Patents

Literature

47 results about "Electro polishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electropolishing is an electrochemical finishing process that removes a thin layer of material from a metal part, typically stainless steel or similar alloys. The part is immersed in a temperature controlled bath of electrolyte (typically mixtures of sulfuric acid and phosphoric acid)...

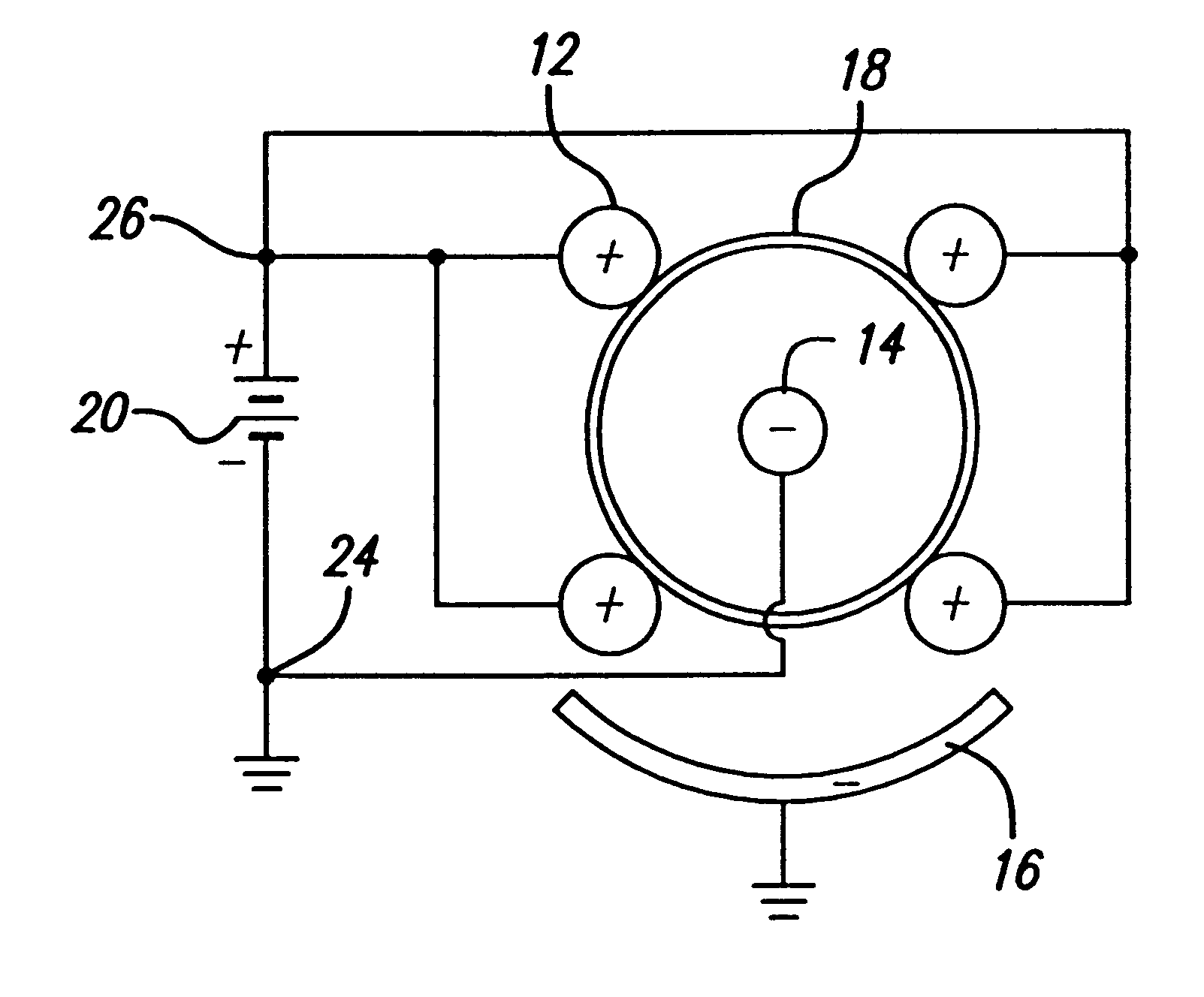

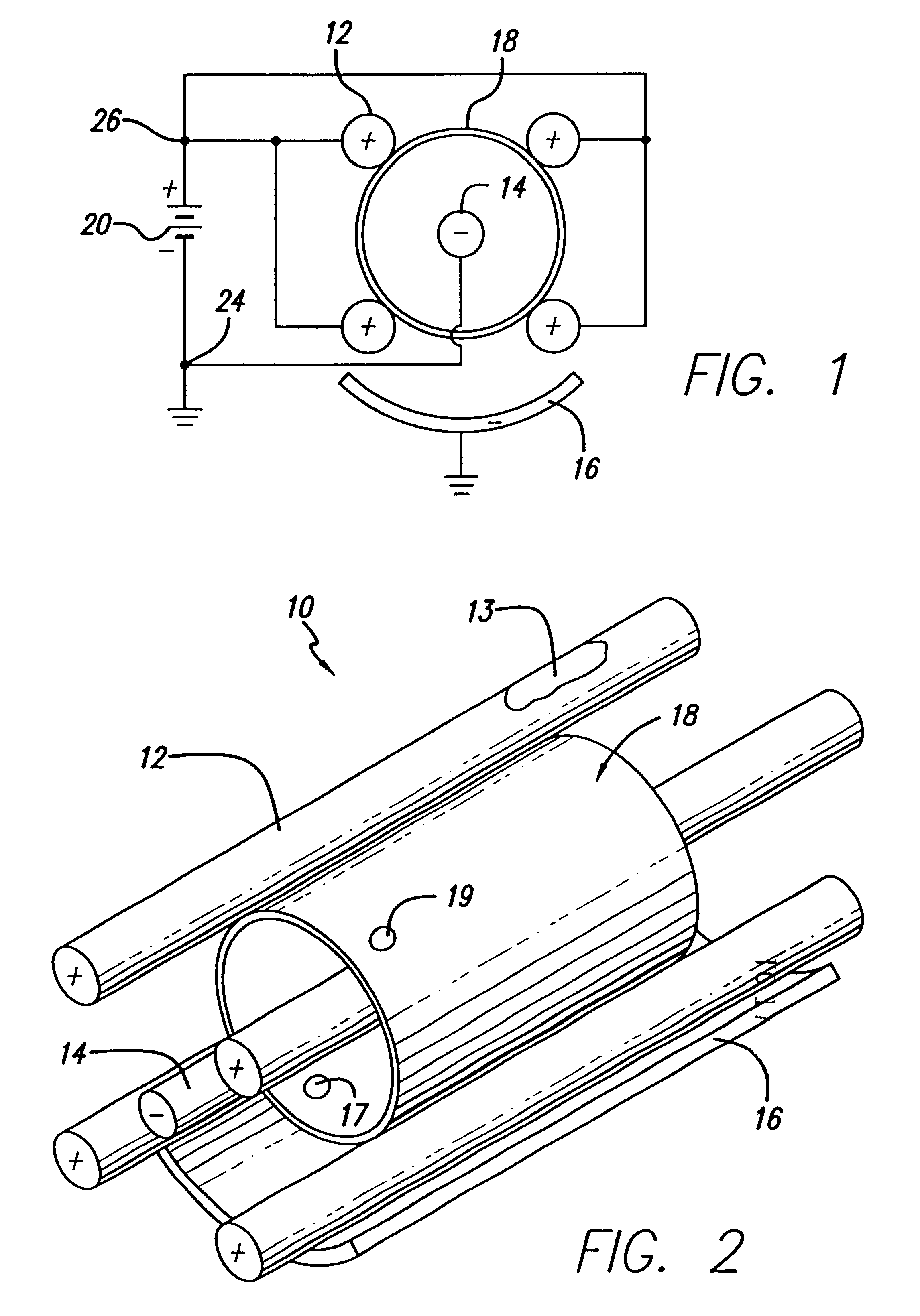

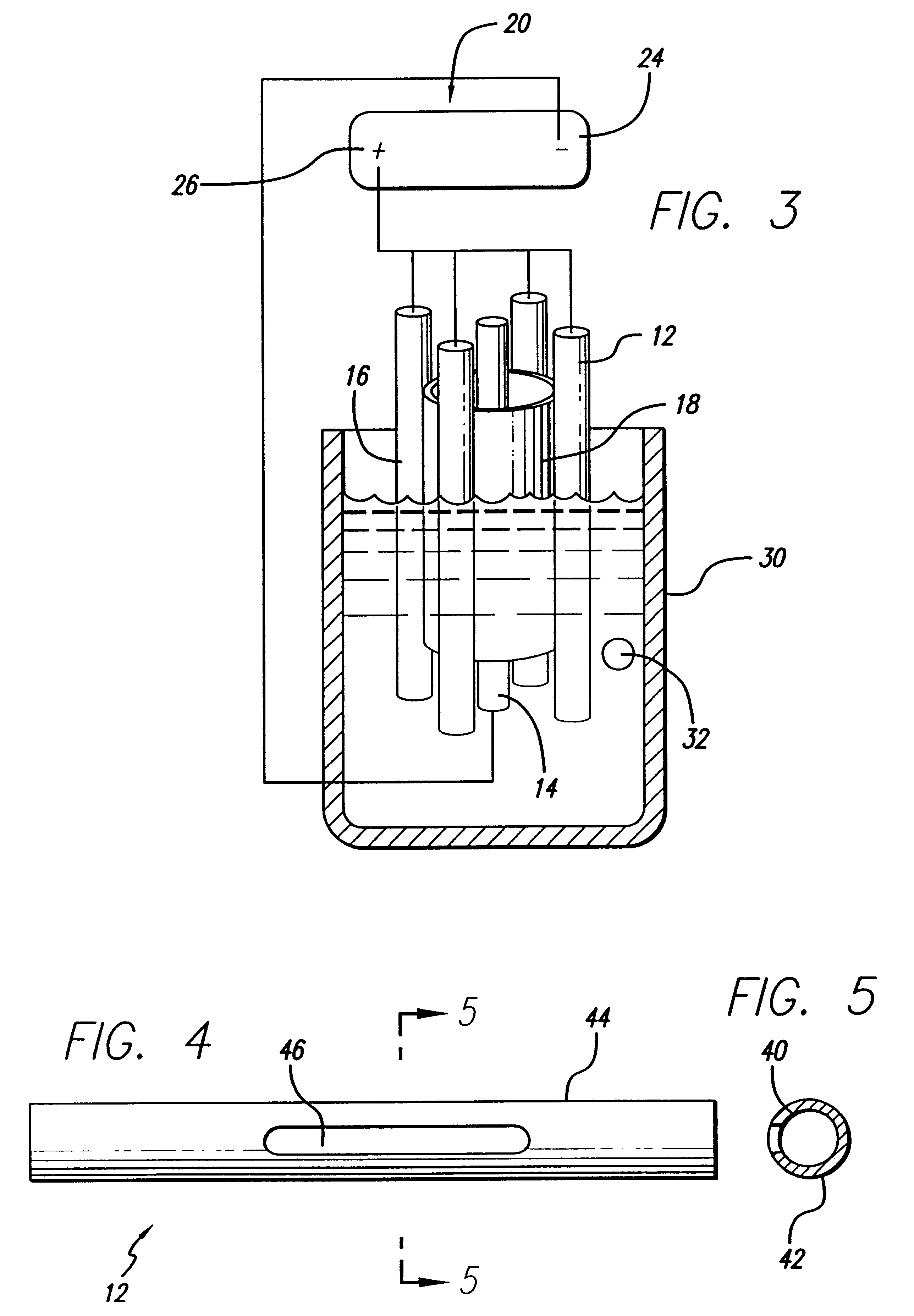

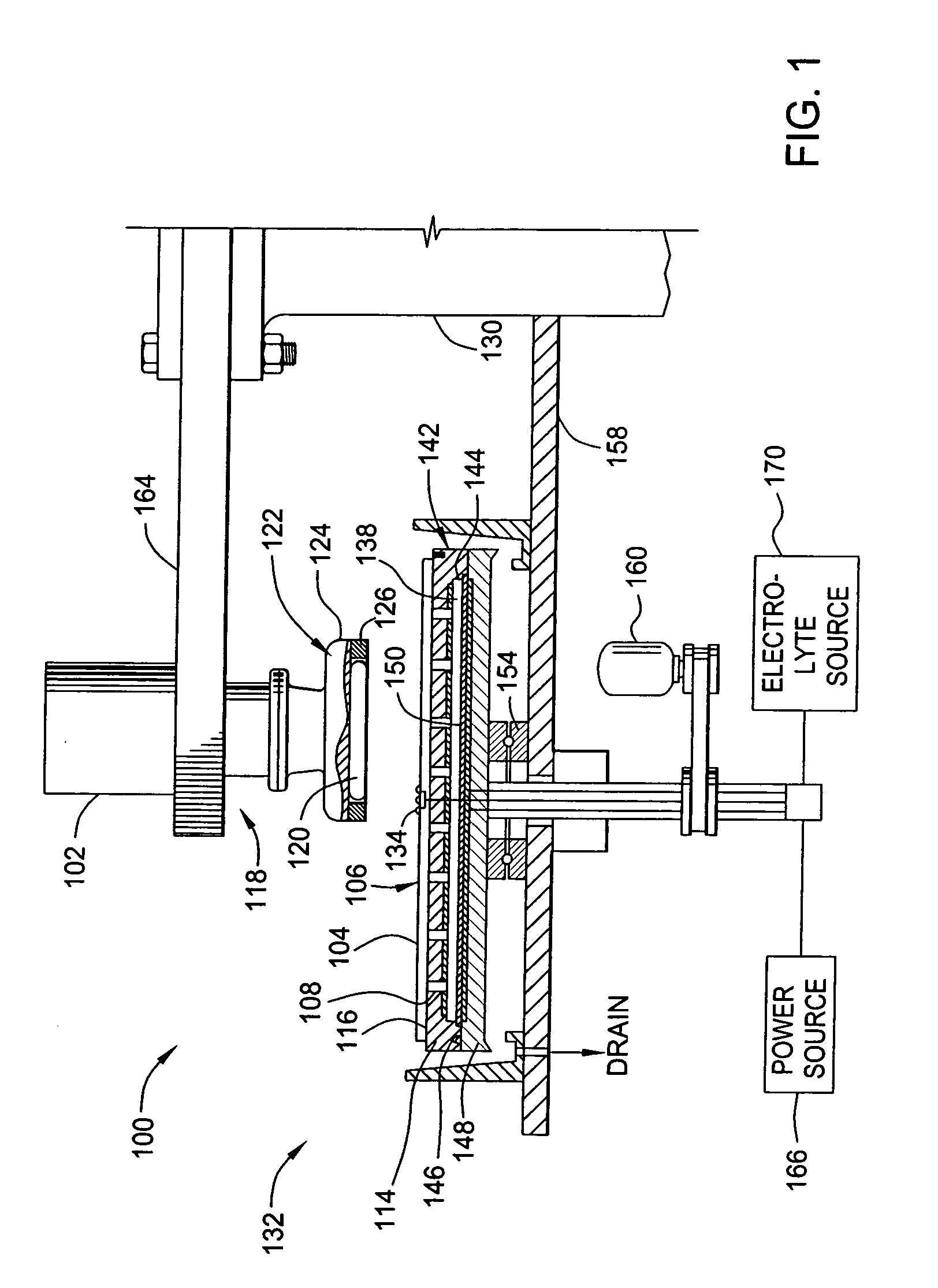

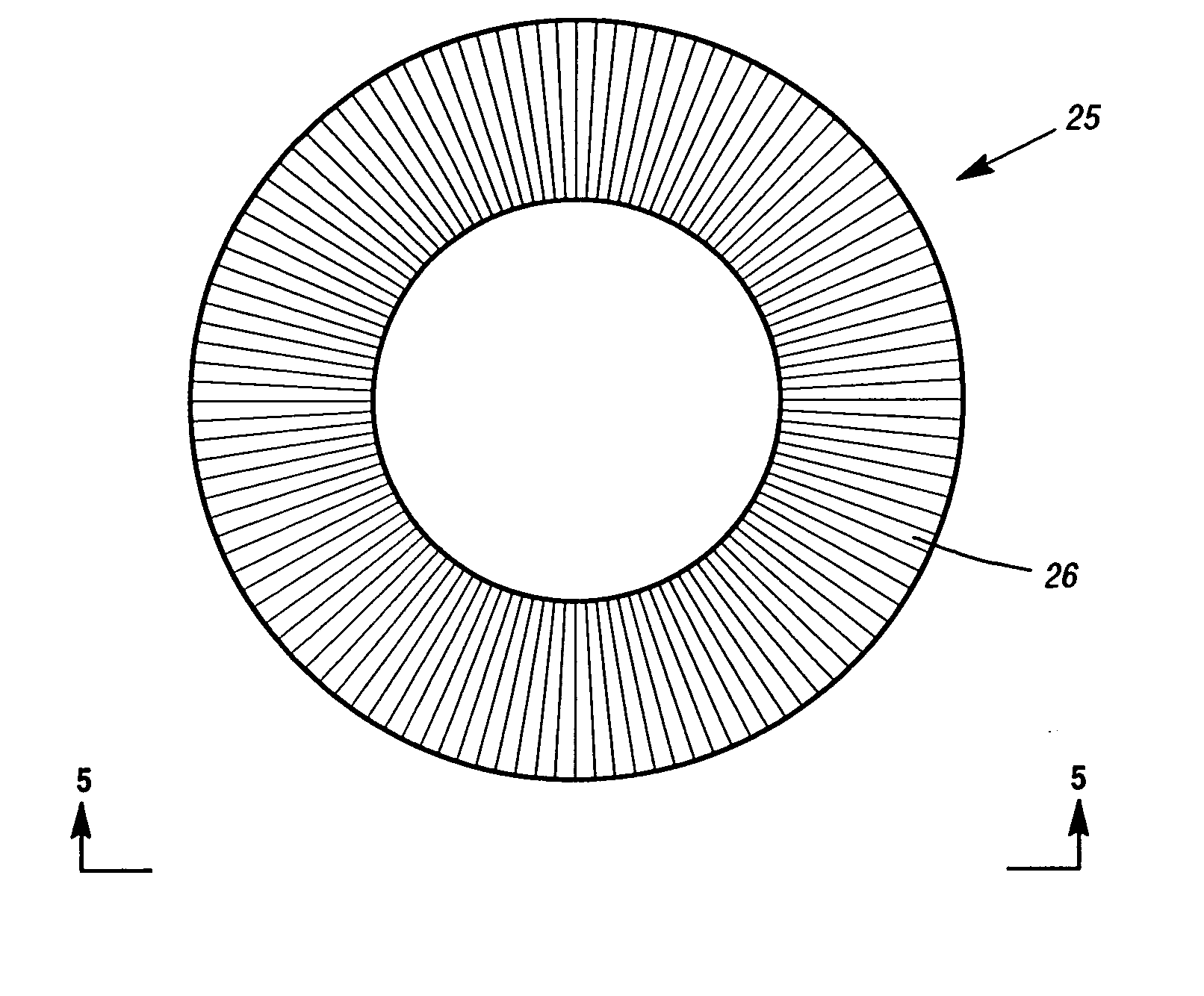

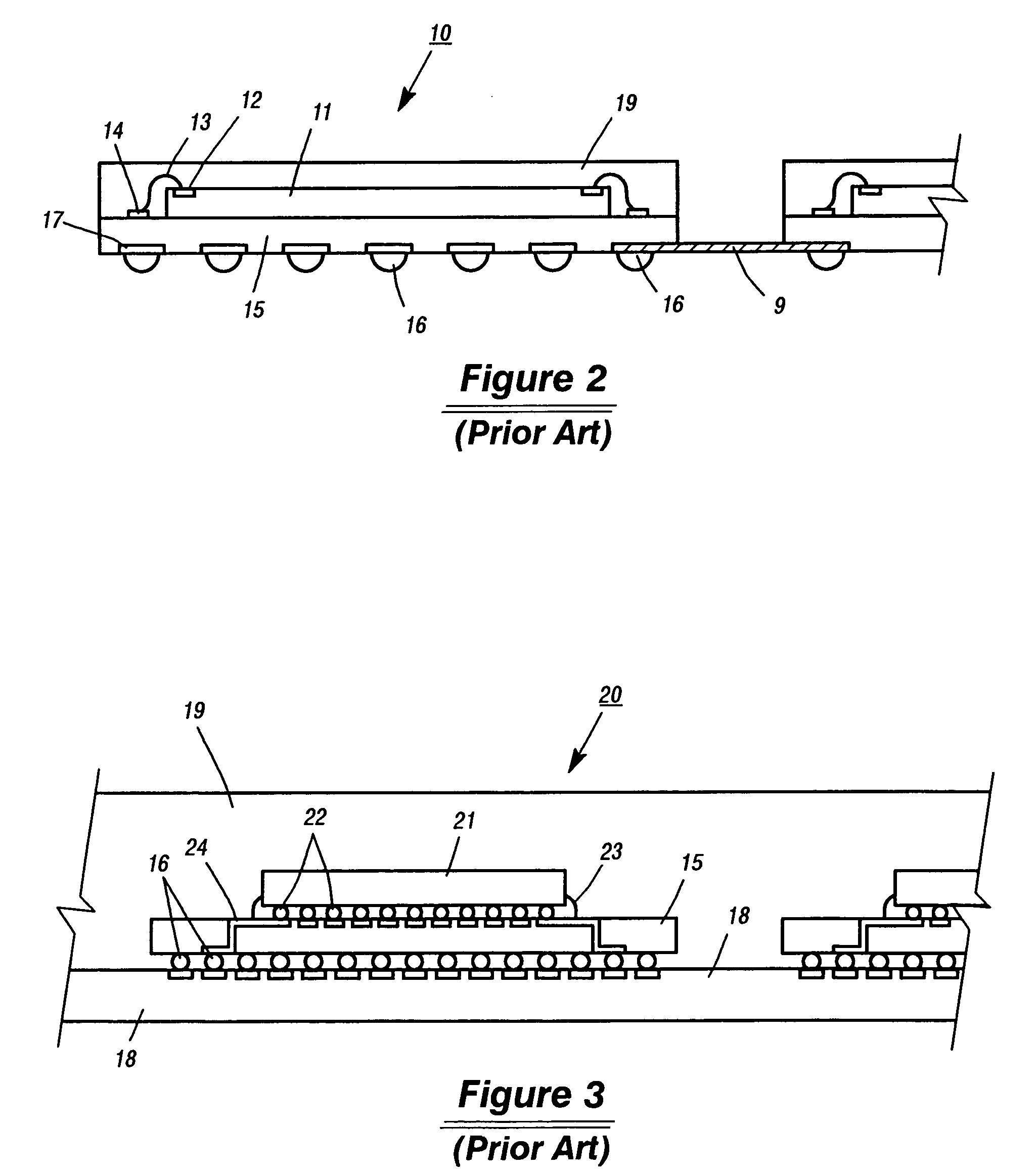

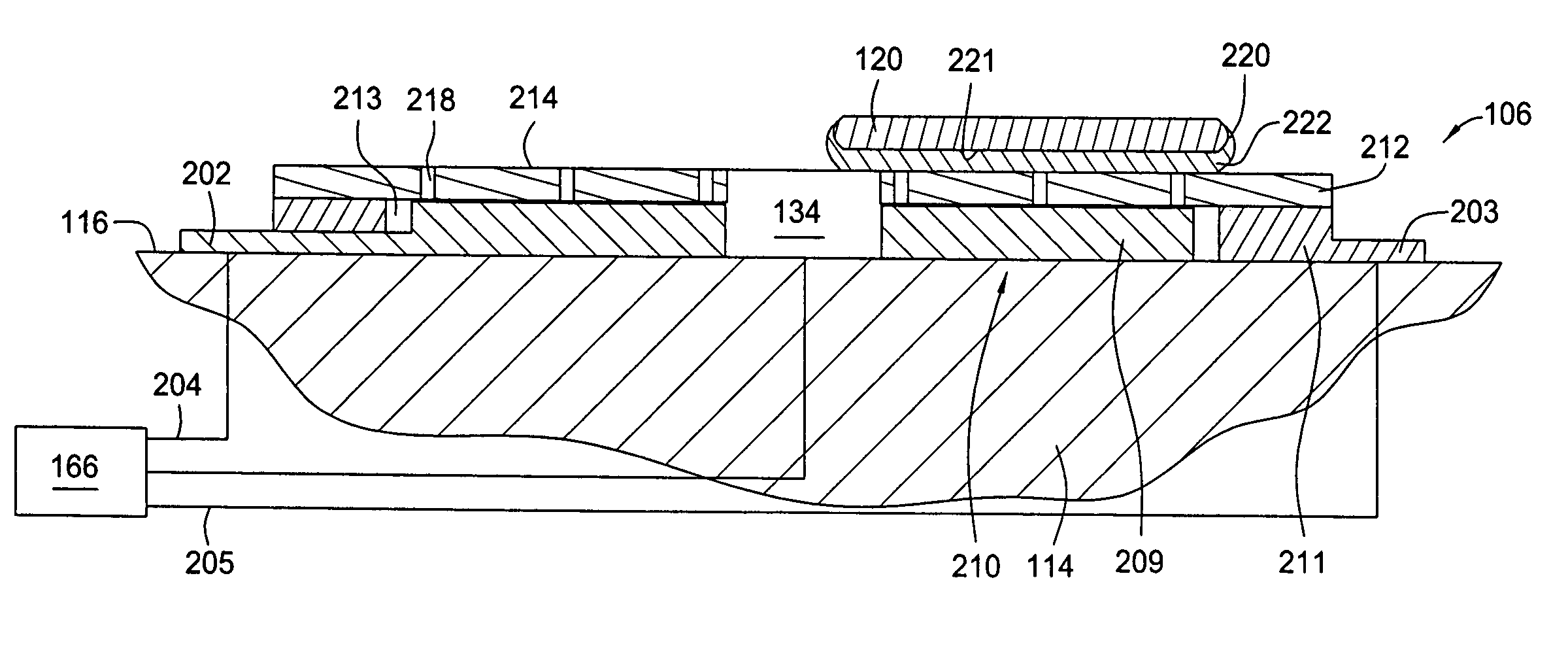

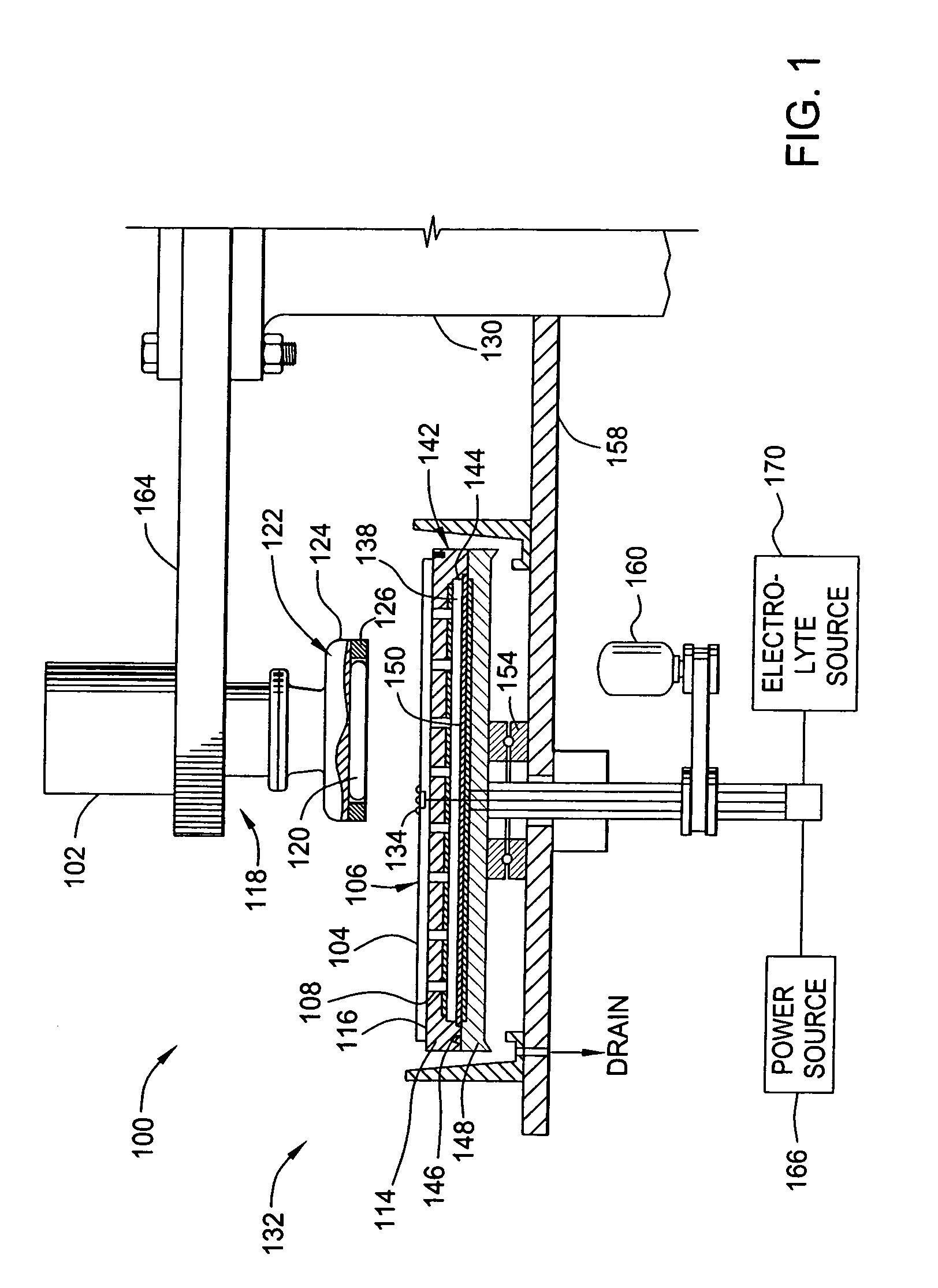

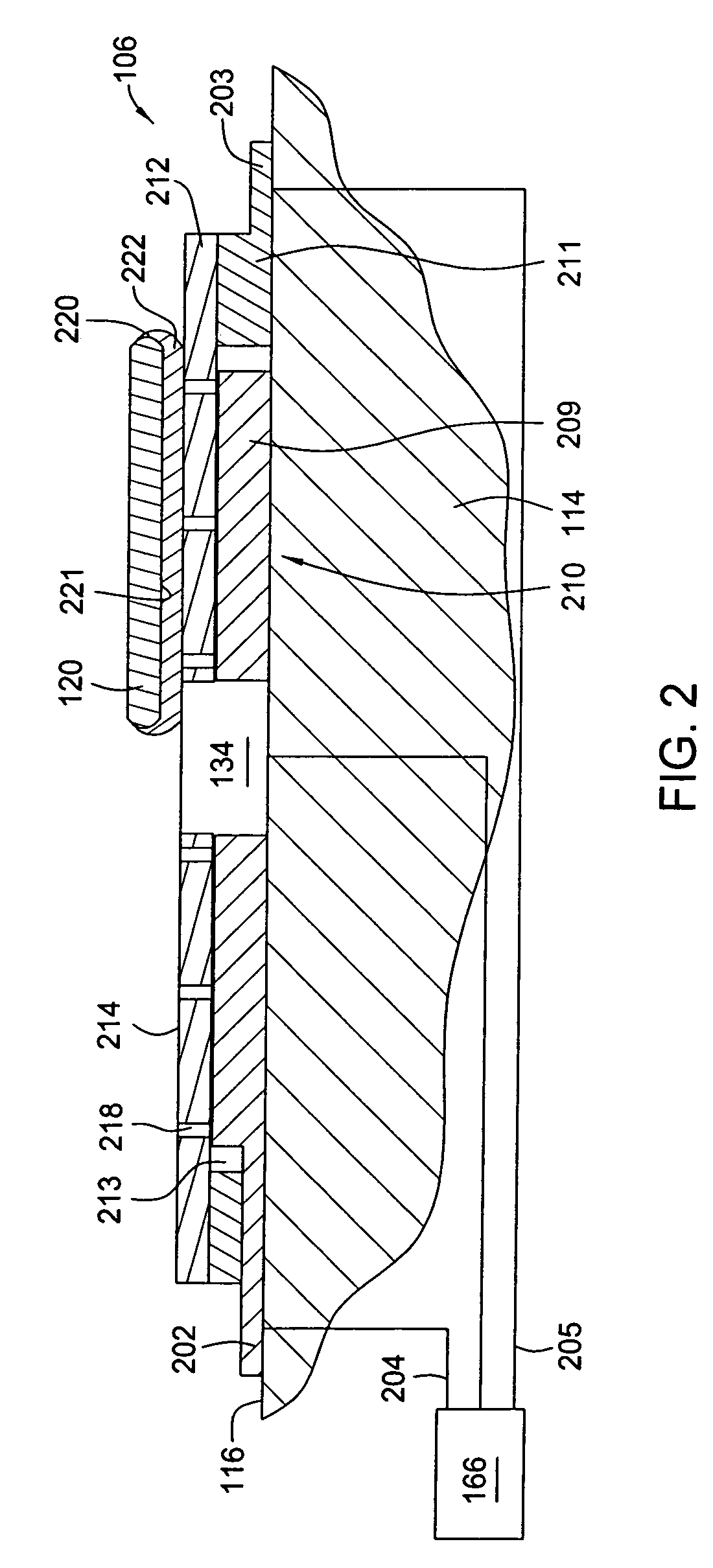

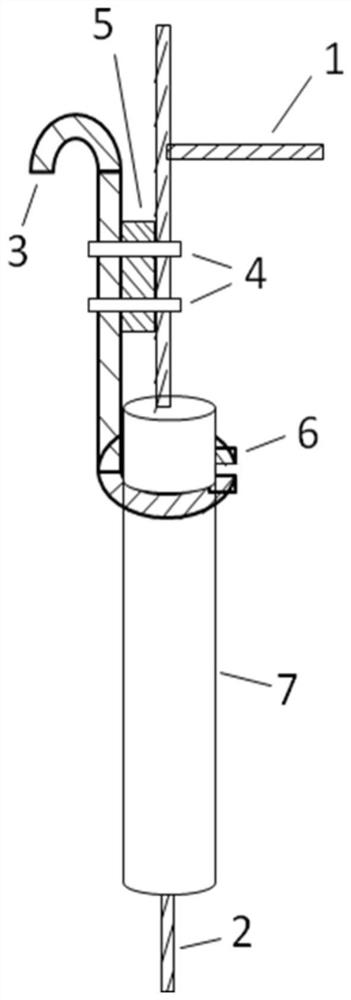

Electro-polishing fixture and electrolyte solution for polishing stents and method

An electro-polishing fixture for polishing stents which incorporates multiple anodes in contact with the stent and a center cathode disposed coaxially within the interior of the stent and a curved exterior cathode disposed about the perimeter of the stent. The invention further includes an electrolyte solution adapted for polishing stents composed of nickel-titanium alloy and a method of using the electrolyte in combination with the electro-polishing fixture.

Owner:ABBOTT CARDIOVASCULAR

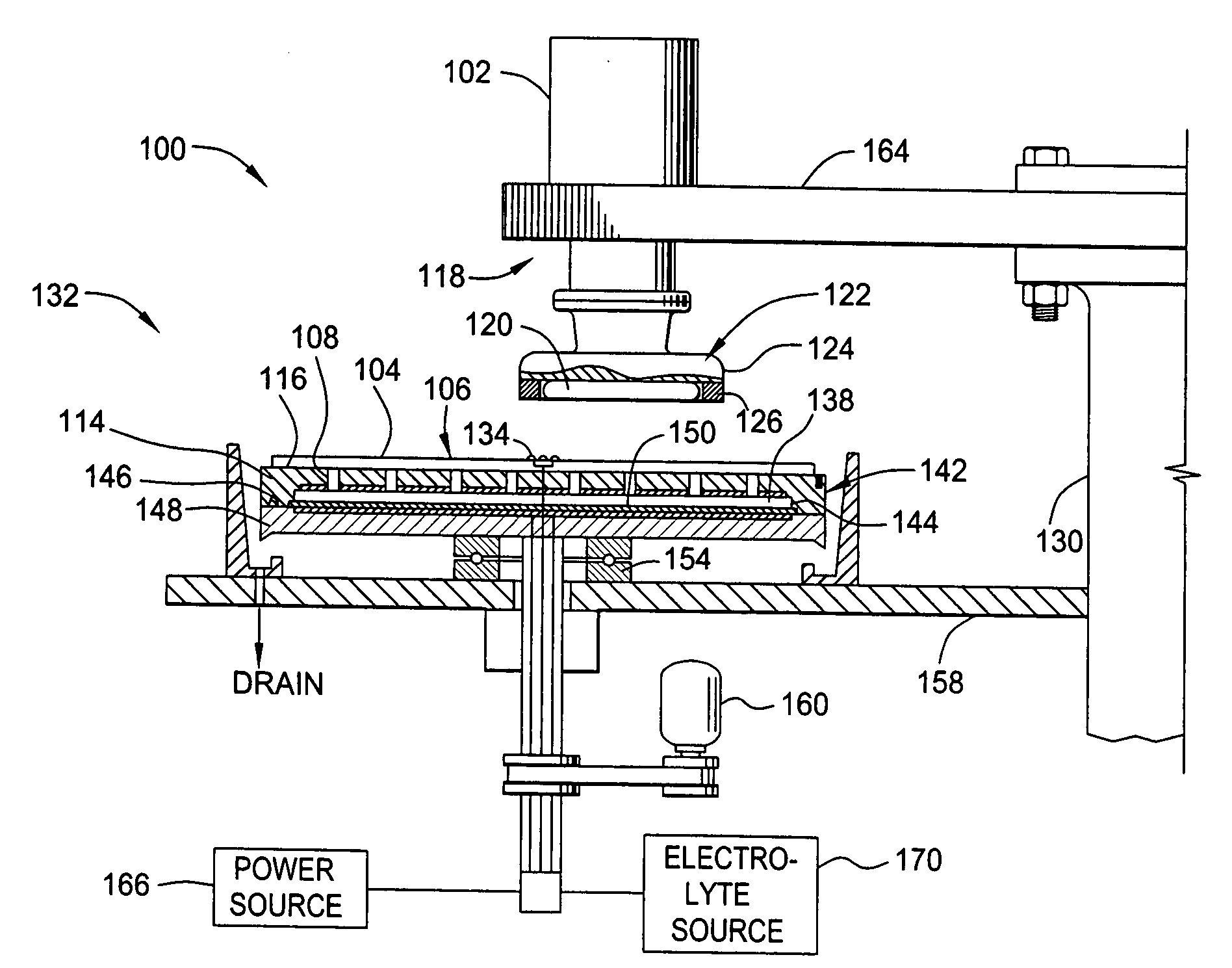

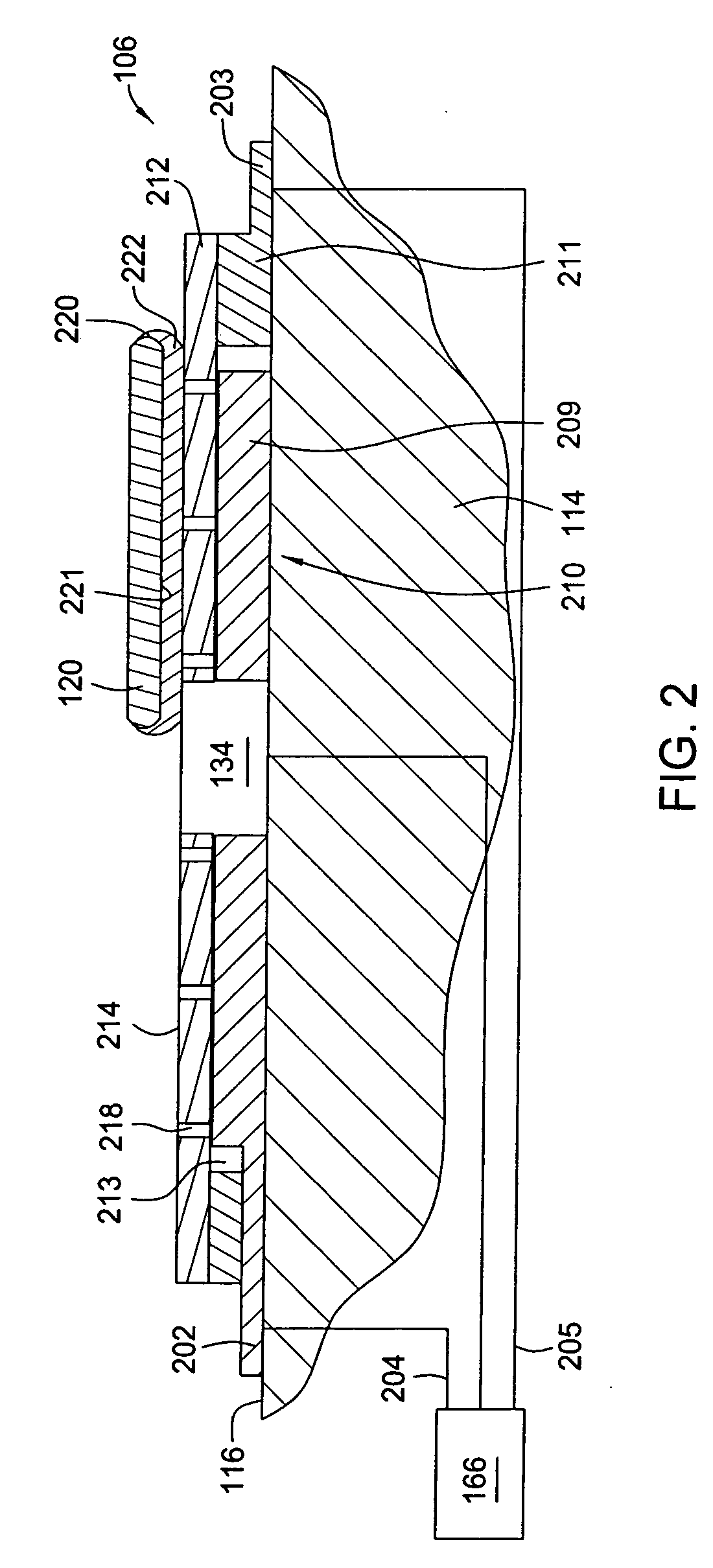

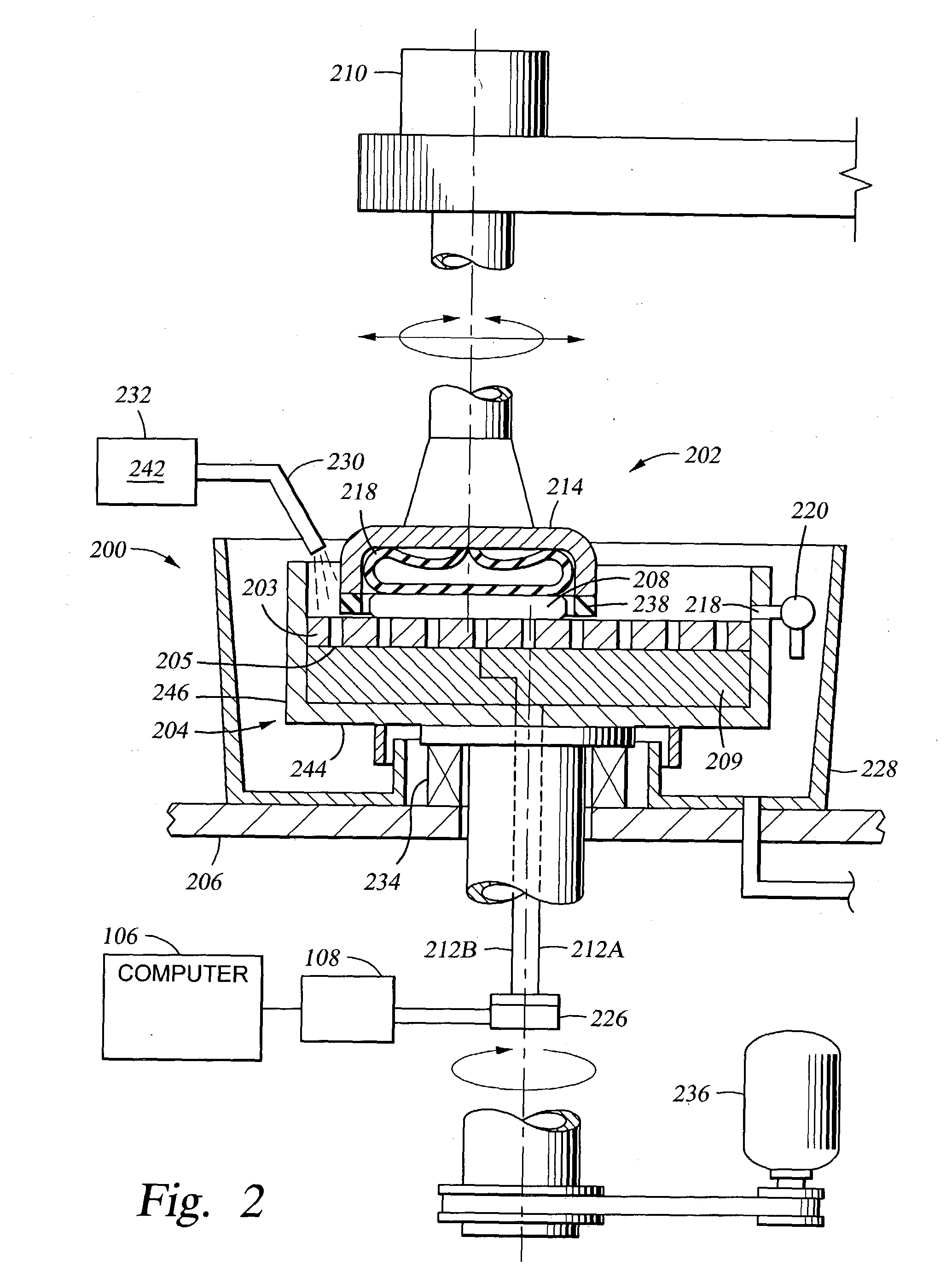

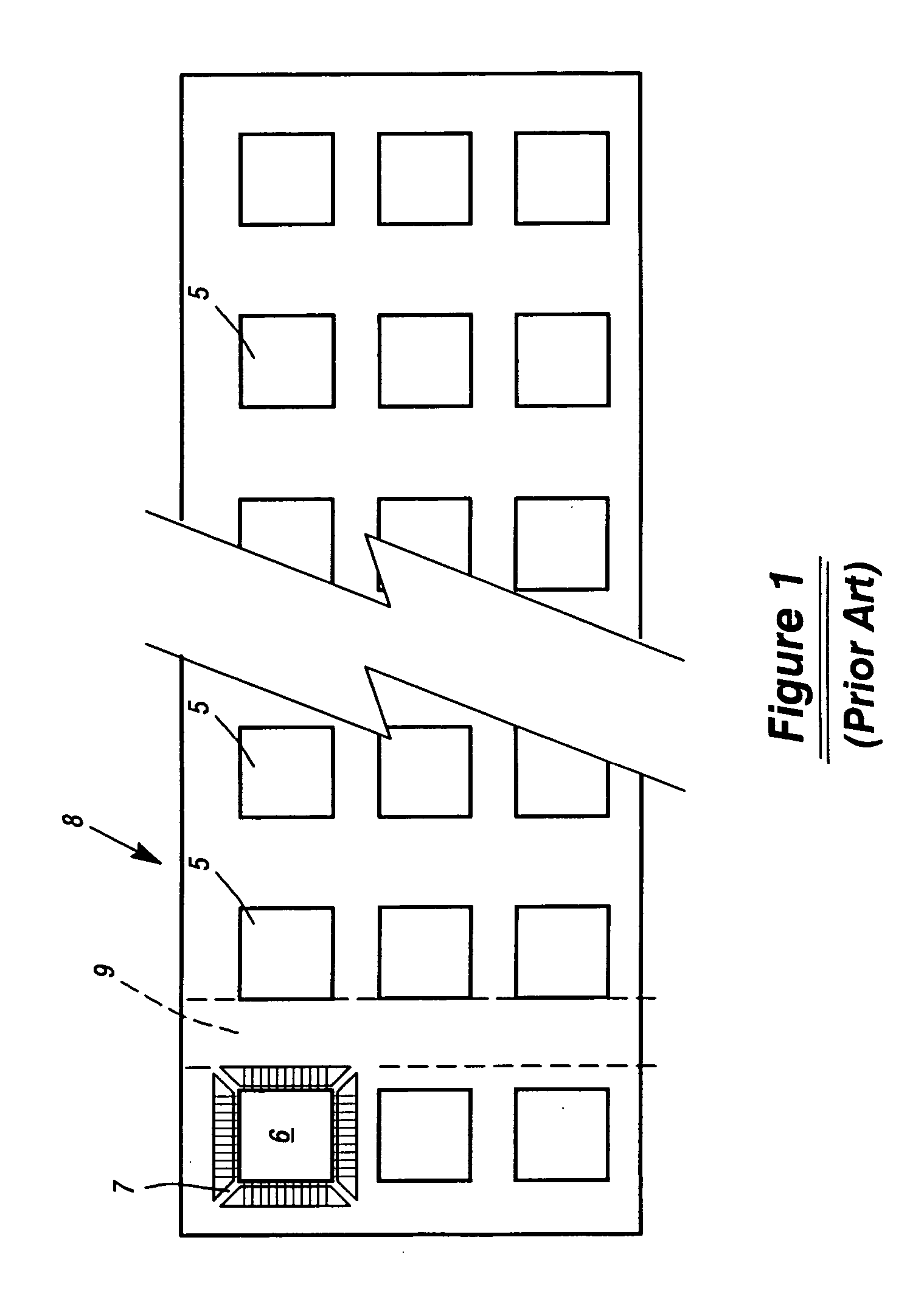

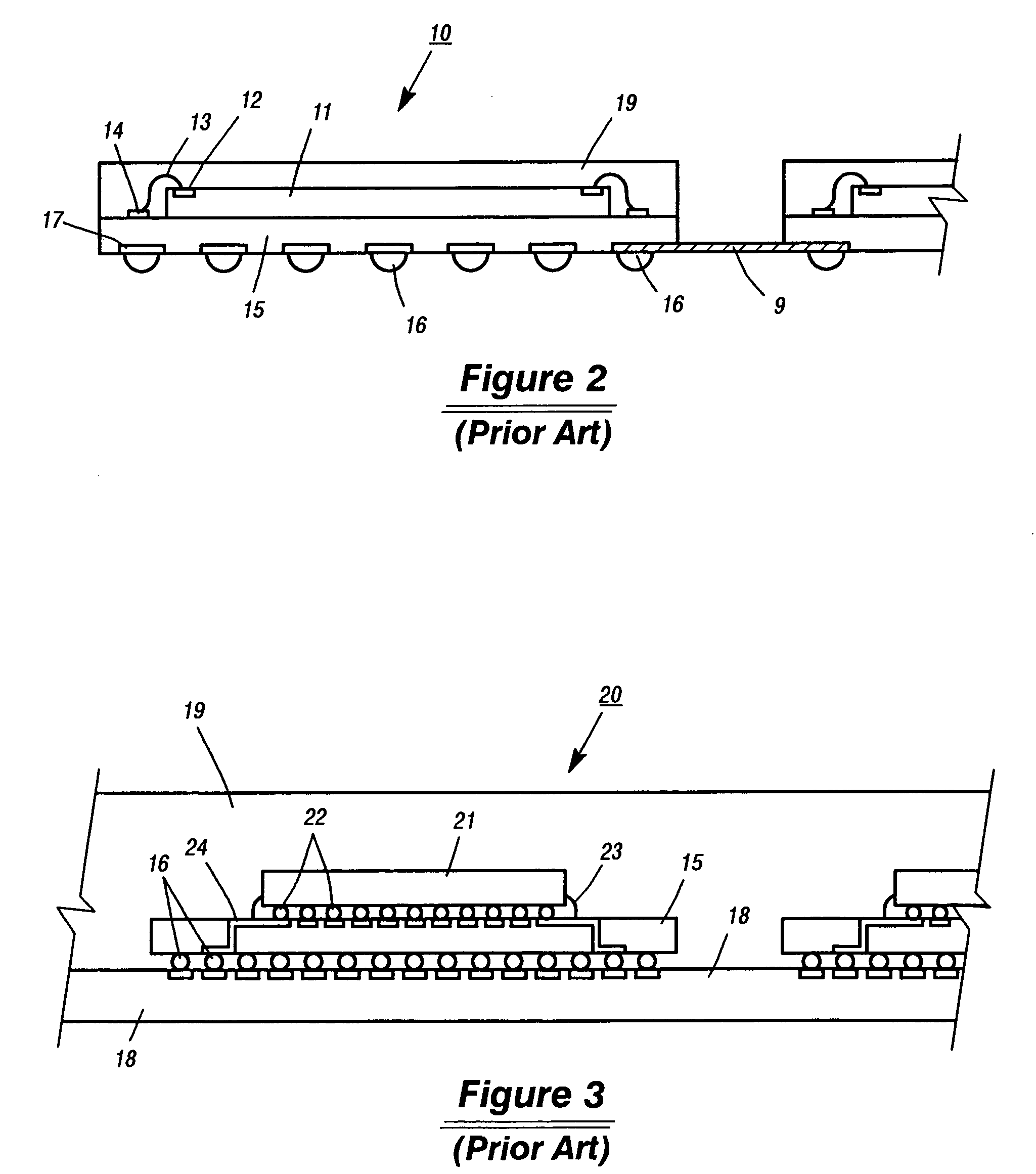

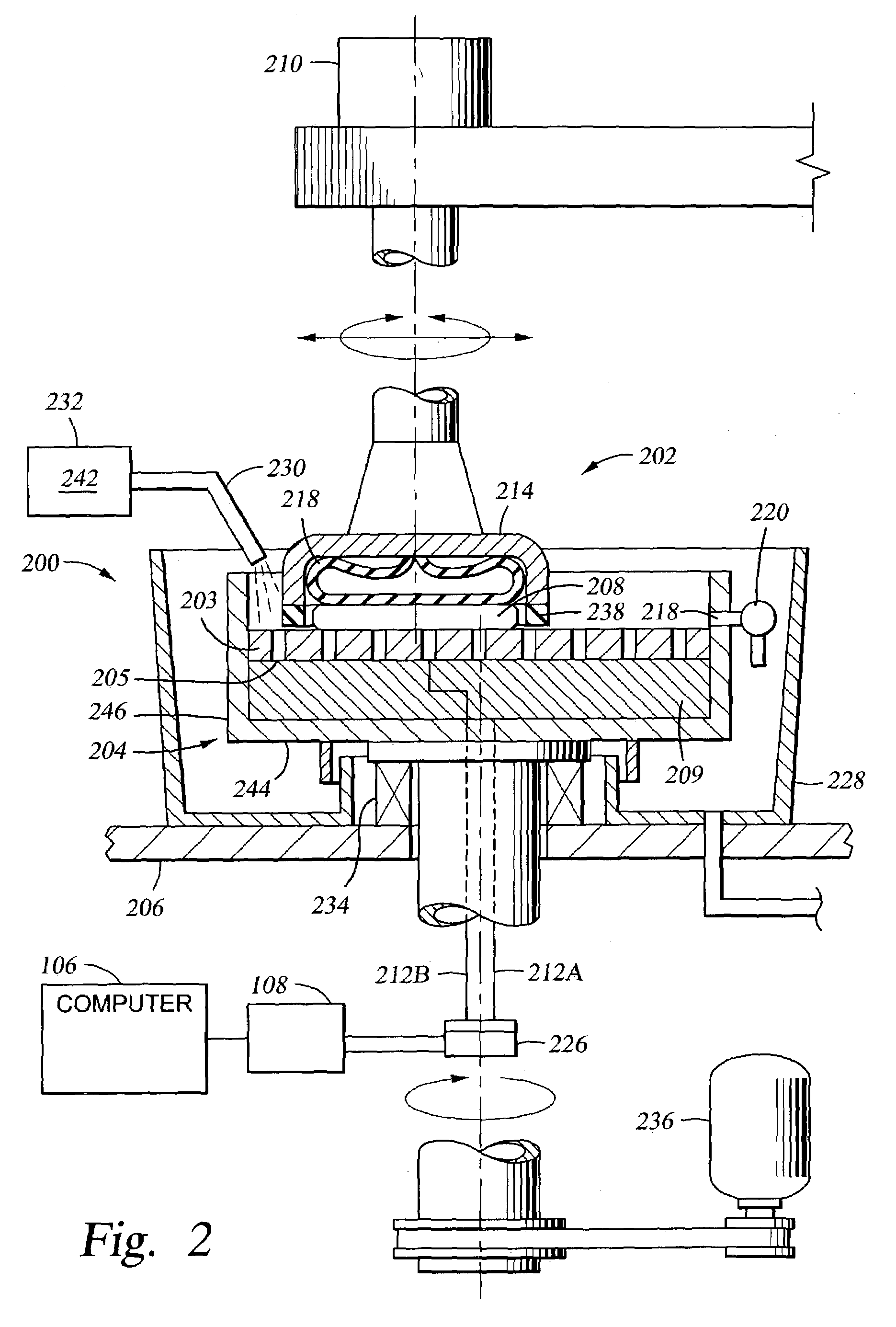

Edge bead removal by an electro polishing process

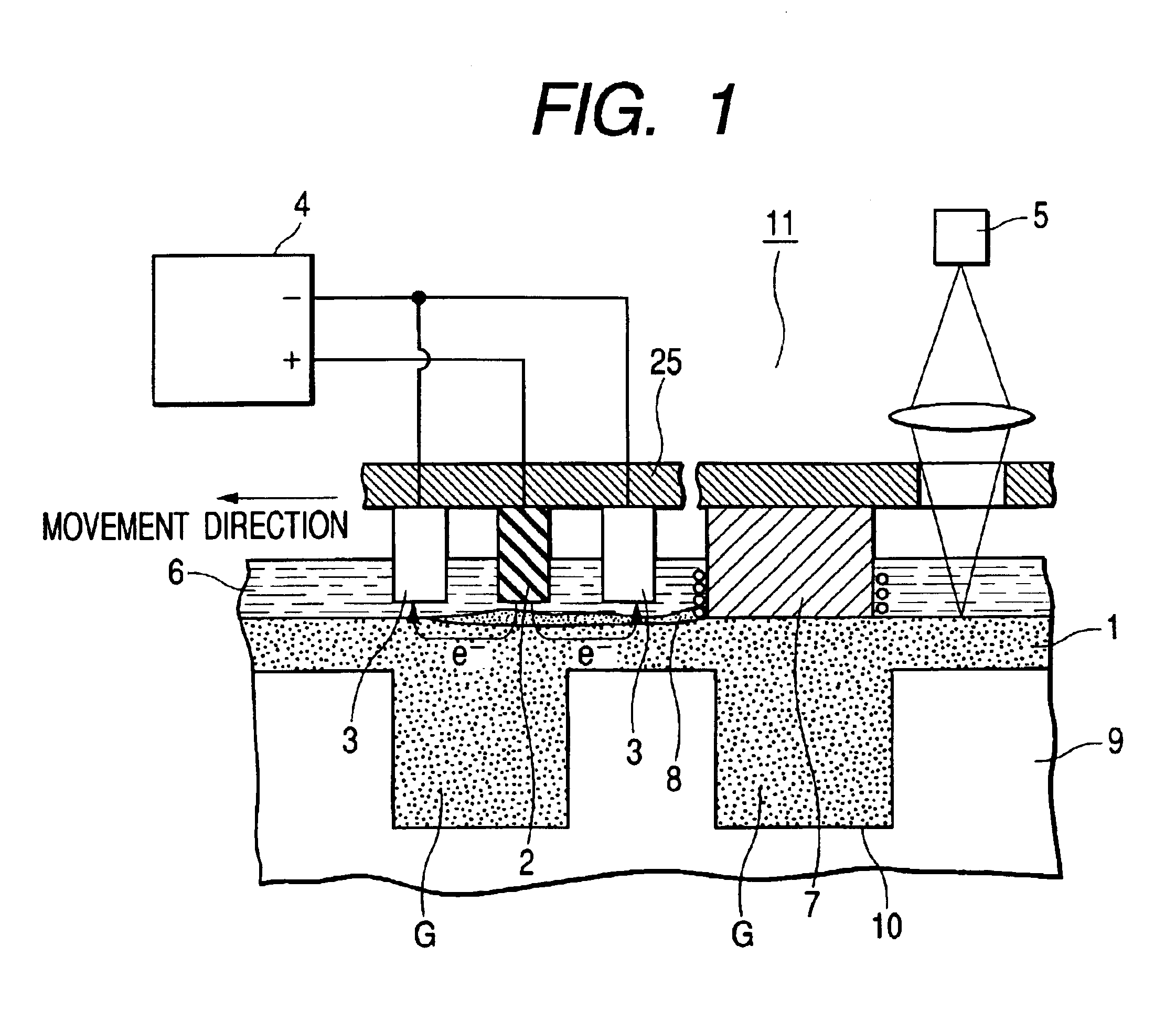

A method and apparatus for the removal of a deposited conductive layer along an edge of a substrate using an electrode configured to electro polish a substrate edge are disclosed. The electro polishing of the substrate edge may occur simultaneously during electrochemical mechanical processing (Ecmp) of a substrate face. In one embodiment, a power source applies a bias between the substrate and at least two electrodes. The electrodes form a first electrode zone proximate the substrate edge at a sufficient potential to electro polish the substrate edge, thereby removing the conductive layer from the substrate edge. A second electrode zone with a lower potential than the first electrode zone is aligned proximate the substrate face during processing to enable Ecmp of the substrate face.

Owner:APPLIED MATERIALS INC

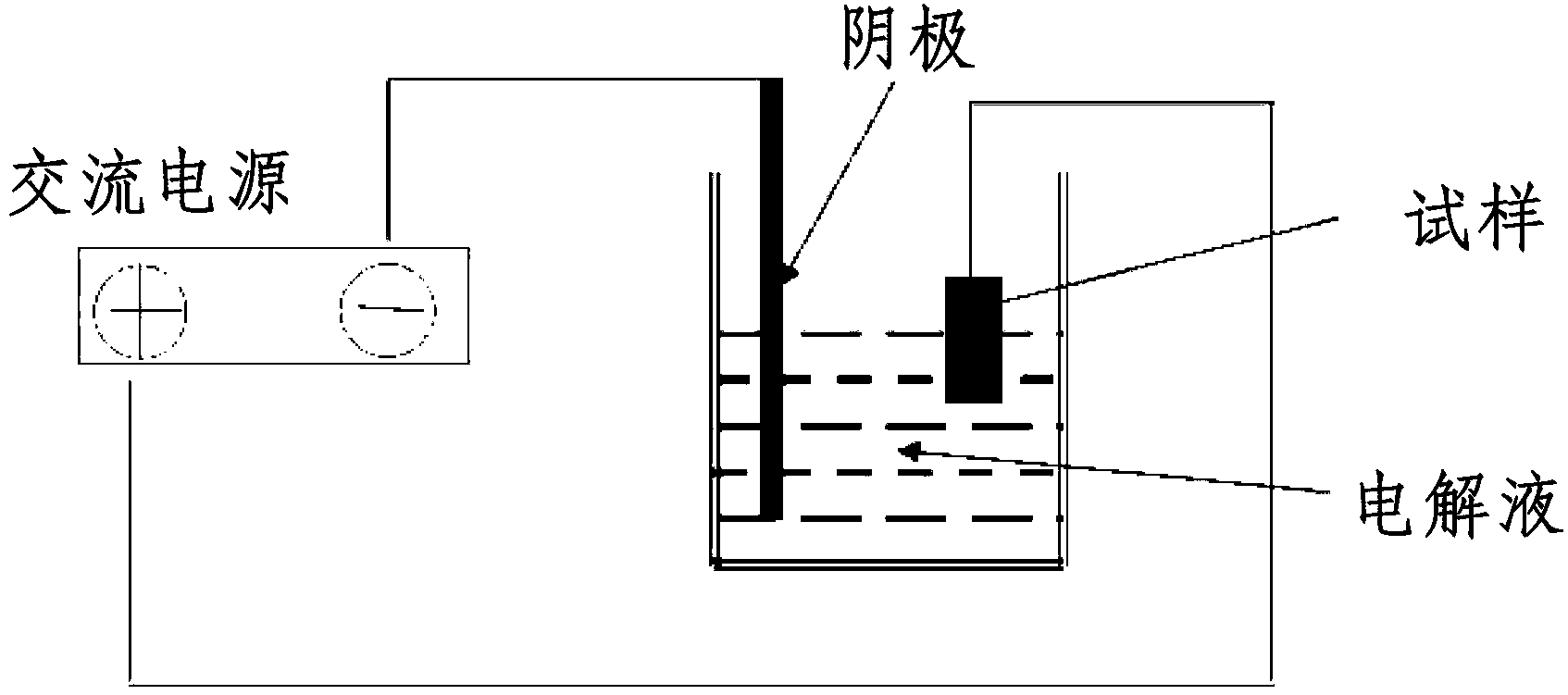

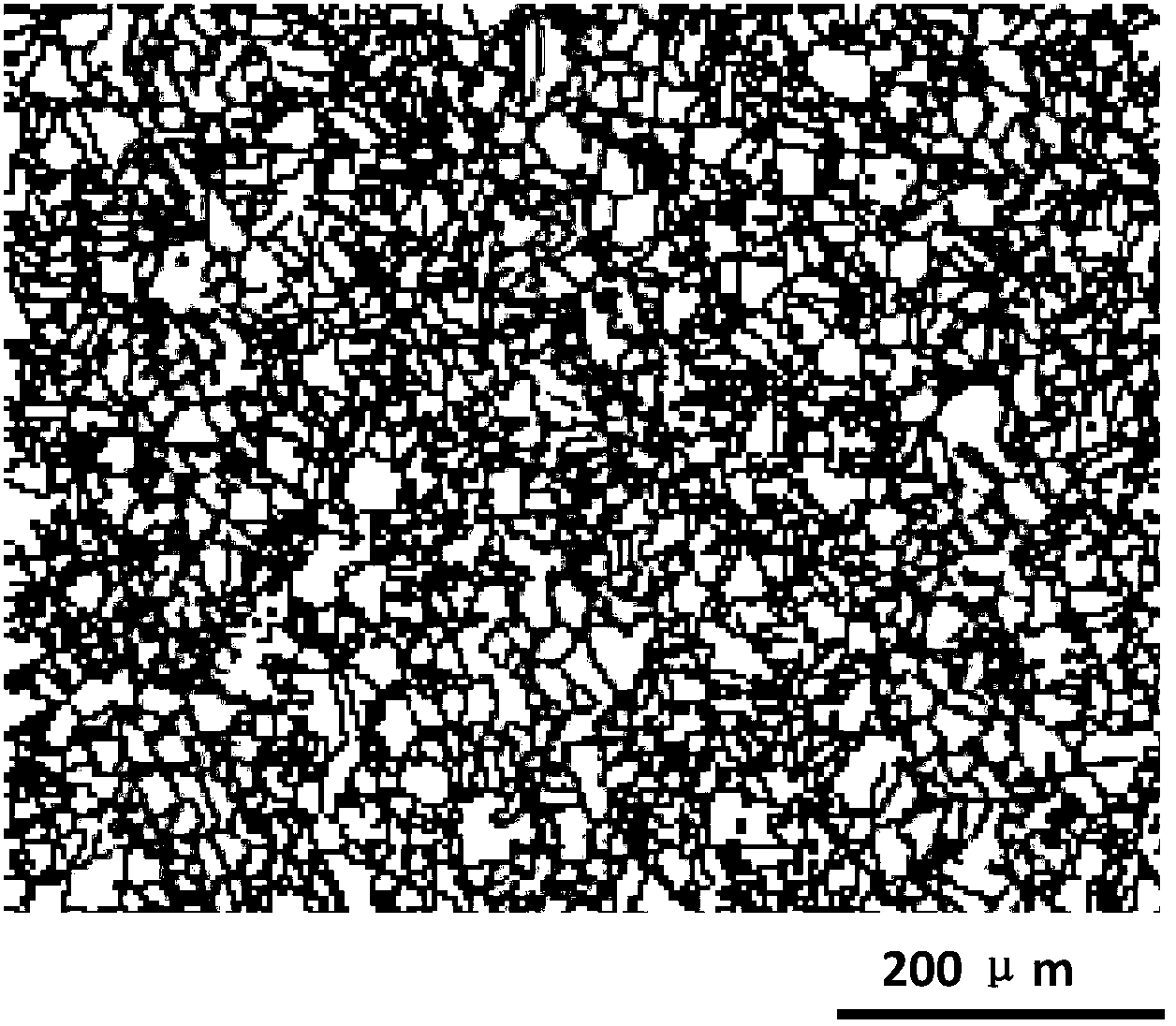

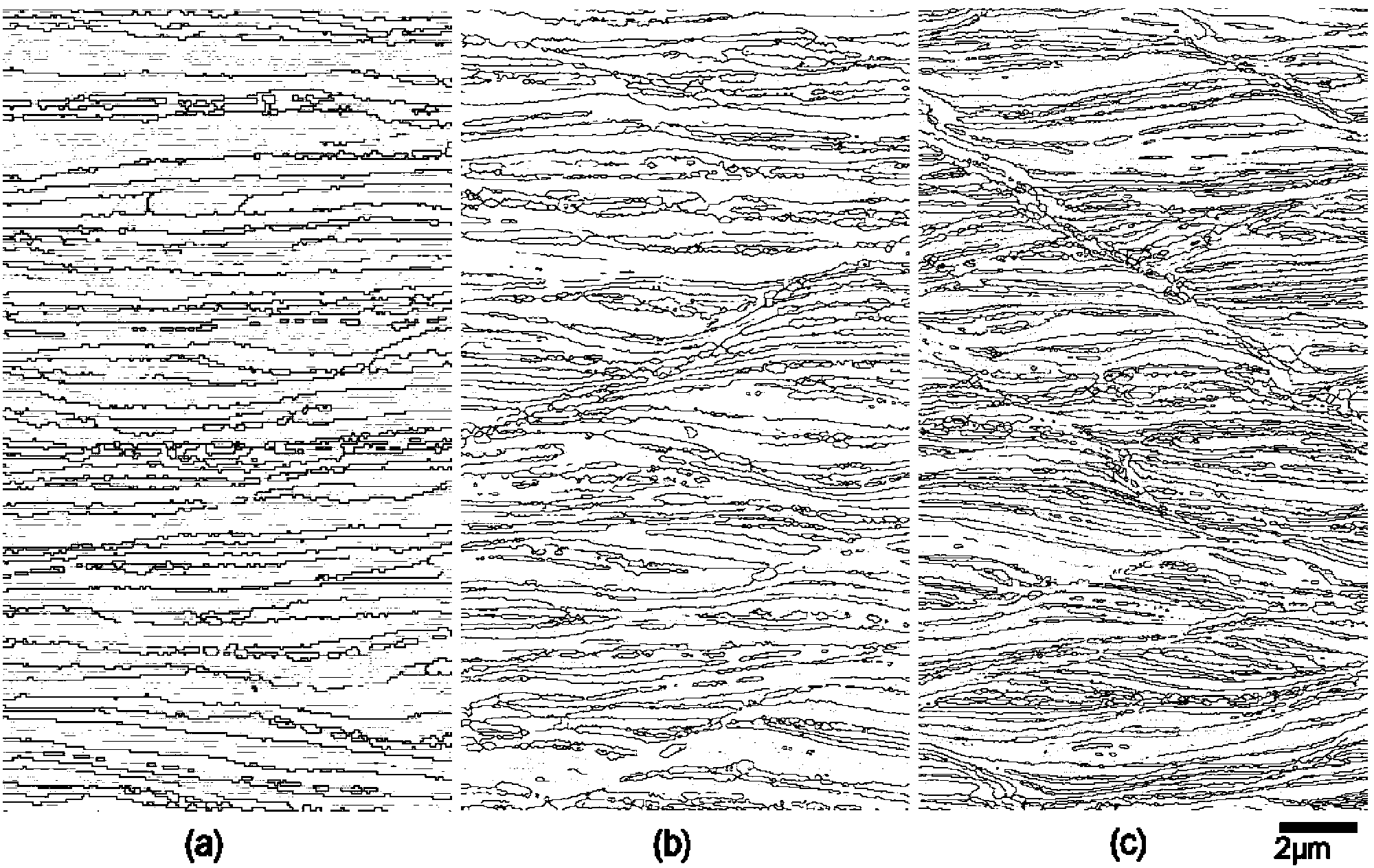

Cu-Ni alloy electro-polishing method used for EBSD test

The invention discloses a Cu-Ni alloy electro-polishing method used for an EBSD (electron back scatter diffraction) test, and relates to researches on microstructure, the texture and the like of a Cu-Ni alloy used for discovering high-temperature superconductive coat conductors through adopting an EBSD technology in the cold rolling and heat treatment processes. The electro-polishing method can be used for the sample processing before the EBSD test of the microstructure and the texture of the surface of the Cu-Ni alloy. The electro-polishing method can effectively remove the stress layer on the surface of a sample, is in favor of the generation of strong diffraction patterns during the EBSD test, and is convenient for the researches on the microstructure and the texture of the Cu-Ni alloy. The method is characterized in that the Cu-Ni alloy sample which undergoes mechanical polishing and ultrasonic cleaning is electro-polished, a cathode material is a metal platinum sheet, a Cu-Ni alloy electro-polishing liquid is stirred in a magnetic stirrer in a low speed (0.5-1r / s) mode, the alternating current voltage during the electro-polishing is 5-15V, the electro-polishing temperature is 10-25DEG C, and the electro-polishing time is 5-20s.

Owner:深创超导(深圳)科技有限公司

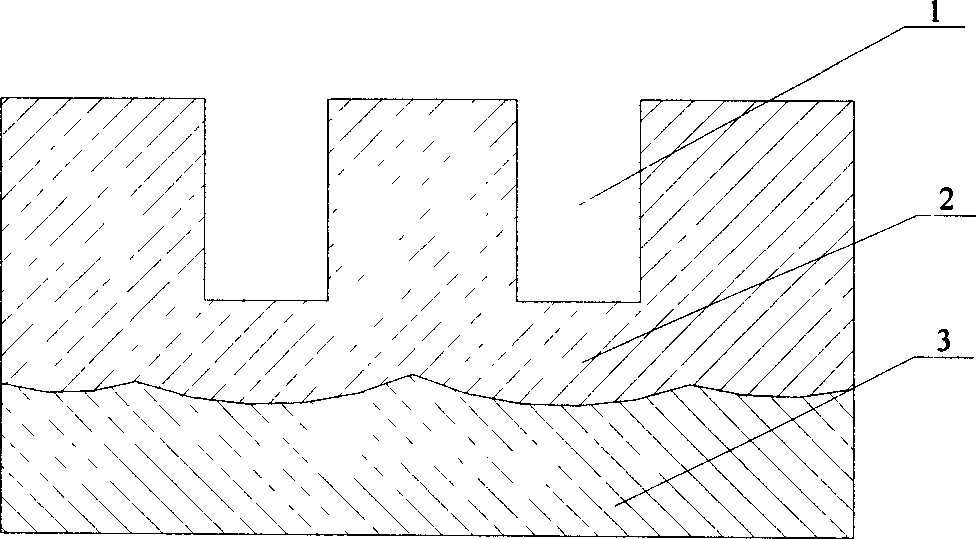

Process for preparing porous anode aluminium oxide mould of height ordered by mixed acid electrolyzing liquid

InactiveCN1793437AOxidation voltage decreasedReduce thicknessSurface reaction electrolytic coatingAnodic Aluminum OxideAnode

The invention relates to a method used mixed acid electrolyte to manufacture high ordered multi-hole anodic alumina die plate. In order to further reduce oxidation voltage, barrier layer thickness, and increase nanometer hole array orderliness, the alumina die plate is manufactured as follows: using the mixed acid of sulfuric acid and oxalic acid as electrolyte; their content are 100-200g / L and 50-150g / L; de-oiling; oxide layer removing; electro polishing; double steps anodic oxidation manufacturing multi-hole anodic alumina die plate. The invention reduces reduce oxidation voltage and barrier layer thickness to make nanometer hole diameter rise from 20nm to 45-55nm. This is good for the further application of multi-hole alumina die plate.

Owner:HARBIN INST OF TECH

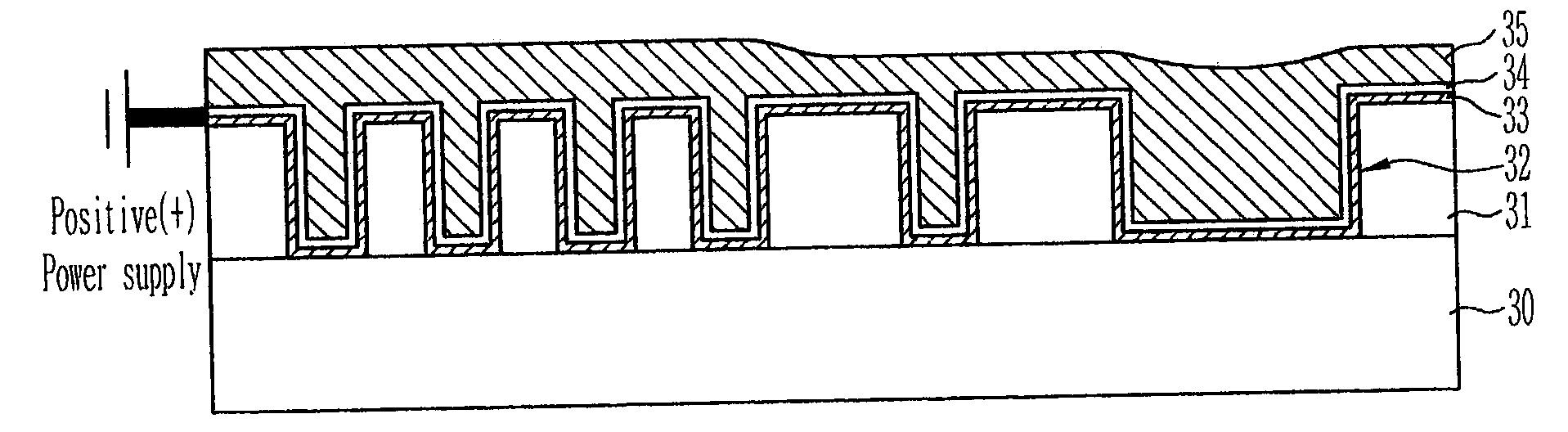

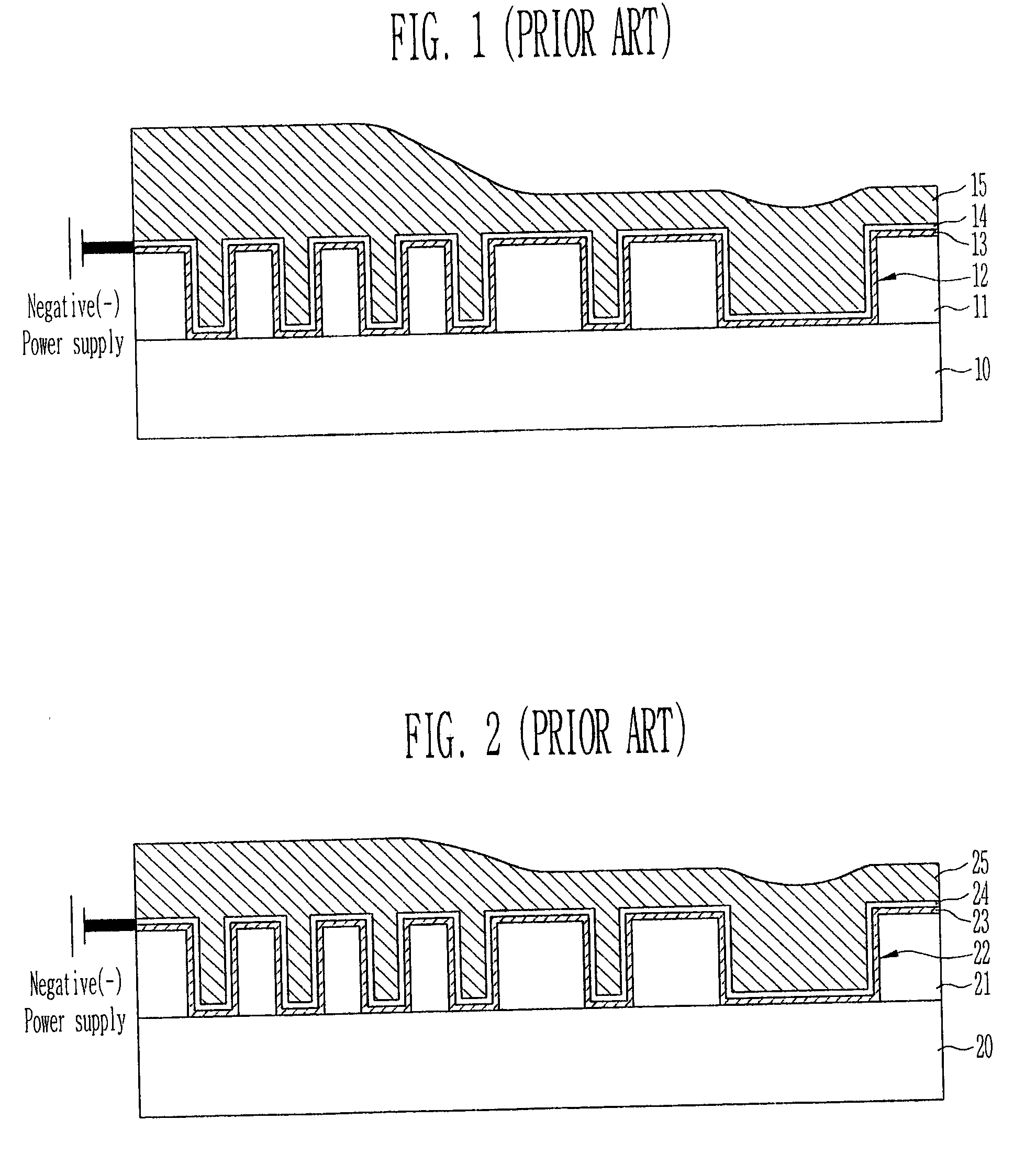

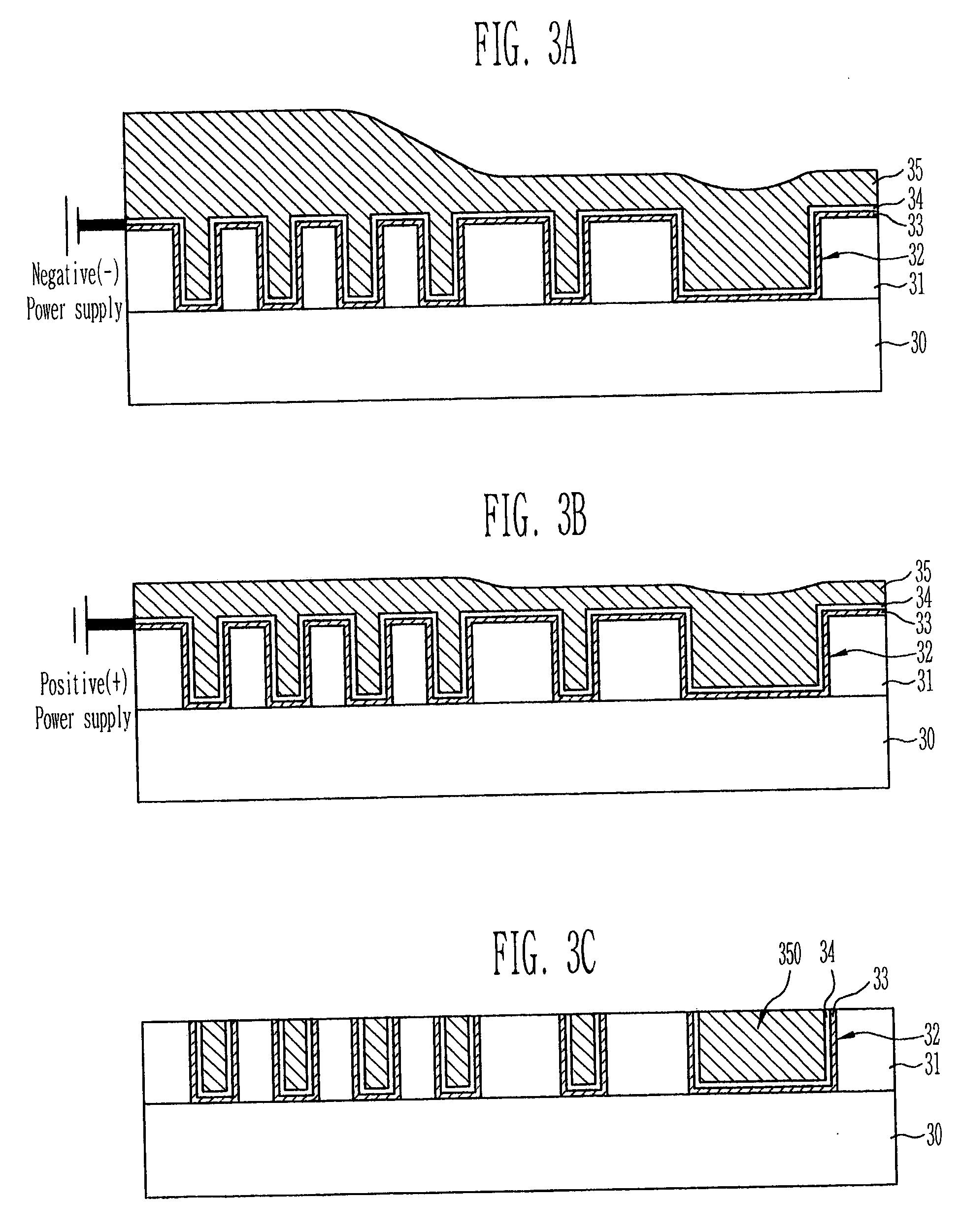

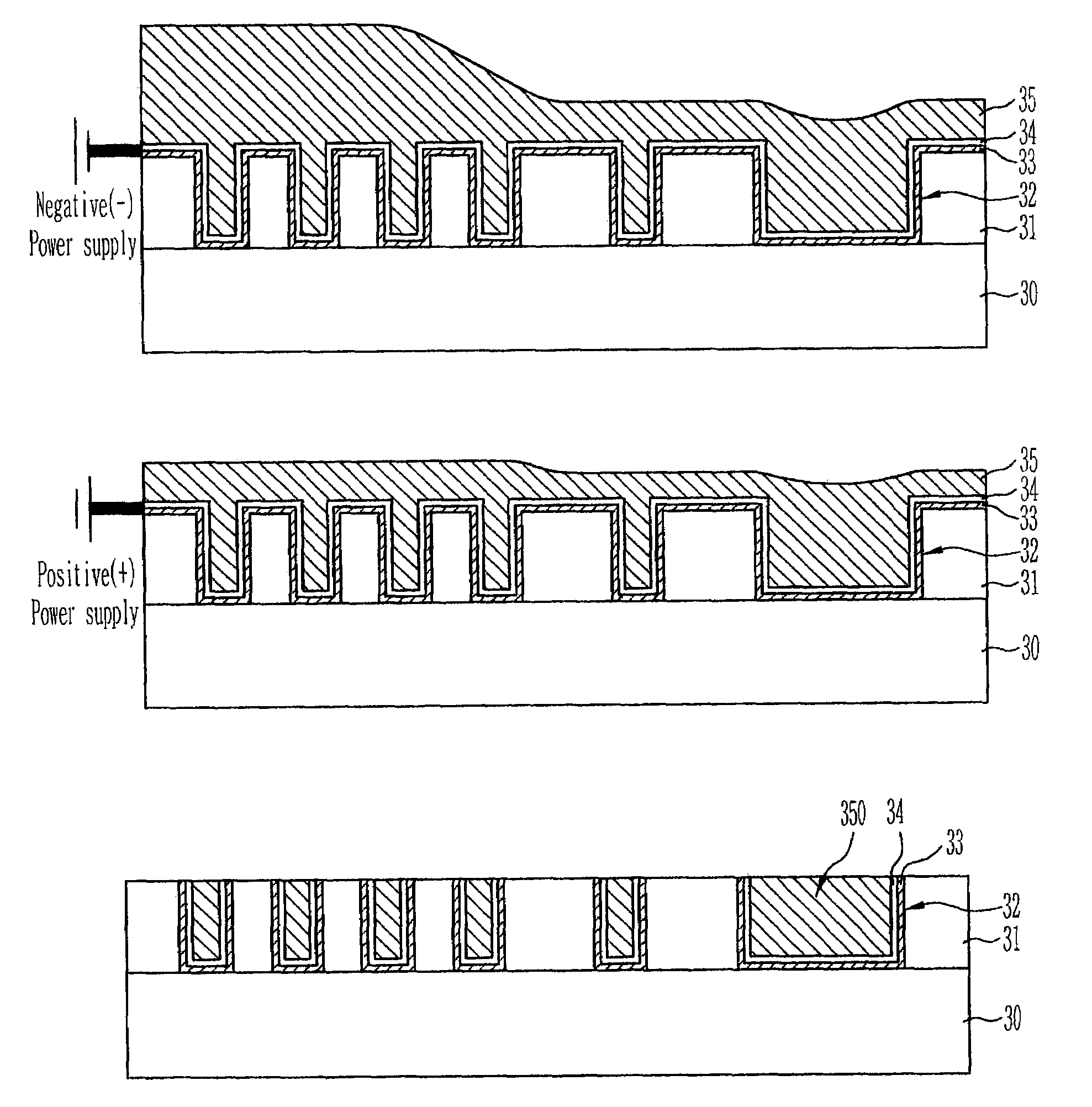

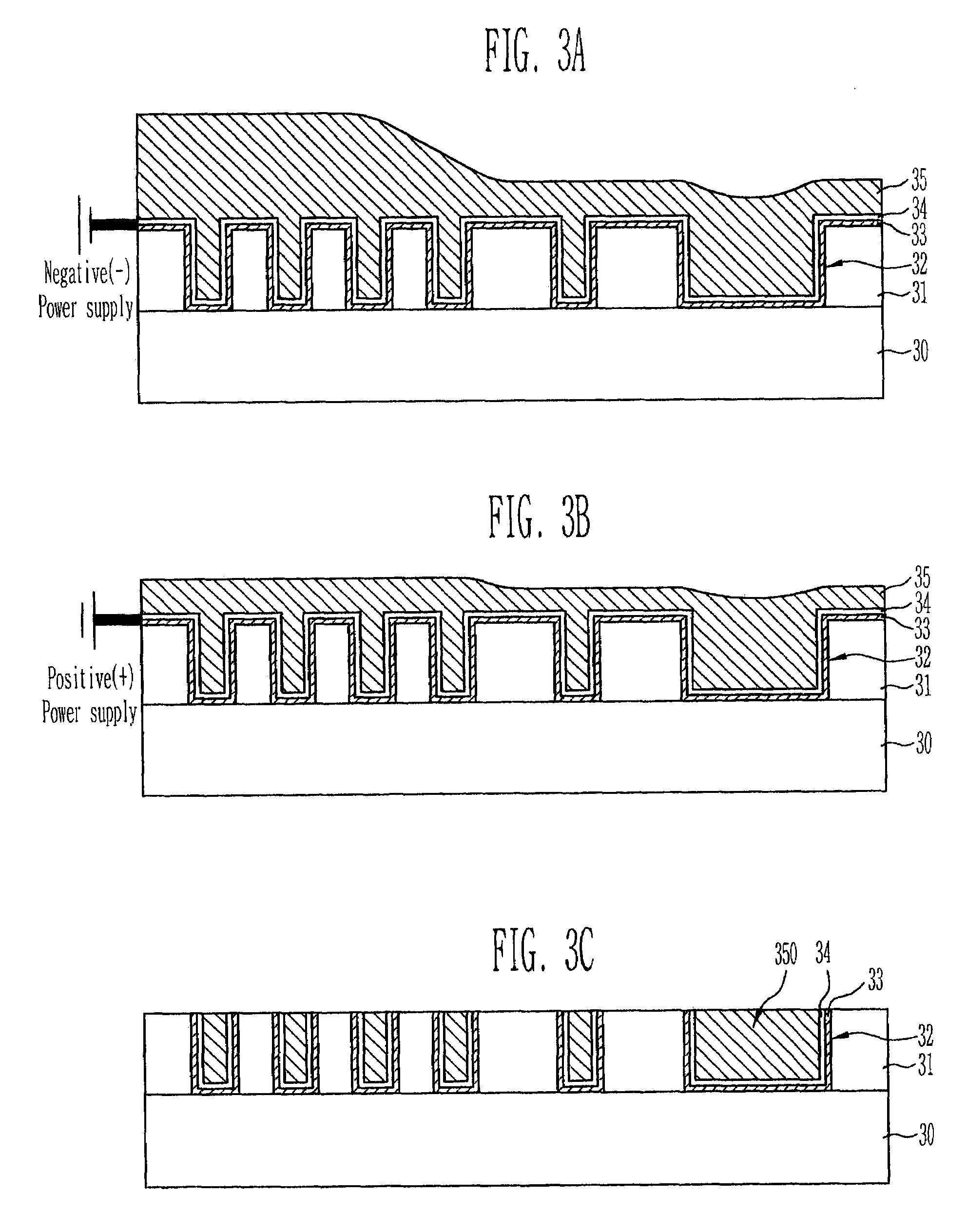

Method of forming copper wiring in a semiconductor device

ActiveUS20040009659A1Excellent characteristicsImprove device reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesCopper platingCopper-wiring

Disclosed is a method of forming a copper wiring in a semiconductor device. A copper barrier metal layer and a copper seed layer are sequentially formed along the surface of an interlayer insulating film including damascene patterns. In a state that a wafer is then loaded onto an electrical plating apparatus in which a copper plating solution is filled and a negative (-) power supply is also applied to the wafer, copper is plated so that the damascene patterns are sufficiently filled, thereby forming a copper layer. Next, the copper layer is polished in the plating solution by means of the electro-polishing process by changing the negative (-) power supply to the positive (+) power supply. Due to this, the surface of the copper layer is flat over the entire wafer. Thereafter, a chemical mechanical polishing process is performed until the surface of the interlayer insulating film is exposed, thereby forming copper wirings within the damascene patterns. As such, an uneven surface of the copper layer plated by the electroplating method is etched in the plating solution, thus making flat the surface of the copper layer and thin the thickness of the copper layer. It is thus possible to prevent a dishing phenomenon or an erosion phenomenon in a subsequent chemical mechanical polishing process. Therefore, the process margin of the chemical mechanical polishing process could be increased and process characteristics could be improved.

Owner:KEY FOUNDRY CO LTD

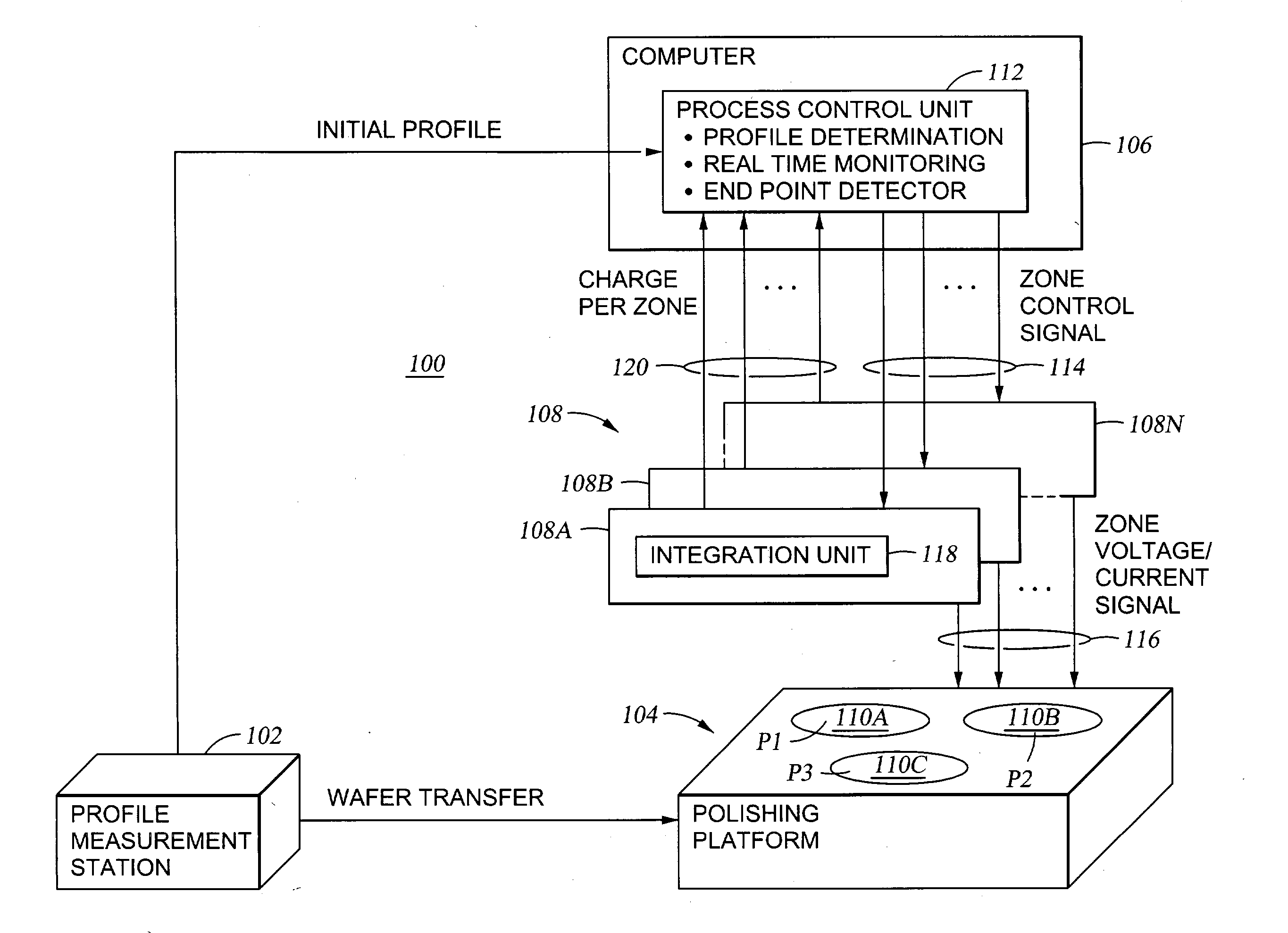

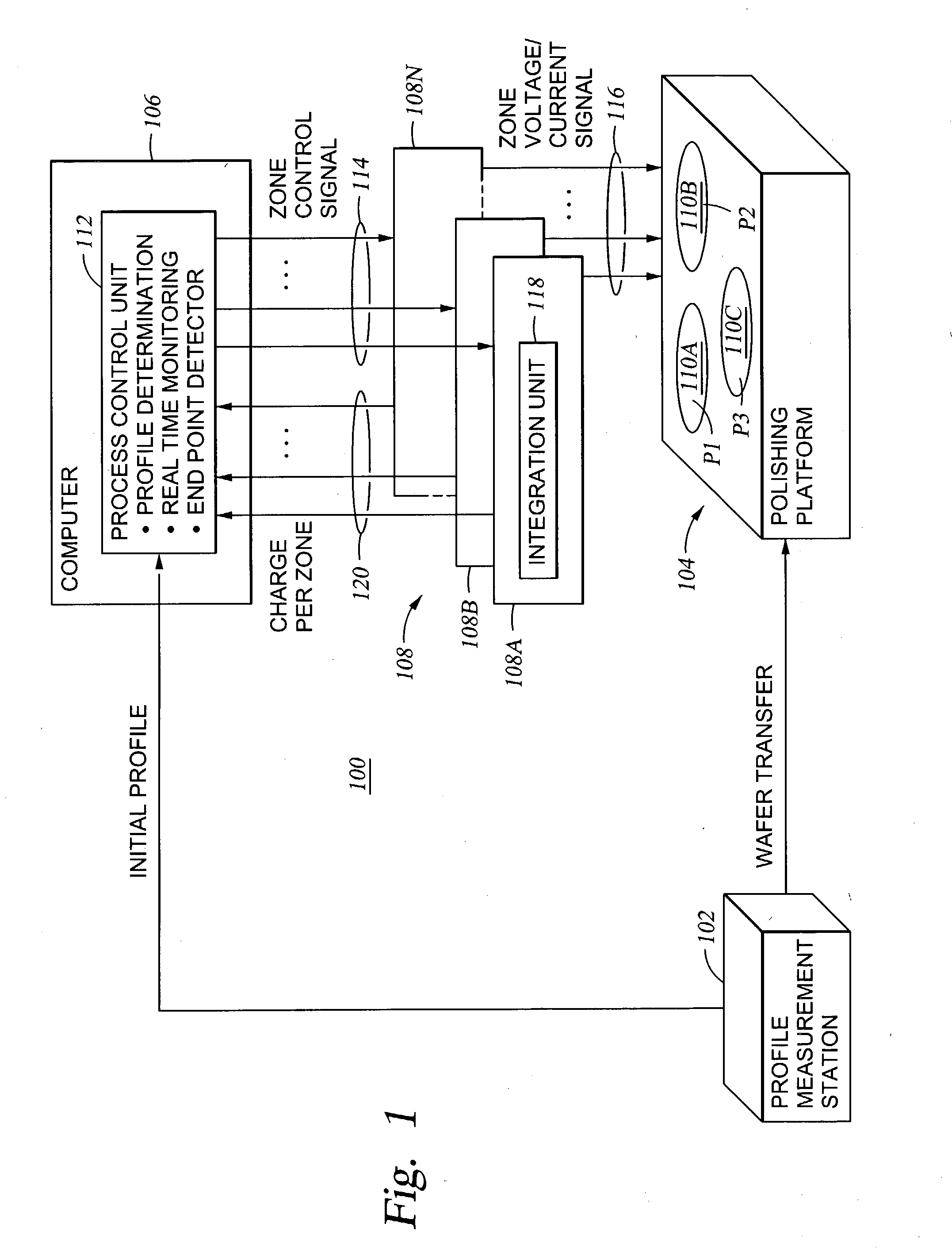

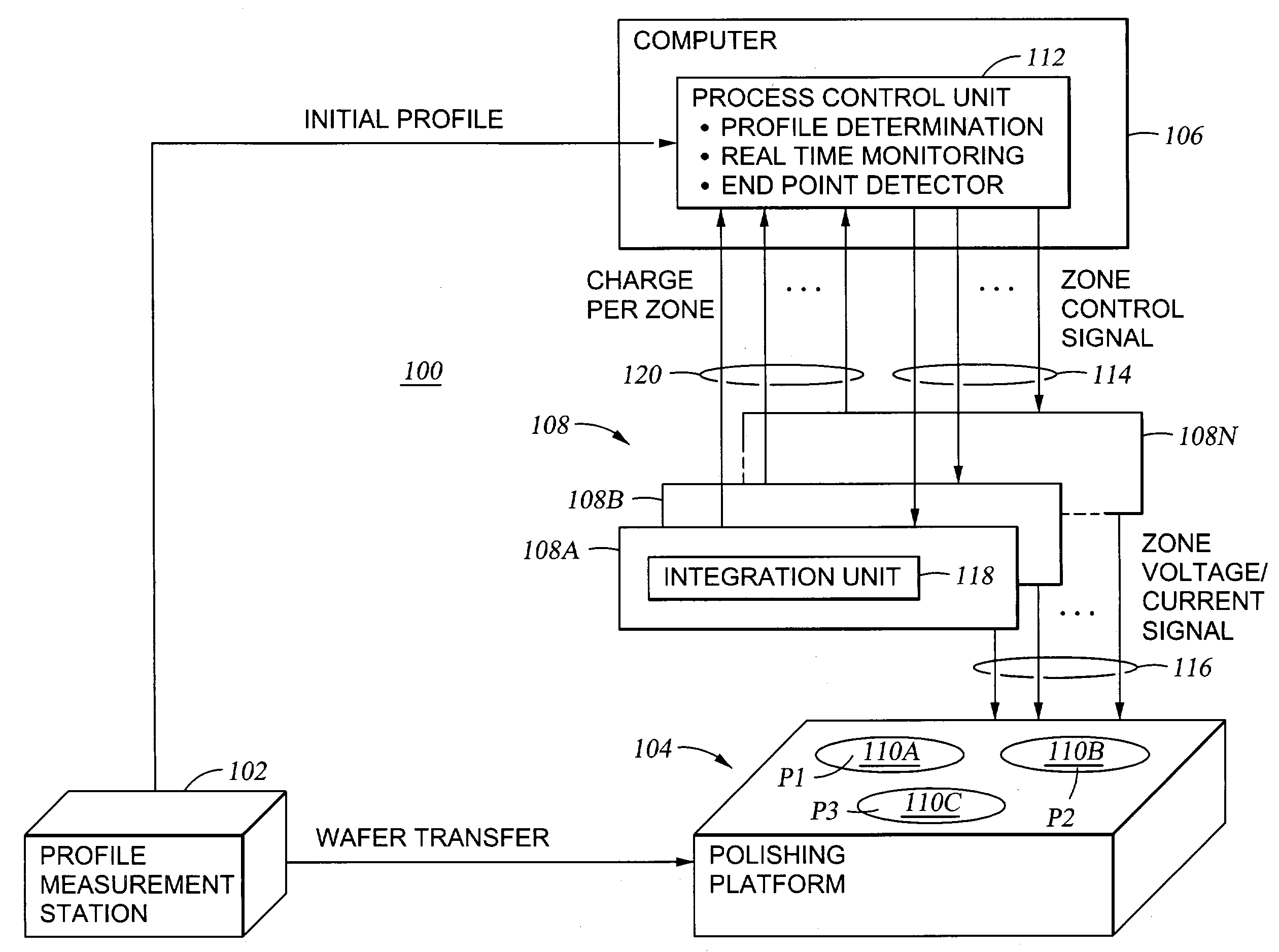

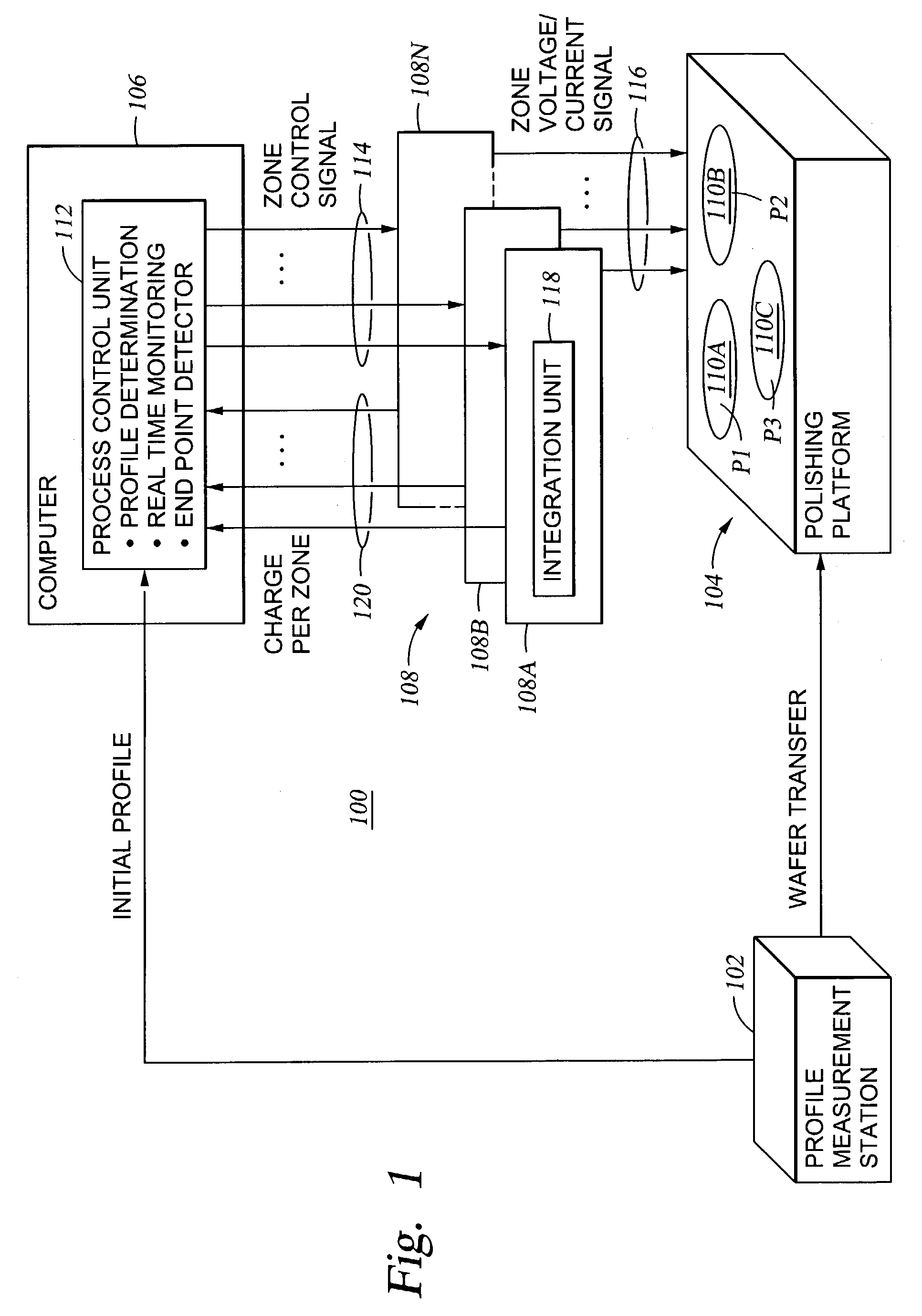

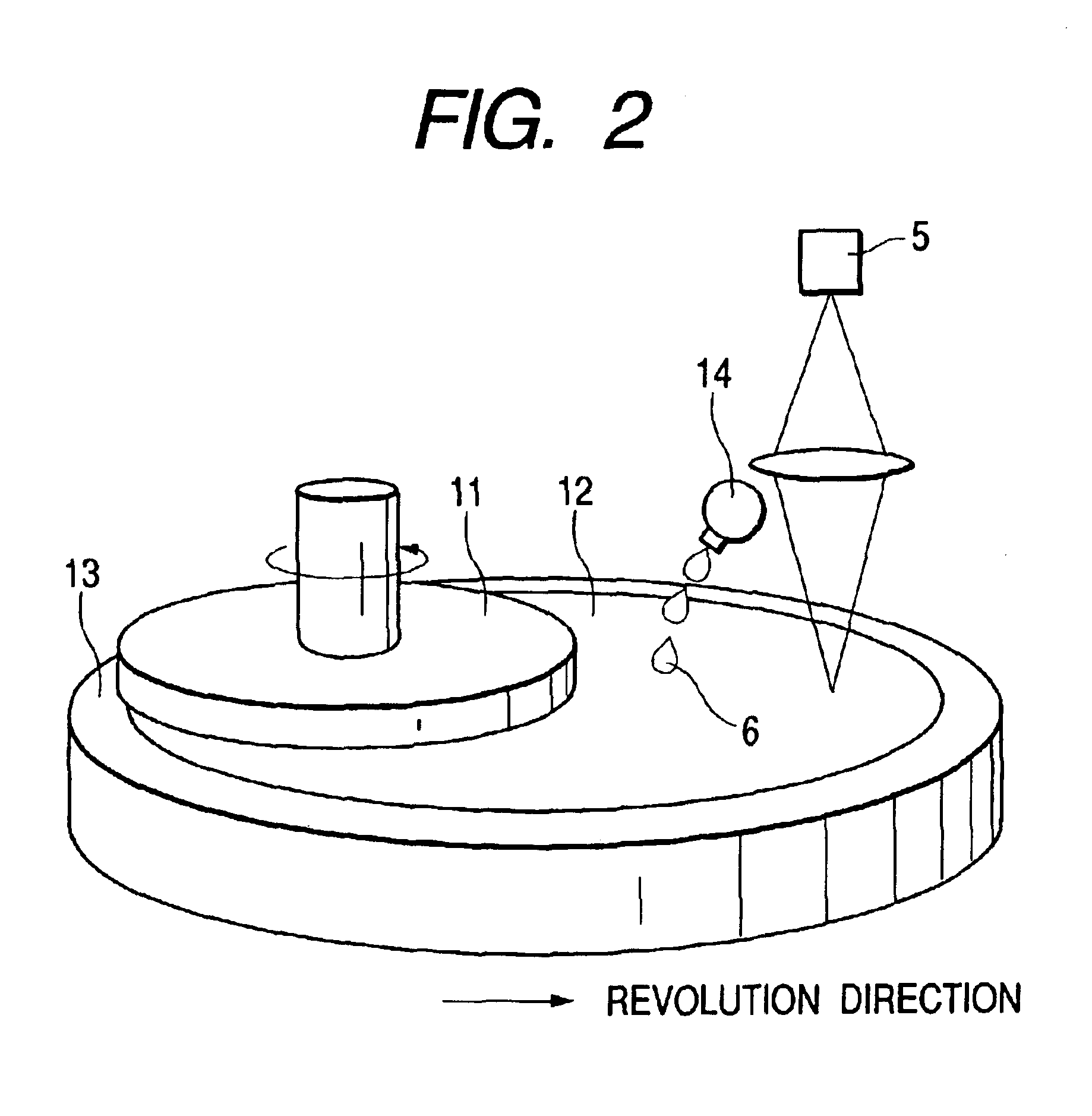

Algorithm for real-time process control of electro-polishing

Method and apparatus for process control of electro-processes. The method includes electro-processing a wafer by the application of two or more biases and determining an amount of charge removed as a result of each bias, separately. In one embodiment, an endpoint is determined for each bias when the amount of charge removed for a bias substantially equals a respective target charge calculated for the bias.

Owner:APPLIED MATERIALS INC

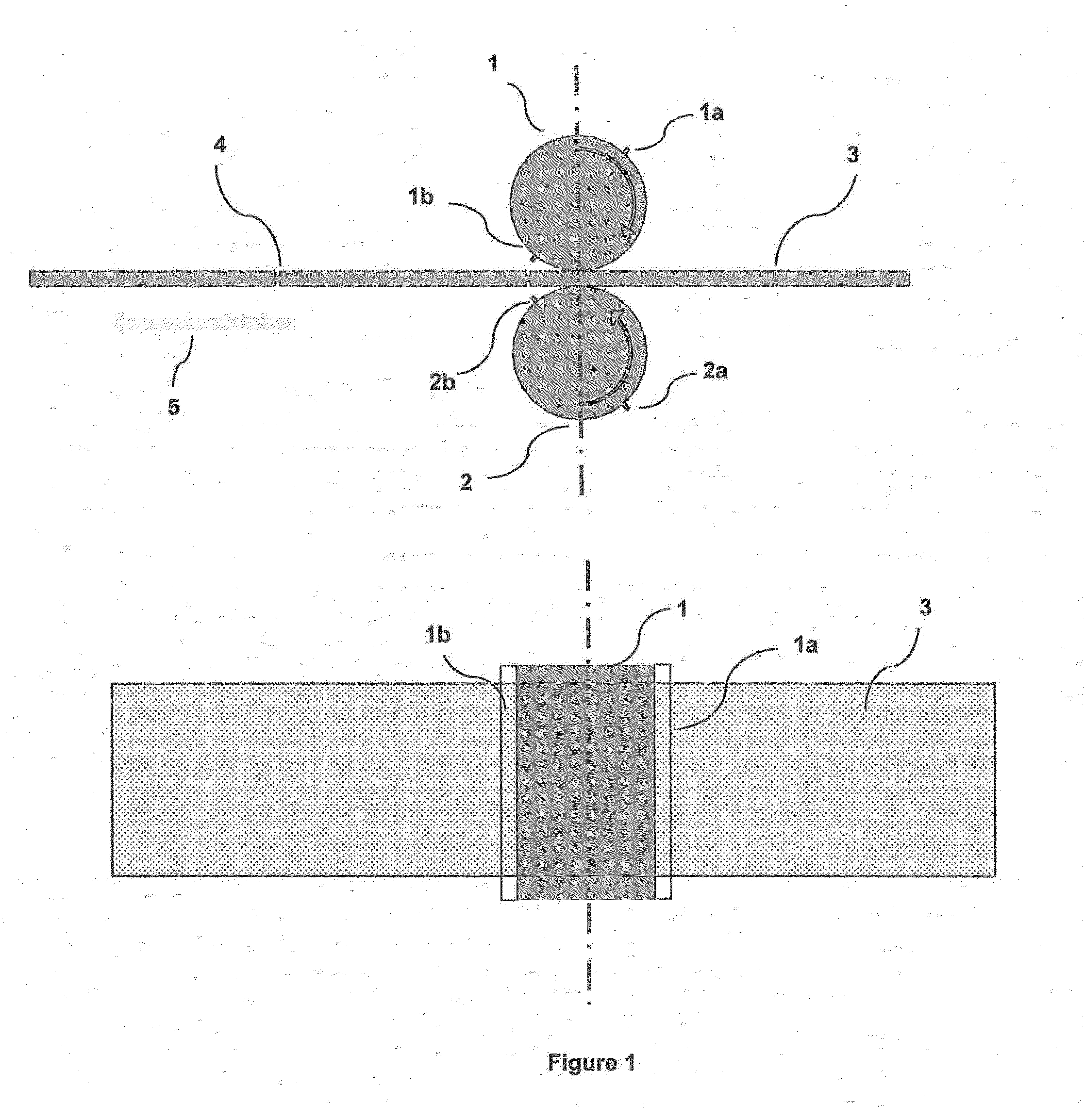

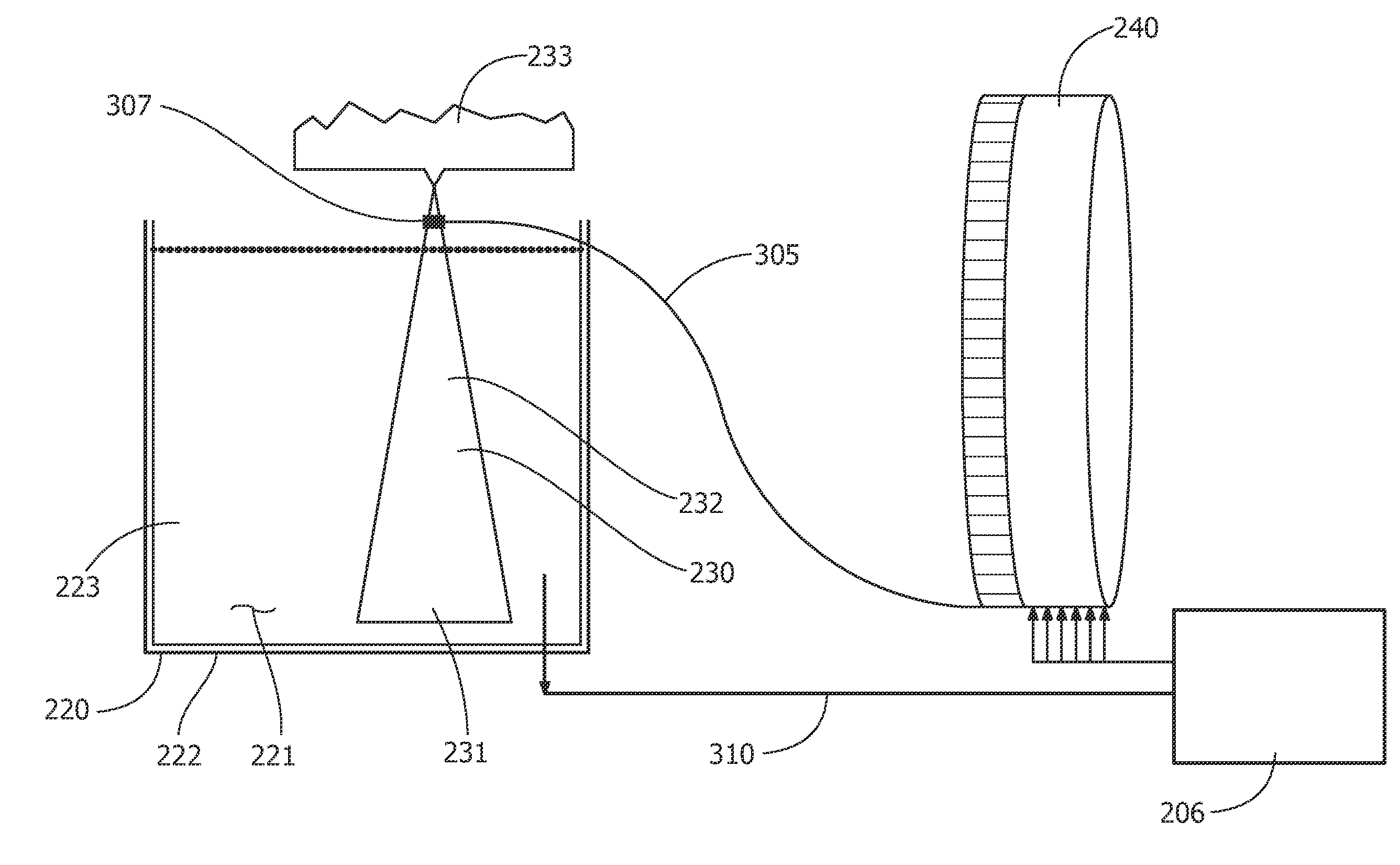

System and method of anodized aluminum oxide nano-porous membrane preparation

InactiveUS20140202868A1Simple methodEffective utilization of crackDuplicating/marking methodsSurface reaction electrolytic coatingEtchingVoltage pulse

A system and method for preparation of nano-porous membrane using anodized aluminium oxide and the membrane / film / thin lamina produced thereof. The system comprises a template forming device that comprises of two rolls provided with one or plurality of projections wherein the Al sheet is passed through the said rolls that are rotatable in opposite direction with respect to each other wherein in operation as the Al sheet is passed through the said rolls, the said projections of the rolls punch depressions to the predetermined depth in the said sheet wherein the depth of the depression is governed by the height of the projections. A method for preparation of anodized aluminum oxide nano-porous membrane comprising electro polishing of Al substrate; first step anodization; chemical etching of alumina; second stage anodization; etching Al for separation of alumina and barrier layer removal or voltage pulse detachment for barrier layer removal and detachment of membrane from Al substrate.

Owner:ASIAN INSTITUTE OF TECHNOLOGY

Lower alkyl carboxylic acid moieties for preventing oxidative corrosion of metals and organoleptic stabilizer for food and beverages

InactiveUS7264847B2Altered dielectric propertyMaximize its propertyDough treatmentOther chemical processesElectricityWater vapor

Compositions and methods are disclosed for preventing the oxidative corrosion of metal surfaces by exposing a metal surface to an anti-corrosion agent characterized as a lower alkyl carboxylic acid or salts and / or other derivatives that conserve or embody the lower alkyl carboxylic acid moiety present in their molecular structures as an active anti-corrosion agent. The anti-corrosion agent may be used in combination with a material capable of forming a moisture retentive barrier over the metal surface. The compositions and methods of the invention provide a practical, non-toxic way of ensuring anti-corrosion protection for metals, or devices containing exposed metals, stored or operated in water or in the presence of water vapor. Exemplary, non-exhaustive uses of the invention include employing the composition as lubricant for the surface of a metal or as a pump oil or brake fluid; using the composition as an undercoating for painting, electro-plating or electro-polishing procedures; and providing a protective coating for any metal or metal-containing machine or device, form automotive assembly plant metal press machines to electronic circuit boards.

Owner:UNIVERSAL SCI +1

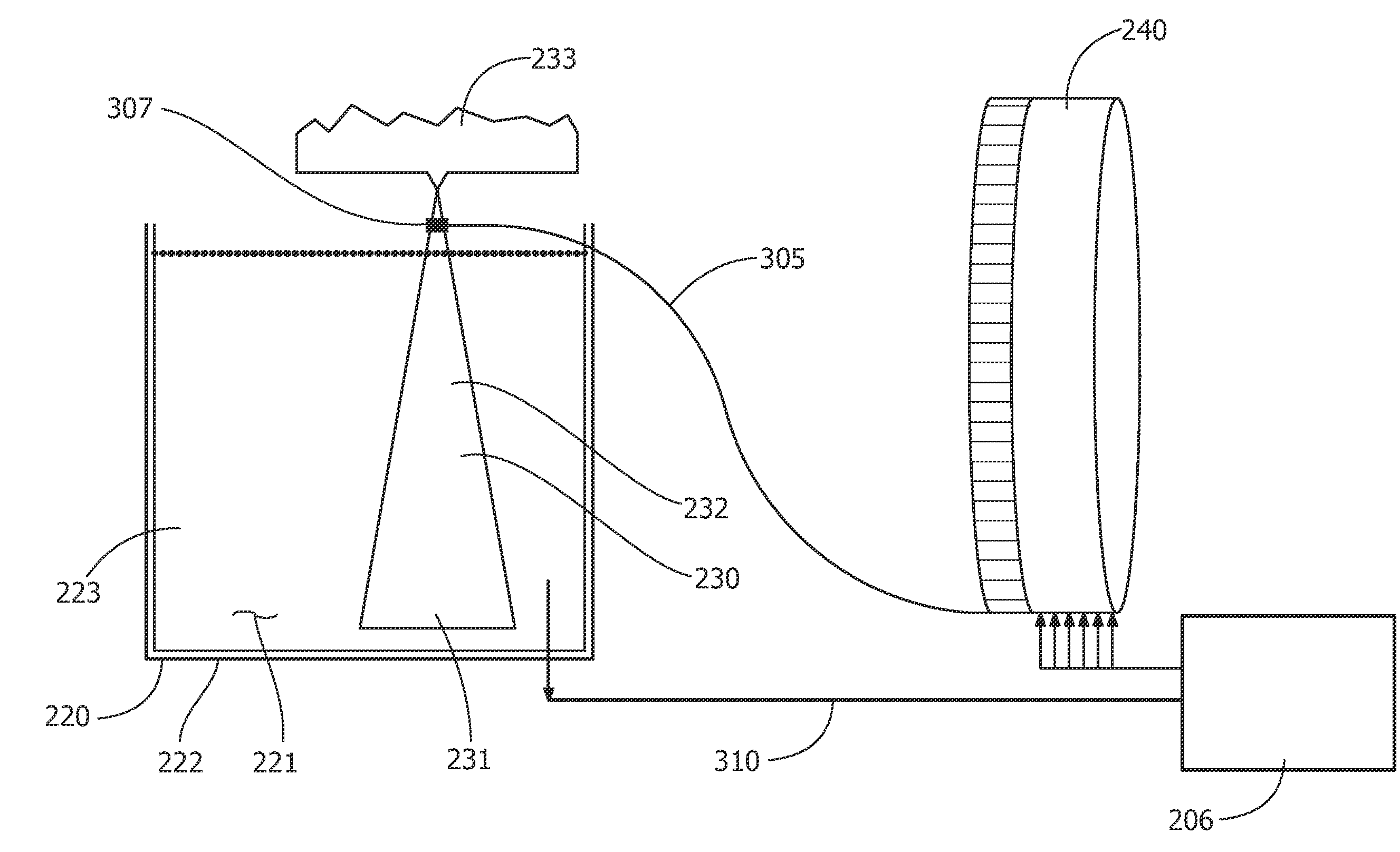

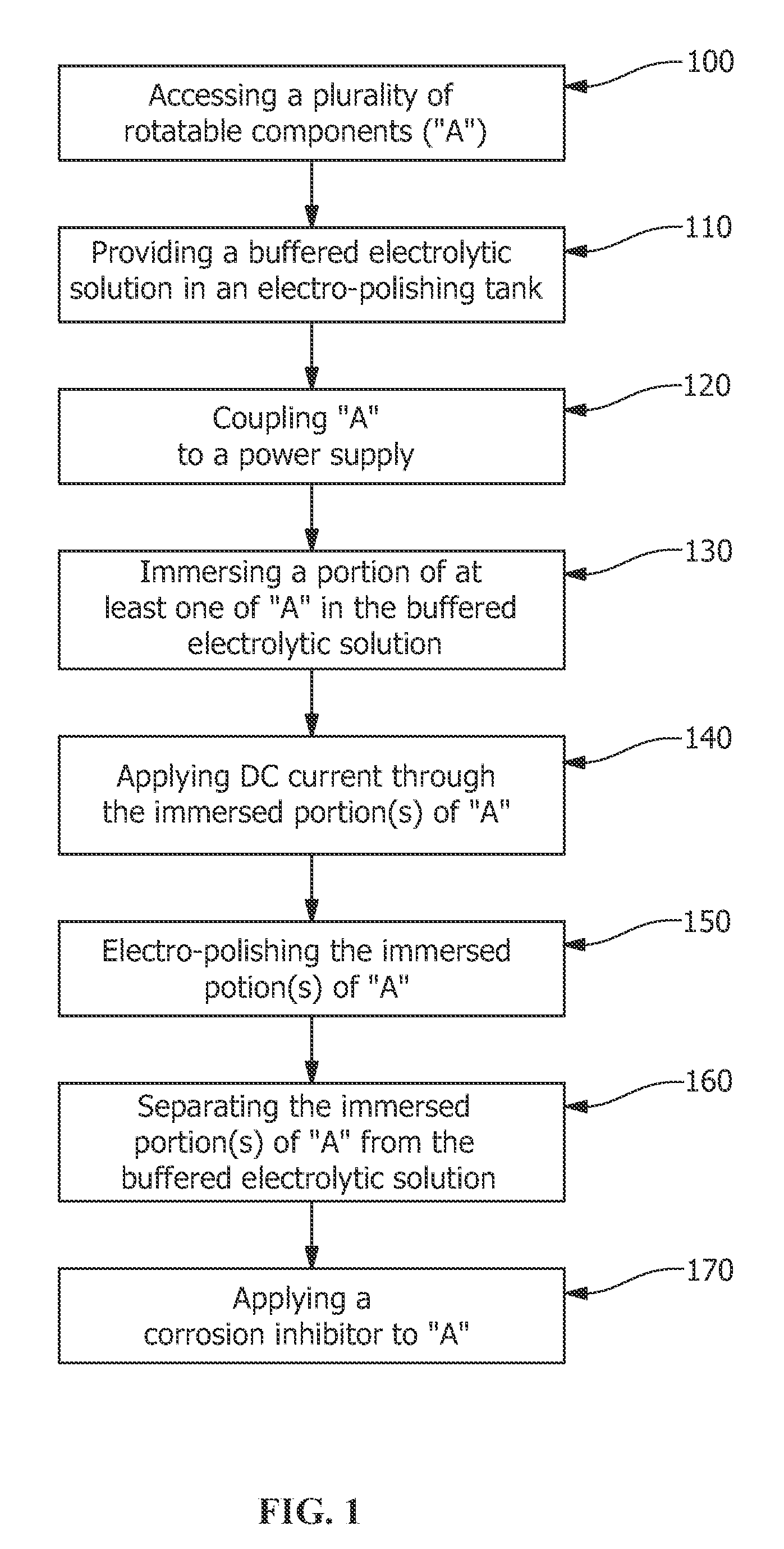

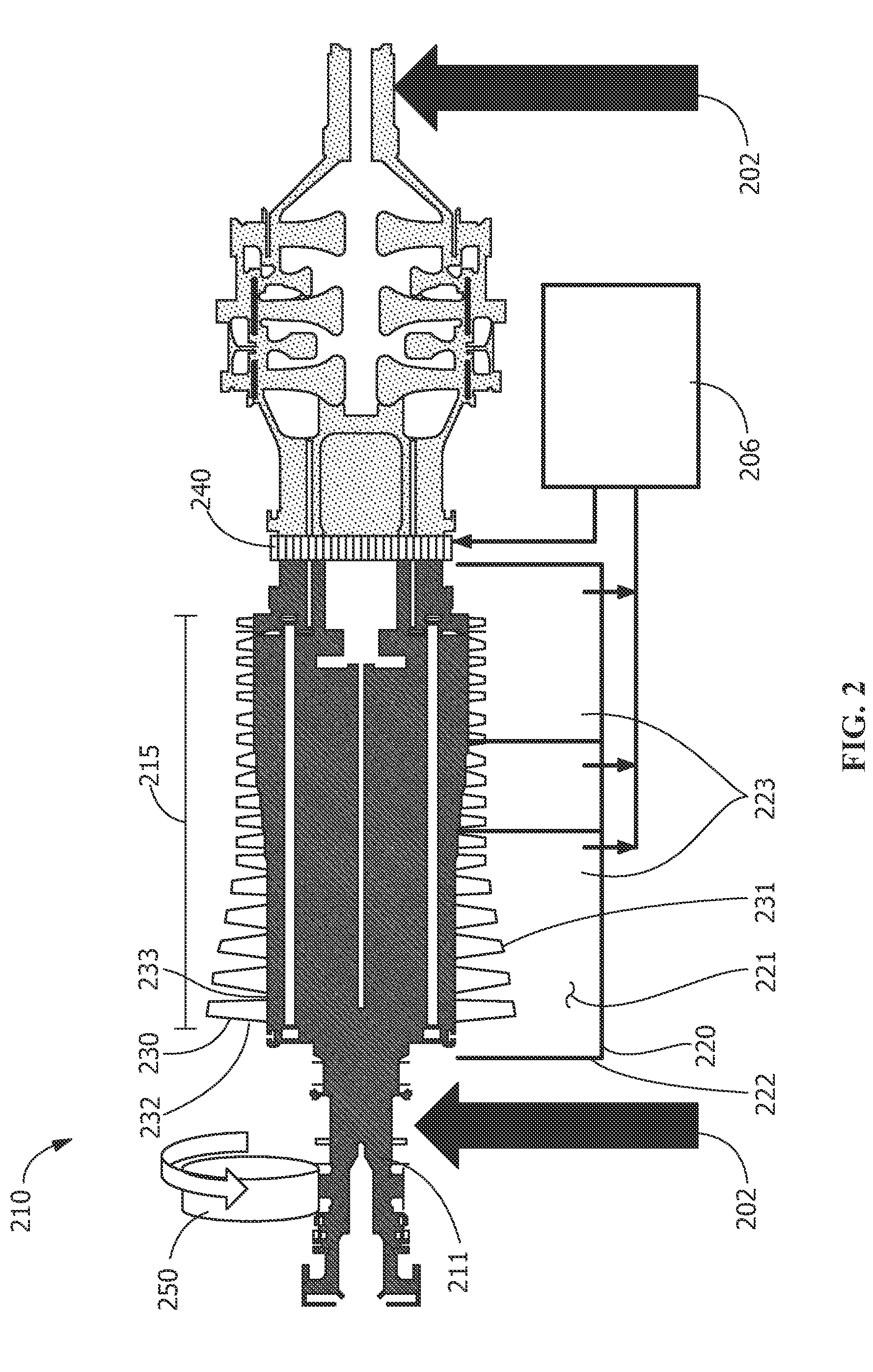

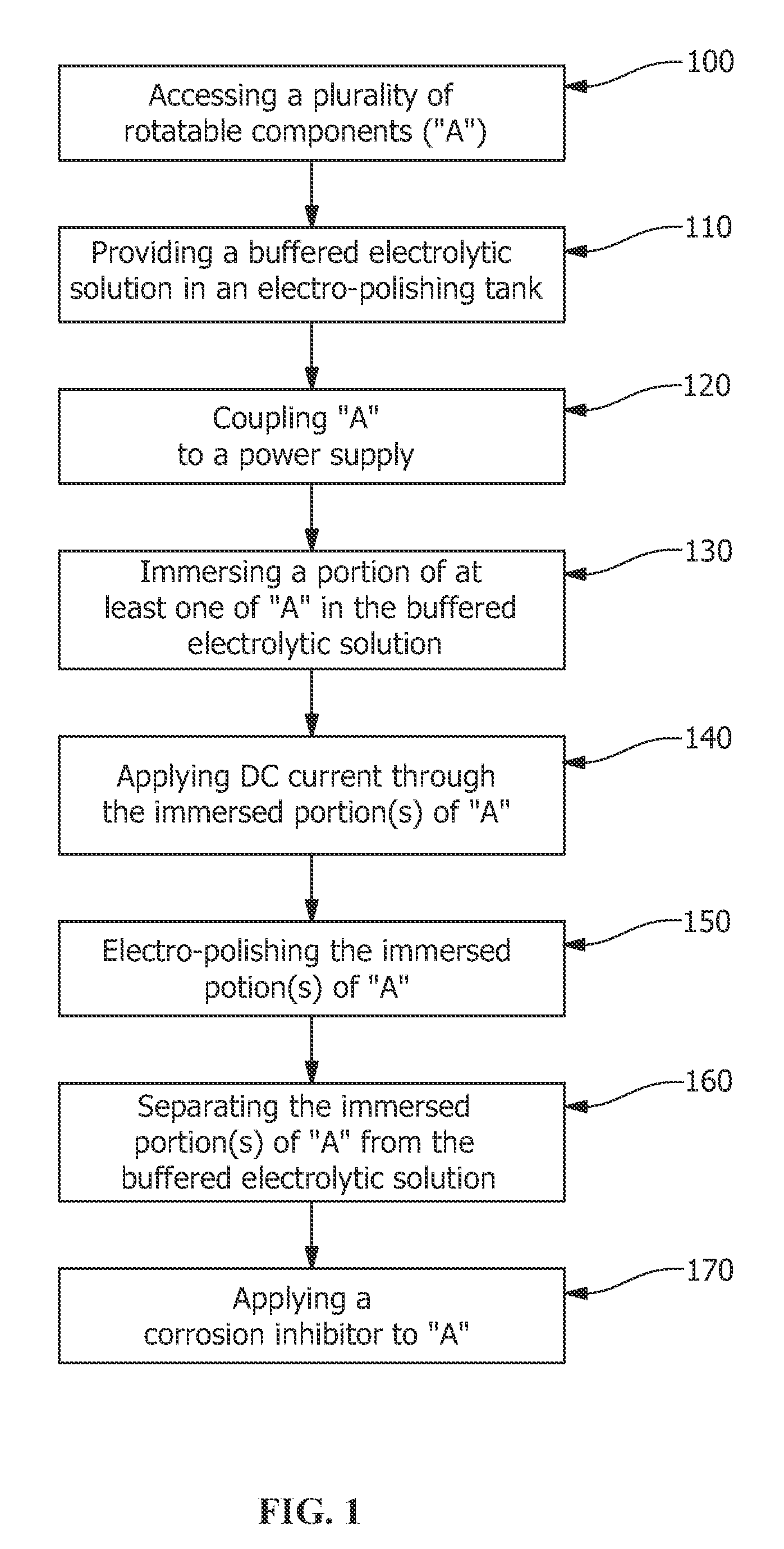

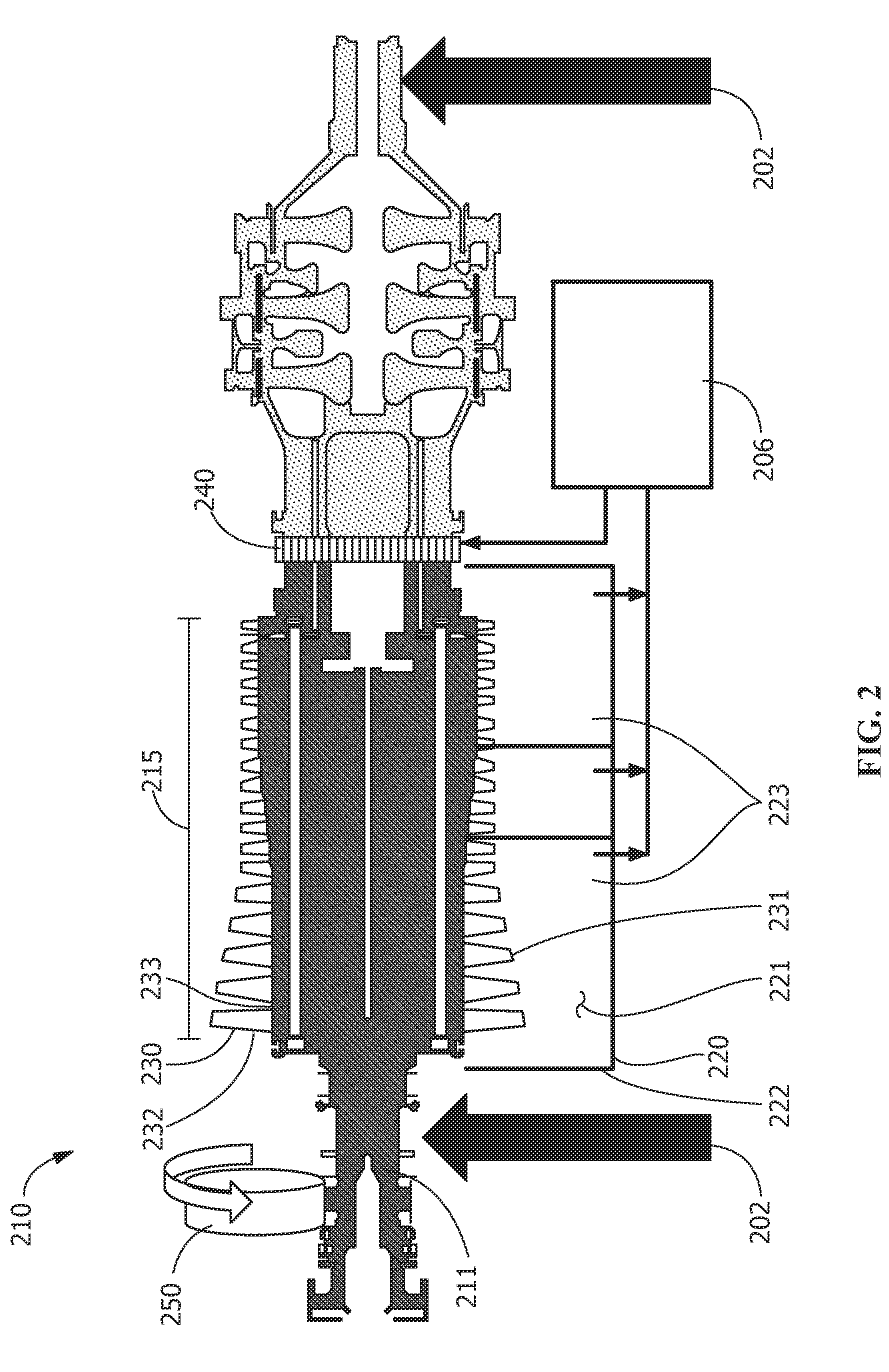

Method and apparatus for refurbishing turbine components

A refurbishing method, refurbishing apparatus and refurbished article are provided. The refurbishing method includes accessing a plurality of rotatable components attached to a turbine assembly, the turbine assembly being a portion of a turbomachine, providing a predetermined volume of a buffered electrolytic solution in an electro-polishing tank, coupling the plurality of rotatable components to a power supply, immersing an immersion portion of at least one of the plurality of rotatable components in the buffered electrolytic solution, passing an electrical energy through the immersion portion of at least one of the plurality of rotatable components while the immersion portion is immersed in the buffered electrolytic solution, wherein an electrical flux to the immersion portion electro-polishes the immersion portion, separating the immersion portion from the buffered electrolytic solution, and applying a corrosion inhibitor to the plurality of rotatable components.

Owner:GENERAL ELECTRIC CO

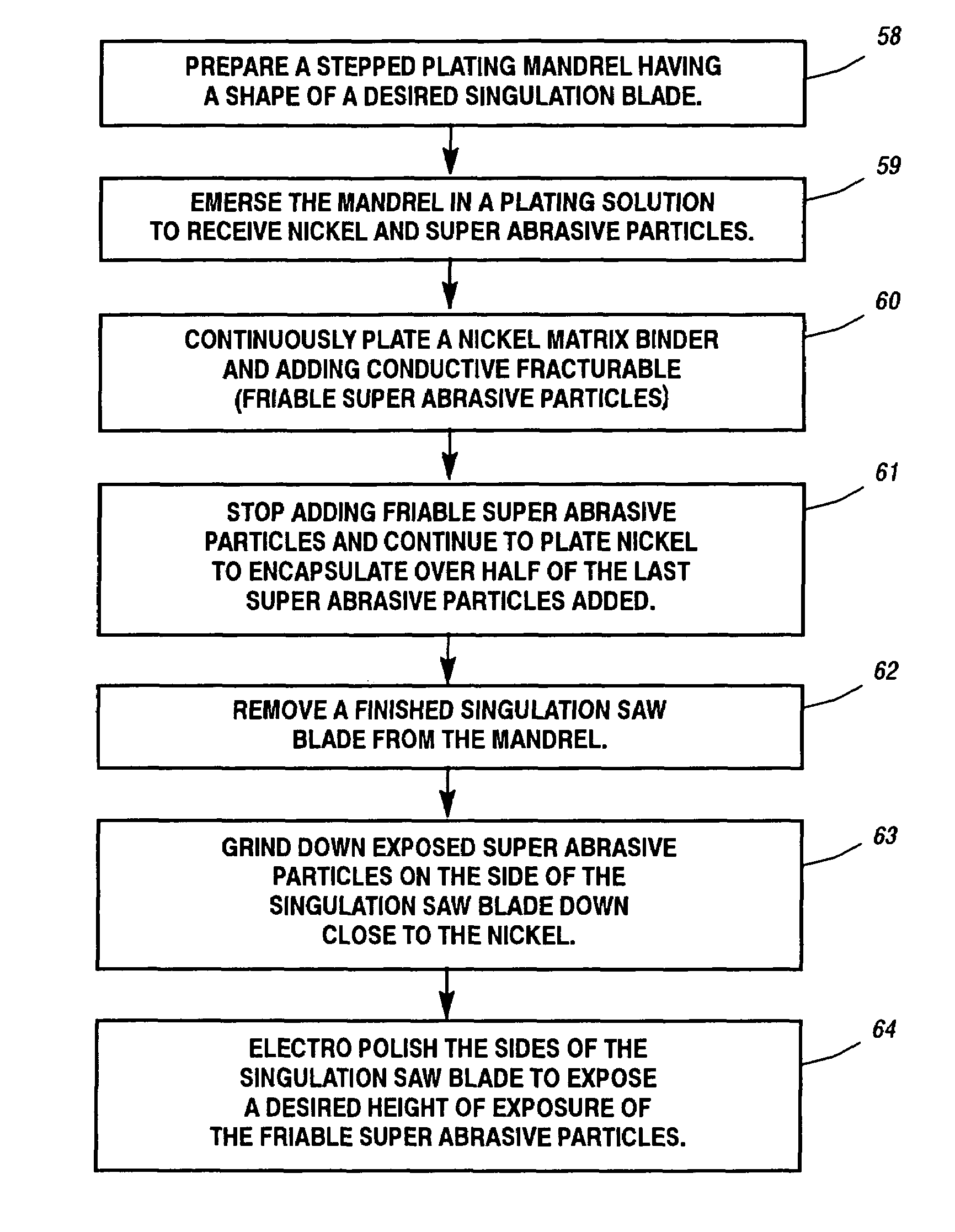

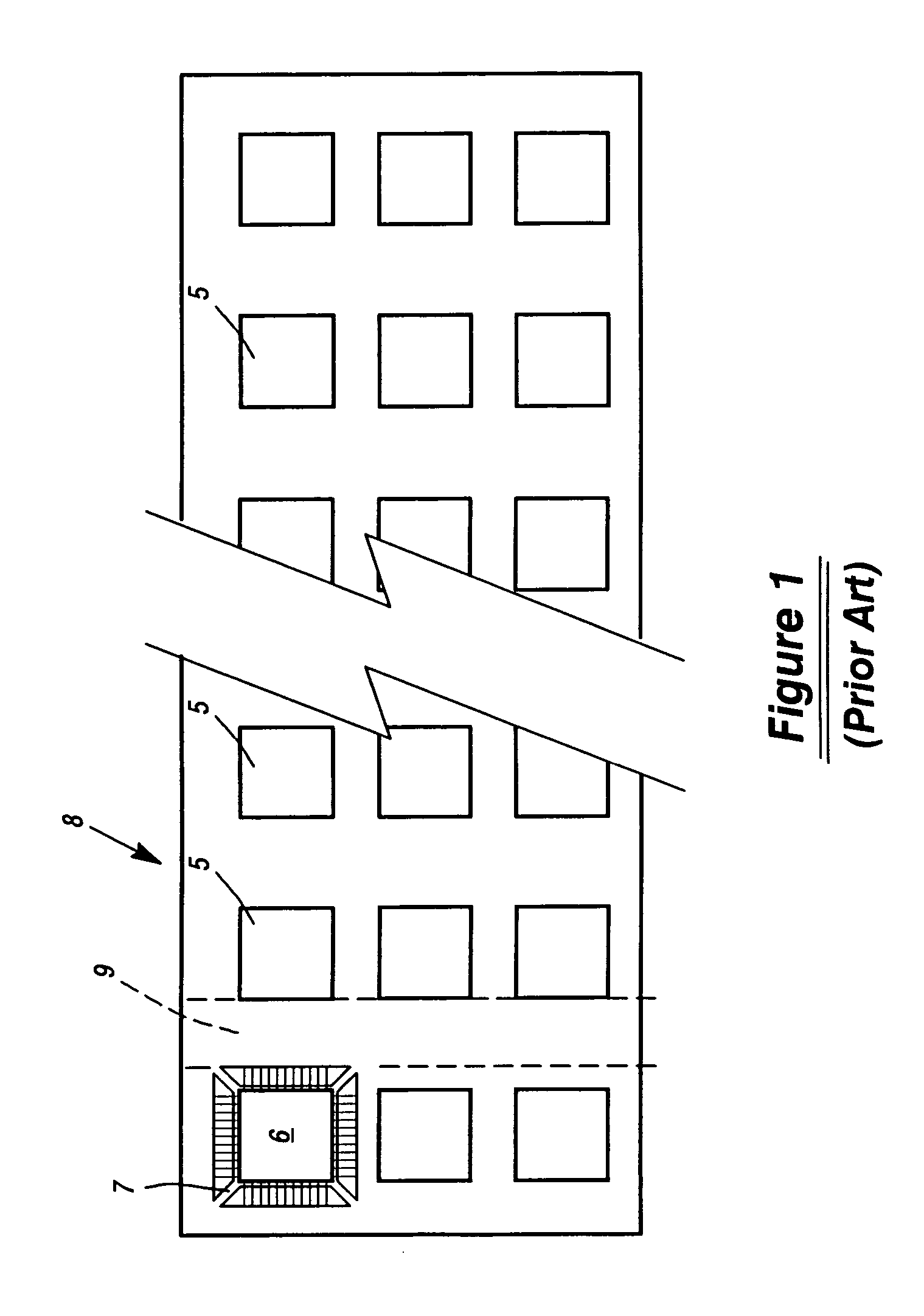

Grindable self-cleaning singulation saw blade and method

InactiveUS20050178241A1Quick cutStrong holdPigmenting treatmentOther chemical processesElectro polishingKnife blades

A super abrasive impregnated singulation saw blade is made by depositing grindable friable super abrasive particles while electro depositing or electroless depositing a strong binder metal such as nickel on a form or mandrel. The deposited super abrasive on the upper side protrudes from the side of the blade and are ground down to or near the binder metal to plannerize the sides of the saw blade and true and balance the saw blade. Post operations include electro polishing to expose equal amounts of super abrasive on the cutting edge or on all sides. Antifriction particles may be added in the side walls or deposited on the outside.

Owner:SMITH DAVID WALTER +1

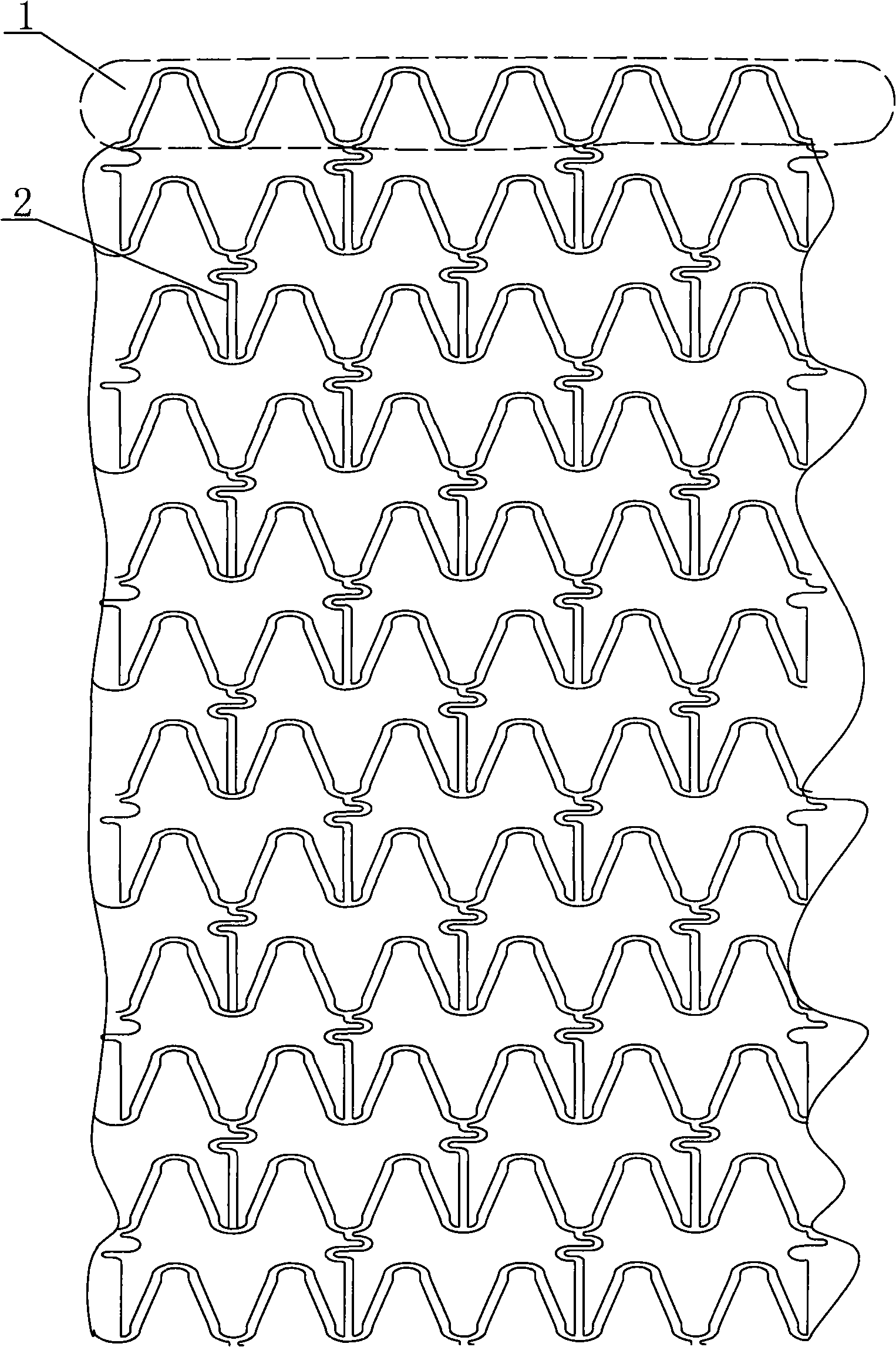

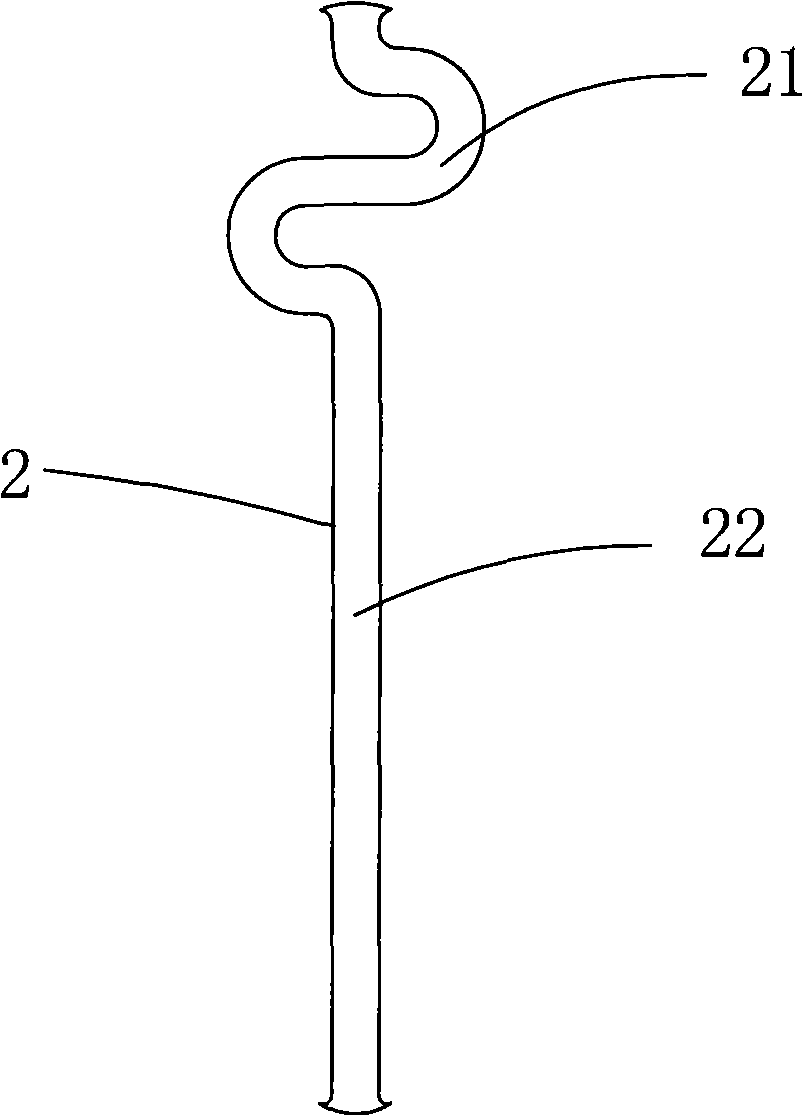

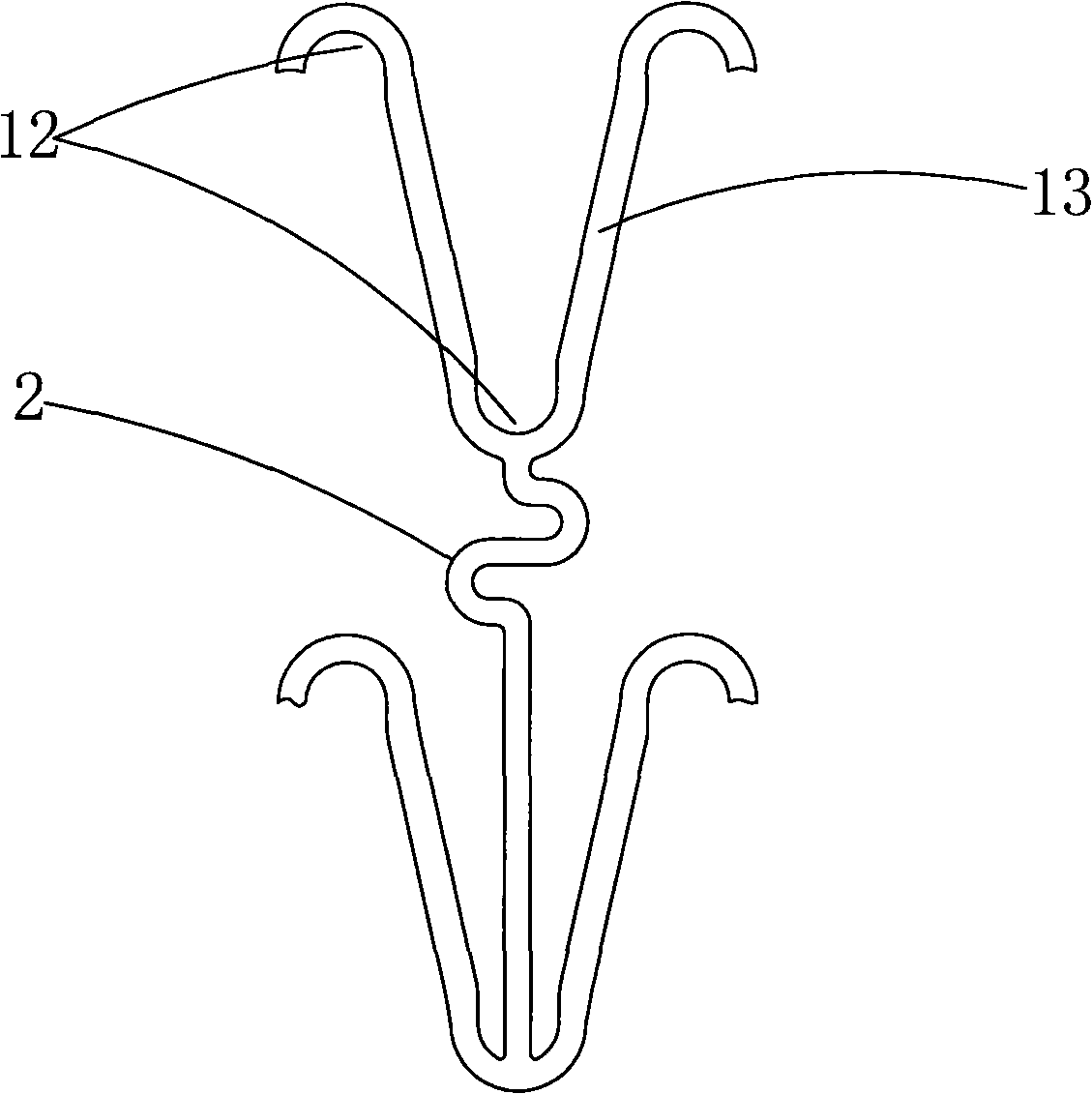

Artery medicine elution bracket

InactiveCN101314059AImprove flexibilitySafe for clinical useStentsSurgeryCurve shapeCobalt chromium alloy

The present invention discloses an artery medicament elution bracket, which is a net-shaped hollow tubular body made by processing a cobalt-chromium alloy with laser engraving and electro-polishing cochrome. The bracket comprises more than one annular-wave-shaped supporting bar and connecting rods which are alternately and spirally connected between the supporting bars. The shape of the connecting rod is an array of waves formed by more than one connected sinusoidal waveform unit, and curve-shaped connected bend angles with different radiuses are positioned at the fold positions of wave crests and the wave troughs of the sinusoidal waveform unit. The shape of the connecting rod is an S-shaped sinusoid section connected with a straight line section. The surface of the bracket is covered by a medicament coating. The fold positioned at the wave crests and the wave troughs of the sinusoidal waveform unit adopt curve-shaped bend angles with unequal radiuses so that the blend pressure of the support bars is reduced, the rebound degree is reduced, and the bracket abscission incidence rate due to the insufficient retentivity is reduced. After being pressed and held, the bracket has a passing outer diameter of between 1 and 1.08mm. The possibility and the operability of the bracket are apparently improved.

Owner:万瑞飞鸿(北京)医疗器材有限公司

Grindable self-cleaning singulation saw blade and method

InactiveUS7086394B2Quick cutStrong holdPigmenting treatmentOther chemical processesElectro polishingMetallic Nickel

A super abrasive impregnated singulation saw blade is made by depositing grindable friable super abrasive particles while electro depositing or electroless depositing a strong binder metal such as nickel on a form or mandrel. The deposited super abrasive on the upper side protrudes from the side of the blade and are ground down to or near the binder metal to plannerize the sides of the saw blade and true and balance the saw blade. Post operations include electro polishing to expose equal amounts of super abrasive on the cutting edge or on all sides. Antifriction particles may be added in the side walls or deposited on the outside.

Owner:SMITH DAVID WALTER +1

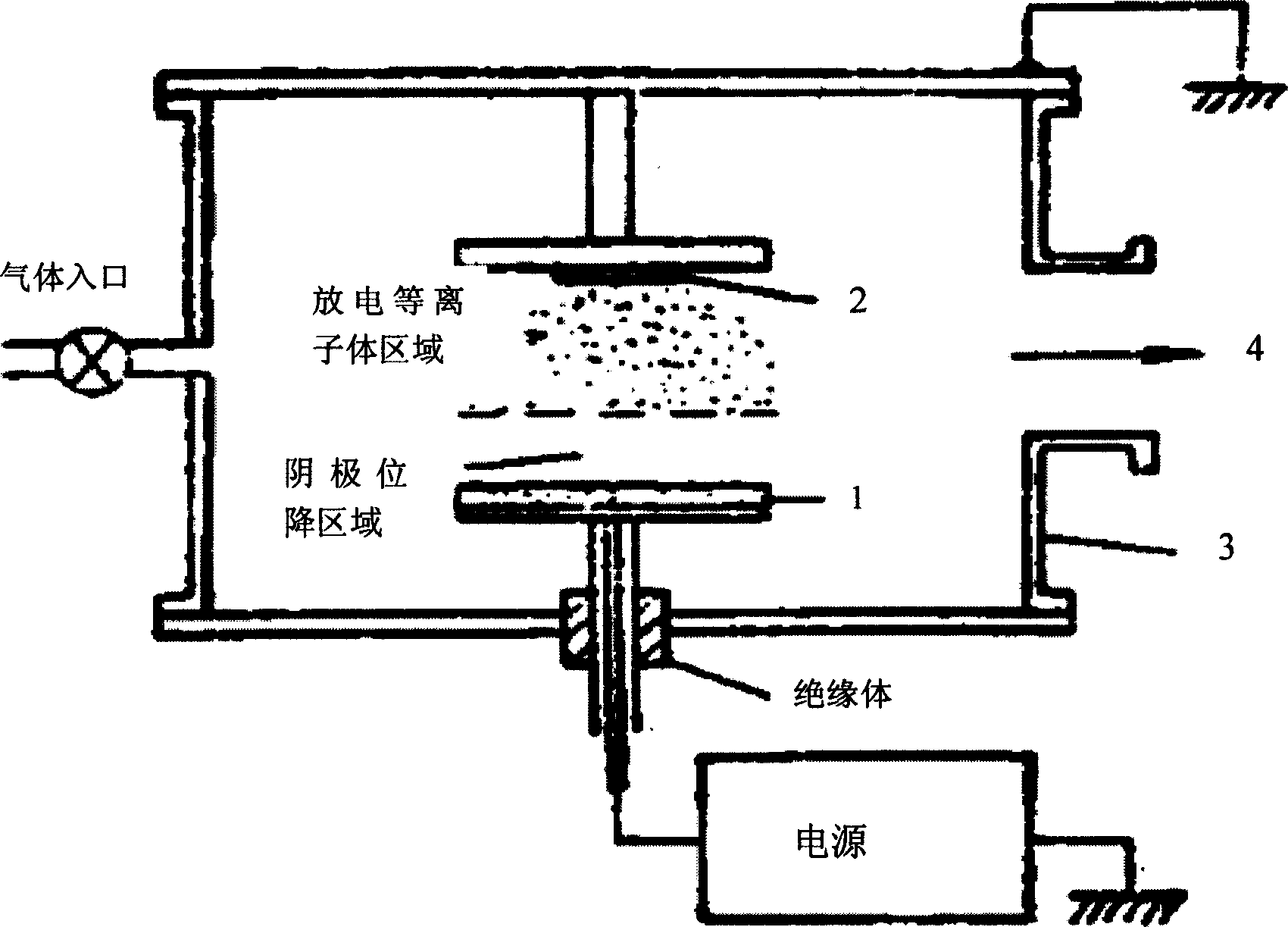

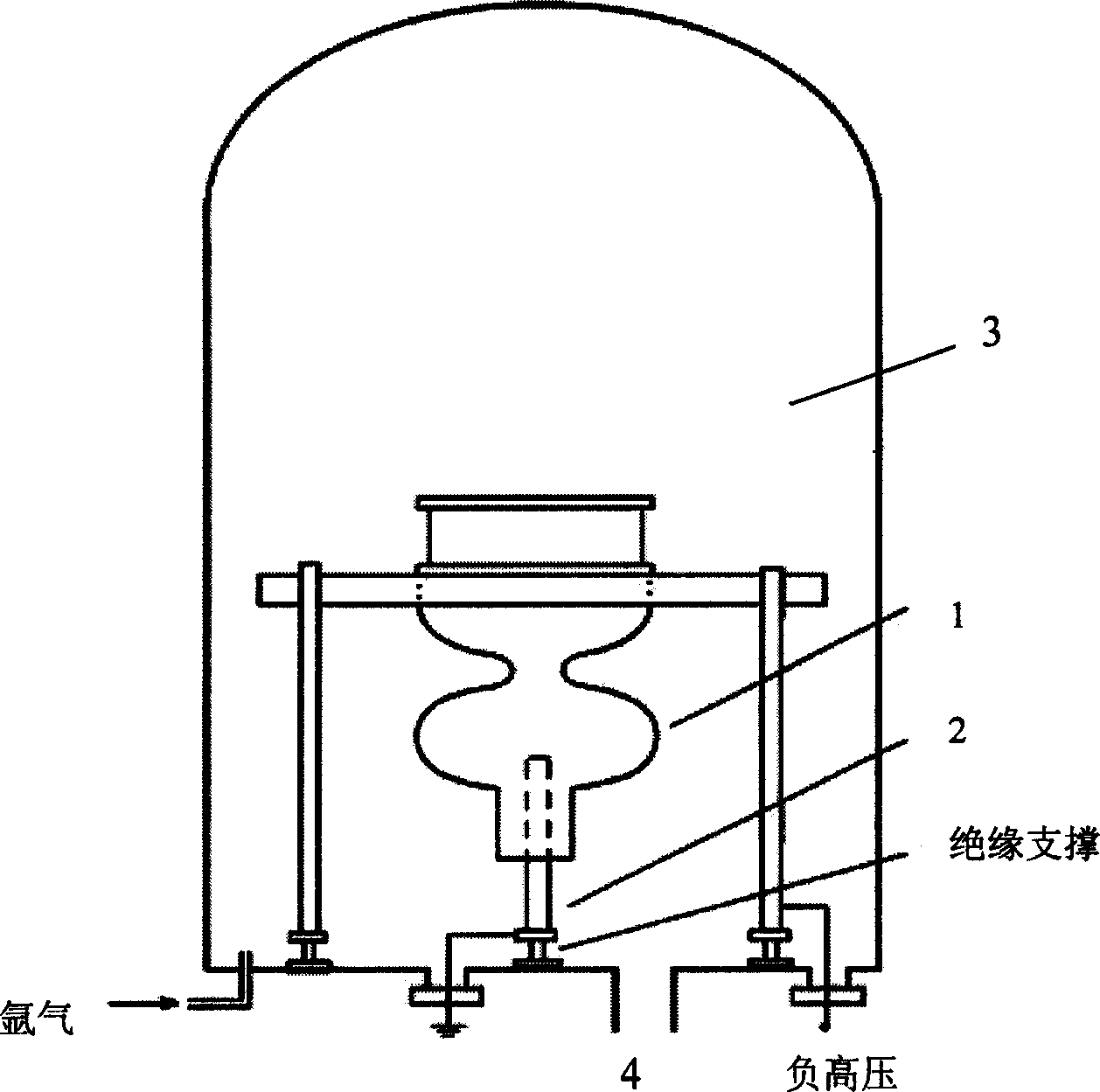

Dry treatment method for superconductor cavity

The invention offers superconducting cavity dry type processing method. Its features are that the superconducting cavity is used as cathode; substrate is used as anode; inert gases is ionized in vacuum; the surface of the superconducting cavity is processed sputtering by plasma; the substrate is metal or alloy with the function of adsorbing gas. Compared with chemical polishing and electro-polishing, it has the advantages of clean, no acid harm, no pollution, simple structure, and easy control. In addition it offers MP practice for superconducting cavity at room temperature to limit cavity MP.

Owner:PEKING UNIV

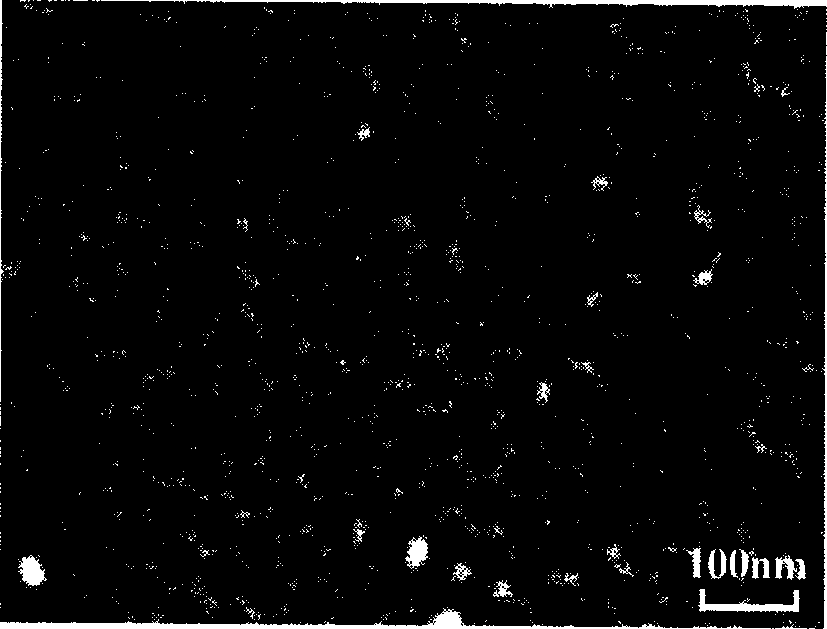

Multi-scale cantilever structures having nano sized holes and method of preparing the same

InactiveUS7432571B2Improved sensitivity and selectivityIncrease surface areaMaterial analysis using sonic/ultrasonic/infrasonic wavesElectric discharge tubesCantileverElectro polishing

Provided are a multi-scale cantilever structure having nano-sized holes prepared by anodic oxidation and a method of preparing the same. The multi-scale cantilever structure is prepared using anodic oxidation and electro-polishing so that a manufacturing process is simple and a manufacturing cost is inexpensive. In addition, the multi-scale cantilever structure has a porous structure having a plurality of nano-sized holes inside thereof, and thus a surface area of the cantilever structure can be maximized. Therefore, when the cantilever structure is used in a sensor, the sensor can have improved sensitivity and selectivity.

Owner:POSTECH ACAD IND FOUND

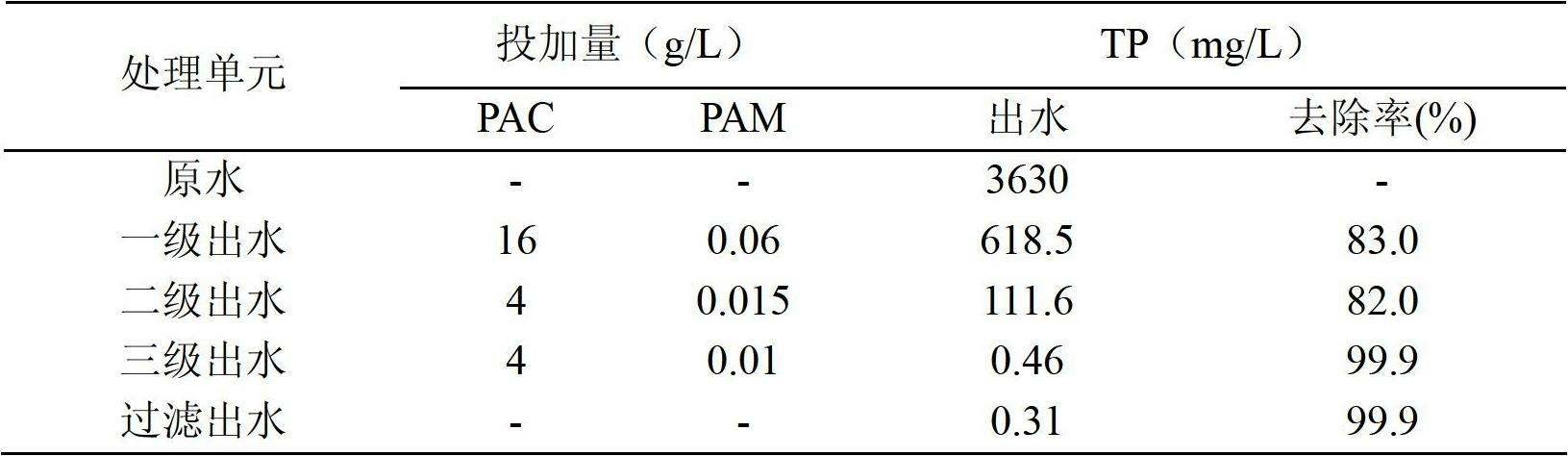

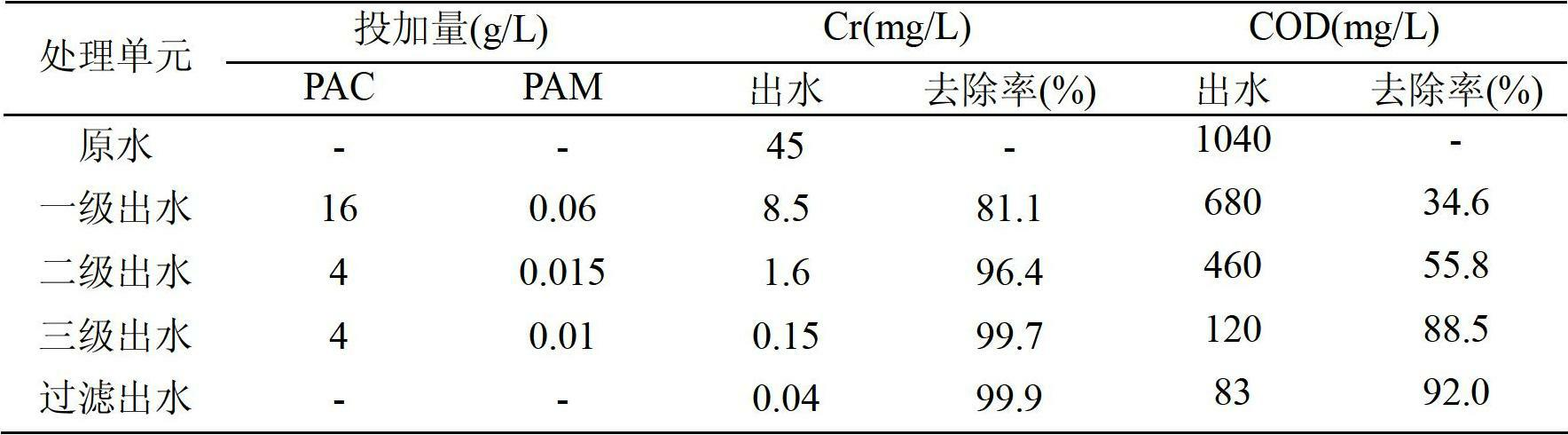

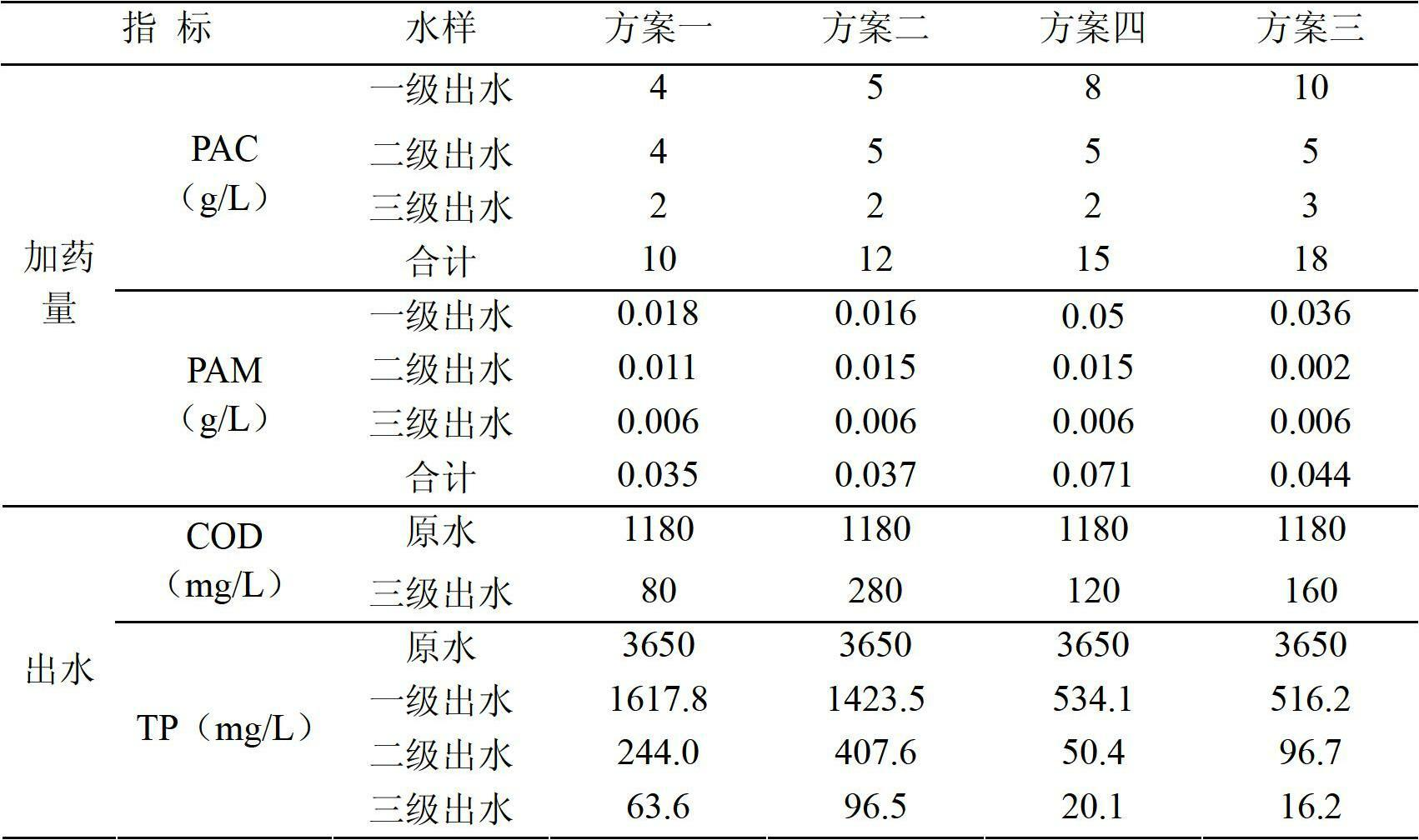

Three-level polyaluminium chloride coagulation treatment method for electro-polishing wastewater

InactiveCN102642901AEfficient removalWaste water treatment from metallurgical processWater/sewage treatment by flocculation/precipitationHigh concentrationThree level

The invention discloses a three-level polyaluminium chloride coagulation treatment process for stainless steel electro-polishing wastewater. By multilevel coagulation treatment, sewage enters an advanced treatment system or is discharged with standards. The test results show that when the three-level polyaluminium chloride coagulation treatment method is adopted for treating high-concentration phosphor-containing electro-polishing wastewater, the concentrations of total phosphorous (TP), chemical oxygen demand (COD) and total chromium (total Cr) in the effluent can respectively reach 0.46, 120 and 0.15 mg / L, and the removal rates are respectively 99.94%, 88.5% and 99.6%. The three-level polyaluminium chloride coagulation treatment method has the characteristics that the operation is simple, various heavy metal ions, COD and TP can be efficiently removed at the same time, and the like; and the three-level polyaluminium chloride coagulation treatment method is also applicable to treating other like high-concentration phosphor-containing wastewater.

Owner:南京特克赛环保科技有限公司

Edge bead removal by an electro polishing process

A method and apparatus for the removal of a deposited conductive layer along an edge of a substrate using an electrode configured to electro polish a substrate edge are disclosed. The electro polishing of the substrate edge may occur simultaneously during electrochemical mechanical processing (Ecmp) of a substrate face. In one embodiment, a power source applies a bias between the substrate and at least two electrodes. The electrodes form a first electrode zone proximate the substrate edge at a sufficient potential to electro polish the substrate edge, thereby removing the conductive layer from the substrate edge. A second electrode zone with a lower potential than the first electrode zone is aligned proximate the substrate face during processing to enable Ecmp of the substrate face.

Owner:APPLIED MATERIALS INC

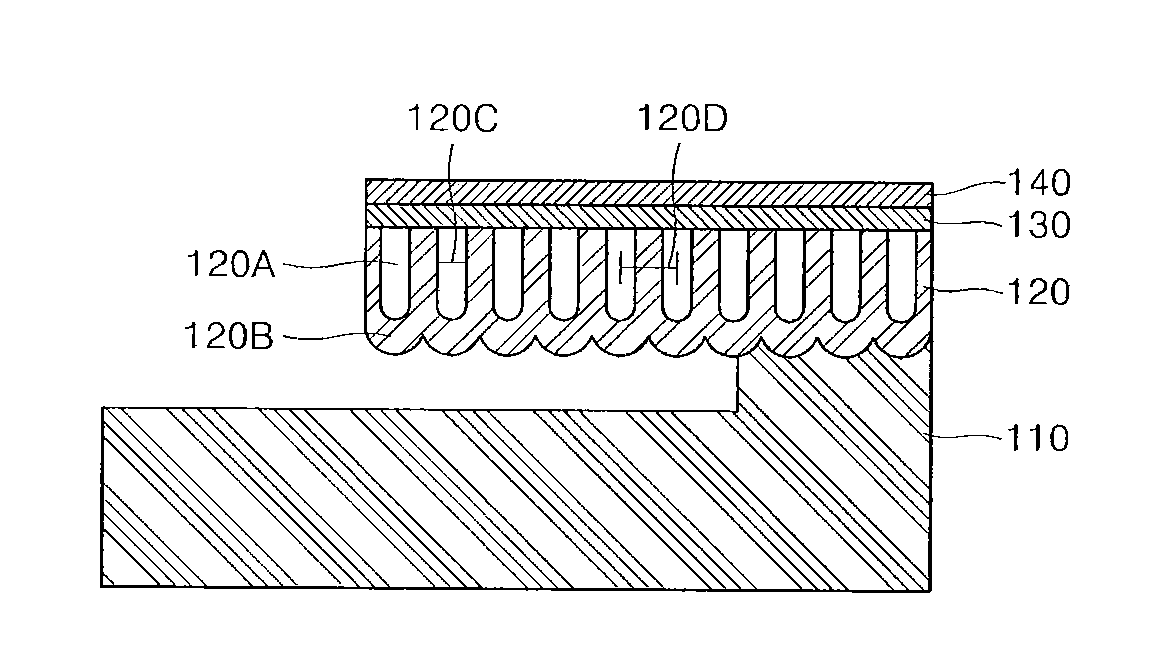

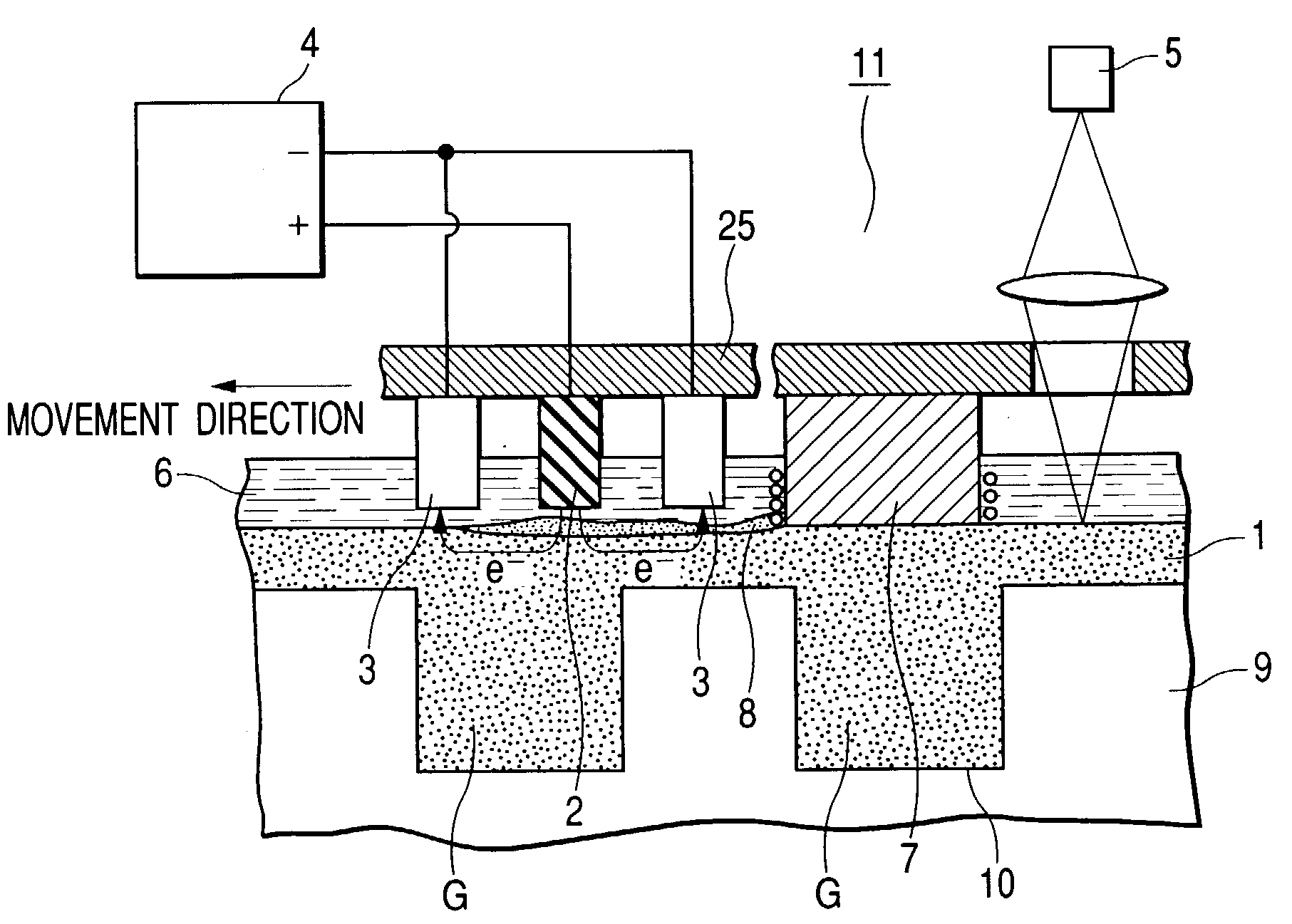

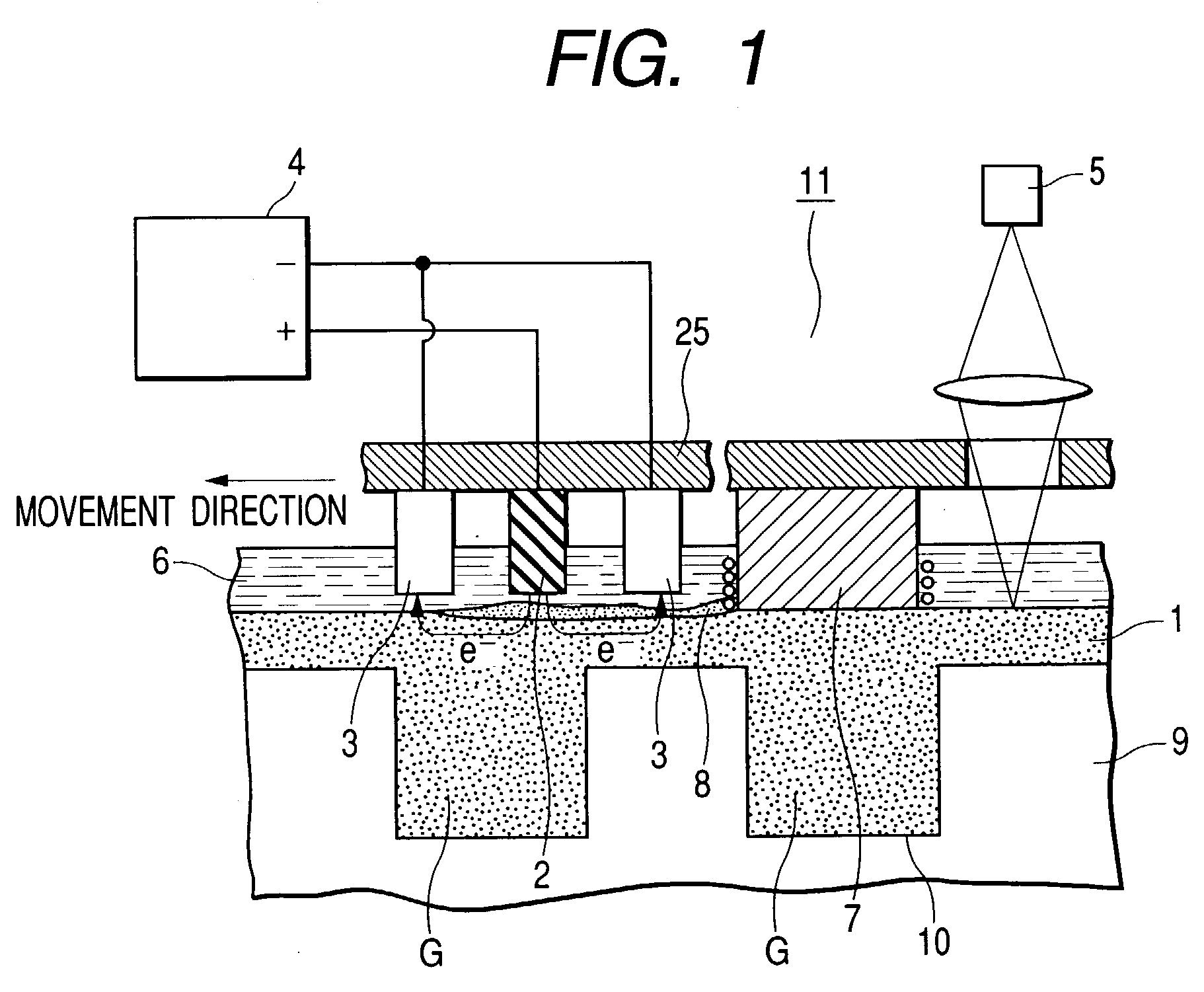

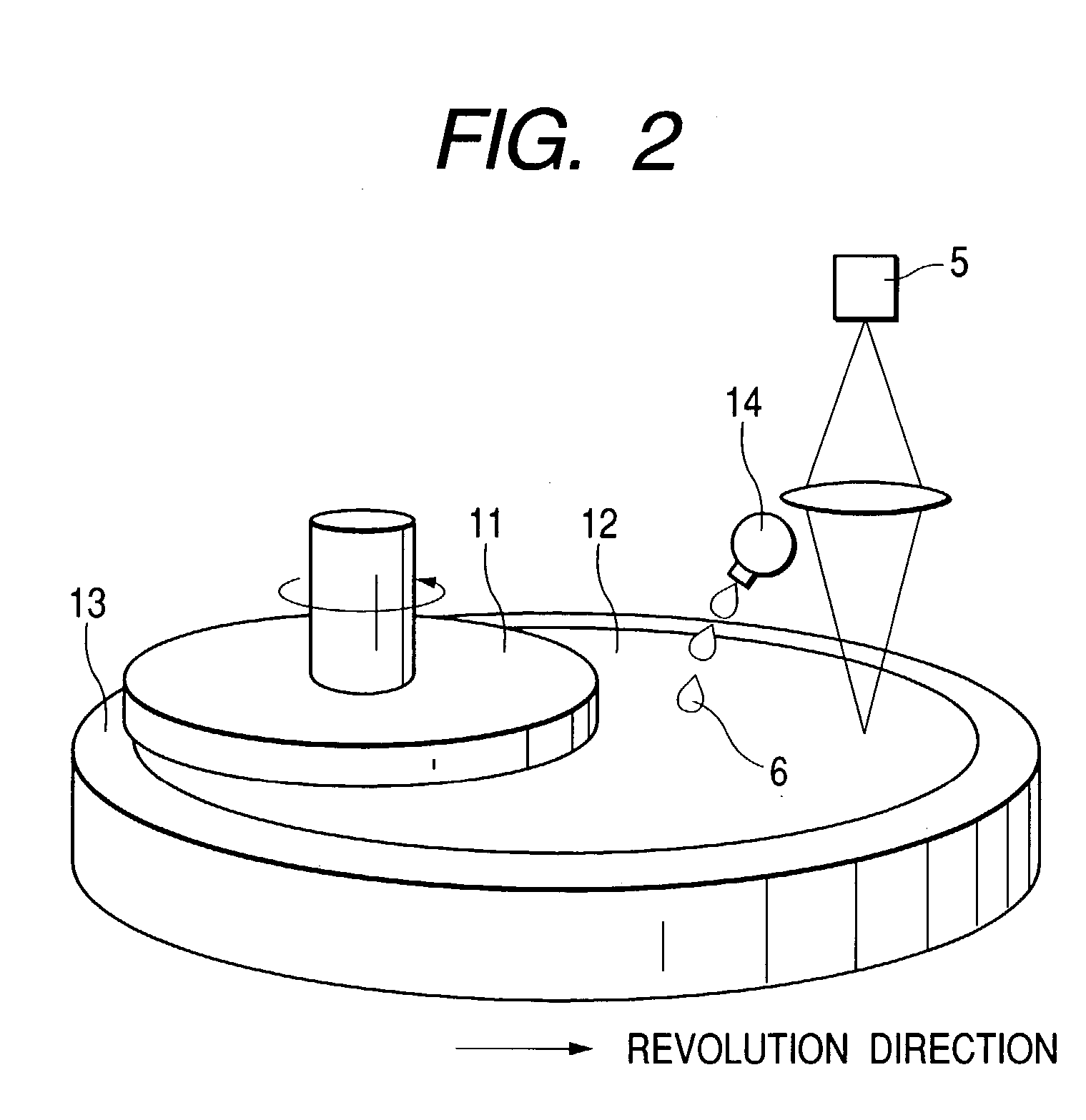

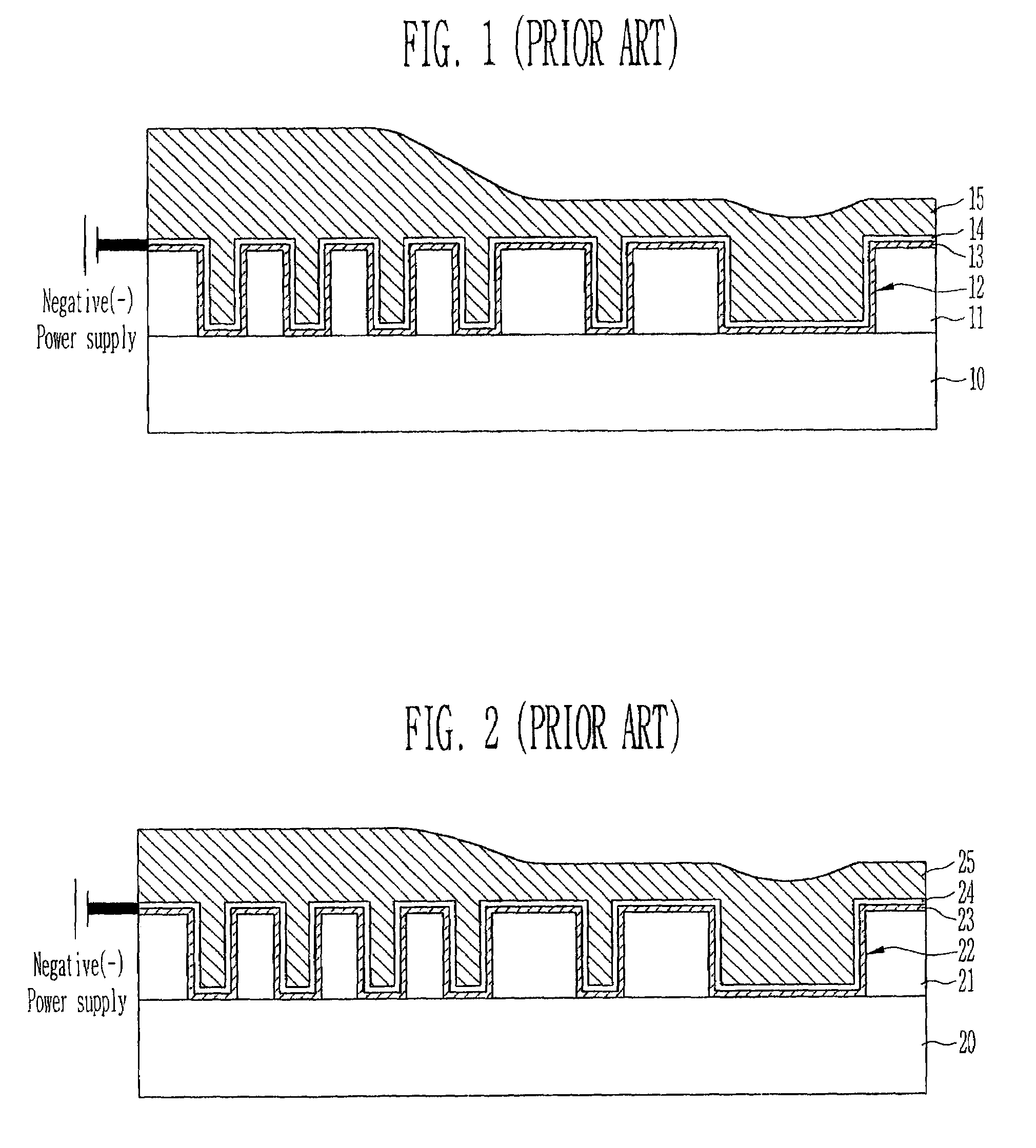

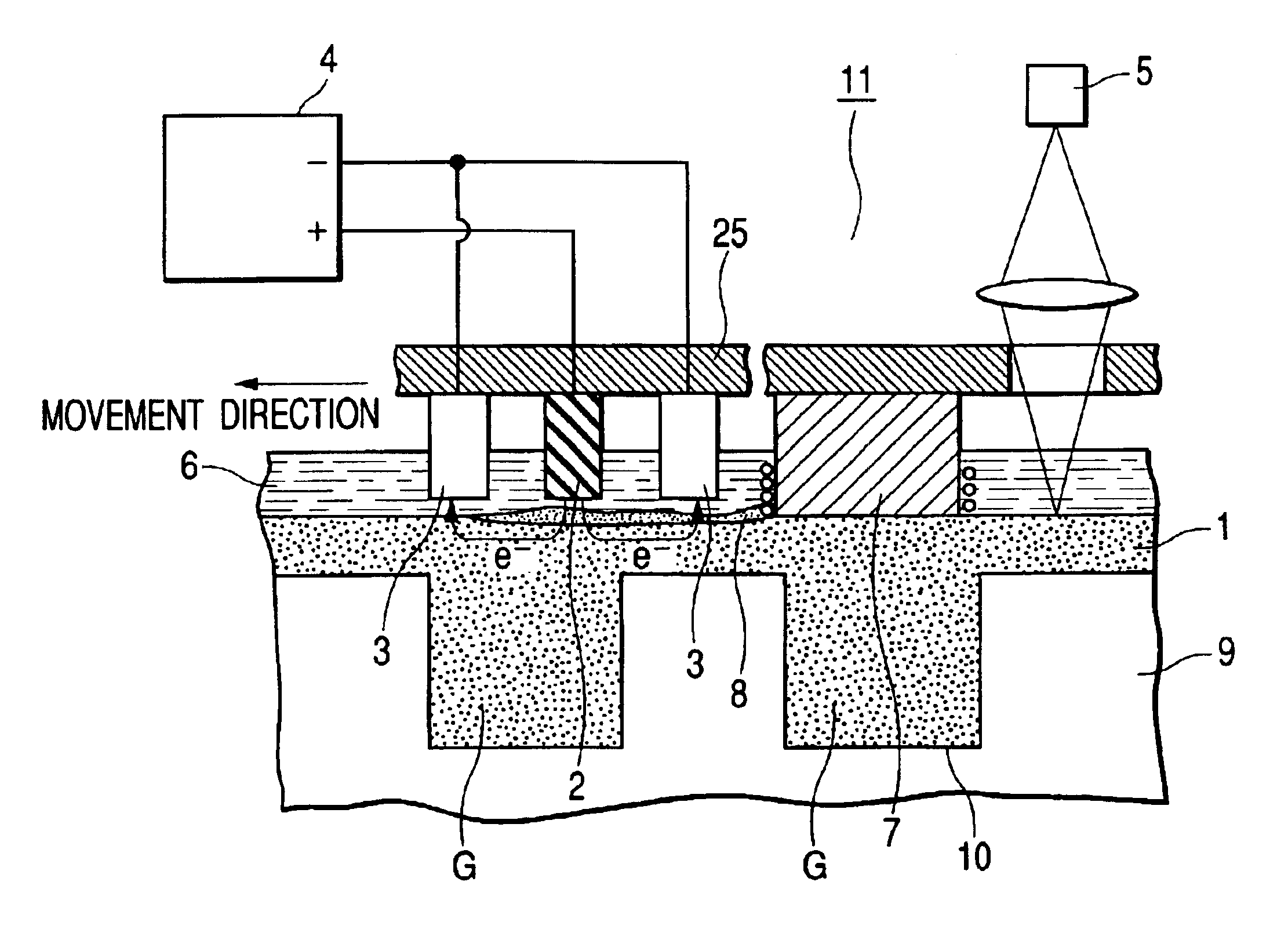

Method for manufacturing semiconductor device and apparatus for manufacturing thereof

InactiveUS20040043608A1Reliable interconnect structureStable structureElectrolysis componentsSemiconductor/solid-state device manufacturingCopper-wiringEngineering

The object of the invention is to provide a method of manufacturing a semiconductor device and a processing apparatus for planarization wherein to form copper wiring in multiple layers. The removal of a residue of polishing by local electro polishing, the enhancement of the performance of planarization by using a grindstone and the reduction by small frictional force in electro polishing of damage, are enabled. To achieve the object, the following measures are taken. A residue of polishing of copper is removed by combining the detection of a local area including the residue of polishing of copper and local processing for electro polishing. As small-load processing for planarization is enabled by using electro polishing, multilayer interconnection structure using low-k material as a dielectric interlayer is also enabled. Plural pairs of small unit electrodes in a pair of which minus electrodes surround a plus electrode are provided to a tool for electro polishing, each electrode is connected to a power supply, pulse voltage is applied to each electrode and copper is electrolytically polished.

Owner:RENESAS ELECTRONICS CORP

Method and apparatus for refurbishing turbine components

A refurbishing method, refurbishing apparatus and refurbished article are provided. The refurbishing method includes accessing a plurality of rotatable components attached to a turbine assembly, the turbine assembly being a portion of a turbomachine, providing a predetermined volume of a buffered electrolytic solution in an electro-polishing tank, coupling the plurality of rotatable components to a power supply, immersing an immersion portion of at least one of the plurality of rotatable components in the buffered electrolytic solution, passing an electrical energy through the immersion portion of at least one of the plurality of rotatable components while the immersion portion is immersed in the buffered electrolytic solution, wherein an electrical flux to the immersion portion electro-polishes the immersion portion, separating the immersion portion from the buffered electrolytic solution, and applying a corrosion inhibitor to the plurality of rotatable components.

Owner:GENERAL ELECTRIC CO

Method of forming copper wiring in a semiconductor device

InactiveUS7098133B2Excellent characteristicsImprove reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesCopper platingCopper-wiring

Owner:KEY FOUNDRY CO LTD

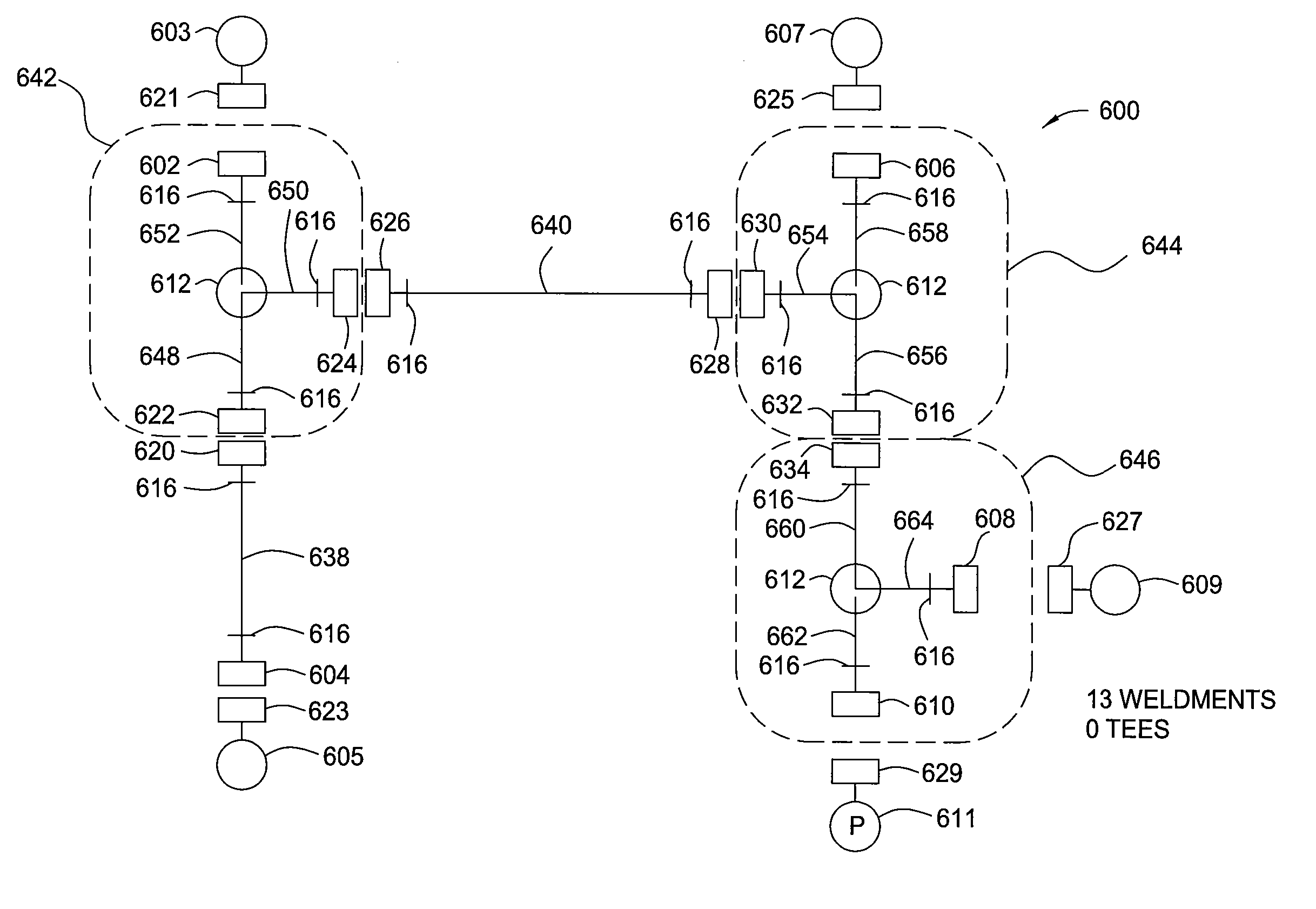

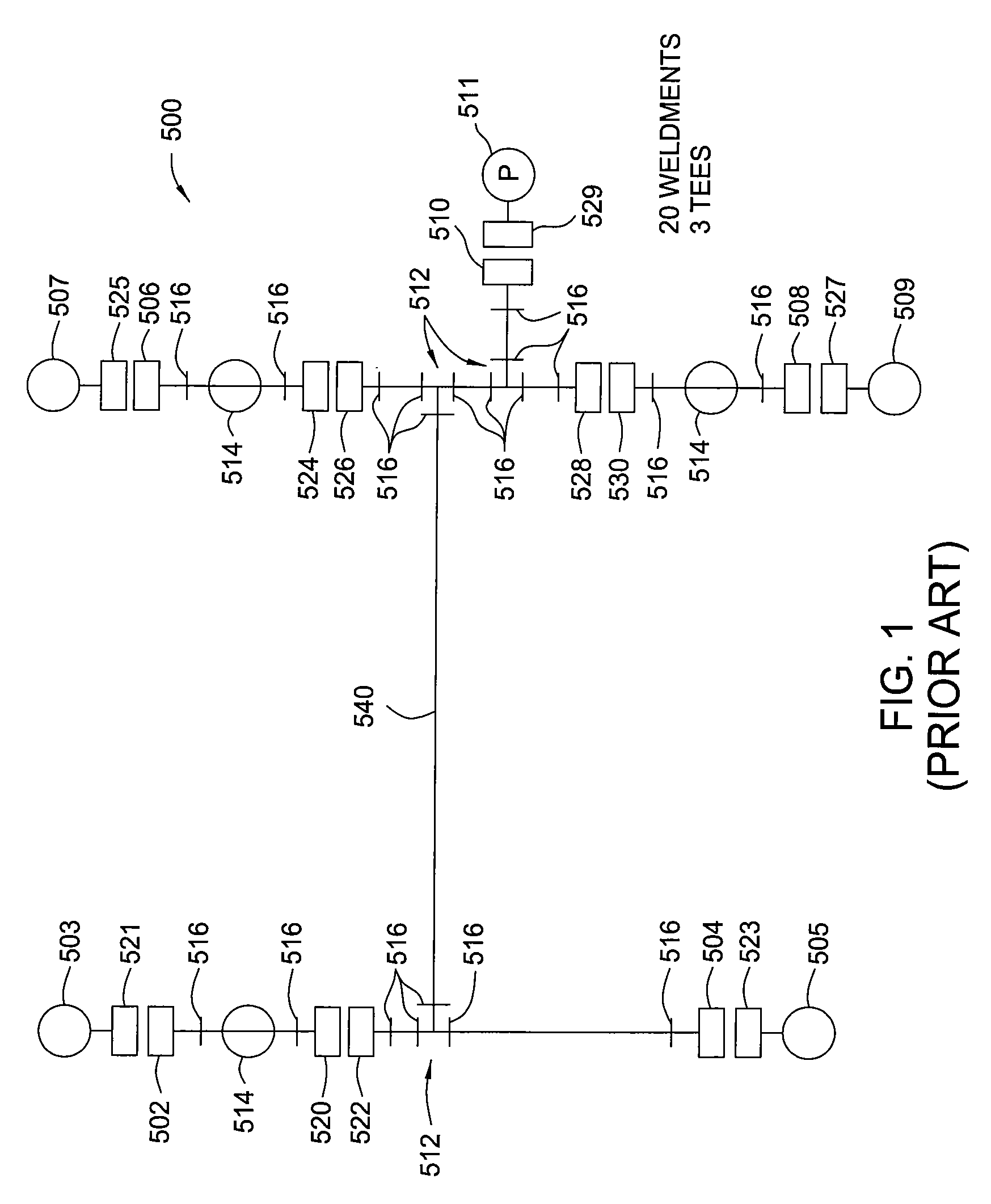

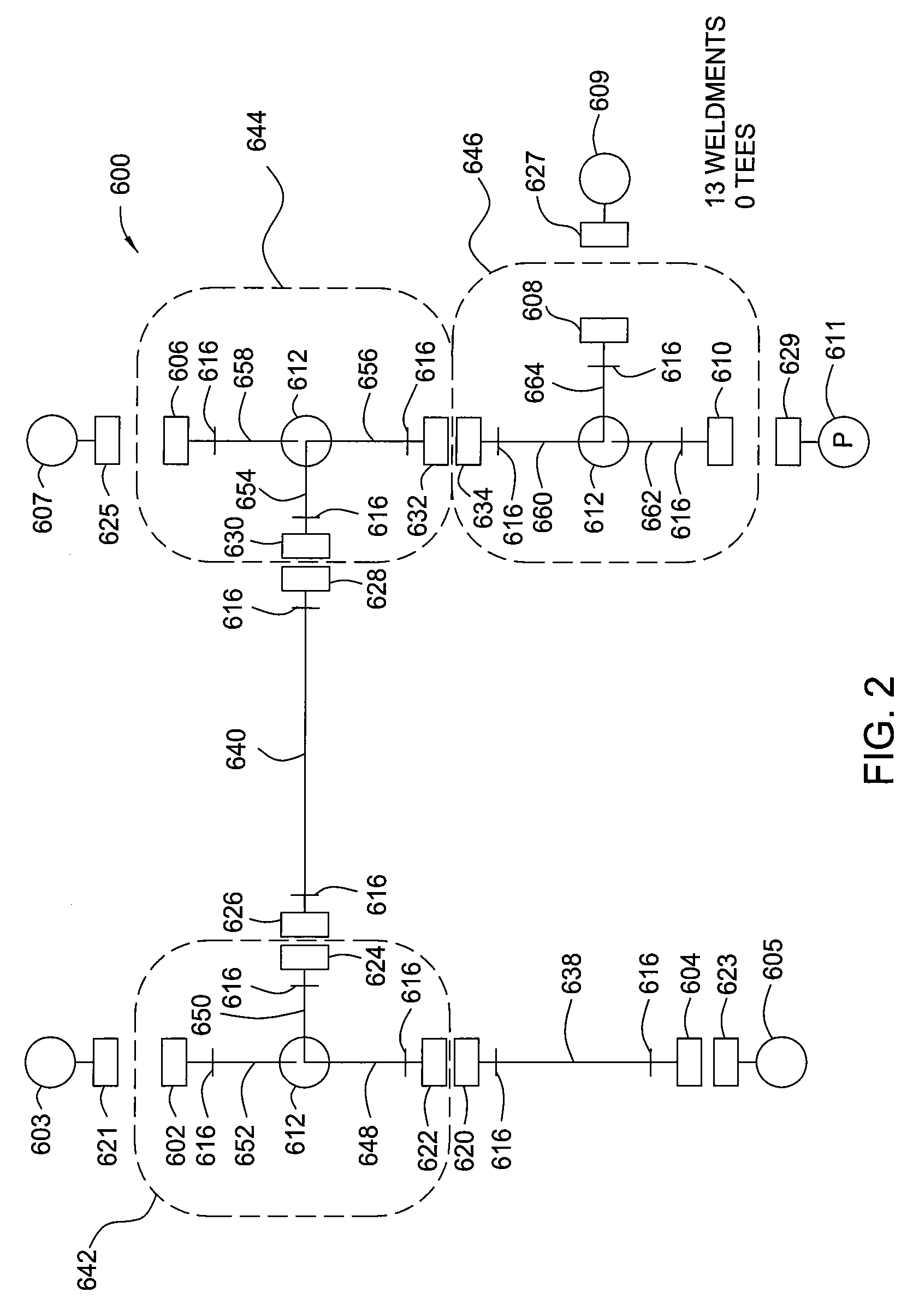

Gas line weldment design and process for CVD aluminum

InactiveUS20070023144A1Reduce particle pollutionEasily electropolishedDecorative surface effectsVacuum evaporation coatingElectrolysisLine tubing

A system of gas lines for a processing chamber and a method of forming a gas line system for a processing chamber are provided. The system of gas lines includes electropolished multi-way valves that connect electropolished linear gas lines. By using multi-way valves rather than tee-fittings and electropolishing the linear gas lines, the nucleation of contaminating particles in the system of gas lines may be reduced.

Owner:APPLIED MATERIALS INC

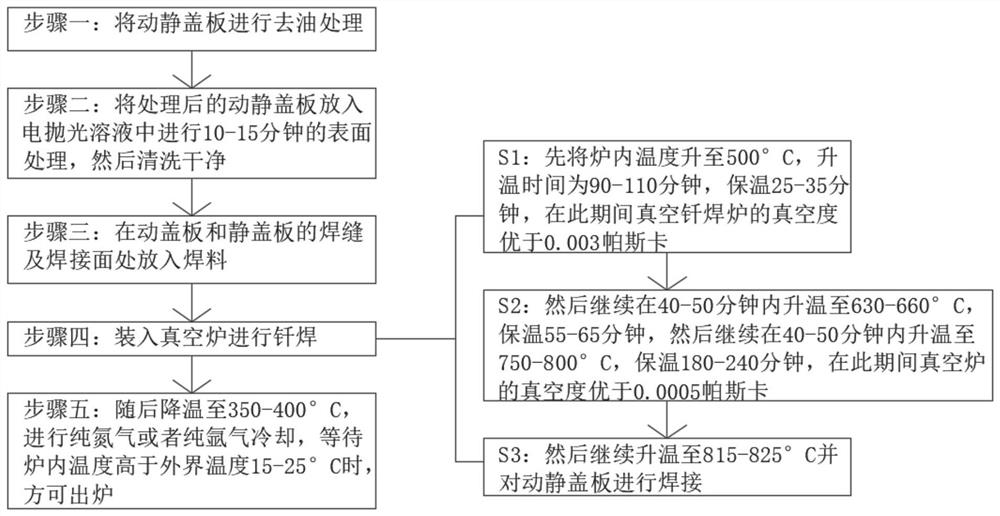

Welding process of movable cover plate and fixed cover plate of vacuum arc-extinguishing chamber

InactiveCN103464854AReduce processingReduce the cost of burning nickelSoldering apparatusEngineeringWeld seam

The invention provides a welding process of a movable cover plate and a fixed cover plate of a vacuum arc-extinguishing chamber. The welding process comprises the steps of A, carrying out deoiling treatment on the movable cover plate and the fixed cover plate; B, placing the movable cover plate and the fixed cover plate in an electropolishing solution for being subjected to surface treatment for 10-15 minutes, and then cleaning; C, placing welding flux at the welding seams and the welding surface of the movable cover plate and the fixed cover plate; D, loading the movable cover plate and the fixed cover plate into a vacuum brazing furnace for brazing; E, afterwards, dropping the temperature to 350-400 DEG C for pure nitrogen cooling or pure argon cooling, and tapping off until the temperature in the furnace is higher than the outside temperature for 15-25 DEG C. The welding process has the advantages that due to the adoption of a chemical electropolishing technology, quality fluctuation points are avoided, so that the cost of burning nickel is reduced, the sewage disposal is relieved, and the production progress is effectively improved.

Owner:浙江旭虹真空电器有限公司

Algorithm for real-time process control of electro-polishing

Owner:APPLIED MATERIALS INC

Method for manufacturing semiconductor device and apparatus for manufacturing thereof

InactiveUS6908860B2Stable structureElectrolysis componentsSemiconductor/solid-state device manufacturingEngineeringCopper-wiring

The object of the invention is to provide a method of manufacturing a semiconductor device and a processing apparatus for planarization wherein to form copper wiring in multiple layers. The removal of a residue of polishing by local electro polishing, the enhancement of the performance of planarization by using a grindstone and the reduction by small frictional force in electro polishing of damage, are enabled. To achieve the object, the following measures are taken. A residue of polishing of copper is removed by combining the detection of a local area including the residue of polishing of copper and local processing for electro polishing. As small-load processing for planarization is enabled by using electro polishing, multilayer interconnection structure using low-k material as a dielectric interlayer is also enabled. Plural pairs of small unit electrodes in a pair of which minus electrodes surround a plus electrode are provided to a tool for electro polishing, each electrode is connected to a power supply, pulse voltage is applied to each electrode and copper is electrolytically polished.

Owner:RENESAS ELECTRONICS CORP

Method for preparing composite film photoelectrode

The invention discloses a method for preparing a composite film photoelectrode, and the method comprises the following steps of: preparing an electrode matrix: taking platinum-plated titanium conductive glass as an electrode substrate, soaking the electrode substrate in a hydrogen peroxide solution, washing the electrode substrate with water, and performing ultrasonic treatment to form a film electrode layer; then, putting the film electrode layer into a sodium hydroxide solution for ultrasonic treatment, repeatedly carrying out ultrasonic cleaning by using deionized water, and then, drying; finally, electropolishing and ultrasonically washing with water in a sodium hypochlorite electrolytic cell to prepare the electrode matrix, and drying the electrode matrix; and pretreating the electrode matrix: adding graphene into a mixed solution of sodium carboxymethylcellulose and styrene to obtain a coating solution; performing coating solution spin-coating on the electrode matrix, and performing annealing treatment to obtain an electrode preform; and preparing a composite film photoelectrode: preparing an LDH electrode from the electrode preform by using an electro-deposition method, placing the prepared LDH electrode in a muffle furnace, and calcining and air-cooling to prepare an MMO electrode; and preparing an MMO photoelectrode covered by a lead dioxide film by using an electrodeposition method, washing with water, and drying.

Owner:陕西易莱德新材料科技有限公司

Lower alkyl carboxylic acid moieties for preventing oxidative corrosion of metals and organoleptic stabilizer for food and beverages

InactiveUS20080003345A1Altered dielectric propertyMaximize its propertyLiquid surface applicatorsDough treatmentWater vaporCarboxylic acid

Compositions and methods are disclosed for preventing the oxidative corrosion of metal surfaces by exposing a metal surface to an anti-corrosion agent characterized as a lower alkyl carboxylic acid or salts and / or other derivatives that conserve or embody the lower alkyl carboxylic acid moiety present in their molecular structures as an active anti-corrosion agent. The anti-corrosion agent may be used in combination with a material capable of forming a moisture retentive barrier over the metal surface. The compositions and methods of the invention provide a practical, non-toxic way of ensuring anti-corrosion protection for metals, or devices containing exposed metals, stored or operated in water or in the presence of water vapor. Exemplary, non-exhaustive uses of the invention include employing the composition as lubricant for the surface of a metal or as a pump oil or brake fluid; using the composition as an undercoating for painting, electro-plating or electro-polishing procedures; and providing a protective coating for any metal or metal-containing machine or device, form automotive assembly plant metal press machines to electronic circuit boards.

Owner:INTELLECTUAL CONCEPTS

Preparation method for porous aluminium oxide bionic multilayer dewatering surface

InactiveCN105039976AImprove hydrophobicitySimple processSurface reaction electrolytic coatingLiquid/solution decomposition chemical coatingEtchingHeat resistance

The invention relates to preparation of a porous aluminium oxide bionic multilayer dewatering surface, belonging to the field of thin films. The invention aims to solve the technical problems that the current process for preparing a porous aluminium oxide dewatering thin film is relatively complex; the cost is high; and the range of a thin film substrate is limited by the preparation method of chemical etching, so that a preparation method for the porous aluminium oxide bionic multilayer dewatering surface is provided. According to the method, a degreased and processed aluminium sheet is subjected to electropolishing, and then is subjected to oxidation for twice; a prepared aluminium oxide film is soaked; a reducing agent is added; an aired aluminium / argentum oxide multilayer film is soaked in an ethanol solution of perfluorodecanethiol; and then the film is taken out and blow-dried by nitrogen so as to obtain the porous aluminium oxide bionic multilayer dewatering surface. The method is simple in process and low in cost; the prepared porous aluminium oxide dewatering thin film has good heat resistance, chemical stability and high mechanical strength and dimensional stability, and can be widely promoted for use.

Owner:CHANGZHOU SIYU ENVIRONMENTAL PROTECTION MATERIAL SCI & TECH

2, 4-Hexadienoic acid, its alkali salts and/or derivatives for preventing oxidative corrosion of metals

Compositions and methods are disclosed for preventing the oxidative corrosion of metal surfaces by exposing a metal surface to an anti-corrosion agent characterized as 2,4-trans, trans-hexadienoic acid (2,4-HDA), its alkali salt identified as potassium sorbate (KHDA), or other derivatives that conserve or embody the 2,4-trans, trans-hexadiene-type moiety present in their molecular structures as an active anti-corrosion agent (ACA), in combination with a material capable of forming a moisture retentive barrier over the metal surface. The compositions and methods of the invention provide a practical, non-toxic way of ensuring anti-corrosion protection for metals, or devices containing exposed metals, stored or operated in water or in the presence of water vapor. Exemplary, non-exhaustive uses of the invention include employing the composition as a lubricant for the surface of a metal or as a pump oil or brake fluid; using the composition as an undercoating for painting, electro-plating or electro-polishing procedures; and providing a protective coating for any metal or metal-containing machine or device, from automotive assembly plant metal press machines to electronic circuit boards.

Owner:INTELLECTUAL CONCEPTS

Electropolishing method for cylindrical stainless steel thin-walled bellows

ActiveCN109594120BHigh glossMeet tolerance requirementsMetallic material coating processesDistilled waterSS - Stainless steel

The invention belongs to the technical field of aerospace surface treatment and particularly relates to an electropolishing method for a cylindrical stainless steel thin-wall corrugated pipe. The electropolishing method comprises the following steps that 1, degreasing treatment is conducted on a stainless steel corrugated pipe blank; 2, acid pickling treatment is conducted on the corrugated pipe degreased in the step 1; 3, the corrugated pipe obtained after acid pickling in the step 2 is clamped; 4, electropolishing treatment is conducted on the corrugated pipe clamped in the step 3; 5, passivating treatment is conducted on the corrugated pipe obtained after electropolishing in the step 4; and 6, after electropolishing, the surface is cleaned with distilled water and is dried through blowing. According to the shape of the compensator corrugated pipe, a special clamping tool and an inner cathode are prepared, meanwhile technological parameters are adjusted again, and electropolishing production is conducted with special bath solution. The electropolishing method is used, the inner and outer surfaces of the polished corrugated pipe are good in glossiness, the thickness and roughnessmeet tolerance requirements, and the surfaces are free of pit or spot phenomenon.

Owner:CAPITAL AEROSPACE MACHINERY +1

Method for coating silicon nitride film layer on piston ring surface

InactiveCN100588738CEasy to useImprove wear resistancePiston ringsMachines/enginesLubricationPollution

The invention discloses a method for applying a silicon nitride film layer on the surface of a piston ring. The method comprises the following steps of: electro-polishing and ultrasonic-cleaning the piston ring; disposing the cleaned piston ring in RF plasma-enhanced chemical vapor deposition equipment, vacuumizing the system to 5*10<-3> Pa, reacting in the presence of silicane and ammonia gas asreaction gas resource at a deposition temperature of 300 to 500 DEG C and RF power of 90 to 150 W for 10 to 30 min to deposit the silicon nitride film on the upper surface and the side surface of thepiston ring, wherein the a flow rate of the silicane is 15 to 45 sccm and the flow rate ratio of the silicane to the ammonia gas is 1 / 2 to 1 / 4; and naturally cooling and taking out. The surface hardness of the piston ring deposited with the silicon nitride film layer is 900 to 1,400 HV, which is far higher than the hardness 800 HV of common chromium-plated products. The film layer has good corrosion resistance, abrasion resistance and self-lubrication characteristic, thus effectively improving the use performance of the piston ring, and improving the operation stability and prolonging the service life. The method overcomes the disadvantages of conventional chromium-plated piston ring such as larger energy consumption, serious pollution and complex process.

Owner:ZHEJIANG SCI-TECH UNIV

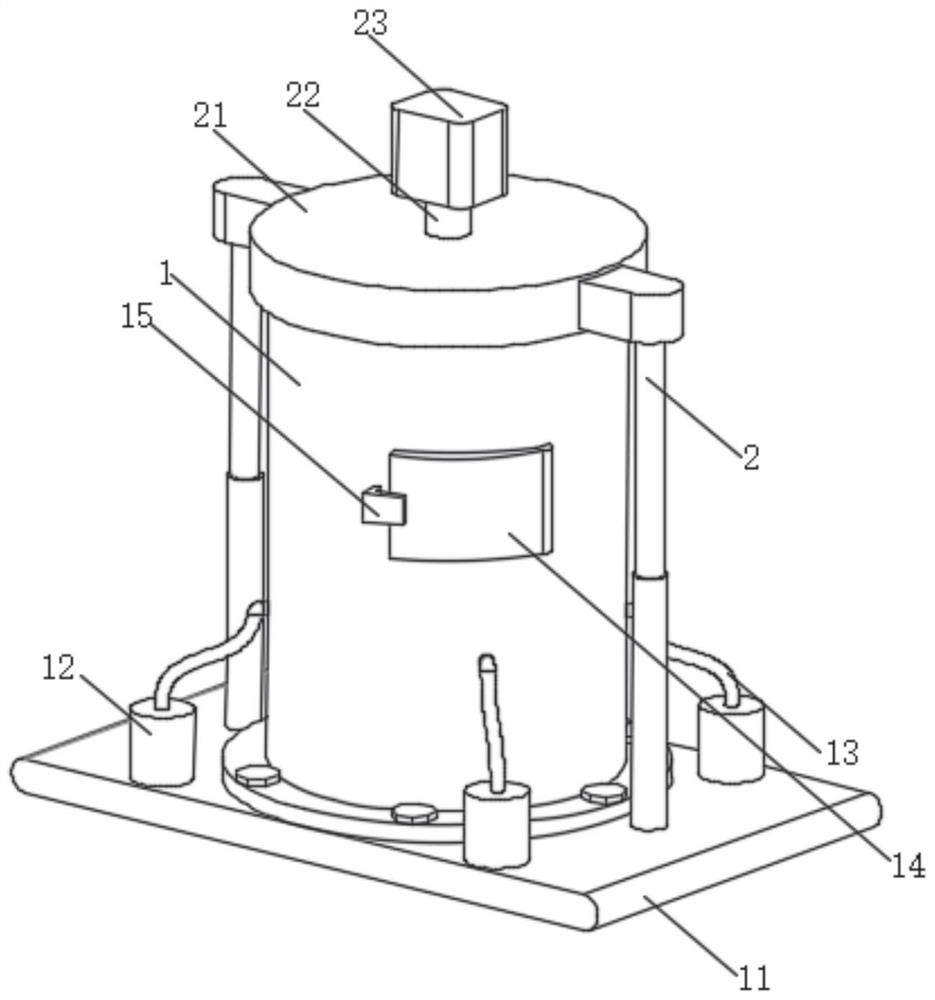

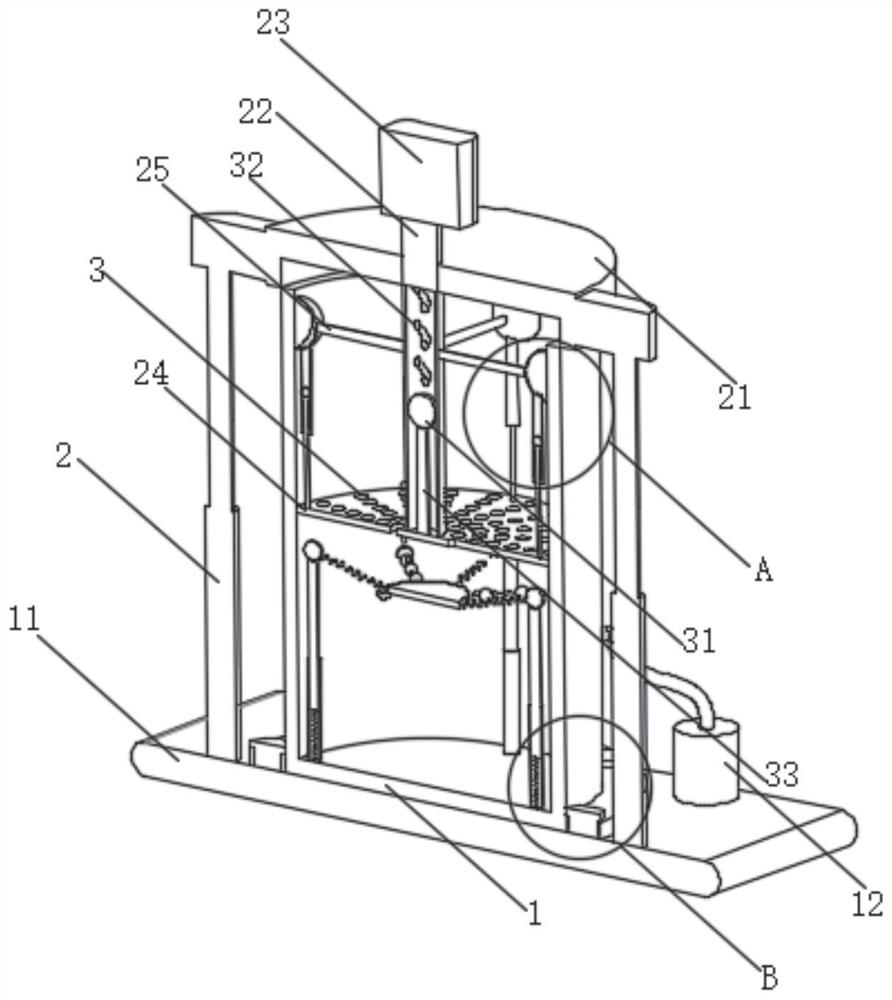

Welding process and welding device of vacuum furnace

InactiveCN114850603ATo achieve the purpose of solder weldingEvenly heatedMetal working apparatusSoldering auxillary devicesRotational axisElectric machinery

The invention discloses a welding process and a welding device for a vacuum furnace. The welding process comprises the following steps: step 1, deoiling a movable cover plate and a static cover plate; secondly, the treated movable and static cover plates are put into an electropolishing solution to be subjected to surface treatment for 10-15 minutes, and then the movable and static cover plates are cleaned up. When a worker places the treated movable and static cover plates on a placing plate in the furnace body, a motor is started to enable the placing plate to rotate under the action of a rotating shaft; meanwhile, a heating pipe and an air suction cylinder are started, the interior of the furnace body can be in a vacuum state through starting of the air suction cylinder, high temperature can be generated in the furnace body through starting of the heating pipe, and therefore the purpose of welding the welding flux between the movable cover plate and the static cover plate is achieved; in this state, compared with a traditional static state, the movable cover plate and the static cover plate can be heated evenly, and therefore the welding effect of the device can be enhanced.

Owner:韶山恒升机械工业有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com