Temp. compensated long period optical fiber grating filter

A technology of long-period gratings and optical fiber gratings, which is applied to clad optical fibers, diffraction gratings, optical waveguides, and light guides, and can solve the problems of undisclosed coating of the outer layer of optical fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

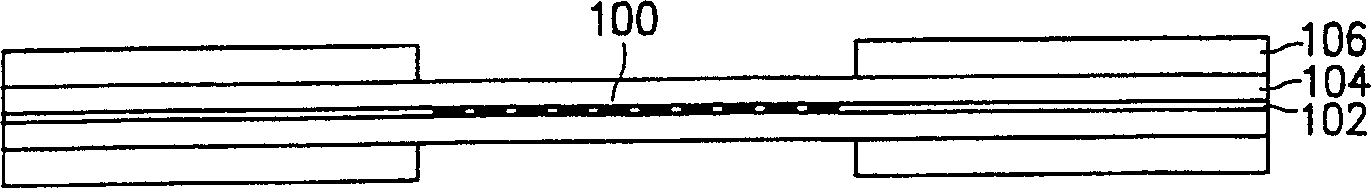

[0024] Figure 1A is a cross-sectional view showing a long period fiber grating filter. Such as Figure 1A As shown, the LPFG filter includes a core 102 forming an LPFG 100 , an outer layer 104 surrounding the core 102 along the LPFG 100 , and a coating surrounding the outer layer 104 .

[0025] The long-period grating 100 is formed by partially removing the coating 106 of an optical fiber sensitive to ultraviolet light, and then irradiating ultraviolet laser light onto the optical fiber while utilizing an amplitude mask (amplitudemask) (not shown) adapted to transmit the ultraviolet laser light at certain periodic intervals. out), so that a periodic refractive index change occurs within the core 102.

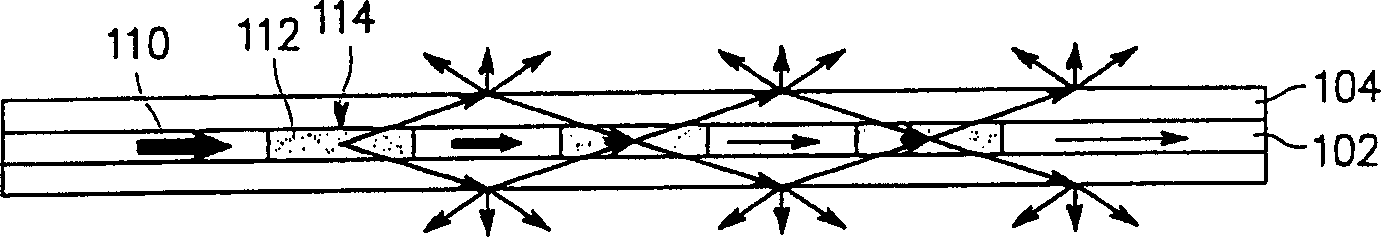

[0026] Figure 1B shown in Figure 1A The operation of coupling the core mode to the outer layer mode in the long-period fiber grating filter of . A fundamental guided mode 110 propagating within the core 102 is scattered while passing through the refractive index change regi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com