Patents

Literature

294 results about "Clean technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Clean technology is any process, product, or service that reduces negative environmental impacts through significant energy efficiency improvements, the sustainable use of resources, or environmental protection activities. Clean technology includes a broad range of technology related to recycling, renewable energy, information technology, green transportation, electric motors, green chemistry, lighting, Greywater, and more. Environmental finance is a method by which new clean technology projects that have proven that they are "additional" or "beyond business as usual" can obtain financing through the generation of carbon credits. A project that is developed with concern for climate change mitigation is also known as a carbon project.

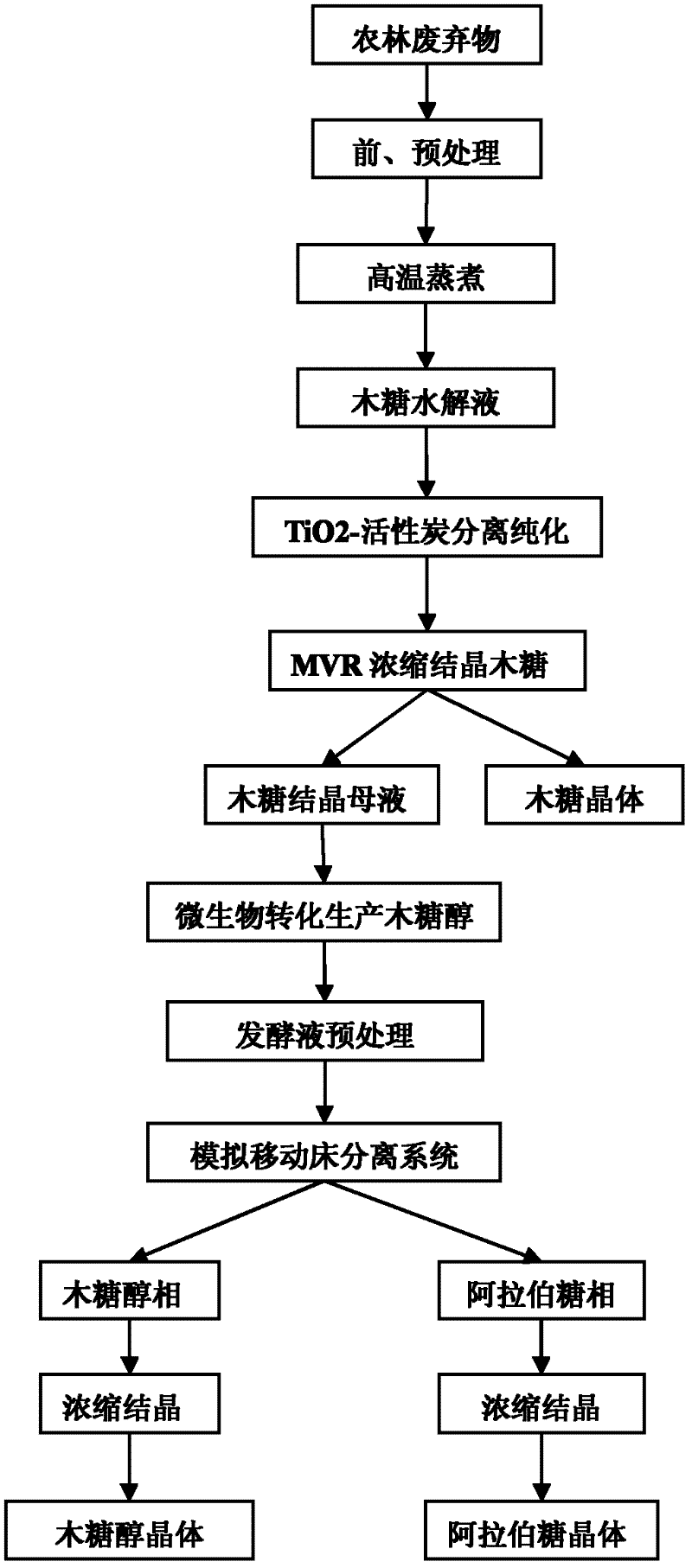

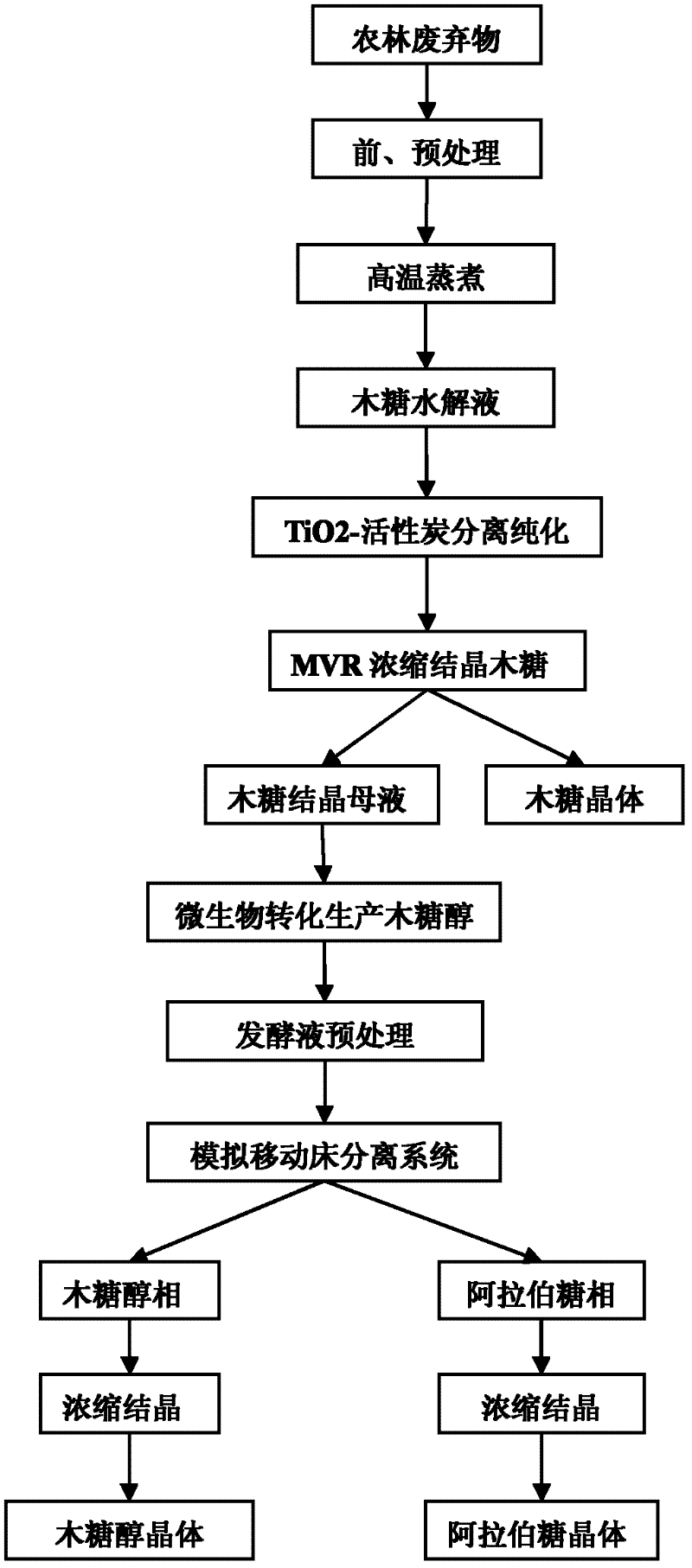

Co-production of xylose, xylitol and arabinose from agricultural and forestry wastes

ActiveCN102268490AEmission reductionReduce salt contentMicroorganism based processesFermentationChromatographic separationHydrolysate

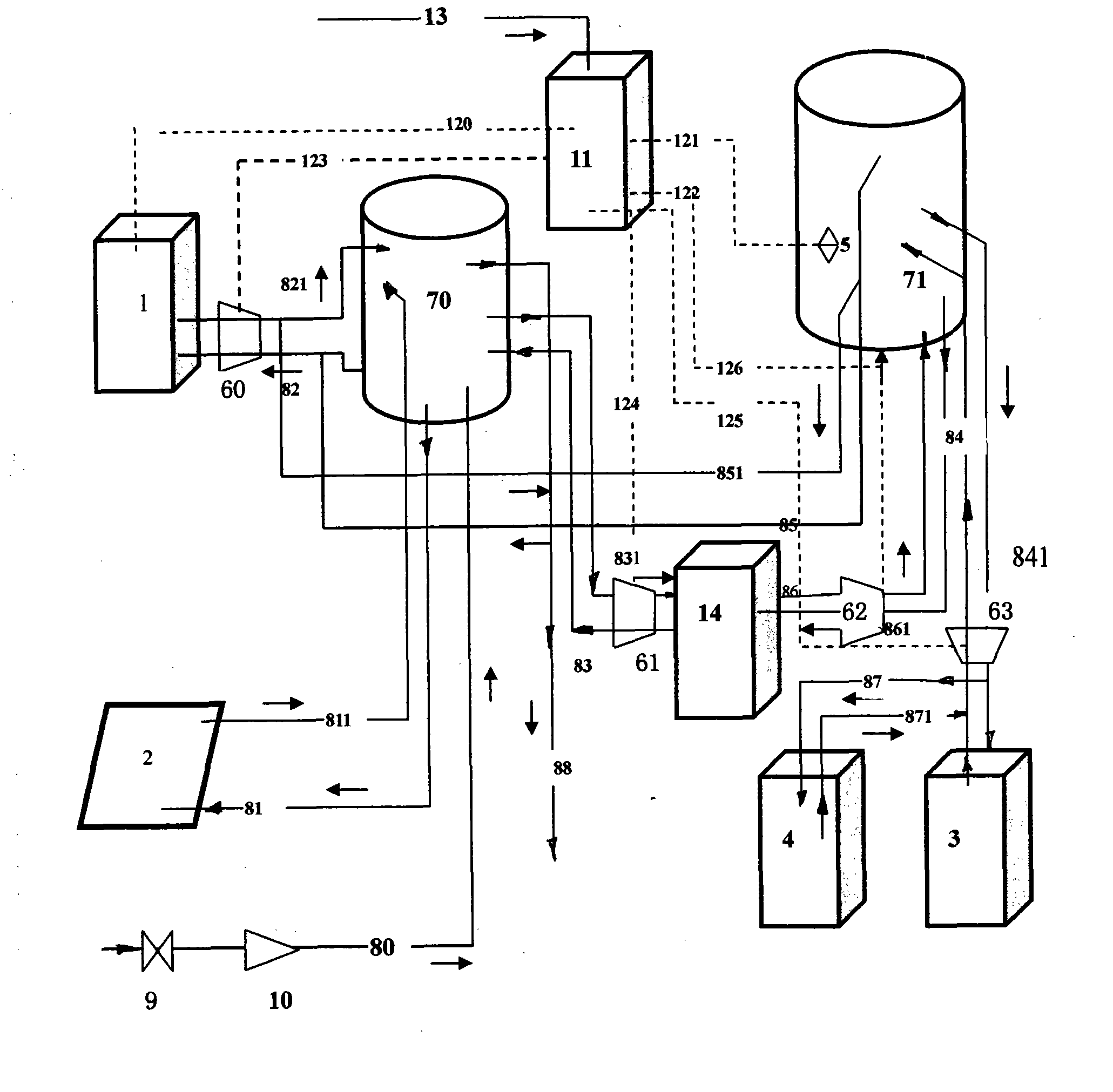

The invention relates to a clean technique for co-producing xylose, xylitol and arabinose from agricultural and forestal waste, belonging to the field of utilization of agricultural and forestal waste. The technique comprises the following steps: pretreating and preprocessing the raw material, and hydrolyzing in a thermophilic digestion mode to prepare a hemicellulose hydrolysate; after centrifugalizing to remove solid residues, carrying out TiO2-loaded activated carbon photocatalysis or ion exchange resin decolorization and detoxification treatment on the hydrolysate; carrying out MVR (mechanical vapor recompression) concentration treatment and gradient-cooling crystallization to obtain a xylose product and a xylose mother solution; fermenting L-arabinose unconverted xylitol fermentationhigh-yield strain xylitol by using the xylose mother solution as the medium to produce the xylitol; centrifugalizing to remove thalli, and carrying out decolorization and desalting treatment by membrane-process or resin adsorption; separating by using a simulated moving bed or chromatographic separation technology to obtain a xylitol phase and an L-arabinose phase; and carrying out MVR or vacuum concentration treatment on the two phases, and crystallizing in a gradient programmed cooling mode to respectively obtaining a xylitol product and an L-arabinose product, wherein the two mother solutions can be recycled.

Owner:BEIJING UNIV OF CHEM TECH

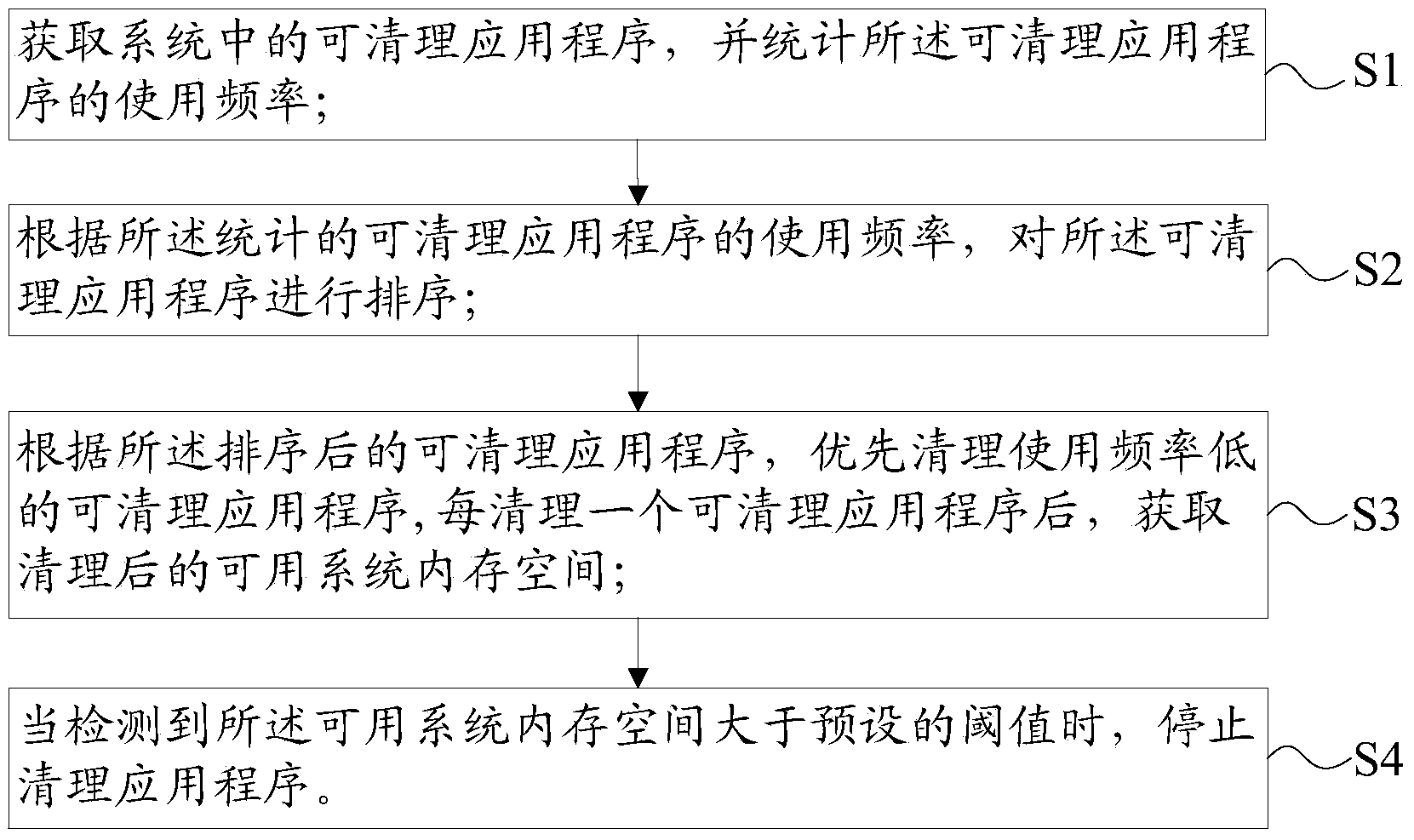

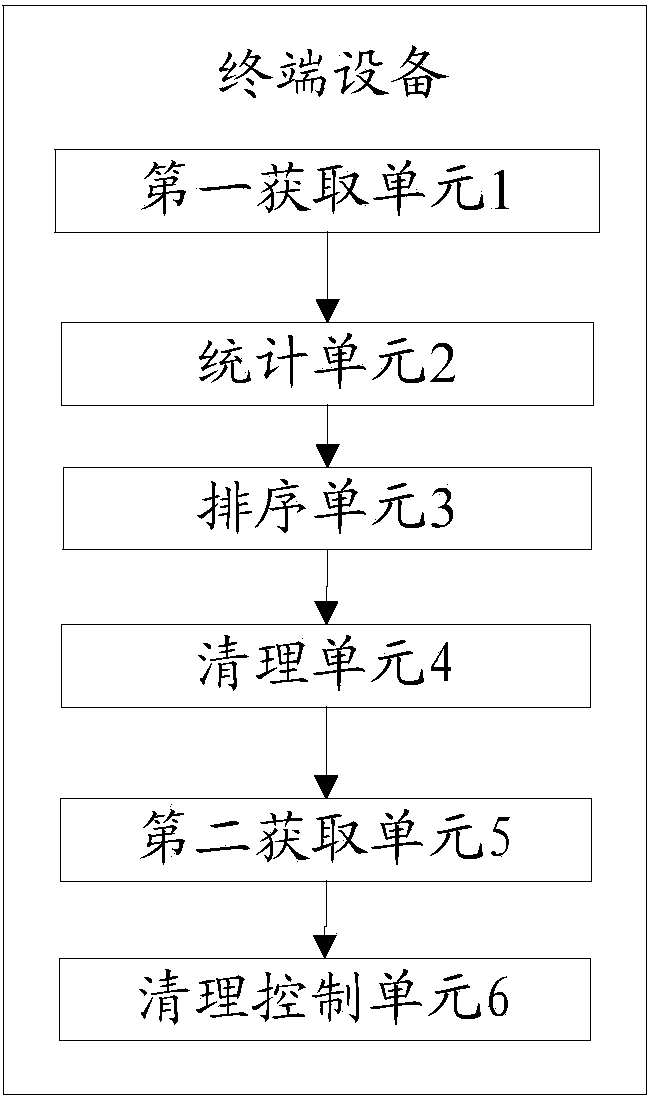

Method for cleaning up system memory and terminal device

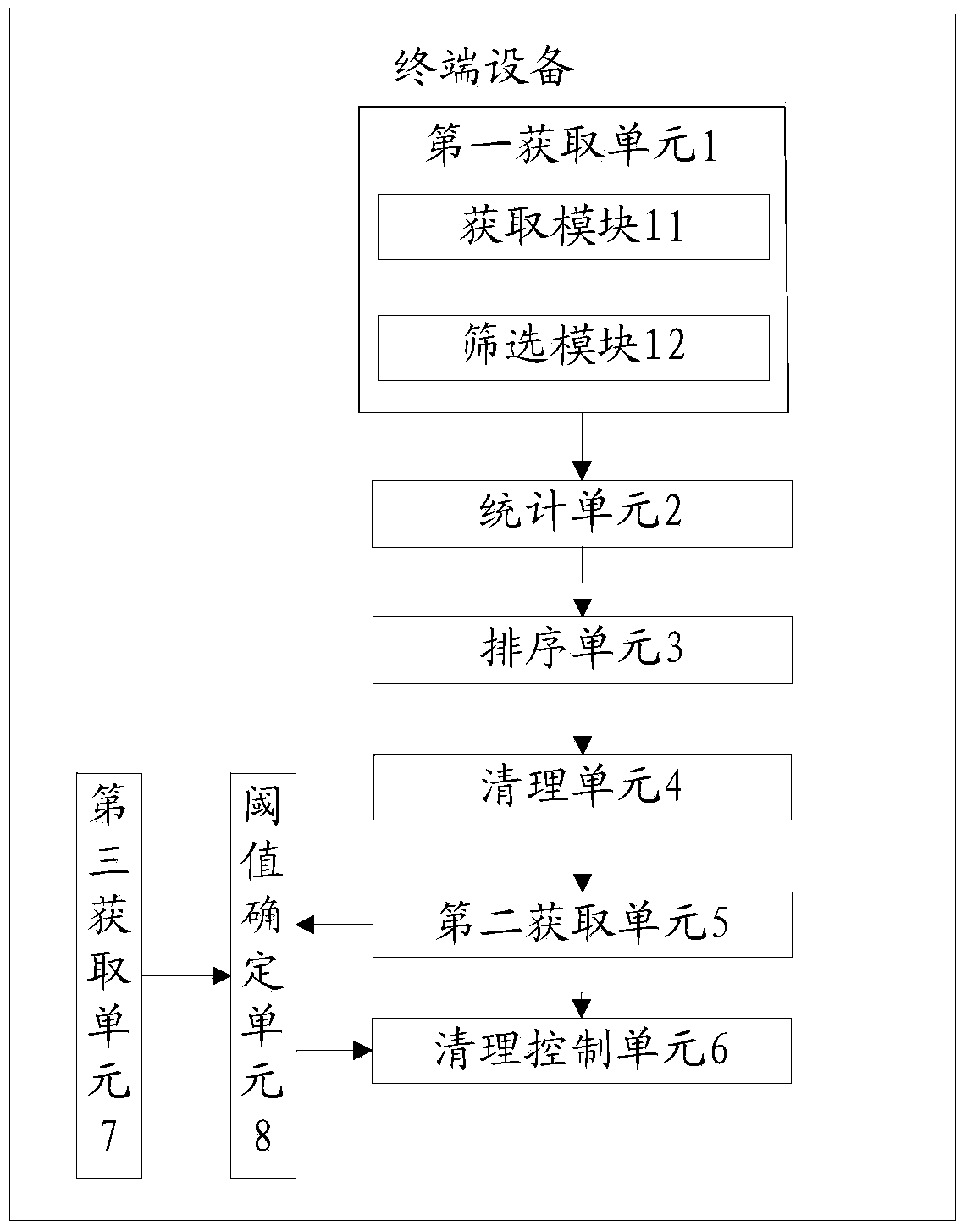

ActiveCN104298613AReduce indiscriminate killingShorten the timeMemory adressing/allocation/relocationClean technologyFrequency of use

The invention discloses a method for cleaning up a system memory and a terminal device. The method for cleaning up the system memory and the terminal device facilitate saving of time used for a user to open an application program. The method for cleaning up the system memory includes steps: obtaining clearable application programs in a system, and gathering use frequency of the clearable application programs in the system; sorting the clearable application programs according to the gathered use frequency of the clearable application programs; preferentially clearing the clearable application programs low in use frequency according to the clearable application programs after being sorted, and obtaining a usable system memory space after being cleaned after clearing each clearable application program; stopping clearing the application programs after detecting that the usable system memory space is larger than preset threshold value. The method for cleaning up the system memory and the terminal device are suitable for the memory cleaning technology field.

Owner:GUANGZHOU KINGSOFT NETWORK TECH

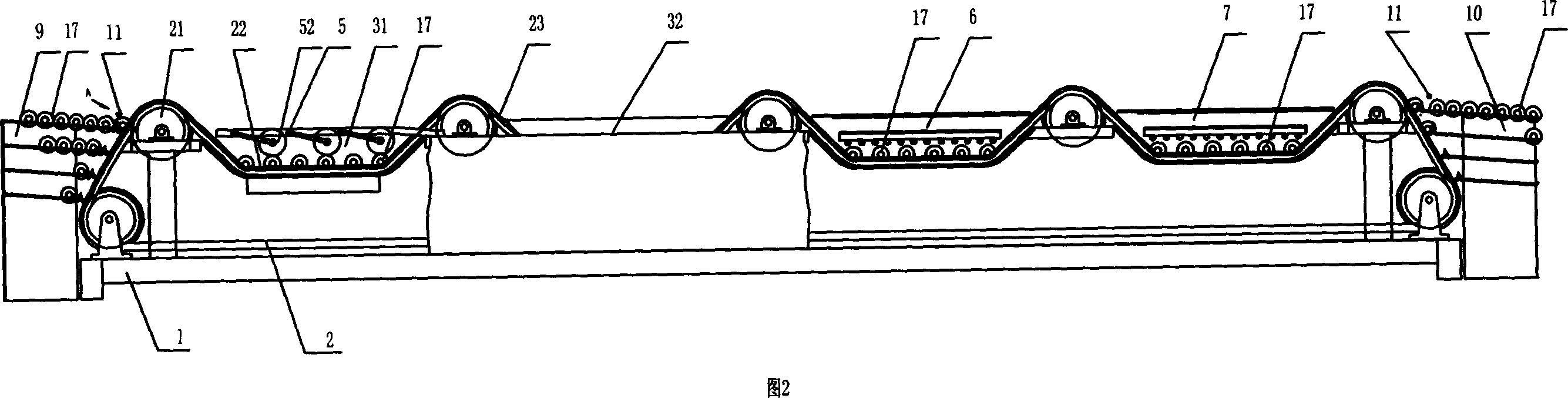

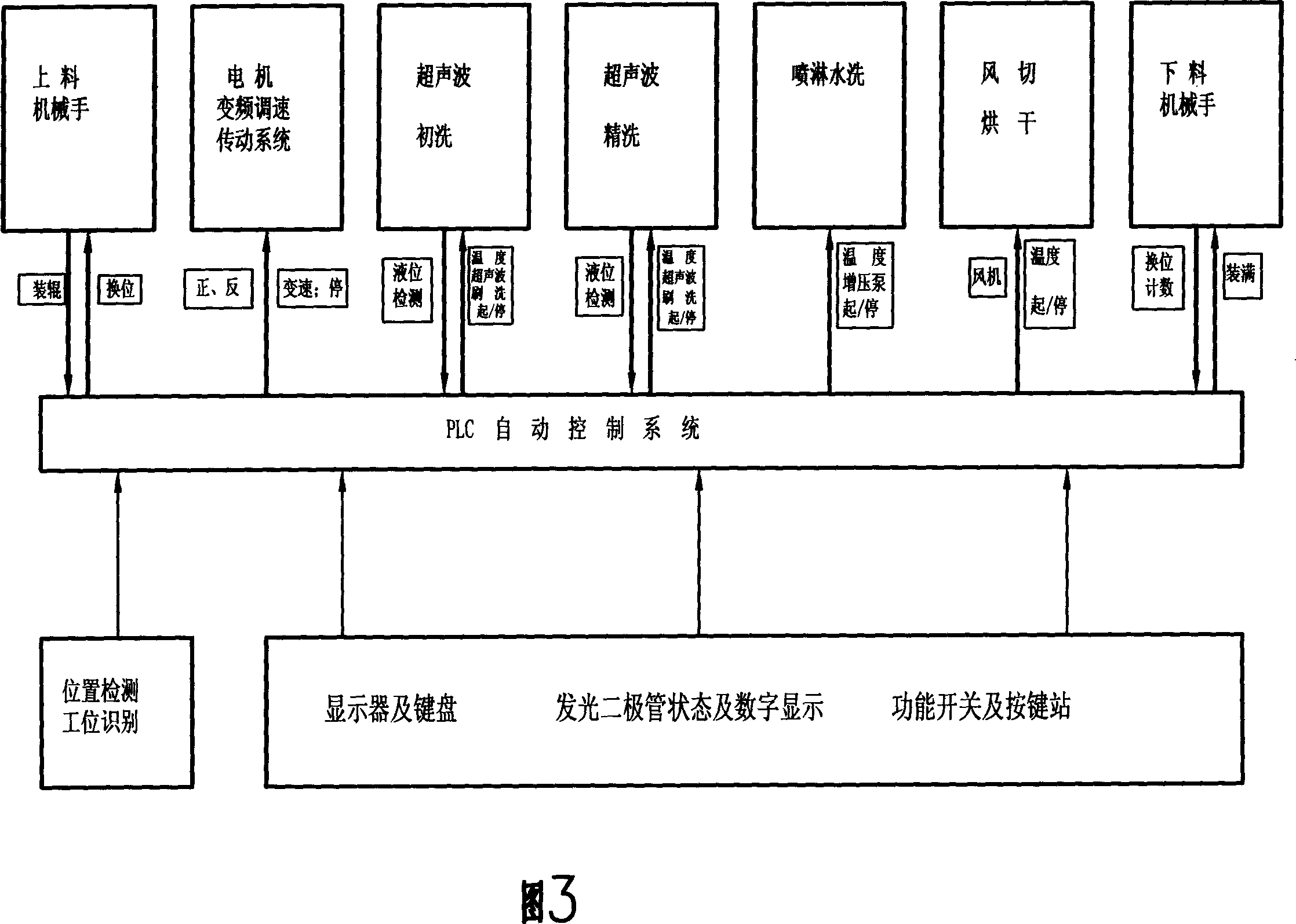

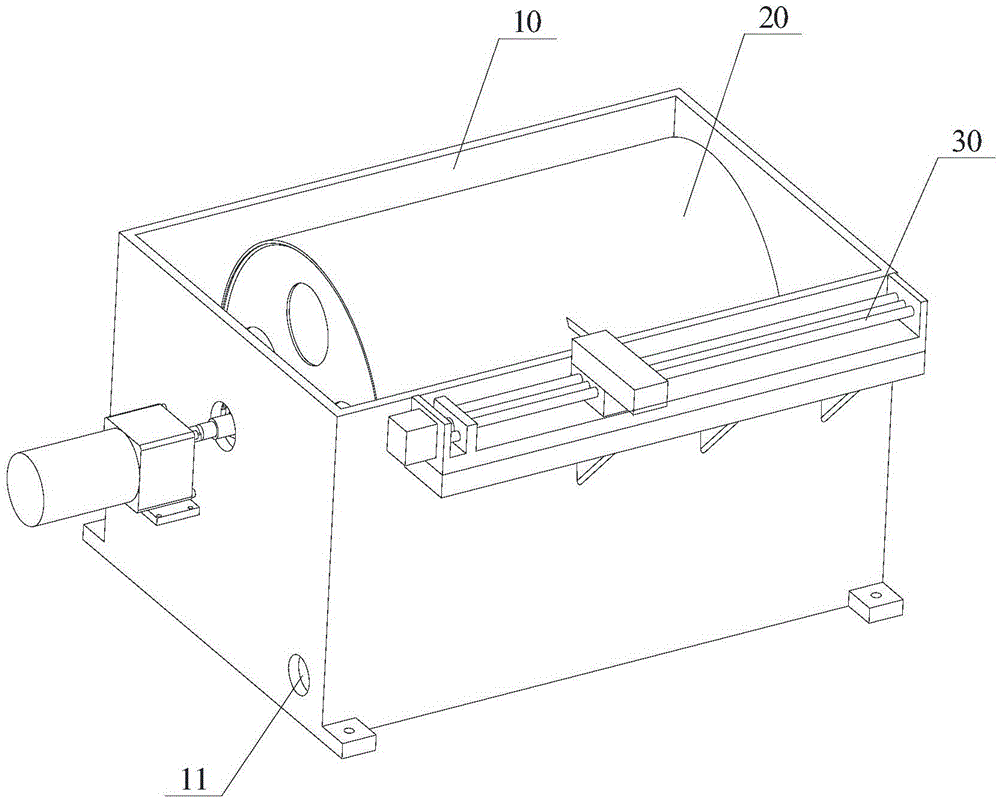

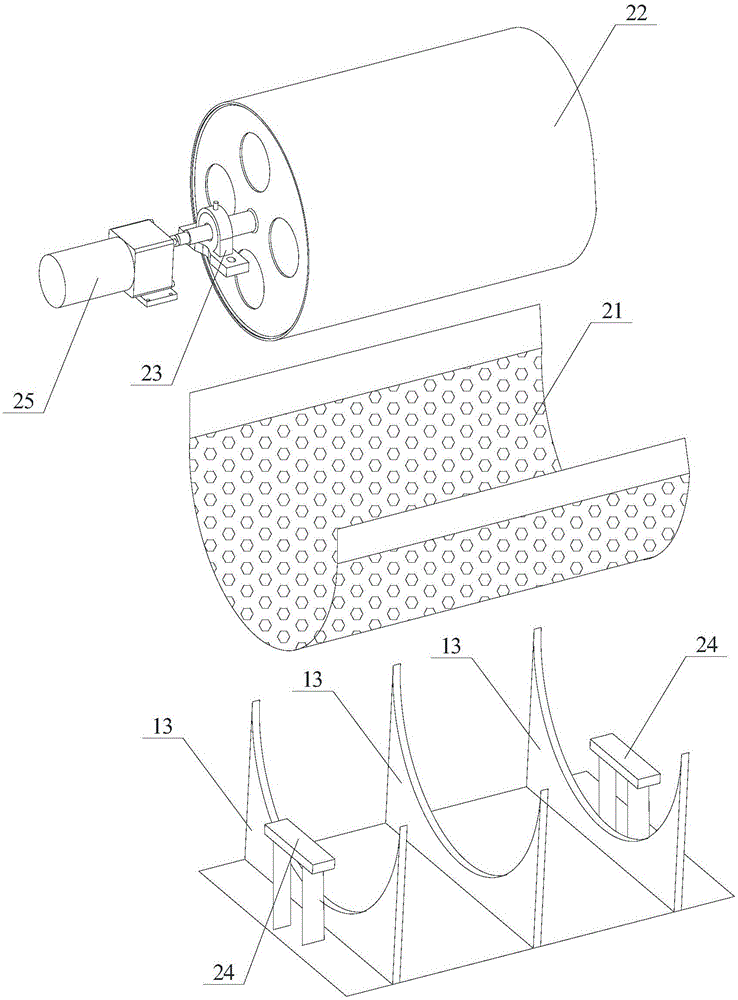

Automatic cleaning apparatus and method for money-printing rubber roll

ActiveCN101007460ANo damageNo harm to the bodyCleaning using liquidsPrinting press partsUltrasonic sensorMegasonic cleaning

The invention discloses a printing bank note rubber-covered roll automatic cleaning equipment and its cleaning method which belongs to equipment cleaning technology field. The printing bank note rubber-covered roll automatic cleaning equipment consists of frame and driving device, ultrasonic cleaning grove, spray groove, heat wind drying groove which are installed on the frame and controlled by control device; the printing bank note rubber-covered roll automatic cleaning method is: the driving device controlled by control device drives the rubber-covered roll pass through ultrasonic cleaning grove, spray groove, heat wind drying groove sequentially, the ultrasonic cleaning grove is equipped with ultrasonic transducer to generating ultrasonic wave cleaning rubber-covered roll, the spray groove sprays water to washing rubber-covered roll and the heat wind drying groove blows the rubber-covered roll; the invention not only has high cleaning efficiency, stable quality and no injury to rubber-covered roll, but also has low labor intensity, no harm for operator body and low cleaning cost.

Owner:CHINA BANKNOTE PRINTING & MINTING

Watt level full solid state ultraviolet laser cleaning machine and laser cleaning method

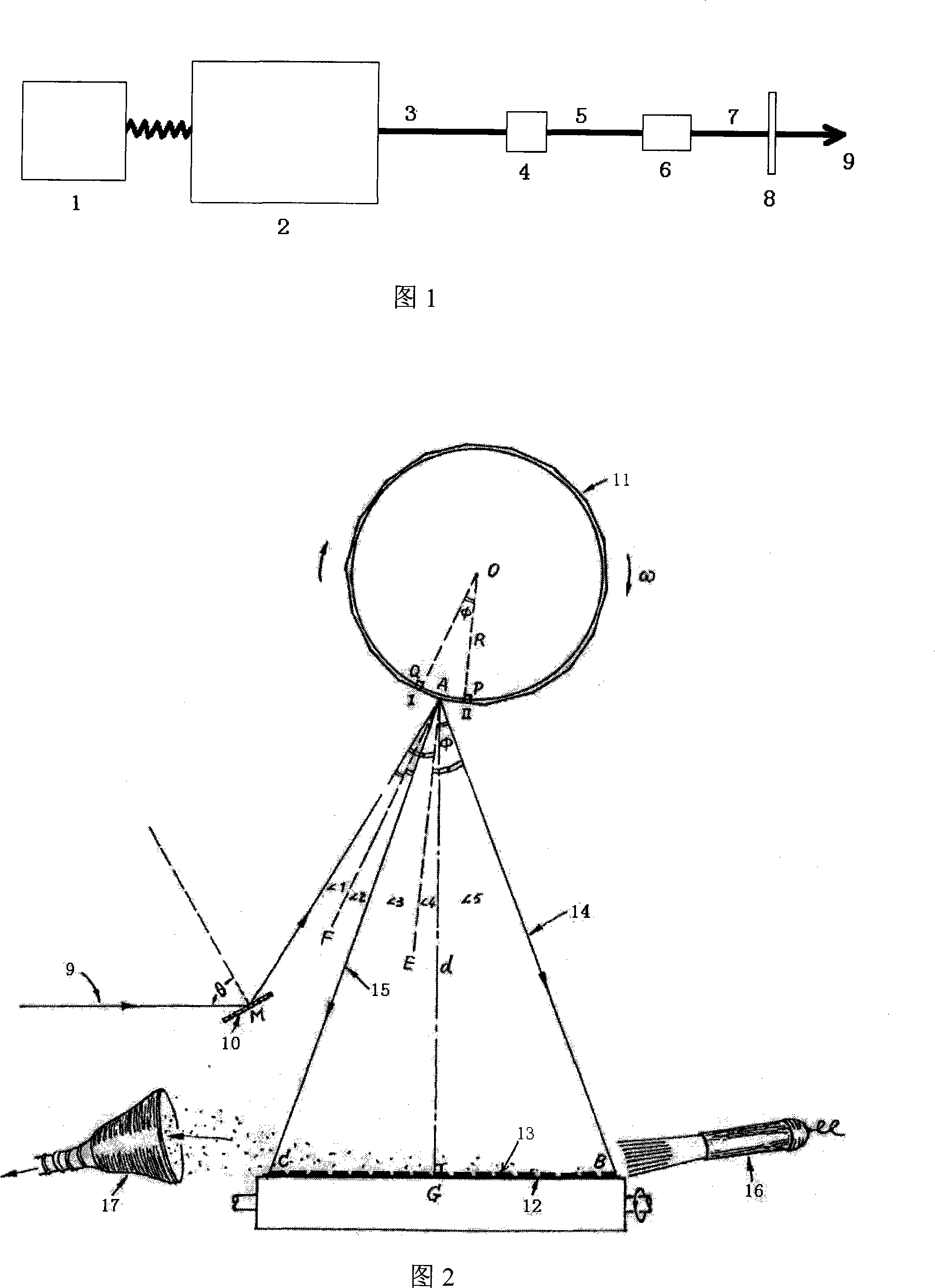

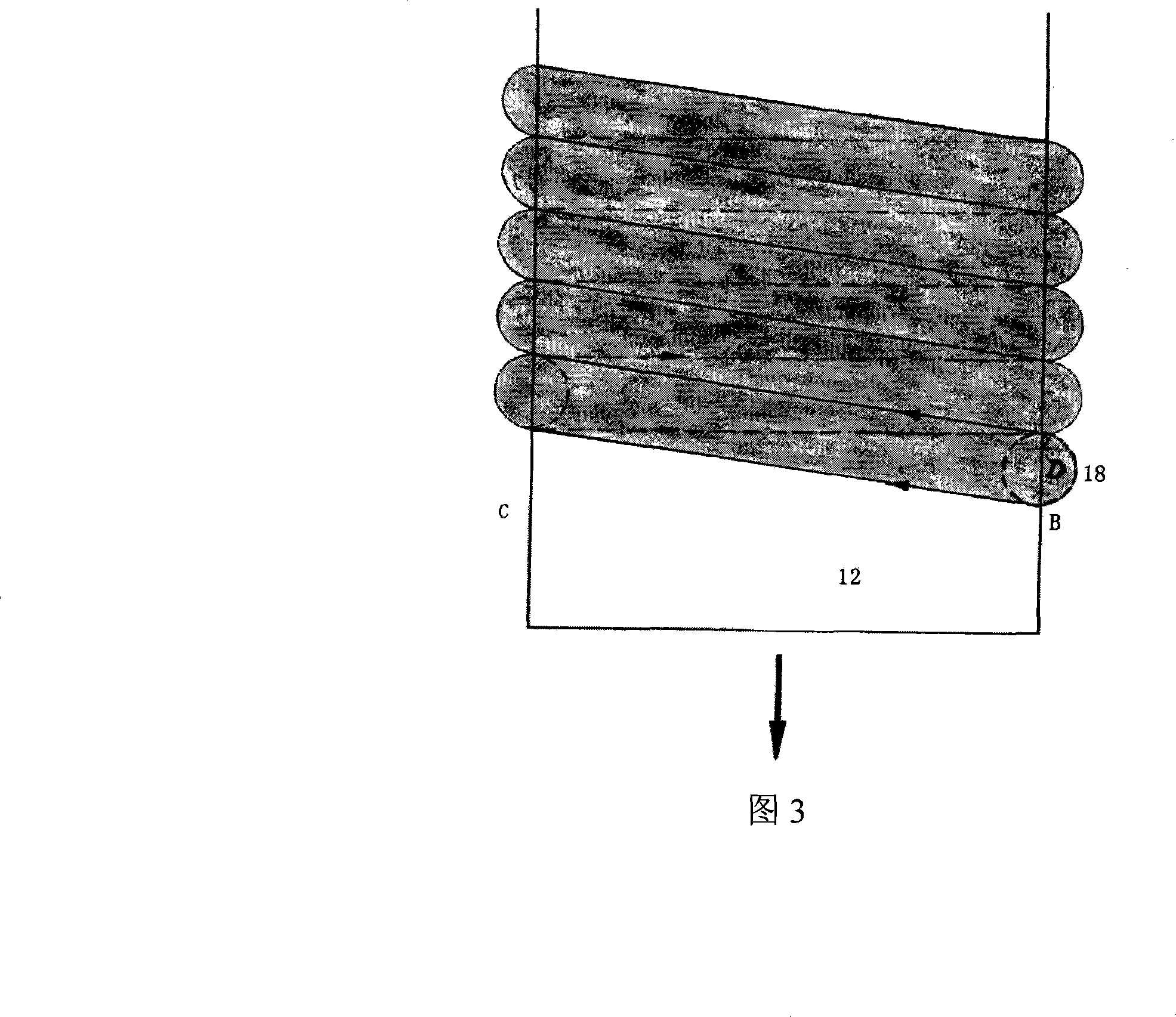

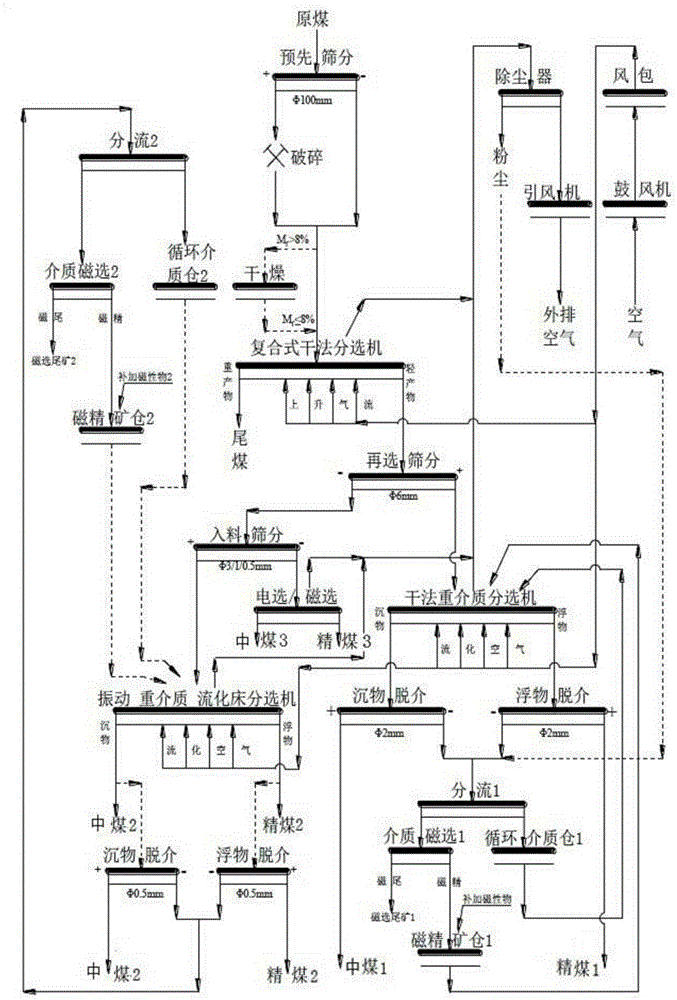

InactiveCN101219430AImprove adhesionEfficient removalCleaning using gasesNonlinear optical crystalUltraviolet

The invention discloses a Watt-level all-solid ultraviolet laser cleaner and a laser cleaning method, which pertains to the optical energy cleaning technology field and are applied to cleaning micro electronic substrate such as the integrated circuit. The power of the cleaner is connected with a laser resonance chamber; two non-linear optical crystals, a selective microscope and a reflector are positioned in the light path of pulsed laser from the laser resonance chamber; a rotating mirror drum is fixed above one side of the reflector; a work piece to be cleaned is arranged on a convey belt; a blower is positioned at one side of the convey belt and a cleaner is arranged at the other side. By adopting the method, substrates to be cleaned can be continuously or discontinuously conveyed to go through the laser which is Watt-level pulse laser with about 266nm and comes from the all-solid laser; proper laser intensity, pulse frequency and irradiation time can be controlled to effectively remove micron and submicron particles, organics, oily contamination, etc. on the surface of the substrate. The adhesion of the coating after cleaning and the product yield rate are greatly improved and the warp or spalling of the coating rarely happens.

Owner:TSINGHUA UNIV +2

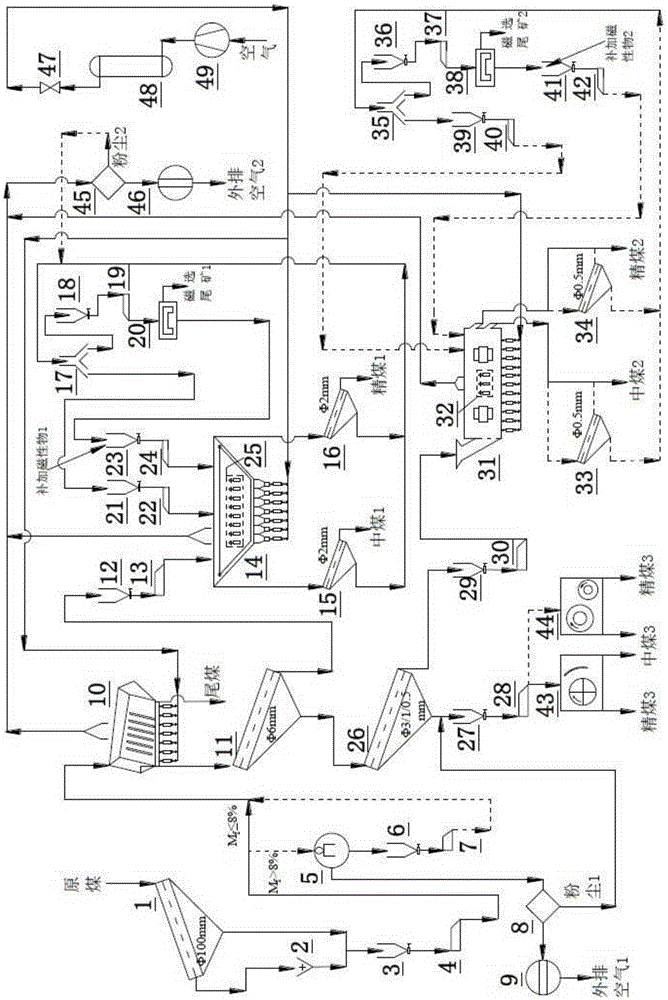

Full-fraction dry method separation clean technology and method for coal

ActiveCN105289985AOvercome limitationsSolve the problem of few selected productsGas current separationGranularityFluidized bed

The invention discloses a full-fraction dry method separation clean technology and method for coal. The technology includes the steps that raw coal to be sorted is screened, crushed and dried and then enters a compound dry method separation machine to obtain rough clean coal and tailings; the rough clean coal is screened through classification screens to obtain products of three fractions; the products of three fractions enter a dry method dense medium separation machine, a vibration dense medium fluidized bed separation machine and a dry method electric separation machine / dry magnetic separator respectively for separation of clean coal and middlings; and after medium solids brought out by the products are removed through a sculping screen, part of the medium solids enter the magnetic separator for removing of non-magnetic substances, then obtained magnetic concentrate flows back to the separator, and the other part of the medium solids are directly and cyclically used. The system comprises a raw coal preparing and drying part, a separating part and a medium purifying circulation and dense control part. According to the full-fraction dry method separation clean technology and method for coal, synchronous efficient separation on coal with large, medium and small granularities can be achieved, and the problems that in a current dry method coal separation field, graded products are fewer, the quality of clean coal is poor, the medium utilization rate is low, and dust is excessively discharged are solved.

Owner:CHINA UNIV OF MINING & TECH

Chamber surface passivation method for semi-conductor laser

InactiveCN101394062AReduce difficultySimple processing methodLaser detailsVacuum evaporation coatingNitrogenLaser light

A method for passivating a cavity surface of a semiconductor laser belongs to the technical field of the process of a semiconductor photoelectronic device. The known technical difficulties in the field are as follows: the output power is greatly improved, and the reliability of the device maintains a high level. The method for passivating the cavity surface of the semiconductor laser effectively improves the output power and the reliability of the semiconductor laser. The passivation method adopts the cleaning technology for reactive ions of a hydrogen ion and a nitrogen ion in sequence, so that an absorption-free area containing a nitride transition layer is generated on the cleavage cavity surface of the laser, and then a passivation and barrier layer, namely a AIN film coats the transition layer, so as to form a passivation film and then carry out normal coating process. The technical proposal can be applied to the manufacture of various semiconductor laser light sources.

Owner:CHANGCHUN UNIV OF SCI & TECH

Laser anti-corrosion and wear-resistant process for trunnion of movable guide vanes of turbines

InactiveCN101629289ASolve technical bottlenecksLow dilution rateMetallic material coating processesNumerical controlWear resistant

The invention relates to a laser anti-corrosion and wear-resistant process for the trunnion of movable guide vanes of turbines. The process comprises the following steps: useing liquid penetrant test detection to detect the whole guide vane trunnion so as to determine cracks, air cavities and slag in the erosive wear area; and making balancing weights according to the shape and poise error of the guide vanes; removing the fatigue layer of the erosive wear area of the guide vanes; and carrying out cleaning technology treatment after clearing. A special powder feeding device is used to carry out laser cladding for special alloy materials which have good fusion property, high bonding strength and good anti-corrosion and wear-resistant properties. The specific parameters of the cladding process are as follows: the laser power is 3,200W, the spot diameter is 3.2 mm, the latus spots are used, the scanning speed of numerical control programming is 700 mm / min, the lapping rate is 25%, argon protection is used, and the alloy materials are delivered into the melting bath of laser cladding in an angle of 15 DEG by a special laser powder feeding device in a synchronous powder feeding way. All movable guide vanes to be repaired in the invention do not need sending to the manufacturer for treating, huge transport expenditure is not needed, and the whole repair period can be greatly shortened.

Owner:岳阳大陆激光技术有限公司

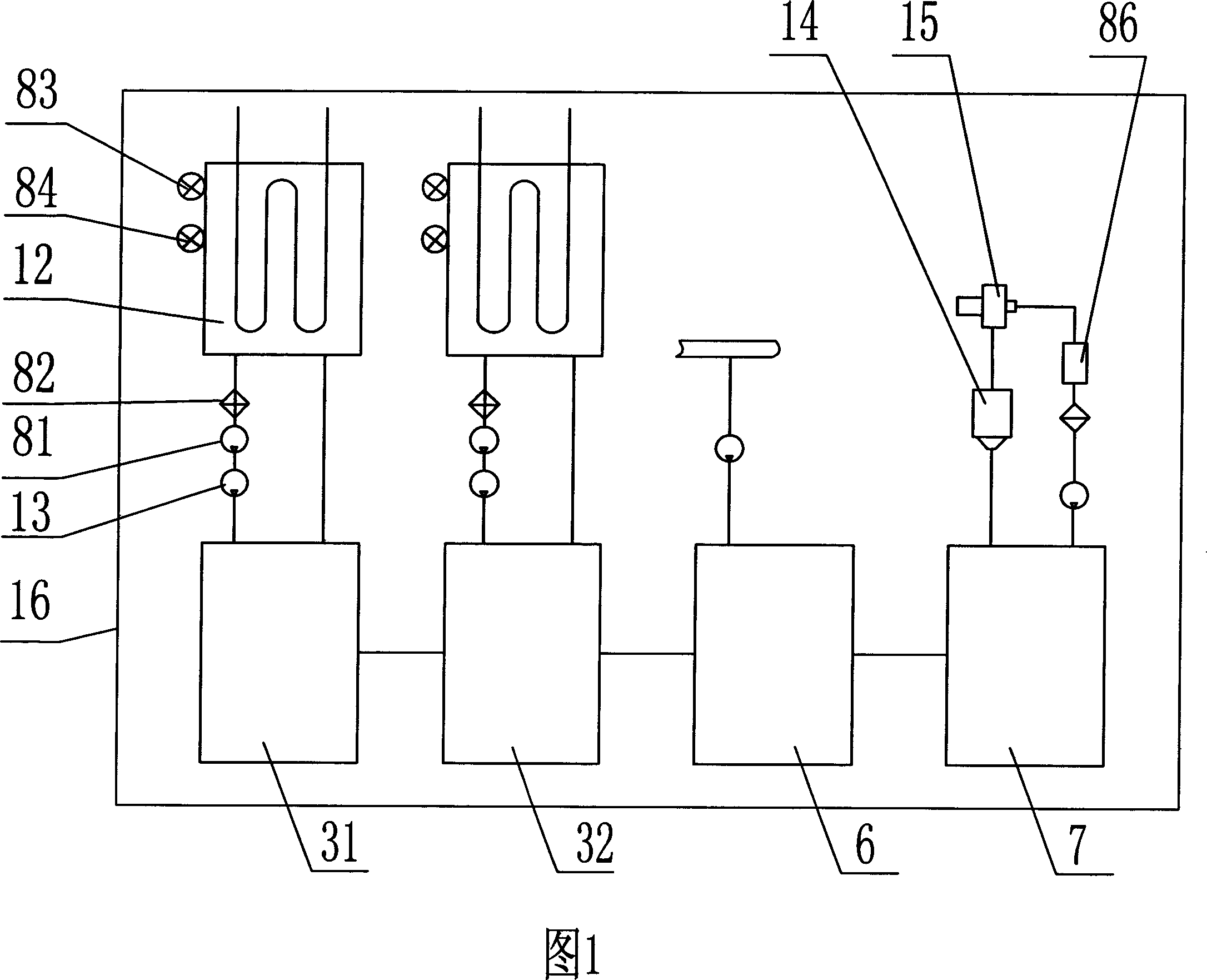

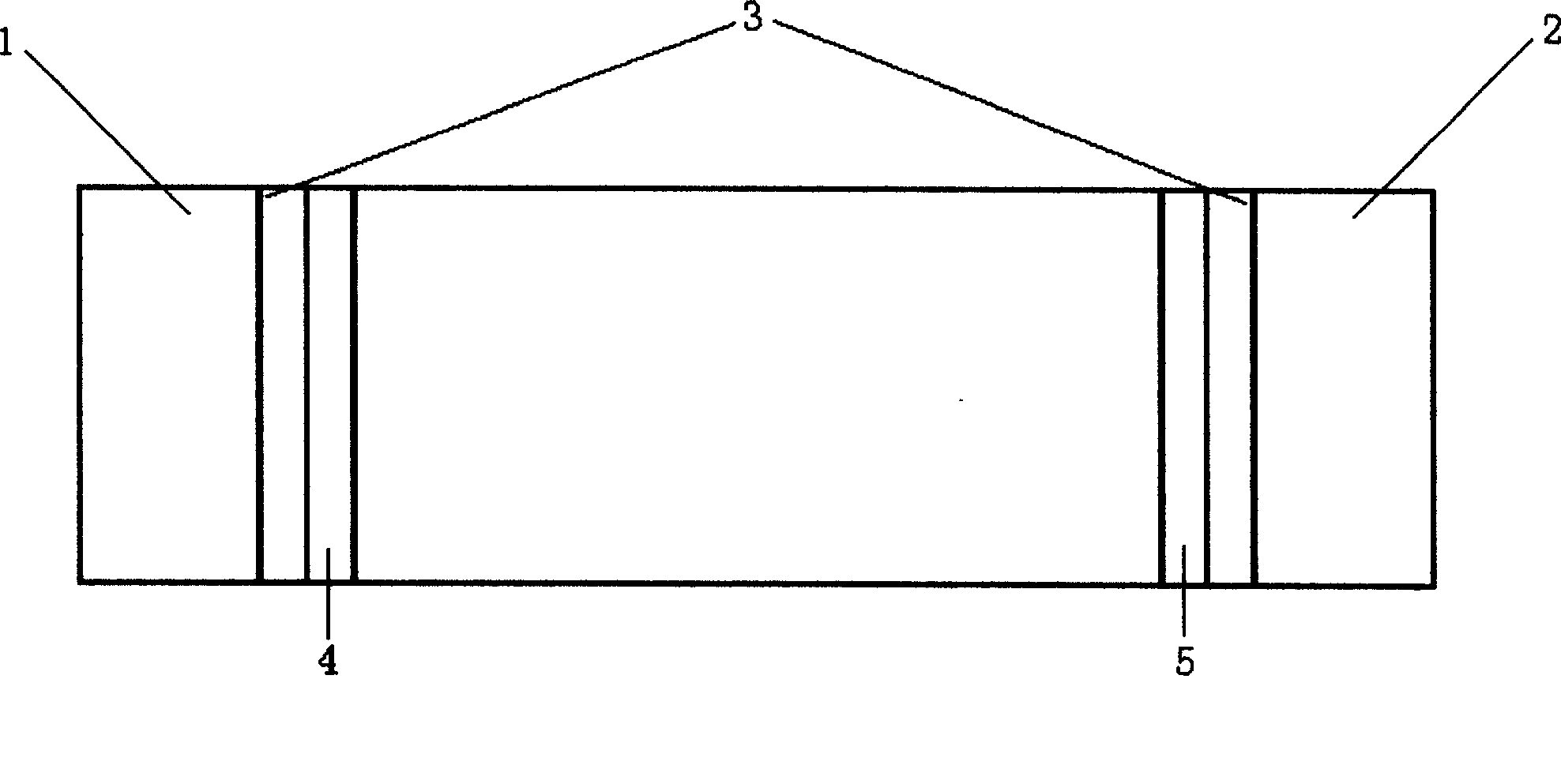

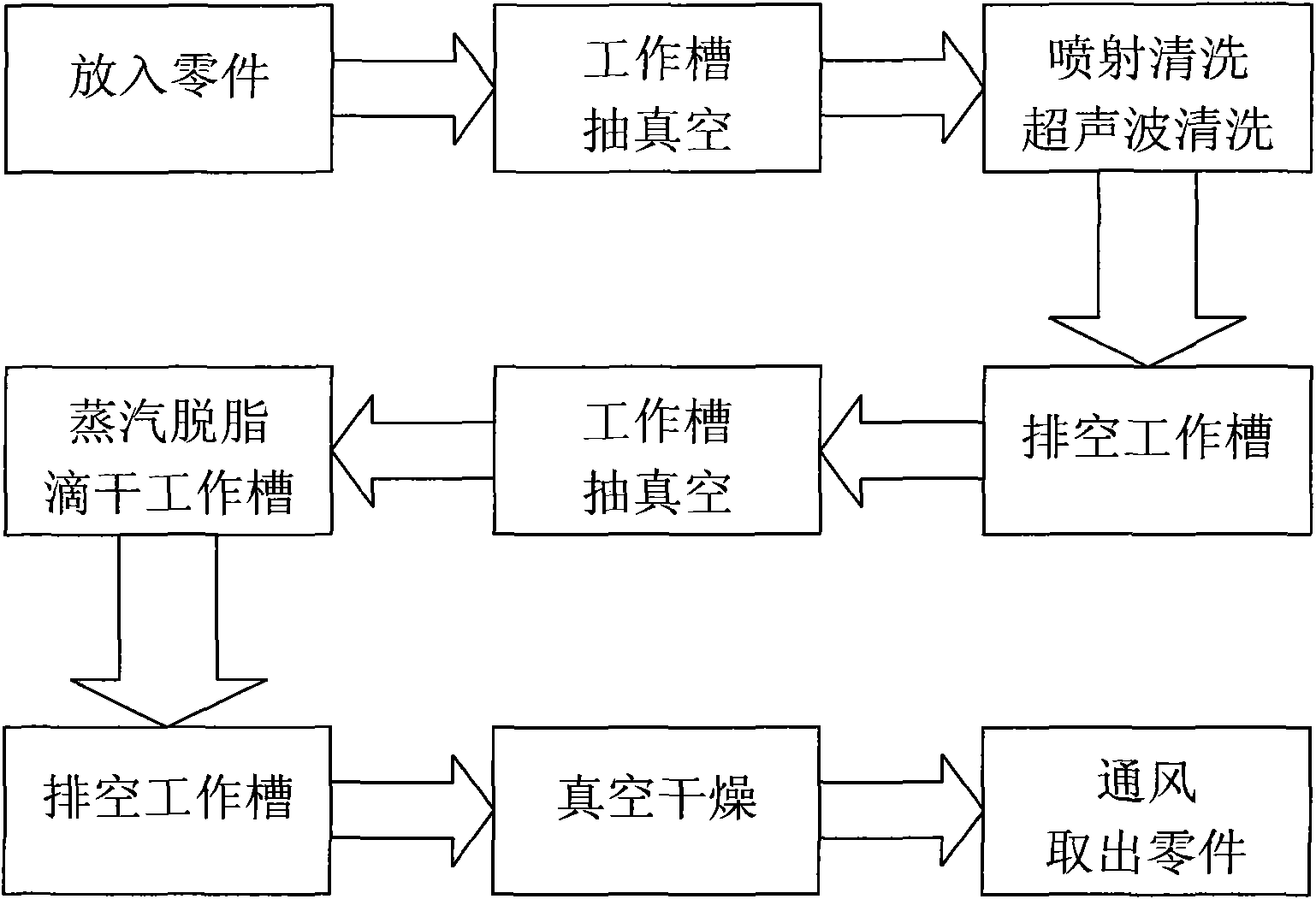

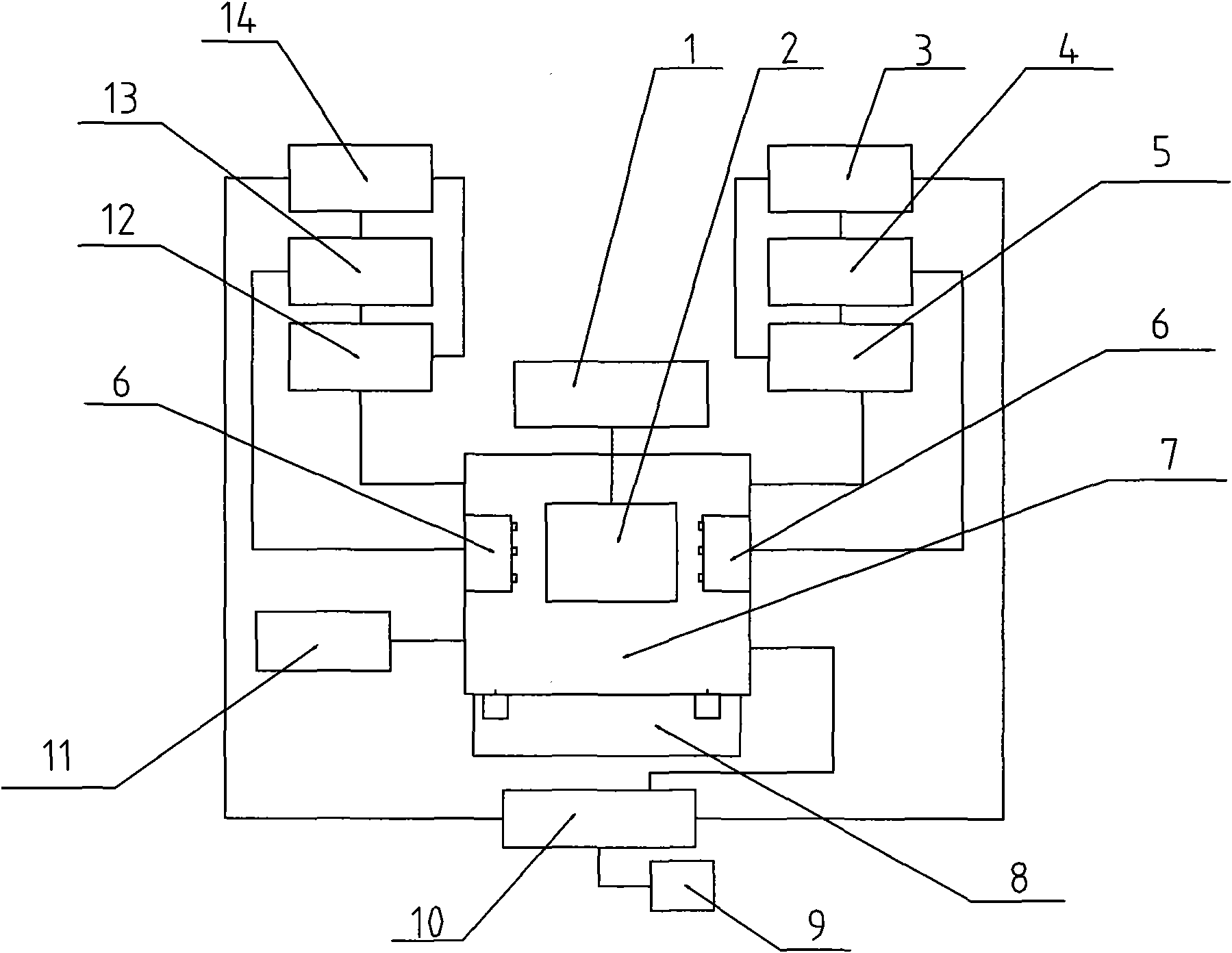

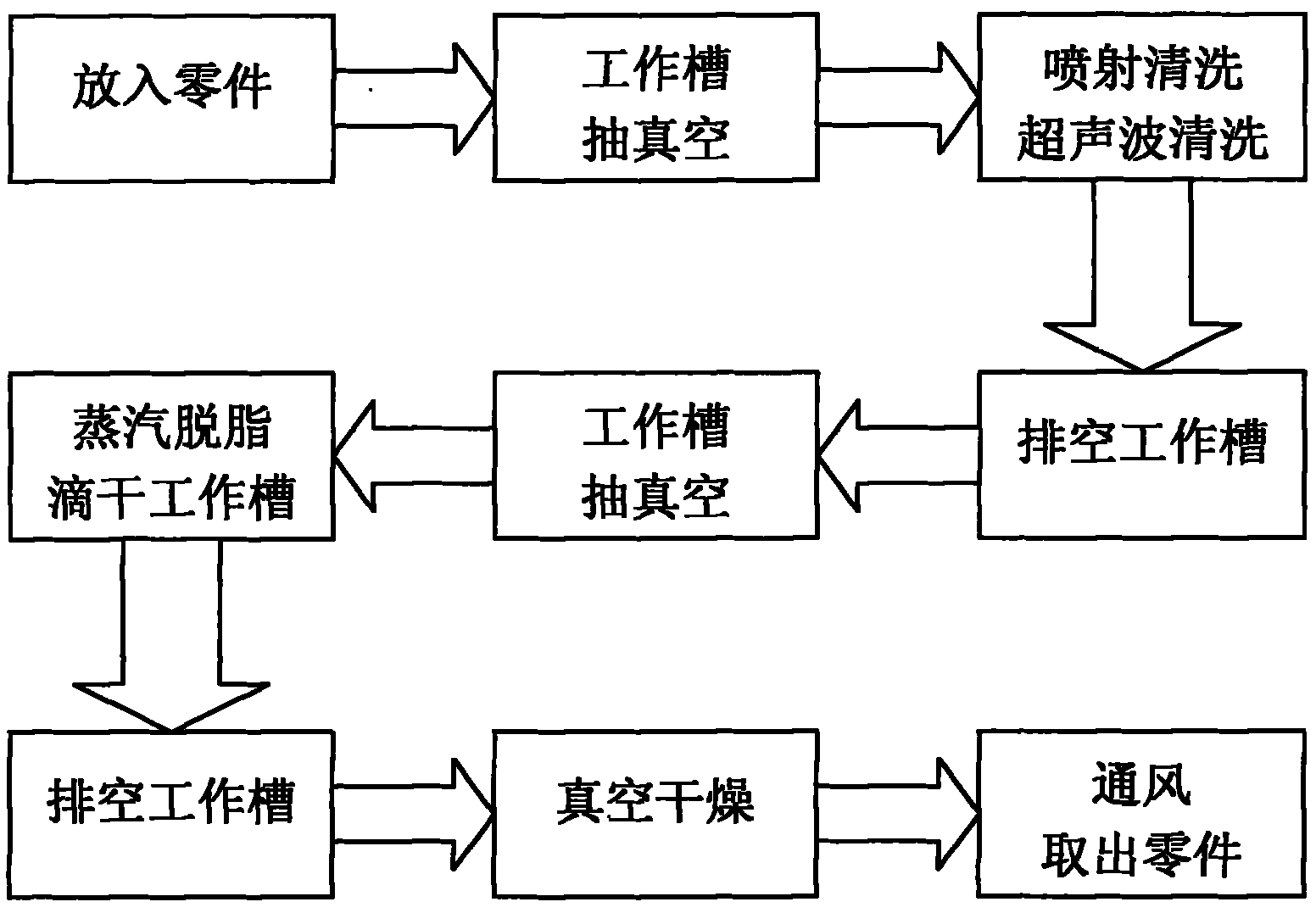

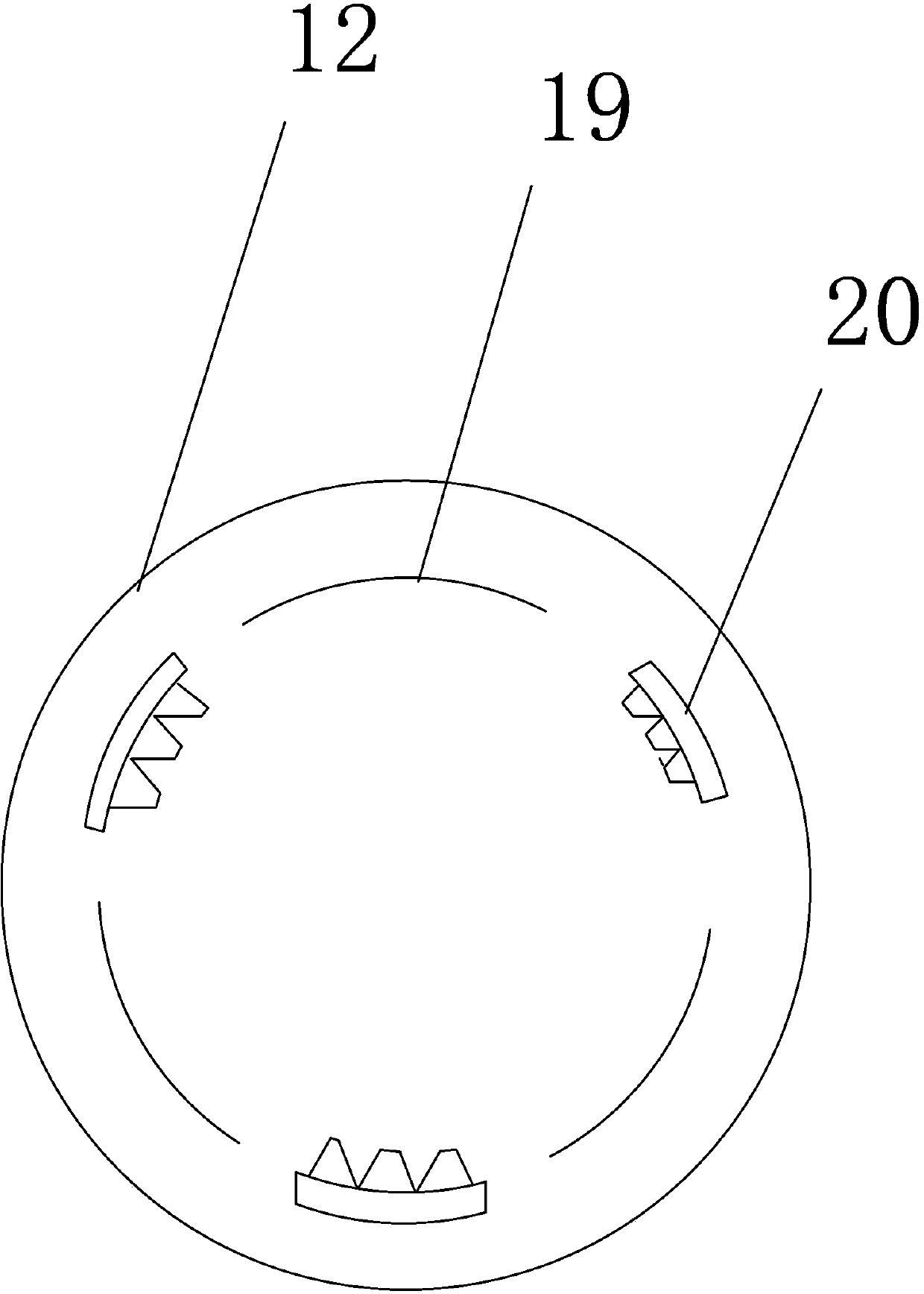

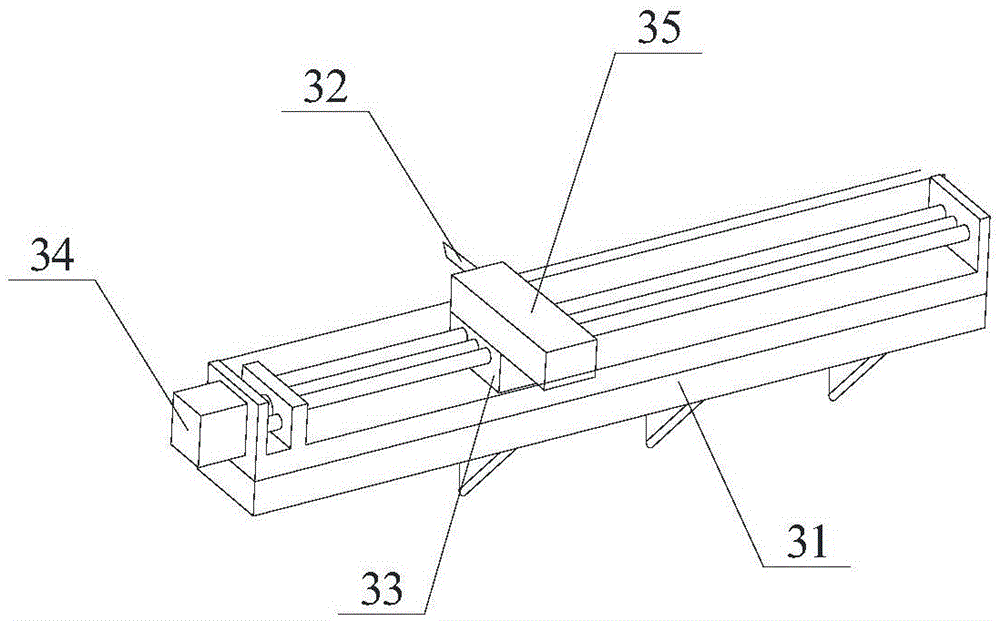

Blind hole internal thread chipless cleaning technology and device thereof

The invention relates to blind hole internal thread chipless cleaning technology and a cleaning device thereof. The cleaning technology comprises the followings steps of: (1) placing a working basket (2) with parts into a working slot (7); (2) vacuumizing the working slot; (3) injecting liquid in an immersion cleaning slot into the working slot to perform jet cleaning and ultrasonic cleaning; (4) discharging residues in the working slot; (5) vacuumizing the working slot; (6) performing vapor degreasing and drip-drying the working slot at the same time; (7) discharging residues in the working slot; (8) vacuum-drying the parts; and (9) ventilating and taking the parts out. The cleaning device is manufactured by the blind hole internal thread chipless cleaning technology. The cleaning technology and the cleaning device can realize complete chip removal of the blind hole internal thread; and multiple experiments on various products with the blind hole internal thread prove that the blind hole internal thread chipless cleaning technology and the cleaning device have good cleaning effect, and can completely guarantee that no metal scraps remain in the blind hole internal thread after the parts with the thread are cleaned.

Owner:SUZHOU INDAL PARK XINKAI PRECISION FASTENERSCO

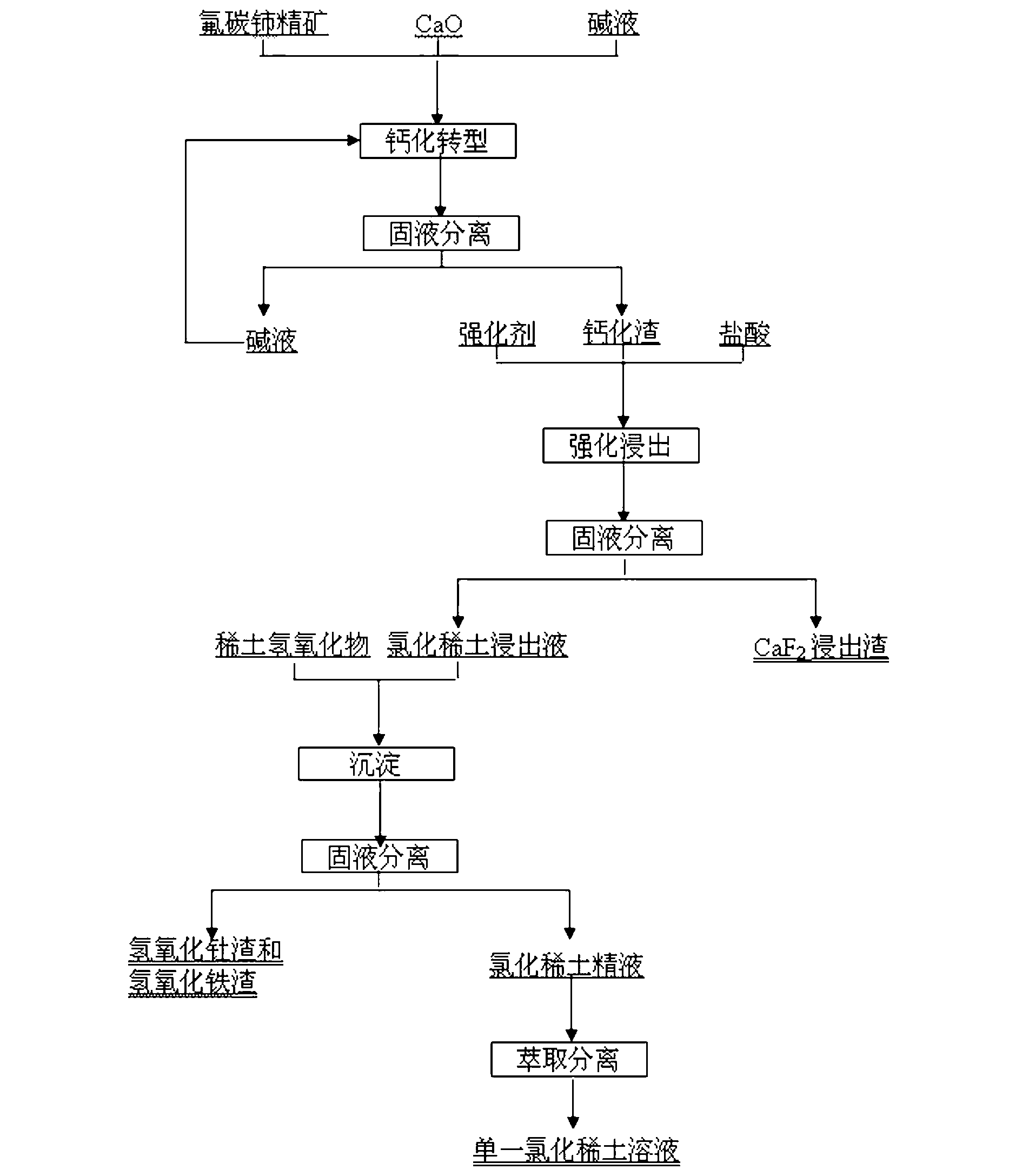

Method for decomposing bastnaesite through calcification transformation-leaching

The invention belongs to the technical field of rare earth metallurgy, and particularly relates to a method for decomposing bastnaesite through calcification transformation-leaching. The method comprises the following the steps of: carrying out activation pretreatment on rare earth ore concentrate, carrying out calcification transformation pretreatment on the activated ore, carrying out acid leaching on transformed slag, extracting rare earth chloride fine liquid to finally obtain a solution with thorium-iron slag and cerium chloride or lanthanum chloride or praseodymium chloride or neodymium trichloride, and efficiently separating valuable elements such as a rare earth element, a fluorine element and a thorium element. According to the method, energy consumption and fuel consumption are reduced, and when the low-temperature baking is carried out below 500 DEG C, only carbonates are decomposed, so that the reaction activity of the rare earth ore concentrate is supplied, and simultaneously the waste of fluorine resources and the emission pollution are avoided; and therefore, the method belongs to a green clean technology.

Owner:NORTHEASTERN UNIV

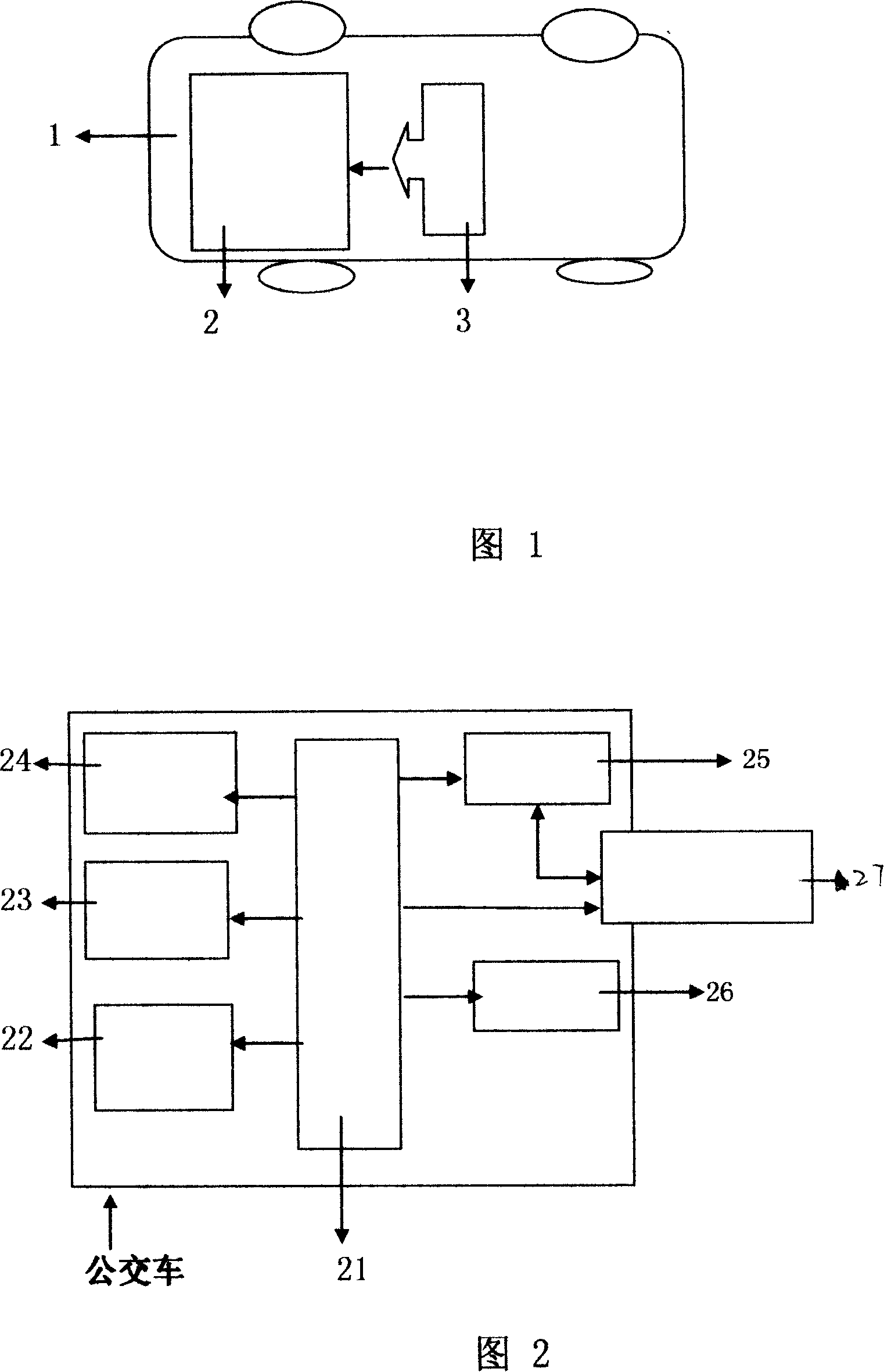

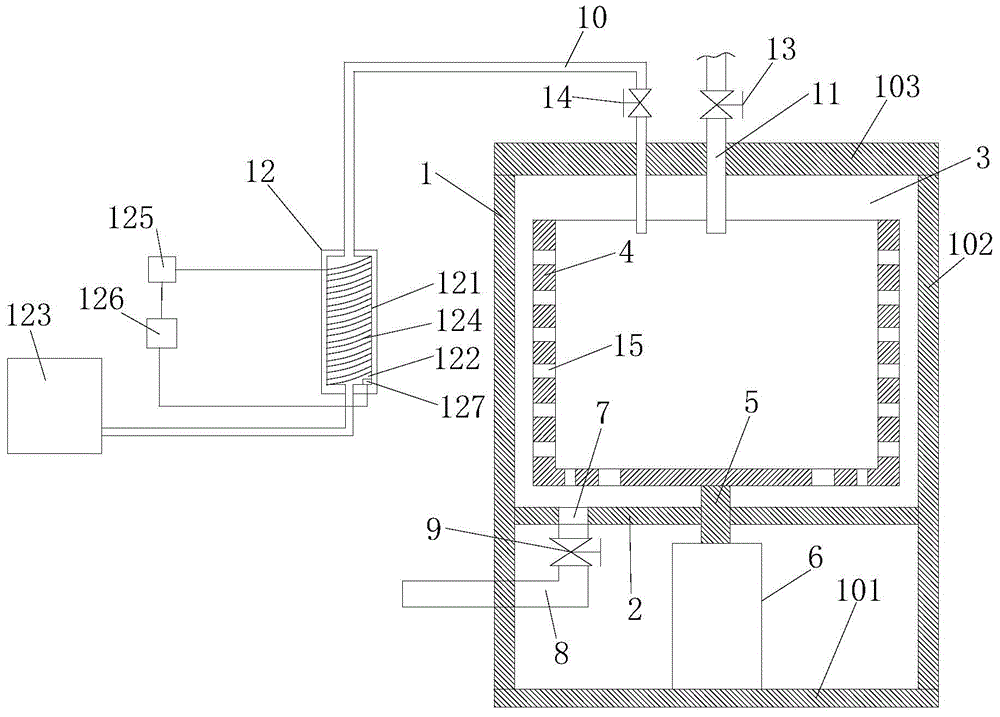

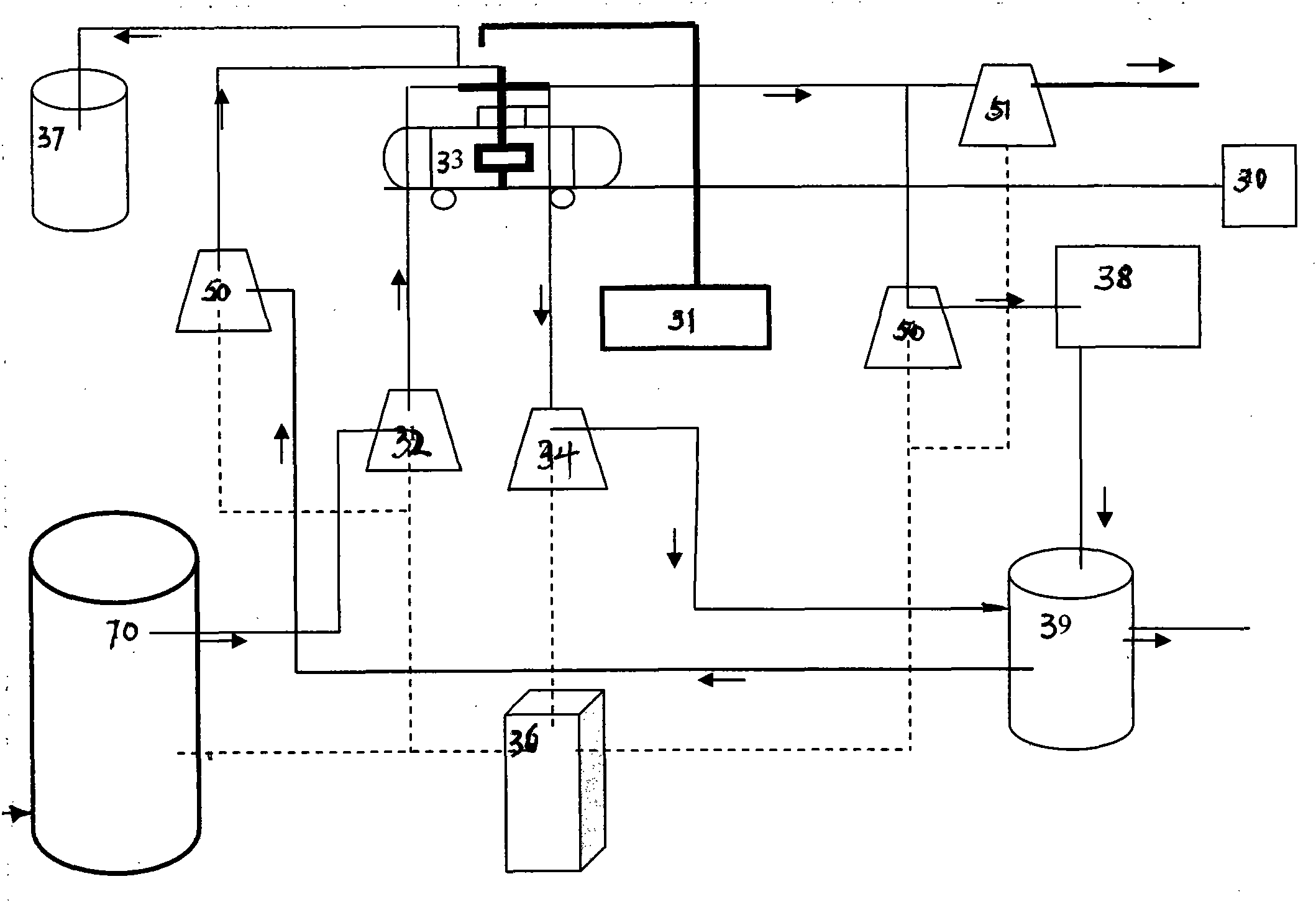

Cleaning system

The invention relates to a cleaning system, pertaining to the technical field of environment protection and bus cleaning. The cleaning of the city needs to develop a plurality of cleaning vehicles for sweeping and aspersing, such as patent number: multifunctional cleaning vehicles / a multifunctional steam snow sweeping machine. At present, the hydrogen energy source cars are developed on cars; the generation of the hydrogen generates water or needs water for hydrogen generating; combining the wide use of the bus (distributed on each road), a water tank, a spraying system, a control system, a positioning system (GPS, wireless positioning, other positioning systems, navigation system, intelligent steering system), a monitoring system / transducer system are arranged on the bus to reach a definite point so as to timely, randomly and remotely clean the city roads according to the need. The invention has the advantages of cleaning the city roads according to the need timely, randomly and remotely, saving cost and simple management.

Owner:SHANGHAI ZHONGCE IND & TRADING +1

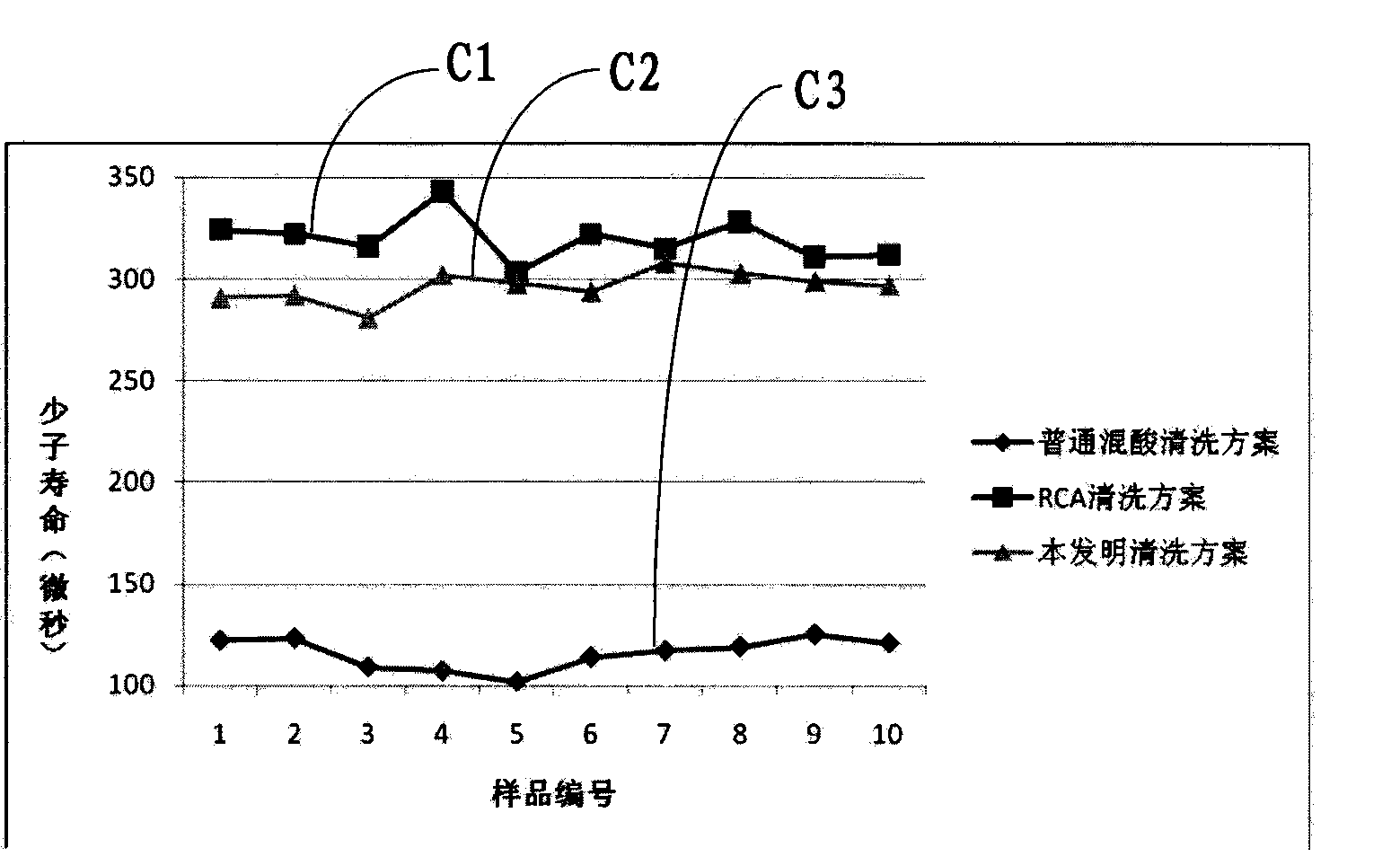

Cleaning technology for sapphire wafers

ActiveCN105280477AGood ratio of decontaminationImprove oxidation effectSemiconductor/solid-state device manufacturingWaferingSapphire wafer

The invention discloses a cleaning technology for sapphire wafers. The method comprises steps of firstly removing most of highly-adhered oil stains and dirty points on surfaces of wafers using a physical cleaning sheet with combination of an ultrasonic method, thoroughly cleaning residual stains on the surfaces using a mixed solution of sulfuric acid and hydrogen peroxide, then performing cleaning in a fast-exhaust rinsing tank, and performing spin drying and blow drying. The surface of a cleaned wafer is clean and damage-free, and the enforcement efficiency is extremely high. The method can be used for cleaning in the epitaxial layer growth process of sapphire wafer GaN-based LED chips, the PSS patterned growth and the tube core front segment manufacturing process.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

Surface cleaning method after sapphire substrate material polishing

InactiveCN101912855AReduce surface tensionImprove uniformityCleaning using liquidsSurface cleaningMachining process

The invention relates to a surface cleaning technology after chemically mechanical polishing (CMP) in the surface high-precision machining process of sapphire substrate materials, and provides a water polishing solution prepared from neutral media. The water polishing solution comprises activator, chelator and corrosion inhibitor. By carrying out water polishing with the water polishing solution at a high output immediately after alkaline polishing is finished, the residual CMP polishing solution can be flushed away, easily-cleaned materials can be adsorbed, the surface tension can be quickly reduced, the reaction can be prevented from continuing (physical adsorption state) to form a unimolecule passive film, and metal ions are enabled to form a soluble chelate, thereby obtaining a clean and perfect polished surface. The water polishing solution has the advantages of low cost, no environmental pollution and no corrosion to equipment.

Owner:HEBEI UNIV OF TECH

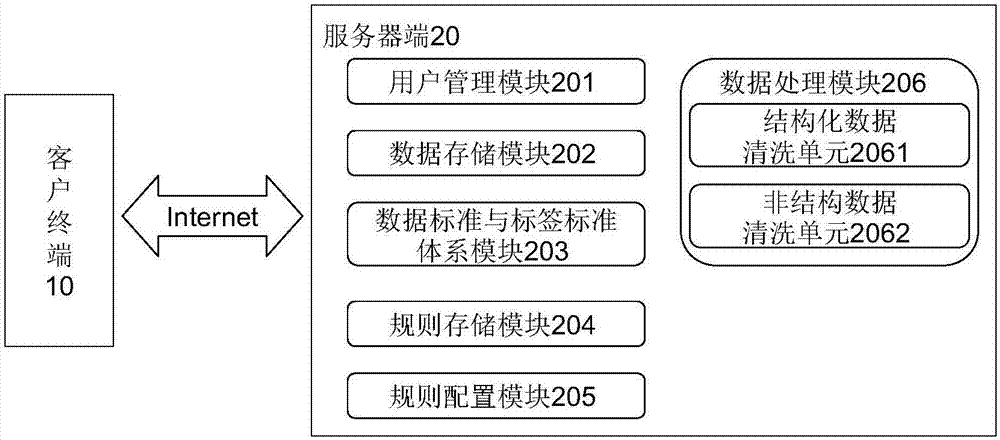

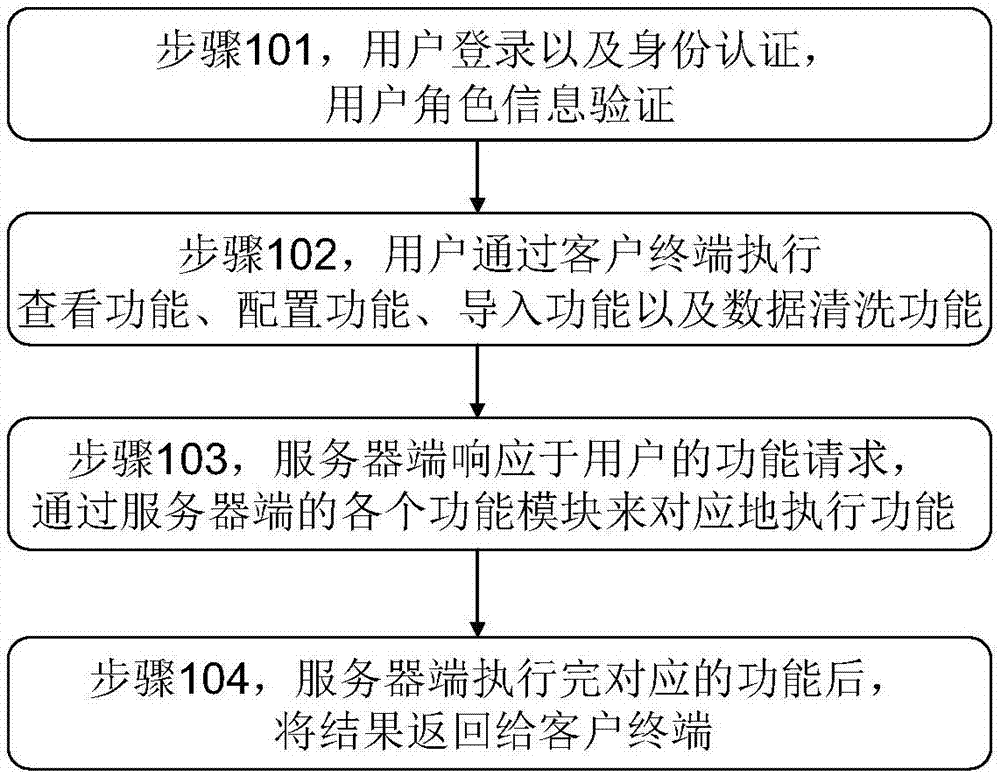

A data management method and management platform

InactiveCN107169073AImprove adaptabilityAchieving Common Data GovernanceSpecial data processing applicationsMulti languageCleaning methods

The invention provides a data management method and management platform. Standardized governance for multi-element, isomeric and multi-language data is carried out. B / S architecture design is adopted and data resource management and governance work configuration is completed via web pages; a distributed data cleaning and governance program is built at a back end via secondary development; the front-end configuration and the rear-end program architecture are combined, so that standardized cleaning and governance work for data can be completed automatically. The web page architecture multi-user mode facilitates man-machine interaction; the multi-thread and distributed technology of the rear end can complete cleaning work rapidly and efficiently; the development of cleaning technology is more inclusive; data cleaning work for multiple regions and multiple languages of the world is finished. A cleaning platform system disclosed by the invention is implemented in the B / S architecture and a synergic cleaning system is built by establishing a distributed environment, so that multi-end and multi-thread joint data governance is achieved and the adaptability of the cleaning methods is improved.

Owner:北京智行创远信息科技有限公司

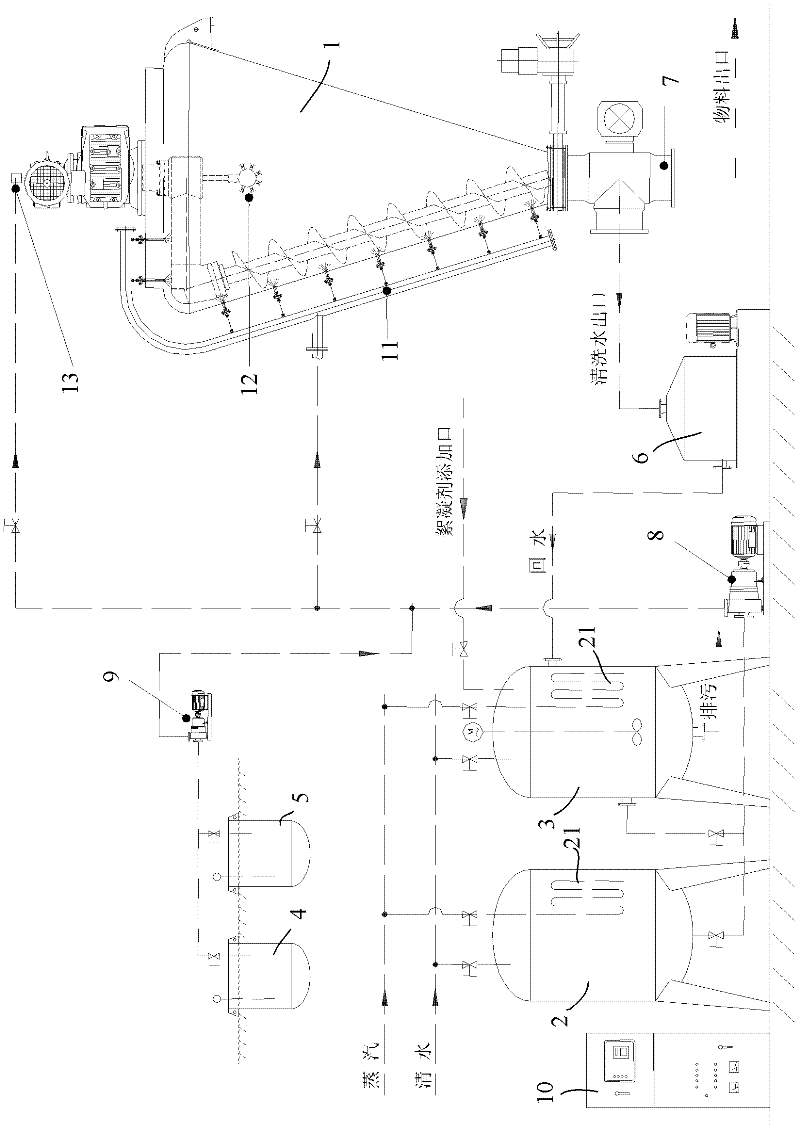

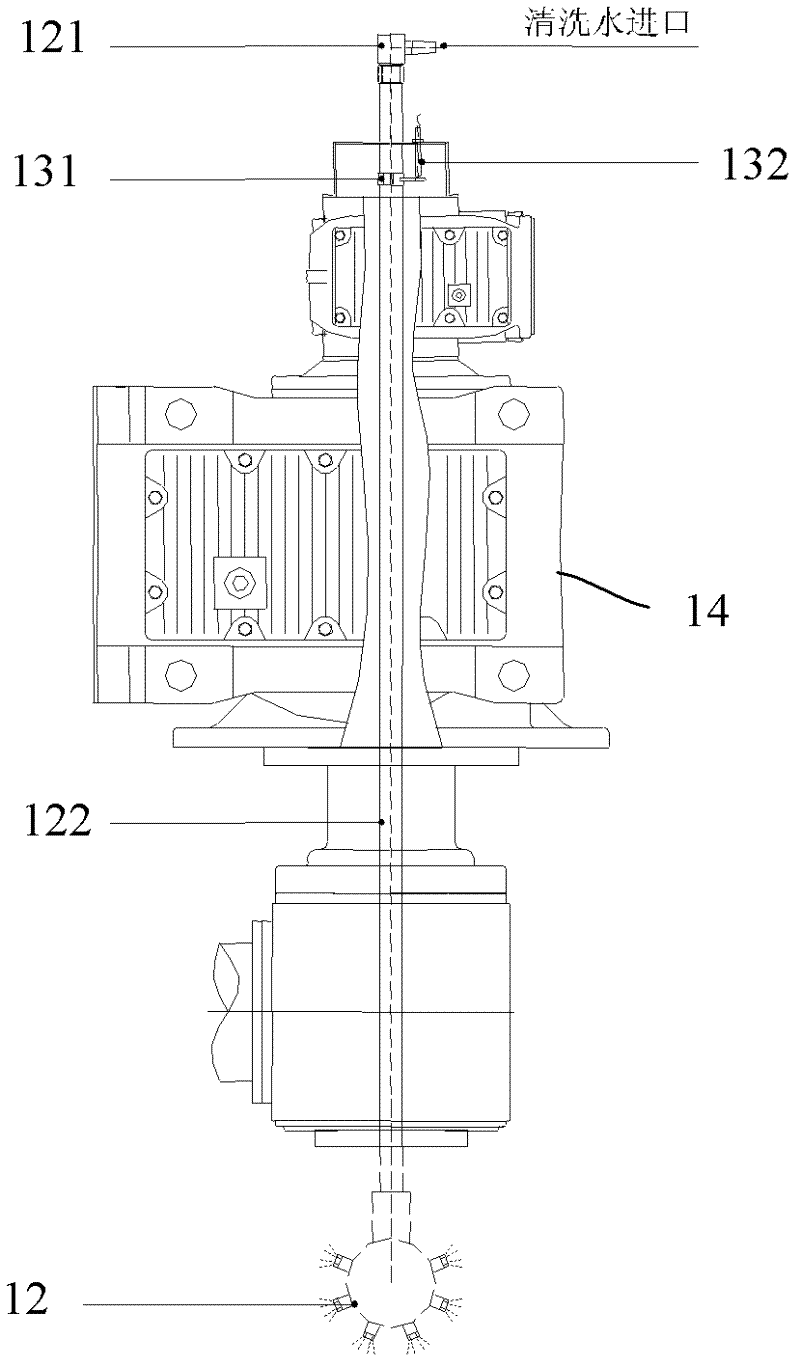

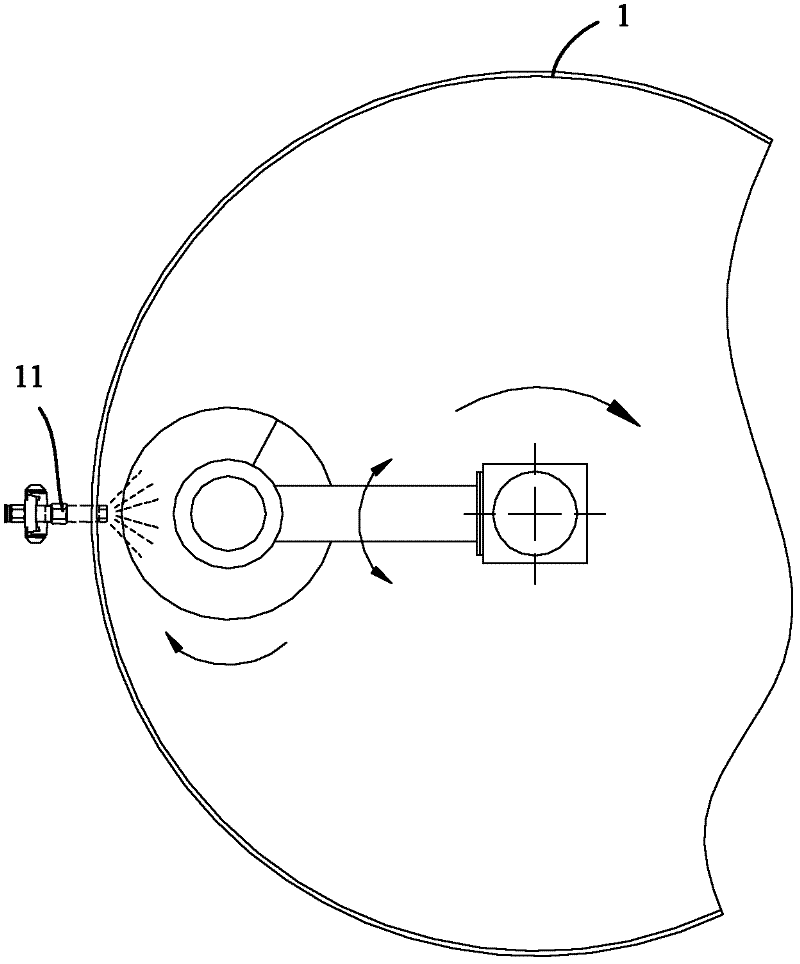

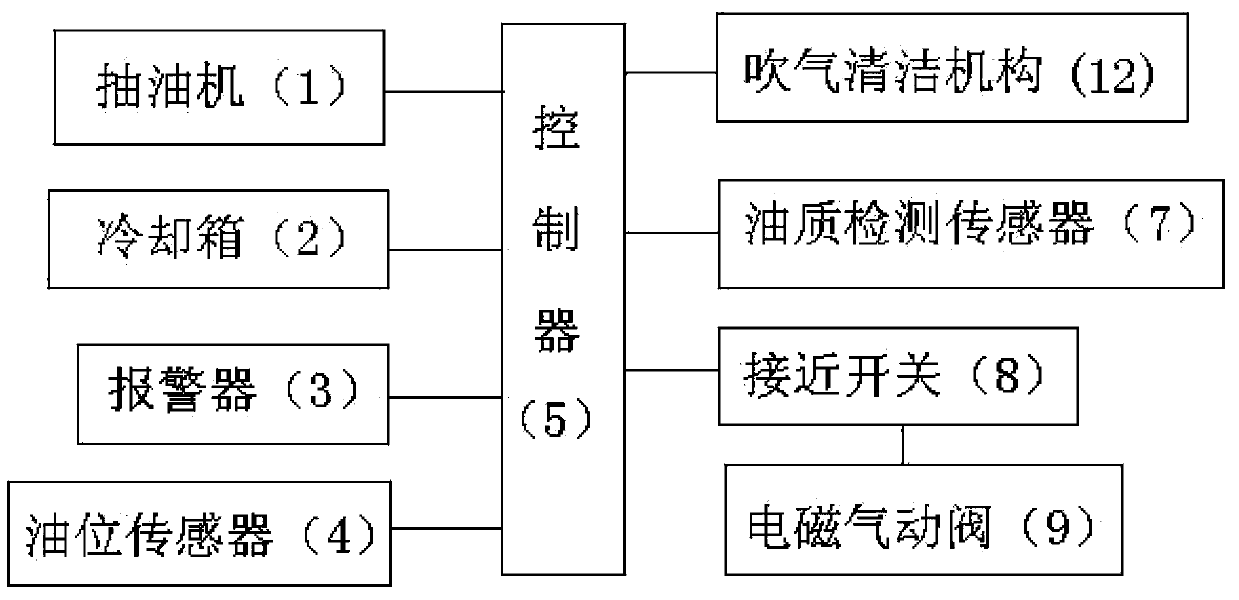

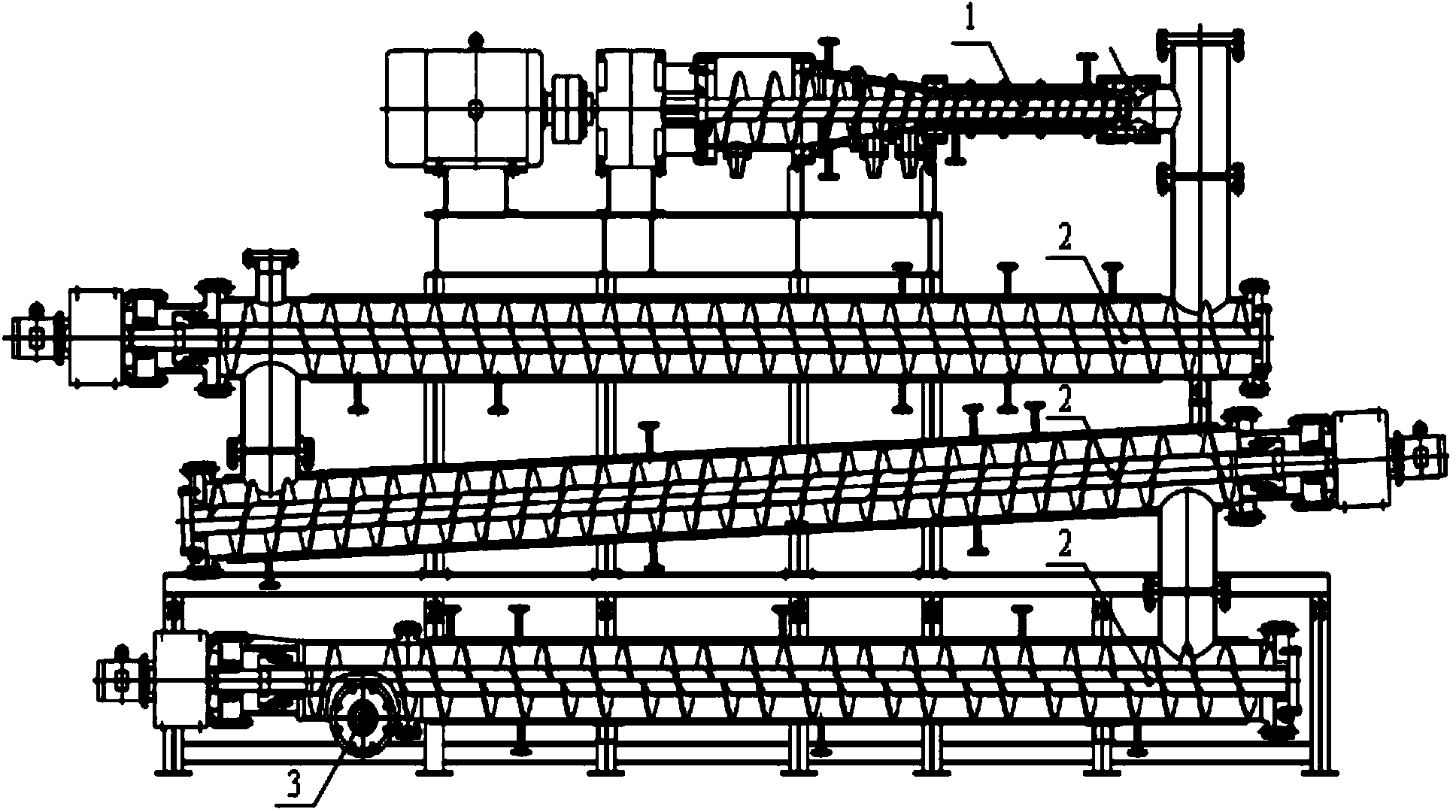

Automatic cleaning system of conical spiral mixer and cleaning technology for conical spiral mixer

ActiveCN102407227AEffective clean-in-placeHigh degree of automationRotary stirring mixersCleaning using liquidsControl systemWater storage tank

Owner:SHUANGLONG GROUP

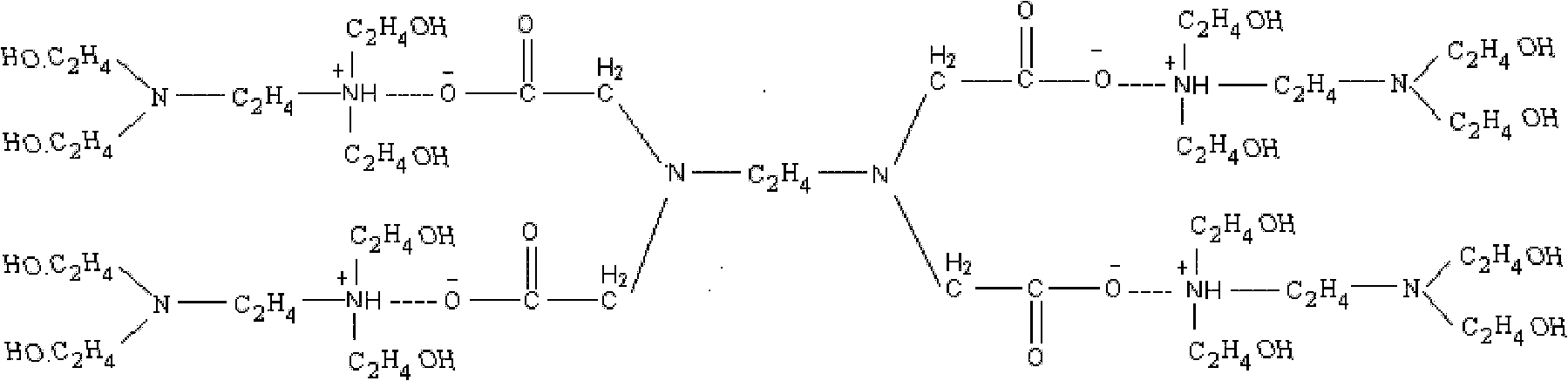

Method for ultrasonic cleaning of polished sapphire substrate wafer

ActiveCN103537453AImprove oxidation capacityAvoid readsorptionCleaning using liquidsElectrolysisMetal impurities

The invention relates to a method for ultrasonic cleaning of a polished sapphire substrate wafer and provides a method for conducting cleaning through ultrasound and a solution to remove particles and metal ions and then conducting cleaning through ultrasound and oxidation liquid to remove organic matters. According to removal of the particles and the metal ions, an FA / O type chelating agent and two kinds of non-ionic surface active agents including JFC and AEO are selected and prepared to mixed liquid in proportion and the ultrasonic action is added so that cleaning can be conducted; anodic oxidation liquid obtained through electrolysis of a diamond film (BDD) is selected to remove organic pollution, the oxidation liquid is high in oxidation function, and therefore most organic matters are resolved. According to the method, comprehensive cleaning of the particles, the organic matters and metal impurities is conducted, the number of steps is small, operation is simple, and the method can satisfy the requirement of the new-period micro-electronic cleaning technology.

Owner:江西伟嘉创展企业管理有限公司

Cleaning technology of polished wafer containing box

ActiveCN103934234AImprove cleanlinessGuaranteed drynessHollow article cleaningDrying gas arrangementsOrganic solventAlcohol

The invention relates to a cleaning technology of a polished wafer containing box. The cleaning technology comprises the following steps that pure water is put in a cleaning tank, hydrophilic organic solvent is added, a cleaning solution is obtained, and the wafer containing box is immersed into the cleaning solution in the cleaning tank and then is taken out; the pure water is used for flushing the taken wafer containing box until the surface of the wafer containing box is free of obvious cleaning agent foam; the flushed wafer containing box is put in a cleaning rack, then the cleaning rack which is provided with the wafer containing box is placed in a cleaning tank of an ultrasonic cleaner for conducting ultrasonic cleaning, and after ultrasonic cleaning is completed, the wafer containing box is taken out; a piece of non-dust cloth is used for being dipped with ethyl alcohol to wipe the surface of the wafer containing box; the gas sprayed by a gas gun is used for drying the wafer containing box in blowing and spraying modes; at last, the dried wafer containing box is conveyed to a clean chamber or a clean workbench for standby application. The wafer containing box cleaned through the cleaning technology can be used for replacing a high-cleanliness wafer containing box, the cost of high-cleanliness auxiliary materials is omitted, and the control over surface particles of the polished wafer surface is enhanced.

Owner:无锡长三角光电新材料有限公司

Intelligent automatic lubricating cleaning device for driving chain

InactiveCN103867873AHigh degree of intelligent automationImprove work efficiencyLubrication elementsCleaning using gasesSpray nozzlePneumatic valve

The invention discloses an intelligent automatic lubricating cleaning device for a driving chain, and belongs to the technical field of chain cleaning lubrication and aims at providing the intelligent automatic lubricating cleaning device for the driving chain with the advantages that a cleaning function is realized, the service lives of the driving chain and a main disc and a sub disc of a driving motor can be prolonged, and the lubricating effect is good. The intelligent automatic lubricating cleaning device comprises a support frame, an oil supply pipeline, a driving chain, a traction chain, a pulling claw, a driving motor, an air blowing cleaning mechanism, a controller, an electromagnetic pneumatic valve and a proximity switch, wherein the proximity switch is connected in series onto a power supply loop of the electromagnetic pneumatic valve, the electromagnetic pneumatic valve is connected onto the oil supply pipeline, an oil spray nozzle of the oil supply pipeline is arranged above the driving chain, the proximity switch is arranged above a chain wheel, an oil collecting disc is arranged under the driving chain, an air blowing opening of the air blowing cleaning mechanism is arranged in a direction facing the driving chain, and the control end of the air blowing cleaning mechanism and the control end of the proximity switch are respectively connected with the controller. The intelligent automatic lubricating cleaning device is mainly used in the automatic lubricating cleaning technology of the chain.

Owner:ZHEJIANG GEELY AUTOMOBILE +2

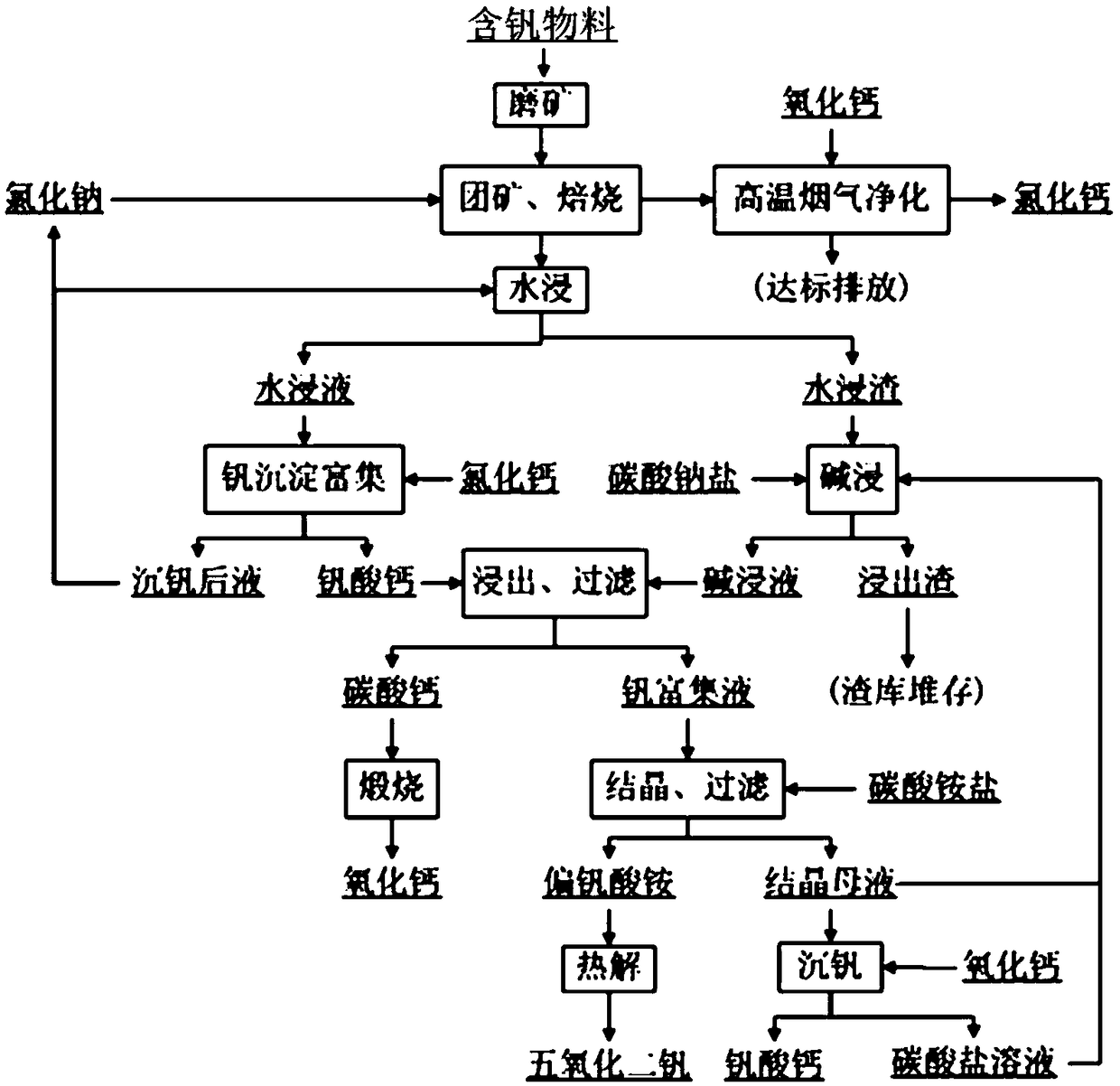

Cleaning technology for extracting vanadium from vanadium containing materials through sodium salt roasting

ActiveCN108754125AHigh recovery rateReduce manufacturing costProcess efficiency improvementSorbentAmmonium metavanadate

The invention discloses a cleaning technology for extracting vanadium from vanadium containing materials through sodium salt roasting. Sodium chloride is added in the vanadium containing material orefor uniform mixing and fine grinding, nodulizing roasting is conducted, after harmful gases in roasting smoke are removed through an adsorbent, the roasting smoke reaches the standard to be exhausted,obtained roasted ore is subjected to water leaching and then subjected to alkaline leaching, and water is added in the roasted ore for leaching; a water leaching solution and water leaching residuesare obtained through filtration, a sodium carbonate salt solution is added in the water leaching residues for leaching, and an alkaline leaching solution and leaching residues are obtained through filtration; calcium chloride is added in the water leaching solution to deposit enriched vanadium, and calcium vanadate filter cakes and a molybdenum precipitation liquid are obtained through filtration;the molybdenum precipitation liquid returns to the roasted ore water leaching procedure or vanadium containing material ore mixing or nodulizing procedure to be circularly used, the obtained calciumvanadate filter cakes are decomposed through the alkaline leaching solution, and calcium carbonate and vanadium enriching liquid are obtained through filtration; after calcium carbonate is roasted andconverted into calcium oxide, the calcium oxide returns to the high-temperature smoke purification procedure to be continuously used; ammonium salt is added in the vanadium enriching liquid, vanadiumis separated by crystallization, and ammonium metavanadate and crystallization mother liquor thereof are obtained through filtration, the ammonium metavanadate is subjected to pyrolysis, a vanadium pentoxide product is obtained, the crystallization mother liquor directly returns to the alkaline leaching procedure, or after calcium is added for vanadium depositing, the crystallization mother liquor returns to the alkaline leaching procedure to be circularly used. Cyclic utilization of sodium chloride, lime, sodium carbonate salt and water in the technology process is achieved, and the beneficial effects that the technology is simple, the vanadium recycling rate is high, the production cost is low, and cleanliness and environment friendliness are achieved are achieved.

Owner:王懿

Silicon material cleaning technology and equipment

InactiveCN104438201AReduce energy consumptionReduce manufacturing costCleaning using liquidsOxygenSolar cell

The invention discloses a silicon material cleaning technology and equipment which can prevent a silicon dioxide layer from being formed on the surface of a silicon material during cleaning of the silicon material. The silicon material cleaning technology comprises the steps that firstly, the silicon material needing to be cleaned is placed into the centrifugal equipment; the centrifugal equipment is started to enable the silicon material to rotate, pure water is injected into the centrifugal equipment to clean the silicon material in the rotating process of the silicon material, pure water is stopped from being sprinkled towards the silicon material after cleaning is completed, the rotation speed of the centrifugal equipment is adjusted to 305-330 r / m for spin-drying processing, and inert gas at the temperature of 60-120 DEG C is led to the silicon material in the spin-drying process. According to the cleaning technology, the insert gas is used for baking the silicon material, the silicon material will not make contact with oxygen under the protection of the inert gas, the silicon dioxide layer will not be formed on the surface of the silicon layer, therefore, the silicon material without the silicon dioxide layer on the surface can be molten easily when the silicon material needs to be molten in a subsequent technology, and energy consumption is reduced. The silicon material cleaning technology and equipment are suitable for being applied and popularized in the field of solar cells.

Owner:LESHAN TOPRAYCELL

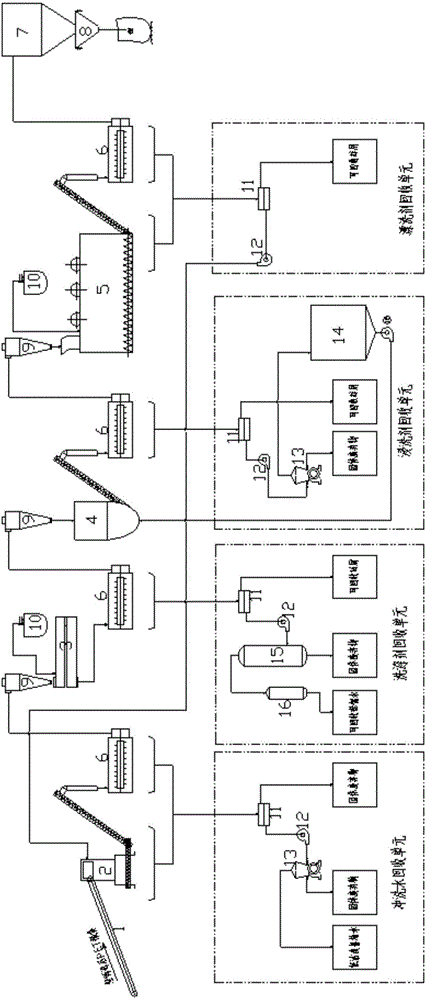

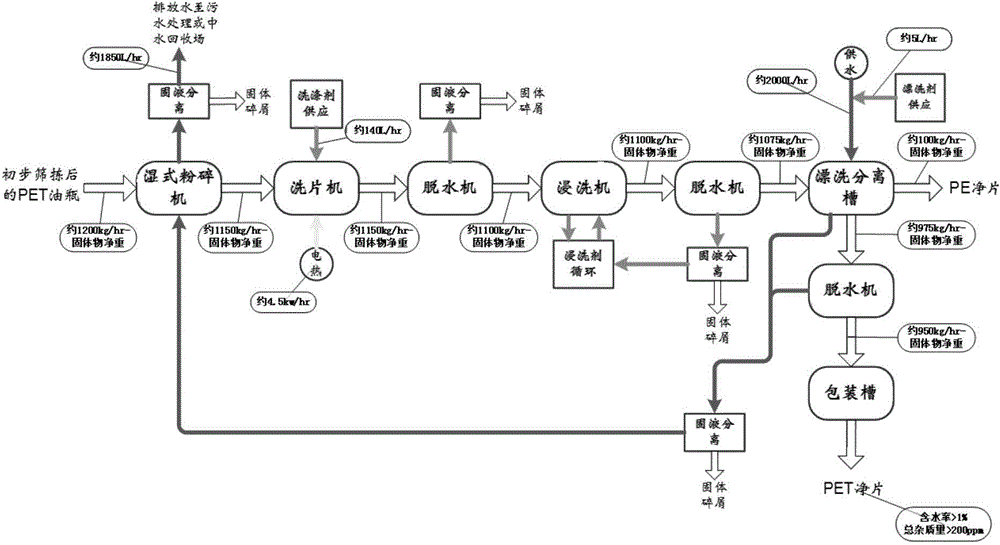

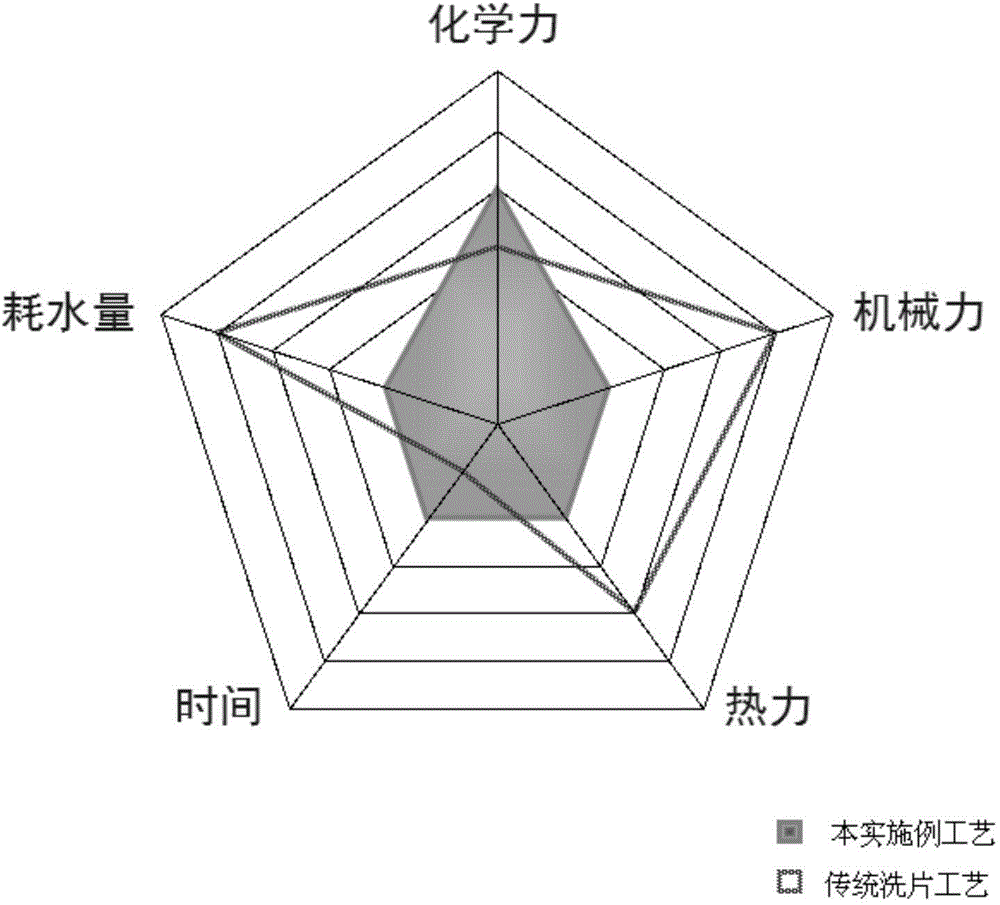

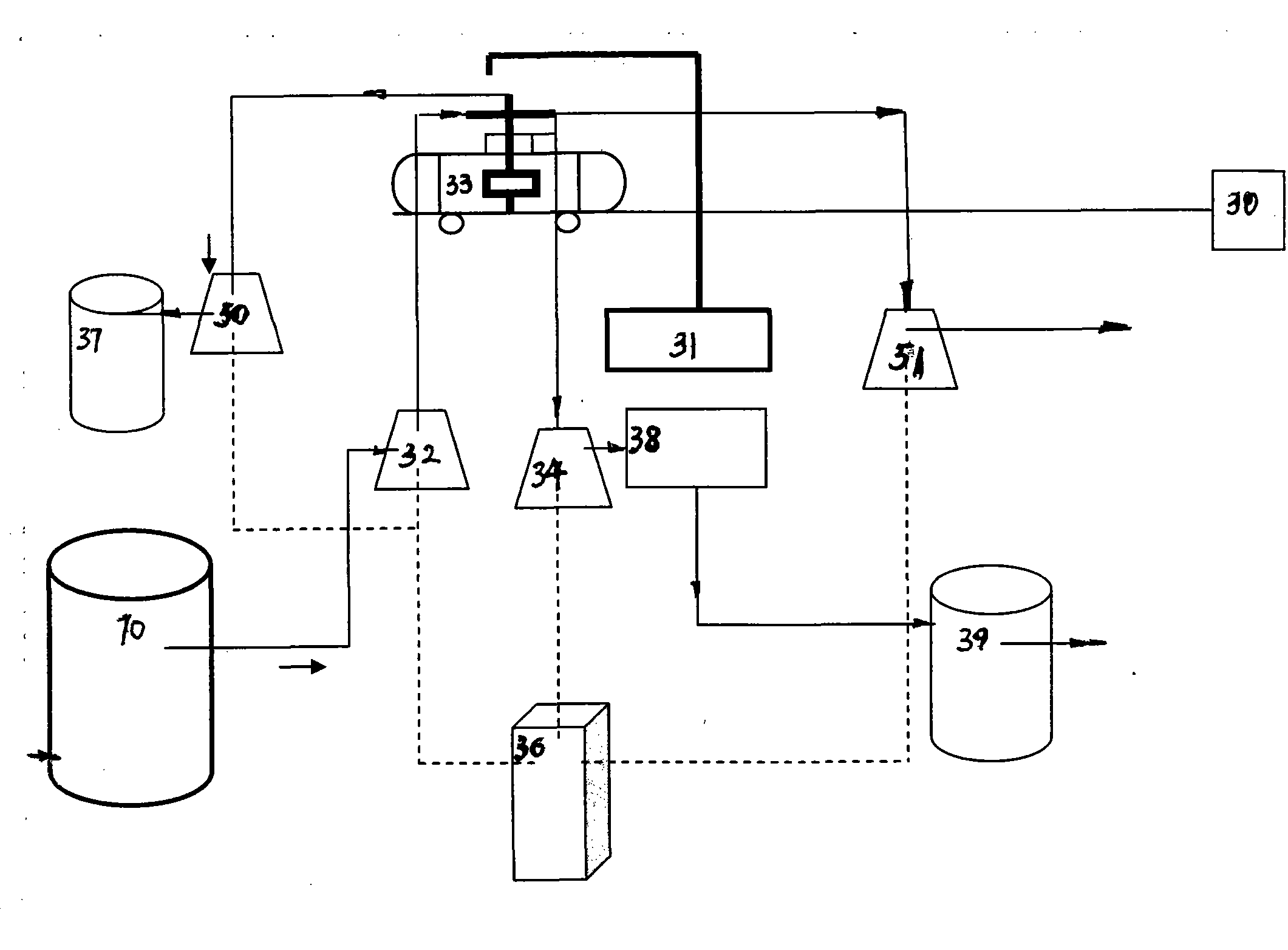

System for cleaning and reusing polyester or plastic fragments and technology of system

InactiveCN104354243AGood removal effectEmission reductionPlastic recyclingMechanical material recoveryHigh concentrationPolyester

The invention relates to a system for cleaning and reusing polyester or plastic fragments and a technology of the system. The system comprises a wet type smashing unit, a rubbing unit, a soaking unit, a rinsing unit and a dehydrating unit, and further comprises a flushing water recycling unit, a washing agent recycling unit, a soaking agent recycling unit and a rinsing agent recycling unit. Compared with the prior art, a cleaning technology combining breakthrough static soaking and flexible rubbing is adopted, so that residual glue on the surface of polyester or a plastic and pollution in capillary holes can be thoroughly removed, and the regenerated polyester or plastic cleaning degree is greatly increased. Electric energy, heat energy and water energy can be greatly saved; furthermore, a washing liquid used by the whole system is subjected to high and low-concentration flow division; a high-concentration washing liquid can meet a zero-emission condition through a respective recycling unit, and a low-concentration washing liquid can be subjected to separation, clarification and circulating use through a respective recycling unit; therefore, the concentration of discharged water can be reduced, and effects of reducing emission and alleviating pollution are achieved.

Owner:CITY RECYCLING

Water treating equipment and full-automatic on-line descaling and sterilizing device thereof

ActiveCN105000677AUnattendedExtended service lifeScale removal and water softeningElectrochemistryChemical agent

Owner:北京润璟昌智能科技有限公司

New energy-saving cleaning technology and device of light oil rail tanker, liquefied gas tanker or ammonia tanker

InactiveCN101884992AReduce intensitySimple methodHollow article cleaningNew energySeparation technology

The invention relates to a new environmentally friendly and energy-saving cleaning technology and device of light oil rail tankers, liquefied gas tankers or ammonia tankers, which adopt the jet cleaning technology, the hot water supply technology and the waste oil / gas recovery technology. The invention belongs to the cleaning equipment of the railway tank car. The technology of the invention is as follows: solar energy is fully utilized, an air heat pump is used to obtain the heat energy of the environment; the obtained 60-90 DEG C hot water is used for cleaning while a three-dimensional tank washer, a centrifugal pump and a self-sucking pump are used to perform cleaning, suction, vacuum suction and oil-water separation at the same time; a waste oil / gas recovery device and an oil-water separation device are used to recover and utilize the waste oil and gas in various light oil rail tankers, liquefied gas tankers or ammonia tankers through the oil-water separation technology. Therefore, the cleaning efficiency is increased and the labor intensity is reduced.

Owner:昆明铁路局科学技术研究所

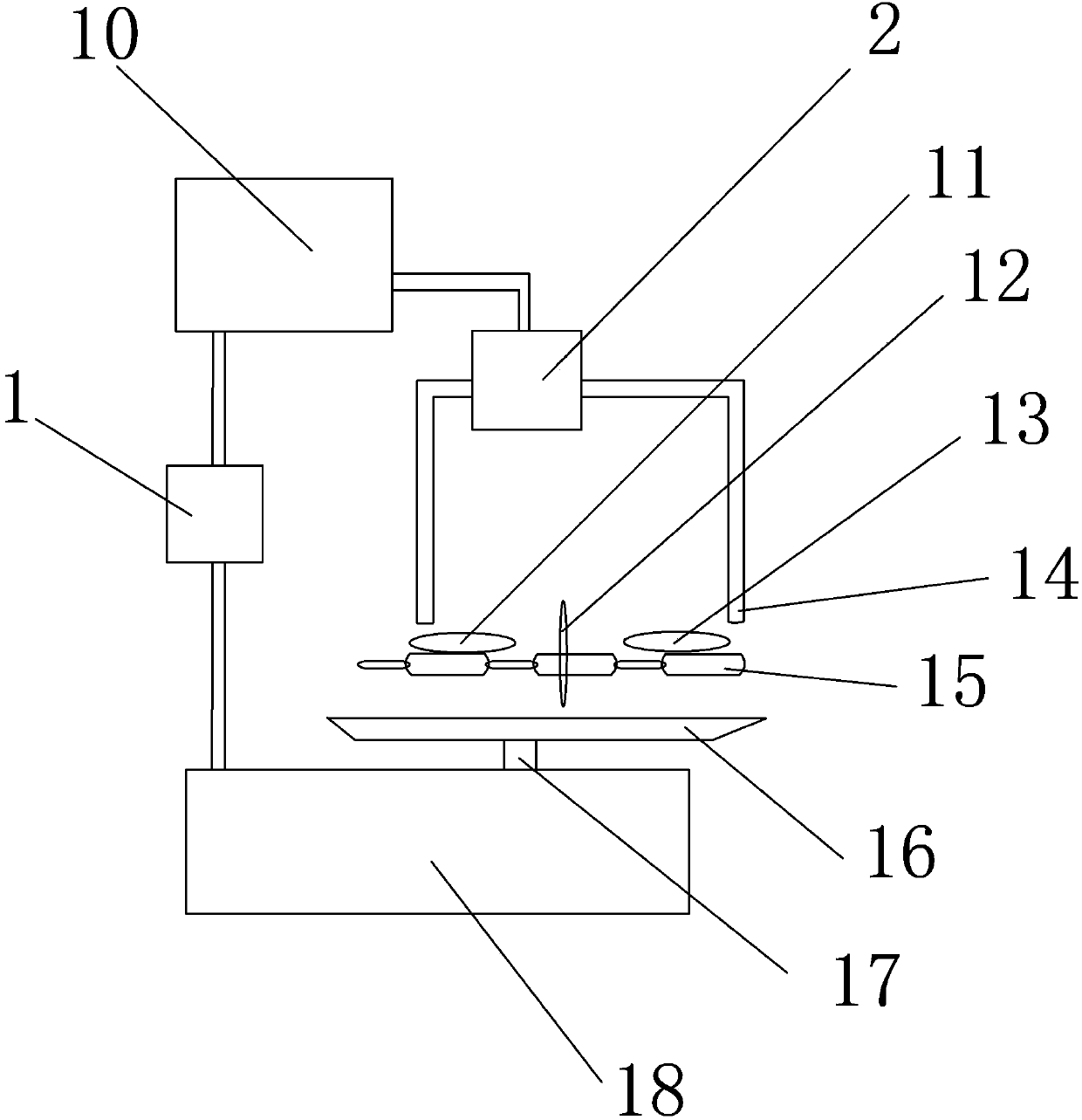

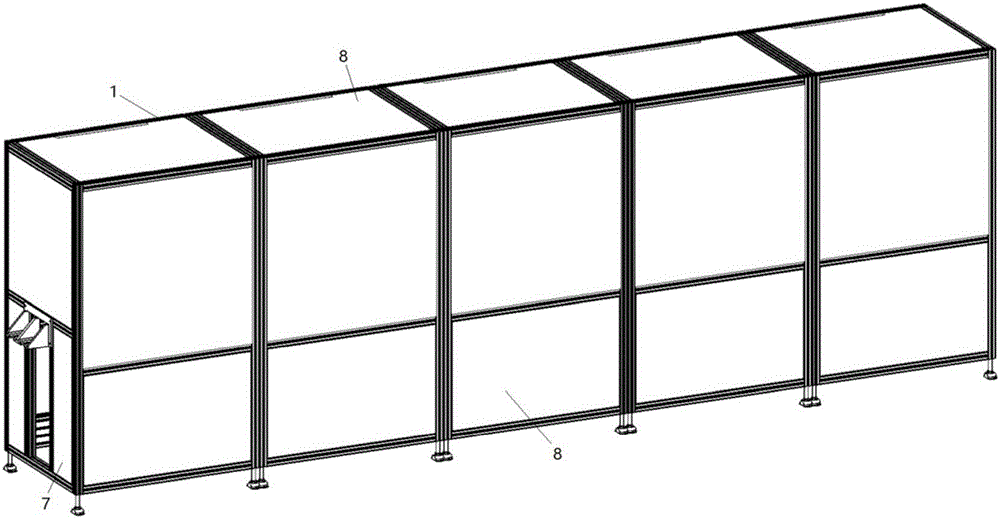

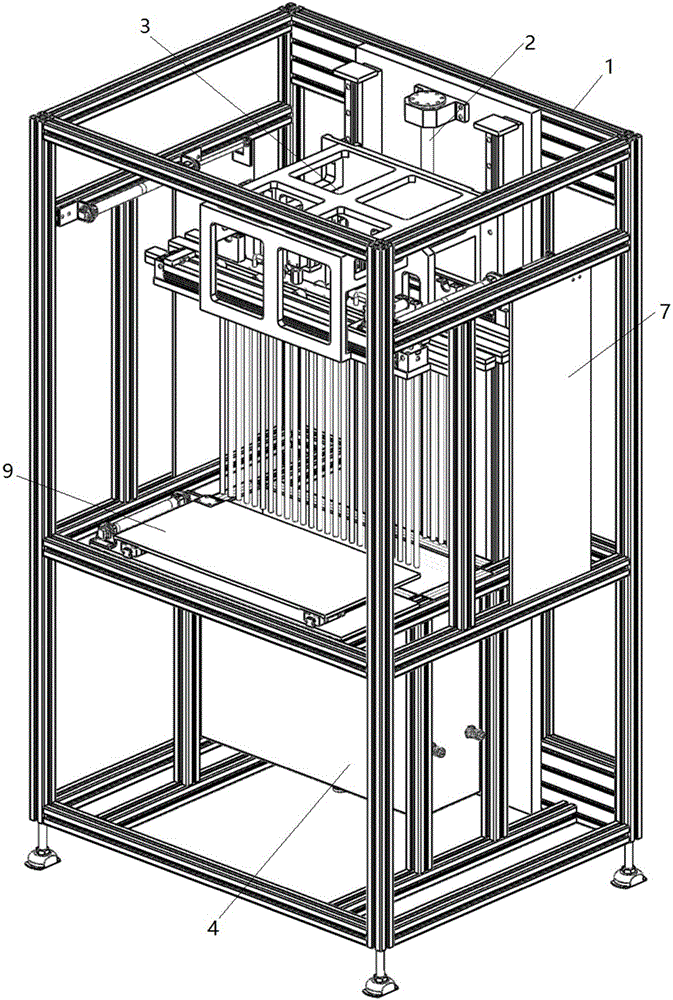

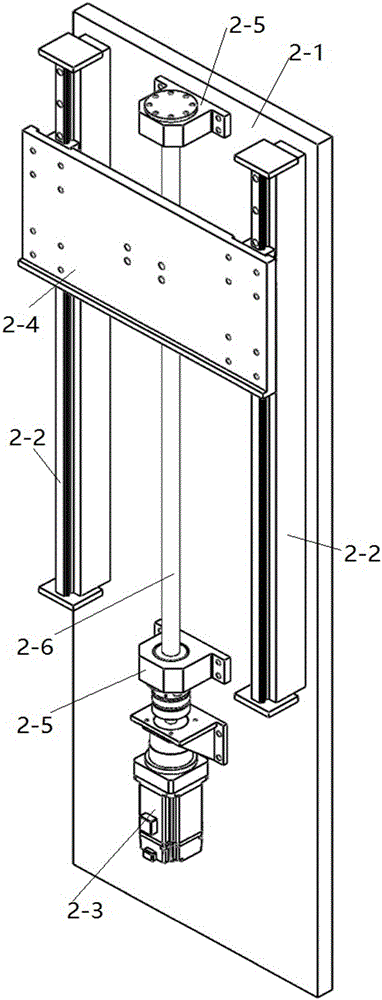

Automatic coating device and coating method of surface coatings of medical catheter

ActiveCN106423719AIncrease productivityIncrease productionPretreated surfacesCatheterDip-coatingBiomedical engineering

The invention discloses an automatic coating device of surface coatings of a medical catheter. The automatic coating device comprises five assemblies which are in sequential series connection, wherein the assemblies comprise racks; and servo mechanisms and moving platforms are mounted inside the racks. The coating operation of the coatings is achieved through sequentially carrying out S1, pre-coating preparation, S2, pre-coating cleaning technology treatment, S3, coating technology treatment, and S4, post-coating final cleaning technology treatment on the catheter. According to the automatic device used for coating the surfaces of the medical catheter with the coatings based on the dip coating principle, the problems that in dip coating of the medical catheter, a liquid accumulates at the head ends of instruments and the coating is relatively thick are solved, the pre-coating cleaning and post-coating final cleaning technologies of dip coating of the medical catheter are integrated, the production efficiency is greatly improved, and the quality of the coatings adhering to the inner and outer surfaces of the catheter is improved.

Owner:成都德信安创新医疗技术有限公司

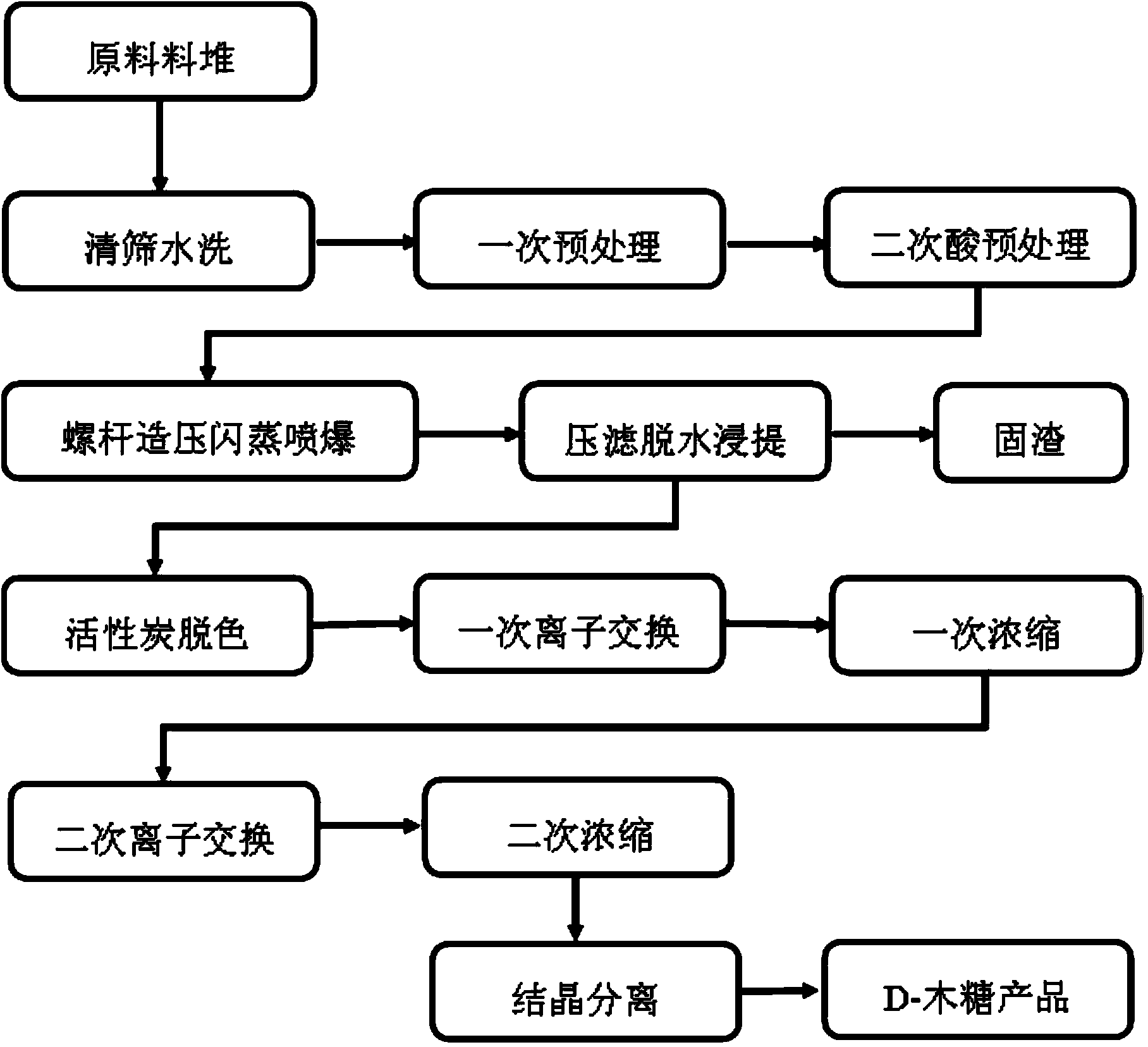

Clean technology for producing D-xylose with screw pressure producing flashing spray explosion method

ActiveCN103467532AIncrease concentrationQuality improvementSugar derivativesSugar derivatives preparationHigh concentrationFiber

The invention belongs to the field of biochemical engineering and relates to a clean technology for producing D-xylose with a screw pressure producing flashing spray explosion method. According to the clean technology, pretreatment is performed on wood fiber raw materials at first, then, a traditional sulfuric acid hydrolysis technology is replaced by the screw pressure producing flashing spray explosion technology to produce spray explosion materials rich in the D-xylose, feed liquid of the D-xylose is extracted through filter-press dehydration in a high concentration mode, therefore, subsequent decoloration, ion exchange, concentration, crystal separation technological processes are improved according to the characteristics of the feed liquid, and D-xylose products are obtained finally. Compared with a traditional sulfuric acid hydrolysis technology, the clean technology has the advantages of being capable of achieving continuous production, small in acid-base dosage, small in waste water discharge amount and low in energy consumption and cost. The obtained feed liquid is high in concentration of the D-xylose and extremely low in acid content, the complicated neutralization process of the technology can be removed, meanwhile, the decoloration, concentration and ion exchange technological processes are simplified, and the burdens in later-stage purification processing are greatly reduced. The clean technology for producing the D-xylose with the screw pressure producing flashing spray explosion method is simple, simple in industrial production, and capable of greatly improving the quality and the yield of D-xylose products.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of polymaleic acid

The invention discloses a preparation method of polymaleic acid, belonging to the field of chemical technology and aiming at providing a preparation method of polymaleic acid with high product yield, low bromine number and stable quality, and meanwhile, the polymaleic acid average molecular weight of which is more than 5500 is suitable for commercial process. The preparation method has the technical key points that 1 part by weight of maleic anhydride, 1.2 to 1.4 parts by weight of distilled water and 0.015 to 0.02 parts by weight of mixture of transition metal ion M compound and ammonium salt are put into a reaction kettle once to be heated from 40 to 60 DEG C to be totally dissolved; then perhydrol is slowly added to polymerize under the condition of continuous stirring, polymerization reaction temperature is controlled to be 90 to 100 DEG C, and heat preservation reaction time is 1 to 2 hours, so that the polymaleic acid whose average molecular weight is bigger than 5500 can be obtained. The yield can be more than 99.0% (counted by maleic anhydride), bromine number is smaller than 30mg / g, and products have stable quality. The preparation method for polymaleic acid has environmentally-friendly and clean technology, produces no three wastes and has the advantages of convenient operation and low production cost, thus the preparation method of polymaleic acid is suitable for large-scale industrial production.

Owner:安徽海瀚水处理科技有限公司

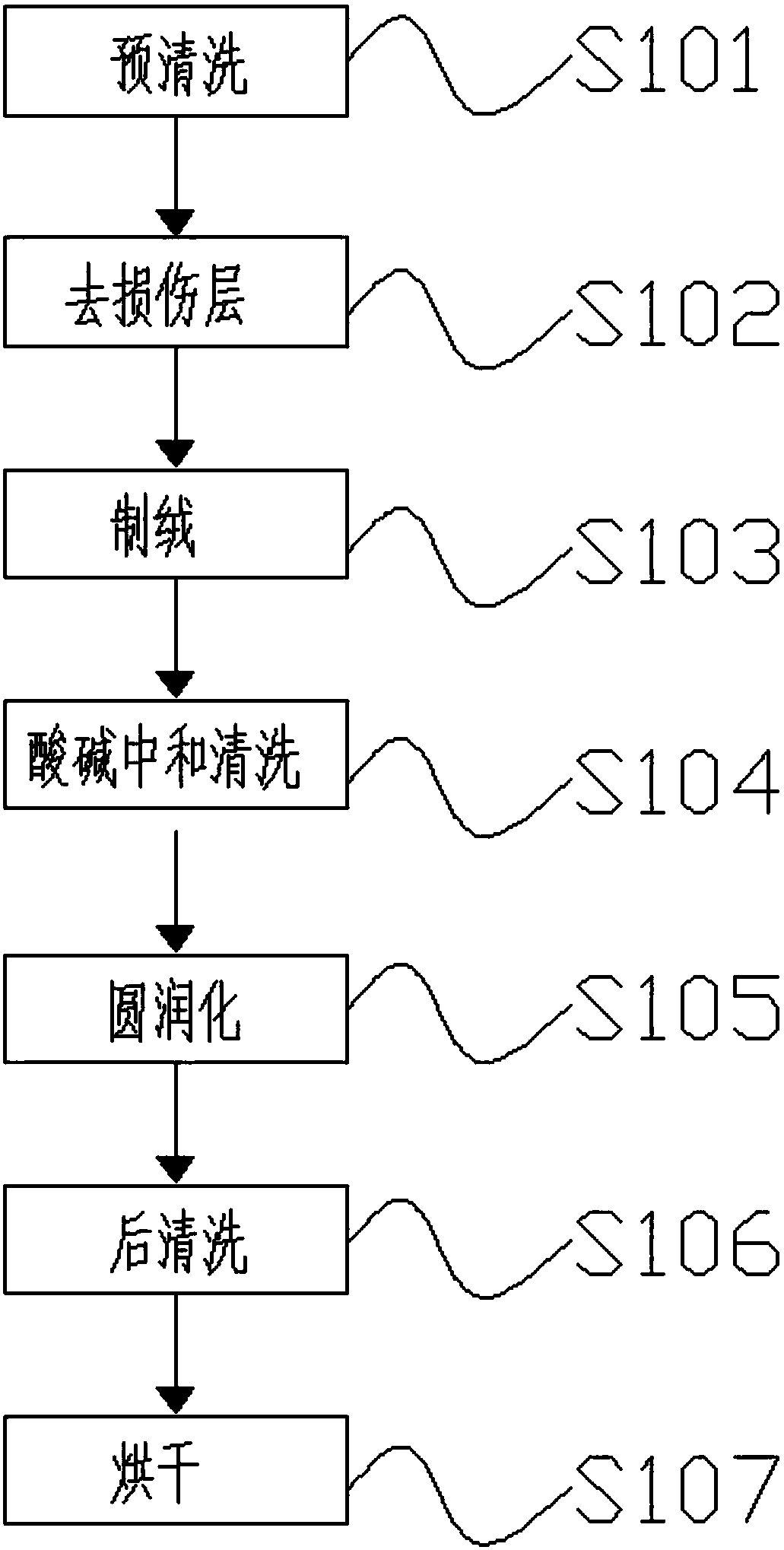

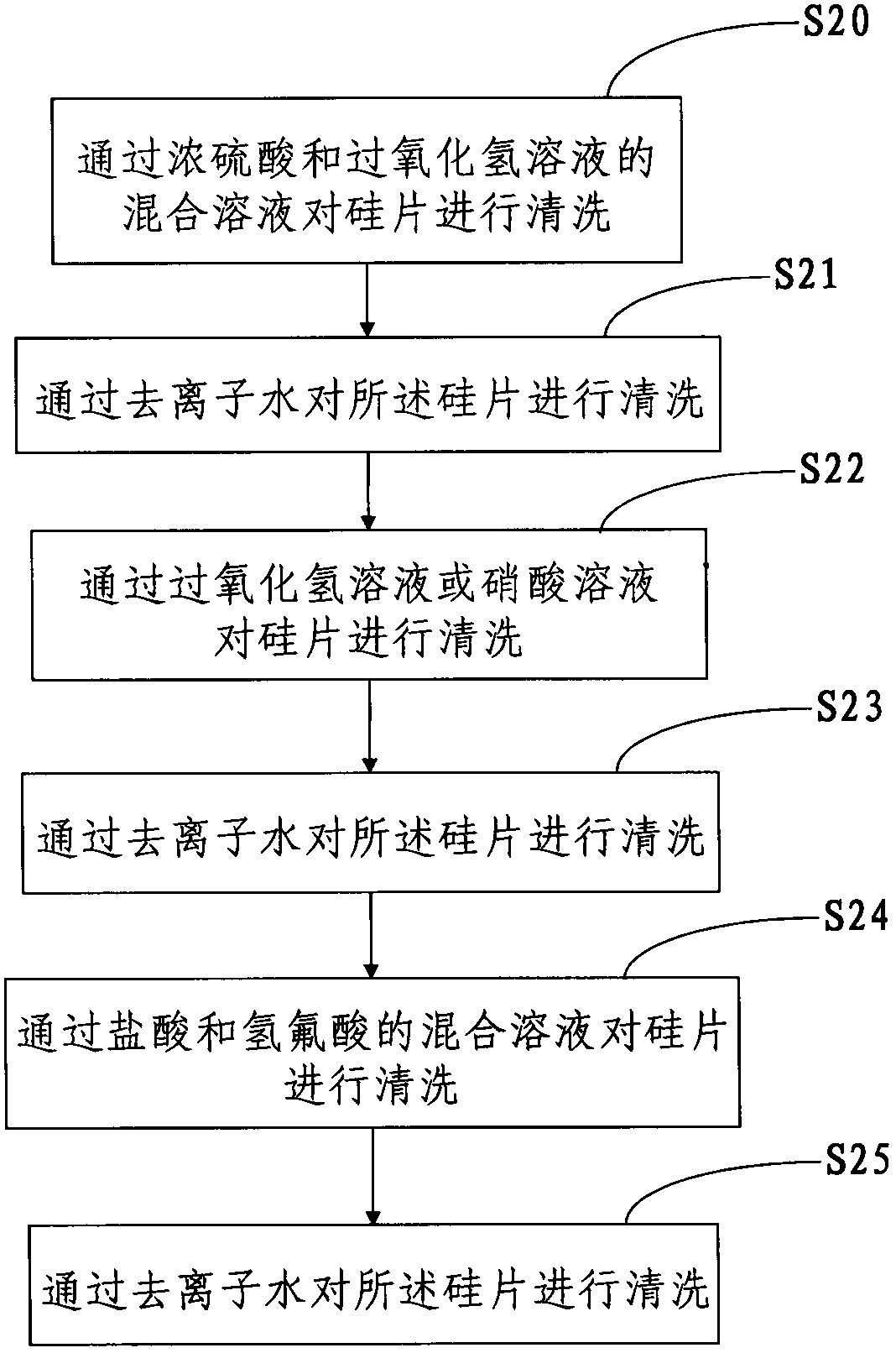

Wet chemical treatment method for heterojunction battery

InactiveCN107658367AReduce usageReduce the use effectFinal product manufactureSemiconductor/solid-state device manufacturingHeterojunctionLiquid waste

The invention discloses a wet chemical treatment method for a heterojunction battery. The wet chemical treatment method comprises the following steps: firstly pre-cleaning a silicon wafer; then carrying out affected layer removal treatment on the silicon wafer; then carrying out texturing treatment on the silicon wafer; then putting the silicon wafer into a mixed solution of hydrochloric acid andhydrofluoric acid for carrying out acid-base neutralization cleaning; then carrying out rounded cleaning on the silicon wafer by using an HF / HCl / O3 mixed solution, removing organic matters and metallic ions and oxidized and etched silicon to round the silicon wafer; carrying out post-cleaning on the silicon wafer after rounded cleaning; and finally slowly pulling and dehydrating the silicon wafer,and drying by using nitrogen. According to the method, O3 is introduced into a wet chemical cleaning technology of the heterojunction battery, the ozone oxidation capacity is high, the oxidizing agents such as H2O2 and nitric acid are effectively replaced, and the application and discharge of highly-pure chemical products are reduced; and moreover, the HF / HCl / O3 mixed solution has multiple effects of removing the organic matters and removing the metal irons and oxidized and etched silicon, the steps and complexity of the cleaning technology are reduced, and the method has the advantages of simple technology process, small using amount of the highly-pure chemical products, small treatment quantity of waste liquid and the like.

Owner:GOLD STONE (FUJIAN) ENERGY CO LTD

Combined type production technology for refining animal oil and fat

InactiveCN106118871AGuaranteed acid valueGuaranteed peroxide valueFatty-oils/fats refiningFatty-oils/fats productionProcess engineeringSewage

The invention provides a combined type production technology for refining animal oil and fat. Through a combined type discontinuous vacuum drying and melting matched clean technology, edible animal oil which is good in color, fragrance and taste is produced, production processes of decoloration, deacidification and peculiar smell removal are omitted, exhausted gas is free from peculiar smell, the discharge amount of solid trash and waste water is reduced, the environment is protected, and the production cost is notably reduced.

Owner:GUANGHAN HANGJIA FOOD CO LTD

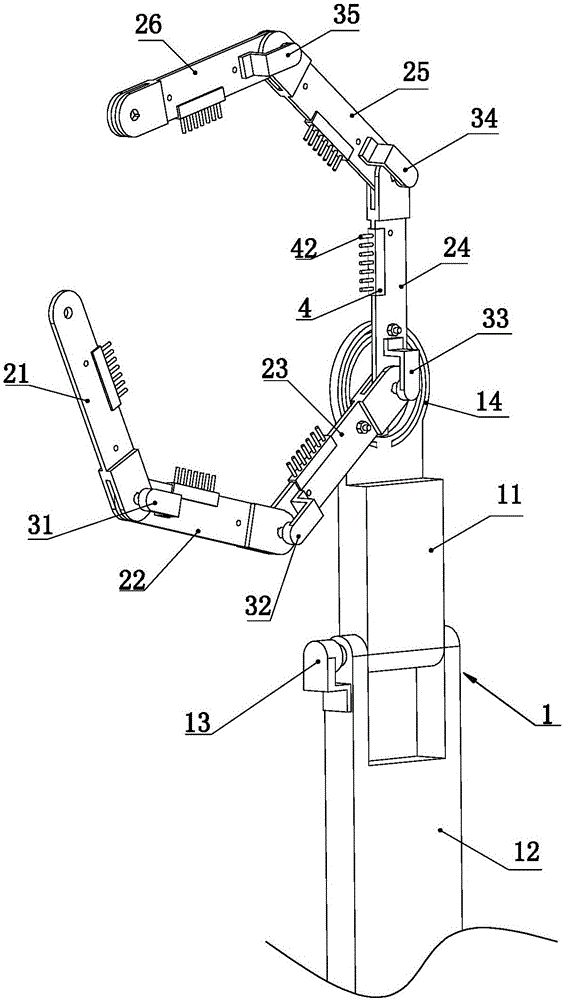

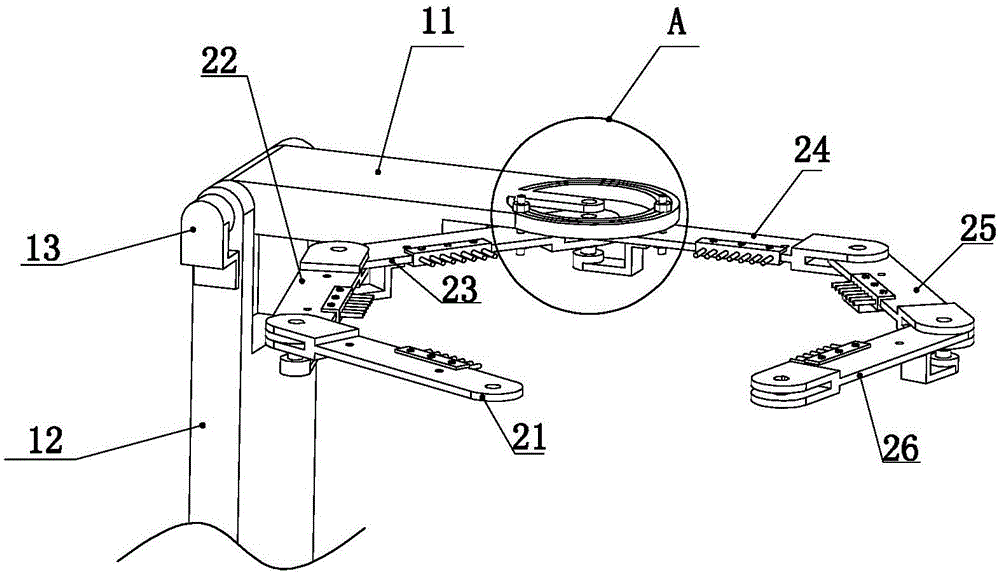

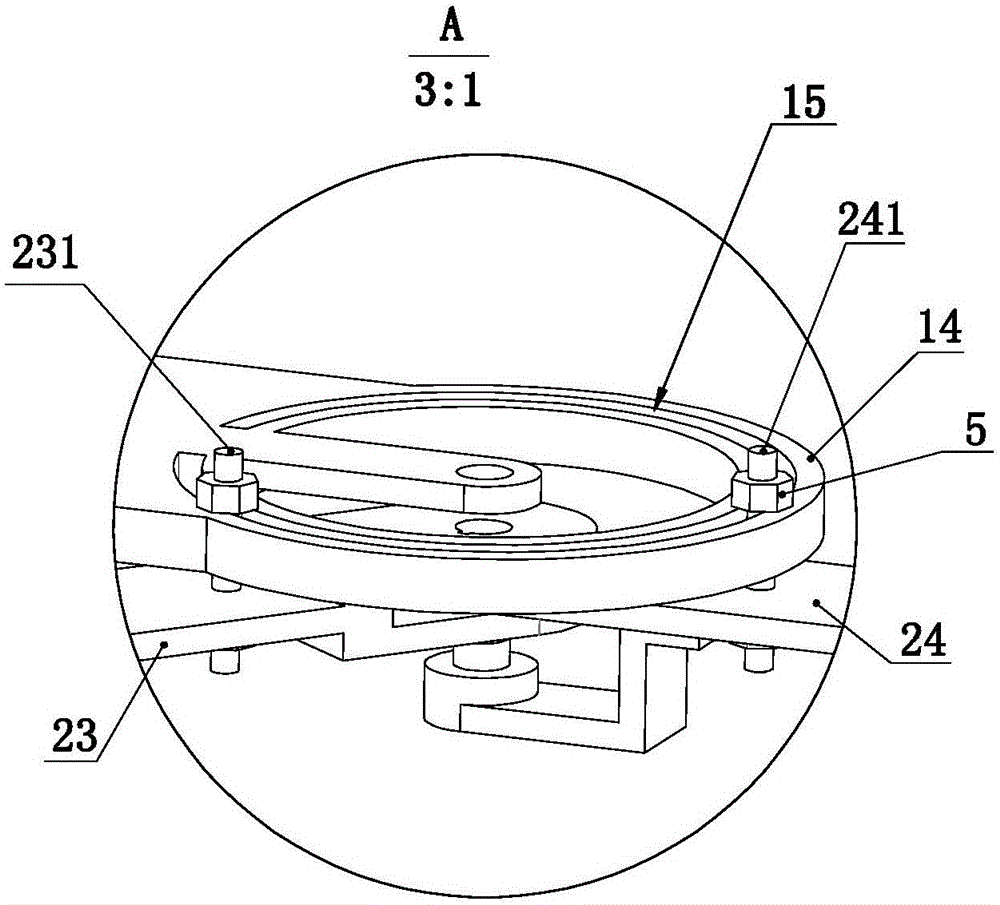

Automatic bird nest cleaning manipulator aiming at angle-steel tower

The invention discloses an automatic bird nest cleaning manipulator aiming at an angle-steel tower, which relates to a bird nest cleaning technology for a power supply system and is used for cleaning a bird nest at a position in which a worker in the angle-steel tower cannot reach directly. The technical scheme is that the automatic bird nest cleaning manipulator aiming at the angle-steel tower is characterized by comprising a lifting arm, a connection frame, a first guide shaft, a second guide shaft and a plurality of clamping joints, wherein the rear end of the front clamping joint is hinged to the front end of the rear clamping joint through a hinge shaft; the hinge shaft is fixedly connected to the rear end of the front clamping joint; the hinge shaft is connected to the front end of the rear clamping joint in a rotatable manner; all the clamping joints form an open-loop structure; a clamping joint motor is arranged between any two of hinged clamping joints; the connection frame comprises a sliding rail; the sliding rail is arc-shaped; and the second guide shaft is fixed in a guide rail. The automatic bird nest cleaning manipulator has the beneficial effect that the bird nest can be taken out from a region with a relatively small space surrounded by a truss extending to the angle-steel tower.

Owner:SHANGHE COUNTY POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

Silicon wafer cleaning method for preparing high-efficiency solar cell and cleaning equipment

ActiveCN103480598AImprove surface hydrophobicityImprove hydrophobicityCleaning using liquidsHydrofluoric acidCleaning methods

The invention provides a silicon wafer cleaning method for preparing a high-efficiency solar cell and cleaning equipment. The surface hydrophobicity of a textured silicon wafer is poorer due to the fact that the proportion by weight of sulfuric acid to hydrogen peroxide is lower in the existing silicon wafer cleaning technology. The silicon wafer cleaning method for preparing the high-efficiency solar cell comprises the following steps of firstly cleaning the silicon wafer by mixed solution of concentrated sulfuric acid and hydrogen peroxide solution by adopting the cleaning equipment, wherein the proportion by weight of the sulfuric acid to the hydrogen peroxide is (65-170):1, then, cleaning by deionized water, then, cleaning the silicon wafer by the hydrogen peroxide solution or salpeter solution so as to remove carbon residues and part of metallics and form a layer of oxidation film, cleaning by the deionized water, and finally, removing the oxidation film on the silicon wafer by the mixed solution of hydrochloric acid and hydrofluoric acid, and cleaning by the deionized water. According to the silicon wafer cleaning method for preparing the high-efficiency solar cell and the cleaning equipment provided by the invention, the hydrophobicity of the silicon wafer can be effectively improved, i.e. the cleaned silicon wafer is completely dehydrated after the oxidation film on the silicon wafer is removed.

Owner:WUXI SUNTECH POWER CO LTD

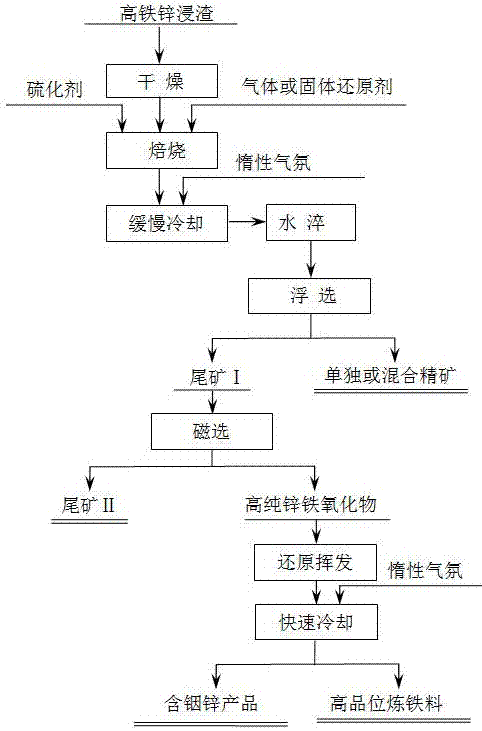

High-iron zinc leaching residue clean utilization method

InactiveCN107012328AReduce or even eliminate pollution problemsLow costProcess efficiency improvementIndiumSlag

The invention relates to a high-iron zinc leaching residue clean utilization method, and belongs to the technical field of beneficiation and metallurgy. Firstly, high-iron zinc leaching residues are dried and dehydrated, then a reducing agent and a vulcanizing agent are added at the same time, carbon-sulphur mixed atmosphere roasting is carried out under the condition that the temperatre ranges from 400 DEG C to 900 DEG C for 0.5 h to 3.5 h, nitrogen or argon is led in to serve as protection gas after roasting is finished, slow cooling is carried out with the speed ranging from 150 DEG C / h to 300 DEG C / h, and water quenching is carried out after the temperature drops to 200 DEG C or below to obtain water-quenched slag; the obtained water-quenched slag is subject to conventional flotation treatment to obtain man-made sulphide concentrate and nonfloat; and the obtained nonfloat is subject to conventional strong magnetism separation to obtain zinc-iron oxide concentrates, a gaseous reducing agent is led into the zinc-iron oxide concentrates, a reduction volatilization reaction is made at the temperature ranging from 950 DEG C to 1300 DEG C for 1.0 h to 4.0 h, after reduction volatilization is finished, volatilizing gas is recovered to obtain an indium-contained zinc product, and solid left after volatilization is cooled to obtain an iron product. The high-iron zinc leaching residue clean utilization method is a new high-valued and clean technology which can efficiently recover valuable metal elements such as copper, lead, zinc, indium and silver and is free of generation of iron slag.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com