Patents

Literature

93 results about "Abrasive flow machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

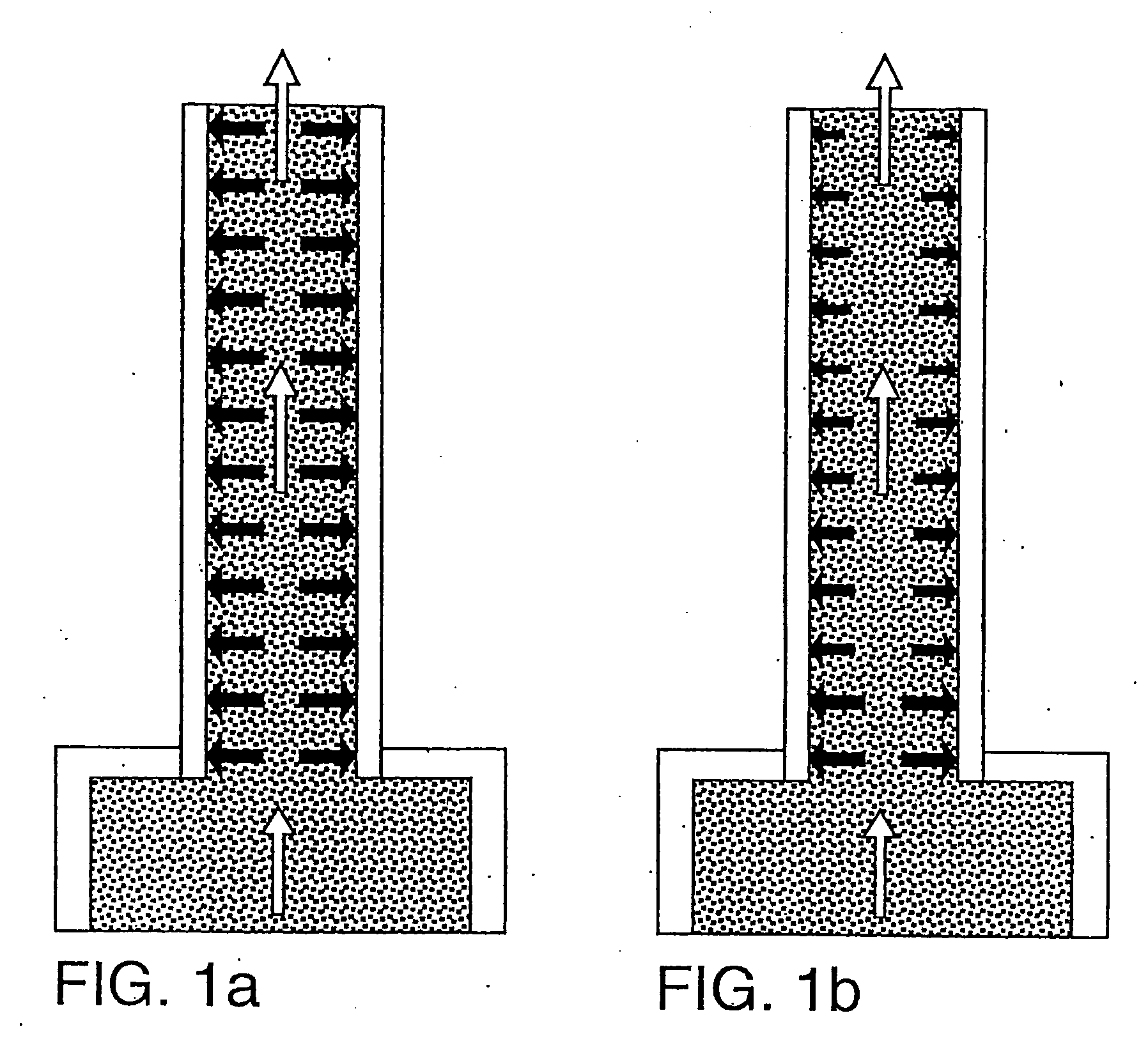

Abrasive flow machining (AFM), also known as abrasive flow deburring or extrude honing, is an interior surface finishing process characterized by flowing an abrasive-laden fluid through a workpiece. This fluid is typically very viscous, having the consistency of putty, or dough. AFM smooths and finishes rough surfaces, and is specifically used to remove burrs, polish surfaces, form radii, and even remove material. The nature of AFM makes it ideal for interior surfaces, slots, holes, cavities, and other areas that may be difficult to reach with other polishing or grinding processes. Due to its low material removal rate, AFM is not typically used for large stock-removal operations, although it can be.

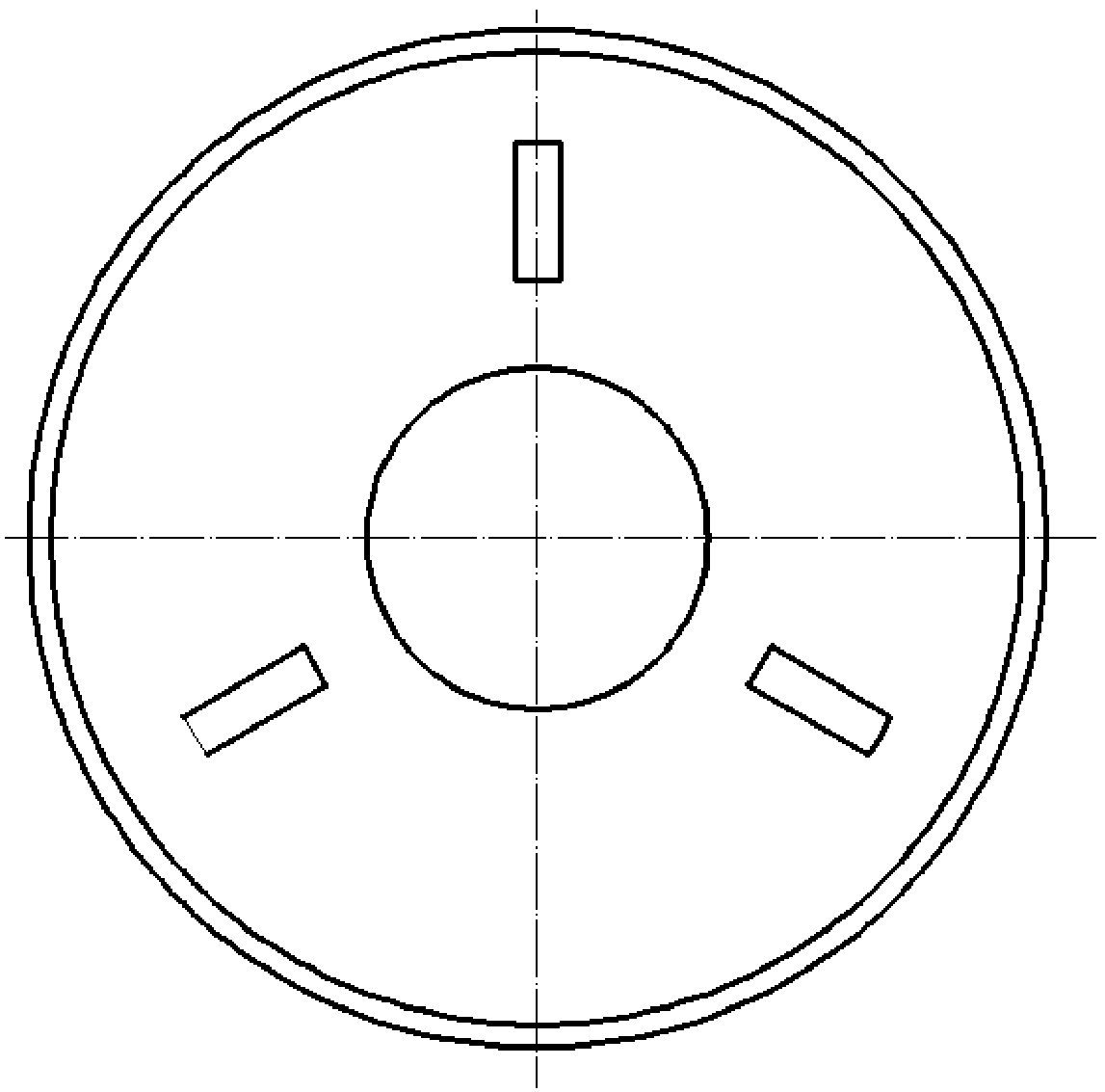

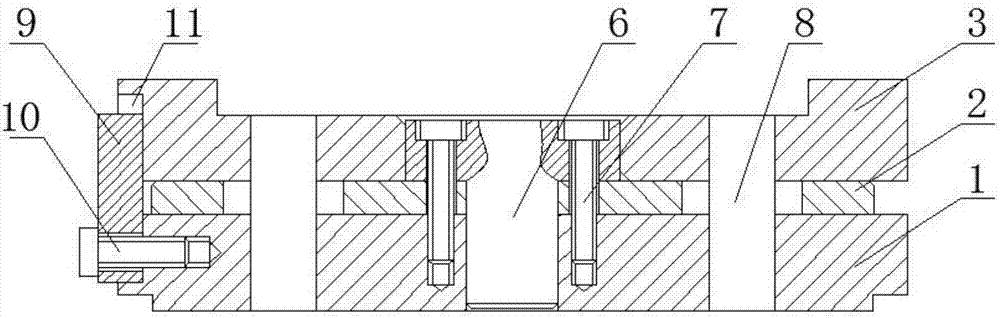

Special clamp for abrasive flow polishing of narrow flow passage closed impeller flow passage

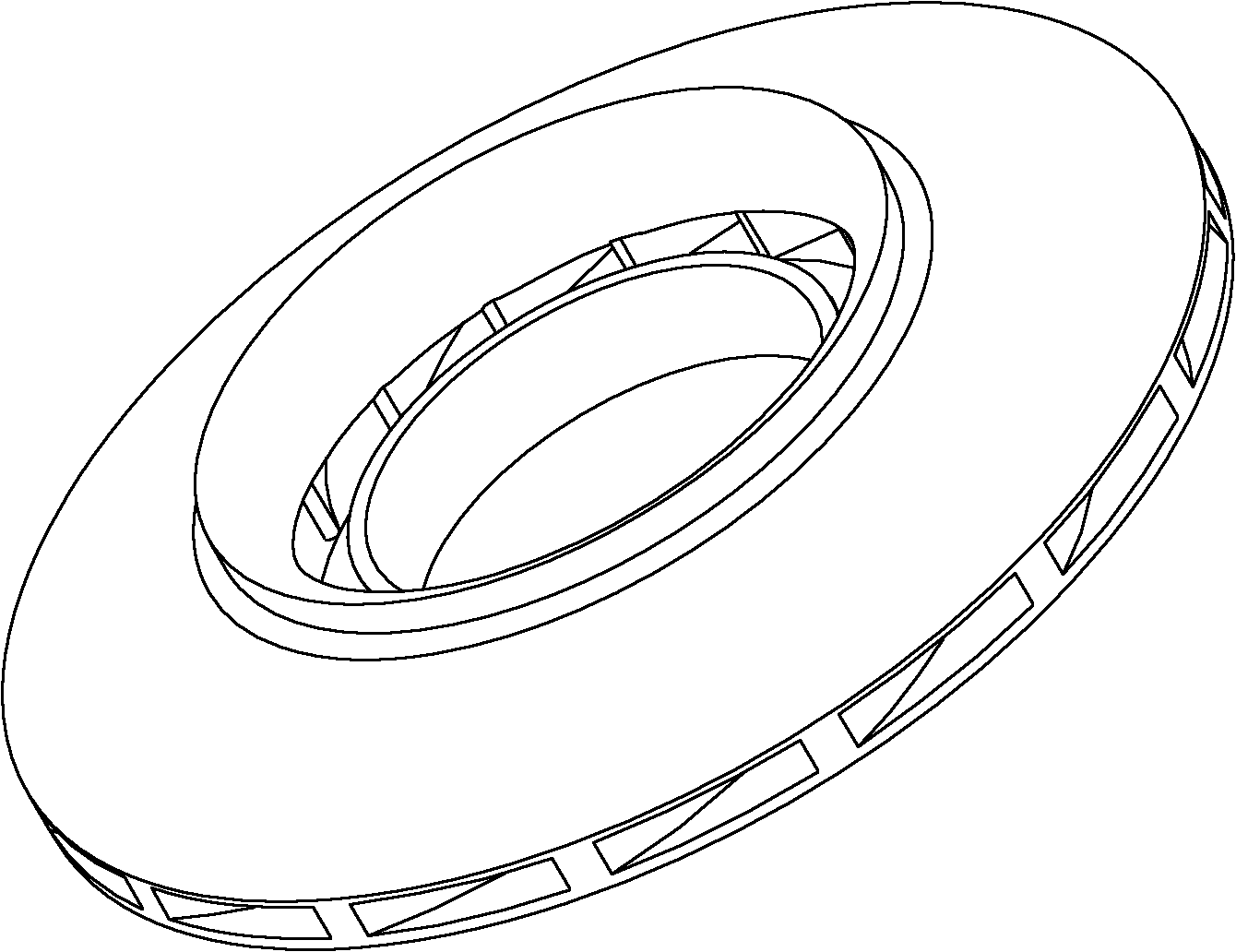

InactiveCN102152244ARealize up and down reciprocating flowAvoid damagePolishing machinesEngine manufactureImpellerCircular disc

The invention discloses a special clamp for abrasive flow polishing of a narrow flow passage closed impeller flow passage. The special clamp comprises an upper mold, a lower mold, a floating lock and a gasket support plate, wherein the upper mold and the lower mold form a cylindrical cavity; the inner diameter of the cylindrical cavity is greater than the diameter of the impellers; the gasket support plate is a round disc having the diameter as the same as the diameter of the impellers; the floating lock consists of an upper round disc and a lower round disc and a double-head stud and a bolt which are used for connecting the two round discs; the mounted floating lock can move between the gasket support plate and the lower mold; the impellers are arranged on the gasket support plate, and are fastened by the upper mold and the lower mold; and the upper mold and the lower mold are positioned through seam allowance, and are fixed by the bolts. The clamp for abrasive flow machining of the narrow plow passage closed impellers can be used for fixing the impellers and can guide abrasive materials to flow through the surface of the impeller flow passage, and keep a given pressure so as to grind and polish the internal part of the impeller flow passage, form a circular loop and realize reciprocating flow of the abrasive materials.

Owner:DALIAN POLYTECHNIC UNIVERSITY

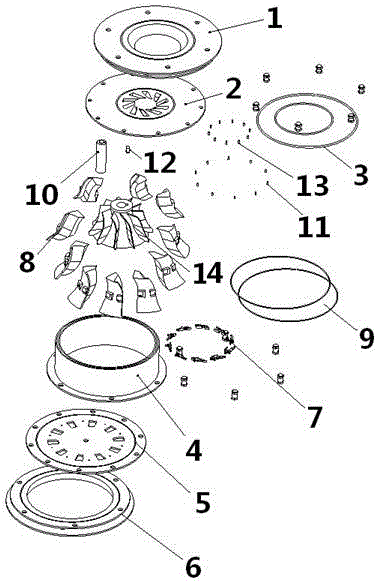

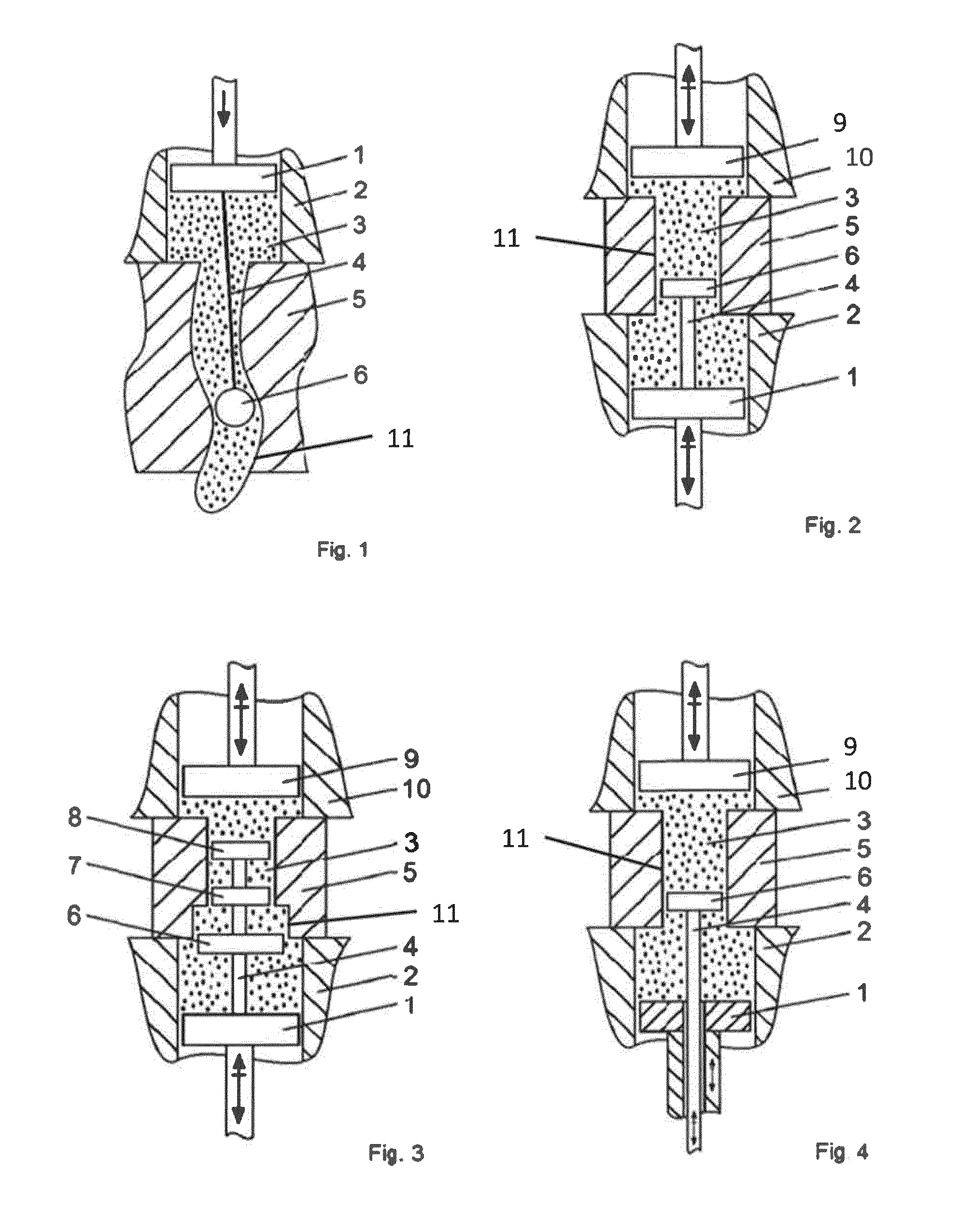

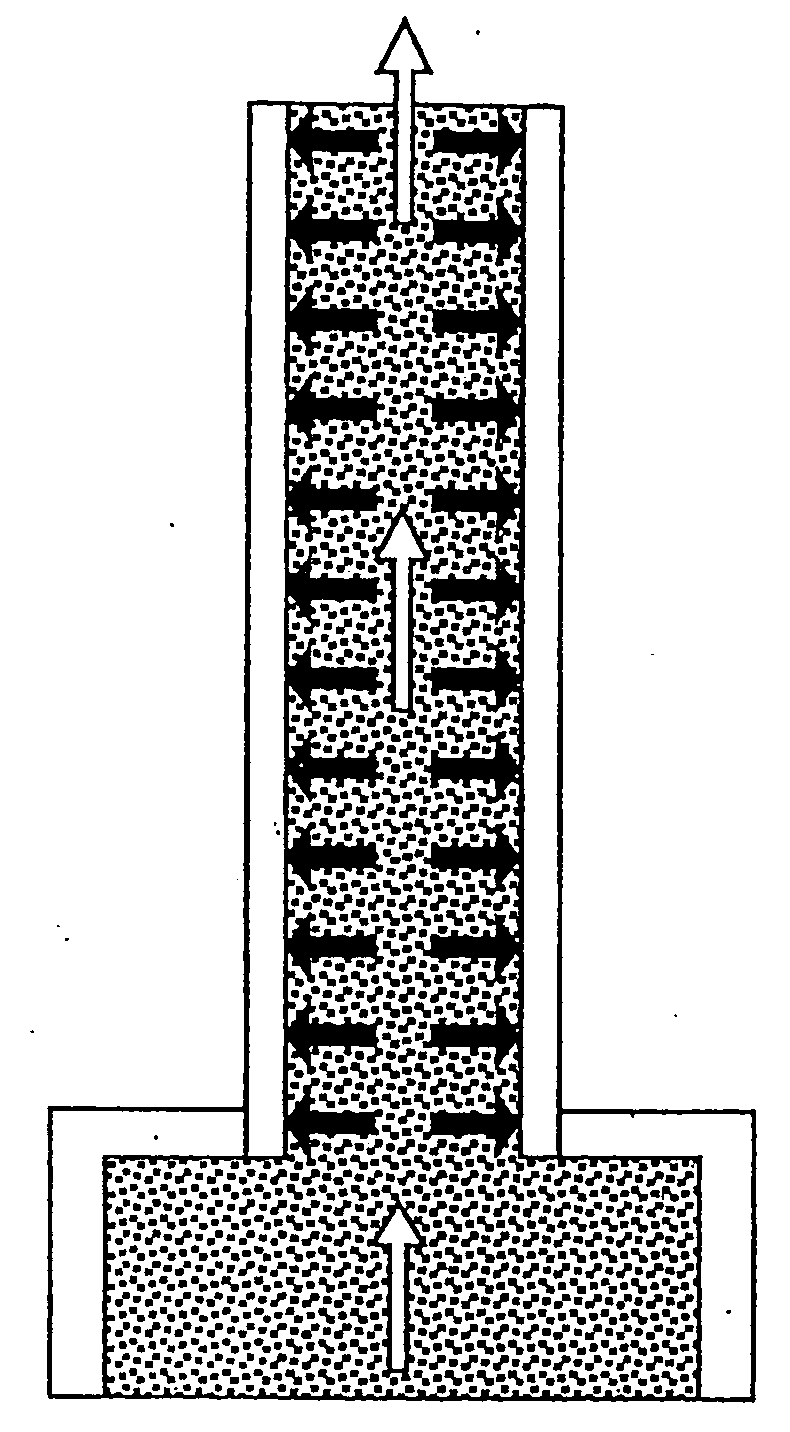

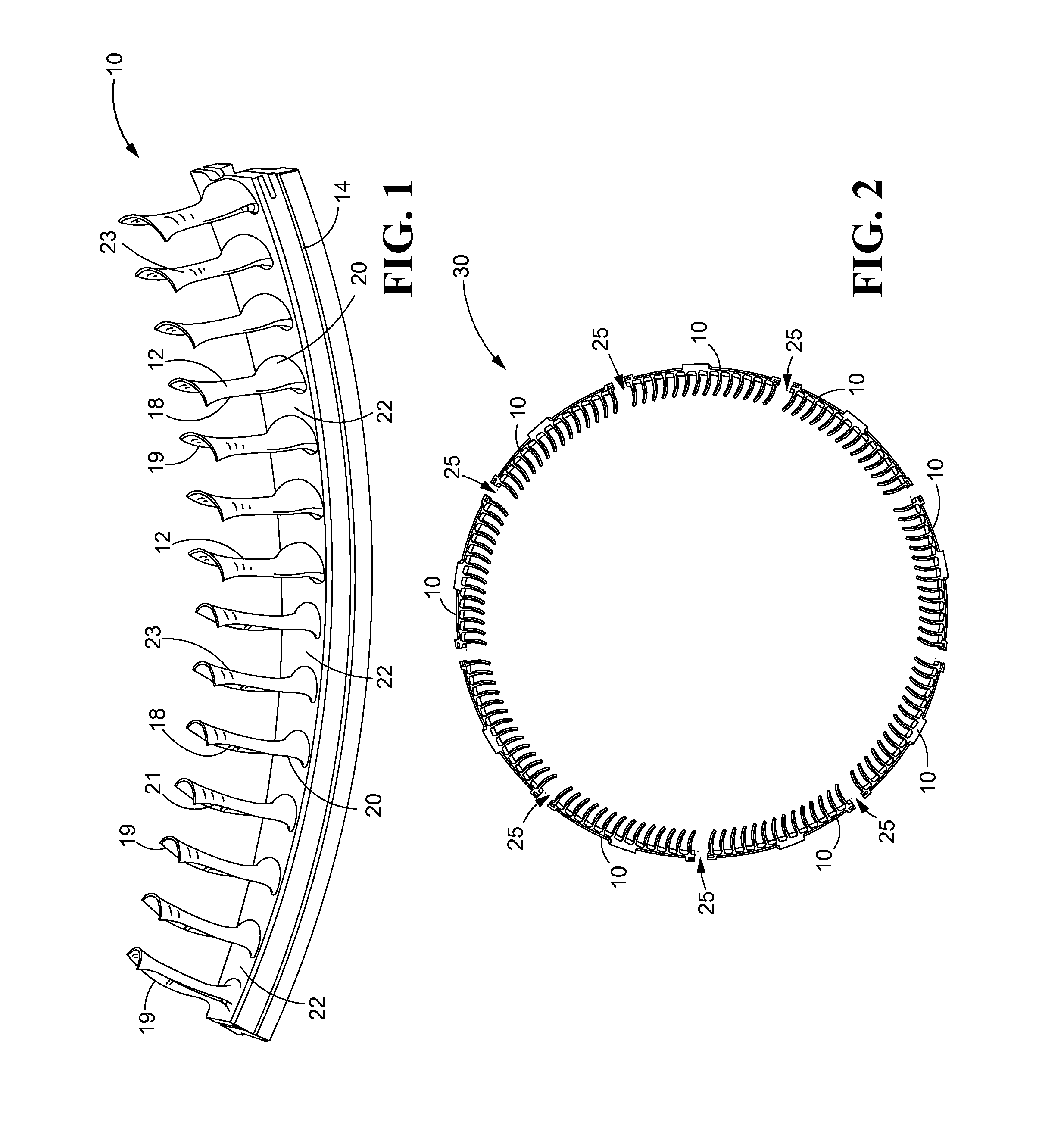

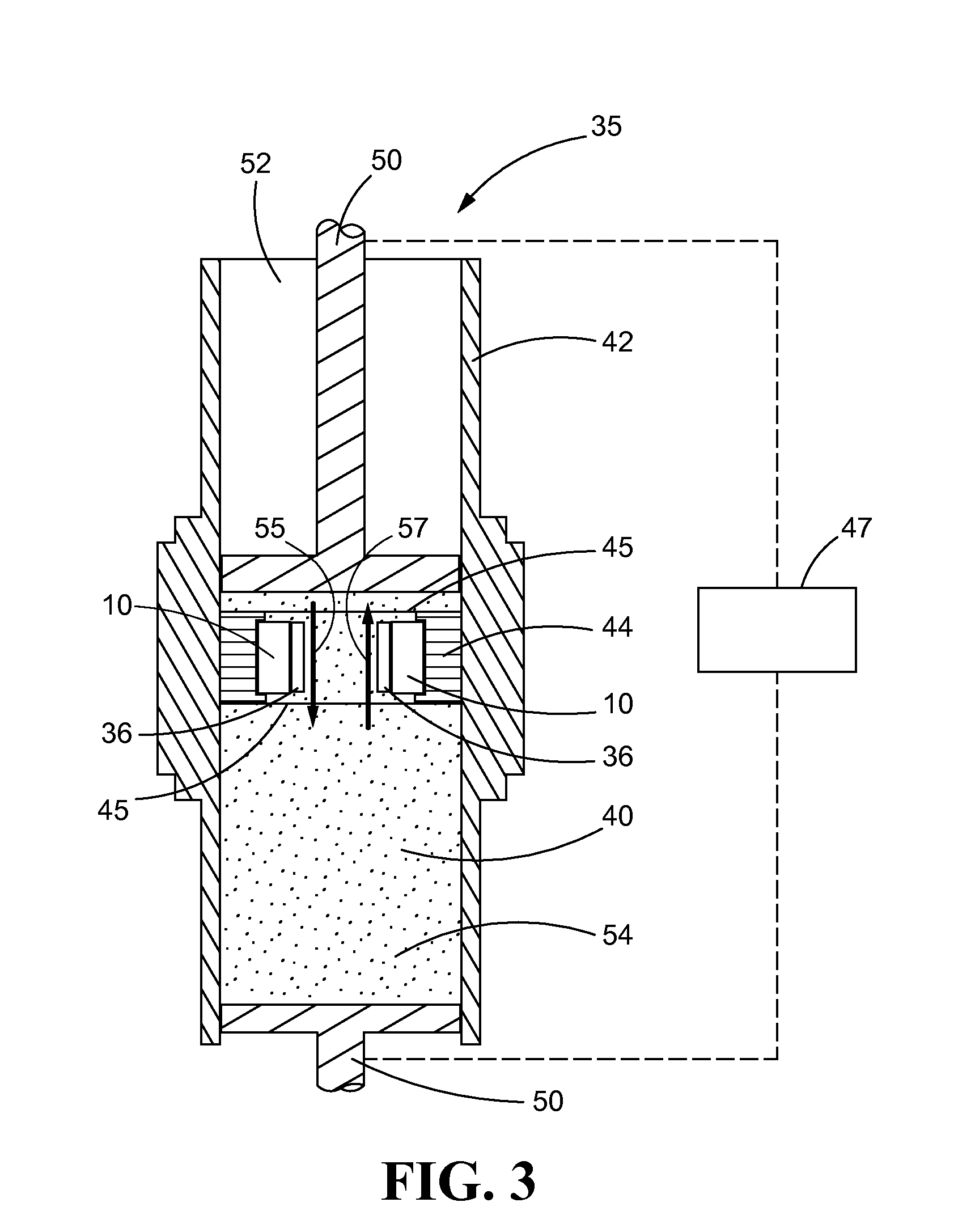

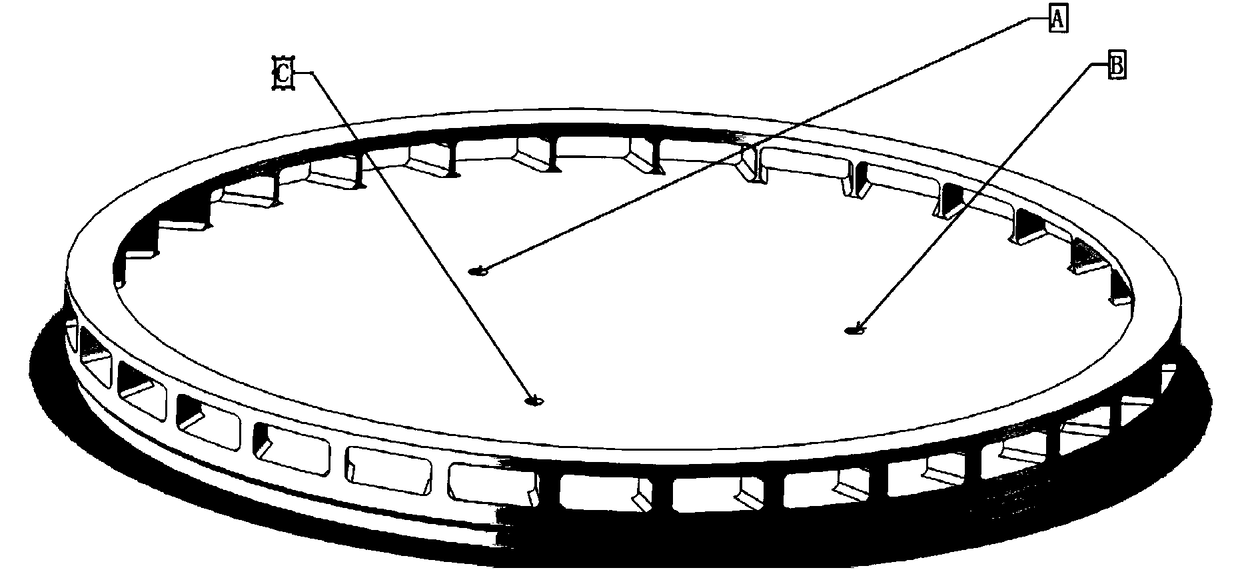

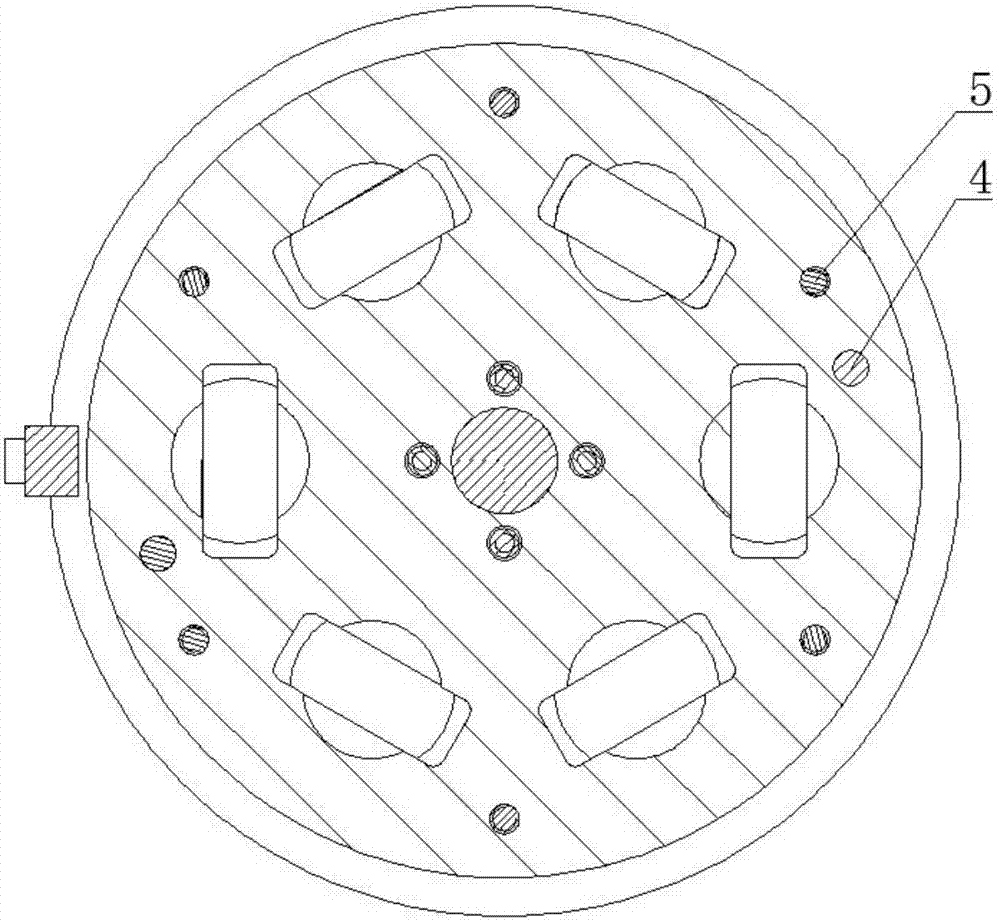

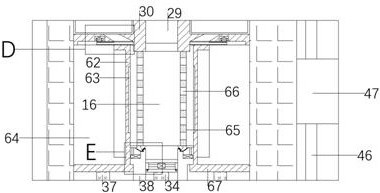

Flexible coupling module type blisk abrasive flow machining polishing clamp

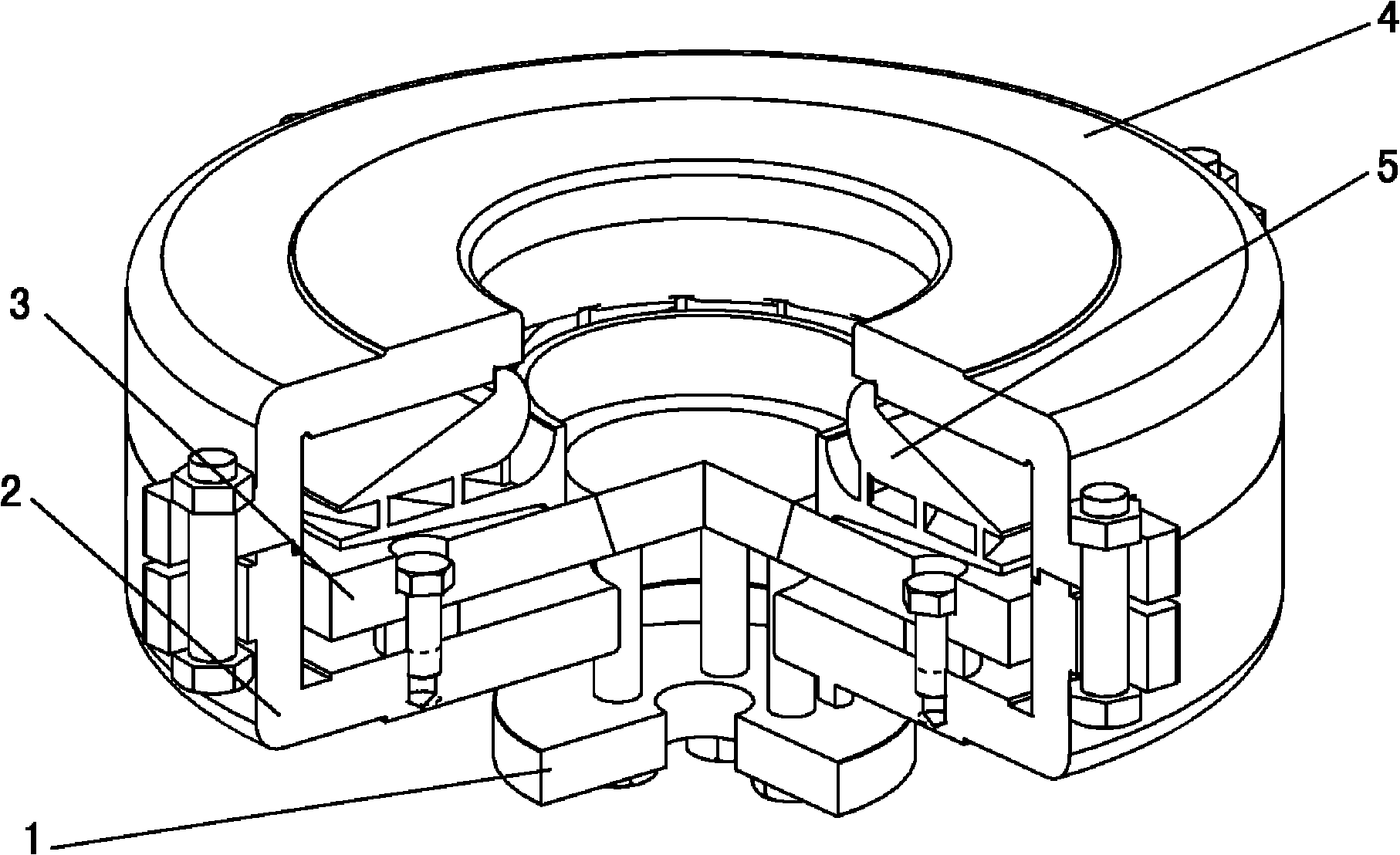

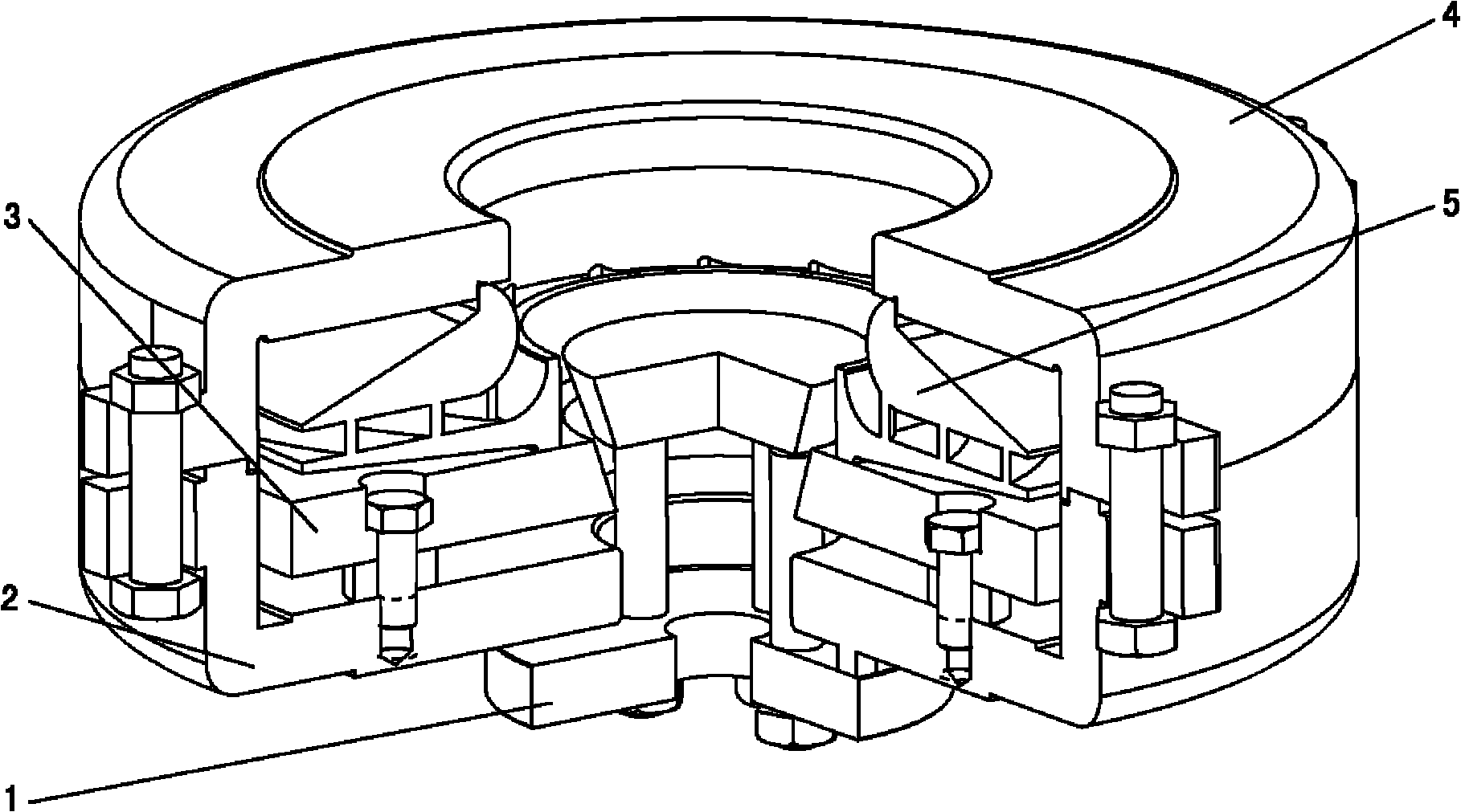

InactiveCN106625193ACause damageGuaranteed uniformityEdge grinding machinesPolishing machinesAbrasive flow machiningTurbine

The invention discloses a flexible coupling module type blisk abrasive flow machining polishing clamp. The flexible coupling module type blisk abrasive flow machining polishing clamp comprises an upper flow distributing plate, an outer sleeve, a lower flow distributing plate, restraining modules, a center shaft and a locating pin. Each restraining module is composed of restraining sub-modules, wherein the number of the restraining sub-modules is identical with that of blades of the turbine blisk. Gap flow channels are formed between the restraining sub-modules and the blades of the turbine blisk. Each restraining sub-module on the corresponding gap flow channel and the surface of the corresponding blade of the turbine blisk are provided with coupled curved surface shapes. The sections, in the direction perpendicular to the curved surface of the blades, of the gap flow channels are identical and have the same width. In the polishing process, abrasive materials flow into the gap flow channels between the restraining sub-modules and the blades of the turbine blisk along a flow distributing channel of the upper flow distributing plate. Double layers of flow guide plates enable the abrasive materials to be continuous and stable when the abrasive materials enter the gap flow channels. In the abrasive flow machining polishing process, the inner surface of each gap flow channel which the abrasive materials pass through always keeps the same distance away from the surface of the corresponding blade, and the surface quality of the blades is guaranteed to be uniform. The combined clamping manner is adopted by the restraining modules, and turbine blisks of different types and sizes can be polished.

Owner:CHANGCHUN UNIV OF SCI & TECH

Abrasive flow machining numerical simulation research method based on molecular dynamics

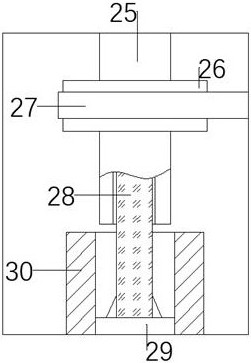

InactiveCN104657564AAchieve micromachiningImplementing Molecular Dynamics SimulationsSpecial data processing applicationsEnergy variationMachined surface

The invention relates to an abrasive flow machining numerical simulation research method based on molecular dynamics. According to the method, numerical simulation researches are carried out on a machining course by taking a single abrasive grain as a tool. Specifically, the method comprises the following steps: (1) carrying out abrasive flow machining course simulation researches on the basis of molecular dynamics; (2) establishing an abrasive micro-cutting molecular dynamic model; (3) discussing the influence of related parameters on energy change in the machining course and analyzing the quality of a machined surface; and (4) exploring the influence of abrasive machining on an abrasive crystal structure at a micro-scale. According to the method disclosed by the invention, by researching and analyzing a single-abrasive micro-cutting process in the abrasive flow machining course by virtue of a molecular dynamics method, atomic displacement in a Newtonian layer of a workpiece during the abrasive micro-cutting process can be calibrated; and the method can be used for achieving molecular dynamic simulation of abrasive grains and pointing out that bond angle of an abrasive grain can be changed in the course of machining the abrasive grains, so as to lay a theoretical foundation for the subsequent researches on the deformation of the abrasive crystal structure in the abrasive flow machining course.

Owner:CHANGCHUN UNIV OF SCI & TECH

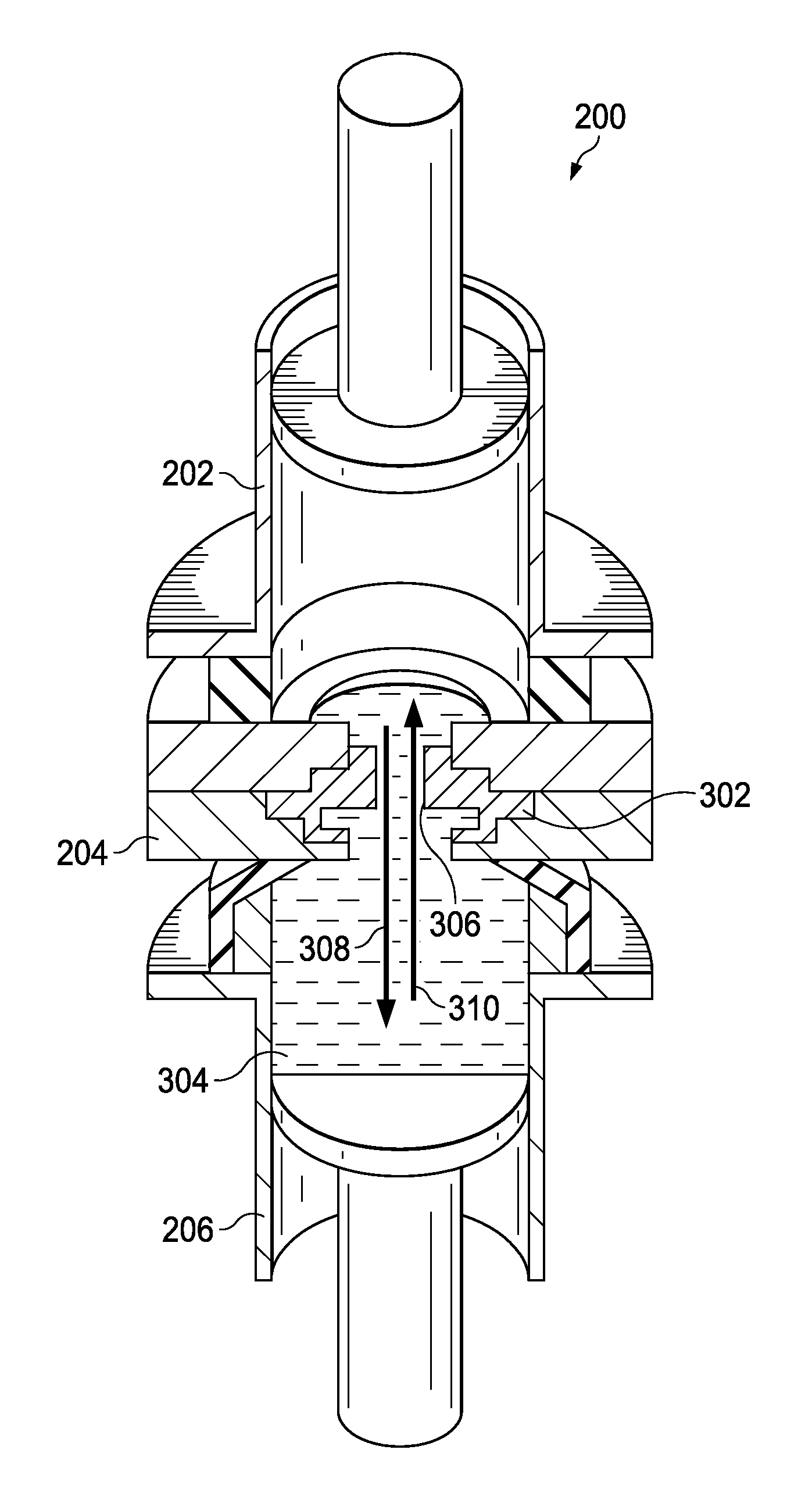

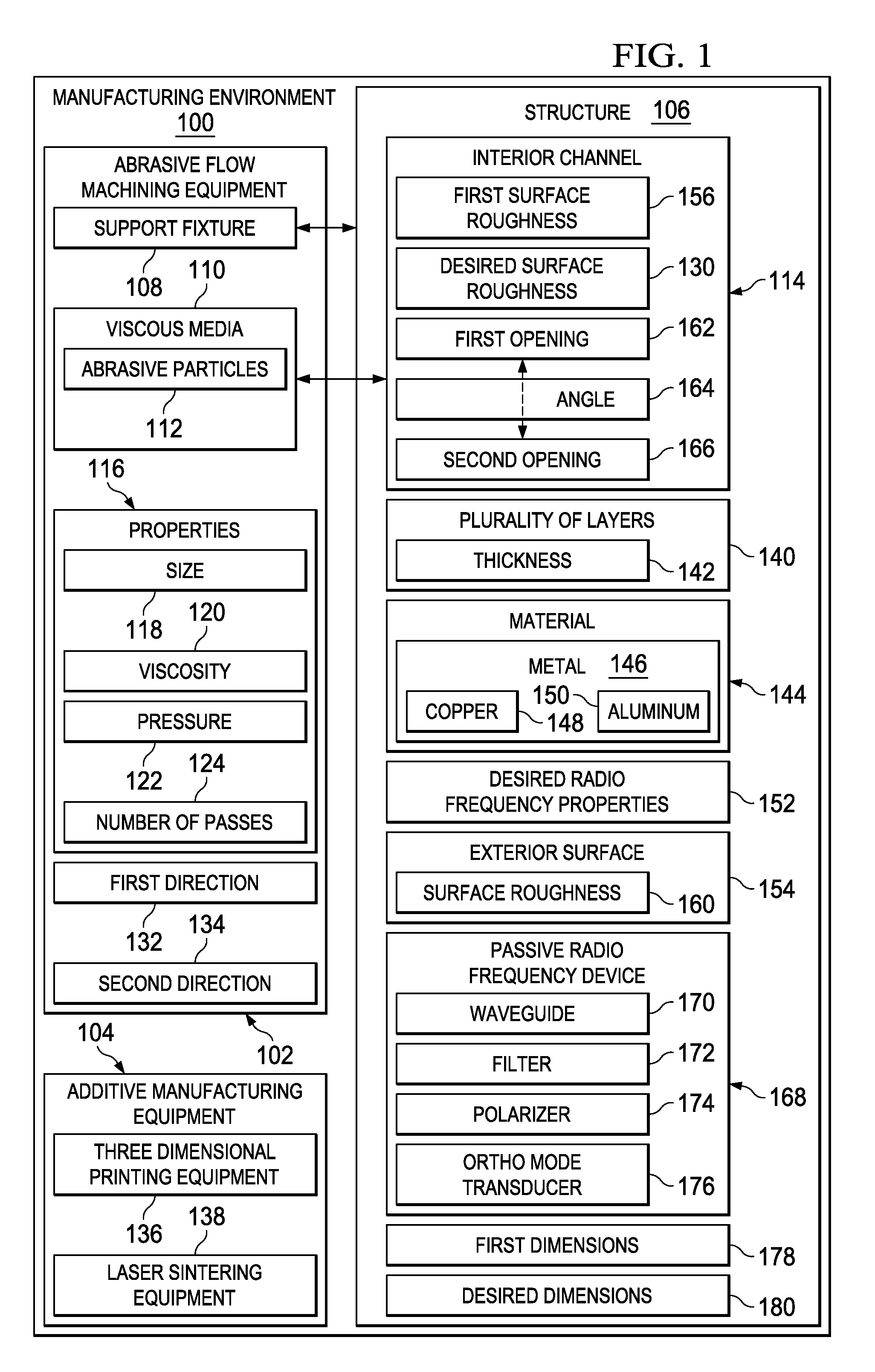

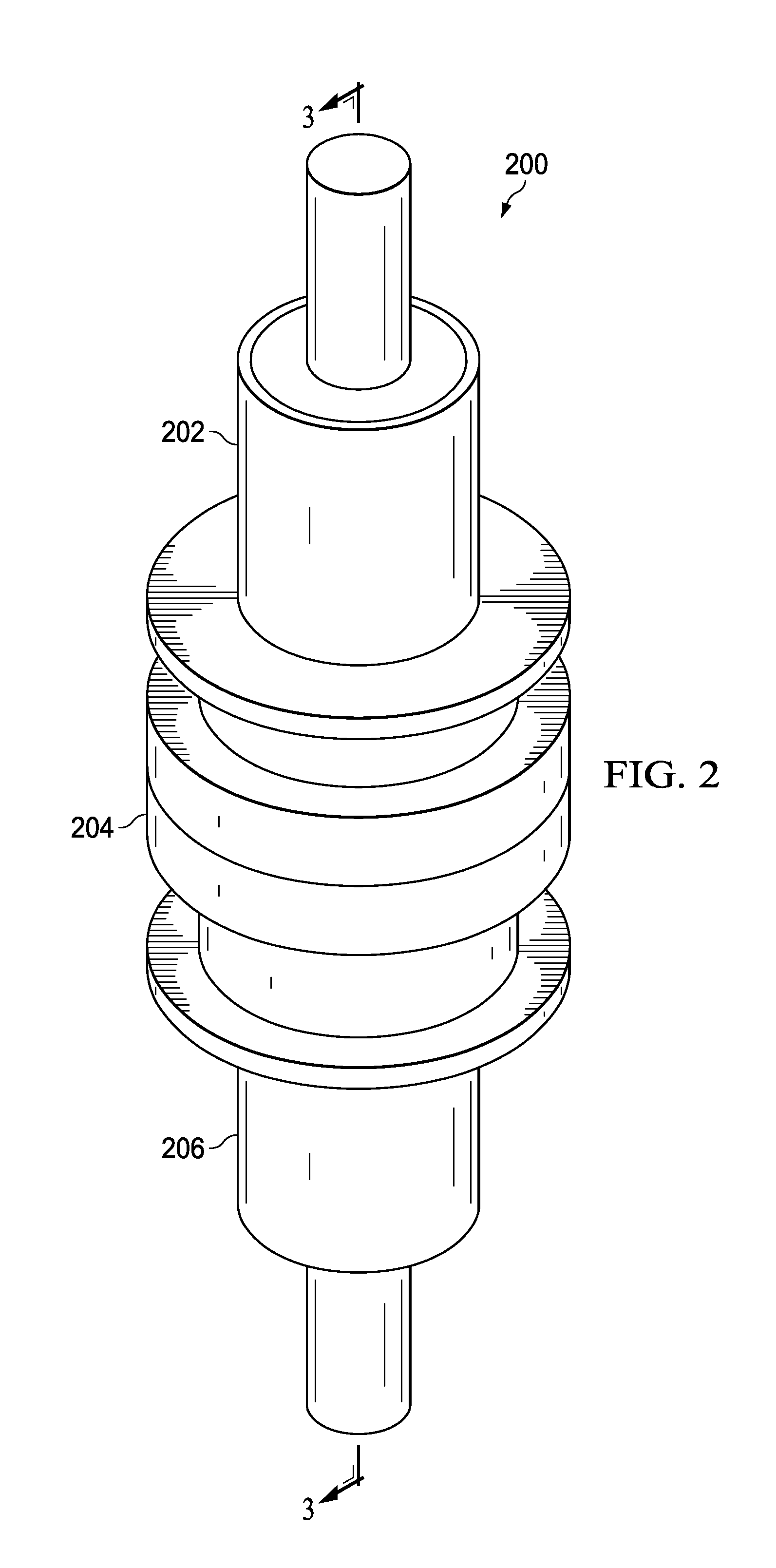

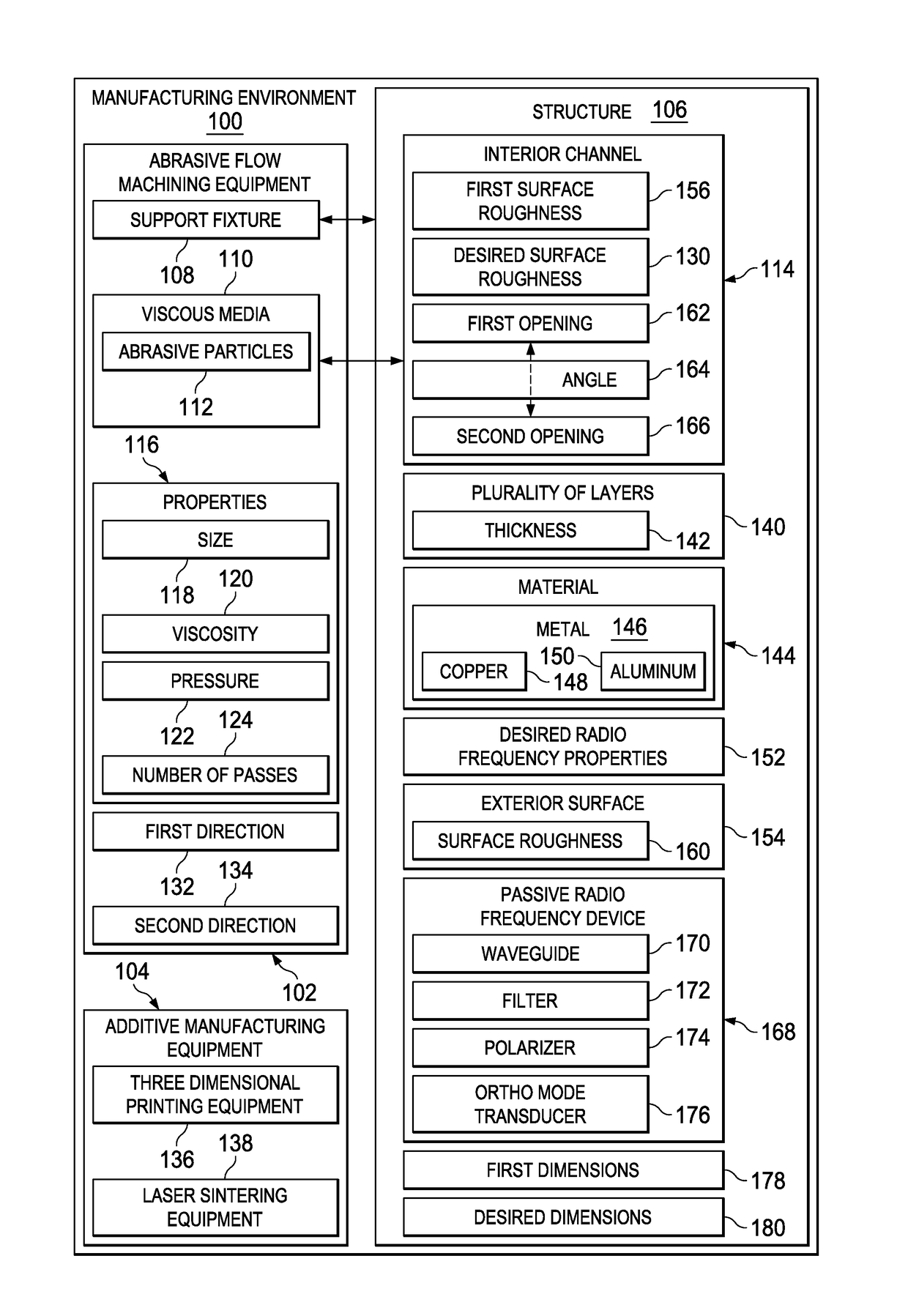

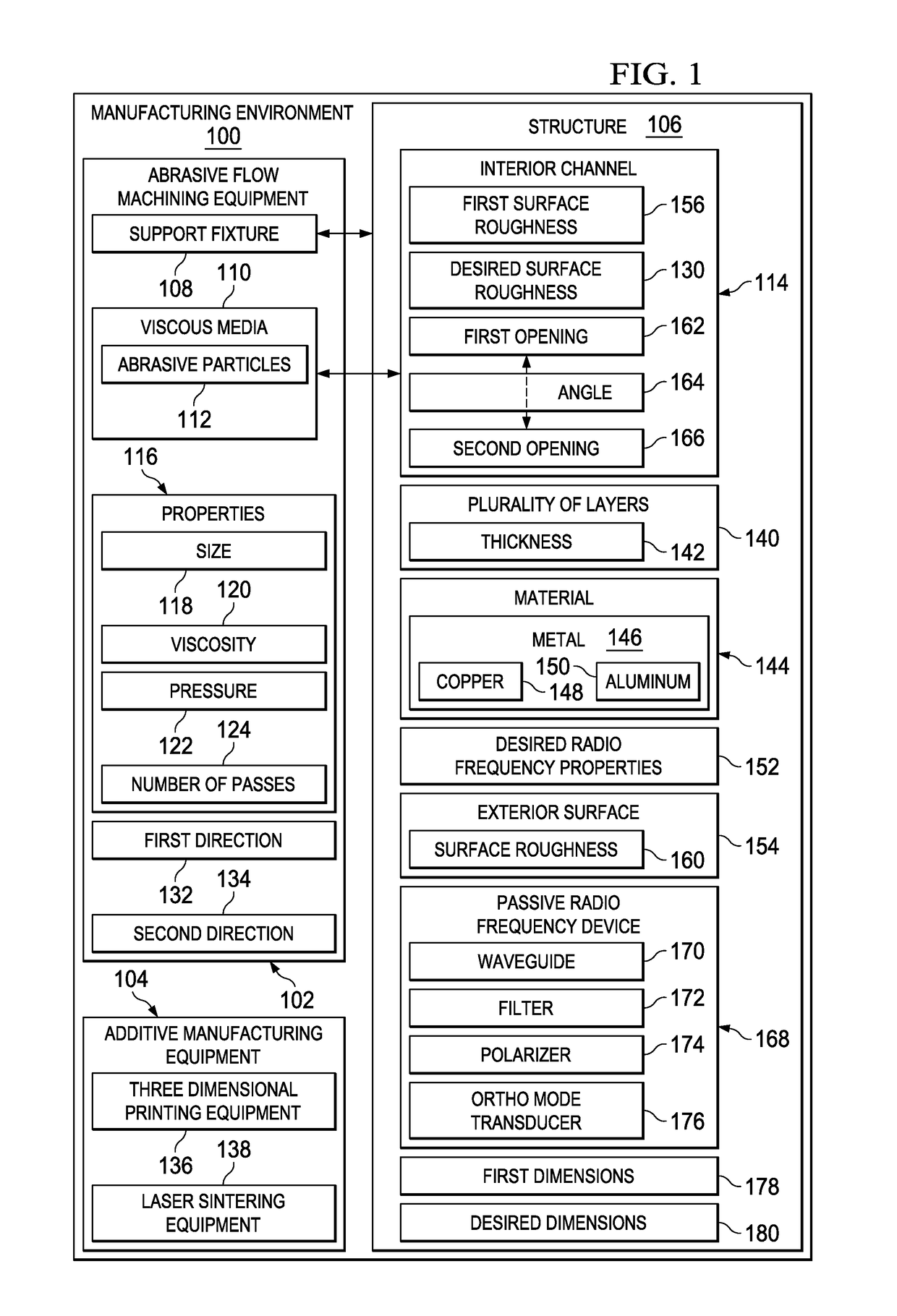

Additive Manufacturing for Radio Frequency Hardware

A method and apparatus is presented. A structure having an interior channel is formed using additive manufacturing equipment. A viscous media containing abrasive particles is sent through the interior channel using abrasive flow machining equipment to form a desired surface roughness for the interior channel.

Owner:THE BOEING CO

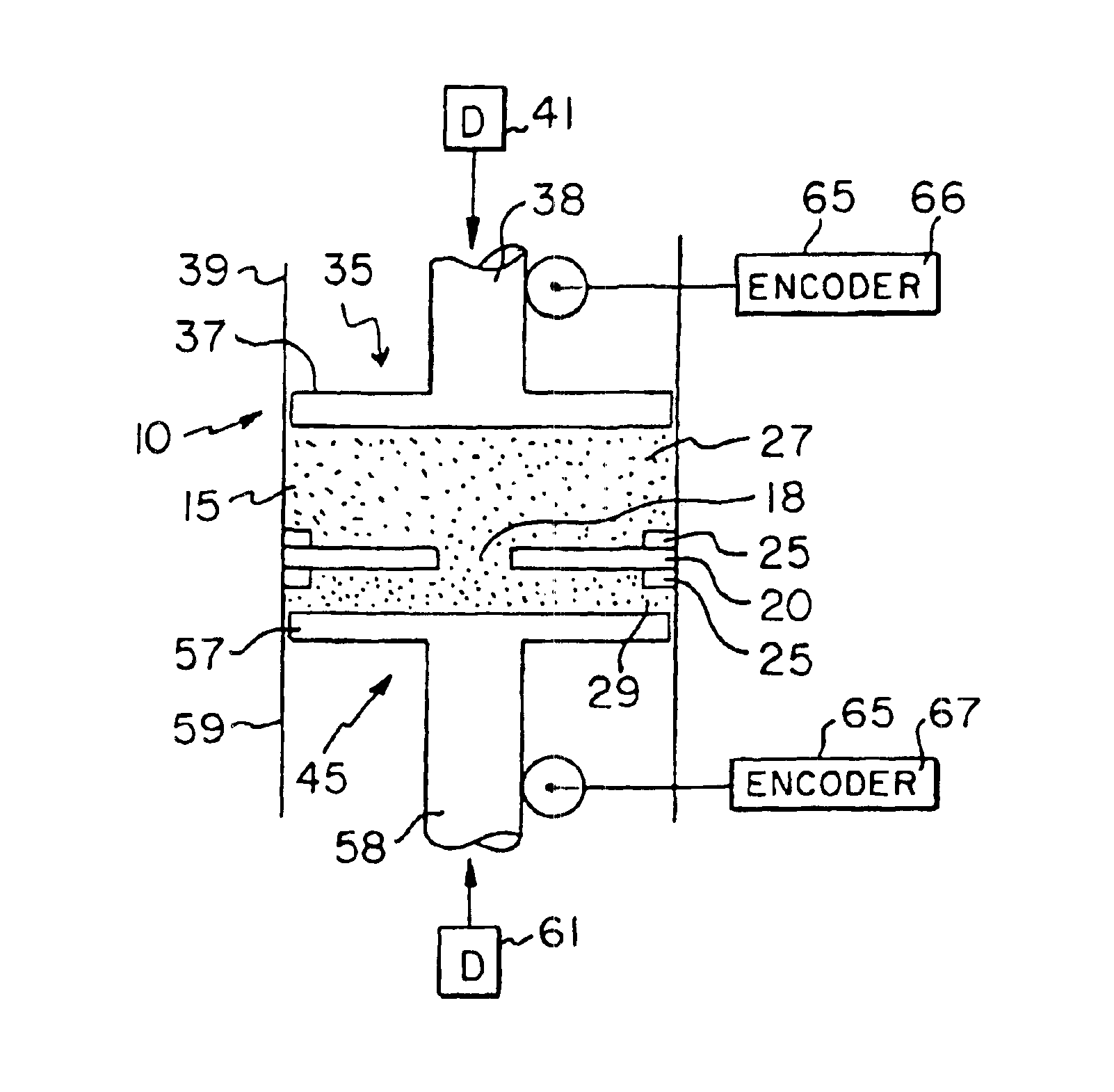

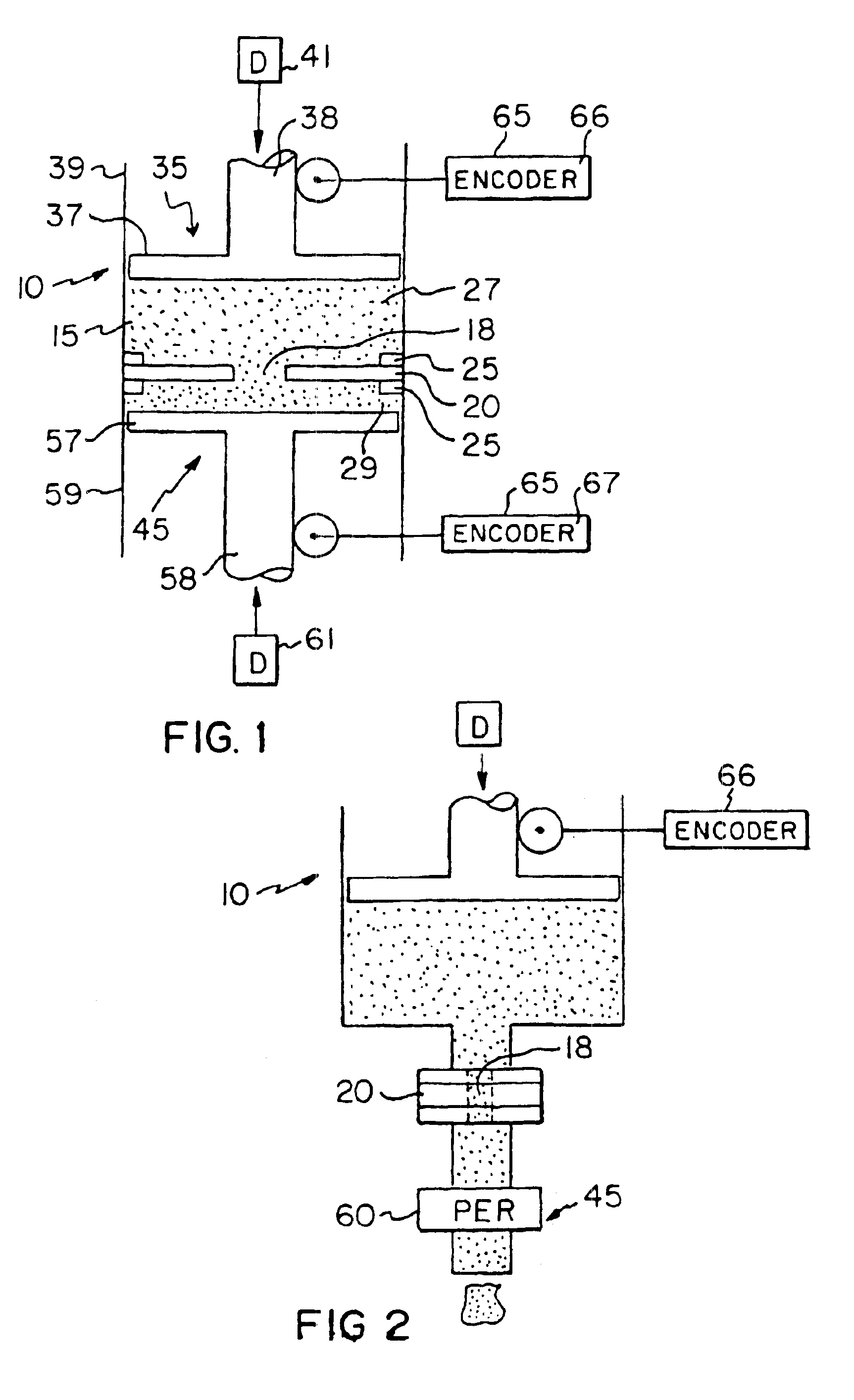

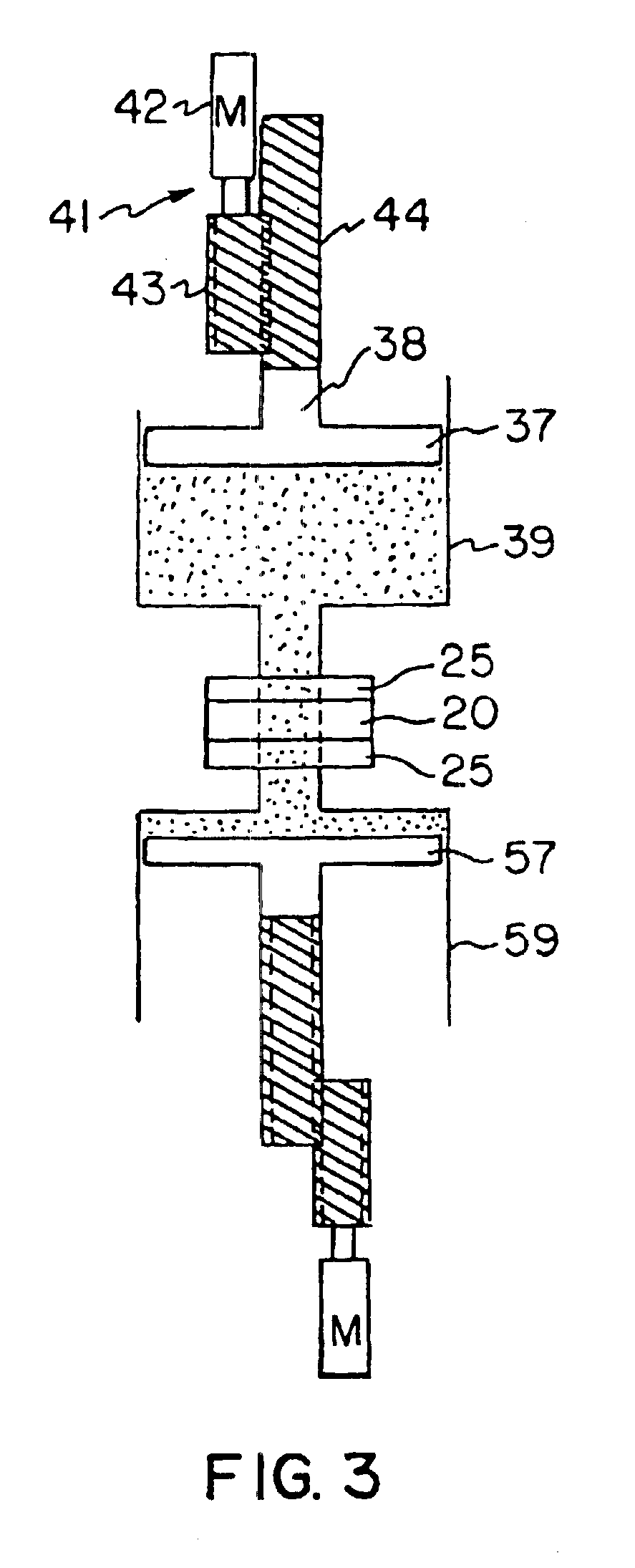

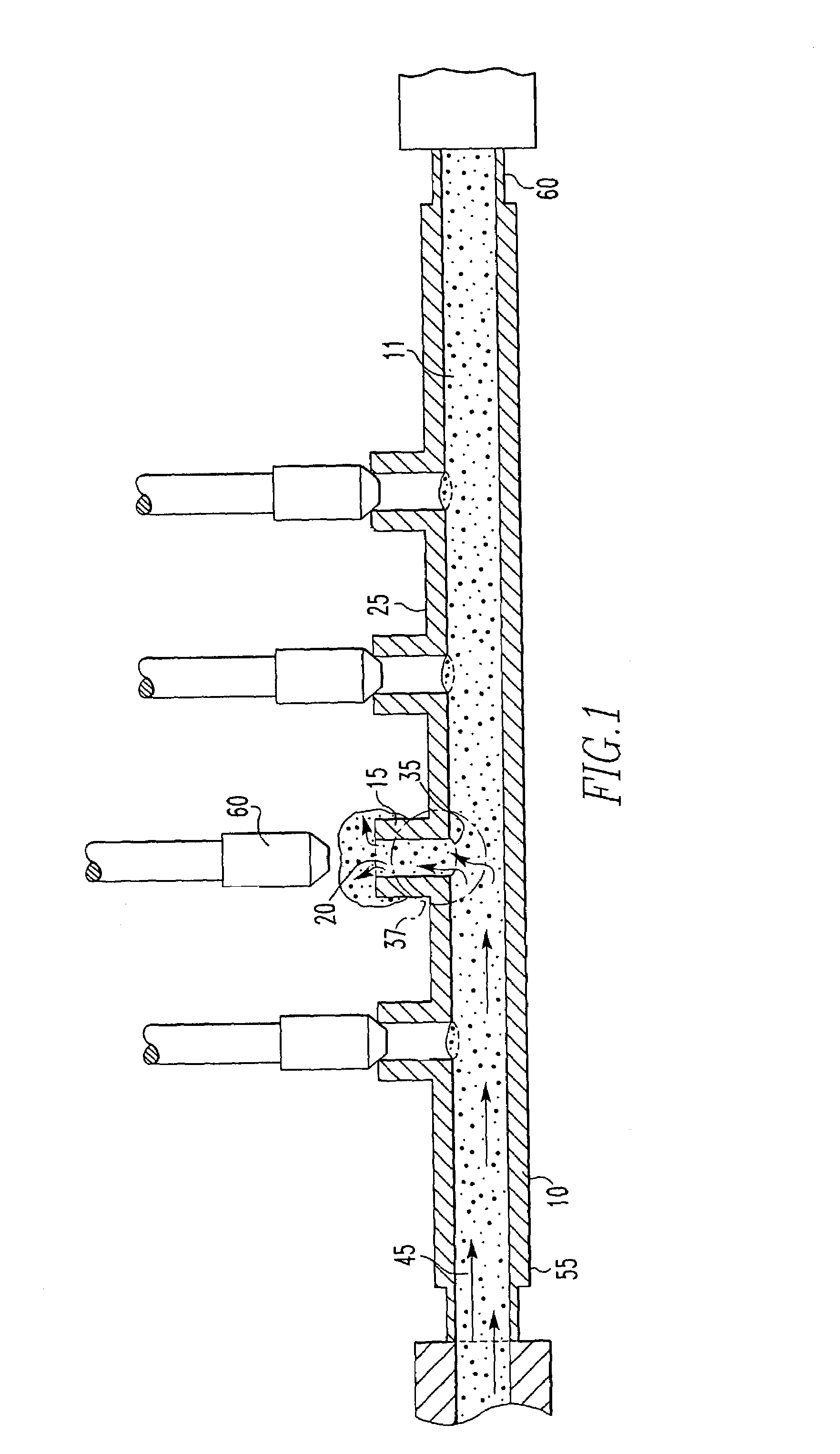

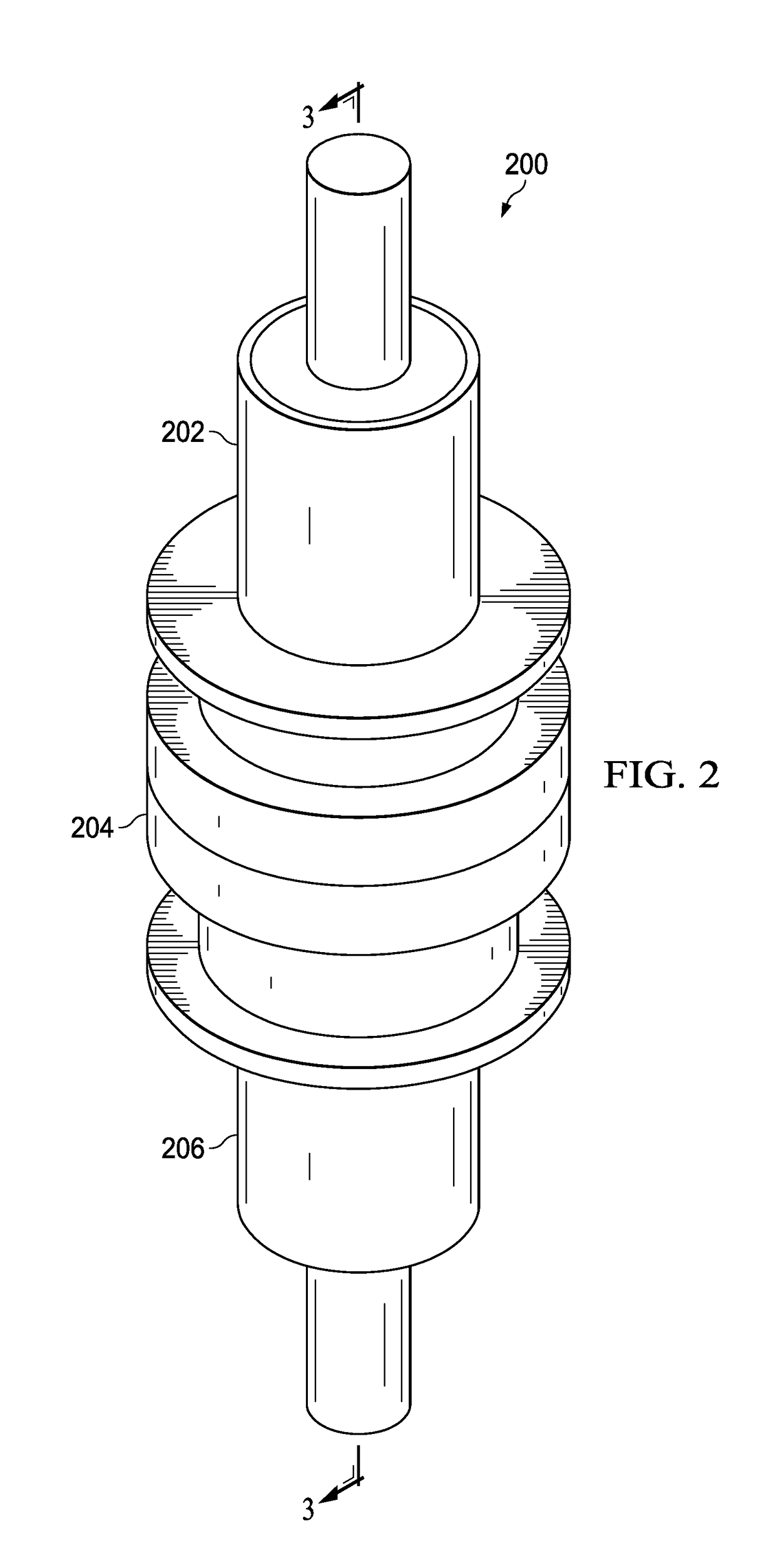

Abrasive flow machining apparatus and method

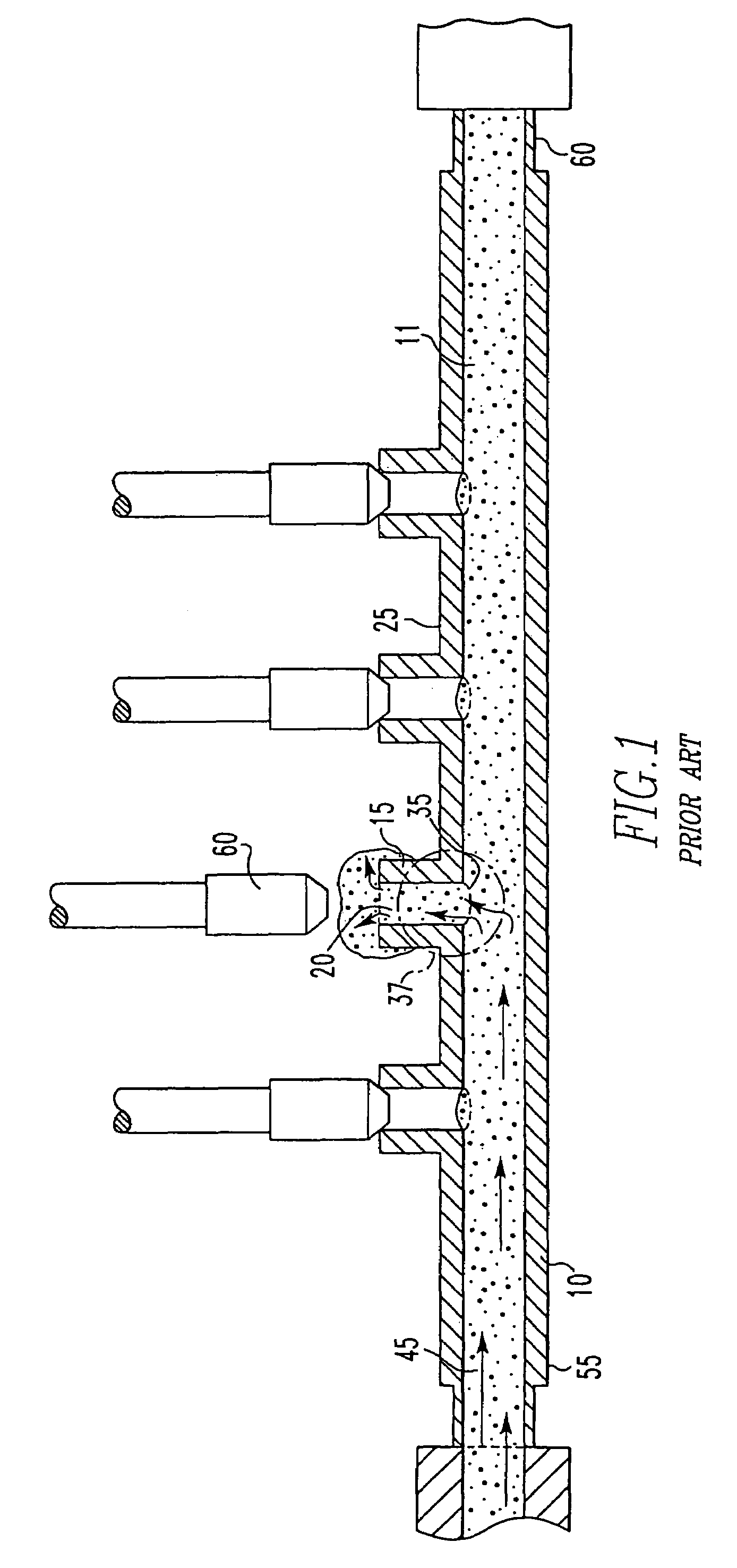

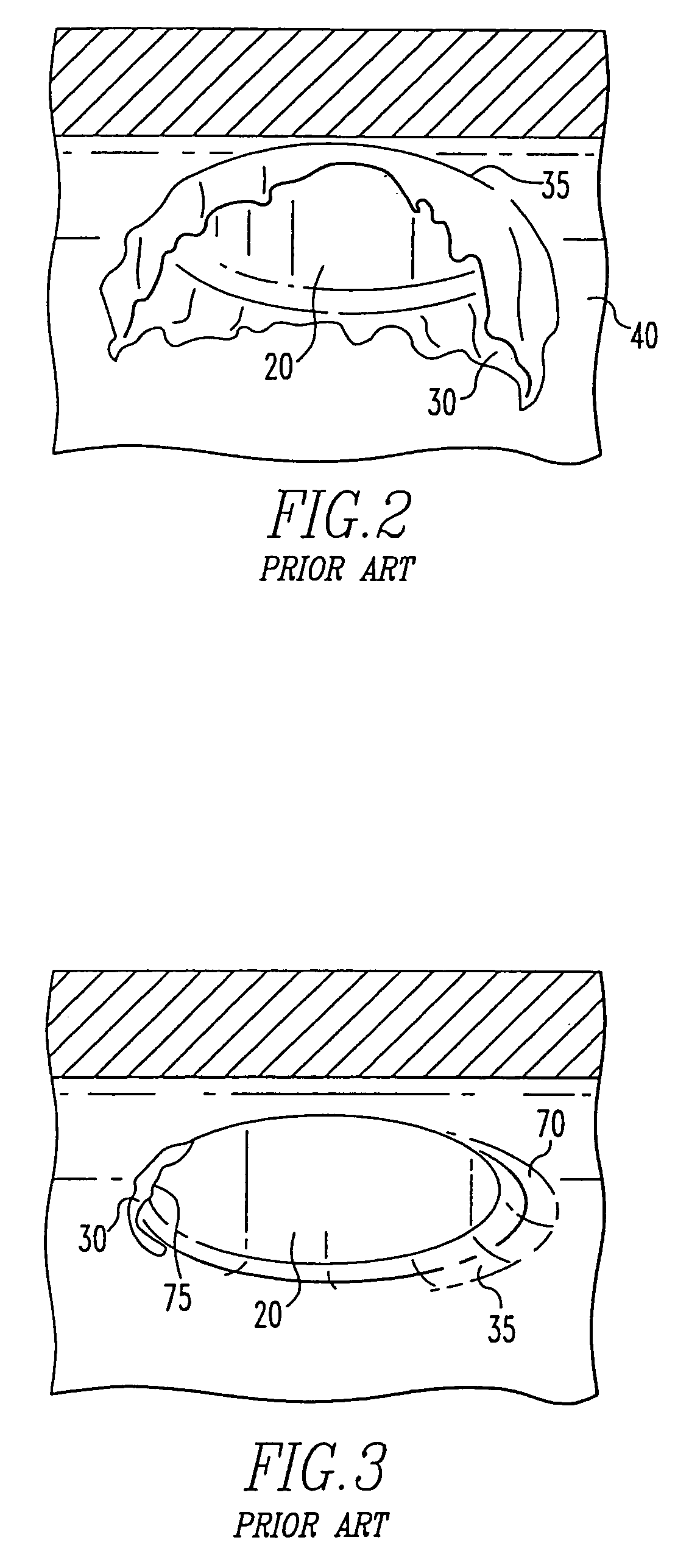

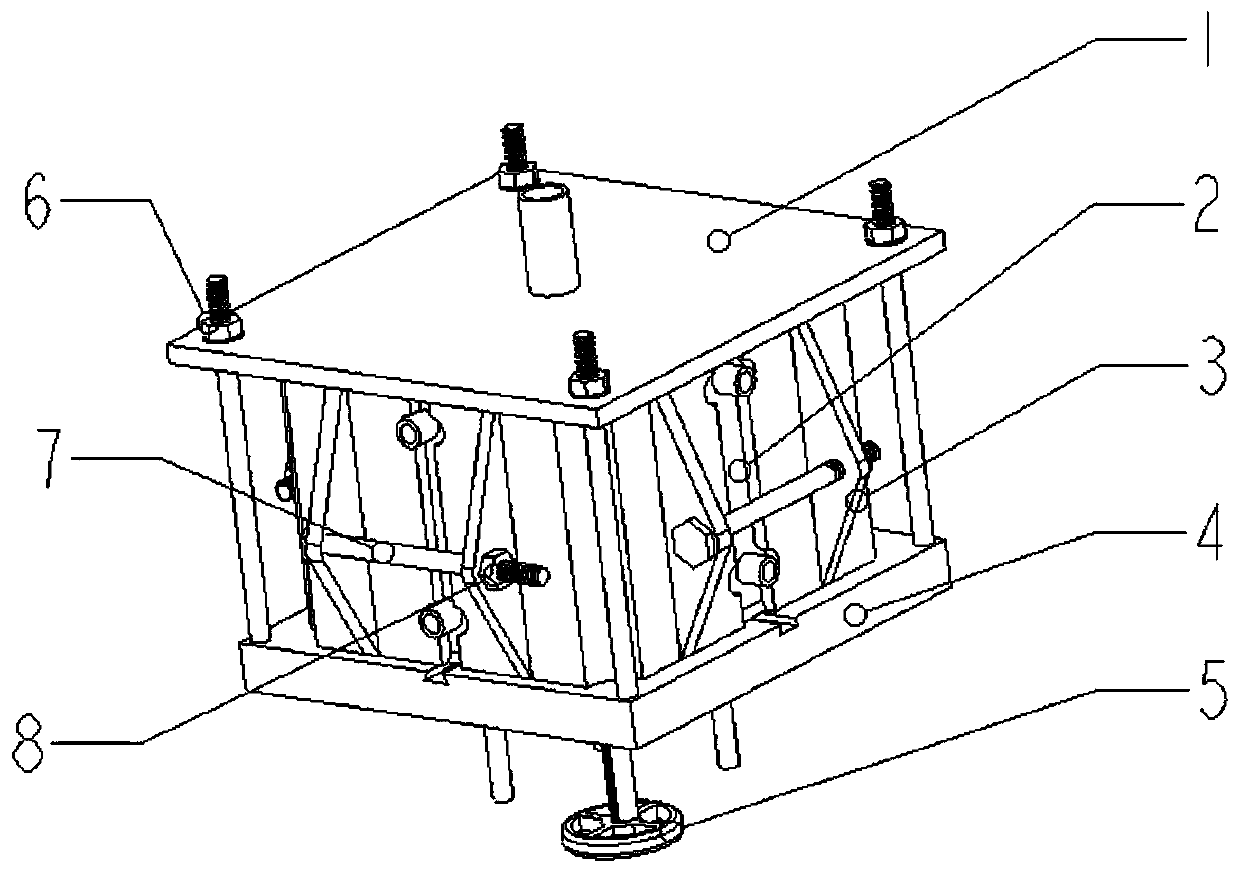

An apparatus and method for abrasive flow machining the orifice (18) of a workpiece (20) by using an abrasive media (15) whereby the apparatus (10) is capable of passing media (15) through the orifice (18) at a predetermined pressure and at a constant flow rate. In the alternative, the apparatus (10) is capable of passing media (15) through the orifice (18) at a fixed flow rate by using variable pressure upon the media (15) through the orifice (18).

Owner:EXTRUDE HONE CORP

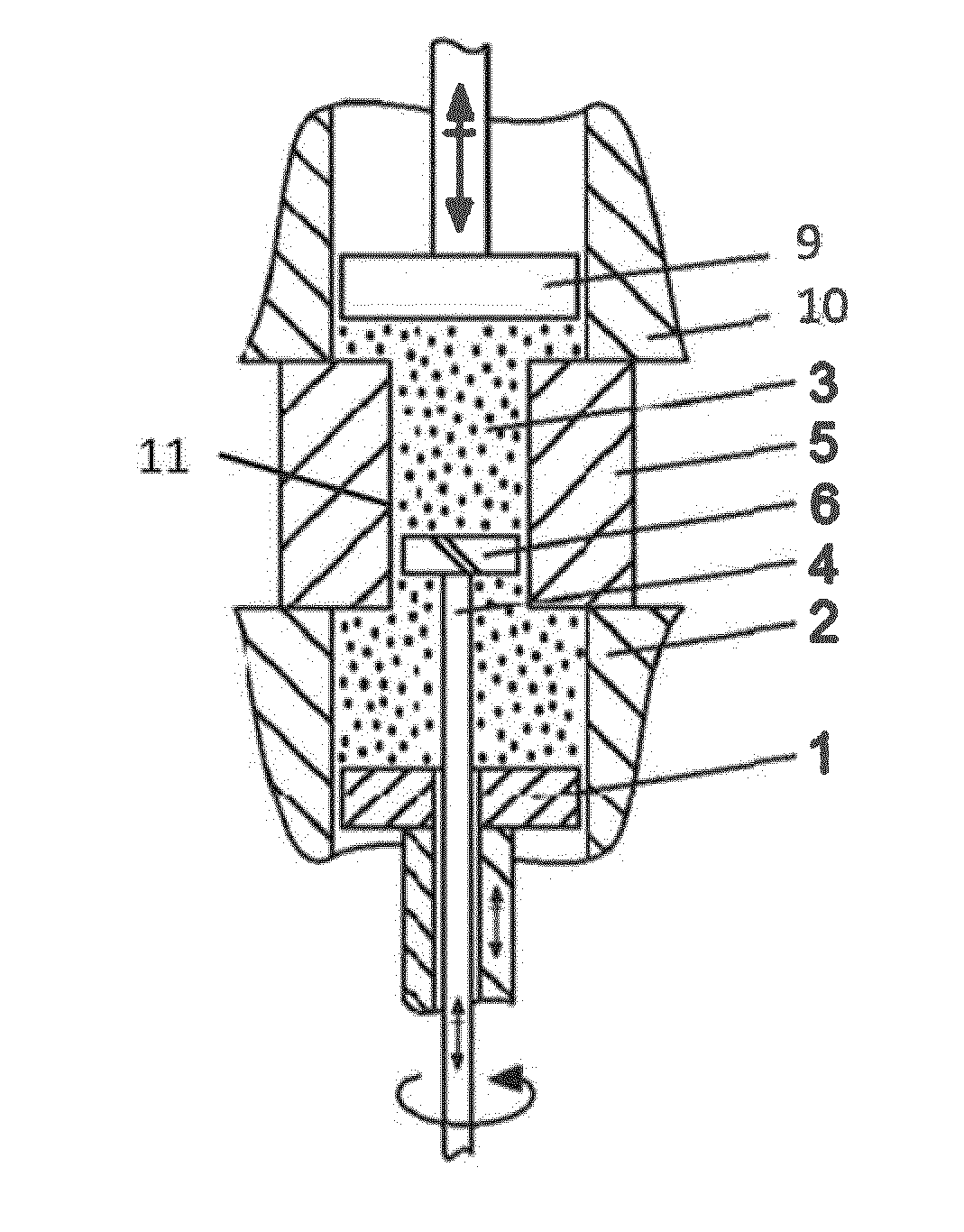

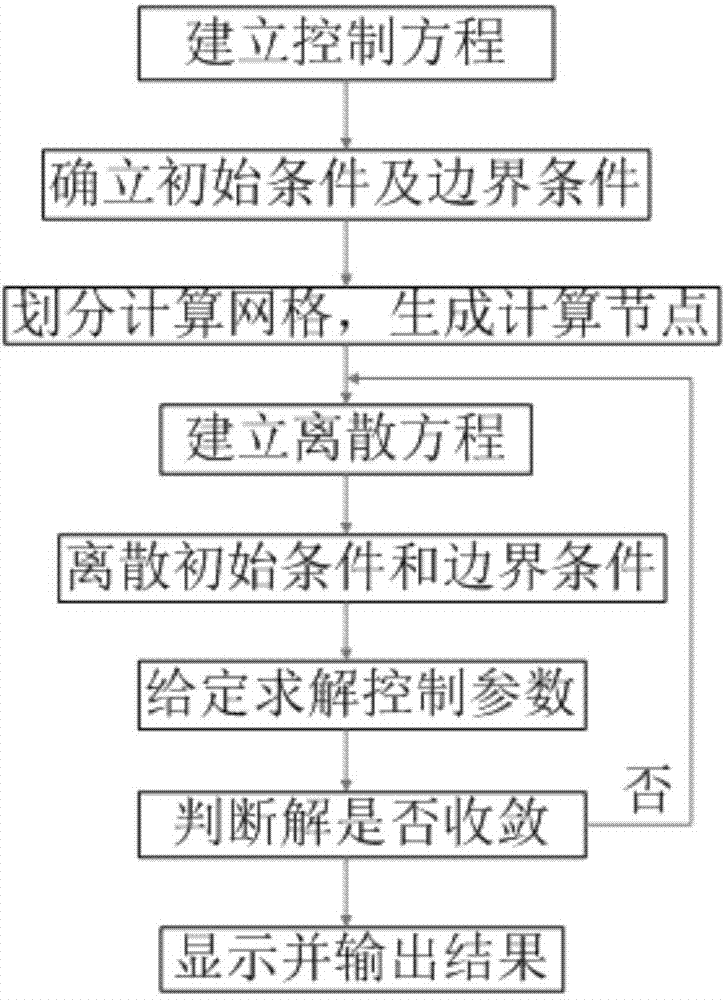

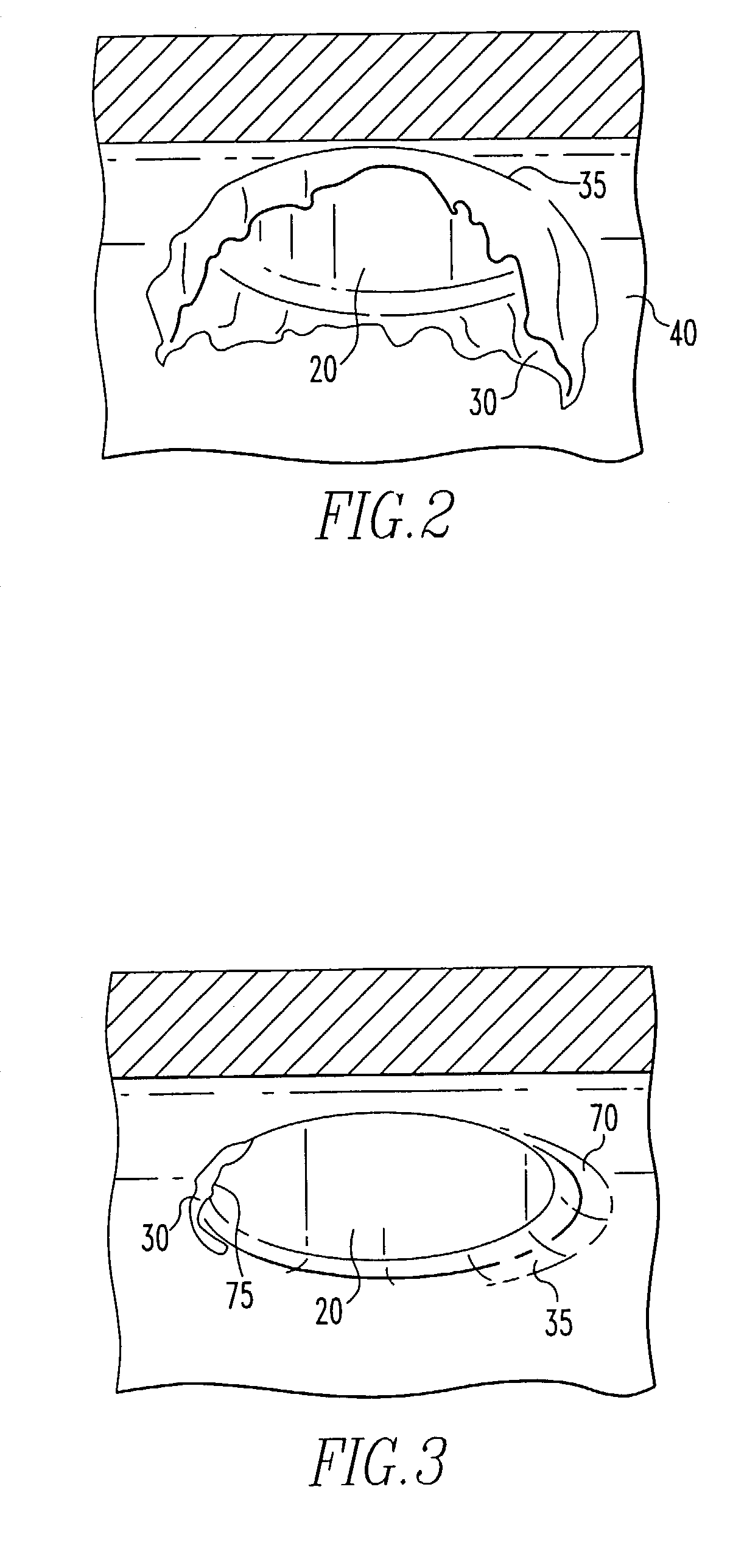

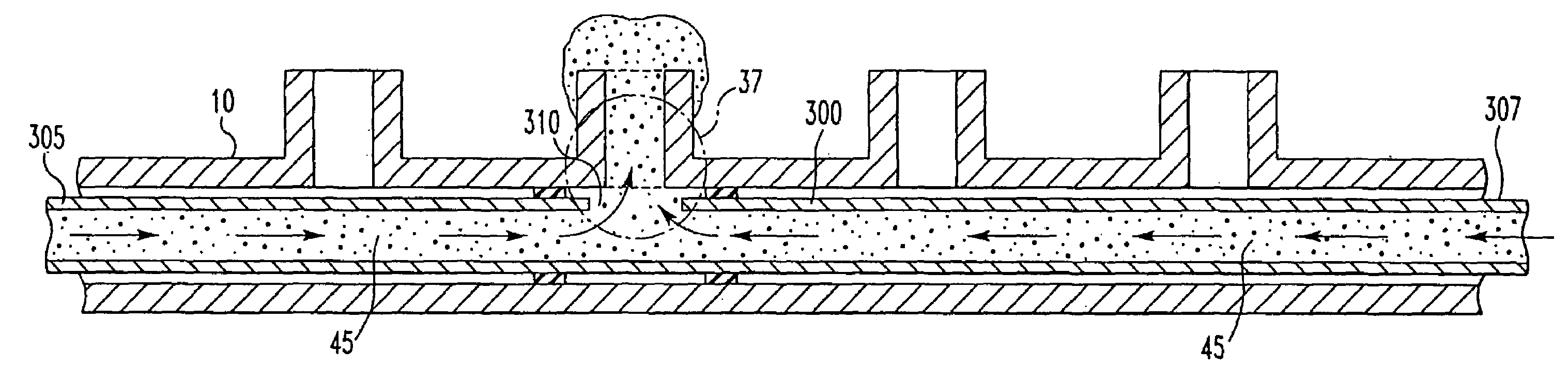

Arrangements and methods for abrasive flow machining

InactiveUS20160082565A1Increase the cross-sectional areaReduce the effective cross-sectional areaEdge grinding machinesPolishing machinesEngineeringAbrasive flow machining

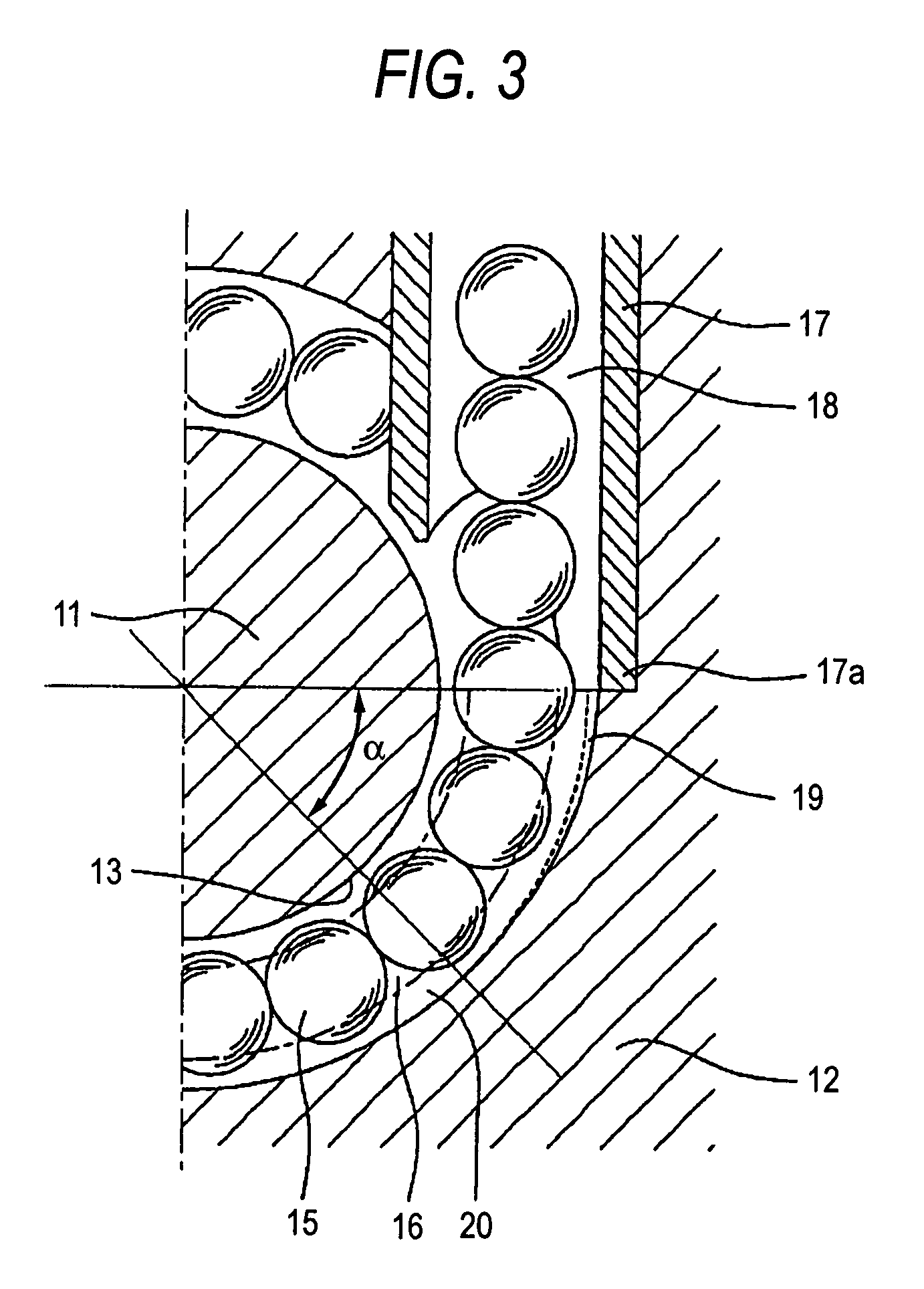

A method of treating an interior surface of a workpiece (5); said method comprising providing a workpiece (5) having an interior passage (11) defined at least partly by said interior surface to be treated, said passage (11) having an inlet section and an outlet section; providing in said interior passage (11) at least one deflecting object (6), said deflecting object (6) having an outer surface, whereby a space is formed between said outer surface of said at least one deflecting object (6) and said interior surface of said workpiece (5); providing an abrasive fluid (3) in said space, such that said space is substantially filled with said abrasive fluid (3); and effecting flow of said abrasive medium (3) through said interior passage (11) from said inlet portion to said outlet portion.

Owner:UNIVERSITY OF LJUBLJANA

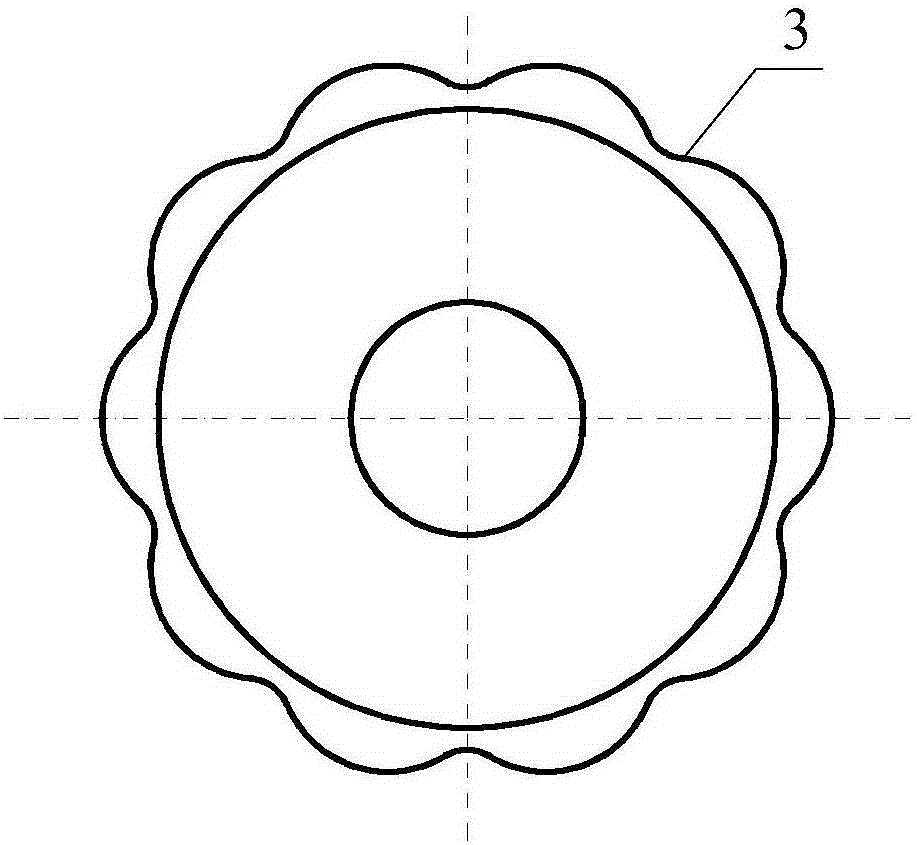

Abrasive flow polishing device for mold processing

ActiveCN104999380AIncrease pressureIncrease surface areaAbrasive feedersAbrasive machine appurtenancesAbrasive flow machiningEngineering

The invention provides an abrasive flow polishing device for mold processing. The device comprises an abrasive flow stirrer, a pressure pump, a pressure gauge, a main polishing tool, an auxiliary polishing tool and an abrasive flow recovery box, wherein the abrasive flow stirrer is sequentially connected with the pressure pump and the pressure gauge and then connected with the main polishing tool, and the auxiliary polishing tool specially used for machining pores and gaps of workpieces is connected to the main polishing tool. The main polishing tool is specially used for machining portions, such as protrusions, of molds, and the auxiliary polishing tool is arranged to be of a flexible thin structure so as to machine pores or gaps. A temperature sensor and a heater are arranged to reduce the influence of temperature and viscosity on abrasive flow machining precision and improve the polishing effect of surfaces of workpieces. The radial cross section shape of an abrasive flow jet orifice in the end of a rotary polishing head is designed to be in a quincunx shape, so that abrasive flow discharge volume and pressure value in unit time are increased, the superficial area of abrasive flow machining is increased, and the mold polishing efficiency is improved.

Owner:CHANGCHUN UNIV OF SCI & TECH

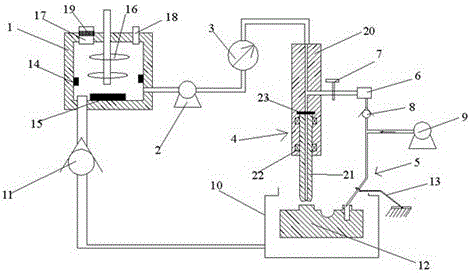

Oil nozzle abrasive flow machining particle movement numerical simulation method

InactiveCN104765940AImprove guidanceSpecial data processing applicationsAbrasive flow machiningEngineering

The invention relates to an oil nozzle abrasive flow machining particle movement numerical simulation method. The method includes the specific steps that 1, a computation model is built; 2, solution parameters are set, wherein before simulation, feather parameters, initial parameters, boundary conditions and the like of abrasive flow are set; 3, a model grid and areas are divided; 4, a solver is set and solution computation is conducted; 5, a calculation result is after-processed, wherein a particle track is displayed, a position distribution graph of particles is displayed, and a particle speed vector diagram is displayed. By means of the method, numerical simulation is conducted on a discrete particle phase in a flow field for oil nozzle abrasive flow machining, coupling of discrete-phase particles and continuous-phase fluid is computed, movement data of the discrete particles are obtained, and it draws a conclusion that the movement condition of the particles in the abrasive flow machining process is related to turbulence intensity of the fluid, the relation among non-linear pipe channel surface quality, the particles and wall face collisions is discussed, and a good guide function is performed.

Owner:CHANGCHUN UNIV OF SCI & TECH

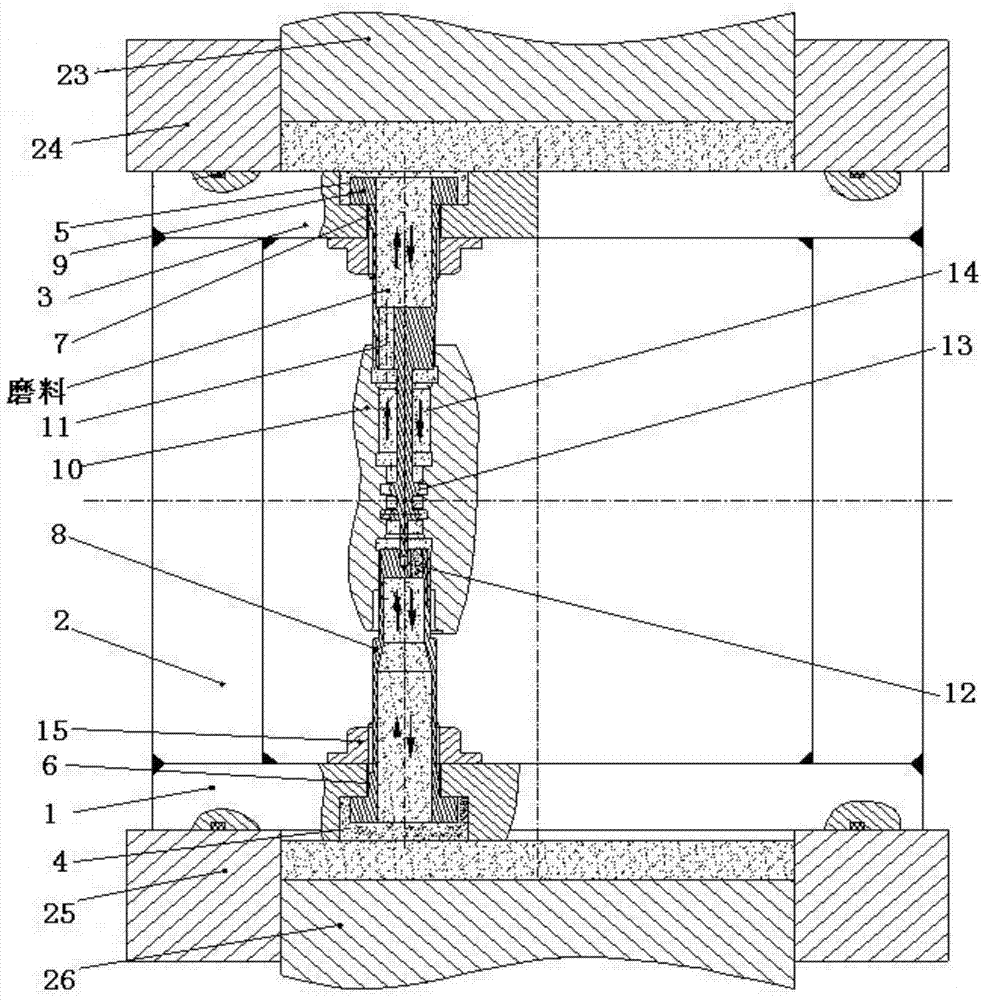

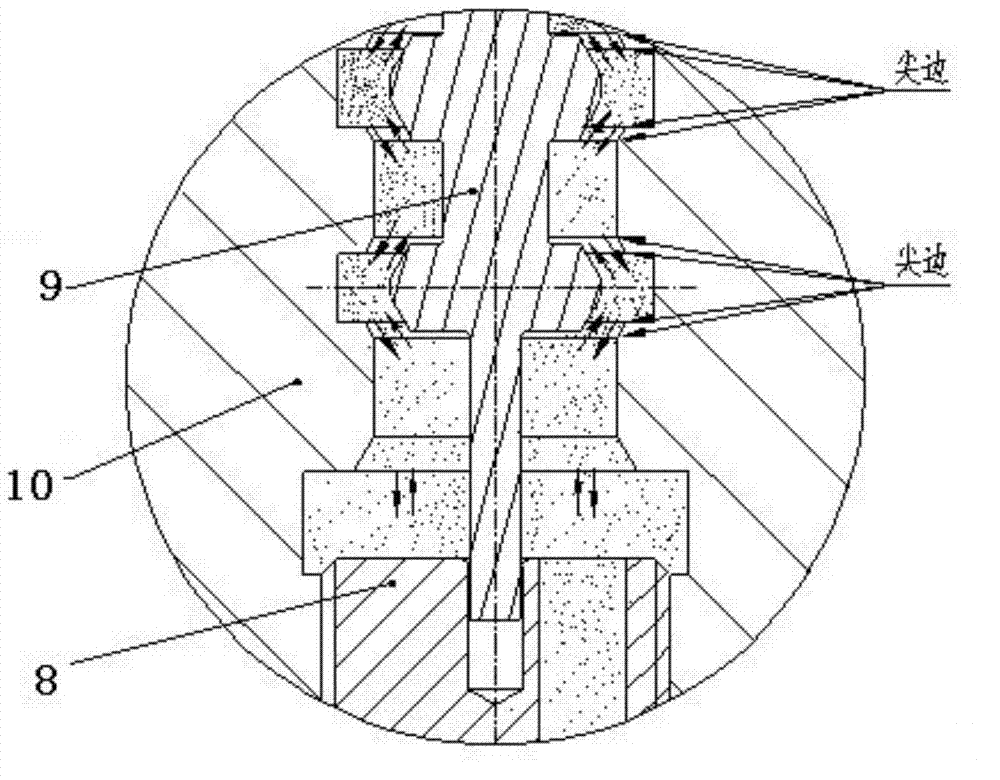

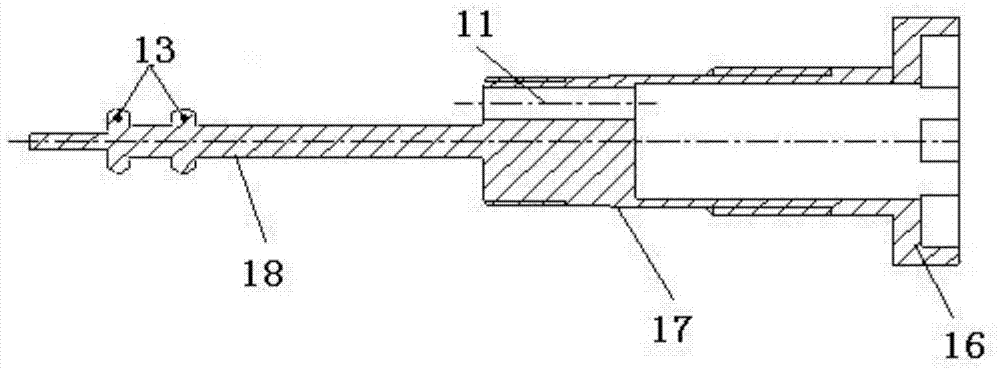

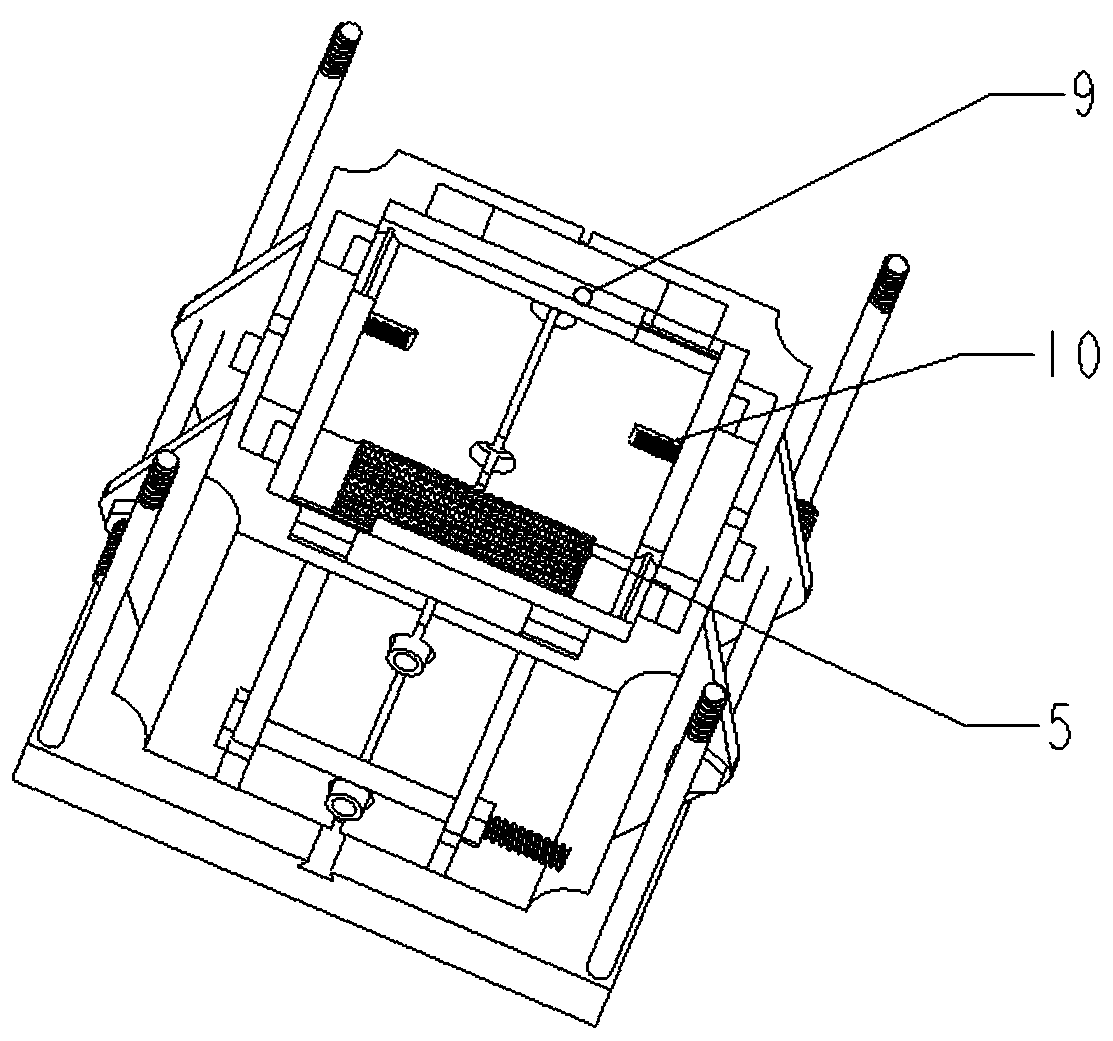

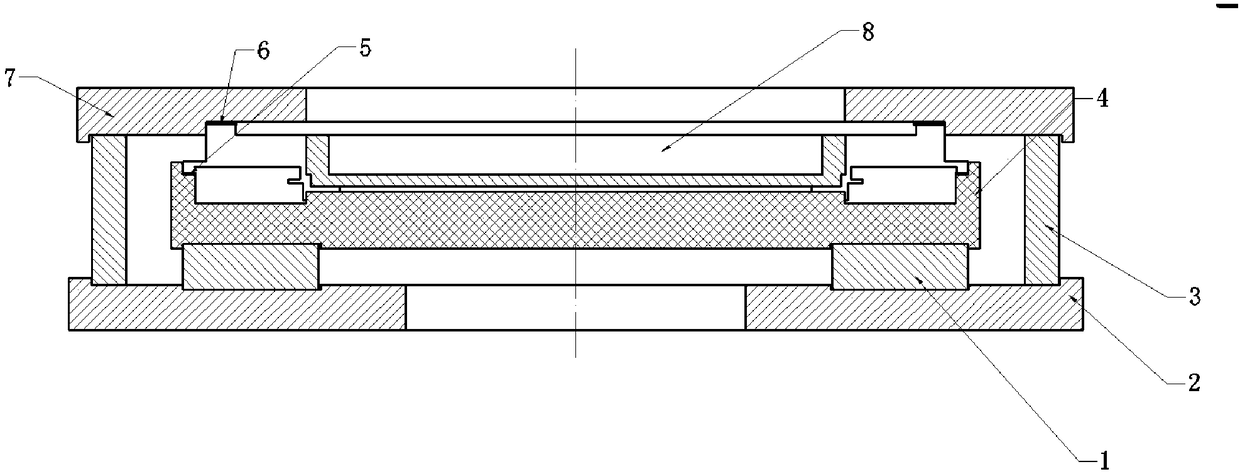

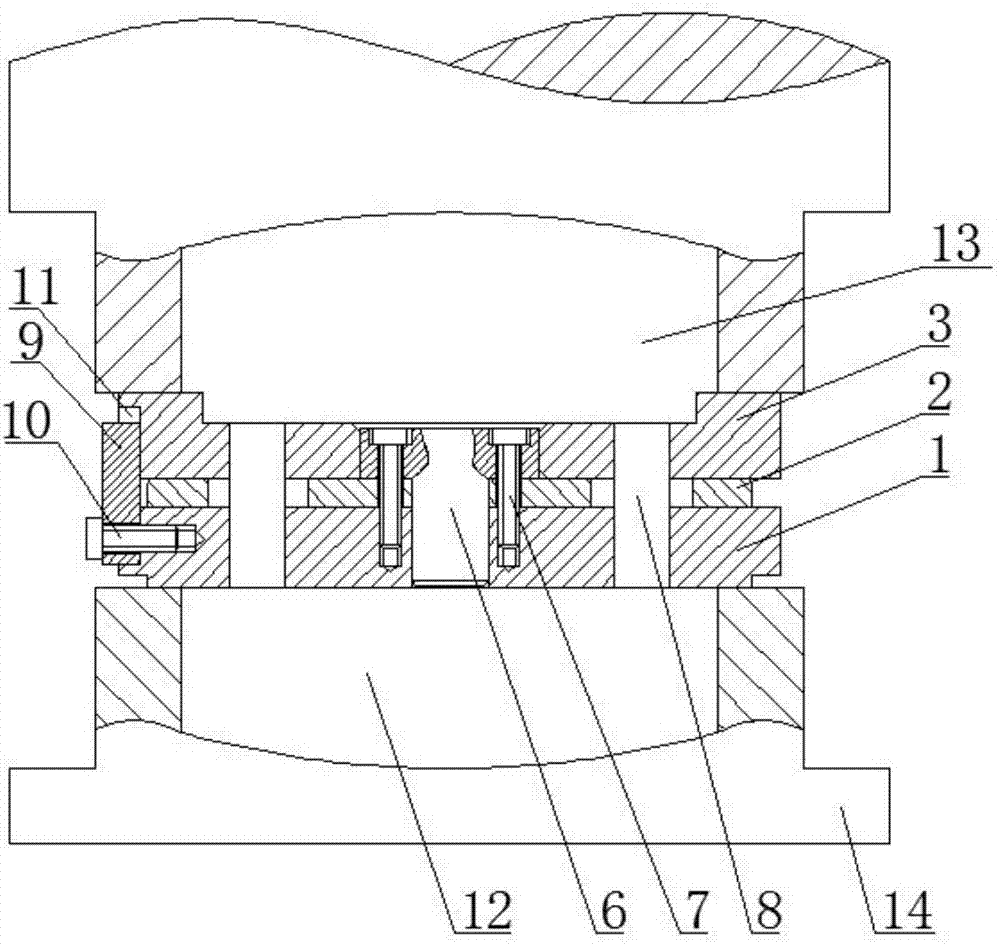

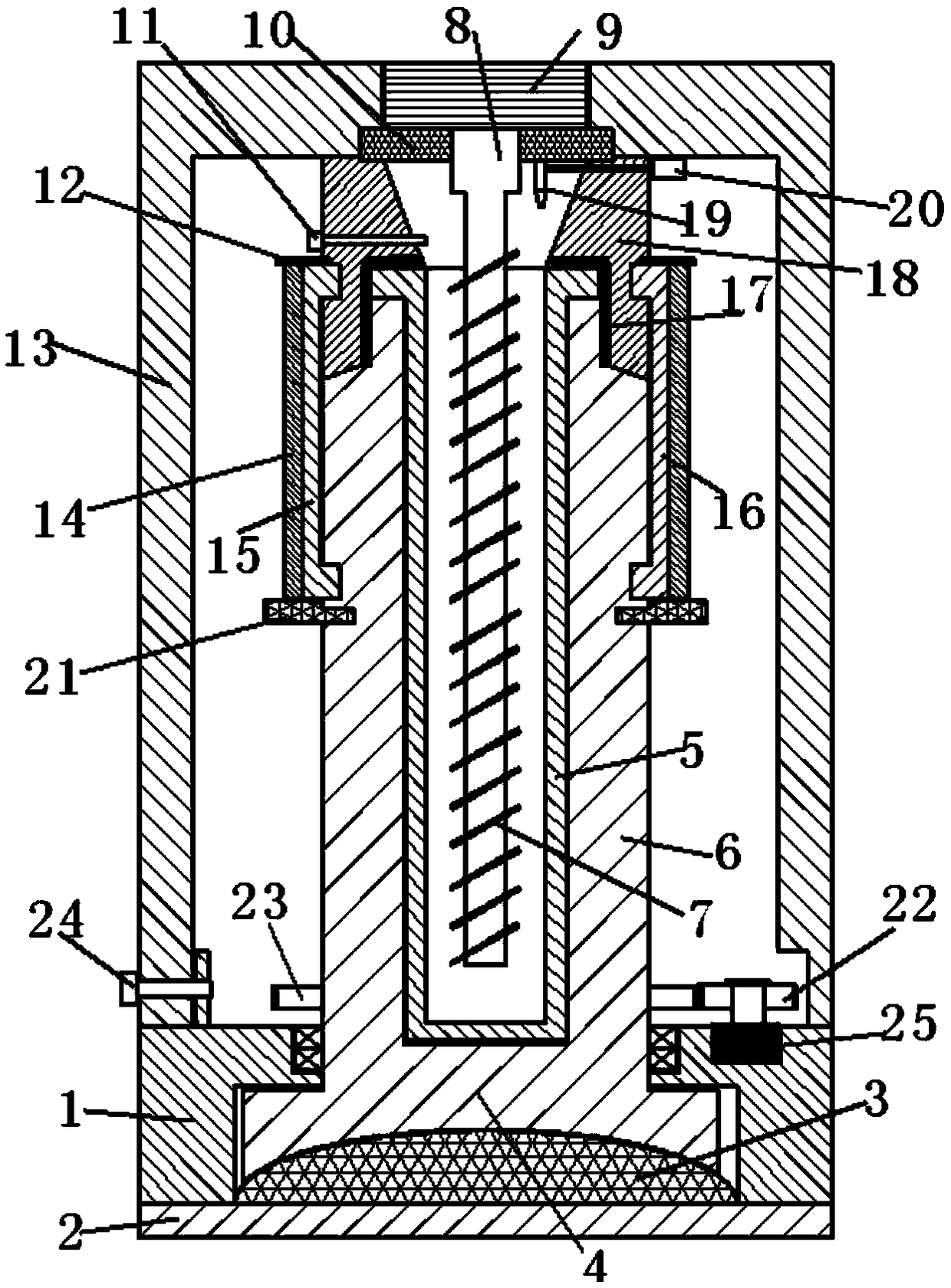

Abrasive flow machining device capable of cleaning sharp edges and burrs at annular grooves in deep holes

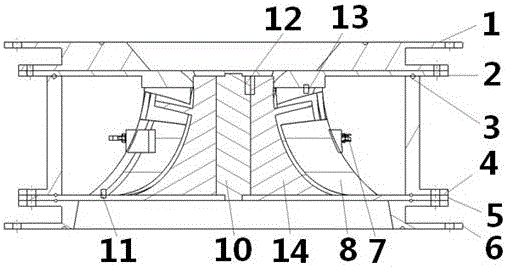

ActiveCN103659619AEasy to processSolve glitchesAbrasive feedersAbrasive blasting machinesAbrasive flow machiningEngineering

The invention discloses an abrasive flow machining device capable of cleaning sharp edges and burrs at annular grooves in deep holes. The device comprises a frame support structure consisting of a base plate (1), a support plate (2) and a cover plate (3), wherein a base plate counter bore (4) and a cover plate counter bore (5) which are arranged towards the outer side are formed in the base plate (1) and the cover plate (3) respectively, a base plate through hole (6) and a cover plate through hole (7) are formed in centers of the base plate counter bore (4) and the cover plate counter bore (5) respectively, a pipe joint (8) penetrating through the base plate through hole (6) is inversely buckled in the base plate counter bore (4), a flow guide rod (9) penetrating through the cover plate through hole (7) is inversely buckled in the cover plate counter bore (5), a work piece (10) is arranged between the pipe joint (8) and the flow guide rod (9), an upper passing hole (11) and a lower passing hole (12) are formed in the flow guide rod (9) and the pipe joint (8) respectively, and flow guide pieces (13) are arranged at one end of the flow guide rod (9). According to the abrasive flow machining device, the problems that the burrs at the annular grooves in the deep holes cannot be cleaned with a traditional manual deburring method and machining cannot be performed on the sharp edges of the annular grooves in the deep holes are solved.

Owner:AVIC LIYUAN HYDRAULIC

Abrasive machining media containing thermoplastic polymer

ActiveUS20100144247A1Good elastic propertiesIncrease relaxation timeEdge grinding machinesPolishing machinesElastomerThermoplastic elastomer

The present invention incorporates at least one thermoplastic or elastomeric polymer in abrasive flow machining media either as the sole or as one of the polymeric constituents. The presence of thermoplastic polymer imparts a greater elastomer characteristic (elasticity, compression resistance, increased relaxation times) as contrasted with traditional media. Enhanced elastomeric characteristics enable more uniform abrasive machining. In a particularly preferred embodiment, silicone- or polyorganosiloxane-based medium contains elastic silicone rubber particles dispersed therethrough to achieve increased relaxation times comparable to those attainable with the inclusion of a thermoplastic polymer.

Owner:KENNAMETAL INC +1

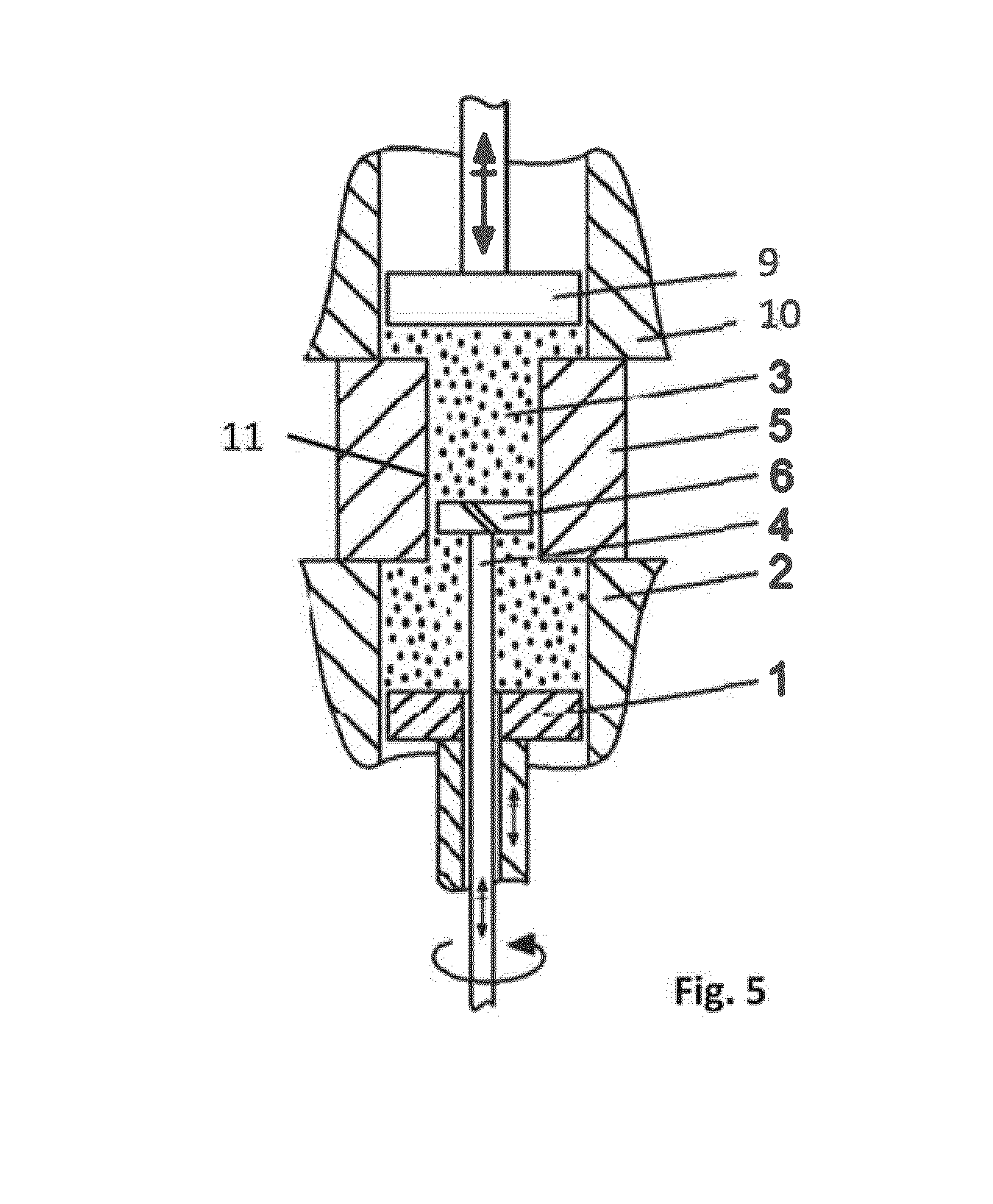

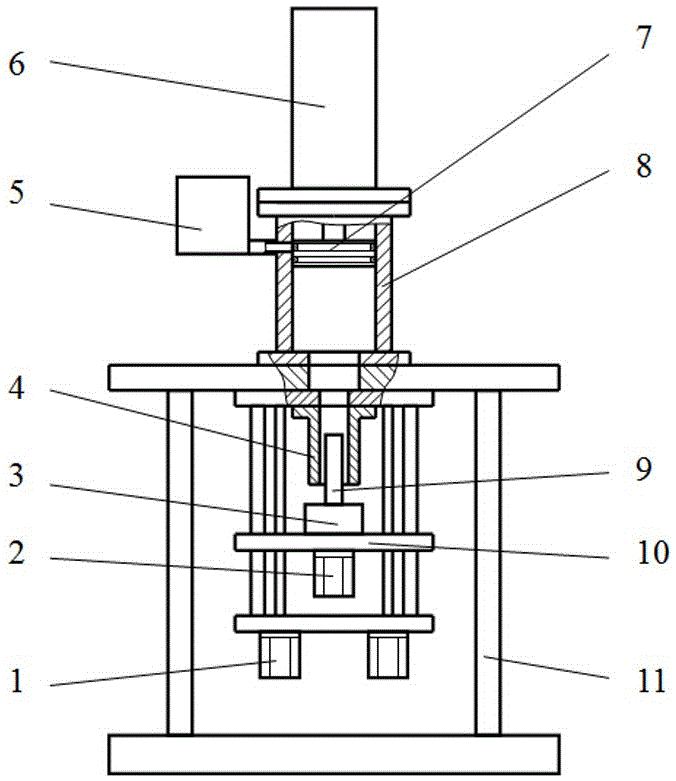

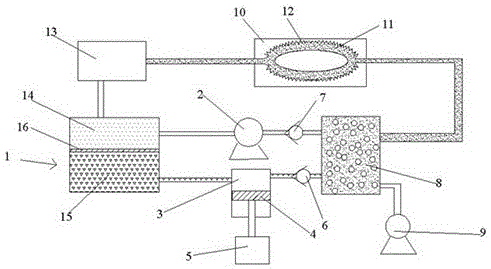

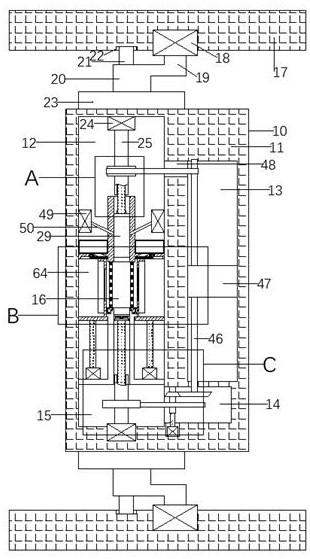

Two-phase fluid abrasive particle sliding speed measuring device and measuring method for viscoelastic fluid abrasive particles

ActiveCN106392864AEasy to measureCompact methodEdge grinding machinesPolishing machinesHydraulic cylinderMotor drive

The invention relates to the technical field of fluid and solid two-phase fluid and abrasive material flow machining in mechanical engineering and discloses a two-phase fluid abrasive particle sliding speed measuring device for viscoelastic fluid abrasive particles. The measuring device comprises a rack, a material pushing cylinder installed on the rack, a material pushing piston installed on the material pushing cylinder, a charging barrel installed on one side of the material pushing cylinder, a hydraulic cylinder providing power for the material pushing piston, material extruding round pipes fixed to the rack and located at the bottom of the material pushing cylinder, a movable workbench installed on the rack and located below the material extruding round pipes, first motors pushing the movable workbench to move up and down, a chuck installed on the movable workbench and used for clamping a cylindrical sample, and a second motor driving the chuck to rotate.

Owner:WUXI WEIHAIDA MACHINERY MFG

Method and apparatus for abrading the region of intersection between a branch outlet and a passageway in a body

A method and apparatus are disclosed for abrading the inner surface at the intersection region of a branch outlet with the wall of a body having a passageway. Using abrasive flow machining, it is possible to abrade the intersection region to provide a smooth transition between the wall and the branch outlet.

Owner:EXTRUDE HONE CORP

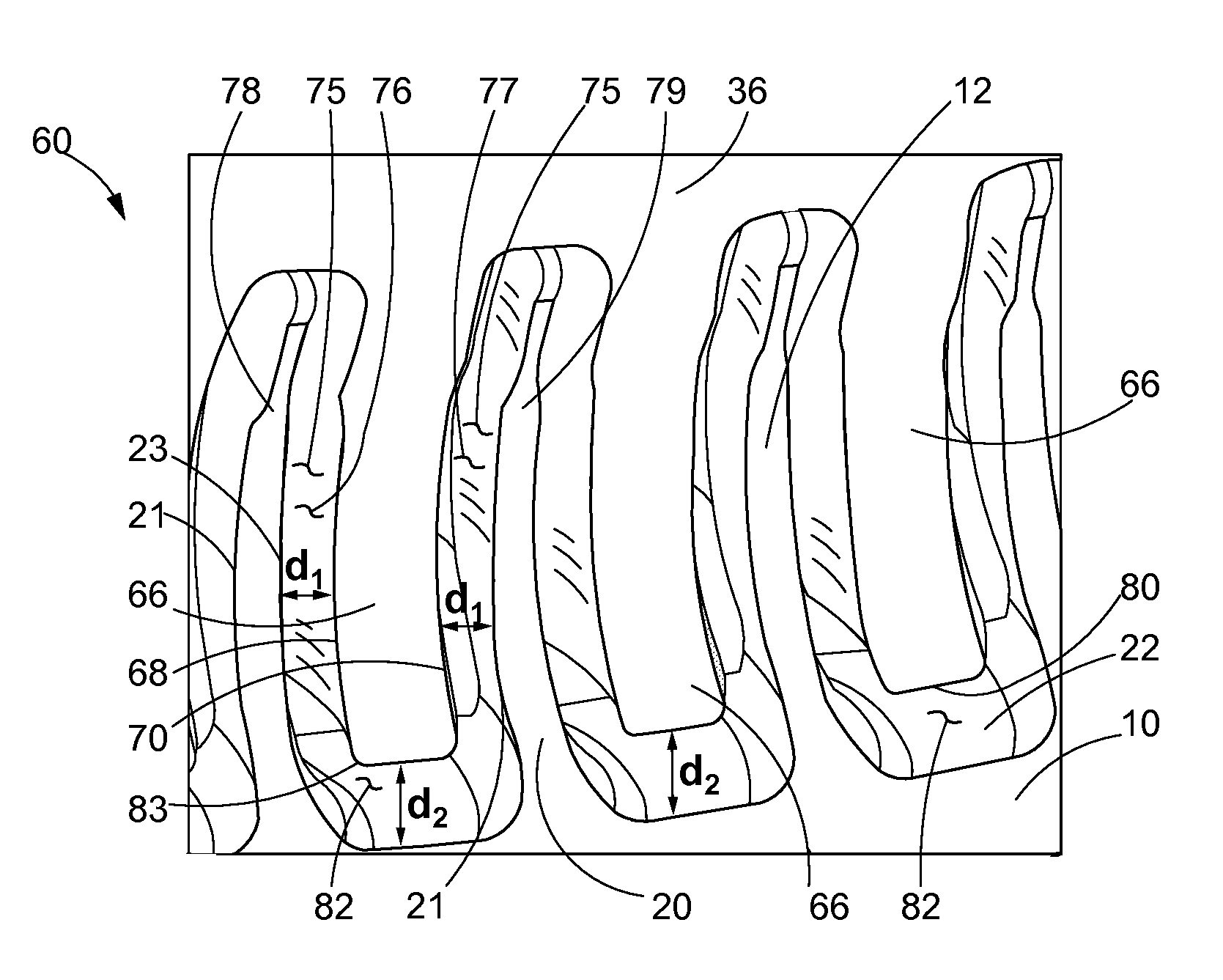

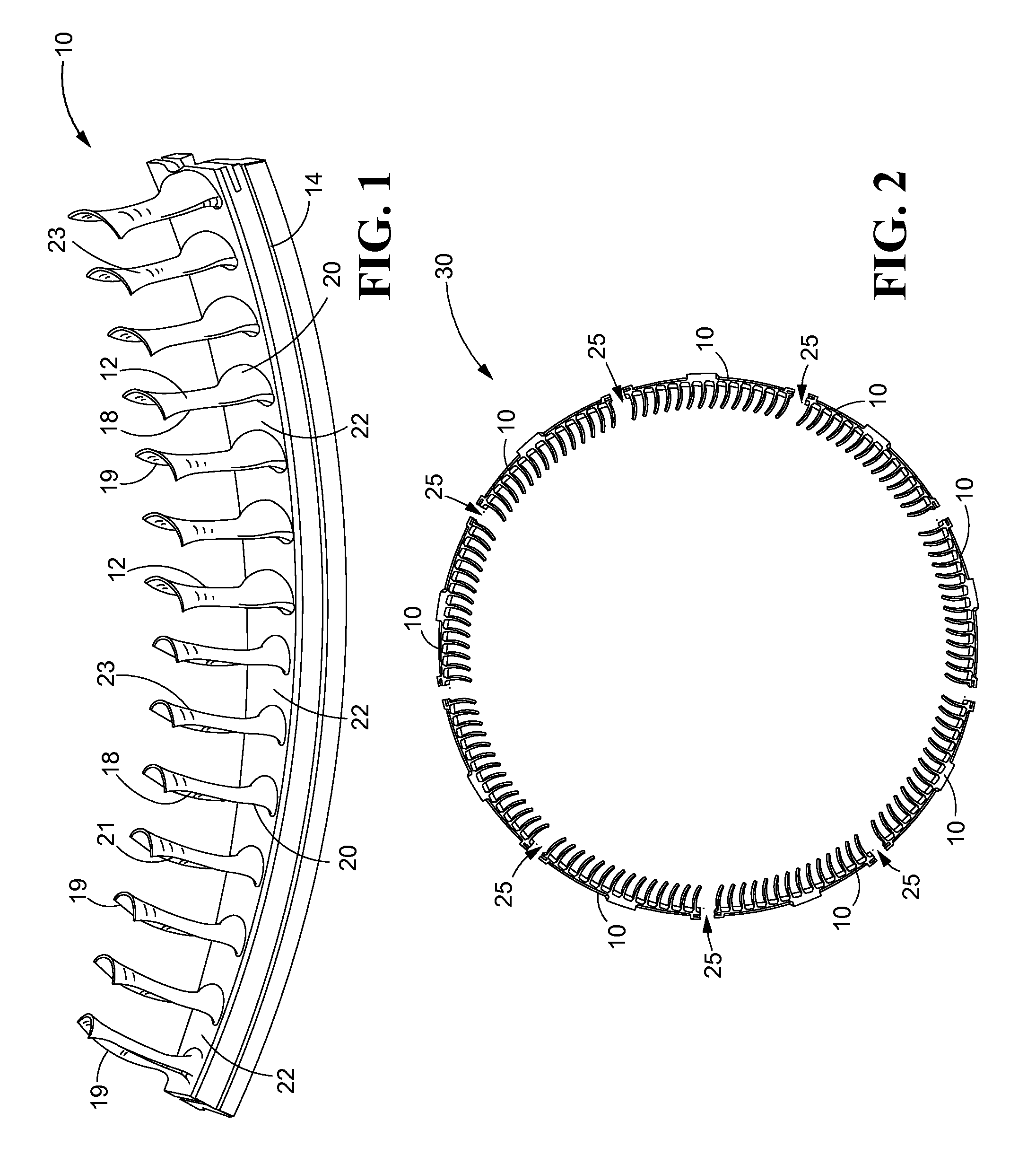

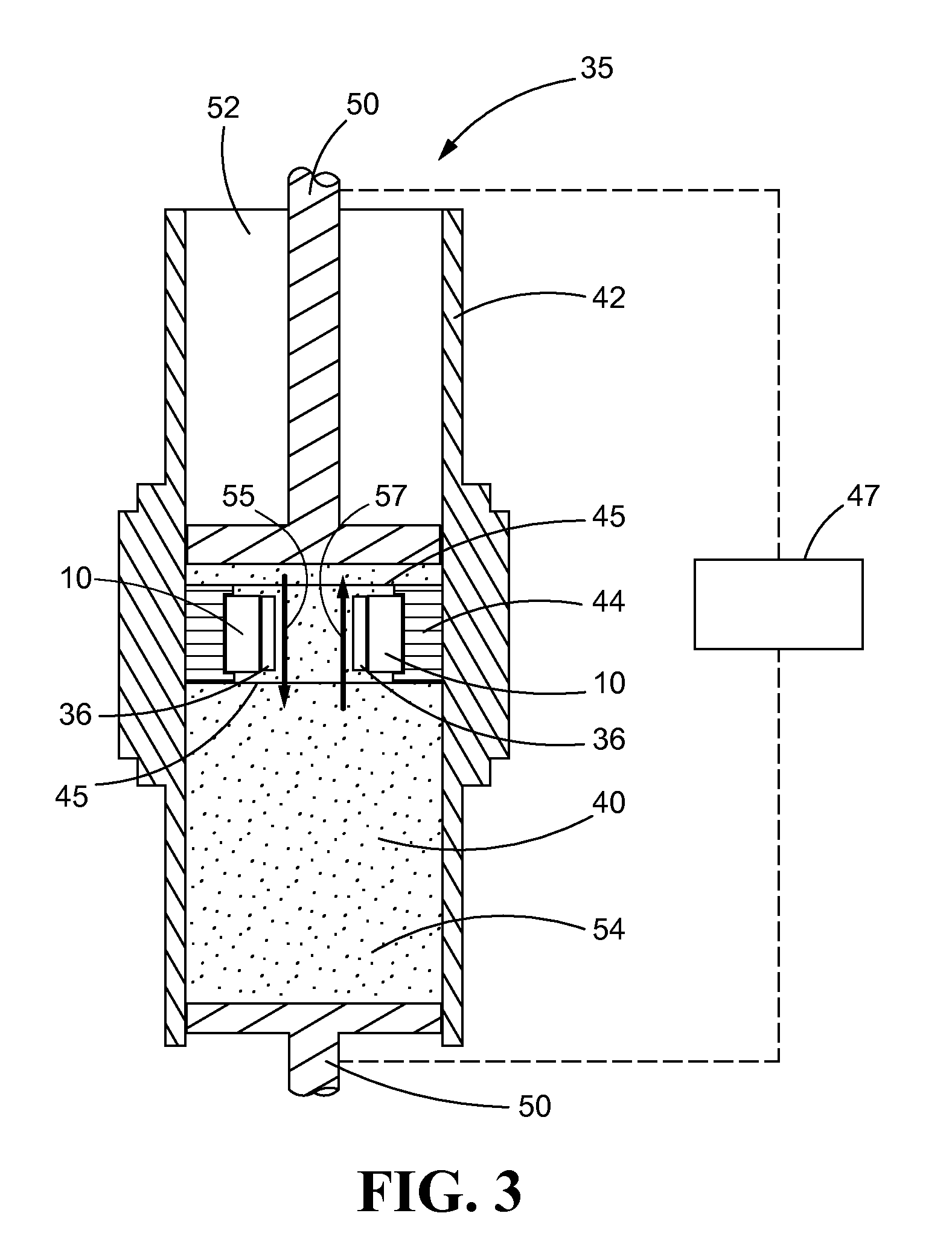

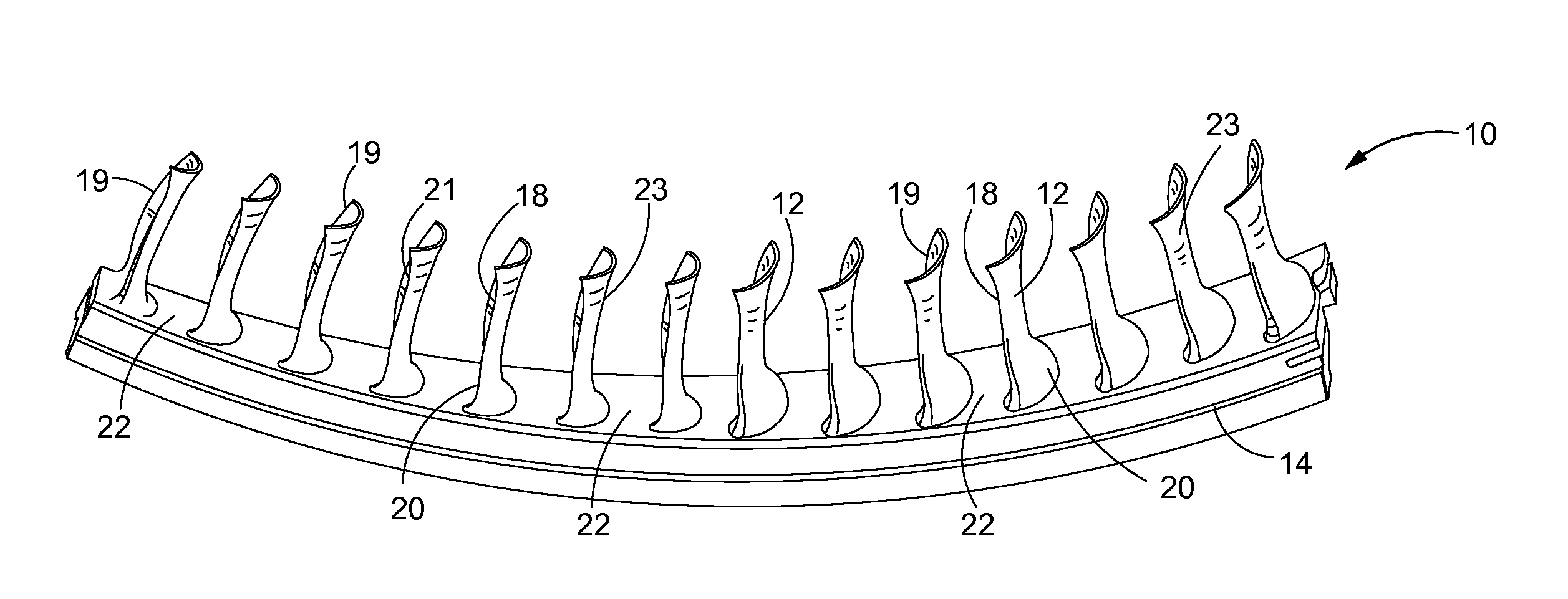

Tool for abrasive flow machining of airfoil clusters

ActiveUS9550267B2Edge grinding machinesPolishing machinesAbrasive flow machiningAerospace engineering

A tool for use during the abrasive flow polishing of an airfoil cluster in an abrasive flow machine is described. The tool may comprise a body and prongs extending from the body. Each prong of the tool may be configured to insert between an adjacent pair of airfoils of the airfoil cluster to create at least one channel therebetween. The channel may allow the flow of an abrasive media therethrough.

Owner:RTX CORP

Tool for Abrasive Flow Machining of Airfoil Clusters

ActiveUS20150375360A1Edge grinding machinesPolishing machinesAbrasive flow machiningMechanical engineering

A tool for use during the abrasive flow polishing of an airfoil cluster in an abrasive flow machine is described. The tool may comprise a body and prongs extending from the body. Each prong of the tool may be configured to insert between an adjacent pair of airfoils of the airfoil cluster to create at least one channel therebetween. The channel may allow the flow of an abrasive media therethrough.

Soft abrasive flow turbulence machining device

ActiveCN105108654AImprove processing efficiencyReduce consumptionAbrasive machine appurtenancesAbrasive blasting machinesAbrasive flow machiningAtmospheric pressure

The invention provides a soft abrasive flow turbulence machining device. An abrasive flow mixing generator is communicated with a pressurization air pump, an abrasive flow channel is arranged in a restraint module, and a sawtooth surface is arranged on the outer wall of the abrasive flow channel. According to the soft abrasive flow turbulence machining device, due to the fact that the outer surface of the abrasive flow channel of the restraint module is arranged to be in a sawtooth shape, a reverse impact effect can be given to abrasive flow in the high-pressure flowing process of the abrasive flow, more energy of the abrasive flow is made to act on a workpiece, and thus the efficiency of soft abrasive flow machining is improved. In addition, due to the fact that the pressurization air pump is arranged, certain small bubbles can be provided for the abrasive flow, a layer of bubbles are attached to abrasives, the bubbles can generate high pressure after making contact with the workpiece, the energy for soft cutting of the workpiece is increased, and the machining efficiency is improved. Meanwhile, a first one-way valve and a second one-way valve are arranged, so that it is guaranteed that air pressure provides energy in the abrasive flow direction, energy consumption is reduced, and machining cost is reduced.

Owner:CHANGCHUN UNIV OF SCI & TECH

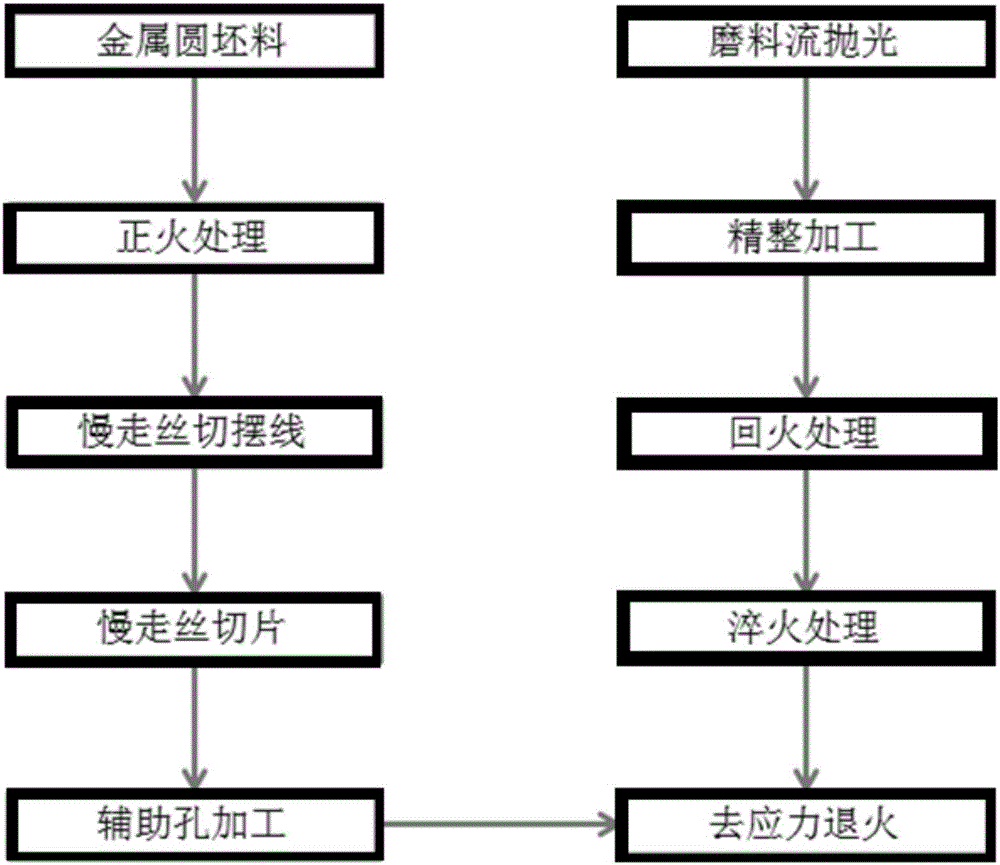

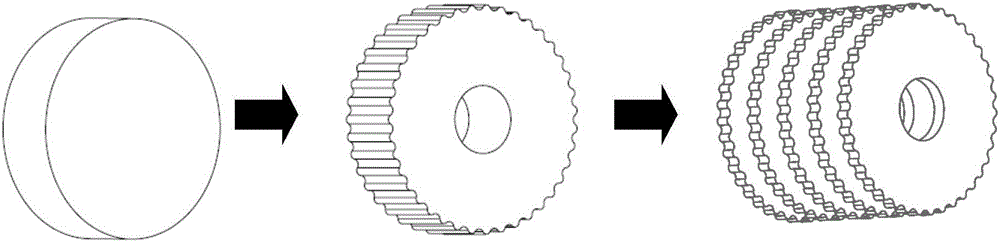

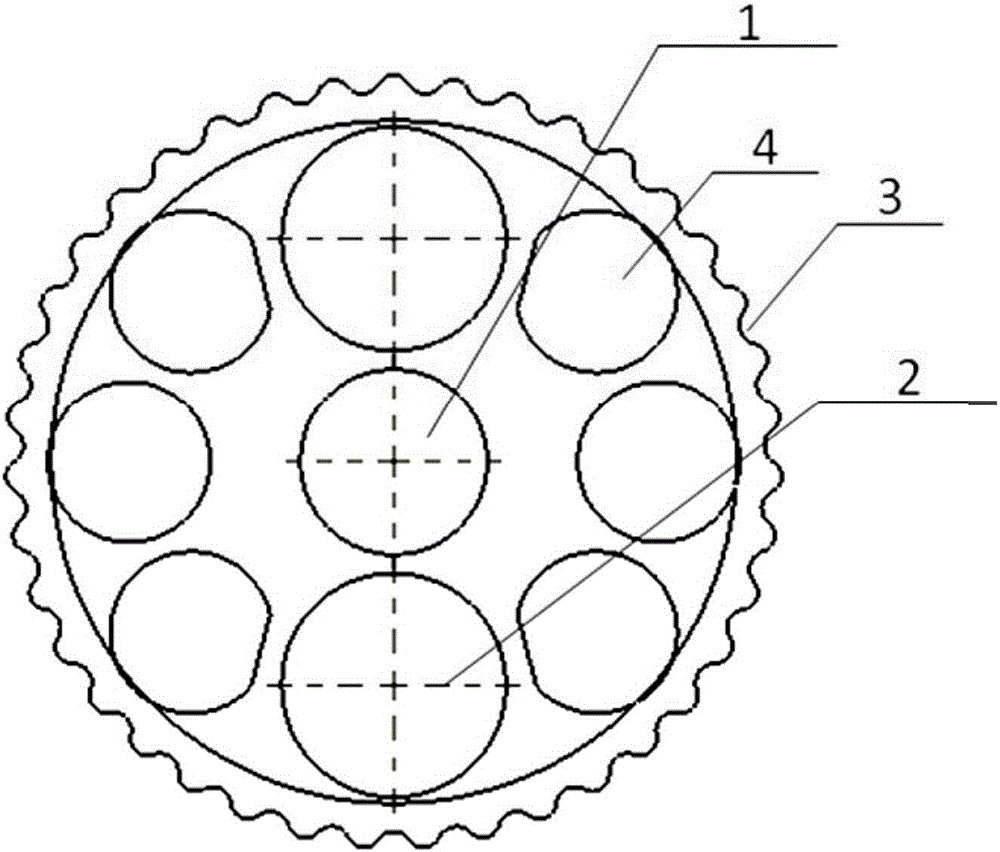

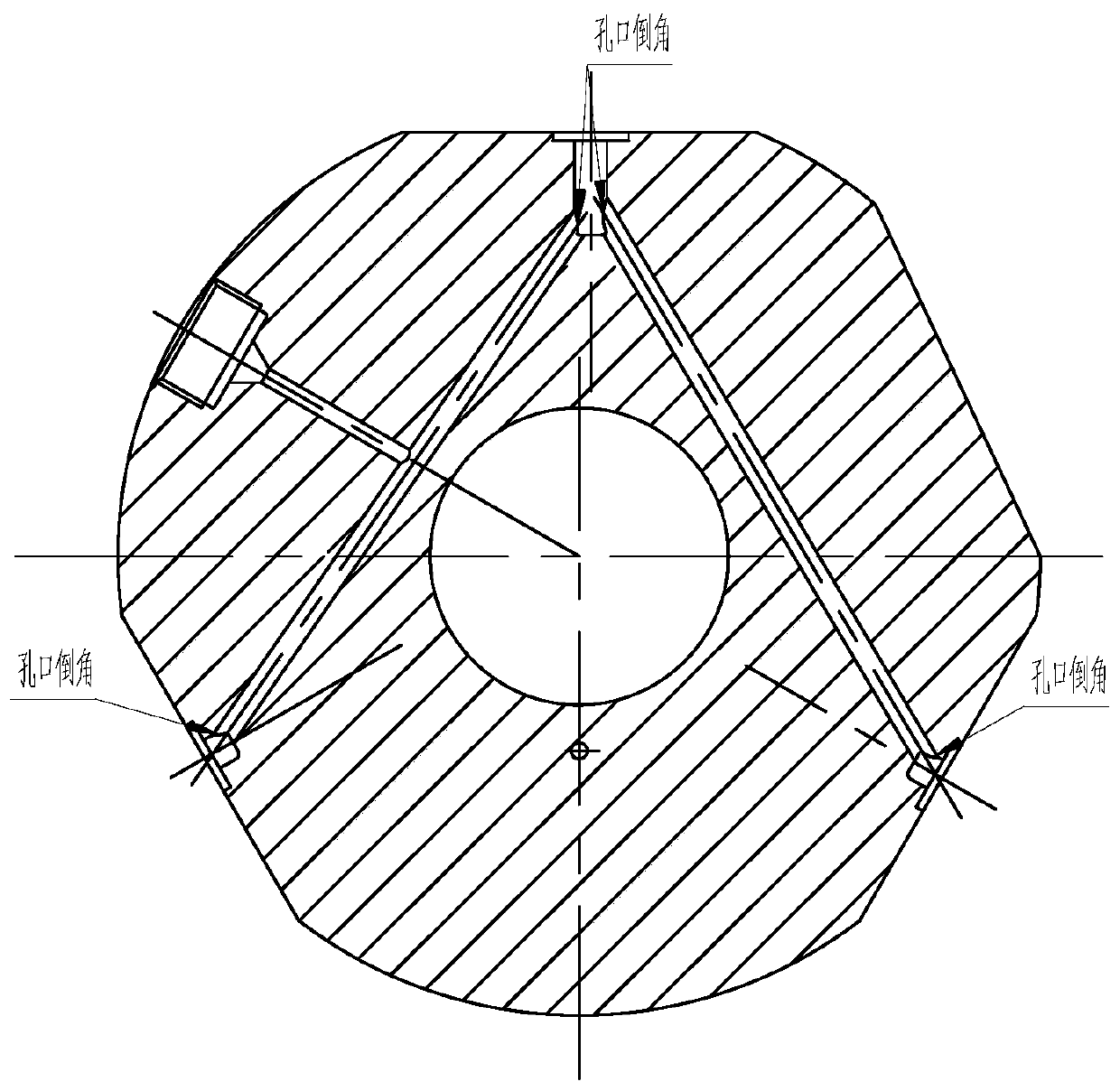

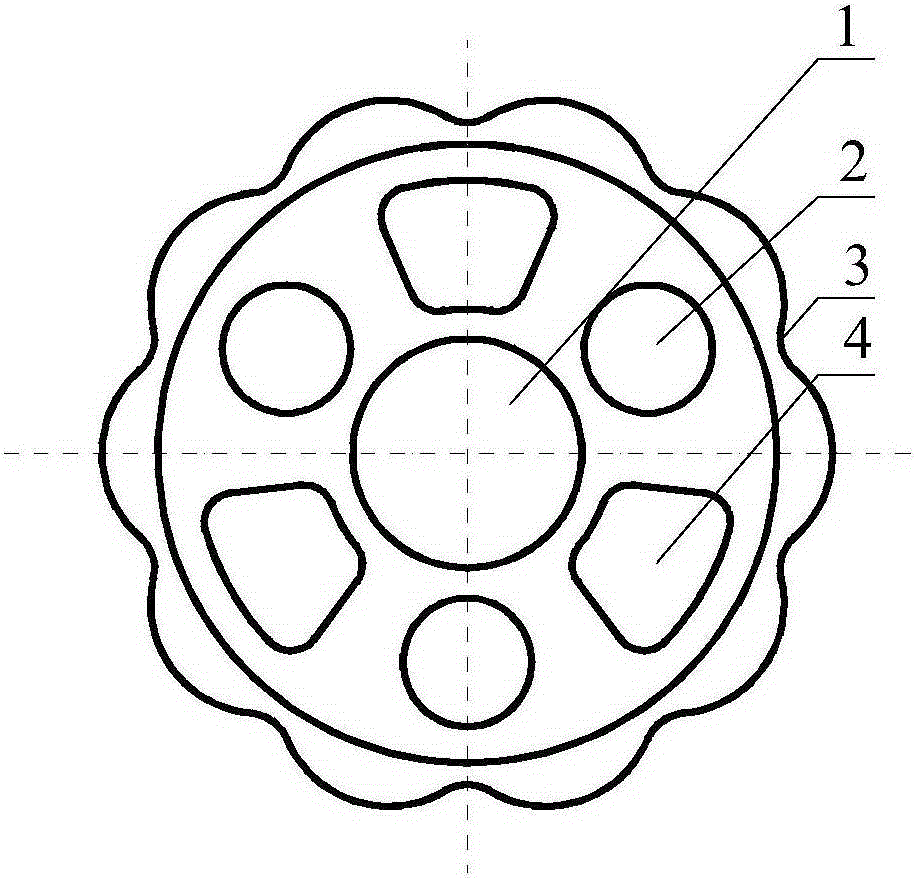

Non-traditional machining method of RV cycloid gear

InactiveCN106425340AReduce manufacturing costSolve the problems of complex production process, high cost and low efficiencyGear grindingHobbing

The invention discloses a non-traditional machining method of a RV cycloid gear. The method comprises following steps: metal round blank material is selected as raw material and is subjected to normalizing and low-speed wire cutting and slicing; a via hole of the workpiece is processed using a cycloid as the reference; the workpiece is subjected to stress relief annealing and quenching; then the workpiece is subjected to drawing temper, finishing and abrasive flow polishing. According to the method of the invention, low-speed wire cutting is adopted to process gear cycloid and abrasive flow is adopted to polish cycloid gears; after processing, the surface roughness of the cycloid gears is low and the dimensional accuracy is high. Compared to the traditional rough turning-fine turning-gear hobbing-gear shaving-gear grinding process, the production efficiency is significantly improved, and the high cost of high accuracy machine tools required in rough turning-fine turning-gear hobbing-gear shaving-gear grinding process; the method has good production prospect.

Owner:SOUTH CHINA UNIV OF TECH

Device for high-pressure jetting, precise polishing and machining of abrasive flows

ActiveCN105033868APromote uniform mixingGuaranteed processing efficiencyAbrasive feedersAbrasive machine appurtenancesAbrasive flow machiningHigh pressure

The invention provides a device for high-pressure jetting, precise polishing and machining of abrasive flows. The device comprises an abrasive flow polishing module, an abrasive flow pressurizing pipeline, an abrasive flow even-mixing box, an abrasive flow generation box, an abrasive flow jet box, a high-pressure abrasive particle solution fog jet orifice, a high-pressure abrasive flow jet orifice and a high-pressure gas jet orifice. According to the device, abrasive flows are automatically configured in a high pressure jetting mode, it is guaranteed that abrasive particles in the abrasive flows are evenly mixed, and abrasive flow machining efficiency and precision are guaranteed. Meanwhile, through the arrangement of the abrasive flow pressurizing pipeline, pressure of the abrasive flows can be guaranteed, and the abrasive flow machining efficiency is further improved. Workpieces freely rotate in the abrasive flow polishing module, and workpiece polishing uniformity and consistency are improved. Moreover, the pressure of the abrasive flows can be adjusted according to actual requirements, and abrasive flow machining efficacy is guaranteed.

Owner:CHANGCHUN UNIV OF SCI & TECH

Abrasive flow deburring precision machining device

ActiveCN105014550AIncrease exercise intensityIncrease movement speedAbrasive machine appurtenancesAbrasive blasting machinesAbrasive flow machiningUltimate tensile strength

The invention provides an abrasive flow deburring precision machining device. The abrasive flow deburring precision machining device comprises an upper abrasive flow shell, a lower abrasive flow shell, a workpiece clamping tool, an upper abrasive flow oscillating piston, a lower abrasive flow oscillating piston, an upper oscillator, a lower oscillator and an abrasive flow feeder. According to the abrasive flow deburring precision machining device, an airtight space is formed among the upper abrasive flow shell, the workpiece clamping tool and the lower abrasive flow shell; flowing of an abrasive flow is achieved through the circulating flowing performance achieved through the abrasive flow feeder by means of the upper oscillator and the lower oscillator; the upper oscillator and the lower oscillator oscillate in opposite directions at the same frequency, in this way, the movement intensity and the movement speed of the abrasive flow are increased, and the deburring capacity is improved; meanwhile, the workpiece clamping tool is only used for being abutted against and fixing a workpiece, and the fixing method is simple and reliable; various special-shaped parts can be clamped; machining efficiency can be guaranteed; in addition, impacting deburring machining of the workpiece by the abrasive flow is not affected. The abrasive flow deburring precision machining device is simple in structure and convenient to use, and abrasive flow machining cost is greatly reduced.

Owner:CHANGCHUN UNIV OF SCI & TECH

Additive manufacturing for radio frequency hardware

A method and apparatus is presented. A structure having an interior channel is formed using additive manufacturing equipment. A viscous media containing abrasive particles is sent through the interior channel using abrasive flow machining equipment to form a desired surface roughness for the interior channel.

Owner:THE BOEING CO

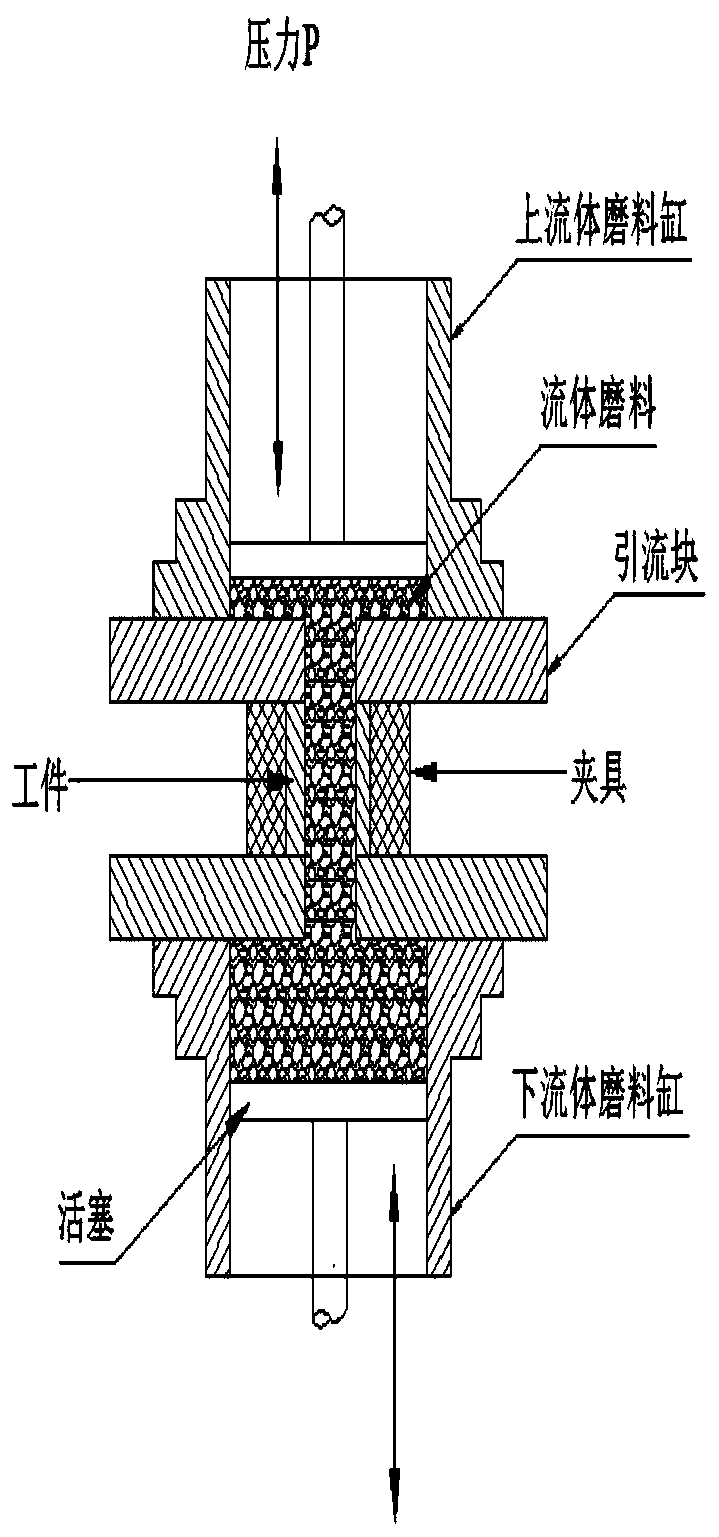

Abrasive flow flexible clamp

PendingCN111113251AQuick squeezeImprove processing qualityEdge grinding machinesPolishing machinesPhysicsAbrasive flow machining

The invention discloses an abrasive flow flexible clamp. The abrasive flow flexible clamp comprises an upper end cover, a cylinder sleeve and a lower end cover; the cylinder sleeve is an annular cylinder, and the upper end cover and the lower end cover are arranged at the upper end and the lower end of the cylinder sleeve correspondingly; a to-be-machined part is located in the cylinder sleeve andarranged on the lower end cover, material passing holes are formed in the upper end cover and the lower end cover, and the material passing hole in the lower end cover is in communication with a to-be-machined hole system in the to-be-machined part; and when abrasive flow machining is conducted on the to-be-machined part, abrasive is fed into the to-be-machined hole system of the part from a lower fluid abrasive cylinder through the material passing hole in the lower end cover, after the abrasive flows out of the to-be-machined hole system and is led out of an upper fluid abrasive cylinder through the material passing hole in the upper end cover, and after the abrasive in the lower fluid abrasive cylinder flows out completely, the abrasive collected in the upper fluid abrasive cylinder isreversely guided so as to machine the to-be-machined hole system, and the process is repeated. According to the abrasive flow flexible clamp, a pump body inclined hole can be rapidly extruded, protruding burrs on the edges of crossed holes are removed, the pump body machining quality is improved, and the pump body cleanliness requirement is met.

Owner:STATE RUN NO 616 FACTORY

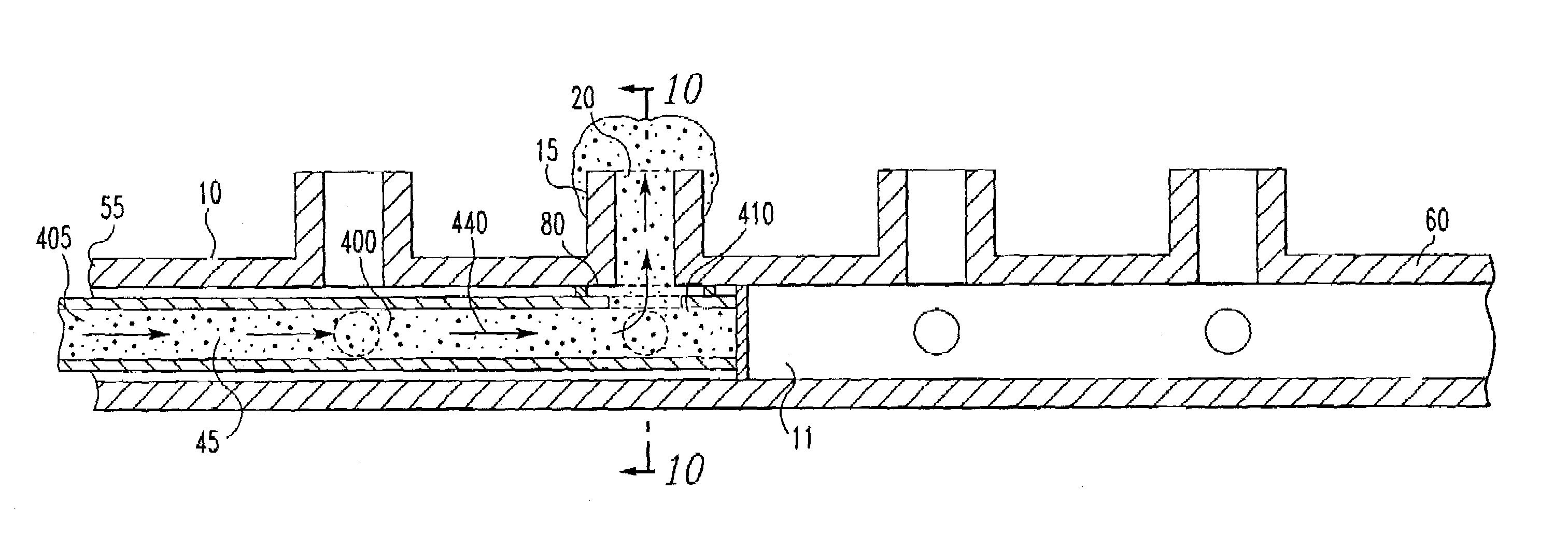

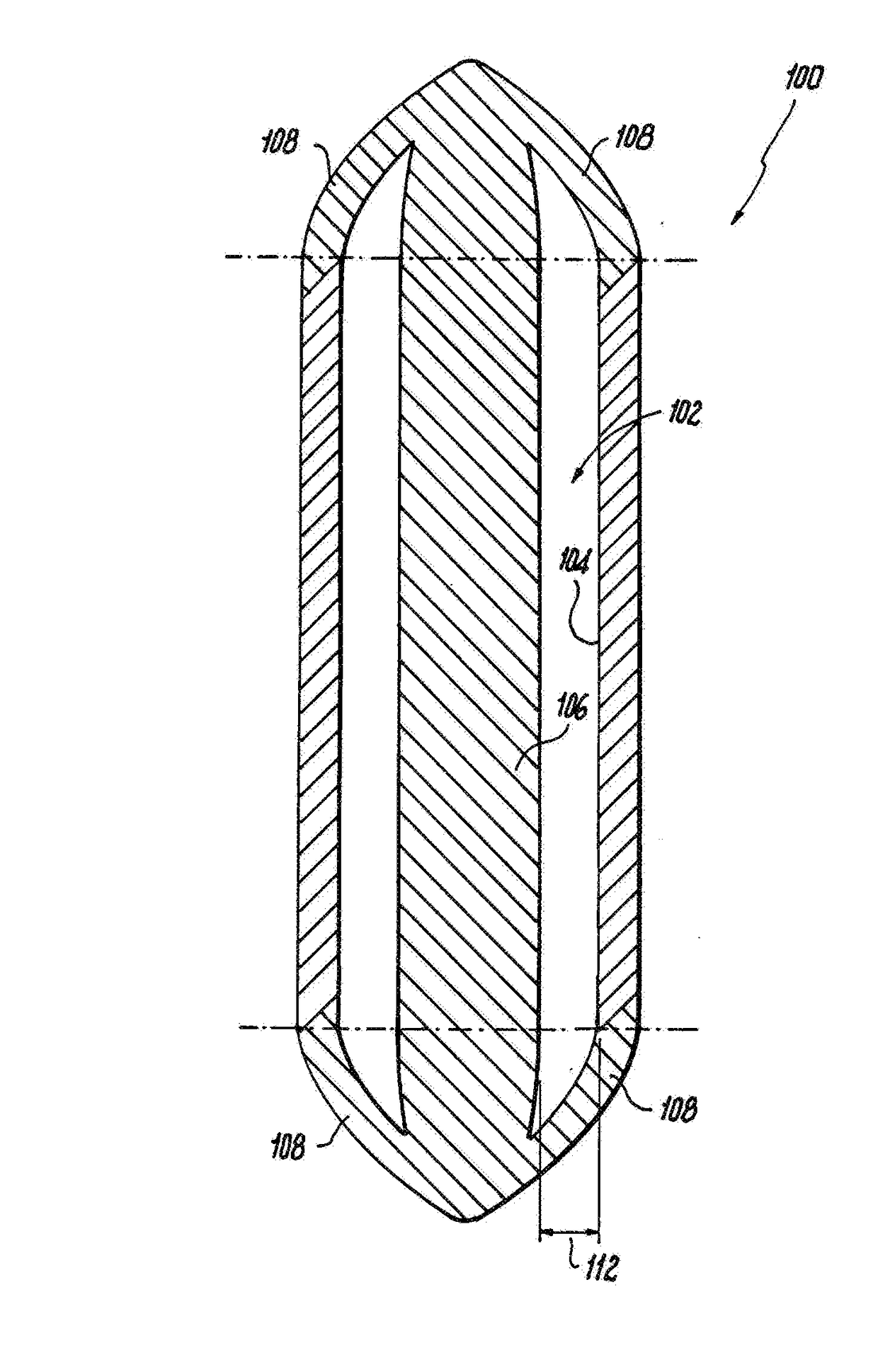

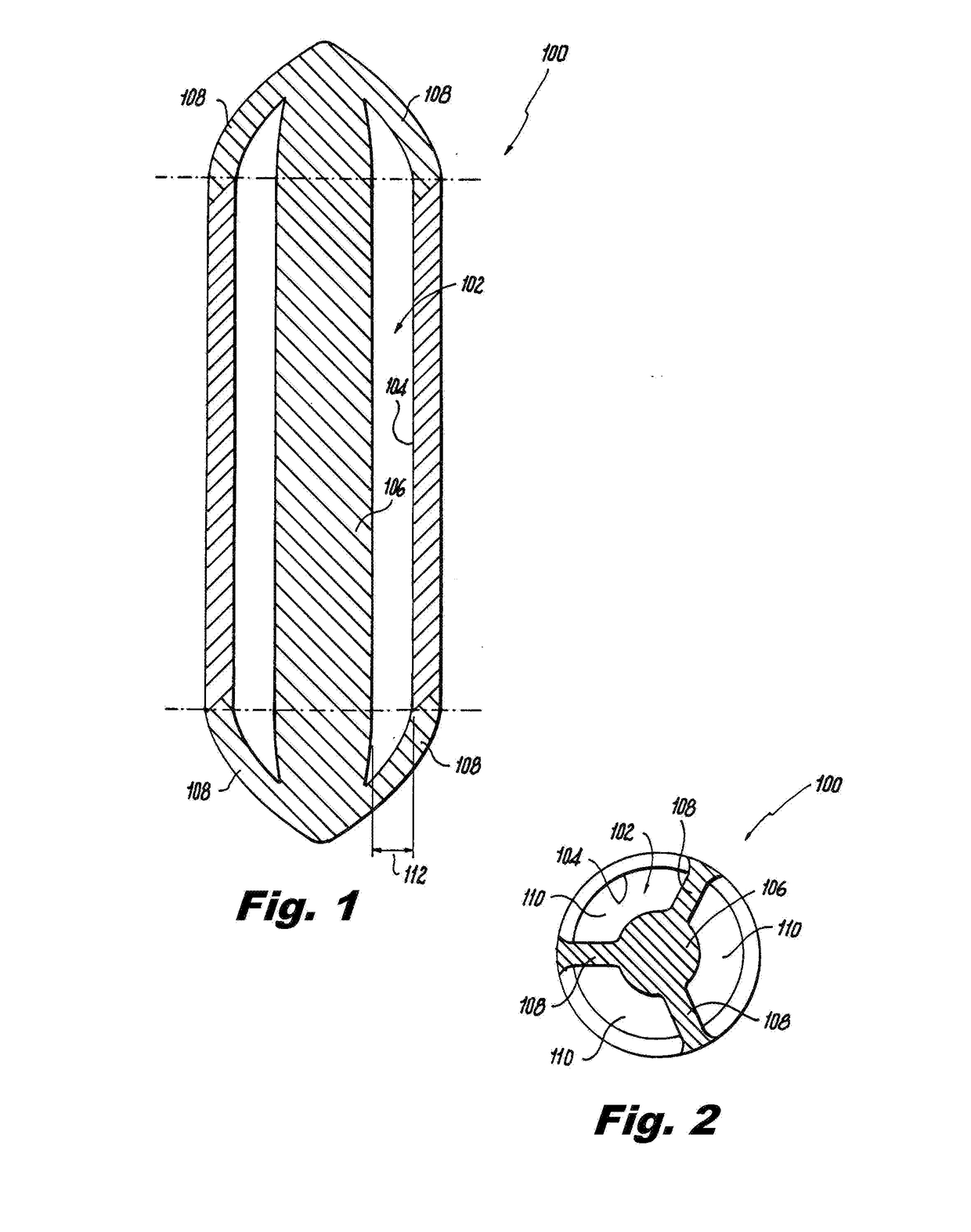

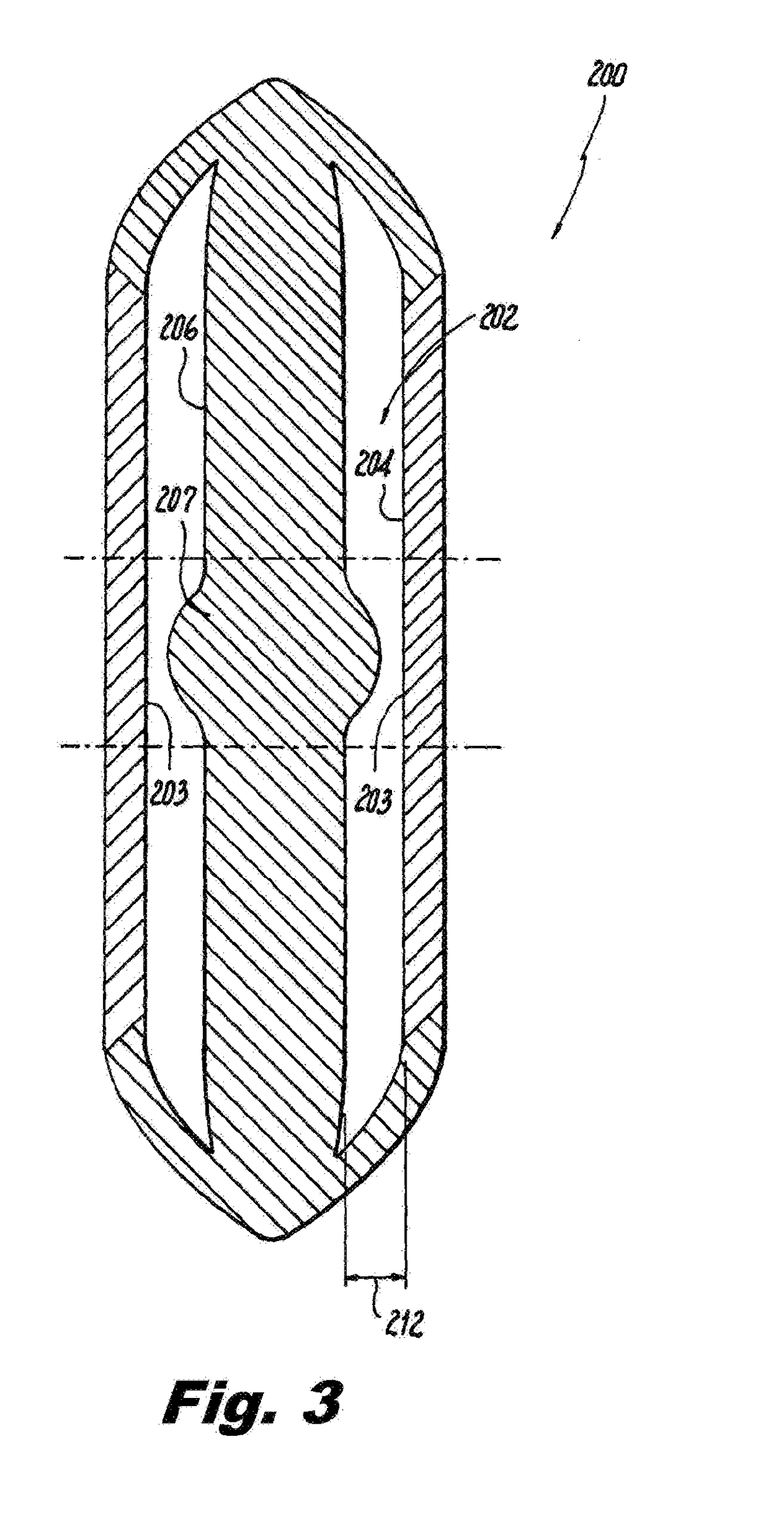

Additive manufacture of interior passages

InactiveUS20170080543A1Edge grinding machinesAdditive manufacturing apparatusAbrasive flow machiningEngineering

A method of additive manufacturing includes additively forming a workpiece. The workpiece defines an interior passage therethrough with a passage surface. Additively forming the workpiece includes additively forming a beam running through the interior passage spaced apart from the passage surface. The method also includes surface treating the passage surface using abrasive flow machining wherein an abrasive flow machining fluid is forced to flow between the beam and the passage surface. The beam can be removed from the workpiece after surface treating the passage surface.

Owner:DELAVAN

Apparatus for abrading the region of intersection between a branch outlet and a passageway in a body

Owner:EXTRUDE HONE CORP

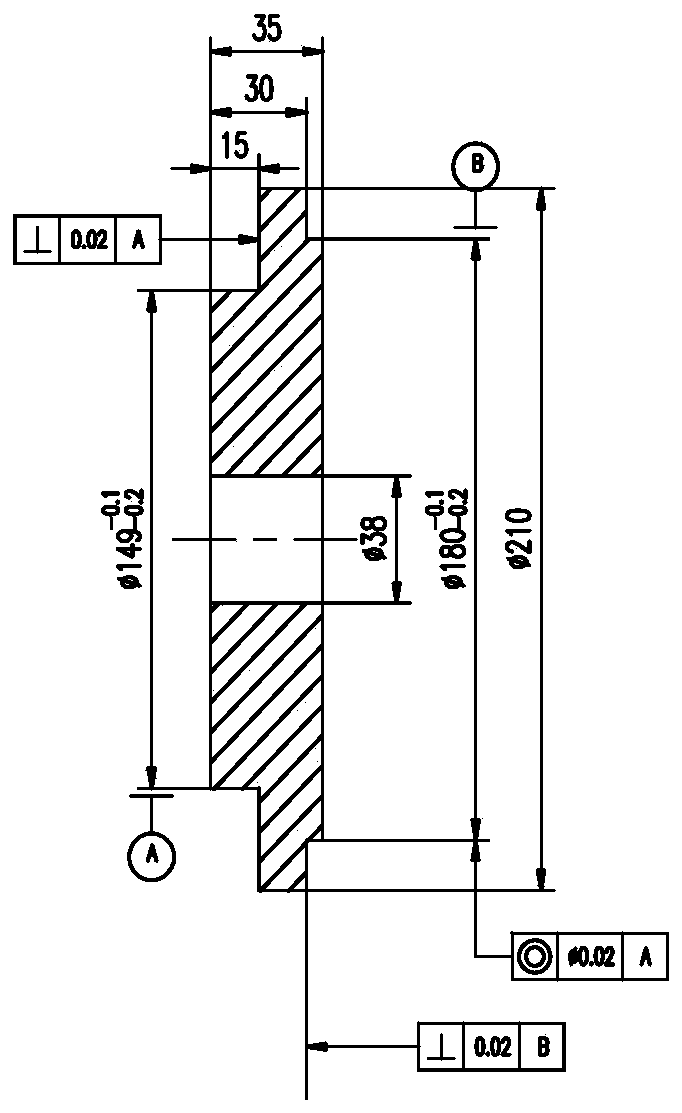

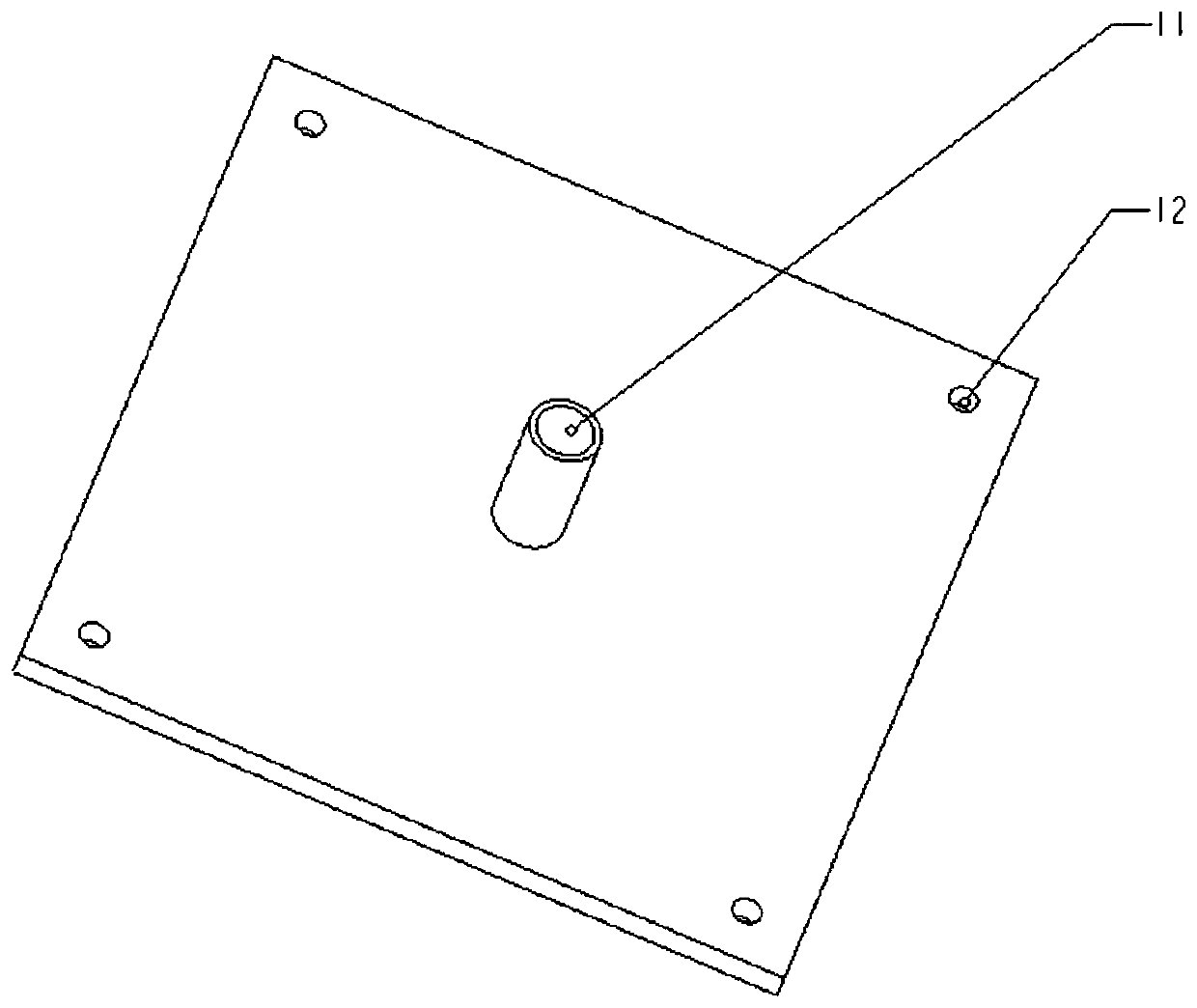

Size-variable clamp for abrasive flow machining of valve block through hole

PendingCN109746837AImprove surface qualityAbrasive blasting machinesEngineeringAbrasive flow machining

The invention discloses a size-variable clamp for abrasive flow machining of a valve block through hole. The size-variable clamp comprises a bottom plate, a cover plate, side plates, angle plates, a supporting plate and a variable washer. The bottom plate comprises a center threaded hole, four positioning holes, four trapezoidal sliding grooves and four fixed threaded rods; the cover plate comprises a center flowing channel and four through holes; each side plate comprises two flowing channel through holes and a trapezoidal sliding rail; each angle plate comprises two sliding grooves matched with the corresponding side plates, four semi-circular holes matched with the flowing channel through holes of the corresponding side plates, an internal partition plate and an external fastening auxiliary plate; the supporting plate at the bottom comprises a threaded rod, a bearing and four positioning rods; and the variable washer is formed by four movable angle sliding blocks in a matched mode.The size-variable clamp is designed specific to abrasive flow machining of the valve block through hole, the innovation point of the size-variable clamp lies in that the size of the clamp can be changed, through hole parts inside regular hexahedrons of different sizes can be machined, mounting is convenient, the machining efficiency is high, and the roughness of an inner hole is significantly reduced.

Owner:CHANGCHUN UNIV OF SCI & TECH

Combined fixture for grinding material flow processing for cross-section-variable special-shaped channels

ActiveCN108527141AAvoid C-notchesProtect pitsEdge grinding machinesPolishing machinesAbrasive flow machiningEngineering

A combined fixture for grinding material flow processing for cross-section-variable special-shaped channels is characterized in that the combined fixture comprises a workpiece exterior fixture and aninner-hole guide mandrel; the workpiece exterior fixture comprises a fixing and supporting block (1), an outer fixture base (2), an upper cover support ring (3), a workpiece base (4), a base gasket (5), an upper cover plate (6) and an upper fixture cover (7); the outer fixture base (2) is fixed to a workbench of a grinding material flow processing machine tool; the workpiece base (4) is mounted onthe outer fixture base (2) through the fixing and supporting block (1) to enable a grinding material channel to be formed between the outer fixture base (2) and the workpiece base (4); a workpiece isfixed to the workpiece base (4) through a limiting groove; the upper cover support ring (3) is mounted between the outer fixture base (2) and the upper fixture cover (7); the inner-hole guide mandrel(8) is located at the center of the workpiece and fixed to the workpiece base (4). The combined fixture has the advantages that the reasonable fixture is provided for reducing surface roughness of the special-shaped channels by grinding material flows, and has a reasonable design, a simple structure and an obvious effect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Machining fixture of irregularly-shaped straight slot and machining method

ActiveCN107309651AImprove surface roughnessImprove machining accuracyElectrical-based machining electrodesOther manufacturing equipments/toolsAbrasive flow machiningEngineering

The invention relates to a machining fixture of an irregularly-shaped straight slot and a machining method. The machining method includes the steps that firstly a large part of allowances of the irregularly-shaped straight slot are removed by using a wire-cut machining method, and the machining allowance of the irregularly-shaped straight slot is reserved to be 0.01mm to 0.05 mm; parts of the irregularly-shaped straight slot are clamped on the fixture; once again the parts of the irregularly-shaped straight slot and the fixture are integrally mounted on an abrasive flow machine tool, the rest of the machining allowances of the irregularly-shaped straight slot are removed by using an abrasive flow machining mode; and finally the parts of the irregularly-shaped straight slot are dismounted from the fixture and the abrasive flow machine tool, the parts of the irregularly-shaped straight slot are inspected and put in storage after being washed. By using the technical scheme provided by the machining method, the machining method by combining fast wire cut with abrasive flow grinding machining together is used, firstly the large part of machining allowances are removed through fast wire cut , rough machining and forming are conducted, and then forming is completed through the abrasive medium grinding mode, so that the roughness of the surface around the irregularly-shaped straight slot is improved greatly, the machining cost is reduced, and the machining accuracy and the machining quality are improved.

Owner:GUIZHOU LIYANG INT MFG

Abrasive flow machining equipment for cylinder-shaped workpiece

InactiveCN112338791ASolve the problem that the inside and outside cannot be polished at the same time, and the polishing efficiency is lowEasy to cleanEdge grinding machinesPolishing machinesWater flowAbrasive flow machining

The invention discloses abrasive flow machining equipment for a cylinder-shaped workpiece. The abrasive flow machining equipment comprises an equipment assembly and a working box arranged in the equipment assembly, and the working box is internally provided with a first extrusion working cavity and a second extrusion working cavity arranged below the first extrusion working cavity. The abrasive flow machining equipment is mainly used for the cylinder-shaped workpiece, the effect that the inner wall and the outer wall of the cylinder-shaped workpiece are polished at the same time can be achieved through abrasive flow, after polishing is completed, the redundant abrasive flow is extruded into one cavity for secondary utilization, after the abrasive flow is extruded, a water pump is lifted tothe inner wall of the cylinder-shaped workpiece to flush the interior of the cylinder-shaped workpiece, and meanwhile part of water flows outside the outer side of the cylinder-shaped workpiece through a gap, meanwhile a whole polishing cavity shakes, the inner wall, the outer wall and the gap of the cylinder-shaped workpiece are effectively cleaned, and the problems that when abrasives are extruded out of a workpiece, part of the abrasives remain in the gap, the cylinder-shaped workpiece needs to be taken out to for removing of the abrasives, procedures are complex, meanwhile, traditional abrasive flow polishing cannot achieve simultaneous polishing of the inside and the outside, and the polishing efficiency is low are solved.

Owner:福州晋安区格撕图科技有限公司

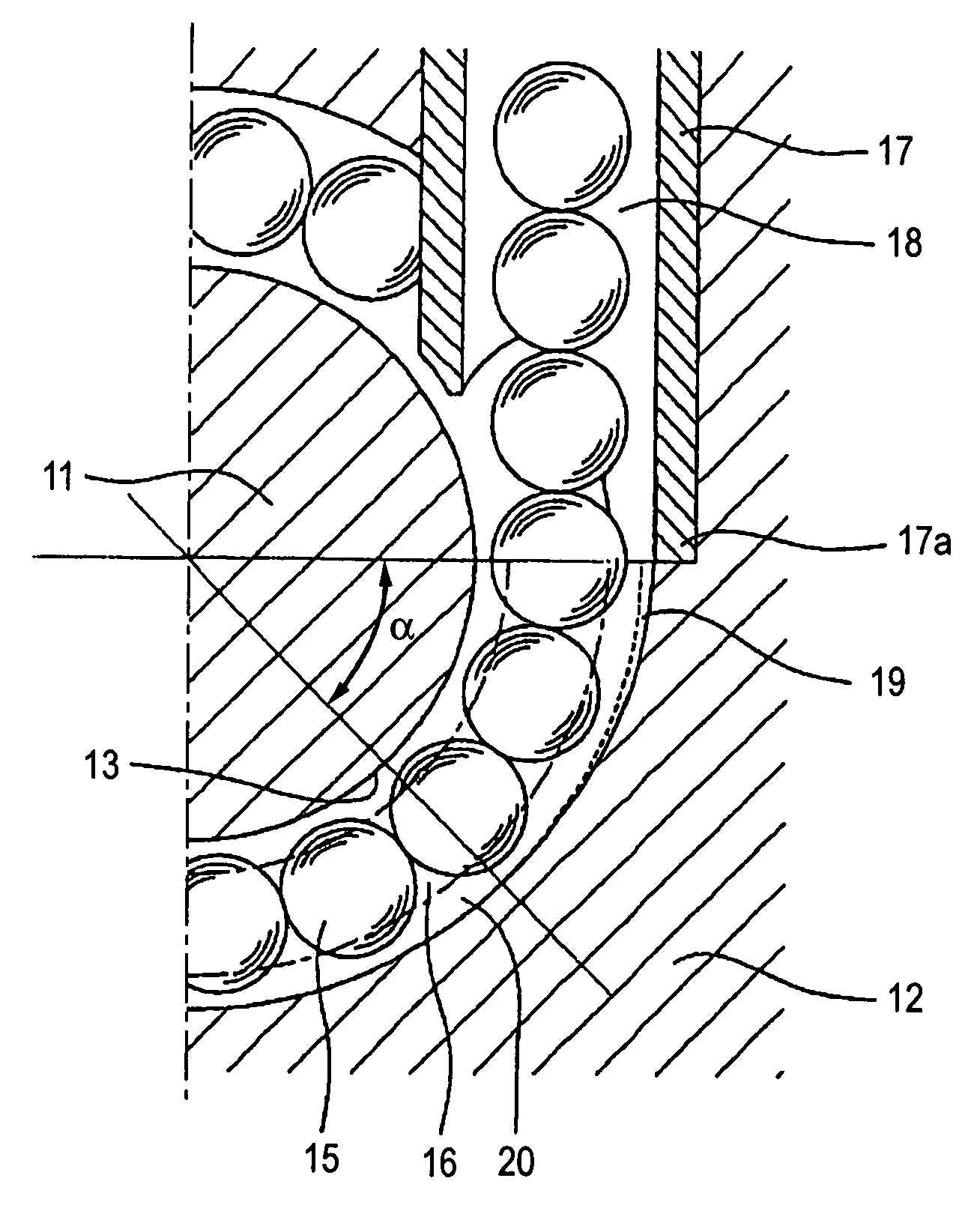

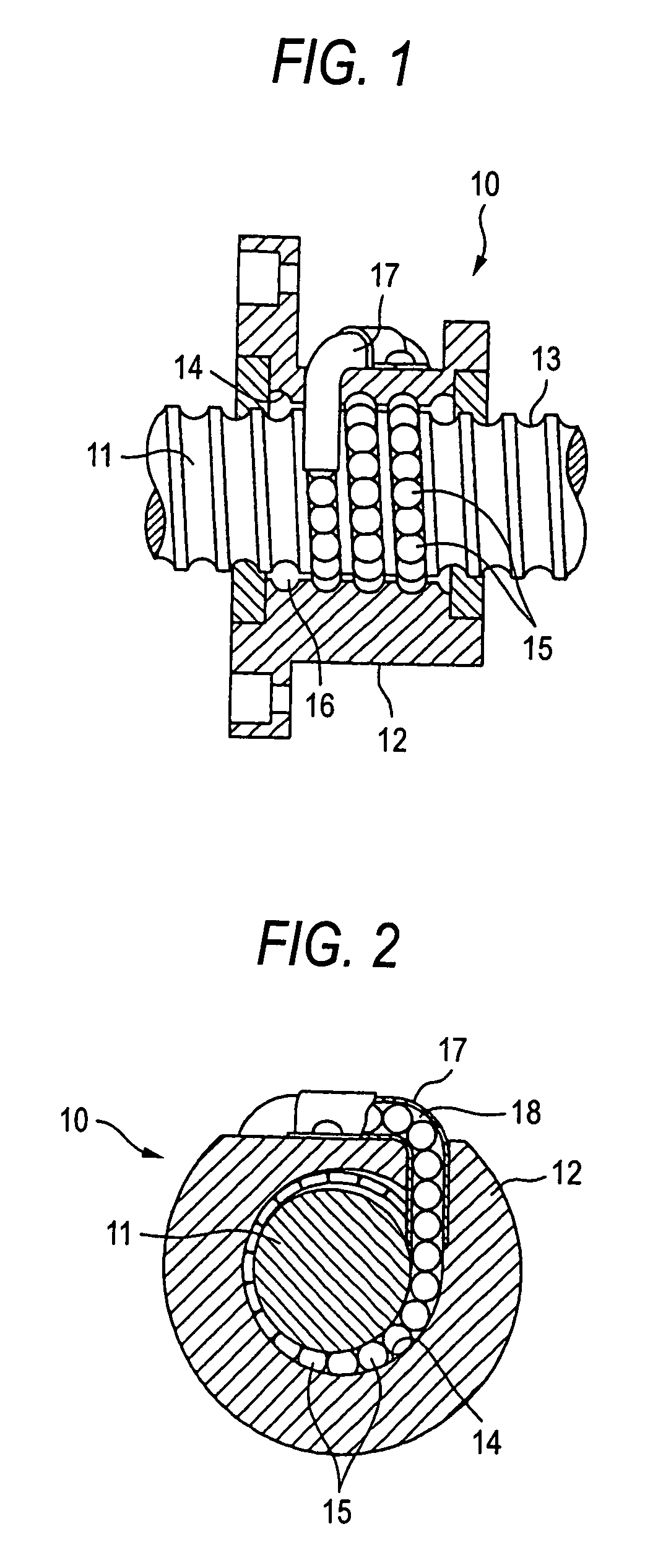

Linear motion apparatus and method for manufacturing thereof

InactiveUS7024958B2Drawback can be obviatedEdge grinding machinesPolishing machinesLinear motionAbrasive flow machining

A linear motion apparatus has a guide shaft including a spiral-shaped or linear-shaped rolling element rolling groove, a movable body including a spiral-shaped or linear-shaped rolling element rolling groove opposed to the rolling element rolling groove of the guide shaft, a large number of rolling elements rollably moving along a rolling element rolling passage formed between the rolling element rolling grooves of the guide shaft and movable body and, a rolling element return passage communicating with the rolling element rolling passage, wherein, in the portion of the rolling element rolling groove of the movable body that is adjacent to an open end of a rolling element return passage, an escape portion is formed by abrasive flow machining in such a manner that the grinding depth thereof increases gradually toward the open end of the rolling element return passage.

Owner:NSK LTD

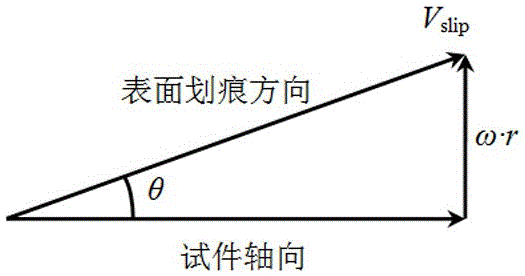

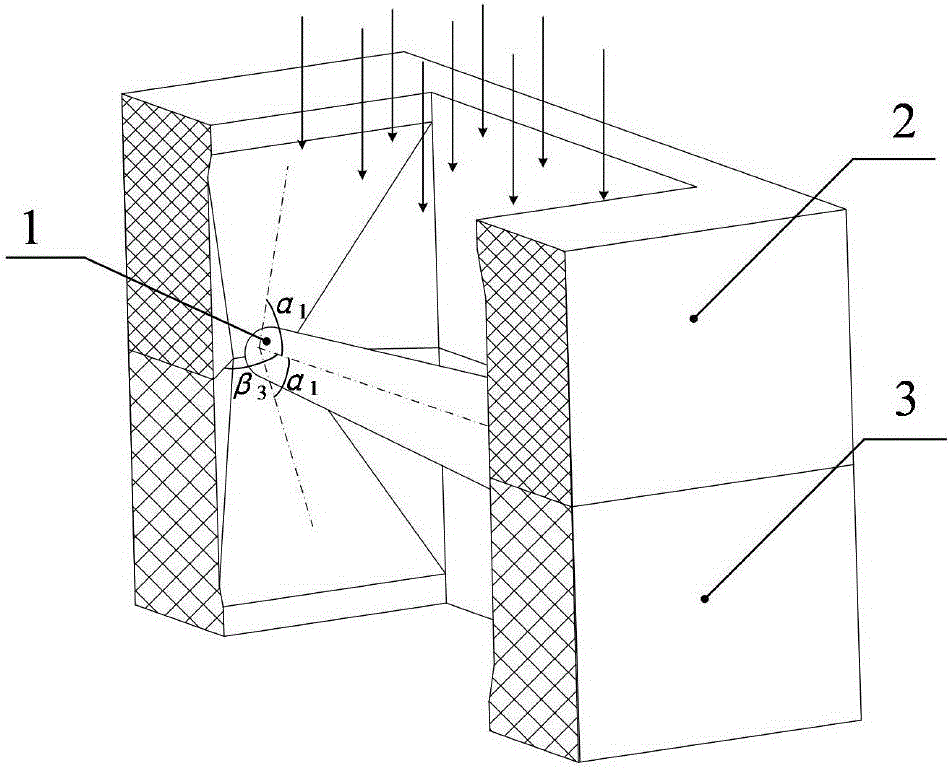

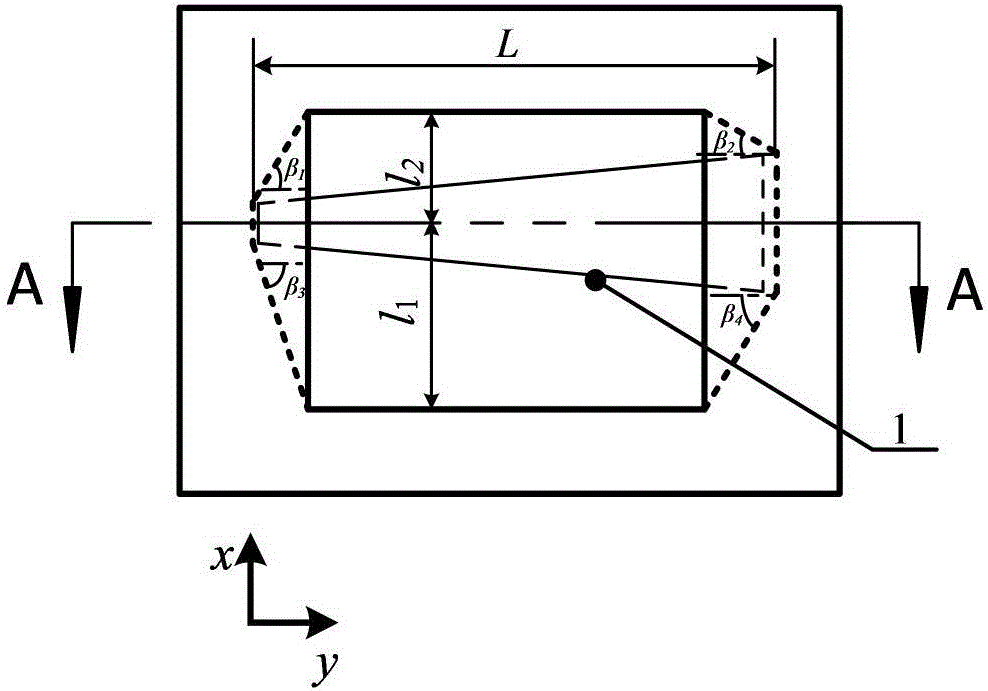

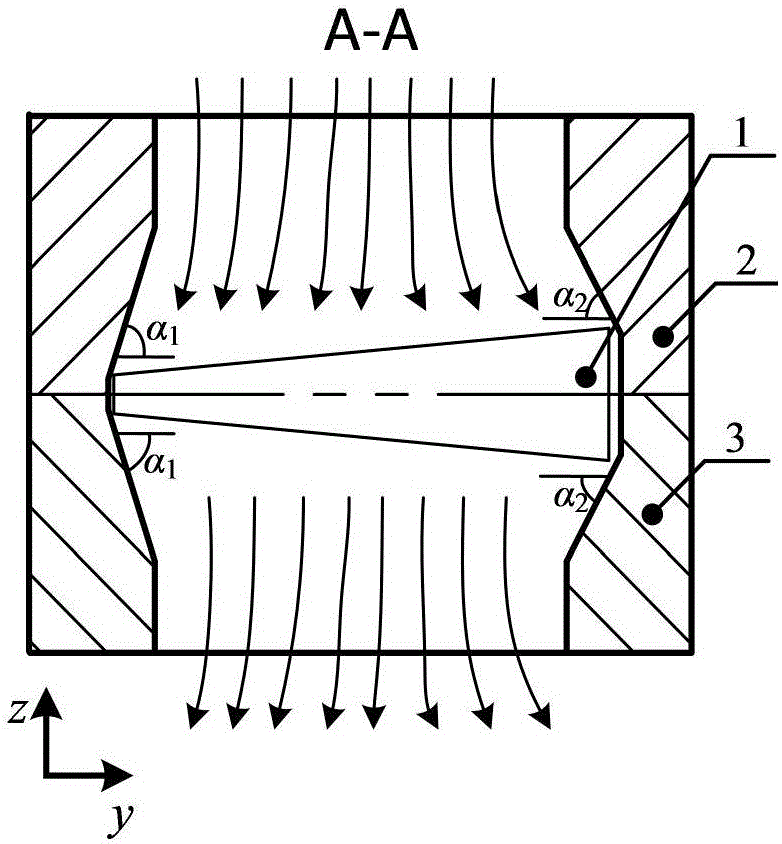

Clamp for polishing of auto-rotation abrasive flow of rotator workpiece and design method thereof

ActiveCN106272025ARestricted movementSolve the problem of no clamping pointEdge grinding machinesPolishing machinesWear particleAbrasive flow machining

The invention discloses a clamp for polishing of auto-rotation abrasive flow of a rotator workpiece and a design method thereof. The clamp comprises a clamp base and moulds, wherein the moulds are uniformly distributed in the clamp base in a layered manner, both an upper cover plate and a lower cover plate of the clamp base are provided with a plurality of runner through holes, the clamp base is used for positioning the moulds and supporting pressure of an external machine tool, each mould comprises an upper runner plate and a lower runner plate which are oppositely fastened to form a runner for storing a workpiece to be machined, and the upper runner plates and the lower runner plates are made of materials with low hardness. An untight clamping mode is proposed, movement of the workpiece is limited by setting sizes of the runners of the moulds and inclination angles of wall surfaces, and the clamp solves the problem that a machined workpiece needing complete polishing has no clamping points. Compared with a non-eccentric rotation abrasive flow machining method, the design method has the advantages that surface machining uniformity is improved, and surface roughness and production cost are reduced.

Owner:DALIAN UNIV OF TECH

Clamp for hydraulic cylinder abrasive flow machining

ActiveCN108942700AQuick clampingRealize impact processingAbrasive machine appurtenancesHydraulic cylinderAbrasive flow machining

The invention discloses a clamp for hydraulic cylinder abrasive flow machining. The clamp comprises a base, a bottom plate, a convex ball base, a rotating base, a hydraulic cylinder clamping base, a spiral disc, a rotation rod, an upper fixed base and an upper cover base; when abrasive flow finish machining is carried out a hydraulic cylinder, the hydraulic cylinder can be rapidly clamped, duringclamping, a connecting pin only needs to be detached, the upper fixed base is taken down, an outer lock sleeve of an axial connecting assembly is drawn out, a first connecting clamping ring and a second connecting clamping ring are separated, the upper cover base and the hydraulic cylinder clamping base are separated, the hydraulic cylinder is fixed into the hydraulic cylinder clamping base, the axial connecting assembly is mounted, the upper fixed base is positioned, the connecting pin is connected, abrasive flow media are led in, the rotating rod and the rotating base are started, and rotatein the opposite directions, the abrasive flow media can achieve impact machining on the surface of the hydraulic cylinder under rotation of the spiral disc, machining efficiency is high, and the finish machining of the surface of the hydraulic cylinder can be comprehensively achieved.

Owner:CHANGCHUN UNIV OF SCI & TECH

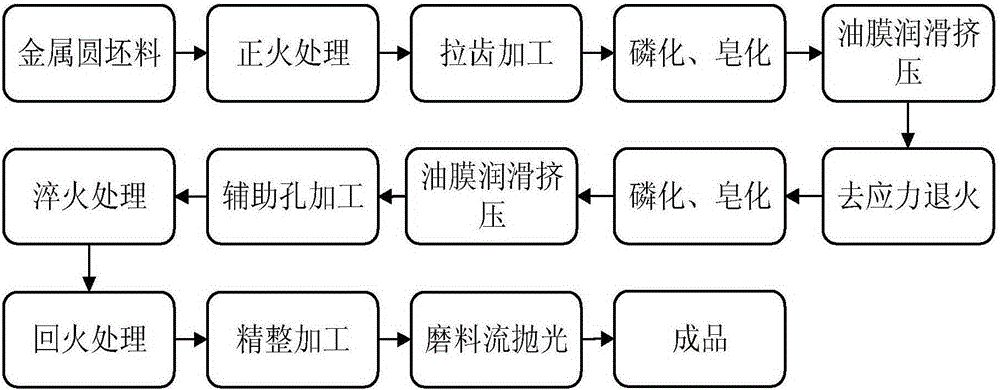

Low-cost and high-efficiency machining method for cycloid gears

The invention relates to a low-cost and high-efficiency machining method for cycloid gears. The method is characterized by comprising the following process steps that (1) round metal billets are selected as raw materials; (2) the round billets are subjected to normalizing treatment; (3) the round billets are subjected to gear broaching; (4) the billets are subjected to phosphating and saponifying treatment in sequence; (5) the billets are subjected to oil film lubrication and extrusion machining; (6) annealing is carried out; (7) the step (4) and (5) are repeated; (8) auxiliary holes of the billets are machined with a cycloid as the benchmark; (9) quenching treatment is carried out; (10) tempering treatment is carried out; (11) workpieces are subjected to finishing machining; and (12) polishing treatment is carried out. According to the method, the cycloid gears are subjected to extrusion machining for two times through the oil film lubrication and extrusion technology; the cycloid gears are subjected to polishing treatment through abrasive flow machining technology; the machined cycloid gears are low in surface roughness and high in dimensional accuracy; and the machining efficiency of the cycloid gears is remarkably improved, and the machining cost is reduced.

Owner:广东中昇华控智能科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com