Novel high-accuracy efficient vertical honing machine

A kind of honing machine, high-precision technology, applied in the direction of honing machine, grinding machine parts, grinding workpiece support, etc., can solve the problems of complex structure of honing rod, large floor area, low production efficiency, etc., and achieve compact structure, Improve processing efficiency and realize the effect of modular design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further elaborated below in conjunction with the accompanying drawings.

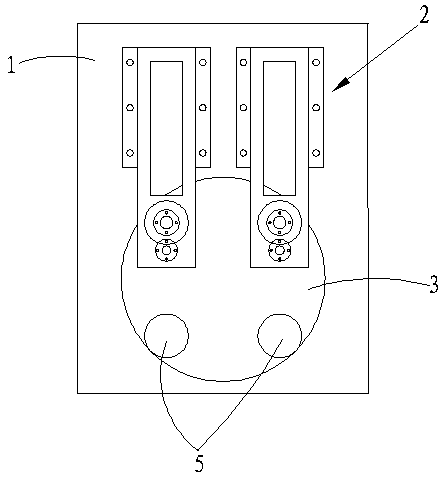

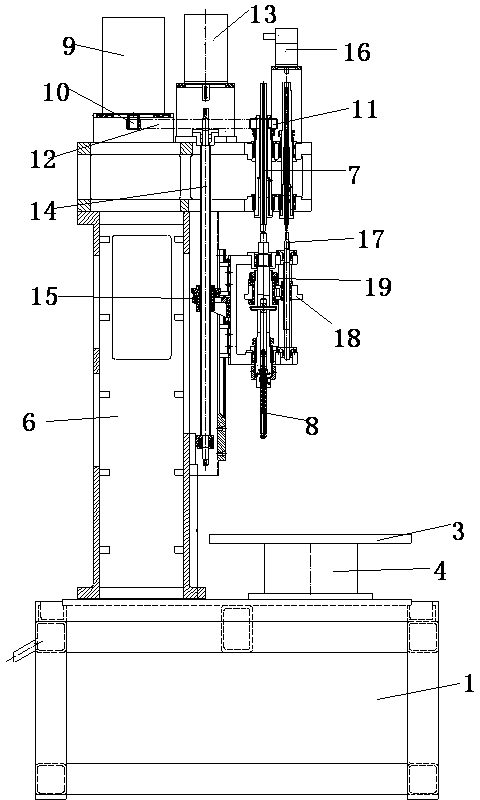

[0019] As shown in the accompanying drawings, a new high-precision and high-efficiency vertical honing machine includes a workbench 1, and the new high-precision and high-efficiency vertical honing machine also includes a plurality of honing assemblies 2 capable of simultaneous honing, which are arranged on the workbench 1 and Servo turntable 3 with a plurality of through holes 5 for fixing the workpiece to be processed, and a first motor 4 for driving the servo turntable 3 to rotate, the number of through holes 5 is more than twice the number of honing components 2 . The distances between two adjacent through holes 5 are equal, and the centers of the plurality of through holes 5 are located on the same circumference. There are two honing assemblies 2 located on one side of the servo turntable 3, four through holes 5 evenly distributed on the servo turntable 3, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com