Patents

Literature

1154results about How to "Improve sanding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

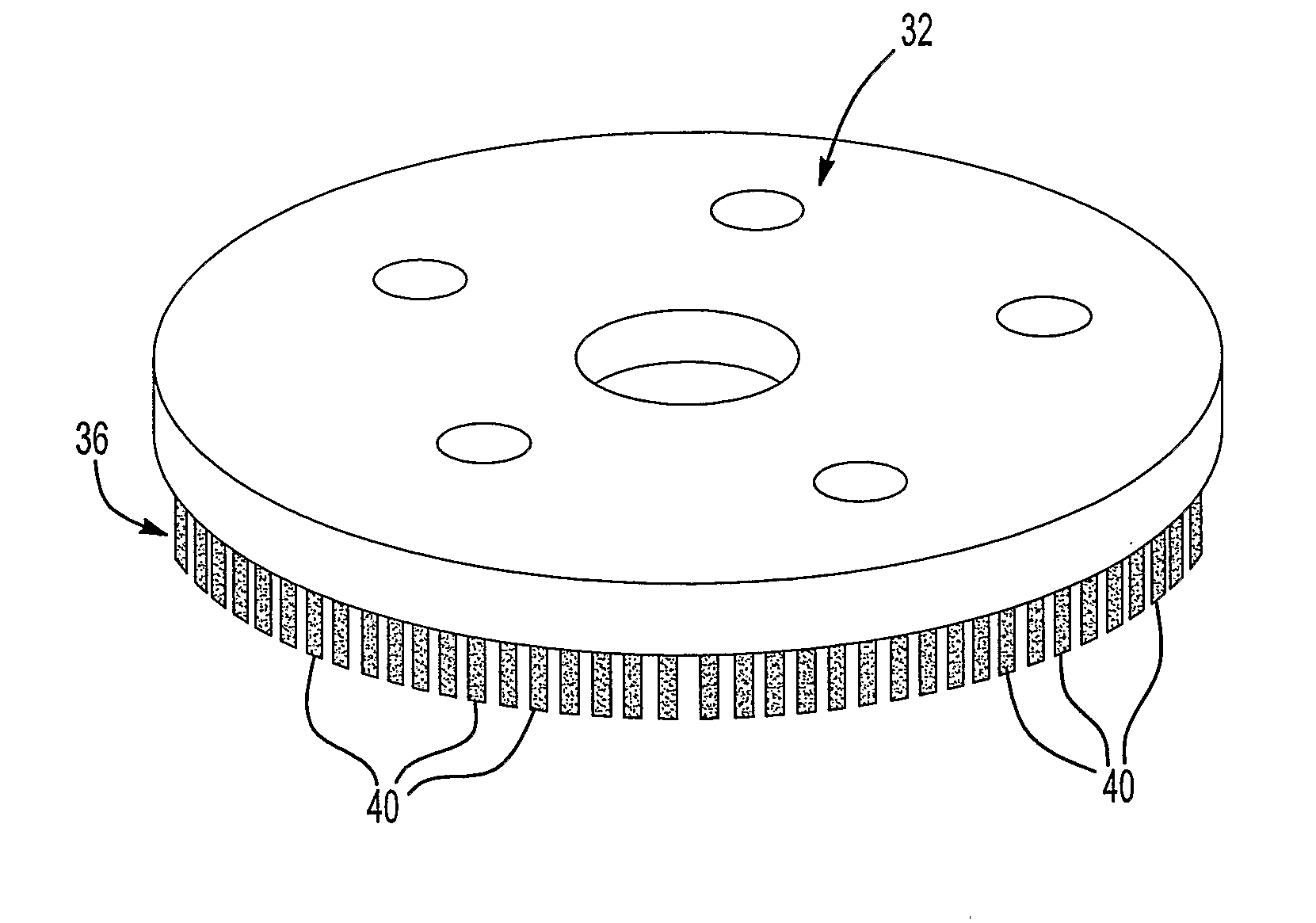

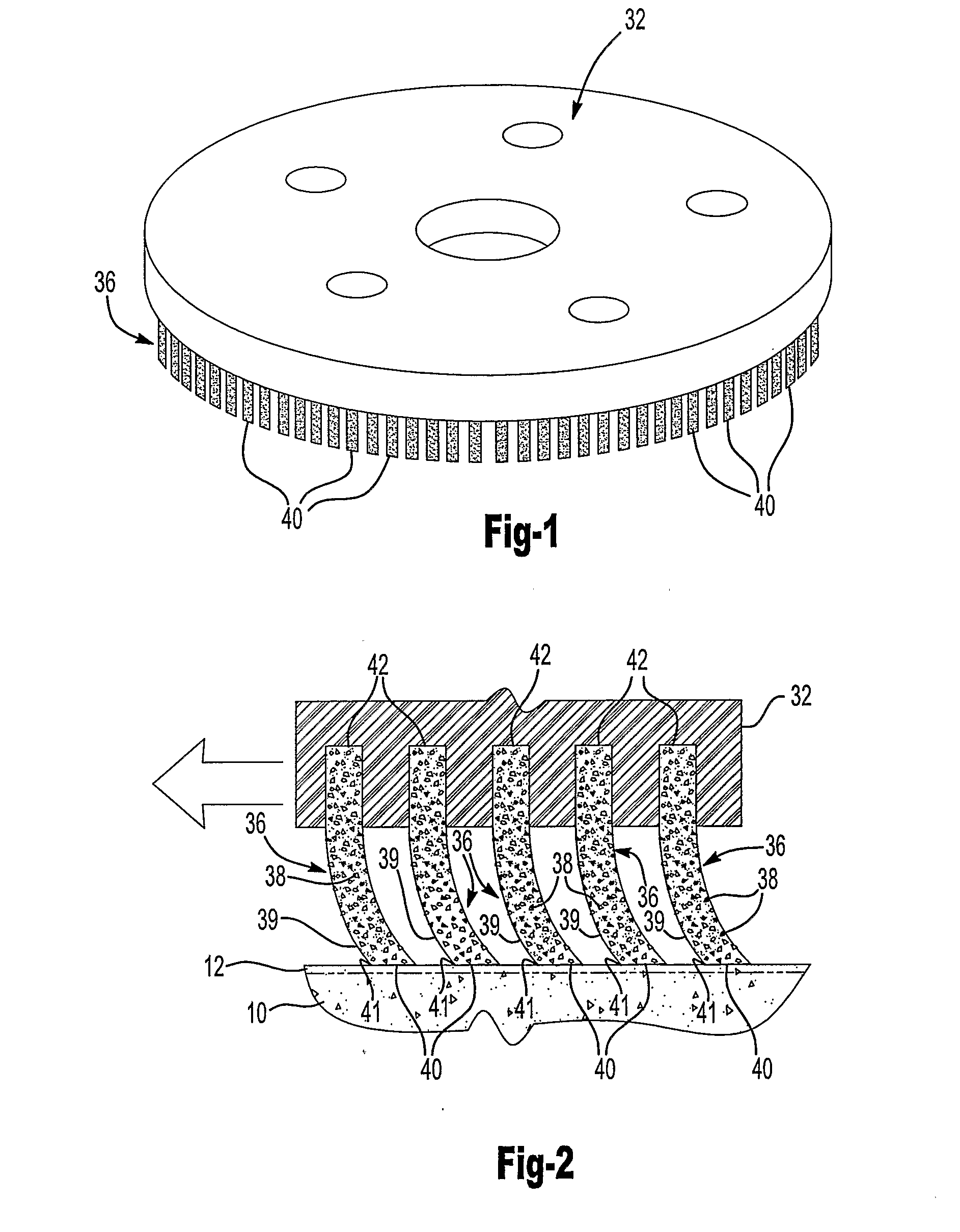

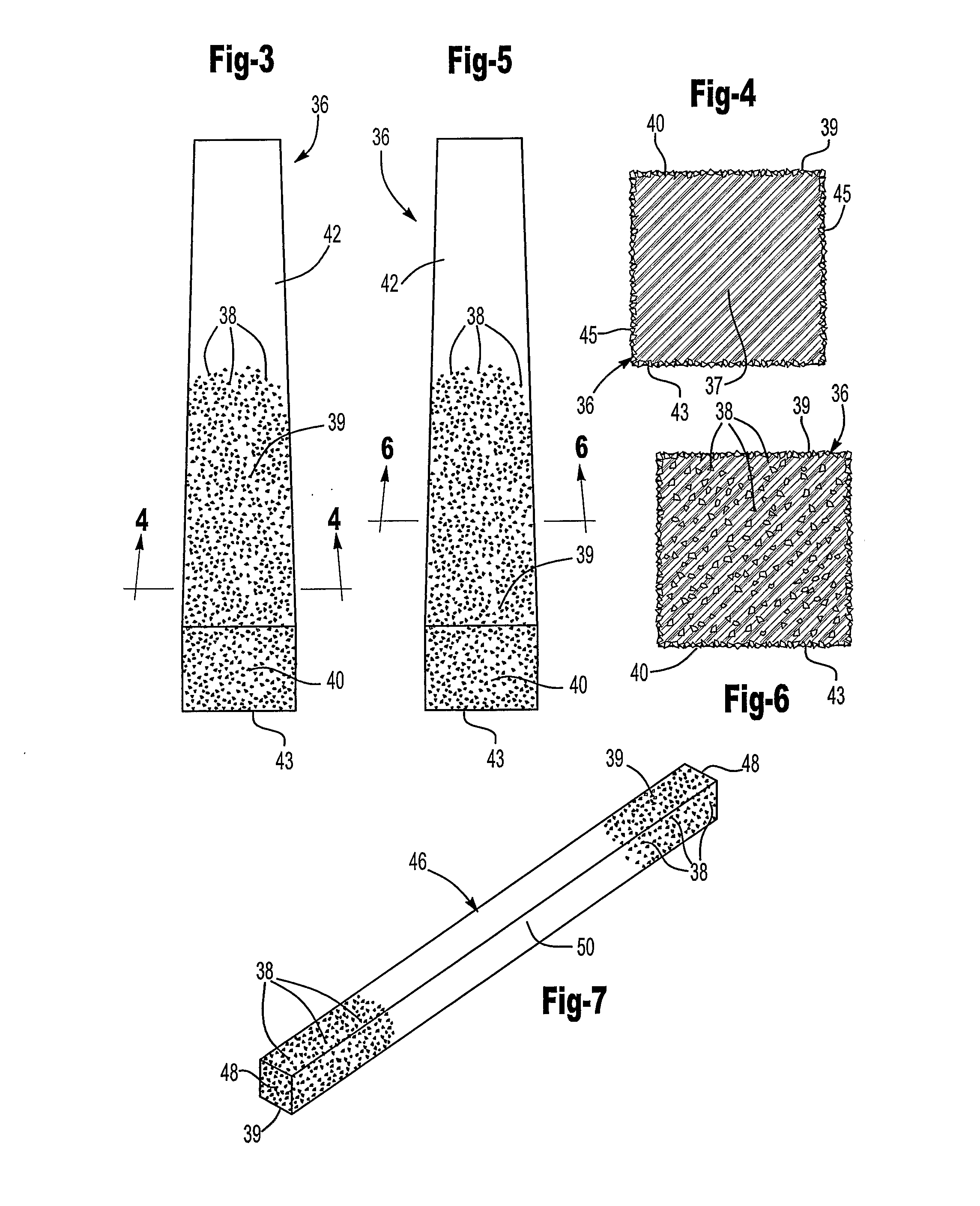

Abrasive Cleaning Device

ActiveUS20080160886A1Improve sanding effectStay flexibleGrinding machine componentsBrush bodiesSurface mountingEngineering

Owner:DIAMABRUSH

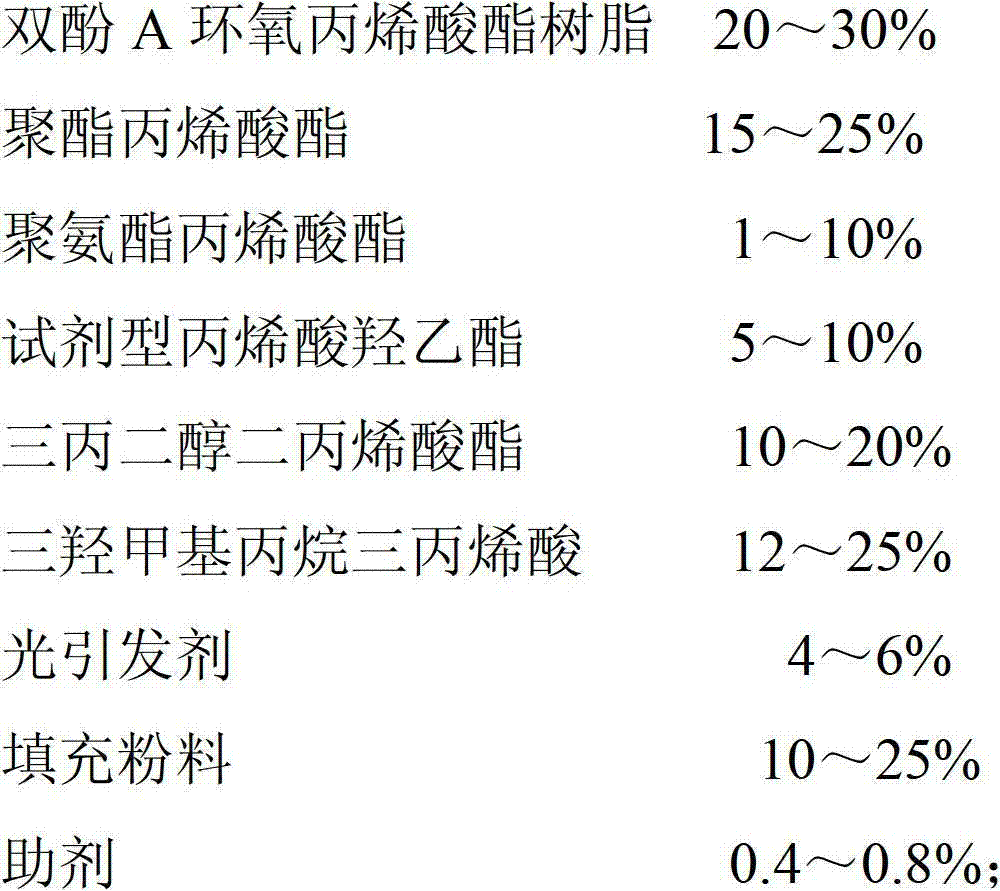

Ultraviolet light curing transparent priming paint and preparation method and use method thereof

ActiveCN102952455AReduce lossImprove product qualityPolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycolPolyester

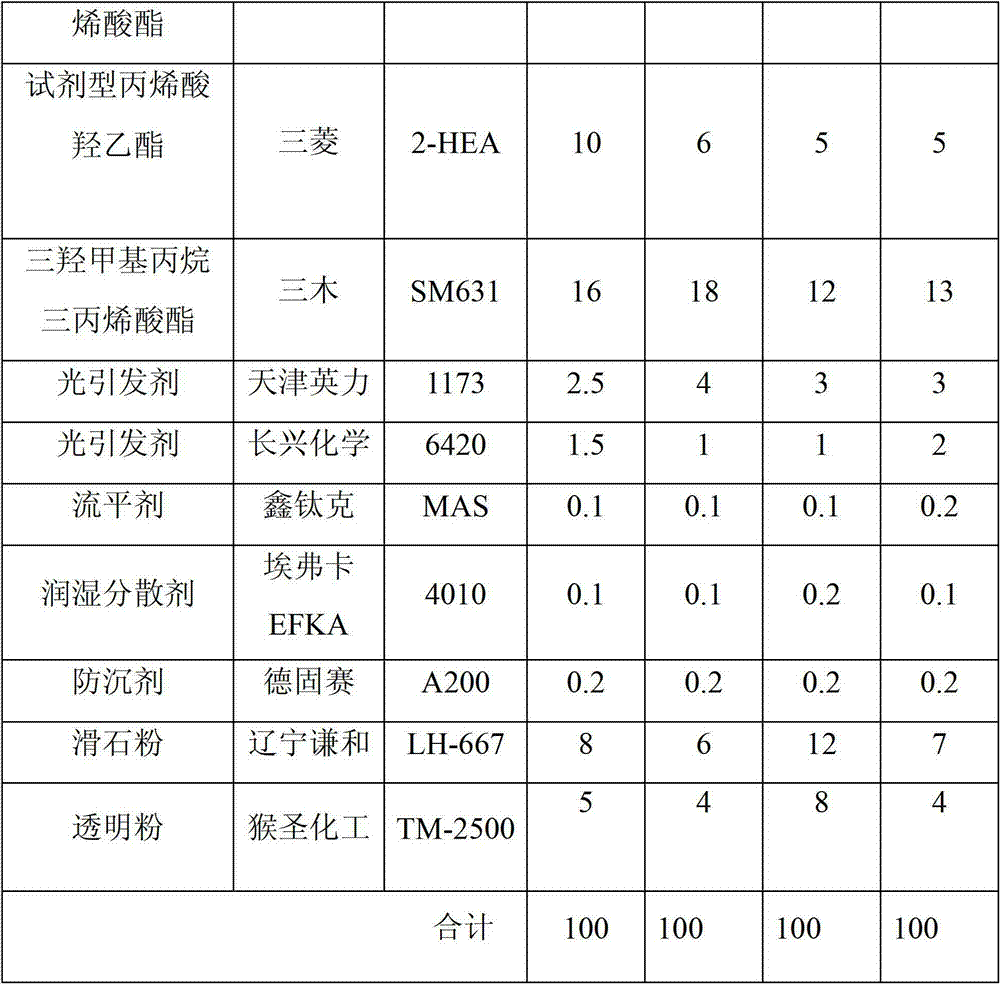

The invention discloses an ultraviolet light curing transparent priming paint and a preparation method and a use method thereof. The ultraviolet light curing transparent priming paint comprises the following components in percentage by weight: 20-30% of bisphenol A epoxy acrylate resin, 15-25% of polyester acrylate, 1-10% of urethane acrylate, 5-10% of reagent type hydroxyethyl acrylate, 10-20% of tripropylene glycol diacrylate, 12-25% of trimethylolpropane triacrylate, 4-6% of photoinitiator, 10-25% of filling powder and 0.4-0.8% of promotor. The ultraviolet light curing transparent priming paint is suitable for laser roller construction, has good grittiness and transparency, has the characteristics that sanding is not needed for semi-curing recoating between film layers and the like, and has thick coating performance and the performance that the surface is similar to a mirror surface, and compared with conventional roller coating, the coating weight is greatly increased, roller coating processes are saved, the priming paint is sanded by a sanding machine without large pressure and with a small number of sanded films, a workpiece has no bright spots, the fullness of a product is guaranteed, the product quality is improved, the loss of the machine is smallreduced, and the use amount of sanding belts is greatly reduced.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

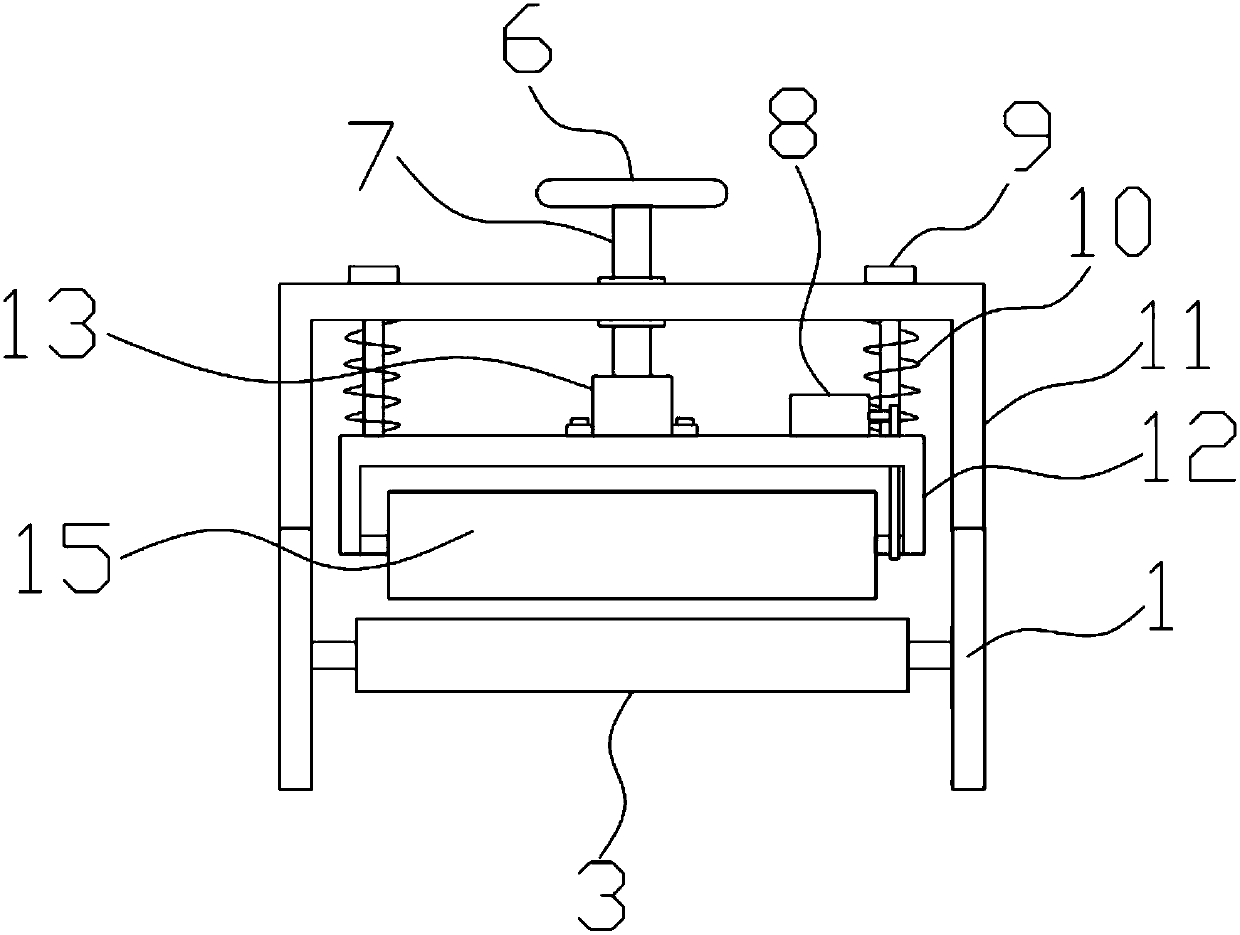

Short steel pipe outer wall polishing device for building engineering

InactiveCN108788952AAffect Fixed GrindingFixed grinding is firm and stableRevolution surface grinding machinesGrinding work supportsHydraulic cylinderArchitectural engineering

The invention discloses a short steel pipe outer wall polishing device for building engineering. The short steel pipe outer wall polishing device comprises a bottom base plate, a supporting rod frameis arranged on the upper end face of the bottom base plate, the upper ends of four connecting rods and the lower sides of four corresponding arc-shaped jacking plates are hinged, the left end of an adjusting transverse shaft penetrates out of a supporting transverse pipe, and a rotating transverse lead screw is provided with a driving spiral sleeve matched with the rotating transverse lead screw;the outer side wall of the driving spiral sleeve is provided with a connecting sleeve, and the upper side of the supporting rod frame is provided with a hydraulic cylinder, wherein the bottom of the hydraulic cylinder is slidably connected with the supporting rod frame; the side end of the supporting rod frame is provided with a double-output-shaft motor, one end of the double-output-shaft motor is connected with the outer side wall of the supporting transverse pipe through a transmission mechanism, and the other end of the double-output-shaft motor is provided with an incomplete bevel gear; and one end of the rotating transverse lead screw is provided with two rotating bevel gears, and the two rotating bevel gears are engaged with the incomplete bevel gear alternately. The short steel pipe outer wall polishing device is simple in structure and convenient to operate, a steel pipe is fixed stably, the polishing effect is obvious, the efficiency is high, and the short steel pipe outer wall polishing device is worth popularizing.

Owner:郑州荣献新材料技术有限公司

Water-based primer for wood enamel sealing and preparation method thereof

ActiveCN104761992AAchieve water resistanceImprove permeabilityAntifouling/underwater paintsPaints with biocidesWater basedTemperature resistance

The invention discloses a water-based primer for wood enamel sealing. The water-based primer for wood enamel sealing contains the following raw materials in percentage by mass: 20-40% of an acrylic emulsion, 20-30% of silica sol, 6-15% of polyurethane, 12-25% of a lead-free pigment and 5-25% of deionized water, and further comprises the following auxiliaries: 0.1-0.5% of a dispersant, 0.1-0.5% of a defoamer, 0.1-0.3% of a wetter, 0.2-0.5% of a leveller, 0.2-1% of a thickener and the like. According to the water-based primer for wood enamel sealing, high-purity stable water-based acidic silica sol is selected, only contains moisture and volatile matters, has the characteristics of no smell, no toxicity, high-temperature resistance, no flash point and flame resistance, cooperates with the homogeneous-phase collocation of the other materials in the formula, and forms a glass enamel sealing film layer which is incapable of being dissolved and deteriorated after coating the surface of a wood material to form a film; the coated wood material can also be effectively protected; the scrubbing resistance and the contamination resistance are obviously improved.

Owner:上海君子兰新材料股份有限公司

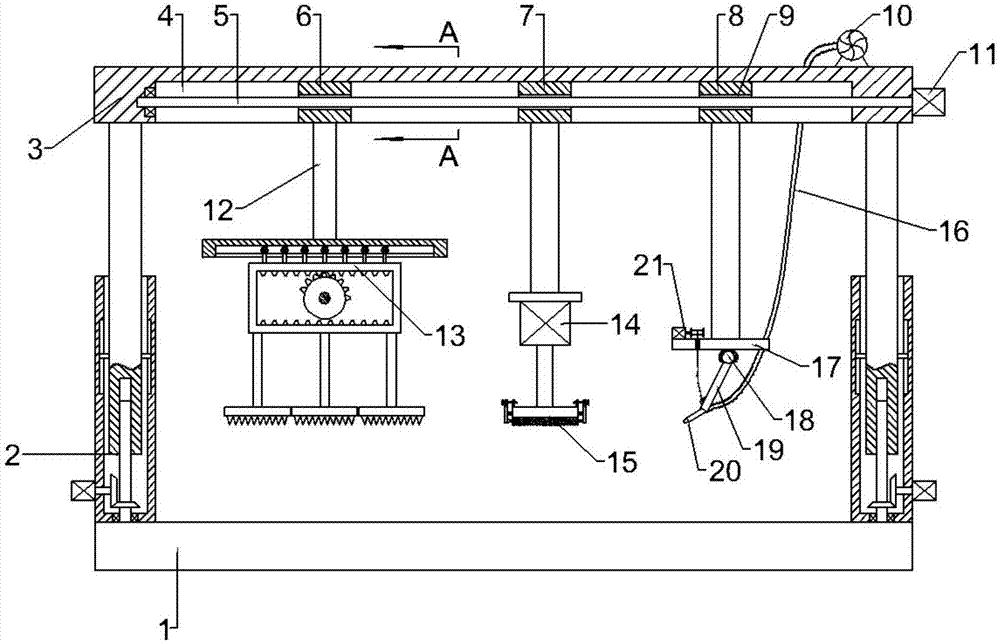

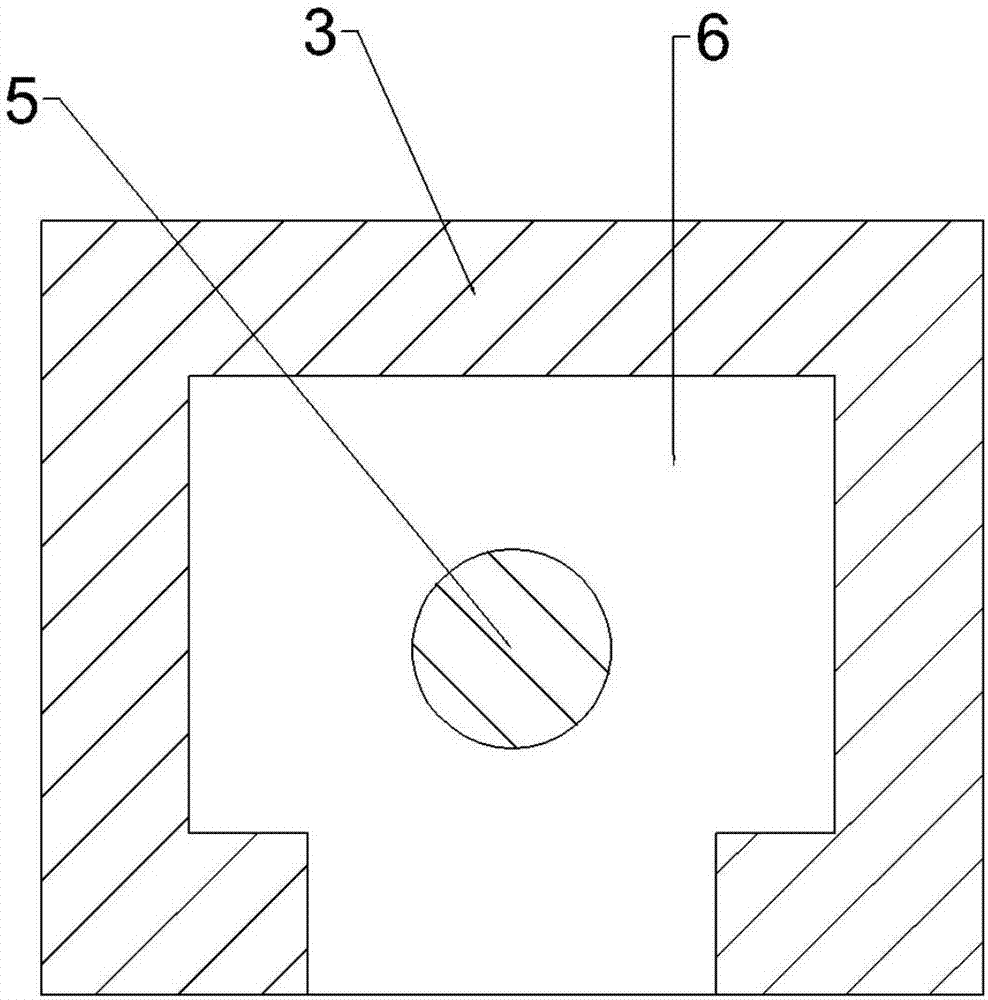

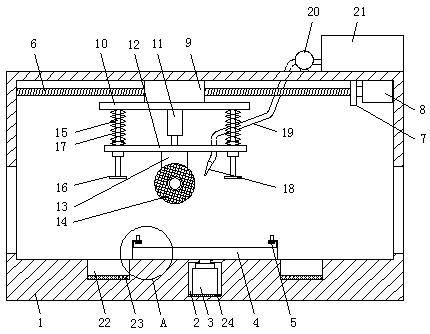

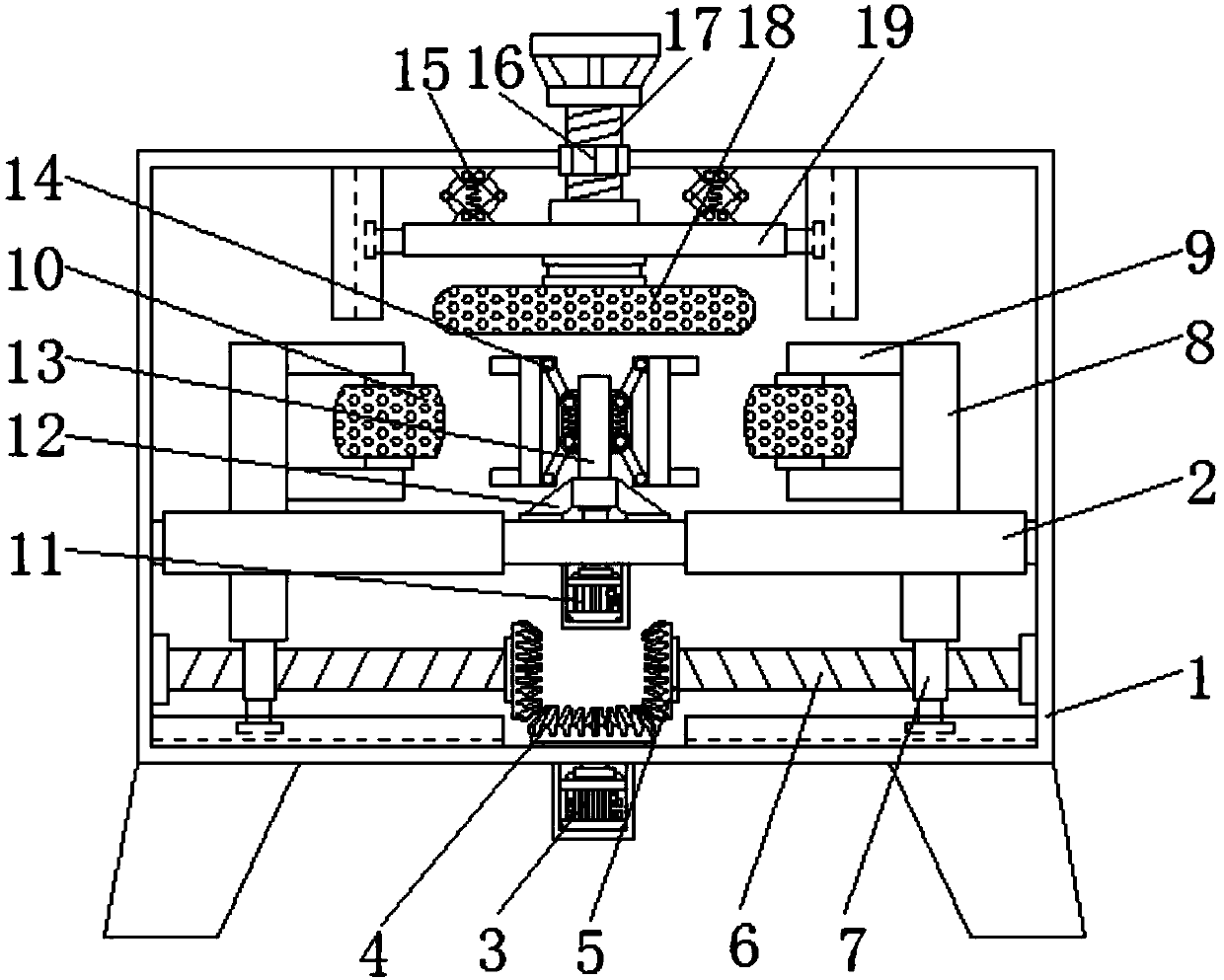

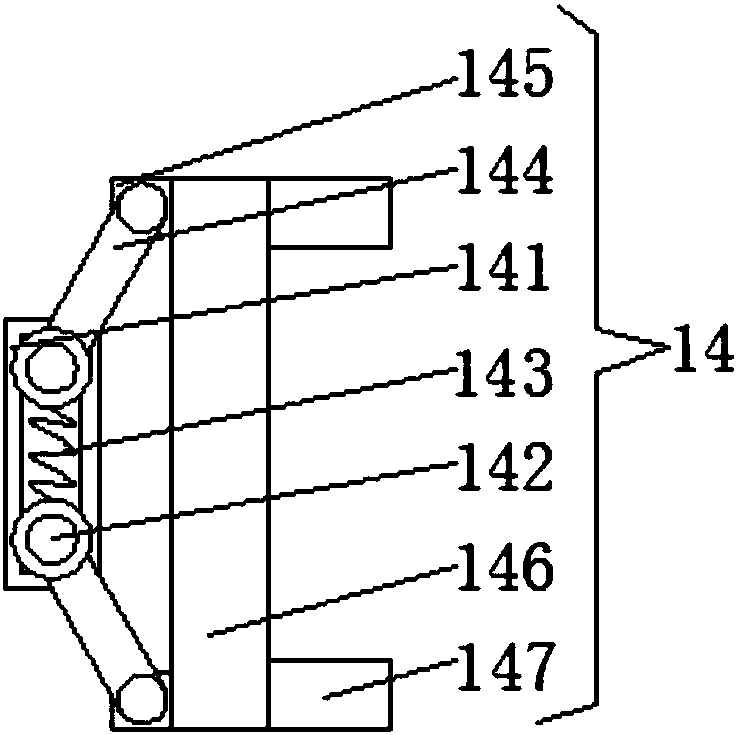

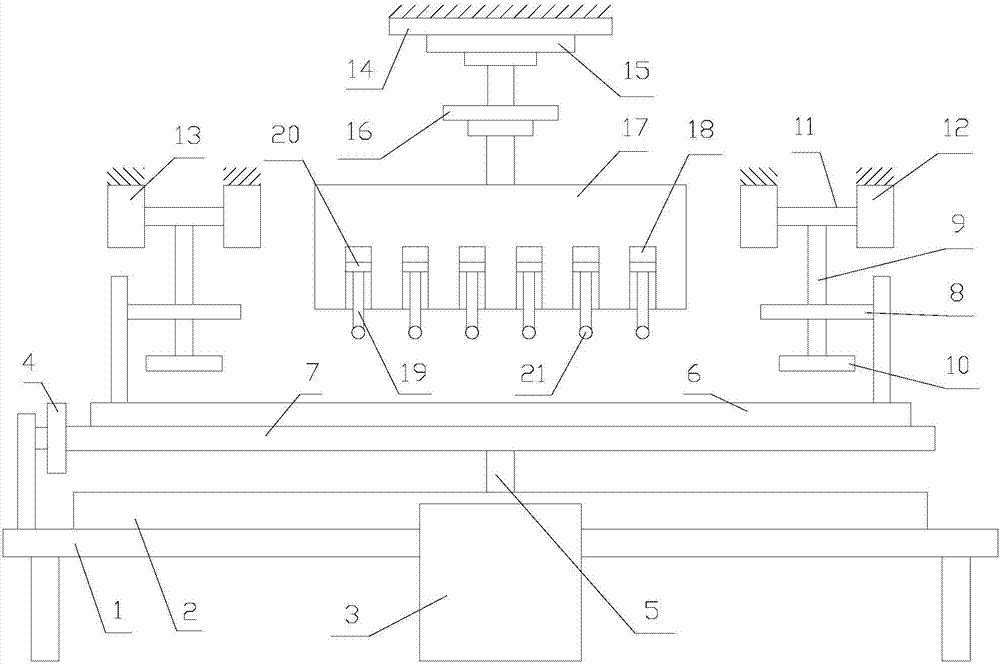

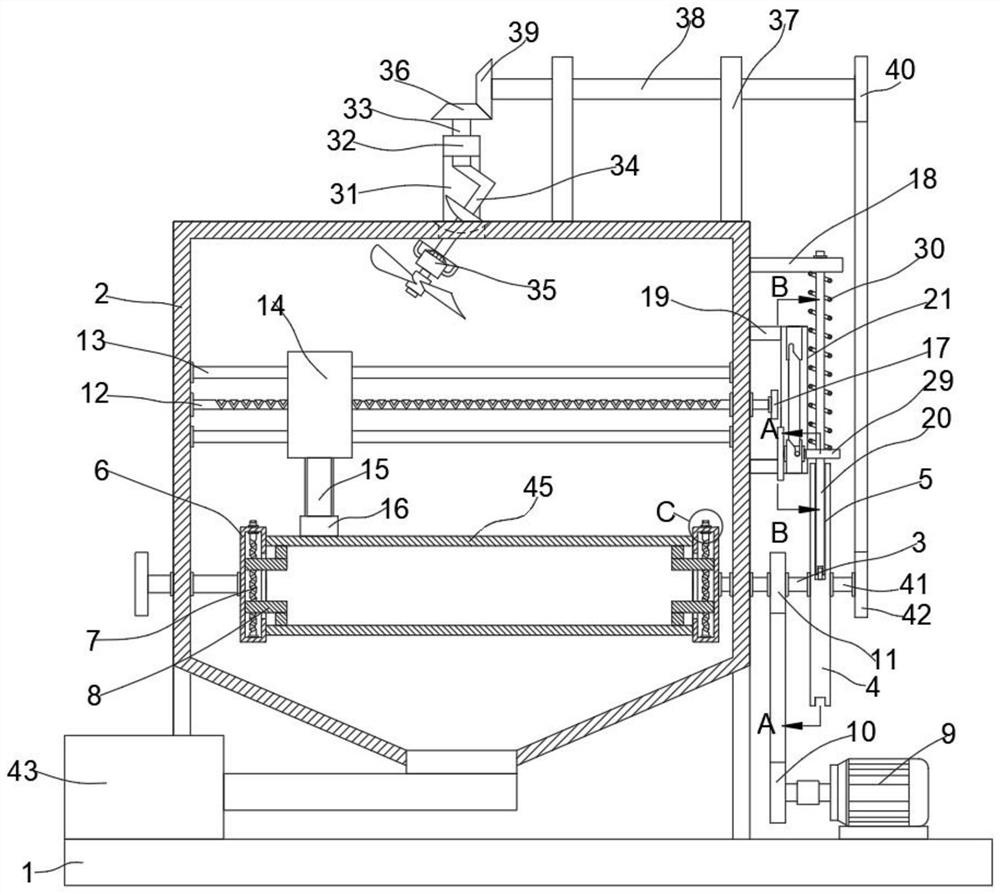

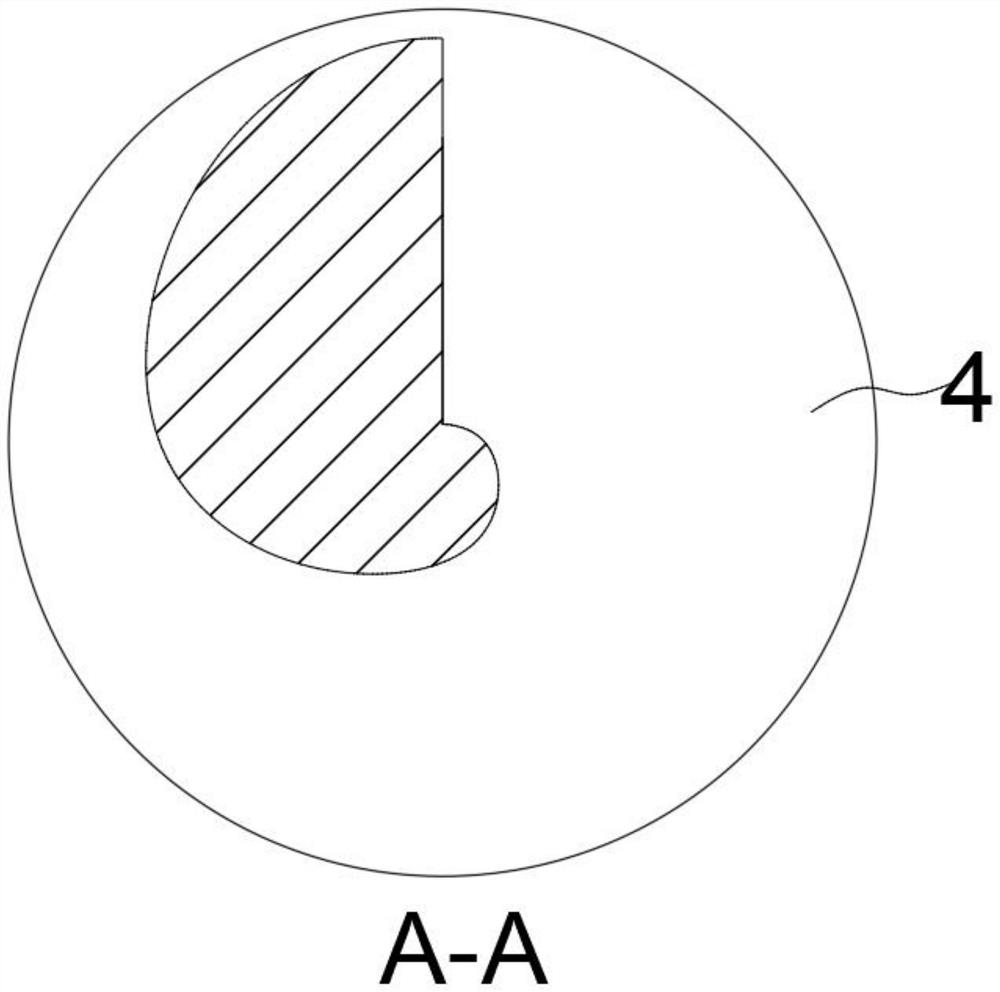

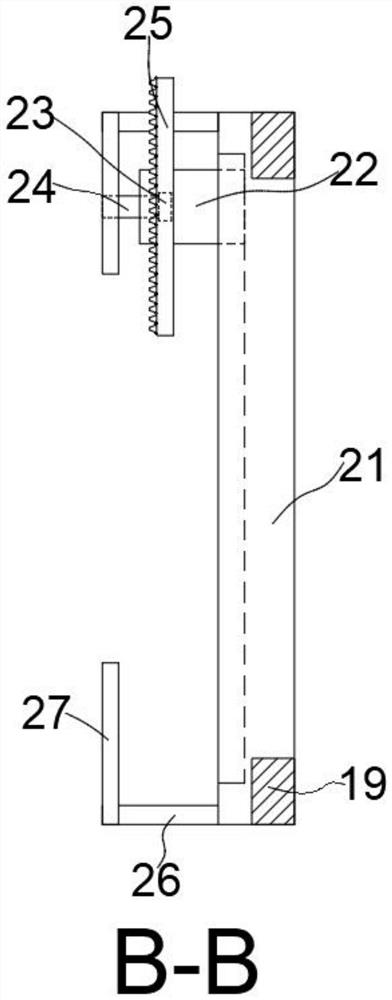

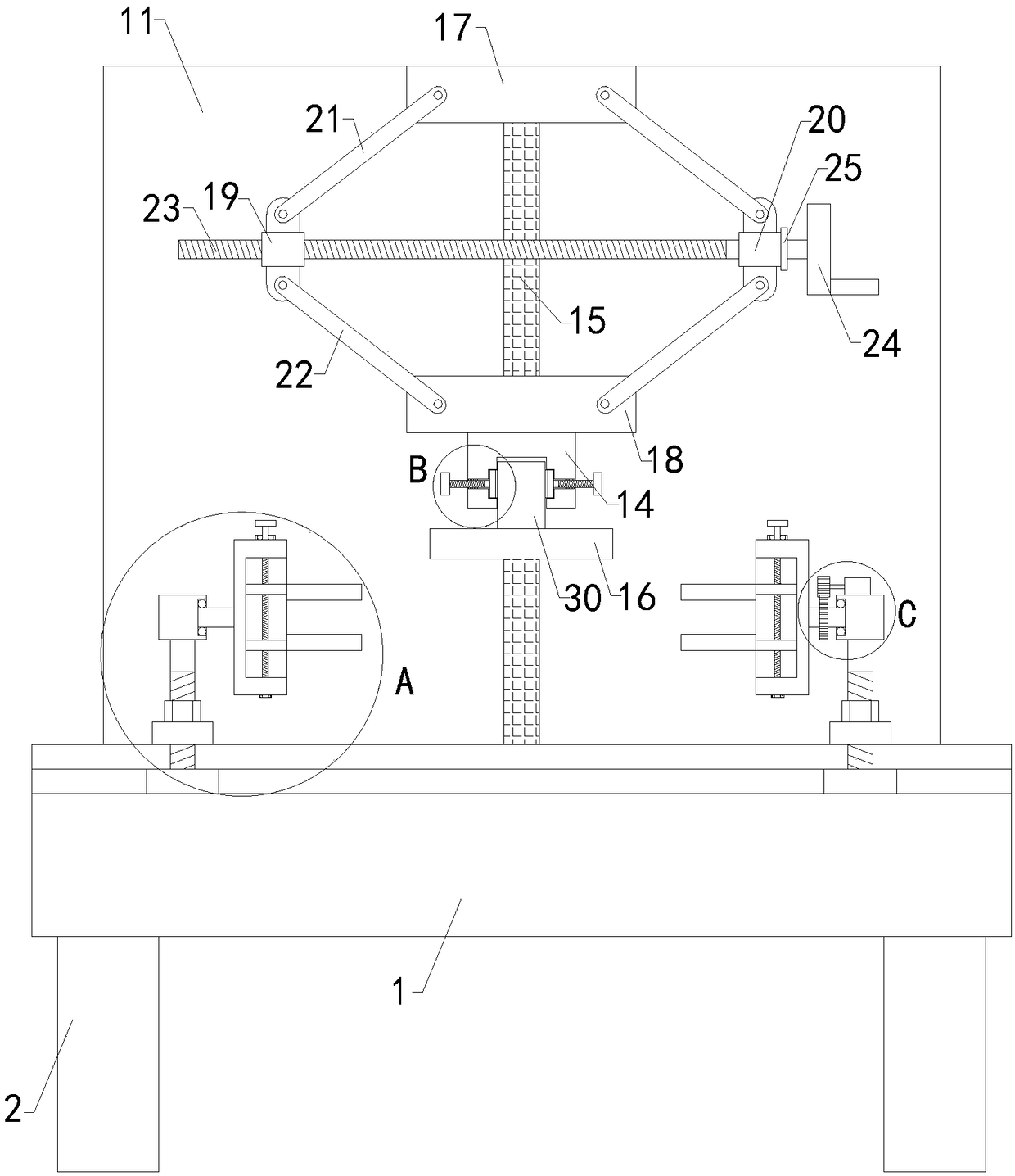

Building artificial stone block integrated machining equipment with reciprocating grinding function

InactiveCN107414625AImprove sanding effectImprove grinding efficiencyGrinding wheel securing apparatusGrinding carriagesProcess efficiencyEngineering

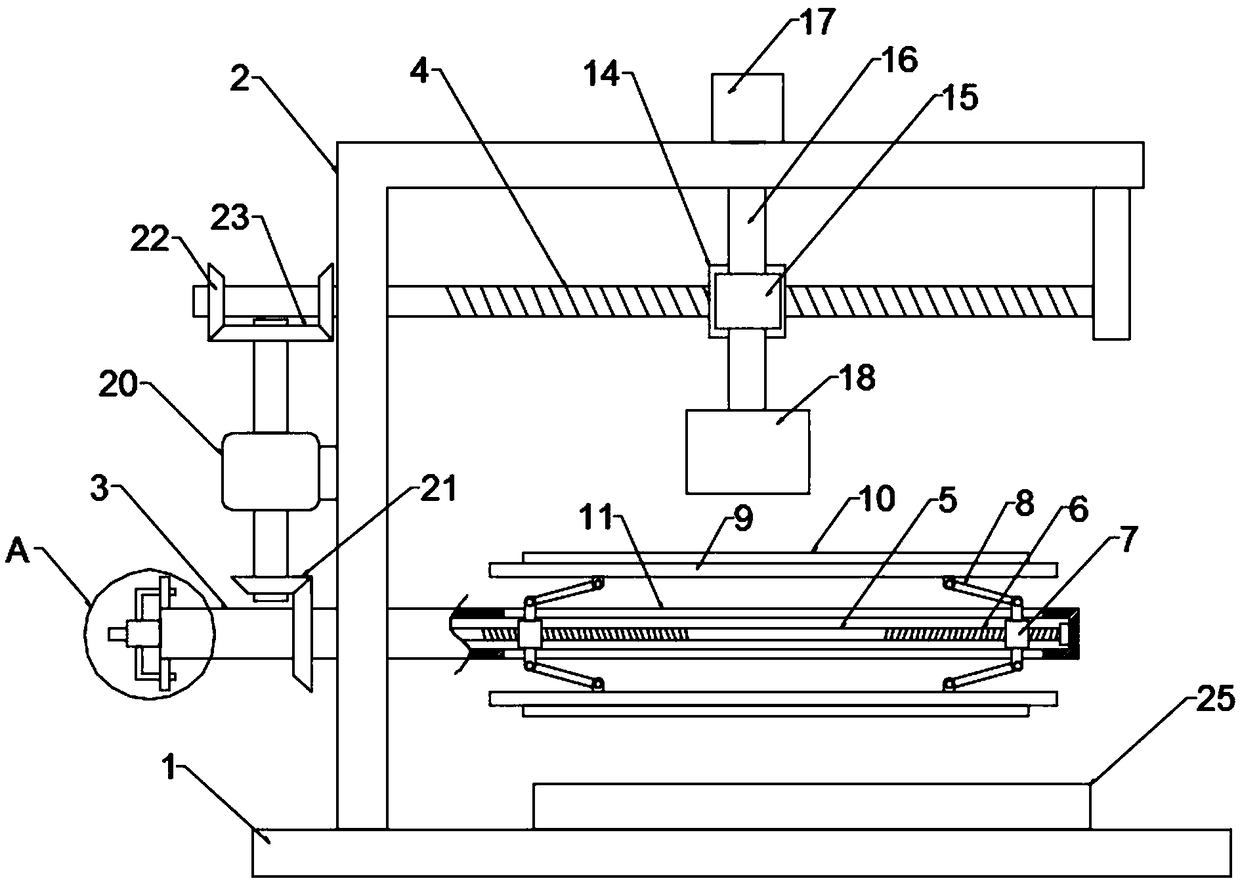

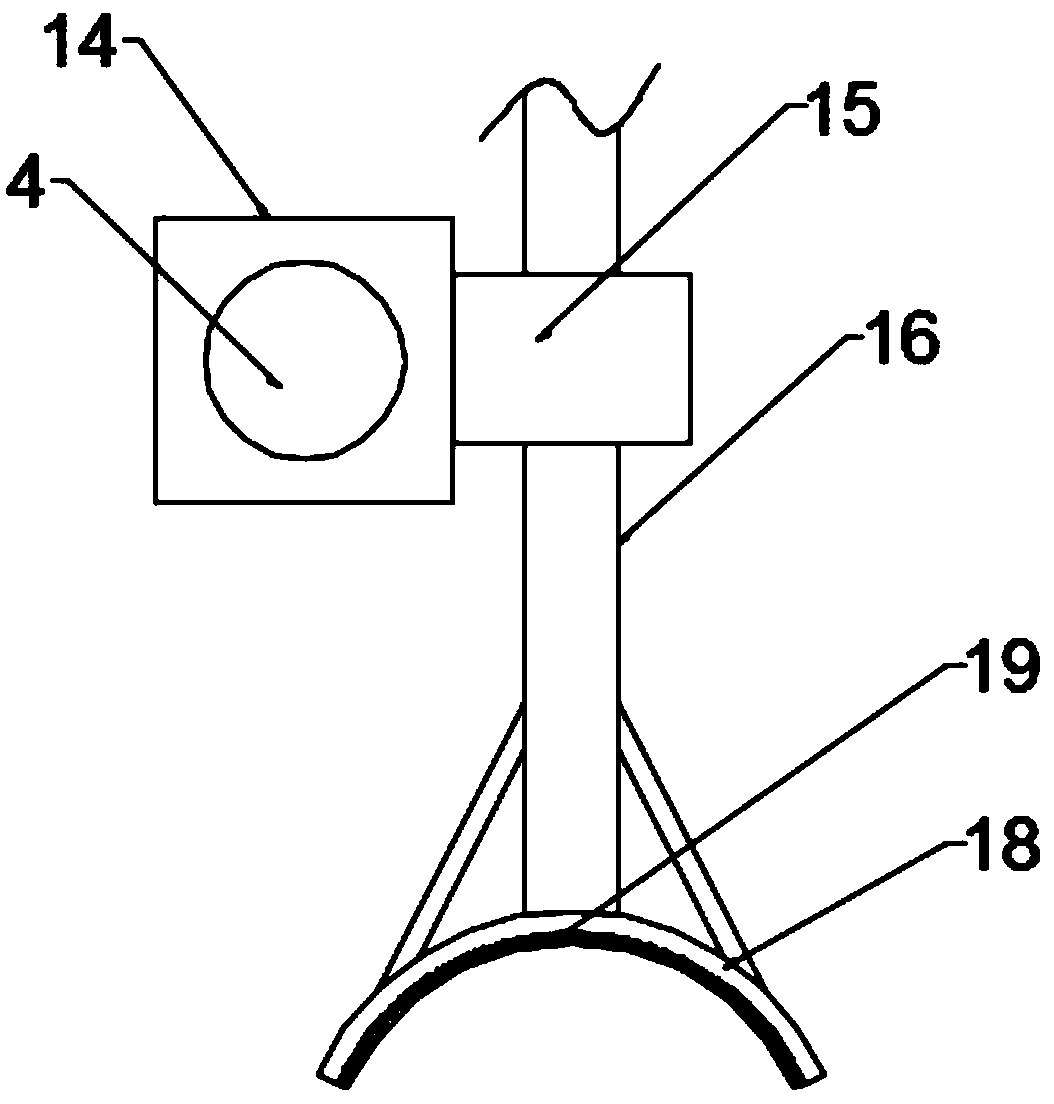

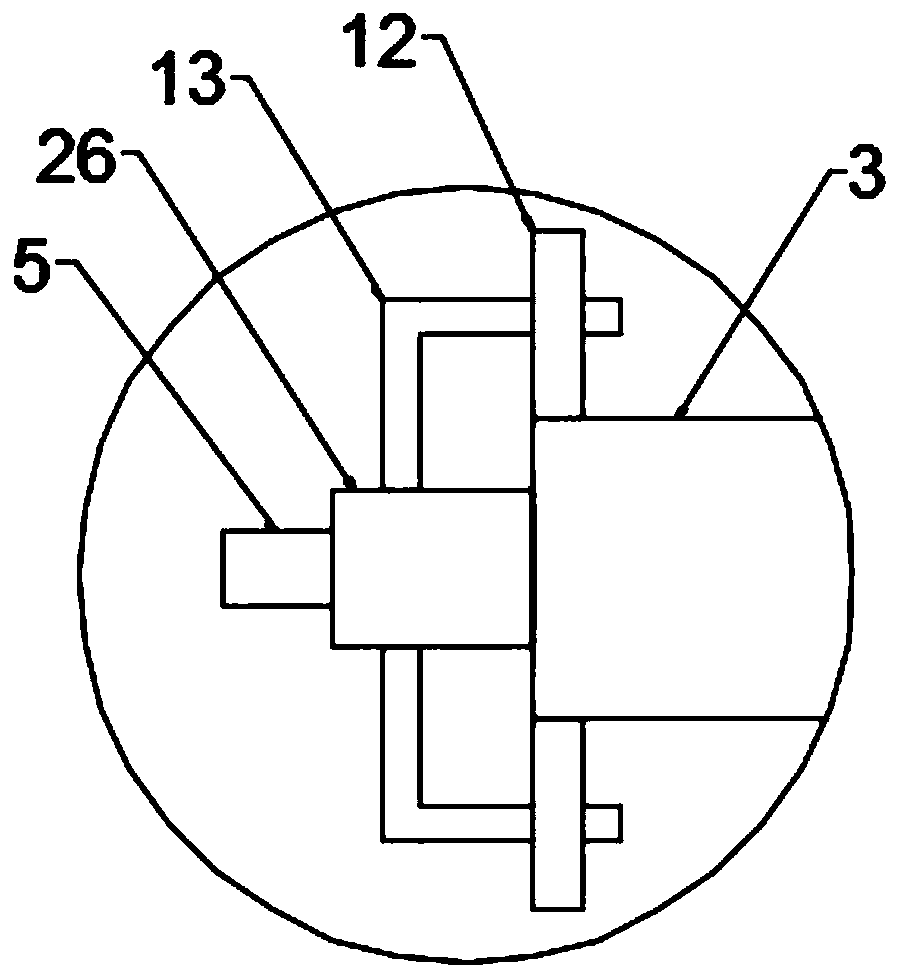

The present invention provides an integrated building artificial stone processing equipment with a reciprocating grinding function, which includes a base, a height adjustment device is fixedly connected to both ends of the base, and a support plate is fixedly connected to the top ends of the two height adjustment devices. The support plate is provided with a moving groove with the opening facing downwards, and the first moving block, the second moving block and the third moving block are arranged in the moving groove from left to right, and the first moving block, the second moving block and the The third moving block is provided with threaded through holes, and the three threaded through holes are jointly threaded with horizontal threaded rods, and the two ends of the horizontal threaded rods are erected at the two ends of the support plate. The invention has the following beneficial effects: it realizes the integrated treatment of grinding, polishing and cleaning, effectively improves the processing efficiency of stone materials, has a high degree of integration, effectively reduces labor input, keeps the operator away from the processing site, and reduces The incidence of occupational diseases among workers has been reduced.

Owner:刘丽

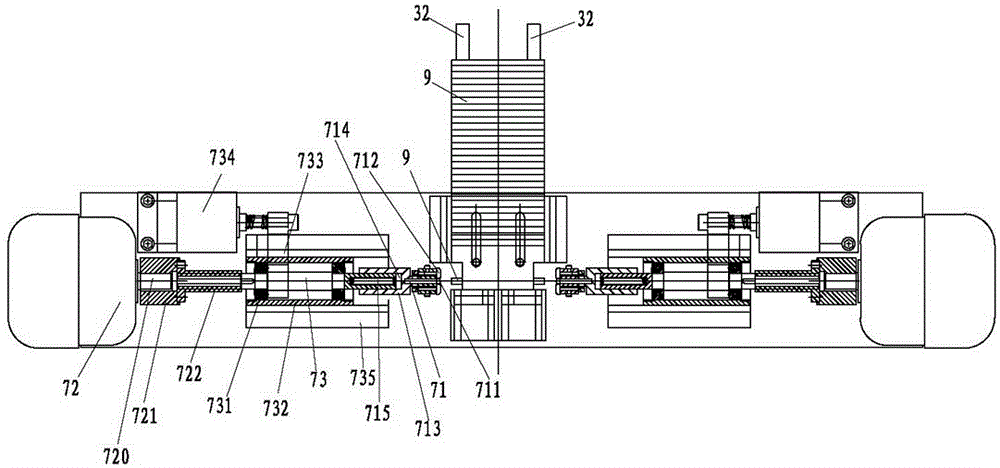

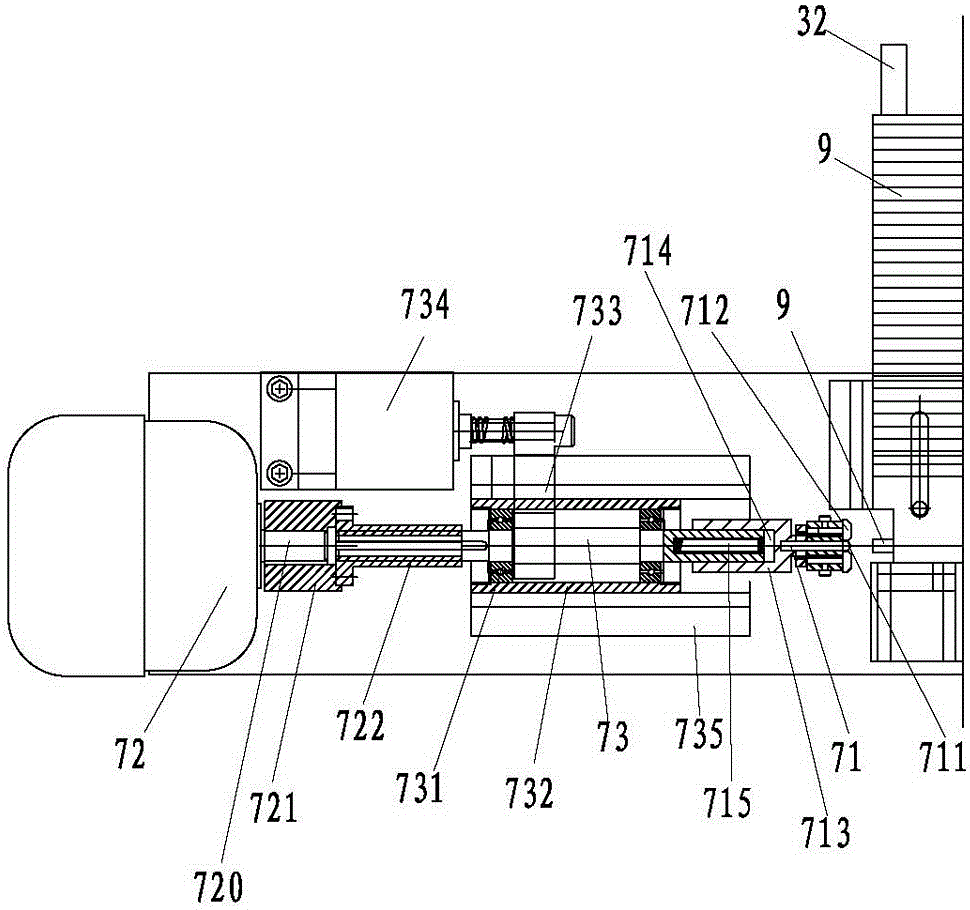

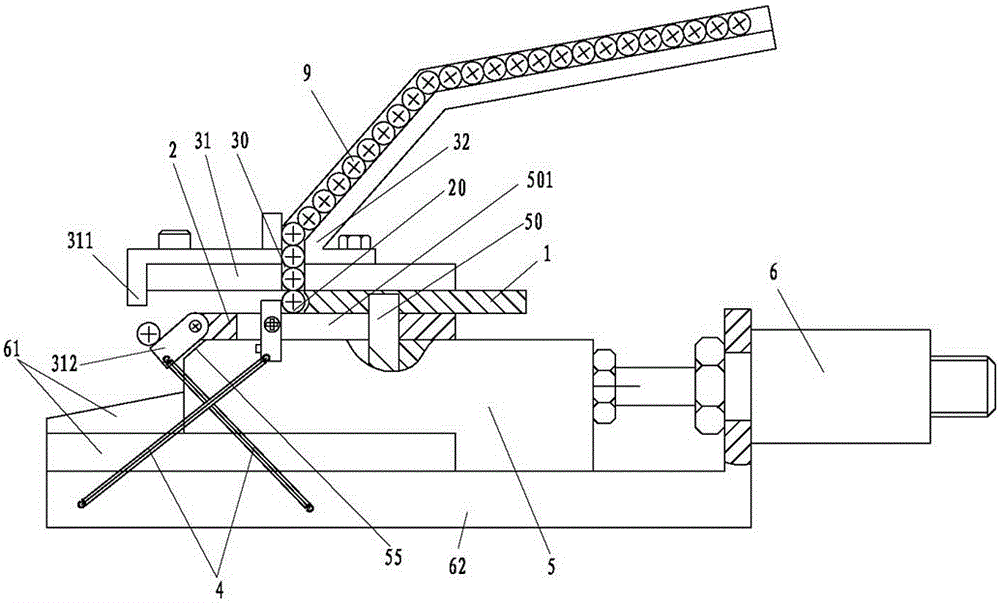

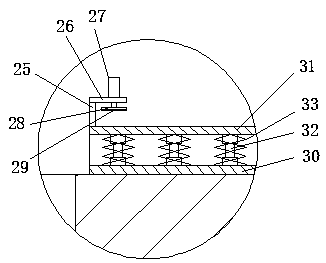

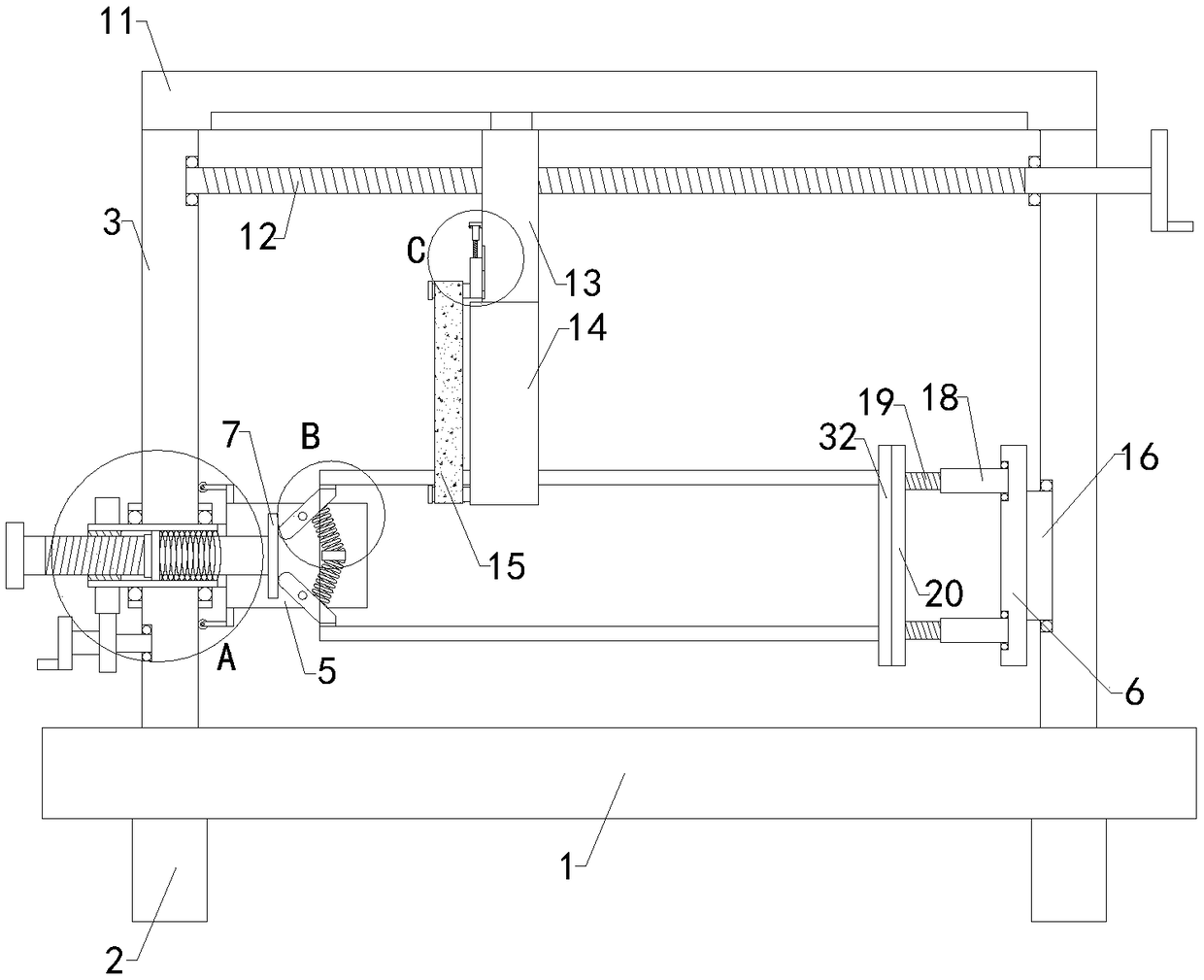

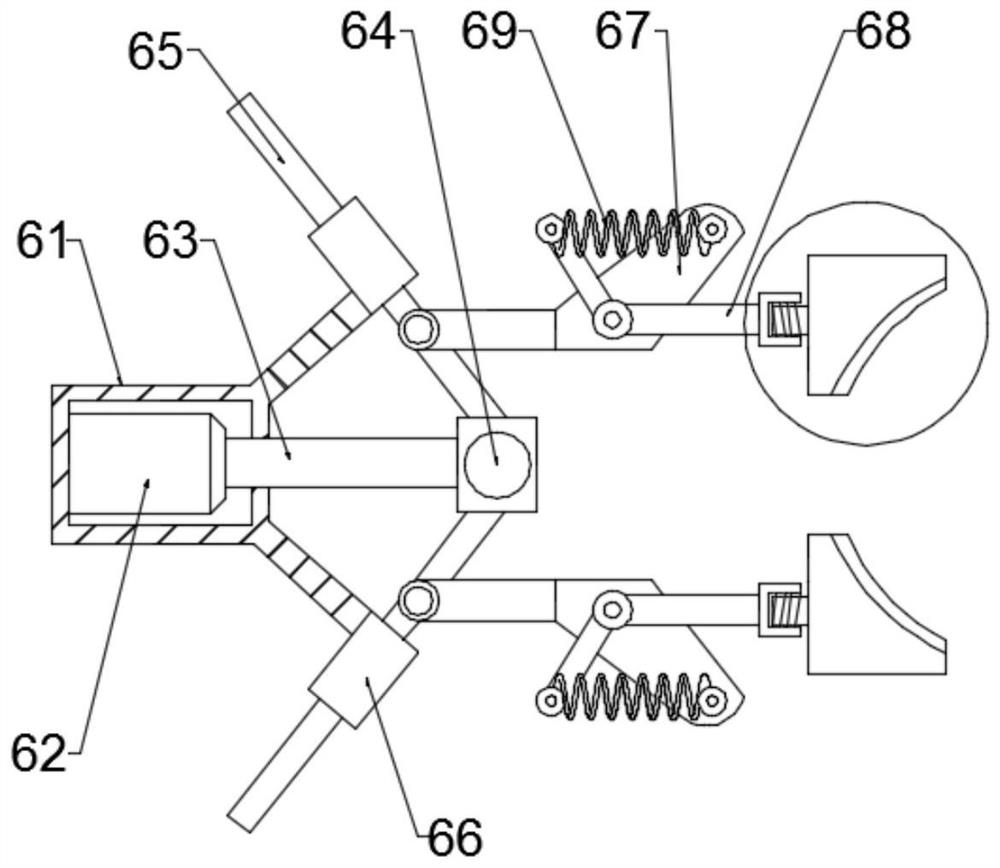

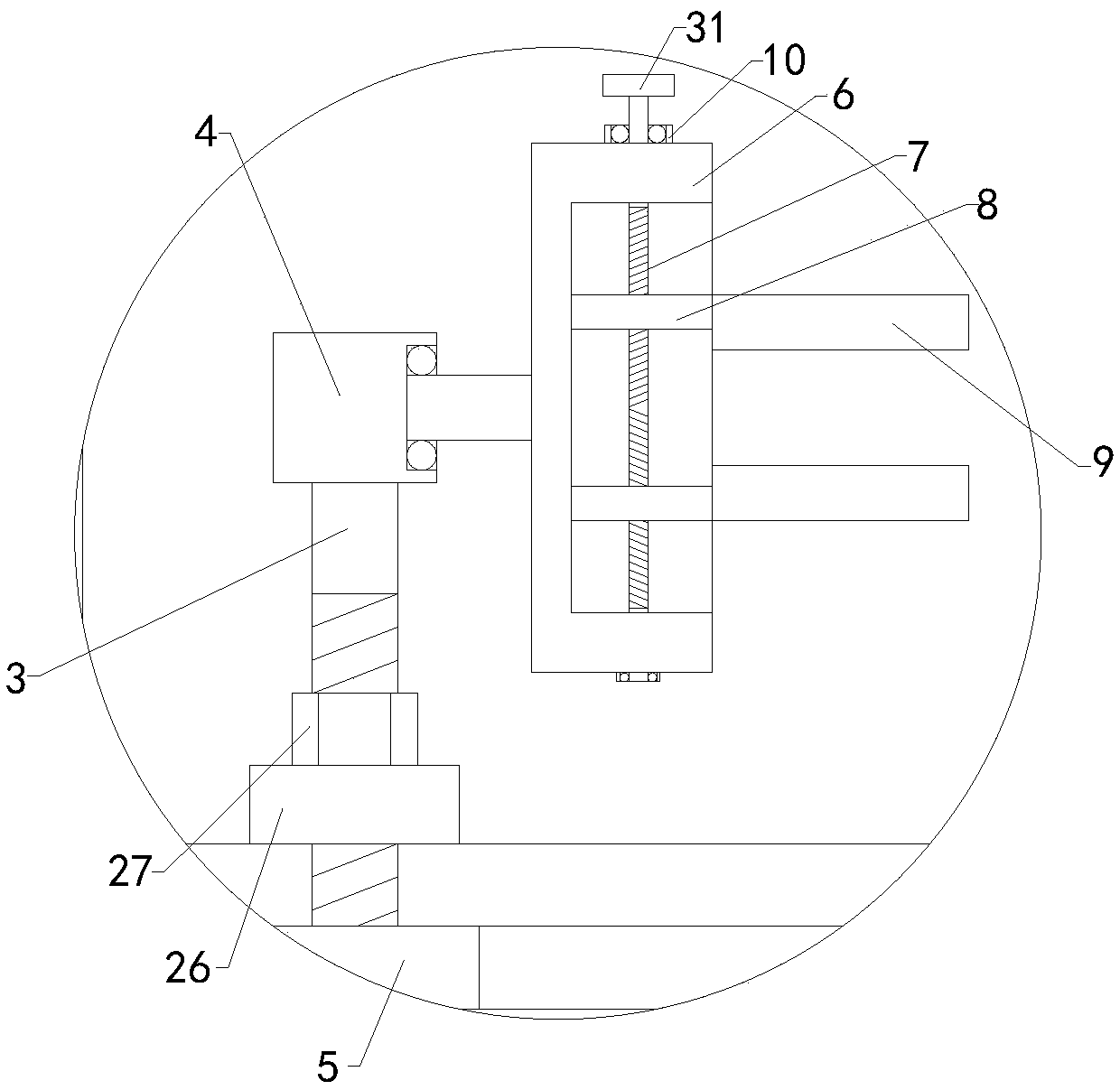

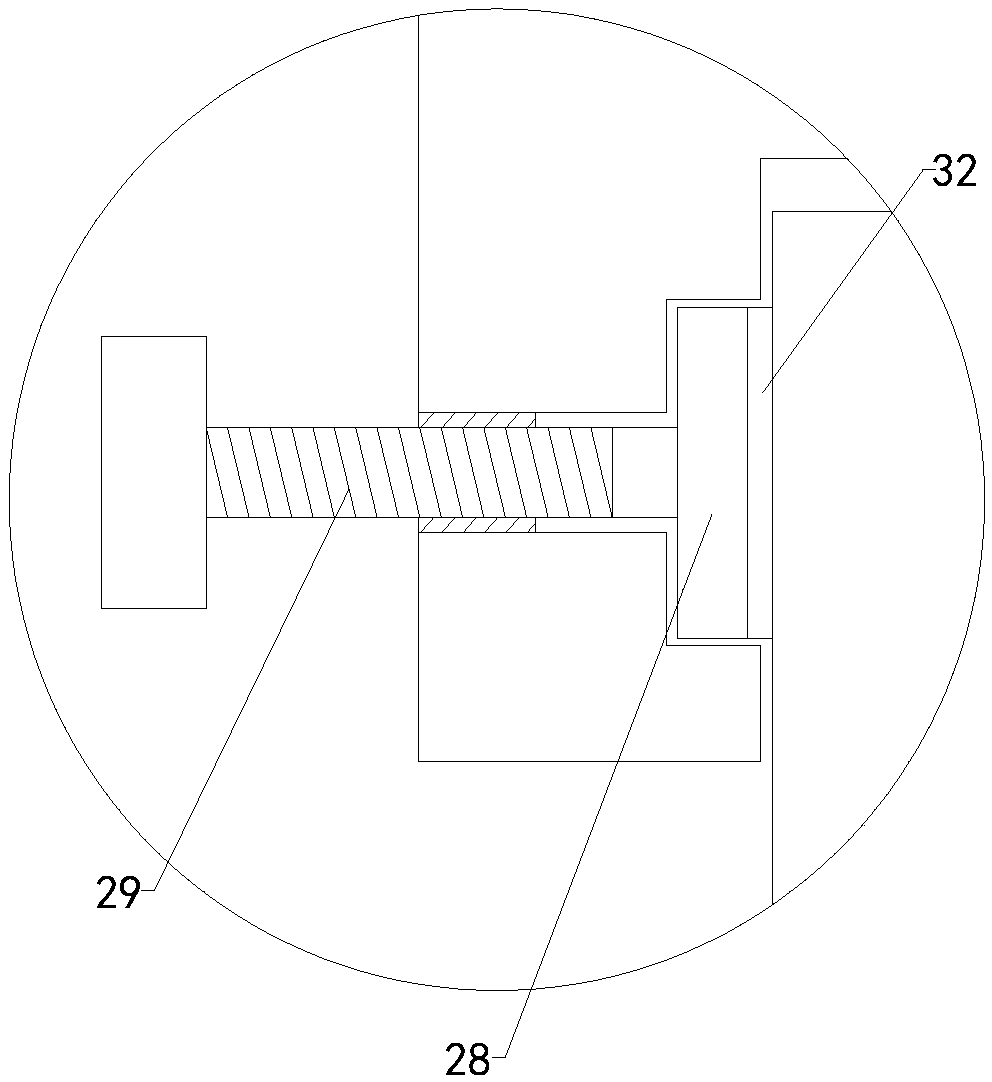

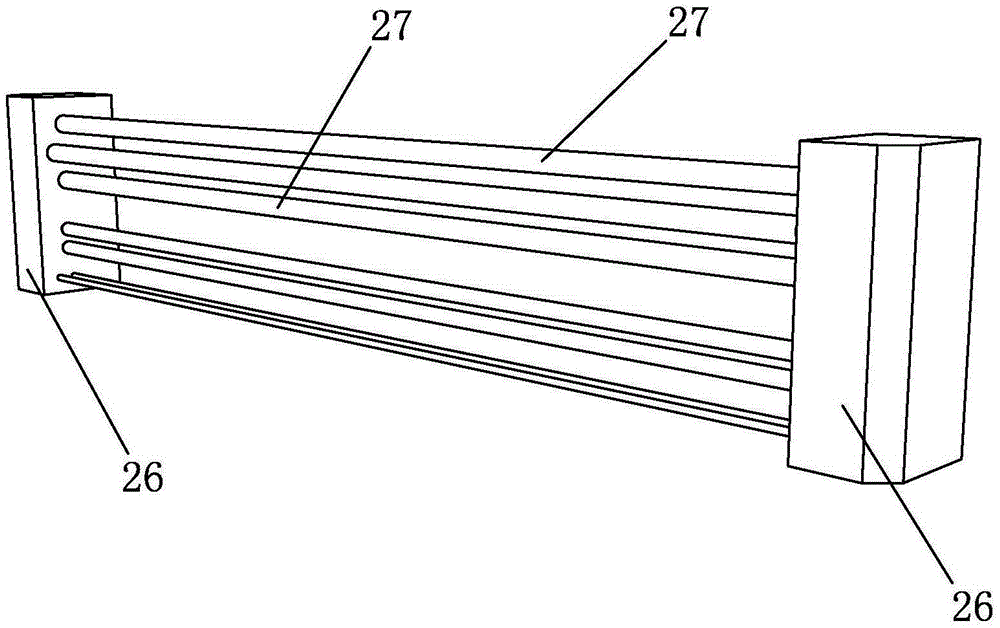

Pipe double-end internal and external chamfering processing apparatus

InactiveCN105108601AImprove mobilityIncrease linkageEdge grinding machinesGrinding feedersElectric machineryEngineering

The invention relates to the technical field of pipe processing equipment, and specifically discloses a pipe double-end internal and external chamfering processing apparatus. The apparatus comprises a feeding mechanism and a pipe double-end internal and external chamfering processing mechanism. The feeding mechanism comprises two feeding devices oppositely arranged on the left and right sides. Each feeding device comprises a feeding plate and a bearing platform, and the bearing platform is provided with an initial falling point from which place the pipe falls. At an initial state, the portion, acting on the pipe, at the front end of each feeding plate is located behind the initial falling point. A front limiting top plate limiting the front part of the pipe is arranged at the position close to the front end of each bearing platform. A discharging plate through which the pipe is supported and discharged is arranged at the front end of each bearing platform. The pipe double-end internal and external chamfering processing mechanism comprises two internal and external chamfering processing devices which are oppositely arranged. Each internal and external chamfering processing device comprises a polishing means including an inner polishing head and an outer polishing head. A motor is arranged on the side, opposite to the pipe, of each polishing means. The pipe double-end internal and external chamfering processing apparatus is safe and stable in operation, high in efficiency and high in fluency, and has good positioning and processing effects.

Owner:ZHEJIANG TENGYUN REFRIGENRATION TECH

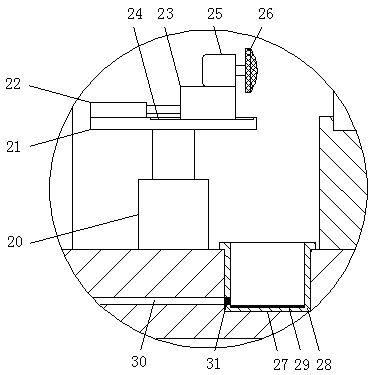

Box shaft hole inner wall grinding device used for speed changing box machining

InactiveCN109015155AReasonable structureInnovative designRevolution surface grinding machinesGrinding/polishing safety devicesEngineeringDrive motor

The invention discloses a box shaft hole inner wall grinding device used for speed changing box machining. The device comprises a base. Supporting frames are mounted on the two sides of the upper endof the base correspondingly. A top plate is mounted at the upper ends of the supporting frames. A driving motor is mounted in the middle of the upper end of the top plate. A driving belt pulley is mounted in the middle of the front end of the driving motor and connected with a driven belt pulley through a belt. The rear end of the driven belt pulley is connected with a rotary cam coaxially. The right end of the rotary cam makes contact with a first guide ball. The right end of the first guide ball is connected with a first limit rod. The right end of the first limit rod is connected with a first limit plate. The right end of the first limit plate is connected with a piston rod. The lower end of the rotary cam makes contact with a second guide ball. The lower end of the second guide ball isconnected with a second limit rod. The lower end of the second limit rod is connected with a second limit plate. The lower end of the second limit plate is connected with a lifting rod. According tothe box shaft hole inner wall grinding device, a grinding head can move up and down along the inner wall of a shaft hole during grinding, and in addition, a gas injection cavity can spray out gas which can be used for blowing away disintegrating slag produced during grinding in time.

Owner:盐城市金发机械厂

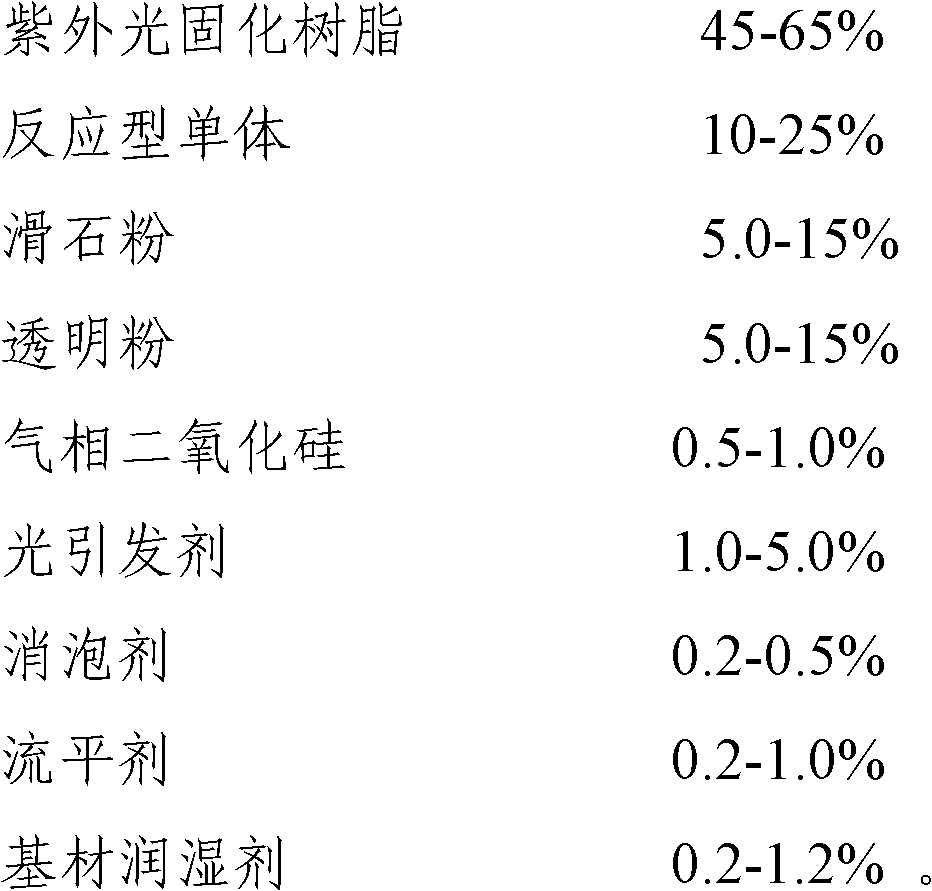

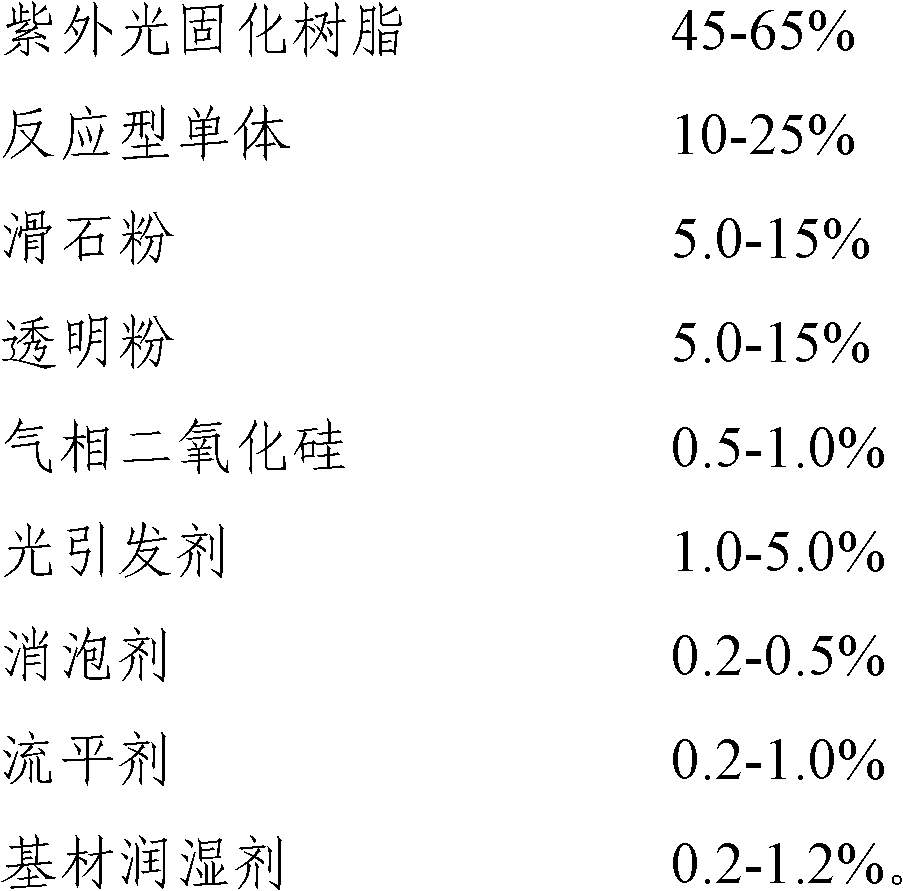

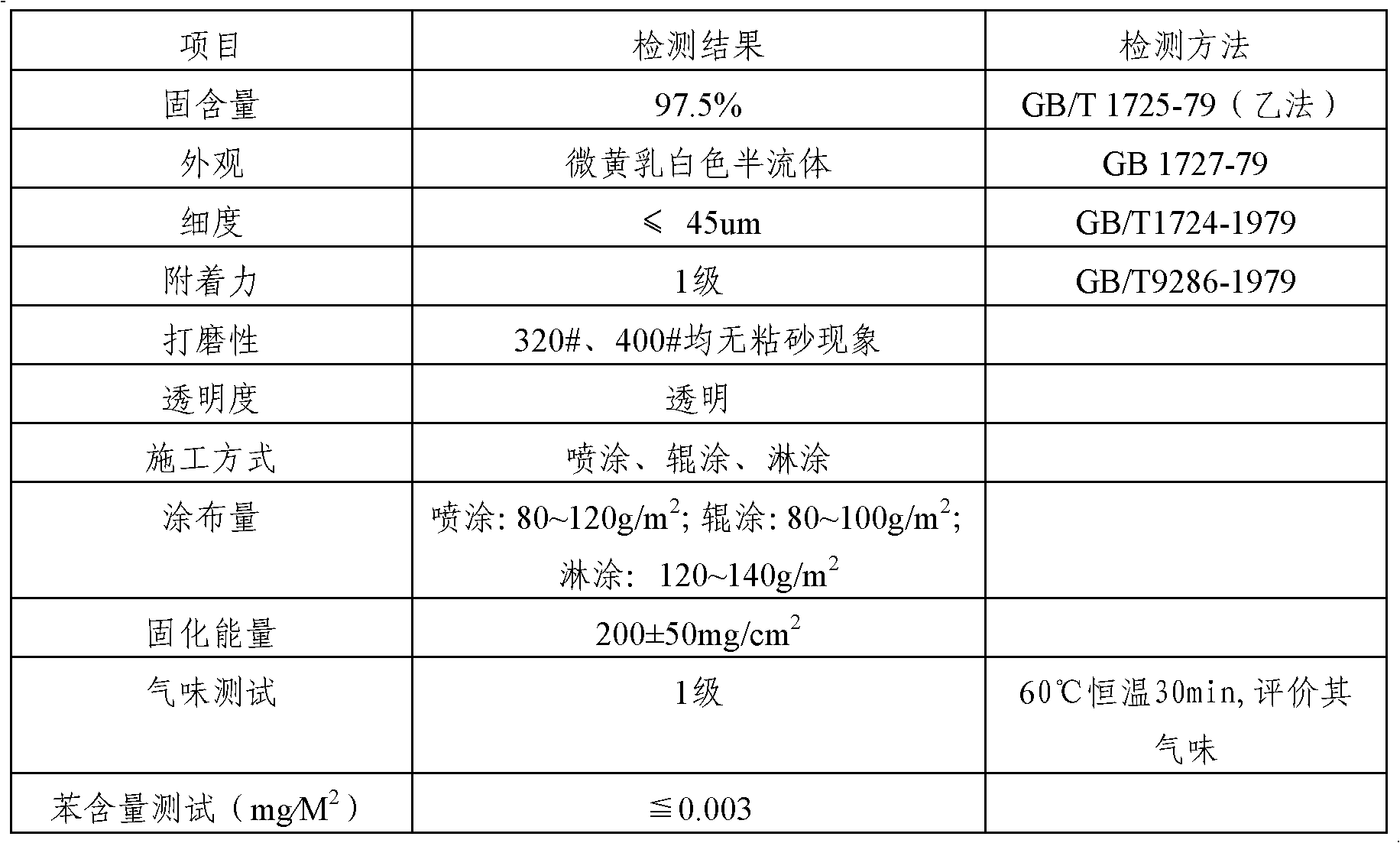

Odorless ultraviolet-curing wood lacquer and preparation method thereof

ActiveCN102352173AEnvironmental protection is goodReduce heavy metal contentEpoxy resin coatingsPolyesterBenzene

The invention relates to an odorless ultraviolet-curing wood lacquer and a preparation method thereof. The wood lacquer is prepared from the following components in percentage by weight: 45-65% of ultraviolet-curing resin, 10-25% of reactive monomer, 5.0-15% of talcum powder, 5.0-15% of transparent powder, 0.5-1.0% of gas-phase silicon dioxide, 1.0-5.0% of photoinitiator, 0.2-0.5% of defoaming agent, 0.2-1.0% of leveling agent and 0.2-1.2% of wetting agent. The odorless ultraviolet-curing wood lacquer does not have irritating odor before and after construction, does not contain benzene, and can be used immediately after construction; and meanwhile, the surface effect and fullness are not inferior to those of nitrocellulose dope, unsaturated paint or polyester paint.

Owner:QINGDAO ZHANCHEN NEW MATERIAL

Efficient polishing device used for metal casting machining and polishing method of efficient polishing device

InactiveCN110125754AReduce the impactAvoid influenceEdge grinding machinesGrinding drivesSlide plateEngineering

The invention discloses an efficient polishing device used for metal casting machining and a polishing method of the efficient polishing device. The efficient polishing device comprises a machine body. An installation cavity is formed in the bottom end of the machine body. A rotation motor is installed in the installation cavity. The output end of the rotation motor is fixedly connected with a work table. The work table is installed at the bottom end in the machine body in a rotating manner. Clamping devices which are symmetrically distributed are arranged on the left side and the right side of the top end of the work table. A lead screw, a stop piece and a slippage motor are sequentially arranged at the top end in the machine body from left to right. The left end of the lead screw is connected with the side wall in the machine body in a rotating manner, and the right end of the lead screw penetrates through the stop piece and is connected to the output end of the slippage motor. A slide block is installed on the lead screw. A slide plate is fixedly arranged at the bottom end of the slide block. A lifting cylinder is installed at the bottom end of the slide plate. By means of the efficient polishing device and the polishing method, castings can be conveniently polished, chippings can be collected during polishing, processing is facilitated, influences of vibration on the polishing effect during polishing are reduced, and the product quality is improved.

Owner:昆山鑫启盛精密配件有限公司

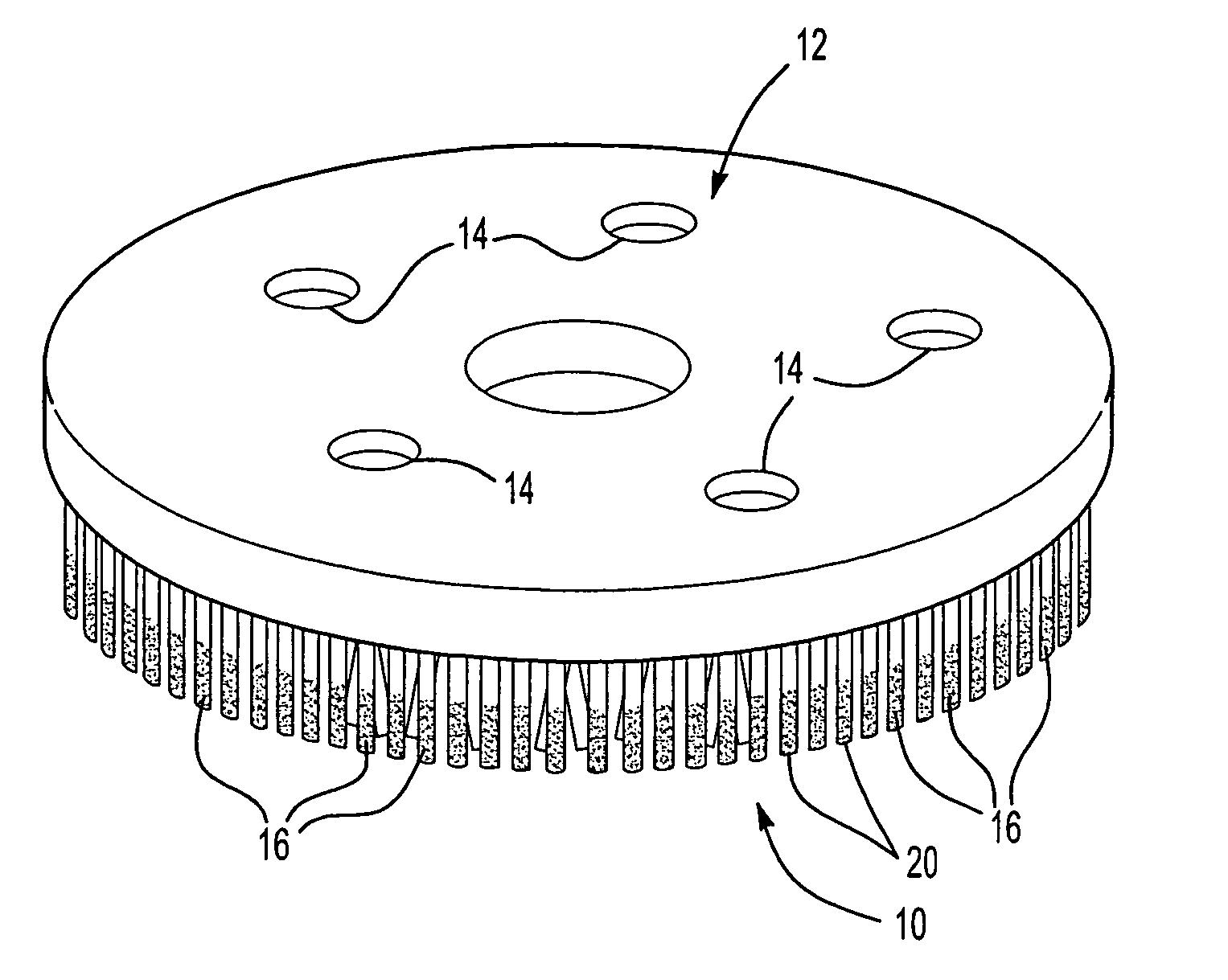

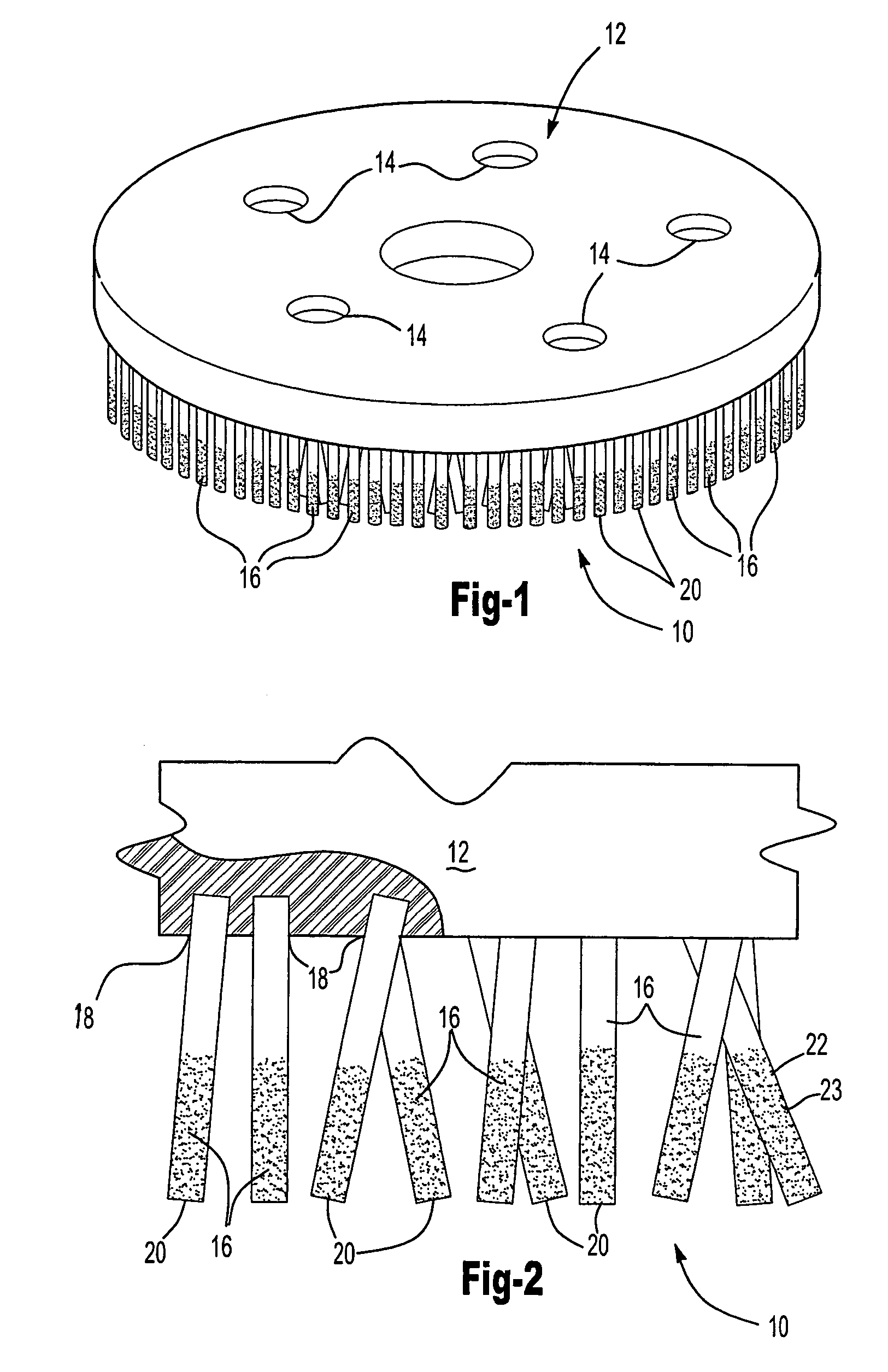

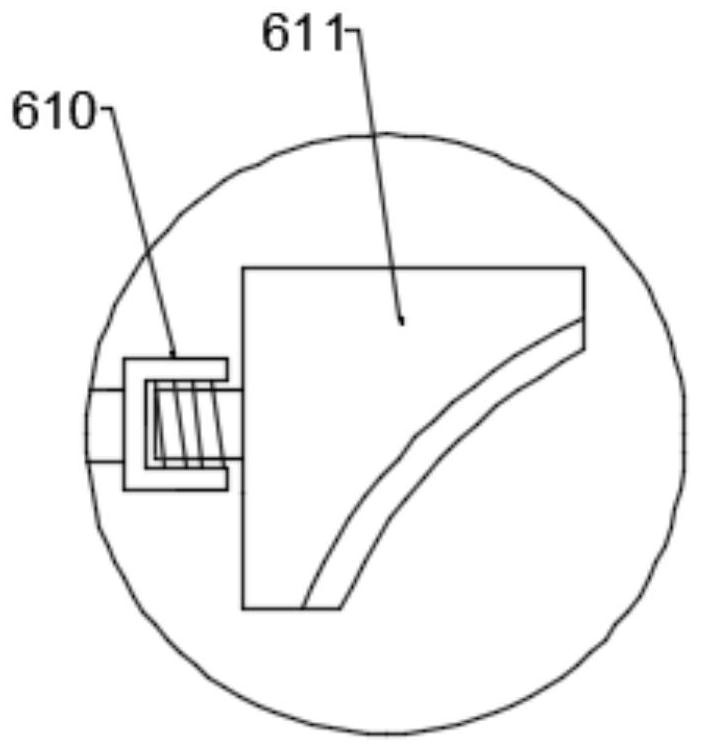

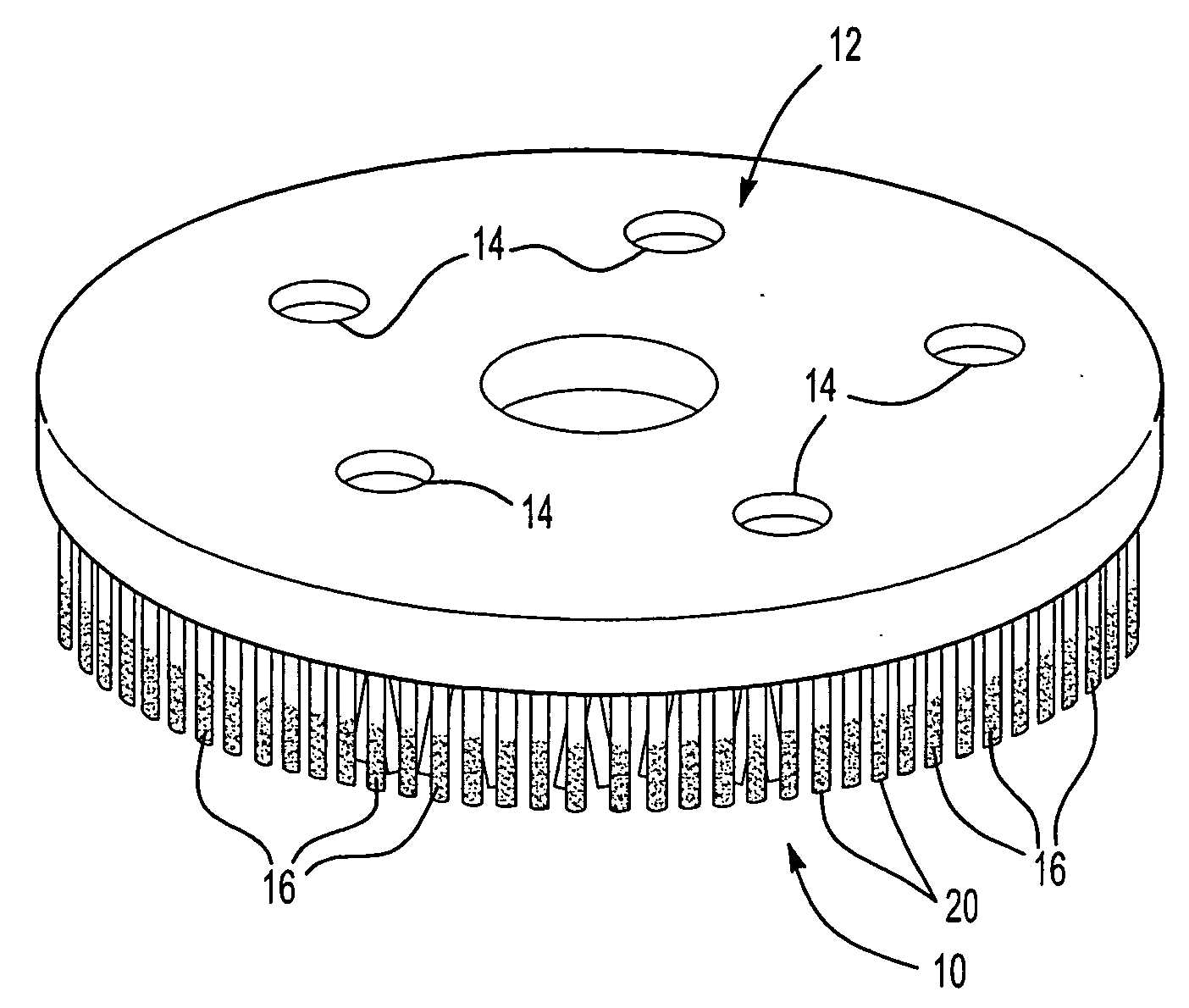

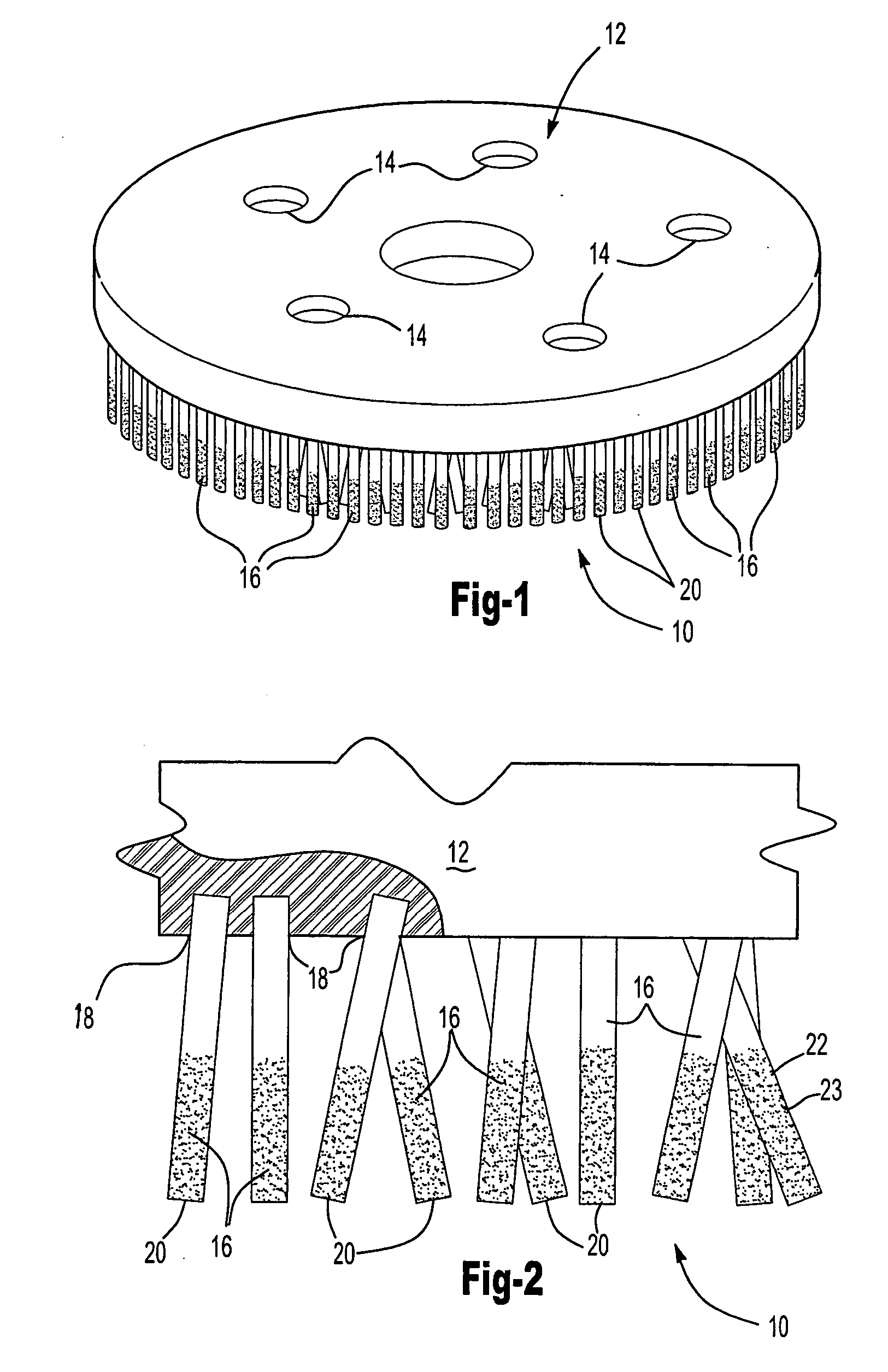

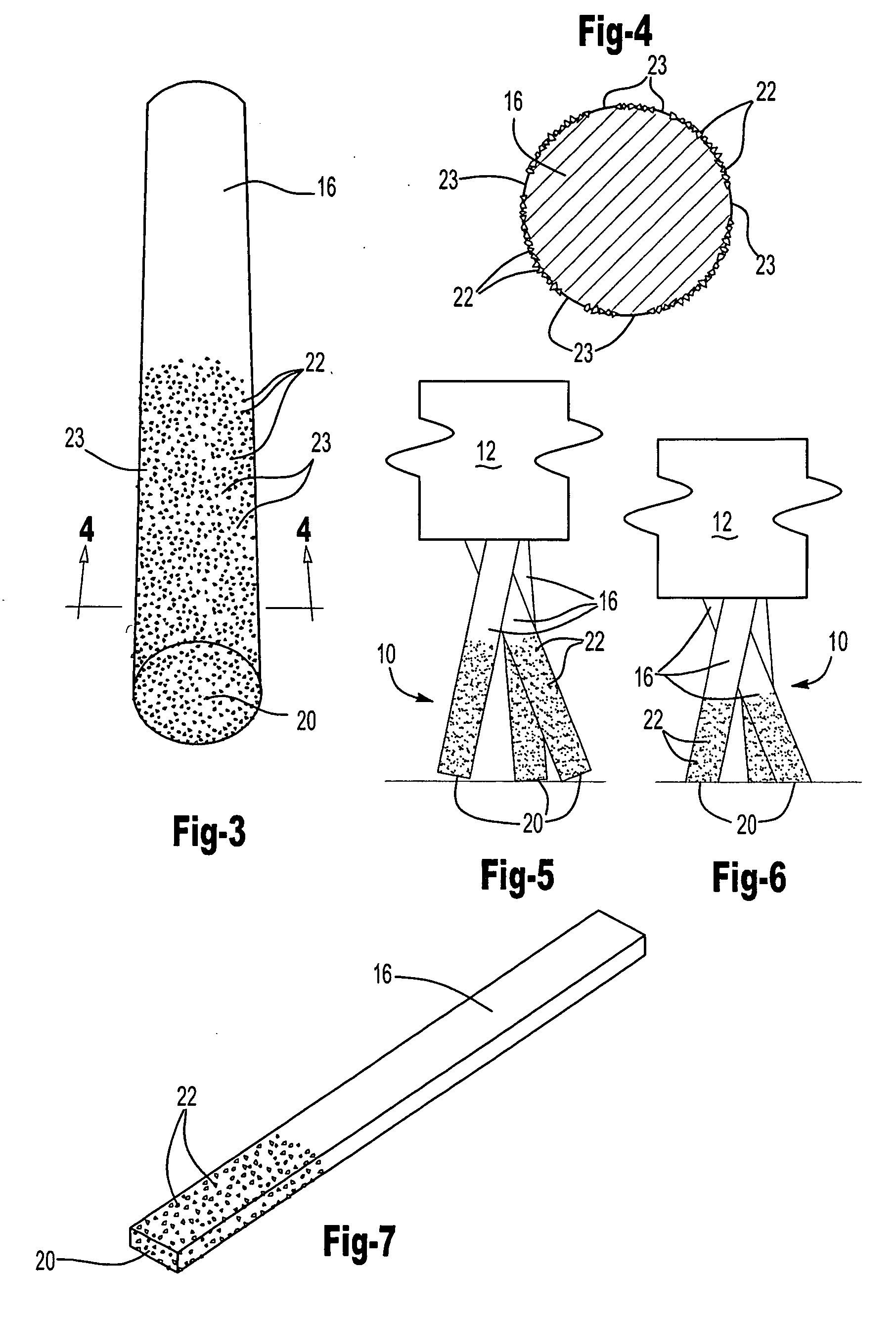

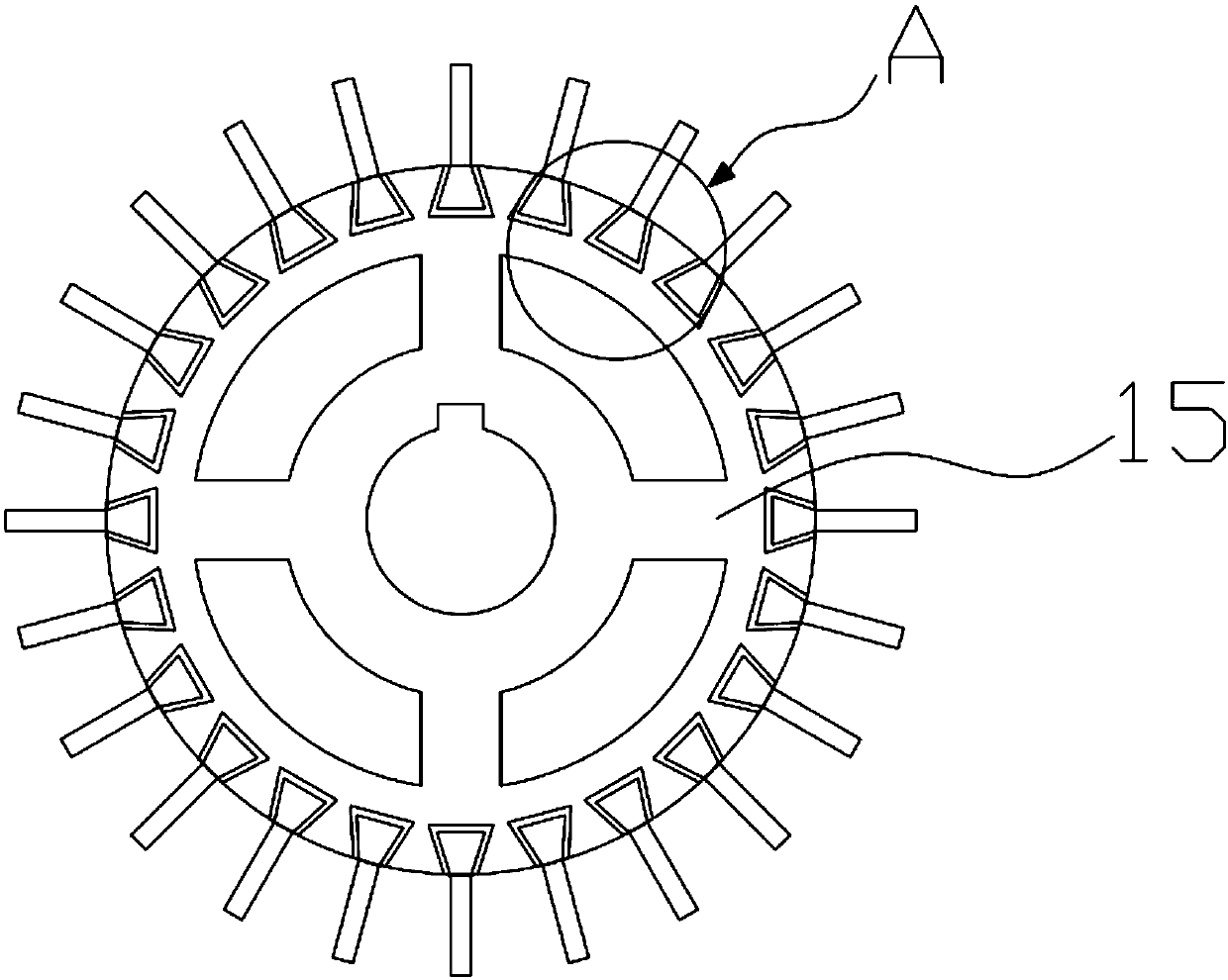

Bristle brush for concrete sanding

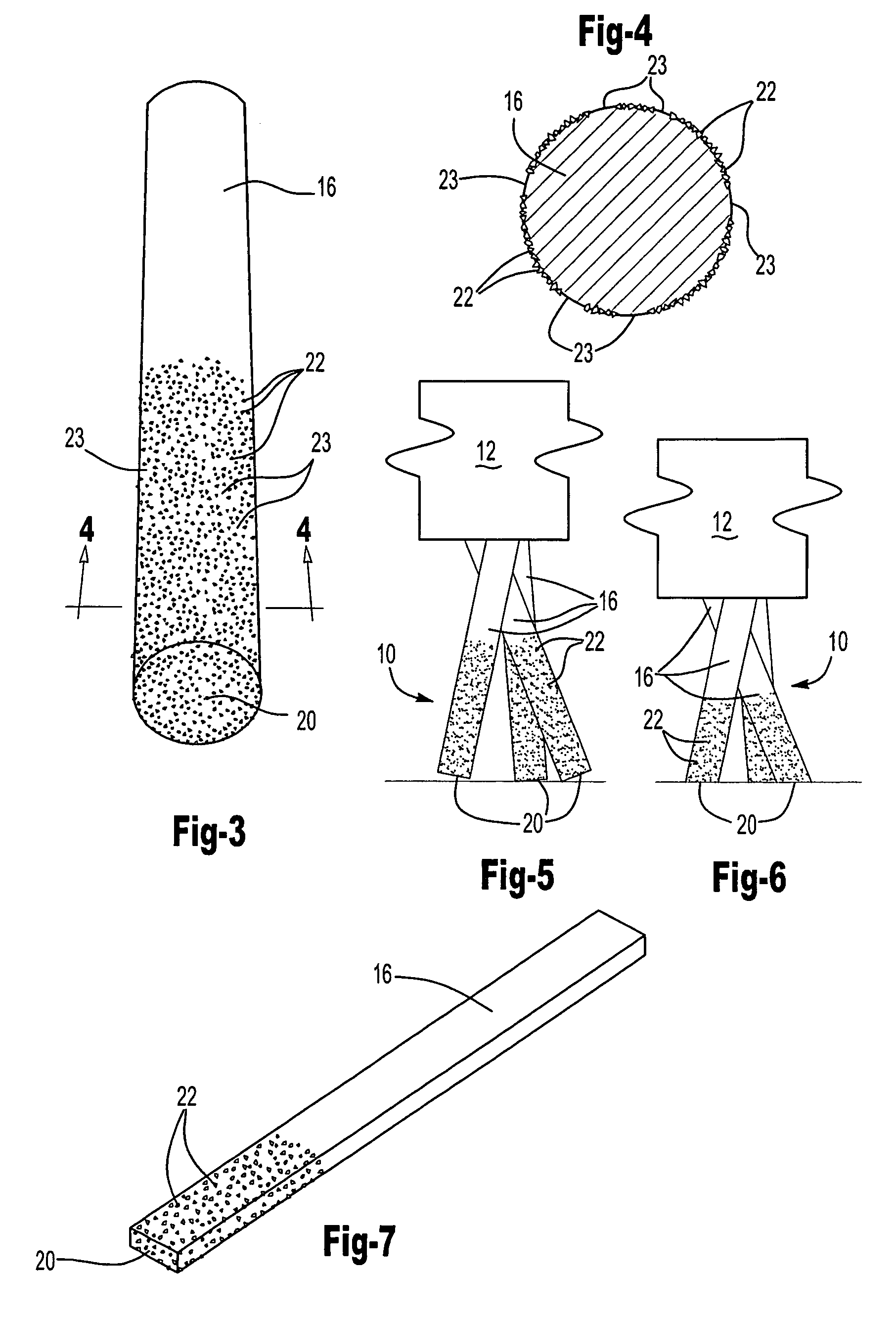

ActiveUS7081047B2Improve sanding effectStay flexibleGrinding machine componentsBrush bodiesSanderBristle

A brush or pad (10) for a power sander for sanding surfaces includes a base (12) for mounting onto a power sander and a plurality of depending bristles (16) with the bristles having a plurality of hard particles (22), for example diamonds particles of grit 70 size, brazed or otherwise secured onto the bristle surface such that as the bristle wears down, new particle surfaces are exposed at the distal end (20) of the bristle to maintain sanding performance of the brush. The particles (22) may be spot brazed in steel with a brazing alloy to retain flexibility of the steel bristle.

Owner:DIAMABRUSH

Grinding device for production of automobile brake disc

ActiveCN107649990AEasy to fixAvoid offsetGrinding carriagesGrinding drivesEngineeringGrinding process

The invention discloses a grinding device for production of an automobile brake disc, and relates to the technical field of automobile parts. The grinding device comprises an outer frame, and a transverse plate is fixedly connected between the two sides of the inner wall of the outer frame; a first motor is fixedly connected to the bottom of the outer frame, and one end of an output shaft of the first motor penetrates through the outer frame and extends to the interior of the outer frame; and a first conical gear is fixedly connected to the end, located at the interior of the outer frame, of the output shaft of the first motor, and second conical gears are engaged with the two sides of the first conical gear. According to the grinding device for production of the automobile brake discs, the purpose of convenient fixing of the brake disc is achieved, the grinding device is convenient to use for people, offset of the brake disc in the grinding process is prevented, the grinding effect isimproved, spacing of two grinding heads can be adjusted so that the grinding device can be suitable for the brake discs with different diameters; and the height of a grinding disc can be adjusted according to needs, controlling of the grinding thickness is facilitated, and different grinding effects can be obtained

Owner:烟台美丰机械集团有限公司

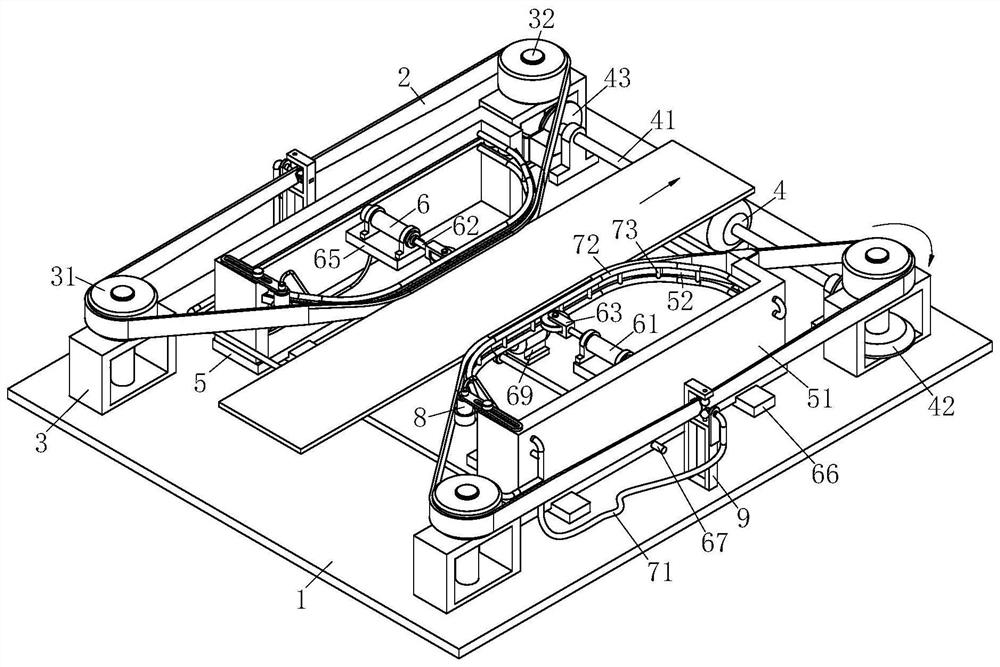

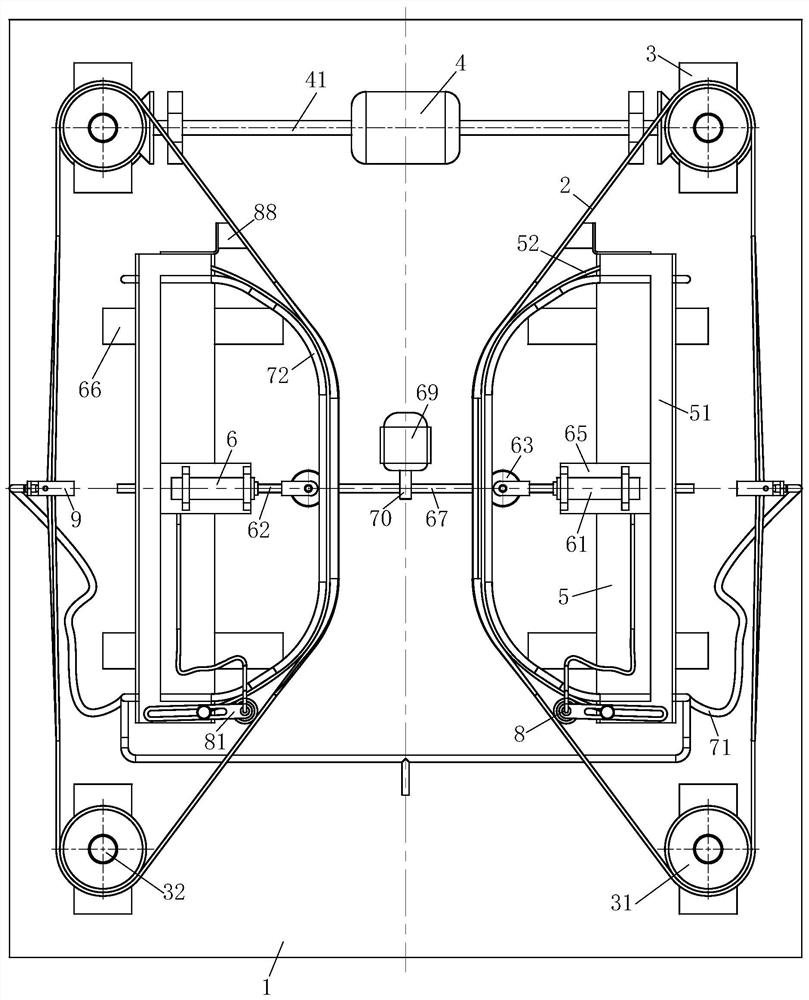

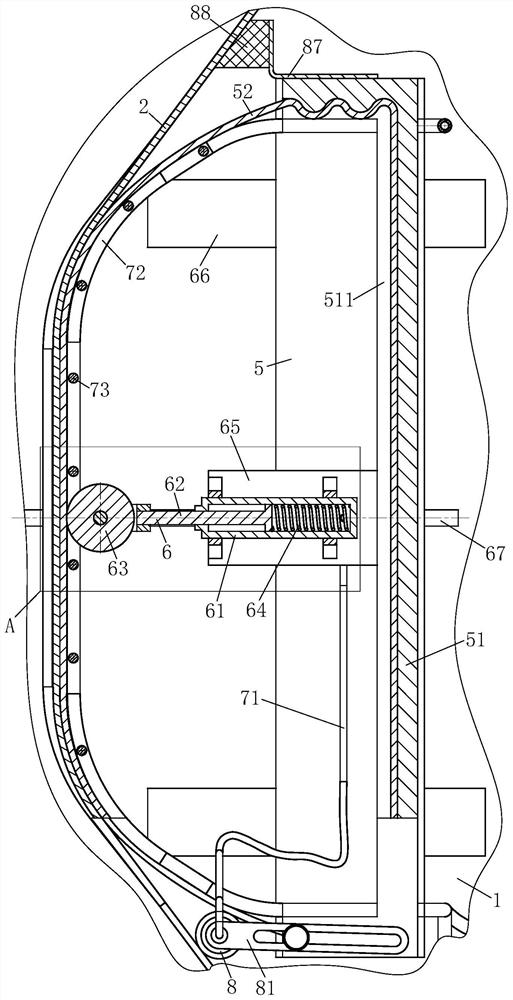

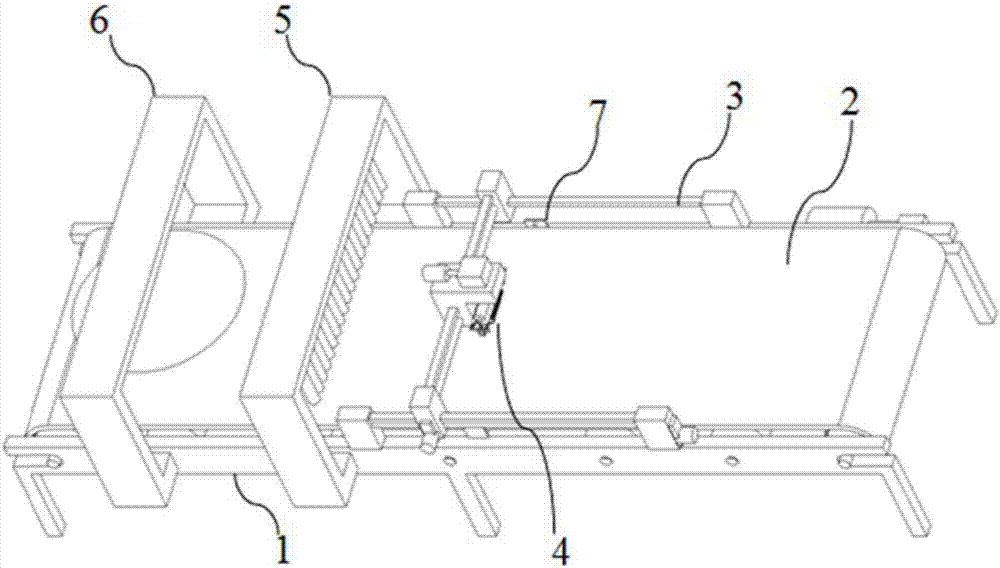

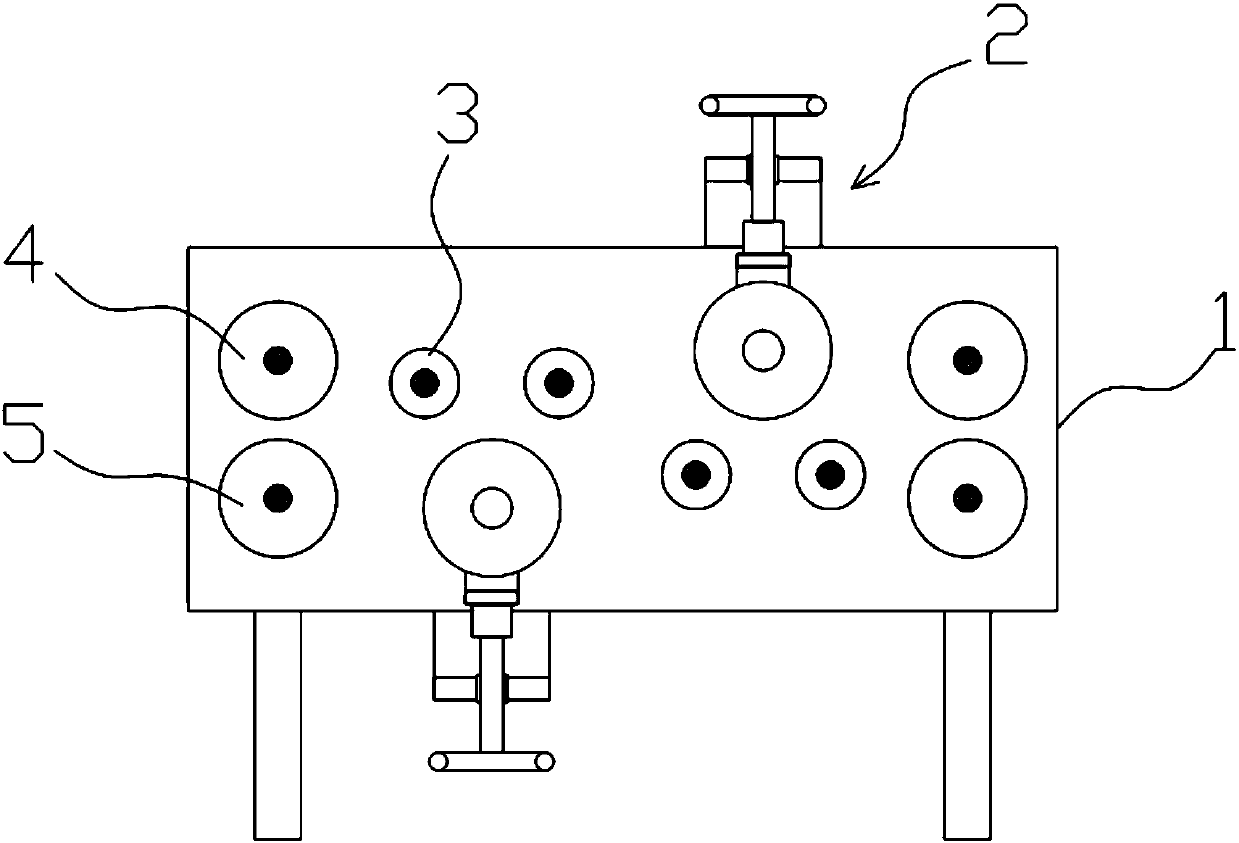

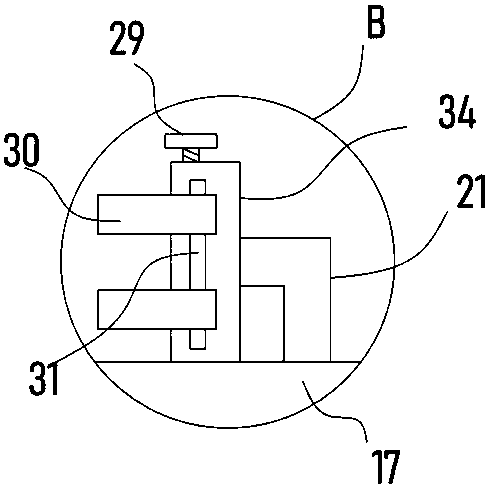

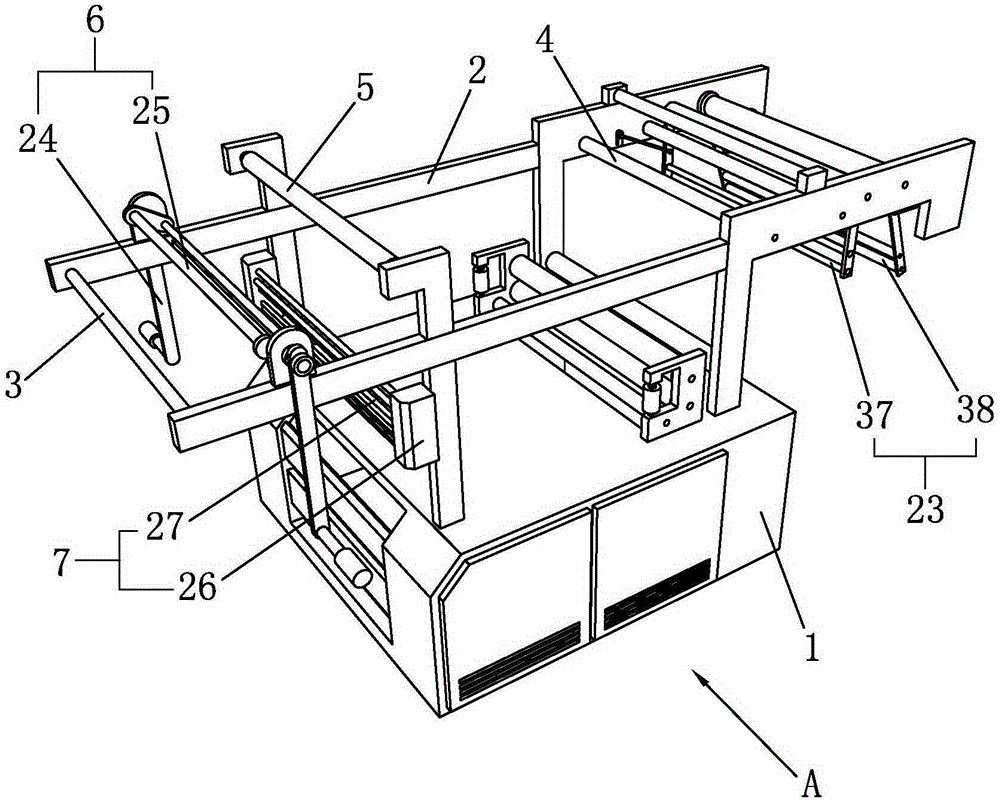

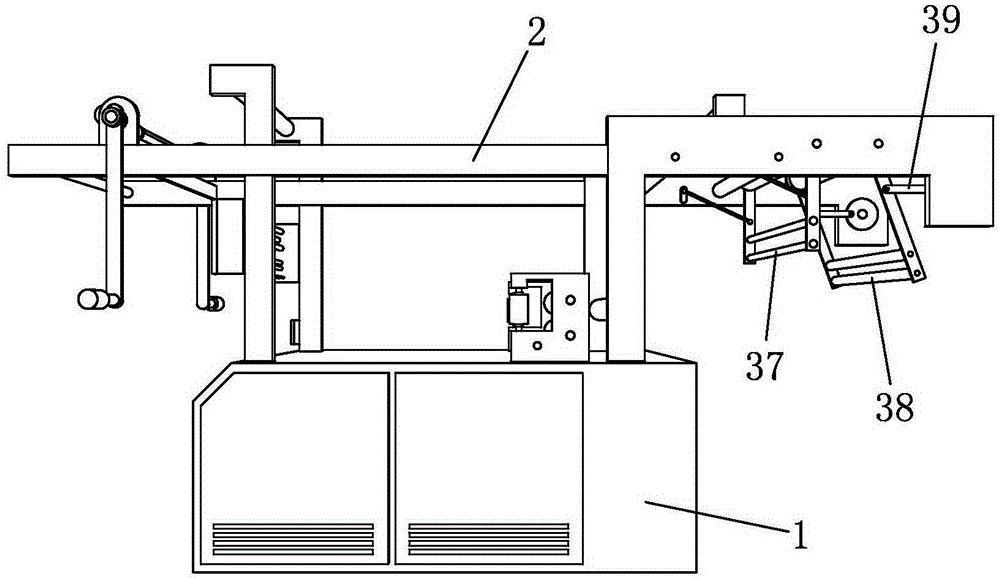

Continuous production equipment

InactiveCN107263230ASimple structureEasy to useEdge grinding machinesPlane surface grinding machinesEngineeringMachining

The invention discloses continuous production equipment. The continuous production equipment is used for machining metal plates and at least comprises a machining table, guide tracks, a machining plate, a driving mechanism, a clamping portion and a machining portion. The guide tracks are horizontally mounted on the machining table, the machining plate is mounted on the guide tracks in a sliding mode, and the driving mechanism is used for driving the machining plate to move in the length direction of the guide tracks. The clamping portion comprises a plurality of clamping mechanisms and first gear racks, and the multiple clamping mechanisms are arranged in sequence in the length direction of the guide tracks. Each clamping mechanism comprises a supporting shaft, a bottom plate, a first gear, supporting plates, screw rods and pressing plates, wherein the supporting shaft is vertically mounted on the machining plate; the bottom plate is horizontally and rotationally mounted on the supporting shaft; the first gear is mounted on the bottom plate, and the center line of the first gear coincides with the center line of the supporting shaft; the supporting plates are arranged horizontally and connected with the bottom plate; threaded holes are formed in the supporting plates; and the screw rods are disposed in the threaded holes and matched with the threaded holes.

Owner:铜陵市得盛机电制品有限责任公司

Circular tube polishing device for metalworking

InactiveCN108747738AEasy to fixImprove clamping effect poorBelt grinding machinesGrinding work supportsMetalworkingDrive shaft

The invention relates to the technical field of metalworking accessory devices, in particular to a circular tube polishing device for metalworking. The circular tube polishing device can improve the poor clamping effect for the metal circular tube, can fix the metal circular tube well, improve the use reliability, does not need to manual sandpaper using for polishing, improves the polishing effect, improves the polishing efficiency, and improves the practicality. The circular tube polishing device includes a bottom plate and four supporting legs, the top ends of the four supporting legs are connected with the front left side, the back left side, the front right side and the back right side of the bottom end of the bottom plate respectively, and the circular tube polishing device includes aleft side plate, a right side plate, an adjusting casing, a fixing plate, a first clamping plate, a pushing plate, a pushing column, an adjusting screw, an upper swivel clip and a lower swivel clip;and a handle is arranged at the left end of the adjusting screw, the circular tube polishing device further includes a top plate, an adjusting lead screw, a moving block, a front supporting plate, a back supporting plate, a polishing belt, a rotating shaft and a driving shaft, the top ends of the left side plate and the right side plate are respectively connected with the left and right sides of the bottom end of the top plate, and a second hand wheel is arranged at the left end of the driving shaft concentrically.

Owner:太仓市凯润尔展示器材有限公司

Grinding belt type strip steel side edge burr removing device

InactiveCN112059852AImprove cleaning efficiencyImprove flatnessBelt grinding machinesGrinding/polishing safety devicesDrive shaftElectric machinery

The invention belongs to the technical field of strip steel manufacturing, and particularly relates to a grinding belt type strip steel side edge burr removing device. The grinding belt type strip steel side edge burr removing device comprises a bottom plate, a grinding belt, a supporting seat, a belt wheel, a rotating shaft, a double-head motor, a transmission shaft, a first bevel gear, a secondbevel gear, a supporting plate, a supporting block, an arc-shaped elastic ring and an elastic supporting mechanism. According to the grinding belt type strip steel side edge burr removing device, thearc-shaped elastic ring is arranged on the inner side of the grinding belt, when the strip steel side edge burrs are removed, the arc-shaped elastic ring deforms, the grinding belt is tightly attachedto the side wall of the strip steel under the elastic force effect of the arc-shaped elastic ring, the situation that the grinding belt makes intermittent contact with the side wall of the strip steel due to vibration generated during rotation of the grinding belt is avoided, the situation that the burrs on the side wall of the strip steel are not completely removed is avoided, and meanwhile, theflatness degree of the edge of the strip steel is improved; and the elastic supporting mechanism is arranged, the middle of the contact part of the arc-shaped elastic ring and the grinding belt is prevented from protruding towards the interior of the arc-shaped elastic ring, the situation that the grinding belt does not make contact with the strip steel is avoided, the contact surface of the grinding belt and the side wall of the strip steel is increased, and the burr removing efficiency is improved.

Owner:王后连

Lightweight anti-abrasion steel casting piece edge polishing device and edge polishing method thereof

InactiveCN110125753AAvoid damageStable jobEdge grinding machinesGrinding drivesMetallurgySteel casting

The invention discloses a lightweight anti-abrasion steel casting piece edge polishing device and an edge polishing method thereof. The lightweight anti-abrasion steel casting piece edge polishing device comprises a base; a workbench is fixedly arranged at the top end of the base and internally provided with a rotary device; the top end of the rotary device is provided with a rotary table, and therotary table is rotationally installed at the top end of the workbench; the left side and the right side of the top end of the base are provided with symmetrically-distributed supporting columns, thetop ends of the supporting columns are fixedly provided with a top plate, and the top plate is provided with a fixing device; the fixing device is arranged over the rotary table; the top end of the base is provided with a polishing device, a cooling device is arranged above the polishing device, and the cooling device is fixed to the top plate and located between the polishing device and the rotary table. The lightweight anti-abrasion steel casting piece edge polishing device can conveniently polish casting pieces, is high in polishing quality and good in polishing effect, and can conduct centralized processing on chippings generated during polishing, and cleaning is convenient.

Owner:昆山鑫启盛精密配件有限公司

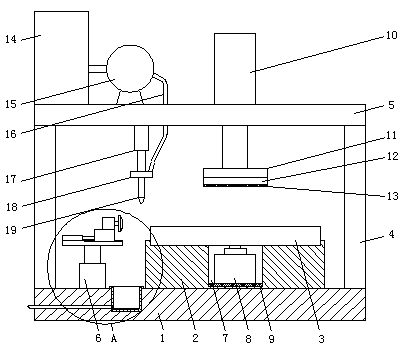

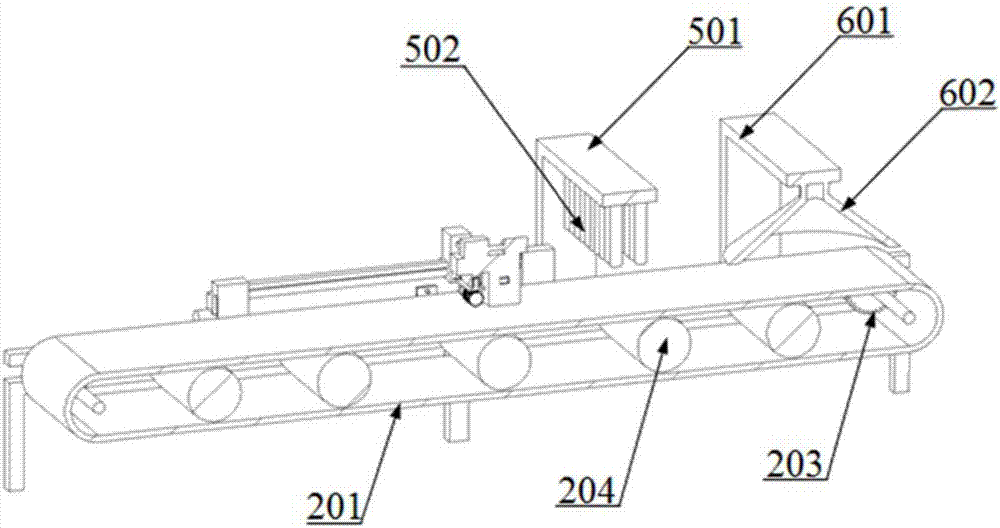

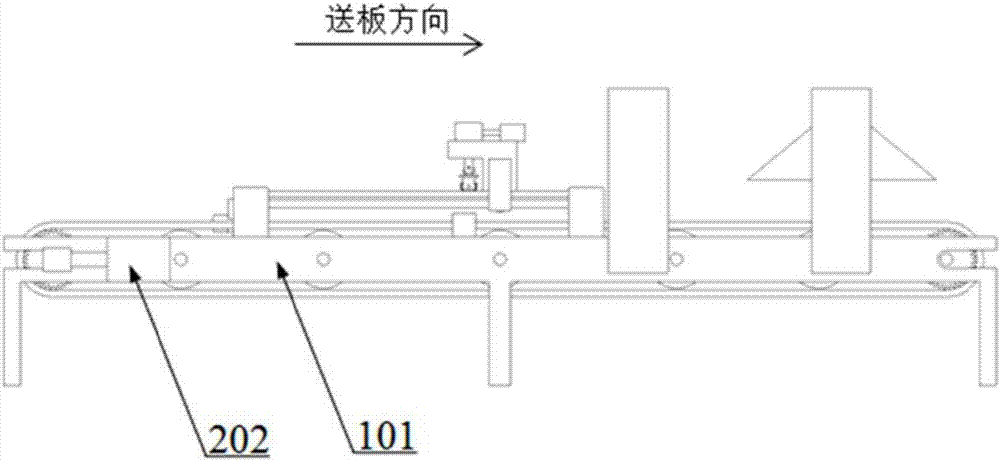

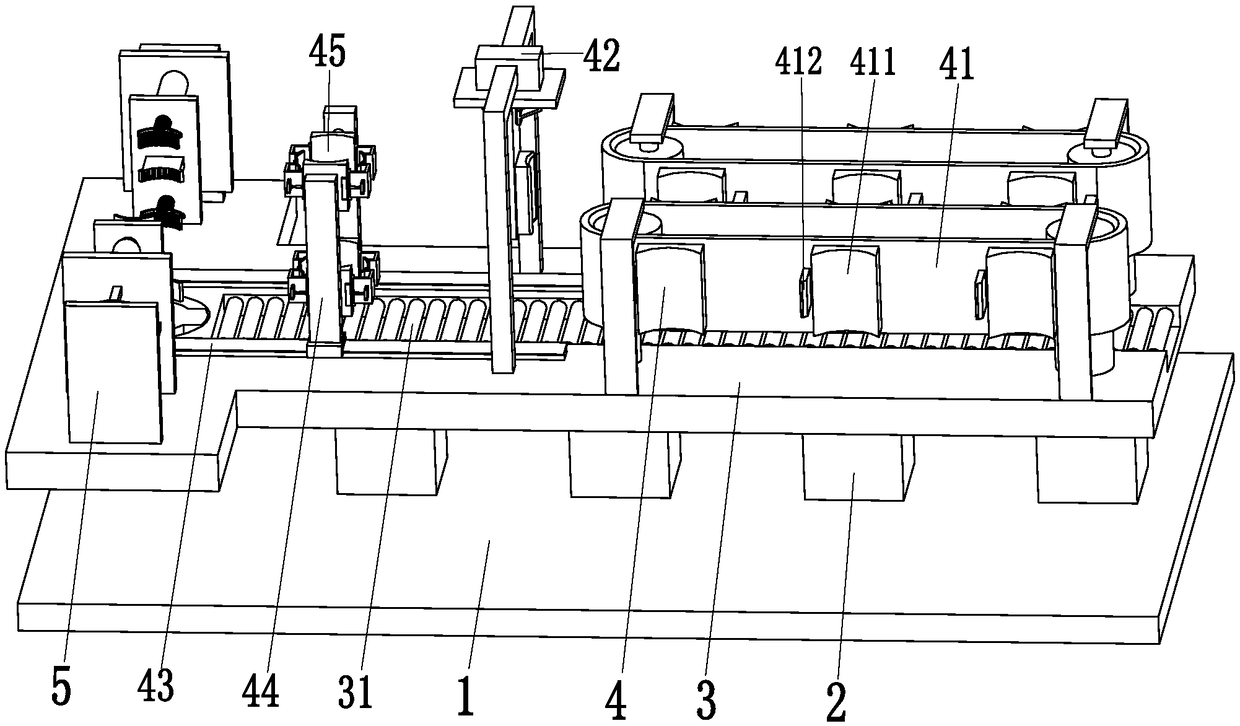

Circuit board grinding production system

PendingCN107175553AImprove the effectImprove work efficiencyEdge grinding machinesGrinding drivesGrindingElectric machinery

The invention discloses a circuit board grinding production system. The circuit board grinding production system comprises a board grinding rack, a board conveying mechanism, a grinding head position adjusting mechanism, a grinding mechanism, a cleaning mechanism and a drying mechanism. The board conveying mechanism is arranged between supporting side plates of the board grinding rack. The grinding head position adjusting mechanism comprises an X-direction movement assembly, a Y-direction movement assembly and a Z-direction movement assembly. The grinding mechanism comprises a grinding roller, a grinding fixing plate and a grinding motor. The cleaning mechanism and the drying mechanism are both arranged in the positions, between the supporting side plates and close to the grinding head position adjusting mechanism part, of the board grinding rack. The circuit board grinding production system is suitable for circuit boards in various shapes, the grinding position can be adjusted, the grinding pressure can be controlled, and the grinding effect is improved. In addition, by additionally arranging the cleaning mechanism and the drying mechanism, the ground circuit boards can be cleaned, and the working efficiency is improved.

Owner:信丰迅捷兴电路科技有限公司

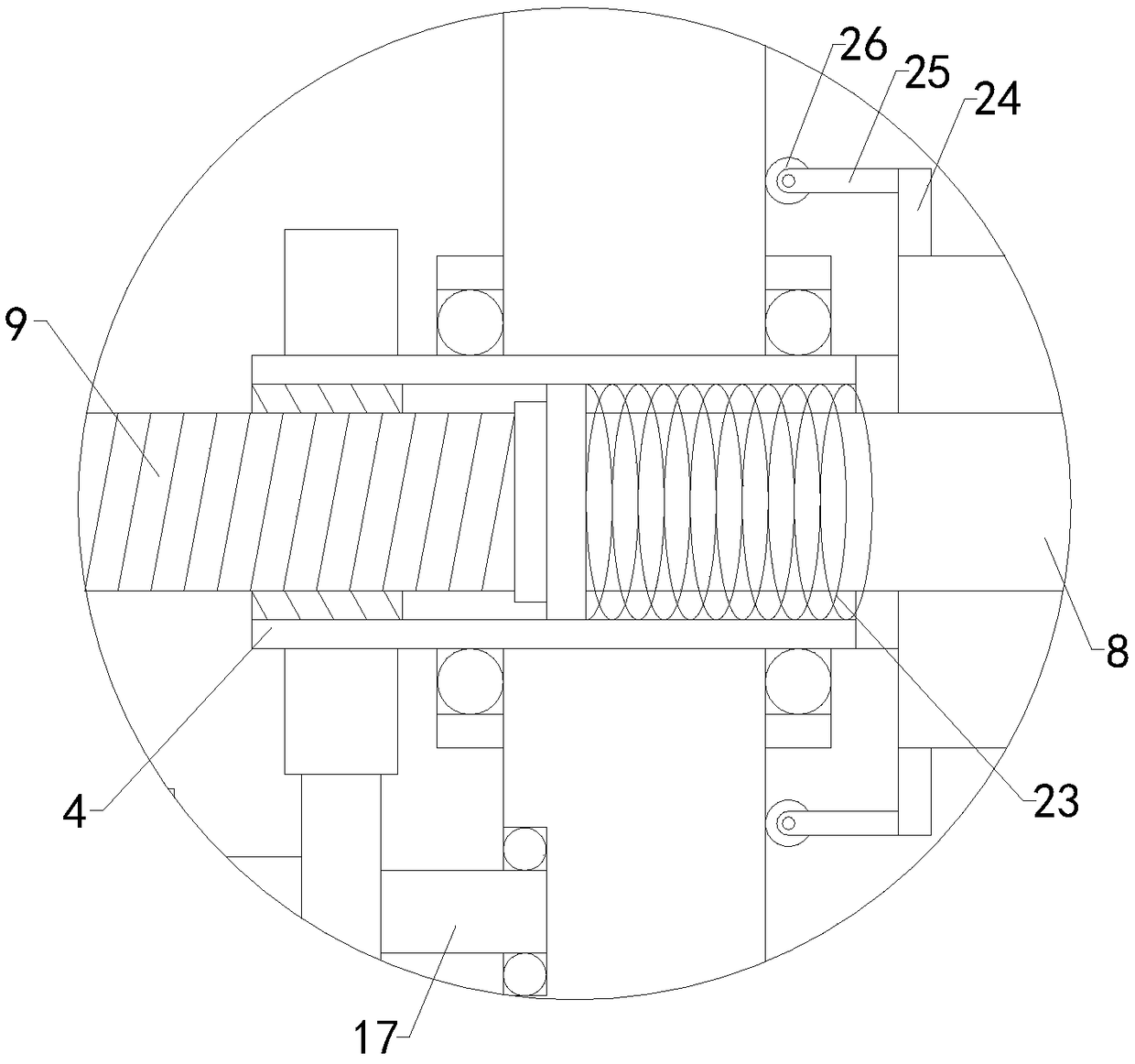

Efficient grinding equipment for pipeline finish machining and polishing

InactiveCN112207643AImprove sanding effectIncrease sanding speedRevolution surface grinding machinesGrinding drivesPolishingDust control

The invention discloses an efficient grinding equipment for pipeline finish machining and polishing. The efficient grinding equipment comprises a base, a shell is fixed to the top of the base, a clamping mechanism, a grinding mechanism and a dust removal mechanism are arranged inside the shell, a driving mechanism used for driving the clamping mechanism to rotate is fixed to the top of the base, and a transmission mechanism is arranged on the outer wall of the shell above the driving mechanism. According to the efficient grinding equipment for pipeline finish machining and polishing, by arranging the driving mechanism, the clamping mechanism, the grinding mechanism and the dust removal mechanism, the phenomenon of missing grinding of the surface of a circular pipe is avoided while the circular pipe is uniformly ground, the grinding effect and the grinding speed of the circular pipe are improved, and meanwhile, the effect of efficiently removing dust in the shell is achieved.

Owner:安徽京远机械有限公司

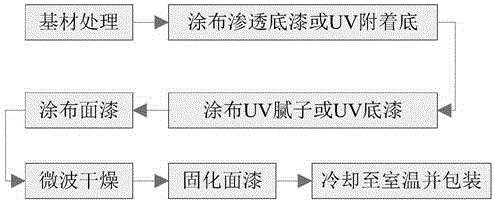

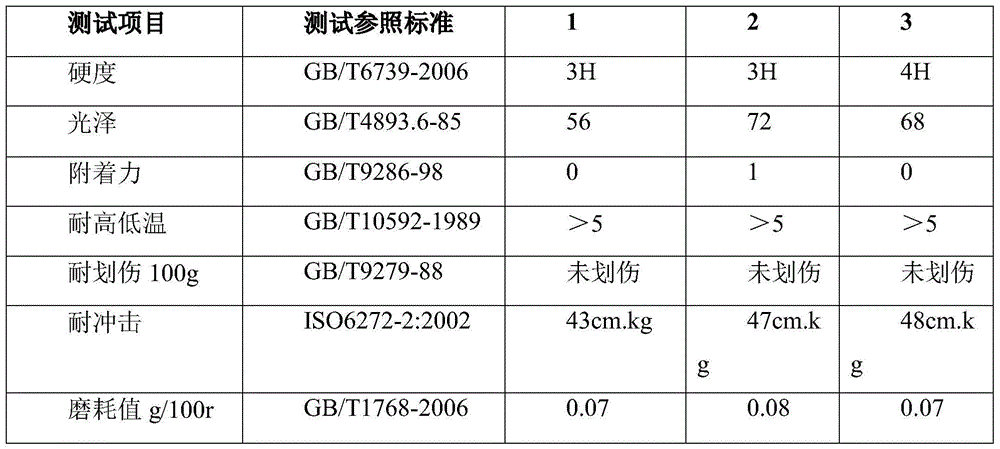

Aqueous UV wood paint, preparation method and application technology thereof

InactiveCN105860792AInhibition releaseGuaranteed to be environmentally friendlyPretreated surfacesPolyurea/polyurethane coatingsHardnessWear resistance

The invention discloses an aqueous UV wood paint. The aqueous UV wood paint comprises the following components: 20-40% of aqueous polyurethane resin, 20-60% of aqueous UV resin, 0.2-0.6% of an antifoaming agent, 0.2-0.8% of a leveling agent, 0.2-0.8% of a wetting agent, 0.2-0.8% of a thickening agent, 0.2-0.8% of an initiator, 0.2-0.8% of a dispersant, 0.2-0.8% of matting powder, 5-40% of water, and 0.2-0.5% of a handfeel auxiliary agent. The invention also discloses a preparation method of the aqueous UV wood paint and an application technology thereof. The aqueous UV wood paint has the advantages of good environmental protection performance, strong adhesive force, high hardness, good wear resistance and coin scratching-resistant performance. The preparation method has the advantage of simple operation, by employing a microwave drying method, the drying speed is fast, drying requirement of a thicker coating can be satisfied, the production efficiency is high, and the aqueous UV wood paint is quit suitable for industrial production.

Owner:HUNAN BANFERT NEW MATERIALS TECH

Preparation method and application of ketoaldehyde resin modified room-temperature self-crosslinked acrylate emulsion

ActiveCN103554378AGood anti-adhesionImprove mechanical propertiesCoatingsPolymer scienceAcrylate ester

The invention discloses a preparation method and application of a ketoaldehyde resin modified room-temperature self-crosslinked acrylate emulsion. The preparation method is characterized by comprising the following steps: adding a composite emulsifier, deionized water, acrylate monomer, ketoaldehyde resin, functional acrylic monomer and electrolyte into an emulsifying cylinder; stirring for emulsifying to obtain a nuclear pre-emulsification solution; adding 1 / 3 of the nuclear pre-emulsification solution into a reaction kettle, adding an initiator, and heating to react; dropwisely adding the rest of nuclear pre-emulsification solution into the reaction kettle while dropwisely adding a right amount of initiator solution, and continuing keeping the temperature; and adding a composite emulsifier, acrylate monomer, functional acrylic monomer and deionized water into a dropwise addition emulsifying cylinder, stirring for emulsifying, dropwisely adding into the reaction kettle while dropwisely adding a right amount of initiator solution, keeping the temperature to react, cooling, adding an amine neutralizer for neutralization, and adding corresponding auxiliary crosslinking monomer. The acrylate emulsion has the advantages of excellent resistance to bond, high hardness, high gloss, high adhesiveness, high decoration property and high fullness of the paint film.

Owner:GUANGDONG YINYANG ENVIRONMENT FRIENDLY NEW MATERIALS CO LTD

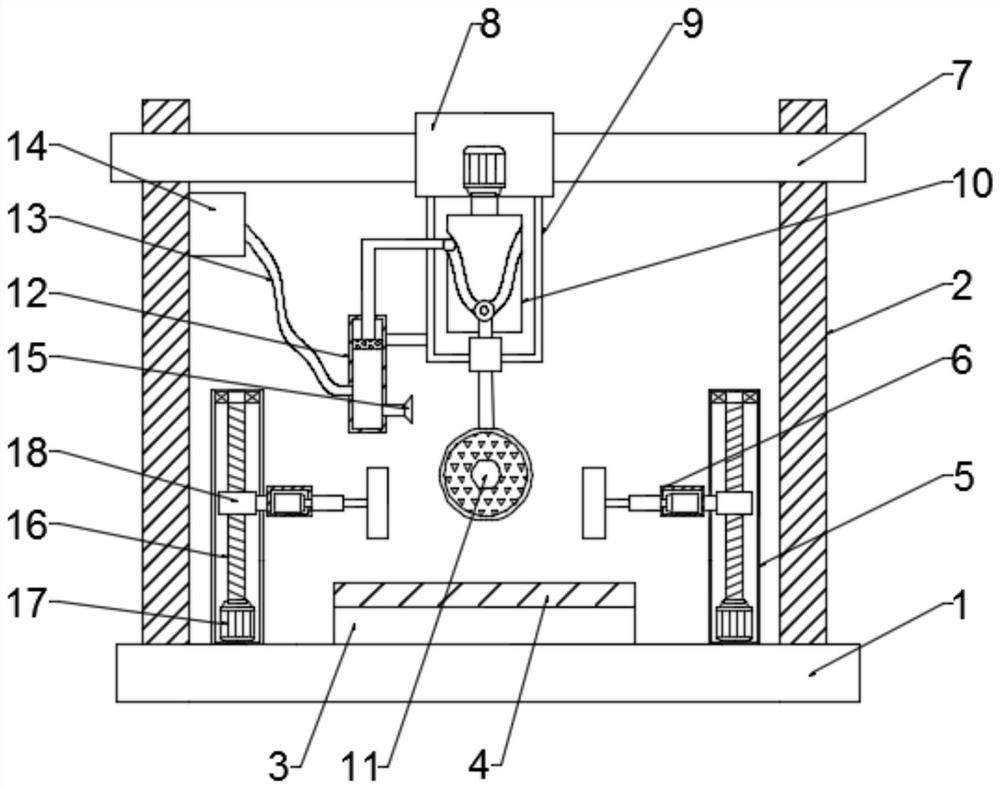

Grinding equipment for hardware machinery fitting processing

InactiveCN111890180AImprove the fixed effectImprove the effectGrinding carriagesGrinding drivesGrindingWorkbench

The invention relates to the technical field of hardware processing, in particular to grinding equipment for hardware machinery fitting processing. The grinding equipment comprises a base, wherein supporting columns are fixedly mounted at the two sides above the base; the center of the base is equipped with a workbench; the surface of the workbench is equipped with a non-slip mat; the two sides ofthe workbench are equipped with fixed columns; sides, close to the workbench, of the fixed columns are equipped with fixed devices; a supporting plate is transversely and fixedly mounted above the supporting columns; the middle part of the supporting plate is equipped with a mounting base; a transmission bin is arranged below the mounting base; a lifting device is arranged in the transmission bin; and a grinding plate is fixedly connected below the lifting device. The grinding equipment for hardware machinery fitting processing provided by the invention is simple in structural design, is highin regulating performance, is high in degree of automation, greatly improves grinding efficiency in workpieces, and provides a good fixing effect for hardware machinery fittings during processing.

Owner:滕云飞

Fire protection pipeline outer wall grinding device

InactiveCN108818168AImprove placement stabilityIncrease contactRevolution surface grinding machinesGrinding work supportsFire protectionArchitectural engineering

The invention relates to the technical field of fire protection equipment machining auxiliary devices, in particular to a fire protection pipeline outer wall grinding device. By means of the fire protection pipeline outer wall grinding device, the containing stability of a ground fire protection pipeline on a grinding table can be improved, and usage reliability is improved; and grinding through manual usage of an electric hand drill is not needed, manpower is relieved, the grinding effect is improved, a grinding wheel can well make contact with the outer wall of the fire protection pipeline,and usage limitation is reduced. The fire protection pipeline outer wall grinding device comprises a grinding table, two left support columns, two right support columns, a left fixing plate, a right fixing plate, two left limiting sliding blocks, two right limiting sliding blocks, a left baffle, a right baffle, a left adjusting lead screw, a right adjusting lead screw, a left upper sliding block,a left lower sliding block, a left upper supporting plate, a left lower supporting plate, a right upper sliding block, a right lower sliding block, a right upper supporting plate and a right lower supporting plate are included. A rear side plate, a left rotation shaft, a right rotation shaft, a gear motor and a fixing block are further included, and a drive gear is arranged at the output end of the left portion of the gear motor and engaged with a driven gear.

Owner:苏州慧安智能科技有限公司

Bristle brush for concrete sanding

ActiveUS20050260941A1Stay flexibleImprove sanding effectGrinding machine componentsBrush bodiesSanderBristle

A brush or pad (10) for a power sander for sanding surfaces includes a base (12) for mounting onto a power sander and a plurality of depending bristles (16) with the bristles having a plurality of hard particles (22), for example diamonds particles of grit 70 size, brazed or otherwise secured onto the bristle surface such that as the bristle wears down, new particle surfaces are exposed at the distal end (20) of the bristle to maintain sanding performance of the brush. The particles (22) may be spot brazed in steel with a brazing alloy to retain flexibility of the steel bristle.

Owner:DIAMABRUSH

Quick polishing device for planks for machining

InactiveCN107584394AImprove grinding efficiencySave sanding timeGrinding carriagesGrinding feed controlPulp and paper industryMachining

The invention discloses a quick polishing device for planks for machining. The quick polishing device comprises a frame and two polishing components, wherein a driven roller and a driving roller are respectively mounted at the two ends of the frame; a support roller is arranged on the middle part of the frame; each polishing component comprises a portal gantry fixed on the frame; a screw rod is inthreaded connection with the portal gantry; the bottom end of the screw rod is moveably connected with the interior of a fixing sleeve; the bottom of the fixing sleeve is fixed on a bracket through abolt; a polishing roller is arranged on the bracket through a rotating shaft. According to the invention, the two sets of polishing components are used for respectively polishing the two surfaces ofthe plank at the same time, so that the polishing efficiency is greatly increased and the polishing time is reduced; a spring is utilized to drive the polishing roller to automatically adjust the acting force on the plank surface, the control on the polishing pressure of the polishing roller is benefited and the polishing quality is guaranteed; the polishing wire on the polishing roller is conveniently replaced and the use cost of the whole polishing roller is lowered.

Owner:WUXI ZHIGURUITUO TECH SERVICE CO LTD

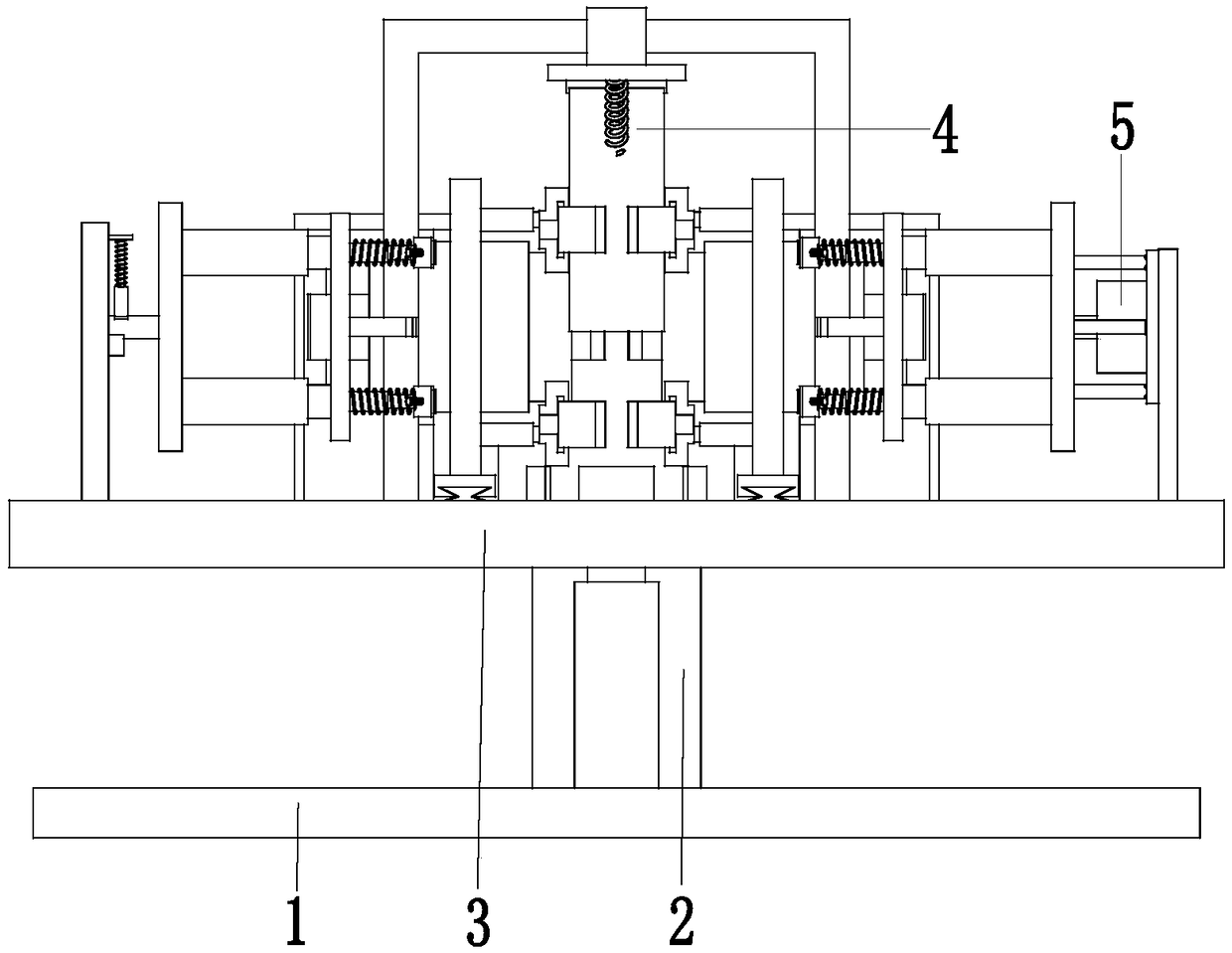

Lithium automatic transmitting and fixing equipment as well as transmitting and fixing process thereof

ActiveCN108750535AImprove teleportation effectShaking will not appearConveyorsGrinding feedersAutomatic controlEngineering

The invention relates to lithium automatic transmitting and fixing equipment as well as a transmitting and fixing process thereof. The lithium automatic transmitting and fixing equipment comprises a supporting bottom plate, supporting columns, a transmitting supporting plate, a transmitting device and a fixing device; a round hole is formed in the middle part of the left end of the transmitting supporting plate; the supporting columns are arranged at the top of the supporting bottom plate uniformly; the transmitting supporting plate is arranged at the top of each supporting column; the transmitting device is arranged at the top of the right end of the transmitting supporting plate; the fixing device is arranged at the top of the left end of the transmitting supporting plate; and the transmitting device comprises a transmitting belt, a limiting mechanism, a transmitting electric sliding block, a transmitting upright column and two transmitting and lamping branched chains. The problems that when the lithium battery needs to be fixed before being polished, the lithium battery cannot be transmitted automatically, omnibearing fixation cannot be conducted when the lithium battery is polished, the lithium battery is waggled when being polished, a negative electrode of the lithium battery needs to be clamped by a special clamp when being polished, the lithium battery cannot be automatically controlled to rotate as well as the placing position of the lithium battery causes deviation are solved.

Owner:领航国创新能源电池技术研究院(北京)有限公司

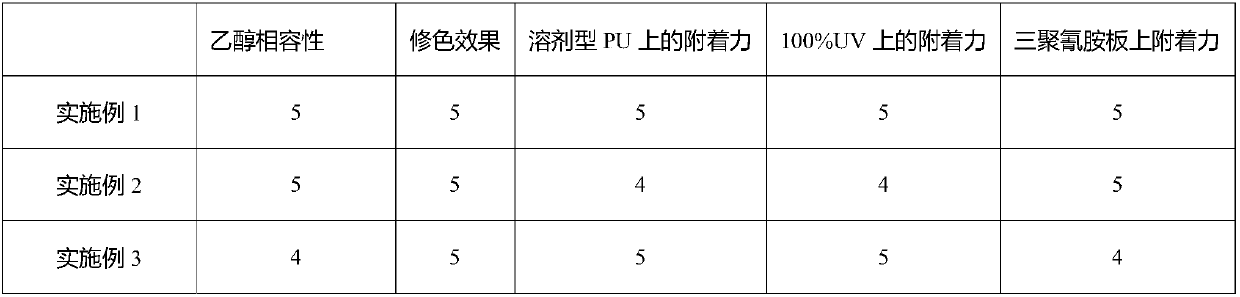

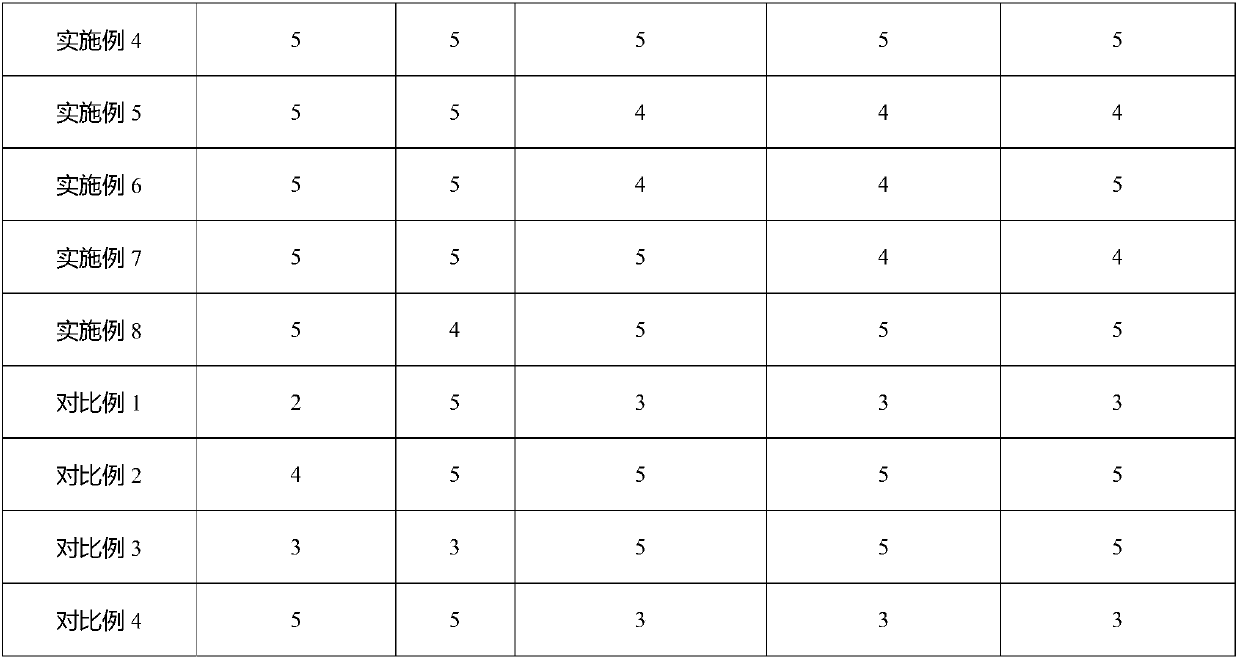

Polyurethane-polyurea aqueous dispersion, as well as preparation method and application in water-based wood coating thereof

ActiveCN109942787AHigh molecular weightReduce surface tensionPolyurea/polyurethane coatingsSolid componentWater based

The invention belongs to the technical field of aqueous dispersion and water-based coating, and provides a polyurethane-polyurea aqueous dispersion, as well as a preparation method and application inwater-based wood coating thereof. The aqueous dispersion and water-based coating is prepared from the following solid components in percentage by weight, totally 100 percent: (a) 10-45 percent of polyol modified vegetable oil; (b) 0-43 percent of non-polypropylene oxide polyol; (c) 10-50 percent of isocyanate having the functionality of 2-4; (d) 1-10 percent of a compound with an ionogenic group;(e) 0-10 percent of a low-molecular compound containing hydroxy and / or amido; (f) 4-20 percent of polypropylene oxide polyol having the functionality of 2-4; and (g) a nonionic hydrophilic compound having single functionality. The aqueous dispersion has excellent ethanol diluting resistance, and realizes excellent perforation, rubbing property, fullness, scratch resistance and chemical resistance.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD +2

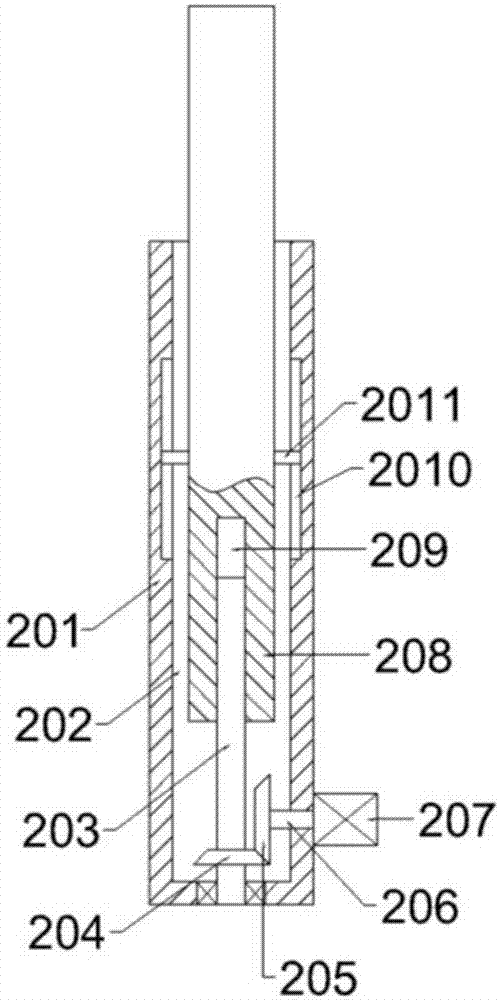

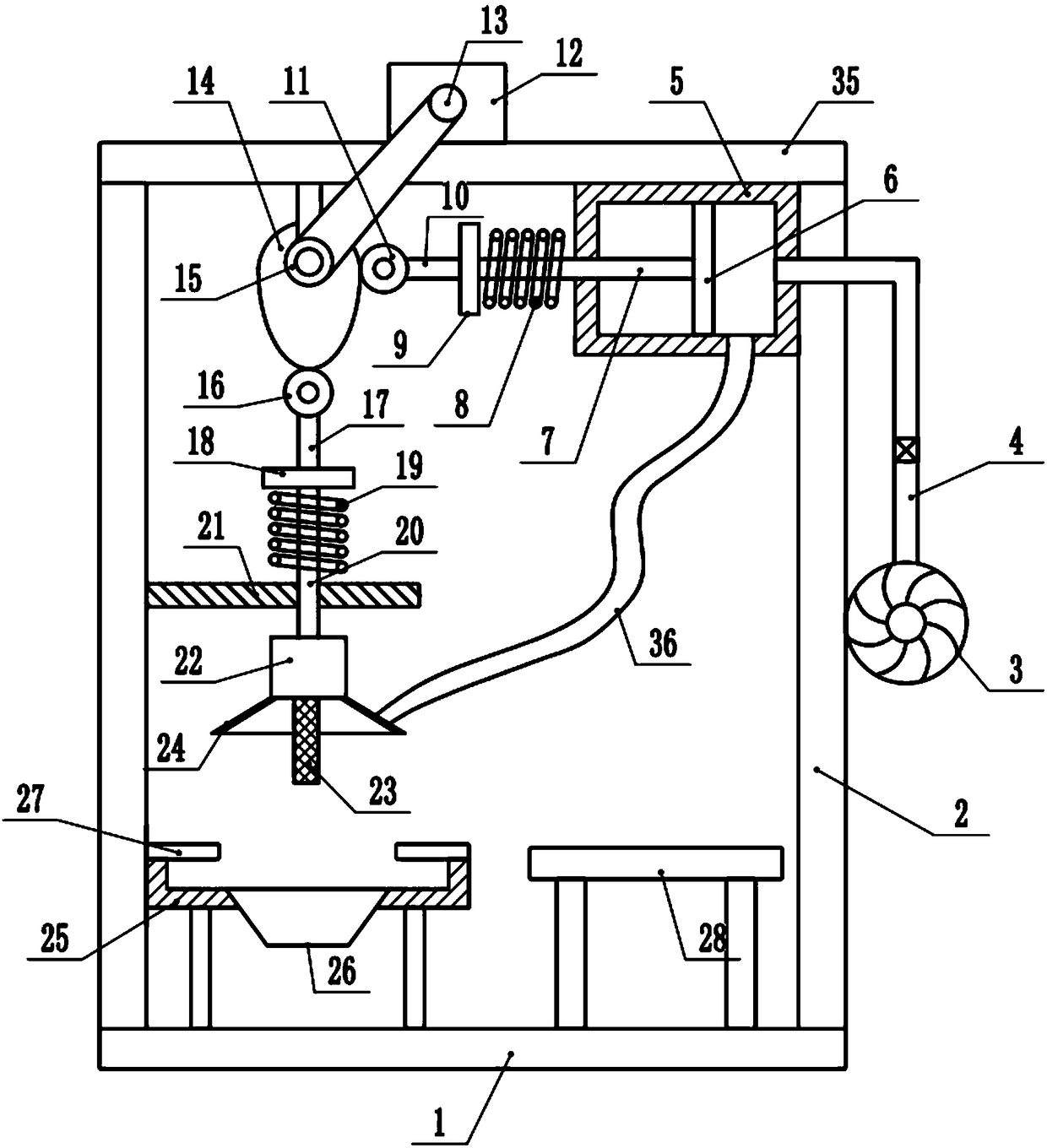

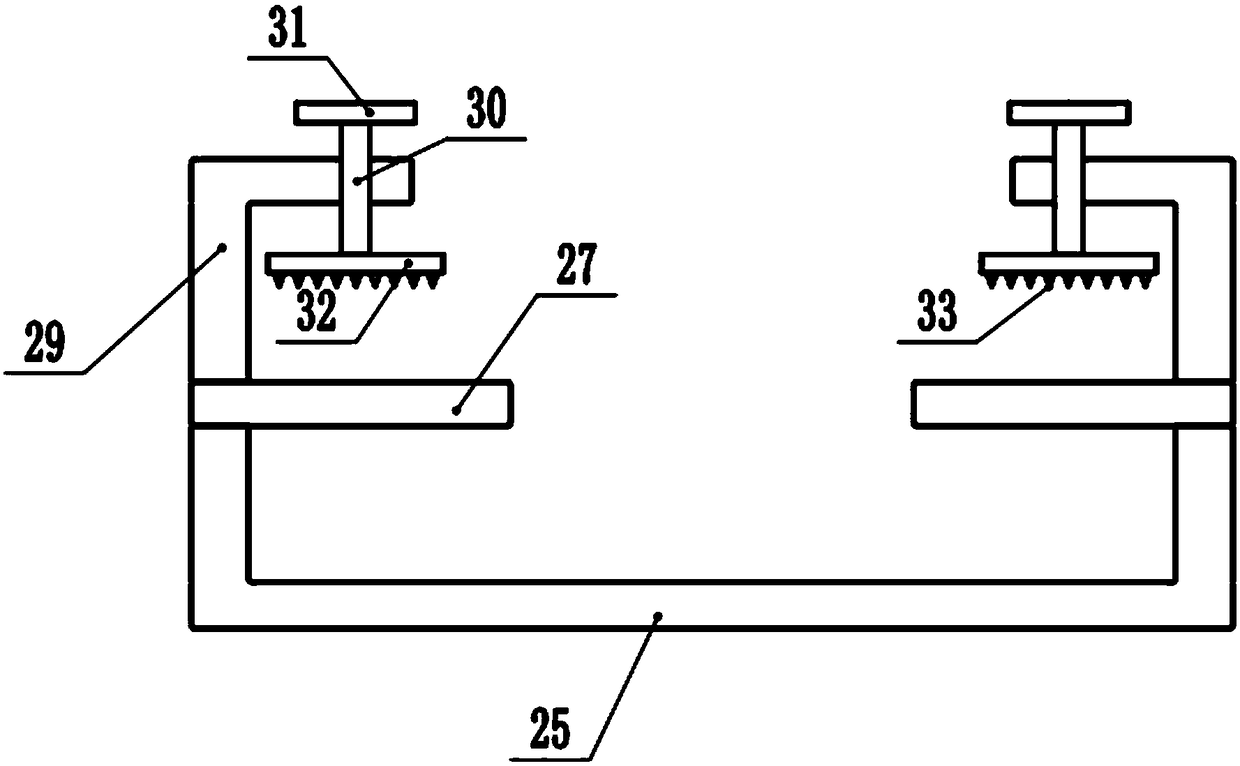

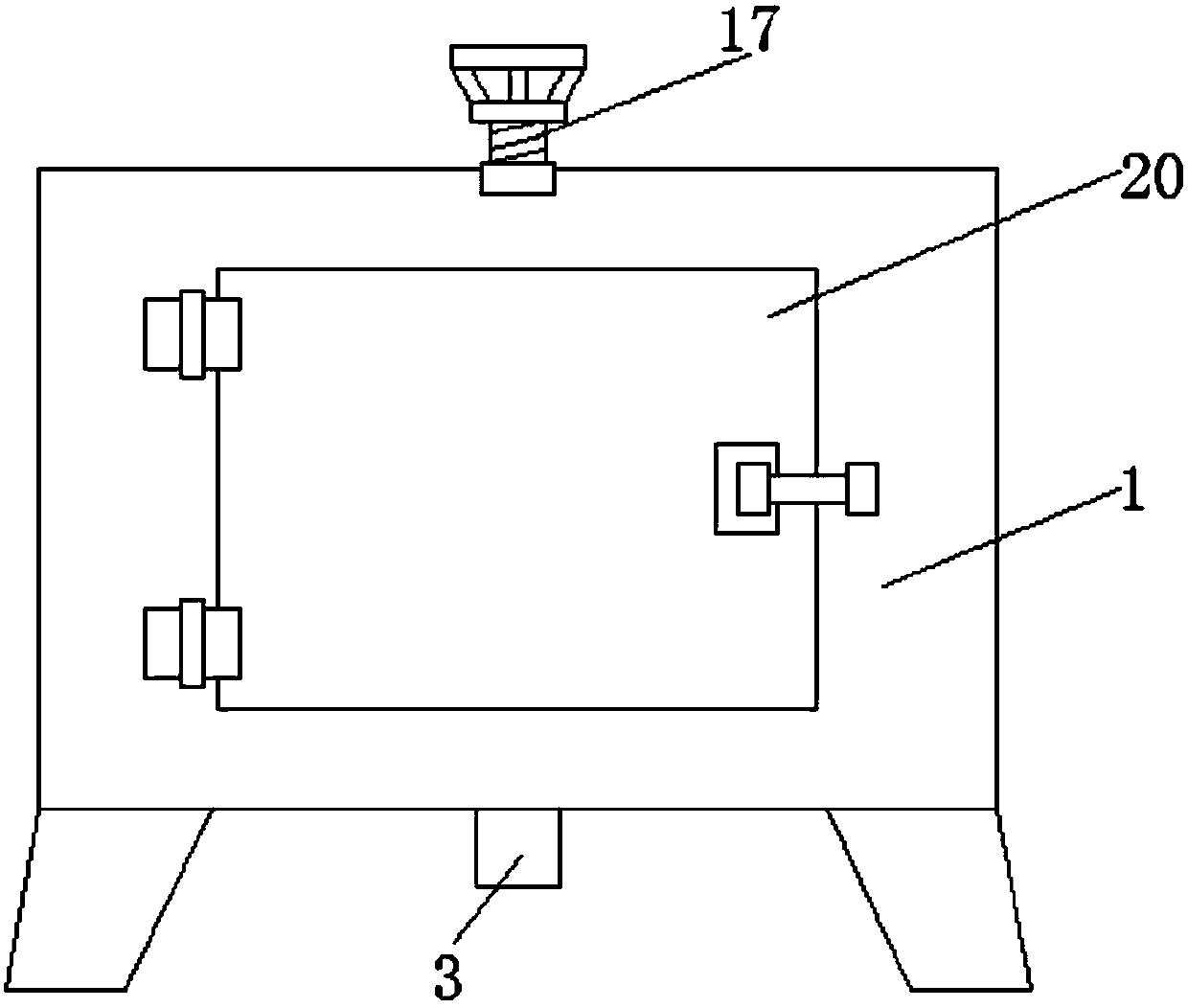

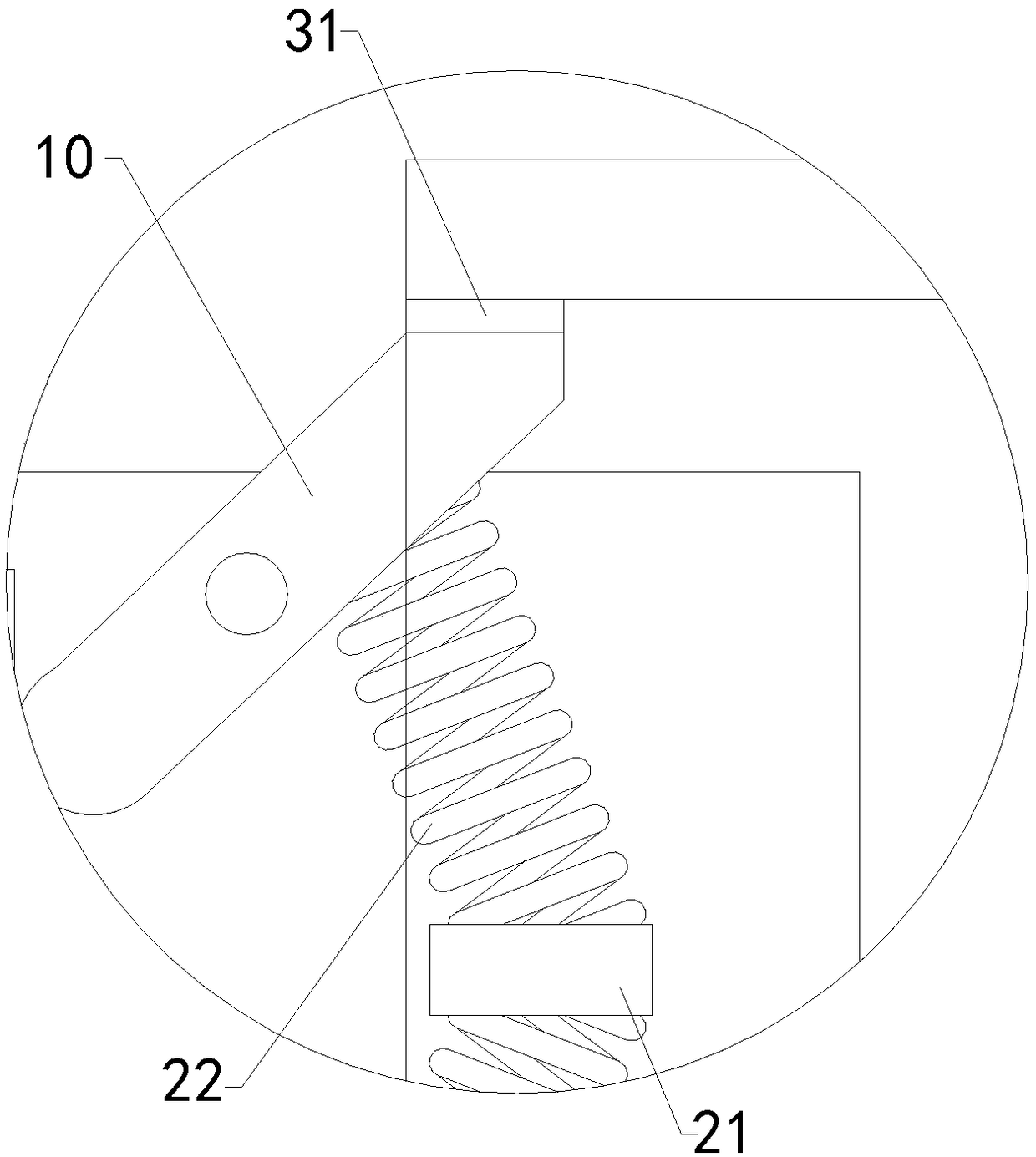

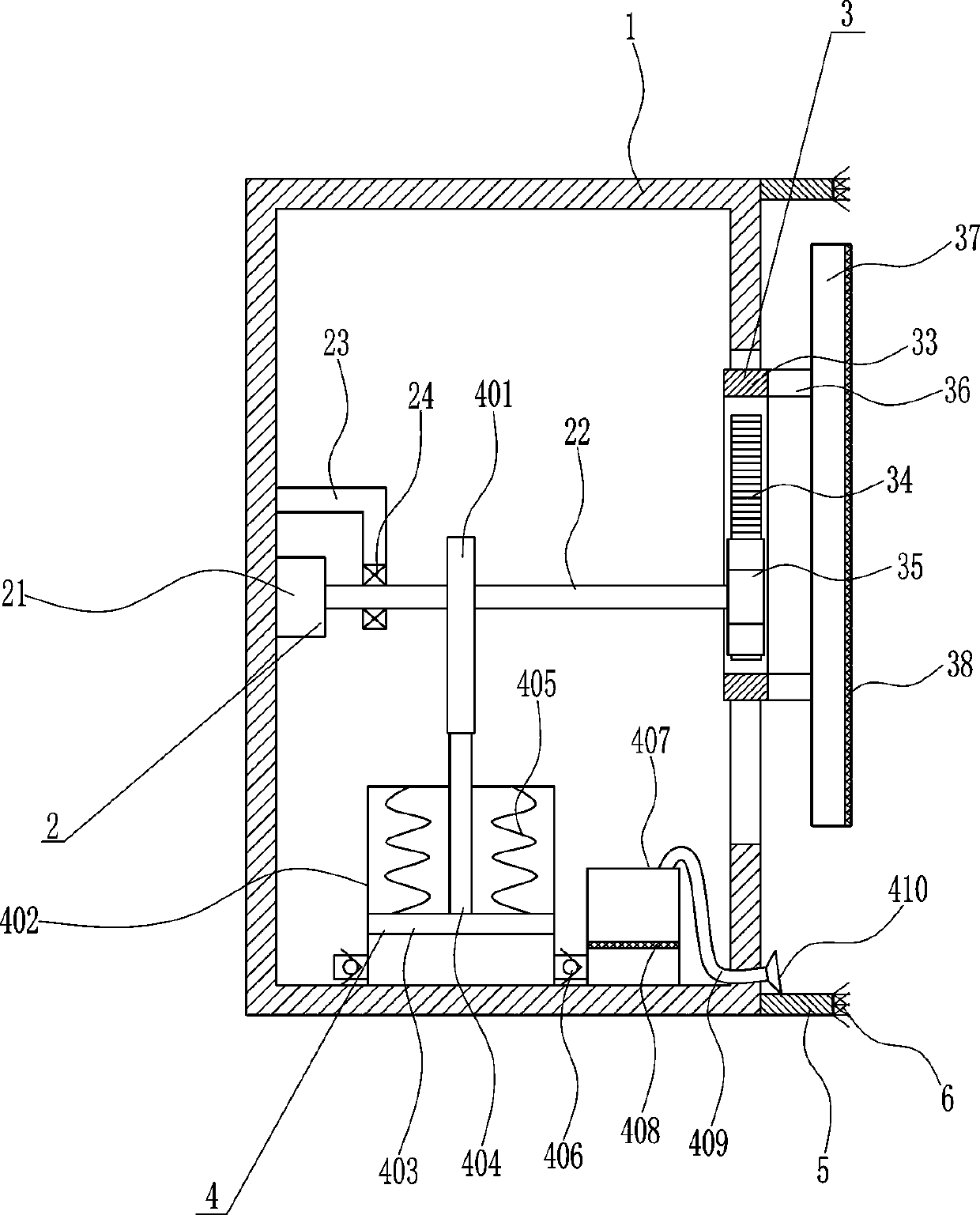

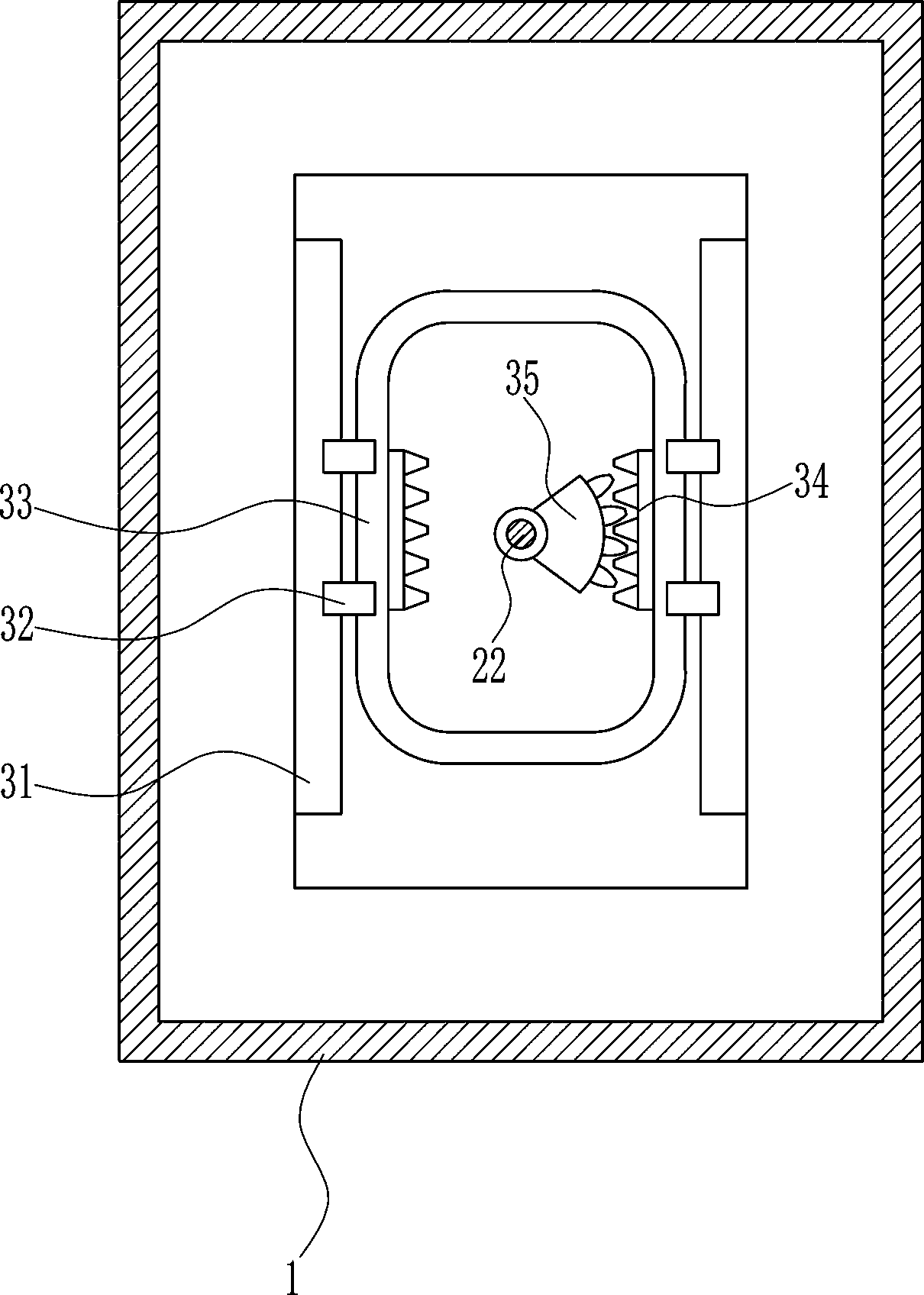

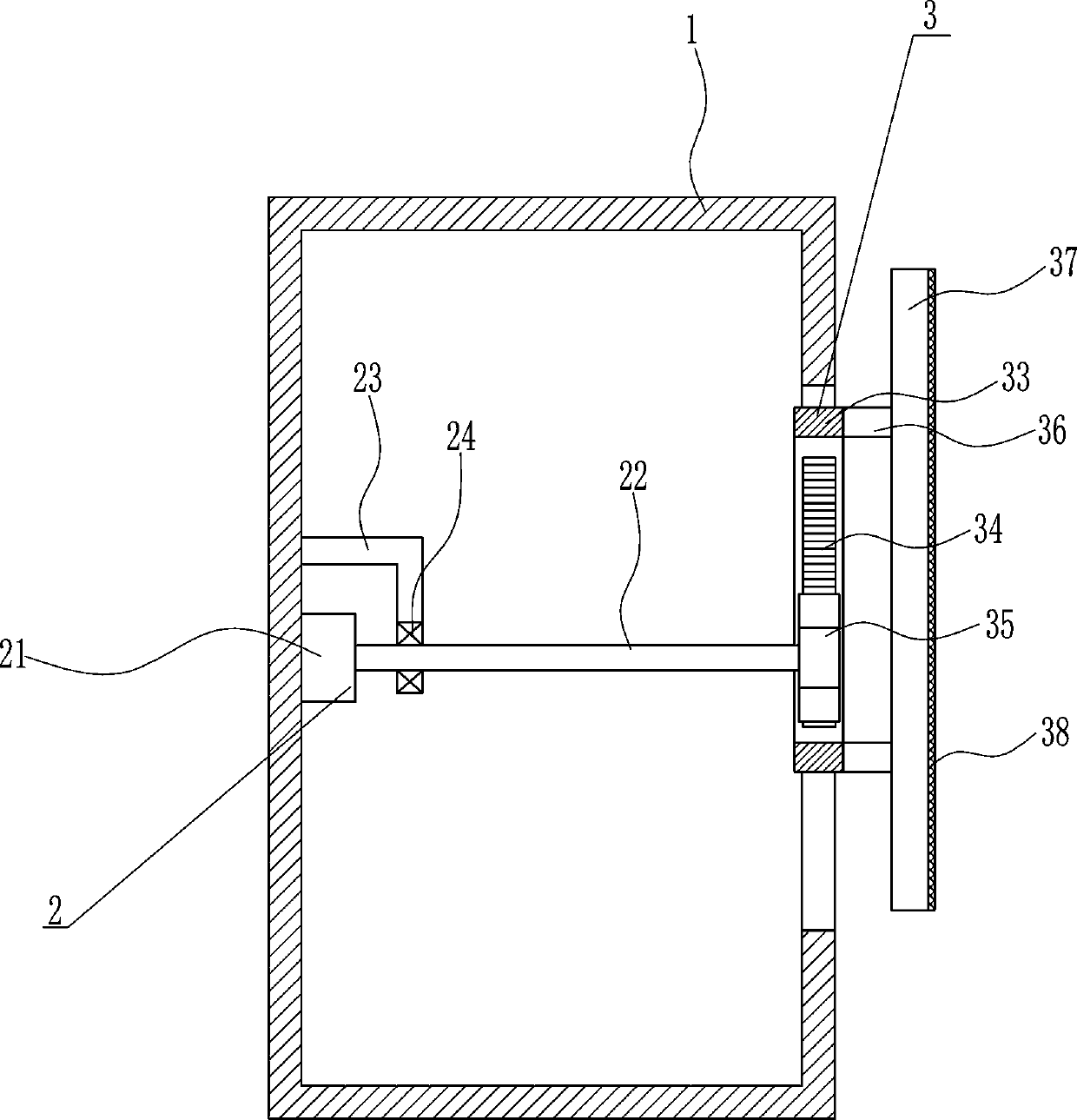

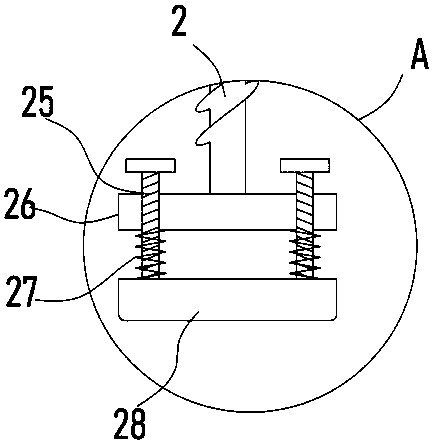

Wall putty sanding device for building decoration

InactiveCN107745299APolished evenlyImprove sanding effectPortable grinding machinesPlane surface grinding machinesSand-paperEngineering

The invention relates to a sanding device, in particular to a wall putty sanding device for the building decoration. The wall putty sanding device for the building decoration is good in sanding effect, high in efficiency and capable of saving time and labor. To solve the technical problem, the wall putty sanding device for the building decoration comprises a box body and the like. A drive device is arranged in the middle of the left side in the box body. A sanding device body is arranged on the right side of the box body. According to the wall putty sanding device for the building decoration,the grinding device body and a dust removal device are driven by the drive device to operate, the sanding device is used for efficiently sanding the wall surface through sand paper, the dust removal device sucks dust generated during sanding, a buffer device enables the sand paper to be tightly attached to the wall surface, and the good sanding effect, the high efficiency and the time-saving and labor-saving effects are achieved.

Owner:刘世荣

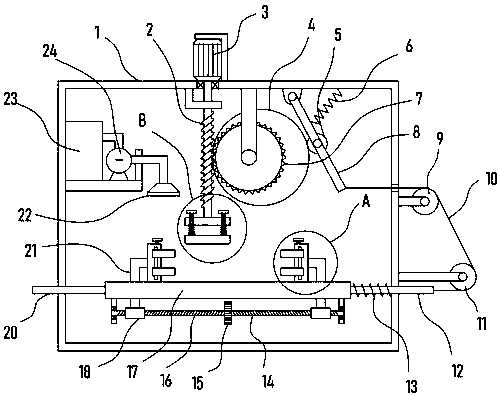

Plastic polishing device for plastic product processing

InactiveCN110000664AExpand the grinding rangeSufficient sanding strengthGrinding machinesGrinding/polishing safety devicesGear wheelReciprocating motion

The invention discloses a plastic polishing device for plastic product processing, and relates to the technical field of plastic product processing. The plastic polishing device comprises a paint spraying chamber, a lifting frame is arranged in the paint spraying chamber, a transverse spur rack is slidably mounted in the paint spraying chamber, a gear I and a gear II which are engaged with each other are rotatably arranged in the paint spraying chamber, an incomplete gear I and an incomplete gear II are coaxially and fixedly mounted on the gear I and the gear II correspondingly, and the incomplete gear I and the incomplete gear II are alternately engaged with the transverse spur rack. Through engagement transmission of the gear I and the gear II, the transverse spur rack drives a paint spraying head at the bottom to reciprocate leftwards and rightwards to carry out repeated paint spraying treatment on the plate, the paint spraying range of the plate is greatly increased, paint sprayingis uniform and efficient, after paint spraying of the plate is finished, the plate can rotate and heat and dry towards the electric heating wire through the driving of a steering motor, the paint drying time is greatly shortened, the paint spraying and drying processes are in place in one step, work efficiency is remarkably improved.

Owner:温州誉诚包装有限公司

Method for producing weft-knitting suede fabric

The invention, which belongs to the technical field of the textile fabric, provides a method for producing weft-knitting suede fabric. The method comprises the following steps: (1), weaving is carried out; to be specific, weft knitting is carried out on 20% to 26% of T400 high stretch yarn and 74 to 80% of sea-island filaments to form fabric; (2), washing is carried out; (3), splitting is carried out; to be specific, the processed fabric is put into a solution including caustic soda and an M-1100 splitting agent, wherein the bath ratio is 1 to 15-20 and the temperature is 90 to 92 DEG C; (4), singeing is carried out; to be specific, the fabric is processed by flame quickly to burn fuzz formed on the surface of a piece of greige cloth, wherein the flame temperature of the fuzz burning is 900 to 1000 DEG C; (5), dyeing is carried out; (6), drying is carried out; (7), sanding is carried out; and (8), drying and sizing are carried out. The product produced based on the method has advantages of high coverage, soft feeling, high lustrousness and flexibility, substantially improved fabric performance, simple production process, high production efficiency, and low cost.

Owner:TONGXIANG HUIQUAN TEXTILE CO LTD

Brushing and arranging device for clothes production

The invention discloses a brushing and arranging device for clothes production. The brushing and arranging device comprises a machine body. A support is arranged on the machine body and provided with a cloth inlet roller and a cloth outlet roller. A feed roller, a tensile force control device and a fabric expanding device are arranged on the support. A transmission roller and a cleaning device are arranged in the machine body. Spray nozzles are arranged on the cleaning device. A transitional roller and a drying device are arranged in the machine body. A first brushing roller, a second brushing roller, a third brushing roller and a fourth brushing roller are arranged in the machine body. A first cloth pressing roller is arranged between the first brushing roller and the second brushing roller. A second cloth pressing roller is arranged between the third brushing roller and the fourth brushing roller. A cloth arranging device is arranged on the machine body. A cloth discharge device is arranged on a machine frame. The brushed fabric is smooth, free of creases, consistent in tightness and good in brushing effect, heat retention property and softness are improved, product quality is improved, brushing is achieved on two sides at the same time, production efficiency is improved, and the technological process is shortened.

Owner:SHAOXING HENRY TIE FASHION

Pearl nickel electroplating additive, pearl nickel electroplating solution and electroplating method

The invention provides a pearl nickel electroplating additive, a pearl nickel electroplating solution and an electroplating method. The pearl nickel electroplating additive comprises a brightening agent and a frosting agent, wherein the brightening agent comprises saccharin sodium and sodium allylsulfonate, and the frosting agent comprises succinate salt type surfactants and carboxylate type surfactants. The pearl nickel electroplating solution comprises a basic electronickelling solution and the pearl nickel electroplating additive. The electroplating method comprises the following steps: preparingthe pearl nickel electroplating solution; regulating the pH value and the temperature of the electroplating solution, and then performing electronickelling by using a preplating piece as a cathode. The pearl nickel electroplating additive disclosed by the invention is reasonable in formula, the dispersibility of the basic electronickelling solution is good, the frosting agent and the brightening agent mutually cooperate and act to enable the surface of the preplating piece to be uniformly frostedin a pearl nickel electroplating process, the frosting effect is good, the internal stress is ecreased, and the obtained pearl nickel plate is glossy, good in brightness and gentle.

Owner:南京宁美新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com