A quantum dot light emitting diode

A quantum dot light-emitting and diode technology, which is applied in organic semiconductor devices, electric solid state devices, semiconductor devices, etc., can solve the problems of reducing the number of electrons, reducing the number of electrons, and decreasing the ability of electron injection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

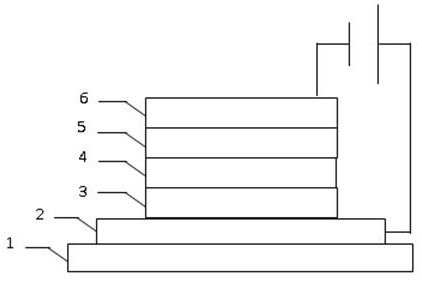

[0042] by figure 1 The structure shown is taken as an example, and the embodiment of the present invention also provides a method for preparing a quantum dot light-emitting diode, including the following steps:

[0043] provide the anode;

[0044] preparing a hole transport layer on the anode;

[0045] preparing a quantum dot luminescent layer on the hole transport layer;

[0046] An electron transport layer is prepared on the quantum dot luminescent layer; wherein, the preparation method of the electron transport layer specifically includes the steps of: preparing an inorganic layer on the quantum dot luminescent layer, preparing a metal layer on the inorganic layer, and preparing an organic layer on the metal layer;

[0047] A cathode is prepared on the electron transport layer.

[0048] In a preferred embodiment, in order to accelerate the alloying between the metal and the inorganic metal oxide, the prepared quantum dot light-emitting diode can be heat-treated. More p...

Embodiment 1

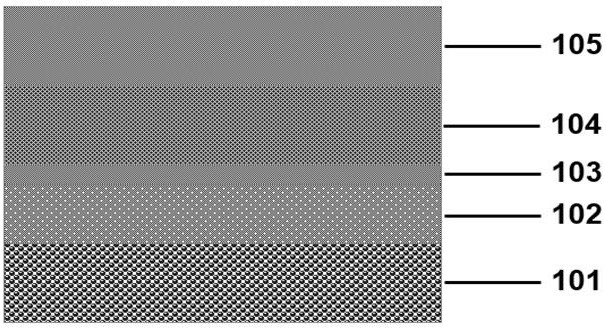

[0054] Example 1: Combining figure 2 As shown, the preparation method of the quantum dot light-emitting diode based on the inorganic / metal / organic composite structure electron transport layer comprises the following steps:

[0055]Using ITO as the anode, deposit 30nm-thick PEDOT:PSS as the hole injection layer on the surface of ITO under air environment, and anneal at 150°C for 10 minutes;

[0056] N 2 Under ambient conditions, a 30nm-thick TFB was deposited on the surface of the hole injection layer as a hole transport layer by solution method, and annealed at 150°C for 30 minutes;

[0057] N 2 Under ambient conditions, 25nm thick CdSe / ZnS quantum dots were deposited on the surface of the hole transport layer by solution method as the quantum dot light-emitting layer, and annealed at 100°C for 30 minutes;

[0058] N 2 Under ambient conditions, deposit 15nm thick ZnO as an inorganic layer on the surface of the quantum dot light-emitting layer by solution method, and annea...

Embodiment 2

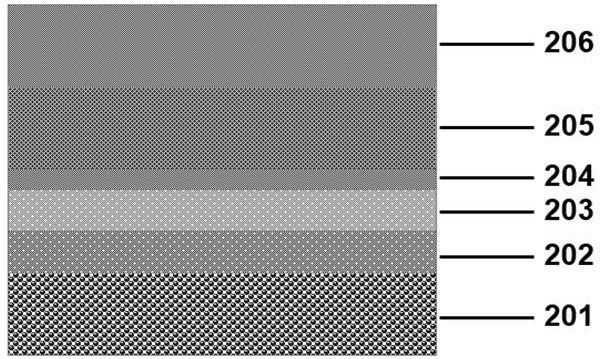

[0063] Example 2: Combining image 3 As shown, the preparation method of the quantum dot light-emitting diode based on the inorganic / inorganic metal / metal / organic composite structure electron transport layer comprises the following steps:

[0064] Using ITO as the anode, deposit 30nm-thick PEDOT:PSS as the hole injection layer on the surface of ITO under air environment, and anneal at 150°C for 10 minutes;

[0065] N 2 Under ambient conditions, a 30nm-thick TFB was deposited on the surface of the hole injection layer as a hole transport layer by solution method, and annealed at 150°C for 30 minutes;

[0066] N 2 Under ambient conditions, 25nm thick CdSe / ZnS quantum dots were deposited on the surface of the hole transport layer by solution method as the quantum dot light-emitting layer, and annealed at 100°C for 30 minutes;

[0067] Transfer the above substrate to the evaporation chamber, and vacuum to Below Pa, then evaporate and deposit 5nm thick ZnO as the inorganic lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com