Patents

Literature

87results about How to "Reduce defect states" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

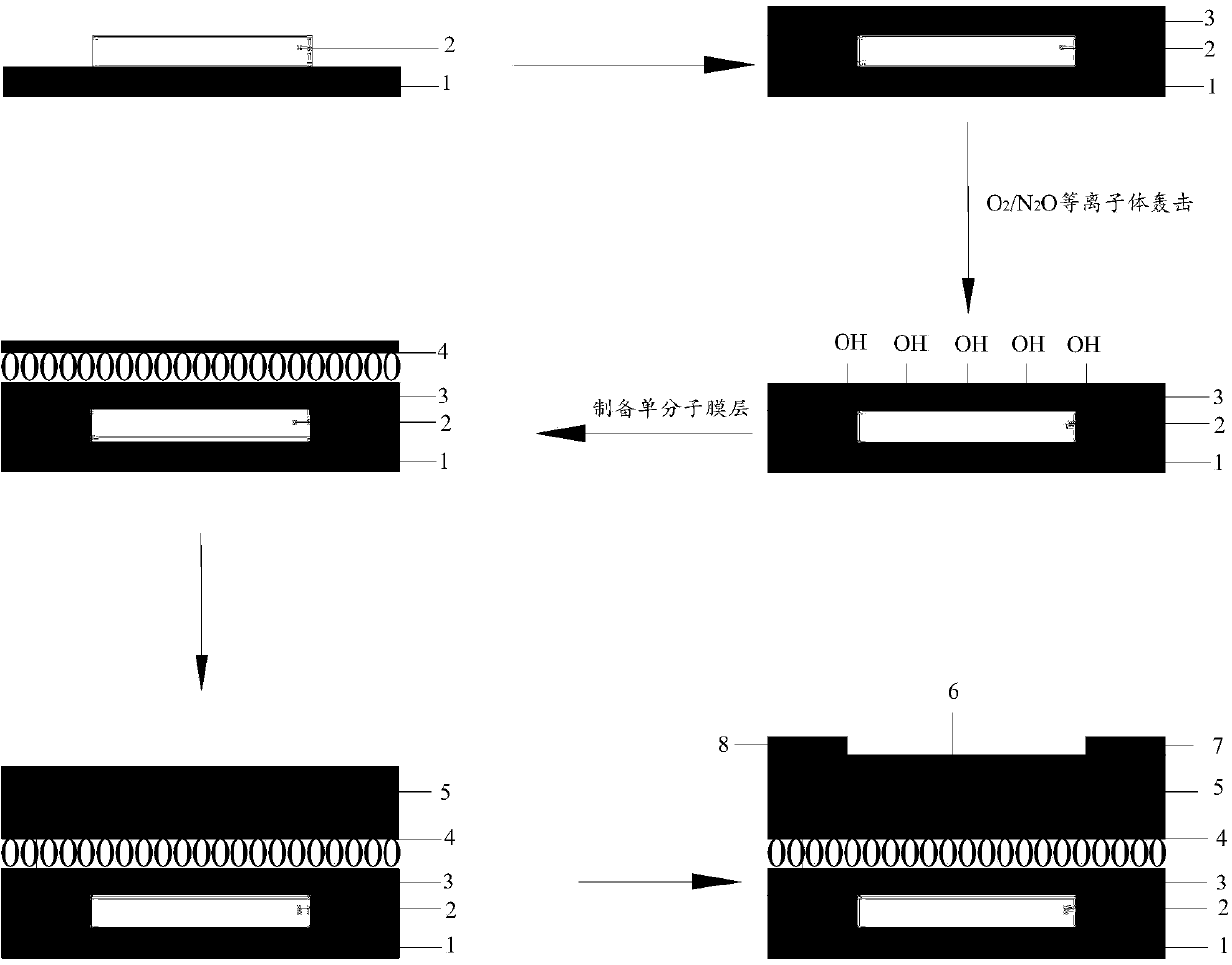

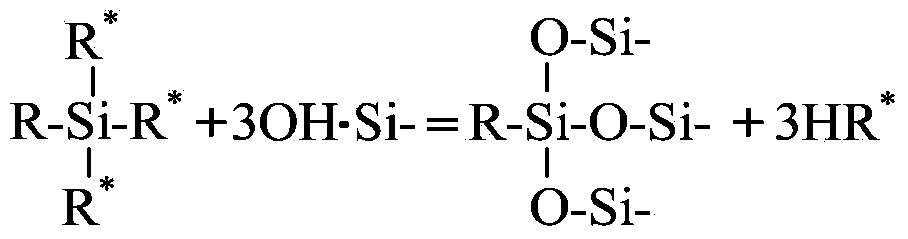

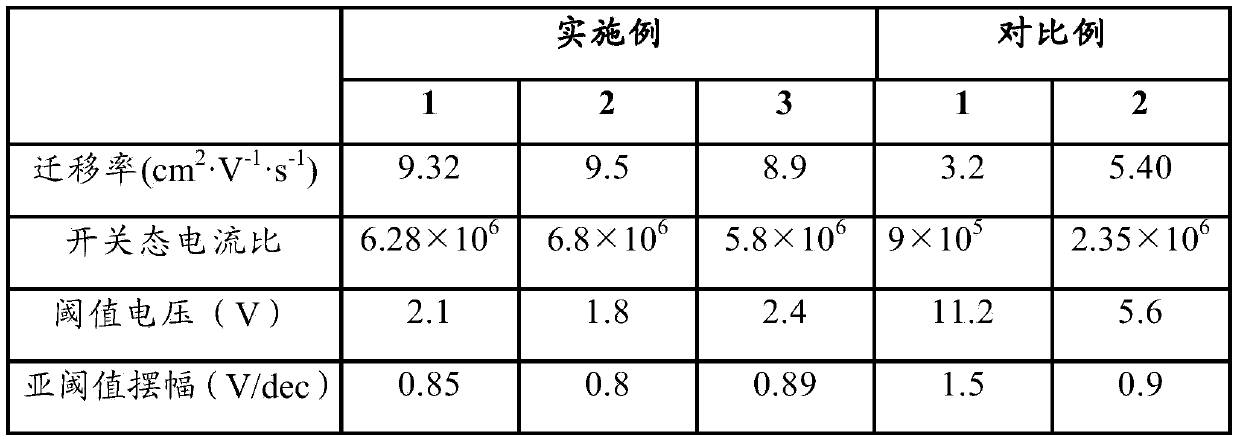

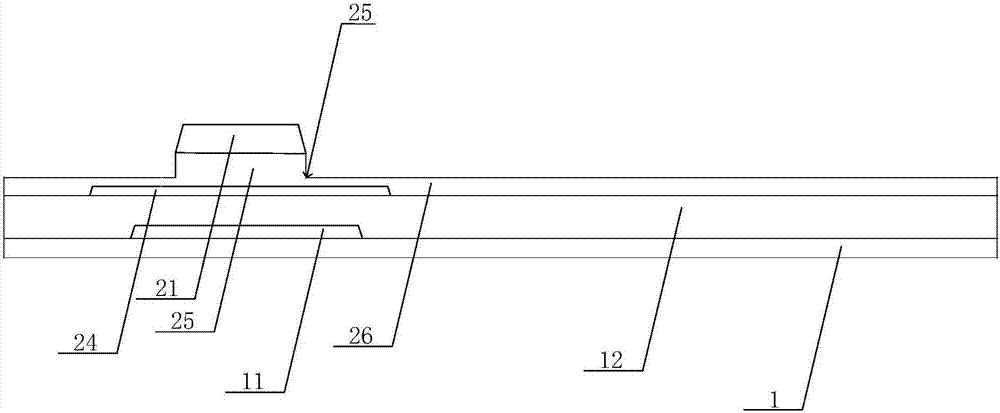

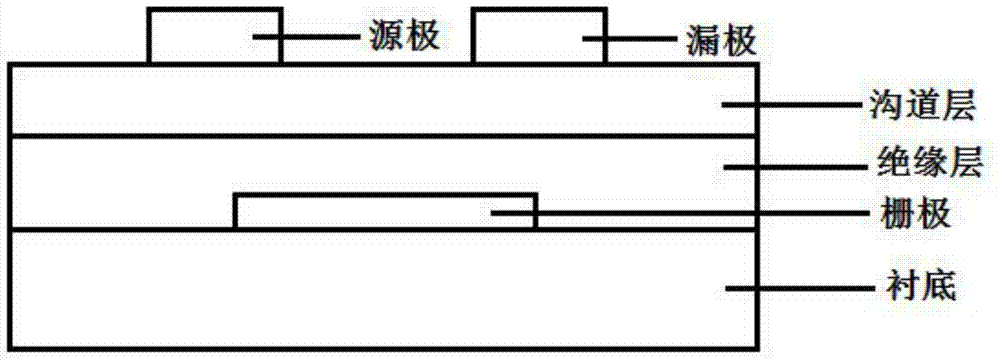

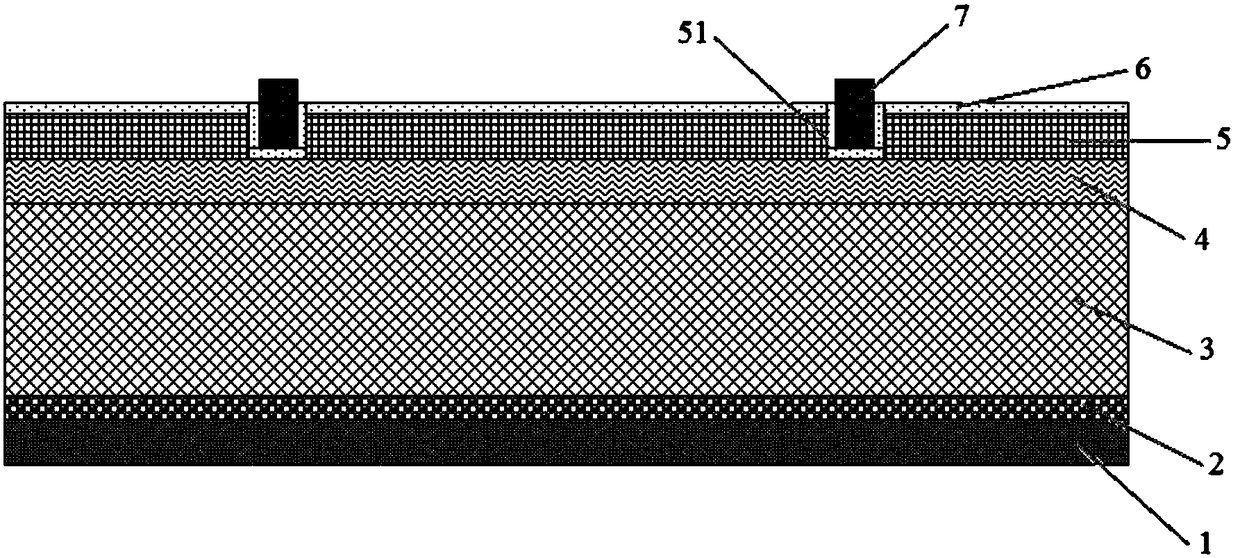

IGZO (indium gallium zinc oxide) thin film transistor and preparing method thereof

ActiveCN103700710AImprove mobilityImprove performanceTransistorSemiconductor/solid-state device manufacturingInsulation layerIndium gallium zinc oxide

The invention discloses an IGZO (indium gallium zinc oxide) thin film transistor and a preparing method thereof, wherein the IGZO thin film transistor comprises a substrate, a grid combined on the substrate surface and a silicide grid insulation layer covering the outer surfaces of the substrate and the grid, wherein the surface of the silicide grid insulation layer is subjected to O2 / N2O plasma bombardment processing; the surface of the silicide grid insulation layer subjected to the O2 / N2O plasma bombardment processing is also combined with a self-assembly single-molecule film layer in a laminating mode, so the film defect state of the silicide grid insulation layer can be reduced after the O2 / N2O plasma bombardment, the charge trap action is inhibited, the roughness of the surface of the insulation layer is reduced by the self-assembly single-molecule film layer, the interface property between the insulation layer and an active layer is well improved, charges are prevented from being captured by an interface defect, the carrier mobility of a device is reduced, the threshold voltage is reduced, leak current is reduced and the performance of the device is more stable.

Owner:TCL CORPORATION

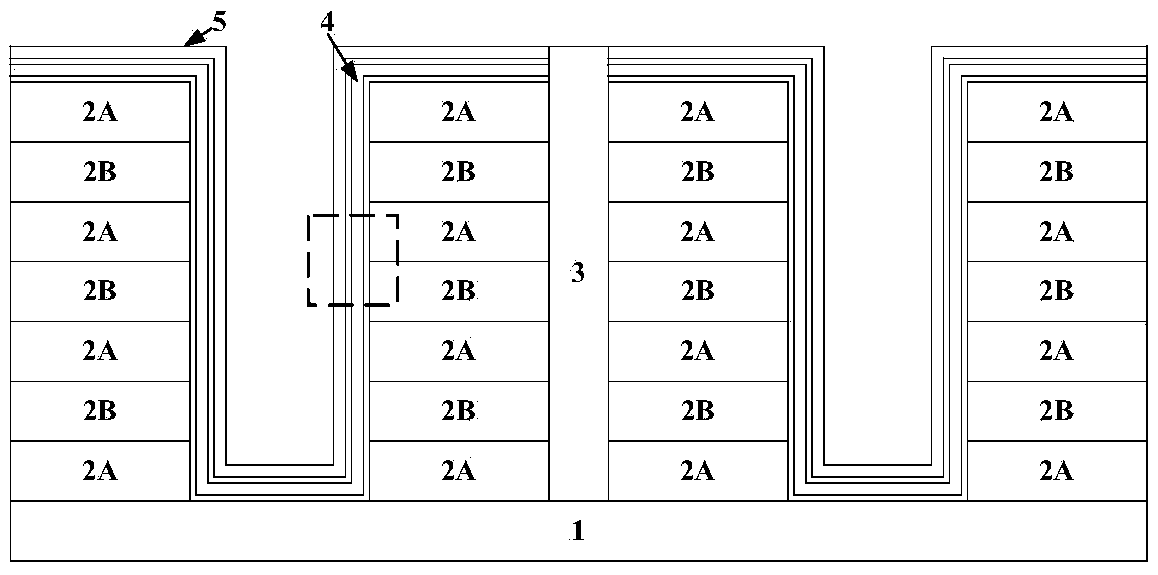

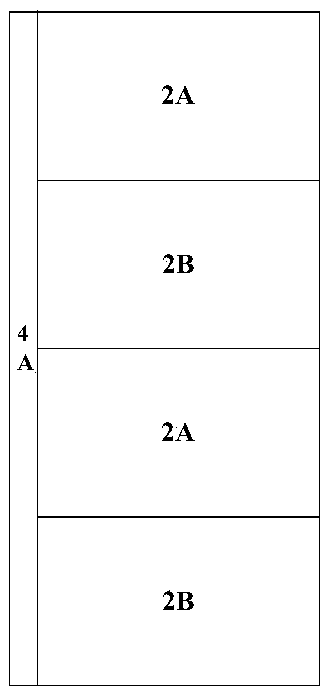

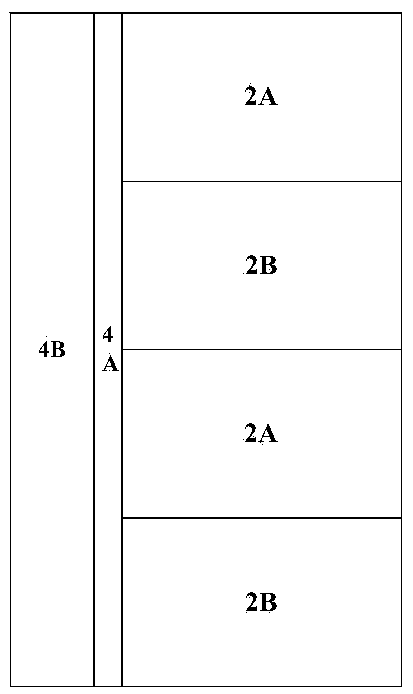

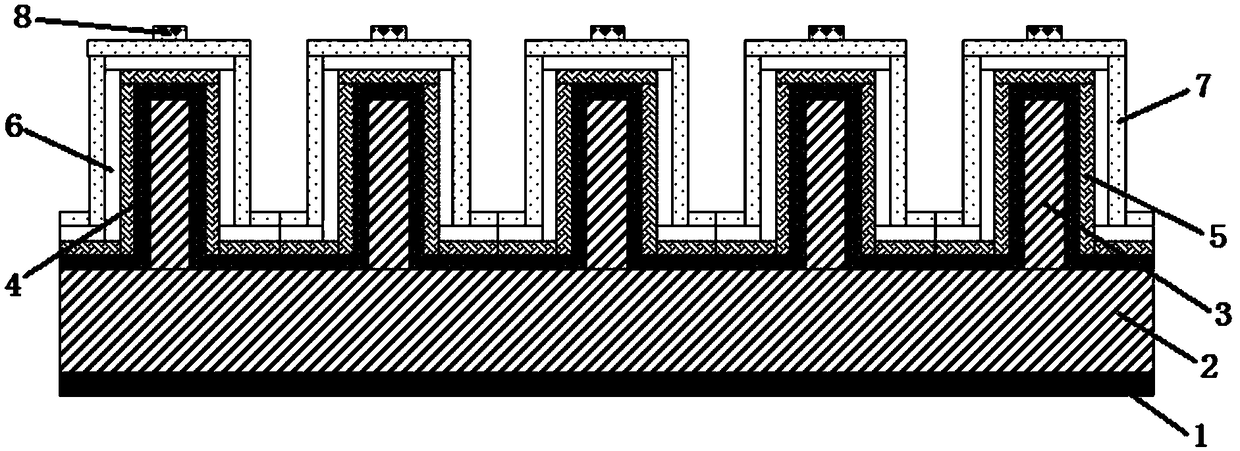

Semiconductor device and manufacture method thereof

ActiveCN105374757AImprove reliabilityFacilitate horizontal diffusionSolid-state devicesSemiconductor/solid-state device manufacturingNitrideSemiconductor

Provided is a semiconductor device manufacture method which comprises steps of: forming a cushion layer mainly containing nitride on the side surface of a pseudo gate electrode; converting the cushion layer into a first barrier layer mainly containing oxide; successively forming a accumulation layer, a tunneling layer, and a channel layer on the first barrier layer; removing the pseudo gate electrode and forming a second barrier layer on the exposed first barrier layer; and forming a gate conductive layer on the second barrier layer. According to a semiconductor device and the manufacture method thereof, the nitride cushion layer is converted into the oxide barrier layers so that defect states can be effectively reduced, threshold voltage drift is inhibited, charge transverse diffusion in the accumulation layer is improved, and device reliability is enhanced.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Oxide-metal multilayer film back contact crystalline silicon solar cell and preparation method thereof

ActiveCN105789342ALow costThe process steps are simpleFinal product manufacturePhotovoltaic energy generationMetal electrodesCrystalline silicon

The invention discloses an oxide-metal multilayer film back contact crystalline silicon solar cell, which comprises a crystalline silicon wafer, wherein passivation layers are arranged on the front surface and the back surface of the crystalline silicon wafer; the passivation layer on the back surface is provided with an emitter, an emitter metal electrode and a base metal electrode; the emitter comprises a first oxide thin film, a metal film and a second oxide thin film; the first oxide thin film or the second oxide thin film is a WO3 thin film, an NiO thin film or a V2O5 thin film; and the metal thin film is an Ag thin film, an Au thin film, a Pd thin film, a Cu thin film, an Ni thin film, an Mo thin film, a W thin film or an Al thin film. The surface of the cell is not shielded by a metal grid line; the raw materials do not include inflammable, explosive or toxic materials and are friendly to environment; expensive devices of a photoetching device, a laser device and the like and a complicated technological process are not needed in the overall preparation process; and the crystalline silicon solar cell disclosed by the invention is free of a high temperature, simple in processing step and suitable for large-scale production, does not need to use a transparent conductive thin film, is low in cost and has a wide application prospect.

Owner:江苏润阳悦达光伏科技有限公司

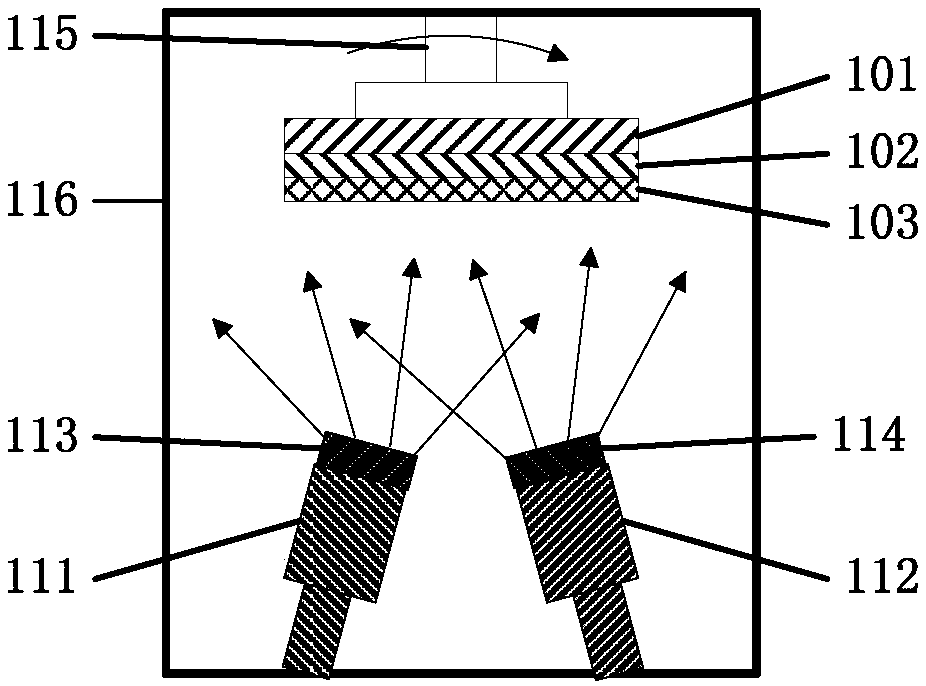

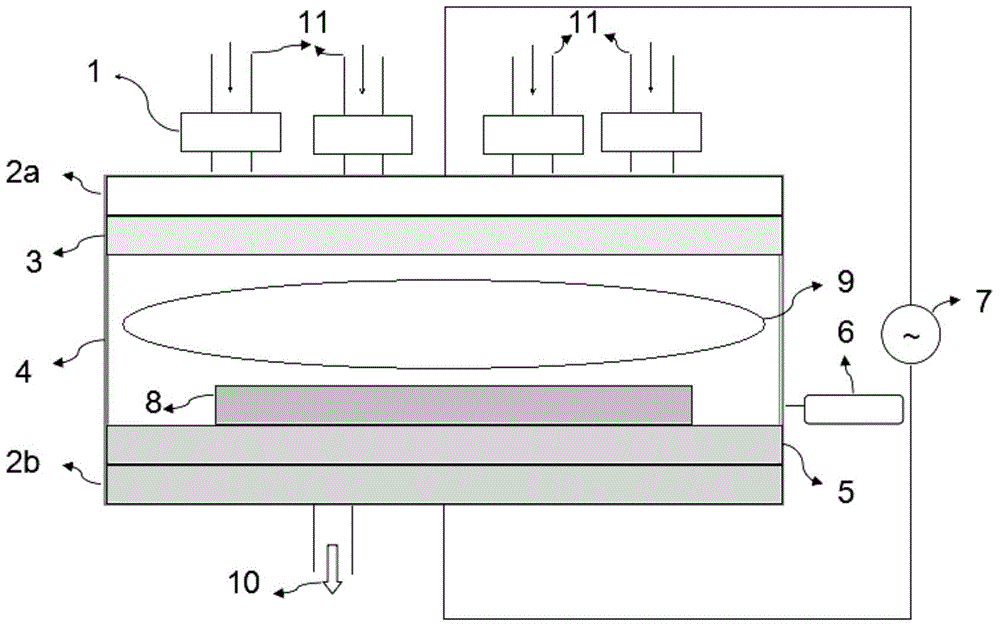

Preparation method of absorption layer of thin film solar cell

ActiveCN101834221AIncrease production capacityIncreased average deposition rateFinal product manufactureSemiconductor devicesDangling bondDeposition process

The invention provides a preparation method of an absorption layer of a thin film solar cell, comprising the following steps of: providing a substrate which is provided with a p-type silica-based thin film layer; and repeatedly and alternatively carrying out hydrogenation treatment on the p-type silica-based thin film layer and depositing an intrinsic silica-based thin film layer, wherein the hydrogenation treatment comprises hydrogen plasma treatment. In the preparation method, the hydrogenation treatment can enable dangling bonds in the p-type or intrinsic silica-based thin film layer to be saturated by hydrogen, which can effectively reduce the defect states at a p-i interface and inside the intrinsic silica-based thin film and ensures that the comprehensive performance of the absorption layer is optimized, thereby improving the cell property; secondly, the deposition rate of the intrinsic silica-based thin film layer gradually increases in the process of repeatedly and alternatively carrying out the hydrogenation treatment and depositing the intrinsic silica-based thin film layer, and the deposition rate of the intrinsic silica-based thin film layer in every deposition process is greater than the former deposition rate, therefore, the average deposition rate can be improved, and the manufacturing capacity of solar cells can be promoted.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Manufacturing method of solar cell

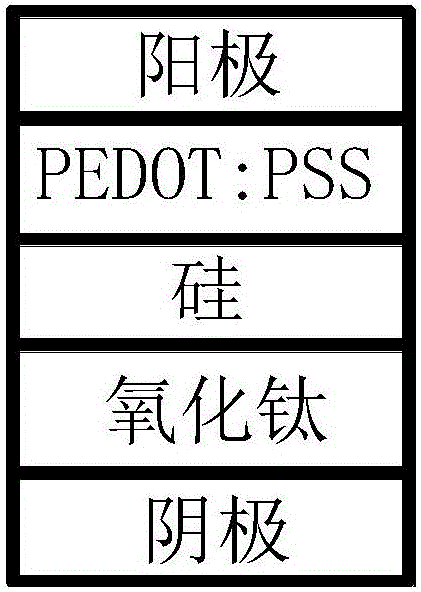

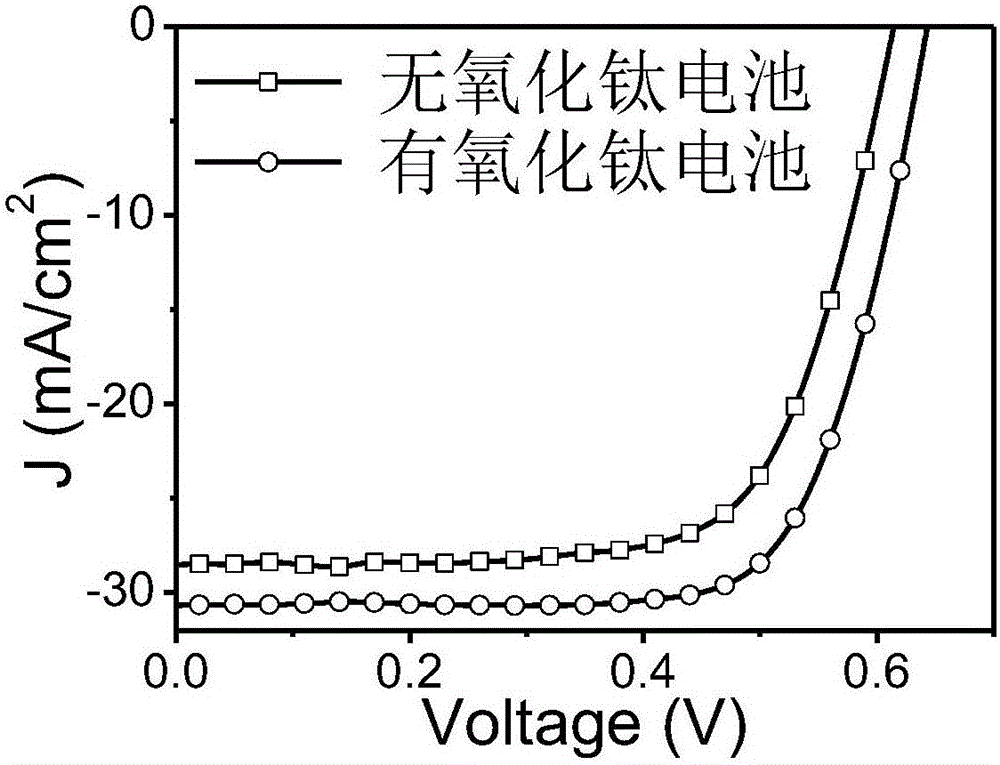

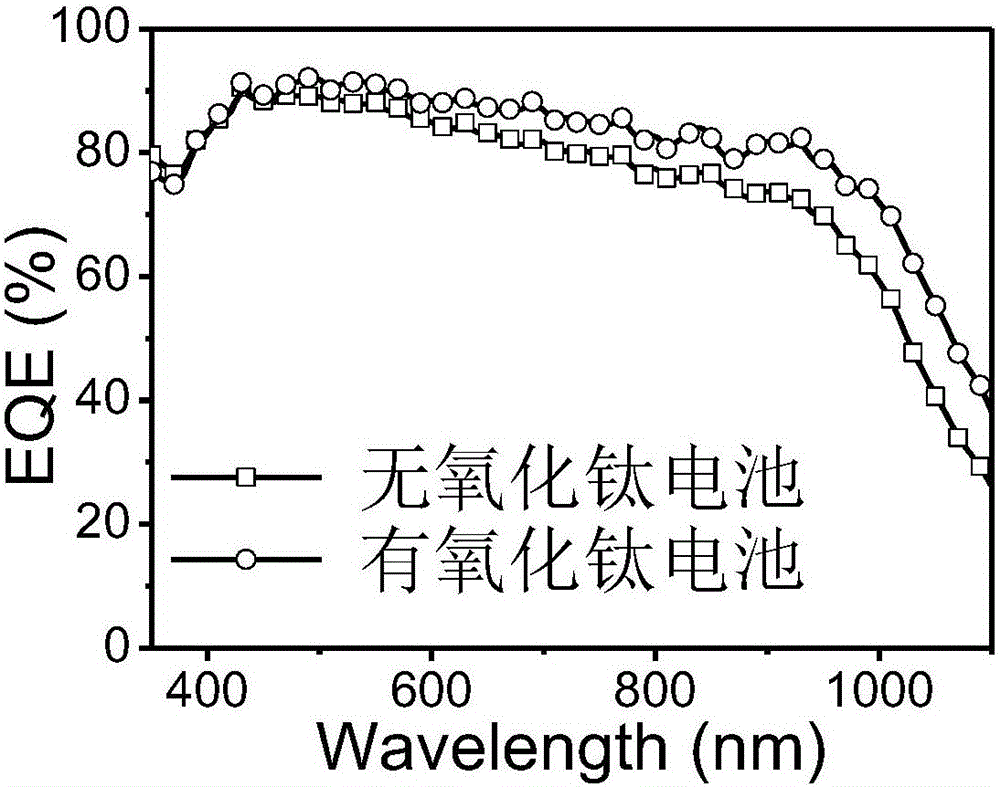

InactiveCN106169537ASimple preparation processLow equipment requirementsFinal product manufactureSolid-state devicesEvaporationTitanium isopropoxide

The invention discloses a manufacturing method of a solar cell. The manufacturing method of the solar cell comprises the following steps: treating a silicon wafer; coating the treated silicon wafer with a passivation layer solution and a PEDOT:PSS aqueous solution in a spinning way; and performing evaporation to obtain the solar cell, wherein the passive layer solution is a titanium oxide precursor solution; and the titanium oxide precursor solution is prepared by the following steps: 1, dispersing titanium isopropoxide in an isopropanol solution to be diluted, and stirring the solution in order that the titanium isopropoxide is uniformly dispersed to obtain a solution I; 2, diluting a hydrochloric acid solution with isopropanol, dropwise adding the diluted hydrochloric acid solution into the solution I, and stirring the mixed solution to obtain a solution II; and coating the treated silicon wafer with the prepared solution II in a spinning way. The manufacturing method is simple in manufacturing process, and the manufactured solar cell has high physical performance.

Owner:SUZHOU UNIV

Process for manufacturing amorphous silicon thin film solar cell

InactiveCN101562220AImprove p/i interfaceIncrease the open circuit voltageFinal product manufactureVacuum evaporation coatingCarbon filmAmorphous silicon

The invention relates to a process for manufacturing an amorphous silicon thin film solar cell, which belongs to the field of semiconductors. The process comprises the following steps: (a) preparing a p-type silicon-carbon film; (b) preparing a buffer layer; (c) preparing an intrinsic layer; and (d) preparing an n layer. In the preparation of each layer, the band gap width, the a P layer with high conductivity and an interface with low defect concentration are obtained by controlling the dilution ratio of H2 and other process parameters, thus the conversion efficiency of the cell is greatly improved, and the attenuating effect of the cell is reduced.

Owner:河南新能光伏有限公司

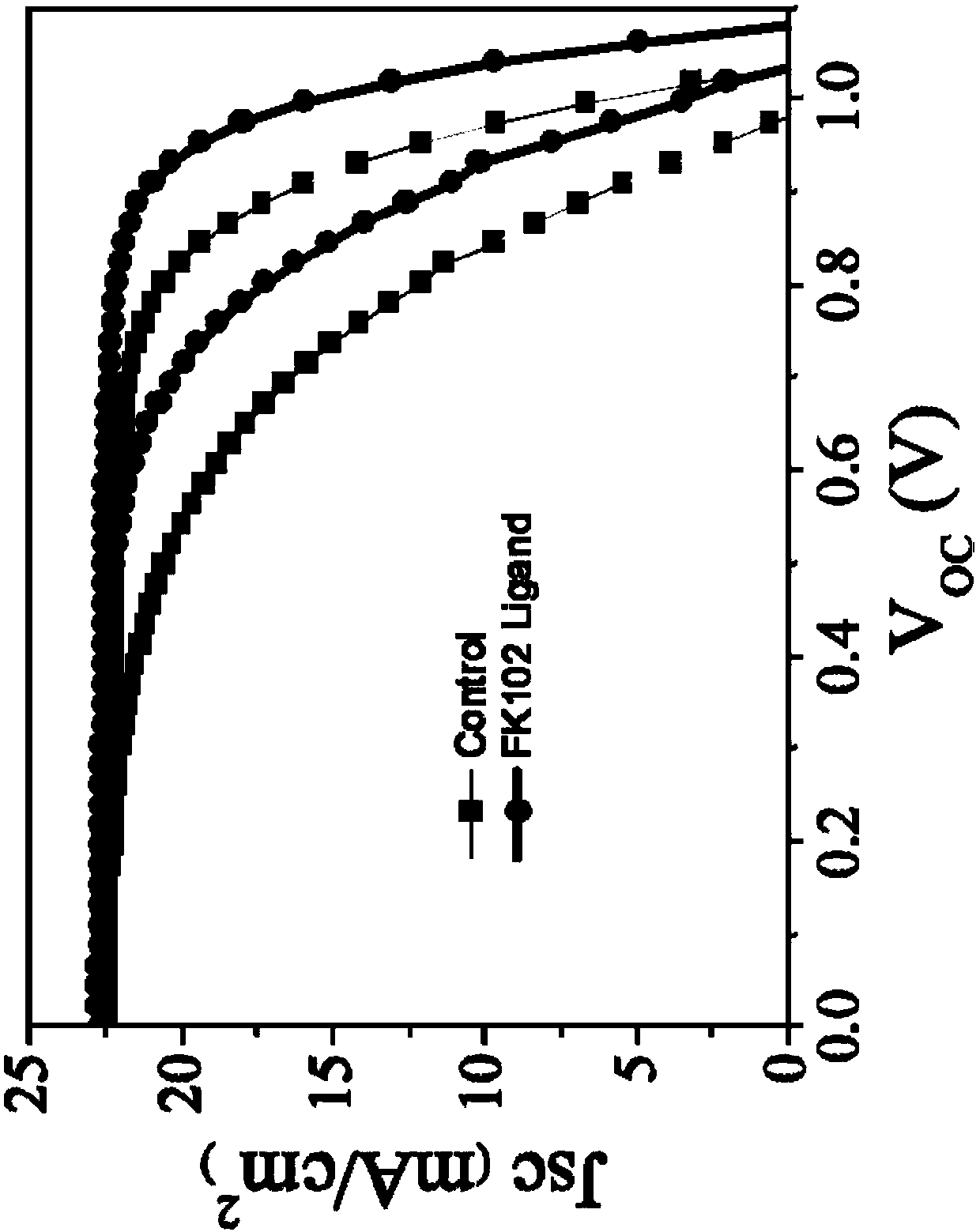

FK102 ligand modified perovskite solar cell and preparation method of perovskite layer thereof

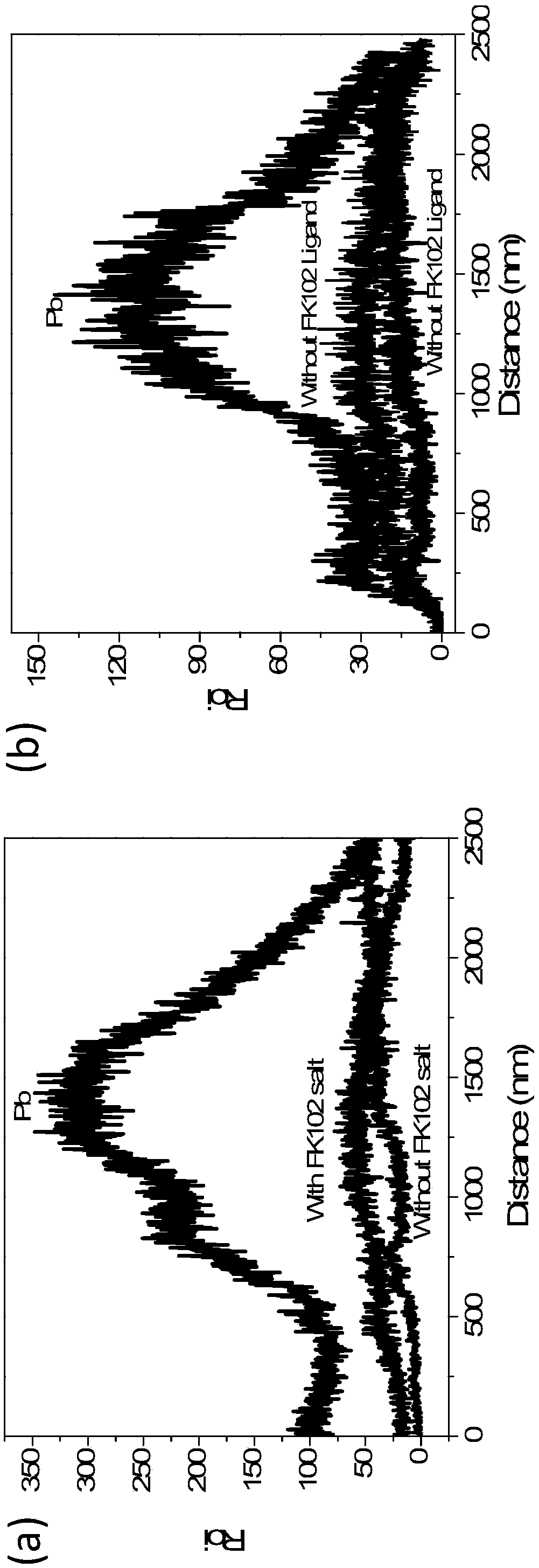

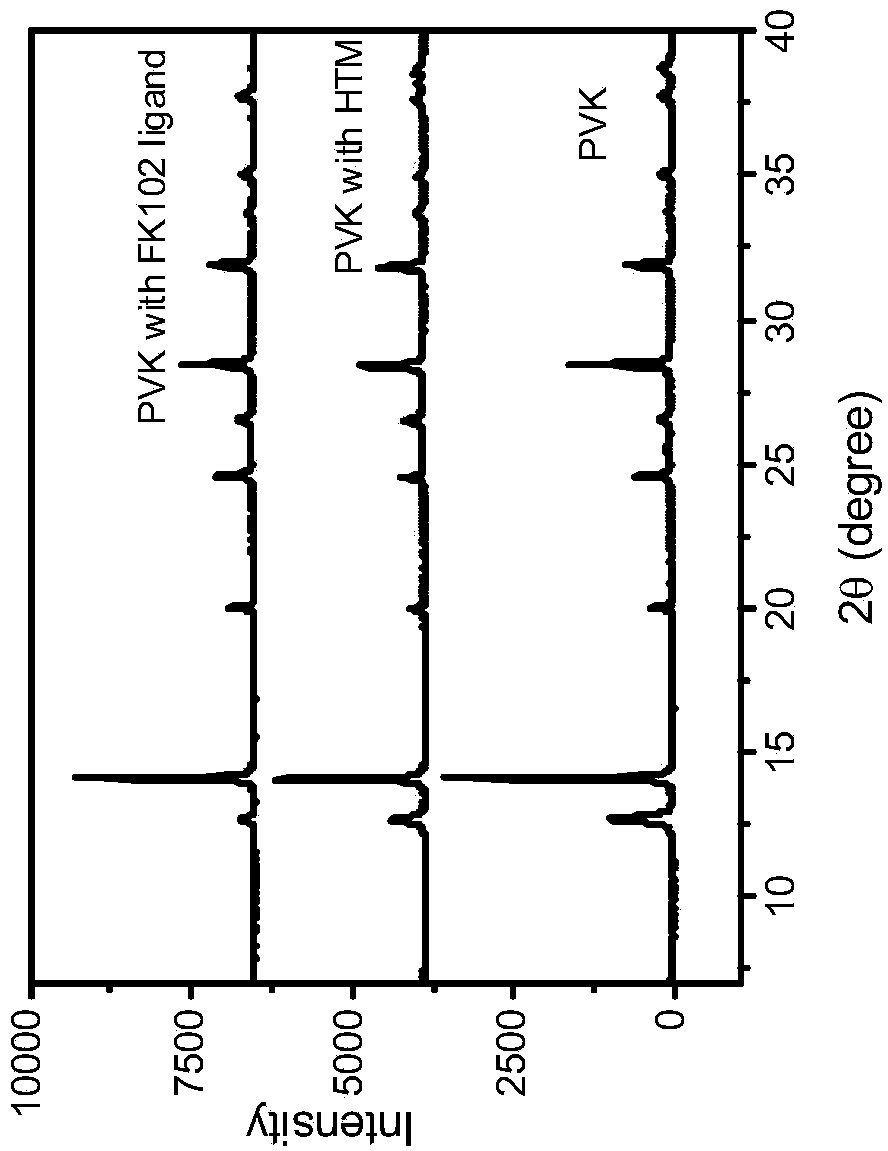

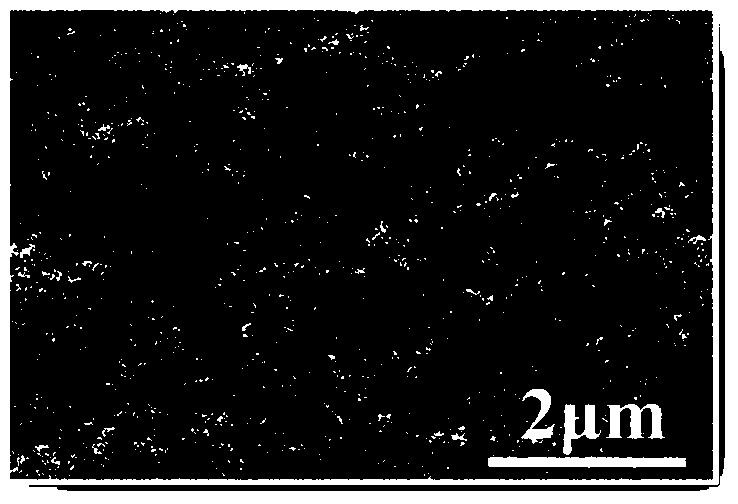

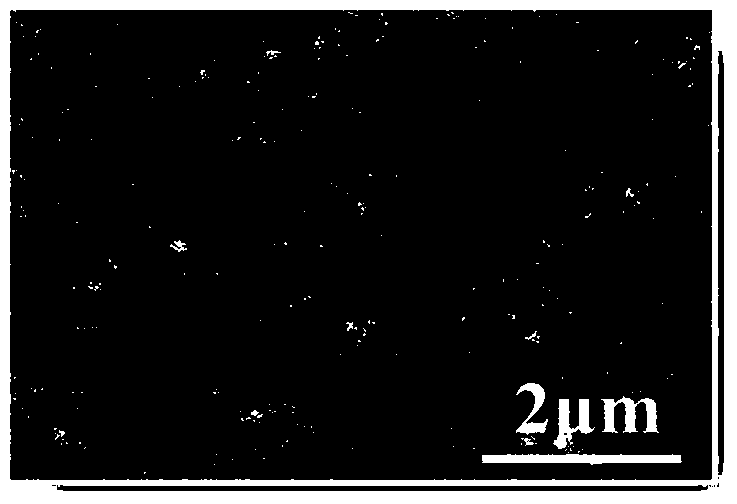

ActiveCN108054279ALow priceEasy to operateSolid-state devicesSemiconductor/solid-state device manufacturingCharge injectionPerovskite solar cell

The invention discloses an FK102 ligand modified perovskite solar cell and a preparation method of a perovskite layer thereof. The perovskite solar cell comprises an electron transmission layer, perovskite, a hole transmission layer and an electrode, wherein a material forming a modification layer is selected from an FK102 ligand. By the interface modification material, Co<3+> in the hole transmission layer can be prevented from diffusing towards the perovskite, so that the decomposition of the perovskite by Co<3+> is prevented, the defect mode is reduced, reverse recombination of charges is prevented, and the charge injection efficiency is improved; and moreover, the material is low in cost, the operation method is simple and is easy to control, and a new idea is provided for research ofinterface behavior of the perovskite solar cell.

Owner:JINAN UNIVERSITY

Method for preparing organic molecule hybridized TiO2 nanometer composite film on titanium substrate

InactiveCN103832021AImprove bindingEvenly distributedMetal layered productsWater bathsComposite film

A method for preparing an organic molecule hybridized TiO2 nanometer composite film on a titanium substrate mainly comprises the following steps: A. soaking a pure titanium sheet in a dopamine solution twice, each time for 10-14 hours, to obtain a coating template; B. preparing a mixed solution of gallic acid and hexamethylenediamine, putting the mixed solution in a water bath at 35-39 DEG C, soaking the coating template in the mixed solution for 3-5 hours, taking the coating template out, performing ultrasonic cleaning for three times to obtain an organic molecular layer template; C. mixing a 0.1-0.2 mol / L (NH4)2TiF6 solution and a 0.2-0.4 mol / L H3BO3 solution according to a volume ratio of 1:1 to obtain a mixed liquid; adjusting the pH value to 2.7-2.9; D. soaking the organic molecular layer template in the mixed liquid, and soaking in a water bath pot at 45-55 DEG C for 10-40 hours to obtain the product. The TiO2 film prepared on the titanium substrate by the method has high bonding force, uniform distribution, high photoelectric conversion efficiency, and good biocompatibility.

Owner:SOUTHWEST JIAOTONG UNIV

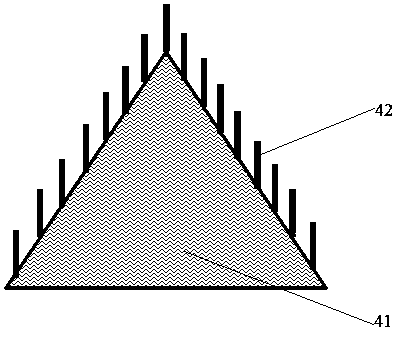

Silicon-based core-shell structure photovoltaic cell and preparation method thereof

ActiveCN108417719ASimple manufacturing methodIncrease the open circuit voltageSolid-state devicesSemiconductor/solid-state device manufacturingEthylenedioxyEvaporation

The invention relates to a silicon-based core-shell structure photovoltaic cell and a preparation method thereof. The method includes the steps: preparing a silicon nanowire array on the upper surfaceof a single crystal silicon wafer; preparing a first interface modified layer; preparing a second interface modified layer; preparing a first PEDOT (polymer ethylenedioxy thiophene):PSS (polystyrenesulfonate) layer; preparing a second PEDOT:PSS layer; performing thermal evaporation of metal silver on the whole surface of the second PEDOT:PSS layer; preparing a front gate electrode; preparing a back electrode. By improving the structure and the preparation process of the silicon-based core-shell structure photovoltaic cell, the photoelectric conversion efficiency of the silicon-based core-shell structure photovoltaic cell is effectively improved.

Owner:苏州宝澜环保科技有限公司

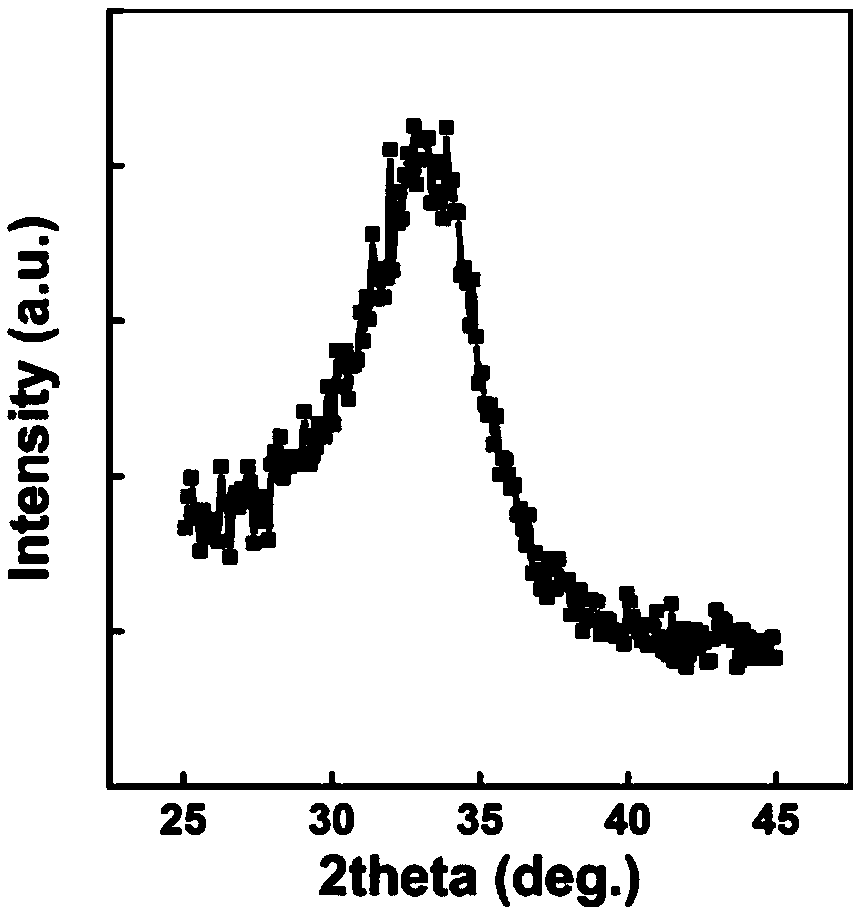

Inorganic metallic oxide thin-film with composite crystal form and manufacturing method thereof

InactiveCN107946365AQuality improvementImprove featuresTransistorVacuum evaporation coatingCharge carrier mobilityEvaporation

The invention discloses an inorganic metallic oxide thin film with a composite crystal form and a manufacturing method thereof. The inorganic metallic oxide thin film comprises a composite crystal form structure, wherein the composite crystal form structure is composed of crystal grains and an amorphous structure, the crystal grains are surrounded by the amorphous structure, and the grain size ofthe crystal grains ranges from 0.5 to 10 nm; and the inorganic metallic oxide thin film is manufactured by depositing a raw material on a substrate by adopting a magnetron sputtering method or an evaporation method. According to the manufacturing method, the raw material is deposited on the substrate by adopting a simple method, so as to form the inorganic metallic oxide thin-film having the crystal grains and the amorphous structure, the presence of the crystal grains makes the atom arrangement of the inorganic metallic oxide thin-film more orderly, and a current carrier mobility of the thinfilm is increased; meanwhile, due to the simultaneous presence of the crystal grains and the amorphous frame, the thin film maintains good spatial uniformity, so that a corresponding small-sized device maintains good and uniform device performance in large-sized application. The inorganic metallic oxide thin-film and the manufacturing method thereof can be widely applied to the semiconductor field.

Owner:SOUTH CHINA UNIV OF TECH

Core-shell quantum dot, preparation method thereof and quantum dot photoelectric device

PendingCN110055073AReduced stabilityImprove stabilityNanoopticsLuminescent compositionsQuantum dotCore shell

The invention discloses a core-shell quantum dot, a preparation method thereof and a quantum dot photoelectric device. The preparation method of the core-shell quantum dot includes the following steps: S1, adding a quantum dot core to a solution comprising first cadmium precursors and first zinc precursors to form a first mixed solution; S2, adding first anion precursors to the first mixed solution, and coating the quantum dot core with a middle shell layer; S3, adding a purified core-shell quantum dot to a solution comprising second zinc precursors to obtain a second mixed solution; S4, adding second anion precursors to the second mixed solution for reaction, and coating the core-shell quantum dot with an outer shell layer. The preparation method is further characterized by at least one of A, B and C: A, in the step S2, after the first anion precursors are added, a first certain amount of second cadmium precursors are added for reaction; B, a step S3' is included between the step S3 and the step S4, and a second certain amount of third cadmium precursors are added to the second mixed solution; C, in the step S4, a third certain amount of the third cadmium precursors are added to the second mixed solution for reaction.

Owner:NANJING TECH CORP LTD

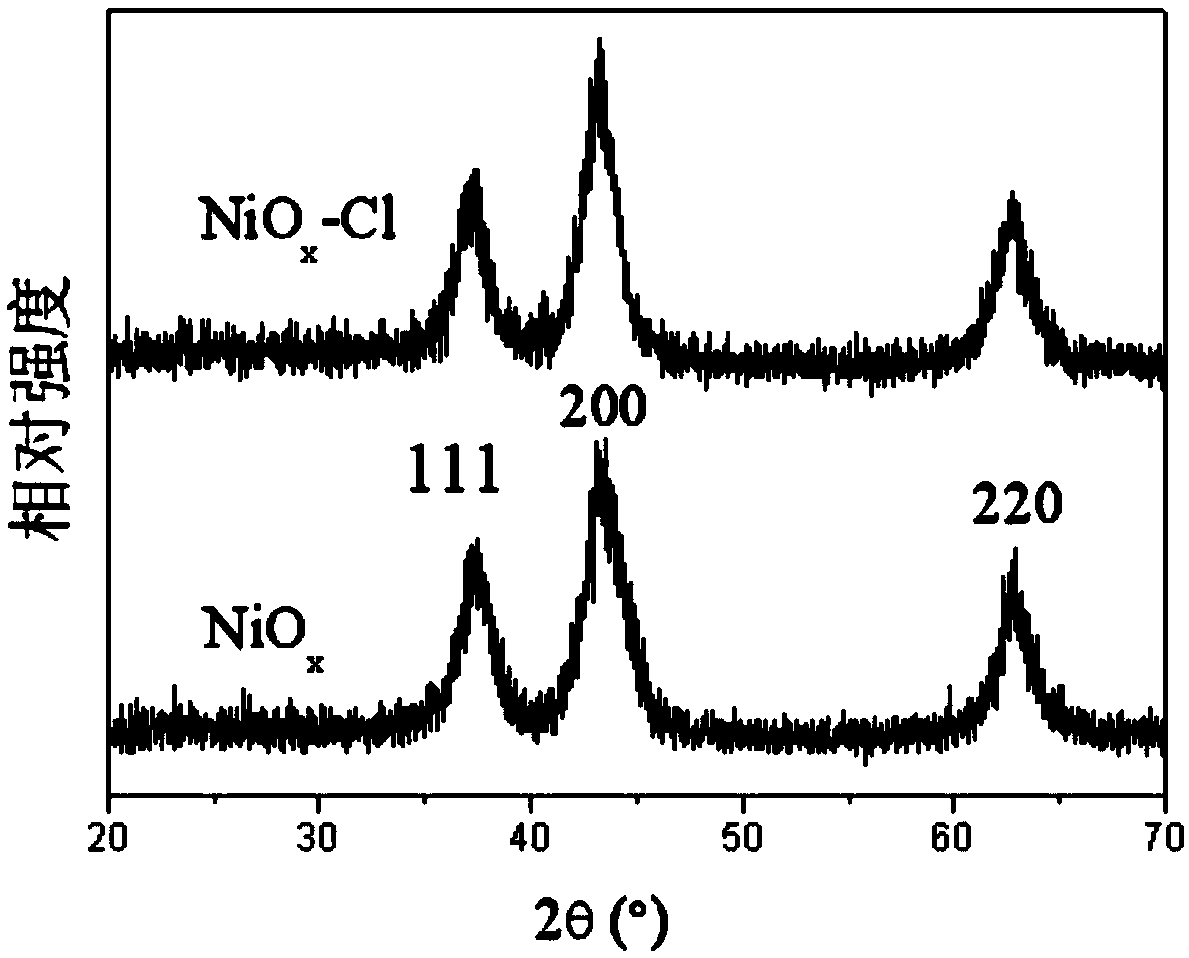

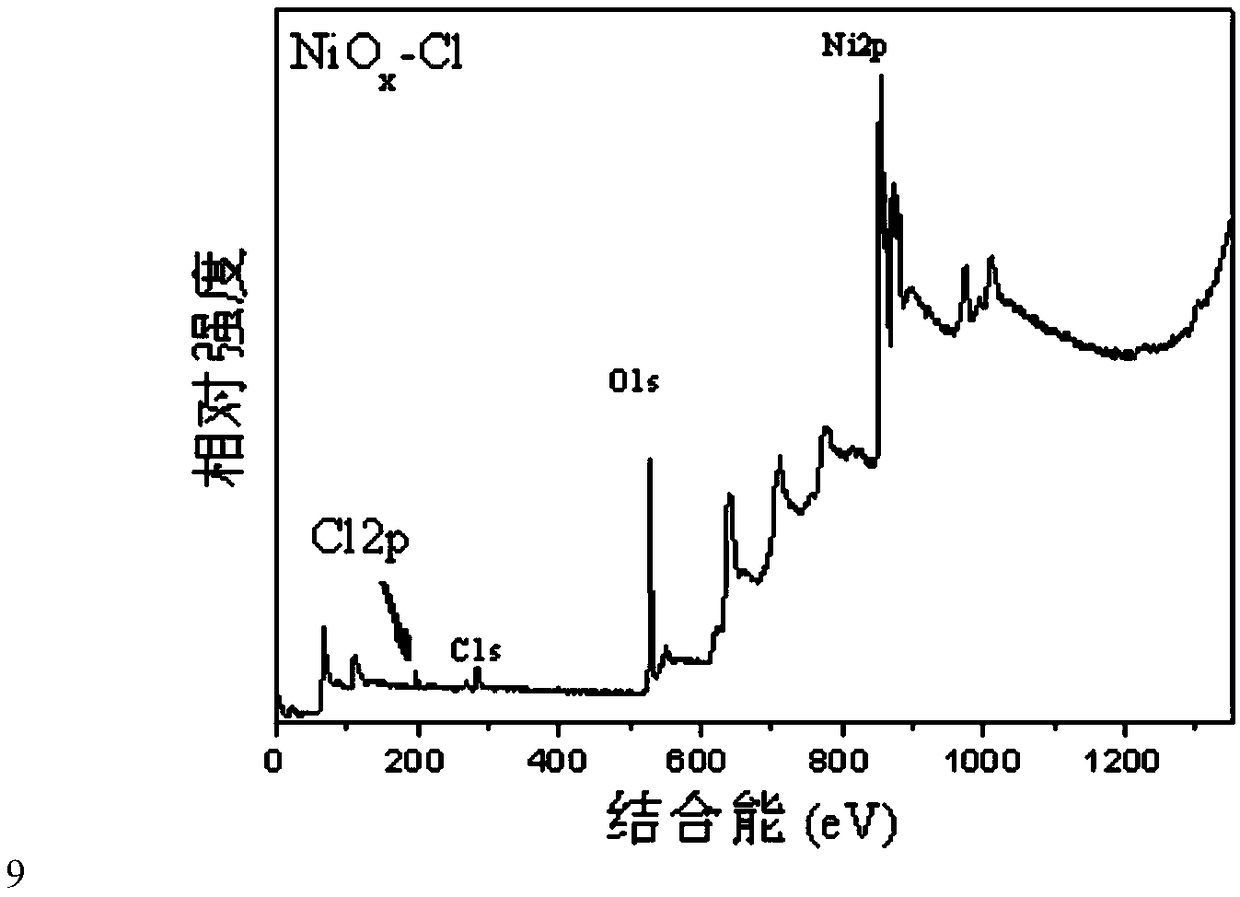

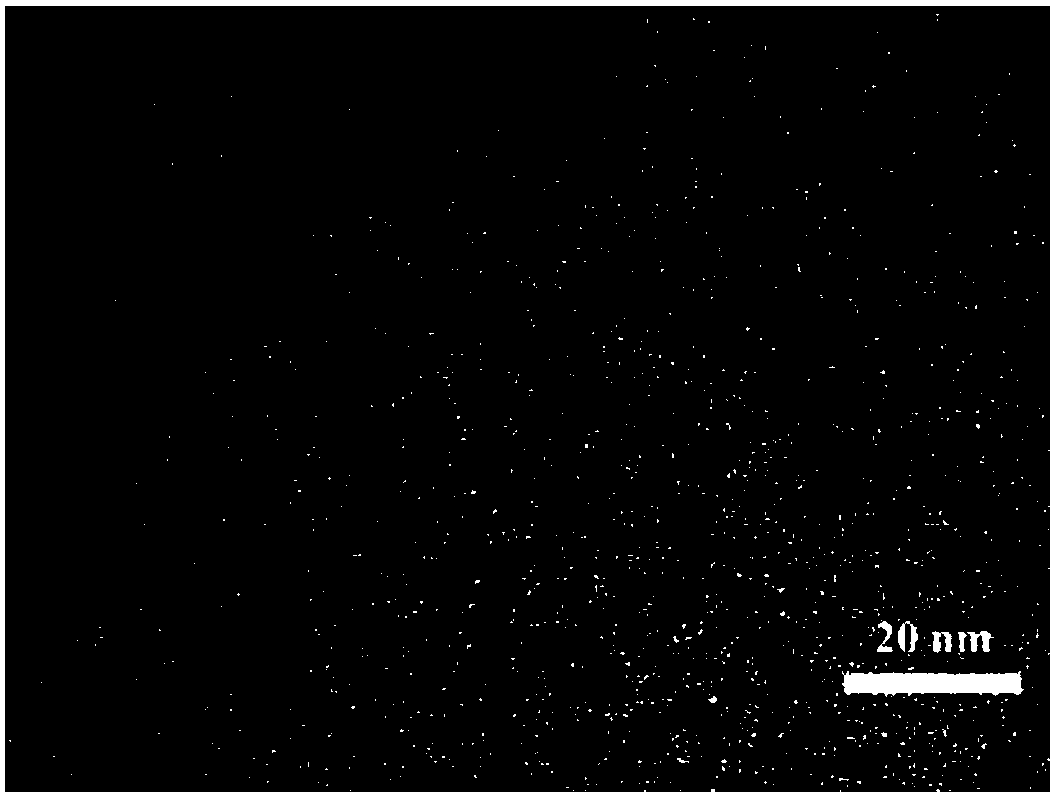

A perovskite battery containing nickel oxychloride nanoparticles as a hole transport layer and a preparation method thereof

ActiveCN109216558AReduce compoundingIncrease current densitySolid-state devicesSemiconductor/solid-state device manufacturingIonPower flow

The invention discloses a perovskite battery containing nickel oxychloride nanoparticles as a hole transport layer and a preparation method thereof. As that perovskite battery take the nickel oxide nanoparticles contain chlorine as a hole transport layer, ammonium chloride is used as a chlorine source in the preparation method, so that the size of the nickel oxide nanoparticles contain chlorine ofthe prepared hole transport layer is controlled below 10nm; As that chloride ion is adsorb on the surface of the nickel oxide, the nickel oxide and the chlorine atom become one body. When the perovskite battery is used, on the one hand, the chloride ion can reduce the defect state of the nickel oxide film and improve the extraction rate of the hole; On the other hand, the chloride ions on the surface of nickel oxide can passivate the interface between the hole transport layer and perovskite layer, which can reduce the recombination of electron holes, so that the charge can be transferred efficiently and the current density of the battery can be increased.

Owner:SHAANXI NORMAL UNIV

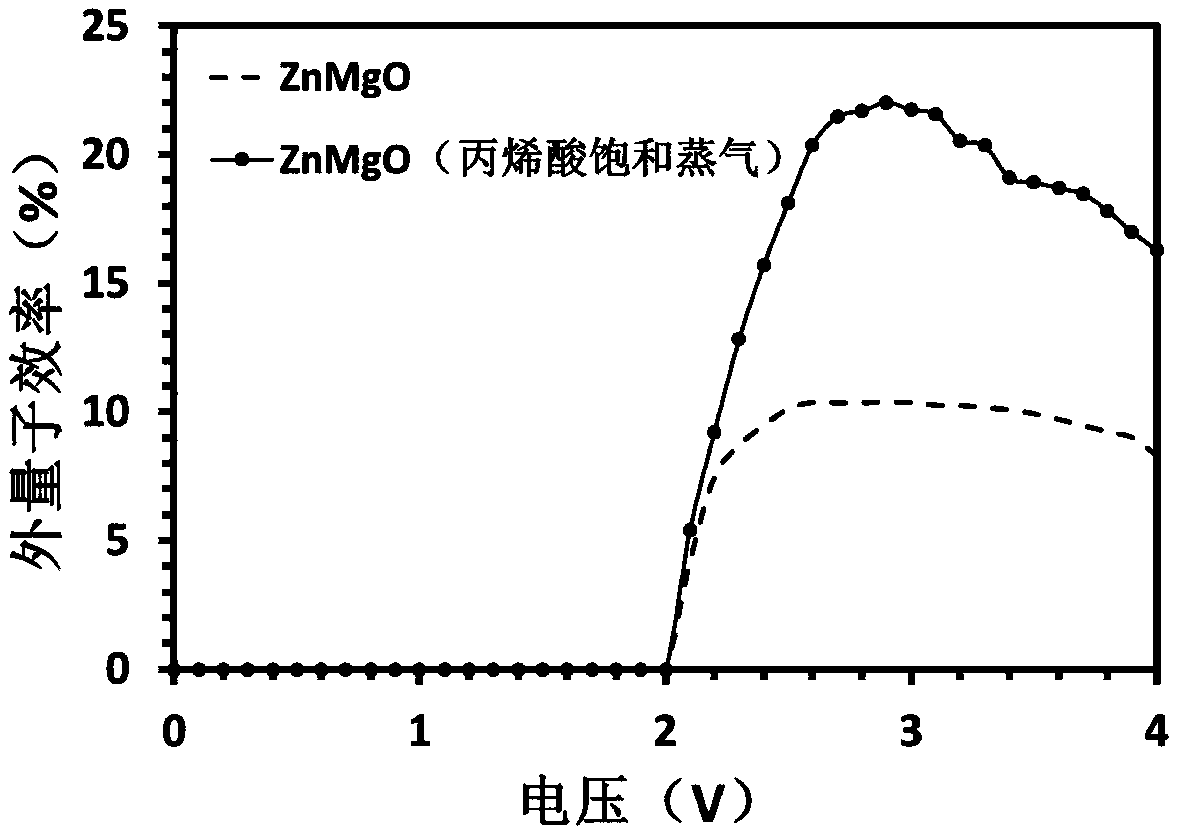

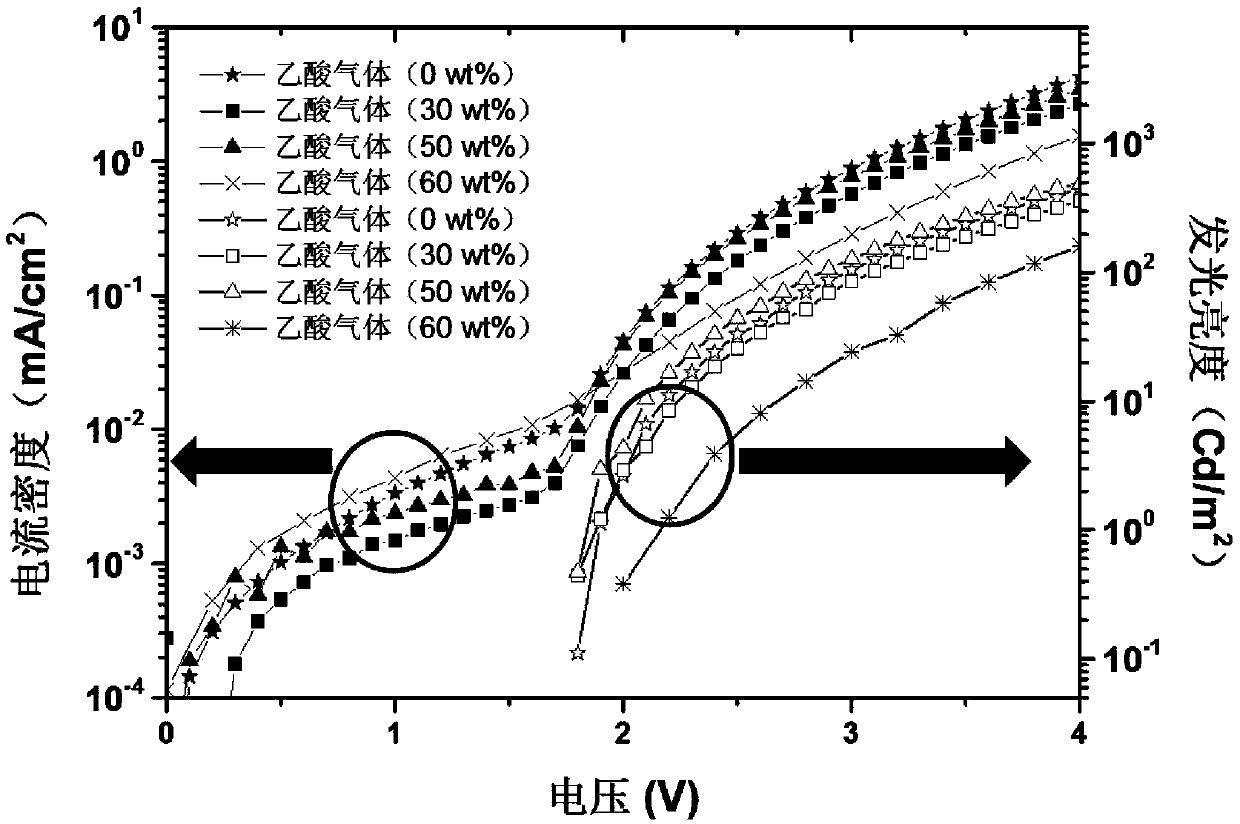

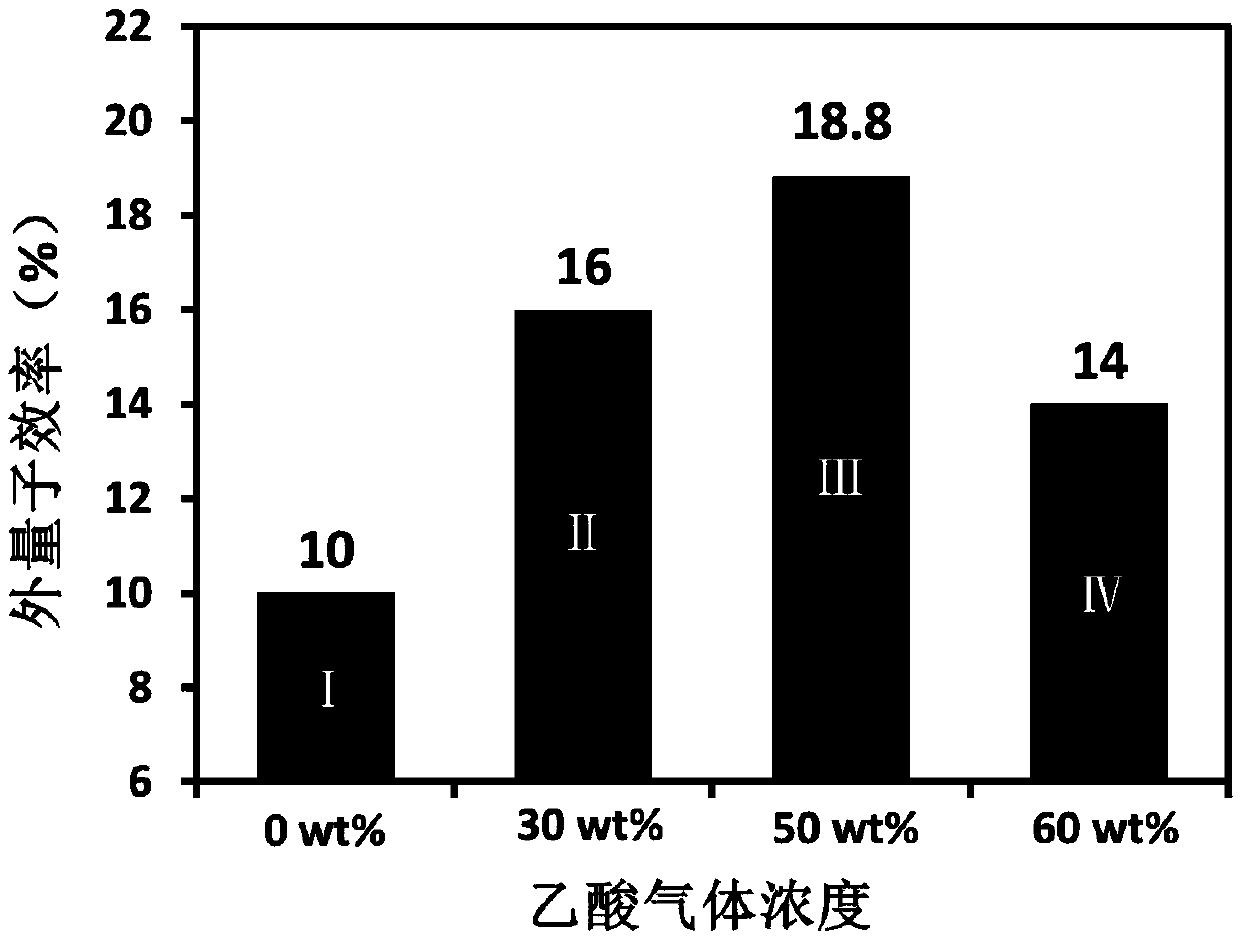

Quantum dot light-emitting device and preparation method thereof

ActiveCN110911570AReduce dangling keysReduce or eliminate dangling keysSolid-state devicesSemiconductor/solid-state device manufacturingOrganic acidQuantum dot

The invention provides a quantum dot light-emitting device and a preparation method thereof. The preparation method comprises the following steps: providing a to-be-processed part containing a nanocrystalline layer of the quantum dot light-emitting device; and carrying out acid treatment on the to-be-processed workpiece containing the nanocrystalline layer by adopting organic acid to obtain the quantum dot light-emitting device. By carrying out the acid treatment on a to-be-processed workpiece containing a nanocrystalline layer, on one hand, acid reacts with hydroxyl ion ligands on the surfaceof the nanocrystal (the surface of the nanocrystal usually carries the hydroxyl ion ligands due to a synthesis process at present) to form acid radical ion ligands and generate water, so that the hydroxyl ion ligands on the surface of the nanocrystal are greatly reduced or eliminated; on the other hand, the acid can be directly used as a surface ligand of the oxide nanocrystal, a large number ofdangling bonds on the surface of the nanocrystal are reduced or even eliminated, and therefore the defect mode of the surface of the nanocrystal is reduced. Therefore, quantum dot fluorescence quenching caused by quenching interaction between the oxide nanocrystalline and the quantum dot can be effectively inhibited, and the luminous efficiency of the device is further improved.

Owner:ZHEJIANG UNIV +1

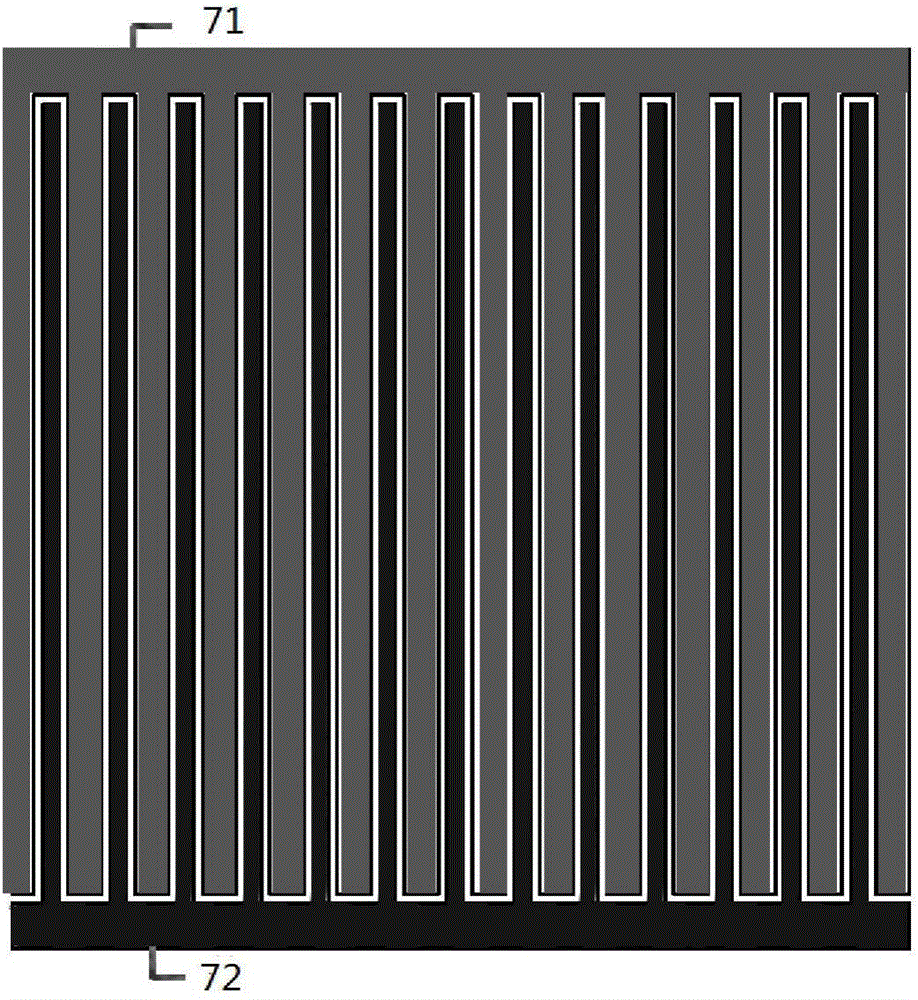

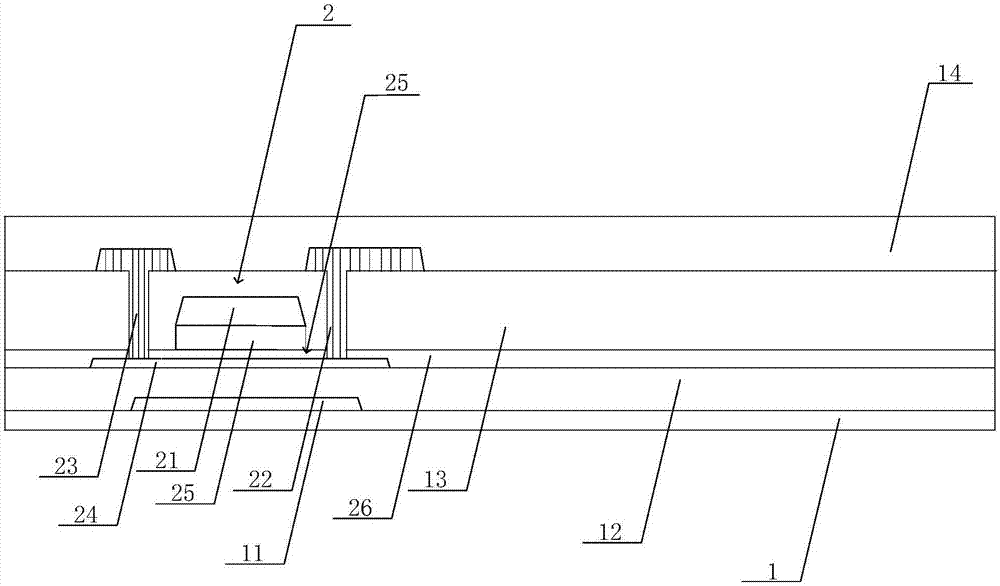

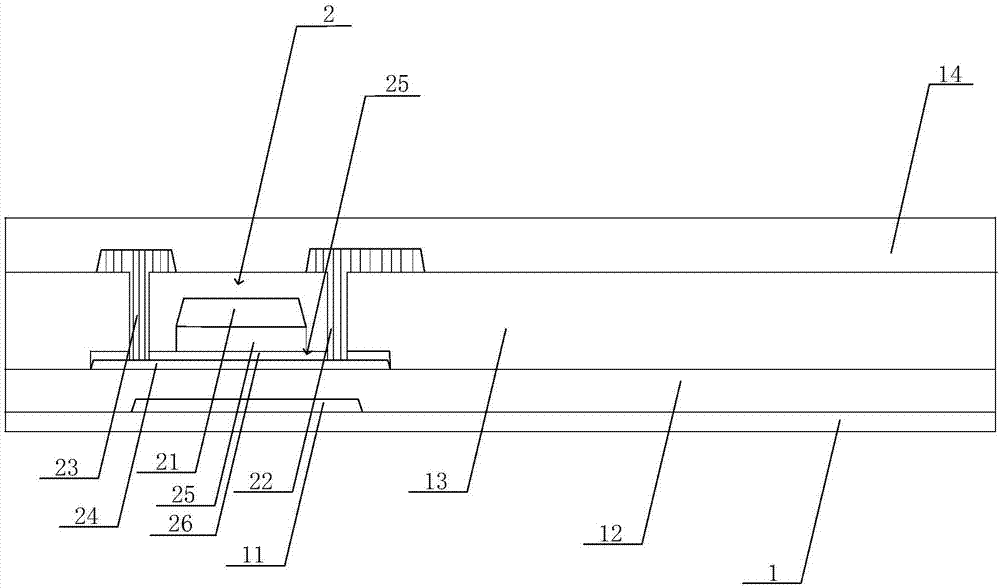

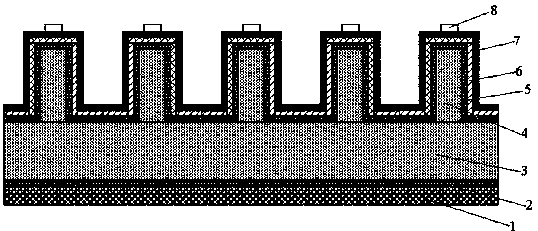

Array substrate and manufacturing method therefor

ActiveCN107507839AAvoid overprocessingReduce the impact of impedanceTransistorSolid-state devicesProtection layerDielectric layer

The invention discloses an array substrate, and the array substrate comprises a substrate; a shading layer which is formed on the substrate; a buffering layer which is formed on the shading layer; a semiconductor layer which is formed on the buffering layer; a protection layer which is formed on the semiconductor layer; an insulating layer which is formed on the protection layer; and an interlayer dielectric layer which is formed on the protection layer. The substrate is also provided with a source electrode layer, a drain electrode layer and a grid electrode layer, wherein the source electrode layer and the drain electrode layer are formed on the interlayer dielectric layer, and are respectively connected to conductor parts at two ends of the semiconductor layer. The insulating layer is disposed between the grid electrode layer and the semiconductor layer, and the interlayer dielectric layer covers the grid electrode and the protection layer. The insulating layer covers the semiconductor layer, thereby effectively guaranteeing that a to-be-conducted semiconductor layer region is not exposed, and effectively reducing the impedance impact of the conductor parts of the semiconductor layers in a subsequent manufacturing process.

Owner:HKC CORP LTD

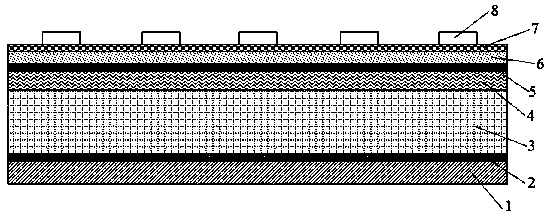

Heterojunction photovoltaic battery and preparing method thereof

ActiveCN108258124AReduce defect statesDefect state efficientSolid-state devicesSemiconductor/solid-state device manufacturingHeterojunctionNanoparticle

The invention provides a heterojunction photovoltaic battery and a preparing method thereof. The method includes the steps of cleaning an n-type silicon wafer, preparing a pyramid-structure suede layer on the upper surface of the n-type silicon wafer, preparing silicon nanowires on the surface of the pyramid-structure in the pyramid-structure suede layer, conducting passivation treatment on the n-type silicon wafer, preparing a molybdenum selenide nanoparticle / Spiro-OMeTAD layer, preparing a PEDOT:PPS layer, preparing a front side silver grid electrode and preparing a back side aluminum electrode, wherein a mixed solution containing potassium hydroxide and aluminum ethoxide is selected for spin-coating in the process of conducting passivation treatment on the n-type silicon wafer, annealing treatment is conducted, the defect mode of the surface of a silicon substrate is effectively reduced, and the photoelectric conversion efficiency of the corresponding heterojunction photovoltaic battery is improved.

Owner:诸暨市冬之宝针织有限公司

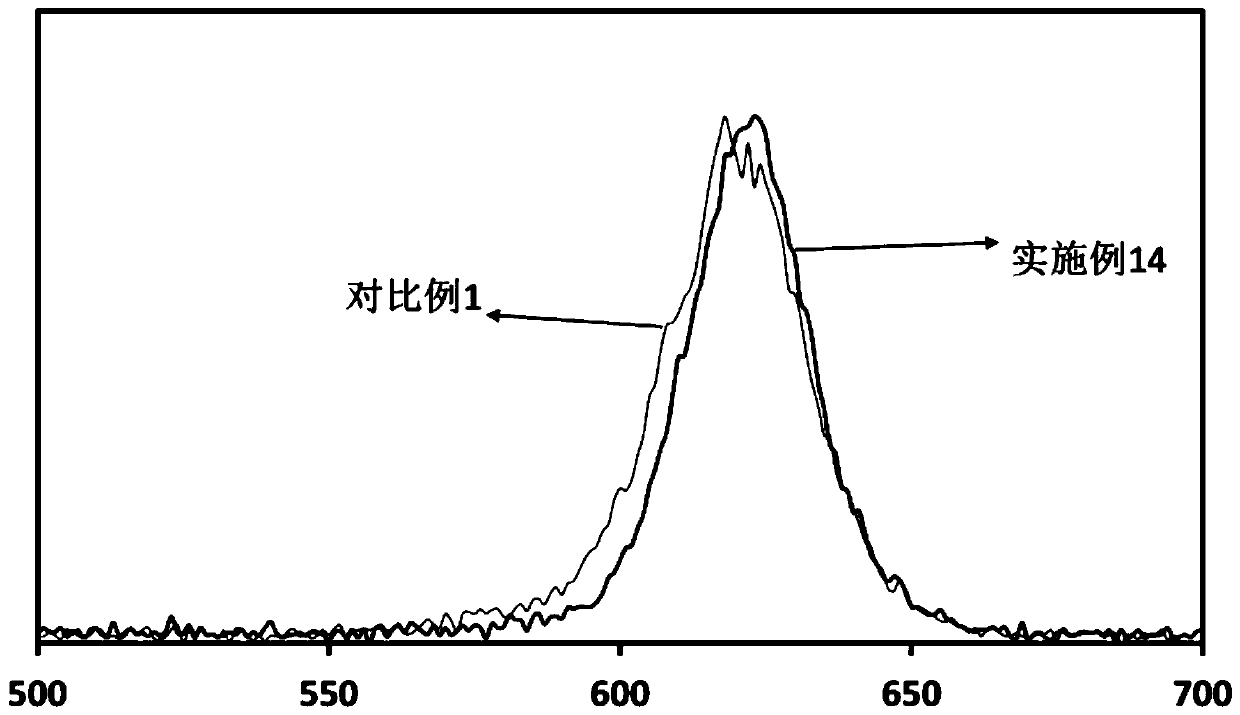

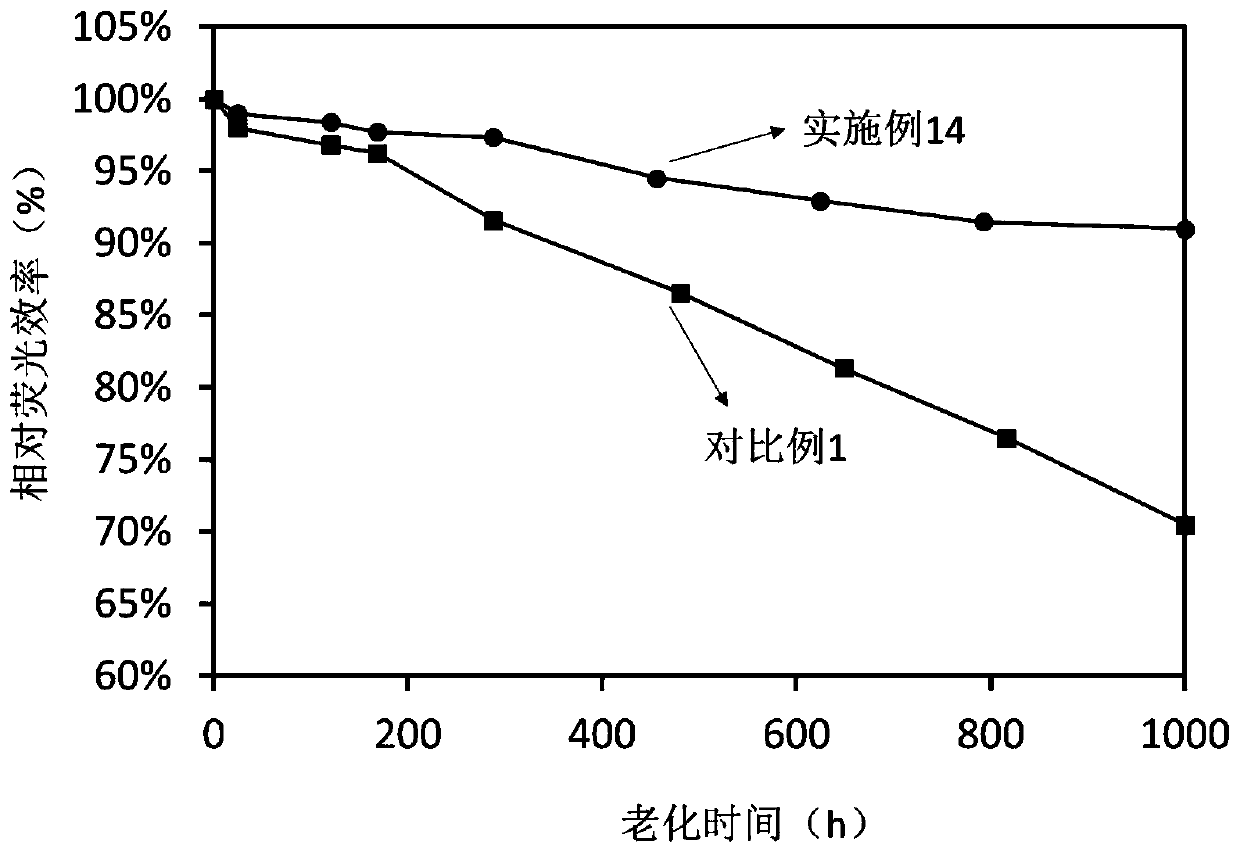

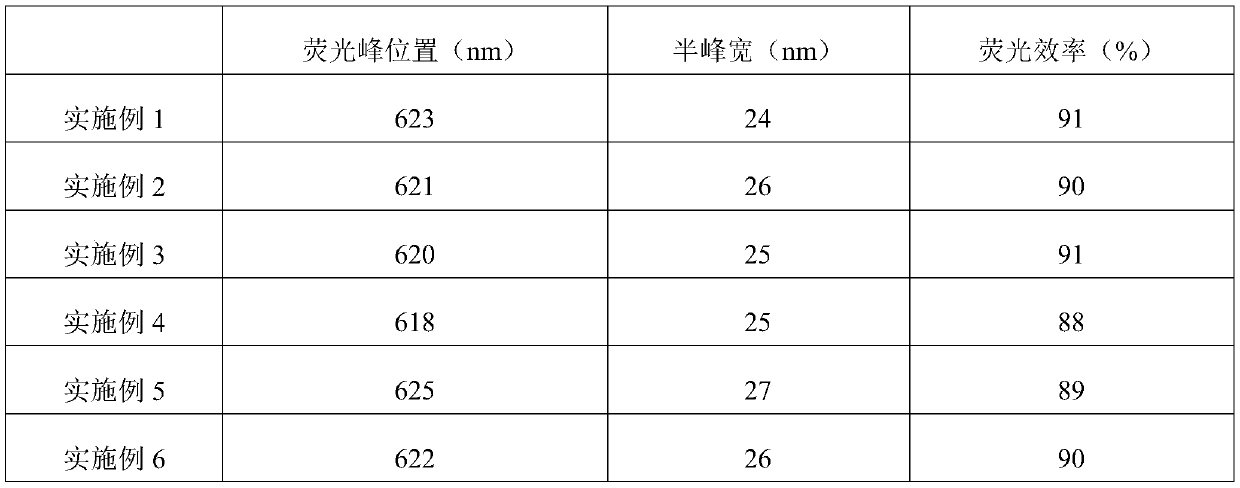

High-performance quantum dot white light LED and preparing method thereof

ActiveCN108110123AImprove luminous efficiencyGood colorSemiconductor devicesLattice mismatchRe absorption

A high-performance quantum dot white light LED and a preparing method thereof belong to the field of semiconductor illumination. The high-performance quantum dot white light LED is based on an electroluminescent blue light LED chip. The high-performance quantum dot white light LED is obtained through successively coating a CdSe / CdS / ZnS quantum dot thin-film layer which emits red light and a Cu:ZnInS / ZnS / ZnS:Al quantum dot thin-film layer that emits green light. According to Cu:ZnInS / ZnS / ZnS:Al quantum dot which emits green light, Al3<+> can be packaged through kernel doped Cu2<+> and an external ZnS housing layer, thereby improving light / thermal stability. The CdSe / CdS / ZnS gradient alloy quantum dot which emits red light supply multiple-housing-layer protection, thereby reducing defects caused by surface crystal lattice mismatch and preventing light degeneration. The coating manner of layered structure can remarkably suppress energy transmission and re-absorption between quantum dots and furthermore improves light emitting efficiency. The prepared quantum dot white light LED is suitable for an occasion wherein low color temperature, high color rendering index and high light emitting efficiency are required, and is particularly suitable for the displaying and illuminating field with relatively high requirement for light emitting stability.

Owner:JILIN UNIV

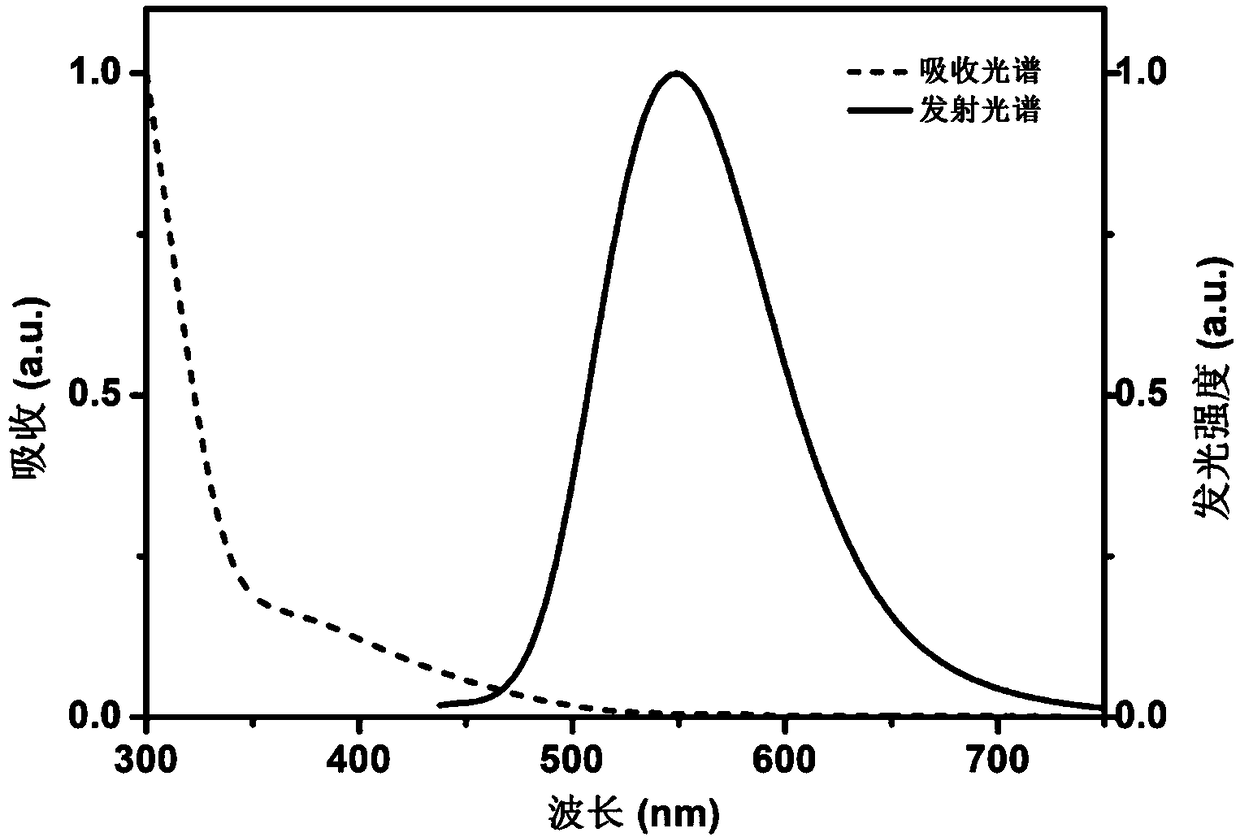

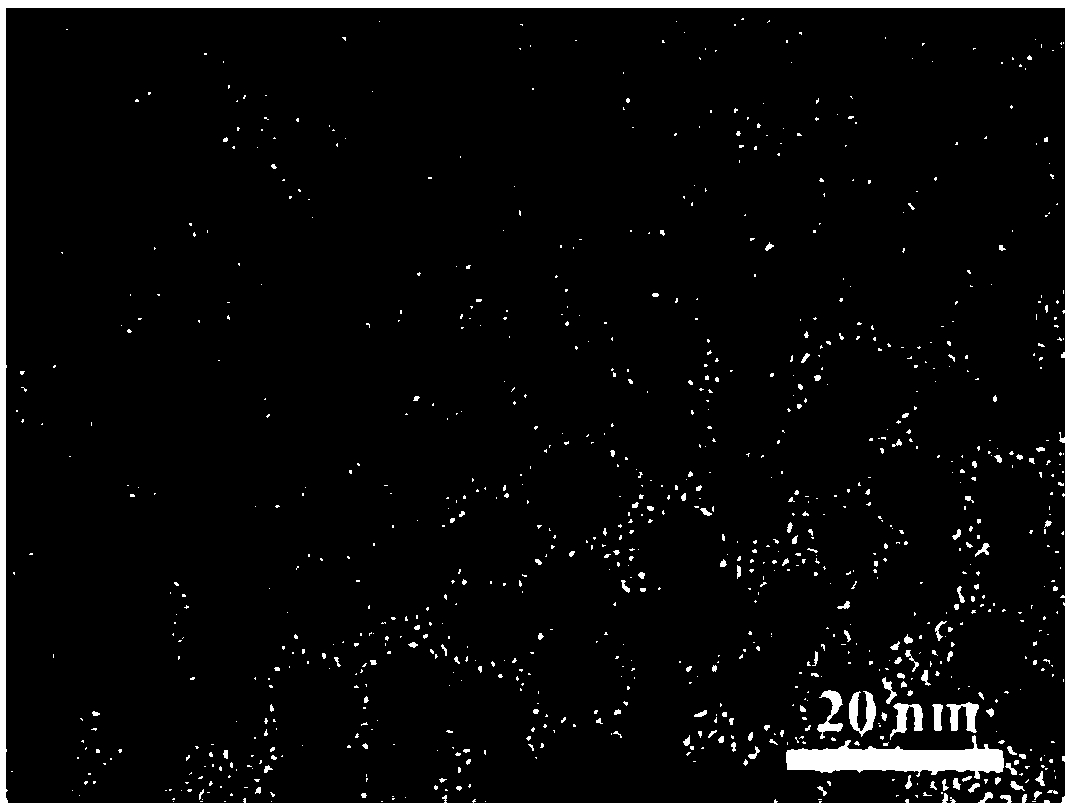

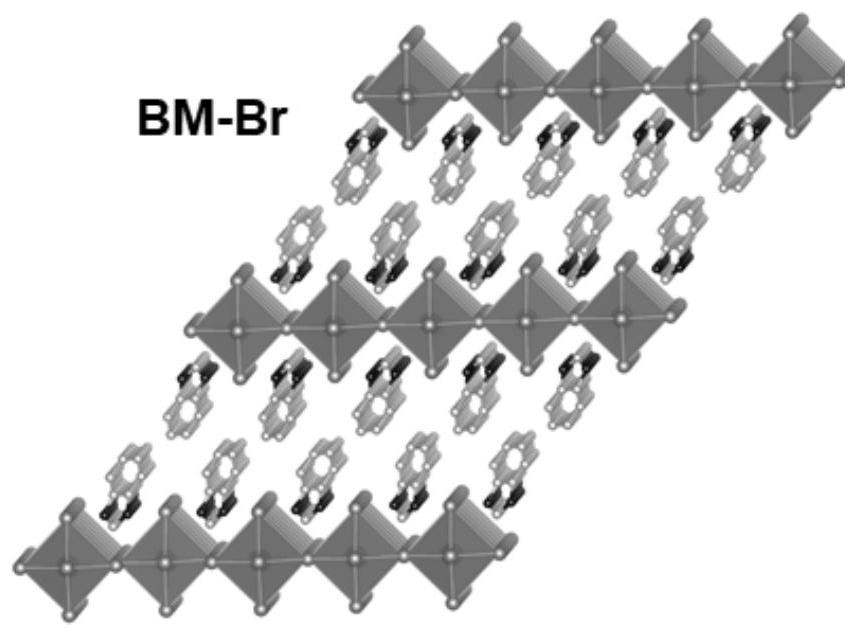

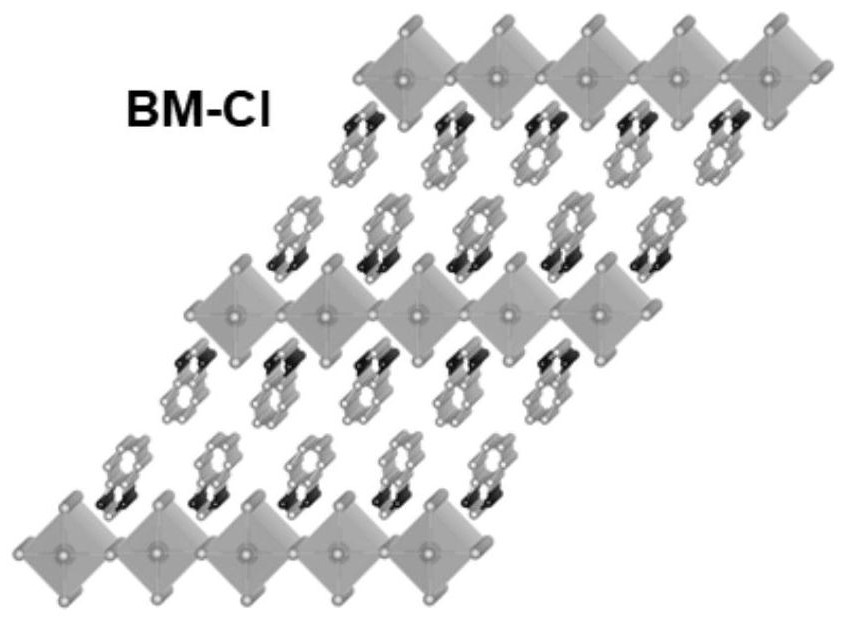

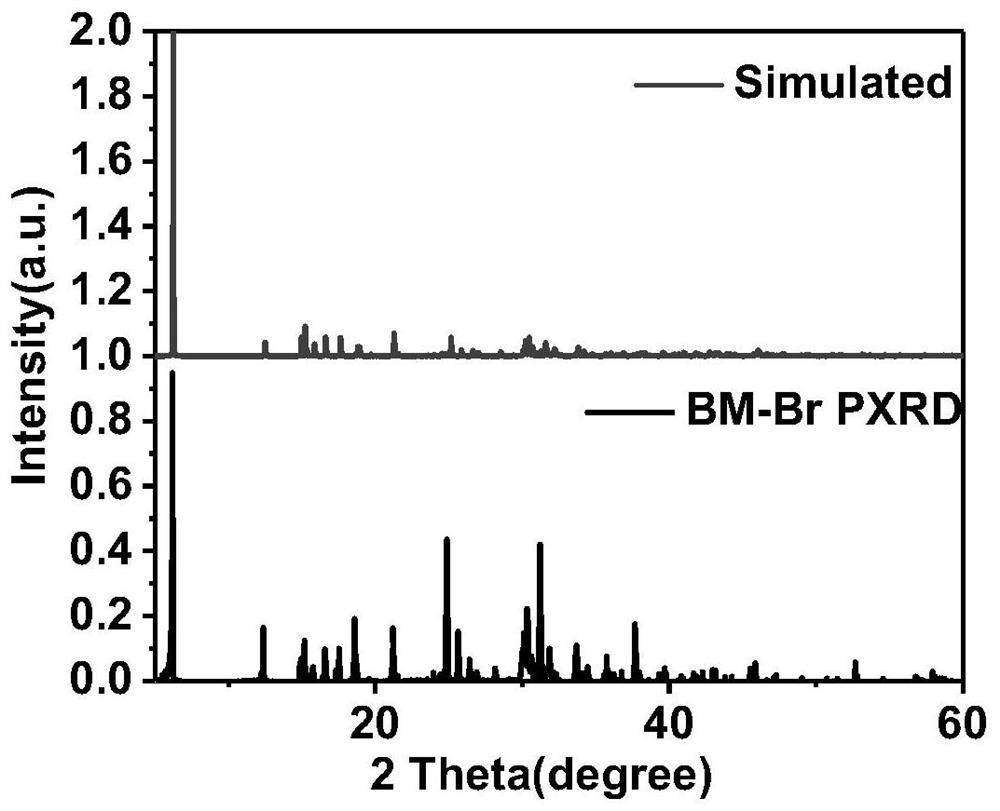

Benzimidazole cationic two-dimensional perovskite material as well as preparation method and application thereof

ActiveCN112624978AImprove stabilityTransparent without obvious grain boundariesOrganic chemistry methodsEnergy efficient lightingPerovskite (structure)Single crystal

The invention relates to a benzimidazole cation <100>-type two-dimensional perovskite material as well as a preparation method and an application thereof, and belongs to the technical field of luminescent materials. The chemical formula of the material is (C7H7N2)2BX4, B is a metal ion Pb<2+>, Sn<2+> or Ge<2+>, and X is a halogen ion Cl<-> or Br<->. The material has high stability, wherein <100>the type 2D perovskite material (C7H7N2) 2PbBr4 shows bright deep blue light emission. The <100>-type 2D perovskite material (C7H7N2)2PbCl4 with a regular structure is a single component white light emitting material. Compared with an anti-solvent method and a volatilization method, the crystal material prepared through the cooling method has a larger size, the obtained crystal is transparent and free of obvious crystal boundary, crystal defect states are few, and the crystal material is a nearly perfect single crystal material with the regular structure and an ordered long range.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

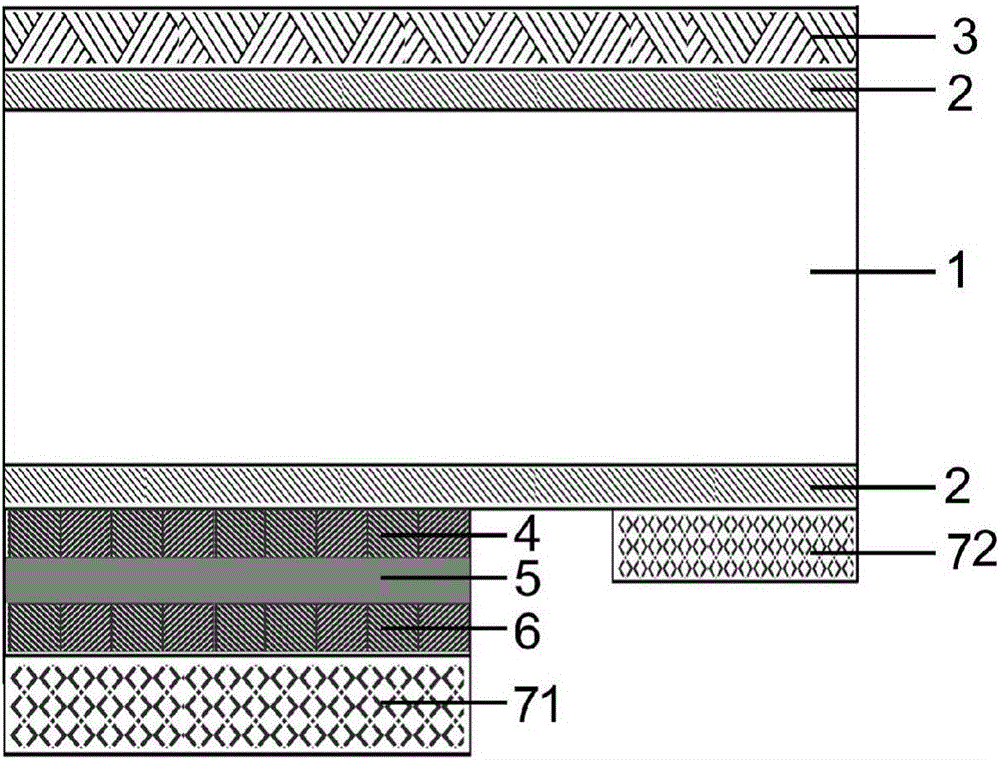

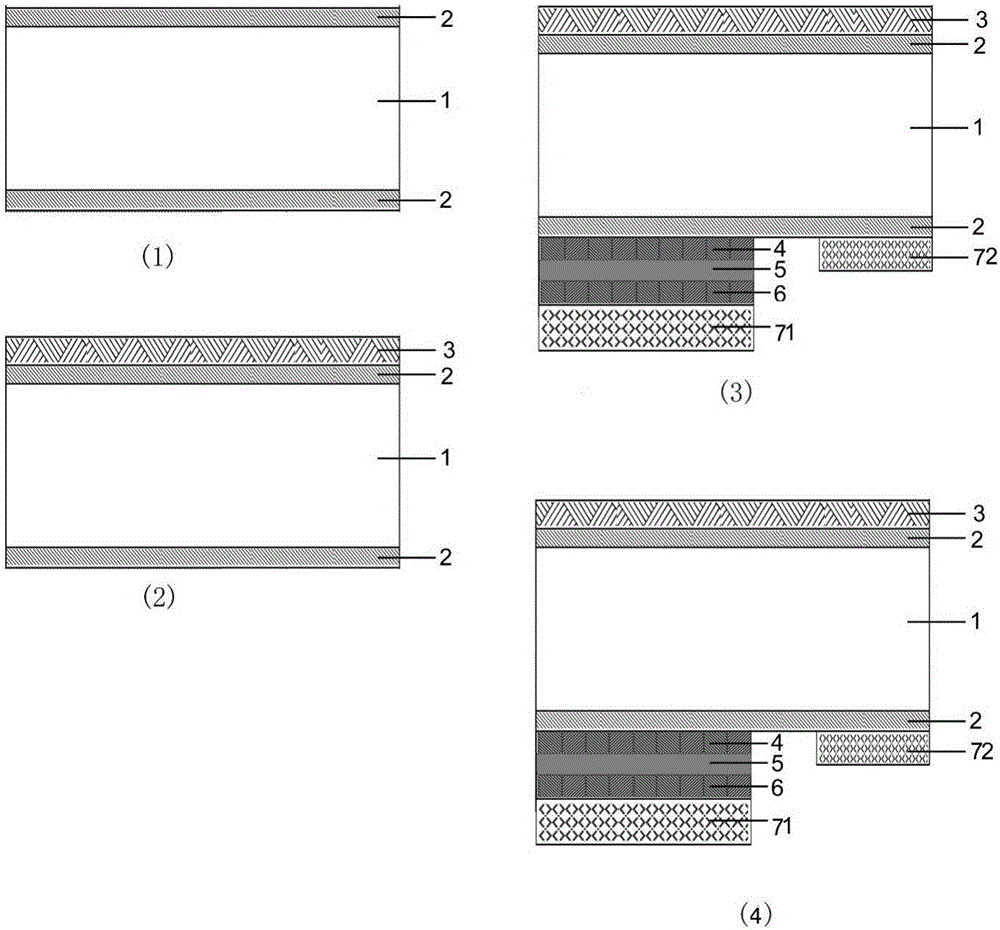

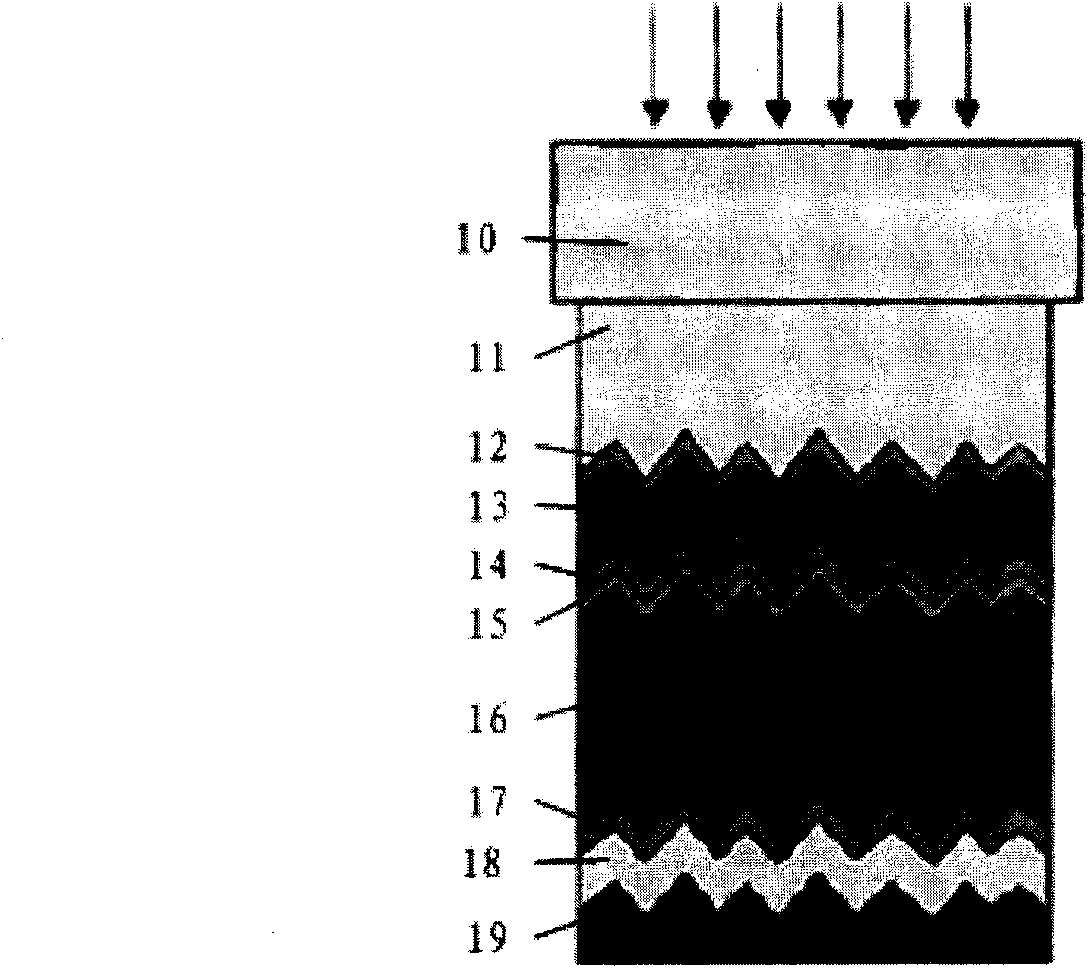

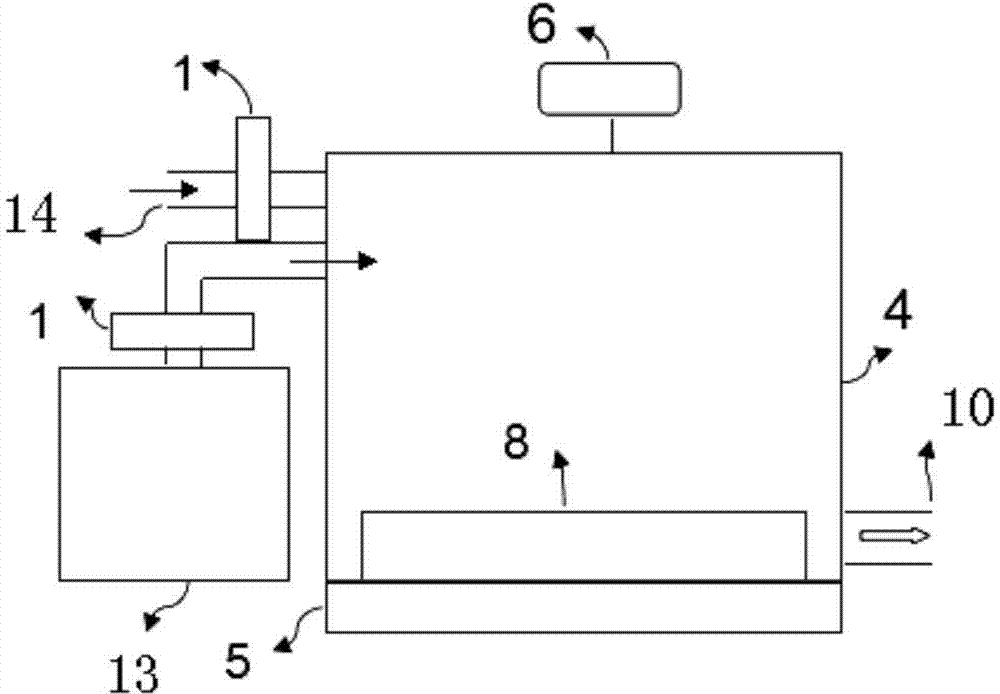

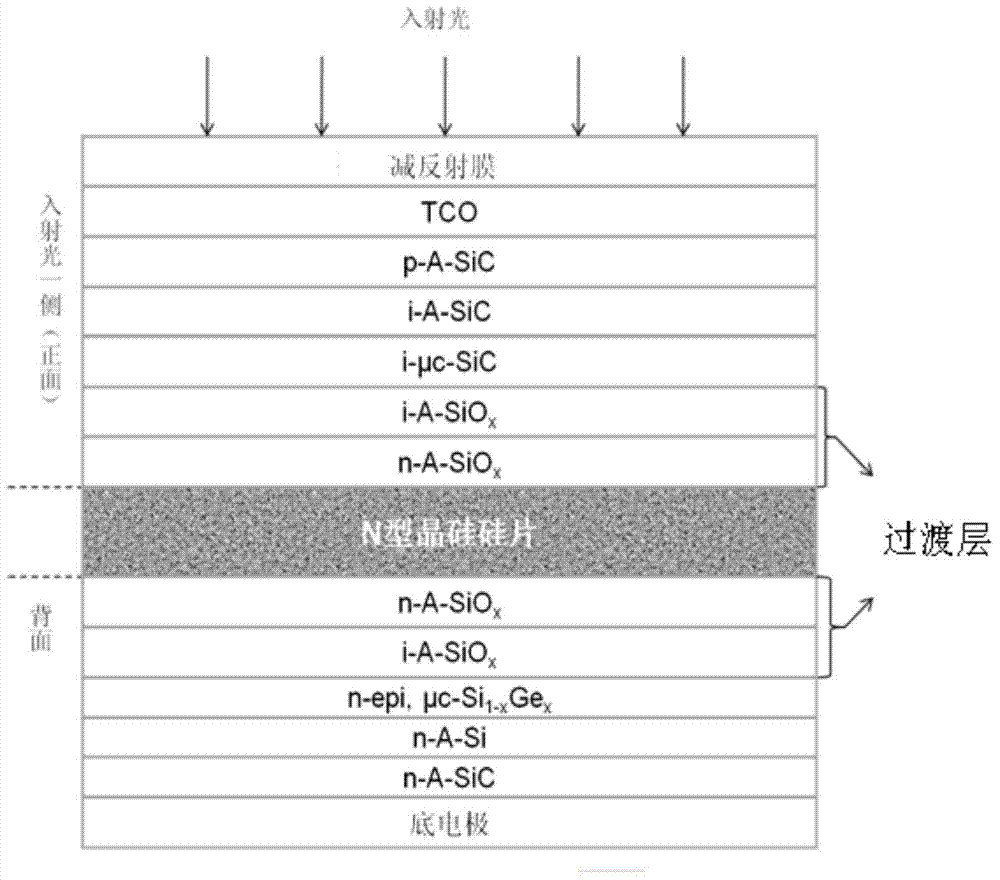

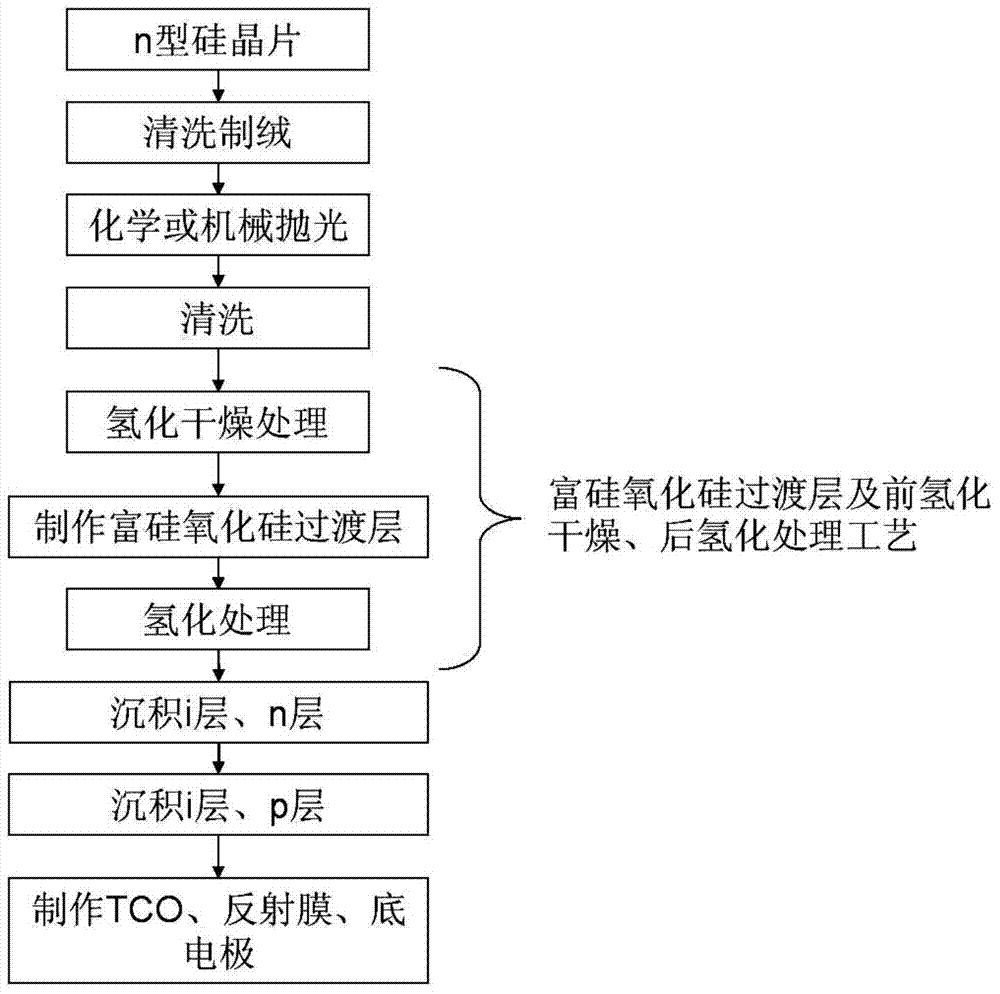

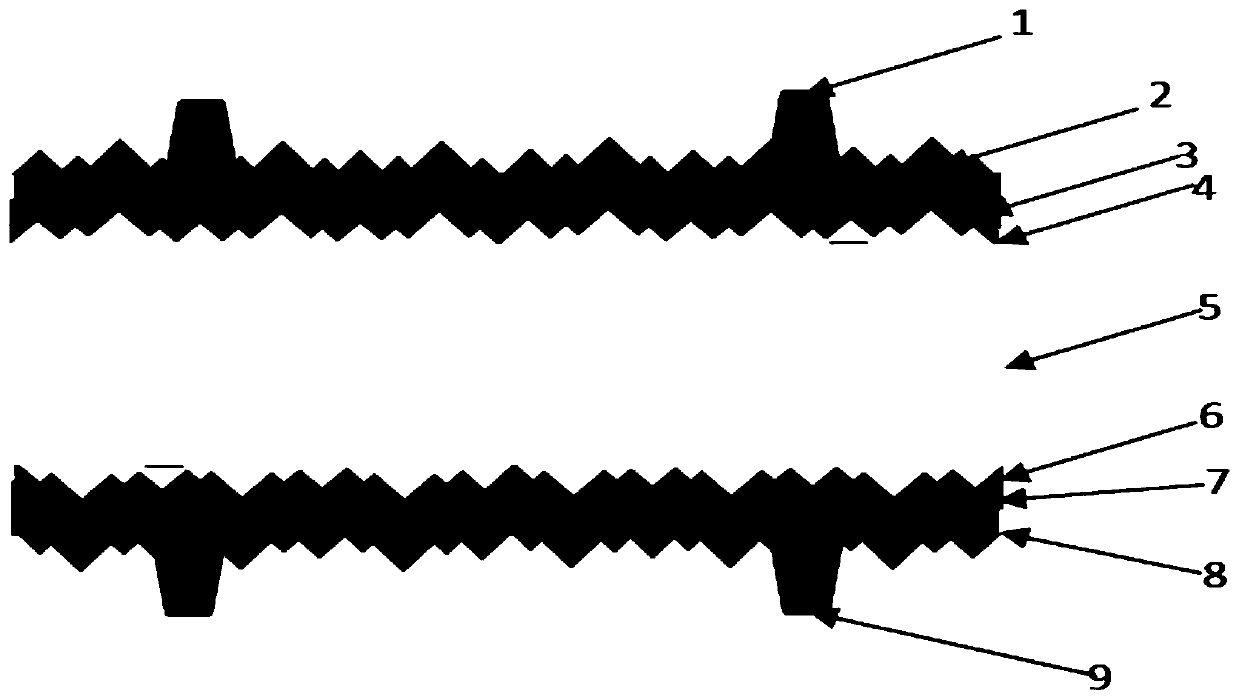

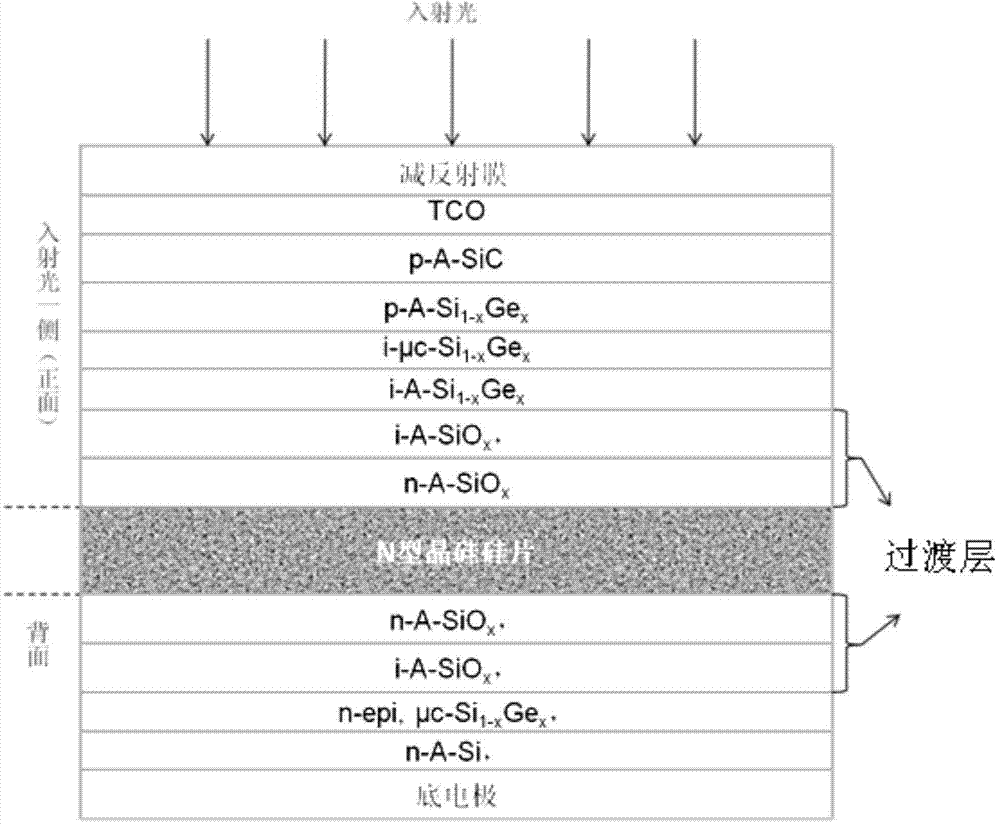

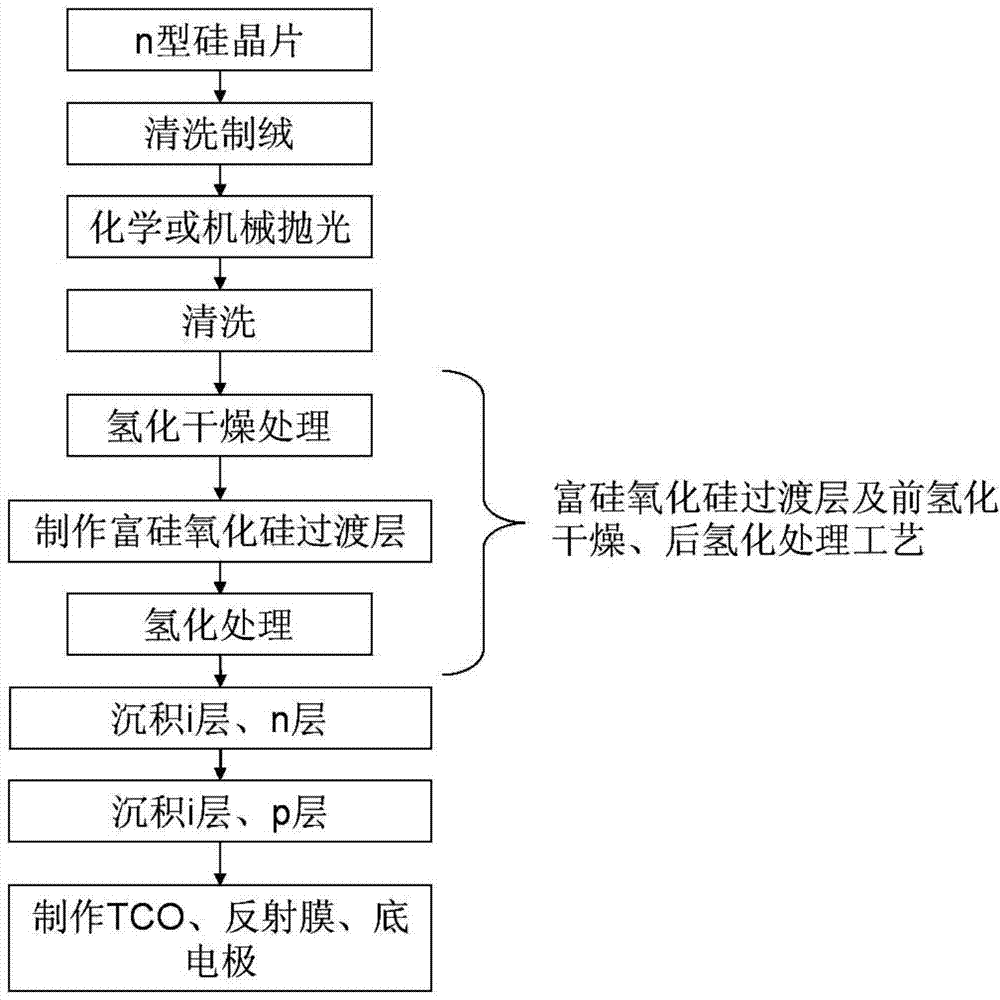

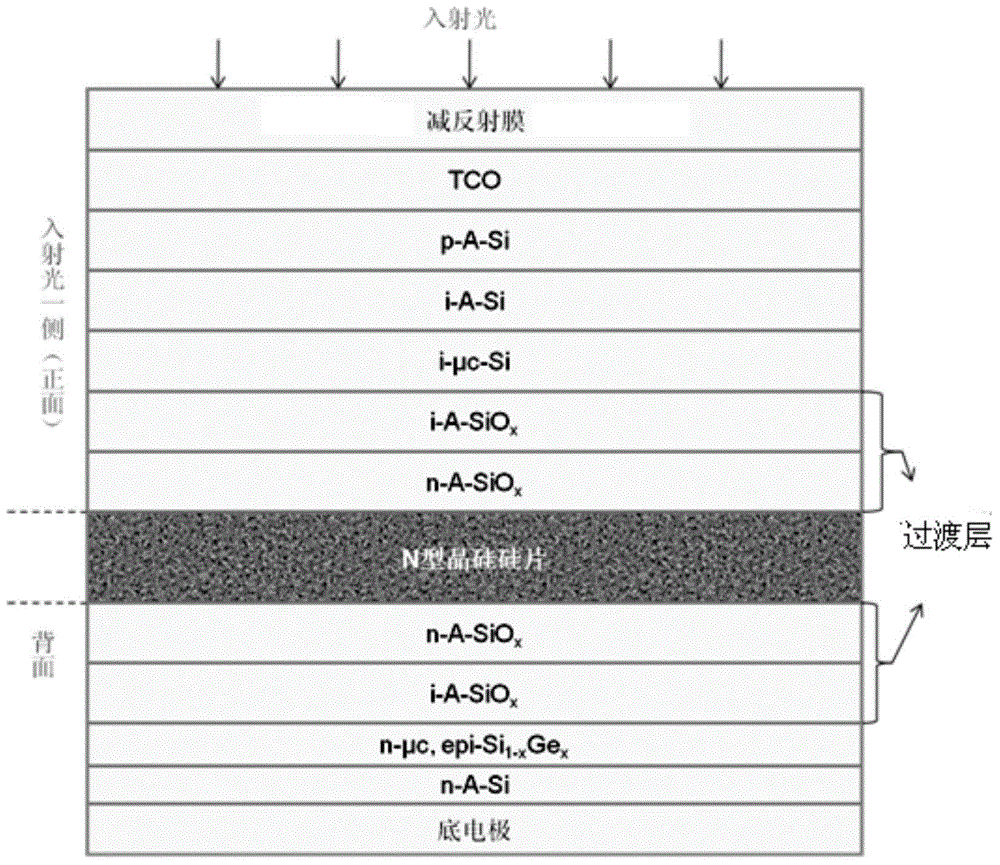

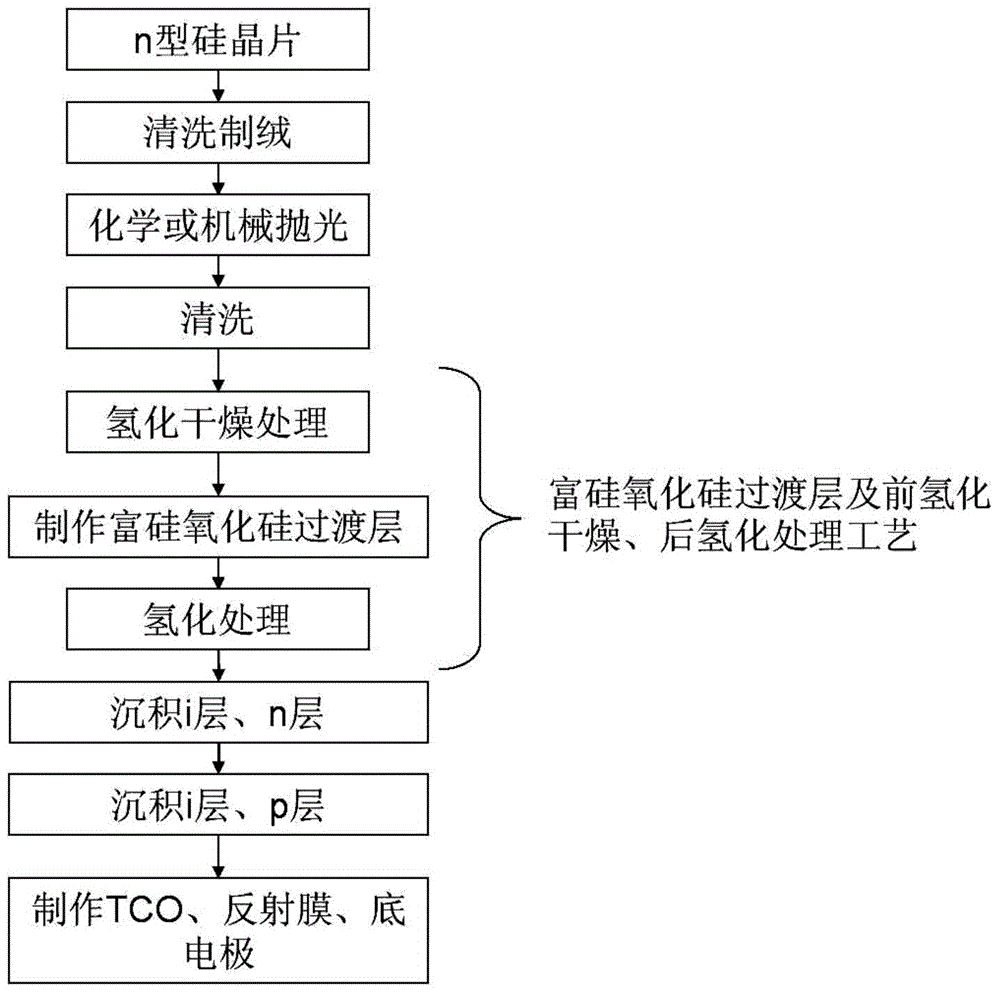

Crystal silicon and silicon carbide film compound unijunction PIN solar battery with transition layer, and preparation method thereof

ActiveCN104505419AReduce defect statesImprove passivation effectFinal product manufacturePhotovoltaic energy generationOxygenSolar battery

The invention provides a crystal silicon and silicon carbide film compound unijunction PIN solar battery with a transition layer, and a preparation method thereof. According to the solar battery, the front surface of an n-type silicon wafer or the back surface of the n-type silicon wafer or both the front surface and the back surface of the n-type silicon wafer are simultaneously provided with the transition layer, the transition layer has one layer or multiple layers, and one layer of the transition layer is a silicon-enriched oxygen ambient silica layer. The preparation method involves adding a pre-hydrogenation drying processing after the silicon wafer is textured, polished and cleaned and at the same time, adding a post-hydrogenation processing mode after the process of the transition layer is finished. The two methods are used for improving the interface quality and the structure stability. By using the transition layer and using the crystal silicon and silicon carbide film compound battery which is subjected to the pre-hydrogenation drying processing and post-hydrogenation processing and is provided with the transition layer, the battery conversion efficiency can be improved by more than 10% on the basis of the prior arts.

Owner:湖南共创光伏科技有限公司

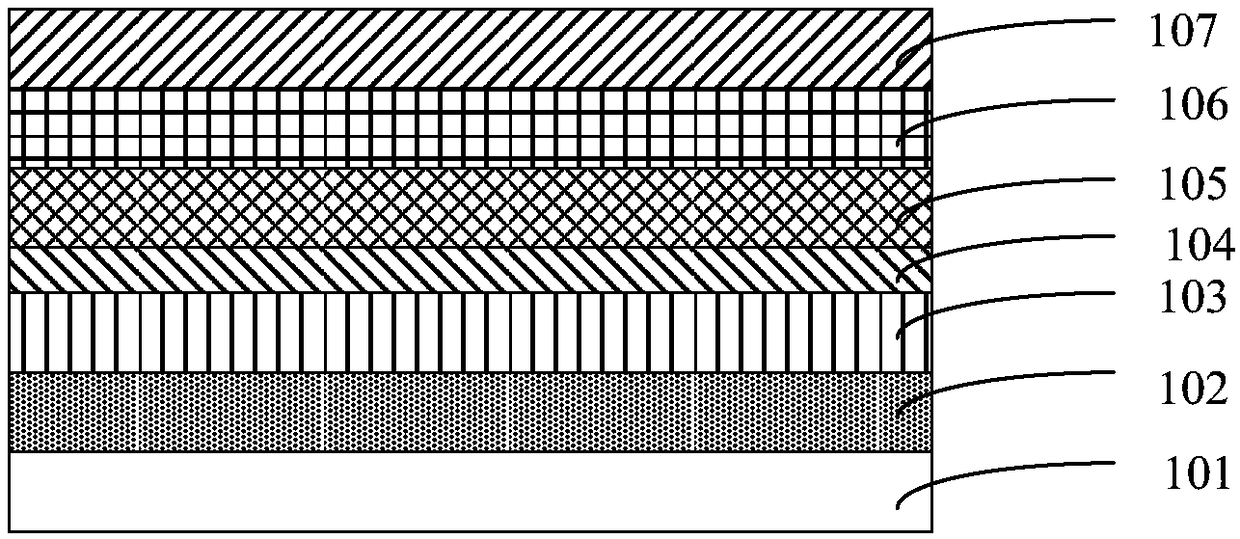

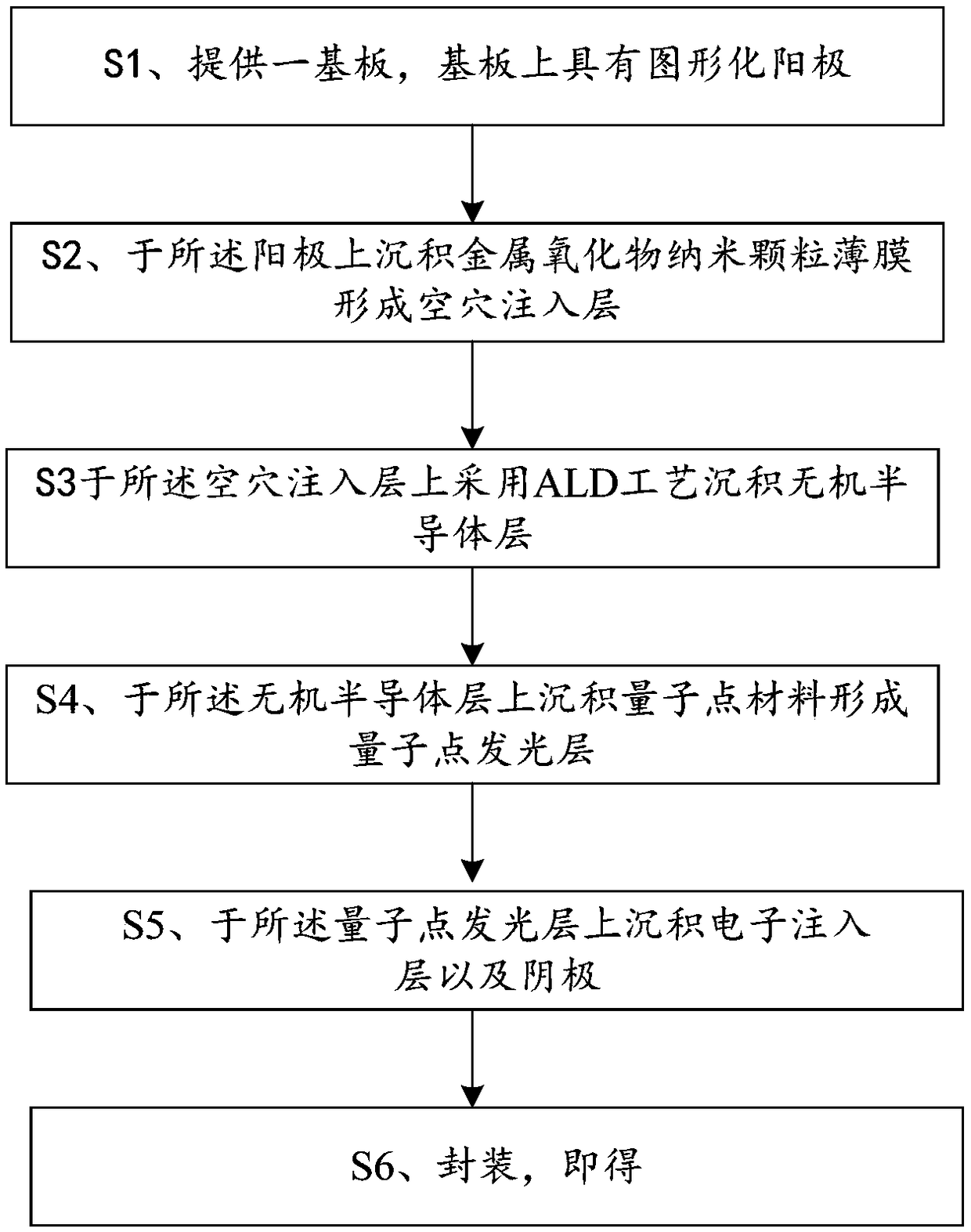

OLED device and preparation method thereof

InactiveCN108346749AImprove stabilityExcellent hole injectionSolid-state devicesSemiconductor/solid-state device manufacturingNanometreQuantum dot

The invention relates to a QLED device and a preparation method thereof. The QLED device comprises a substrate, an anode, a hole injection layer, an inorganic semiconductor layer, a quantum dot light-emitting layer, an electron injection layer and a cathode which are sequentially arranged in a laminated manner, wherein the hole injection layer is made of metal oxide nanoparticles. The QLED deviceadopts the metal oxide nano to serve as the hole injection layer and introduces an inorganic semiconductor film with the same composition as a quantum dot shell layer between the quantum dot light-emitting layer and the hole transport layer at the same time, thereby ensuring good hole injection performance between the inorganic semiconductor layer and the quantum dot light-emitting layer, and thuseffectively improving the injection transport from the hole injection layer to the inorganic semiconductor film. The stability of the device can be effectively improved by adopting an all-inorganic material to prepare a quantum dot light-emitting diode.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

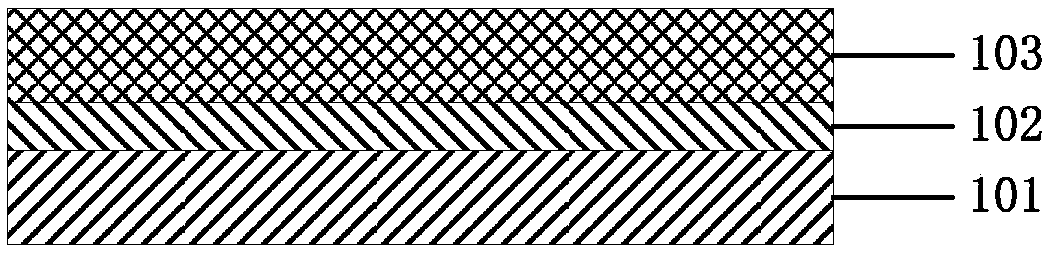

Solar cell antireflection film and manufacturing method thereof

InactiveCN104241402AHas a passivation effectImprove passivation effectFinal product manufacturePhotovoltaic energy generationCrystalline siliconSilicon nitride

The invention provides a solar cell antireflection film. The solar cell antireflection film is composed of a non-crystalline silicon layer, a first silicon nitride film and a second silicon nitride film, wherein the non-crystalline silicon layer, the first silicon nitride film and the second silicon nitride film are stacked in sequence. The non-crystalline silicon layer is arranged on the surface of a solar cell silicon wafer. The invention further provides a manufacturing method of the solar cell antireflection film. In the manufacturing process of the antireflection film, the non-crystalline silicon layer, the first silicon nitride film and the second silicon nitride film are deposited on the surface of the solar cell silicon wafer with a plasma enhanced vapor deposition method. The solar cell antireflection film has both the inactivation function and the antireflection function, and therefore the conversion efficiency of a solar cell can be improved easily.

Owner:JINKO SOLAR CO LTD +1

Preparation method of quantum dots

InactiveCN111019633ALarge lattice stressReduce lattice defectsNanoopticsLuminescent compositionsCarboxylic acidAmine binding

The invention provides a preparation method of quantum dots. The preparation method comprises the following steps: providing an initial quantum dot core, and mixing the initial quantum dot core and organic amine to combine the organic amine to the surface of the initial quantum dot core; performing a shell layer growth reaction on the surface of the initial quantum dot core to prepare a shell layer; mixing the solution system after the shell growth reaction and an organic carboxylic acid, and heating; or mixing the system after the shell growth reaction and organic phosphine, and heating; or mixing the solution system after the shell growth reaction and a mixed solution of an organic carboxylic acid and organic phosphine, and heating.

Owner:TCL CORPORATION

Preparation method of core-shell structure nanocrystal

InactiveCN111019631ALarge lattice stressImprove photothermophotometric qualityMaterial nanotechnologyNanoopticsQuantum dotCarboxylic acid

The invention provides a preparation method of nanocrystal with a core-shell structure. The preparation method comprises the following steps: providing a solution containing a quantum dot core; carrying out shell layer growth on the surface of the quantum dot core N times to prepare N layers of shell layers so as to obtain a core-shell structure nanocrystal, wherein a shell source for shell growthcomprises a shell source cationic precursor and a shell source anionic precursor, the shell source cationic precursor is a metal organic carboxylate, and between the M adjacent shell layer growth steps in different sequences, the shell layer growth reaction system with the formed previous shell layer is added with an organic amine and subjected to mixing heating, and then the next shell layer grows, wherein N is a positive integer of greater than or equal to 2, M is a positive integer, and M is greater than or equal to N / 3 and less than or equal to N-1; and dispersing the nanocrystal with thecore-shell structure in a solution containing organic phosphine, and carrying out heating treatment.

Owner:TCL CORPORATION

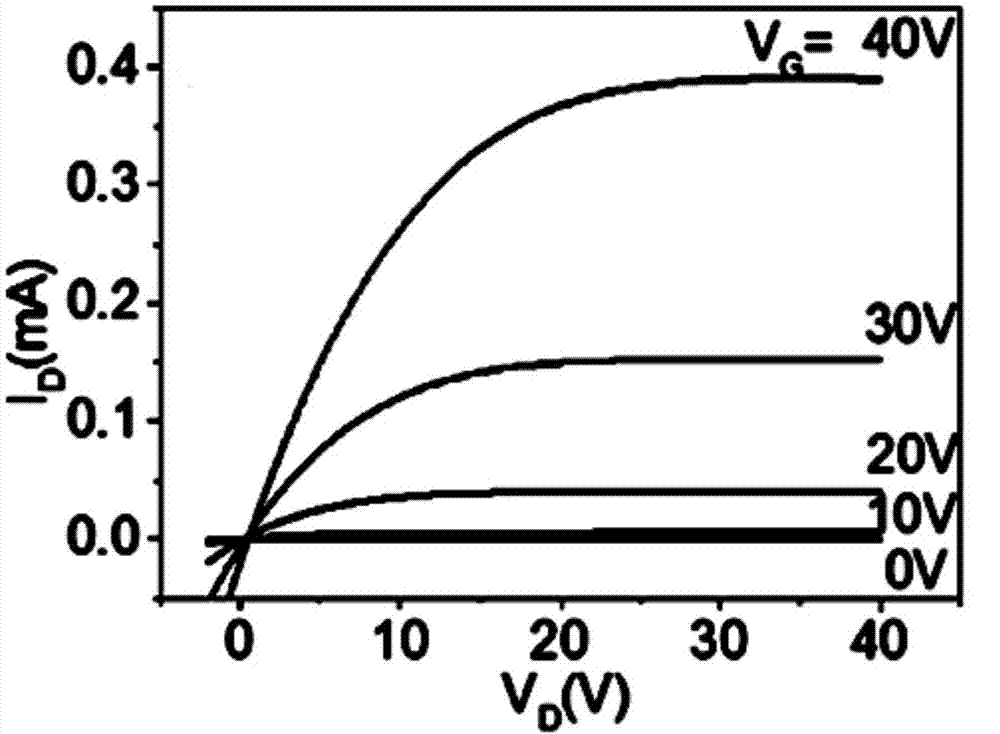

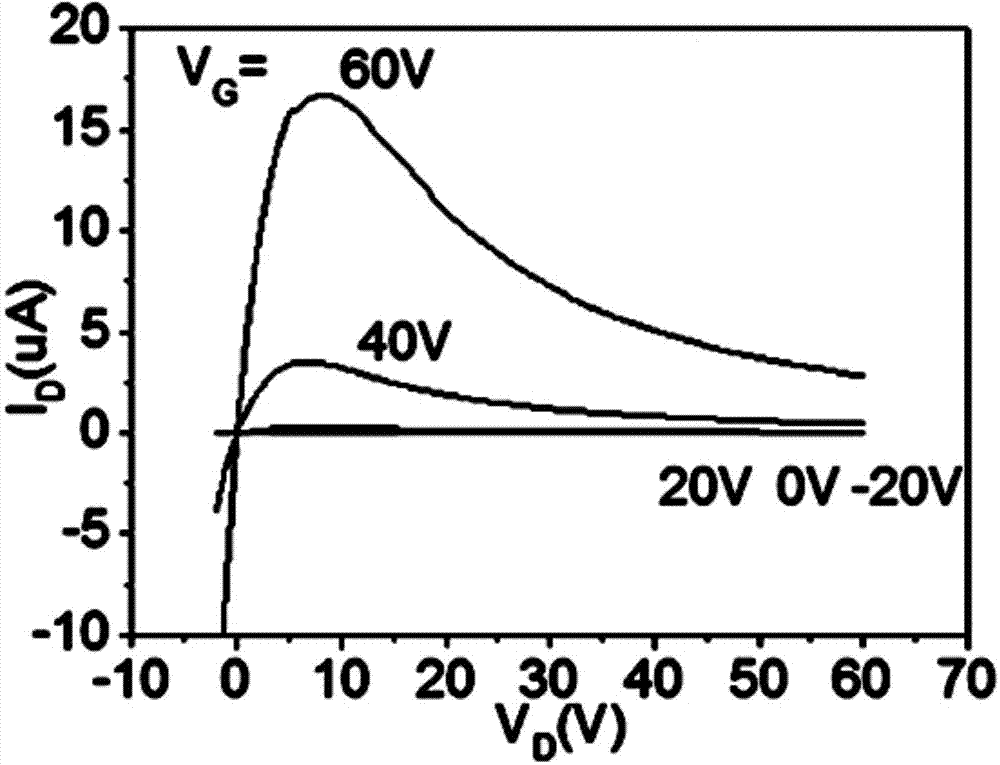

Method for improving thin-film semiconductor transistor electrical property

InactiveCN104716024AImprove performanceReduce negative impactSemiconductor/solid-state device manufacturingCharge carrierTransistor

The invention relates to a method for improving thin-film semiconductor transistor electrical property, in particular to that the surface of a thin-film semiconductor transistor is covered with an organic layer or an inorganic layer. Due to the fact that the surface of the thin-film semiconductor transistor is covered with the organic layer or the inorganic layer, on the one hand that the thin-film semiconductor transistor is separated from external air to a large extent, and the negative effects on the thin-film semiconductor transistor electrical property from substances such as H2O, O2, (OH)- and the like are greatly reduced; on the other hand that the defect mode of the surface of the thin-film semiconductor transistor is reduced to a large extent, since the surface defect mode can constrain the conveying of charge carriers in a device to lead to the deterioration of the thin-film semiconductor transistor property, the thin-film semiconductor transistor property can be greatly improved by covering the thin-film semiconductor transistor with the organic layer or the inorganic layer.

Owner:SHANDONG UNIV

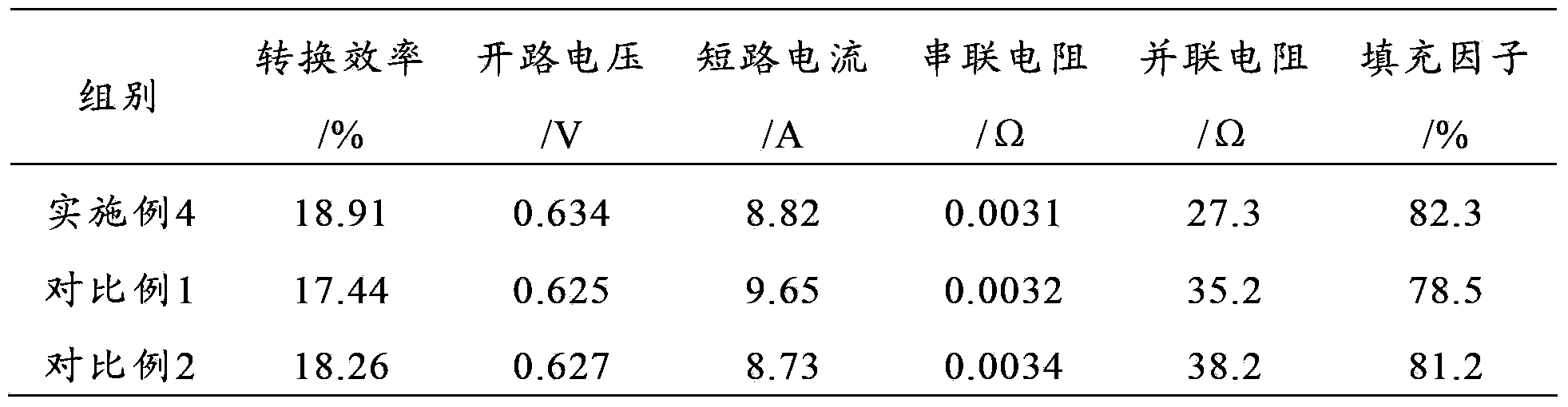

Monocrystalline silicon solar cell and production method thereof

ActiveCN108281512AImprove fill factorImprove photoelectric conversion efficiencyFinal product manufacturePhotovoltaic energy generationInterface layerN type silicon

The invention relates to a monocrystalline silicon solar cell and a production method thereof. The production method includes: forming a texturizing layer on the upper surface of a P-type monocrystalline silicon wafer; forming an N-type silicon layer on the upper surface of the P-type monocrystalline silicon wafer; depositing a silicon nitride passivation layer on the N-type silicon layer, and etching the silicon nitride passivation layer to forming an opening in an area for forming an upper electrode so as to expose the N-type silicon layer; coating the upper surface of the P-type monocrystalline silicon wafer with a solution containing acetyl alkoxy aluminum diisopropoxide in a spin manner, and annealing; sequentially coating the lower surface of the P-type monocrystalline silicon waferwith a solution containing a tungsten sulfide two-dimensional nano material and a solution containing a titanium sulfide two-dimensional nano material in a spin manner, and annealing to form a composite interface layer; forming the upper electrode on the upper surface of the P-type monocrystalline silicon wafer, and forming a lower electrode on the lower surface of the P-type monocrystalline silicon wafer. The monocrystalline silicon solar cell produced by the method is excellent in photoelectric conversion efficiency.

Owner:宁波欧达光电有限公司

Preparation method of quantum dots

PendingCN111019656ALow freezing pointHigh fluorescence intensityNanoopticsLuminescent compositionsPhosphineMaterials science

The invention provides a preparation method of quantum dots. The preparation method comprises the following steps: providing an initial quantum dot core, and mixing the initial quantum dot core and anorganic carboxylic acid to combine the organic carboxylic acid to the surface of the initial quantum dot core; preparing a shell layer on the surface of the initial quantum dot core, wherein the stepfor preparing the shell layer on the surface of the initial quantum dot core is carried out in a shell layer growth reaction system containing an organic carboxylic acid; mixing the solution system after the shell growth reaction and an organic amine, and complexing the organic amine and the residual cationic precursor shell; or mixing the system after the shell growth reaction and organic phosphine, and heating; or mixing the solution system after the shell growth reaction and a mixed solution of an organic amine and organic phosphine, and heating.

Owner:TCL CORPORATION

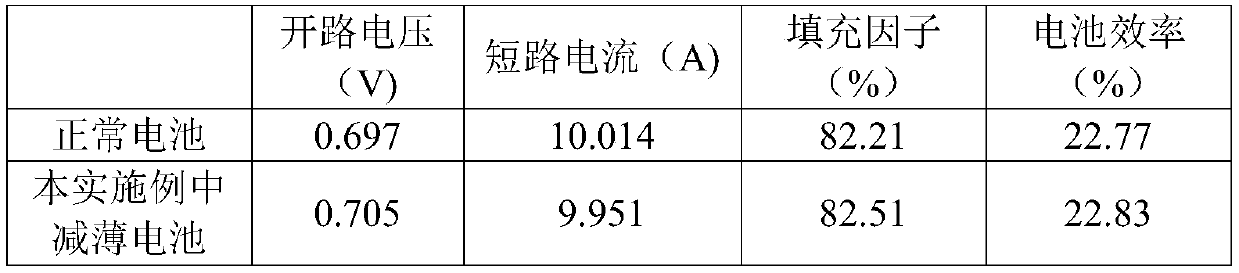

High-efficiency passivated contact crystalline silicon solar cell and preparation method thereof

InactiveCN110190155AReduce defect statesIncrease the open circuit voltageFinal product manufacturePhotovoltaic energy generationFill factorSilicon oxide

The invention discloses a high-efficiency passivated contact crystalline silicon solar cell and a preparation method thereof. The method comprises the following steps of preprocessing and thinning a silicon wafer: conventionally cleaning the silicon wafer and then thinning the silicon wafer by using a TMAH alkali solution having a concentration of 10-30%; texturing: conventionally texturing the silicon wafer; diffusion: performing conventional boron diffusion on the silicon wafer; removing a borosilicate glass layer on the back side of the silicon wafer; texturing the back side of the siliconwafer and then depositing a silicon oxide layer on the back side of the silicon wafer; depositing a polycrystalline silicon film on the silicon oxide layer on the back side of the silicon wafer; cleaning the silicon wafer with HF, then depositing an aluminum oxide film and a silicon nitride film on the front side of the silicon wafer, and depositing a silicon nitride film on the back side of the silicon wafer; and silk printing a front side electrode and a back side electrode. In order to fundamentally solve the low fill factor due to high volume resistivity, the method directly thins the silicon wafer by alkali solution corrosion in large-scale production, thereby significantly increasing the fill factor of the battery and thus improving photoelectric conversion efficiency.

Owner:TRINA SOLAR CO LTD

Crystal silicon and silicon germanide film compound unijunction PIN solar battery with transition layer, and preparation method thereof

ActiveCN104505418AReduce defect statesImprove passivation effectFinal product manufacturePhotovoltaic energy generationGermanideOxygen

The invention provides a crystal silicon and silicon germanide film compound unijunction PIN solar battery with a transition layer, and a preparation method thereof. According to the solar battery, the front surface of an n-type silicon wafer or the back surface of the n-type silicon wafer or both the front surface and the back surface of the n-type silicon wafer are simultaneously provided with the transition layer, the transition layer has one layer or multiple layers, and one layer of the transition layer is a silicon-enriched oxygen ambient silica layer. The preparation method involves adding a pre-hydrogenation drying processing after the silicon wafer is textured, polished and cleaned and at the same time, adding a post-hydrogenation processing mode after the process of the transition layer is finished. The two methods are used for improving the interface quality and the structure stability. By using the transition layer and using the crystal silicon and silicon germanide film compound battery which is subjected to the pre-hydrogenation drying processing and post-hydrogenation processing and is provided with the transition layer, the battery conversion efficiency can be improved by more than 10% on the basis of the prior arts.

Owner:湖南共创光伏科技有限公司

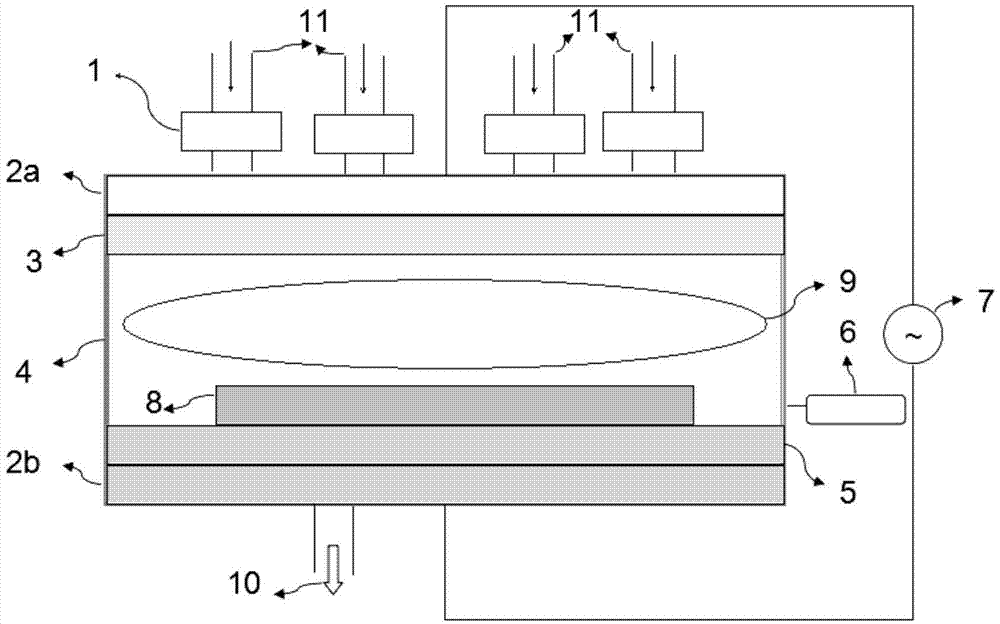

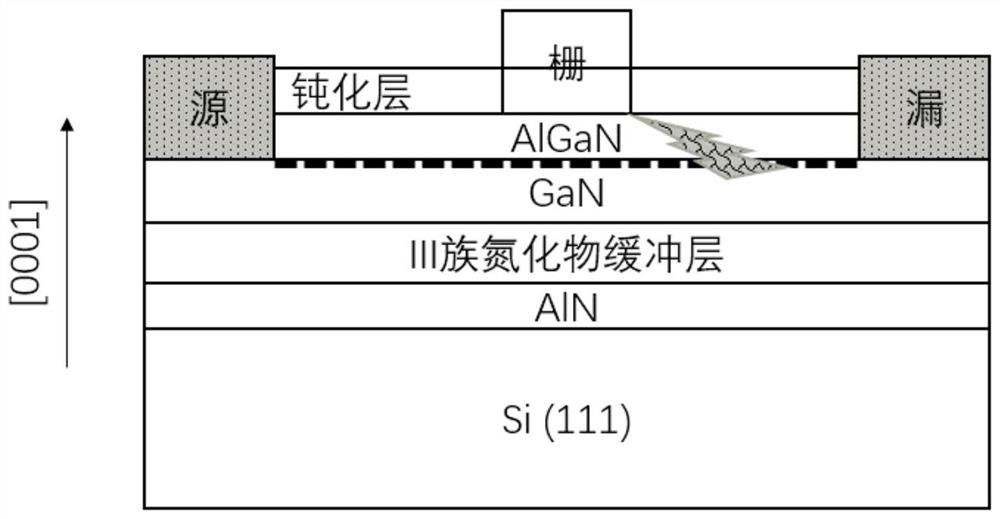

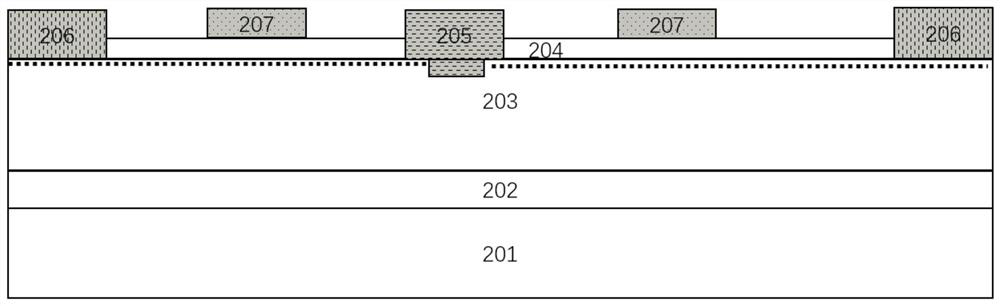

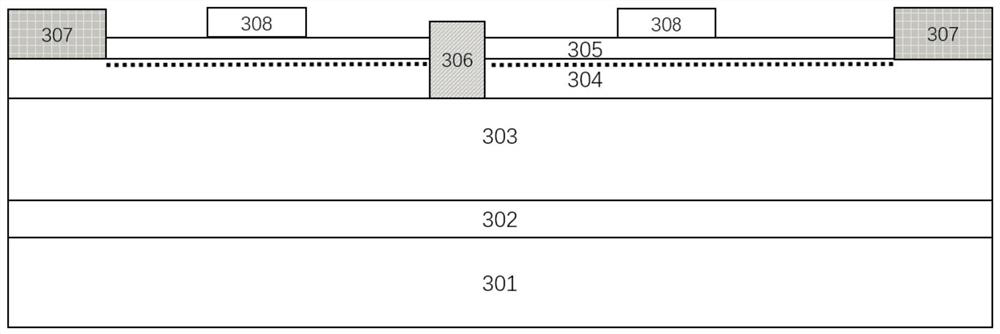

A high electron mobility transistor having high withstand voltage capability

PendingCN112447836AAvoid uneven distributionImprove pressure resistanceTransistorSemiconductor/solid-state device manufacturingPhysical chemistryEngineering

The invention relates to a semiconductor power device, in particular to a high-voltage-withstanding high-electron-mobility transistor (HEMT). The high-voltage-withstanding high-electron-mobility transistor comprises a gate electrode, a source electrode, a drain electrode, a barrier layer, a P-type nitride semiconductor layer and a substrate, the P-type nitride semiconductor layer is located between the barrier layer and the substrate, which is insufficient to significantly deplete the two-dimensional electron gas in the channel other than the gate stack, and the source electrode is in electrical contact with the P-type nitride semiconductor layer, and both the source electrode and the drain electrode are in electrical contact with the two-dimensional electron gas.

Owner:GUANGDONG ZHINENG TECH CO LTD

Crystalline silicon and silicon film composite type unijunction PIN solar cell with transition layers and preparation method for crystalline silicon and silicon film composite type unijunction PIN solar cell

ActiveCN104576801AReduce defect statesImprove passivation effectFinal product manufacturePhotovoltaic energy generationSilicon oxideCrystalline silicon

The invention provides a crystalline silicon and silicon film composite type unijunction PIN solar cell with transition layers and a preparation method for the crystalline silicon and silicon film composite type unijunction PIN solar cell. The solar cell is provided with one or more transition layers on the front surface of an n-type silicon wafer, the back surface of the n-type silicon wafer or both the front surface and the back surface of the n-type silicon wafer, and any transmission layer is a silicon-rich silicon oxide layer. The preparation method for the crystalline silicon and silicon film composite type unijunction PIN solar cell comprises the following steps: after finishing texturing, polishing and cleaning of the silicon wafer, adding a pre-hydrogenation drying process, and after finishing a process of the transition layers, adding a post-hydrogenation drying process; the two methods are used for improving the interface quality and the structure stability. The cell conversion efficiency of the crystalline silicon film composite cell adopting the transition layers and subjected to the pre-hydrogenation drying process and the post-hydrogenation drying process can be improved by more than 10% in comparison with that of an original cell.

Owner:湖南共创光伏科技有限公司

Solar cell and preparation method thereof

ActiveCN108336181AReduce defect statesSimple methodPhotovoltaic energy generationSemiconductor devicesElectrical batteryMaterials science

The invention provides a solar cell and a preparation method thereof. The preparation method of the solar cell comprises the steps of cleaning an n-type silicon substrate; preparing a silicon nanowirearray on an upper surface of the n-type silicon substrate; performing passivation on the n-type silicon substrate; preparing a cobalt sulfide nanowire / P3HT layer; preparing PEDOT:PSS; preparing a front-surface silver gate; and preparing a back-surface aluminum electrode. In the process of performing passivation on the n-type silicon substrate, a mixed solution containing sodium hydroxide and silicon propoxide is selected and spin-coated, annealing is performed, the defect state of a surface of the silicon substrate is effectively reduced, and the photoelectric conversion efficiency of the corresponding solar cell is improved.

Owner:南通鸿图健康科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com