Patents

Literature

42results about How to "Avoid overprocessing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

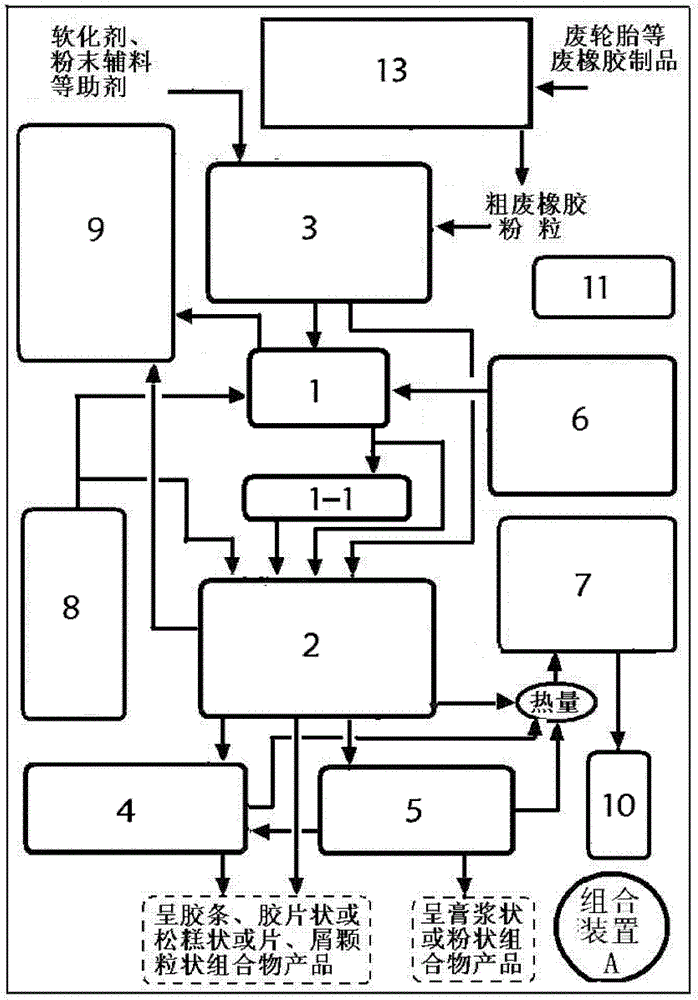

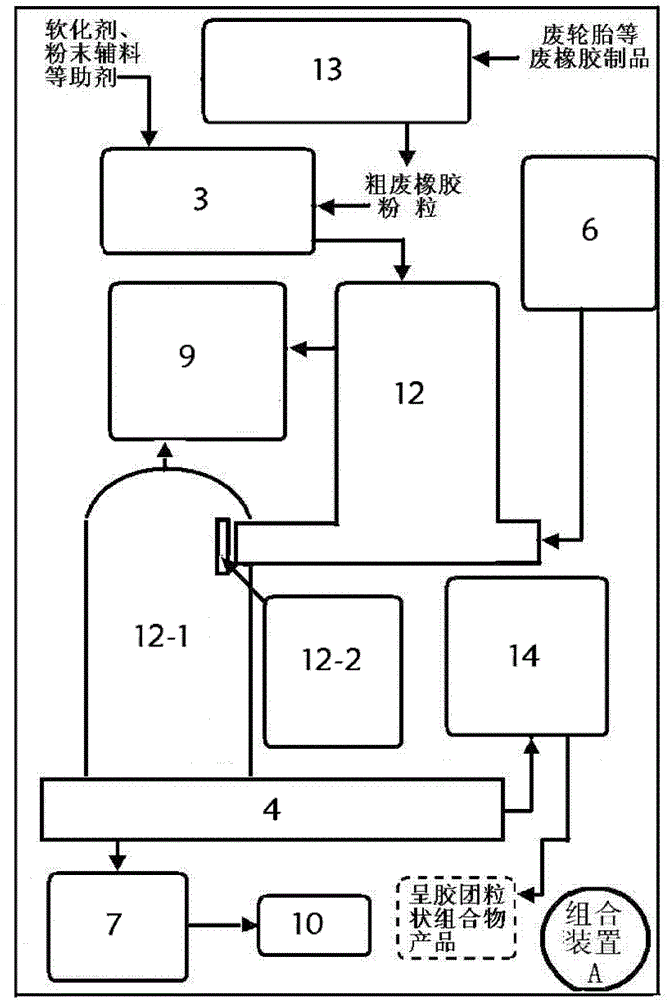

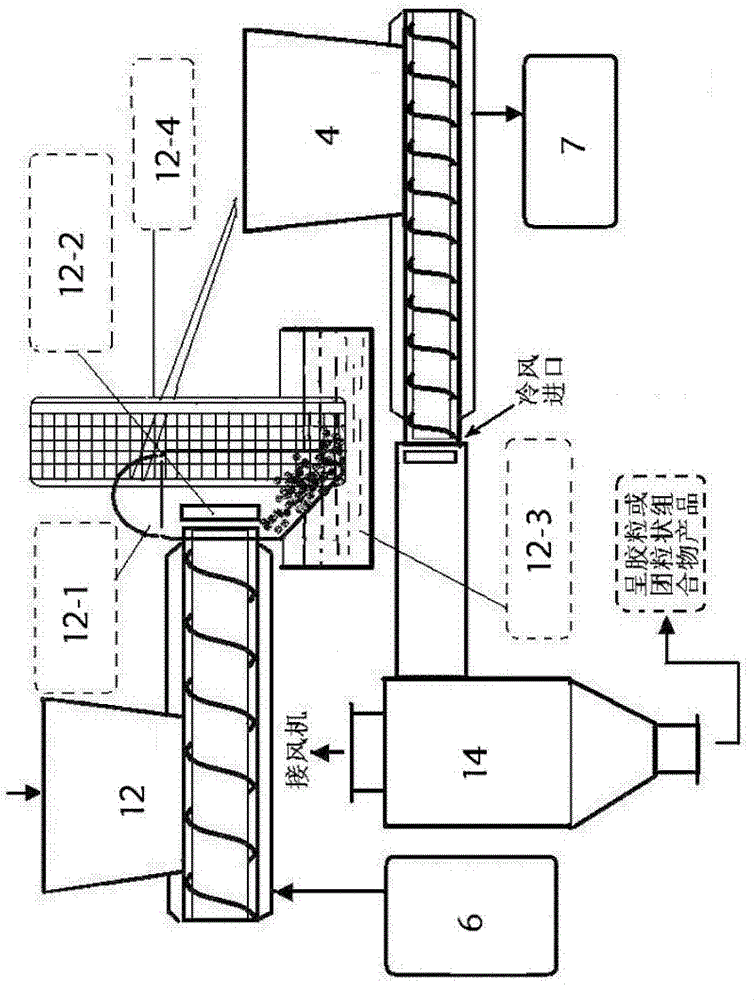

Heat regeneration method for waste rubber

InactiveCN102030934AMeet the environmental protection requirements of cleaner productionMeet environmental protection requirementsPlastic recyclingLiquid hydrocarbon mixture productionPolymer scienceWaste rubber

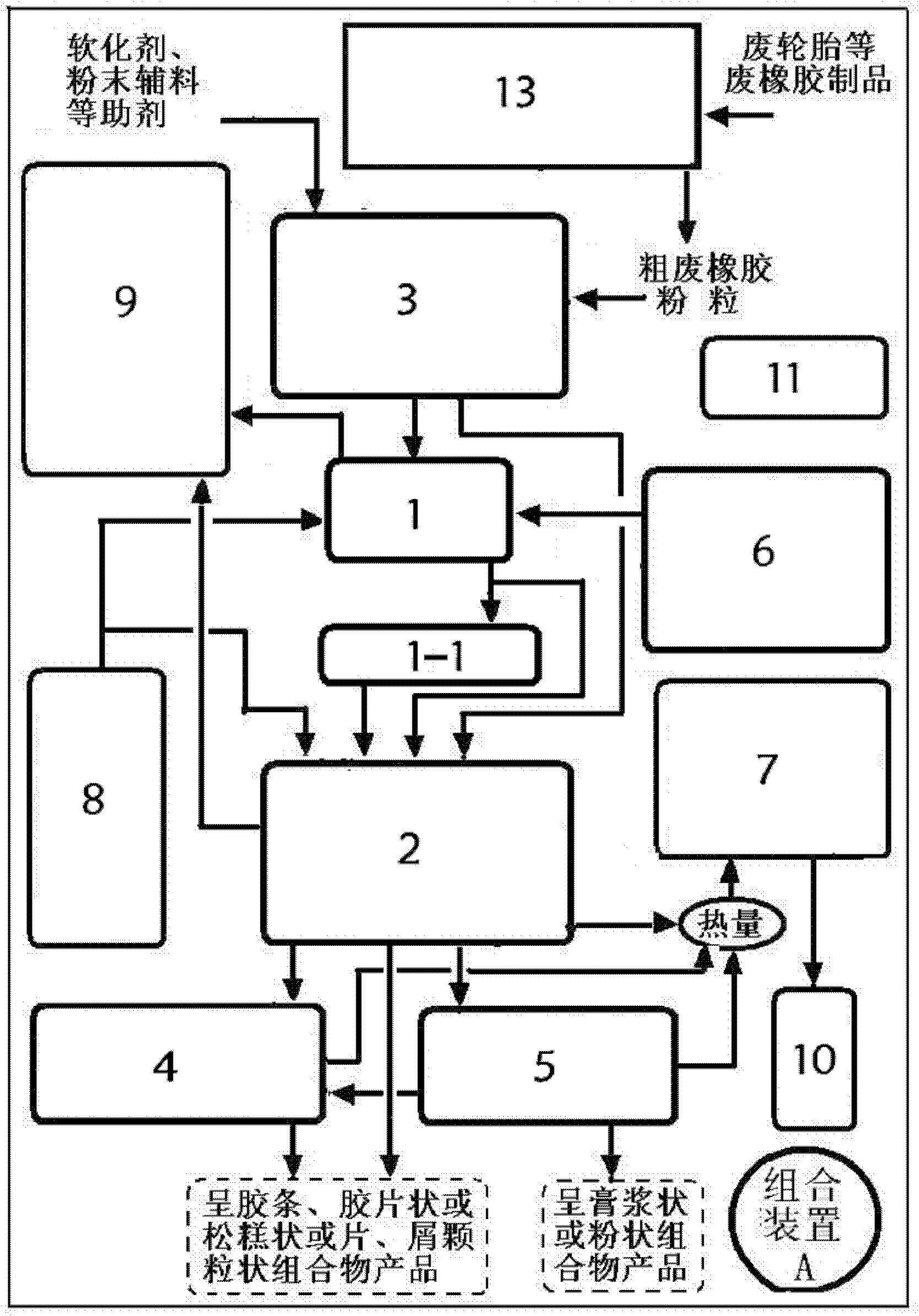

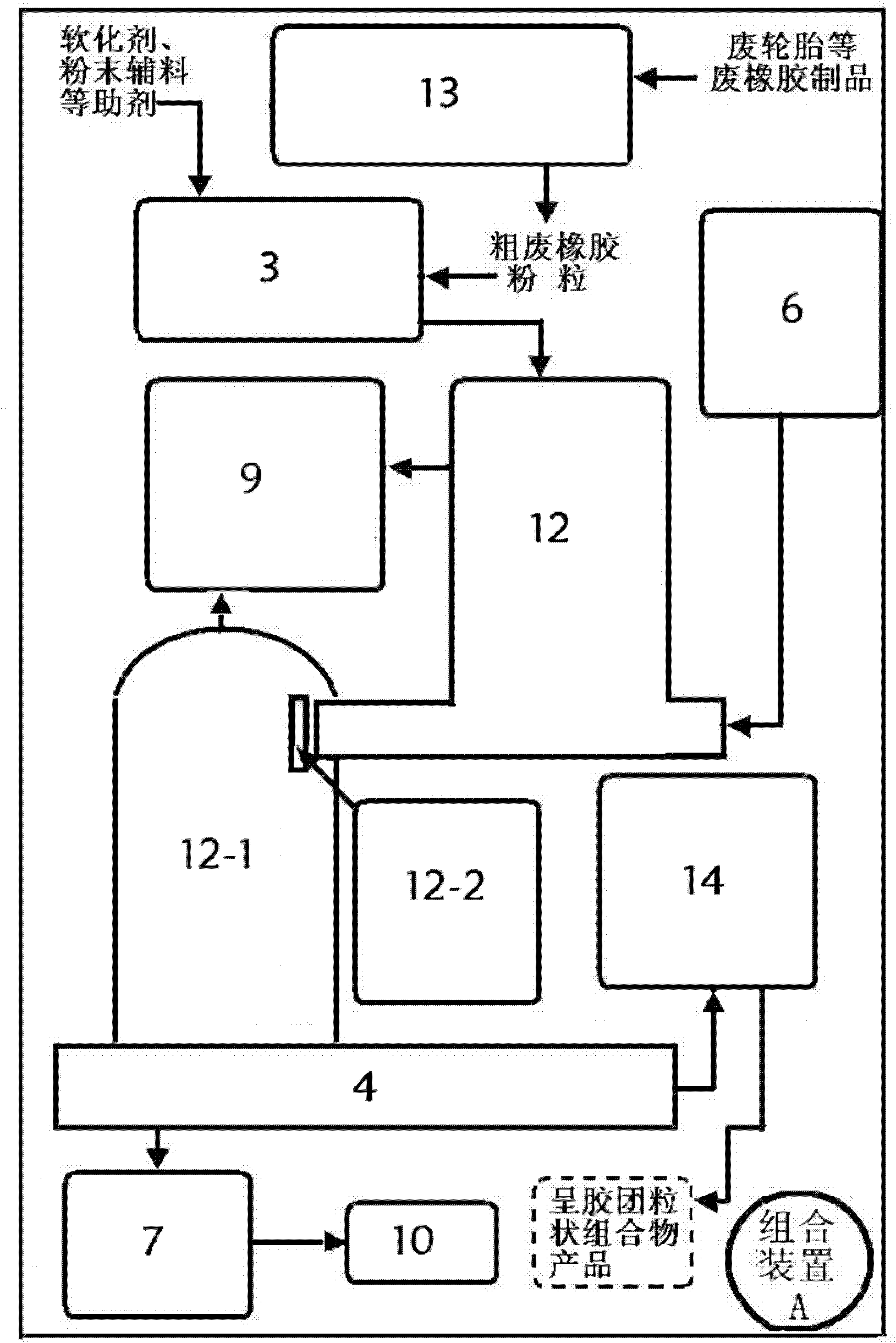

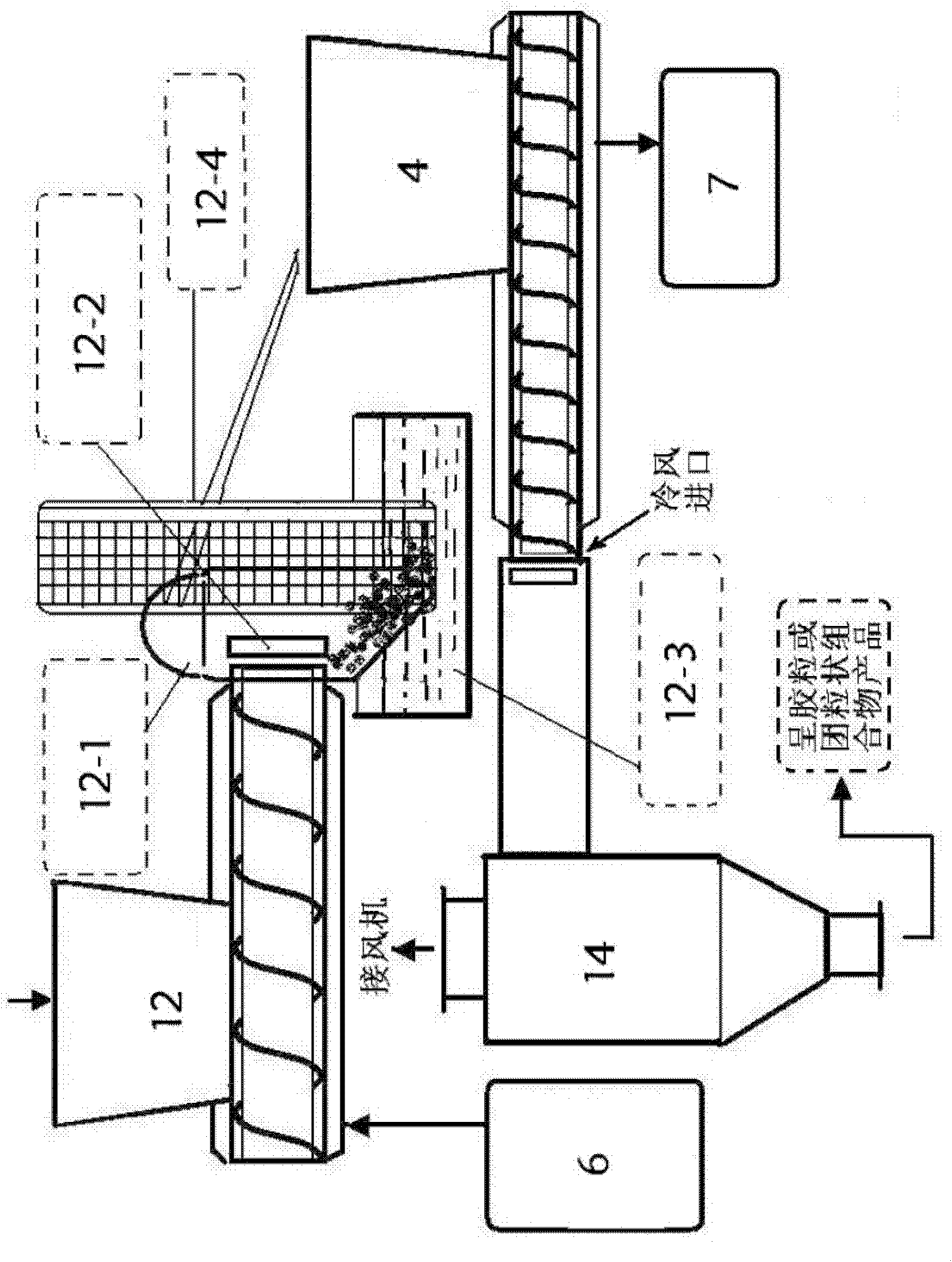

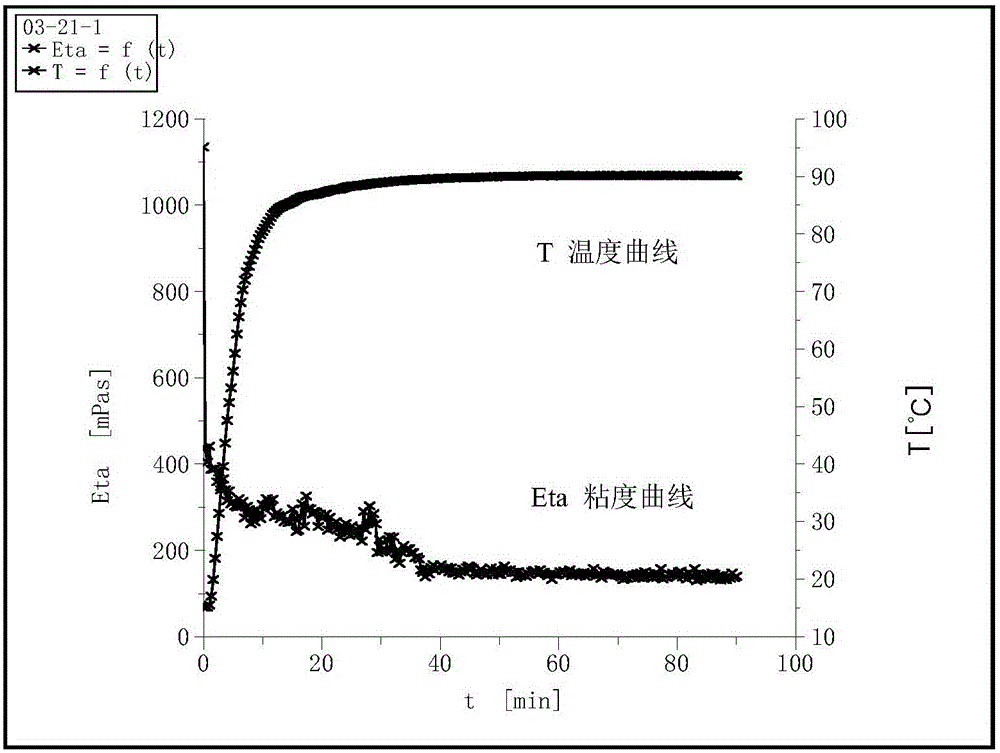

The invention provides a heat regeneration method for waste rubber. The method comprises the following steps of: feeding a waste rubber crude powder material / environmentally-friendly softening agent / powder auxiliary material in the weight ratio of 100 / 8-150 / 20-1,500 into a stirring heater, performing anoxybiotic heating, introducing into a stirring cooler and cooling to the temperature of less than 100 DEG C so as to obtain a product; or partially or completely extracting the powder auxiliary material in the fed materials for slow feeding, adding the extracted powder auxiliary material into the stirring heater before the materials which are put into the stirring heater at an early stage are discharged, or / and adding the extracted powder auxiliary material when a hot material is introduced into the stirring cooler, cooling the mixture to the temperature of less than 100 DEG C and discharging; or initially mixing the materials in a formula, guiding the mixture into a screw extruder, allowing the mixture to pass through a heating section and a mixing section, cooling the material to the temperature of less than 100 DEG C and discharging a product; or performing thermal cracking on all-known waste rubber through heat regeneration or establishing a multi-direction migration relation for a material or / and energy in the process of preparing carbon black from fuel oil and fuel gas.

Owner:陈汇宏 +1

Method for superfinishing of metal part with thin-wall large curved surface

ActiveCN103600284AHigh precisionIncrease productivityPolishing machinesGrinding feed controlNumerical controlSurface roughness

The invention discloses a method for superfinishing of a metal part with a thin-wall large curved surface. The method comprises the steps of numerical control processing, preliminary detection, primary polishing, primary detection, secondary polishing and secondary detection and the like. The part does not need to be clamped in the superfinishing process, and deformation caused by the clamping is avoided; and simultaneously due to the fact that the part is not subjected to cutter cutting, curved surface deformation caused by stress in the processing is avoided. Superfinishing is performed on the metal part with the thin-wall large curved surface through the processing steps of polishing and detection and the like, and the requirement of the surface profile within 0.015 and the requirement of surface roughness of below Ra0.2 are met.

Owner:HEBEI HUABEI DIESEL ENGINE

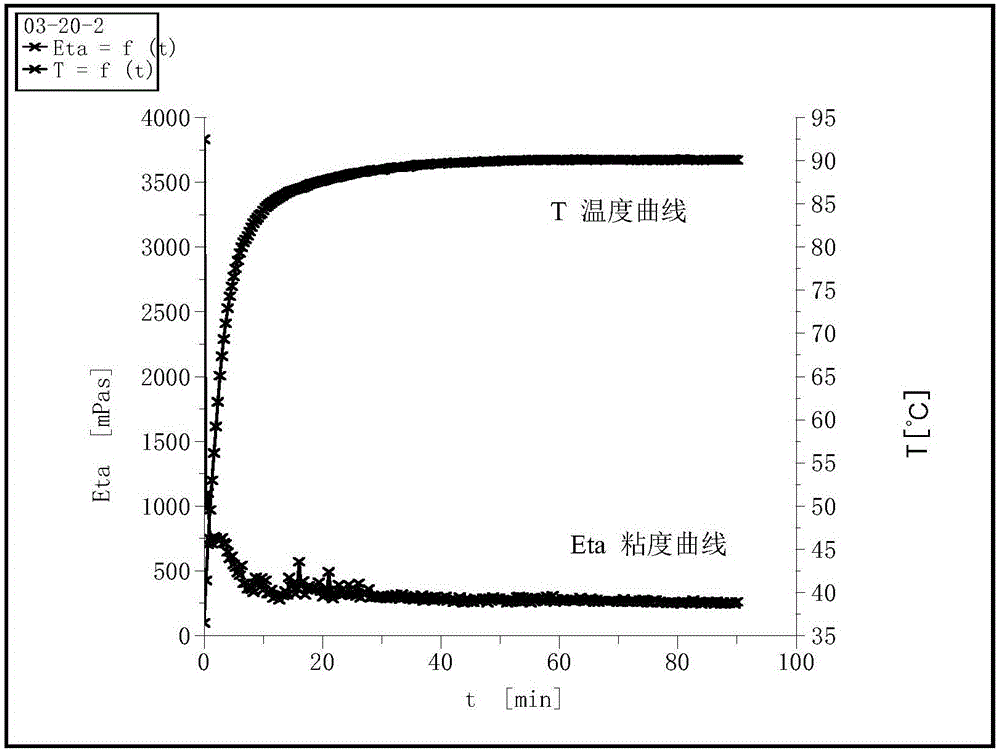

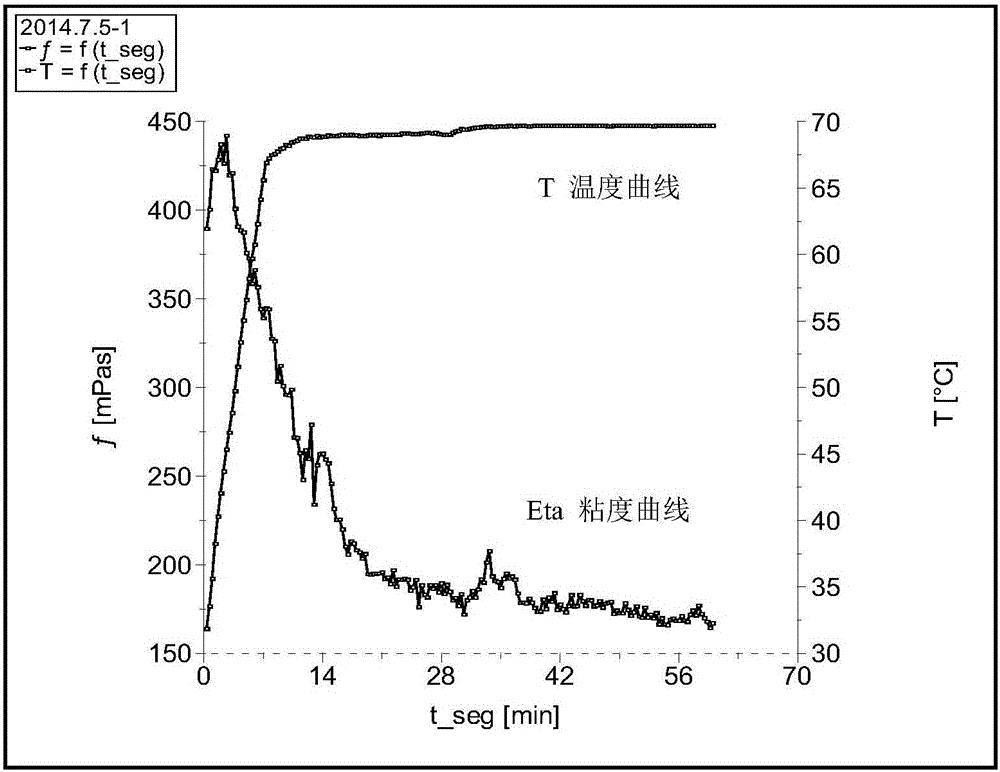

Gel fracturing fluid prepared from oilfield sewage and preparation method thereof

InactiveCN105038757AImprove temperature and shear resistanceGood Compatibility FeaturesDrilling compositionEconomic benefitsWater resources

The invention discloses a gel fracturing fluid prepared from oilfield sewage and a preparation method thereof. The gel fracturing fluid comprises the following components in percentage by weight: 0.01-1% of water quality regulator, 0.01-0.5% of bactericide, 0.1-0.8% of thickener, 0.1-0.5% of crosslinking agent, 0.01-0.5% of viscosity breaker and the balance of oilfield sewage. The gel fracturing fluid prepared from oilfield sewage has favorable temperature resistance and shear resistance, and satisfies the demands for on-site construction. The gel fracturing fluid prepared from oilfield sewage relieves the demands of hydraulic fracturing for water resources, and solves the problem of treatment of oilfield sewage. The gel fracturing fluid prepared from oilfield sewage has the advantages of favorable clay swelling resistance and low formation damage rate, thereby reducing the use of the antiswelling agent and saving the cost. The gel fracturing fluid prepared from oilfield sewage has wide formation application range, avoids damage to the formations which are sensitive to alkali, acid and the like, has favorable economic benefit and environmental benefit, and is suitable for popularization and application.

Owner:CHINA PETROLEUM & CHEM CORP +1

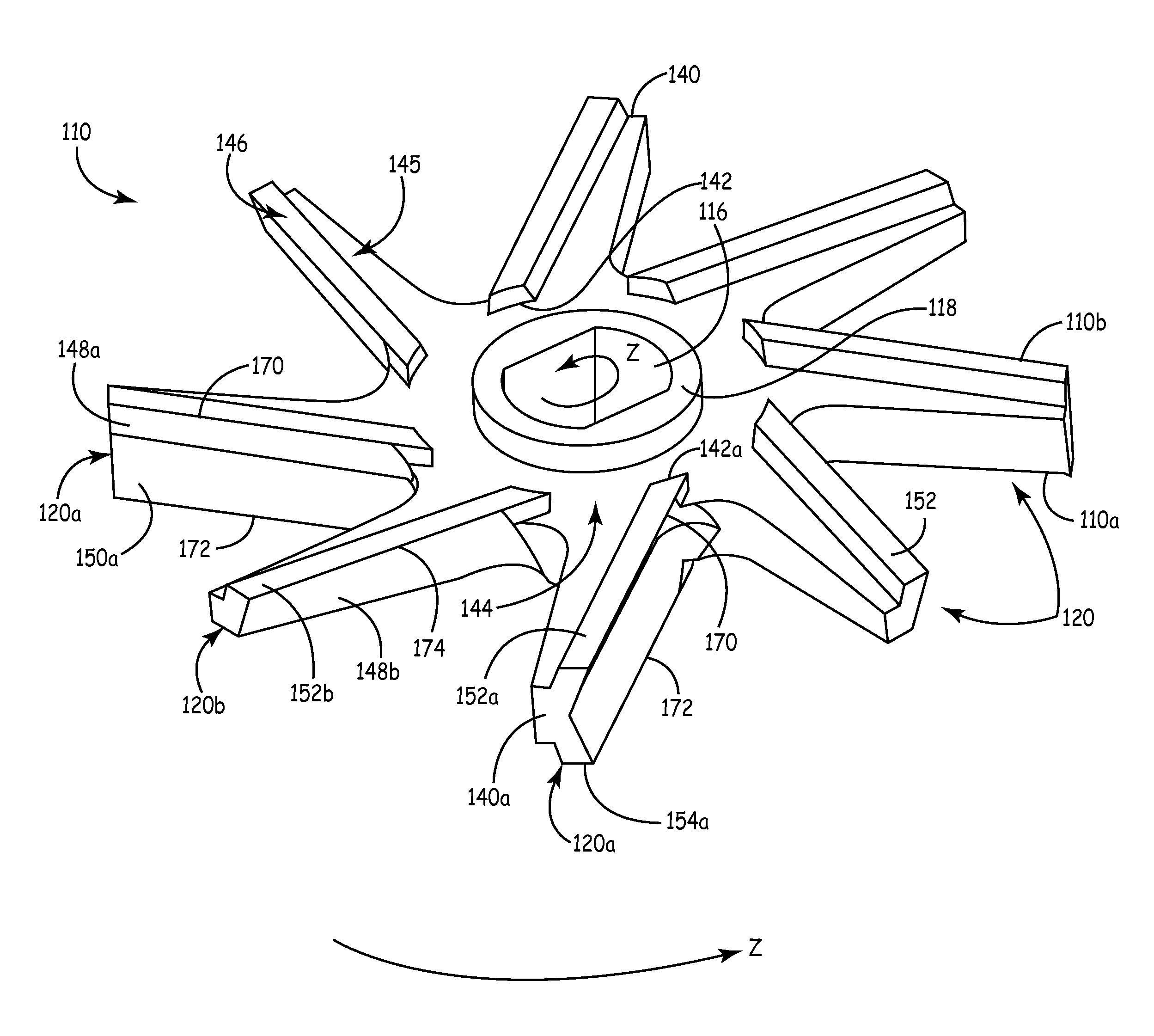

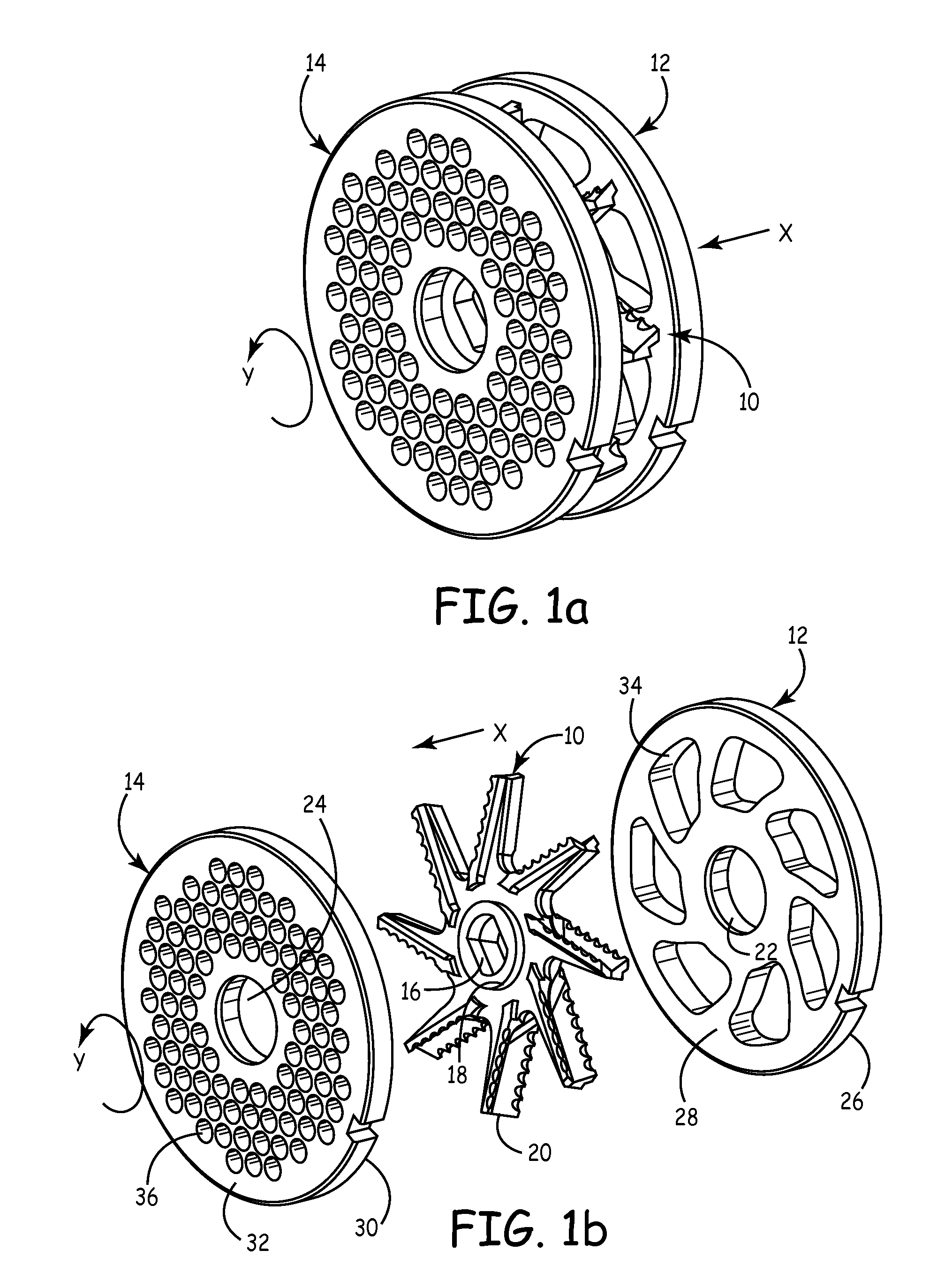

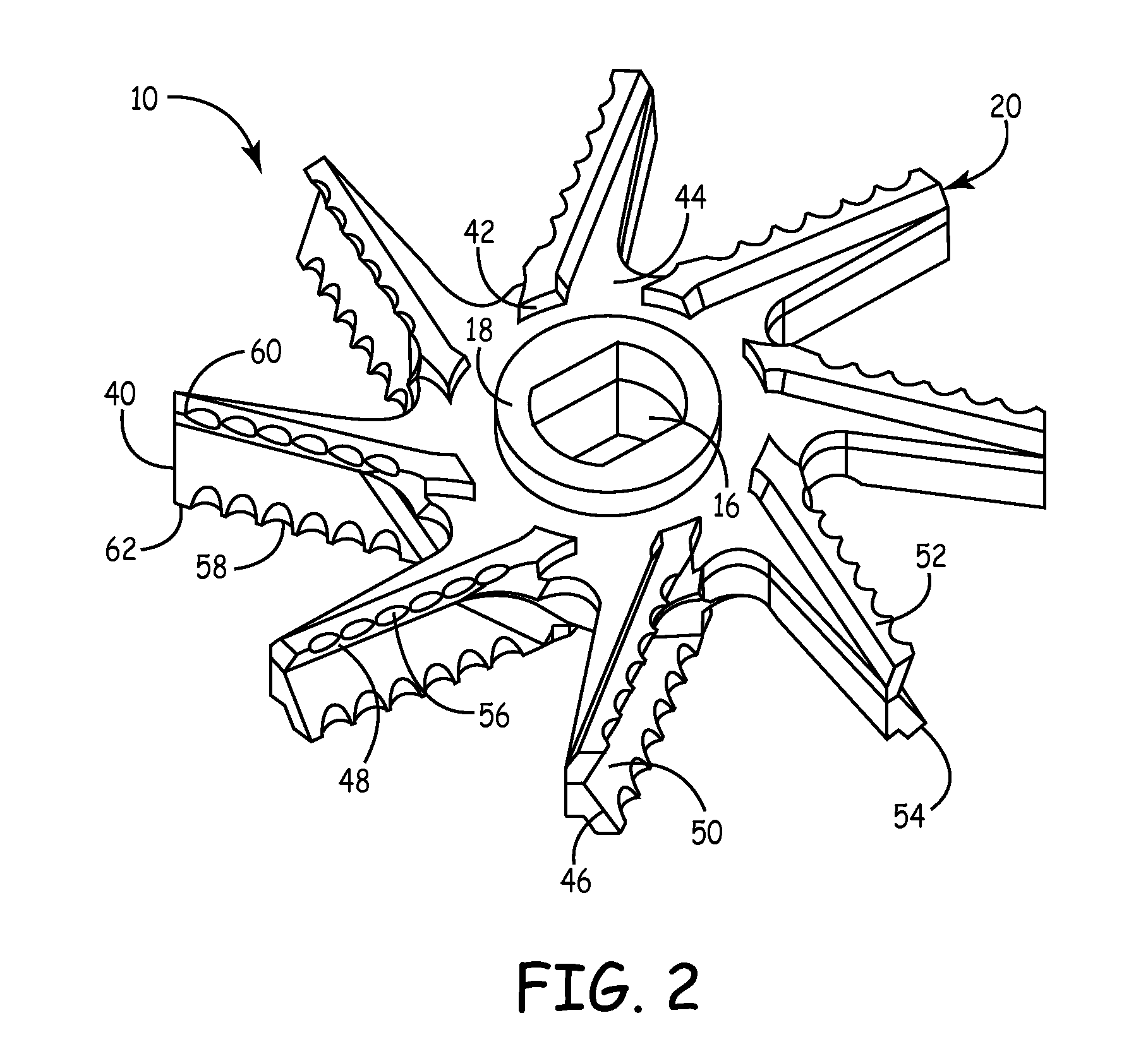

Rotary knife

InactiveUS20100282887A1Avoid overprocessingReduce frictionKitchen equipmentGrain treatmentsRotational axisRotary engine

There is described a rotary knife for use in a cutting apparatus. The rotary knife comprises a central hub, first and second sides of the knife, a plurality of arms, and a plurality of blades. The central hub defines an axis of rotation of the knife. The first and second sides of the knife are spaced apart in the axial direction. The plurality of arms extend outwardly from the hub. The plurality of blades are carried by the arms such that a number of blades disposed on the second side of the knife is greater than a number of blades disposed on the first side of the knife. There is also described a cutting apparatus comprising a rotary knife as described above.

Owner:COMBICUT

Method for preparing ternary ethylene propylene vulcanized rubber powder master batches, products and application

The invention discloses a method for preparing ternary ethylene propylene vulcanized rubber powder master batches, products and application. The preparation method comprises the following steps of: mixing 40 to 100-mesh rubber powder of waste ternary ethylene propylene rubber and a large amount of softening agent or a softening agent and a vulcanization system material at normal temperature, and standing the mixture for one day and one night under common room temperature condition to obtain the ternary ethylene propylene vulcanized rubber powder master batch 1; or adding the ternary ethylene propylene vulcanized rubber powder master batch 1 into common ternary ethylene propylene mixing glue to obtain the ternary ethylene propylene vulcanized rubber powder master batch 2; or adding the ternary ethylene propylene vulcanized rubber powder master batch 1 into common conductive or antistatic ternary ethylene propylene mixing glue to obtain the conductive or antistatic ternary ethylene propylene vulcanized rubber powder master batch 3. The ternary ethylene propylene vulcanized rubber powder master batches 1, 2 and 3 can be used as independent products. The products are applied to any rubber product of a rubber plate, a coiled material, a sealing element, a shock absorption piece and a rubber roller of any one or a combined system rubber material of ternary ethylene propylene rubber and butyl rubber, wherein the tensile strength of the rubber product is 1.8 to 18MPa.

Owner:上海西郊橡胶制品厂

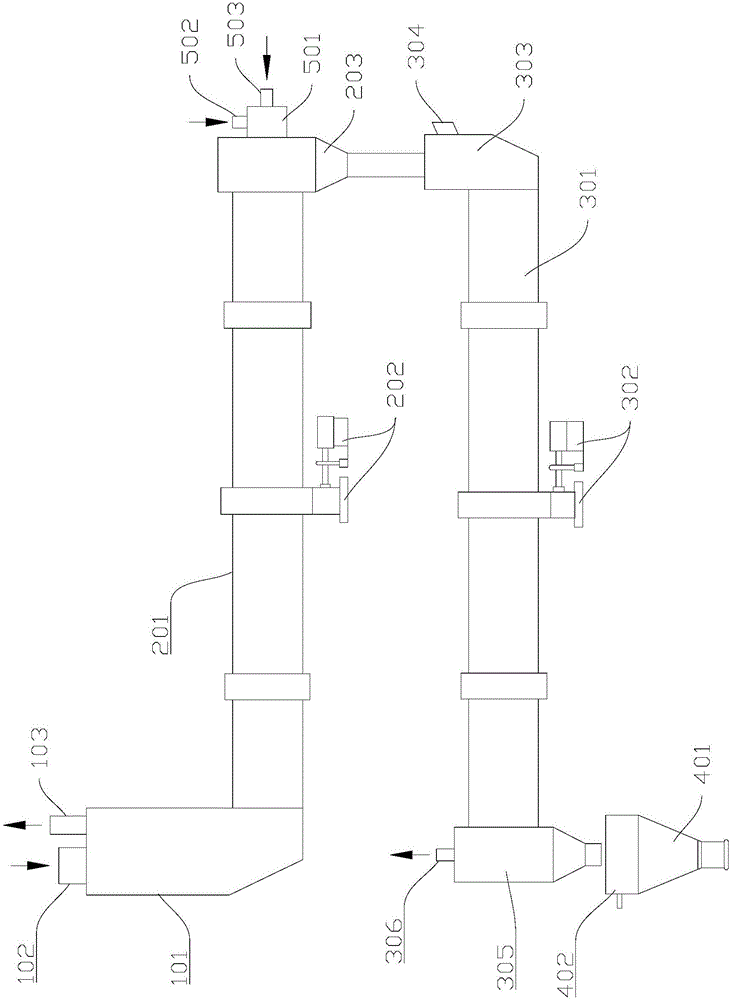

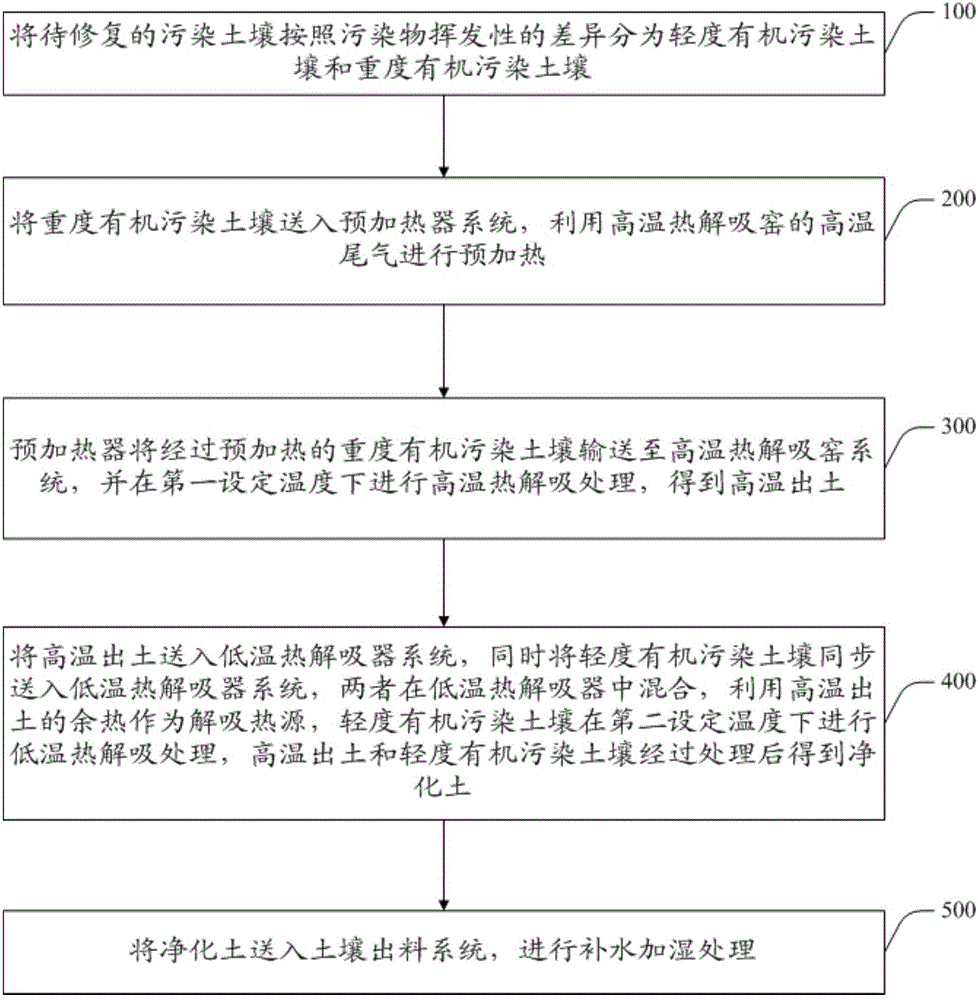

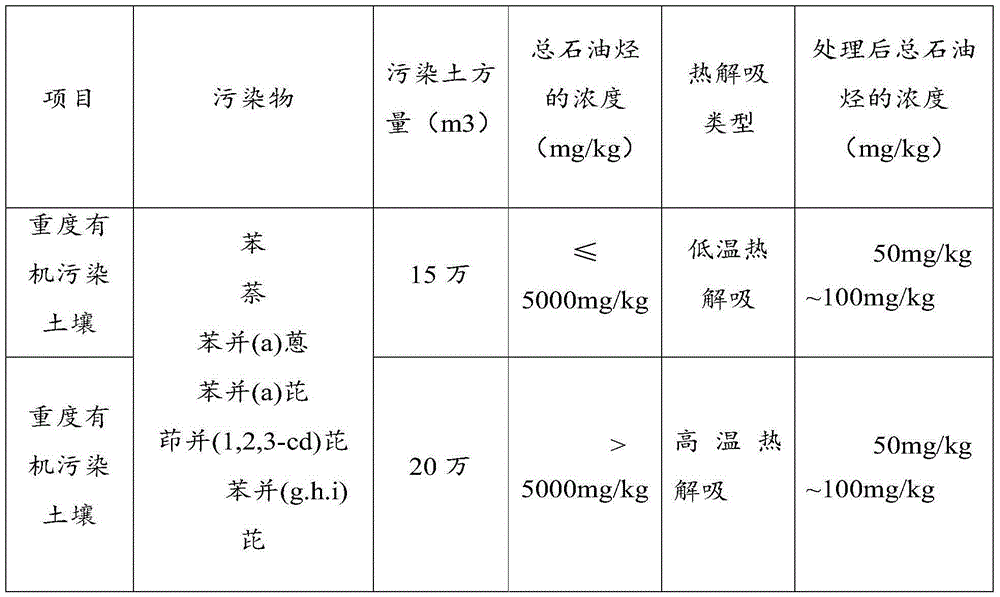

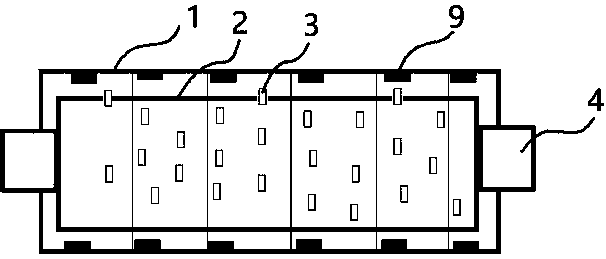

Classified thermal desorption repair system and technology of organic contaminated soil

ActiveCN105080958ARealize fine processingEfficient repairContaminated soil reclamationThermal energySoil remediation

The invention relates to the technical field of contaminated soil remediation, particularly to a classified thermal desorption repair system and technology of organic contaminated soil. The classified thermal desorption repair system of organic contaminated soil comprises a preheater system, a high-temperature thermal desorption kiln system, a low-temperature thermal desorption device system and a soil discharging system, wherein the preheater system, the high-temperature thermal desorption kiln system, the low-temperature thermal desorption device system and the soil discharging system are communicated in sequence. According to the classified thermal desorption repair system and technology of organic contaminated soil, the high-temperature tail gas generated by the high-temperature thermal desorption kiln system is fully used through arranging the preheater system, so that the use ratio of thermal energy is improved; organic contaminated soil with different degrees of contamination is treated through the high-temperature thermal desorption kiln system and the low-temperature thermal desorption device system, so that the energy consumption of thermal desorption treatment is greatly decreased, and the operation cost is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

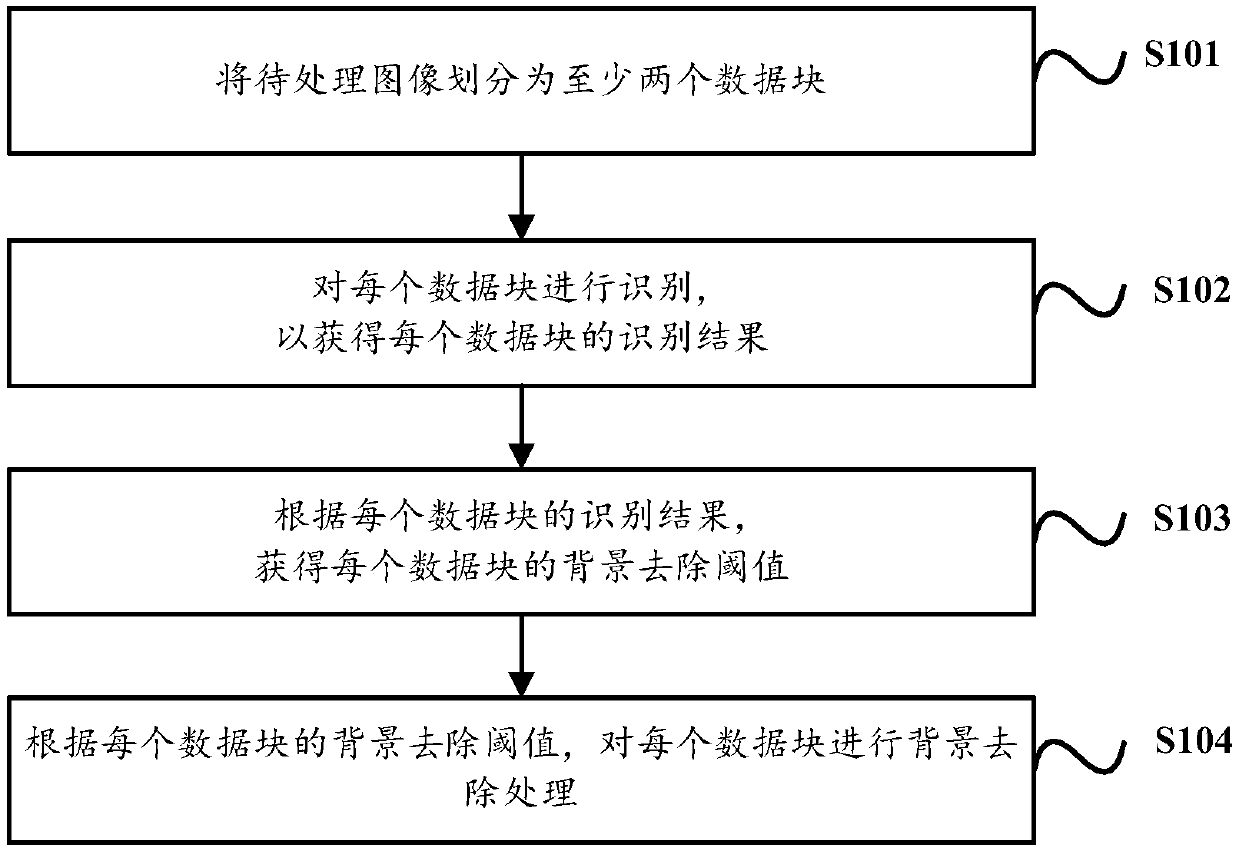

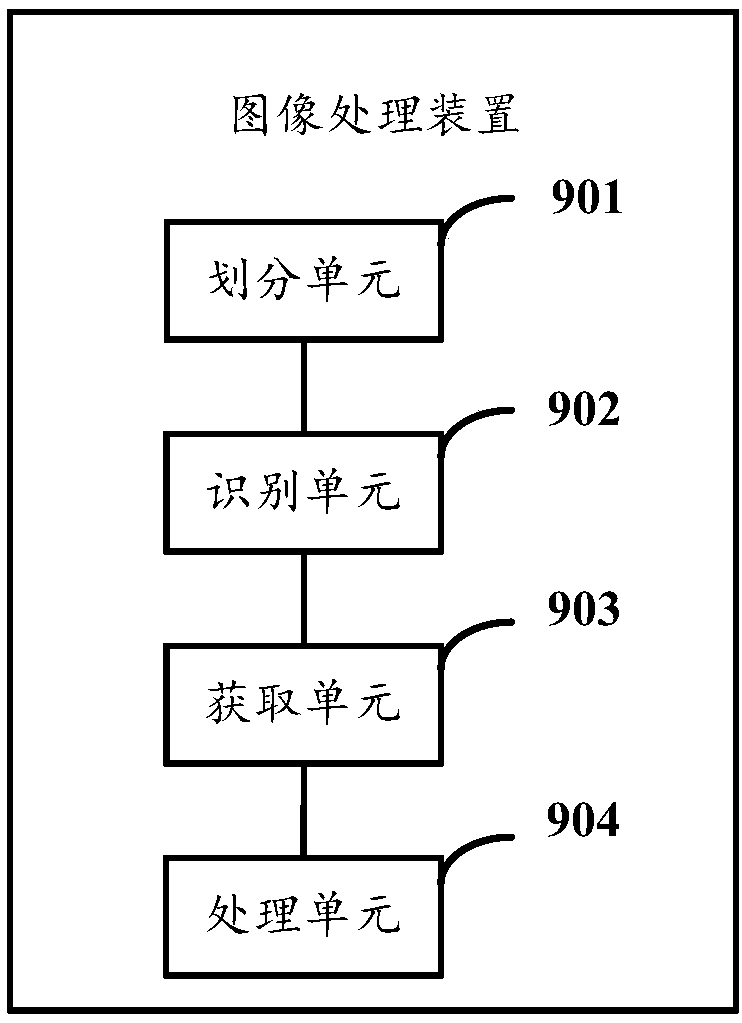

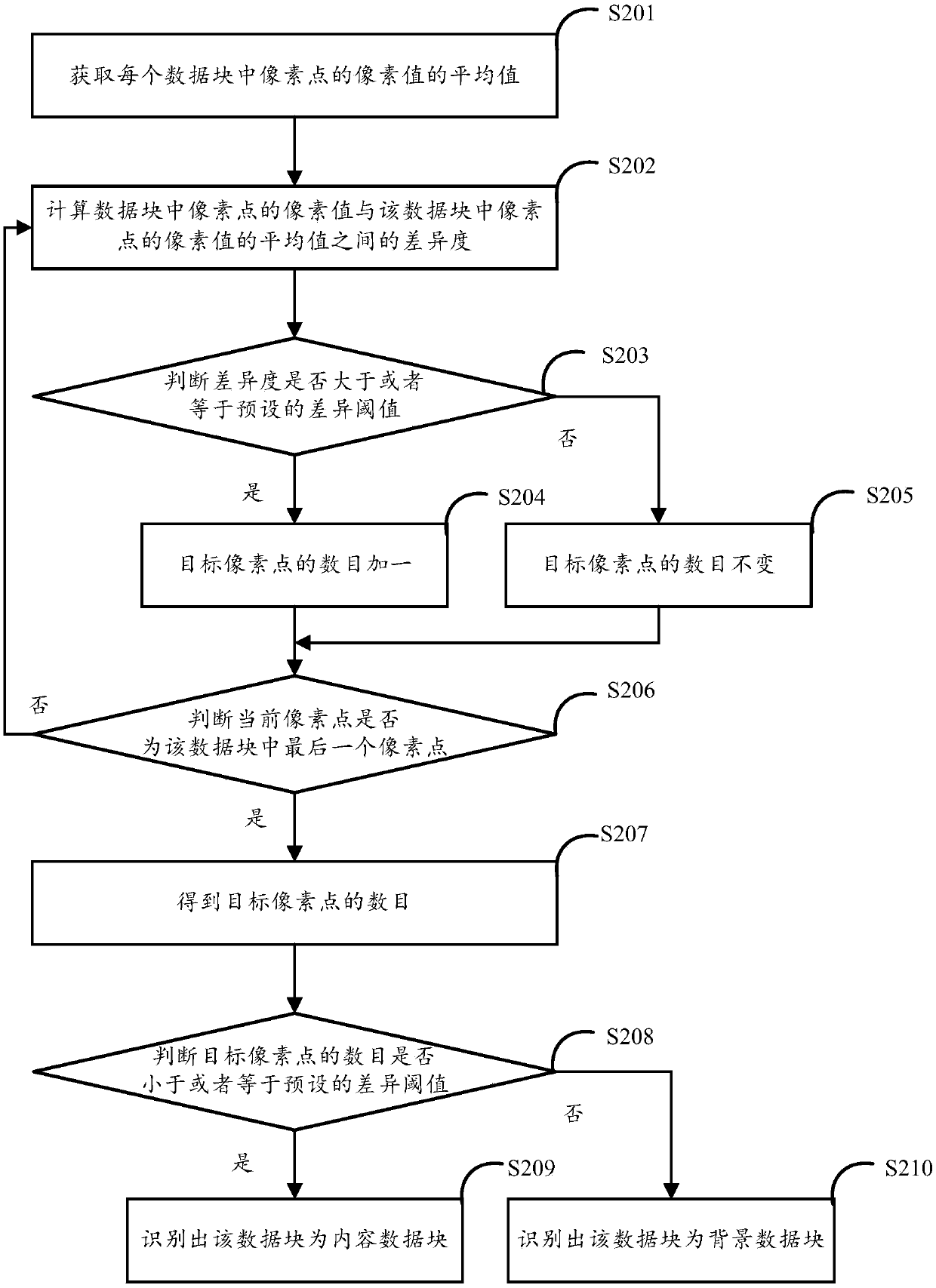

Image processing method and image processing device

ActiveCN106251358AImprove removal qualityImprove removal efficiencyImage enhancementImage analysisPattern recognitionImaging processing

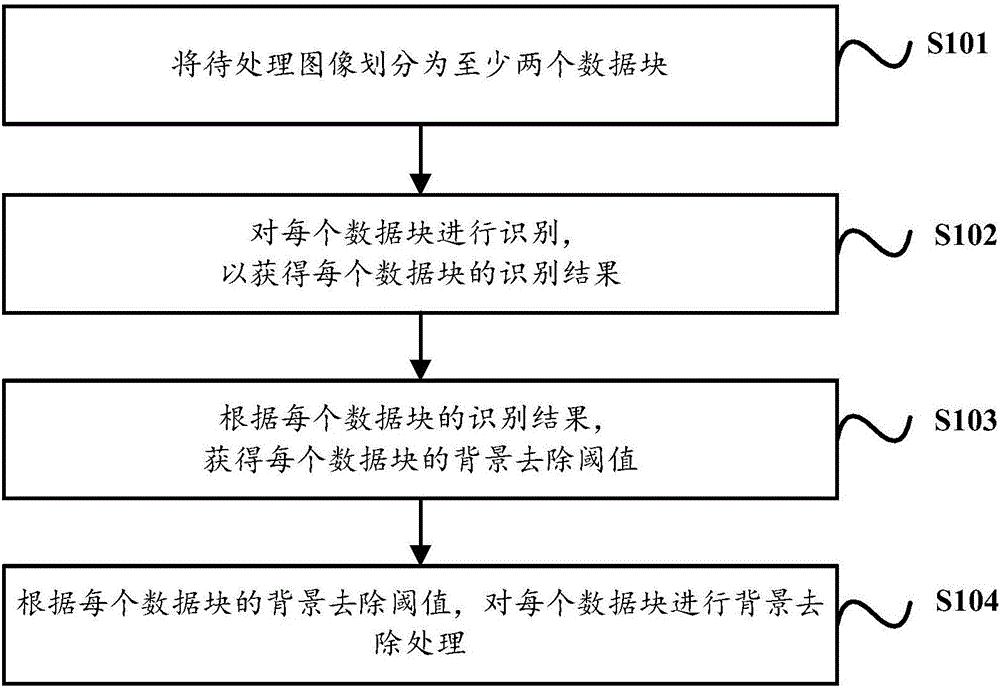

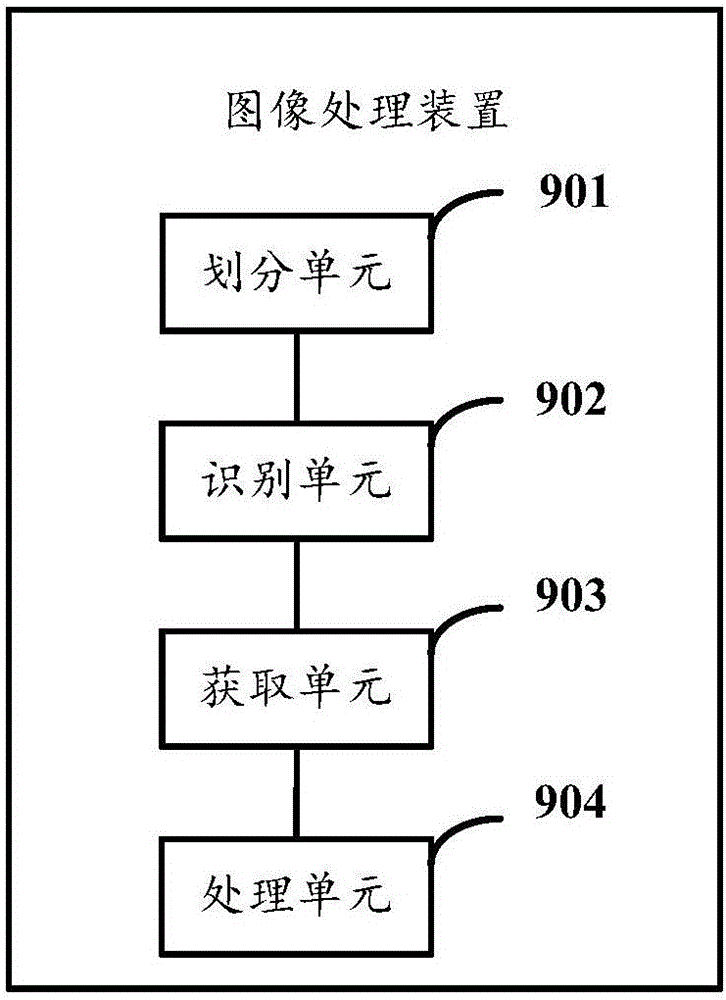

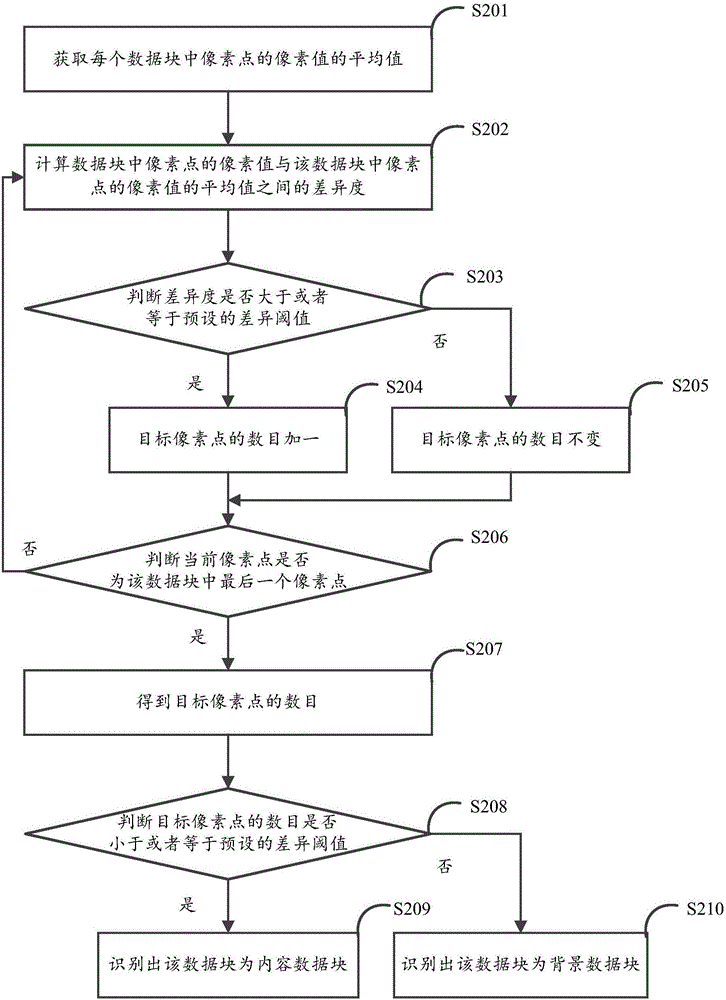

Embodiments of the invention provide an image processing method and an image processing device. On one hand, a to-be-processed image is divided into at least two blocks; then, each data block is identified to get the identification result of each data block, wherein the identification result of each data block indicates whether each data block is a content data block or a background data block; a background removal threshold of each data block is obtained according to the identification result of each data block; and the background of each data block is removed according to the background removal threshold of each data block. Therefore, through the technical scheme provided by the embodiments of the invention, the problem of over-processing and partial loss of image content caused thereby due to unified background removal of a whole image in the prior art is solved.

Owner:ZHUHAI PANTUM ELECTRONICS

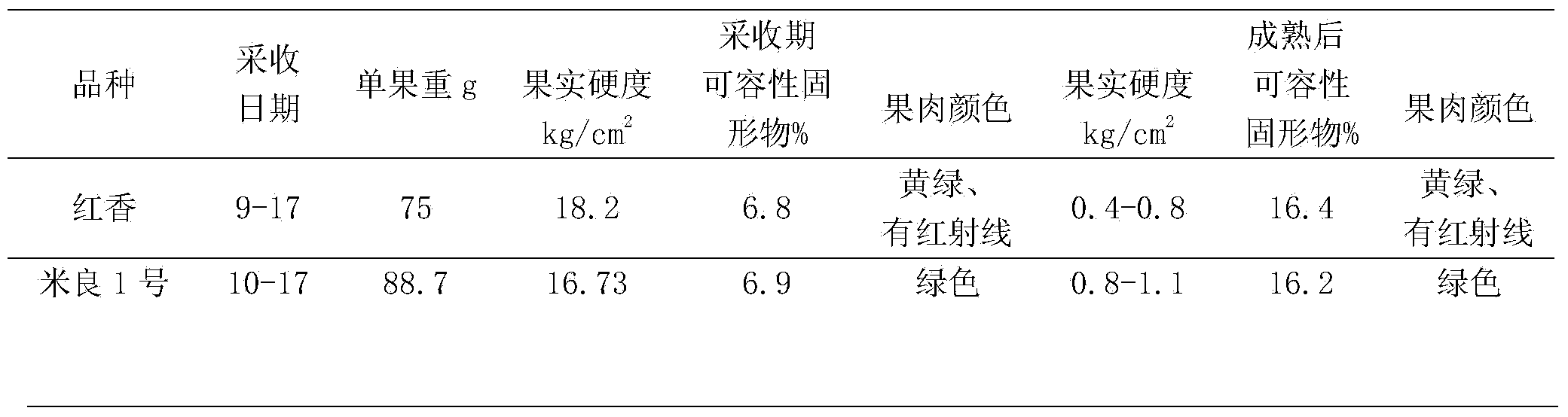

Post-ripening method for kiwi fruits

The invention discloses a post-ripening method for kiwi fruits. The method comprises the following steps of: selecting high-quality kiwi fruits, and dipping the stem parts of the kiwi fruits in 1000 ppm ethephon solution for 1-2 seconds with a dipping depth of 0.4-0.6 cm, and taking the kiwi fruits out and shaking to remove excess solution; placing the processed kiwi fruits in a plastic box in two layers, wherein a polyethylene film of 3 cm in thickness is padded in the plastic box, and a white paper layer is placed on the film at the bottom of the plastic box, between the two layers of kiwi fruits and on the upper layer of the kiwi fruits, respectively, for absorbing moisture produced by the kiwi fruits, and then sealing the film; placing the plastic box in which the processed kiwi fruits are stored in a room with controllable indoor temperature, taking the processed kiwi fruits out from the plastic box and placing the kiwi fruits under normal temperature. When becoming a little soft, the kiwi fruits are edible. The post-ripening method for kiwi fruits disclosed by the invention is convenient and quick, and can meet the requirement of marketing. The kiwi fruits can be sold immediately after being processed, and has good taste specific to kiwi fruits.

Owner:广西乐业县乐宝电子商务有限公司

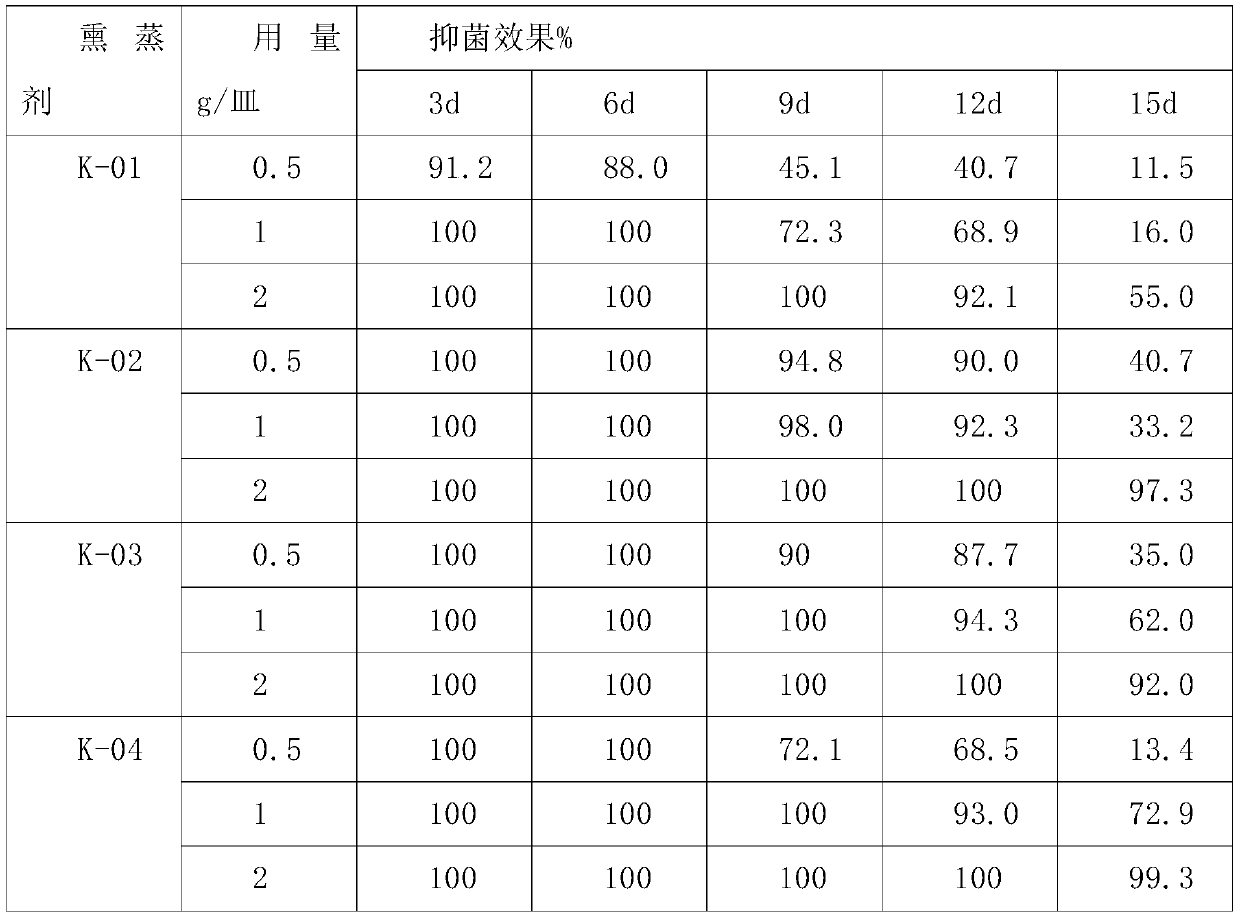

Natural fruit and vegetable anti-mildew and antibacterial combined fumigation granule

InactiveCN110178893AWide variety of sourcesSignificant attractant activityFruit and vegetables preservationVegetable oilAntioxidant

The invention relates to a natural fruit and vegetable anti-mildew and antibacterial combined fumigation granule. The combined fumigation granule comprises a fumigation composition and an adsorbing granule. The fumigation composition is prepared from the following components by weight percent, 15-65% of essential oil, 35-85% of vegetable oil and 0.1-1% of antioxidant. The adsorbing granule is madeof a porous material of natural origin, and the adsorbing granule is made from one or a combination of corn cob, activated carbon, akadama soil and vermiculite. Essential oil slow-release fumigationgranule raw materials are all derived from nature or plants itself, and are safe and non-toxic to use; excessive treatment of fruits and vegetables is avoided, and space, equipment and personnel inputrequired for treatment are saved; the use method is simple, only a certain quantity of granule products is weighed and placed in a net bag, the net bag is placed and / or hung in different positions ofa storage space, and finally continuously protecting fruits and vegetables from being contaminated by bacteria is realized, and the granule does not directly touch the surfaces of fruits and vegetables. The granule can be widely used in the fields of fruit and vegetable transportation and fruit and vegetable storage.

Owner:四川绿品源贸易有限公司

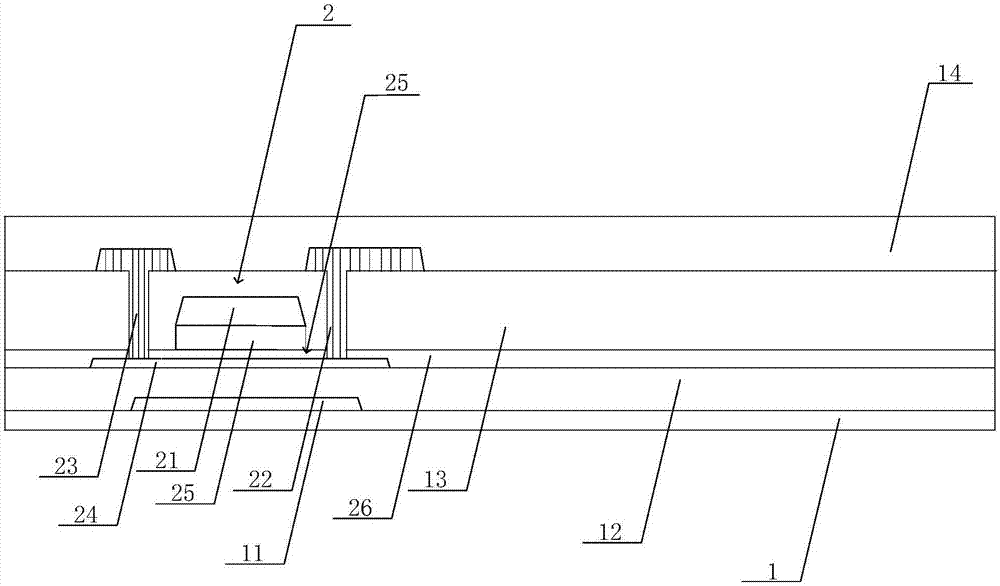

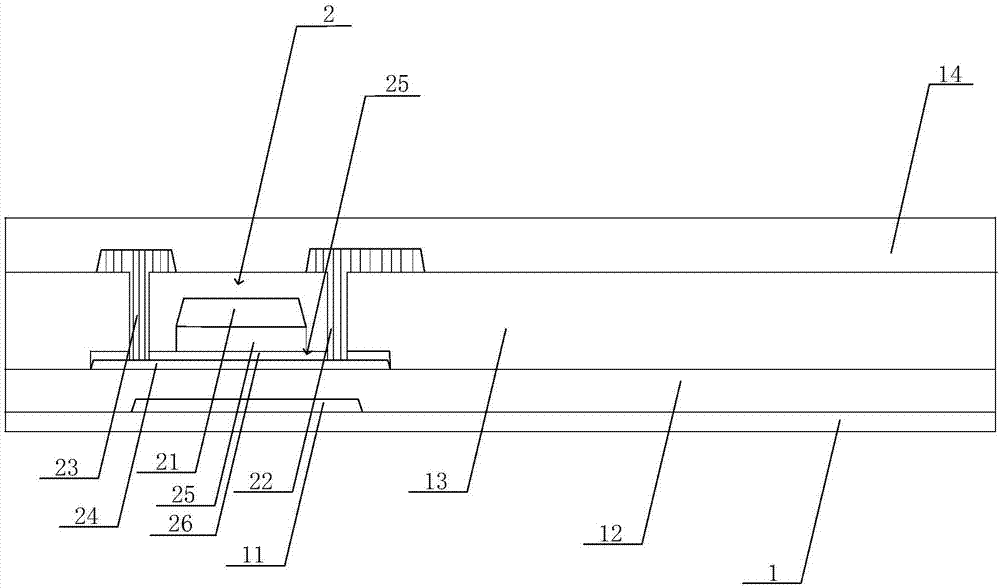

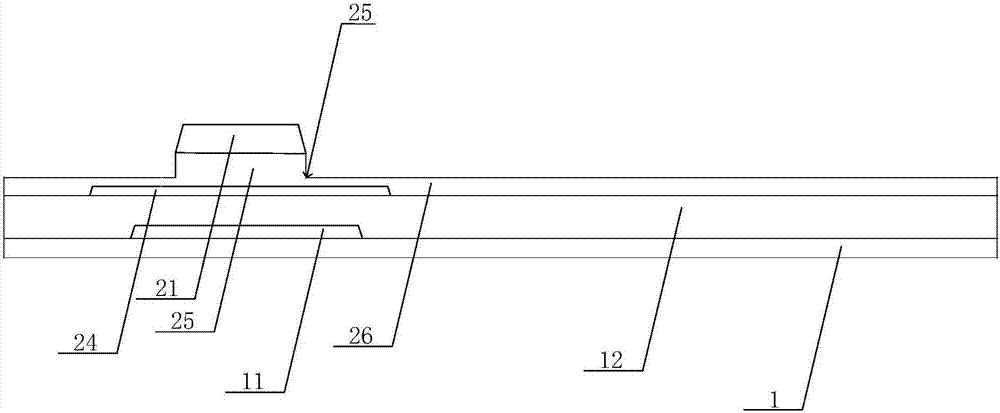

Array substrate and manufacturing method therefor

ActiveCN107507839AAvoid overprocessingReduce the impact of impedanceTransistorSolid-state devicesProtection layerDielectric layer

The invention discloses an array substrate, and the array substrate comprises a substrate; a shading layer which is formed on the substrate; a buffering layer which is formed on the shading layer; a semiconductor layer which is formed on the buffering layer; a protection layer which is formed on the semiconductor layer; an insulating layer which is formed on the protection layer; and an interlayer dielectric layer which is formed on the protection layer. The substrate is also provided with a source electrode layer, a drain electrode layer and a grid electrode layer, wherein the source electrode layer and the drain electrode layer are formed on the interlayer dielectric layer, and are respectively connected to conductor parts at two ends of the semiconductor layer. The insulating layer is disposed between the grid electrode layer and the semiconductor layer, and the interlayer dielectric layer covers the grid electrode and the protection layer. The insulating layer covers the semiconductor layer, thereby effectively guaranteeing that a to-be-conducted semiconductor layer region is not exposed, and effectively reducing the impedance impact of the conductor parts of the semiconductor layers in a subsequent manufacturing process.

Owner:HKC CORP LTD

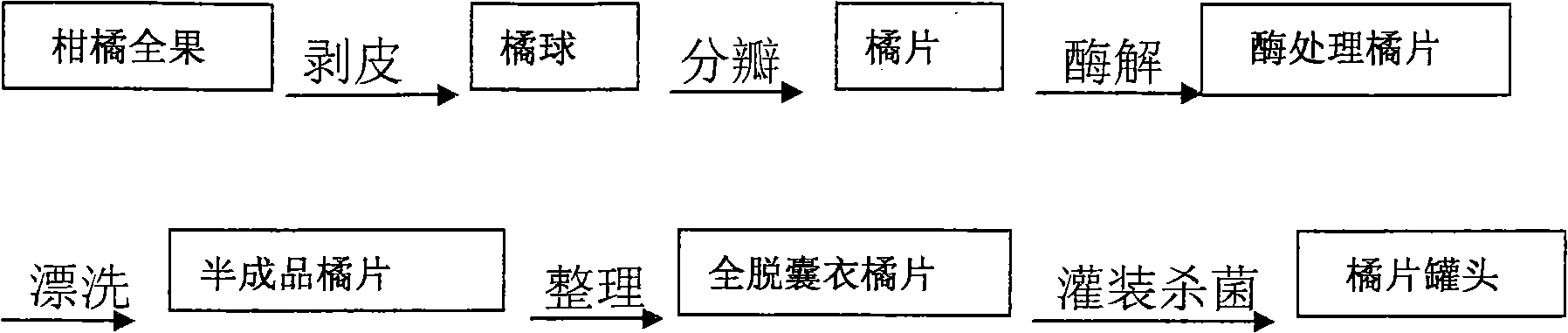

Method for removing segment membranes from citrus

InactiveCN101803791AReduce rinse water consumptionReduce pollutionFood treatmentPectinaseMembrane configuration

The invention provides a method for removing segment membranes from citrus. The method is characterized by comprising the following steps: (1) adding the alkaline liquid of 0.8%-1% pectinase with the activity thereof being higher than 150,000U / ml to water, and adjusting the pH value of the water to 9 by sodium carbonate to obtain enzymolysis liquid; (2) heating the enzymolysis liquid until the temperature of the enzymolysis liquid is increased to 45 to 50 DEG C; (3) feeding the enzymolysis liquid and citrus segments by weight ratio of 2:1 to an enzymolysis tank; (4) stirring in the presence of compressed air with the pressure thereof being 0.2MPa to 0.4MPa for 25 to 35 minutes; and (5) taking out and rinsing the citrus segments with clear water after visually indicating that most segment membranes are removed from the citrus, manually sorting, canning, adding syrup, sealing and sterilizing to obtain citrus cans.

Owner:ZHEJIANG CITRUS RES INST

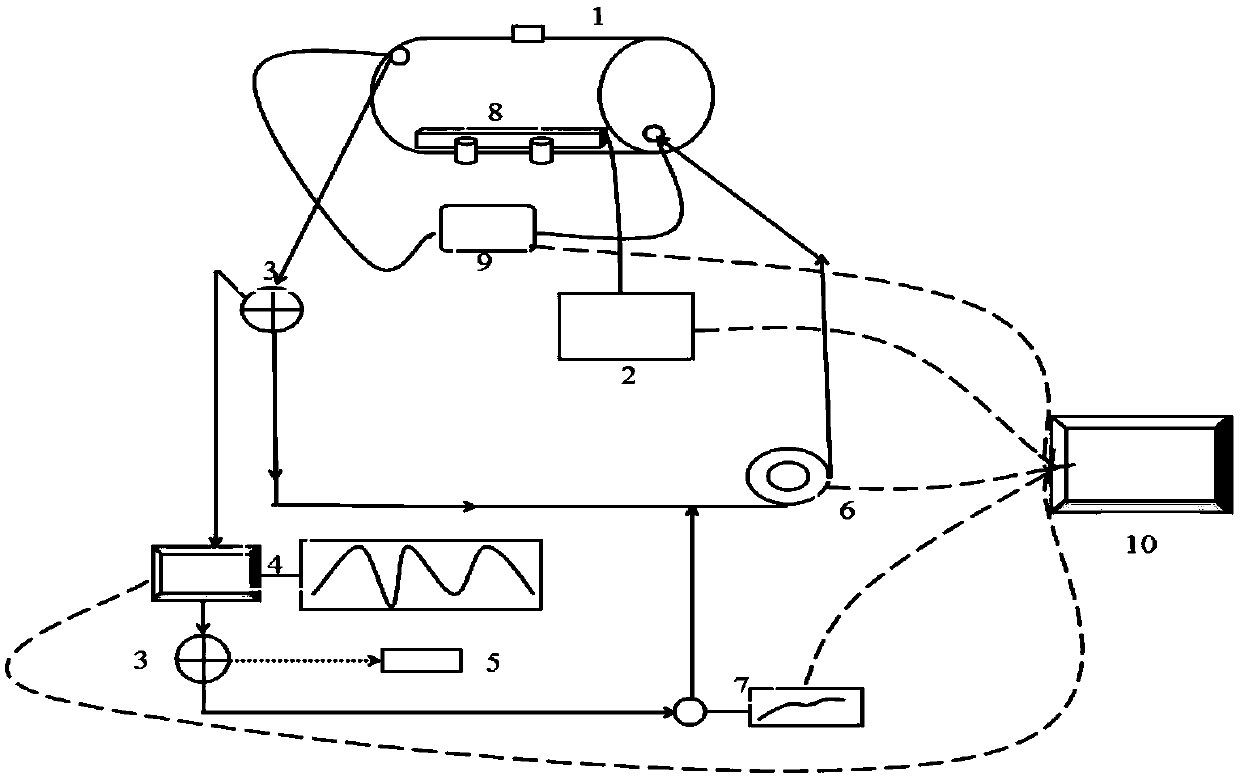

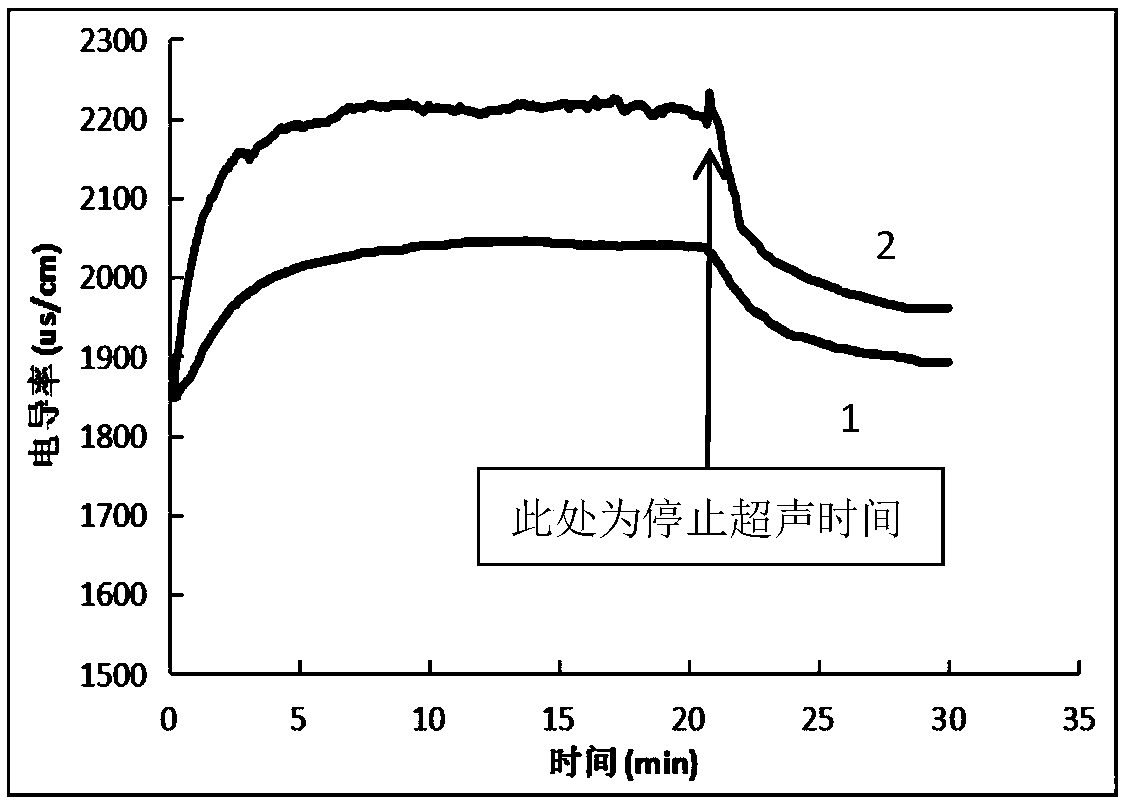

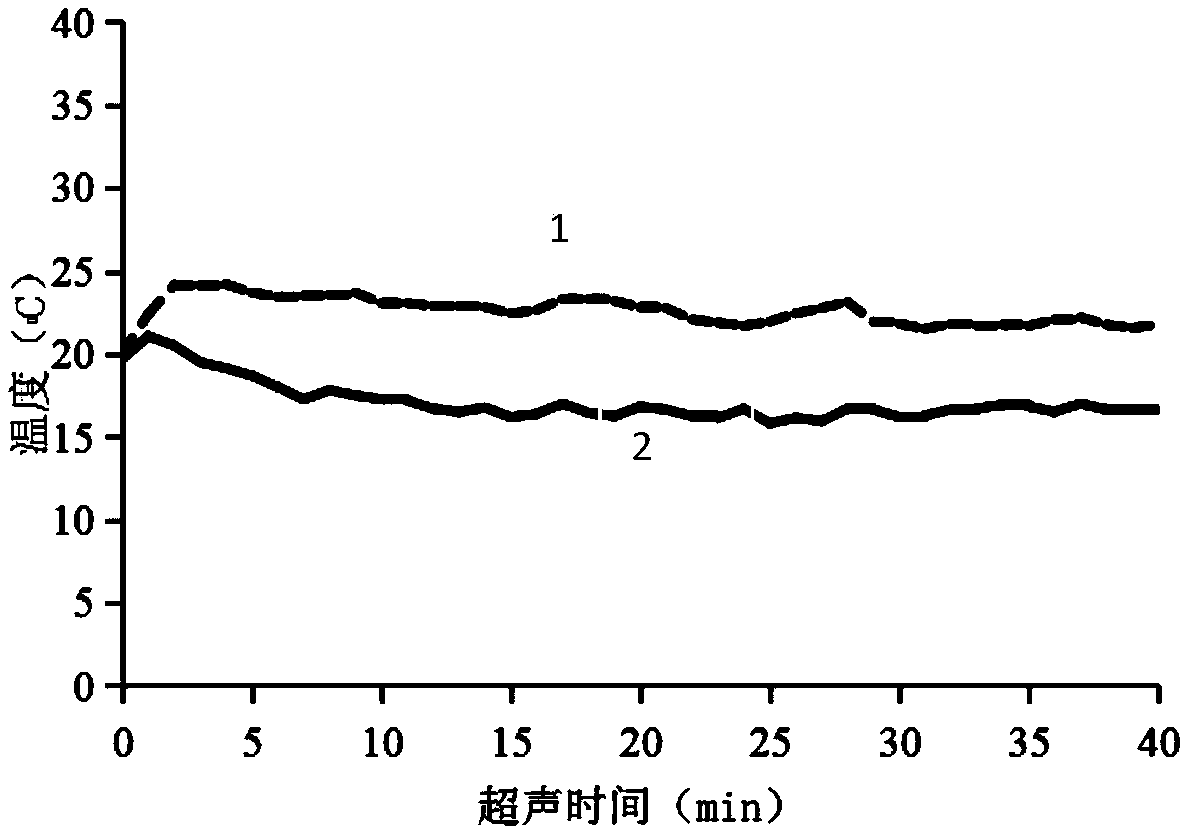

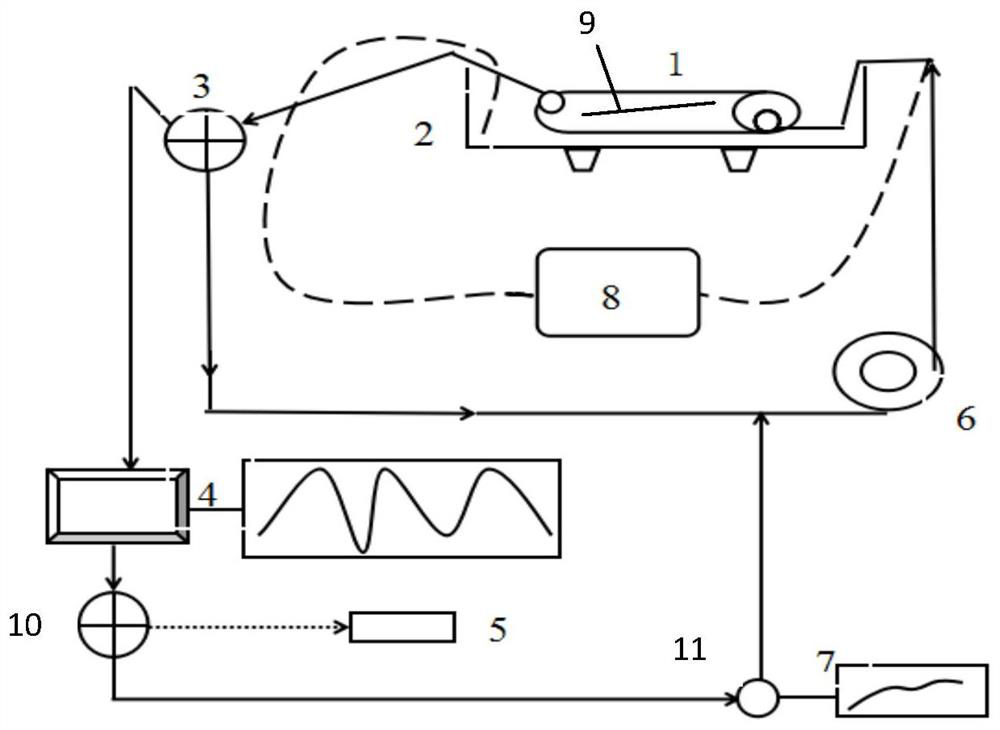

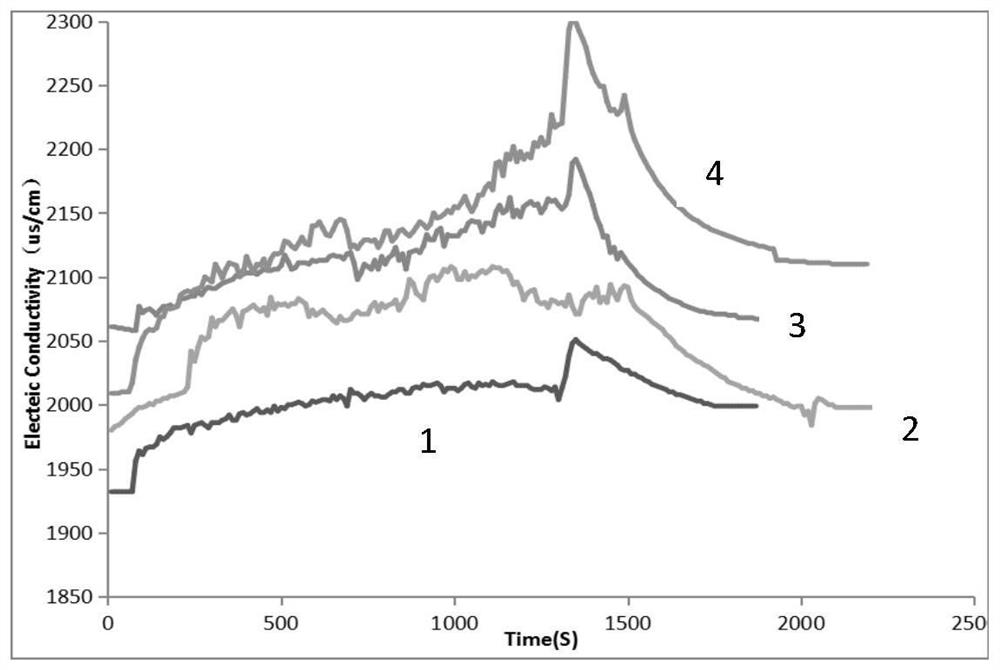

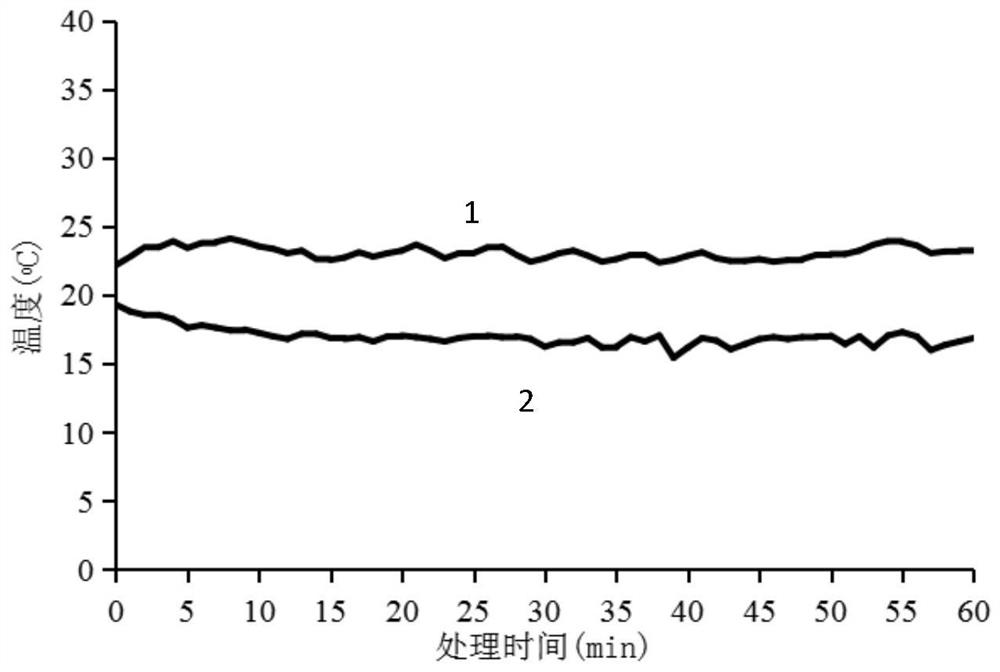

System and method for fast curing wine by coupling ultrasonic waves and oak barrel

ActiveCN109517713ARipe fastShorten aging timeMaterial analysis by observing effect on chemical indicatorAlcoholic beverage preparationPeristaltic pumpFruit wine

The invention discloses a system and method for fast curing wine by coupling ultrasonic waves and an oak barrel, and belongs to the technical field of wine curing technologies. The system specificallycomprises an ultrasonic generator, an ultrasonic transducer, the oak barrel, a first diverging valve, a spectrum detection instrument, a peristaltic pump, a conductivity detection instrument, a temperature sensor and a general control platform; the curing method comprises the steps that 1, the oak barrel is filled with the wine; 2, initial ultrasonic frequency, ultrasonic temperature and ultrasonic power are set; 3, data is fed back to the general control platform; 4, an optimal treatment condition is determined. By means of the system and method for fast curing the wine by coupling the ultrasonic waves and the oak barrel, dynamic circulating wine sample treatment in a wine-making process can be achieved, ageing time is shortened, a flavor substance is improved, and the system and methodfor fast curing the wine by coupling the ultrasonic waves and the oak barrel can be further applied in a making process of brandy or whisky or yellow rice wine or fruit wine.

Owner:SHAANXI NORMAL UNIV

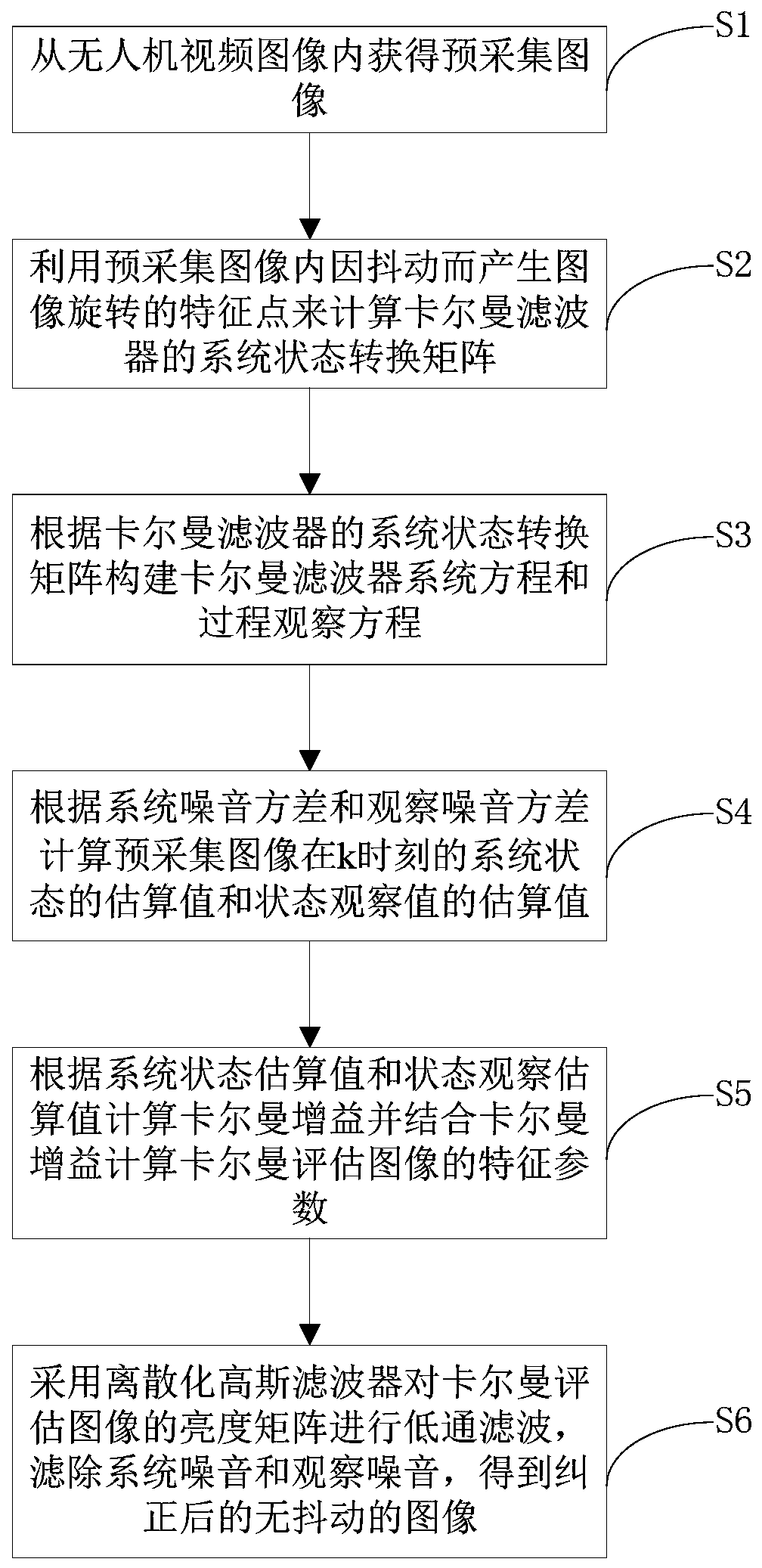

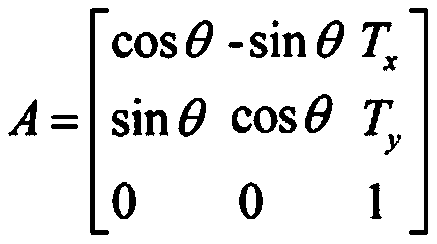

Hybrid Jitter Correction Method for UAV Video Acquisition

ActiveCN107516300BProcessing speedAvoid the problem of inaccurate prediction of changing trendsImage enhancementImage analysisKaiman filterComputer graphics (images)

The invention provides a hybrid jitter correction method for UAV video collection. The method includes: obtaining a pre-collected image from the UAV video image; using the characteristic points of image rotation due to jitter in the pre-collected image to calculate the Kalman The system state transition matrix A of the filter; construct the Kalman filter system equation and process observation equation; calculate the estimate of the system state of the pre-acquired image at time k and the estimate of the state observation value based on the system noise variance Q and the observation noise variance R value; calculate the Kalman gain and combine it with the Kalman gain to calculate the characteristic parameters of the Kalman evaluation image; use a discretized Gaussian filter to perform low-pass filtering on the brightness matrix of the Kalman evaluation image to filter out system noise and observation noise, and obtain the corrected results jitter-free images.

Owner:HANGZHOU DIANZI UNIV

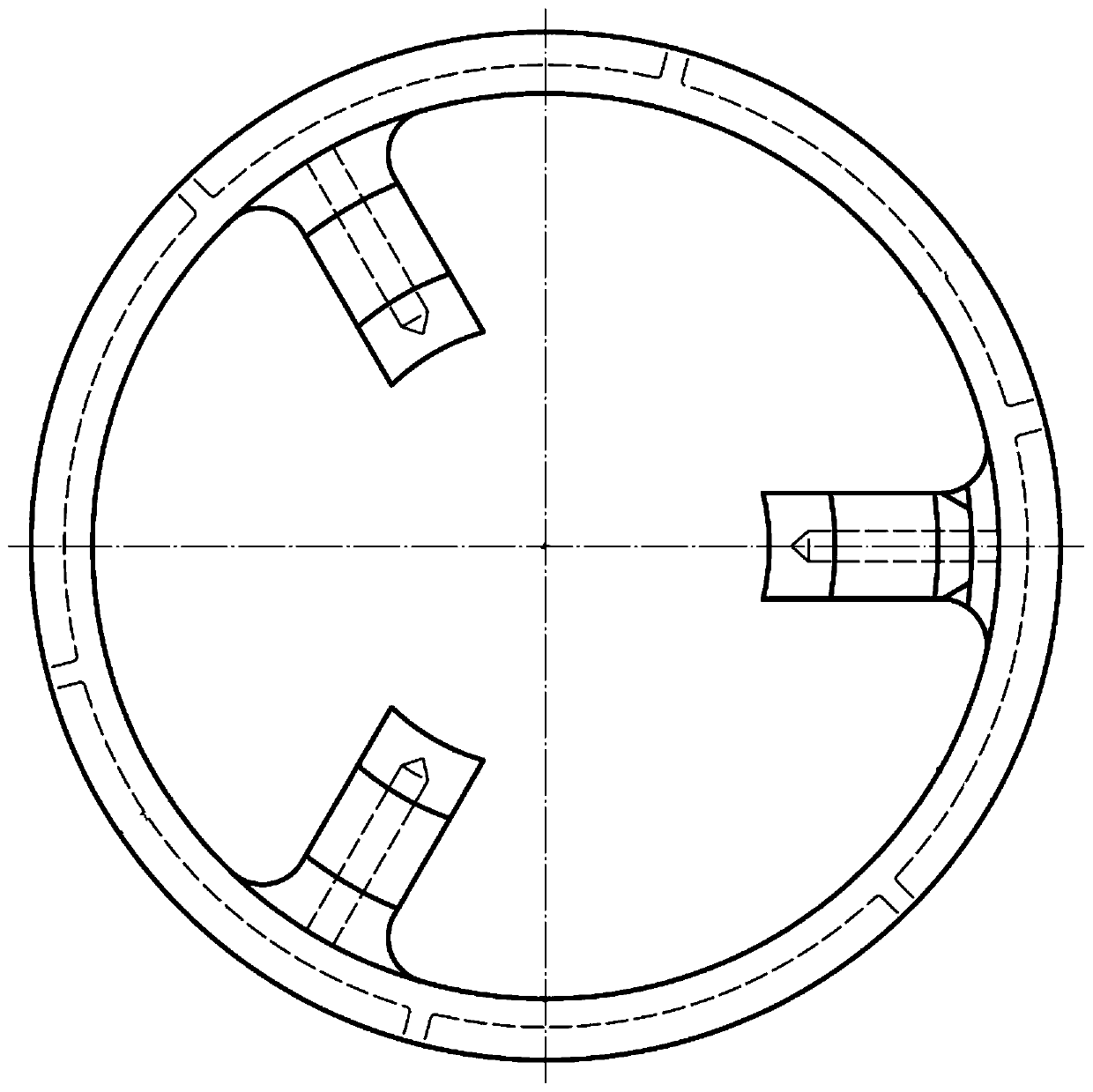

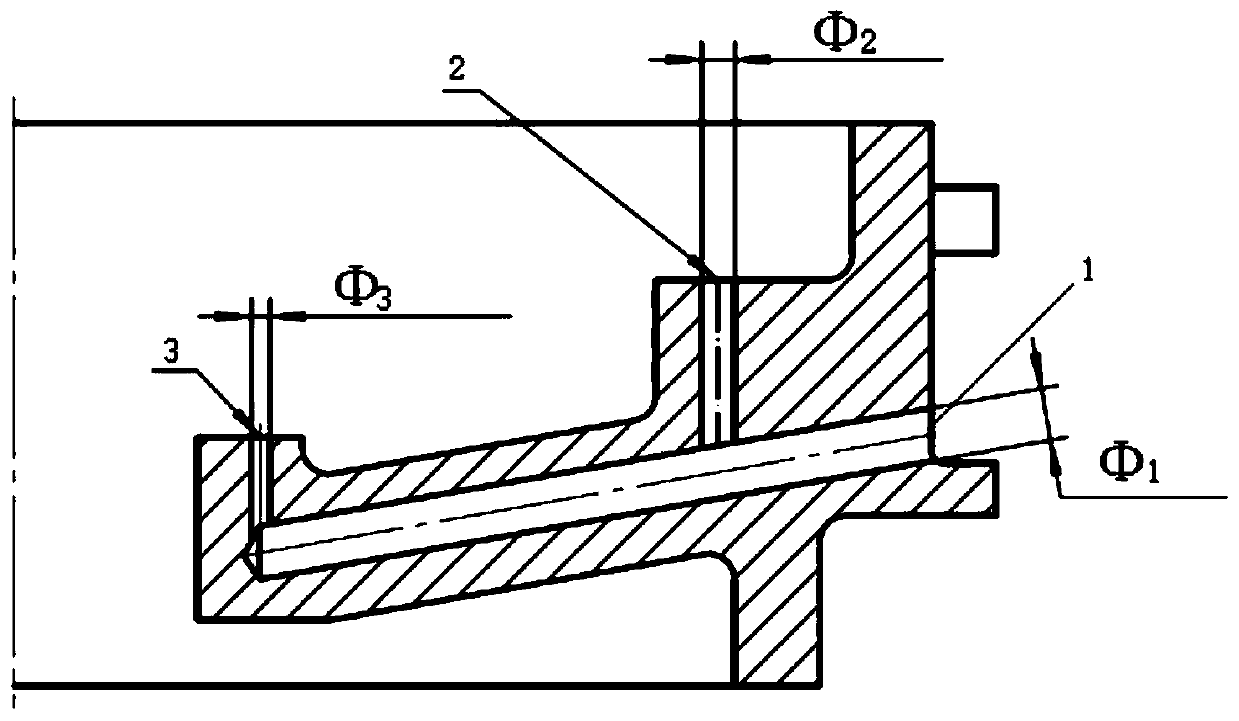

Processing method for improving flow precision of oil injecting ring

The present invention discloses a processing method for improving the flow precision of an oil injecting ring. Drilling and reaming processes are adopted for forming oil injecting holes and oil feeding holes of an oil path, a single-oil-path flow process test is performed, and the diameter phi 1 of one oil feeding hole and the diameters phi 2 and phi 3 of two oil injecting holes, which meet the median flow requirements under the processing precision level of the reaming process are determined; then the oil feeding holes and the oil injecting holes are formed according to the drilling and reaming processes, after all the oil feeding holes and oil injecting holes are formed, the oil path test is performed, a reamer is adopted for polishing the oil injecting holes when the flow test is not qualified, the smaller feeding amount is adopted in polishing, and the whole oil path of the oil injecting holes is completely polished, so that polishing of only the oil path near oil discharging holesof the oil injecting holes is avoided; the better inner hole surface roughness and the smaller geometric tolerance in the oil path are improved, the flow test frequency is greatly reduced, and the problem of part scrapping caused by flow out-of-tolerance is eliminated; and on-time on-demand delivery of the oil injecting ring is ensured.

Owner:AECC AVIATION POWER CO LTD

A method for thermal regeneration of waste rubber

InactiveCN102030934BAvoid the disadvantages of smelly hot steamRubber hydrocarbon content decreasedPlastic recyclingLiquid hydrocarbon mixture productionPolymer scienceWaste rubber

The present invention proposes a method for thermal regeneration of waste rubber, which is to feed materials with a weight ratio of "waste rubber coarse powder / environmentally friendly softener / powder auxiliary material" in the range of 100 / 8-150 / 20-1500, stir and heat In the container, it is first heated by anaerobic, and then introduced into the stirring cooler, cooled to below 100 ℃, and the product is obtained; or part or all of the powder auxiliary materials in the feeding are deducted and slowly thrown, and the materials that are fed into the stirring heater in the early stage Before the material is to be discharged, add the powder auxiliary material deducted first to the stirring heater, or / and add it when the hot material is introduced into the stirring cooler, and discharge the material after the mixture is cooled to below 100°C; or the formula After initial mixing, the material is introduced into the screw extruder, and after heating and mixing, the material is cooled to 100°C to obtain the product; Or in addition, between the process of preparing carbon black from combustible fuel and combustible gas, a multi-directional migration relationship of materials or / and energy is established.

Owner:陈汇宏 +1

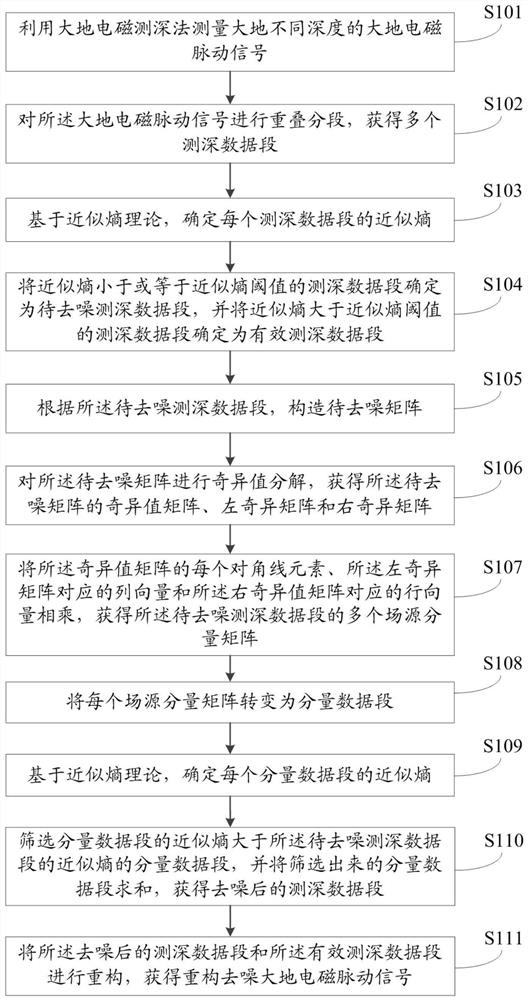

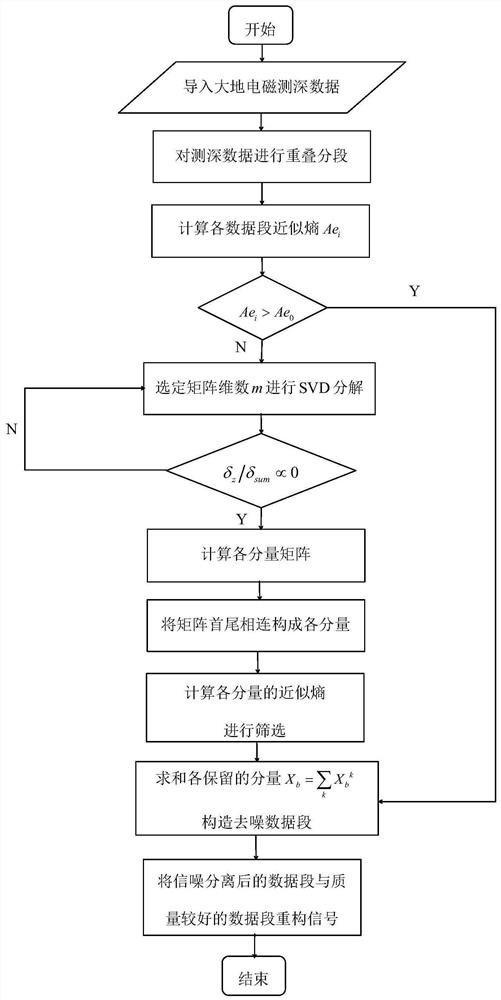

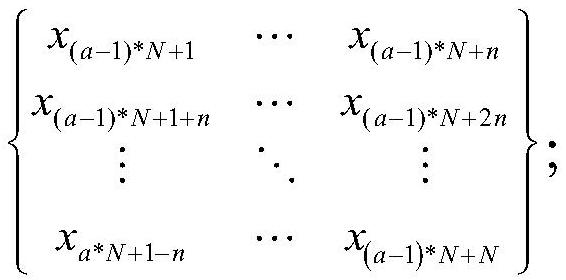

Magnetotelluric denoising method and system

ActiveCN112285793AAvoid overprocessingTo achieve the purpose of denoisingElectric/magnetic detectionAcoustic wave reradiationSingular value decompositionData segment

The invention relates to a magnetotelluric denoising method and system. The method comprises the steps of carrying out the overlapping segmentation of a magnetotelluric pulsation signal, determining the approximate entropy of each sounding data segment, determining the sounding data segment with the approximate entropy greater than an approximate entropy threshold as an effective sounding data segment, and determining other sounding data segments as to-be-denoised sounding data segments; selecting approximate entropy to screen the data segments, so that 'over-processing' of the effective sounding data segments is prevented; performing singular value decomposition on the to-be-denoised sounding data segments, multiplying the decomposed singular value matrix, the left singular matrix and theright singular matrix to obtain a plurality of component matrixes, constructing corresponding component data segments, determining the approximate entropy of each component data segment, and summingthe screened component data segments of which the approximate entropy is greater than the approximate entropy of the sounding data segments; obtaining denoised sounding data segments, and achieving the purpose of denoising; and finally, reconstructing the denoised sounding data segments and the effective sounding data segments to obtain a reconstructed denoised magnetotelluric pulsation signal, thereby improving the accuracy of data denoising.

Owner:JILIN UNIV

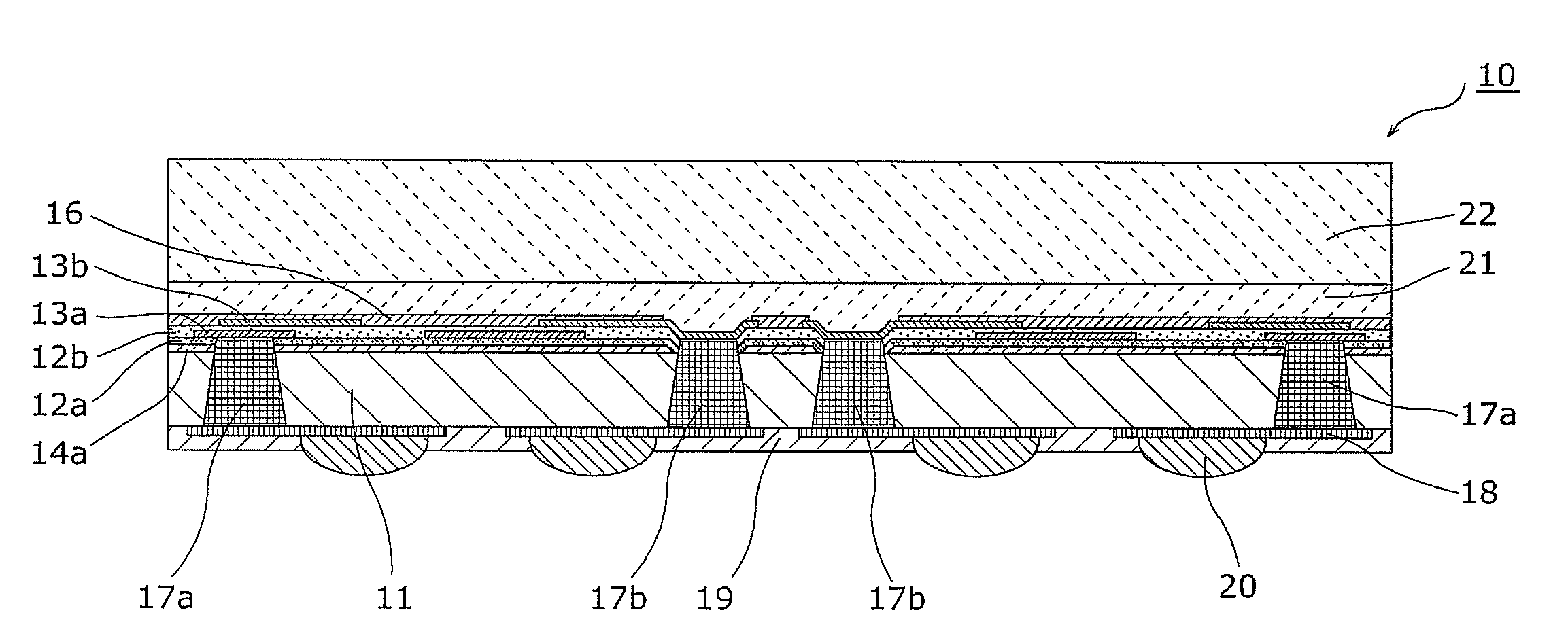

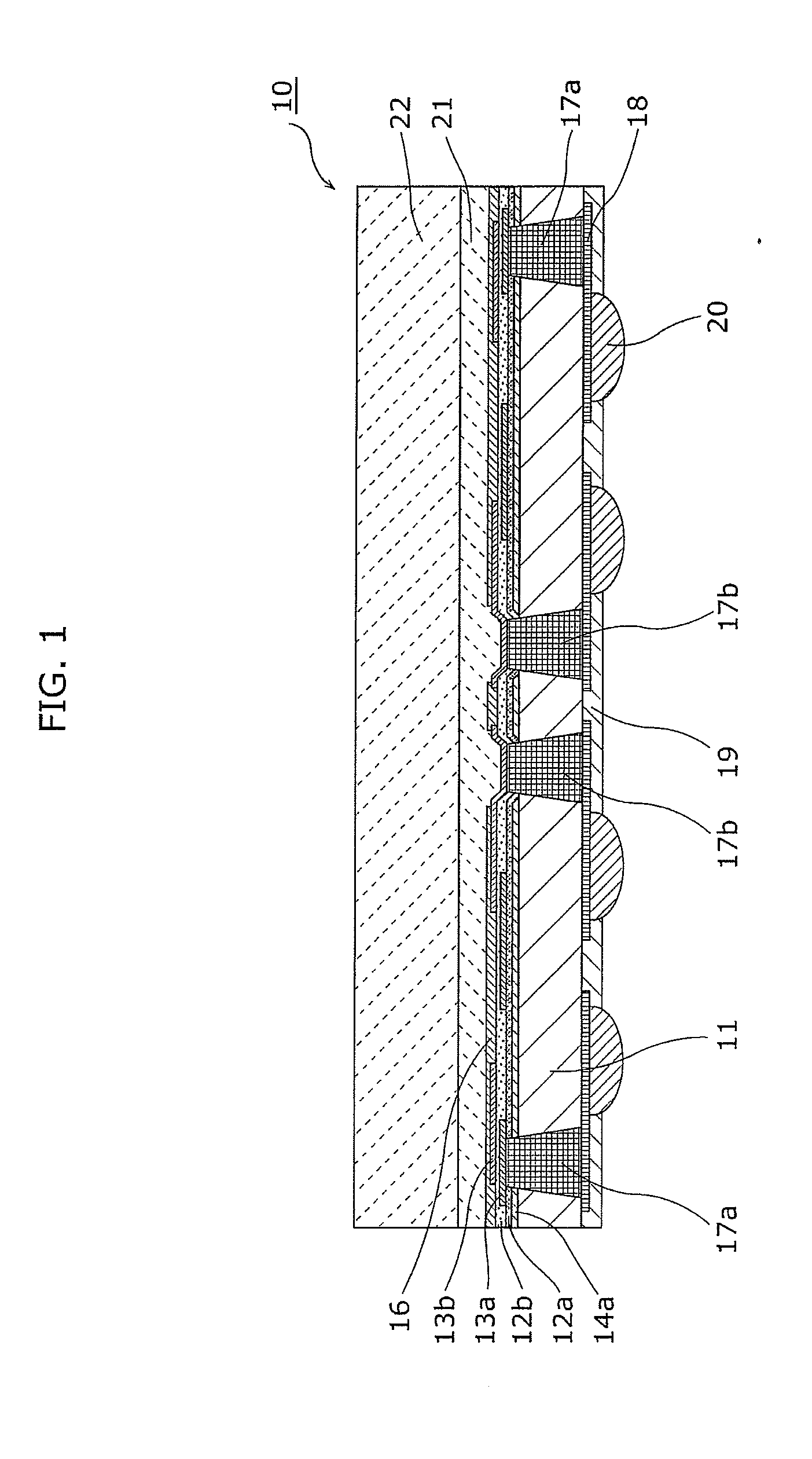

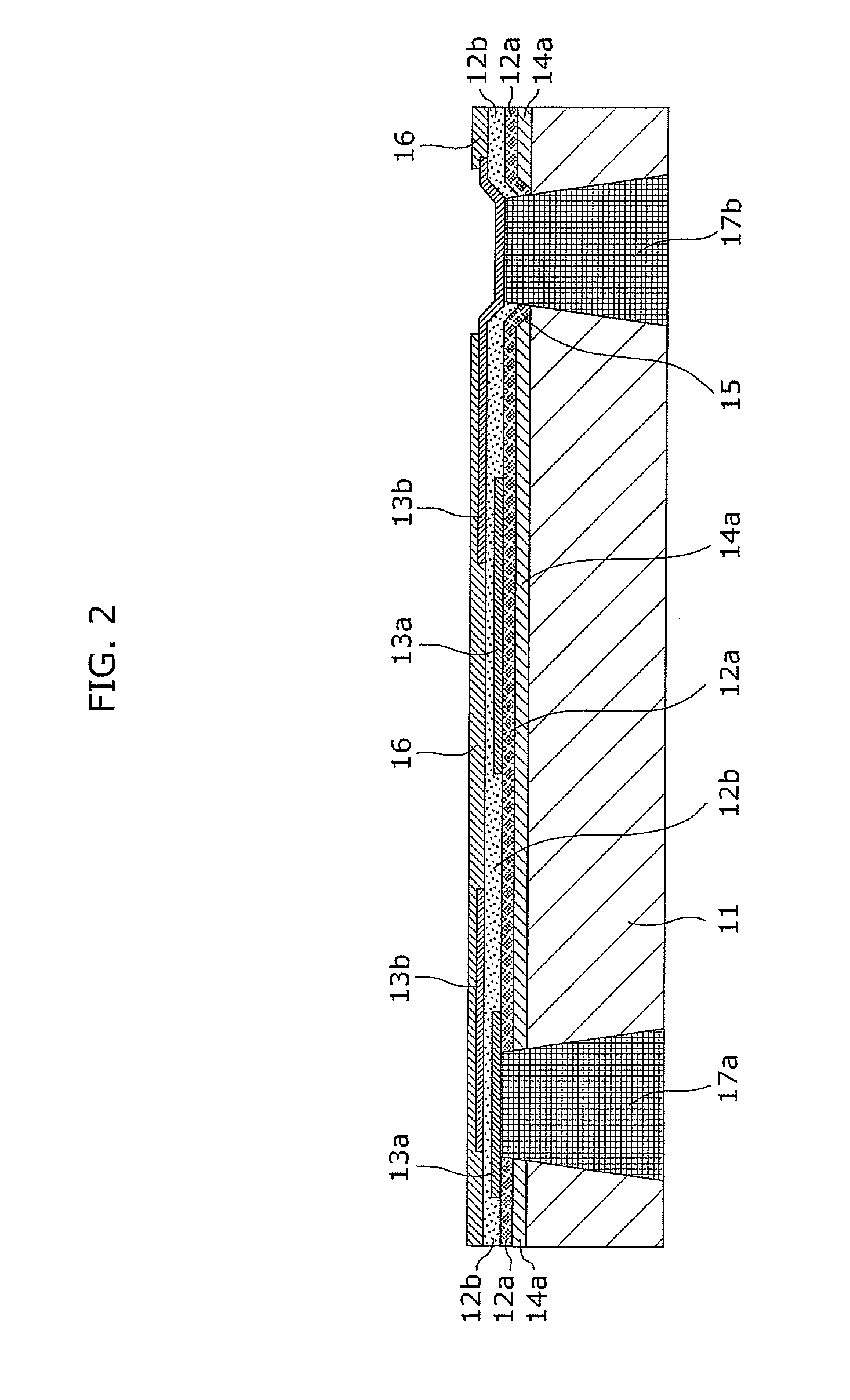

Semiconductor device and electronic apparatus including the same

InactiveUS20120043665A1Reduced flexibilityIncrease the number ofSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A semiconductor device according to the present invention is a semiconductor device that includes: a semiconductor substrate having metal wiring formed on a bottom surface of the semiconductor substrate; and a plurality of wiring layers formed above the semiconductor substrate. The wiring layers include a first wiring layer and a second wiring layer that is formed above the first wiring layer. The semiconductor device further includes: a first through electrode which electrically connects the first wiring layer and the metal wiring; a second through electrode which electrically connects the second wiring layer and the metal wiring; and at least one layer difference adjustment film formed between the semiconductor substrate and the wiring layers. The at least one layer difference adjustment film includes a layer difference adjustment film formed on a region excluding a region corresponding to the second through electrode.

Owner:PANASONIC CORP

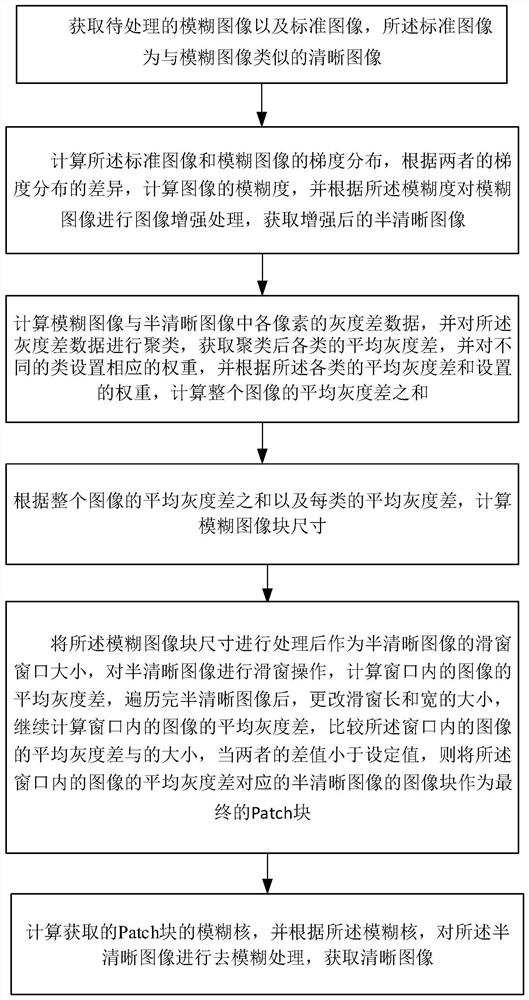

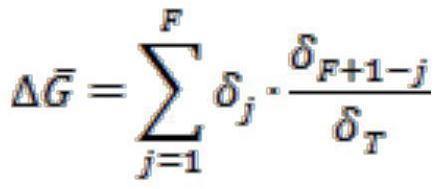

Image fuzzy processing method of intelligent inspection system of power transmission lines based on artificial intelligence

ActiveCN113327206AAvoid overprocessingImprove clarityImage enhancementCharacter and pattern recognitionPattern recognitionDeblurring

The invention relates to an image fuzzy processing method of an intelligent inspection system of power transmission lines based on artificial intelligence, and the method comprises the steps: obtaining gradient distribution of a standard image and a fuzzy image, calculating fuzzy degree of the images according to the difference between the gradient distribution of the standard image and the fuzzy image, enhancing the fuzzy image, and obtaining a semi-clear image; clustering the calculated gray difference data of each pixel in the blurred image and the semi-clear image, obtaining the average gray difference and the weight of each class, calculating the sum of the average gray differences of the whole image, and calculating the size of a blurred image block in combination with the average gray difference of each class so as to obtain a sliding window, and carrying out sliding window operation on the semi-clear image; and obtaining an image block corresponding to the window equal to the sum of the average gray difference as a final Patch block, calculating a blurring kernel, and deblurring the semi-clear image to obtain a clear image. When the invention is used for deblurring, the image information of the blurred image is reserved, and the subsequent over-processing on the partial region of the semi-clear image can be effectively avoided.

Owner:江苏电百达智能科技有限公司

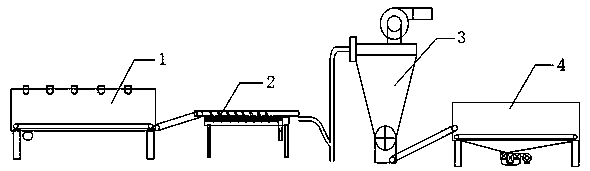

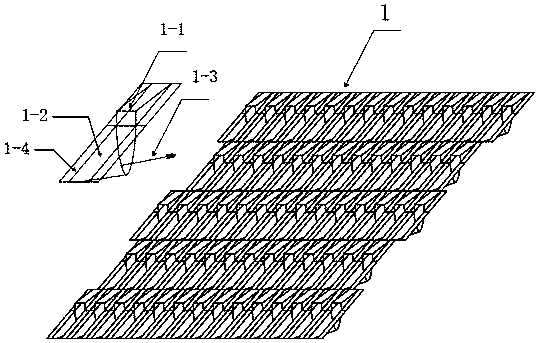

Method for improving quality of cut tobacco in recovered silver cut stems and treatment system

InactiveCN108771284ASensory quality impactHigh precisionTobacco preparationTobacco treatmentPulp and paper industryAir separation

The invention relates to a method for improving quality of cut tobacco in recovered silver cut stems and a treatment system and belongs to the technical field of tobacco processing. Firstly, the silver cut stems are subjected to moisture regain treatment with a normal-temperature moisture regain process and then sieved and loosened with a special-shaped sieve, then, cut stems and cut tobacco are separated through air separation equipment, finally, the recovered cut tobacco is dried with a normal-temperature drying process. The separation accuracy and effect of the cut stems and the cut tobaccoare improved, the sensory quality of the recovered cut tobacco is not affected by thermal processing treatment, the application range of the recovered cut tobacco is enlarged, and the economic valueof the recovered cut tobacco is increased.

Owner:HONGTA TOBACCO GRP

Hydraulic tensioning method for fixing gear

InactiveCN103934515AIngenious ideaReasonable structureGear-cutting machinesGear teethGear wheelEngineering

The invention discloses a hydraulic tensioning method for fixing a gear. The method comprises the following steps that firstly, clamp fixing is carried out, and a clamp penetrates through a through hole in the middle of the gear; secondly, hydraulic pressure output is carried out, a hydraulic machine outputs hydraulic pressure to enable the clamp to move or rotate, and therefore the clamp in the through hole in the middle of the gear to shift, the gear is tensioned, and the gear can be machined conveniently; thirdly, hydraulic resetting is carried out, after machining is completed, hydraulic resetting is carried out, the clamp moves or rotates reversely, and therefore the clamp in the through hole in the middle of the gear is reset to an initial state; fourthly, a workpiece is taken out, and the machined workpiece is taken out. According to the method, the clamp moves or shifts through the hydraulic pressure, and therefore the gear is tensioned, the output hydraulic pressure is ingeniously converted into tensile force, the gear is tensioned in the through hole in the middle of the gear, the conception is ingenious, the structure is reasonable, and excessive machining due to the fact that the fixing clamp clamps the gear due to vibration can be avoided.

Owner:TAIZHOU XINGHUA GEAR MFG CO LTD

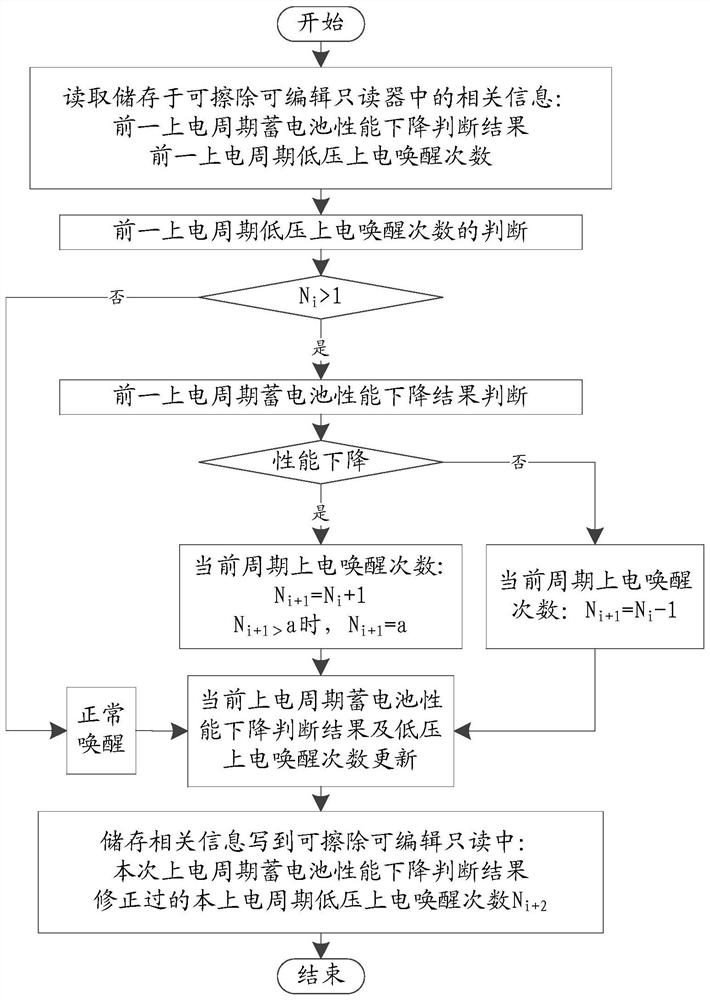

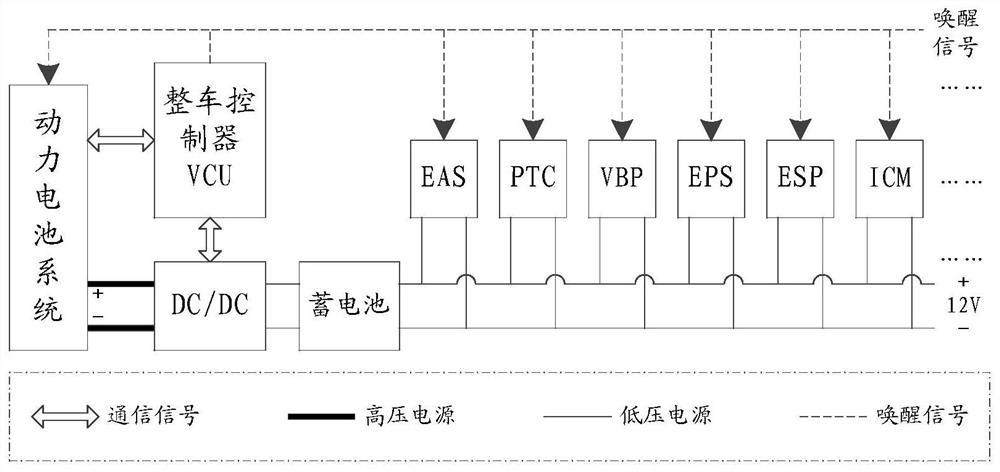

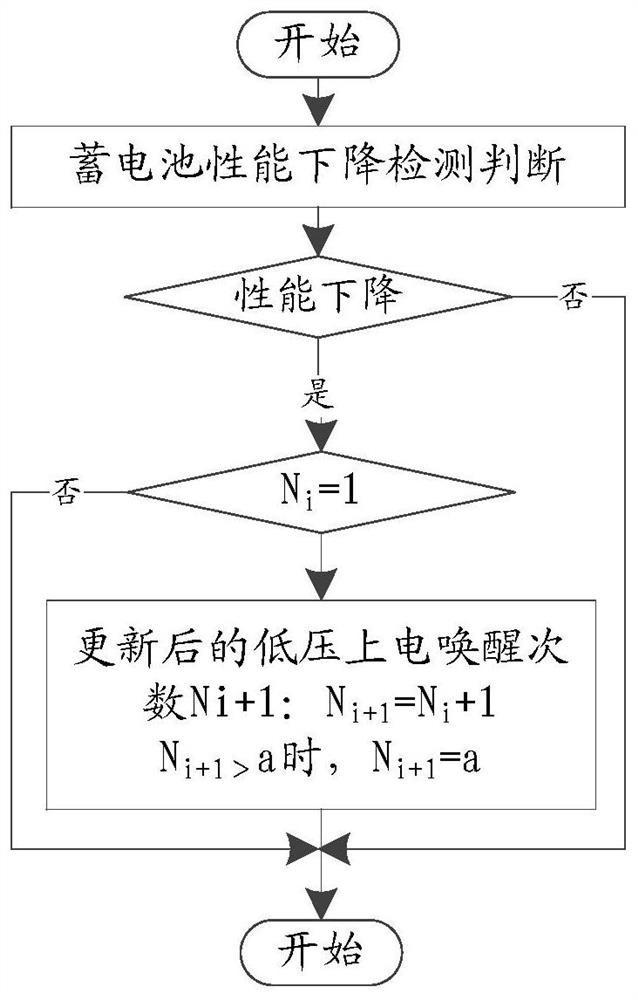

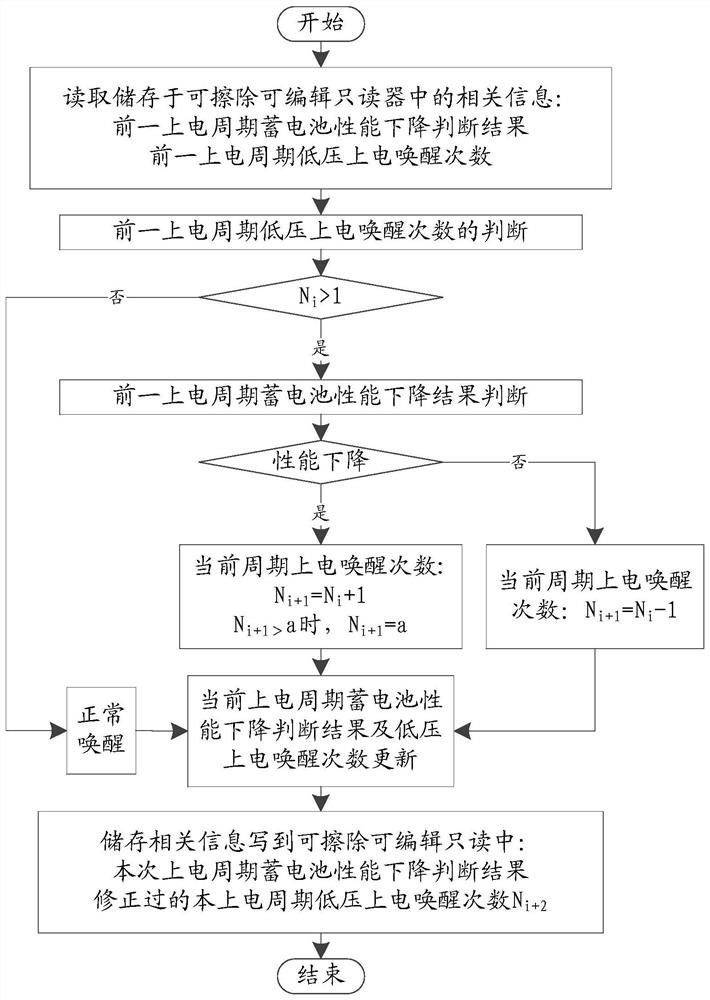

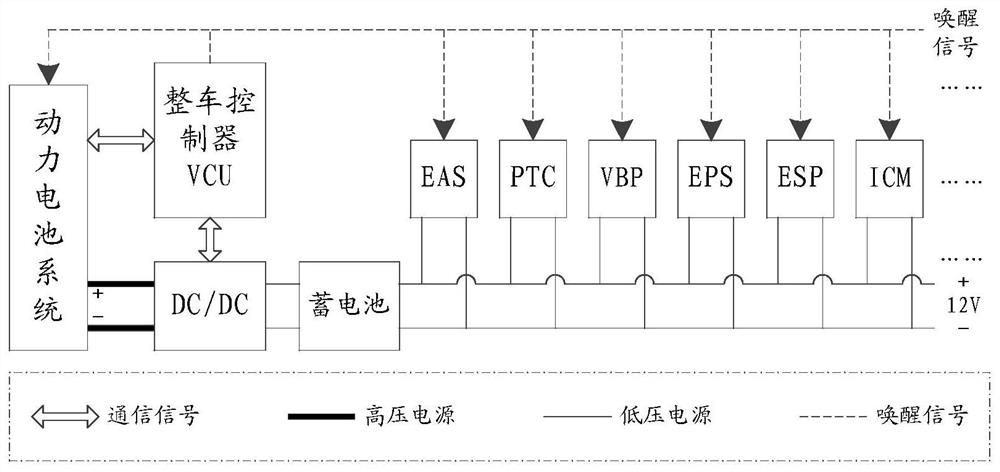

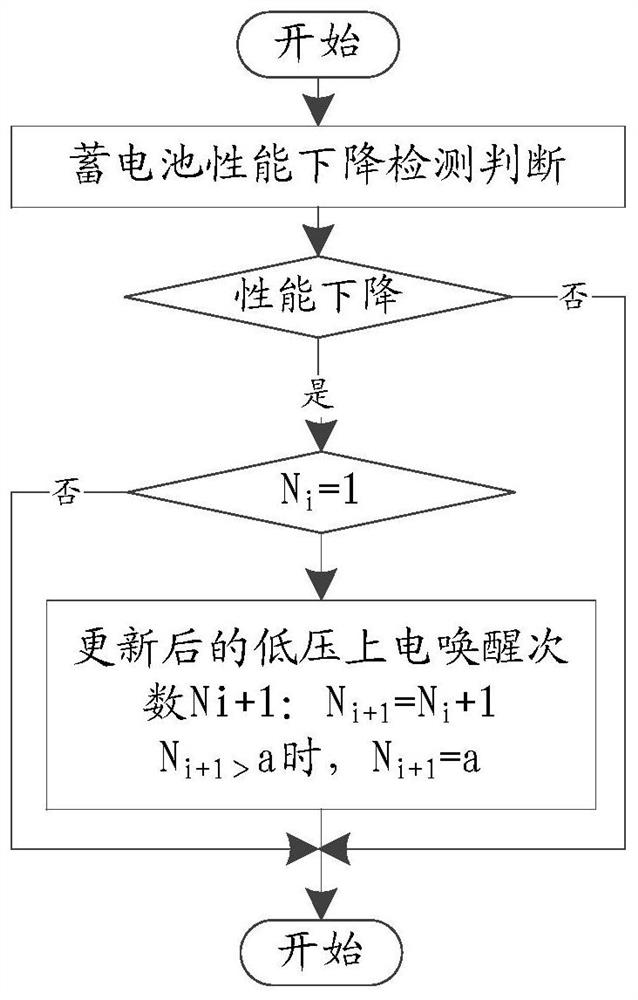

Power-on control method and device for low-voltage storage battery of electric automobile and electric automobile

ActiveCN112537203AReduced non-reality performanceGuaranteed non-authenticity performanceElectric devicesElectric powerControl theoryElectrical and Electronics engineering

The invention provides a power-on control method and device for a low-voltage storage battery of an electric automobile and the electric automobile, and relates to the field of power-on processing ofthe low-voltage storage battery of the electric automobile. The power-on control method for the low-voltage storage battery of the electric automobile comprises the steps: obtaining a performance reduction judgment result of a previous power-on period of a current power-on period of the low-voltage storage battery and the awakening frequency Ni of a controller in the power-on process of the low-voltage storage battery; determining a low-voltage power-on mode of the current power-on period of the low-voltage storage battery according to the performance reduction judgment result and the wake-upfrequency Ni; and obtaining a performance reduction judgment result of the low-voltage storage battery in the current power-on period when the low-voltage storage battery is powered on according to the low-voltage power-on mode and the awakening frequency of the controller. According to the embodiment of the invention, the stability and stationarity of the output voltage in the power-on process ofthe low-voltage storage battery are ensured by detecting the performance degradation of the storage battery and awakening the controller by stages, and the driving feeling is ensured.

Owner:BEIJING ELECTRIC VEHICLE

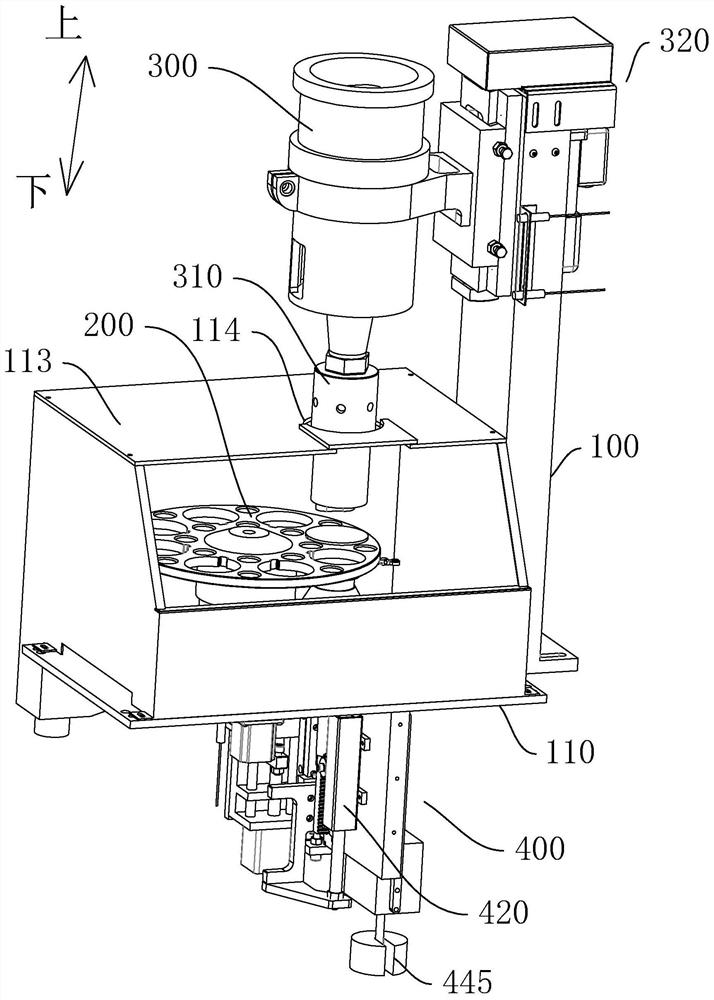

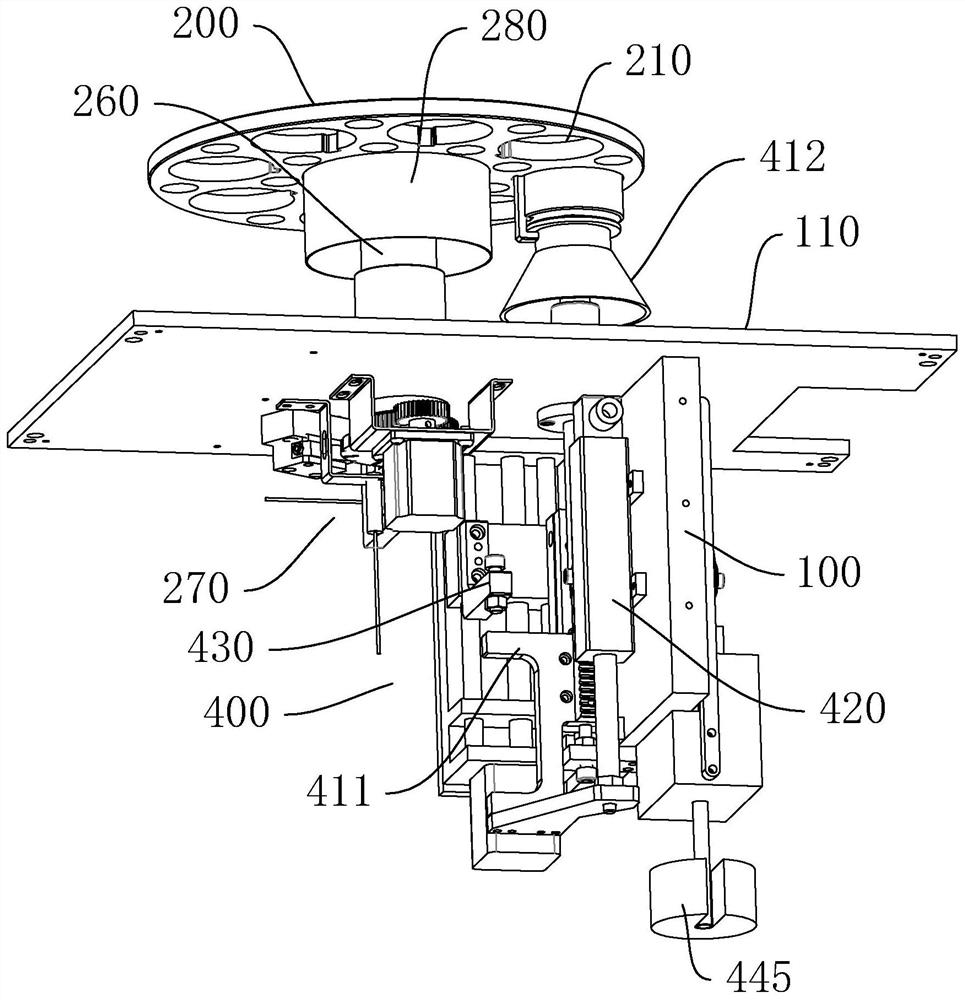

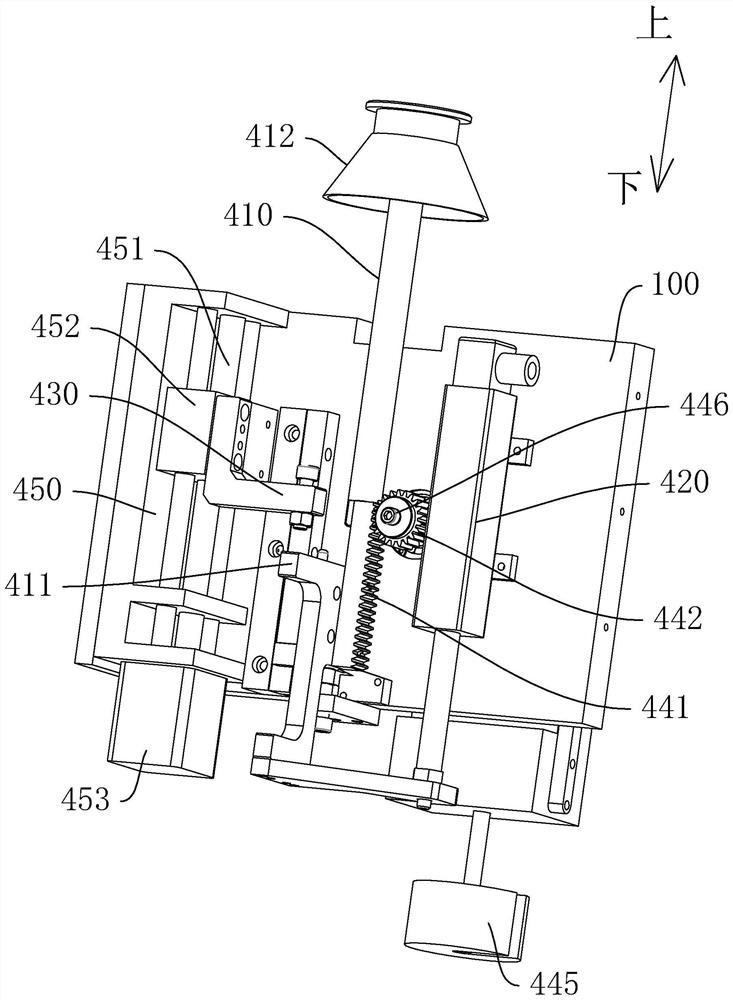

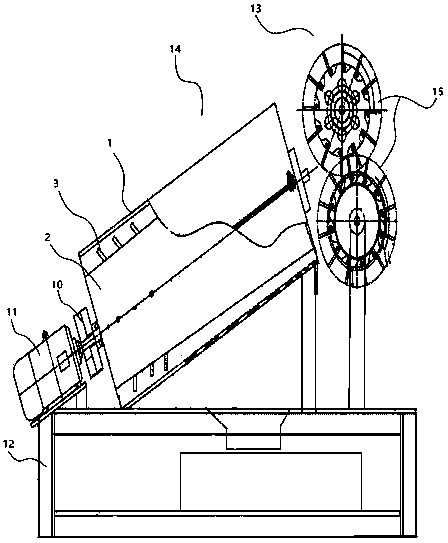

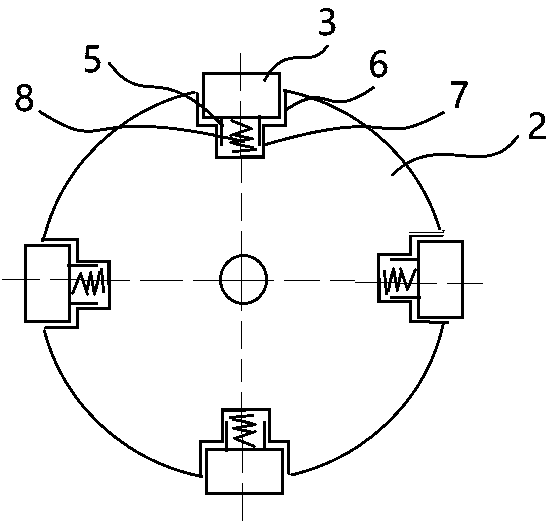

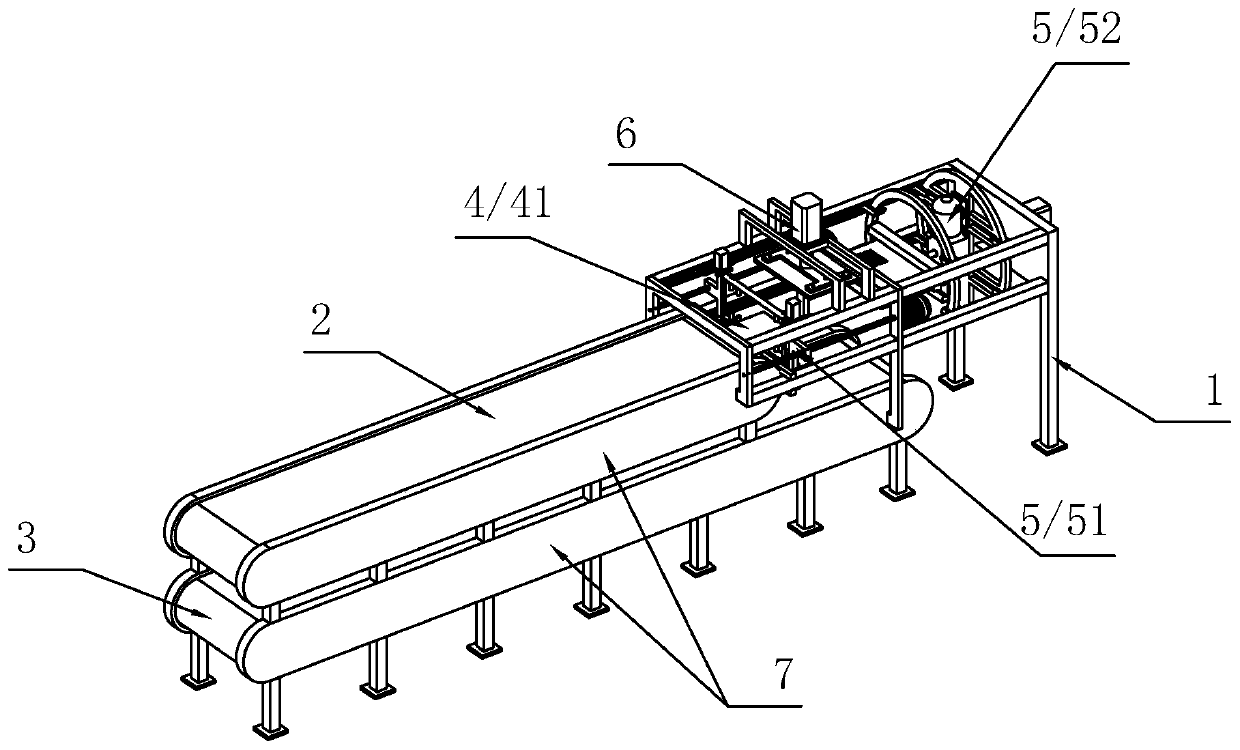

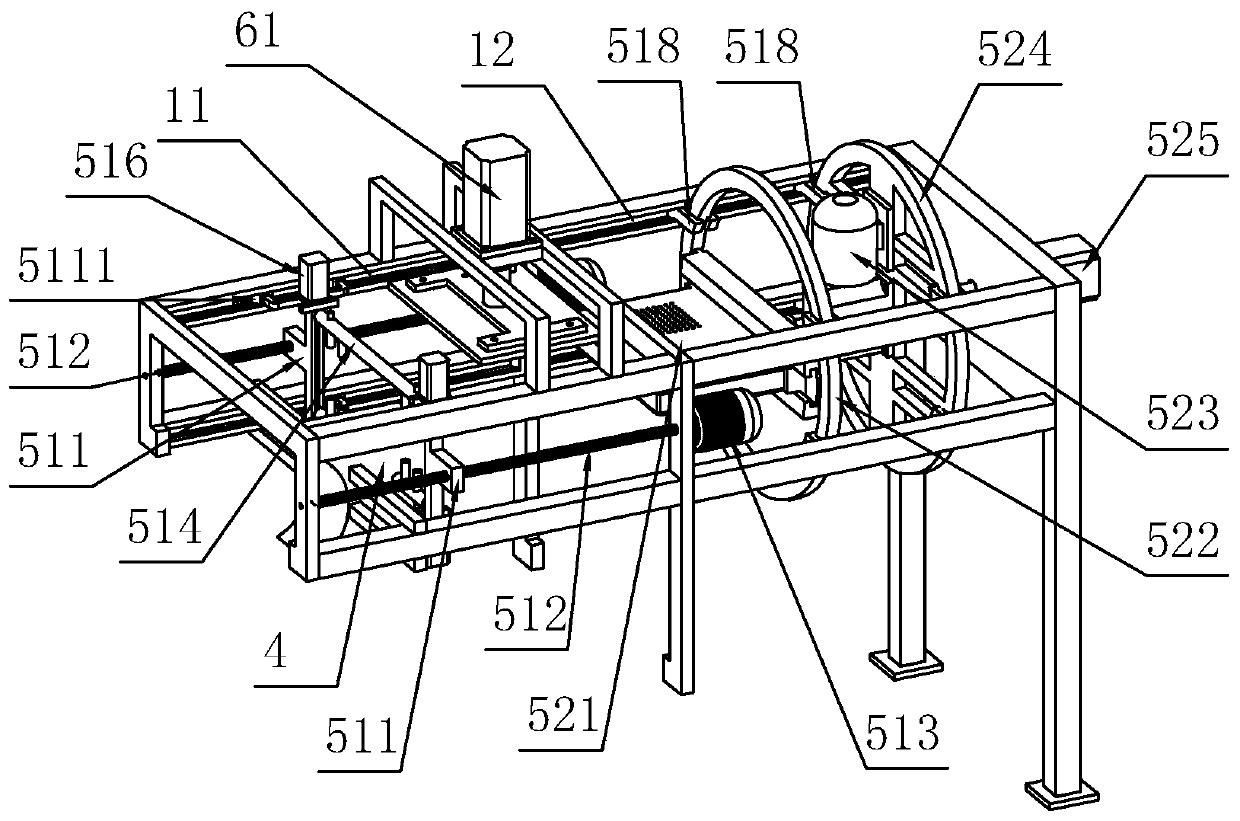

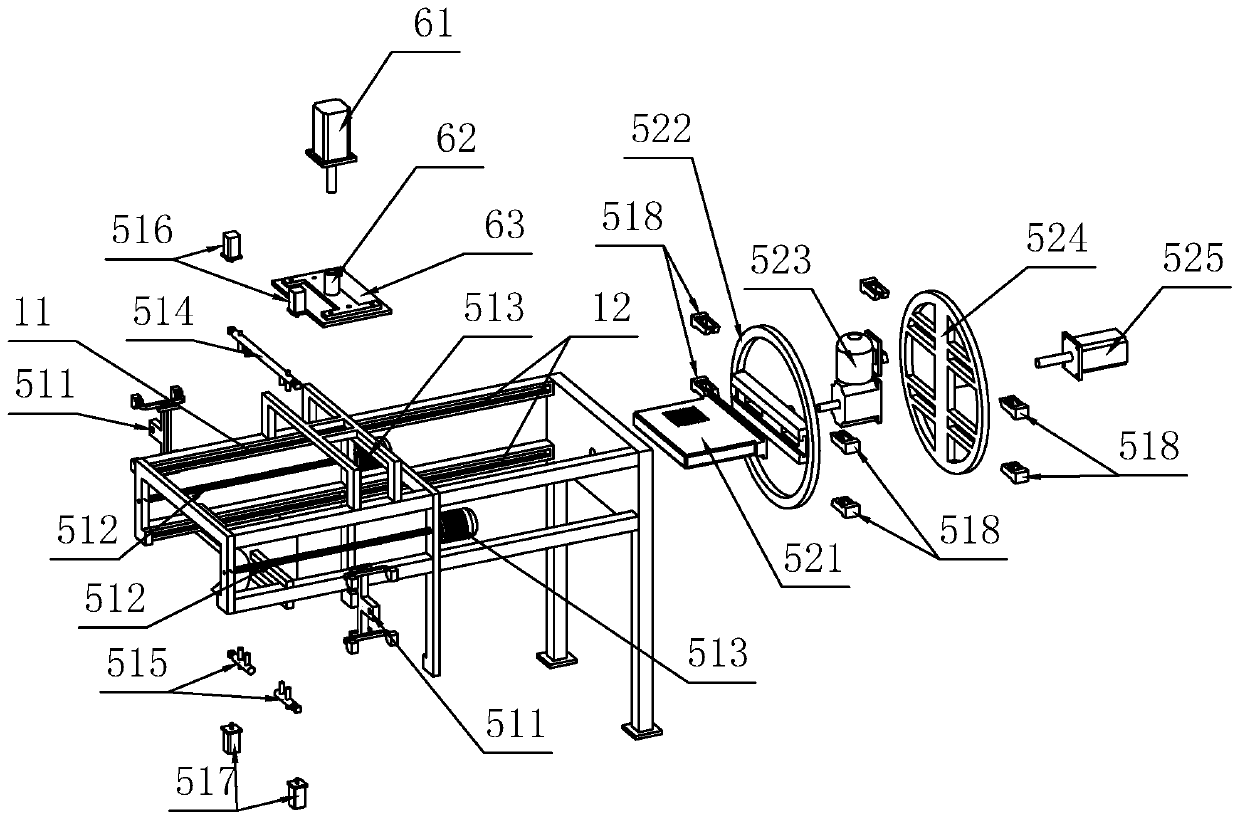

Jade ultrasonic engraving machine

InactiveCN112248705ARealize continuous engraving processingAvoid overprocessingOther artistic work equipmentsEngravingEngineeringElectric control

The invention discloses a jade ultrasonic engraving machine. The machine comprises a machine base, a conveying device, an ultrasonic engraving device and a workpiece feeding device; the conveying device comprises a rotating disc and a rotating driving mechanism; a plurality of tool groove holes are annularly and evenly distributed in the rotating disc; the rotating driving mechanism is in transmission connection with the rotating disc; the ultrasonic engraving device comprises an engraving head; the workpiece feeding device comprises an ejector rod part, an electronic ruler, a balance weight mechanism, a limiting mechanism and a controller; the engraving head and the ejector rod part are vertically and oppositely arranged on the upper side and the lower side of the rotating tracks of the tool groove holes; the balance weight mechanism is in transmission connection with the ejector rod part; the electronic ruler is used for detecting the position of the ejector rod part in the verticaldirection in real time; the limiting mechanism comprises an electric control limiting driving assembly capable of being in transmission connection with the ejector rod part; and the controller is configured to be used for controlling the electric control limiting driving assembly to operate after receiving signals of the electronic ruler. According to the jade ultrasonic engraving machine, the real-time machining progress can be fed back through the electronic ruler, and meanwhile pressure needed in the machining process is set through the balance weight mechanism.

Owner:四会市金东泰机械设备有限公司

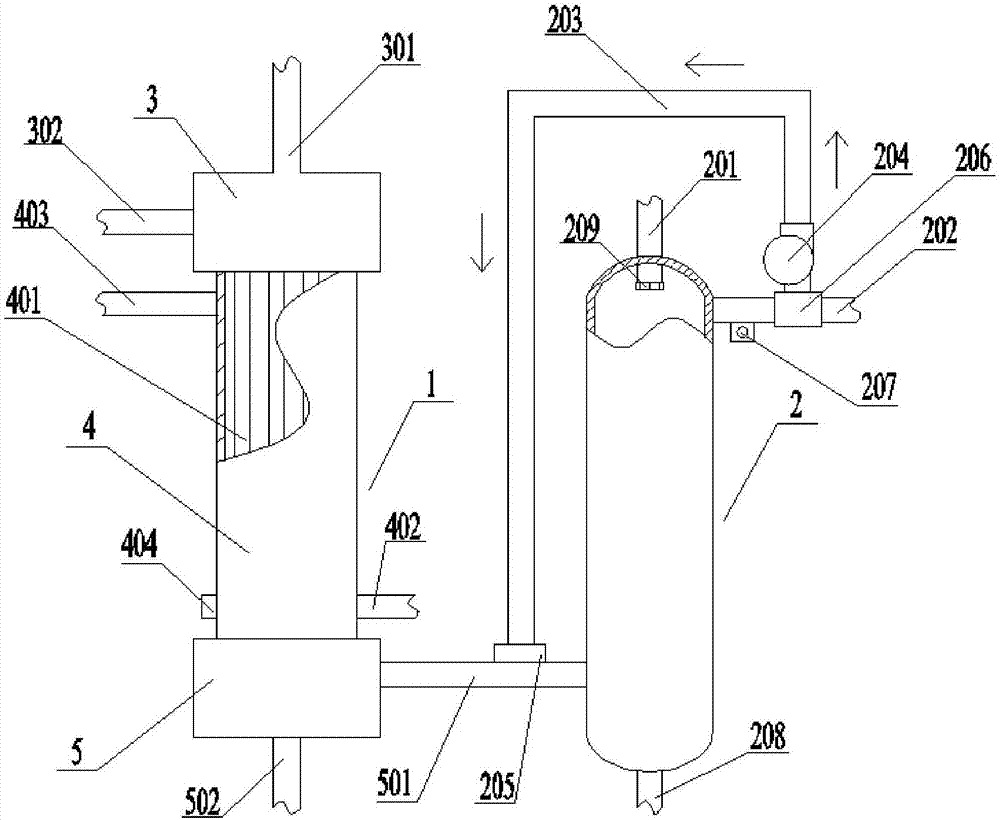

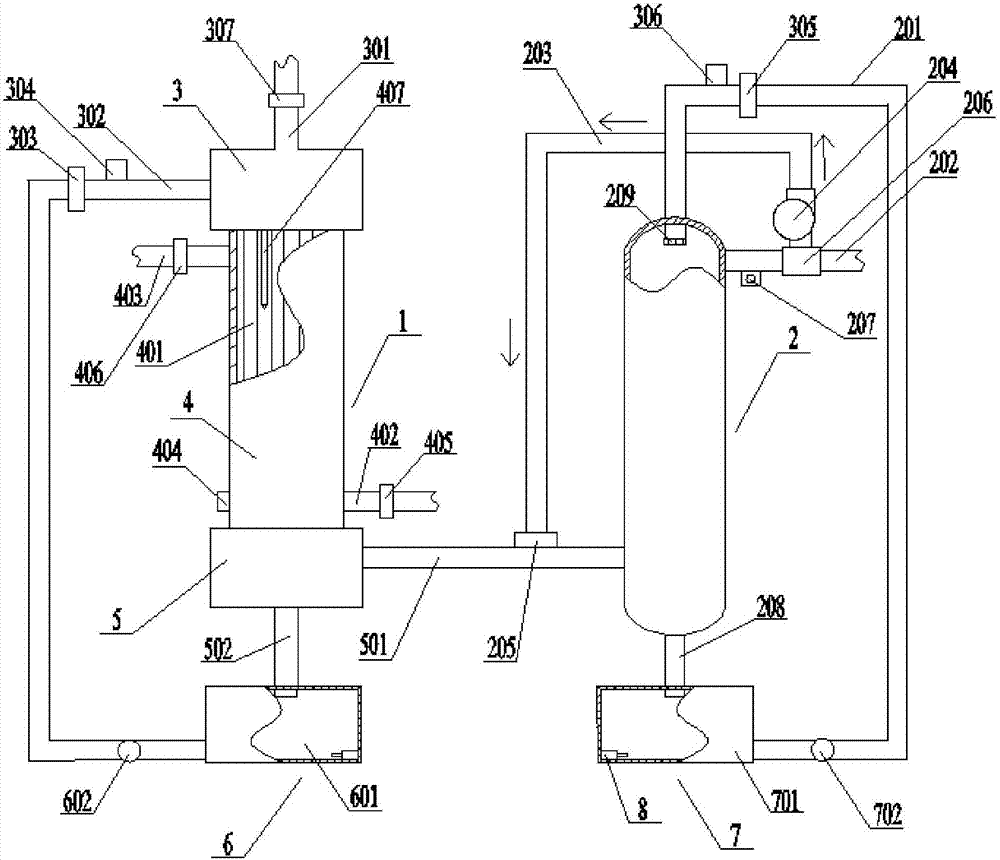

Tail gas treating method and treating system for preparing zirconium oxychloride by boiling chlorination process

PendingCN107261758AReduce difficulty and costAvoid overprocessingDispersed particle separationHydrogen chlorideZirconium oxychloride

The invention relates to the field of tail gas treatment by preparing zirconium oxychloride by a boiling chlorination process, in particular to a tail gas treating method and treating system for preparing the zirconium oxychloride by the boiling chlorination process. The tail gas treating method by preparing the zirconium oxychloride by the boiling chlorination process comprises the following steps: respectively introducing a liquid-state absorbing medium into a falling film absorber and a packing absorbing column; firstly introducing the tail gas containing hydrogen chloride into the falling film absorber, introducing the residual tail into the packing absorbing column along a tail gas conveying pipe, then performing hydrogen chloride gas concentration detection and exhausting tail gas. The tail gas treating method disclosed by the invention has the beneficial effects that dilute hydrochloric acid or water is utilized for absorbing hydrogen chloride gas, finally chlorine is converted into hydrochloric acid, alkali liquor is prevented from being utilized in a tail gas treating process, a sodium hypochlorite solution is prevented from being generated, tail gas treating cost and difficulty are reduced, effects of other components in the tail gas are avoided, the problem of excessively treating in the prior art is avoided, and the problems in the prior art are economically and effectively solved.

Owner:赤峰盛森硅业科技发展有限公司

A method for rapid aging and on-line monitoring of wine maturation by dynamic circulation ultrasonic

ActiveCN109777706BReal-time mastery of maturityReduce lossesComponent separationAlcoholic beverage preparationPeristaltic pumpEngineering

The invention discloses a method for rapidly aging by dynamic circulation ultrasonic and on-line monitoring of wine maturation, which belongs to the technical field of wine brewing. The system specifically includes an ultrasonic treatment tube, oak chips, an ultrasonic treatment pool, a diverter valve, and an ultraviolet-visible spectrophotometer. , a peristaltic pump, a conductivity meter, a temperature measuring sensor and a master control machine; the method includes: loading oak chips into an ultrasonic treatment tube; ultrasonic treatment; monitoring the aging; determining the aging state. The method of the invention can not only rapidly age the wine, but also realize the dynamic on-line monitoring of the wine, so as to facilitate real-time grasp of the ripening degree of the wine.

Owner:SHAANXI NORMAL UNIV

Multi-grade double-effect damage-prevention bast fiber treatment device

InactiveCN107805846AKeep stableImprove gripMechanical fibre separationEngineeringMechanical engineering

The invention relates to a multi-grade double-effect damage-prevention bast fiber treatment device. A treatment roller is provided with several groove holes, roller teeth are buried in the groove holes, springs and sleeves are arranged at the lower portion of the roller teeth, when under the effect of large external force, the roller teeth can be retracted into the groove holes, and then it is avoided that when the external force is too large, the roller teeth are damaged, so that the roller teeth are protected. The treatment roller is divided into several different areas in sequence accordingto the walking direction of a to-be-processed material, each area is internally provided with a corresponding treatment plate, groove hole, roller teeth, sleeve and spring, wherein the sleeves and the springs are matched with the roller teeth, the springs in the sleeves in different areas have different kinds of maximum elastic force, and the springs in spring rods in different areas have different kinds of maximum elastic force. Besides, according to different to-be-treated materials, the springs with the different kinds of maximum elastic force are replaced, so that the adaptability of a roller is also further improved, and the bast fiber can also be prevented from being damaged.

Owner:桐乡佳车科技股份有限公司

An image processing method and device

ActiveCN106251358BImprove removal qualityImprove removal efficiencyImage analysisPattern recognitionPartial loss

Embodiments of the present invention provide an image processing method and apparatus. In one aspect, the embodiments of the present invention relate to dividing an image to be processed into at least two data blocks, and then identifying each data block to obtain the identification result of each data block, the identification result of each data block comprising the data block being a content data block or the data block being a background data block; obtaining a background removal threshold of each data block according to the identification result of each data block; and removing the background of each data block according to the background removal threshold of each data block. Therefore, the technical solution provided by the embodiments of the present invention can solve the problems in the prior art of over-processing and partial loss of image content caused thereby due to unified background removal of an entire image.

Owner:ZHUHAI PANTUM ELECTRONICS

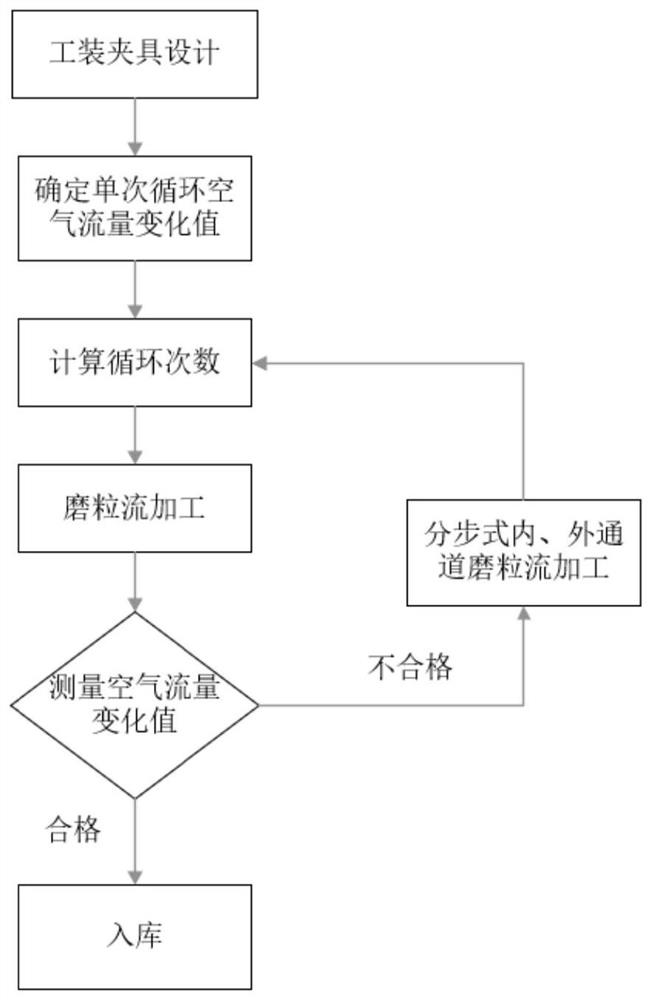

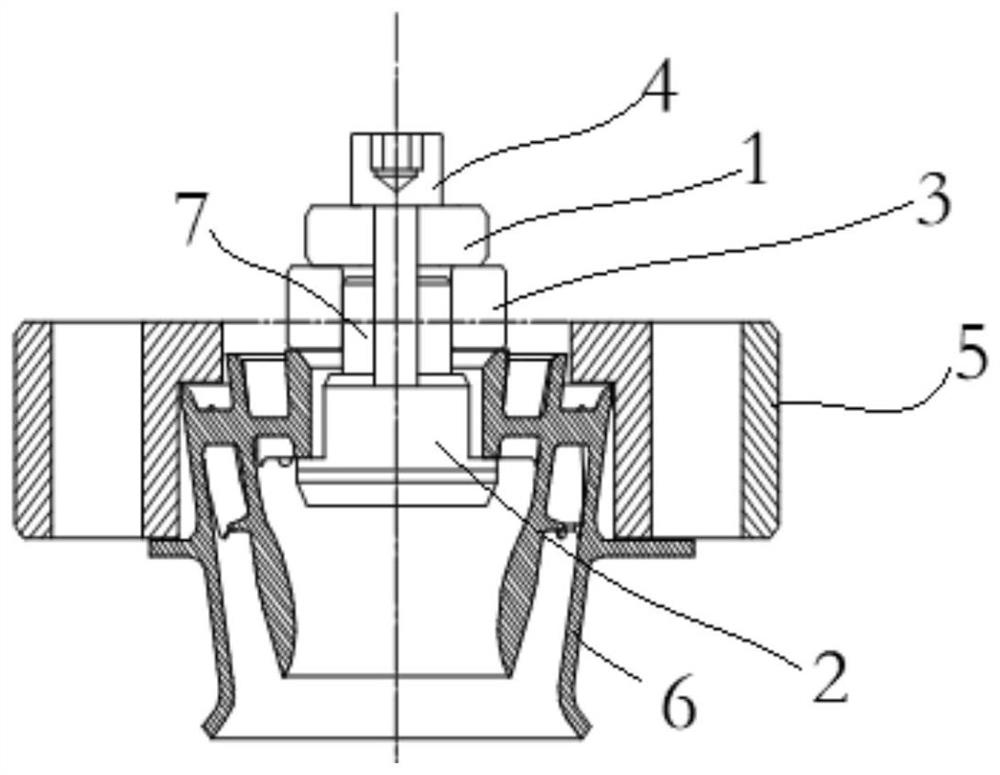

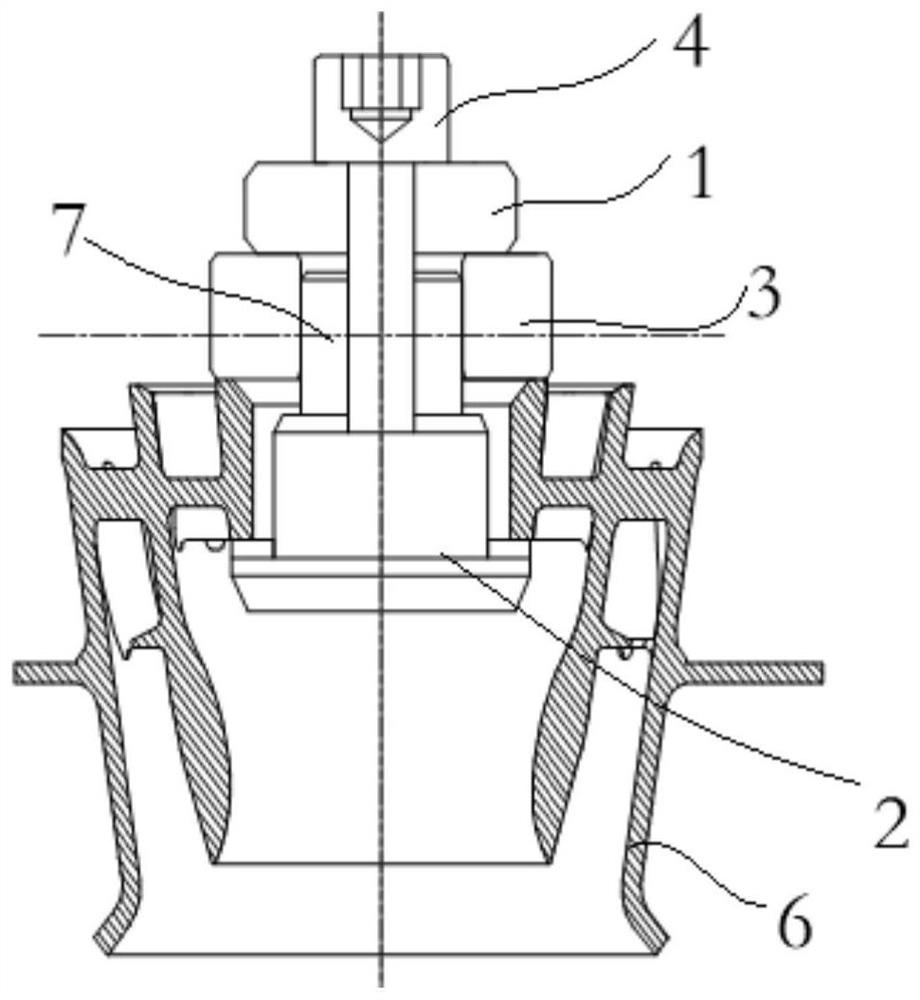

Swirler air flow controllable abrasive flow machining method and machining plugging device

InactiveCN112059892AAvoid the problem of uneven manual polishingMeet the design requirementsEdge grinding machinesPolishing machinesEngineeringAbrasive flow machining

The invention discloses a swirler air flow controllable abrasive flow machining method and machining plugging device. The method comprises the steps that: an air flow initial value of a to-be-machinedchannel on a to-be-machined swirler is measured, a variable quantity is determined through a circulating abrasive flow machining method, the maximum machining cycle index is determined according to the air flow maximum value of the channel to be machined and the variable quantity of one-cycle machining, the product of the maximum machining cycle index and the variable quantity of one cycle machining is smaller than the air flow maximum value of the to-be-machined channel, and abrasive flow machining is conducted on the to-be-machined channel according to the maximum machining cycle index, andthe to-be-machined channel is subjected to finish machining till air flow of the to-be-machined channel meets the design requirement. The controllable abrasive flow machining is used, the requirementthat an air flow value of a swirler meets the requirement of a high-precision design drawing can be met, a design flow requirement can be met through one-time machining, repeated rework is not needed, and uniform thinning of the surface of a part flow channel is not needed. The problem of uneven manual polishing and repairing of workers is avoided, and the machining quality stability is improved.

Owner:AECC AVIATION POWER CO LTD

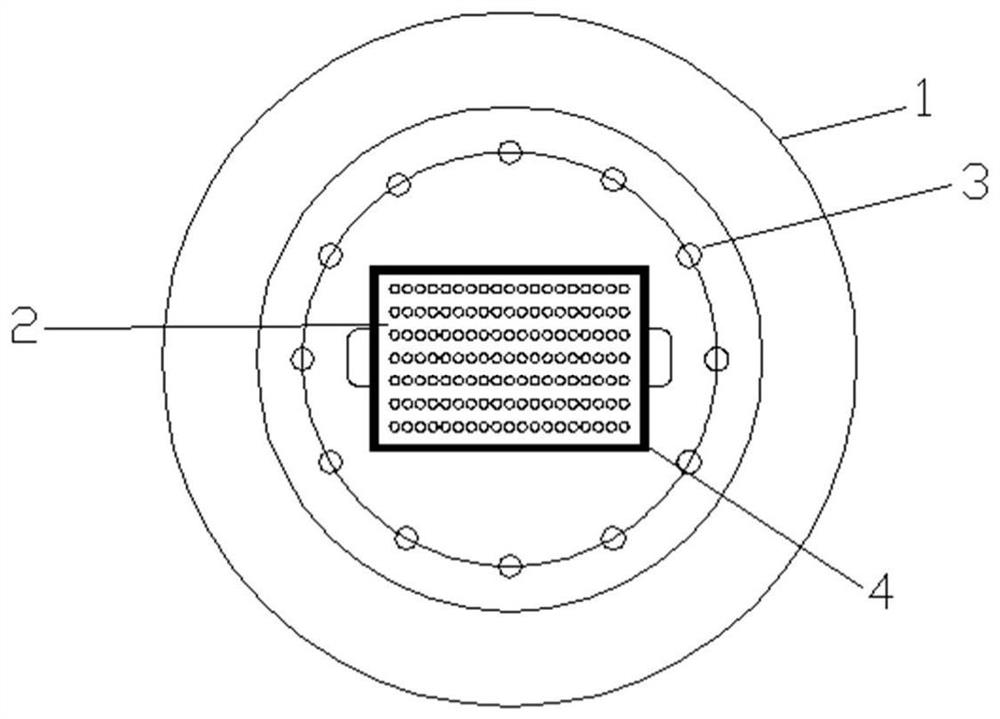

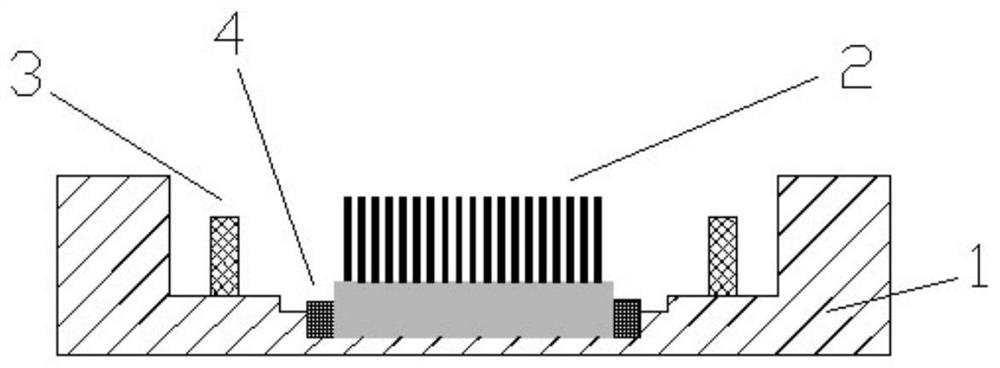

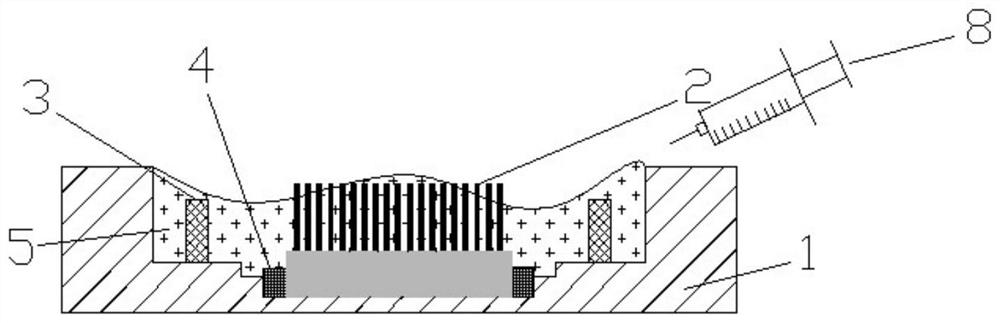

Non-destructive grinding method and device for welding column of CCGA device

ActiveCN113421830ANon-destructive grindingWear leveling achievedSemiconductor/solid-state device manufacturingGrinding machinesEconomic benefitsStructural engineering

The invention discloses a non-destructive grinding method and device for a welding column of a CCGA device. The method comprises the steps of carrying out potting on the welding column end of the CCGA device to be trimmed through adopting a method for carrying out potting on the welding column of the CCGA device to be trimmed through injection molding resin, then grinding the potted welding column end of the CCGA device to be trimmed until the remaining height of the welding column meets the design requirement, fixing the welding column through adopting an injection molding method before being ground so as to ensure that the side wall of the welding column cannot be damaged in the grinding process, the perpendicularity of the welding column cannot become poor, and finally, removing injection molding resin for potting the welding column in a chemical dissolution mode after grinding is completed. Therefore, no mechanical stress exists in the whole process, lossless grinding of the welding column is achieved, the welding column deformation and damage caused by mechanical clamping can be greatly reduced, and the method has important application value for manufacturing high-reliability CCGA and has good application prospects and economic benefits. Through detection, high-quality welding column grinding with the perpendicularity within 3 degrees and no mechanical damage to the side wall can be achieved, and the method is superior to a column planting grinding method in the current industry.

Owner:珠海天成先进半导体科技有限公司

Low-voltage battery power-on control method and device of electric vehicle and electric vehicle

ActiveCN112537203BReduced non-reality performanceGuaranteed non-authenticity performanceElectric devicesElectric powerEngineeringElectric vehicle

The invention provides a low-voltage battery power-on control method and device of an electric vehicle and the electric vehicle, and relates to the field of power-on processing of the low-voltage battery of the electric vehicle. The low-voltage battery power-on control method of the electric vehicle includes: obtaining the performance degradation judgment result of the previous power-on cycle of the current power-on cycle of the low-voltage battery and the wake-up times N of the controller in the power-on process of the low-voltage battery i ; According to the performance degradation judgment result and the wake-up times N i , determining the low-voltage power-on mode of the current power-on cycle of the low-voltage battery; acquiring the performance degradation judgment result of the low-voltage battery when the low-voltage battery is powered on according to the low-voltage power-on mode in the current power-on cycle and the wake-up times of the controller . In the embodiment of the present invention, the stability and smoothness of the output voltage during the power-on process of the low-voltage battery are ensured through the detection of the performance degradation of the battery and the wake-up of the controller in stages, thereby ensuring a better driving experience.

Owner:BEIJING ELECTRIC VEHICLE

Non-woven fabric bag trepanning machine

ActiveCN111438992APrecise processingPrecise hole positionBag making operationsPaper-makingElectric machineryStructural engineering

The invention relates to a non-woven fabric bag trepanning machine. A rack is included and provided with a feeding platform, a bag body expanding mechanism and a trepanning mechanism. The bag body expanding mechanism comprises a transmission assembly and a tight expanding assembly. The transmission assembly comprises a horizontal sliding frame, a lead screw, a horizontal drive motor, an upper negative pressure suction pipe, a lower negative pressure suction pipe, an upper drive air cylinder and a lower drive air cylinder. The rack is provided with a horizontal track. A vertical track is arranged on the horizontal sliding frame. The lead screw is rotationally arranged on the rack. The horizontal sliding frame is in threaded connection to the lead screw. The vertical downward side of the upper negative pressure suction pipe is provided with an upper adsorption port, and the vertical upward side of the lower negative pressure suction pipe is provided with a lower adsorption port. The tight expanding assembly comprises a tight expanding module, and the tight expanding module is provided with hole-position-corresponding die hole positions. By adoption of the above scheme, the non-wovenfabric bag trepanning machine is provided, sewn non-woven fabric bags can be expanded, the parts needing trepanning are directly punched, and quantitative and high-precision production of non-woven fabric bags is achieved.

Owner:浙江中宇节能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com