Patents

Literature

115 results about "Particle injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

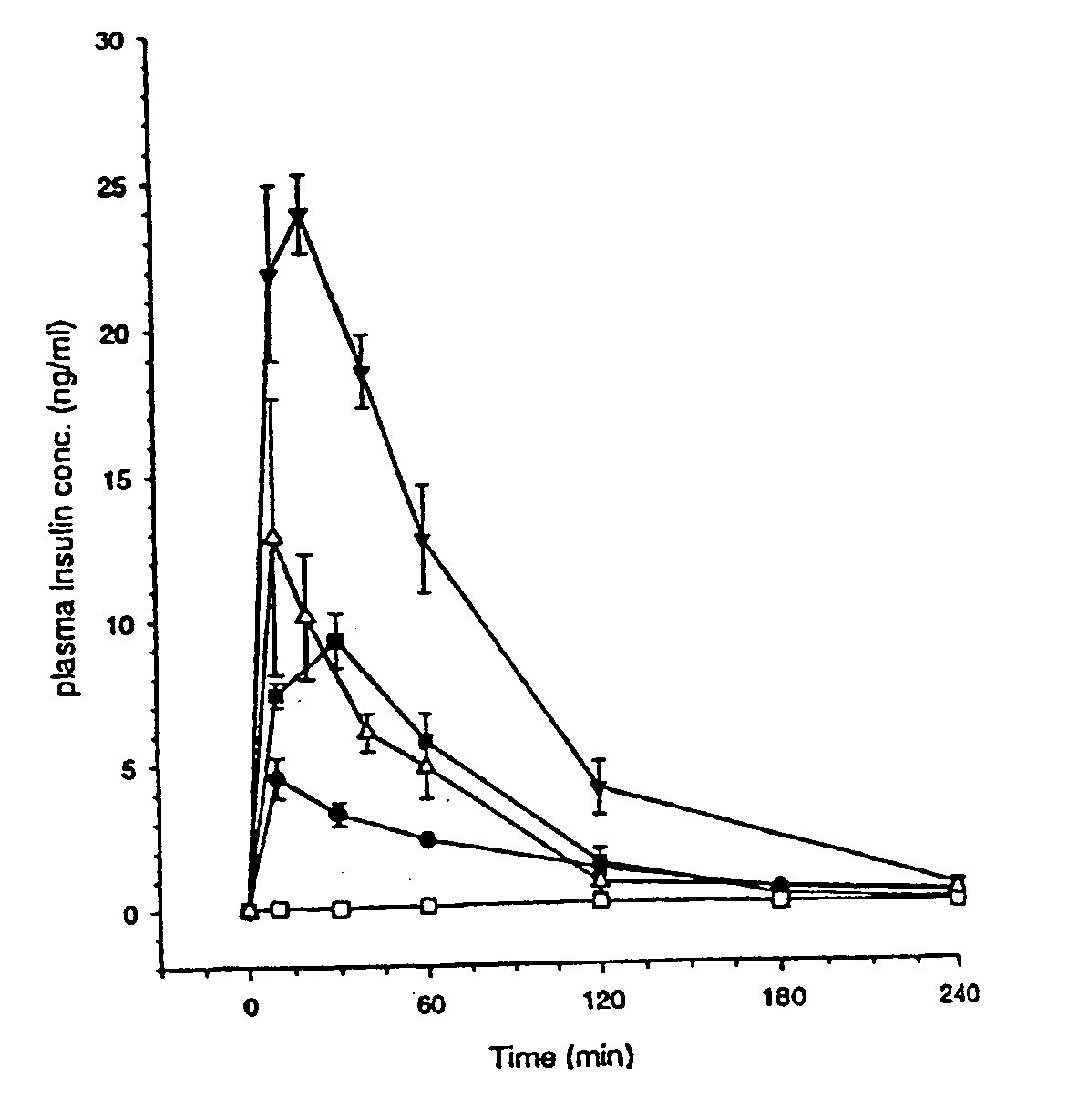

Hydrogel particle formulation

InactiveUS7022313B2Avoid lostEasy to customizePowder deliveryPeptide/protein ingredientsDiagnostic agentParticle injection

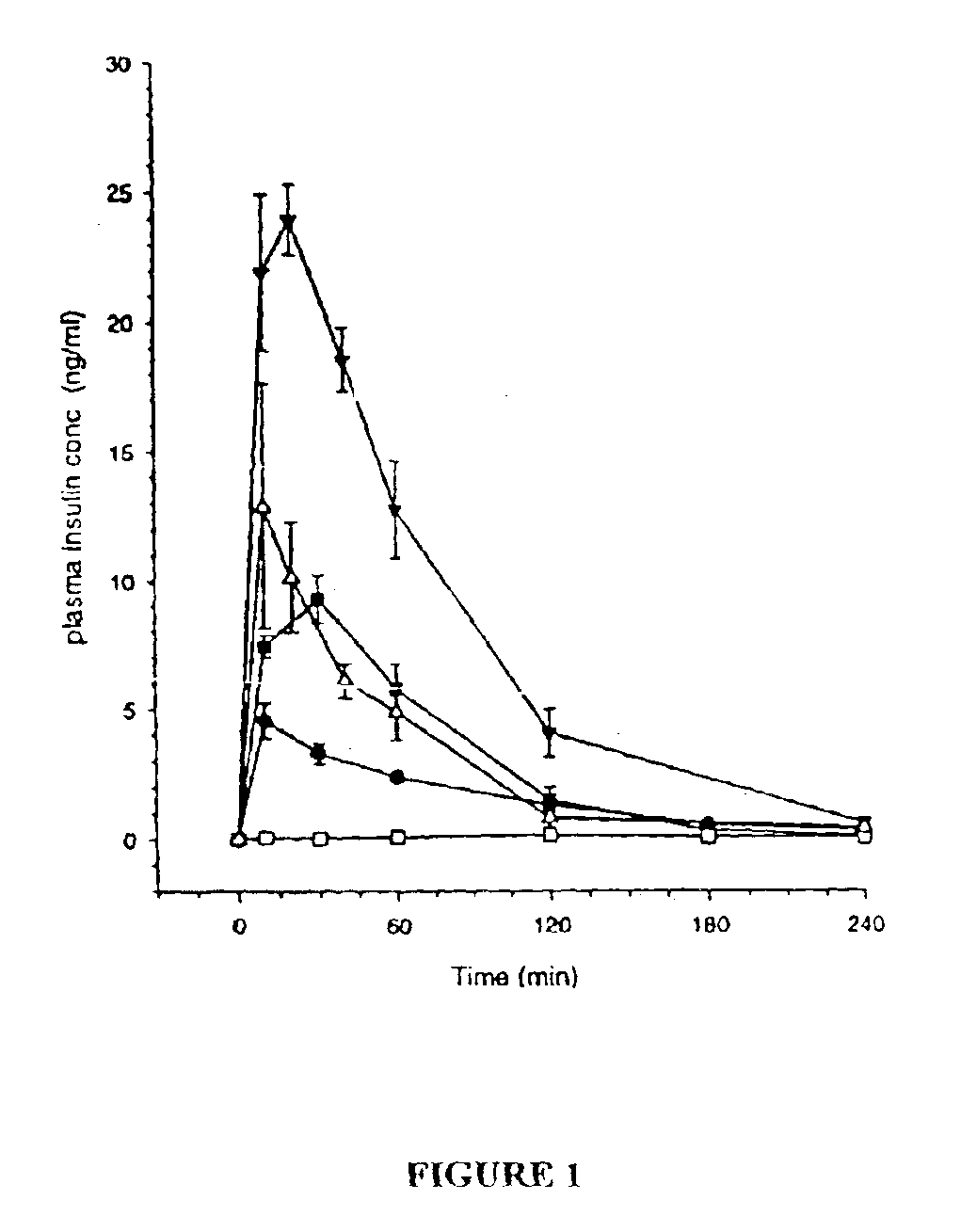

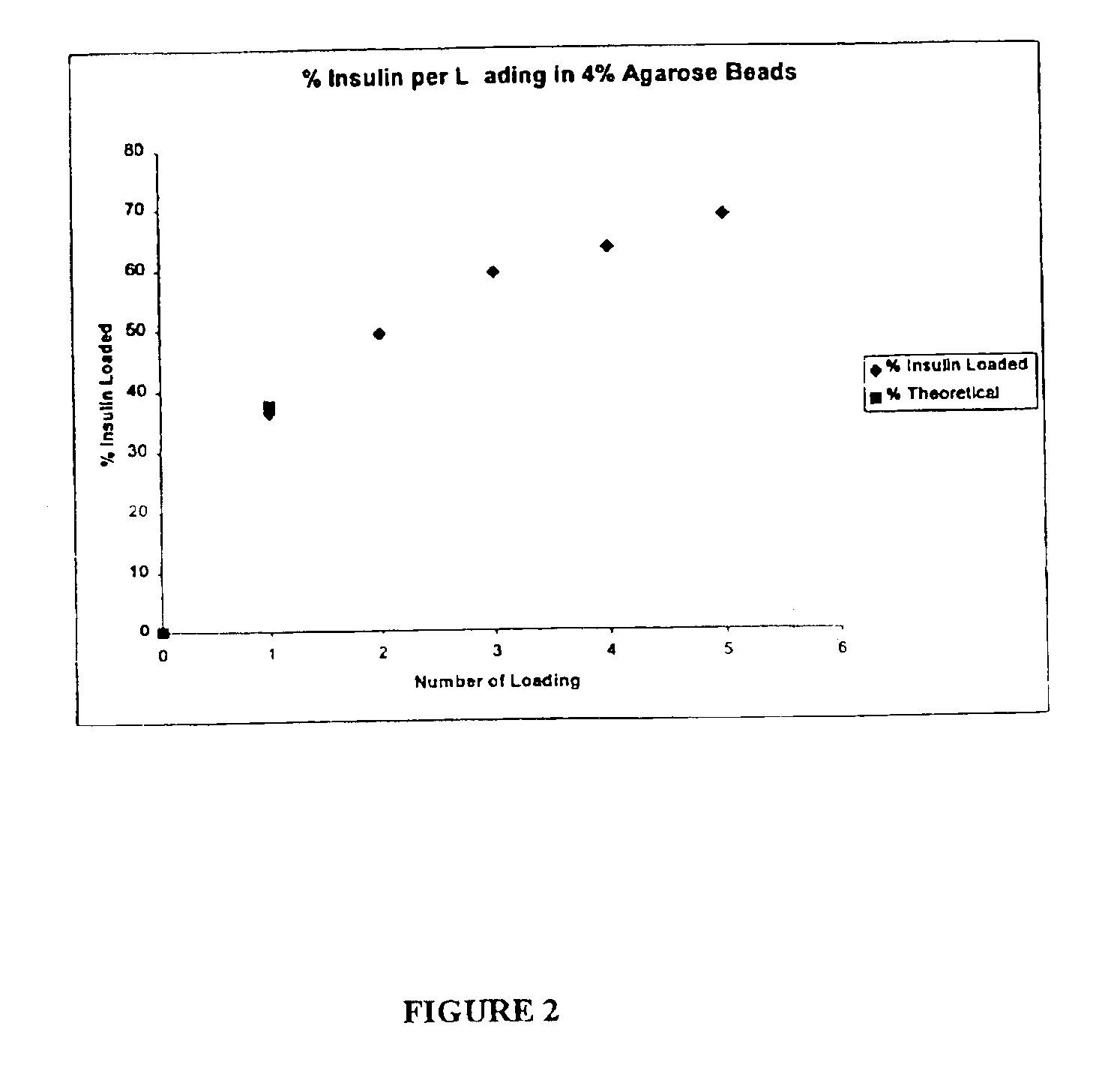

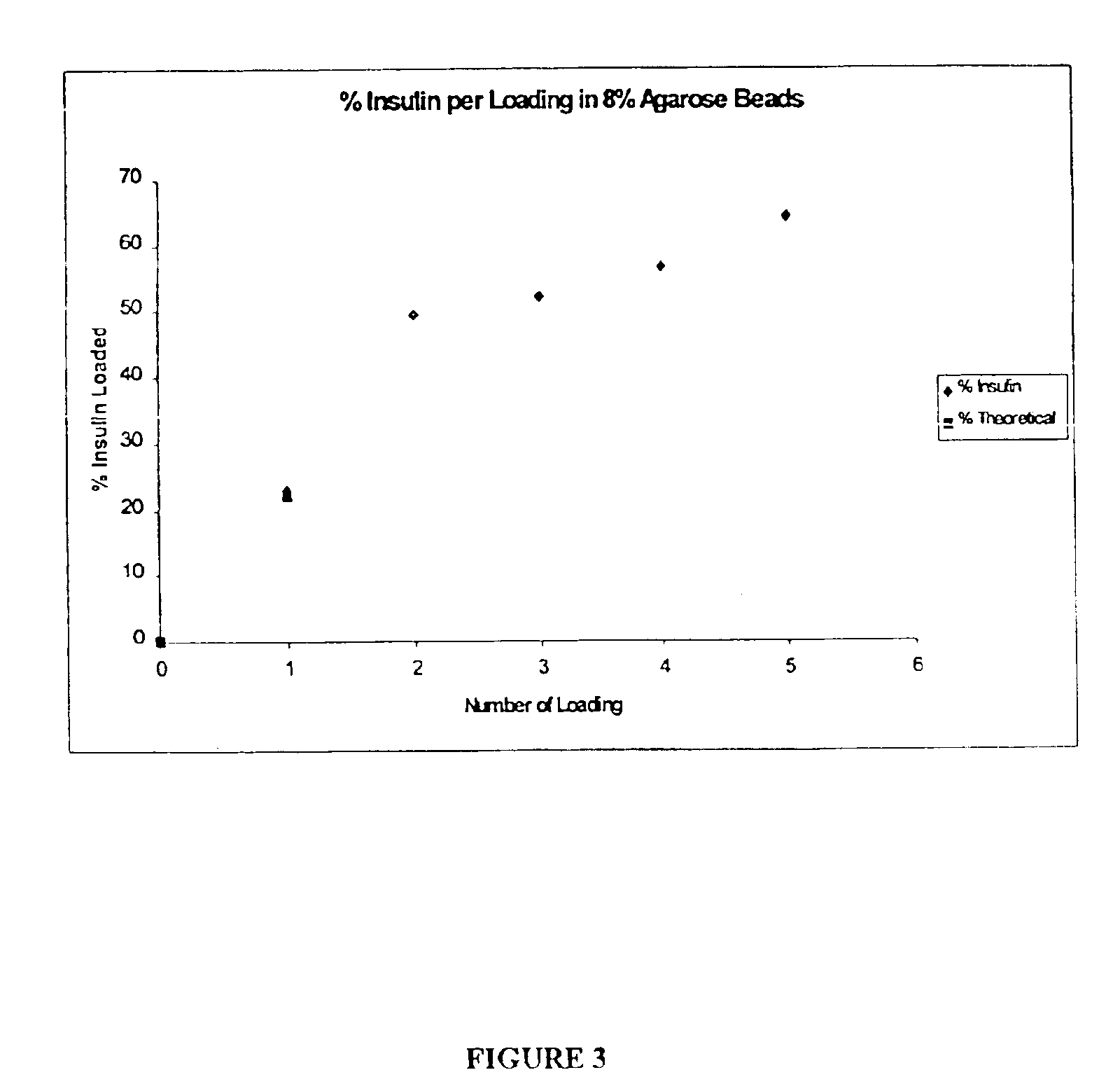

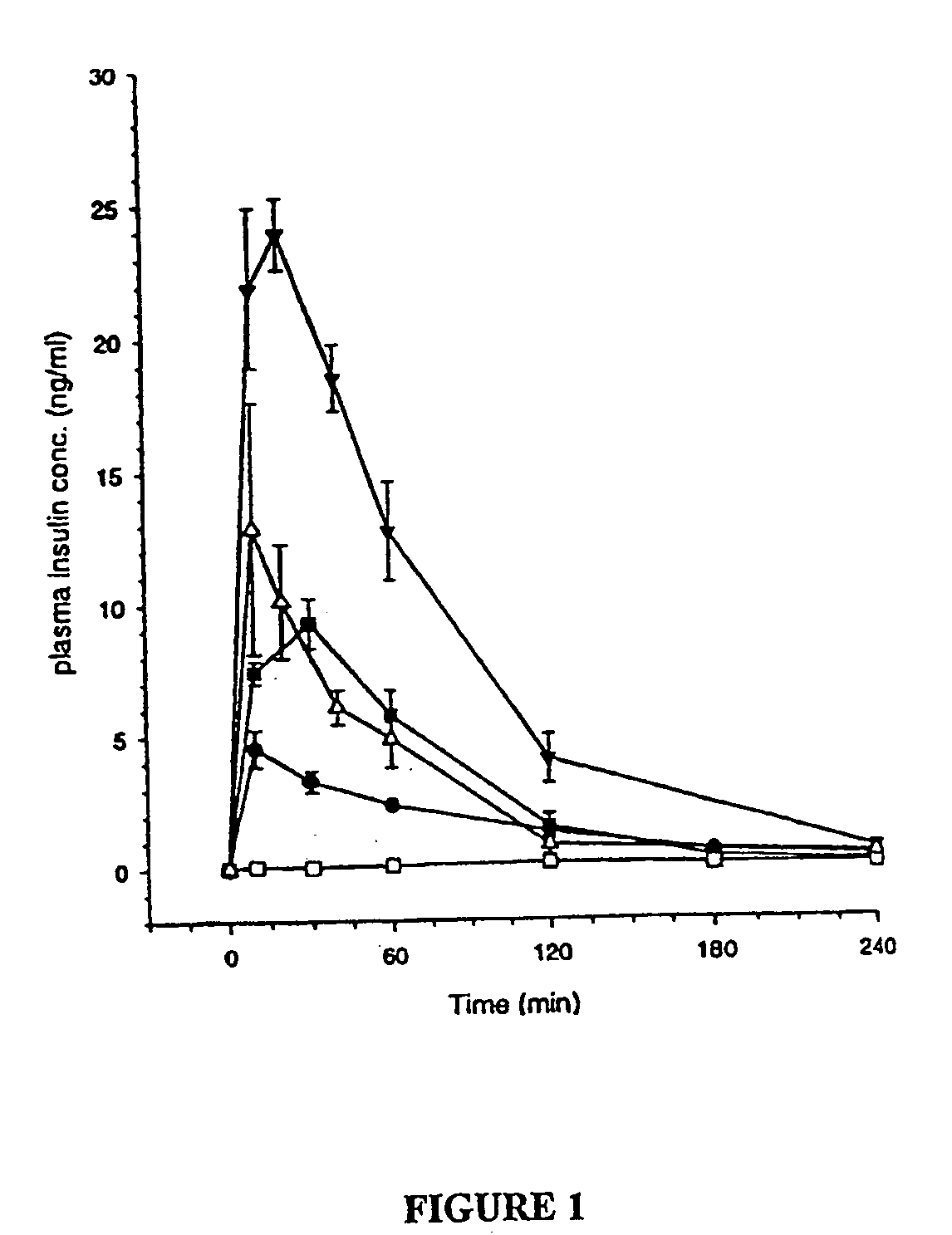

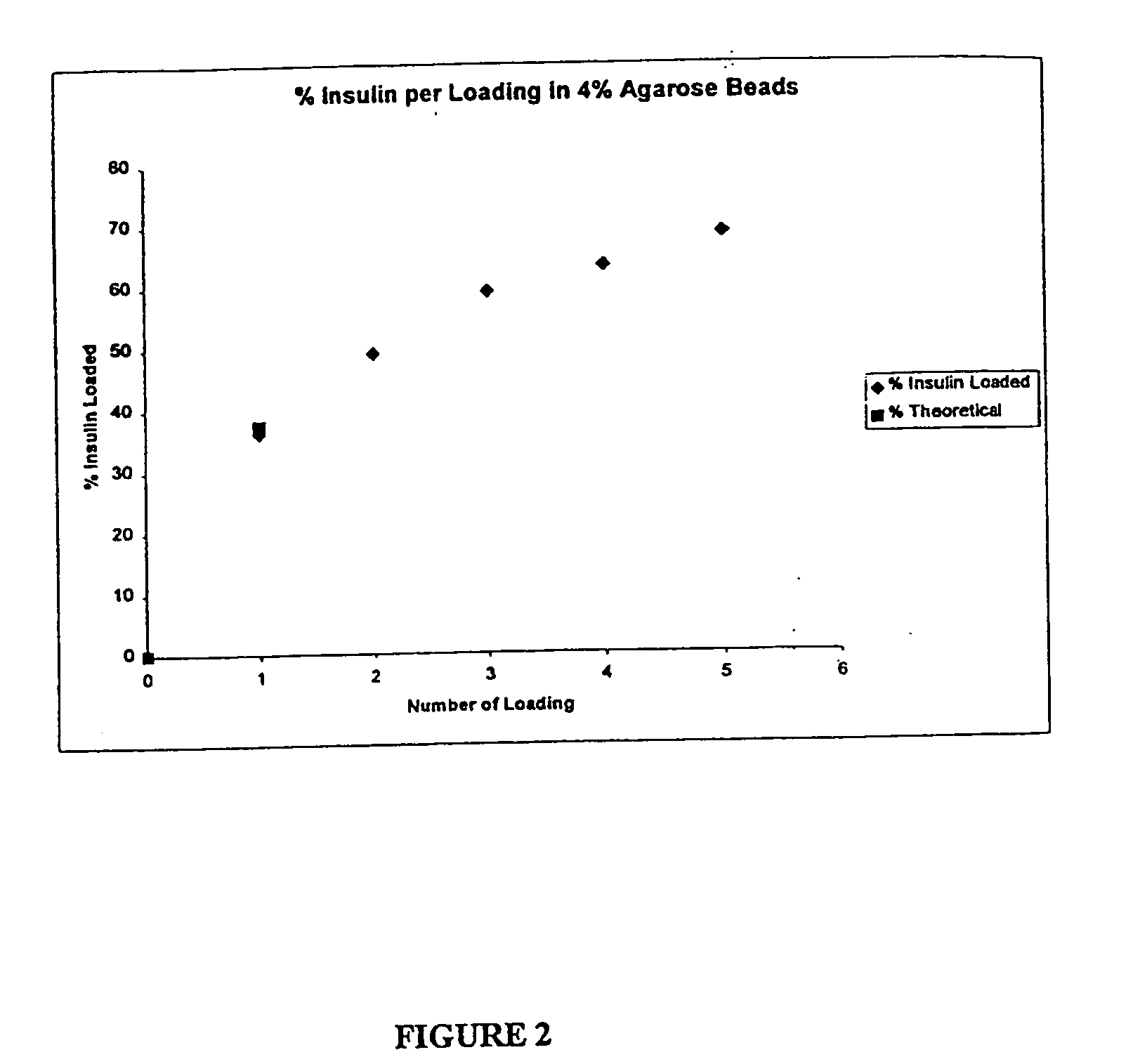

New compositions formed from the combination of an active substance with a hydrogel carrier moiety are provided. The compositions are suitable for use in high-velocity transdermal particle injection techniques. Methods of providing the new compositions are also provided. In addition, methods for administering pharmacologically active agent to a subject are provided. These methods are useful for delivering drugs, biopharmaceuticals, vaccines and diagnostics agents.

Owner:POWDERJECT RES LTD OXFORD (GB)

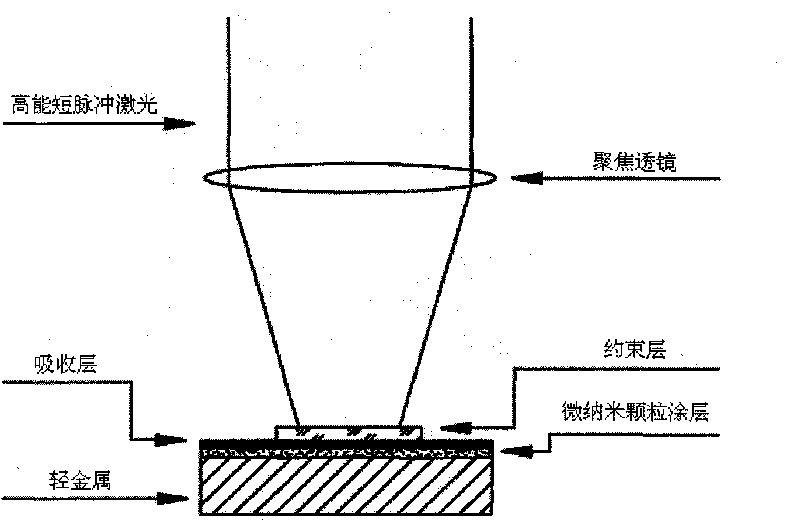

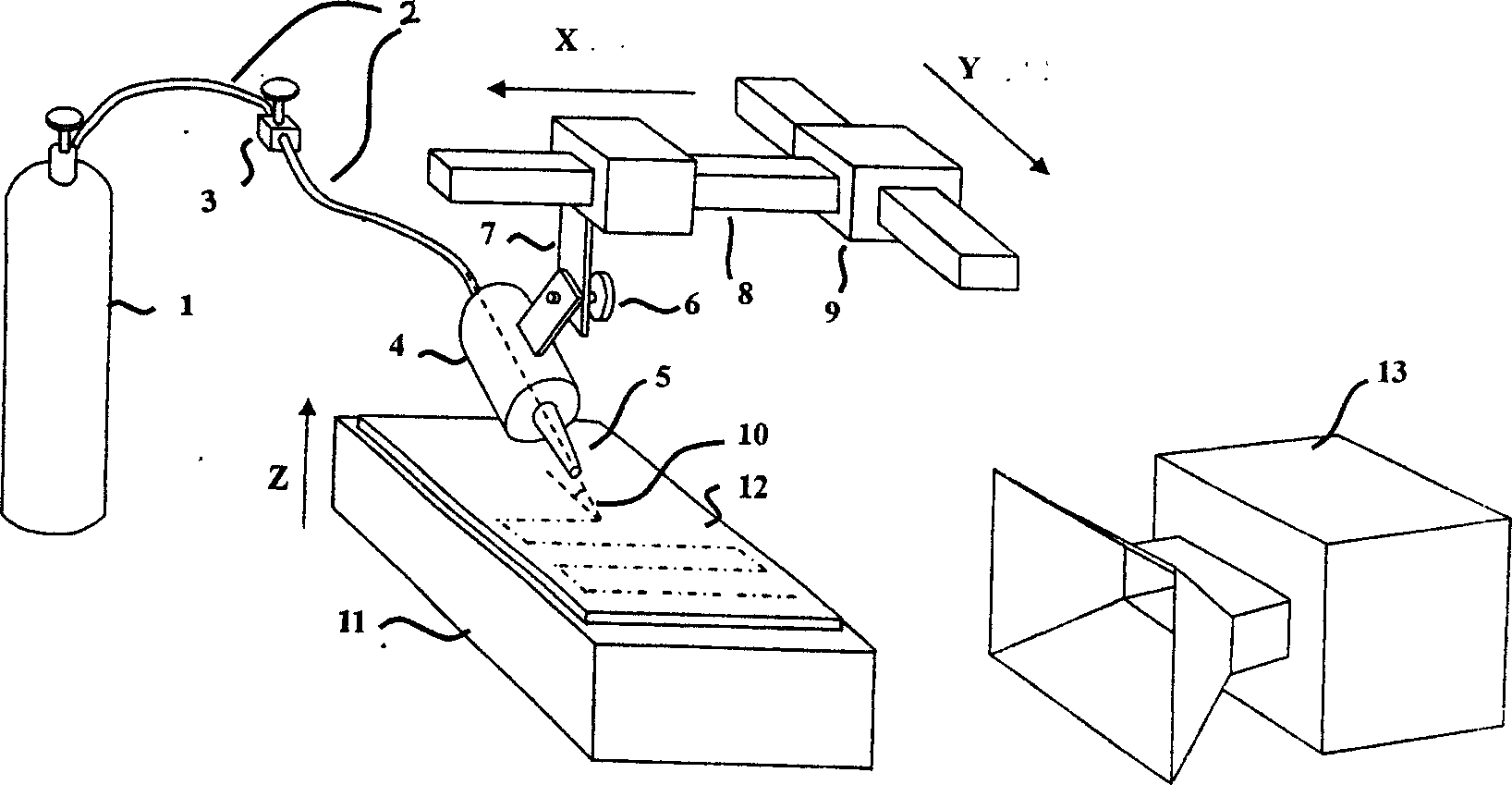

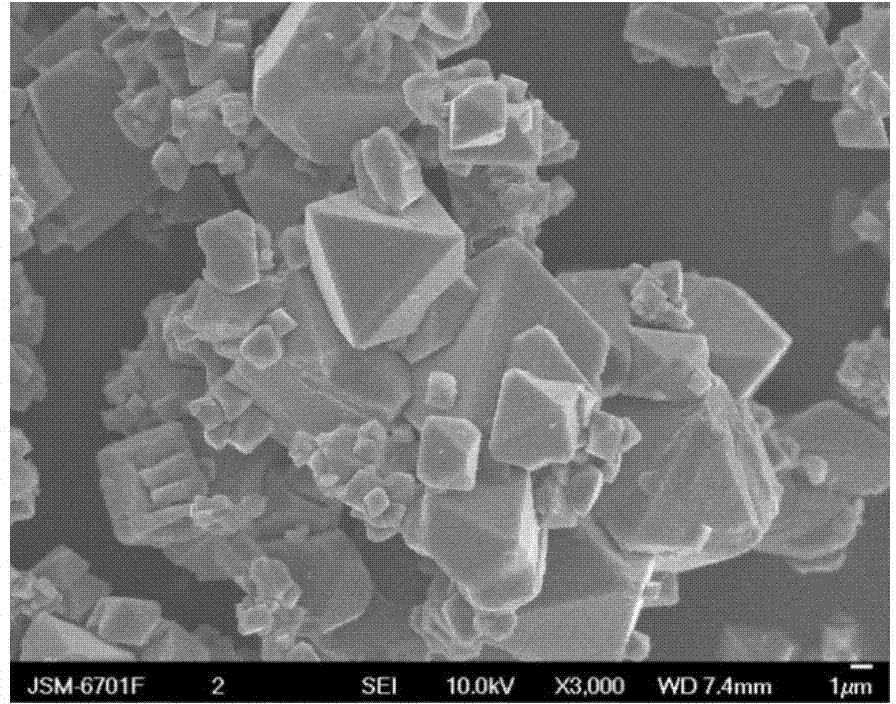

Light metal surface laser impact micronano particle injection reinforcing method

The invention relates to a light metal surface laser impact micronano particles injection reinforcing method, comprising the following steps: 1) removing the oxide layer probably existing on the surface of the light metal by a mechanical polishing or chemical corrosion method, then grinding and polishing with sand paper, and finally cleaning the surface of the light metal alloy with acetone or alcohol; 2) precoating the micronano particles on the surface of the light metal with inorganic bonding agent, recoating a layer of black paint on the surface of the micronano particle coating layer to serve as the absorption layer of laser impact after drying, and drying naturally; 3) impacting the absorption layer and the micronano particle layer with high-energy short pulse laser, and utilizing K9 glass or running water as a restriction layer during laser impact; and 4) soaking the micronano particle coating layer processed by acetone, and then removing the absorption layer through washing with running water or ultrasonic washing to obtain the micronano particle injection reinforcing layer. The invention integrates the actions of laser impact reinforcement, nano particle reinforcement and nano particle reinforcement, can dramatically improve hardness, abrasion resistance and fatigue resistance property of light metal surface layer, and has wide application prospect.

Owner:TSINGHUA UNIV

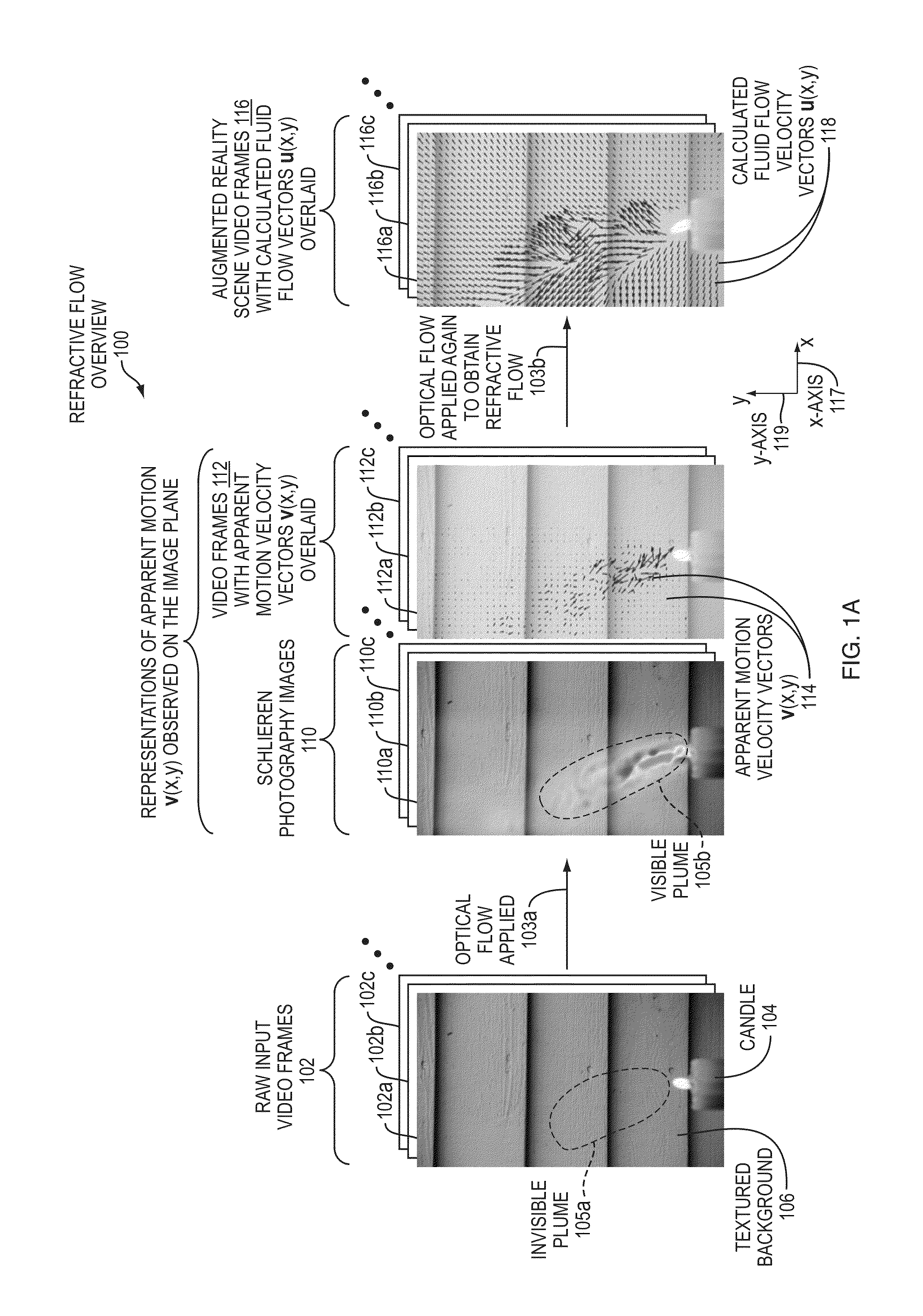

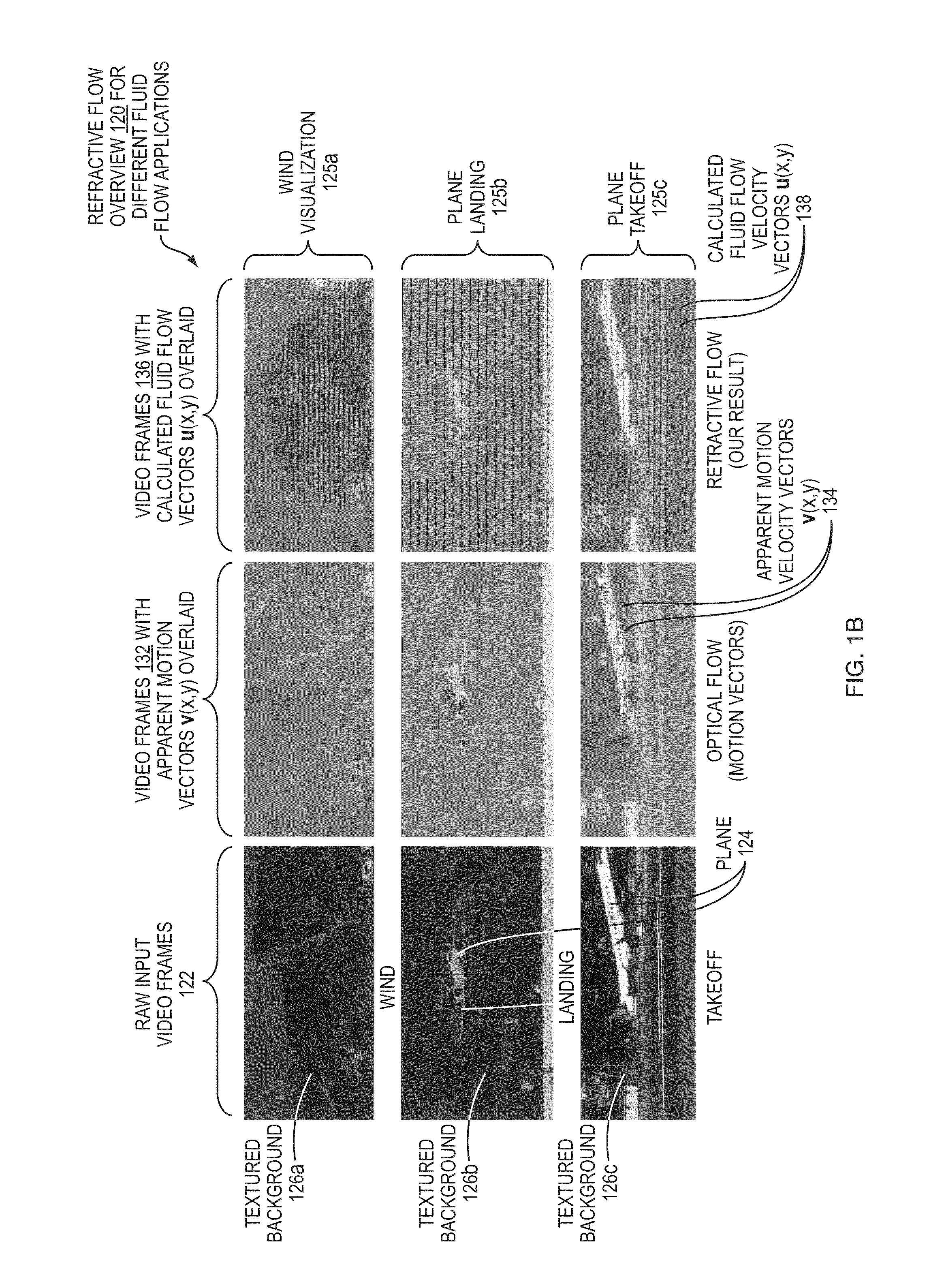

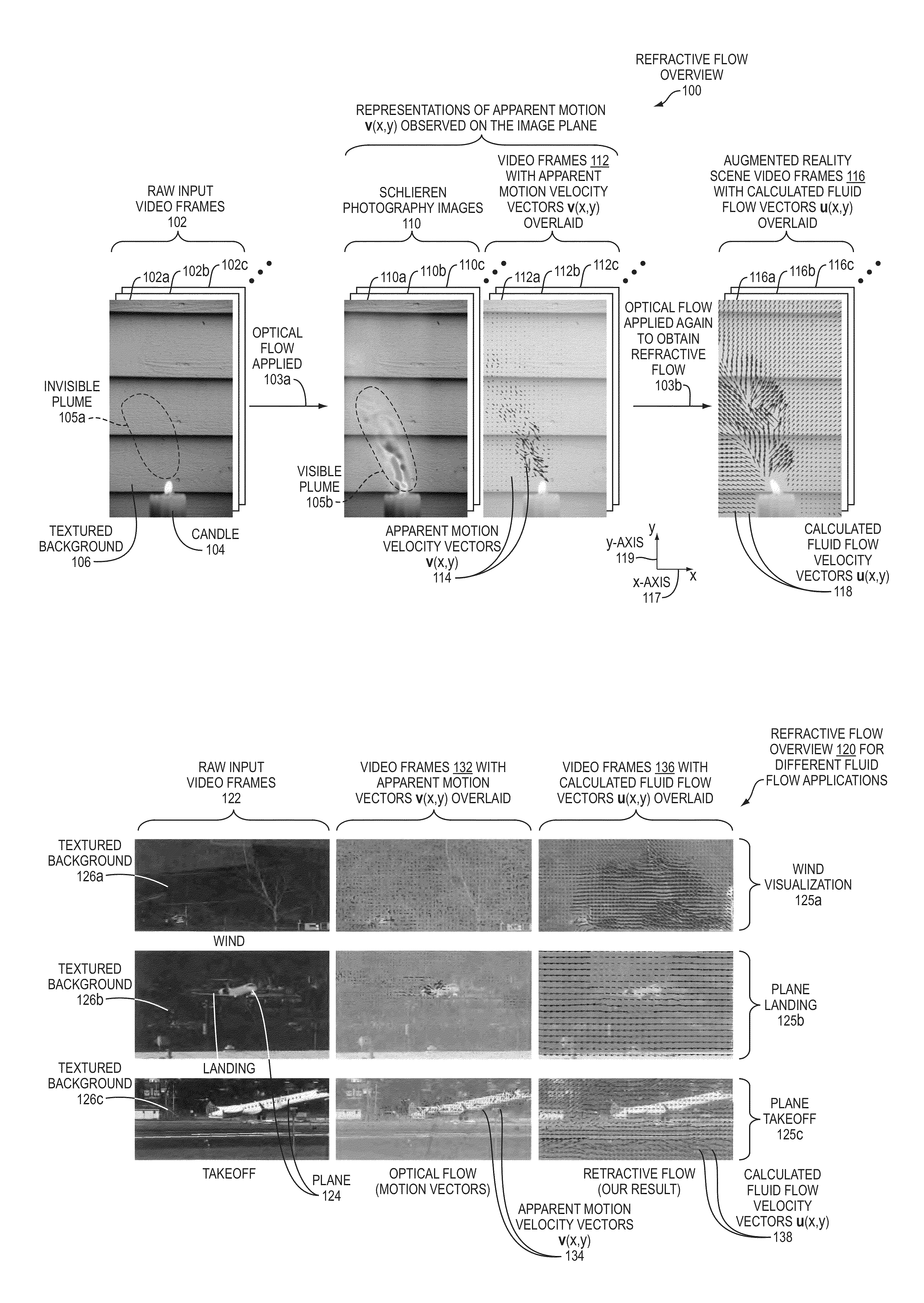

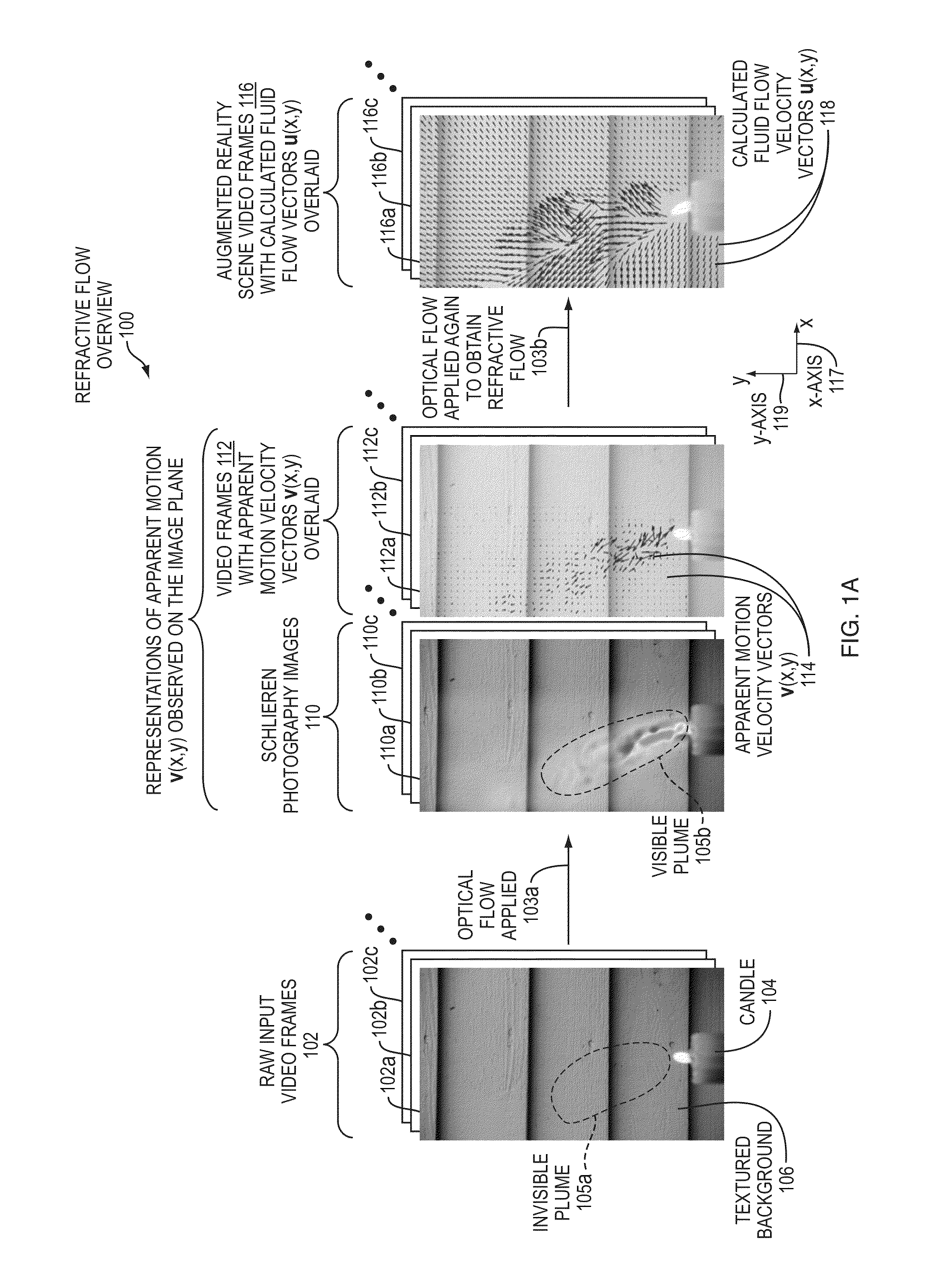

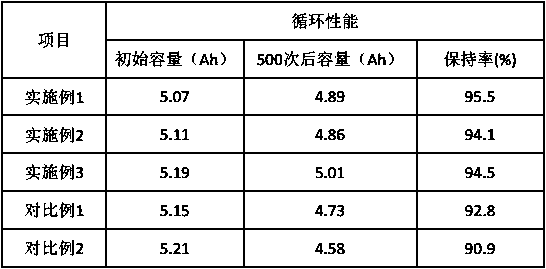

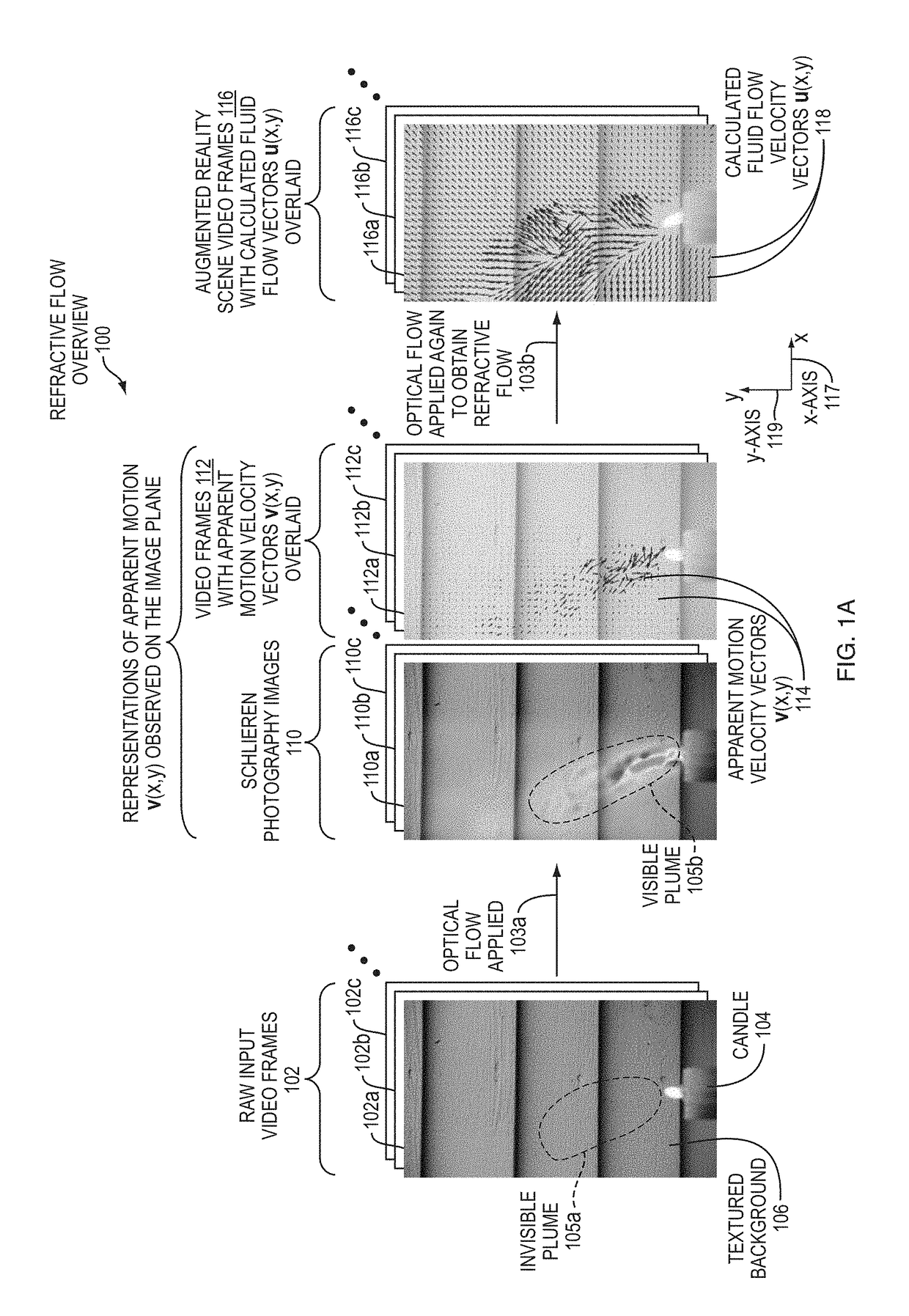

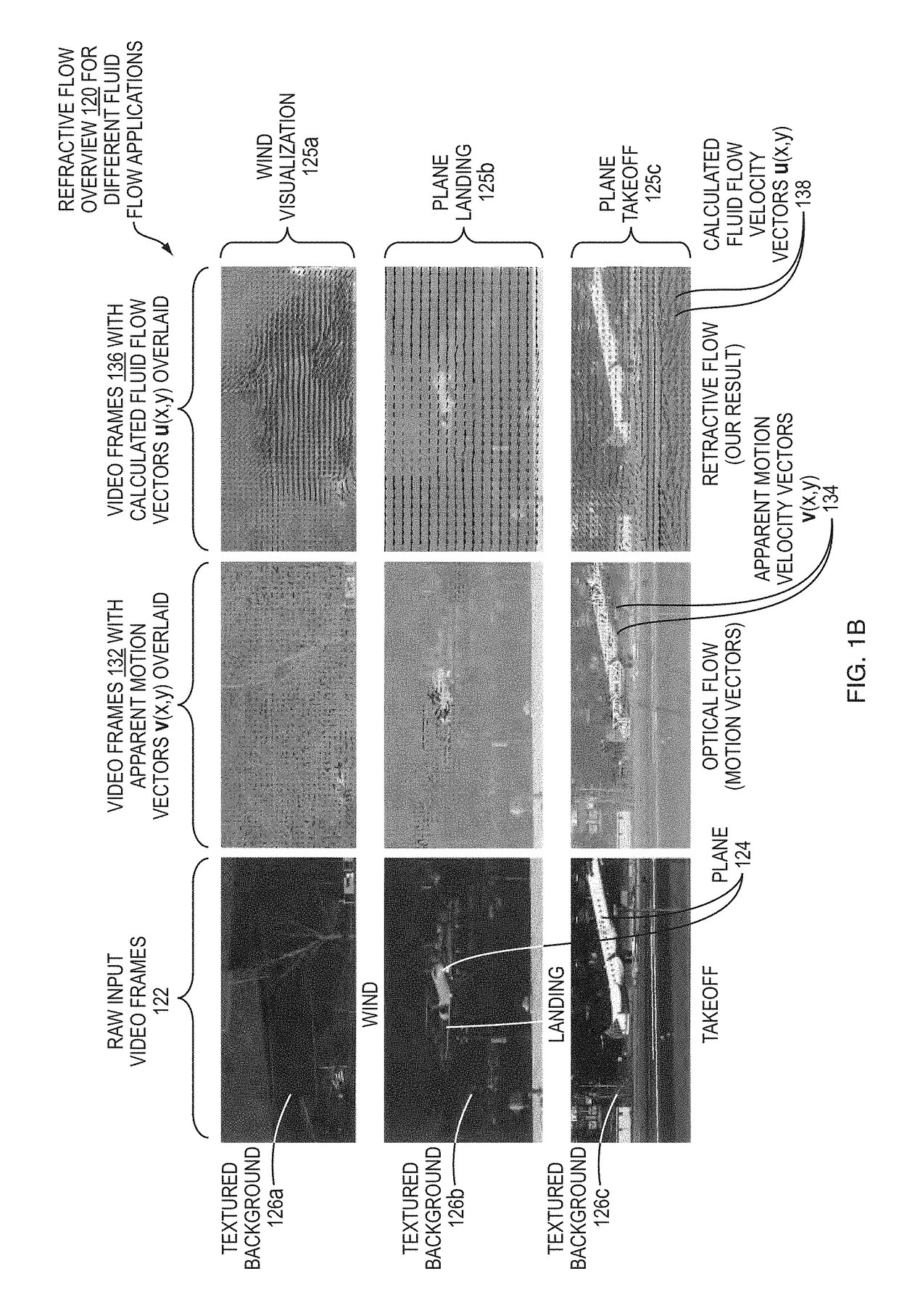

Methods and apparatus for refractive flow measurement with three dimensions and uncertainty

An imaging method and corresponding apparatus according to an embodiment of the present invention enables measurement and visualization of fluid flow. An embodiment method includes obtaining video captured by a video camera with an imaging plane. Representations of motions in the video are correlated. A textured background of the scene can be modeled as stationary, with a refractive field translating between background and video camera. This approach offers multiple advantages over conventional fluid flow visualization, including an ability to use ordinary video equipment outside a laboratory without particle injection. Even natural backgrounds can be used, and fluid motion can be distinguished from refraction changes. Depth and three-dimensional information can be recovered using stereo video, and uncertainty methods can enhance measurement robustness where backgrounds are less textured. Example applications can include avionics and hydrocarbon leak detection.

Owner:MASSACHUSETTS INST OF TECH

Method and apparatus for processing transparent conductive glass surface by dry ice particle spraying technique

The method of ice particle injection treating transparent electric conductive glass surface uses carbon dioxide ice with radius ranging from several millimeter and 100 millimeter in certain speed, injection angle and distance to spray the transparent glass surface to complete the polishing and cleaning of the transparent electric conductive thin film. It comprises high pressure carbon dioxide gas bottle, air transmission air pipe, gas flow control valve, nozzle connector, nozzle and its angel adjuster, through linkage to connect with the working platform and the gas recovery device. It can improve the surface treatment quality free from water or small quantity of water. It can save water source, reduce the discharge of exhaust water and goods, recover the generated carbon dioxide to reduce contamination to the environment.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Method for manufacturnig silicon high-speed semiconductor switch device

InactiveCN1471146AExcellent electrical performanceDensity Spatial Distribution OptimizationSemiconductor/solid-state device manufacturingGate turn-off thyristorPlatinum

The method is applicable to manufacture silicon semiconductor binistor with at least one PN junction such as GTO, IGBT etc. General manufacturing steps is carried out till the step of making metalized electrode. Platinum-silicon alloy is made on surface of silicon. Using proton or particle injection forms local high density defect area. Heating and annealing makes the defect area absorb platinum to convert to platinum impurity range. Then, General manufacturing steps is carried out till manufacturing completion. The performances of the invention are better than present life control technique. The parts made by the invention possesses higher switching speed and backward recovery speed, but the forward voltage drop and reverse leakage are not increased visibly.

Owner:BEIJING UNIV OF TECH

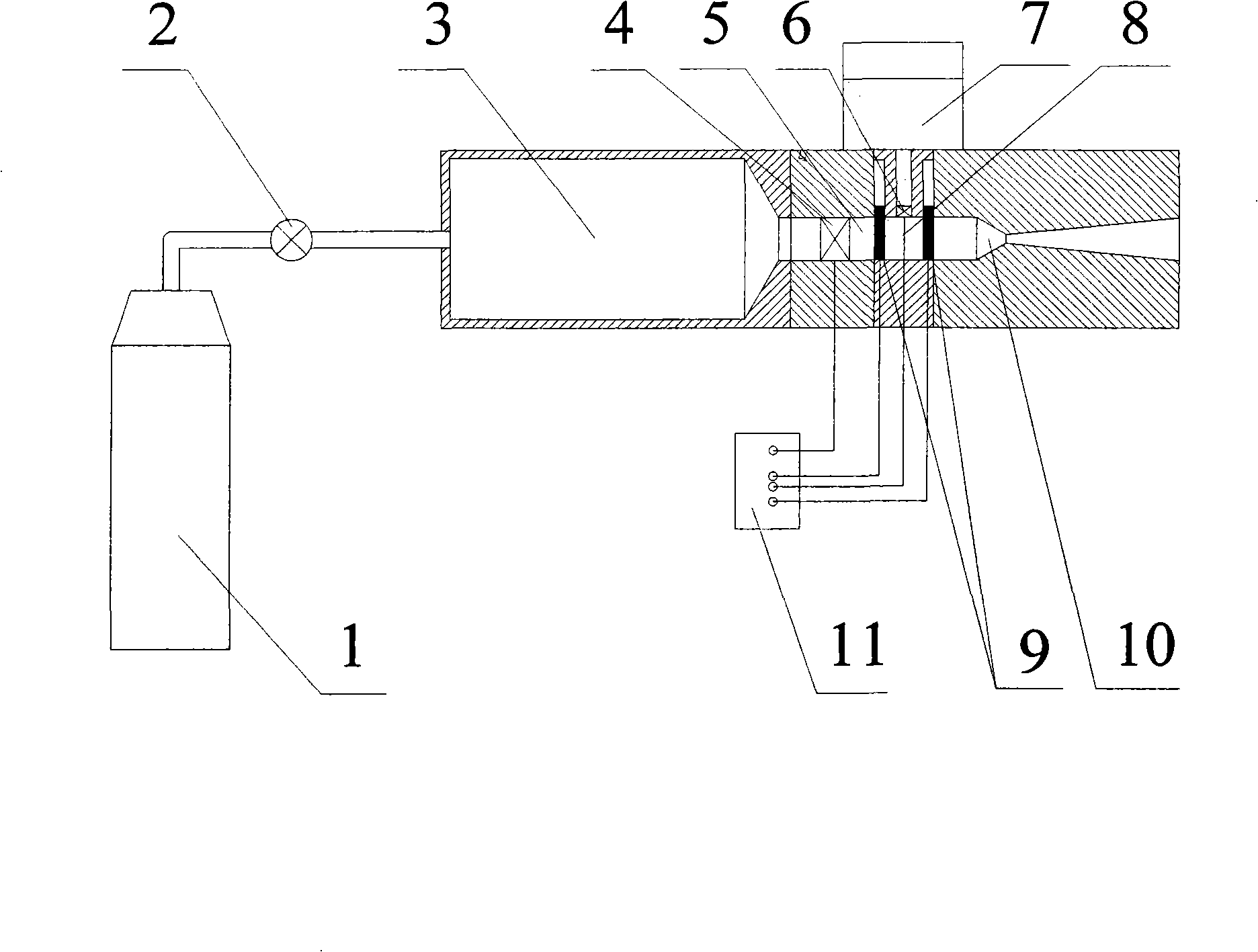

Solid particle group accelerating device for shock tube-Laval nozzle

InactiveCN101274710ALong rangeIncreased spray coverageSpray nozzlesFire rescueParticle injectionSolid particle

The invention discloses a shock wave tube-Laval nozzle accelerating device of a solid particle group. A compressed gas source is connected with a high pressure gas chamber of a shock wave tube by a compressed gas check valve, a powder storage chamber is surrounded by tube walls and movable clapboards at the two ends of the powder storage chamber, one of the movable clapboard separates a low pressure air chamber and the powder storage chamber and the other moveable clapboard separates the powder storage chamber and the Laval nozzle; a particle injection hole is cut on the side wall of the powder storage chamber to be connected with a powder supply source; a powder supply switch valve is arranged in the particle injection hole to separate the powder supply source and the powder particle in the powder storage chamber; a control circuit board is respectively connected with a transient switch valve, the powder supply switch valve and the two movable clapboards. As a chemical powder extinguisher, since the shock wave tube and the Laval nozzle function synchronously to accelerate the solid particle group to cause the shooting range of extinguisher to be sufficiently far off and an ejection covering area can be appropriately enlarged by enlarging the expansion angle of the gradual-widening section of the Laval nozzle, the shock wave tube-Laval nozzle accelerating device has high extinguishing efficiency, good effect, long shooting range and energy conservation; as an ultrasonic cool spraying device, the particle adhesive strength and the coating strength are great.

Owner:ZHEJIANG SCI-TECH UNIV

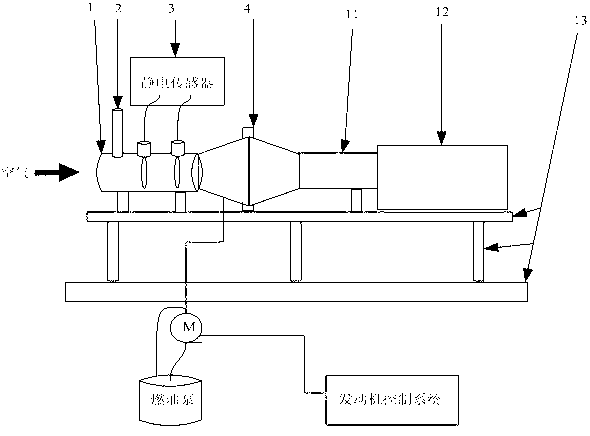

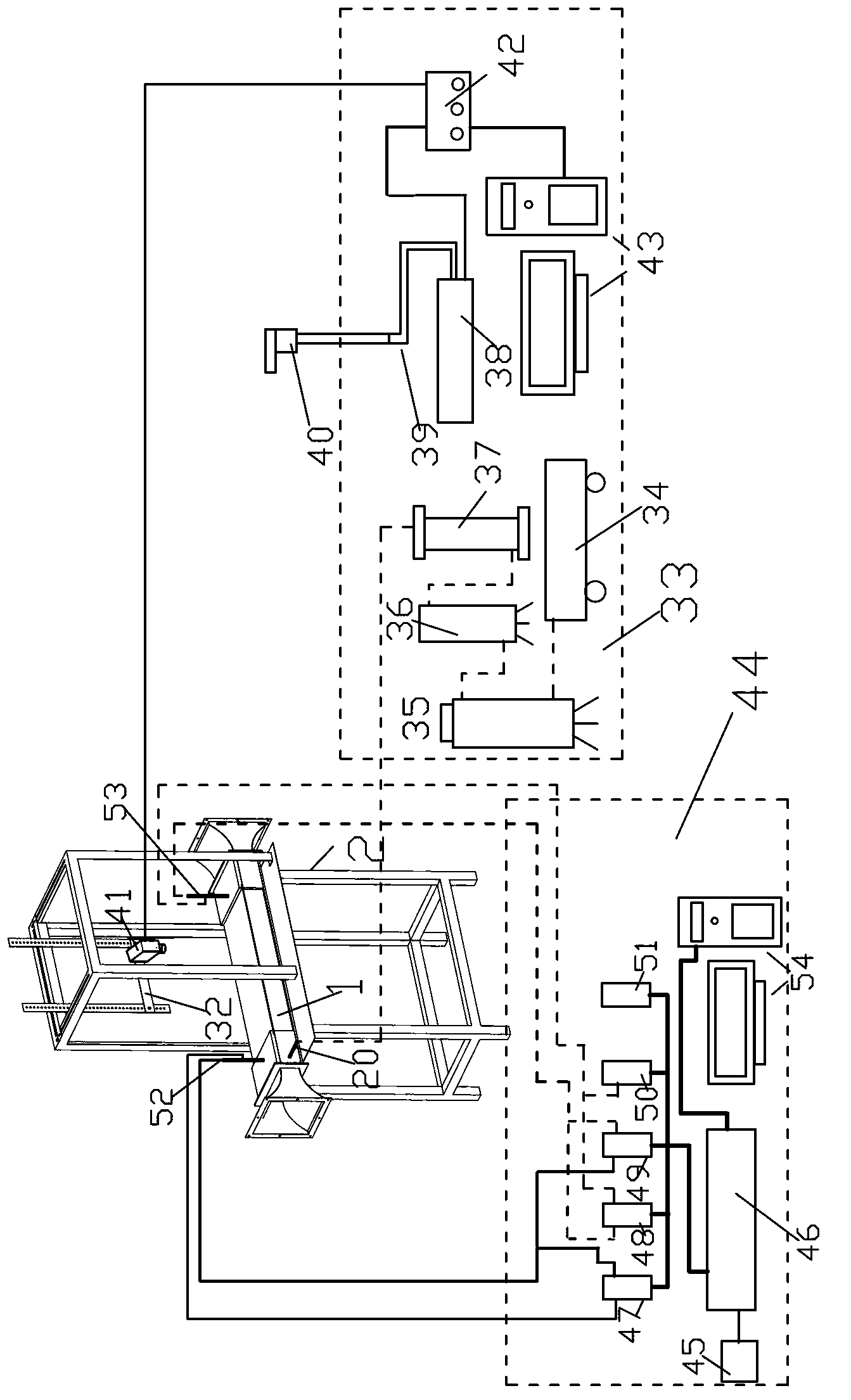

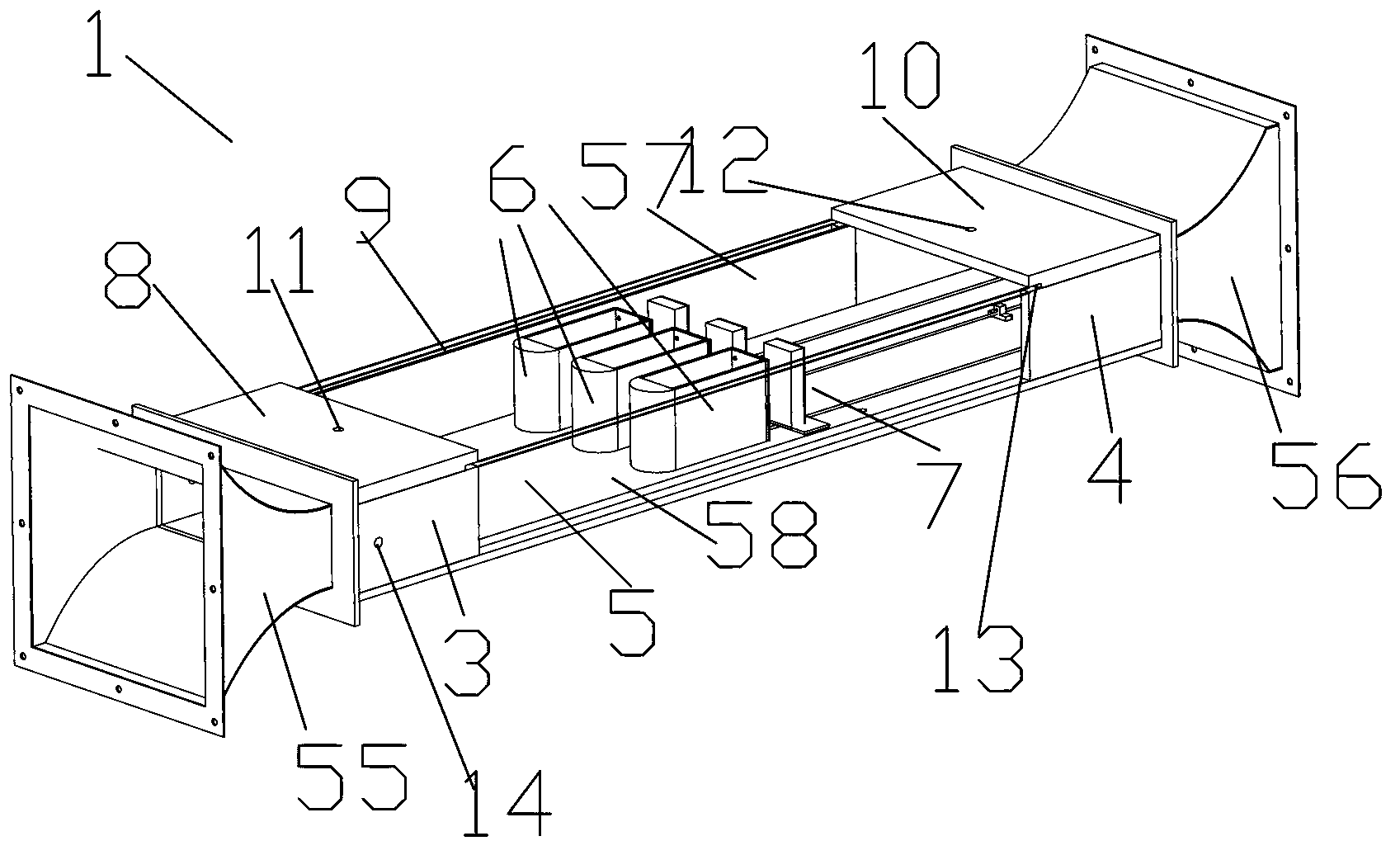

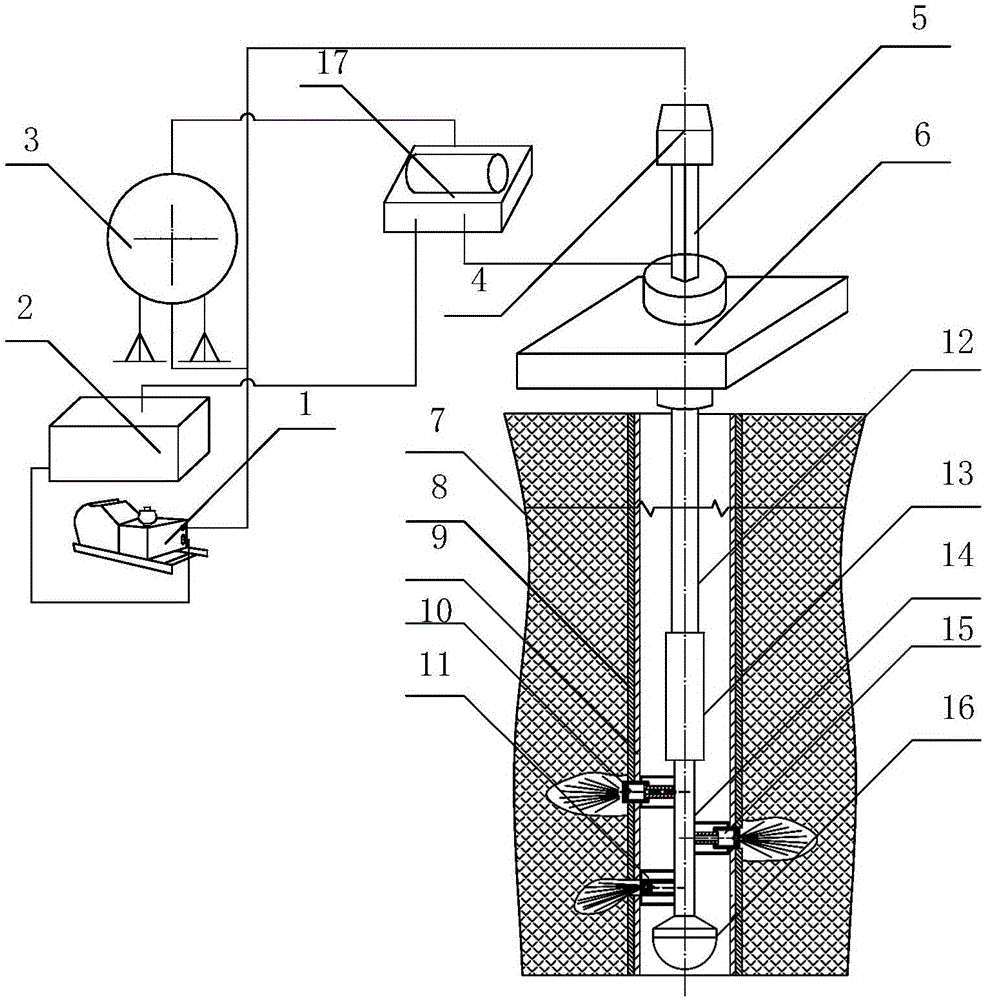

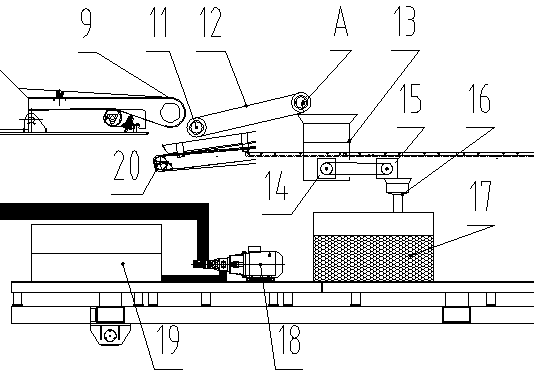

Simulation experiment device for aero-engine suction object on-line static monitoring system

InactiveCN103063437AEffective simulationLow costEngine testingElectrostatic field measurementsAviationImpeller

The invention relates to a simulation experiment device for an aero-engine suction object on-line static monitoring system. An air inlet extension pipe is connected with an air inlet end of an aviation turbojet engine, a particle injection device is communicated with the air inlet extension pipe through an injection port in the air inlet extension pipe, and the air inlet extension pipe is provided with monitoring devices in a subsection mode. One end of an exhaust nozzle extension pipe is connected with a jet end of the aviation turbojet engine, and the other end of the exhaust nozzle extension pipe is connected with a tail gas cooling device. The air inlet extension pipe, the particle injection device, the aviation turbojet engine, the exhaust nozzle extension pipe and the tail gas cooling device are fixed on a mounting platform. The simulation experiment device can provide warning information at an early stage when the engine sucks abnormal particles and impeller damage breakdowns happen, effectively simulate engine gas path environment, and provide a low-cost and high-simulation effective experiment platform for research of the aero-engine suction object on-line static monitoring system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

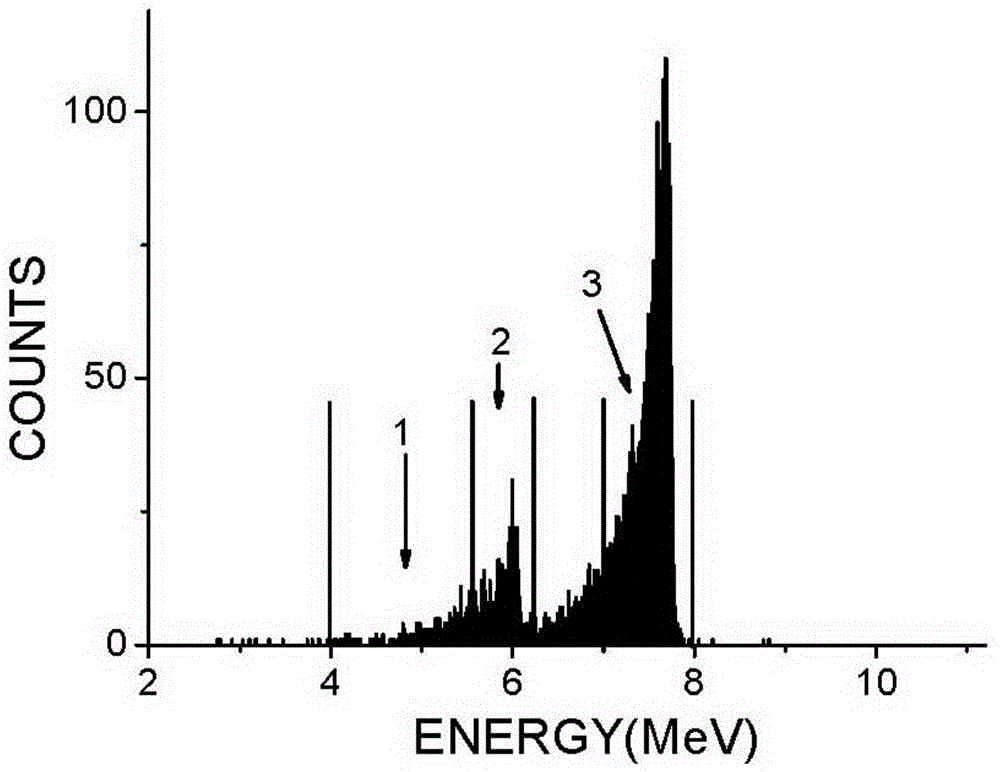

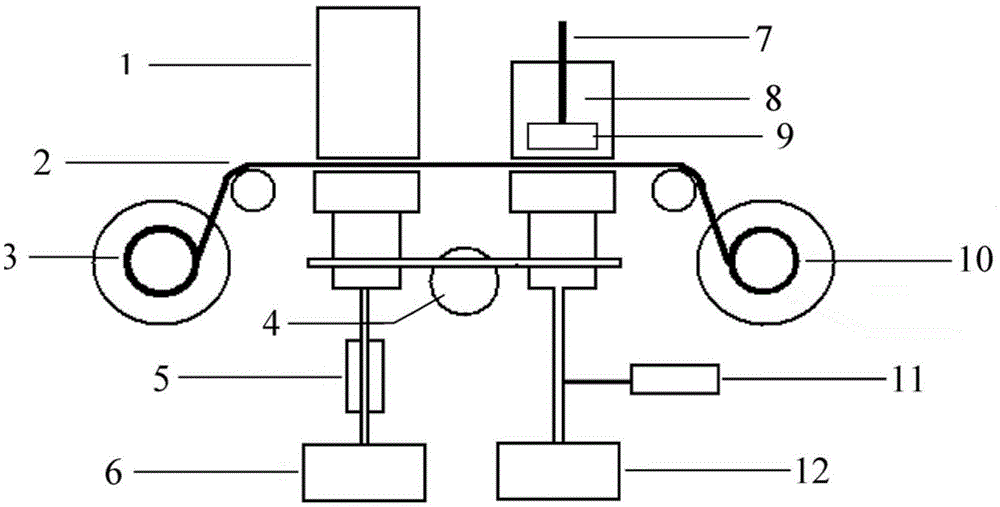

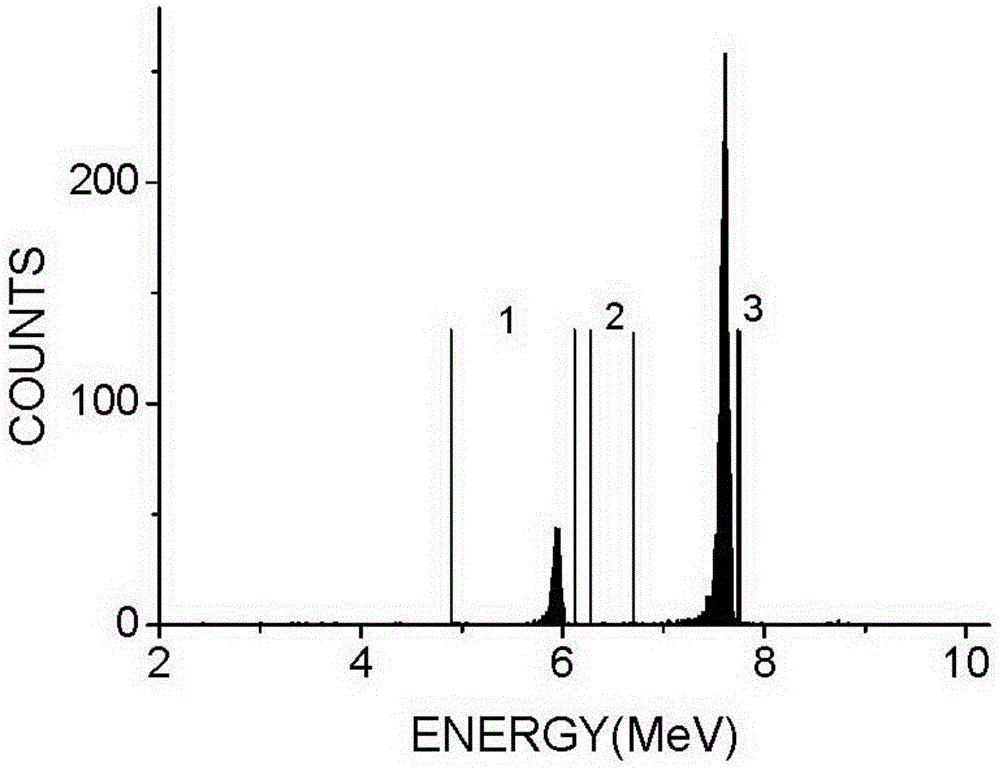

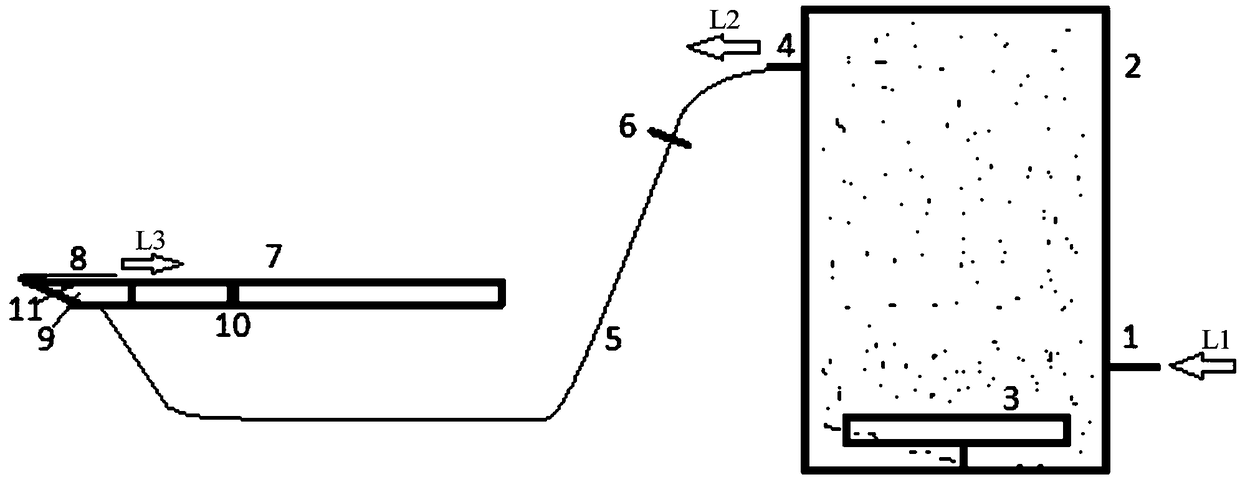

High-sensitivity radioactive aerosol continuous monitor

InactiveCN104360371AMeet the requirements of continuous monitoringX/gamma/cosmic radiation measurmentParticle injectionReciprocating motion

The invention belongs to the technical field of designing and improving of environmental radiation monitoring equipment, and particularly relates to a high-sensitivity radioactive aerosol continuous monitor which comprises a sampling module and a measuring module. The upper halves of the sampling module and the measuring module are mounted in an upper-portion supporting module, a sampling module moving unit and a vacuumizing measuring module moving unit can be in up-down reciprocating motion and are mounted in a lower-portion supporting module, a U-019-300-100 particle injection type silicon detector and a vacuum adapter are mounted in a right-side vacuum chamber of the upper-portion supporting module, an annular silica sealing gasket is mounted above the sampling module moving unit and the vacuumizing measuring module moving unit and used for sealing, and a spring sleeves the outer side of each of the sampling module moving unit and the vacuumizing measuring module moving unit. The high-sensitivity radioactive aerosol continuous monitor is mainly used for the field of environmental monitoring.

Owner:63653 FORCES PLA

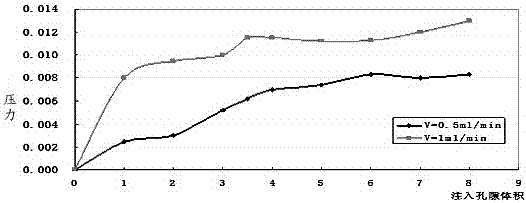

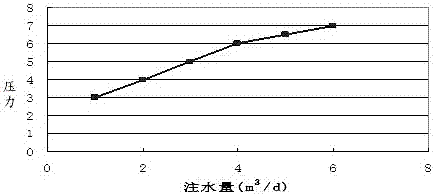

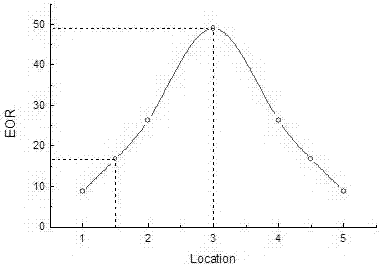

Composite profile control system and construction method for plugging by using composite profile control system

InactiveCN106947451AAvoid pollutionImprove injection abilityFluid removalDrilling compositionCross-linkParticle injection

The invention relates to a composite profile control system, which comprises a high-strength cross-linked polymer profile control agent, a water displacement flowing direction change agent, a compound flocculation profile control agent and an oil displacement agent. According to the present invention, in order to improve the profile control effect and prolong the profile control lasting period, by considering the synergetic effect among the plugging agents, the plugging agents are subjected to cross injection in slugs; and by following the combined principle of plugging, controlling and displacement, the high-strength cross-linked polymer profile control agent capable of improving the swept volume and the displacement efficiency, the water displacement flowing direction change agent capable of improving the lasting period and the compound flocculation profile control agent are used and are subjected to alternating injection, and then the oil displacement agent is injected, such that the profile control and displacement requirements of the oil reservoir deep part can be met, the oil reservoirs having different permeabilities can be met, different profile control purposes and different process requirements can be met, the shear resistance and the swelling are improved, the cost is reduced, the strength and the temperature resistance are improved, and the particle injection and the injection depth are improved.

Owner:河南易发石油工程技术有限公司

Hydrogel particle formation

InactiveUS20050191361A1Improve performanceAvoid lostPowder deliveryGenetic material ingredientsDiagnostic agentActive agent

New compositions formed from the combination of an active substance with a hydrogel carrier moiety are provided. The compositions are suitable for use in high-velocity transdermal particle injection techniques. Methods of providing the new compositions are also provided. In addition, methods for administering pharmacologically active agent to a subject are provided. These methods are useful for delivering drugs, biopharmaceuticals, vaccines and diagnostics agents.

Owner:POWEDERJECT RES

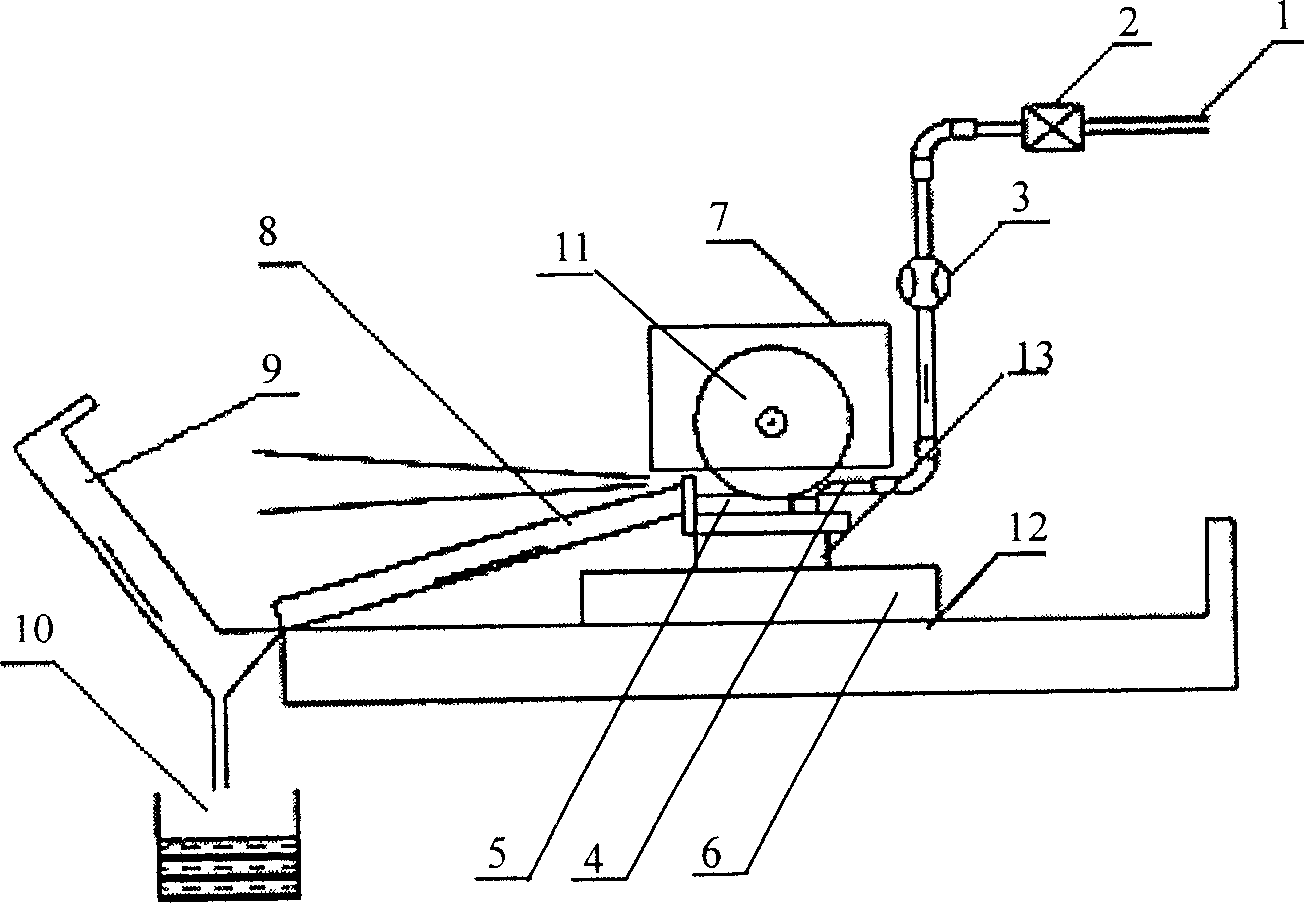

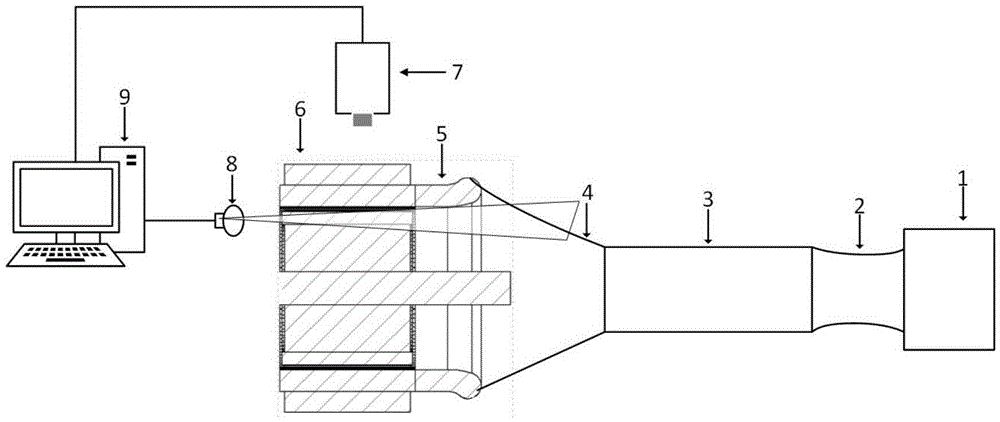

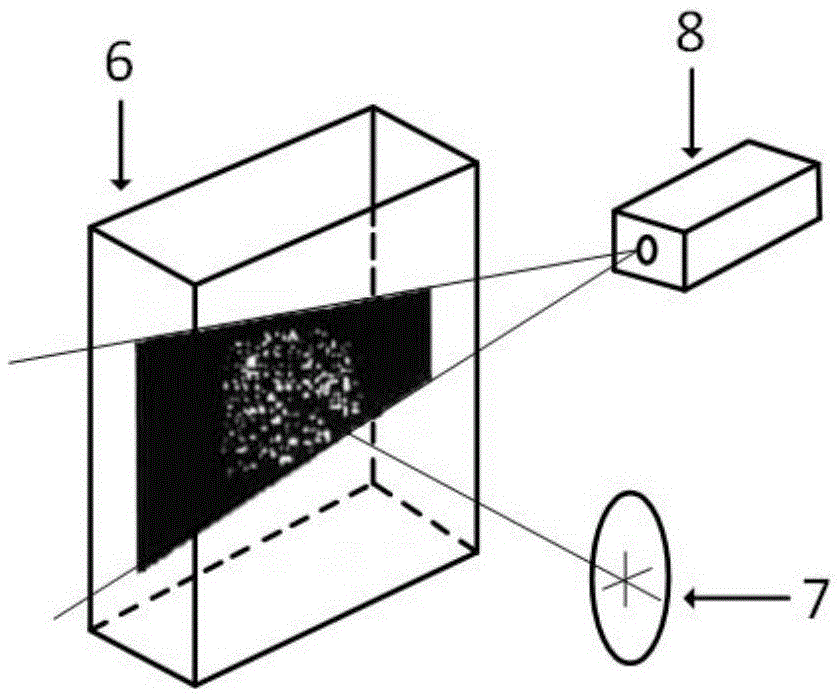

Flow field characteristic experiment device of combustion chamber of hydrogen-burning gas turbine

InactiveCN103017999AEvenly distributedReduced commissioning timeAerodynamic testingHydrogenCombustion chamber

The invention discloses a flow field characteristic experiment device of a combustion chamber of a hydrogen-burning gas turbine. The flow field characteristic experiment device comprises three pairs of bluff body arrangement combustion chamber experiment pieces, a particle image velocimetry (PIV) test platform frame, a PIV test system and a pressure difference and environment temperature test system. The three pairs of bluff body arrangement combustion chamber experiment pieces comprise a front lateral plate, a front bluff body, a back bluff body, an affiliation mechanism of the back bluff body, a front top plate and a back top plate. A tracer particle injection pipe jack is arranged on the front lateral plate, an inlet speed probe jack is arranged on the front top plate, and an outlet speed probe jack is arranged on the back top plate. A tracer particle generator is connected with the tracer particle injection pipe jack on the front lateral plate. The device adopts the PIV test technology, selects reasonable combustion chamber position, reasonably mingles tracer particles into a main gas flow under the effects of the tracer particle generator and a tracer particle injection pipe, enables tracking particles in the test area to be evenly distributed and conducts visualization experiment of cold state flowing speed vector distribution of three pairs of bluff arrangement combustion chambers.

Owner:DALIAN MARITIME UNIVERSITY

Methods and apparatus for refractive flow measurement

Owner:MASSACHUSETTS INST OF TECH

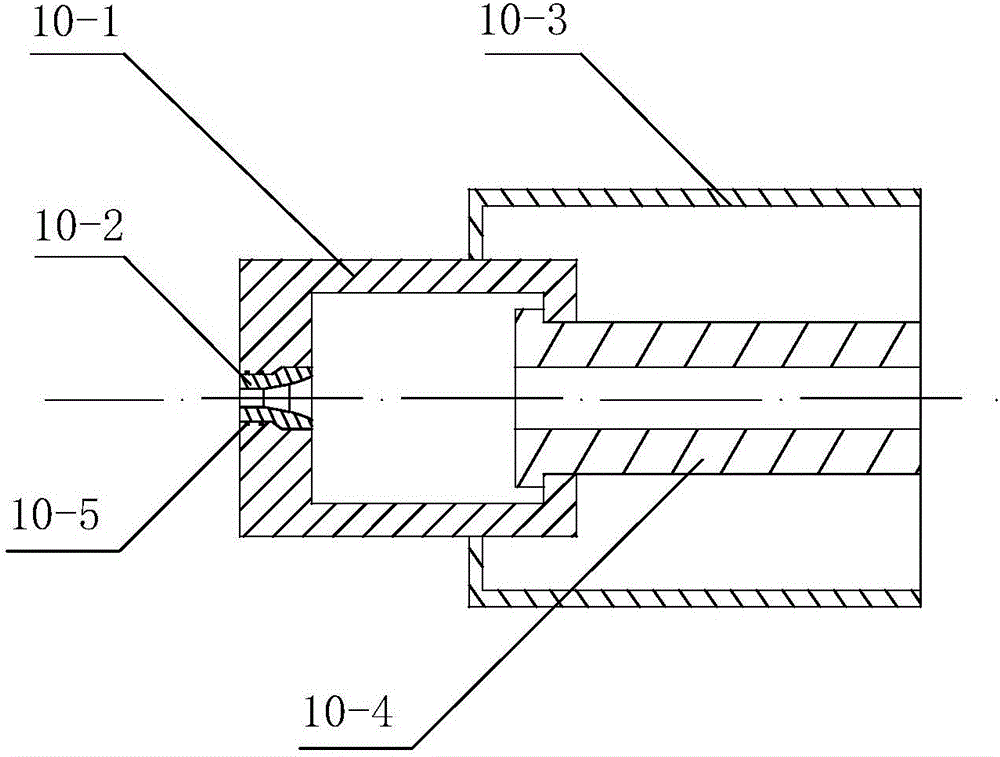

Injection device for particle impact drilling

InactiveCN102619468AInjection speed controllableInjection speed adjustableDrilling machines and methodsParticle injectionPropeller

The invention discloses an injection device for particle impact drilling. The injection device comprises a ground high-pressure main pipeline, a shunt pipeline, a shunt pipeline control valve, a steel particle storage tank, a hydraulic (or manual) charging valve, a storage tank pressure relief pipeline, a storage tank pressure relief control valve, steel particles, a screw propeller, a steel particle injection control valve and flow limiting devices, and is characterized in that: the flow limiting devices are arranged after the shunt pipeline; the shunt pipeline control valve is arranged between the ground high-pressure main pipeline and the steel particle storage tank; the storage tank pressure relief control valve is arranged between the steel particle storage tank and a drilling liquid bath; the screw propeller is positioned below the steel particle storage tank; and the steel particle injection control valve is positioned between the screw propeller and the ground high-pressure main pipeline. By the injection device, a plurality of problems of the conventional grinding material injection devices at home and abroad can be solved, the conventional foreign devices can be simplified, injection reliability can be improved, and steel particle injection for the particle impact drilling can be realized.

Owner:CHINA PETROCHEMICAL CORP +1

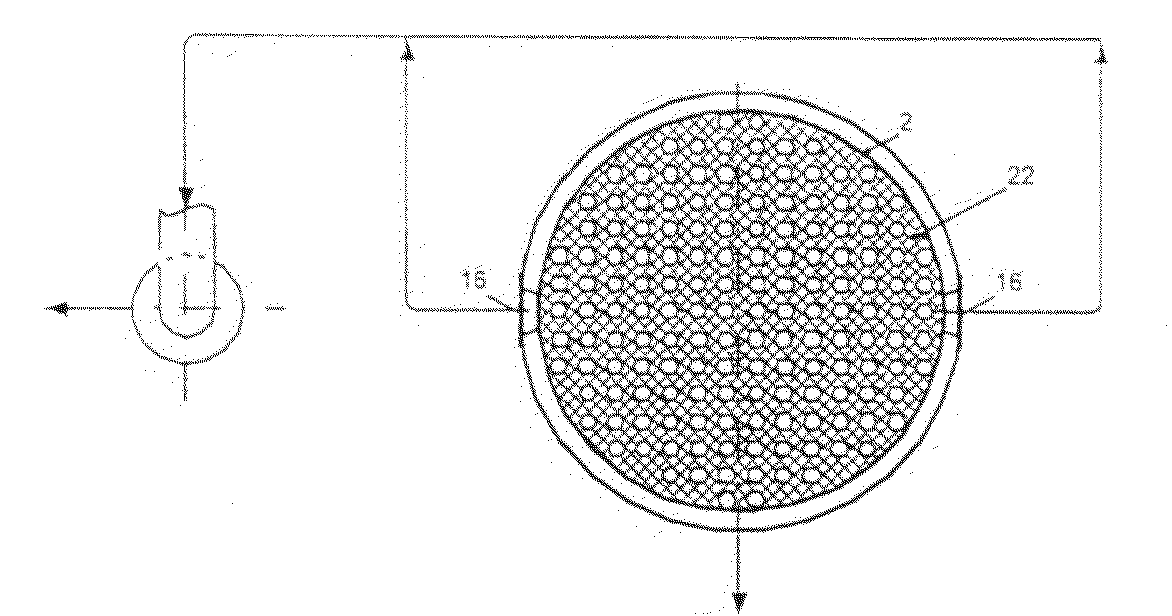

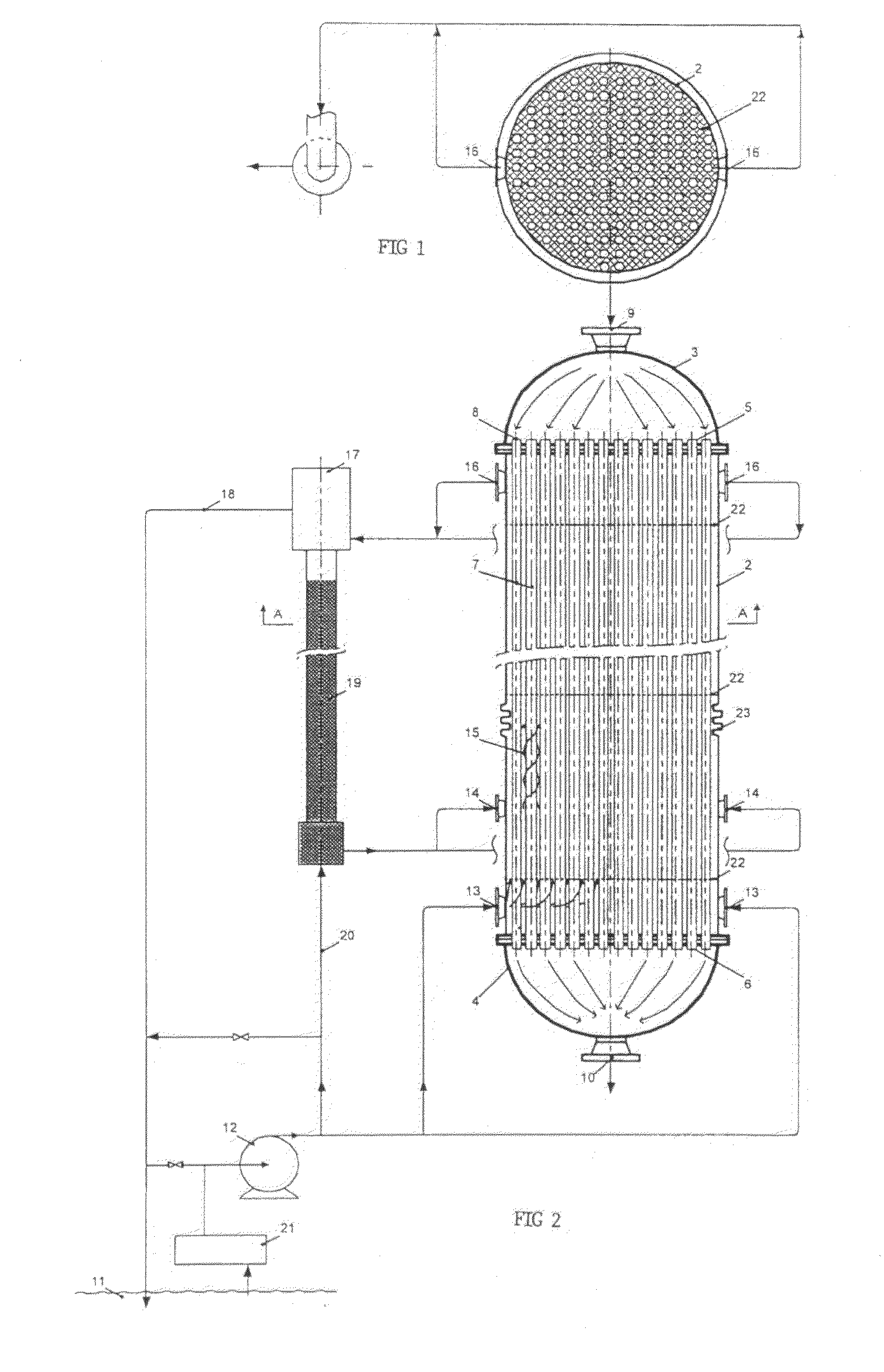

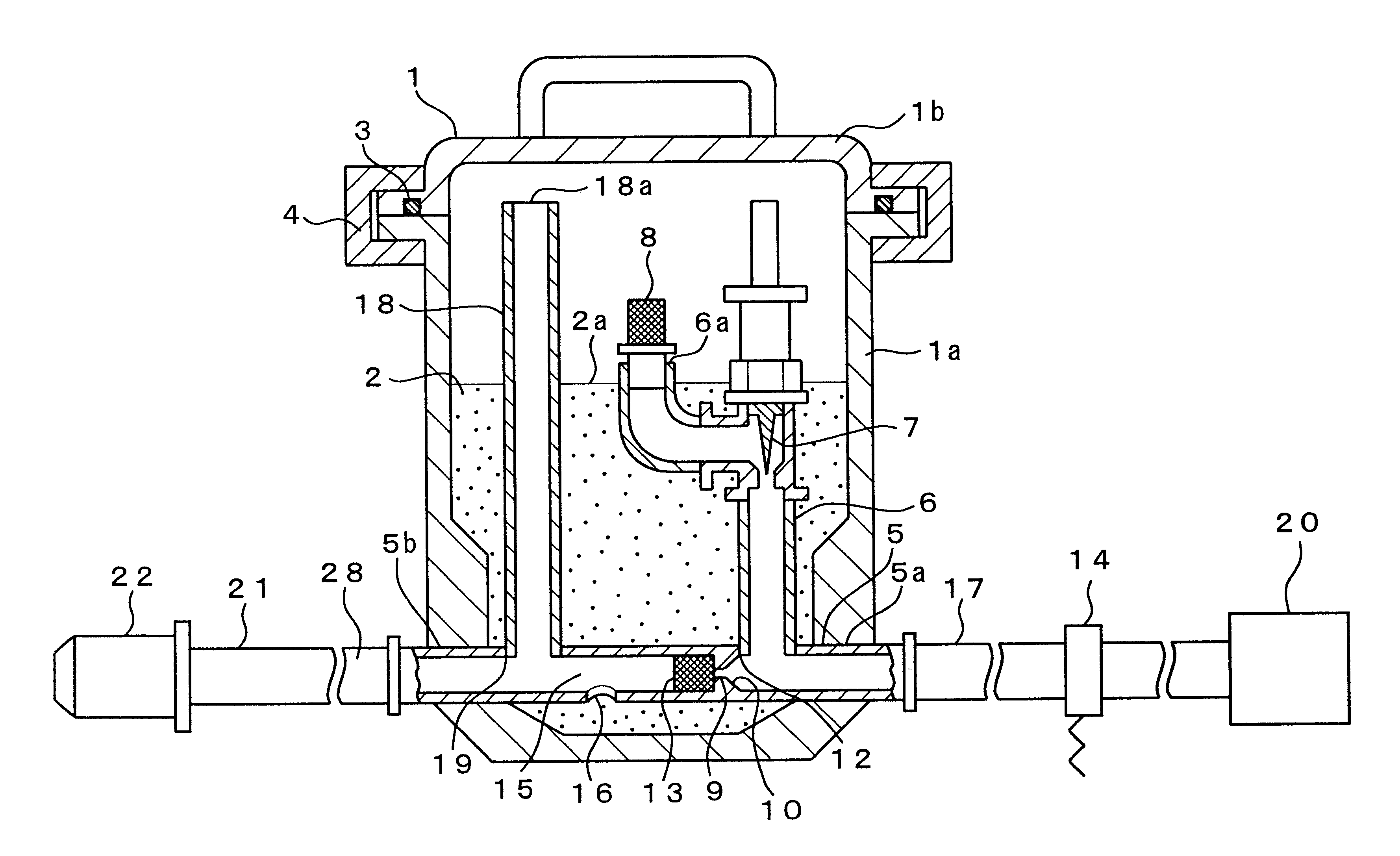

Heat Exchanger Vessel With Means For Recirculating Cleaning Particles

InactiveUS20080302511A1Prevent backflowMinimized pressure dropHollow article cleaningStationary tubular conduit assembliesParticle injectionEngineering

A heat exchanger vessel (1) comprises a tubular outer shell (2) in which a bundle of heat exchanging tubes (7) is arranged, which bundle of heat exchanger tubes is coupled to an inlet (9) and outlet (10) for a first fluid, such as high-pressure natural gas, and the tubular outer shell (2) comprises at least one inlet (13,14) and at least one outlet (16) for a second fluid, such as seawater, wherein at least one inlet (14) for the second fluid is provided with particle injection means for injecting cleaning particles into the space between the outer surfaces of the heat exchanger tubes (7) and the inner surface of the tubular shell (2) of the heat exchanger vessel (1) and at least one outlet (16) for the second fluid is connected to means for removing particles from the second fluid and for recirculating particles to at least one inlet (14) of the second fluid. The mildly abrasive cleaning particles will remove any fouling or scaling from the space between the heat exchanger tubes (7) and the outer shell (2) so that the second fluid, such as seawater, can be heated to a relatively high temperature and circulated at low velocity, resulting in a relatively compact and lightweight heat exchanger vessel with low maintenance requirements; enabling (direct) subsea seawater cooling.

Owner:TWISTER BV

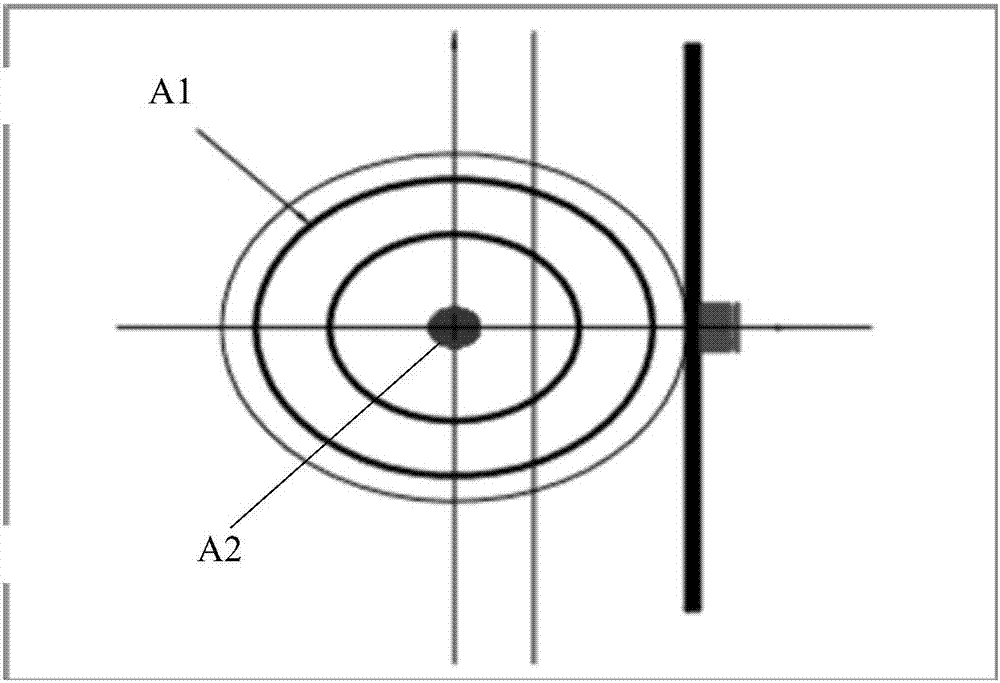

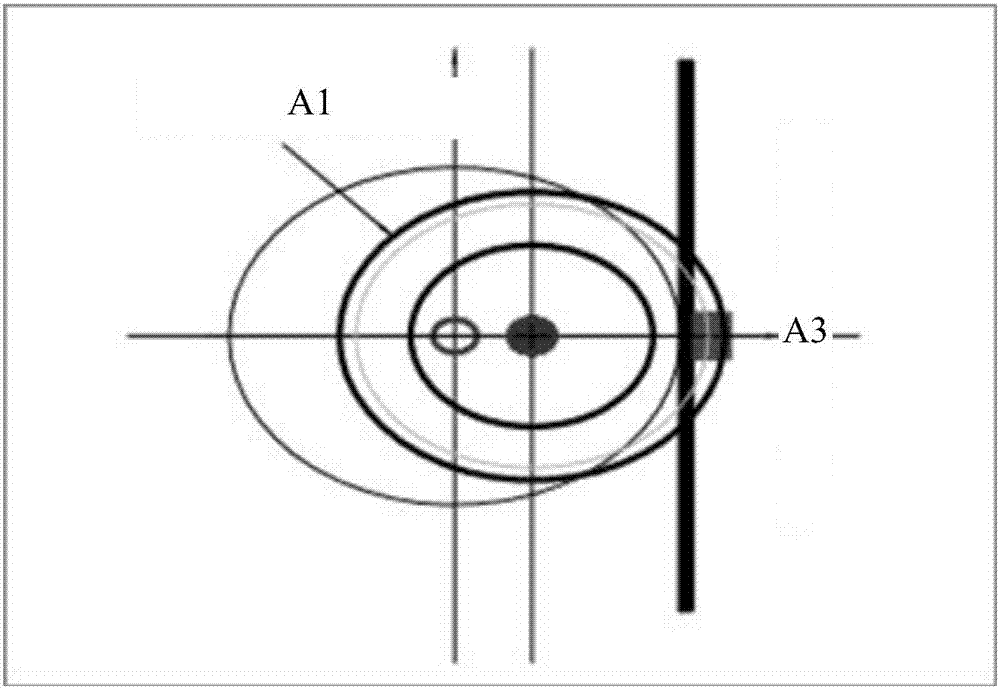

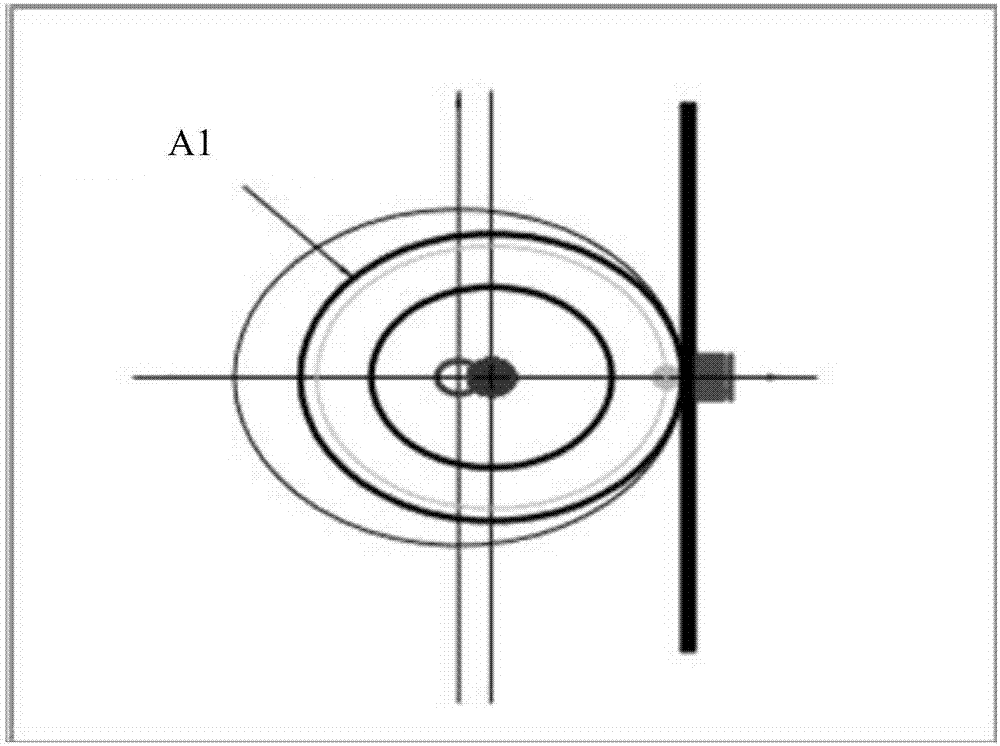

Particle injection system and annular particle accelerator

The invention discloses a particle injection system and an annular particle accelerator. The particle injection system adopts jumping magnet to provide a pulse magnetic field having a preset cycle to an injection beam, and the jumping of the transmission speed and the transmission direction of the injection beam occur, when the injection beam passes through the incident gap of the jumping magnet, and the jumping of the emittance phase ellipse of the injection beam occurs, and therefore the emittance phase ellipse of the injection beam falls into the acceptability phase ellipse of the annular particle accelerator, and the injection process of the injection beam is completed. The ratio between pulse width of the pulse magnetic field provided by the jumping magnet and the circling cycle of the storage beam of the particle accelerator is smaller than a set value, and therefore the injection beam can be captured by the radio frequency acceleration electric field of the annular particle accelerator after entering the annular particle accelerator with help of a horizontal oscillation amplitude damping oscillation attenuation process. Because the pulse width of the pulse magnetic field is small, disturbances on the storage beam of the annular particle accelerator cannot be caused by the pulse magnetic field.

Owner:UNIV OF SCI & TECH OF CHINA

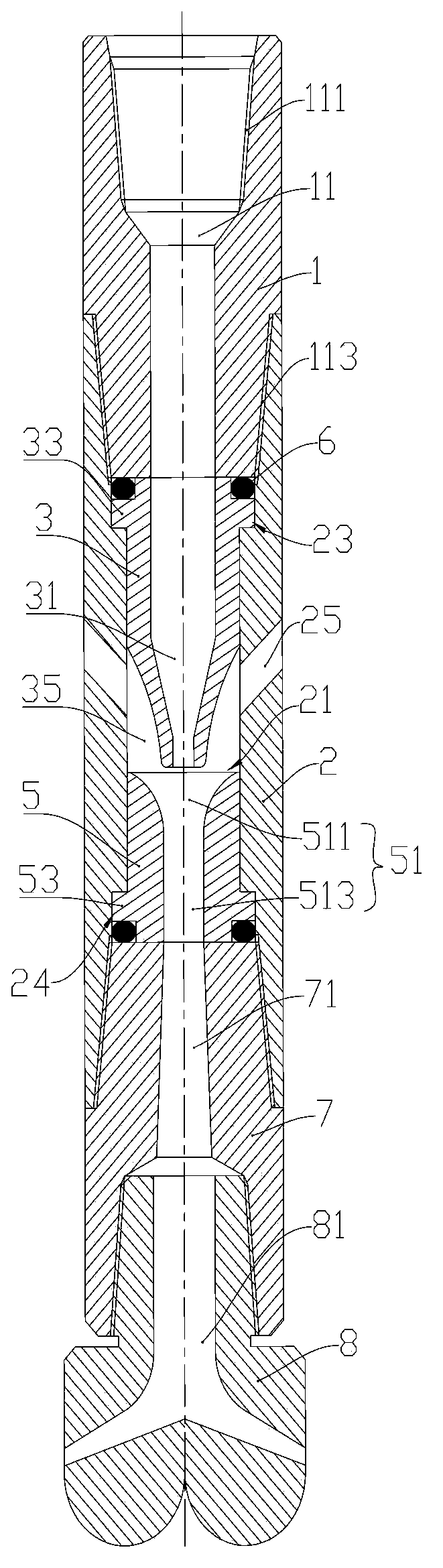

Downhole particle jet perforation device

The invention relates to the field of oil drilling and completion, in particular to a downhole particle jet perforation device comprising a particle injection tank, a perforated short circuit, a retractable perforating nozzle, a fixed perforating nozzle, and a pilot drill bit. The high pressure mud and particles are mixed by the particle injection tank to reach the perforation short circuit, ejected from the retractable perforating nozzle and the fixed perforating nozzle at an adjustable angle to quickly penetrate the casing, the cement ring and the formation rock, and the pilot drill bit is mounted on the lower part of the perforation short circuit. The retractable perforating nozzle can achieve large depth perforation, and the perforation depth can be adjusted, the position, type and quantity of the retractable perforating nozzle and the fixed perforating nozzle can be selected according to the actual needs of the site. The downhole particle jet perforation device can effectively improve the efficiency of the downhole perforation operation, increase the perforation depth and the working area, enhance the fluid flow capacity of the stratum, and effectively improve the reservoir productivity.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Shaft bottom particle injection drilling speed increasing tool

The invention discloses a shaft bottom particle injection drilling speed increasing tool and belongs to the field of matched devices of petroleum and natural gas drilling. The tool comprises an upper connector, a contracting nozzle, a casing and a lower connector. The lower connector is connected with a drill bit provided with a water hole. The contacting nozzle is provided with a nozzle channel, an annular space is formed between the contacting nozzle and the casing, the nozzle channel is communicated with the annular space, the casing is provided with a particle suction port, a conical diffusion flowing channel is arranged on the lower connector, and the diameter of the inlet position where the diffusion flowing channel is communicated with the annular space is smaller than the diameter of the outlet position where the diffusion flowing channel is communicated with the water hole. In the drilling process, drilling liquid forms high speed injection flow through the contacting nozzle to be sprayed, a low pressure area is formed in the annular space under the injection effect of the injection flow, steelmaking particles in the annular space is sucked into the annular space through pressure difference of high pressure and low pressure, and the particle suction effect is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

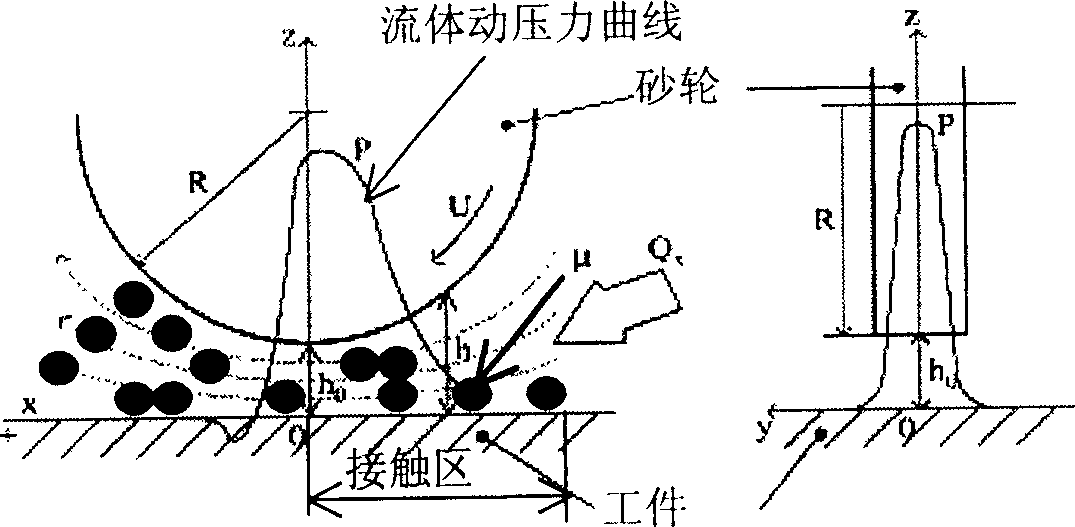

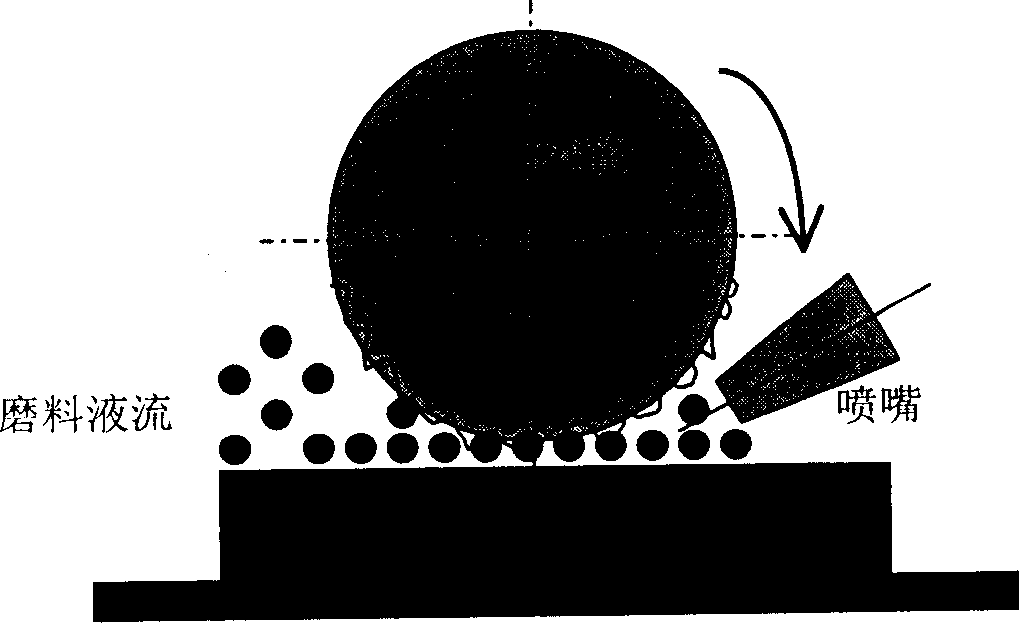

Grinding wheel constraining abrasive particle injection precise dressing processing method and device

InactiveCN1686668AUncomplicated design and manufactureEasy installationParticle injectionHigh pressure

A blasting precise machining technology by use of abrasive wheel to restrict the abrasive particles including grinding by adrasive wheel and blasting the abrasive particles. It features that after the abrasive particle stream is blasted by high-pressure pump, it can obtain the momentum under the action of the centrifugal force and attracting force of abrasive wheel, and the fluid pressure field and speed field between abrasive wheel and workpiece. Its apparatus is composed of grinder, abrasive wheel, bench, pump, control valve, flowmeter, nozzle, shielding cover, liquid collecting both, stop plate and liquid tank.

Owner:NORTHEASTERN UNIV

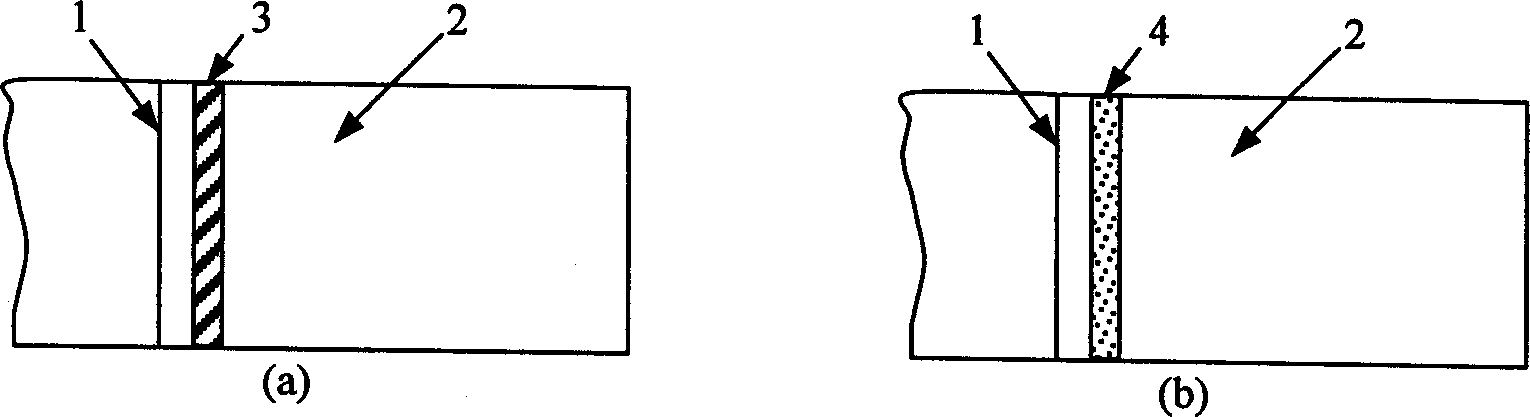

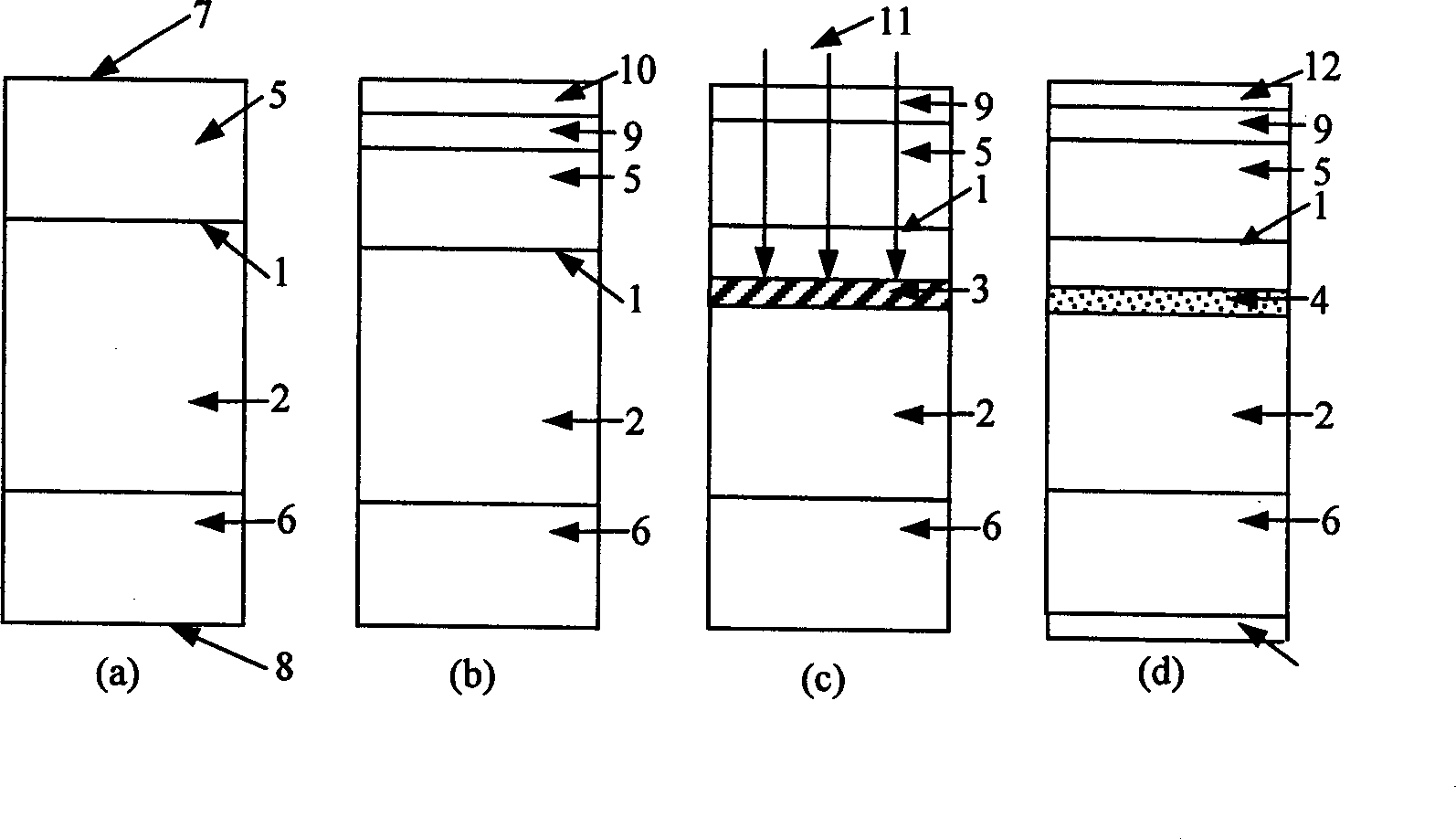

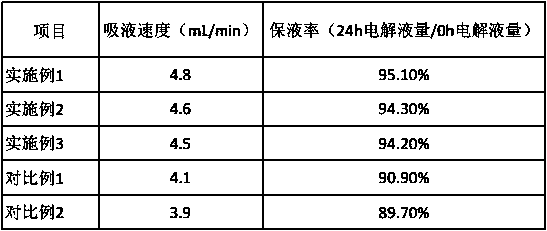

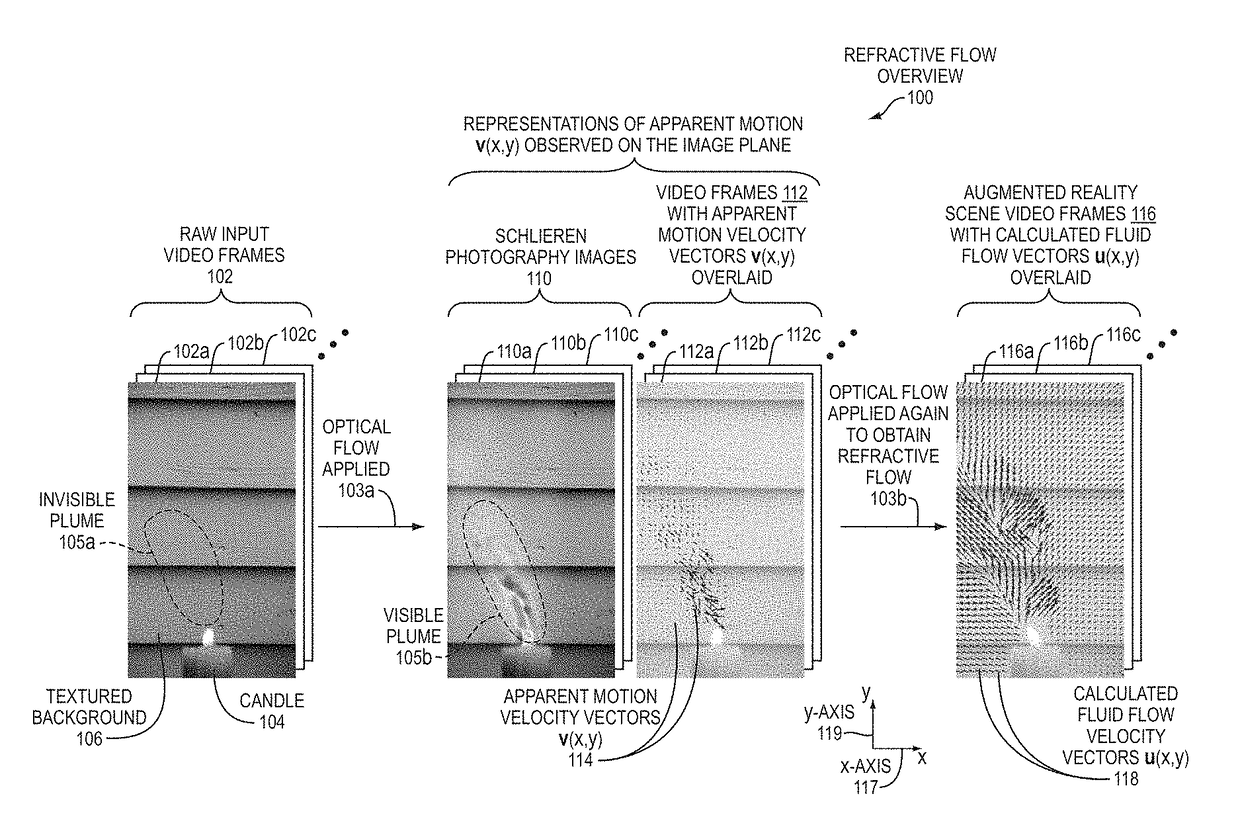

Modification method for lithium nickel cobalt manganese oxide ternary composite material

InactiveCN108448076AImprove liquid absorption capacityHigh specific capacityCell electrodesSecondary cellsSodium bicarbonateParticle injection

The invention belongs to the field of lithium-ion battery material preparation and particularly discloses a modification method for a lithium nickel cobalt manganese oxide ternary composite material.The method comprises the steps of firstly preparing nickel hydroxide cobalt-manganese sediments through a coprecipitation method, introducing acid gases to adjust pH of a solution to be 6.0-7.0 and then carrying out suction filtration and drying to obtain a precursor nickel hydroxide cobalt-manganese ternary material; sequentially carrying out lithium metaaluminate coating, sintering, crushing andgrading; and finally injecting inert lithium powder into the surface of the material through a particle injection method to obtain a lithium-rich ternary composite material. The acid gases, such as carbon dioxide are combined with residual sodium hydroxide and ammonium hydroxide separately to form sodium bicarbonate and ammonium bicarbonate, and nano-holes are left after sintering, so that the liquid absorption capacity of the material is improved; and meanwhile, lithium supplement is carried out on the material by adopting the lithium powder injected into the surface of the material and enough lithium ions are provided for the charging and discharging processes, so that the specific capacity and the rate capability of the ternary composite material are improved.

Owner:SHANDONG FENGYUAN CHEM CO LTD

Methods and apparatus for refractive flow measurement

An imaging method and corresponding apparatus according to an embodiment of the present invention enables measurement and visualization of fluid flow. An embodiment method includes obtaining video captured by a video camera with an imaging plane. Representations of motions in the video are correlated. A textured background of the scene can be modeled as stationary, with a refractive field translating between background and video camera. This approach offers multiple advantages over conventional fluid flow visualization, including an ability to use ordinary video equipment outside a laboratory without particle injection. Even natural backgrounds can be used, and fluid motion can be distinguished from refraction changes. Depth and three-dimensional information can be recovered using stereo video, and uncertainty methods can enhance measurement robustness where backgrounds are less textured. Example applications can include avionics and hydrocarbon leak detection.

Owner:MASSACHUSETTS INST OF TECH

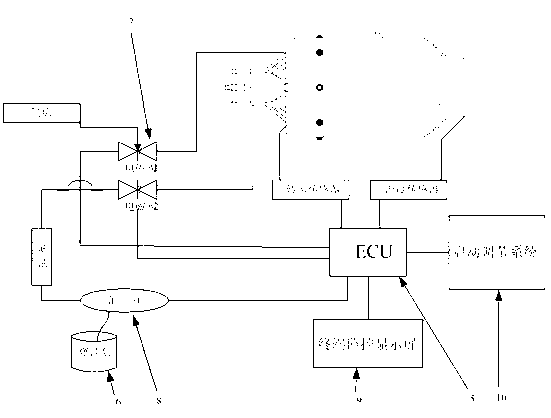

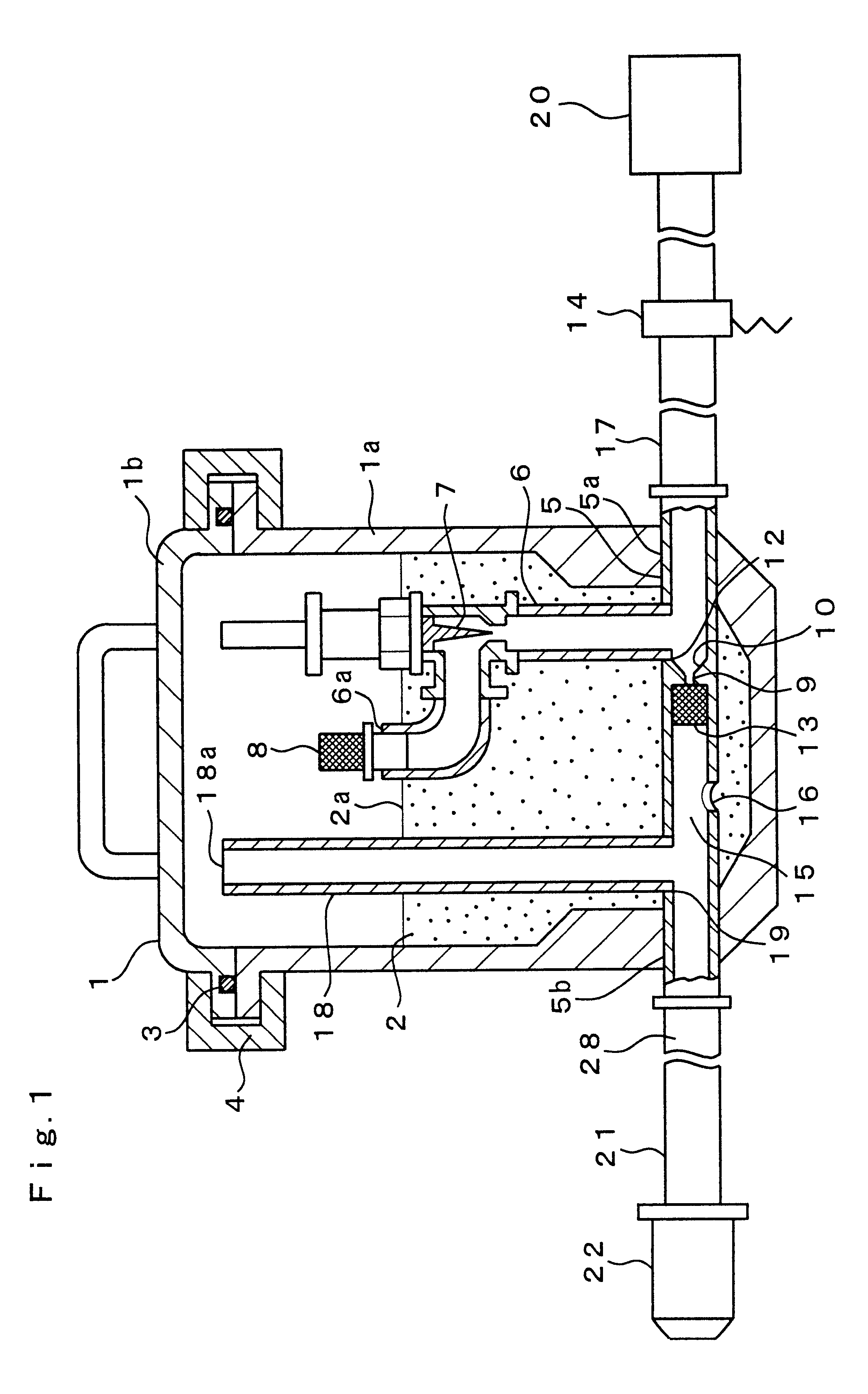

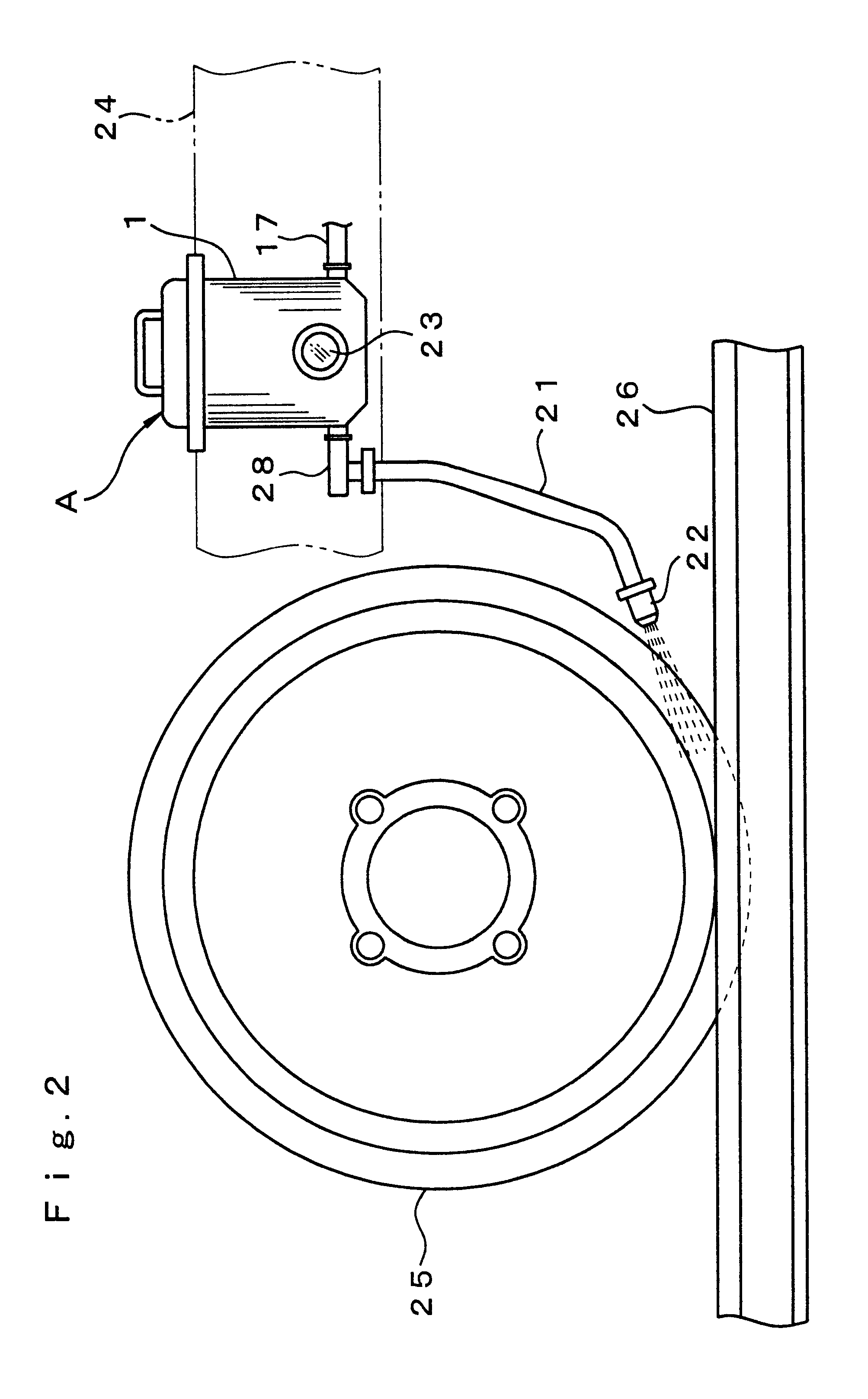

Slip prevention particle injection device

InactiveUS6722589B1Simple structureImprove cost efficiencyFertiliser distributersManure distributersPipeline.airParticle injection

Problems are posed by slip prevention particle injection devices by wheels of railway rolling stock. Namely, if the injected quantity of slippage-preventing particles is adjusted so as not to be excessive and to be a suitable quantity, it is not possible to obtain a predetermined injection pressure and it is not possible to inject the particles at the target location. The injector device of the present invention is constituted by providing an air through-flow duct 5 inside a particle retainer tank 1, and connecting an air supply duct 17 to this air through-flow duct 5. In the above mentioned tank 1, in addition to an air inflow duct 6 being provided in the vicinity of the inlet side of the air through-flow duct 5, an air discharge duct 18 is provided in the vicinity of the outlet side of the air through-flow duct 5. This air inflow duct 6 and air discharge duct 18 are connected to the air through-flow duct 5 and one end of these ducts 6 and 18 is open into the tank 1. Further, in addition to a mixing chamber 15 and a smaller-diameter air passage section 9 being provided in the air through-flow duct 5, a particle introduction hole 16 is provided in the mixing chamber 15, and an injector duct 21 that injects a fluid mixture of slippage-preventing particles and compressed air is provided at the outlet side of the air through-flow duct 5.

Owner:RAILWAY TECH RES INST +1

Novel motor flow field observation device and method

InactiveCN105486479AAccurately capture flow field conditionsThe flow field is fully restoredAerodynamic testingThermodynamicsParticle injection

The invention discloses a novel motor flow field observation device and a method. A wind source is connected to a tracer particle injection area through a first wind path conversion tube; the tracer particle injection area is connected to a wind path interface of a test motor model through a second wind path conversion tube; the main structure of the test motor model is made of a light transmission material; a CCD high speed camera and a laser sheet light source are arranged on the sides of the test motor model and face to an internal flow field; the CCD high speed camera and the laser sheet light source are connected to a PIV special purpose computer; the laser is irradiated into the flow field with the tracer particle in the test motor model; and the distribution and moving state of the flow field are displayed through the tracer particle and is collected by the CCD high speed camera. The invention can be used for observing the cooling air flow field in the motor, can accurately simulate the working condition of the practical motor, guarantees the observation accuracy of the motor cooling flow field and observes the cooling air flow field in the microcosm in order to optimize the motor heat radiation structure.

Owner:ZHEJIANG UNIV

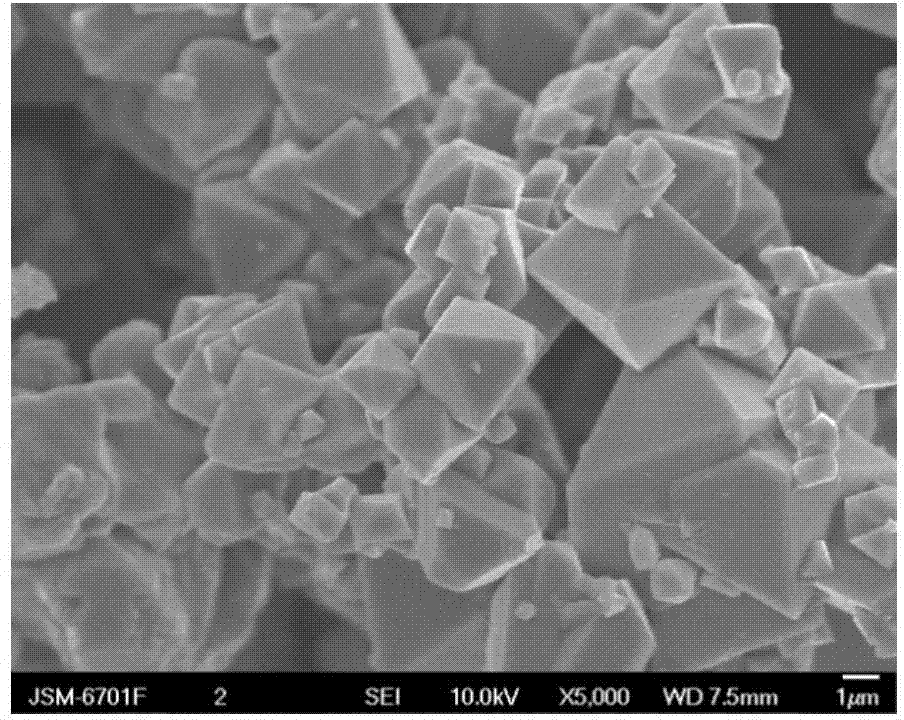

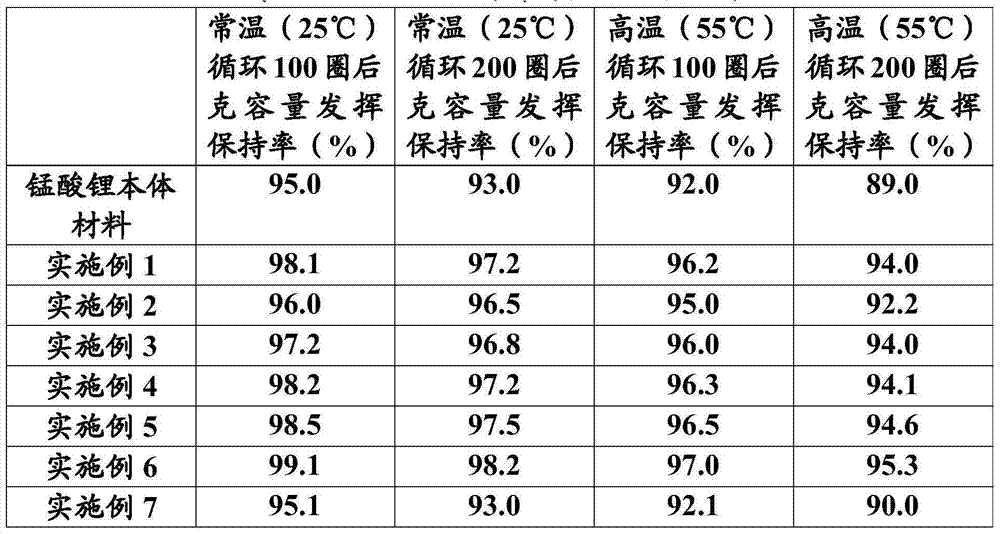

Modification method of lithium ion battery cathode material

ActiveCN104733714AImprove consistencyImprove cycle stabilityCell electrodesSurface layerParticle injection

The invention provides a surface modification method of a lithium ion battery cathode material lithium manganate. The method comprises the steps of implanting a coating material into a surface layer of the lithium manganate body material by virtue of the bombardment of high-speed particle beams. The surface modification method is good in coating uniformity, and the coating thickness is controllable. The electrochemical performance test shows that the lithium manganate cathode material with the surface modified by adopting the high-speed particle injection method is high in cycling stability and obviously high in high-temperature performance.

Owner:INST OF CHEM CHINESE ACAD OF SCI +2

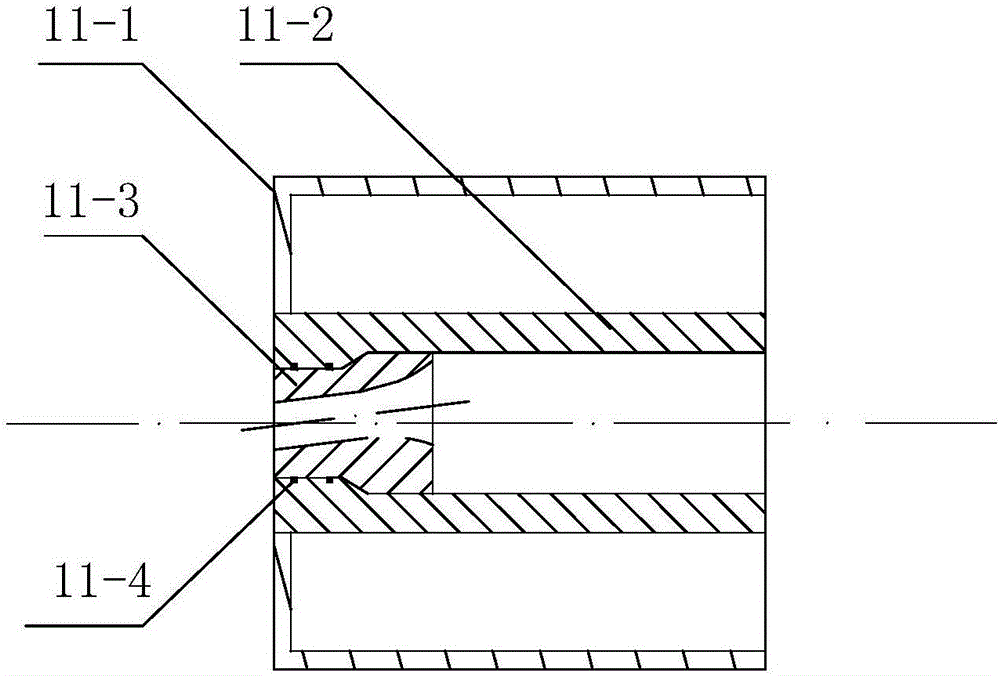

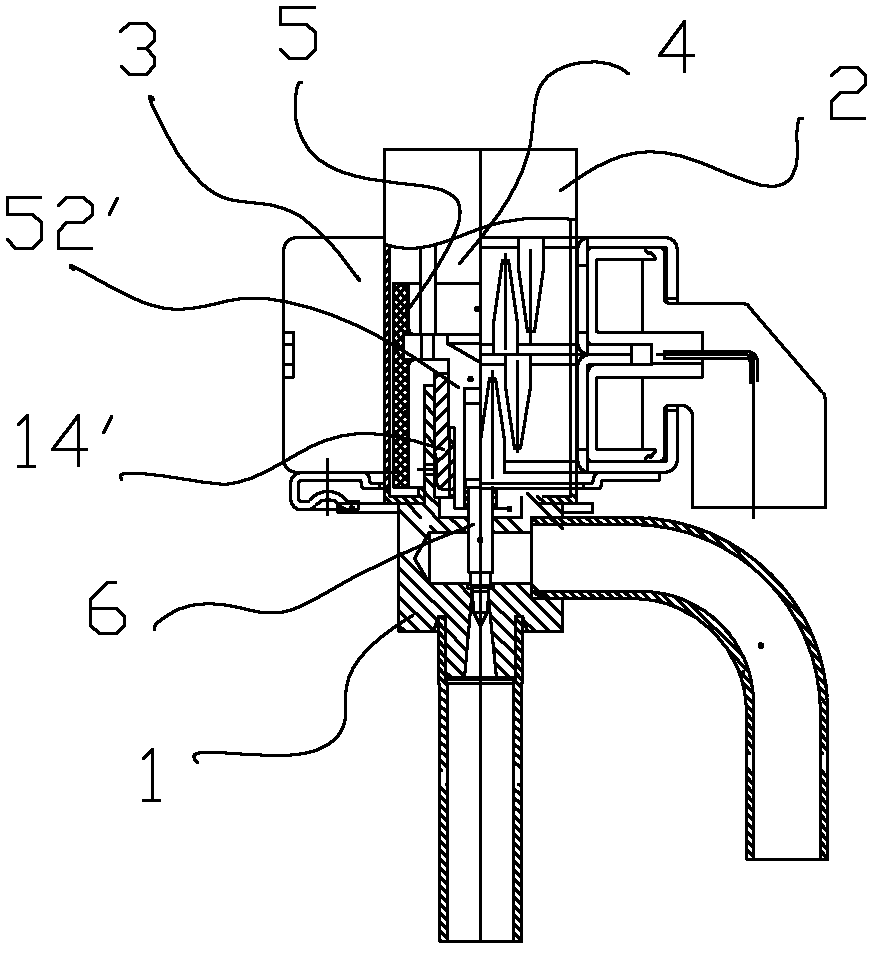

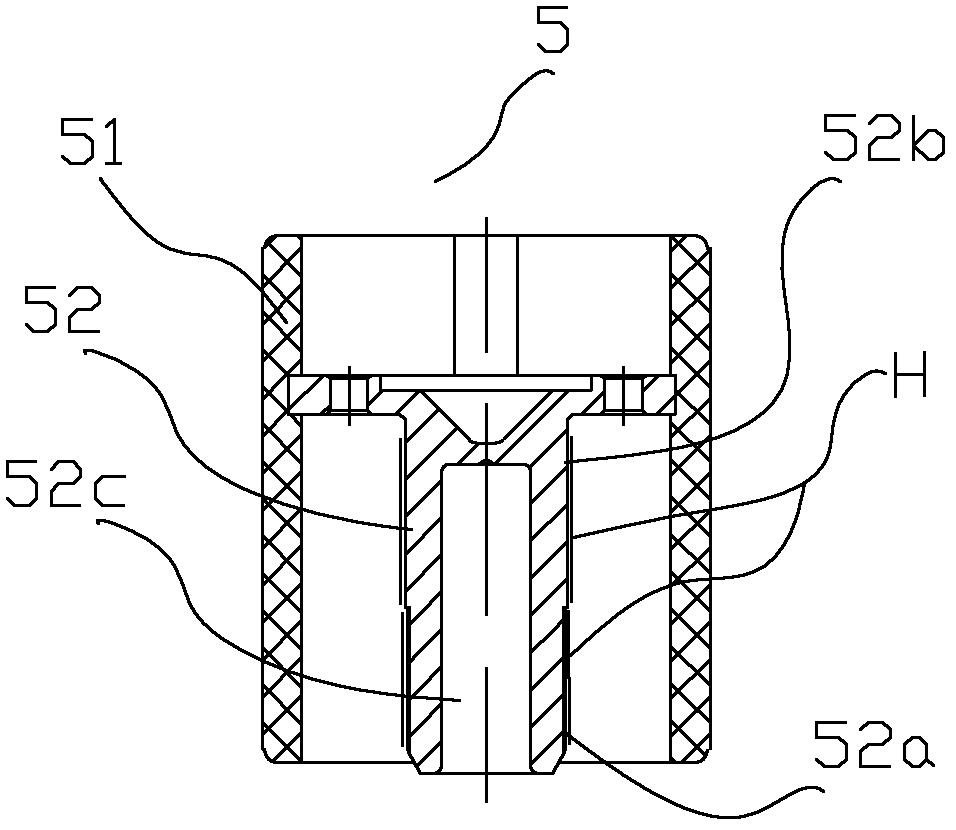

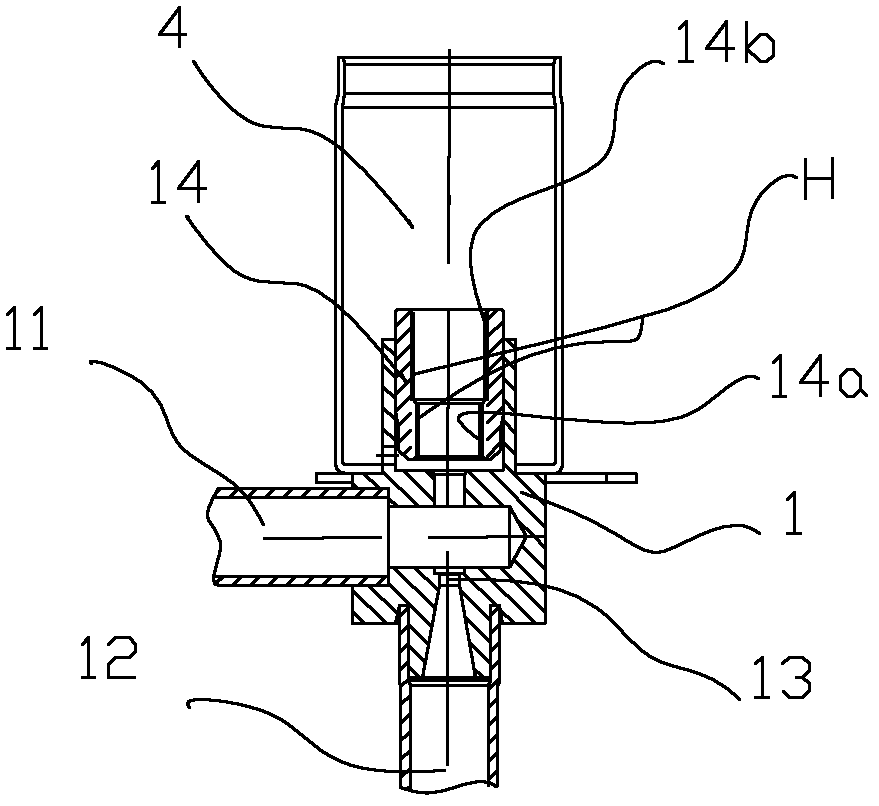

Electronic expansion valve and machining method thereof

InactiveCN103115190AReduce the driving voltageGuaranteed reliabilityOperating means/releasing devices for valvesEfficient regulation technologiesParticle injectionSand blasting

The invention discloses an electronic expansion valve and a machining method thereof and relates to the technical field of control valves. The electronic expansion valve comprises a valve seat (1), a nut (14), a sleeve (2) and a coil (3), wherein the nut (14) and the sleeve (2) are fixed on the valve seat (1), the coil (3) is fixed on an outer side of the sleeve, the sleeve (2) and the valve seat (1) form a cavity (4), a magnet rotor component (5) which senses the magnetic field of the coil and rotates is arranged in the cavity (4), and the lower end of the magnet rotor component (5) is provided with a valve rod (6). The magnet rotor component (5) is provided with a screw rod (52), and a first thread section (52a) and a second thread section (14a) are respectively arranged on the screw rod (52) and the nut (14). The electronic expansion valve and the machining method thereof are characterized in that the first thread section (52a) of the screw rod (52) is provided with a hardened layer which is treated through a micro particle injection process or a precision sand blasting process. A surface of a component is conducted with hardening and anti-wear treatment directly, the fatigue strength and the surface hardness of the surface of the nut and the screw rod are improved, the service life of the component is greatly prolonged and the working precision is improved greatly.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

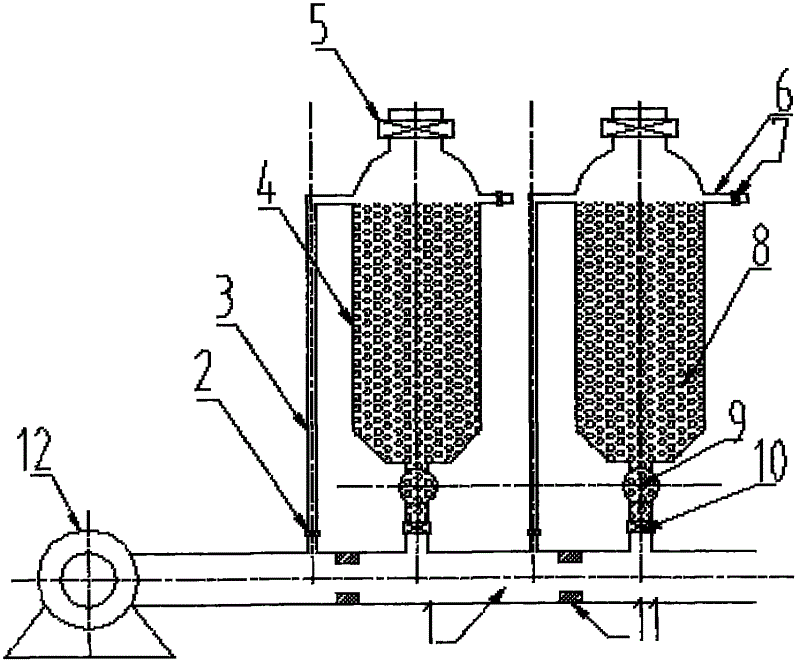

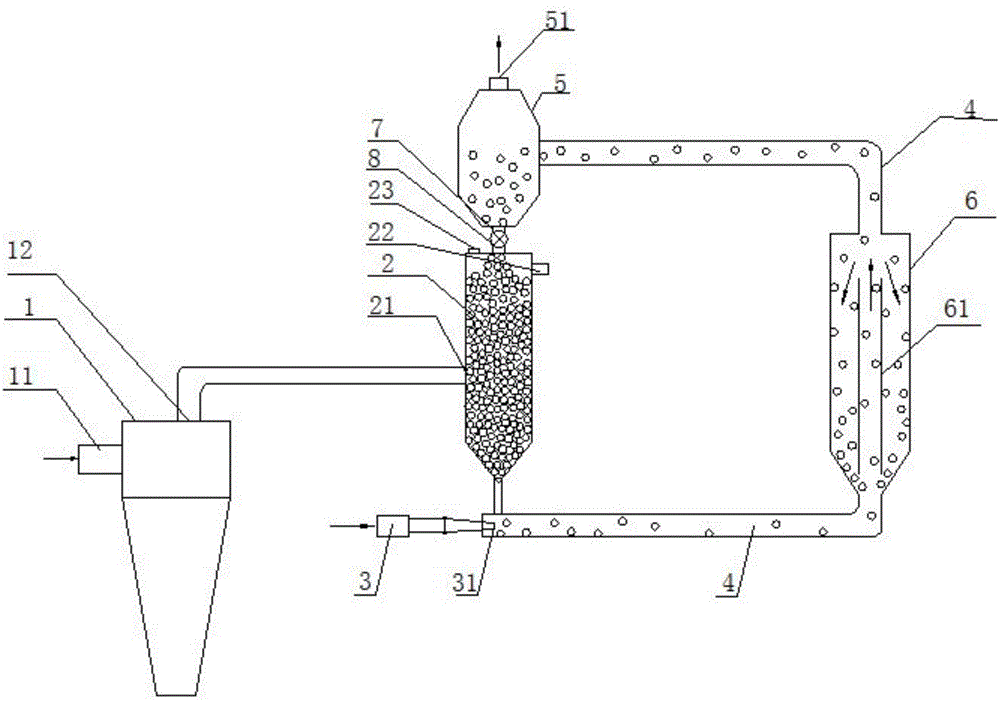

Particle matter moving bed dust removal device and dust removal method used by dust removal device

ActiveCN104971569AGuaranteed uptimeAvoid the disadvantage of being easily blockedCombination devicesDispersed particle filtrationParticulatesParticle injection

The invention relates to the technical field of dust-containing air treatment devices and in particular relates to a particle matter moving bed dust removal device and a dust removal method used by the dust removal device. The particle matter moving bed dust removal device comprises a particle bed, a particle injection conveyor, a particle ash removal device and an injection bed, wherein a first air inlet and a first air outlet are formed in the particle bed; the lower end of the particle bed is connected with the lower end of the injection bed by a particle conveying pipe; the upper end of the injection bed is connected with the particle ash removal device by the particle conveying pipe; the particle ash removal device is connected with the upper end of the particle bed by a descending pipe; an air injection opening of the particle injection conveyor is connected with one end of the particle conveying pipe positioned at the lower end of the particle bed; the particle injection conveyor is inserted in one end of the particle conveying pipe by the air injection opening; a waste air outlet is formed in the particle ash removal device. According to the device and the method, dust-containing particles are pre-cleaned by adopting the injection bed, so that the separation efficiency of the dust-containing particles is improved, the cleanness of particles subjected to secondary air dust removal is ensured, and further the dust removal efficiency of the dust removal device is improved.

Owner:北京恒丰亚业科技发展有限公司

Silicon-carbon composite material prepared in particle injection method and preparation method thereof

InactiveCN109428063AImprove consistencyImprove cycle stabilityMaterial nanotechnologyCell electrodesCarbon compositesSurface layer

The invention discloses a silicon-carbon composite material prepared in a particle injection method and a preparation method thereof. Specifically, through a particle injection method, high-speed particle beams are used for bombardment to implant a silicon material to a surface layer of a carbon series main body material; then, coating and carbonization of a graphene base material is carried out.The material prepared by the method can reduce expansion of the material and improve the doping consistency between silicon and carbon while improving the gram volume of the material; meanwhile, graphene base composite liquid is coated on the surface of the material, which improves the electrical conductivity of the material and the compatibility of the electrolyte; the prepared silicon-carbon composite material has the characteristics of high gram volume, good rate capability, high cycle performance and the like and improves the rate capability, the cycle performance and the consistency of the lithium ion battery.

Owner:内蒙古欣源石墨烯科技股份有限公司

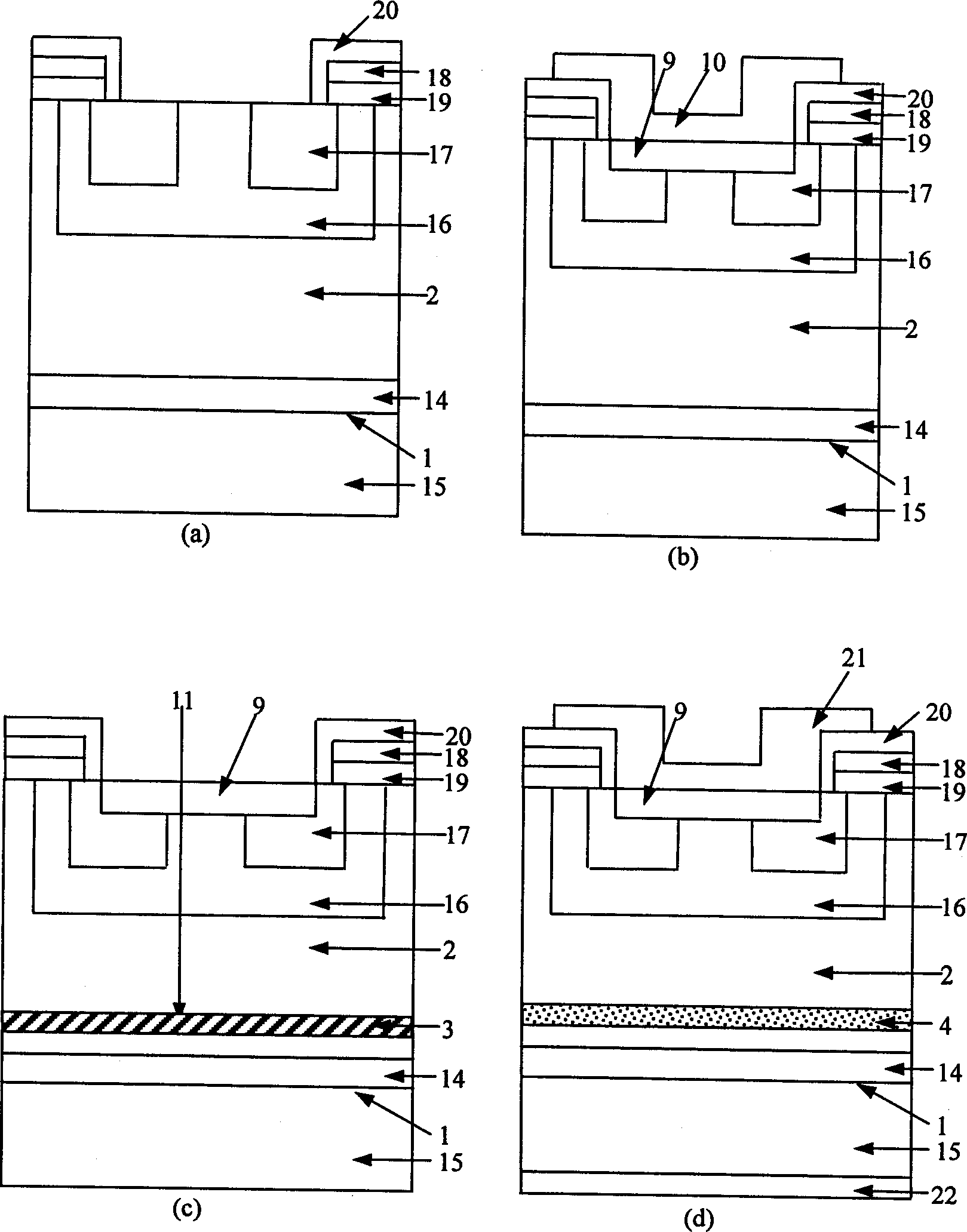

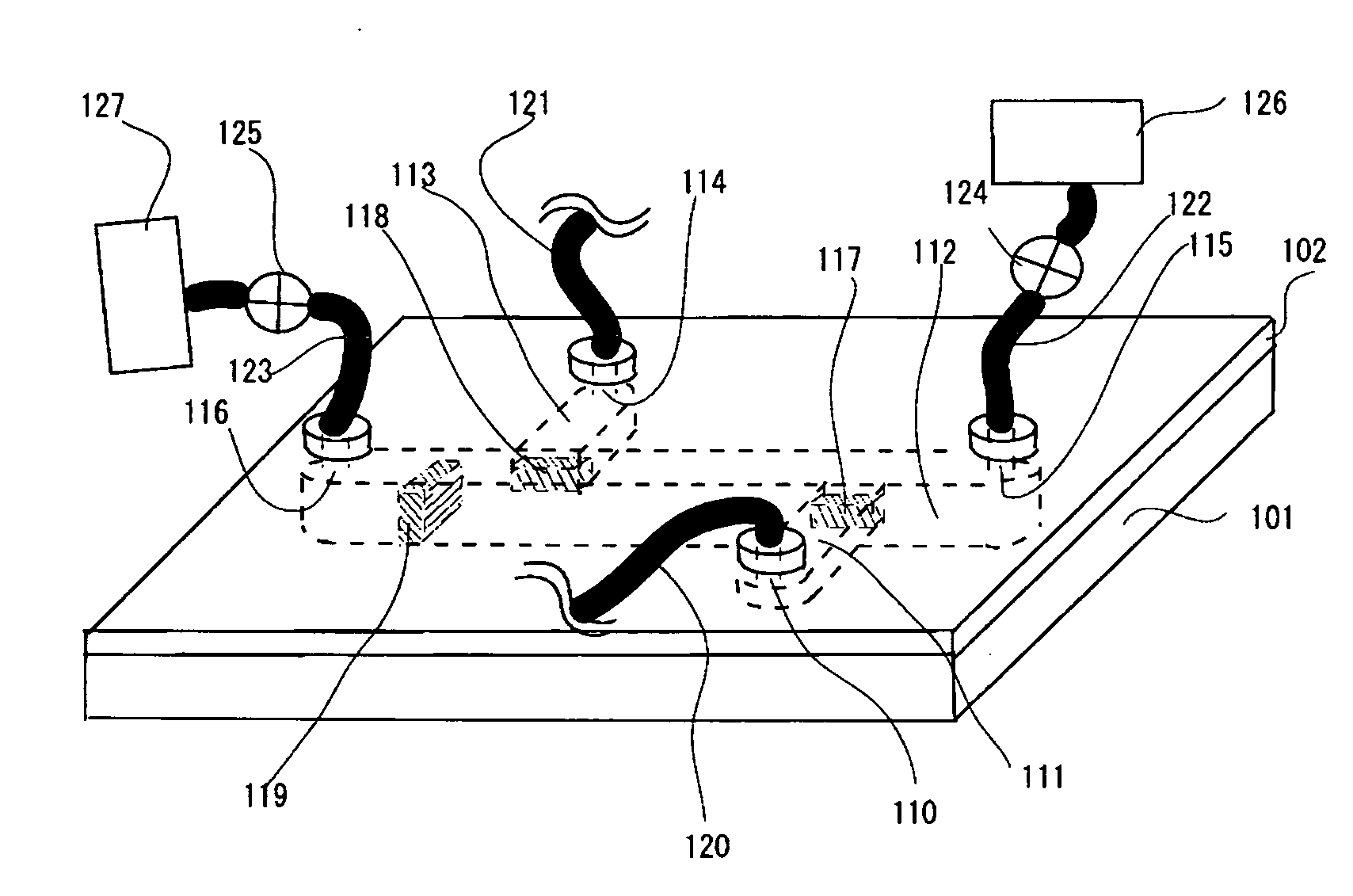

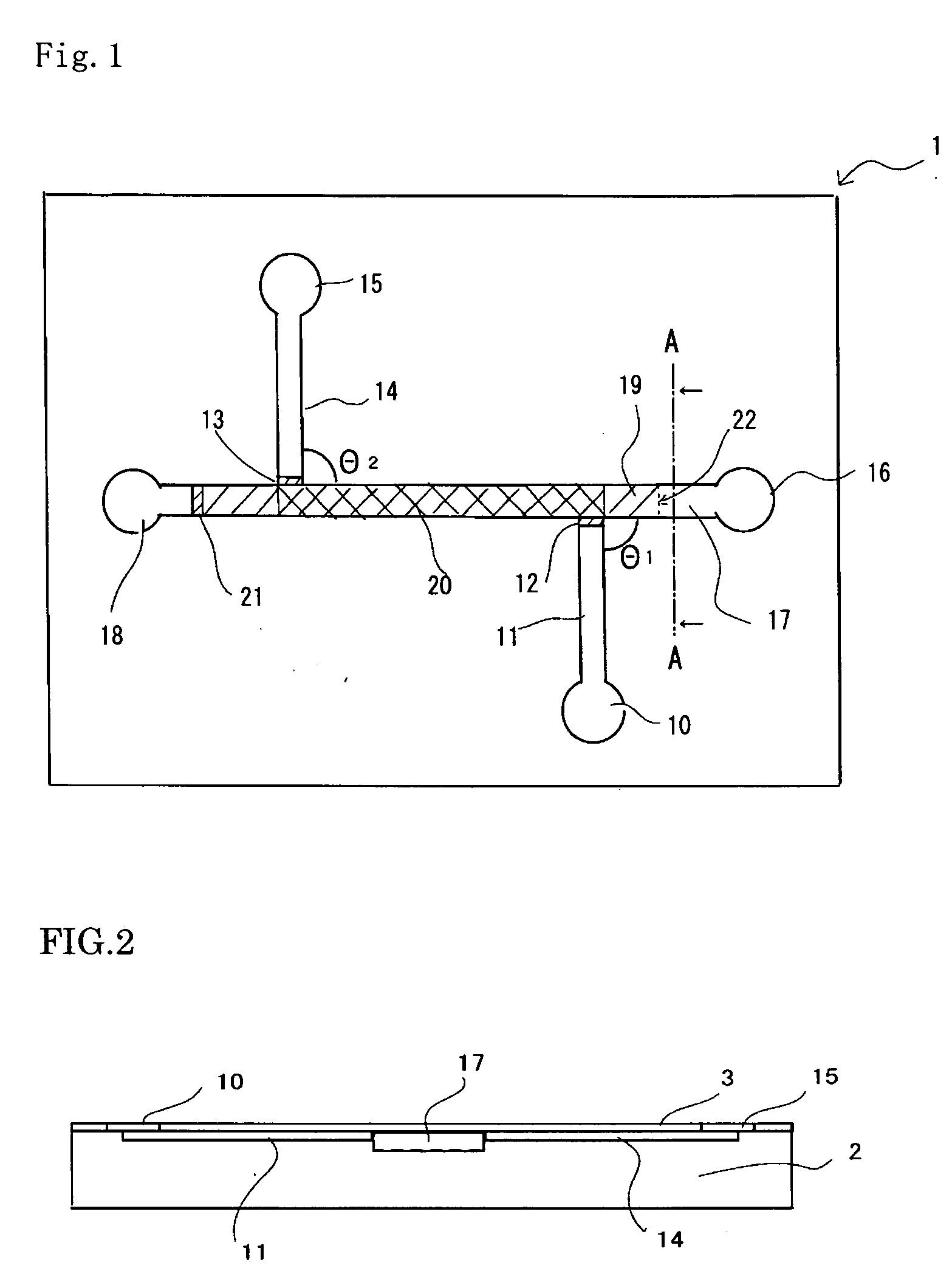

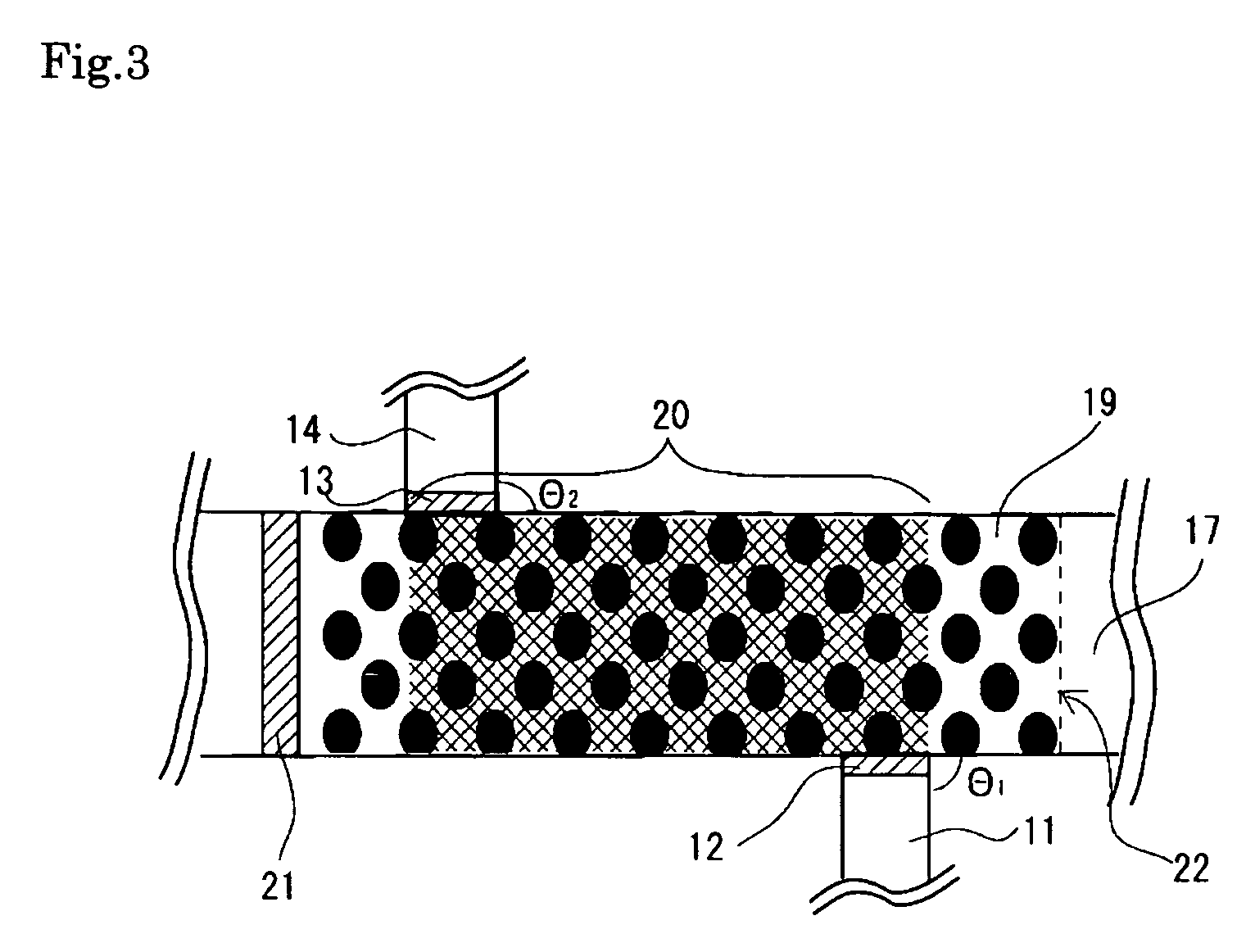

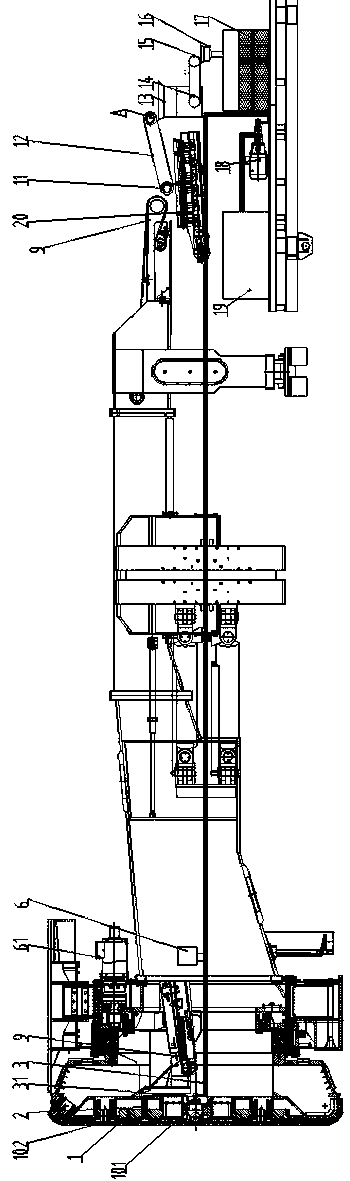

Analytical microchip

InactiveUS20070116594A1Inhibit migrationPrevent fluctuationsAnalysis using chemical indicatorsLaboratory glasswaresParticle injectionSolid particle

The detection accuracy and detection reproducibility of an analytical microchip utilizing beads are improved. To this end the analytical microchip has a reaction path 17 having a particle-filled area 19 filled with a group of solid particles, a test-solution introducing path 11 for introducing a test solution into the reaction path, a test-solution discharging path 14 for discharging a test solution inside the reaction path to outside of the microchip, and a particle injection aperture 16 provided on one end side of the reaction path 17. The test-solution discharging path 14 has a direct communication with the particle-filled area 19 in the reaction path 17. The test-solution introducing path 11 has a direct communication with the reaction path 17 on the upper stream side relative to the test-solution discharging path 14 and within the upper-stream-side end surface 22 of the particle-filled area 19. A first damming portion 12 is provided at the point of connection of the test-solution introducing path 11 and the reaction path 17. A second damming portion 13 is provided at the point of connection of the test-solution discharging path 14 and the reaction path 17.

Owner:SHARP KK

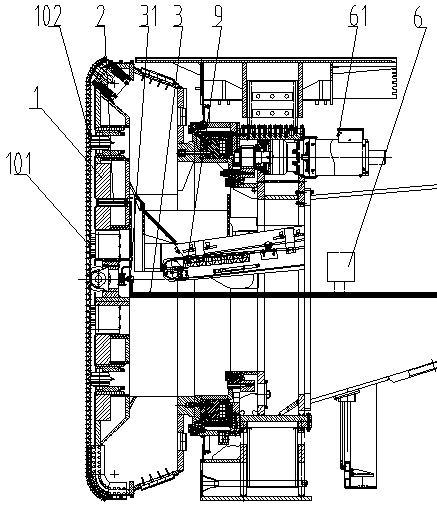

Novel tunnel boring machine based on high speed particle impact-mechanical combined rock breaking

PendingCN109441471AExpand the scope of excavationImprove construction efficiencyTunnelsParticle injectionHigh intensity

The invention discloses a novel tunnel boring machine based on high speed particle impact-mechanical combined rock breaking. The problems of low penetration, slow tunneling speed, fast tool abrasion and the like of an existing tunneling machine in high strength hard rock environments are solved. The novel tunnel boring machine based on the high speed particle impact-mechanical combined rock breaking comprises a tunnel boring machine body, the tunnel boring machine body is provided with a cutterhead, the cutterhead is provided with a hob, and the cutterhead is further provided with a particle nozzle. According to the novel tunnel boring machine based on the high speed particle impact-mechanical combined rock breaking, a novel cutterhead structure of a full-section tunnel boring machine is designed, wherein the novel cutterhead structure is provided with the particle nozzle, the disk-shaped hob and a scraper, high speed particle impact-mechanical tool coupling rock breaking is used, a particle injection system and a particle recovery system are designed, the excavation scope of the full-section tunnel boring machine is expanded, and the construction efficiency is improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

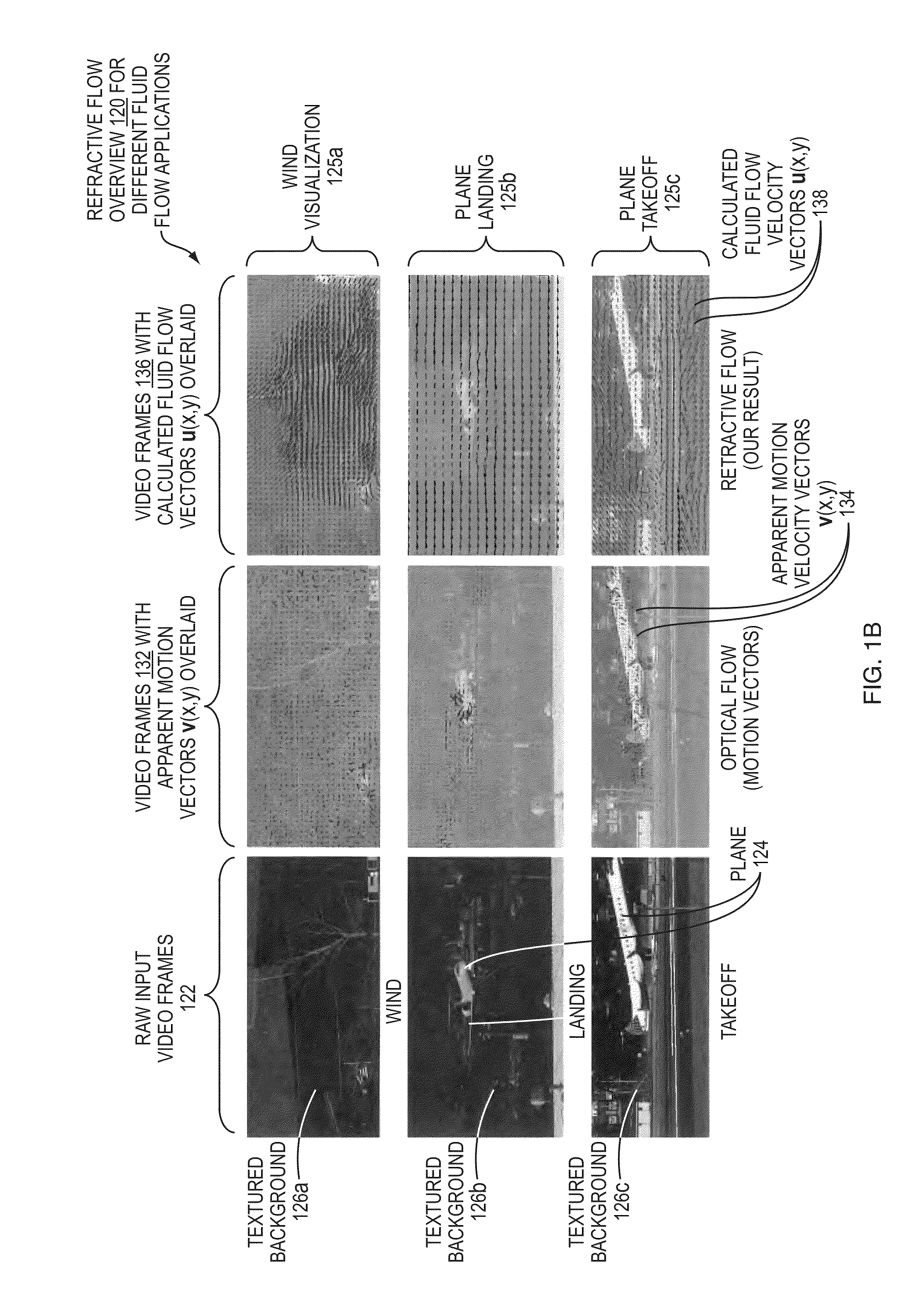

PIV tracer particle wall spreading device

ActiveCN108627673ASolve the problem that the PIV tracer particles cannot enter the boundary layerTroubleshooting the interior of a supercavitationFluid speed measurementParticle injectionHigh pressure

The invention discloses a PIV tracer particle wall spreading device and belongs to the field of flow measurement in the near wall area. The device comprises a particle generator, a high pressure softpipe and a wall particle injection device, wherein the particle generator comprises an air inlet, a particle outlet and a stirrer, the particle outlet of the particle generator is connected with the wall particle injection device through the high pressure soft pipe, the wall particle injection device has a chamber, a particle injection hole and a thin cover plate, the chamber is provided with theparticle injection hole, the particle injection hole is provided with a pressure sensor at the downstream, and the thin cover plate is arranged above the chamber. The device is advantaged in that a problem that the existing PIV tracer particle spreading method cannot make PIV tracer particles enter the boundary layer or the supercavitation is solved, injection of the PIV tracer particles into thenear wall region is achieved, and the good technical support is provided for research of the supersonic or hypersonic boundary layer transition and ventilated supercavitation flow mechanism.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

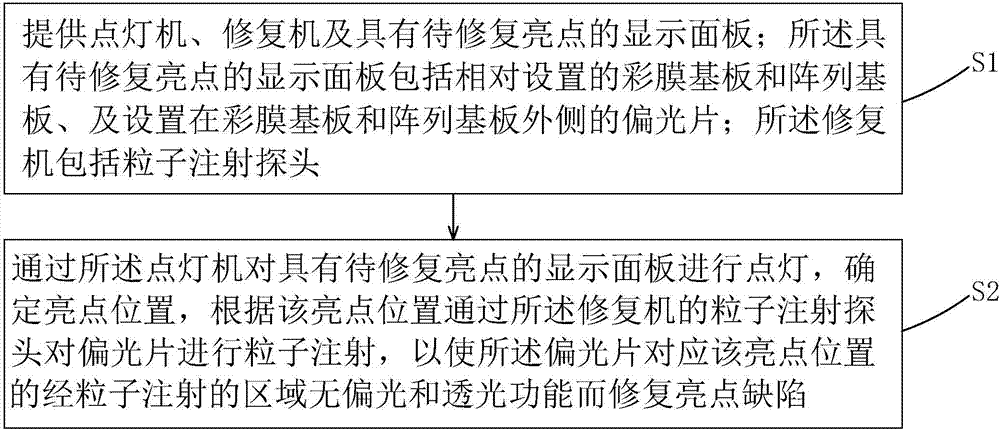

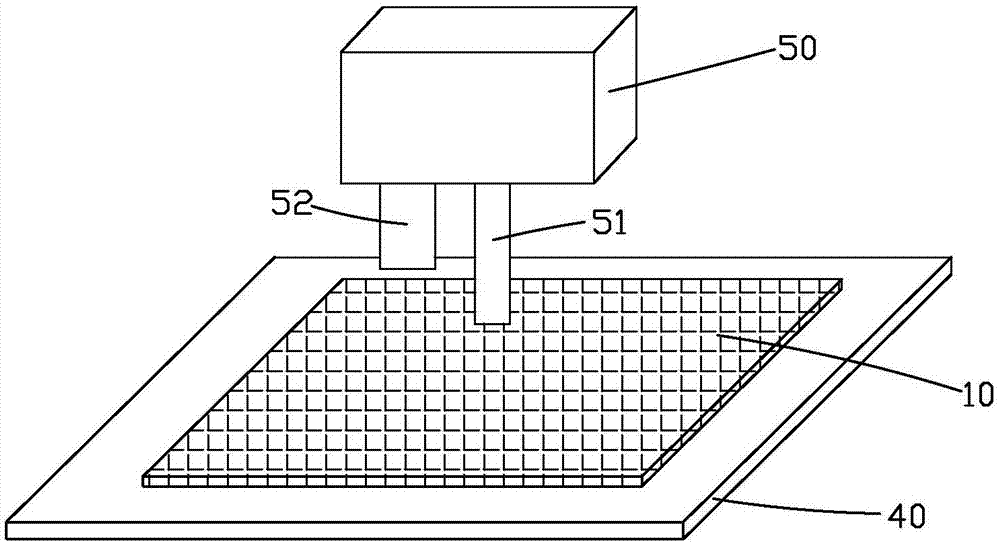

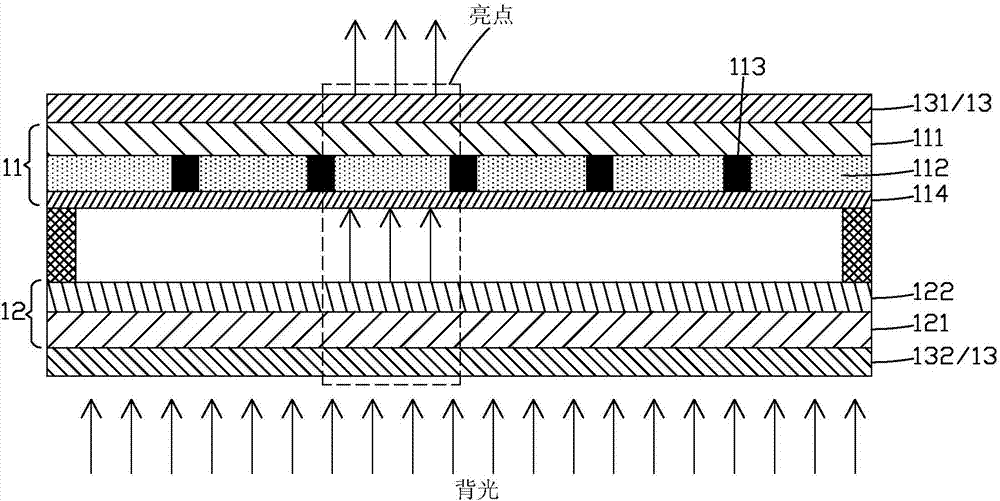

Display panel bright spot fixing method

InactiveCN107390395AImprove repair success rateImprove reliabilityNon-linear opticsParticle injectionTransmittance

The invention provides a display panel bright spot fixing method. After a display panel with to-be-fixed bright spots is lighted with a lighting machine, the positions of the bright spots are determined, then particle injection is performed on a polarizer through a particle injection probe of a fixing machine according to the positions of the bright spots, and the area, corresponding to the positions of the bright spots and subjected to particle injection, of the polarizer is free of polarization and light transmittance so as to fix the bright spots. Compared with the existing method for fixing the bright spots with laser, the method has the advantages that damage is not caused to the film layer of the display panel, fixing success rate can be increased, and further product reliability and quality can be improved effectively.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com