Patents

Literature

429results about "Work manipulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

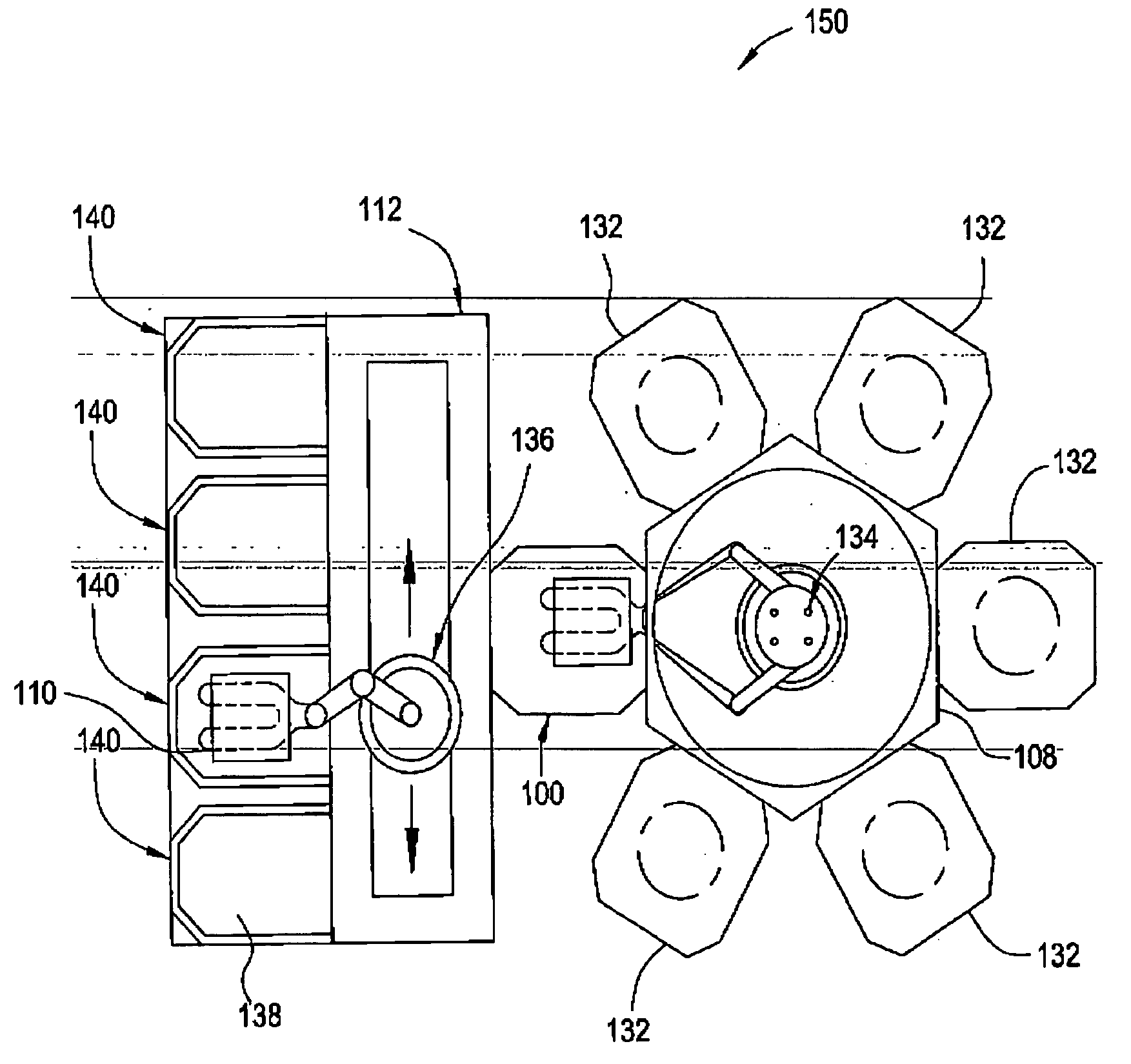

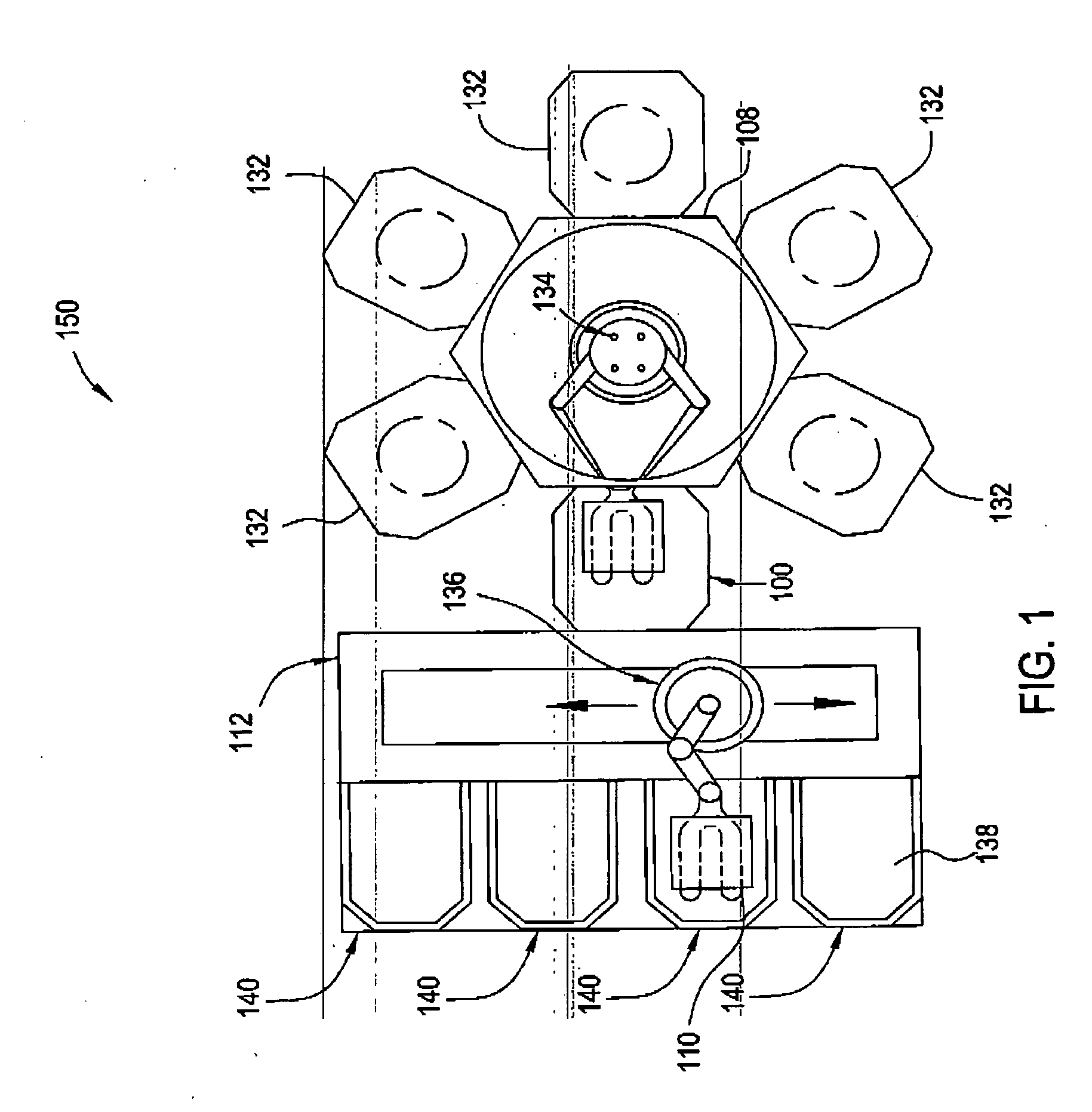

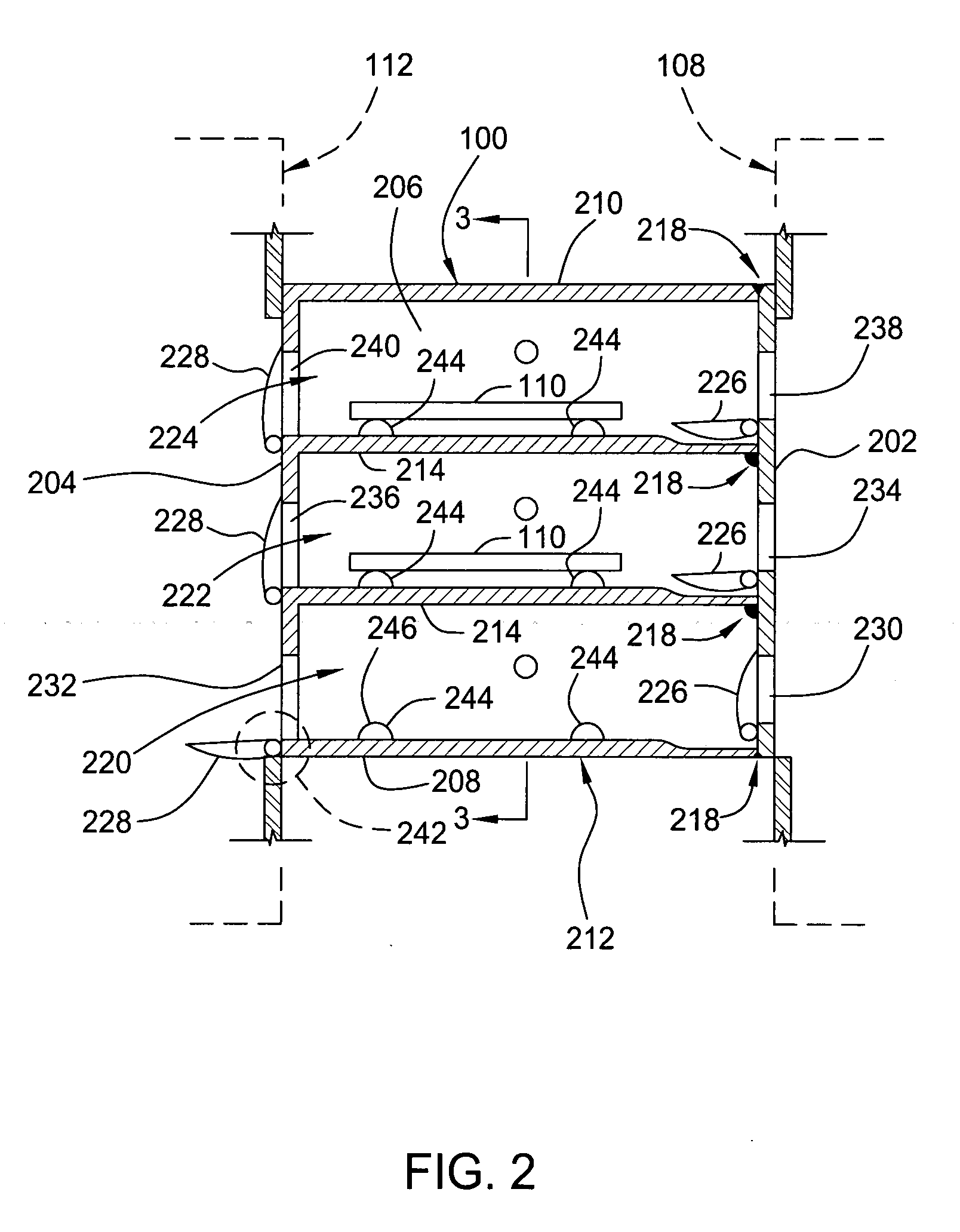

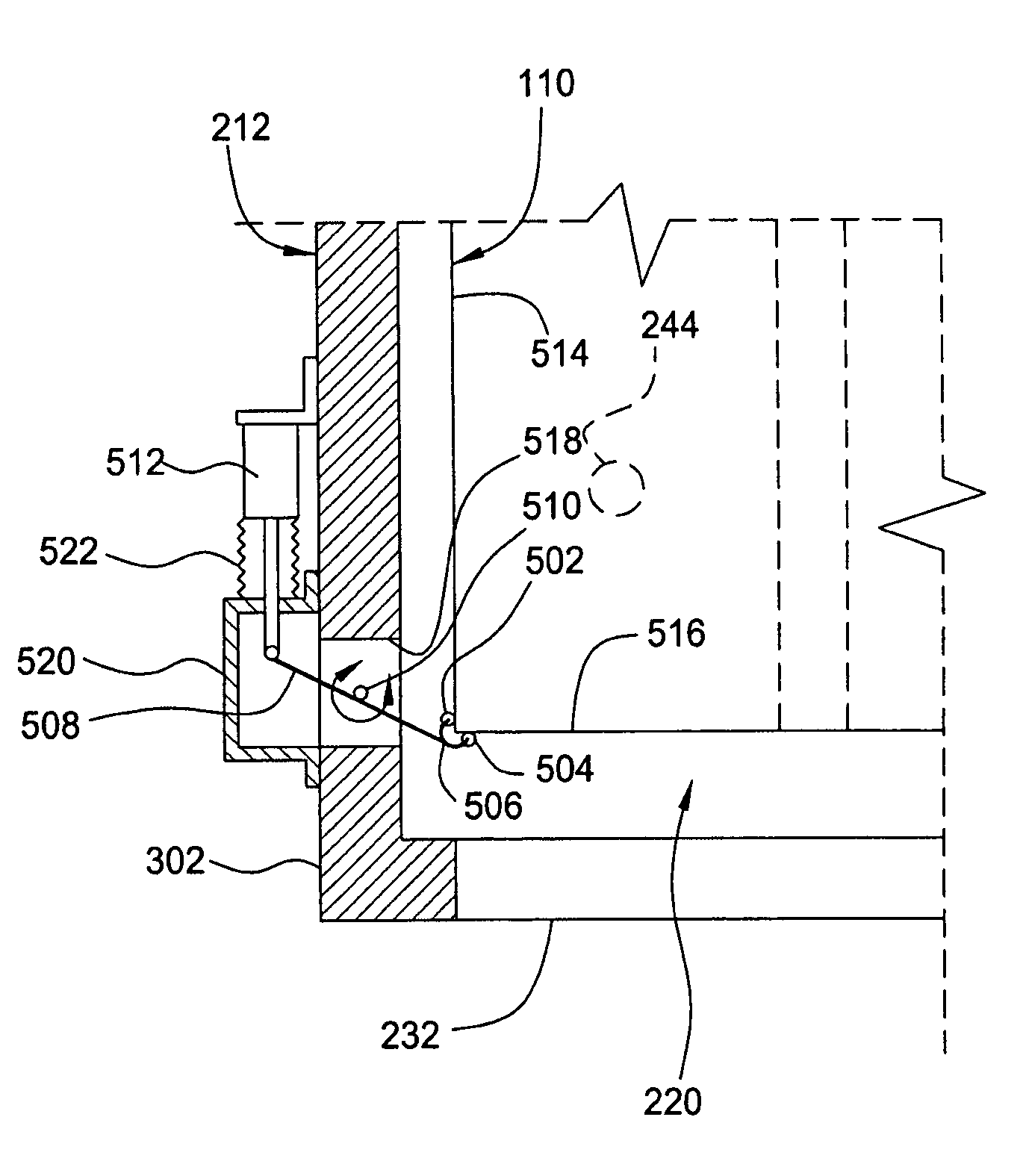

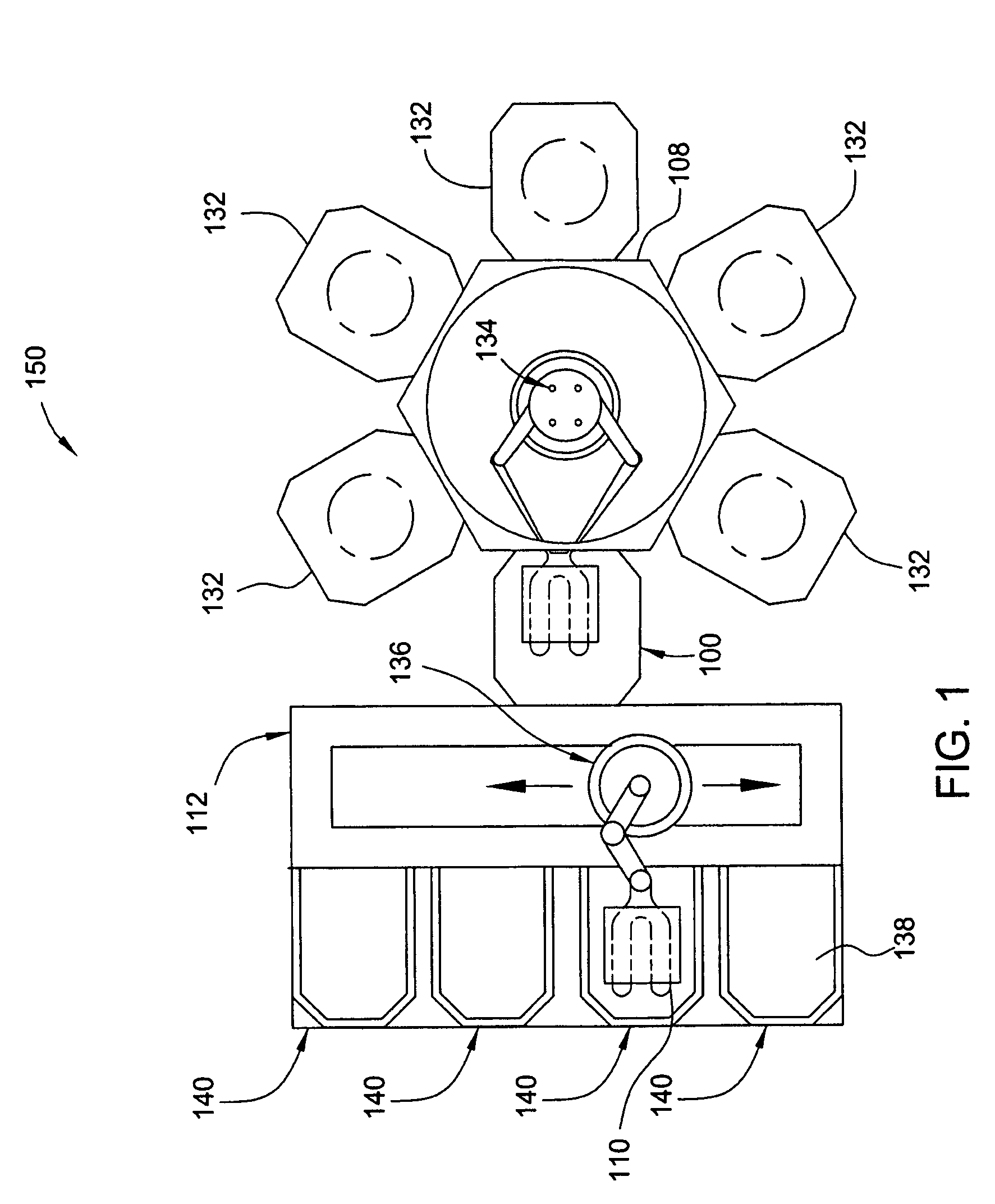

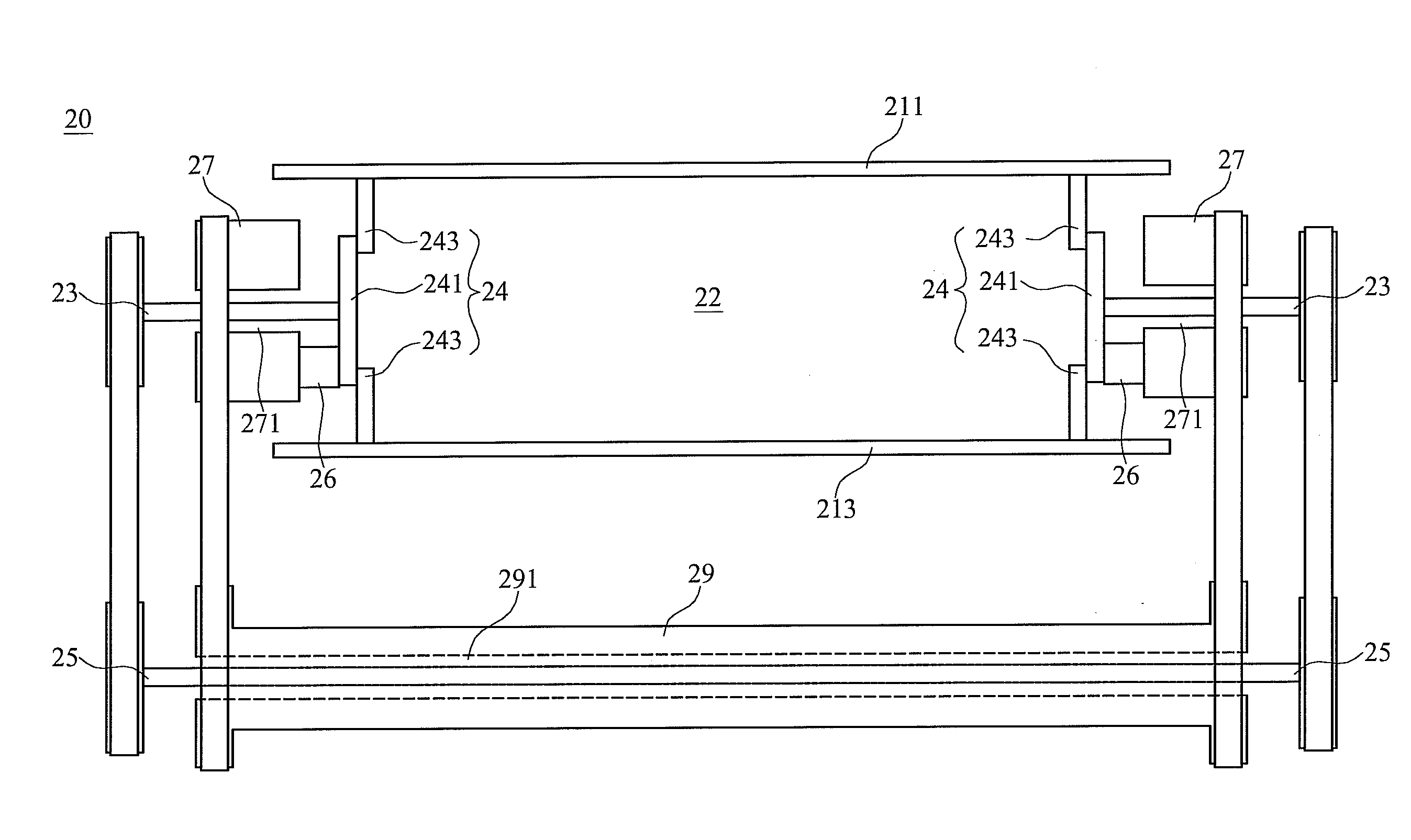

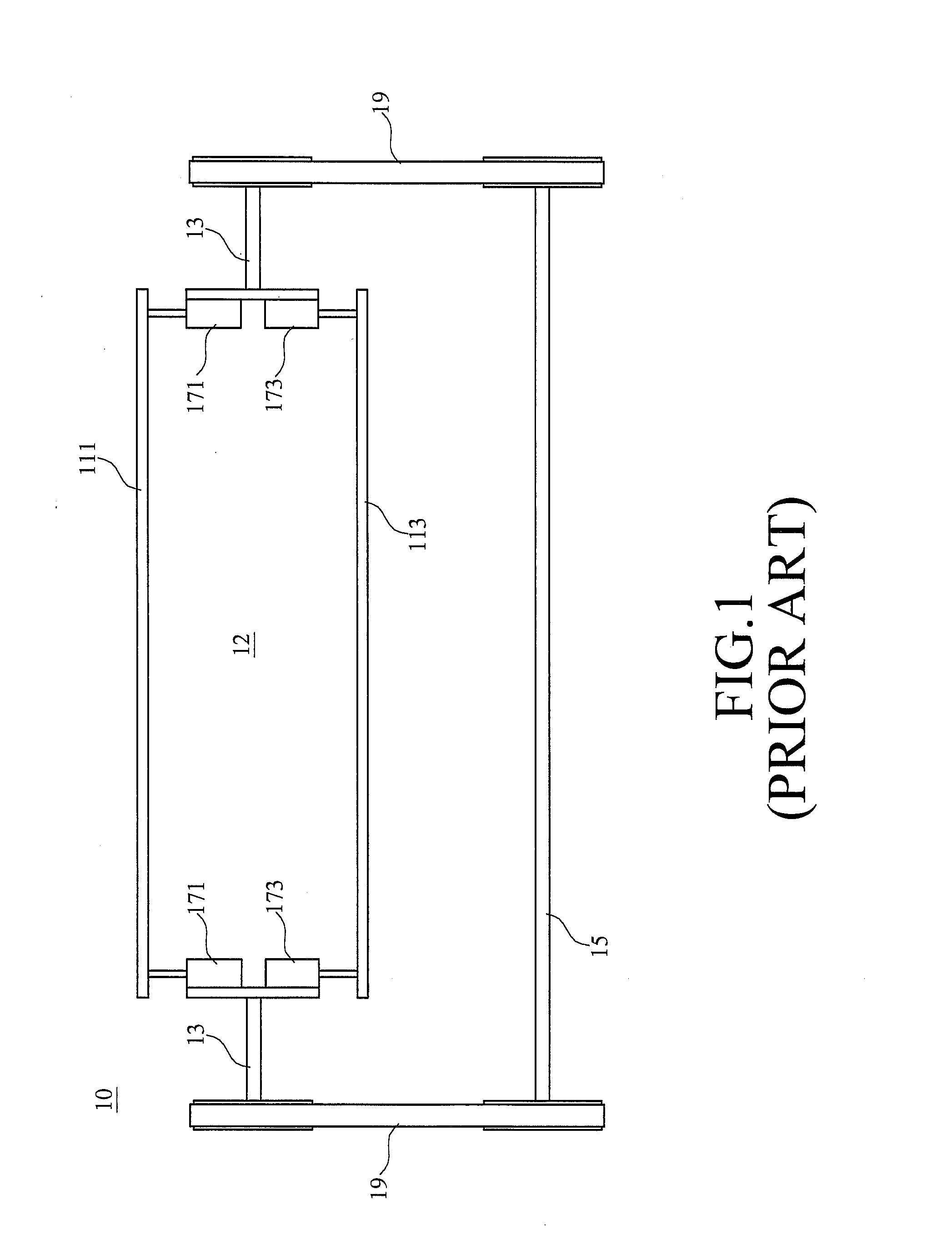

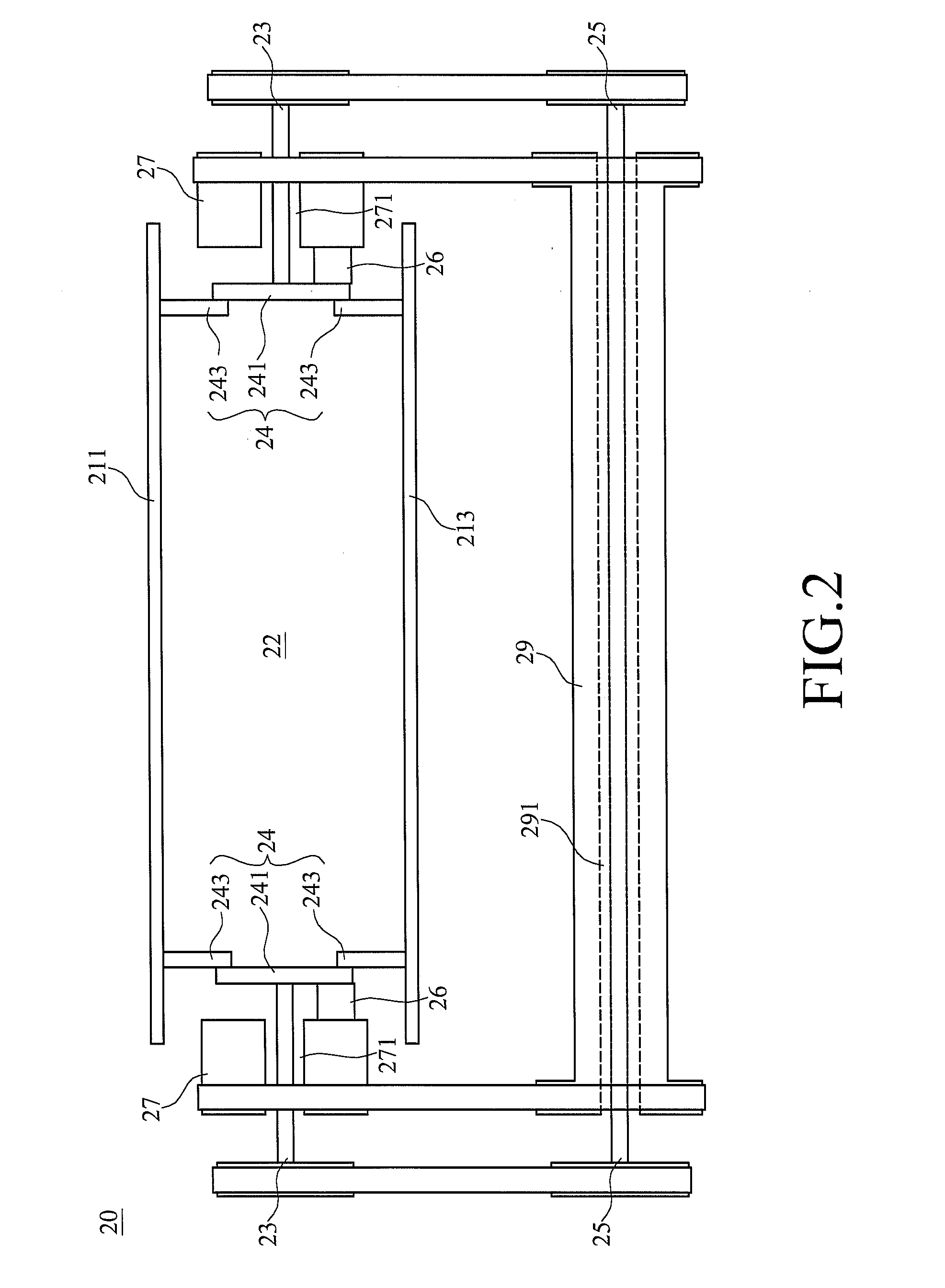

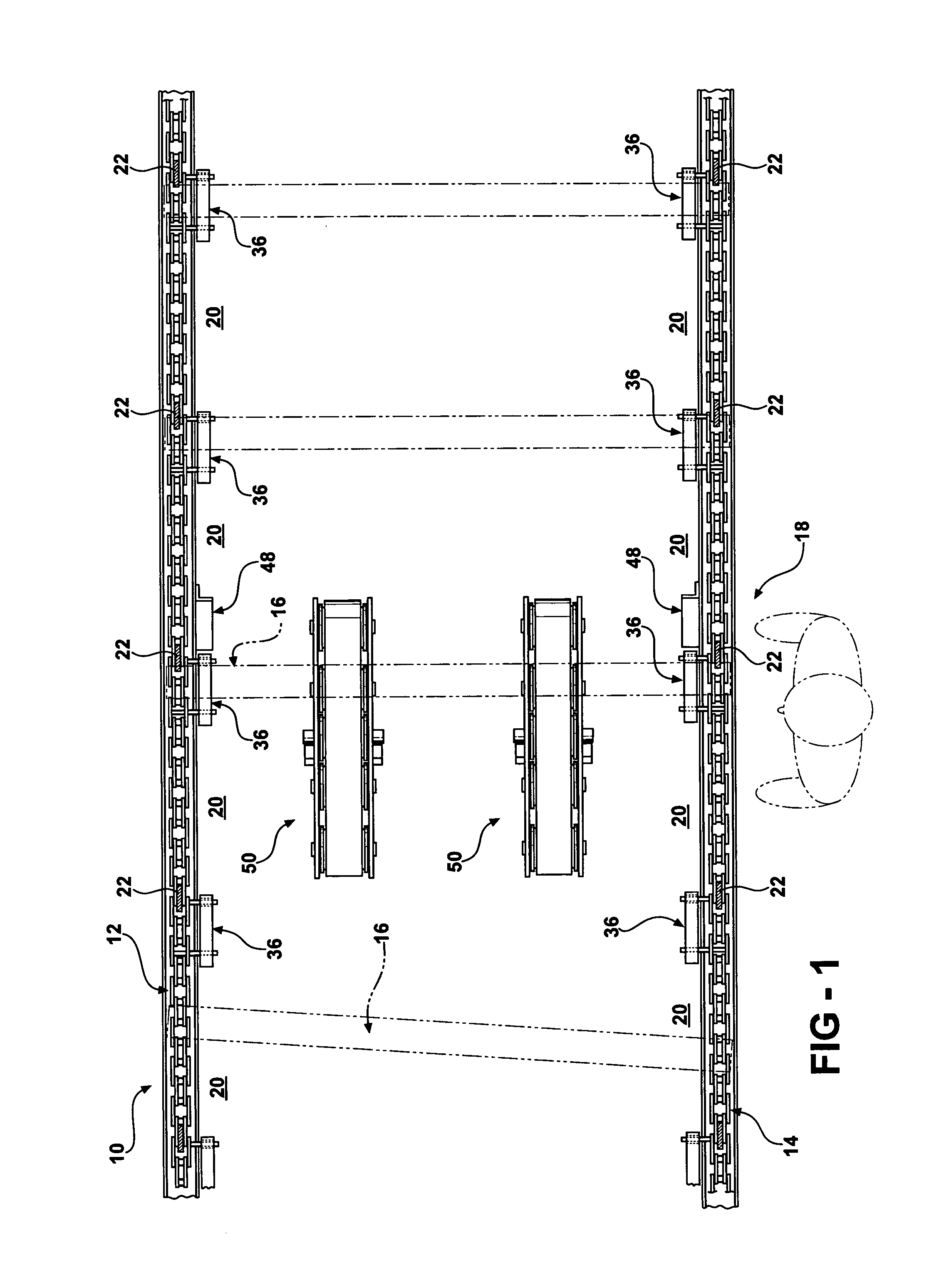

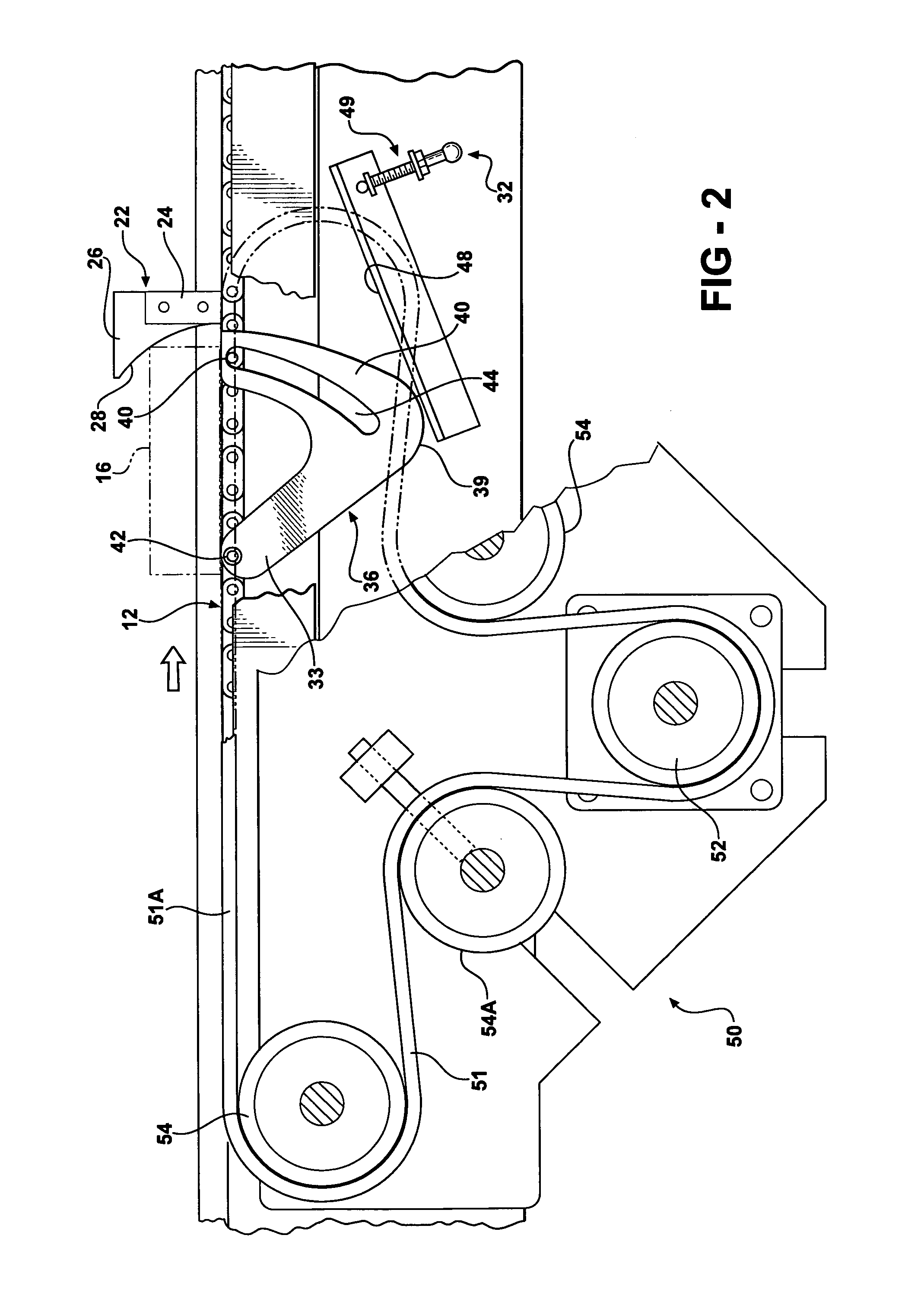

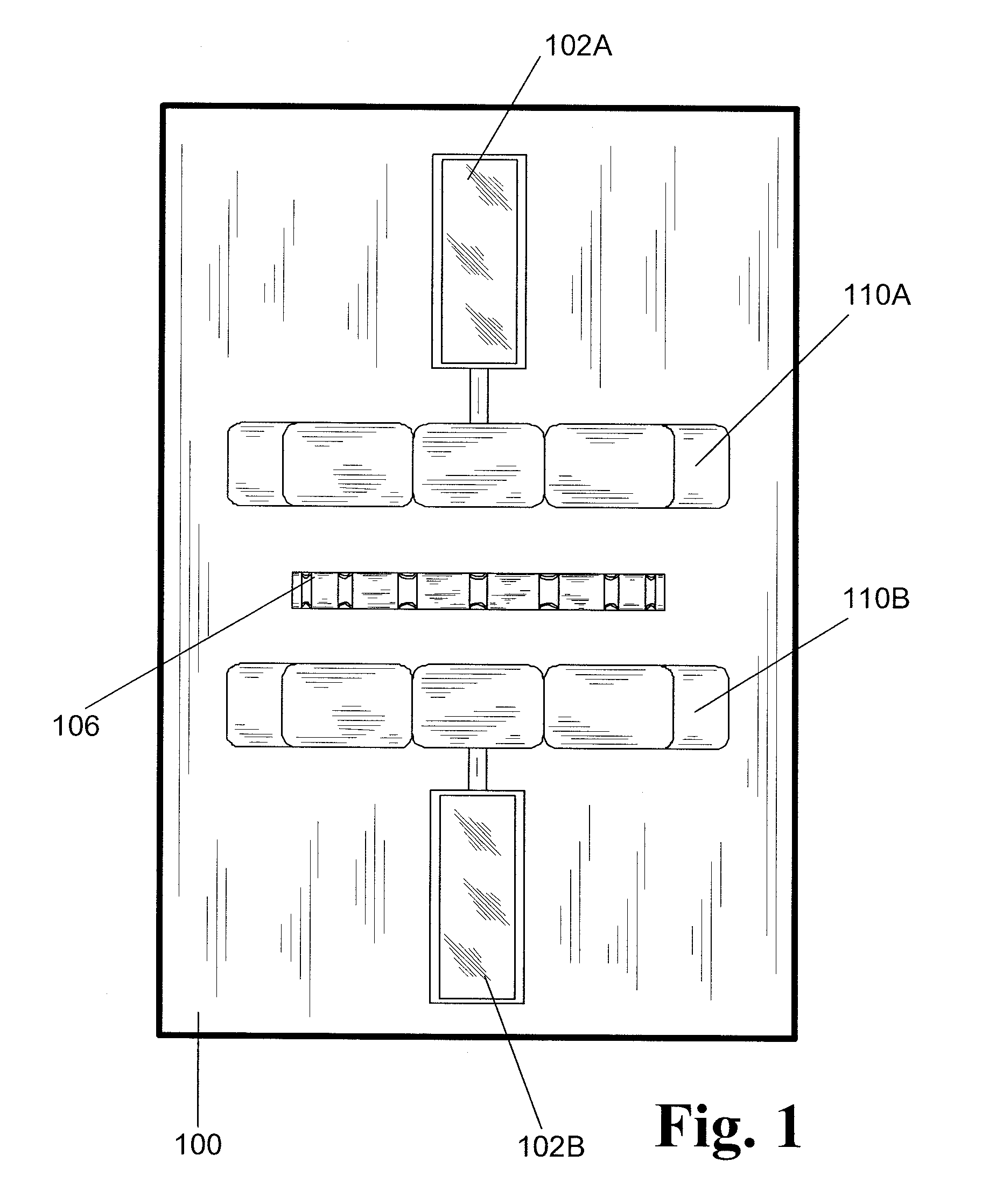

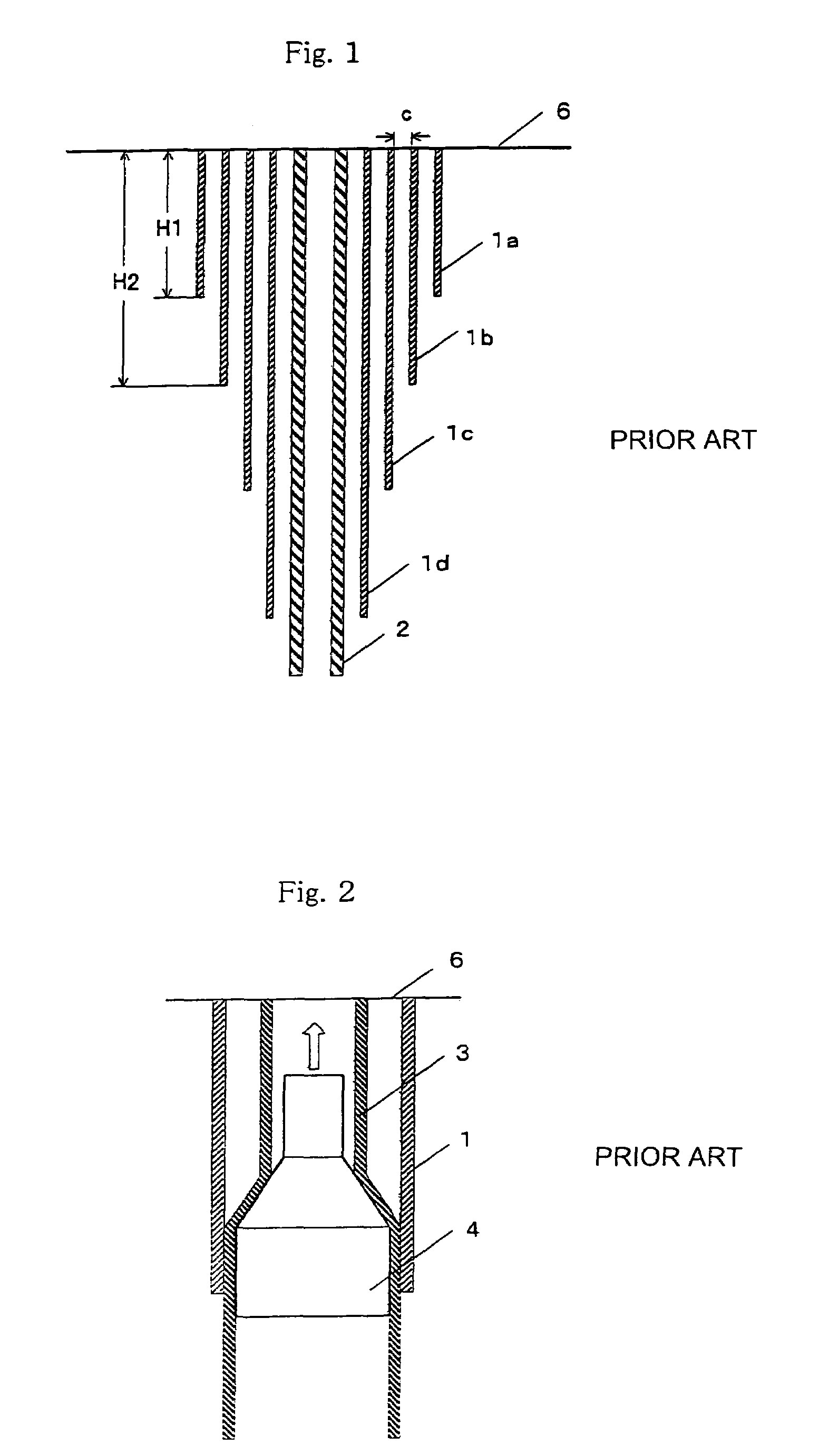

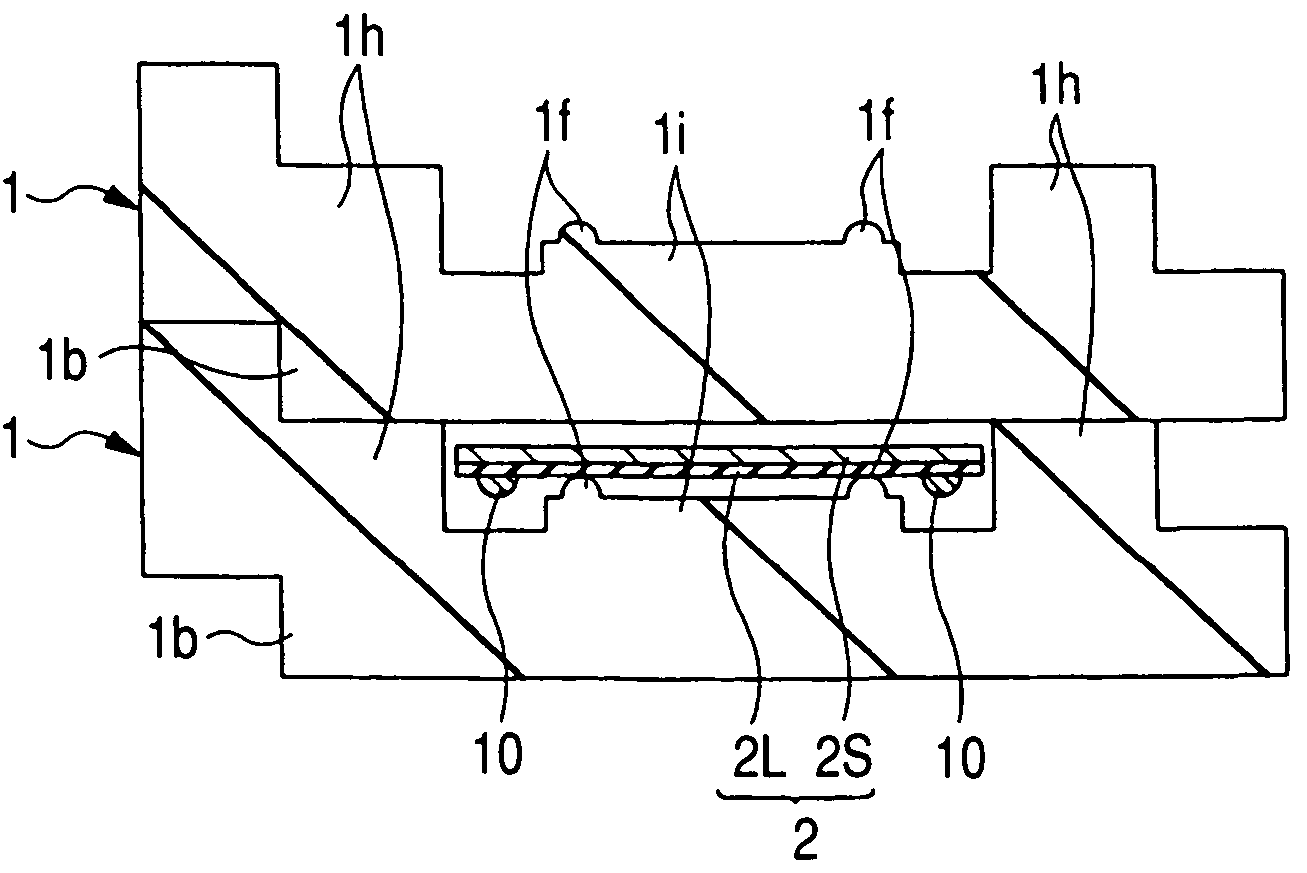

Load lock chamber for large area substrate processing system

ActiveUS20050095088A1Large displayIncrease productionConveyorsWork manipulationParticulatesReduced size

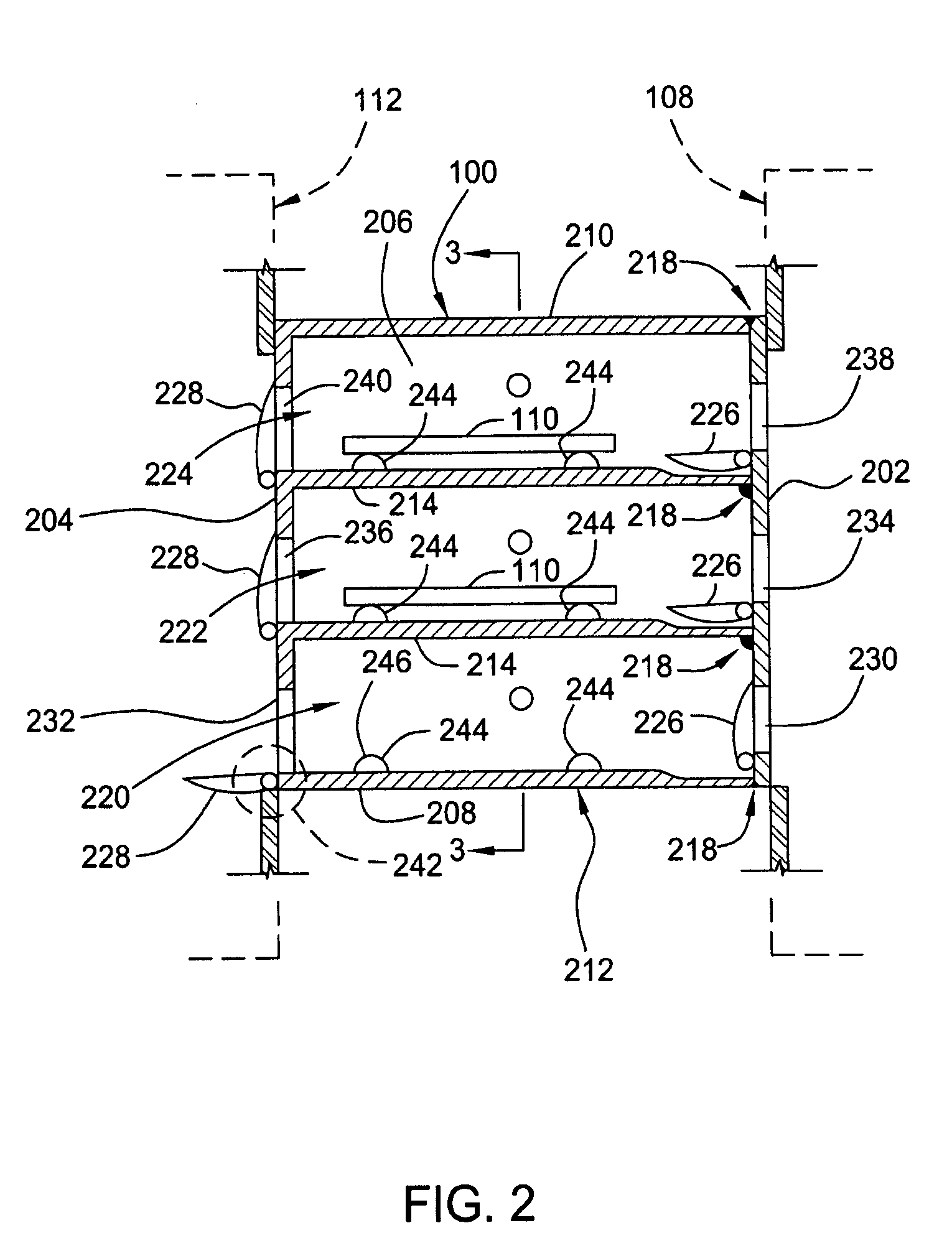

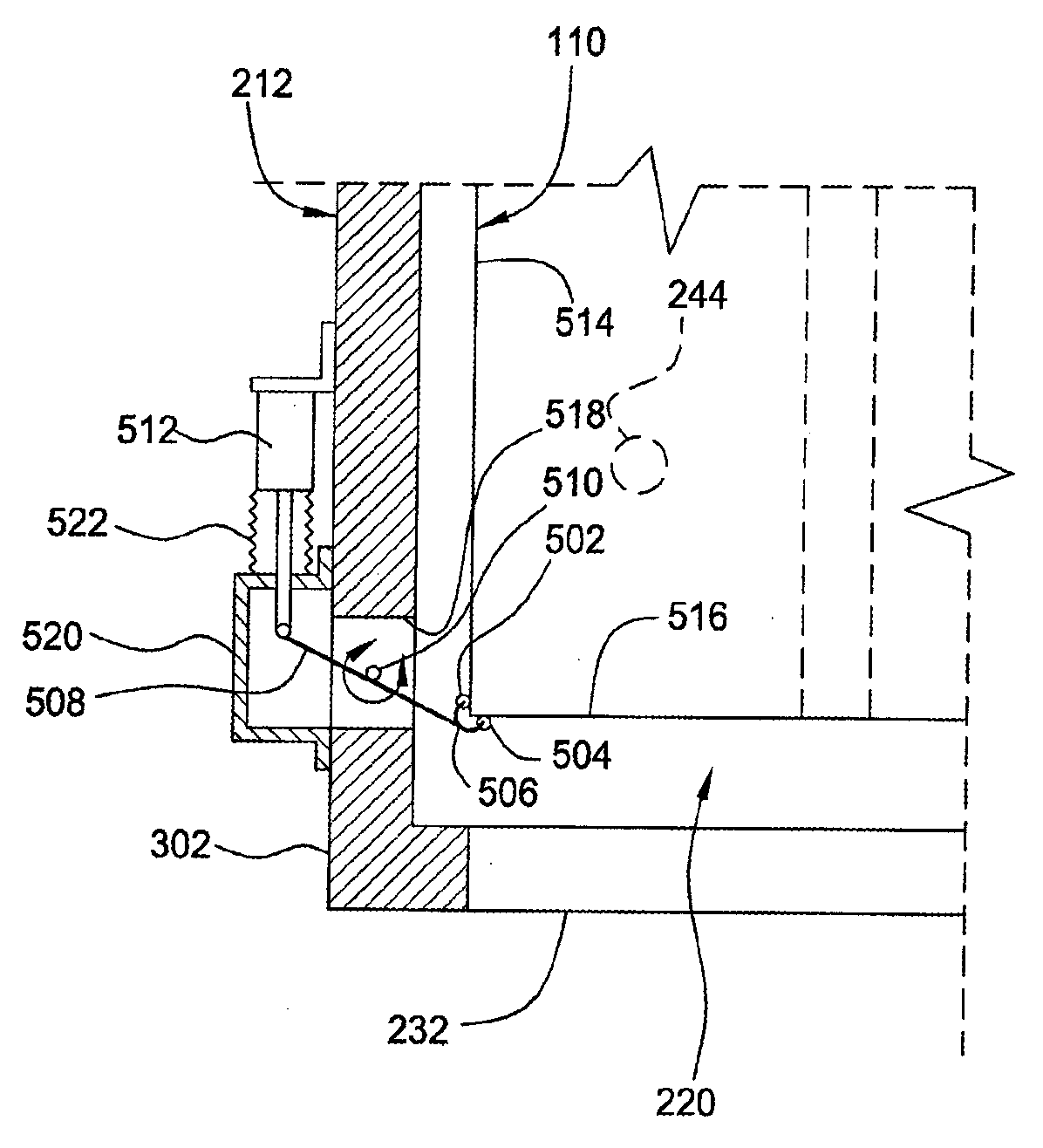

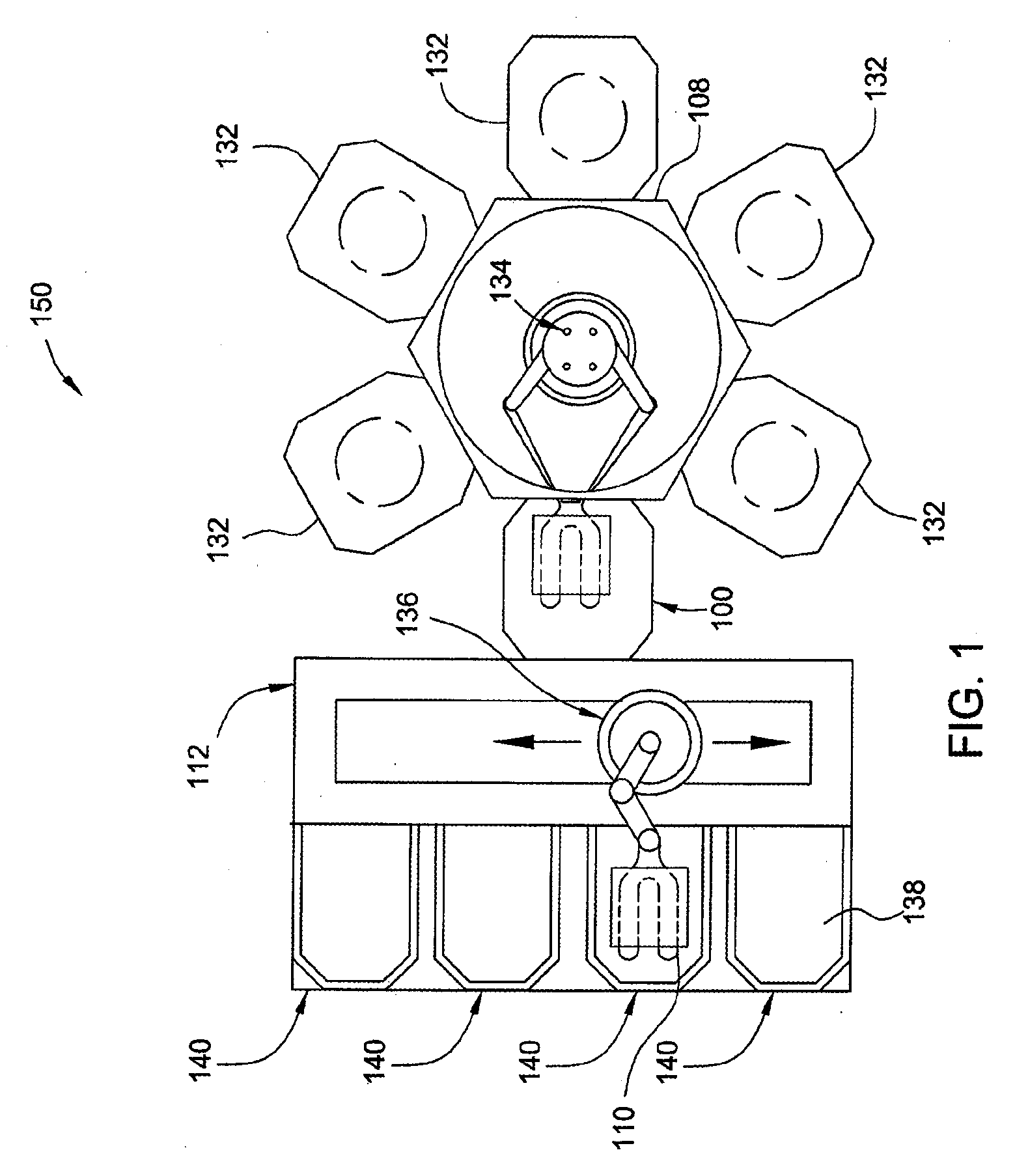

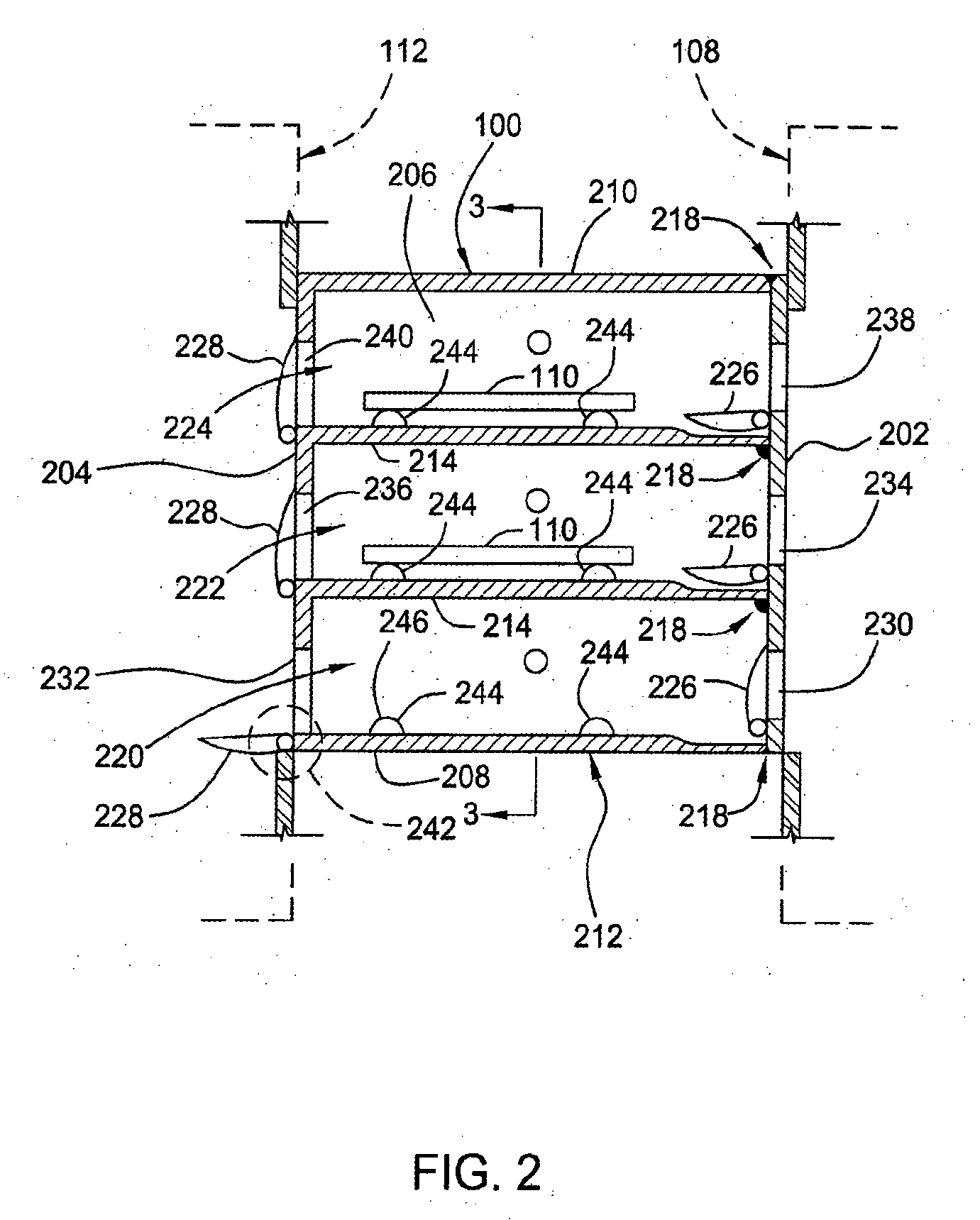

A load lock chamber and method for transferring large area substrates is provided. In one embodiment, a load lock chamber suitable for transferring large area substrates includes a plurality of vertically stacked single substrate transfer chambers. The configuration of vertically stacked single substrate transfer chambers contributes to reduced size and greater throughput as compared to conventional state of the art, dual slot dual substrate designs. Moreover, the increased throughput has been realized at reduced pumping and venting rates, which corresponds to reduced probability of substrate contamination due to particulates and condensation.

Owner:APPLIED MATERIALS INC

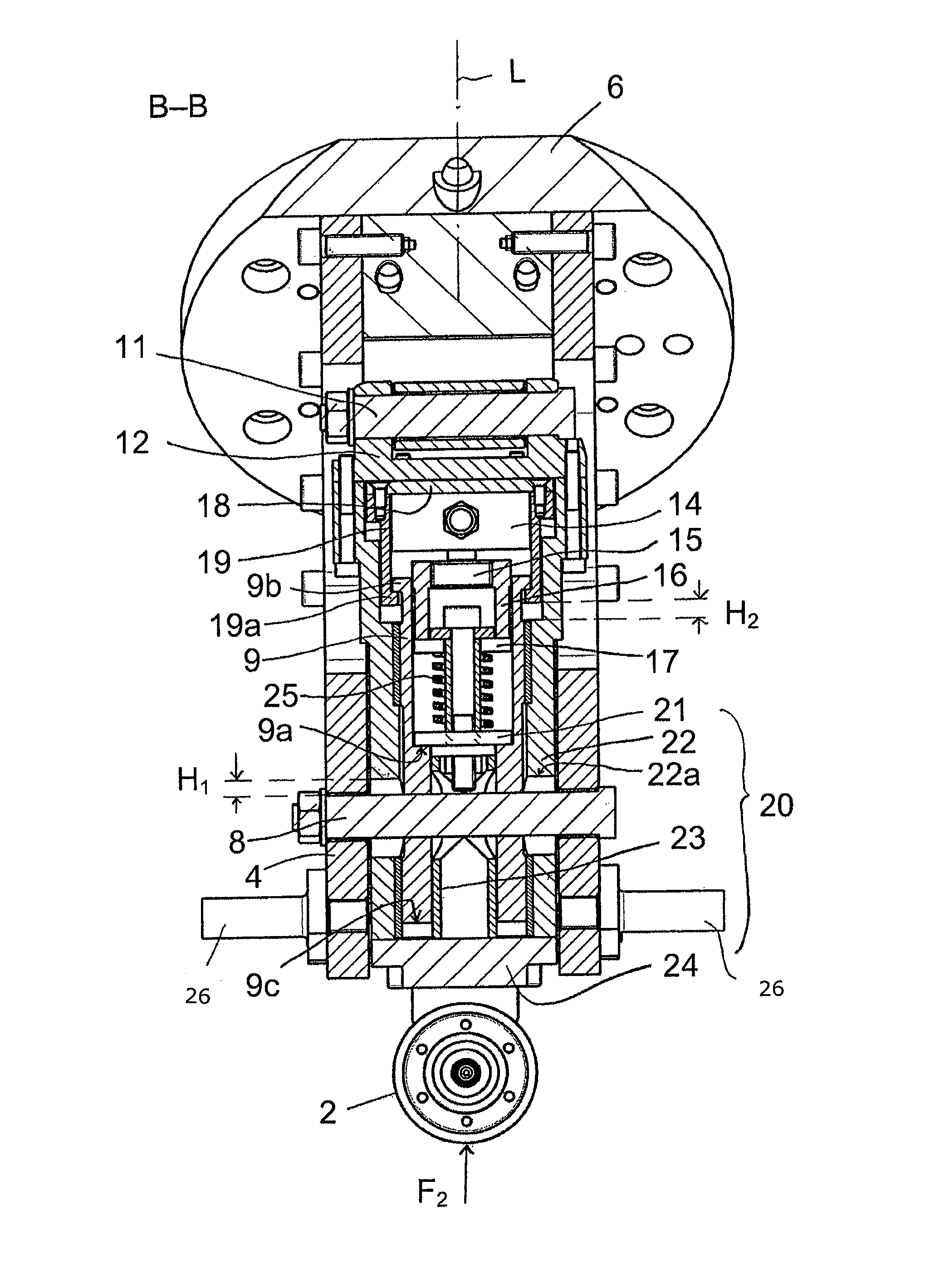

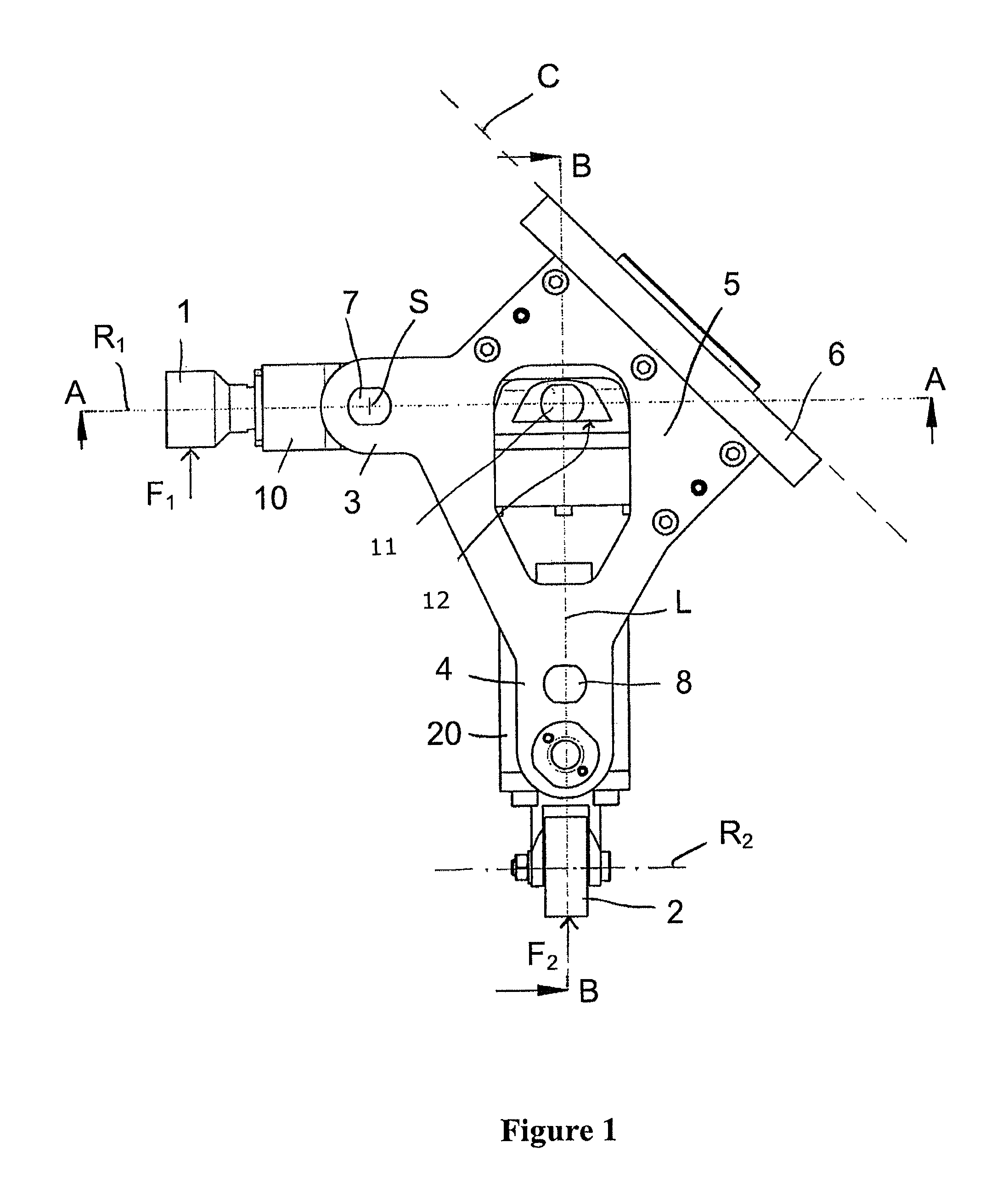

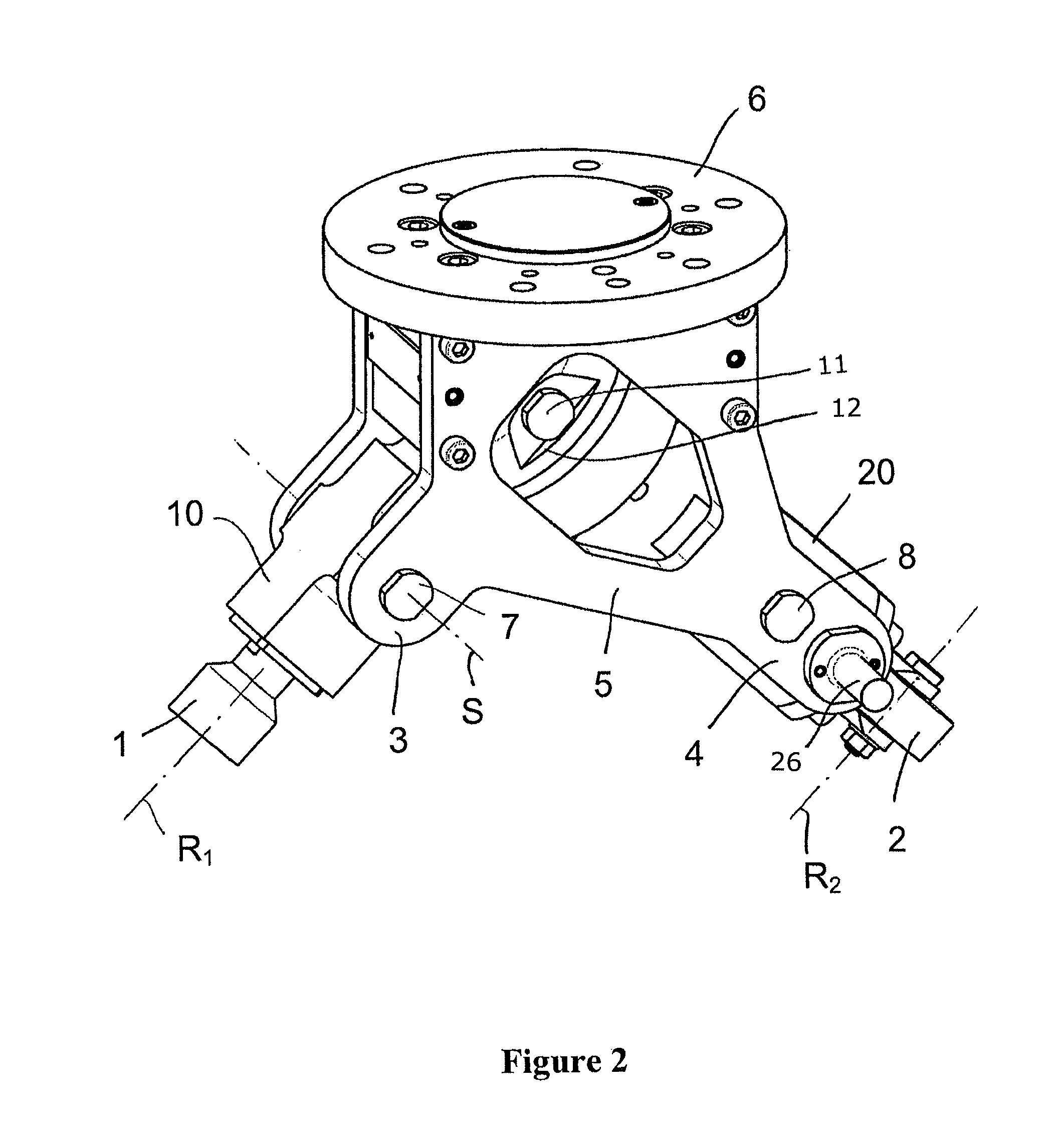

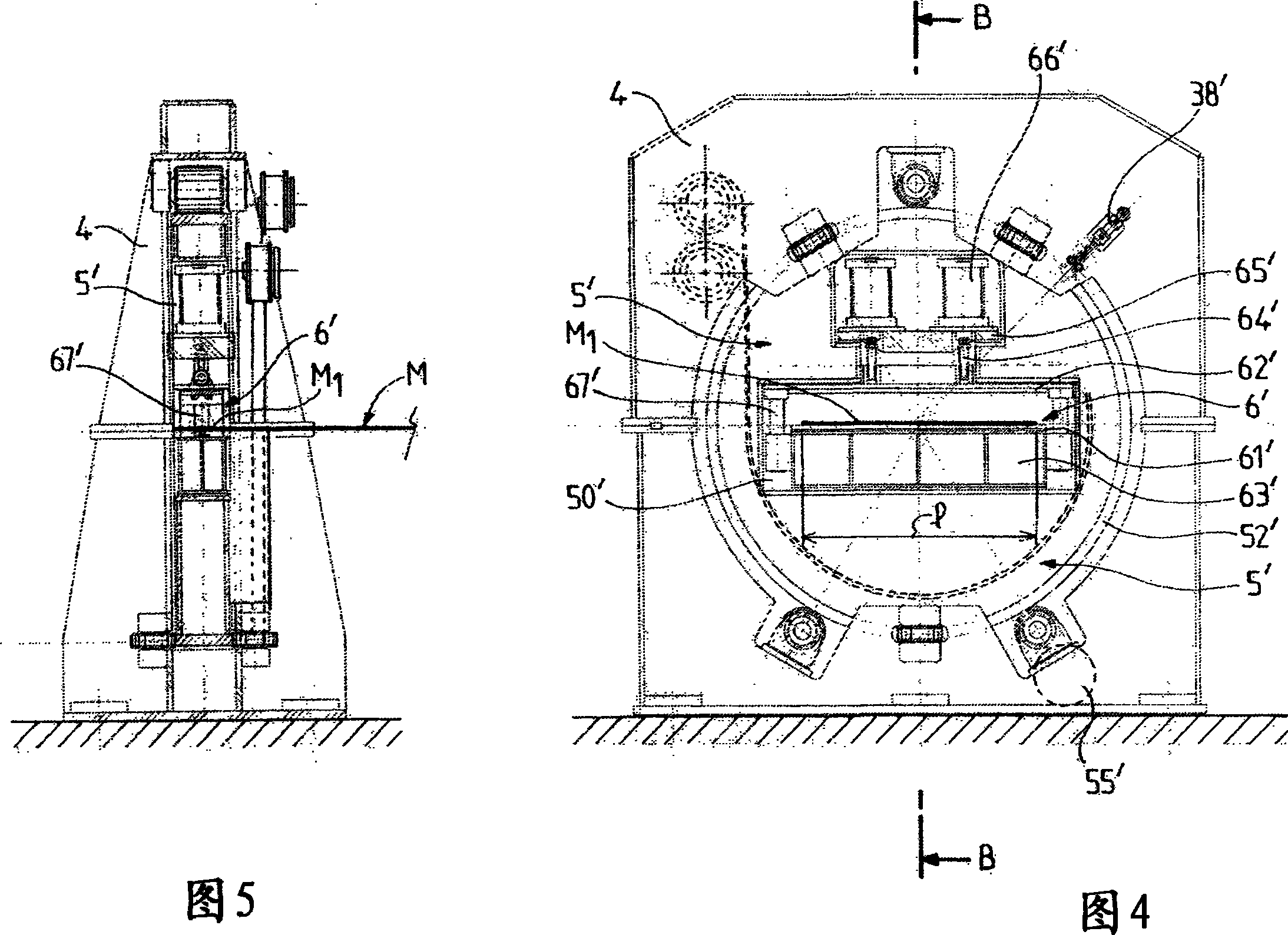

Edge curling tool

A roll-flanging tool, including a bearing structure having a connector, by which the tool can be connected via a connection plane to an actuator which can be moved spatially. A first arm and a second arm are spread apart from each other and connected to each other in a connection portion which includes the connector. A first flanging roller is mounted on an end of the first arm which faces away from the connection plane, such that it can be rotated about a first rotational axis which extends along the first arm and pierces the connection plane. A second flanging roller is mounted on an end of the second arm which faces away from the connection plane, such that it can be rotated about a second rotational axis. The first rotational axis intersects or crosses a perpendicular dropped onto the second rotational axis, in or on the roll-flanging tool.

Owner:FFT PRODIONSSYST

Load lock chamber for large area substrate processing system

A load lock chamber and method for transferring large area substrates is provided. In one embodiment, a load lock chamber suitable for transferring large area substrates includes a plurality of vertically stacked single substrate transfer chambers. The configuration of vertically stacked single substrate transfer chambers contributes to reduced size and greater throughput as compared to conventional state of the art, dual slot dual substrate designs. Moreover, the increased throughput has been realized at reduced pumping and venting rates, which corresponds to reduced probability of substrate contamination due to particulates and condensation.

Owner:APPLIED MATERIALS INC

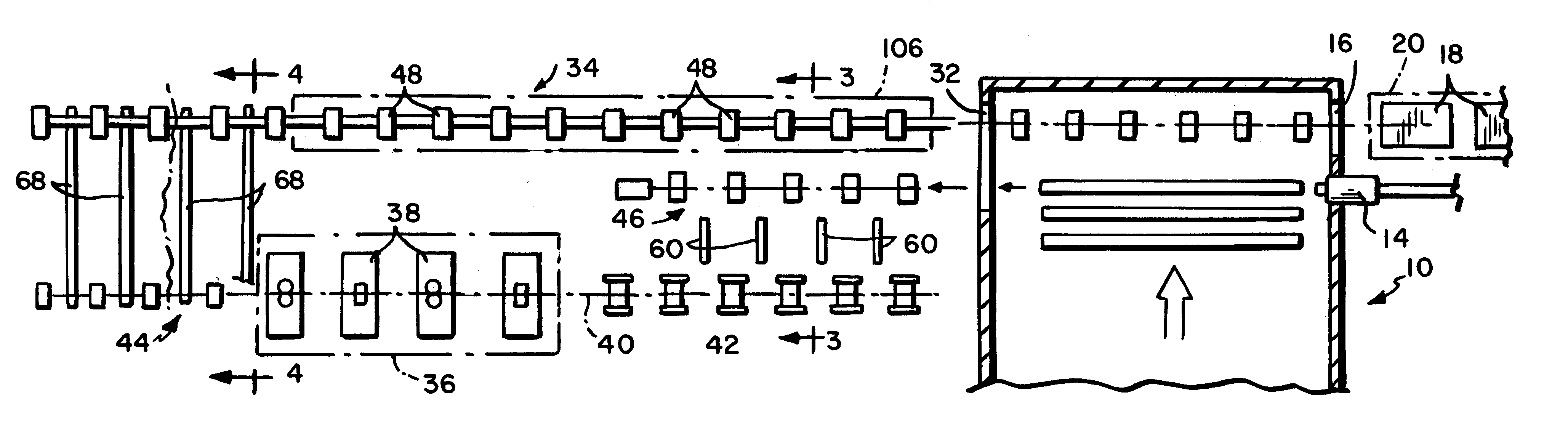

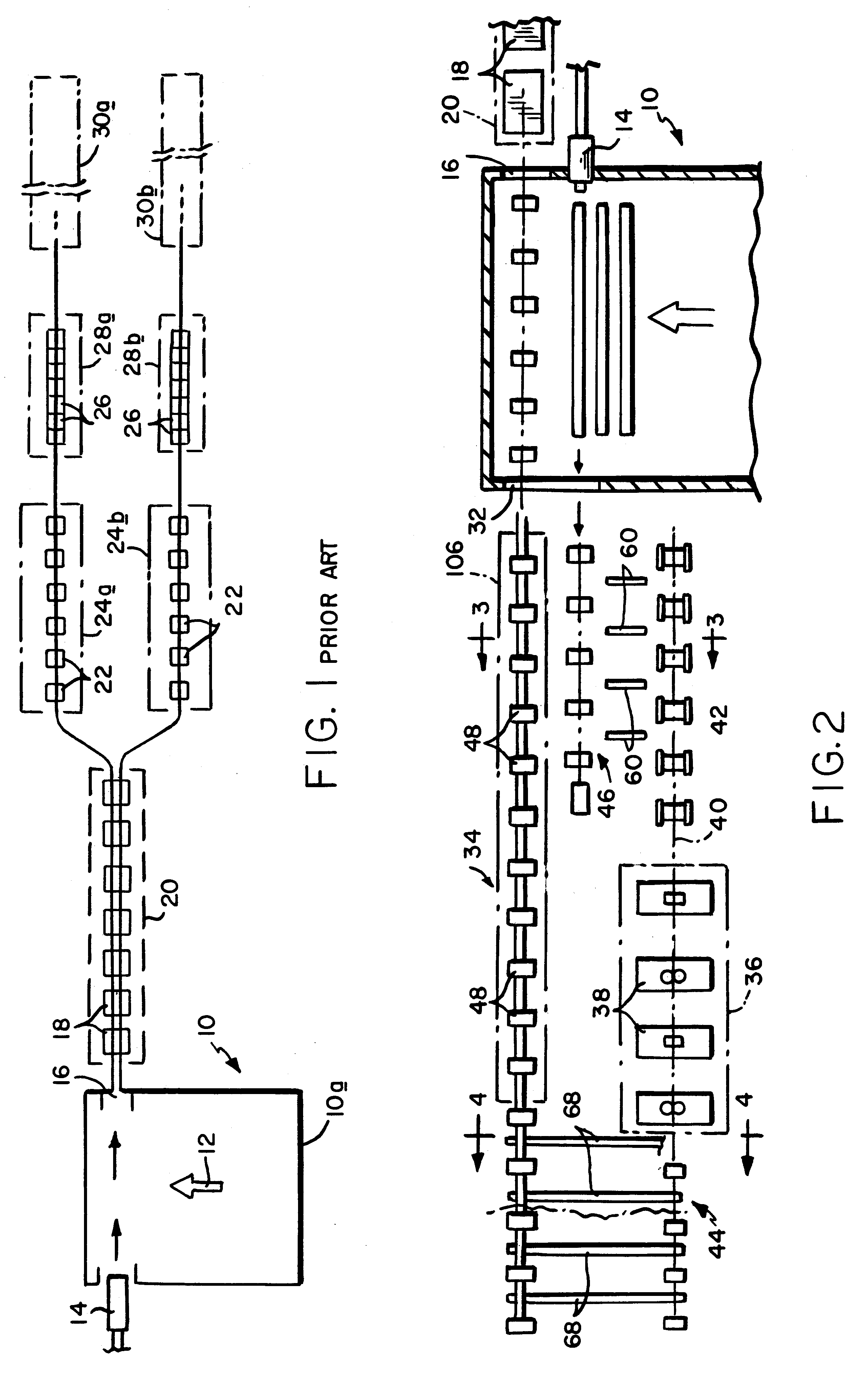

Apparatus for and method of processing billets in a rolling mill

A rolling mill has roughing, intermediate and finishing roll stands on a first side of a billet reheating furnace, and a breakdown mill on an opposite second side of the furnace. Billets are heated to an elevated rolling temperature in the furnace and are then ejected to the second side of the furnace for rolling in the breakdown mill before being directed back through the furnace for continued rolling into finished products at the first side of the furnace in the roughing, intermediate and finishing roll stands.

Owner:MORGAN CONSTR CO

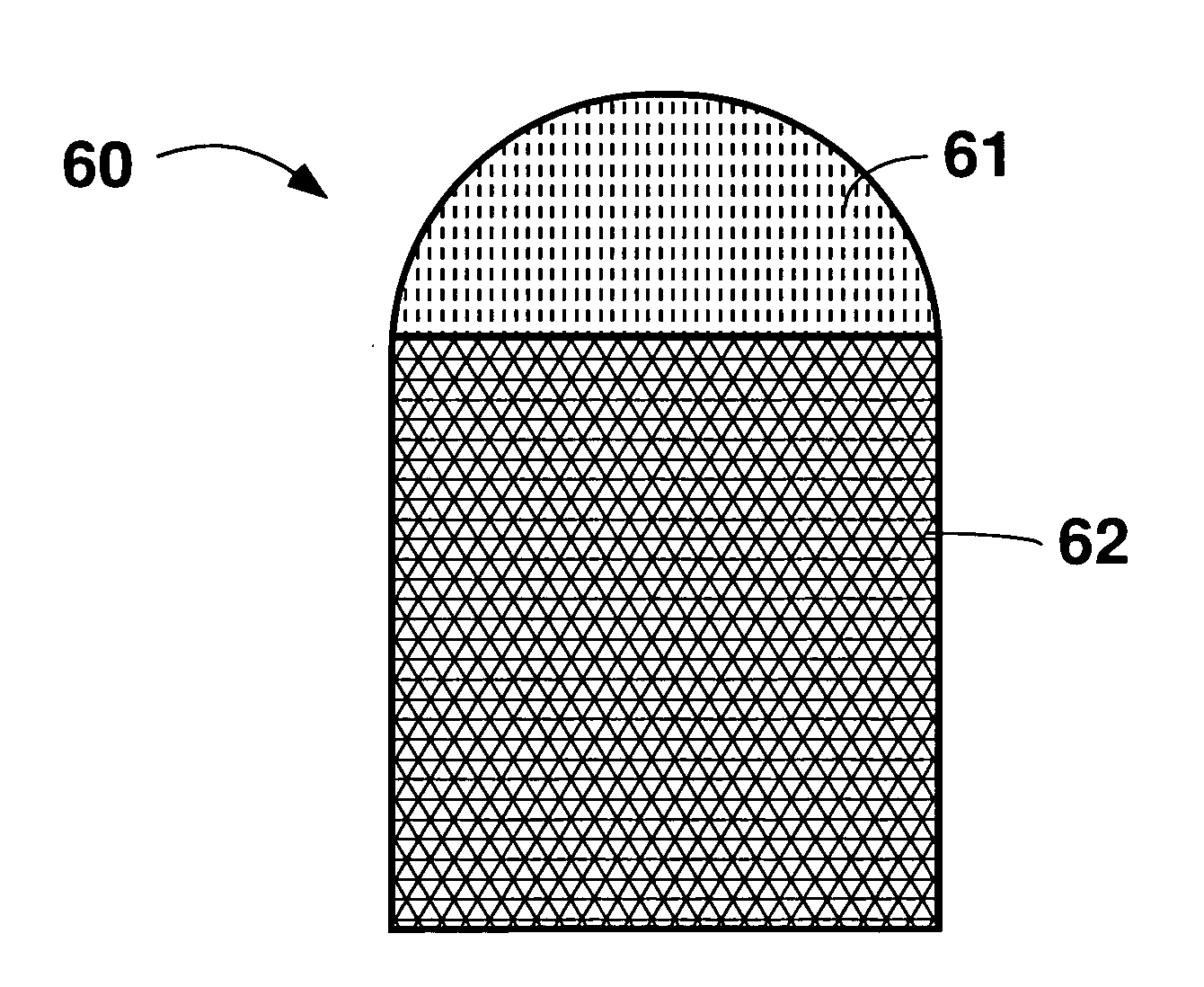

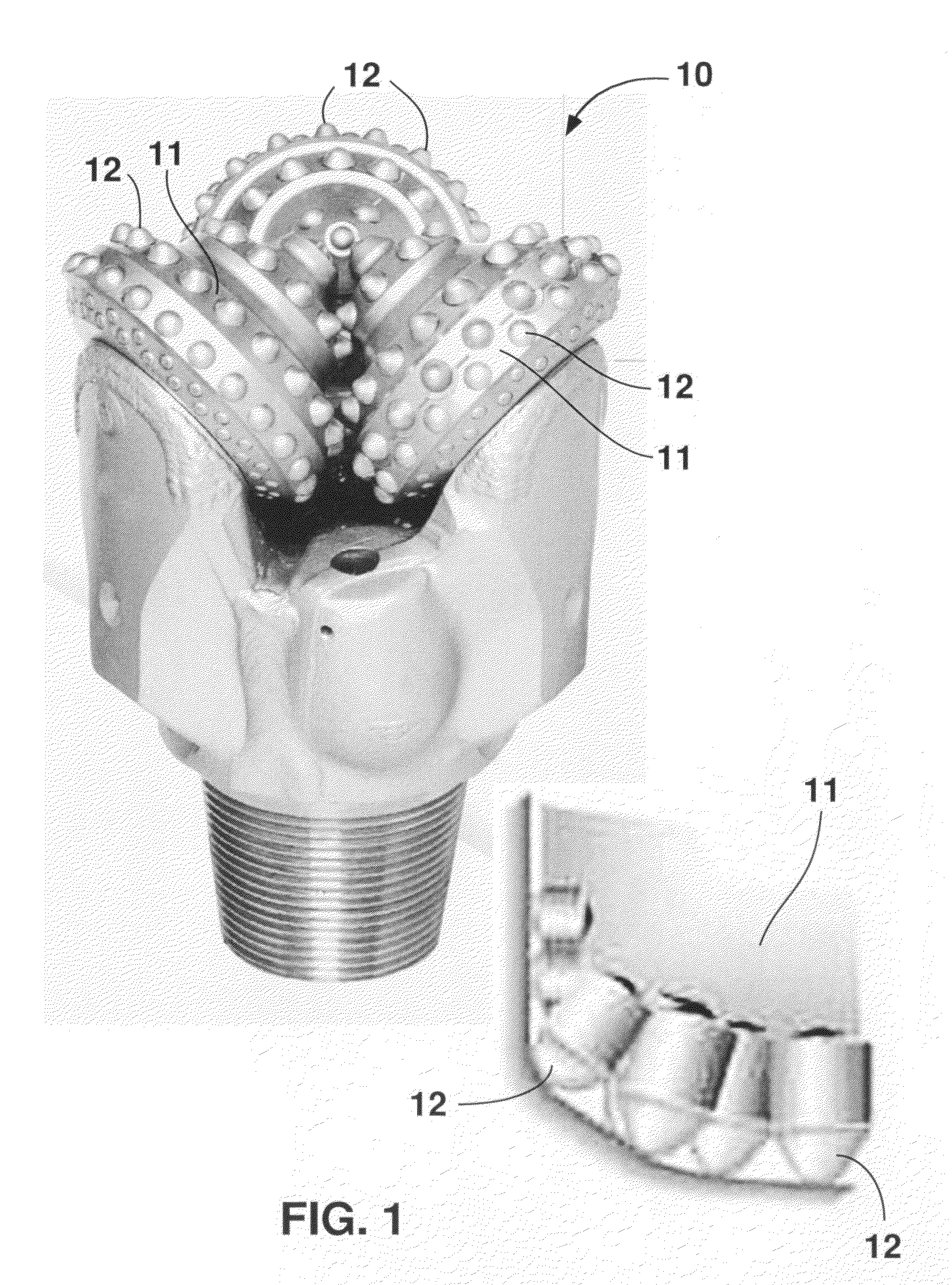

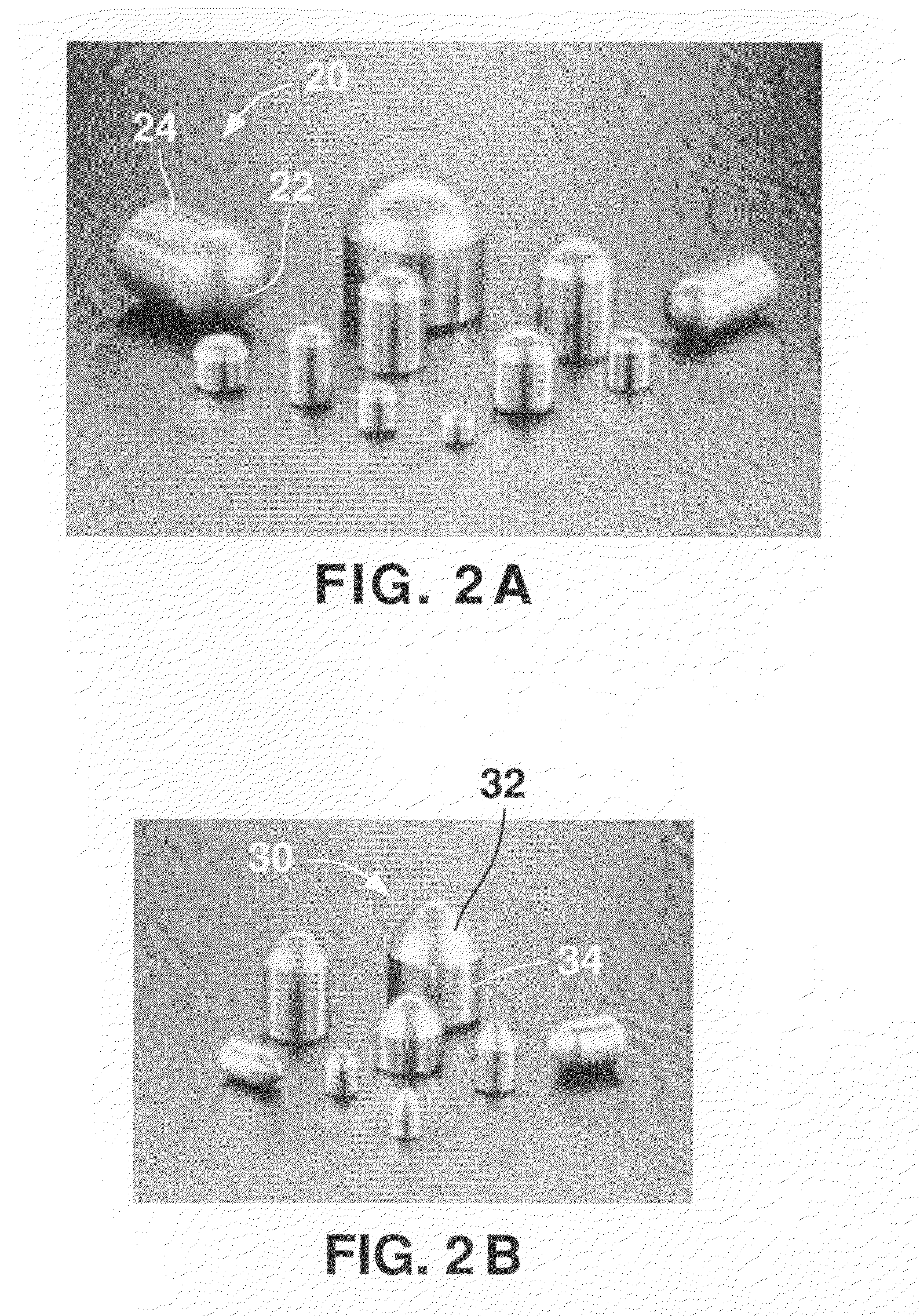

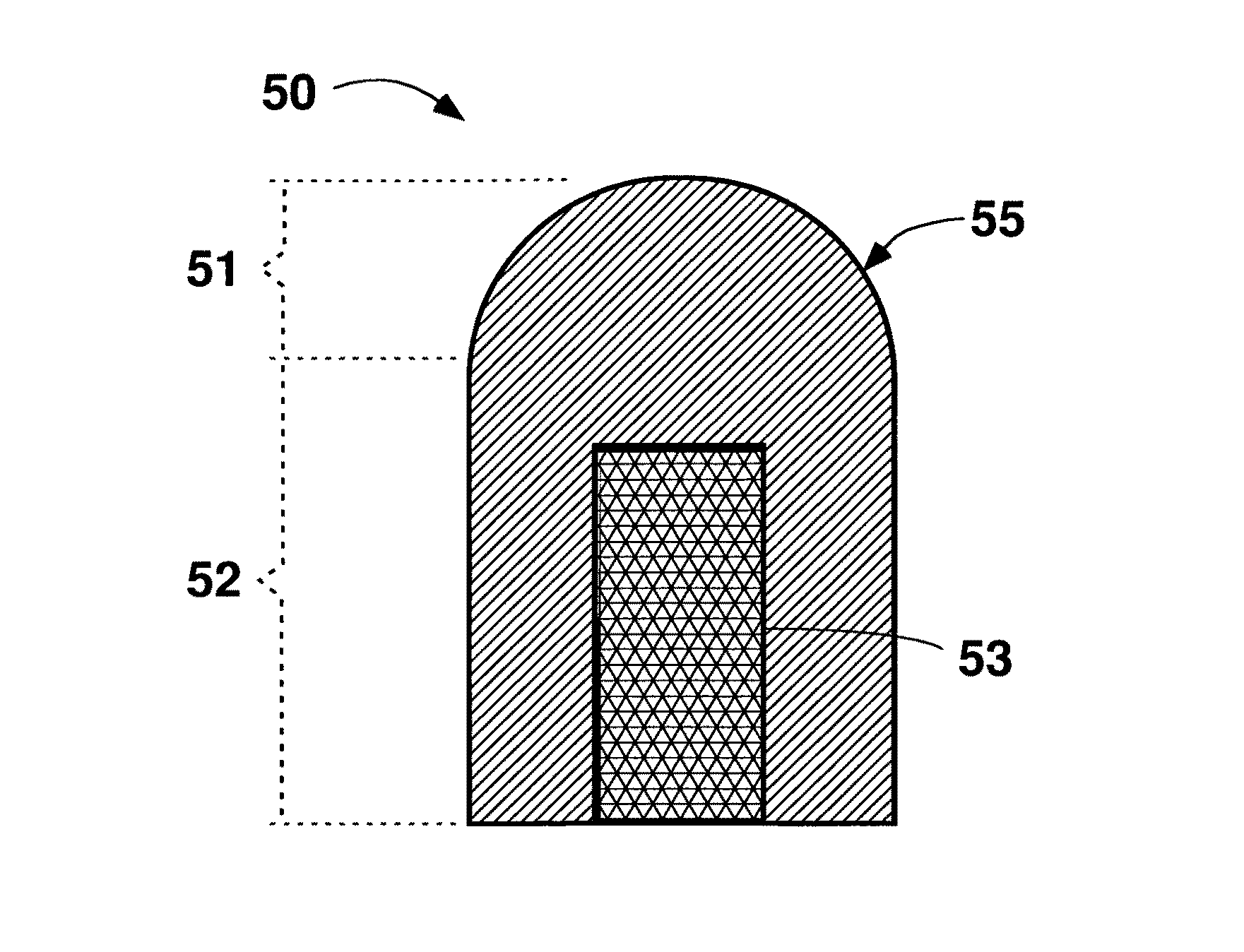

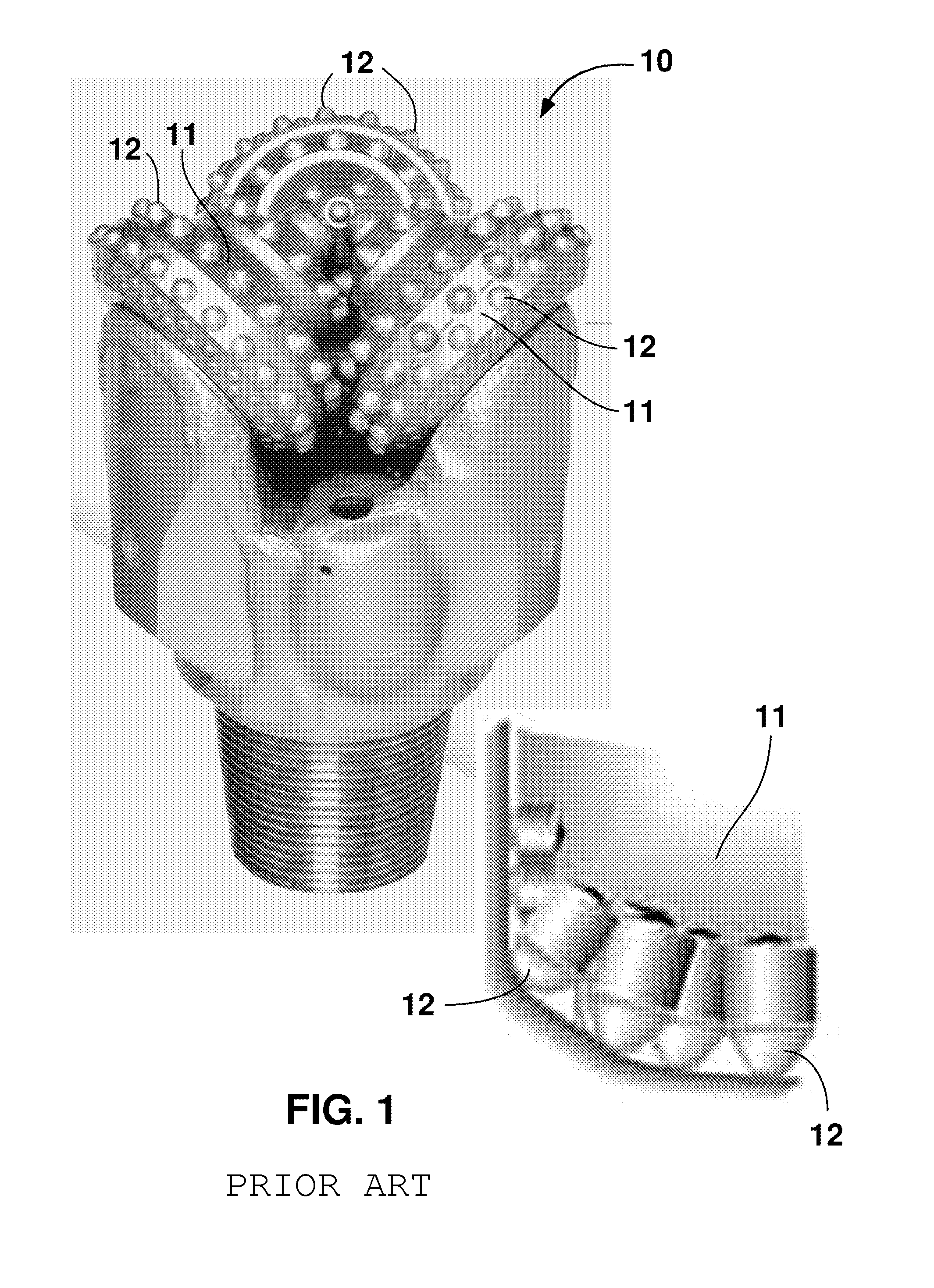

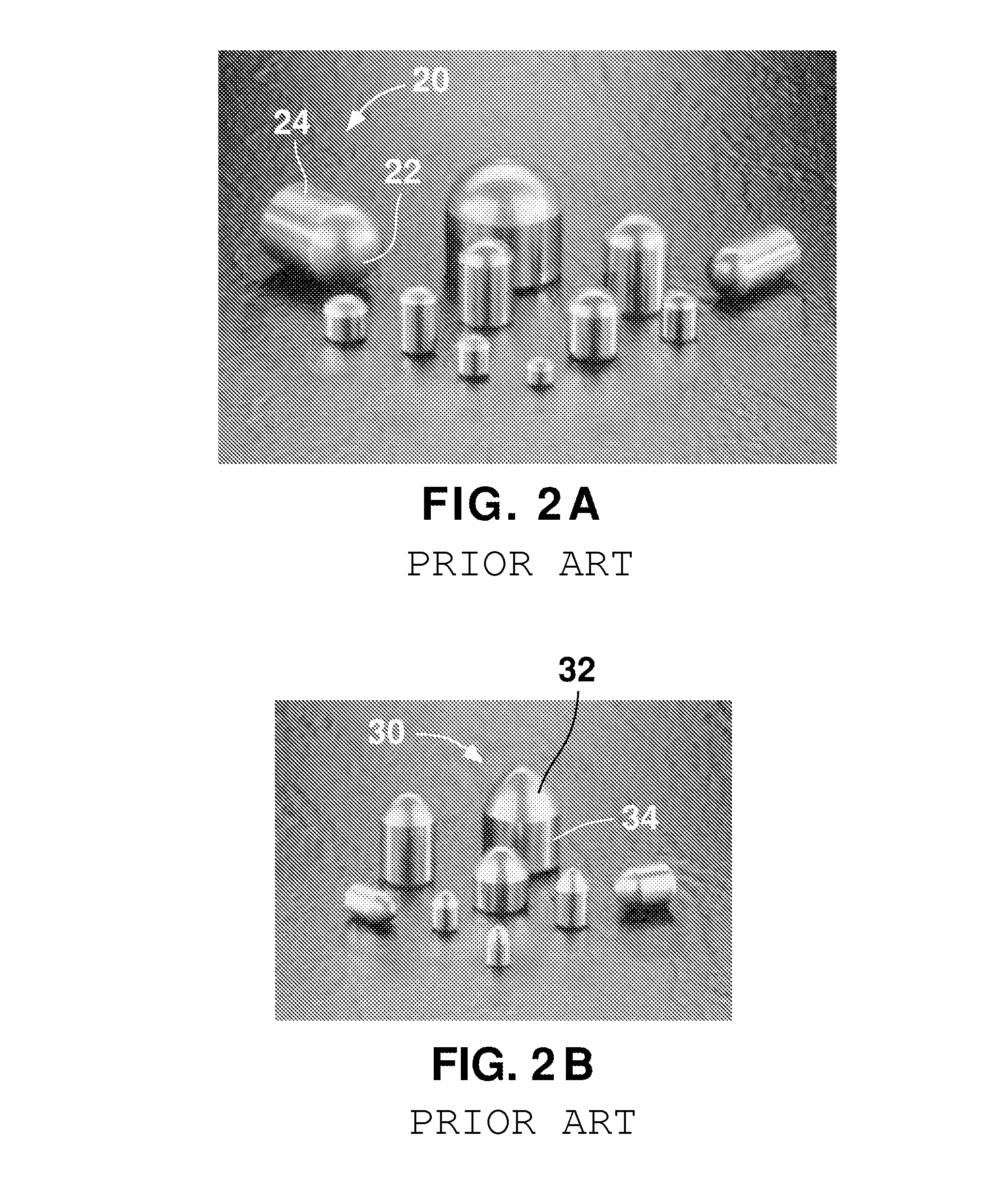

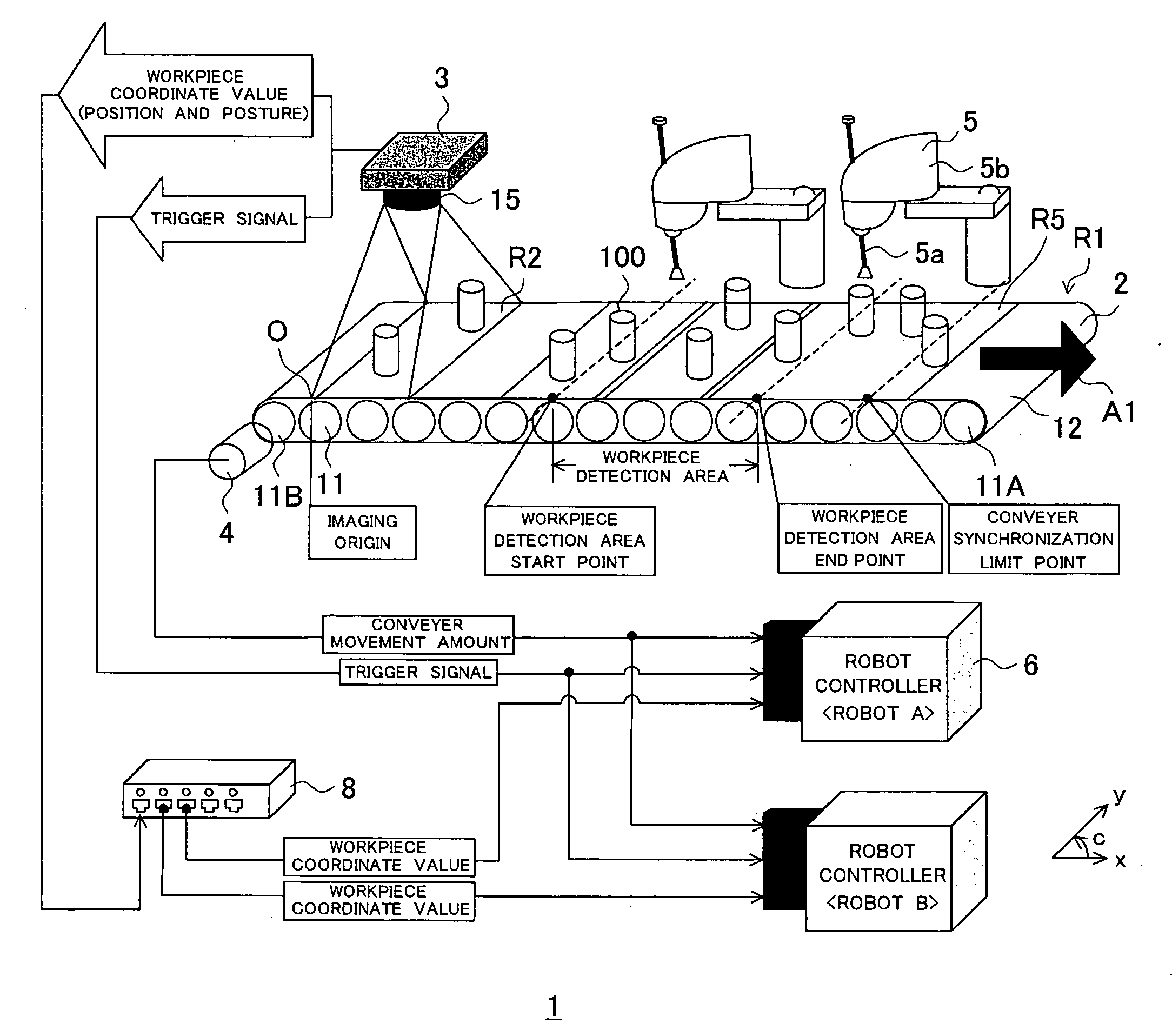

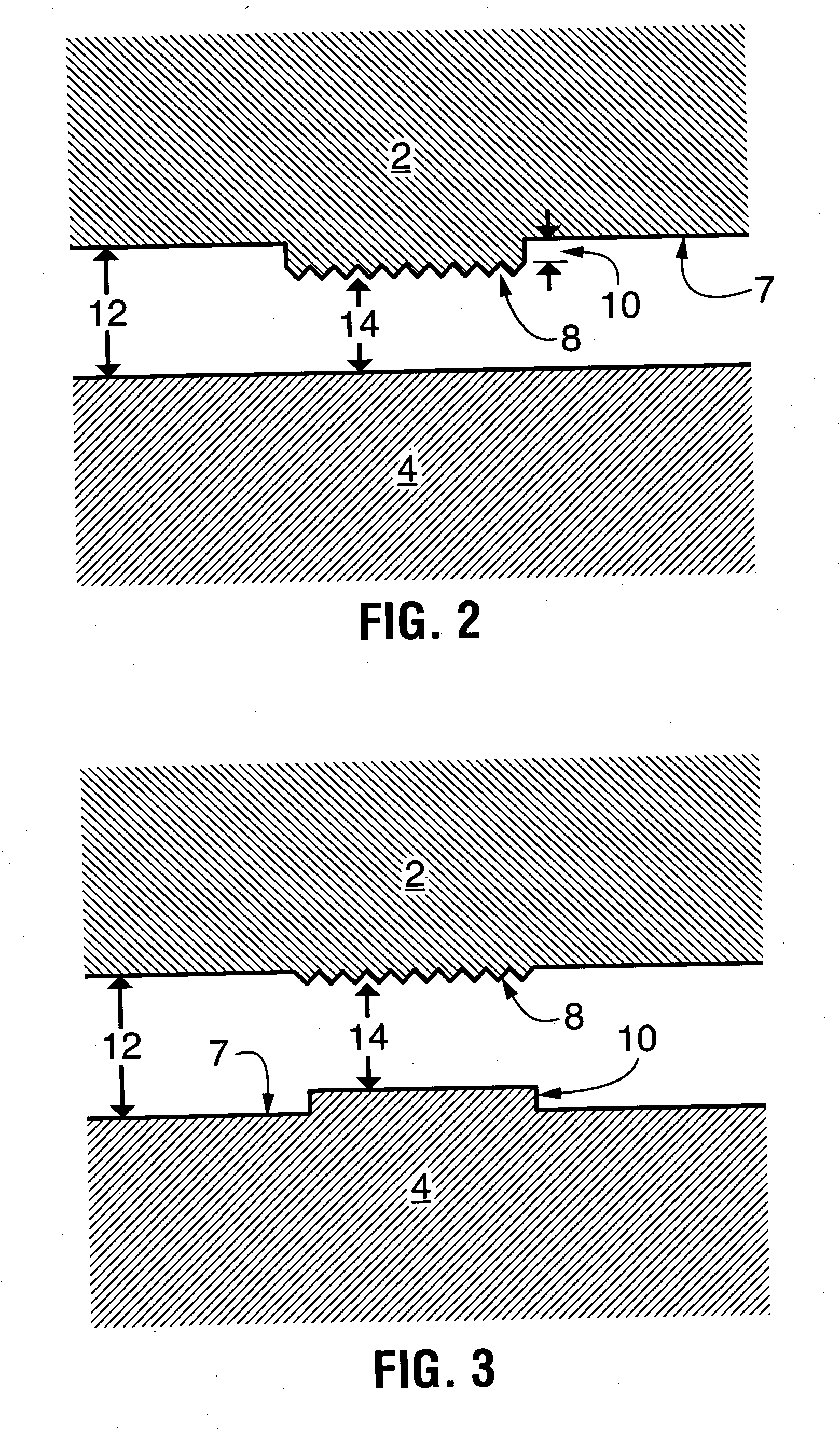

Articles Having Improved Resistance to Thermal Cracking

An article includes a working portion including cemented carbide, and a heat sink portion in thermal communication with the working portion. The heat sink portion includes a heat sink material having a thermal conductivity greater than a thermal conductivity of the cemented carbide. Also disclosed are methods of making an article including a working portion comprising cemented carbide, and a heat sink portion in thermal communication with the working portion and including a heat sink material having a thermal conductivity that is greater than a thermal conductivity of the cemented carbide. The heat sink portion conducts heat from the working portion.

Owner:KENNAMETAL INC

Articles having improved resistance to thermal cracking

An article includes a working portion including cemented carbide, and a heat sink portion in thermal communication with the working portion. The heat sink portion includes a heat sink material having a thermal conductivity greater than a thermal conductivity of the cemented carbide. Also disclosed are methods of making an article including a working portion comprising cemented carbide, and a heat sink portion in thermal communication with the working portion and including a heat sink material having a thermal conductivity that is greater than a thermal conductivity of the cemented carbide. The heat sink portion conducts heat from the working portion.

Owner:KENNAMETAL INC

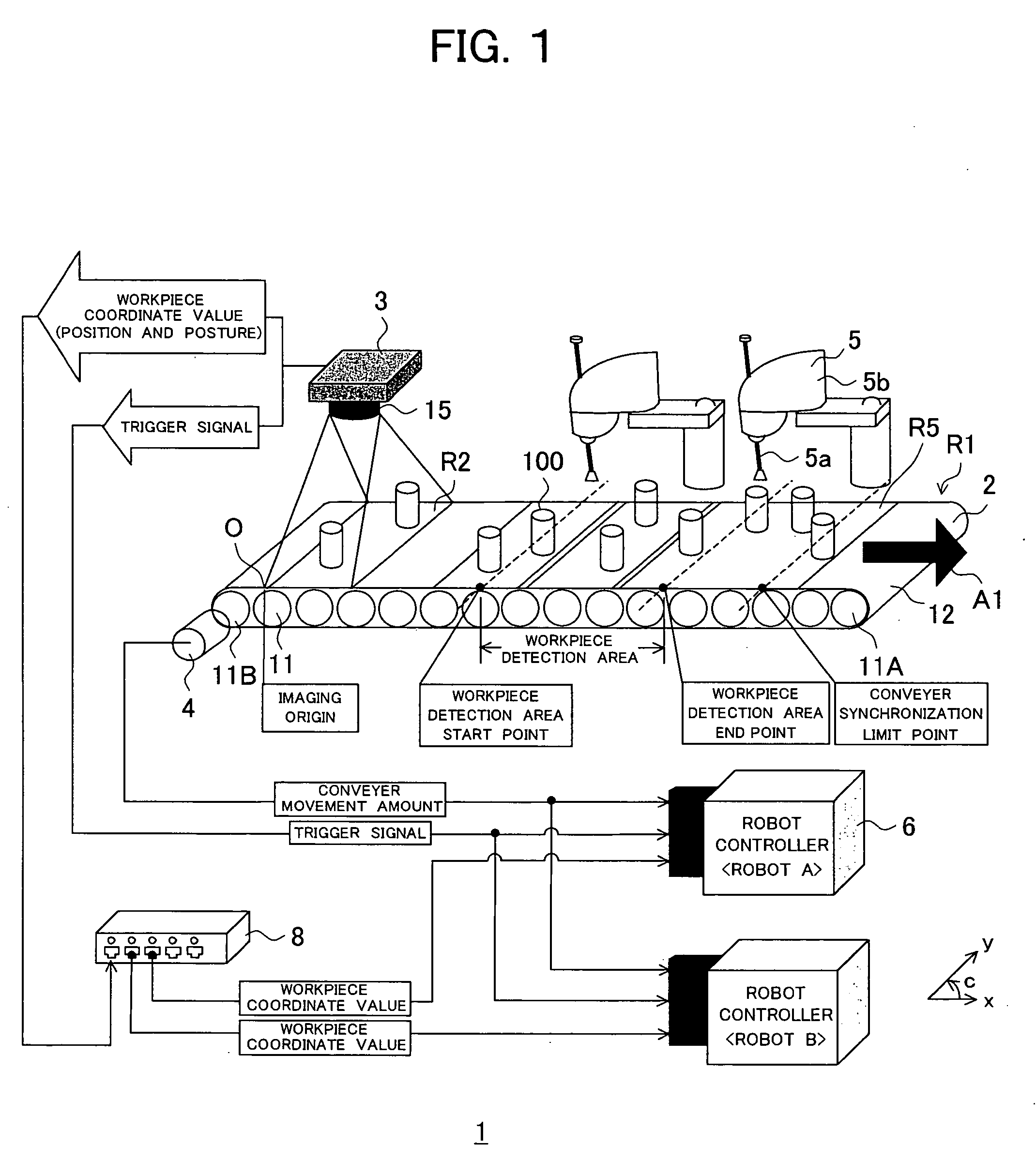

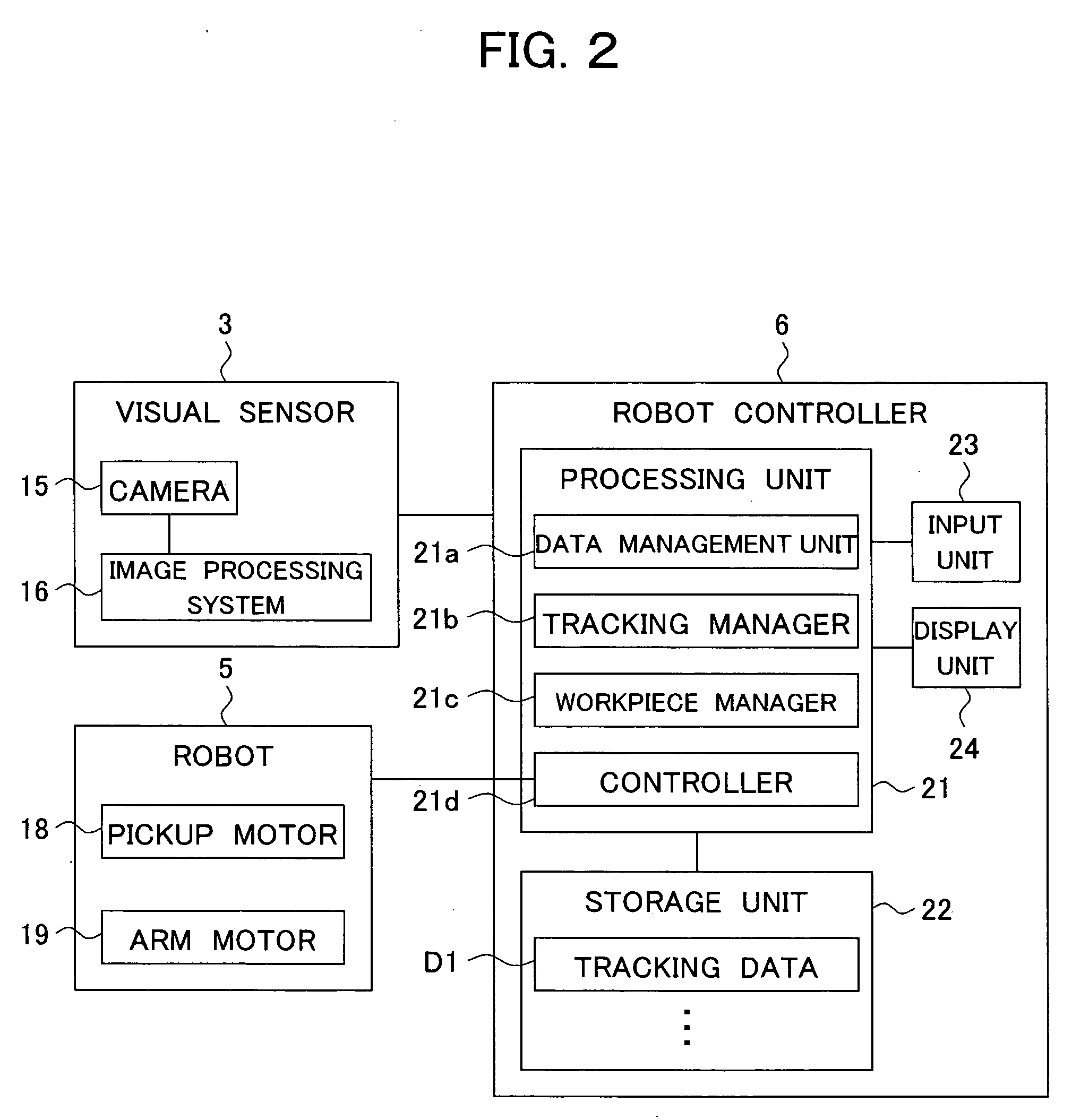

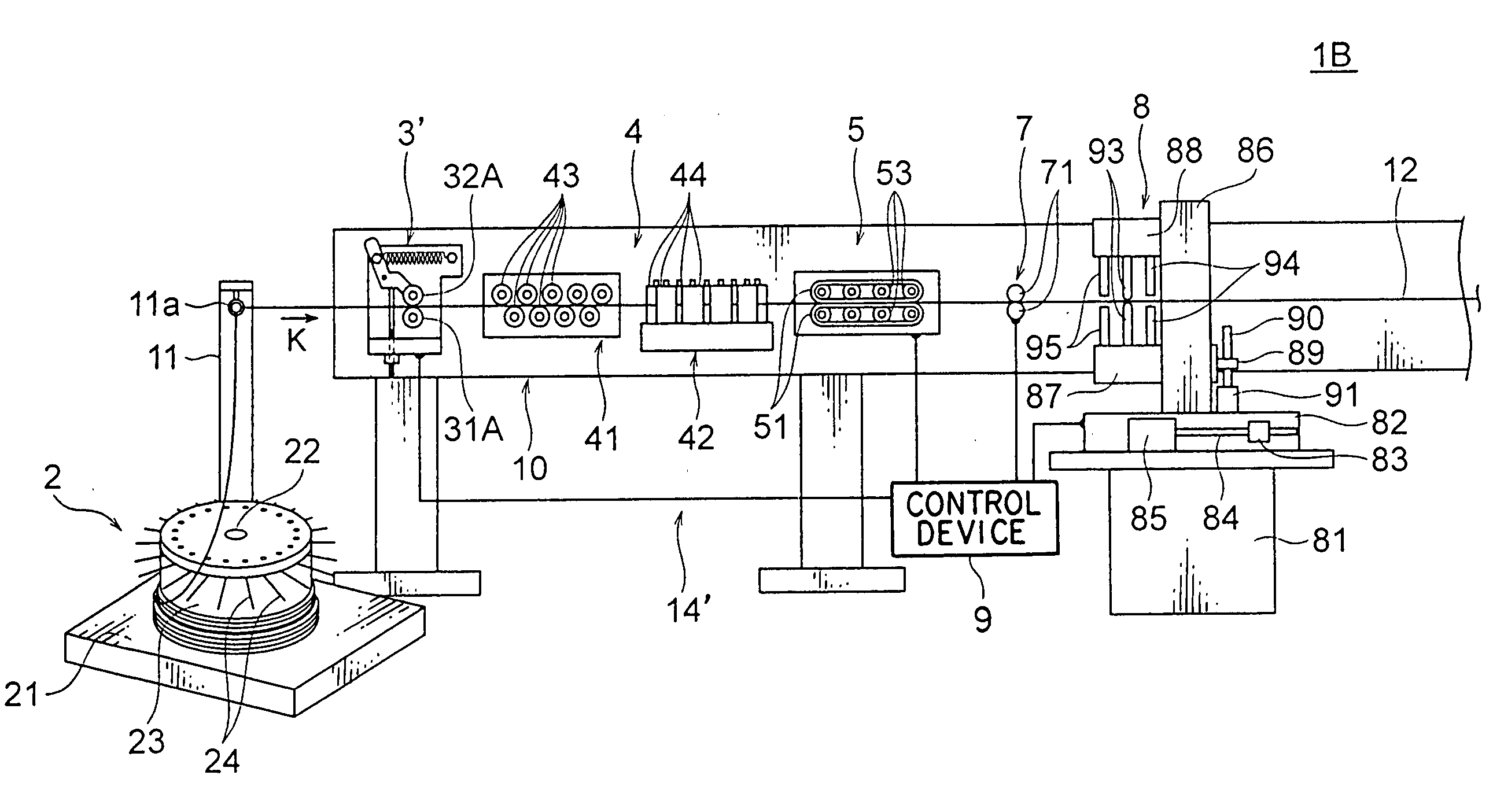

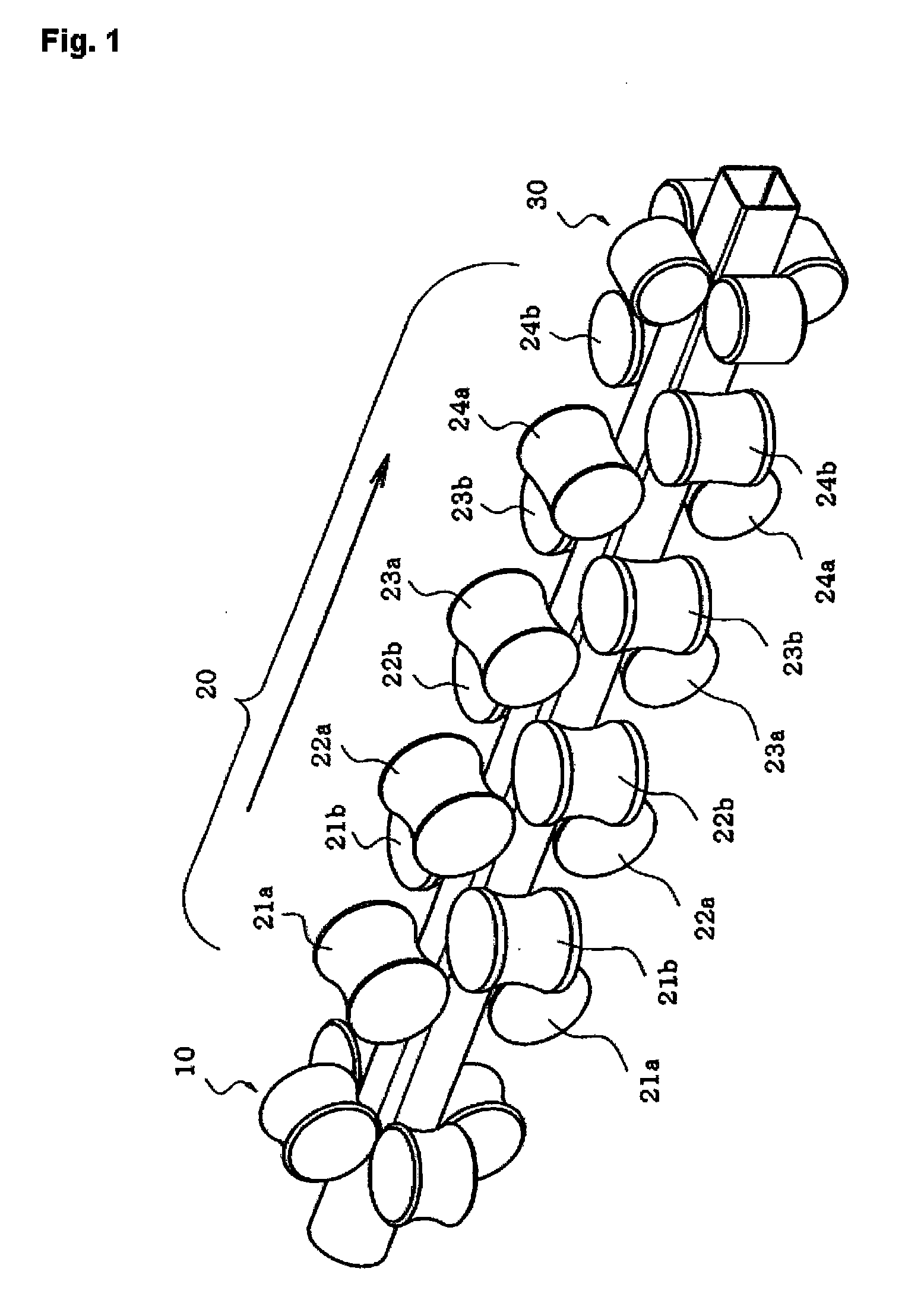

Handling system, work system, and program

ActiveUS20070007924A1Efficient processingProgramme-controlled manipulatorSemiconductor/solid-state device manufacturingHandling systemVision sensor

A handling system able to efficiently process information relating to a plurality of conveyed articles, the handling system provided with a conveyer for conveying workpieces, a visual sensor for detecting positions of workpieces by acquiring images of a plurality of tracking ranges obtained by dividing a belt into sections, an encoder for detecting an amount of movement of the belt, a tracking manager for monitoring amounts of movement of the plurality of tracking ranges based on the amount of movement detected by the encoder and specifying the tracking range passing through a workpiece detection area, a workpiece manager for selecting the article in the tracking range specified by the tracking manager, and a controller for controlling operations of robots so as to hold the workpiece selected by the workpiece manager.

Owner:TOSHIBA MASCH CO LTD

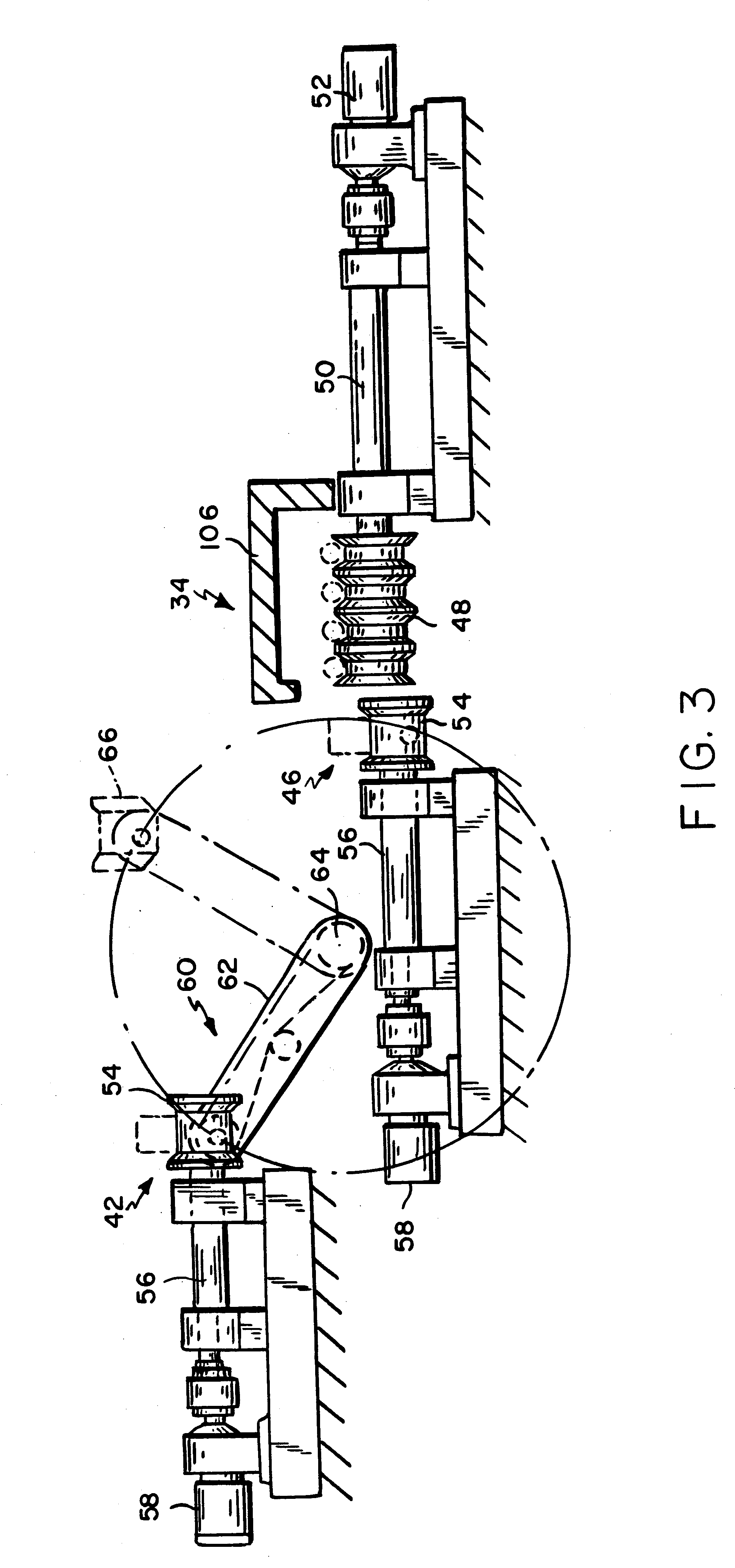

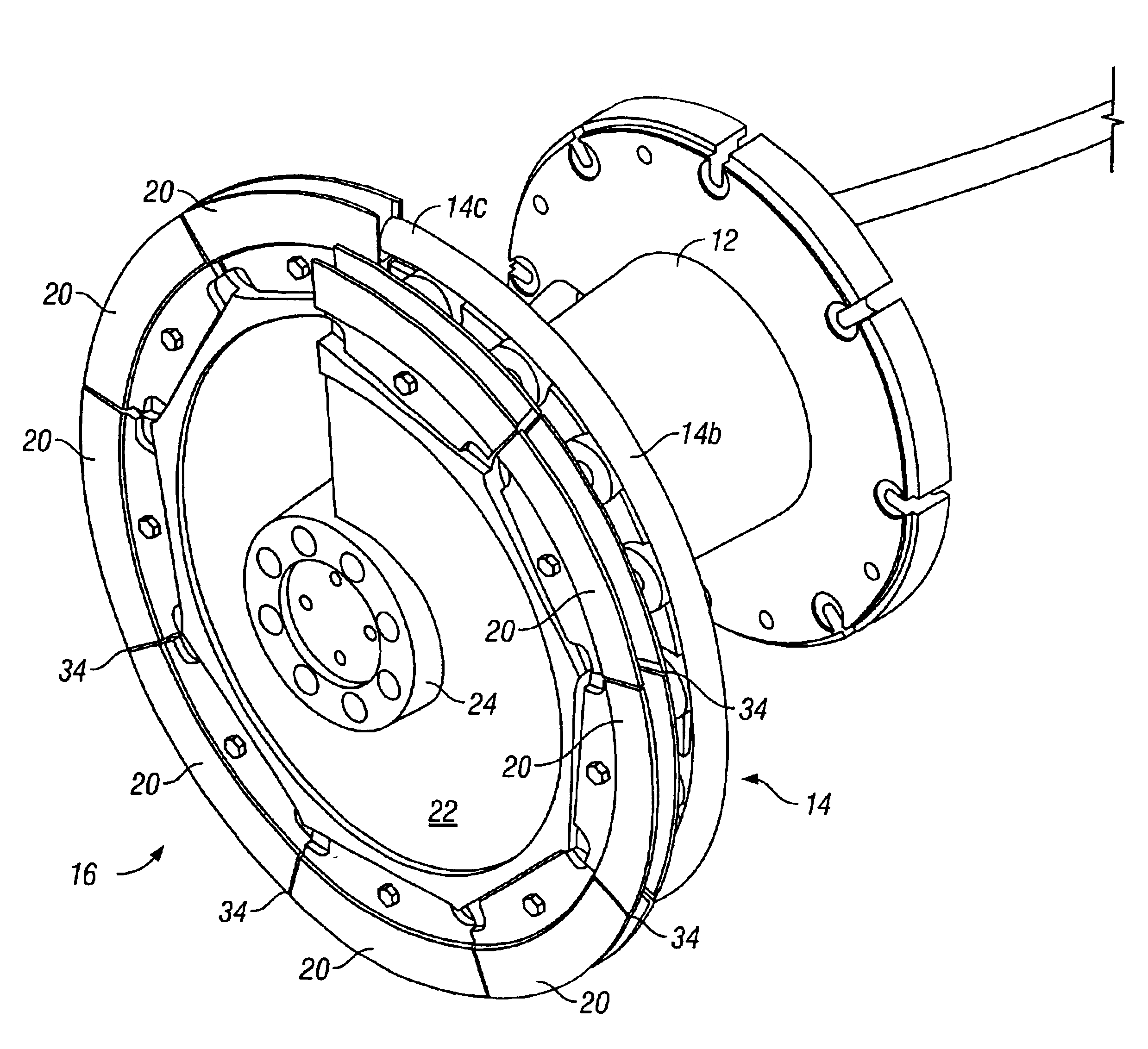

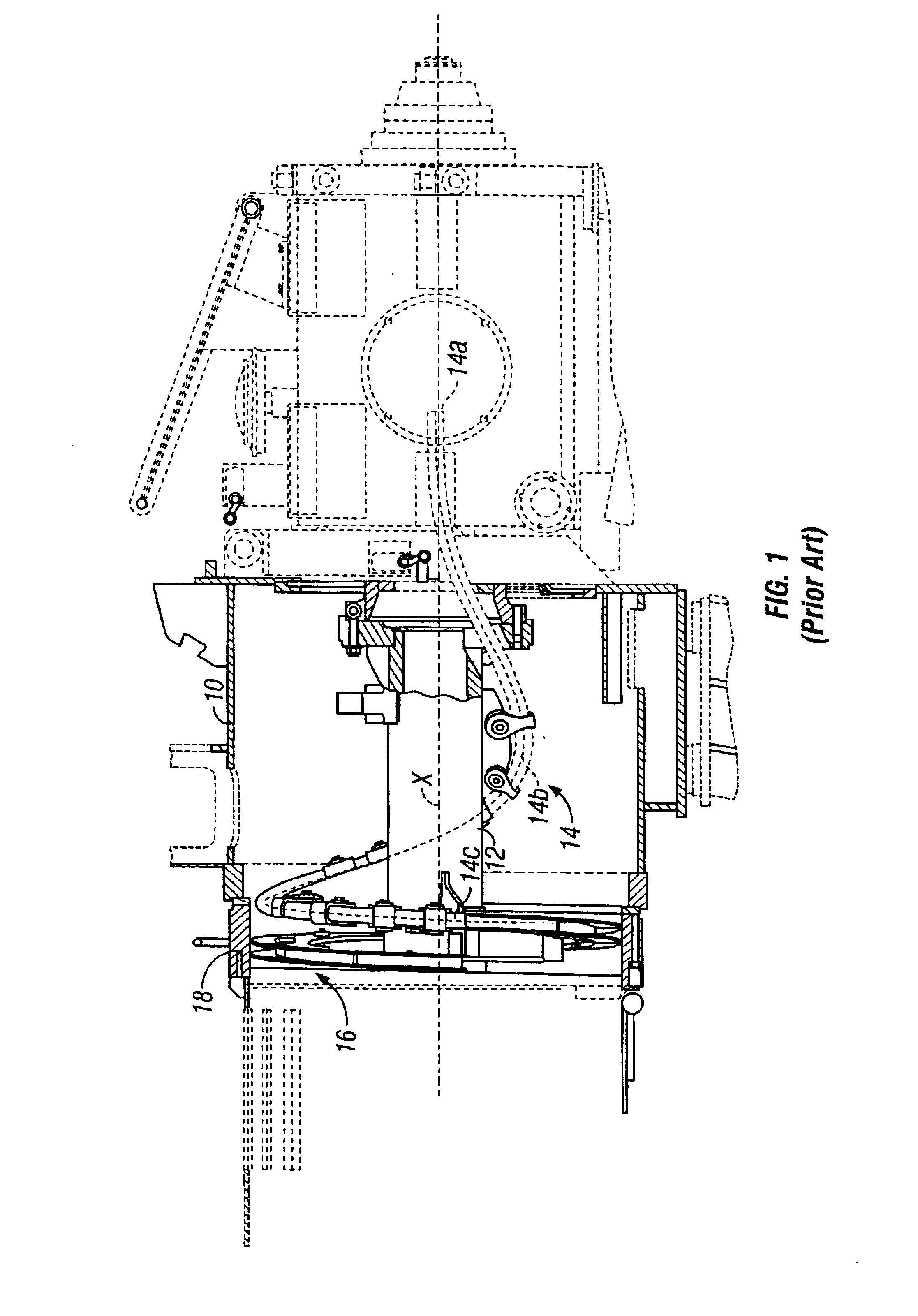

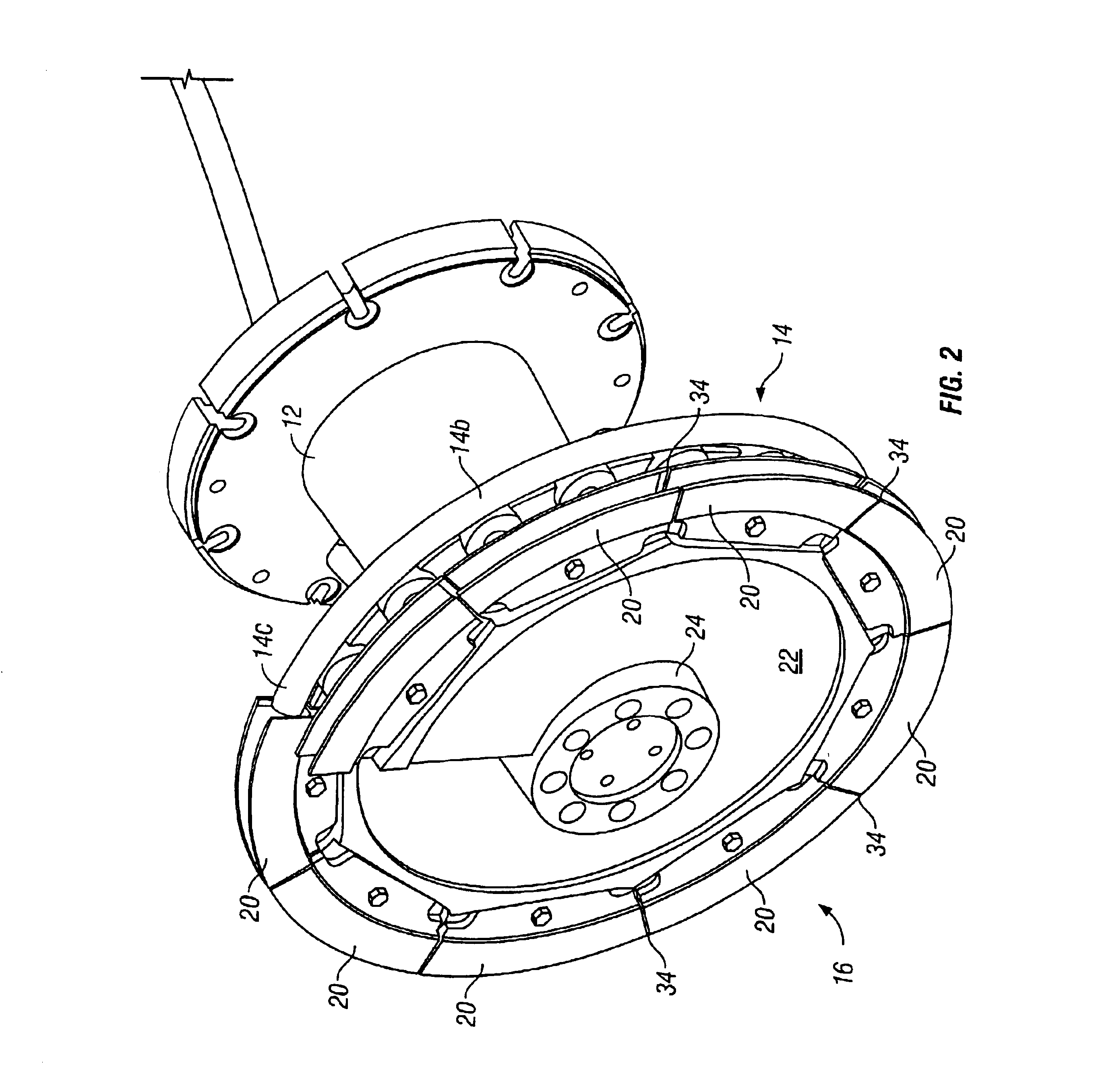

Segmented ring guide for rolling mill laying head

InactiveUS6769641B2Guiding/positioning/aligning arrangementsWork manipulationEngineeringRolling mill

A laying has a quill rotatable about an axis, and a pipe carried on the quill. The pipe has an entry end arranged to receive a product, and an intermediate portion defining a curved guide path leading from the entry and to a delivery end spaced radially from the quill axis and from which the product is discharged as a helical series of rings. A guide defines a helical extension of the guide path, and comprises a helical support plate projecting outwardly from the quill. A plurality of channel-shaped guide sections supported end to end on the support plate. The guide sections form a segmented radially outwardly facing helical trough surrounded by a cylindrical shroud that cooperates with the guide sections to definee radially and axially confined helical extension of the guide path.

Owner:PRIMETALS TECH USA

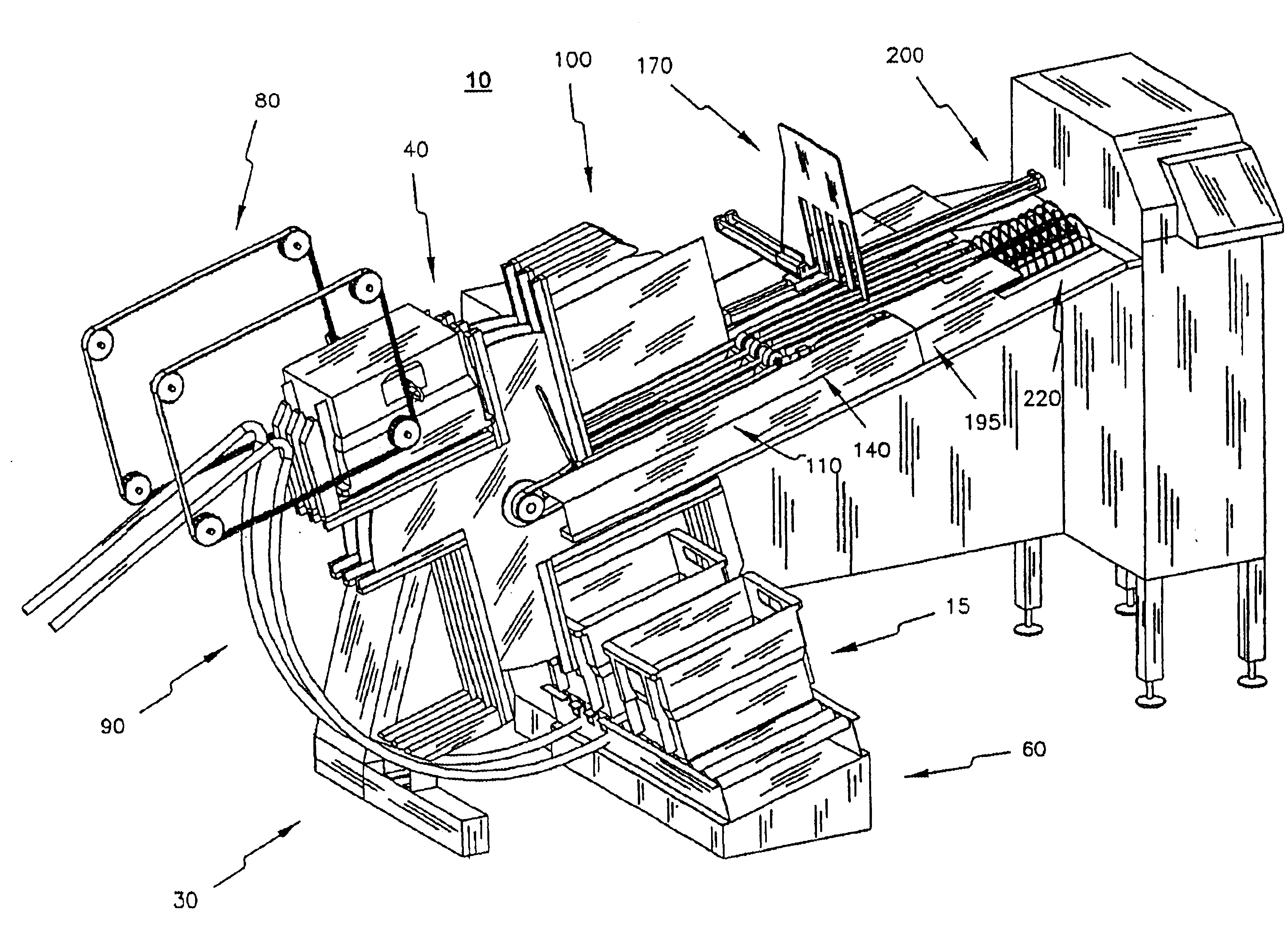

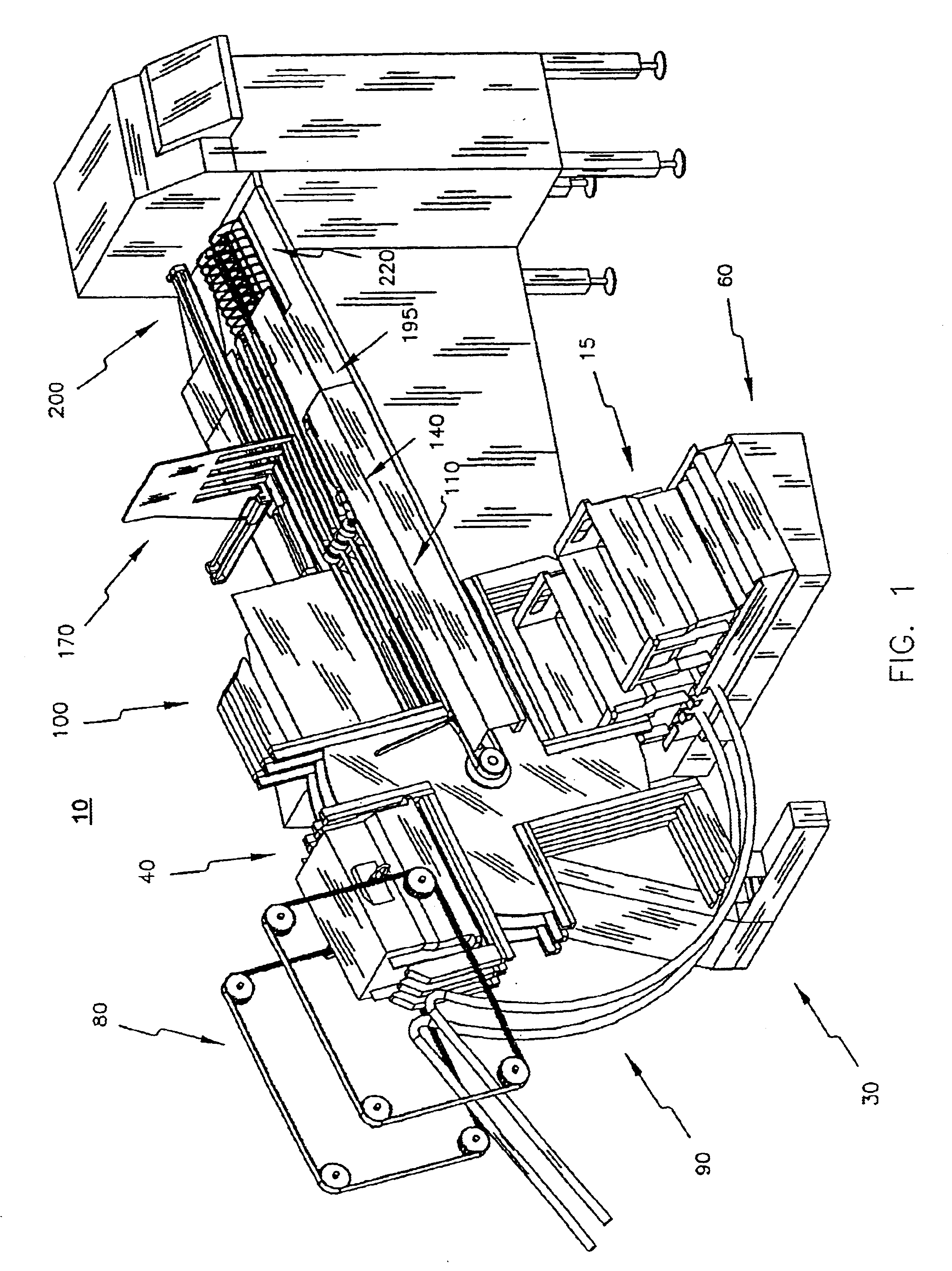

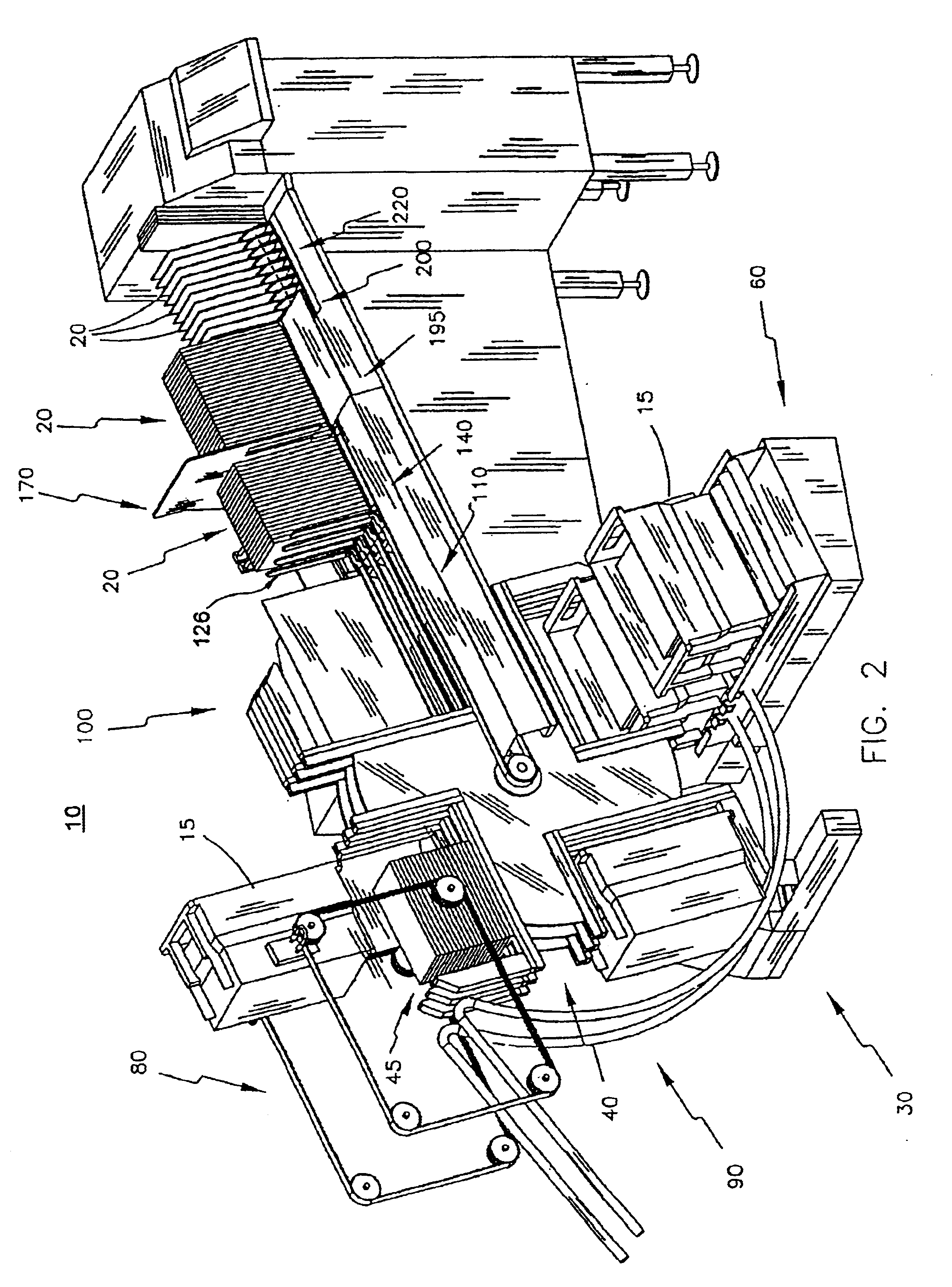

Method and system for high speed tray unloading and mail transporting

InactiveUS6896471B2Prevent the mail from fallingReadily apparentWork manipulationArticle unpackingTransport systemTransit system

A method and apparatus for high speed tray unloading and mail transporting includes a tray unloading apparatus which receives a continuous stream of mail trays and sequentially unloads them in proper orientation onto a conveyor assembly; a dual conveyor system for delivering the unloaded mail to a transport system; and a spiral transport system having optimal drive means for controllably moving mail pieces from one location to another.

Owner:BOWE BELL HOWELL

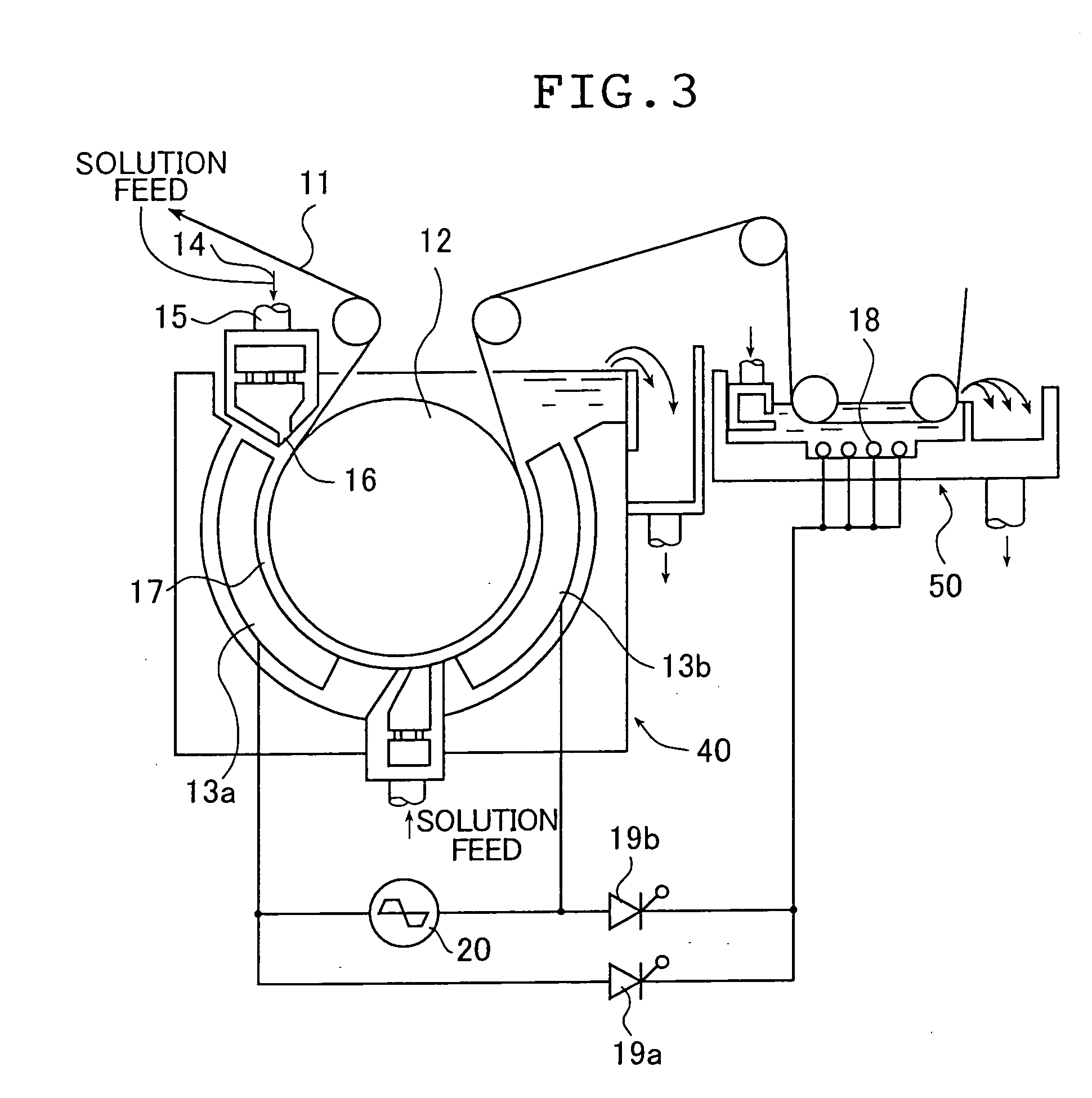

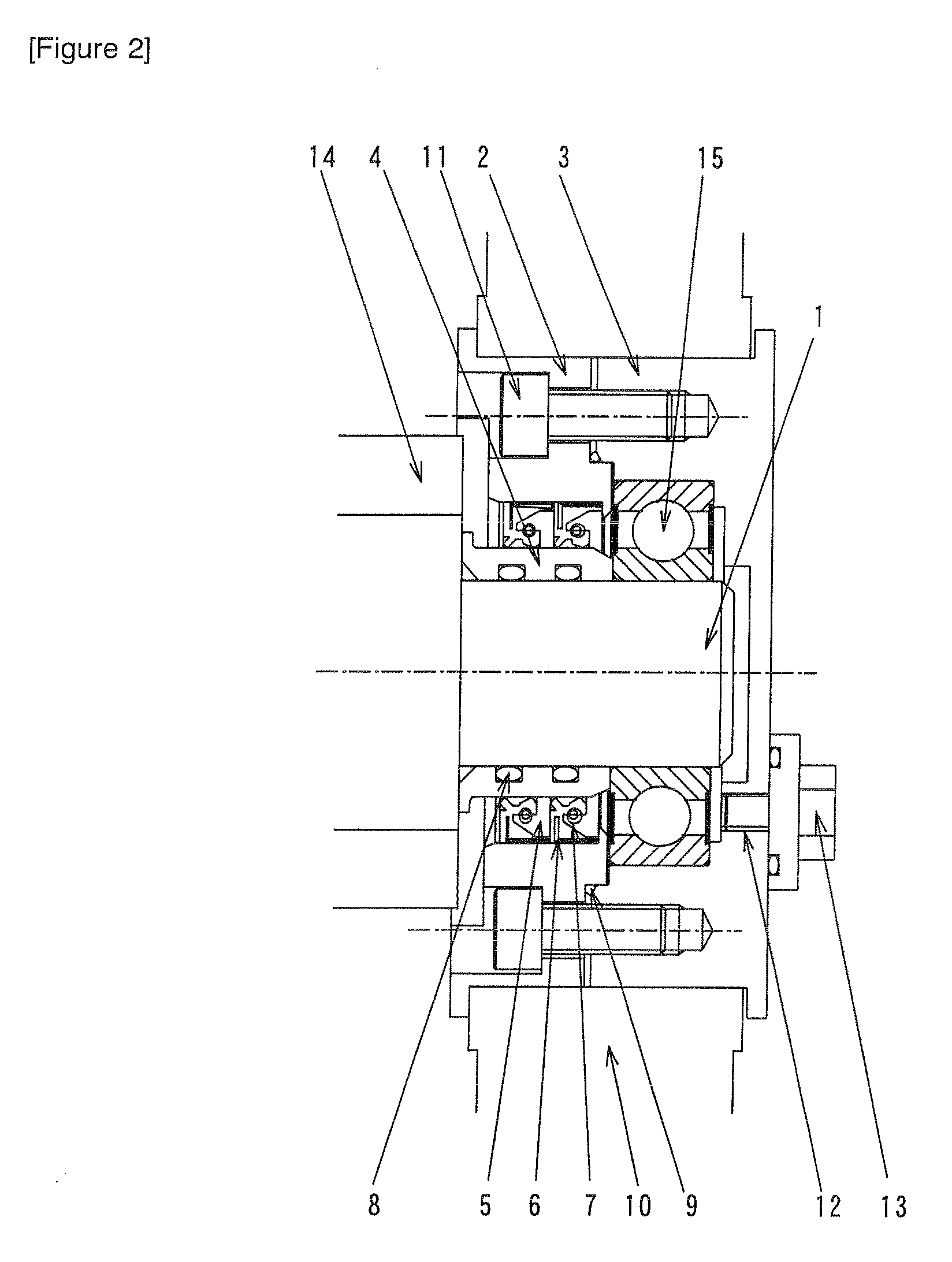

Device for clamping and rotating the object

InactiveUS20120163952A1Small device sizeLower the volumeWork manipulationSemiconductor/solid-state device manufacturingMechanical engineeringEngineering

Owner:CHAN LI MACHINERY

Roll embossing of discrete features

ActiveUS20060123867A1Effective widthReduce compressionShaping toolsDecorative surface effectsUltimate tensile strengthMaterials science

A cold rolling process for impressing a pattern on a surface of a sheet metal article involves passing the sheet article through a pair of rolls and engaging a patterning feature with isolated areas of a surface of the sheet article, at a localized pressure to plastically deform at least the surface of the sheet article. A rolling pressure is maintained on other areas of the sheet article that is less than the bulk elastic yield strength of the metal. A cold rolling apparatus is also described having a pair of rolls, each with partially cylindrical outer surfaces. The rolls have a gap between the cylindrical parts. One of the rolls has a localized surface region that is displaced relative to the surface of the roll. When the localized region is brought near the other roll, a spacing exists that is narrower than the gap. One of the rolls has a localized patterning feature that aligns with the localized surface region to impress a pattern into the sheet article. The gap allows the rolls to engage opposite surfaces of the sheet article while imparting compression less than a bulk elastic yield strength of the metal.

Owner:NOVELIS INC

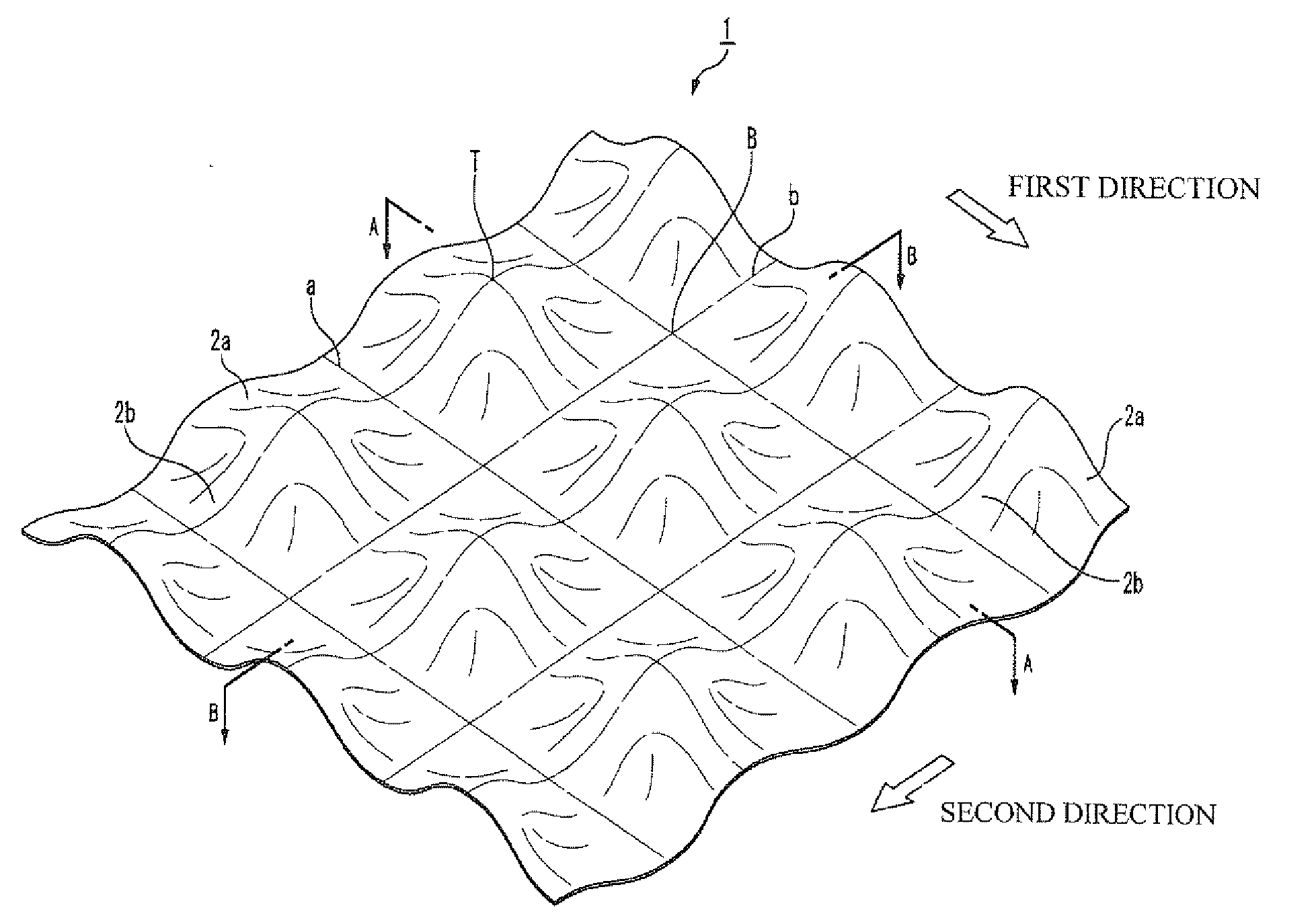

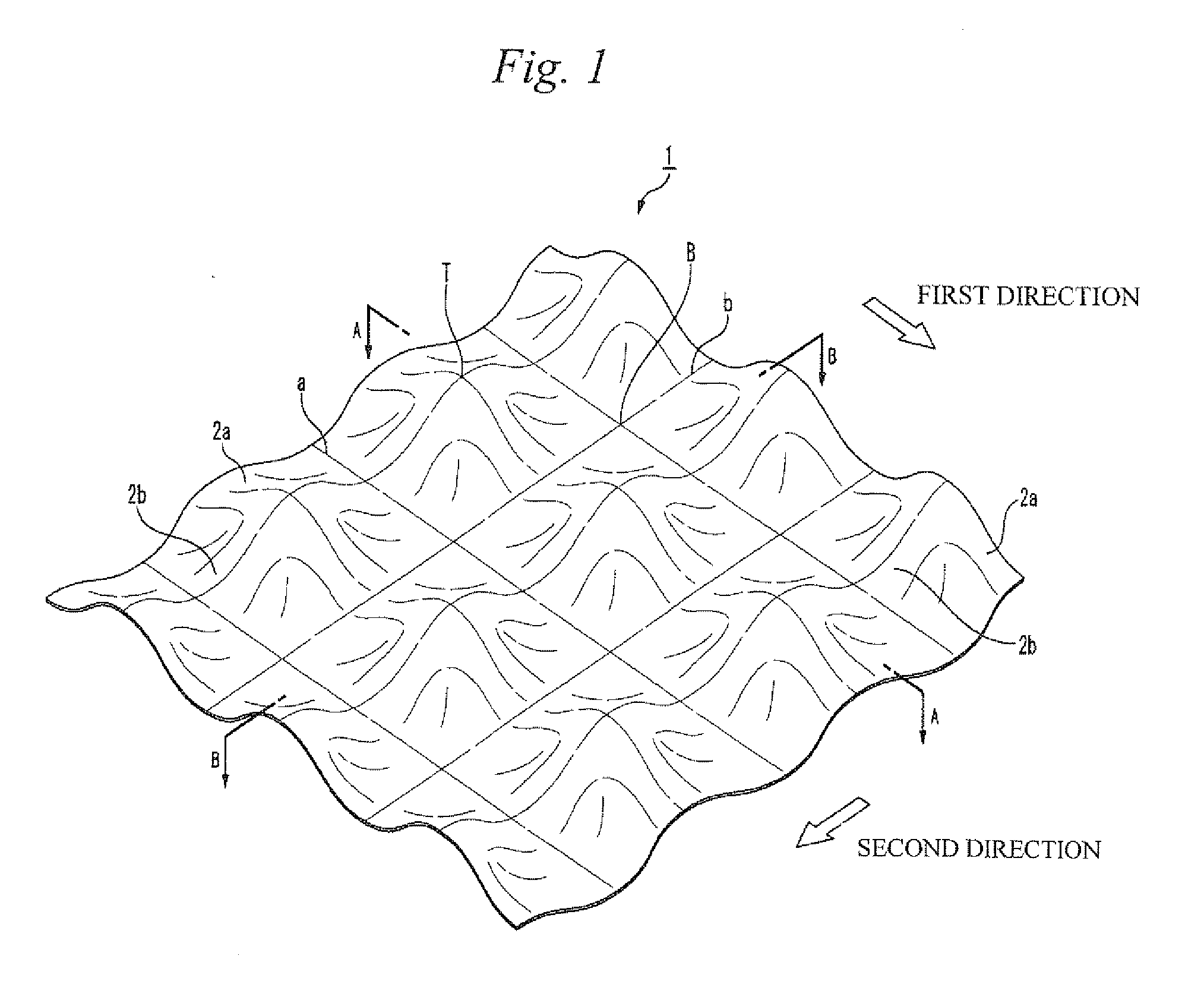

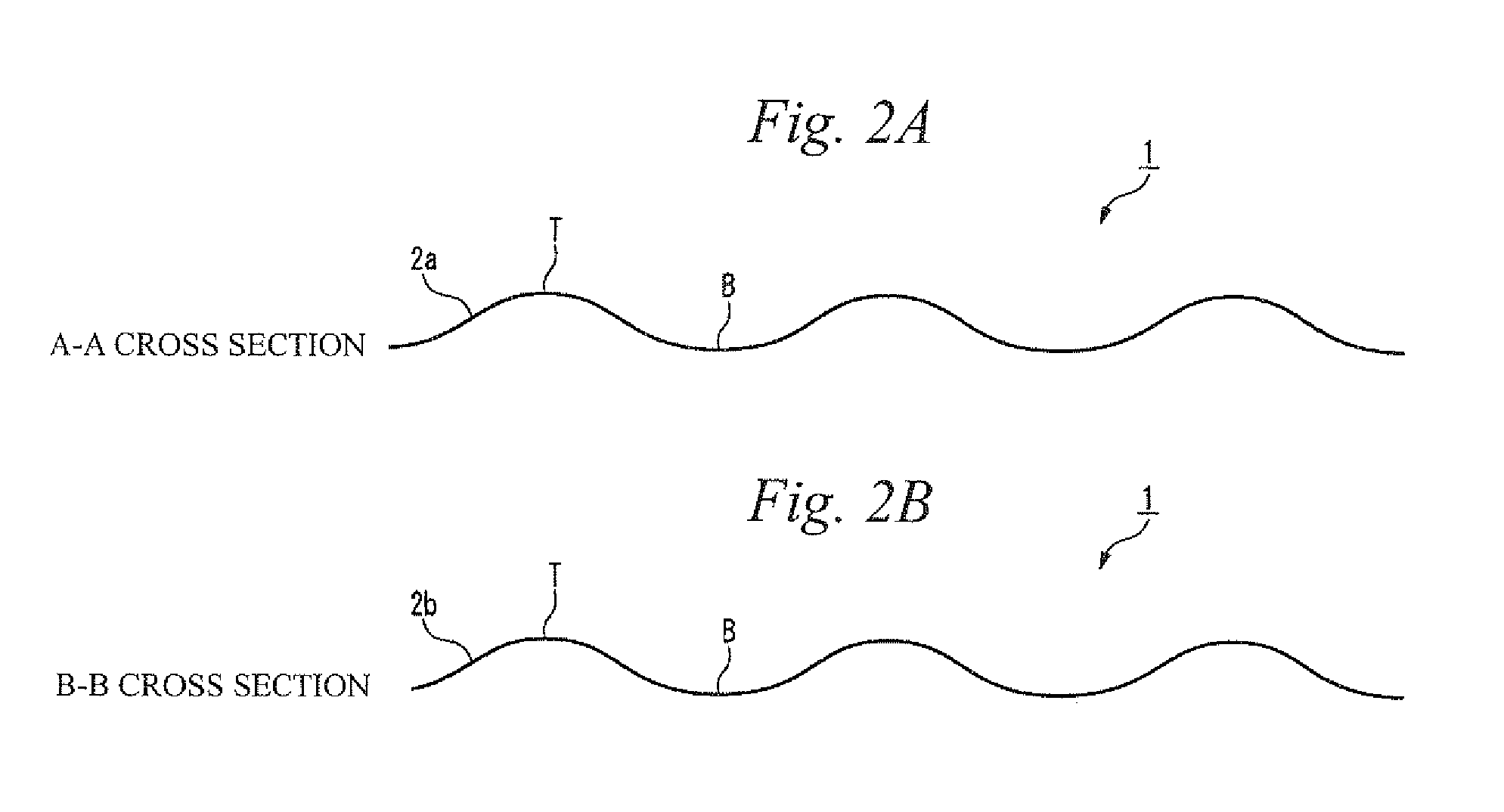

Metallic molded sheet and heat shielding cover

InactiveUS20090202856A1Light weightSufficient shape retainabilityExhaust apparatusLayered productsMaterials scienceRidge

The present invention relates to a metallic molded sheet including a metallic sheet having first ridges continuously formed along a first direction and second ridges continuously formed along a second direction which is perpendicular to the first direction, in which the metallic molded sheet has cross-sectional shapes along the first direction and the second direction, each having an identical thickness and continuing sinusoidally, and the metallic molded sheet has a planar shape being a corrugated surface in which ridge lines of first waveforms along the first direction and ridge lines of second waveforms along the second direction perpendicularly intersect each other.

Owner:NICHIAS CORP

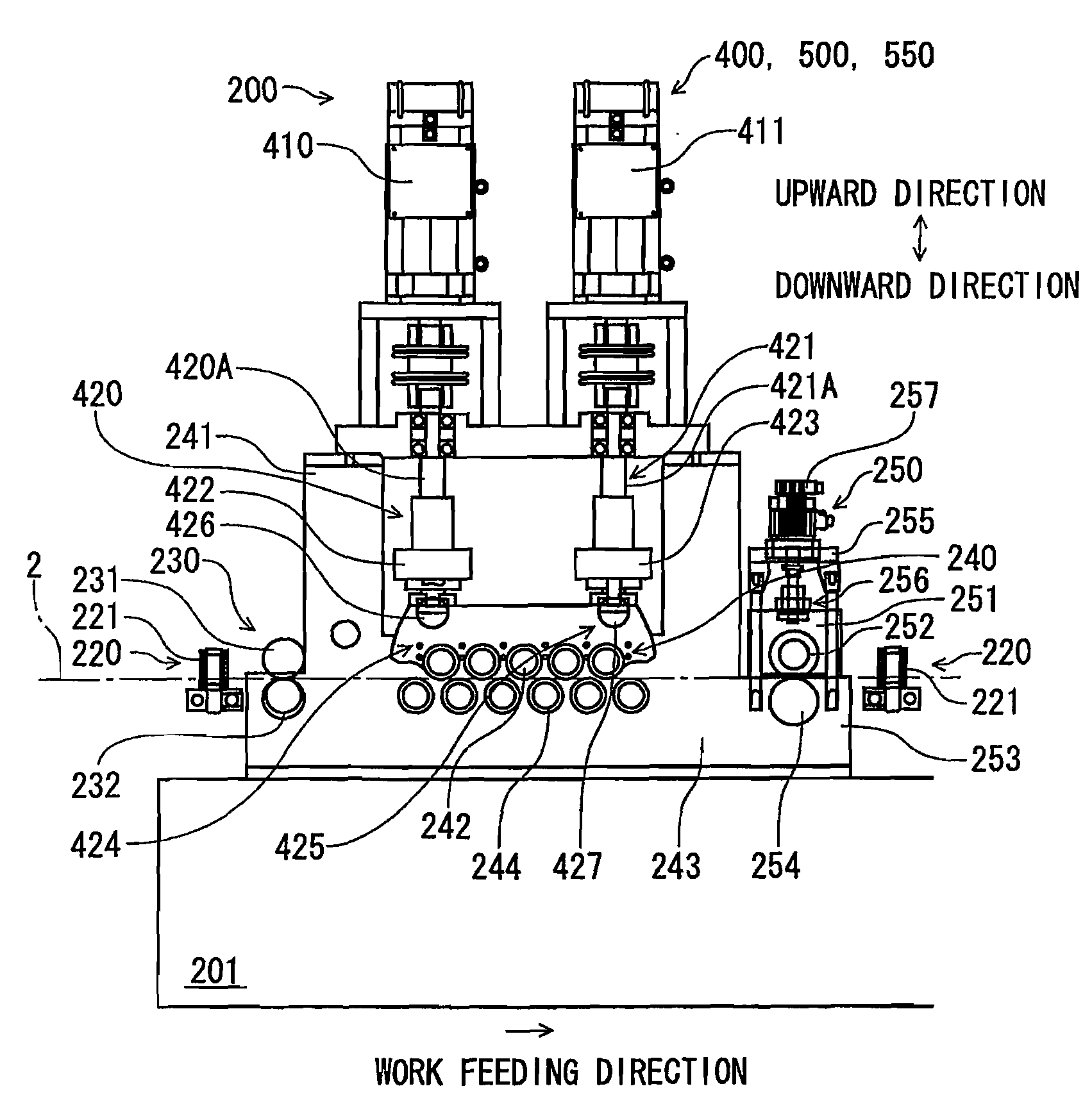

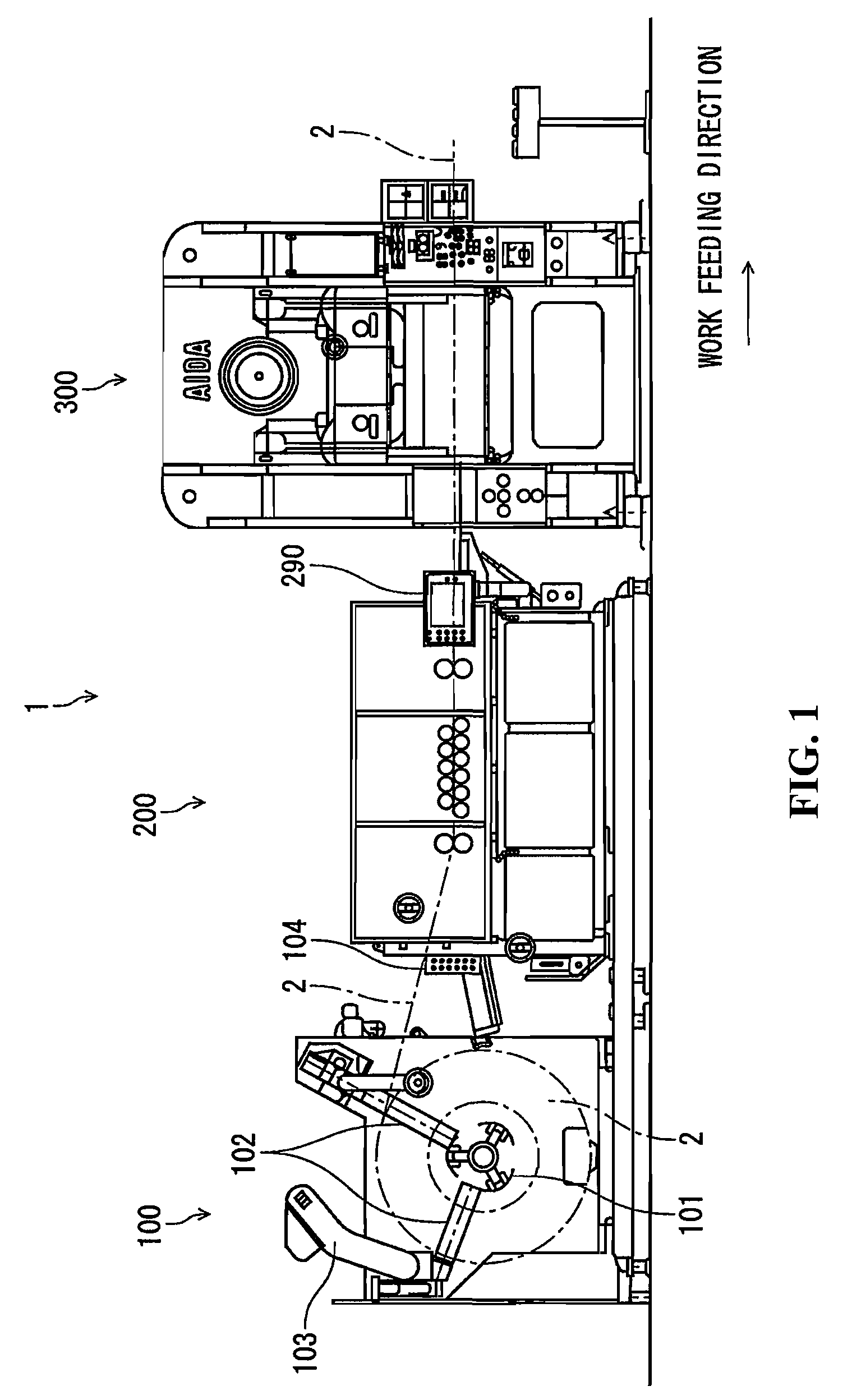

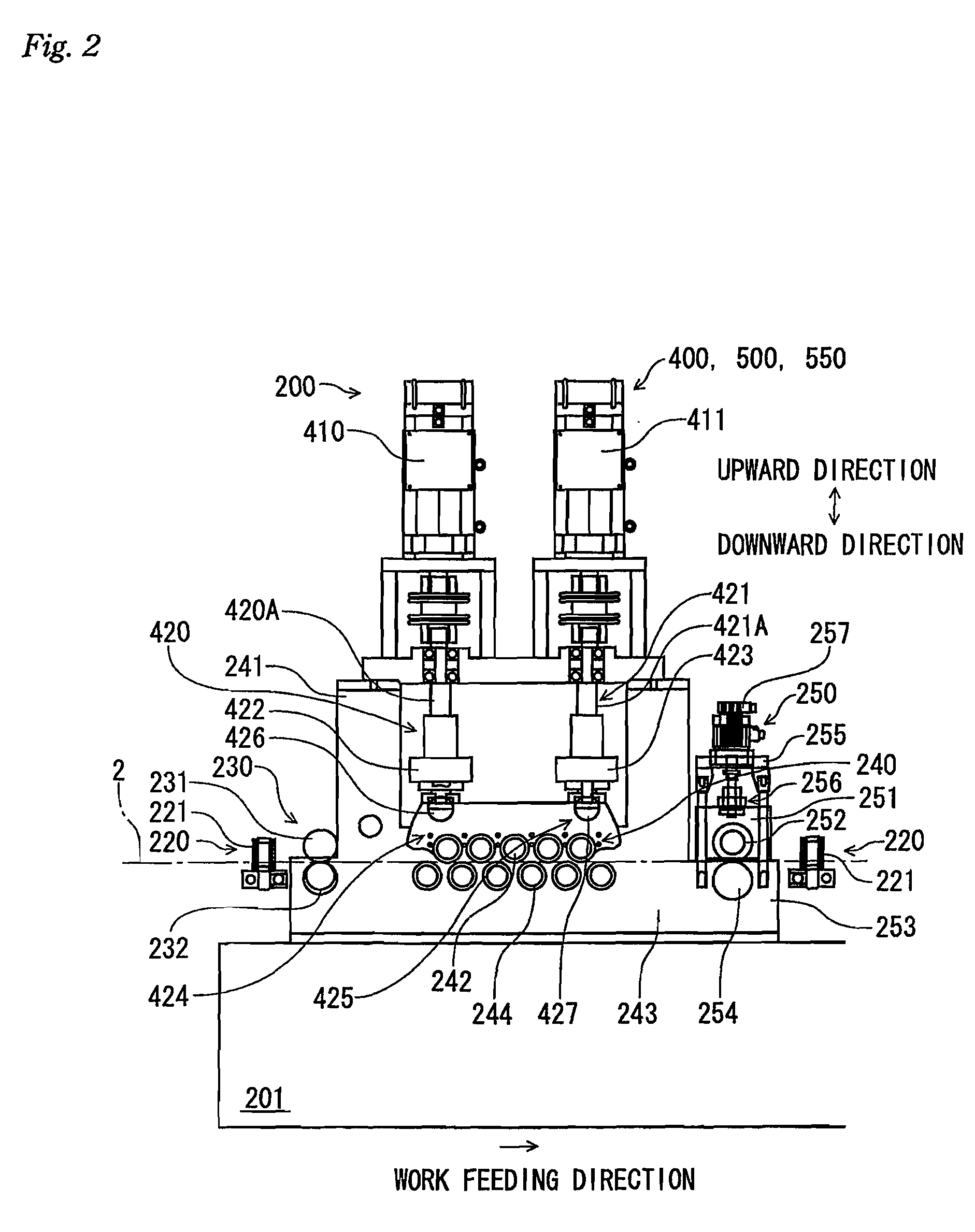

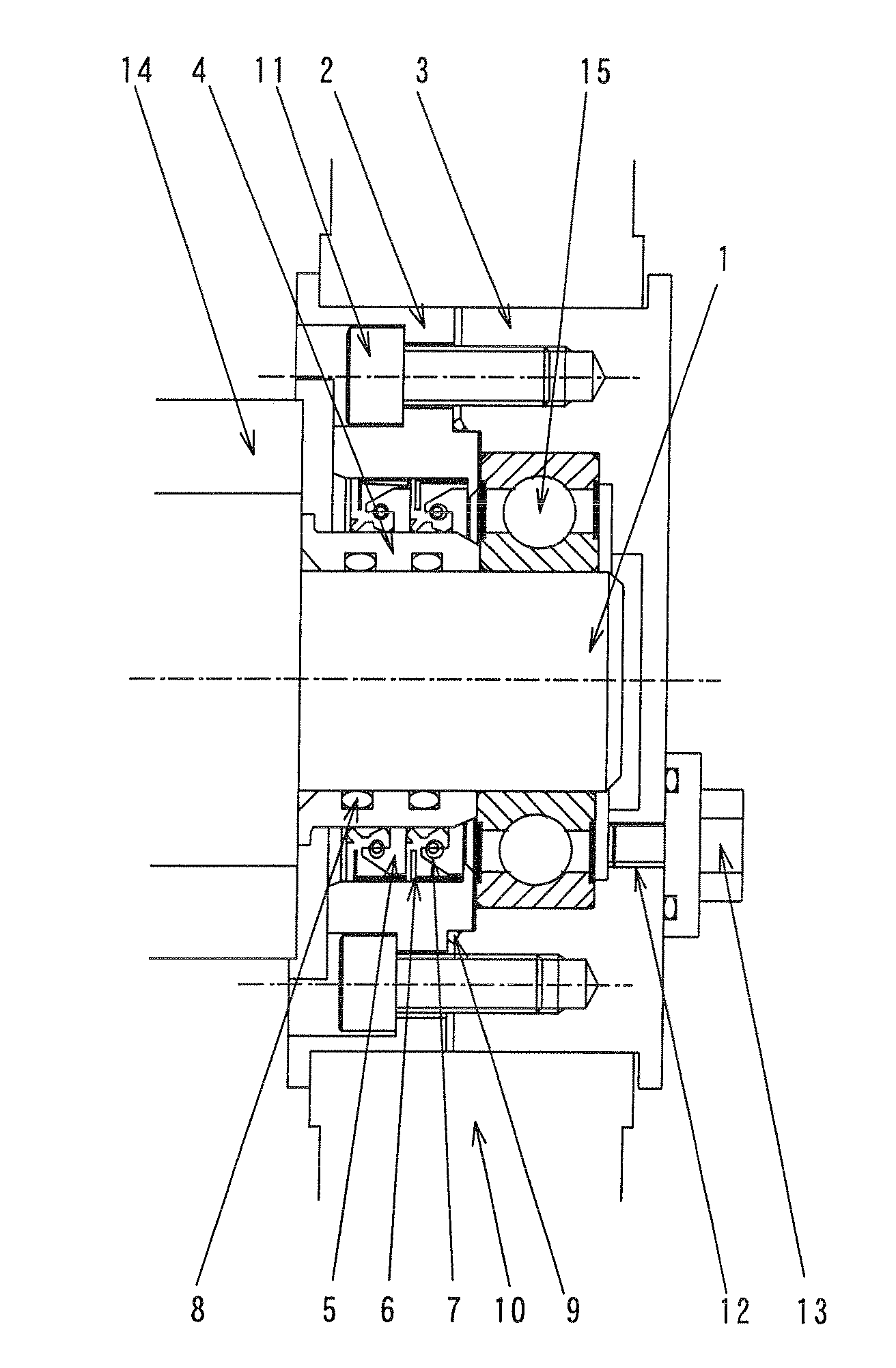

Releasing mechanism and leveling apparatus

ActiveUS20080098786A1Improve responseReduce noiseMetal-working feeding devicesWork manipulationWork rollWork clamp

A release mechanism for use in a leveling apparatus that performs a leveling process on a work object that has been wound in a coil configuration as a result of the work object being passed between a front side work roll in contact with the front side surface of the work object and a back side work roll that is in contact with the back side surface of the work, wherein the releasing mechanism switches between a work clamp state that allows performance of the leveling process and a release state that releases the work object from the clamp state by displacing a work roll support member that supports one of the work rolls relative to the another support member to change a distance between the work rolls by utilizing rotational movement of an electric motor.

Owner:AIDA ENG LTD

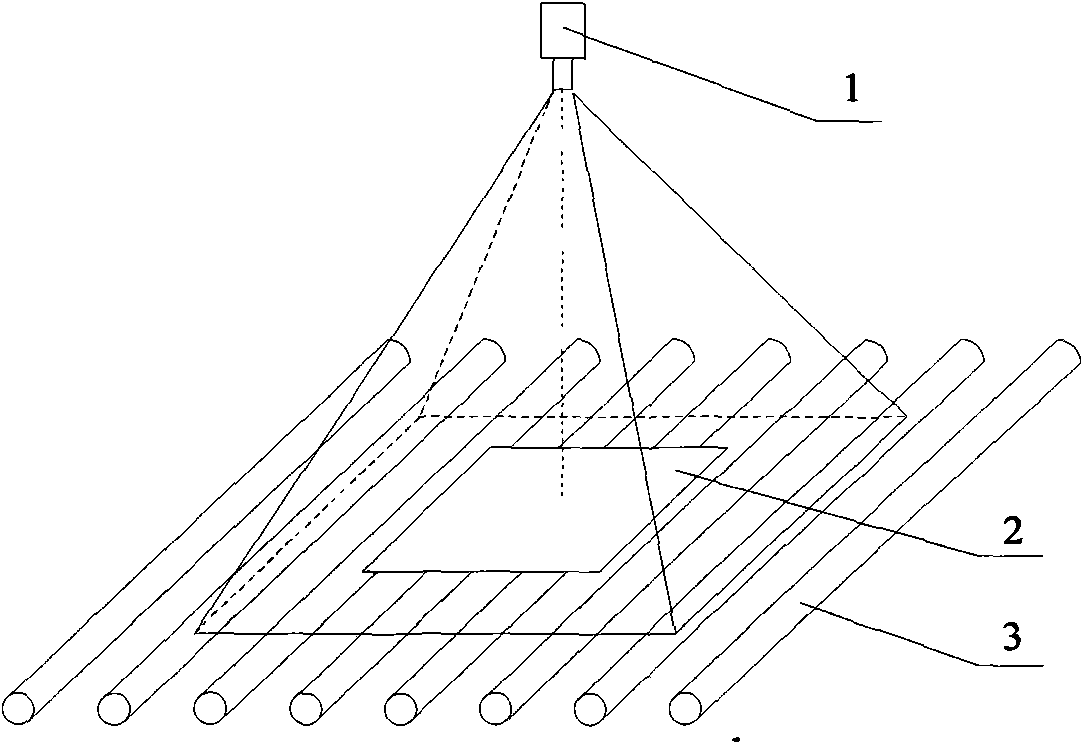

Automatic steel rotation method for medium plates

InactiveCN101574709AEasy to installThe detection process is fastImage analysisWork manipulationIndustrial EthernetRotation method

The invention relates to an automatic steel rotation method for medium plates, which belongs to the technical field of steel rolling. The method comprises the following steps of: 1, performing acquisition on a plate blank image; 2, performing edge detection on the plate blank image; 3, performing image distortion and calibration processing; 4, performing image binarization; 5, performing plate blank boundary tracking to obtain a boundary point set; 6, performing linear detection on plate blank boundary and calculating an rotating angle of a plate blank; 7, driving a steel rotation conical roller bed for steel rotation; 8, performing judgment of steel rotation in-place; 9, performing processing of steel rotation timeout; and 10, performing processing of steel rotation completion. The method has the advantages that the method has simple equipment installation and quick detection speed, can execute one-time detection and control within 100 ms, is based on an industrial Ethernet interface and basic automation communication, has stable and reliable steel rotation process, and is suitable to be embedded into an automatic steel rolling system of the medium plates for application.

Owner:NORTHEASTERN UNIV

Aluminum sheet embossing roll

InactiveUS20050159281A1Improve printing effectExtended press lifePhotosensitive materialsWork manipulationElectricityAbrasive blasting

Disclosed is a roll for embossing aluminum sheet, which is obtainable by subjecting a surface of a steel roll to at least the steps of, in order: blasting treatment, electrolytic treatment with 1,000 to 20,000 C / dm2 of electricity in which the steel roll is used as the anode, and chromium plating treatment. The aluminum sheet embossing roll of the present invention has on the surface thereof peaks, or asperities, which are of uniform height and very numerous. As a result, aluminum sheets obtained using such a roll, when employed as lithographic printing plate supports, have excellent printing characteristics, particularly a long press life and a high sensitivity.

Owner:FUJIFILM CORP +1

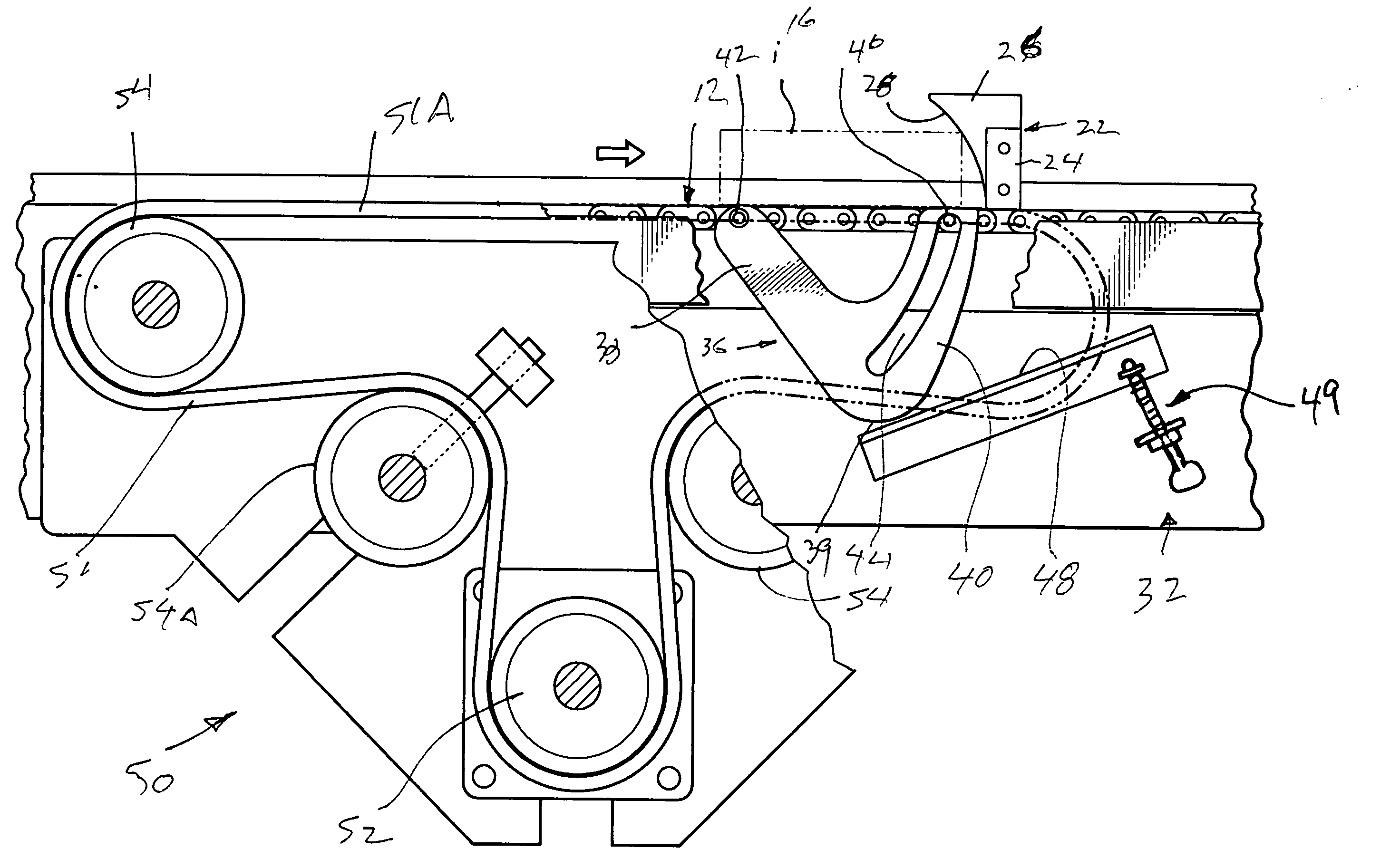

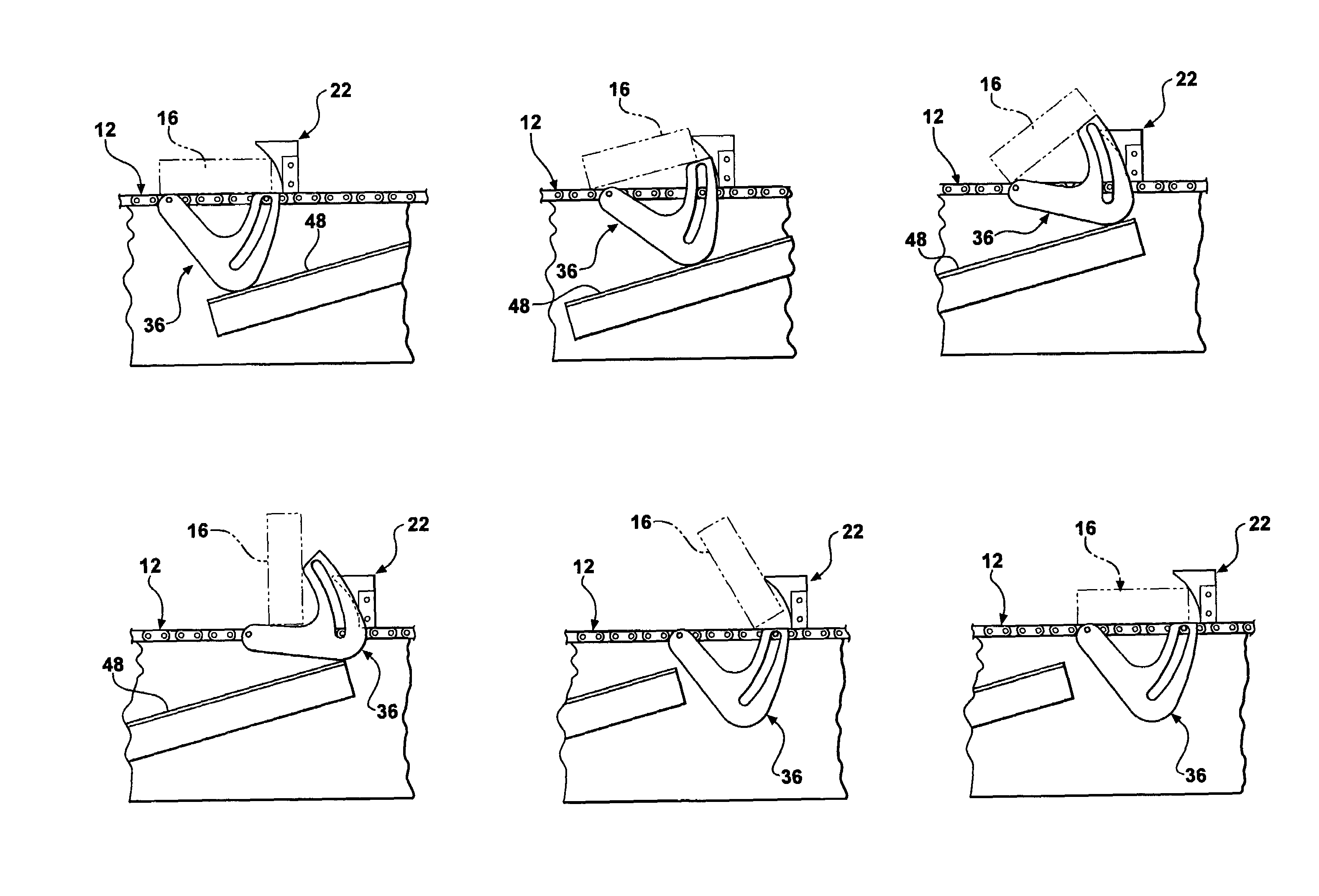

High speed turnover apparatus and method

A turnover apparatus and method for inverting articles such as lumber or board pieces being conveyed sideways on two or more conveyor chain loops in which each article is advanced on the conveyor chain loops by speed up belts engaging the underside of the articles to force a leading side against a pair of lugs mounted on a respective conveyor chain loop, the article thereafter flipped up to an on edge position by flipper arms also mounted on the conveyor chain loops which each engage an adjustable cam ramp at a turnover station, the article thereafter tipped over backward by being driven by the speed belts against an elevated overhung trailing edge on the lugs to complete the turnover. Optional pivoted let down elements may be arranged to engage the trailing side of the articles to controllably lower the same by motion induced by a second cam ramp at the turnover station.

Owner:KAUPPILA RICHARD W +1

High speed turnover apparatus and method

Owner:KAUPPILA RICHARD W +1

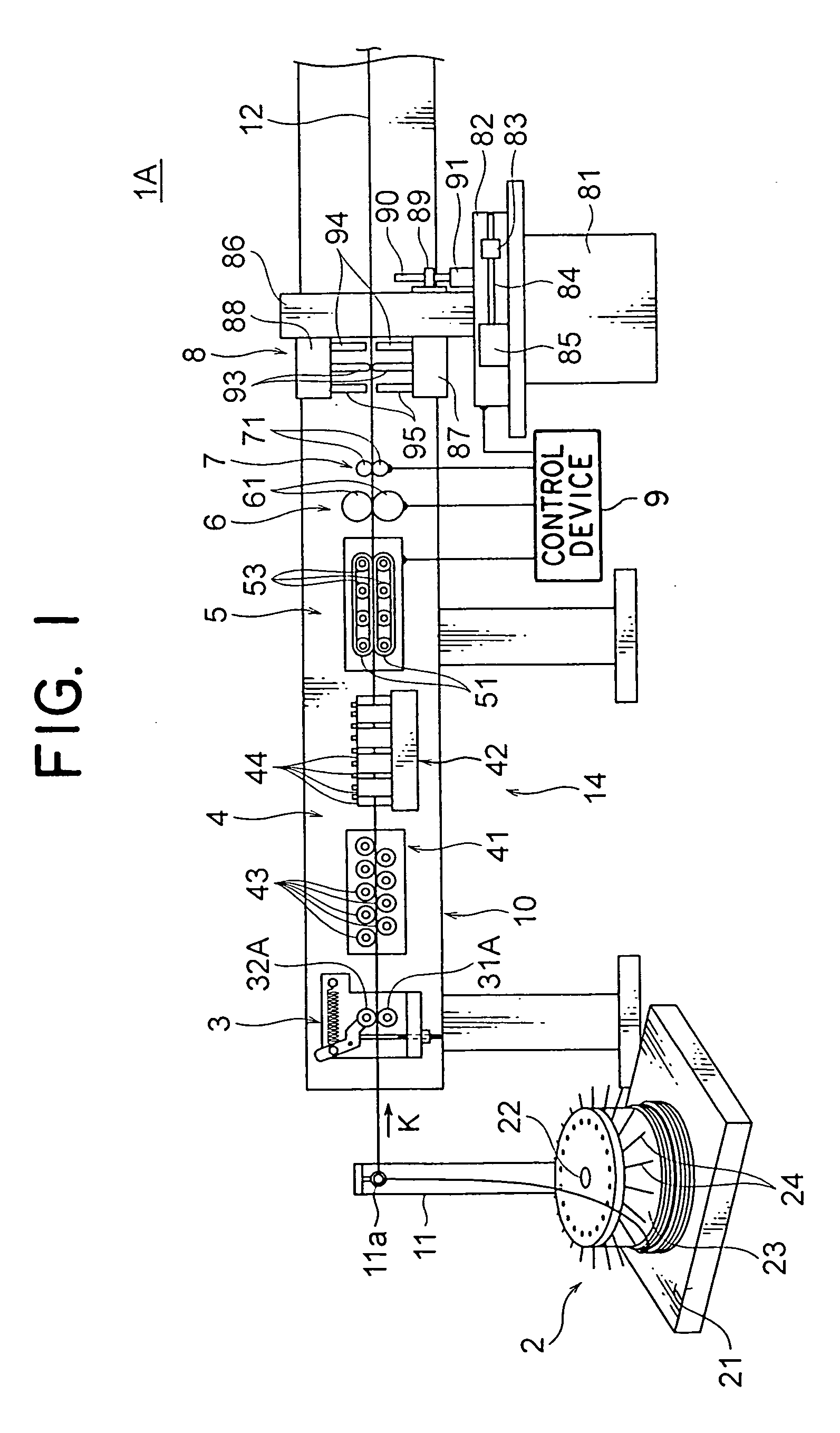

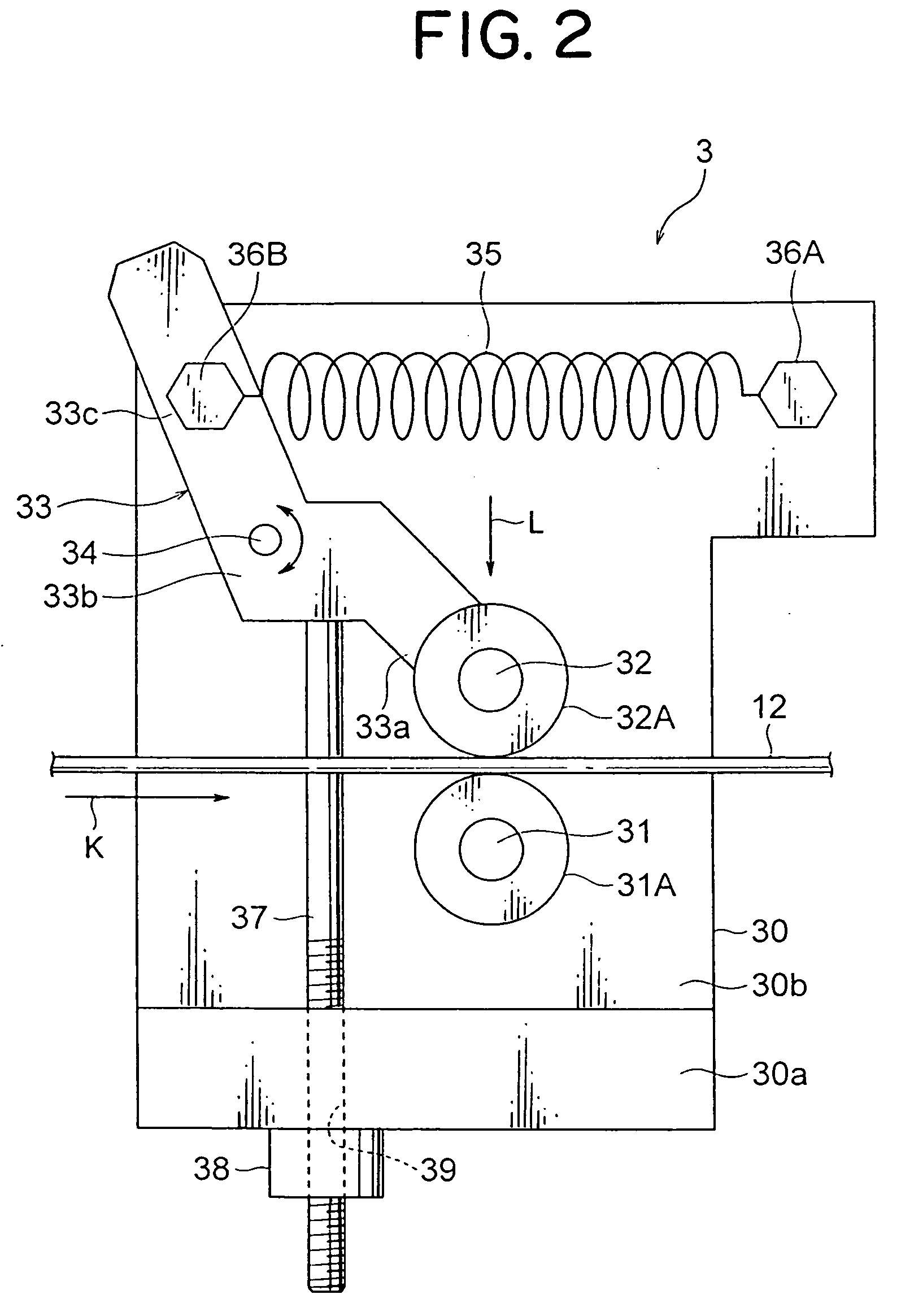

Electric wire delivery apparatus and electric wire sizing-cutting apparatus including the same

ActiveUS20080314473A1Improve productivityFree generationWire articlesMetal-working feeding devicesRotation controlSizing

An electric wire sizing-cutting apparatus including an electric wire delivery apparatus, which is easily handled and can smoothly supply the electric wire without generating a kink, is provided. The electric wire delivery apparatus includes: a transfer means transferring an electric wire, which is delivered from an electric wire reel, along a longitudinal direction of the electric wire; a correcting means arranged between the electric wire reel and the transfer means and correcting a bending habit of the electric wire by allowing the electric wire to pass through between a plurality of rollers arranged zigzag; and a rotation controlling means arranged on an upstream-side of the correcting means and putting the electric wire between a pair of rollers biased in a direction approaching each other.

Owner:YAZAKI CORP

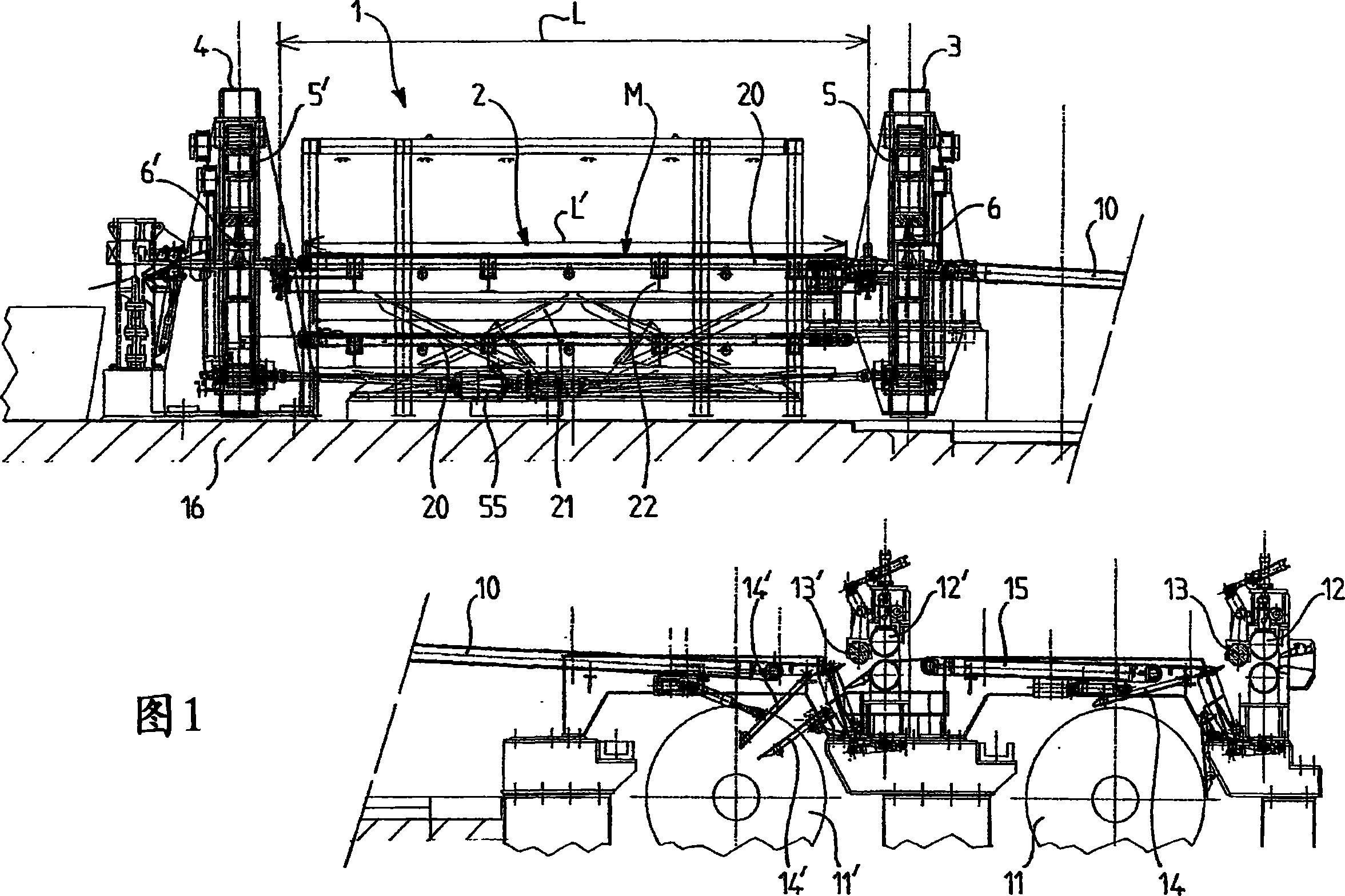

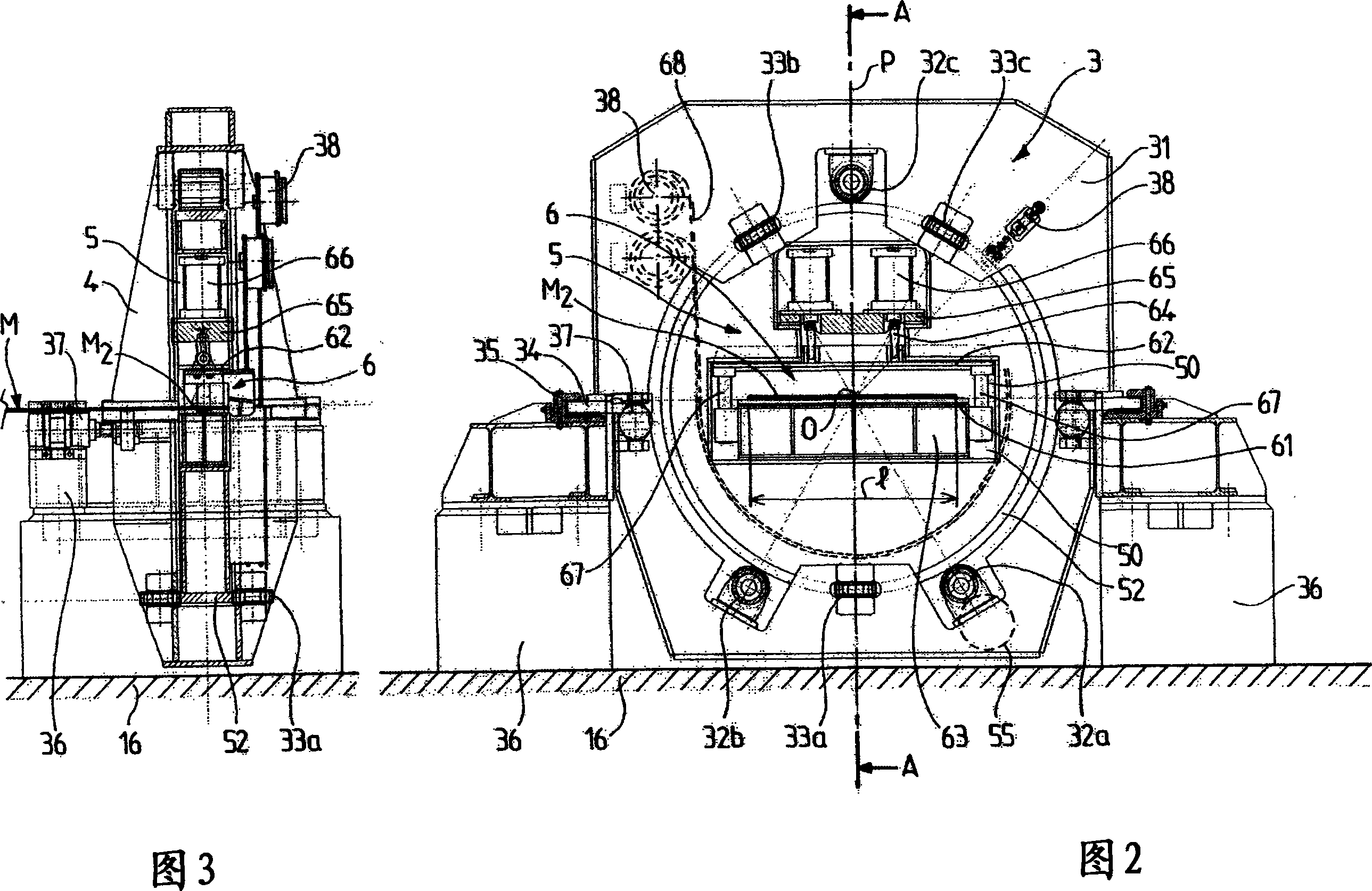

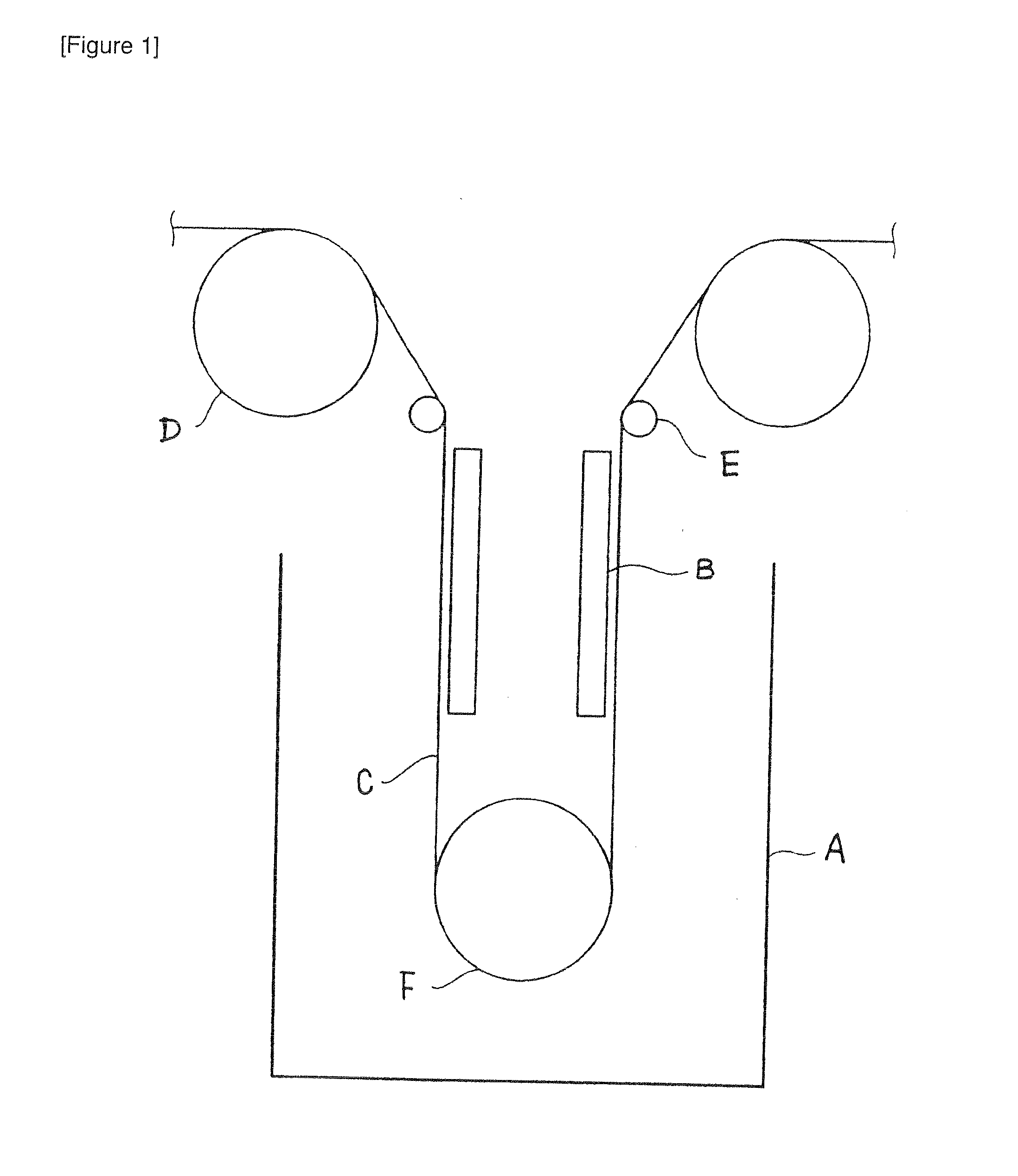

Method and device for the inspection of a rolled strip

ActiveCN101084076AVisual inspectionCheck implementationWithdrawing sample devicesWork manipulationProduction lineVisual inspection

The invention relates to a method and device for the inspection of a rolled strip, wherein a strip sample (M) is inspected on a first surface thereof and then turned over in order to inspect the second surface thereof. According to the invention, by displacement parallel to the longitudinal axis thereof, the strip sample (M) is placed is placed between two spaced squeezing devices (6, 6') (7, 7') which are respectively tightened on each transversal extremity (M1, M2) of the sample (M); the two squeezing devices (6, 6') (7, 7') are longitudinally separated from each other in order to place the sample in a state of tension for the visual inspection of a first surface, then the sample is turned over by simultaneous rotation of the two squeezing devices (6, 6') (7, 7') about the longitudinal axis O, with maintenance of the applied tension, in order to carry out inspection of the second surface, said tension being sufficient in order to carry out inspection without the need for placement on a table. The invention makes it possible to inspect a strip as it exits from a continuous rolling line.

Owner:PRIMETALS TECH AUSTRIA GMBH

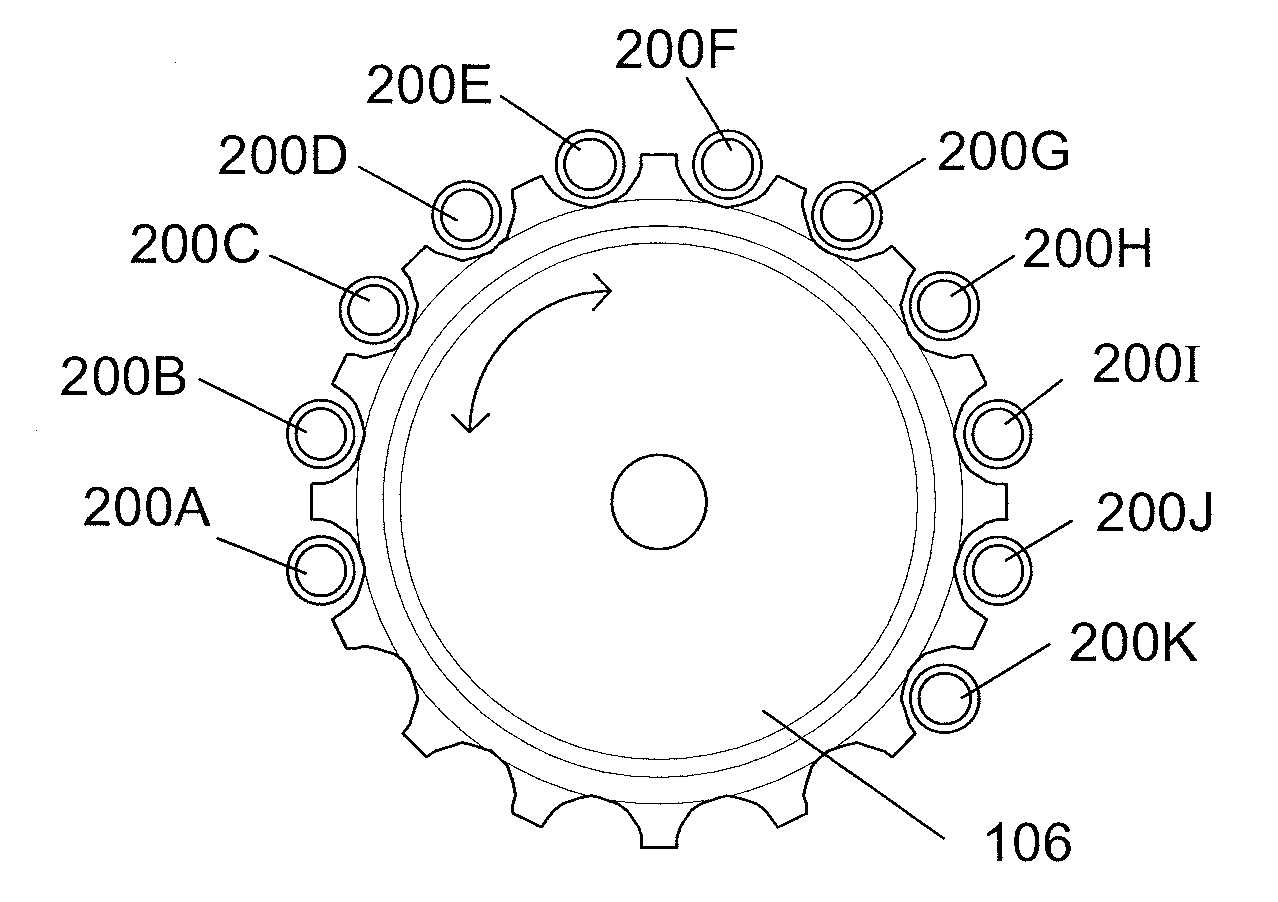

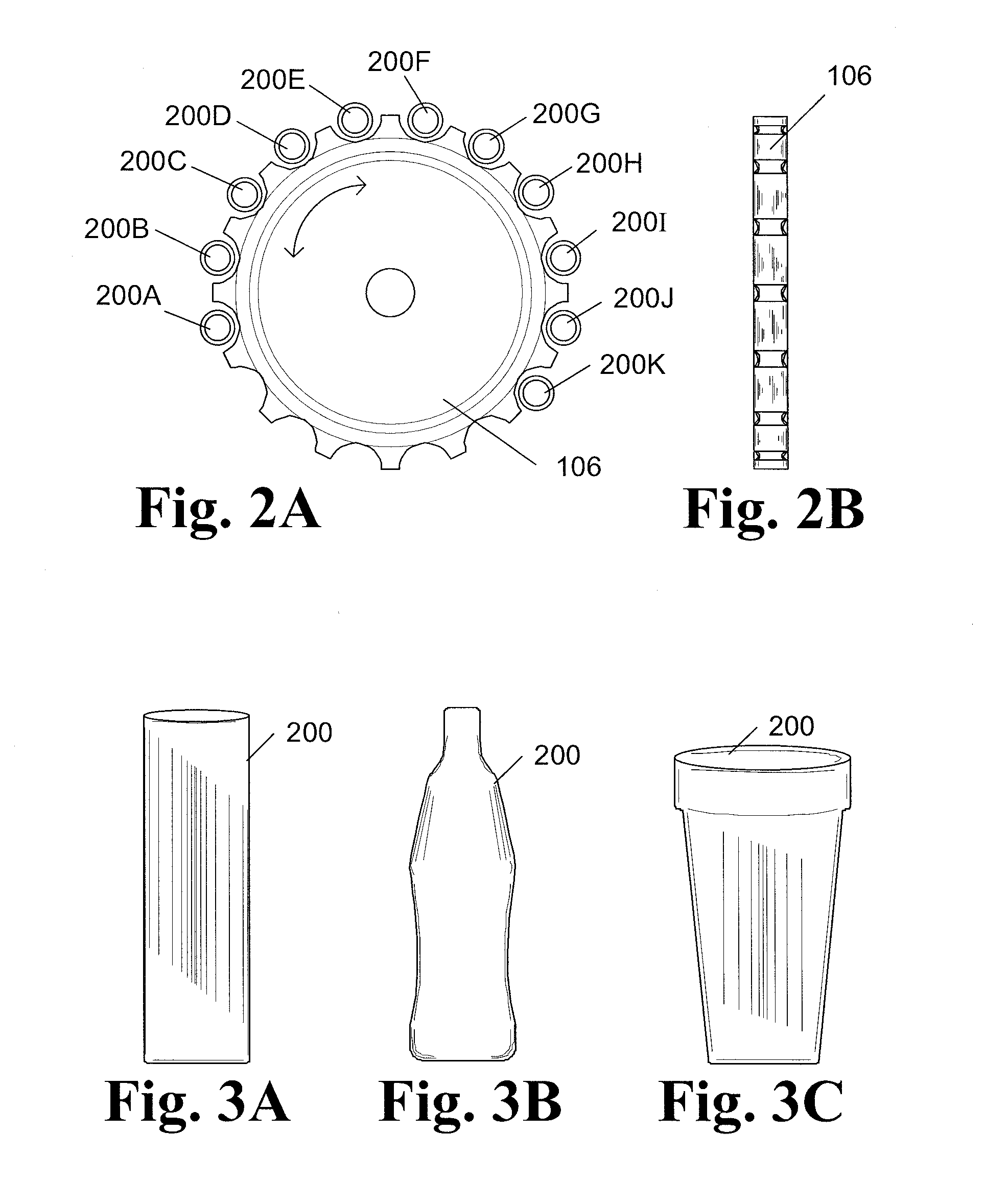

Method of shape forming vessels controlling rotational indexing

ActiveUS20100095723A1Efficient and accurate manufactureEasy to operateWork manipulationWork treatment devicesMarine engineeringContour length

An embodiment of the present invention is a method of shape forming vessels, the method comprising selecting a pathway to index the vessel across an operation wheel, indexing the vessel, controlling rotational indexing direction of the vessel across selected pathway, and operating on the vessel as the vessel is indexed across the operation wheel along selected pathway.Other embodiment include shaping by contouring length of the vessel, applying decoration to the vessel, wherein the decoration is added at a precise location based in part on reference to the registration spot, and using a controller to select the pathway based in part on desired shape of the vessel.

Owner:THE COCA-COLA CO

Large area substrate transferring method

InactiveUS20070140814A1Large displayIncrease productionConveyorsWork manipulationParticulatesReduced size

A load lock chamber and method for transferring large area substrates is provided. In one embodiment, a load lock chamber suitable for transferring large area substrates includes a plurality of vertically stacked single substrate transfer chambers. The configuration of vertically stacked single substrate transfer chambers contributes to reduced size and greater throughput as compared to conventional state of the art, dual slot dual substrate designs. Moreover, the increased throughput has been realized at reduced pumping and venting rates, which corresponds to reduced probability of substrate contamination due to particulates and condensation.

Owner:APPLIED MATERIALS INC

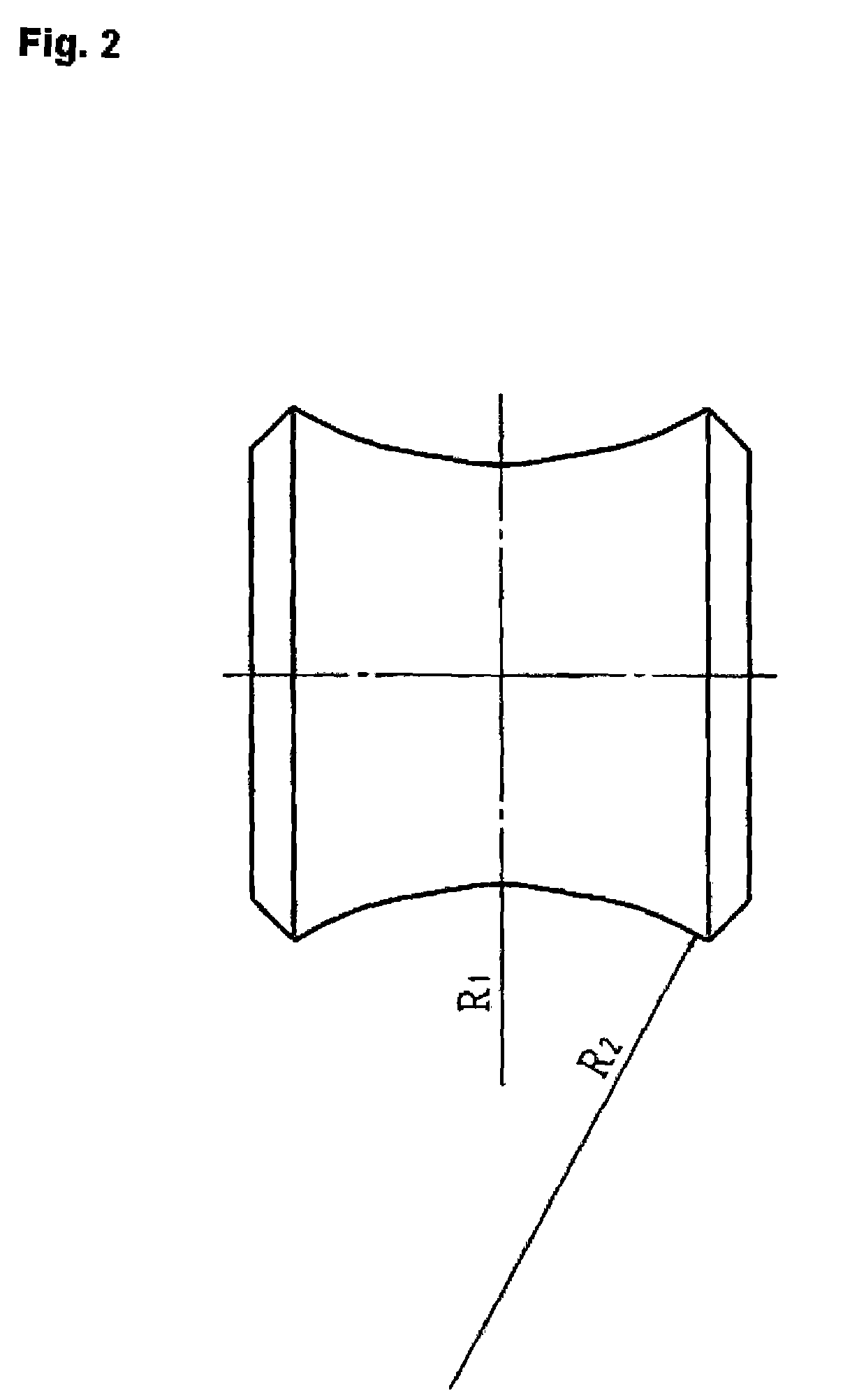

Square Tube Forming Roll, Square Tube Forming Method, and Forming Device

InactiveUS20080302160A1Improve molding efficiencyReduce forming stageMetal rolling stand detailsWork manipulationRoll formingTube forming

Roll forming a round tube to a square tube without applying excessive load to the raw tube scheduled portions to become corner portions and shoulder portions. This invention structures the curvature of the rotation axis direction of the forming roll surface in a way that in relation to other raw tube locations (straightening precedes for the raw tube locations adjacent to the corner portion scheduled locations of the square tube. It disposes stands of four-direction roll structure at the forming roll stand furthest upstream and furthest downstream sides and disposes stands of upper-lower and left-right two-direction roll structure between the upstream and downstream roll stands, and by adopting forming roll with a structure having a curvature for constricting the raw tube locations to become the shoulder portions adjacent to the corner portions of the square tube at a smaller curvature than that constricting the raw tube portions to become the side portion centers of the square tube cross section.

Owner:NAKATA MFG

Roll Unit Dipped in Surface Treatment Liquid

Provided is a roll unit to be dipped in a surface treatment liquid of a copper foil, wherein a bearing box for housing a roil shaft is configured from two bearing boxes that are divisible, one of the bearing boxes is configured from a roll-side bearing box arranged on a roll main body-side and the other bearing box is configured from a shaft end-side bearing box arranged on the shaft end-side of the roll, a shaft sleeve covering an outer periphery of the roll shaft is provided in the roll-side bearing box and an oil seal is provided along an outer periphery of the shaft sleeve, and a bearing for rotatably supporting the shaft is disposed in the shaft end-side bearing box. Specifically, the present invention provides a roll unit to be used in electrochemical surface treatments such as roughening treatment, rust prevention treatment, and oxidized surface treatment (blackening treatment) to be continuously performed on a surface of a rolled copper foil or an electrolytic copper foil, and which is capable of inhibiting the abrasion and corrosion of the roll shaft of such roll unit by controlling the corrosion caused by the infiltration of the treatment liquid, and which enables the simple replacement of the bearing box, bearing, and other components.

Owner:JX NIPPON MINING& METALS CORP

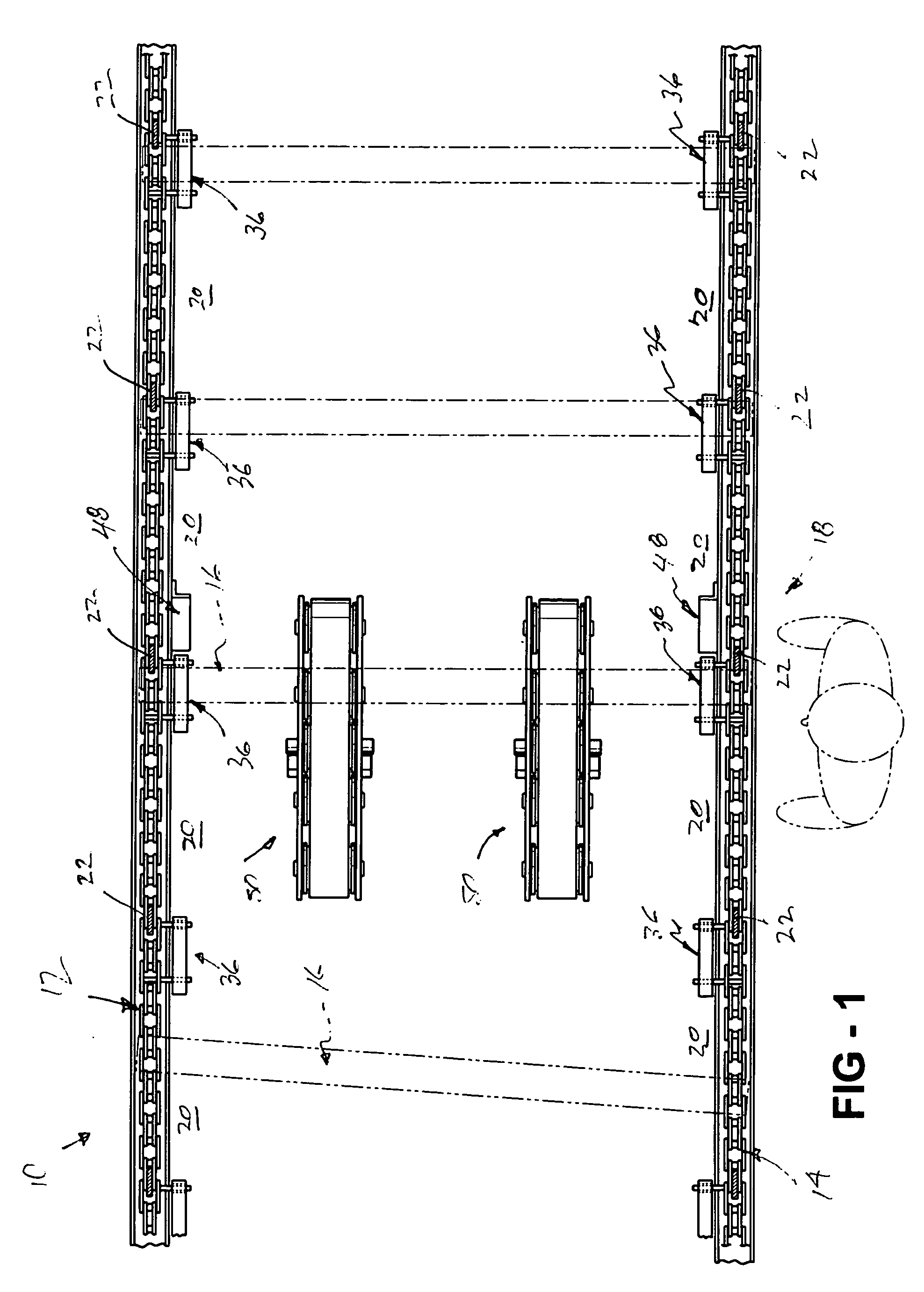

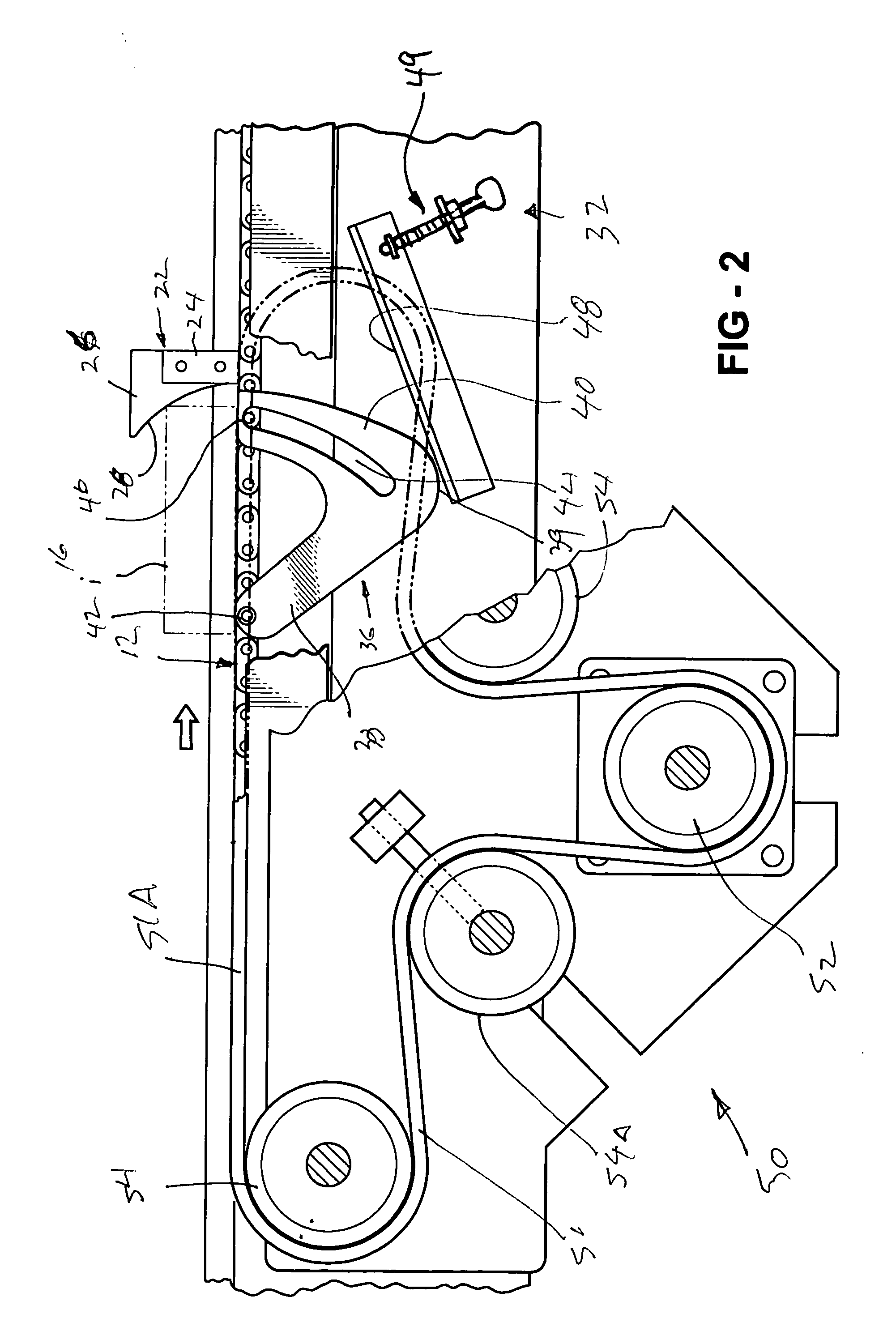

Rolling mill product handling system

ActiveUS7219521B1Guiding/positioning/aligning arrangementsWork manipulationHandling systemRotating drum

A product handling system comprises a support structure defining a pair of stationary inverted first channels with downwardly facing open sides. At least one cylindrical drum is interposed between each of the first channels and an underlying receiver. The drums are rotatable about their axes, with their surfaces arranged to close the open sides of the respective first channels. The drum surfaces are interrupted by second channels, with the first and second channels and the drum axes being arranged in a parallel relationship. Successive product lengths are alternately delivered longitudinally into one and then the other of the first channels. The drums are rotated about their axes resulting in the thus delivered product lengths being sequentially: (i) temporarily retained in the first channels by the rotating drum surfaces; (ii) deposited from the first channels into the second channels when the second channels rotate into radial alignment and communication with the first channels and (iii) downwardly deposited from the second channels to the receiver when the second channels rotate to discharge positions over the underlying receiver.

Owner:PRIMETALS TECH USA

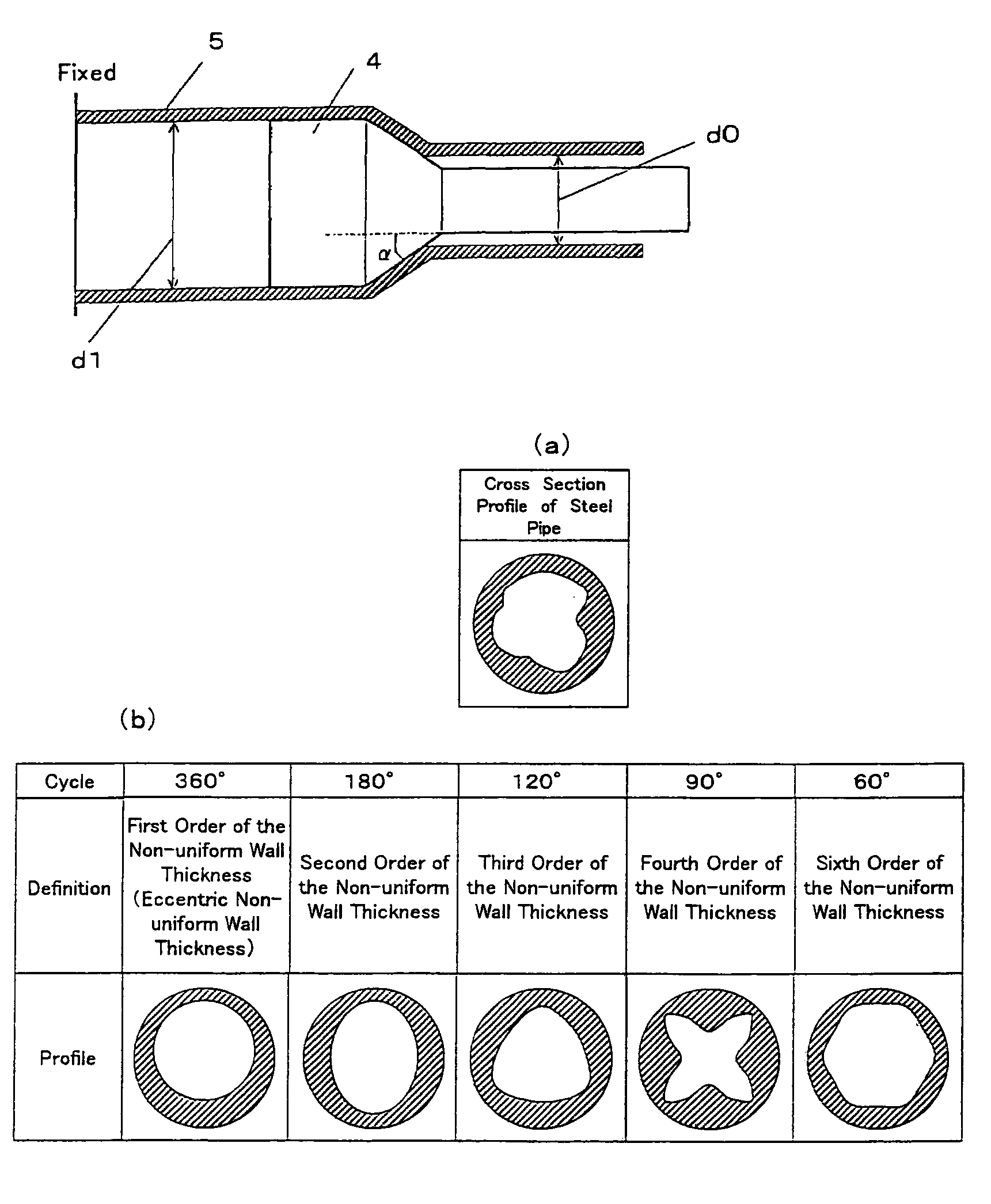

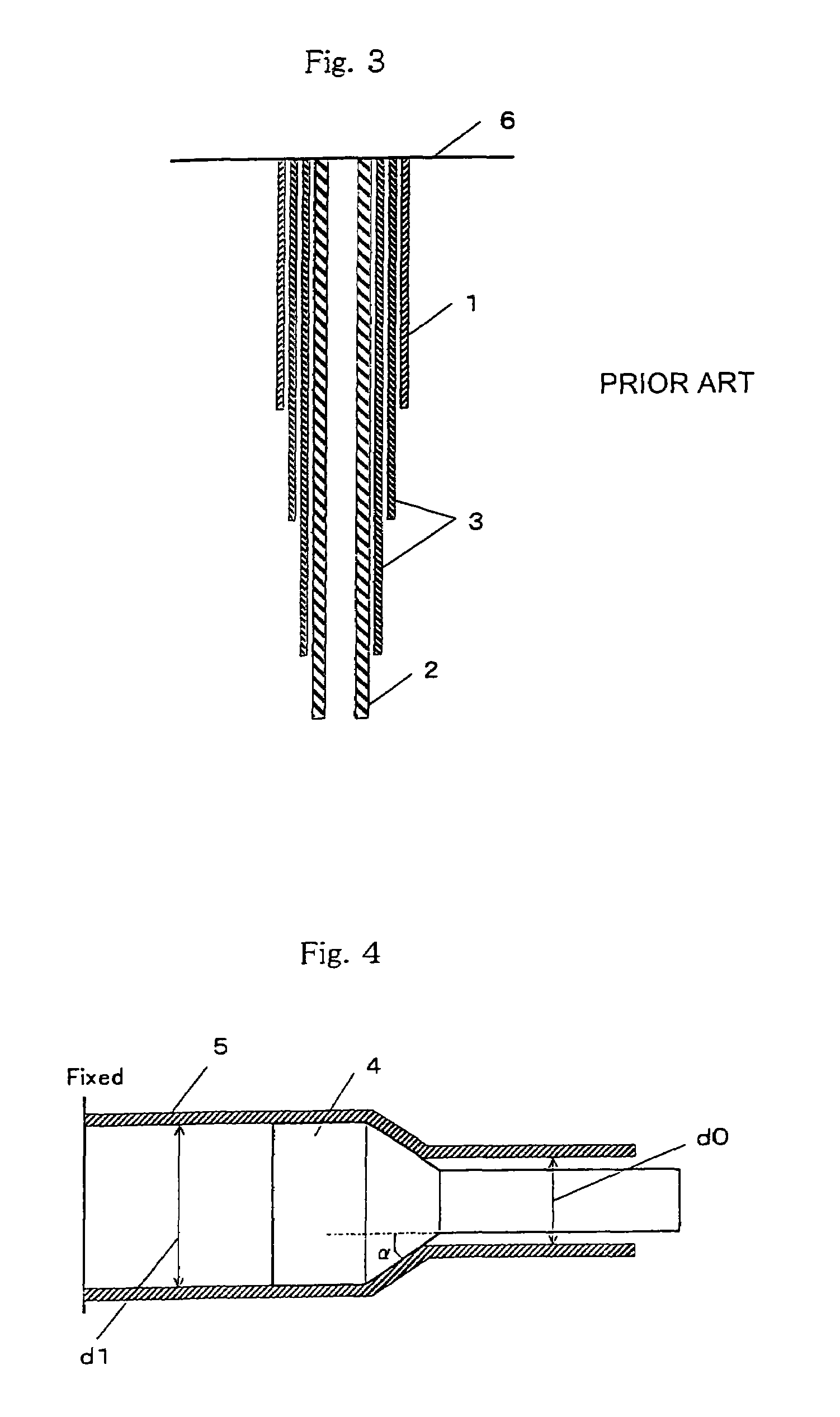

Steel pipe for embedding-expanding, and method of embedding-expanding oil well steel pipe

InactiveUS7225868B2Reduced strengthDeterioration of roundnessDrilling rodsWork manipulationUltimate tensile strengthOil well

(1) A steel pipe that is expanded radially in a state wherein it was inserted in a well such as an oil well, characterized in that the non-uniform wall thickness ratio E0 (%) before expanding satisfies the following expression ①.E0≦30 / (1+0.018α)①Wherein α is the pipe expansion ratio (%) calculated by the following expression ②.α=[(inner diameter of the pipe after expanding−inner diameter of the pipe before expanding) / inner diameter of the pipe before expanding]×100②(2) A steel pipe that should be expanded radially in a state wherein it is inserted in a well, such as an oil well, characterized in that the eccentric non-uniform wall thickness ratio is 10% or less.When the embedding-expanding method is performed with use of the steel pipe of (1) or (2), lowering of collapse strength of the expanded steel pipe is prevented and bending thereof can be decreased.

Owner:NIPPON STEEL CORP

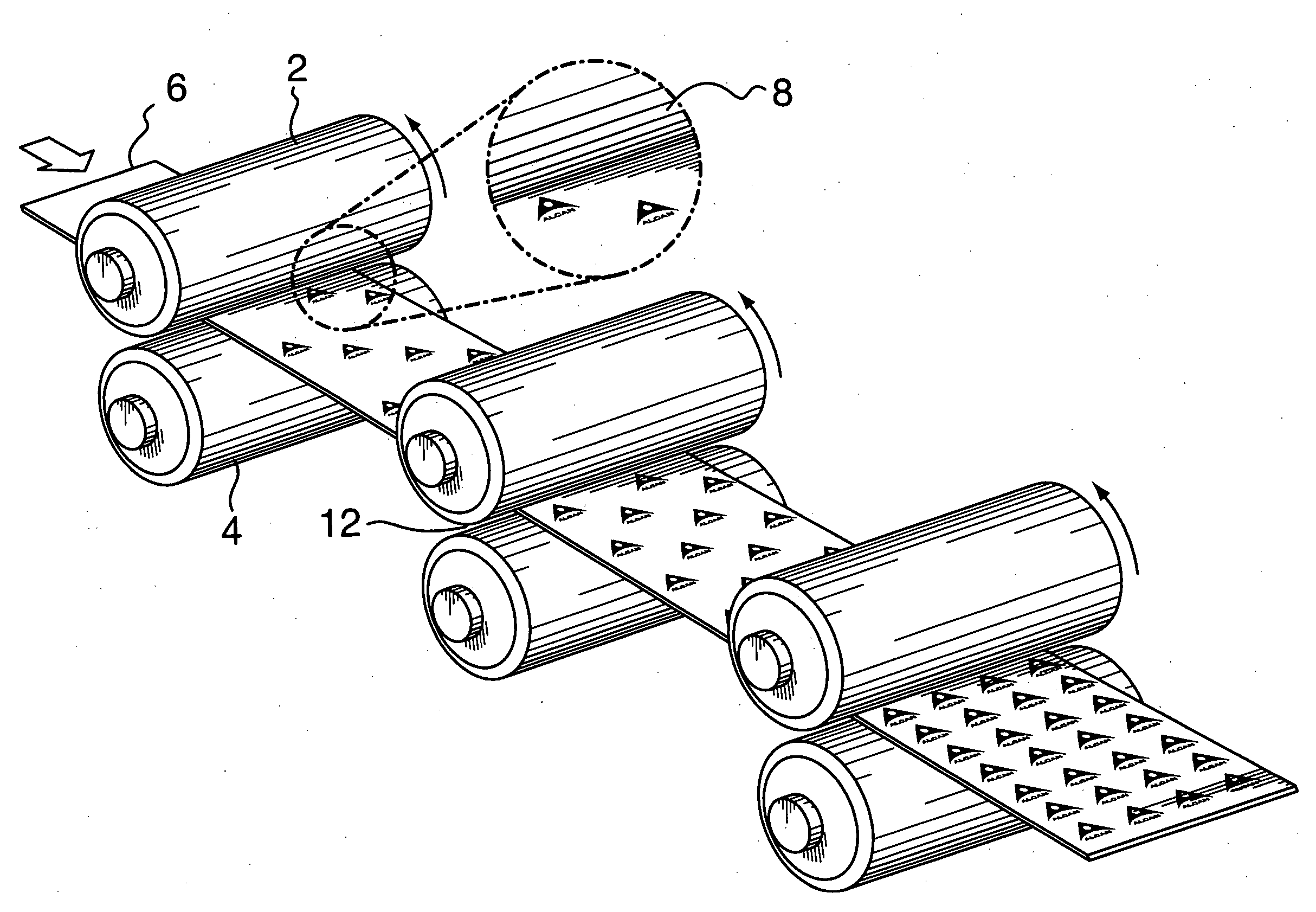

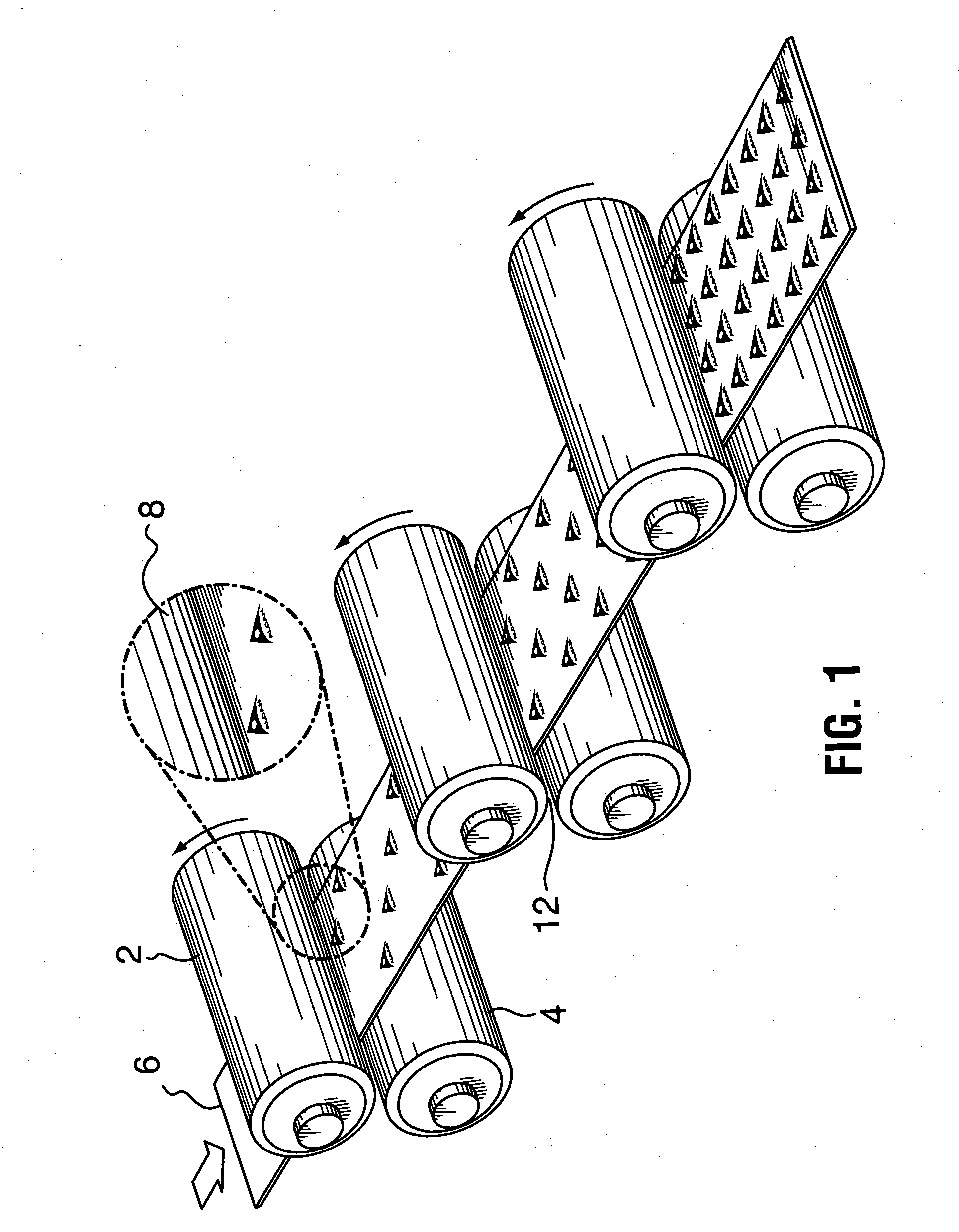

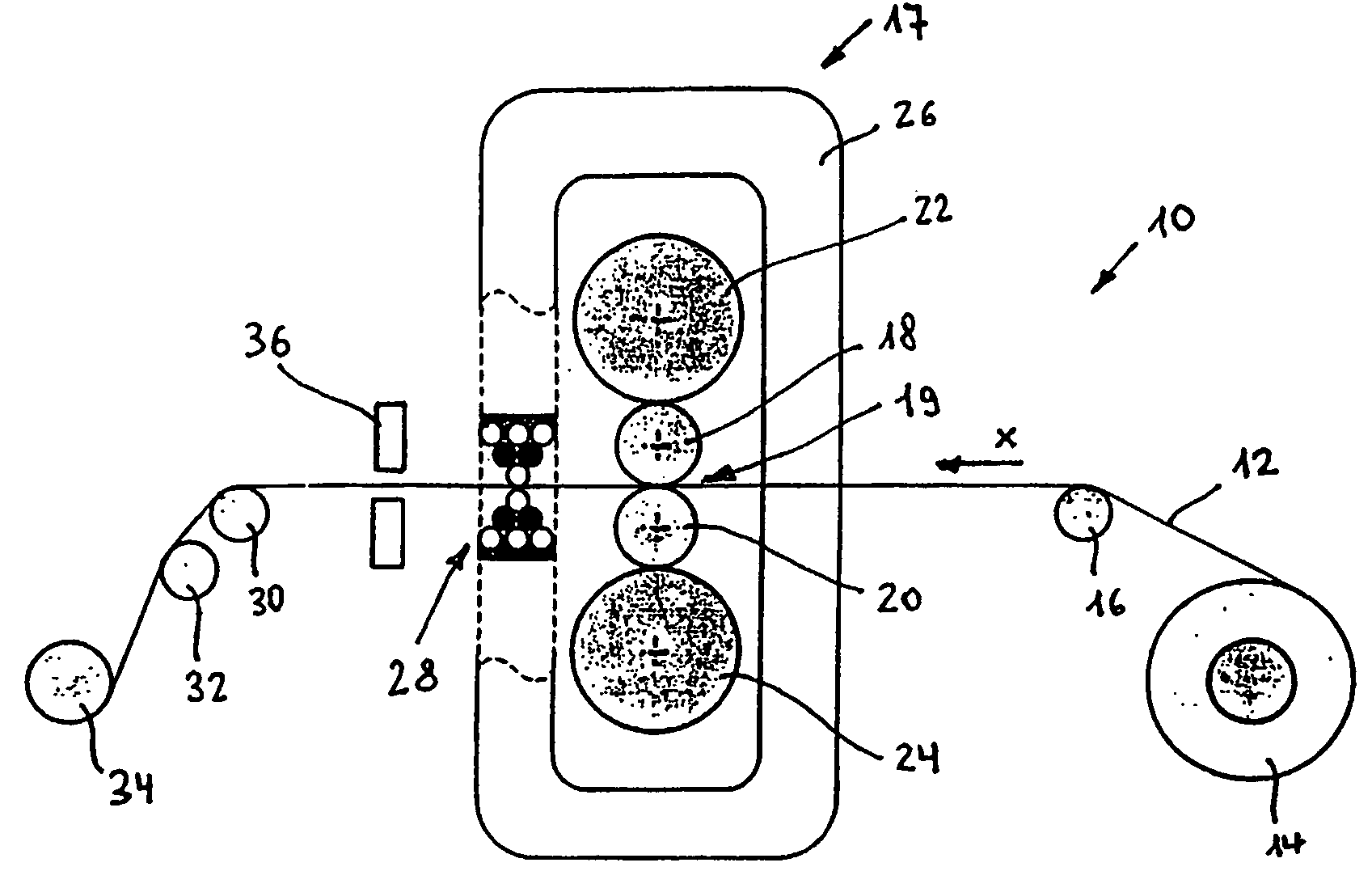

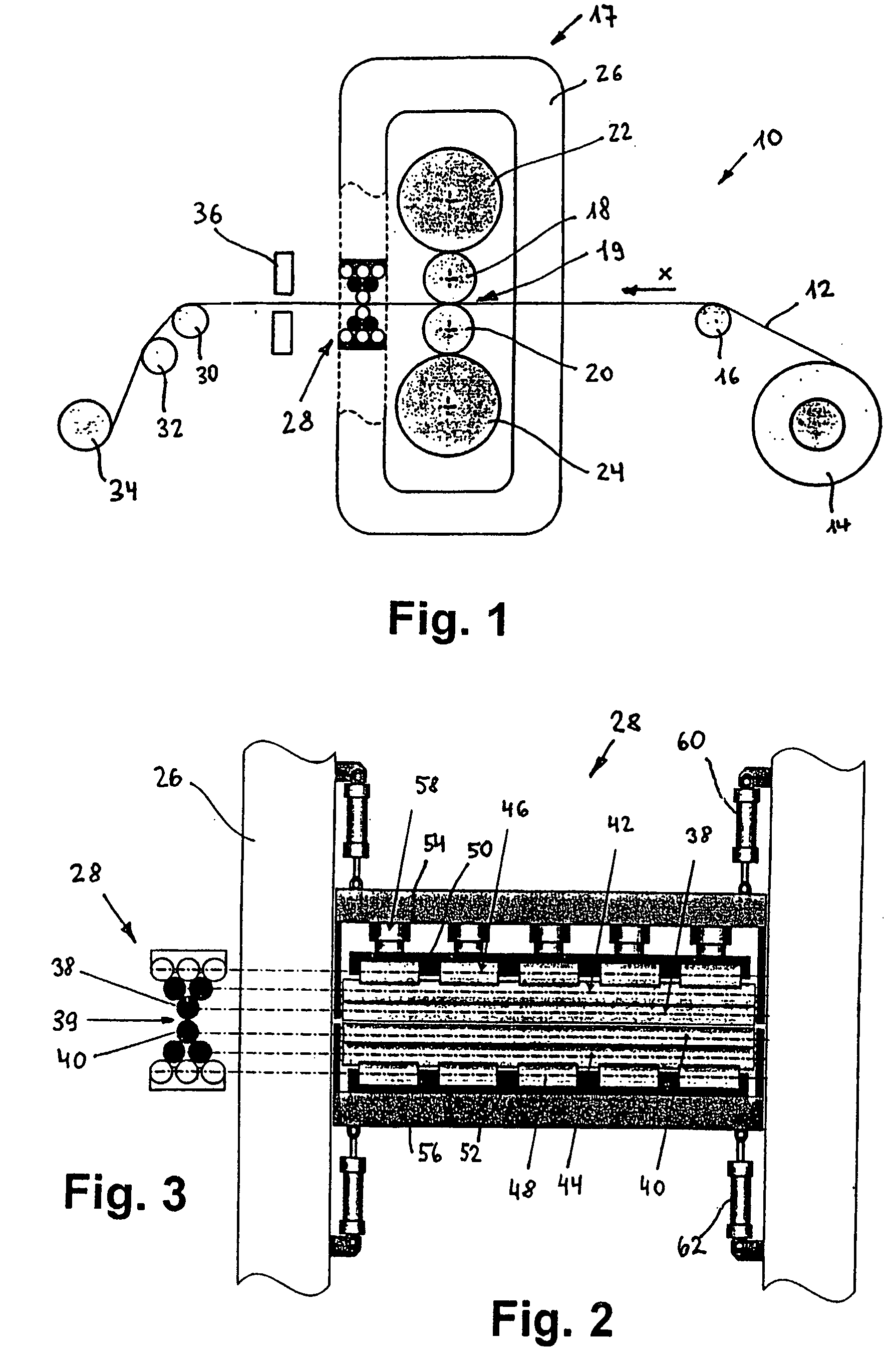

Method and installation for the production of an aluminum sheet with a textured surface

A method for producing a sheet made of aluminum or an aluminum alloy, which is provided with a textured surface. According to the method, a cold rolled sheet is fed through the gap between two texturing rollers which are provided with a roughness pattern immediately after exiting a cold rolling mill, and the textured sheet is wound. The roughness pattern is transferred to the surface of the sheet by means of a force acting from the texturing rollers on the sheet. The installation for producing a cold rolled sheet made of aluminum or an aluminum alloy, which is provided with a textured surface, comprises a texturing rolling mill that encompasses texturing rollers and is disposed immediately after the cold rolling mill in the running direction (x) of the sheet. The method and installation make is possible to save a separate texturing pass and therefore one roller pass as opposed to methods known in prior art.

Owner:ALCAN TECH & MANAGEMENT LTD

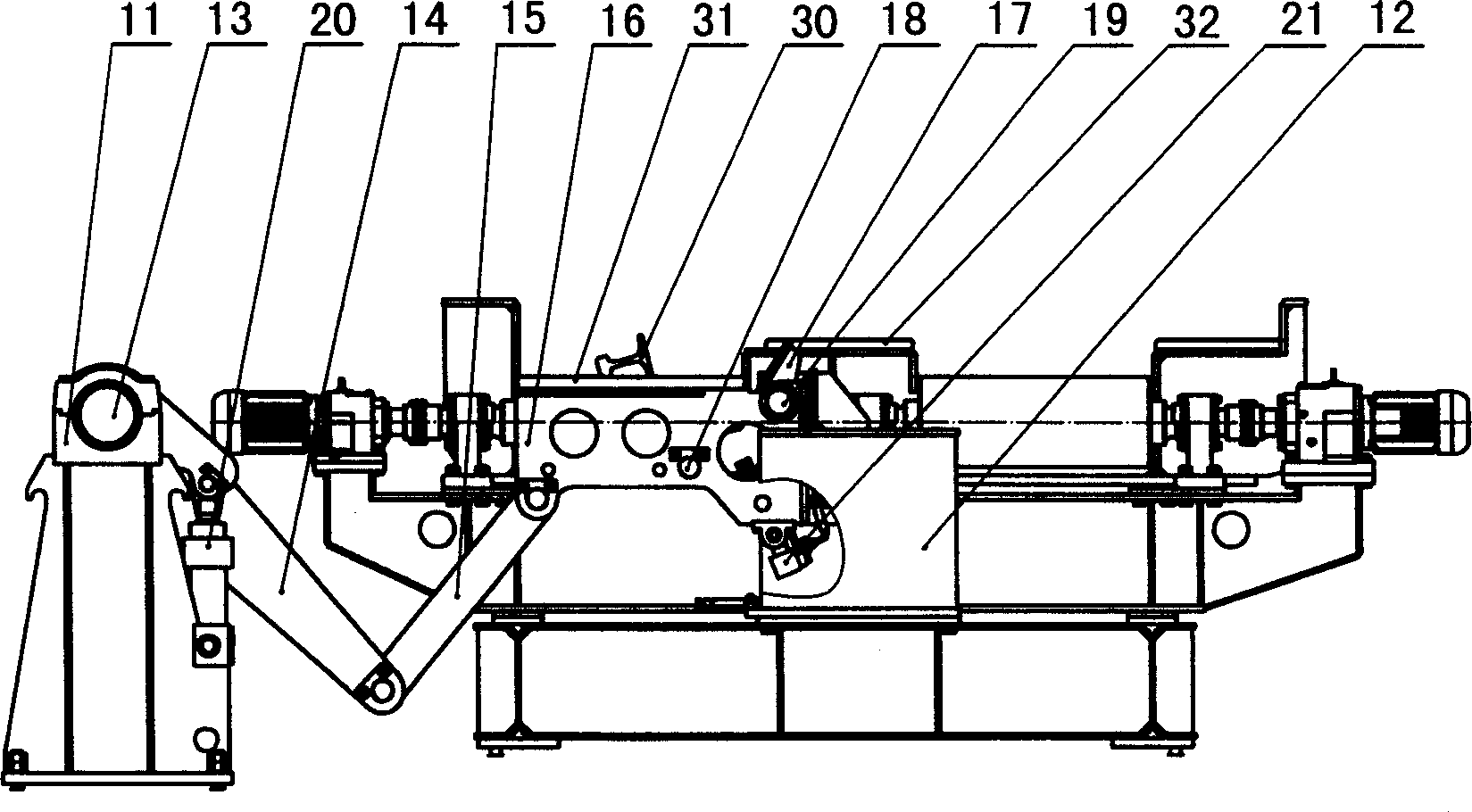

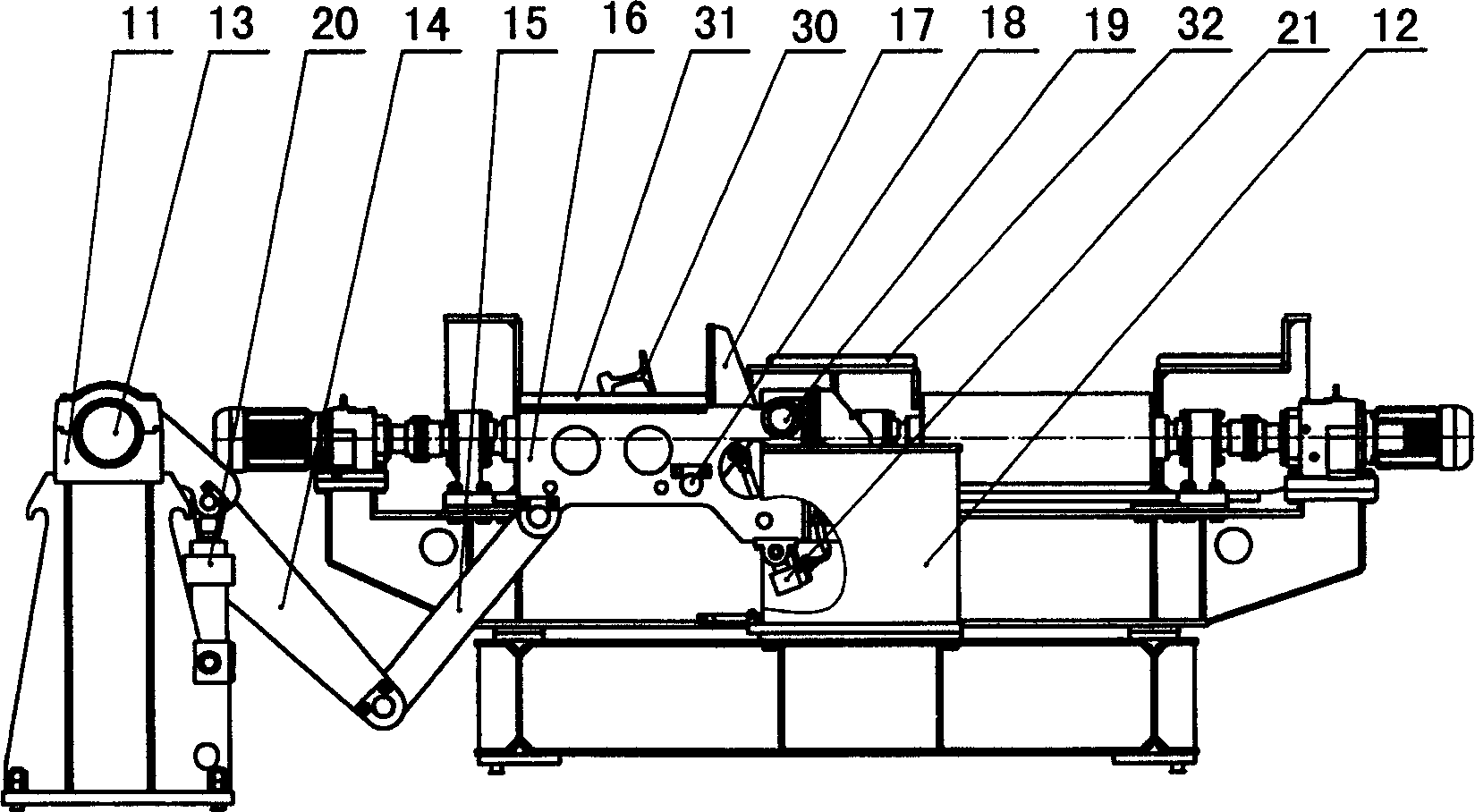

Steel turning machine

ActiveCN1810401AOvercoming technical difficulties in turning over steelSimple structureWork manipulationIngotEngineering

The ingot tilter for turning high temperature ingot in conveying rollers includes at least two ingot turning mechanisms, each of which includes ingot turning arm provided with ingot accepting claw and hinged through pinshaft to the support seat. The ingot turning mechanisms are longitudinally along the roller line and the support seat is set between conveying rollers of the roller line. There are one front support seat corresponding to the support seat set outside the conveying rollers, and one driving mechanism set between the front support seat and the support seat to make the ingot turning arm deflect and swing around the pinshaft. The ingot tilter has simple structure and reliable action.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

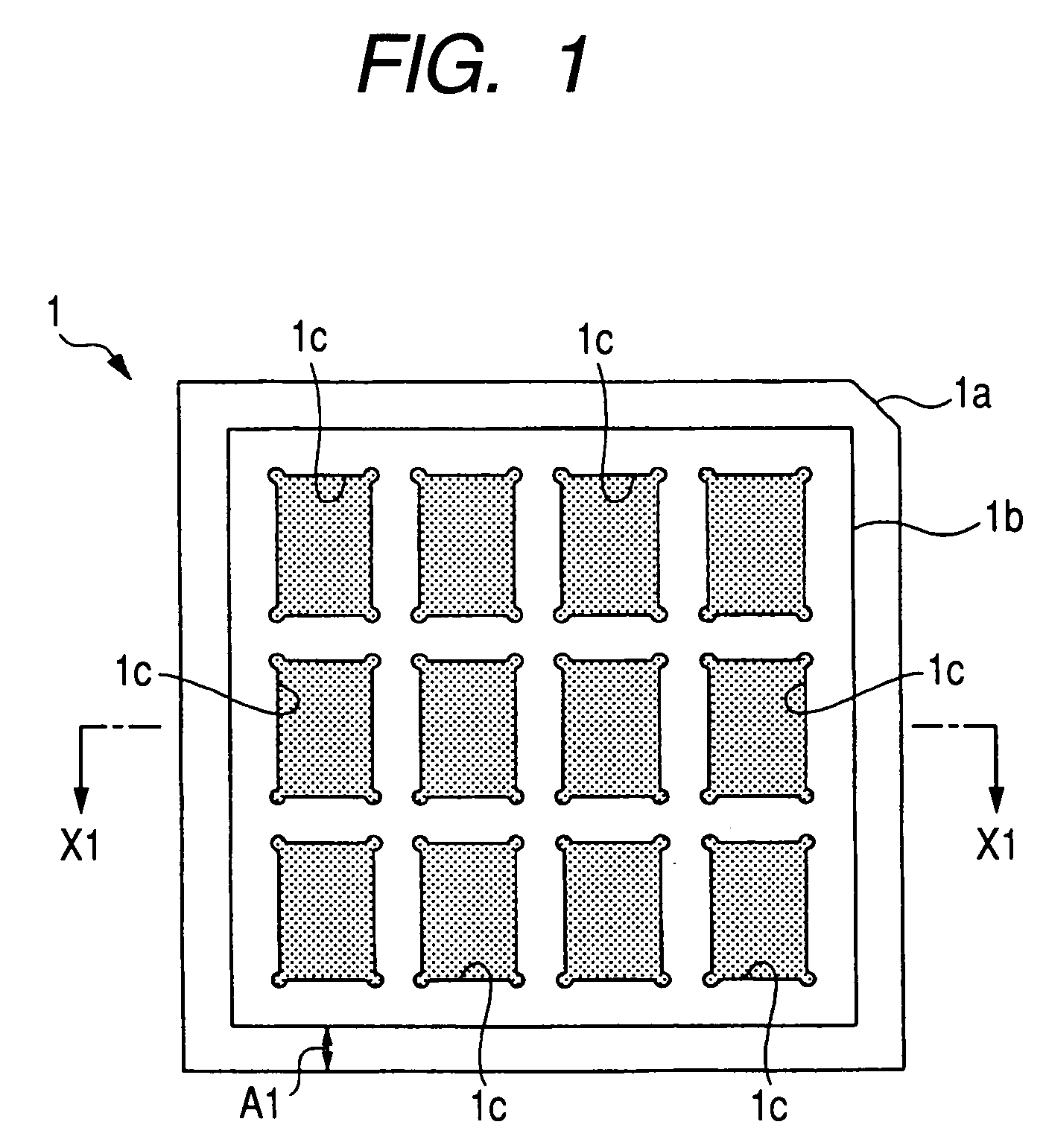

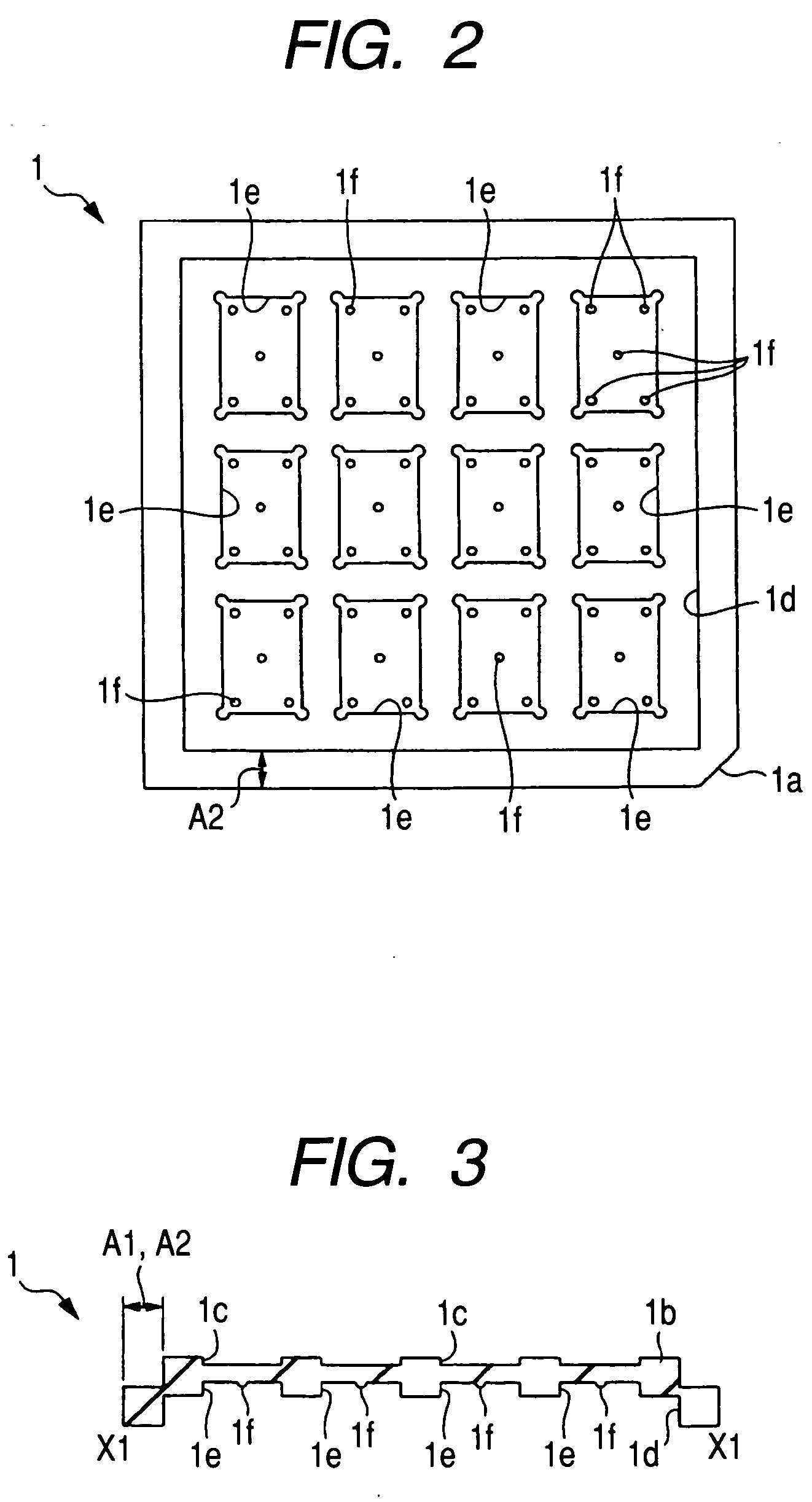

Method of transporting semiconductor device and method of manufacturing semiconductor device

ActiveUS20050147488A1Avoid stickingSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor chip

To prevent semiconductor chips from adhering to the trays during transport, a method is employed which transports semiconductor chips in the following state. When trays provided with a plurality of accommodating portions having a recessed cross section for accommodating semiconductor chips on a main surface thereof are stacked in a plurality of stages, the semiconductor chips are accommodated in spaces defined by the accommodating portions formed over the main surface of the lower-stage tray and corresponding accommodating portions formed over the back surface of the upper-stage tray. Here, on bottom surfaces of the accommodating portions formed over the back surface of the upper-stage tray, isolated projections having a height which prevents the projections from coming into contact with the semiconductor chips are arranged in a scattered manner. In this way, it is possible to prevent the semiconductor chips from adhering to the back surface of the upper-stage tray.

Owner:RENESAS ELECTRONICS CORP

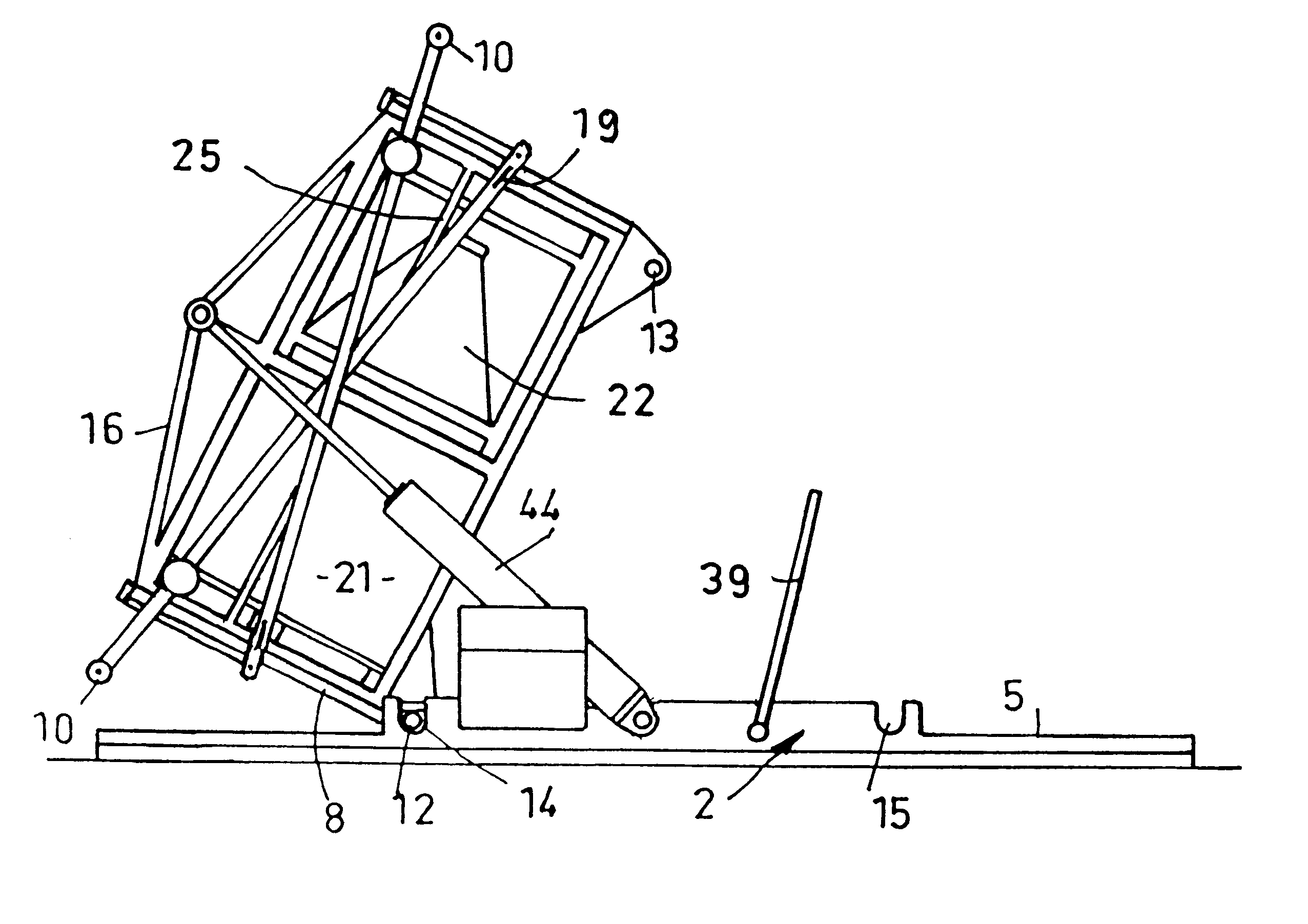

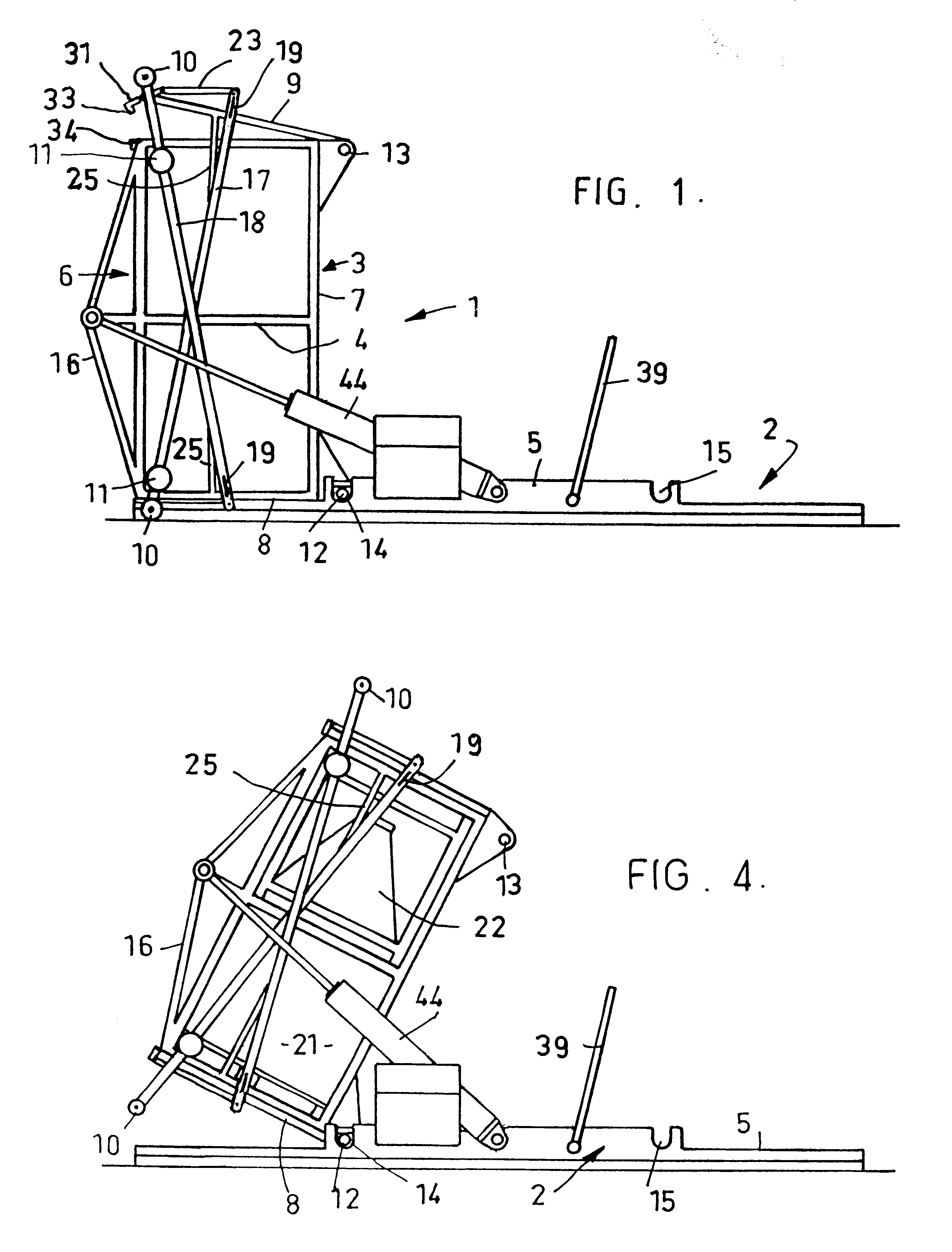

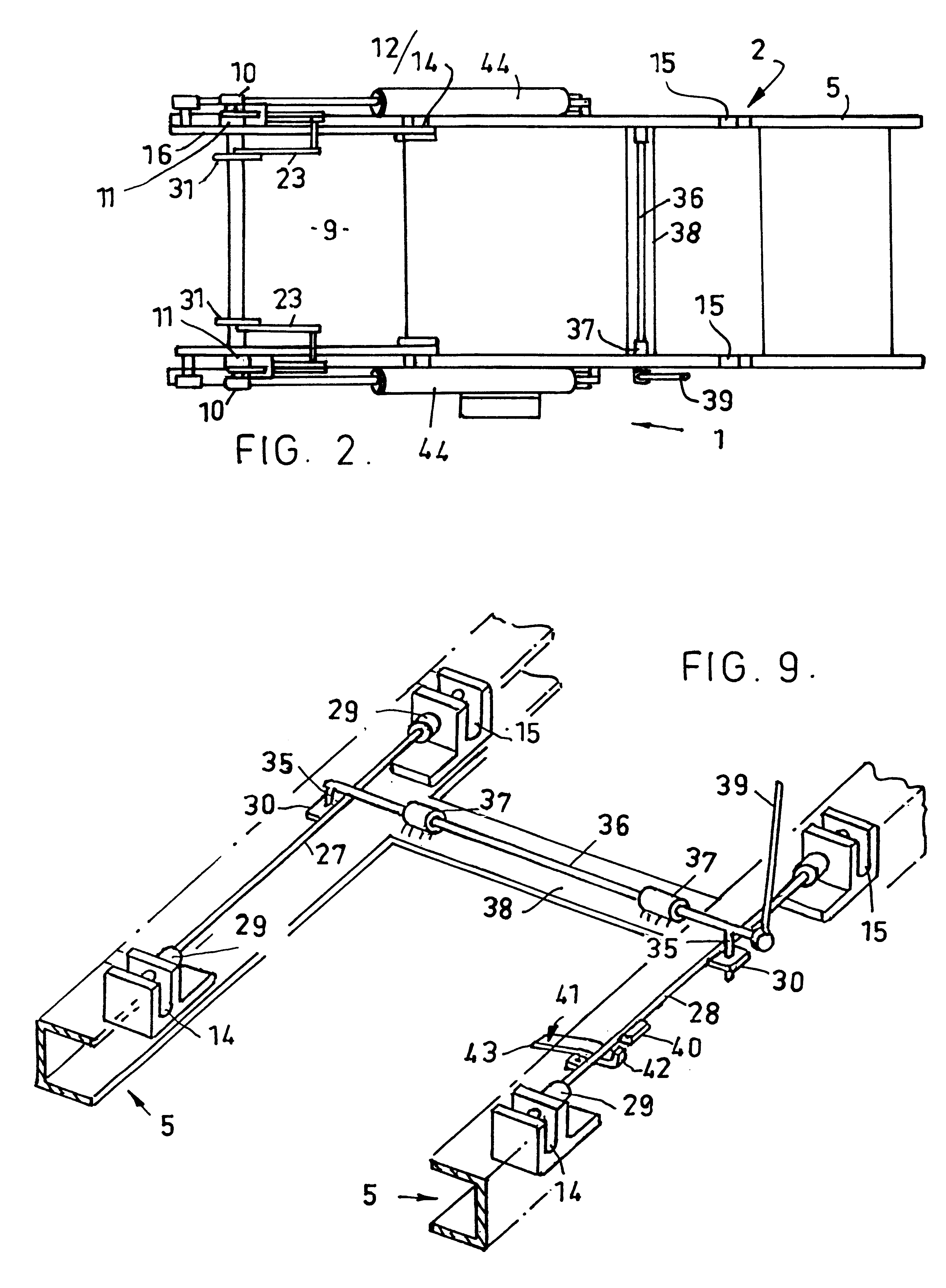

Apparatus for inverting containers

A container turn-over apparatus (1) including a base (2) and a container cradled (3) with openable latchable ends (8,9) and an open side (6) to allow a container to be placed in the cradle (3). Two selectively engagable spaced apart pivotal connections (12,14 & 13,15) allow the cradle (3) to be turned end over by means of piston and cylinder assemblies (44). When the cradle (3) is turned over to stand on one of its ends (8,9) the other end of the cradle (3) is automatically unlatched and opened.

Owner:KARPISEK LADISLAV STEPHAN

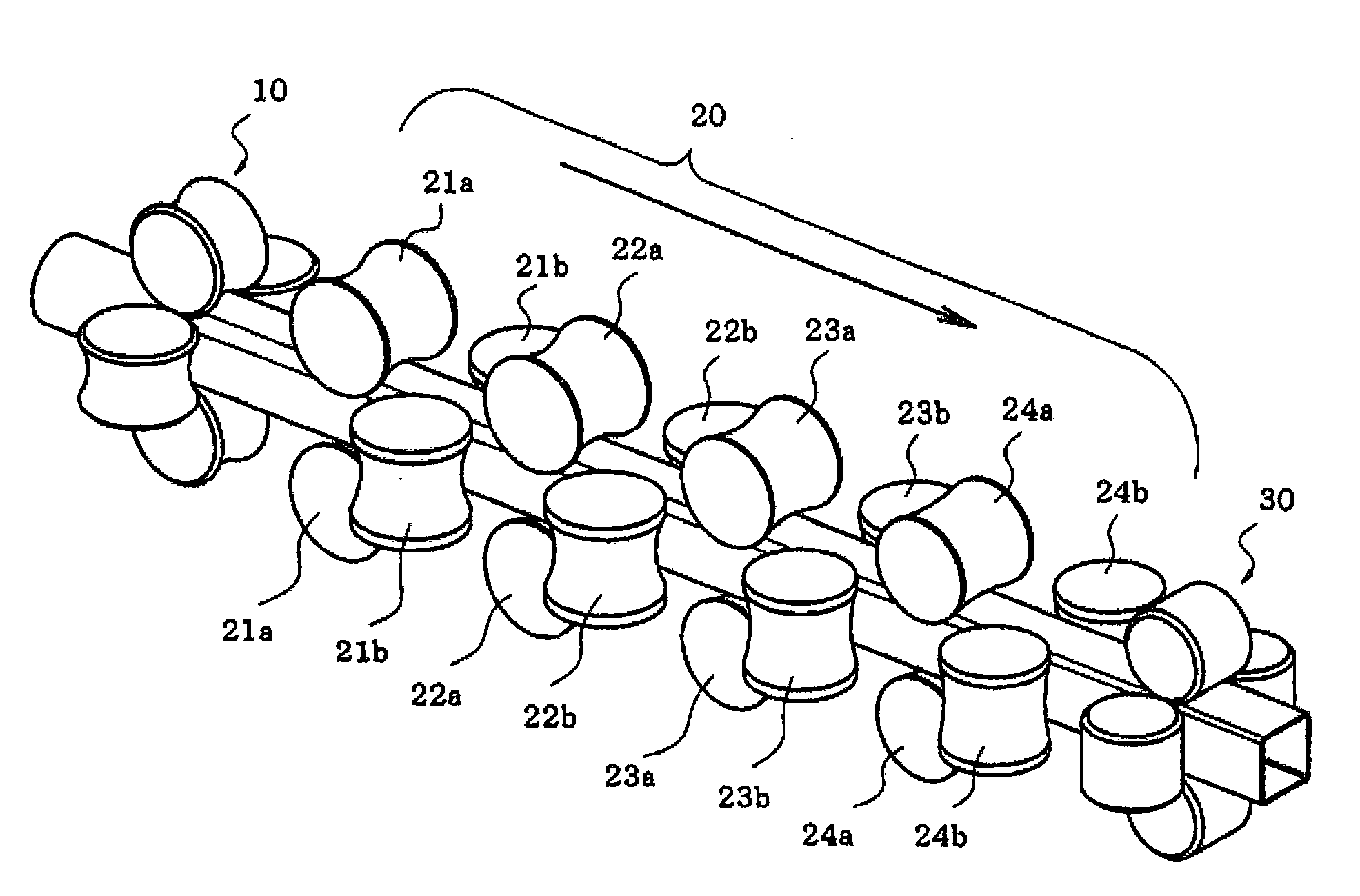

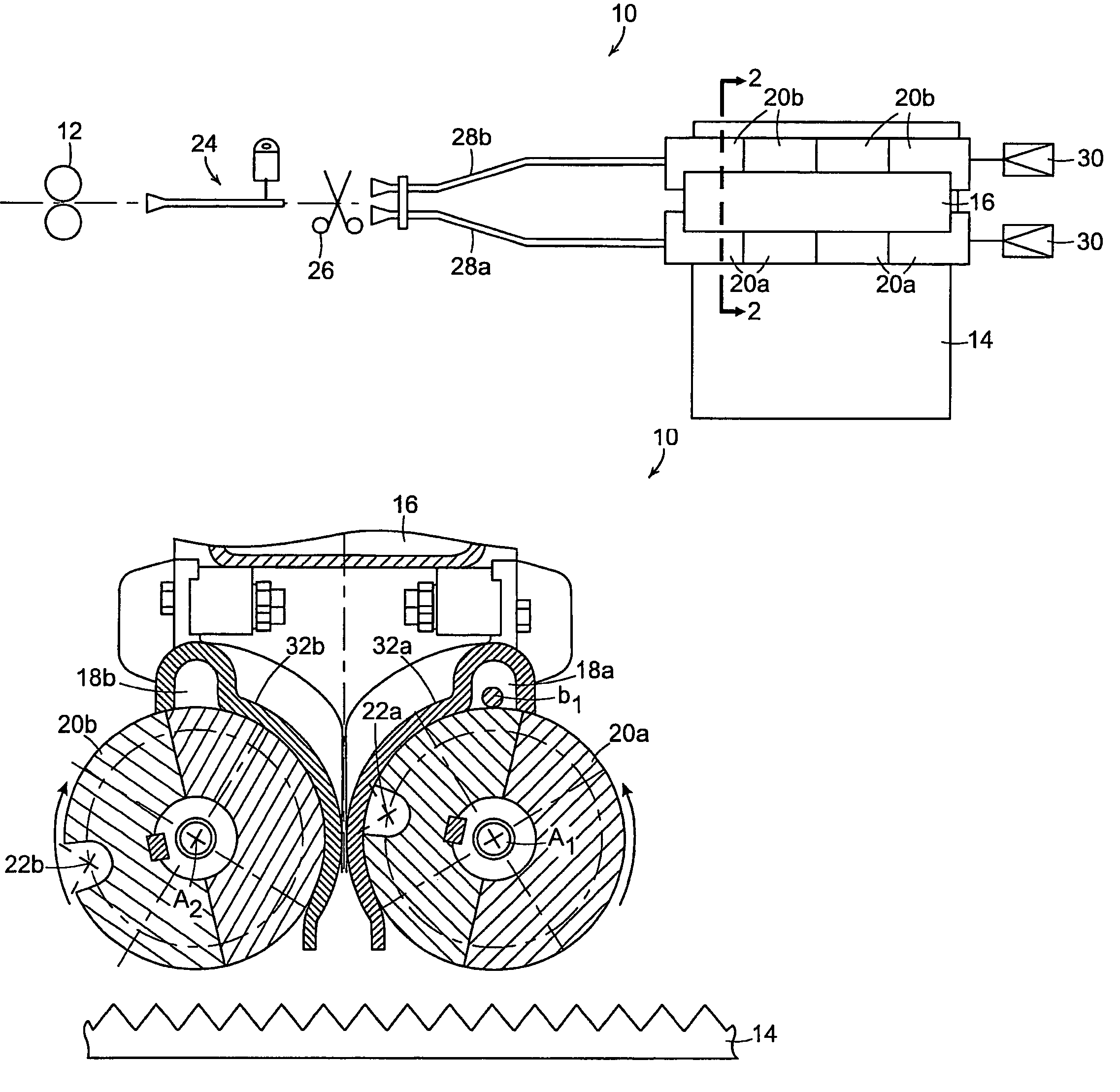

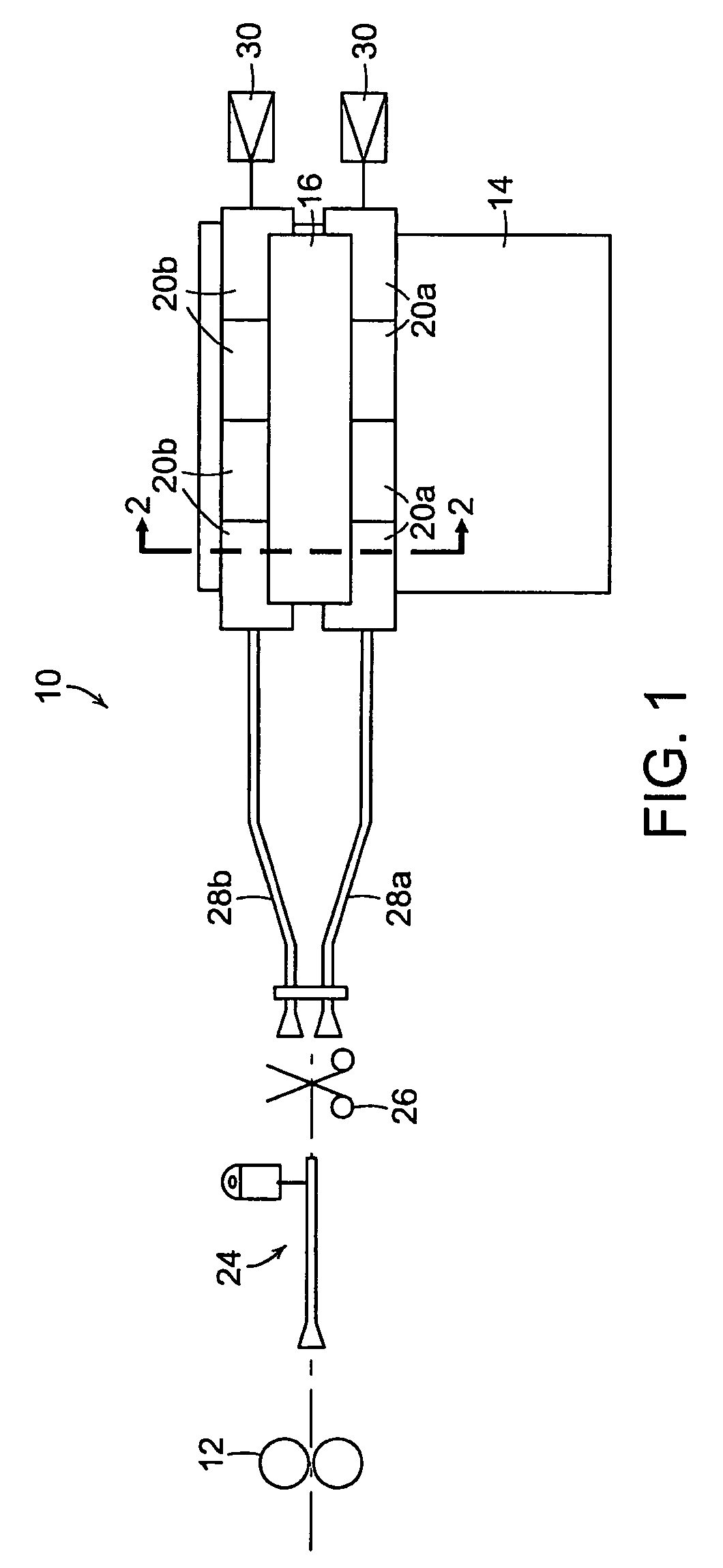

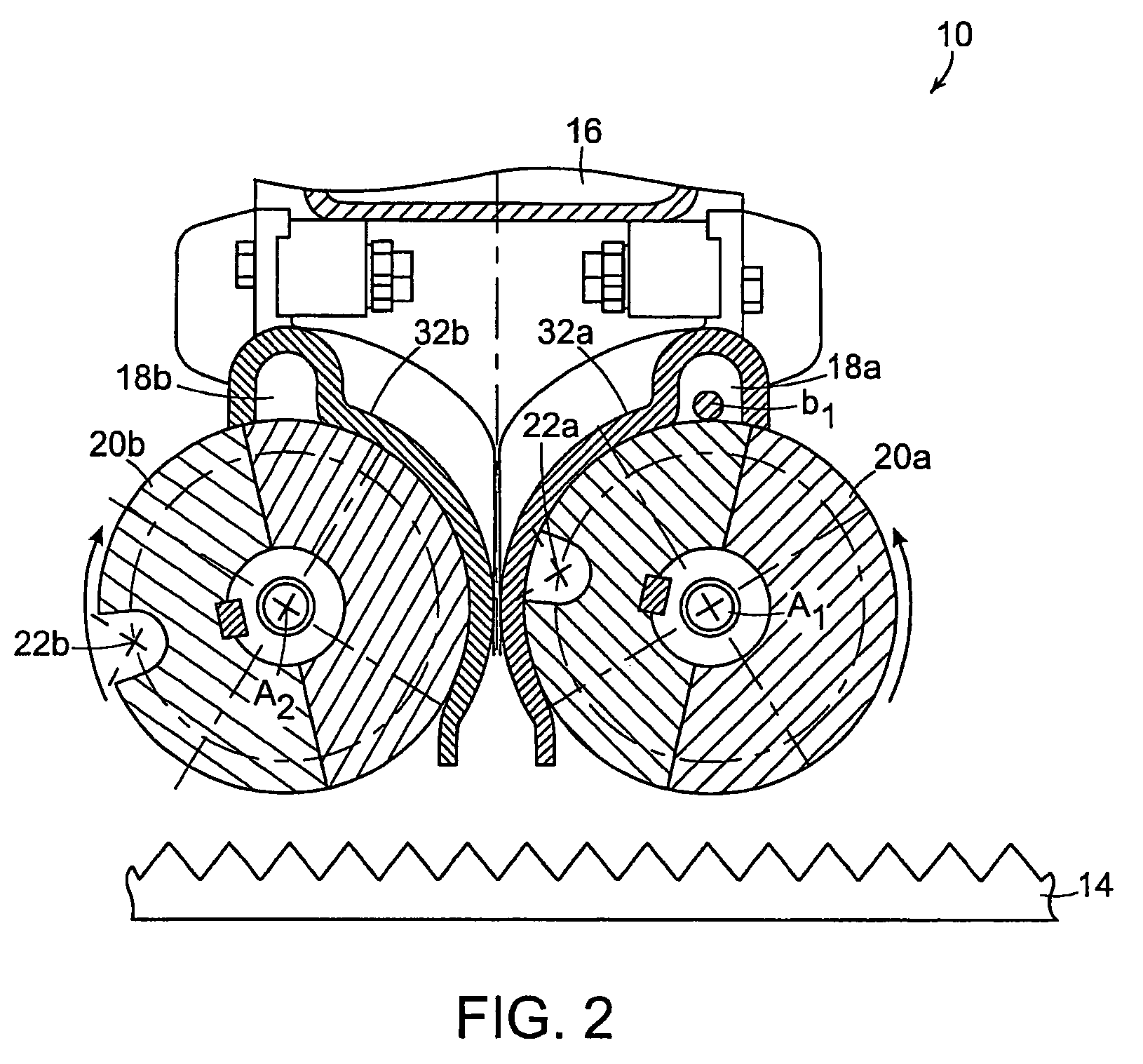

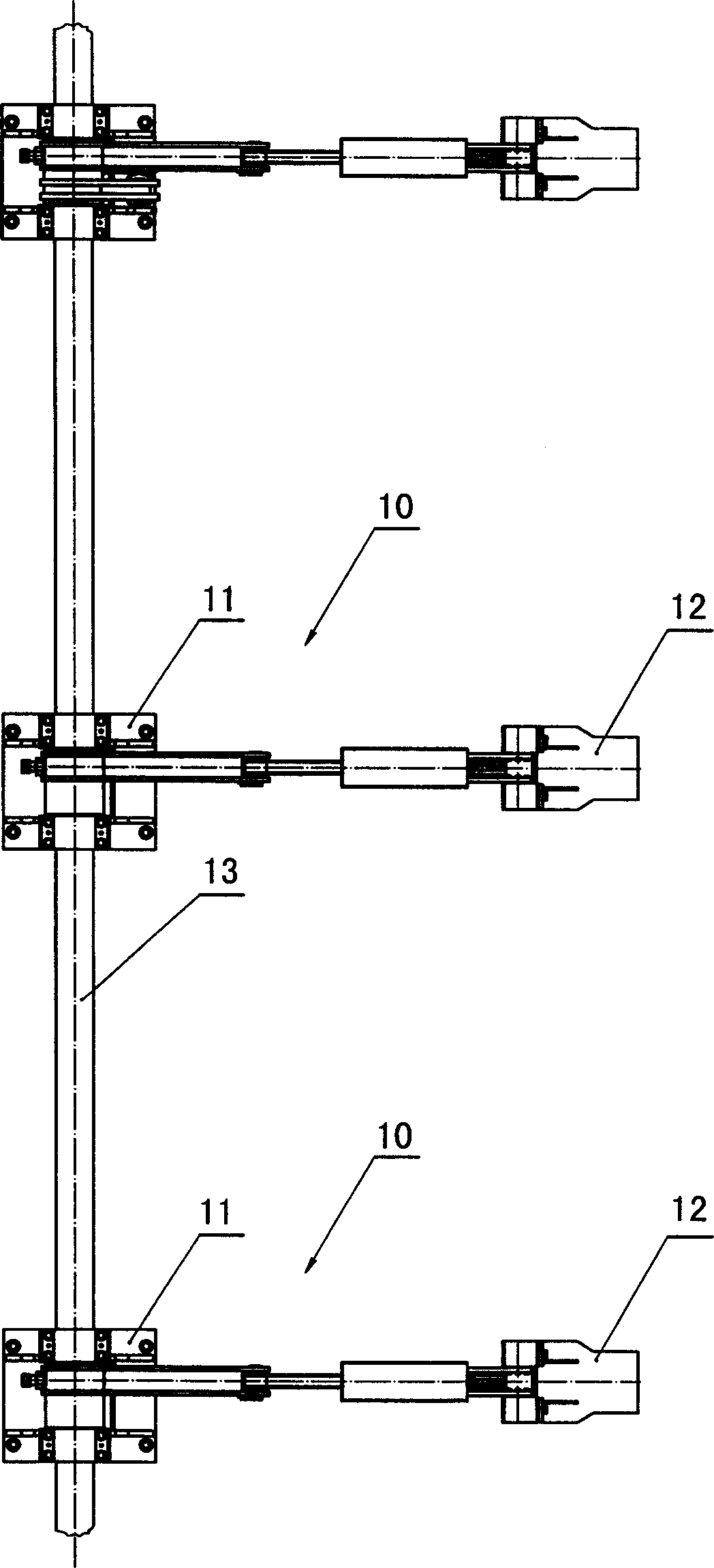

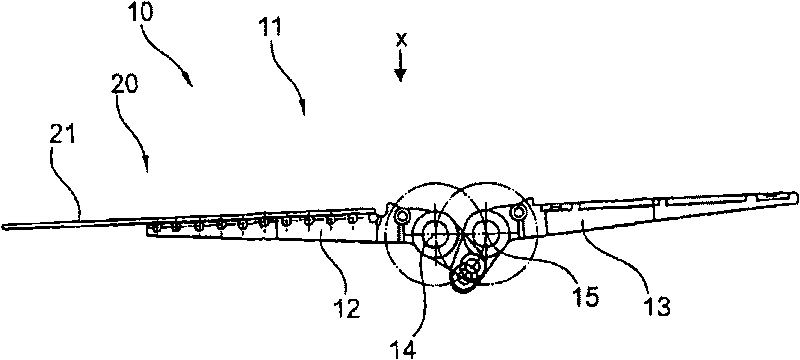

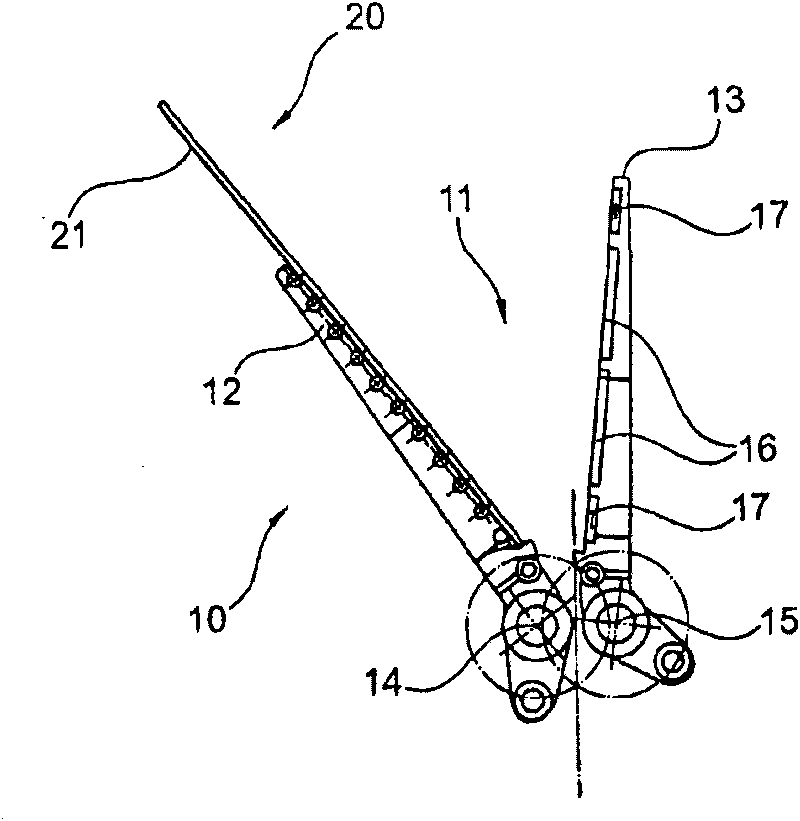

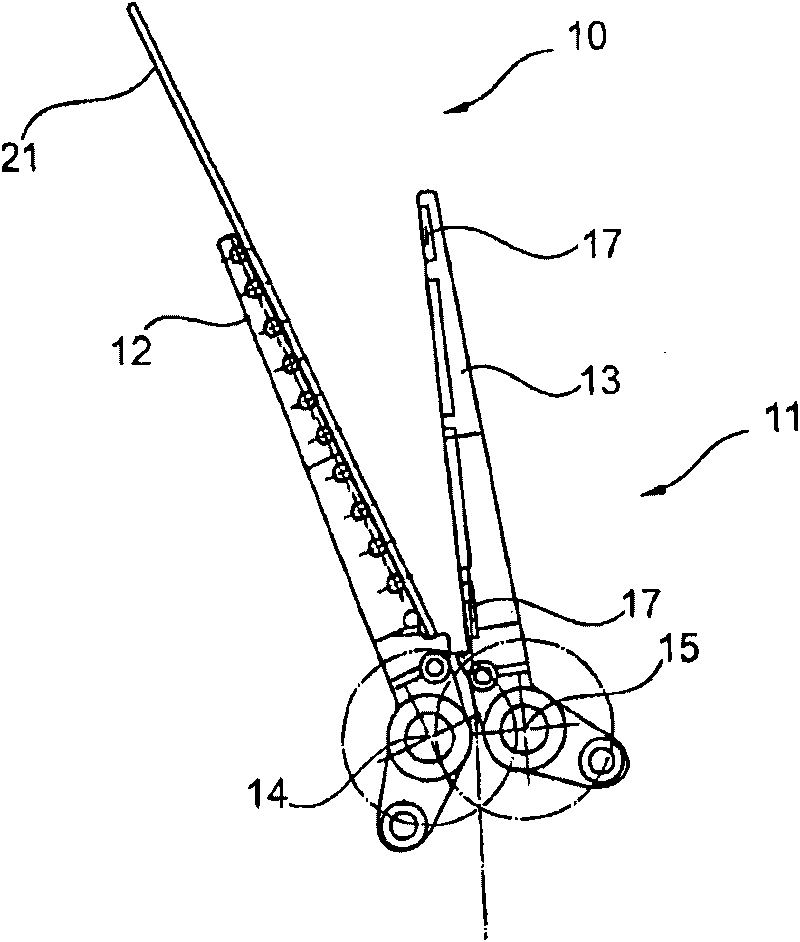

Inspection system for rolled products and method for assessing the surface of rolled products of a rolling installation

ActiveCN101754819AReduce noiseLow running costWork manipulationMeasuring devicesEngineeringMechanical engineering

The invention relates to an inspection system (10) for rolled products (20) of a rolling installation, comprising at least one sheet turner (11) comprising an arrangement of transferring turning arms (12) located on a turner shaft (14) and receiving turning arms (13) located on a turner shaft (15). It is provided according to the invention that the turner shaft (15) of the receiving turning arms (13) is arranged offset with respect to the turner shaft (14) of the transferring turning arms (12). The invention also relates to a method for assessing the surface of rolled products (20) of a rolling installation.

Owner:SMS DEMAG AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com