Continuous production equipment

A technology for producing equipment and racks, which is applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve the problems of insufficient grinding effect, poor use effect of the slide, affecting the loading and unloading of bulk materials, etc., and achieves a simple structure. , easy to use, good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other; the present invention will be described in detail below with reference to the accompanying drawings and in combination with the embodiments.

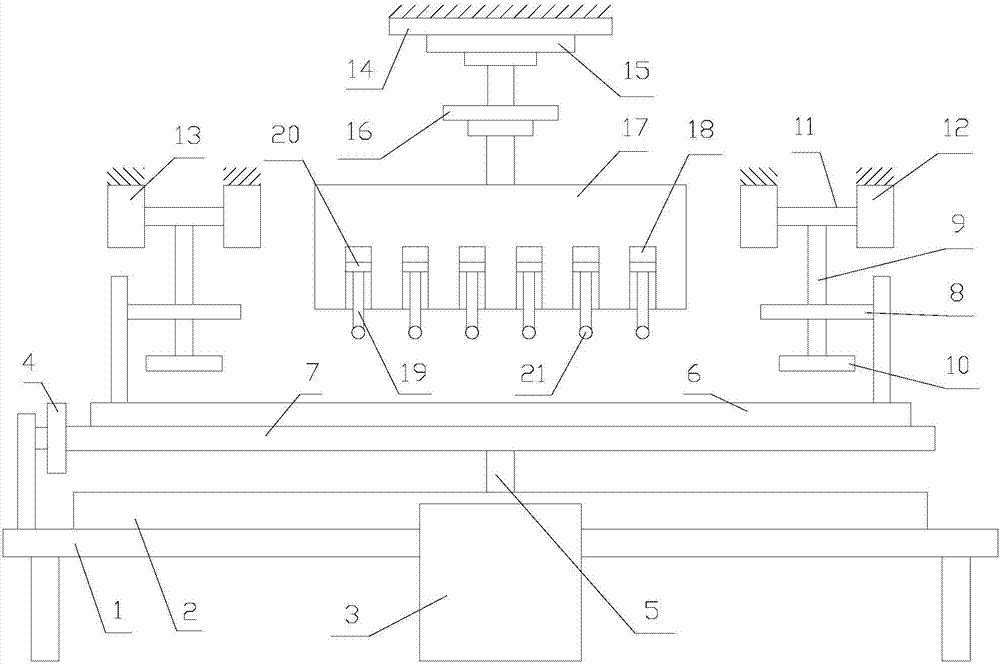

[0026] refer to figure 1 :

[0027] A continuous production equipment proposed by the present invention is used for metal plate processing, at least including a processing table 1, a guide rail, a processing plate 2, a driving mechanism 3, a clamping part, and a processing part.

[0028] The guide rail is horizontally installed on the processing table 1; the processing plate 2 is slidably installed on the guide rail.

[0029] The driving mechanism 3 is used to drive the processing plate 2 to move along the length direction of the guide rail; the driving mechanism 3 can be an air cylinder or the like.

[0030] The clamping part includes a plurality of clamping mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com