Soft abrasive flow turbulence machining device

A processing device and abrasive flow technology, applied in the direction of used abrasive processing devices, metal processing equipment, abrasives, etc., can solve the problems of energy consumption, inability to meet the needs of processing a large number of workpieces, and low processing efficiency. Enhance processing efficiency, reduce processing cost and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

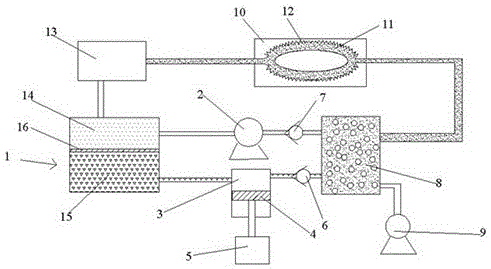

[0022] Such as figure 1 As shown, the present invention provides a soft abrasive flow turbulent flow processing device, which includes a soft abrasive flow supply box 1, a high-pressure carrier fluid injection pump 2, an abrasive injection pressurized cylinder 3, and an abrasive flow mixing generator 8 , pressurized air pump 9, constraint module 10 and filter recovery box 13, the upper end of the soft abrasive flow supply box 1 is connected with the input end of the high-pressure carrier fluid jet pump 2, the soft abrasive flow supply box 1 The lower end is connected to the input end of the abrasive particle injection pressurized cylinder 3, and the output end of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com