System for cleaning and reusing polyester or plastic fragments and technology of system

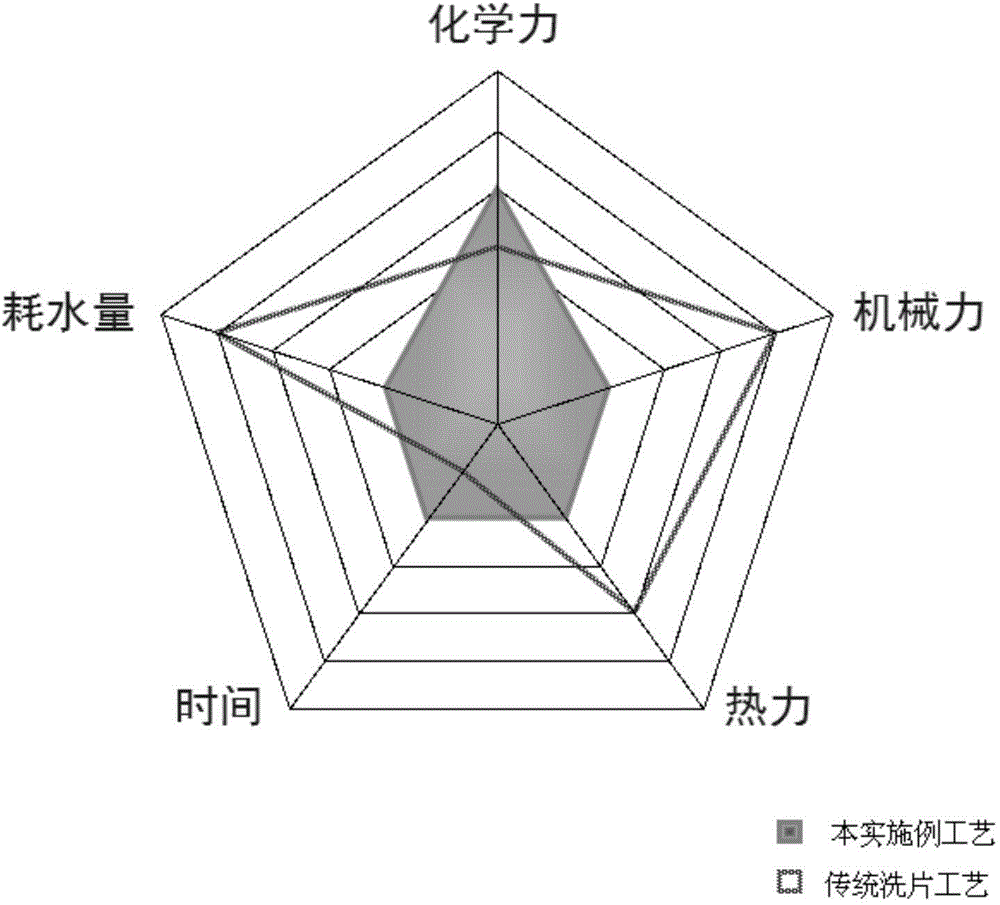

A technology of plastic fragments and polyester, applied in the direction of plastic recycling, recycling technology, mechanical material recycling, etc., can solve the problem of increased improper wear and tear of machinery and materials, large electricity, heat, and water energy, and large wear and tear of processing materials and mechanical structures. and other problems, to achieve the effect of reducing water consumption and sewage discharge, reducing power demand and high utilization rate of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

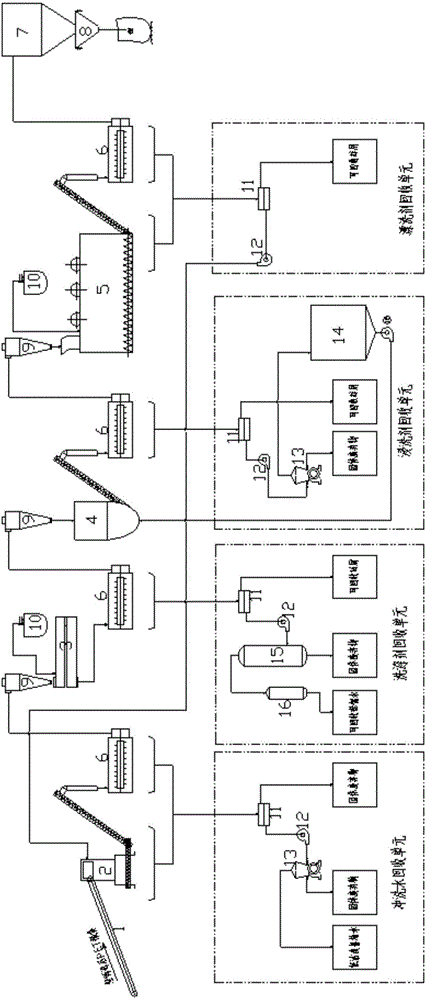

[0077] This embodiment provides a system for cleaning and reusing polyester or plastic debris. structured as figure 1 shown. Includes the following units:

[0078] 1. Wet crushing unit: used for wet crushing the polyester or plastic bottles that have been screened initially to obtain polyester or plastic fragments.

[0079] First, the recycled polyester or plastic bottles (heavy substances with a higher specific gravity than water except the polyester or plastic bottle caps and labels on the bottle body) that have been preliminarily screened are transported at a stable rate through the belt conveyor 1. Feed into the wet pulverizer 2, and use the cutting ability of the pulverizer to convert the large-volume polyester or plastic bottle body into polyester or plastic fragments of about 10-25mm, so as to achieve the purpose of volume reduction. Wet crushing is to inject water into the crushing chamber to crush polyester or plastic bottles, which is especially beneficial for pro...

Embodiment 2

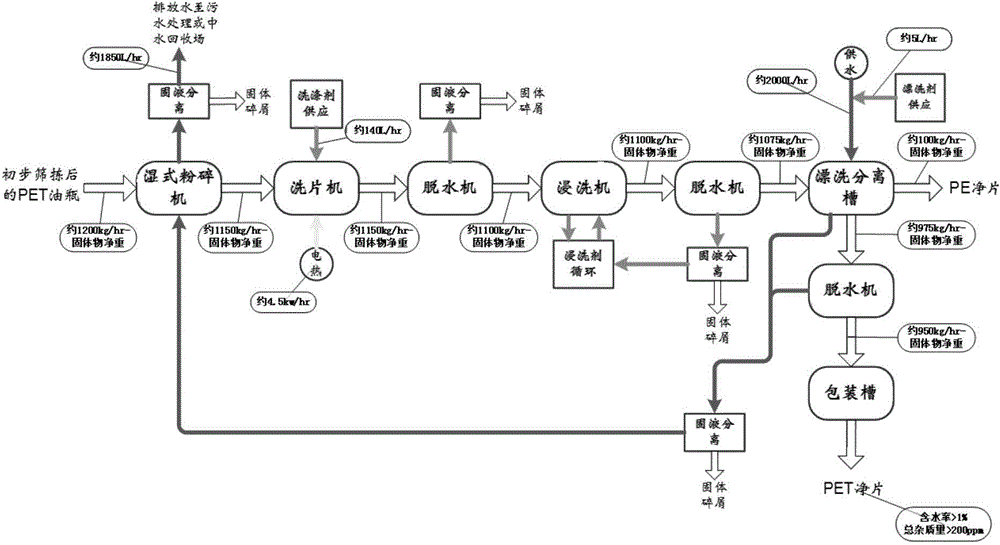

[0115] This embodiment provides a process for washing and reusing polyester or plastic debris using the system described in Embodiment 1.

[0116] The process of washing and recycling polyester or plastic chips includes the following steps:

[0117] (1) Wet crushing: perform wet crushing on the preliminarily screened polyester or plastic bottles to obtain polyester or plastic fragments with a size of 10-25 mm, and perform dehydration treatment;

[0118] (2) Rubbing and washing treatment: rubbing polyester or plastic fragments, cleaning the main pollutants on polyester or plastic bottle flakes, adding detergent during rubbing and washing, and keeping the detergent / polyester or plastic fragments clean The dosage ratio is 80-150ml / kg, and the residence time of polyester or plastic chips in the kneading washing machine is 10-20 minutes. The kneading and washing machine runs at a constant speed of about 45rpm. It adopts continuous feeding and discharging. In terms of design, debris ...

Embodiment 3

[0126] Use the system described in Example 1 to carry out the cleaning process for PET wool flakes or oil bottle flakes, using Figure 4 The process flow shown, the specific process parameters can be freely selected according to the actual situation.

[0127] In this embodiment, raw flakes is a general term in the market, referring to PET bottle flakes that are directly crushed into flakes without washing; oil bottle flakes is a general term in the market, referring to bottle flakes directly crushed from edible oil PET bottles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com