Method and device for the inspection of a rolled strip

An inspection method and inspection device technology, applied in the field of rolling metal strips, capable of solving problems such as scar formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

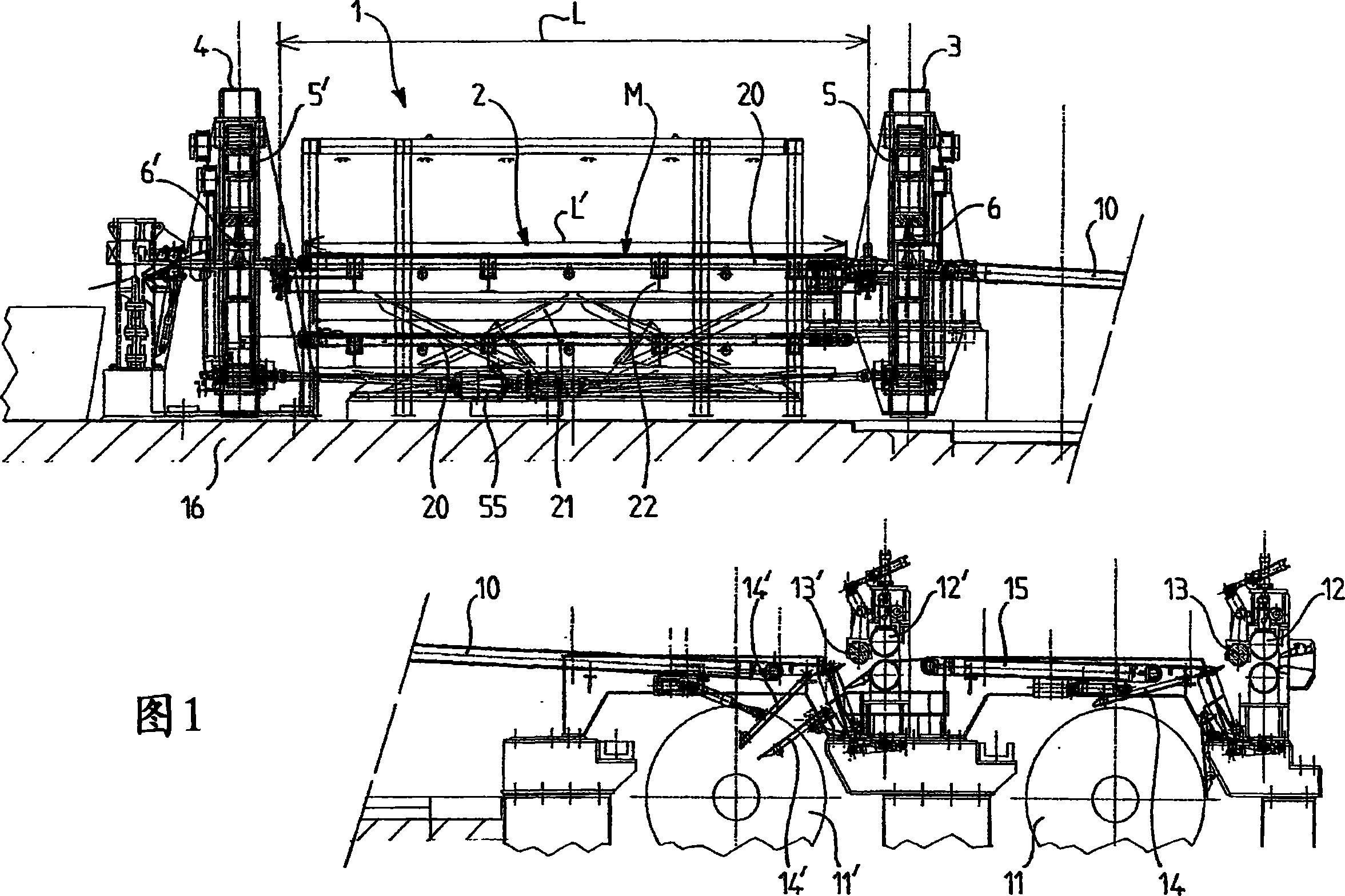

[0036] [36] FIG. 1 shows in elevation the whole of an inspection device 1 located downstream of a continuous strip processing facility such as a rolling facility. The device is not shown in the figures, only the outlet of the device is shown, which comprises, as usual, two coilers 11, 11' which operate alternately to enable continuous travel of the rolled strip.

[0037] [37] Each winder 11, 11' is equipped with a pair of pressure rollers 12, 12', a vertically movable shunt roller (rouleau aiguilleur) 13, 13' and a guide device 14, 14'. At the end of the winding of a strip, for example on the first winder 11 , a clipper located upstream and not shown in the figure can cut the tail of the first strip. The strip finishes its winding on the winder 11, and the head of the next part of the strip is led by an intermediate station 15 to the second winder 11', and through the diverting roller 13' and the guide 14' to the second winder 11'. The chuck of the second winder 11' moves. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com