Field effect transistor with amorphous oxide layer containing microcrystals

a field effect transistor and amorphous oxide technology, applied in the field of amorphous oxide, can solve the problems that the transistor employing silicon thin film cannot be directly formed on a less heat-resistant resin substrate, and the performance of tfts using conventional oxide semiconductor thin films is not on the same level as that of tfts using silicon, and achieves excellent properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

Amorphous Oxide Having a Microcrystals

[0059]The invention according to the first embodiment relates to an amorphous oxide, characterized in that the amorphous contains a microcrystal(s). Where a microcrystal(s) are contained or not in the amorphous oxide is determined by taking a TEM (transmission electron microscopic) photograph of a section of a formed amorphous oxide film. An amorphous oxide film according to the present invention comprises In—Ga—Zn—O and the composition of the amorphous oxide film in a crystalline state is represented by InGaO3(ZnO)m (m is a natural number of less than 6).

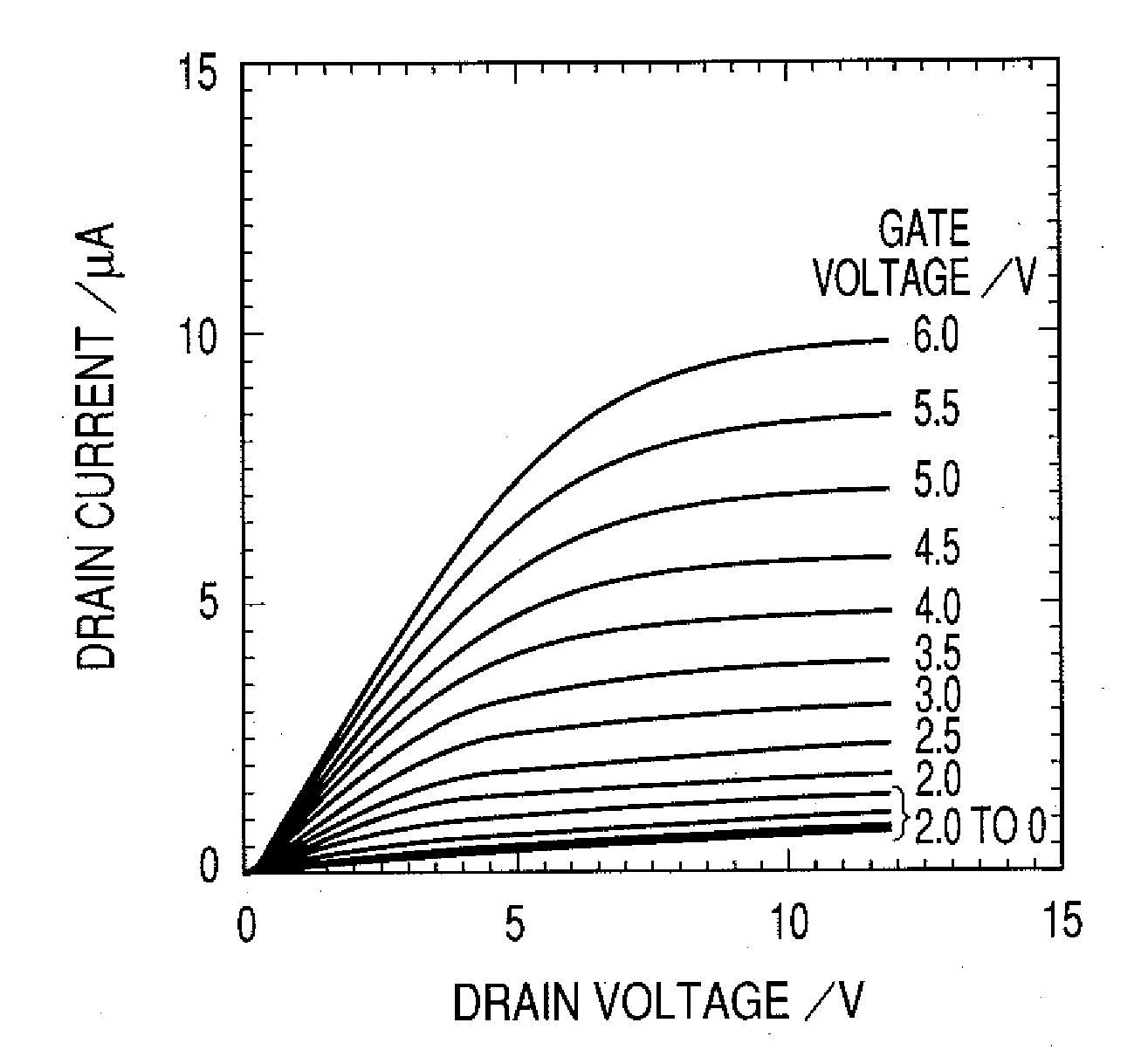

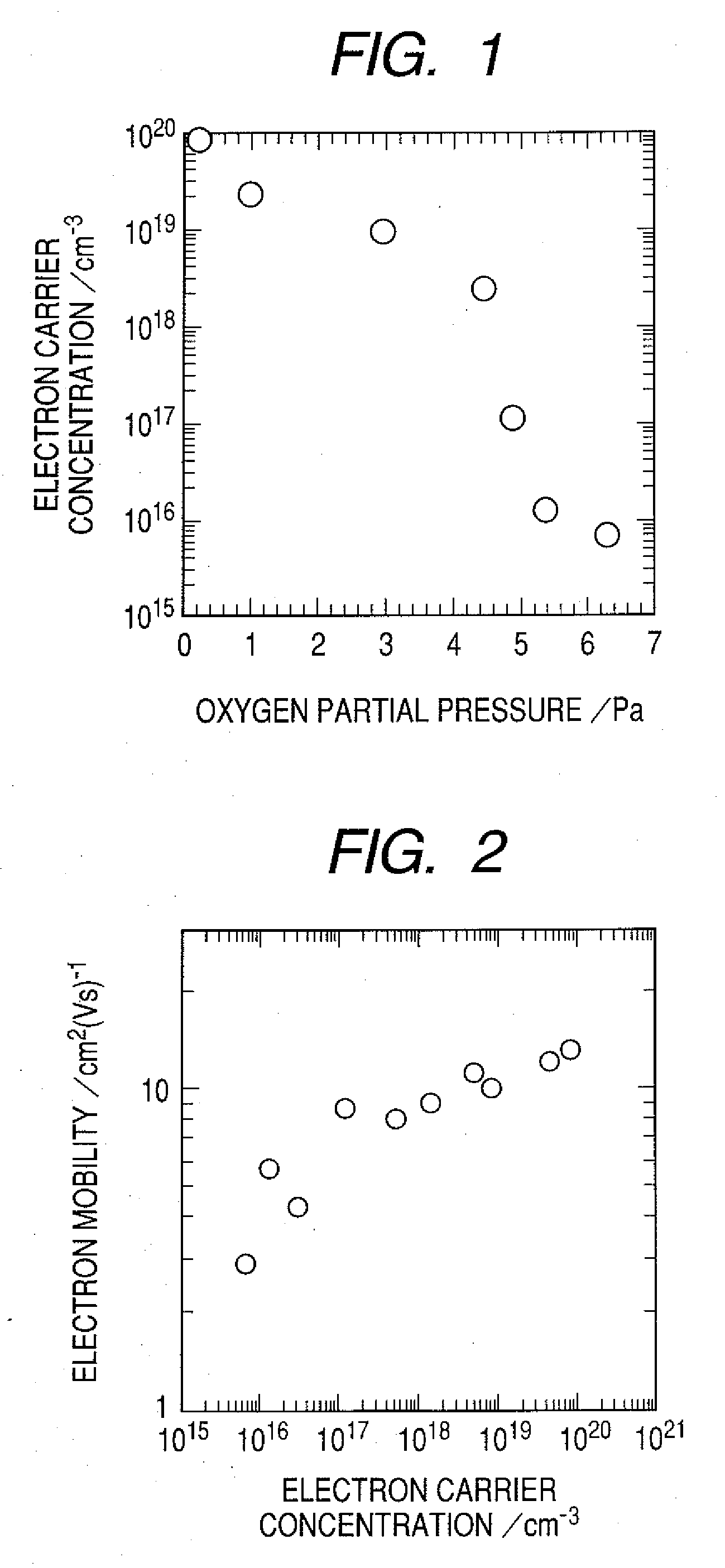

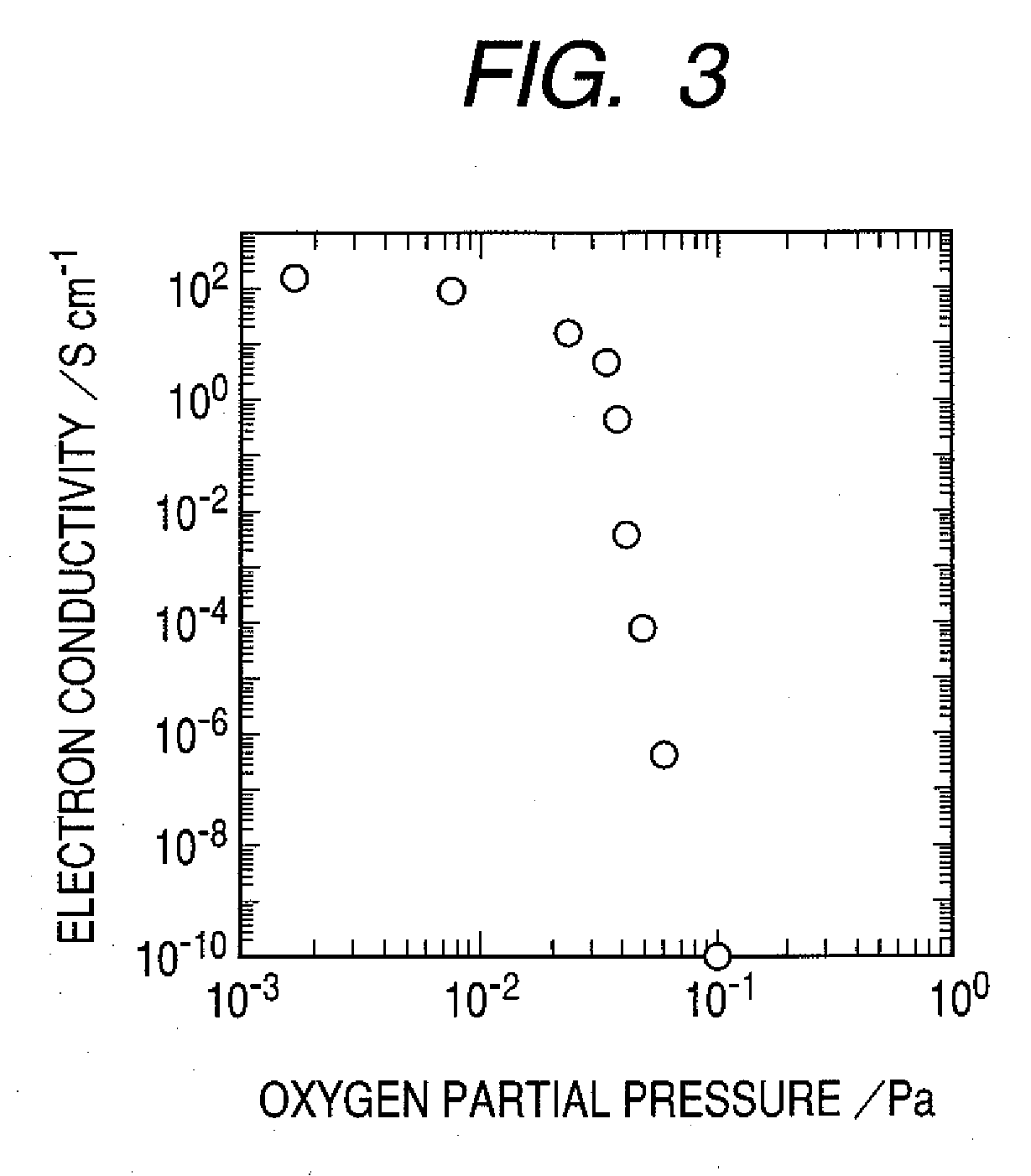

[0060]Oxides represented by the term “amorphous oxide” in the specification has an electron carrier concentration is less than 1018 / cm3 or shows a tendency that the electron mobility increases as the electron carrier concentration increases, or and so forth. Although depending on the kind of use of a TFT, it is preferable to use the amorphous TFT for fabricating normally off type TFT.

[0061]Alte...

second embodiment

Compositional Distribution of Amorphous Oxide

[0080]According to this embodiment, an amorphous oxide is characterized by a composition varying in a film-thickness direction.

[0081]The phrase “composition varying in a film-thickness direction” means that the oxygen amount contained in an oxide changes in the film thickness direction and elements constituting an oxide changes in the middle (that is, the composition changes), and the contents of the elements constituting an oxide change.

[0082]Therefore, when the amorphous oxide is used as the active layer (also called channel layer) of a field effect transistor, for example, the following constitution is preferable. In a transistor having an active layer containing an amorphous oxide and a gate insulator in contact with each other at an interface, the amorphous oxide layer is constituted such that the concentration of oxygen near the interface is set higher than the region away from the interface. In this case, since the electric resista...

third embodiment

Amorphous Oxide Containing an Additive(s)

[0103]An amorphous oxide according to this embodiment is characterized in that the amorphous oxide contains at least one or plurality of types of elements selected from the group consisting of Li, Na, Mn, Ni, Pd, Cu, Cd, C, N, P, Ti, Zr, V, Ru, Ge, Sn, and F are contained as an additive. Introduction of an additive into an amorphous oxide is attained by introducing the additive in a gas for use in a film formation apparatus or in the film formation apparatus, or in a target material that is used in the apparatus. As a matter of course, after a film is formed from an amorphous oxide without an additive, the additive may be introduced into the film as is described later in Examples.

[0104]The electron carrier concentration of the amorphous oxide is preferably less than 1018 / cm3.

[0105]An amorphous oxide according to the present invention may include a transparent amorphous oxide comprising In—Ga—Zn—O and whose composition in a crystalline state i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com