Polishing grain type rice polishing machine

A polishing machine and rice technology, applied in grain finishing, grain processing, application, etc., can solve the problem of uneven polishing of rice grains, and achieve the effect of large and uniform polishing contact surface, efficient polishing, and reducing broken rice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

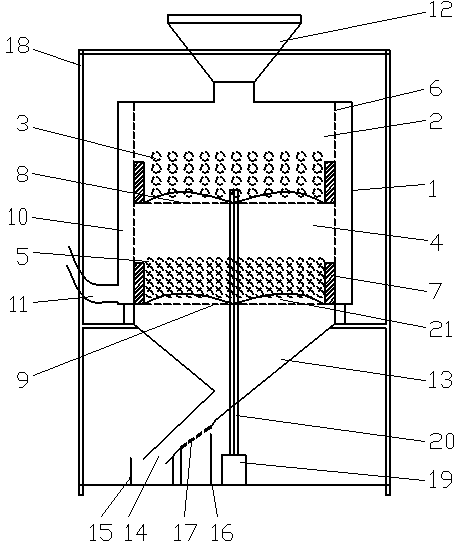

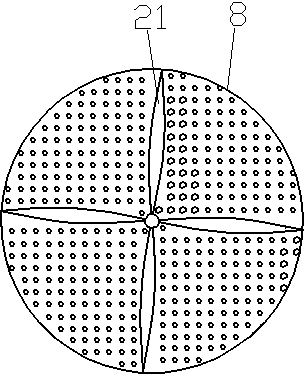

[0012] Further illustrate the implementation of the present invention with reference to the accompanying drawings (as shown in Figure 1, figure 2 , as shown):

[0013] Option 1: A polishing shot type rice polishing machine, including: polishing cylinder 1, rice inlet to be polished 12, polishing cylinder funnel chamber 13, polished rice outlet 14, polished rice container 15, broken rice collection box 16, broken rice sieve Net 17, polishing machine support 18, the top of the polishing cylinder 1 is the rice entrance 12 to be polished, the rice entrance 12 to be polished is fixed on the top of the polishing machine support 18, the polishing cylinder 1 below is the polishing cylinder funnel chamber 13, and the polishing cylinder funnel chamber 13 is fixed on In the middle of the polishing machine support 18, the polished rice outlet 14 is below the polishing cylinder funnel chamber 13, and the broken rice screen 17 is between the polishing cylinder funnel chamber 13 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com