Patents

Literature

49 results about "Recoating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Recoating is the process of restoring the primary coating to stripped optical fiber sections after fusion splicing. In the recoating process, the spliced fiber is restored to its original shape and strength, using a recoater. The stripped fiber section is recoated by filling a recoating resin, usually acrylate into transparent moulds. The resin is then cured with UV light. It is often desirable to perform a proof-test after recoating, to ensure that the splice is strong enough to survive handling, packaging and extended use.

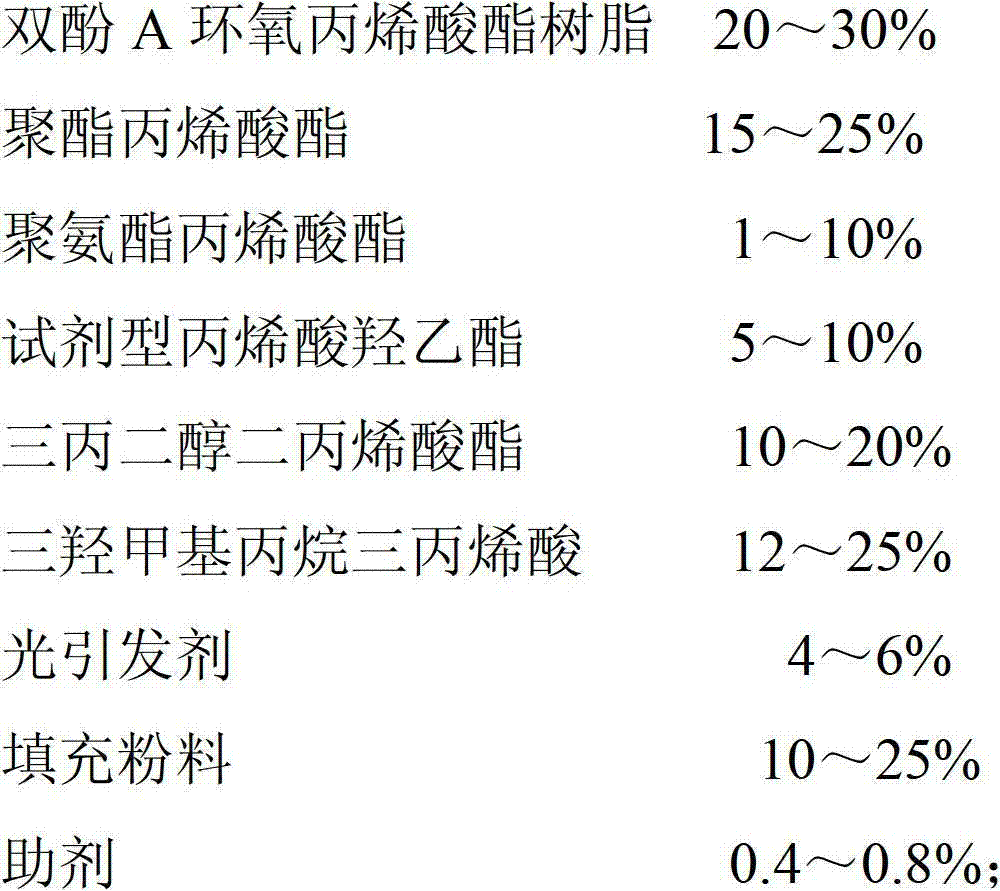

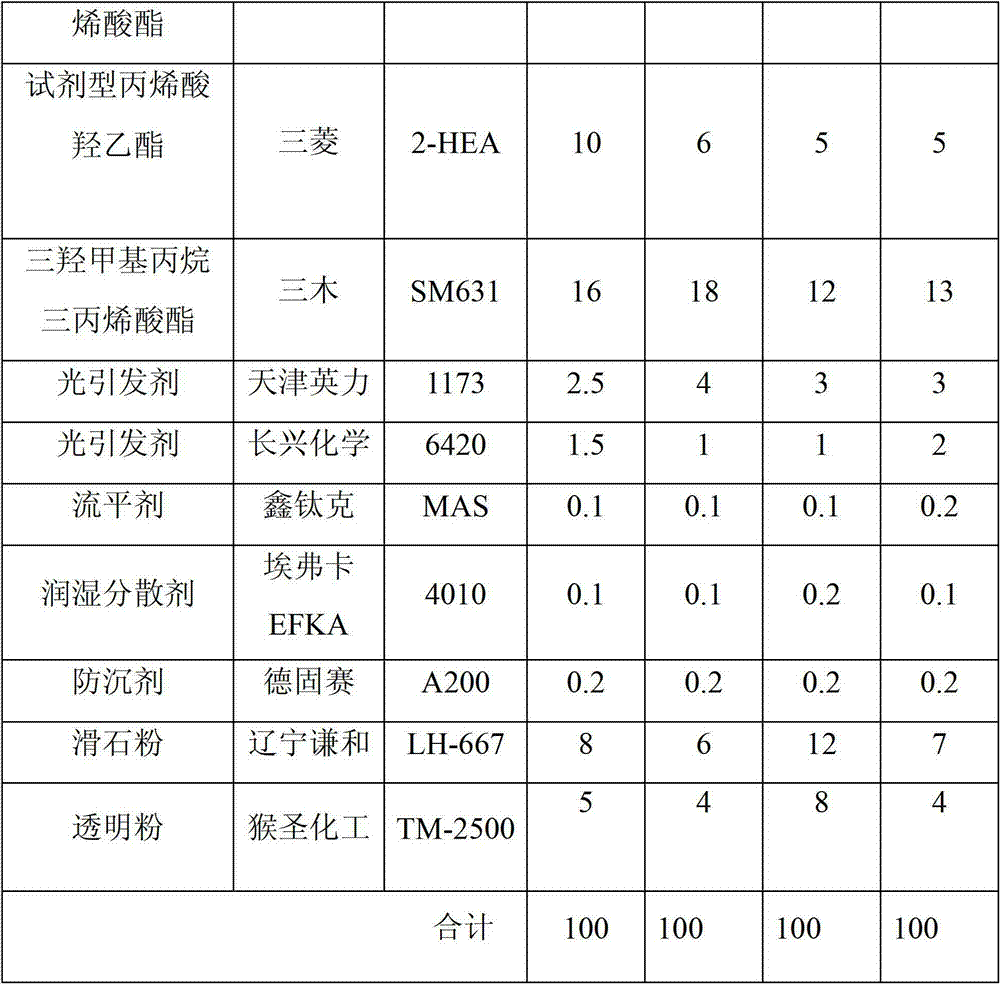

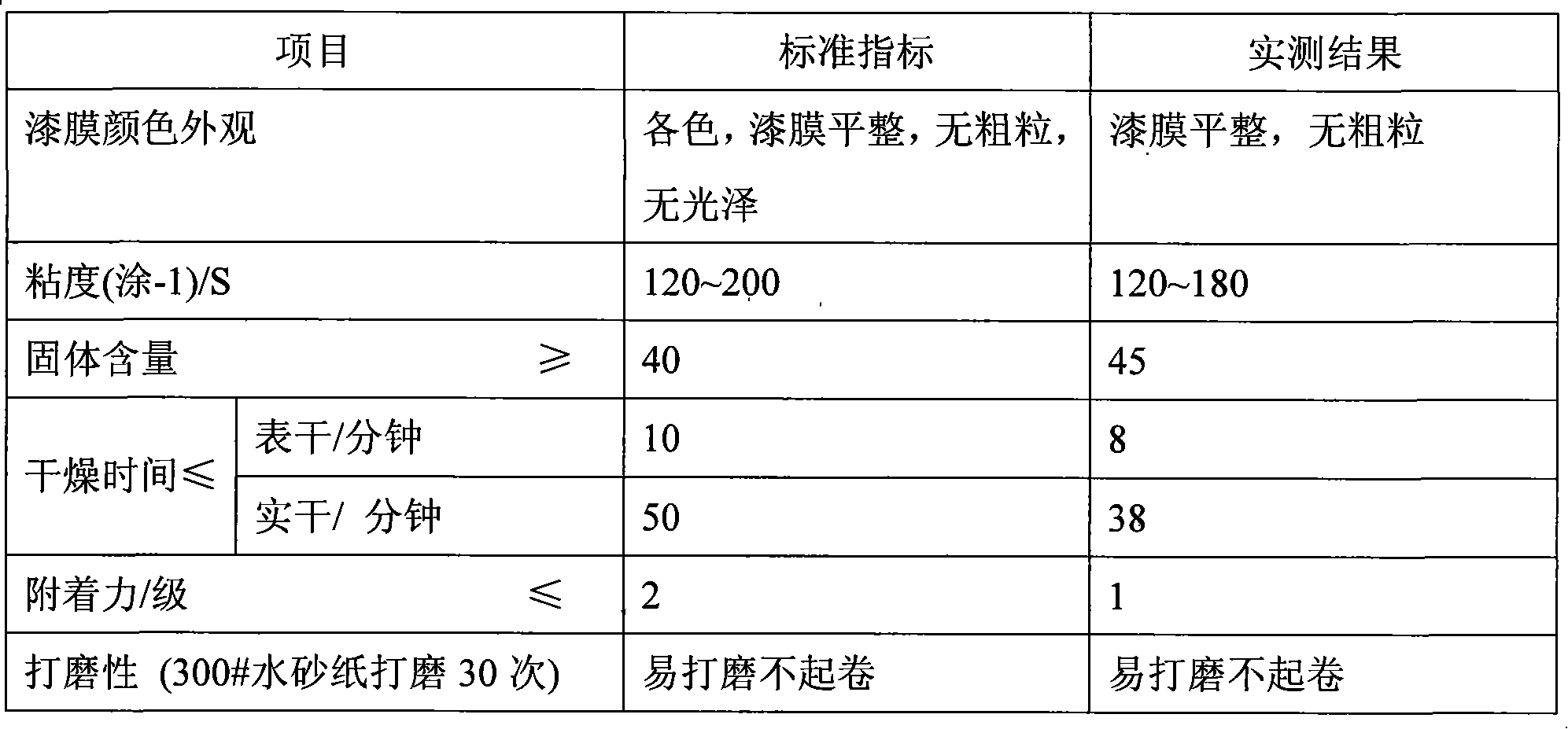

Ultraviolet light curing transparent priming paint and preparation method and use method thereof

ActiveCN102952455AReduce lossImprove product qualityPolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycolPolyester

The invention discloses an ultraviolet light curing transparent priming paint and a preparation method and a use method thereof. The ultraviolet light curing transparent priming paint comprises the following components in percentage by weight: 20-30% of bisphenol A epoxy acrylate resin, 15-25% of polyester acrylate, 1-10% of urethane acrylate, 5-10% of reagent type hydroxyethyl acrylate, 10-20% of tripropylene glycol diacrylate, 12-25% of trimethylolpropane triacrylate, 4-6% of photoinitiator, 10-25% of filling powder and 0.4-0.8% of promotor. The ultraviolet light curing transparent priming paint is suitable for laser roller construction, has good grittiness and transparency, has the characteristics that sanding is not needed for semi-curing recoating between film layers and the like, and has thick coating performance and the performance that the surface is similar to a mirror surface, and compared with conventional roller coating, the coating weight is greatly increased, roller coating processes are saved, the priming paint is sanded by a sanding machine without large pressure and with a small number of sanded films, a workpiece has no bright spots, the fullness of a product is guaranteed, the product quality is improved, the loss of the machine is smallreduced, and the use amount of sanding belts is greatly reduced.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

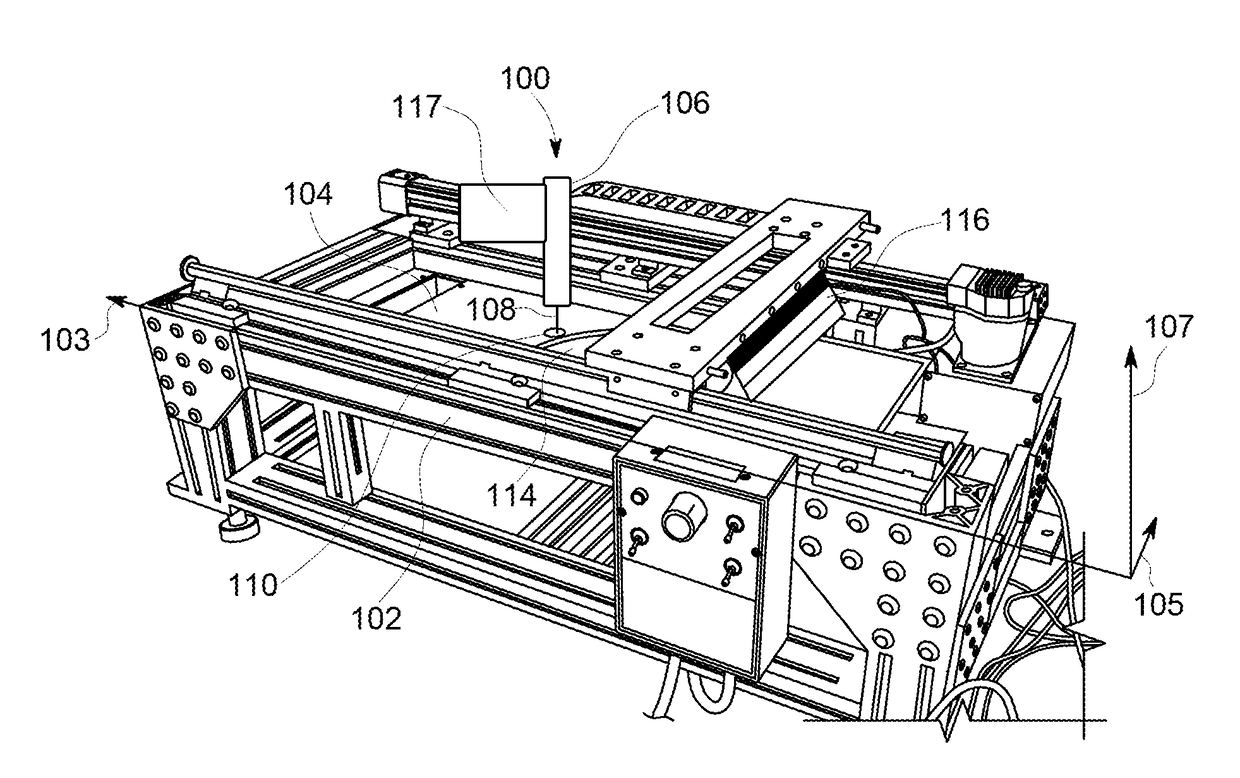

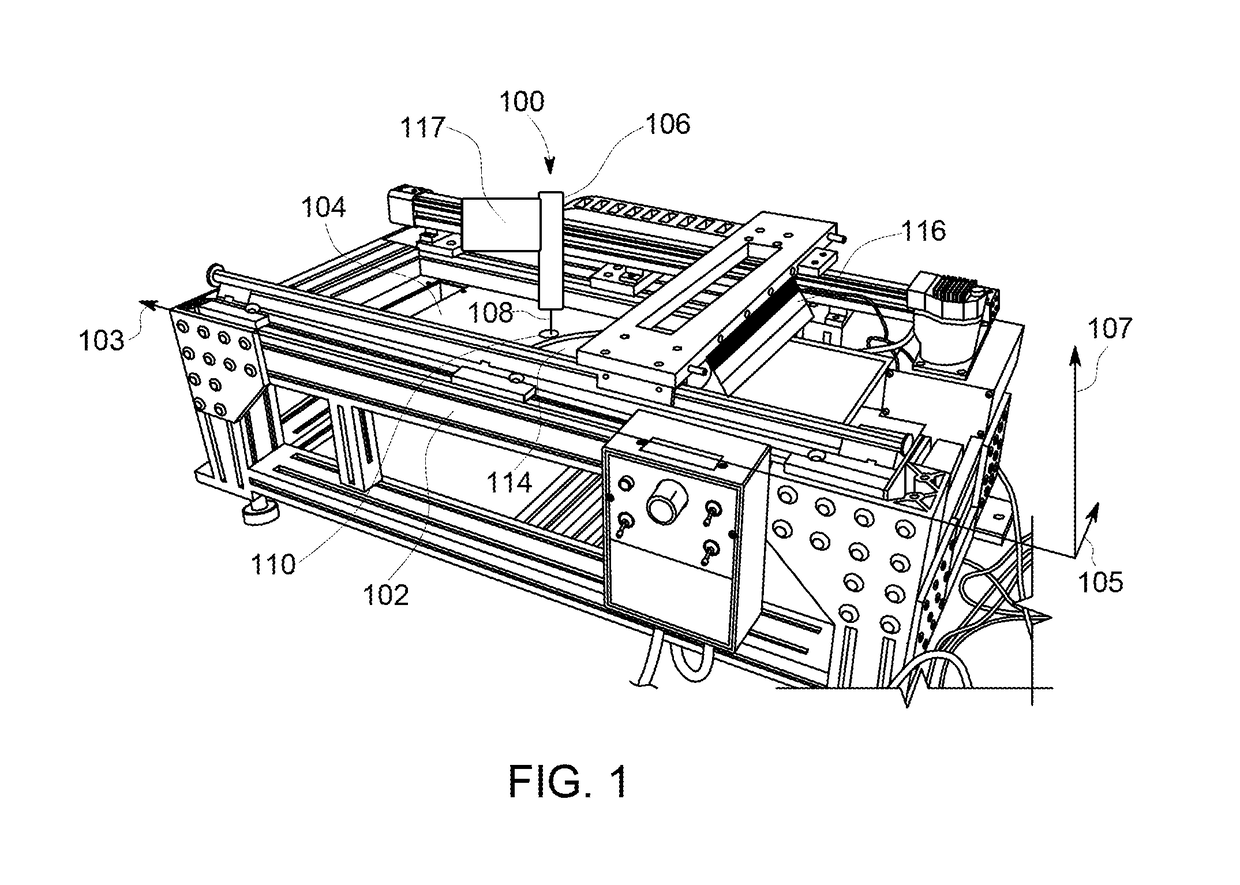

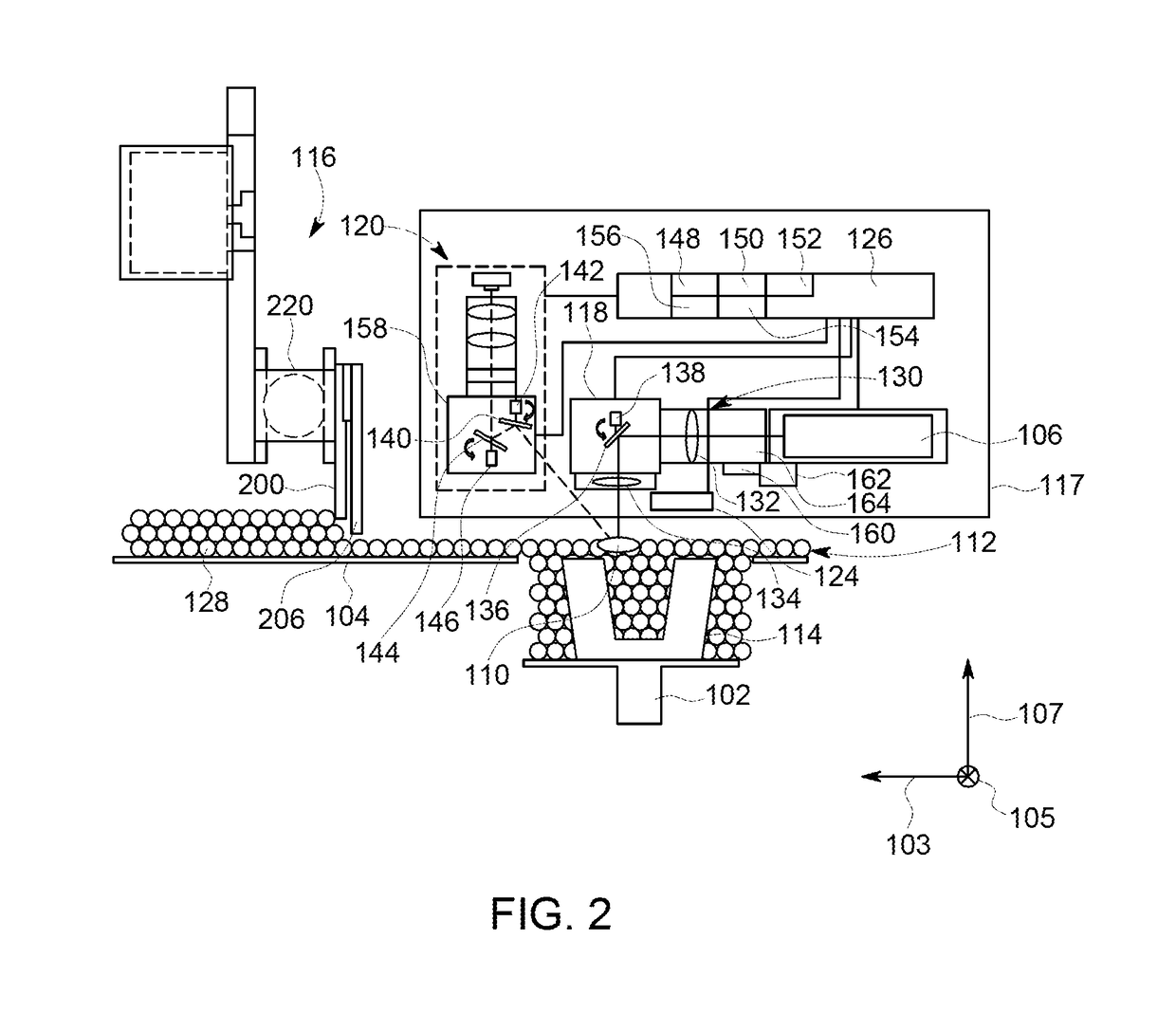

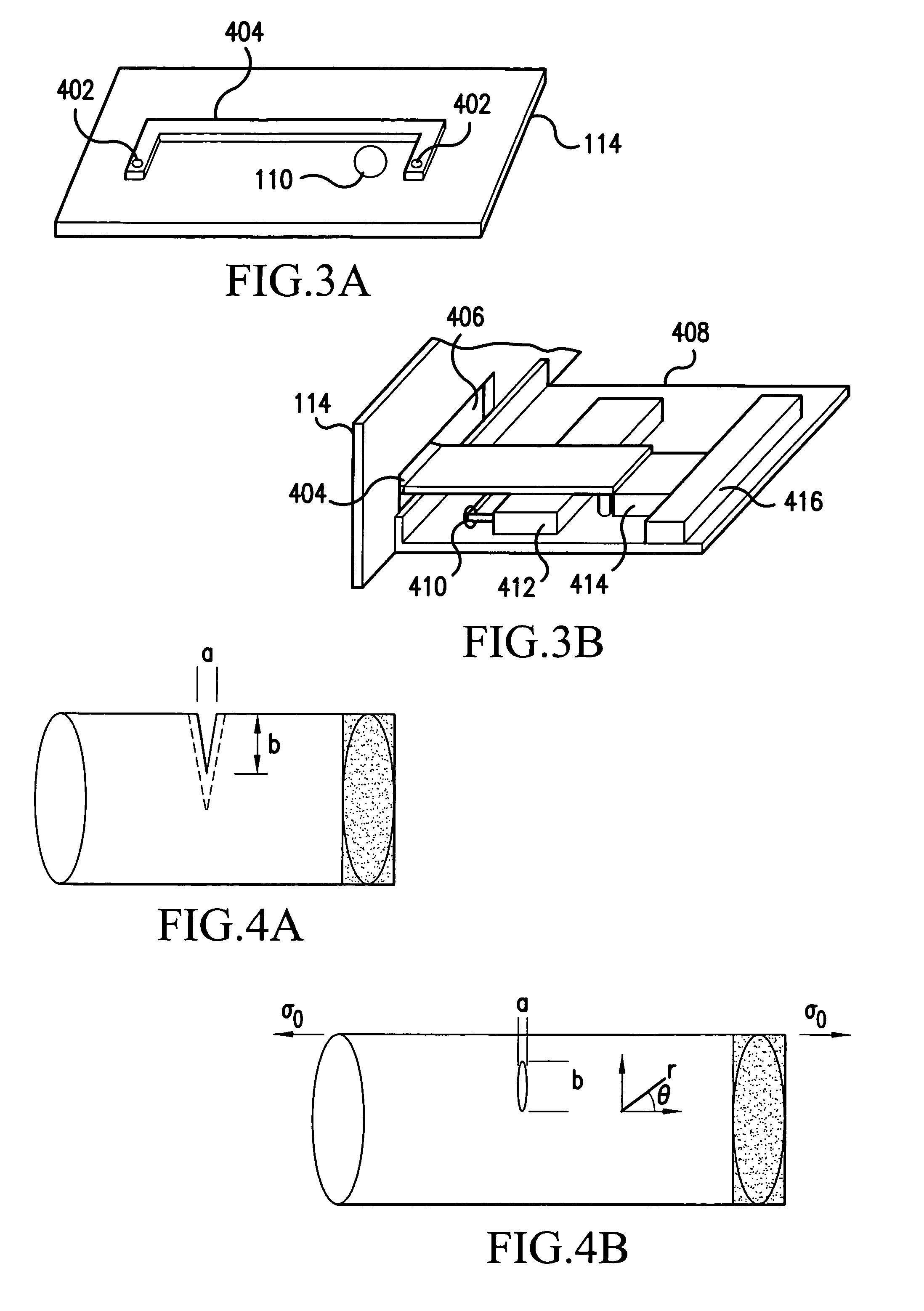

Systems and methods for additive manufacturing recoating

ActiveUS20180194074A1Additive manufacturing apparatusCeramic shaping apparatusRecoatingManufacturing systems

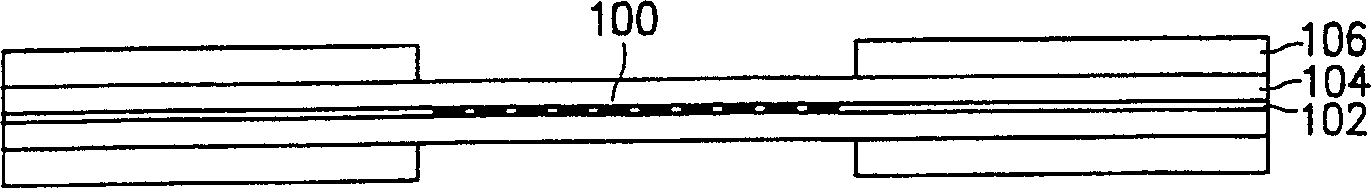

A recoating device for an additive manufacturing system includes a plurality of recoater blades which include a first stage and a second stage. The first stage includes a plurality of rows of the plurality of recoater blades and extends in the transverse dimension. The second stage includes a plurality of recoater blades and is configured substantially similar to the first stage of the plurality of recoater blades. The second stage of recoater blades is displaced from the first stage of recoater blades in the vertical dimension.

Owner:GENERAL ELECTRIC CO

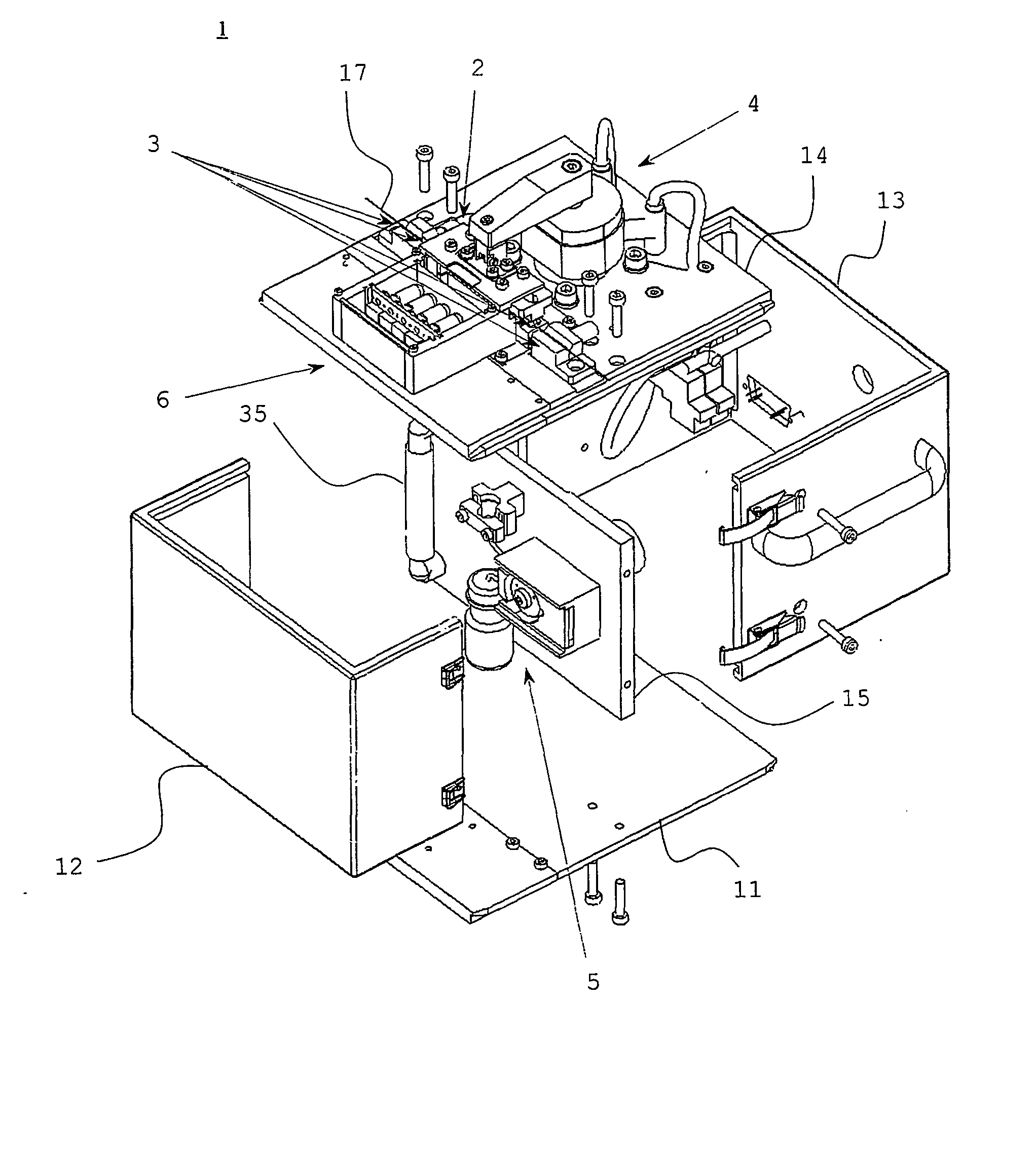

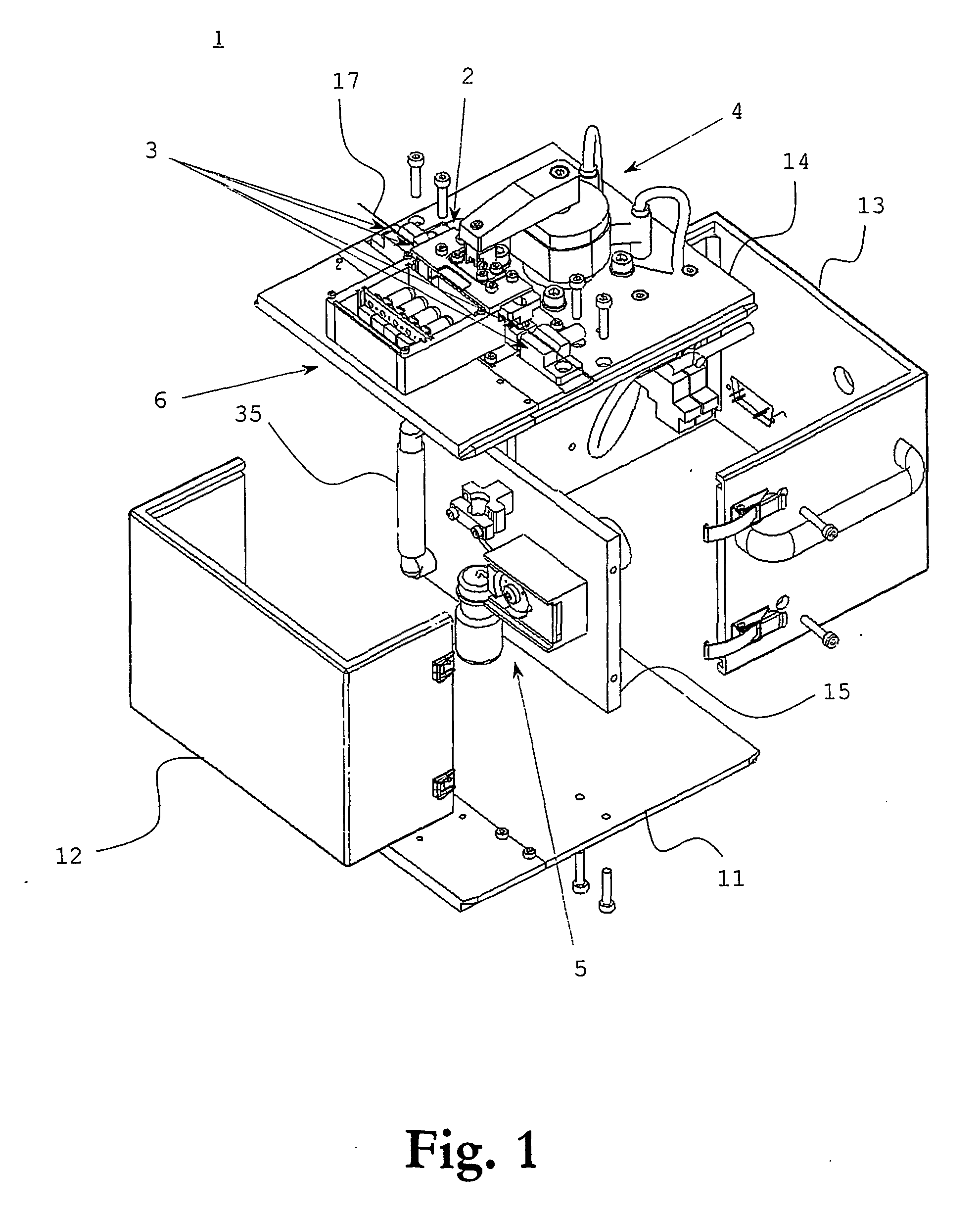

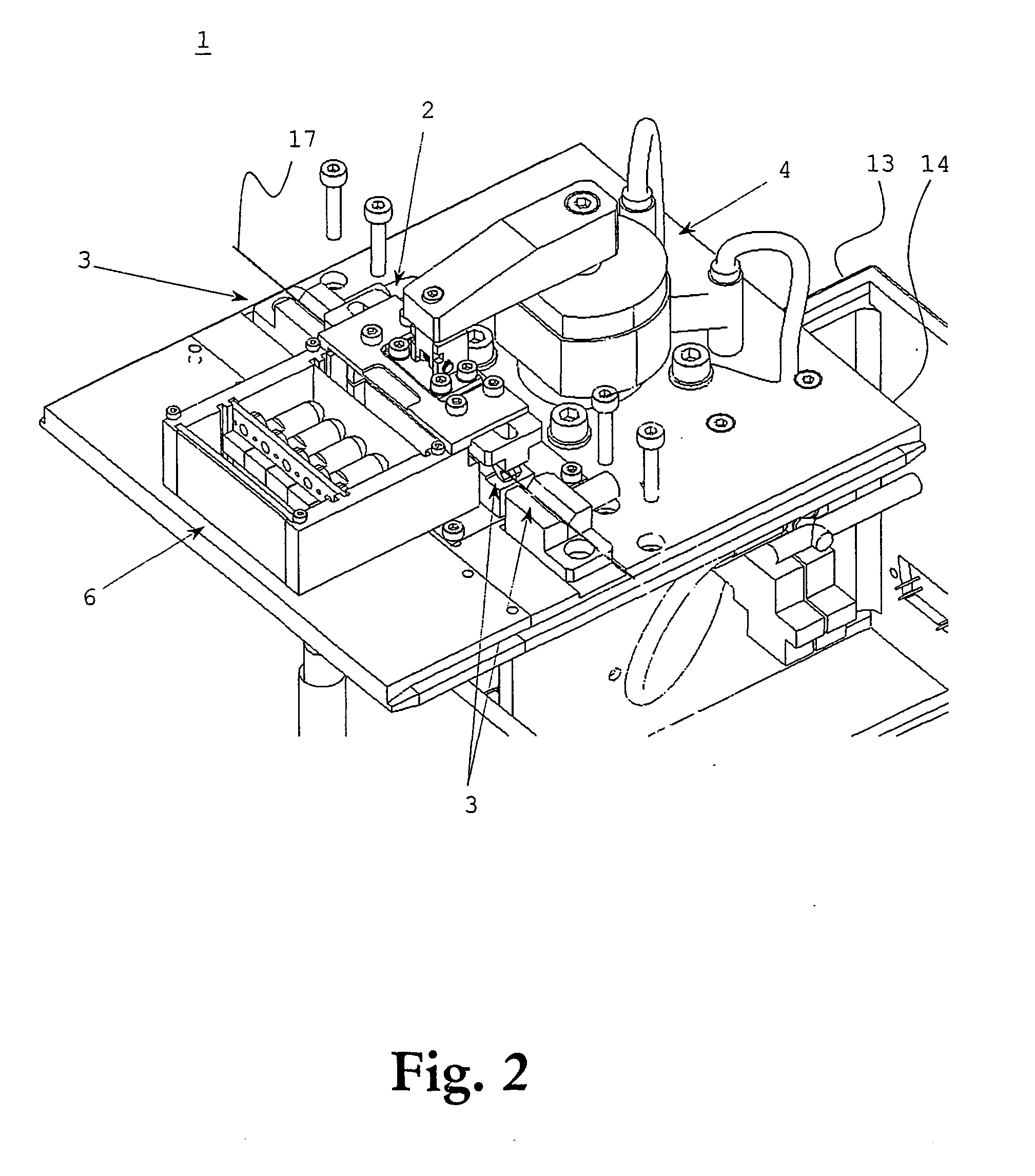

Recoating of optical fiber

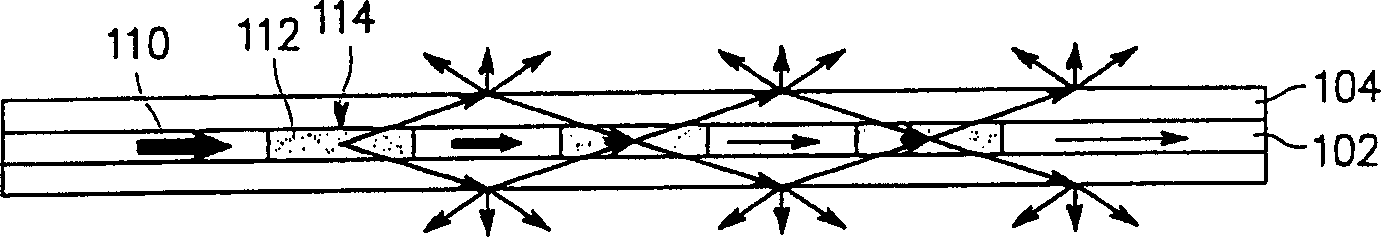

InactiveUS20040036188A1Long-term useFast and reliable recoatingTailstocks/centresConfectioneryFiberUV curing

An apparatus (1) for recoating uncoated and spliced end portions of optical fibers (17) comprises two mold blocks (21a, 22b), each of which includes a groove (22a, 22b), the mold blocks being arrangable in a closed state, wherein the grooves cooperate to form a mold cavity for the fiber end portions, and in an open state, wherein the fiber end portions are insertable into the grooves. The apparatus further includes an injection system (5) for injecting a recoating material into the mold cavity, and a UV curing system (6) for irradiating the recoating material with UV light, thus curing the recoating material. At least one mold block is made of a plastic material comprising a fluoroplastic, e.g. PCTFE, the plastic material being at least partly transparent to UV light to enable the curing system to irradiate the UV curable recoating material with UV light through this mold block.

Owner:ARBOIX ESTEBAN +1

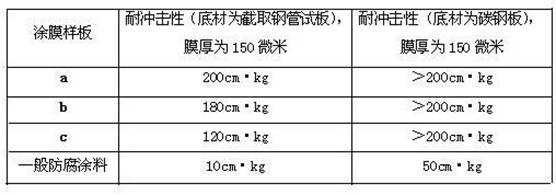

High-performance impact-resistance steel structure paint

ActiveCN102086337AImprove mechanical propertiesGood chemistryEpoxy resin coatingsPolymer scienceRecoating

The invention relates to the field of coating technology in chemical technology, in particular to high-performance impact-resistance steel structure paint, which comprises a component A and a component B, wherein the component A and the component B are used in combination according to the mass ratio of the component A to the component B of (3-5):1. In the invention, dimer acid addition modified toughened epoxy resin is added with potassium hexatitanate whisker with a tunnel-like structure and phenolic aldehyde modified amine is used as a curing agent, so the paint has high mechanical performance, chemical performance and high impact resistance; besides high anticorrosion performance, the 200-micrometer-thick coating on carbon steel plate can resist 200kg.cm impact; a coating process is safe and exerts fewer influences on the environment; and the damage rate of coated steel pipes in a transport process is greatly reduced, supplementary coating or recoating times are reduced, labor and materials are saved, cost is lowered and construction efficiency is improved.

Owner:SHANGHAI HILONG SHINE NEW MATERIAL

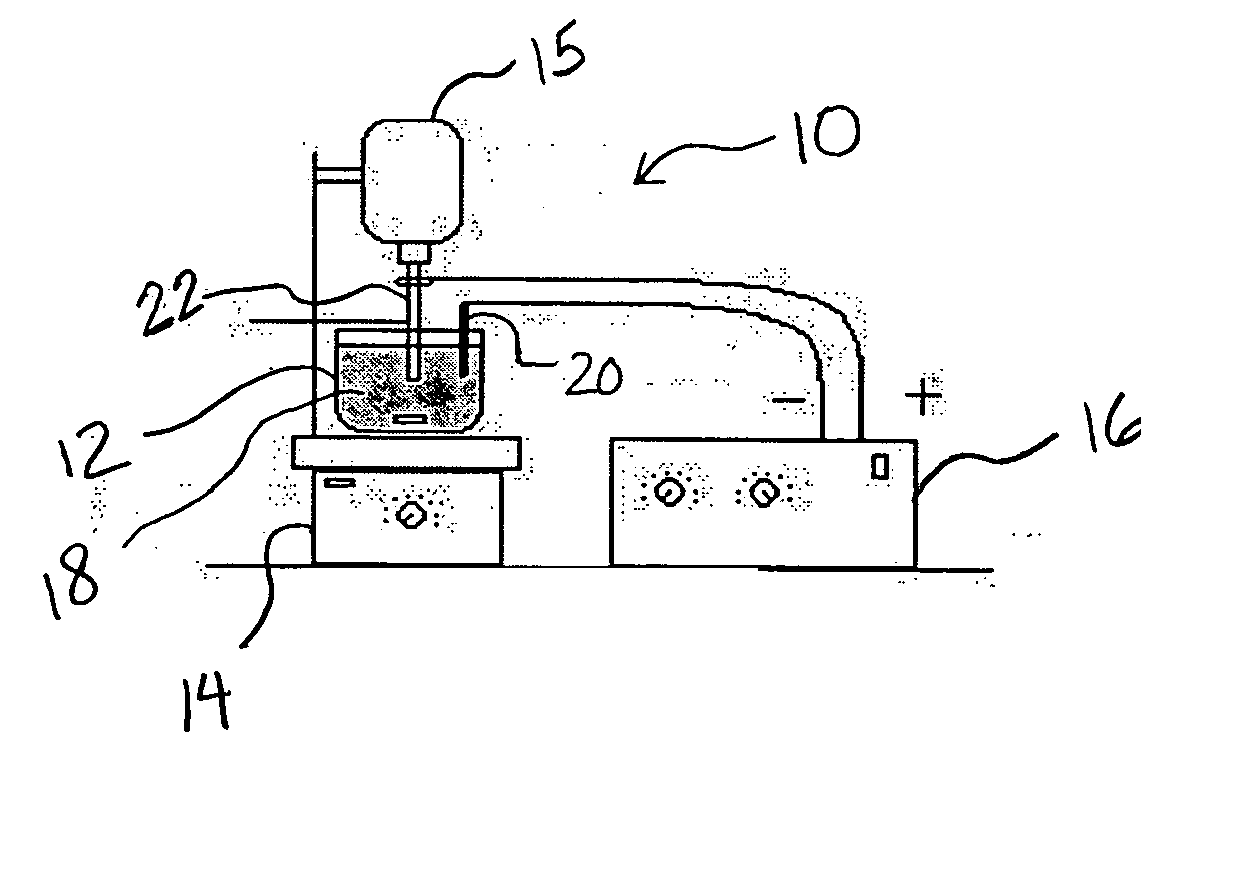

Electrochemical removal of die coatings

InactiveUS20060226025A1Low costDiminishing the costs associated with frequent discarding and replacement of the used substratesElectrolysis componentsElectrochemical machining apparatusRecoatingCarbide

Methods of uniformly removing coatings from metallic substrates, such as tools and dies, without damaging the surface of the underlying substrate are provided. The processes are optimized for steel substrates with metallic carbide or nitride coatings. The methods encompass aqueous electrochemical removal using stirred, low temperature, basic electrolytes. Following removal of an old coating, a new coating may be applied, allowing recycle and reuse of the underlying metal substrate. The ability to recoat and reuse tools represents a significant cost savings.

Owner:COLORADO SCHOOL OF MINES

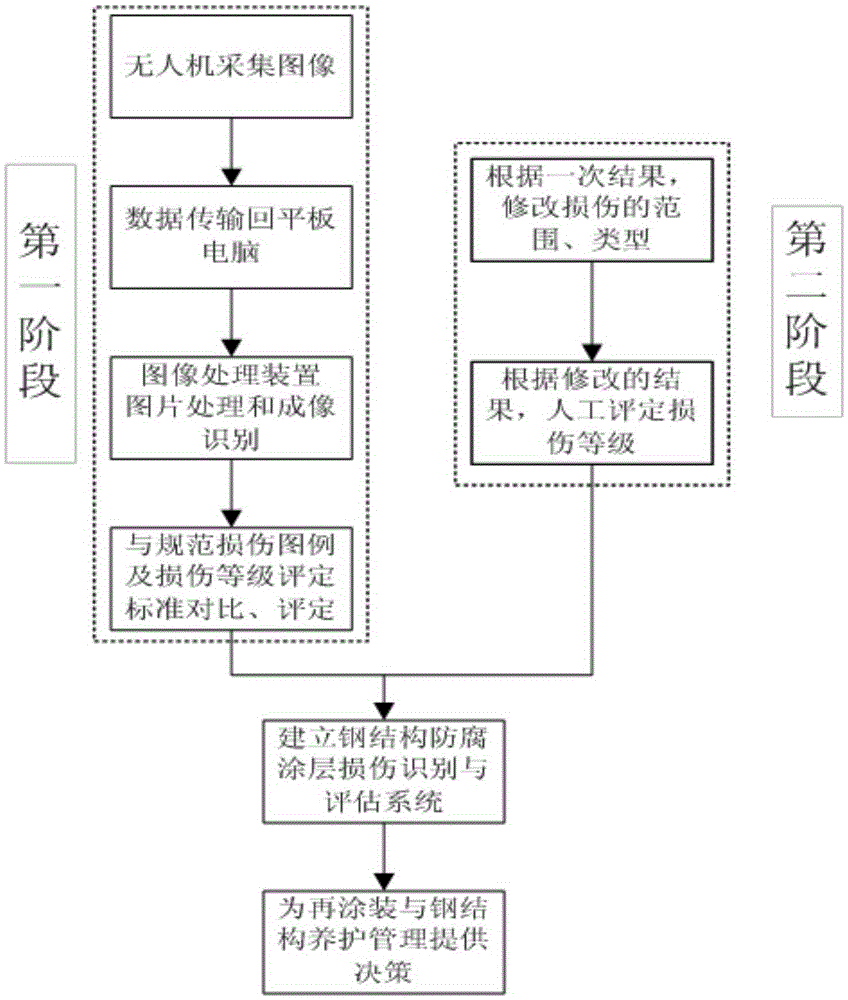

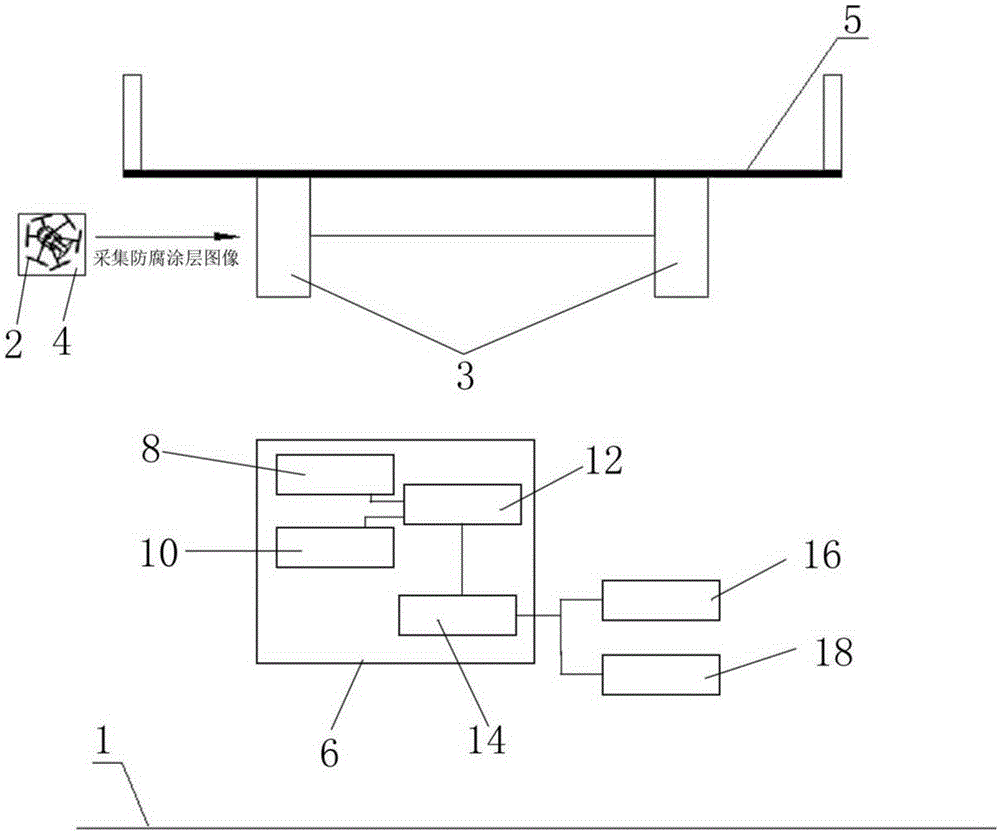

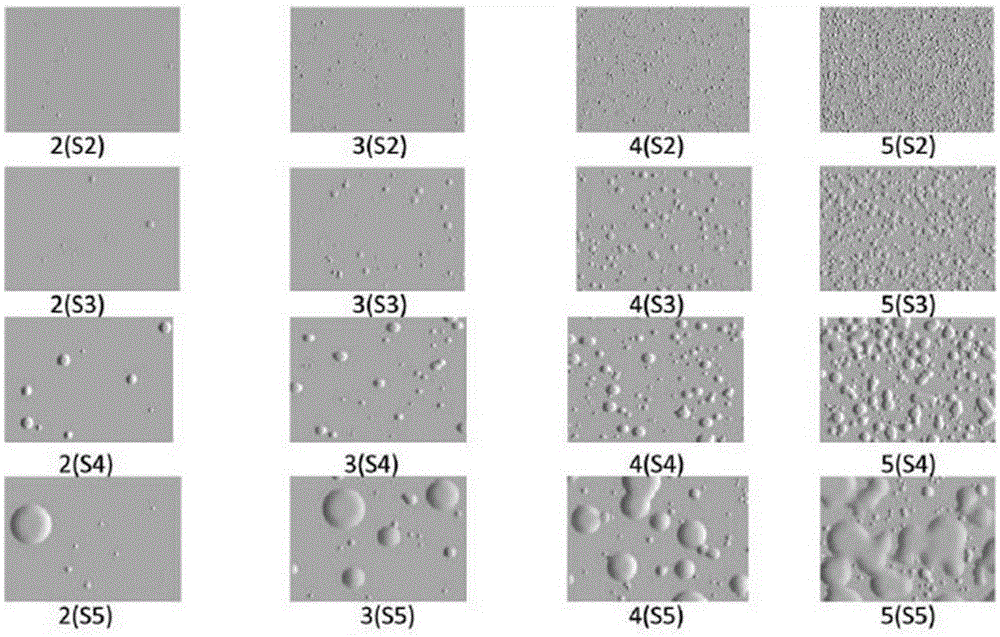

Anticorrosive coating damage distinguishing system and assessment method thereof

InactiveCN105243672AGuaranteed accuracyShorten the timeImage enhancementImage analysisSurface layerRecoating

The invention provides an anticorrosive coating damage distinguishing system, which comprises a camera shooting device, an unmanned aerial vehicle and a server terminal, wherein the camera shooting device is installed on the unmanned aerial vehicle; the output end of the camera shooting device is connected with the server terminal; and a coating damage category memory, a damage grading standard memory, an image processor connected with the output end of the camera shooting device, and an image comparison recognizer are arranged in the server terminal, wherein the image comparison recognizer carries out comparison recognition on an output result of the image processor on the basis of data stored in the coating damage category memory and the damage grading standard memory. The anticorrosive coating damage distinguishing system abandons a traditional way that a damage surface layer image is artificially collected, adopts the unmanned aerial vehicle to load the camera shooting device to collect image data, and carries out processing and recognition on the images collected by camera shooting in virtue of the server terminal so as to obtain a coating damage position, a coating damage category and a coating damage level. A damage assessment method based on the damage distinguishing system is stable and reliable in assessment result and provides a decision basis for recoating and steel structure maintenance management.

Owner:JSTI GRP CO LTD +1

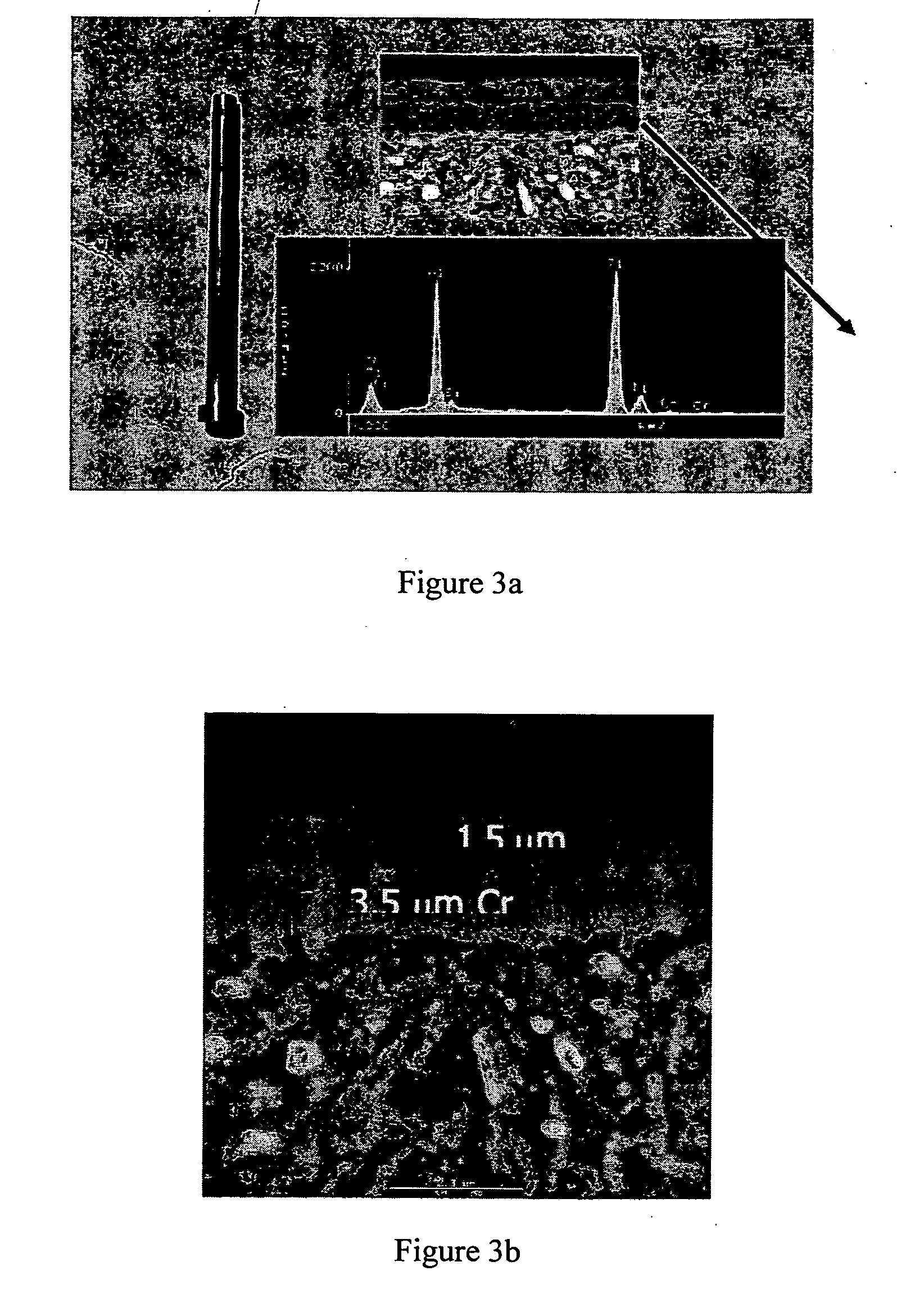

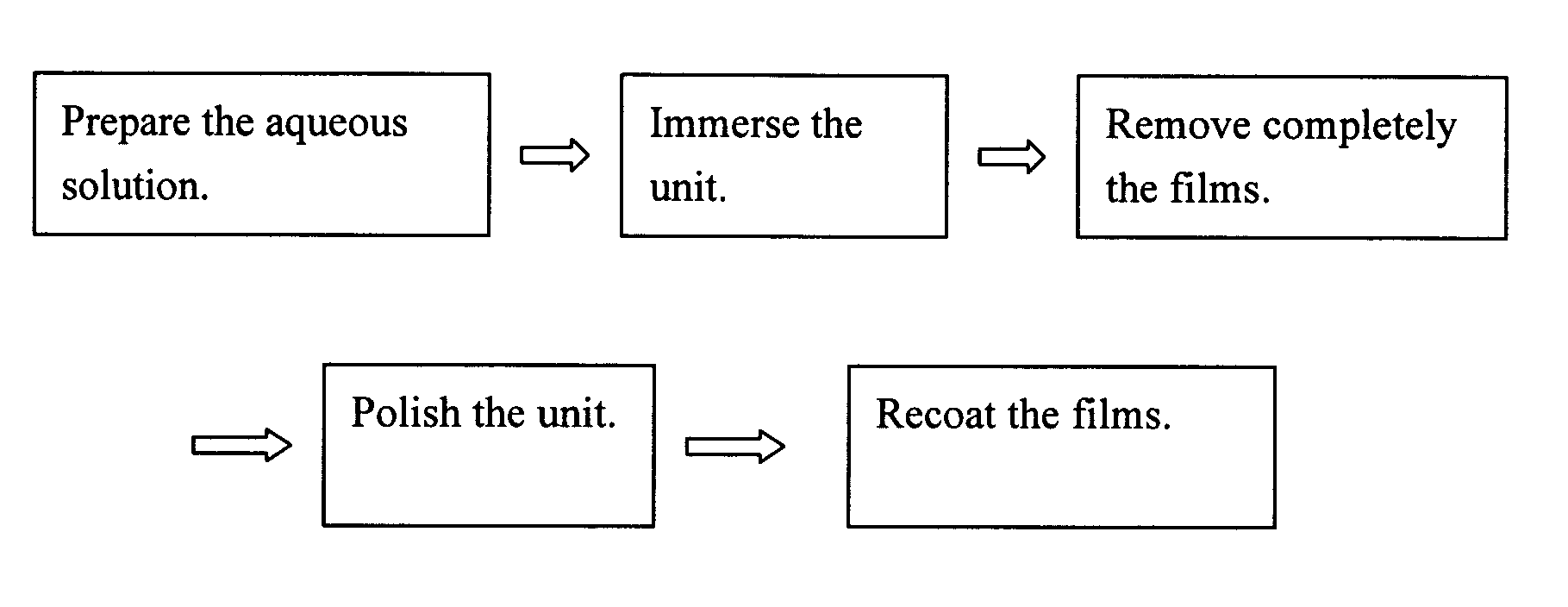

Method for removing and recoating of diamond-like carbon films and its products thereof

InactiveUS20060151433A1Thorough removalImprove efficiencyDecorative surface effectsChemical vapor deposition coatingDiamond-like carbonRecoating

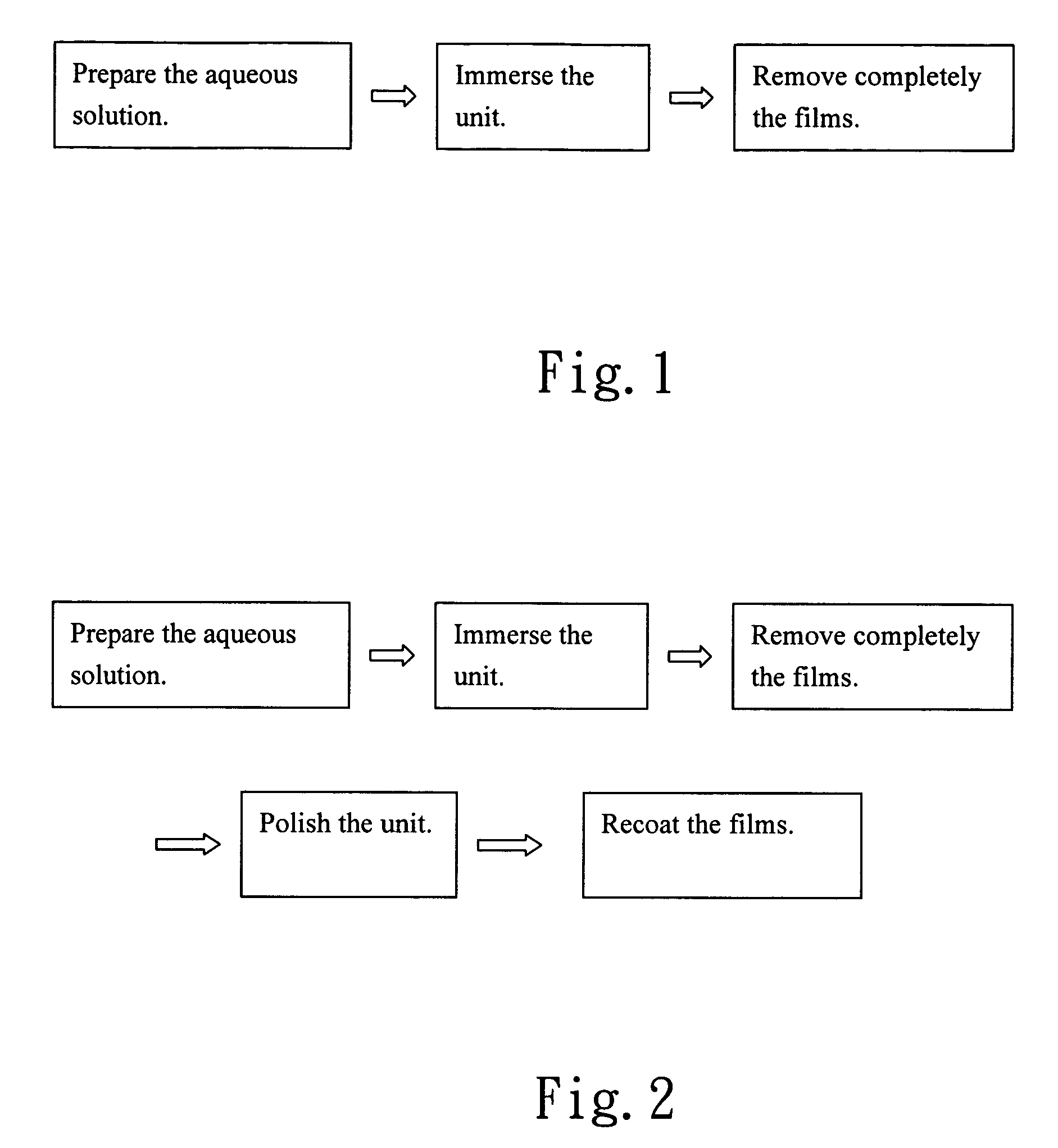

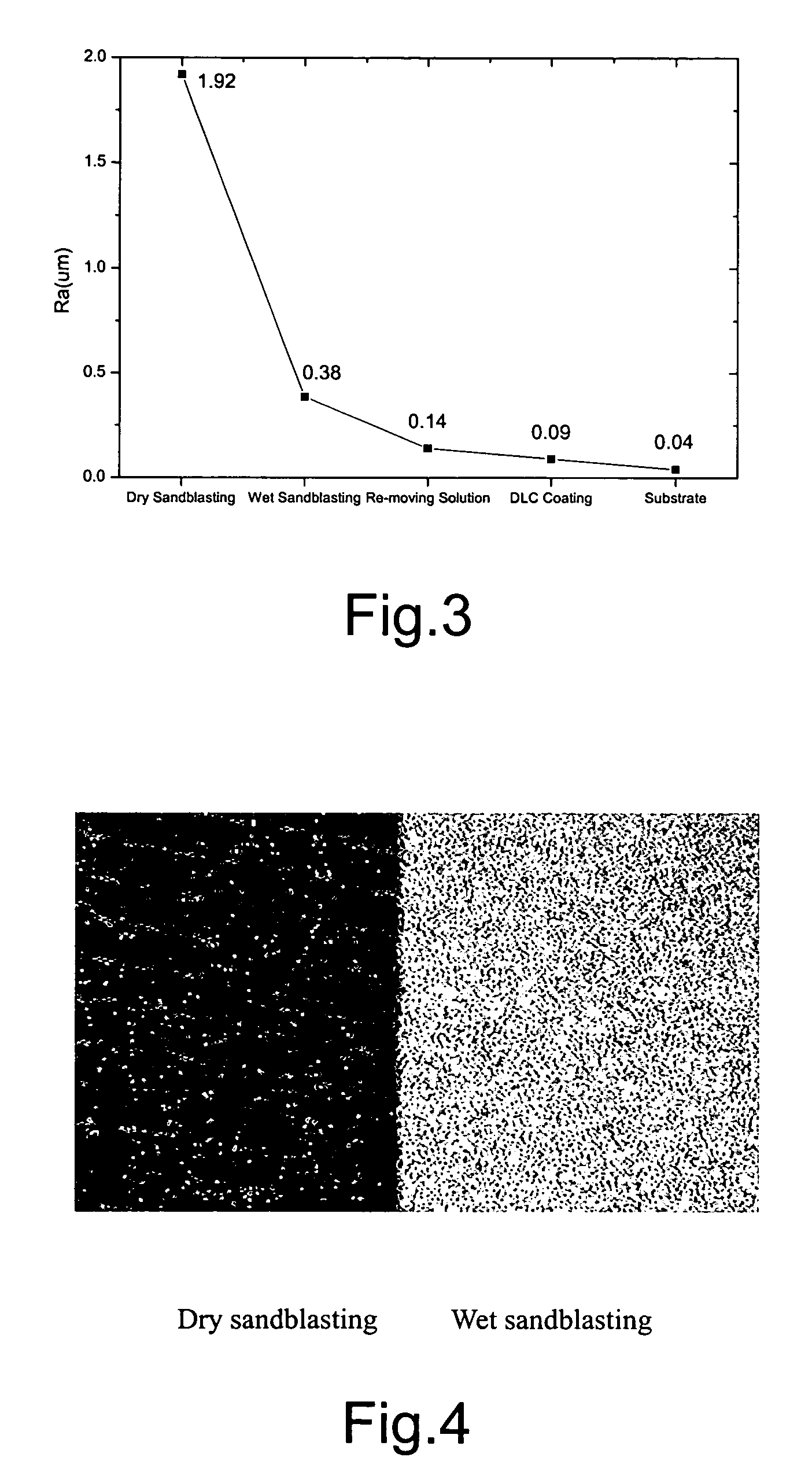

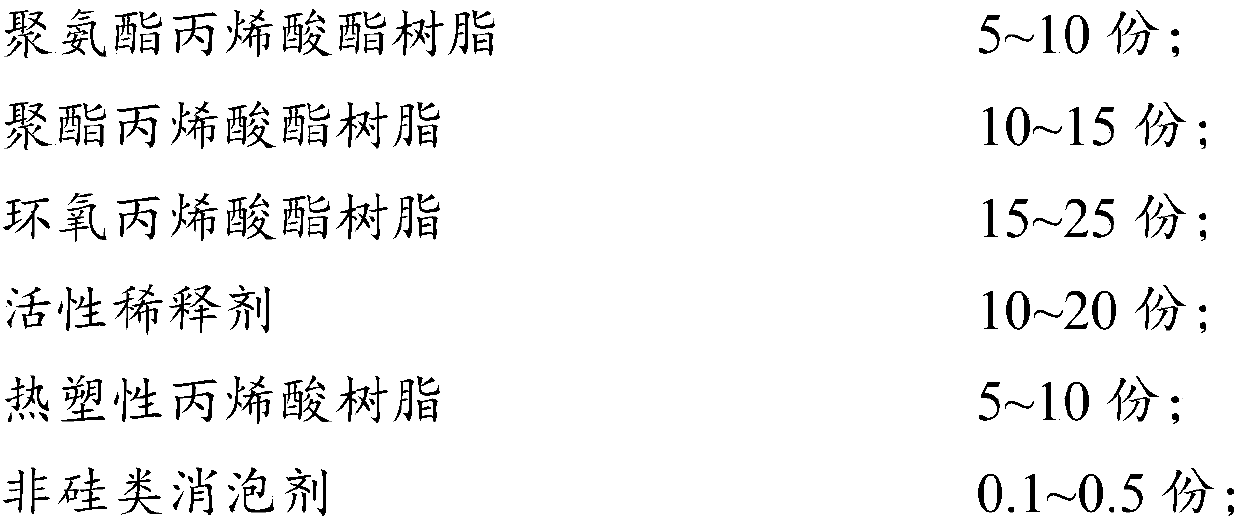

The invention relates to a method for removing and recoating of diamond-like carbon films and its products thereof. The method is to immerse the units that are coated with diamond-like carbon films into the hydrogen chloride solution to come off the coating, which was located on the units' surface. In addition, the method can effectively improve the past fault of poor adhesion, resulting from excessive residual stress and damaged unit surface due to the conventional sandblasting film removing process.

Owner:CHANG +2

Metal surface imitation exterior paint

InactiveCN101875798ARealistic metal decoration effectGood weather resistanceRubber derivative coatingsEpoxy resin coatingsEpoxyRecoating

The invention discloses metal surface imitation exterior paint which comprises 10-15 parts of higher chlorinated polyethylene, 10-15 parts of thermoplastic acrylic resin, 7-10 parts of chlorinated rubber resin, 3-8 parts of epoxy resin, 30-50 parts of dimethylbenzene, 5-10 parts of butyl acetate, 20-40 parts of non-leafing silver powder, 5-10 parts of pearl powder, 6-16 parts of plasticizer, 2-5 parts of metal directing agent and 0.7-1.5 parts of ultraviolet absorber. The metal surface imitation exterior paint has excellent weather resistance, is resistant to various corrosive substances, protects outer walls of a building for a long time, prolongs the service life of the building, and is applicable to areas where air is seriously polluted. A paint film has high strength, water resistance, wear resistance, collision resistance and low maintenance cost and is not easy to damage. Simultaneously, the paint film is smooth, has a certain self-cleaning ability, and can remain brightness for a long time. When damaged, the paint film can be repaired by repainting, which is simple and practicle and has a good repair effect.

Owner:刘昆虎

Ultraviolet-curable coating for spraying furniture and preparation method of ultraviolet-curable coating

InactiveCN109593445AEasy to sprayImprove adhesionPolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterAcrylic resin

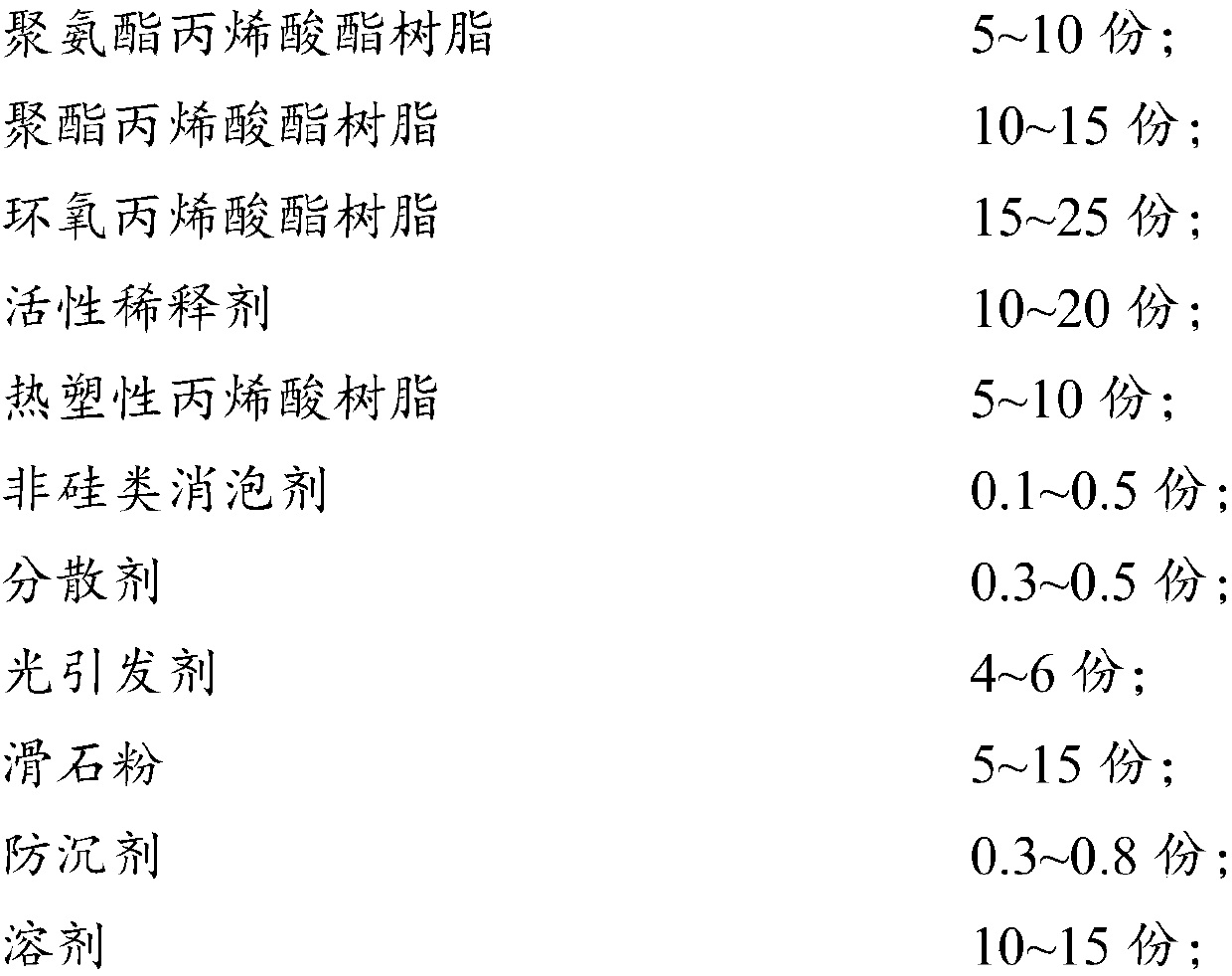

The invention belongs to the technical field of coatings and specifically relates to an ultraviolet-curable coating for spraying furniture and a preparation method of the ultraviolet-curable coating.Measured by the total weight part (100), the ultraviolet-curable coating provided by the invention comprises the following components in parts by weight: 5-10 parts of polyurethane acrylate resin, 10-15 parts of polyester acrylate resin, 15-25 parts of epoxy acrylate resin, 10-20 parts of activated diluent, 5-10 parts of thermoplastic acrylic resin, 0.1-0.5 part of non-silicon defoaming agent, 0.3-0.5 part of dispersant, 4-6 parts of photoinitiator, 5-15 parts of talcum powder, 0.3-0.8 part of anti-settling agent and 10-15 parts of solvent, wherein the solvent is a volatile organic solvent capable of dissolving the thermoplastic acrylic resin. Compared with the prior art, the ultraviolet-curable coating provided by the invention is free of sanding before being recoated and capable of simplifying the coating spraying process and effectively increasing the interlayer adhesion force of a film.

Owner:珠海展辰新材料股份有限公司

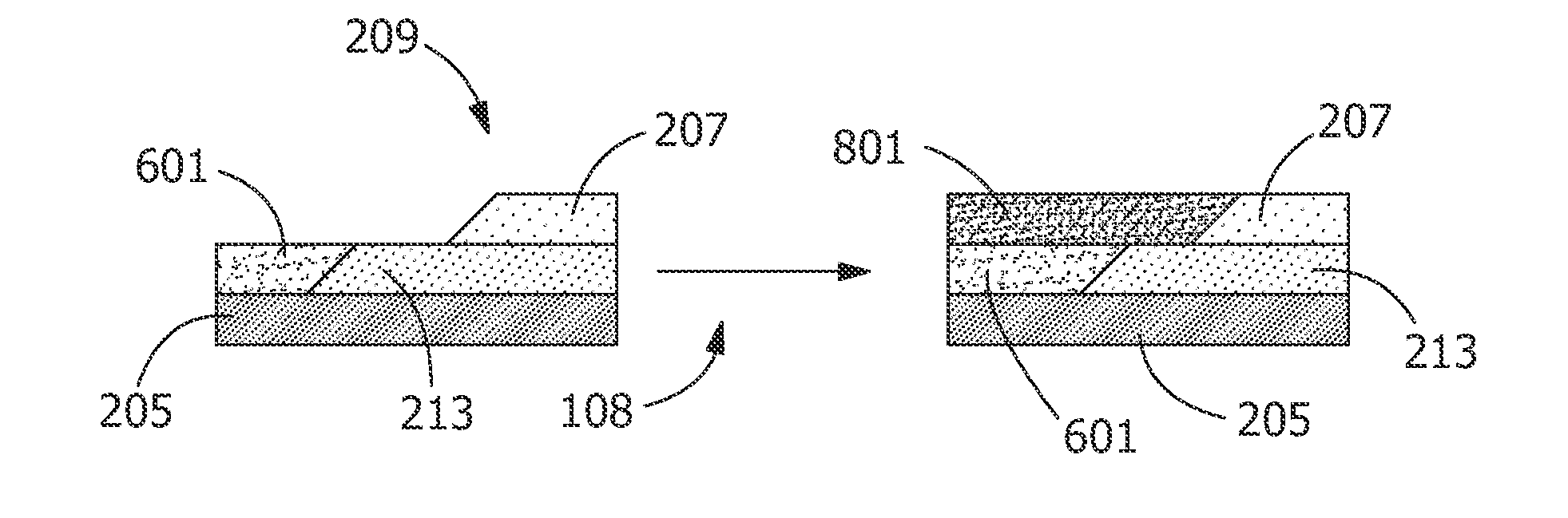

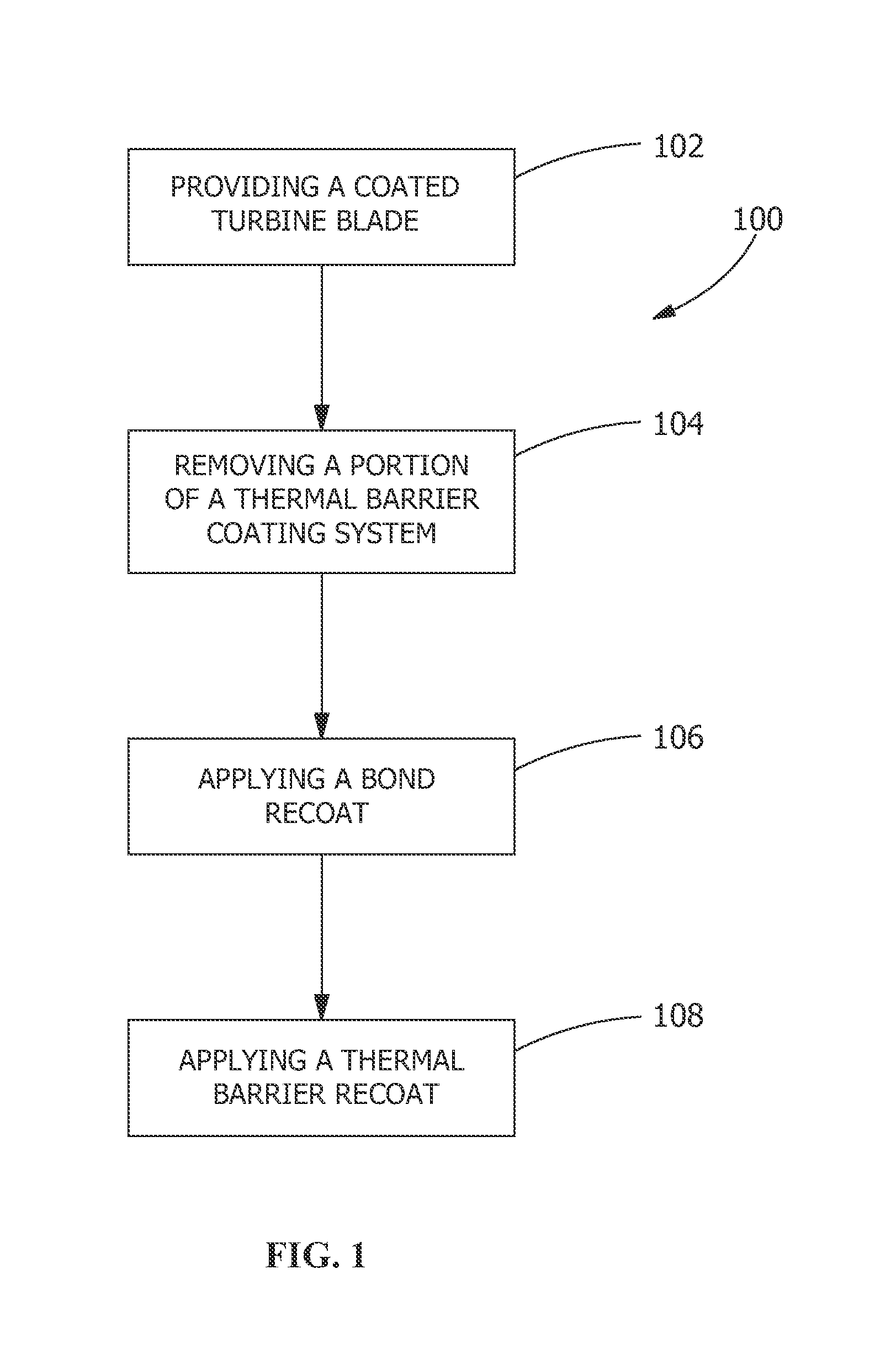

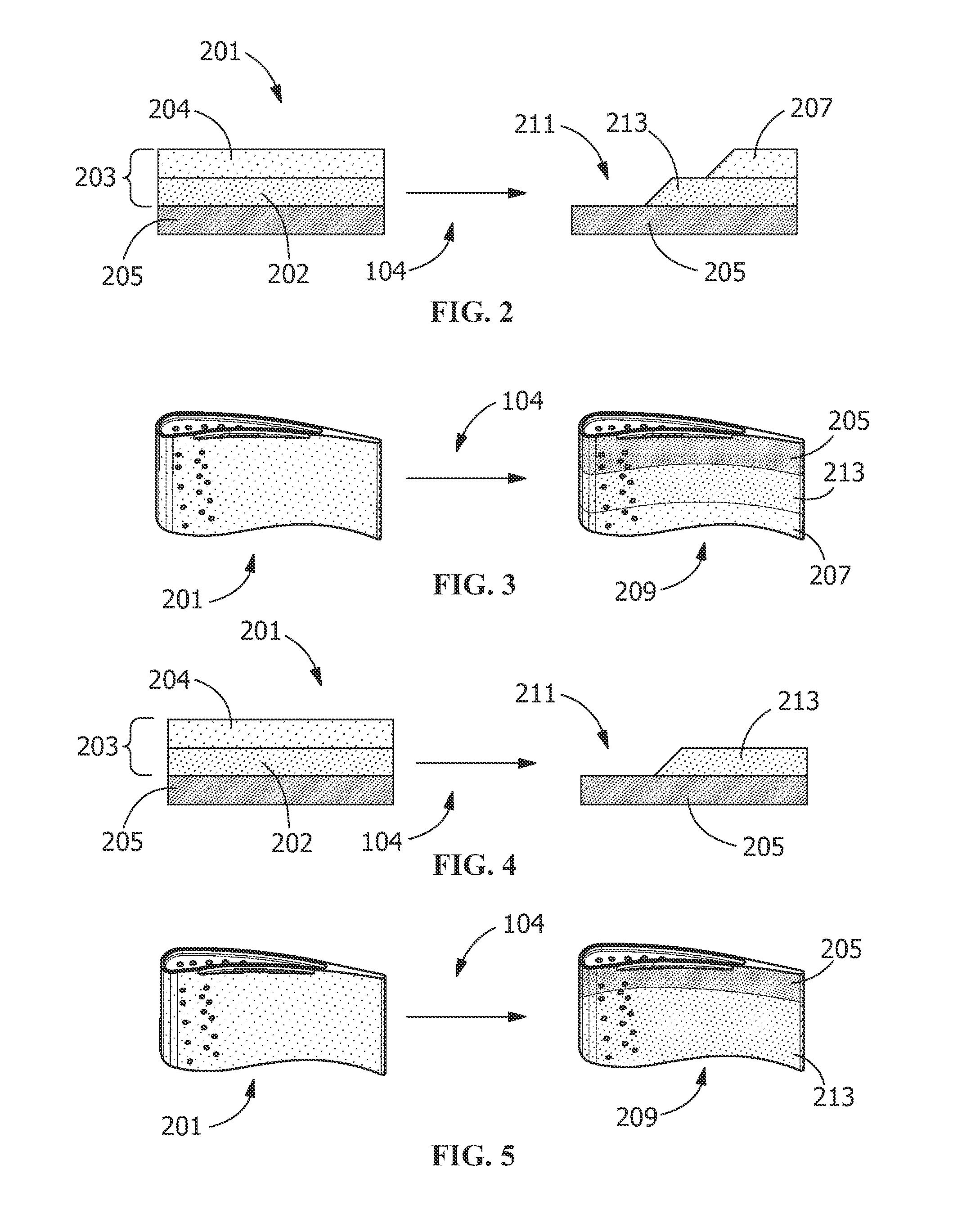

Recoating process and recoated turbine blade

Recoating process and recoated turbine blade are disclosed. The recoating process includes providing a coated turbine blade, then removing a portion of the thermal barrier coating system to form a partially-stripped turbine blade, then applying a bond recoat to the stripped region of the partially-stripped turbine blade; and then applying a thermal barrier recoat to the bond recoat to form a recoated turbine blade. The recoated turbine blade comprises the bond coating portion abutting the bond recoat, the thermal barrier coating portion abutting the thermal barrier recoat, and the stepped configuration. The coated turbine blade has a thermal barrier coating system positioned on a substrate. The partially-stripped turbine blade has a stripped region, a bond coating portion, a thermal barrier coating portion, and a stepped configuration.

Owner:GENERAL ELECTRIC CO

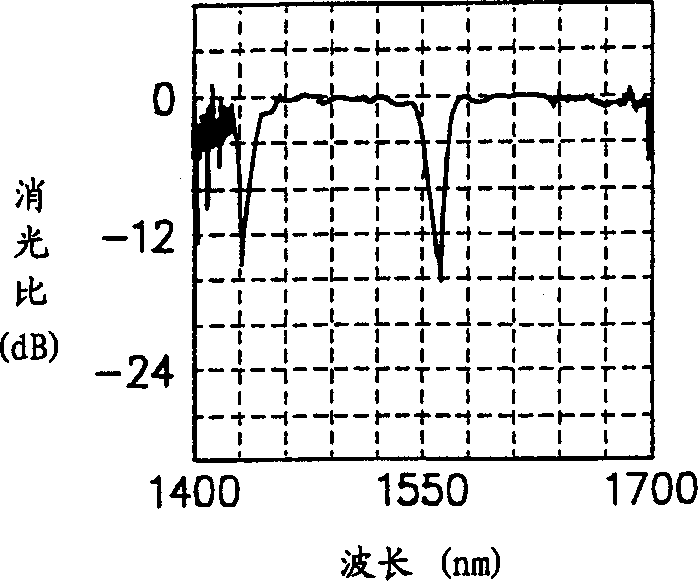

Temp. compensated long period optical fiber grating filter

Disclosed is a temperature compensated long period optical fiber grating filter. The long period optical fiber grating filter includes a core formed with a long period grating, a cladding surrounding the core, a coating coated over a portion of the cladding not surrounding the long period grating, and a re-coating coated over a portion of the cladding surrounding the long period and made of a material exhibiting an increase in refractive index in accordance with an increase in temperature, the recoating serving to allow a coupling wavelength shift caused by the increase in refractive index to be carried out in a direction opposite to that of a coupling wavelength shift caused by a refractive index difference between the core and the cladding. In accordance with this long period optical fiber grating filter, a temperature compensation can be more easily achieved without any inconvenience caused by an adjustment of refractive index in the filter or an addition of a material for avoiding a variation in refractive index depending on temperature.

Owner:SAMSUNG ELECTRONICS CO LTD

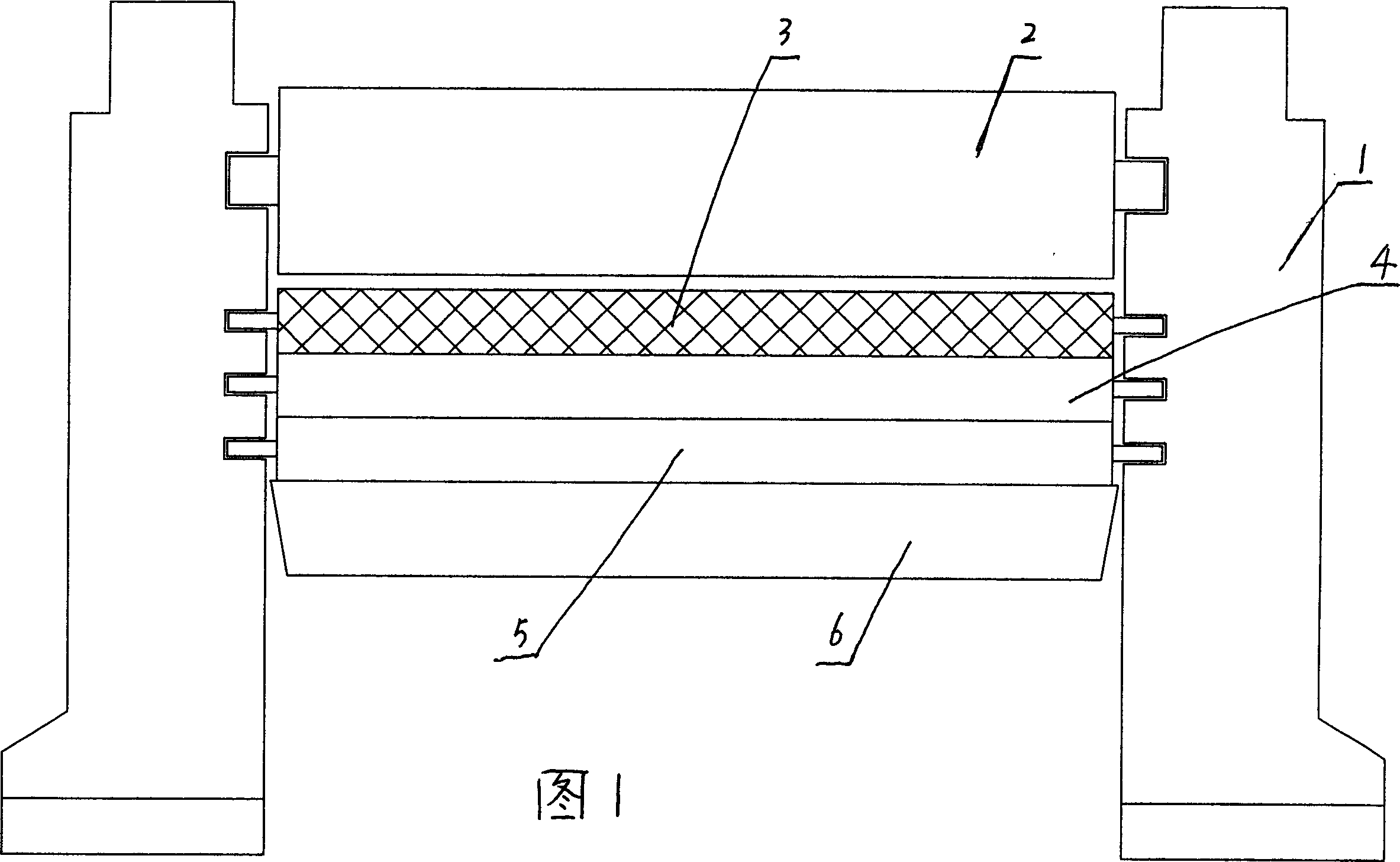

Steel sheet continuous recoating and printing process

InactiveCN1775545ALess investmentImprove efficiencyNatural patternsOther printing apparatusChemical treatmentSheet steel

The invention relates to a steel plate continuous coating and printing process, and the flow of the process is as follows: raw material coiling-->linking-->edge straightening--> steel belt storing-->degreasing-->water washing-->spray cooling-->hot air drying--> chemical processing-->indirect cooling-->bottom layer dyeing--> bottom dyeing drying--> hot air drying-->surface dyeing and back dyeing-->primary dyeing--> intermediate coating-->third coating-->drying-->surface checking-->steel belt storing-->hot air drying-->spray cooling-->drying-->fine coating-->separate coiling of products-->product packaging or size cutting-->product finishing; the invention has less investment and high benefit. And the invention adopts the printing technical theory and replaces wood with steel, and can produce various wood pattern effects and various patterns.

Owner:葛勇智

Multilayer recoating high-transparence fast-drying easy-polishing sanding nitrocellulose primer

InactiveCN101168636AHigh transparencyHigh Transparency Fast TransparencyRosin coatingsAnti-corrosive paintsRecoatingPrice ratio

The invention discloses multi-layer recoating, high transparent, quick drying and superior buffing nitryl transparent primer. The nitryl transparent primer comprises components with the parts by weight being as follows: 36 to 45 parts of ester solvent, 20 to 25 parts of nitro cotton, 18 to 22 parts of maleic modified abietic resin, 1.5 to 2.0 parts of dicapryl phthalate, 4 to 7 parts of zinc stearate, and 1.5 to 2.3 parts of talcum powder. The multi-layer recoating, high transparent, quick drying and superior buffing nitryl transparent primer has the characteristic of keeping the high transparency after being recoated, and has the characteristics of quick drying and superior buffing at the same time. Moreover, the product has the advantages that the product formula is simple, the cost is inexpensive, and the performance-price ratio is high.

Owner:BAUHINIABLAKEANA PAINTSHENZHEN

Method for achieving recoat adhesion over a fluorinated topcoat

Owner:AXALTA COATING SYST IP CO LLC

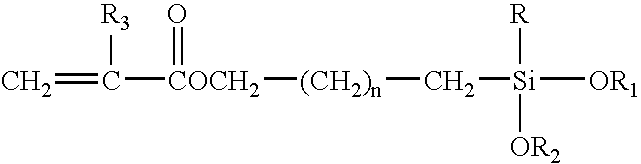

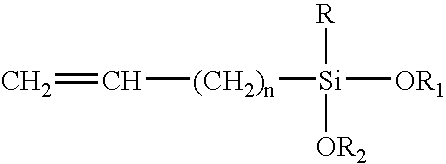

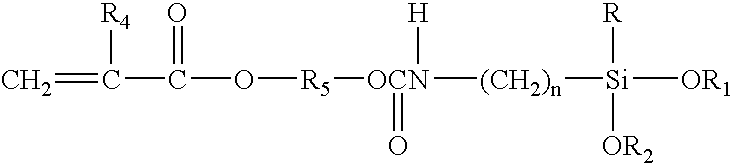

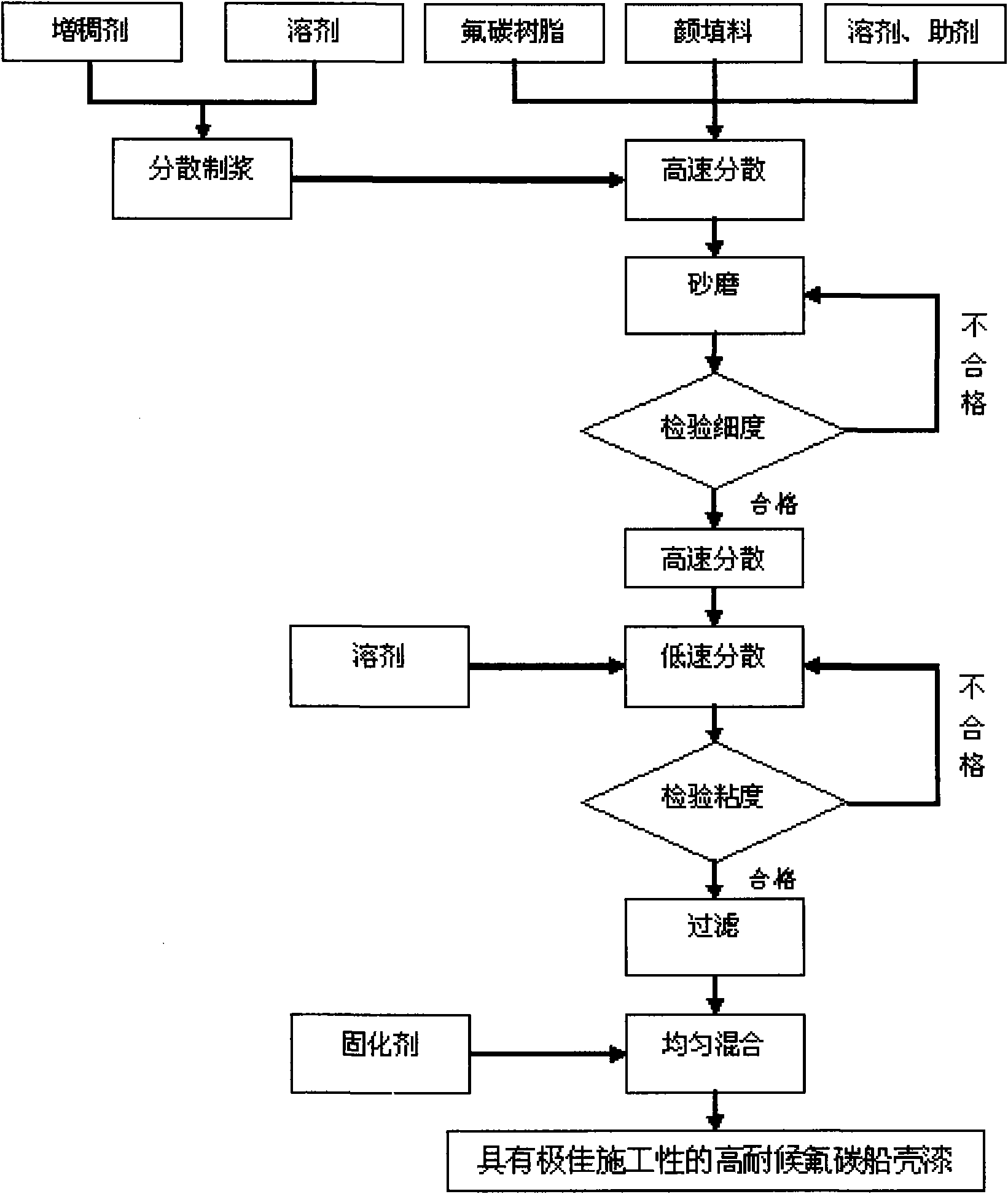

High-weatherability fluorocarbon ship hull paint with good application properties

InactiveCN101638539AGood construction performanceImprove densification performanceAntifouling/underwater paintsPaints with biocidesButyl acetateRecoating

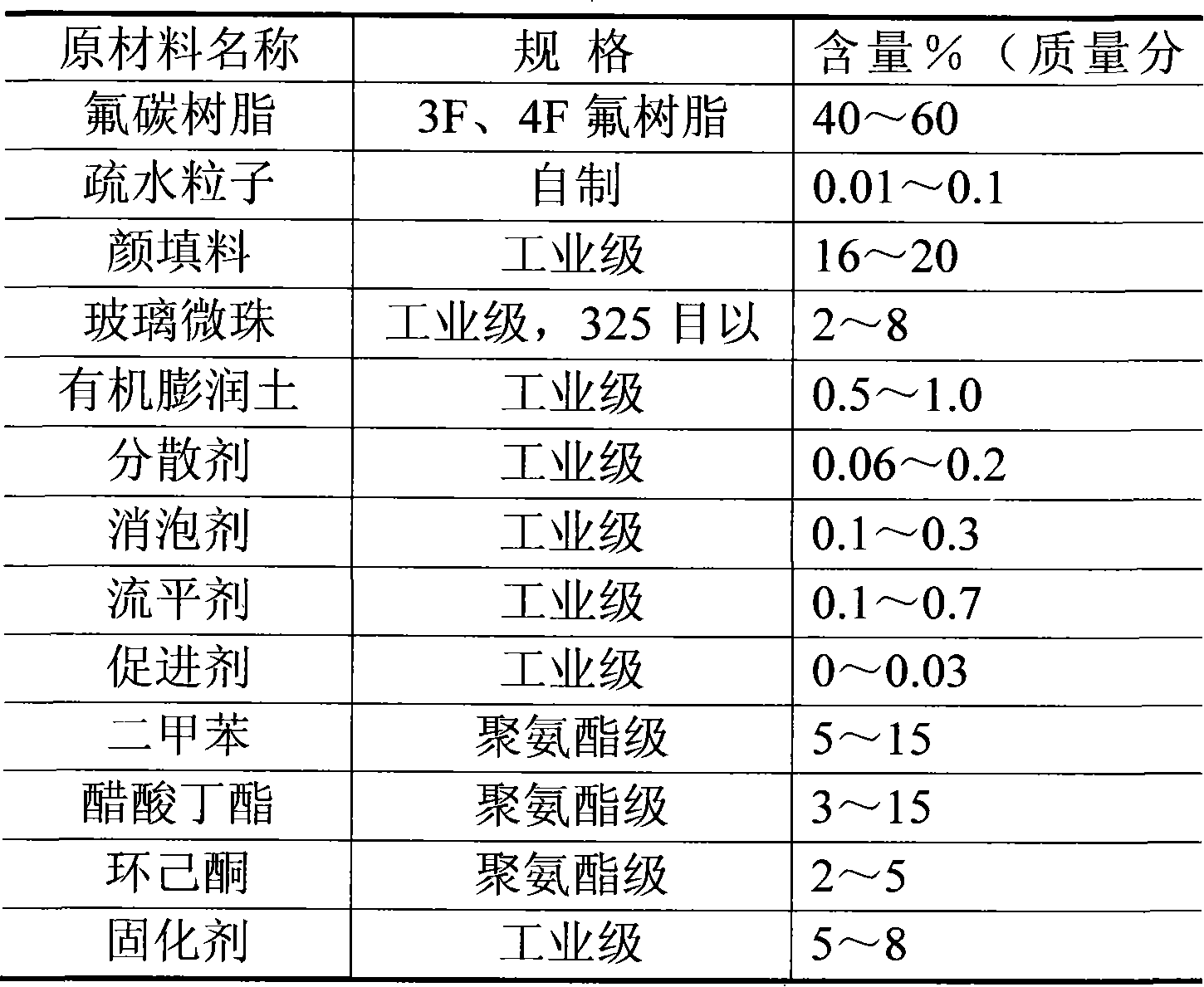

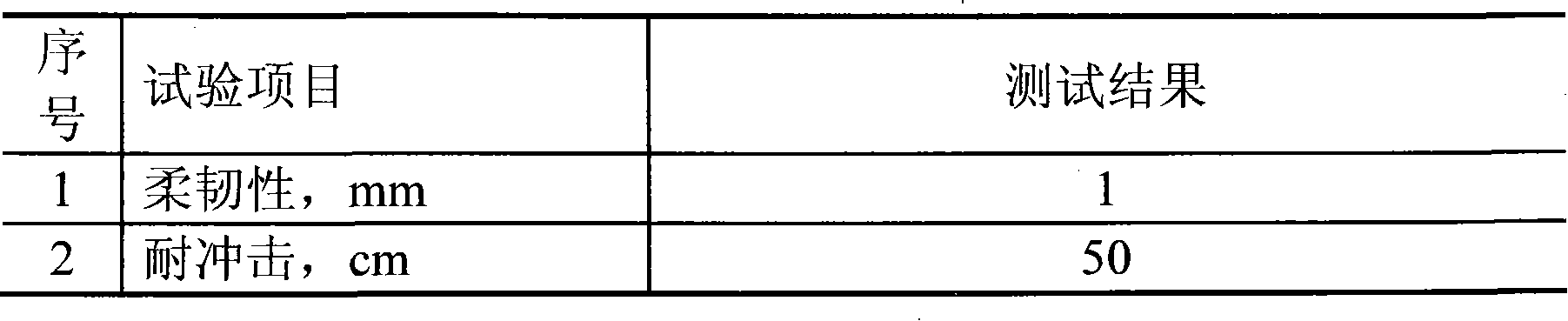

The invention discloses a high-weatherability fluorocarbon ship hull paint with good application properties. The fluorocarbon ship hull paint uses a fluorocarbon resin as a main base material, improves the application properties of a fluorocarbon coating system by adjusting a solvent system and adding hydrophobic particles and glass microballoons, and adopts a compound solvent system compounded with butyl acetate, dimethyl benzene and cyclohexanone. The developed fluorocarbon coating can be used through brushing, roller coating, air spraying and airless spraying, and has simple construction control and excellent application properties; by adding the hydrophobic particles and the glass microballoons, the compactness of a fluorocarbon paint film is improved so that the fluorocarbon coating has excellent weatherability and corrosion resistance; and the high-weatherability fluorocarbon ship hull paint provides long acting coating layer protection for a steel structure, reduces the workloads for surface protection and maintenance and recoating, can be mainly applied to ship hulls to play a role of high weathering, heavy corrosion protection and high decoration, and can also be applied in the fields of bridges, offshore facilities and the like.

Owner:XIAMEN SUNRUI SHIP COATING

Automated UV recoat inspection system and method

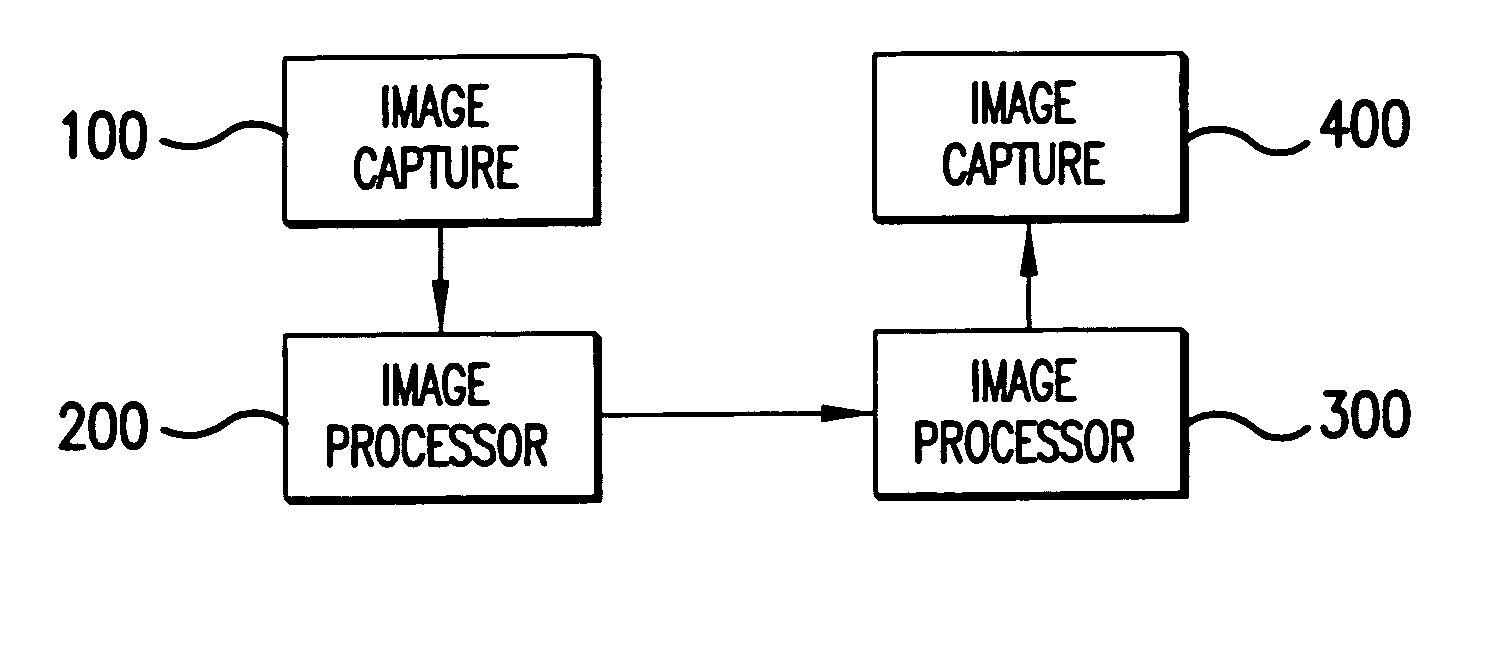

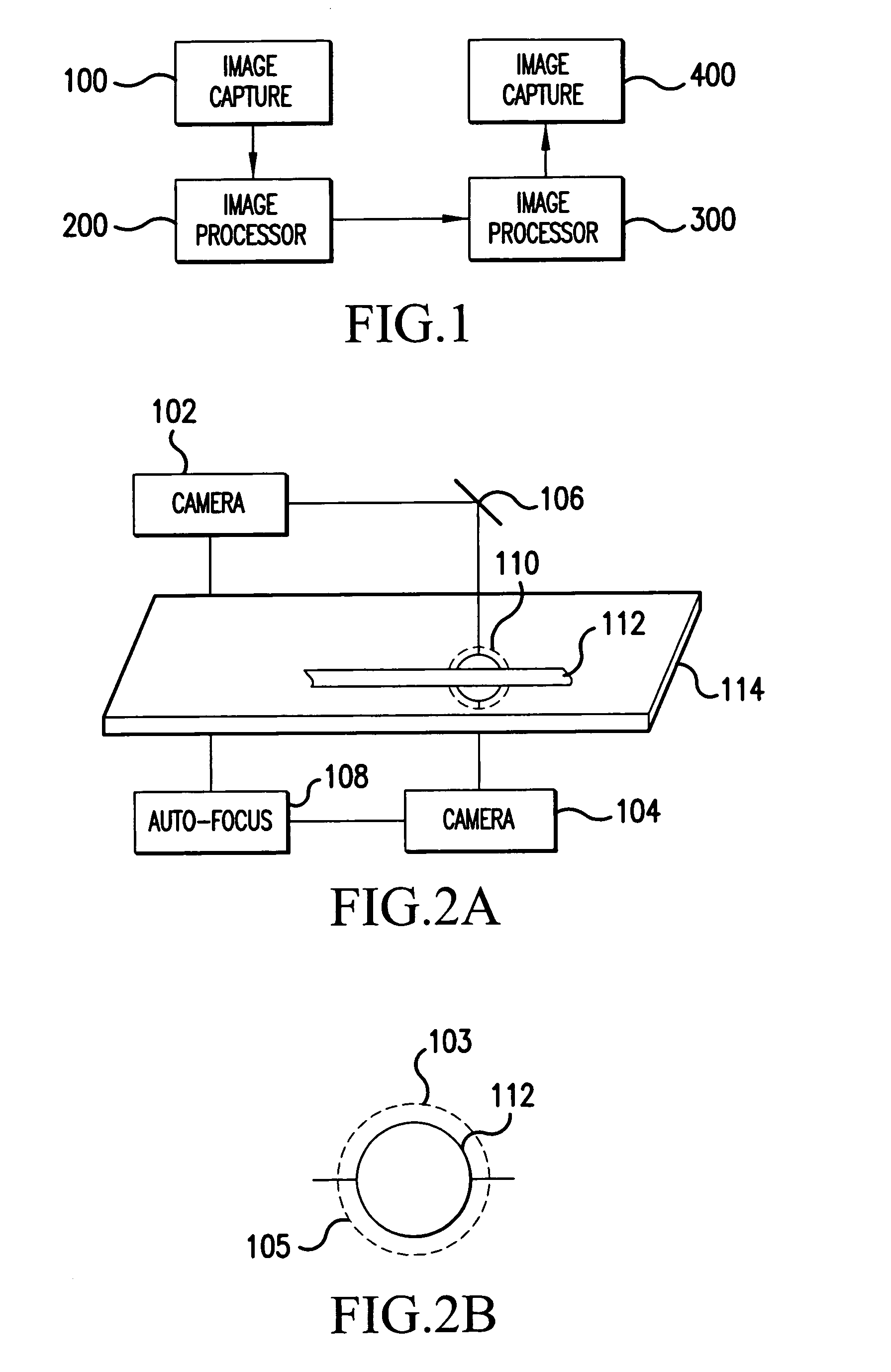

InactiveUS7113626B1Automate the determinationCharacter and pattern recognitionTesting fibre optics/optical waveguide devicesFiberRecoating

A camera system and automated translation system allows automatic image capture of a recoat of a fiber which has undergone a number of processes. These images may be used to automatically inspect the recoat of the fiber in accordance with objective criteria. A stability index may be determined based on the thickness of the recoat on the fiber, a uniformity of the recoat on the fiber, a depth of any surface cracks on the recoat, and a depth of any bubbles in the recoat. A desired stability index may be determined in accordance with a desired lifetime of the fiber and an intended use of the fiber.

Owner:CIENA

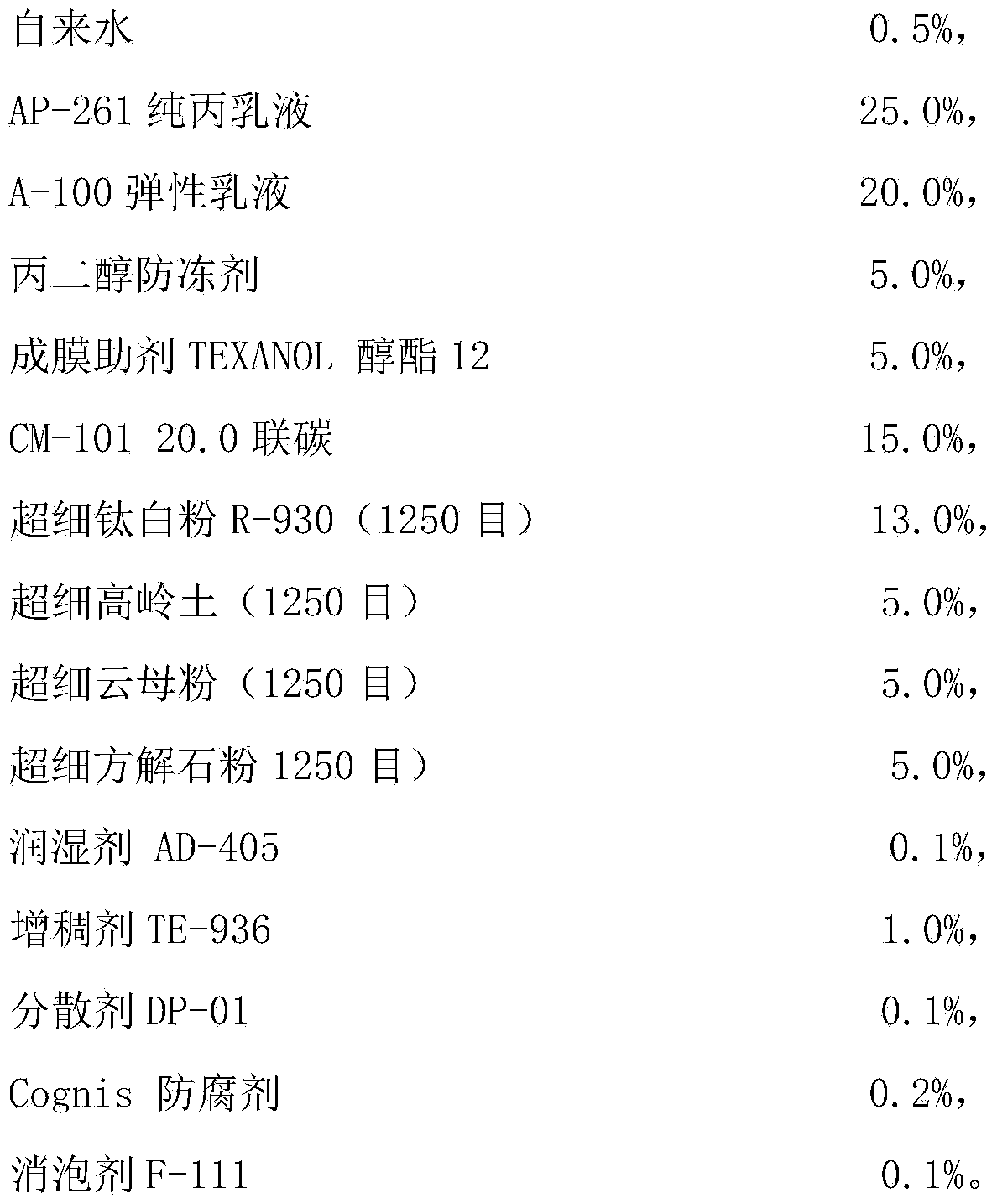

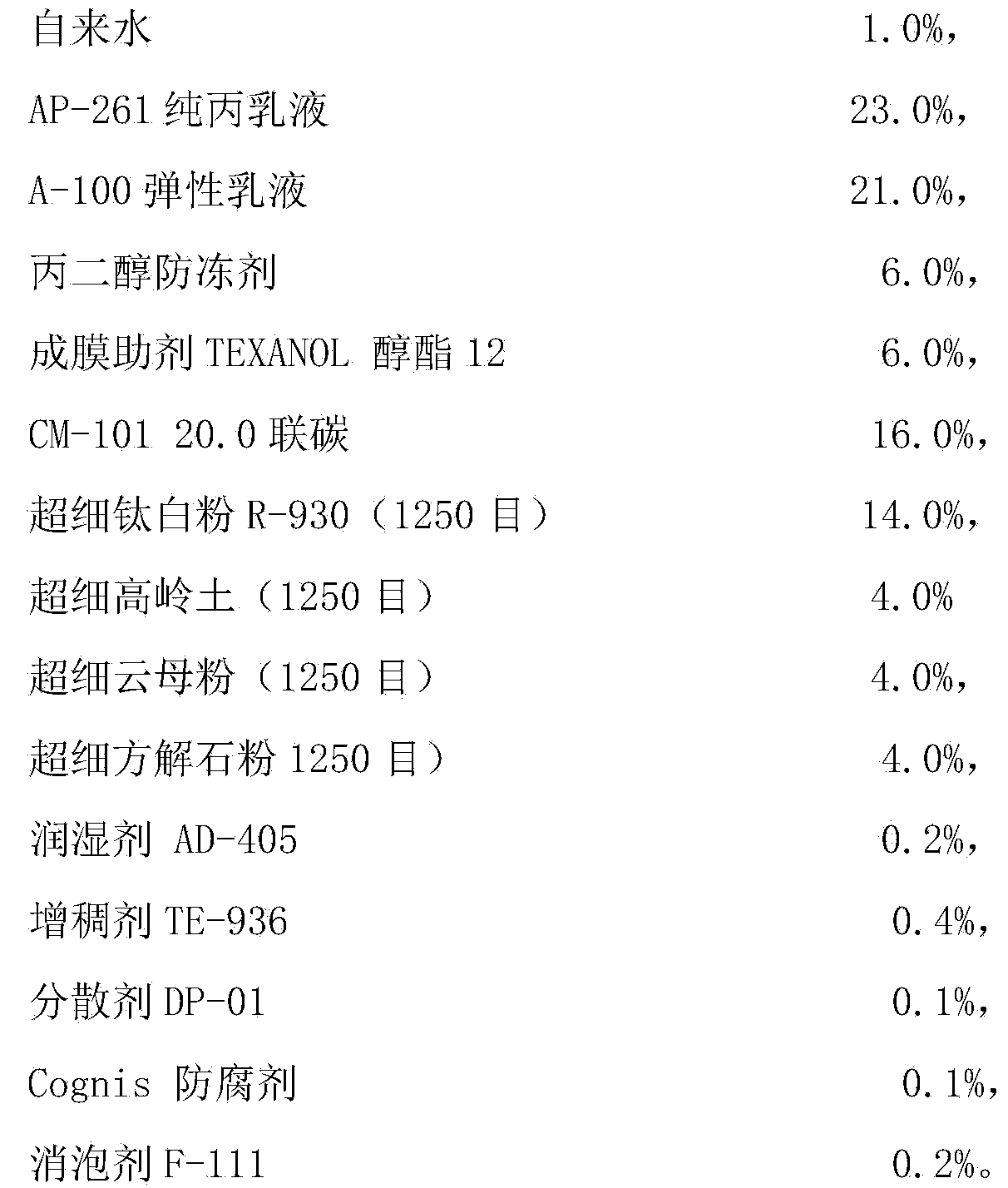

Aqueous elastic exterior-wall coating and preparation method thereof

The invention discloses an aqueous elastic exterior-wall coating and a preparation method thereof. The coating comprises the compositions in percent by mass: 0.5-2% of water, 20-25% of AP-261 pure acrylic emulsion, 19-22% of A-100 elastic emulsion, 5-8% of propylene glycol antifreezing agent, 4-6% of a film-forming auxiliary agent, 15-17% of CM-10120.0 union carbide, 12-17% of ultrafine titanium dioxide R-930, 4-6% of ultrafine kaolin powder, 4-6% of ultrafine mica powder, 4-6% of ultrafine calcite powder, 0.1-0.3% of a wetting agent AD-405, 0.2-1.0% of a thickening agent TE-936, 0.1-0.5% of a dispersant DP-01, 0.1-0.3% of Cognis antiseptic, and 0.1-0.3% of an antifoaming agent F-111. The coating has the advantages of being high in weatherability, high in chemical corrosion resistance, good in water resistance, scrubbing resistance and artificial ageing resistance, abundant in expressive force, strong in stereoperception, flexible, extremely strong in plasticity, strong in adhesive force, resistant to acids and alkalis, free of color fading, free of peeling, free of cracking, and easy for maintenance and recoating. The preparation technology is simple, cost is low and benefit is good.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Anti-after-tack epoxy curing agent and preparation method and application thereof

ActiveCN109134829AHigh molecular weightEasy to dryAnti-corrosive paintsEpoxy resin coatingsEpoxyHigh humidity

The invention relates to the technical field of curing agents, in particular to an anti-after-tack epoxy curing agent and a preparation method and application thereof. The anti-after-tack epoxy curingagent is mainly prepared by, by weight, 35-40 parts of anacardol, 8-12 parts of formaldehyde, 13-17 parts of toluene, 3-7 parts of diethylenetriamine, 8-12 parts of triethylene tetramine and 15-25 parts of epoxy resin. The anti-after-tack epoxy curing agent and the preparation method thereof have the advantages that by introducing epoxy resin fragments into the epoxy curing agent, the molecular weight of the epoxy curing agent is further increased, and the epoxy curing agent is fast in drying and excellent in compatibility with the epoxy resin; the epoxy curing agent can have reaction fast under a low-temperature and high-humidity condition, phase separation is avoided due to the fact that the epoxy curing agent has good compatibility with the epoxy resin, the surface of a formed paint film is dry, a sticky oil surface is avoided, good ply adhesion after the recoating of the epoxy curing agent or the mixed-coating of the epoxy curing agent and other finish paint, and the dry paint film without the oil surface can be formed at 0 DEG C.

Owner:重庆南方漆业有限公司

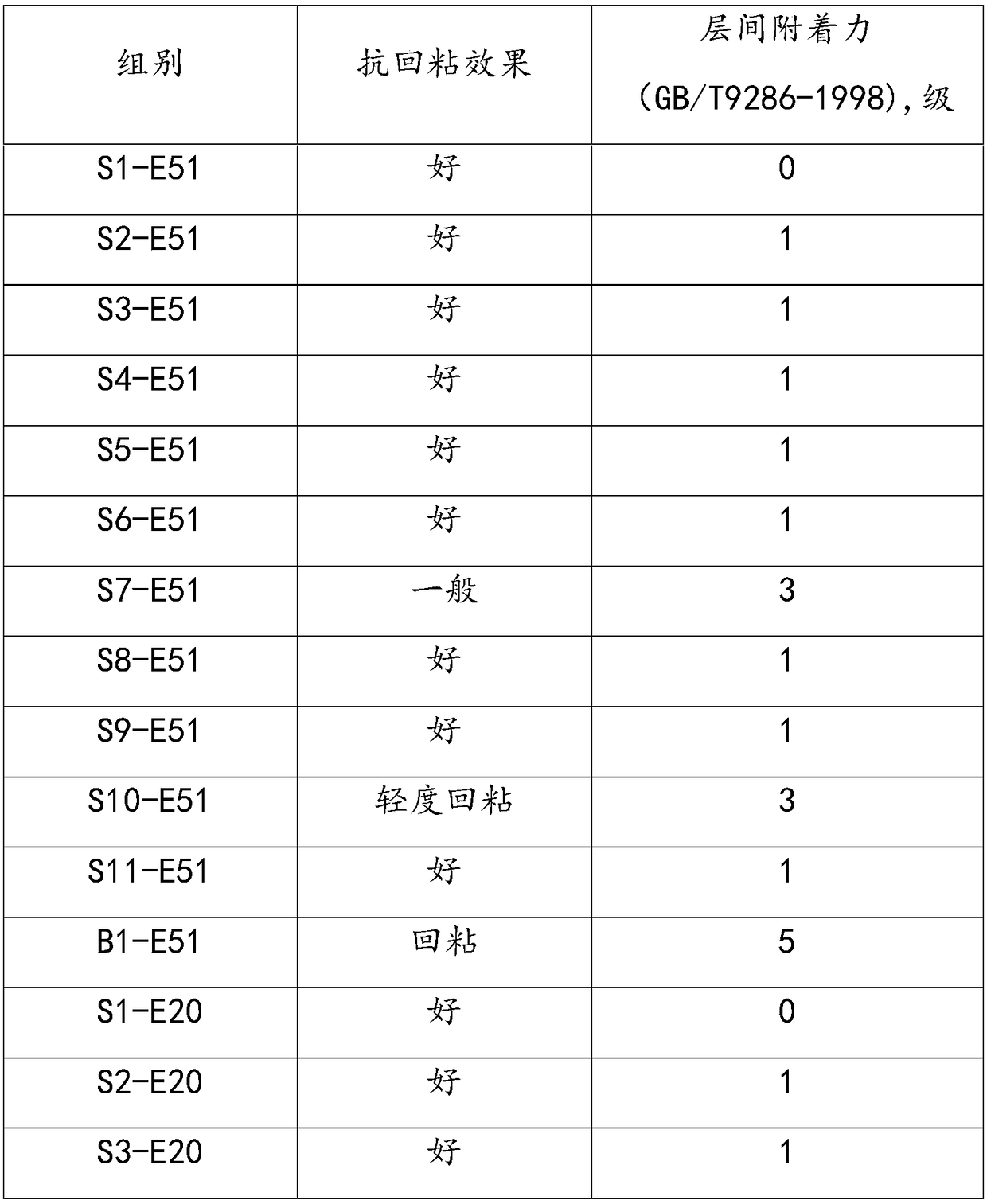

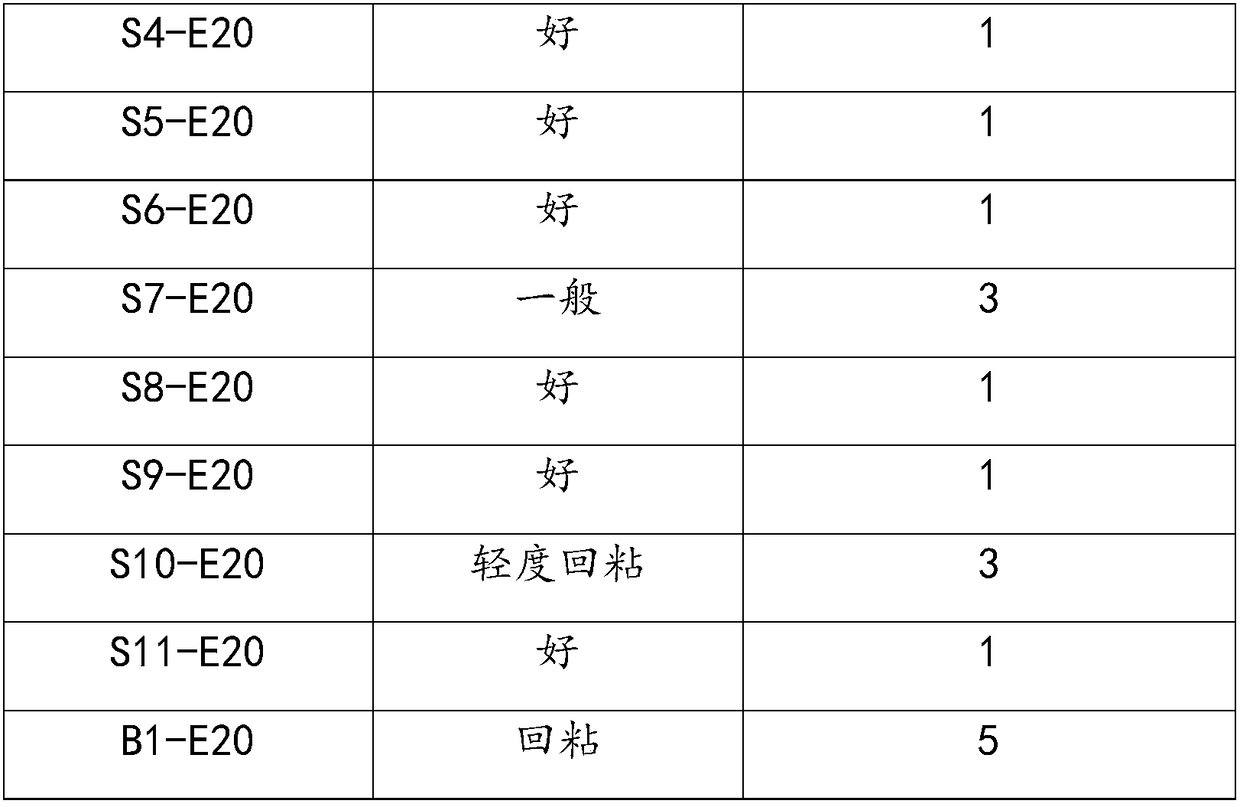

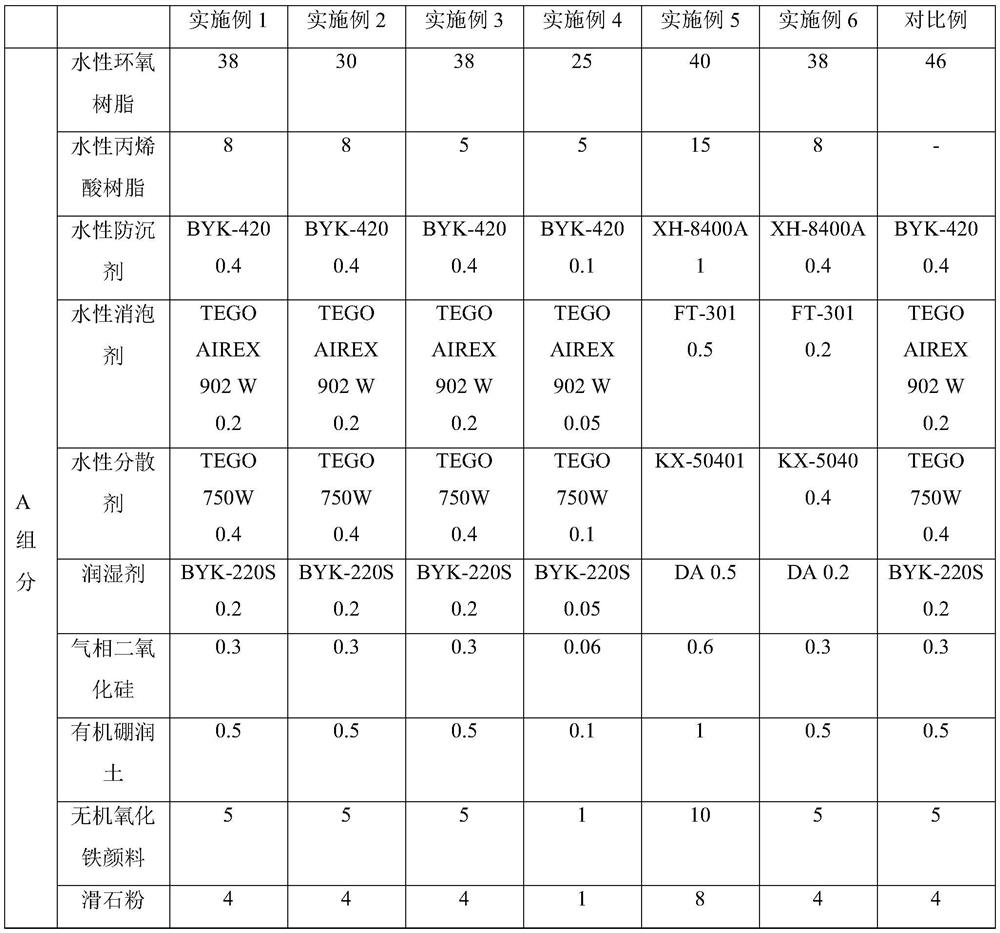

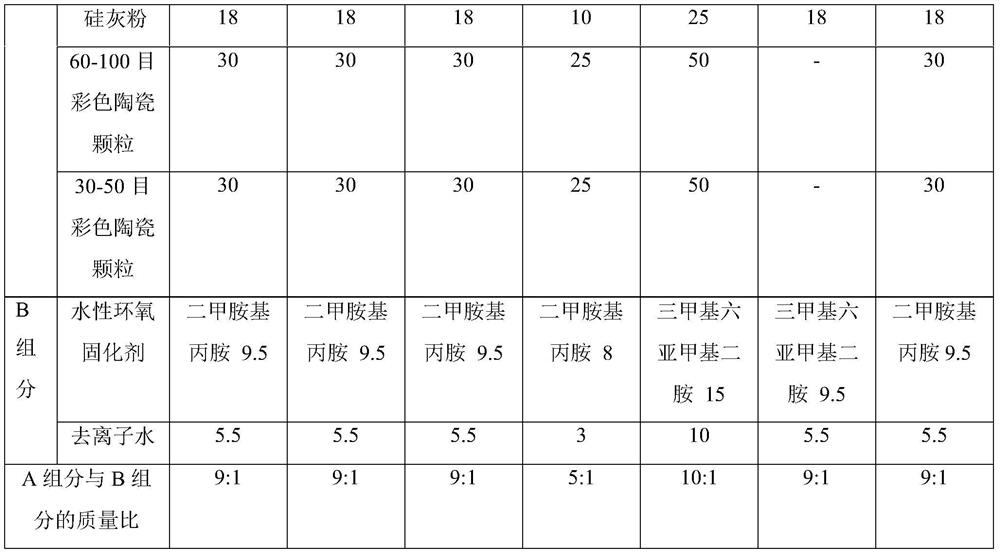

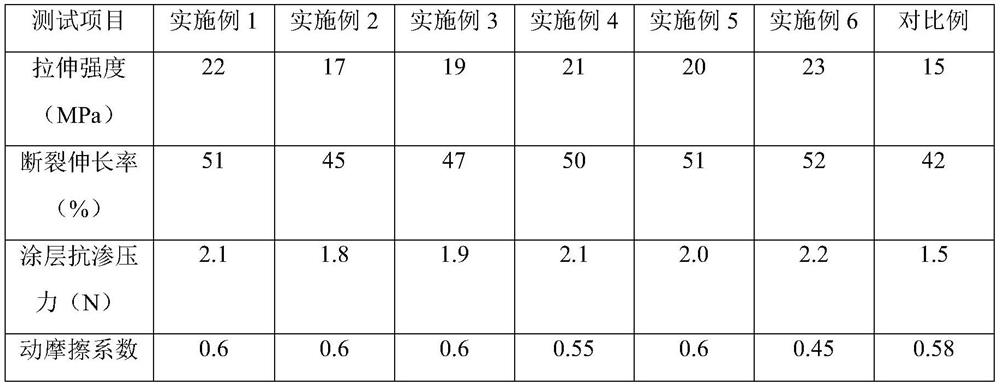

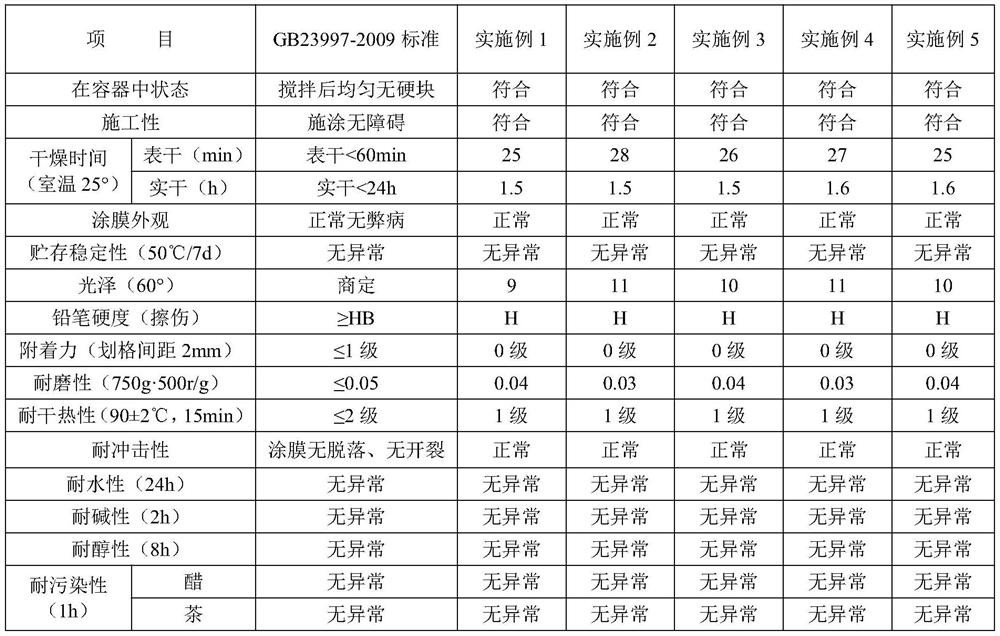

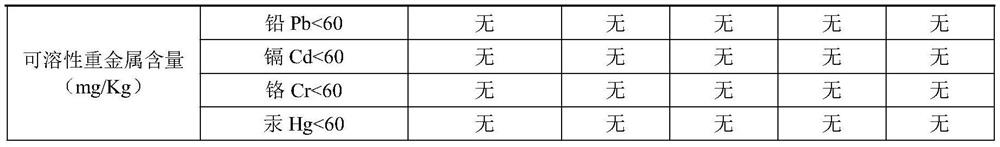

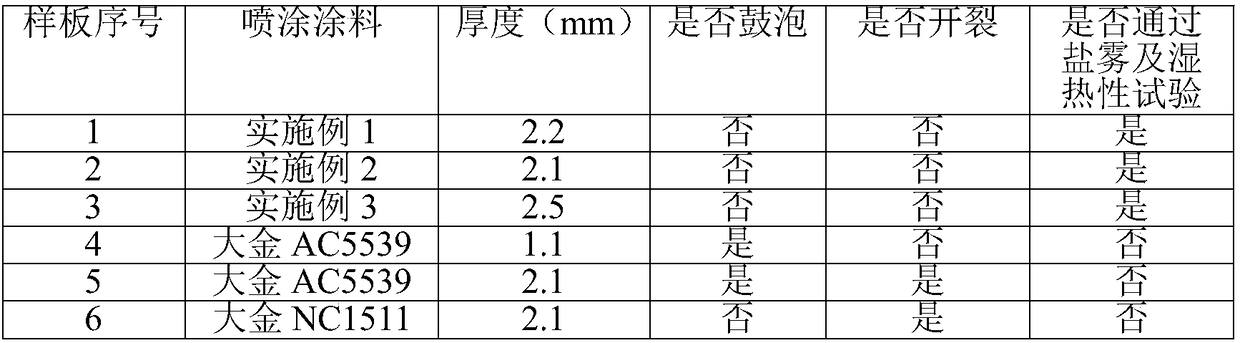

Waterborne epoxy acrylic acid modified two-component pavement antiskid coating and preparation method thereof

The invention provides a waterborne epoxy acrylic acid modified two-component pavement antiskid coating. The waterborne epoxy acrylic acid modified two-component pavement antiskid coating comprises acomponent A and a component B, wherein the component A contains water-borne epoxy resin and water-borne acrylic resin at the same time, so that the coating has better ductility, toughness and strengthafter being cured. In a preferred scheme of the invention, the colored ceramic particles with different particle sizes are added into the coating to serve as aggregate, so that the formed pavement has very good skid resistance and wear resistance. The invention further provides a preparation method of the pavement anti-skid coating. The method enables construction to be simpler and faster, the two components are mixed and stirred to be directly used, and auxiliary materials do not need to be additionally added. The use amount of materials is lower, repeated recoating can be achieved, secondary renovation is rapid and convenient, and the cost is low.

Owner:江苏美沥特道路面材料有限公司

High-permeability matte top-coat coating and preparation method thereof

InactiveCN112694826AGood compatibilityImprove permeabilityPolyurea/polyurethane coatingsXylyleneCellulose

The invention relates to the technical field of coating preparation, and discloses a high-permeability matte top-coat coating which comprises a main agent, a curing agent and a diluent, wherein the main agent comprises the following components in parts by weight: 65-80 parts of alkyd resin, 1-10 parts of butyl acetate, 3-8 parts of ethyl acetate, 1-5 parts of nitrocellulose, 5-10 parts of organic extinction powder, 0.1-0.5 part of an antifoaming agent, 0.3-1 part of a dispersing agent, 1-5 parts of an anti-settling agent and 0.1-0.5 part of a leveling agent; the diluent is prepared from the following components in parts by weight: 15 to 25 parts of xylene, 55 to 75 parts of butyl acetate and 5 to 20 parts of propylene glycol methyl ether acetate; and the curing agent is prepared from the following components in parts by weight: 45 to 70 parts of aromatic isocyanate, 15 to 35 parts of trimer isocyanate and 20 to 35 parts of butyl acetate. The invention also discloses a preparation method of the high-permeability matte top-coat coating. According to the invention, the influence of the matting powder and the addition amount thereof on the transparency of the coating is eliminated, and the effects of good matte degree and transparency, especially good recoating transparency, of the high-permeability matte top-coat coating are achieved.

Owner:CHENGDU ZHANCHEN PAINT

Mastic fluorine paint and preparation method thereof

The invention relates to mastic fluorine paint and a preparation method of the paint. The paint is prepared from the following raw materials in parts by weight: 30-60 parts of fluororesin, 1-5 parts of propylene glycol, 5-10 parts of glycerol, 1-3 parts of plasticizer, 1-3 parts of defoaming agent, 1-3 parts of anti-settling agent, 1-2 parts of wetting agent, 20-40 parts of water, 1-2 parts of pigment and 0.1-0.5 parts of antirust agent. A coating formed after paint spraying is uniform in thickness, and the surface of a film is smooth and dense and free from cracking and blistering. Furthermore, the baked coating is good in acid resistance and alkali resistance and has excellent corrosion resistance. The paint is applicable to the corrosion resistance of ships, offshore petroleum drillingderricks, immersed parts and steel piles of bridges, equipment in chemical plants and the like and reduces the workload of surface protection maintenance and recoating of above steel structures.

Owner:SHANGHAI 3F NEW MATERIAL TECH CO LTD

Processing technique of polish-free recoating-available high-light white paint

InactiveCN104592865AHigh fullnessSynthetic fatty acid resin with high hydroxyl value can improve fullnessPolyester coatingsLow speedRecoating

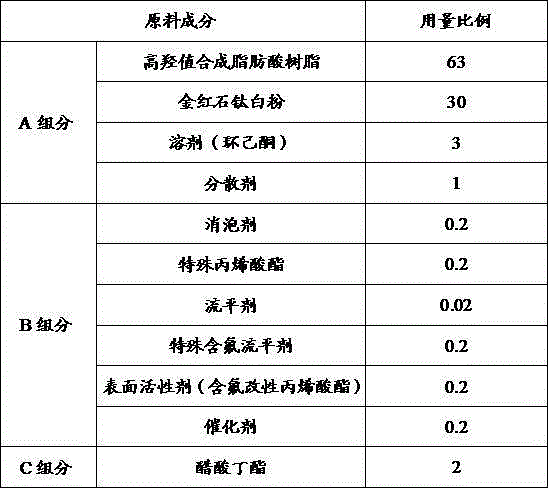

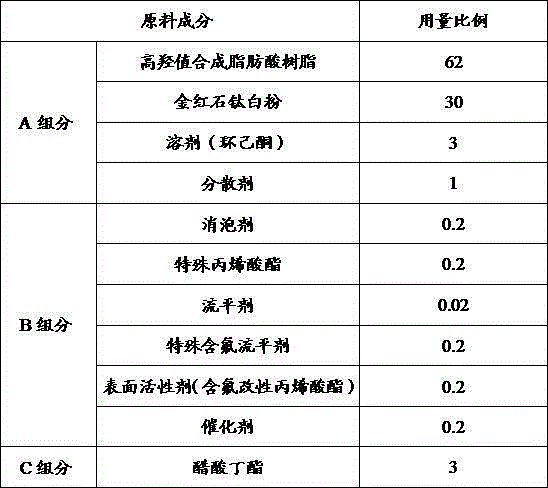

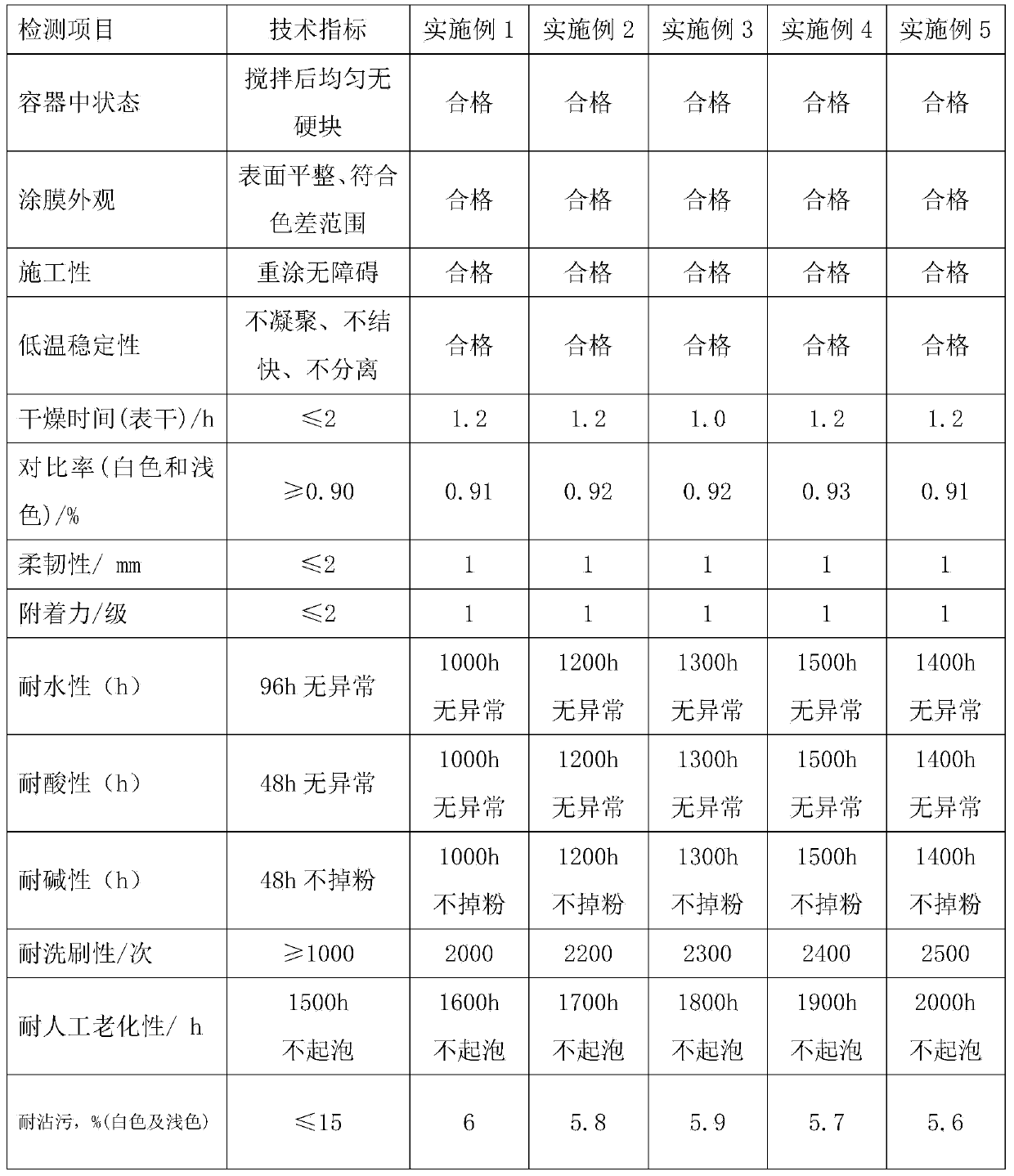

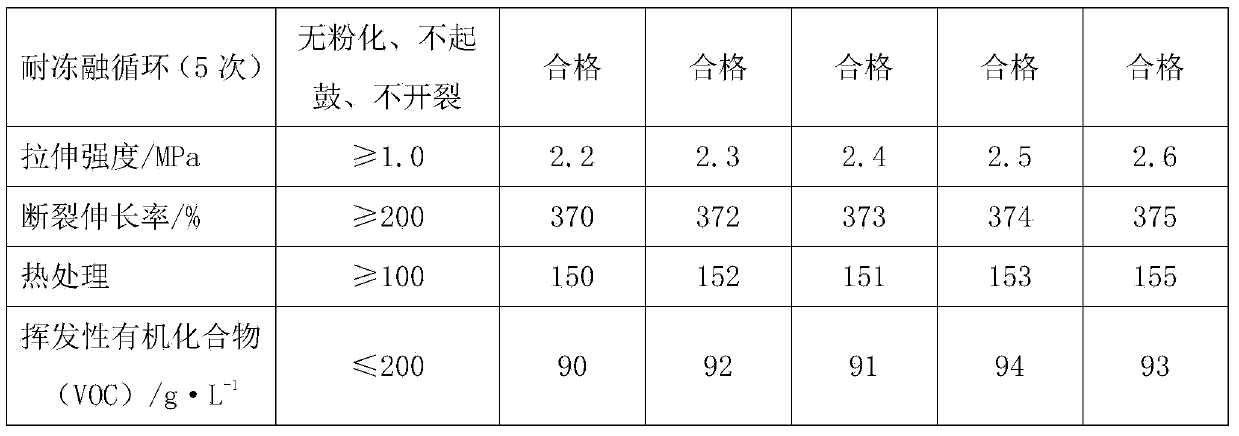

The invention discloses a processing technique of polish-free recoating-available high-light white paint. The processing technique of the invention comprises the following steps: putting a component A (including high-hydroxyl value synthetic fatty acid resin 63, rutile titanium dioxide 30, a solvent 3 and a dispersant 1) into a dispersing cylinder, adjusting rotate speed to 1000-1500r / min to disperse at a high speed for 30 minutes, detecting degree of fineness, adjusting rotate speed to 800r / min when the degree of fineness is lower or equal to 15 mu m, putting a component B (including an antifoam agent 0.2, special acrylate 0.2, a levelling agent 0.02, a special fluorine-containing levelling agent 0.2, a surfactant 0.2, and a catalyst 0.2) into a dispersing cylinder, stirring for 10 minute, adjusting rotate speed to 300-400r / min, then adding a component C (including butyl acetate 2-3) and stirring at a low speed for 5 minutes. The processing technique is characterized by simper construction technique, direct recoating without polish, saving of plenty of manpower and time and raised production efficiency.

Owner:YINGDE YAJIA PAINT

Aqueous environment-friendly interior-wall nano-elastic architectural paint and preparation method

The invention discloses an aqueous environment-friendly interior-wall nano-elastic architectural paint and a preparation method. The paint is composed of the following components, by weight, 10-13% of water, 17-21% of an high-elasticity nano-emulsion, 10-14% of a SD-688 nano-pure acrylic emulsion, 7-11% of CM-101 carbon / carbon, 15-17% of nano-anatase titanium dioxide, 5-8% of nano-talcum powder, 12-16% of nano-calcium carbonate, 5-7% of nano-bentonite, 2-6% of an auxiliary agent, 0.1-0.3% of a BEK-500 bactericide, 0.1-0.4% of a S-220 antifoaming agent, 0.1-0.3% of a thickening agent and 0.1-0.3% of a dispersant. The paint provided by the invention has high weatherability, high chemical corrosion resistance, water resistance, scrubbing resistance and good artificial aging resistance, and has advantages of rich expressive force, strong stereo perception, flexibility, high plasticity, high adhesive force, acid and alkali resistance, fastness, non-scale, non-cracking and easy recoating during maintenance. The preparation method has advantages of simple technology, low cost and good benefit.

Owner:广东马斯柯新型建材有限公司

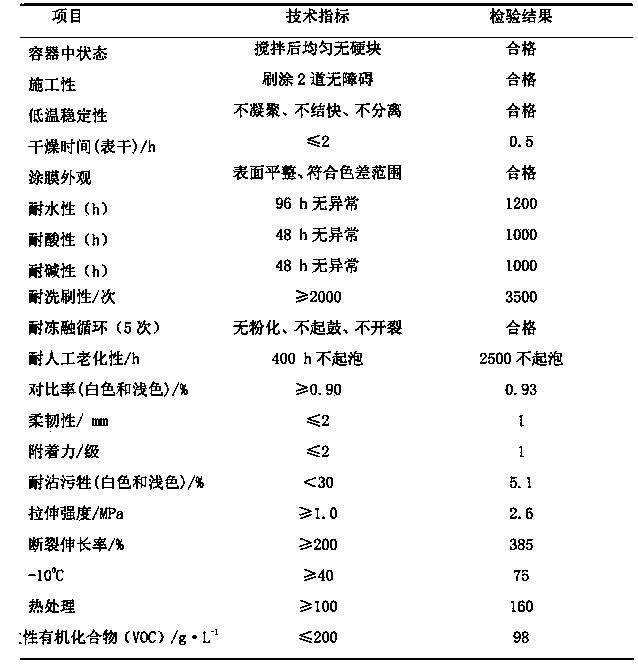

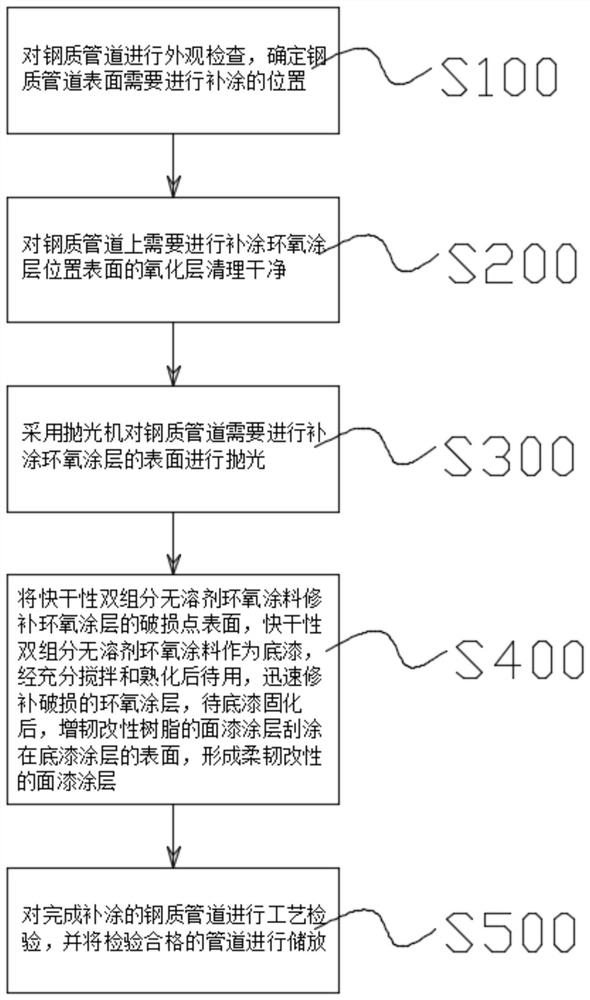

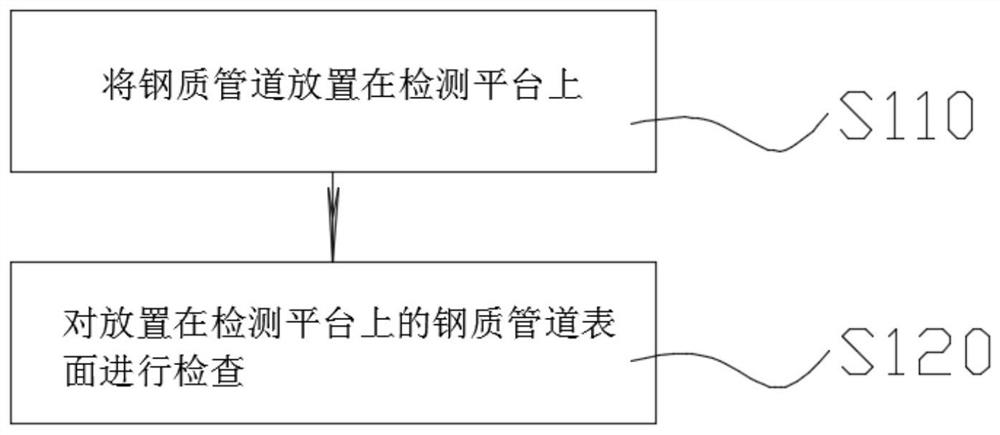

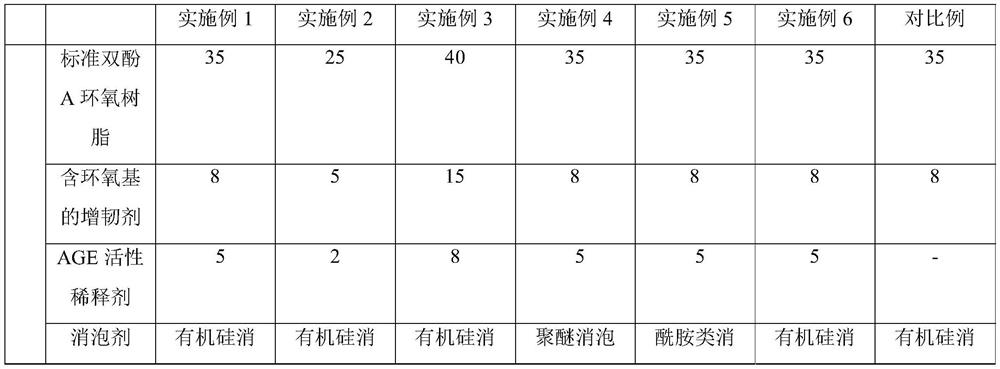

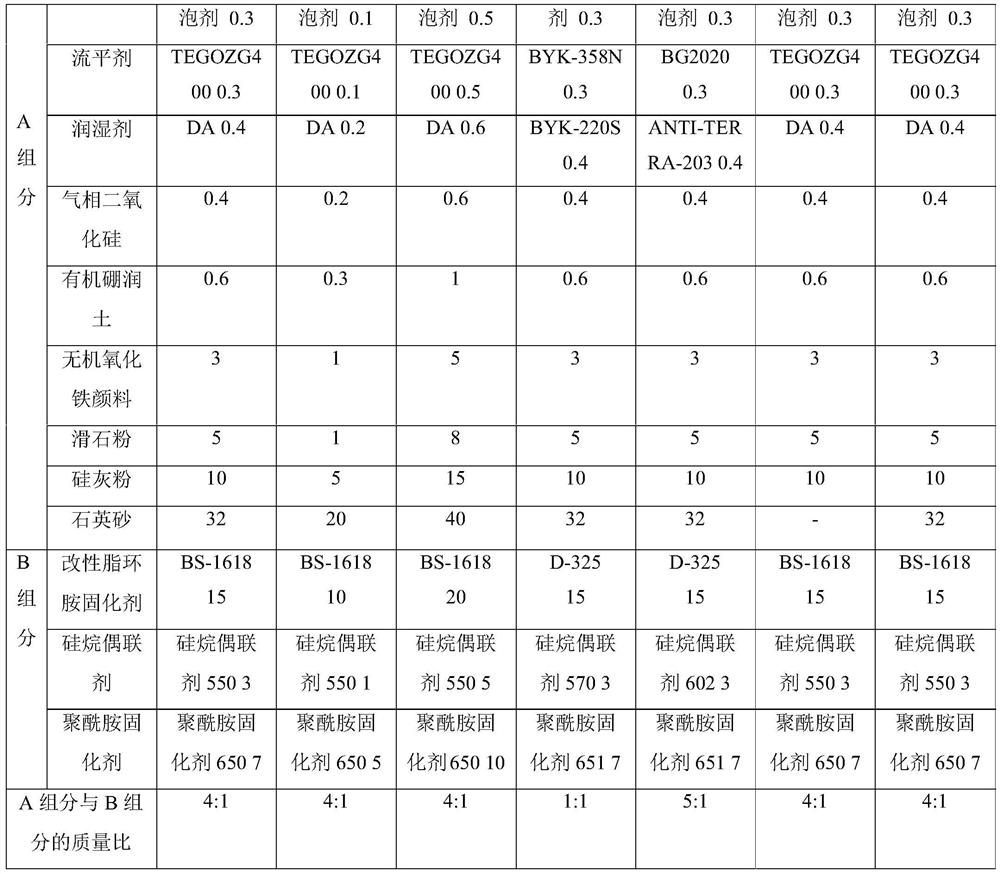

Epoxy coating on-site recoating method for steel pipeline

PendingCN111842071AImprove the effect of surface processingHigh hardnessPretreated surfacesSpecial surfacesEpoxyPolymer science

The embodiment of the invention relates to the field of steel pipeline surface treatment, and particularly discloses an epoxy coating on-site recoating method for a steel pipeline. The method comprises the following specific steps of 100, performing appearance inspection on the steel pipeline, and determining the position of the surface needing to be recoated of the steel pipeline; 200, removing an oxide layer on the surface of the position needing to be recoated with an epoxy coating on the steel pipeline; 300, polishing the surface needing to be recoated with the epoxy coating by using a polishing machine; 400, repairing a damaged point of the epoxy coating by using a quick-drying bi-component solvent-free epoxy coating, taking the quick-drying bi-component solvent-free epoxy coating asa primer, sufficiently stirring and curing for later use, rapidly repairing the damaged epoxy coating, and after the primer is cured, scraping a finishing coating of a toughening modified resin onto the surface of a primer coating to form the flexible modified finishing coating; and 500, performing process inspection on the steel pipeline subjected to recoating, and storing the pipeline qualifiedfor inspection. According to the epoxy coating on-site recoating method for the steel pipeline , the surface of the steel pipeline can be conveniently recoated with the epoxy coating on site, and theuse is convenient.

Owner:SHAANXI YUYANG PETROLEUM TECH ENG CO LTD

Epoxy-modified two-component pavement antiskid coating and preparation method thereof

InactiveCN111909597ASmooth dischargePrevent hollowing and delaminationEpoxy resin coatingsPolymer scienceRecoating

The invention provides a reduction-oxygen-modified two-component pavement antiskid coating. The coating comprises a component A and a component B, an epoxy group-containing toughening agent is used inthe component A and is matched with the modified alicyclic amine curing agent, the silane coupling agent and the polyamide curing agent in the component B. Therefore, the pavement antiskid coating has stronger bonding force and excellent toughness, and can better adapt to the ductility of an asphalt pavement. In a preferred scheme of the invention, quartz sand is added into the component A, so that tiny air holes can be formed after the coating is cured, and hollowing and delaminating caused by pressure formed by water vapor below the coating are prevented. The invention further provides a preparation method of the pavement anti-skid coating, the method enables construction to be simpler and faster, the two components are mixed and stirred to be directly used, and auxiliary materials do not need to be additionally added. The use amount of materials is lower, repeated recoating can be achieved, secondary renovation is rapid and convenient, and the cost is low.

Owner:江苏美沥特道路面材料有限公司

Polyurethane finish paint

The invention relates to a polyurethane finish paint. The invention is characterized in that the polyurethane finish paint is prepared by mixing aids, resins, a filler, matting powder, a solvent and a curing agent. The acrylic resin and polyurethane resin used as film formers are compounded with the polyurethane resin and hydroxyacrylate resin to obtain the coating with excellent drying property and mechanical properties. The paint has favorable ply adhesion, and thus, is beneficial to coating repair. The paint has high solid content, can effectively lower VOCs (volatile organic compounds), and satisfies the serious requirements for the environment. By selecting hexamethylene diisocyanate biuret as the curing agent, the finish paint has better impact resistance and water resistance. The dispersing agent, leveling agent, defoaming agent and other aids are proportionally added in the formula to perform favorable surface effects, but can obviously lower the surface tension of the coating, influence the recoating of the paint film and lower the overcoatability.

Owner:张学健

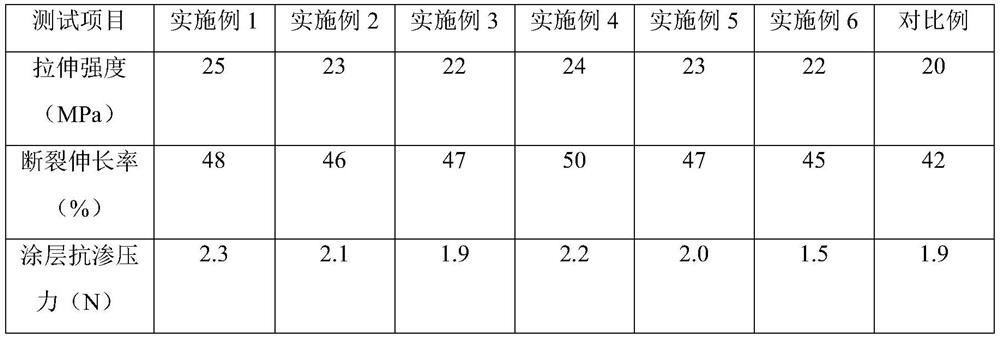

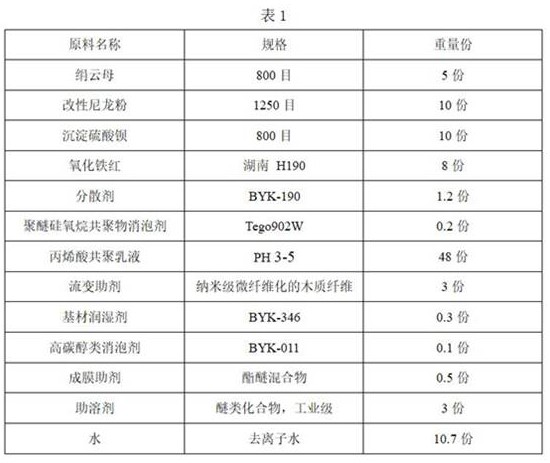

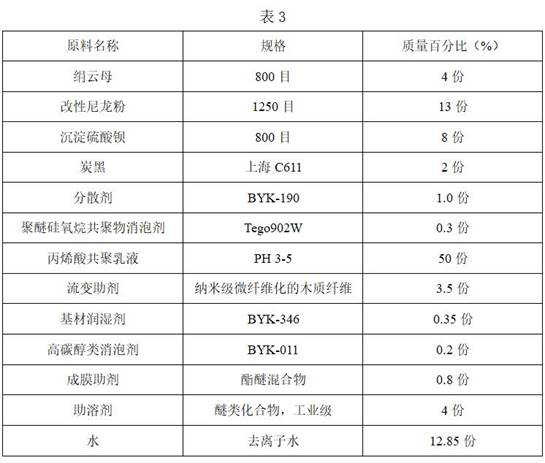

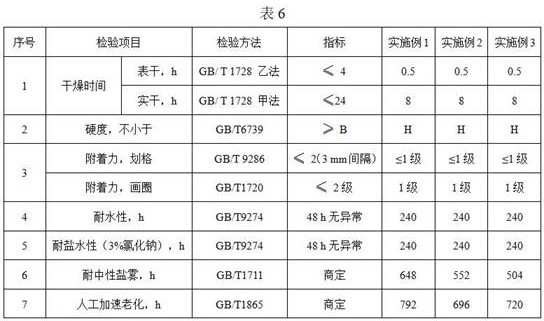

Water-based acrylic acid primer-topcoat coating applicable to rusty steel structure and to renovation coating of steel structure as well as preparation method and application method of water-based acrylic acid primer-topcoat coating

PendingCN113652131AGood paintabilityExtended opening hoursAnti-corrosive paintsPolymer scienceEmulsion

The invention discloses a water-based acrylic primer-topcoat coating applicable to a rusted steel structure and to renovation coating of a steel structure as well as a preparation method and an application method of the water-based acrylic primer-topcoat coating, belonging to the field of coatings. The invention solves the problem that treatment of rusty steel structures and renovation coating of steel structures are difficult. The water-based acrylic primer-topcoat coating comprises water, sericite, modified nylon powder, precipitated barium sulphate, a pigment, a dispersant, a polyether siloxane copolymer defoaming agent, a weakly acidic acrylic acid copolymer emulsion, a rheological aid, a base material wetting agent, a high-alcohol defoaming agent, a coalescing agent and a cosolvent. The preparation method comprises the following steps: dispersing a part of water, the dispersing agent, the polyether siloxane copolymer defoaming agent, the sericite, the modified nylon powder, the precipitated barium sulfate, the pigment and the rheological aid, carrying out grinding, adding the rest raw materials, performing dispersing, and carrying out sieving with tiffany. The application method comprises the step that the coating directly coats the surface of the rusty steel structure or is directly used for renovating and recoating of an aged coating of the steel structures. The coating provided by the invention can perfectly convert corrosion, has good compatibility with different types of old paint films, and has good adhesion after being combined with the old paint films.

Owner:西北永新涂料有限公司

Hard coat preparation method convenient for recoating of hard alloy workpiece

InactiveCN102899607AReduce adverse effectsImprove bindingVacuum evaporation coatingSputtering coatingIon bombardmentRecoating

A hard coat preparation method convenient for recoating of a hard alloy workpiece comprises the following steps: 1, preprocessing the hard alloy workpiece with a traditional process (refacing and decoating are carried out before the processing if the workpiece is a coated workpiece); 2, filling the hard alloy workpiece into a vacuum chamber, and pumping the vacuum chamber to a background vacuum; 3, heating the workpiece to a required temperature; 4, bombarding the workpiece through energetic ions to expose a fresh surface; 5, depositing at least one layer of a protection film on the surface of the workpiece, wherein the protection film cannot be dissolved by a hard coat decoating solution; and 6, depositing a hard coat on the surface of the workpiece through using a routine hard coat preparation method. The hard coat preparation method provided by the invention well combines the traditional solution decoating technology and the vacuum ion etching technology, has the advantages of simple operation and low cost, and well solves adverse influences of the decoating solution to a base material in the recoating of the hard alloy workpeice.

Owner:WUXI QIHENG TECH

Process for preventing corrosion of wet and rusted coating steel structure

InactiveCN113663892ALow standard requirementsReduce the impactPretreated surfacesAnti-corrosive paintsRecoatingGraphite

The invention relates to the technical field of steel structure treatment, in particular to a process for preventing corrosion of a wet and rusted coating steel structure. The process comprises the steps of step 1, steel structure rust removal, step 2, steel structure cleaning, step 3, environment-friendly graphene metal rusted corrosion prevention coating preparation, step 4, steel structure coating and step 5, paint coating quality inspection and acceptance inspection. The whole recoating work time is short, the safety risk is small, rust removal and coating are fast, the recoating quality is good, the service life is long, the total manufacturing cost of the whole recoating project is not higher than that of common paint, the service life is at least doubled, the whole recoating process is environmentally friendly, no harm is caused to the environment and the human body, the standard requirement for steel structure surface treatment and the influence of environment humidity and temperature on coating work are reduced, the technology is simple, operation is convenient and fast, the working efficiency of the anti-corrosion technology is effectively improved, and the working time is shortened.

Owner:深圳瑞腾船舶与海洋工程防腐科技有限公司

Waterborne environment-friendly glass paint

InactiveCN109749542AFull paint filmShorten drying timeWax coatingsPolyurea/polyurethane coatingsRecoatingHardness

The invention relates to the technical field of coatings, in particular to waterborne environment-friendly glass paint which has the advantages of plump paint film, rapidness in drying, short recoating time, excellent chemical resistance, blocking resistance, scratch resistance and adhesive force, high hardness and water resistance, non-flammable and non-explosive properties, no toxicity and foreign taste and the like. The glass paint has good functions of preserving and insulating heat and saving energy. When the glass paint is applied to building curtain walls, glass and the like, heat insulation and heat preservation capability of a building can be effectively improved, and energy consumption is reduced. The preparation method of the waterborne environment-friendly glass paint is simplein process, water can be added into the glass paint to dilute the glass paint in the using process, construction is convenient and rapid, and construction efficiency can be effectively improved.

Owner:吴春燕

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com