Patents

Literature

299 results about "Honing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive stone against it along a controlled path. Honing is primarily used to improve the geometric form of a surface, but may also improve the surface texture.

High-silicon aluminum alloy cylinder sleeve material and preparation method thereof

InactiveCN101457318AImprove mechanical propertiesImprove tribological propertiesRefining (metallurgy)Manufacturing technology

The invention discloses a high silicon aluminum alloy cylinder sleeve material and a manufacturing method thereof., Ingredients of the material by weight percent are as follows: Si: 18.0%-25.0%; Fe: 3.5%-6.0%; Ni: 1%-2%; Cu: 1.5%-3.0%; Mg: 0.5%-1.0%; Mn: 0.5%-1.5%; V: 0.1%-0.5%; Sr: 0.05%-0.15%; and the balance of Al. The manufacturing method thereof comprises the following steps: 1, composition design and accurate mixture which uses an intermediate alloy for quantitative mixture; 2, smelting, covering and refining; 3, injection deposition; 4, extrusion processing; 5, heat treatment; 6, mechanical processing and honing processing. The material and the manufacturing method lead the high silicon aluminum alloy products to have high comprehensive mechanical property characteristics which are superior to mechanical property characteristics of cast iron cylinder sleeve material, have frictional property which are superior to frictional property of steel and cast iron cylinder sleeve material, and have great compatibility with thermophysical property of aluminum piston alloy material, thereby obviously narrowing the gap for cylinder matching. The manufacturing method is characterized in that: the manufacturing process of injection deposition is employed, which serves as a primary means in manufacturing the high silicon aluminum alloy, is superior to the powder metallurgy process and the die-casting process, and can use conventional processing equipment and process conditions.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

Gear machining and treating process

InactiveCN104999240AReduce thicknessImprove performanceSolid state diffusion coatingGear grindingCarbon potential

The invention relates to a gear machining and treating process. The gear machining and treating process includes the steps that blanking and blank manufacturing are carried out; a gear blank is machined; rough machining and semi-finish machining of a tooth form are conducted, i.e., according to a precision requirement, tooth grooves are cut in the whole blank and a corresponding allowance for finish machining is reserved on the groove side at the same; the gear end is chamfered and burrs are removed; heat treatment is carried out; tooth form machining is carried out on an unfinished product subjected to heat treatment by adopting the method of gear grinding or gear honing or gear lapping again; strengthened shot peening is carried out so as to improve the endurance bending strength and contact fatigue strength of a gear; and cleaning is carried out. Through the gear machining and treating process, the content of retained austenite on the surface of the gear and the thickness of a non-martensite layer on the surface of the gear are reduced; by the adoption of the high-temperature carbon potential changing method, production efficiency is improved; thus, the tissue performance of the tissue surface is greatly improved, and the phenomenon of tooth breakage cannot occur.

Owner:JIANGSU YAOYAO CASTING IND

Machining technology of cylinder barrel of steering oil cylinder

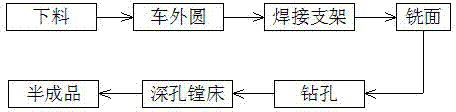

The invention discloses a machining technology of a cylinder barrel of a steering oil cylinder and belongs to the field of hydraulic oil cylinders. The machining technology comprises the main steps that of (1) blanking, (2) turning, (3) support welding, (4) milling, (5) drilling, (6) machining of an inner hole and (7) forming of a semi-finished product. In the step of support welding, the mode of semi-automatic welding with protection is adopted, the working efficiency and the machining precision are improved, and welding is safer. The step of inner hole turning and the step of honing are combined through a deep hole boring machine, inner hole turning and honing are conducted at the same time, the surface smoothness and the surface hardness of the inner hole are improved, and the errors of the inner diameter are reduced; besides, the procedure is simplified, and efficiency is improved.

Owner:ANQING TIANRUN ENG MACHINERY

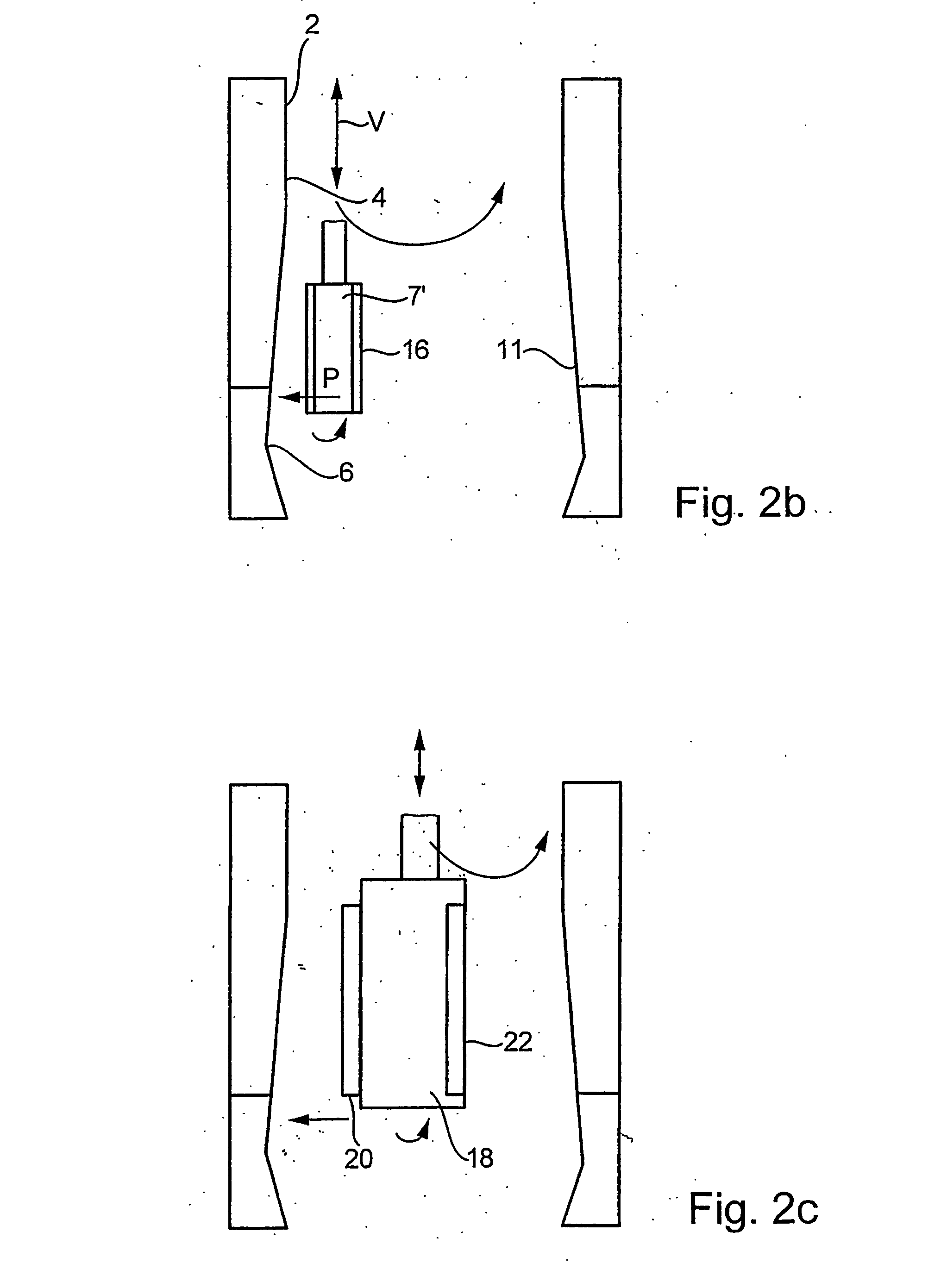

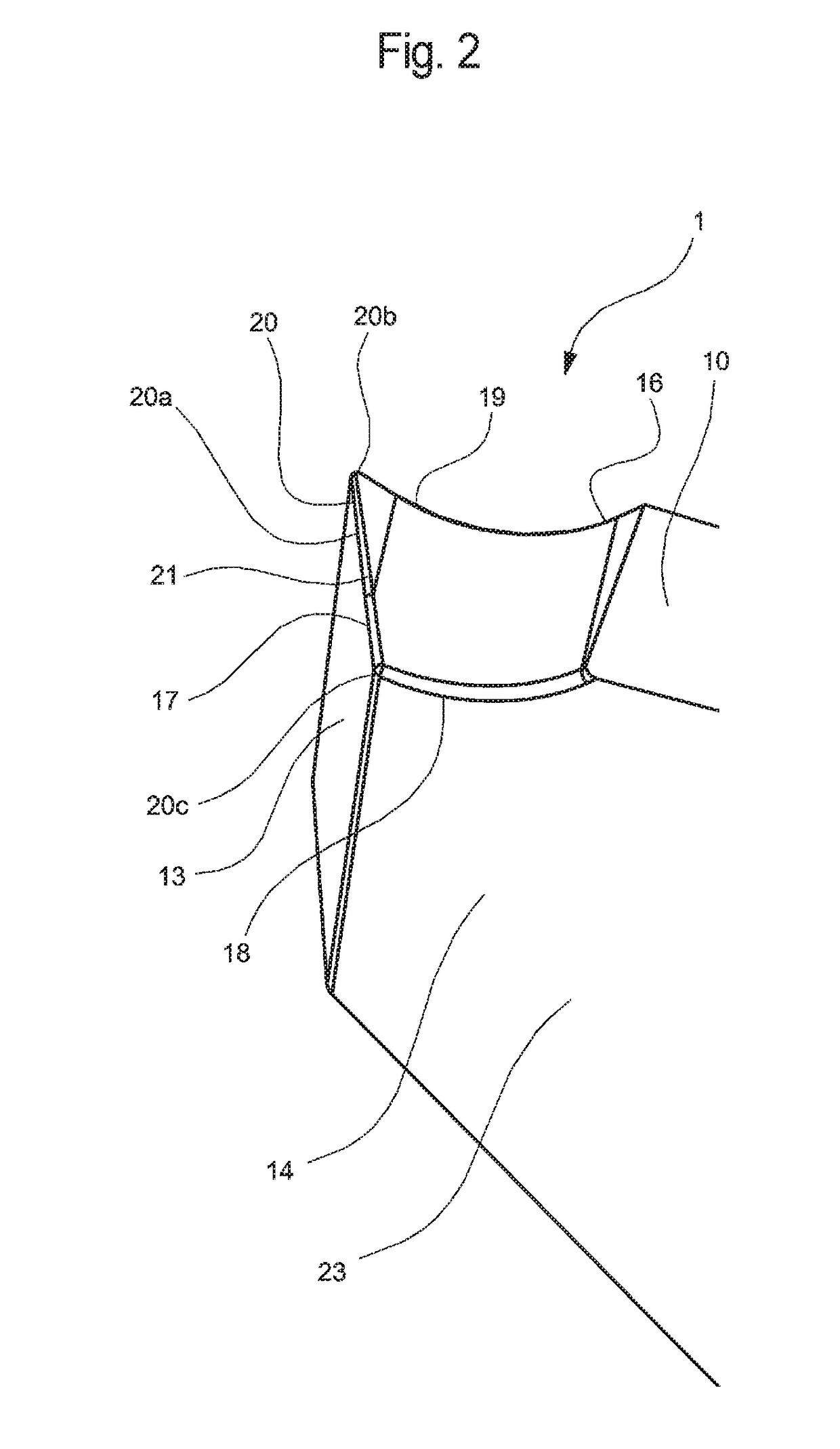

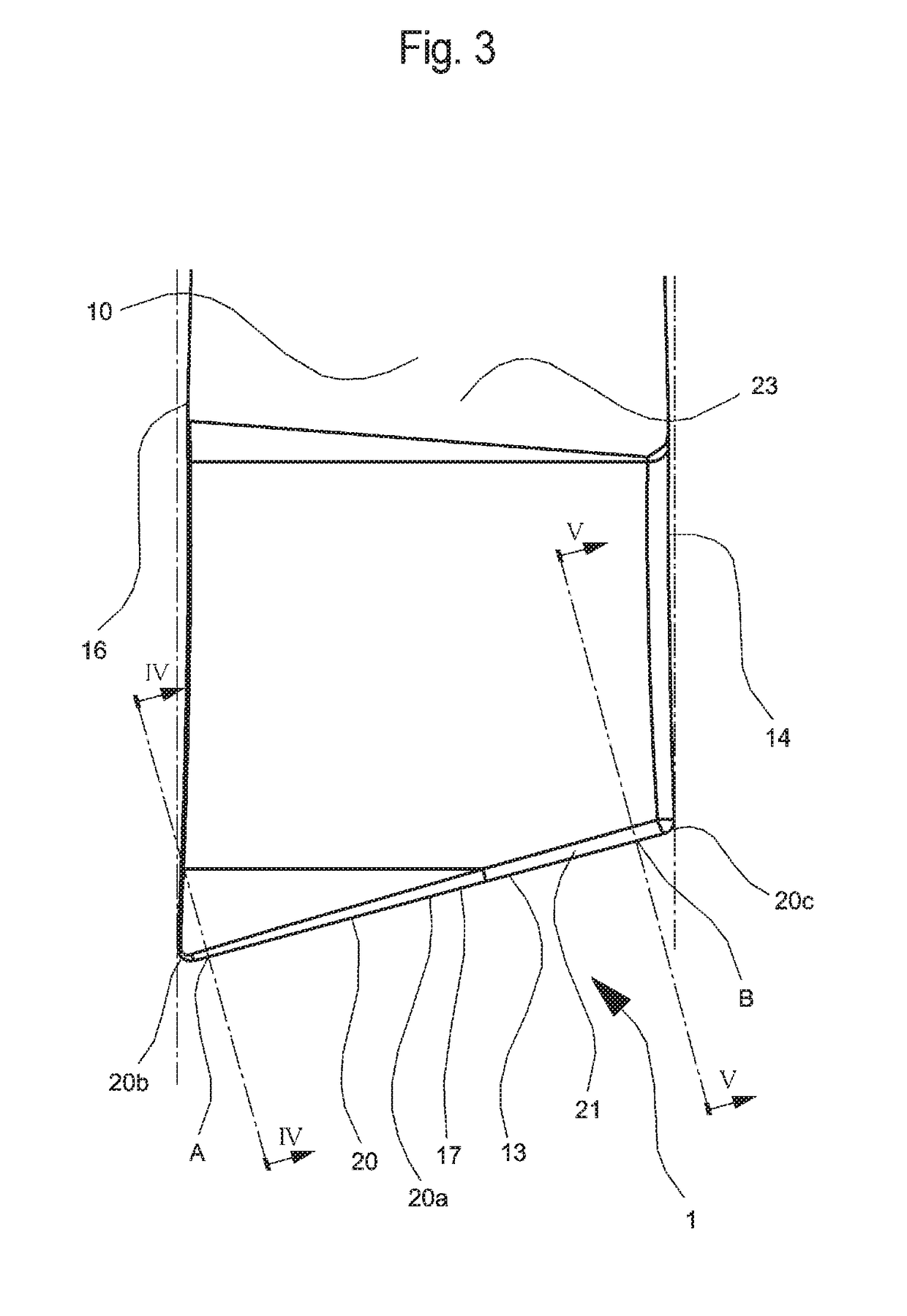

Method and apparatus for finish machining crankshaft bearing borehole

In a method for finishing a borehole in a workpiece, particularly for finishing a crankshaft bearing borehole in a cylinder crankcase of an internal combustion engine, a machined borehole is generated based on a prepared borehole, the machined hole has a settable theoretical size, a settable theoretical structure of the inner surface of the borehole and a settable theoretical position of the borehole axis. The method is characterized in at least one high efficient honing operation. A degradation of 0.5 millimeter is generated under the use of a honing tool by the honing of the borehole relative to the diameter of the borehole during the high efficient honing operation. The high efficient honing operation is executed as honing operation such that a shifting of the borehole axis takes place in the direction of the target position by the engine power honing operation.

Owner:NAGEL MASCHEN UND WERKZEUGFAB

Honing abrasive belt

The invention relates to a honing abrasive belt which is made of an adhesive and a grinding material, wherein the adhesive consists of the following raw materials in percentage by volume: 5-15 percent of zinc powder, 30-60 percent of cobalt powder, 10-35 percent of copper powder and 15-30 percent of silver powder; the grinding material is self-sharpening artificial diamond particles on which Ni coatings are plated; the particles have particle diameters of D76-D181; and the grinding material content is 3-15 percent of the adhesive in volume. In the abrasive belt, the adhesive belt with a reasonable proportion is selected and used; the hardness of the manufactured honing abrasive belt reaches HB40-60; and the honing abrasive belt has a good application effect. The geometric dimensions of the abrasive belt are as follows: the length is 100-200mm, the width is 1.5-6mm and the height is 6mm; and a reticulated pattern of a cylinder liner which meets the European VI emission standard can be processed.

Owner:GKN ZHONGYUAN CYLINDER LINER CO LTD

Air cylinder sleeve finish machining process

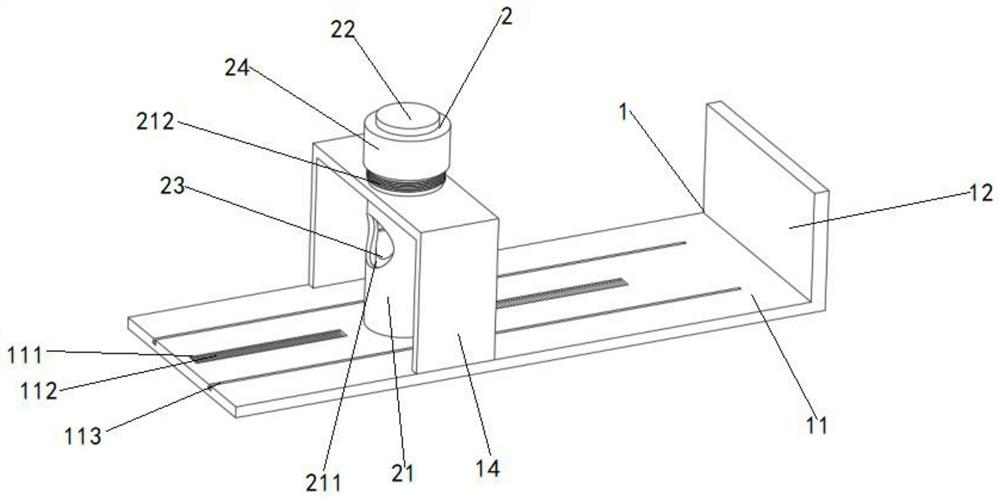

ActiveCN112059794AGood effectAvoid swingingEdge grinding machinesGrinding carriagesMachining processMechanical engineering

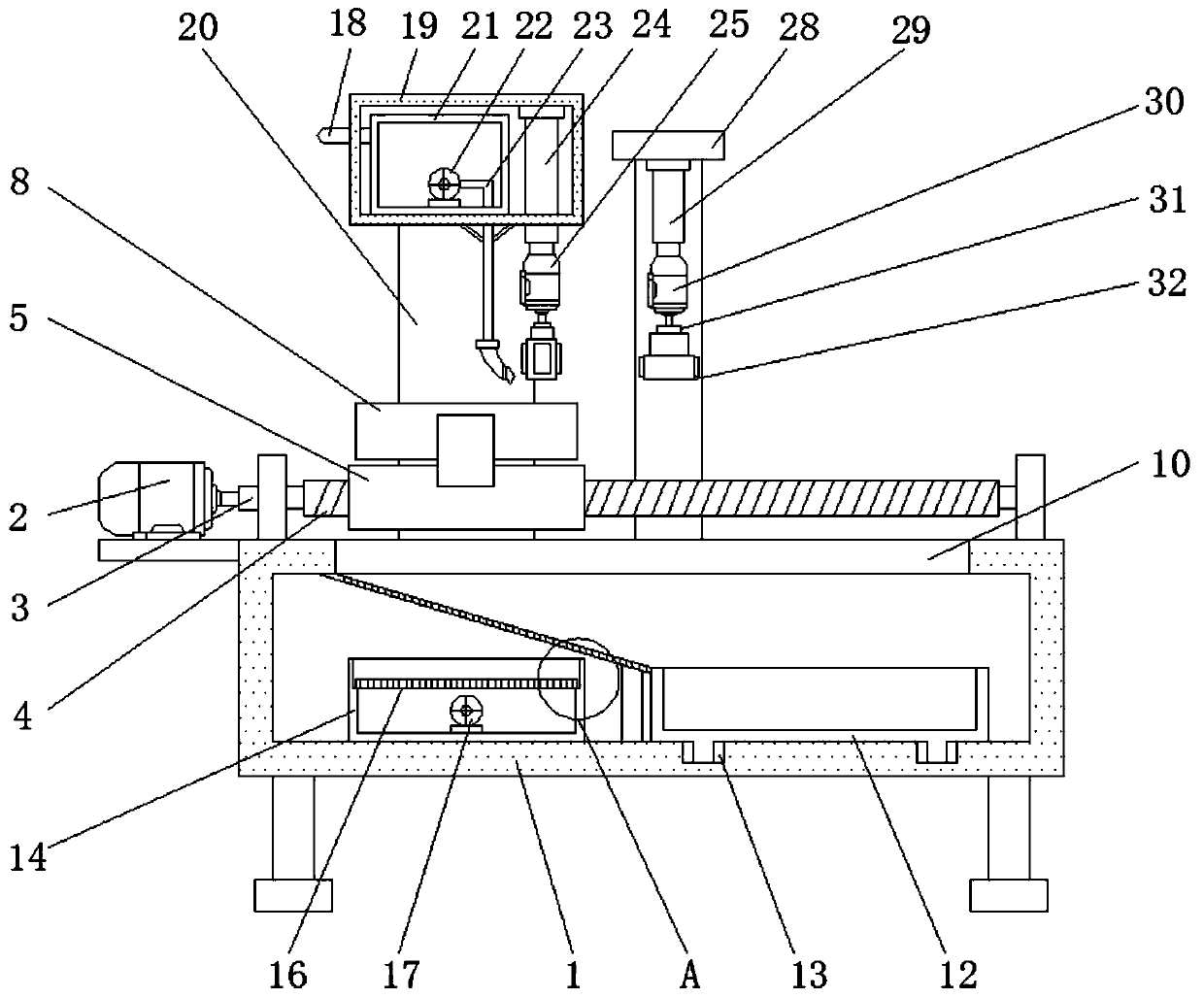

The invention discloses an air cylinder sleeve finish machining process. The air cylinder sleeve finish machining process adopts a following air cylinder sleeve finish machining treatment device. Theair cylinder sleeve finish machining treatment device comprises a base, a fixing device, clamping devices and a machining device, the fixing device is fixedly installed on the base, and the clamping devices are installed at the two sides of the fixing device; and the machining device is installed on the base and comprises a grinding mechanism, a honing mechanism and a machining power mechanism. The air cylinder sleeve finish machining process adopting the air cylinder sleeve finish machining treatment device comprises the following steps that S1, air cylinder sleeves are fixed; S2, clamping and positioning are carried out; and S3, inner wall treatment is carried out. According to the air cylinder sleeve finish machining process, the air cylinder sleeves of different sizes and specifications can be clamped and fixed through cooperation of the fixing device and the clamping devices, the application range of the air cylinder sleeve finish machining process is enlarged, the machining device can repeatedly conduct grinding and honing work on the inner walls of the air cylinder sleeves at the same time, the working efficiency is improved, and the machining effect is improved.

Owner:威海众海智能科技有限公司

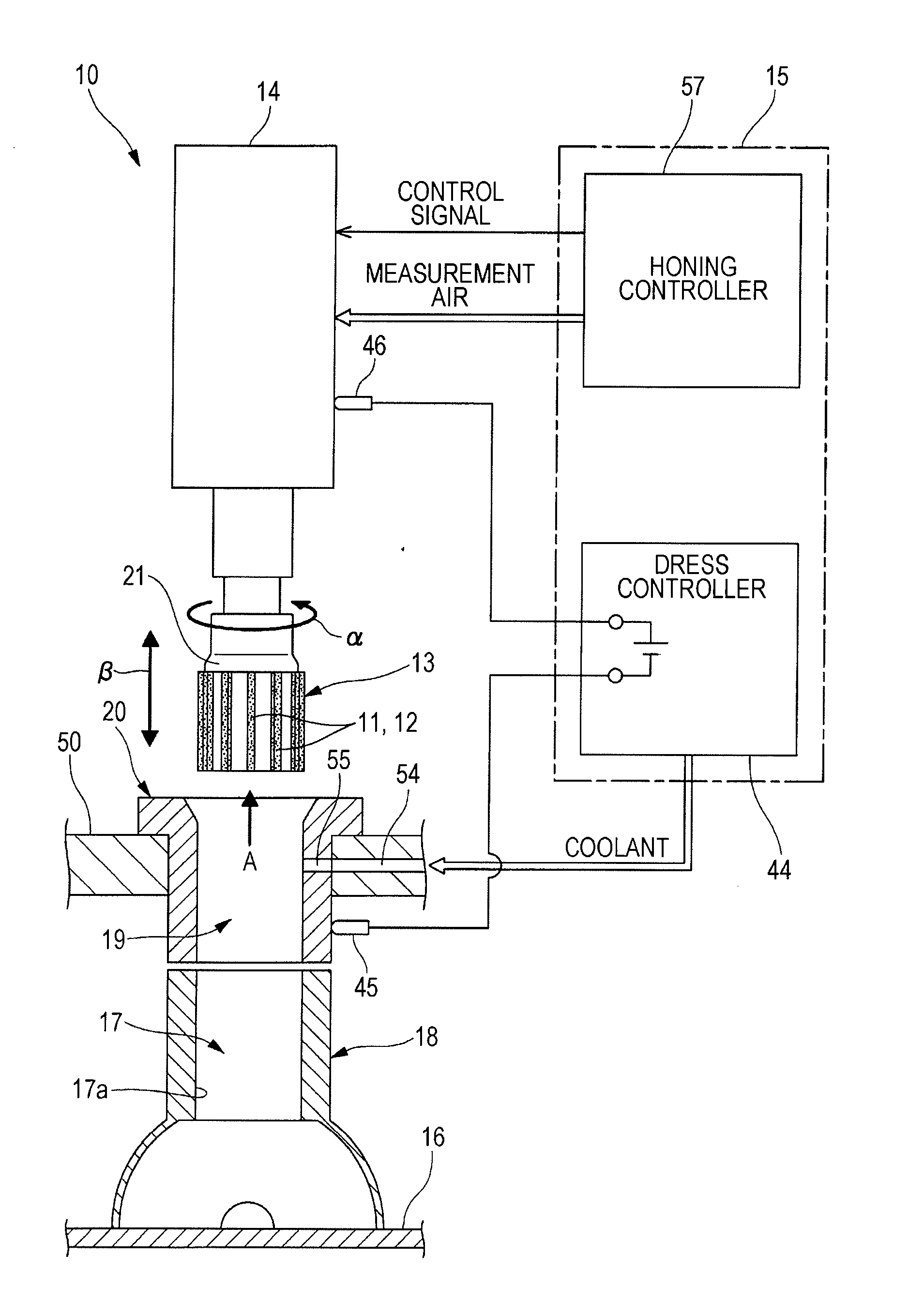

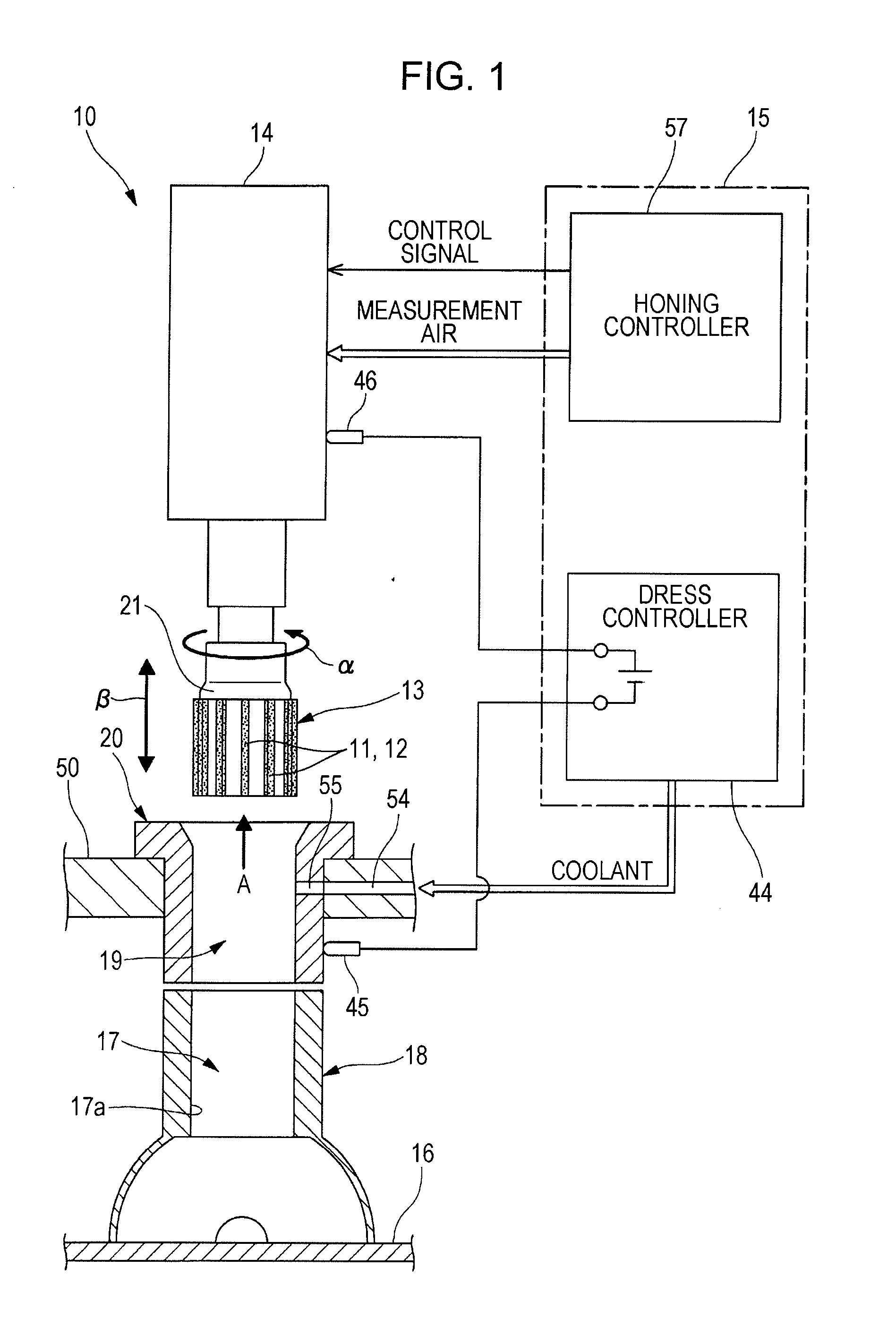

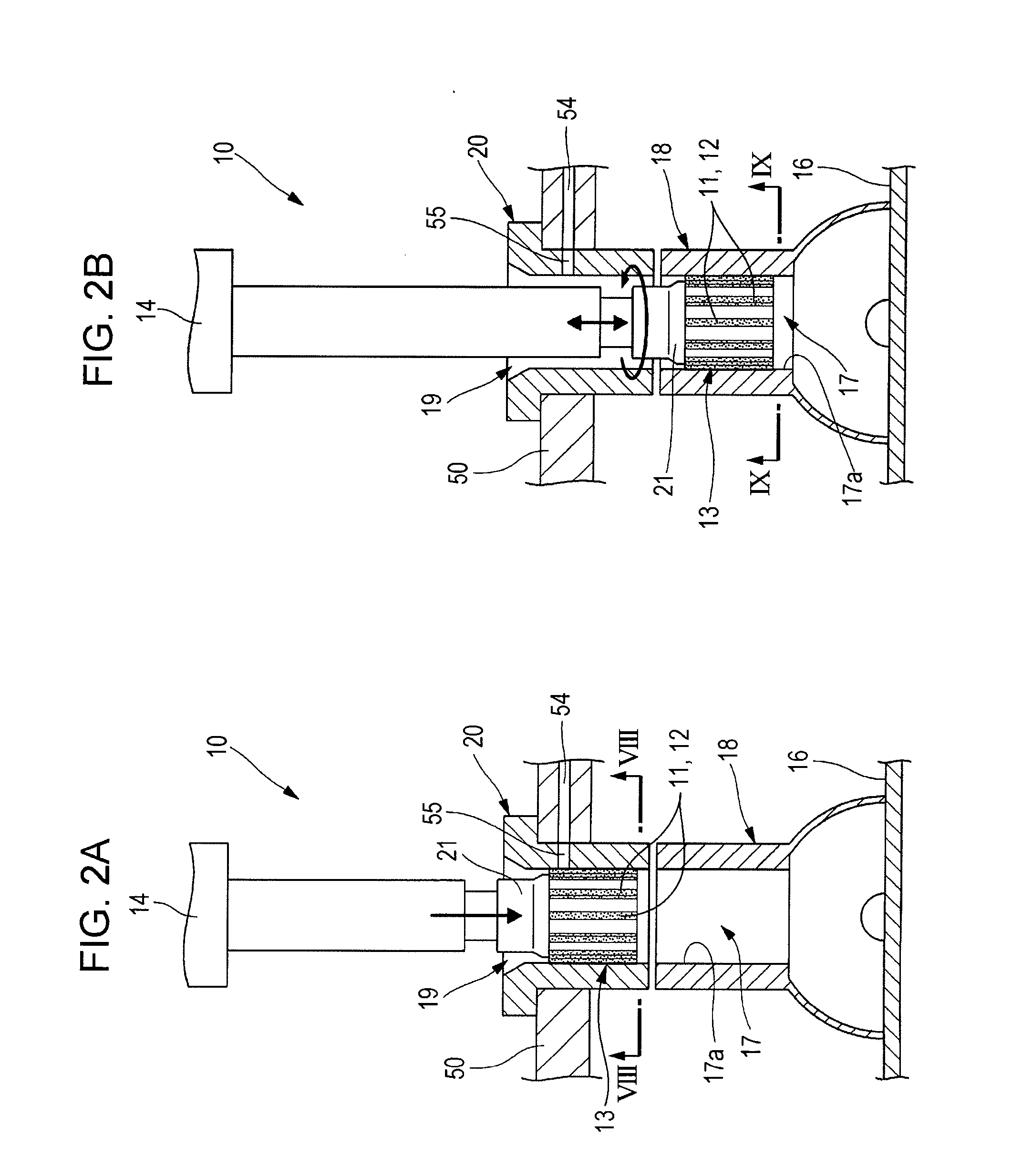

Method and apparatus for the measurement-aided fine machining of workpiece surfaces, and measuring system

InactiveUS8961265B2Improve accuracyHigh precisionGrinding feed controlMeasurement/indication equipmentsMaterial removalRadar radiation

In the case of a method for the material-removing fine machining of a workpiece surface of a workpiece, in particular for the honing or finishing of workpiece portions having substantially rotationally symmetrically curved workpiece surfaces, at least one fine machining tool machines the workpiece surface and, by means of a measuring system, a measurement of the workpiece surface is performed. In this case, at at least one measuring position, radar radiation is directed onto the workpiece surface, and the radar radiation reflected from the workpiece surface is acquired and evaluated for the purpose of determining at least one surface measurement value.

Owner:NAGEL MASCHEN UND WERKZEUGFAB

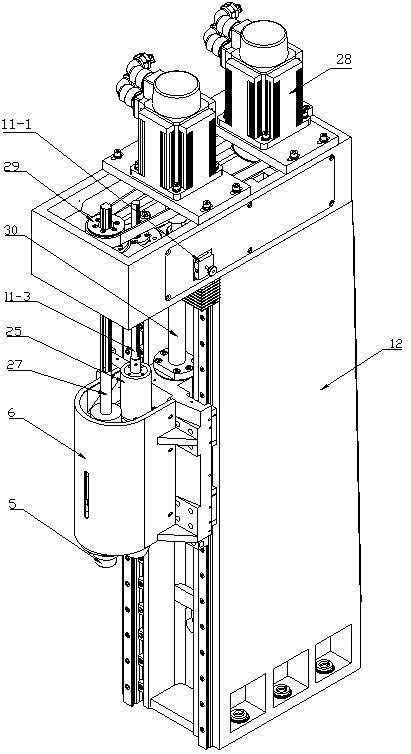

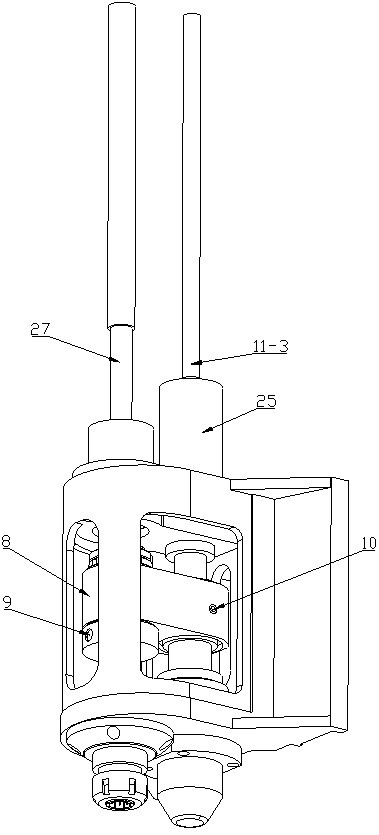

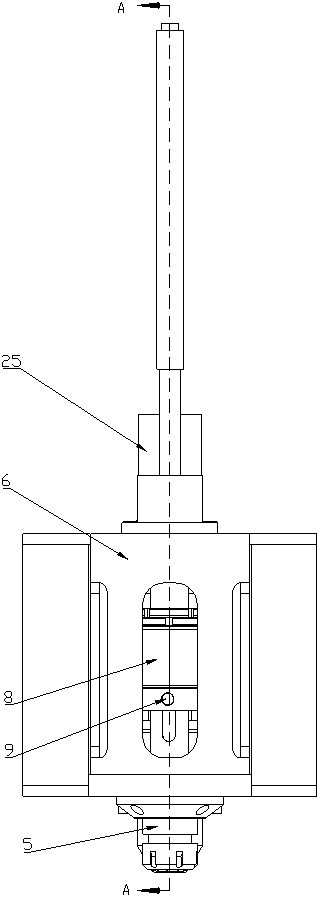

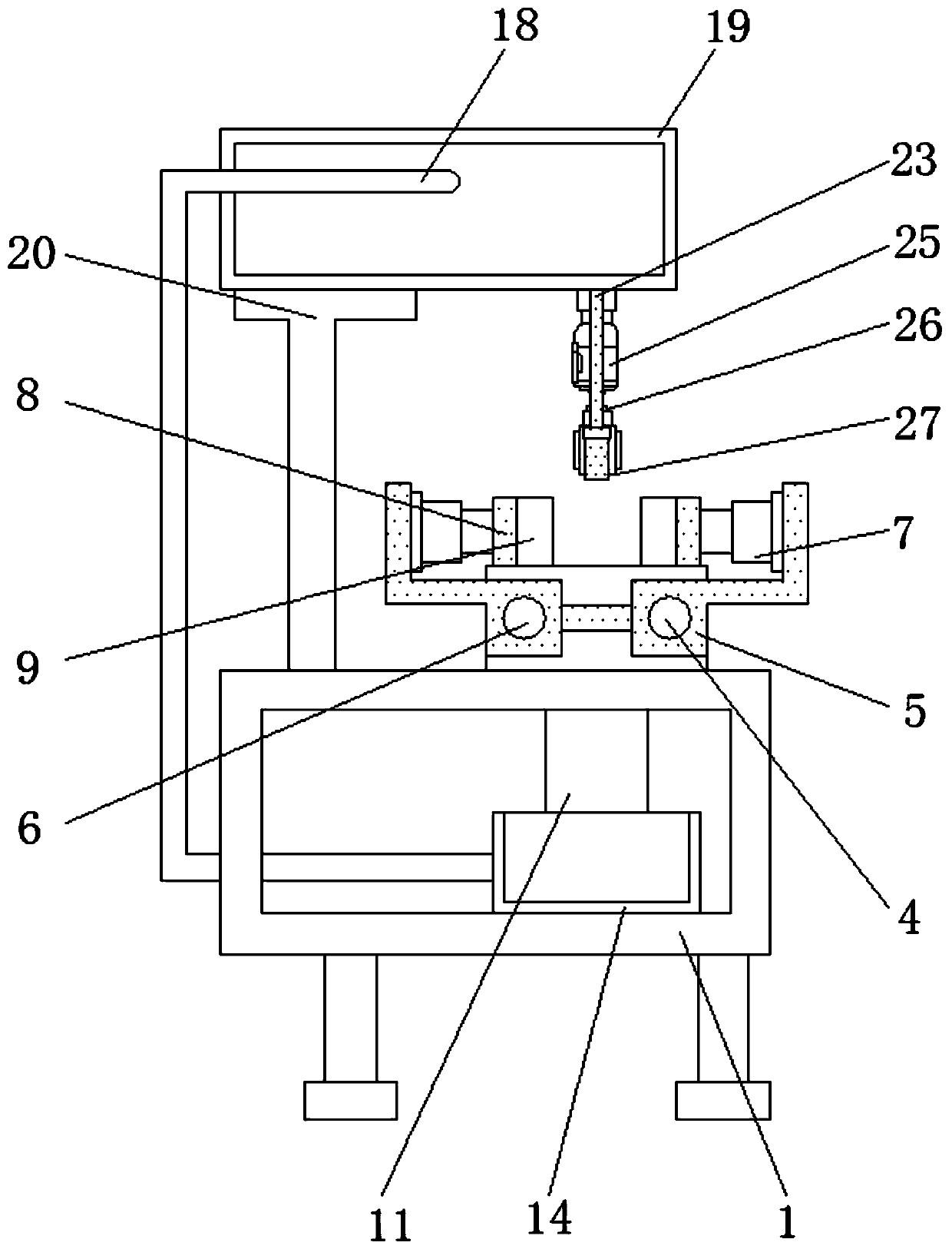

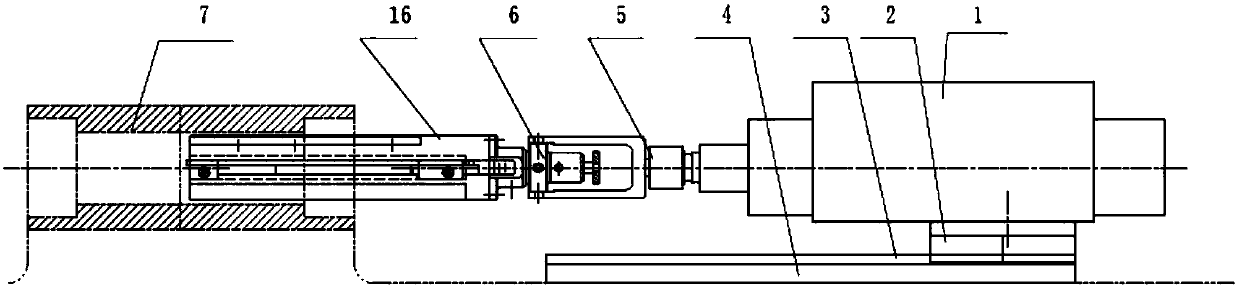

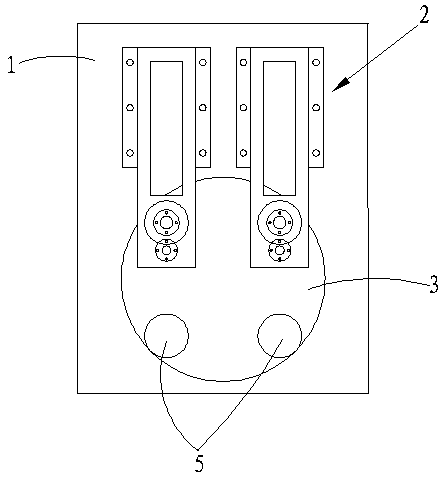

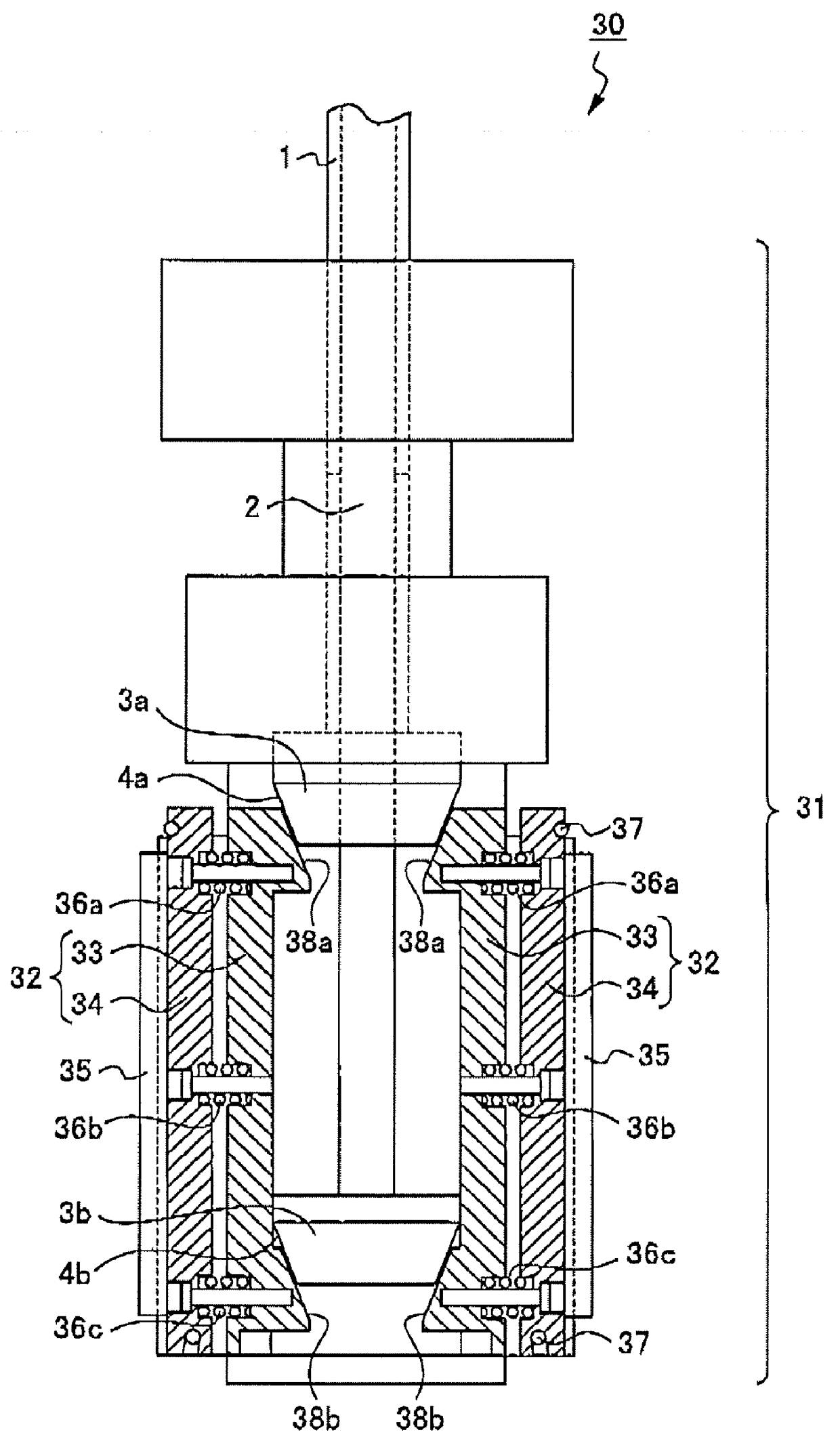

Honing feeding mechanism and vertical honing machine with same

ActiveCN112975734AQuality improvementGood precisionGrinding drivesHoning machinesBiotechnologyAgricultural science

The invention relates to a honing feeding mechanism and a vertical honing machine with the same. The honing feeding mechanism comprises a feeding rod, a linkage mechanism, a feeding driving mechanism, a feeding hollow shaft, a center inner shaft and a feeding elastic piece, wherein the feeding rod is arranged in a main shaft of the honing machine in an axial sliding mode, the center inner shaft is arranged in the feeding hollow shaft in an axial sliding and penetrating mode, the feeding driving mechanism acts on the center inner shaft, so as to drive the center inner shaft for sliding feeding in the feeding hollow shaft, the feeding elastic piece is arranged between the feeding hollow shaft and the center inner shaft and used for transmitting the sliding feeding acting force of the center inner shaft to the feeding hollow shaft through the elastic force of the feeding elastic piece, and the feeding hollow shaft drives the feeding rod for synchronous sliding feeding through the linkage mechanism. The vertical honing machine comprises the honing feeding mechanism for honing feeding. The honing feeding mechanism has the beneficial effects that the honing feeding mechanism conducts flexible feeding through the feeding elastic piece, and the honing surface quality and the honing precision can be improved.

Owner:常州凯瑞莱精密工具有限公司

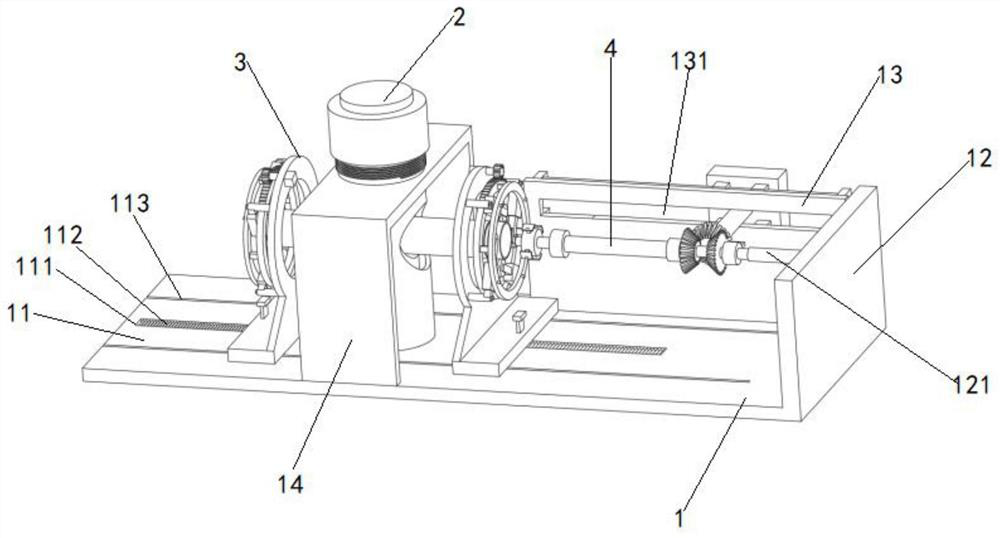

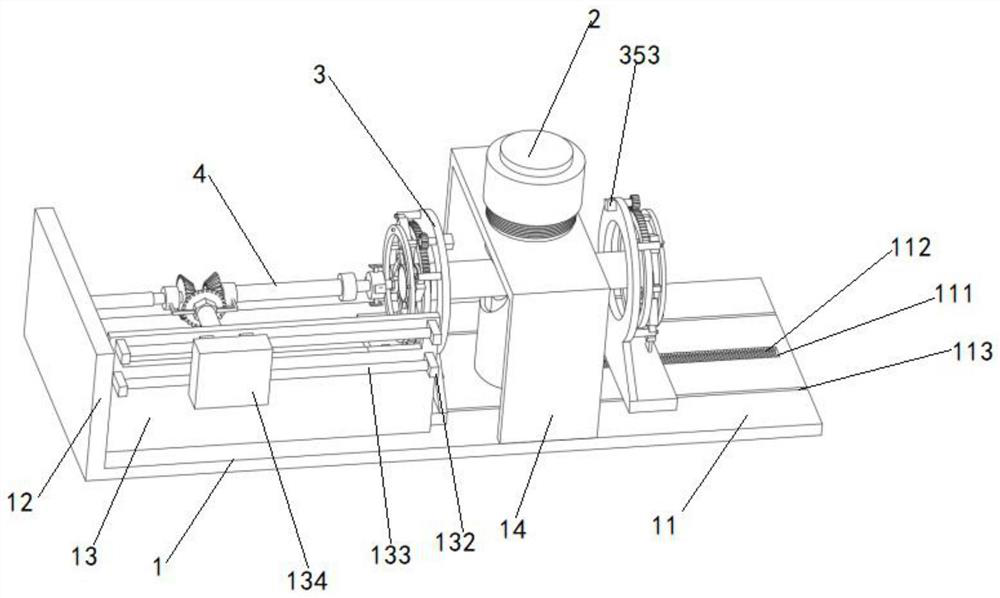

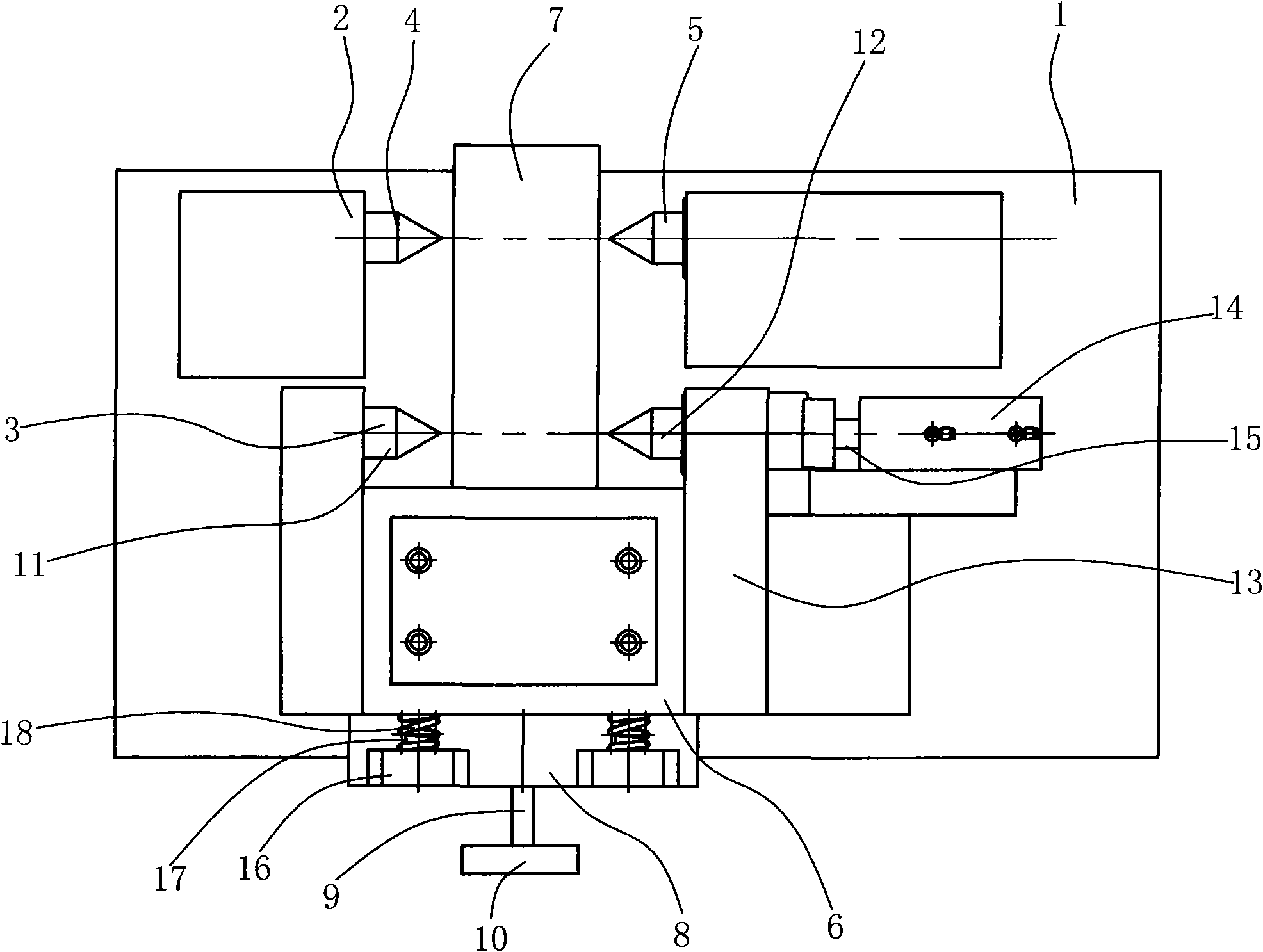

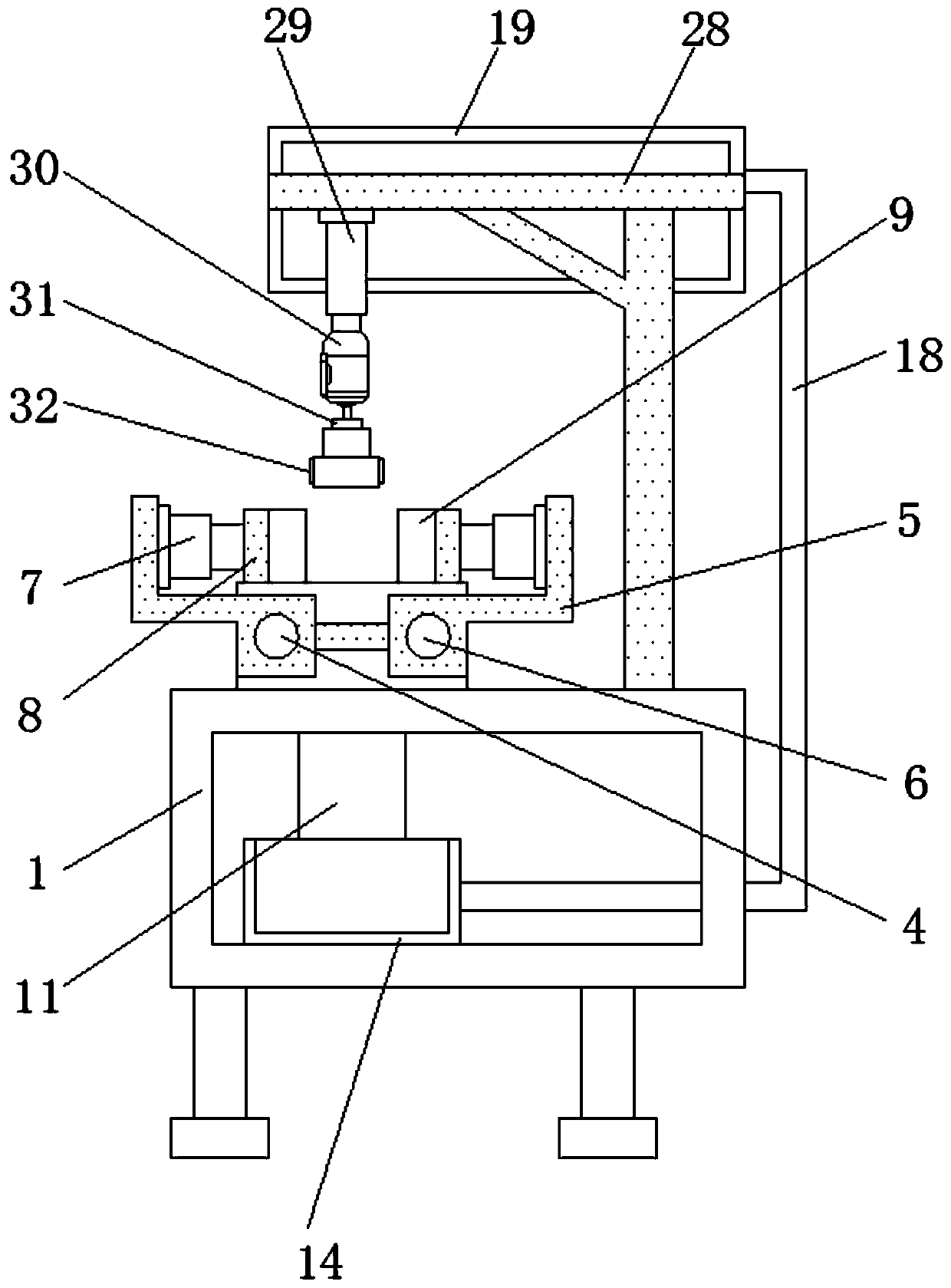

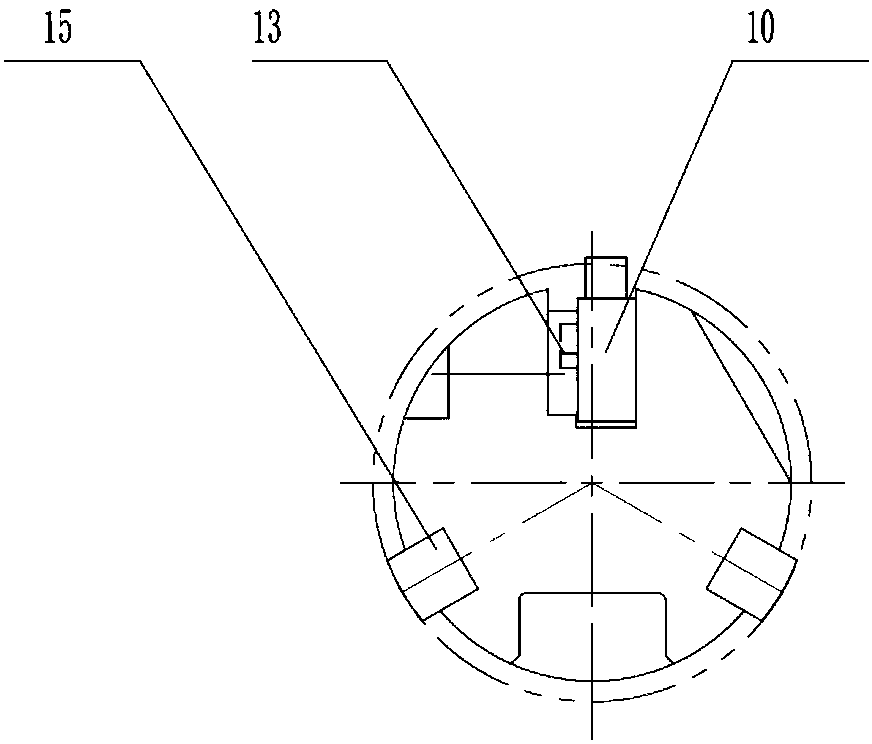

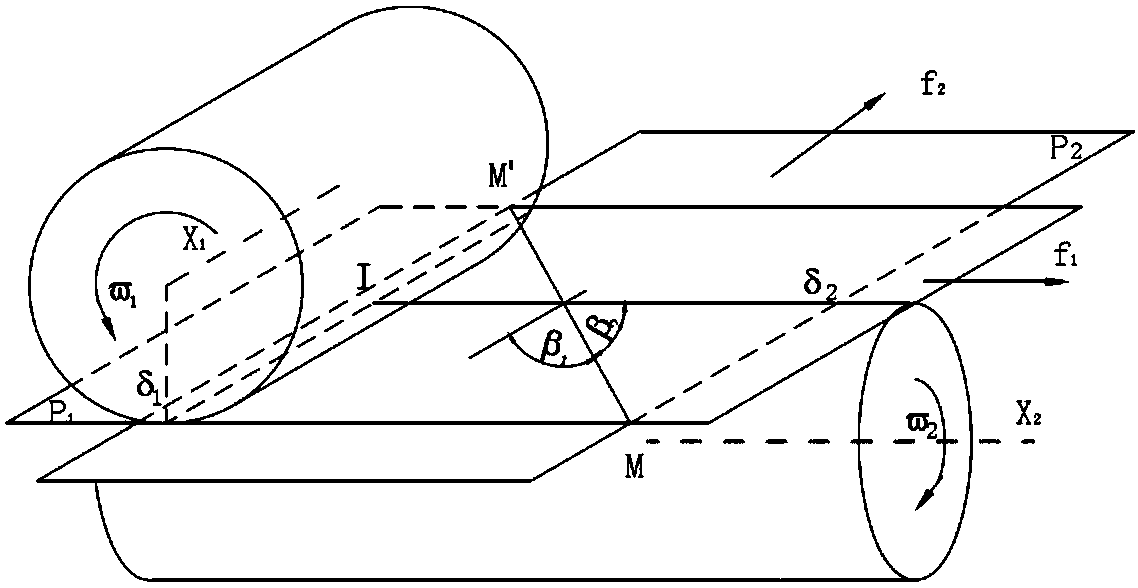

Gear honing method and device

The invention relates to a gear honing method and device, belonging to the technical field of a gear processing method and gear processing mechanical equipment. The gear honing method comprises the following steps: (1) clamping two gear workpieces to be mutually meshed on a first centre group and a second centre group with parallel axes so that the two gear workpieces are mutually meshed and certain pressing force is formed between the meshing surfaces of the two gears; (2) marking the initial meshing positions of mutual meshing on the two gear workpieces respectively; (3) driving one gear workpiece to rotate and move with the other gear workpiece in a meshed manner by the first centre group or the second centre group; and (4) after the two gear workpieces are subject to meshed movement for a period of time, removing the two gear workpieces for pair package or installation.

Owner:许晓华

Honing machine with function of washing workpieces for cylinder barrel

ActiveCN110640616AWith the function of cleaning the workpieceConvenient for honingBurnishing machinesHoning machinesMachineMachining process

The invention discloses a honing machine with a function of washing workpieces for a cylinder barrel. The honing machine comprises a machine body and an L-shaped support plate, wherein a first motor is arranged on the left side of the machine body, the right end of a first rotating shaft is connected with a threaded rod, and a movable seat is arranged on the threaded rod; a first hydraulic telescopic rod is arranged on the movable seat, and a connecting plate is arranged at the inner end of the first hydraulic telescopic rod; an inclined plate is arranged below a through hole groove, clampinggrooves are formed in the left side wall and the right side wall of the interior of a first water tank correspondingly, and filter screens are arranged on the clamping grooves; a third hydraulic telescopic rod is arranged at the inner top end of the L-shaped support plate; and a third motor is connected with a third rotating shaft, and the lower end of the third rotating shaft is connected with arolling device. According to the honing machine with the function of washing the workpieces for the cylinder barrel, water in a second water tank can be sprayed out through a spray pipe under the action of a second water pump, the cylinder barrel in the honing machining process can be washed, and the situation that due to chips generated by honing machining of the cylinder barrel, the precision ofmachining the inner wall of the cylinder barrel is influenced is reduced.

Owner:JIANHU BADA HYDRAULIC MACHINERY CO LTD

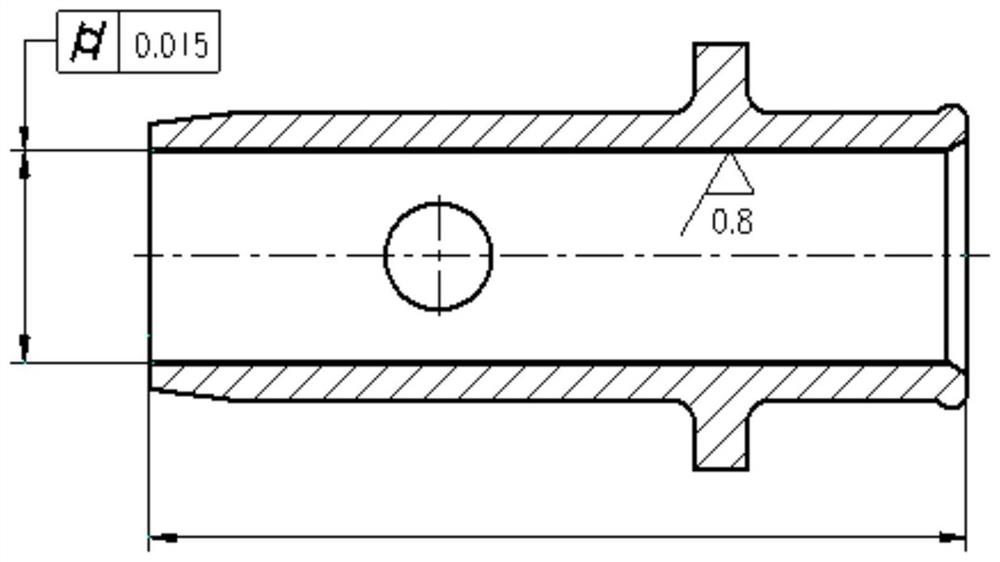

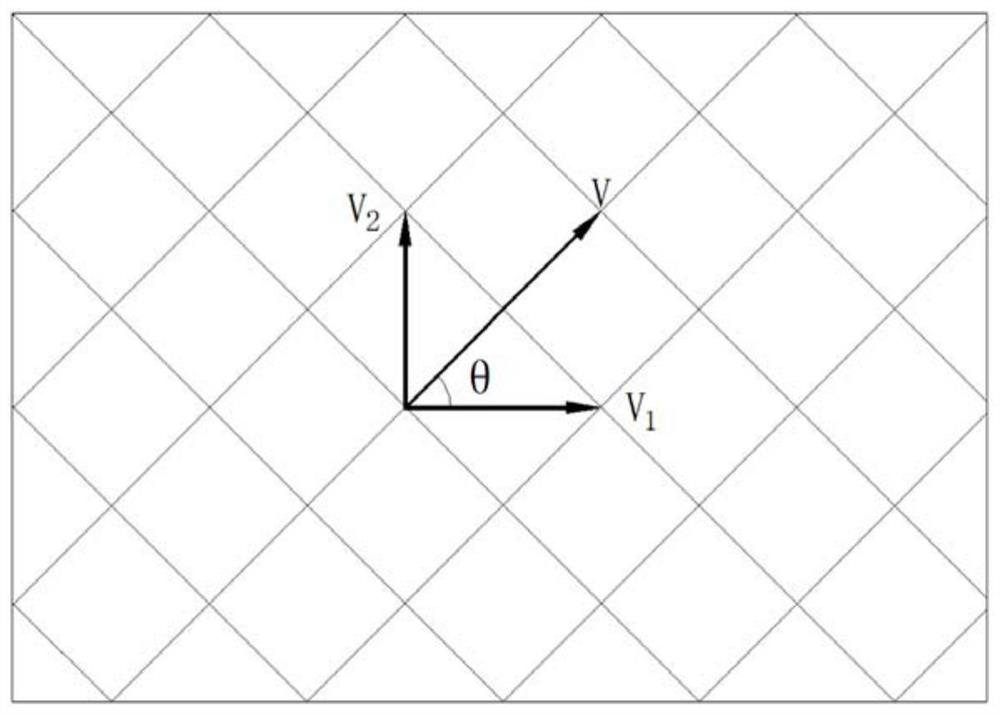

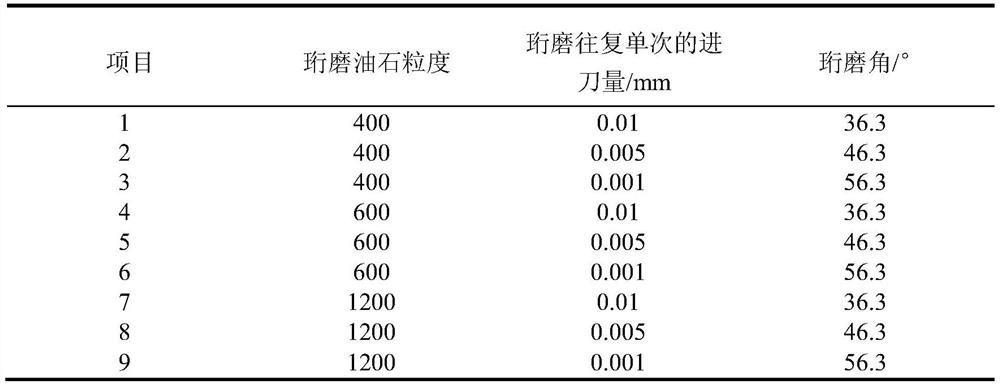

Honing machining method for inner hole net patterns of aero-engine actuator cylinder

InactiveCN110695837AImprove sealingExtended service lifeHoning machinesMachine partsProcess engineering

The invention discloses a honing machining method for inner hole net patterns of an aero-engine actuator cylinder. The method comprises the following steps that 1, a tool is taken and installed on a honing machine; 2, a to-be-machined part is taken, placed on the tool and aligned, and then the aligned to-be-machined part is subjected to flexible press fitting and stabilized on the tool; 3, the honing machine is operated to conduct crude honing machining and fine honing machining on the to-be-machined part in sequence, a honing technology is adopted for uniformly machining deep grooves and small platforms, cross grain surfaces meeting the technological requirement are generated, and during machining, honing cooling liquid is adopted for cooling. Through the mode, the honing machining methodcan improve the sealing performance of the aero-engine actuator cylinder, and the service life is prolonged.

Owner:苏州航发航空零部件有限公司

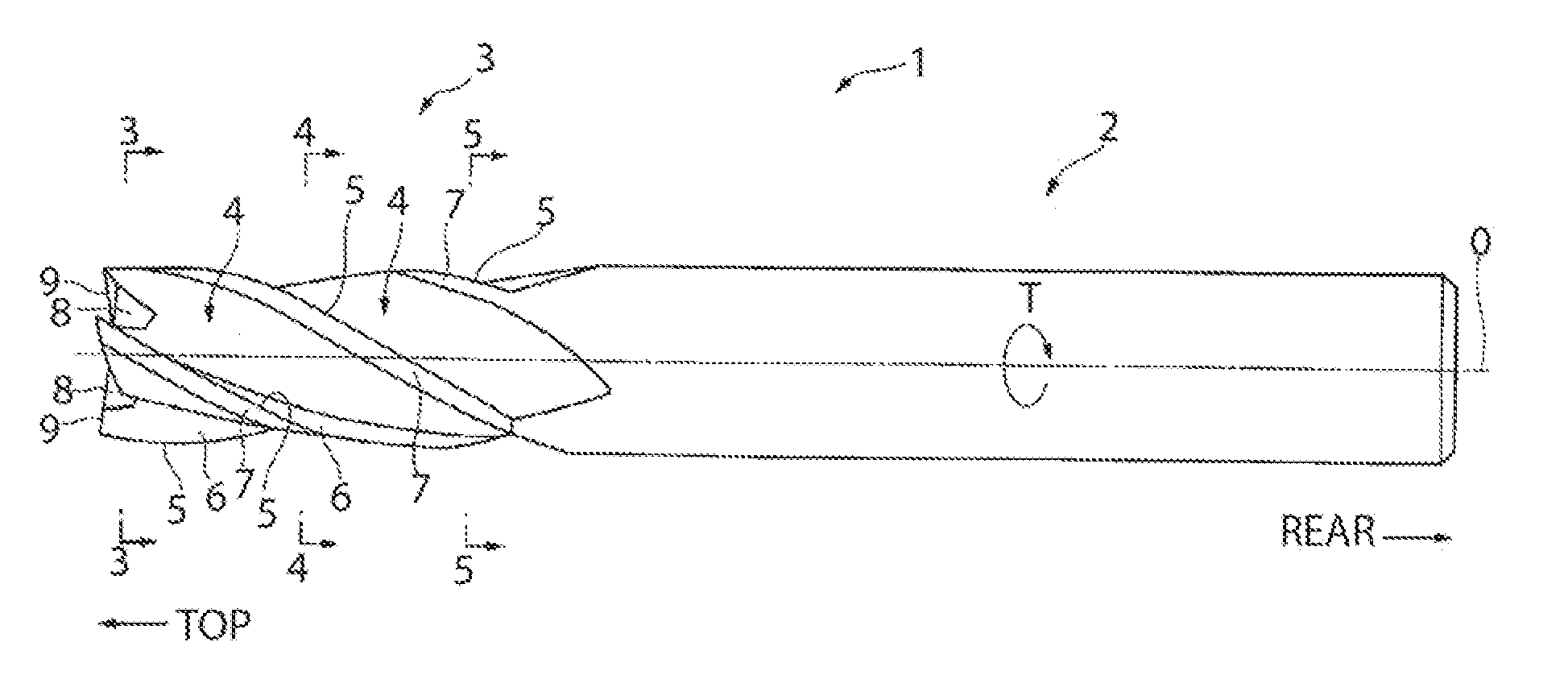

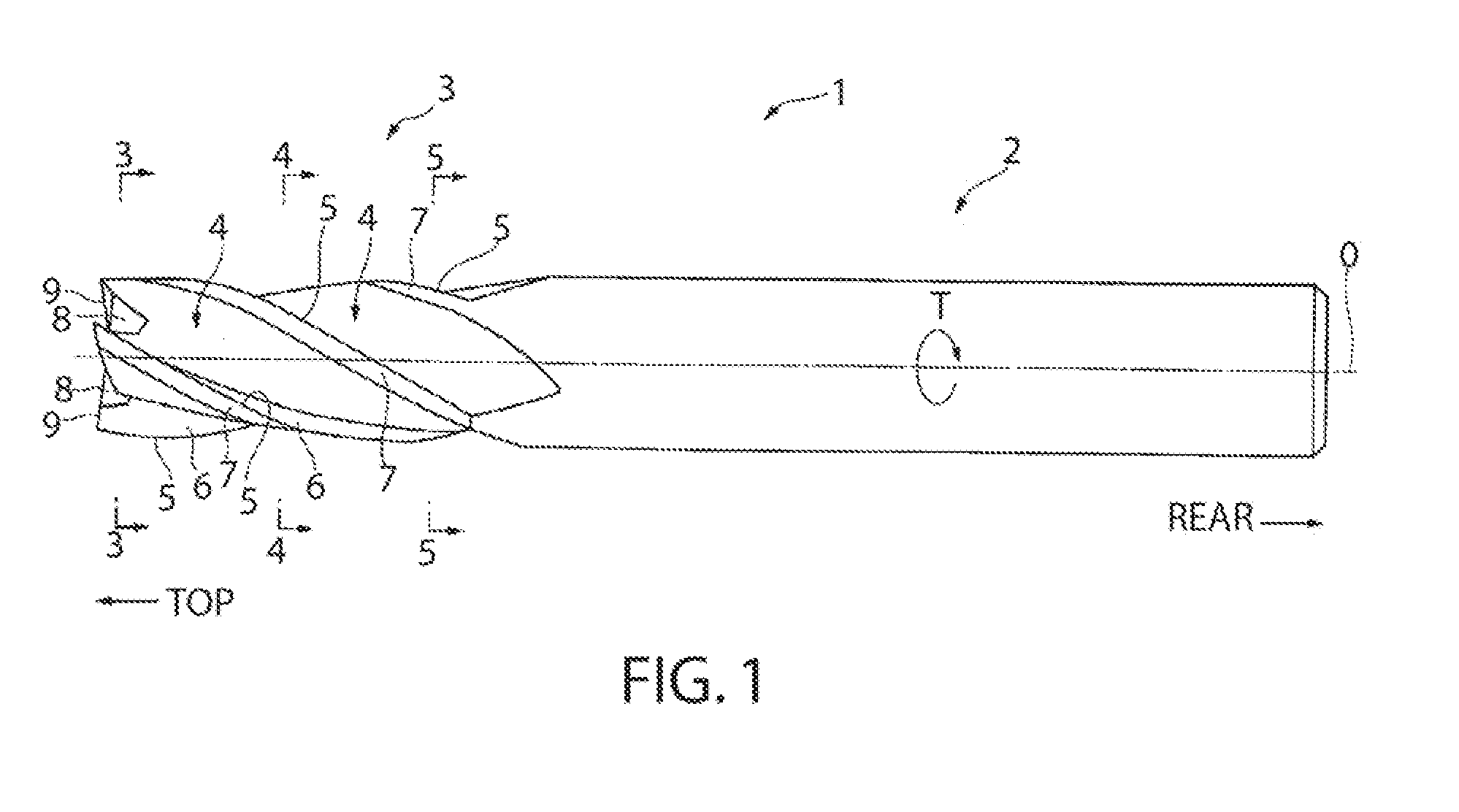

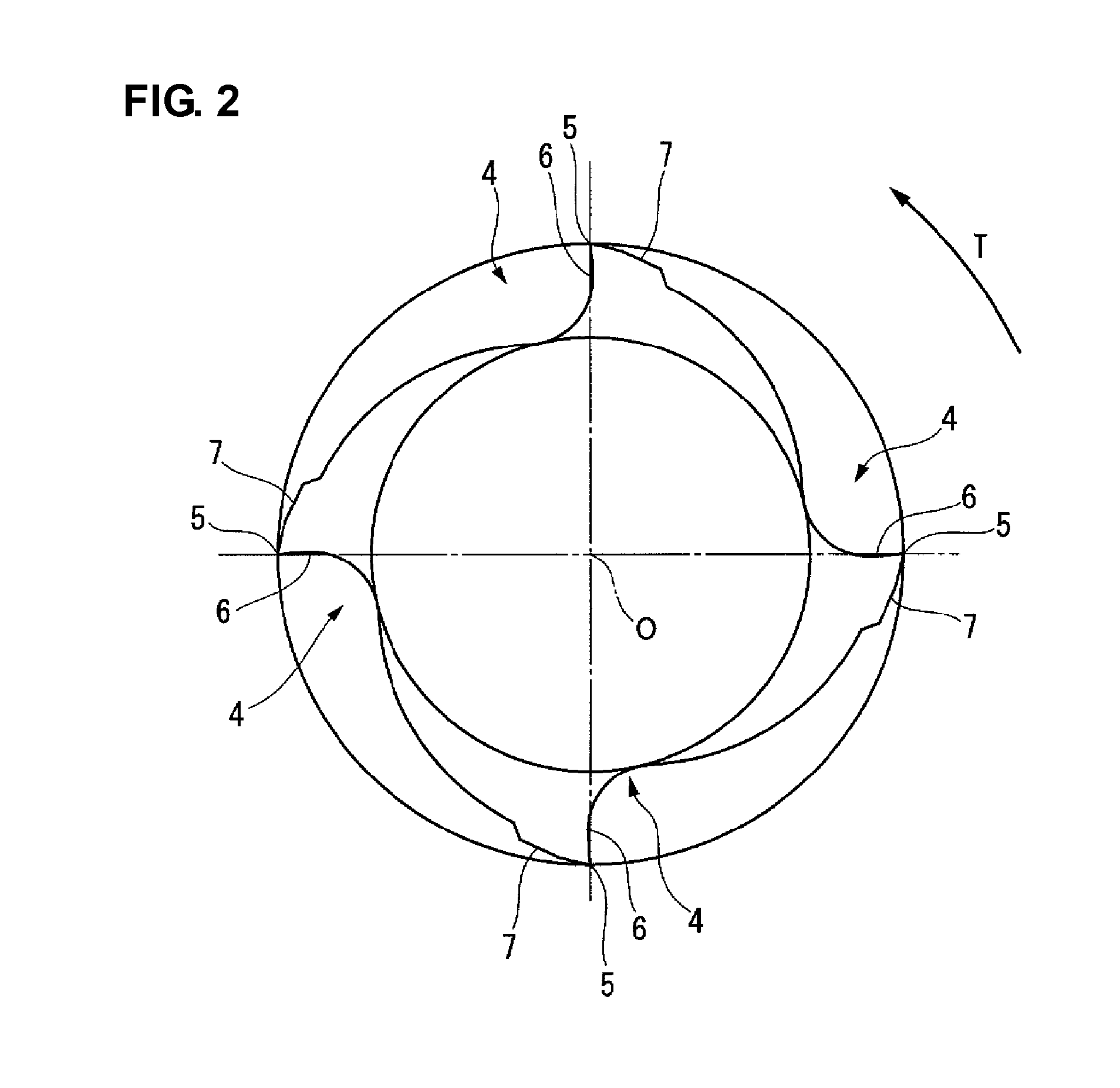

End mill

ActiveUS20120148352A1Improve fracture resistanceAvoid glitchesMilling cuttersShaping cuttersFluteStructural engineering

An end mill including multiple spiral flutes in a helical shape around an axis that are formed in a periphery of the top portion of an end mill body which rotates on the axis. Cutting edges are formed at peripheral side ridge portions of wall surfaces of the flutes facing a front side in an end mill rotating direction. Honing is applied along each peripheral cutting edge such that the cutting edge has a variable honing width in the direction of the axis.

Owner:MITSUBISHI MATERIALS CORP

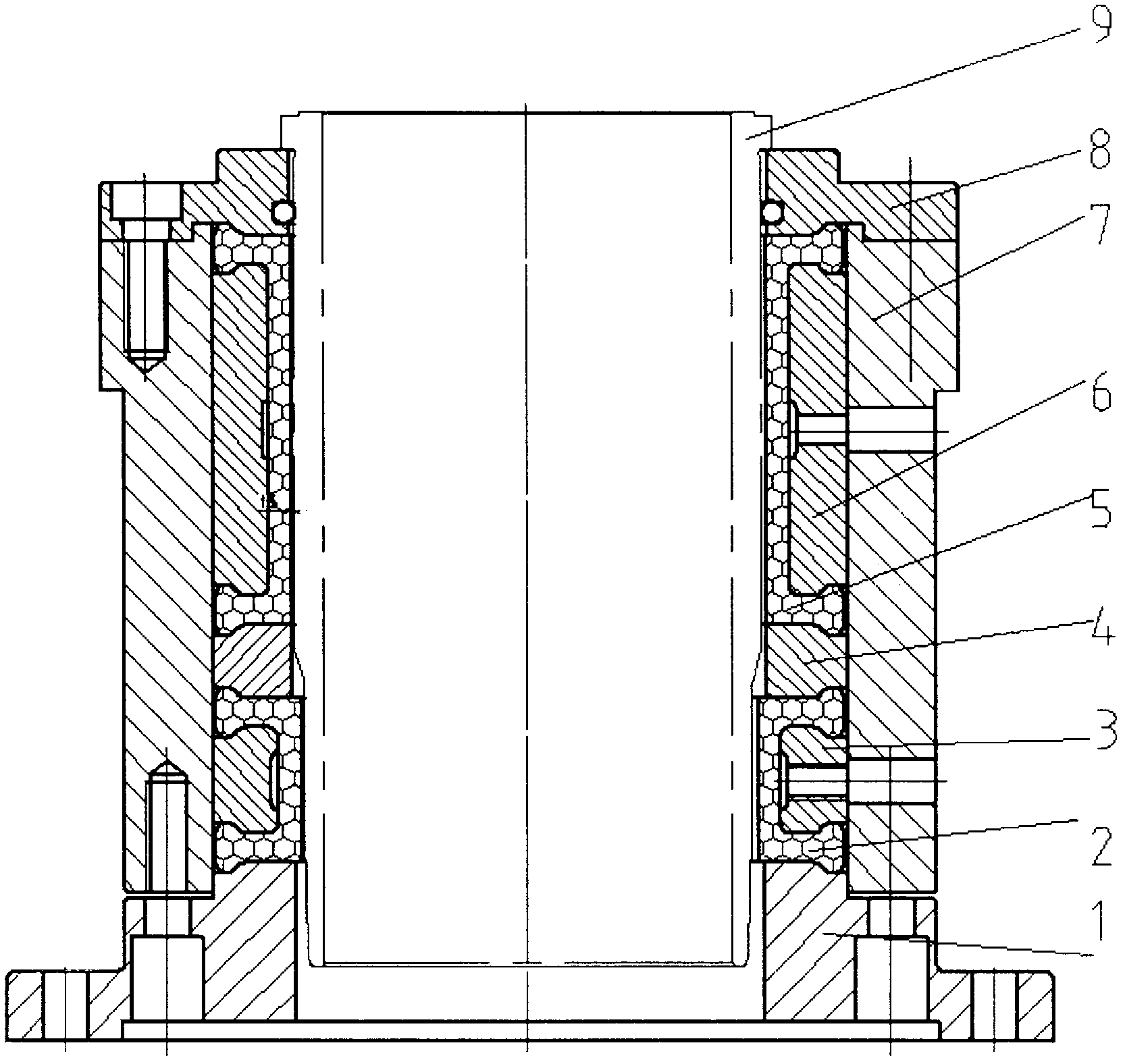

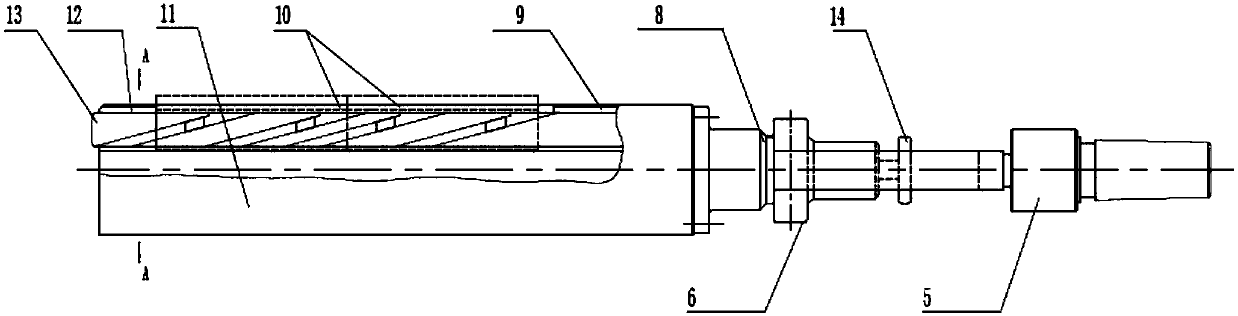

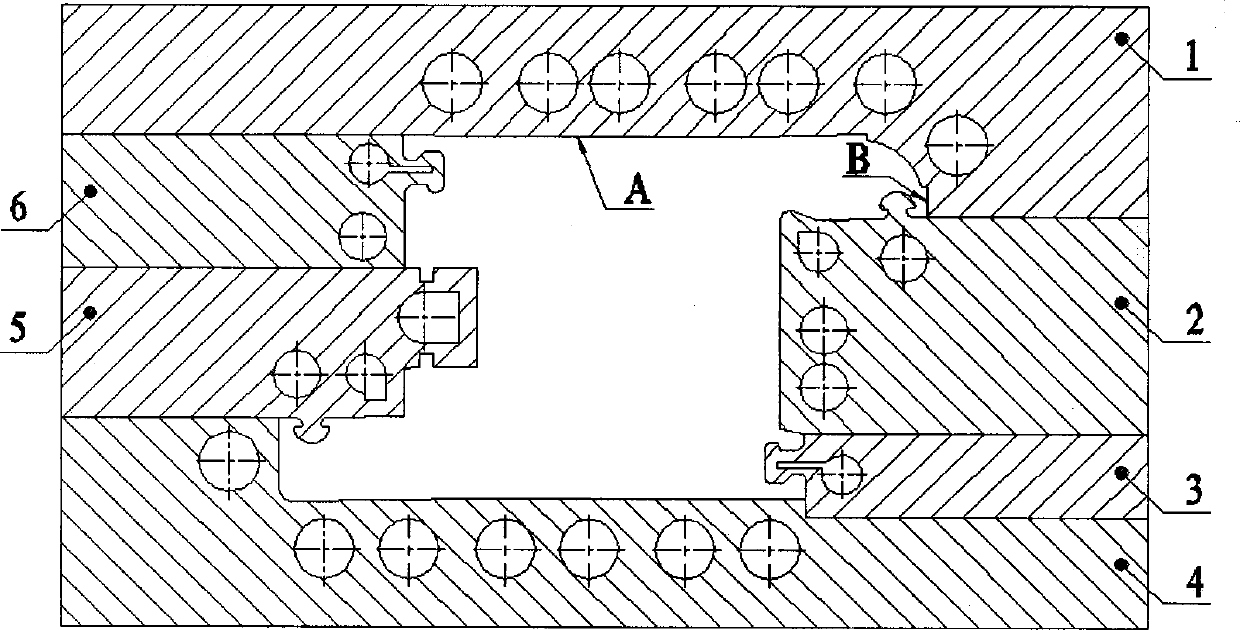

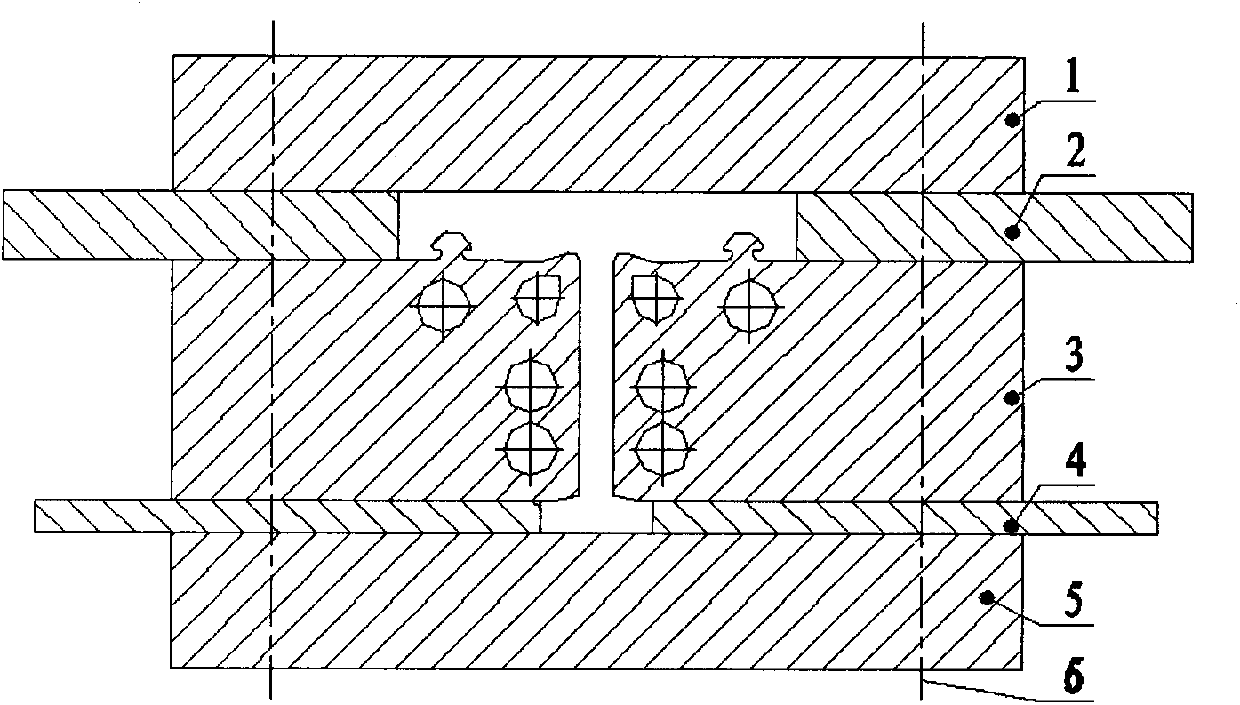

High-precision internal grinding processing procedure

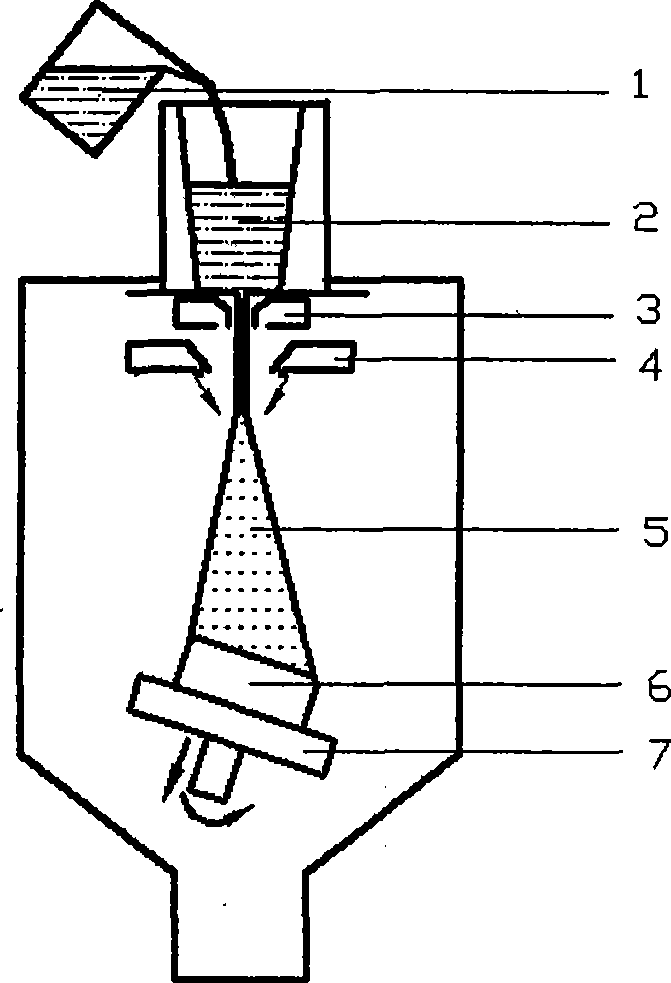

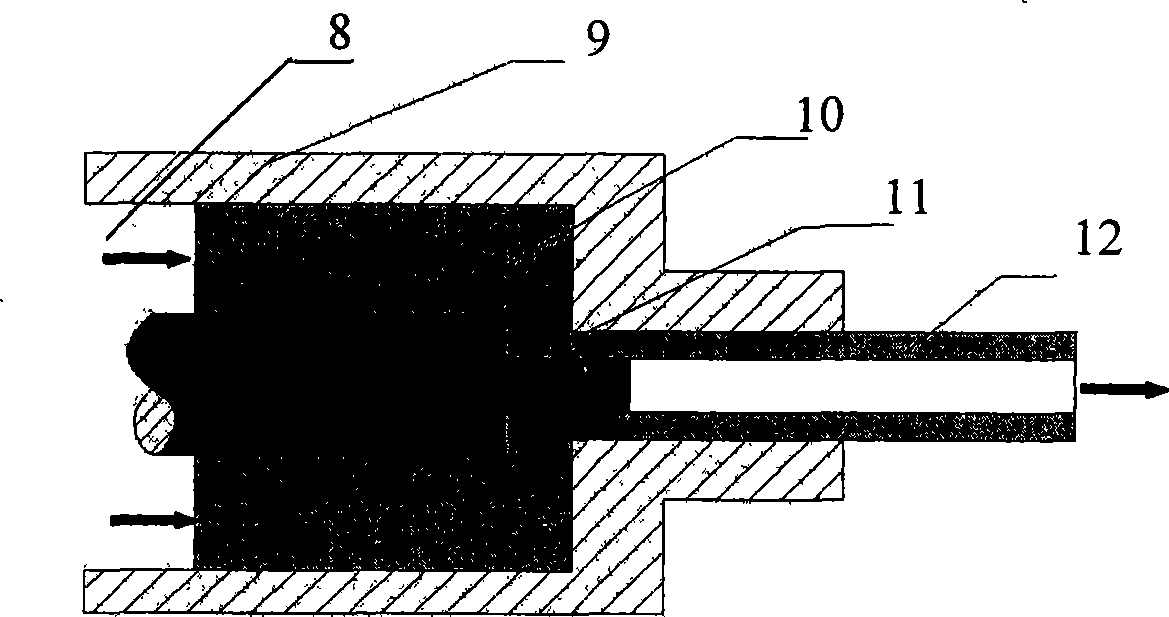

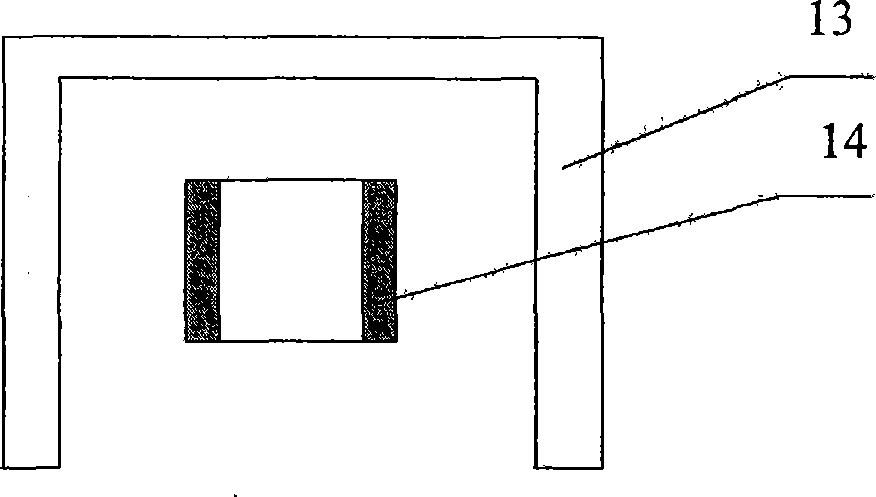

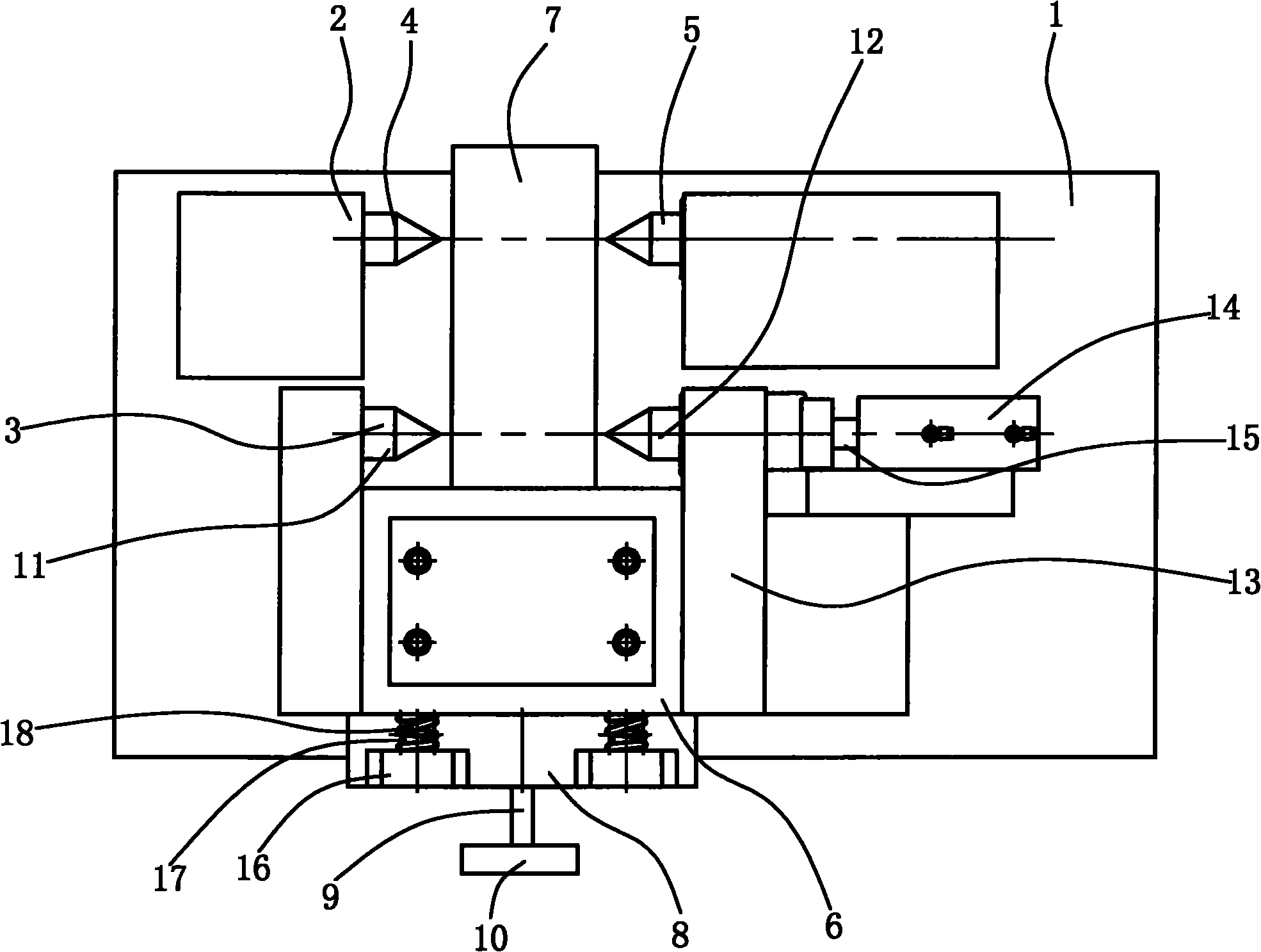

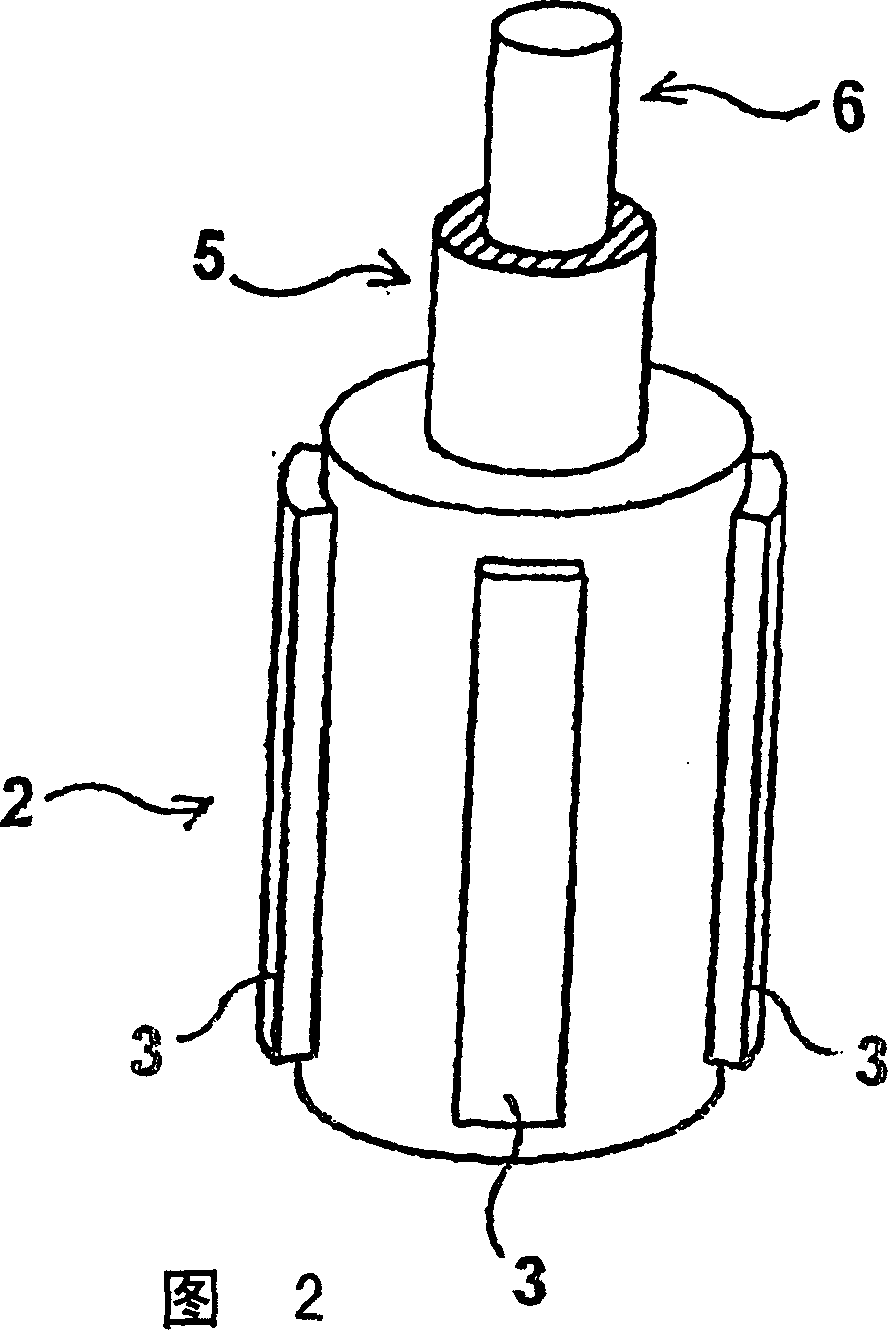

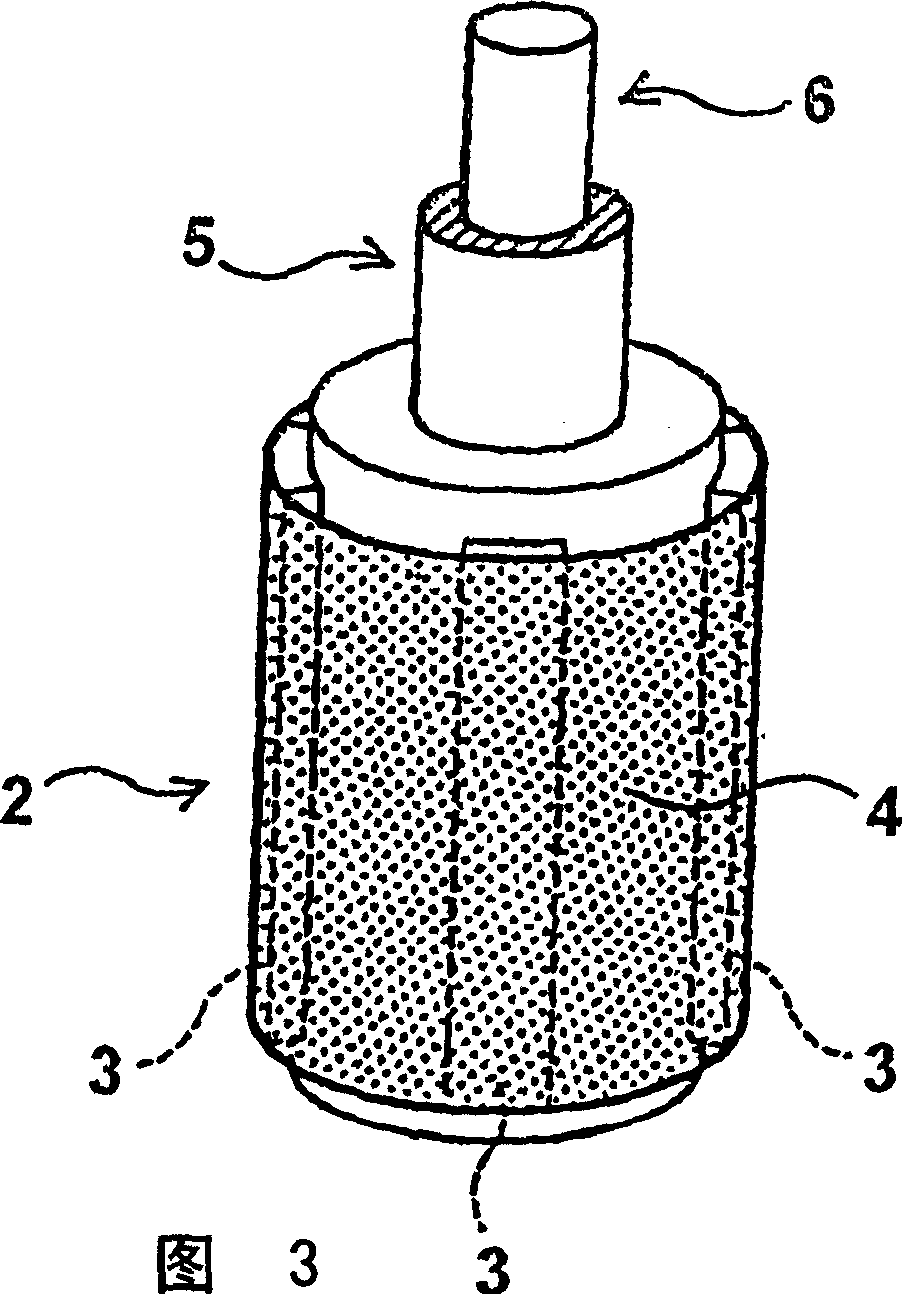

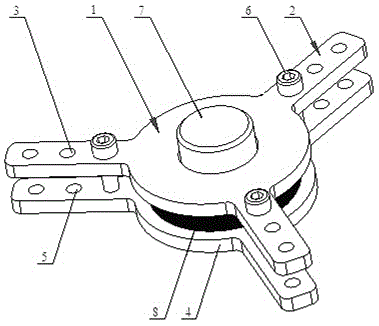

The invention relates to a high-precision internal grinding processing procedure. A clamp which is used for a honing procedure of a technology of the high-precision internal grinding processing procedure is as shown in the figure that a base (1) and a clamp body (7) are connected in a fastening mode through bolts, a lower rubber sleeve (2) and an upper rubber sleeve (5) are respectively installed on a lower bush (3) and an upper bush (6), and meanwhile a closed chamber is formed by a space ring (4) and a gland (8), and a cylinder sleeve (9) is placed in inner chambers of the lower rubber sleeve (2) and the upper rubber sleeve (5). Honing adopts rough honing and fine honing. The rough honing adopts an adamas sanding belt, wherein the mesh number of the sanding belt is 180, and machining pressure of the sanding belts is 1.4 Mpa. The fine honing adopts a double feeding honing head. The mesh number of an adamas sanding belt of the double feeding honing head is 150, and machining pressure of the adamas sanding belt of the double feeding honing head is 0.8-1.0 Mpa. A particle size of a silicon carbide sanding belt adopted by the double feeding honing head is 400, and honing pressure of the silicon carbide sanding belt adopted by the double feeding honing head is 0.5 Mpa. Space cylinder sleeve machining is alternate machining of corotation and inversion, and parameters of inner bore cobwebbing are kept that Rpk is smaller than 0.25 micrometer, Rvk is equal to 1.0-2.0 micrometers, and Rk is equal to 0.4-1.2 micrometers.

Owner:贾维静

Preparation method of high-hardness viscoelastic abrasive material and product

The invention discloses a preparation method of a high-hardness viscoelastic abrasive material and a product for a special honing machine, and belongs to the technical field of abrasive material manufacturing. The high-hardness viscoelastic abrasive material comprises the following components in parts by weight: 30-50 parts of polystyrene, 10-30 parts of plasticizer dioctyl phthalate, 50-70 parts of silicone rubber, 5-30 parts of ploydimethylsilicon oil and 80-120 parts of abrasive grains. The high-hardness viscoelastic abrasive material provided by the invention has liquidity and elasticity, and can be used by a special honing machine to hone a super-hard complex surface of a workpiece into a misty mirror with Ra=0.012 [mu] m, which cannot be achieved with the conventional machine tool technologies.

Owner:XUZHOU POLISH MACHINE TOOL CO LTD

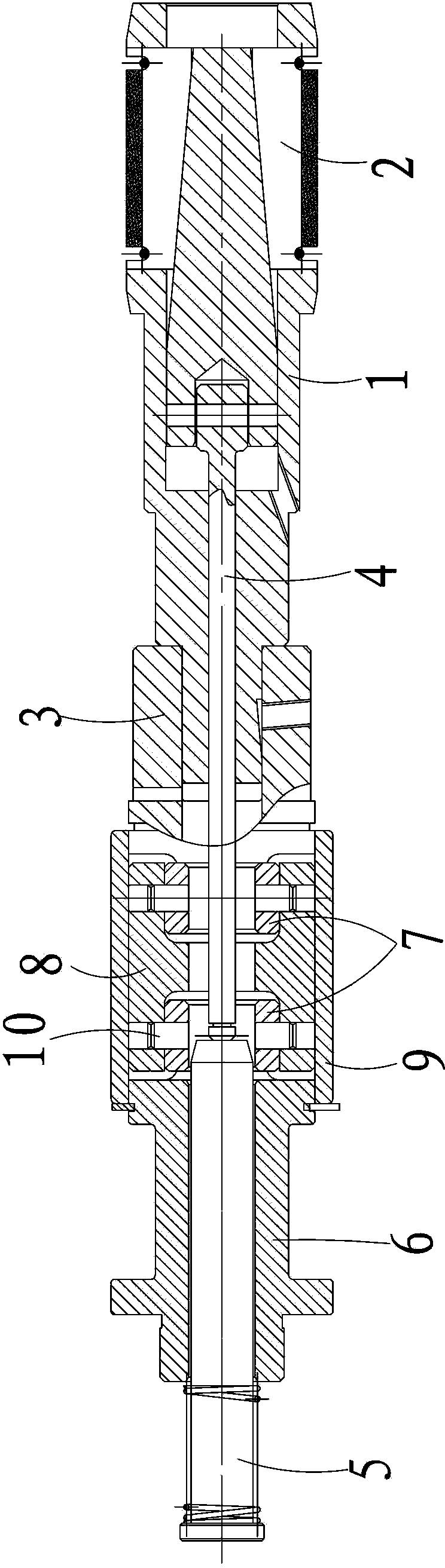

Self-limited universal honing rod

ActiveCN103358220ARealize self-limiting functionNovel and compact structureHoning machinesUpper jointStructural engineering

The invention relates to a self-limited universal honing rod comprising an outer pipe, a honing head, a lower joint, a push rod, a supporting rod and an upper joint, wherein the honing head is connected with one end part of the outer pipe, the lower joint is fixedly connected with the other end of the outer pipe, the push rod is arranged in the outer pipe, the supporting rod is connected with the push rod, and the upper joint is sleeved on the supporting rod; the honing rod further comprises one or more cross-shaped blocks, a connection pipe and a limiting sleeve, wherein the one or more cross-shaped blocks are sleeved on the push rod, the connection pipe is fixedly sleeved out of the one or more cross-shaped blocks, the limiting sleeve is sleeved out of the connection pipe, and the two end parts of the limiting sleeve are respectively connected with the upper joint and the lower joint. According to the self-limited universal honing rod disclosed by the invention, the cross-shaped blocks are sleeved on the push rod, so that the honing rod can realize multidirectional floatation; through a space between the connection pipe and the limiting sleeve, the floating displacement of the honing rod can be controlled within the certain range, so that the self-limiting function of the honing rod is realized, and a complex guiding system can be saved; and the honing rod has the advantages of novel and compact structure, simple manufacturing and low machining cost.

Owner:SUZHOU XINNENG PRECISE MACHINERY

Honing apparatus

InactiveUS20120231709A1Reduce operating costsMinimizing abrasionEdge grinding machinesAbrasive surface conditioning devicesEngineeringCemented carbide

A rotary tool of a honing apparatus is provided with honing grindstones that grind a cylinder bore, and guide members that slide in a guide hole of a tool guide. The guide members are each constituted of a base member fixed to the tool body and a slide member fixed to the base member. The base member is composed of a ceramic material, and the slide member is composed of a cemented carbide material. With the guide members having such a configuration, electrolytic dressing is performed on the honing grindstones.

Owner:SUBARU CORP

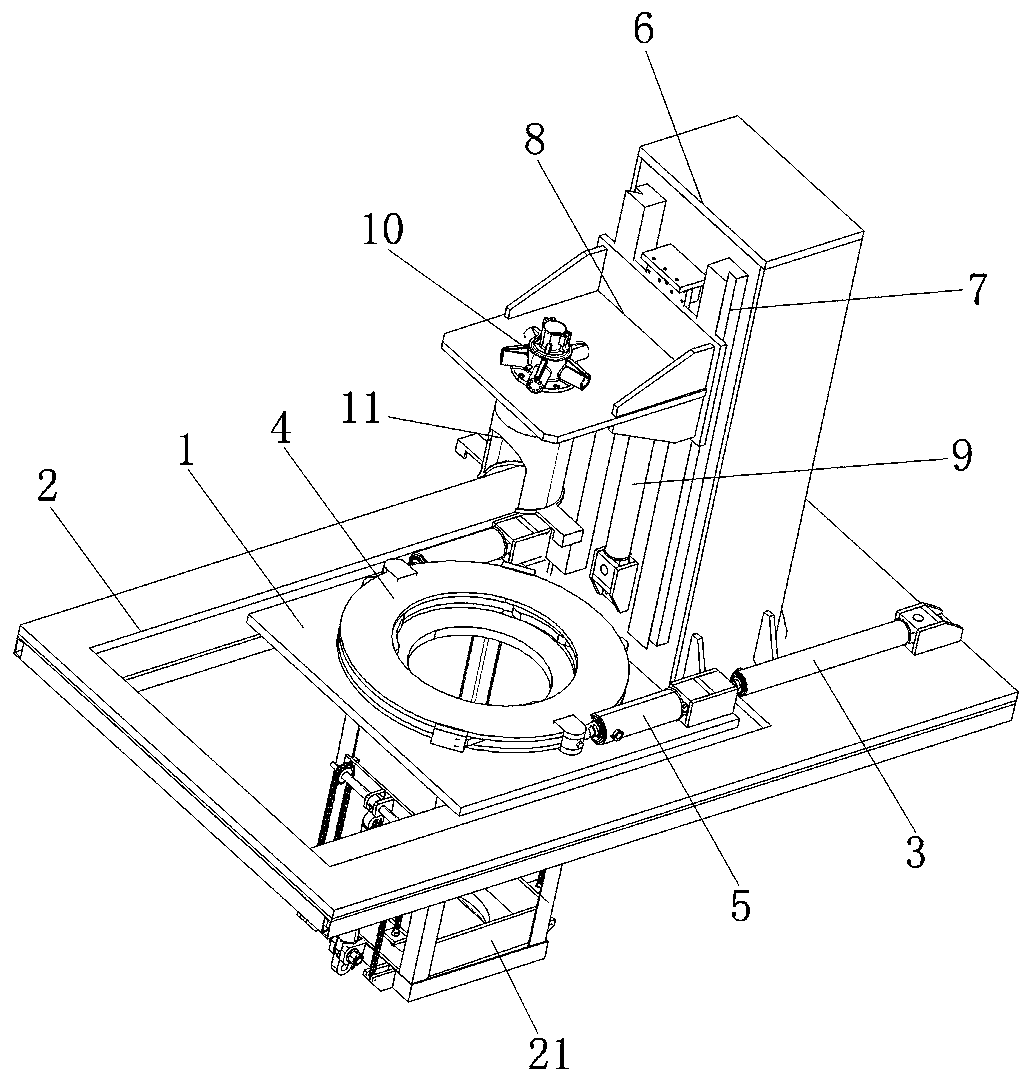

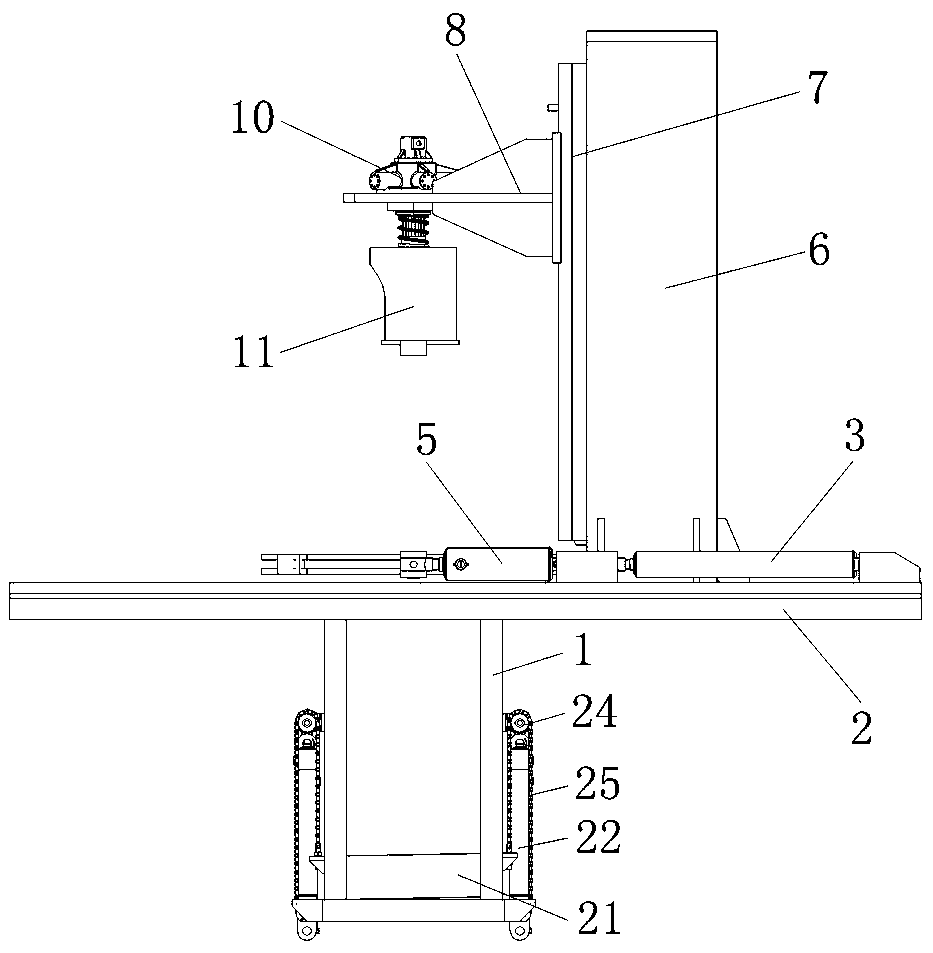

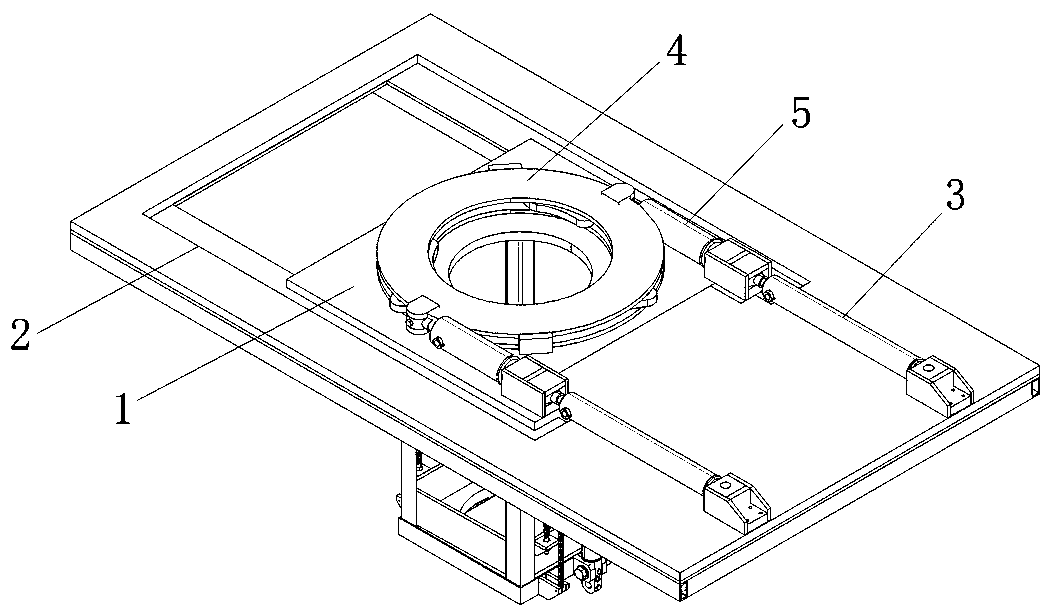

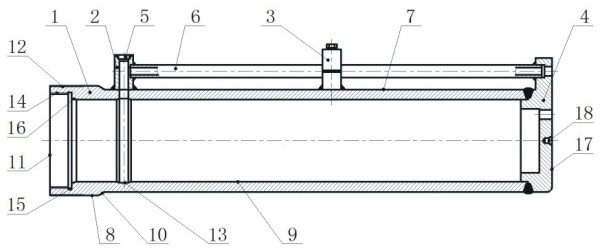

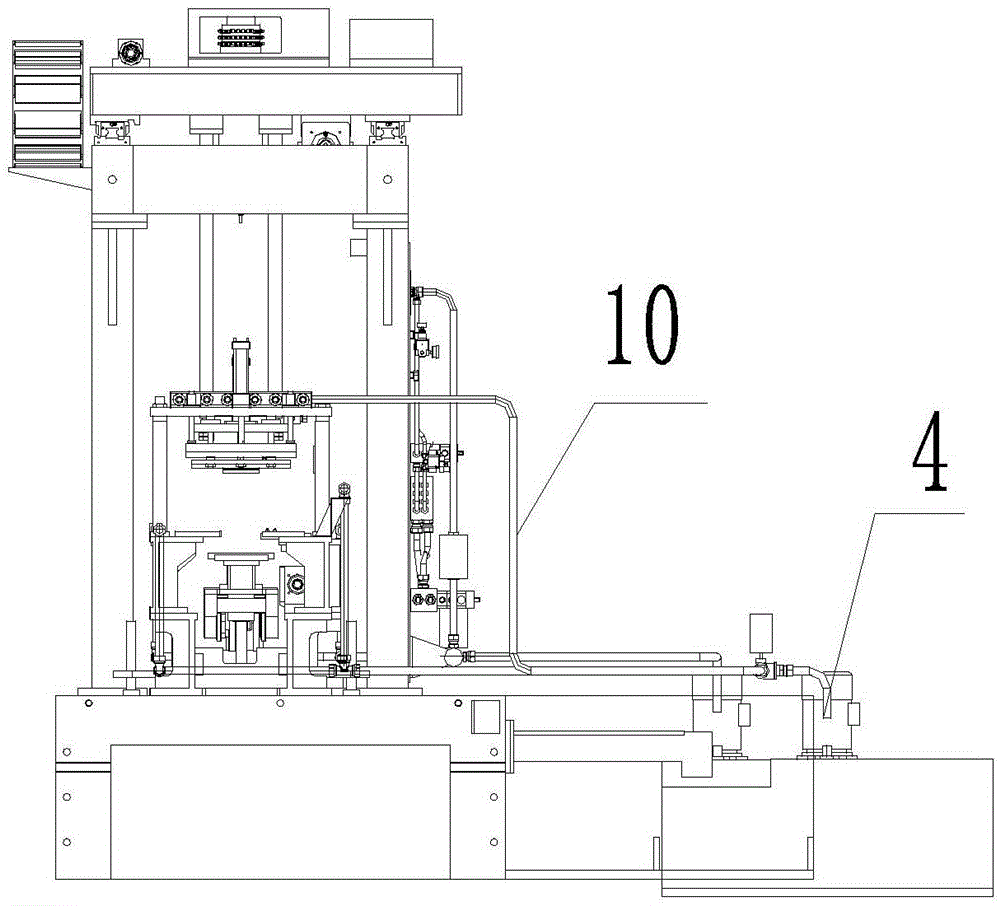

Dismounting and honing device for hydraulic cylinder

InactiveCN110640422AEasy to cleanImprove efficiencyGrinding drivesHollow article cleaningHydraulic motorHydraulic cylinder

The invention belongs to the technical field of hydraulic cylinders, and particularly relates to a dismounting and honing device for a hydraulic cylinder. The dismounting and honing device comprises acylinder dismounting machine and a cylinder barrel honing machine. The cylinder dismounting machine comprises a working platen frame and a platen support frame, the working platen frame is erected onthe platen support frame, a first cylinder used for driving the working platen frame to move is arranged on the platen support frame, a hollow turntable is arranged on the working platen frame, a positioning mechanism is arranged on the turntable, two second cylinders used for driving the turntable to rotate are arranged on the working platen frame and oppositely arranged on the two sides of theturntable, the working platen frame is further provided with a lifting mechanism and a stand column, the stand column is provided with a track plate, a lifting head is in up-down sliding connection with the track plate, the stand column is provided with a third cylinder used for driving the lifting head to move up and down, the lifting head is provided with a hydraulic motor, and the output end ofthe bottom of the hydraulic motor is provided with a buckle cover.

Owner:河南欣柯奕舟重工科技有限公司

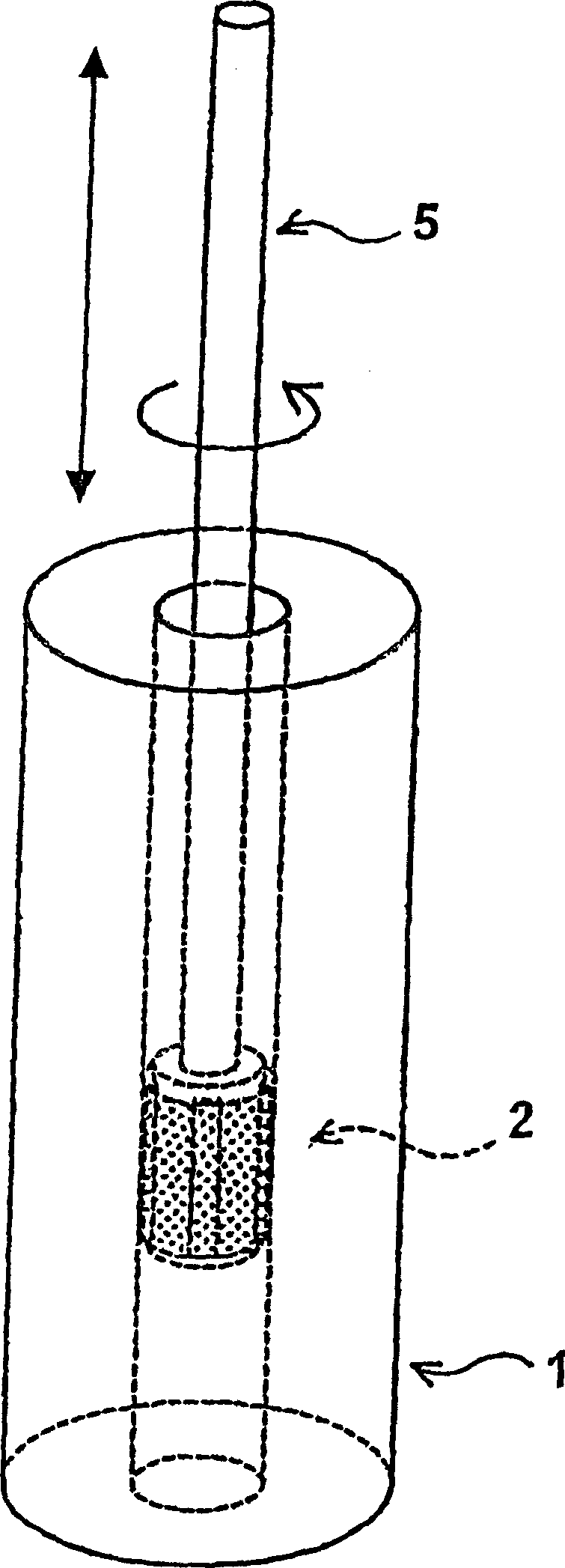

Polishing method for inner surface of tubular brittle material and material obtained by the method

InactiveCN1750906AWon't scratchImprove surface accuracyRevolution surface grinding machinesHoning machinesPolishingHigh surface

An object of the present invention is to provide a polishing method for producing, in a relatively short period of time, a tubular brittle material having an inner surface of high surface precision with a maximum roughness Rmax of 0.1 mum or smaller and a center line average roughness Ra of 0.01 mum or smaller, and to provide a tubular brittle material with high precision using said polishing method. The polishing method according to the invention is characterized by that the inner surface of the tubular material being pre-cut into a tubular shape using a honing machine is further polished with a sheet material having diamond abrasives attached thereon. Also claimed is a tubular brittle material obtained by said polishing method.

Owner:HERAEUS QUARZGLAS +1

Machining method for cutting inner hole of grinding wheel

ActiveCN105619271AIncrease productivityImprove processing efficiencyAbrasion apparatusGrinding devicesStress concentrationBoron nitride

The invention discloses a machining method for cutting an inner hole of a grinding wheel. The machining method comprises the following steps: fastening and installing a honing head provided with oilstone on a main shaft of a honing machine at first, then installing a honing fixture fixed with a grinding wheel blank on the honing head in a sleeving manner, locking the honing fixture on the honing machine and keeping the honing fixture fixed, adjusting a cross-hatch honing movement stroke, then inspecting the honed grinding wheel by a plug gauge, and finally ultrasonically cleaning and drying the grinding wheel, wherein the oilstone is metal-bonded diamond oilstone or metal-bonded cubic boron nitride oilstone. According to the invention, during a honing process, the grinding wheel blank is clamped in a floating manner relative to the honing head, and easy to centre; the contact area of the oilstone and the surface of the inner hole is large, and a honing pressure is adjustable; moreover, low relative movement speed, stress concentration and deformation are achieved; and therefore, high dimensional accuracy and roundness, and low surface roughness can be obtained.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

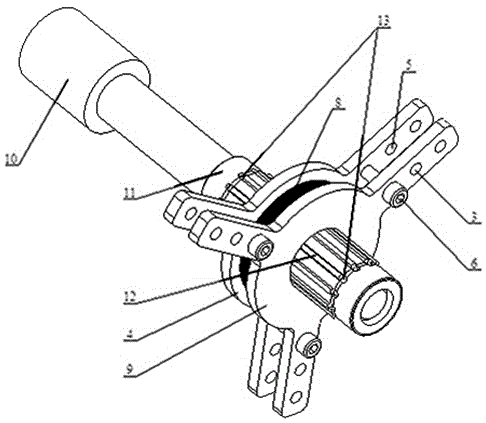

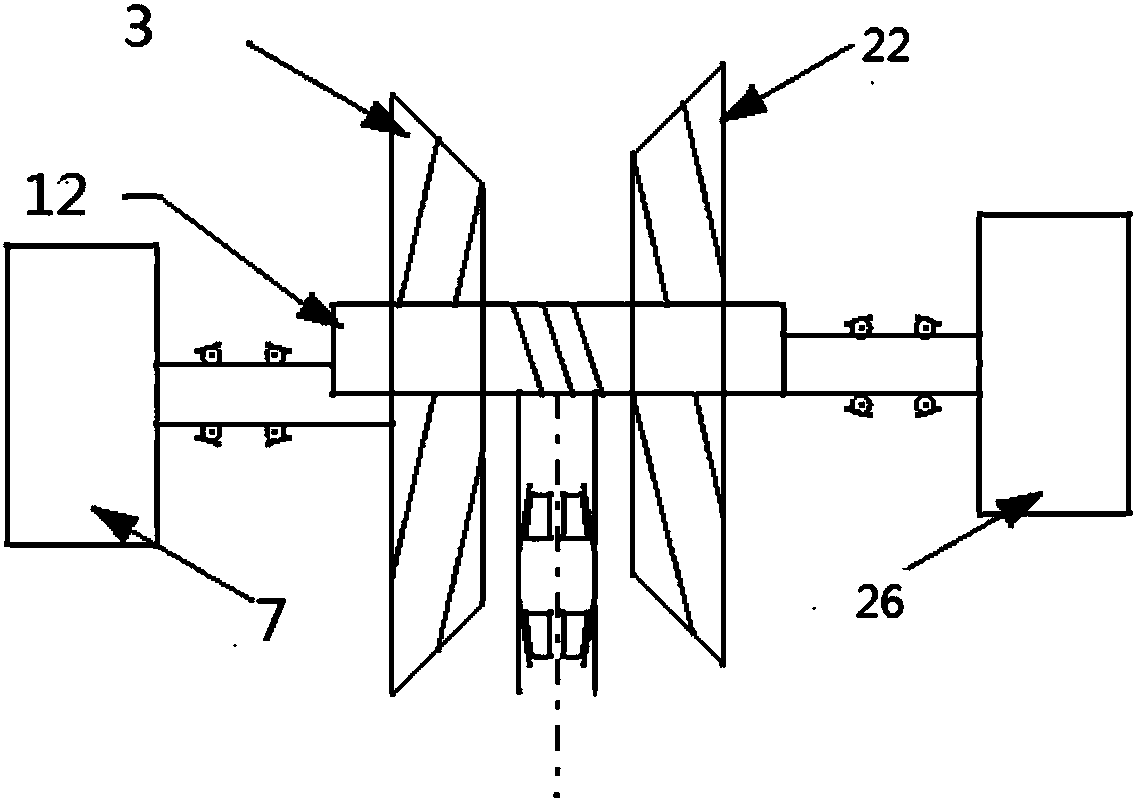

Field honing system with guiding rail and method for steam turbine rotor coupling nut hole

PendingCN107825279AReduce adjustment requirementsEase of workHoning toolsHoning machinesTurbine wheelCoupling

The invention discloses a field honing system with a guiding rail and method for a steam turbine rotor coupling nut hole. The field honing system mainly comprises a guiding rail assembly, a driving tool and a honing tool. The guiding rail assembly is composed of the guide rail, a sliding block and an installing base plate. The driving tool composed of a power unit and a driving unit is installed on the guiding rail assembly to drive the honing tool, feeding is conducted manually or automatically, and grinding work of the steam turbine rotor coupling nut hole is completed. The driving tool andthe honing tool are connected through a coupling B and a coupling A. The coupling B and the coupling A adopt each adopt a universal or floating connection structure. The honing tool is installed to beof two kinds of structures of center arrangement installation and offset installation relative to the guiding rail assembly. The field honing system has the beneficial effects that the field honing system meets the requirement of a narrow field construction space of a power plant, the working difficulty of operators is reduced, and the machining reliability is enhanced.

Owner:HANGZHOU FROMO ELECTROMECHANICAL TECH

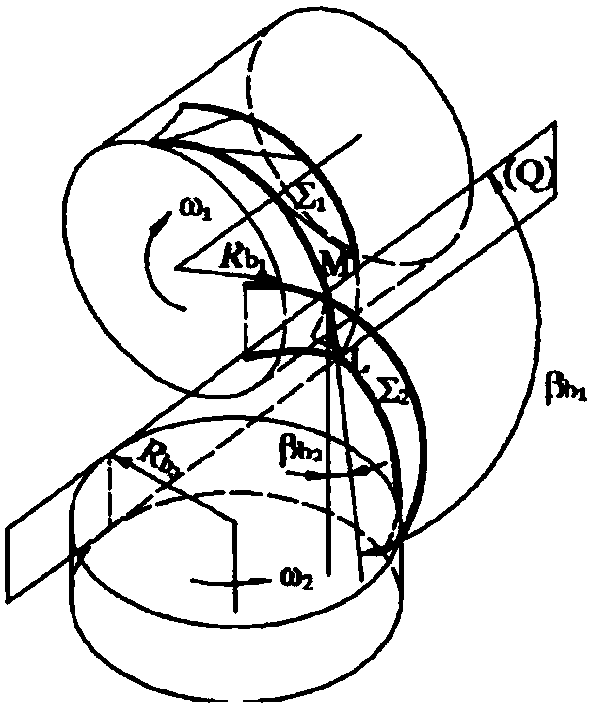

Gear honing machine tool without axial feed and gear honing method

The invention discloses a gear honing machine tool without axial feed and a gear honing method. A left tooth face honing wheel is fixedly connected with a thread at the tail end of a left tooth face honing wheel transmission shaft through a cone hole of the left tooth face honing wheel by means of a first fastening nut; a right tooth face honing wheel is fixedly connected with a thread at the tailend of a right tooth face honing wheel transmission shaft through a cone hole of the right tooth face honing wheel by means of a second fastening nut; a machined gear is placed parallel to a work table, and two cooling hoses are placed close to a grinding area. The left tooth face honing wheel and the right tooth face honing wheel are meshed with the machined helical gear, and the honing qualityand the honing allowance of the honing wheels for the machined helical gear are controlled by adjusting the rotating speed of two servo motors and the relative phase angle phi of the two servo motors.The gear honing machine tool is a special machine tool for finish machining of cylindrical hardened helical gears produced in batches or in large quantities. Compared with other similar machine tools, the gear honing machine tool has the advantages of simple mechanism, convenient operation, and low cost of manufacturing and later maintenance.

Owner:JILIN UNIV

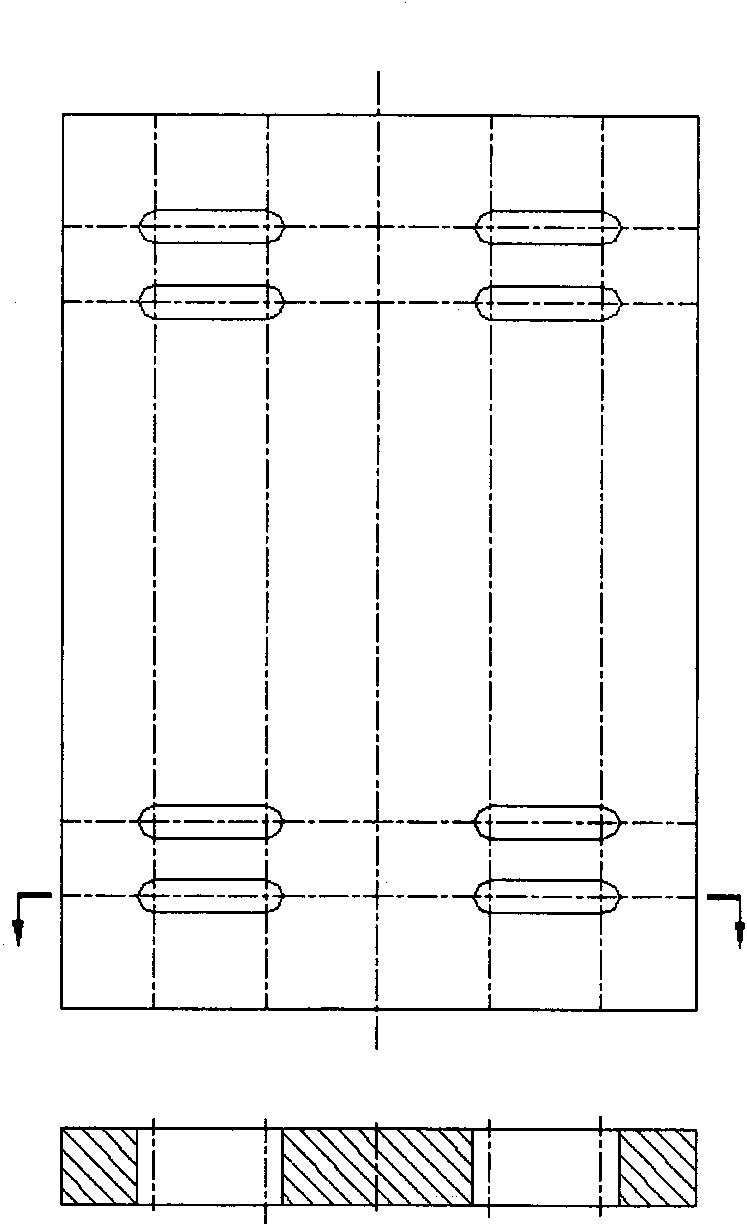

Extrusion honing device for profile shaping mold

InactiveCN103624956APolished evenlyExtrusion Honing Pressure EqualizationGrinding work supportsEngineeringMechanical engineering

The invention provides an extrusion honing device for a profile shaping mold, and belongs to the field of design and manufacturing of extrusion molds. The extrusion honing device consists of shaping mold templates, an upper cover plate, a lower cover plate and corresponding adjustable base plates which are assembled through bolts. The shaping mold templates are part of parts of a shaping mold component; a shaping mold part generally consists of 2-6 subassemblies, namely consist of 2-6templates, and one or two same ones are taken as component parts of a clamp; the clamp and the upper cover plate, the lower cover plate and the corresponding adjustable base plates are matched to form a closed combined clamp with a gap of 5-10mm; the gap of the clamp can be controlled by only replacing the corresponding base plates according to the change of a honing object.

Owner:HUAIHAI INST OF TECH

Hydraulic integrated oil cylinder barrel and machining method thereof

ActiveCN114046287AUniform wall thicknessReduce processing difficultyMaterial strength using tensile/compressive forcesFluid-pressure actuatorsNumerical controlEngineering

The invention provides a hydraulic integrated oil cylinder barrel and a machining method thereof. The machining method comprises the steps of workpiece blanking and rough turning machining, primary welding and flaw detection after welding, boring and grinding combination and fractional finish turning, secondary welding and flaw detection after welding, center hole punching and end face turning and grinding, third welding and flaw detection after welding, pressure resistance testing and follow-up treatment. On the premise that special tools, tools and equipment are not needed, an existing numerical control lathe, an existing deep hole boring machine, an existing deep hole honing machine tool and an existing universal cylindrical grinding machine are directly utilized, the technological process is reasonably arranged, technological parameters are determined, the machining precision of workpieces is reliably guaranteed, machining deformation is greatly prevented, and the flatness of the connecting plane of the cylinder bottom valve seat and the control valve set is guaranteed.

Owner:HUBEI JIANGSHAN HEAVY IND

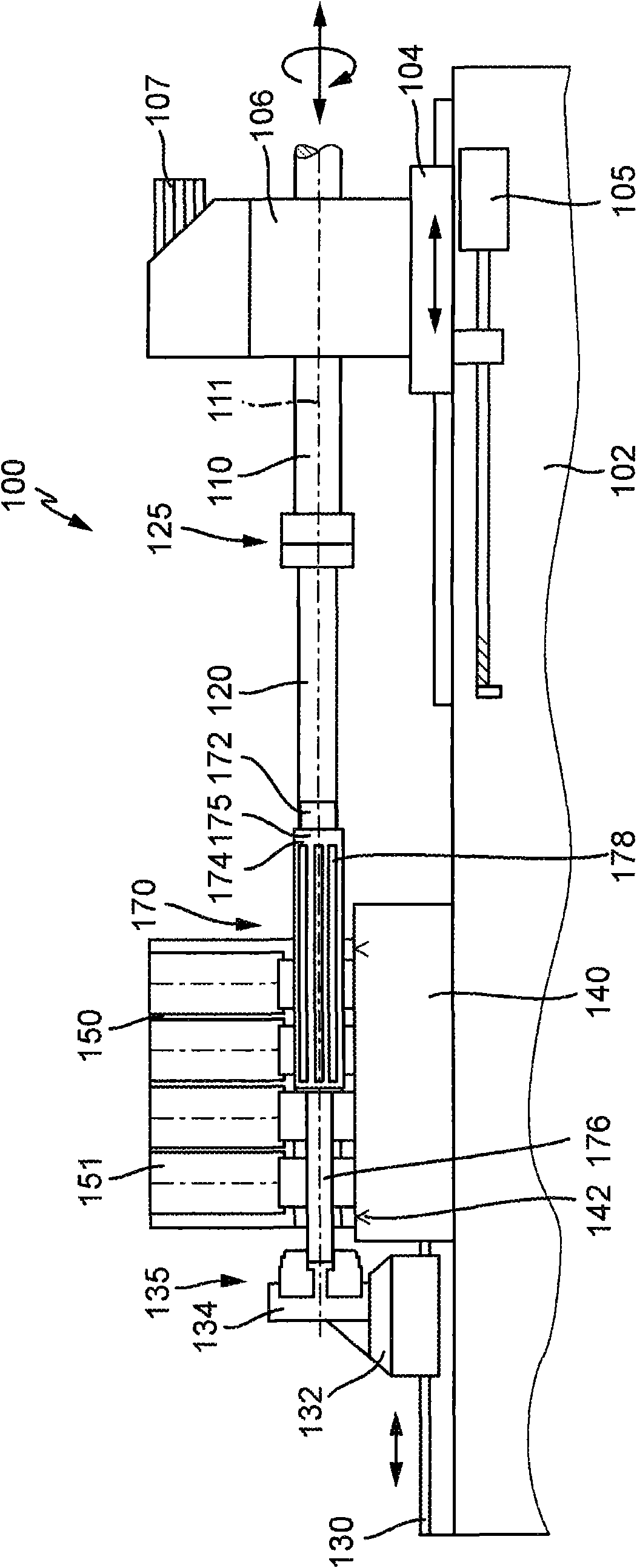

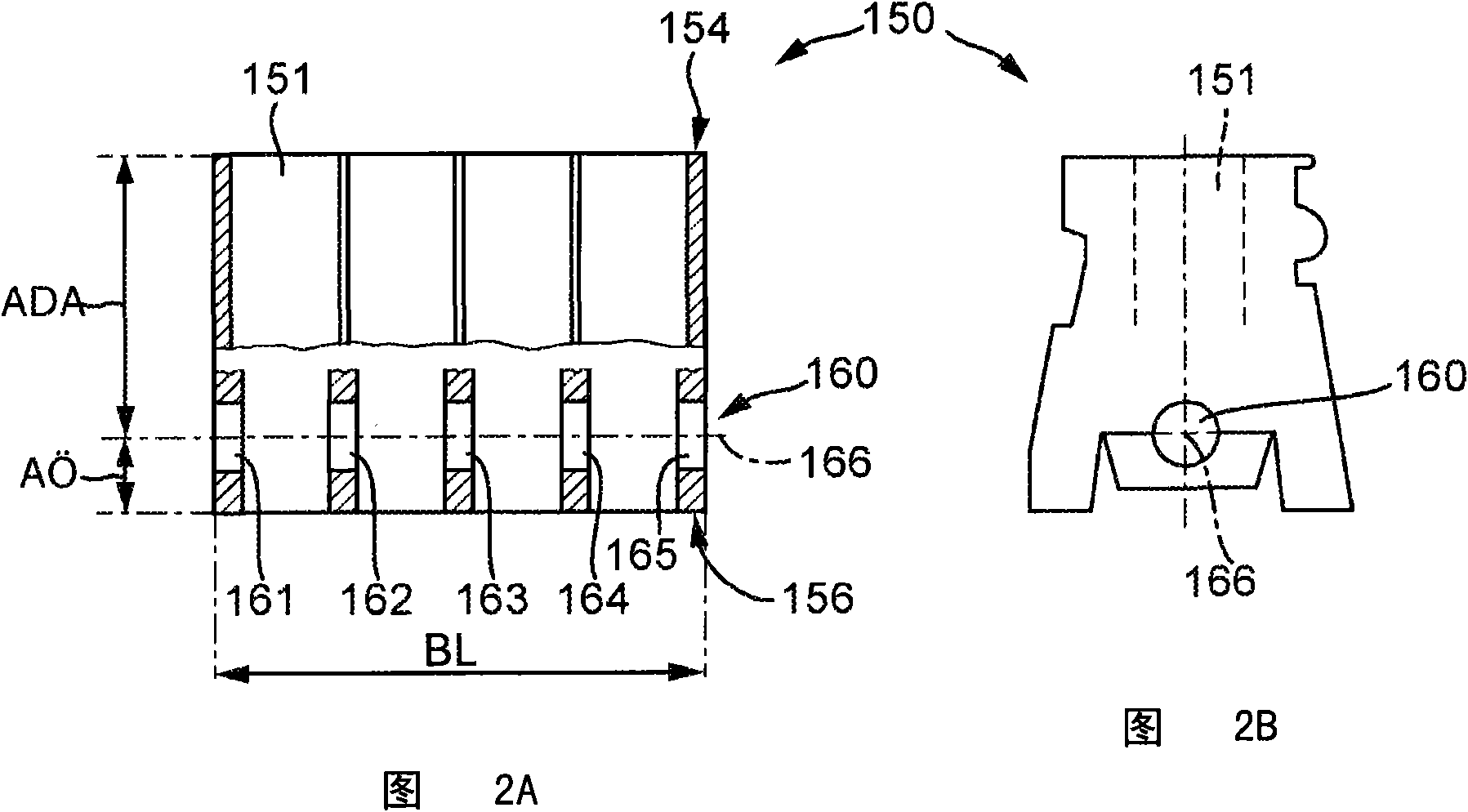

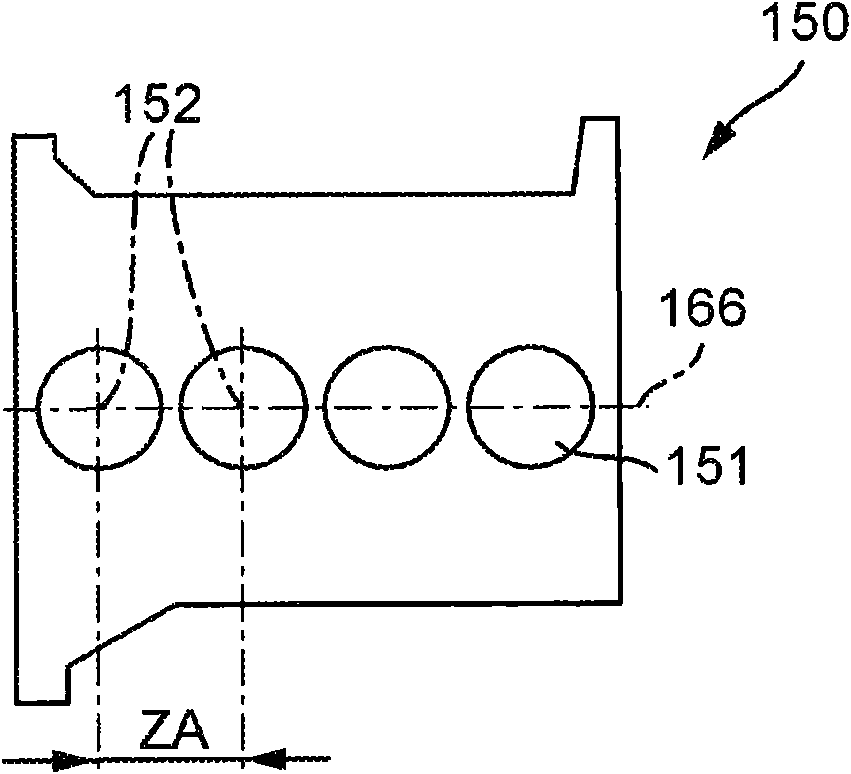

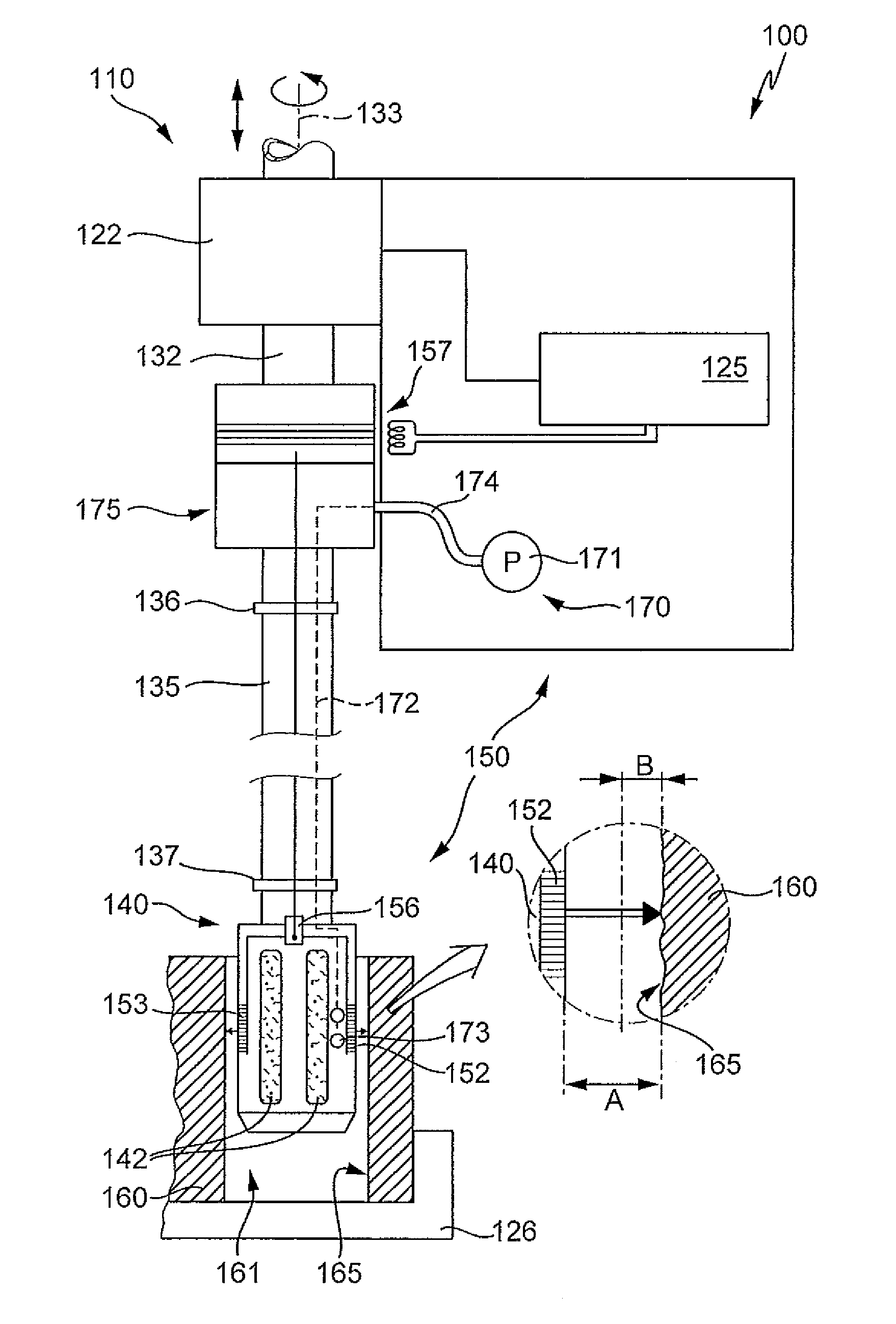

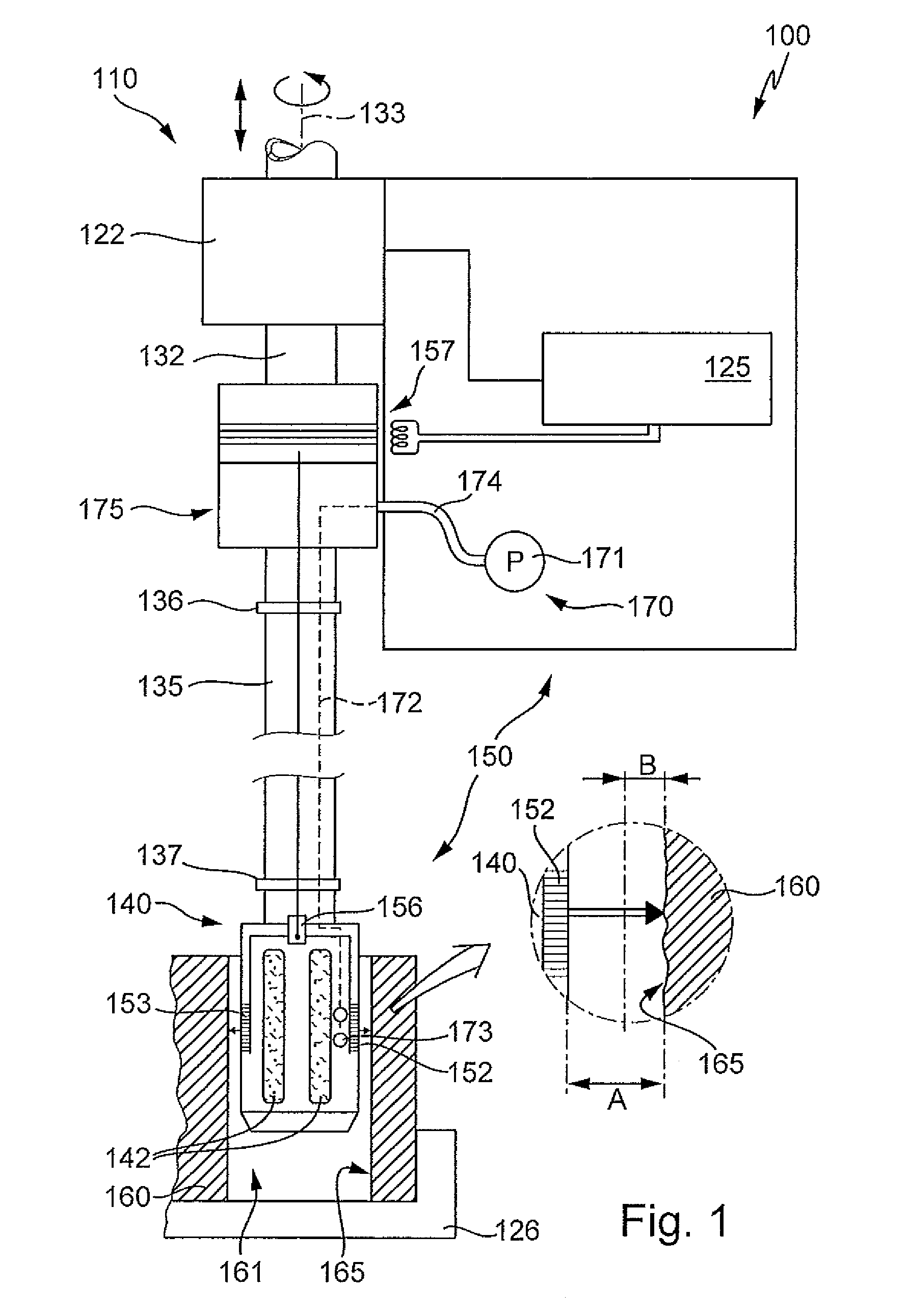

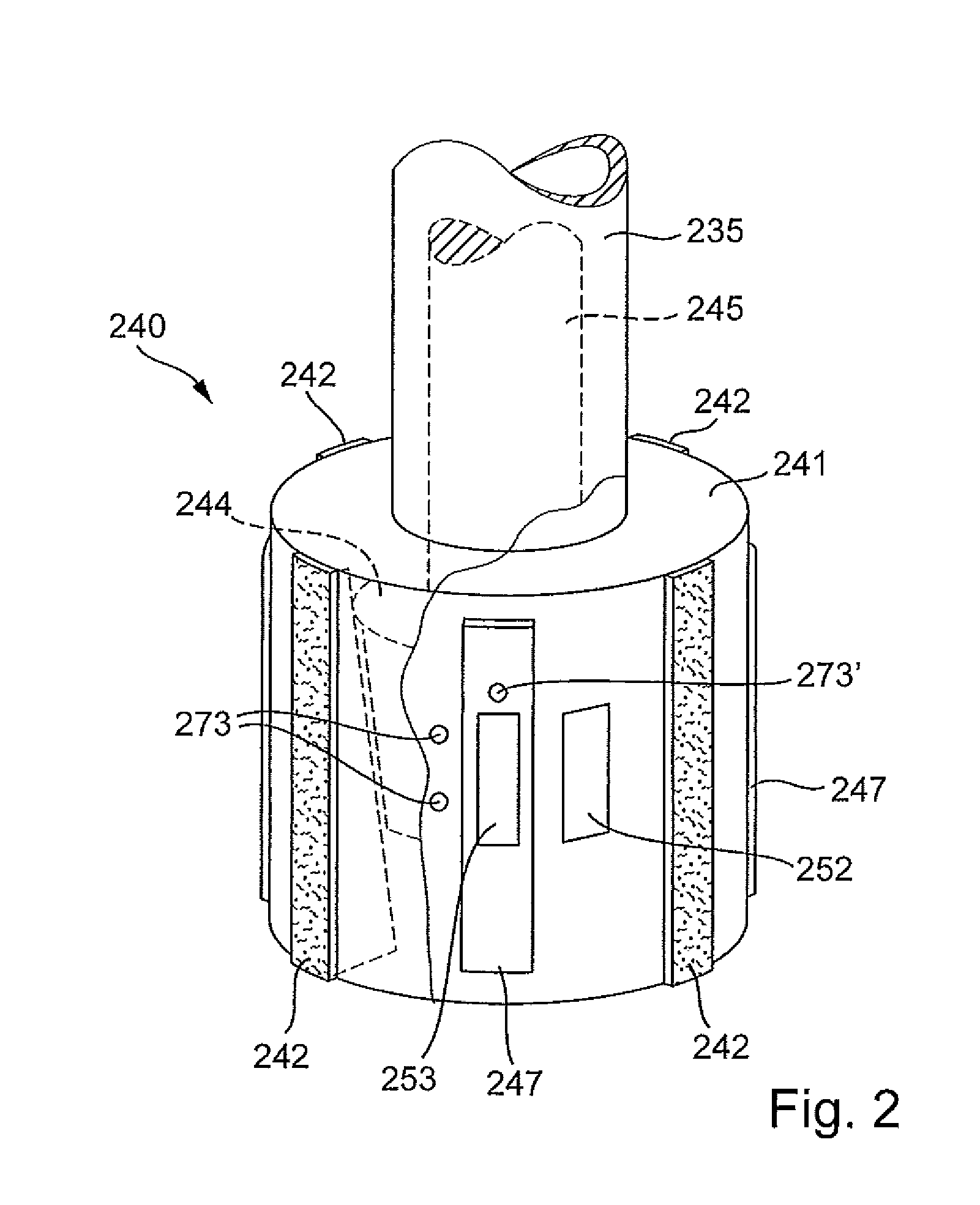

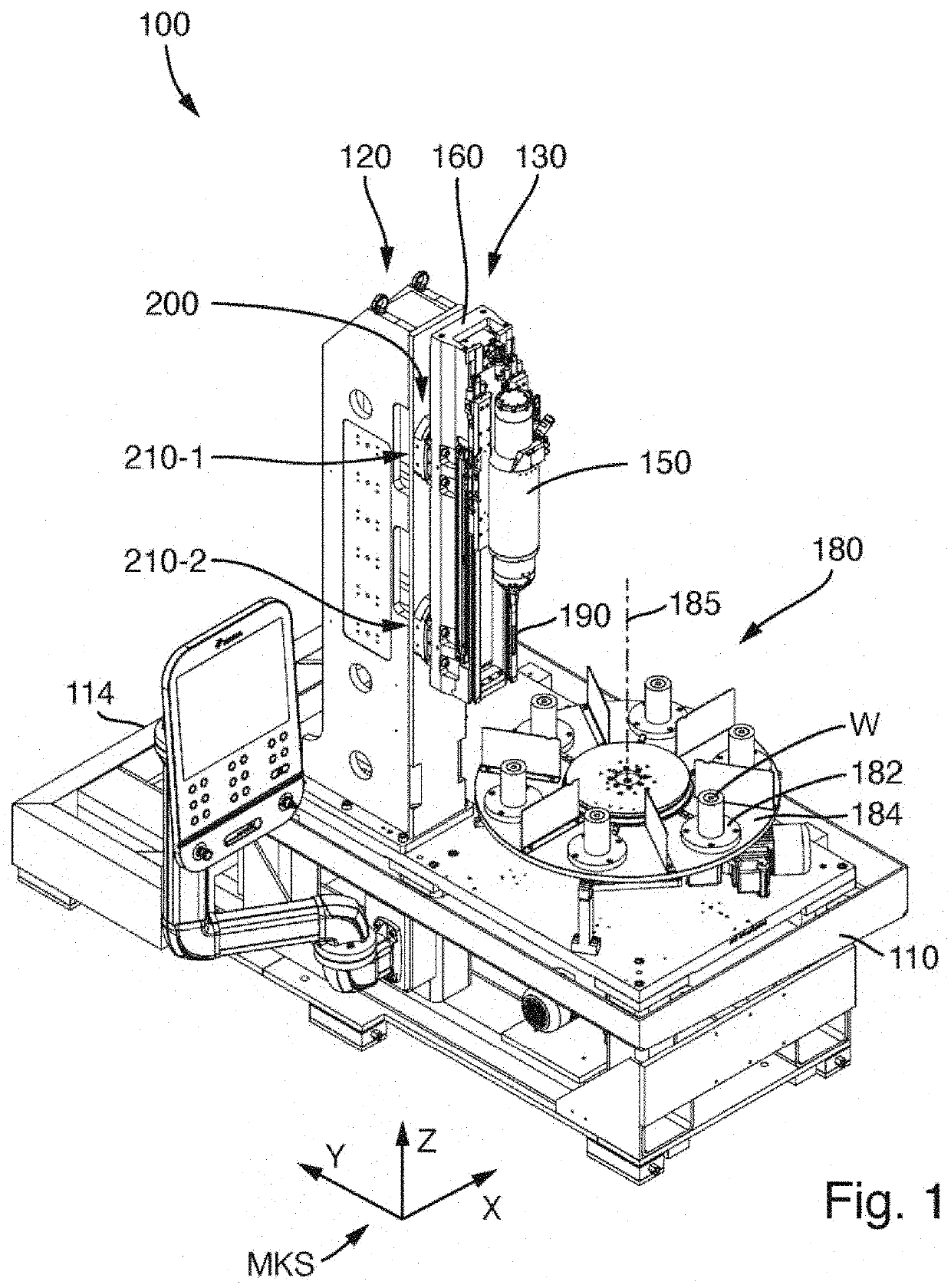

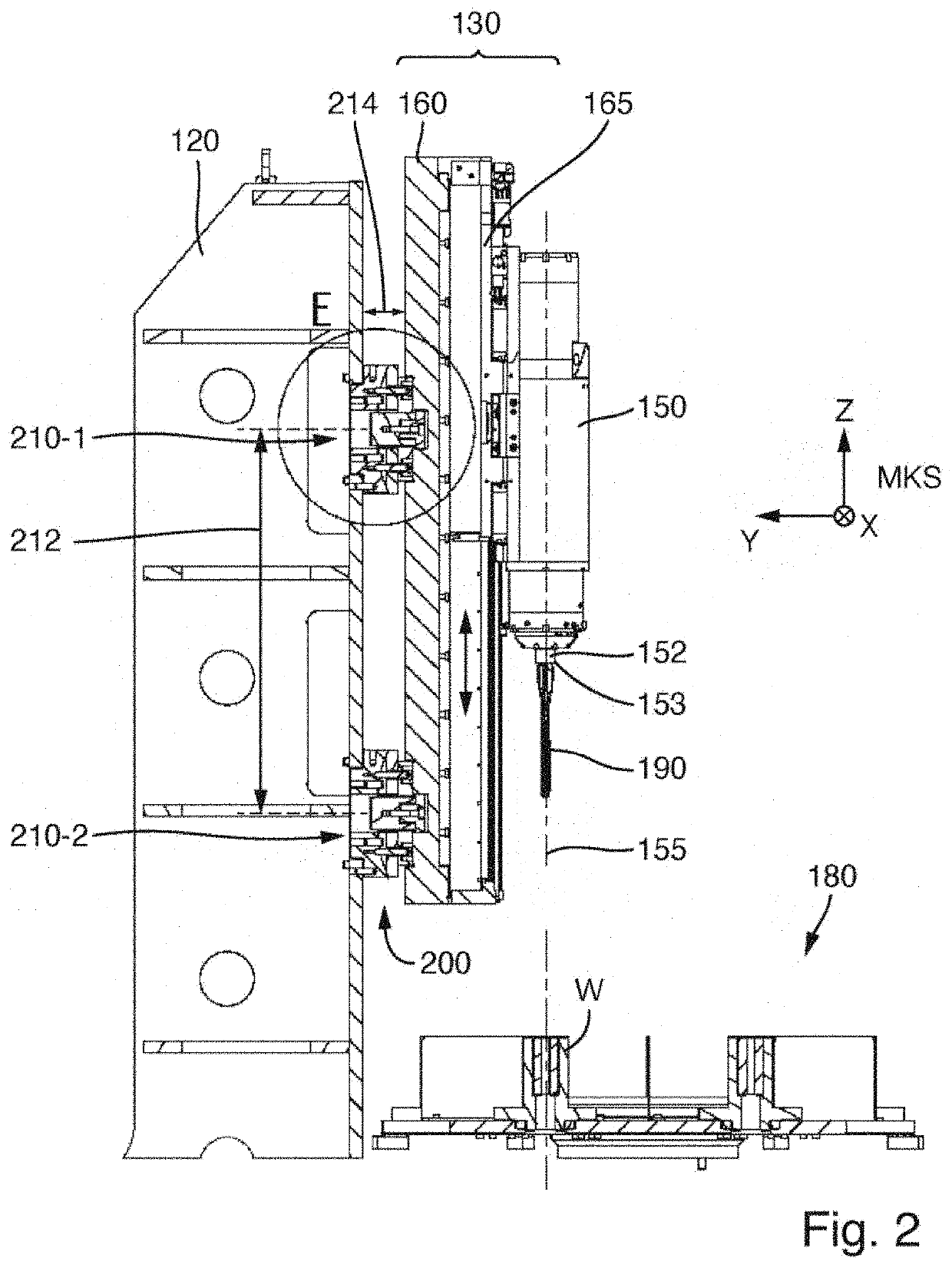

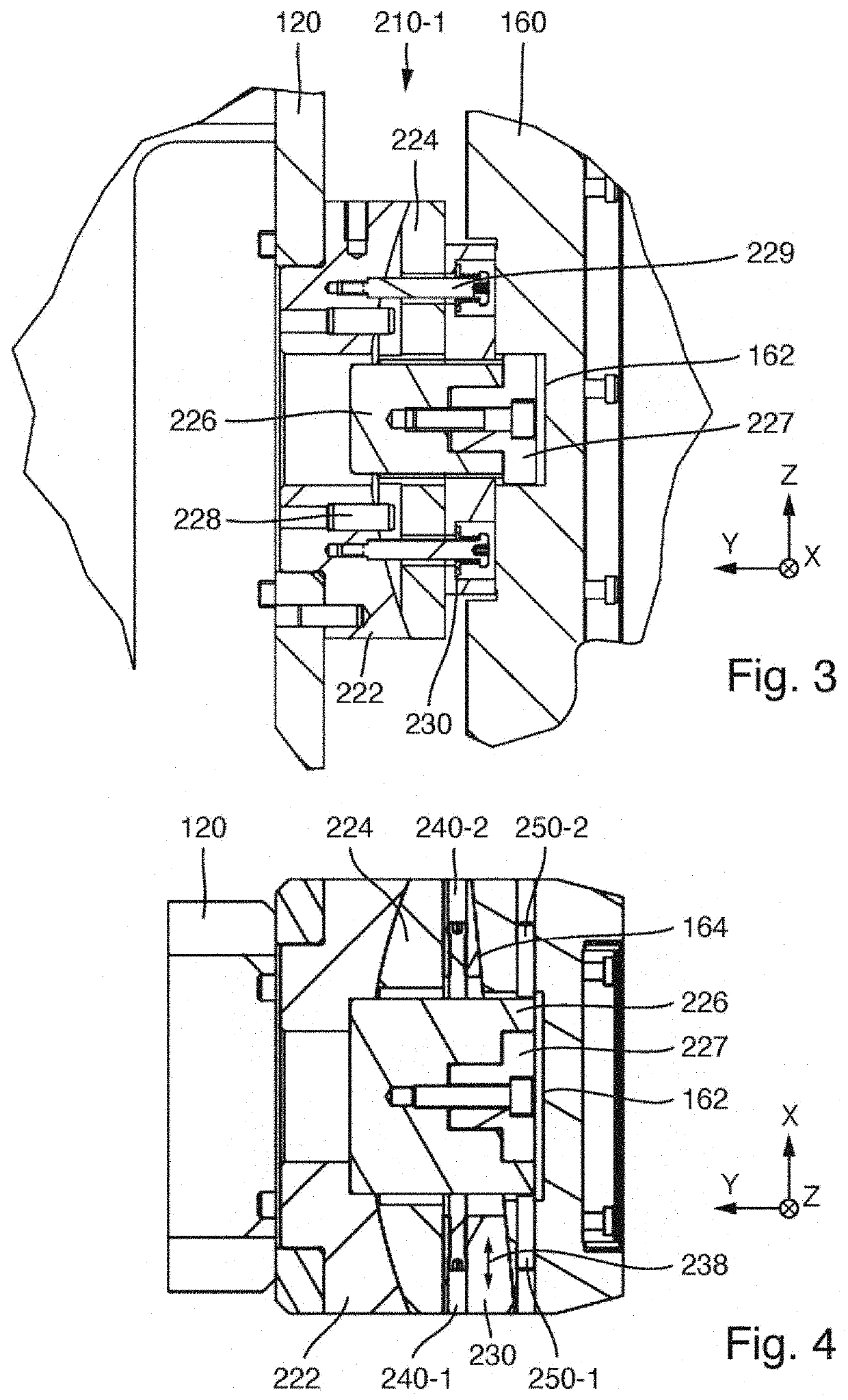

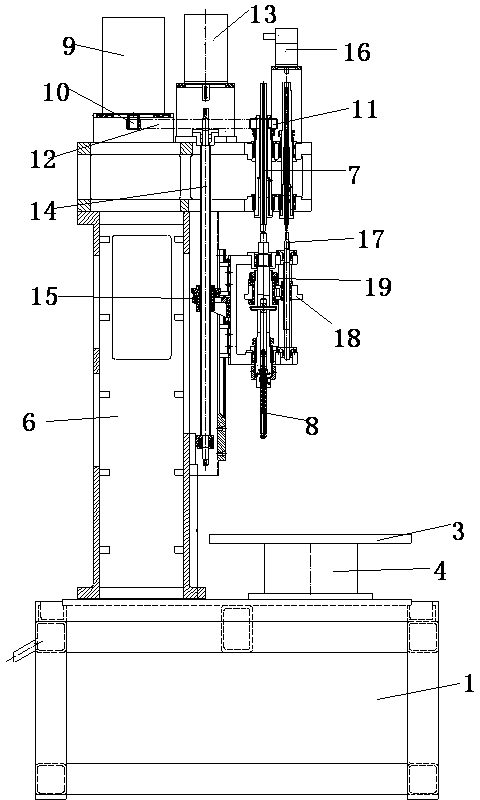

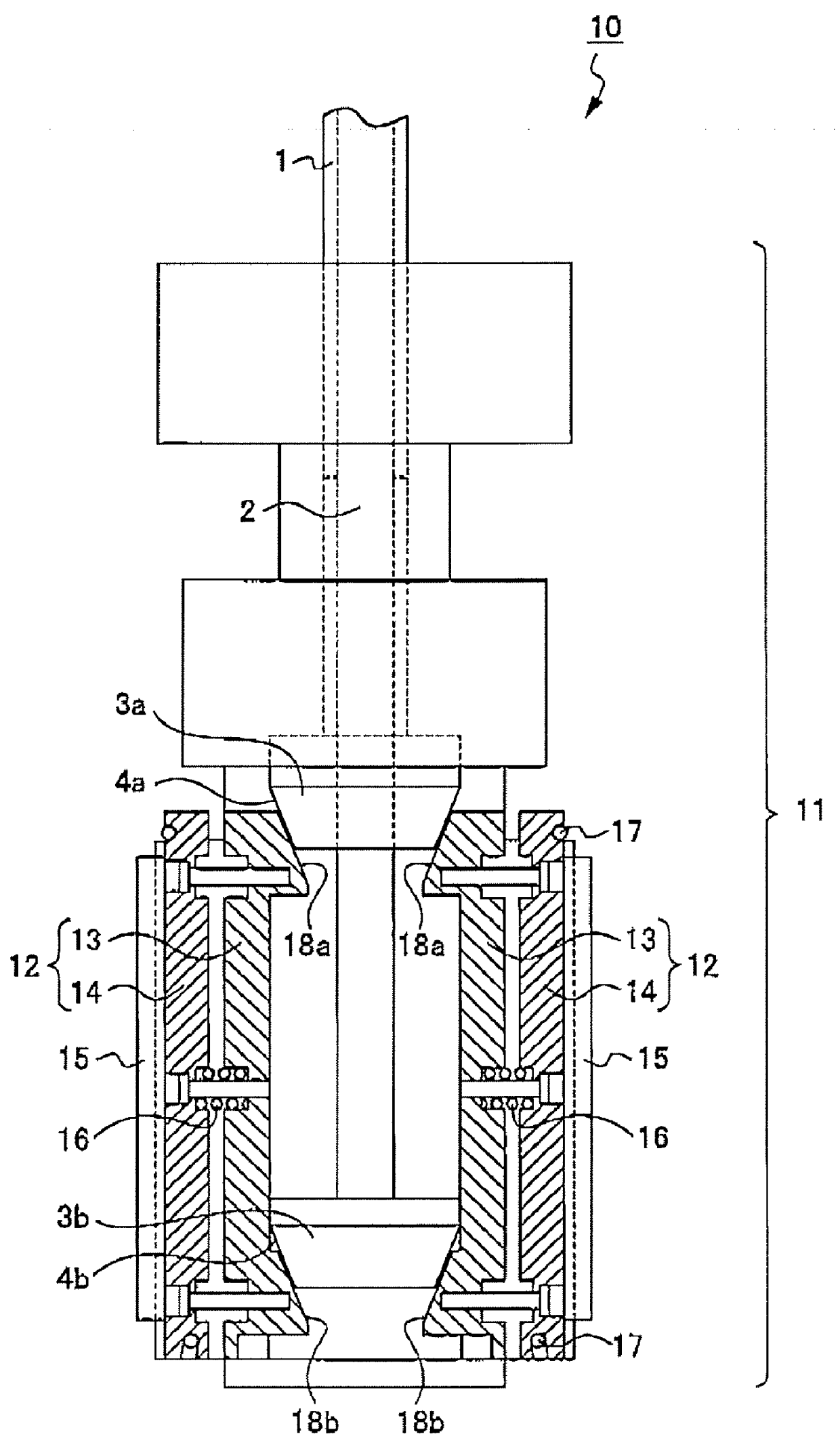

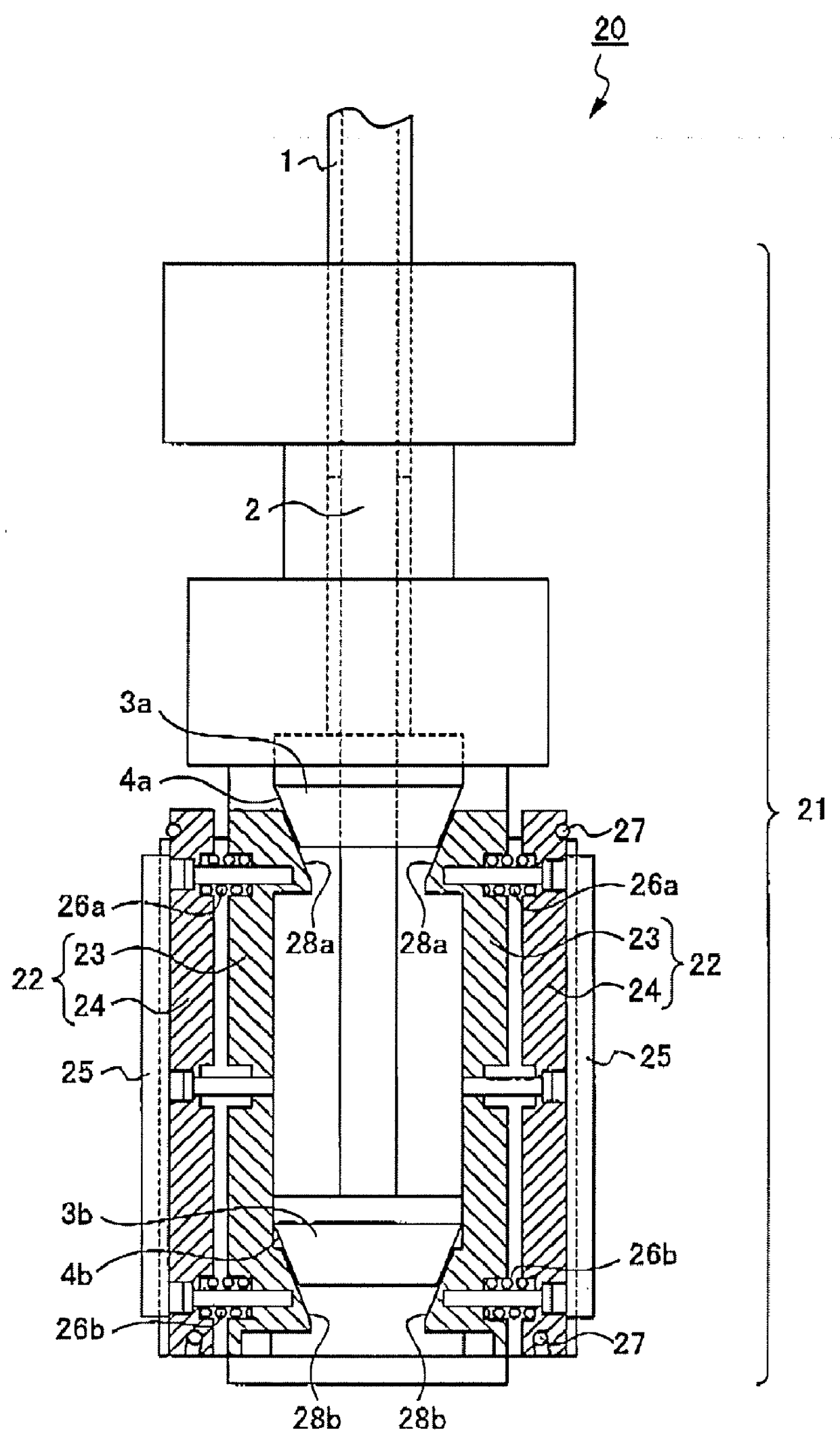

Honing machine

A honing machine for honing a bore in a workpiece comprises a support structure fixed to the machine and at least one honing unit which is mounted on the support structure and which has a spindle unit (150) in which a spindle shaft (152) is rotatably mounted, wherein the spindle shaft (152) is rotatable about a spindle axis (155) by means of a rotary drive (450) and, at a tool-side end (153), has a device for the fastening of an expandable honing tool. The honing machine furthermore comprises a stroke drive for generating a stroke movement of the spindle unit (150) and an expansion drive (550) for expanding the honing tool, wherein the expansion drive is coupled to an advancing rod (460) which runs in the interior of the spindle shaft. The spindle unit (150) has a spindle unit housing (310) which has a first housing portion (310-1) for accommodating the rotary drive (450) and a second housing portion (310-2) for accommodating the expansion drive (550). The rotary drive (450) is accommodated in an exchangeable first cartridge (400) and the expansion drive (550) is accommodated in a second cartridge (500) which is exchangeable independently of the first cartridge (400), wherein the first cartridge (400) is introducible into the first housing portion (310-1) and the second cartridge (500) is introducible into the second housing portion (310-2).

Owner:KADIA PRODN

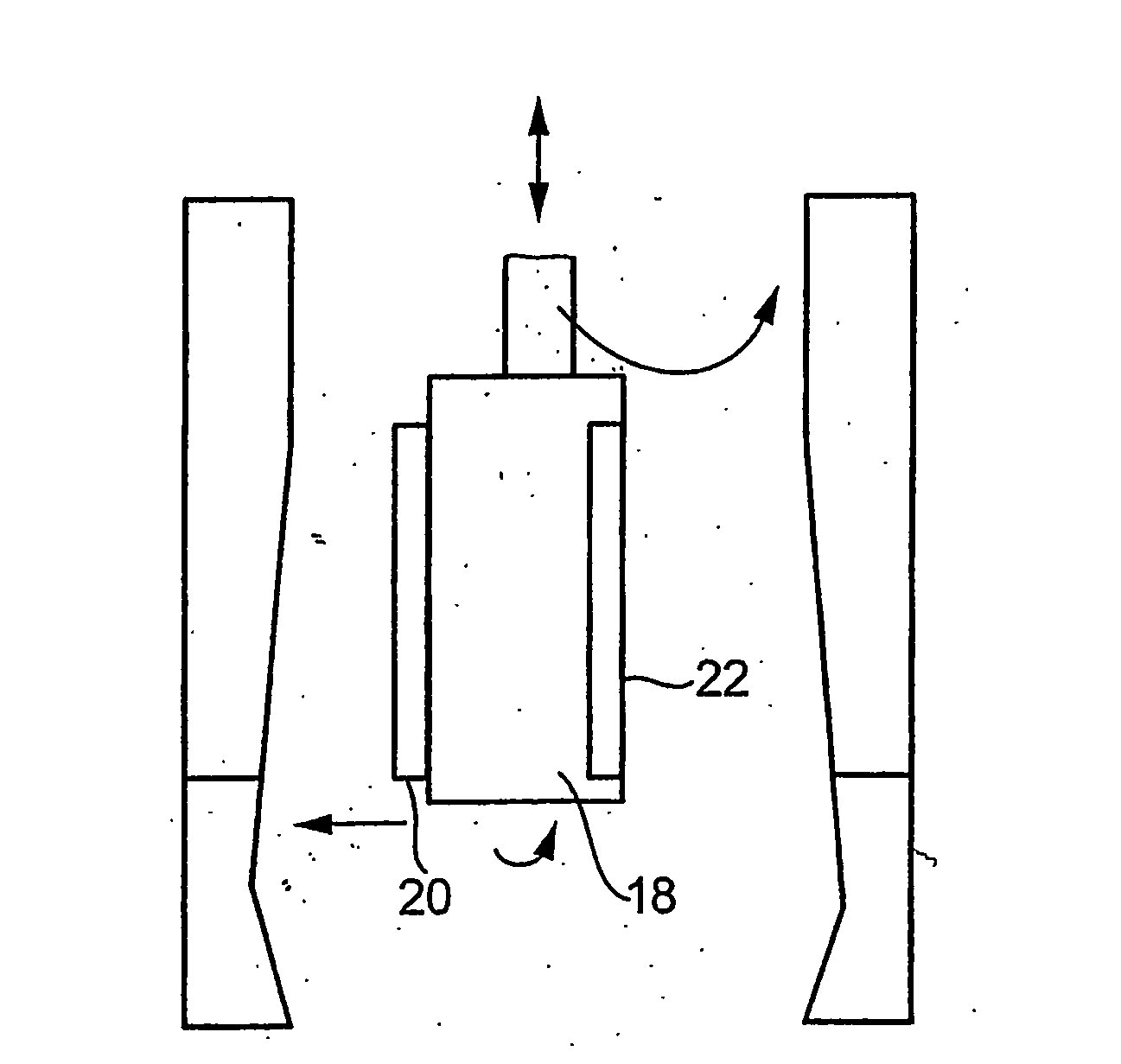

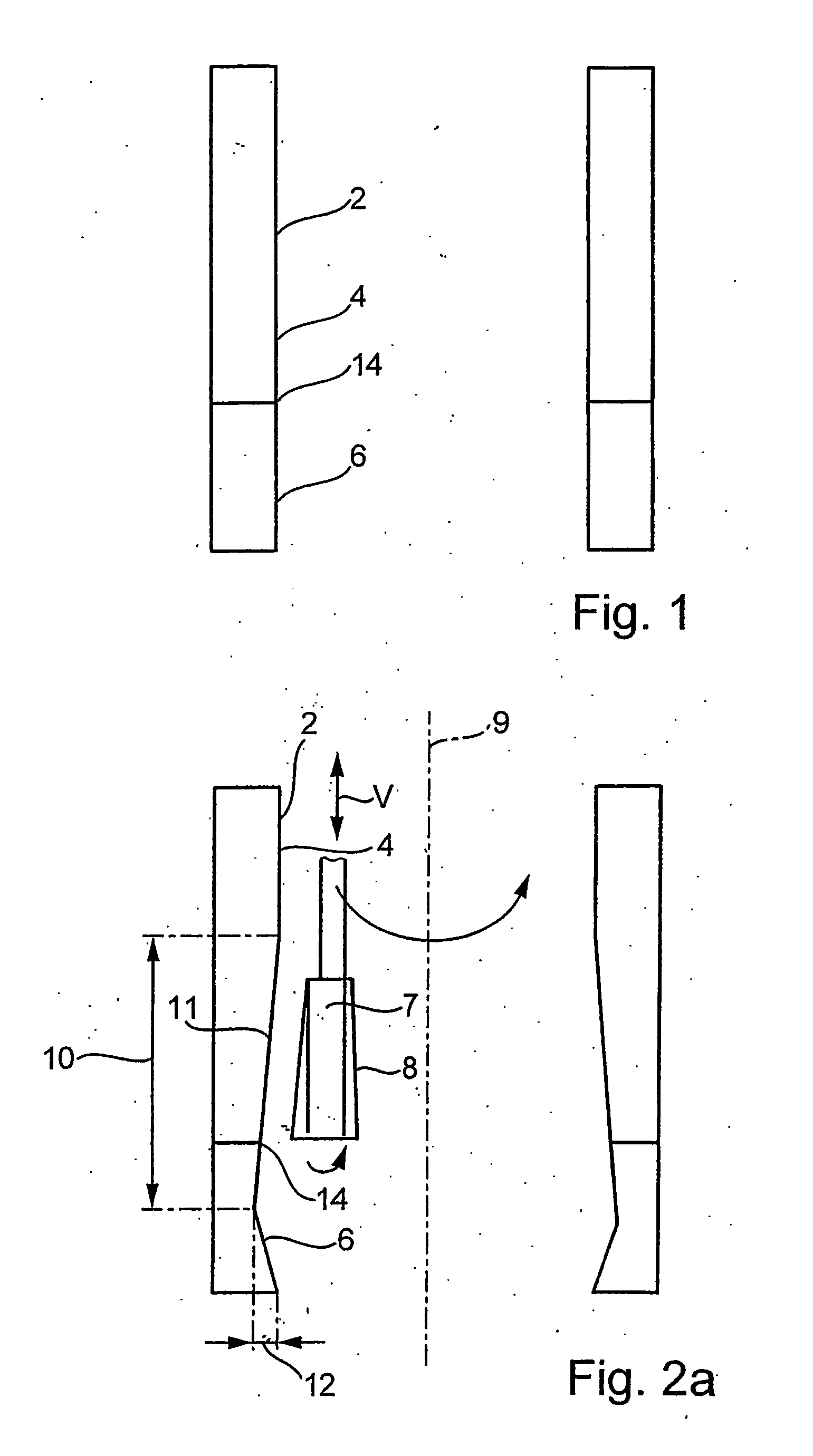

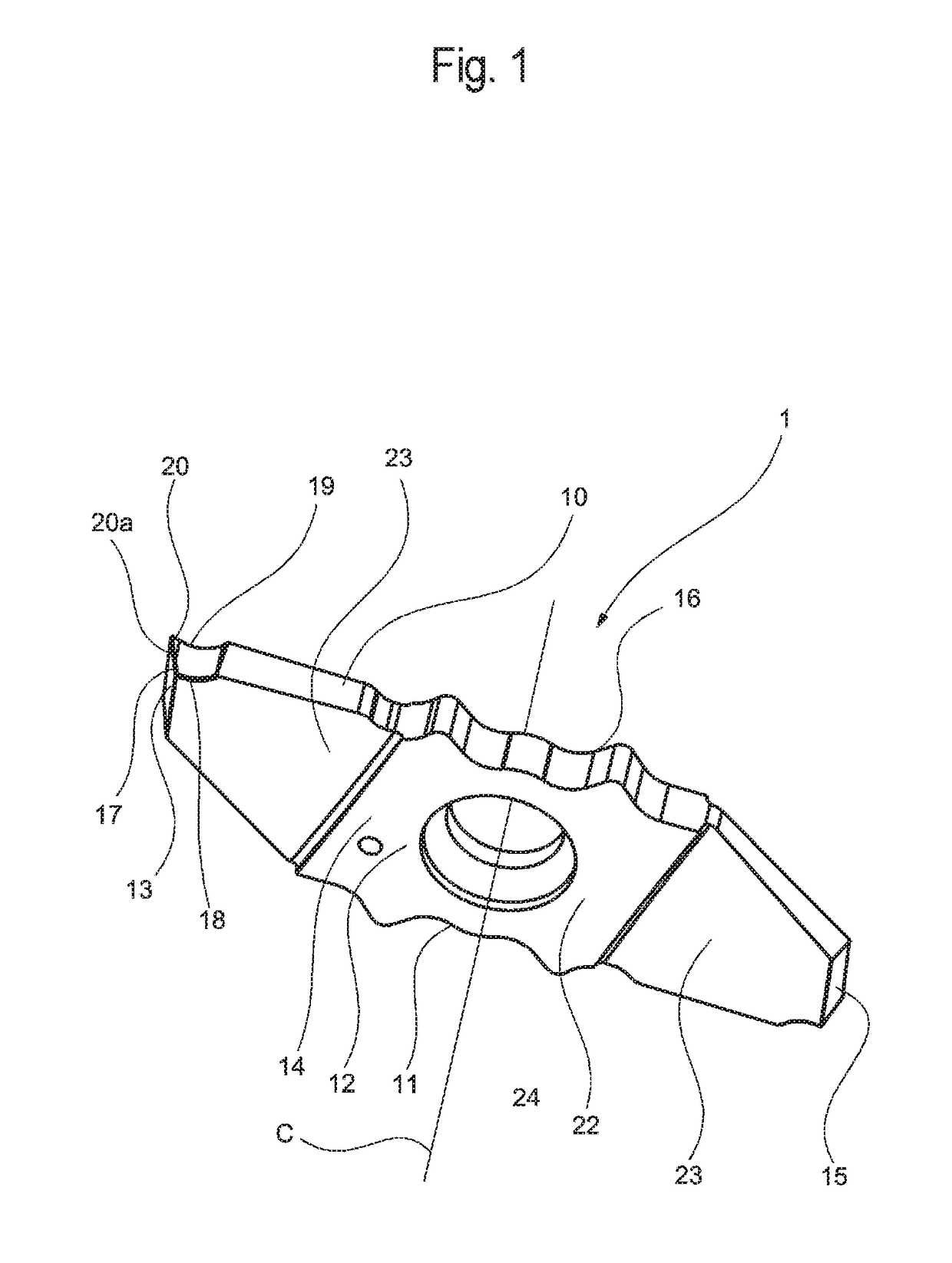

Method for finely processing a cylindrical inner surface

InactiveUS20070060025A1Extended service lifeAvoid cloggingHoning machinesPlane surface grinding machinesEngineeringHardness

The invention relates to a process for precision-machining a cylindrical inner surface, in particular a cylinder bearing surface, which has material of different hardnesses in the axial direction. The cylindrical inner surface is subjected to a precision-turning step, a preliminary honing step and a precision-honing step. The process is distinguished by the fact that the preliminary honing step produces a cone (11) in the cylindrical inner surface, in such a way that the cone (11) widens out from a harder region (4) toward a softer region (6). In the subsequent precision-honing step, the cone (11) is compensated for again in the harder region (4) to produce a cylindrical inner surface, whereas the cone (11) is retained in the softer region (6). This prevents the fine abrasive particles on the precision-honing stone from becoming clogged as a result of contact with the softer region.

Owner:DAIMLER AG

Novel high-accuracy efficient vertical honing machine

ActiveCN103639882ACompact structureImprove processing efficiencyGrinding drivesHoning machinesElectric machineEngineering

The invention relates to a novel high-accuracy efficient vertical honing machine which comprises a working table. The novel high-accuracy efficient vertical honing machine further comprises a plurality of honing assemblies, a servo rotation disc and a first motor, the honing assemblies can conduct horning at the same time, the servo rotation disc is arranged on the working table and provided with a plurality of through holes where workpieces to be machined are fixed, the first motor is used for driving the servo rotation disc to rotate, and the number of the through holes is larger than the number which is two times larger than the number of the honing assemblies. According to the novel high-accuracy efficient vertical honing machine, the honing assemblies are arranged, the through holes where the workpieces to be machined are fixed are formed in the servo rotation disc, the multiple workpieces to be machined can be machined by the honing machine at the same time, the novel high-accuracy efficient vertical honing machine is compact in structure, the machining efficiency is improved, and the modular design can be achieved.

Owner:SUZHOU XINNENG PRECISE MACHINERY

Cutting tool

ActiveUS20190061016A1Improve cut resistanceQuality improvementCutting insertsWorkpiecesWear resistanceMechanical engineering

Provided is a cutting tool that simultaneously improves both fracture resistance and wear resistance. The cutting tool according to the present invention has an end surface, a peripheral side surface intersecting with the end surface, and a cutting edge in an intersecting ridge part along the end surface and the peripheral side surface, and when first and second points A and B are defined on the cutting edge, the first point A protrudes further toward an outer side of the cutting tool than the second point B. The cutting edge has a honing surface. The honing surface has a portion, the width of which gradually increases from the first point A toward the second point B.

Owner:TUNGALOY CORP

Grind-stone-mount of honing head

InactiveUS20120094583A1Smoothly follow inside shapeConstant contact pressureGrinding drivesBelt grinding machinesEngineeringMechanical engineering

A plurality of grind-stone-mounts 12 each having a grind stone 15 on its outer side are attached to a holder 11 of a honing head 10 expandably along a radial direction. Each of the grind-stone-mounts 12 is provided with a support part 13 disposed inside along the radial direction, and a grind part 14 including the grind stone 15 and disposed outside along the radial direction. The grind part 14 is swingably attached to the support part 13 through one or more spring members 16 disposed at intervals along an axial direction of the holder 11.

Owner:HONDA MOTOR CO LTD

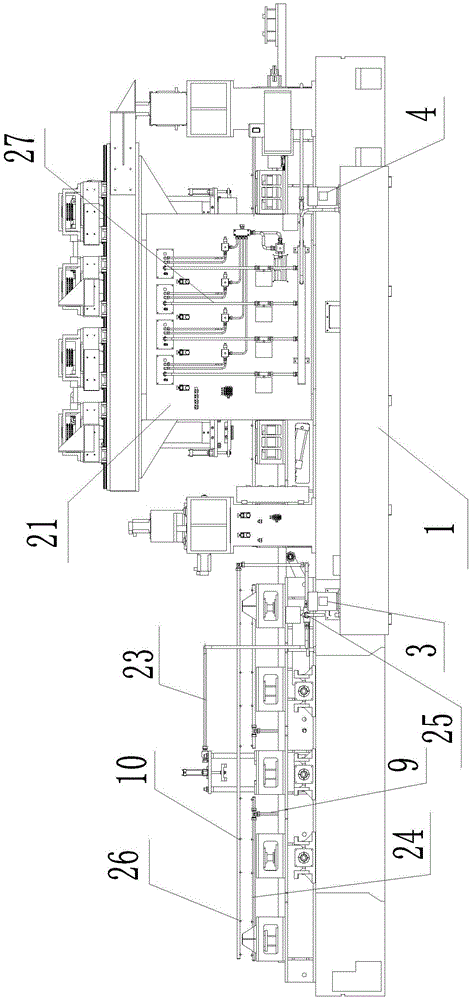

Honing solution collecting and cooling system for honing production line

PendingCN107175582AGuaranteed cleanlinessLow costHoning machinesGrinding/polishing safety devicesEngineeringManufacturing line

The invention relates to a honing solution collecting and cooling system for a honing production line. The system comprises a water tank arranged on the ground and further comprises a first water pump, a second water pump and a third water pump which are arranged on the water tank; the first water pump discharges water in the water tank into a water pipe, and honing and reaming scraps on a lathe bed is flushed through a scrap flushing pipe connected with the water pipe; and the third water pump discharges water in the water tank into a water pipe, and honing and reaming scraps on a lathe bed is flushed through a scrap flushing pipe connected with the water pipe. The honing solution collecting and cooling system for the honing production line is suitable for being applied to the field of honing machine honing and reaming production lines, and the water in the water tank is pumped to the lathe bed through the water pumps to complete the honing and reaming scrap flushing function; a honing solution is pumped out from the lathe bed, filtered through a filtering device and flows back to the water tank, and liquid in the water tank can be recycled; and the honing solution can be collected, and the honing and reaming scraps can be cleared.

Owner:NINGXIA YINCHUAN DAHE CNC MACHINE

Honing machining method for carburizing hole of tappet guide sleeve of aero-engine

ActiveCN112743442AUniform grinding forceHigh cooling frequencyGrinding drivesGrinding feed controlNumerical controlEngineering

The invention discloses a honing machining method for a carburizing hole of a tappet guide sleeve of an aero-engine. The honing machining method comprises the following steps that the carburizing hole of the tappet guide sleeve is machined by adopting a numerical control boring cutter to remove the allowance to 0.2-0.3 mm, the tappet guide sleeve is mounted on a honing machine, the carburizing hole of the tappet guide sleeve is aligned, the carburizing hole is honed for four times until the surface smoothness Ra of the carburizing hole is less than or equal to 0.02, the four times of honing machining comprise rough honing machining, semi-fine honing machining, fine honing machining and super-fine honing machining, and honing machining parameters are optimized, so that the carburizing hole of the tappet guide sleeve does not have burn and crack defects, and the internal surface smoothness of the carburizing hole of the tappet guide sleeve is close to the level of a mirror surface. The honing machining method for the carburizing hole of the tappet guide sleeve of the aero-engine has the advantages of being high in machining efficiency, even in grinding force, high in cooling frequency, sufficient in cooling and free of burn and crack defects, and the surface smoothness of the inner hole is close to the level of a mirror surface.

Owner:AVIC POWER ZHUZHOU AVIATION PARTS MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com