Downhole particle jet perforation device

A particle and perforating technology, applied in the production of fluids, wellbore/well components, earthwork drilling, etc., can solve the problem that the perforating effect of the perforating gun is not very good, so as to increase the perforation depth and action area, improve the Efficiency, flow-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

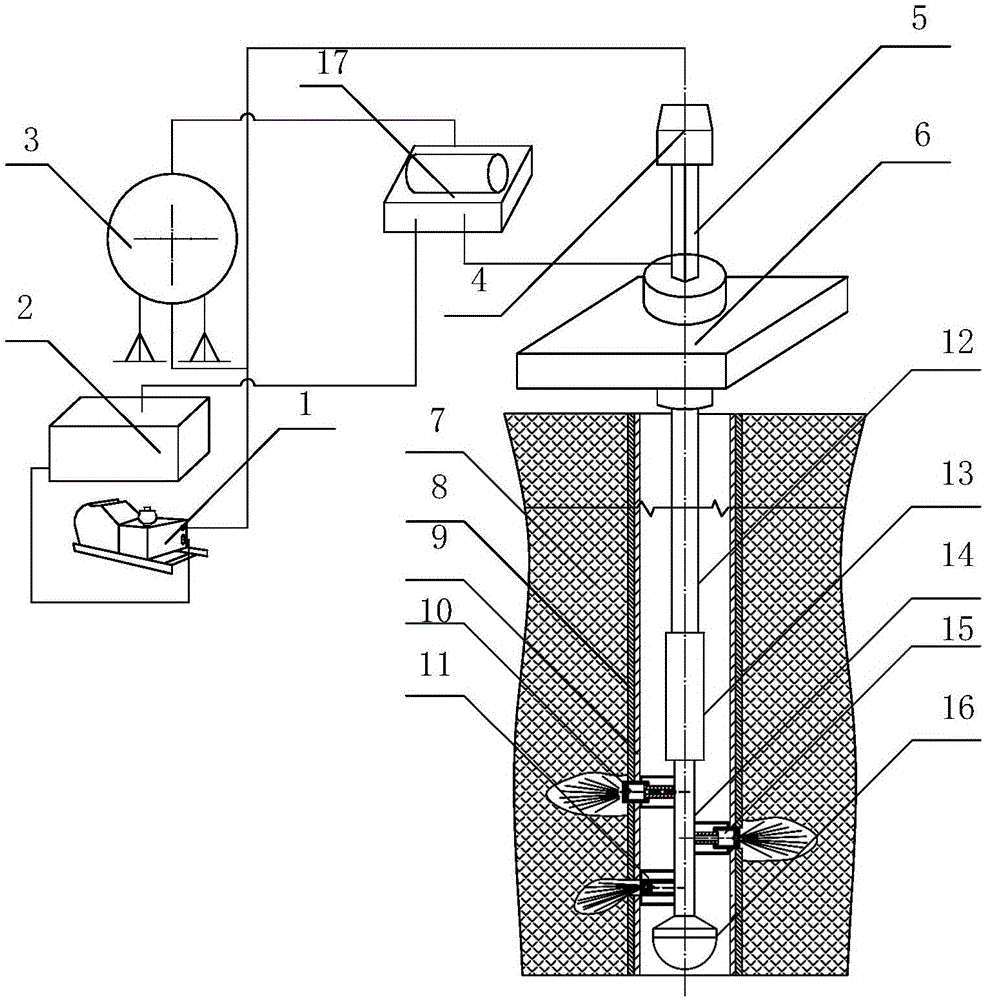

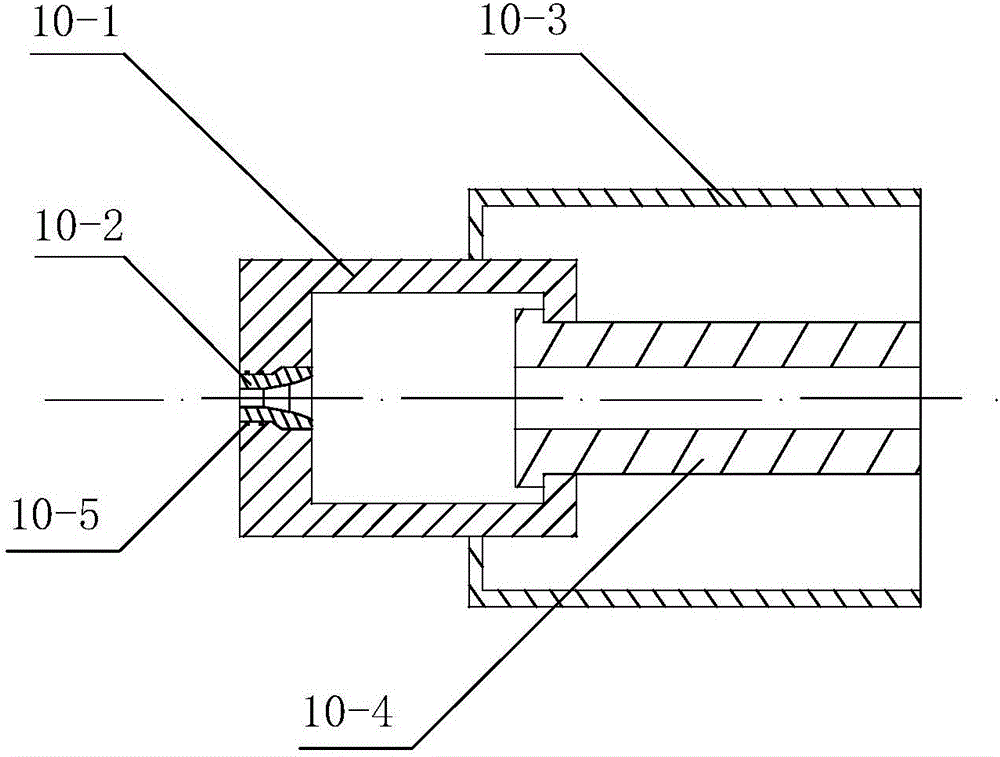

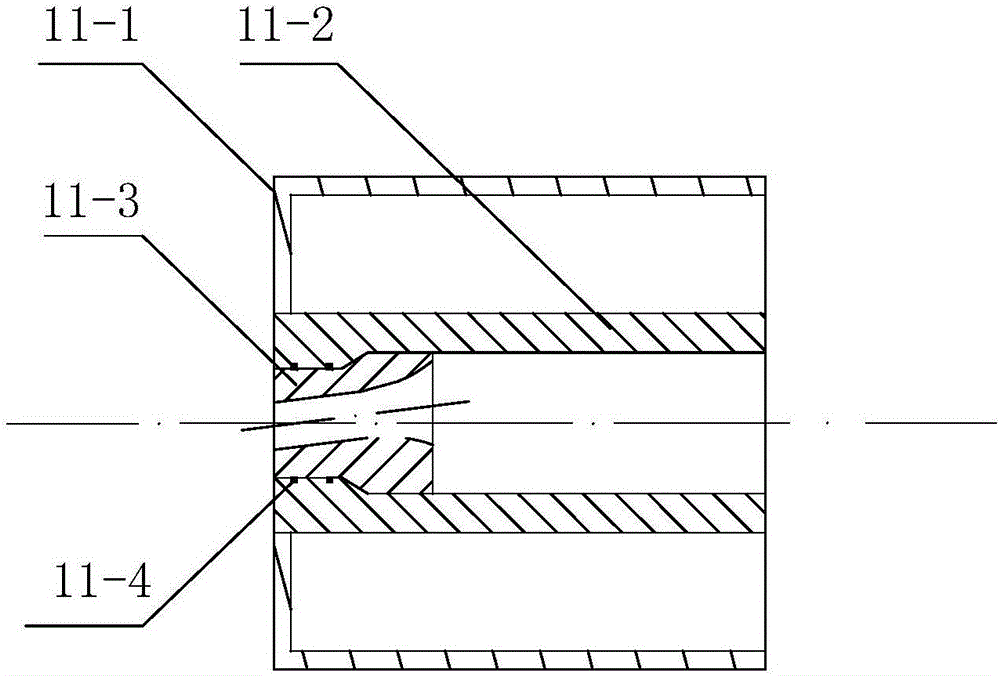

[0018] Such as figure 1 As shown, the downhole particle jet reaming device according to the present invention includes: mud pump 1, mud pool 2, particle injection tank 3, faucet 4, kelly 5, drill floor 6, formation rock 7, cement sheath 8, Casing 9, 1# telescopic perforating nozzle 10, fixed perforating nozzle 11, drill pipe 12, drill collar 13, perforating short connection 14, 2# telescopic perforating nozzle 15, pilot drill bit 16, Particle separation device 17. The mud pump 1 sucks the mud in the mud pool 2 to form high-pressure mud, and the high-pressure mud is transported to the particle injection tank 3 through the high-pressure pipeline, and the particles in the particle injection tank 3 are mixed with the high-pressure mud to form a mixture of particles and mud, which is then sent to the faucet 4. After going down through the kelly 5, the drill floor 6, the drill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com