System and method of anodized aluminum oxide nano-porous membrane preparation

a technology of anodized aluminum oxide and nanoporous membrane, which is applied in the direction of electrolytic coating, surface reaction electrolytic coating, duplicating/marking methods, etc., to achieve the effect of reducing the wastage of al substra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

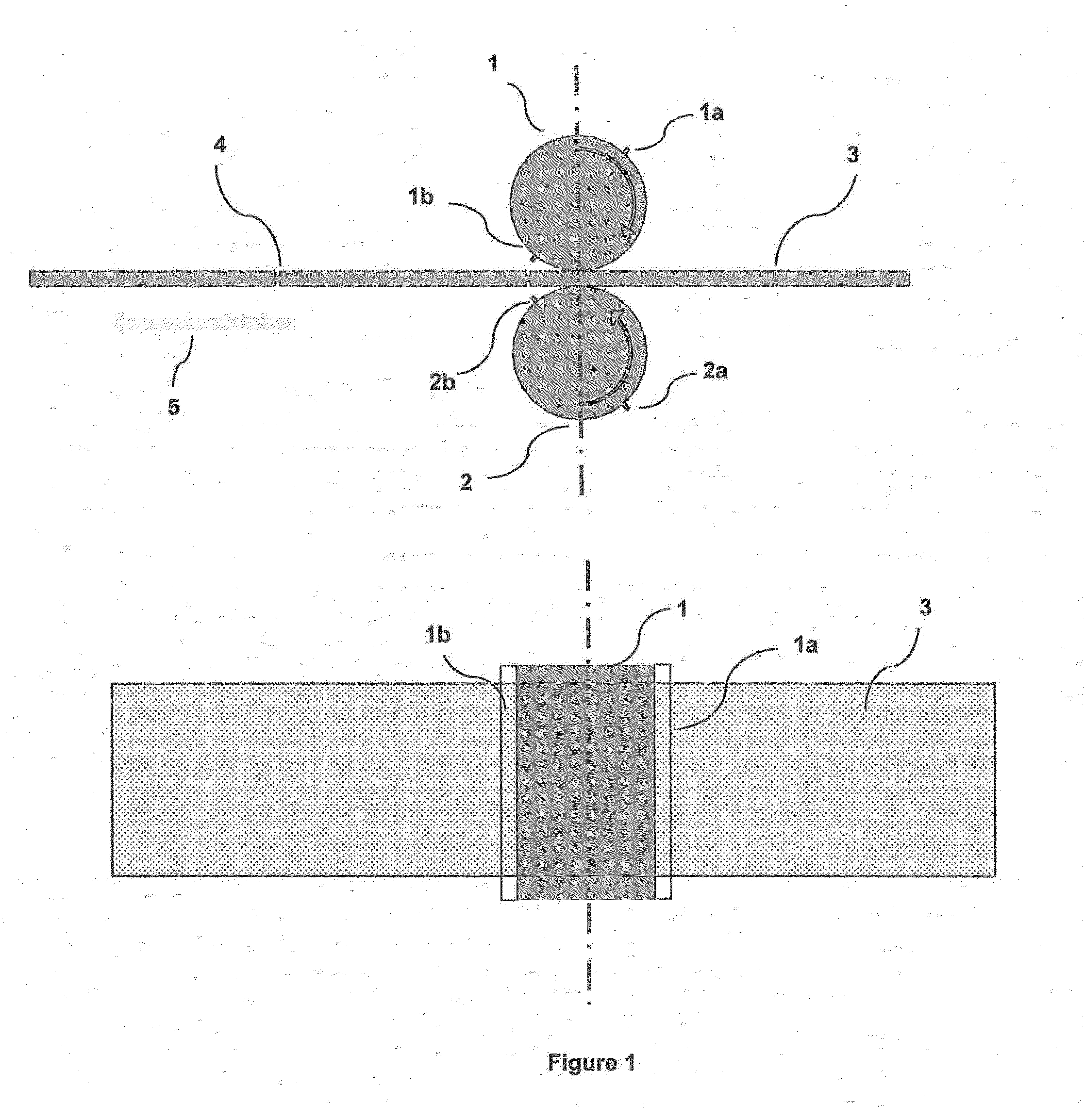

[0108]As illustrated in FIG. 6(a), Al block 60 is used as a substrate to establish the aspect of the invention of using cracks at the edges to produce membranes from the five faces of the said substrate. One of the ends 61 is used as electrode in the anodization process. The said substrate 60 is treated using method of the present invention comprising steps of electro polishing of Al substrate, first step anodization, chemical etching of the alumina, second stage anodization and etching Al for separation of alumina and barrier layer as elaborated in the description of the invention.

[0109]FIG. 6(b) represents schematically the aspect of Al substrate 62 and formation of AAO and development of the crack 64 at the edge. FIG. 6(c) depicts SEM image of the said substrate 60 after anodization wherein cracks 64 at the edges are observed. Further AAO 63 on the surfaces of the said substrate are observed in this SEM image. FIG. 6(d) depicts the magnified image of the AAO surface 63 (exploded ...

example 2

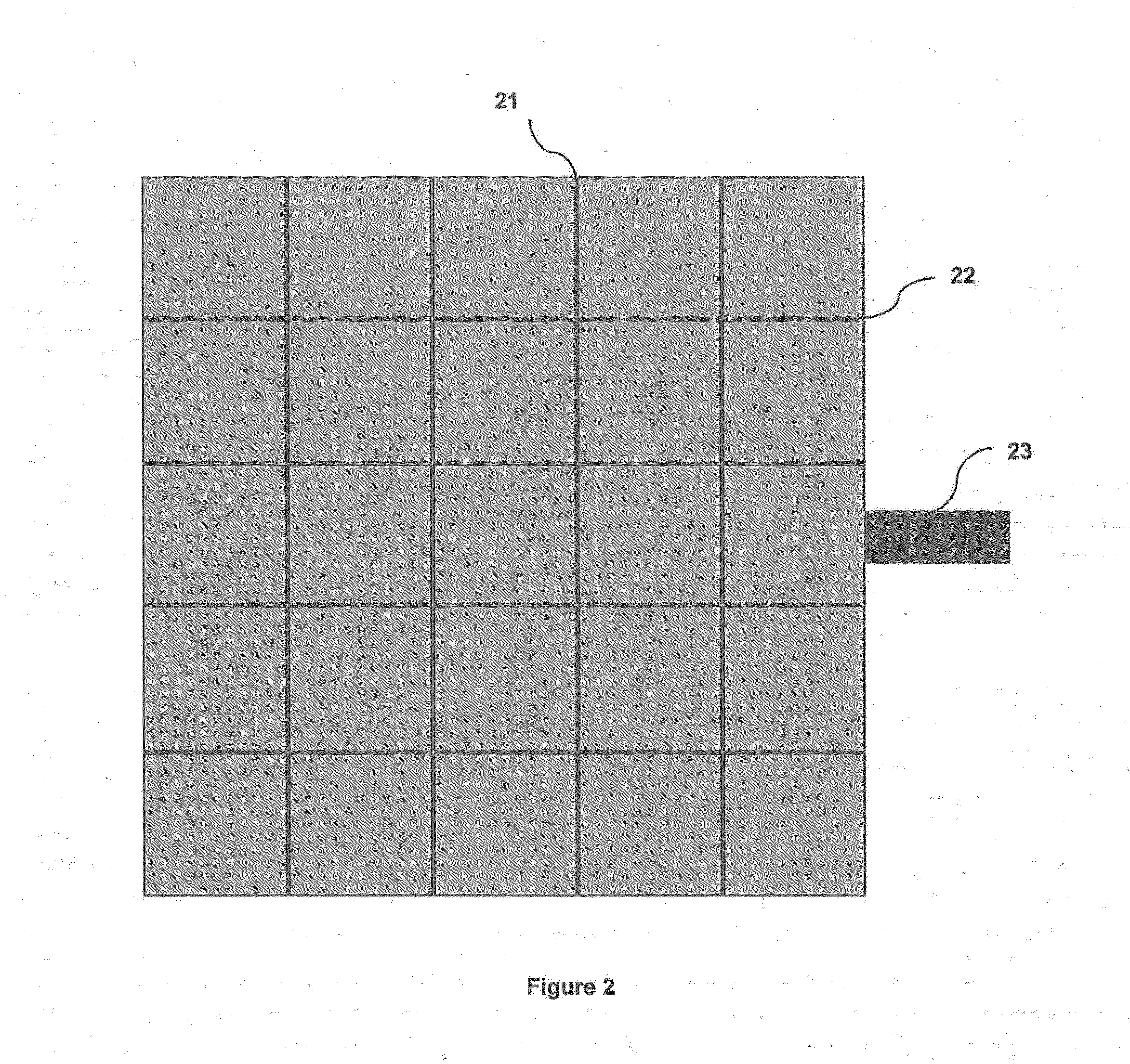

[0111]Using the method of the present invention, three dimensional nano-porous tubular membranes are obtained.

[0112]FIG. 7(a) depicts SEM image of the nano-porous tubular membrane. The FIG. 7(b) depicts image of the top surface plane membrane separated from tubular membrane. The rectangle in the image indicates the cut edge of the top plane membrane magnified image of which is depicted in FIG. 7(c). Further the FIG. 7 (d) indicates the blown up image of the portion indicated by rectangle in FIG. 7(c). The pores 70 of AAO as well as the barrier layer 71 are seen in FIG. 7(d).

example 3

[0113]Using the method of the present invention, nano-porous membranes are obtained. The Al substrate used in this non-limiting example is 99.999% pure. The characterization at each of the process stages is depicted in FIG. 8.[0114]The surface SEM result of 99.999% pure electro-polished Al is depicted in FIG. 8(a). The process of electro polishing results in the removal of micro size roughness from the said Al substrate surface. However nano size random pits can be seen in this image. These nano size pits causes the initiation of pores in first step of anodization.[0115]In first step of anodization the AAO forms with random pores as shown in FIG. 8(b). These pores initiates in nano pits or concave surfaces on the Al substrate surface. As these pores propagate inside (in the form of a nano-channel) the substrate some of the pores proceed and some are blocked. Pores are further arranged in hexagonal order with substantially equal distance from each other.

[0116]The AAO formed in first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com