Silicon material cleaning technology and equipment

A technology for cleaning equipment and silicon materials, applied in the field of solar cells, can solve the problems of high power consumption, high production cost, consumption, etc., and achieve the effect of reducing energy consumption and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

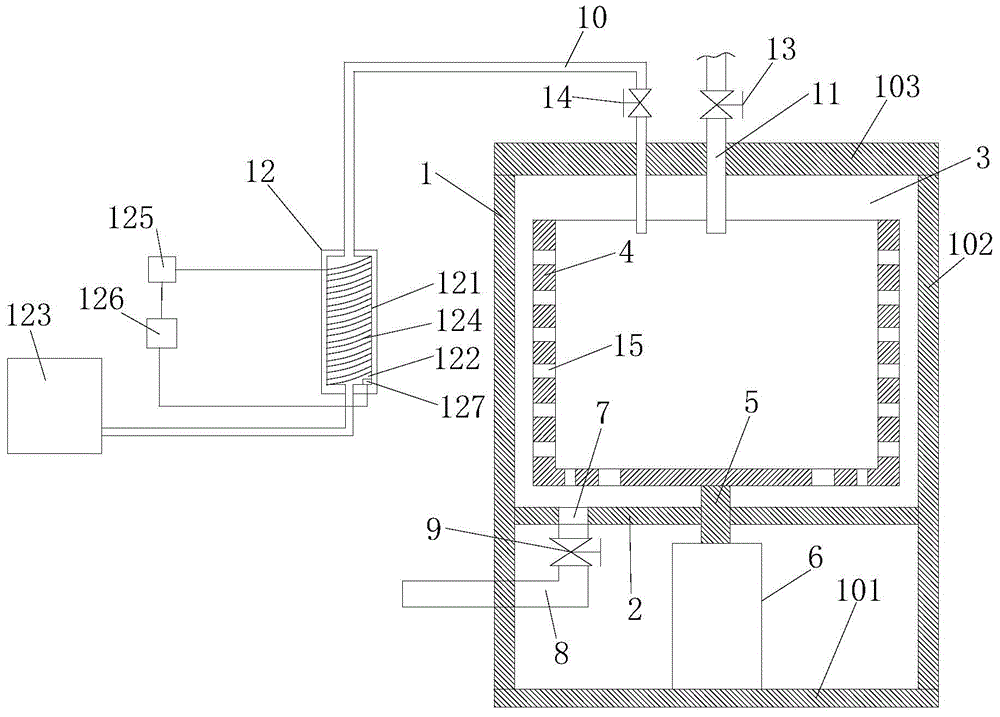

[0021] The silicon material cleaning process first puts the silicon material to be cleaned into the centrifugal equipment; then starts the centrifugal equipment to rotate the silicon material, and injects pure water into the centrifugal equipment to clean the silicon material during the rotation of the silicon material. The cleaning time is 80-120 seconds. During the cleaning process, the rotating speed of the centrifugal device is 280-300 rpm. After cleaning, stop spraying pure water on the silicon material and adjust the rotating speed of the centrifugal device to 305-330 rpm. The drying process is carried out in minutes. During the drying process, an inert gas with a temperature of 60-120 degrees is introduced into the silicon material. The drying time is 1400-1800 seconds. The dried silicon material is sealed and stored. The cleaning process uses 60- The inert gas at 120 degrees bakes the silicon material. Under the protection of the inert gas, the silicon material will not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com