Fast hole punching device for shoe making

A piercing device and fast technology, applied in shoemaking machinery, footwear, applications, etc., can solve the problems of low perforation efficiency, achieve strong corrosion resistance, fast and convenient movement, and are not easy to be damaged by corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

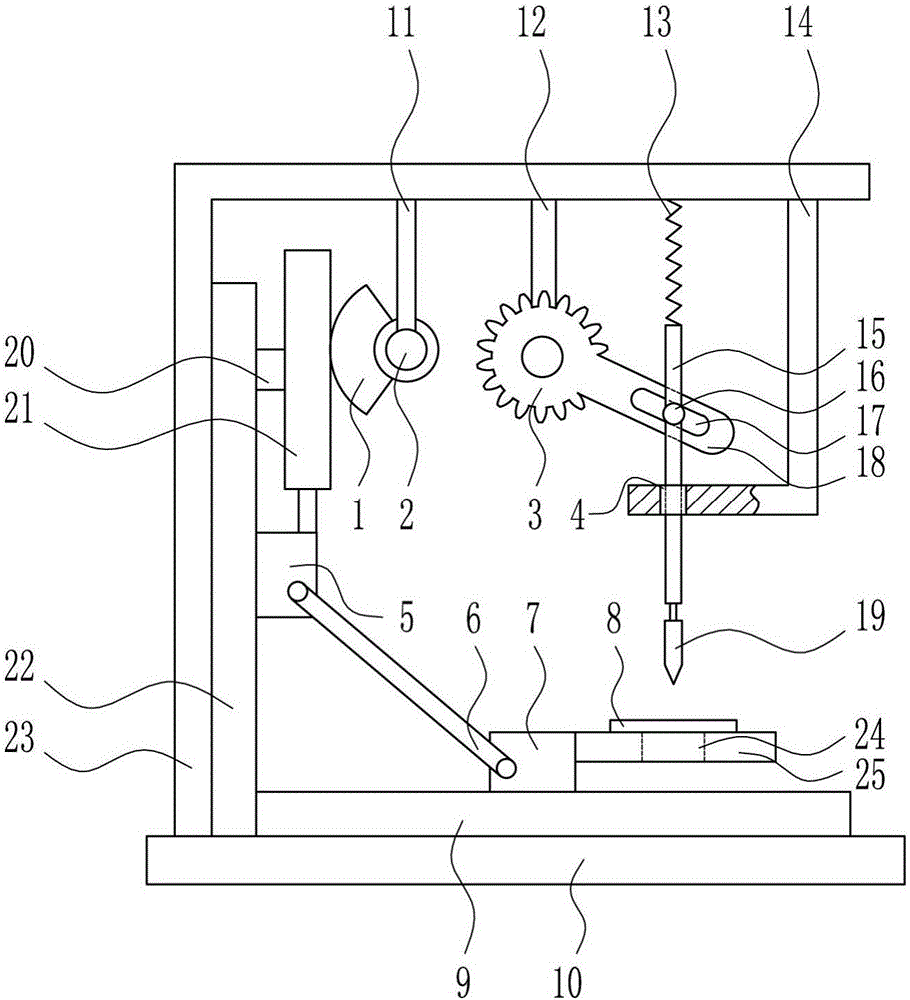

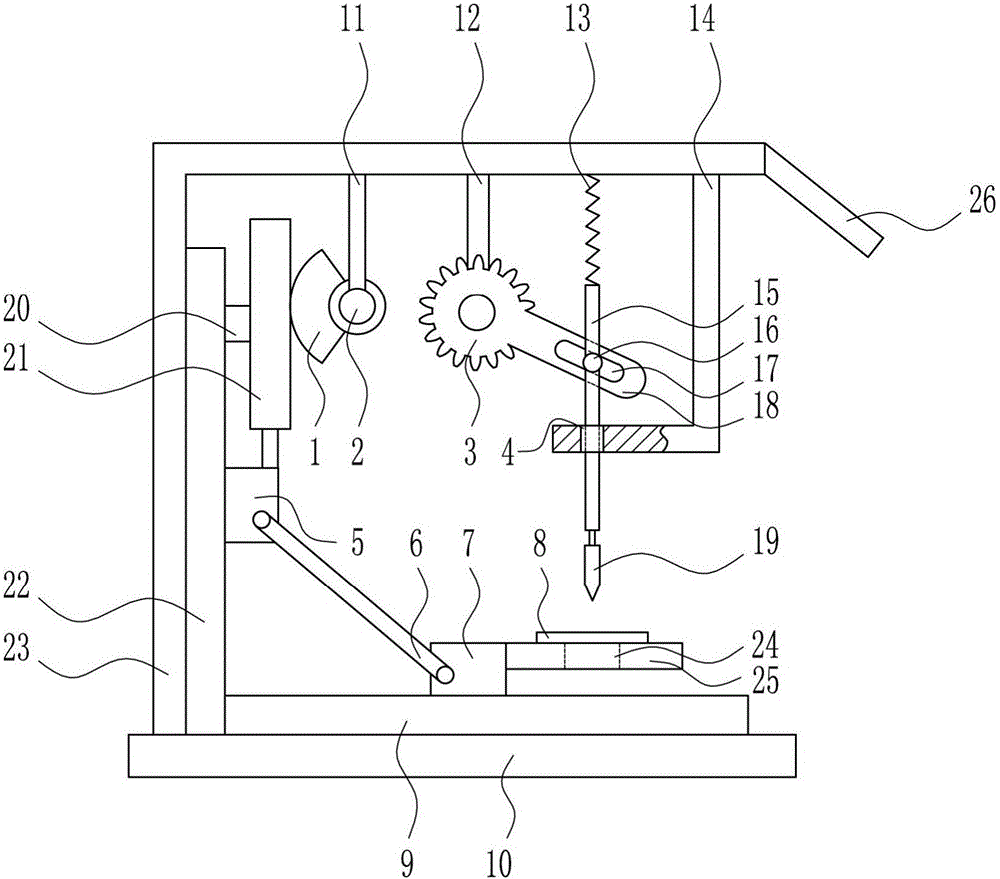

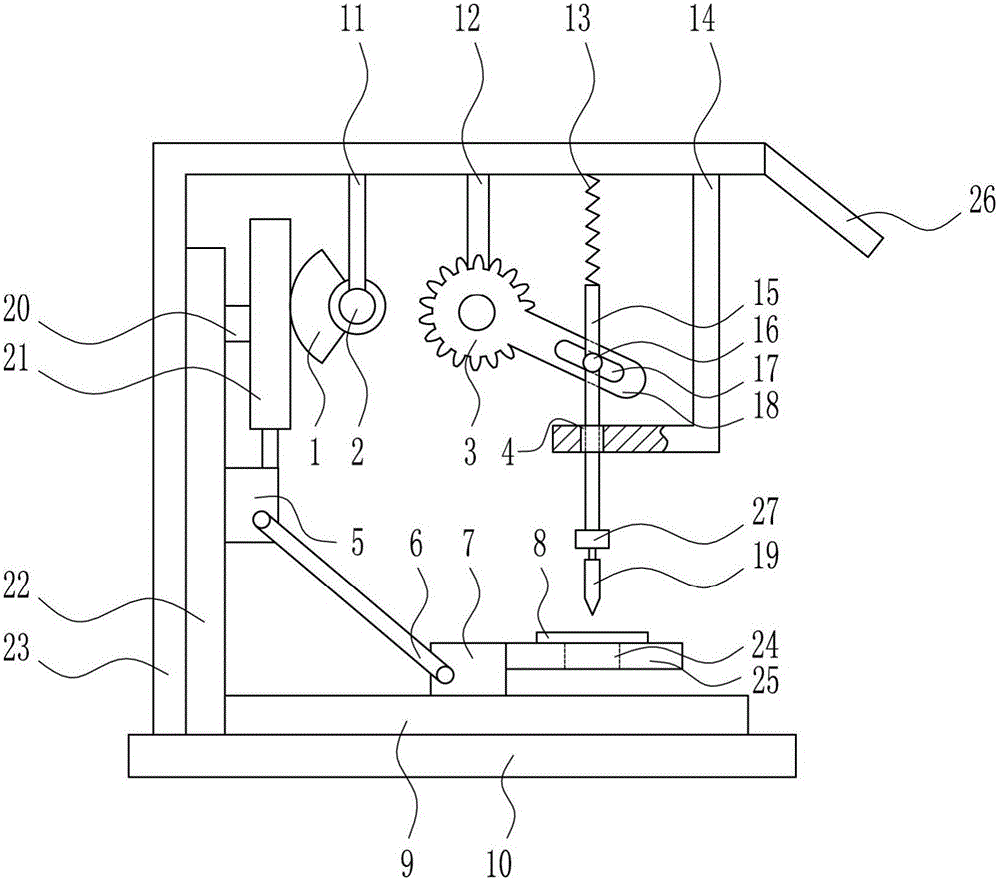

[0041] A quick perforating device for shoemaking, such as Figure 1-9 As shown, it includes a sector gear 1, a first rotating motor 2, a first gear 3, a first slider 5, a first swing lever 6, a second slider 7, a second slide rail 9, a bottom plate 10, a first support Rod 11, second pole 12, spring 13, guide plate 14, lifting rod 15, slide shaft 16, second swing rod 18, drill rod 19, third slider 20, rack 21, first slide rail 22, Support 23 and placement plate 25; Base plate 10 top is provided with support 23, first slide rail 22 and second slide rail 9 successively from left to right, and first slide rail 22 is positioned on the left side in support 23, and first slide rail 22 The third slider 20 and the first slider 5 are arranged on the top, the third slider 20 is located above the first slider 5, the third slider 20 is provided with a rack 21, the bottom of the first slider 5 and the rack 21 connection, the first slider 5 is hingedly connected with the first swing lever 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com