Patents

Literature

124 results about "Charge-carrier density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Charge carrier density, also known as carrier concentration, denotes the number of charge carriers in per volume. In SI units, it is measured in m⁻³. As with any density, in principle it can depend on position. However, usually carrier concentration is given as a single number, and represents the average carrier density over the whole material.

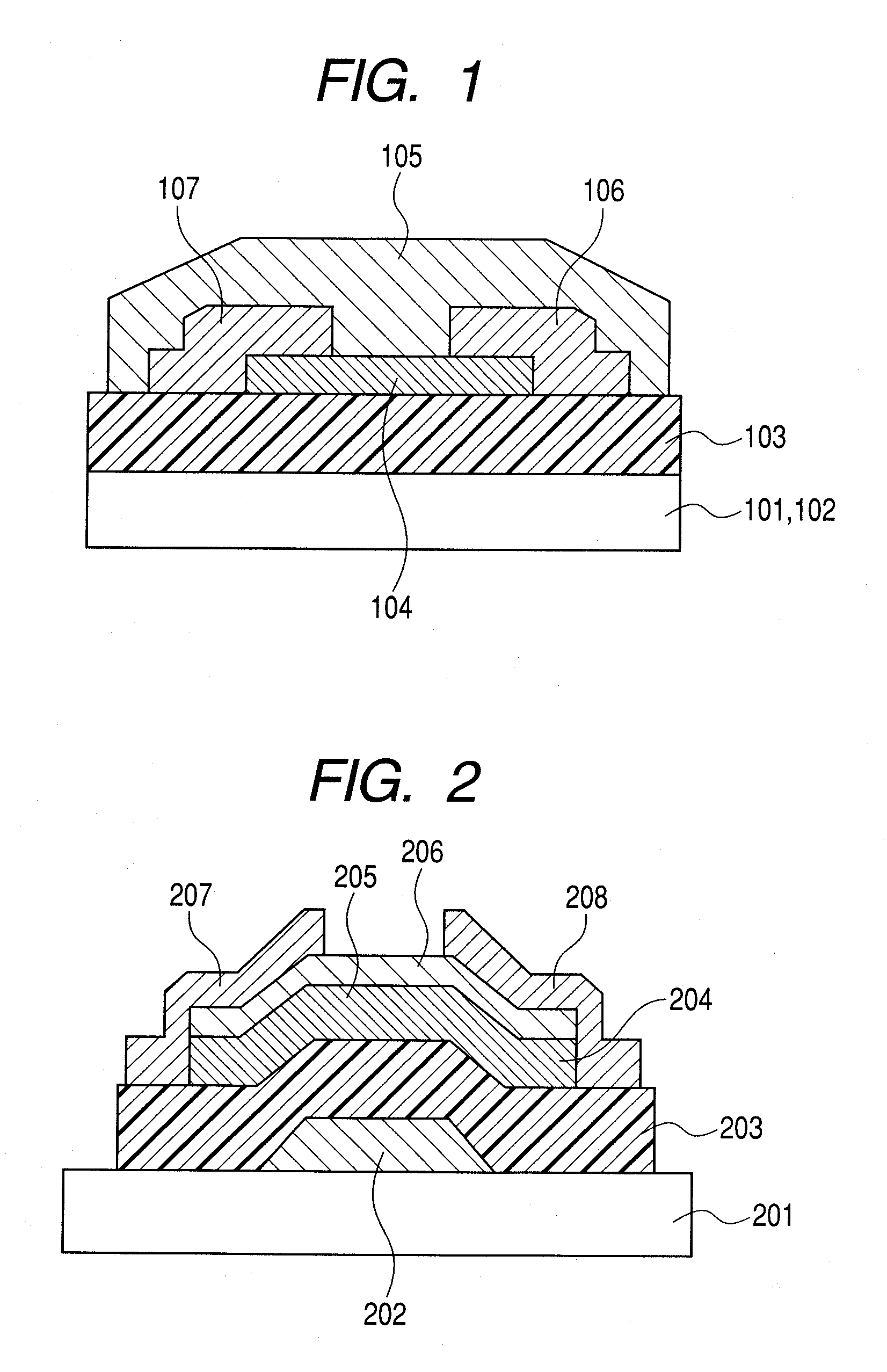

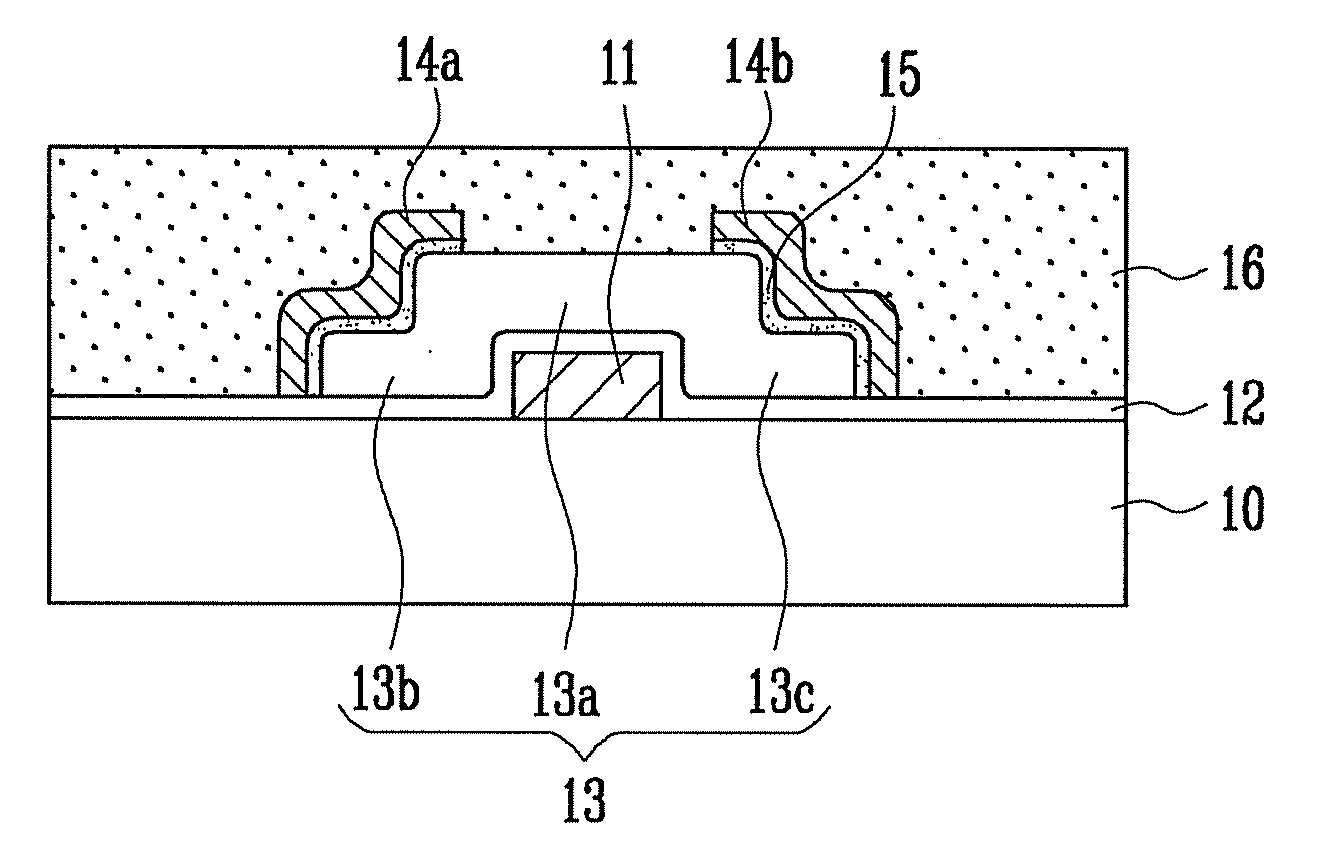

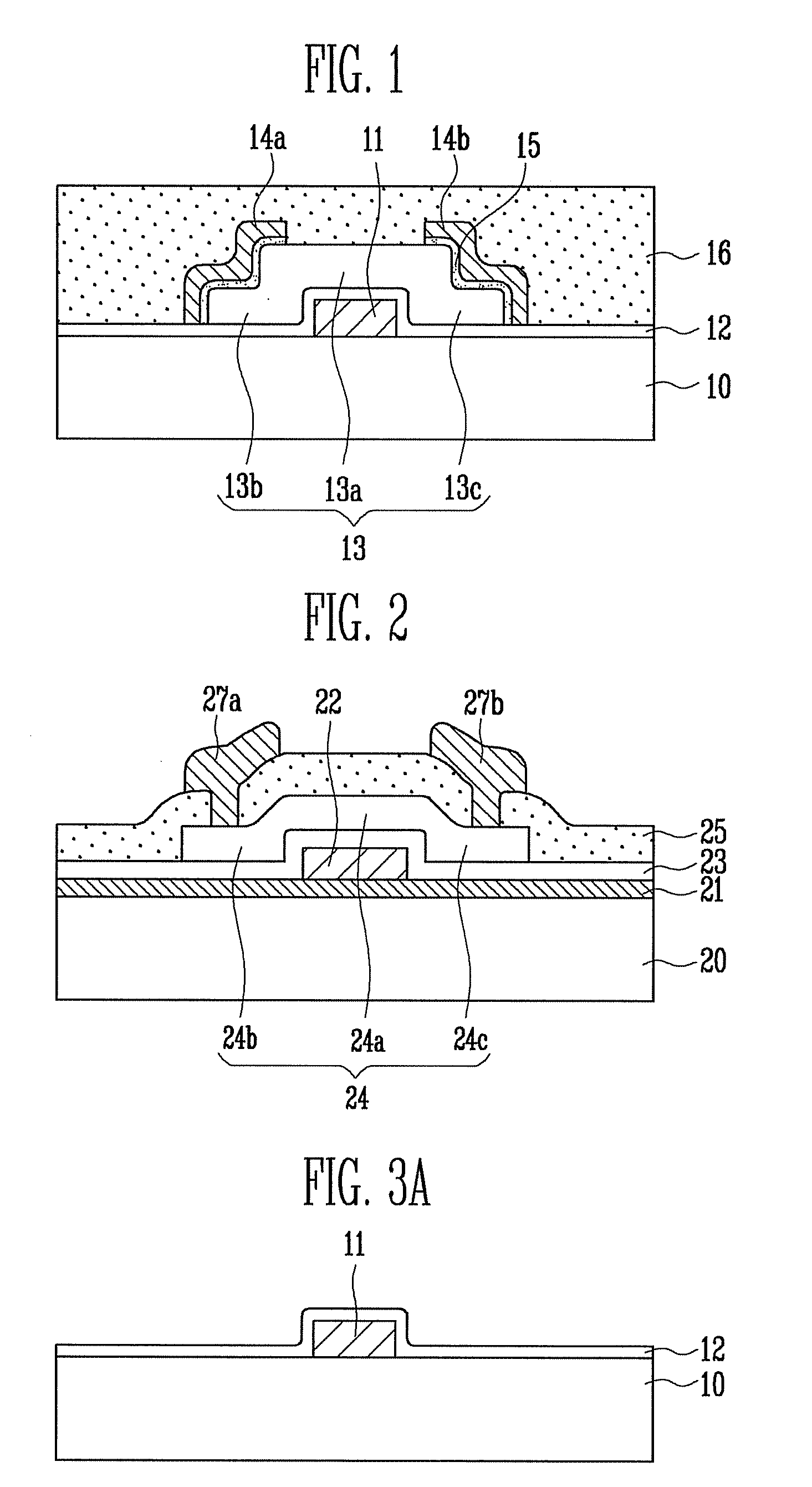

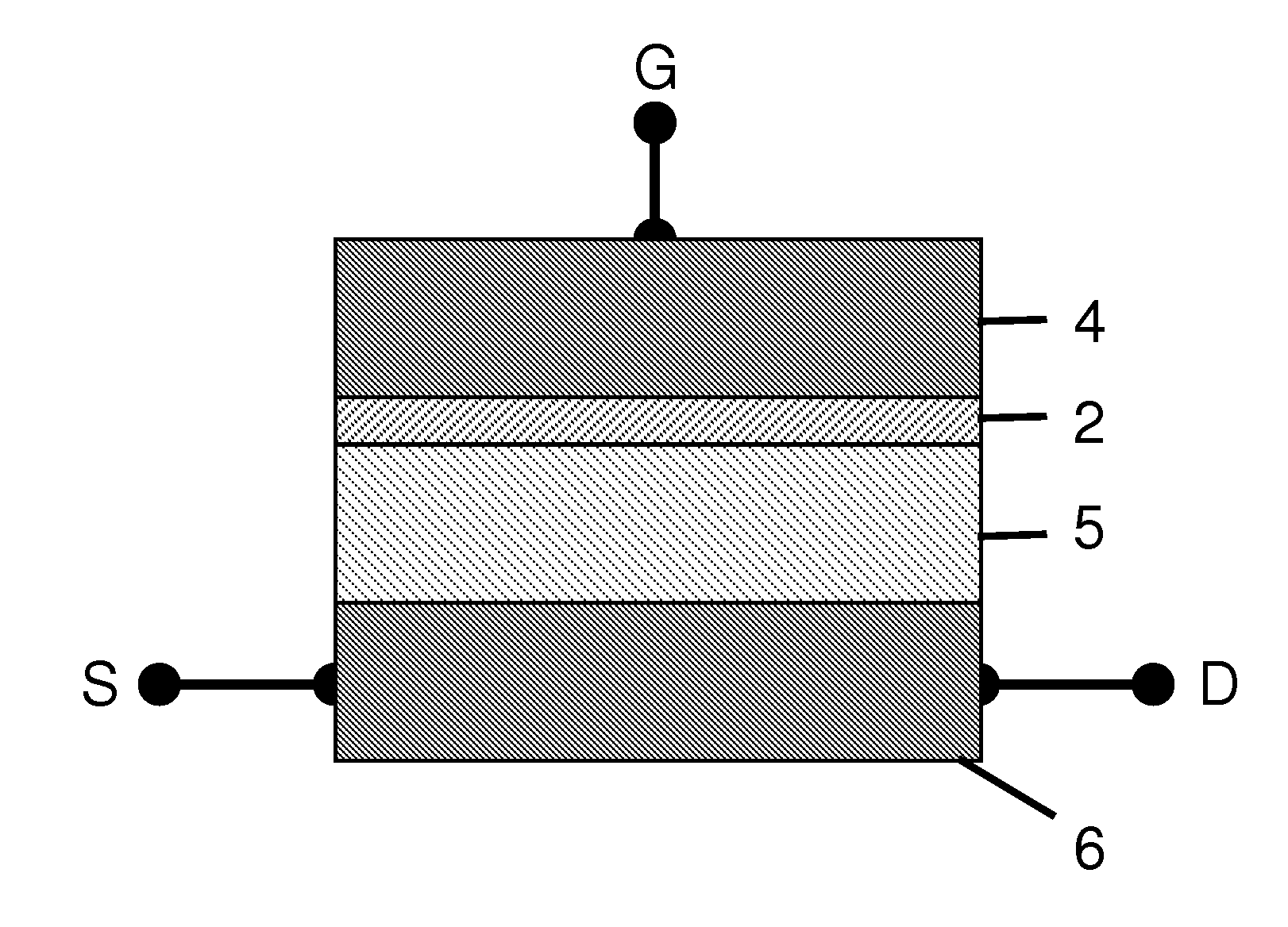

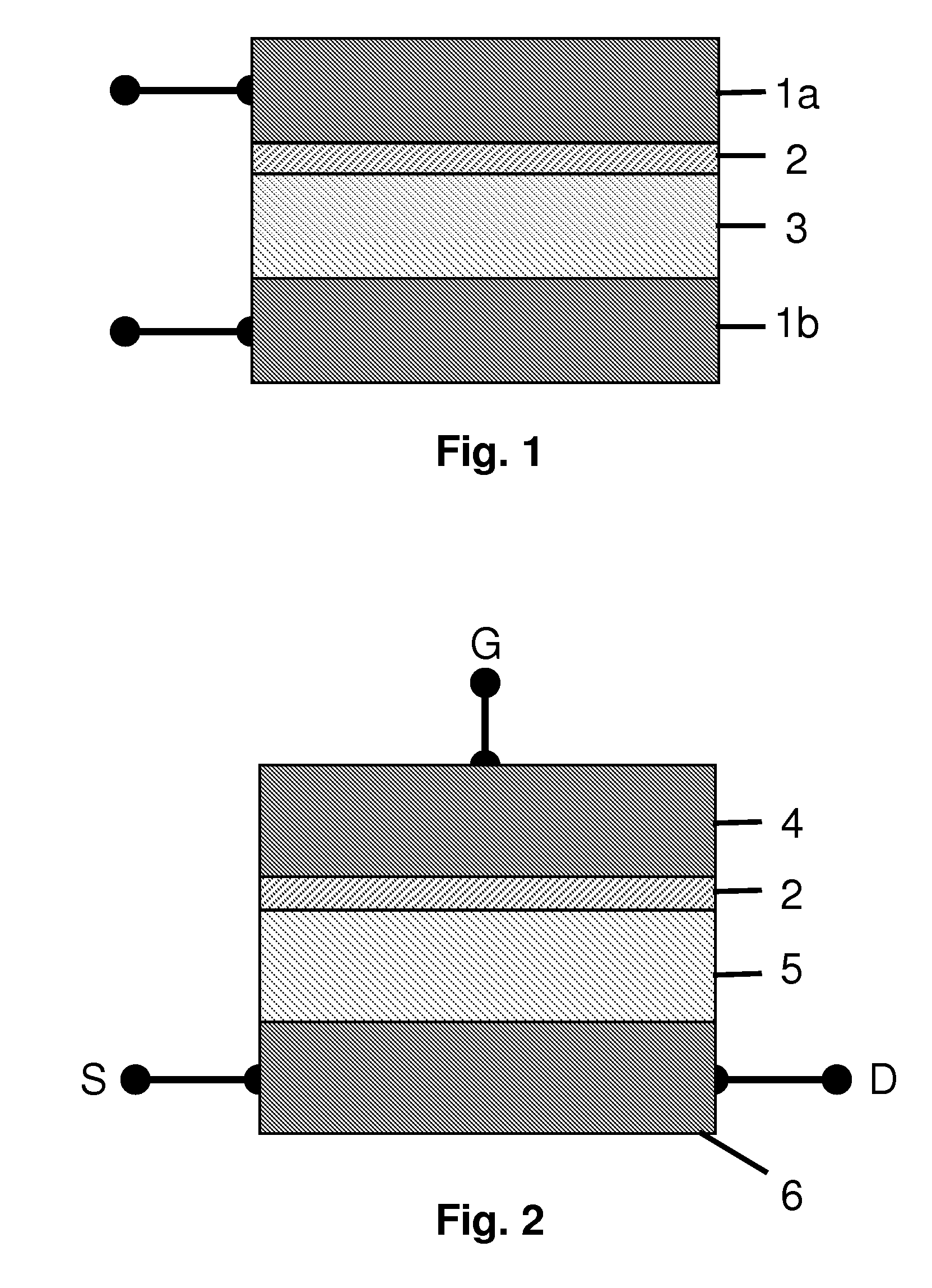

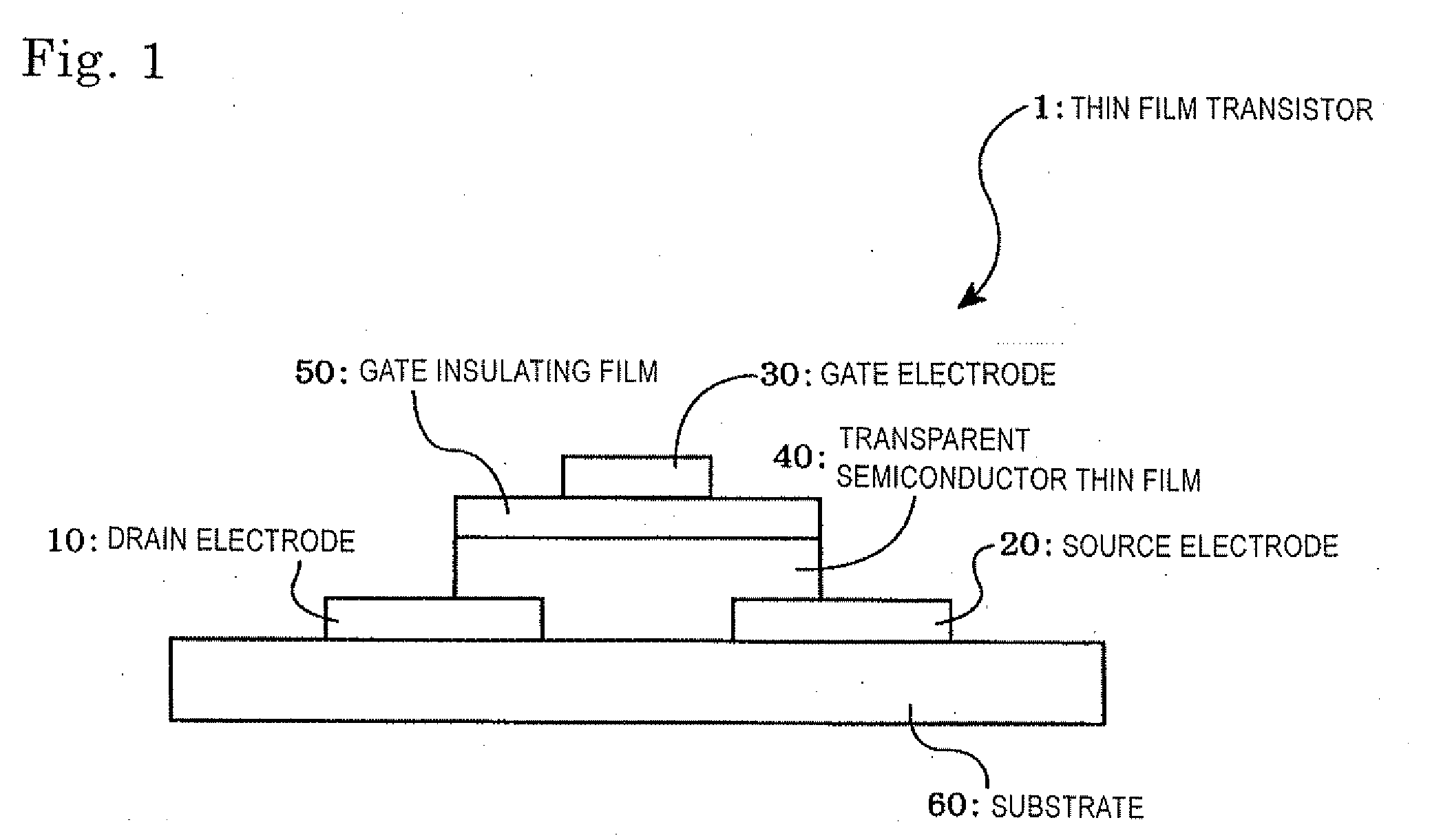

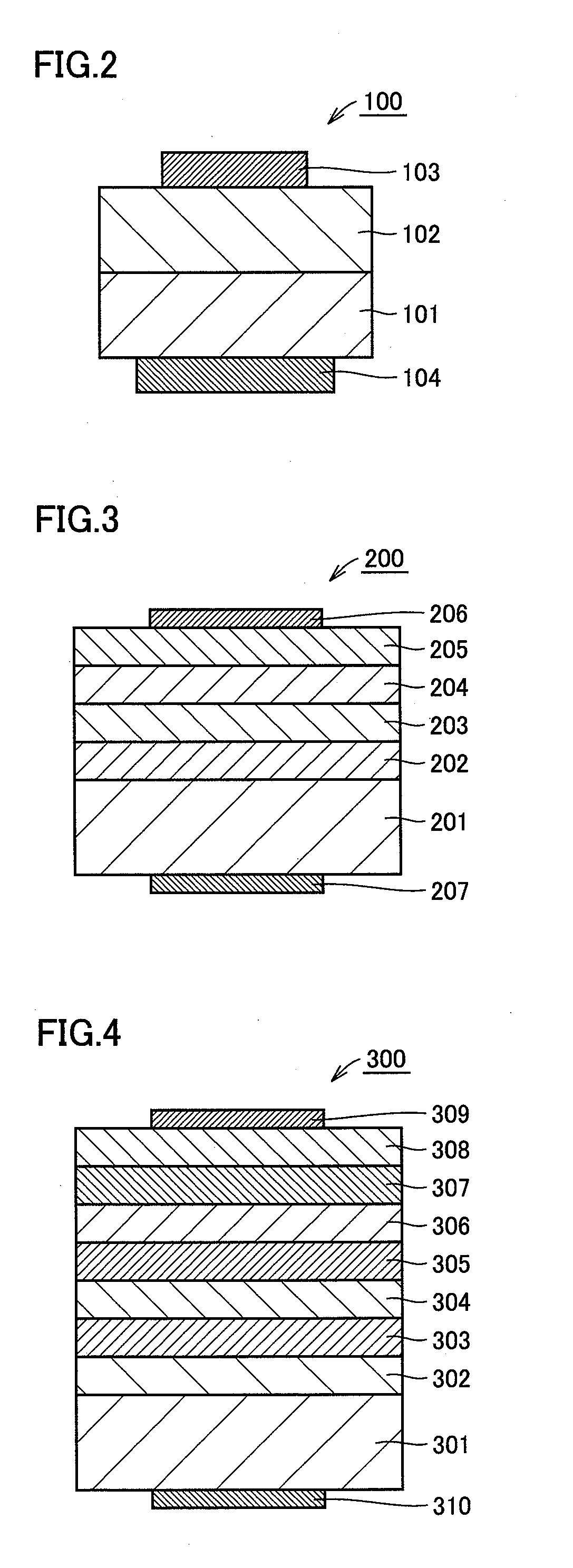

Thin-film transistor and method of manufacturing same

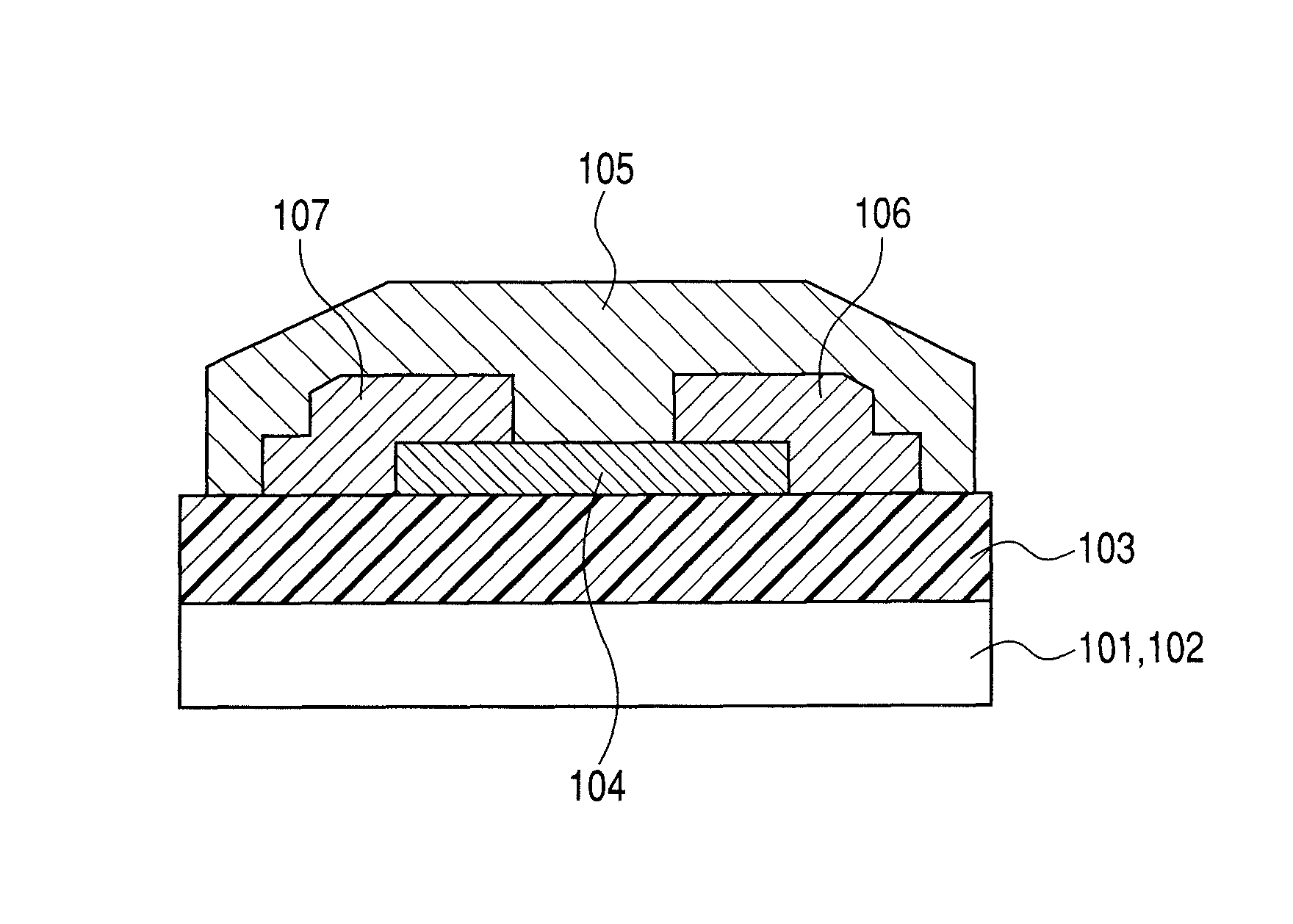

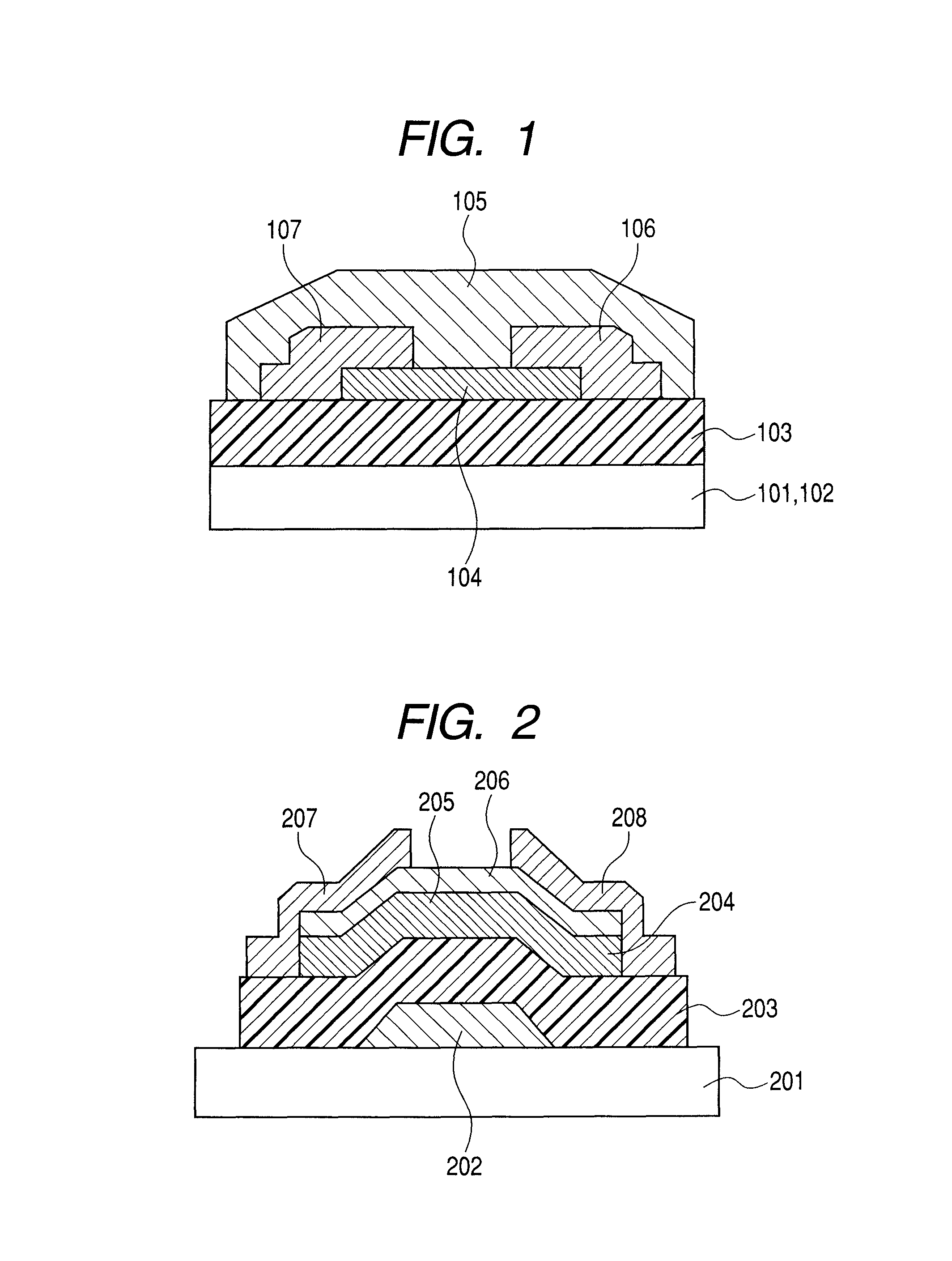

There is provided a thin-film transistor including at least a substrate, a gate electrode, a gate insulating layer, an oxide semiconductor layer, a source electrode, a drain electrode and a protective layer, wherein the oxide semiconductor layer is an amorphous oxide containing at least one of the elements In, Ga and Zn, the gate electrode-side carrier density of the oxide semiconductor layer is higher than the protective layer-side carrier density thereof, and the film thickness of the oxide semiconductor layer is 30 nm±15 nm.

Owner:CANON KK

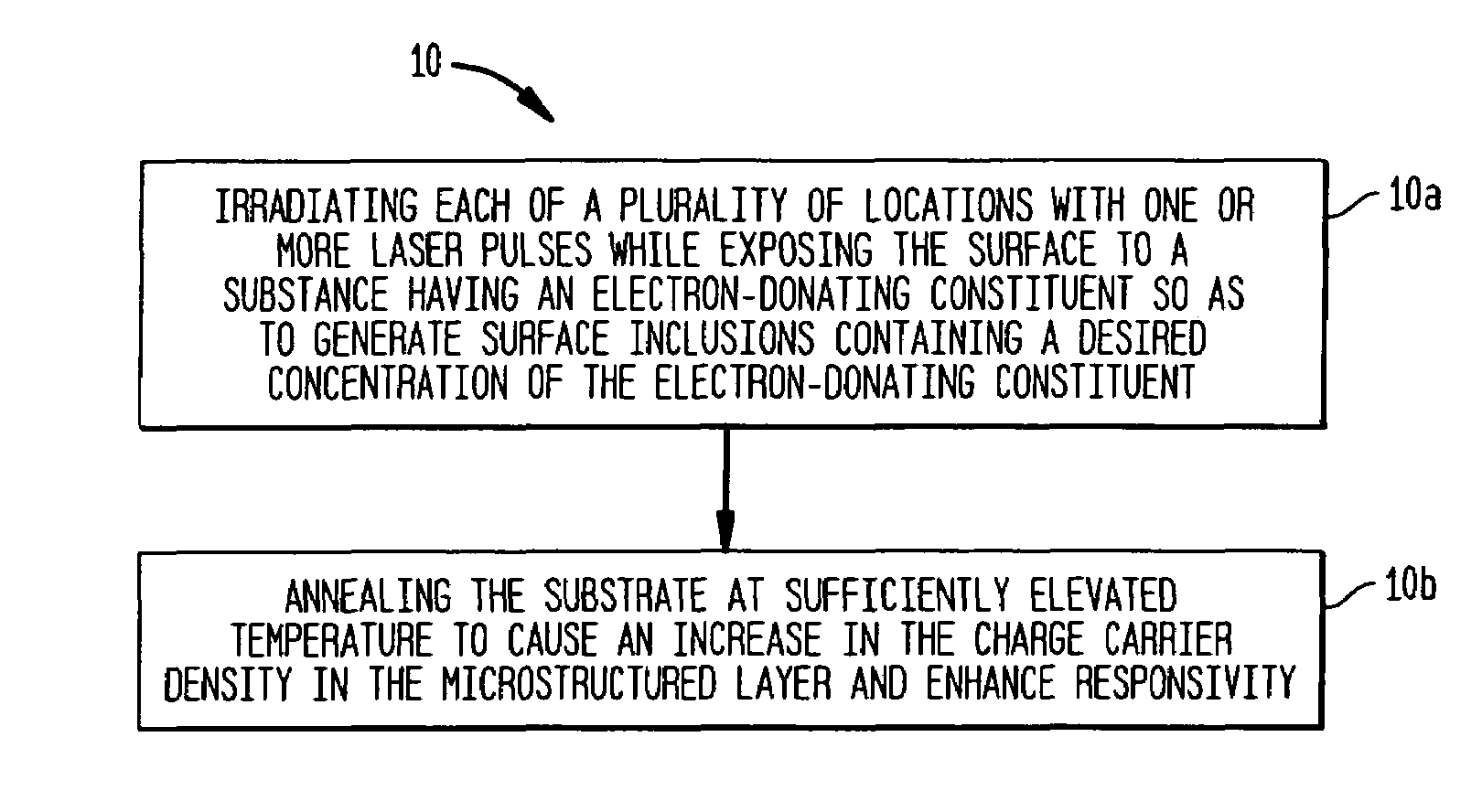

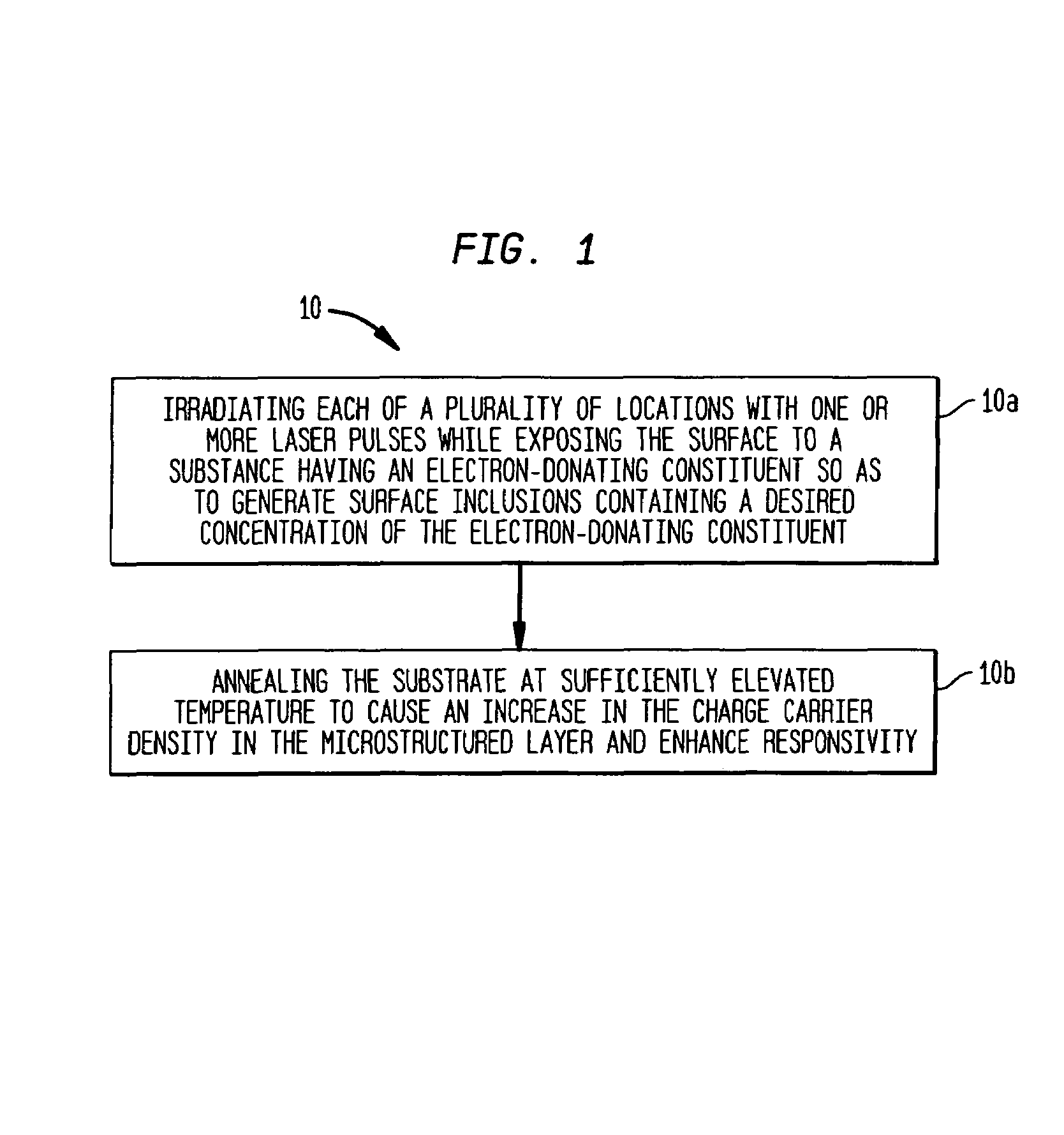

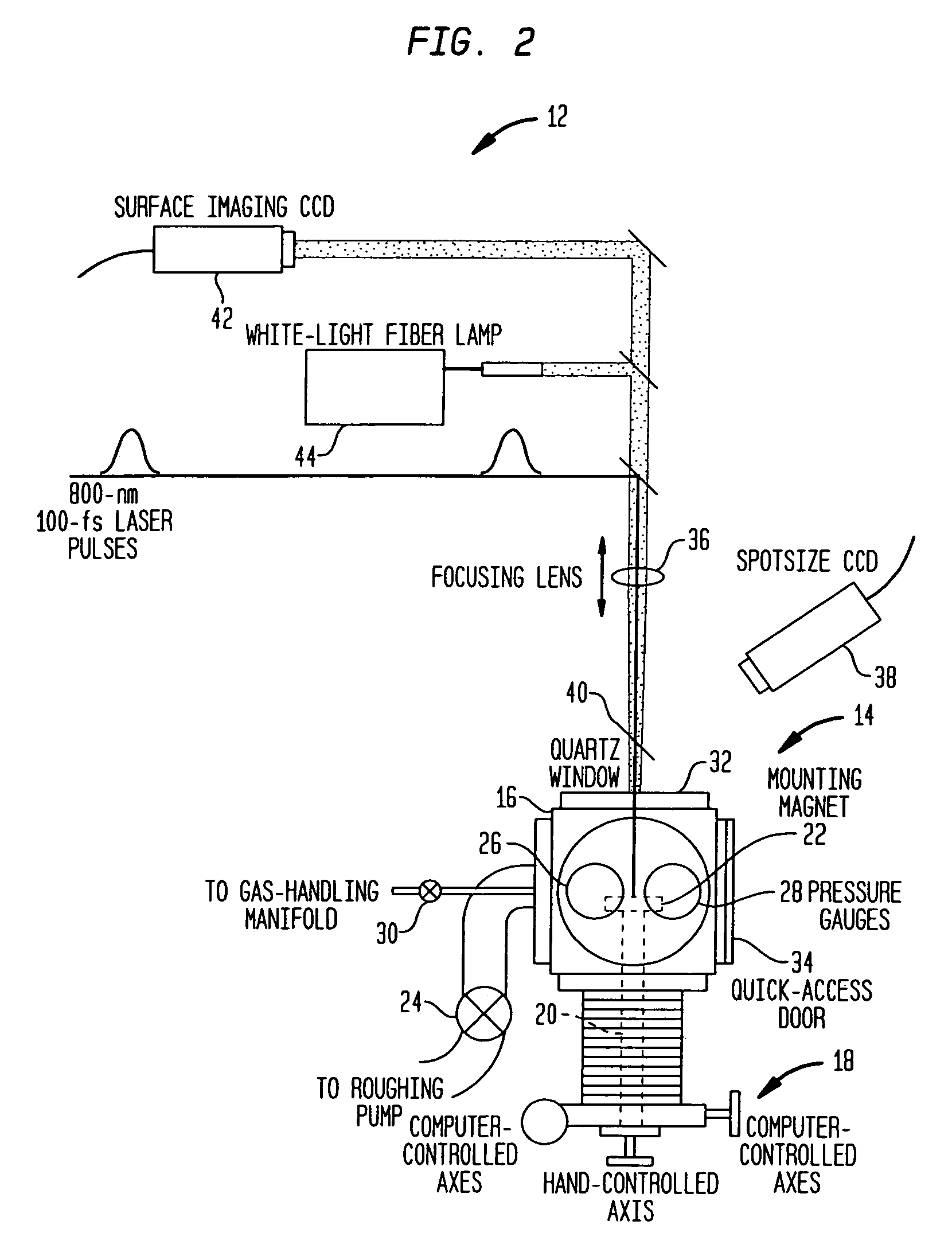

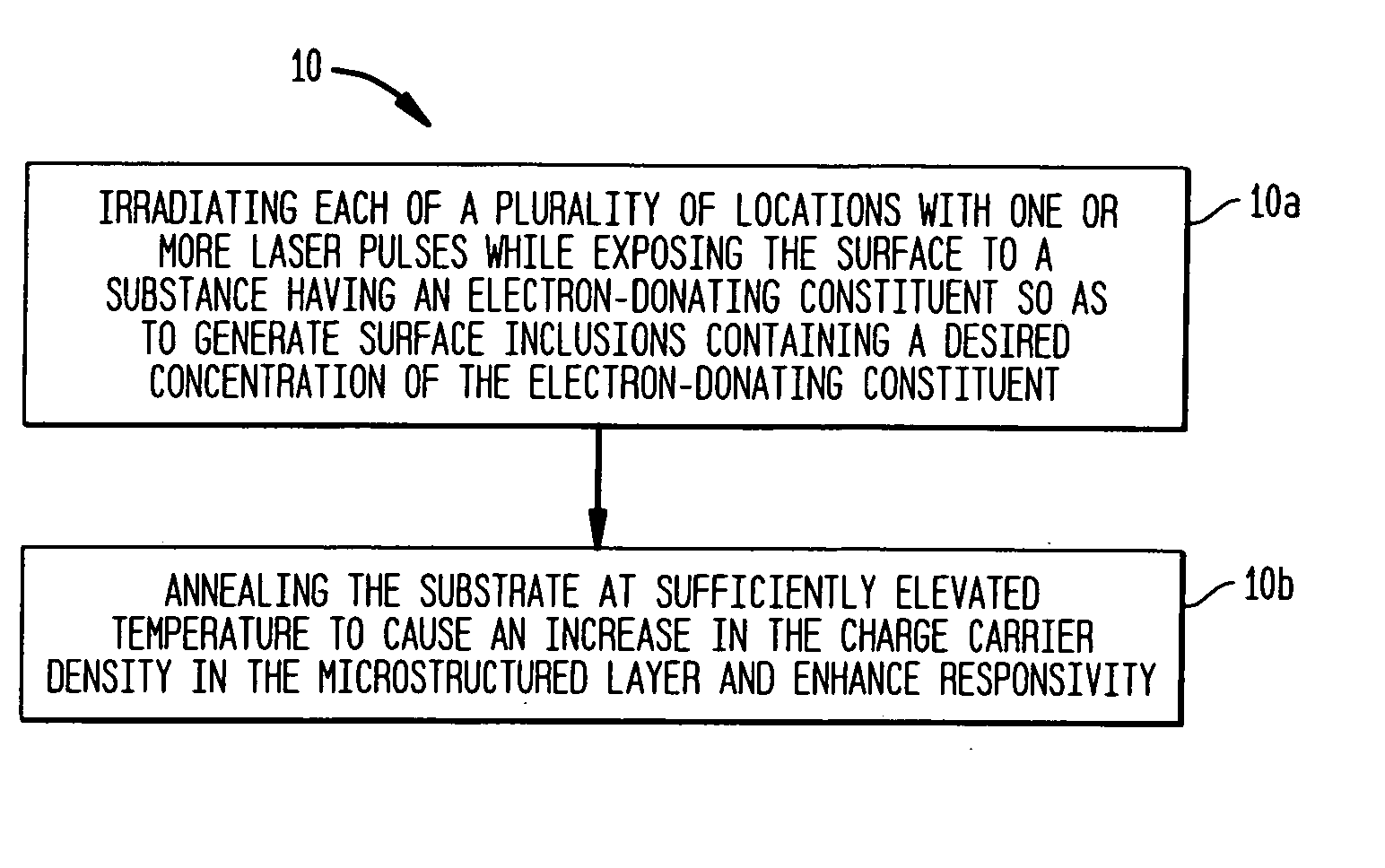

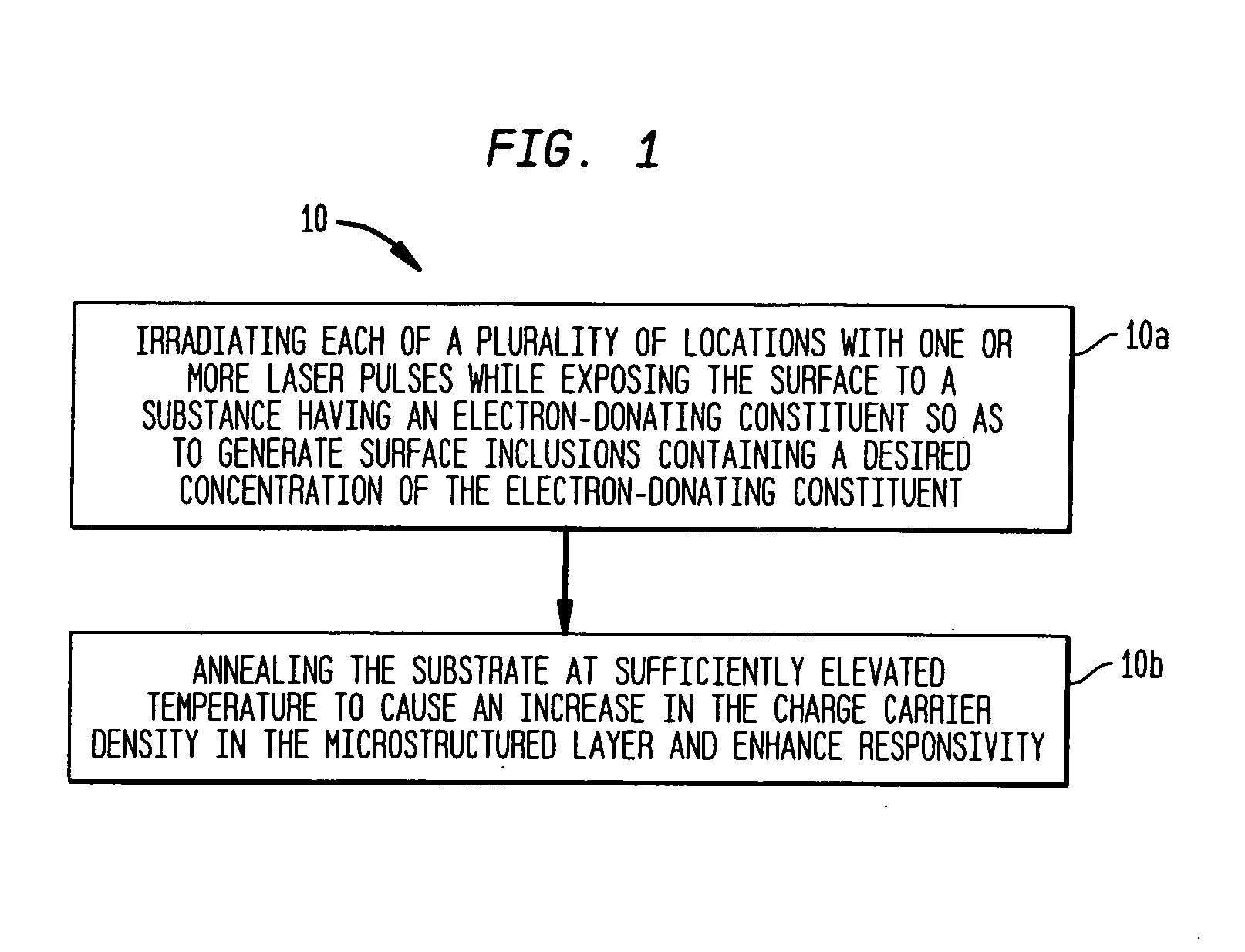

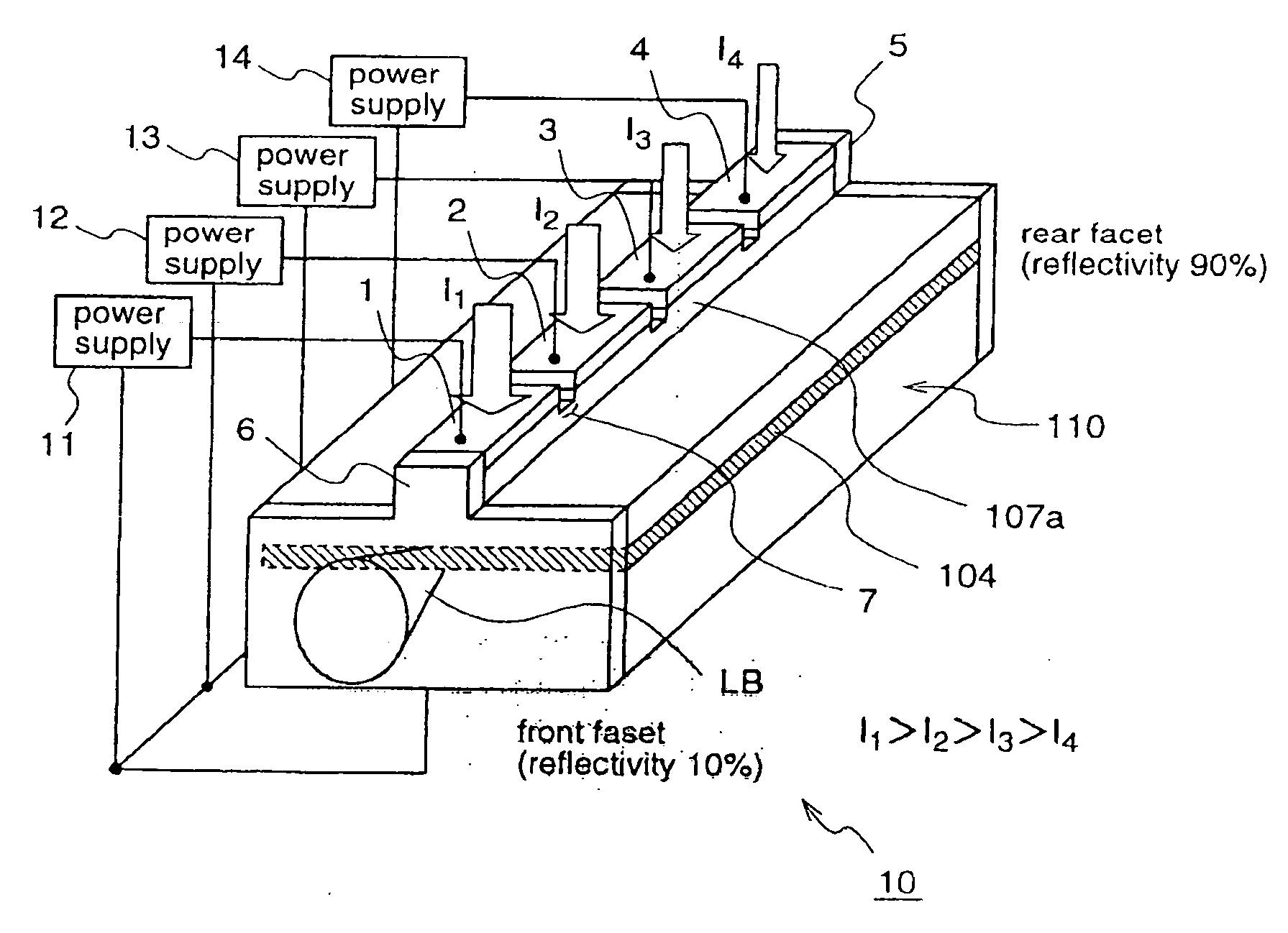

Manufacture of silicon-based devices having disordered sulfur-doped surface layers

InactiveUS7354792B2Final product manufactureSemiconductor/solid-state device manufacturingSurface layerCharge-carrier density

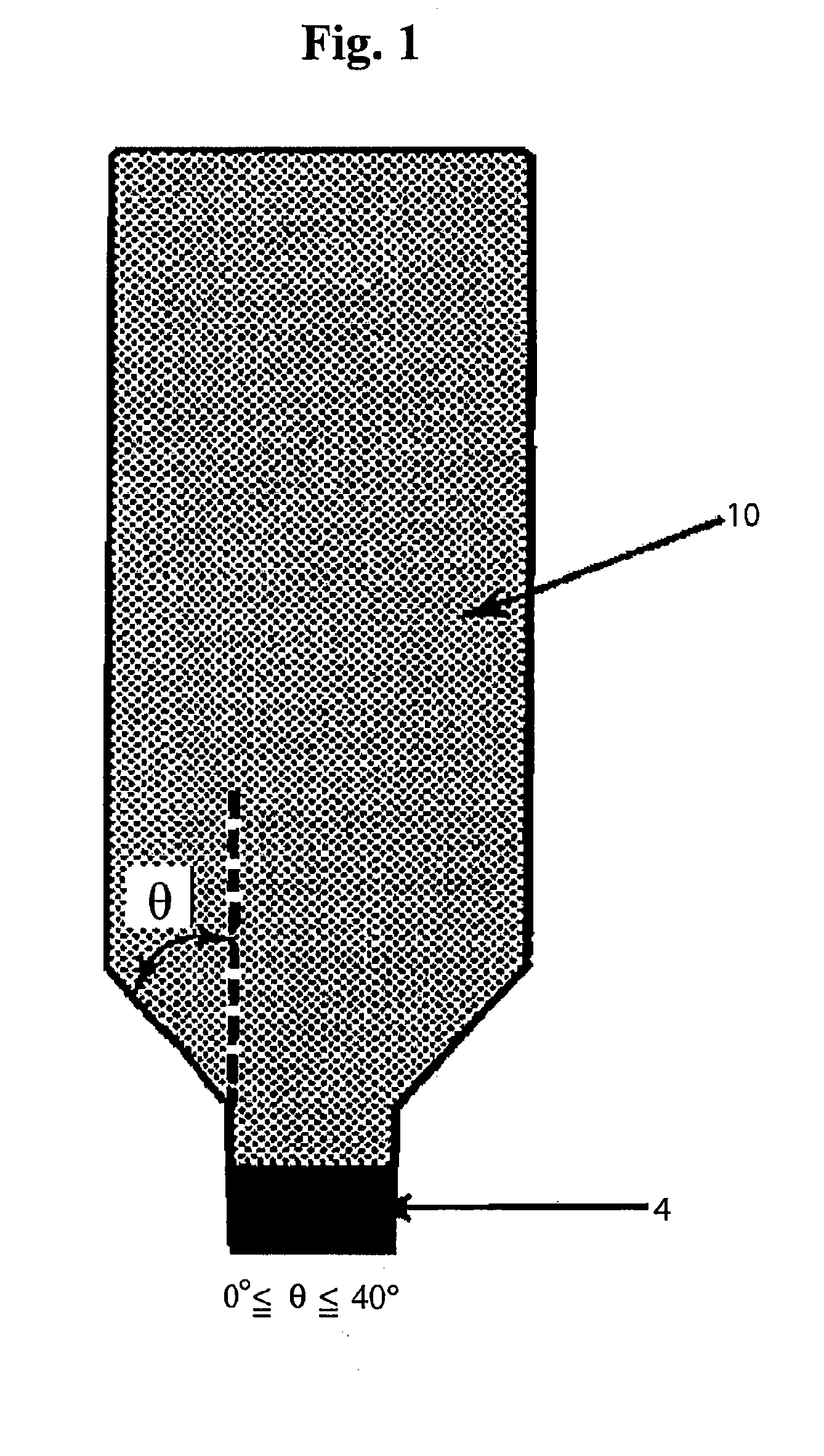

The present invention provides methods of fabricating a radiation-absorbing semiconductor wafer by irradiating at least one surface location of a silicon substrate, e.g., an n-doped crystalline silicon, by a plurality of temporally short laser pulses, e.g., femtosecond pulses, while exposing that location to a substance, e.g., SF6, having an electron-donating constituent so as to generate a substantially disordered surface layer (i.e., a microstructured layer) that incorporates a concentration of that electron-donating constituent, e.g., sulfur. The substrate is also annealed at an elevated temperature and for a duration selected to enhance the charge carrier density in the surface layer. For example, the substrate can be annealed at a temperature in a range of about 700 K to about 900 K.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

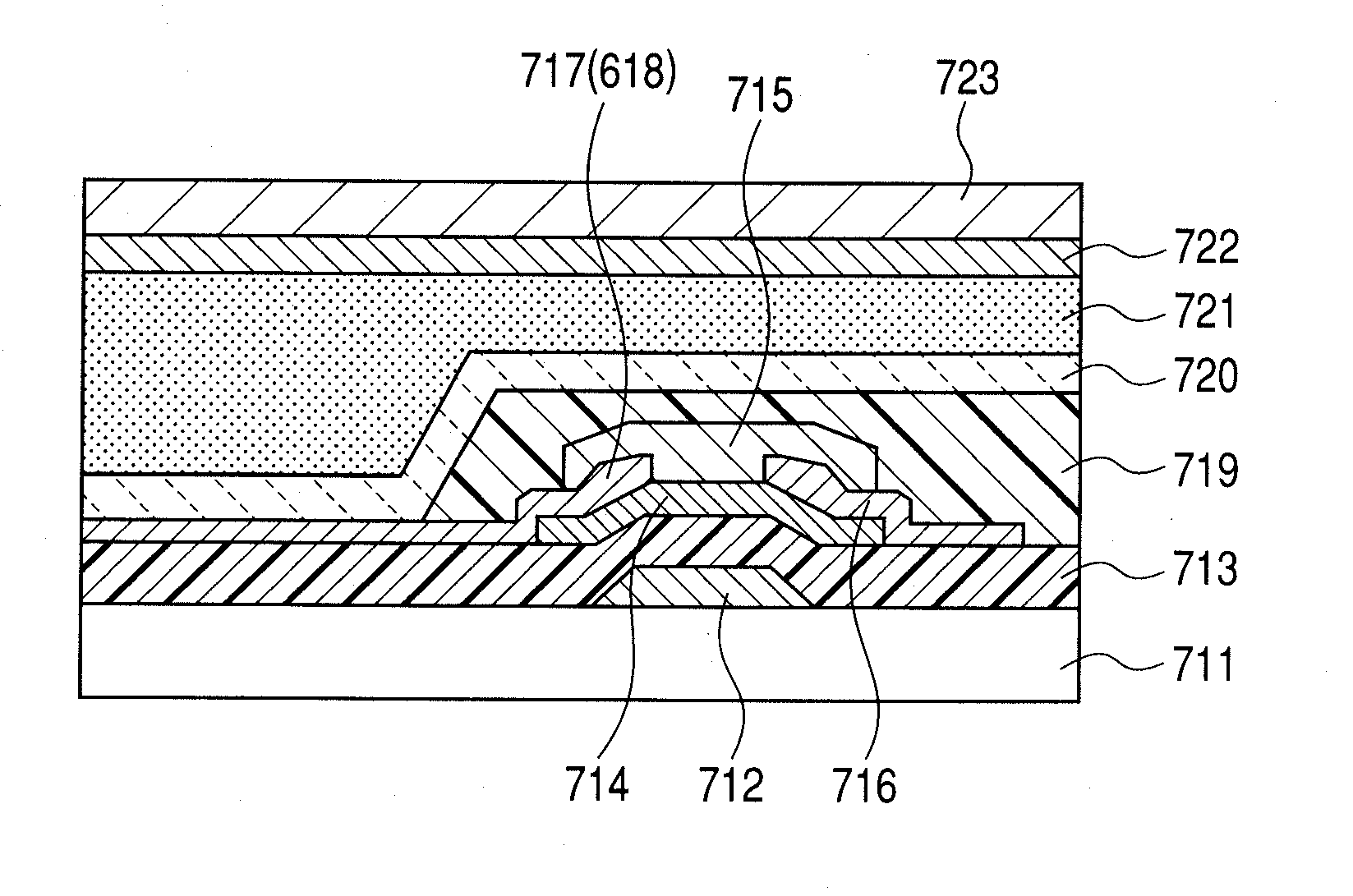

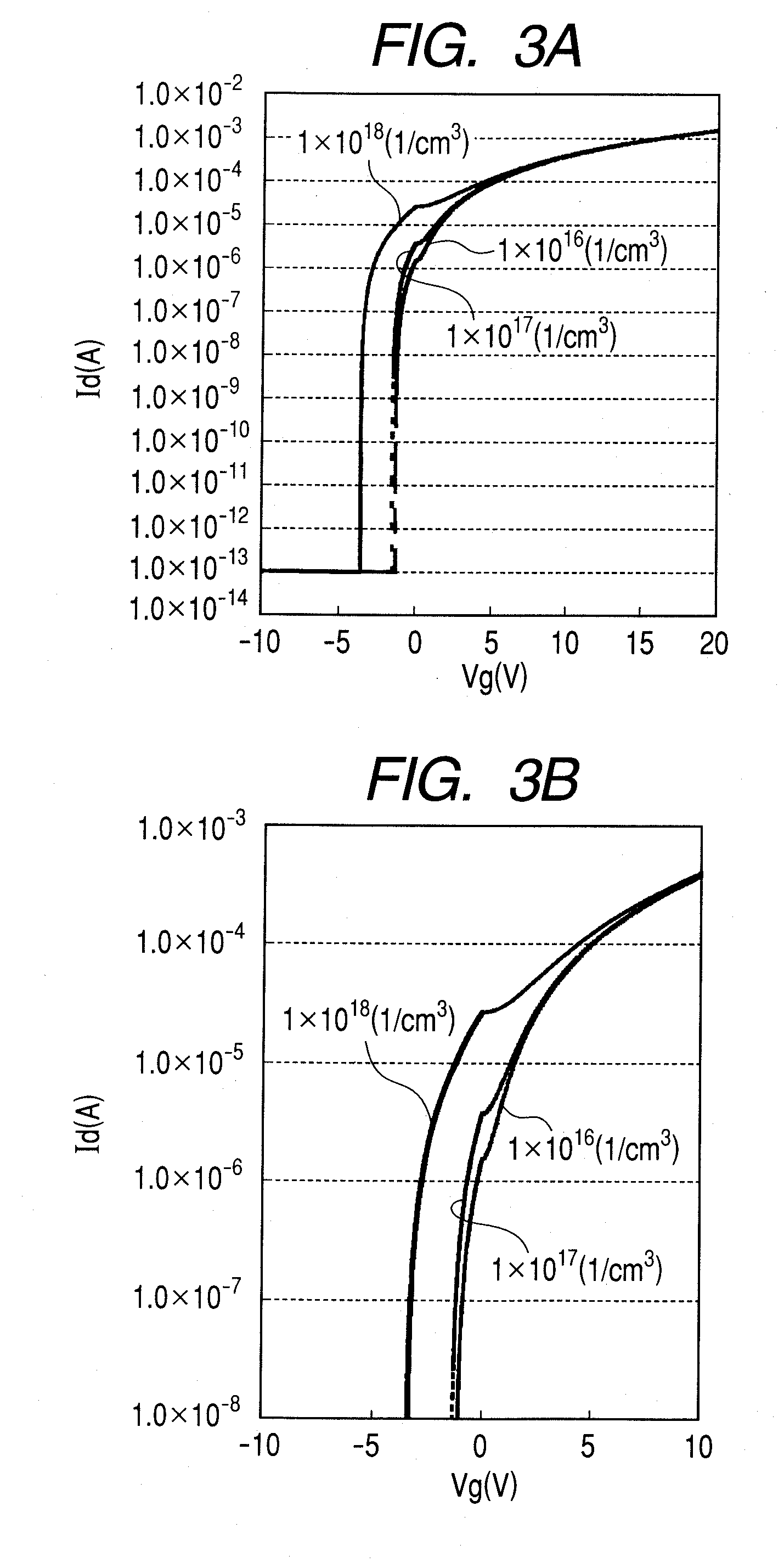

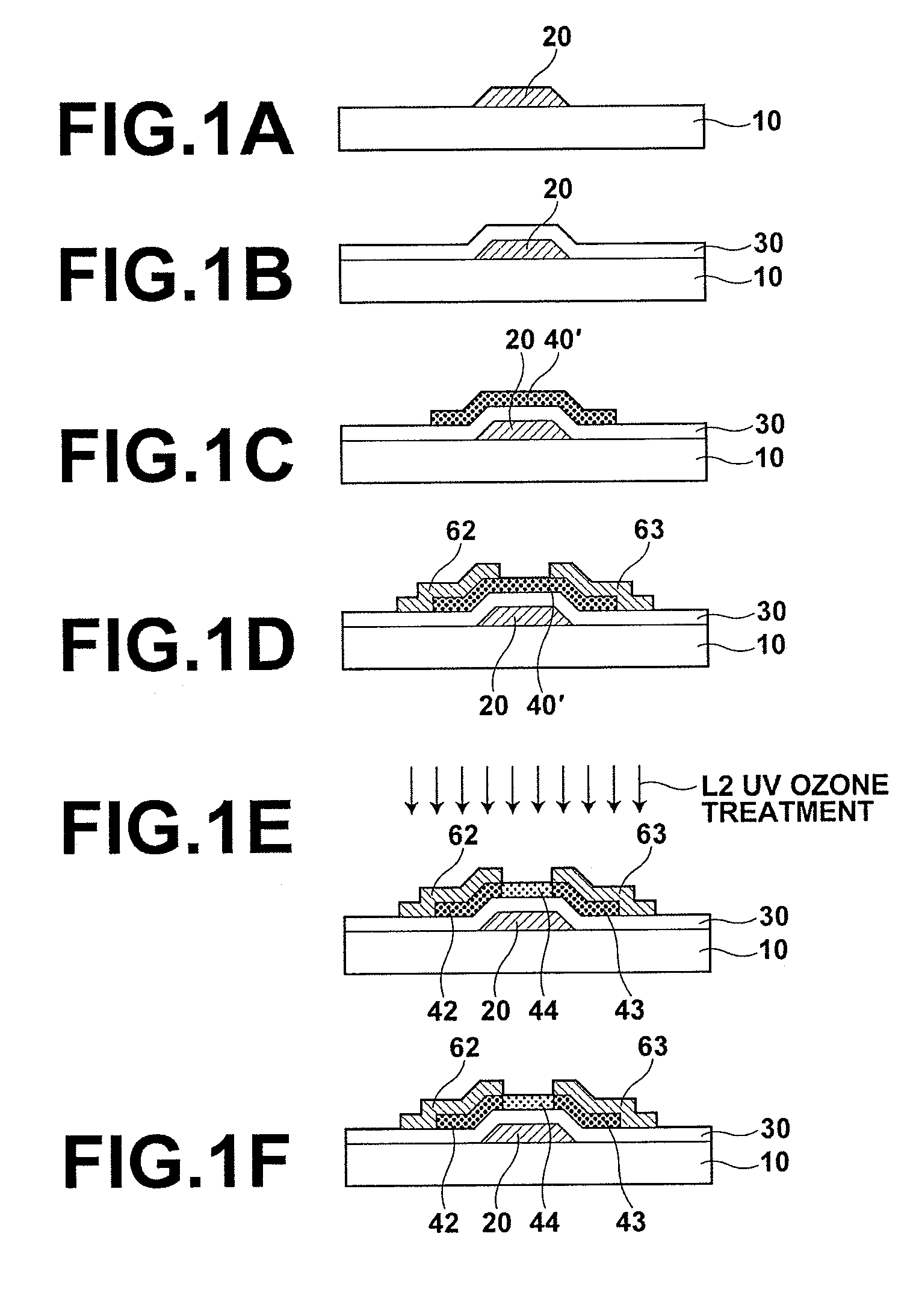

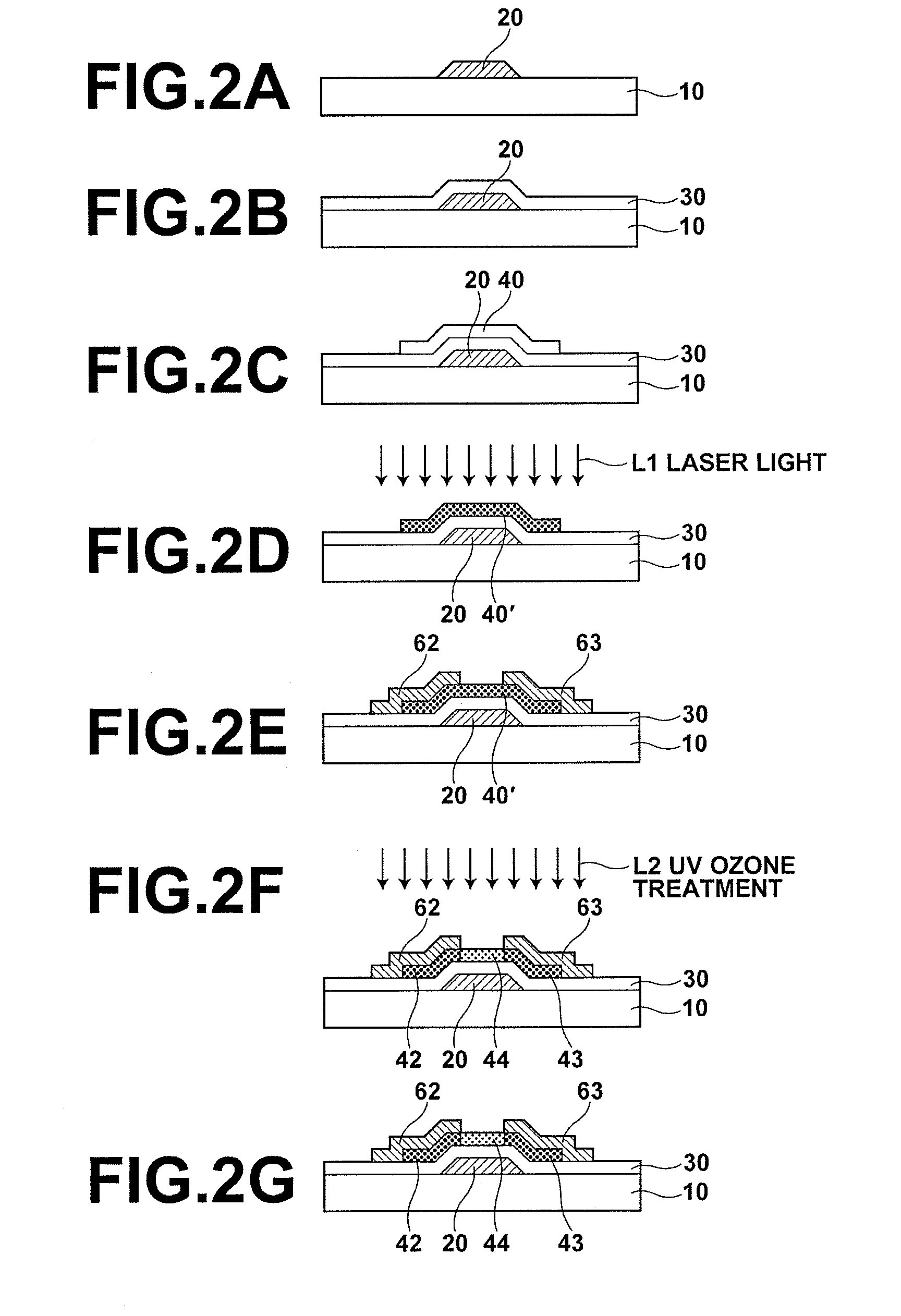

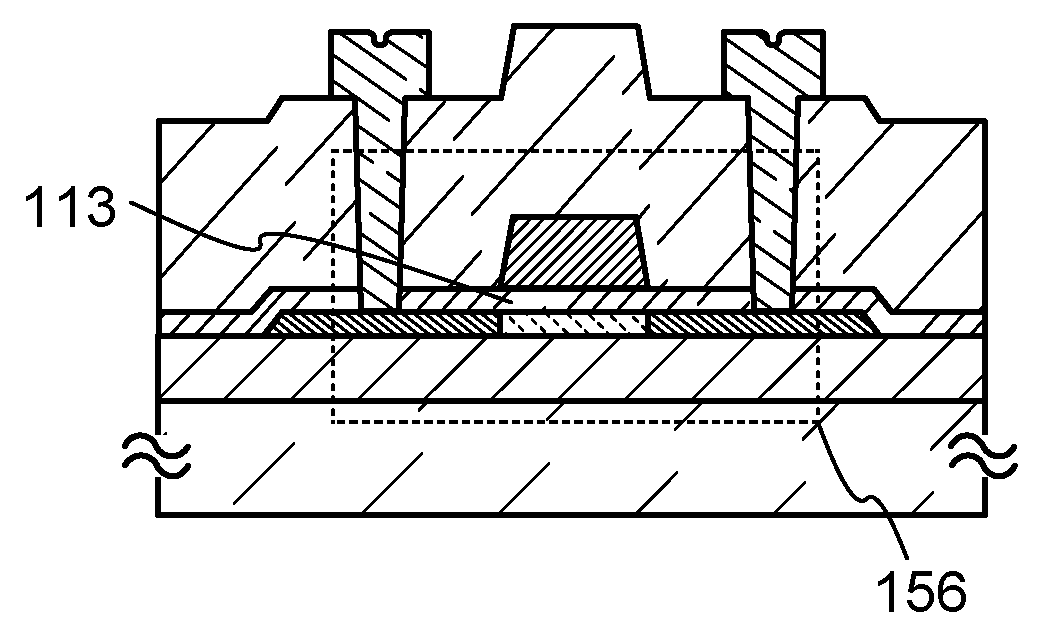

Method of manufacturing thin film transistor and method of manufacturing organic light emitting display having thin film transistor

ActiveUS20090155940A1Preventing and reducing property changeReliability and electrical property is raisedTransistorSolid-state devicesCharge-carrier densityOxygen ions

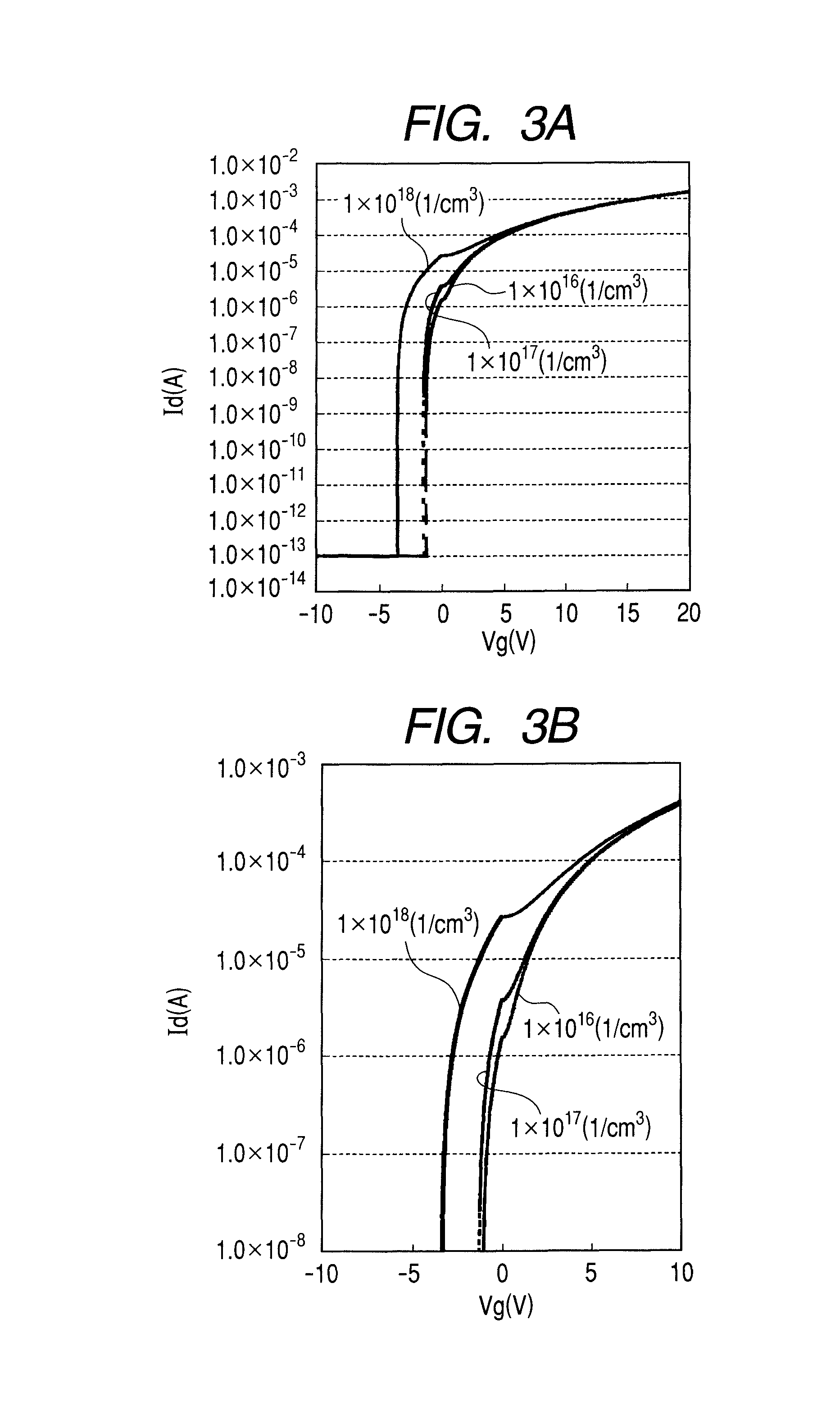

A method of manufacturing a thin film transistor having a compound semiconductor with oxygen as a semiconductor layer and a method of manufacturing an organic light emitting display having the thin film transistor include: forming a gate electrode on an insulating substrate; forming a gate insulating layer on the gate electrode; forming a semiconductor layer including oxygen ions on the gate insulating layer, and including a channel region, a source region, and a drain region; forming a source electrode and a drain electrode to contact the semiconductor layer in the source region and the drain region, respectively; and forming a passivation layer on the semiconductor layer by coating an organic material, wherein a carrier density of the semiconductor layer is maintained in the range of 1E+17 to 1E+18 / cm3 to have stable electrical property.

Owner:SAMSUNG DISPLAY CO LTD

Semiconductor device and method for manufacturing the same

ActiveUS20110127522A1High on-off ratioHigh puritySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsElectron donor

Objects are to provide a semiconductor device for high power application in which a novel semiconductor material having high productivity is used and to provide a semiconductor device having a novel structure in which a novel semiconductor material is used. The present invention is a vertical transistor and a vertical diode each of which has a stacked body of an oxide semiconductor in which a first oxide semiconductor film having crystallinity and a second oxide semiconductor film having crystallinity are stacked. An impurity serving as an electron donor (donor) which is contained in the stacked body of an oxide semiconductor is removed in a step of crystal growth; therefore, the stacked body of an oxide semiconductor is highly purified and is an intrinsic semiconductor or a substantially intrinsic semiconductor whose carrier density is low. The stacked body of an oxide semiconductor has a wider band gap than a silicon semiconductor.

Owner:SEMICON ENERGY LAB CO LTD

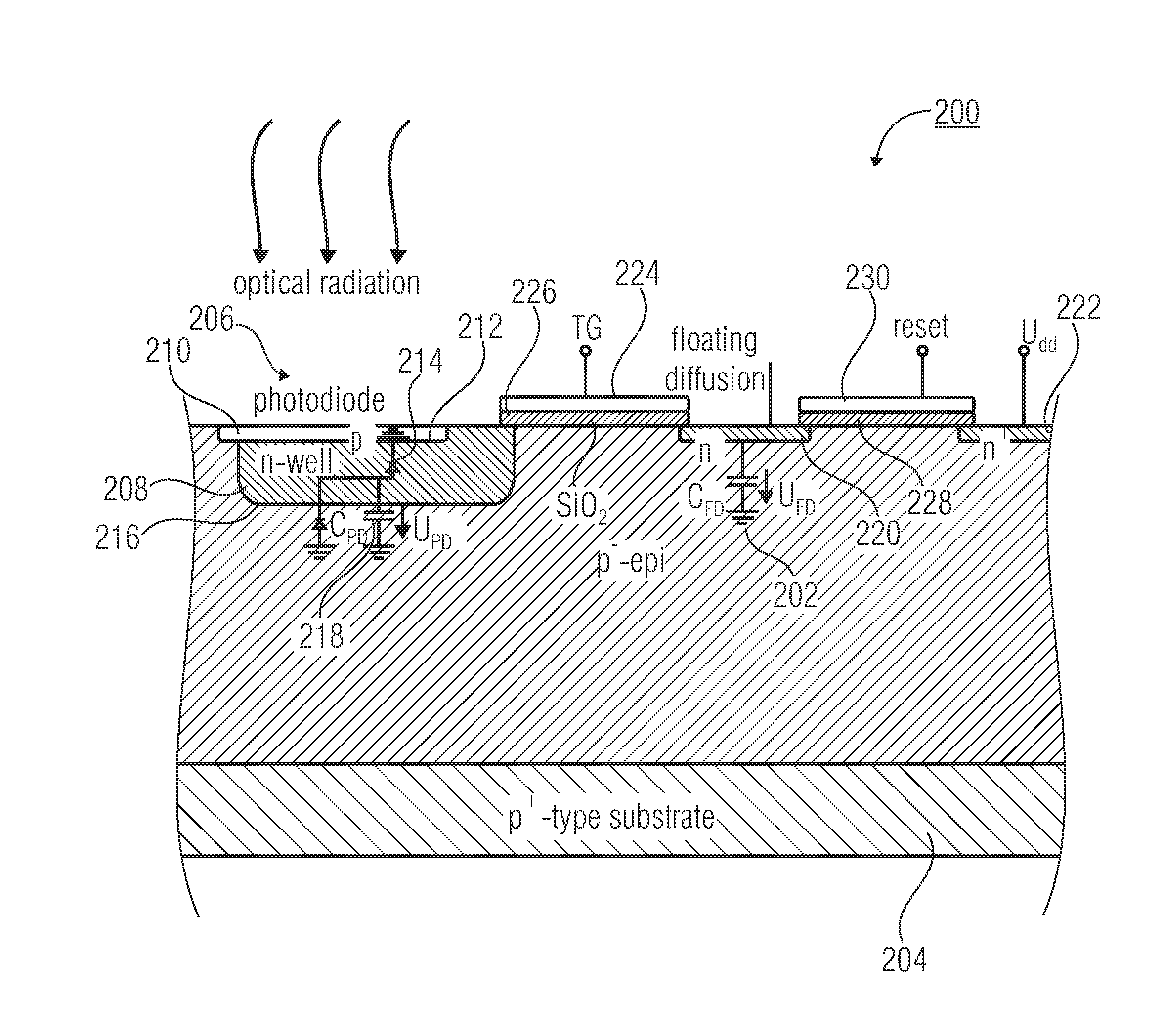

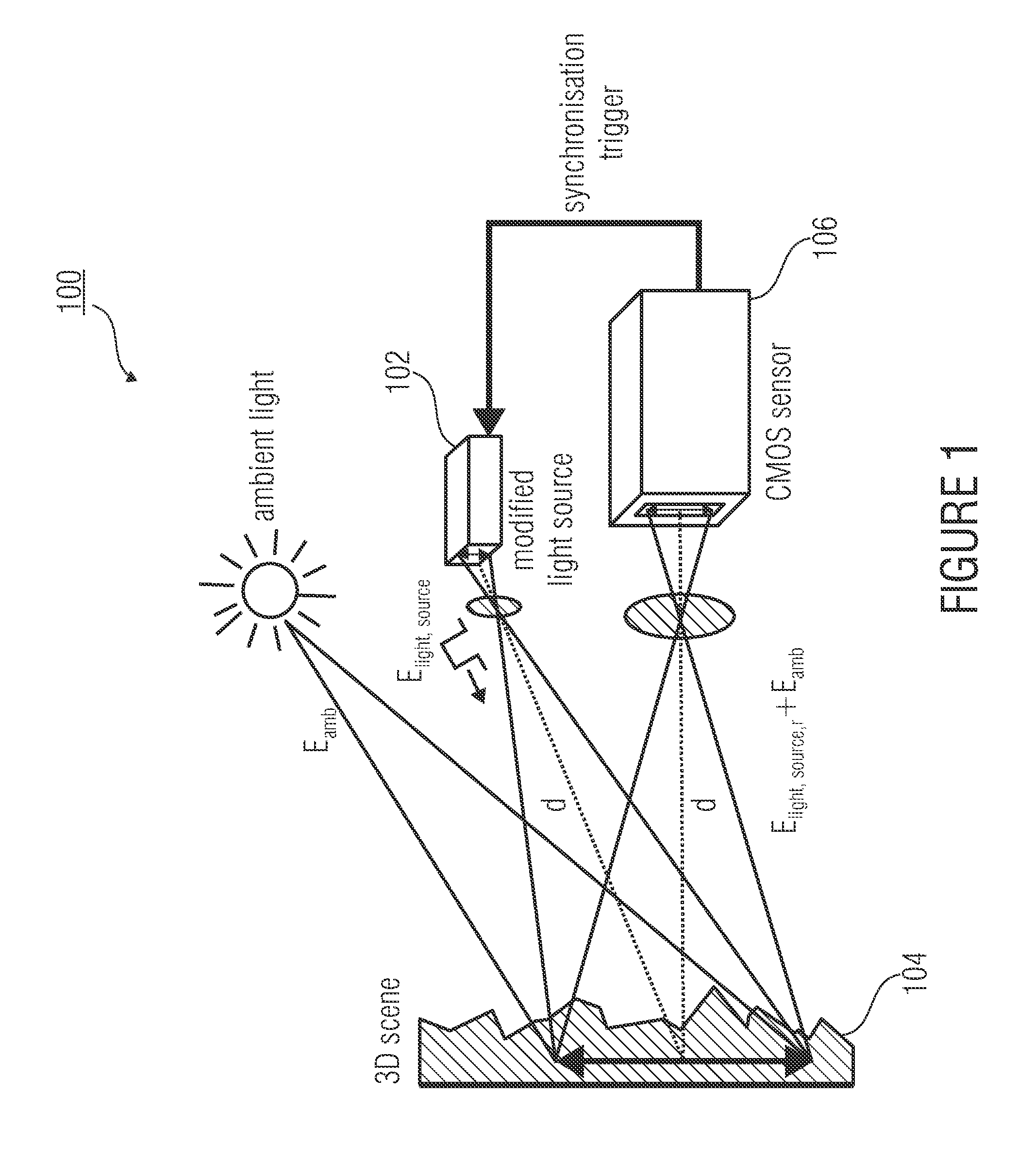

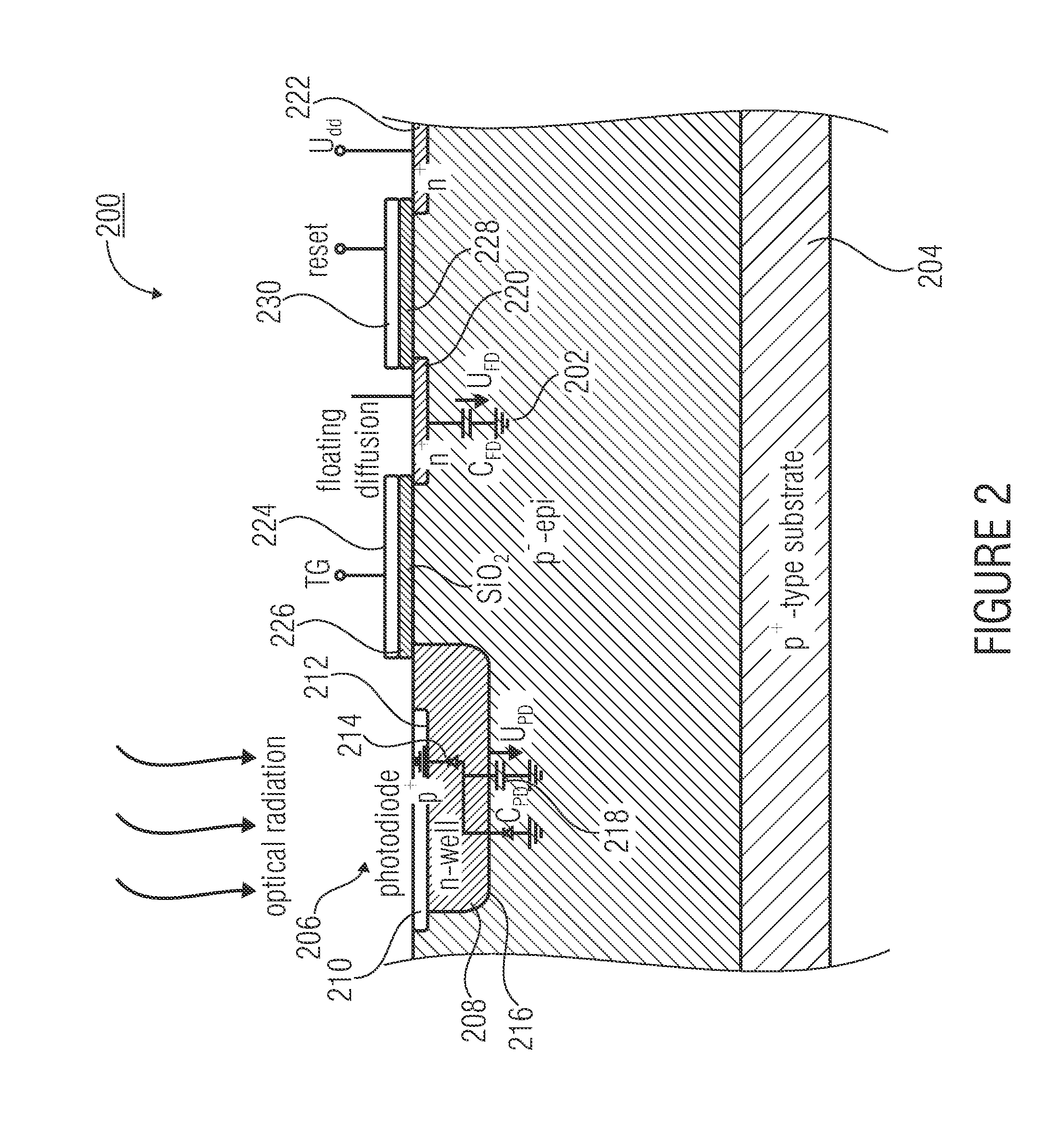

Concept for optical distance measurement

ActiveUS20110037969A1Halving laser energyDoubling measuring speedOptical rangefindersDiodeCharge-carrier densityCharge carrier

The present invention relates to a concept for optical distance measurement, wherein a radiation pulse is emitted in the direction of an object of measurement. At least two different transfer gates which couple a photoactive region to at least two different evaluating capacities are driven during different drive intervals so that charge carriers generated during the drive intervals by a radiation pulse reflected from the object of measurement and / or by ambient radiation can be transported from the photoactive region to the evaluating capacities each coupled to the at least two transfer gates. Another transfer gate is driven during a time outside the drive intervals of the at least two transfer gates to connect the photoactive region to a reference potential terminal acting as a charge carrier sink during the time outside the drive intervals of the at least two transfer gates.

Owner:VOLKSWAGEN AG

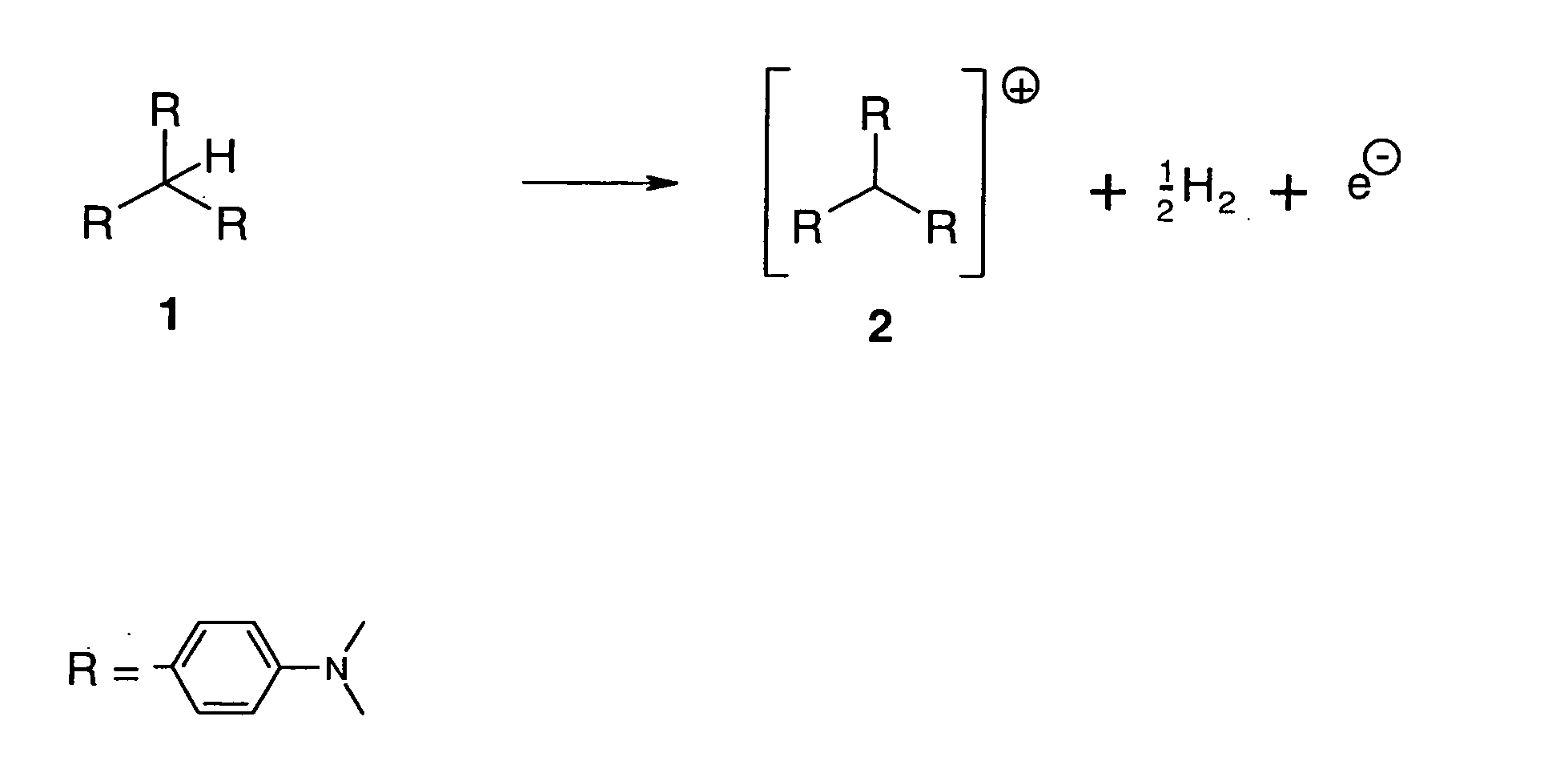

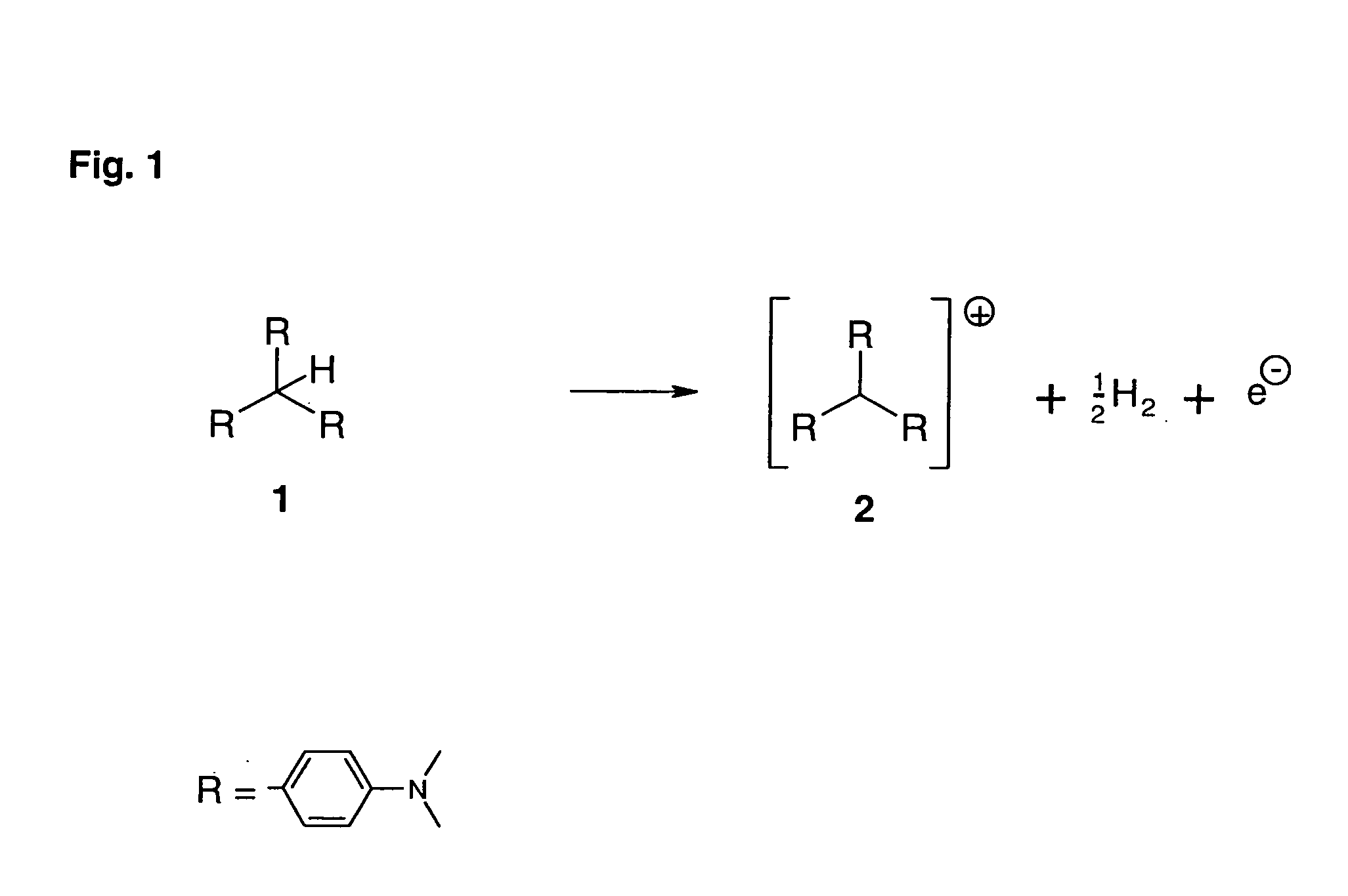

Doped organic semiconductor materials and process for their preparation

ActiveUS20050061232A1Simple materialHigh light efficiencyOrganic chemistryFinal product manufactureSemiconductor materialsCharge carrier mobility

The present invention relates to a process for the preparation of doped organic semiconductor materials having an increased charge carrier density and effective charge carrier mobility, by doping with a dopant, a process in which after mixing the dopant into the organic semiconductor material, hydrogen, carbon monoxide, nitrogen or hydroxyl radicals are split off and at least one electron is transferred to the semiconductor material or from the semiconductor material. The process is distinguished by the fact that an uncharged organic compound is used as dopant. Doped organic semiconductor materials are obtainable by one of the processes. The semiconductor materials are distinguished by the fact that the doped layer contains cations of at least one organic compound, the uncharged form of the organic compound being unstable in air.

Owner:NOVALED GMBH

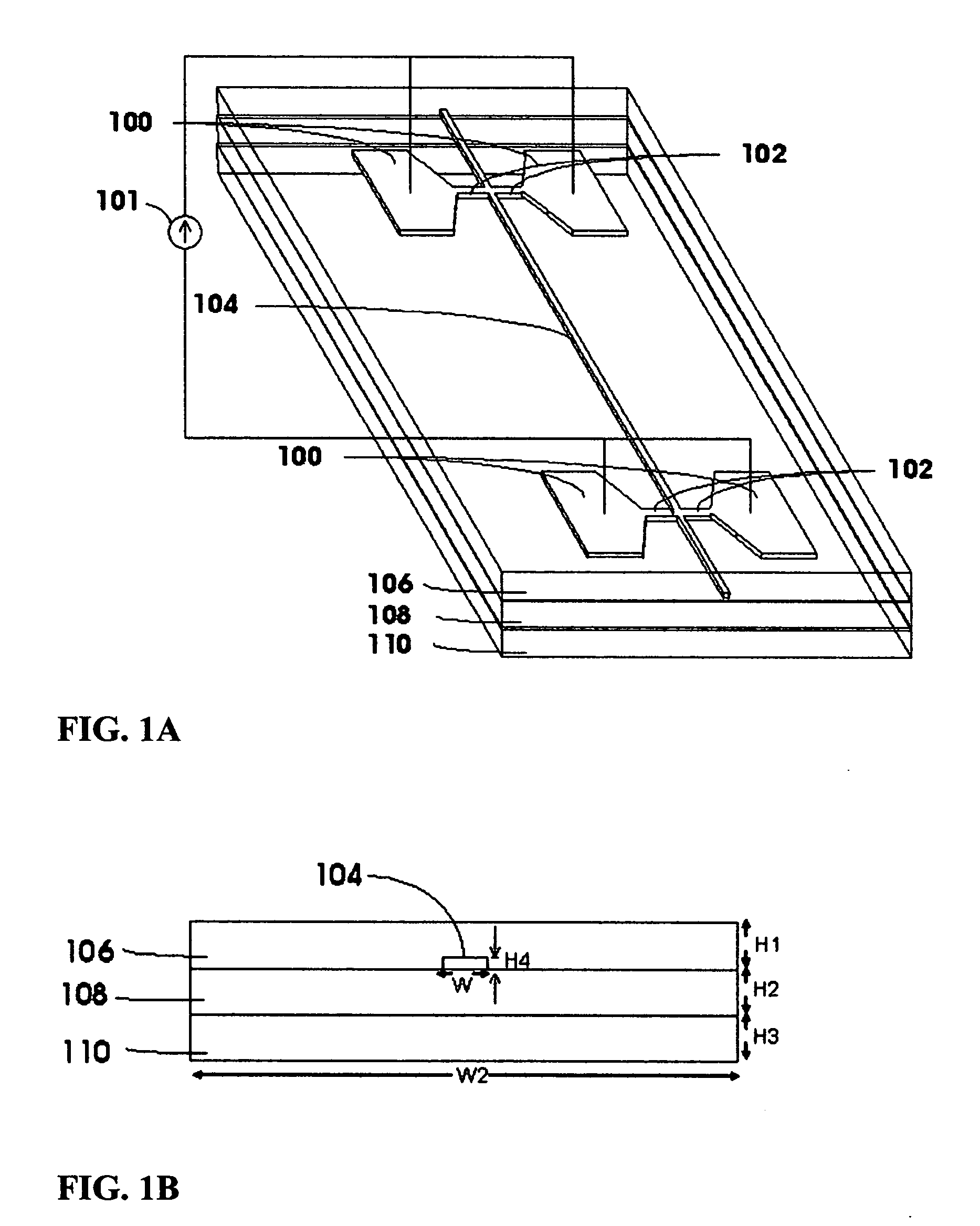

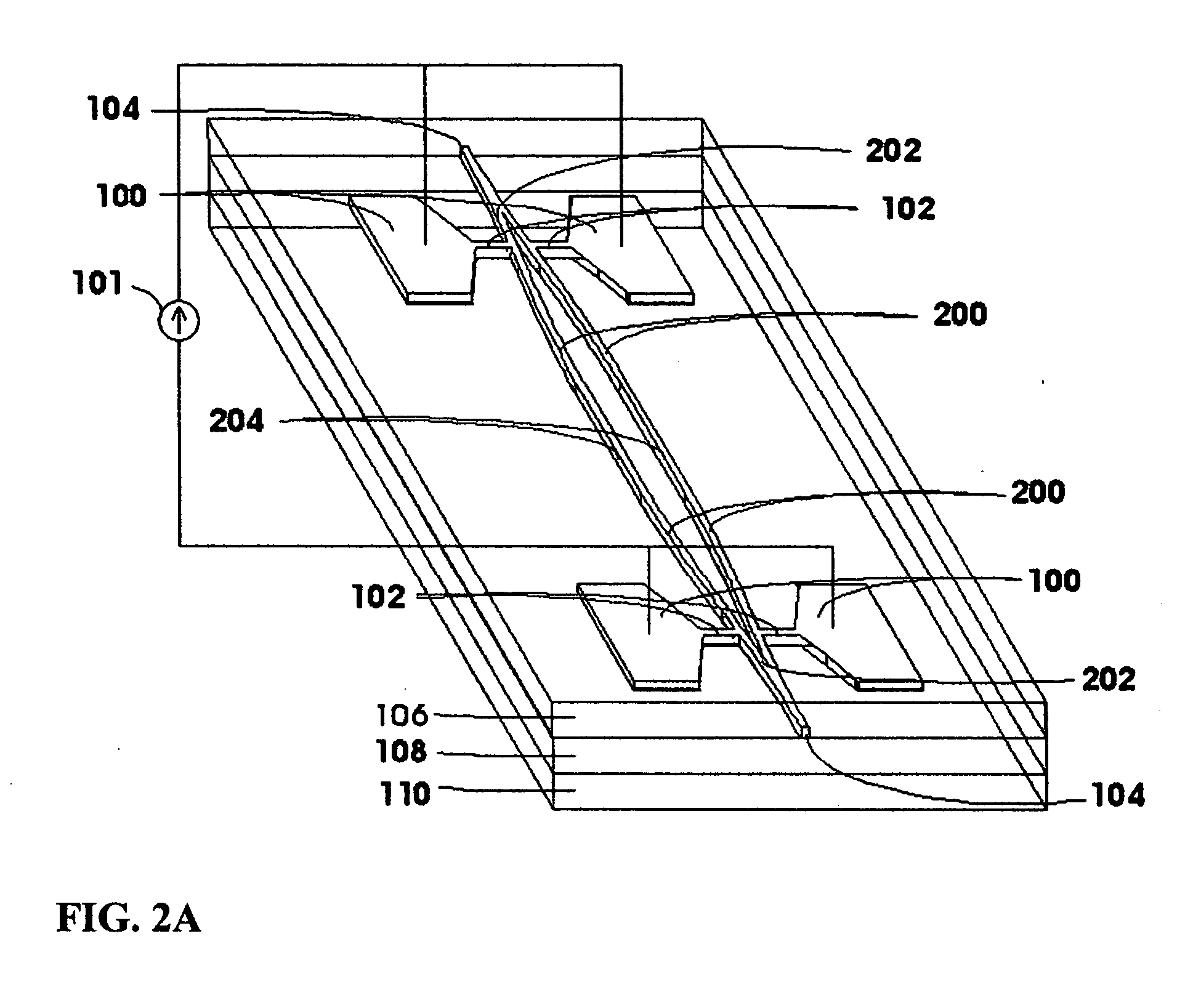

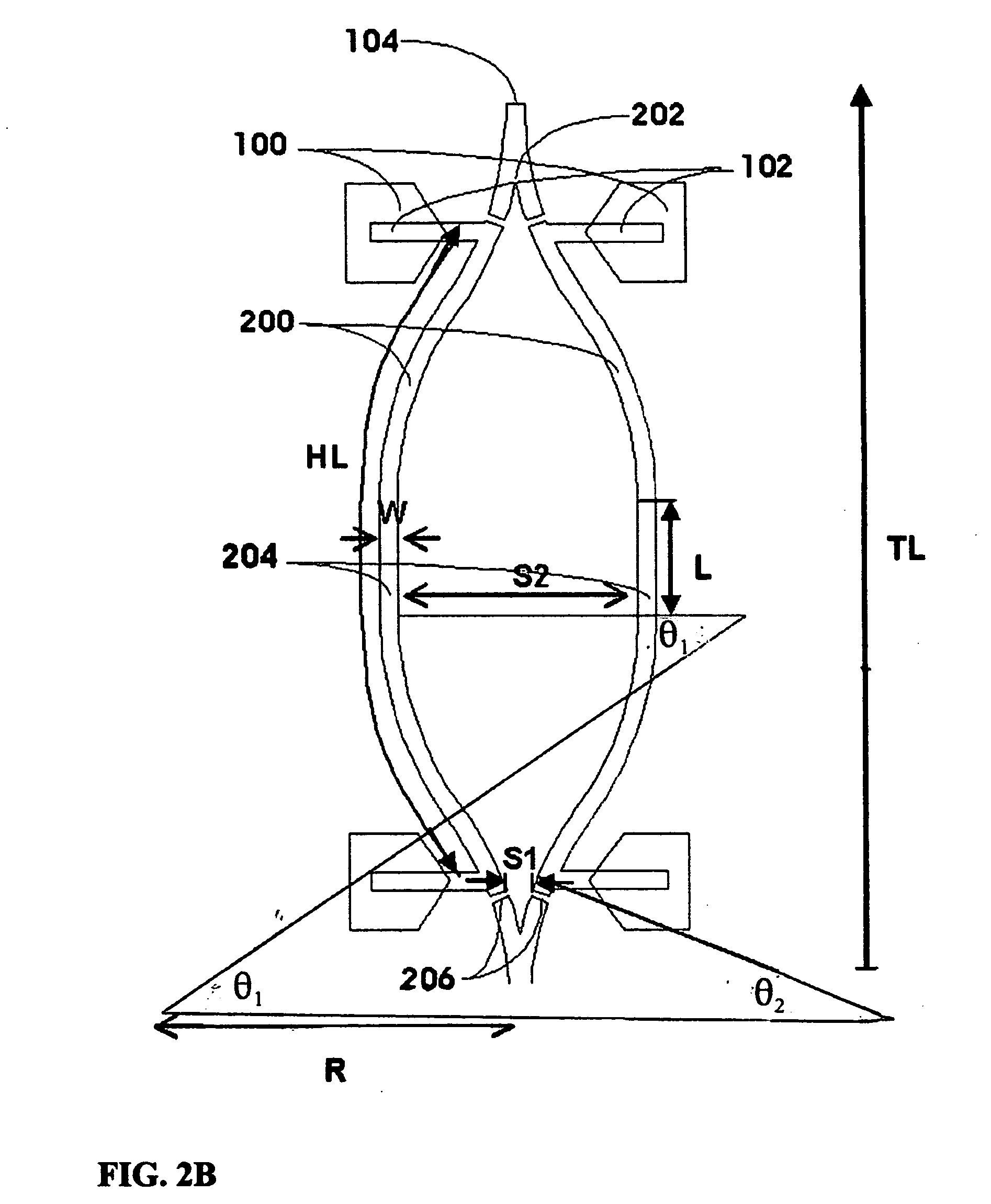

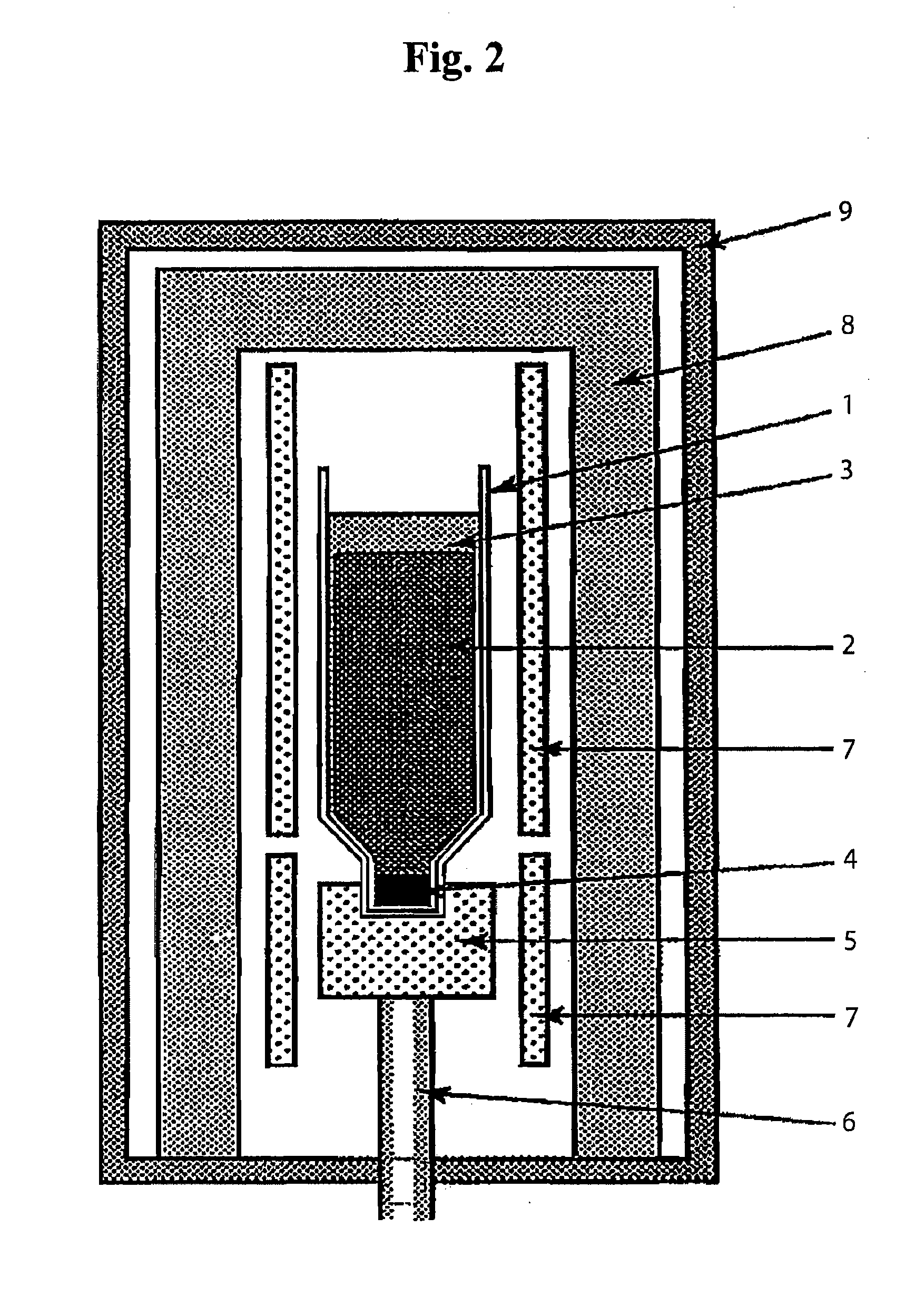

Thermo-optic plasmon-polariton devices

A waveguide structure comprises a thin strip of material having a relatively high free charge carrier density surrounded by material having a relatively low free charge carrier density. The width and thickness of the strip are dimensioned such that optical radiation having a wavelength in a predetermined range couples to the strip and propagates along its length as a plasmon-polariton wave. The device includes a waveguide heater for passing a current through the strip to heat it and the surrounding material, so as to vary propagation of the optical radiation, or means for monitoring propagation of the optical radiation to determine a change in temperature of the strip. Some embodiments provide both heating of the strip and monitoring of its temperature.

Owner:SPECTALIS

Manufacture of silicon-based devices having disordered sulfur-doped surface layers

InactiveUS20080044943A1Increase carrier densityFinal product manufactureSemiconductor/solid-state device manufacturingSurface layerSulfur

The present invention provides methods of fabricating a radiation-absorbing semiconductor wafer by irradiating at least one surface location of a silicon substrate, e.g., an n-doped crystalline silicon, by a plurality of temporally short laser pulses, e.g., femtosecond pulses, while exposing that location to a substance, e.g., SF6, having an electron-donating constituent so as to generate a substantially disordered surface layer (i.e., a microstructured layer) that incorporates a concentration of that electron-donating constituent, e.g., sulfur. The substrate is also annealed at an elevated temperature and for a duration selected to enhance the charge carrier density in the surface layer. For example, the substrate can be annealed at a temperature in a range of about 700 K to about 900 K.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

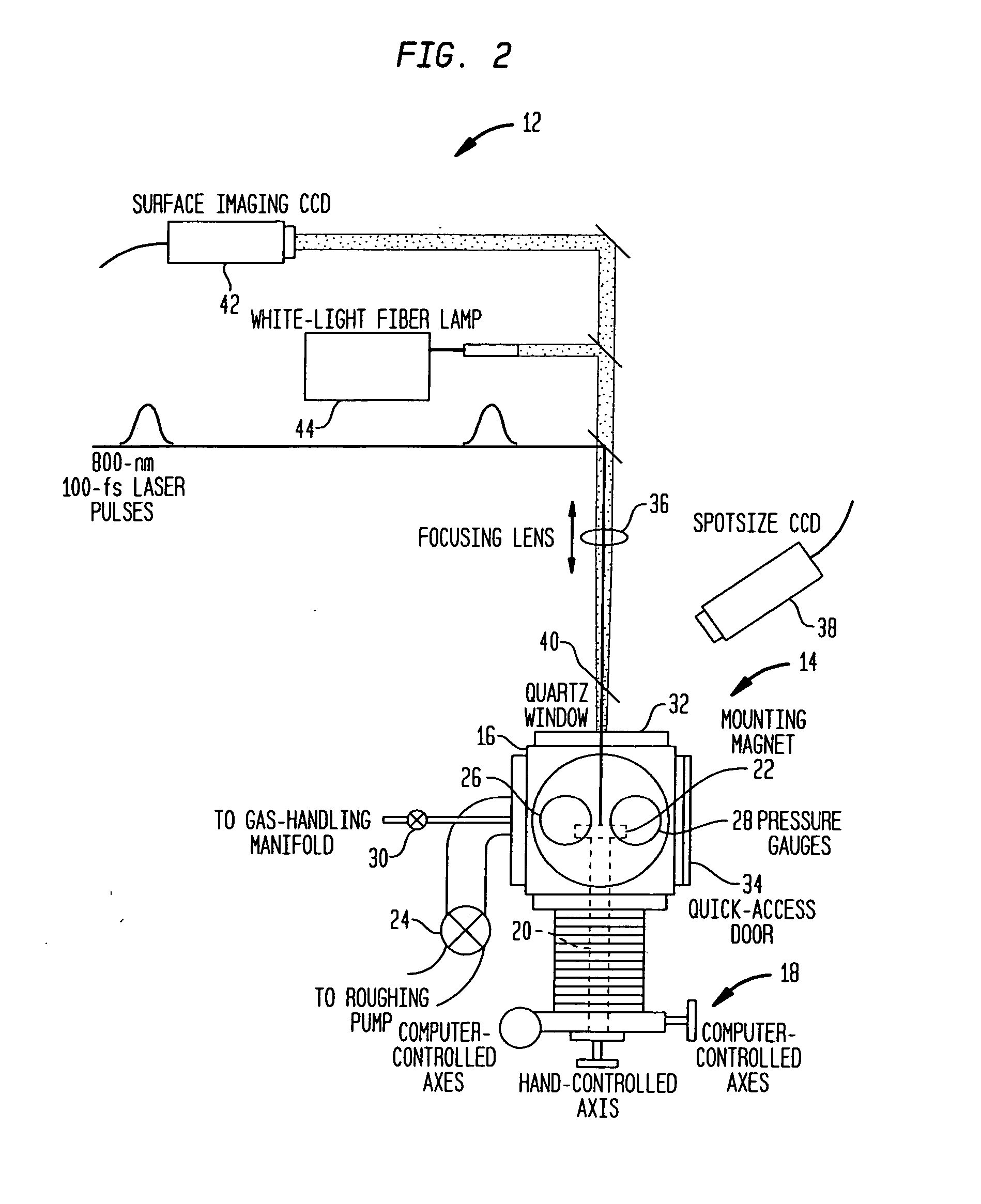

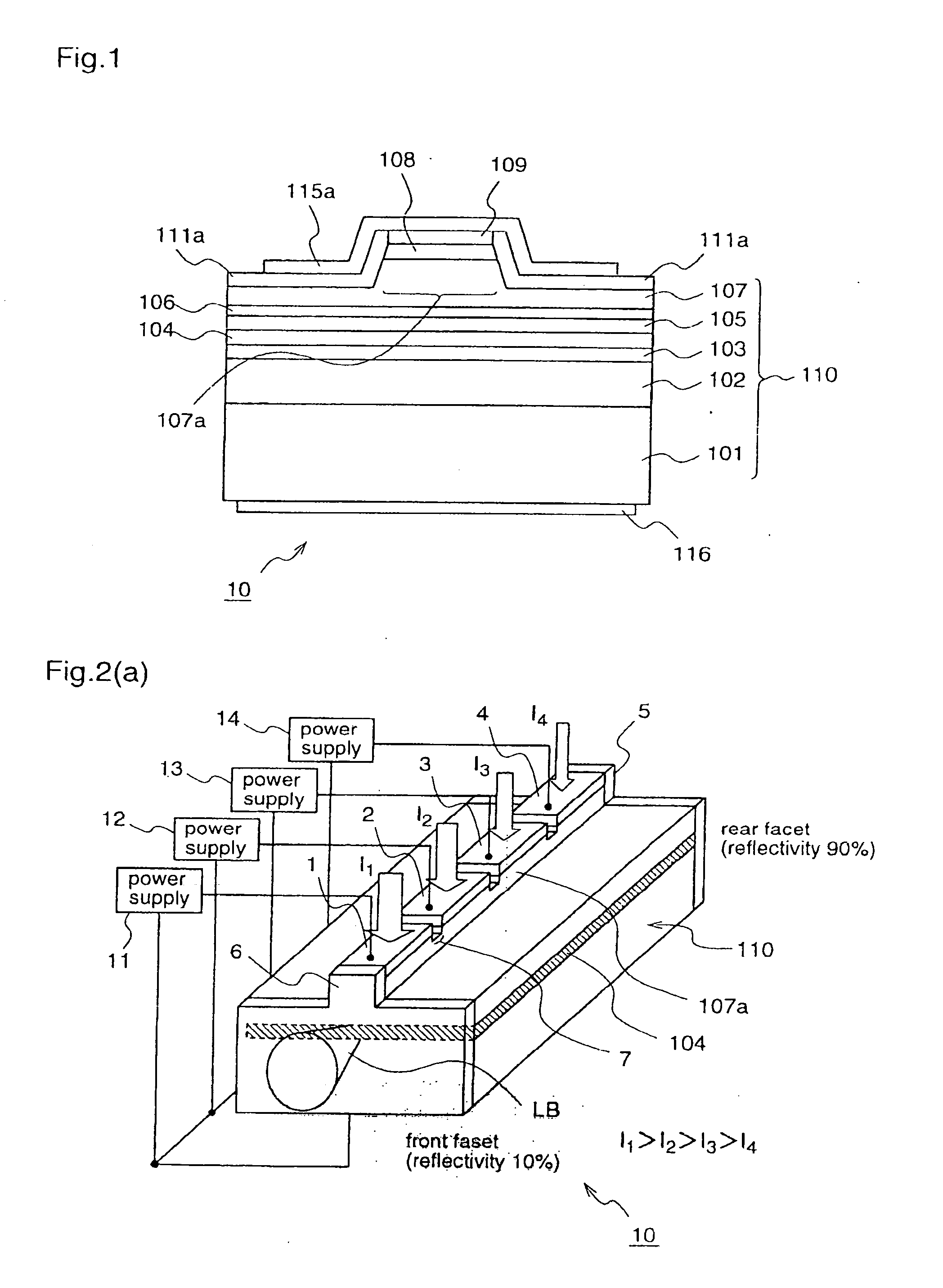

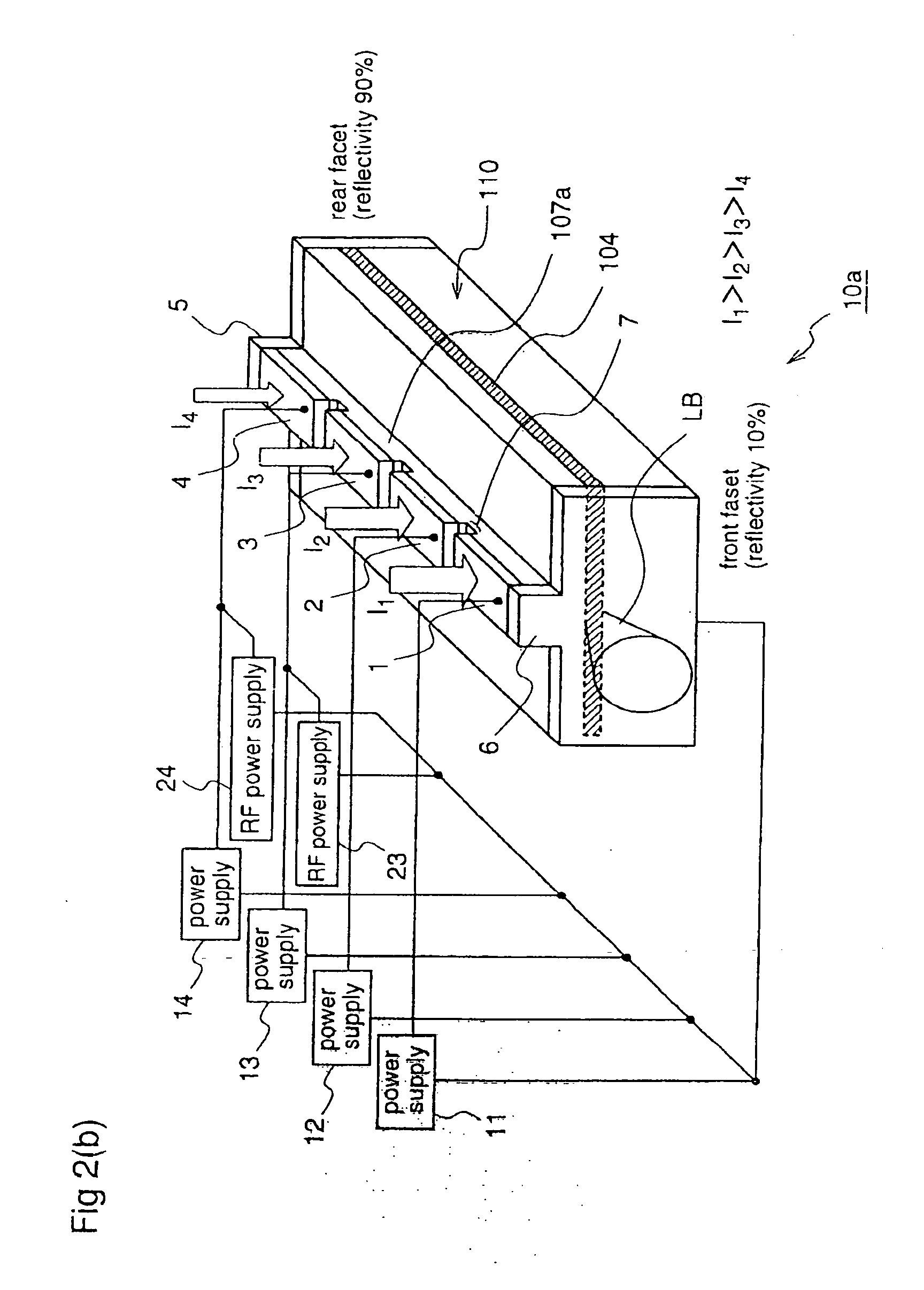

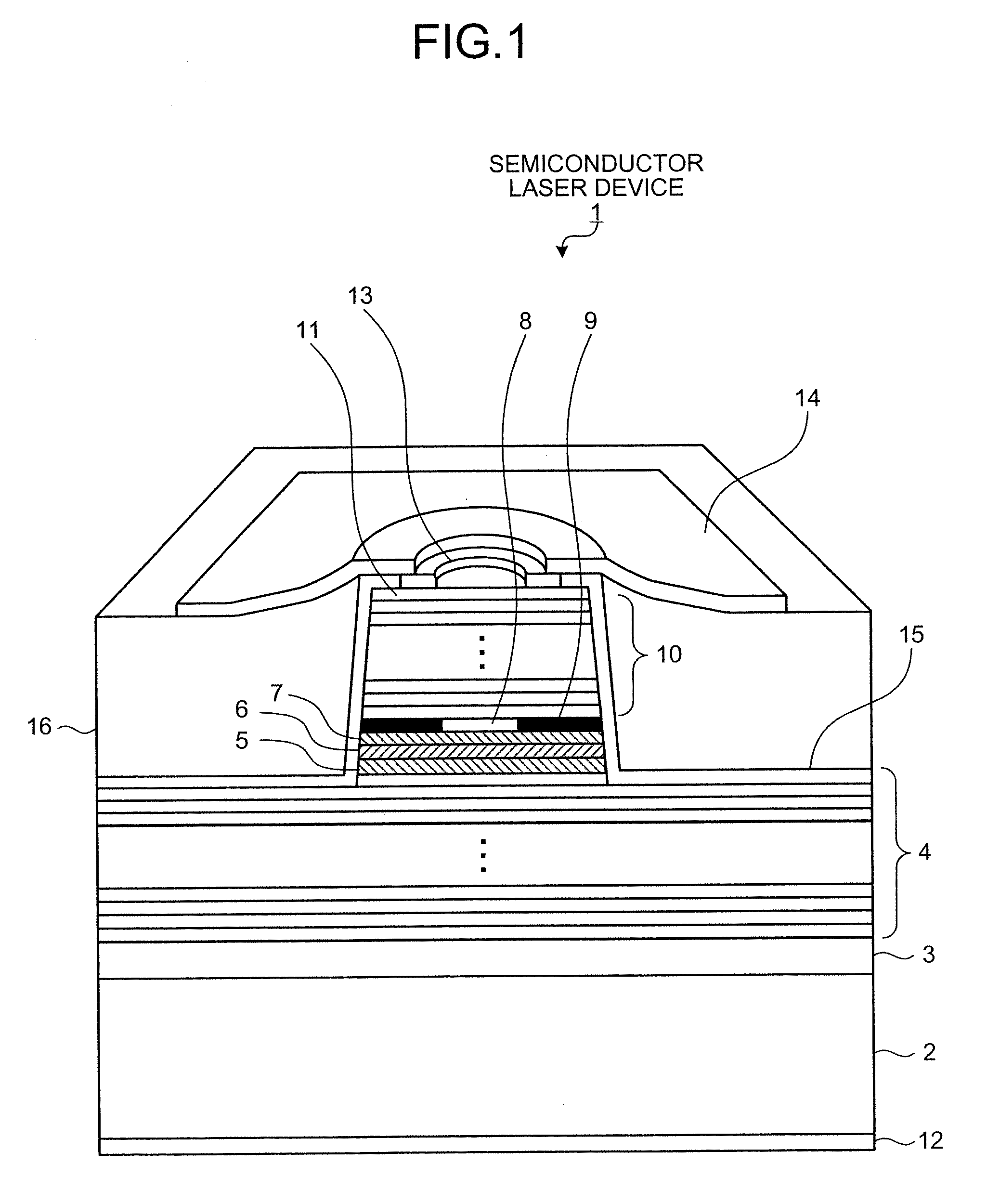

Semiconductor laser device and laser projector

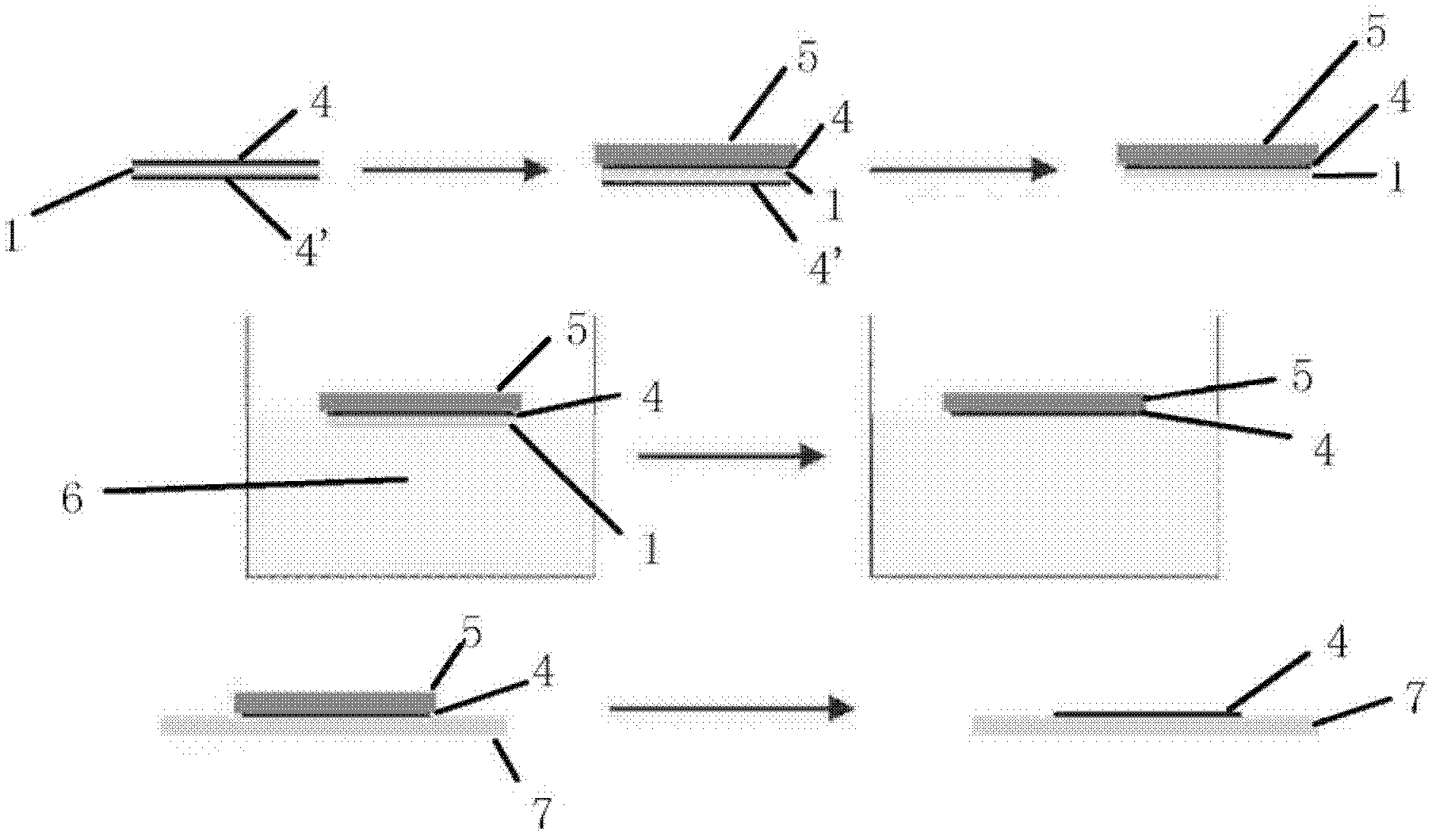

ActiveUS20070165685A1High densityHigh differential gainOptical wave guidanceLaser detailsCharge-carrier densityDensity distribution

According to the present invention, in a semiconductor laser device (10) having different facet reflectivities, an electrode disposed on a stripe ridge (107a) is divided into four electrode parts (1), (2), (3), and (4), and a larger injection current is injected to an electrode part that is closer to a light emission facet side. According to this semiconductor laser device, a carrier density distribution in an active layer that is opposed to the stripe ridge can be matched to a light intensity distribution in the active layer, thereby preventing degradation in high output characteristic due to destabilization of transverse mode and reduction in gain which are caused by spatial hole burning.

Owner:PANASONIC CORP

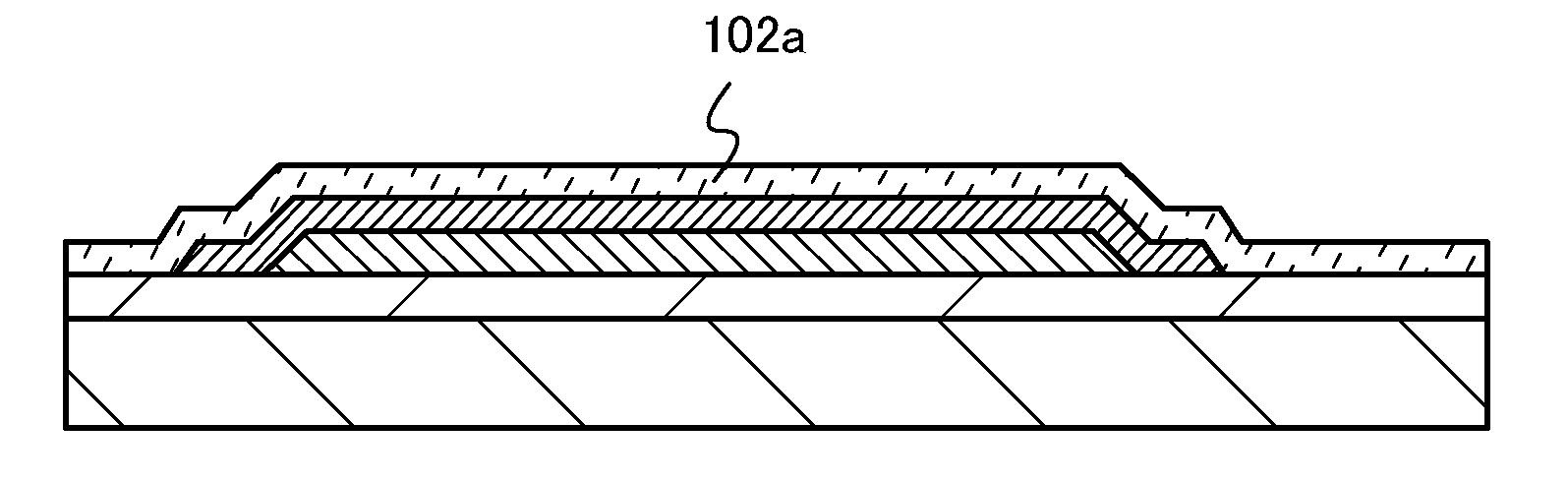

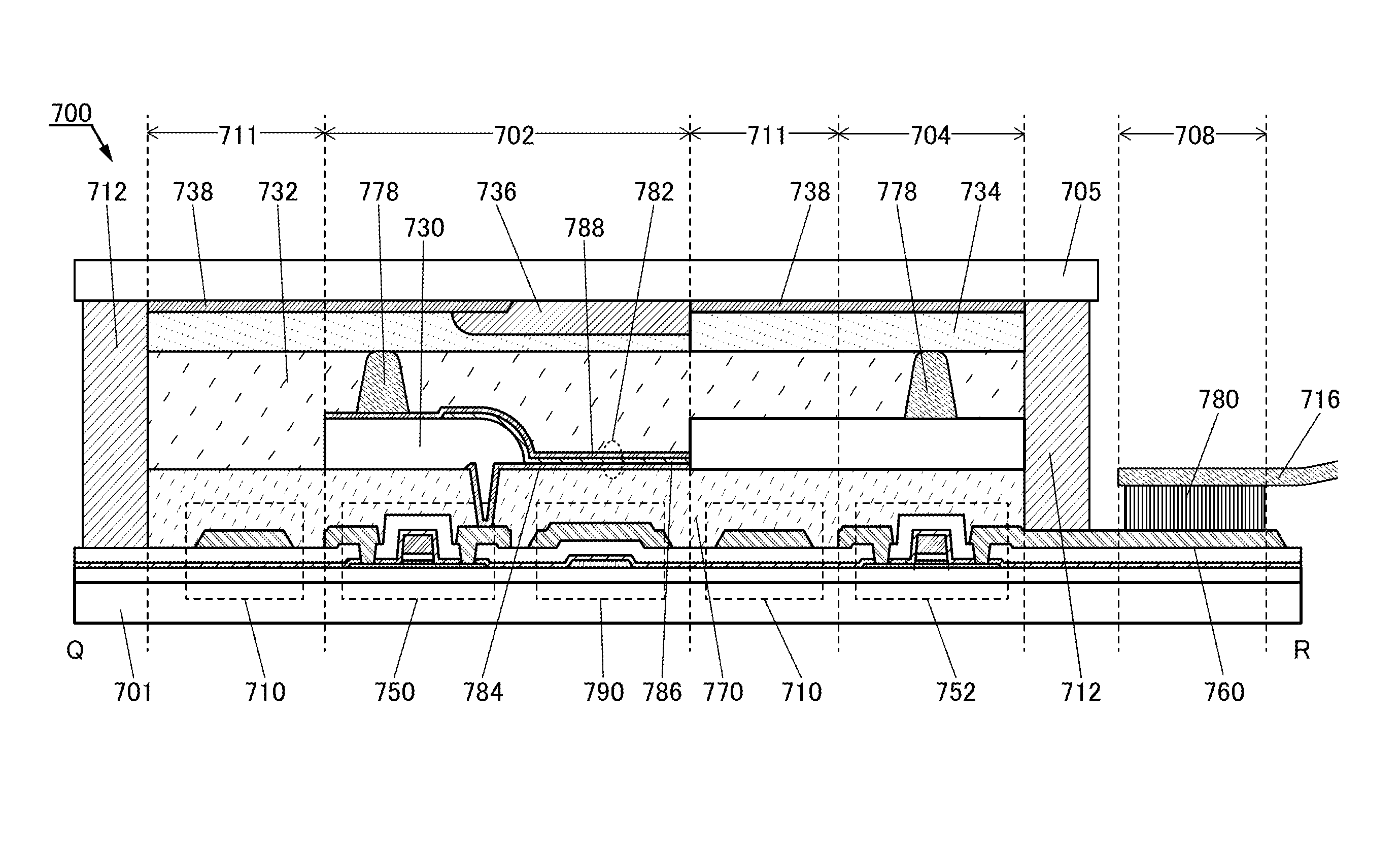

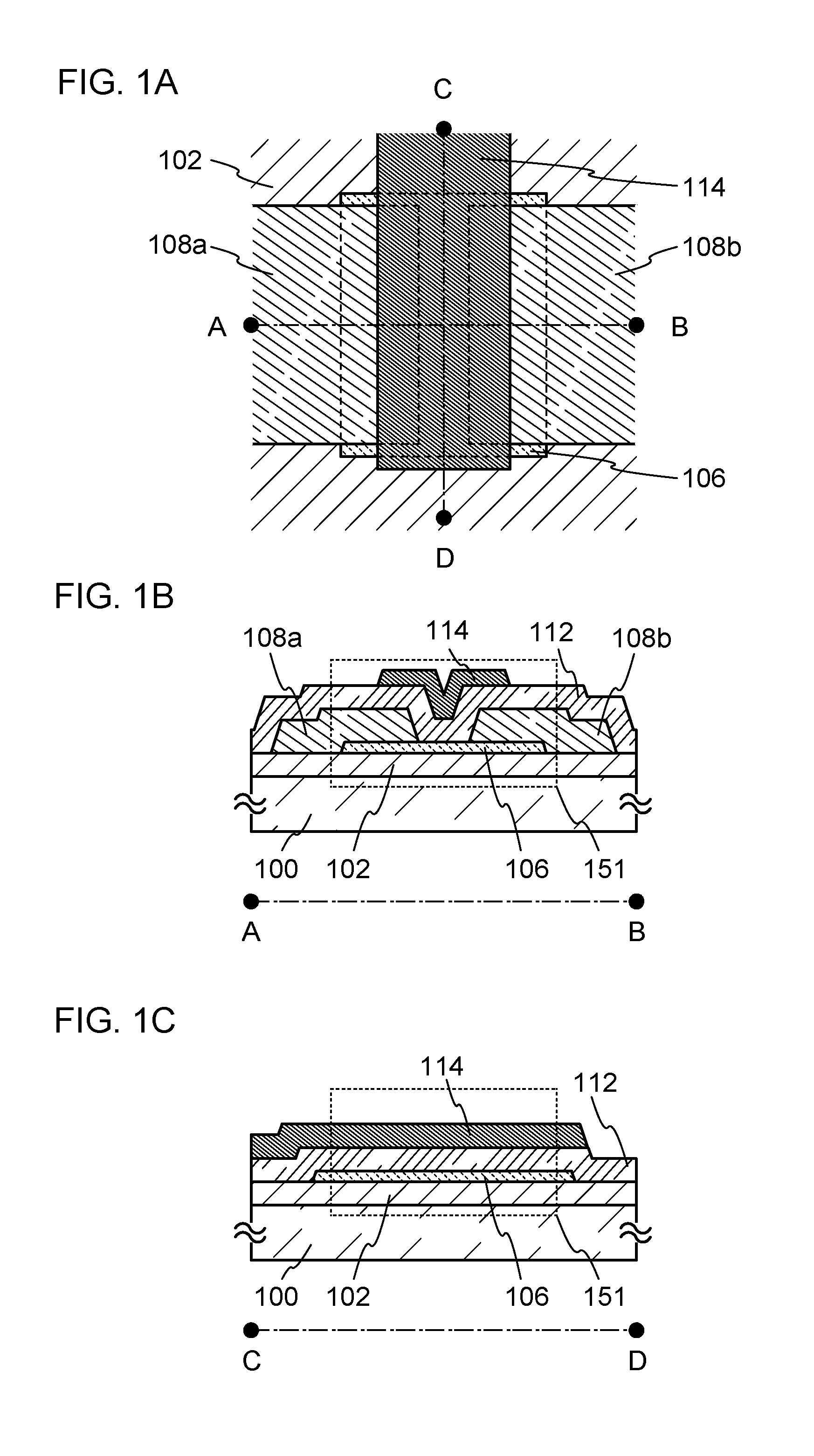

Semiconductor device and display device including the semiconductor device

InactiveUS20160343868A1Stable semiconductor characteristicSimple manufacturing processTransistorSolid-state devicesDevice materialCharge-carrier density

The reliability of a transistor including an oxide semiconductor is improved. The transistor in a semiconductor device includes a first oxide semiconductor film over a first insulating film, a gate insulating film over the first oxide semiconductor film, a second oxide semiconductor film over the gate insulating film, and a second insulating film over the first oxide semiconductor film and the second oxide semiconductor film. The first oxide semiconductor film includes a channel region overlapping with the second oxide semiconductor film, a source region and a drain region each in contact with the second insulating film. The channel region includes a first layer and a second layer in contact with a top surface of the first layer and covering a side surface of the first layer in the channel width direction. The second oxide semiconductor film has a higher carrier density than the first oxide semiconductor film.

Owner:SEMICON ENERGY LAB CO LTD

RESURF III-nitride HEMTs

ActiveUS8759879B1TransistorSemiconductor/solid-state device manufacturingCharge-carrier densityNitride

A semiconductor device containing a GaN FET has n-type doping in at least one III-N semiconductor layer of a low-defect layer and an electrical isolation layer below a barrier layer. A sheet charge carrier density of the n-type doping is 1 percent to 200 percent of a sheet charge carrier density of the two-dimensional electron gas.

Owner:TEXAS INSTR INC

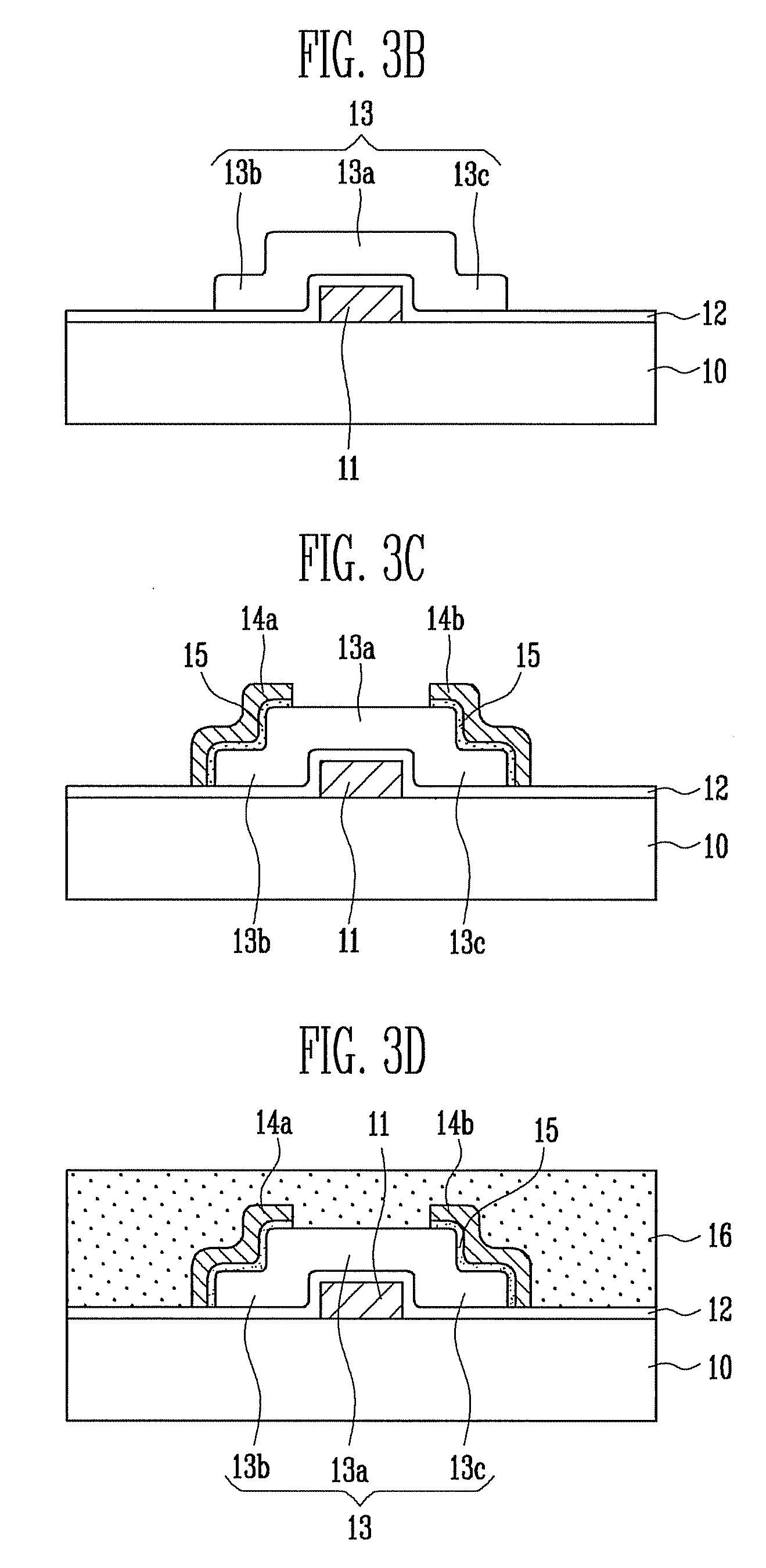

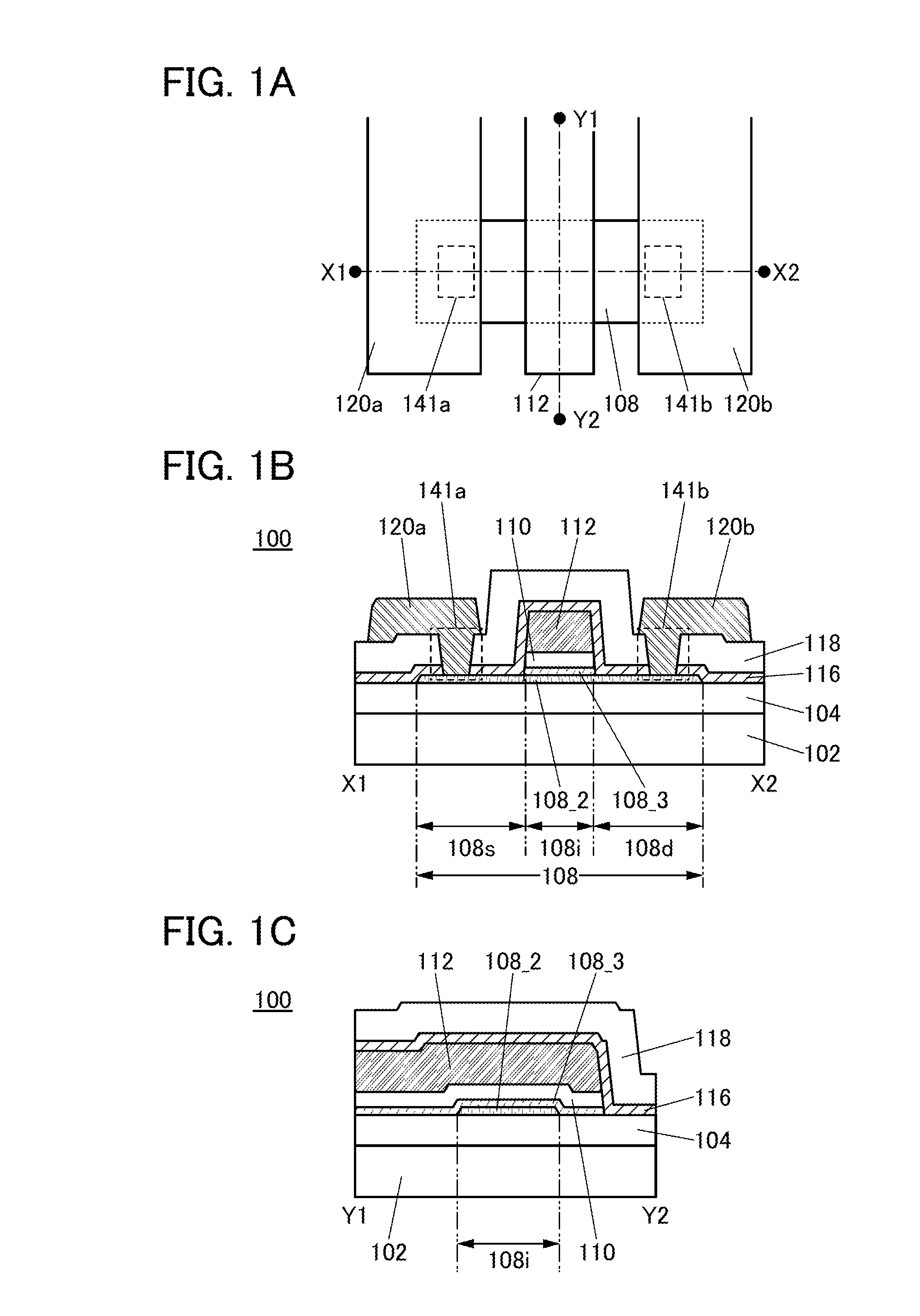

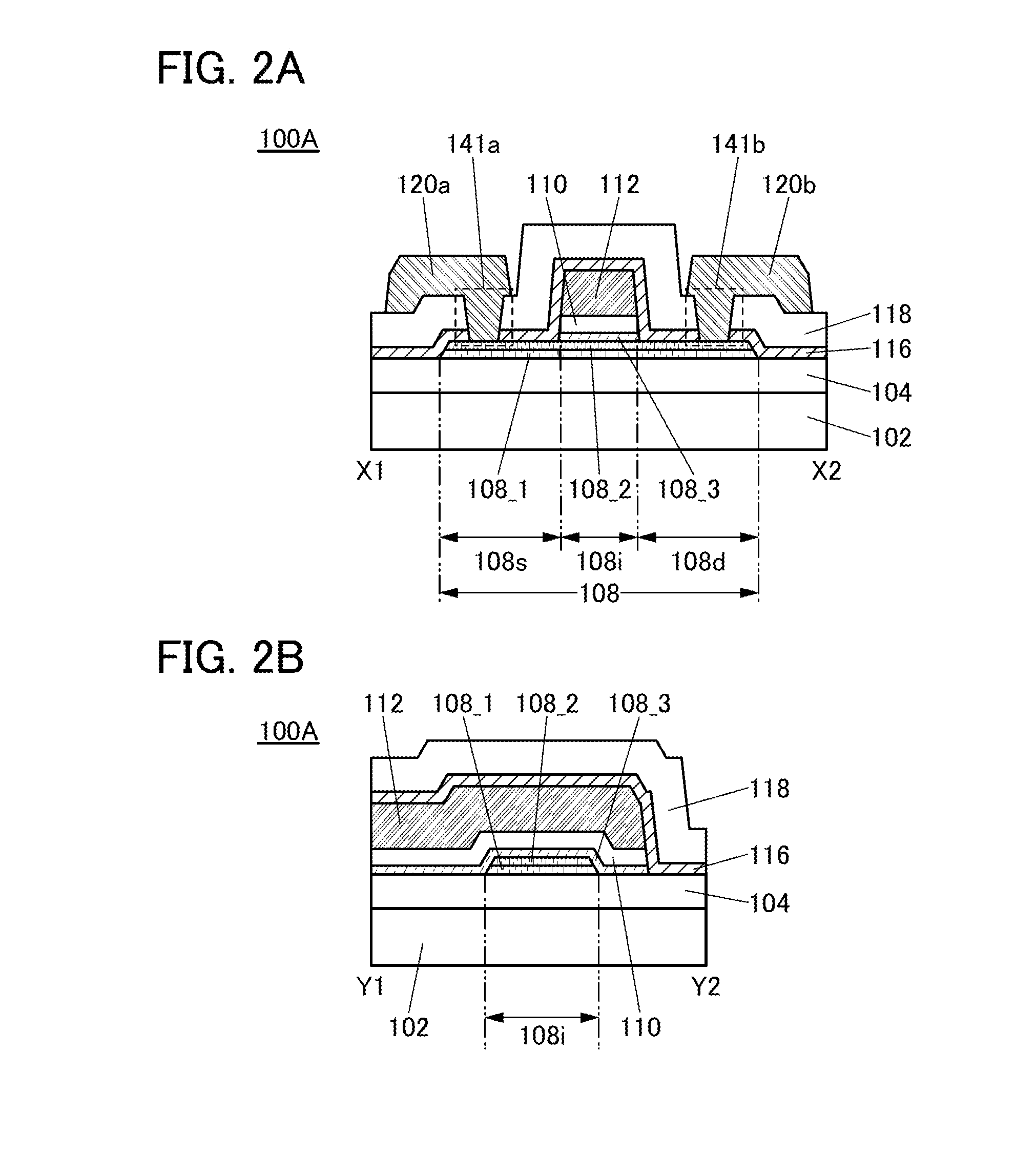

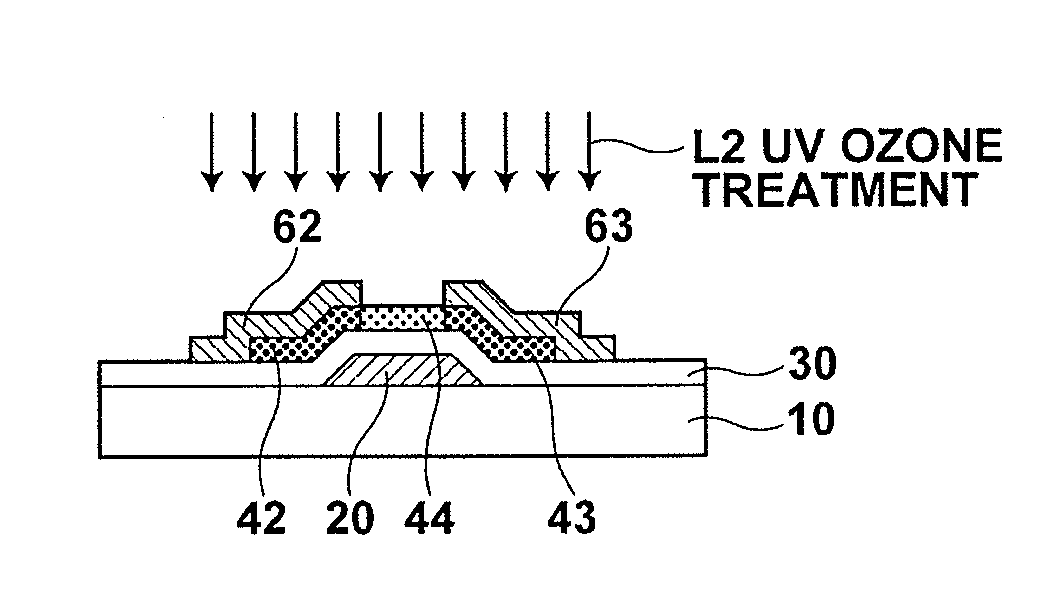

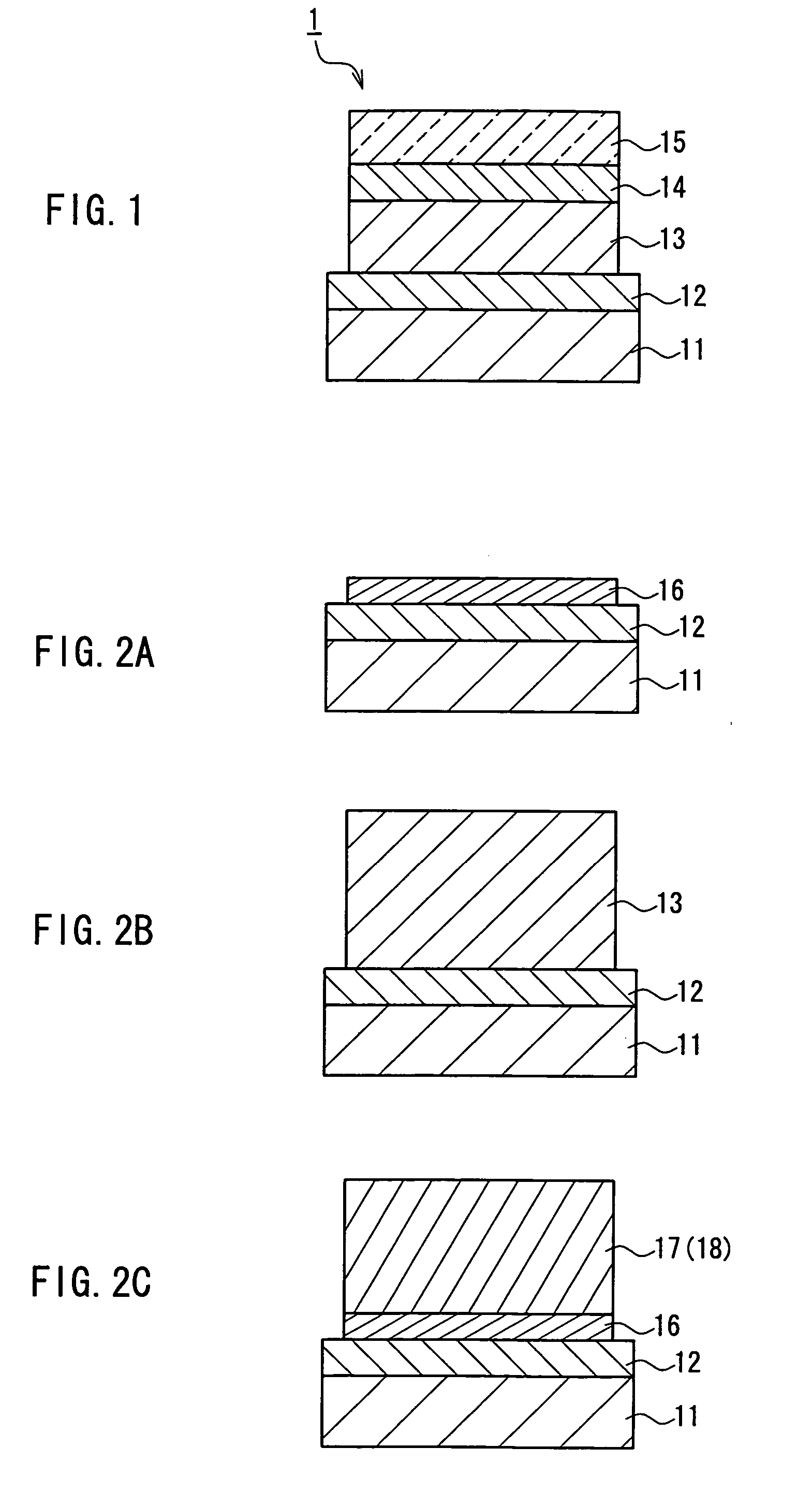

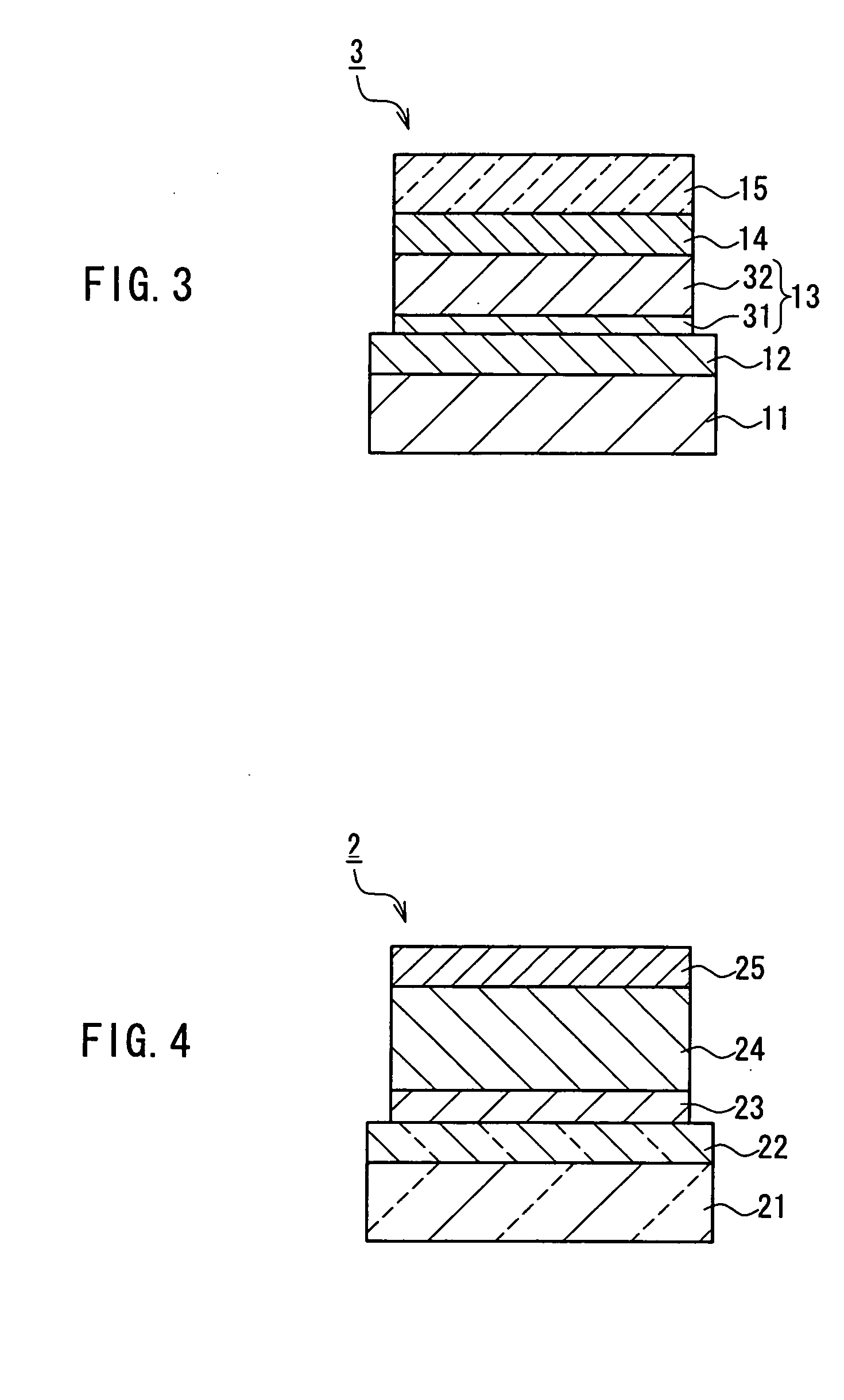

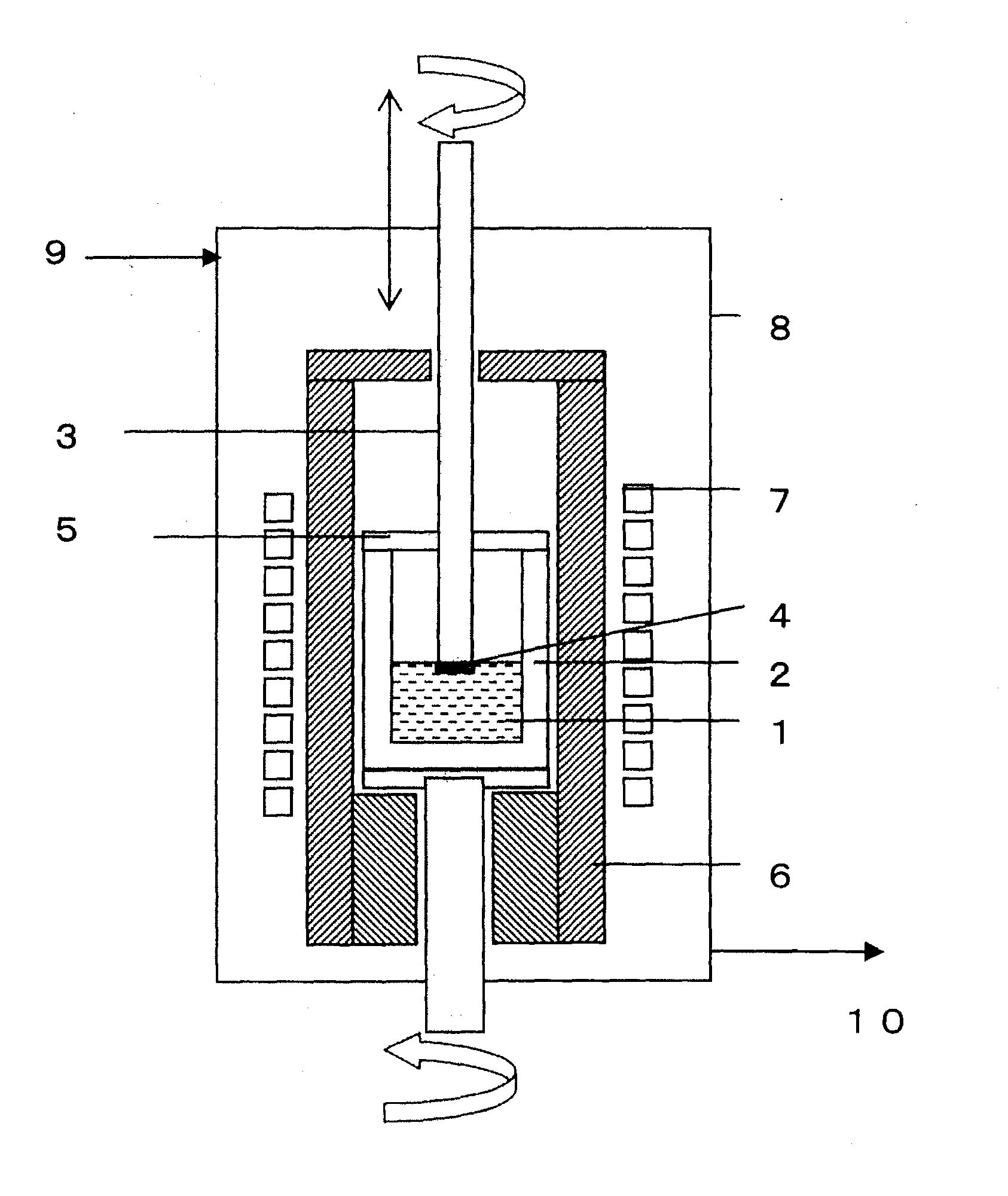

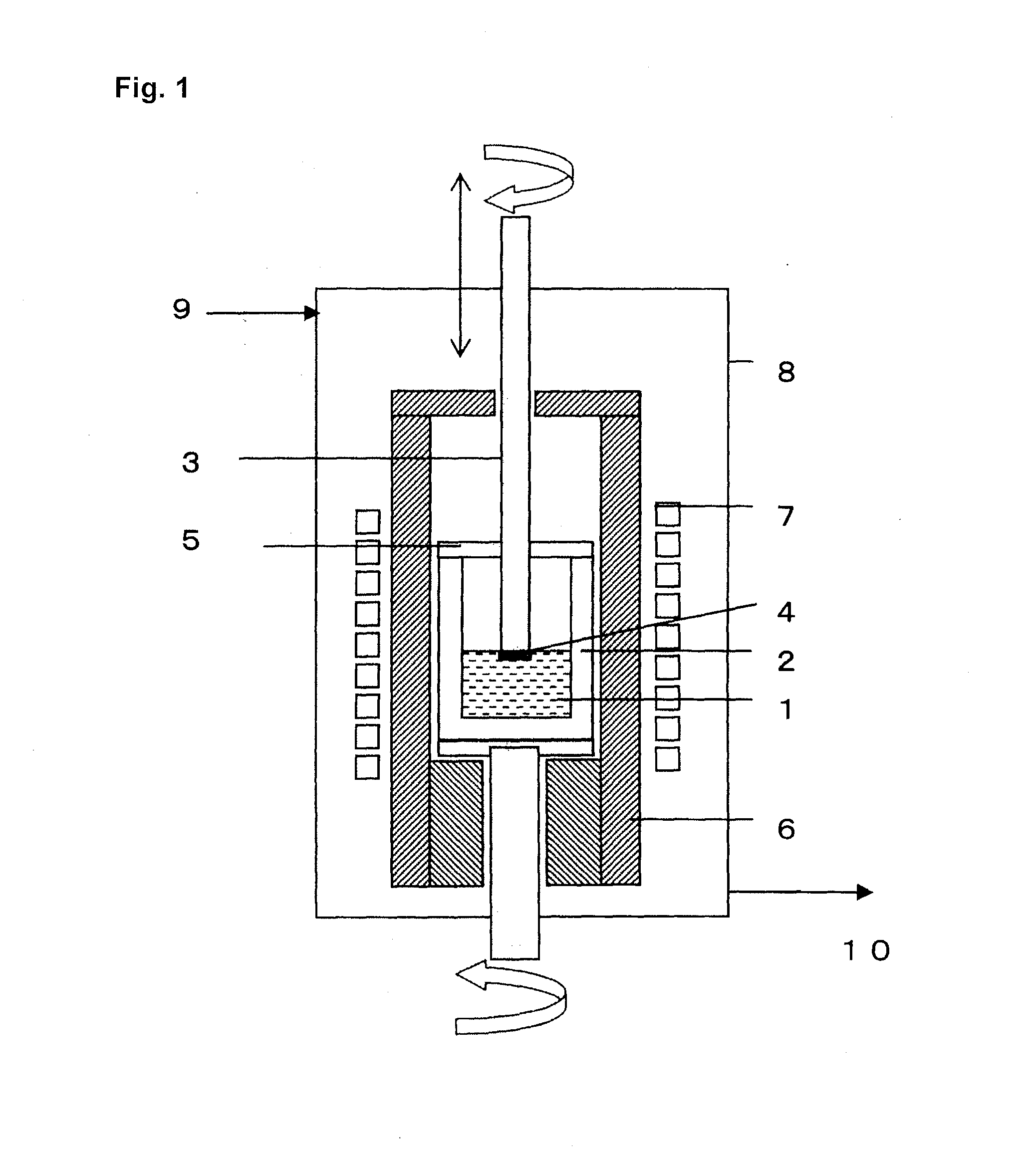

Thin-film transistor and method of manufacturing same

InactiveUS9153703B2Reduce power consumptionTransistorSemiconductor/solid-state device manufacturingCharge-carrier densityProtection layer

There is provided a thin-film transistor including at least a substrate, a gate electrode, a gate insulating layer, an oxide semiconductor layer, a source electrode, a drain electrode and a protective layer, wherein the oxide semiconductor layer is an amorphous oxide containing at least one of the elements In, Ga and Zn, the gate electrode-side carrier density of the oxide semiconductor layer is higher than the protective layer-side carrier density thereof, and the film thickness of the oxide semiconductor layer is 30 nm±15 nm.

Owner:CANON KK

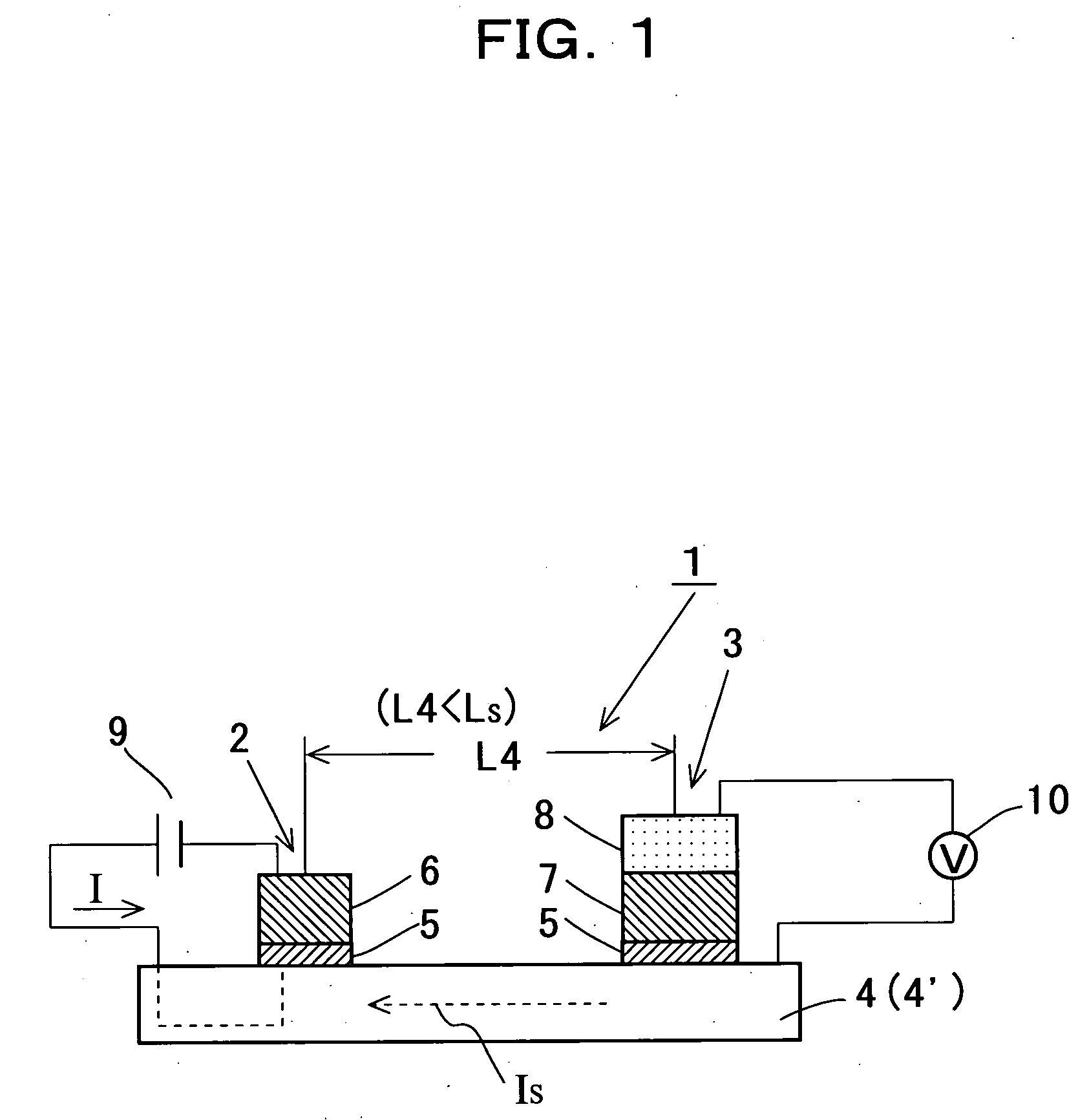

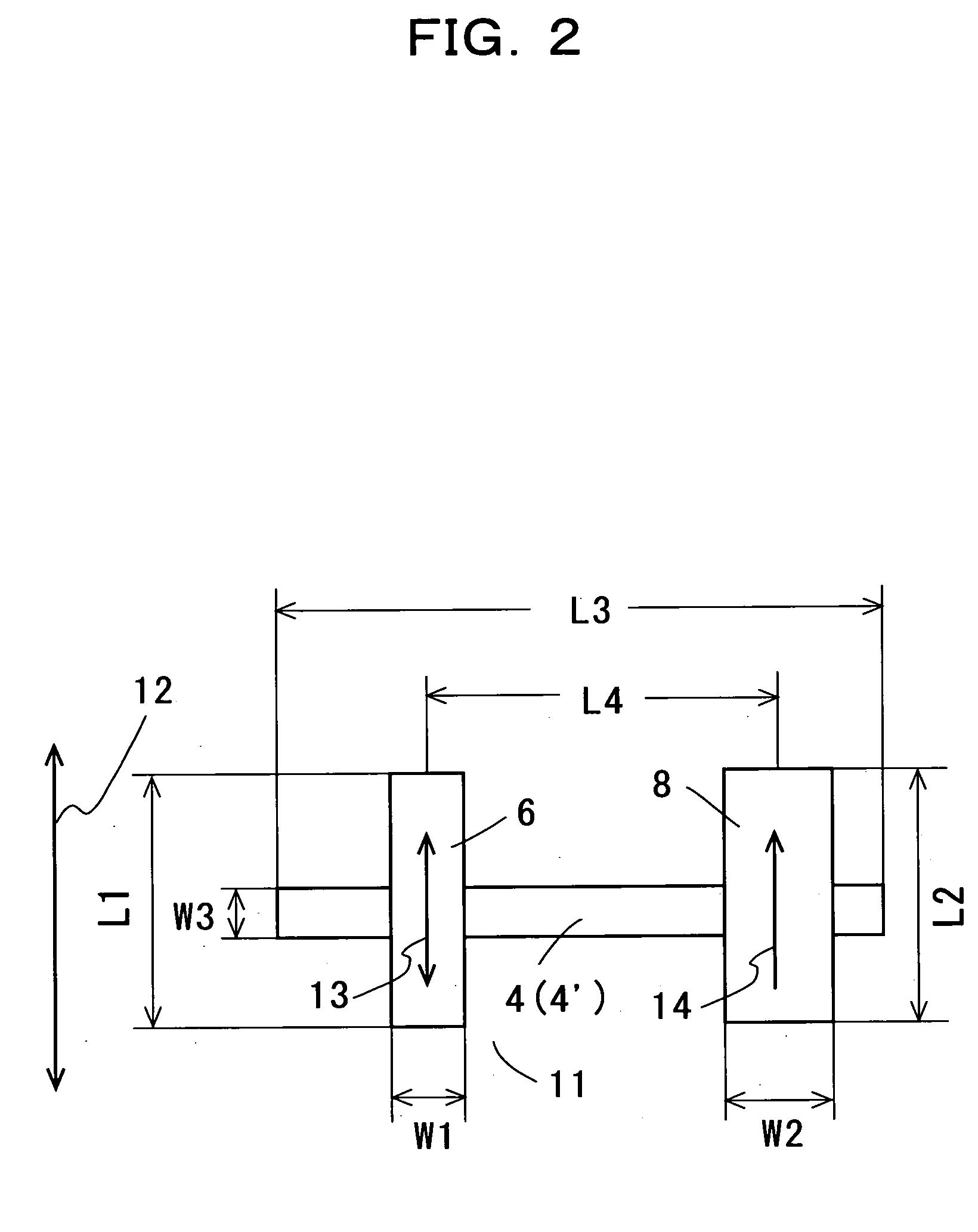

Spin-injection device and magnetic device using spin-injection device

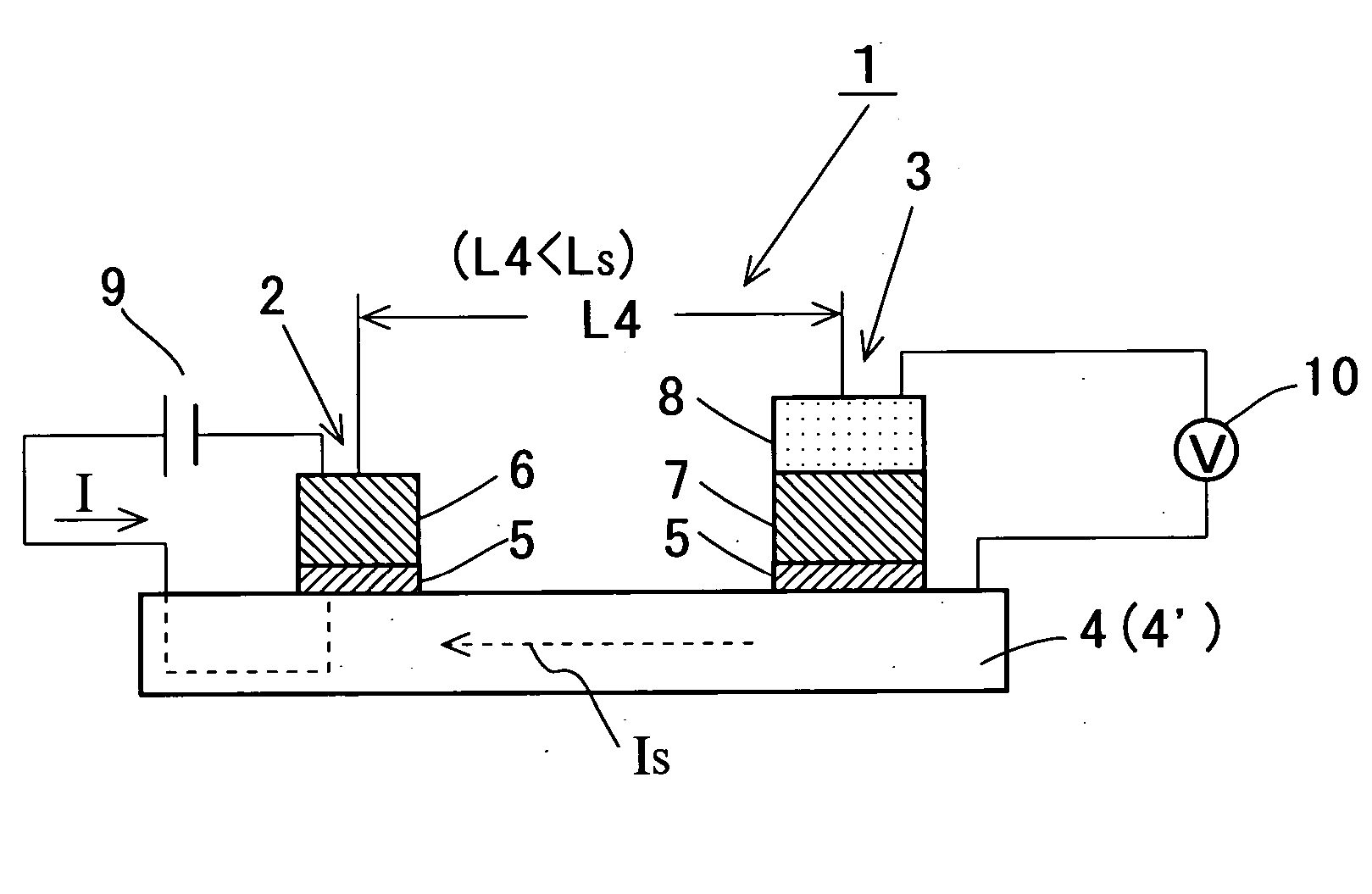

InactiveUS20060022220A1Large output resistanceLarge signal voltageNanomagnetismNanoinformaticsElectrical conductorCharge-carrier density

A first and a second tunnel junctions (2 and 3) which have a common electrode composed of a nonmagnetic conductor (4) and each of which has a counterelectrode composed of a ferromagnet (6, 8) are disposed spaced apart from each other by a distance that is shorter than a spin diffusion length of the nonmagnetic conductor (4) wherein the first tunnel junction (2) acts to inject spins from the ferromagnet (6) into the nonmagnetic conductor (4) and the second tunnel junction (3) serves to detect, between the ferromagnetic metal (8) and the nonmagnetic conductor (4), a voltage that accompanies spin injection of the first tunnel junction (2) and wherein the nonmagnetic conductor (4) is a nonmagnetic conductor, such as a semiconductor or a semimetal, that is lower in carrier density than a metal. The common electrode alternatively may be composed of a superconductor (4′). A spin injection device thus provided can exhibit a large signal voltage with low current and under low magnetic field and can be miniaturized in device size. Magnetic apparatuses utilizing such a spin injection device are also provided.

Owner:JAPAN SCI & TECH CORP

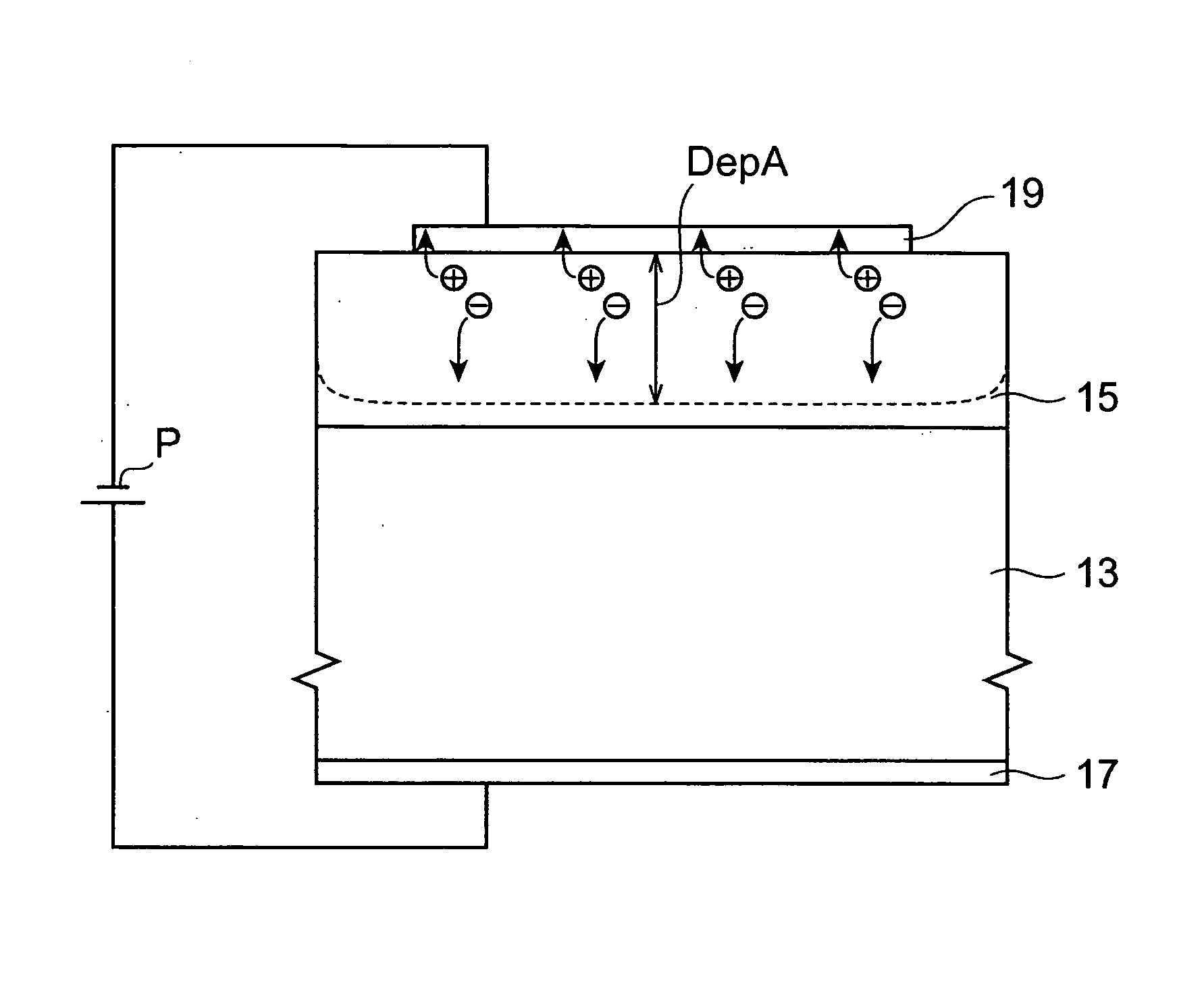

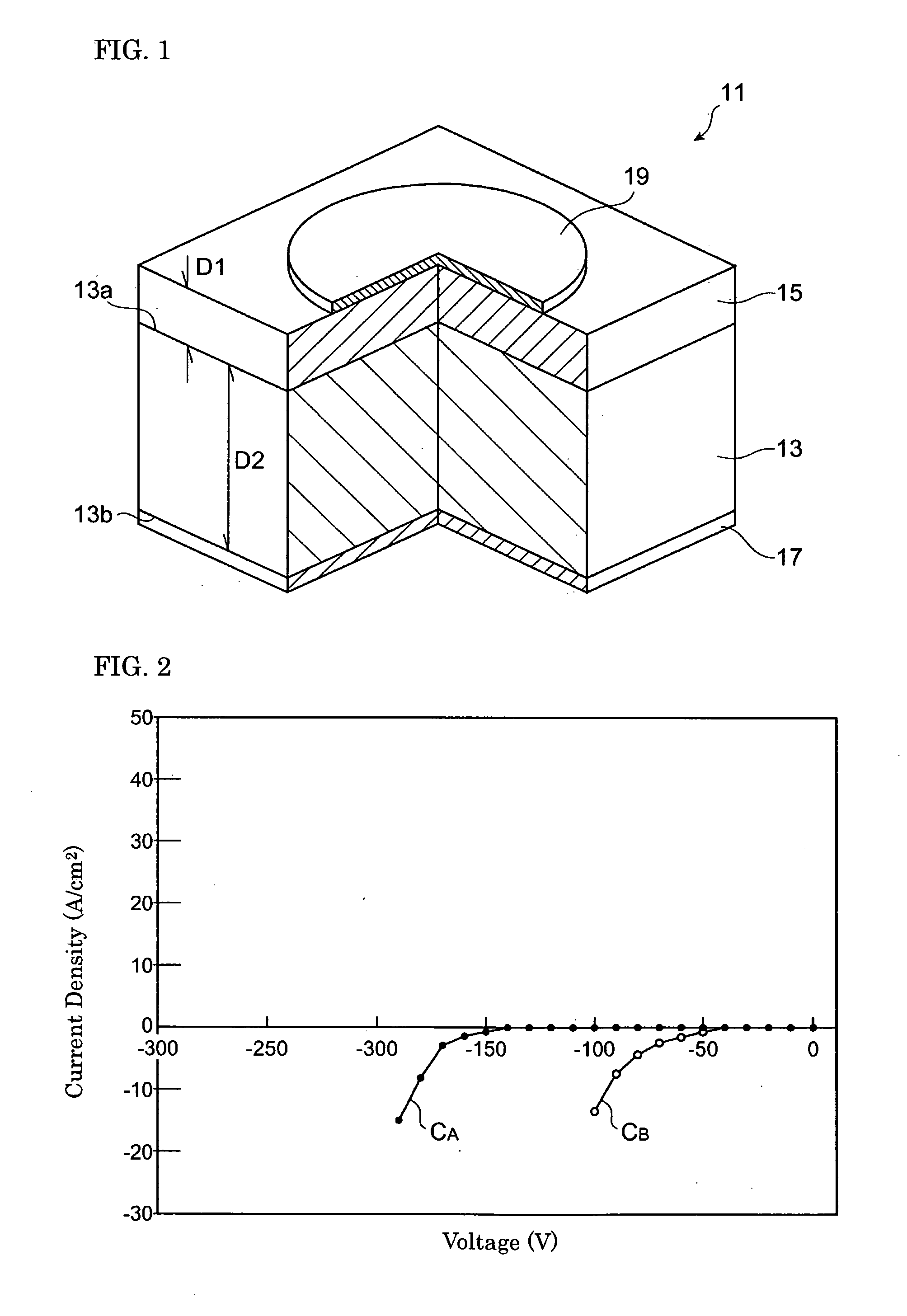

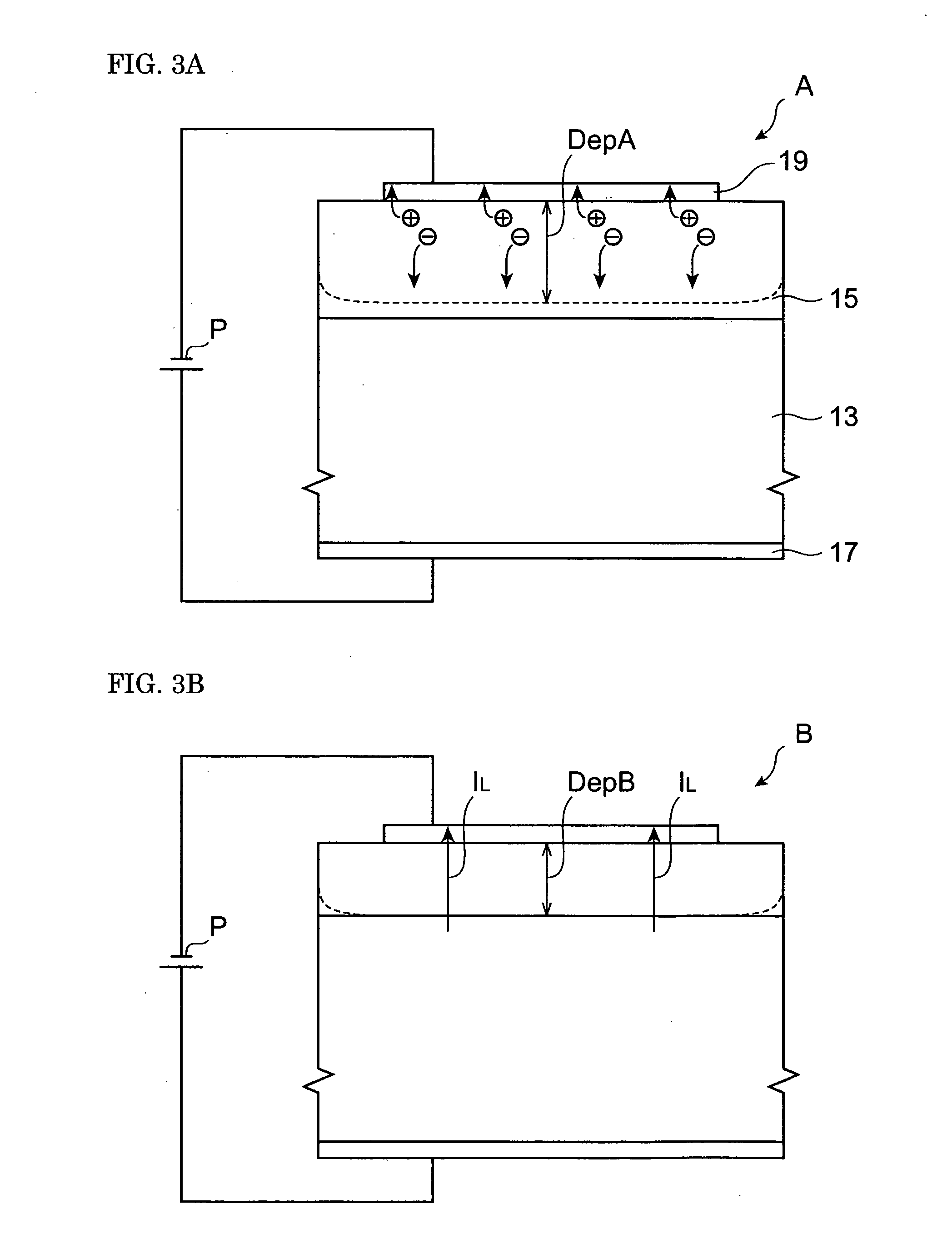

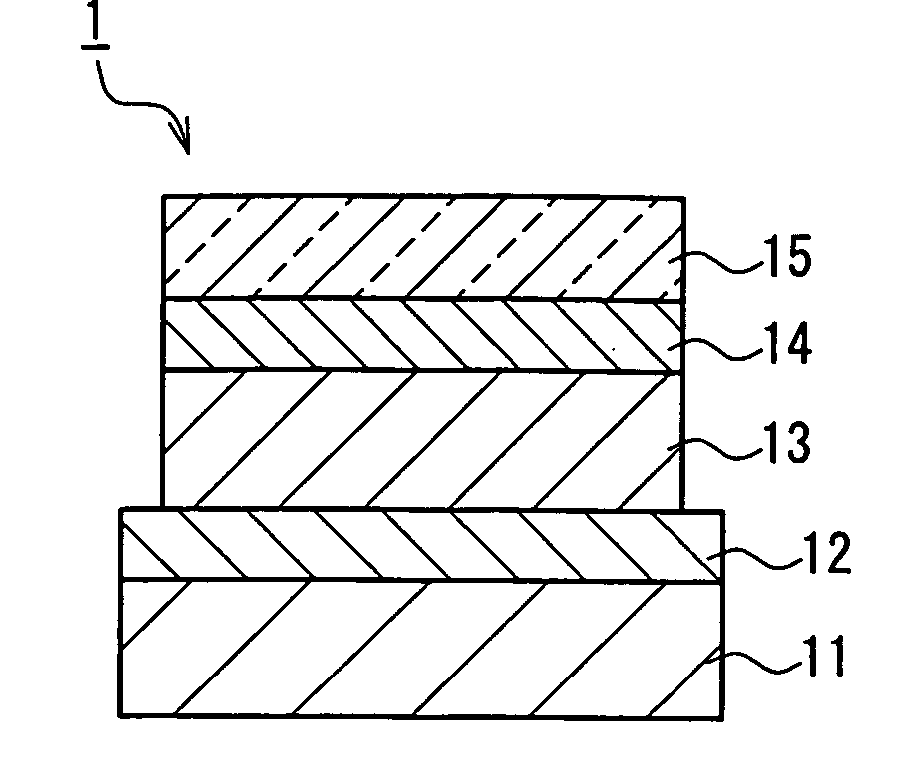

Epitaxial substrate and semiconductor element

ActiveUS20060046331A1Reduce layeringReduce leakage currentSemiconductor/solid-state device manufacturingSemiconductor devicesCharge-carrier densityGallium nitride

In a Schottky diode 11, a gallium nitride support base 13 includes a first surface 13a and a second surface 13b opposite from the first surface and has a carrier concentration exceeding 1×1018 cm−3. A gallium nitride epitaxial layer 15 is disposed on the first surface 13a. An Ohmic electrode 17 is disposed on the second surface 13b. The Schottky electrode 19 is disposed on the gallium nitride epitaxial layer 15. A thickness D1 of the gallium nitride epitaxial layer 15 is at least 5 microns and no more than 1000 microns. Also, the carrier density of the gallium nitride epitaxial layer 15 is at least 1×1014 cm−3 and no more than 1×1017 cm−3.

Owner:SUMITOMO ELECTRIC IND LTD

Semiconductor device, method for producing the same, sensor and electro-optical device

ActiveUS8278136B2Reduce carrier densityReduce resistanceElectric discharge heatingVacuum evaporation coatingPower semiconductor deviceSemiconductor

A gate electrode, a gate insulation film and an inorganic oxide film are formed in this order on a substrate, and a source electrode and a drain electrode are formed to partially cover the inorganic oxide film. Then, oxidation treatment is applied to reduce the carrier density at a region of the inorganic oxide film which is not covered by the electrodes and is used as a channel region of a semiconductor device.

Owner:SAMSUNG DISPLAY CO LTD

Novel capacitors and capacitor-like devices

InactiveUS20100084697A1Capacity of device is enhanced and decreasedIncrease capacityTransistorFixed capacitor electrodesCapacitive effectVan Hove singularity

A capacitor and capacitor-like device or any other device showing capacitive effects, including FETs, transmission lines, piezoelectric and ferroelectric devices, etc., with at least two electrodes, of which at least one electrode consists of or comprises a material or is generated as electron system, whose absolute value of the electronic charging energy as defined by the charging-induced change of Ekin+Eexc+Ecorr exceeds 10% of the charging-induced change of the Coulomb field energy of the capacitor according to E=Ecoul+Ekin+Eexc+Ecorr. Therein, E is the energy of a capacitor and Ecoul=Q2 / 2 Ccoul=Q2d / (2ε0 εx A), A is the area of the capacitor electrodes, d is the distance and ε0εx the dielectric constant between them. Ecorr describes the correlation energy, Ekin the electronic kinetic energy and Eexc the exchange energy of the electrode material. Particularly in miniaturized devices, Ecoul is becoming so small that, by using certain materials or material combinations for the capacitor, Ekin, Eexc, and / or Ecorr provide significant contributions to E. Preferred are materials with strongly correlated electron systems such as perovskites like La1-xSrxTiO3, YBa2Cu3O7-d, vanadates such as (V1-xAx)2O3 with A=Cr, Ti, materials with free electron gases of typically low densities such as Cs, Bi or Rb, or of materials the carrier density of which is reduced by diluting these materials in other materials with smaller carrier densities, metals like Fe, or Ni, materials with van-Hove singularities in the electronic density of states such as graphite or Bechgaard salts or even or 2D-electron gases generated by graphene or by heterostructures, such as the electron gases generated at LaAlO3 / SrTiO3 or ZnO / (MgxZn1-x)O multilayers and more.

Owner:KOPP THILO +1

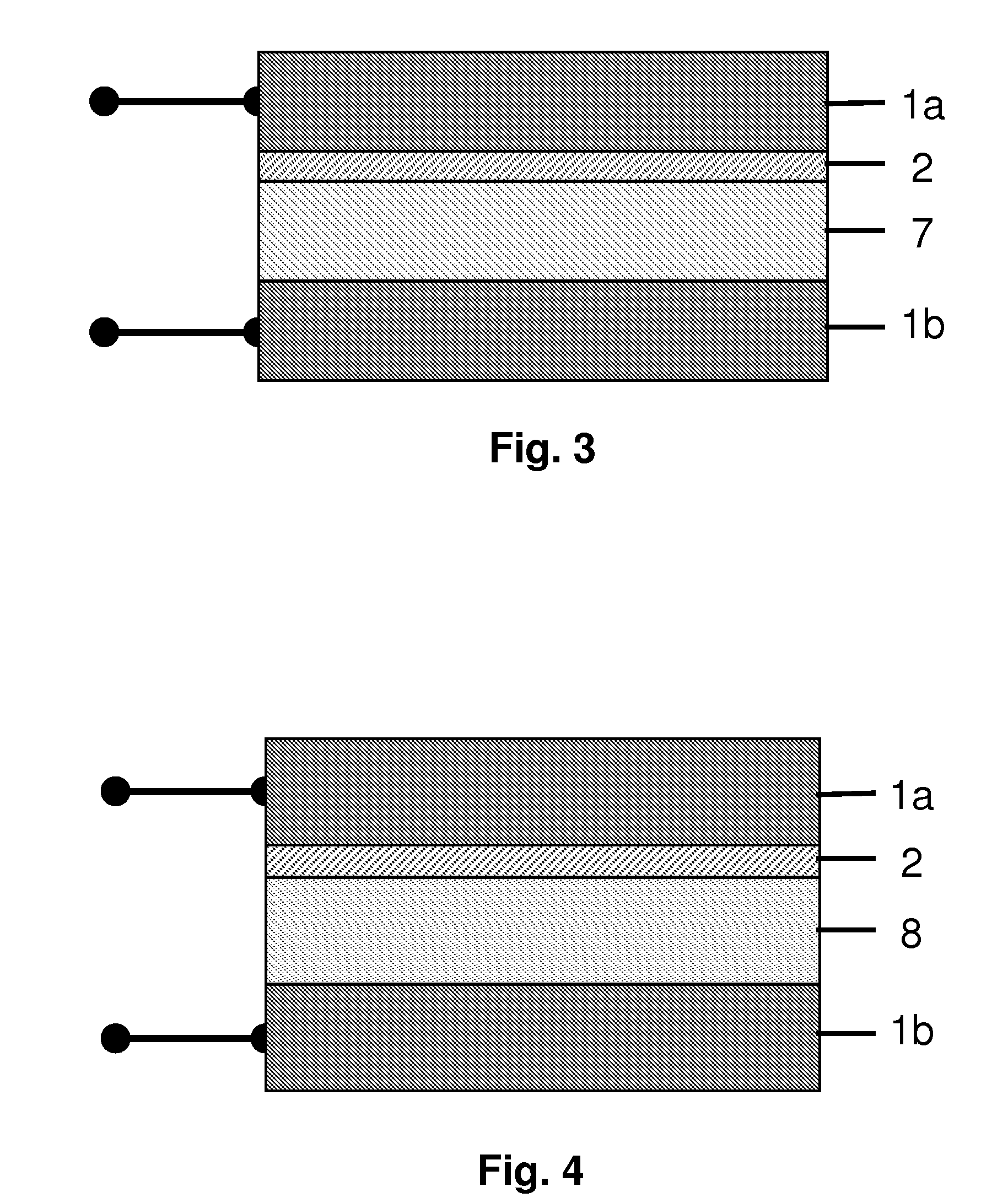

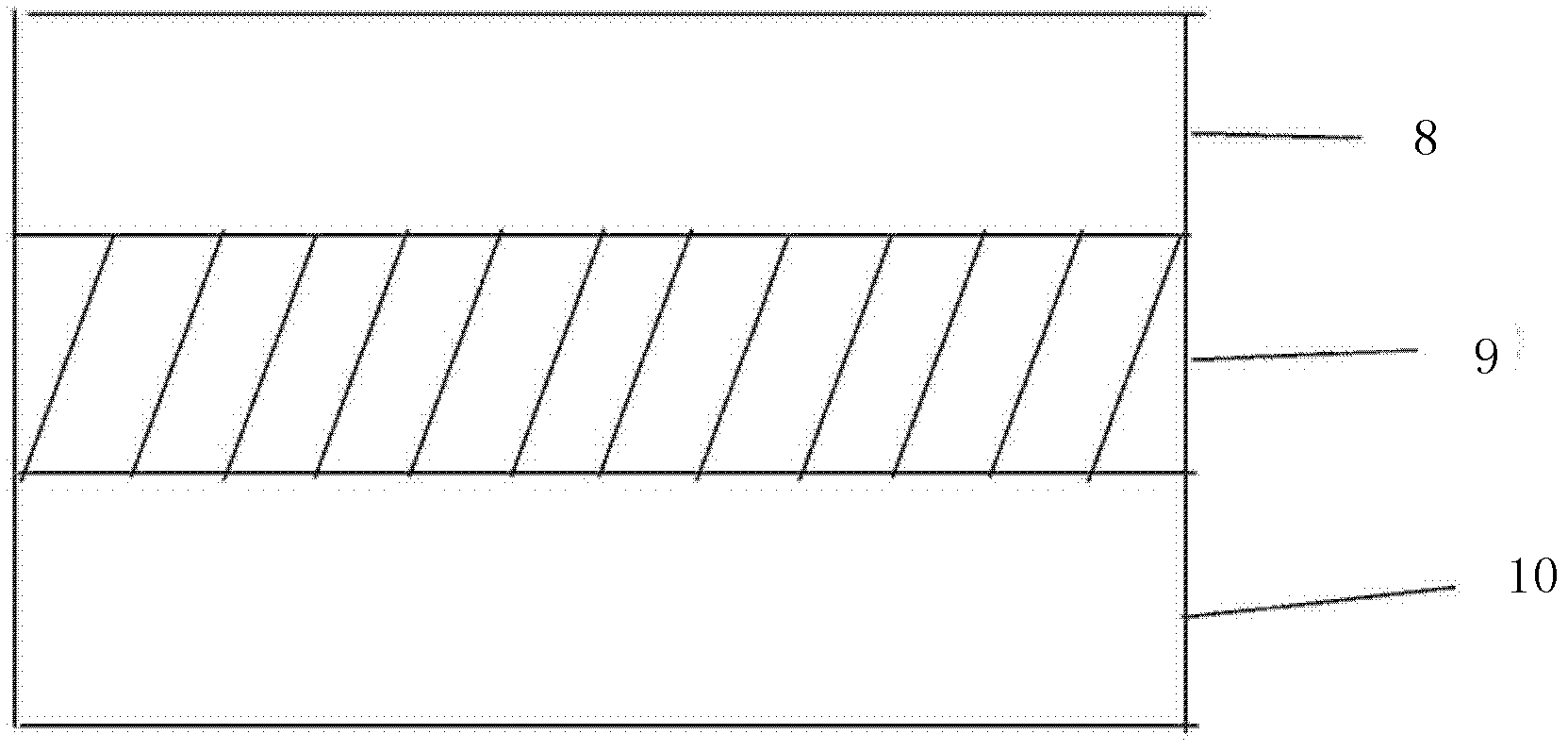

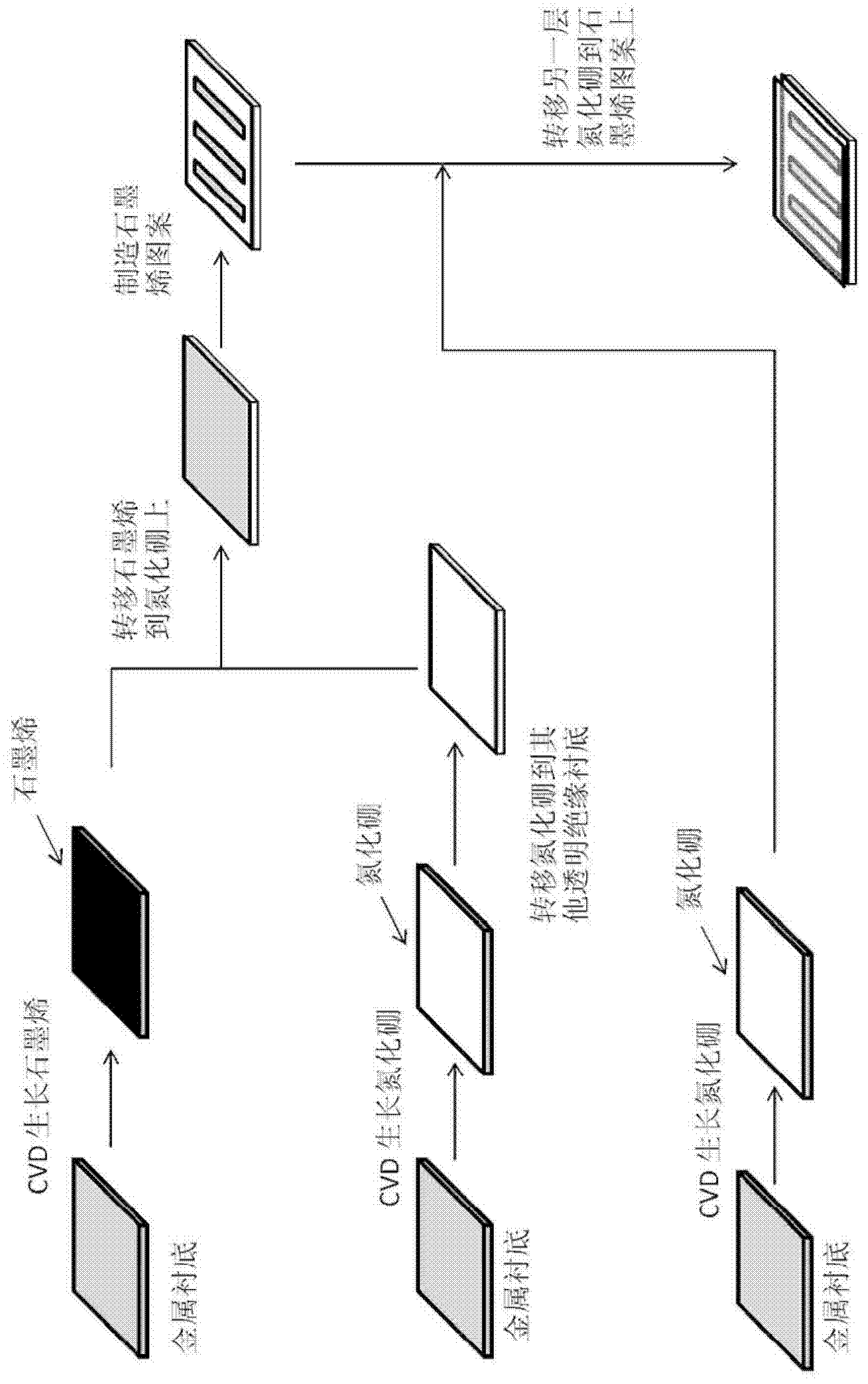

Boron nitride-graphene composite material, preparation method and purpose thereof

InactiveCN102496668AImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingCharge carrierBoron nitride

The invention relates to a boron nitride-graphene composite material which sequentially comprises a boron nitride film (8), a graphene film (9) and the boron nitride film (10). By using the composite material, under the condition that a carrier density is not increased, conductivity of the grapheme can be substantially increased. In addition, the invention also relates to a preparation method of the composite material and a purpose of preparing a transparent electrode.

Owner:金虎

Semiconductor film, method for manufacturing the semiconductor film, solar cell using the semiconductor film and method for manufacturing the solar cell

InactiveUS20050056863A1Low densityFinal product manufacturePhotovoltaic energy generationHigh energyCharge-carrier density

A semiconductor film has a composition in which a Group Ia element and a Group Vb element are added to a compound semiconductor with a chalcopyrite structure containing a Group Ib element, a Group IIIb element and a Group VIb element. This allows the provision of a semiconductor film whose carrier density can be controlled effectively. A solar cell of the present invention includes: a substrate and the semiconductor film of the present invention that is provided as a light-absorption layer on the substrate. With this configuration, a light-absorption layer whose carrier density can be controlled effectively can be provided, so that a solar cell having a high energy conversion efficiency can be provided.

Owner:PANASONIC CORP

Method of manufacturing a silicon carbide single crystal

InactiveUS20110200833A1Efficient preparationReduce carrier densityPolycrystalline material growthLiquid-phase epitaxial-layer growthBulk crystalAlloy

A method capable of stably manufacturing a SiC single crystal in the form of a thin film or a bulk crystal having a low carrier density of at most 5×1017 / cm3 and preferably less than 1×1017 / cm3 and which is suitable for use in various devices by liquid phase growth using a SiC solution in which the solvent is a melt of a Si alloy employs a Si alloy having a composition which is expressed by SixCryTiz wherein x, y, and z (each in atomic percent) satisfy0.50<x<0.68, 0.08<y<0.35, and 0.08<z<0.35, or (1)0.40<x≦0.50, 0.15<y<0.40, and 0.15<z<0.35. (2)x, y, and z preferably satisfy 0.53<x<0.65, 0.1<y<0.3, and 0.1<z<0.3.

Owner:NIPPON STEEL & SUMITOMO METAL CORP

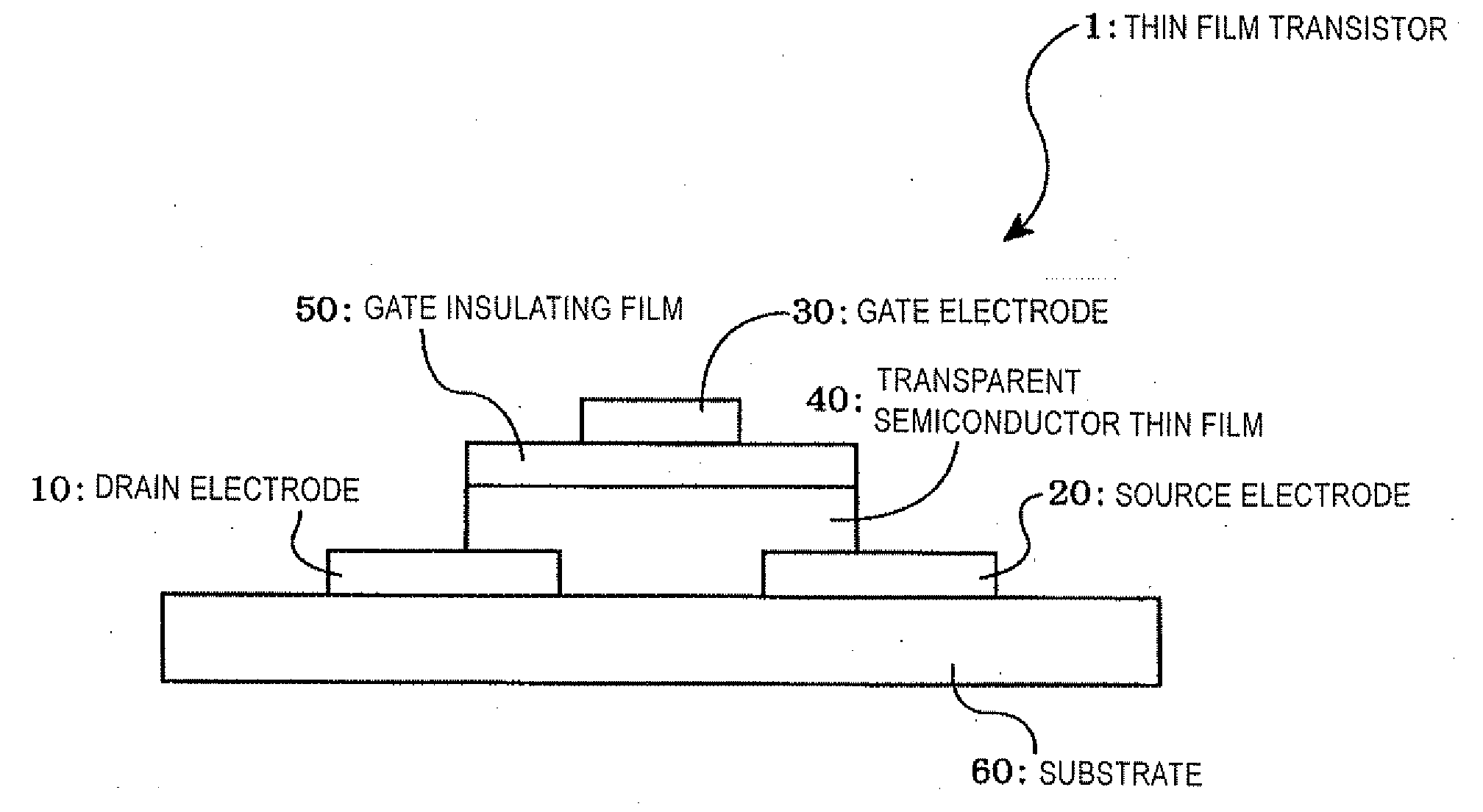

Semiconductor thin film, method for manufacturing the same, thin film transistor, and active-matrix-driven display panel

ActiveUS20100163860A1Hardly erroneously operatesSmall currentNanotechConductive materialIndiumActive matrix

Disclosed is a semiconductor thin film which can be formed at a relatively low temperature even on a flexible resin substrate. Since the semiconductor thin film is stable to visible light and has high device characteristics such as transistor characteristics, in the case where the semiconductor thin film is used as a switching device for driving a display, even when overlapped with a pixel part, the luminance of a display panel does not deteriorate. Specifically, a transparent semiconductor thin film 40 is produced by forming an amorphous film containing zinc oxide and indium oxide and then oxidizing the film so that the resulting film has a carrier density of 10+17 cm−3 or less, a Hall mobility of 2 cm2 / V·sec or higher, and an energy band gap of 2.4 EV or more.

Owner:IDEMITSU KOSAN CO LTD

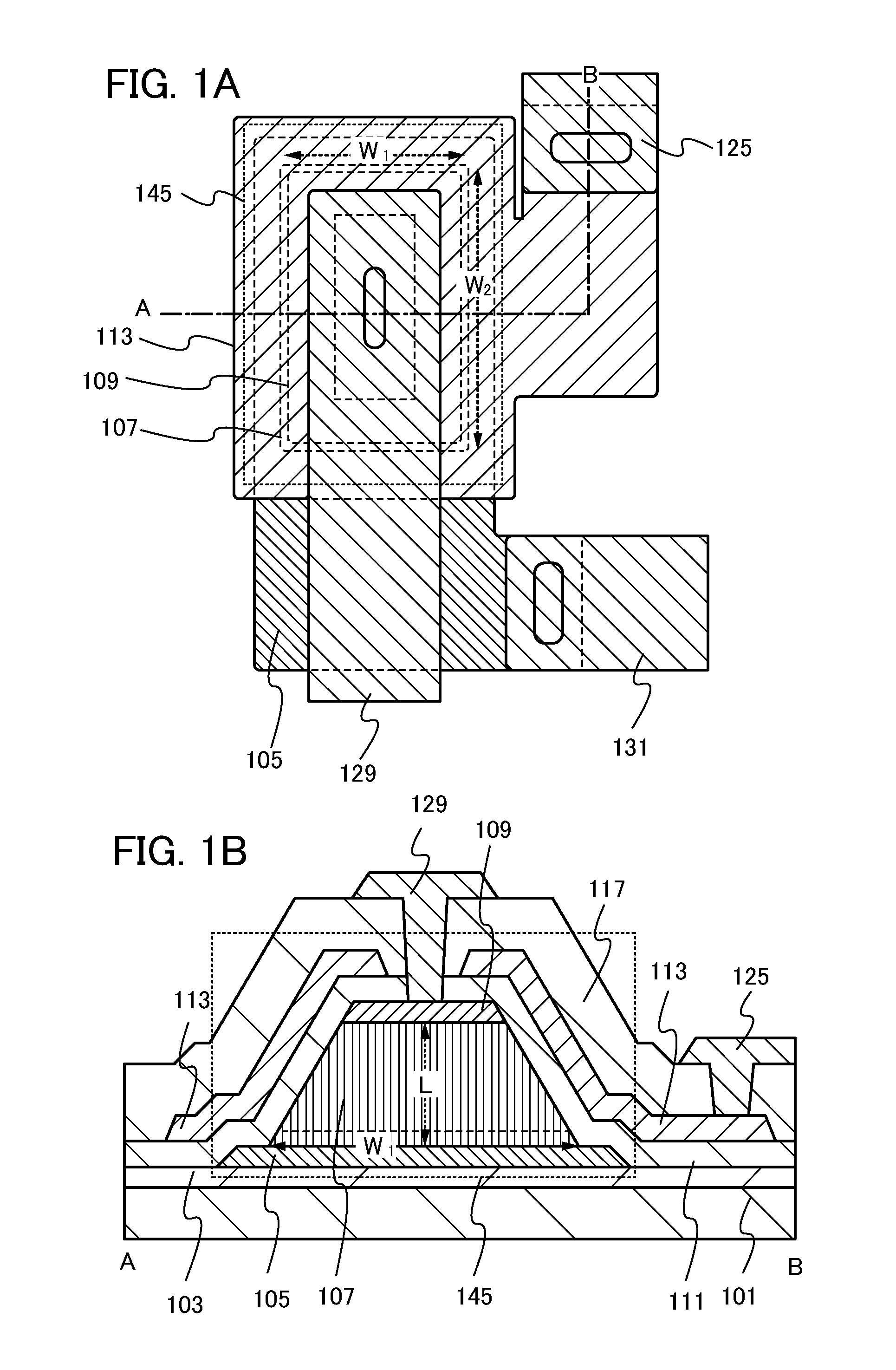

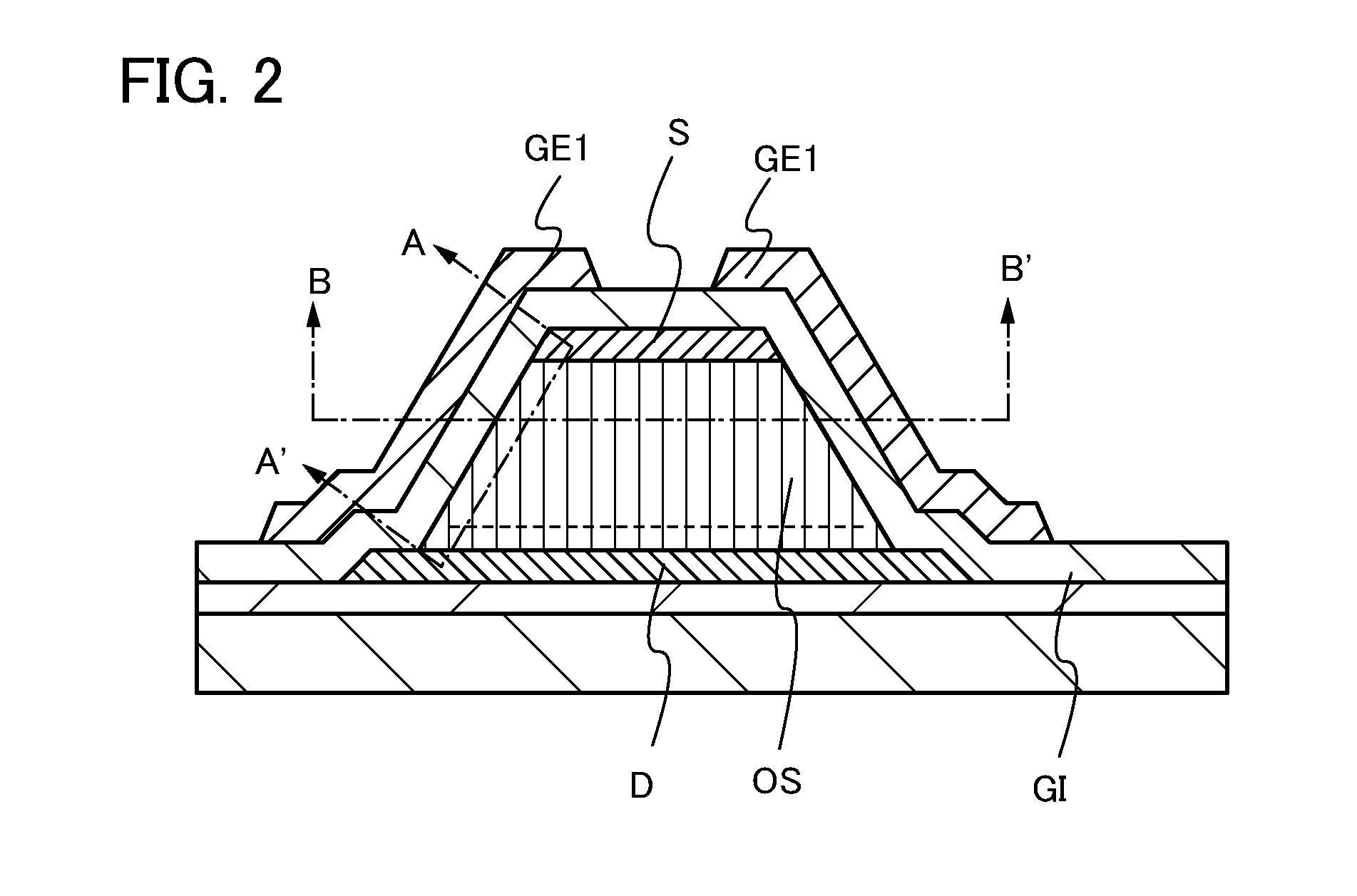

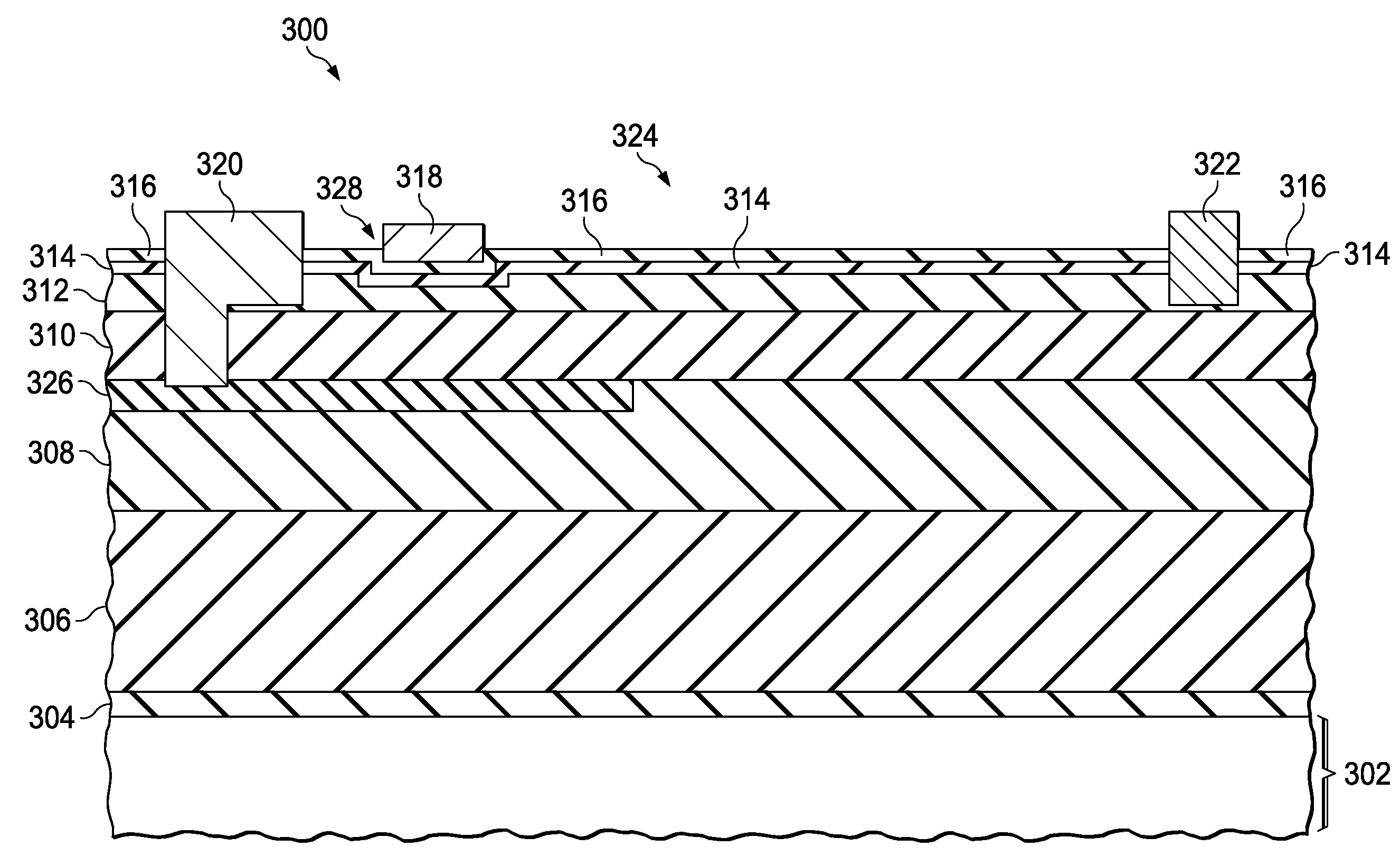

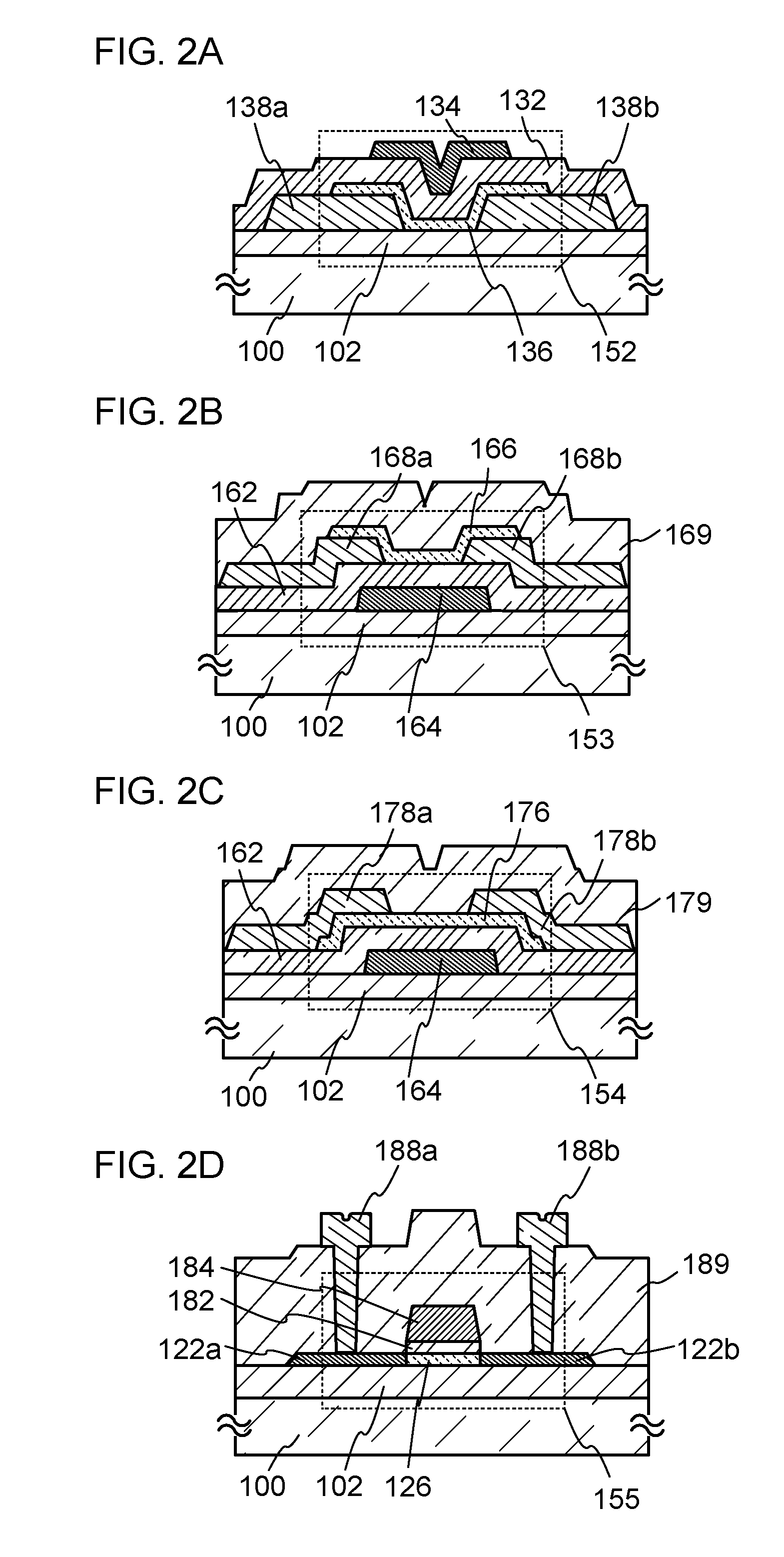

Semiconductor device and method for manufacturing the same

ActiveUS20120112183A1Sufficient characteristicImproved contact characteristicsTransistorSolid-state devicesCharge-carrier densityNitrogen

An object is to provide a semiconductor device including an oxynitride semiconductor whose carrier density is controlled. By introducing controlled nitrogen into an oxide semiconductor layer, a transistor in which an oxynitride semiconductor having desired carrier density and on characteristics is used for a channel can be manufactured. Further, with the use of the oxynitride semiconductor, even when a low resistance layer or the like is not provided between an oxynitride semiconductor layer and a source electrode and between the oxynitride semiconductor layer and a drain electrode, favorable contact characteristics can be exhibited.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device

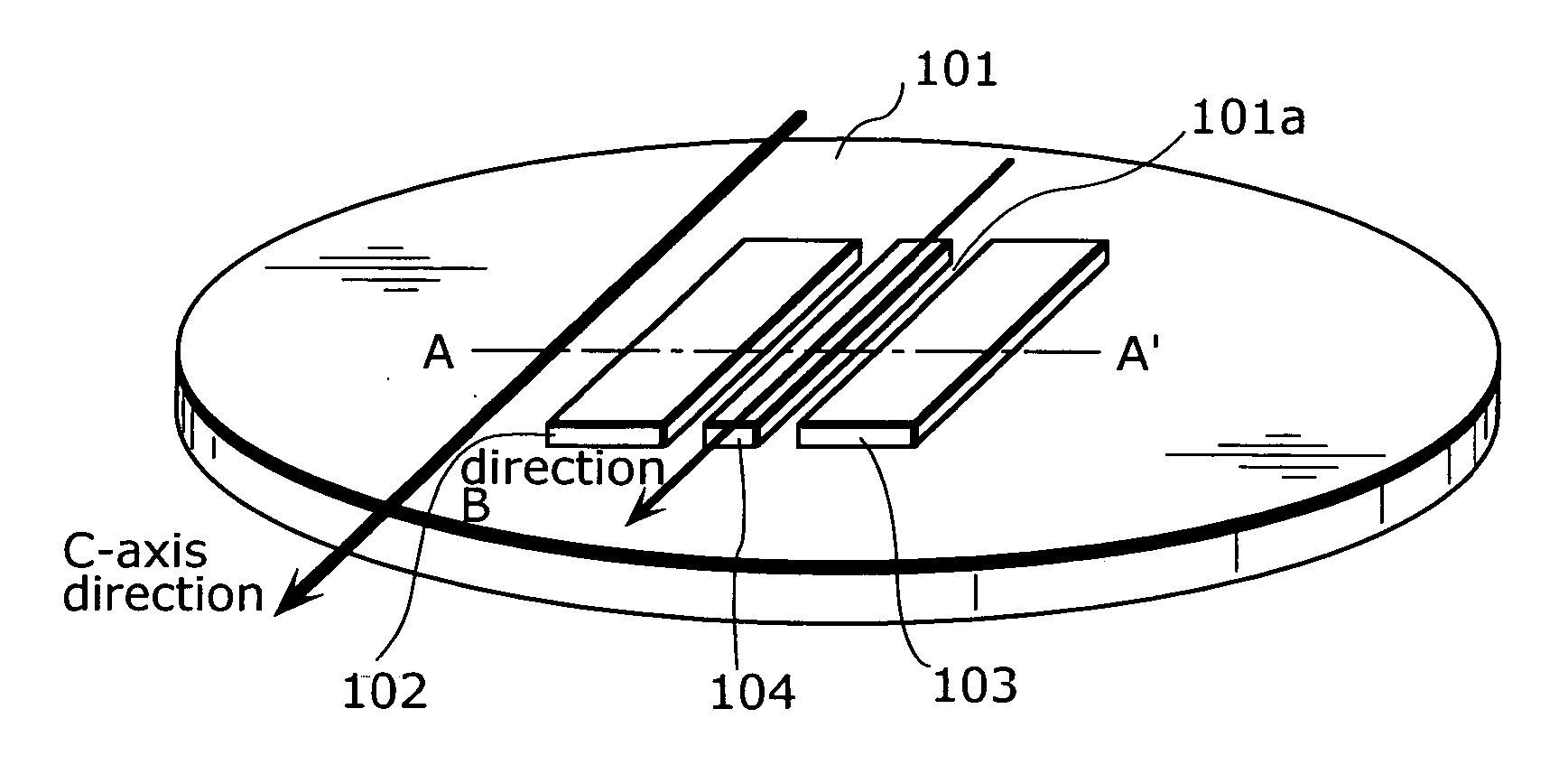

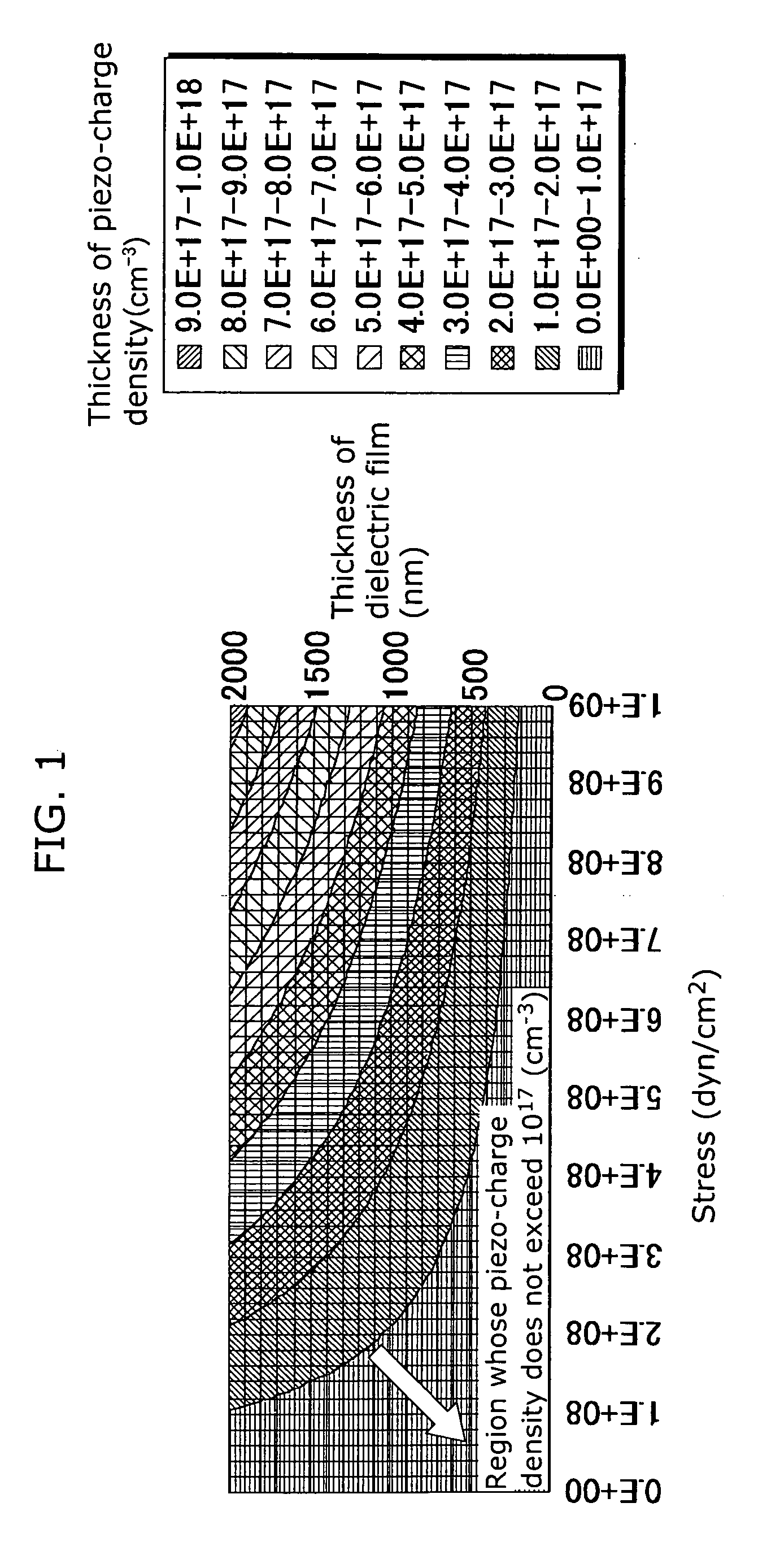

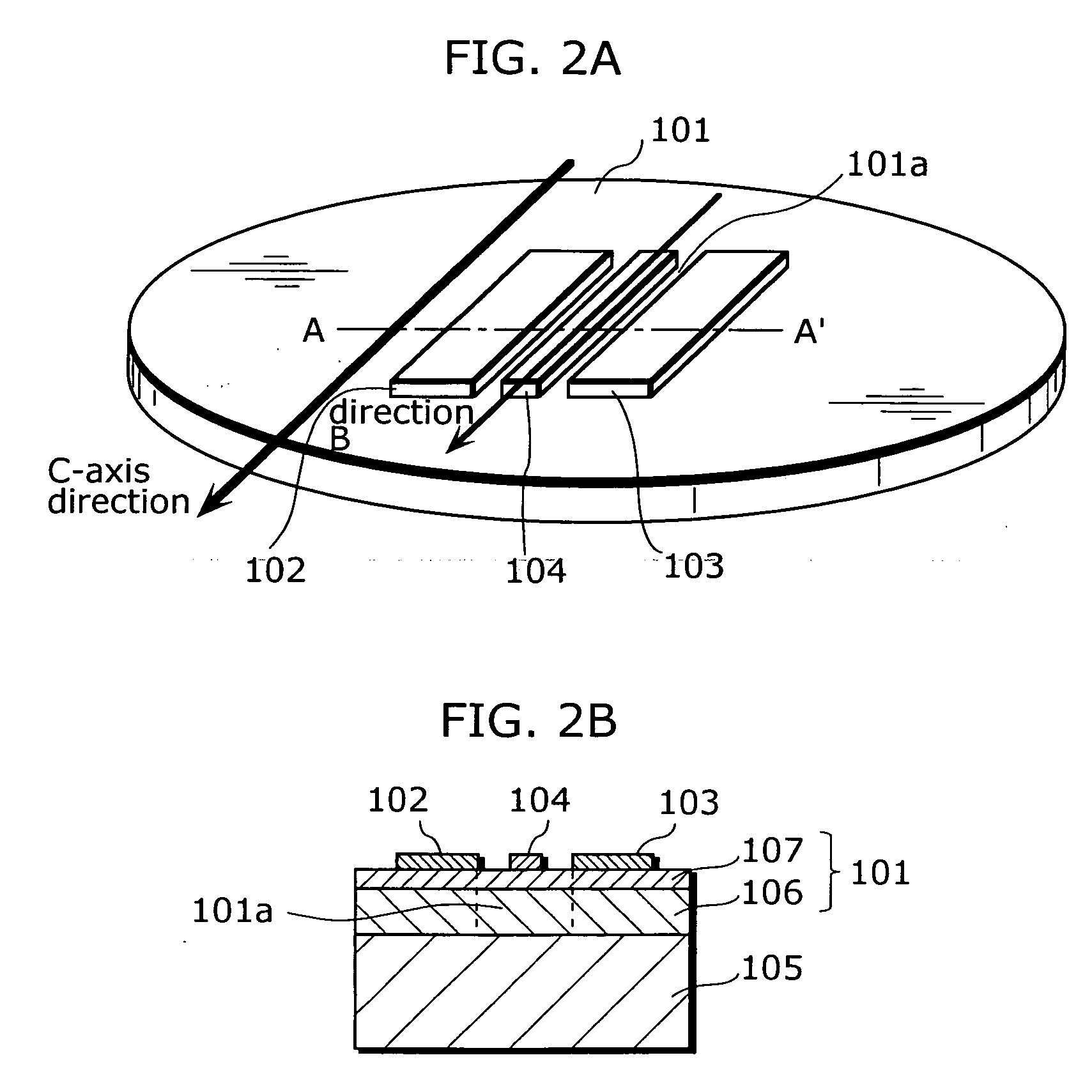

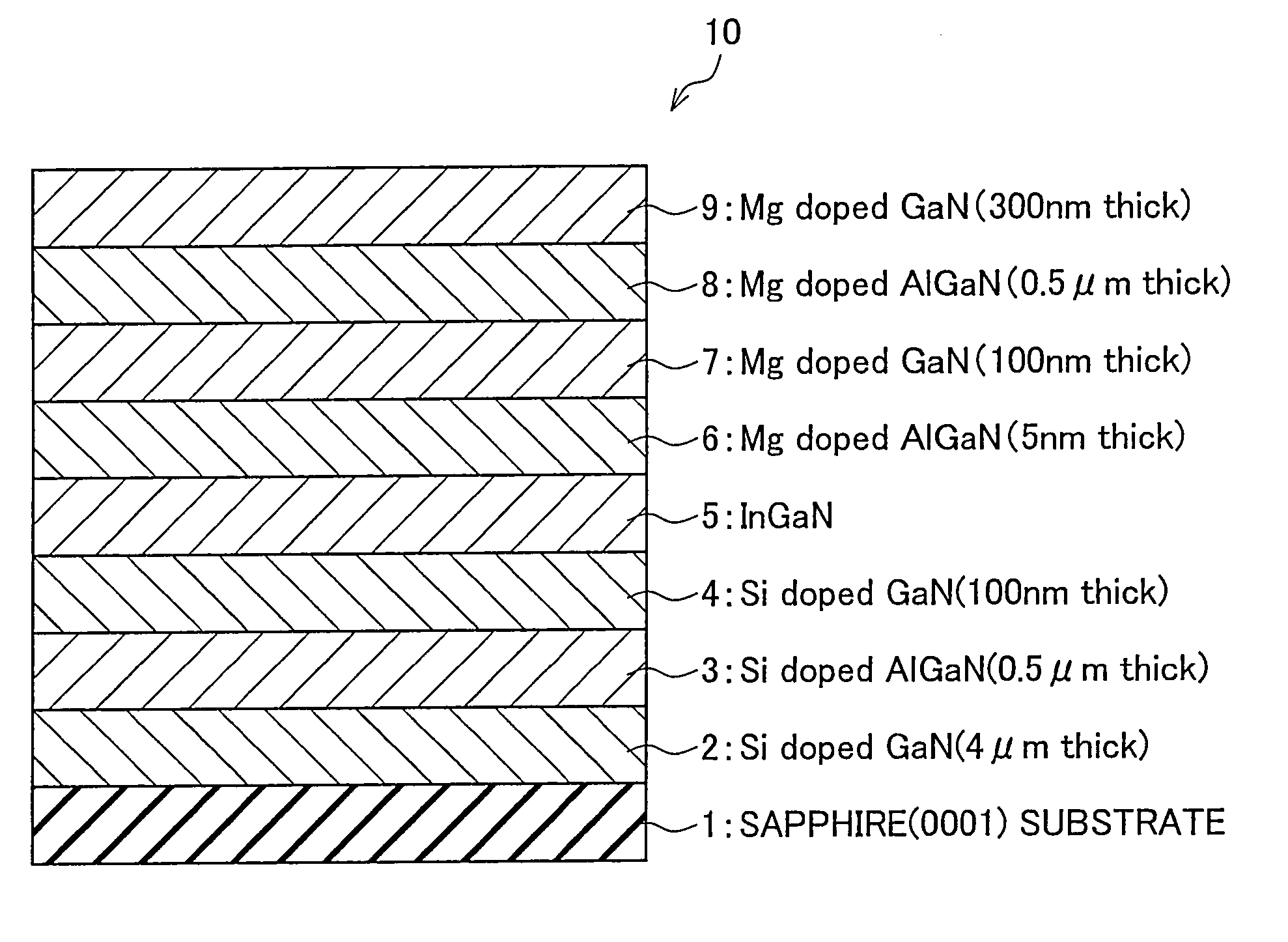

ActiveUS20060175618A1Suppress local generationEasy to controlSolid-state devicesNanoopticsDevice materialCharge-carrier density

A semiconductor device, which can accurately control carrier density, includes: a single crystal substrate; a semiconductor layer which is made of hexagonal crystal with 6 mm symmetry and is formed on the single crystal substrate; a source electrode, a drain electrode and a gate electrode which are formed on the semiconductor layer, where the main surfaces of a GaN layer and an AlGaN layer constituting the semiconductor layer respectively include C-axis of the hexagonal crystal, and a length direction of a channel region in the semiconductor layer is parallel to the C-axis of the hexagonal crystal.

Owner:PANASONIC CORP

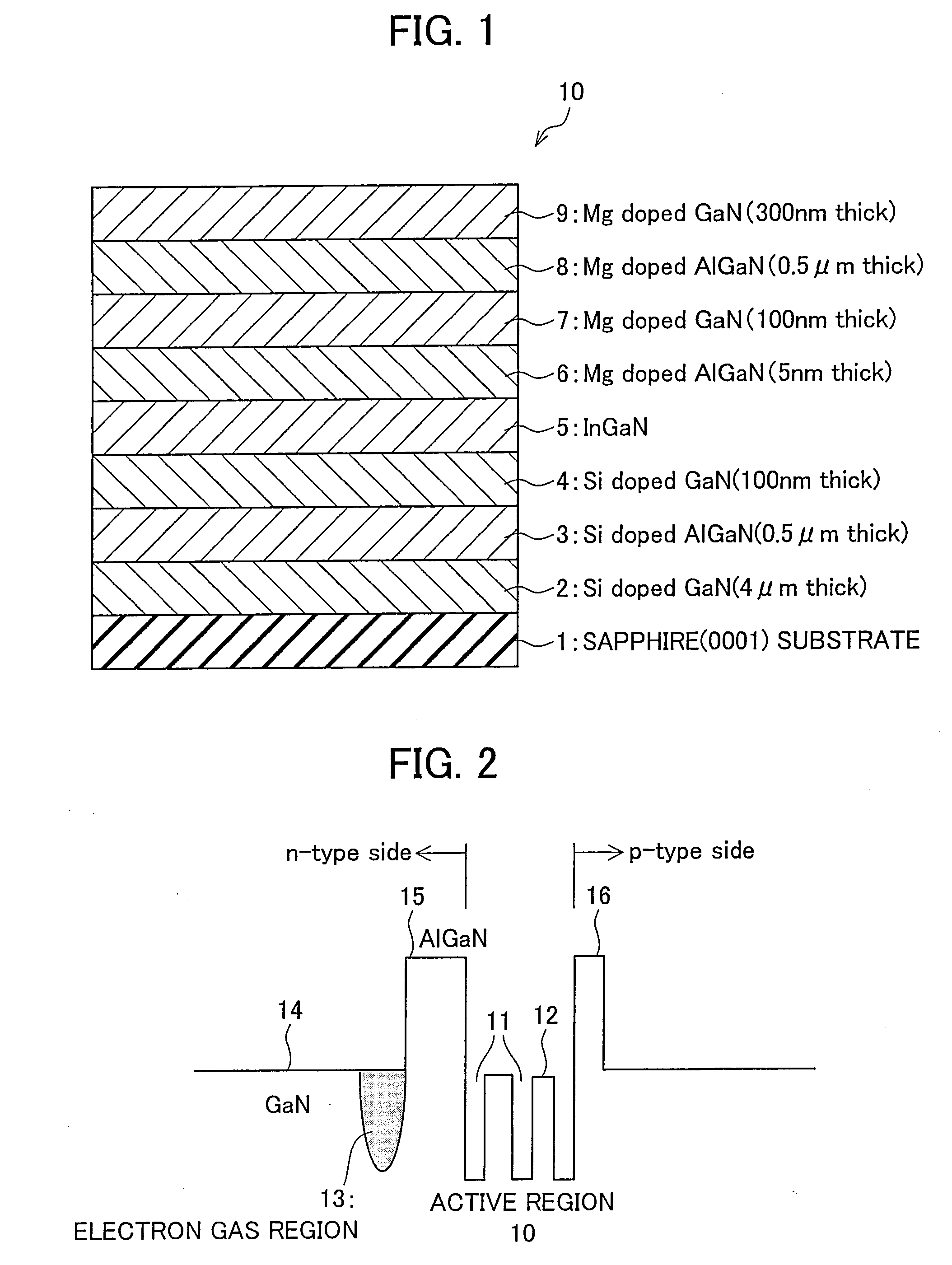

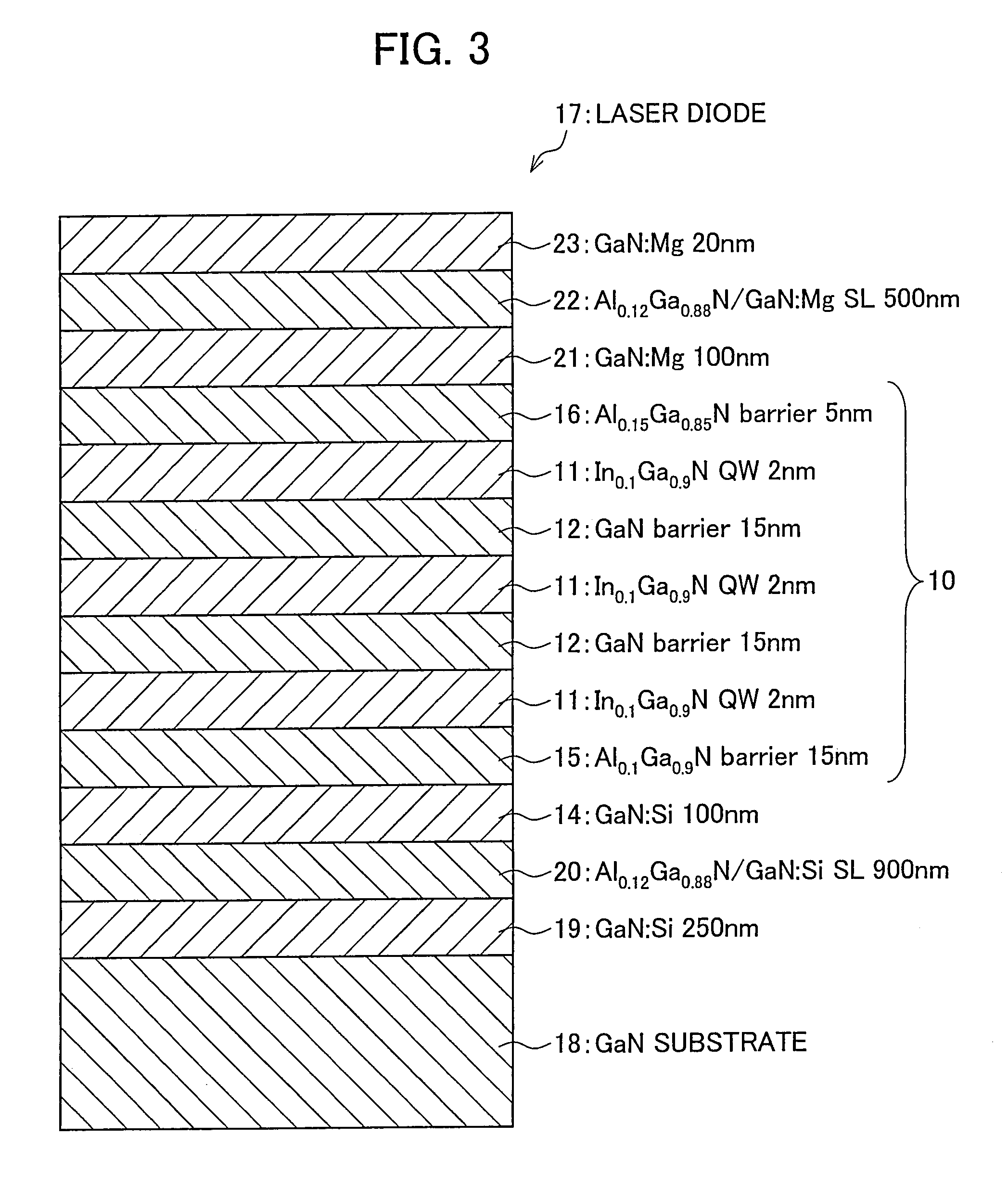

A semiconductor light-emitting device, and a method of manufacture of a semiconductor device

InactiveUS20060244002A1High possible improvement in optical efficiency of deviceFacilitates electron injectionSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialCharge-carrier density

A method of manufacturing a nitride semiconductor device comprises the steps of: growing an InxGa1-xN (0≦x≦1) layer, and growing an aluminium-containing nitride semiconductor layer over the InxGa1-xN layer at a growth temperature of at least 500° C. so as to form an electron gas region at an interface between the InxGa1-xN layer and the nitride semiconductor layer. The nitride semiconductor layer is then annealed at a temperature of at least 800° C. The method of the invention can provide an electron gas having a sheet carrier density of 6×1013 cm−2 or greater. An electron gas with such a high sheet carrier concentration can be obtained with an aluminium-containing nitride semiconductor layer having a relatively low aluminium concentration, such as an aluminium mole fraction of 0.3 or below, and without the need to dope the aluminium-containing nitride semiconductor layer or the InxGa1-xN layer.

Owner:SHARP KK

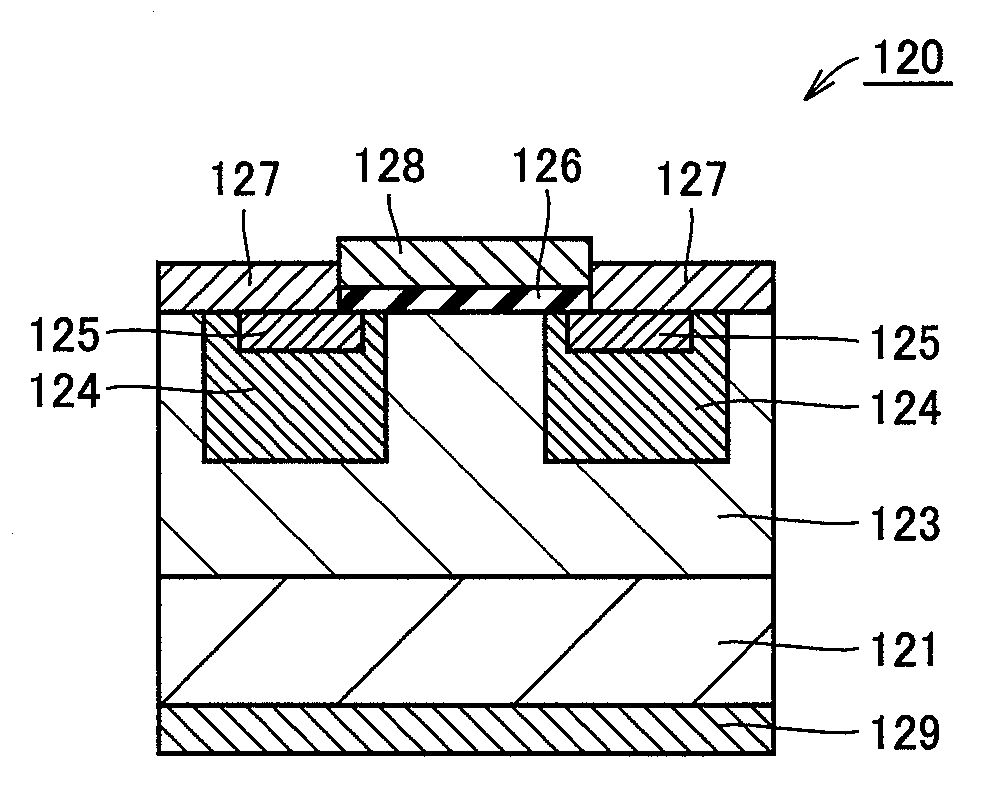

Method of producing group iii-v compound semiconductor, schottky barrier diode, light emitting diode, laser diode, and methods of fabricating the diodes

InactiveUS20080251801A1Reduced n type carrier densityReduce carrier densitySemiconductor/solid-state device manufacturingNanoopticsSchottky barrierGas phase

There are provided a method of producing a group III-V compound semiconductor, a Schottky barrier diode, a light emitting diode, a laser diode and methods of fabricating the diodes, that can achieve a reduced n type carrier density. The method of producing a group III-V compound semiconductor is a method of producing the compound semiconductor by metal organic chemical vapor deposition employing a material containing a group III element. Initially the step of preparing a seed substrate is performed. Then the step of growing a group III-V compound semiconductor on the seed substrate is performed by employing as a group III element-containing material an organic metal containing at most 0.01 ppm of silicon, at most 10 ppm of oxygen and less than 0.04 ppm of germanium.

Owner:SUMITOMO ELECTRIC IND LTD

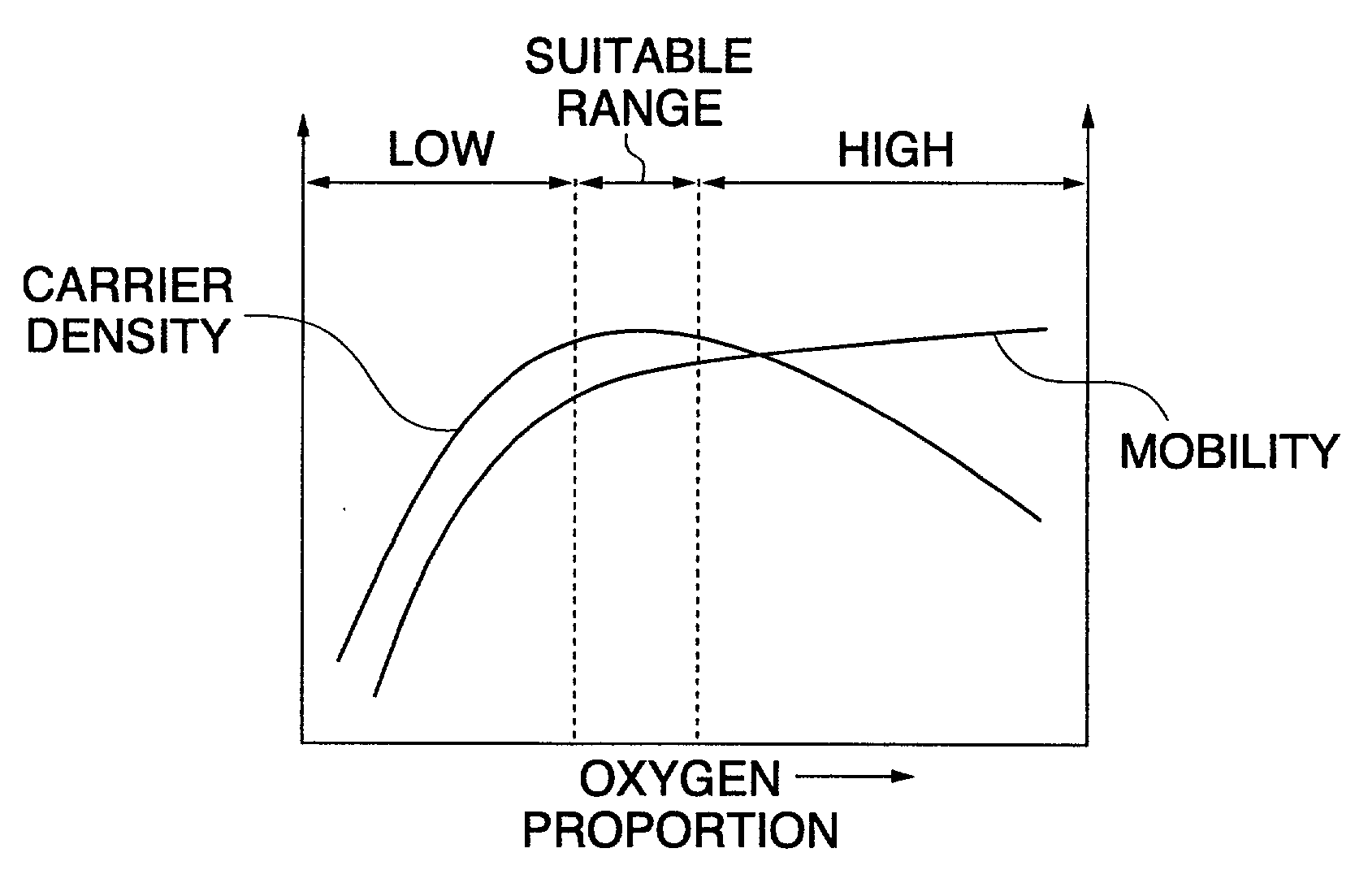

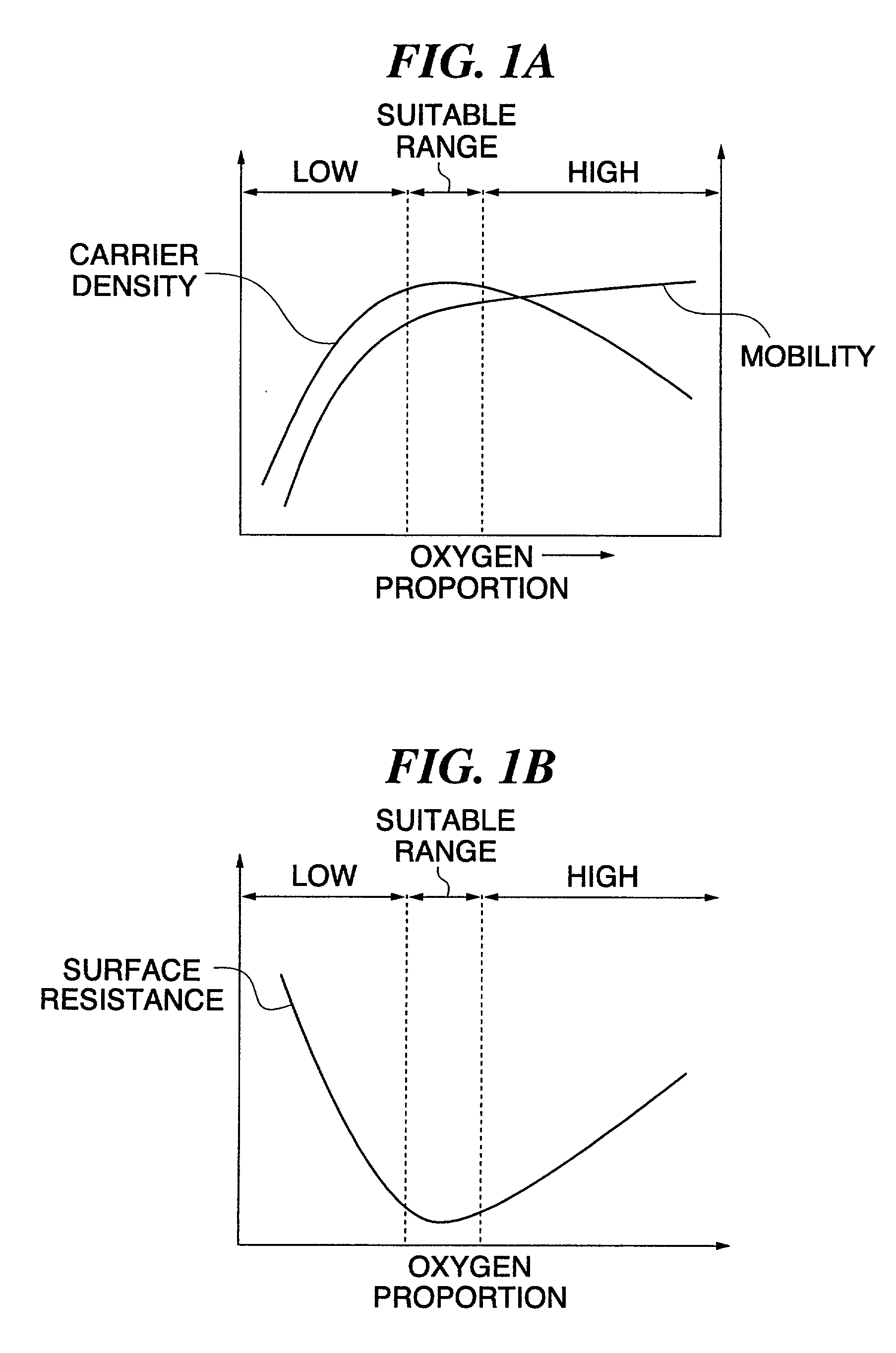

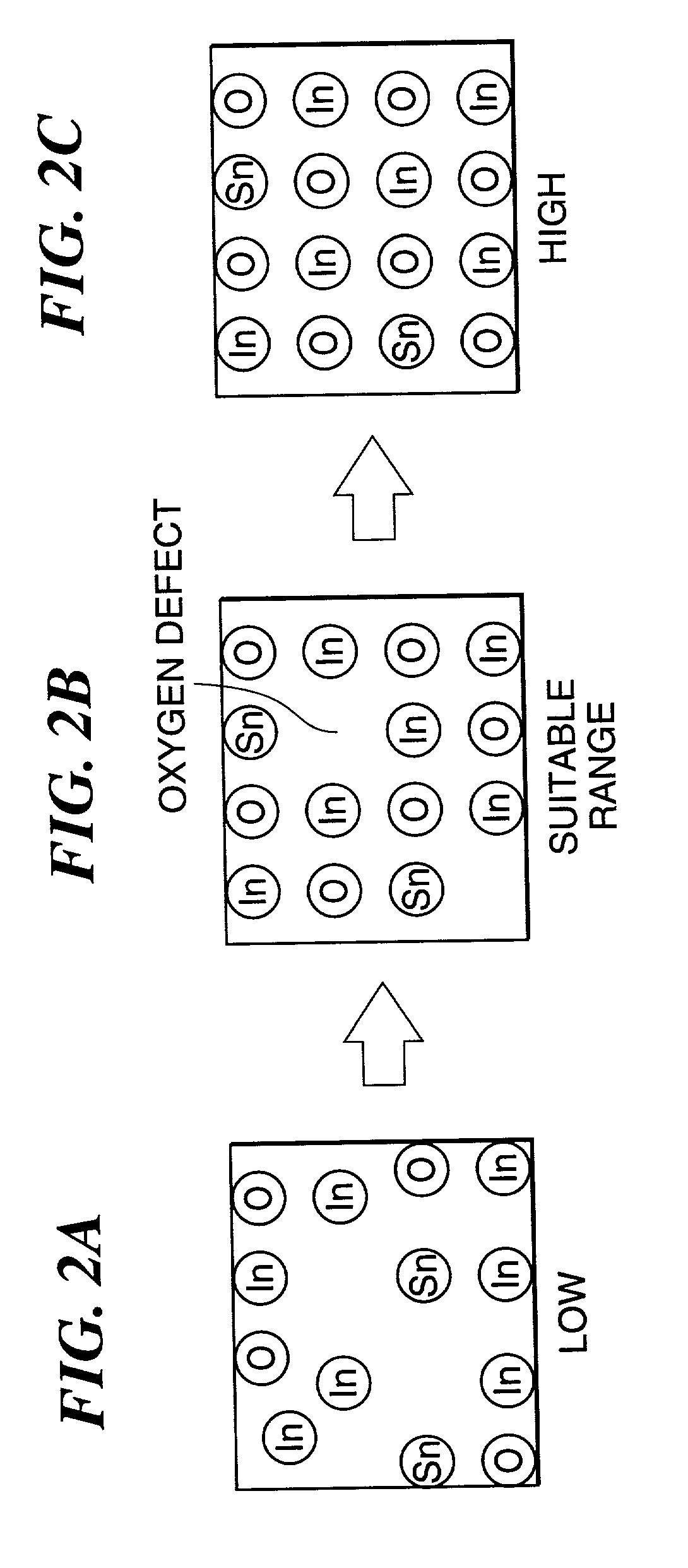

Method of manufacturing substrate having transparent conductive film, substrate having transparent conductive film manufactured using the method, and touch panel using the substrate

InactiveUS20020034836A1Conductive layers on insulating-supportsVacuum evaporation coatingIndiumOxygen

In a method of manufacturing a substrate having a transparent conductive film in which sputtering is carried out on a transparent insulating substrate using an indium oxide / tin oxide target under an atmosphere of a mixed gas containing argon and oxygen, when the ratio of oxygen to argon in the mixed gas is in a suitable range of 0.016 to 0.018, the carrier density of the transparent conductive film becomes a maximum, while the mobility rises progressively as the ratio of oxygen to argon increases. The surface resistance of the transparent conductive film, that is the reciprocal of the product of the carrier density and the mobility, 1 / (carrier densityxmobility), takes a minimum value when the ratio of oxygen to argon is in the above suitable range. In this case, crystallization of the film is promoted and the percentage change between the surface resistance of the film before heat treatment and the surface resistance of the film after heat treatment can be kept down to within ±10%.

Owner:NIPPON SHEET GLASS CO LTD

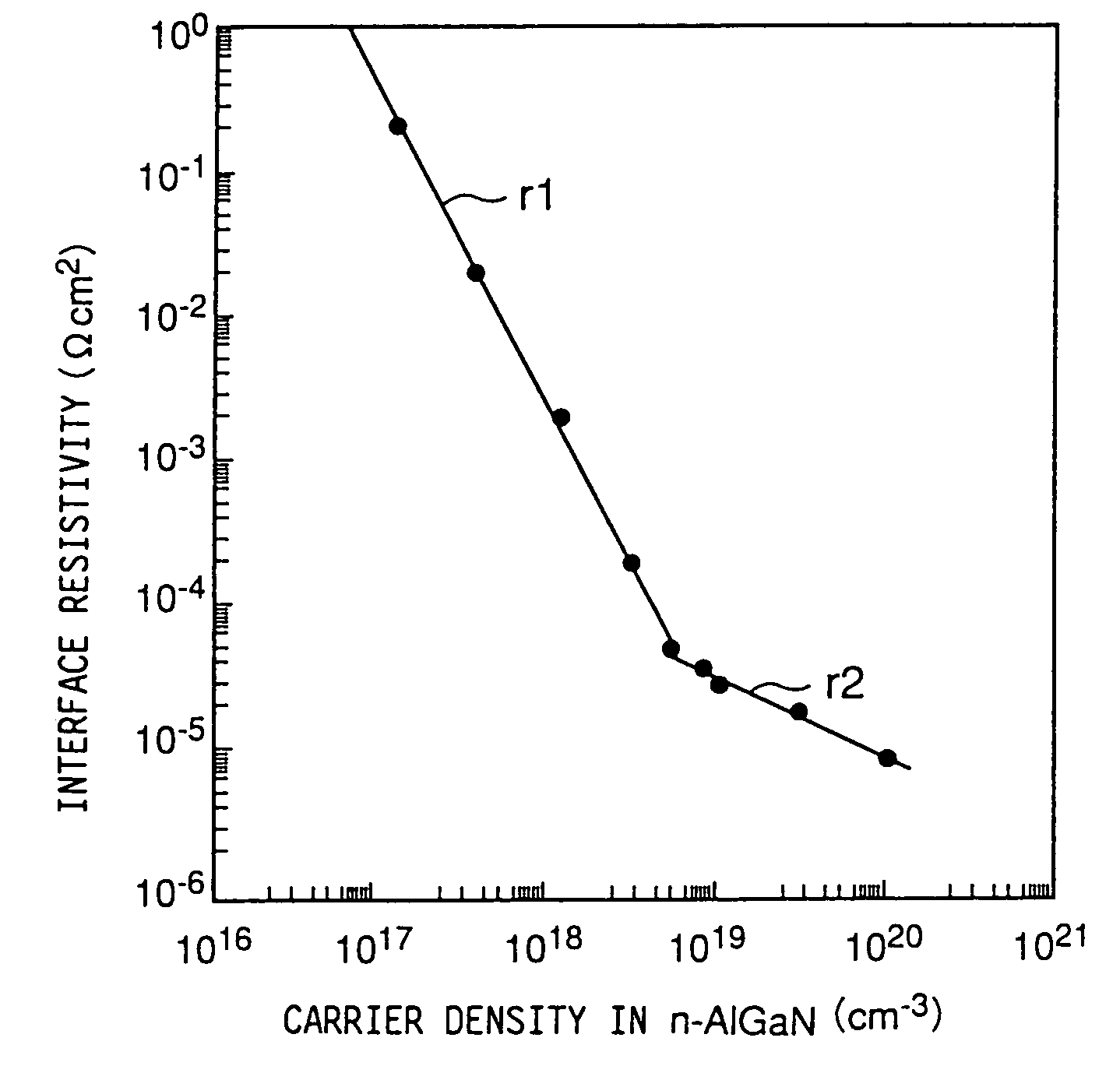

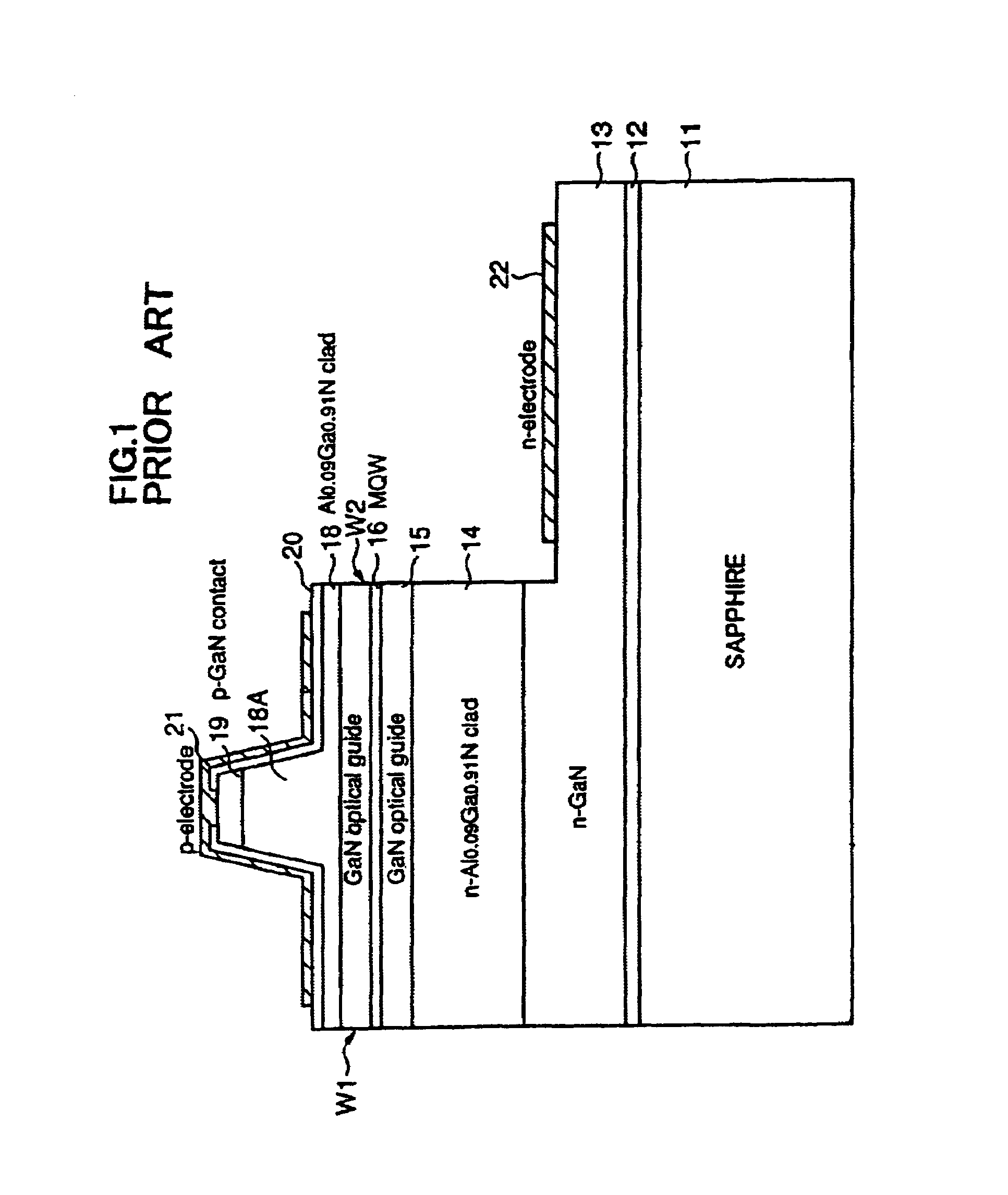

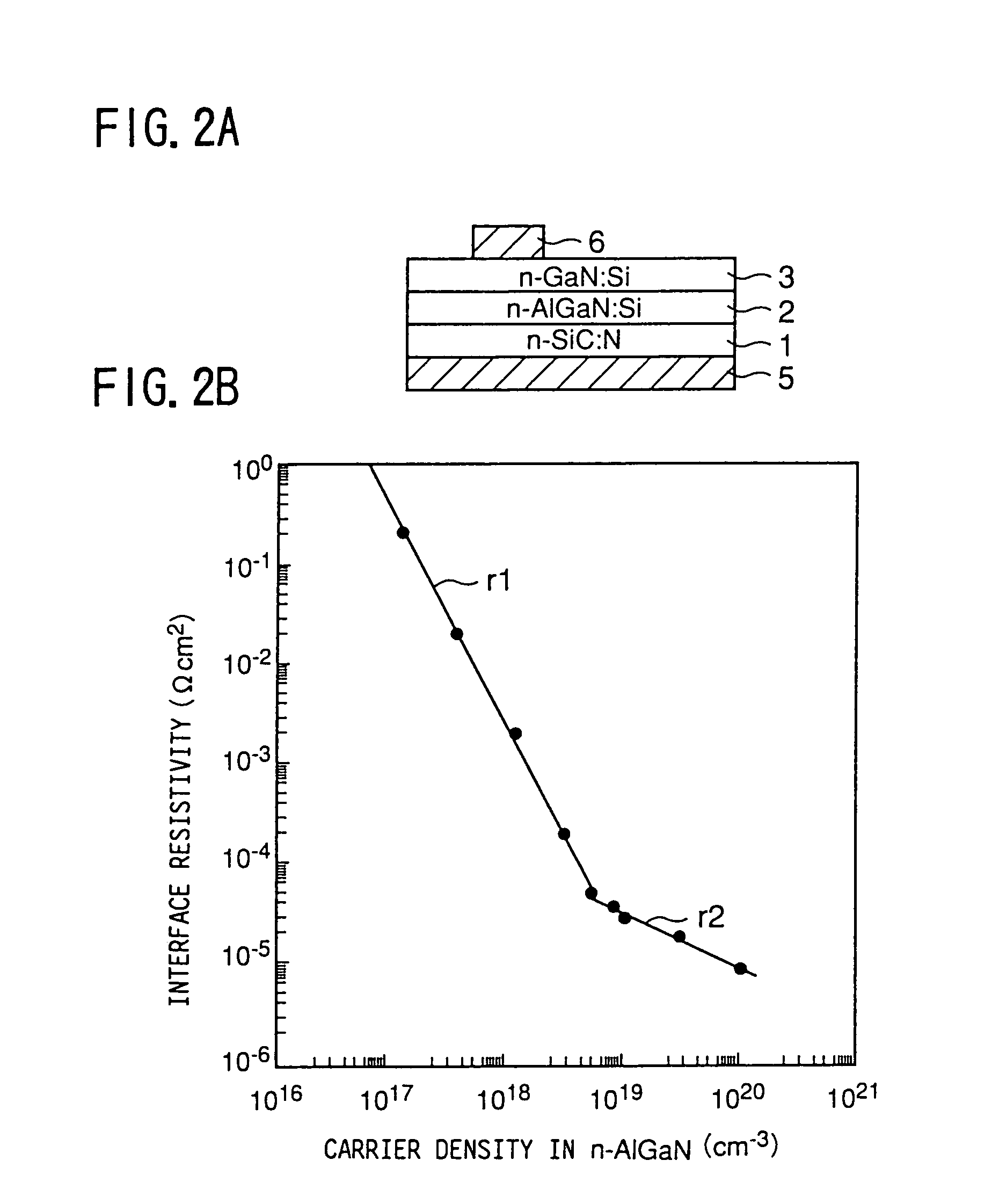

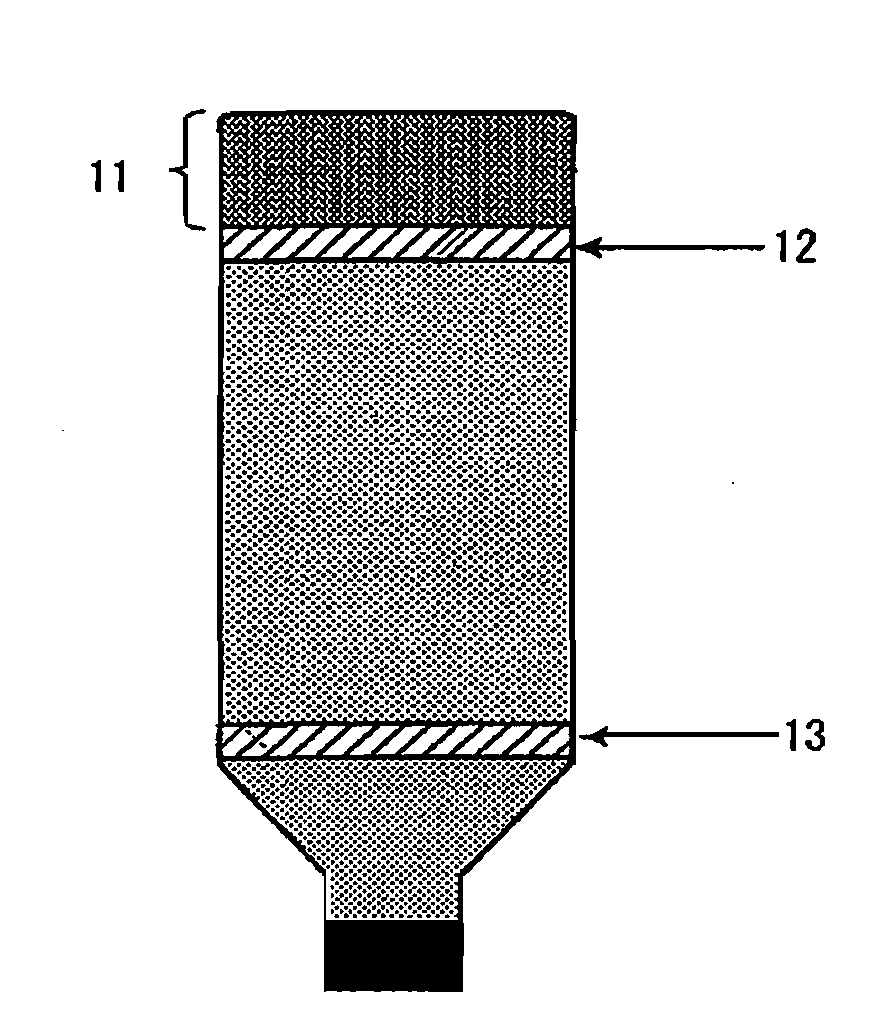

Optical semiconductor device having an epitaxial layer of III-V compound semiconductor material containing N as a group V element

InactiveUS6984840B2Resistance at interfaceDrag minimizationLaser detailsNanoinformaticsCharge-carrier densityDevice material

An optical semiconductor device includes an SiC substrate having an n-type conductivity, and an AlGaN buffer layer having an n-type conductivity formed on the SiC substrate with a composition represented as AlxGa1-xN, wherein the AlGaN buffer layer has a carrier density in the range between 3×1018–1×1020 cm−3, and the compositional parameter x is larger than 0 but smaller than 0.4 (0<x<0.4).

Owner:FUJITSU LTD

Indium phosphide substrate, indium phosphide single crystal and process for producing them

InactiveUS20090072205A1High strengthLarge deformationNon-metal conductorsPolycrystalline material growthDevice materialVolumetric Mass Density

An indium phosphide substrate for semiconductor devices is obtained as follows. In order to have the direction of growth of the crystal in the <100> orientation, a seed crystal having a specified cross-sectional area ratio with the crystal body is placed at the lower end of a growth container. The growth container housing the seed crystal, indium phosphide raw material, dopant, and boron oxide is placed in a crystal growth chamber. The temperature is raised to at or above the melting point of indium phosphide. After melting the boron oxide, indium phosphide raw material, and dopant, the temperature of the growth container is lowered in order to obtain an indium phosphide monocrystal. An average dislocation density is a function of a carrier density and diameter of the substrate, dislocation density, and a dopant concentration on the wafer is substantially uniform in the depth direction.

Owner:SUMITOMO ELECTRIC IND LTD

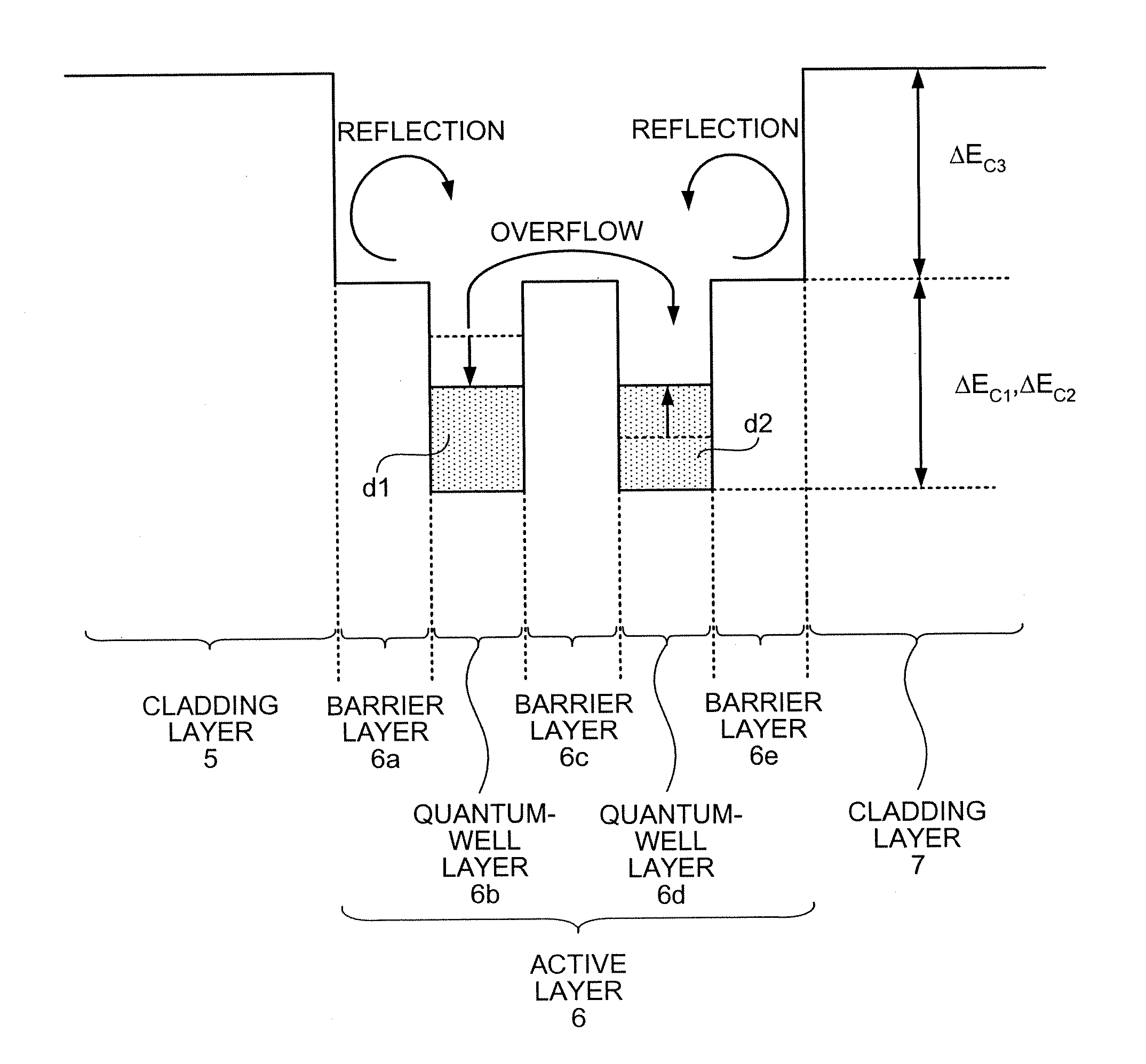

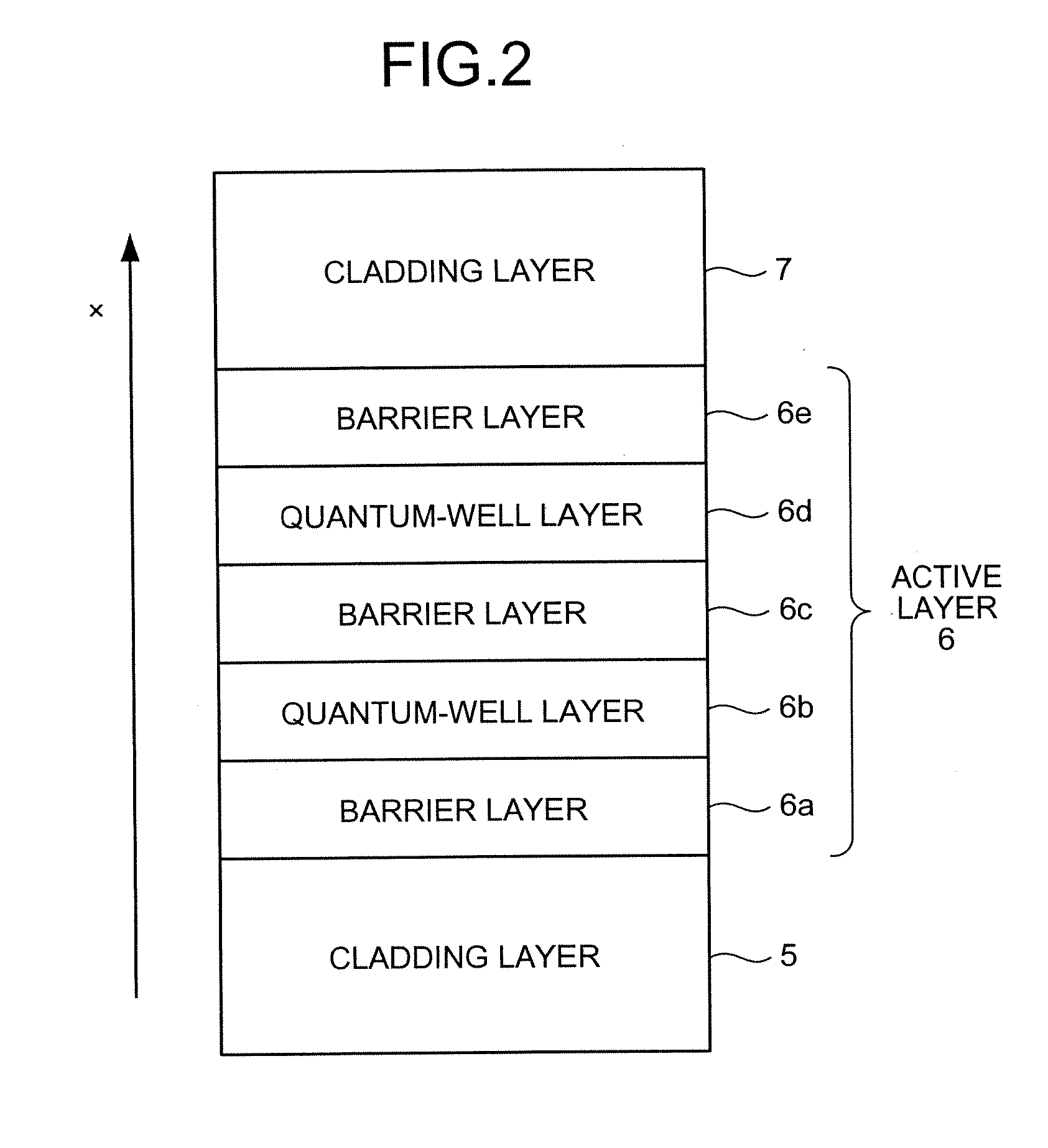

Semiconductor laser device

InactiveUS20070153856A1Solve problemsOptical wave guidanceLaser detailsQuantum wellCharge-carrier density

An active layer is formed by arranging a plurality of quantum-well layers and a plurality of barrier layers alternatively. An amount of band discontinuity in a conduction band between a barrier layer that is sandwiched by the quantum-well layers and adjacent quantum-well layers is equal to or more than 26 meV and less than 300 meV, so that an overflow of injected carriers due to a thermal excitation between the quantum-well layers is intentionally caused to make the carrier density uniform between the quantum-well layers.

Owner:FURUKAWA ELECTRIC CO LTD

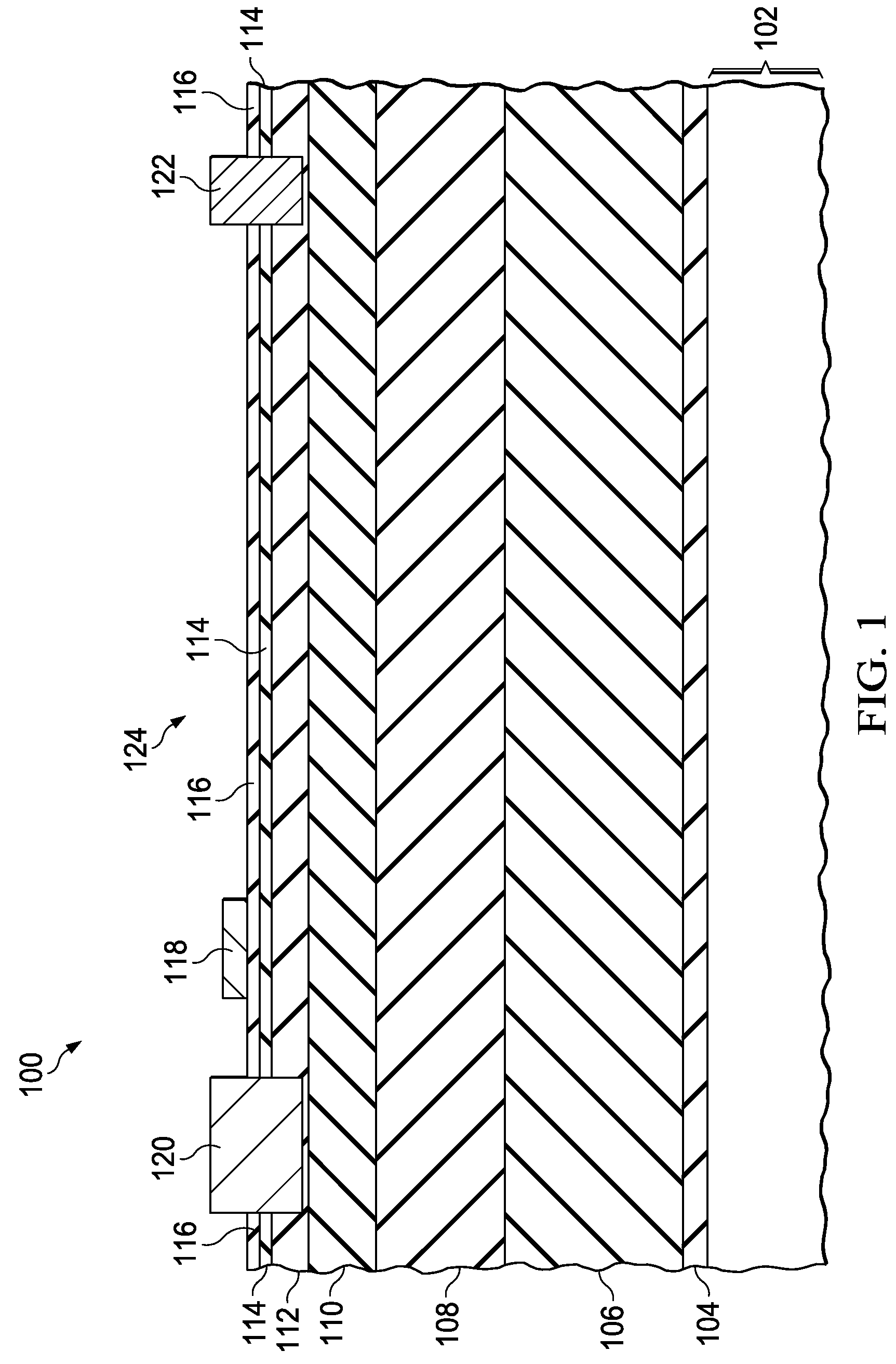

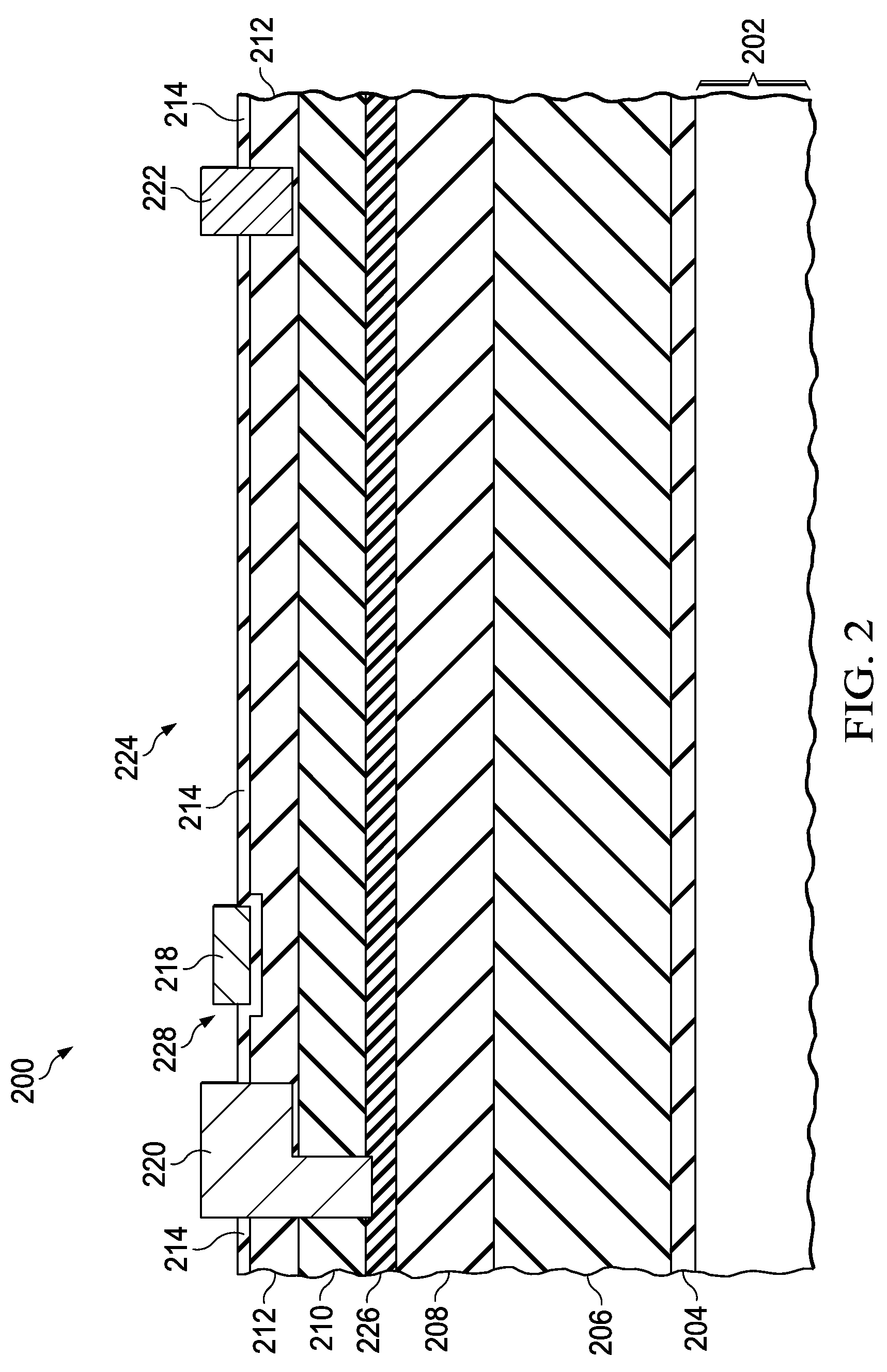

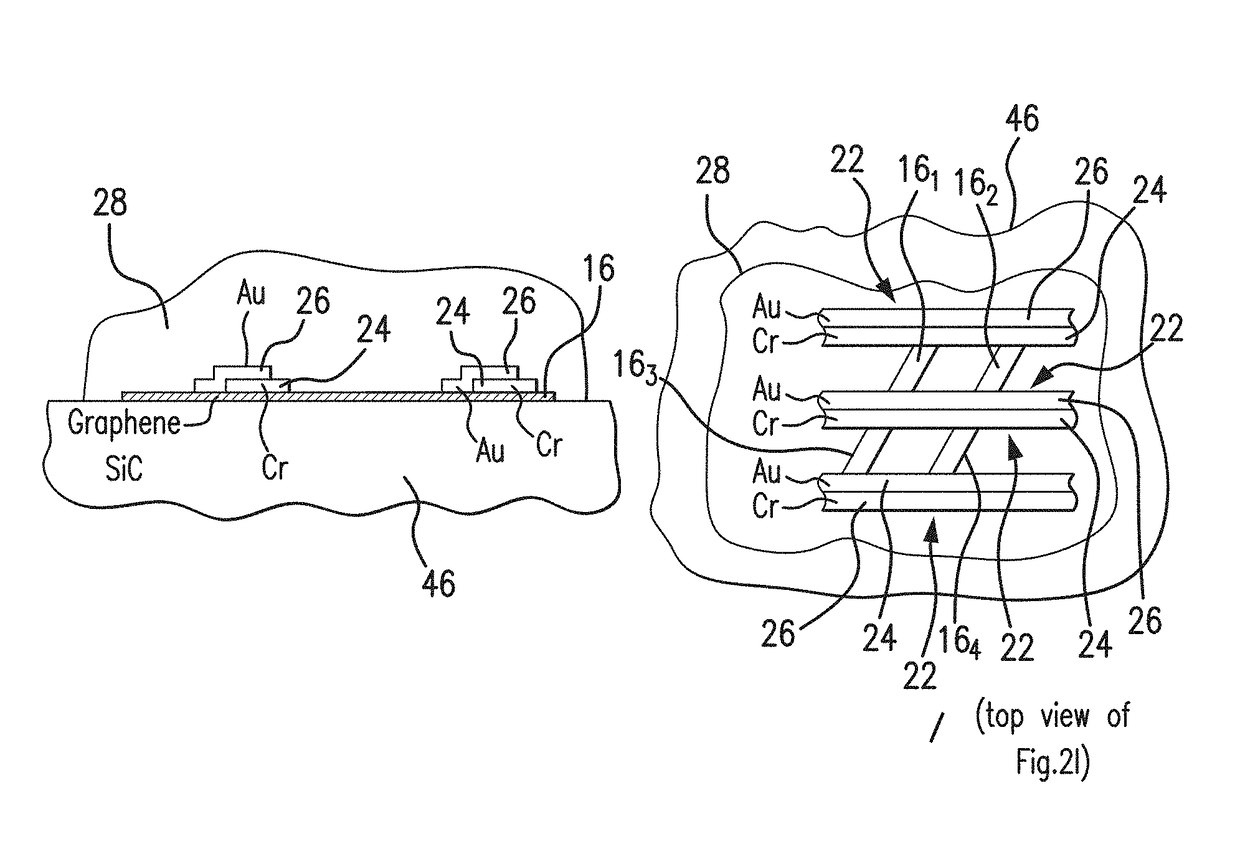

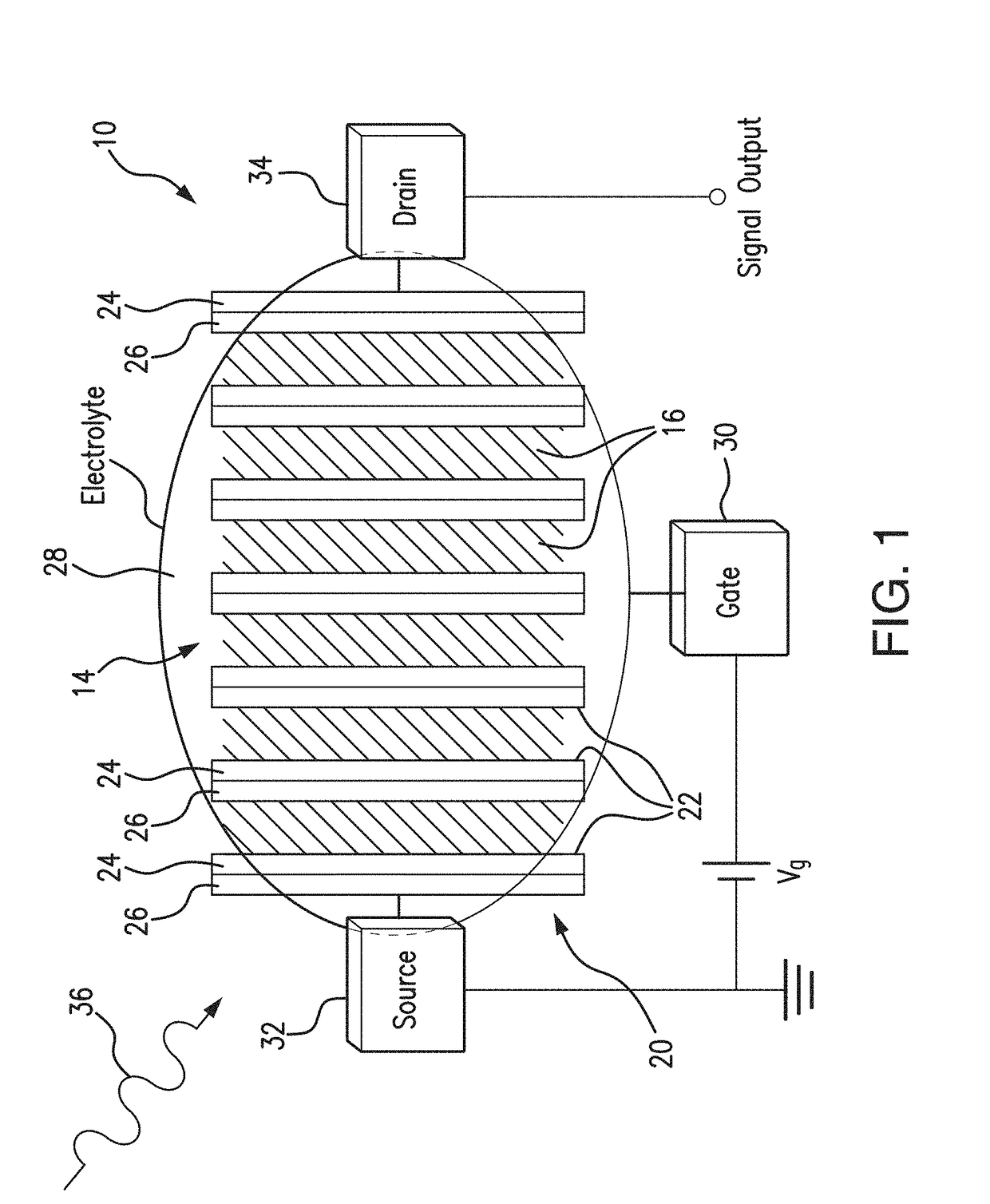

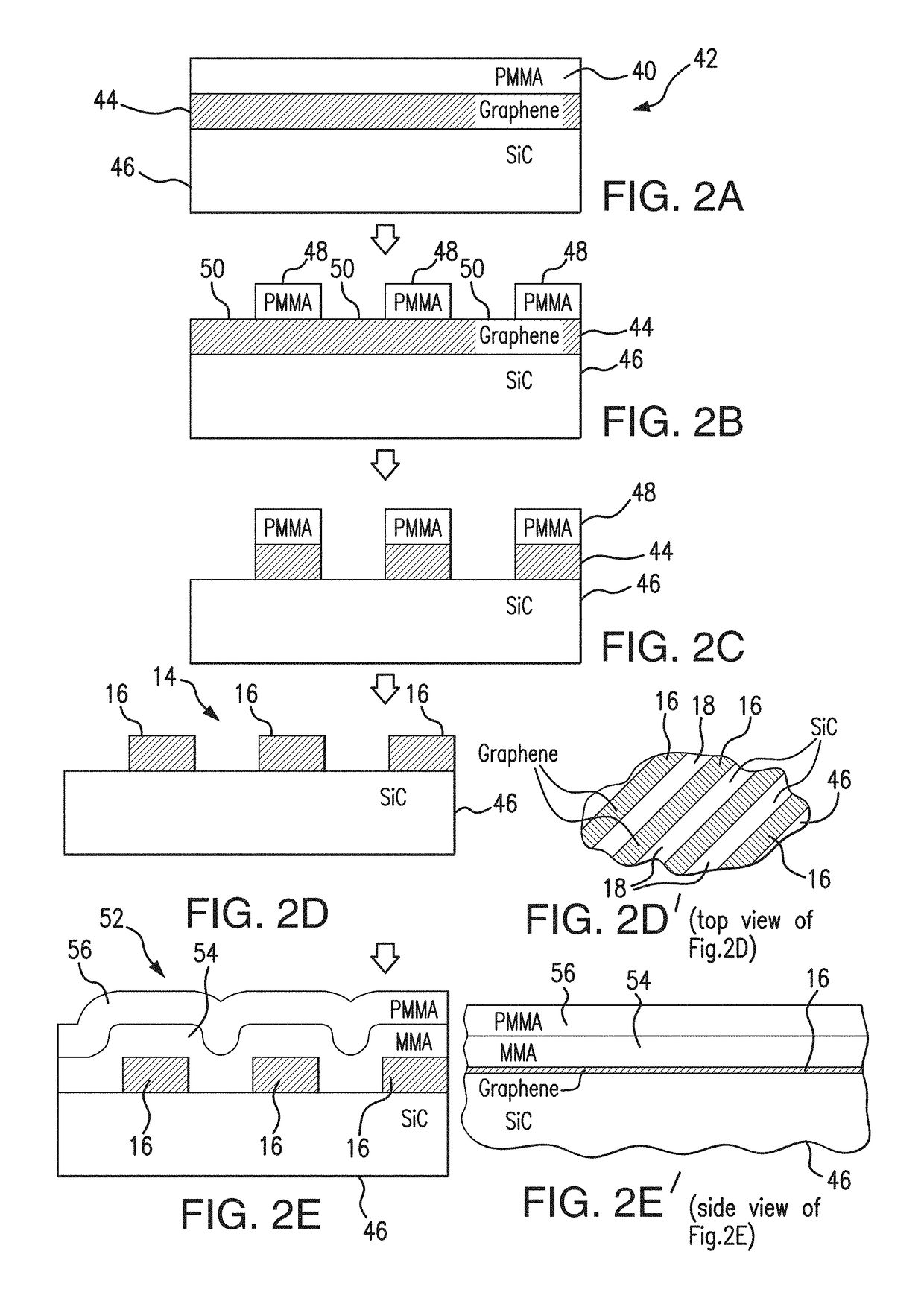

Plasmon-enhanced terahertz graphene-based photodetector and method of fabrication

ActiveUS20180047856A1Improve responsePromote absorptionMaterial nanotechnologyWave amplification devicesMetallic electrodePhotodetector

A plasmon-enhanced terahertz graphene-based photodetector exhibits an increased absorption efficiency attained by utilizing a tunable plasmonic resonance in sub-wavelengths graphene micro-ribbons formed on SiC substrate in contact with an array of bi-metallic electrode lines. The orientation of the graphene micro-ribbons is tailored with respect to the array of sub-wavelengths bi-metallic electrode lines. The graphene micro-ribbons extend at the angle of approximately 45 degrees with respect to the electrode lines in the bi-metal electrodes array. The plasmonic mode is efficiently excited by an incident wave polarized perpendicular to the electrode lines, and / or to the graphene micro-ribbons. The absorption of radiation by graphene is enhanced through tunable geometric parameters (such as, for example, the width of the graphene micro-ribbons) and control of a carrier density in graphene achieved through tuning the gate voltage applied to the photodetector.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

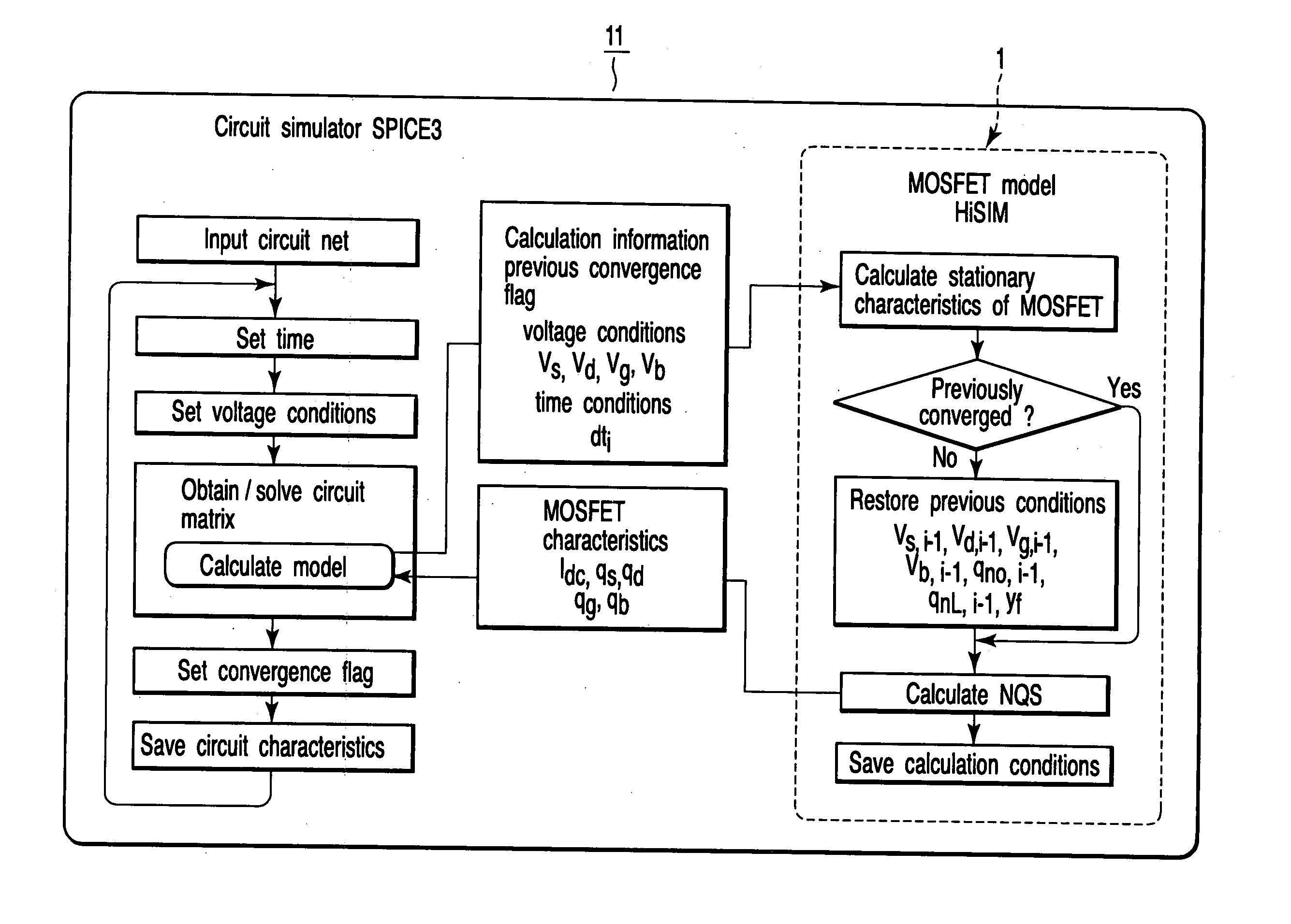

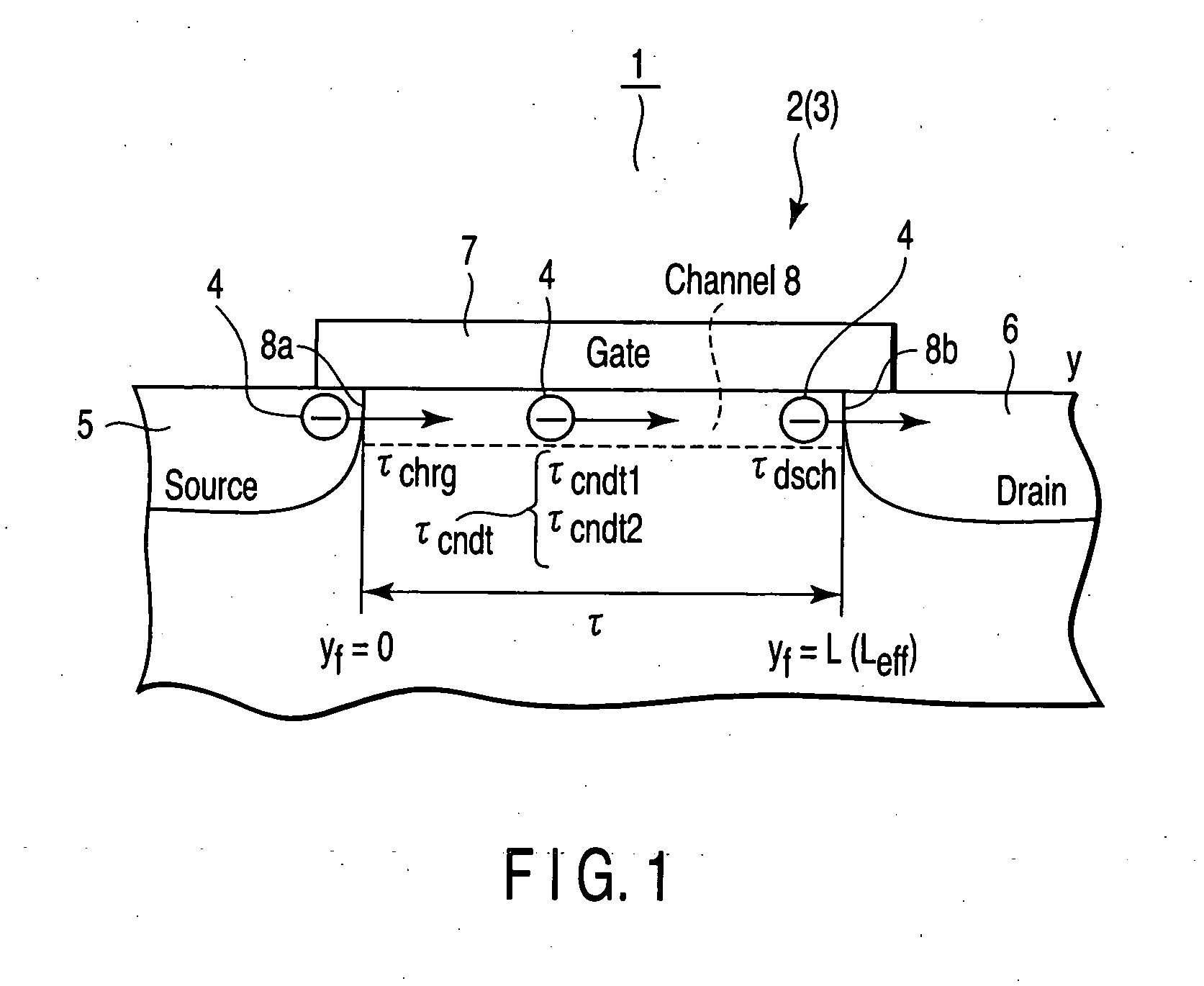

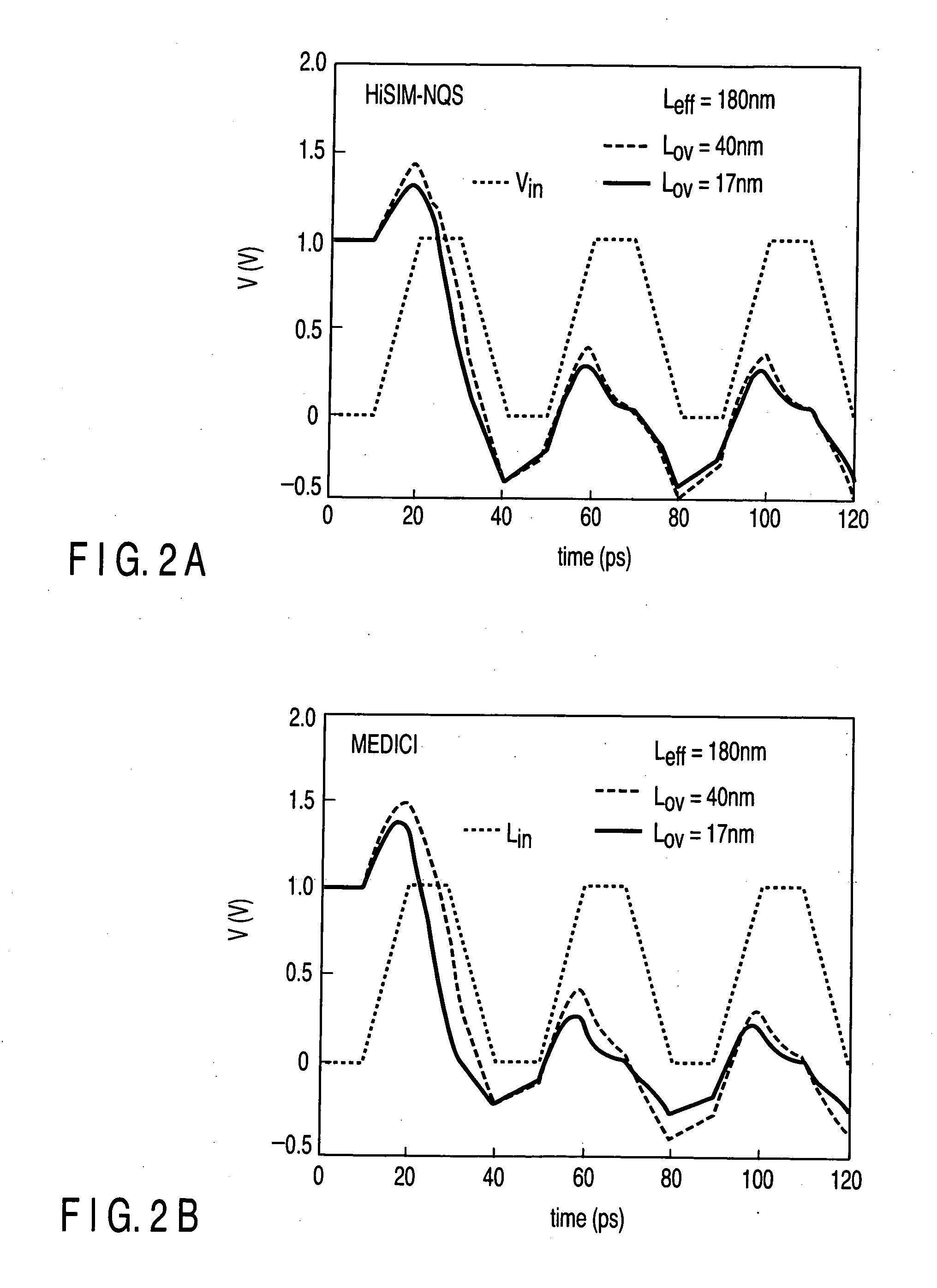

Simulation model for designing semiconductor devices, apparatus for simulating the designing of semiconductor devices, method of simulating the designing of semiconductor devices, computer-readable recording medium storing a program for simulating the designing of semiconductor devices, semiconductor device, and method of manufacturing the semiconductor device

InactiveUS20050120315A1Easy to operateImprove accuracySemiconductor/solid-state device testing/measurementAnalogue computers for electric apparatusTransient stateDevice material

There is disclosed a simulation model for designing a semiconductor device, comprising adding at least a part of a difference between a density of a carrier described in a quasi-static manner with respect to a voltage applied between electrodes at a first time and a density of the carrier described in a transient state at a second time before the first time to the carrier density at the second time in accordance with a running delay of the carrier between both the times to thereby describe the carrier density at the first time in the transient state with respect to a semiconductor element having the first and second electrodes. A current flowing between the electrodes is described as a sum of a current flowing between the electrodes in the quasi-static manner, and a displacement current between the electrodes.

Owner:SEMICON TECH ACADEMIC RES CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com