Extrusion honing device for profile shaping mold

A technology of extrusion honing and setting molds, which is applied in the direction of grinding workpiece supports, etc., can solve the problems of difficult standardization and generalization of mold core design and manufacture, and achieve uniform polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

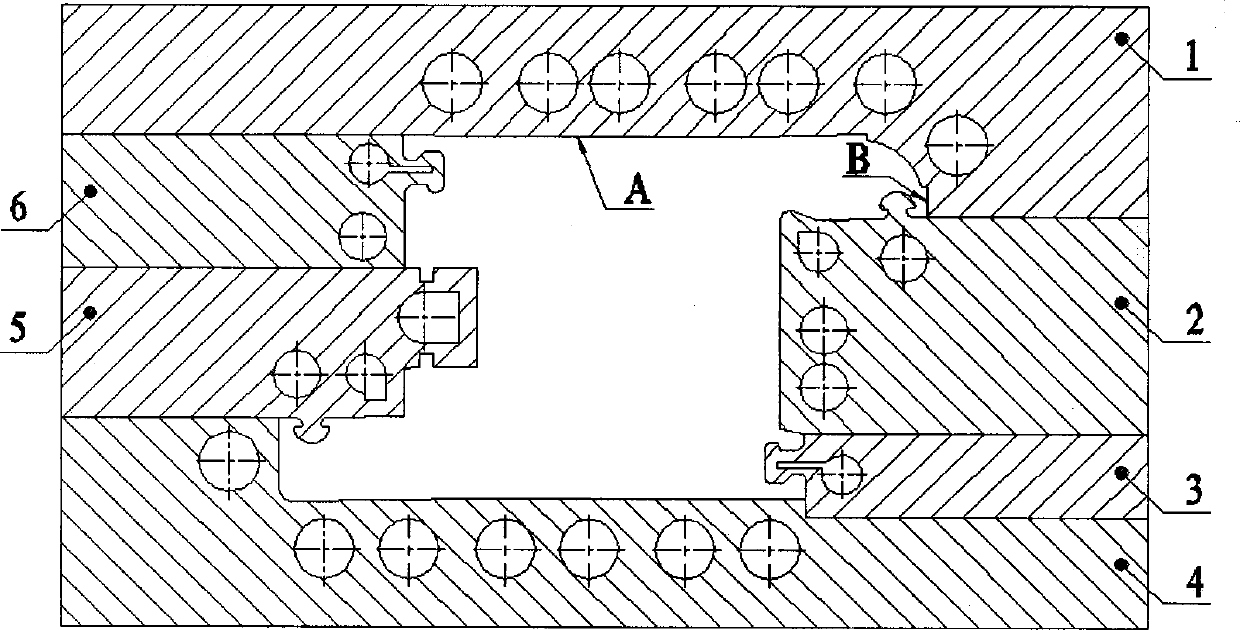

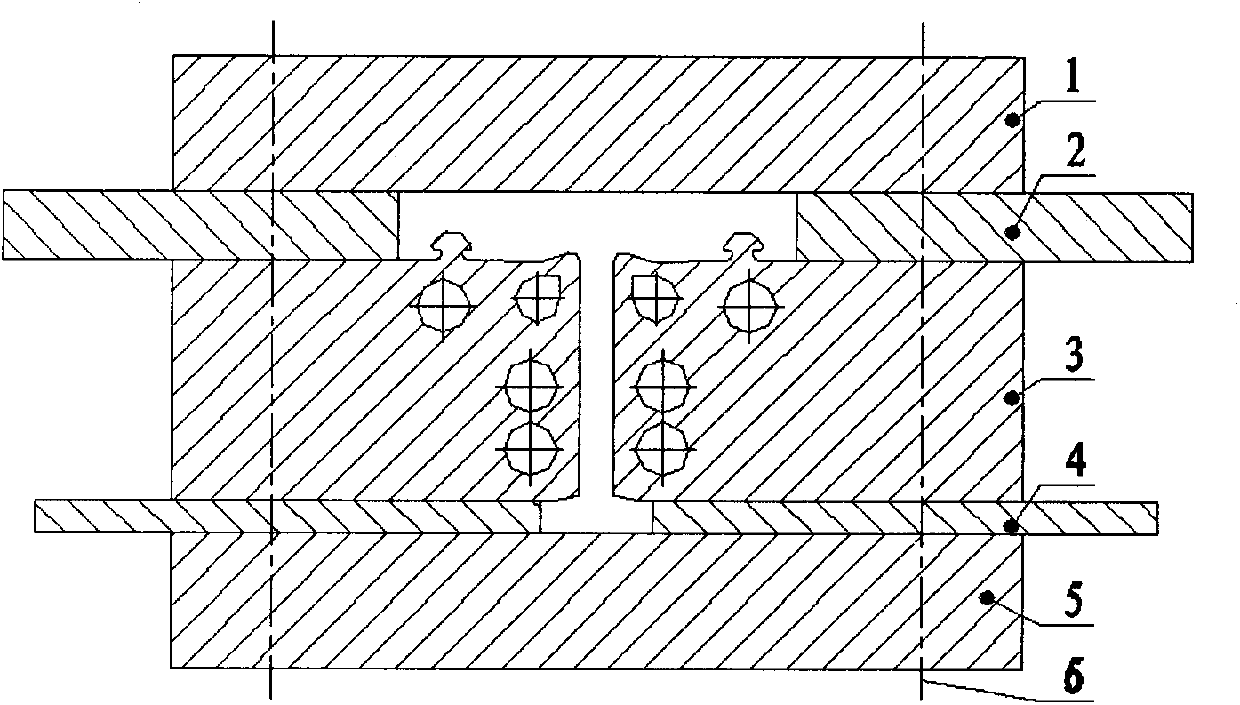

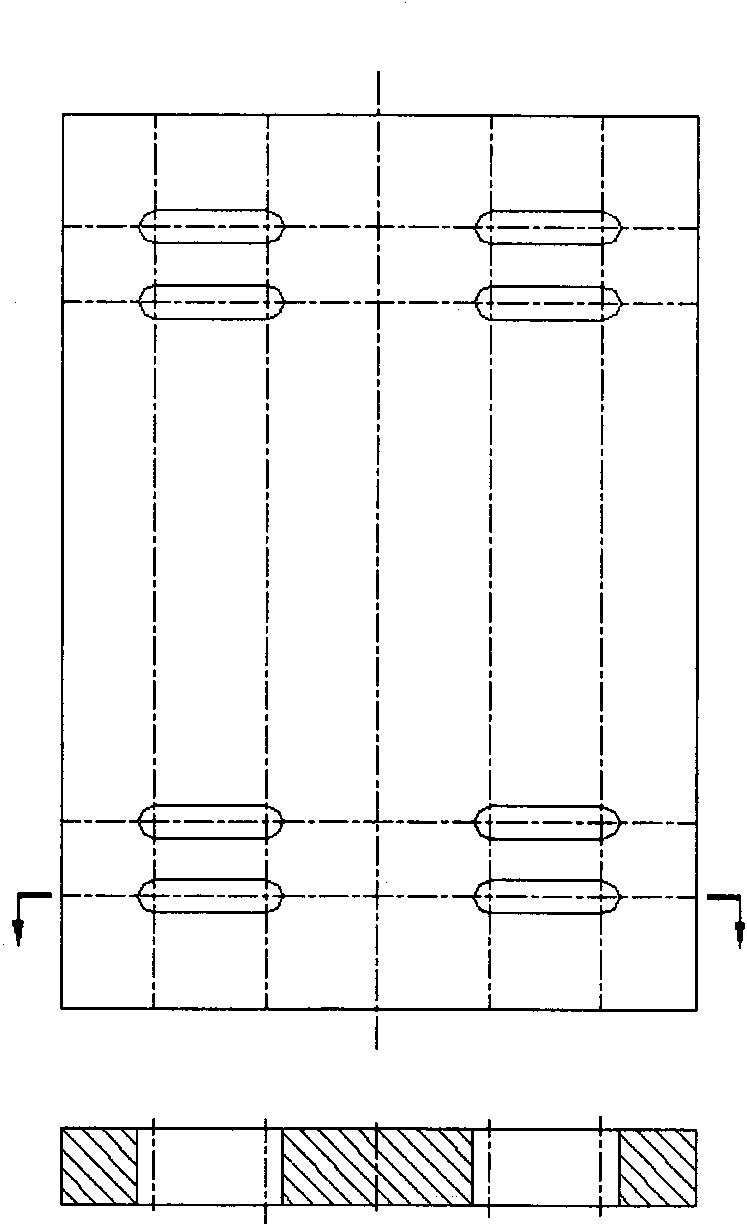

[0017] Attached below Figure 1-6 , taking a single-piece extrusion honing device for the shaping die template of a plastic profile extrusion die for a building door leaf as an example, further explaining how the shaping die template of the plastic profile extrusion die is effectively polished by the extrusion honing device. attached figure 1 It is a schematic diagram of the assembly structure of a plastic profile extrusion molding die for a building door leaf. The shaping mold part is composed of 4 parts, that is, figure 1 Quantity of each template shown is 4 pieces, take figure 1 2 of the 4 pieces of the template on the right shown are used as the components of the fixture, together with the upper and lower cover plates and the corresponding adjustable backing plate, assembled through the modified bolts to form a closed combined fixture with a gap of 5-10mm, such as figure 2 As shown, according to the change of the honing object, it can be solved only by replacing the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com