Patents

Literature

4775results about "Electrical-based auxillary apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

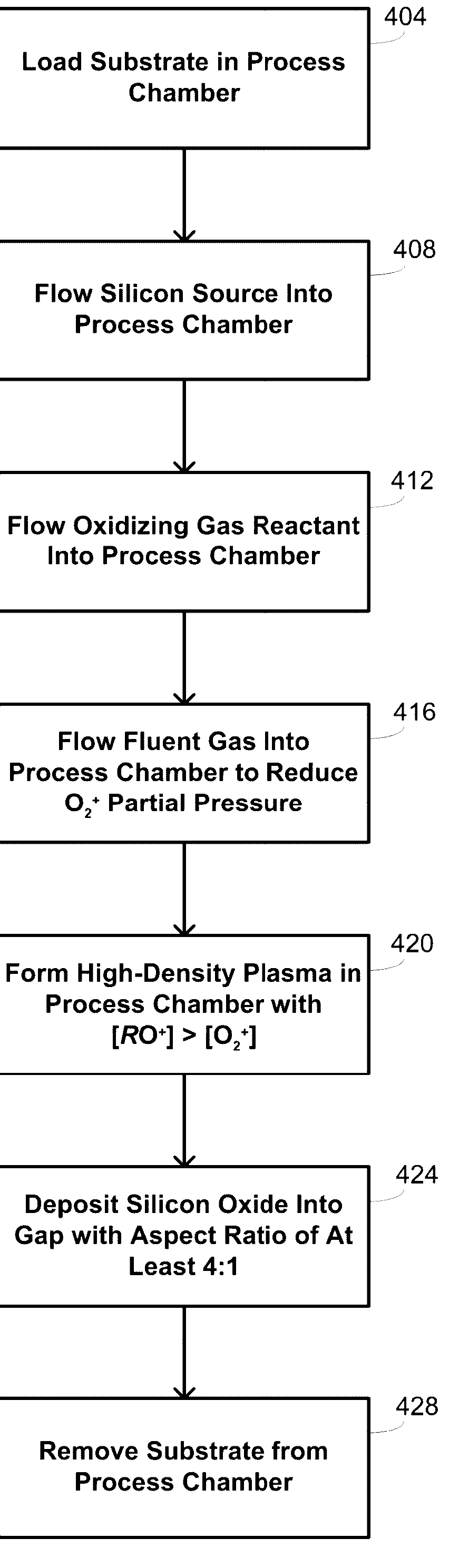

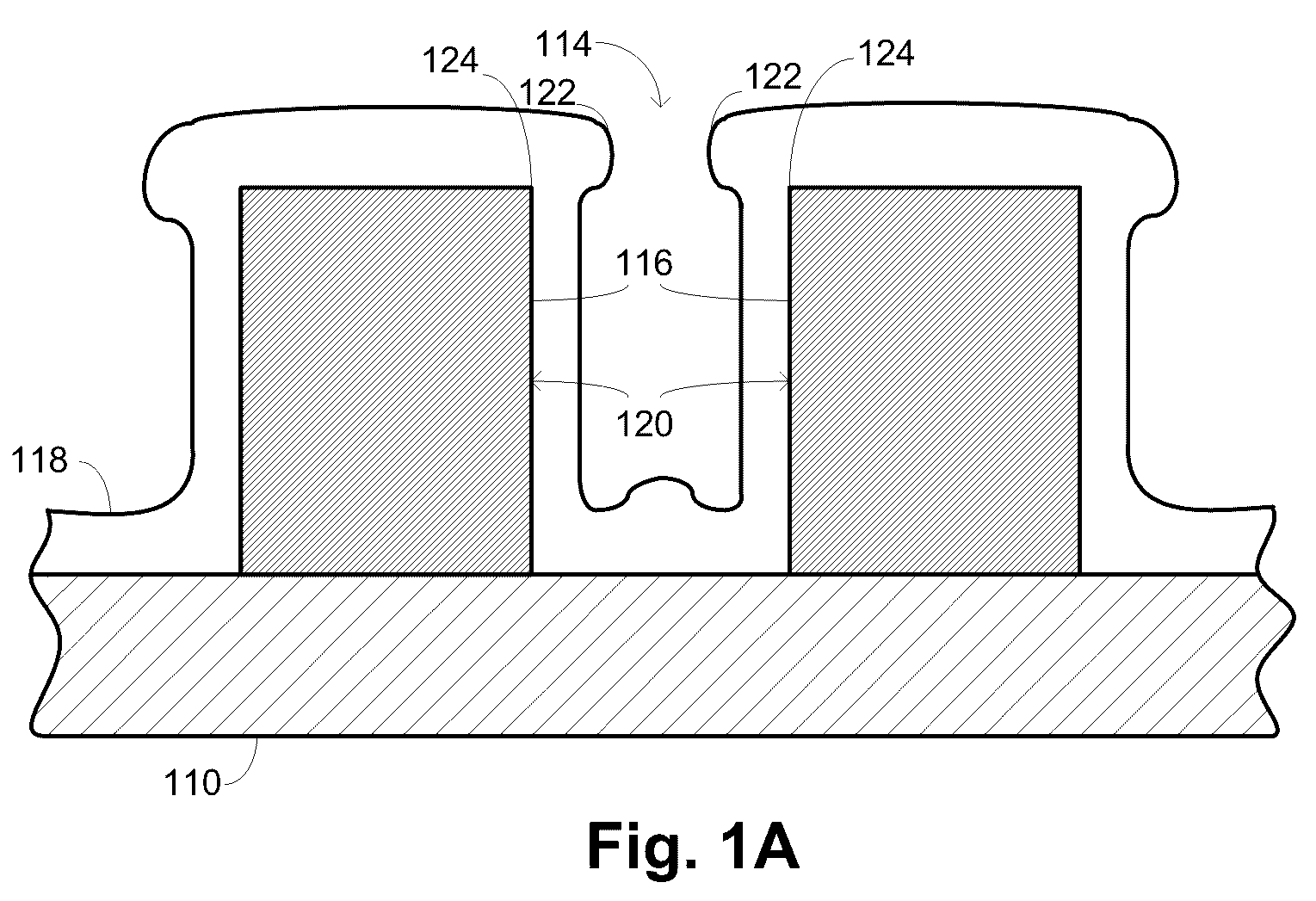

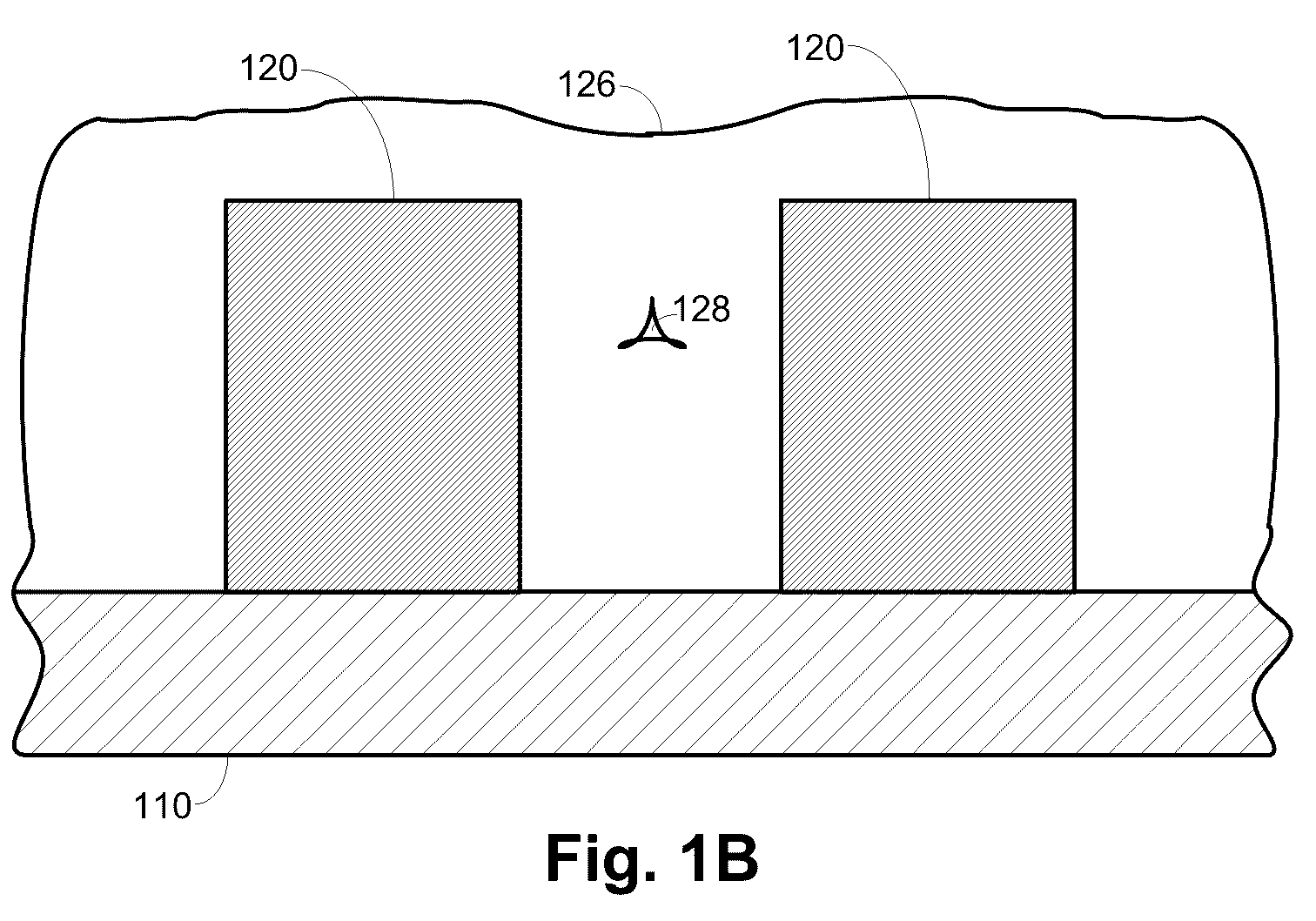

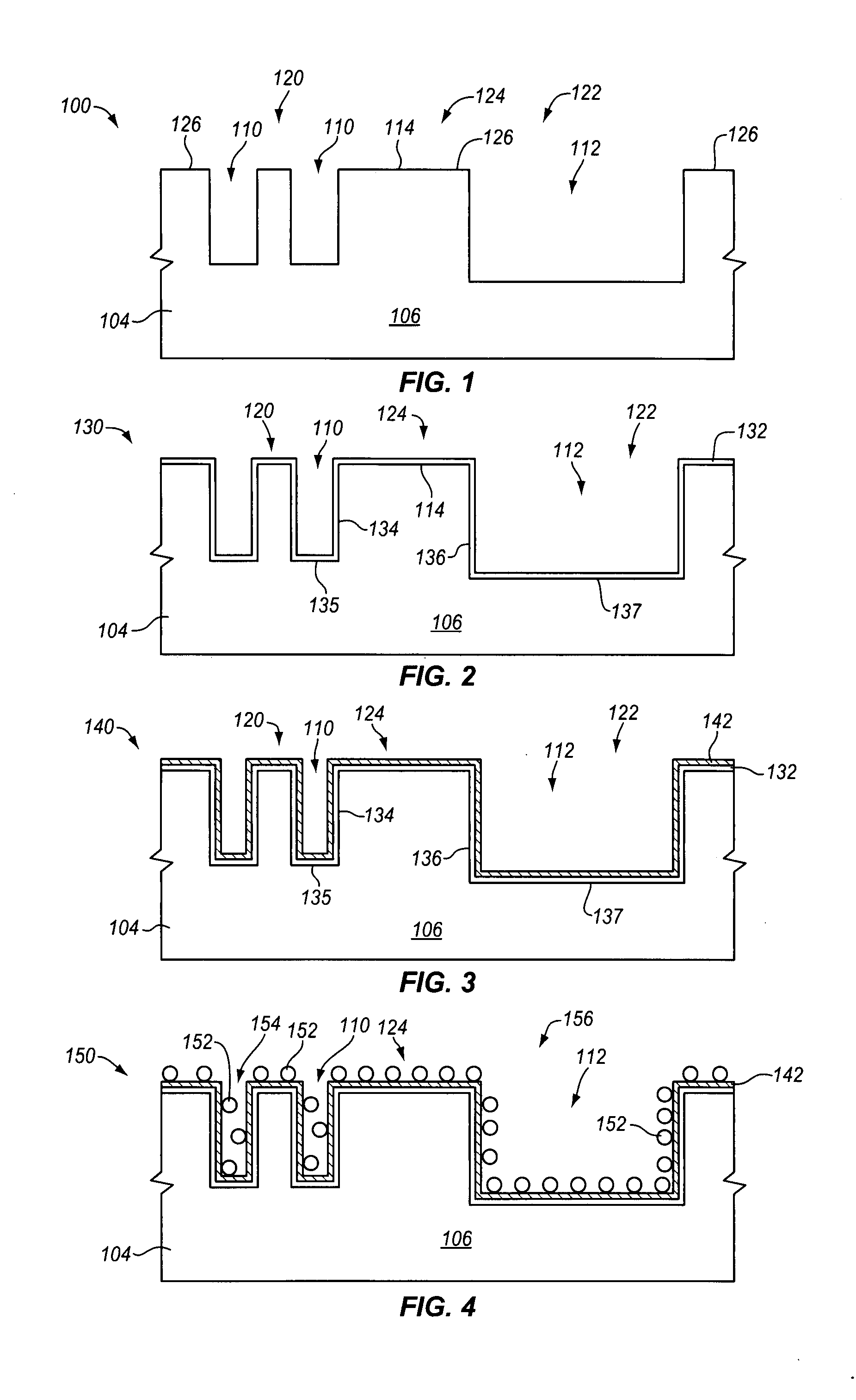

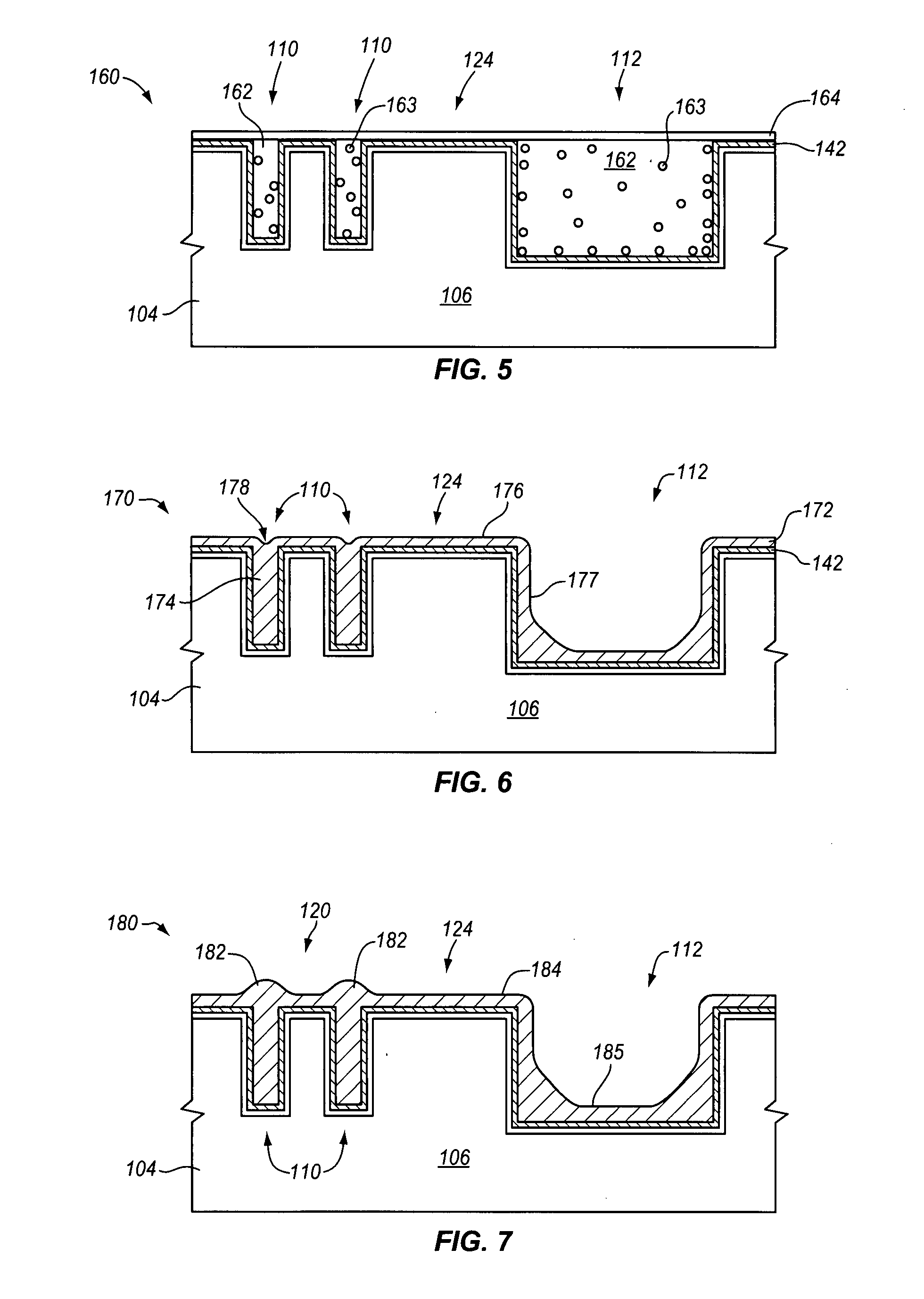

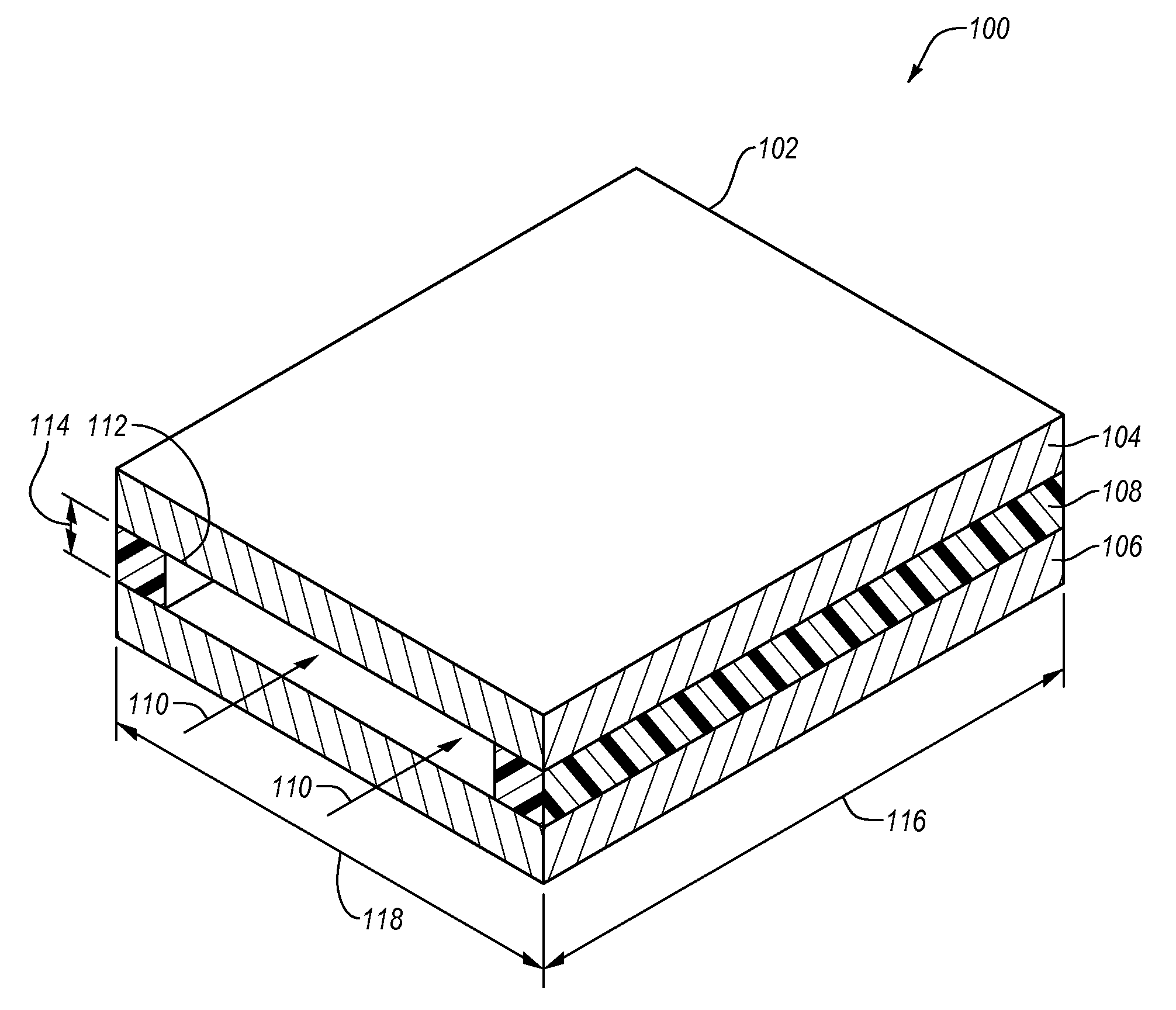

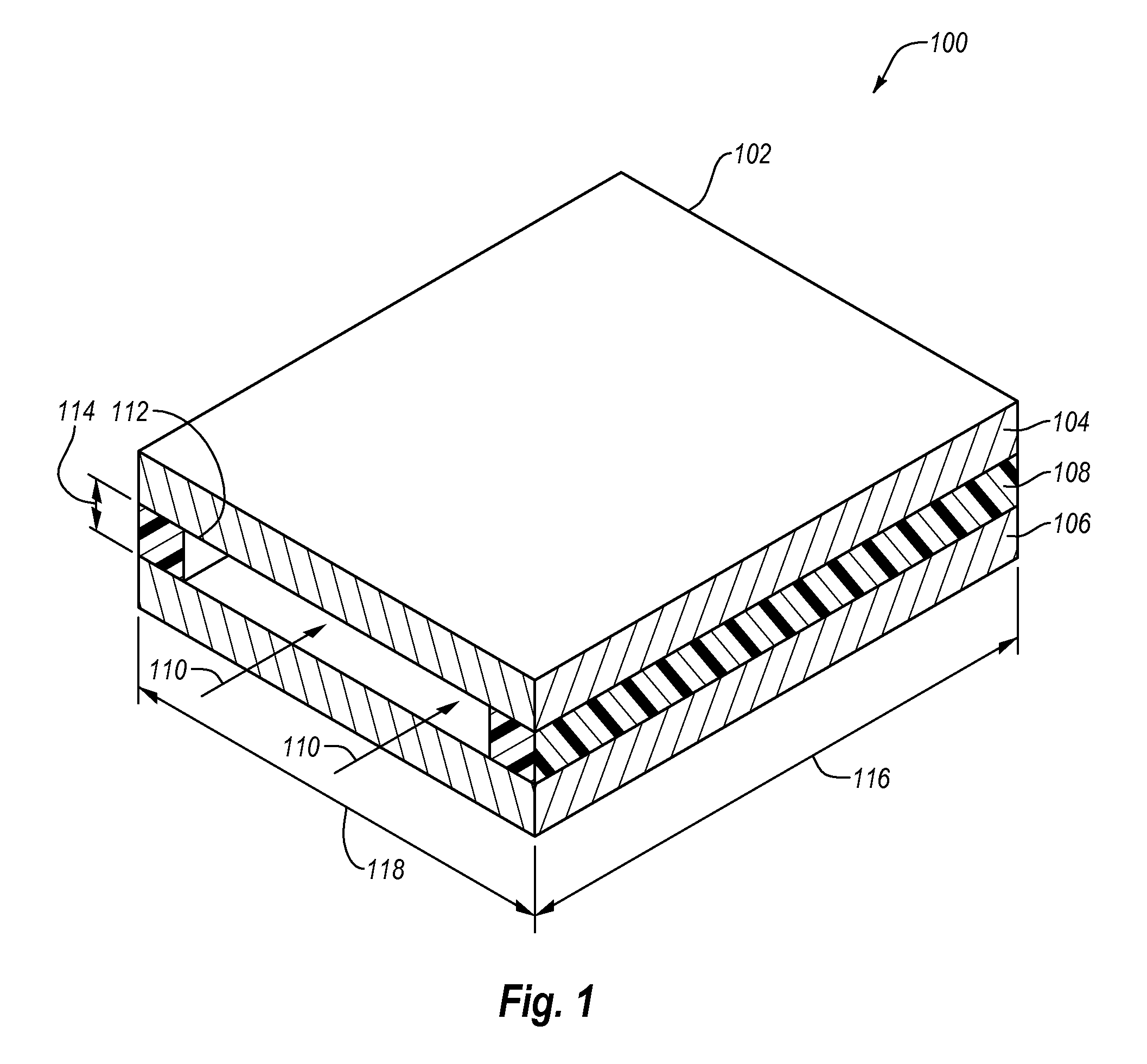

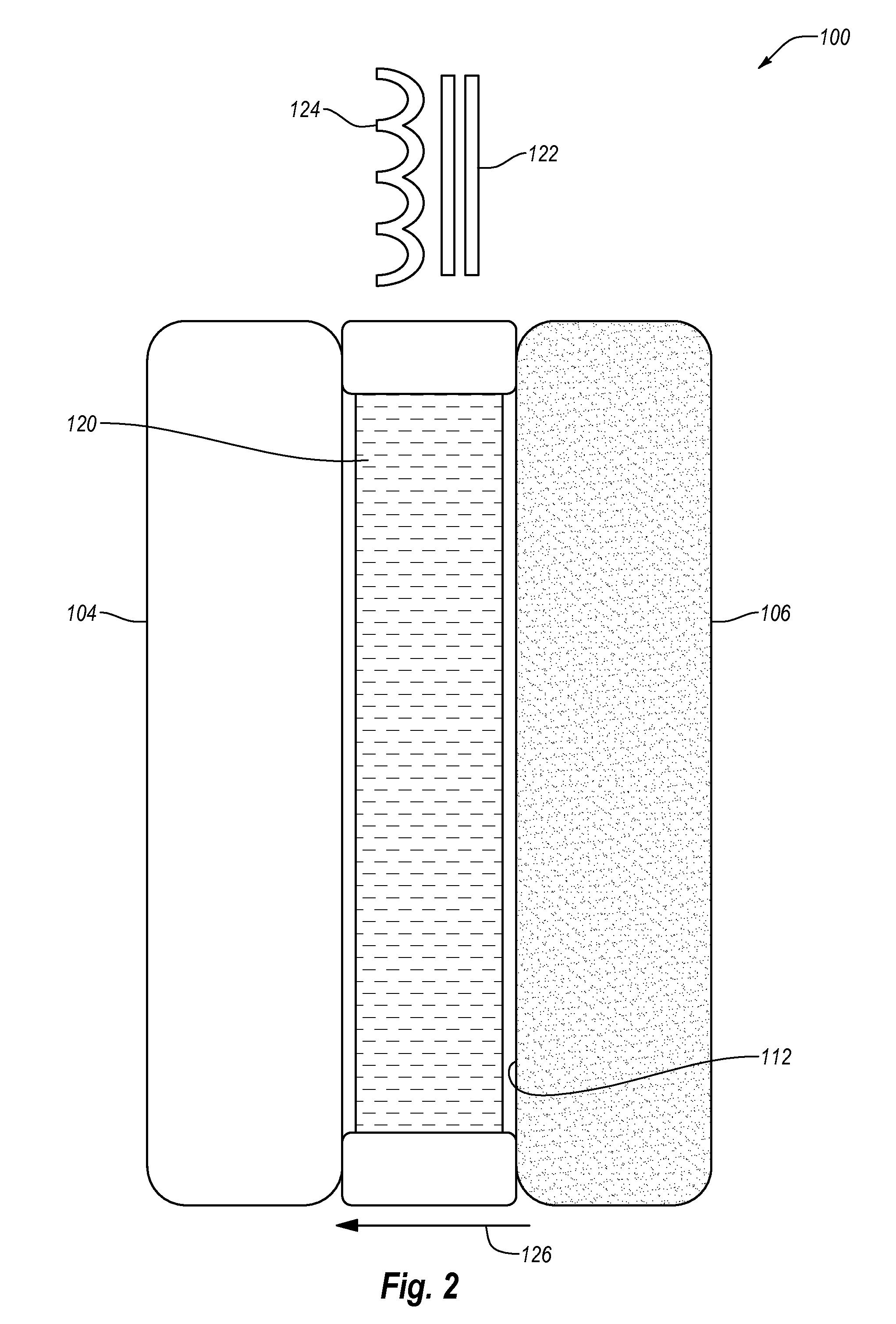

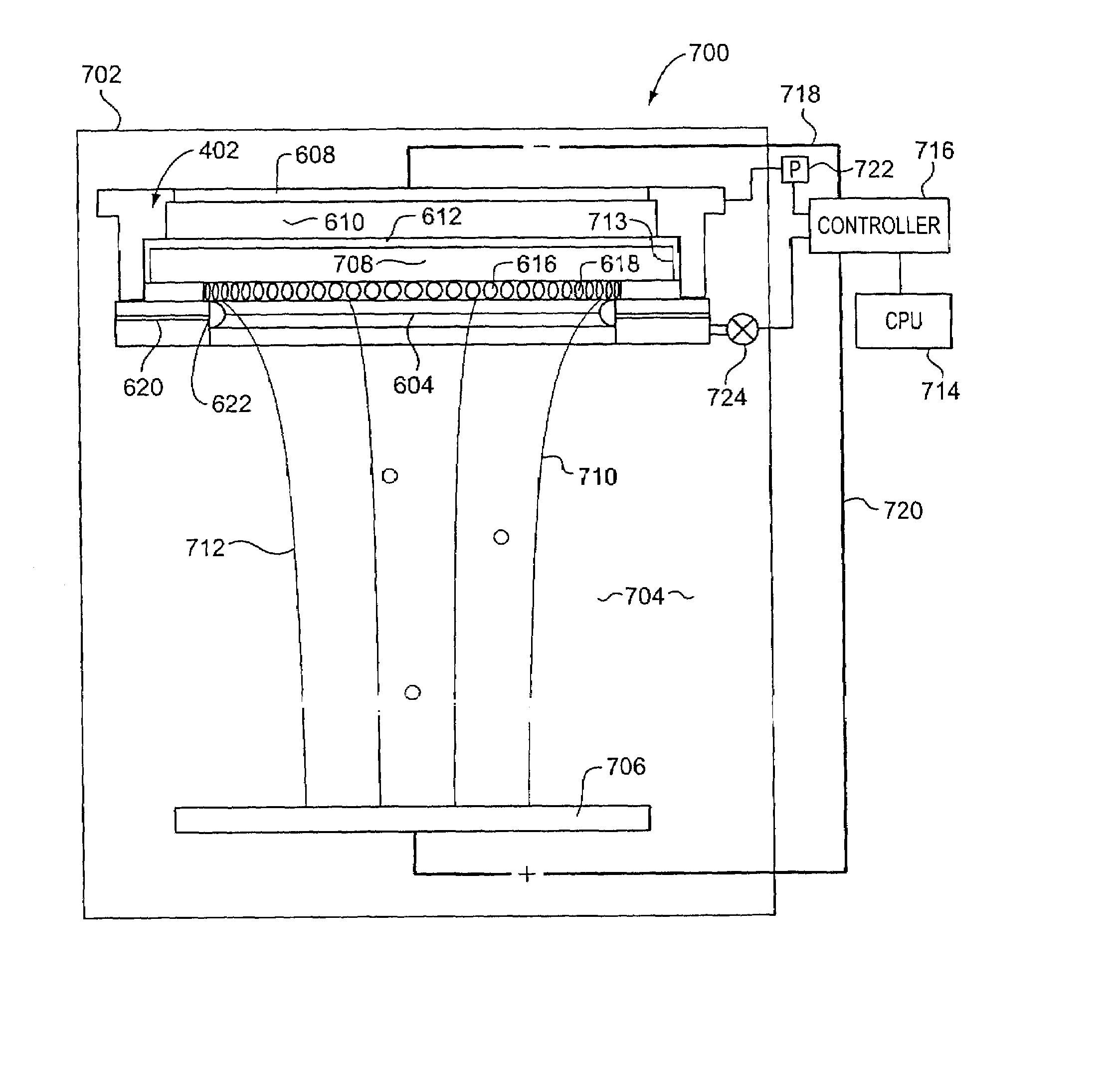

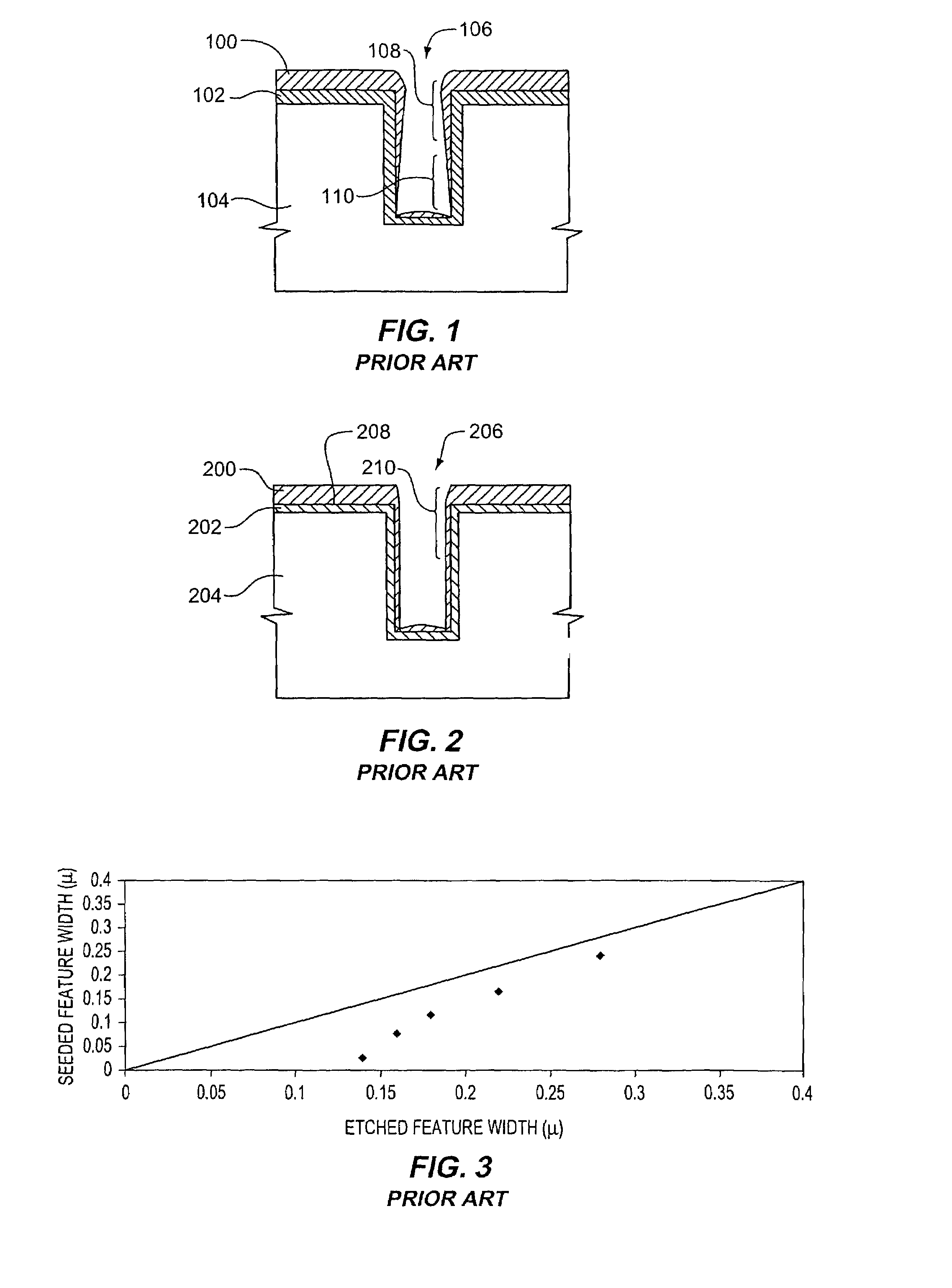

Hdp-cvd multistep gapfill process

InactiveUS20040245091A1Reduce molecular weightReduced sputtering characteristicVacuum evaporation coatingSputtering coatingProduct gasChemistry

Abstract of the Disclosure A gapfill process is provided using cycling of HDP-CVD deposition, etching, and deposition step. The fluent gas during the first deposition step includes an inert gas such as He, but includes H2 during the remainder deposition step. The higher average molecular weight of the fluent gas during the first deposition step provides some cusping over structures that define the gap to protect them during the etching step. The lower average molecular weight of the fluent gas during the remainder deposition step has reduced sputtering characteristics and is effective at filling the remainder of the gap.

Owner:APPLIED MATERIALS INC

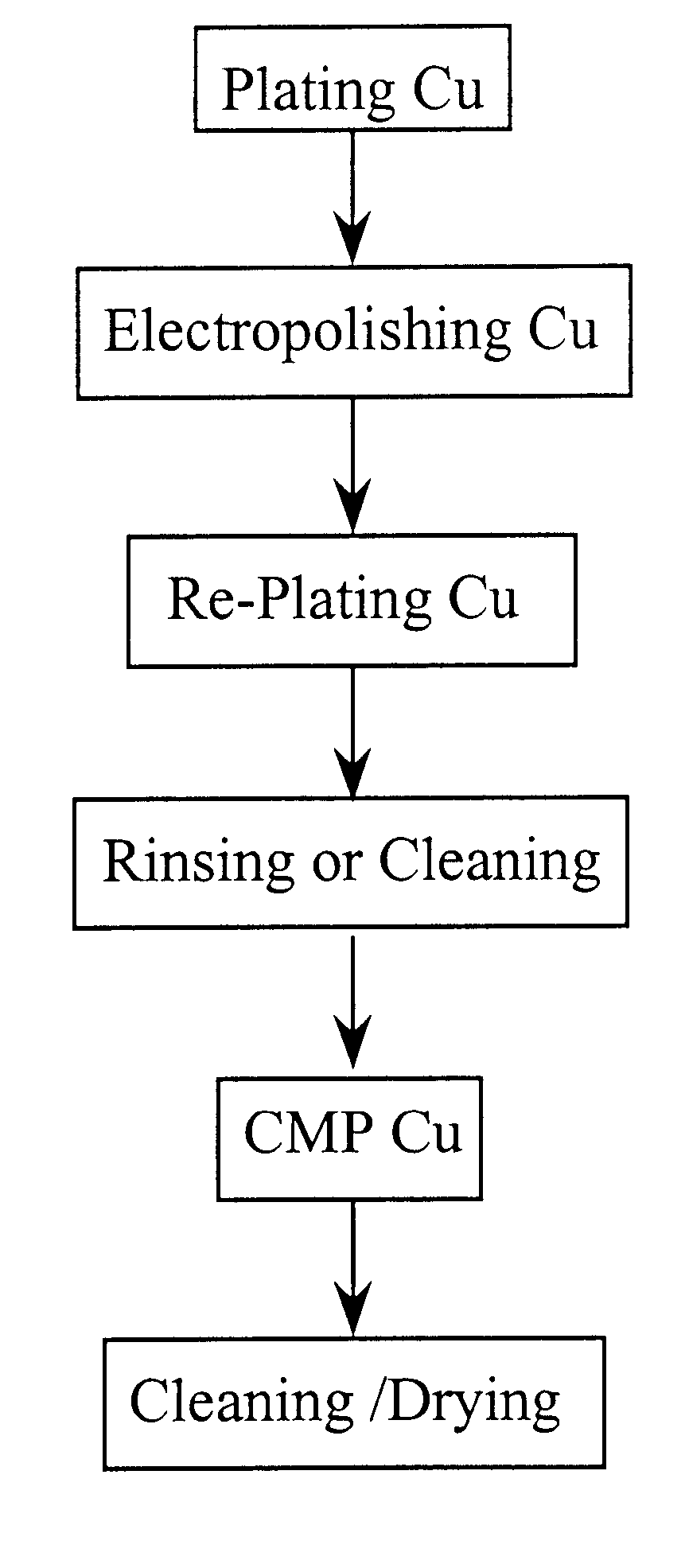

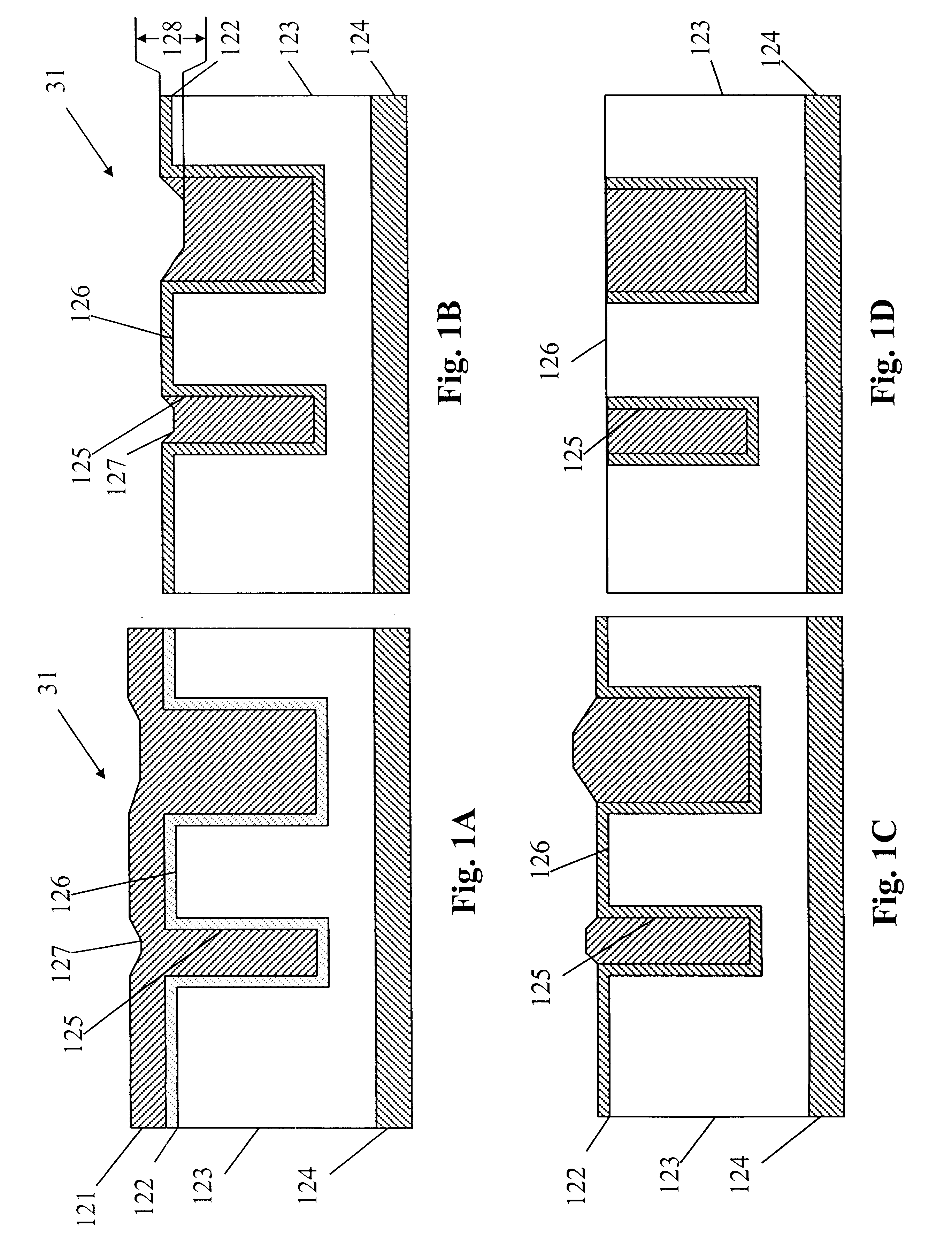

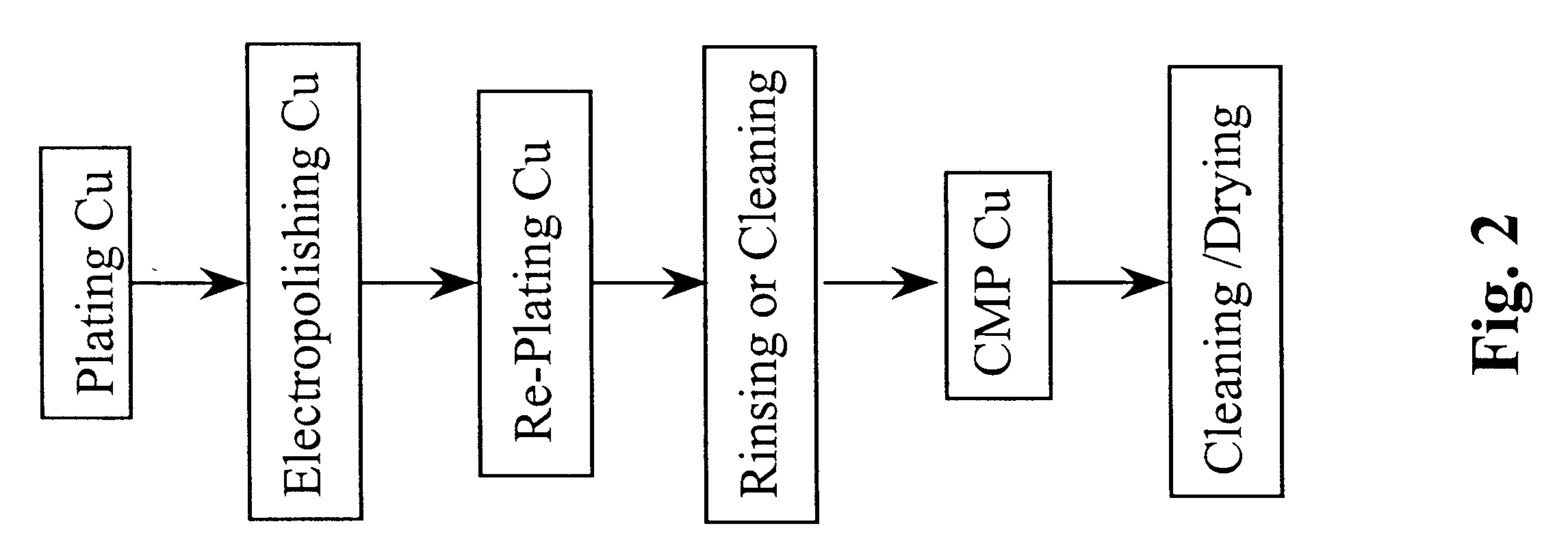

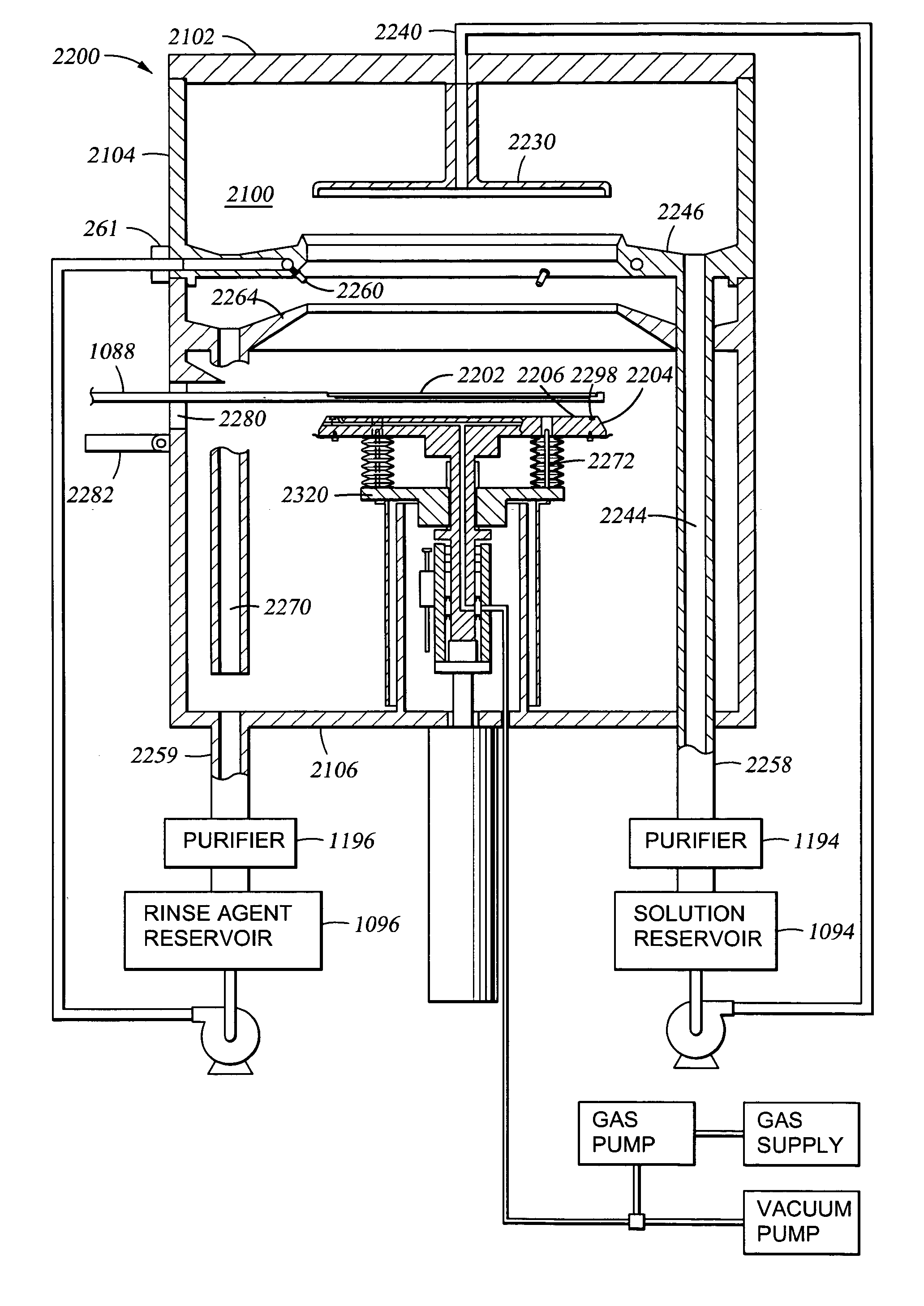

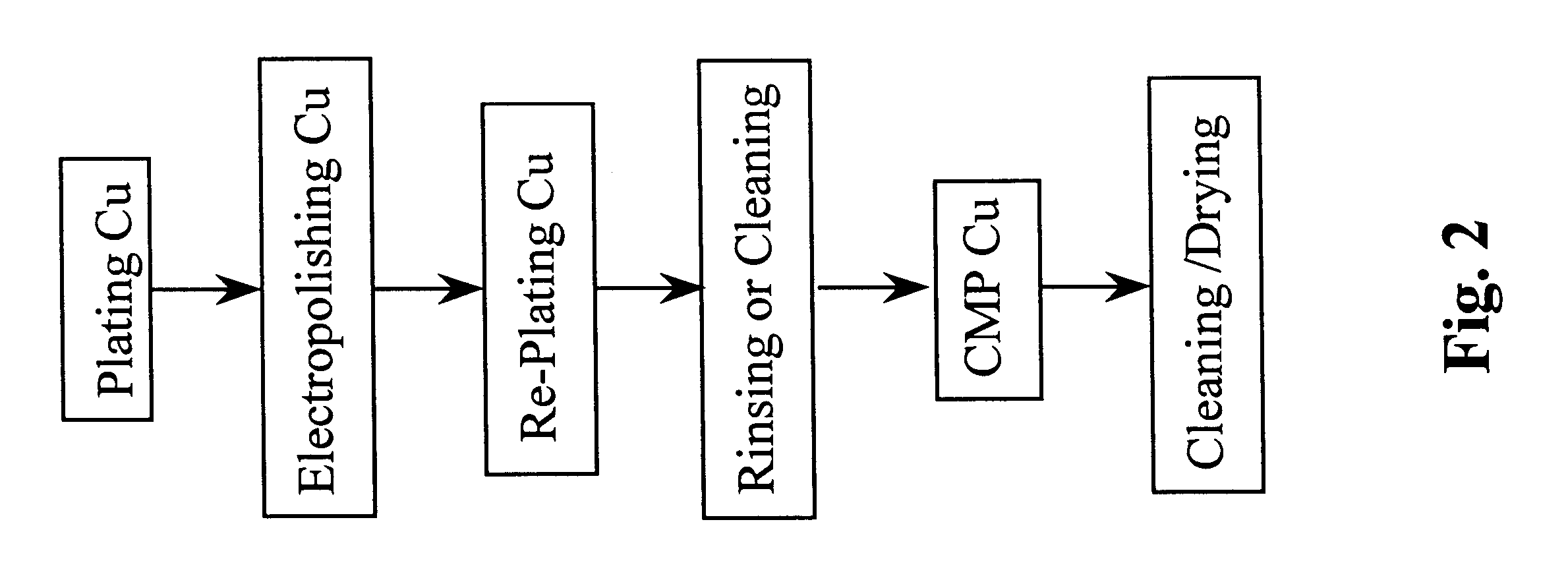

Method for electropolishing metal on semiconductor devices

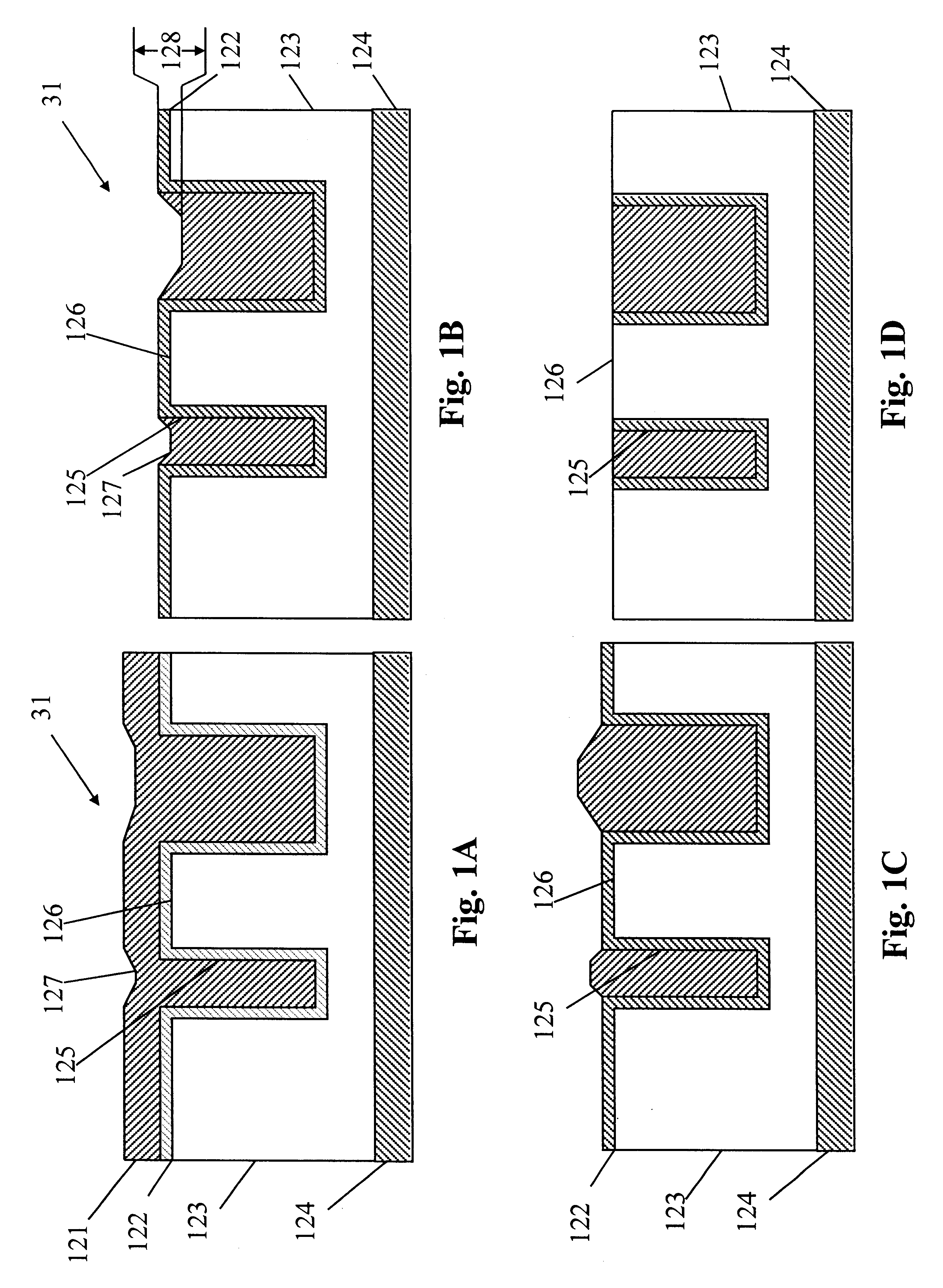

An electropolishing apparatus for polishing a metal layer formed on a wafer (31) includes an electrolyte (34), a polishing receptacle (100), a wafer chuck (29), a fluid inlet (5, 7, 9), and at least one cathode (1, 2, 3). The wafer chuck (29) holds and positions the wafer (31) within the polishing receptacle (100). The electrolyte (34) is delivered through the fluid inlet (5, 7, 9) into the polishing receptacle (100). The cathode (1, 2, 3) then applies an electropolishing current to the electrolyte to electropolish the wafer (31). In accordance with one aspect of the present invention, discrete portions of the wafer (31) can be electropolished to enhance the uniformity of the electropolished wafer.

Owner:ACM RES

Electroless deposition apparatus

An apparatus and a method of depositing a catalytic layer comprising at least one metal selected from the group consisting of noble metals, semi-noble metals, alloys thereof, and combinations thereof in sub-micron features formed on a substrate. Examples of noble metals include palladium and platinum. Examples of semi-noble metals include cobalt, nickel, and tungsten. The catalytic layer may be deposited by electroless deposition, electroplating, or chemical vapor deposition. In one embodiment, the catalytic layer may be deposited in the feature to act as a barrier layer to a subsequently deposited conductive material. In another embodiment, the catalytic layer may be deposited over a barrier layer. In yet another embodiment, the catalytic layer may be deposited over a seed layer deposited over the barrier layer to act as a “patch” of any discontinuities in the seed layer. Once the catalytic layer has been deposited, a conductive material, such as copper, may be deposited over the catalytic layer. In one embodiment, the conductive material is deposited over the catalytic layer by electroless deposition. In another embodiment, the conductive material is deposited over the catalytic layer by electroless deposition followed by electroplating or followed by chemical vapor deposition. In still another embodiment, the conductive material is deposited over the catalytic layer by electroplating or by chemical vapor deposition.

Owner:APPLIED MATERIALS INC

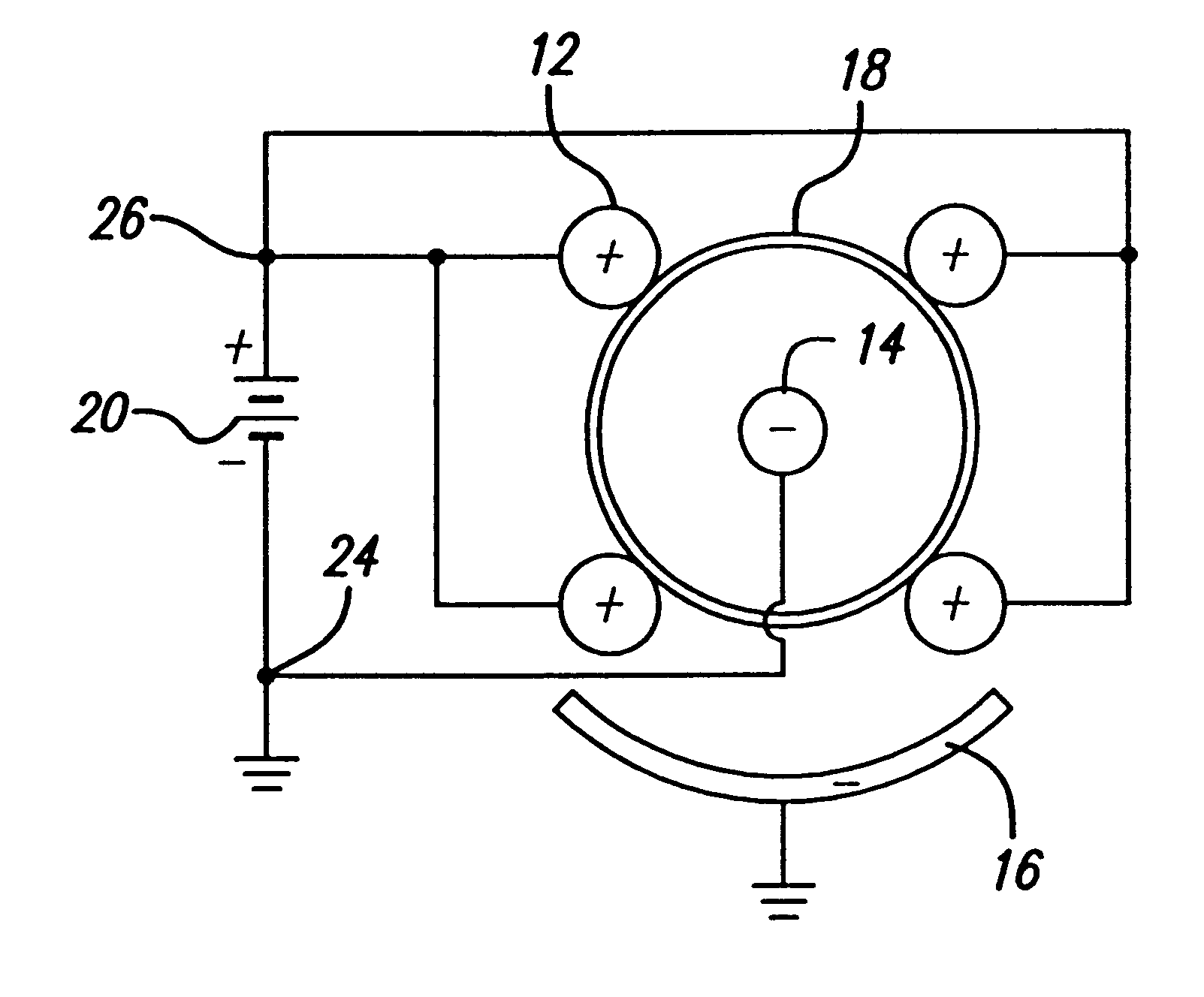

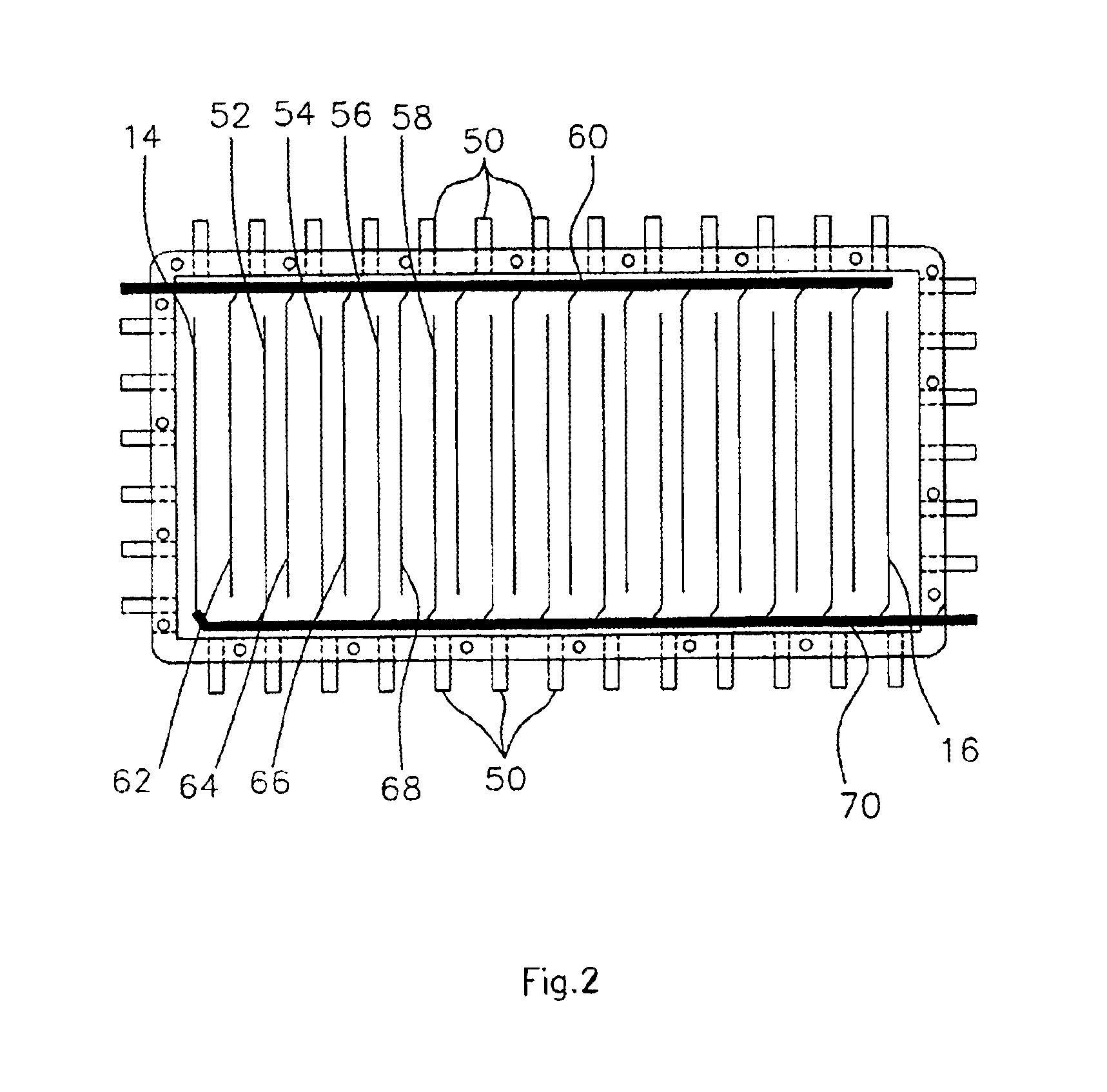

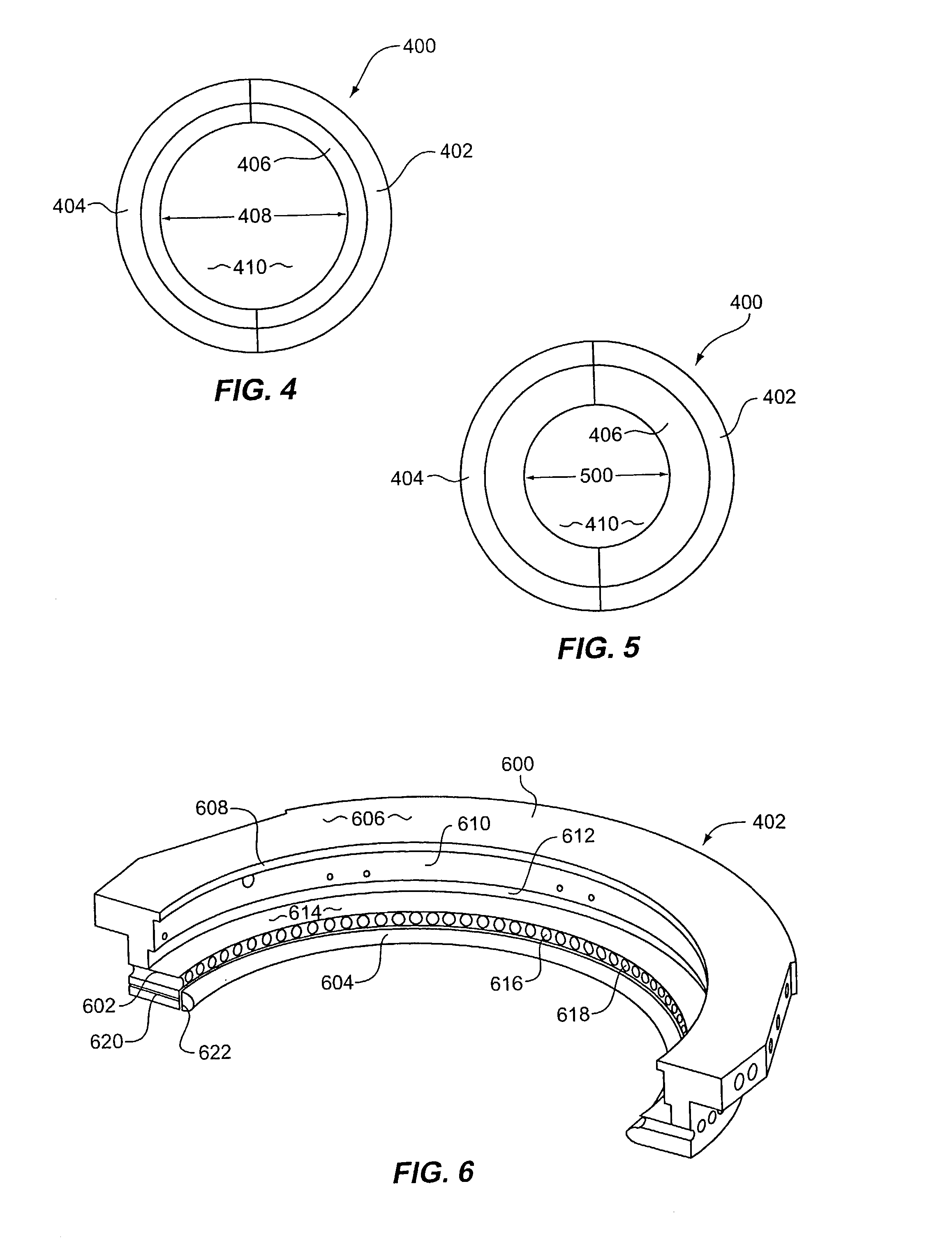

Electro-polishing fixture and electrolyte solution for polishing stents and method

An electro-polishing fixture for polishing stents which incorporates multiple anodes in contact with the stent and a center cathode disposed coaxially within the interior of the stent and a curved exterior cathode disposed about the perimeter of the stent. The invention further includes an electrolyte solution adapted for polishing stents composed of nickel-titanium alloy and a method of using the electrolyte in combination with the electro-polishing fixture.

Owner:ABBOTT CARDIOVASCULAR

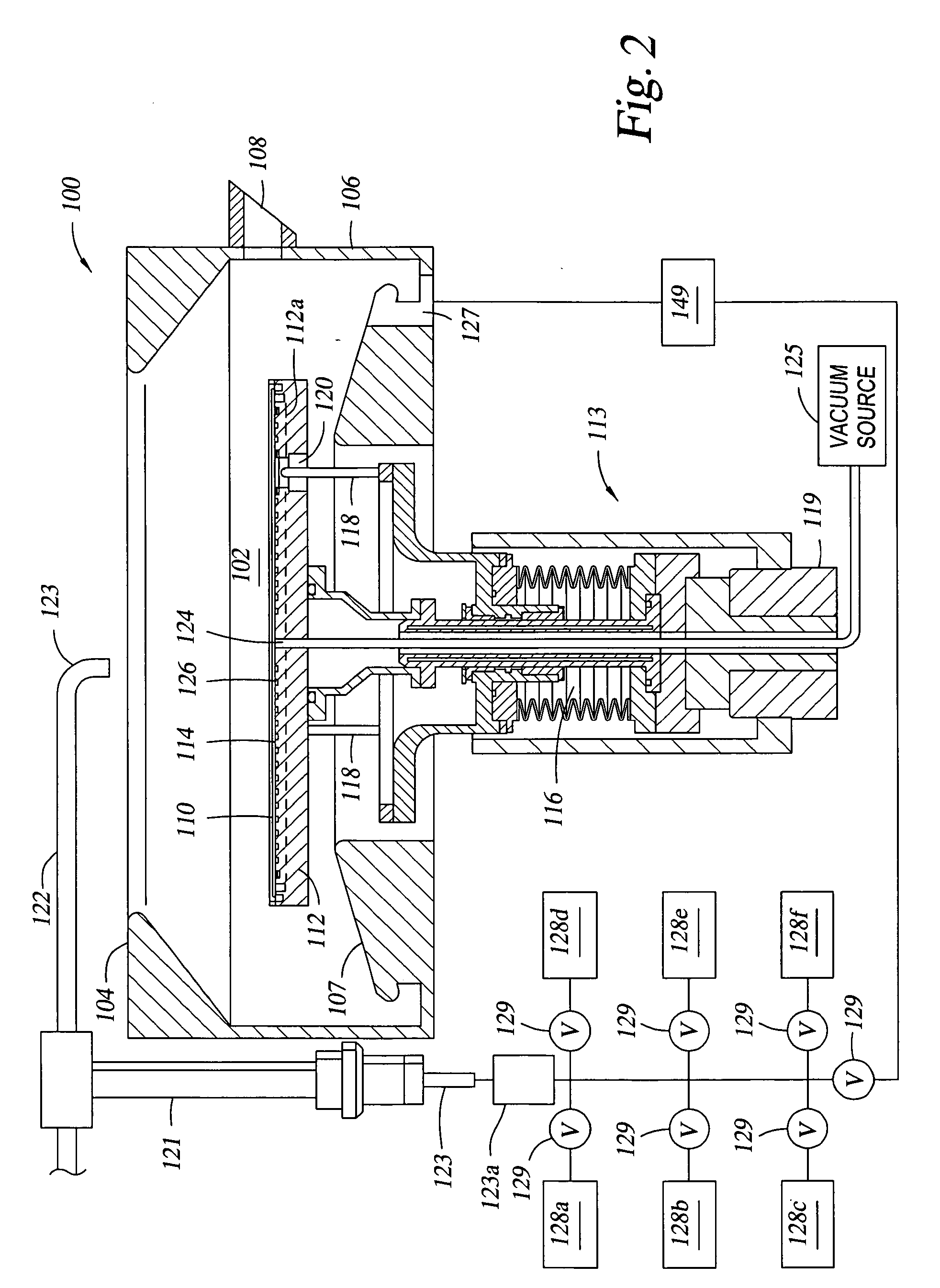

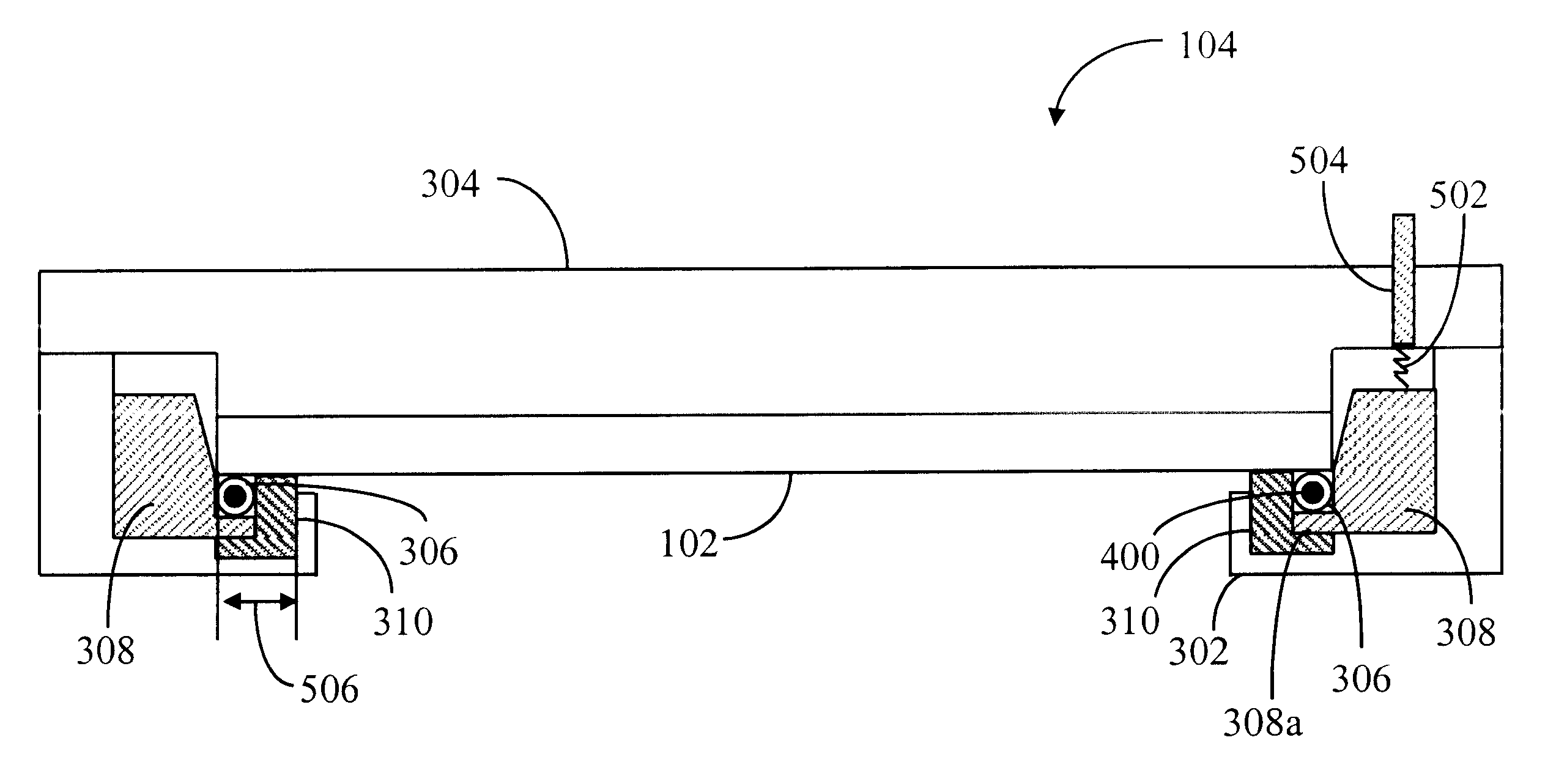

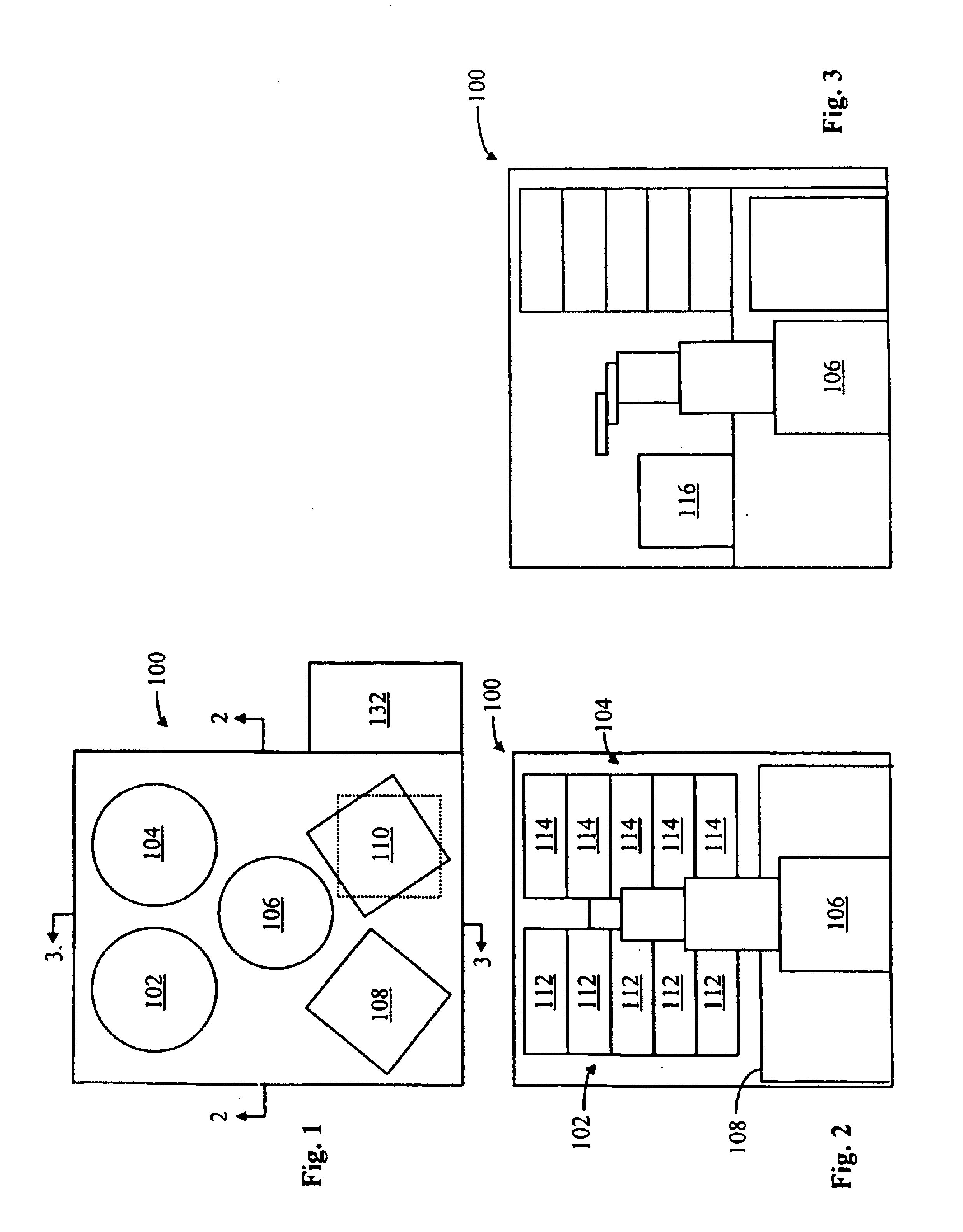

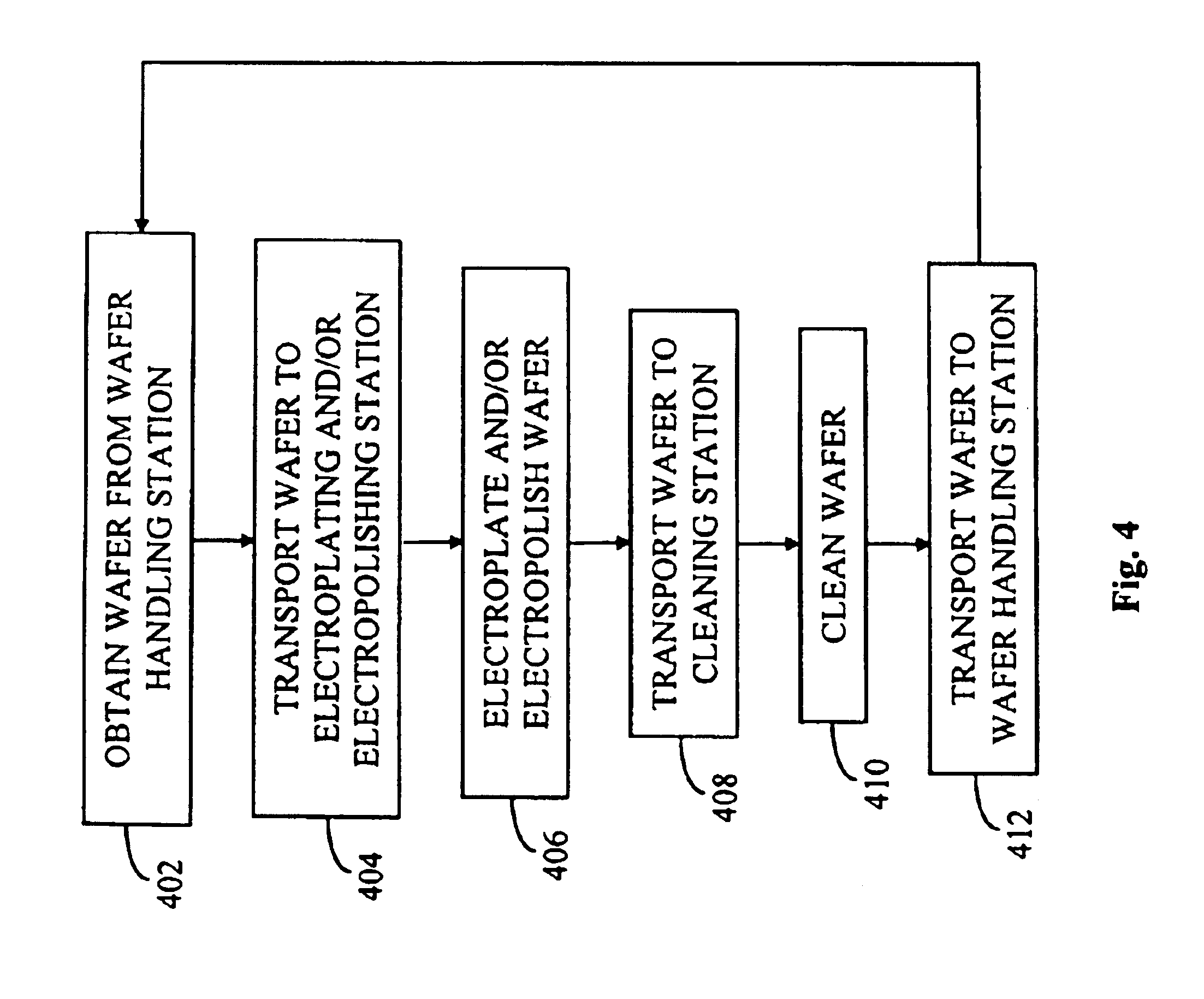

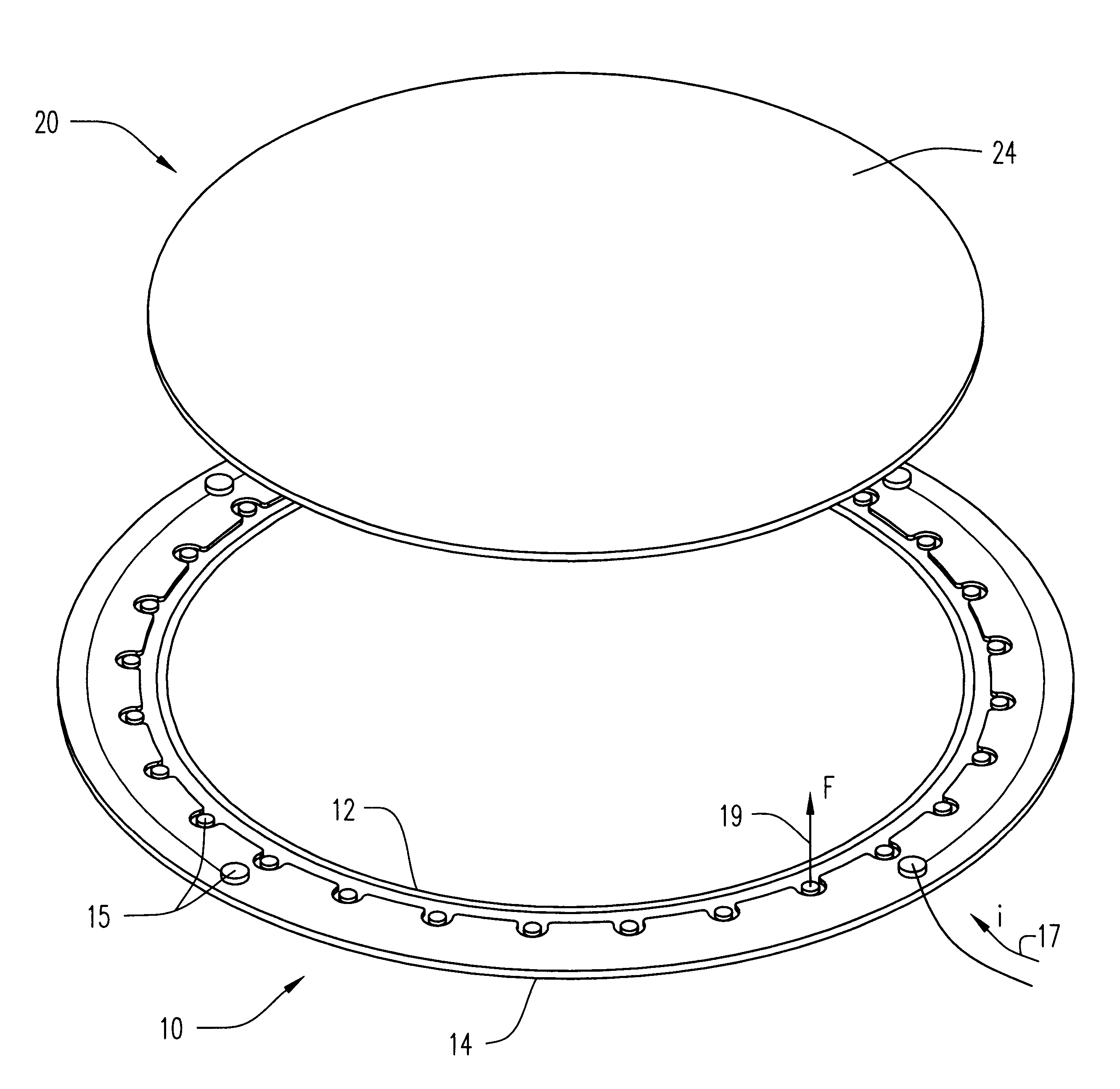

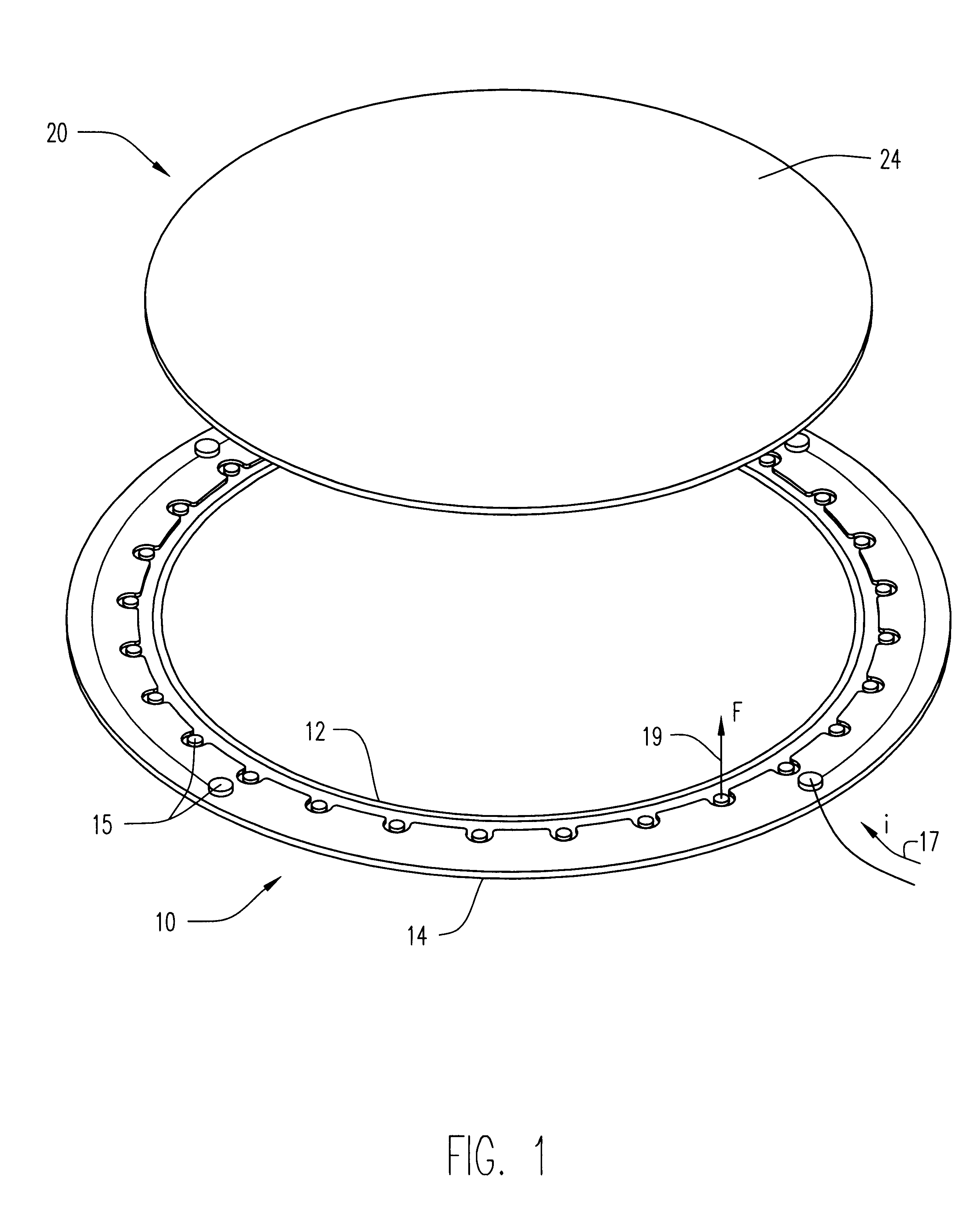

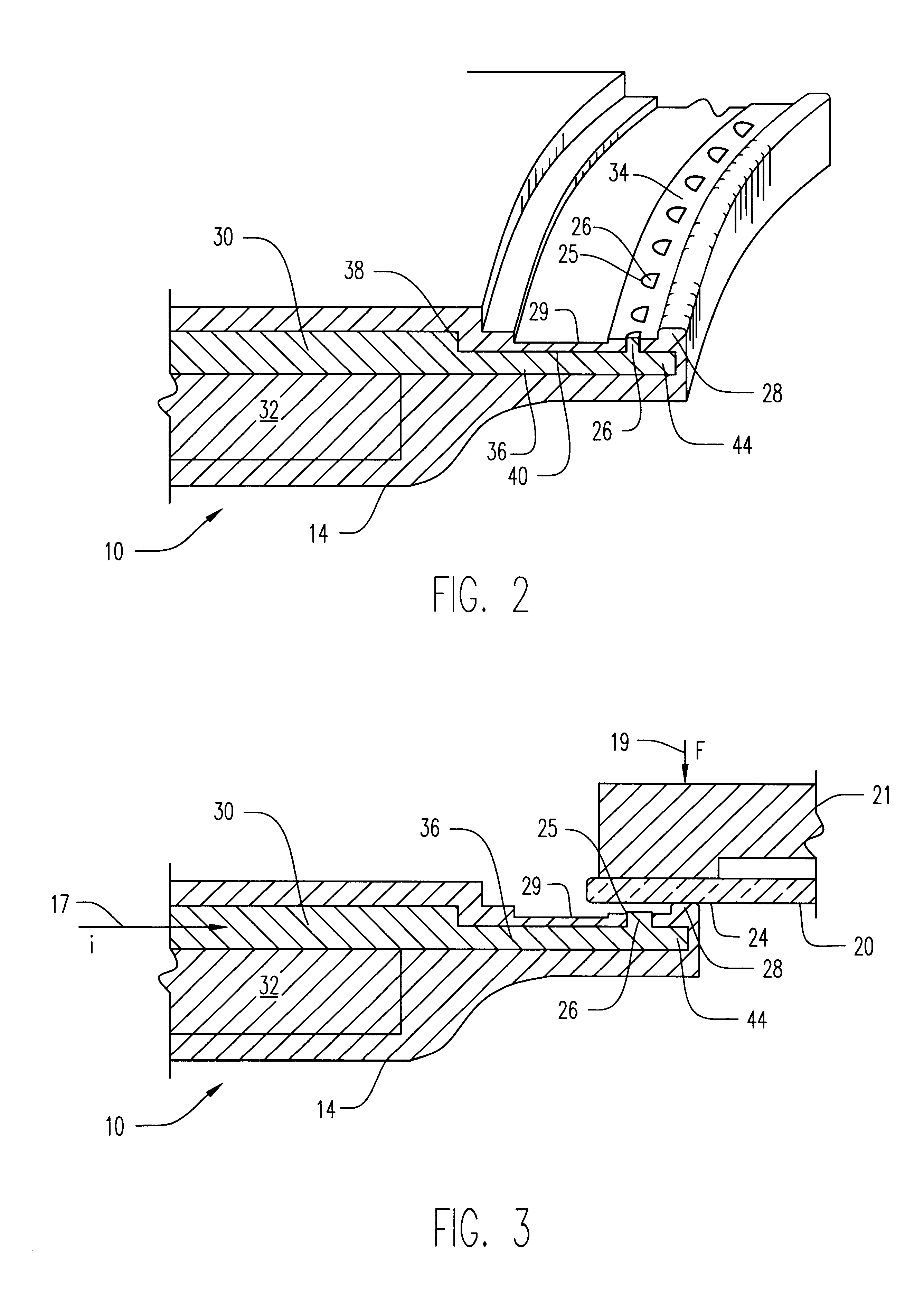

Methods and apparatus for holding and positioning semiconductor workpieces during electropolishing and/or electroplating of the workpieces

A wafer chuck for holding a wafer during electropolishing and / or electroplating of the wafer includes a top section, a bottom section, and a spring member. In accordance with one aspect of the present invention, the top section and the bottom section are configured to receive the wafer for processing. The spring member is disposed on the bottom section and configured to apply an electric charge to the wafer. In accordance with another aspect of the present invention, the spring member contacts a portion of the outer perimeter of the wafer. In one alternative configuration of the present invention, the wafer chuck further includes a seal member to seal the spring member from the electrolyte solution used in the electropolishing and / or electroplating process.

Owner:ACM RES

Electroplating workpiece fixture having liquid gap spacer

A fixture for supporting a workpiece during electroplating of a metal upon the workpiece in a conductive electroplating bath includes a non-conductive frame member for receiving the workpiece therein. The fixture further includes a current distribution means having a plurality of contacts. The plurality of contacts is disposed inwardly for providing an equally distributed electrical contact with an outer perimeter region of the workpiece. The workpiece is supported between the frame member and the current distribution means. Lastly, a thief electrode is perimetrically disposed about the workpiece and spaced a prescribed distance from the workpiece by a gap region. During plating of a metal upon the workpiece, the gap region between the thief and the workpiece is filled with the conductive electroplating bath. An electroplating apparatus having a fixture for supporting a workpiece during an electroplating process and a method of supporting the workpiece to be electroplated are also disclosed.

Owner:NOVELLUS SYSTEMS

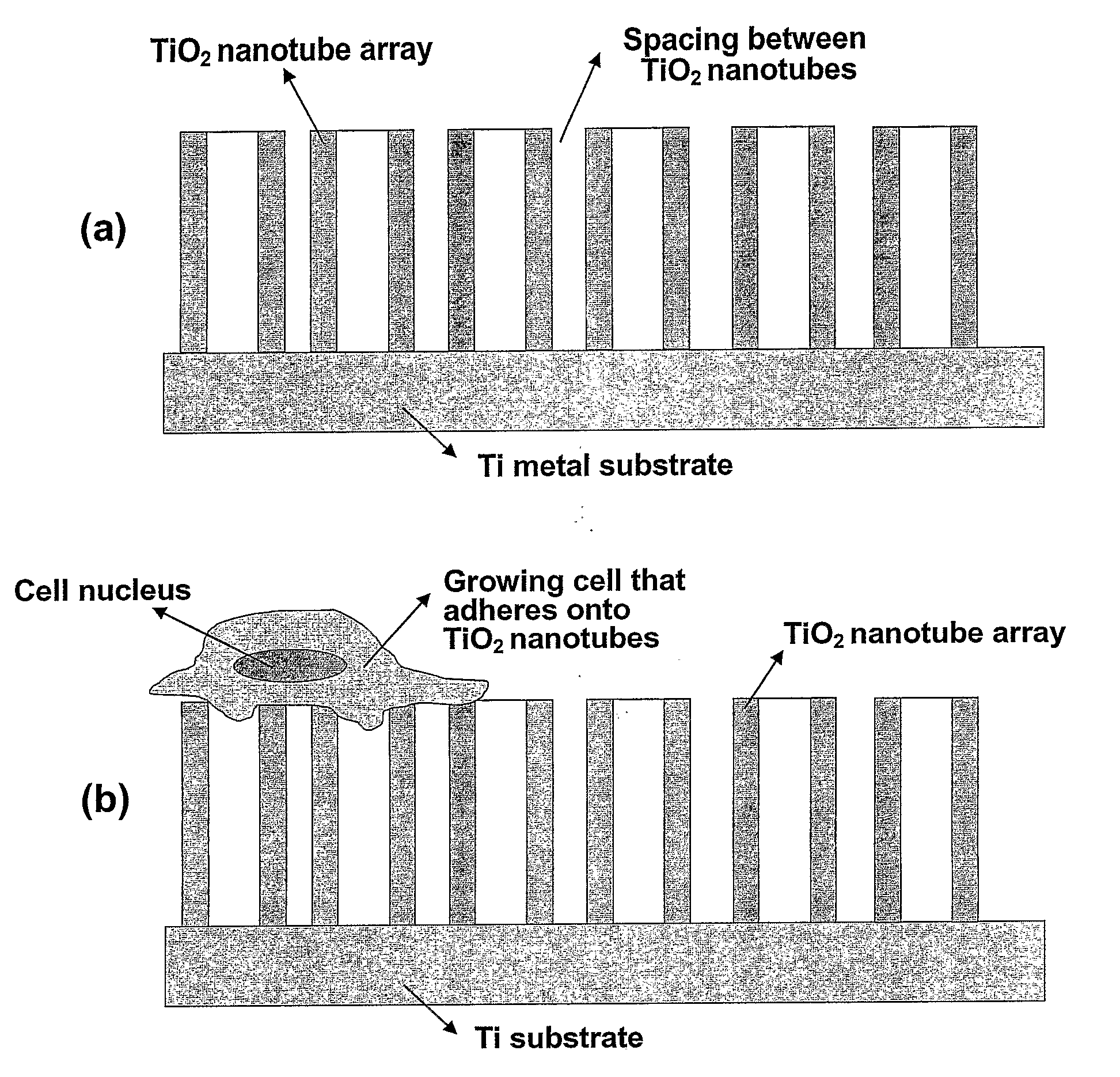

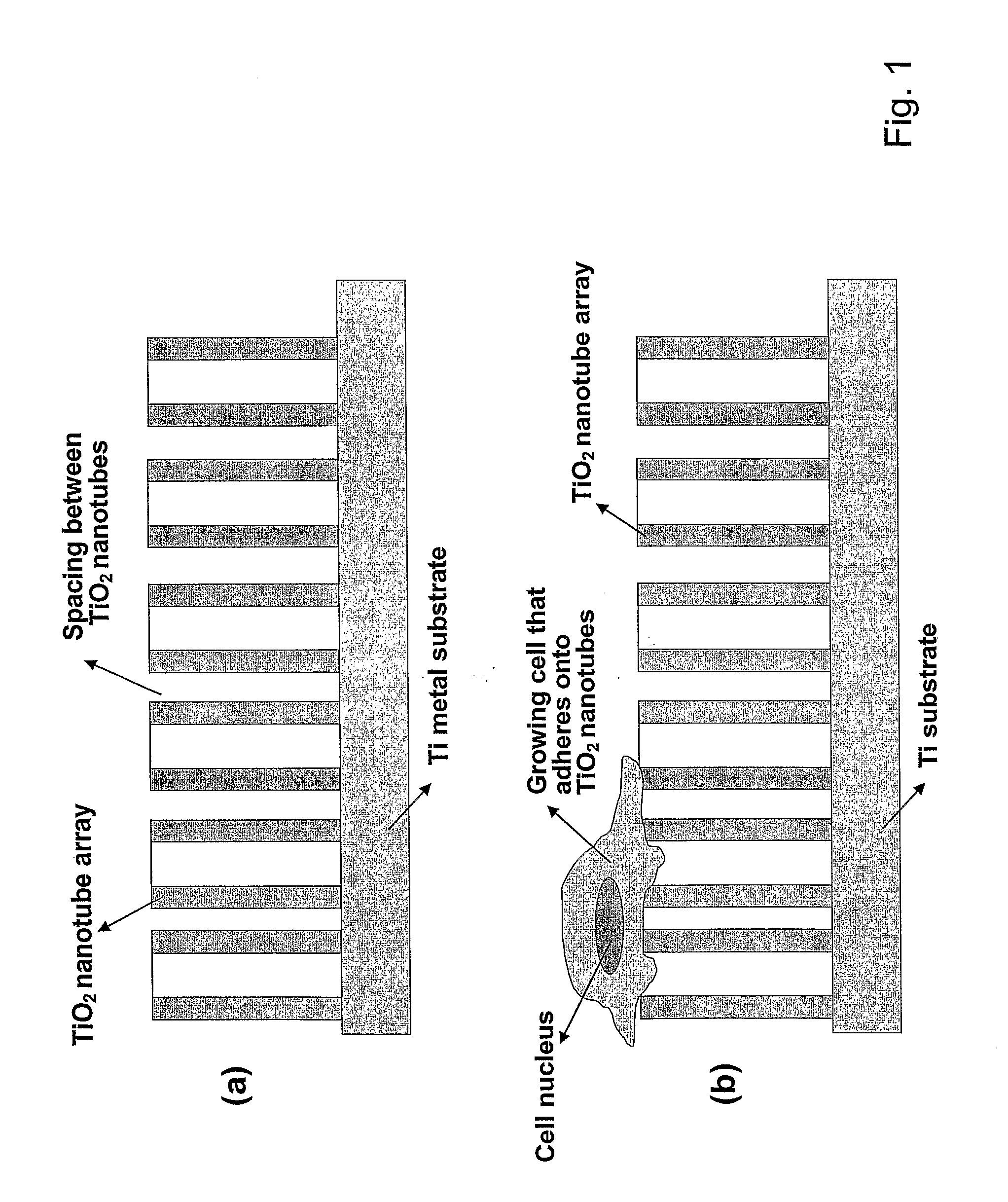

Compositions comprising nanostructures for cell, tissue and artificial organ growth, and methods for making and using same

ActiveUS20090220561A1Improve bone formationIncreased durabilityBioreactor/fermenter combinationsElectrolysis componentsIn vivoNanostructure

The invention provides articles of manufacture comprising biocompatible nanostructures comprising nanotubes and nanopores for, e.g., organ, tissue and / or cell growth, e.g., for bone, kidney or liver growth, and uses thereof, e.g., for in vitro testing, in vivo implants, including their use in making and using artificial organs, and related therapeutics. The invention provides lock-in nanostructures comprising a plurality of nanopores or nanotubes, wherein the nanopore or nanotube entrance has a smaller diameter or size than the rest (the interior) of the nanopore or nanotube. The invention also provides dual structured biomaterial comprising micro- or macro-pores and nanopores. The invention provides biomaterials having a surface comprising a plurality of enlarged diameter nanopores and / or nanotubes.

Owner:RGT UNIV OF CALIFORNIA

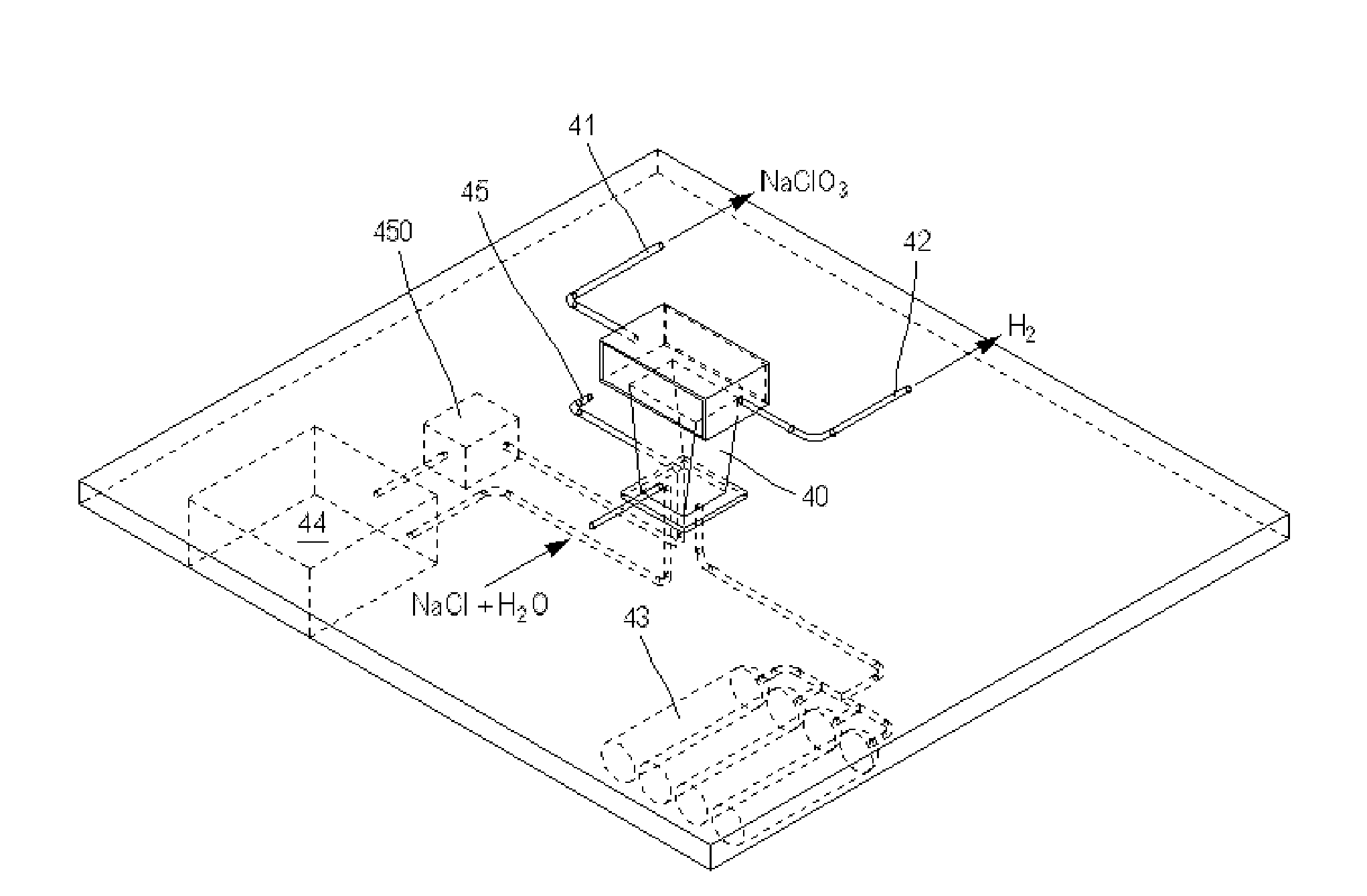

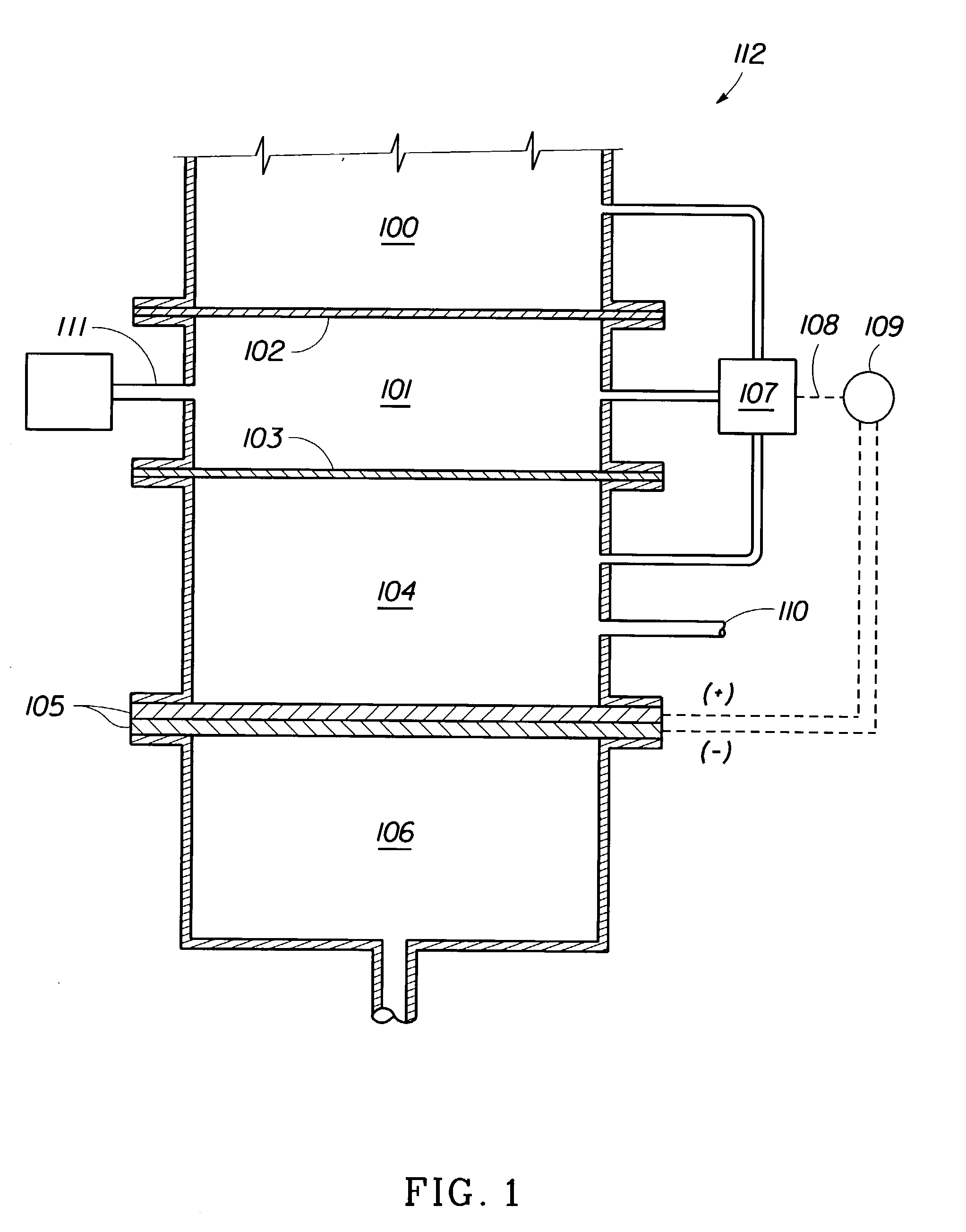

System for Producing and Supplying Hydrogen and Sodium Chlorate, Comprising a Sodium Chloride Electrolyser for Producing Sodium Chlorate

InactiveUS20130115535A1Increase supplyIncrease productionCellsReactant parameters controlElectrolysisSodium chlorate

A system is provided for producing hydrogen and oxygen based on decomposition of sodium chlorate (NaClO3). In a service station, NaClO3 is produced by a sodium chloride (NaCl) electrolyser. The service station is supplied with water (H2O), NaCl, and energy in order to carry out an electrolysis reaction in the electroyser, to produce NaClO3 and gaseous hydrogen (H2). The NaClO3 and H2 are supplied to vehicles. Each vehicle includes a reactor for decomposing the NaClO3 and producing reaction products of NaCl and oxygen, with the oxygen being supplied to a fuel cell.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

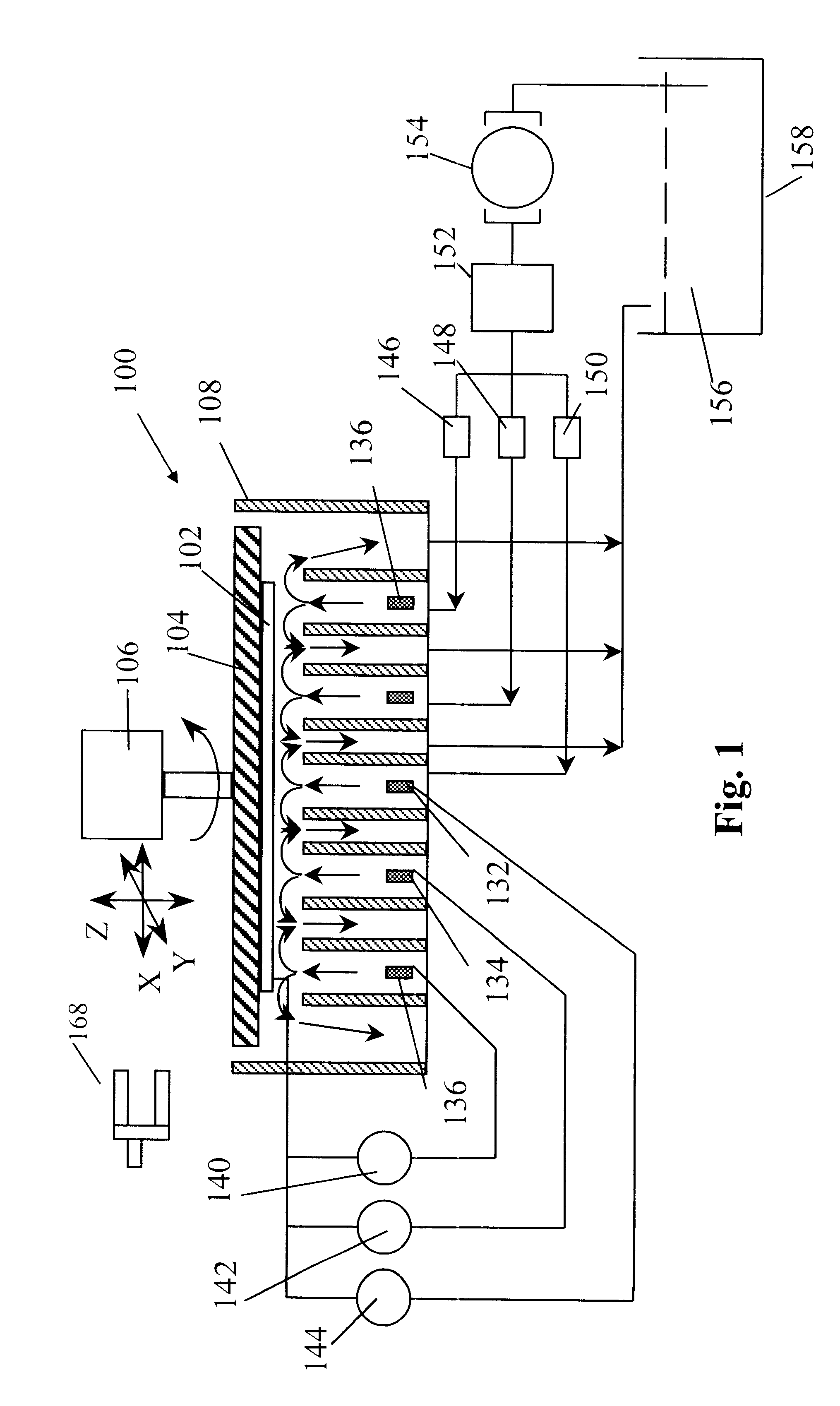

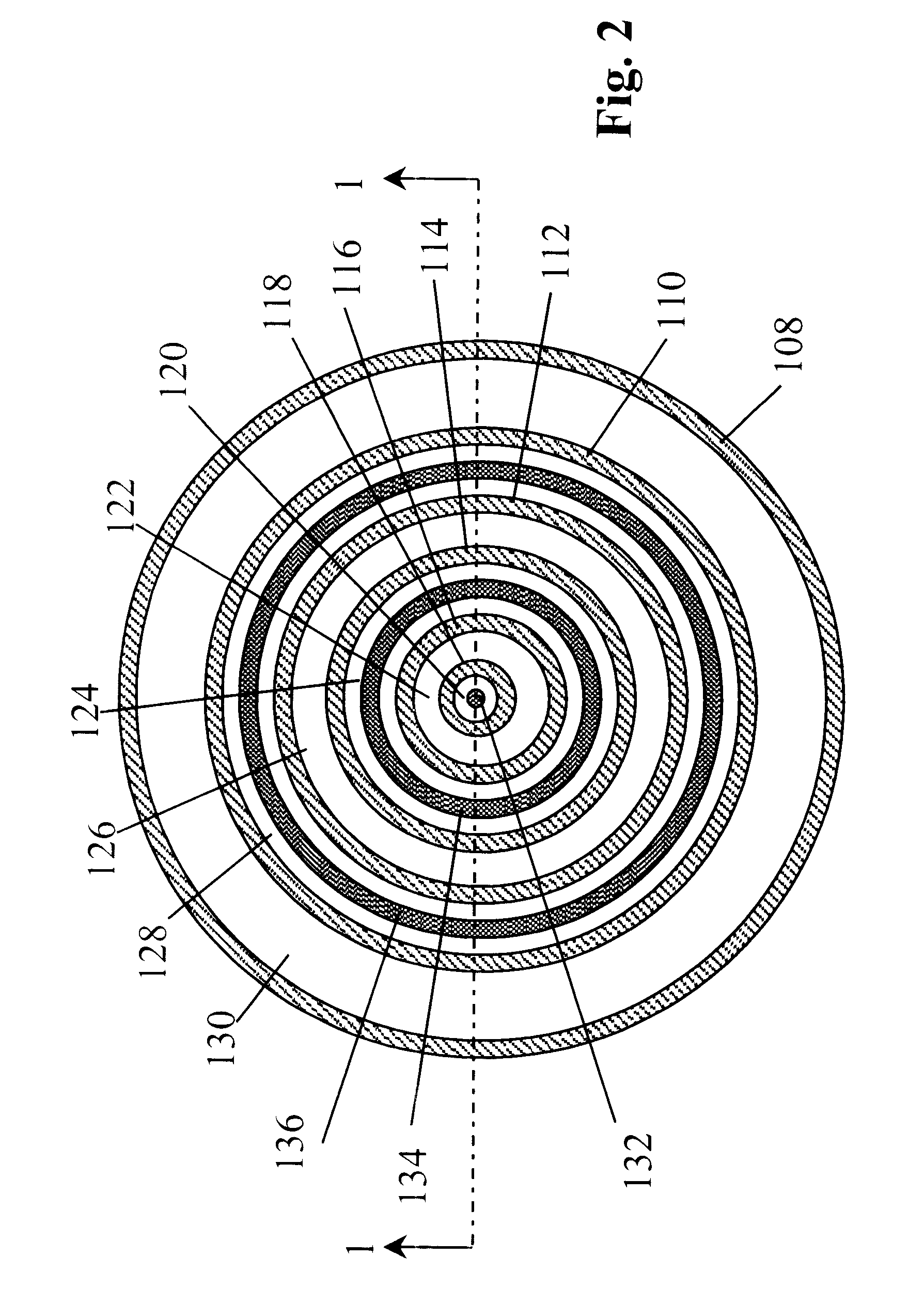

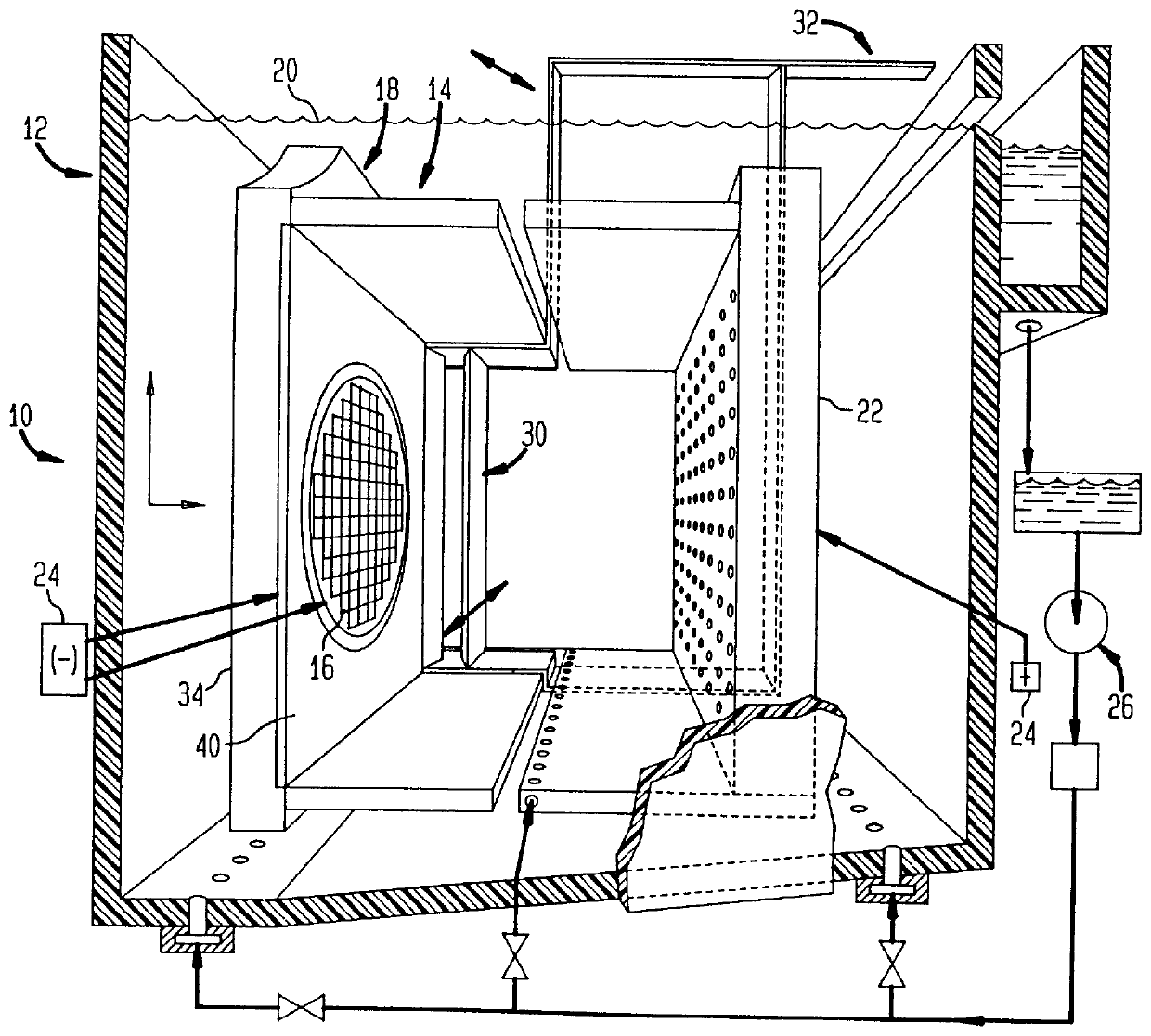

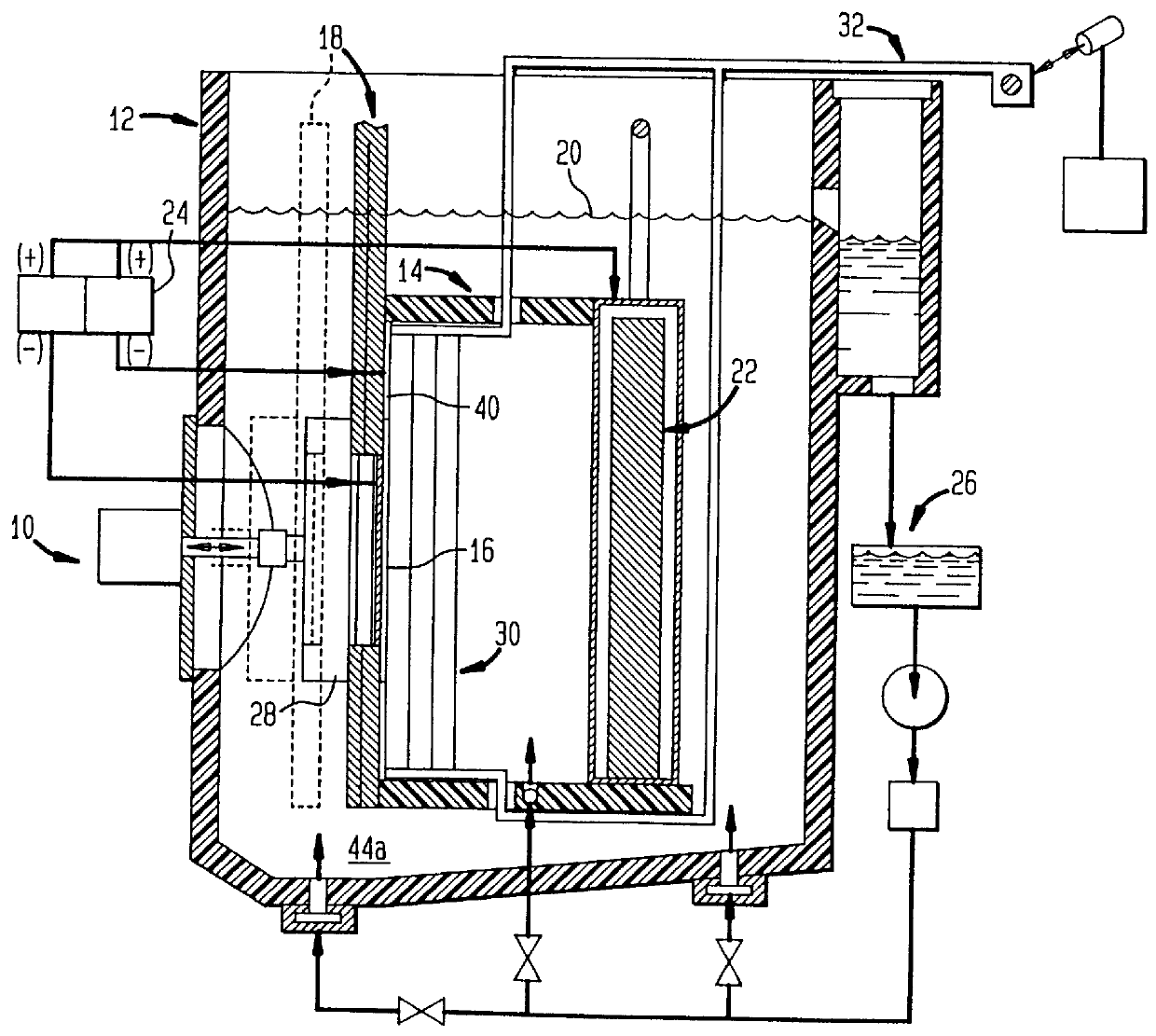

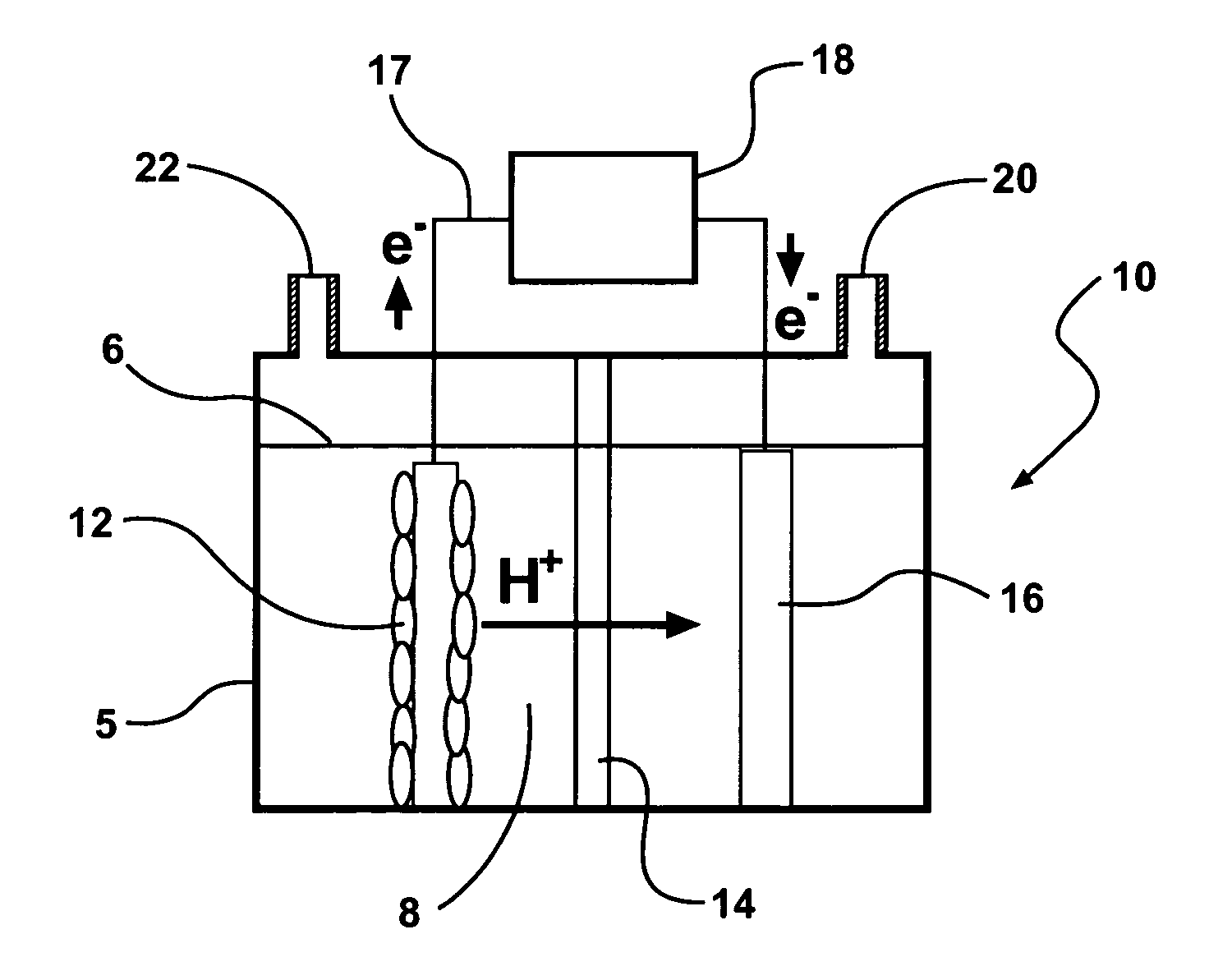

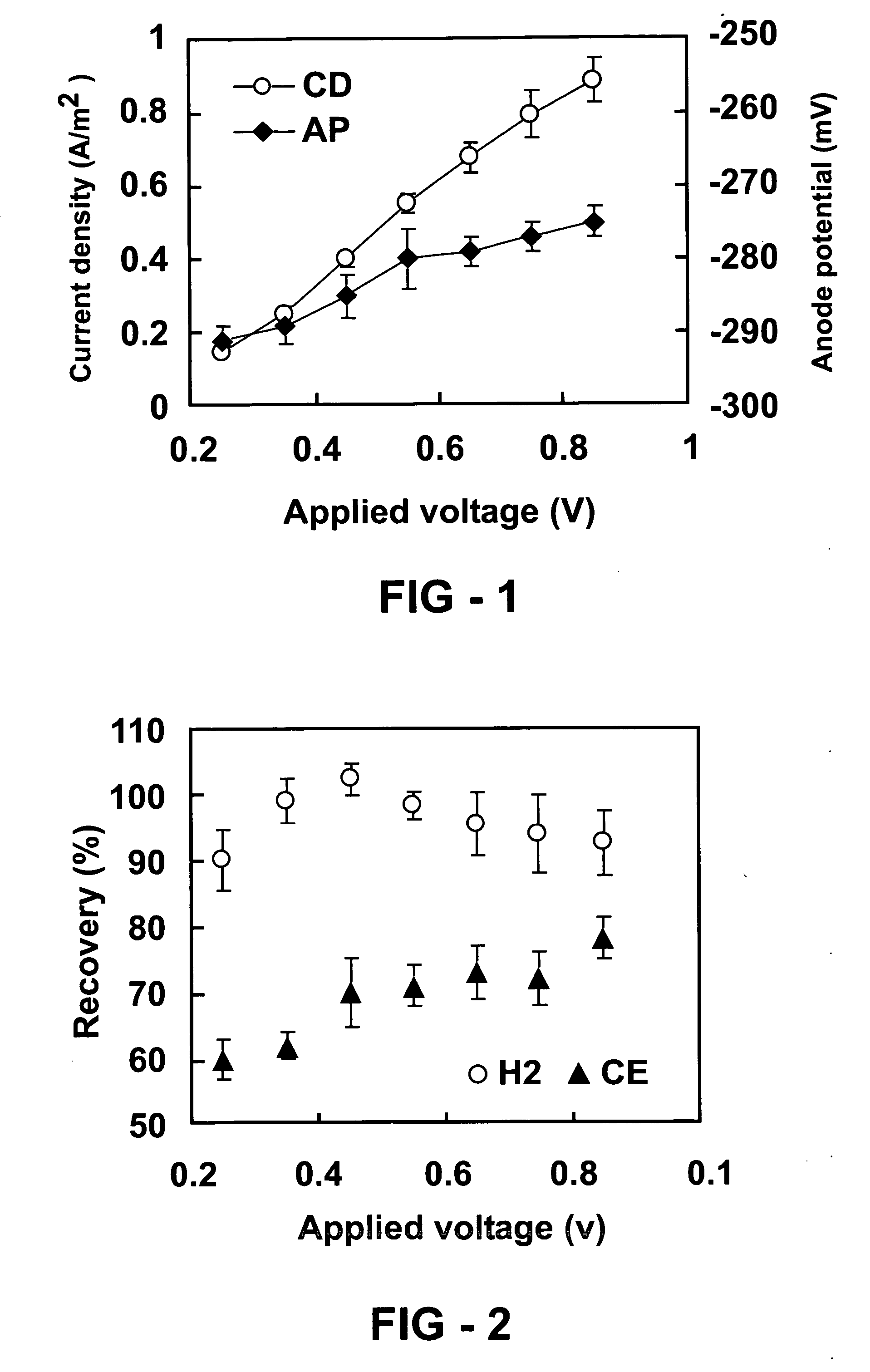

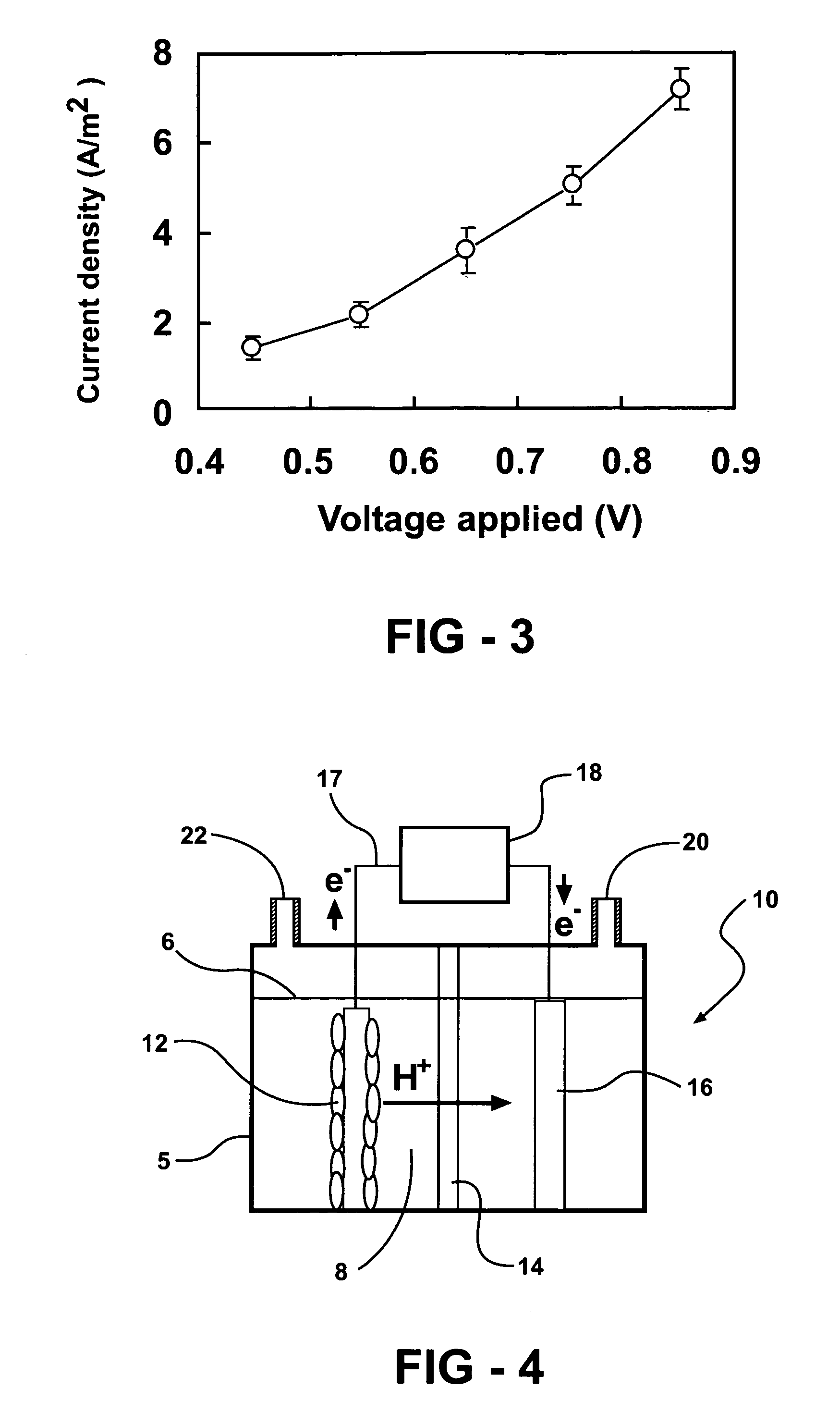

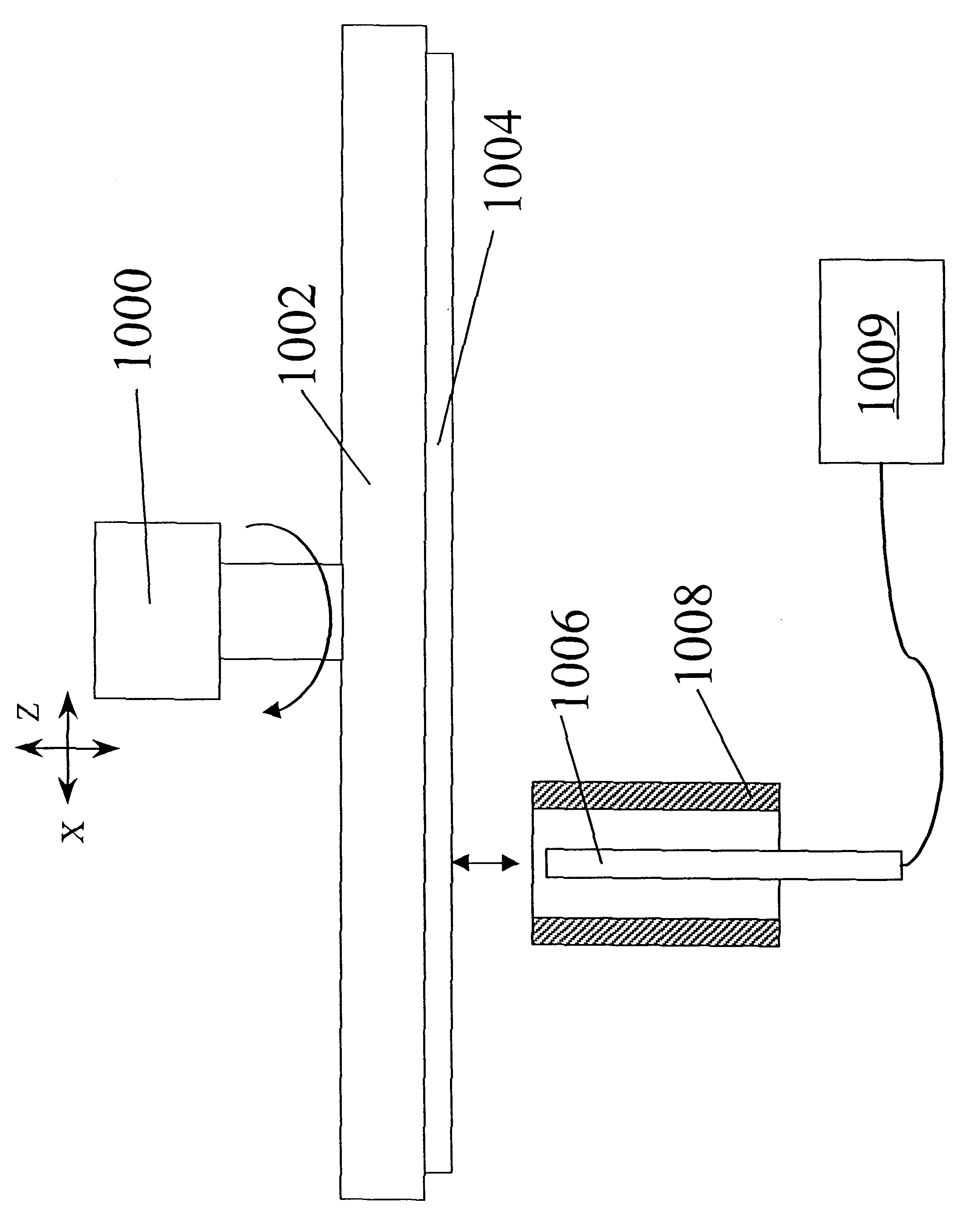

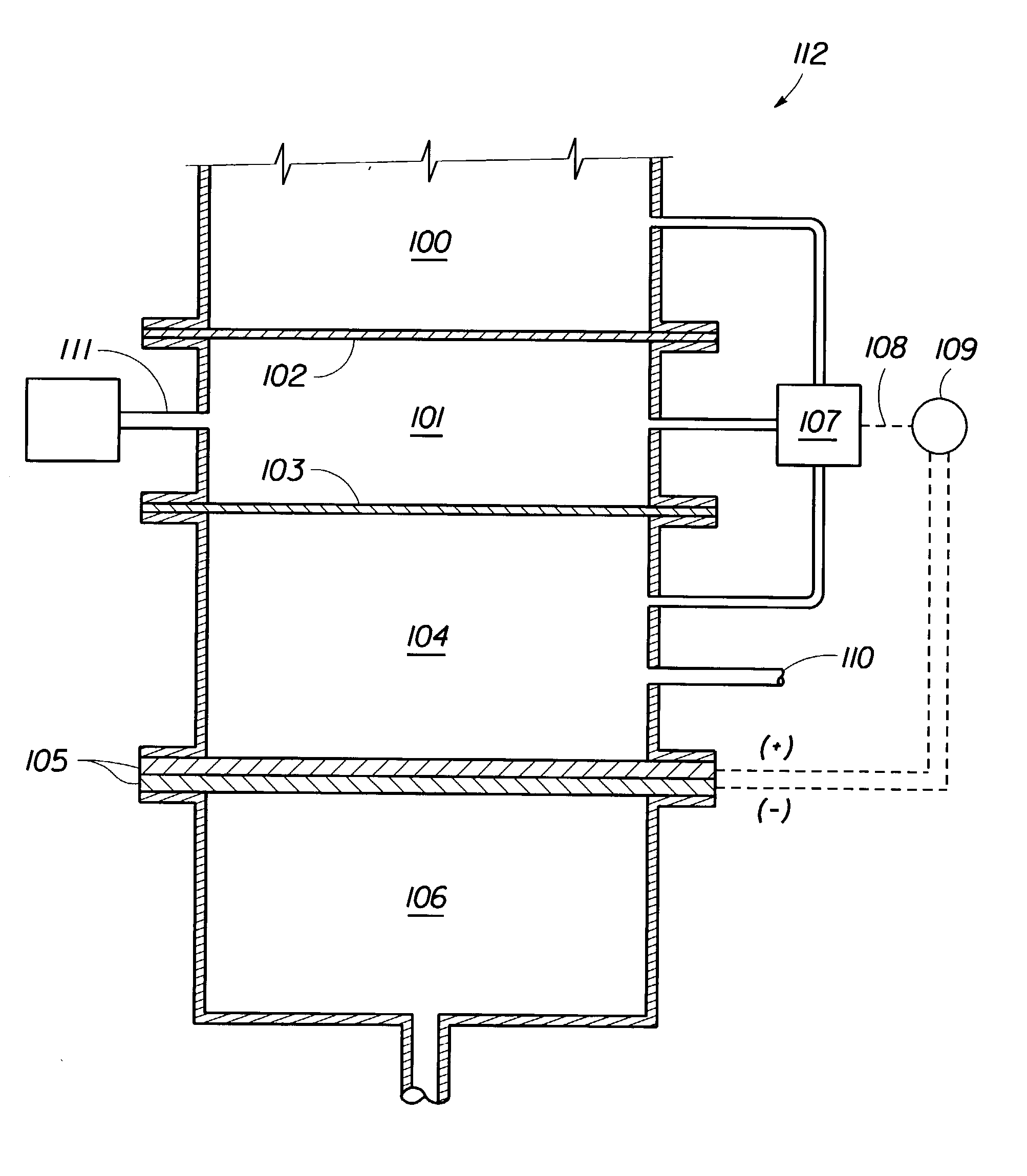

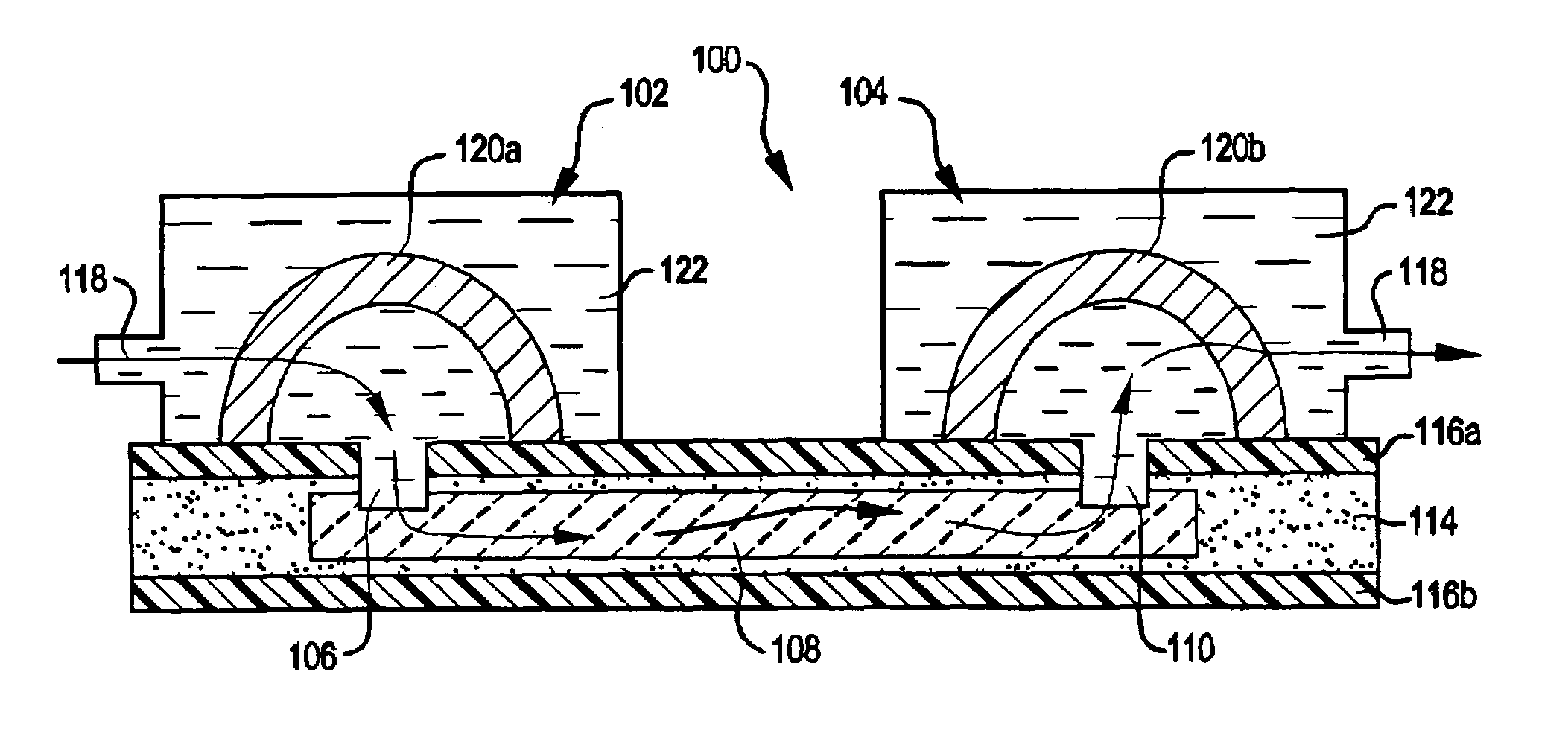

Bio-electrochemically assisted microbial reactor that generates hydrogen gas and methods of generating hydrogen gas

ActiveUS20060011491A1Provide supportGrowth inhibitionBioreactor/fermenter combinationsBiological substance pretreatmentsElectricityHydrogen

Systems and processes for producing hydrogen using bacteria are described. One detailed process for producing hydrogen uses a system for producing hydrogen as described herein, the system including a reactor. Anodophilic bacteria are disposed within the interior of the reactor and an organic material oxidizable by an oxidizing activity of the anodophilic bacteriais introduced and incubated under oxidizing reactions conditions such that electrons are produced and transferred to the anode. A power source is activated to increase a potential between the anode and the cathode, such that electrons and protons combine to produce hydrogen gas. One system for producing hydrogen includes a reaction chamber having a wall defining an interior of the reactor and an exterior of the reaction chamber. An anode is provided which is at least partially contained within the interior of the reaction chamber and a cathode is also provided which is at least partially contained within the interior of the reaction chamber. The cathode is spaced apart at a distance in the range between 0.1-100 centimeters, inclusive, from the anode. A conductive conduit for electrons is provided which is in electrical communication with the anode and the cathode and a power source for enhancing an electrical potential between the anode and cathode is included which is in electrical communication at least with the cathode. A first channel defining a passage from the exterior of the reaction chamber to the interior of the reaction chamber is also included.

Owner:PENN STATE RES FOUND +1

Methods and apparatus for end-point detection

An apparatus for detecting the end-point of an electropolishing process of a metal layer formed on a wafer includes an end-point detector. The end-point detector is disposed adjacent the nozzle used to electropolish the wafer. In one embodiment, the end-point detector is configured to measure the optical reflectivity of the portion of the wafer being electropolished.

Owner:ACM RES

Planarization of substrates using electrochemical mechanical polishing

InactiveUS20020130049A1Electrolysis componentsSemiconductor/solid-state device manufacturingEngineeringSubstrate surface

A method and apparatus are provided for planarizing a material layer on a substrate. In one aspect, a method is provided for processing a substrate including forming a passivation layer on a substrate surface, polishing the substrate in an electrolyte solution, applying an anodic bias to the substrate surface, and removing material from at least a portion of the substrate surface. In another aspect, an apparatus is provided which includes a partial enclosure, polishing article, a cathode, a power source, a substrate carrier movably disposed above the polishing article, and a computer based controller to position a substrate in an electrolyte solution to form a passivation layer on a substrate surface, to polish the substrate in the electrolyte solution with the polishing article, and to apply an anodic bias to the substrate surface or polishing article to remove material from at least a portion of the substrate surface.

Owner:APPLIED MATERIALS INC

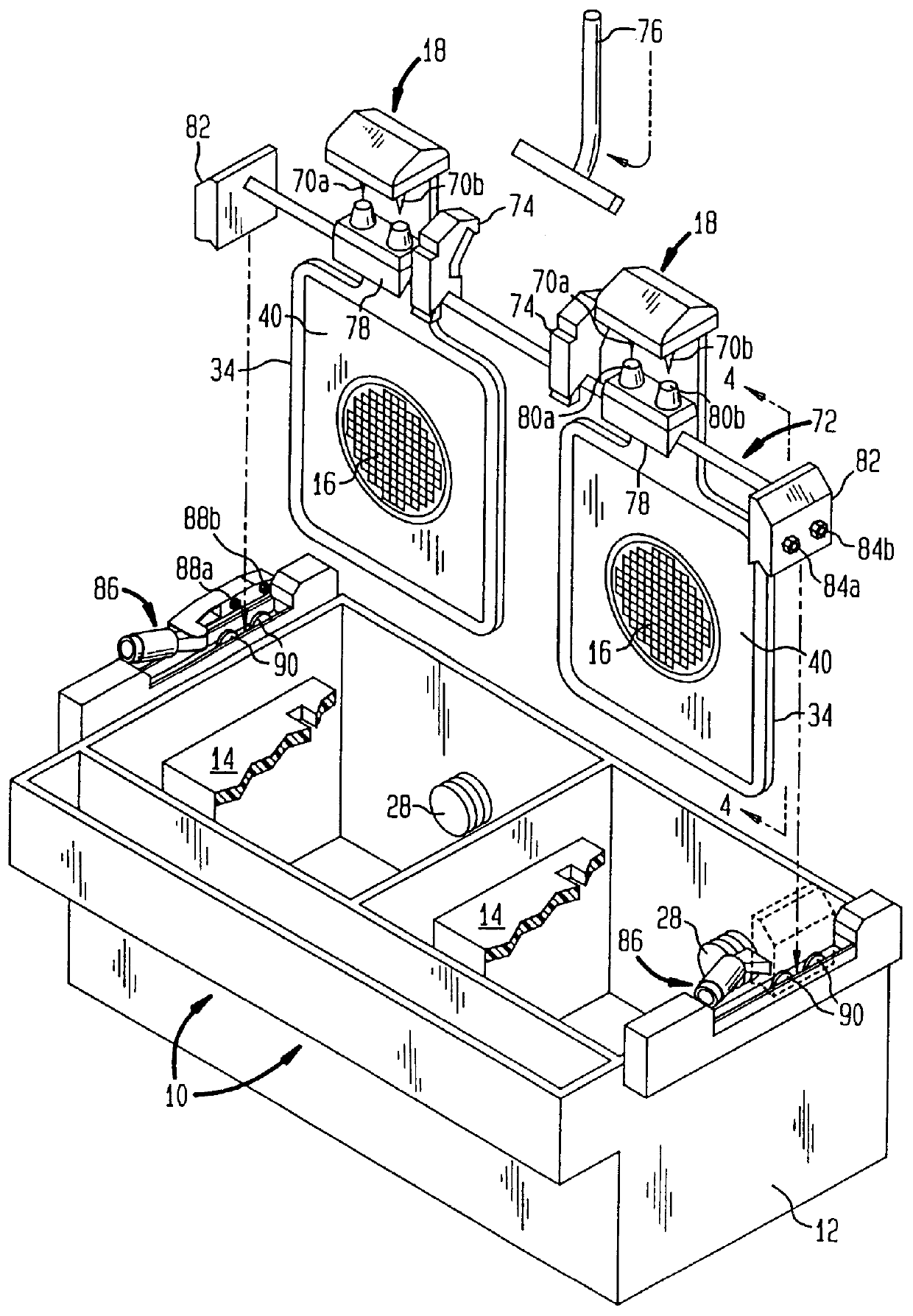

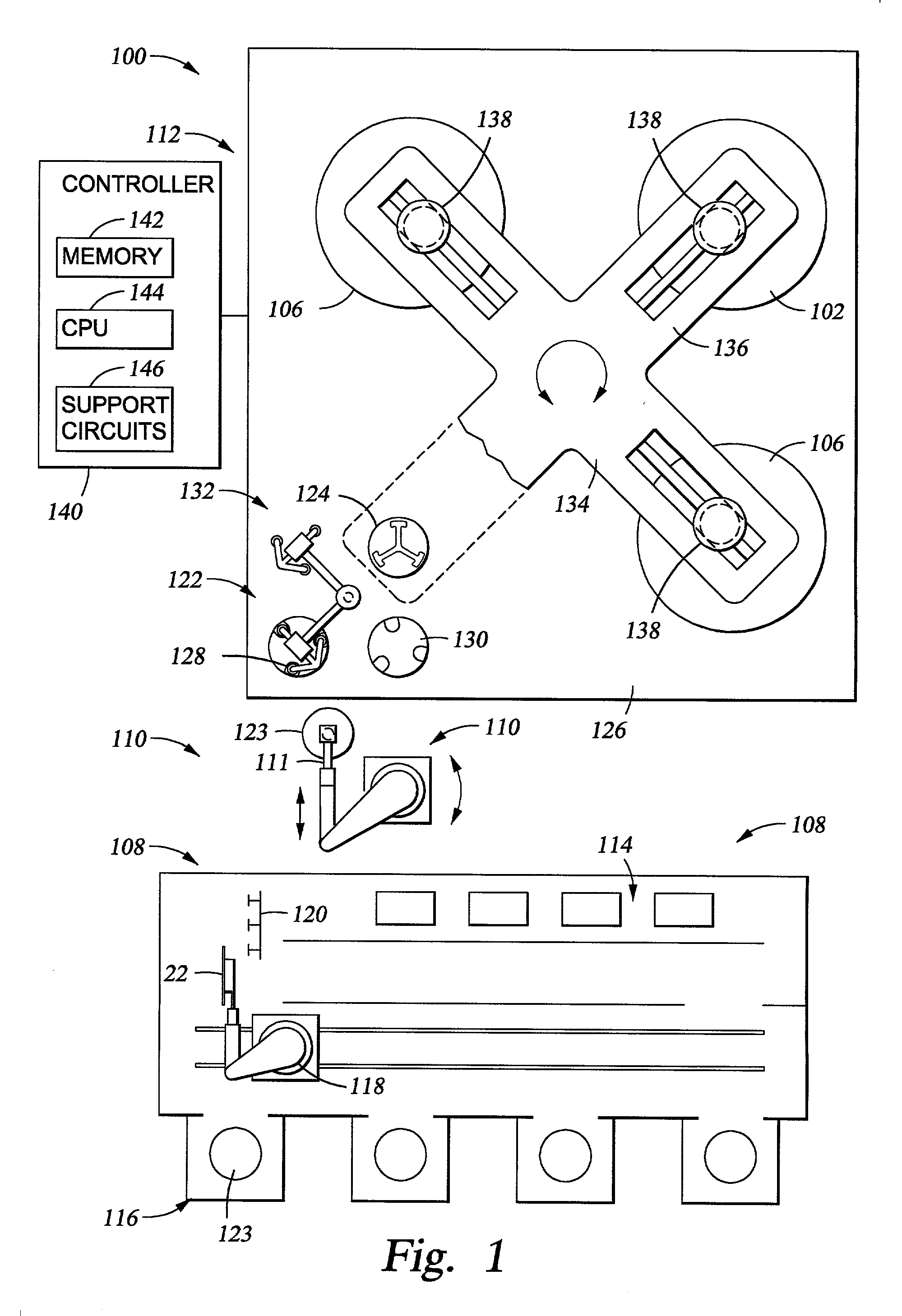

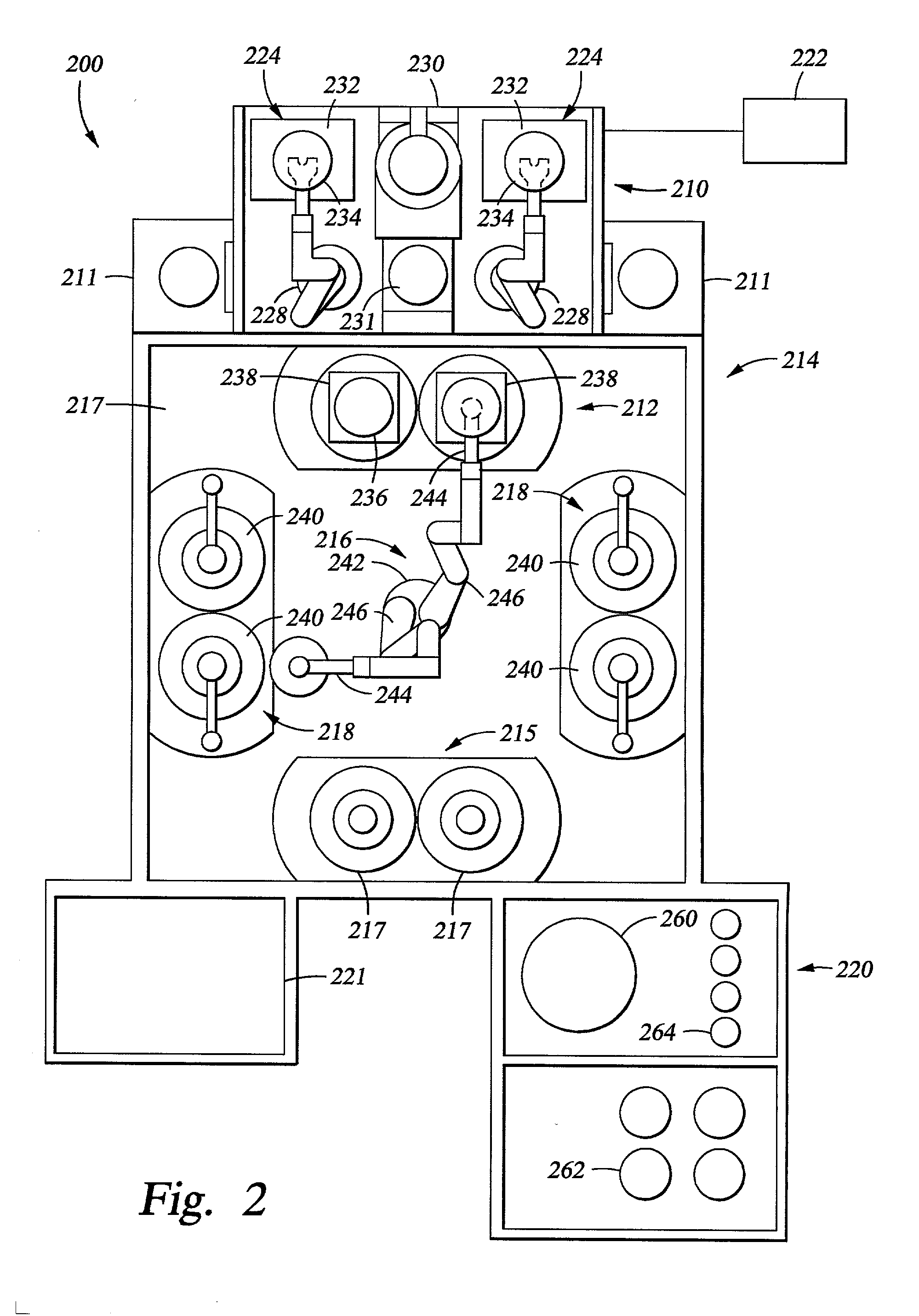

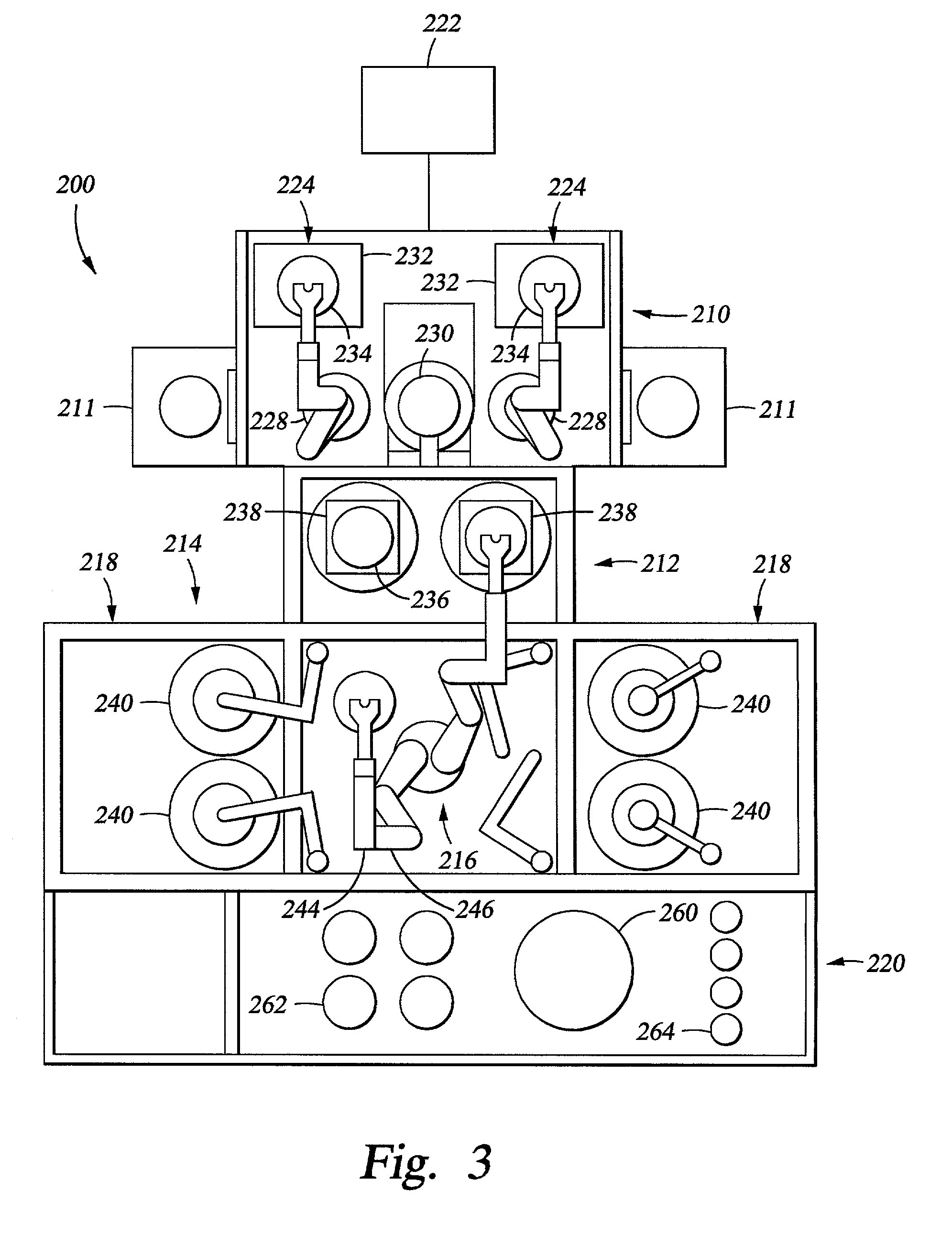

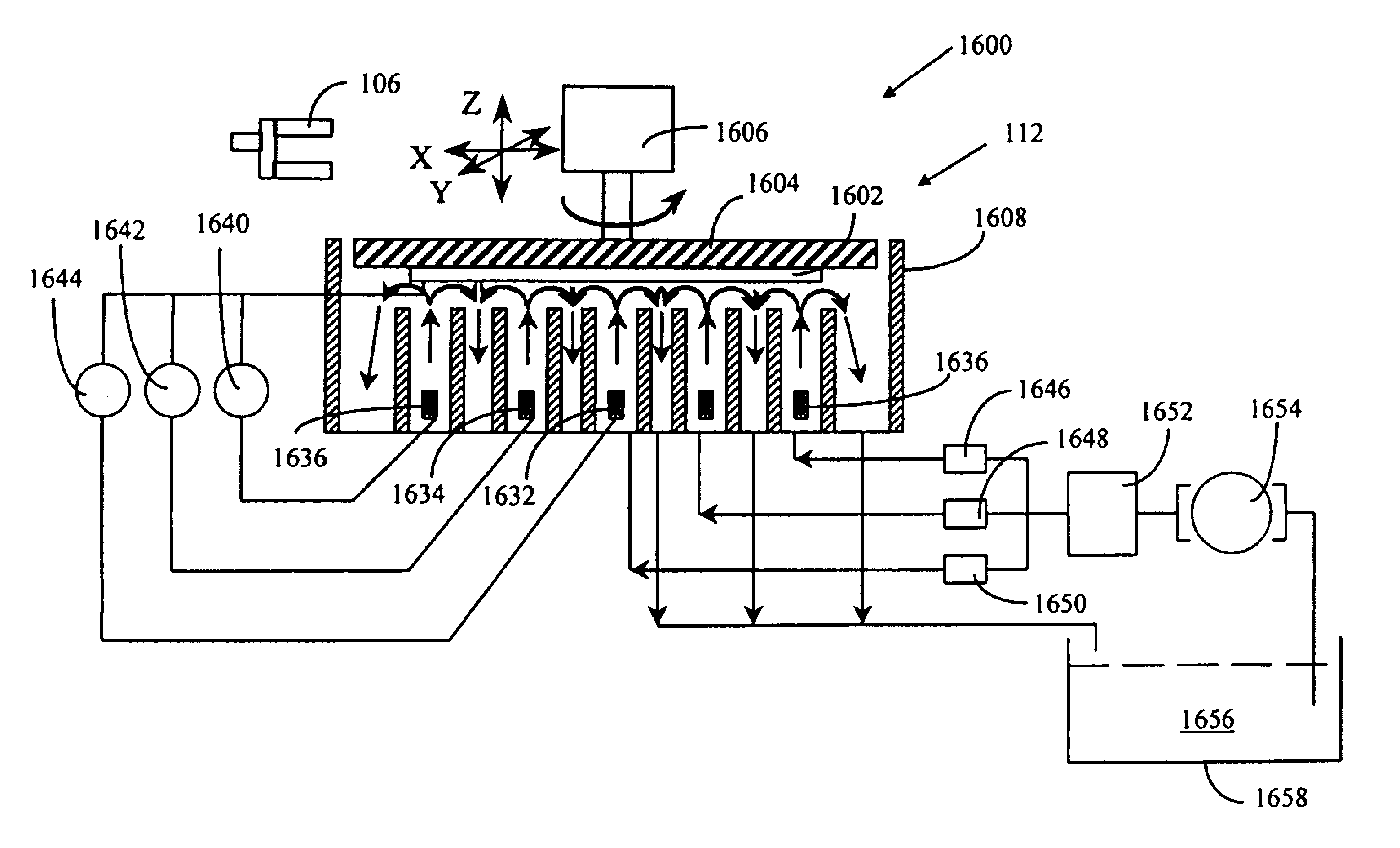

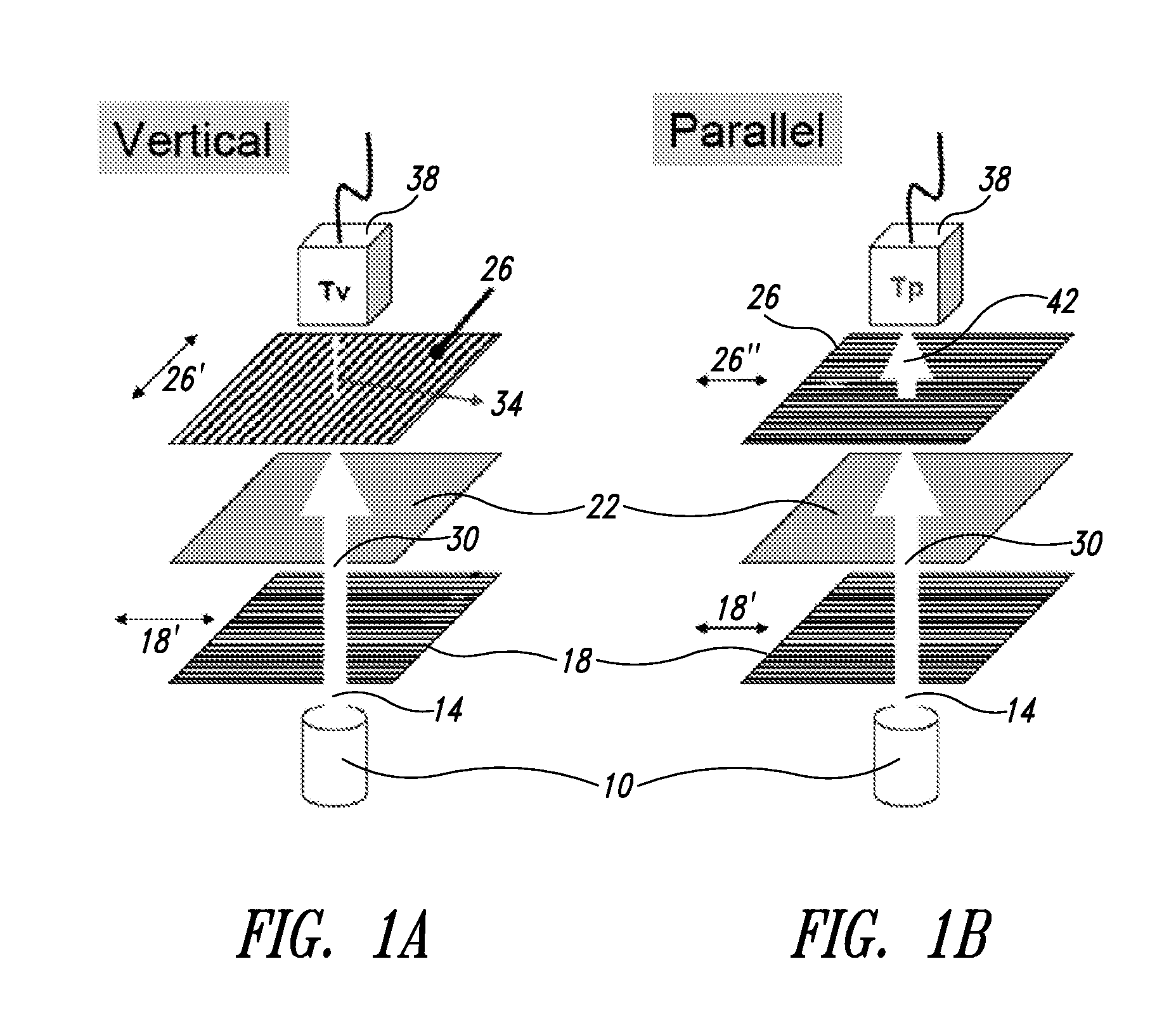

Method of and apparatus for controlling fluid flow and electric fields involved in the electroplating of substantially flat workpieces and the like and more generally controlling fluid flow in the processing of other work piece surfaces as well

A novel method and apparatus of wet processing workpieces, such as electroplating semiconductor wafers and the like, that incorporates reciprocating processing fluid agitation to control fluid flow at the workpiece, and where electric fields are involved as in such electroplating, controlling the electric field distribution.

Owner:HERCULES TECH GROWTH CAPITAL +1

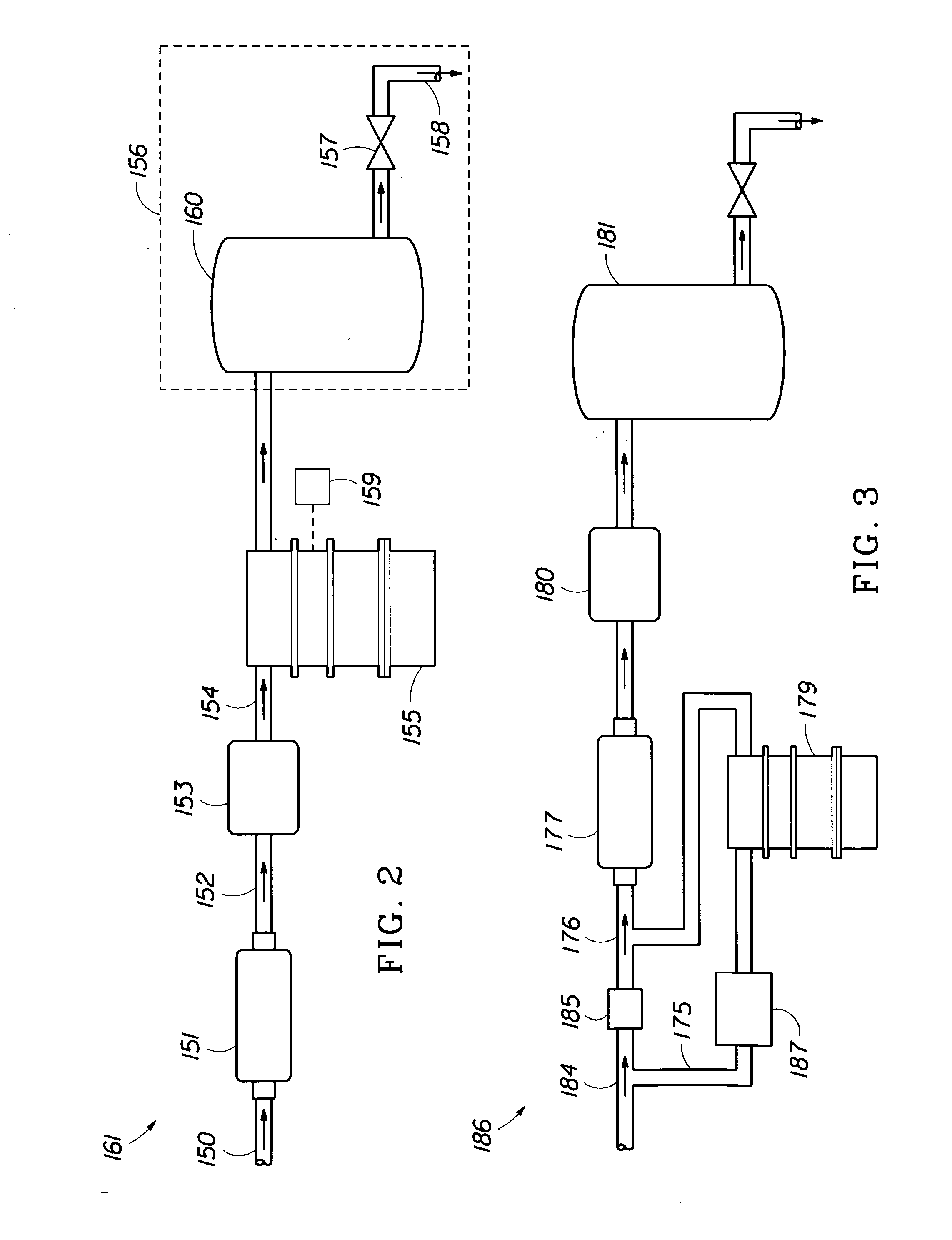

Methods and apparatus for holding and positioning semiconductor workpieces during electropolishing and/or electroplating of the workpieces

A wafer chuck assembly for holding a wafer during electroplating and / or electropolishing of the wafer includes a wafer chuck for receiving the wafer. The wafer chuck assembly also includes an actuator assembly for moving the wafer chuck between a first and a second position. When in the first position, the wafer chuck is opened. When in the second position, the wafer chuck is closed.

Owner:ACM RES

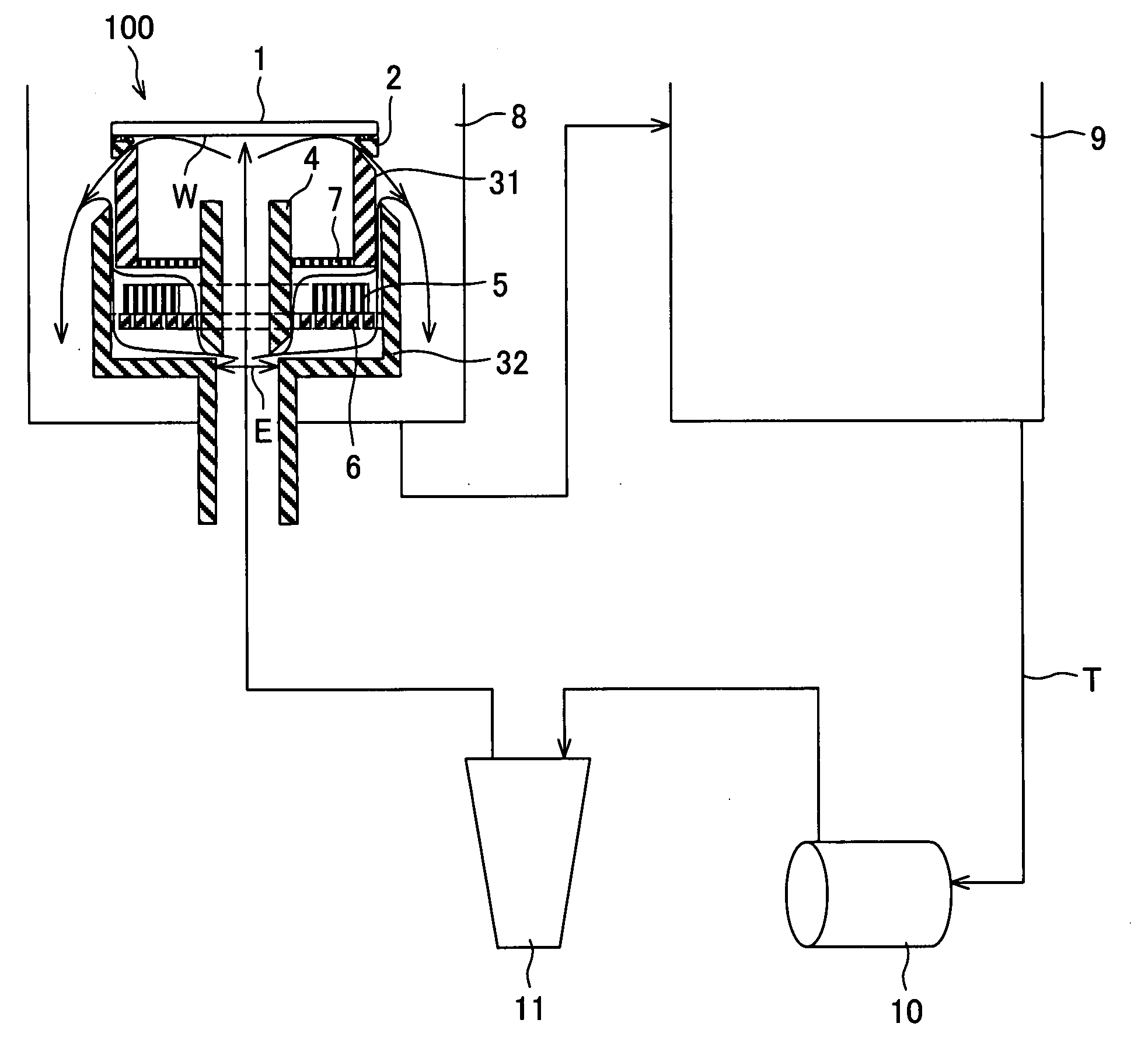

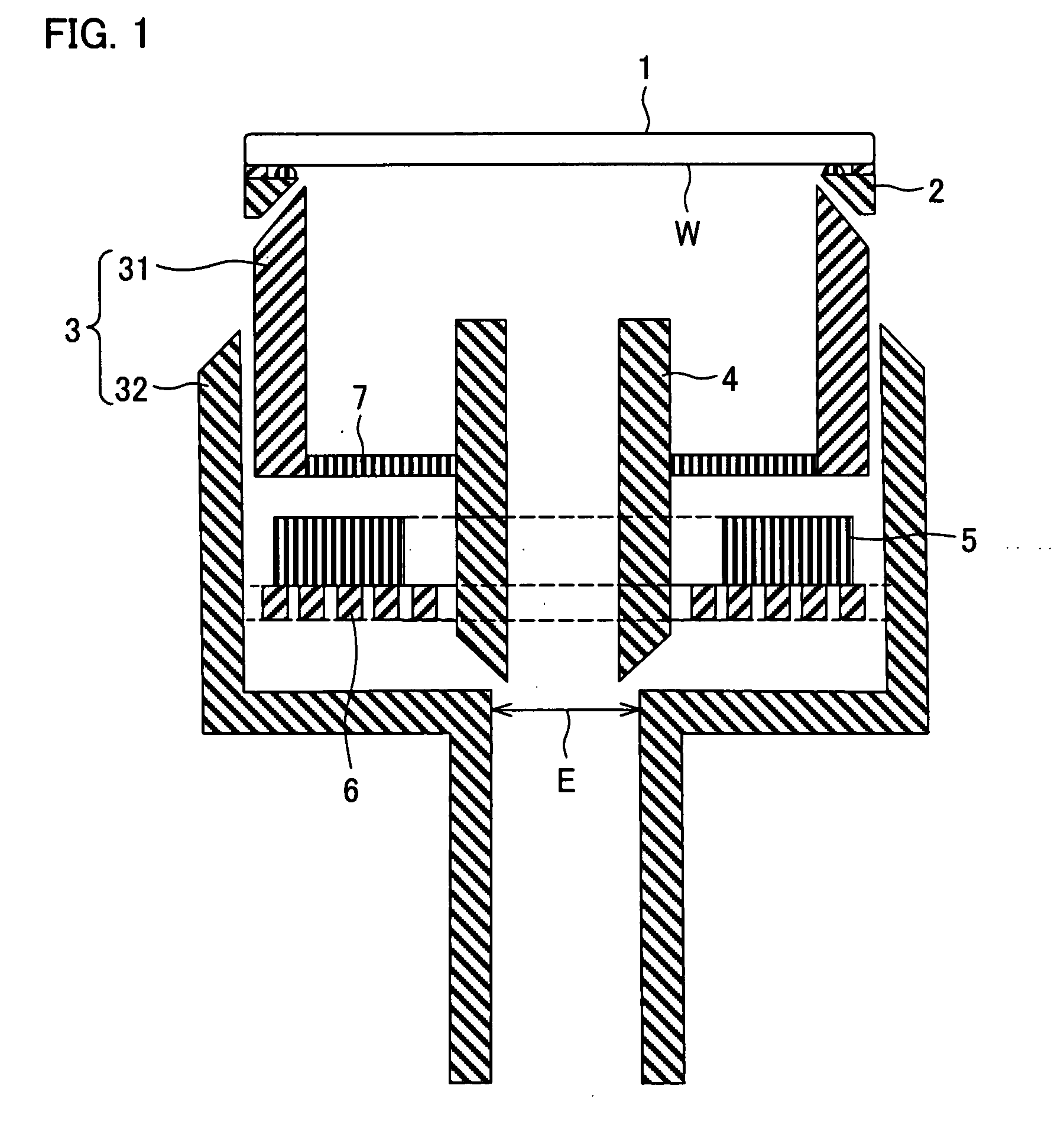

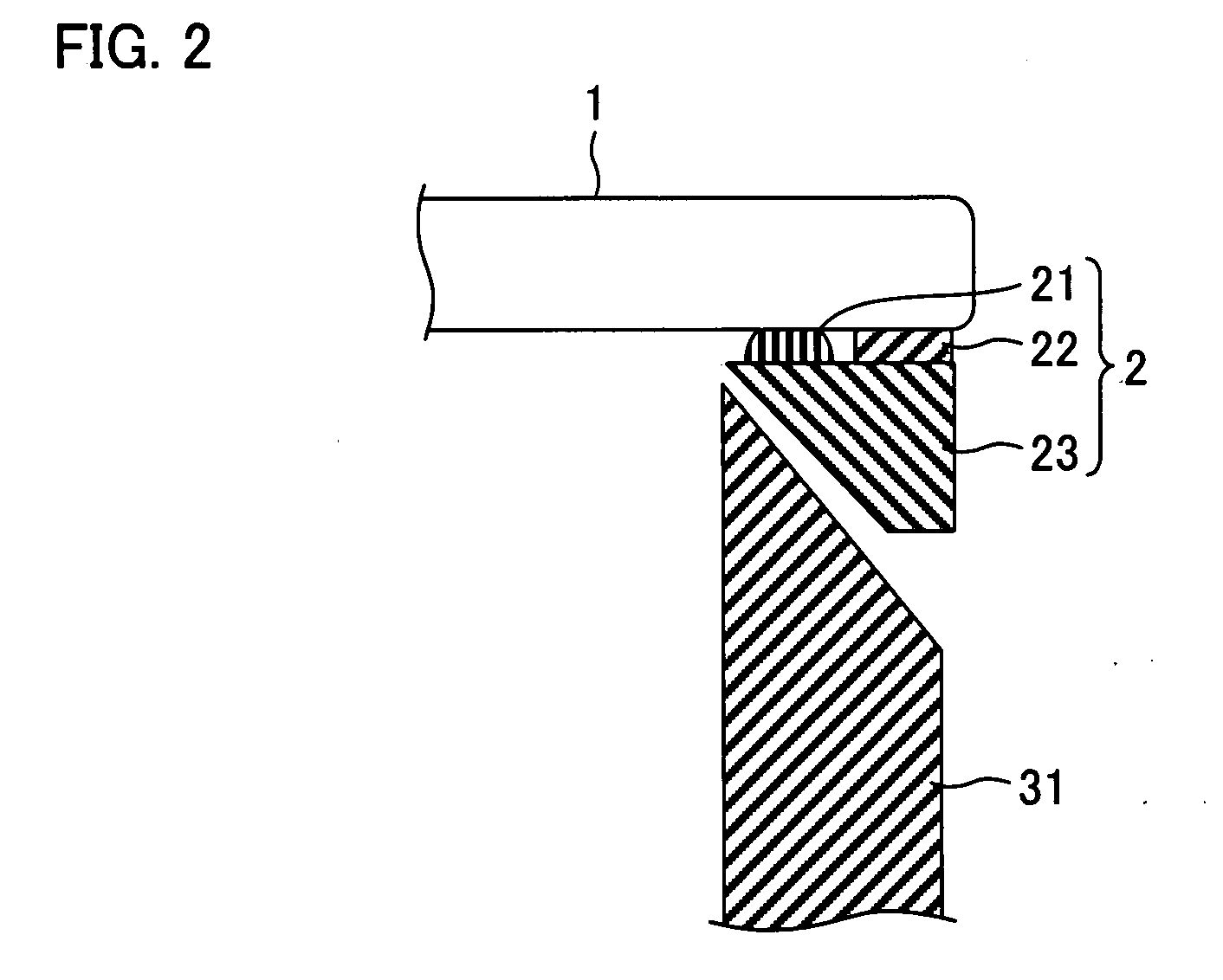

Plating Device, Plating Method, Semiconductor Device, And Method For Manufacturing Semiconductor Device

An object of the present invention is to provide a face-down type jet plating device in which deterioration in plating quality due to minute solid foreign matters derived from a black film etc. is prevented without impairing operativity. The plating device is designed such that a partition (7) is provided between a semiconductor wafer (1) and an anode (5) so that the anode (5) and the semiconductor wafer (7) are separated from each other and a plating tank (100) is divided into a substrate-to-be-plated chamber and an anode chamber.

Owner:SHARP KK

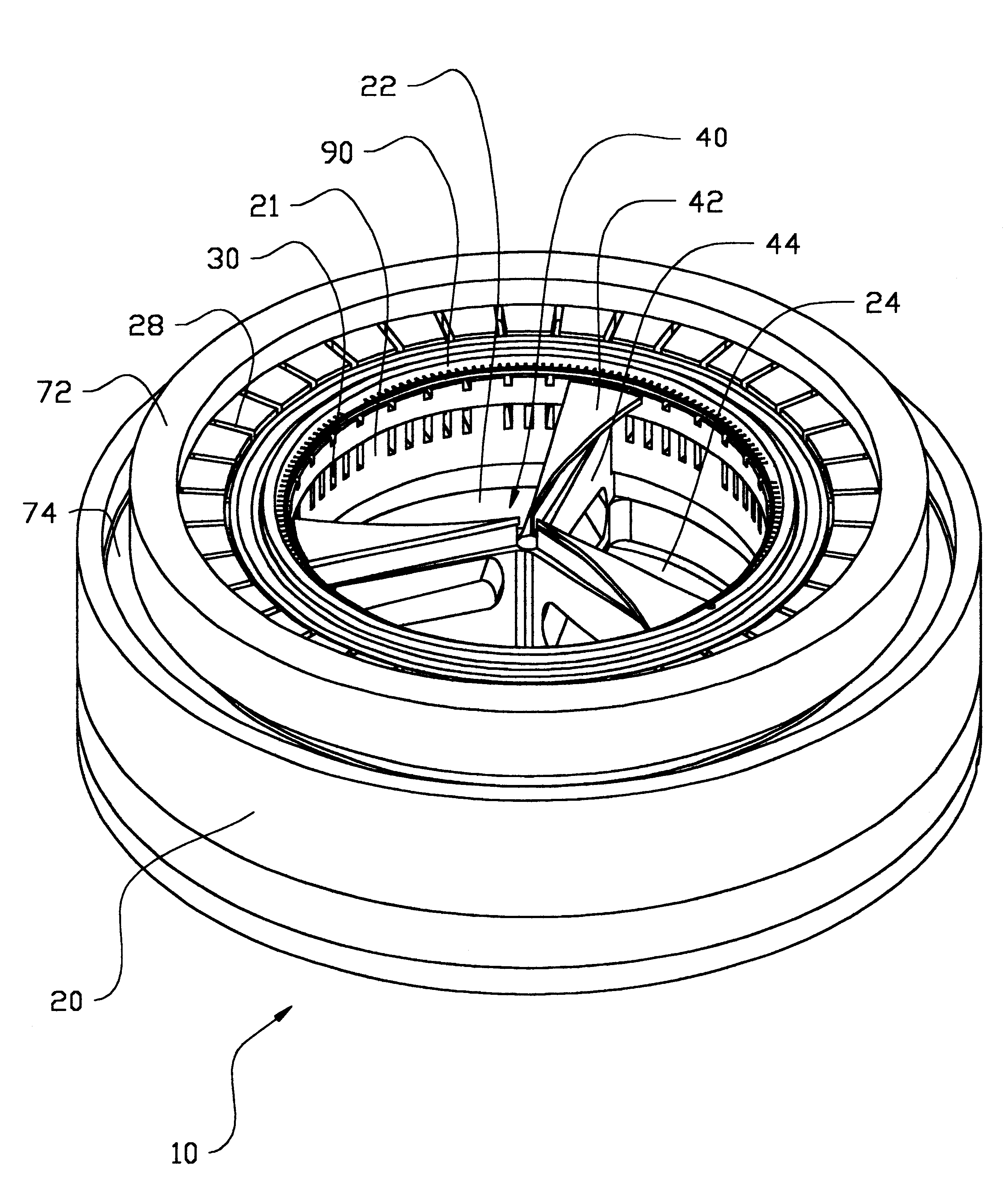

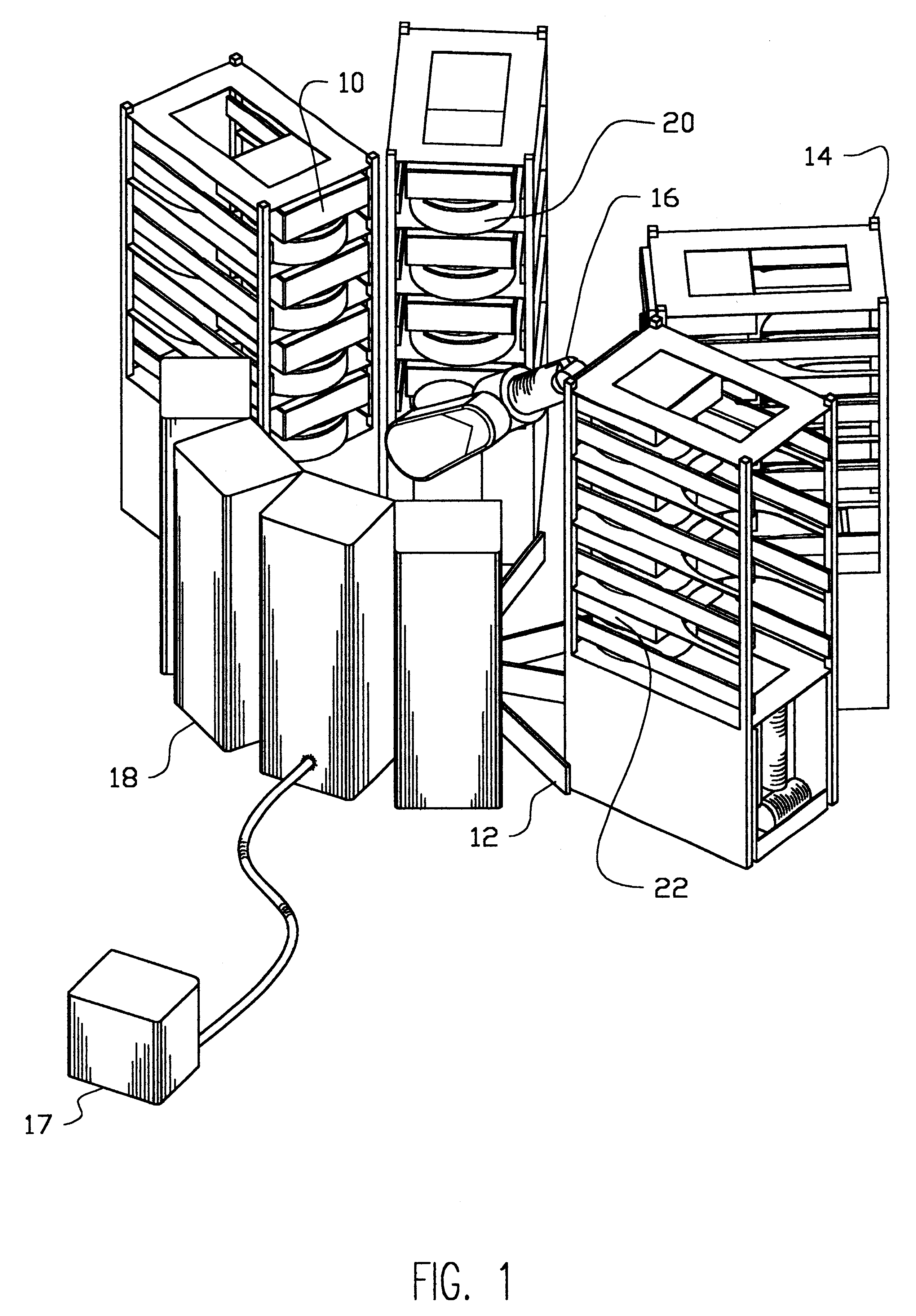

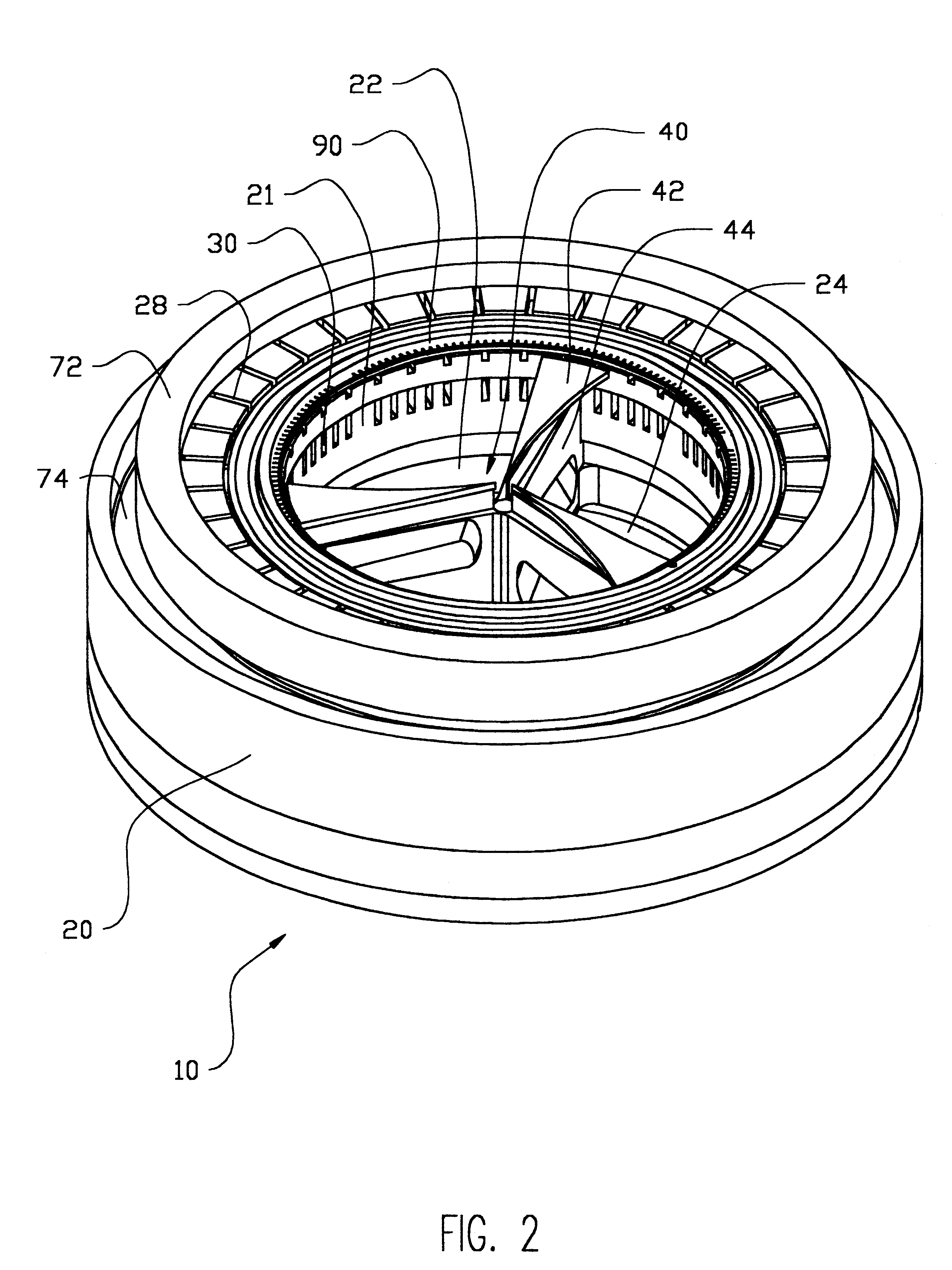

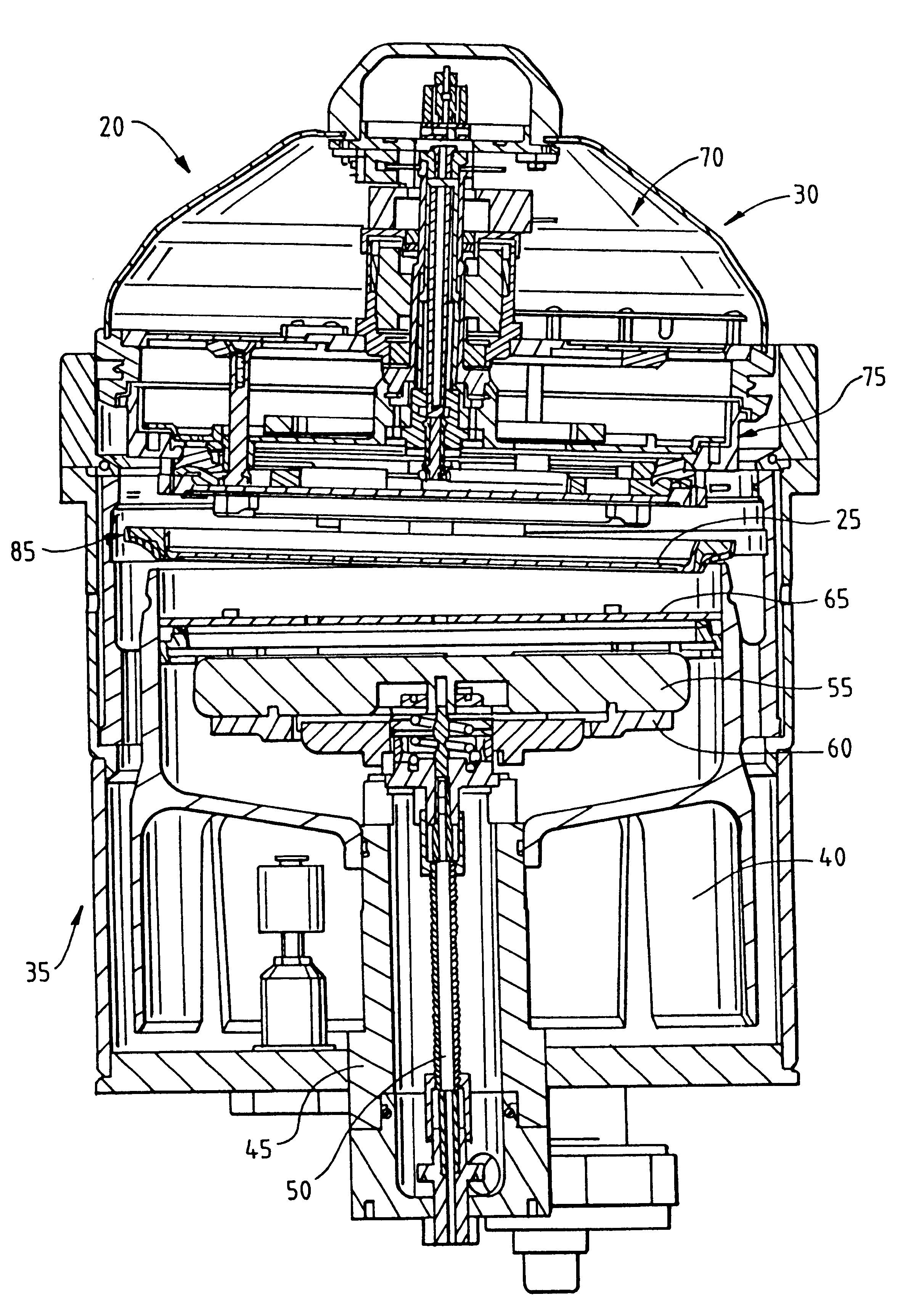

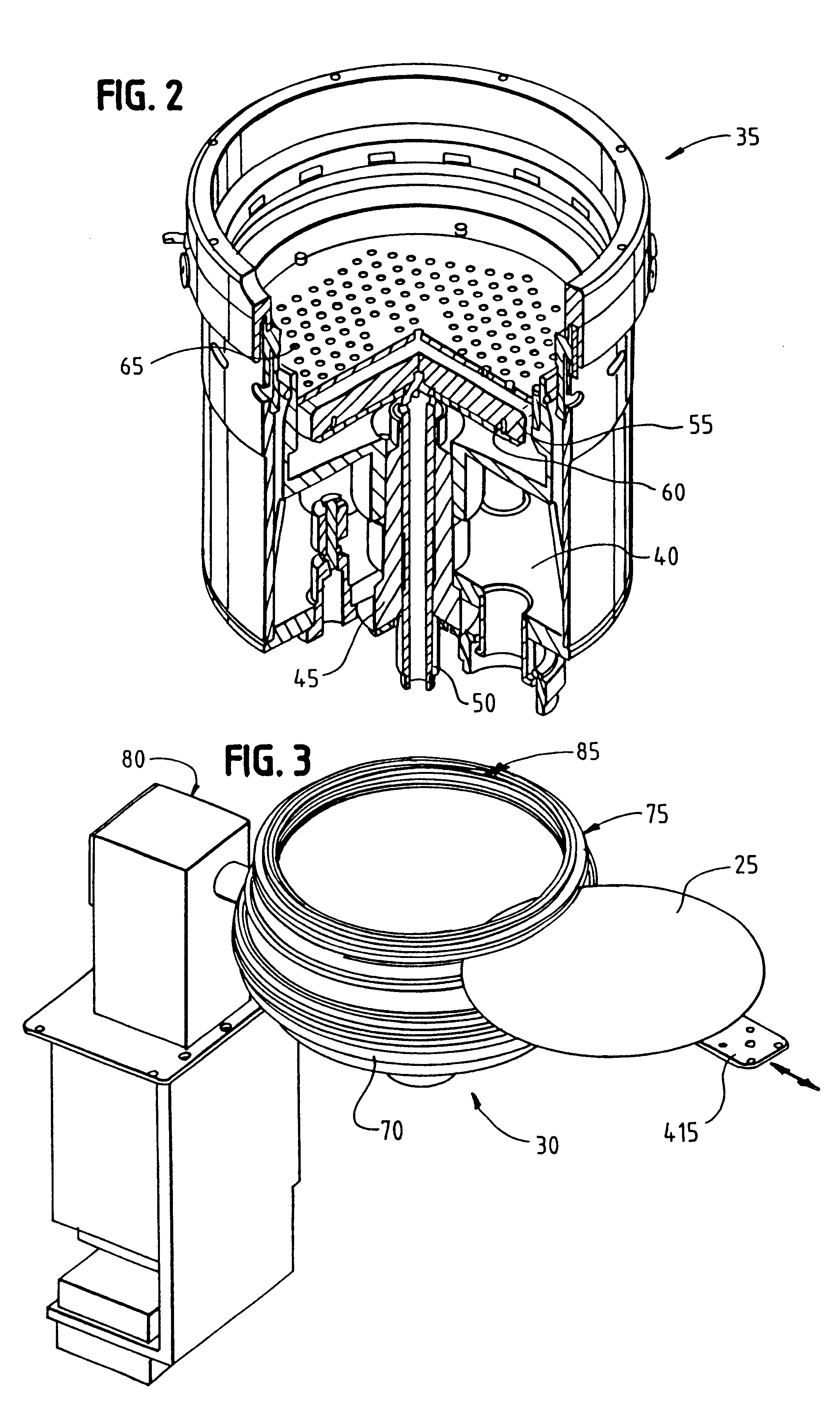

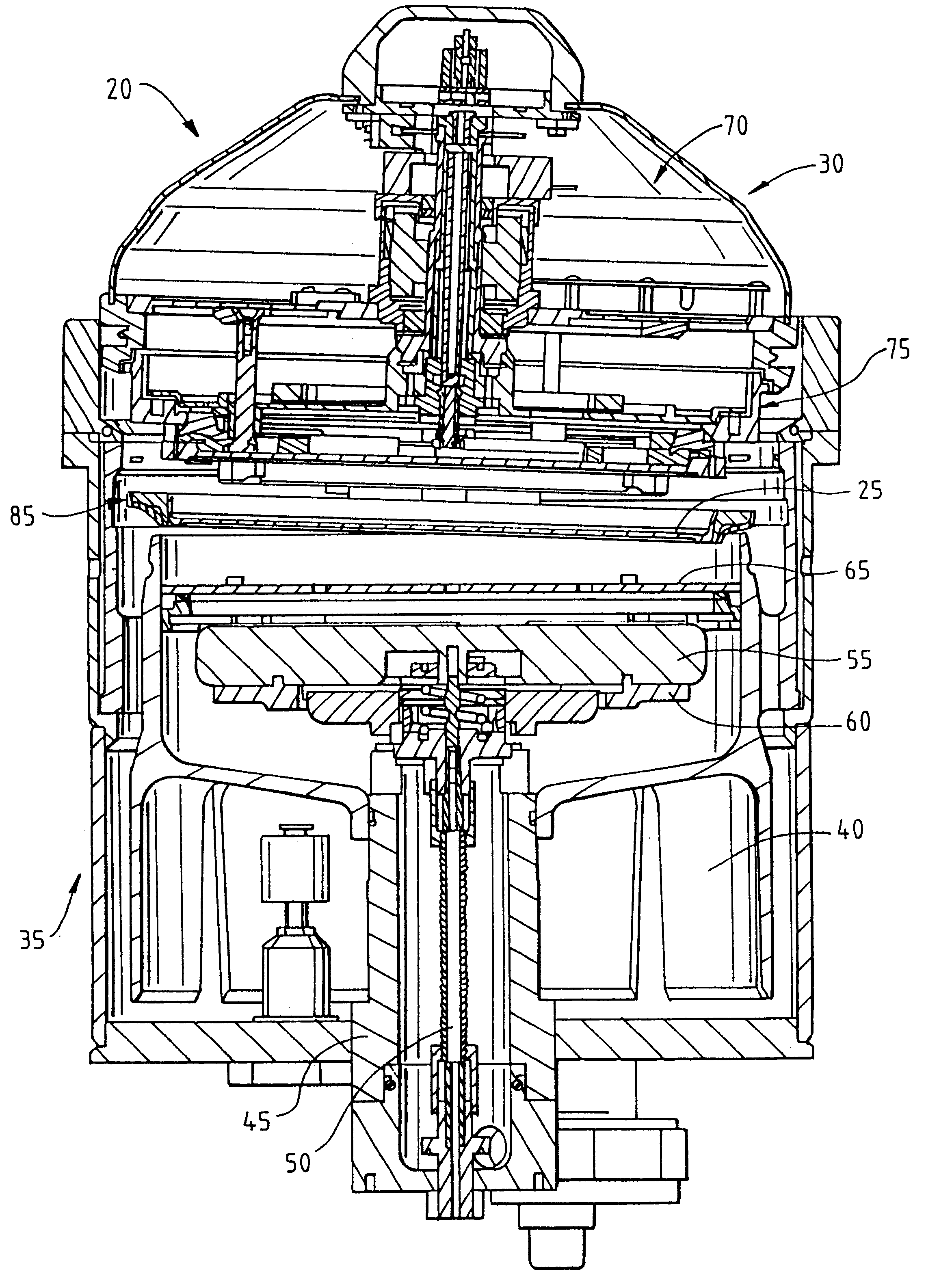

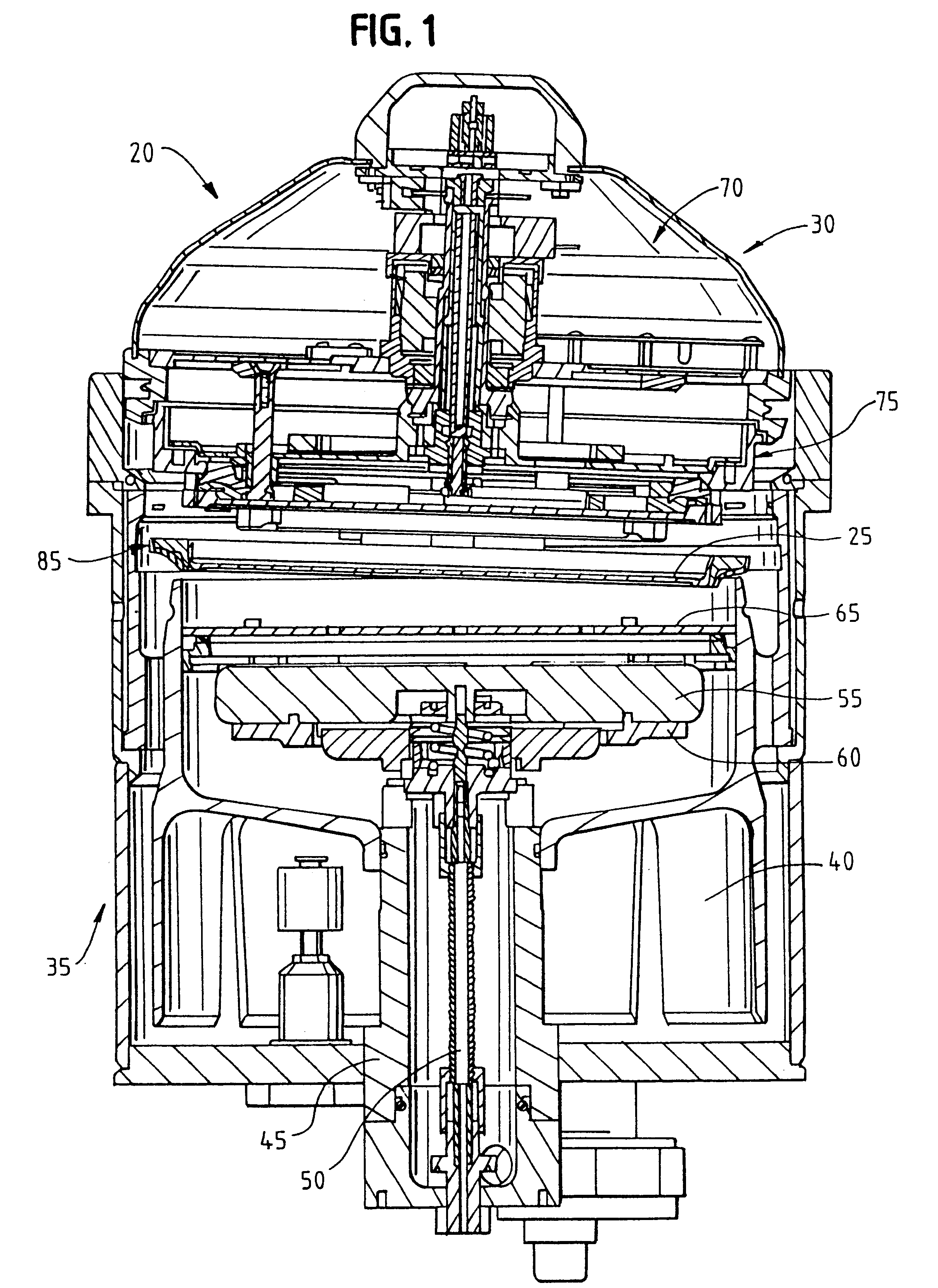

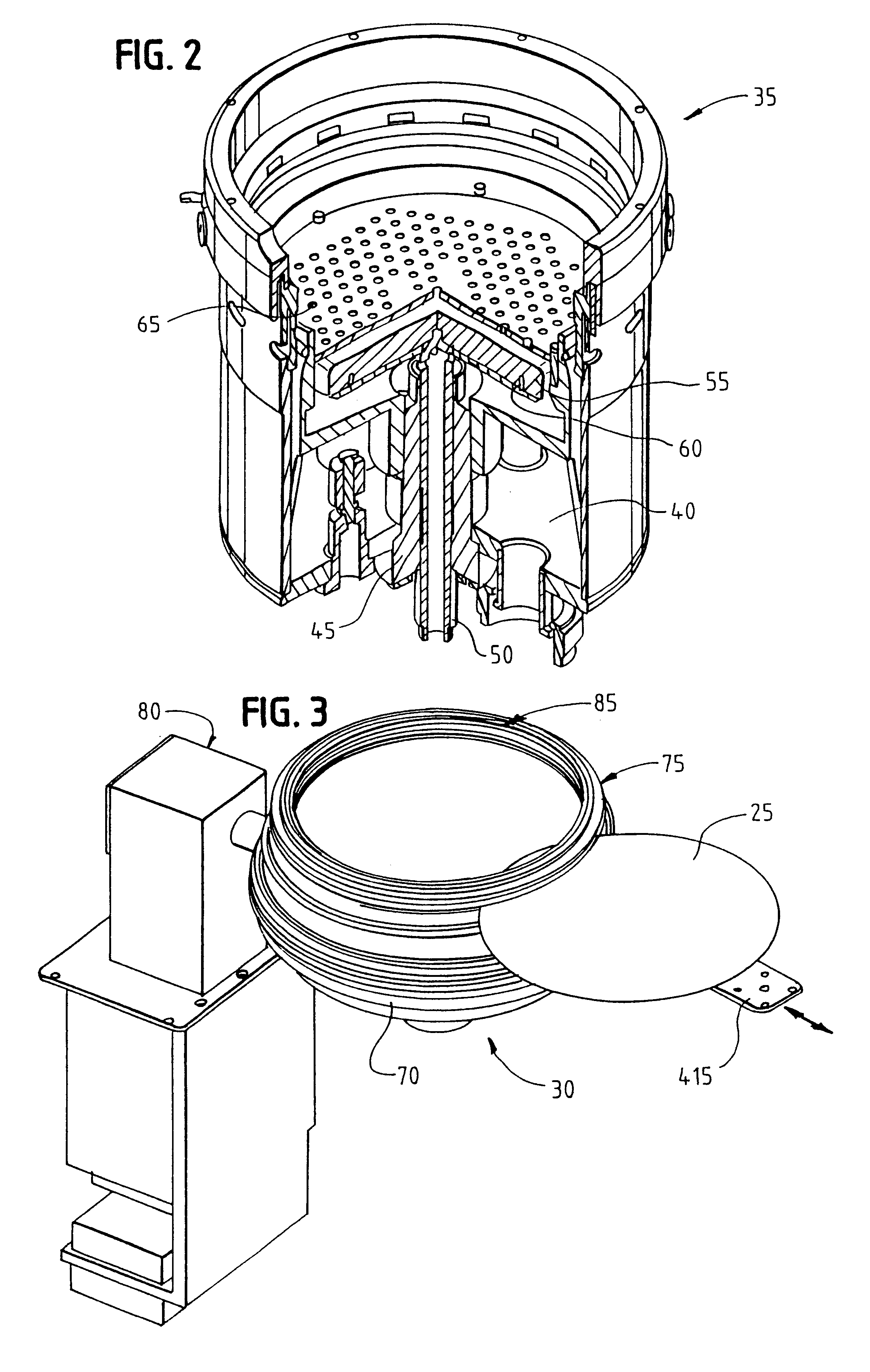

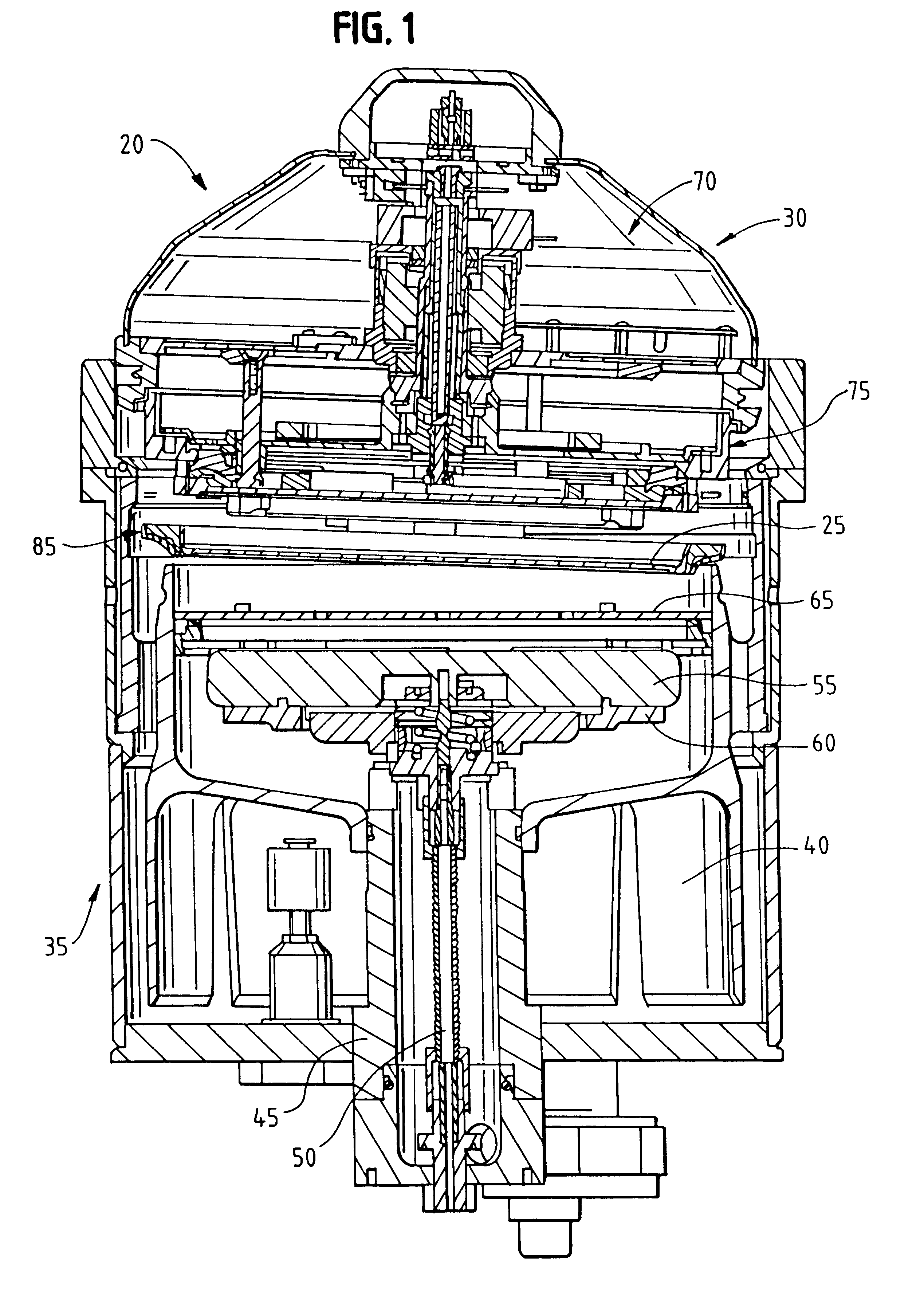

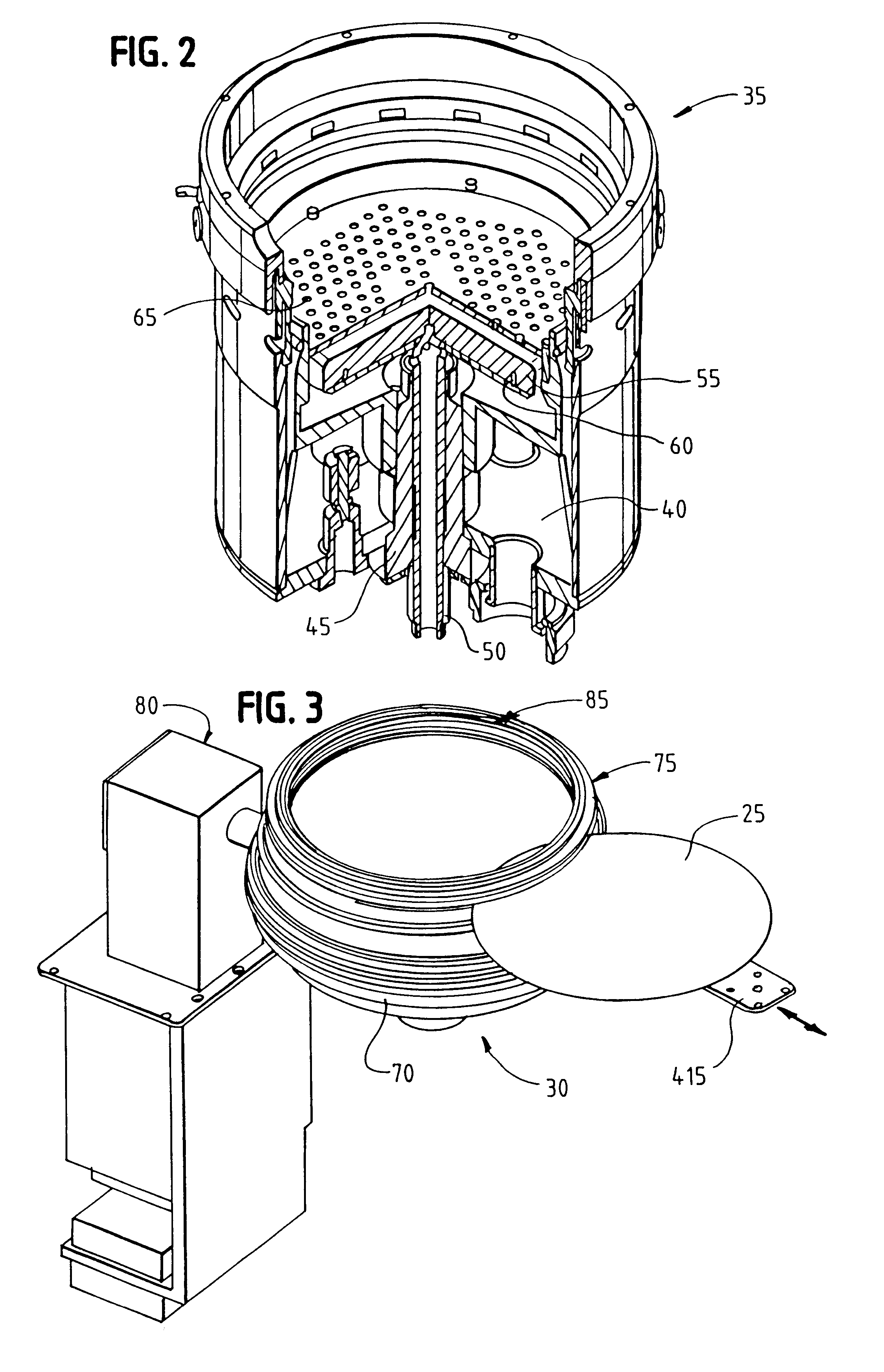

Methods and apparatus for processing the surface of a microelectronic workpiece

InactiveUS6309524B1Reduce the risk of contaminationReduce downtimeCellsTanksEngineeringMechanical engineering

A reactor for plating a metal onto a surface of a workpiece is set forth. The reactor comprises a reactor bowl including an electroplating solution disposed therein and an anode disposed in the reactor bowl in contact with the electroplating solution. A contact assembly is spaced from the anode within the reactor bowl. The contact assembly includes a plurality of contacts disposed to contact a peripheral edge of the surface of the workpiece to provide electroplating power to the surface of the workpiece. The contacts execute a wiping action against the surface of the workpiece as the workpiece is brought into engagement therewith. The contact assembly also including a barrier disposed interior of the plurality of contacts. The barrier includes a member disposed to engage the surface of the workpiece to assist in isolating the plurality of contacts from the electroplating solution. In one embodiment, the plurality of contacts are in the form of discrete flexures while in another embodiment the plurality of contacts are in the form of a Belleville ring contact. A flow path may be provided in the contact assembly for providing a purging gas to the plurality of contacts and the peripheral edge of the workpiece. The purging gas may be used to assist in the formation of the barrier of the contact assembly. A combined electroplating / electroless plating tool and method are also set forth.

Owner:APPLIED MATERIALS INC

Apparatus for high deposition rate solder electroplating on a microelectronic workpiece

The present invention is directed to an improved electroplating method, chemistry, and apparatus for selectively depositing tin / lead solder bumps and other structures at a high deposition rate pursuant to manufacturing a microelectronic device from a workpiece, such as a semiconductor wafer. An apparatus for plating solder on a microelectronic workpiece in accordance with one aspect of the present invention comprises a reactor chamber containing an electroplating solution having free ions of tin and lead for plating onto the workpiece. A chemical delivery system is used to deliver the electroplating solution to the reactor chamber at a high flow rate. A workpiece support is used that includes a contact assembly for providing electroplating power to a surface at a side of the workpiece that is to be plated. The contact contacts the workpiece at a large plurality of discrete contact points that isolated from exposure to the electroplating solution. An anode, preferably a consumable anode, is spaced from the workpiece support within the reaction chamber and is in contact with the electroplating solution. In accordance with one embodiment the electroplating solution comprises a concentration of a lead compound, a concentration of a tin compound, water and methane sulfonic acid.

Owner:APPLIED MATERIALS INC

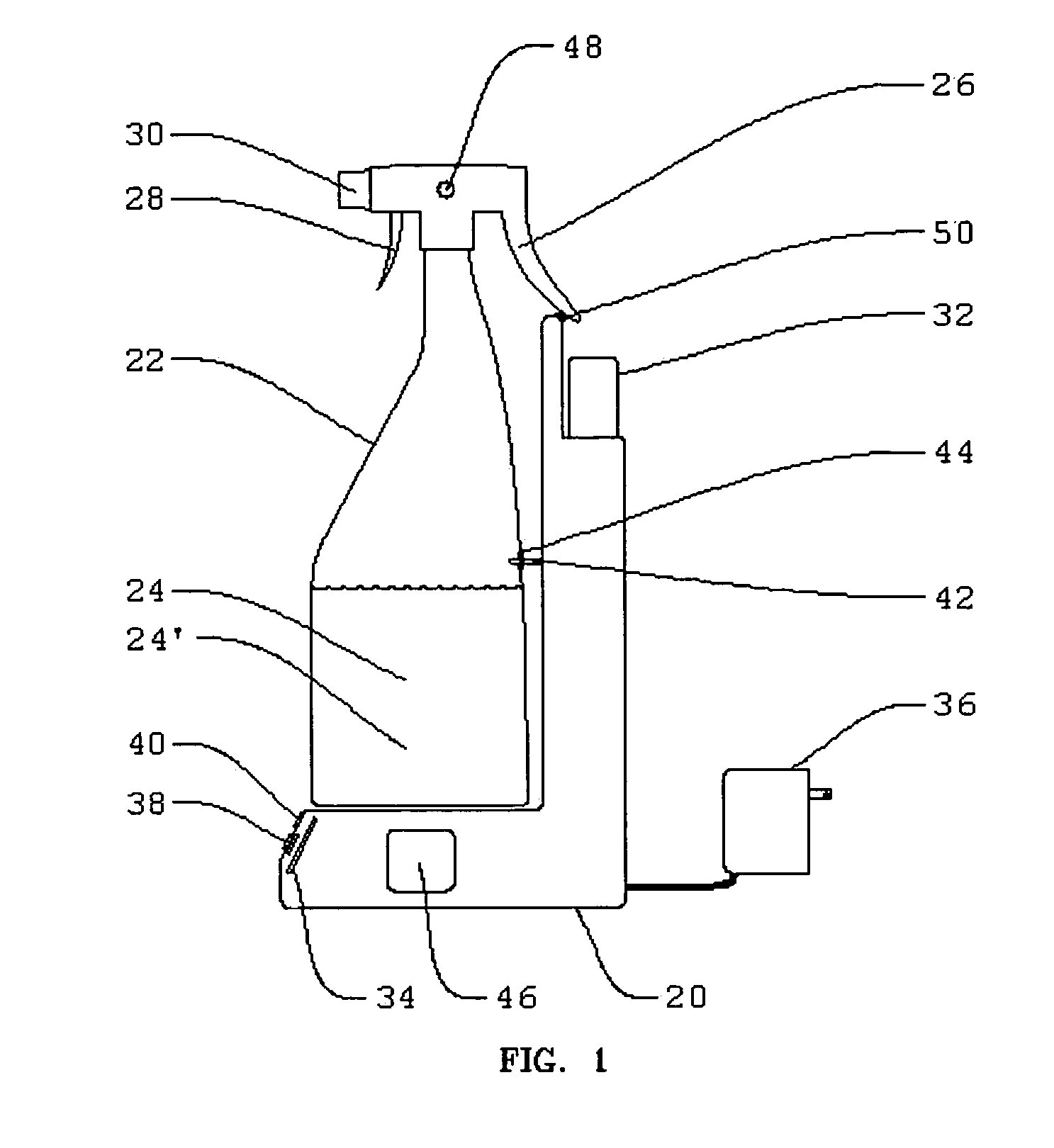

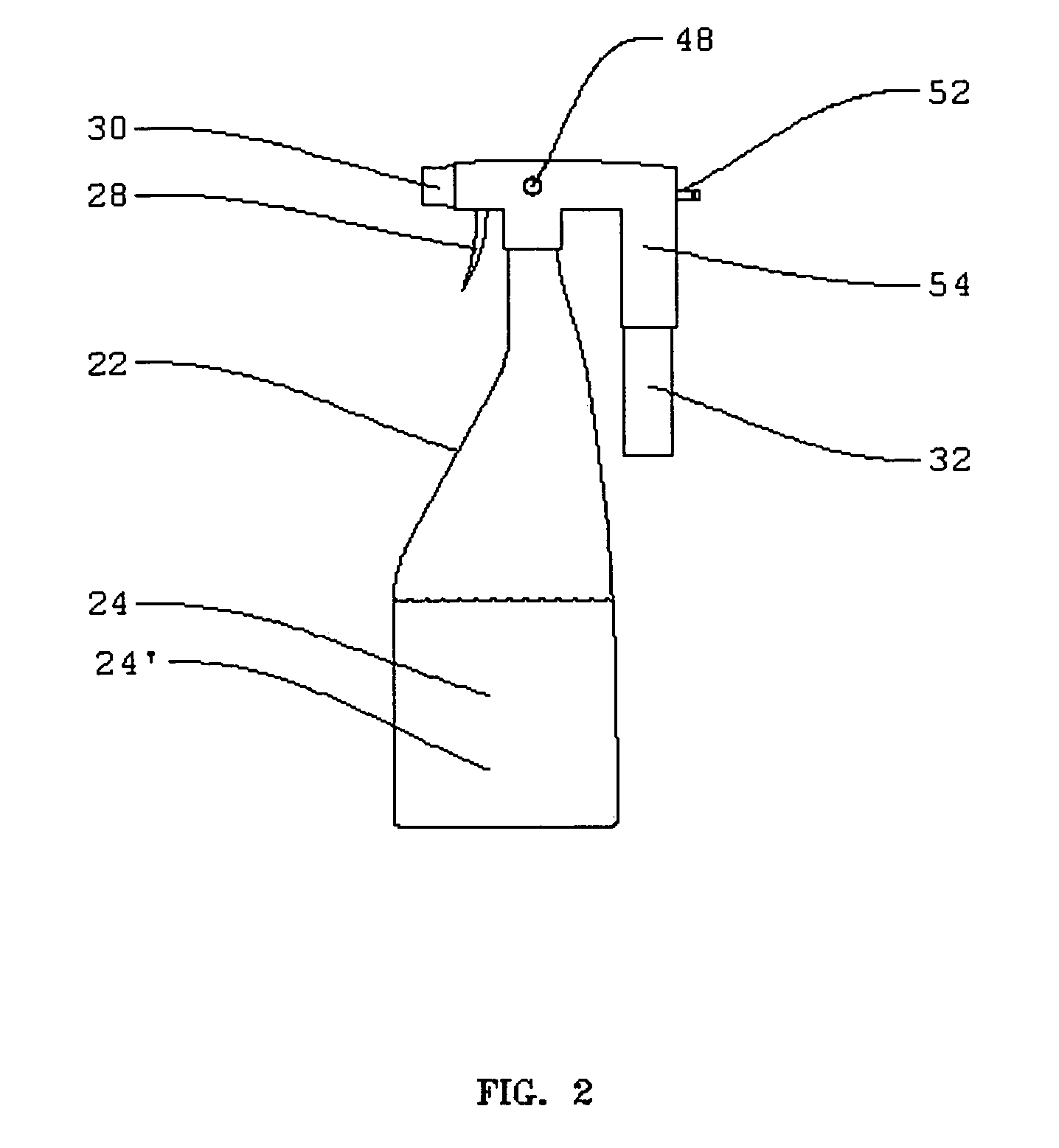

Microorganism control of point of use potable water sources

InactiveUS20030080467A1Keep it cleanPrevent freezingCellsSpecific water treatment objectivesMedical equipmentWater source

The present invention provides for the electrochemical generation of ozone for use in "point-of-use" applications. The electrochemical ozone generators or systems of the present invention may be used to provide disinfected water, ozone-containing water, and / or ozone gas. Disinfected water may be produced by introducing ozone gas into a potable or purified water source for the purpose of disinfecting or controlling the microorganisms in the water source. Ozonated water or ozone gas may be produced and provided for various anti-microbial and cleansing applications of the consumer, such as washing food, clothing, dishes, countertops, toys, sinks, bathroom surfaces, and the like. Furthermore, the ozone generator may be used to deliver a stream of ozone-containing water for the purpose of commercial or residential point-of-use washing, disinfecting, and sterilizing medical instruments and medical equipment. For example, the ozone-containing water may be used directly or used as a concentrated sterilant for the washing, disinfecting, and sterilizing of medical instruments or equipment. Ozone gas may also be used in many of the foregoing examples, as well as in the deodorization of air or various other applications. The invention allows the electrochemical ozone generator to operate in a nearly or entirely passive manner with simplicity of design.

Owner:LYNNTECH INT

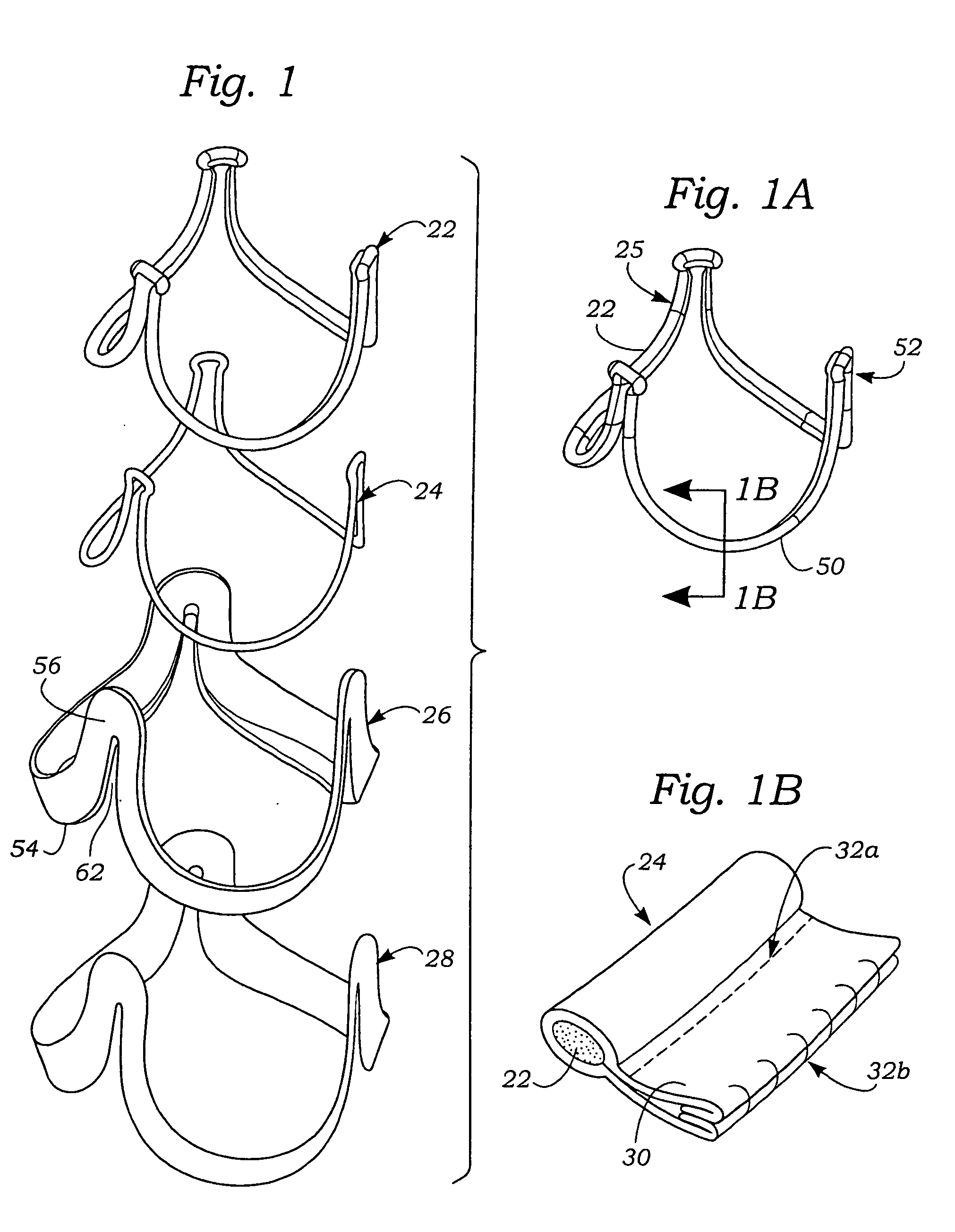

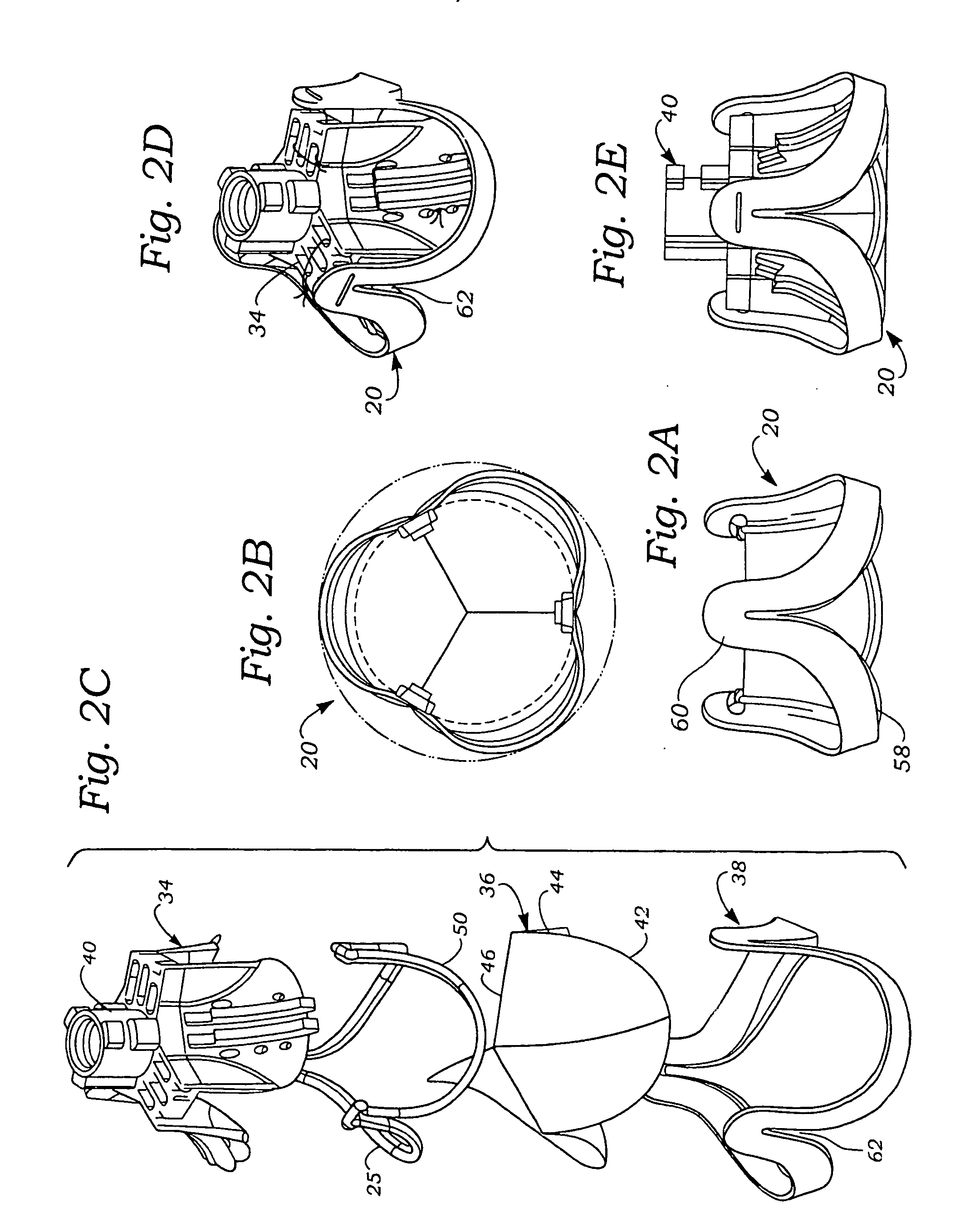

Method of manufacture of a heart valve support frame

InactiveUS20050150775A1Eliminate unevennessIncrease flexibilityElectrolysis componentsFrom normal temperature solutionsEngineeringReady to use

Methods for forming a support frame for flexible leaflet heart valves from a starting blank include converting a two-dimensional starting blank into the three-dimensional support frame. The material may be superelastic, such as NITINOL, and the method may include bending the 2-D blank into the 3-D form and shape setting it. A merely elastic material such as ELGILOY may be used and plastically deformed in stages, possibly accompanied by annealing, to obtain the 3-D shape. Alternatively, a tubular blank could be formed to define a non-tubular shape, typically conical. A method for calculating the precise 2-D blank shape is also disclosed. A mandrel assembly includes a mandrel and ring elements for pressing the blank against the external surface of the mandrel prior to shape setting.

Owner:EDWARDS LIFESCIENCES CORP

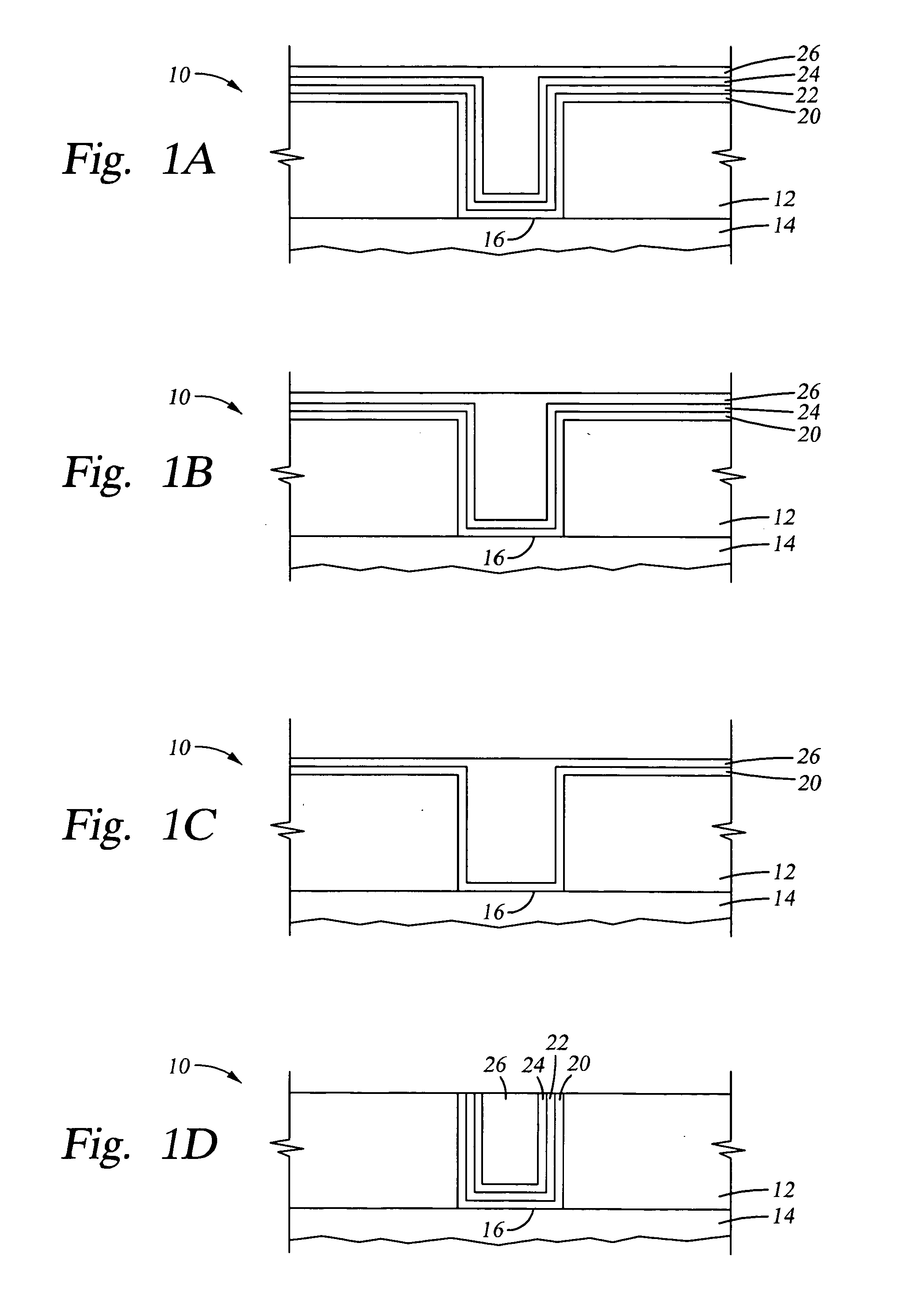

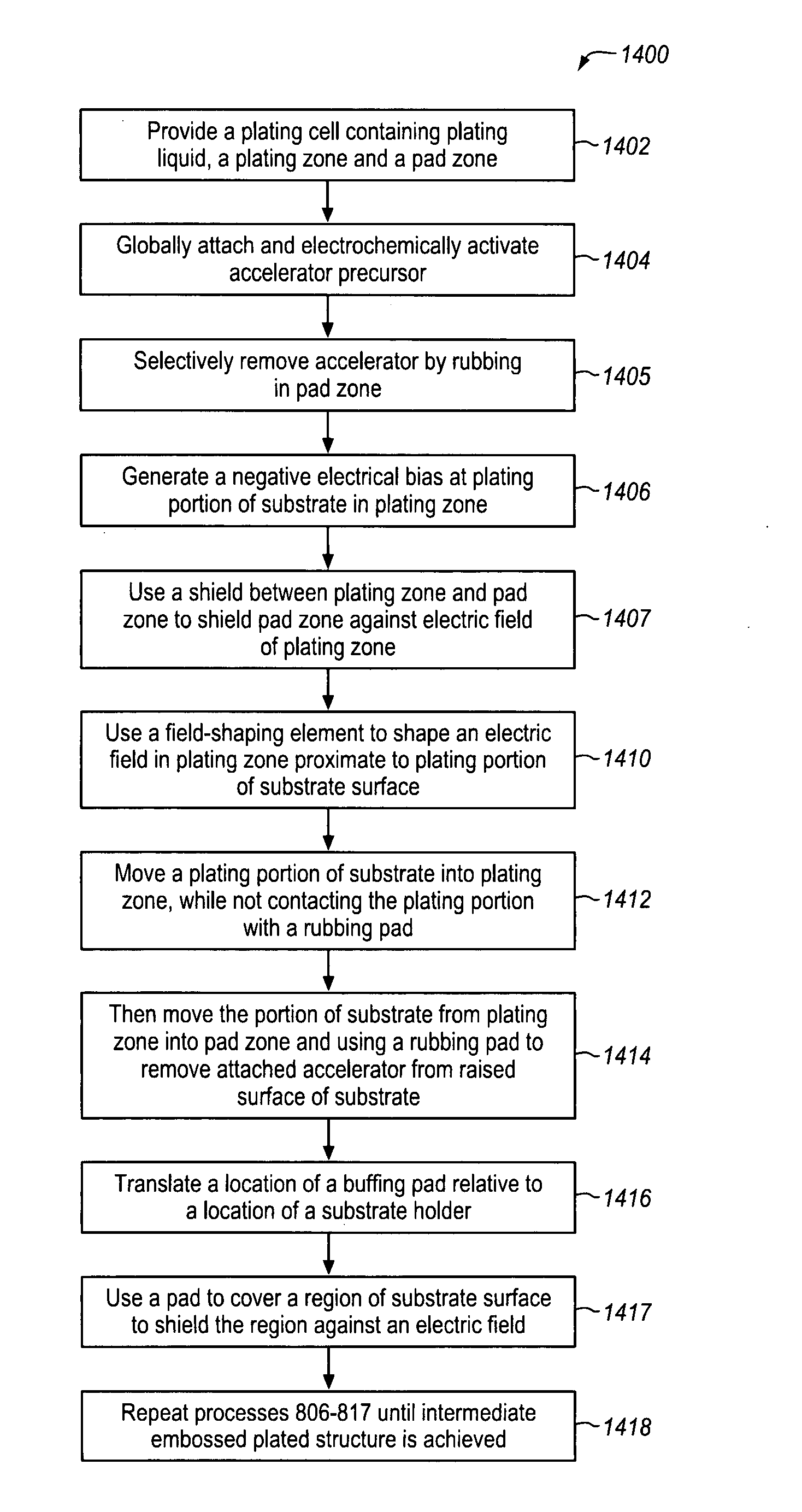

Topography reduction and control by selective accelerator removal

ActiveUS20090280649A1Improve throughputLow costCellsDecorative surface effectsMetal interconnectEtching

Plating accelerator is applied selectively to a substantially-unfilled wide (e.g., low-aspect-ratio feature cavity. Then, plating of metal is conducted to fill the wide feature cavity and to form an embossed structure in which the height of a wide-feature metal protrusion over the metal-filled wide-feature cavity is higher than the height of metal over field regions. Most of the overburden metal is removed using non-contact techniques, such as chemical wet etching. Metal above the wide feature cavity protects the metal-filled wide-feature interconnect against dishing, and improved planarization techniques avoid erosion of the metal interconnect and dielectric insulating layer. In some embodiments, plating of metal onto a substrate is conducted to fill narrow (e.g., high-aspect-ratio feature cavities) in the dielectric layer before selective application of plating accelerator and filling of the wide feature cavity.

Owner:NOVELLUS SYSTEMS

Method of and apparatus for fluid sealing, while electrically contacting, wet-processed workpieces

A method and apparatus for fluid sealing the underside of a workpiece, such as a semiconductor wafer and the like, during wet-processing such as electrodeposition and the like, employing an elastomeric encased ring of flexible fingers against which the periphery of the workpiece underside is forced to deflect the fingers downwardly and engage a peripheral sealing bead against the underside periphery of the workpiece; and where electrical contact with the workpiece is desired, resiliently engaging electrical contact tips protruding through peripheral openings in the elastomeric covering within the sealing ring, with the underside periphery of the workpiece.

Owner:HERCULES TECH GROWTH CAPITAL

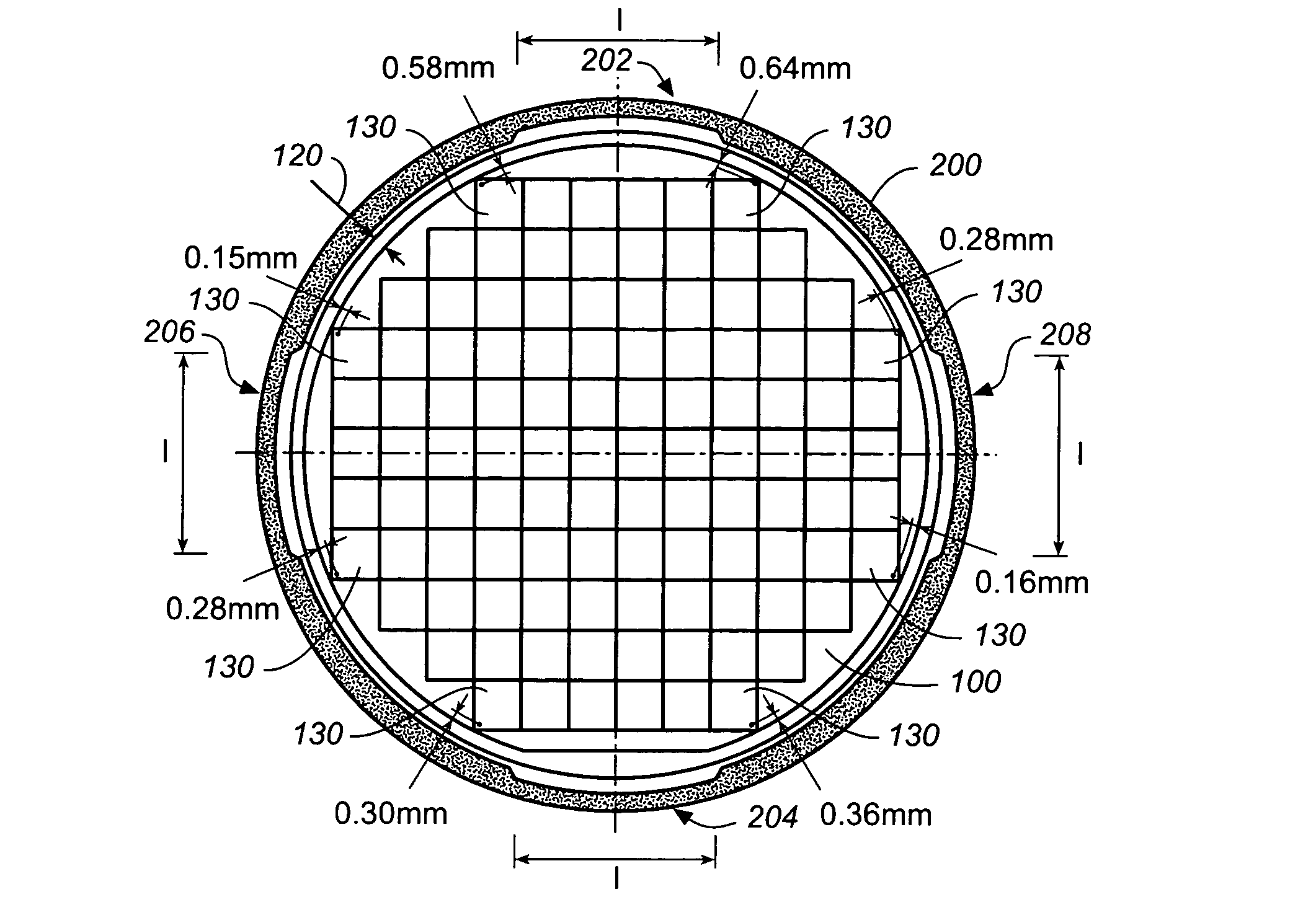

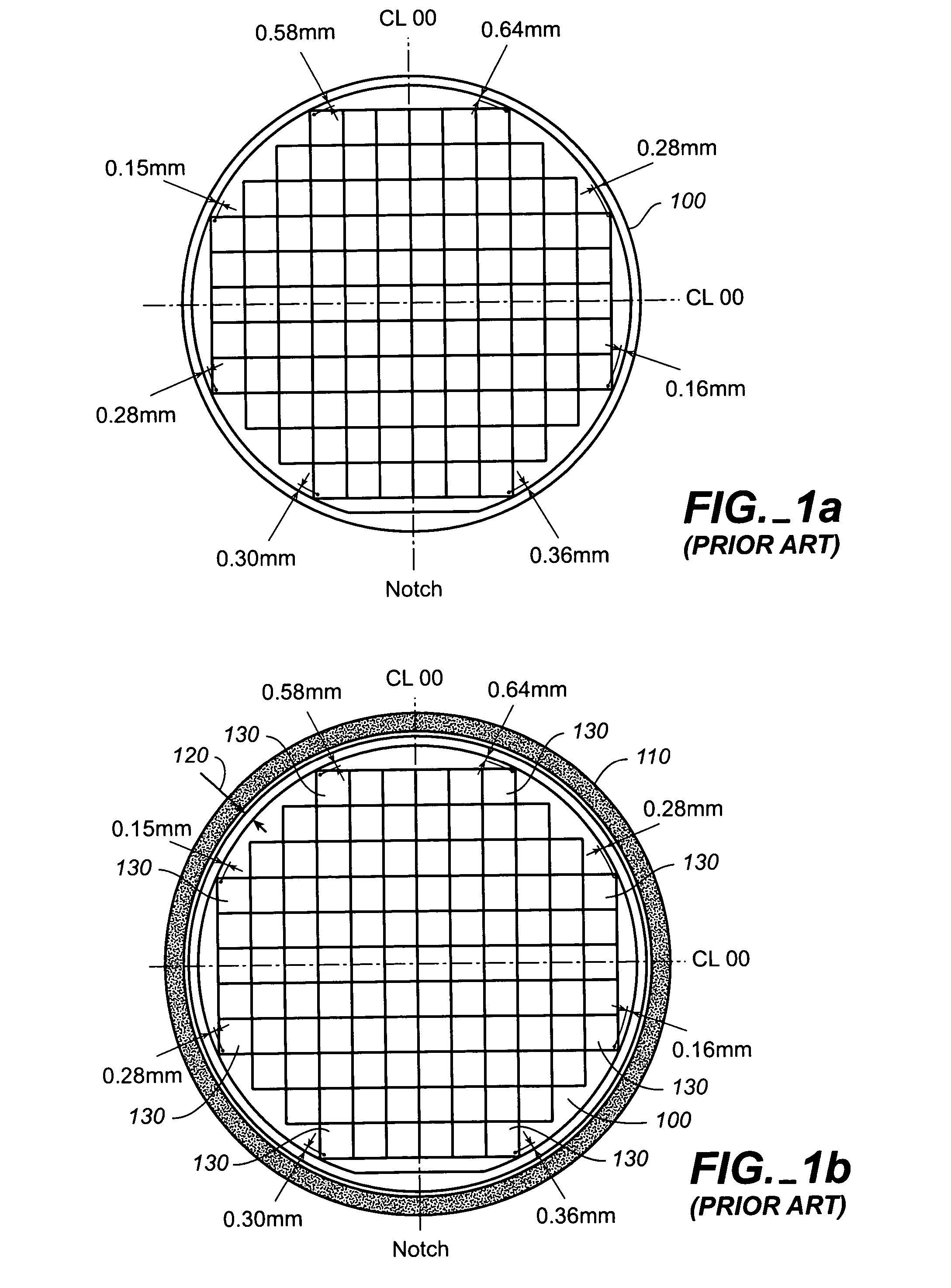

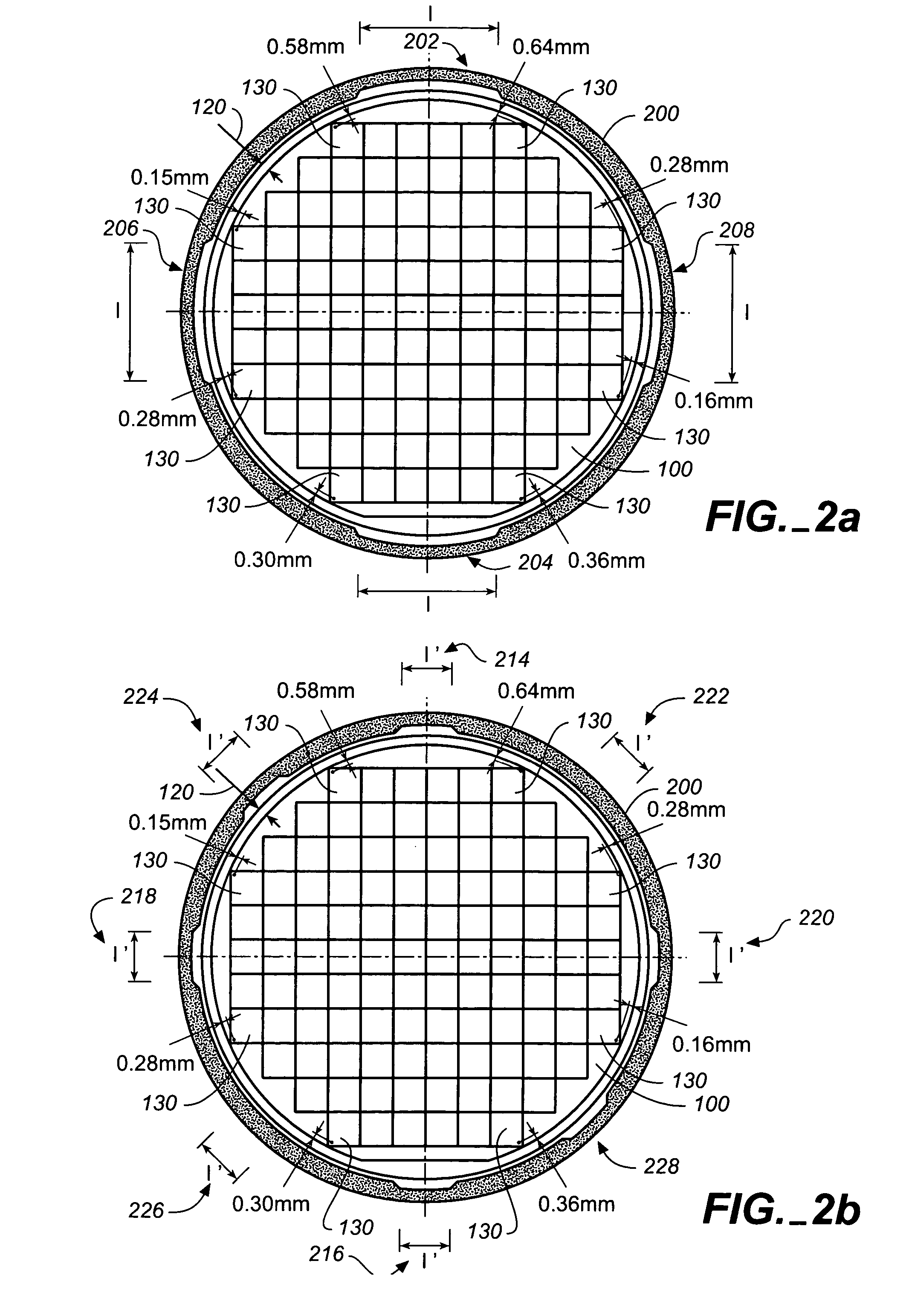

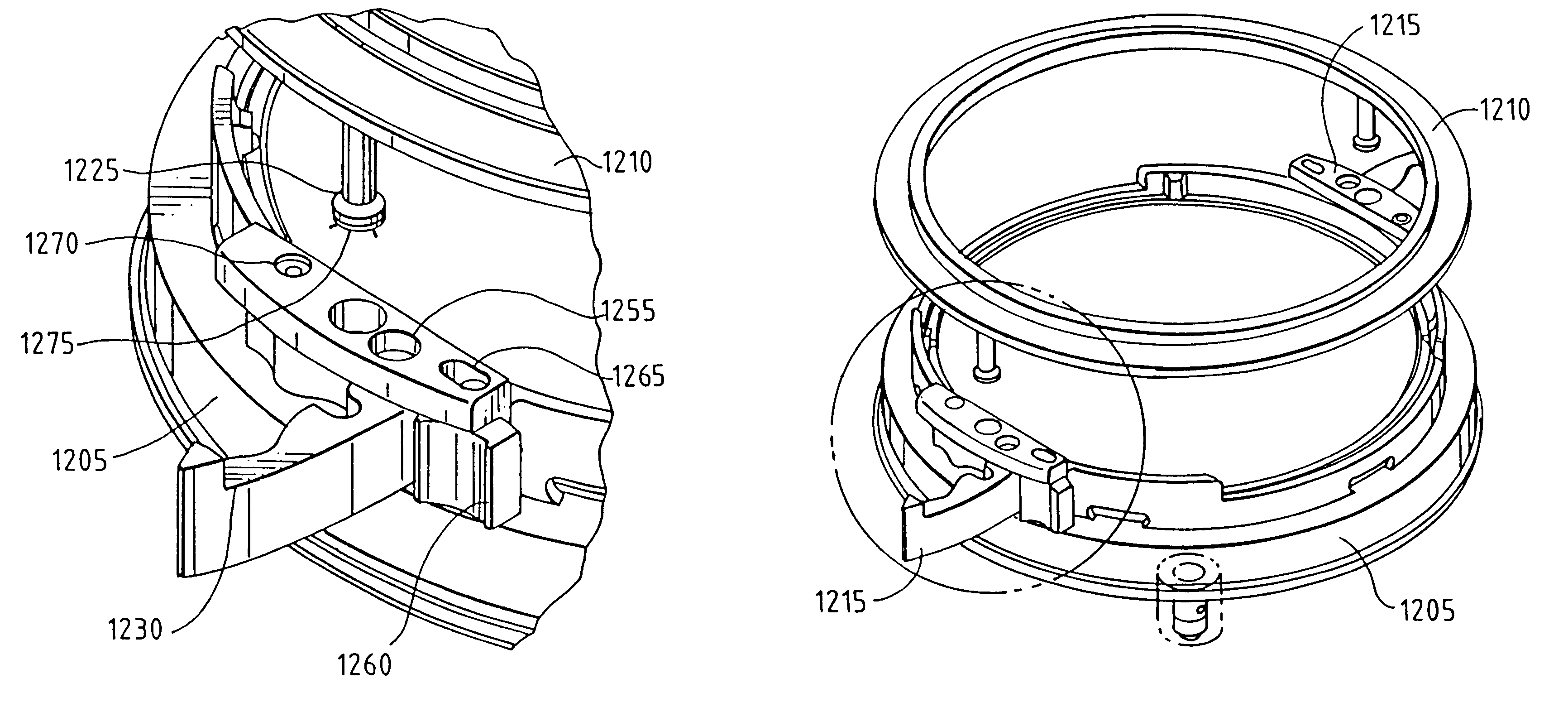

System and method for increasing yield from semiconductor wafer electroplating

ActiveUS7641776B2Potential for defects on the edge dies is reducedAvoid overlapCellsAnodisationEngineeringElectroplating

A system and method increase yield from semiconductor wafer electroplating. The aspects include a semiconductor wafer, the semiconductor wafer comprising a plurality of die areas. A plating ring for holding the semiconductor wafer in position during electroplating is also included, the plating ring substantially surrounding a circumference of the semiconductor wafer and having a width that varies in order to avoid overlap near edge die areas of the semiconductor wafer.

Owner:BELL SEMICON LLC

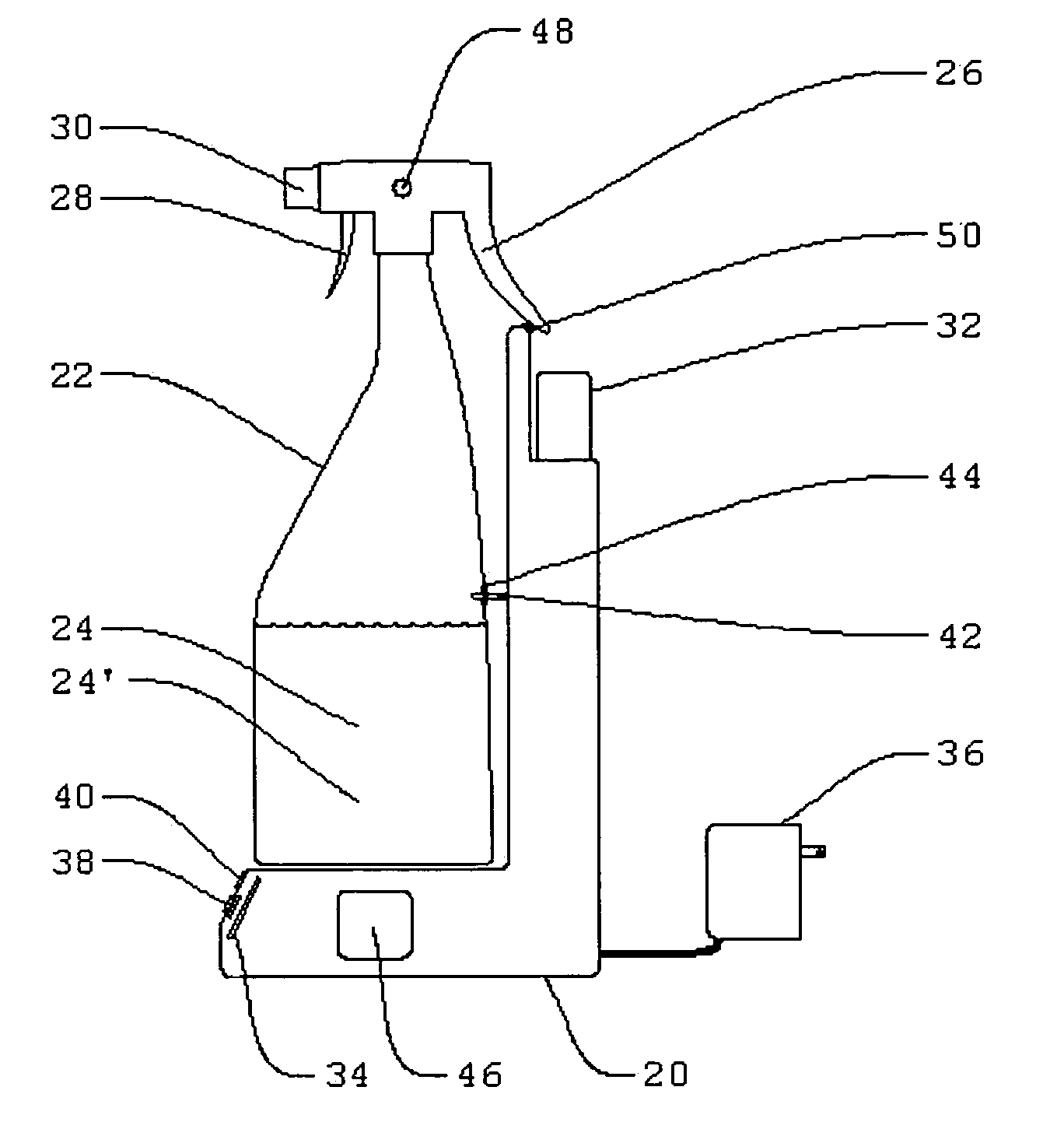

Electrolytic cell for surface and point of use disinfection

InactiveUS7008523B2Suitable for useCellsWater treatment parameter controlDisinfectantElectrical battery

The present invention is an apparatus and method for disinfecting or sanitizing a desired object. The apparatus includes a container for an aqueous solution; the container may be a spray bottle. The apparatus includes an electrolytic cell, containing an electrolyte, an electrical power source, a control circuit for providing an electric charge to the electrolyte to create an oxidant, and a fluid connection between the cell and container to permit introduction of the oxidant into the aqueous solution to create a disinfectant.

Owner:DE NORA HLDG US INC

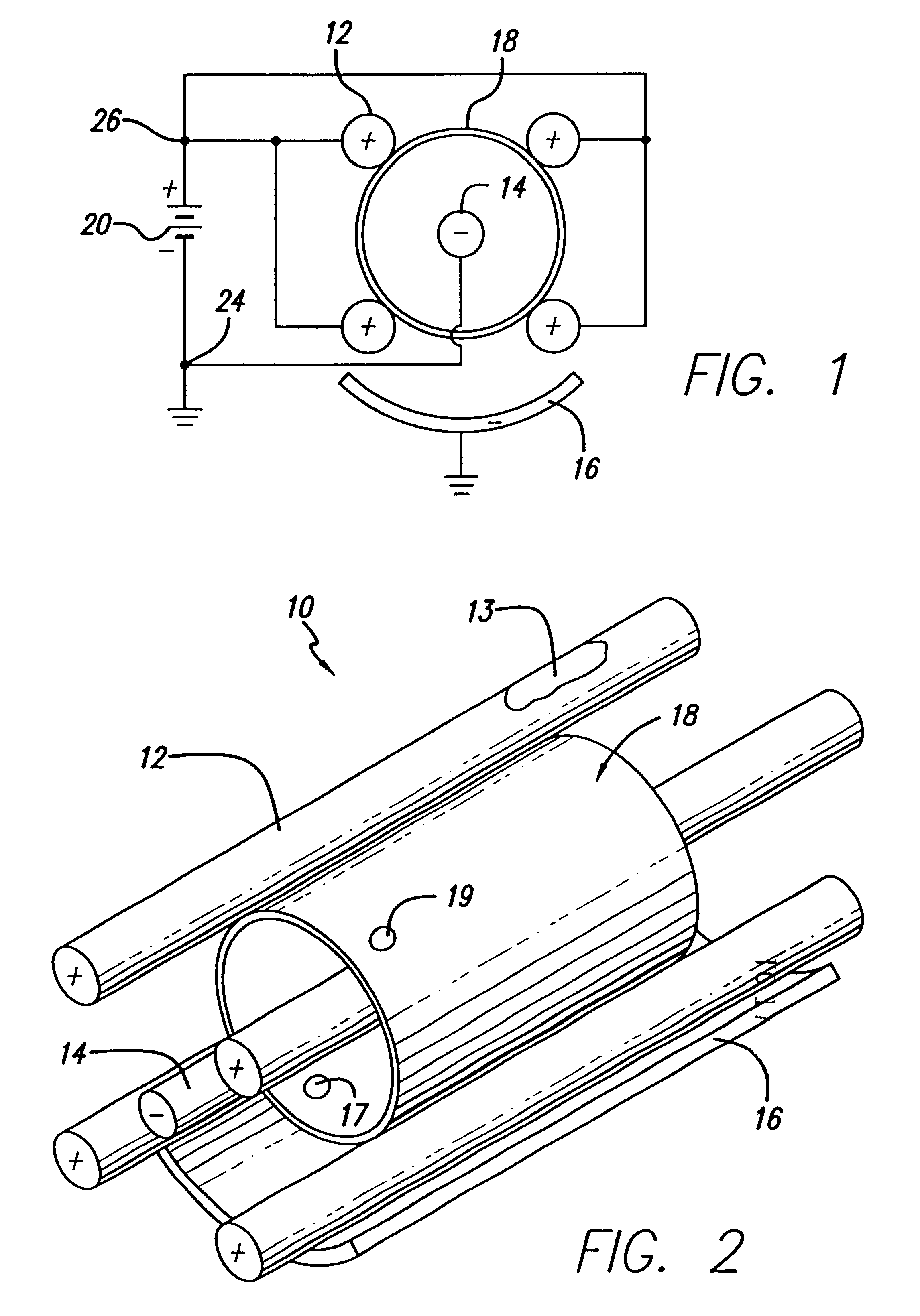

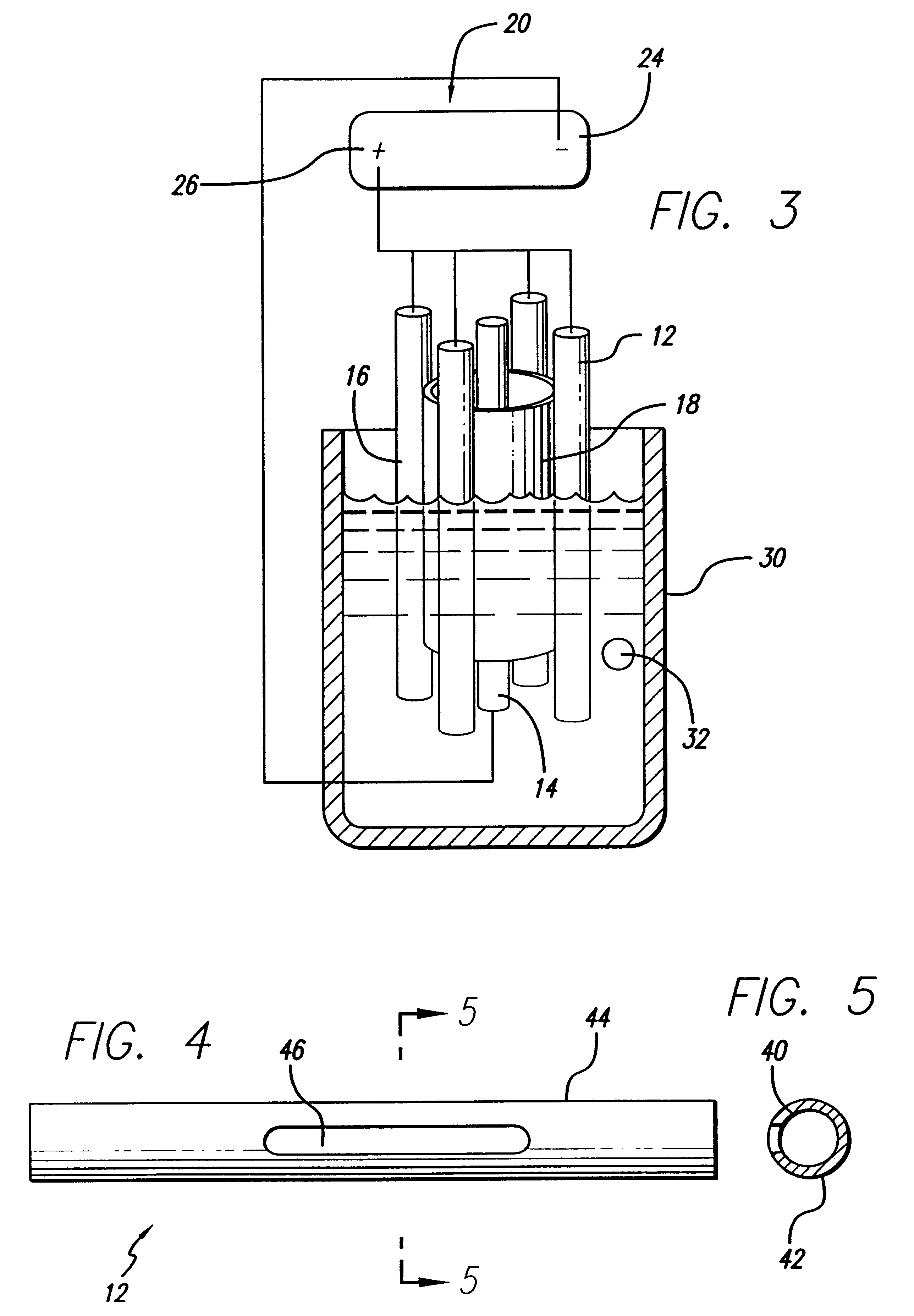

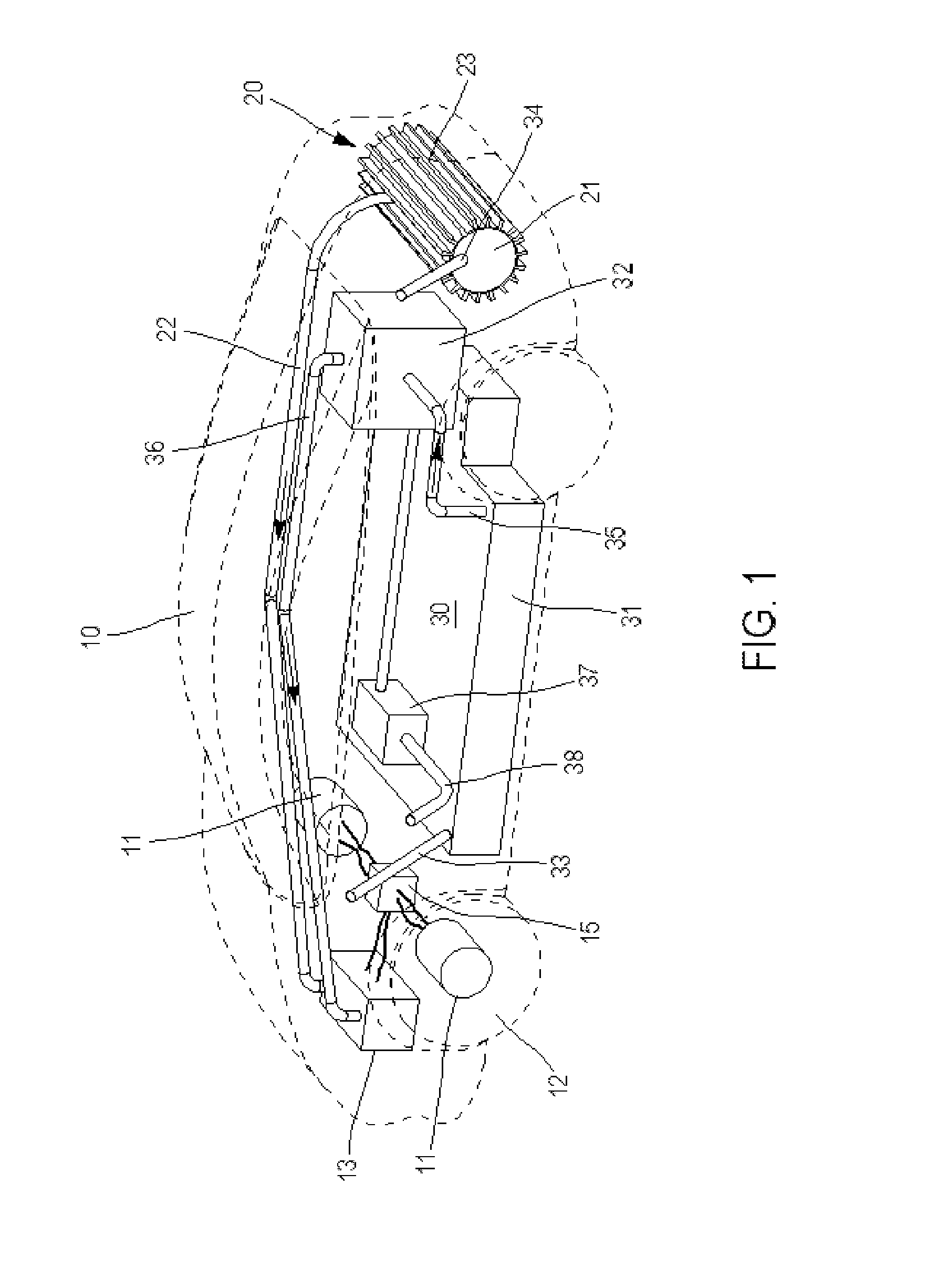

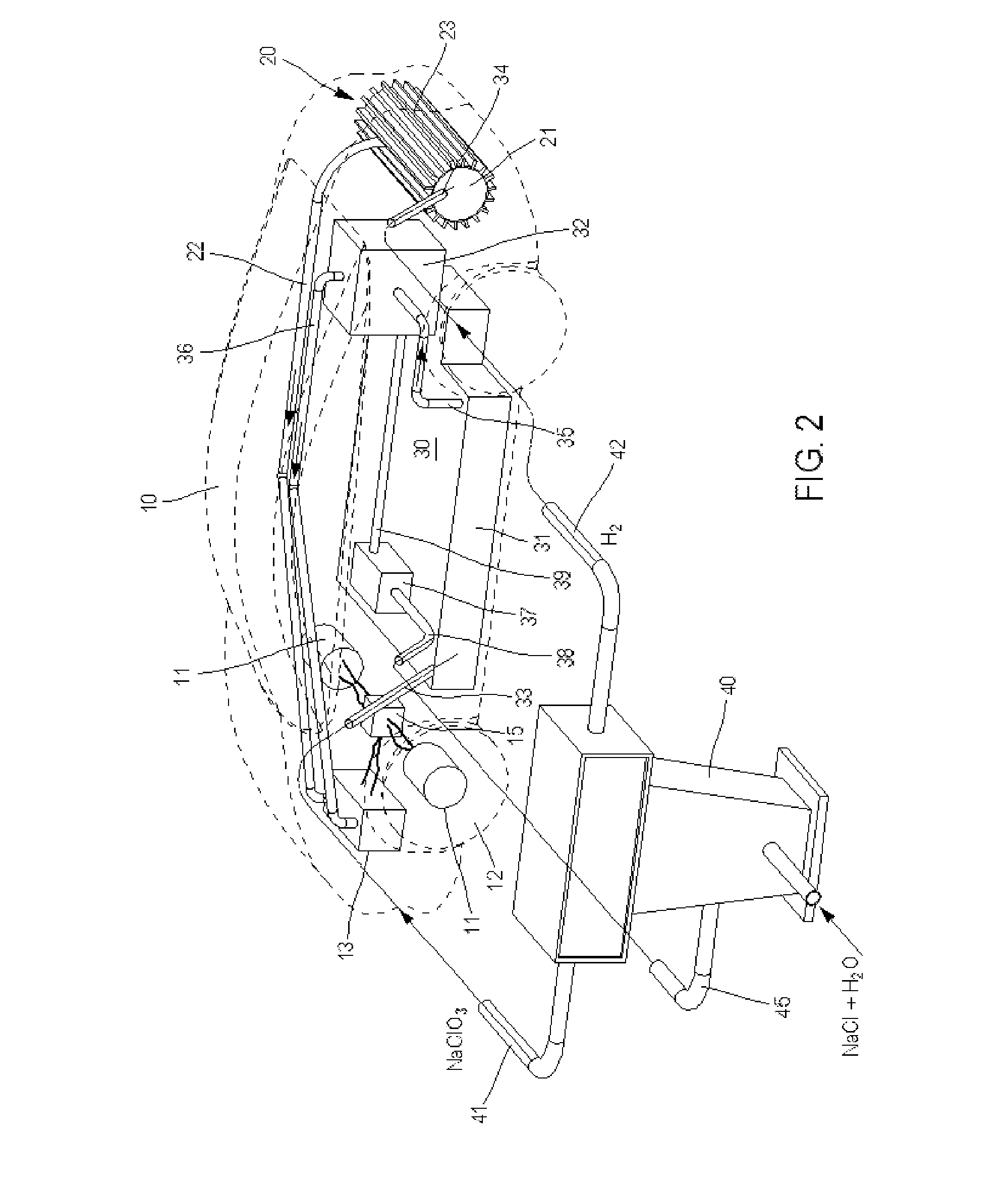

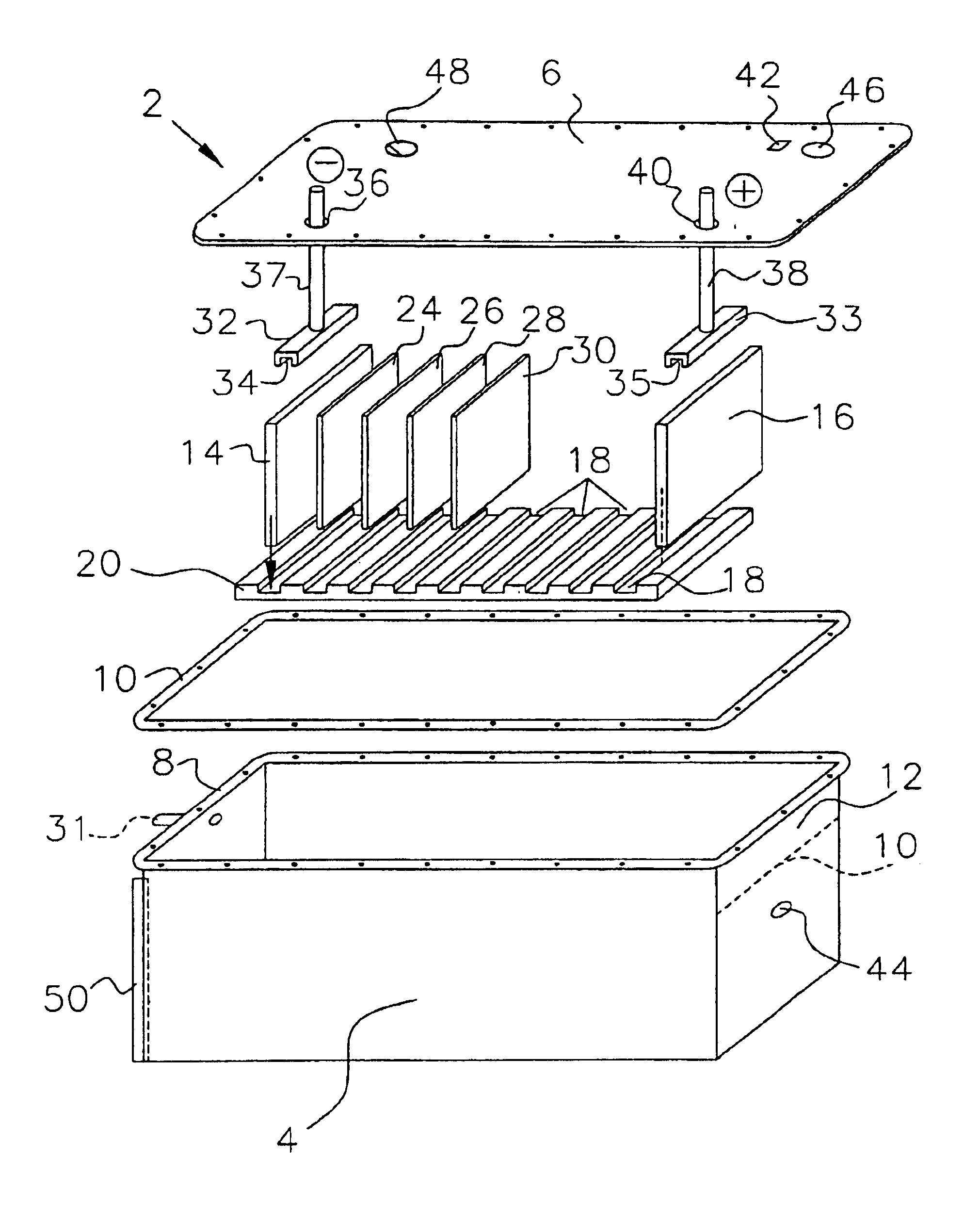

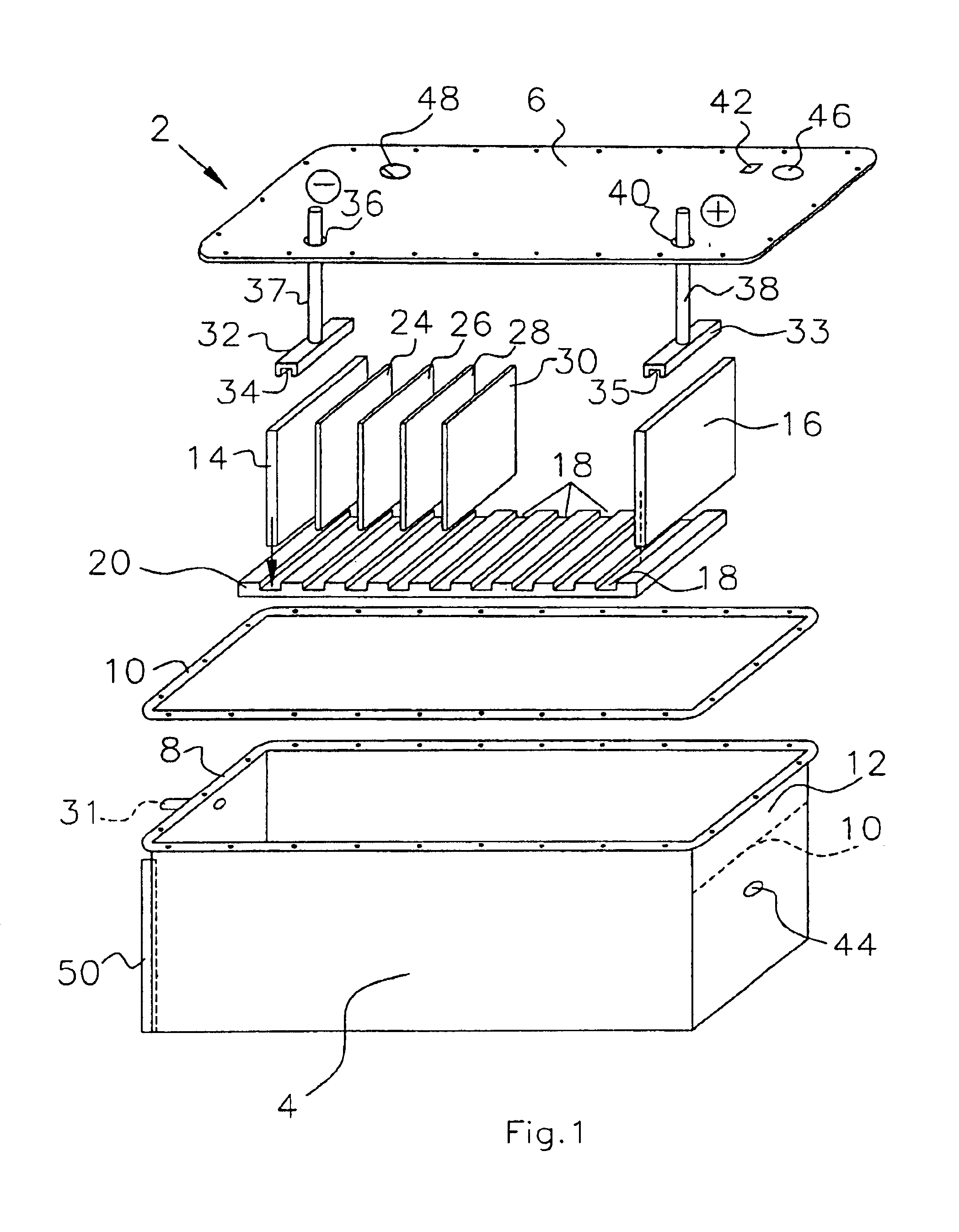

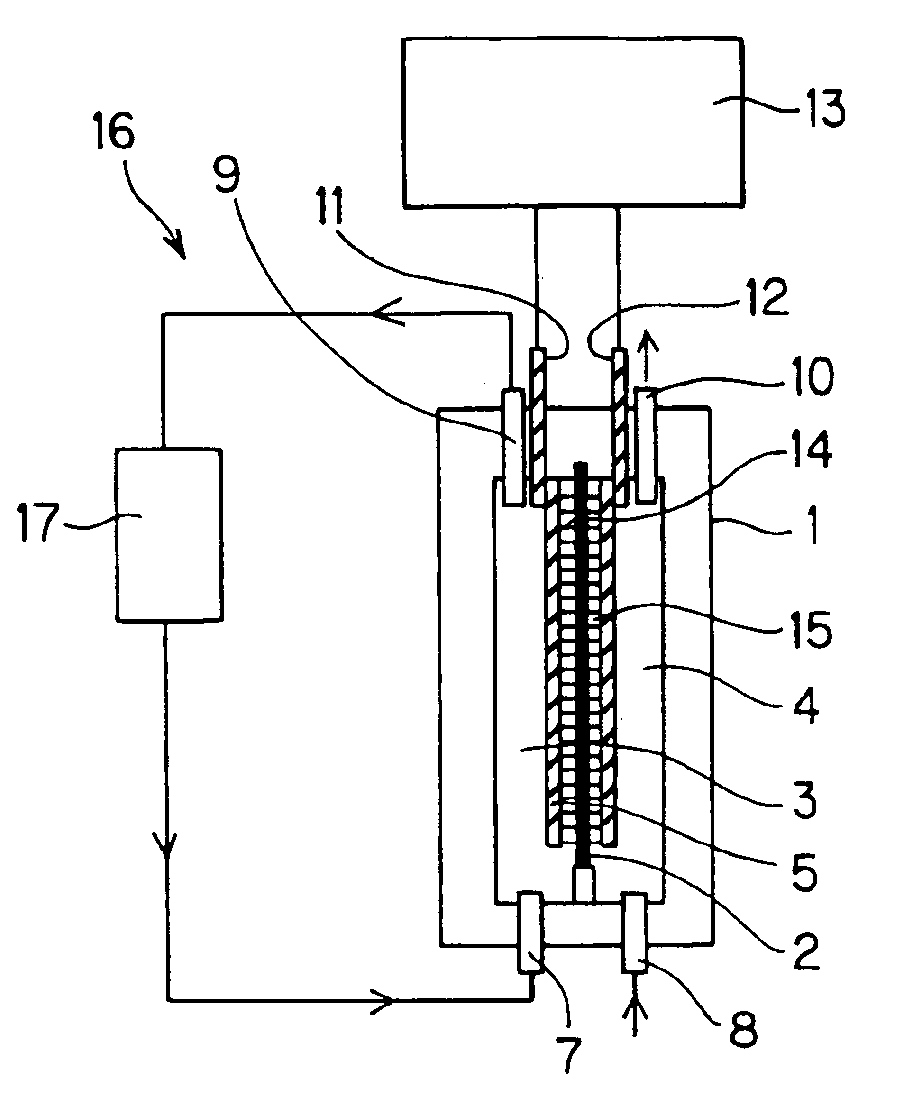

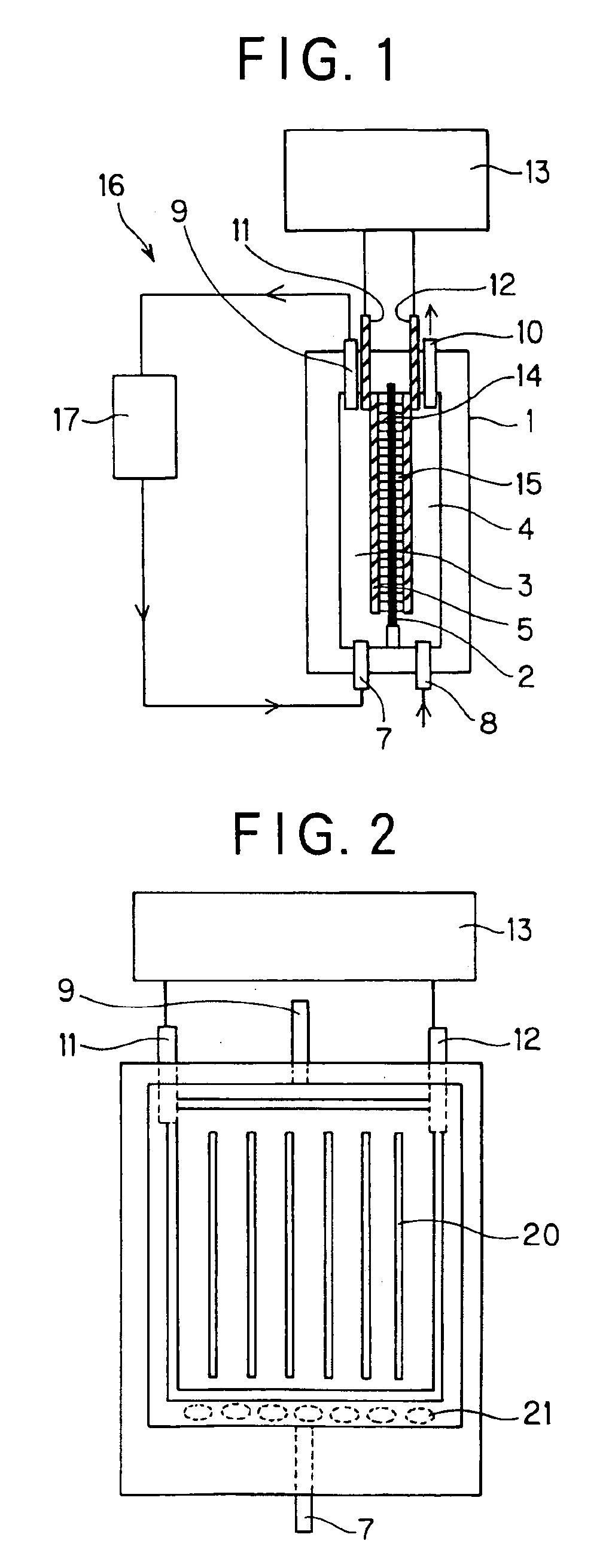

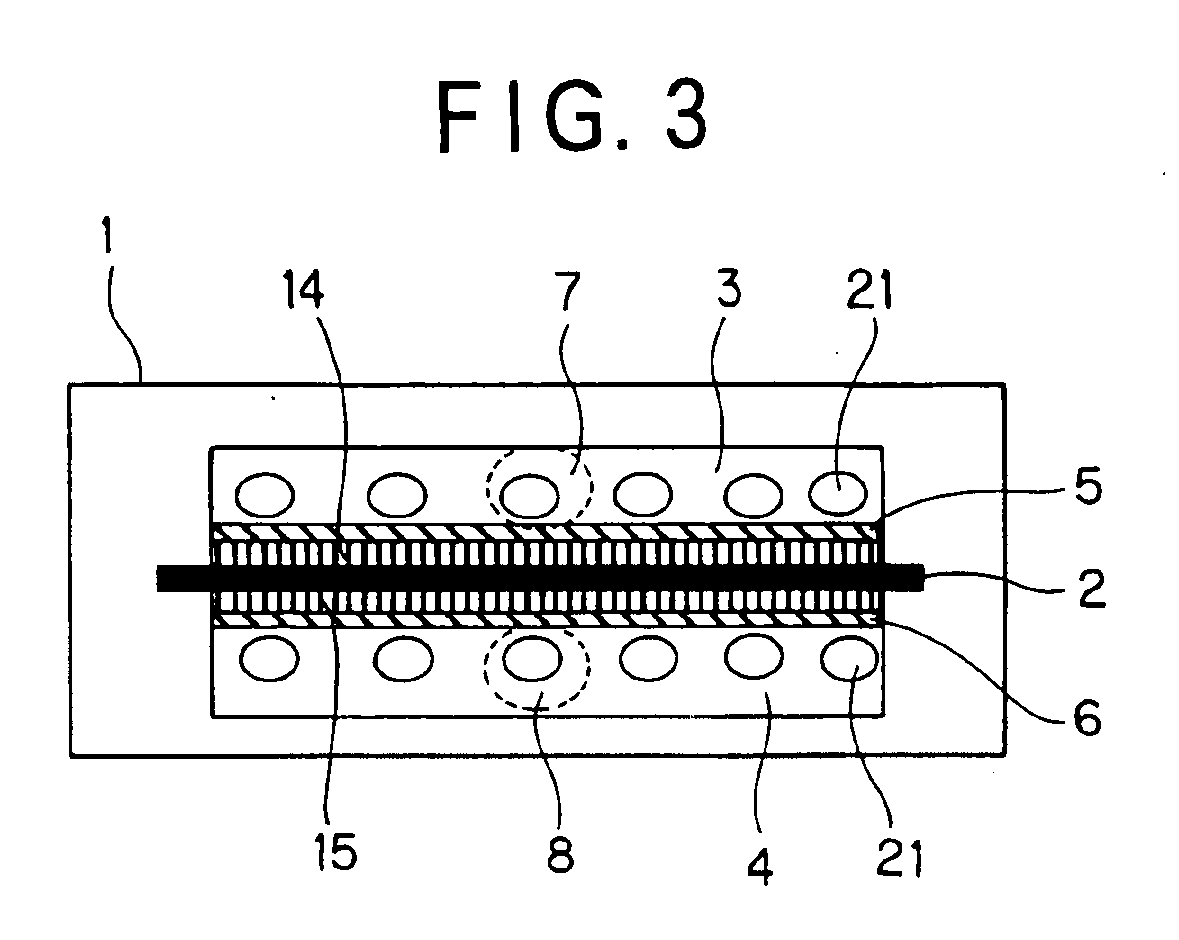

Hydrogen generator for uses in a vehicle fuel system

InactiveUS6866756B2Increase electrode surface areaSimple designCellsPhotography auxillary processesHydrogenElectrolysis

The present invention discloses an electrolyzer for electrolyzing water into a gaseous mixture comprising hydrogen gas and oxygen gas. The electrolyzer is adapted to deliver this gaseous mixture to the fuel system of an internal combustion engine. The electrolyzer of the present invention comprises one or more supplemental electrode at least partially immersed in an aqueous electrolyte solution interposed between two principle electrodes. The gaseous mixture is generated by applying an electrical potential between the two principal electrodes. The electrolyzer further includes a gas reservoir region for collecting the generated gaseous mixture. The present invention further discloses a method of utilizing the electrolyzer in conjunction with the fuel system of an internal combustion engine to improve the efficiency of said internal combustion engine.

Owner:HYDROGEN TECH APPL

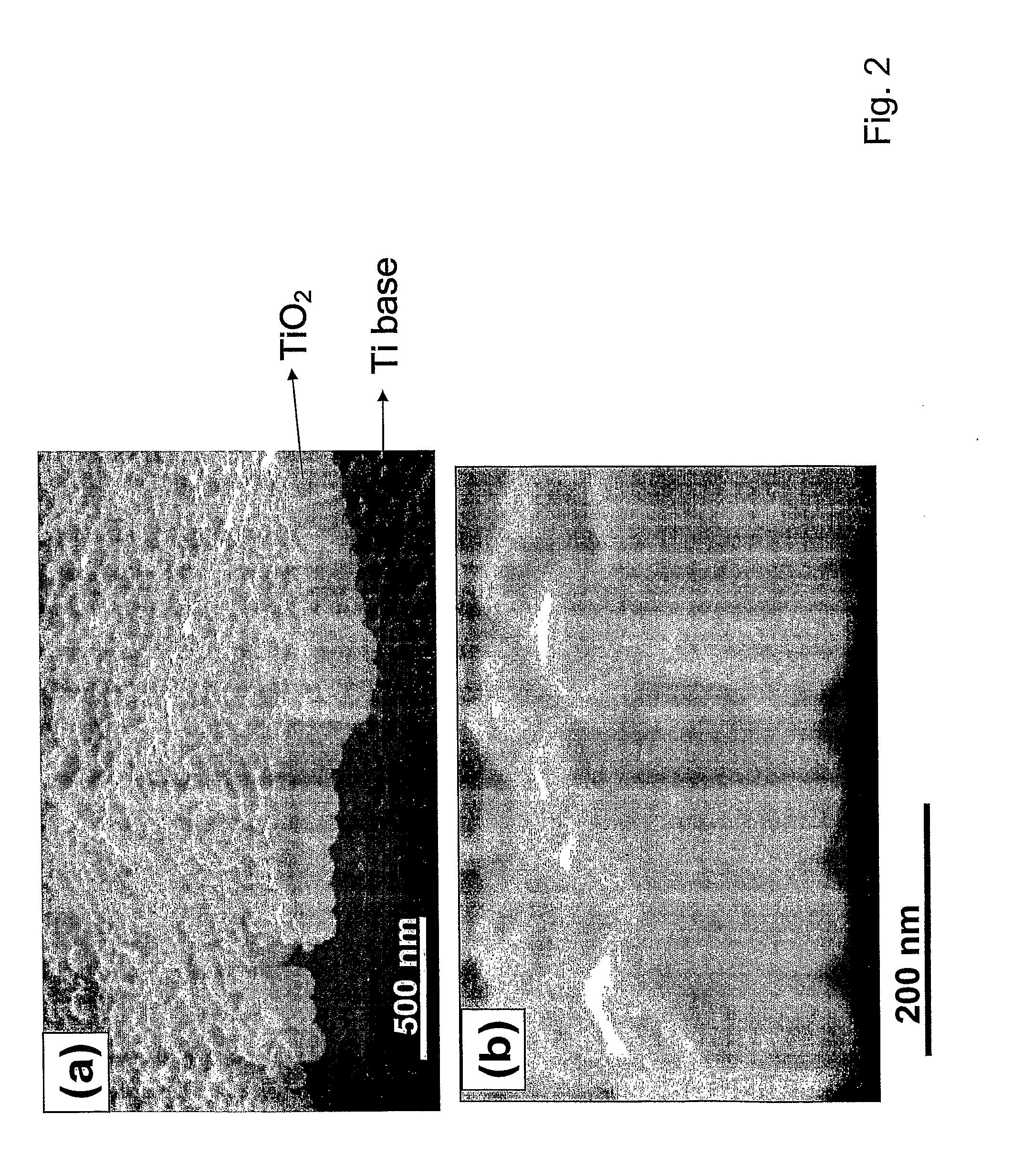

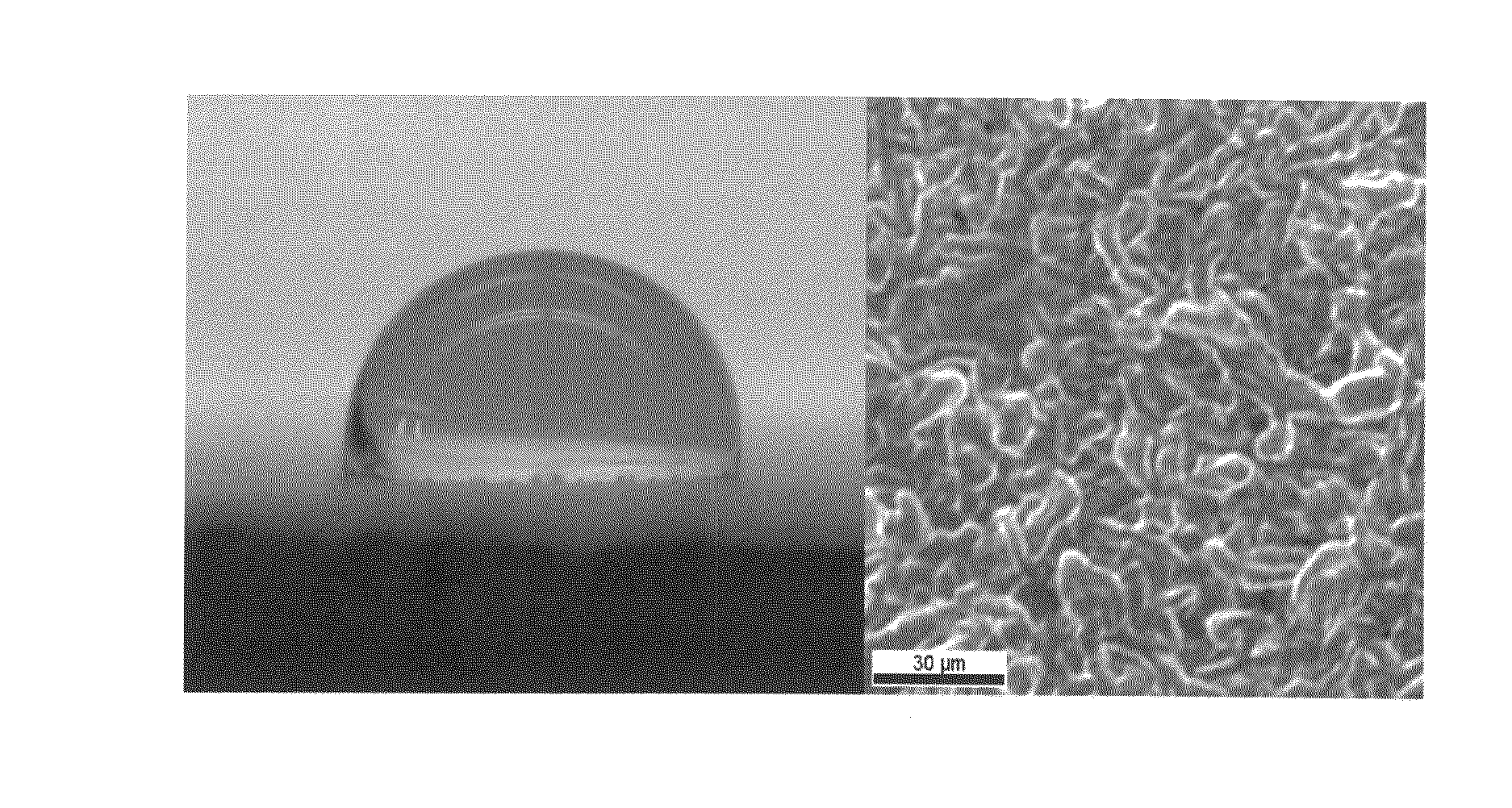

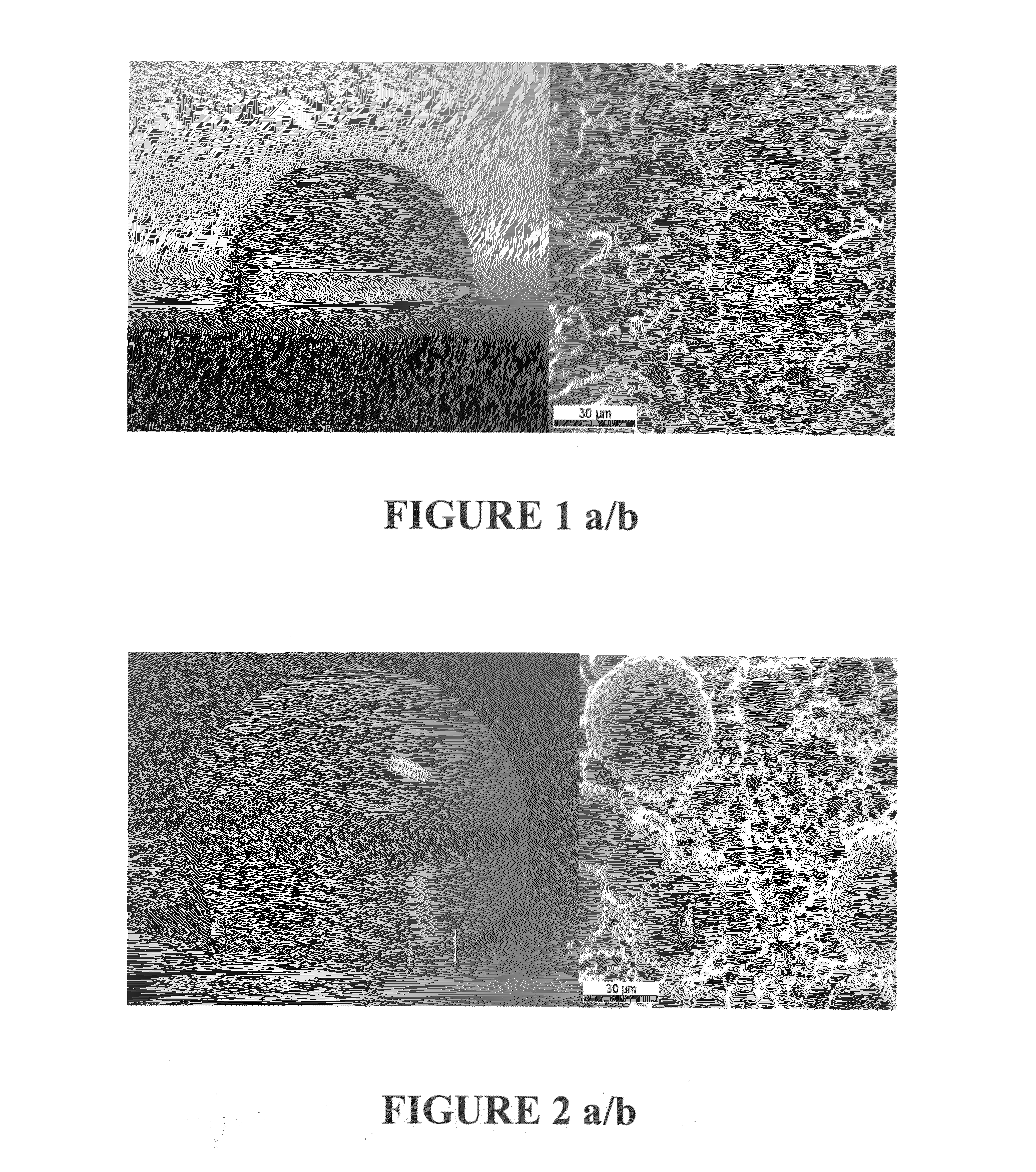

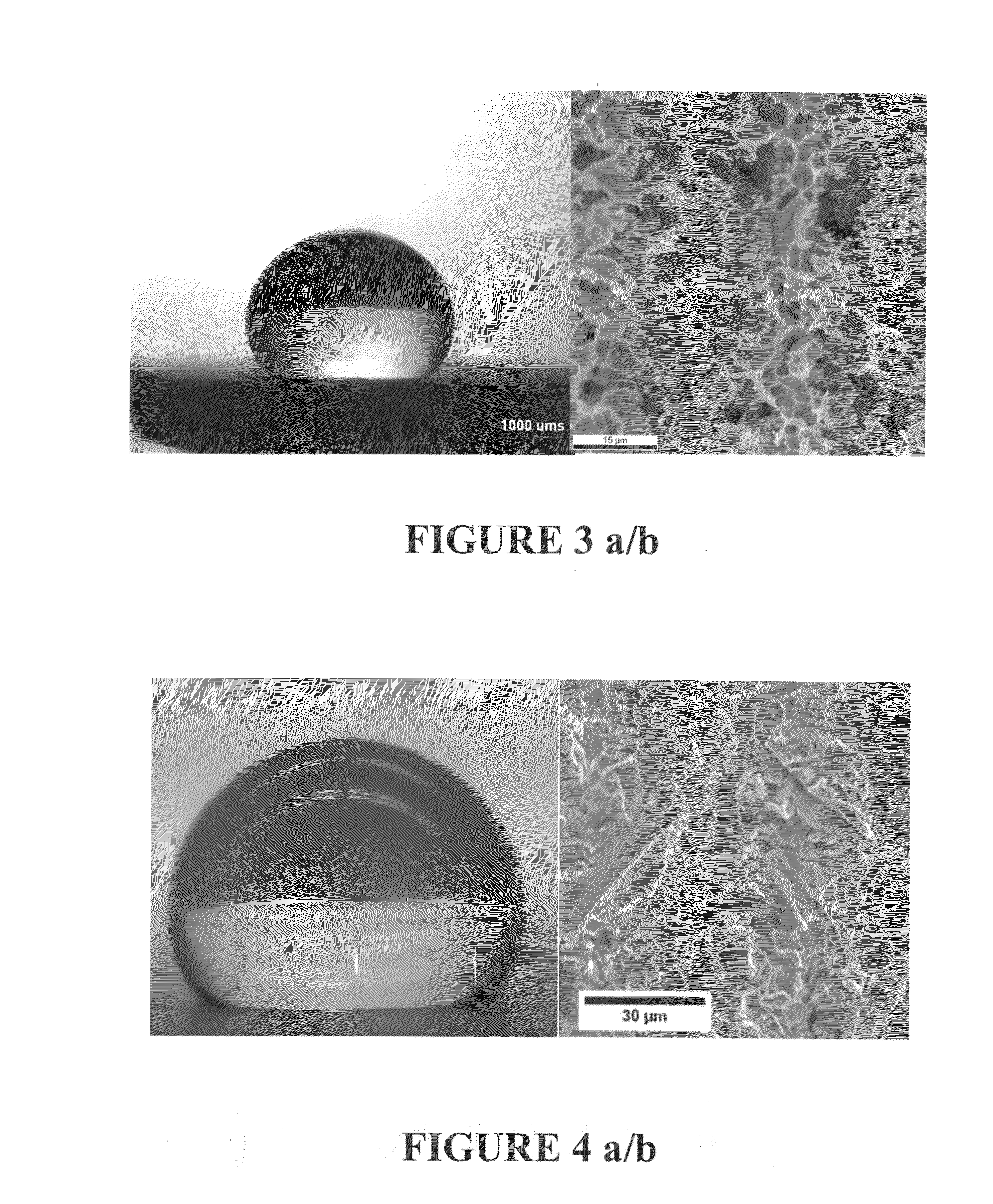

Metallic articles with hydrophobic surfaces

ActiveUS20110287223A1Lower contact angleLarge scaleElectrolysis componentsPretreated surfacesMetal coatingMetallic materials

Articles containing fine-grained and / or amorphous metallic coatings / layers on at least part of their exposed surfaces are imprinted with surface structures to raise the contact angle for water in the imprinted areas at room temperature by equal to or greater than 10°, when compared to the flat and smooth metallic material surface of the same composition.

Owner:INTEGRAN TECH

Systems, apparatuses, and methods for extracting non-polar lipids from an aqueous algae slurry and lipids produced therefrom

InactiveUS20110095225A1Increase volume flowEasy extractionLiquid separation by electricityMicroorganism lysisLipid formationPhospholipid

Methods, systems, and apparatuses for extracting non-polar lipids from microalgae are achieved using a lipid extraction device having an anode and a cathode that forms a channel and defines a fluid flow path through which an aqueous slurry is passed. An electromotive force is applied across the channel at a gap distance in a range from 0.5 mm to 200 mm to cause the non-polar lipids to be released from the algae cells. The non-polar lipids can be extracted at a high throughput rate and with low concentrations of polar lipids such as phospholipids and chlorophyll.

Owner:ORGINOIL INC

Dynamically variable field shaping element

InactiveUS7070686B2Uniform current distributionUniform currentAnodisationMachining electric circuitsElectrical resistance and conductanceElectrochemical response

In an electrochemical reactor used for electrochemical treatment of a substrate, for example, for electroplating or electropolishing the substrate, one or more of the surface area of a field-shaping shield, the shield's distance between the anode and cathode, and the shield's angular orientation is varied during electrochemical treatment to screen the applied field and to compensate for potential drop along the radius of a wafer. The shield establishes an inverse potential drop in the electrolytic fluid to overcome the resistance of a thin film of conductive metal on the wafer.

Owner:NOVELLUS SYSTEMS

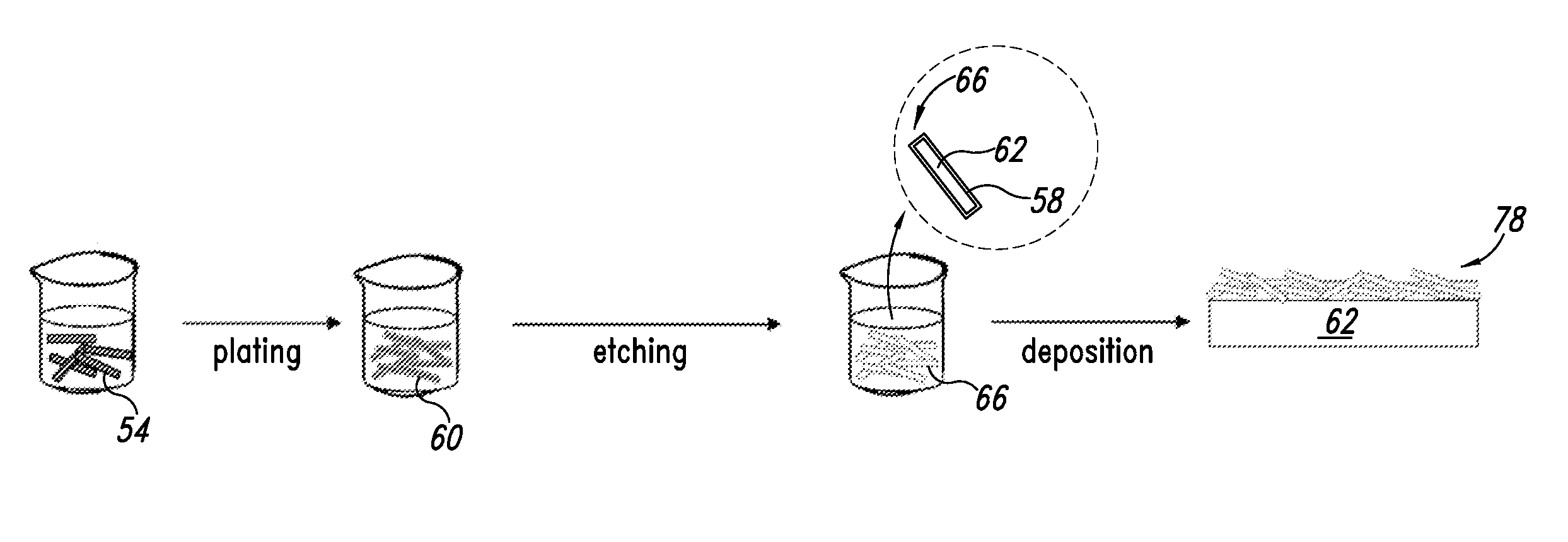

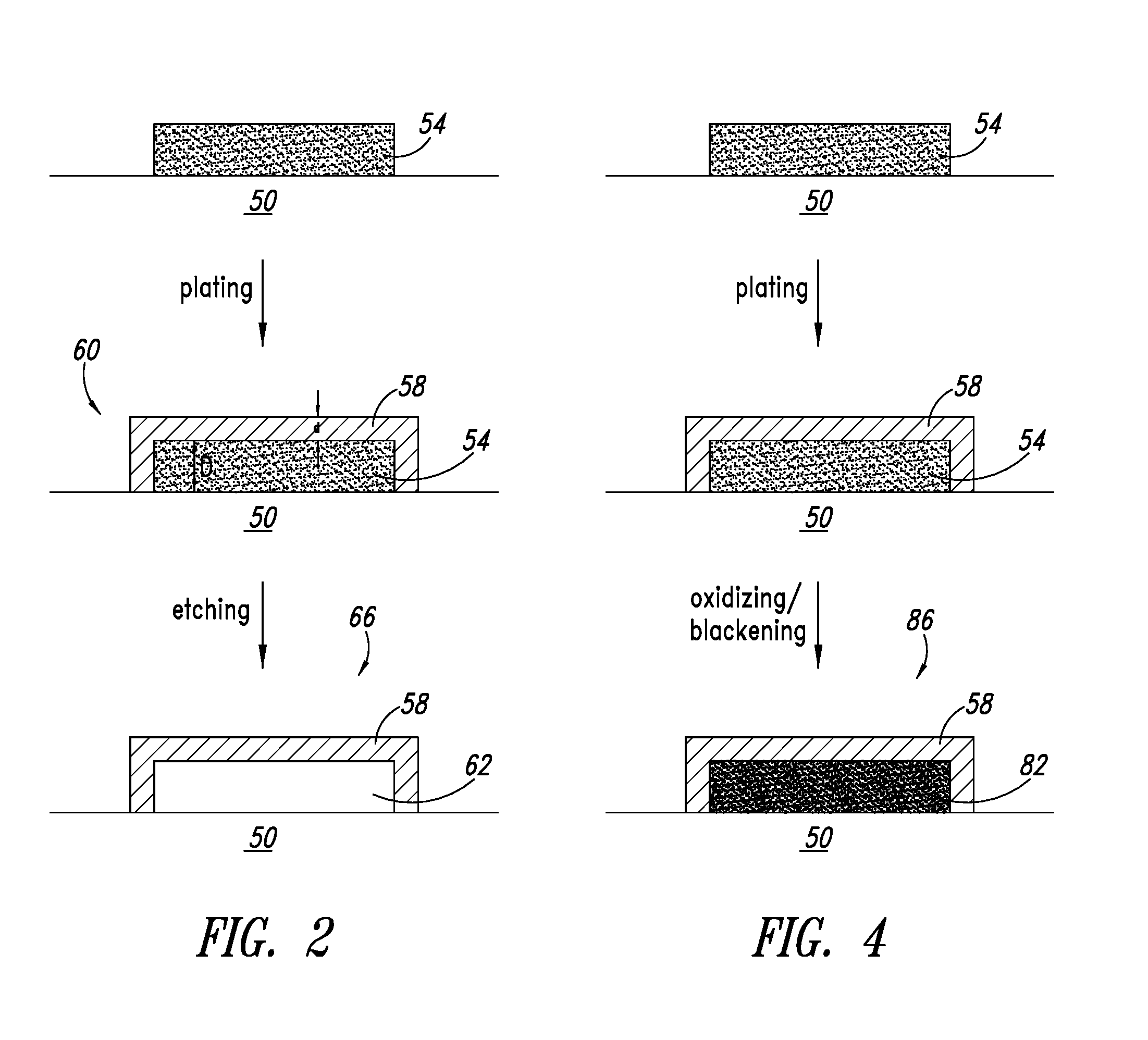

High contrast transparent conductors and methods of forming the same

InactiveUS20090321113A1Material nanotechnologyElectrolysis componentsElectrical conductorNanostructure

Methods of enhancing contrast ratio of conductive nanostructure-based transparent conductors are described. Contrast ratio is significantly improved by reduction of light scattering and reflectivity of the nanostructures through steps of plating the conductive nanostructures followed by etching or oxidizing the underlying conductive nanostructures.

Owner:CAM HLDG CORP +1

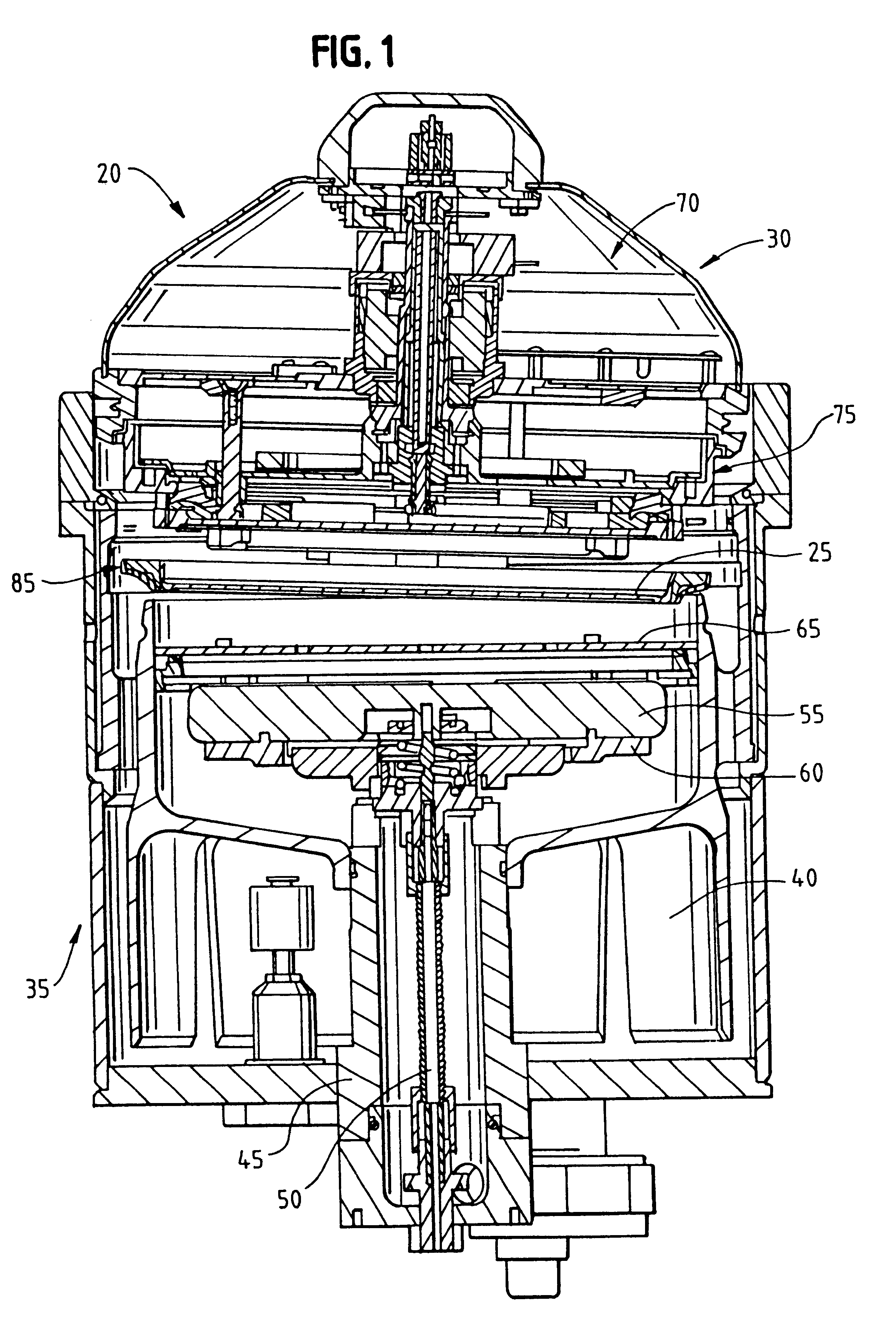

Aparatus for processing the surface of a microelectronic workpiece

InactiveUS6303010B1Reduce the risk of contaminationReduce downtimeCellsTanksEngineeringMechanical engineering

A reactor for plating a metal onto a surface of a workpiece is set forth. The reactor comprises a reactor bowl including an electroplating solution disposed therein and an anode disposed in the reactor bowl in contact with the electroplating solution. A contact assembly is spaced from the anode within the reactor bowl. The contact assembly includes a plurality of contacts disposed to contact a peripheral edge of the surface of the workpiece to provide electroplating power to the surface of the workpiece. The contacts execute a wiping action against the surface of the workpiece as the workpiece is brought into engagement therewith The contact assembly also including a barrier disposed interior of the plurality of contacts. The barrier includes a member disposed to engage the surface of the workpiece to assist in isolating the plurality of contacts from the electroplating solution. In one embodiment, the plurality of contacts are in the form of discrete flexures while in another embodiment the plurality of contacts are in the form of a Belleville ring contact. A flow path may be provided in the contact assembly for providing a purging gas to the plurality of contacts and the peripheral edge of the workpiece. The purging gas may be used to assist in the formation of the barrier of the contact assembly. A combined electroplating / electroless plating tool and method are also set forth.

Owner:APPLIED MATERIALS INC

Apparatus for production of strong alkali and acid electrolytic solution

There is provided an apparatus for producing strong alkaline reductive electrolyzed water and acidic water that enables efficient production of electrolyzed water that has excellent washing and sterilizing effects. There is provided an apparatus for producing strong alkaline reductive electrolyzed water and acidic water, which includes an electrolyzer provided with a strong alkaline reductive electrolyzed water-producing chamber, an acidic water-producing chamber and a partitioning membrane, wherein a flow path diffusing device is provided in the electrolyzer, and a gap between the cathode plate and the anode plate of 0.1 mm to 1 mm.

Owner:AQUA ECO

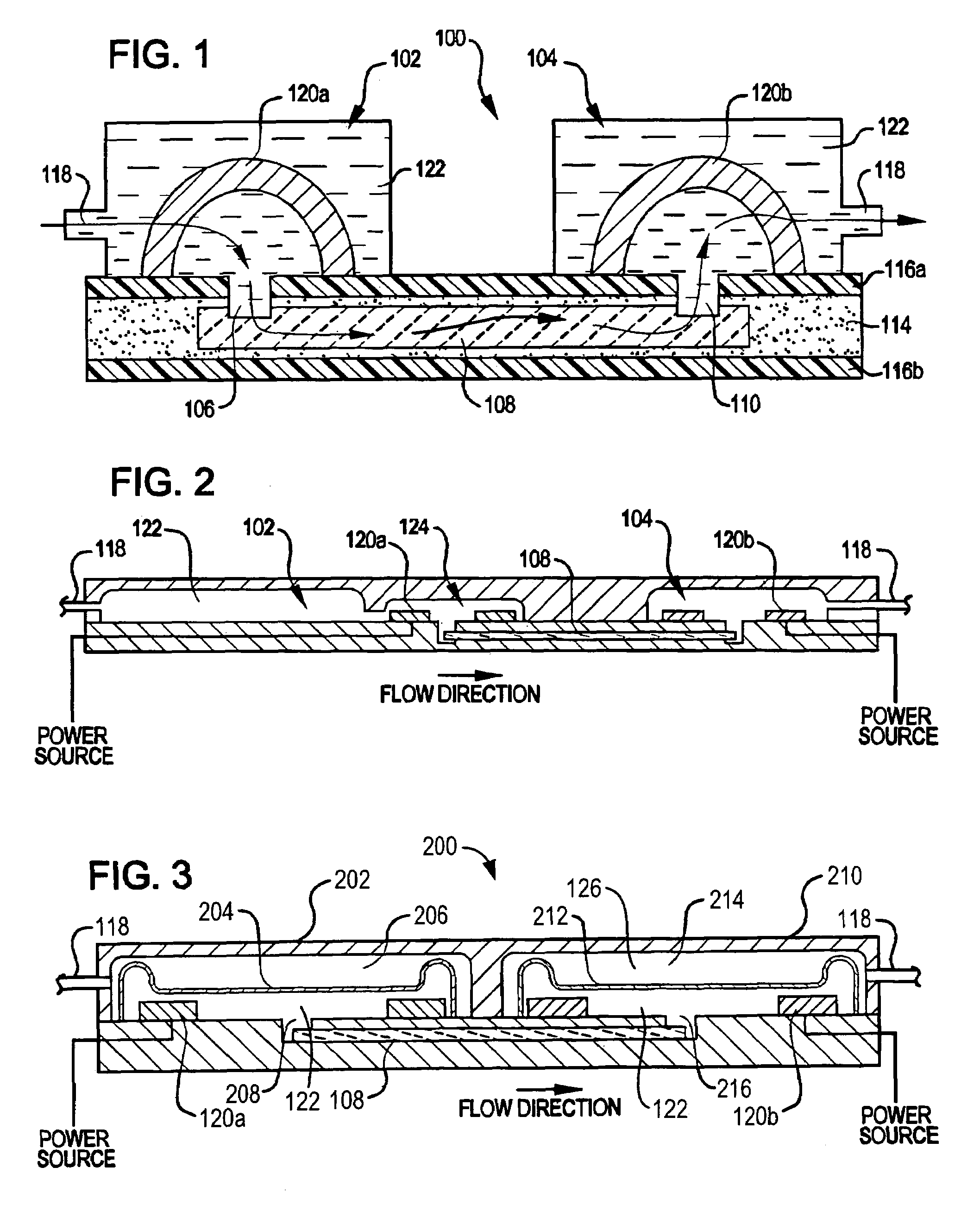

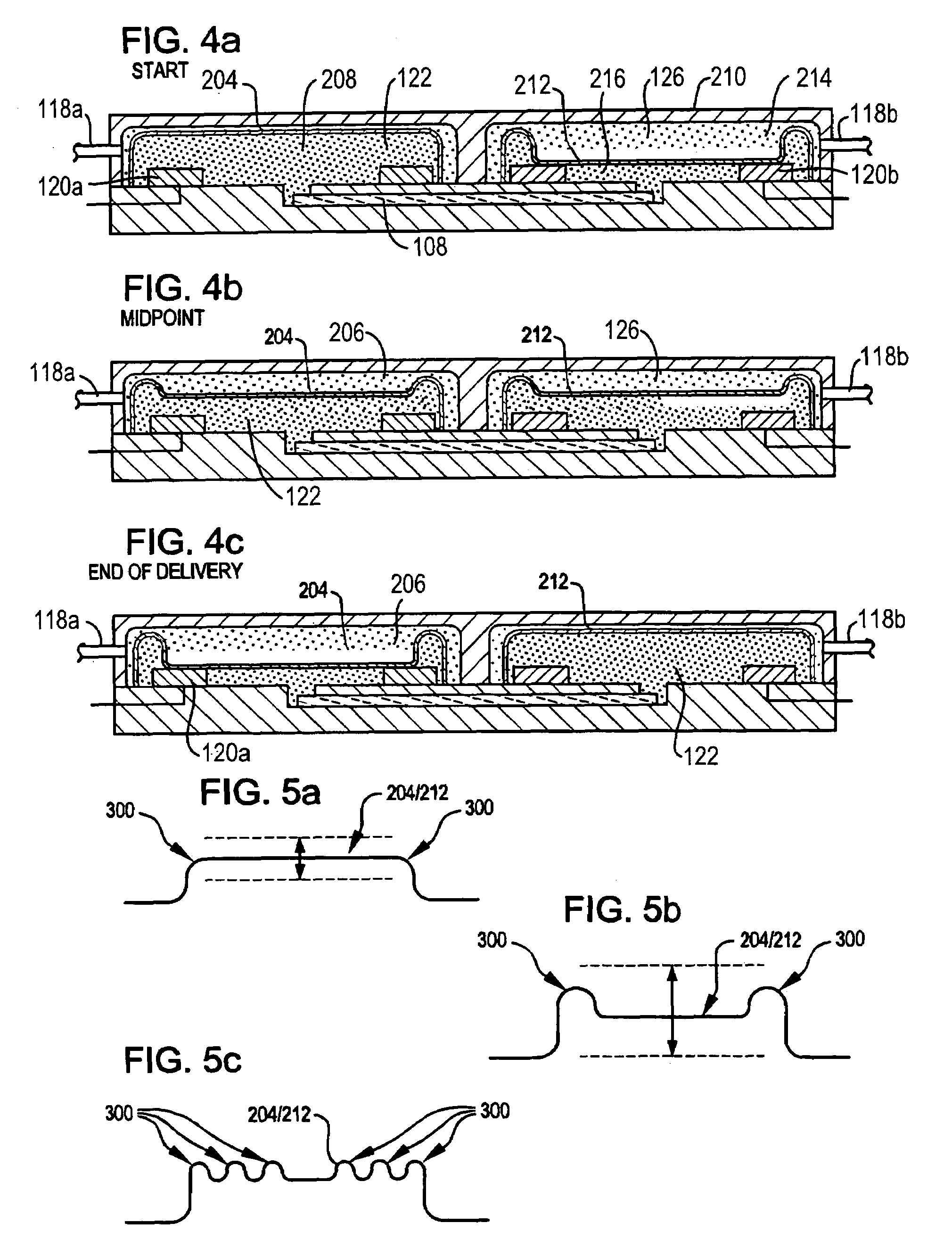

Electrokinetic delivery systems, devices and methods

InactiveUS7517440B2Efficient and reliable and highly movementSludge treatmentVolume/mass flow measurementElectricityCapacitance

A method of pumping fluid including the steps of providing an electrokinetic pump comprising a pair of double-layer capacitive electrodes having a capacitance of at least 10−2 Farads / cm2 and being connectable to a power source, a porous dielectric material disposed between the electrodes and a reservoir containing pump fluid; connecting the electrodes to a power source; and moving pump fluid out of the reservoir substantially without the occurrence of Faradaic processes in the pump. The invention also includes an electrokinetic pump system having a pair of double-layer capacitive electrodes having a capacitance of at least 10−2 Farads / cm2; a porous dielectric material disposed between the electrodes; a reservoir containing pump fluid; and a power source connected to the electrodes; the electrodes, dielectric material and power source being adapted to move the pump fluid out of the reservoir substantially without the occurrence of Faradaic processes in the pump.

Owner:TELEFLEX LIFE SCI PTE LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com