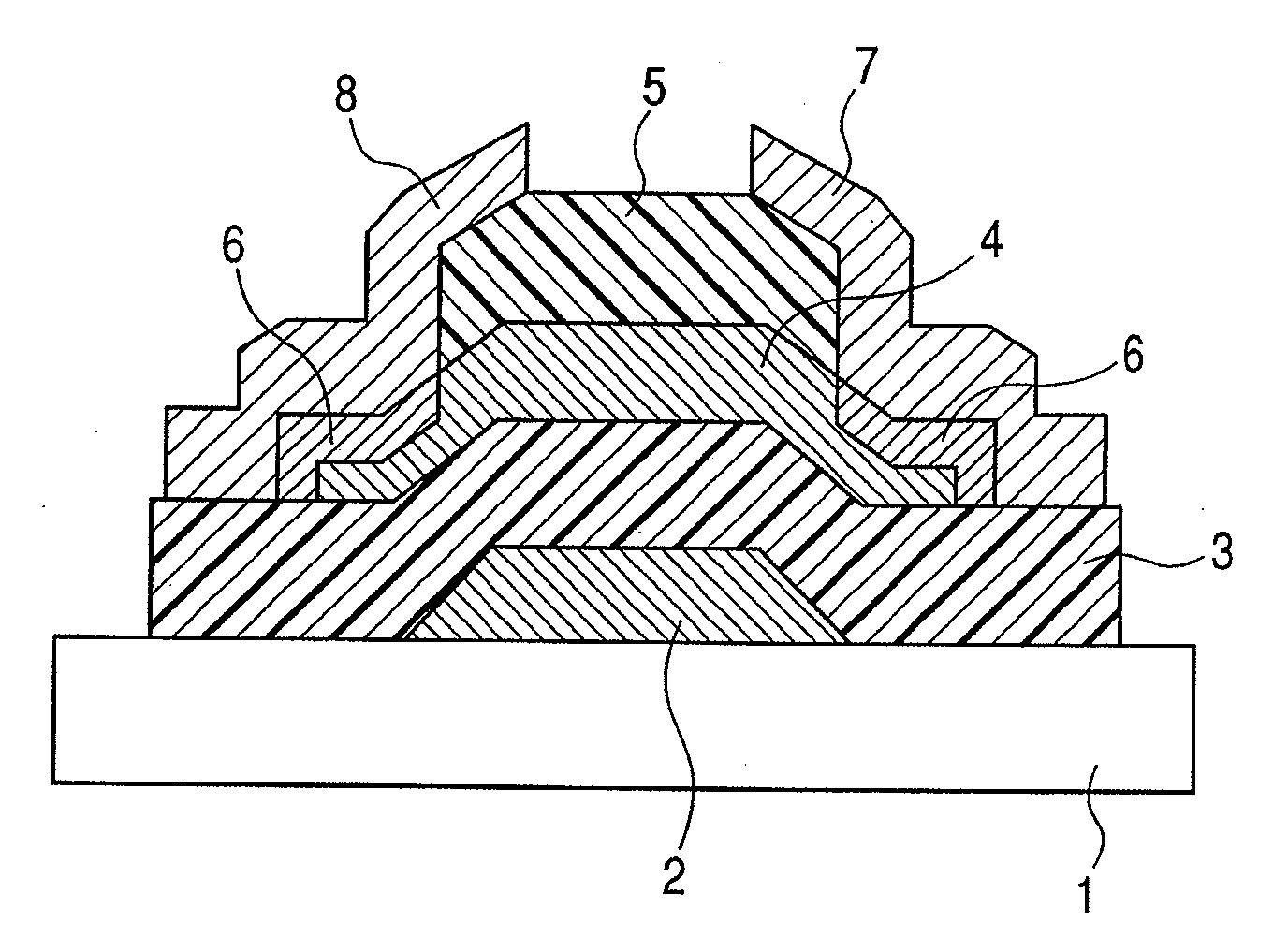

A manufacturing method of a thin film transistor having at least a gate electrode, a gate insulation film, an oxide semiconductor layer, a first insulation film, a source electrode, a drain electrode, and a second insulation film on a substrate, including: forming the gate electrode on the substrate; forming the gate insulation film on the gate electrode; forming a semiconductor layer including amorphous oxide on the gate insulation film; patterning the gate insulation film; patterning the oxide semiconductor layer; reducing the oxide semiconductor layer in resistance by forming the first insulation film on the oxide semiconductor layer in the atmosphere not including an oxidized gas; patterning the first insulation film and forming a contact hole between the source electrode and the drain electrode and the oxide semiconductor layer; forming a source electrode layer and a drain electrode layer in the oxide semiconductor layer through the contact hole; forming the source electrode and the drain electrode through the contact hole and allowing the first insulation film to be exposed; patterning the exposed first insulation film and allowing a channel region of the oxide semiconductor layer to be exposed; and increasing the channel region in resistance by forming the second insulation film on the surface including the channel region of the oxide semiconductor layer in the atmosphere including an oxidized gas.

Owner:CANON KK

Field effect transistor using amorphous oxide film as channel layer, manufacturing method of field effect transistor using amorphous oxide film as channel layer, and manufacturing method of amorphous

An amorphous oxide containing hydrogen (or deuterium) is applied to a channel layer of a transistor. Accordingly, a thin film transistor having superior TFT properties can be realized, the superior TFT properties including a small hysteresis, normally OFF operation, a high ON / OFF ratio, a high saturated current, and the like. Furthermore, as a method for manufacturing a channel layer made of an amorphous oxide, film formation is performed in an atmosphere containing a hydrogen gas and an oxygen gas, so that the carrier concentration of the amorphous oxide can be controlled.

Owner:CANON KK

Light-emitting device

ActiveUS7872259B2Desired characteristicTransistorElectroluminescent light sourcesField-effect transistorActive layer

An object of the present invention is to provide a new light-emitting device with the use of an amorphous oxide. The light-emitting device has a light-emitting layer existing between first and second electrodes and a field effect transistor, of which the active layer is an amorphous.

Owner:CANON KK +2

Bottom gate type thin film transistor, method of manufacturing the same, and display apparatus

InactiveUS20100051936A1Excels in mass productionOptimise total massTransistorElectroluminescent light sourcesDesorptionBottom gate

Provided is a bottom gate type thin film transistor including on a substrate (1) a gate electrode (2), a first insulating film (3) as a gate insulating film, an oxide semiconductor layer (4) as a channel layer, a second insulating film (5) as a protective layer, a source electrode (6), and a drain electrode (7), in which the oxide semiconductor layer (4) includes an oxide including at least one selected from the group consisting of In, Zn, and Sn, and the second insulating film (5) includes an amorphous oxide insulator formed so as to be in contact with the oxide semiconductor layer (4) and contains therein 3.8×1019 molecules / cm3 or more of a desorbed gas observed as oxygen by temperature programmed desorption mass spectrometry.

Owner:CANON KK

Method for manufacturing thin film transistor using oxide semiconductor and display apparatus

ActiveUS20100065837A1Improve transistor characteristicsLower resistanceTransistorSolid-state devicesSemiconductorOxide semiconductor

A thin film transistor is manufactured by forming a gate electrode on a substrate, forming a first insulating film on the gate electrode, forming an oxide semiconductor layer on the first insulating film with an amorphous oxide, patterning the first insulating film, patterning the oxide semiconductor layer, forming a second insulating film on the oxide semiconductor layer in an oxidative-gas-containing atmosphere, patterning the second insulating film to expose a pair of contact regions, forming an electrode layer on the pair of contact regions, and patterning the electrode layer to for a source electrode and a drain electrode.

Owner:CANON KK

Field effect transistor

ActiveUS7868326B2Inhibit currentMaintain good propertiesSolid-state devicesSemiconductor/solid-state device manufacturingField-effect transistorElectron

A novel field-effect transistor is provided which employs an amorphous oxide. In an embodiment of the present invention, the transistor comprises an amorphous oxide layer containing electron carrier at a concentration less than 1×10−18 / cm3, and the gate-insulating layer is comprised of a first layer being in contact with the amorphous oxide and a second layer different from the first layer.

Owner:CANON KK +2

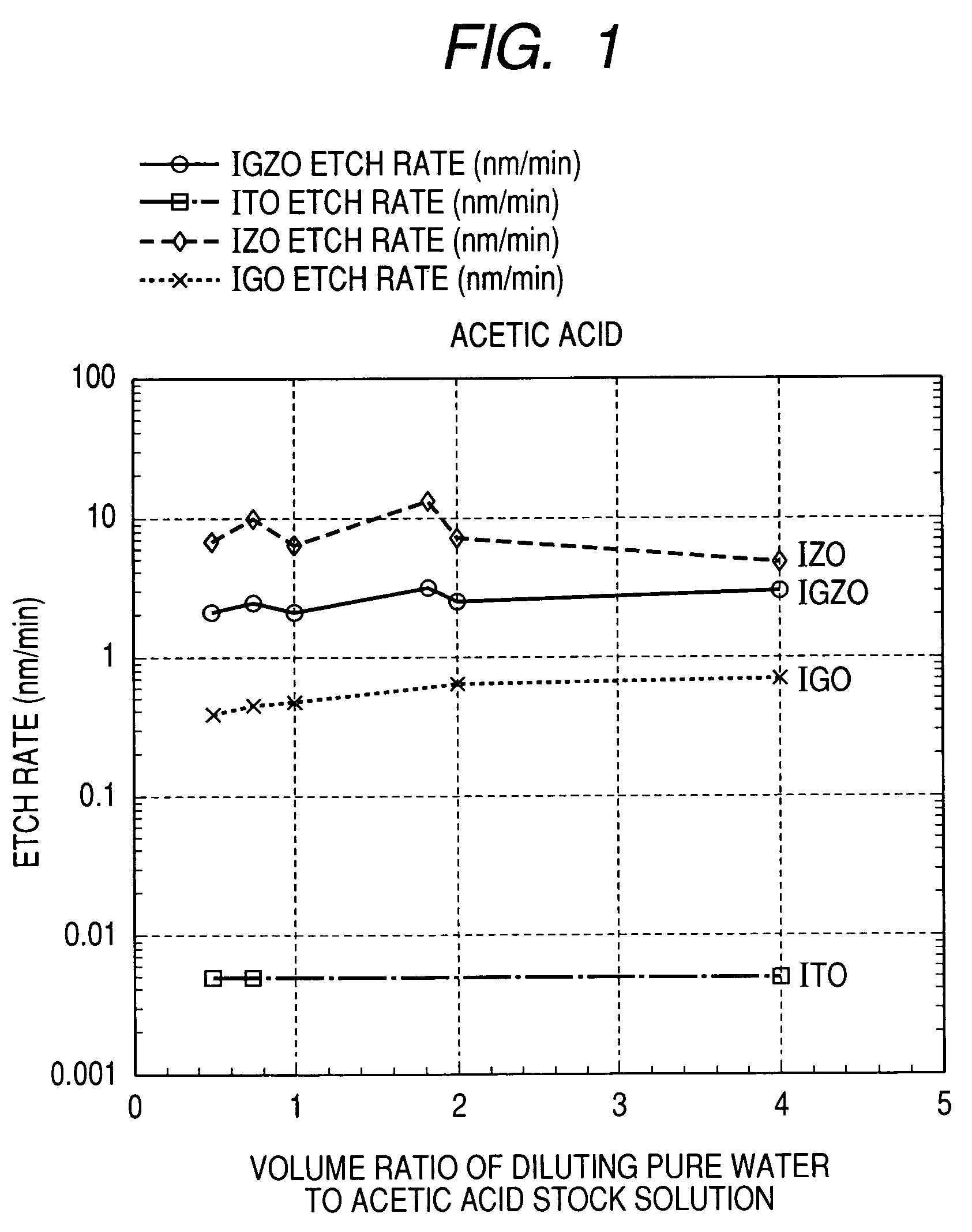

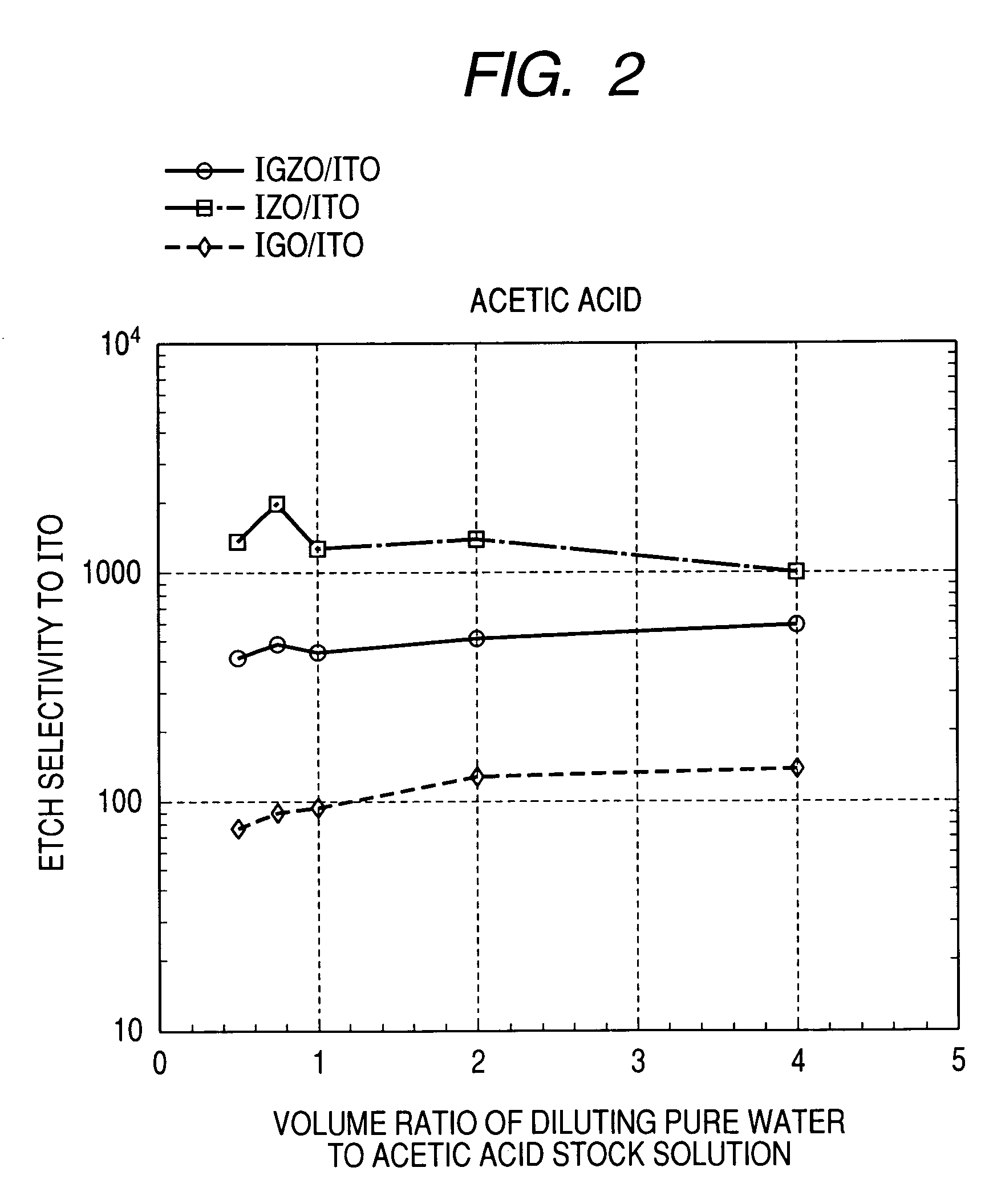

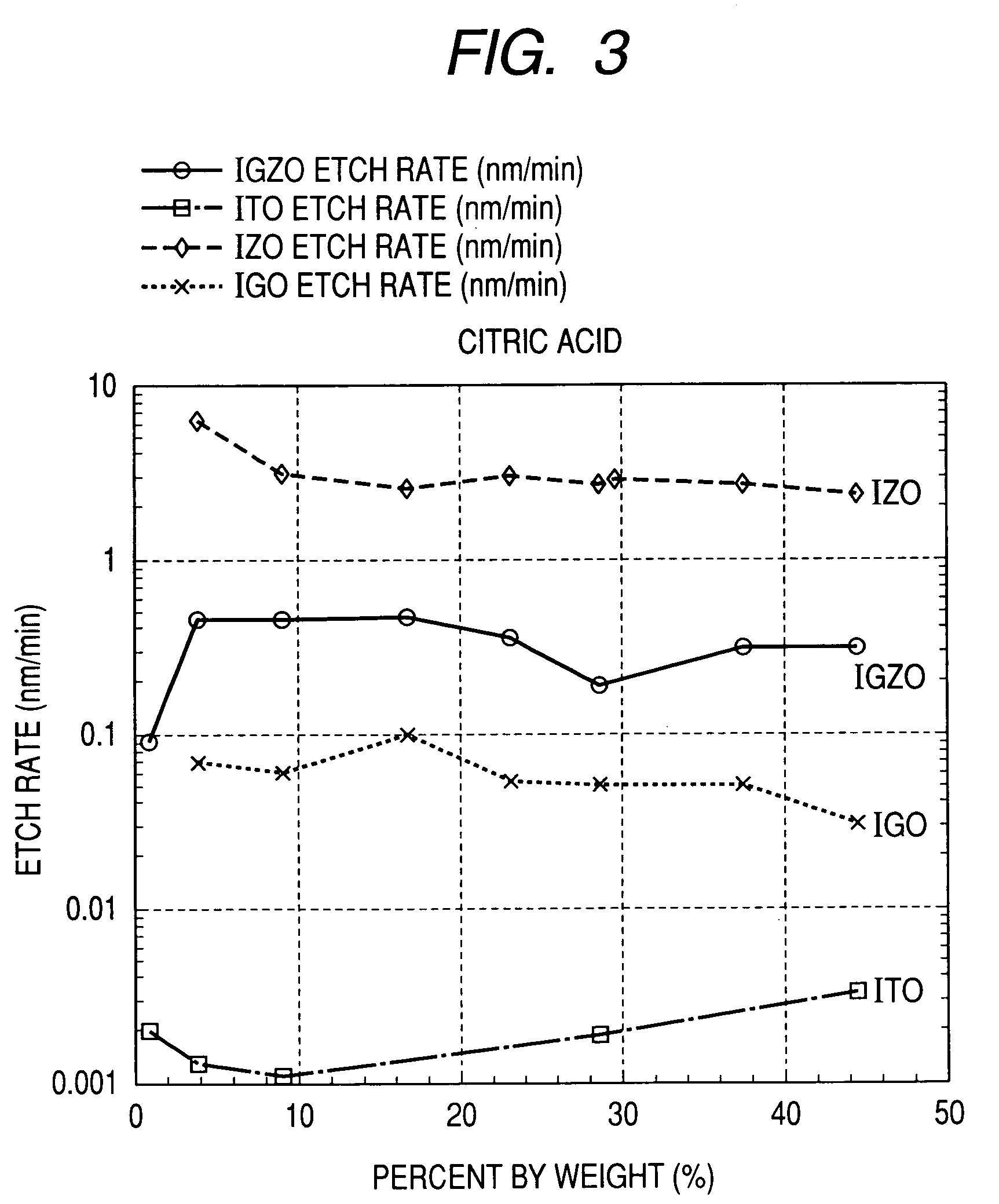

Oxide etching method

InactiveUS8168544B2Precise and easy etchingPrecise and highly selective wet etchingDecorative surface effectsFinal product manufactureAcetic acidEtching

There is provided an etching method of an amorphous oxide layer containing In and at least one of Ga and Zn, which includes etching the amorphous oxide layer using an etchant containing any one of acetic acid, citric acid, hydrochloric acid, and perchloric acid.

Owner:CANON KK

Organic EL device

InactiveUS6280861B1Reduce displayEasy to produceDischarge tube luminescnet screensElectroluminescent light sourcesThin metalMono layer

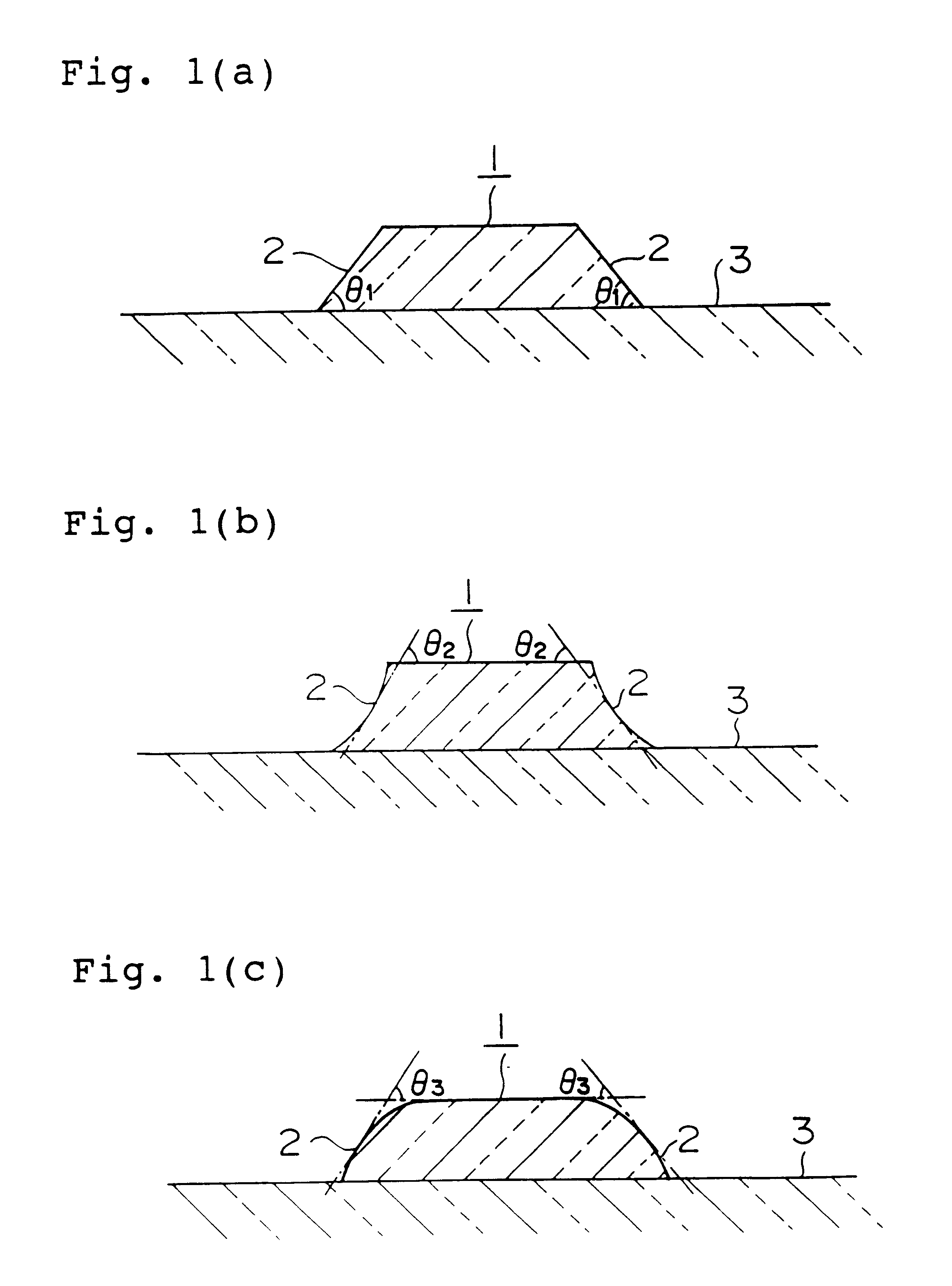

An amorphous electrically conductive oxide such as In-Zn-O-containing amorphous oxide or amorphous ITO is used alone, or a laminate having a two- or three-layer structure constituted of the amorphous electrically conductive oxide and at least a thin metal layer is used, to form a transparent electrode whose side surface has a tapered form and whose top layer is formed of a layer of the above amorphous electrically conductive oxide, an organic single-layer portion or an organic multi-layer portion containing at least an organic light-emitting material is formed on the above transparent electrode, and further, an opposing electrode is formed on the above organic single-layer portion or the above organic multi-layer portion, whereby an organic EL device is obtained. A flattening layer is optionally provided so as to abut on the side surface of the transparent electrode for moderating a height-level difference between the above transparent electrode and the surface of the above substrate. Further, the above organic EL device is used to form an organic EL display panel.

Owner:IDEMITSU KOSAN CO LTD

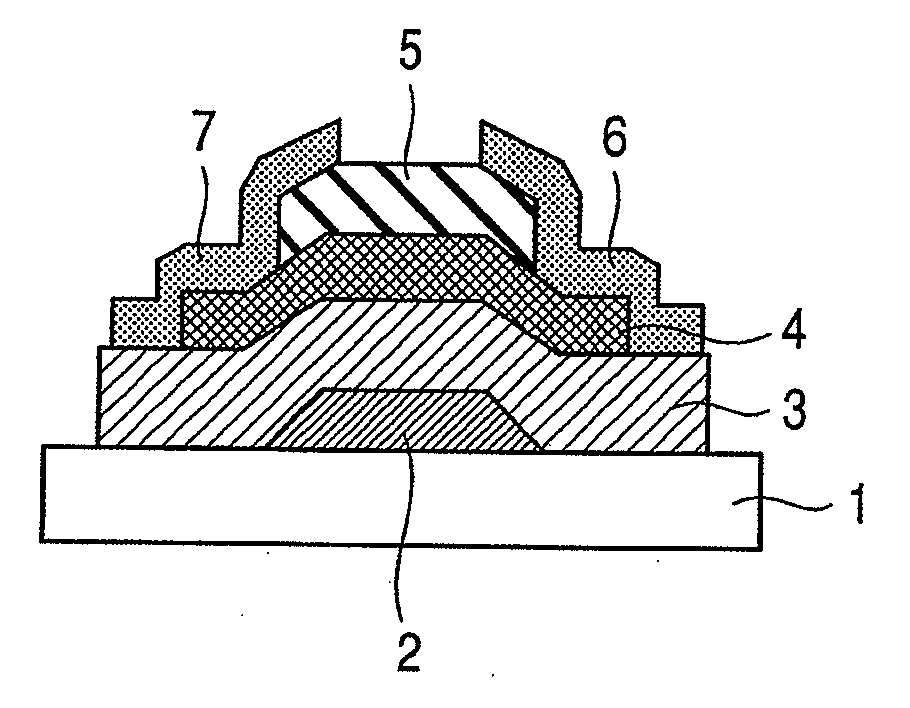

Thin film transistor having a two-layer semiconductor, manufacturing method therefor, and display apparatus using the same

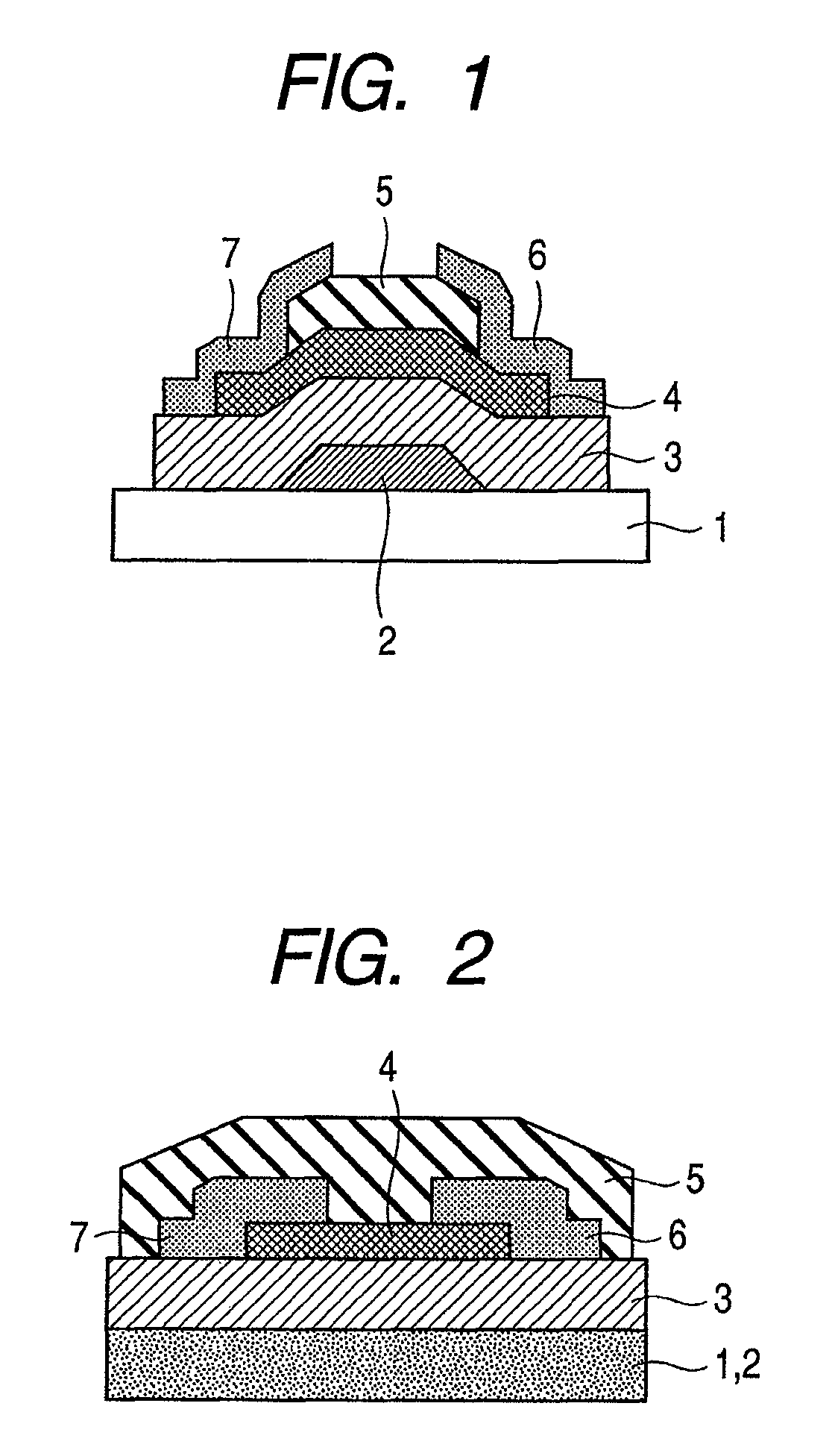

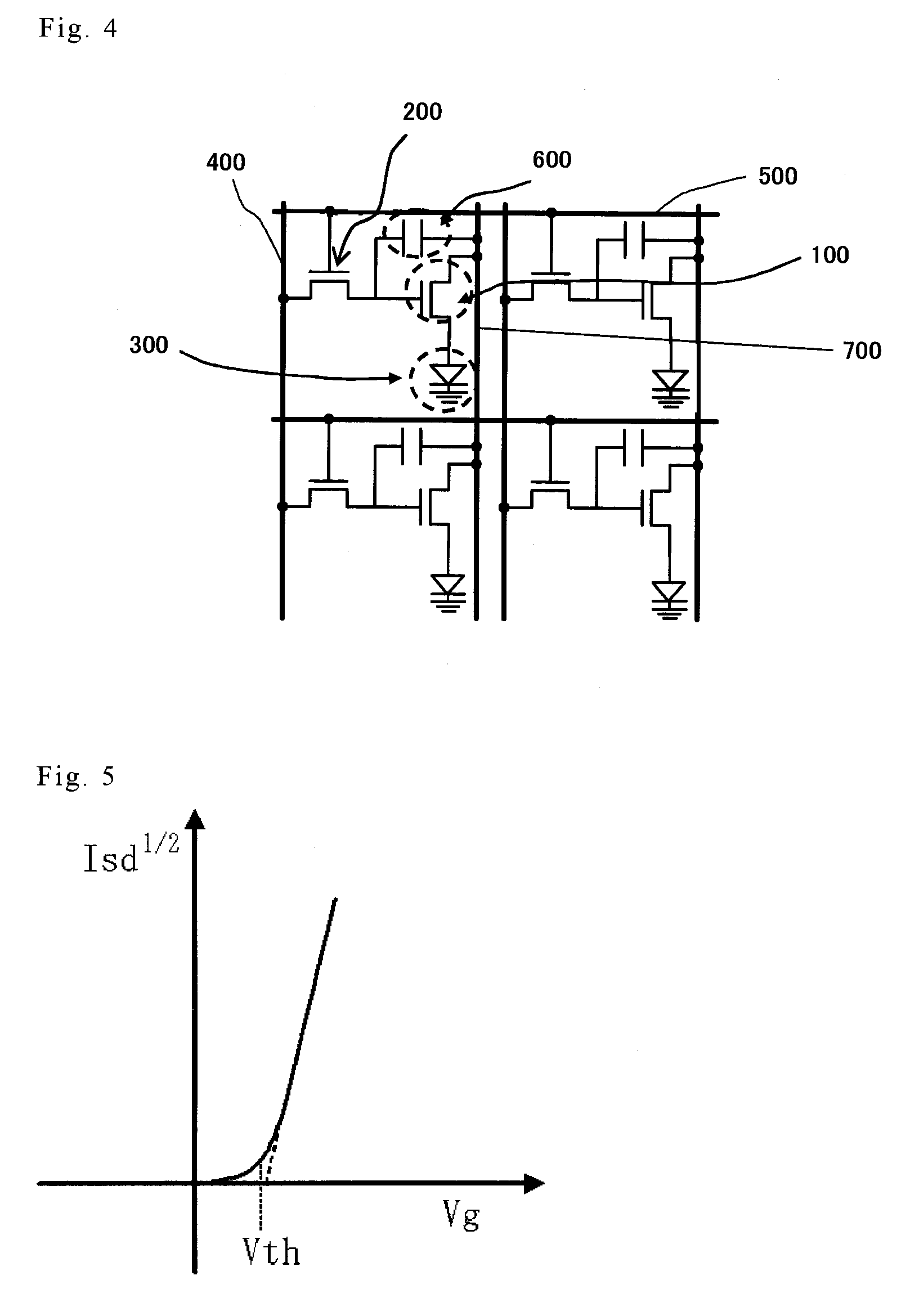

InactiveUS20120132911A1Lower resistanceGood dispersionTransistorSemiconductor/solid-state device manufacturingHigh resistanceInsulation layer

A transistor is constituted of a gate electrode 2, a gate insulation layer 3, a semiconductor layer 4 formed of an amorphous oxide, a source electrode 5, a drain electrode 6 and a protective layer 7. The protective layer 7 is provided on the semiconductor layer 4 in contact with the semiconductor layer 4, and the semiconductor layer 4 includes a first layer at least functioning as a channel layer and a second layer having higher resistance than the first layer. The first layer is provided on the gate electrode 2 side of the semiconductor layer 4 and the second layer is provided on the protective layer 7 side of the semiconductor layer 4.

Owner:CANON KK

Thin film field effect transistor and display

ActiveUS20090236596A1Small band gapHigh concentrationTransistorElectroluminescent light sourcesDisplay deviceField-effect transistor

A TFT is provided which includes, on a substrate, at least a gate electrode, a gate insulating layer, an active layer containing an amorphous oxide semiconductor, a source electrode and a drain electrode, wherein a resistance layer containing an amorphous oxide and having a thickness of more than 3 nm is disposed between the active layer and at least one of the source electrode or the drain electrode, and a band gap of the active layer is smaller than a band gap of the resistance layer. Also, a display using the TFT is provided.

Owner:SAMSUNG DISPLAY CO LTD

Amorphous oxide and field effect transistor

ActiveUS8212248B2Improve featuresIncrease profitSemiconductor devicesField-effect transistorAtomic composition

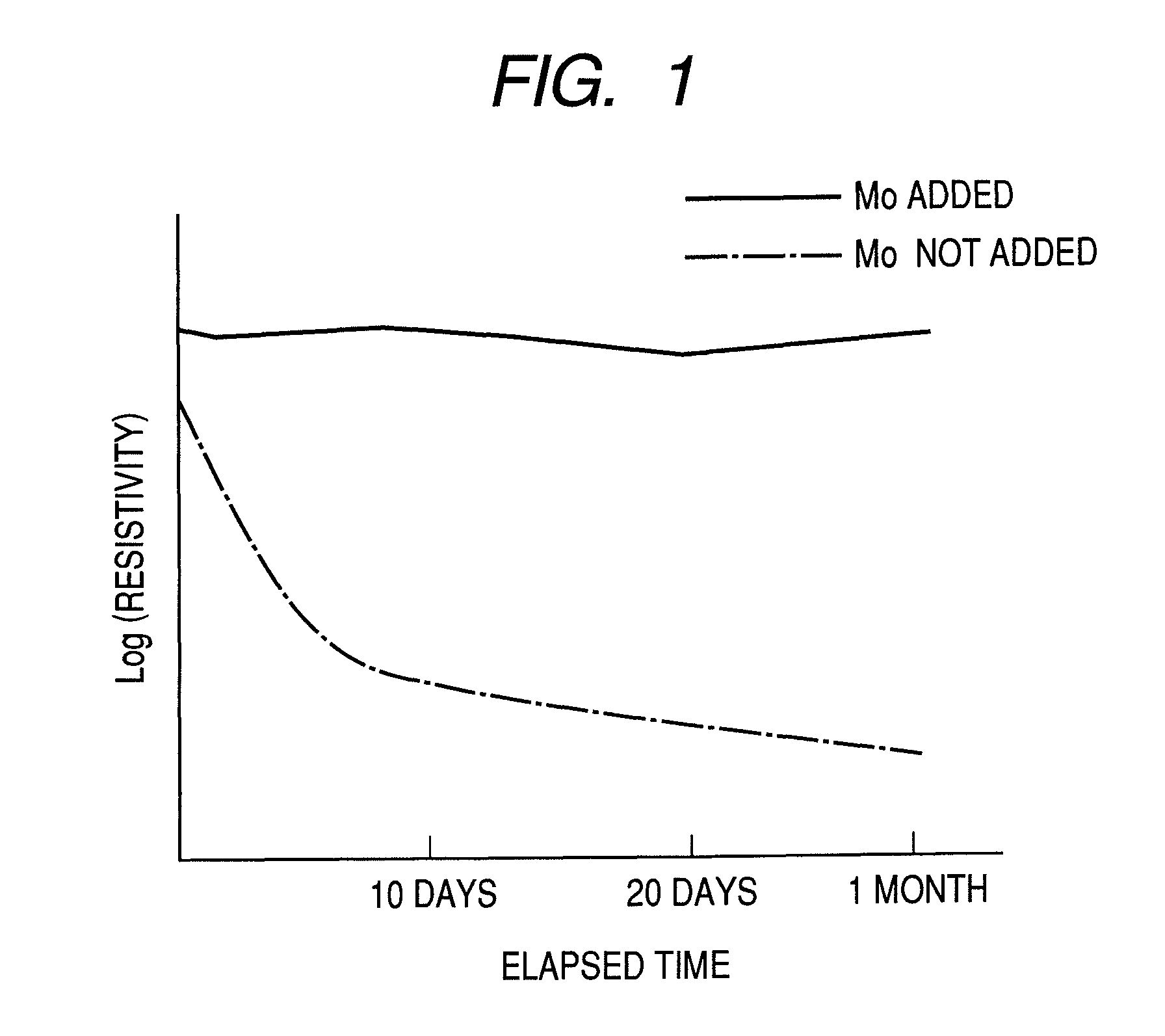

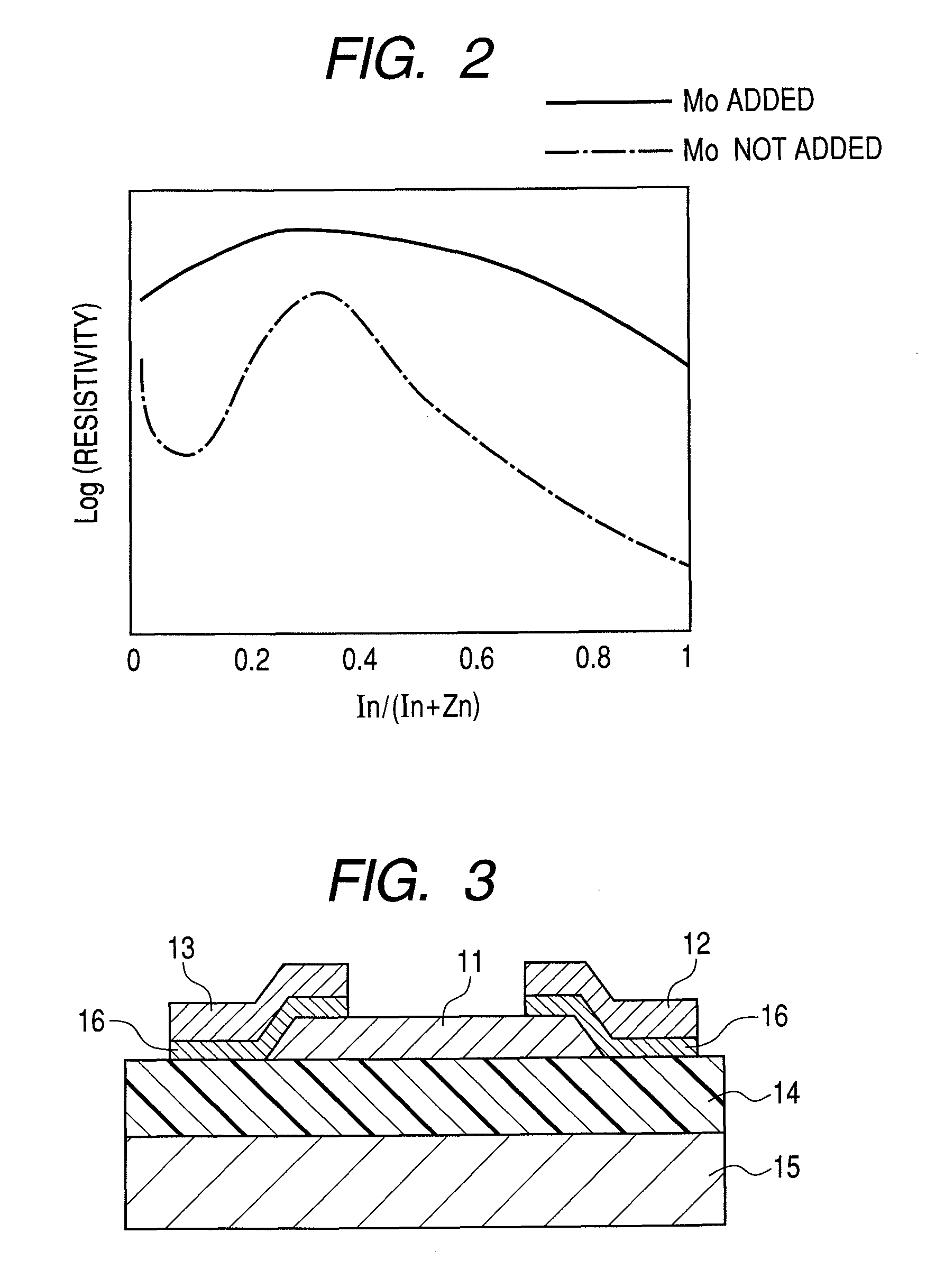

An amorphous oxide at least includes: at least one element selected from the group consisting of In, Zn, and Sn; and Mo. An atomic composition ratio of Mo to a number of all metallic atoms in the amorphous oxide is 0.1 atom % or higher and 5 atom % or lower.

Owner:CANON KK

Semiconductor apparatus and method of manufacturing the same

It is an object of the present invention to provide a technology of controlling a threshold voltage of a thin film transistor in which an amorphous oxide film is applied to a channel layer. There is provided a semiconductor apparatus including a plurality of kinds of transistors, each of the plurality of kinds of transistors including a channel layer made of an amorphous oxide containing a plurality of kinds of metal elements; and threshold voltages of the plurality of kinds of transistors are different from one another by changing an element ratio of the amorphous oxide.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com