Patents

Literature

466results about How to "Achieve stripping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recycling metal and combustibles from domestic waste incineration slag

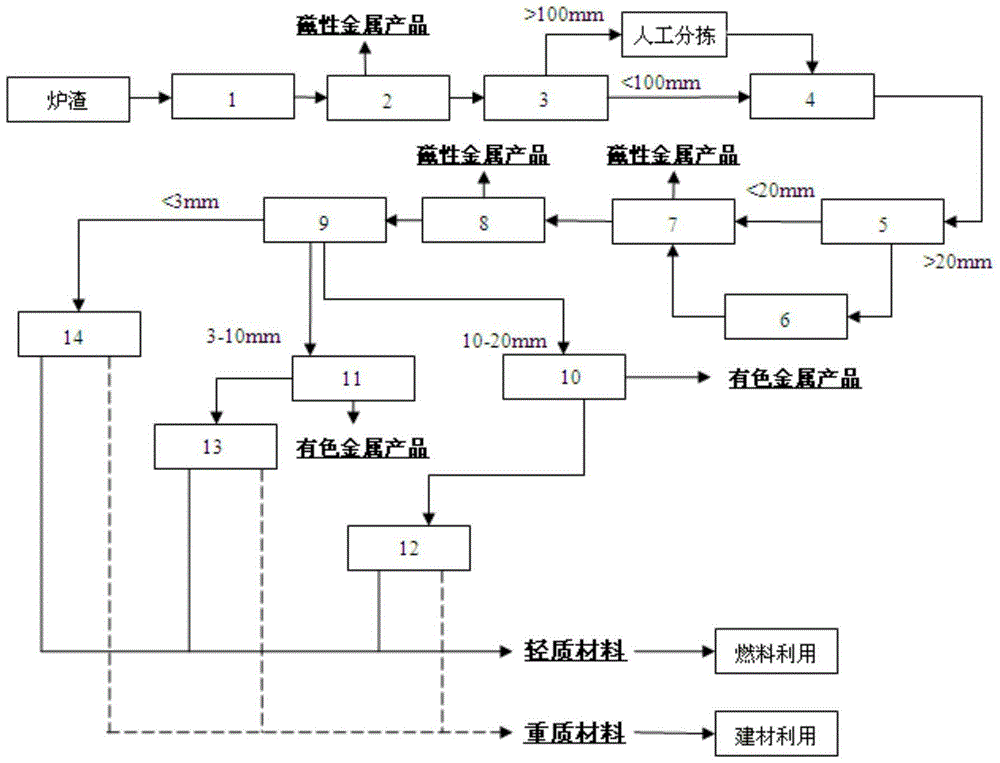

The invention relates to a method for recycling metal and combustibles from domestic waste incineration slag, and belongs to the field of the solid waste harmless and recycling technology. By means of multi-stage gradient magnetic separation, separation of magnetic metal in the slag is achieved. By means of two-stage eddy current, nonferrous metal in the slag is separated and recycled. According to the grain size distribution and chemical morphological characteristics of the metal in the slag, the metal is crushed and screened in multiple steps so that separated slag particles can be uniform, the recycling rate of magnetic separation and eddy current separation is effectively increased, and finally, according to the density difference of materials, air separation is used for recycling the combustibles in the slag. Finally, the magnetic separation recycling rate of iron in the technological process is 60-80%, the recycling rate of the nonferrous metal aluminum is 60-70%, the recycling rate of the nonferrous metal copper is 40-50%, and separation of the metal in the slag and slag particles can be effectively achieved. The separated metal products can be directly sold or sold after refining, the combustibles can serve as waste incinerator fuel, and the remaining slag can be used as building materials.

Owner:TONGJI UNIV

Efficient Web form validation method and framework thereof

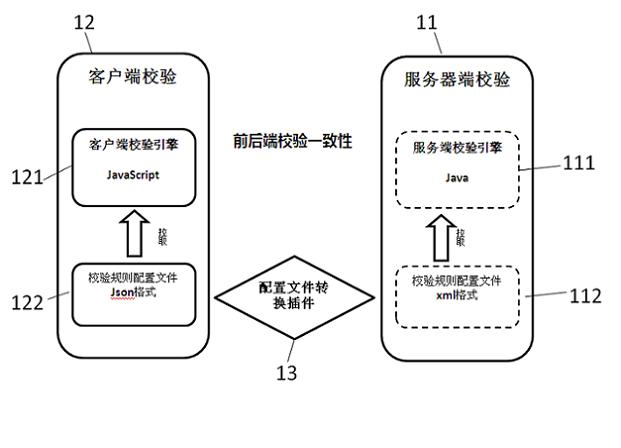

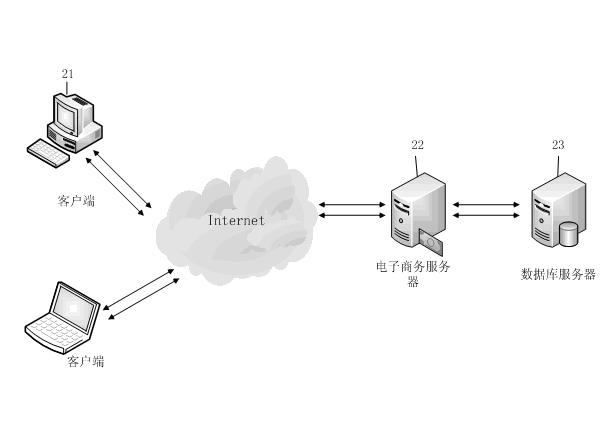

InactiveCN102426549ATake up less resourcesFacilitate JavaScript data transferSoftware testing/debuggingXML validationClient-side

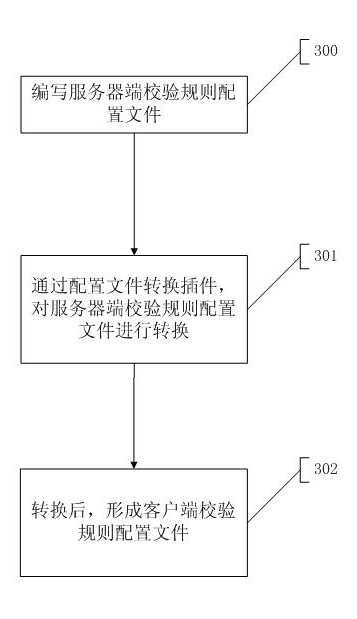

The invention provides an efficient Web form validation method and a framework thereof, which aim at solving the problem of validating user data of an electronic commerce platform. In the embodiment of the invention, a file conversion plug-in unit is configured, and server-side validation rule configuration files (xml-formatted files) are converted into client-side validation rule configuration files (json-formatted files) by one keystroke. The efficient Web form validation method and the framework thereof are responsible for server-side data validation and client-side data validation and canensure that the server-side validation rules and the client-side validation rules are logically consistent, so that the disunity between the server-side validation logic and the client-side validation logic is eliminated, further, the workload for overlapping development is reduced, the quality of codes is improved, and the performance and the stability of the electronic commerce platform are improved.

Owner:XINYIZHAN INSURANCE AGENT CO LTD +1

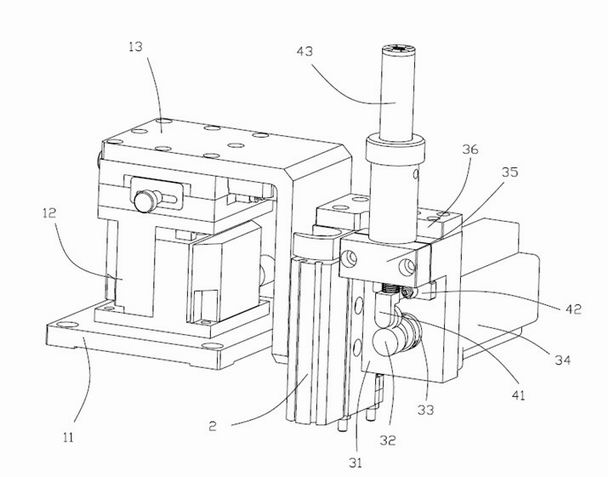

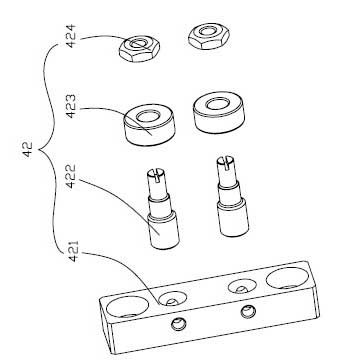

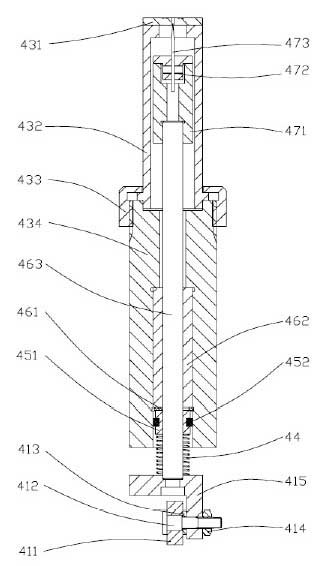

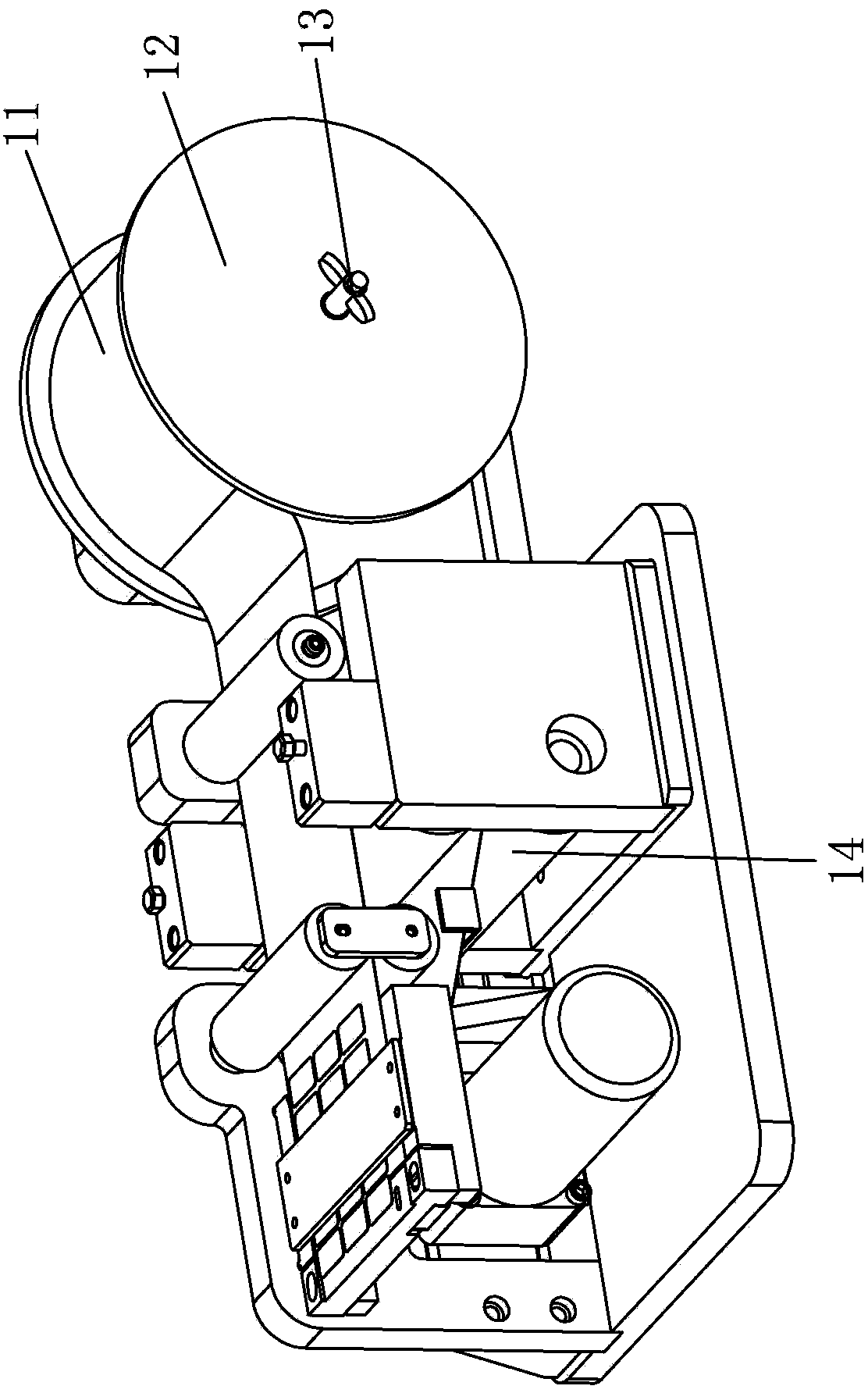

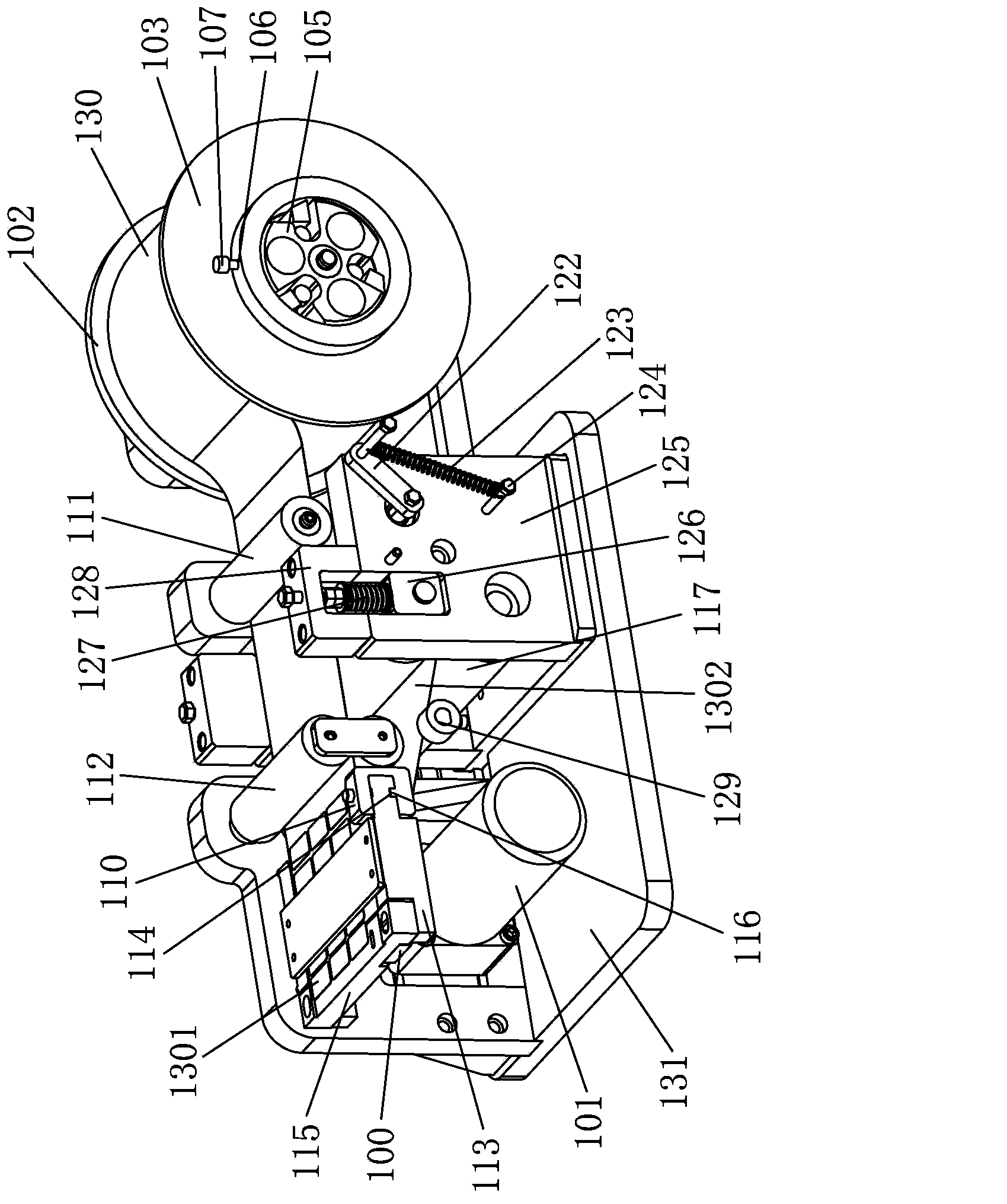

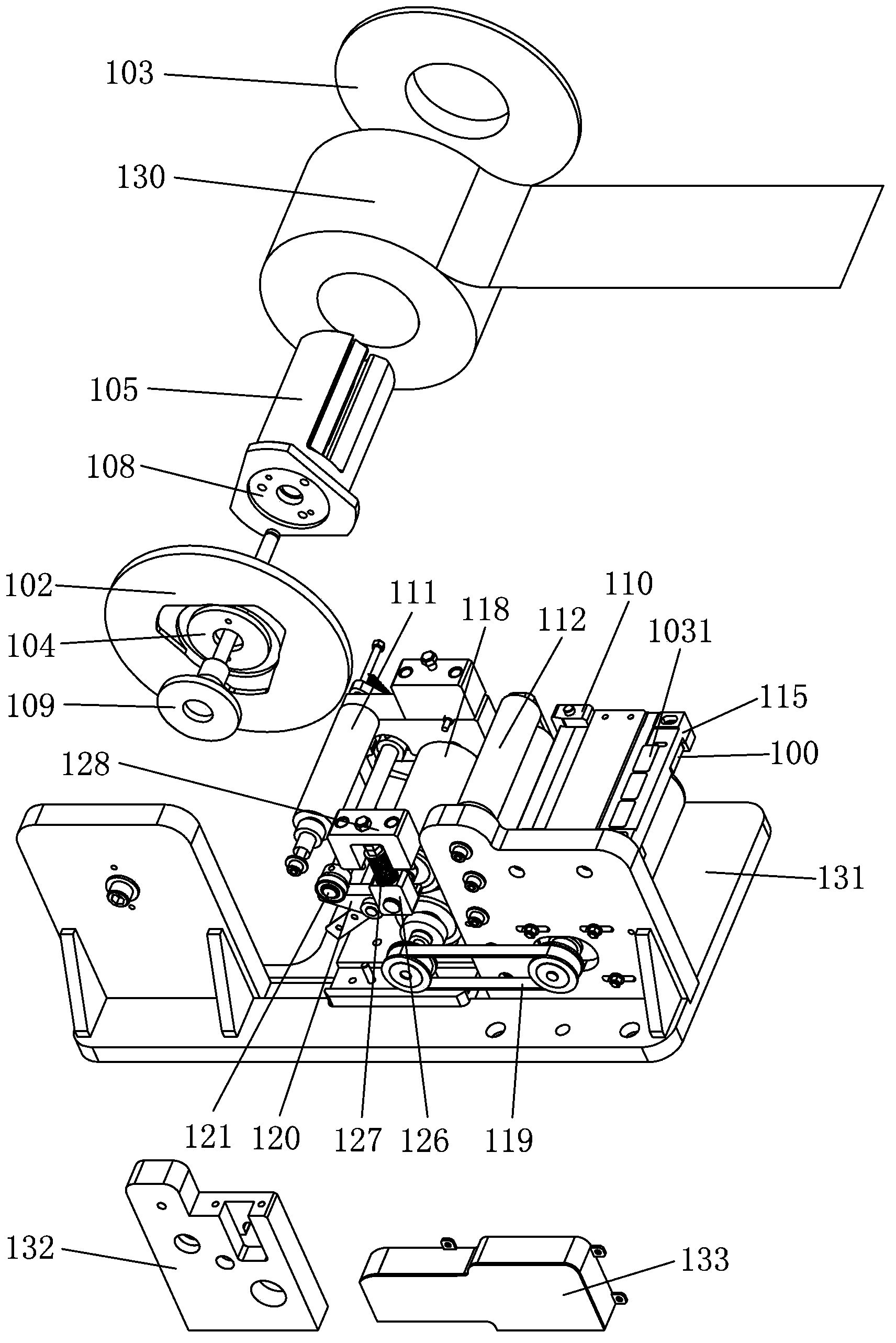

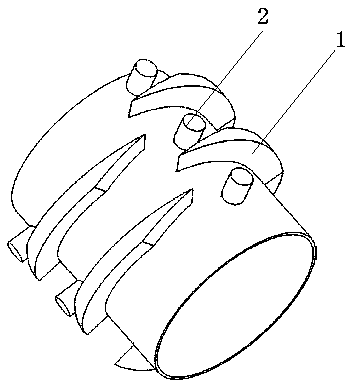

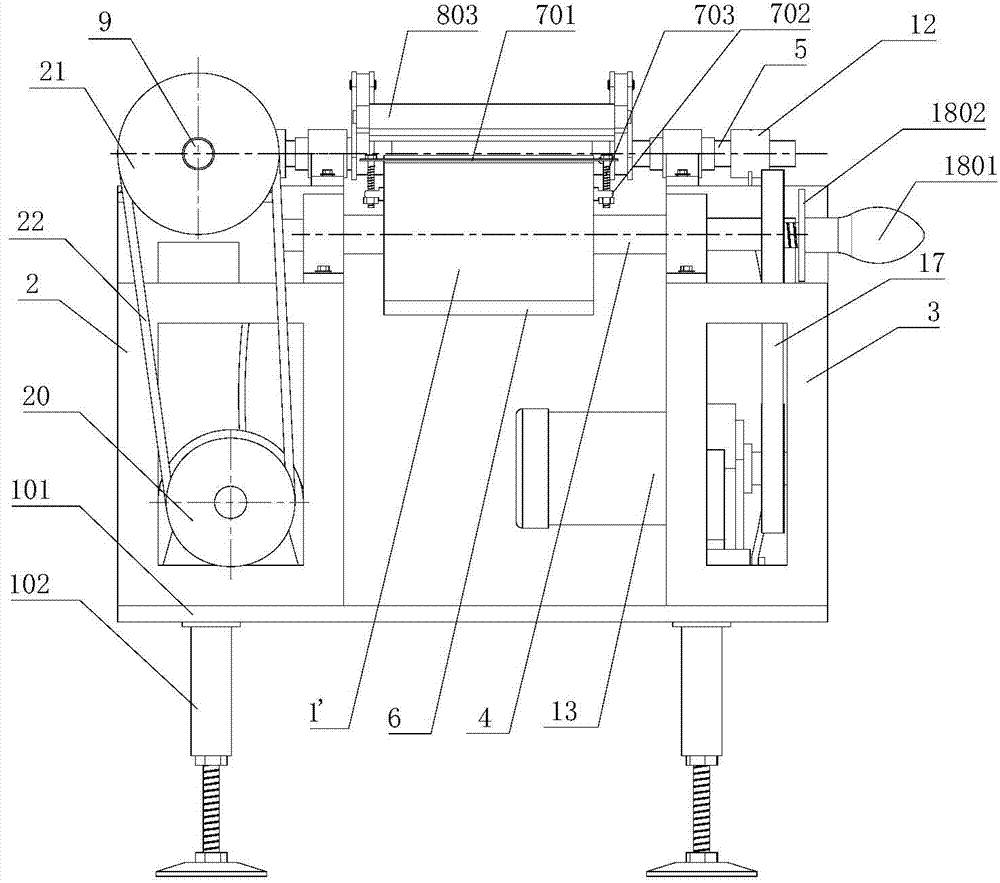

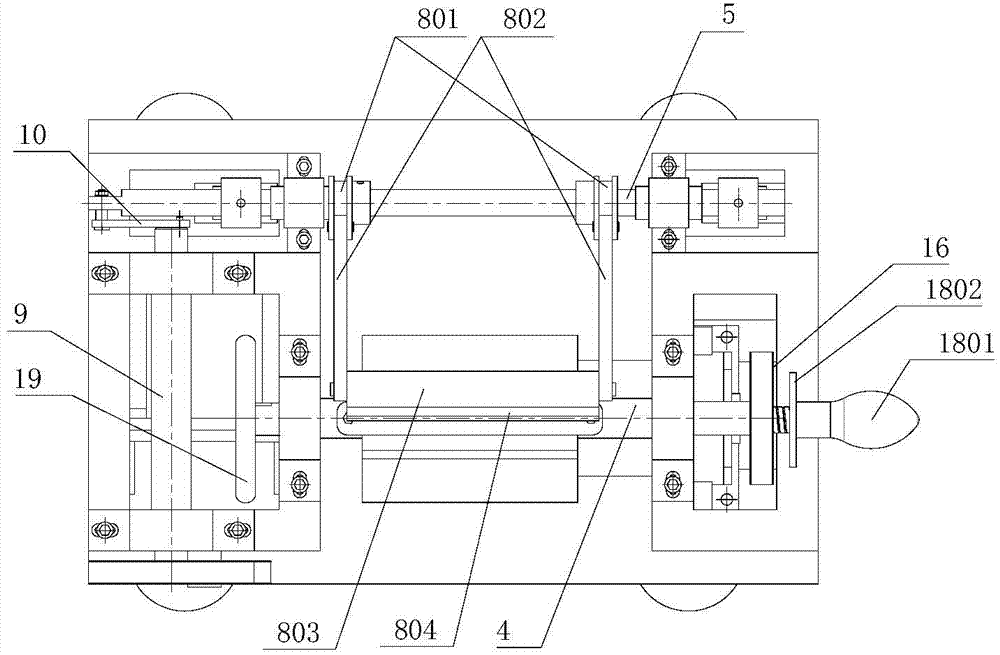

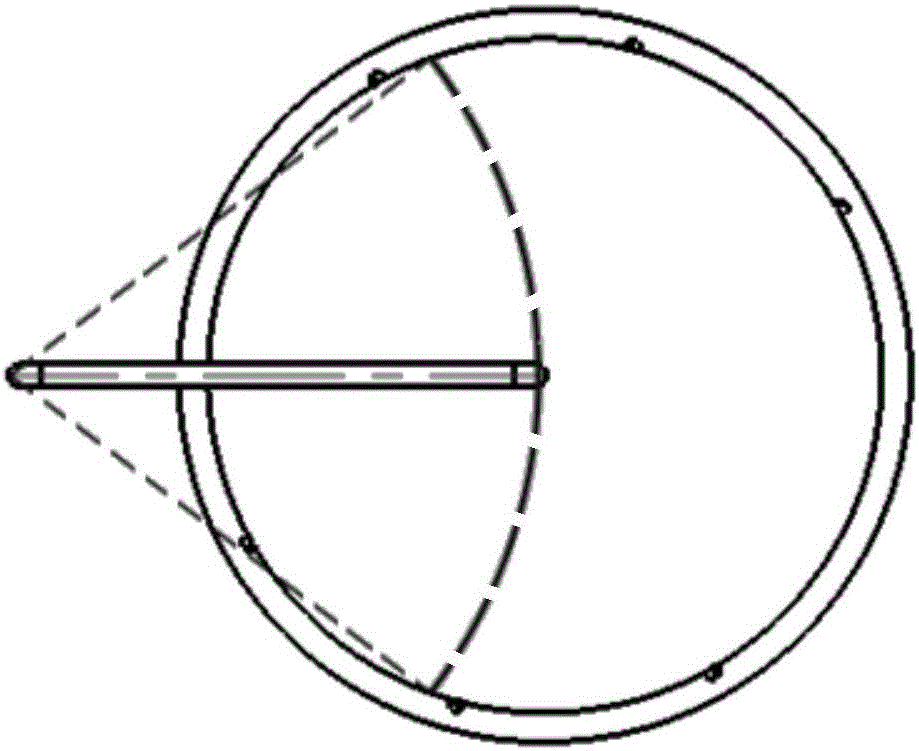

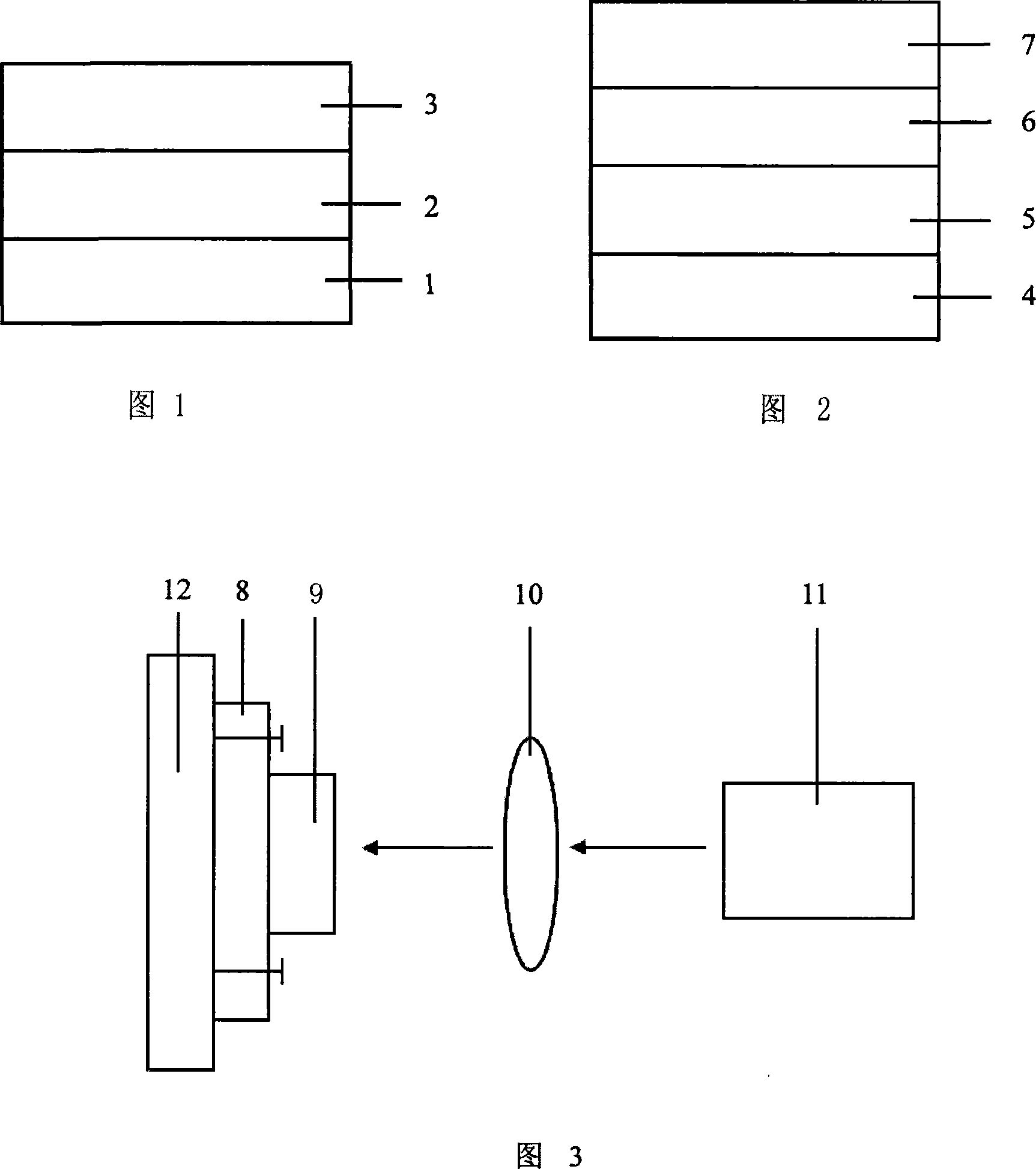

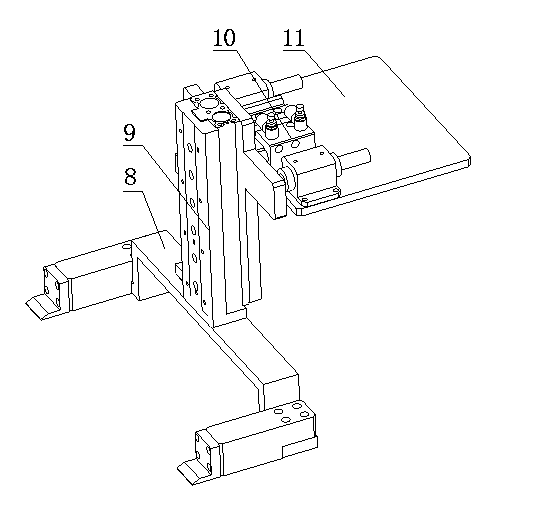

Chip peeling device

InactiveCN102074458AAchieve strippingGuaranteed repeatabilitySemiconductor/solid-state device manufacturingThree degrees of freedomEngineering

The invention provides a chip peeling device, which comprises a thimble clamping and moving assembly and a rotary driving assembly, wherein the thimble clamping and moving assembly comprises a thimble shaft supporting piece, a thimble shaft is fixed on the thimble shaft supporting piece, the exterior of the thimble shaft is provided with a thimble shaft sleeve, the top of the thimble shaft extends out of the thimble shaft sleeve and is connected with a thimble clamping piece, and the bottom of the thimble shaft is sleeved with a compression spring; and the exterior of the thimble clamping piece is provided with a thimble outer cover, and the top center of the thimble outer cover is provided with a pore through which a thimble extends out. As optimization, the chip peeling device also comprises a lifting mechanism and a three-degree-of-freedom alignment platform, wherein the lifting mechanism is used for realizing integral lifting of the thimble clamping and moving assembly and the rotary driving assembly; and the three-degree-of-freedom alignment platform is used for adjusting the position of the thimble in three directions X, Y and Z. The chip peeling device is very convenient to adjust the position of the center of the thimble, ensures that the center of the thimble is aligned with the center of a pickup device, is also very convenient to realize replacement of the thimble, and ensures the height and position consistency of the replaced thimble.

Owner:HUAZHONG UNIV OF SCI & TECH

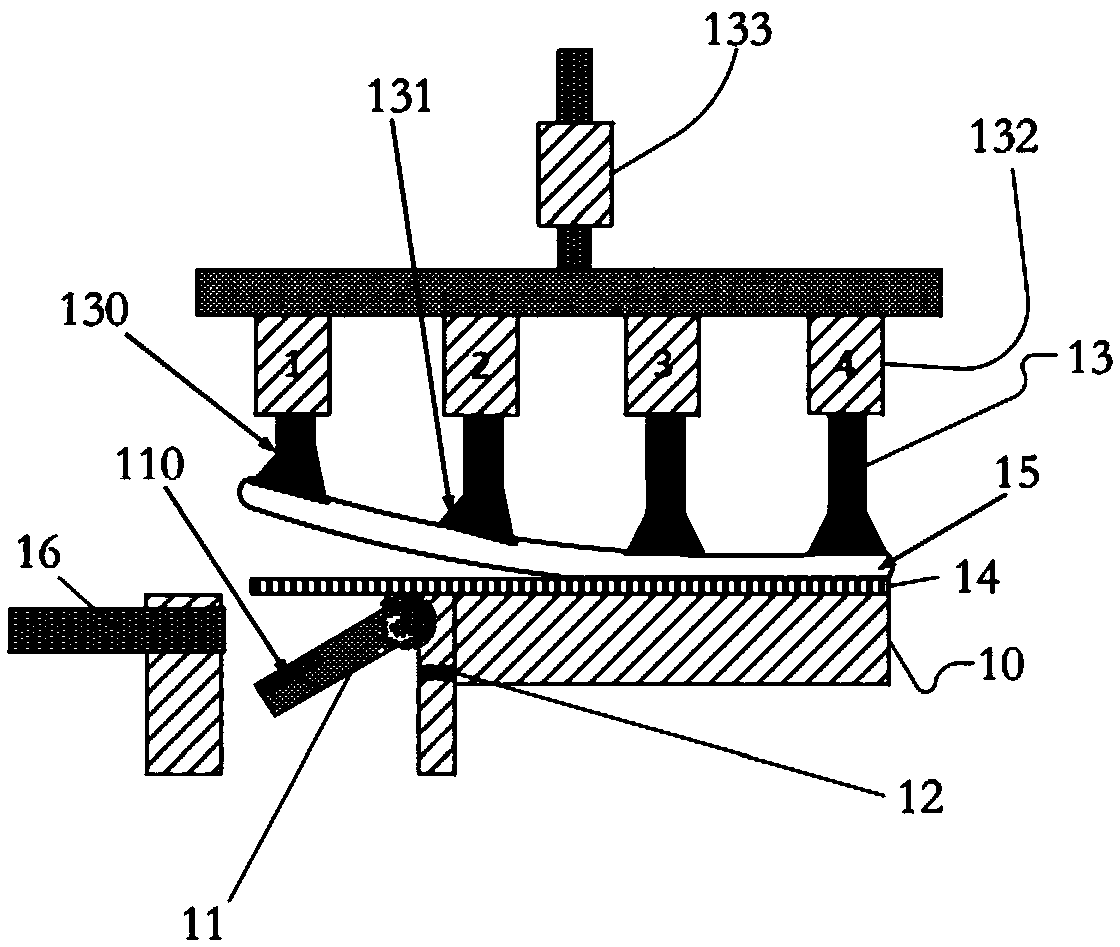

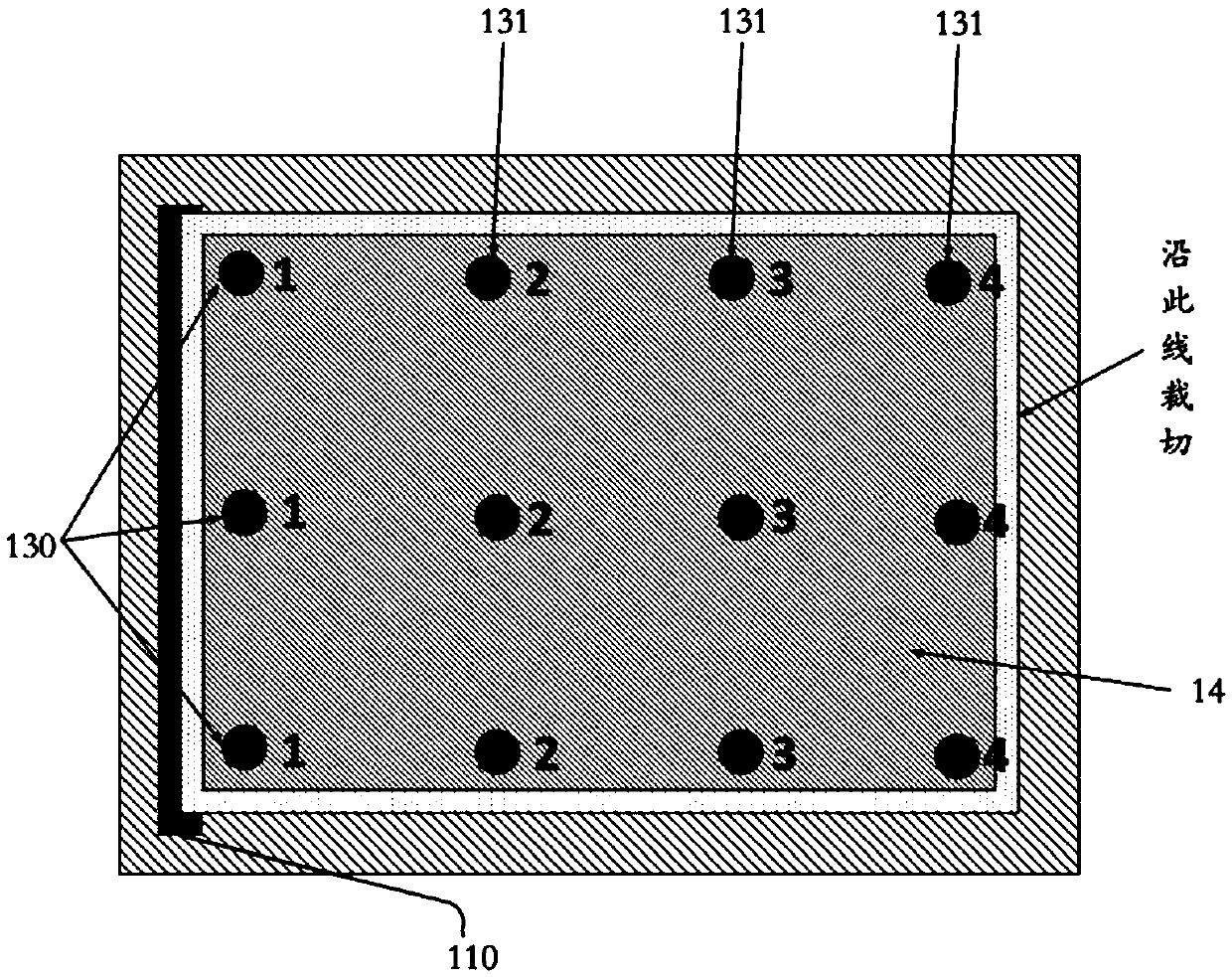

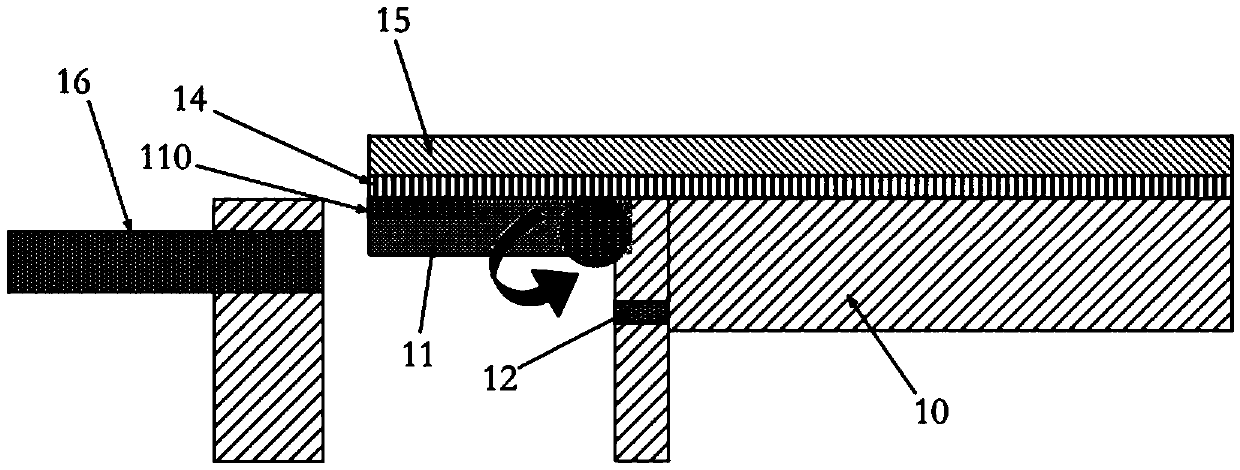

Peeling device and peeling method for display substrate

ActiveCN105511130AReduce adsorptionAchieve strippingLayered productsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention provides a peeling device and a peeling method for a display substrate. The peeling device for the display substrate comprises a base board, at least one adhesive plate, a detection unit and a separation unit, wherein each adhesive plate is arranged in a region, which corresponds to the corner or edge of the display substrate, of the base board, and is connected with the base board in a rotatable manner, so that the upper surface of each adhesive plate and the upper surface of the base board are rotated in a coplanar state to the upper surface of the base board to form a non-coplanar state; the detection unit is used for detecting whether the edge region of the display substrate is adhered to the adhesive plate; the separation unit is arranged above the base board and the adhesive plate and comprises a first adsorption terminal and a second adsorption terminal which are capable of moving in the vertical direction; at least one first adsorption terminal is correspondingly arranged above the adhesive plate; a plurality of second adsorption terminals are correspondingly arranged above the base board; projections of the multiple second adsorption terminals on the base board are arranged in sequence along the region away from the corner or edge of the adhesive plate.

Owner:BOE TECH GRP CO LTD

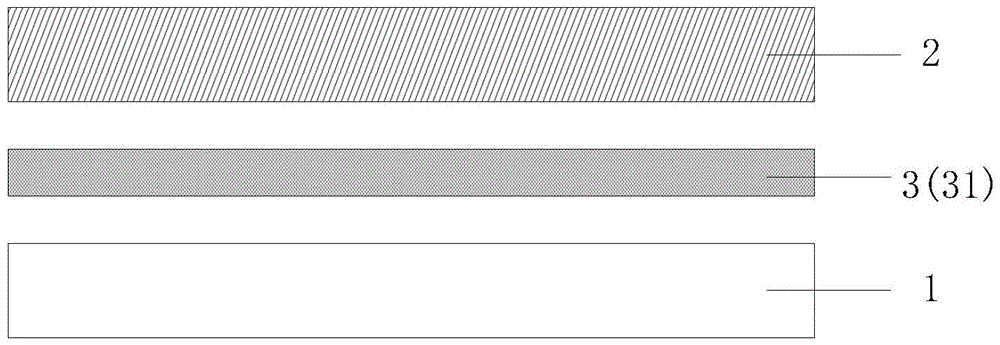

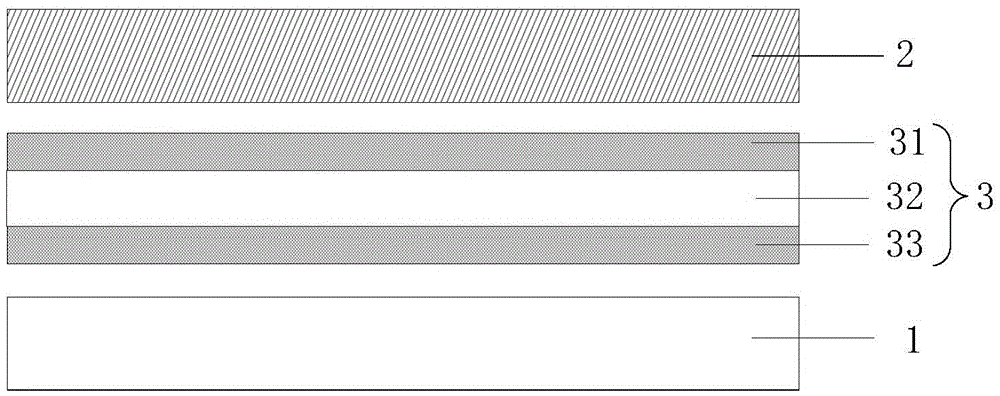

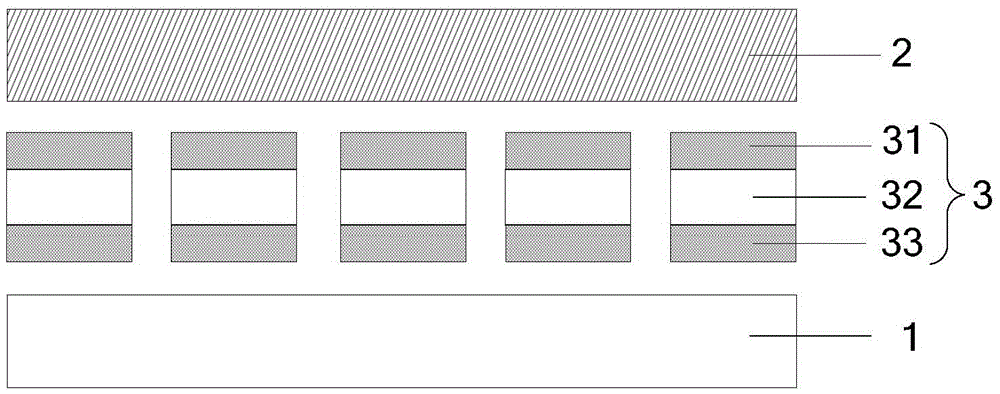

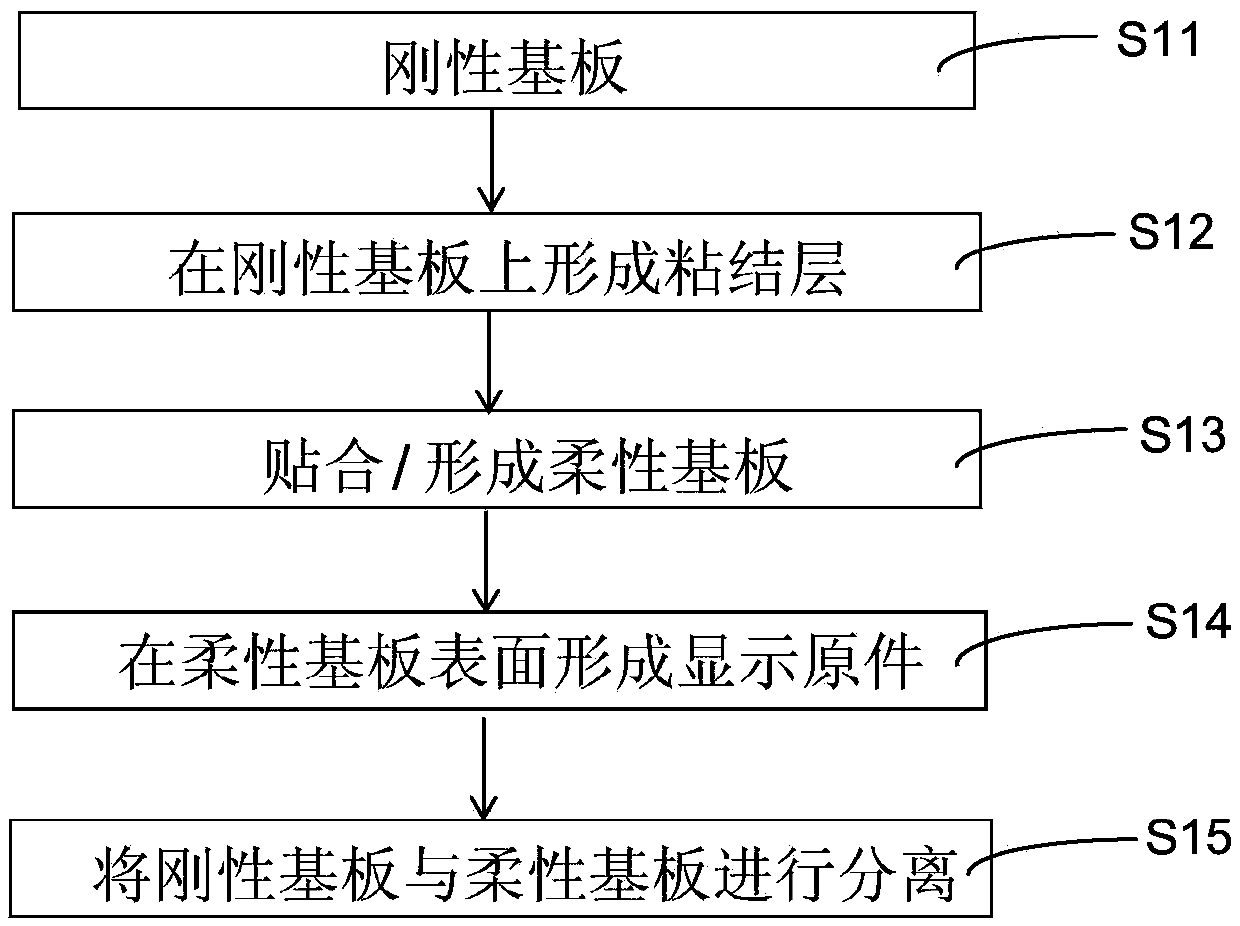

Base plate structure, adhering method and peeling method of flexible base plate thereof

ActiveCN105552089AAchieve strippingLamination ancillary operationsSolid-state devicesEngineeringMagnetic field

The invention discloses a base plate structure, an adhering method and peeling method of a flexible base plate thereof. The base plate structure comprises a carrier base plate, a flexible base plate arranged on the carrier base plate, one or more parallelly arranged adhering layers clamped between the carrier base plate and the flexible base plate; the adhering layers comprises magnetic adhering layers with converting adhering strength under the effect of a magnetic field; the sides of the adhering layers contacting with the flexible base plate are equipped with magnetic adhering layers. Because the magnetic adhering layers with converting adhering strength under the effect of the magnetic field are arranged on one side of the flexible base plate in the base plate structure, the flexible base plate can be adhered and peeled in the manufacturing process through the magnetic adhering layers under the effect of the magnetic field; and the carrier base plate and the adhering layers can be recycled.

Owner:BOE TECH GRP CO LTD +1

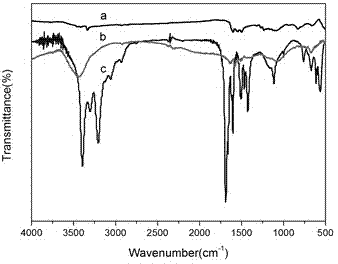

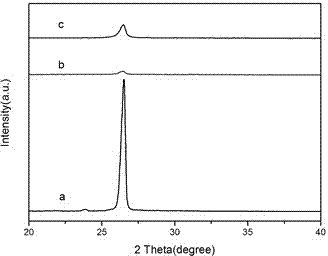

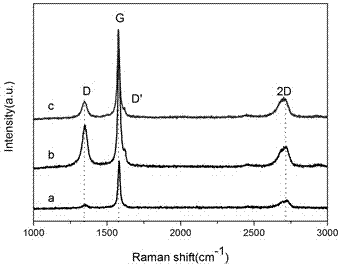

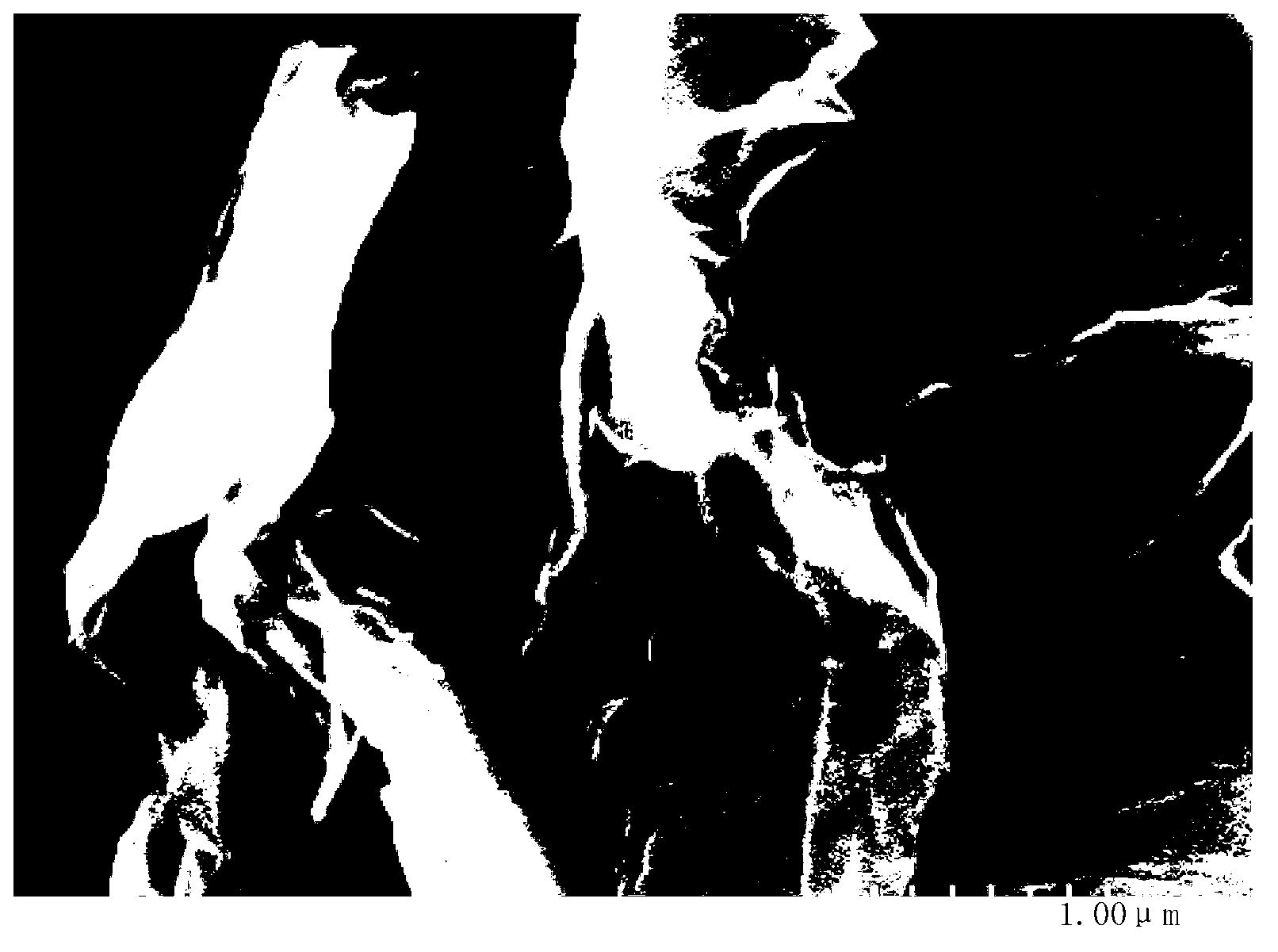

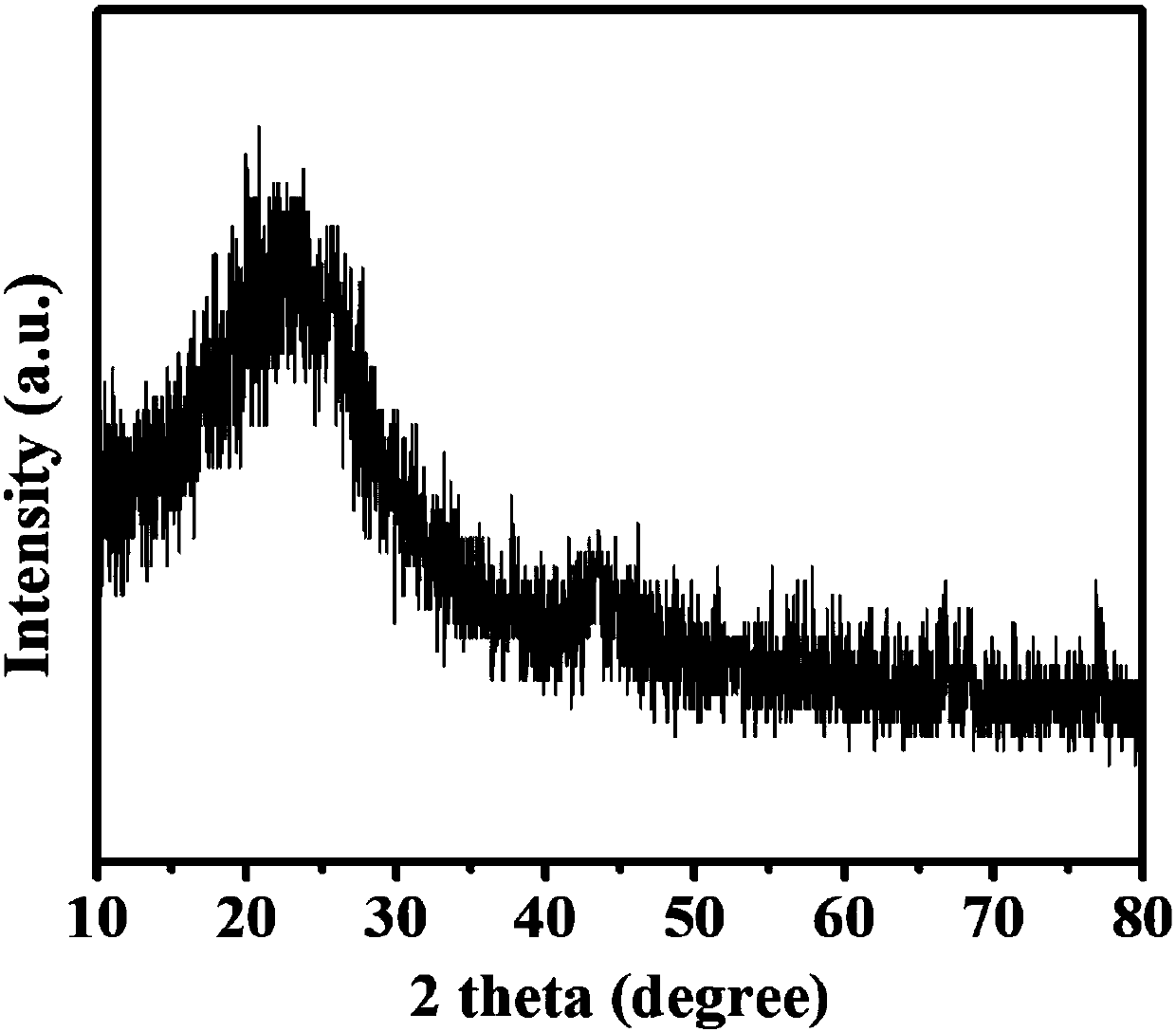

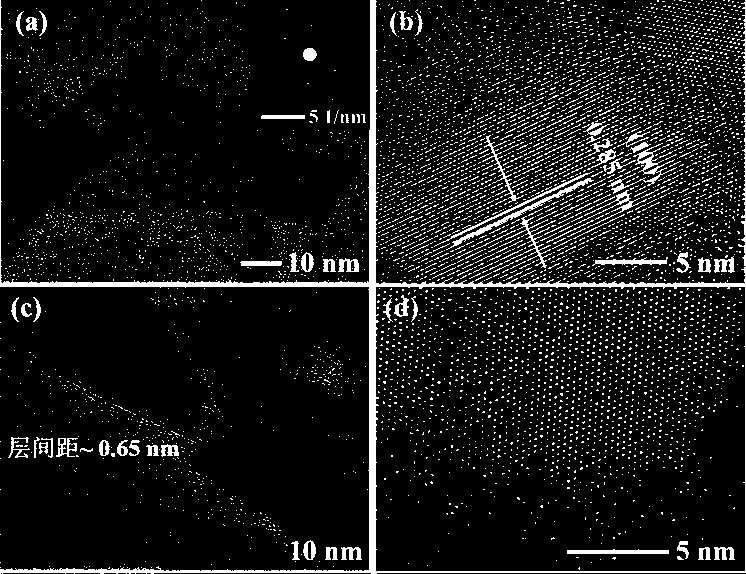

Method for preparing few-layer graphene by using auxiliary reagent

The invention discloses a method for preparing few-layer graphene by using an auxiliary reagent. The method specifically comprises the following steps: (a) adding graphite and the auxiliary reagent into a ball-milling tank for ball-milling; (b) adding a dispersing solvent into the mixture, and performing suction filtration on the obtained upper-layer dispersion liquid; (c) adding the dispersing solvent into the filtrate, stirring, leaving the mixture to stand, and centrifuging the upper-layer dispersion liquid twice; (d) performing suction filtration to the upper-layer suspension, and drying so as to obtain a dried product, that is, the few-layer graphene. The few-layer graphene obtained by using the method disclosed by the invention is complete in plane structure, small in structural defects and relatively high in conductivity, heat conduction and mechanical property, and meanwhile the reagents used in the method are all ordinary chemical reagents, so that the method is simple to operate and easy to popularize and use.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

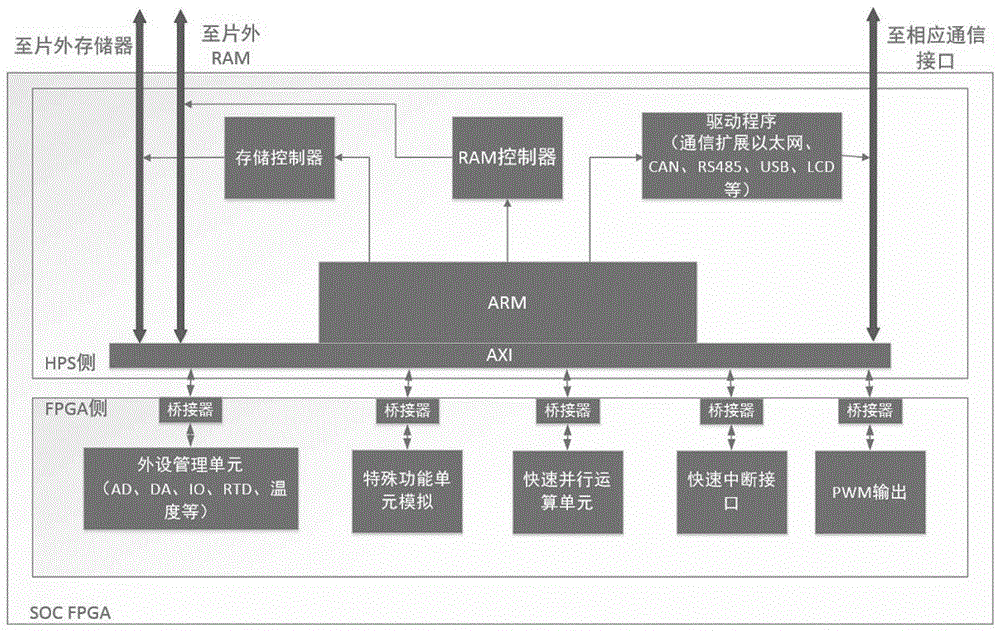

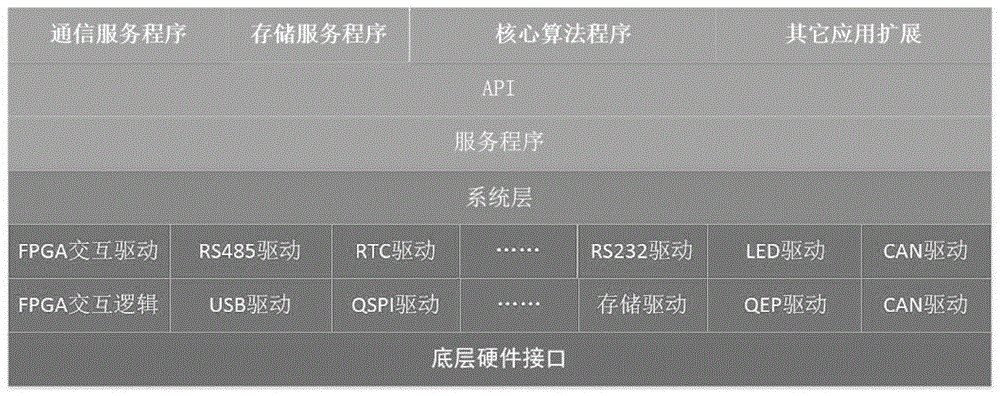

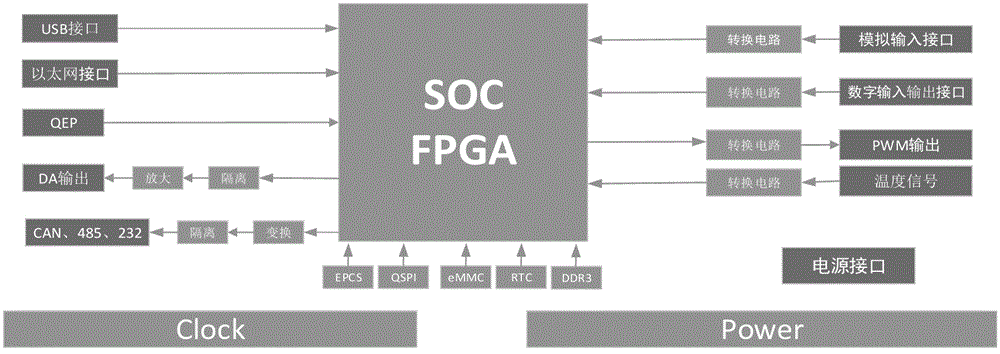

Motor single chip control device and method based on SoC-FPGA

InactiveCN106249658AAchieve strippingEnsure real-time requirementsProgramme controlComputer controlHardware structureCommunication interface

The invention discloses a motor single chip control device based on an SoC-FPGA, which comprises an SoC-FPGA unit and an external function unit, wherein the SoC-FPGA unit comprises an FPGA module and an HPS module; the FPGA module comprises a peripheral management unit, a special function unit, a fast parallel computing unit, a fast interrupt interface and a PWM output interface; the peripheral management unit is used for being in charge of work control on the external function unit and comprises an analog input interface, a digital input / output interface, a temperature signal interface, a DA output interface, a QEP interface and a communication interface; and the HPS module mainly comprises an ARM, an RAM controller, a memory controller and a driver interface. according to the control structure of the invention, advantages of flexibility and strong expansibility of the FPGA are exerted, the HPS computing ability and the strong system management function are made full use of, rich wiring resources and the high-efficiency bus system between the FPGA and the HPS can greatly improve the performance of the control system, the cost is reduced, and the hardware structure provided by the invention has strong practical value.

Owner:中国船舶重工集团公司第七一二研究所

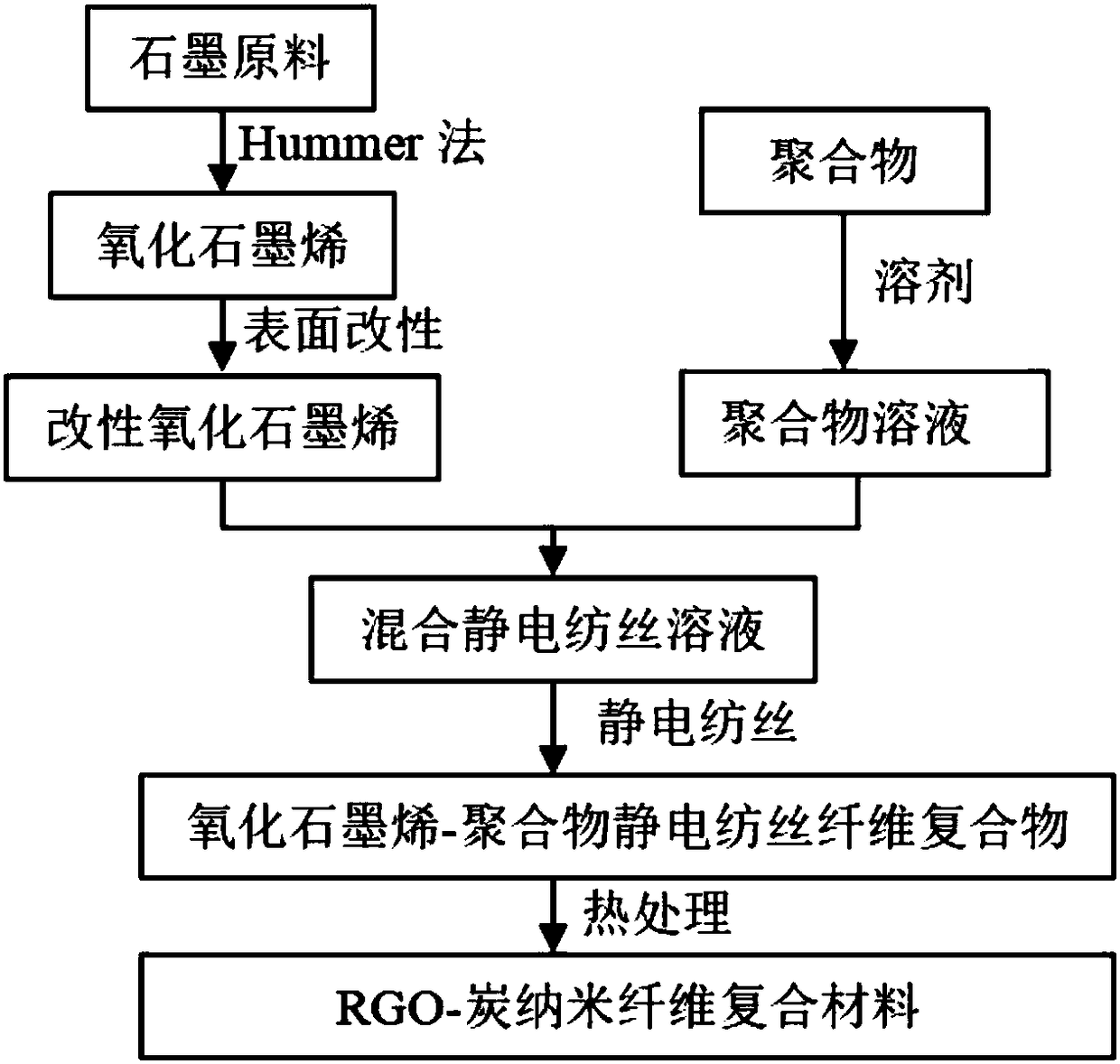

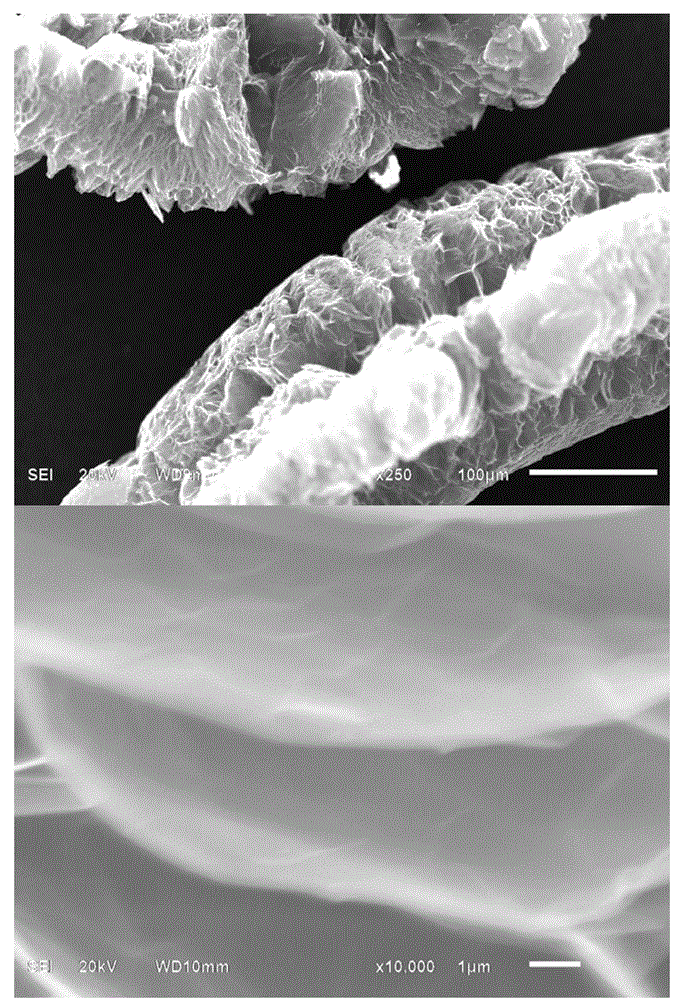

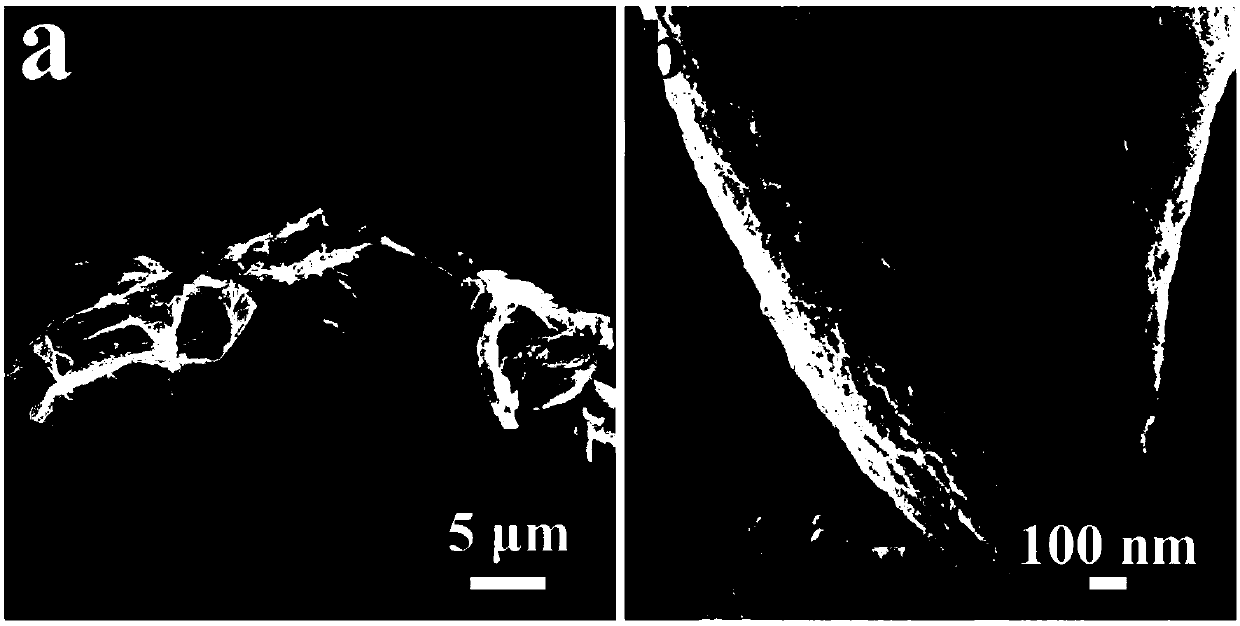

Carbon nanofiber supported orderly-arranged reduced graphene oxide (RGO) electrode material

ActiveCN108335917AAchieve reductionAchieve strippingCarbon compoundsHybrid capacitor electrodesFiberUltrasound - action

The invention discloses a preparation method of a carbon nanofiber supported orderly-arranged reduced graphene oxide (RGO) electrode material. The preparation method comprises the following steps: preparing graphene oxide from flake graphite by a Hummer method, performing surface modification on the graphene oxide by ionic liquid to obtain ionic liquid surface-modified graphene oxide, adding a polymer into a solvent, and stirred strongly under the action of ultrasonic waves to form an electrostatic spinning solution; and performing electrostatic spinning on the electrostatic spinning solution,and performing heat treatment on graphene oxide-polymer electrostatic spinning fibers obtained on an electrostatic spinning receiver to obtain a composite material in which RGO is arranged verticallyand orderly on the surfaces of the carbon nanofibers in an embedded manner. The preparation method has the advantages of reasonable process and stable performance, can prevent RGO agglomeration, increase the specific surface area and increase the charge storage density and charge transfer rate, is taken as an electrode of a high-capacity power supercapacitor, and can be up to 99.5 to 99.7 percentin charging and discharging efficiency.

Owner:锦州凯美能源有限公司

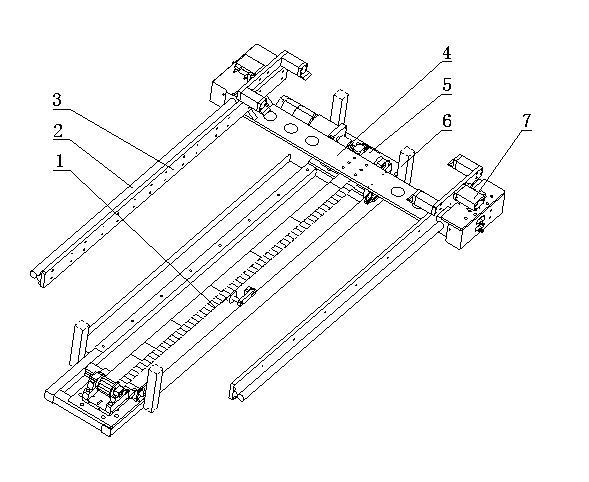

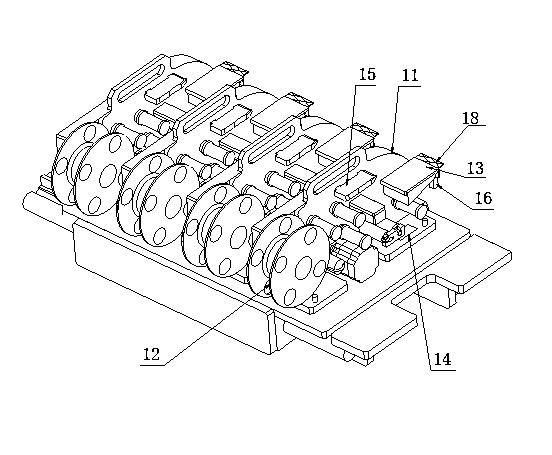

Automatic feeding and stripping mechanism

ActiveCN103832872AReduce labor costsImprove work efficiency and product yieldArticle deliveryEngineeringPhotoelectric sensor

An automatic feeding and stripping mechanism comprises a working platform, a feeding device, a photoelectric sensor, an electric motor, a control device, an adjustable roller device and a material stripping device are arranged on the working platform, the material peeling device comprises a first adjusting block and a guide wheel, a pair of material rolling pressing wheels is arranged on one side of the guide wheel in parallel, a stripping plate is arranged on one side of the material rolling pressing wheels, a sliding groove is formed in one end of the stripping plate, a material temporary containing plate is arranged at the other end of the stripping plate, and a gap is reserved between the material temporary containing plate and the stripping plate. According to the automatic feeding and stripping mechanism, automatic feeding and stripping of rolled materials of different widths and various kinds of materials can be achieved, automatic stripping of materials on release paper is achieved, the materials are conveyed to a product by being matched with a material taking mechanical device, the automatic feeding and stripping mechanism saves labor cost, and working efficiency and product yield are improved.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

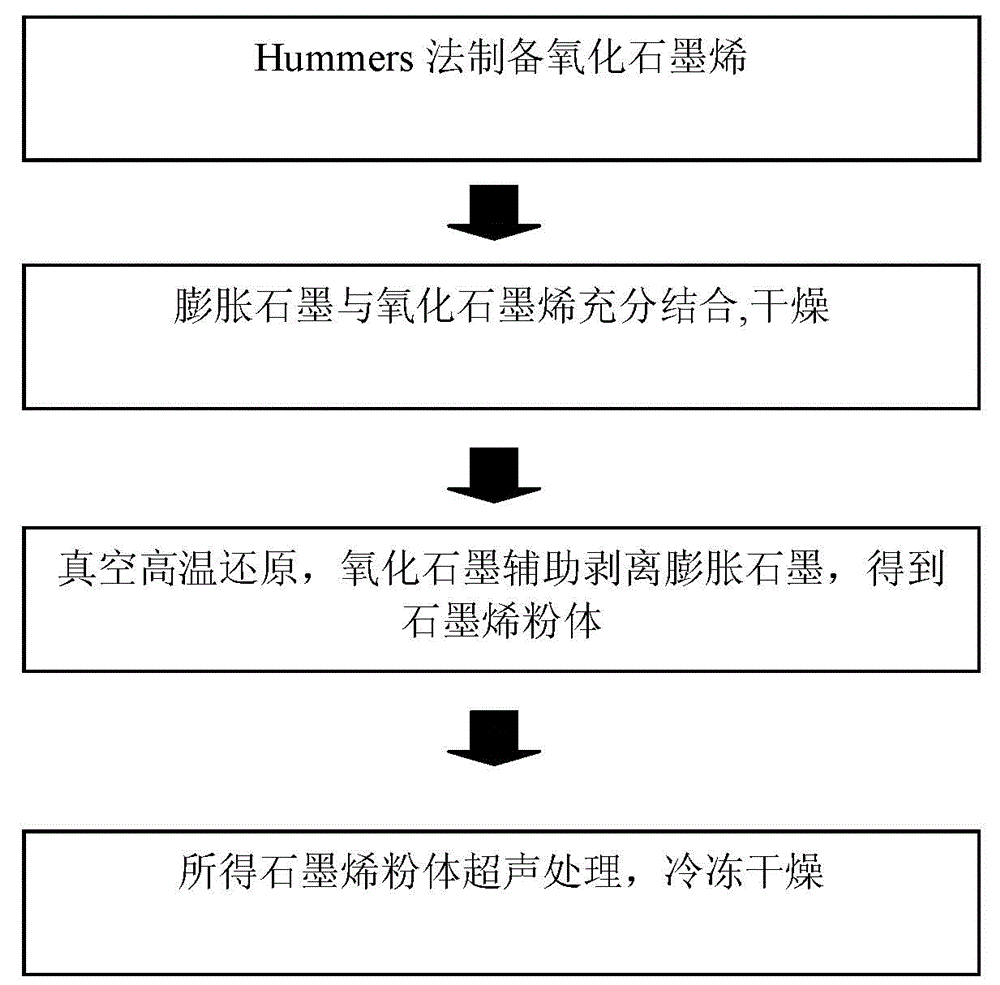

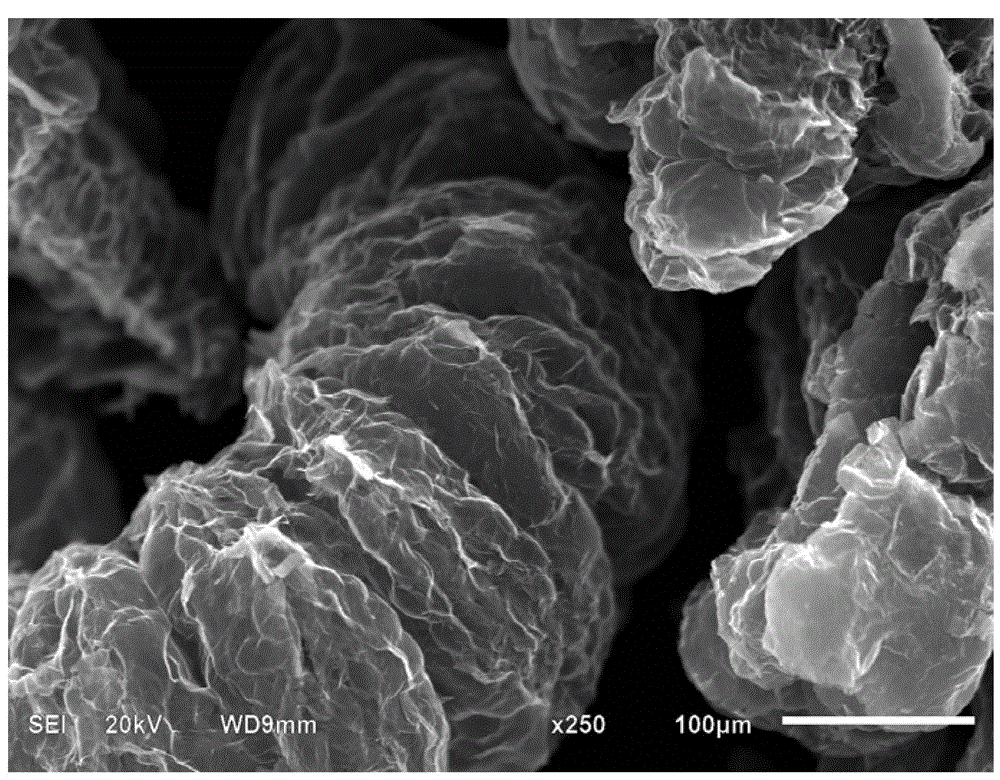

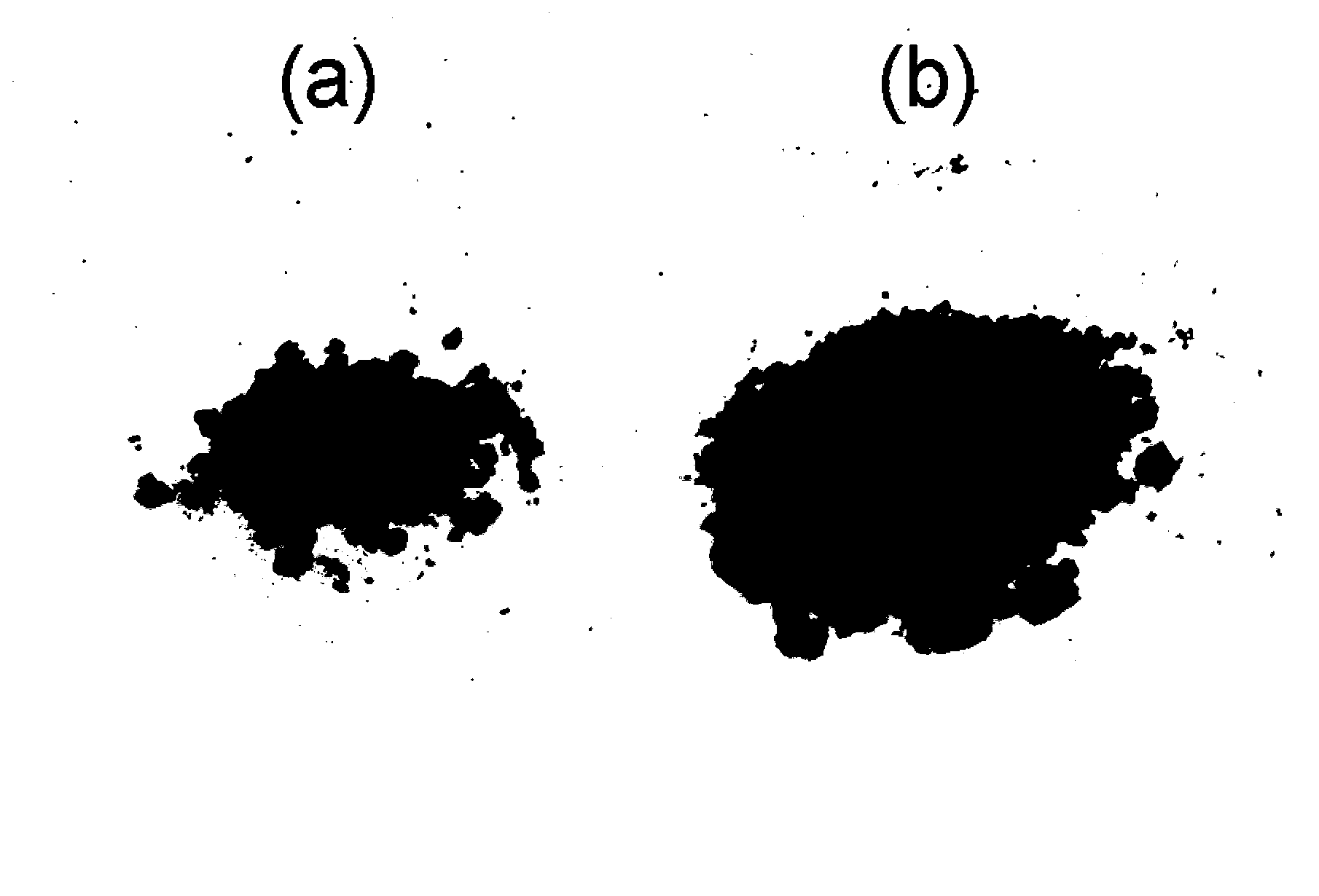

High-quality graphene and preparation method thereof

The invention relates to high-quality graphene and a preparation method thereof. The preparation method includes the steps of (1) wrap-embedding graphene oxide into the lamellas in expanded graphite to obtain a graphene oxide / expanded graphite mixture; and (2) performing thermal-treatment to the graphene oxide / expanded graphite mixture so that the expanded graphite can be stripped with assistance of a reaction force from high-temperature expansion reduction of the graphene oxide, thereby preparing the graphene powder. In the invention, the graphene oxide is wrap-embedded into the lamellas in the expanded graphite, and the expanded graphite is stripped-away with the impact force of a violent reaction in the high-temperature expansion reduction of the graphene oxide, thereby obtaining loosen graphene powder. The expanded graphene is controllable in the number of layers, is free of defect, is less in impurities and is high in purity.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

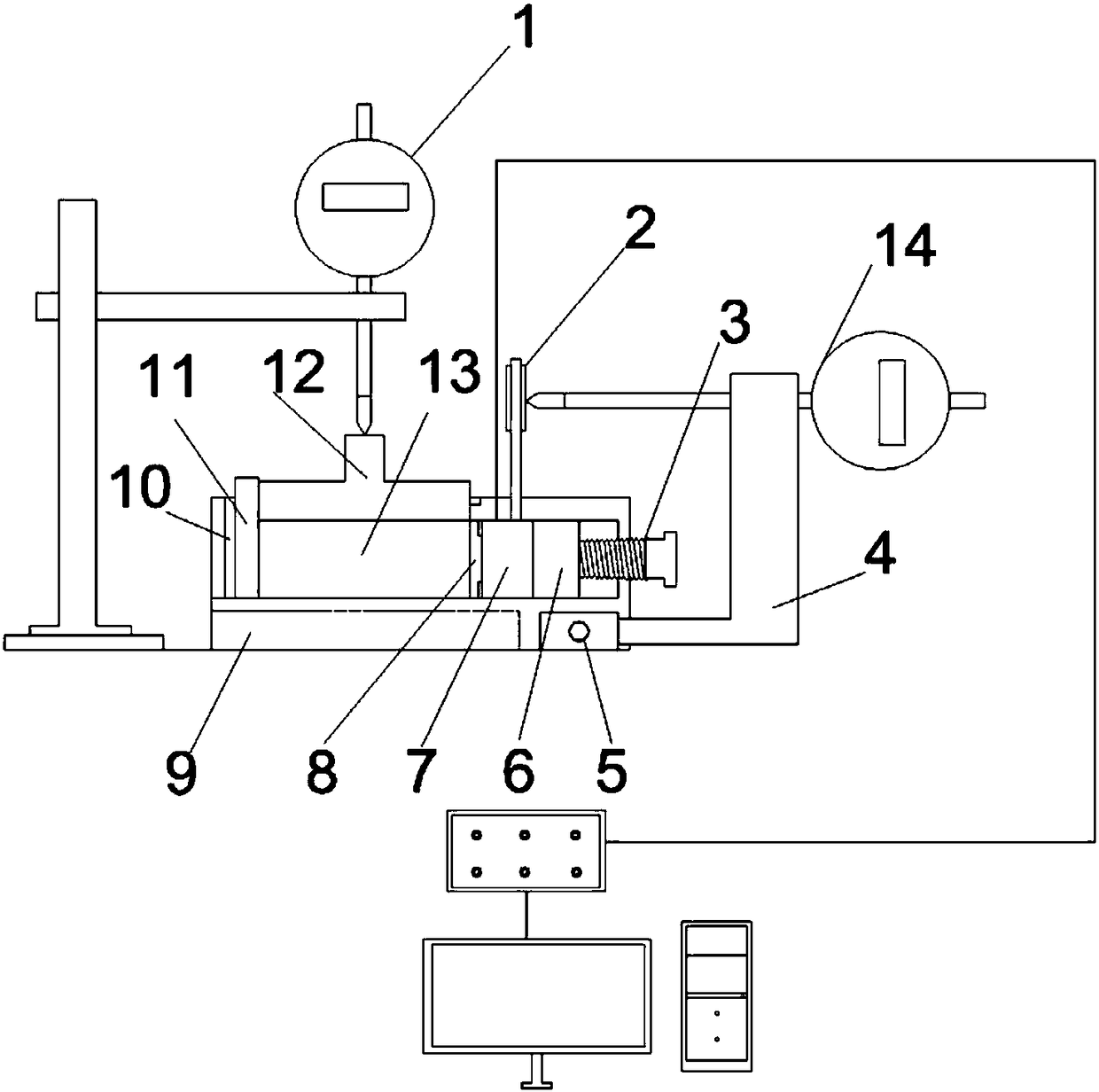

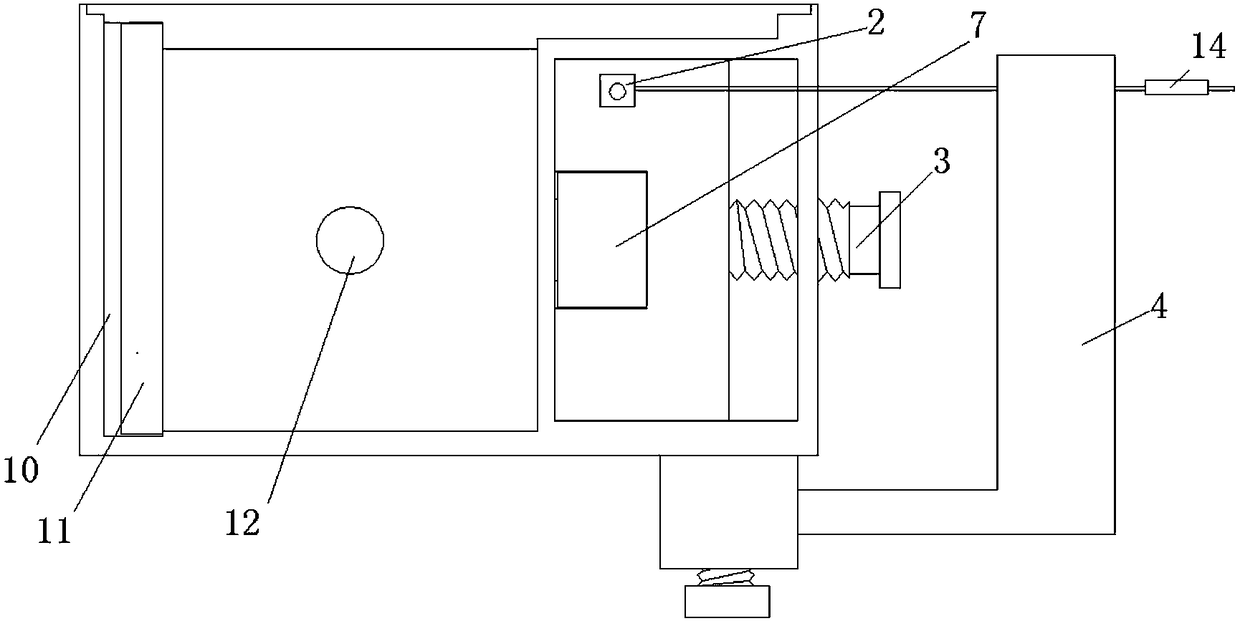

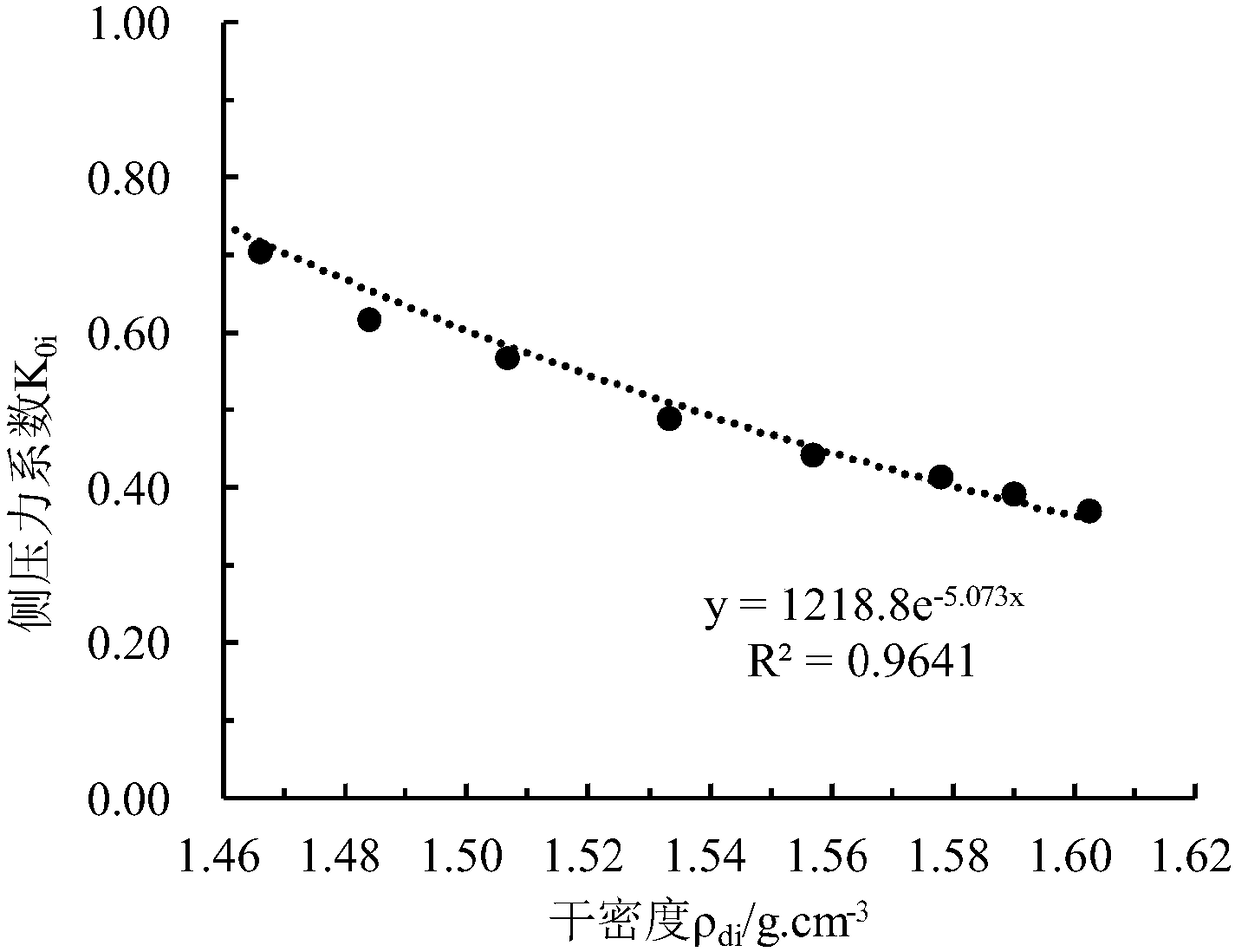

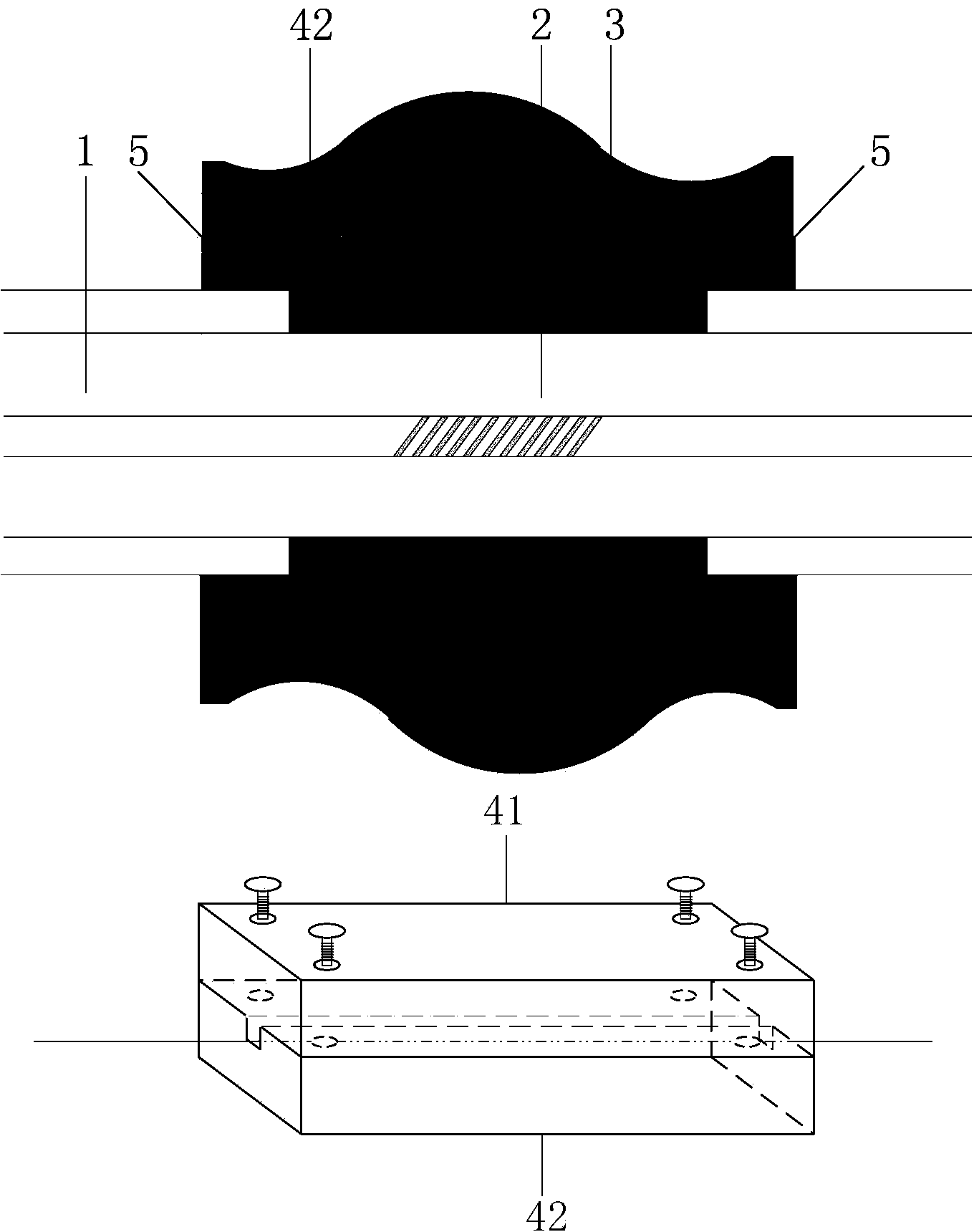

Strain type lateral expansion force testing device and measuring method

ActiveCN108593883AAchieve strippingIn line with actual working conditionsPreparing sample for investigationEarth material testingEngineeringSoil science

The invention relates to a strain type lateral expansion force testing device and a measuring method. The strain type lateral expansion force testing device comprises a measuring device, a data collecting device and a loading device. The measuring method comprises the following steps of performing water soaking expansion testing on specimens with same initial wet density states under non-load andnon-lateral strain conditions, and obtaining the expansion limit water content and corresponding dry density of the specimens with same initial wet density states under the condition of stable expansion; performing gradual loading type cementing testing on the specimens with same initial wet density states under the conditions of expansion limit water content and corresponding dry density, measuring the lateral pressure coefficient K0 at different dry densities, and stripping the lateral expansion force from the lateral resultant force. The strain type lateral expansion force testing device and the measuring method have the advantages that the testing method and the device are simple, the operation is convenient, the structure is reasonable, and the manufacturing cost is economical; the problem of stability of expanded soil edge slope after wetting expansion in the long-time expected precise evaluation process of the field is solved, the important design parameters are provided for thedesign of engineering structures and wall back buffer layers in the expanded soil area, and the device and the method are suitable for being popularized and applied in engineering.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

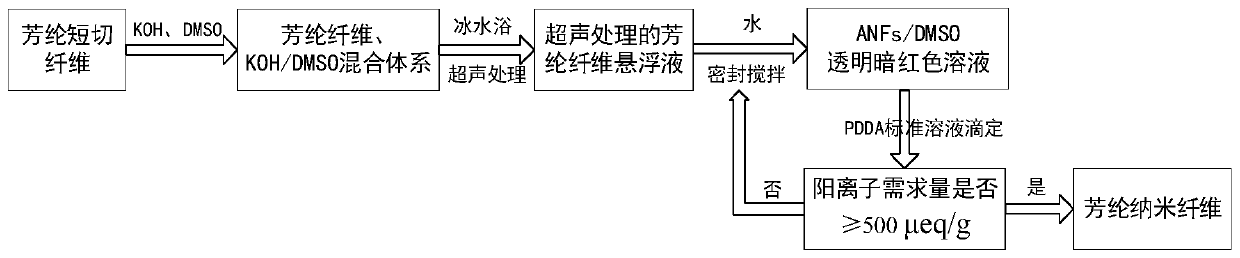

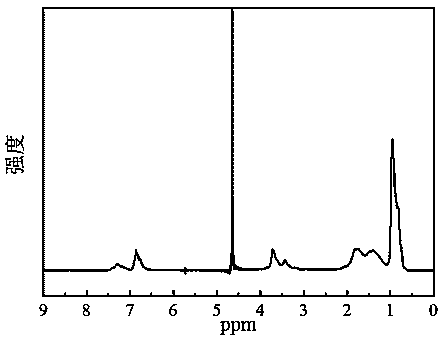

Method for preparing aramid nanofibers

ActiveCN110055797ASpeed up the deprotonation reaction rateImprove rigidityPaper material treatmentIce waterNanofiber

The invention discloses a method for preparing aramid nanofibers. Para-aramid fibers and KOH are added into DMSO (dimethylsulfoxide) solution to obtain a mixed system of para-aramid fibers, KOH and DMSO; the mixed system of para-aramid fibers, KOH and DMSO is ultrasonically treated in an ice water bath to obtain a para-aramid fiber suspension A; water is added into the para-aramid fiber suspensionA to obtain a para-aramid fiber suspension B; after being sealed, the para-aramid fiber suspension B is stirred to obtain an ANFs / DMSO (aramid nanofibers / DMSO) solution; the ANFs / DMSO solution is subjected to colloidal titration through a cation standard liquid; whether a reaction endpoint is reached is judged according to cation demand; if the reaction endpoint is reached, aramid nanofibers areprepared; if the reaction endpoint is not reached, the previous step is repeated until the reaction endpoint is reached. The method has the advantages that reaction time is shortened greatly, reactionconcentration is increased, reaction efficiency is improved evidently, and the method is easy to apply to large-scale production.

Owner:SHAANXI UNIV OF SCI & TECH

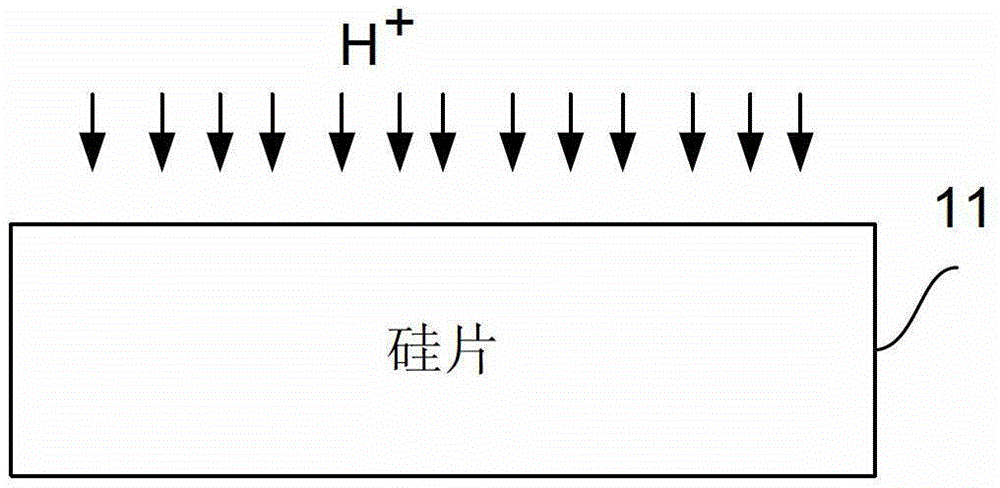

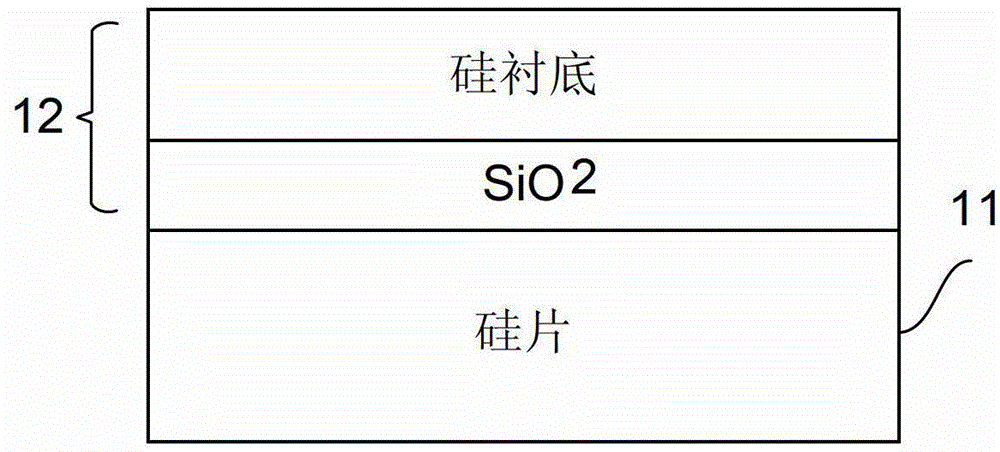

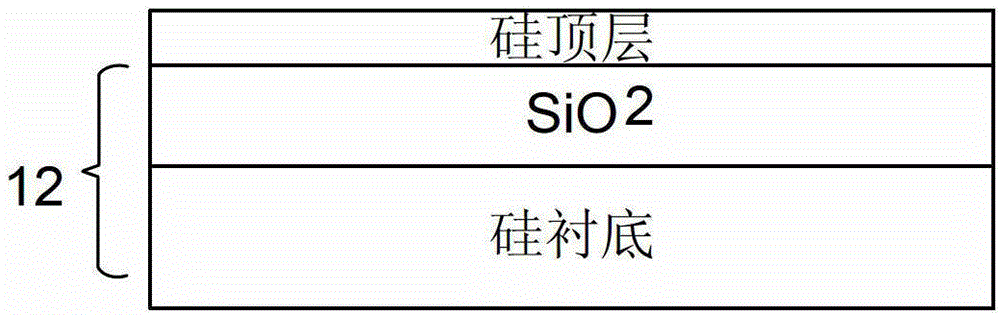

Enhanced absorption based method for preparing material-on-insulator

ActiveCN103943547AAchieve strippingImprove crystal qualitySemiconductor/solid-state device manufacturingInsulation layerEnhanced absorption

The invention provides an enhanced absorption based method for preparing a material-on-insulator. According to the method provided by the invention, first of all, a doped monocrystalline film with a superlattice structure, an intermediate layer, a buffer layer and a top film are successively grown on a first substrate in an epitaxial mode; afterwards, a low-dosage ion implantation is carried out on a structure with the formed top film to enable ions to be implanted on the upper surface or under the lower surface of the doped monocrystalline film with the superlattice structure; and then a second substrate with an insulation layer is bonded with a structure already subjected to the ion implantation, and annealing processing is performed so that micro cracks are generated at the doped monocrystalline film with the superlattice structure so as to realize atom-grade peeling. According to the invention, effective peeling of a bonding pad is realized by use of enhanced adsorption, the peeled surface is smooth, the roughness is low, and the top film crystal quality is high.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

All-fiber stimulated Raman scattering light stripper

InactiveCN104112970AAchieve strippingImplement segmentation strippingActive medium shape and constructionLong-period fiber gratingGrating

Disclosed is an all-fiber stimulated Raman scattering light stripper. The all-fiber stimulated Raman scattering light stripper comprises a blazed fiber grating or a long-period fiber grating, an optical adhesive and a cooling metal block. A coating of a grating area of the blazed fiber grating or a long-period fiber grating is removed to be placed in a metal block lower block with a straight groove, the integral straight groove is filled with the optical adhesive and the solidification is performed, and a metal block upper block covers the straight groove to achieve the encapsulation. According to the all-fiber stimulated Raman scattering light stripper, the structure is simple, the sustainable laser and stimulated Raman scattering light is high in power, the multistage stimulated Raman scattering light can be stripped, and accordingly the all-fiber stimulated Raman scattering light stripper can be applied to a high-power fiber laser and a high-power fiber amplifier.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

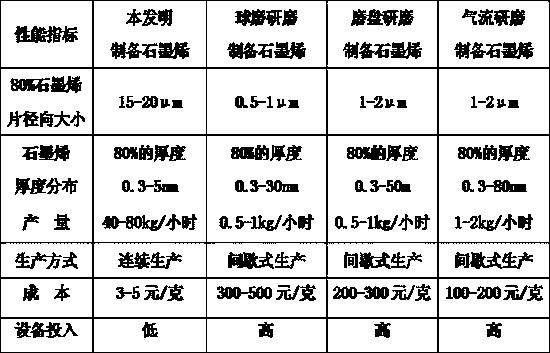

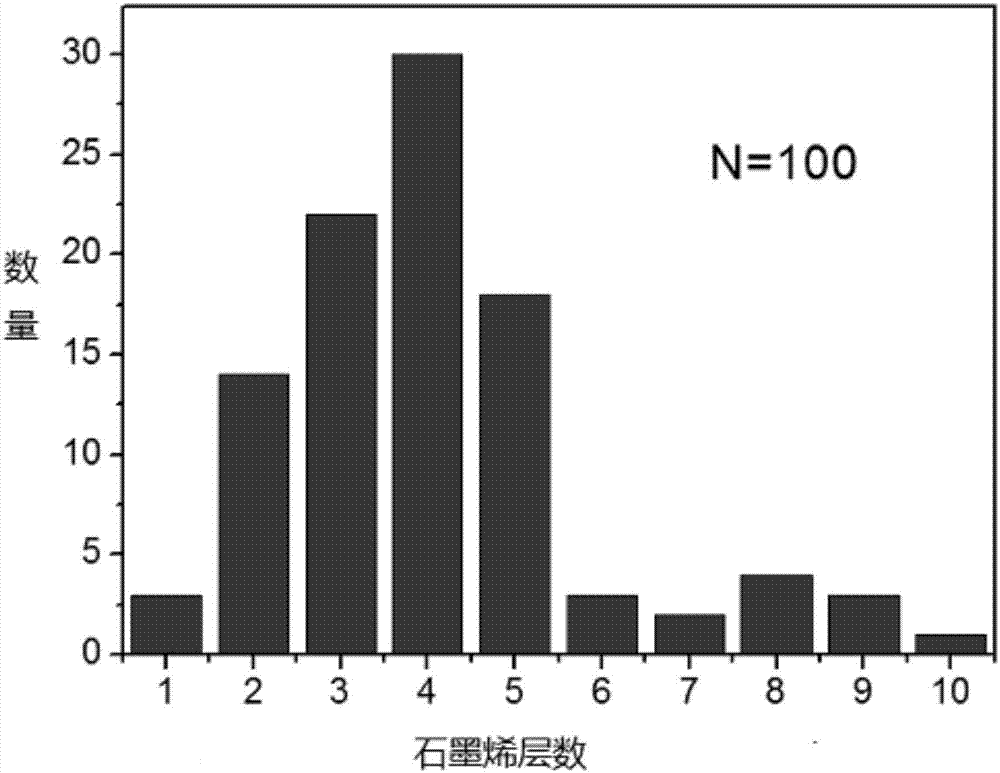

Method for preparing graphene by pulling jelly

ActiveCN105502367AReduce the number of layersThe number of layers is evenly distributedMaterial nanotechnologyGraphenePhysicsChemistry

The invention relates to the field of a graphene material, in particular to a method for preparing graphene by pulling jelly by a low cost mechanical continuous stripping method. The method comprises the steps of graphite is dispersed into high viscosity jelly by using shearing and axial reciprocated pulling of a rotating reciprocating screw extruder in a screw spiral direction, a graphite sheet layer is continuously stripped in a jelly pulling process without damaging a layer structure, thus furthest protecting the layer structure of the graphene and realizing continuous stripping; the obtained graphene is less in layer number and uniform in layer number distribution. Continuous and stable preparing of the graphene is realized, severe harm to the environment and damage to a graphene crystal lattice caused by that a chemical reduction method and direct grinding are used for preparing the graphene, and high quality and low cost volume production of the graphene is further promoted. The method has obvious market application value.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

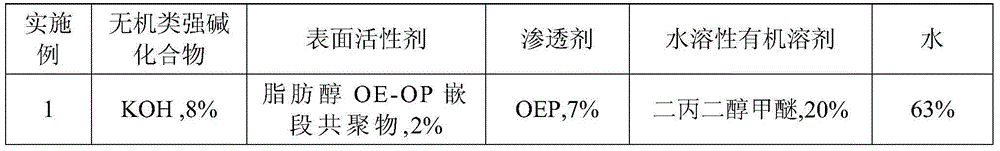

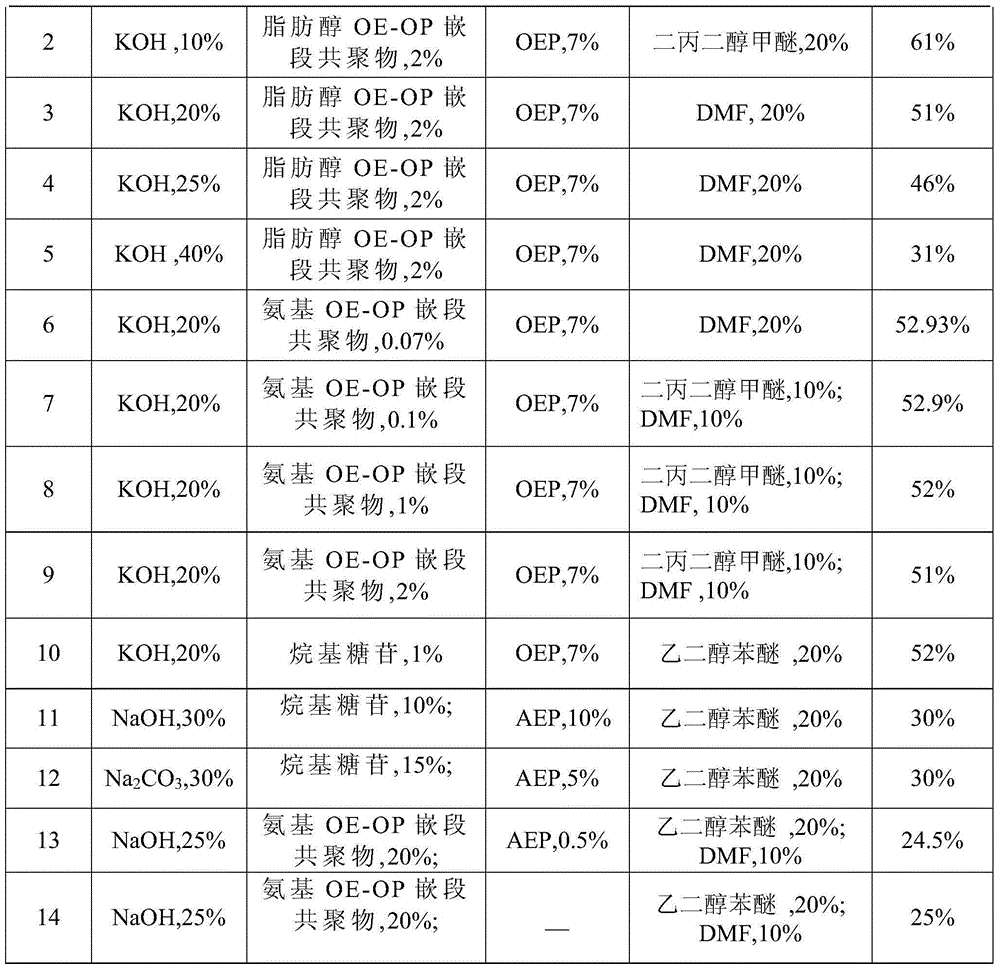

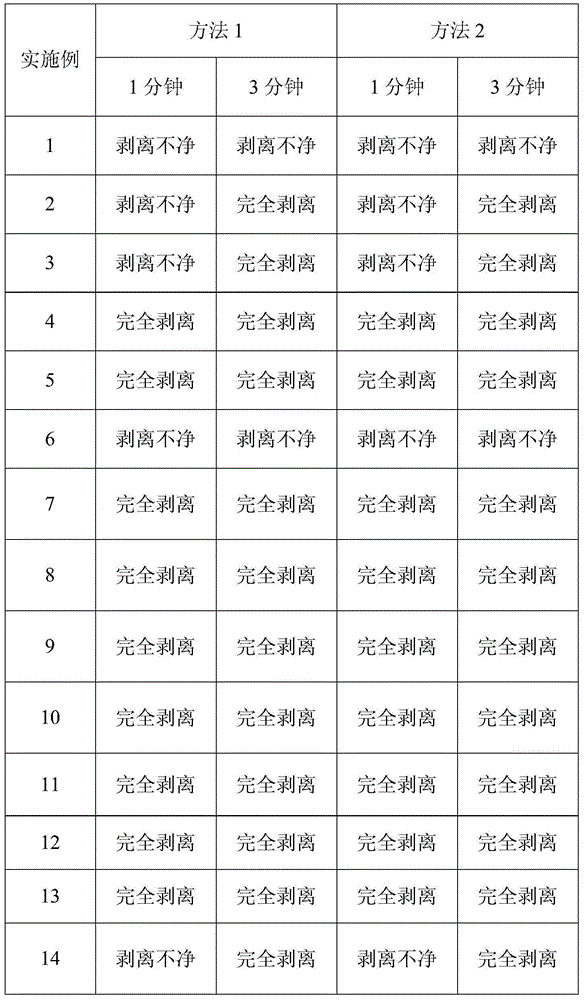

Low-temperature photoresist reworking stripping liquid and application thereof

ActiveCN104155854AAchieve strippingExcellent peelabilityPhotosensitive material processingGlycosideAlcohol

The invention relates to low-temperature photoresist reworking stripping liquid and application thereof. The low-temperature photoresist reworking stripping liquid comprises 10-40% of inorganic strong base compound, 0.1-20% of a surfactant, 0.5-10% of a permeating agent, 10-60% of a water-soluble organic solvent and 20-65% of water, wherein the surfactant is selected from alkyl glycosides, fatty alcohol OE-OP block copolymer and amido OE-OP block copolymer; the water-soluble organic solvent is selected from water-soluble alcohol ether solvent and water-soluble amide solvent. By adopting the stripping liquid, various photoresist and the OC glue protective layer on the surface of a color filter can be completely stripped off within 1-3 minutes at the temperature of 50-60 DEG C, and after stripping, the solution can be recycled after being filtered, so that the cost is reduced, and in addition, the stripping liquid is stable in stability, lower in cost and less harmful to person and environment.

Owner:SUZHOU RUIHONG ELECTRONIC CHEM CO LTD

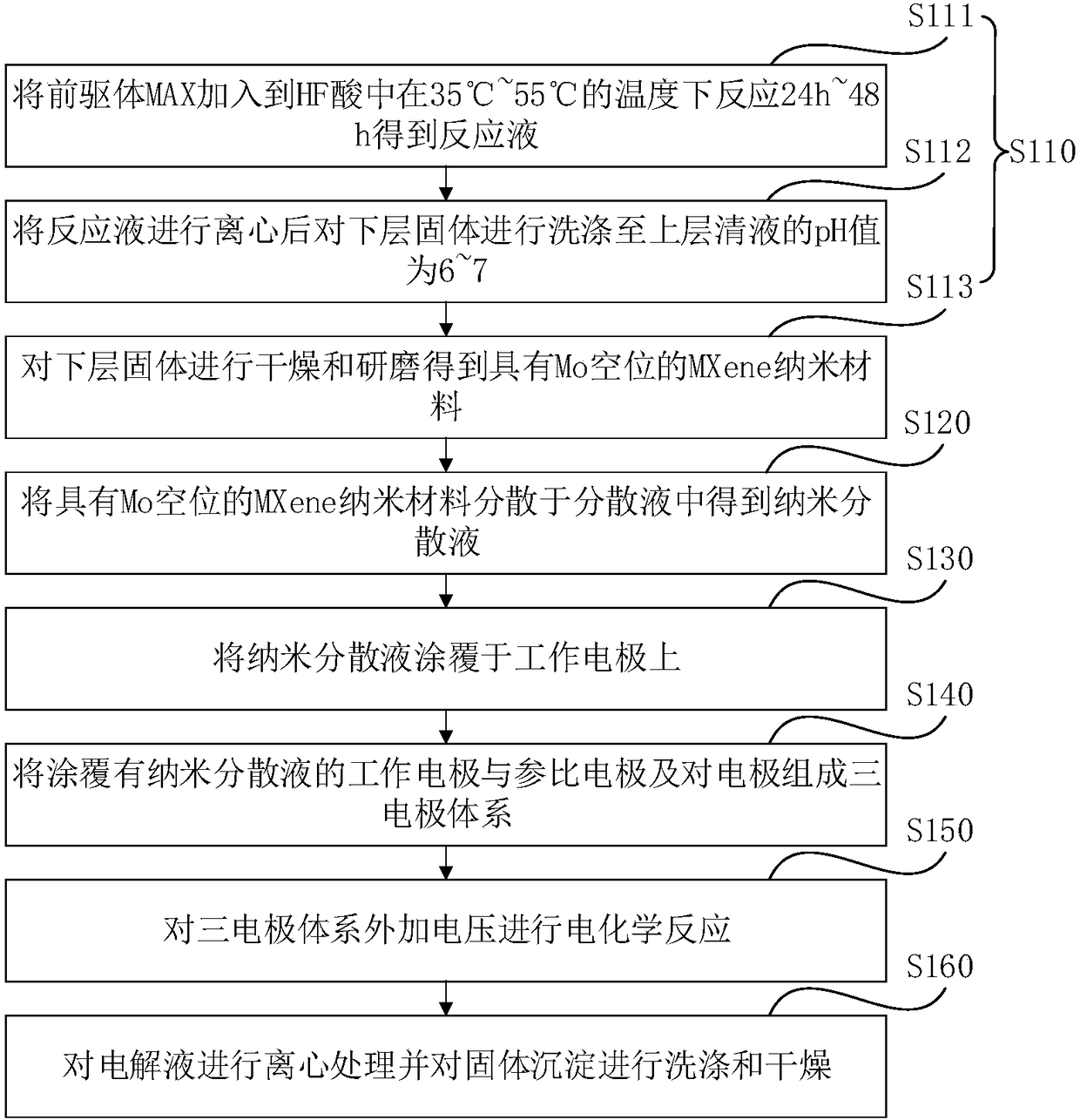

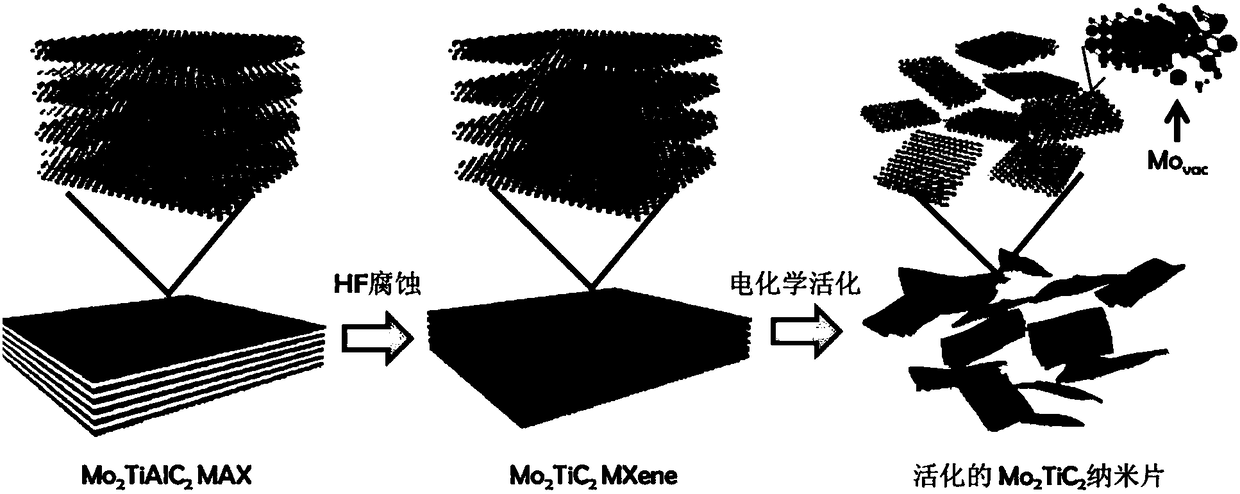

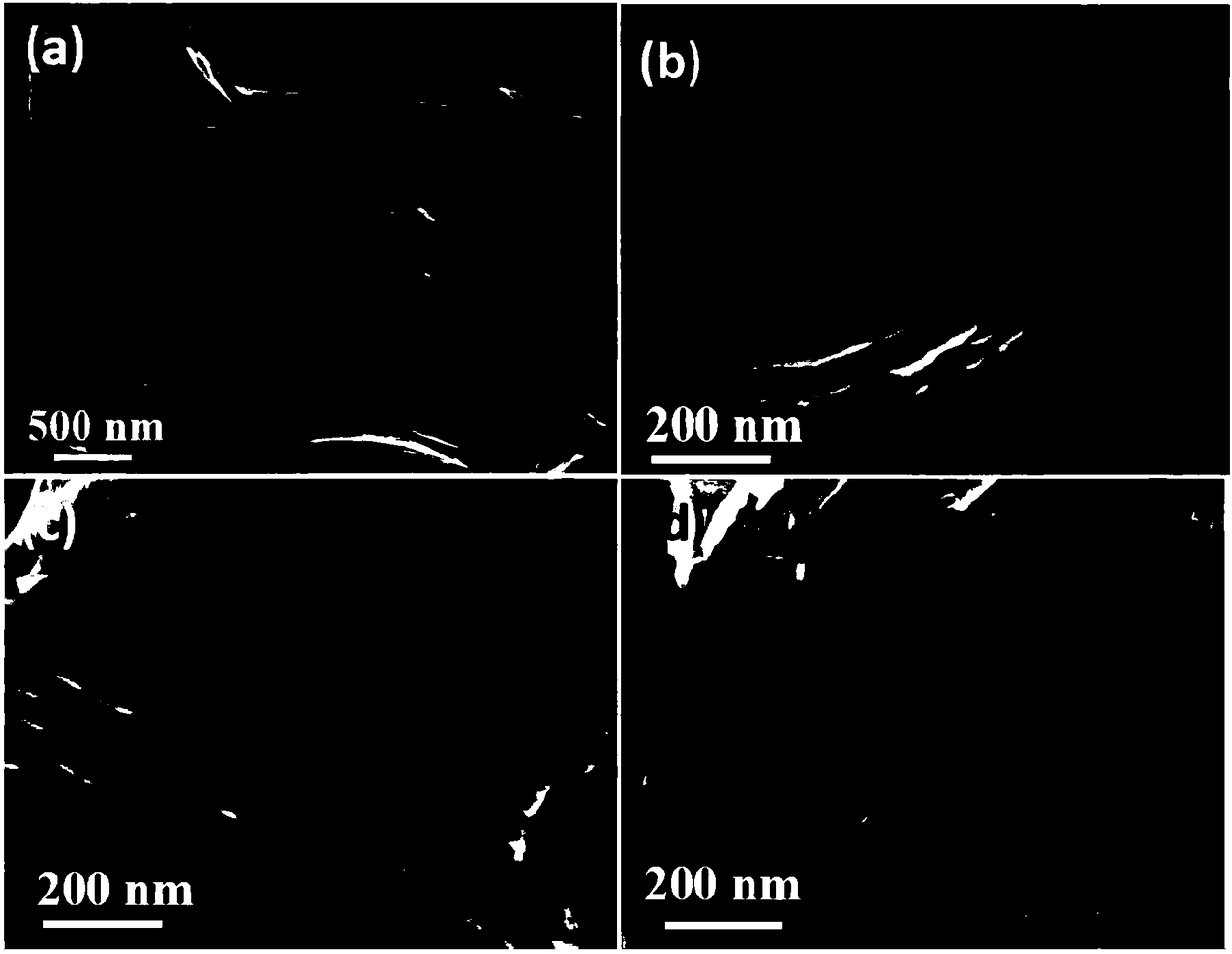

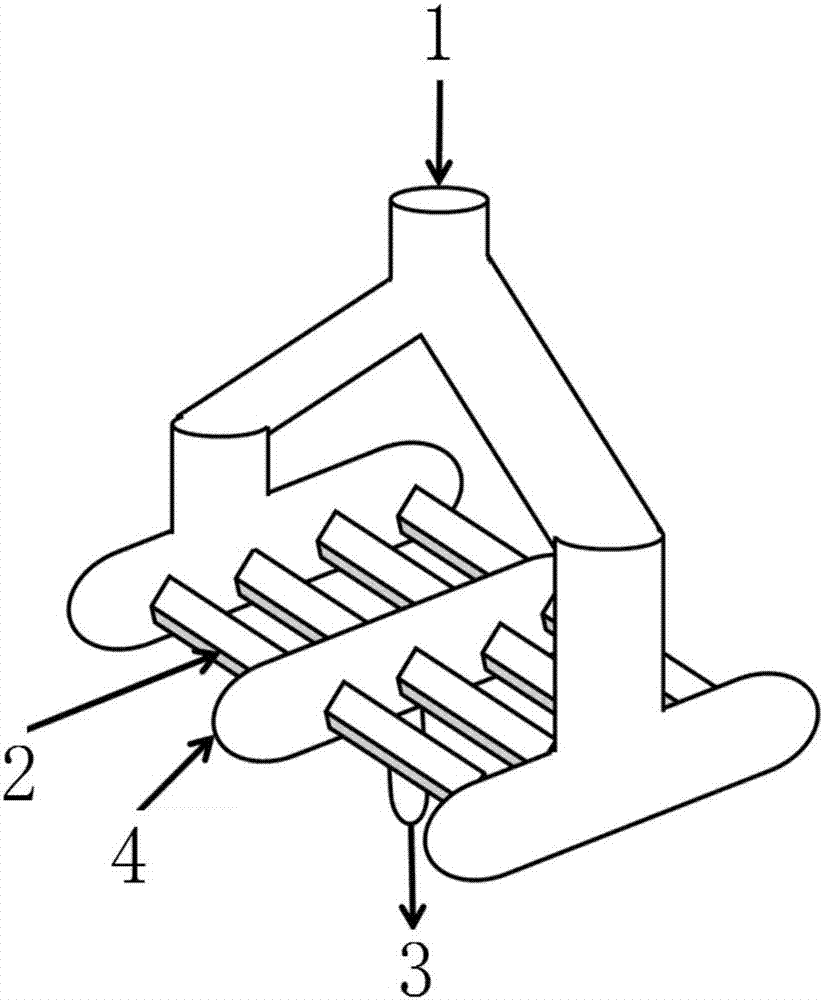

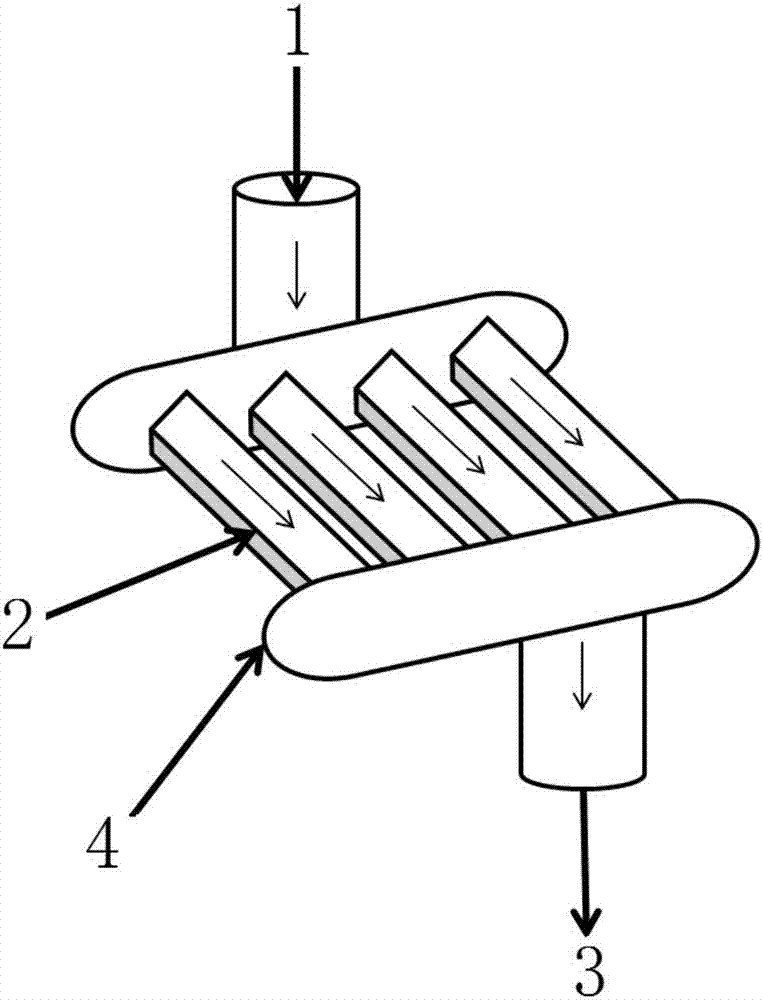

Preparation method and application of MXene nano-sheet with Mo vacancy

ActiveCN108383121AAchieve strippingReduce usageCell electrodesTitanium carbideElectrochemical responseOrganic solvent

The invention relates to a preparation method and application of an MXene nano-sheet with a Mo vacancy. The preparation method of the MXene nano-sheet with the Mo vacancy comprises the following steps: dispersing an MXene nano-material containing Mo into a dispersion solution to obtain a nano dispersion solution; coating a working electrode with the nano dispersion solution; forming a three-electrode system by the working electrode coated with the nano dispersion solution, a reference electrode and a counter electrode, wherein the pH (Potential of Hydrogen) value of electrolyte of the three-electrode system is 0 to 6; applying additional voltage to the three-electrode system and carrying out electrochemical reaction to obtain the MXene nano-sheet with the Mo vacancy. According to the preparation method of the MXene nano-sheet with the Mo vacancy, complete peeling of a nano-sheet layer material can be realized, and a lot of organic solvents are not used; a technology is simpler and theyield is remarkably improved; a lot of the MXene nano-sheets with the Mo vacancy can be prepared through regulating and controlling surface characteristics, so that the MXene nano-sheets with the Mo vacancy have better electro-catalytic hydrogen evolution reaction activity.

Owner:DONGGUAN UNIV OF TECH

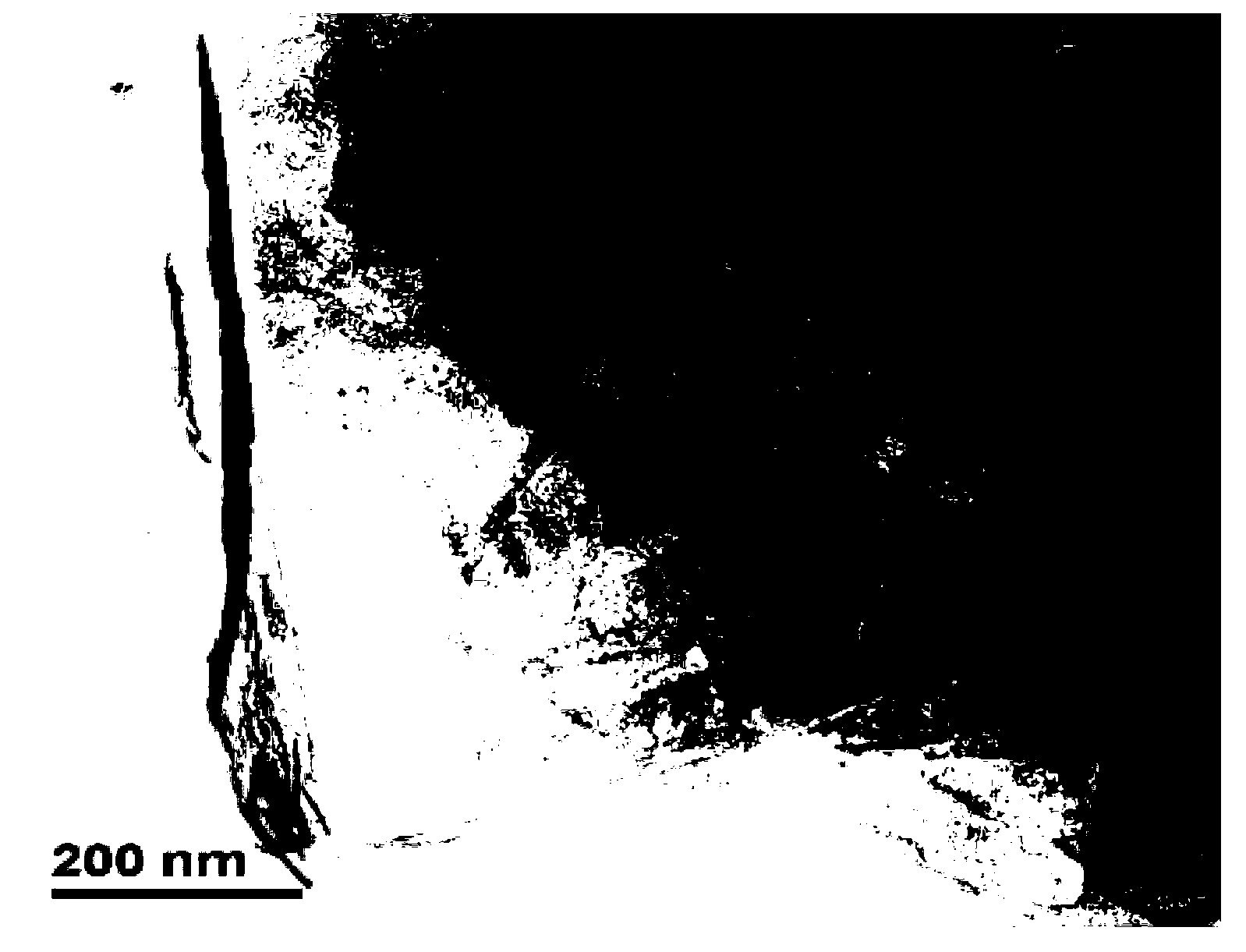

Method for preparing large-sized graphene by highly-efficiently exfoliating graphite powder

ActiveCN106976870AAchieve strippingPrevent overlapping againSingle layer grapheneDefective grapheneGraphite

The invention discloses a method for preparing large-sized graphene by highly-efficiently exfoliating graphite powder. The method comprises the following steps: 1) dissolving an intercalating agent in deionized water to prepare an intercalating agent solution, wherein the intercalating agent is a water-soluble polymer; 2) adding graphite powder to the intercalating agent solution, and uniformly mixing the graphite powder and the intercalating agent solution to obtain a graphite powder suspension; 3) allowing the graphite powder suspension to go through a microfluidizer at a rate of 50-450 mL / min, and carrying out circulating treatment multiple times to obtain a suspension I; and 4) filtering the suspension I, repeatedly washing the filtered suspension I with deionized water, carrying out filtration drying to obtain a graphene filter cake, and using the graphene filter cake directly or carrying out spray drying and vacuum drying to remove water in order to obtain dry graphene powder. The method utilizes the microfluidizer to exfoliate the graphite powder, and the water-soluble intercalating agent is combined, so abuses which can not be avoided by ultrasonic separation are avoided, and the water-soluble intercalation agent is easy to remove; and the finally prepared graphene has few defects, and the size is 3-15 [mu]m.

Owner:TIANJIN POLYTECHNIC UNIV

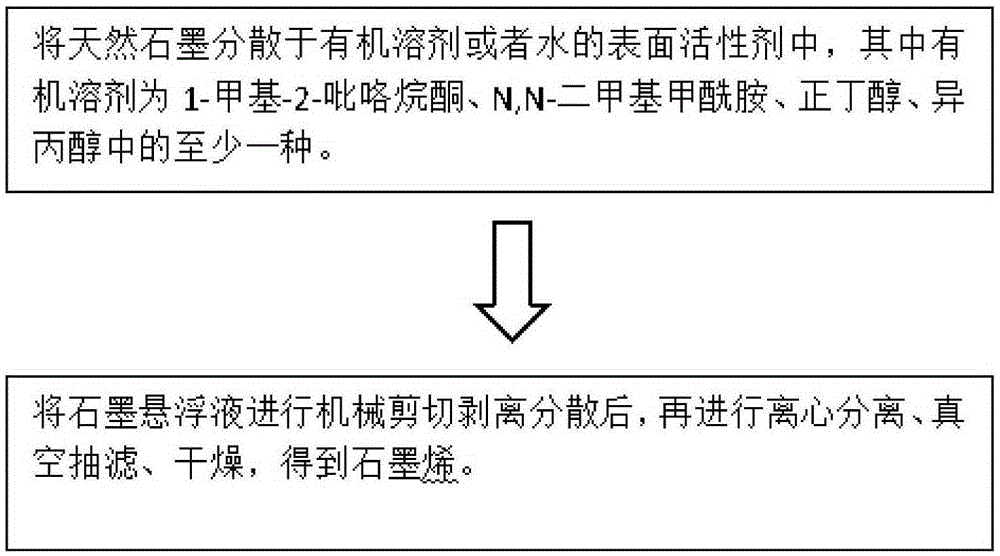

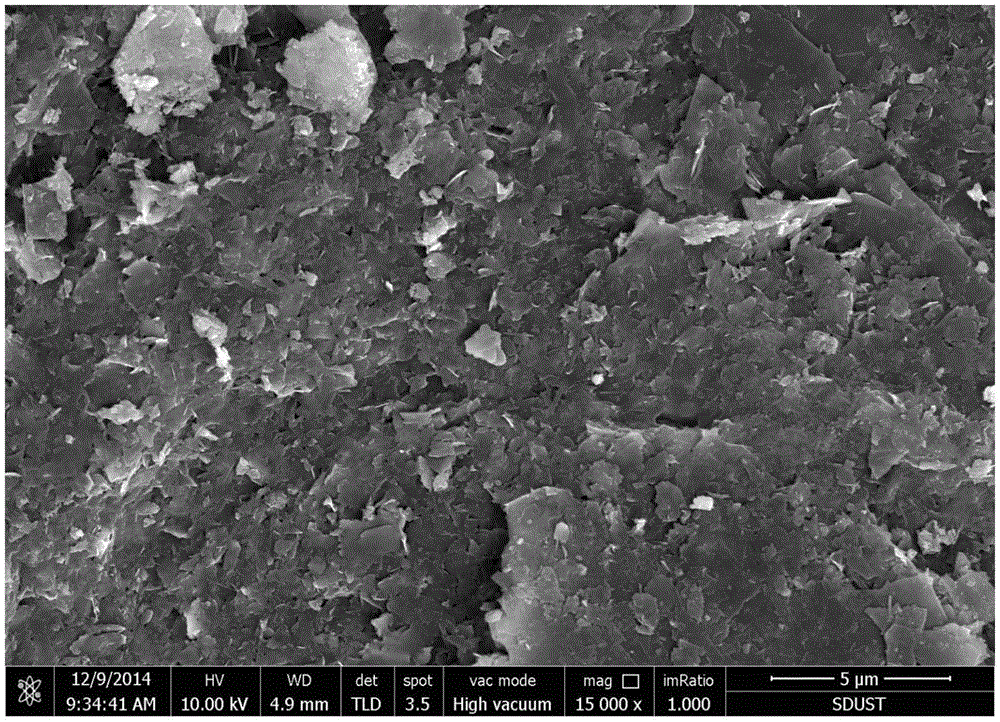

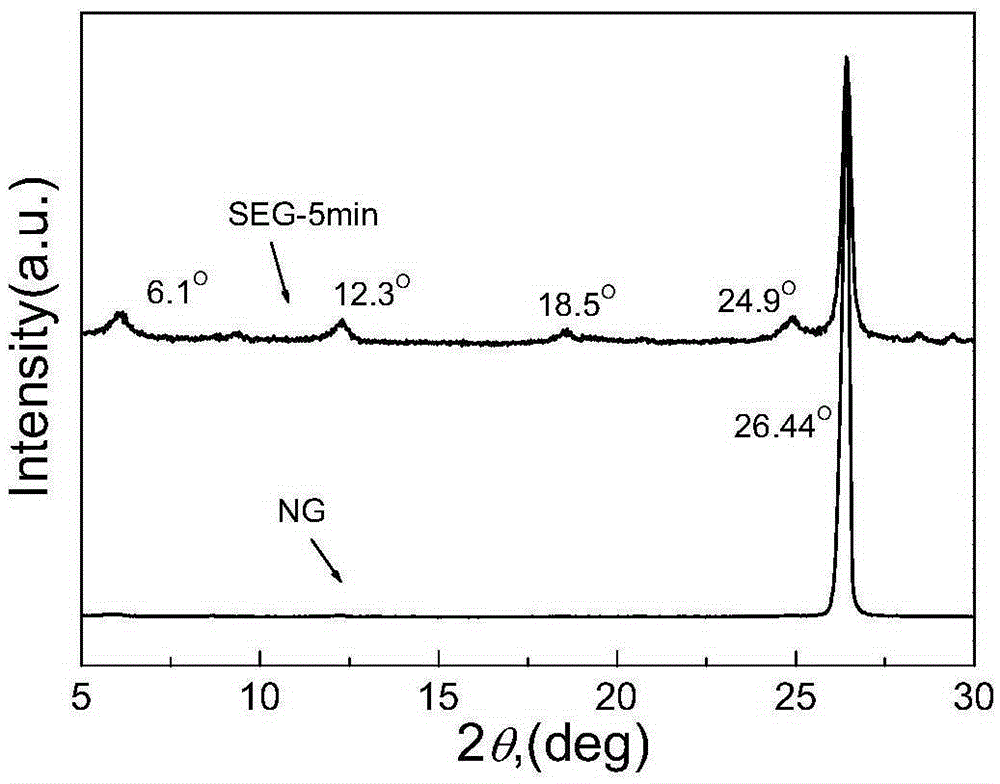

Preparation method for graphene

InactiveCN105347332AIncrease path lengthIncrease shearing and grinding time and frequencyDefective grapheneSolvent

The invention provides a preparation method for graphene. The preparation method comprises: S1, dispersing natural graphite in a solvent to obtain a graphite suspension; S2, shearing the graphite suspension in a colloid mill; and S3, carrying out centrifugal separation on the sheared graphite suspension to obtain a supernatant, and carrying out vacuum suction filtration and drying on the supernatant to obtain graphene. By using the natural graphite powders which are wide in raw material source and cutting the graphite with the colloid mill, graphite granules can be effectively stripped through a physical action of a severe shear force, a frictional force, high-frequency vibration and high-speed vortex, so that the production efficiency is greatly improved and the graphene can be industrially prepared in batches. Meanwhile, the prepared graphene is few in defect, high in yield, low in cost, good in dispersity and high in quality, and the application range of the graphene is greatly expanded.

Owner:SHANDONG UNIV OF SCI & TECH

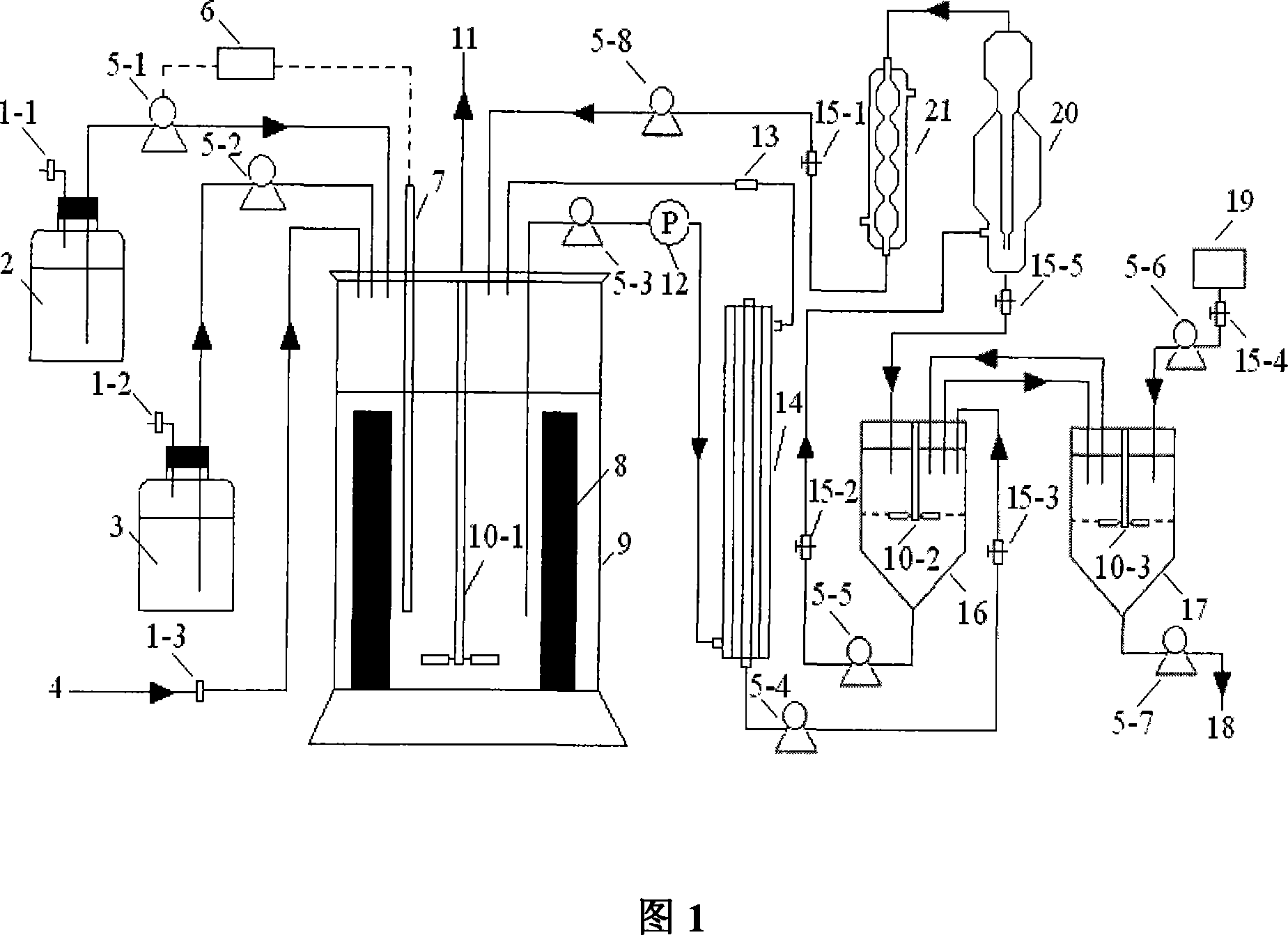

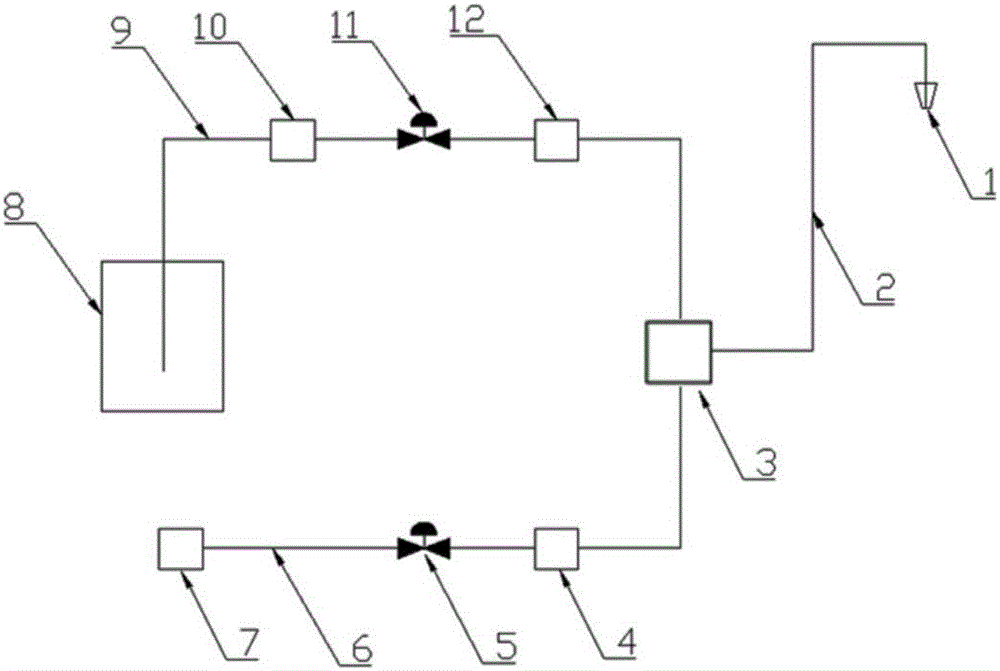

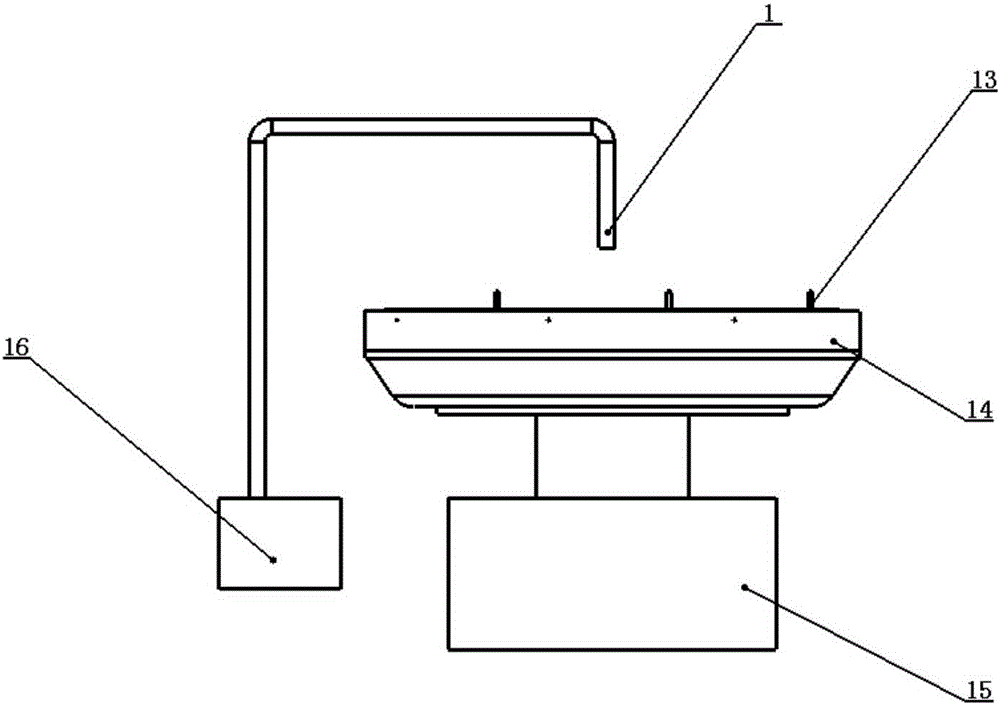

Device and technique for producing propanoic acid by coupling of fibrous bed bioreactor with extraction separation

InactiveCN101182455AEfficient fermentationImprove adsorption capacityBioreactor/fermenter combinationsBiological substance pretreatmentsHigh densityPropanoic acid

The invention discloses a fibrous bed reactor and the equipment and process for extracting separation and coupling production of propionic acid. The invention utilizes an immobilized fibrous bed reactor unit, a membrane separation unit, an extraction and anti-extraction unit and an elution and condensation unit to realize the efficient production of propionic acid. The device has strong feasibility, simple operation, easy realization of automation, immobilized materials, long using life of the membrane and the matching equipment, convenient maintenance and good application prospect. Through extracting separation and coupling production technology, the separation of propionic acid is realized. The invention radically eliminates the feedback inhibition of propionic acid, implements the high density fermentation of propionibacterium and greatly improves the production efficiency of propionic acid through the fermentation method. The extracted water phase is returned to the reactor for recycle after elution and condensation by an elution device, which eliminates the harm of extractant for propionibacterium from the root.

Owner:NANJING UNIV OF TECH

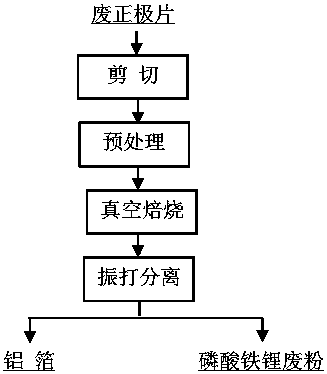

Vacuum separation method of waste lithium iron phosphate battery positive plate

ActiveCN110148801AAvoid pollutionEasy to recycleWaste accumulators reclaimingBattery recyclingLithium iron phosphateSteel ball

A vacuum separation method of a waste lithium iron phosphate battery positive plate comprises the following steps: cutting the waste lithium iron phosphate battery positive plate into loose sheets, and putting the loose pole plates into a vacuum furnace for vacuum roasting at the temperature of 350-450 DEG C for 1-6 hours; putting the calcined waste pole sheets into a vibrating screen in batches;adding steel balls with different particle sizes at the same time; and vibrating and screening to obtain aluminum foils on the vibrating screen and lithium iron phosphate waste powder under the vibrating screen. According to the method, the situation that aluminum foils are damaged and enters the lithium iron phosphate waste powder in the vibrating and screening process is reduced; and meanwhile,lithium is activated, and a foundation is laid for direct repair and recovery of a lithium iron phosphate pyrogenic process.

Owner:ZHUZHOU SMELTER GRP

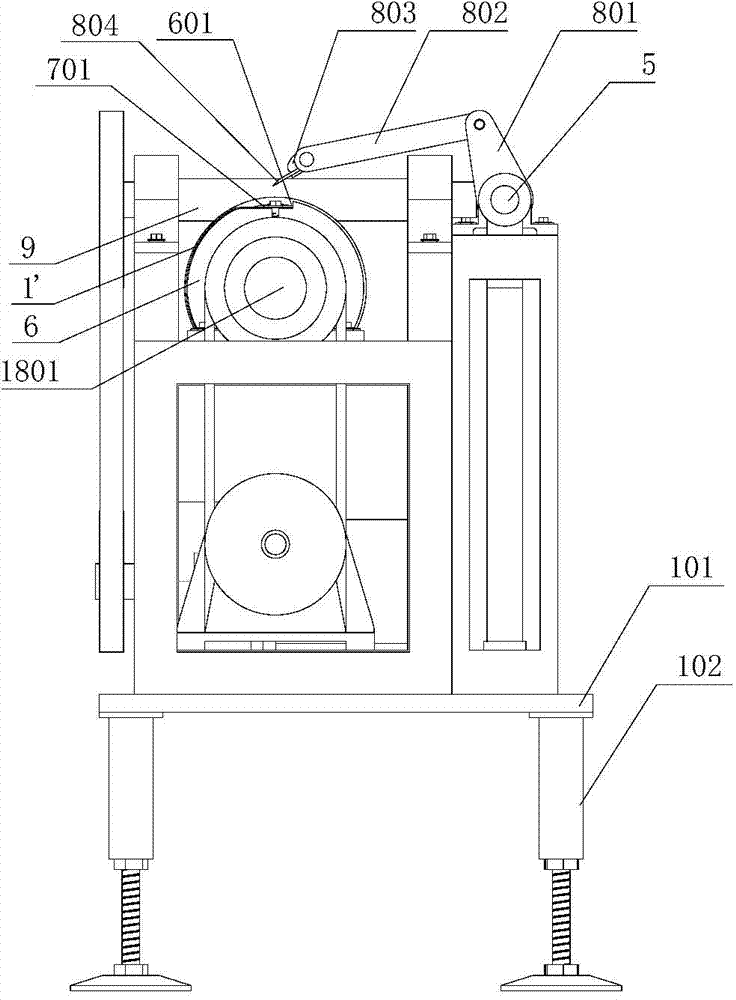

Integument stripping machine

The invention provides an integument stripping machine which comprises a machine base. A left supporting frame and a right supporting frame are installed on a machine base platform. The integument stripping machine comprises a first shaft and a second shaft, wherein the first shaft and the second shaft stretch across and are supported by the supporting frames on the two sides. A rotating roller with a positioning notch formed in the surface is fixedly arranged on the first shaft, a skin graft compressing structure is arranged in the positioning notch, the second shaft is connected with a corresponding bearing block through a linear bearing, and a cutter assembly is installed on the second shaft. The cutter assembly is formed by connecting two supporting arms, two connecting rods A, a cutter rack and a cutter. The integument stripping machine comprises a cutter transverse motion driving mechanism composed of a third shaft, a connecting rod B and two leaf springs, the third shaft is supported by the supporting frame on one side, one end of the connecting rod B is eccentrically hinged to one end of the third shaft, the other end of the connecting rod B is hinged to the corresponding end of the second shaft, and the upper ends and the lower ends of the two leaf springs are fixedly connected with the second shaft and the machine base platform respectively. The integument stripping machine comprises a first gear motor and a second gear motor, wherein the first gear motor and the second gear motor are installed above the machine base platform. The two gear motors are in driving connection with the first shaft and the third shaft respectively through a first drive mechanism and a second drive mechanism. According to the integument stripping machine, integuments with different thicknesses can be stripped, and the stripping thicknesses are uniform and consistent.

Owner:TIANJIN HONGJIUDI ENG MACHINERY

Method for preparing graphene by solution phase

The invention discloses a method for preparing graphene by a solution phase, and relates to grephene. The invention provide a method for preparing graphene by the solution phase, which is low in cost, simple and easy to implement, low in device requirements, and beneficial to large-scale industrial production. The method comprises the following steps: (1) adding graphite powder to a tetrahydrofuran solution and obtaining graphite-powder tetrahydrofuran dispersion liquid by carrying out ultrasonic dispersion under the protection of nitrogen gas; (2) adding alkali metal and naphthalene to the graphite-powder tetrahydrofuran dispersion liquid obtained in the step (1), stirring under the protection of the nitrogen gas to obtain the mixed solution; (3) adding halogenated organic reagent to the mixed solution obtained in the step (2), and reacting under the protection of the nitrogen gas to obtain a solid product; and (4) washing and drying the solid product obtained in the step (3) to obtain the graphene powder. According to the method disclosed by the invention, liquid-phase chemical intercalation is carried out to the graphite by using the graphite powder as material; and then, the chemical modification of the halogenated organic reagent to the graphite is utilized for further opening the graphite, so that the graphene can be prepared by peeling the graphite under the non-ultrasonic action or the light ultrasonic action.

Owner:XIAMEN UNIV

Preparation method of porous graphene active carbon material as well as product and application thereof

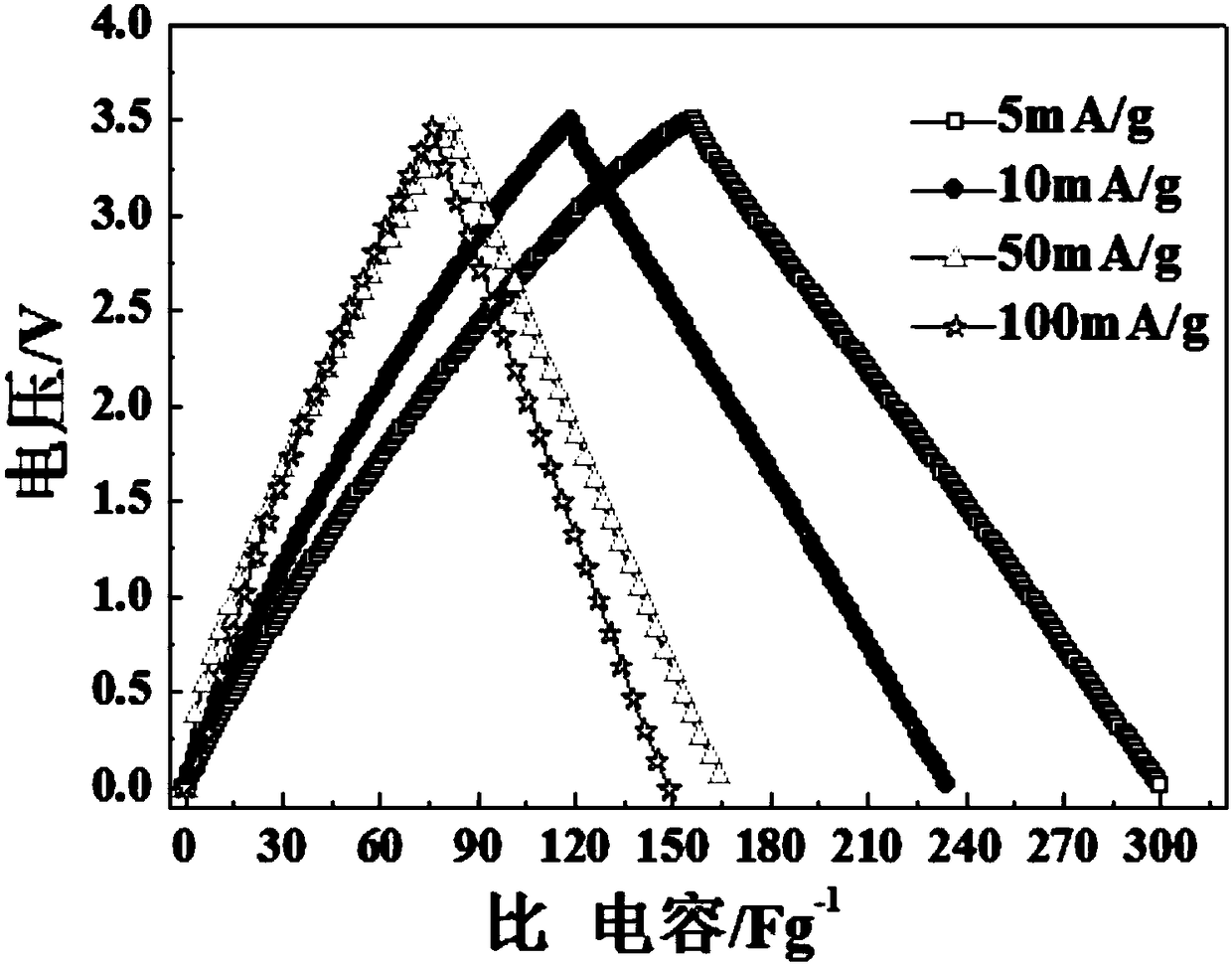

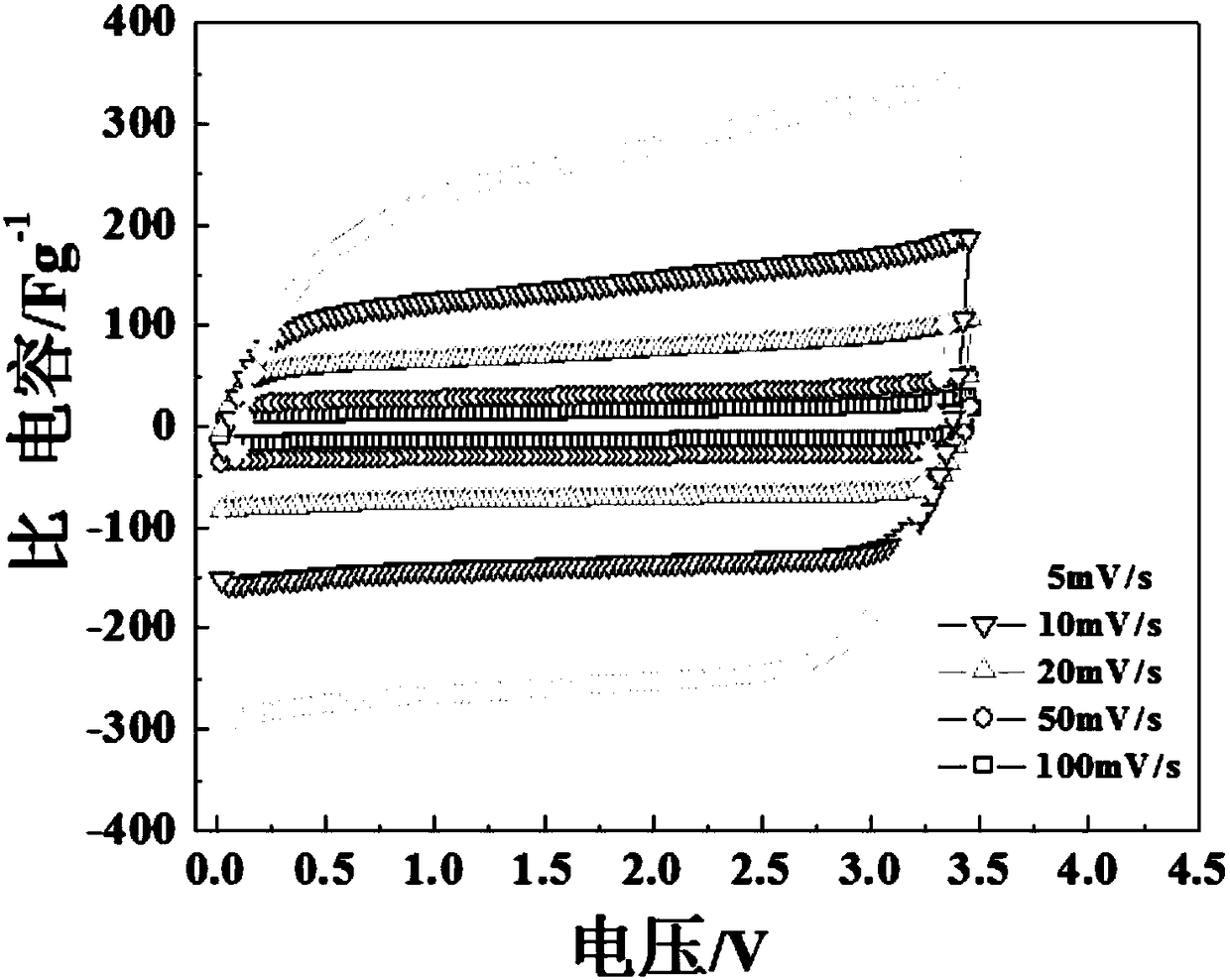

InactiveCN107555424ALarge specific surface areaRich in mesoporesHybrid capacitor electrodesGraphenePorous grapheneMaterials science

The invention relates to a preparation method of a porous graphene active carbon material as well as a product and application thereof, and belongs to the technical field of materials. The method comprises the following steps: pretreating a biomass material with an oxidant and weak acid or salt under a condition of hydrothermal assistance to realize stripping and pore forming of the biomass material, and then performing high-temperature pyrolysis to convert the biomass material into a carbon material. The method is easy to operate; the finally prepared carbon material is high in graphitizationdegree, and also has the characteristics of high specific surface area, rich mesoporous and micropore porosity, unique layered structure and heteroatomic doping. The material is applied to a supercapacitor; an electrochemical test result shows that compared with a common active carbon material for the supercapacitor, the material has the advantages that the capacity is 4.5 times that of the common active carbon material; the material is widely applied to the fields of energy storage and conversion, electric catalysis, biosensing, environmental purification and the like, and has an important application value.

Owner:SOUTHWEST UNIVERSITY

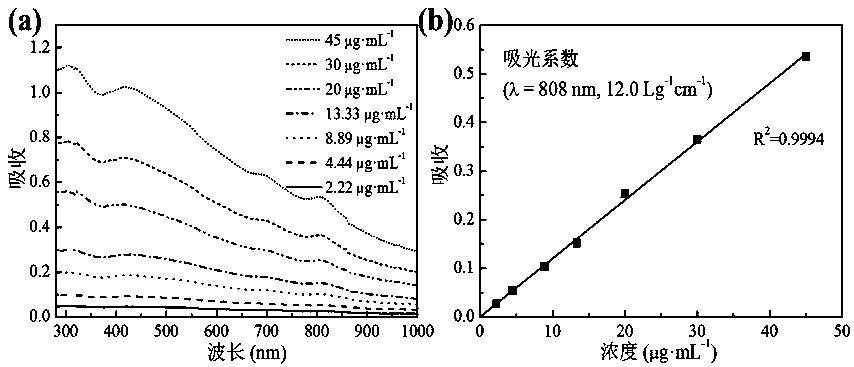

Preparation method of stripping, functional modification and intelligent composite gel of disulfide

InactiveCN105502311AReversible temperature responseTunable near-infrared light responseMolybdenum sulfidesMetal selenides/telluridesCross linkerAqueous solution

The invention belongs to the technical field of functional materials and particularly relates to a preparation method of stripping, functional modification and dual response intelligent composite gel of transition metal disulfide. A temperature-sensitive functional poly ionic liquid aqueous solution is used for ultrasonic stripping of transition metal disulfide powder, so that a nano layer laminated aqueous solution of the transition metal disulfide modified by polymer can be obtained directly; then a cross-linking agent is added so that intelligent gel with temperature and near-infrared dual response can be further prepared, and the intelligent gel can be taken as a shape memory material and an optothermal response intelligent gel material. The method is easy and convenient to operate, the production cost is low, batch production is easy, the prepared intelligent composite gel has multiple stimuli response, and the method can be applied widely and has large scale preparation potential and wide commercial application prospect.

Owner:FUDAN UNIV

Wafer cleaning device and method

InactiveCN106252260AMinimizes microetchingReduce manufacturing costSemiconductor/solid-state device manufacturingClean technologyEngineering

The invention discloses a wafer cleaning device and a cleaning method. The cleaning device includes a cleaning medium spray part and a cleaning medium control part. The cleaning medium spray part includes a nozzle, a movable spray pipeline connected to the nozzle, and a cleaning medium control part. It includes first and second pipelines connected in parallel with a mixing chamber, and the mixing chamber is connected to the spray pipeline; wherein, the first pipeline has a Venturi tube structure at its interface with the mixing chamber, and the first pipeline The liquefied first gas fed through the first pipeline is ejected to the mixing chamber through the Venturi tube structure, forming a three-phase state in which solid, liquid and gas coexist, and is jointly formed by the second gas fed through the second pipeline. The cleaning medium is sprayed onto the surface of the wafer to be cleaned through the nozzle along the spraying pipeline, which can realize physical cleaning of the wafer without damage, simplify the cleaning process, and reduce production costs at the same time.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

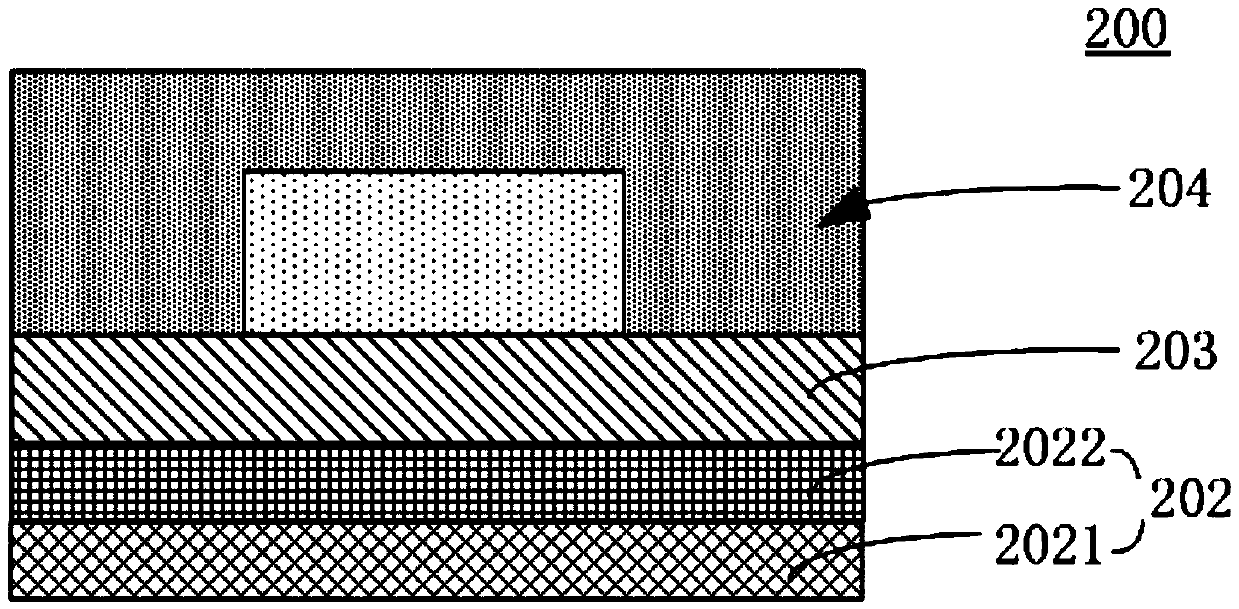

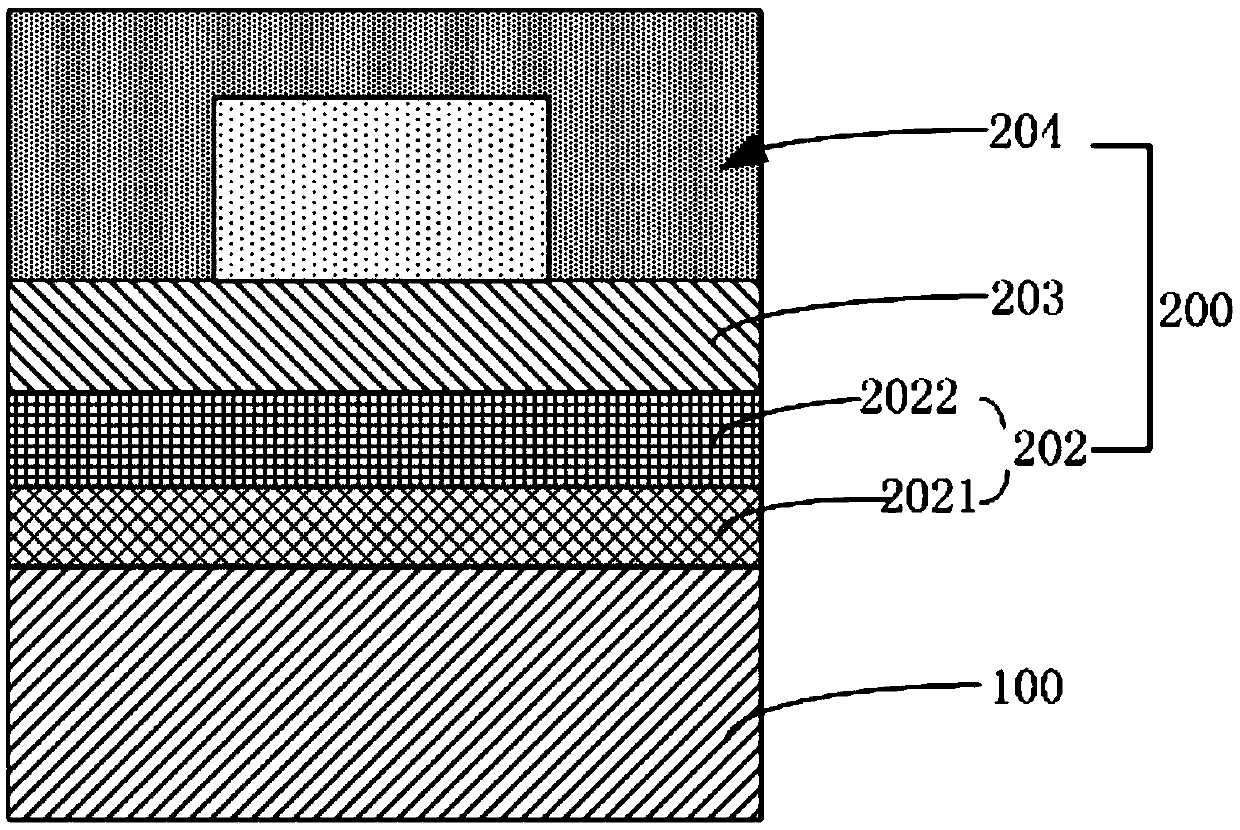

Flexible display substrate and preparation method thereof

ActiveCN105374829AImprove yieldEasy film formationSolid-state devicesSemiconductor/solid-state device manufacturingChemistryRadiation

The present invention relates to a flexible display substrate, a flexible display substrate structure and the preparation method of the flexible display substrate. The release layer in the flexible display substrate structure employs inorganic material containing an intermolecular hydrogen bonding. When there is provided enough illumination radiation received by the release layer, the intermolecular hydrogen bonding in the material is broken and hydrogen elements are overflowed to cause the crushing of the release layer and the conversion of the release layer to a stripped structure, so that the stripping of the flexible substrate is realized. The release layer is not able to generate bubbles in the subsequent preparing process as a result of the influence of temperature so that the flexible substrate may maintain flat in the overall preparing process of the flexible display device; and the stripping process of the release layer is not able to influence display elements on the flexible substrate and the like. Therefore, the yield of a flexible display device may be greatly improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

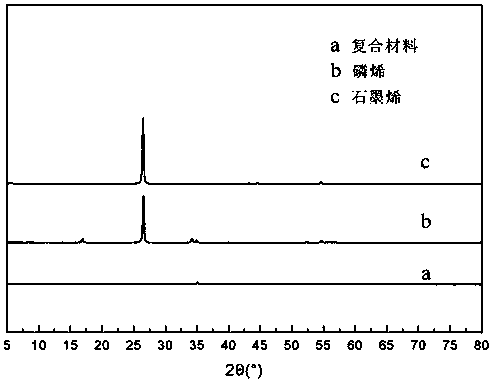

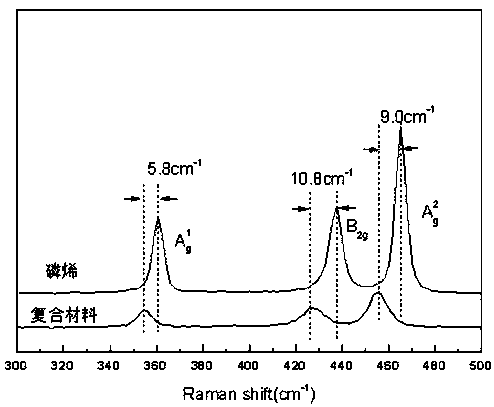

Preparation method of phosphoene-graphene composite material

The invention relates to a preparation method of a phosphoene-graphene composite material and belongs to the technical field of composite materials. The preparation method comprises the following steps: respectively grinding lamellar black phosphorus and lamellar graphite into powder; adding the powder into a solvent and uniformly mixing to obtain a mixed solution A, wherein the solvent is deionized water, an organic solvent or ionic liquid; carrying out ultrasonic pretreatment on the mixed solution A for 0.5 to 2 hours; emptying air in a high pressure homogenizer by using inert gas, putting the mixed solution A subjected to the ultrasonic pretreatment into the high pressure homogenizer and carrying out high pressure homogenization treatment under the condition that the pressure is 500 to4000 bar for 5 to 60 minutes to obtain suspension; centrifugally separating the suspension to obtain precipitate and supernatant; and carrying out freeze drying or vacuum filtration drying on the supernatant to obtain the phosphoene-graphene composite material. The phosphoene-graphene composite material prepared by the preparation method disclosed by the invention has the advantages of high electrical conductivity, thermal conductivity, flexibility, large specific surface area and high stability; and the method disclosed by the invention has the characteristics of simple operation, high efficiency, capability of realizing continuous operation, low requirements on equipment and the like.

Owner:KUNMING UNIV OF SCI & TECH

Laser stripping method using metallic passage beds to transfer GaN substrate

InactiveCN101118850AChange structureAchieve strippingSemiconductor/solid-state device manufacturingSputteringLaser scanning

The present invention relates to a laser lift-off method to transfer the GaN liner by using a metal transition layer, in particular to a method of bonding silicon and GaN by using the metal transition layer and transferring GaN on a sapphire liner to a Si liner by combining the laser lift-off technology; and provides a method for transferring the GaN liner by using the metal transition layer. The Si liner is sputtered with Ti and Au in sequence to form a silicon chip sputtered with Ti and Au; GaN on the sapphire liner is sputtered with Ni and Au in sequence to obtain a GaN chip sputtered with Ni and Au; the silicon chip and the GaN chip are jointed front to front and then put into a bonding machine under 100 to 200 DEG C. After pre-bonding, the temperature of the bonding machine is raised to 200 to 600 DEG C. Then, the bonding machine anneals and a GaN / metal / Si bonded chip forms. After that, the GaN / metal / Si bonded chip gets adhesively connected onto a glass piece and fixed on an electric-driven platform. Laser wave with 365nm above are to radiate the bonded piece from one side of the sapphire.

Owner:XIAMEN UNIV

Automatic labeling machine

The invention relates to an automatic labeling machine which comprises a mounting rack as well as a first shifting mechanism, a second shifting mechanism, a material identifying mechanism, a label peeling device, a controller and a production system, which are arranged on the mounting rack, wherein the first shifting mechanism is used for conveying materials; the second shifting mechanism is used for fixing and conveying the materials; the material identifying mechanism is used for identifying the materials; the label peeling device is applied to peeling and continuous working of a plurality of labels; the controller is used for receiving label information read by the material identifying mechanism, and is used for controlling the first shifting mechanism, the second shifting mechanism and the label peeling device; the production system is used for sending control instructions and data to the controller. According to the automatic labeling machine, material discs on an assembly line are shifted to machining positions by the first shifting mechanism and fixed by the second shifting mechanism, and after the labels are adhered, the material discs are conveyed to the assembly line through the second shifting mechanism. Compared with the prior art, the automatic labeling machine is high in automation degree, manual transportation is not needed, labor resource is saved, and meanwhile peeling and continuous working of the plurality of labels are realized by a plurality of label adhering units, and the working efficiency is improved.

Owner:苏州弘瀚自动化科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com