Patents

Literature

69results about How to "Improve perforation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

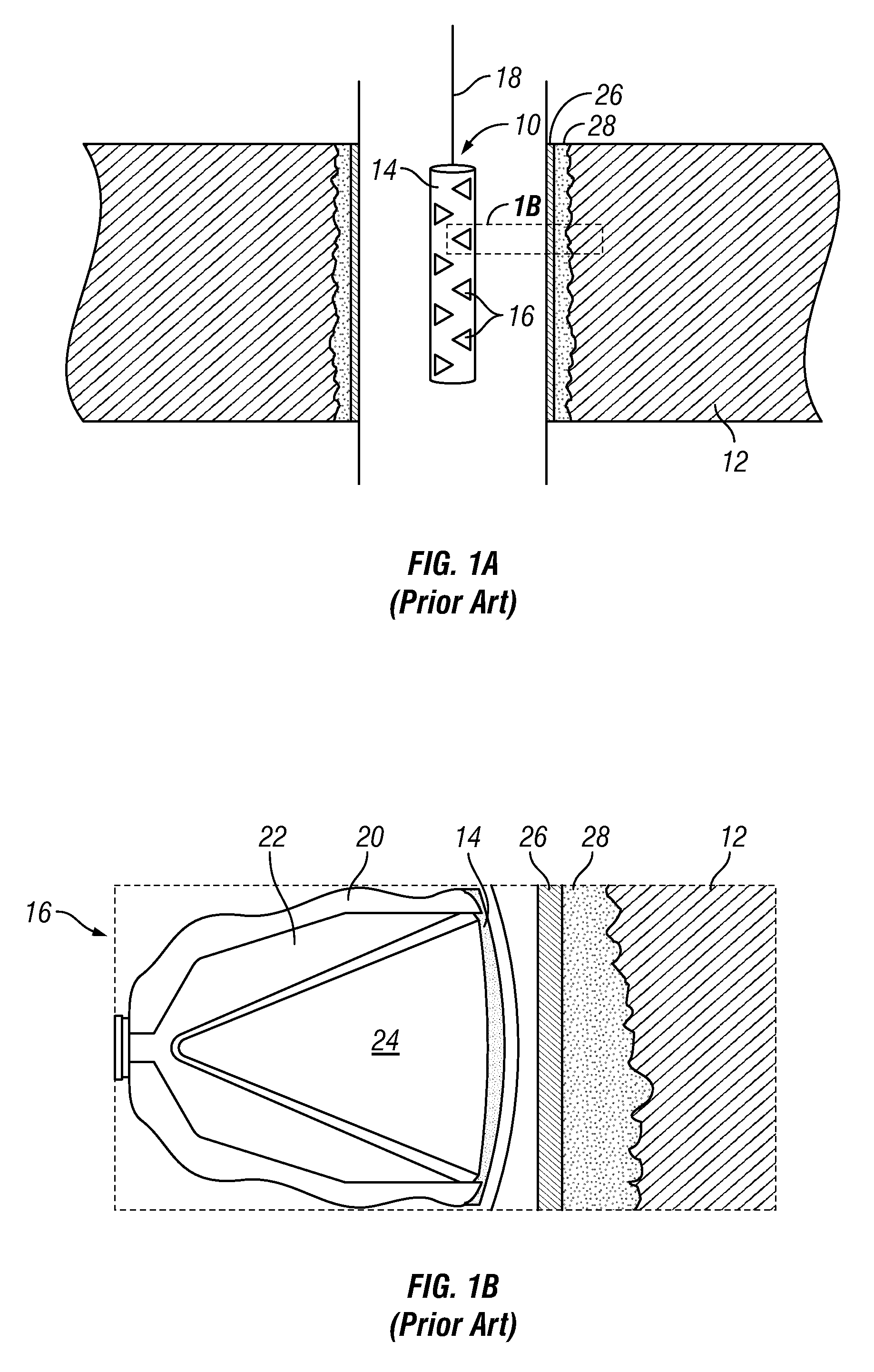

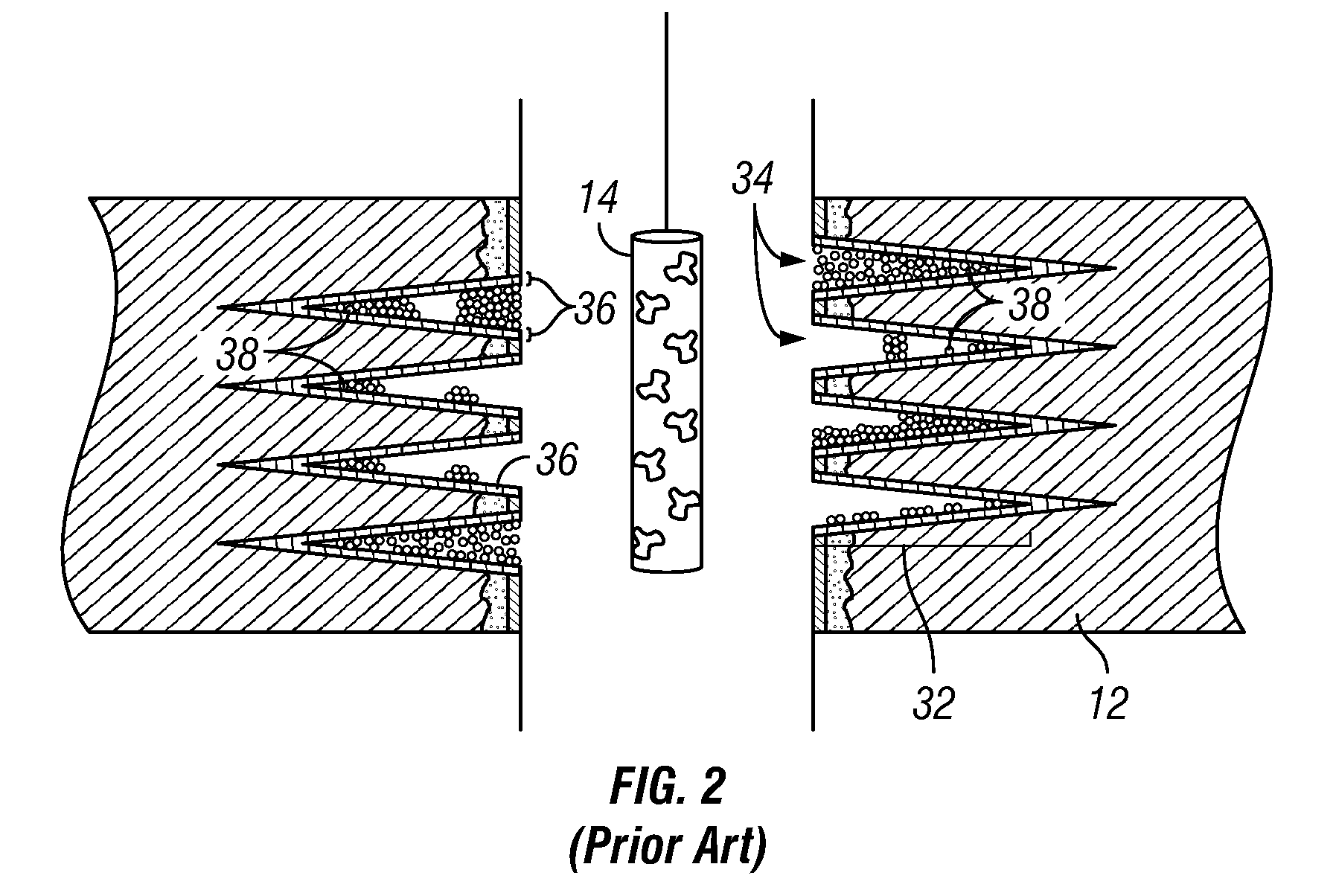

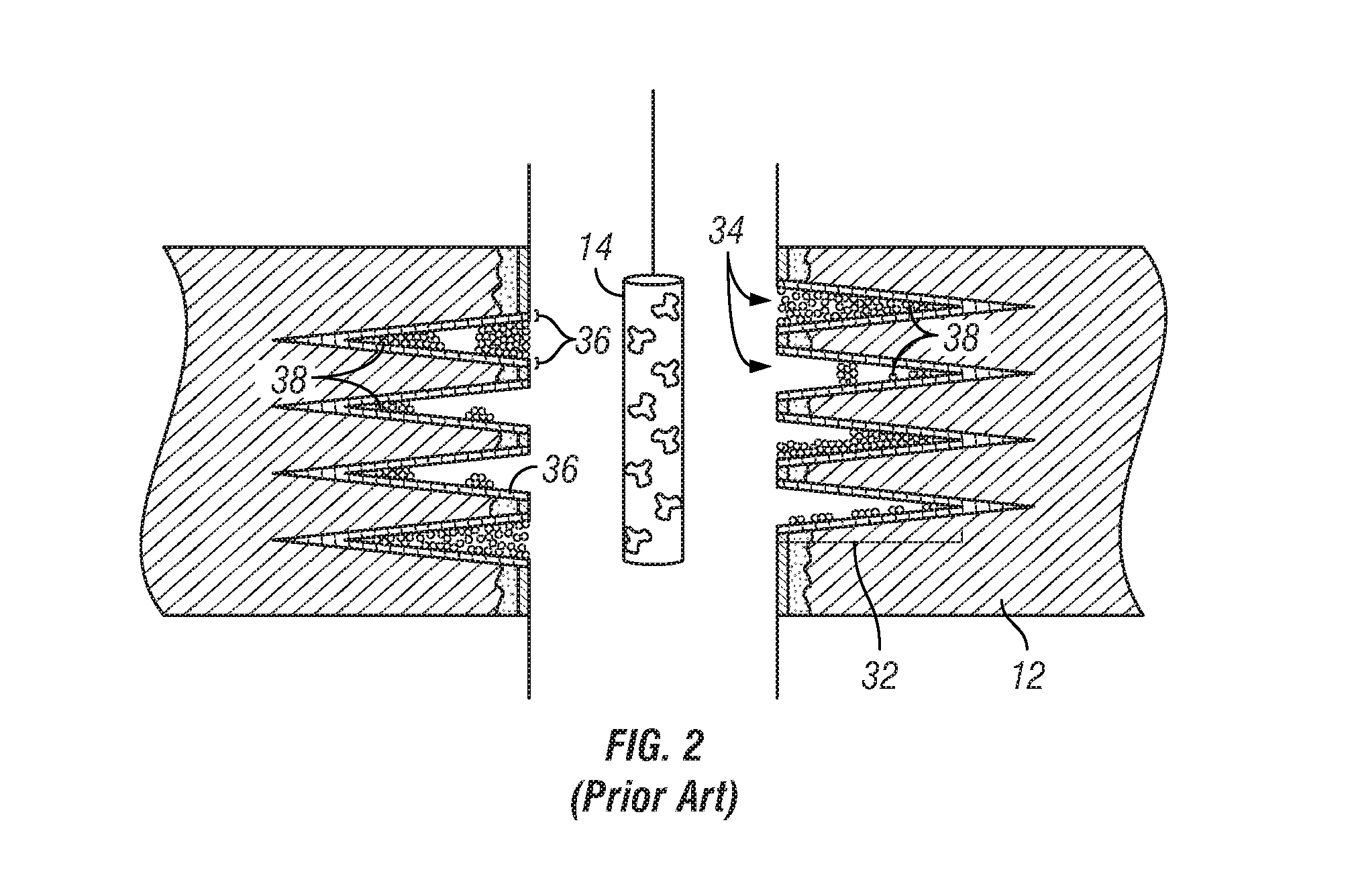

Method for the Enhancement of Injection Activities and Stimulation of Oil and Gas Production

InactiveUS20100132946A1Reduce fluid pressureIncrease the number ofExplosive chargesBlasting cartridgesDetonationCharge carrier

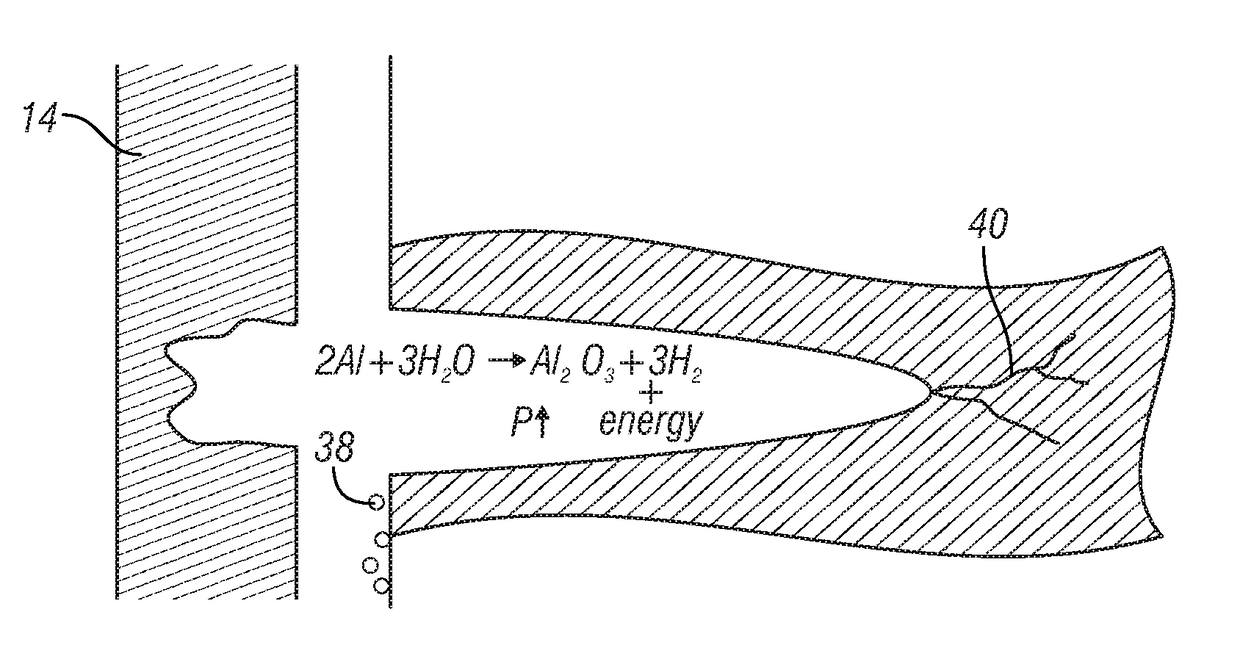

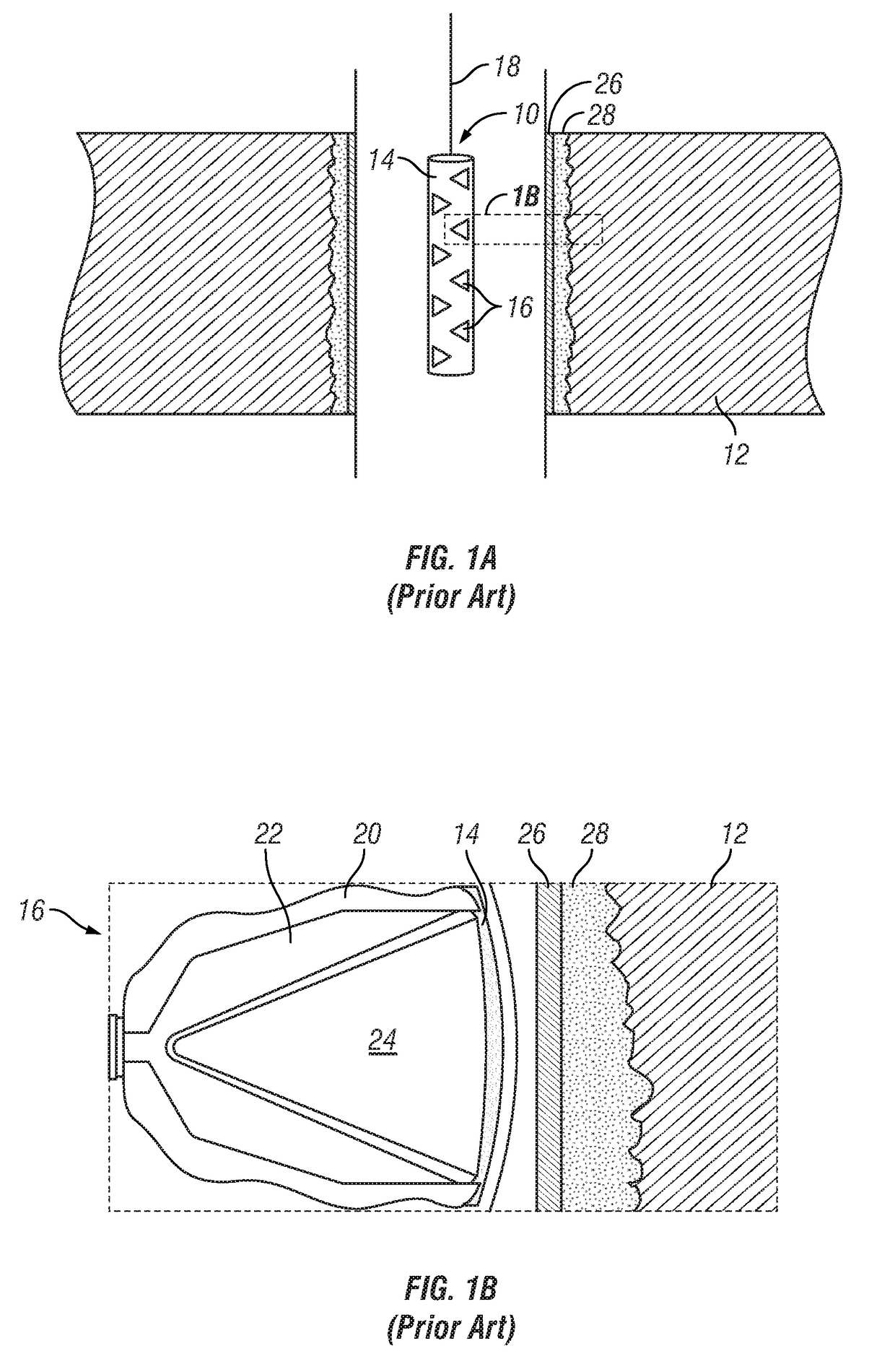

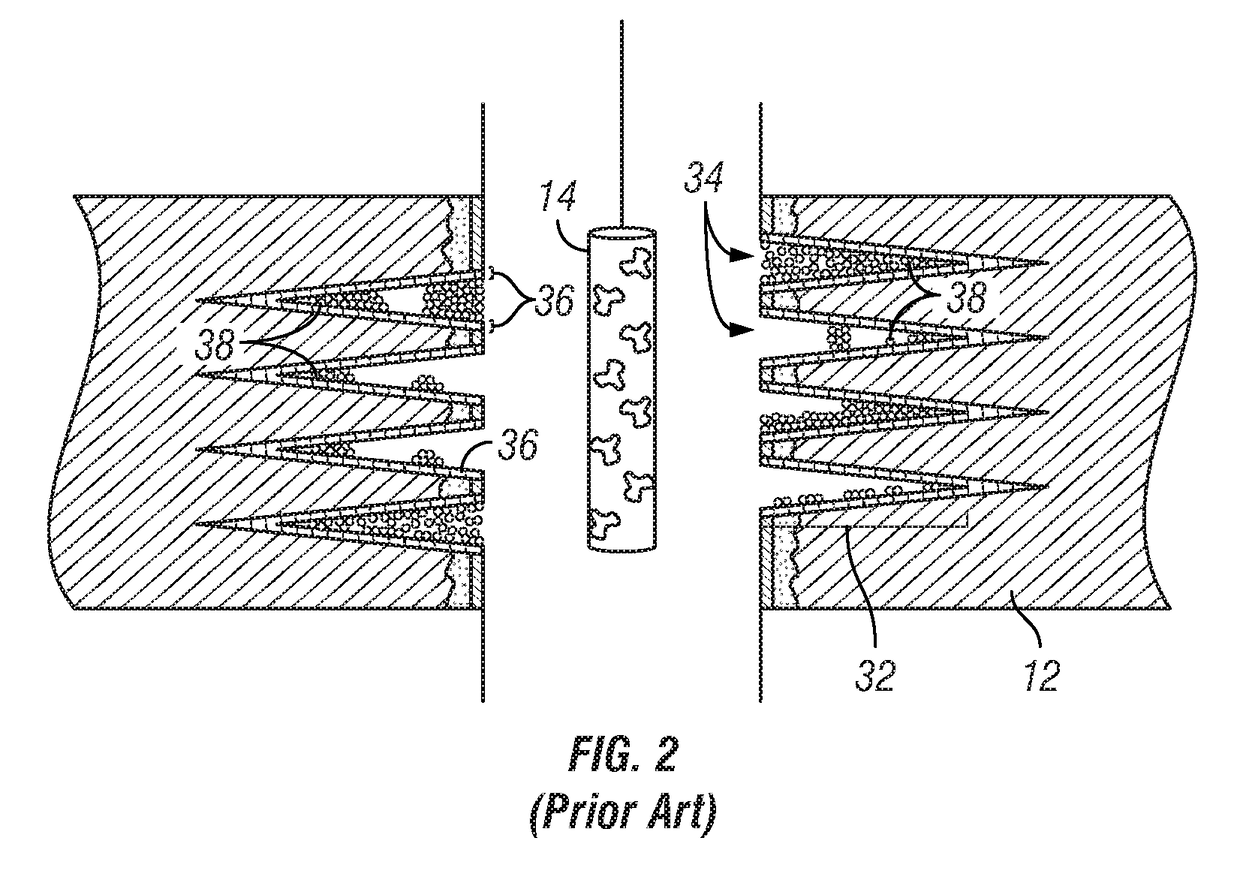

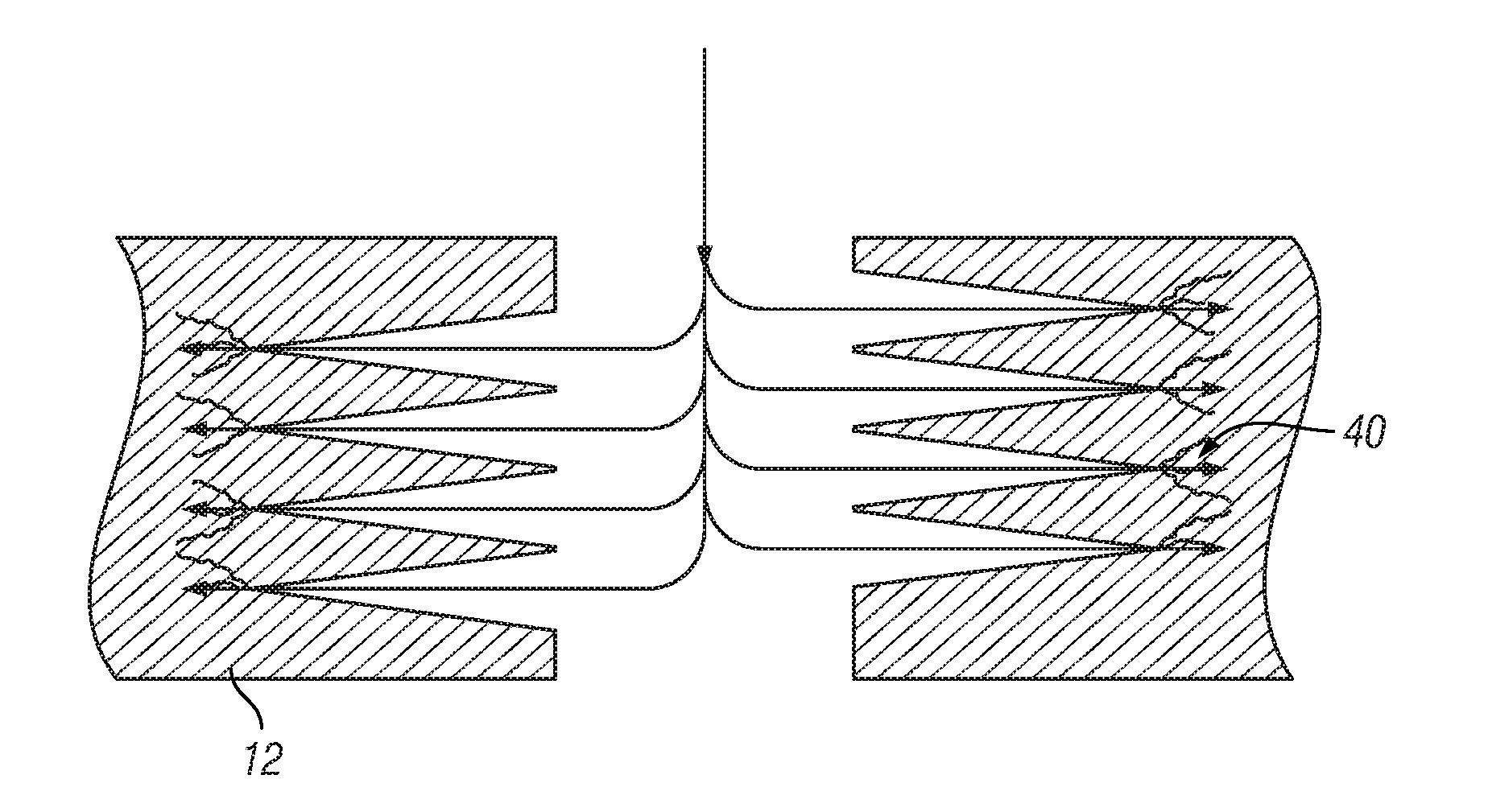

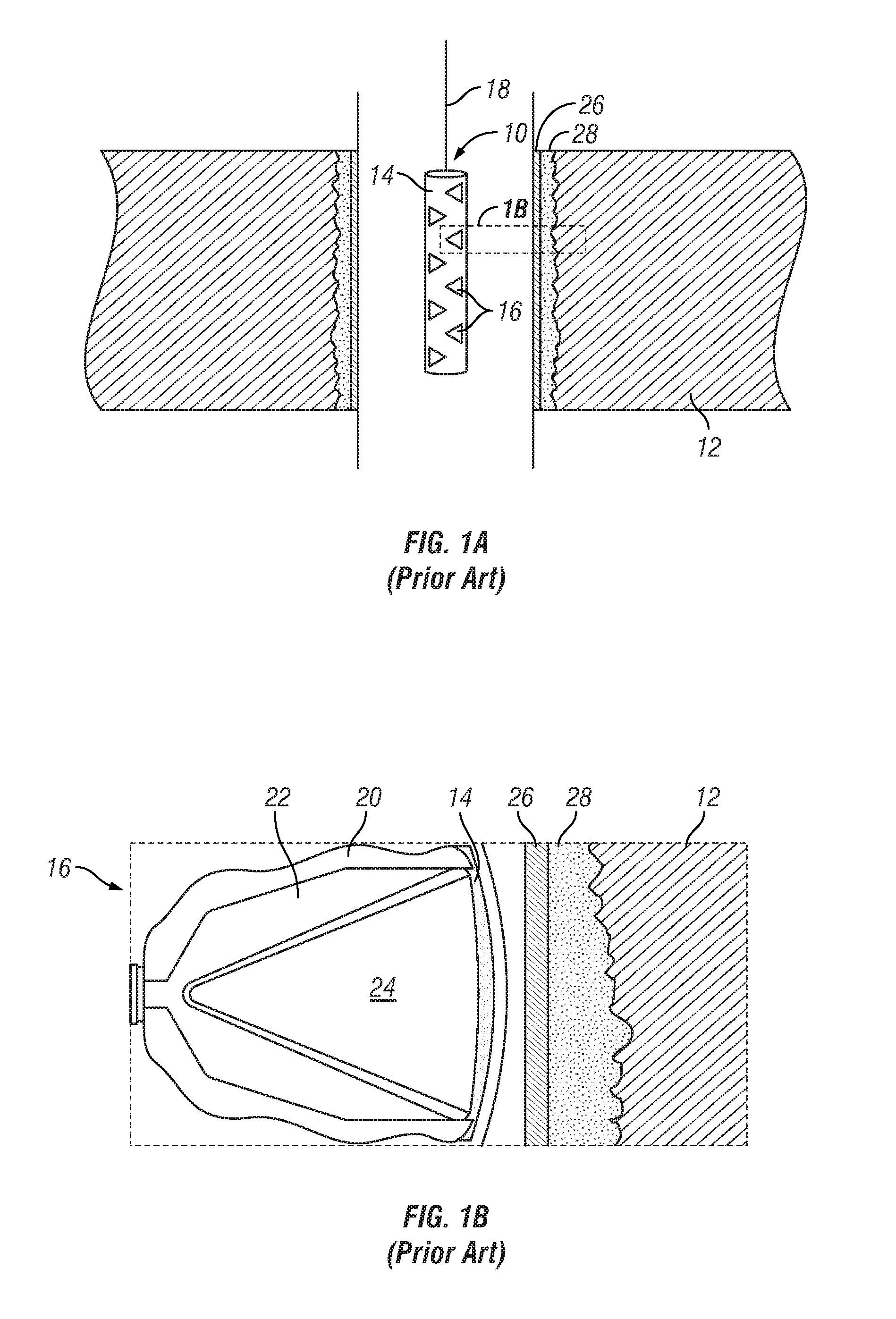

By removing material of low permeability from within and around a perforation tunnel and creating at least one fracture at the tip of a perforation tunnel, injection parameters and effects such as outflow rate and, in the case of multiple perforation tunnels benefiting from such cleanup, distribution of injected fluids along a wellbore are enhanced. Following detonation of a charge carrier, a second explosive event is triggered within a freshly made tunnel, thereby substantially eliminating a crushed zone and improving the geometry and quality (and length) of the tunnel. In addition, this action creates substantially debris-free tunnels and relieves the residual stress cage, resulting in perforation tunnels that are highly conducive to injection under fracturing conditions for disposal and stimulation purposes, and that promote even coverage of injected fluids across the perforated interval.

Owner:GEODYNAMICS

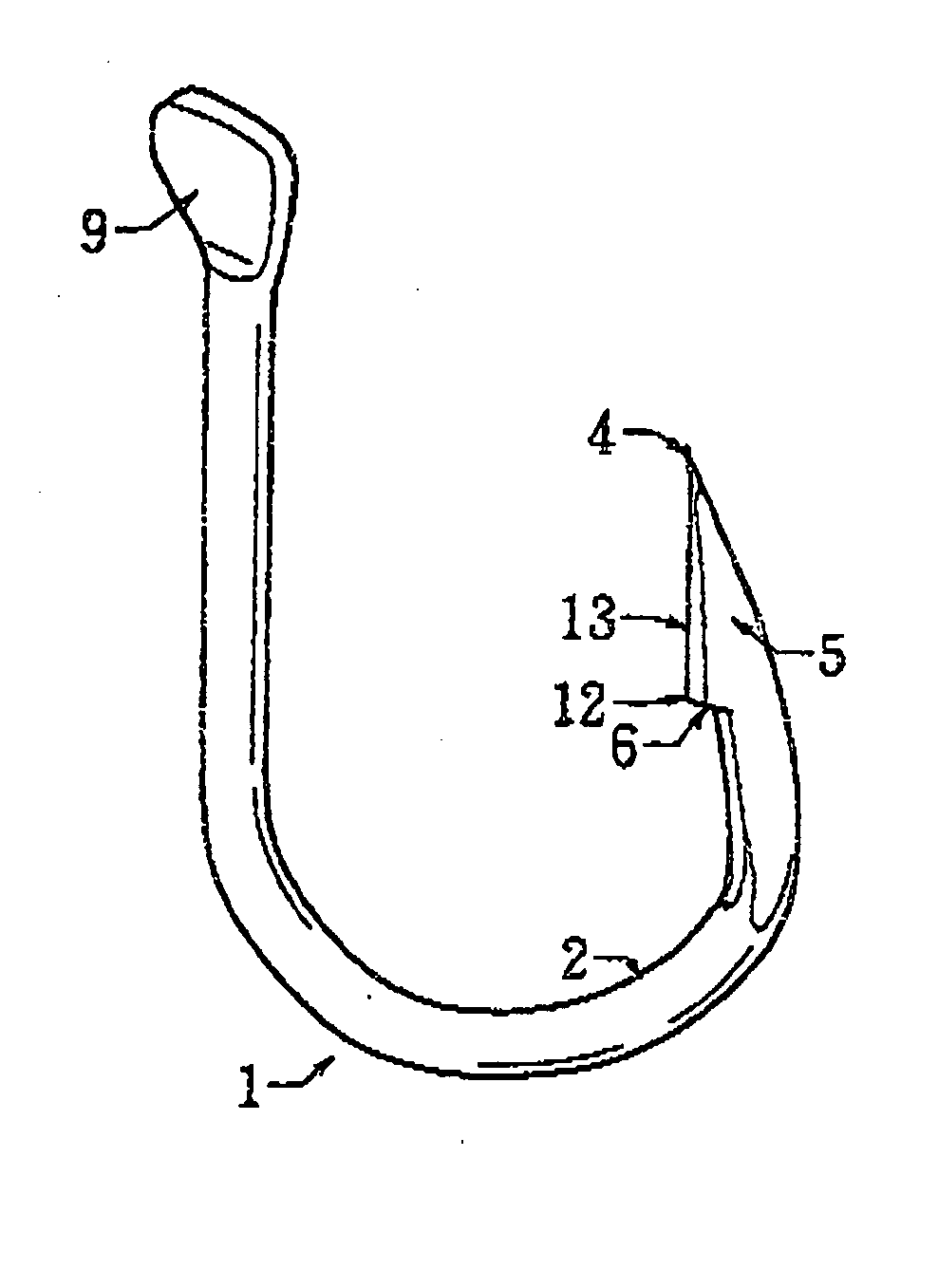

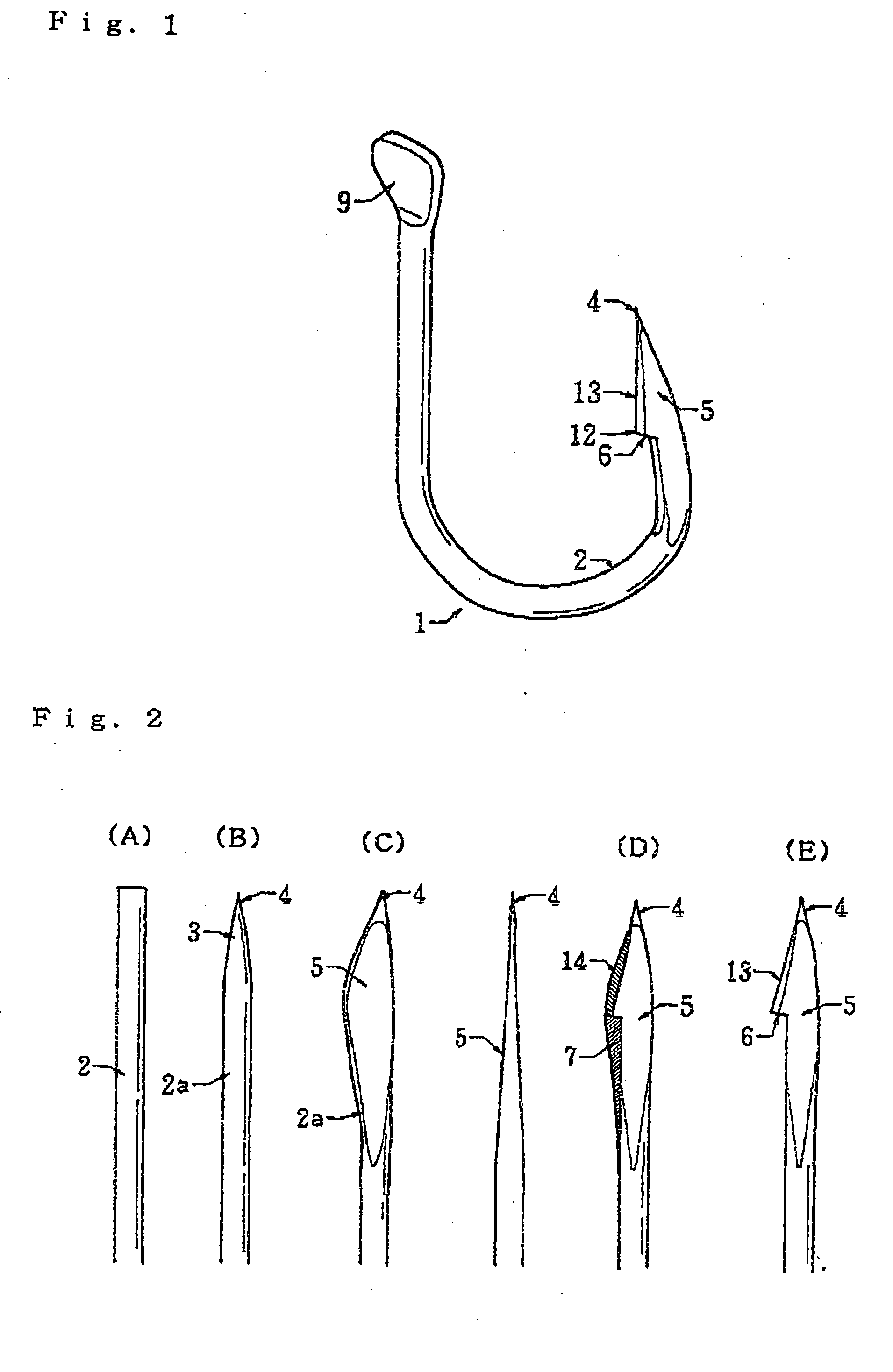

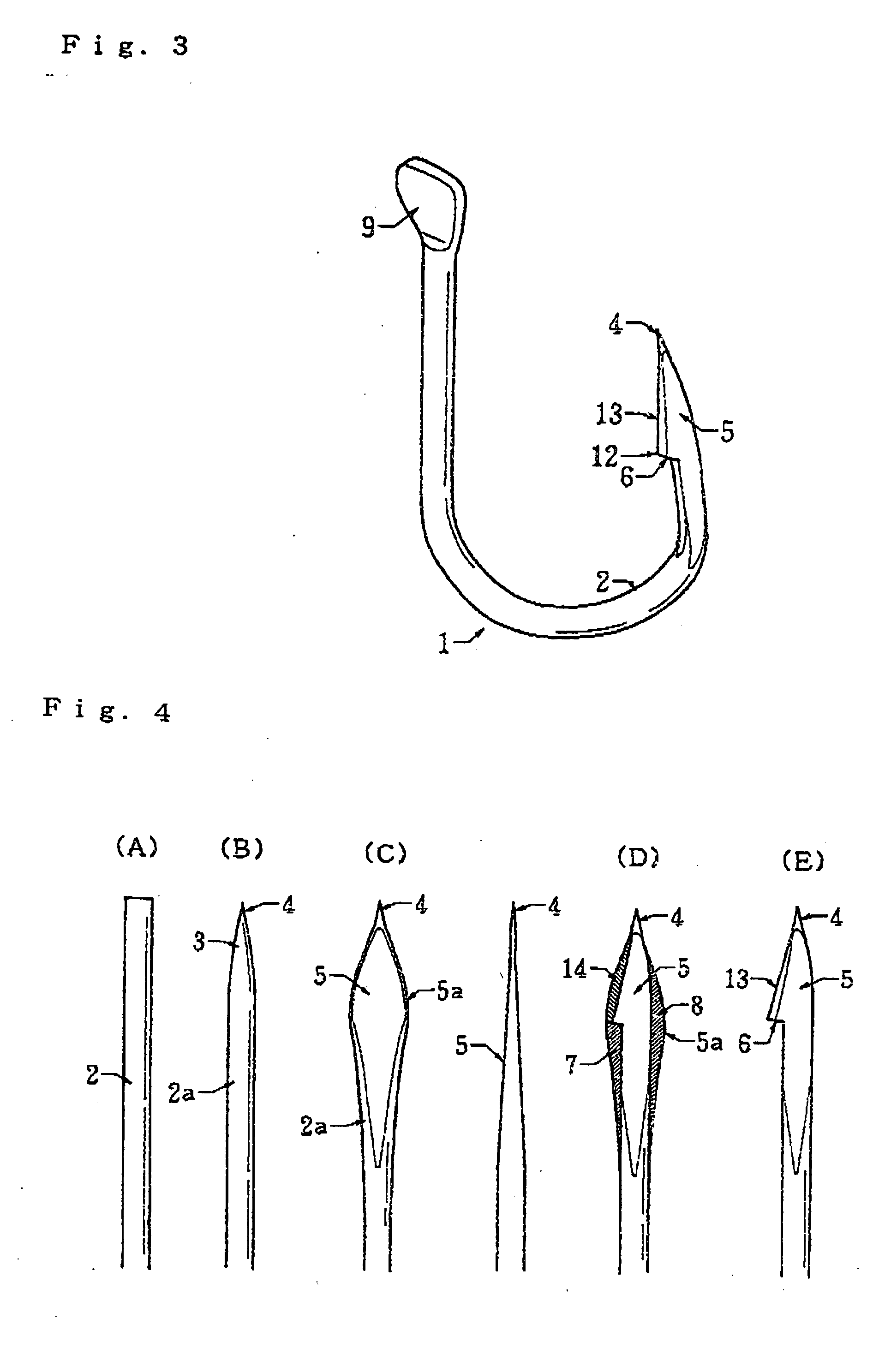

Method of manufacturing a fishhook, and a fishhook

InactiveUS20050076557A1Reduced strengthHigh strengthWire articlesFish-hooksMachining processMechanical engineering

An object of the present invention is to provide a readily manufacturing a fishhook having the barb whose angles and shapes can be freely changed correspondingly to purposes of use. A method of manufacturing a fishhook according to the present invention is characterized by: applying machining process for providing a sharpened part at a tip of wire to constitute a fishhook; and applying pressing process for making into a plate-like shape a part in continuation to the sharpened tip part; and further applying simultaneously or sequentially in free order machining process for forming a stepped part at one lateral side of the plate-like part and machining process for cutting out a swollen portion produced at the other lateral side of the plate-like part, whereby forming a point part or a fishhook.

Owner:GAMAKATSU CO LTD

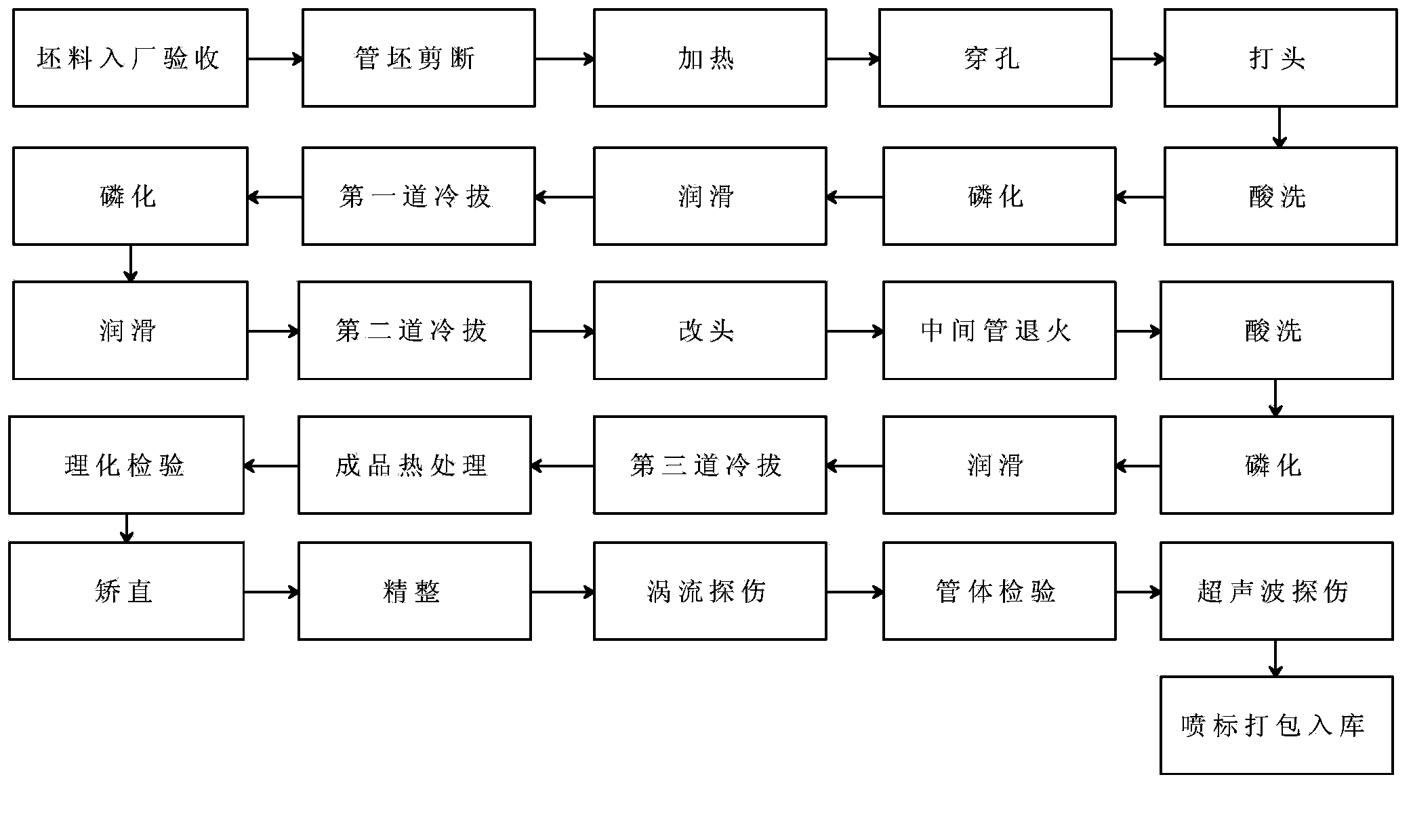

ND steel seamless steel pipe production process

The present invention relates to a steel pipe production process, particularly to a ND steel seamless steel pipe production process, which mainly comprises: 1) carrying out a peeling treatment on a round rod pipe billet; 2) heating the round rod pipe billet to a temperature of 1000-1100 DEG C, wherein the piercing temperature is 950-1050 DEG C; 3) carrying out acid washing, phosphorization and lubrication; 4) carrying out first cold drawing; 5) carrying out acid washing, phosphorization and lubrication; 6) carrying out second cold drawing; 7) carrying out acid washing, phosphorization and lubrication; 8) carrying out intermediate annealing on the pipe; 9) carrying out acid washing, phosphorization and lubrication; 10) carrying out third cold drawing; 11) carrying out a heat treatment on the finished product; and 12) carrying out physical and chemical inspection, straightening, finishing, eddy current testing, pipe inspection, ultrasonic testing, and steel pipe stenciling and warehousing. According to the present invention, the surface of the ND steel seamless steel pipe obtained by adopting the process does not have hot cracks, and the ND steel seamless steel pipe has good sulfuric acid dew point corrosion resistance.

Owner:CHANGZHOU SHENGTAK SEAMLESS STEEL TUBE

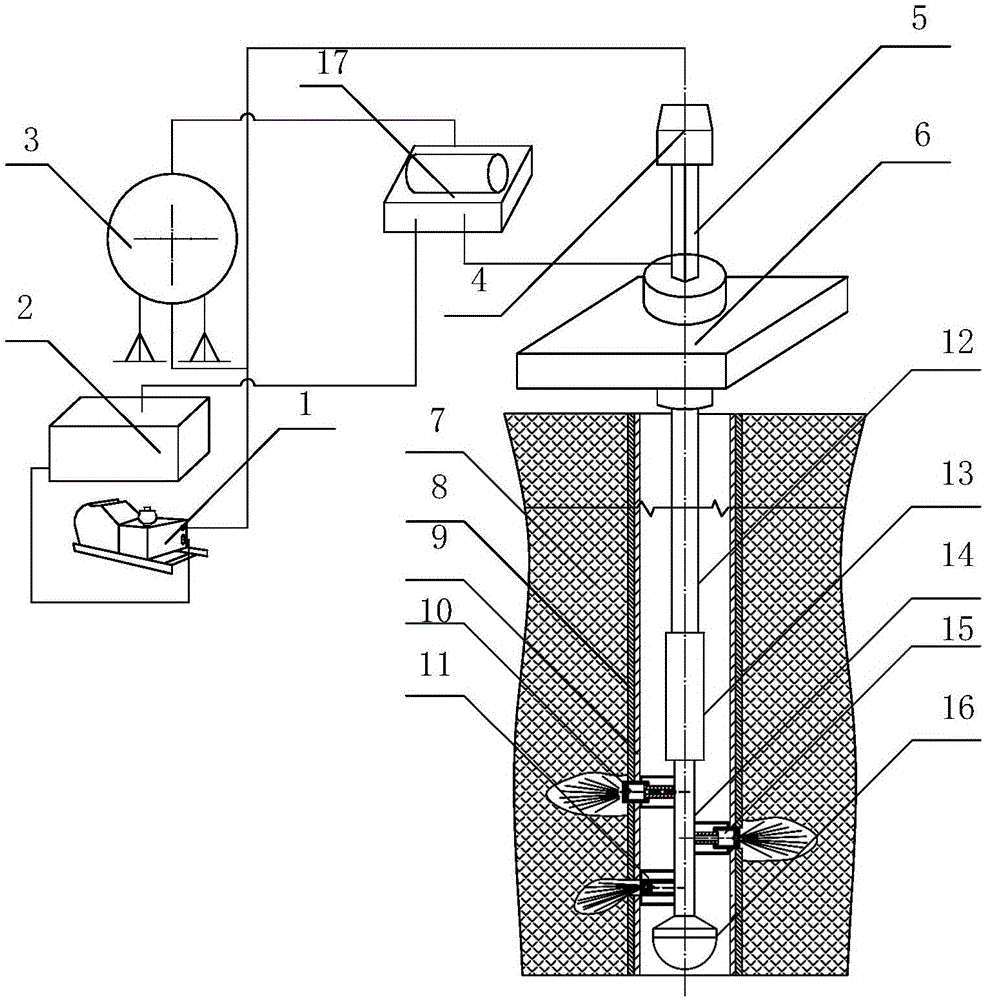

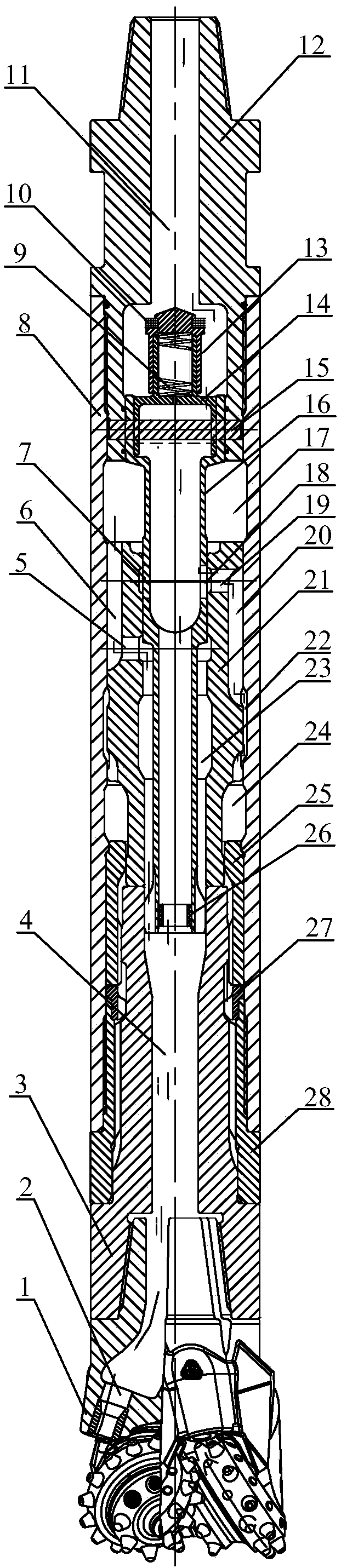

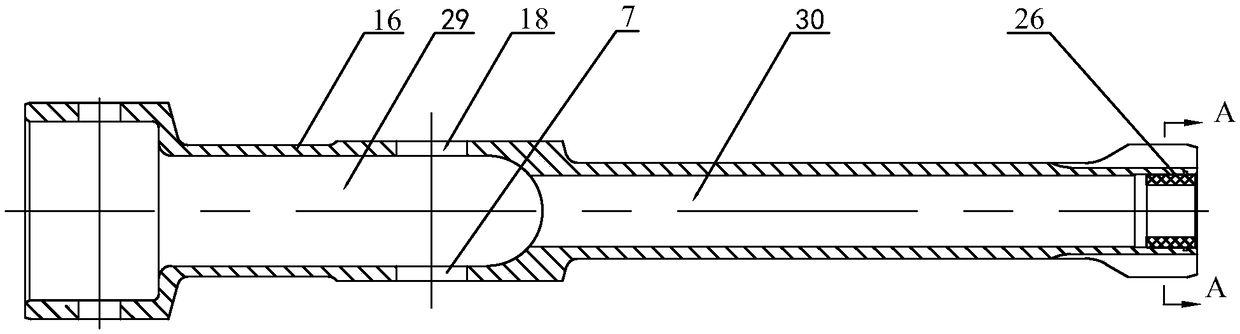

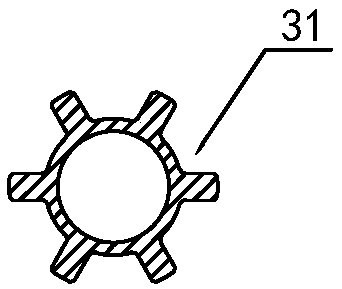

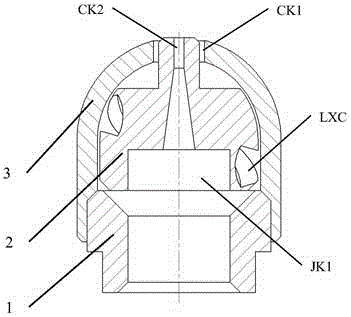

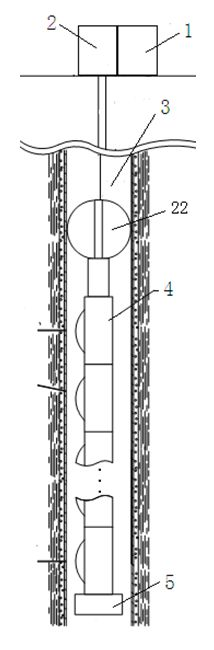

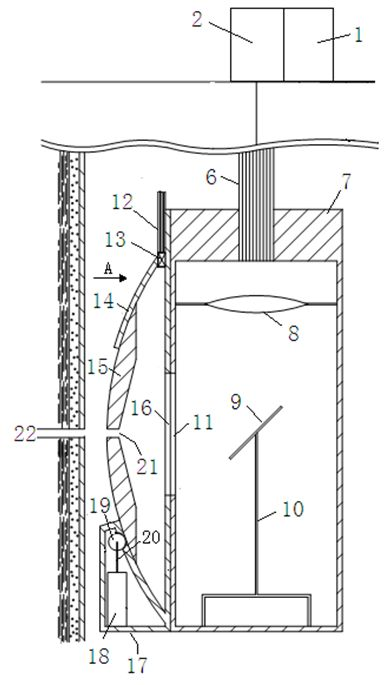

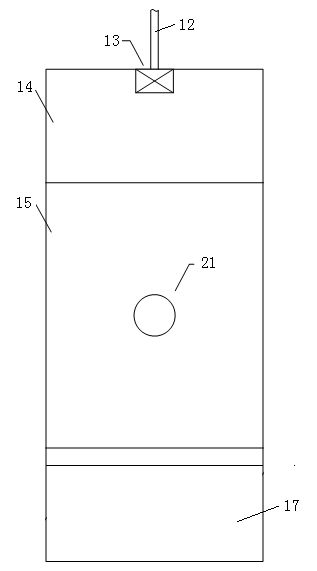

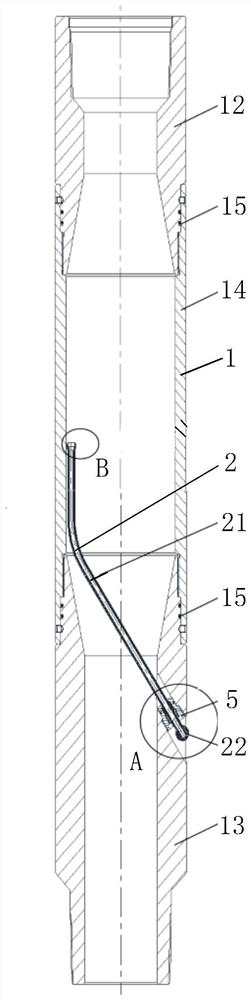

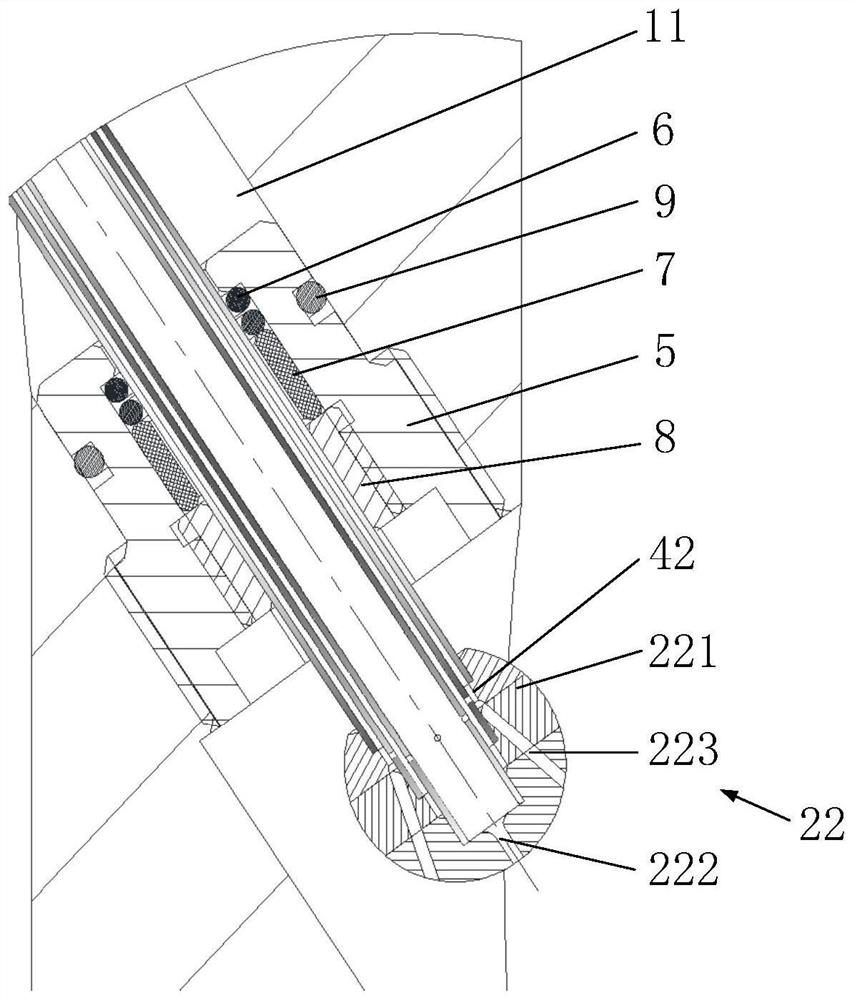

Downhole particle jet perforation device

The invention relates to the field of oil drilling and completion, in particular to a downhole particle jet perforation device comprising a particle injection tank, a perforated short circuit, a retractable perforating nozzle, a fixed perforating nozzle, and a pilot drill bit. The high pressure mud and particles are mixed by the particle injection tank to reach the perforation short circuit, ejected from the retractable perforating nozzle and the fixed perforating nozzle at an adjustable angle to quickly penetrate the casing, the cement ring and the formation rock, and the pilot drill bit is mounted on the lower part of the perforation short circuit. The retractable perforating nozzle can achieve large depth perforation, and the perforation depth can be adjusted, the position, type and quantity of the retractable perforating nozzle and the fixed perforating nozzle can be selected according to the actual needs of the site. The downhole particle jet perforation device can effectively improve the efficiency of the downhole perforation operation, increase the perforation depth and the working area, enhance the fluid flow capacity of the stratum, and effectively improve the reservoir productivity.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

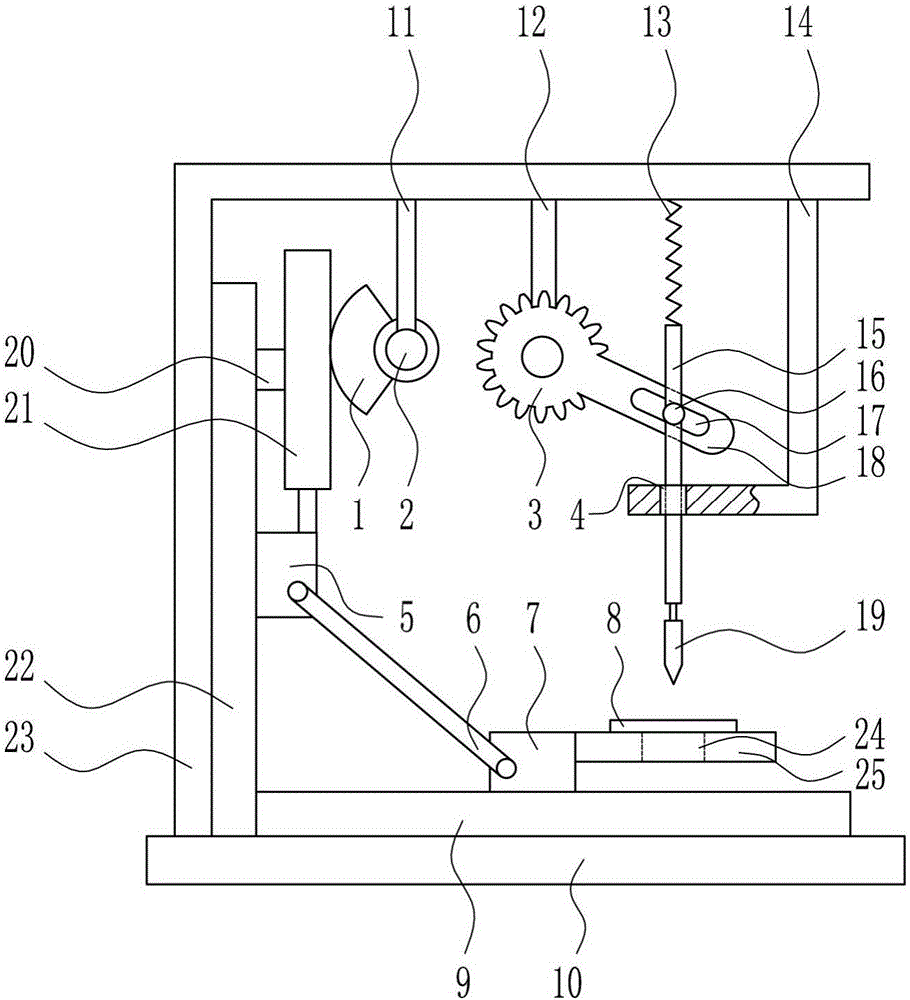

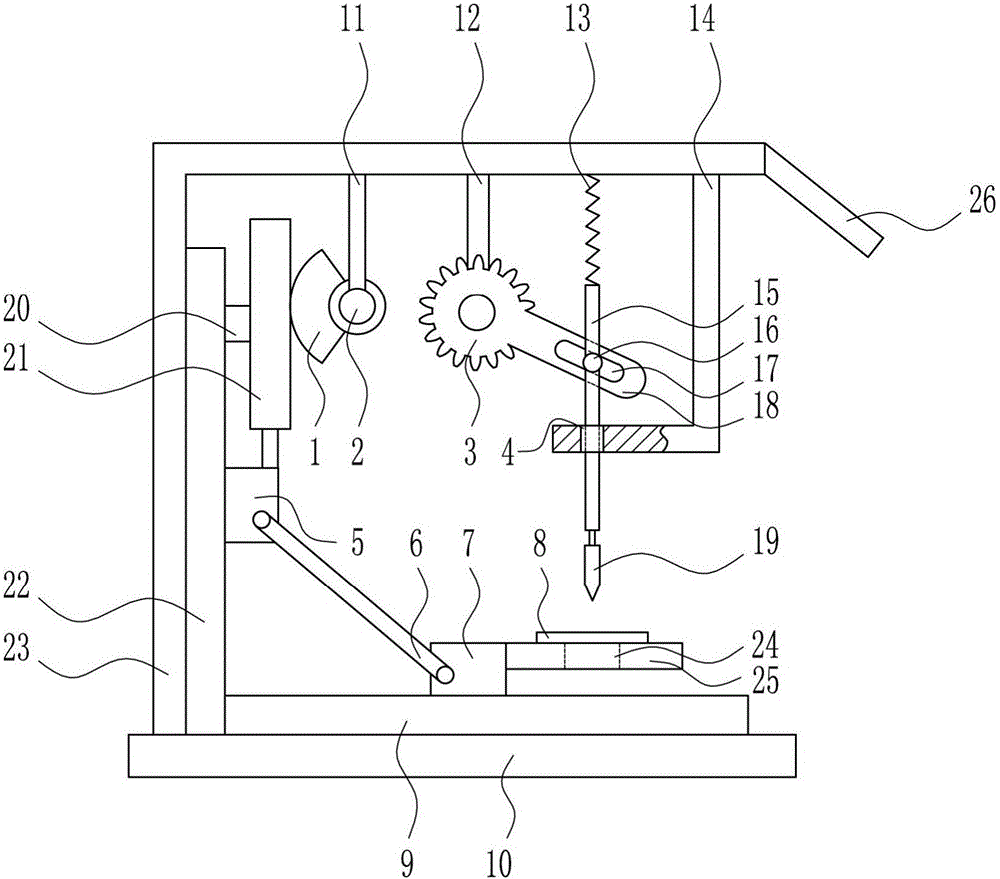

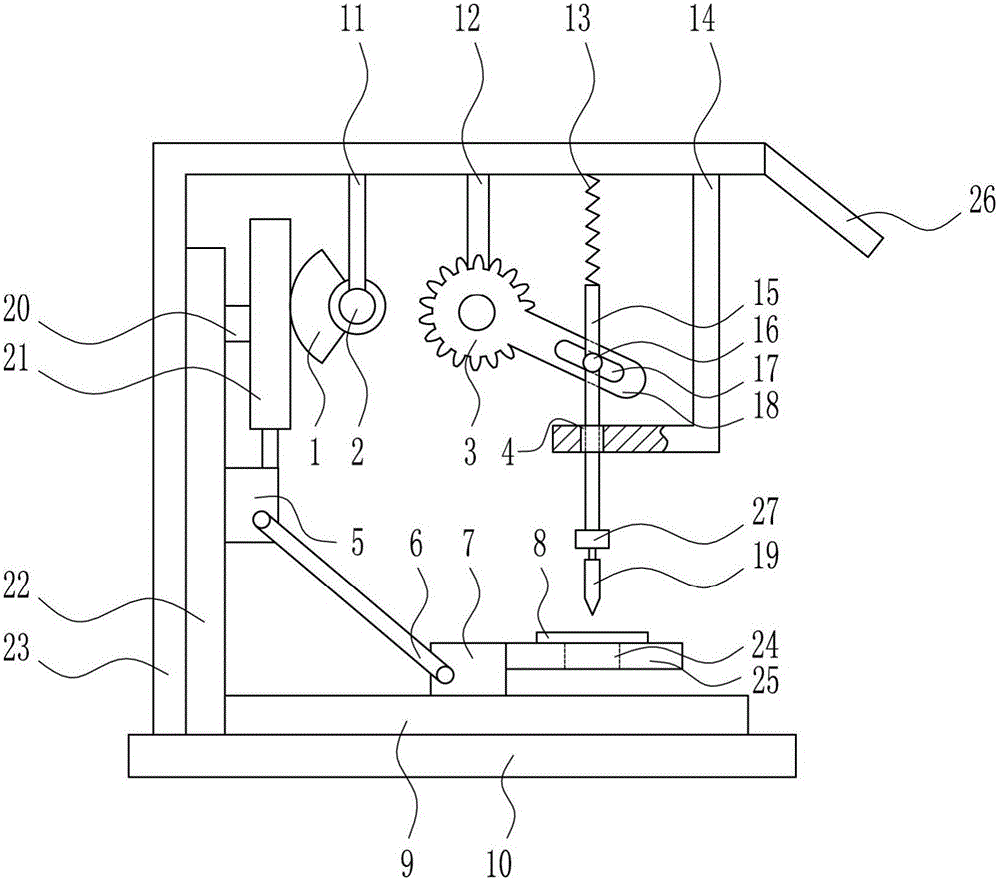

Fast hole punching device for shoe making

ActiveCN106346553AHigh speedImprove perforation efficiencyShoemaking devicesMetal working apparatusHigh rateEngineering

The invention relates to a hole punching device, particularly to a fast hole punching device for shoe making. The to-be-solved technical problem in the invention is to provide a highly efficient, fast hole punching device for shoe making. To solve the above technical problem, the present invention provides a fast hole punching device for shoe making. The device includes a fan-shaped toothed wheel, a first rotating motor, a first toothed wheel, a first sliding block, a first swinging rod, a second sliding block, a second sliding track, a base plate, a first supporting rod, a second supporting rod, a spring, a guiding board, a lifting rod, a sliding shaft, a second swinging rod, a drilling rod, a third sliding block, a rack, a first sliding track, a support and a placement board; from the left to the right the top part of the base pate is installed in sequence the support, the first sliding track and the second sliding track, with the first sliding track located on the left side of the support inside. The present invention achieves the effects of high rate of hole punching, through starting the first rotating motor and rotating backwards, to move the fan-shaped toothed wheel to rotate backwards. The fan-shaped toothed wheel respectively touches intermittently with the rack and the first toothed wheel.

Owner:德州金博机床附件有限公司

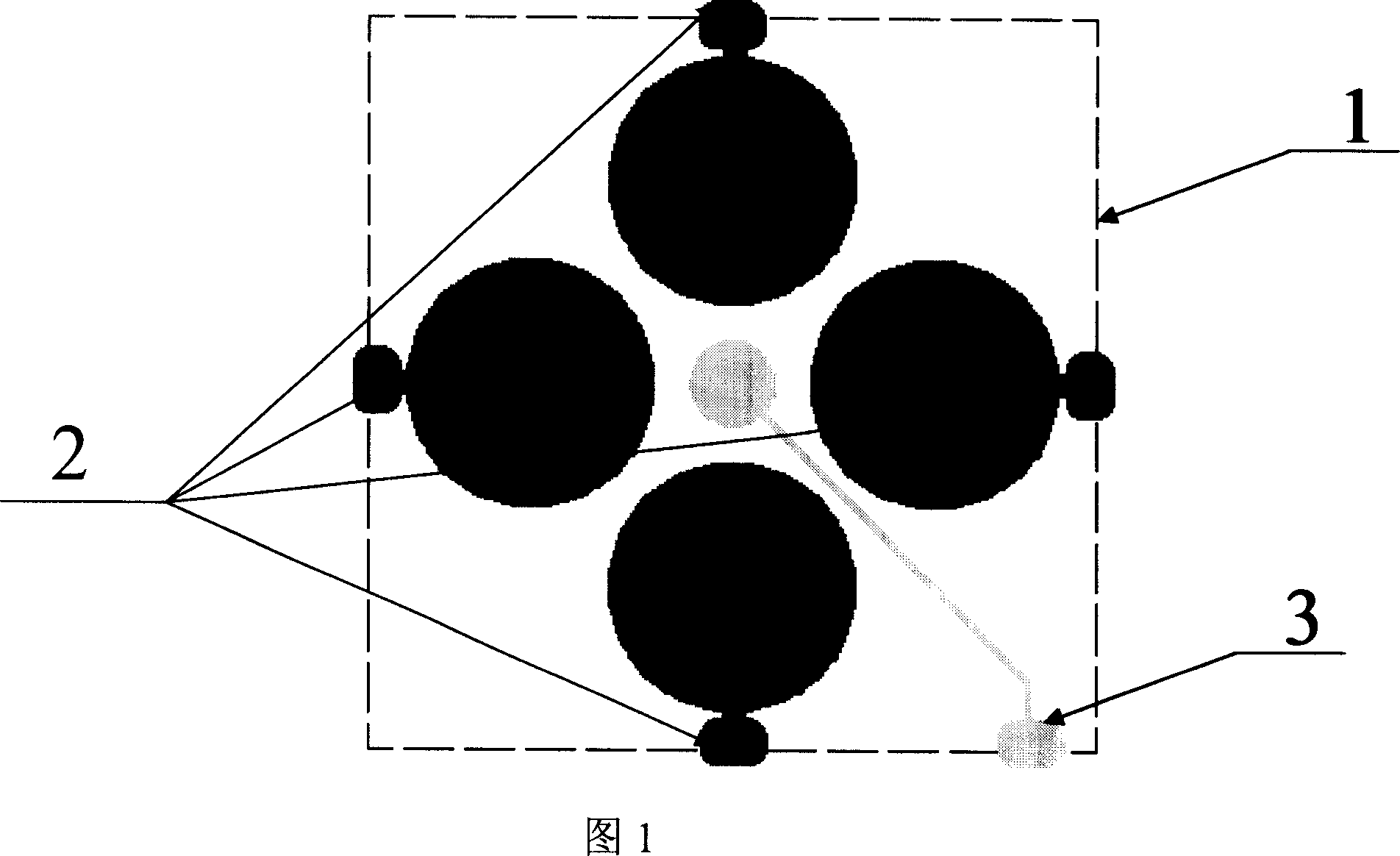

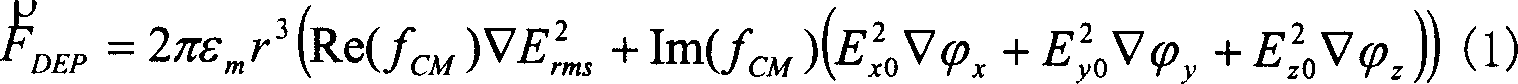

Method for promoting electroporation efficiency utilizing dielectrophoresis for assisting cell positioning

InactiveCN1995361AImprove perforation efficiencyOther foreign material introduction processesElectrical/wave energy microorganism treatmentElectricityDielectric

The invention discloses an improving method of electric punching efficiency located by dielectric electrophoretic auxiliary cell, which is characterized by the following: locating the cell; exerting electricity to pierce cell; improving the punching efficiency; controlling electric field to operate cell; integrating on the micro-flow biological chip; realizing full-automatic cell operation and electric punching operation.

Owner:CAPITALBIO CORP +1

High-alloy steel pipe piercing plugand manufacturing method thereof

InactiveCN104988416AHigh temperature strengthImprove toughnessMandrelsSolid state diffusion coatingUltimate tensile strengthToughness

The invention discloses a high-alloy steel pipe piercing plug. The high-alloy steel pipe piercing plug comprises the following chemical elements in percentage by mass: 0.25-0.35% of C, 0.35-1.5% of Si, 0.35-1.0% of Mn, 1.0-3.0% of Cr, 2.0-3.0% of Mo, 1.0-2.0% of Ni, 1.5-2.5% of W, 0.2-1.0% of V, and the balance of Fe and inevitable impurities; the surface of the high-alloy steel pipe piercing plug has an oxide film; and the outer surface of the high-alloy steel pipe piercing plug has a screw way. The invention further discloses a manufacturing method of the piercing plug; and the manufacturing method comprises the step of: manufacturing of a plug blank; annealing; machining of the steel pipe piercing plug and machining of the screw way on the surface of the plug; and formation of the oxide film through the surface high-temperature oxidation treatment. The piercing plug is higher in high-temperature strength and better in toughness. The oxide film on the surface of the piercing plug is excellent in adhesive force.

Owner:BAOSHAN IRON & STEEL CO LTD

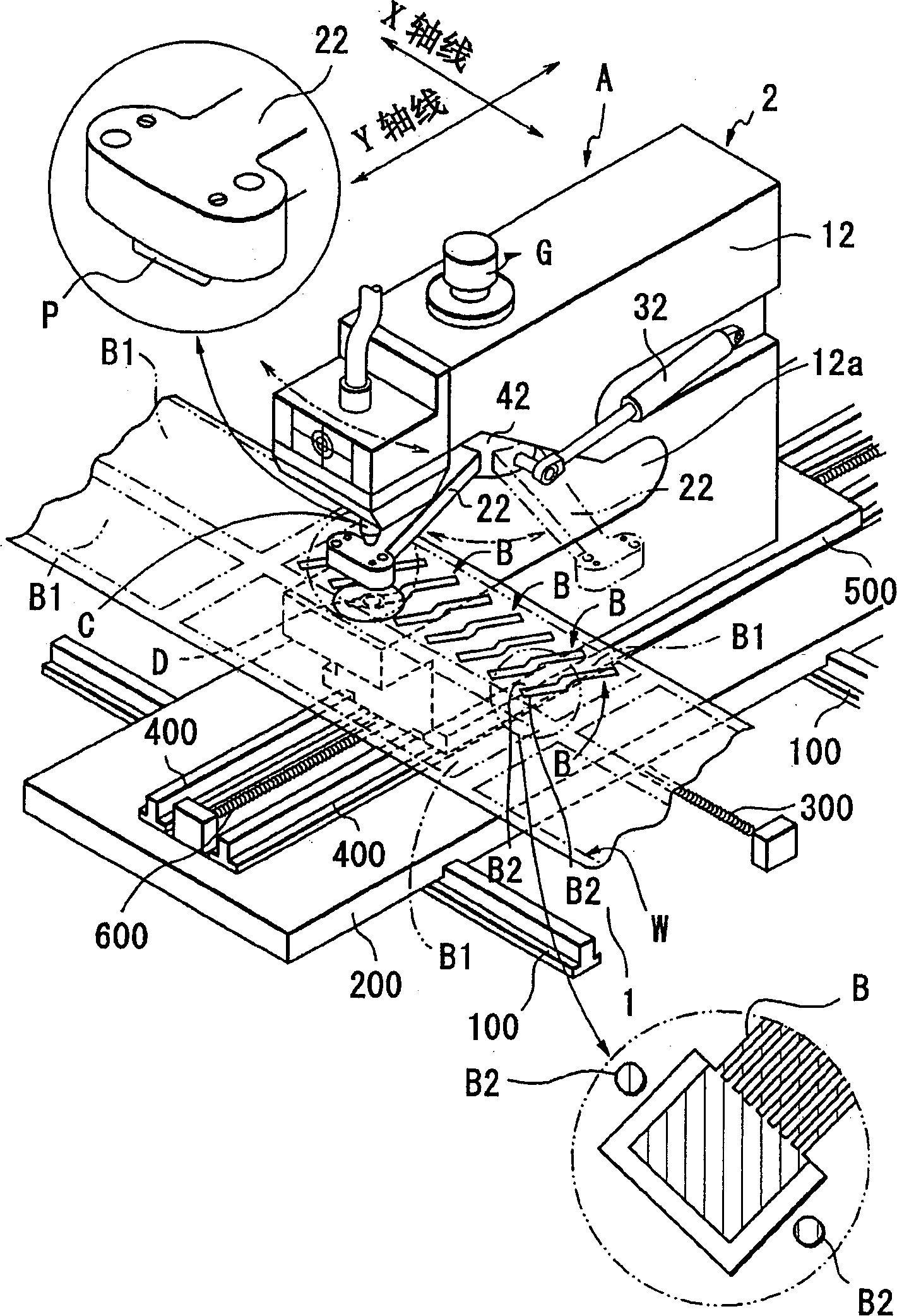

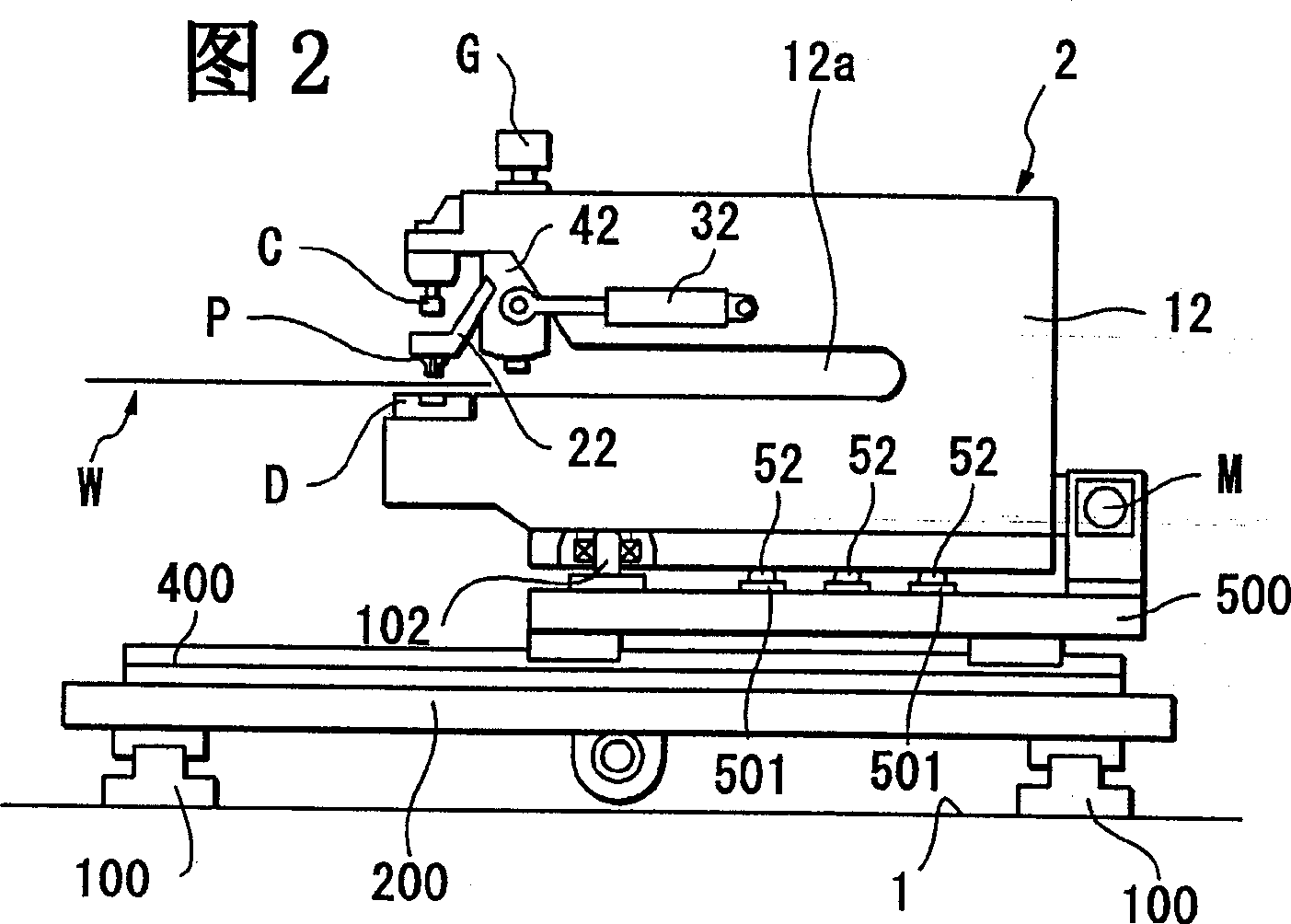

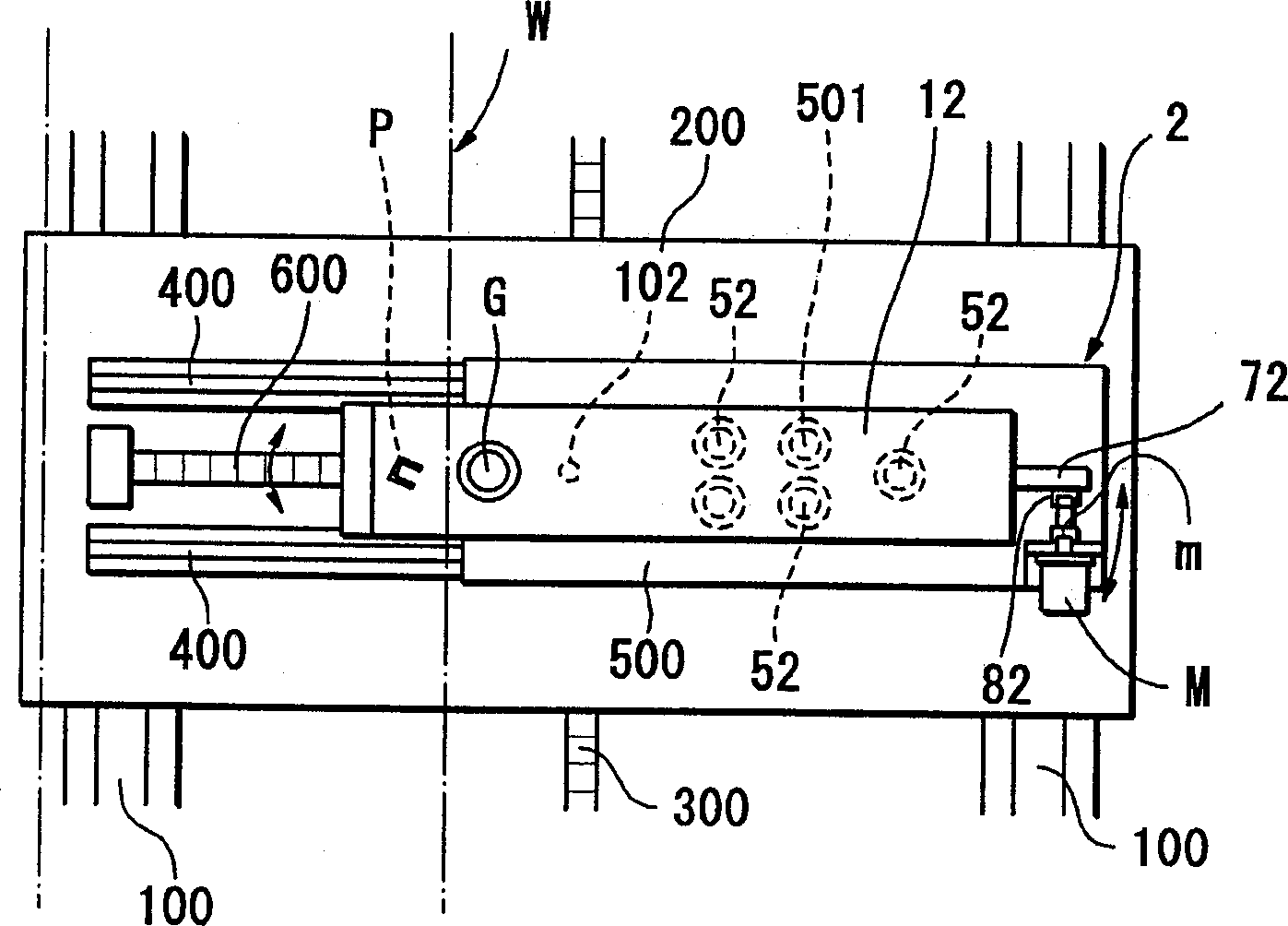

Punching device for workpiece with flexibility

InactiveCN1404970ACorrect misalignmentEasy to punchMetal working apparatusPunchingImaging processing

The invention provides a punching device for a flexible workpiece capable of punching a flexible workpiece with high precision even if the position of the noncircular part of the flexible workpiece to be punched is displaced in a theta direction by more than a predetermined angle. While the coordinate values of the centers of reference points B2 and B2 whose images are picked up by a camera C and subjected to image processing (binarization) and image data subjected to graying process are being varied and displaced relative to the coordinate values of the centers of the reference points previously inputted to an image processor as teaching data, and relative to the image data of the outer periphery of an end of a product B subjected to graying process, a punching part 2 is controlled to move in the theta direction and in the directions of X and Y axes, or the workpiece is controlled to move in the theta direction as the punching part is controlled to move in the directions of the X and Y axes, whereby the coordinate values are matched for punching.

Owner:UHT CORP

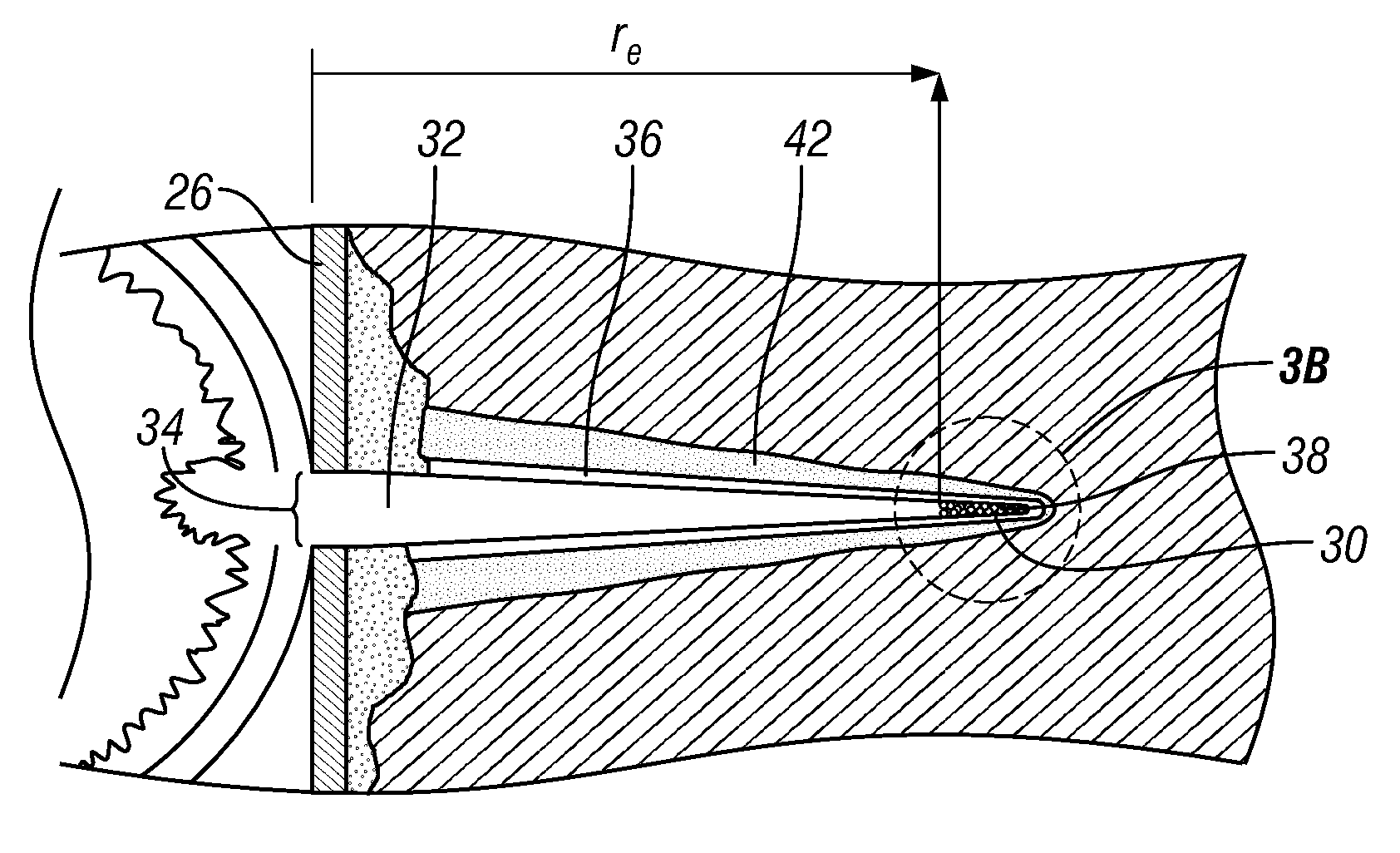

Method for the enhancement of injection activities and stimulation of oil and gas production

ActiveUS9644460B2Optimize allocationDetermine effectivenessExplosive chargesBlasting cartridgesDetonationPetroleum

By removing material of low permeability from within and around a perforation tunnel and creating at least one fracture at the tip of a perforation tunnel, injection parameters and effects such as outflow rate and, in the case of multiple perforation tunnels benefiting from such cleanup, distribution of injected fluids along a wellbore are enhanced. Following detonation of a charge carrier, a second explosive event is triggered within a freshly made tunnel, thereby substantially eliminating a crushed zone and improving the geometry and quality (and length) of the tunnel. In addition, this action creates substantially debris-free tunnels and relieves the residual stress cage, resulting in perforation tunnels that are highly conducive to injection under fracturing conditions for disposal and stimulation purposes, and that promote even coverage of injected fluids across the perforated interval.

Owner:WELLS FARGO BANK NAT ASSOC +1

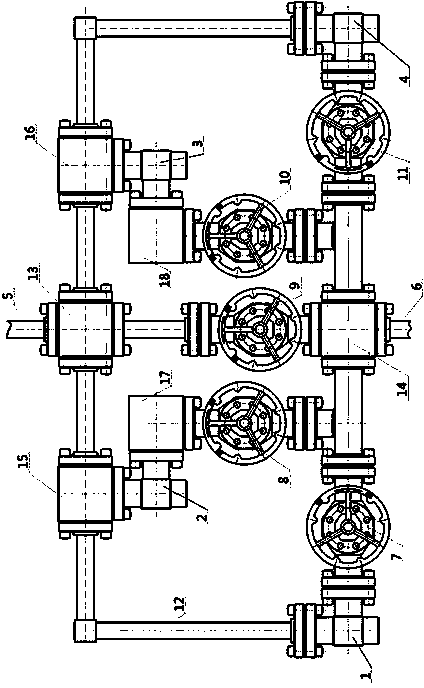

Hydraulic sand jet perforation choke manifold

ActiveCN104405346AReduce erosionEasy to replaceFluid removalWell/borehole valve arrangementsEngineeringHigh pressure

The invention discloses a hydraulic sand jet perforation choke manifold. The hydraulic sand jet perforation choke manifold comprises a first pipeline cross and a second pipeline cross, and a first flat gate valve, a third flat gate valve and a fifth flat gate valve are arranged between the first pipeline cross and second pipeline cross in parallel; the first flat gate valve and the fifth flat gate valve are located at two sides of the third flat gate valve; a first fixed throttle valve is arranged between the first flat gate valve and one horizontal end of the first pipeline cross, and a fourth fixed throttle valve is arranged between the fifth flat gate valve and the other horizontal end of the first pipeline cross. The hydraulic sand jet perforation choke manifold is capable of precisely controlling the casing pressure in the hydraulic sand jet perforation process so as to avoid the pipeline crack due to over-high pressure or the stratum sand spray or perforation tool failure due to low pressure, the fixed throttle valves are good in erosion wearing resistance and convenient to change, the cost is saved, and the working efficiency is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for the Enhancement of Injection Activities and Stimulation of Oil and Gas Production

ActiveUS20160341018A1Optimize allocationDetermine effectivenessExplosive chargesBlasting cartridgesDetonationCharge carrier

By removing material of low permeability from within and around a perforation tunnel and creating at least one fracture at the tip of a perforation tunnel, injection parameters and effects such as outflow rate and, in the case of multiple perforation tunnels benefiting from such cleanup, distribution of injected fluids along a wellbore are enhanced. Following detonation of a charge carrier, a second explosive event is triggered within a freshly made tunnel, thereby substantially eliminating a crushed zone and improving the geometry and quality (and length) of the tunnel. In addition, this action creates substantially debris-free tunnels and relieves the residual stress cage, resulting in perforation tunnels that are highly conducive to injection under fracturing conditions for disposal and stimulation purposes, and that promote even coverage of injected fluids across the perforated interval.

Owner:WELLS FARGO BANK NAT ASSOC +1

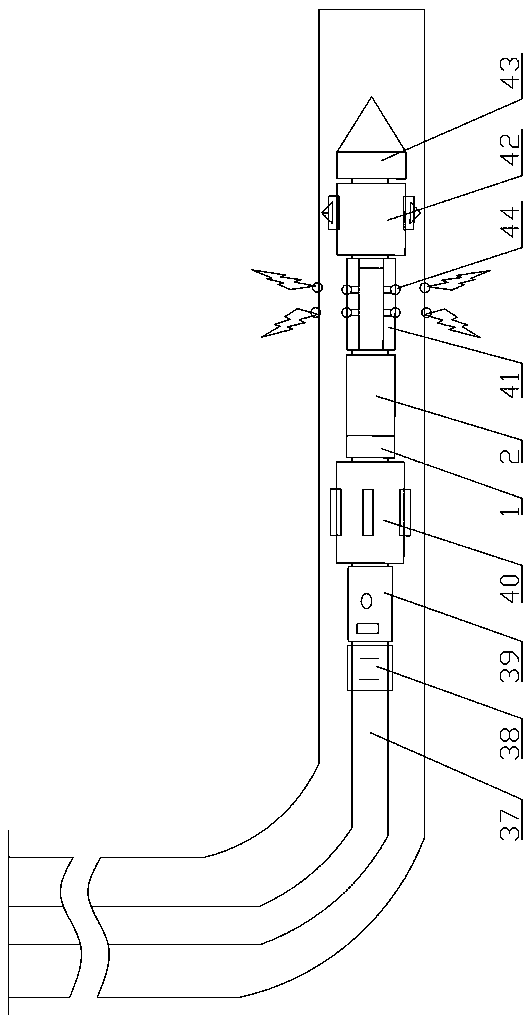

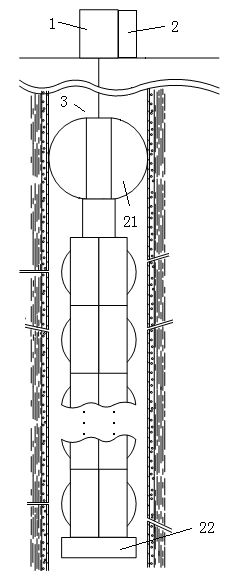

Pulse horizontal well volume fracturing device and horizontal well volume fracturing method

ActiveCN111577234ARapid crackingEnergizeGeothermal energy generationFluid removalHorizontal wellsCoiled tubing

The invention relates to the technical field of oil and gas field exploitation, and provides a pulse horizontal well volume fracturing device and a horizontal well volume fracturing method. The devicecomprises a coiled tubing, a horizontal section of the coiled tubing is sequentially connected with a connector, a motor head assembly, a centralizer, a pulse tool, an ejector, a positioner and a guide shoe, and the pulse tool, the ejector, the positioner and the guide shoe can generate a high-pressure fluid body. The method comprises the following step of (1) drilling down and determining a perforation position. According to the device and the method, the structure is reasonable and compact, the use is facilitated, through the arrangement, the disassembled and assembled can be quickly achieved, the construction cost can be reduced, a pulse fluid body can be generated by the pulse tool, the pulse fluid body can improve the perforation efficiency during volume fracturing through a nozzle,the generation of micro-cracks in a perforation hole eyelet can be increased, the energy increasing in the perforation hole eyelet is realized, cracks is quickly formed on stratum, the construction pressure is reduced, and the device and the method solve the problem that a traditional volume fracturing reforming technology is relatively limited in a method of reforming a target layer section whenformation fracture pressure is high.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

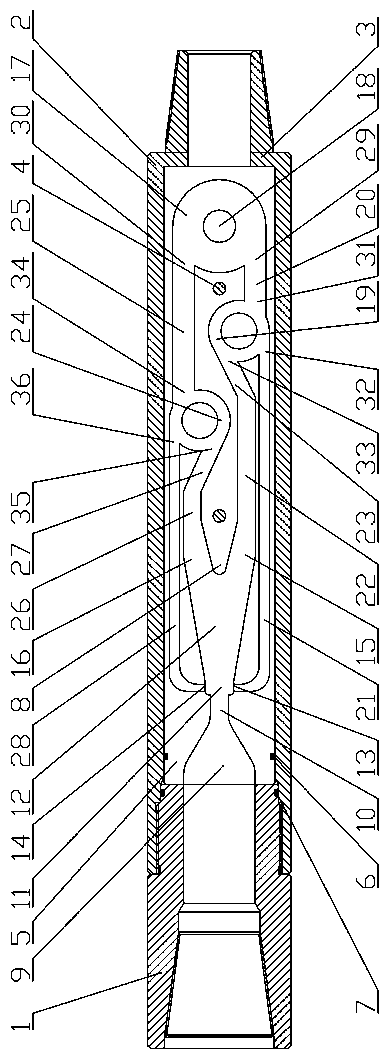

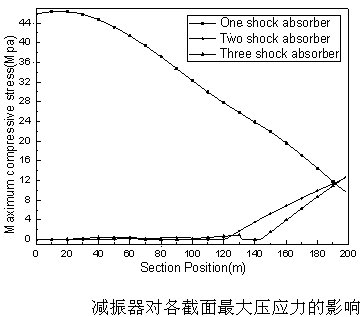

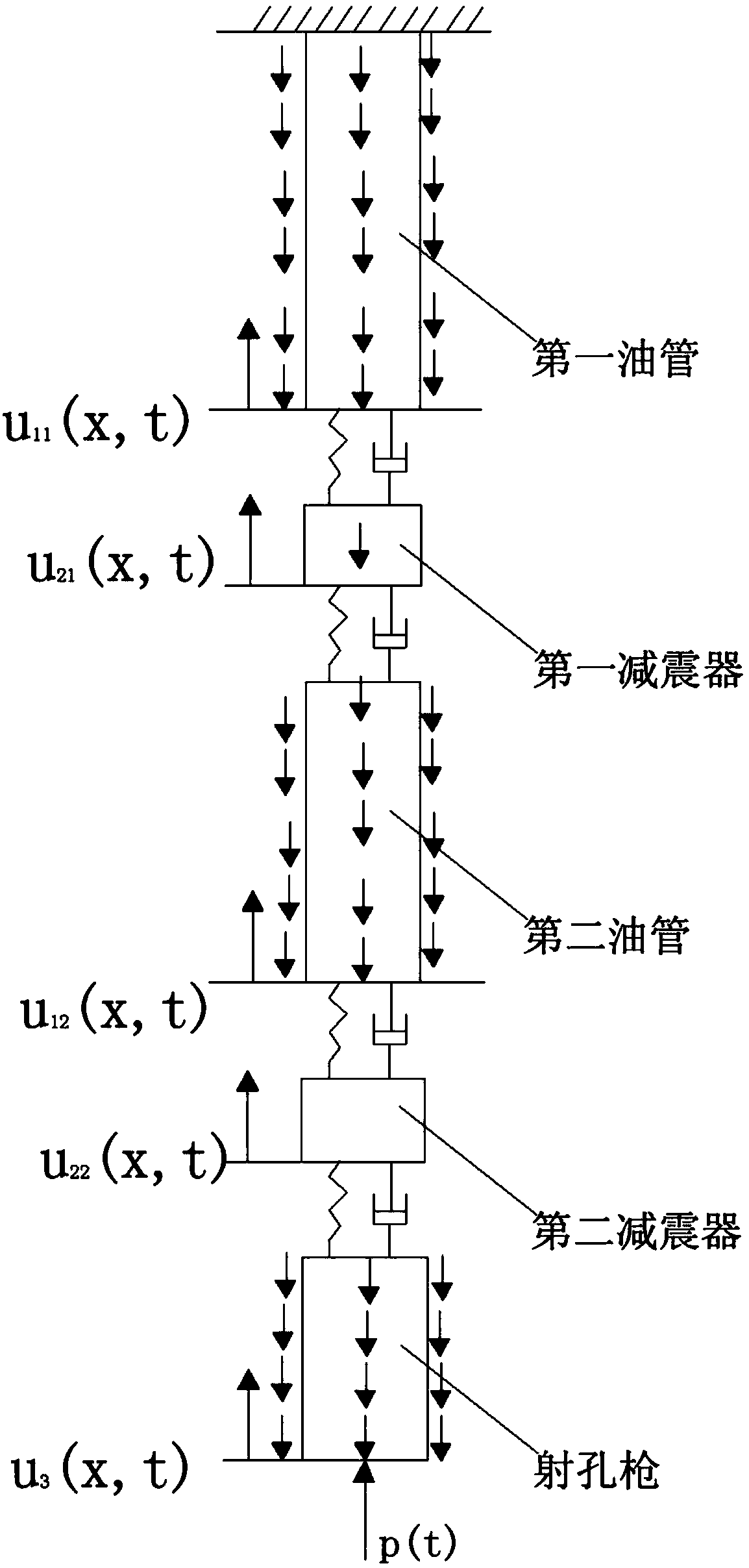

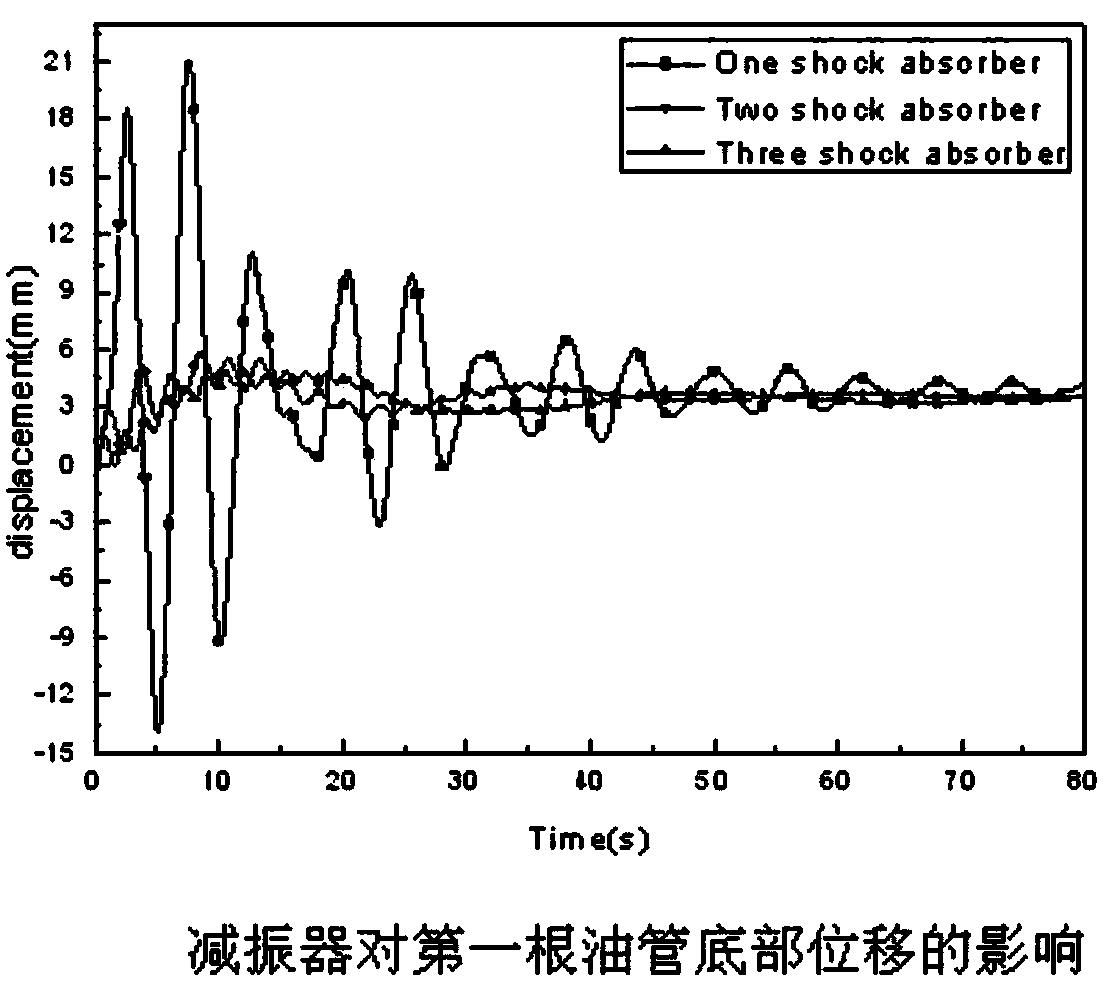

Kinetic analysis method of underground perforation tool under effect of multiple absorbers

PendingCN107844666AOvercoming the paradox between injuriesReduce risk of sabotageGeometric CADDesign optimisation/simulationStructure analysisEngineering

The invention discloses a kinetic analysis method of an underground perforation tool under effect of multiple absorbers, which includes steps of S1, structure analysis and perforation technique analysis according to the underground perforation tool; S2, establishment of kinetic models of two absorbers; S3, establishment of oscillatory differential equation of the underground tool; S4, establishment of a coupling condition of an oil pipe pillar-absorbers-perforation gun, wherein the pipe pillar kinetic model based on the effect of two absorbers has two coupling borders, the border at the coupling place adopts a force continuity condition, thus the coupling equation can be acquired; S5, solution of the kinetic model of the pipe pillar. The kinetic analysis method has the beneficial effects of reducing the accidents of unsealing failure of a packer for excessive stress, reducing the risk of tester damage caused by excessive acceleration, and avoiding unstability and damage of the oil pipepillar.

Owner:SOUTHWEST PETROLEUM UNIV

Down-the-hole holding-up hammer

PendingCN108756730AImprove perforation efficiencyExtended service lifeBorehole drivesEngineeringMaterial Perforation

A down-the-hole holding-up hammer comprises an outer casing pipe, a piston, an air distribution rod, an impact joint and a roller bit. An air inlet is formed in the upper end of the outer casing pipe,the lower end of the outer casing pipe is connected with the roller bit through the impact joint, and the impact joint is provided with a joint ventilating hole communicating with an inner hole spraying nozzle of the roller bit; the air distribution rod is fixedly arranged in the outer casing pipe, and the upper end outer wall of the air distribution rod and the inner wall of the outer casing pipe are fixed in a contact mode; the lower end of the air distribution rod extends into the joint ventilating hole in the impact joint, and the lower end outer wall of the air distribution rod is in contact fit with the inner wall of the joint ventilating hole in the impact joint; and the piston is arranged between the outer casing pipe and the air distribution rod, the piston can do up-down reciprocating impact movement in the axial direction of the outer casing pipe, and the bottom end face of the piston serves as an impact acting face acting on the impact joint. According to the down-the-holeholding-up hammer, the higher perforation efficiency and long service life are achieved under the pressure of 6-7.5 bar.

Owner:SHAREATE TOOLS

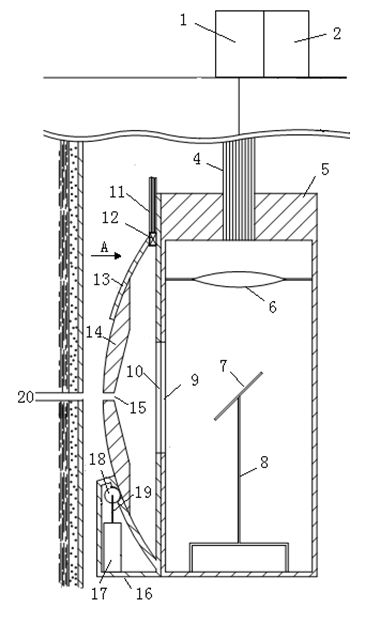

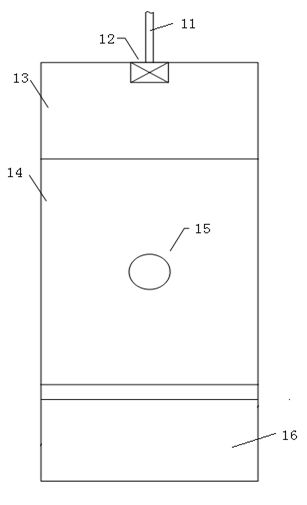

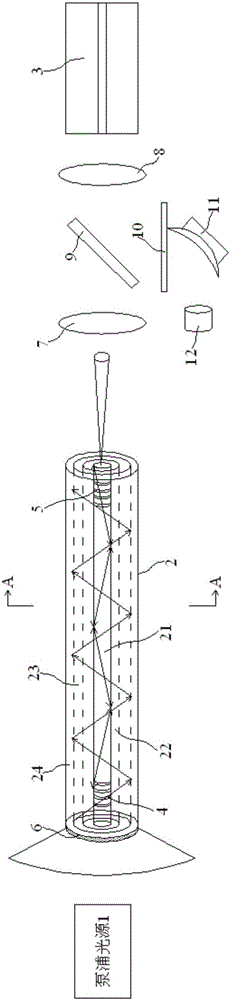

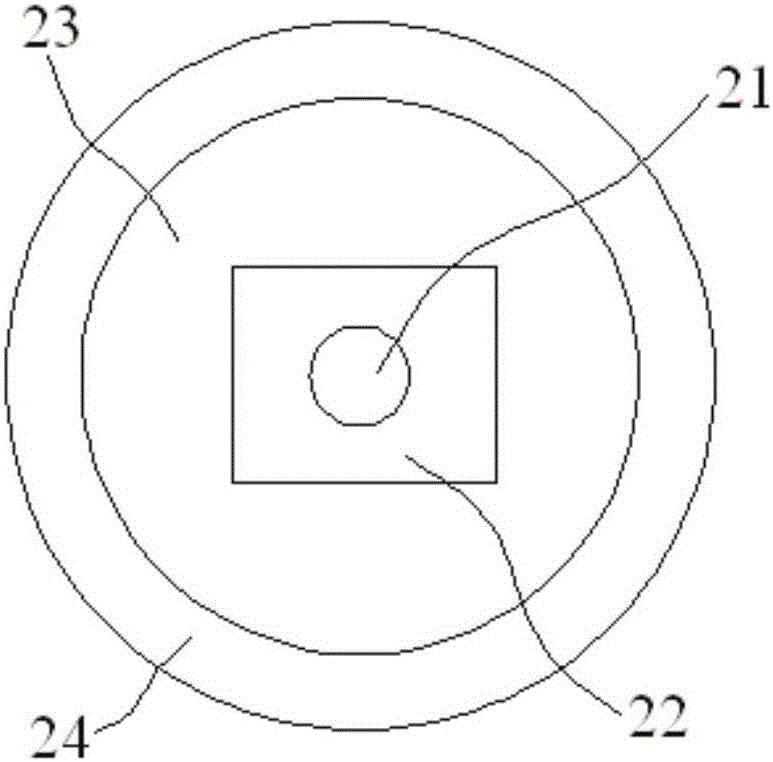

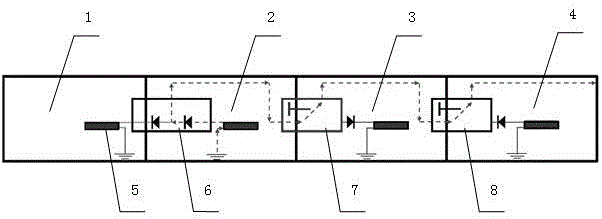

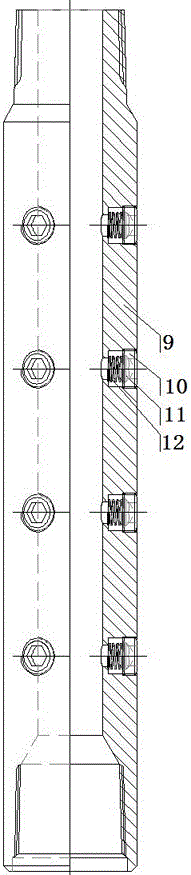

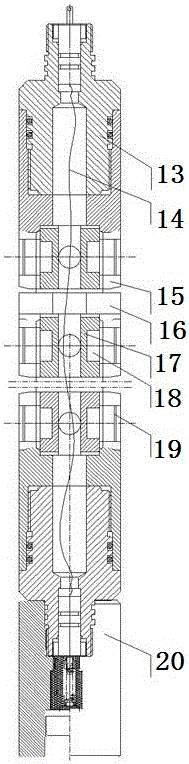

Multi-control-unit multi-beam laser perforation device in oil well

InactiveCN102155195AImprove permeabilitySo as not to damageConstructionsFluid removalLight beamControl cell

The invention belongs to the field of well completion technology of oil wells, and particularly relates to a multi-control-unit multi-beam laser perforation device in an oil well. The device mainly comprises a laser source, a high-pressure gas source and an underground laser perforator, wherein the laser source generates high-energy laser; the underground laser perforator comprises multiple laserperforation devices which are arranged orderly, controls the high-energy laser to perform the perforation operation in the oil well and controls to eject the gas output by the high-pressure gas source along the emergent direction of the laser so as to provide a clean channel for the laser perforation. The device provided by the invention controls multiple beams of high-energy laser to perform theperforation operation in the oil well at the same time, realizes high perforation efficiency, deep perforation and flexible and controllable perforation direction, improves the formation permeabilityand obviously increases the oil well capacity.

Owner:NORTHWEST UNIV(CN)

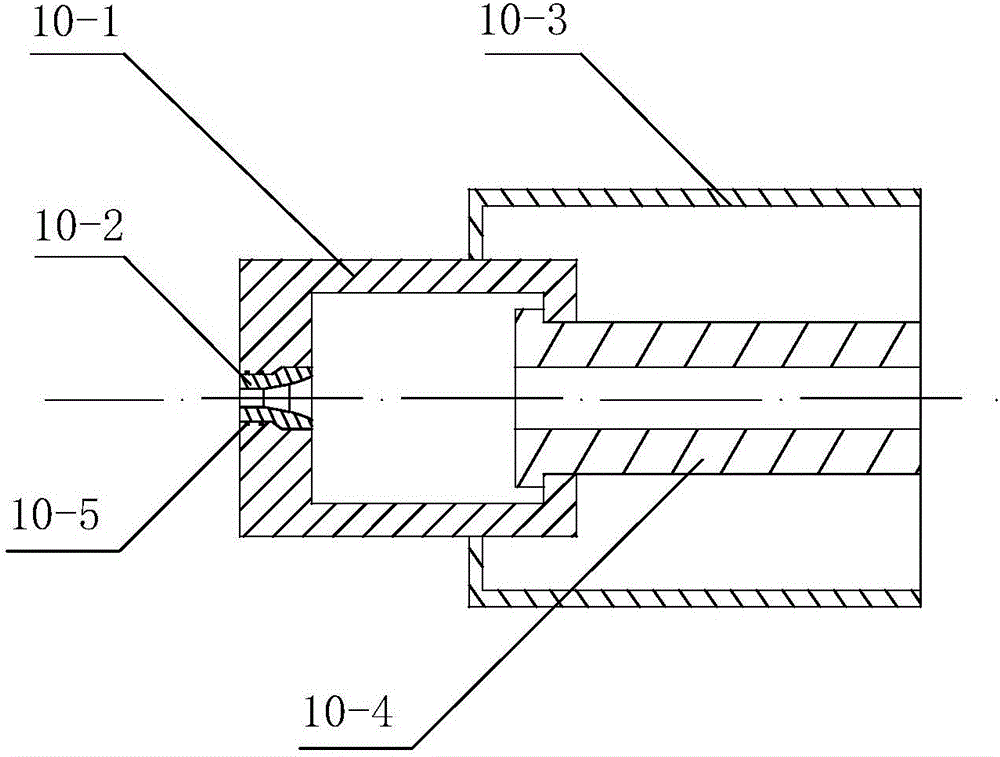

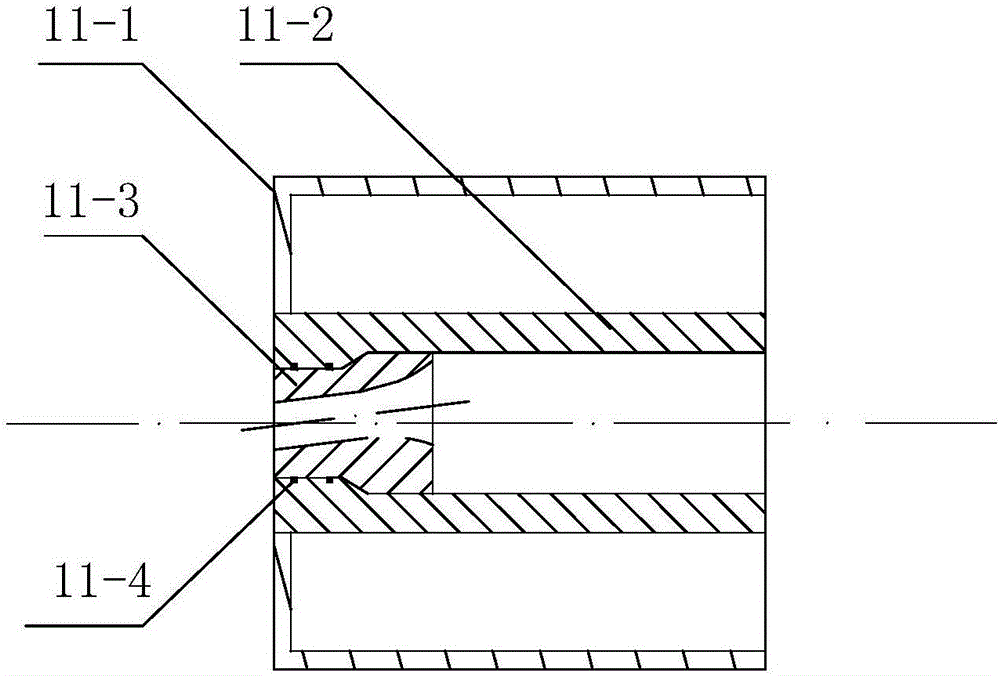

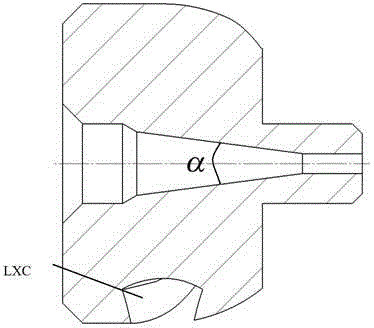

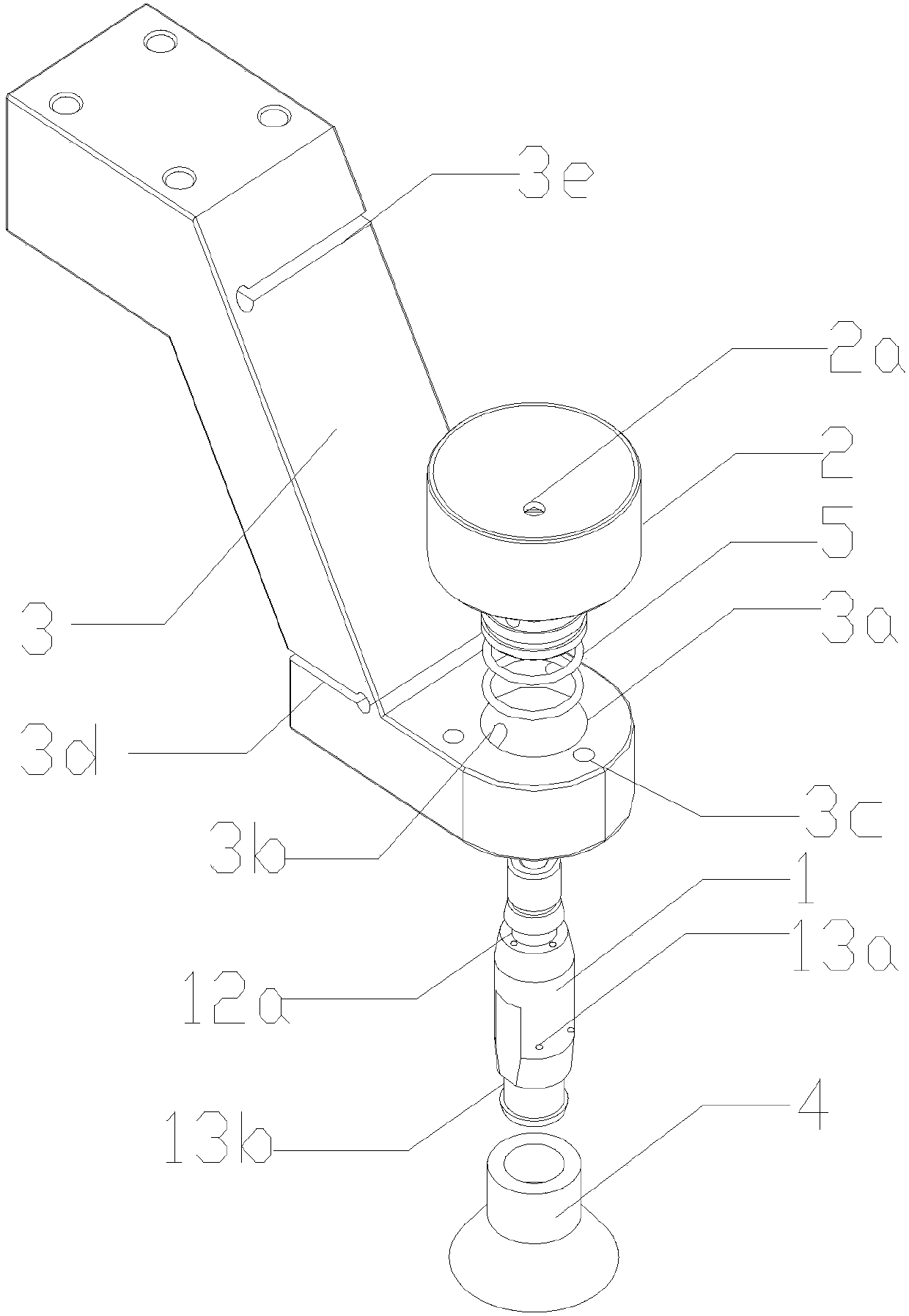

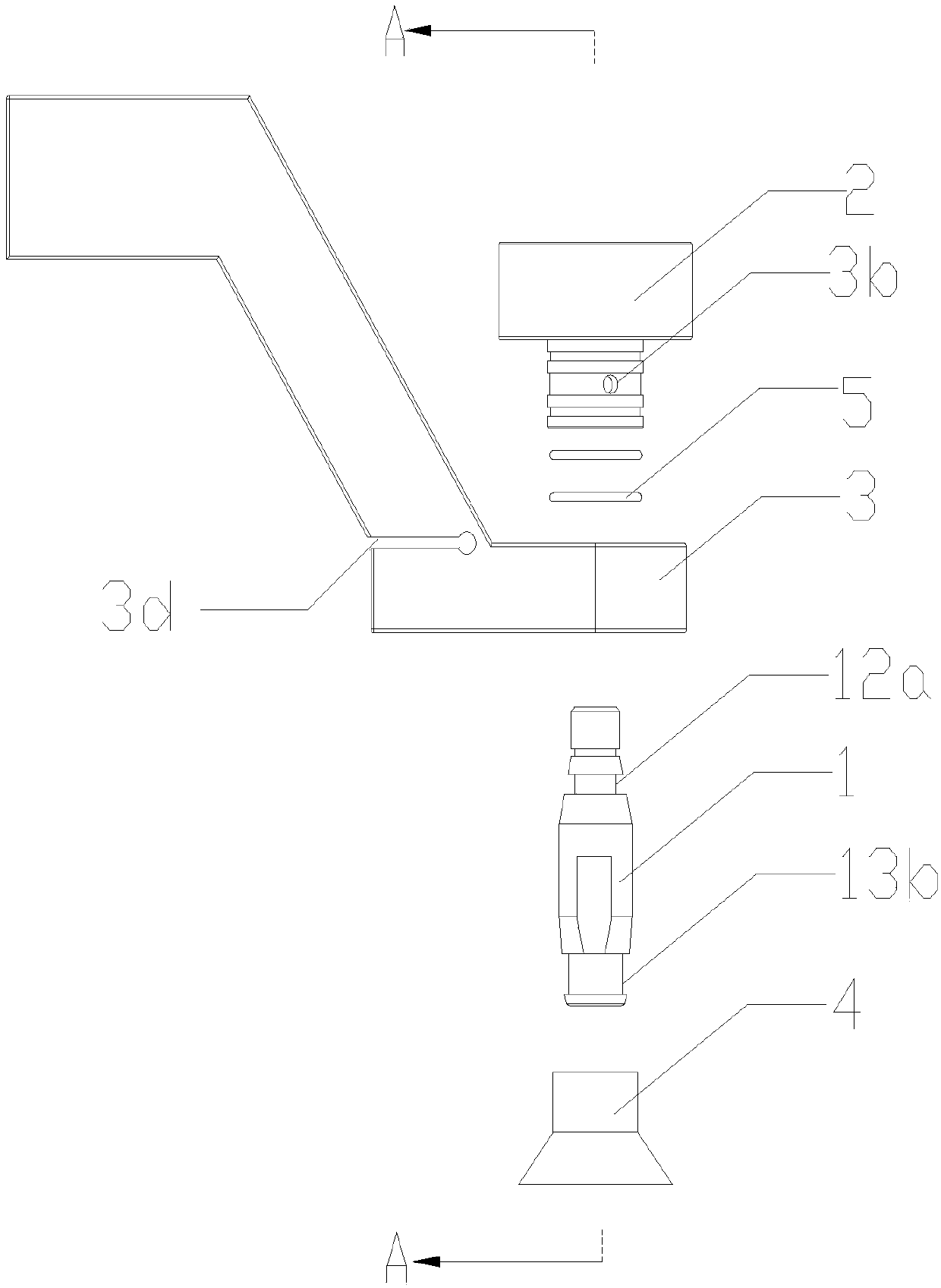

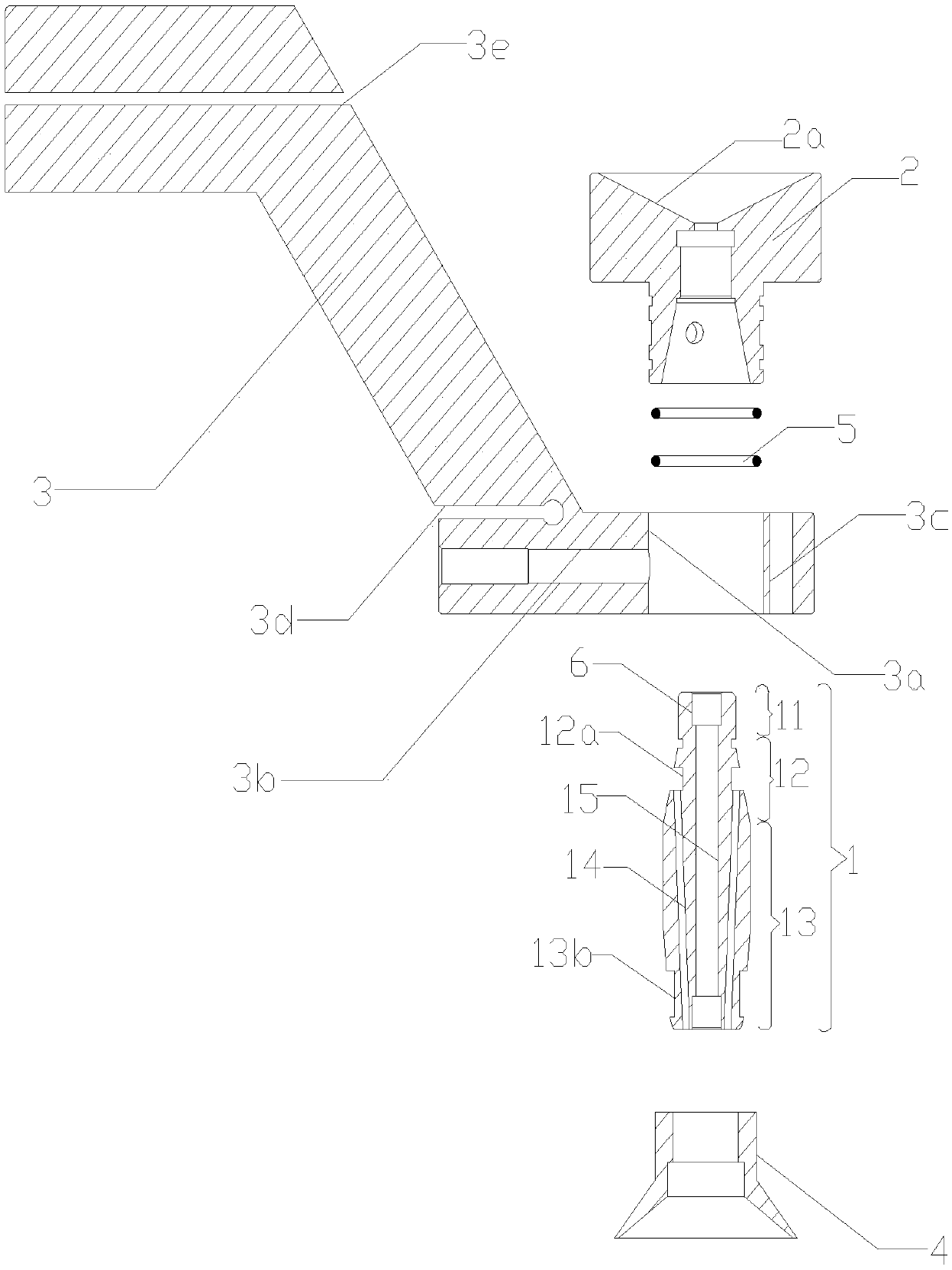

Combined type double jet flow nozzle

InactiveCN105903586AImprove perforation efficiencyEliminate helical bendsMovable spraying apparatusLiquid/gas jet drillingJet flowSpray nozzle

The invention relates to the technical field of oil field oil production engineering and belongs to a combined type double jet flow nozzle used for an oil-water well oil layer ground control underground level drilling device. The nozzle is designed for solving problems that a prior nozzle can only produce common continuous jet flows and rock crushing efficiency is low. The nozzle is composed of a pressing cap 1, a rotation body 2 and a nozzle base 3, wherein the right end of the pressing cap 1 is threaded to the left end of the nozzle base 3; the rotation body 2 is disposed in the nozzle base 3 and is pressed with the aid of the pressing cap 1. The nozzle is mainly applied to field construction of the oil-water well oil layer ground control underground level drilling device and has advantages of being simple in structure and capable of converting common continuous jet flows into rotation jet flows and thus achieving high rock crushing efficiency and the like.

Owner:PETROCHINA CO LTD +1

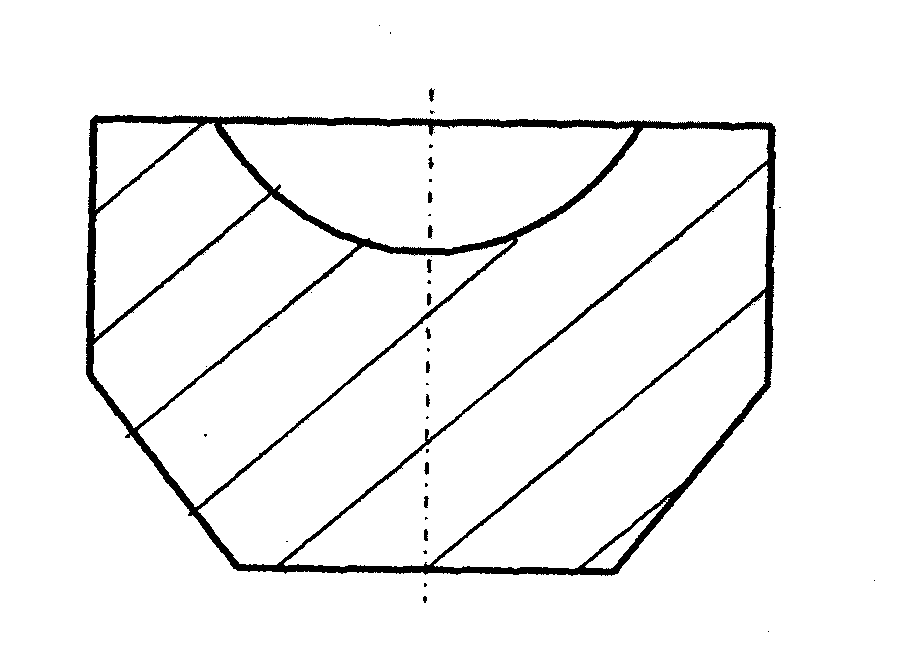

Perforating charge body powder metallurgy billet and cold extrusion forming process method

The invention relates to a perforating charge body powder metallurgy billet and a cold extrusion forming process method, and belongs to petroleum exploitation tools. The billet is formed through compatibility of iron powder, copper powder, nickel powder, graphite powder, molybdenum powder and a binder according to different weight ratios, mechanical mixing, pressing and sintering are performed on the raw materials to prepare a charge body billet, cold extrusion is adopted to carry out extrusion on the whole charge body billet to obtain a charge body with the final shape, and sintering and precise pressing shaping are performed to obtain the perforating charge body. According to the present invention, the low alloy content powder metallurgy formula and the cold extrusion technology are adopted to process the charge body, and the following characteristics are provided, wherein the characteristics are that the material formula is novel, scientific and reasonable property is provided, mechanical property of the charge body is good, a penetration depth value of the perforation is large, use is safe and reliable, the production process is simple, the cost is low, perforating operation efficiency is increased, and petroleum exploitation cost is reduced.

Owner:HEILONGJIANG SERVICE CENT FOR SMALL & MEDIUM SIZED ENTERPRISES

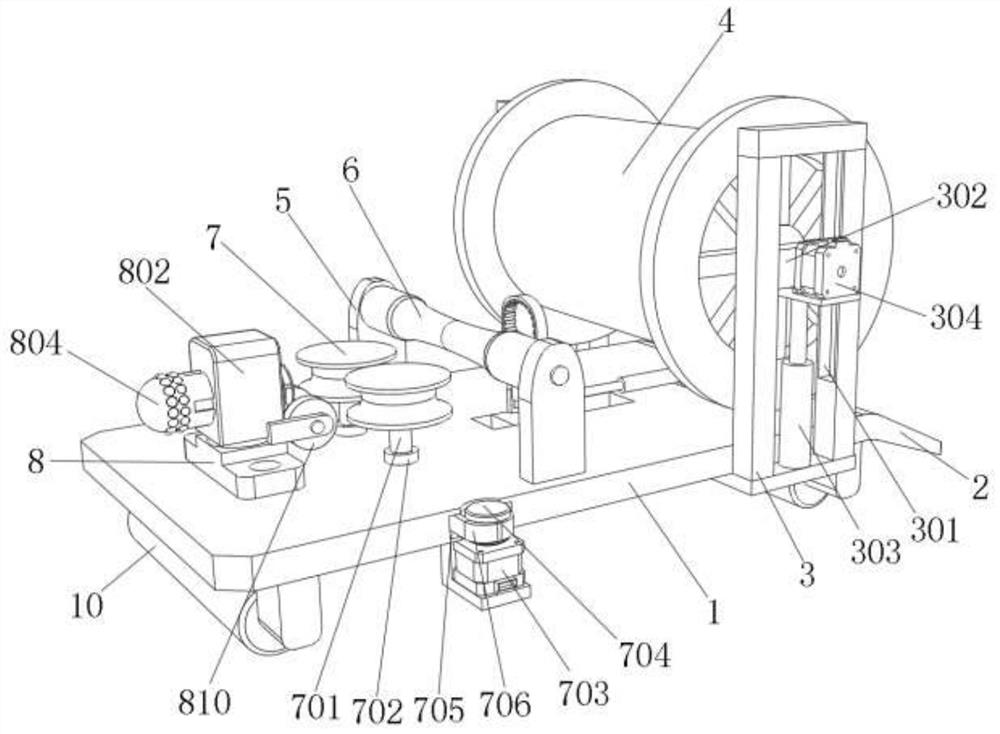

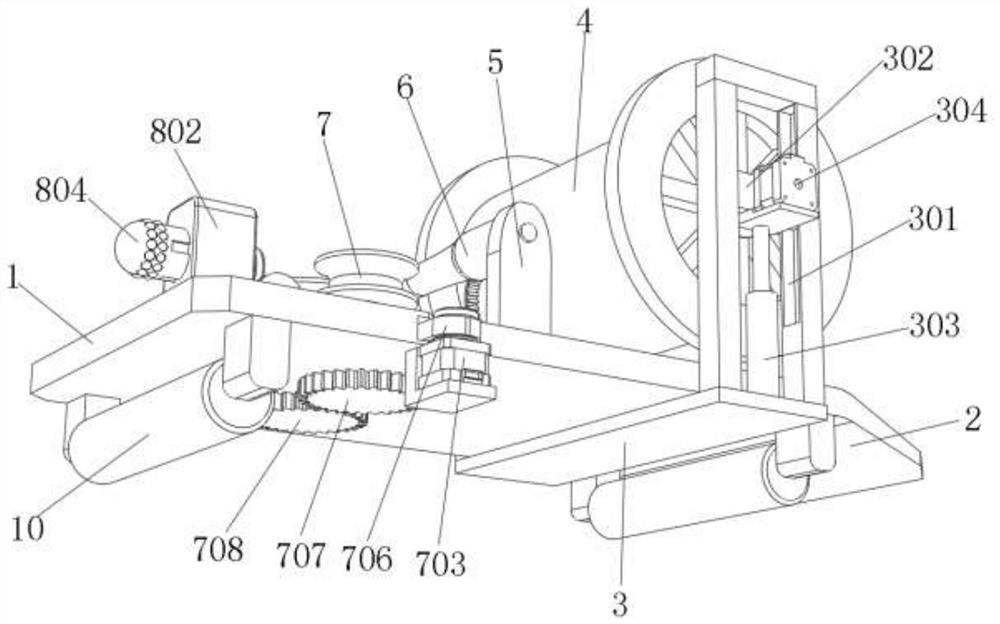

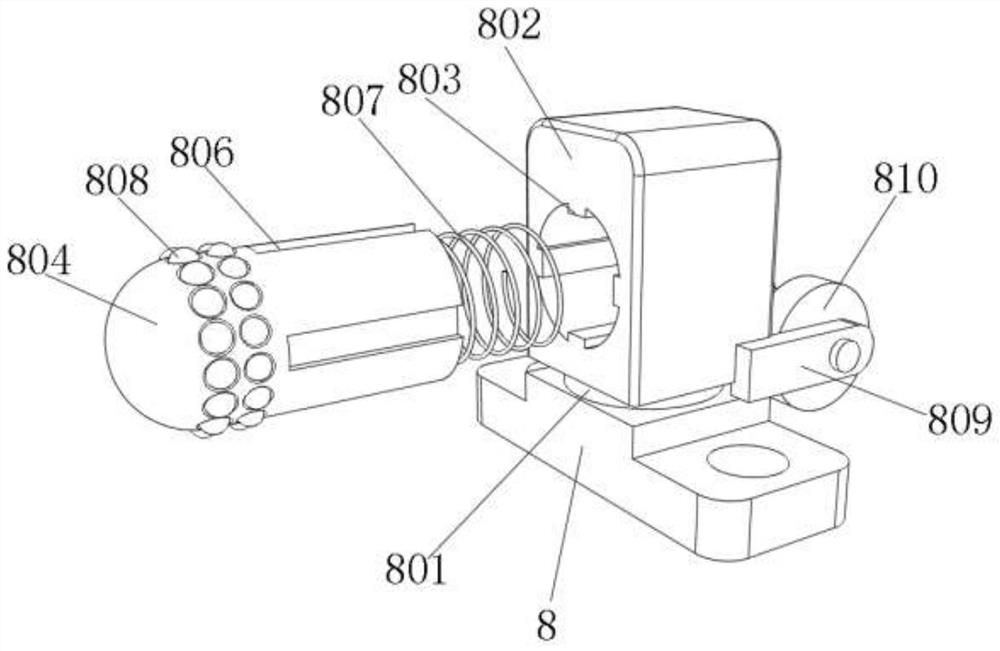

High-voltage cable perforating equipment

InactiveCN113258498AQuality improvementReduce frictionFilament handlingApparatus for laying cablesStructural engineeringPower engineering

The invention relates to the technical field of electric power engineering tools, and discloses high-voltage cable perforating equipment which comprises a bottom plate. A lifting mechanism is fixedly connected to one side of the bottom plate, a winding disc is inserted into the inner side of the lifting mechanism, a pushing mechanism is arranged on one side of the bottom plate, and a base is fixedly connected to the top of the bottom plate. A rotating shaft is movably connected to the top of the base, a clamping block is fixedly connected to the top of the rotating shaft, a clamping hole is formed in one side of the clamping block in a clamped mode, a protruding block is integrally formed on the inner wall of the clamping hole, a perforating sleeve is movably connected to the inner wall of the clamping hole, an inserting groove is formed in one side of the perforating sleeve and connected with the protruding block in a clamped mode, and a first spring is fixedly connected to one end of the perforating sleeve. The equipment can prevent cable blockage from affecting perforation to a great extent, can improve the perforation efficiency so as to improve the cable laying quality, can also prevent rigid perforation of the cable and damage to the cable, can also perform perforation again, and improves the perforation quality.

Owner:刘红国

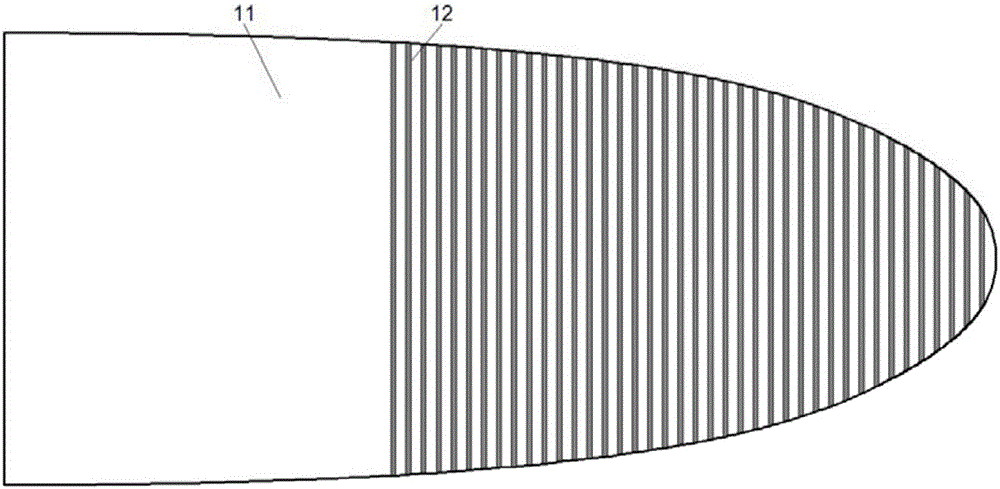

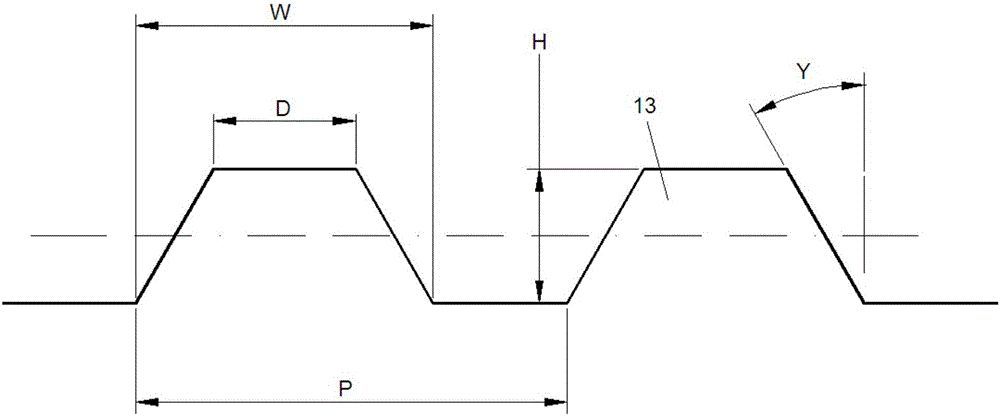

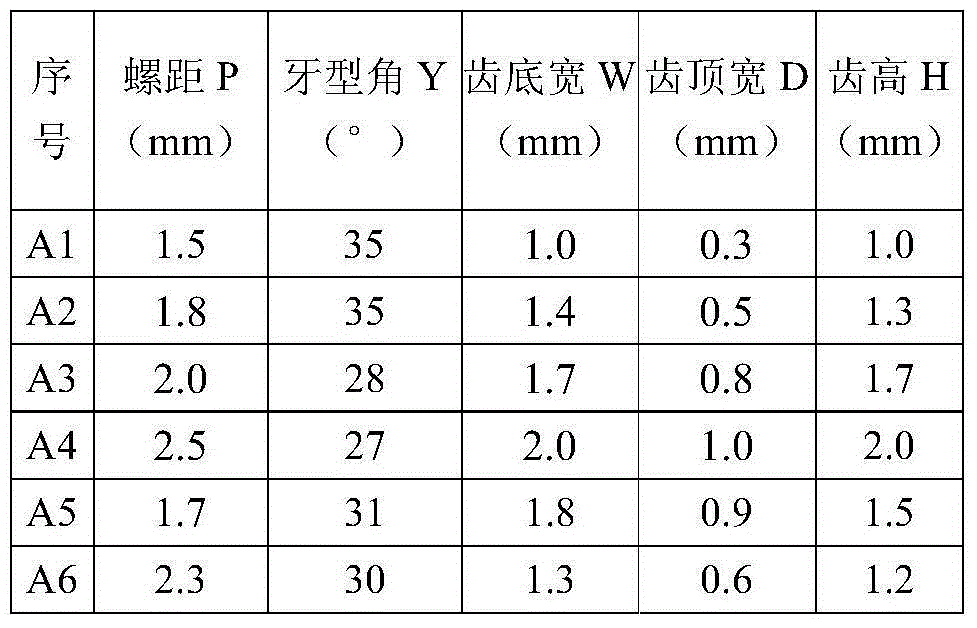

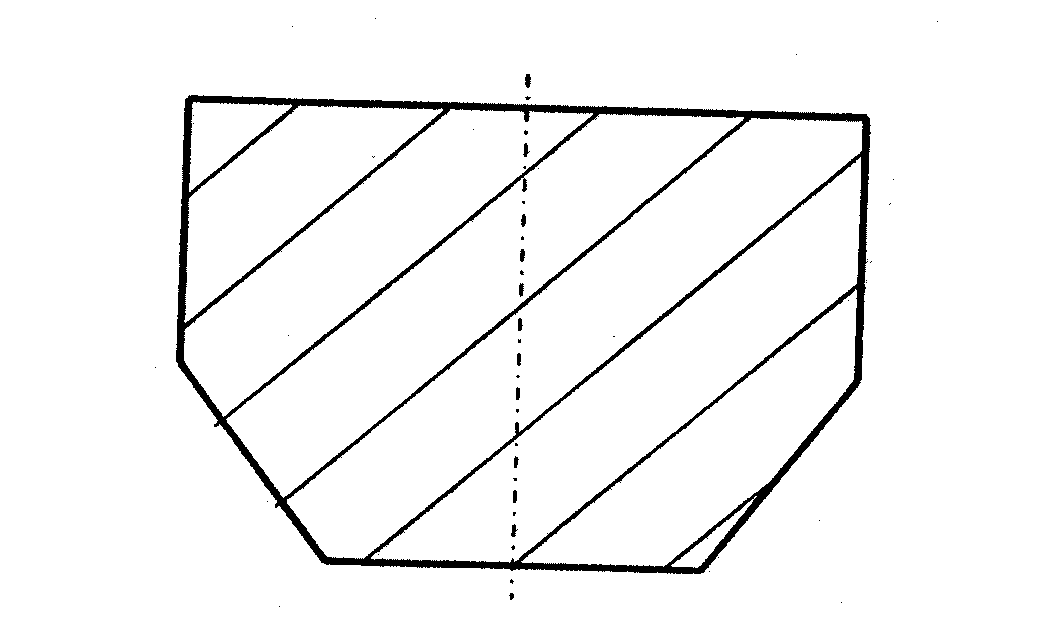

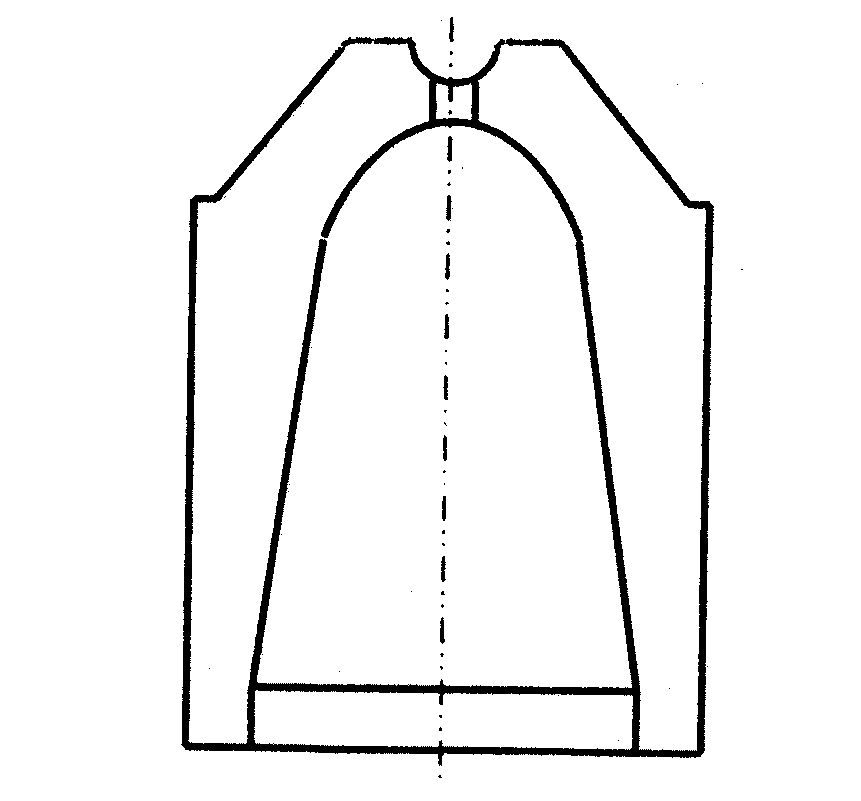

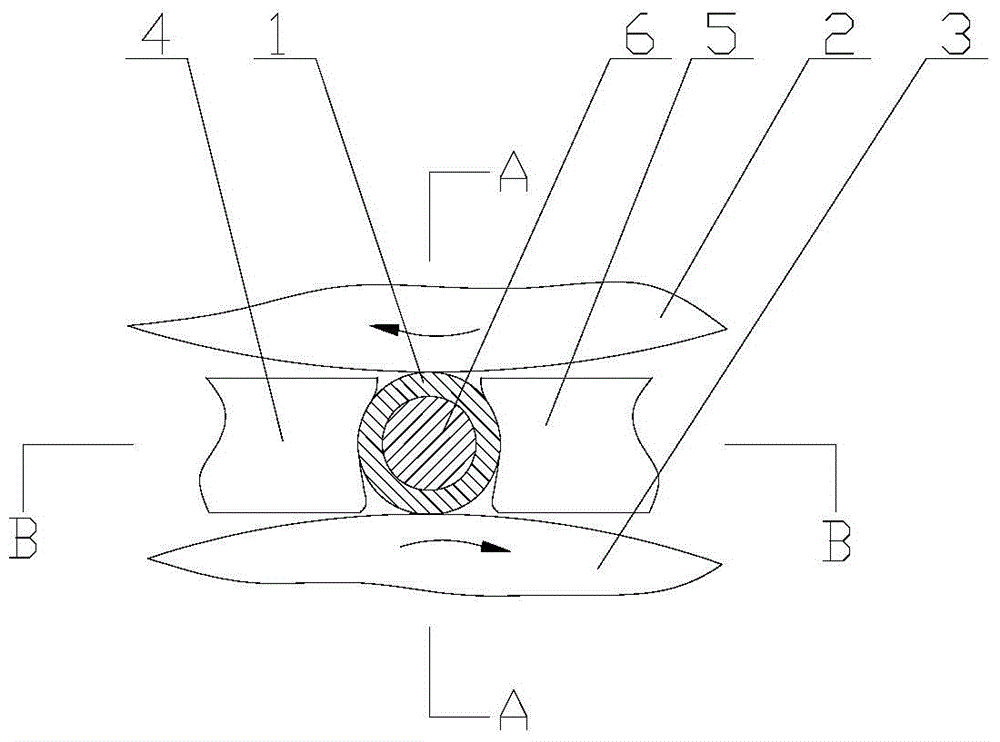

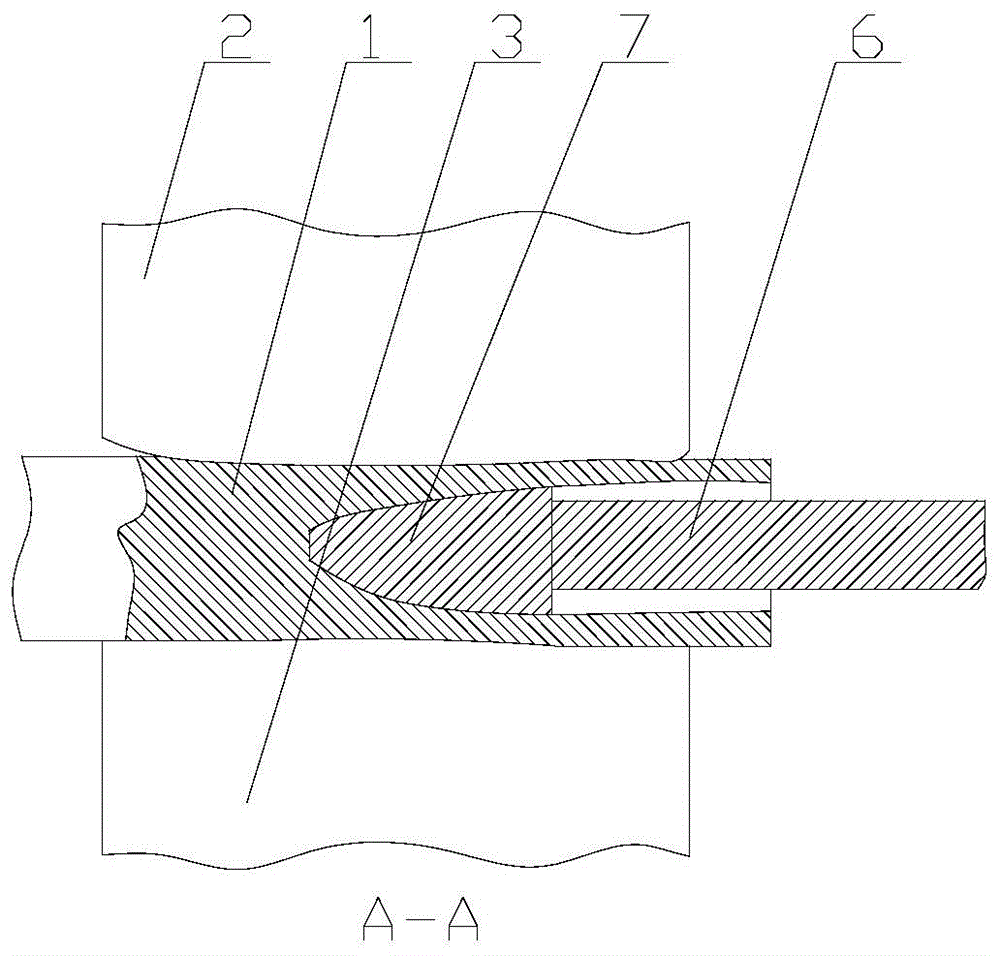

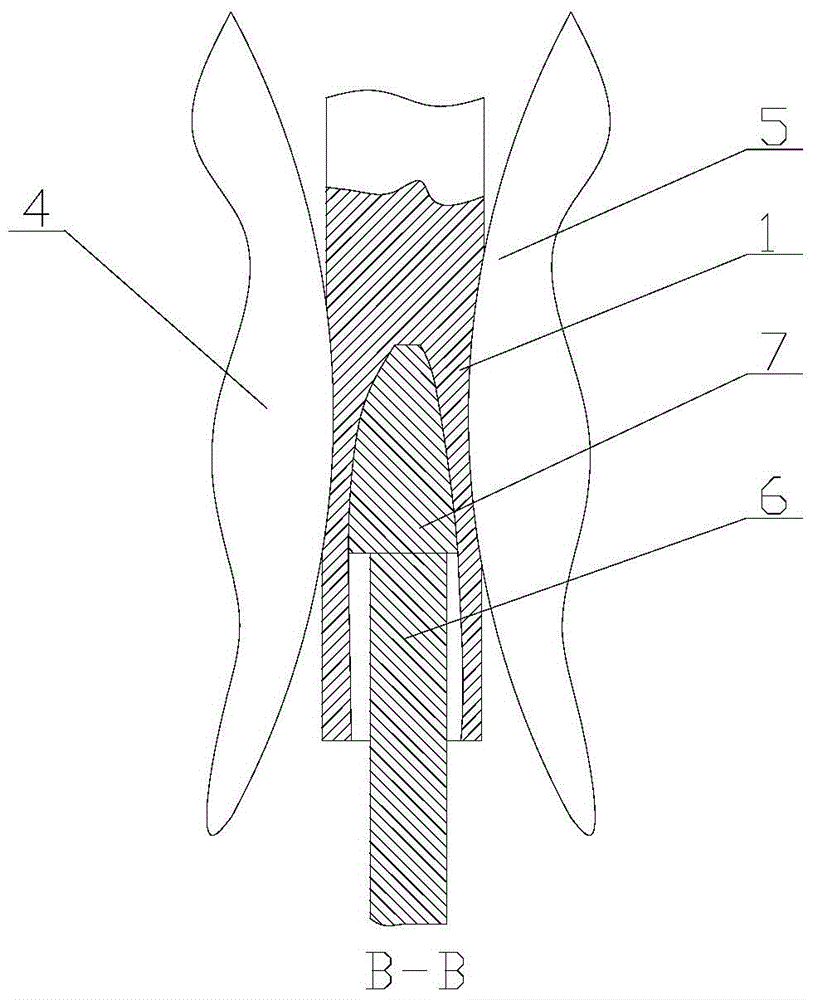

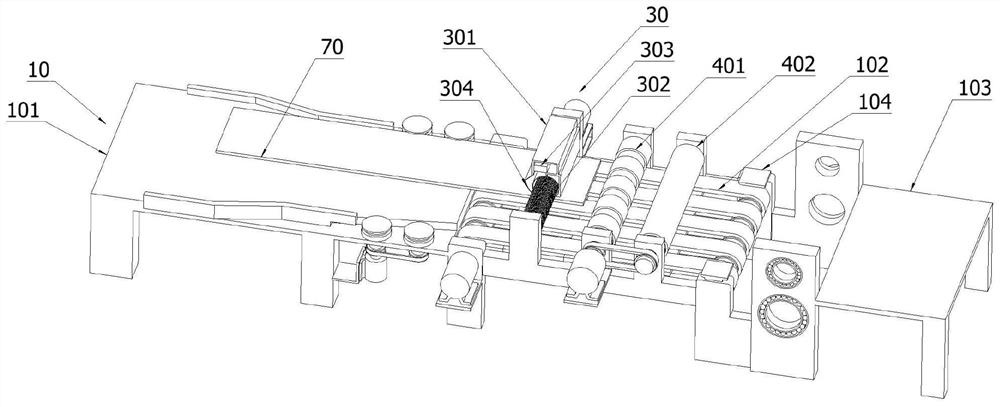

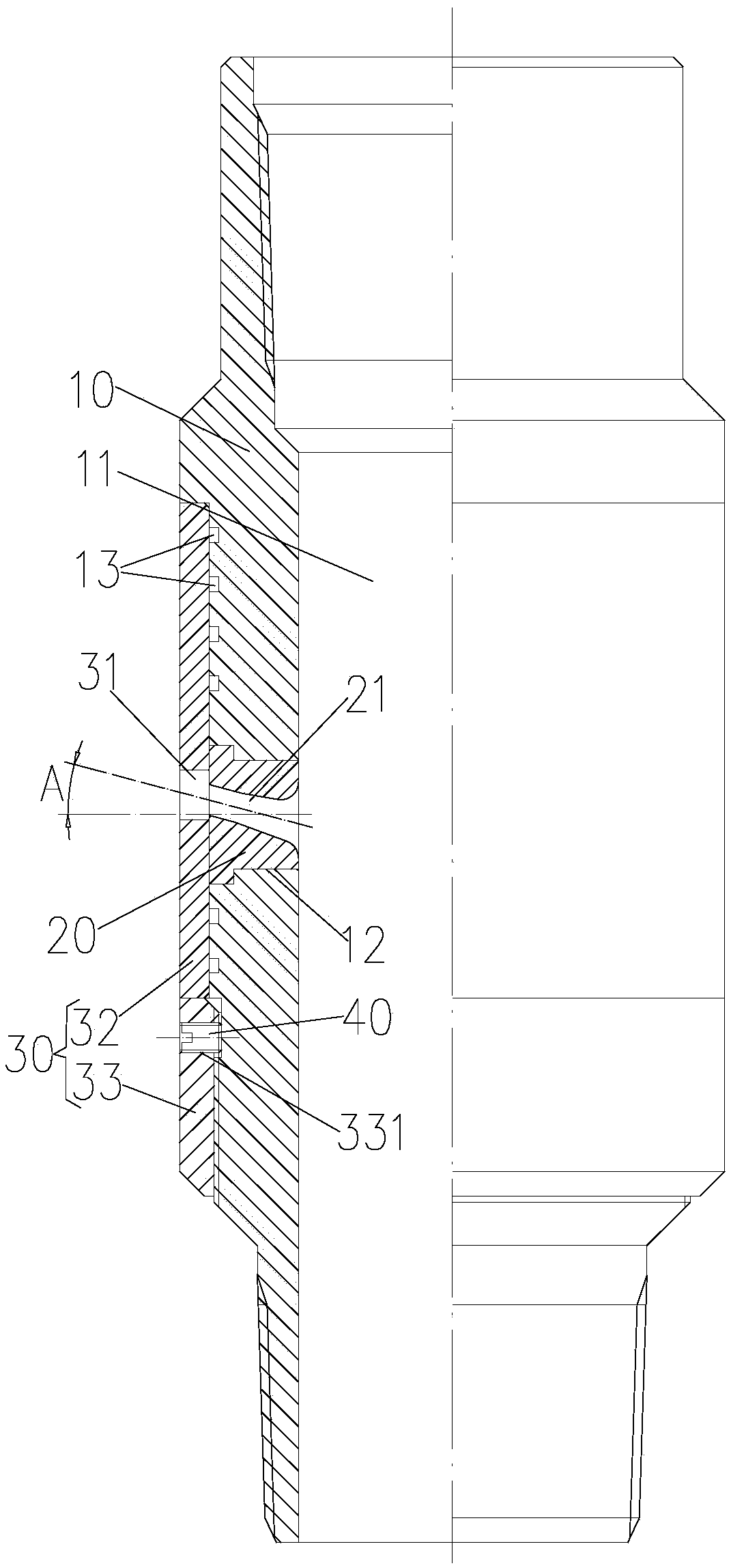

Perforating machine for producing seamless steel tube

InactiveCN104588411ACompact structureReasonable designMetal rolling arrangementsMetallurgyMirror image

The invention relates to the technical field of seamless steel tube production equipment, in particular to a perforating machine for producing a seamless steel tube. The perforating machine comprises an upper roller positioned on the upper surface of the seamless steel tube, a lower roller positioned on the lower surface of the seamless steel tube, a front guide disc positioned on the front surface of the seamless steel tube and a rear guide disc positioned on the rear surface of the seamless steel tube, wherein the upper roller and the lower roller are arranged in a mirror image mode, and the front guide disc and the rear guide disc are arranged in the mirror image mode; a perforating mechanism is inserted in a cavity on the right side of the seamless steel tube, the perforating mechanism comprises a top rod for applying pressure to the perforating mechanism by a pressure mechanism, a top head is fixedly mounted at the left end of the top rod, and a chip removal gap is formed between the perforating mechanism and the cavity on the right side of the seamless steel tube. The perforating machine for producing the seamless steel tube is compact in structure and high in perforating efficiency, and the inner bore shape and size of the obtained seamless steel tube meet the technological requirements.

Owner:ZHANGJIAGANG XINGYE STEEL TUBE

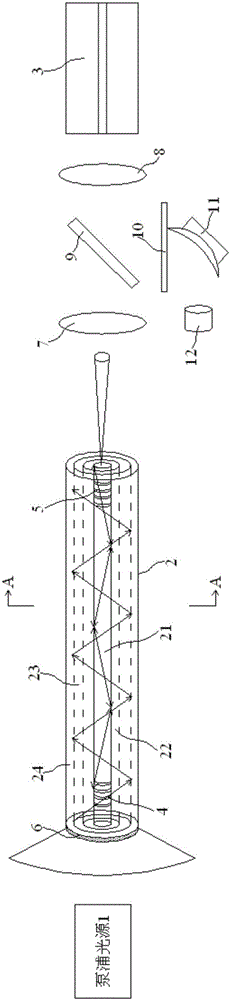

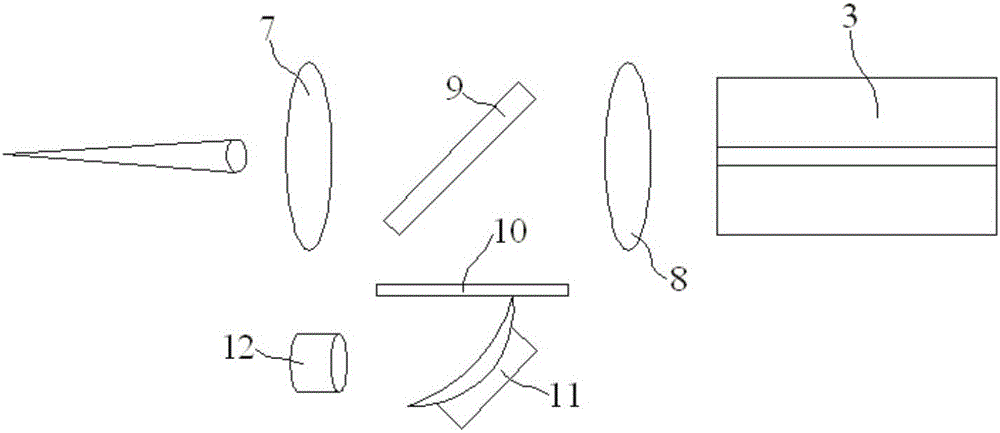

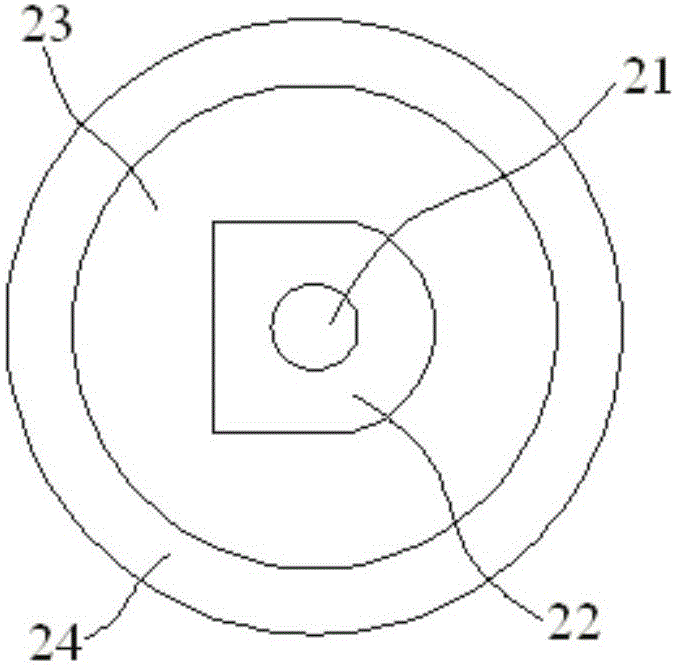

Laser capable of monitoring cutting state in real time

ActiveCN105846294AIncrease profitFast perforationActive medium shape and constructionLaser beam welding apparatusAcute angleFiber Bragg grating

The invention discloses a laser capable of monitoring cutting state in real time. A laser gain medium fiber core is wrapped by a glass isolation layer, a fluorescent material layer and an external wrapping layer from the inside out in sequence; the refractive index of the laser gain medium fiber core is larger than that of the glass isolation layer; the refractive index of the glass isolation layer is larger than that of the fluorescent material layer; and the refractive index of the fluorescent material layer is larger than that of the external wrapping layer. The input end and the output end of a clad fiber are provided with a first fiber Bragg grating and a second fiber Bragg grating respectively. The end surface, arranged at the side of a pump light source, of the clad fiber is provided with a tail mirror. A first convex lens and a second convex lens are sequentially arranged between the clad fiber and a transmission fiber. A semi-reflection semi-permeable wafer is arranged between the first convex lens and the second convex lens; and the semi-reflection semi-permeable wafer and the light path are arranged in a manner that an acute angle is formed therebetween. When the cutter cuts a high-reflecting material, that laser wavelength surpasses a set threshold value can be detected in real time, so that the cutter can stop quickly to prevent the laser from returning in the original path; and response time is short due to light speed.

Owner:SUZHOU LEAD LASER TECH

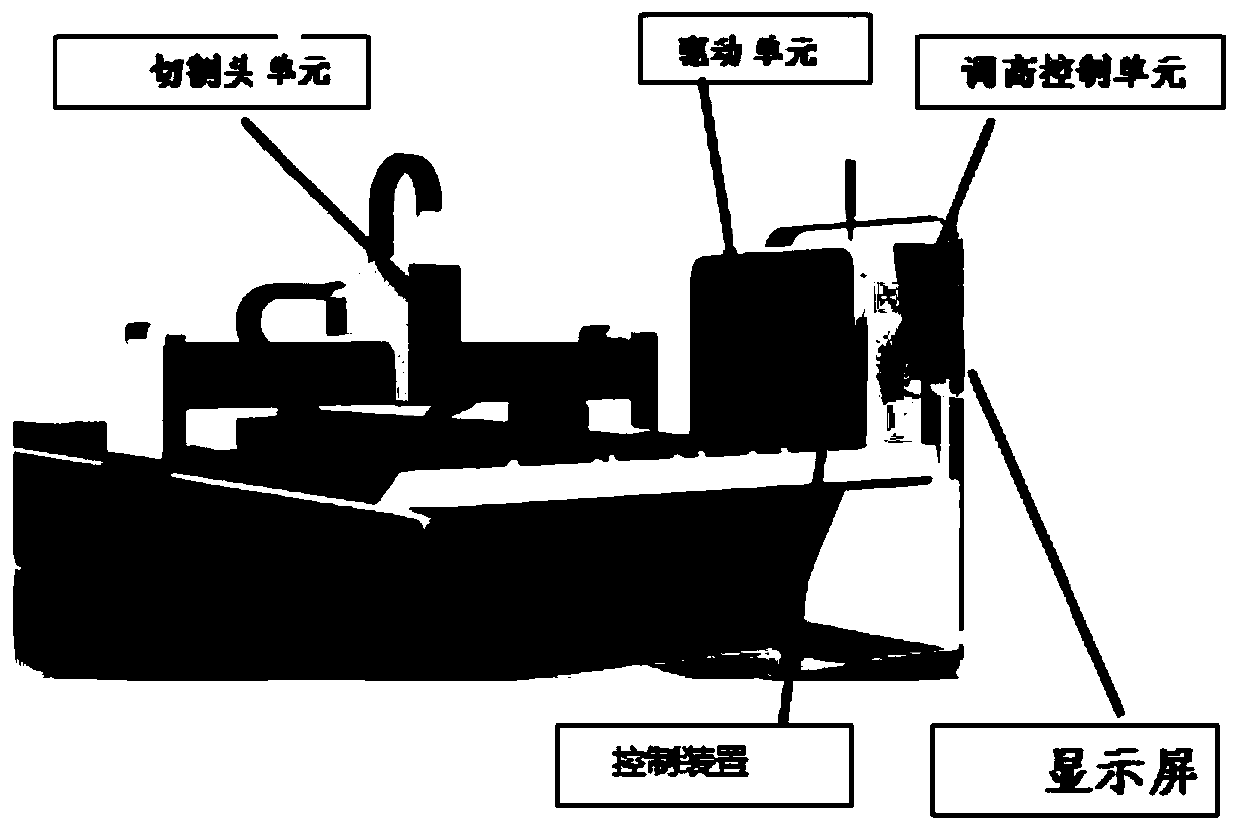

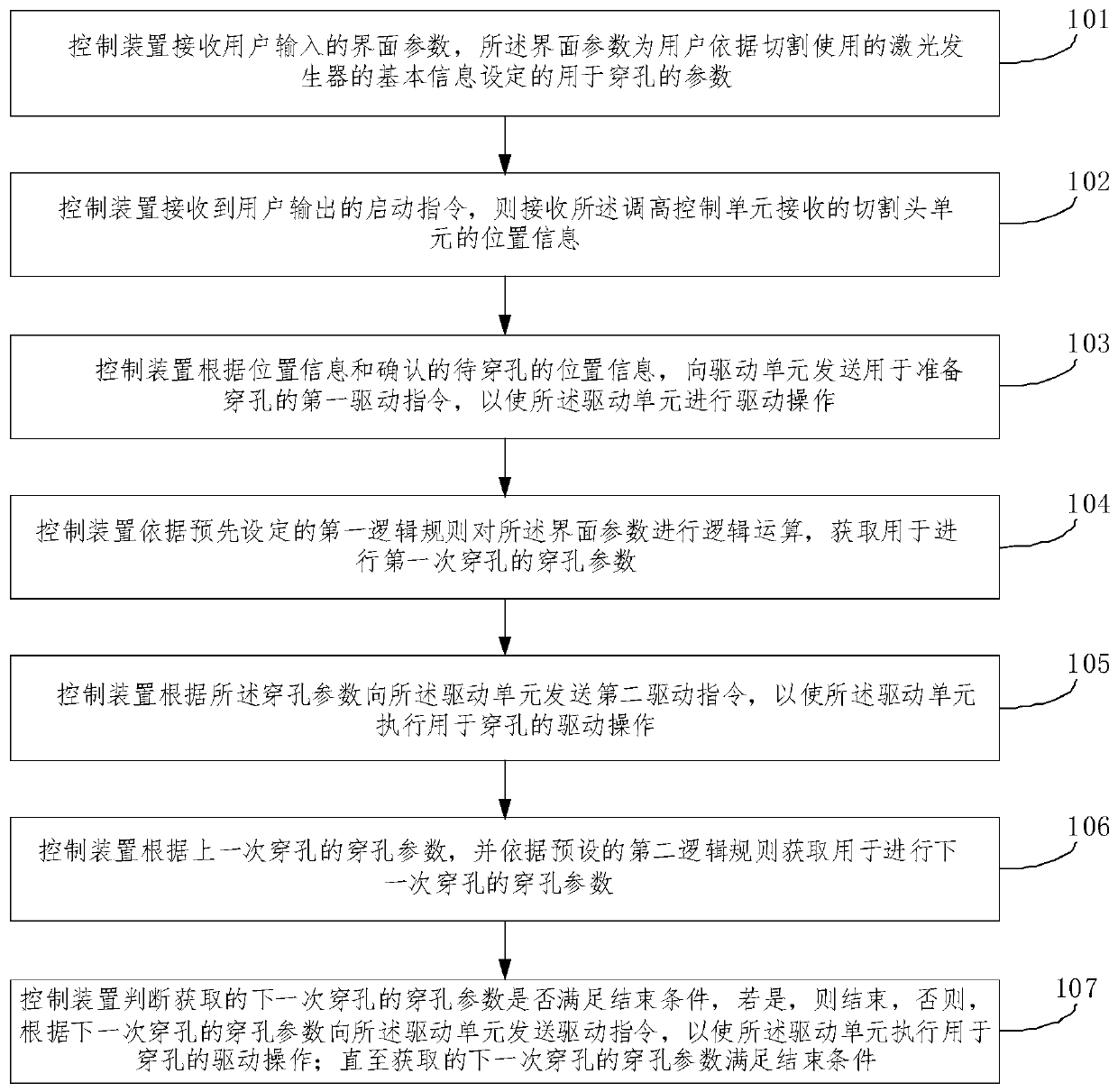

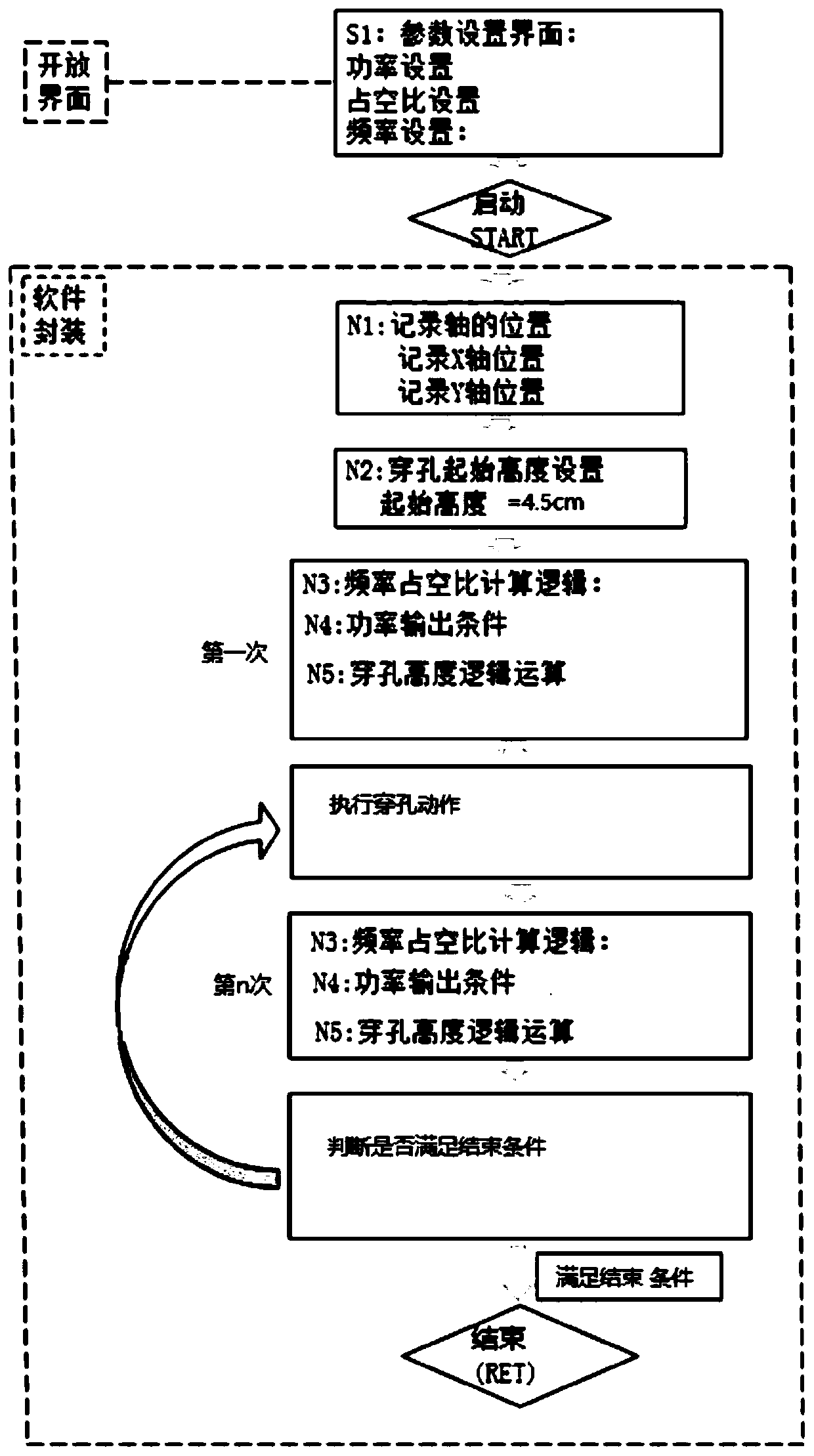

Intelligent perforating method for laser cutting and laser cutting device

ActiveCN110788497AReduced professional skill requirementsEasy to operateLaser beam welding apparatusLogical operationsEngineering

The invention discloses an intelligent perforating method for laser cutting and a laser cutting device. The method includes the steps of receiving interface parameters input by a user, obtaining position information of a cutting head unit, driving the cutting head unit to move to a to-be-perforated position, performing logical operation on the interface parameters according to a first preset logical rule to obtain perforating parameters of primary perforating, making a driving unit to perform driving operation according to the perforating parameters, obtaining perforating parameters of next perforating according to the perforating parameters of last perforating and a second preset logical rule, judging whether the perforating parameters of next perforating meet ending conditions, and if yes, ending the process, otherwise making the driving unit to perform driving operation according to the perforating parameters until the obtained perforating parameters meet the ending conditions. By means of the method, the interface setting time of an operator can be shortened, meanwhile perforating efficiency is improved, and machining stability is improved.

Owner:JINAN BODOR LASER CO LTD

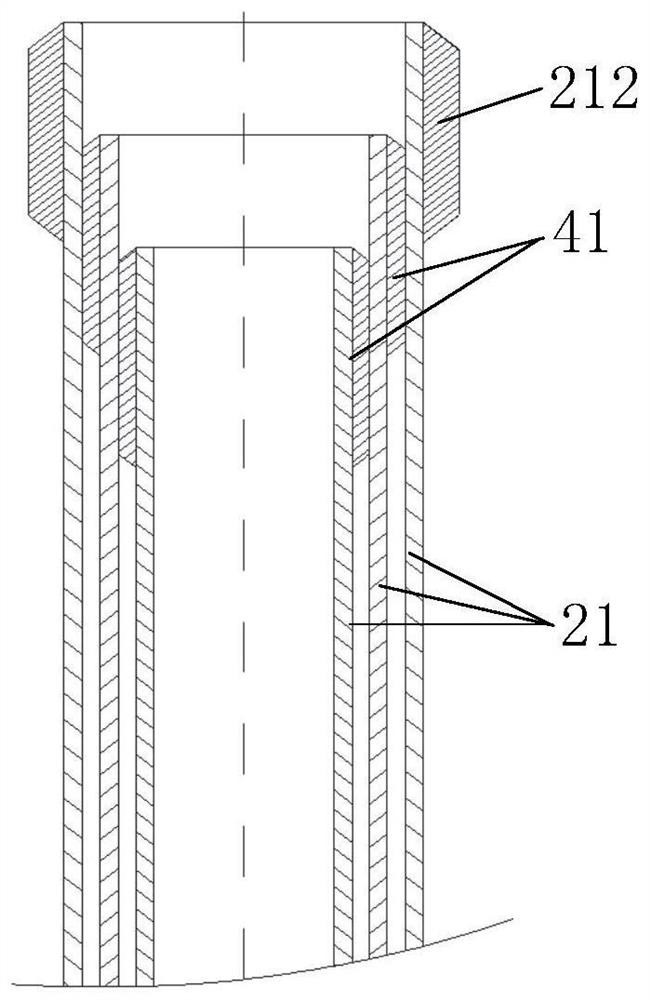

Continuous tube cluster perforation intelligent ignition device and process

InactiveCN106223909AImprove perforation efficiencyImprove protectionFluid removalHorizontal wellsInlet valve

The invention discloses a continuous tube cluster perforation intelligent ignition device and a process. The continuous tube cluster perforation intelligent ignition device comprises a continuous tube, an automatic liquid inlet valve, an electronic detonator, a perforation single-core flexible connecting device and a cluster perforated string which are sequentially connected with one another. The automatic liquid inlet valve comprises a body, and a plurality of automatic liquid inlet check valves are arranged on the body; the perforation single-core flexible connecting device comprises an upper connector assembly, H clamps and a lower connector assembly, the upper connector assembly is connected with the lower connector assembly by the H clamps, and two pins are arranged at the ends of the upper connector assembly and the lower connector assembly and are connected with each other by an electric wire. The continuous tube cluster perforation intelligent ignition device and the process have the advantage that the continuous tube perforation operation efficiency can be improved, and the continuous tube cluster perforation intelligent ignition device and the process are favorable for protecting oil and gas reservoirs; pressure perforation operation is carried out, accordingly, the problem of oil and gas reservoir contamination risks during original drilling fluid perforation well completion can be solved, and delivery capacity of the cluster perforated and the handling capacity in response to complicated well conditions of unconventional oil and gas horizontal wells with shale gas, tight oil and gas and the like further can be improved.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Petroleum underground laser perforation well completion device

The invention belongs to the technical field of oil well completion device, specifically relating to a petroleum underground laser perforation well completion device. The device mainly comprises a laser light source, a high pressure gas source and an underground laser perforator. The laser source is capable of producing high energy lasers, and the underground laser perforator comprises at least two sets of laser perforation devices which are connected with each other in sequence, wherein each set of laser perforation device is responsible for petroleum underground single-hole perforation work; and after being effectively combined, the two sets of laser perforation can control multi beam high energy lasers simultaneously so as to perform petroleum underground laser perforation work. The device has great perforation depth, is flexible and controllable in perforation direction, enhances stratum permeability, has high perforation efficiency, and improves the oil well productivity obviously.

Owner:NORTHWEST UNIV(CN)

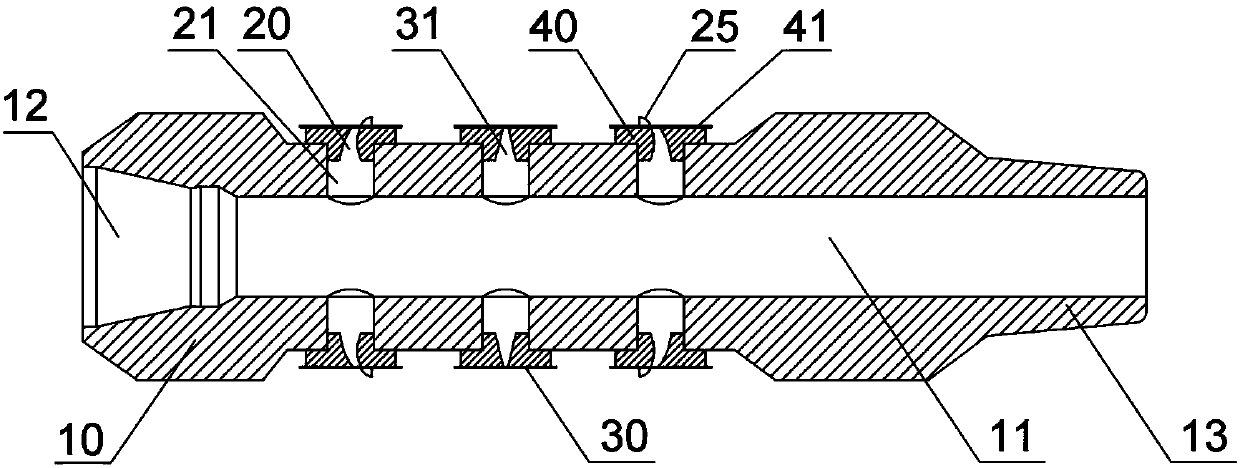

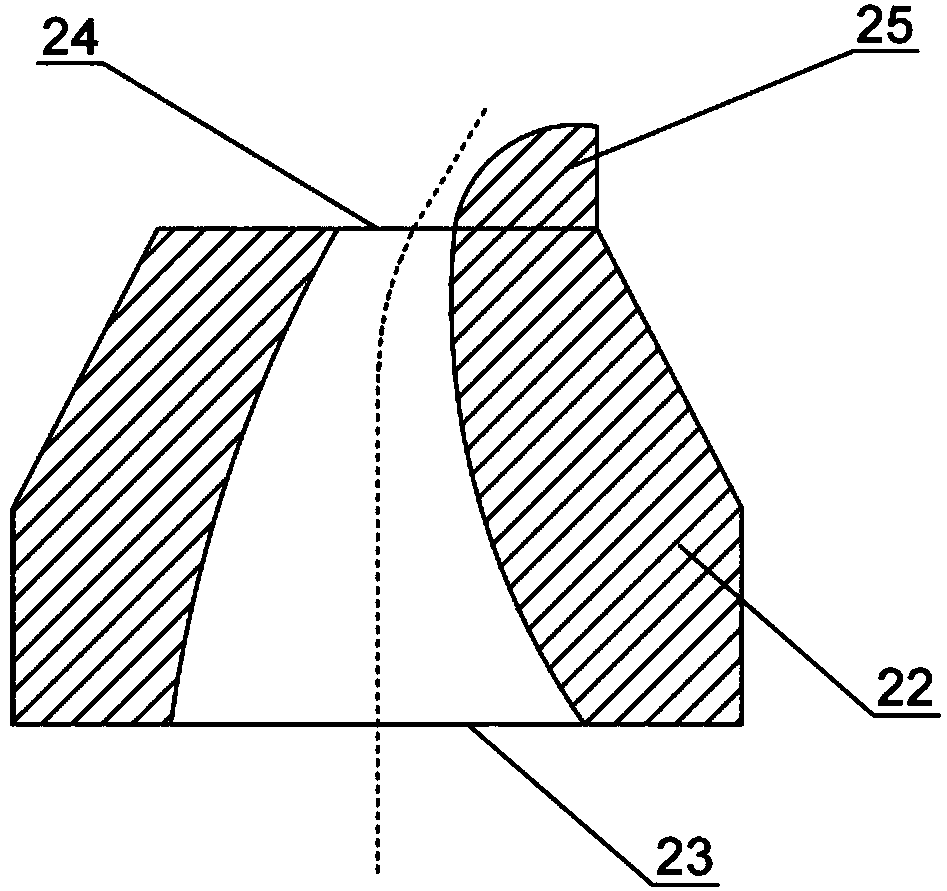

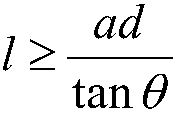

A perforating device for well completion

ActiveCN110118077BStretch out step by step reliableIncrease drainage areaFluid removalStructural engineeringPetroleum engineering

Owner:CHINA PETROLEUM & CHEM CORP +1

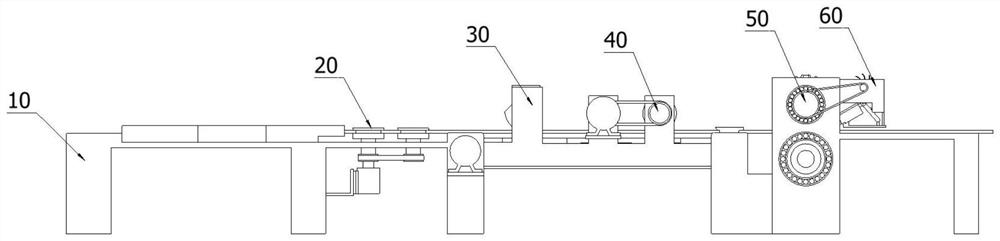

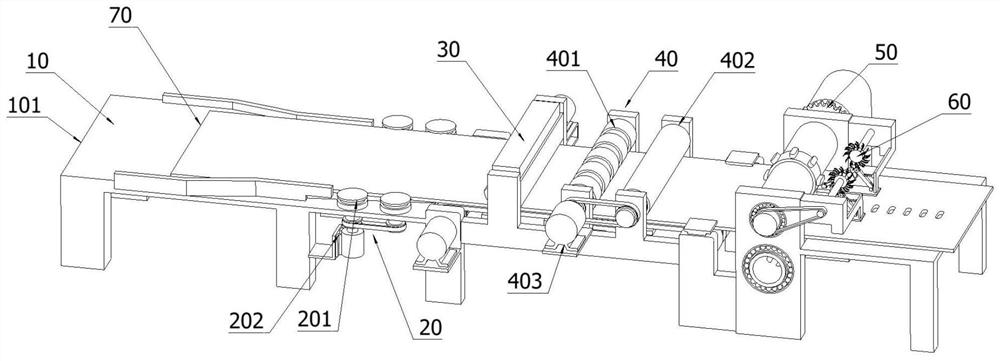

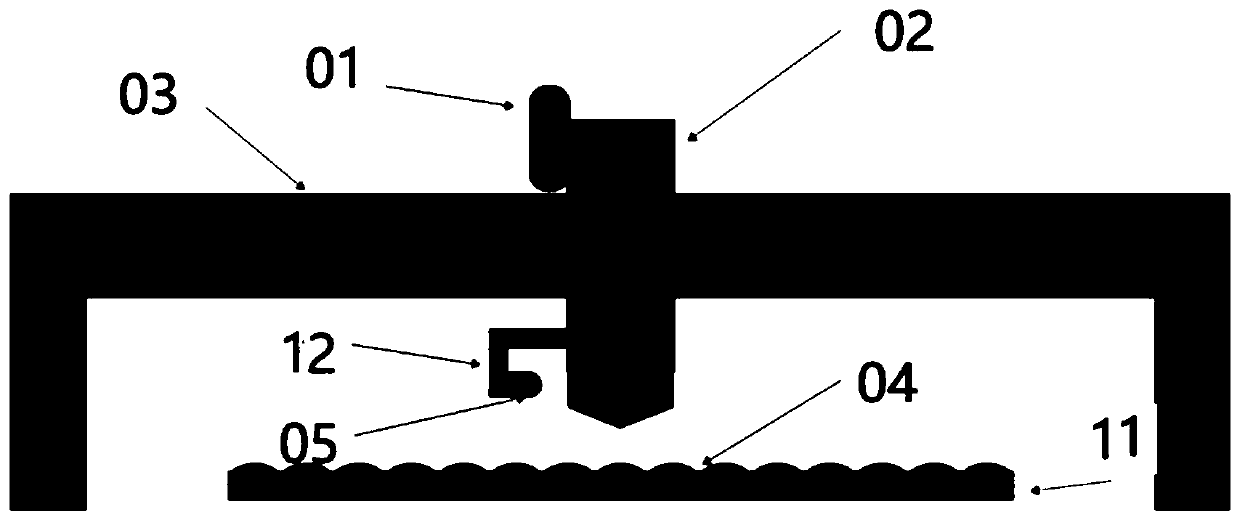

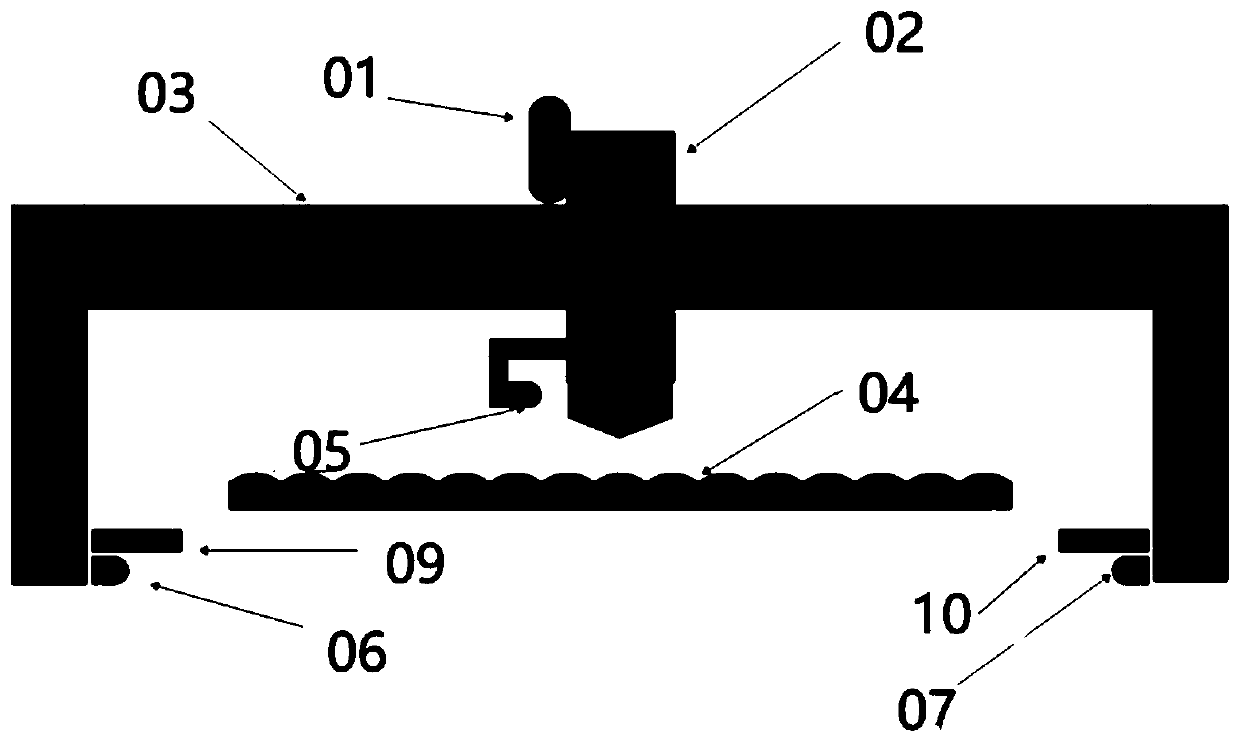

Flexible plate surface drilling device and drilling method

ActiveCN112157731AReduce qualityPrevent reduction of compaction effectStationary drilling machinesBark-zones/chip/dust/waste removalPunchingEngineering

The invention discloses a flexible plate surface drilling device, and relates to the technical field of plate punching. The flexible plate surface drilling device comprises a machine body, a conveyingdevice, a brushing device, a leveling device and a punching device; the machine body is arranged on a flat face, and the machine body comprises a first conveying channel, a second conveying channel,a third conveying channel and a limiting plate; the first conveying channel is located on the left side of the machine body, a guide plate is arranged on the surface of the first conveying channel, and the guide plate is in a contraction shape; the second conveying channel is located on the right side of the first conveying channel, and a conveying belt is arranged in the middle of the second conveying channel and movably connected with the second conveying channel; the third conveying channel is located on the right side of the second conveying channel, and the limiting plate is arranged at the tail end of the second conveying channel; and the conveying device is arranged on the surface of the first conveying channel, the brushing device is arranged above the second conveying channel, theleveling device is arranged above the second conveying channel, and the punching device is arranged above the third conveying channel. The flexible plate surface drilling device is used for solving the problem that the plate drilling efficiency is low due to the fact that a plate advances a little and then stops for drilling when the plate needs to be drilled every time in the prior art.

Owner:ZHANGJIAGANG SHENGGANG FIREPROOF BOARD IND & TECH

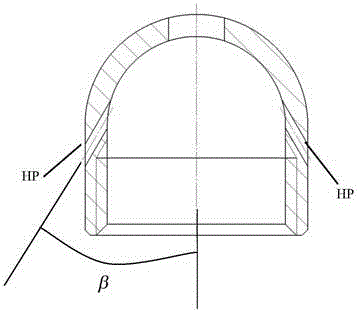

Jet gun

InactiveCN109798093AEffective ejectionRealize sandblasting and perforating operationsFluid removalRadial planeEngineering

The invention provides a jet gun used for fracturing operation. The jet gun comprises a body and a jet nozzle, wherein the body is provided with a cavity, the jet nozzle is formed in the body and provided with a jet hole, the jet hole is used for communicating the cavity with the outside, and a jet included angle A is formed between the axis of the jet hole and the radial plane of the body. The jet gun solves the problems of low sand jet perforation efficiency and short service life due to imperfect perforation of a jet gun in the prior art.

Owner:PETROCHINA CO LTD

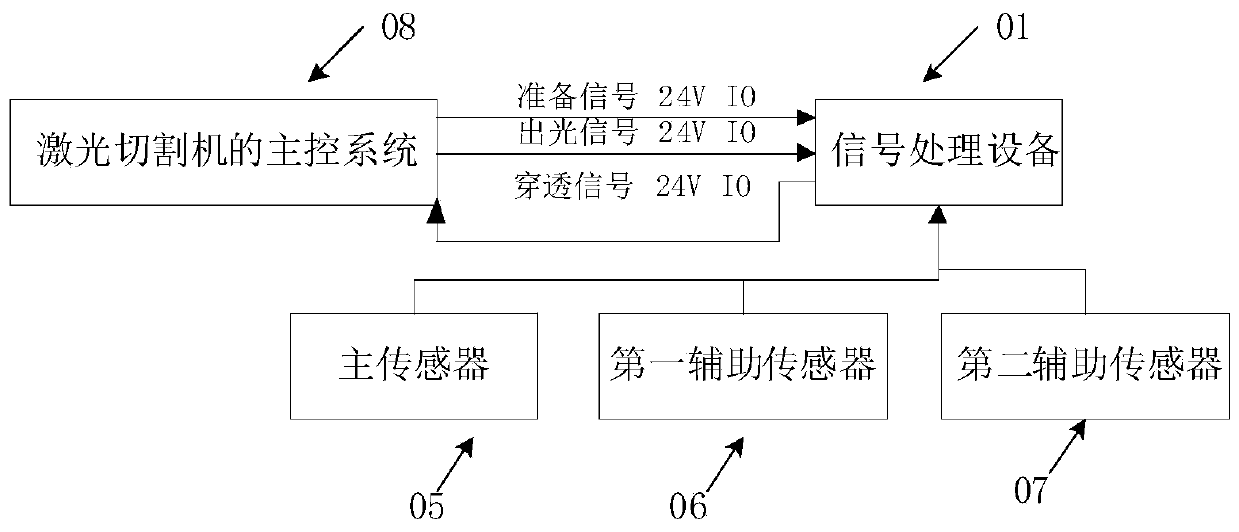

Laser perforating detection method and laser cutting machine

ActiveCN110480191AReduce processing efficiencyImprove processing efficiencyOptical detectionPhotometry using electric radiation detectorsElectricityCycle control

The invention discloses a laser perforating detection method and a laser cutting machine. A signal processing unit and at least one sensor for detecting signals indicating that laser penetrates through a plate are arranged on a laser head body of the laser cutting machine, and the sensors are located on the outer portion of the laser head body and electrically connected with the signal processingunit. The method comprises the steps that a main control system of the laser cutting machine sends a laser emitting signal to the signal processing unit; the main control system receives a penetrating-through signal fed back by the signal processing unit; in the laser-emitting period of the laser head body, the signal processing unit processes detecting signals of all the sensors, and a signal with a penetrating-through state as a obtained laser perforating state is the penetrating-through signal; and the main control system carries out closed-cycle control over the laser perforating detectingprocess according to the penetrating-through signal. By means of the method, the defect that the cutting technology descends as a fixed duration is set for laser perforating in the existing technology can be overcome.

Owner:JINAN BODOR LASER CO LTD

Laser for laser cutting machine

ActiveCN105846293AAvoid backtrackingIncrease profitActive medium shape and constructionLaser beam welding apparatusLow-pass filterFiber Bragg grating

The invention discloses a laser for a laser cutting machine. A clad fiber comprises a laser gain medium fiber core arranged in the middle. The laser gain medium fiber core is wrapped by a glass isolating layer, a fluorescent material layer and an outer cladding layer from the inside out in sequence. The input end and the output end of the clad fiber are provided with a first fiber Bragg grating and a second fiber Bragg grating respectively; the end surface, arranged at the side of a pump light source, of the clad fiber is provided with a tail mirror; a first lens and a second lens are arranged between the clad fiber and a transmission fiber in sequence; a low-pass filter mirror and a focusing mirror are sequentially arranged right under a semi-reflection semi-permeable lens from upward down; the focusing mirror receives reflection light from the semi-reflection semi-permeable lens; an imager is arranged at one side of the focusing mirror and is used for receiving light rays from the focusing mirror; and the cross section of the glass isolating layer is in D shape. Cutting speed is improved; high-power cutting can be tried, and cutting speed is fast and power redundancy is small; and laser energy can be utilized fully.

Owner:沧州领创激光科技有限公司

Combined type jet perforating device

PendingCN109751030AStrong backflow vortex phenomenonImprove perforation efficiencyLiquid/gas jet drillingFluid removalSpray nozzleNatural gas

The invention relates to a combined type jet flow perforating device which is used for treating hard rocks and stratums in an exploitation process of natural gas and the like and comprises a body in acylindrical shape, at least one direct flow nozzle disposed on the body, and at least two inclined jet nozzles arranged on the body, wherein the inclined jet flow nozzles with opposite inclined directions are symmetrically arranged on two sides of the direct flow nozzle. A reverse flow of the inclined jet flow nozzle is mixed with a direct flow before being sprayed to the surface of the perforating device, so that the reverse flow is reduced, the damage of the jet reverse flow to the spraying tool is reduced, and the service life of the perforating device is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Spark-erosion perforating machine guide device

PendingCN107824916AImprove perforation efficiencyIncrease water pressureElectrical-based auxillary apparatusElectric dischargePulp and paper industry

The invention relates to a guide device for an electric spark perforator, which includes a guide, a guide seat and a guide bracket. The upper section matches the middle section of the guide, the guide bracket includes a positioning through hole, the upper part of the guide seat is set above the positioning through hole, and the lower part of the guide seat matches the positioning through hole, and is set in the cavity of the guide seat The middle section of the guider is located in the positioning through hole, and the lower section of the guider is located below the positioning through hole; there is a circle of water tank outside the middle section of the guider, and the guide bracket is provided with a water inlet hole that is connected to the water tank, and the lower end surface of the water tank passes to the guider. A plurality of water channels are arranged through the bottom of the lower section, the water inlet holes are connected with the water channels, a center hole is arranged in the center of the guide, and the water channels are arranged outside the center hole. The invention can concentrate flushing of multiple water channels, increase the water pressure, prevent the water flow from spilling outwards, and ensure the chip flushing effect.

Owner:苏州亚马森机床有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com