Patents

Literature

276results about How to "Low dilution rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

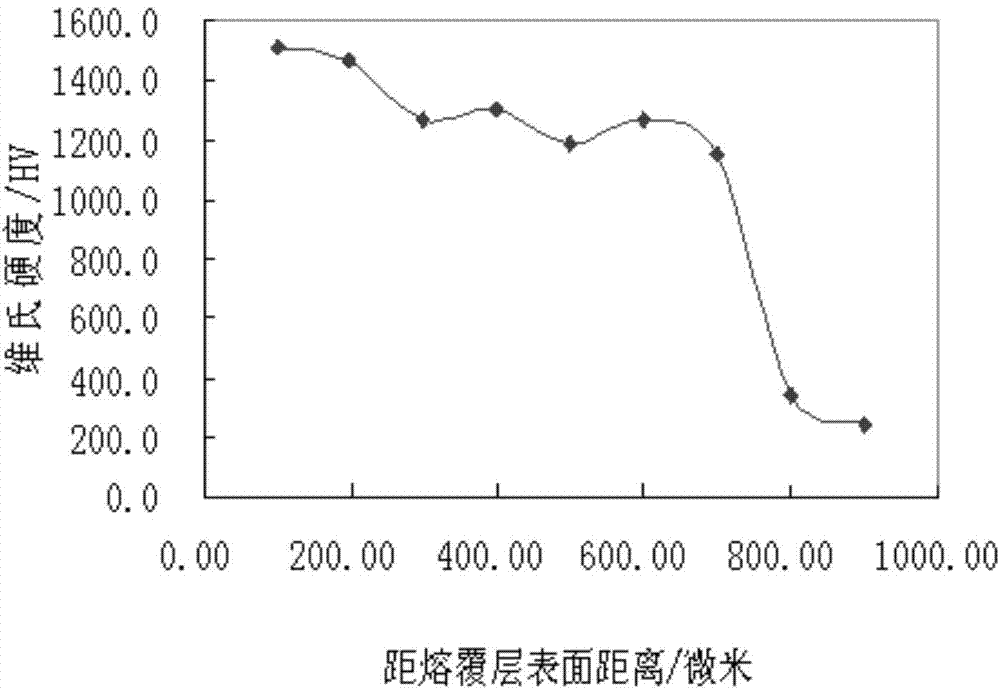

Method for carrying out laser-cladding on high-hardness nickel-based alloy material in large area

ActiveCN102465294AImprove wear and corrosion resistanceDense tissueMetallic material coating processesLaser beam welding apparatusSurface engineeringHeat-affected zone

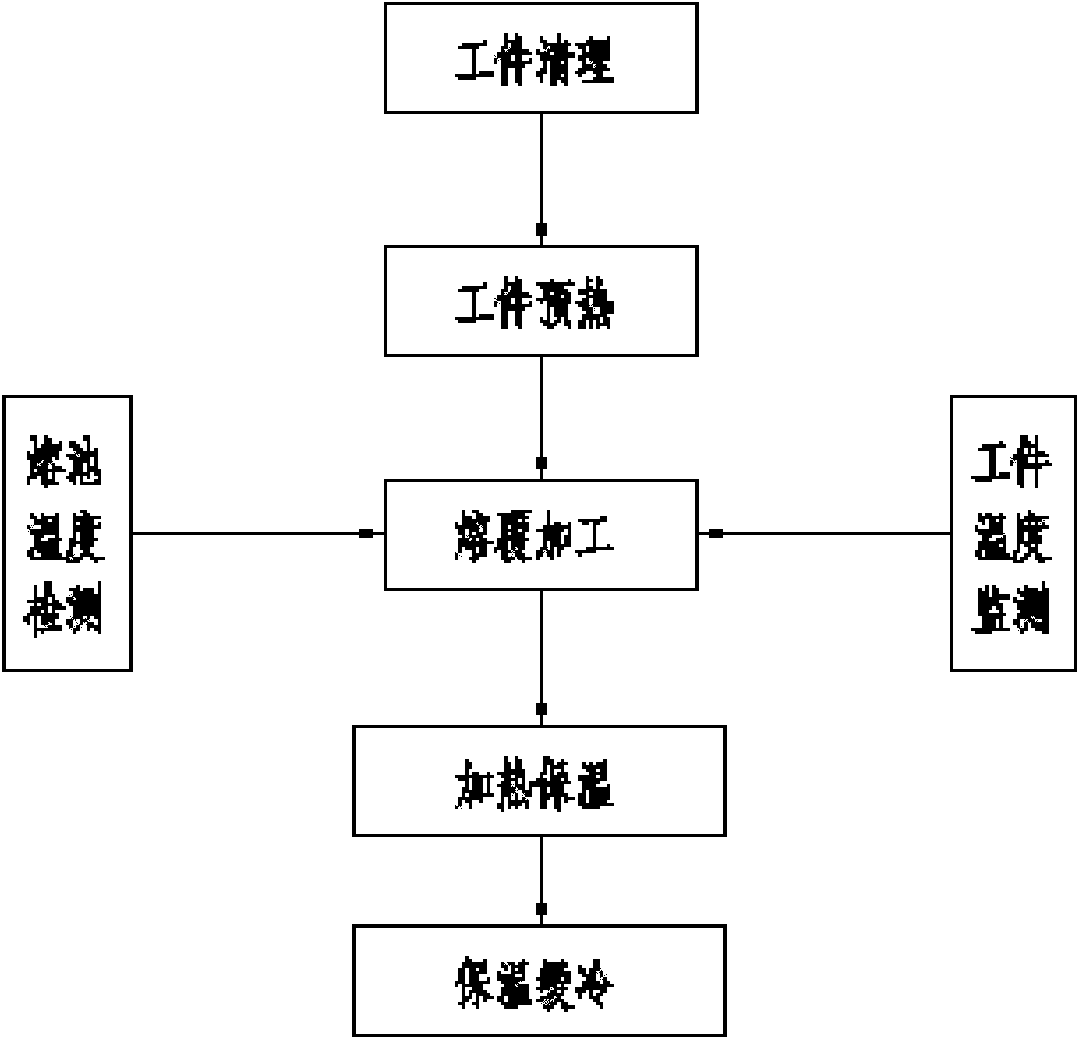

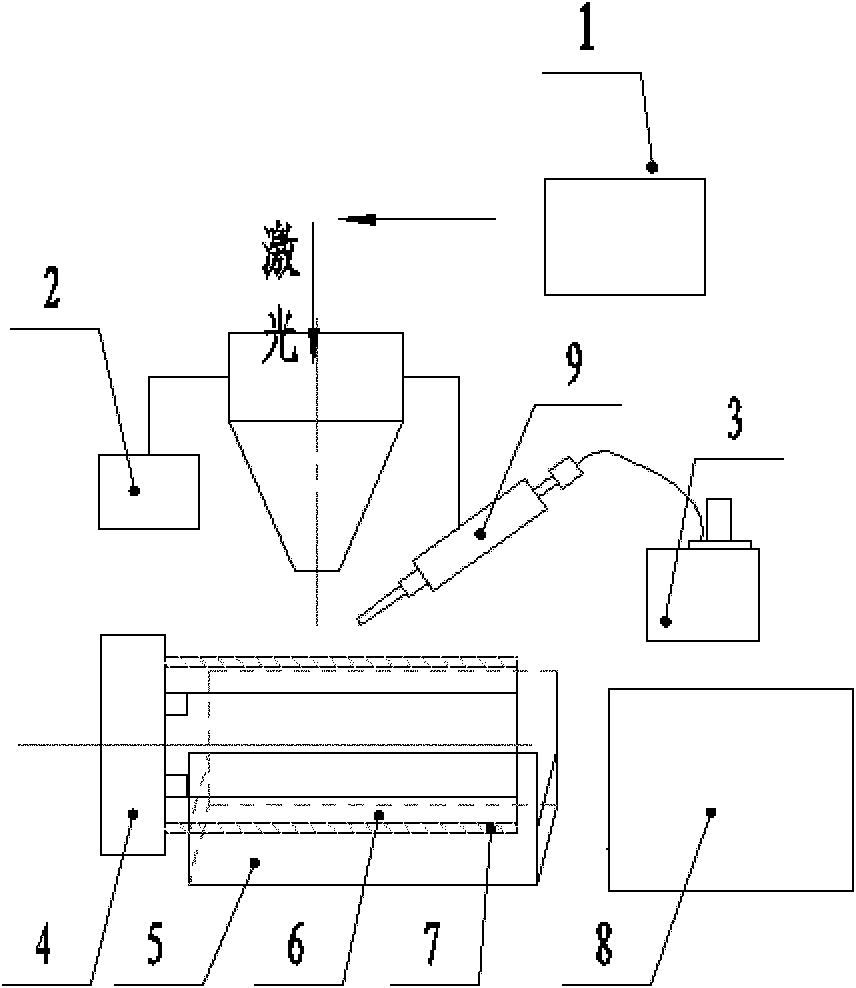

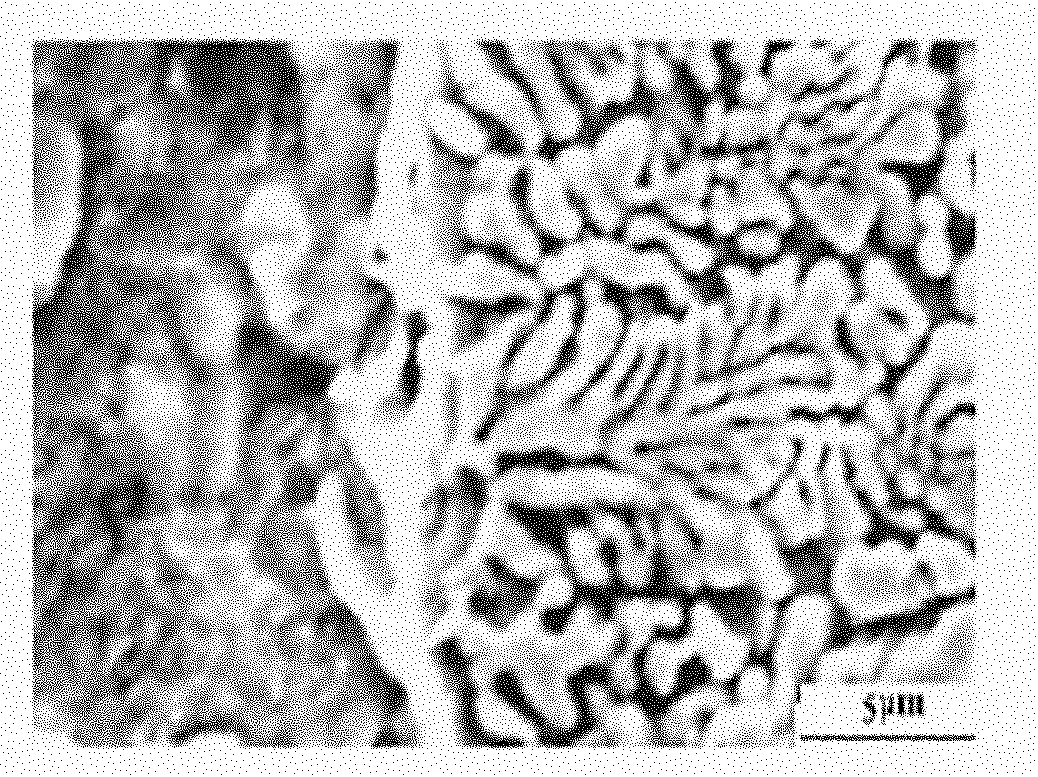

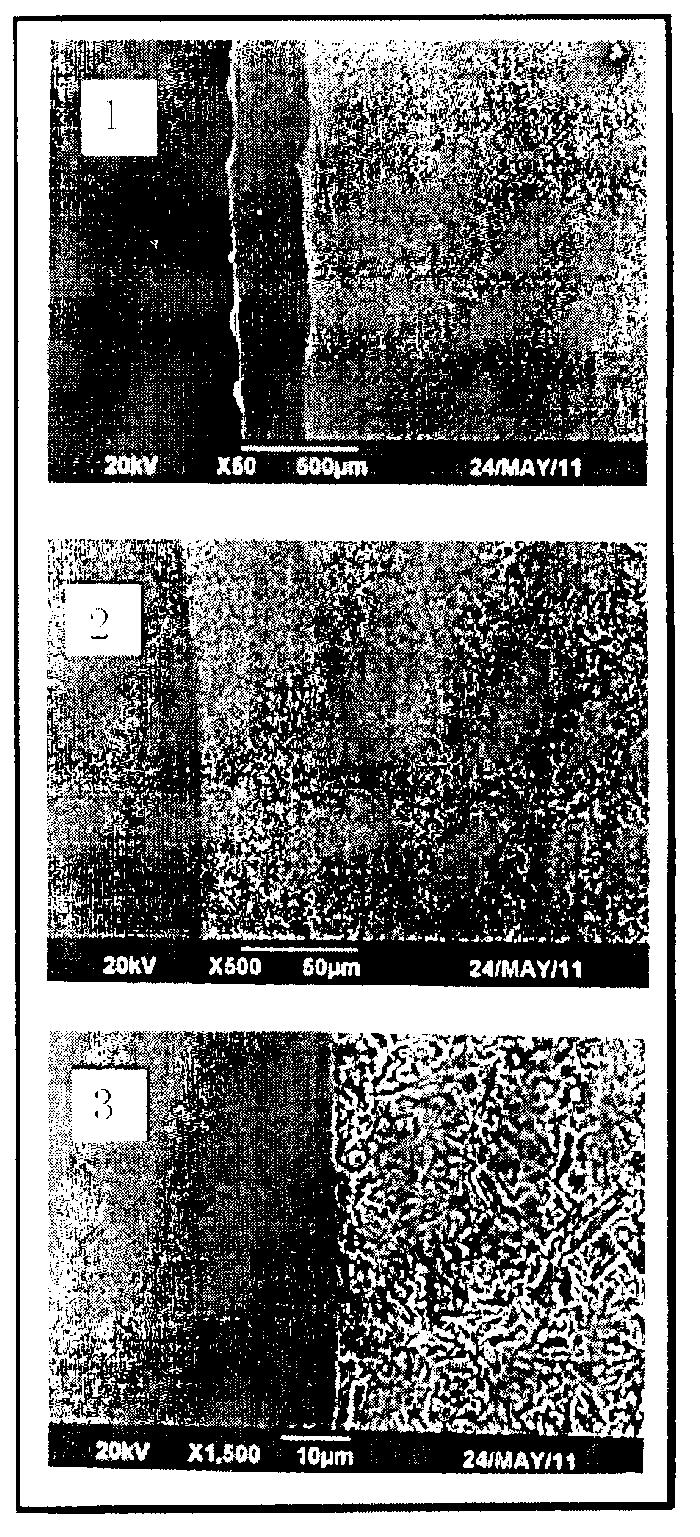

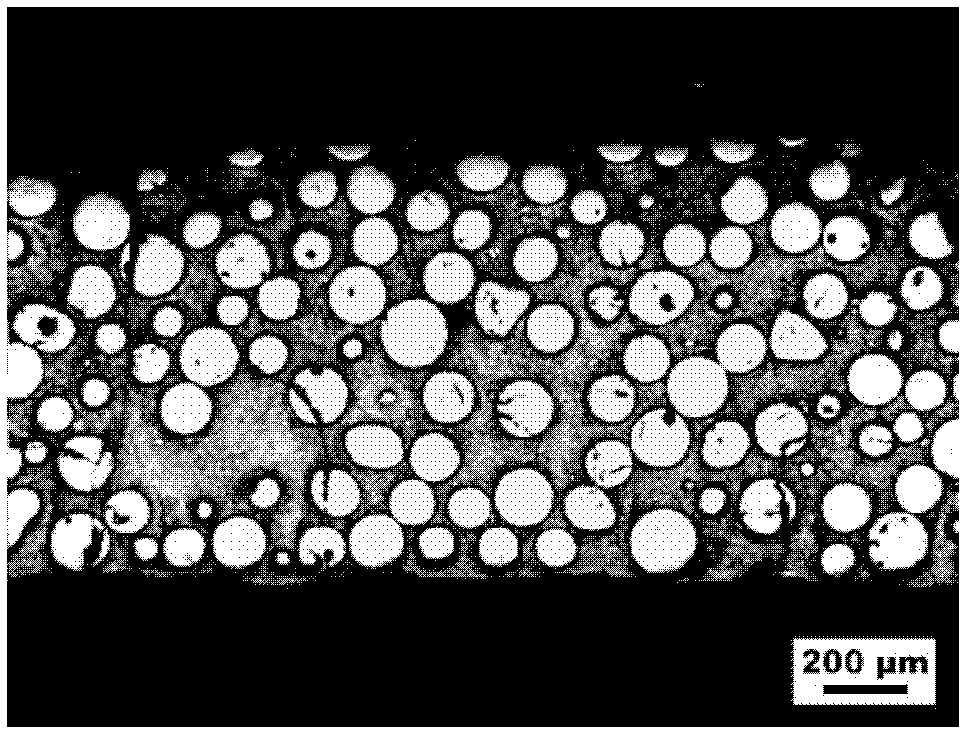

The invention belongs to the field of material surface engineering and more particularly relates to a method for carrying out cladding on a high-hardness wear-resistant anti-corrosion nickel-based alloy material on a metal substrate E in a large area by applying a laser cladding technology, solving the problem of cracks generated in the laser cladding process of the high-hardness wear-resistant nickel-based alloy, in particular the cladding defects, such as cracks with the thickness of more than 1mm, pores and the like during large-area cladding. According to the invention, the high-hardness nickel-based alloy powder material is cladded on the surface of the metal substrate in the large area to form a high-hardness wear-resistant anti-corrosion nickel-based alloy coating by applying the laser cladding technology and adopting a scientific and reasonable process method. According to the method disclosed by the invention, stability and consistency of laser cladding are foundationally ensured, defects, such as cracks, pores, impurities can be prevented from generating, heat affected regions of the substrate are reduced, dilution rate is reduced, the high-wear-resistance anticorrosion nickel-based alloy coating with firm metallurgical bonding and fine and compact grains is obtained and has the hardness reaching 58-63HRC, and the service life of the processed workpiece can be prolonged by more than 1-2 times.

Owner:NINGBO SIASUN ROBOT TECH CO LTD

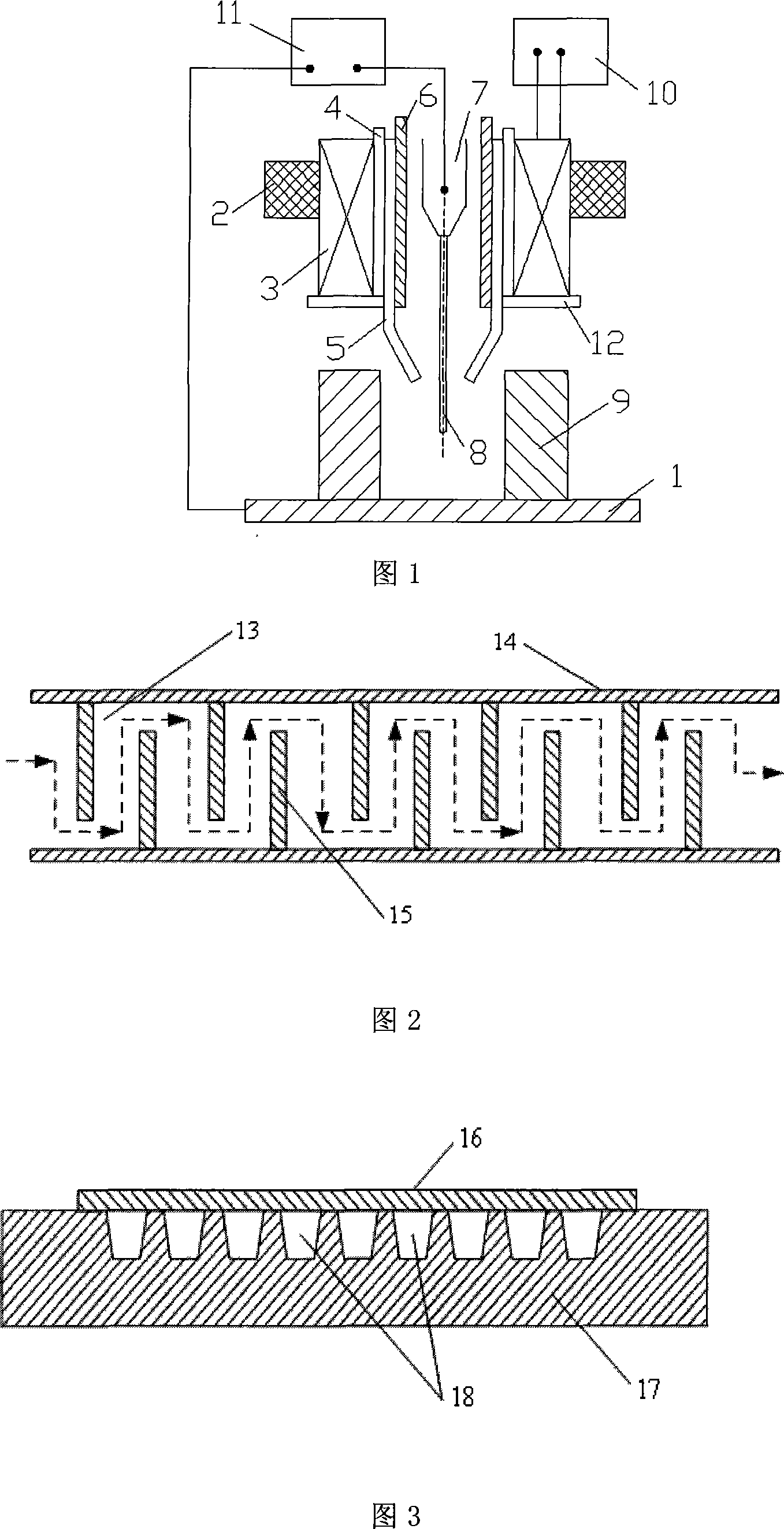

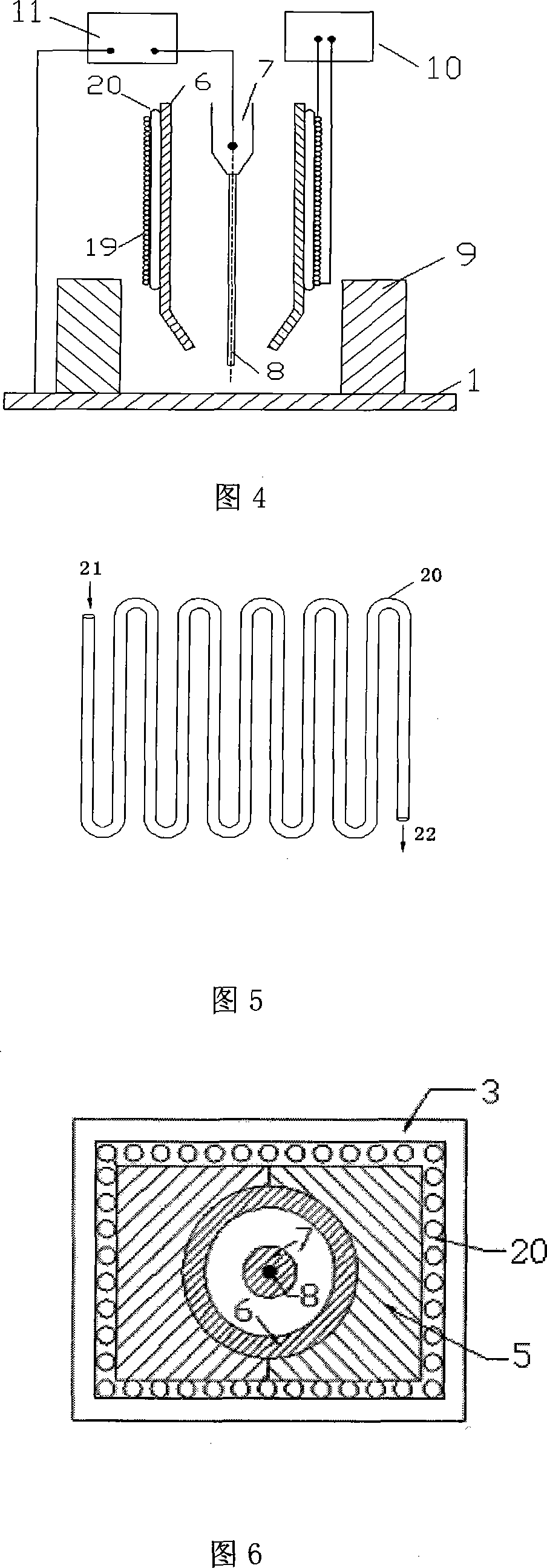

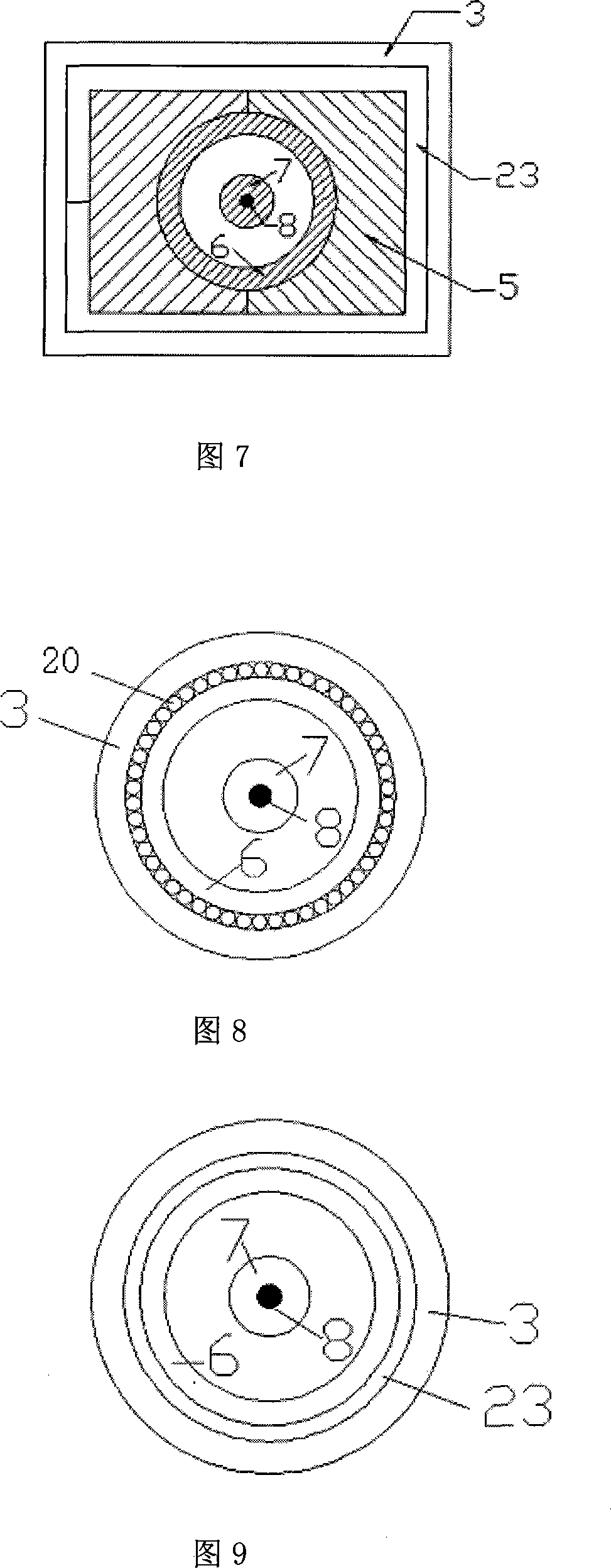

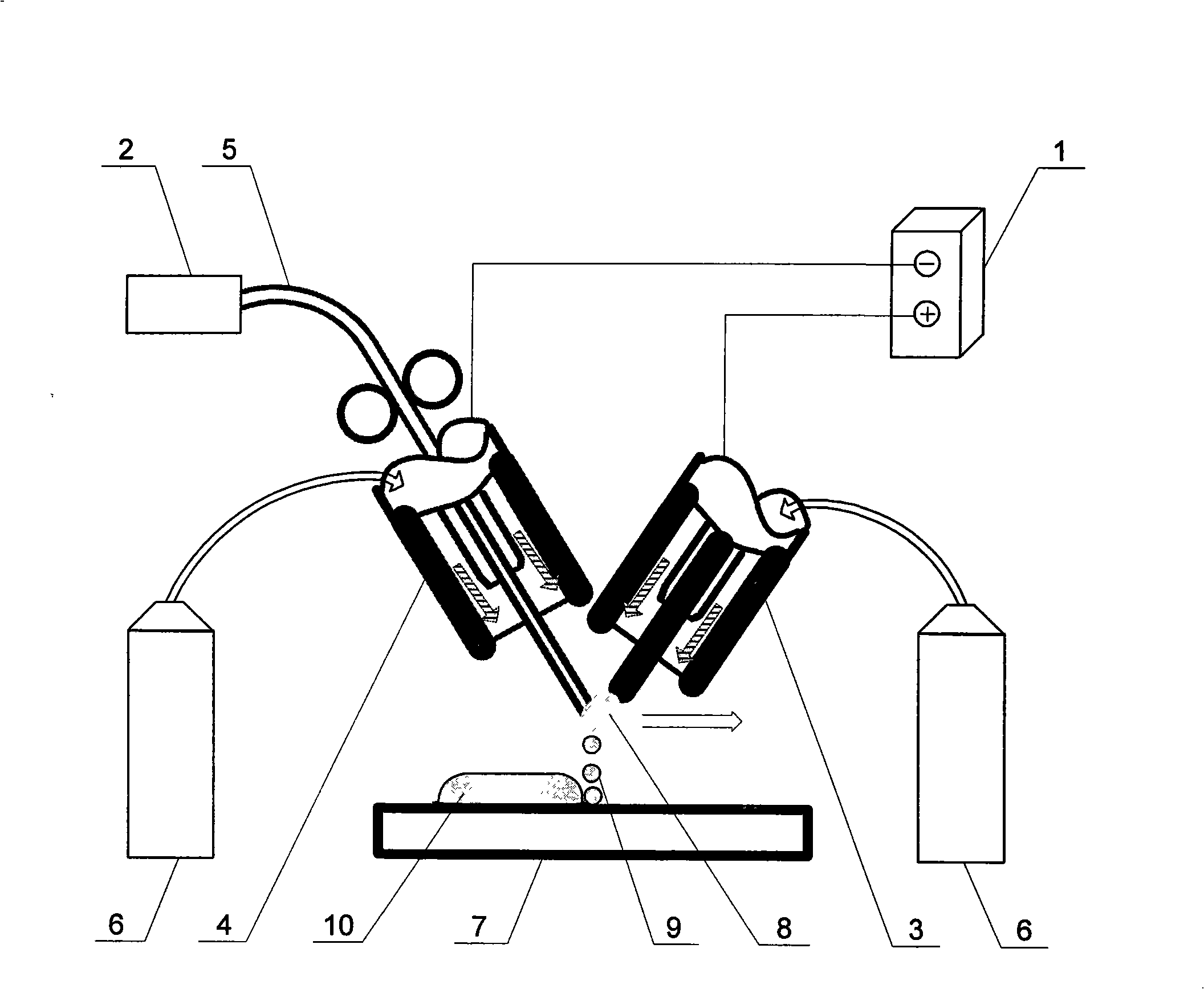

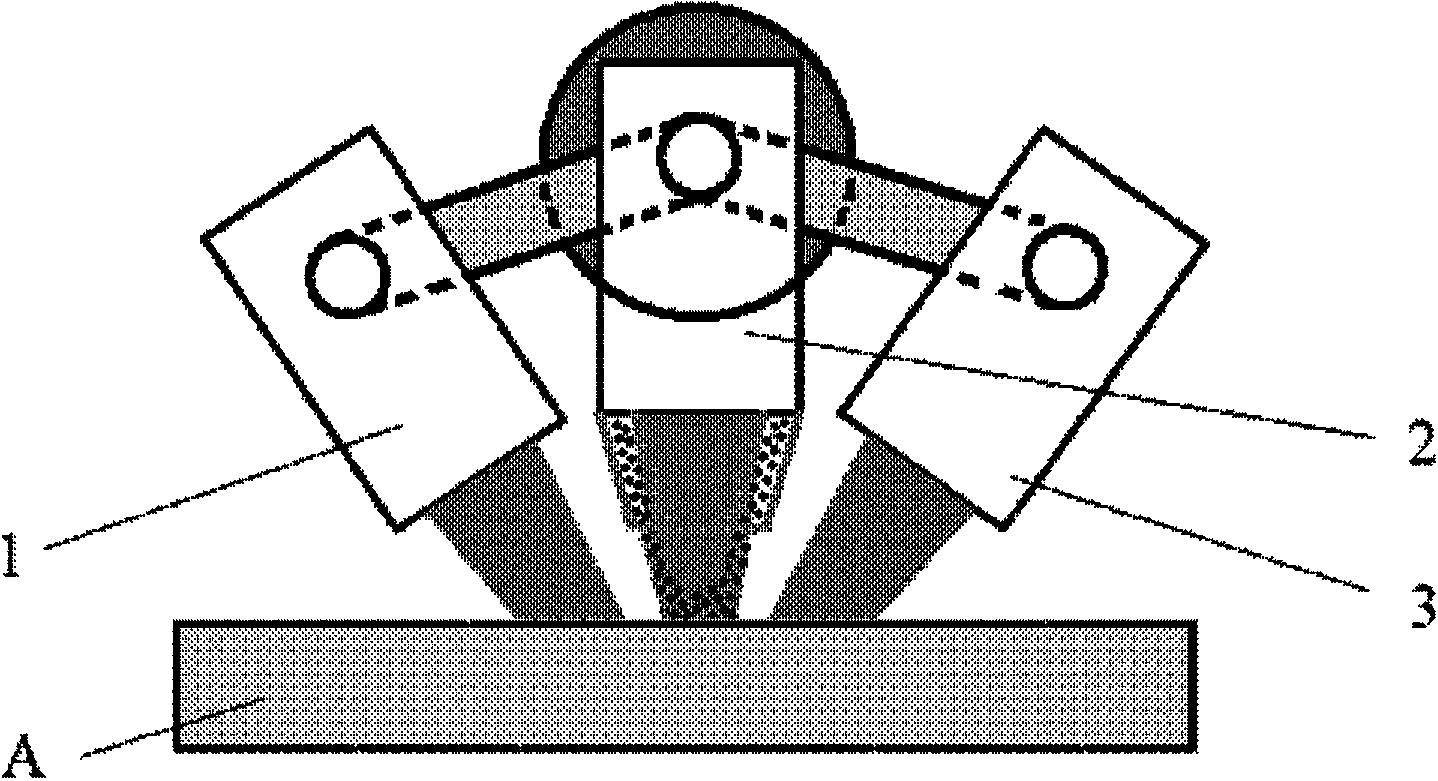

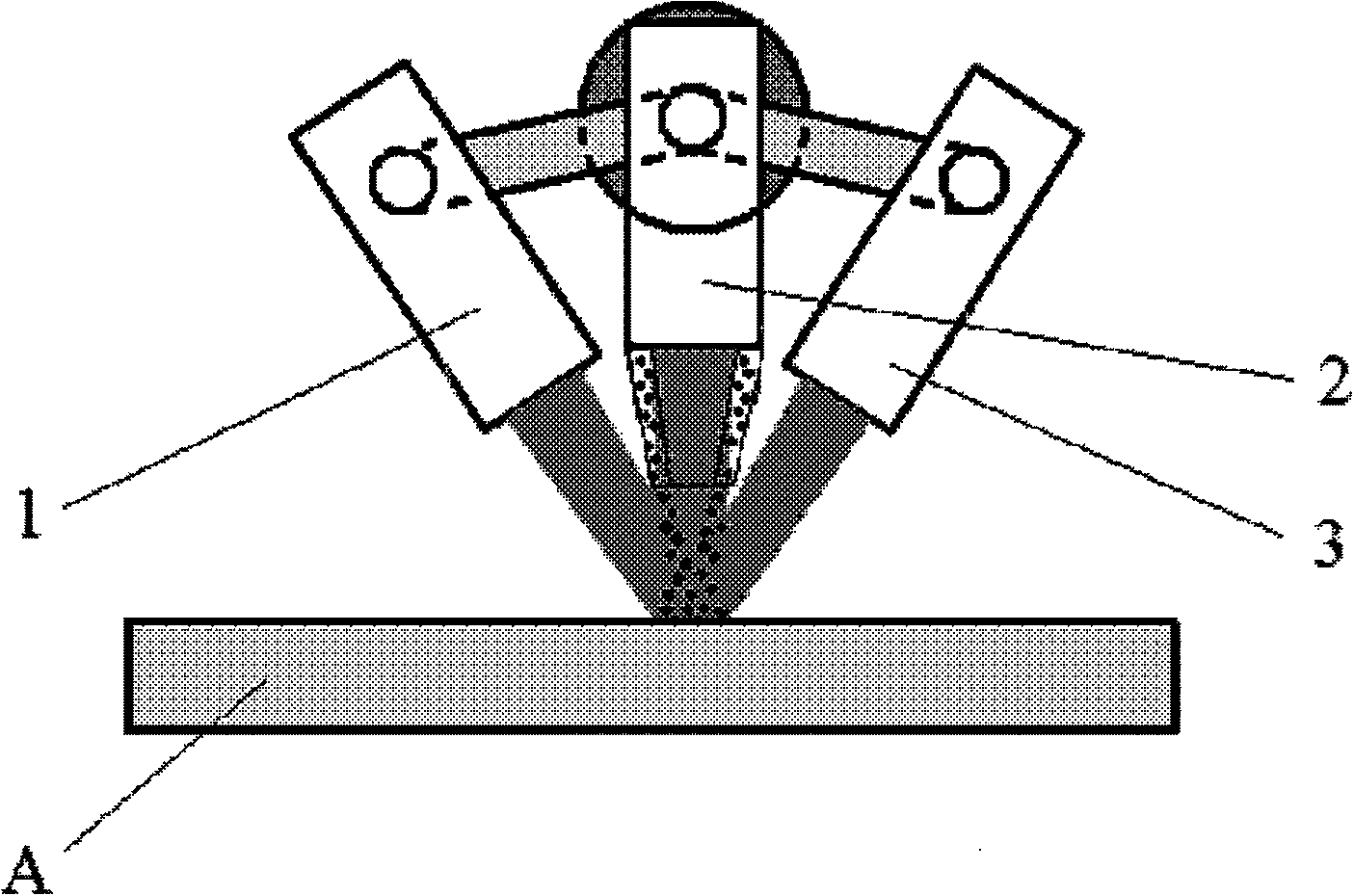

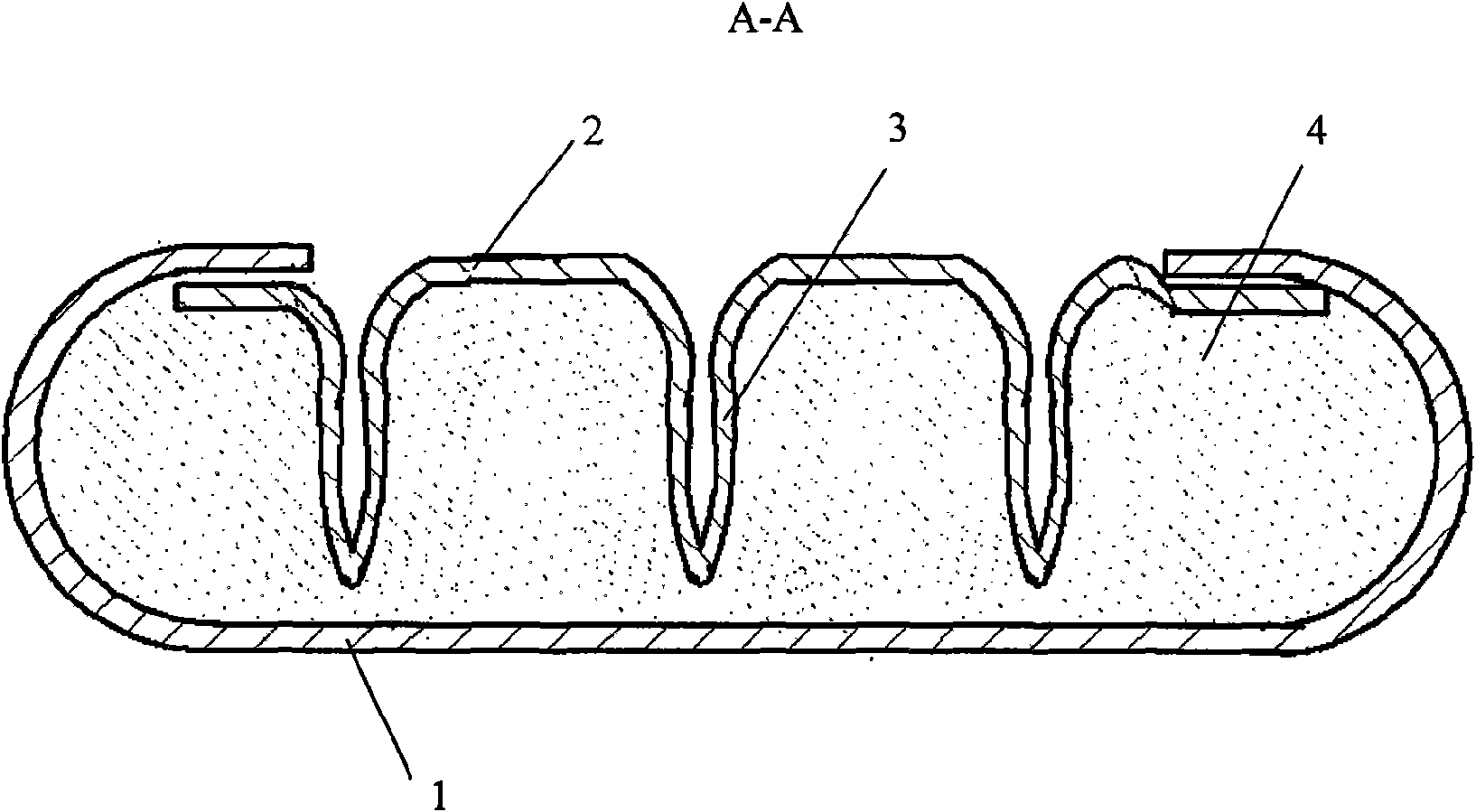

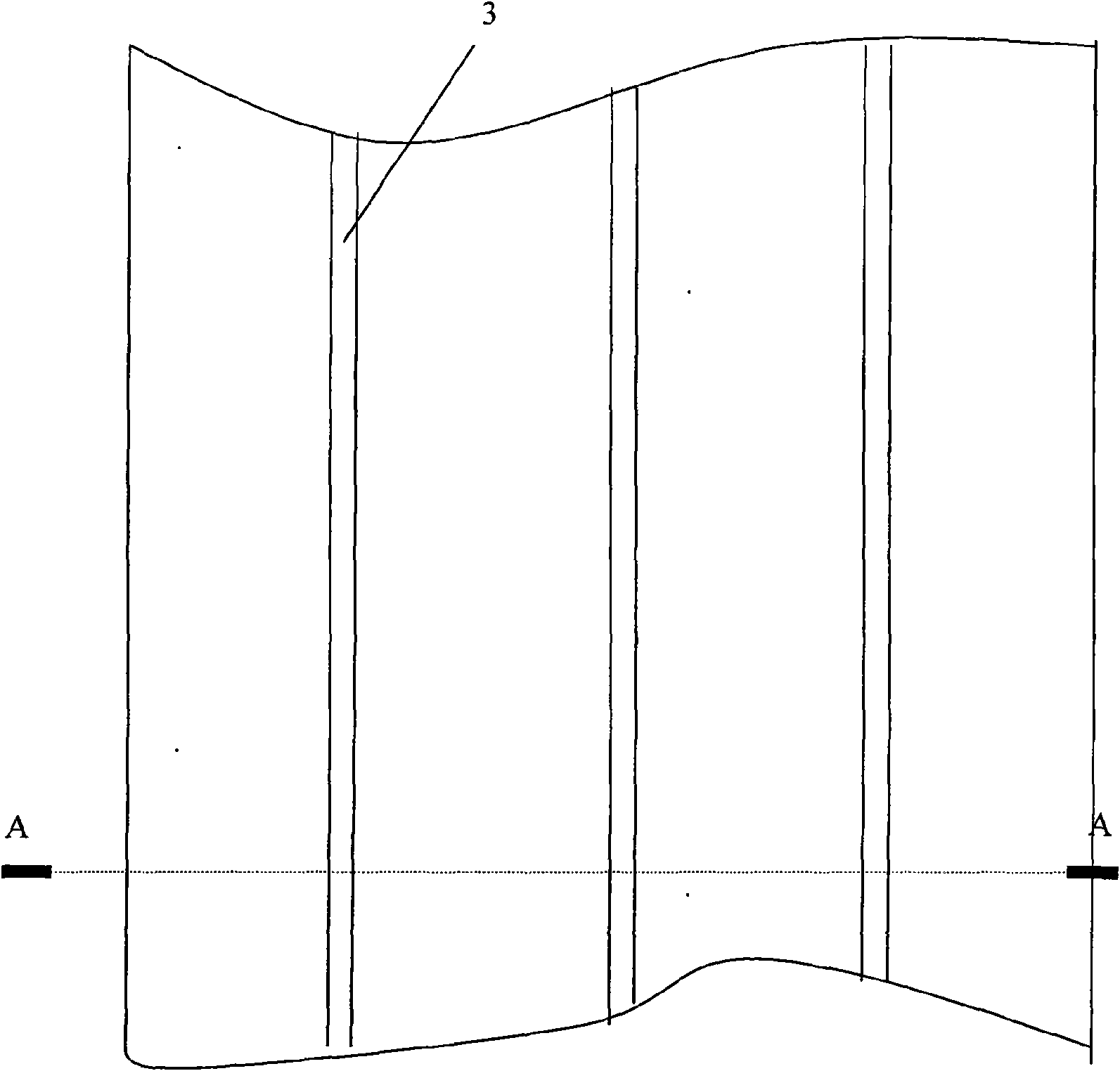

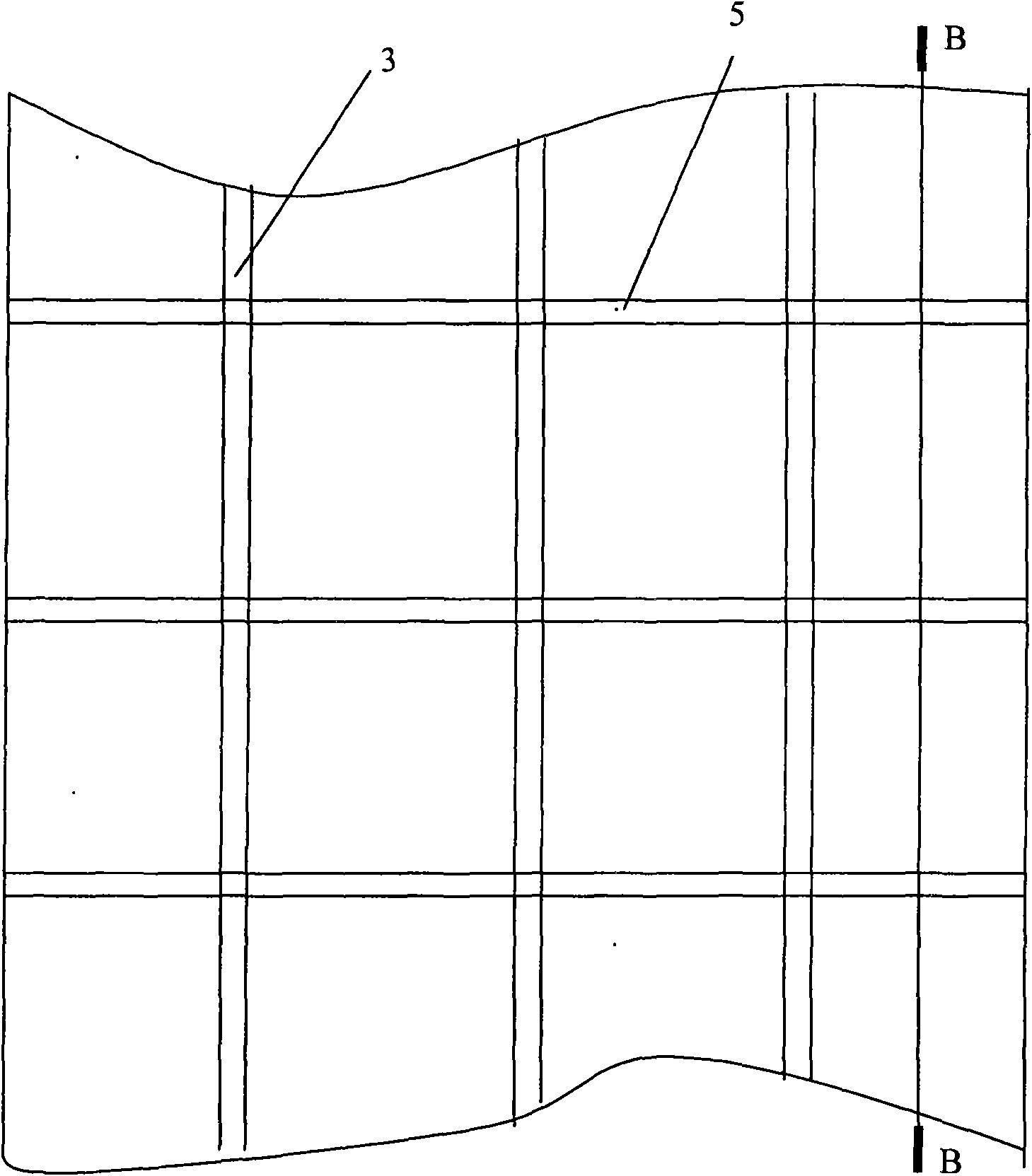

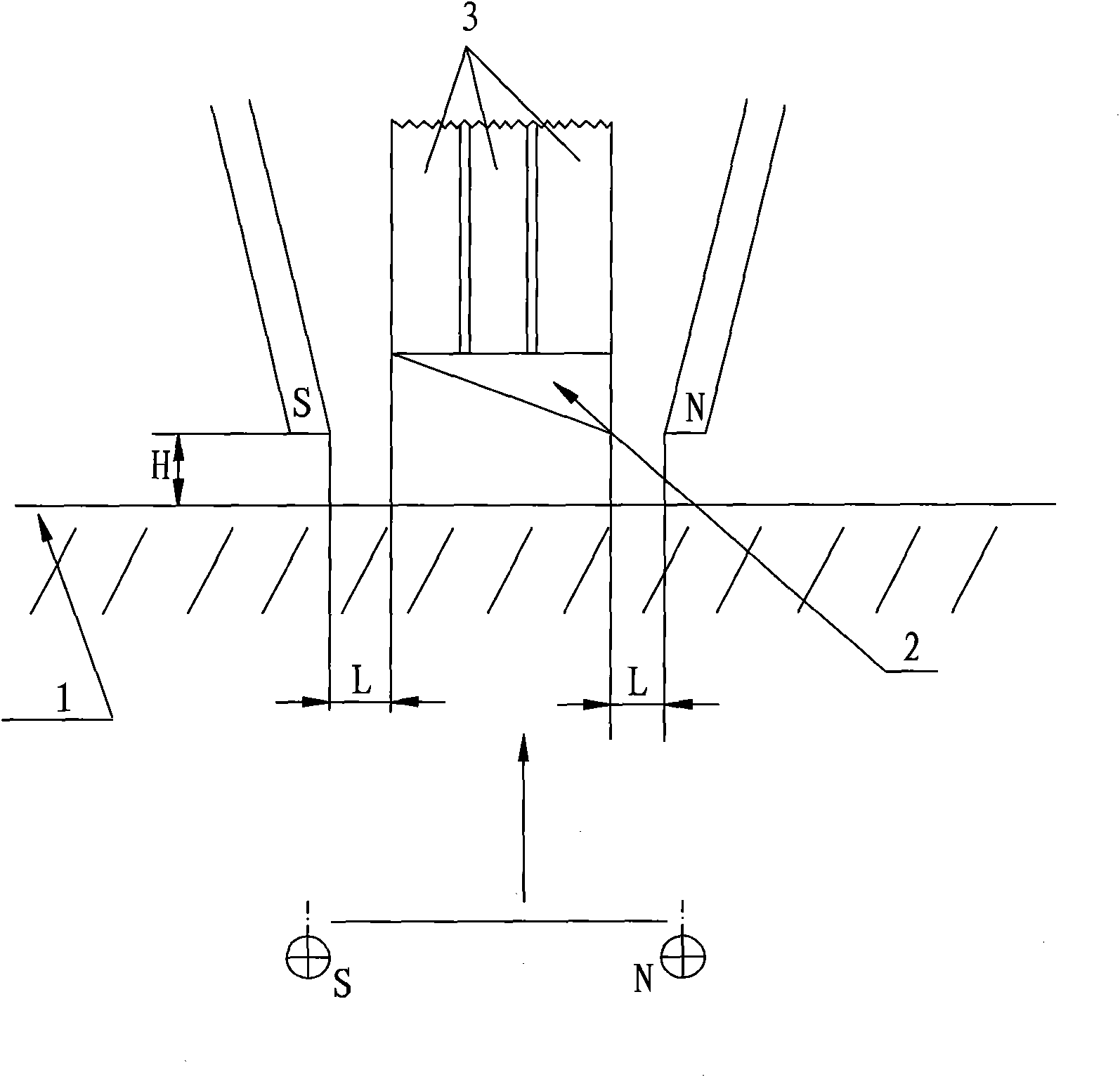

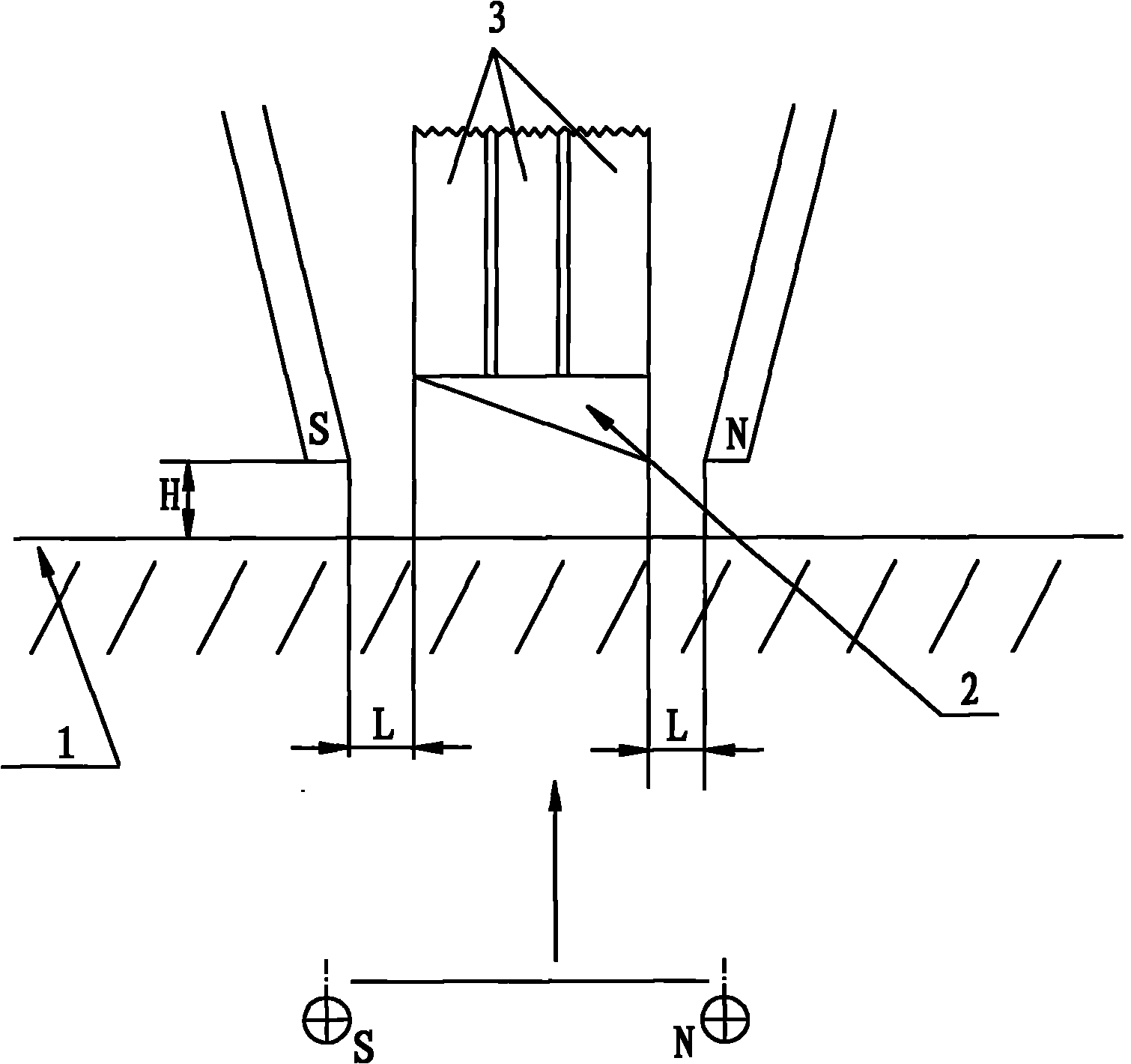

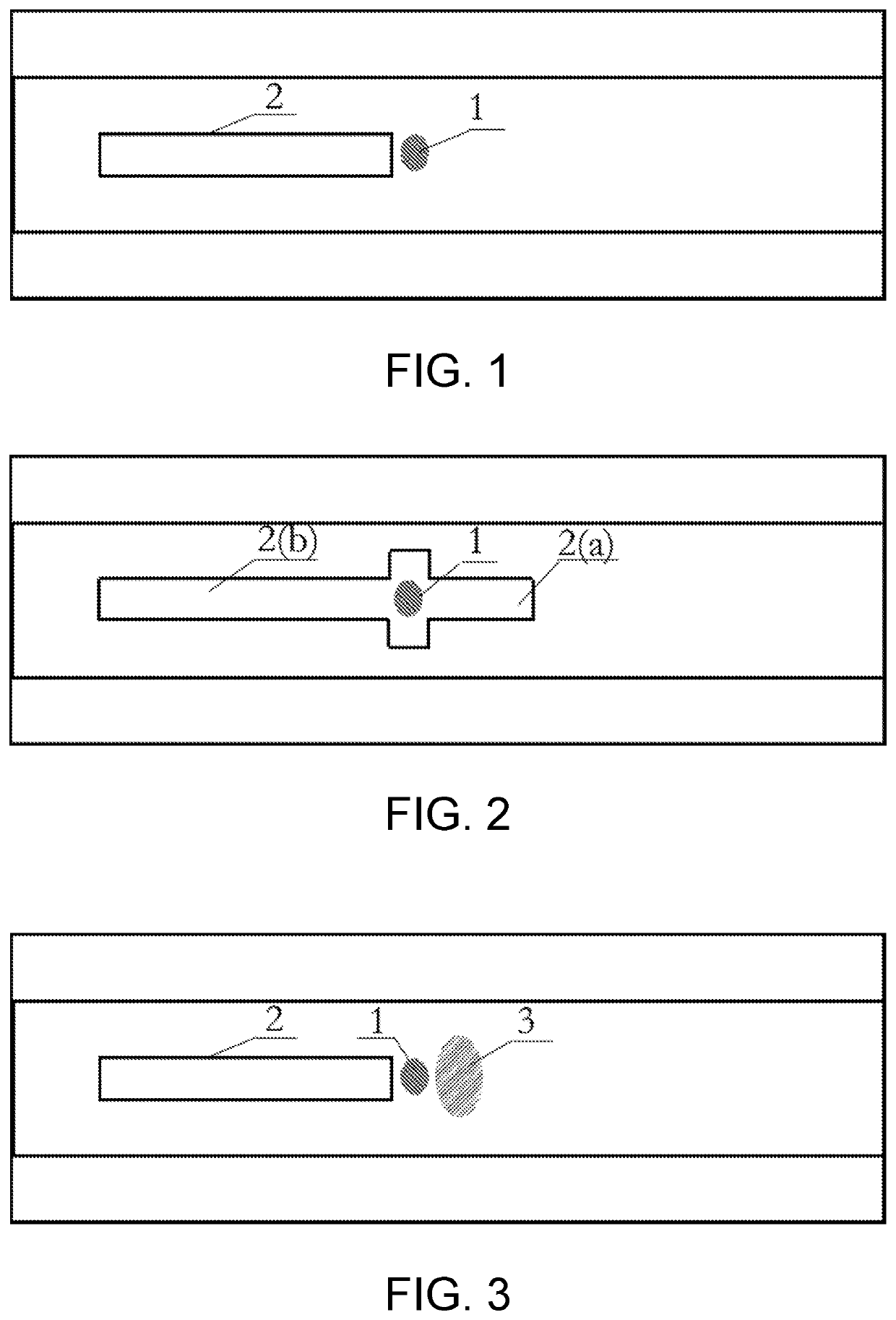

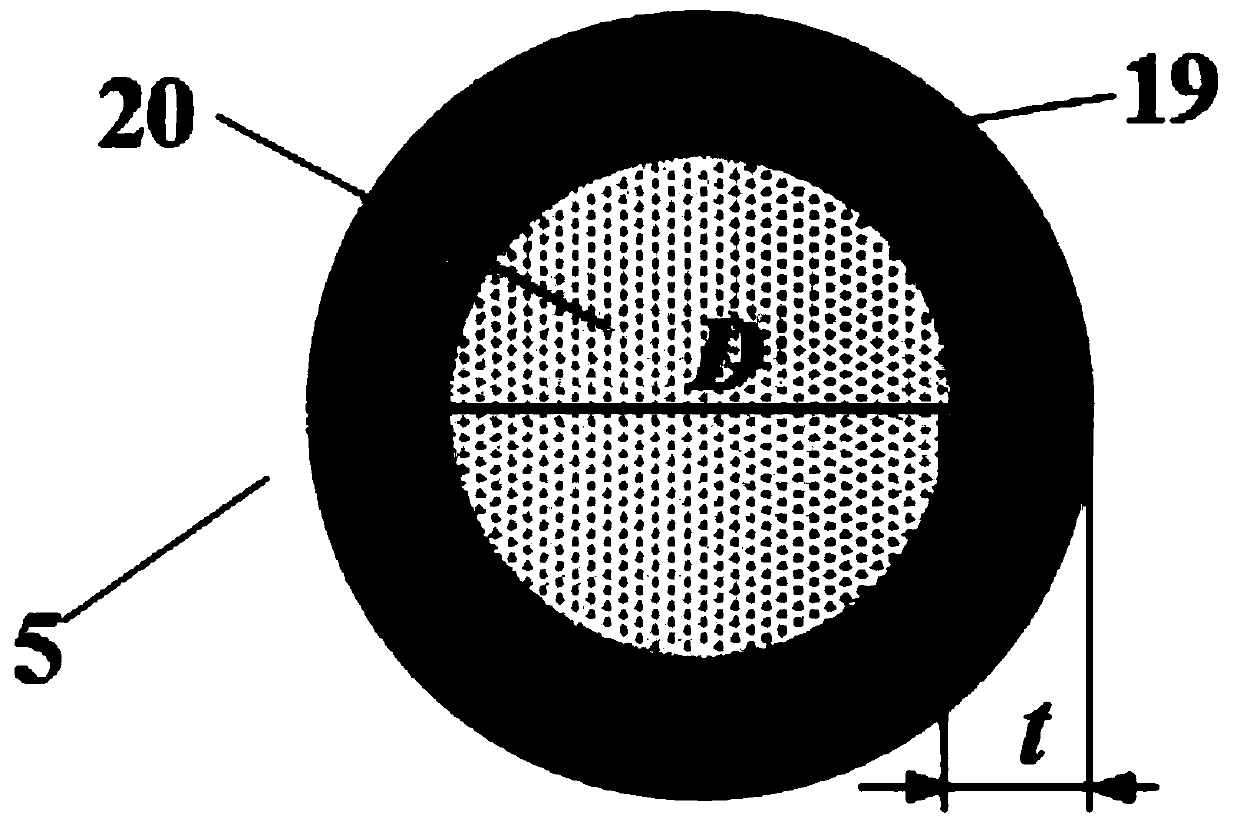

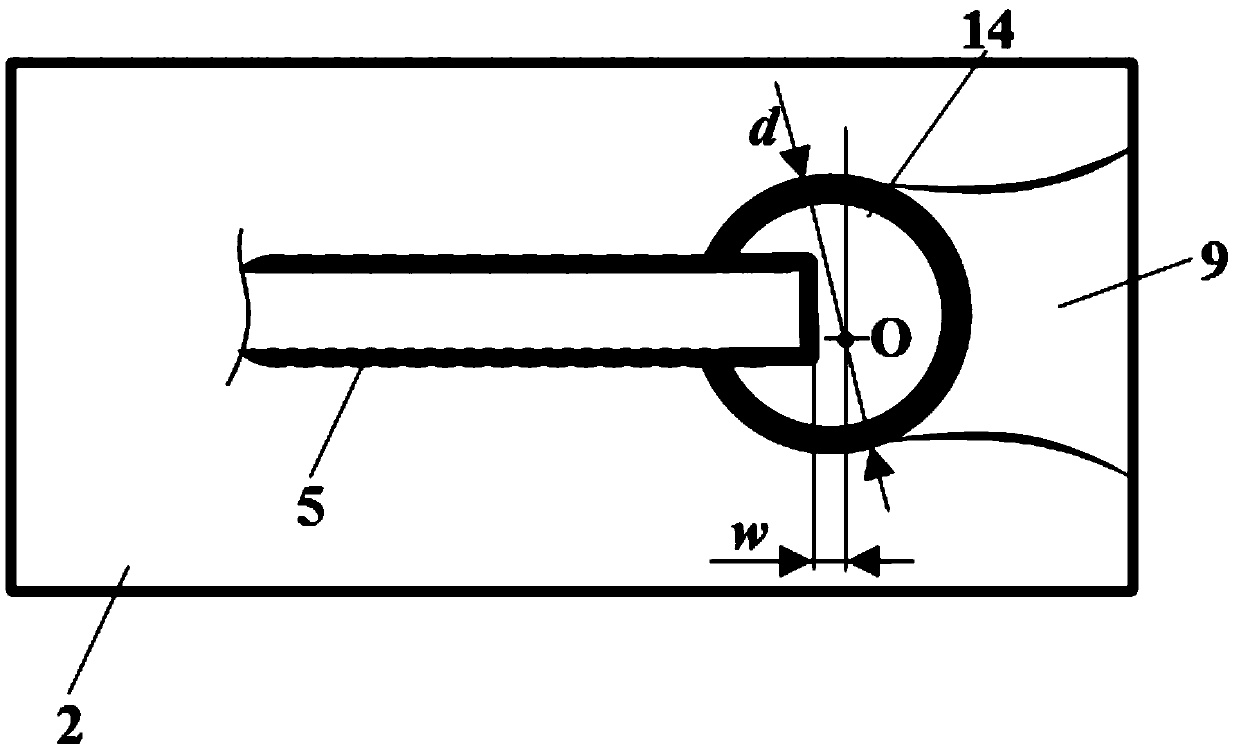

Moderate and high strength large-thickness component electromagnetic controlling narrow gap or ultra-narrow gap pulse efflux molten electrode gas-shield welding method and equipment

InactiveCN101143401AOvercoming arcingImprove crystallizationTransformers/inductances coolingWelding/cutting media/materialsElectric arcEngineering

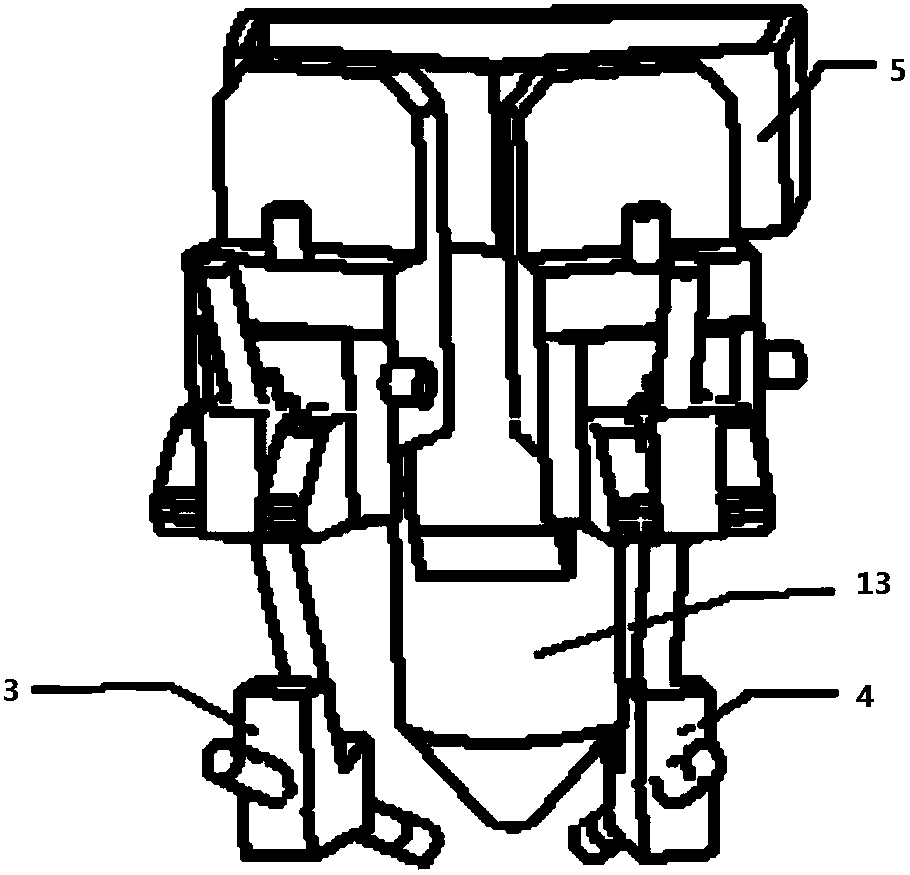

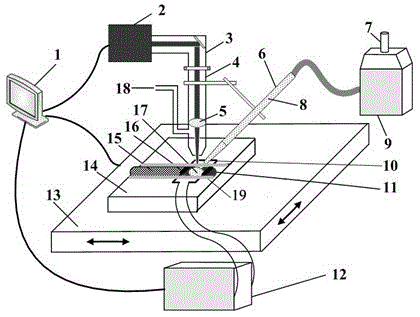

The invention relates to a gas shielded welding method and device of a narrow gap or a super-narrow gap impulse jet current consumable electrode controlled by electromagnetic of the heavy section part with middle and high strength. The invention uses a magnetic coil (3) to provide excitation current processed by an excitation source, which can generate an extra magnetic field. Under the conditions of narrow gap or super-narrow gap, high feed rate, fused drop spray transfer and impulse welding current, the process of the gas shielded welding of the rotating jet current consumable electrode with high-melting frequency pulse that is controlled by the electromagnetic for the heavy section part with middle and high strength can be realized. The device of the invention comprises the excitation source, excitation equipment, auxiliary equipment and a water cooling system. The excitation equipment is the magnetic coil (3) with or without a conducting core (5). The excitation equipment is fixed on a welding burner (6), which is positioned above a work piece (9). The excitation current provided by the excitation source (10) produces stationary or time-varying electromagnetic mixing magnetic field that has the combination control over the processes of arc welding, wire burn-off, drop transfer, melting bath flow and welding line coagulation, which finally forms the welding line of good quality.

Owner:CHONGQING UNIV

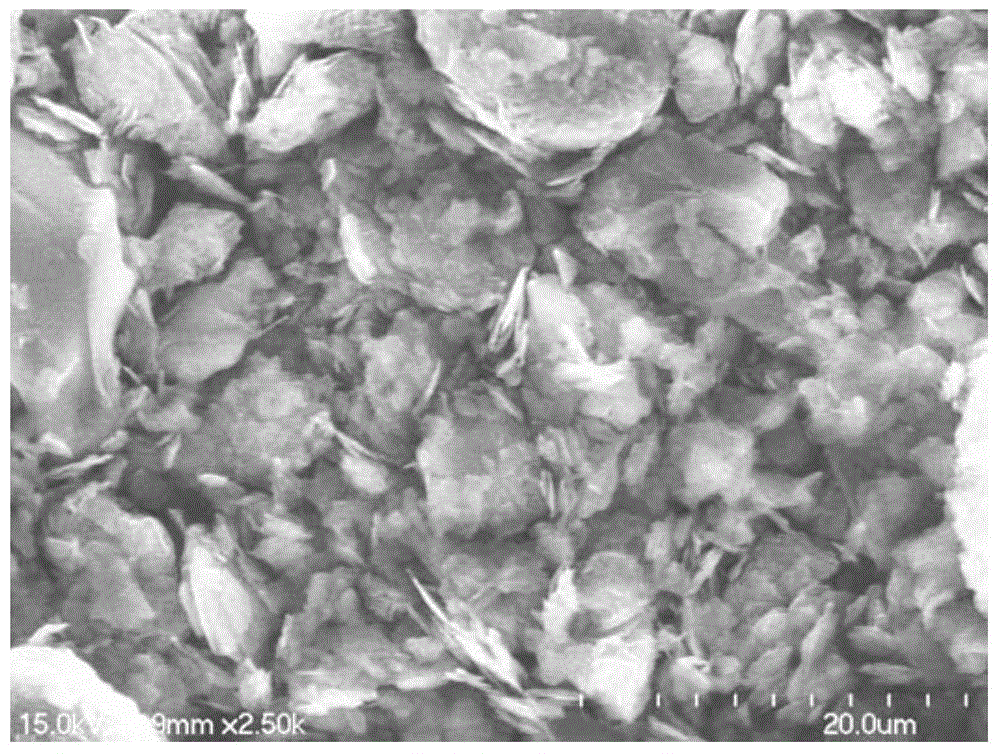

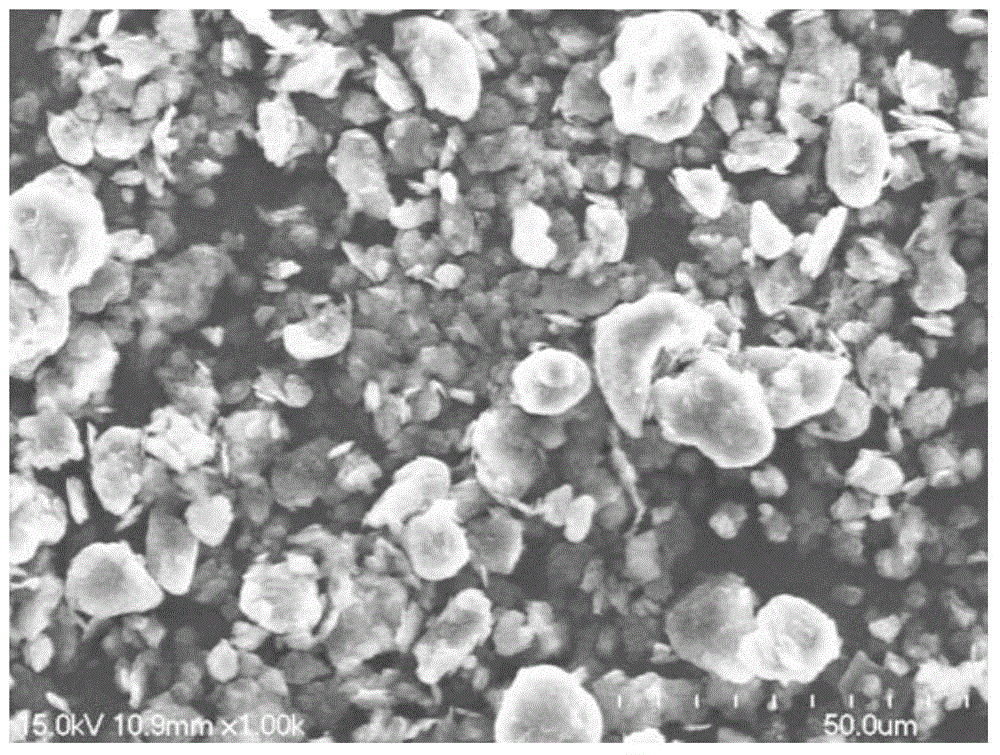

Iron-based amorphous powder for wear-resisting and corrosion-resisting coating and preparation method thereof

InactiveCN103302287AImprove wear and corrosion resistanceWear and corrosion resistance and long service lifeMetallic material coating processesSurface engineeringThermal spraying

The invention discloses iron-based amorphous powder for wear-resisting and corrosion-resisting coating and a preparation method thereof, and belongs to the technical field of surface engineering. Iron-based amorphous alloy coating adopts iron as a main component, and also comprises amorphous phase (in at least 30 percent by volume), and the representation formula of all elements in percentage by weight is FeaCrbNicSidBeMnfCgMohNbiCujCokRel. The powder is prepared through direct ball-milling mixing in proportion of all components according to the required weight ratio. The powder can be used for not only laser cladding but also thermal spraying technology, mixed powder is melt by high-energy density laser beams, an iron-based amorphous or amorphous composite cladding layer is formed on the outer surface of a matrix, the cladding layer has the characteristics of higher wear and collision resistance, the dilution rate is low, the wear-resisting and collision-resisting service lives of a petroleum drill rod, an air compressor screw rod, a roller, a water-cooled wall pipe and an economizer pipe are remarkably prolonged, the process is simpler, and the manufacturing cost is low.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

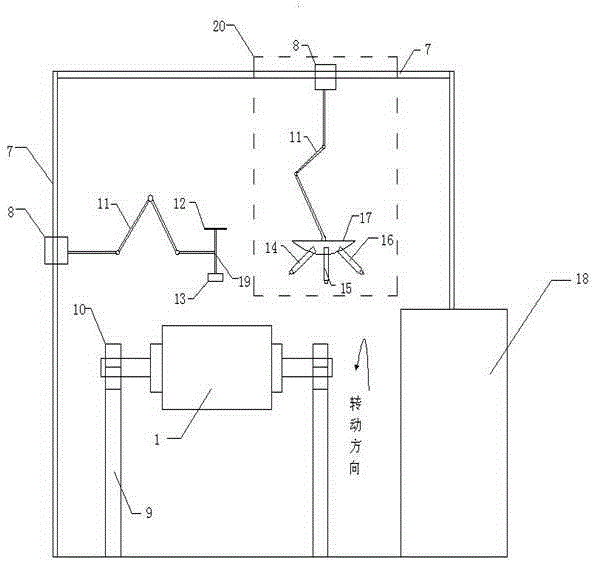

Automatic additive manufacturing method and device for robot plasma arc double-cooled filler rod

ActiveCN108067715ALow dilution rateImprove tissue performancePlasma welding apparatusEngineeringRobot control

The invention discloses an automatic additive manufacturing method and device for a robot plasma arc double-cooled filler rod. The device comprises a working platform, a base plate, a plasma welding gun, two wire feeding nozzles, clamps of the wire feeding nozzles, two wire feeders, a twin-wire coordination controller, a robot control cabinet and the like. The method mainly includes the steps thatthe two wire feeders are adopted to feed cold wire materials, and the robot control cabinet and the twin-wire coordination controller are in communication so as to control the two wire feeders to achieve synchronous or alternate feeding; and meanwhile the control cabinet controls a welding machine to achieve synchronization of wire feeding and arc ignition. By adoption of the device, plasma arc additive manufacturing of the double-cooled filler rod made of the same wire material and different types of the wire materials can be achieved by controlling different wire feeding signals by a robotand further changing the varieties and textures of the wire materials. By means of the method and device, plasma arc additive manufacturing of the same type of the double-cooled filler rod made of carbon steel, stainless steel and the like is realized, and the additive manufacturing efficiency is doubled compared with a single-wire mode. Plasma arc additive manufacturing of the double-cooled filler rod different from welding wires can further be realized, and a novel composite material structural member which is low in cost and high in efficiency can be manufactured.

Owner:NANJING UNIV OF SCI & TECH

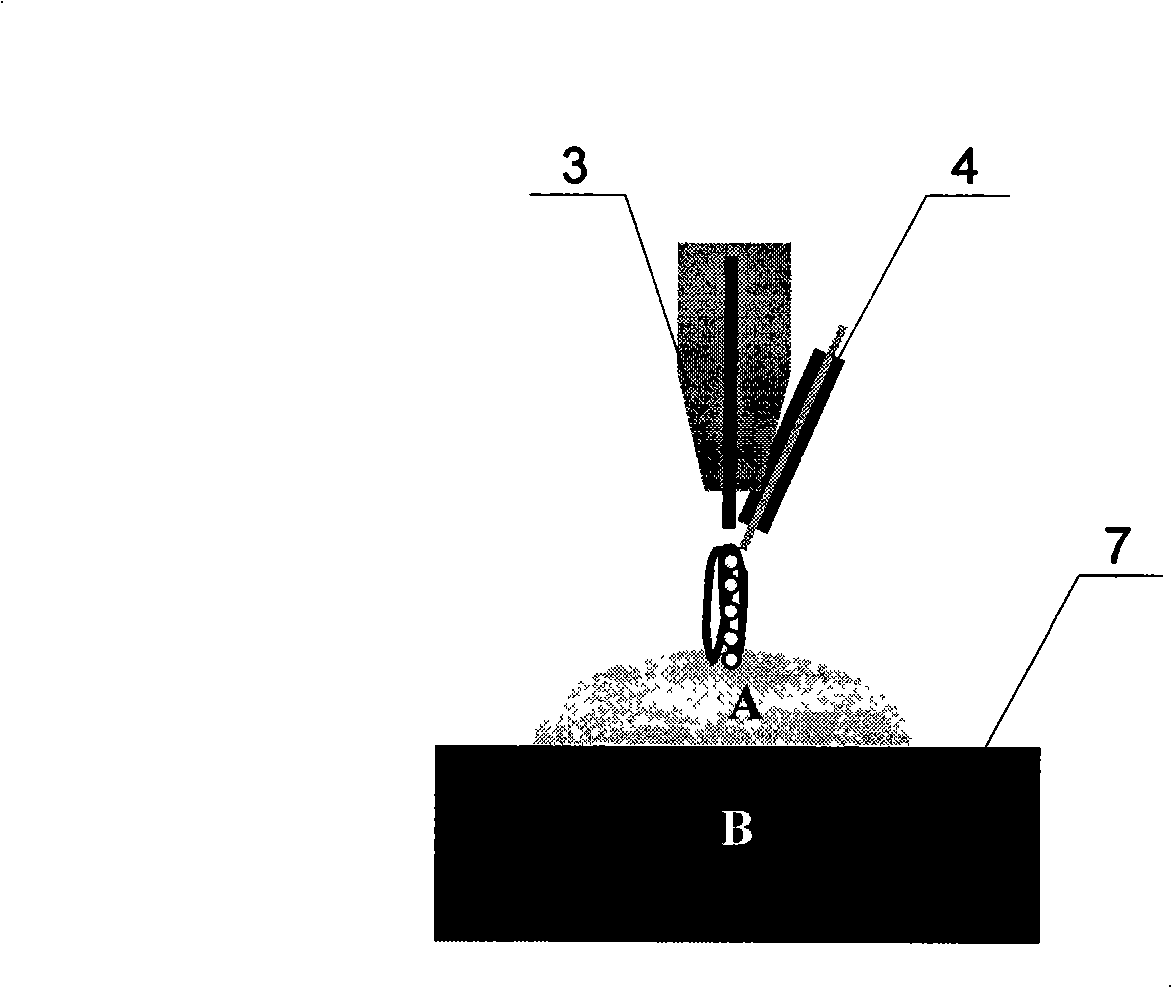

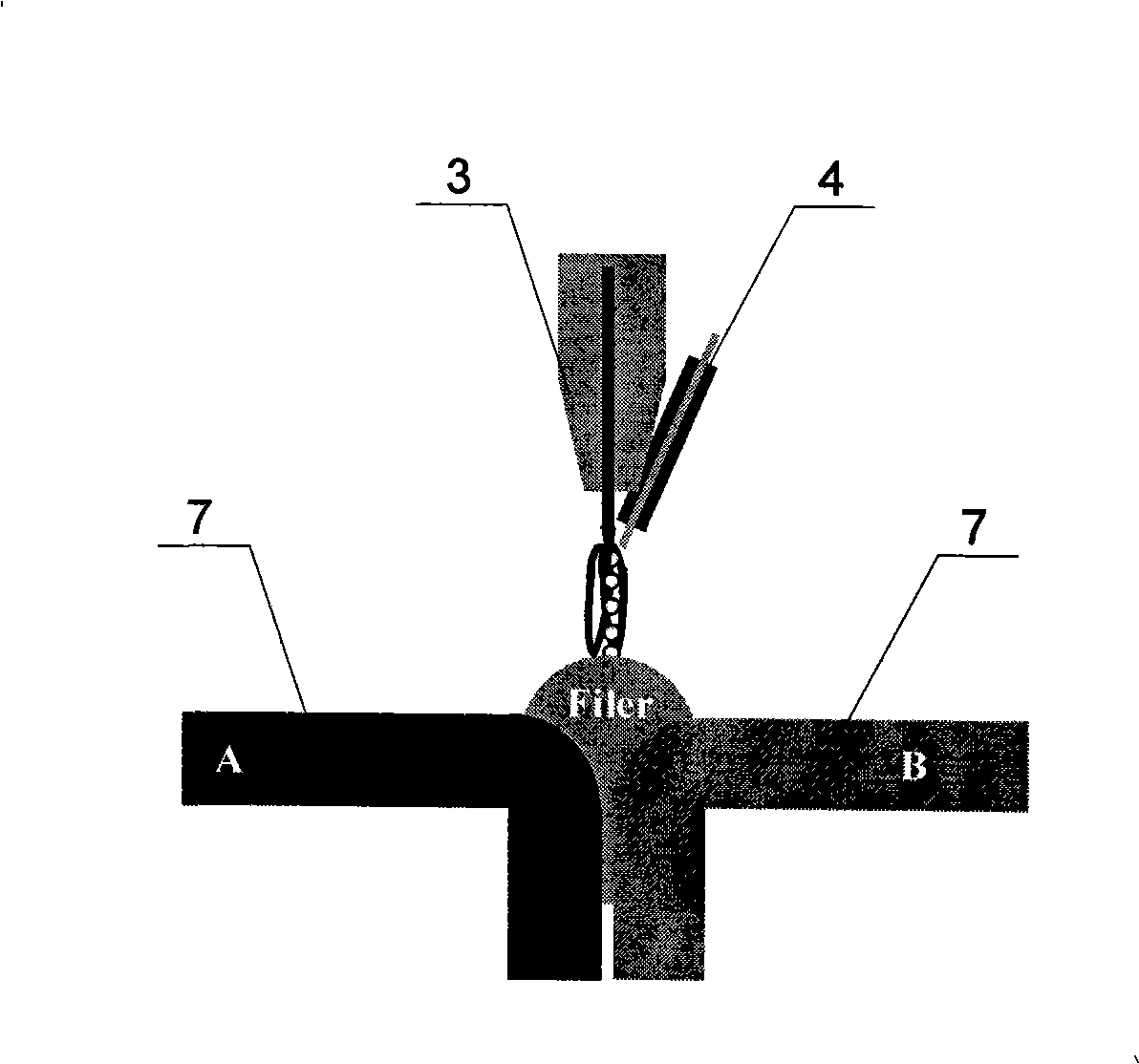

Tungsten electrode-consuming electrode indirect electric arc welding device and its welding method

The invention relates to an indirect arc welding device between tungsten electrode and melting electrode and a welding method thereof, belonging to the technical field of material welding device and welding method, which is used to solve the problems in the prior arc welding devices, such as high hot input, low weld joint deposited ratio and high dilution ratio. The two ends of the welding wire are respectively connected with a wire feeder and a melting electrode welding torch, and exposed outside of the conductive mouth of the melting electrode welding torch. The welding wire is connected with a power supply, and the tungsten electrode welding torch and the melting electrode welding torch are connected respectively with the positive and negative electrodes of GTAW, and the axial point of the two welding torches is on the top of the weldment to be welded, and two protection gas cylinders are connected respectively with the protection gas inlets. Based on the device to weld in a certain welding process, turning on the arc generating switch, and using arc only generated between the tungsten electrode and melting electrode to quickly heat to melt the welding wire, and the droplet of the melted welding wire with heat heats the device indirectly and welds. The welding method has the advantages that the weld joint deposited ratio is increased up to 50g / min and the dilution ratio is controlled within 5%.

Owner:HARBIN INST OF TECH

Flux-cored steel belt for build-up welding and preparation method thereof

InactiveCN101306493AIncrease varietyIncrease weld widthWelding/cutting media/materialsSoldering mediaHigh carbonFerrosilicon

The invention discloses a resurfacing welding used drug cored steel strap and the preparation method. The steel strap is prepared from a mild steel strap and drug powder enwrapped therein, the shape of the steel strap is a tube with the longitudinal cross-section to be in a long and flat shape or in a similar rectangle shape, the longitudinal length can be determined randomly, and the transverse sides of the steel strap are connected in a seam manner or a related joint manner; the drug powder is uniformly filled in the tube rolled from the steel strap, wherein the particle diameter of the drug powder is smaller than 120 Mum, the components include (by weight) 45-70 parts of high carbon ferrochrome, 5-35 parts of ferrovanadium, 1-8 parts of No.75 ferrosilicon, 1-10 parts of high carbon ferromanganese, 2-16 parts of ferroboron, 1-8 parts of ferrotitanium, 0-5 parts of ferroniobium, 2-8 parts of ferromolybdenum, 0-10 parts of graphite, 0-5 parts of fluorite and 0-6 parts of potassium titanate. The drug cored steel strap adopting the invention can efficiently improve the abrasion resistance of the metal on the resurfacing welding layer and the stability of the electric arc, and can be coiled into coils, thereby being suitable for continuous automatic resurfacing welding.

Owner:SHANDONG UNIV

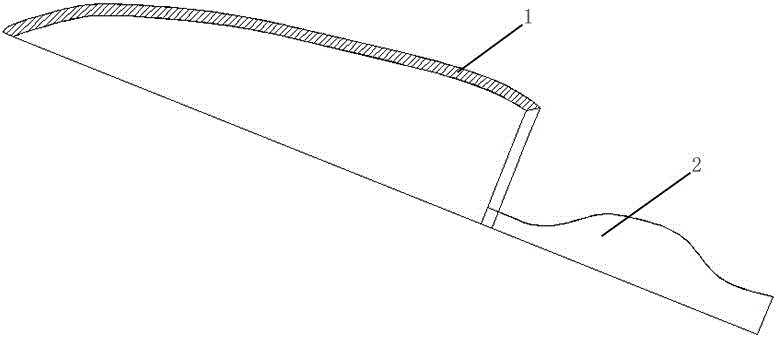

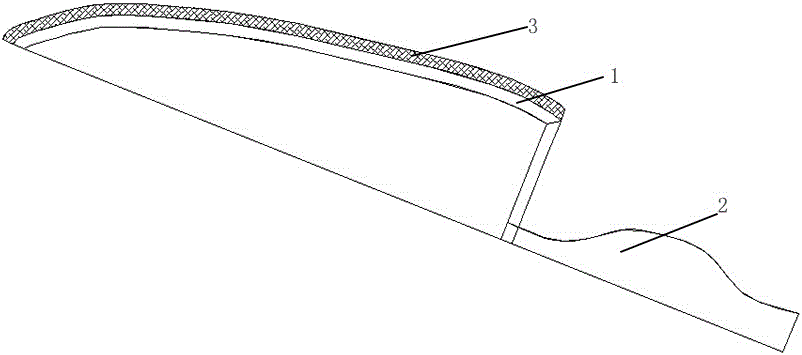

Tool for strengthening blade through laser cladding technology

ActiveCN106119838ASmall and uniform tissueLow dilution rateMetallic material coating processesMetal working apparatusAlloyLaser

The invention discloses a tool for strengthening a blade through the laser cladding technology. The tool comprises a tool body and a handle. The position of a cutting edge line of the tool body is provided with a cladding layer in a cladding manner, wherein the cladding layer is formed by abrasion-resisting hard alloy mixed powder. The hard alloy mixed powder is formed by mixing nickel-base alloy powder and tungsten carbide powder according to the proportion. By mass percent, the nickel-base alloy powder accounts for 40%-70%, and the tungsten carbide powder accounts for 30%-60%. The nickel-base alloy powder comprises, by mass percent, 18%-23% of Cr, 4%-7% of Fe, 2%-4.5% of Nb, 8%-11.5% of Mo, 0.2%-0.4% of Al, 1%-2.5% of Ti, 0.1%-0.6% of C, 0.2%-0.5% of Si, 0.2%-0.6% of Mn, 1.5%-2.5% of V and the balance Ni. The tool has the beneficial effects that the cladding layer and the tool body are in well metallurgy combination, the structure of the cladding layer is fine and uniform, and the dilution rate is low; after the tool body is sharpened, the hardness, sharpness, abrasion resistance and corrosion resistance of a blade part are greatly improved, cost is low, the hardness of the blade part is improved, and meanwhile tenacity cannot be reduced.

Owner:YANGJIANG KNIFESCISSOR HARDWARE RES INSTITUTION OF IND TECH +1

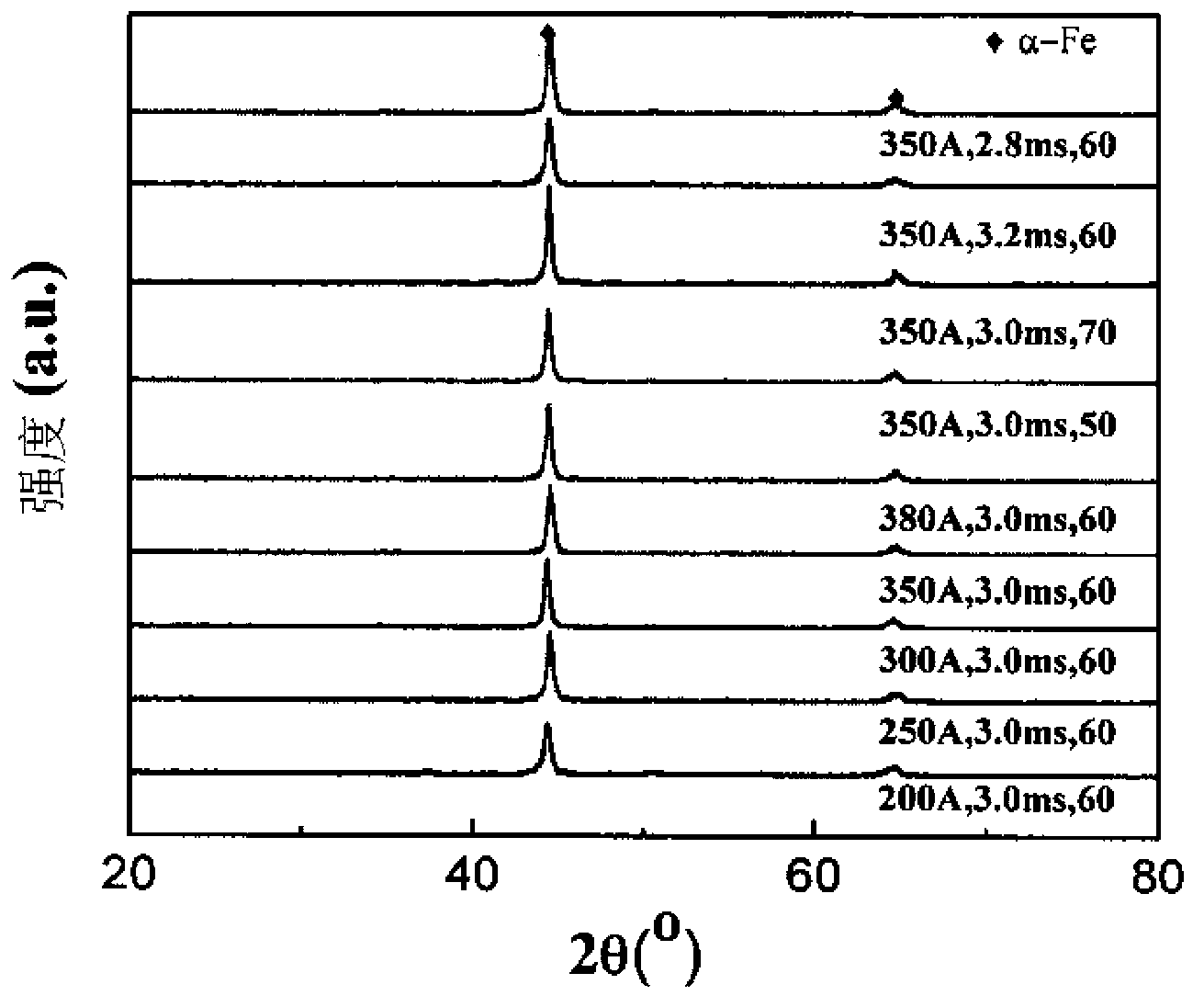

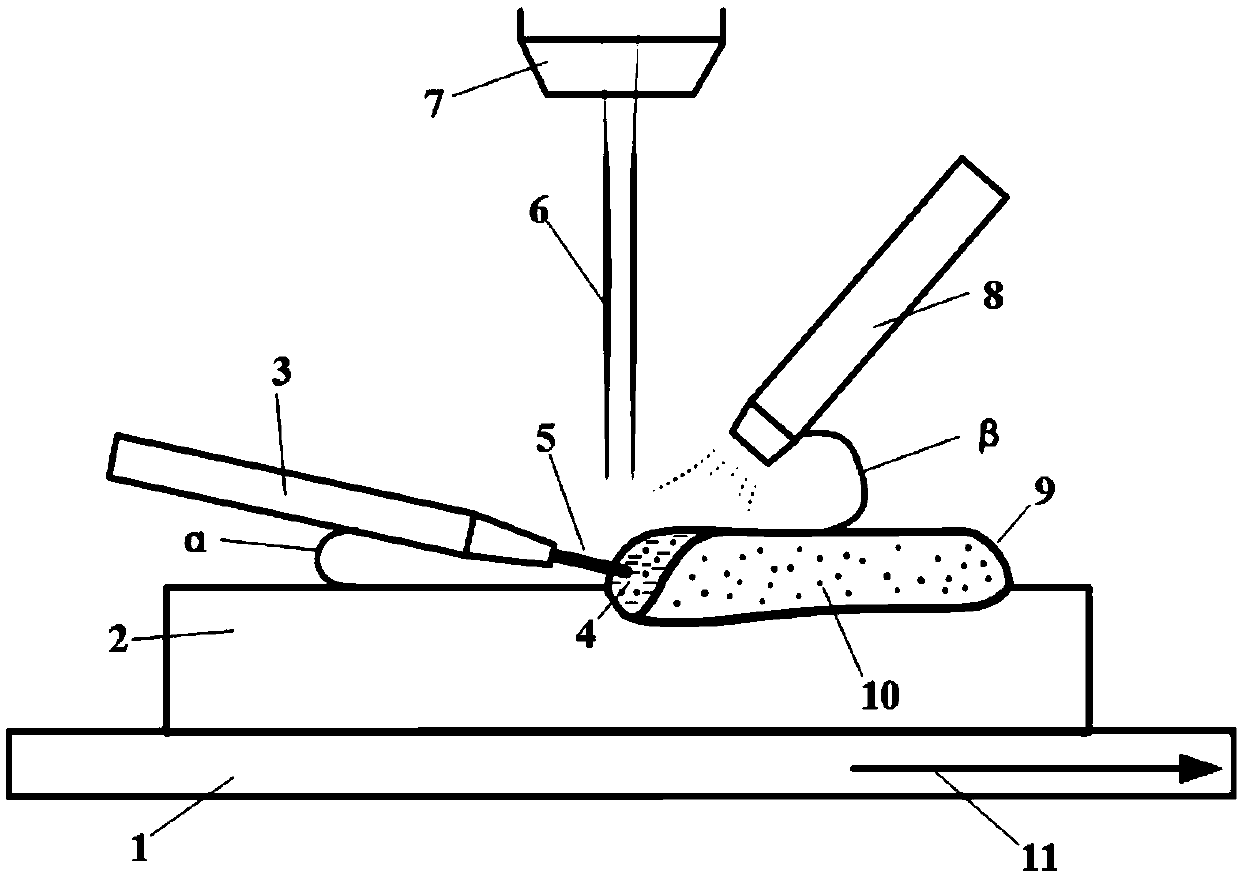

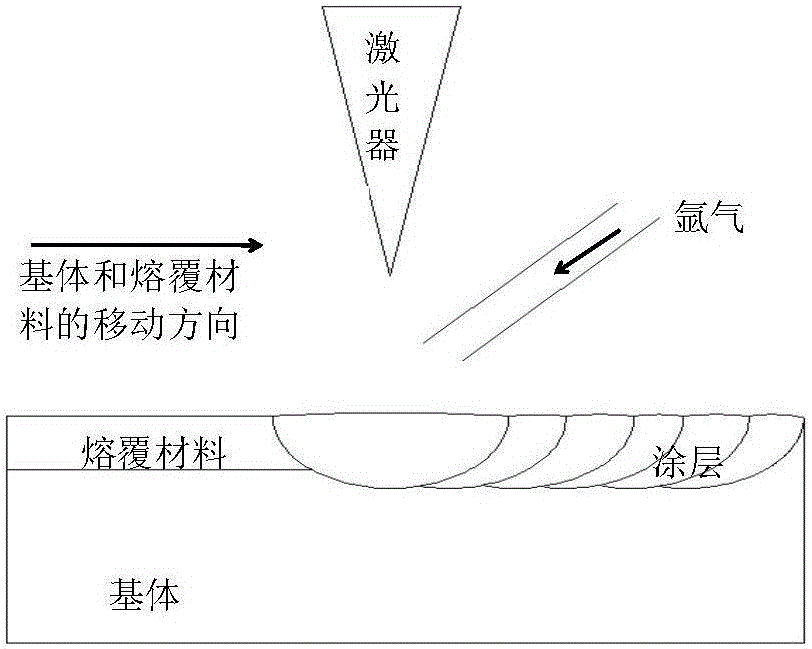

Method for efficiently compounding fusion-covering reinforced steel rail through laser and auxiliary heat source

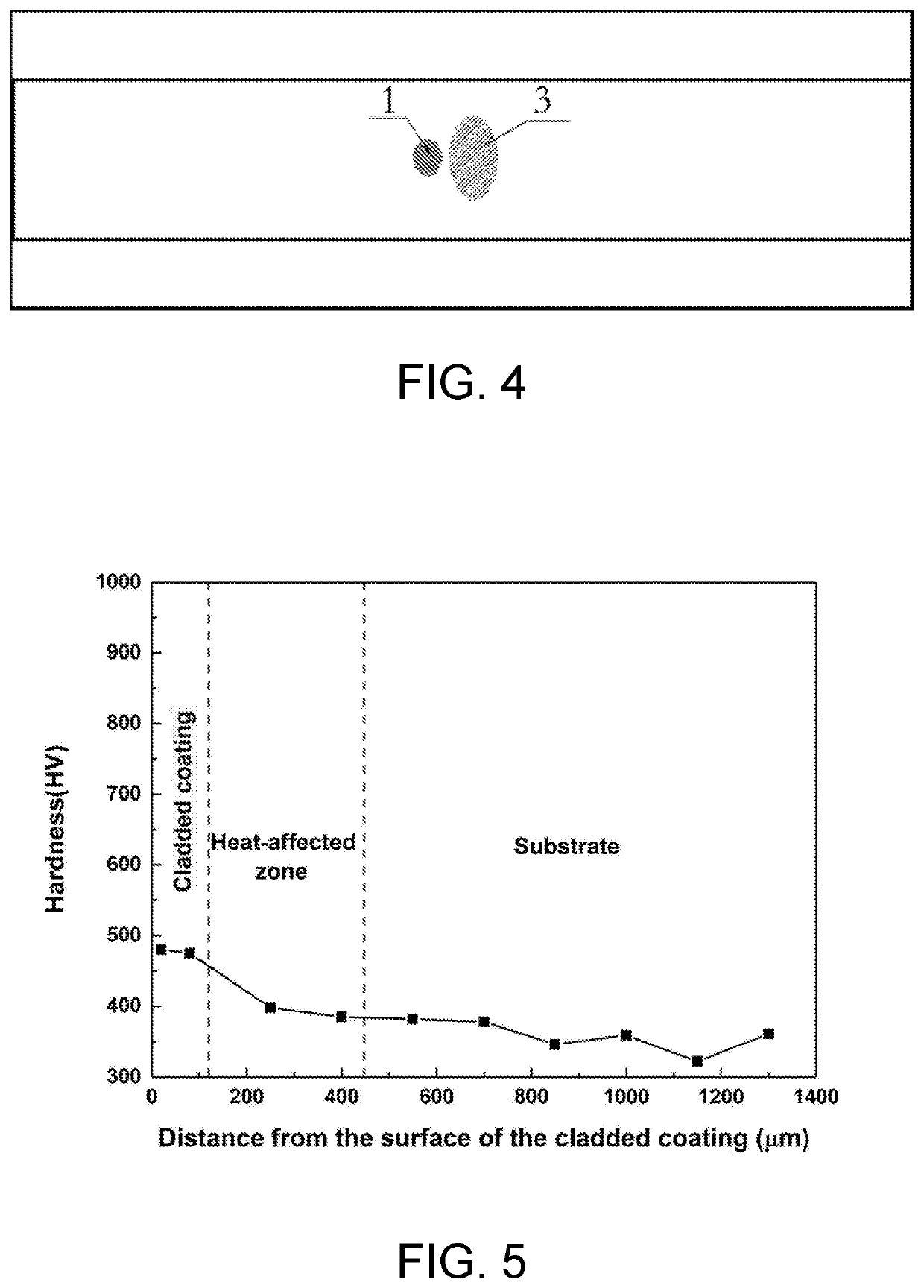

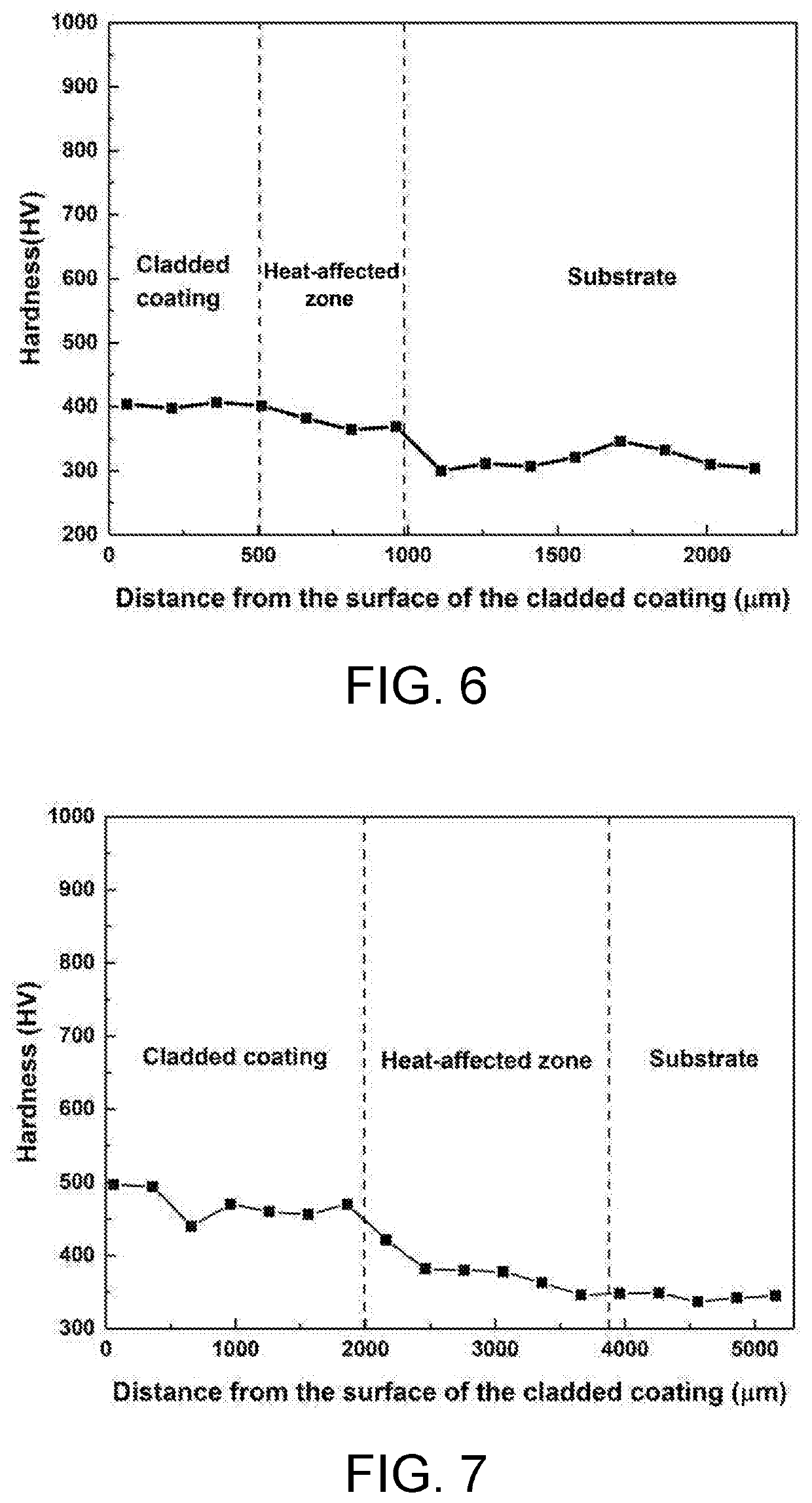

ActiveCN108456879AReduce temperature gradientAvoid crackingFurnace typesMetallic material coating processesMelting tankHeat-affected zone

The invention discloses a method for efficiently compounding a fusion-covering reinforced steel rail through laser and an auxiliary heat source. The laser and the auxiliary heat source act on a to-be-fusion-covered area on the surface of the steel rail simultaneously, as a main heat source, the laser makes the material of a fusion-covering layer and the material on part of the base of the surfaceof the steel rail quickly fused simultaneously to form a fusion pool, the auxiliary heat source and the laser heat source move in the same direction at the same speed and preheat and / or postheat the laser fusion pool, a heat influence area and the surface layer of the base of the steel rail, the temperature gradient of the steel rail is lowered, thus the cooling speed of the steel rail is lowered,and the phenomena of transforming of a martensite in a heat influence area and cracking are avoided. Through the compounding effect, the critical cooling time for transforming an austenite to a pearlite is shortened in the heat influence area wherein the cooling time is larger than a CCT curve or a TTT curve, so that the mechanical performance among the fusion-covering layer, the heat influence area and the base is reasonably matched, the rigidity curve is smooth in distribution, and the overall fatigue performance is good. The method can fuse-cover a metal layer on the surface of a field ofa railway steel rail on line and can also achieve fuse-covering machining on the surface of the steel rail in a production workshop.

Owner:HUAZHONG UNIV OF SCI & TECH +1

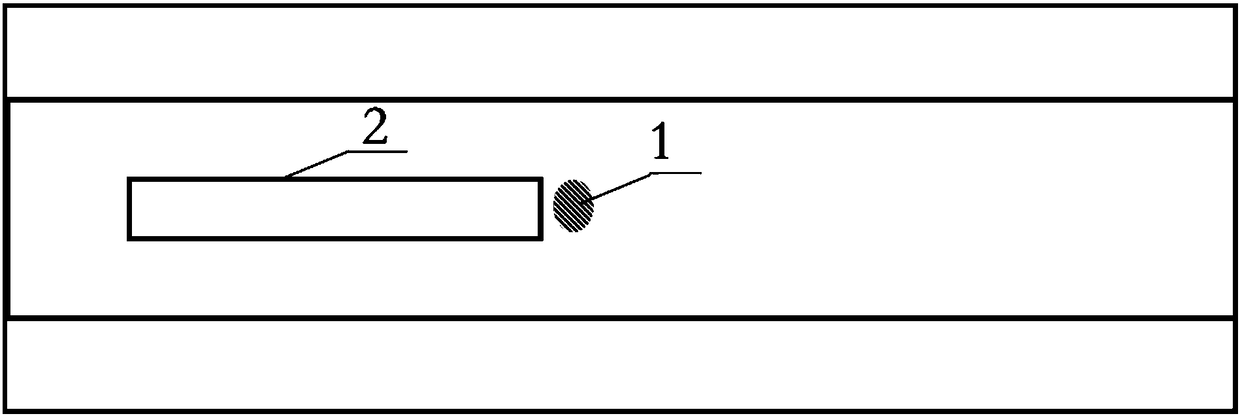

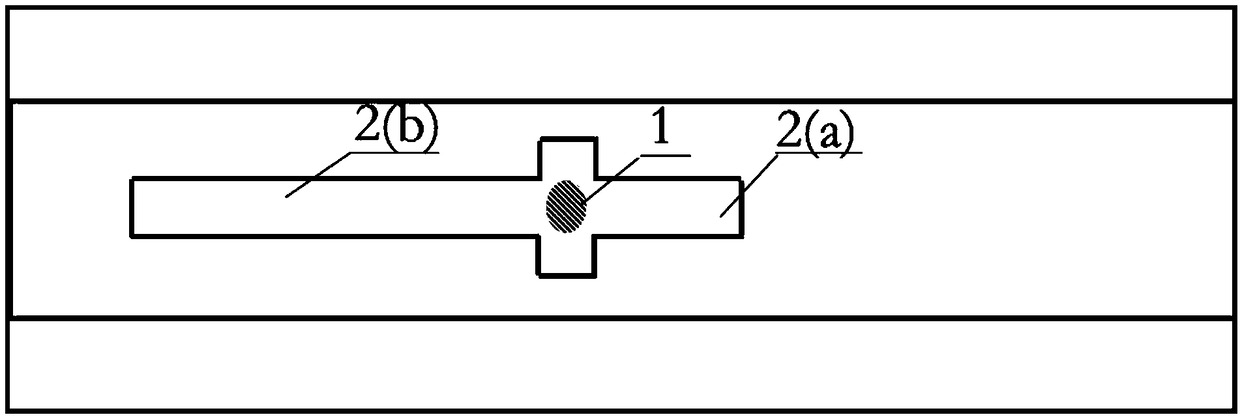

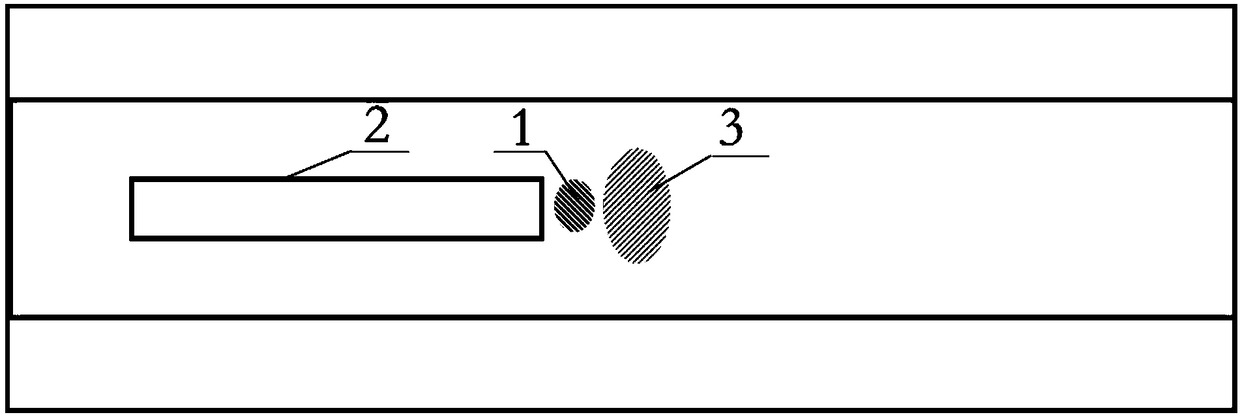

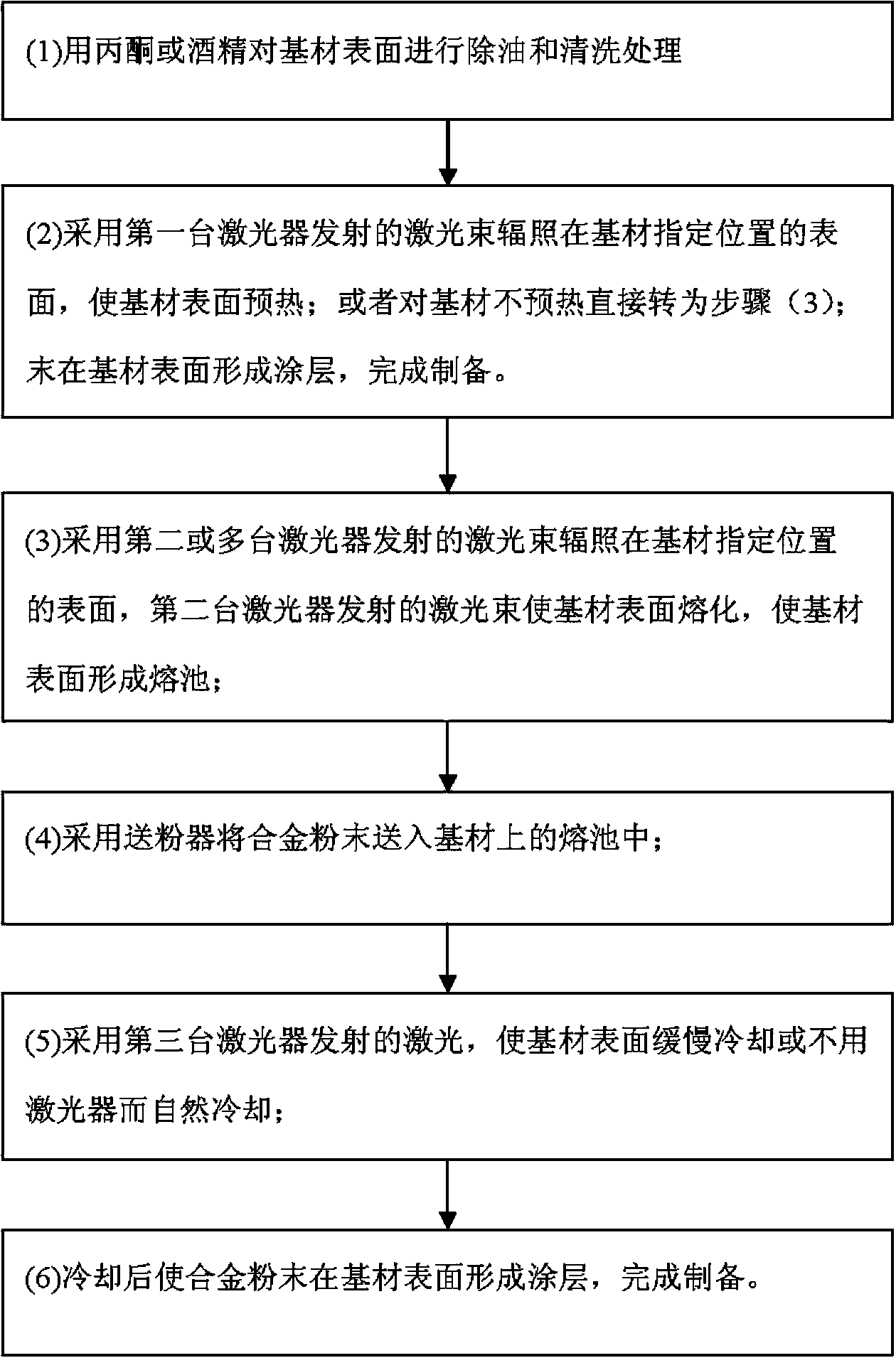

Method for performing laser cladding by using multiple lasers

InactiveCN103774137AEasy loading and unloadingEasy to operateMetallic material coating processesFree coolingOptoelectronics

The invention discloses a method for performing laser cladding by using multiple lasers. The method comprises the following steps: performing oil-removing and cleaning treatment on the surface of a substrate by using acetone or alcohol; irradiating laser beams emitted by a first laser onto the surface of a specified position on the substrate to preheat the surface of the substrate; or directly turning to step 3 without preheating the substrate; irradiating laser beams emitted by a second or multiple lasers onto the surface of a specified position on the substrate to melt the surface of the substrate in order to form a molten pool on the surface of the substrate; feeding alloy powder into the molten pool on the substrate by using a powder feeder; and slowly cooling the surface of the substrate by using laser light emitted by a third laser or naturally cooling without using the laser to form a coating on the surface of the substrate in order to complete preparation. The method has the advantages of laser cladding efficiency, lower machining cost, good bonding of the substrate, convenience in operation and high automation degree.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Self-lubricating wear-resistant composite coating for titanium alloy surface and preparation method of self-lubricating wear-resistant composite coating

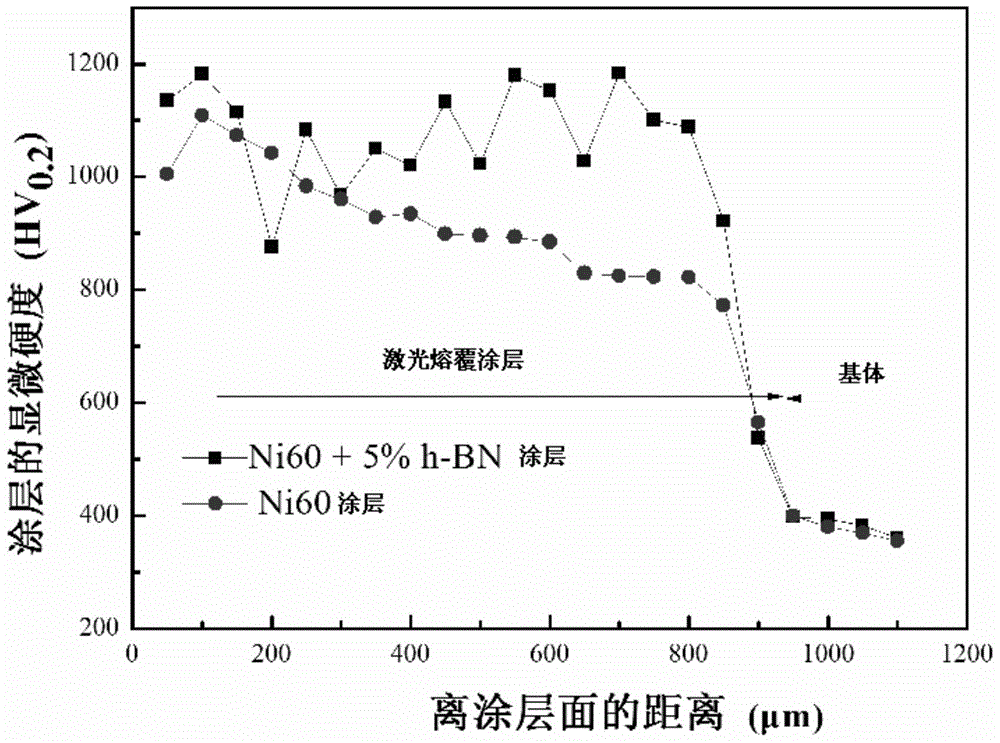

ActiveCN104087789AImprove high temperature wear lifeGood value for moneyMetallic material coating processesMicro structureHexagonal boron nitride

The application provides a self-lubricating wear-resistant composite coating for a titanium alloy surface and a preparation method of the self-lubricating wear-resistant composite coating. The method comprises the following steps: mixing mixed alloy powder and a binding agent, and then coating on the titanium alloy surface to form a pre-paving coating, wherein the mixed alloy powder comprises the following components in percentage by weight: 59-62% of nickel, 18.5-21% of chromium, 5-8% of boron, 6.5-10% of silicon and 3-7% of hexagonal boron nitride. The pre-paving coating is irradiated by adopting laser beams so as to obtain the self-lubricating wear-resistant composite coating. The mixed alloy powder comprises nickel, chromium, boron and silicon with the contents and can take an excellent anti-wear effect; and meanwhile, the mixed alloy powder comprises a proper amount of h-BN, thus the frictional wear of the coating and the frictional wear between the coating and a mating plate can be reduced, and the high-temperature wear-resistance service life of a titanium alloy can be significantly prolonged. The self-lubricating wear-resistant composite coating provided by the application adopts a laser cladding technology, ensures that a coating micro-structure is fine and compact and can be firmly combined with a titanium alloy matrix, and can be used for significantly improving the comprehensive mechanical performance of the titanium alloy.

Owner:SUZHOU UNIV

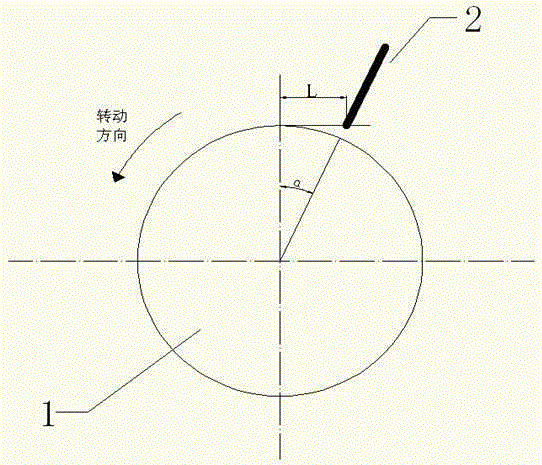

Laser anti-corrosion and wear-resistant process for trunnion of movable guide vanes of turbines

InactiveCN101629289ASolve technical bottlenecksLow dilution rateMetallic material coating processesNumerical controlWear resistant

The invention relates to a laser anti-corrosion and wear-resistant process for the trunnion of movable guide vanes of turbines. The process comprises the following steps: useing liquid penetrant test detection to detect the whole guide vane trunnion so as to determine cracks, air cavities and slag in the erosive wear area; and making balancing weights according to the shape and poise error of the guide vanes; removing the fatigue layer of the erosive wear area of the guide vanes; and carrying out cleaning technology treatment after clearing. A special powder feeding device is used to carry out laser cladding for special alloy materials which have good fusion property, high bonding strength and good anti-corrosion and wear-resistant properties. The specific parameters of the cladding process are as follows: the laser power is 3,200W, the spot diameter is 3.2 mm, the latus spots are used, the scanning speed of numerical control programming is 700 mm / min, the lapping rate is 25%, argon protection is used, and the alloy materials are delivered into the melting bath of laser cladding in an angle of 15 DEG by a special laser powder feeding device in a synchronous powder feeding way. All movable guide vanes to be repaired in the invention do not need sending to the manufacturer for treating, huge transport expenditure is not needed, and the whole repair period can be greatly shortened.

Owner:岳阳大陆激光技术有限公司

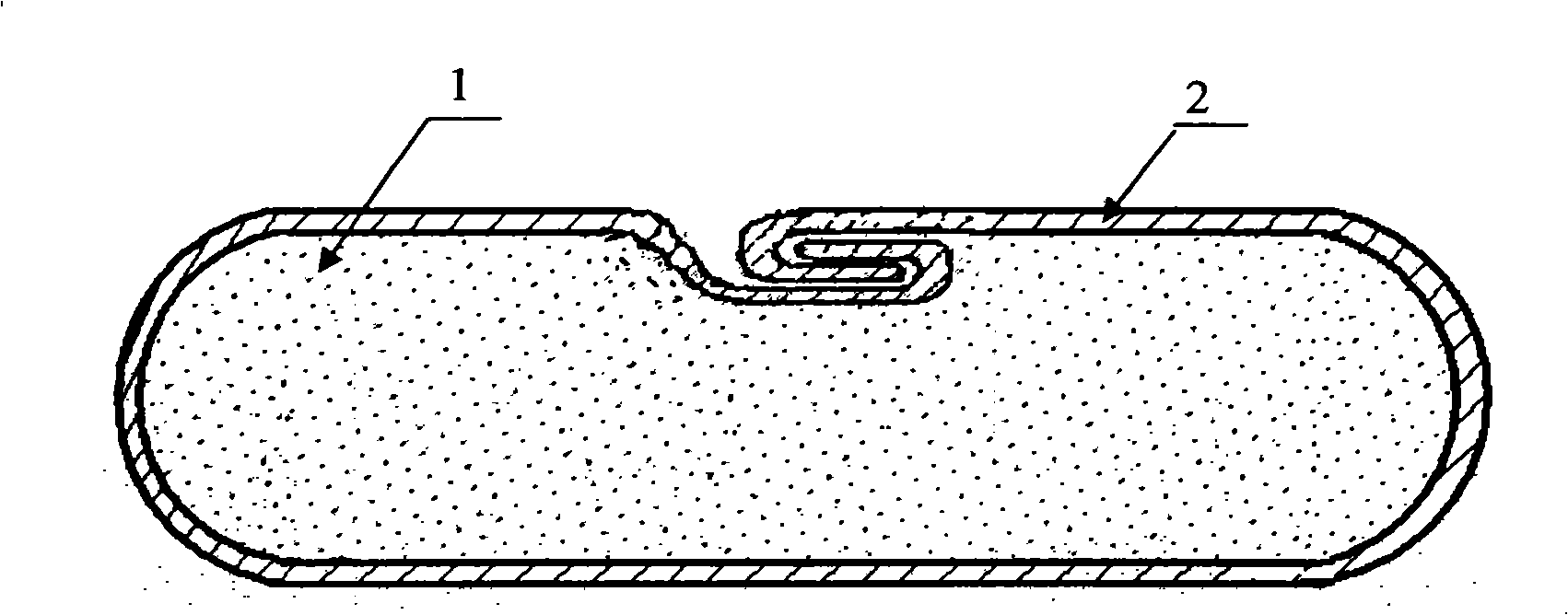

Cored welding strip applied in resurfacing welding and preparation method thereof

InactiveCN101596653AImprove wear resistanceImprove stabilityWelding/cutting media/materialsSoldering mediaSteel beltDrug powder

The invention discloses a novel resurfacing welding cored welding strip which consists of a steel tube circled by steel strips and drug powder wrapped in the steel tube, the steel strips comprises an upper steel strip and a lower steel strip which can be purchased in the market. The shape of the steel tube circled by steel strips is that the longitudinal cross section is long flat form or rectangle-like shape, the longitudinal length is determined at will, and the steel tube can be cut out at will or winded into a tray according to requirements. The transverse edges of the upper steel strip and the lower steel strip are connected at the upper steel strip side in a related joint form, and the drug powder is filled in the steel tube circled by the steel strips evenly with the filling rate being 20-80%. According to the different types of resurfacing metals, the content of alloy element in the resurfacing welding cored welding strip is different. The cored welding strip has simple production equipment and technique, and low production cost, thus overcoming the defect that alloy welding filament used for filament resurfacing welding is difficult to produce and the problems of large investment on production equipment, high production cost and expensive price in cored welding filament production.

Owner:SHANDONG UNIV

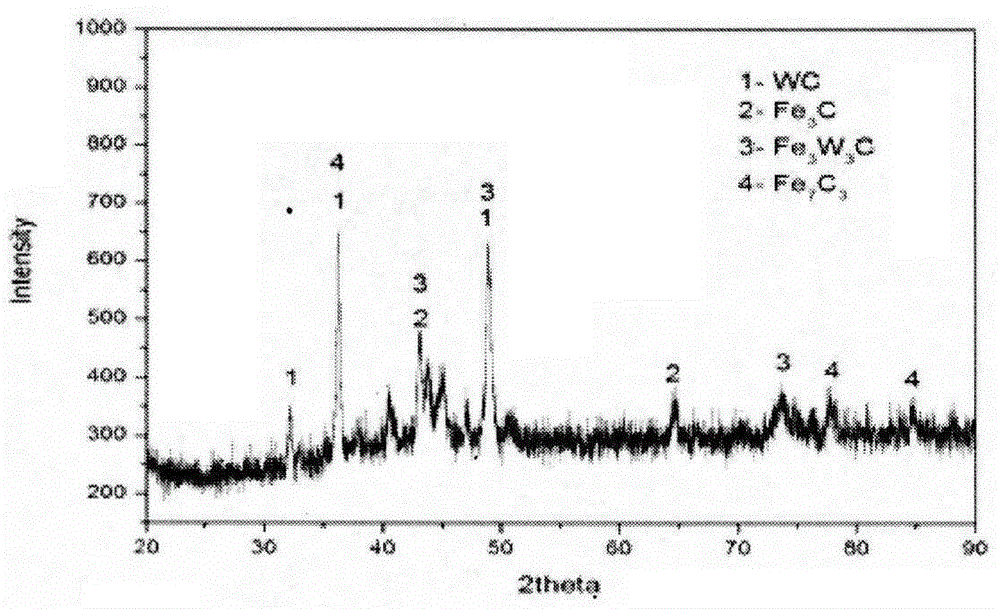

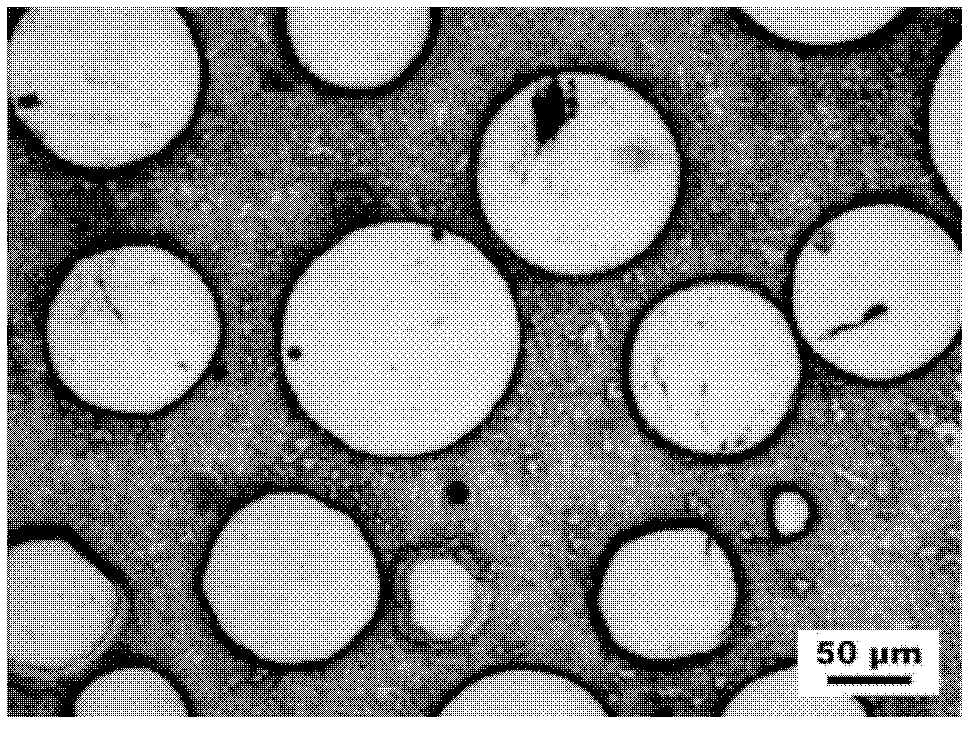

Laser-cladding tungsten carbide ceramic particle reinforced metal-based coating and processing method thereof

ActiveCN105112908AImprove bindingImprove wettabilityMetallic material coating processesAlloyMetallic Nickel

The invention discloses a laser-cladding tungsten carbide ceramic particle reinforced metal-based coating. The coating comprises alloy powder; the alloy powder comprises tungsten powder and graphite with the mole ratio of 2:1 and further comprises reduced iron powder, chromium powder, nickel powder, boron powder, silicon powder and copper powder; further, the alloy powder preferentially comprises the following components in percentage by mass: 55-60% of tungsten powder, 7-9% of graphite, 23-30% of reduced iron powder, 0-3% of chromium powder, 2-6% of nickel powder, 0.3-1% of boron powder and 0.4-1% of silicon powder. The invention further discloses a processing method for the laser-cladding tungsten carbide ceramic particle reinforced metal-based coating. According to the invention, a tungsten carbide particle reinforcing phase for reinforcing the iron-based composite is successfully prepared through a laser cladding in-situ synthesis technology, and a transition layer is arranged between the coating and the matrix, so that atom binding between the coating and the matrix is realized and the bonding strength is relatively high.

Owner:WENZHOU UNIVERSITY

Surfacing welding method for abraded large roll shaft

ActiveCN105382378AReduce defectsImprove forming qualityArc welding apparatusWelding/cutting media/materialsFatigue damageSlag

The invention discloses a surfacing welding method for an abraded large roll shaft. The surfacing welding method is characterized by comprising the following steps that 1, preweld material analysis is carried out, preweld cleaning is carried out on the roll shaft, and preweld preparation is carried out; 2, after preweld preparation is finished, preweld preheating is carried out; 3, after preweld preheating is finished, automatic submerged arc welding is adopted for surfacing welding; 4, after surfacing welding is finished, welding slag is broken down, and postweld heat treatment is carried out; and 5, after heat treatment is finished, finally machining is carried out according to requirements. After the surfacing welding method is adopted, surfacing welding layer defects at the surfacing welding position are few, and the forming quality of a welding channel is good; the hardness of the surfacing welding position is distributed in a ladder manner from low to high from inside to outside, and the hardness of the outermost layer even ranges from 55 HRC to 60 HRC; the impact toughness and strength of the surfacing welding position are equal to those of the roll shaft and even exceed those of a base material by 1-2 times; the capacity for resisting spalling fatigue damage is high, the surfacing welding effect is remarkable, and the welding quality requirement can be completely met; and the whole surfacing welding process is easy to master and control, and good economical efficiency is achieved.

Owner:JIANGSU JINHANG MACHINERY MFG CO LTD

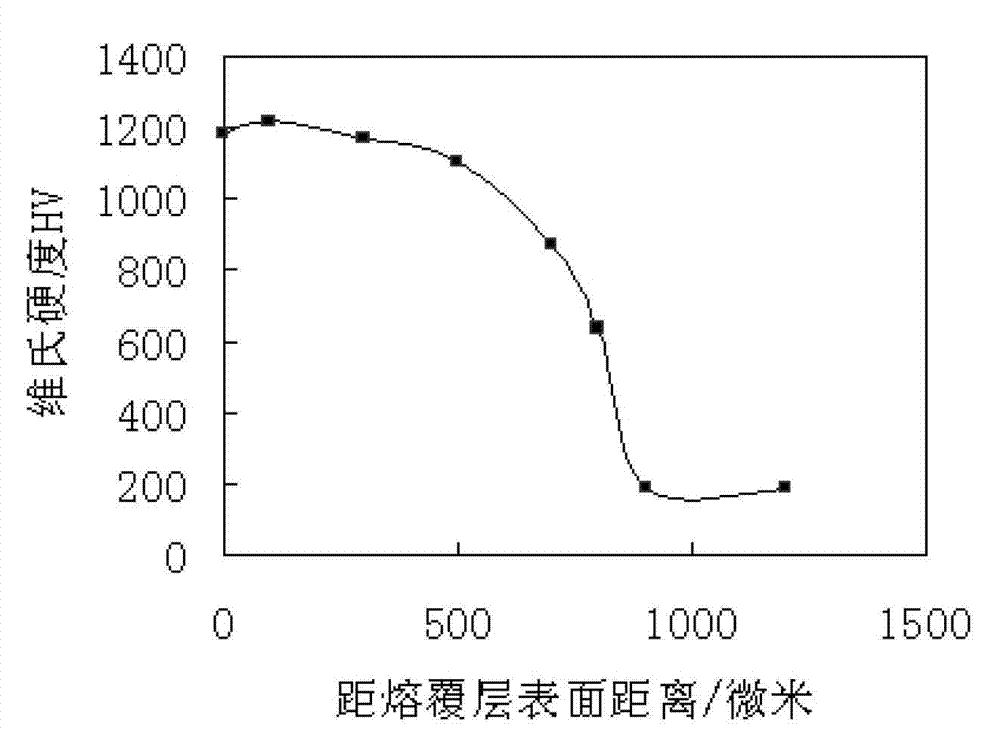

Powdered material used for preparing high-temperature wear-resistant cladding layer and preparation method thereof

InactiveCN102965665AImprove wear lifeLow dilution rateMetallic material coating processesSurface engineeringImpeller

The invention discloses a powdered material used for preparing a high-temperature wear-resistant cladding layer and a preparation method thereof, belonging to the technical field of surface engineering. The powdered material comprises the following components by weight percent: 6-28% of TiB2, and the balance of Ni-Cr-Mo-Fe-Nb-B-Si-C alloy powder, wherein the Ni-Cr-Mo-Fe-Nb-B-Si-C alloy powder comprises the following ingredients by weight percent: 23-28% of Cr, 1-3% of Mo, 2-4% of Fe, 0.5-1% of Nb, 3-4.5% of B, 3.5-4.5% of Si, 0.5-1.3% of C and the balance of Ni. The preparation method comprises the steps of preparing powdered raw materials and mixed powder, and preparing the mixed powder to be the cladding layer used for the anti-abrasion treatment of a water cooling wall tube of a circulating fluidized bed boiler, or used for the anti-abrasion treatment of mill exhausters in a thermal power plant or an impeller of an induced draft fan. A TiB2 ceramic particle reinforced wear-resistant cladding layer is prepared by adopting a laser cladding technology, the surface microhardness ranges from 1000-1200HV, the technical requirements of high temperature and wear resistance of the water cooling wall tube of the circulating fluidized bed boiler are met, and the service life of the water cooling wall tube can be prolonged obviously.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

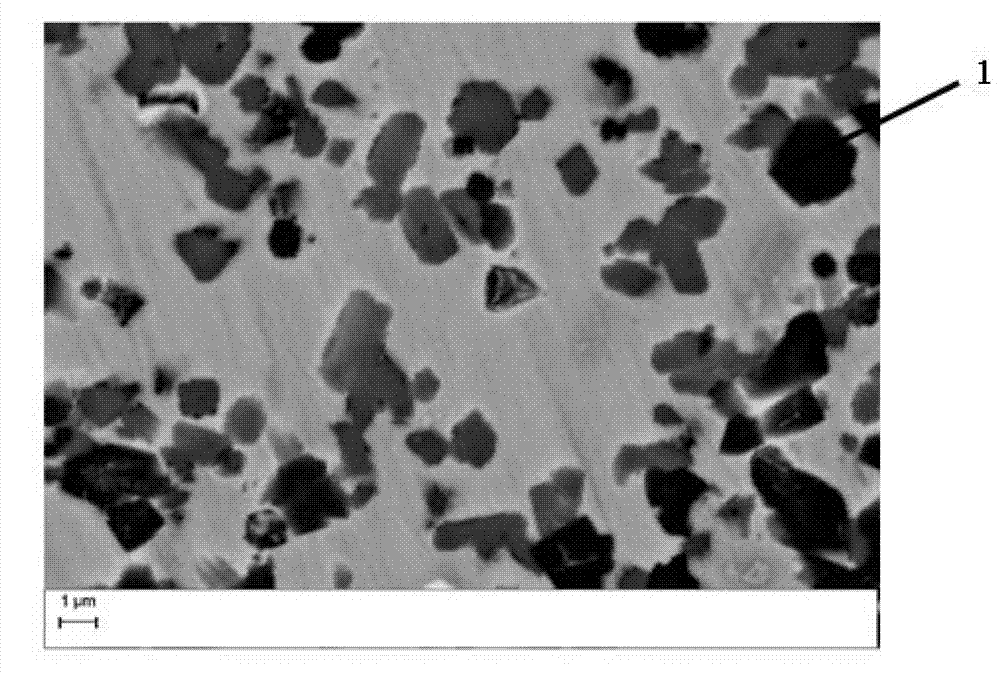

Powder material for boiler tube high temperature resistance and wear resistance protecting and preparation method thereof

InactiveCN103878363AHigh hardnessImprove wear resistanceMetallic material coating processesSurface engineeringWear resistant

The invention relates to powder material for boiler tube high temperature resistance and wear resistance protecting and a preparation method thereof, and belongs to the technical field of surface engineering. The power material comprises the following components, by weight percentage, 10-20% of titanium-nickel alloy powder, 1.5-3.5% of graphite powder, 0.5-1% of silica powder, 8-25% of nickel-chromium alloy powder Ni80Cr20, 5-10% of iron boride powder and the balance of tri-chromium dicarbide powder. The preparation method comprises the following steps that power material is prepared, mix powder is formed, liquid-containing binders are prepared, sizing agents are prepared from the mix powder, prilling is completed through spray drying, and finished product powder is prepared from screening the prilling powder and is used for preparing a cladding layer. The metal cladding layer with high wear resistant duplex ceramic is formed through laser cladding, and the hardness ranges from 1100 HV to 1600 HV, so that the powder material for boiler tube high temperature resistance and wear resistance protecting and the preparation method thereof has the advantages that efficiency of the laser cladding is higher, loss of powder spattering is low, grain of the cladding layer is tiny, wear resistance of the cladding layer is high and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

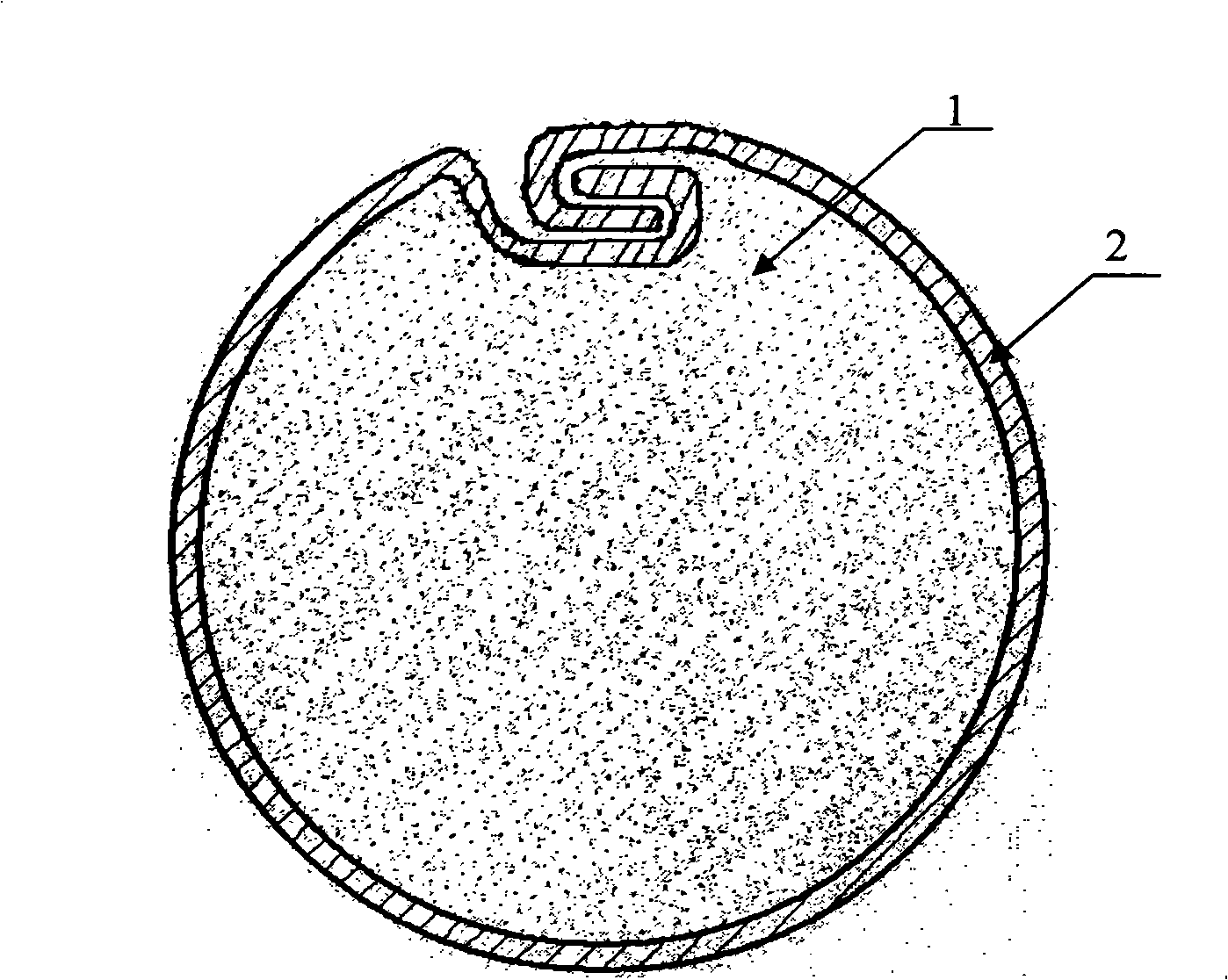

Laser-induction compounded cladding method for repairing continuous casting crystallizer

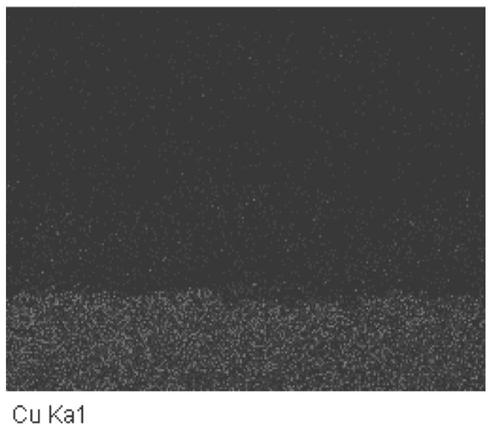

InactiveCN102909325AThickness is easy to controlLow dilution rateMetallic material coating processesAlloyCopper

A laser-induction compounded cladding method for repairing a continuous casting crystallizer is characterized by comprising the following steps: conducting deoiling, derusting, crack or scratch excavating, activating, and electronickelling or chemical nickel plating on a damaged part of the continuous casting crystallizer; then adopting laser-induction compounded cladding dedicated copper-base alloy powder to repair the damaged part of the continuous casting crystallizer, wherein the dedicated copper-base alloy powder comprises the following chemical constituents by weight percent: 7 to 9 percent of Ni, 8 to 12 percent of Sn, 5 to 15 percent of Al, 0.8 to 2 percent of Si and Cu in balancing amount. According to the invention, laser-induction compounded cladding repairing can be conducted on the damaged part of the continuous casting crystallizer under the condition that the cladding efficiency is improved by 1 to 5 times, so as to solve the problem that the conventional repairing coating of the continuous casting crystallizer is thin, easy to peel and low in thermal conductivity.

Owner:NANCHANG HANGKONG UNIVERSITY

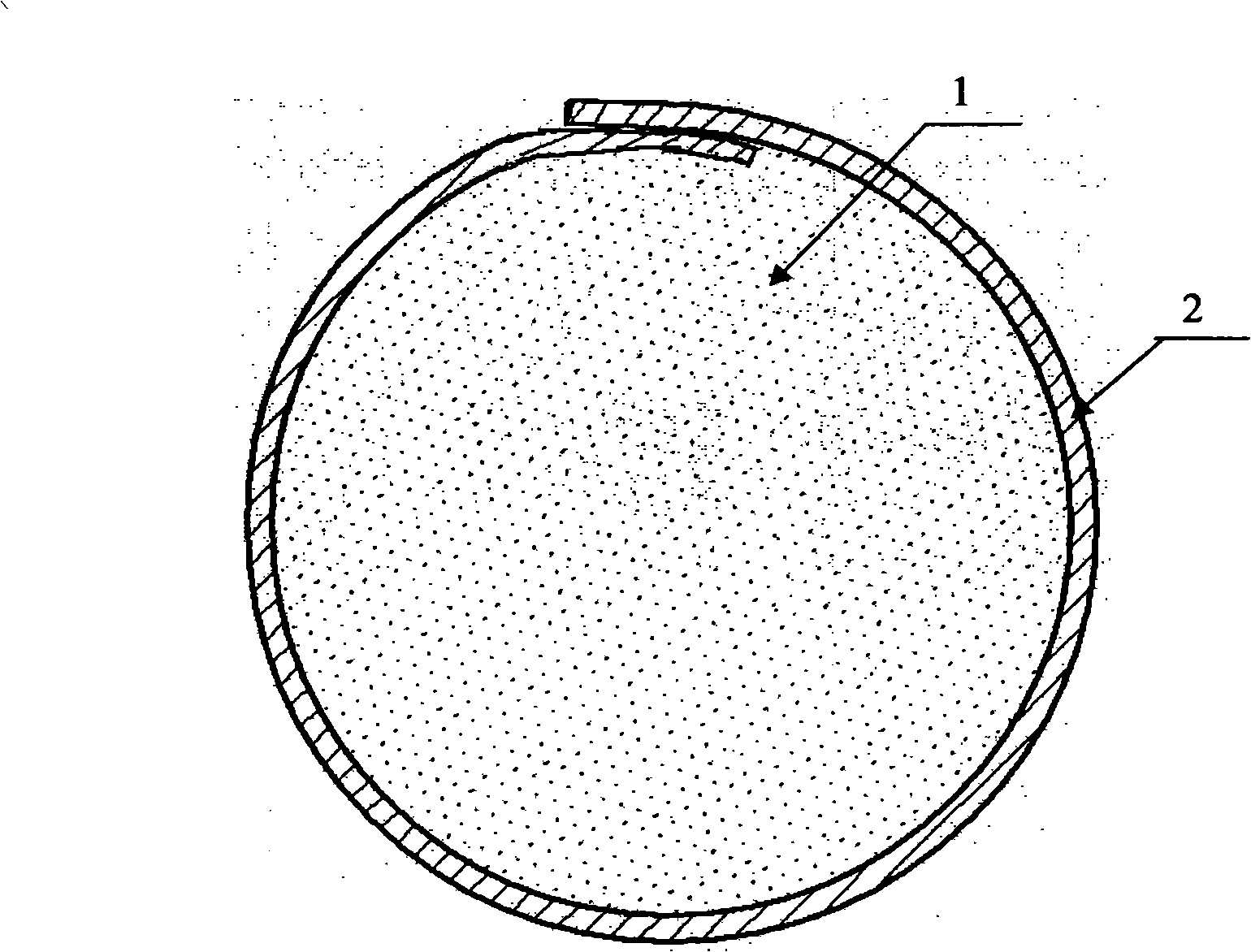

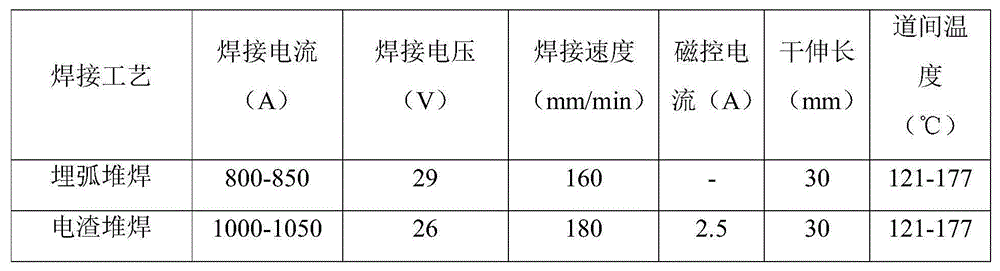

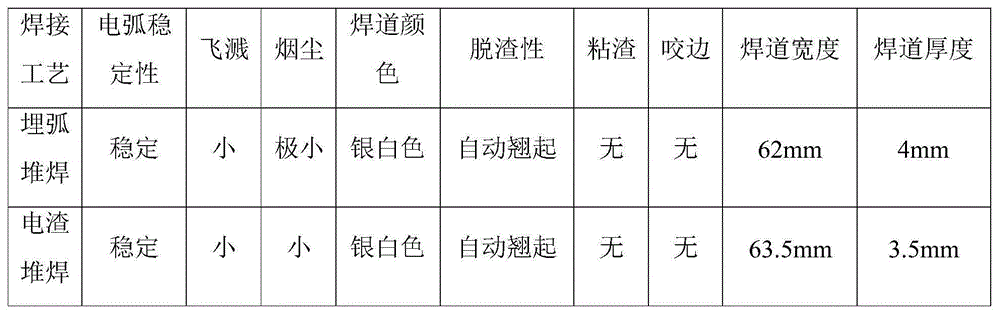

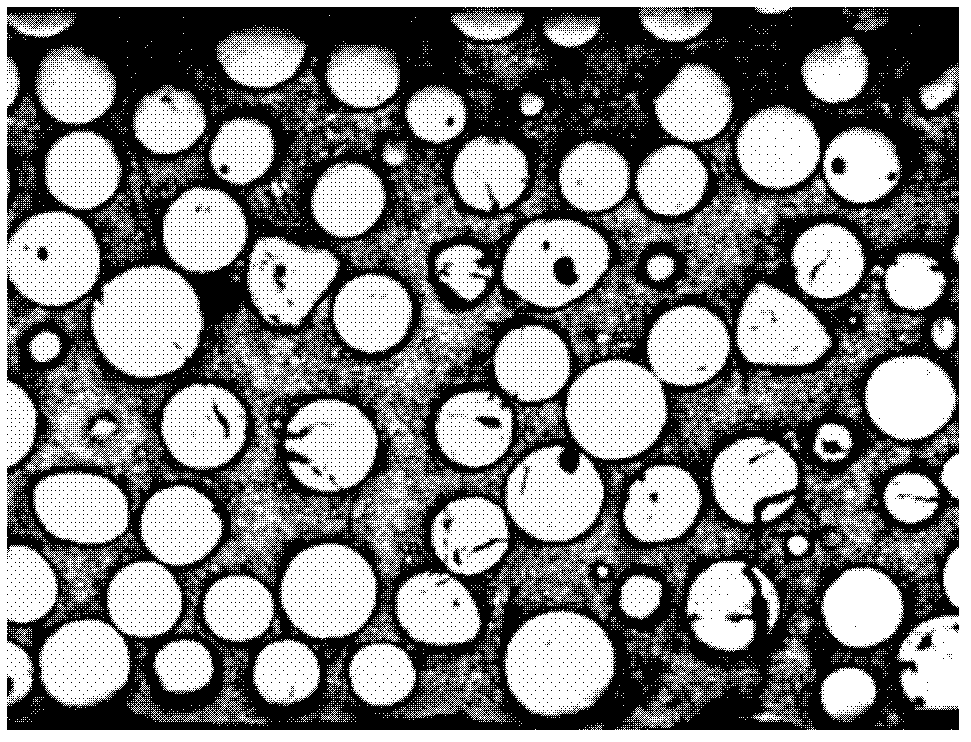

Strip electrode electroslag surfacing process of nickel-based alloy of tube plate of nuclear power steam generator

InactiveCN101797660AImprove deposition efficiencyLow dilution rateArc welding apparatusNuclear powerAlloy

The invention discloses a strip electrode electroslag surfacing process of nickel-based alloy of a tube plate of a nuclear power steam generator, which comprises the following steps of: detecting the surface before surfacing; preheating; carrying out surfacing welding; carrying out post-heat treatment; polishing the surface of a surfacing layer; and detecting the surface after surfacing. When used for large-area surfacing of the tube plate, the strip electrode electroslag surfacing process can greatly improve the quality of the surfacing layer, reduce the surfacing time of the nickel-based alloy of the tube plate, quicken the proceeding of subsequent procedures, increase the production efficiency of the whole steam generator manufacturing, and shorten the manufacturing period.

Owner:SHANGHAI ELECTRIC NUCLEAR POWER EQUIP CO LTD

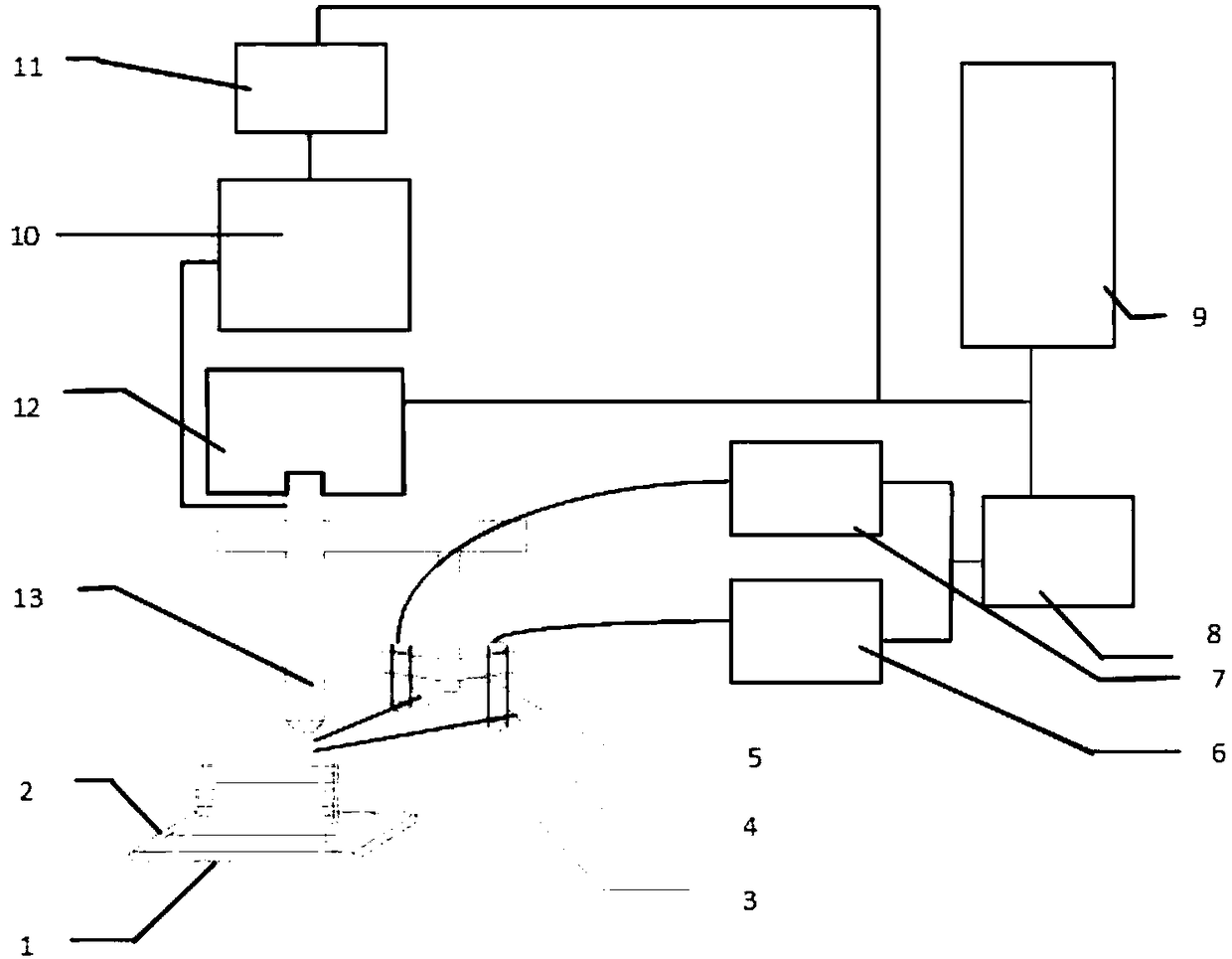

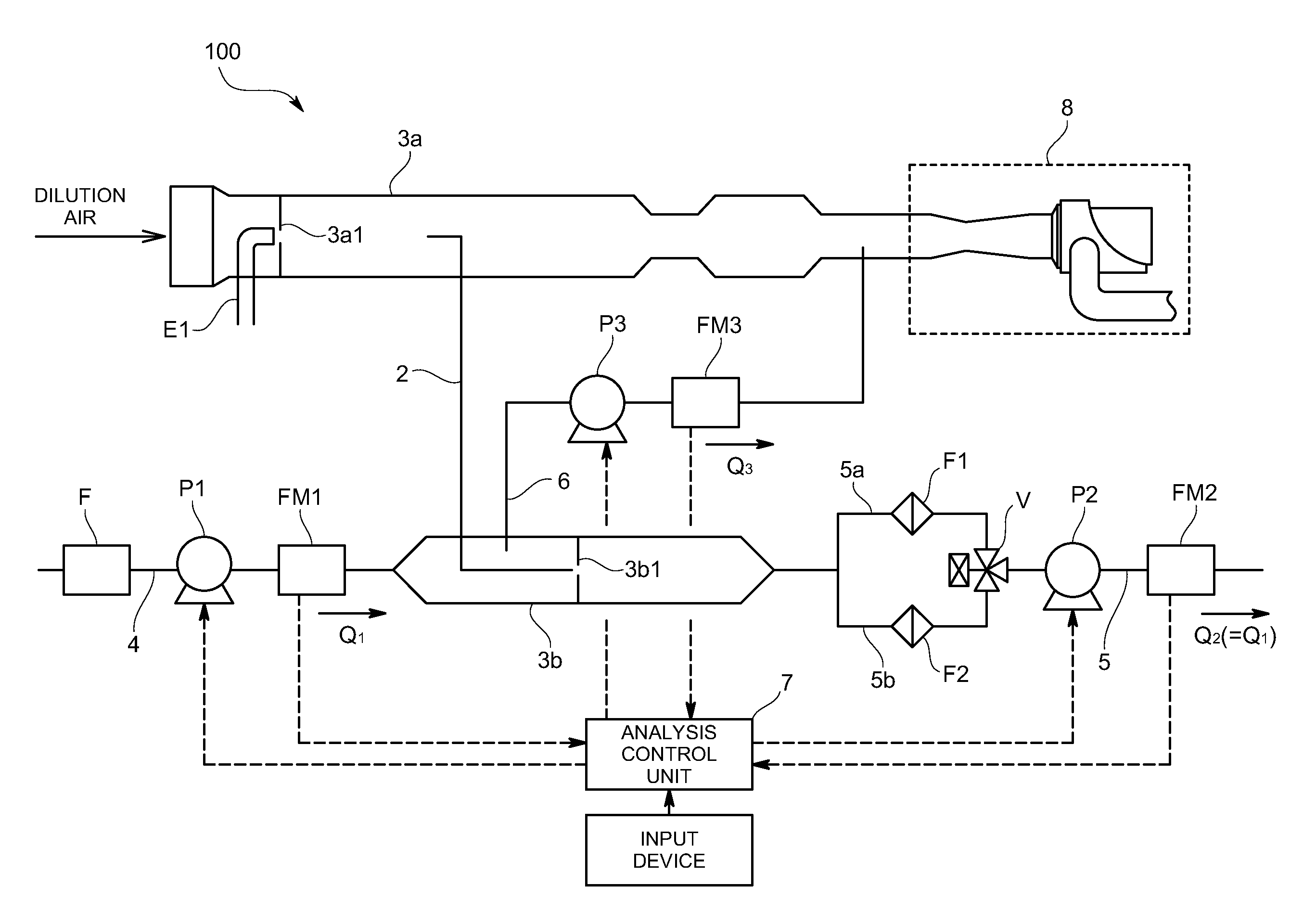

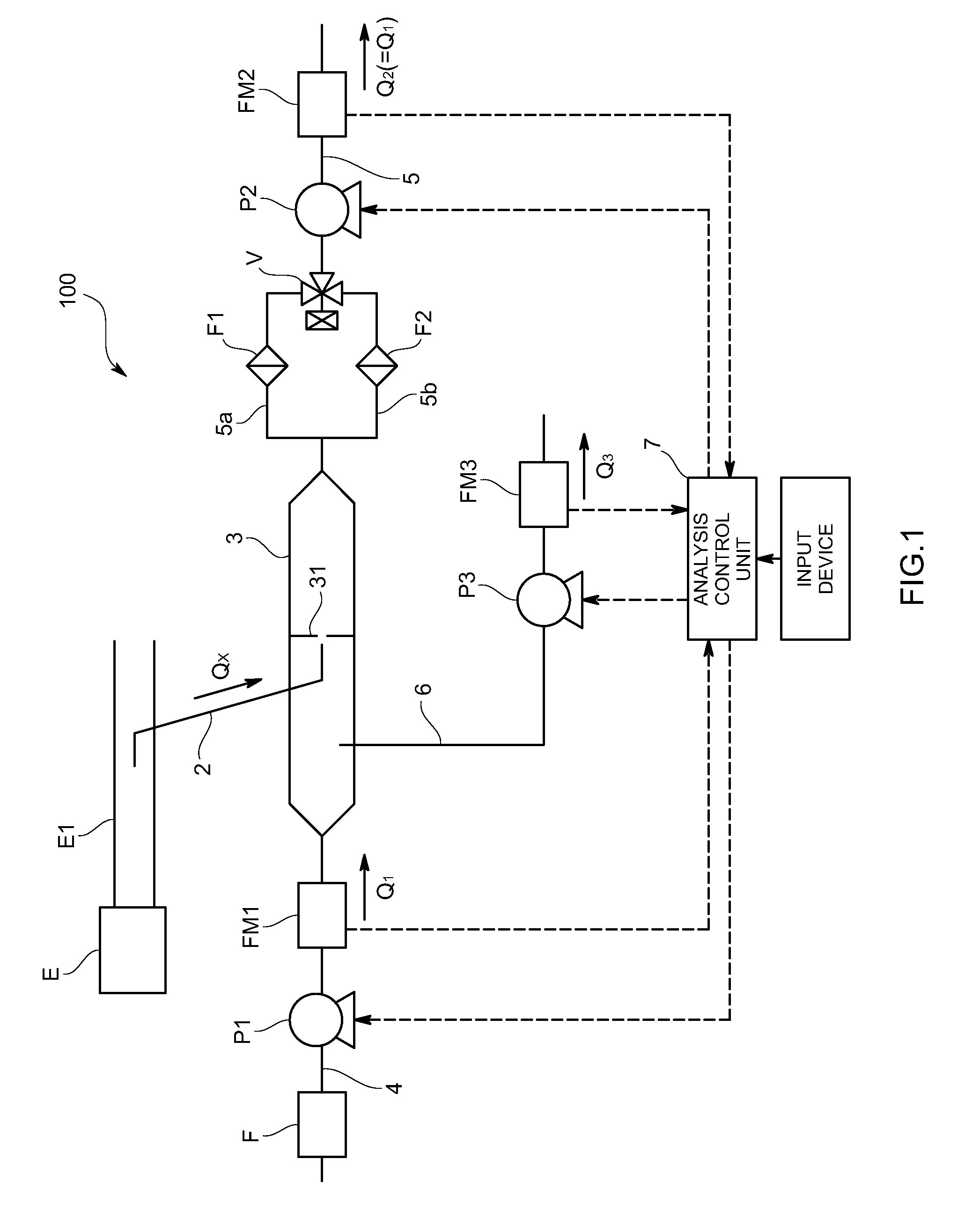

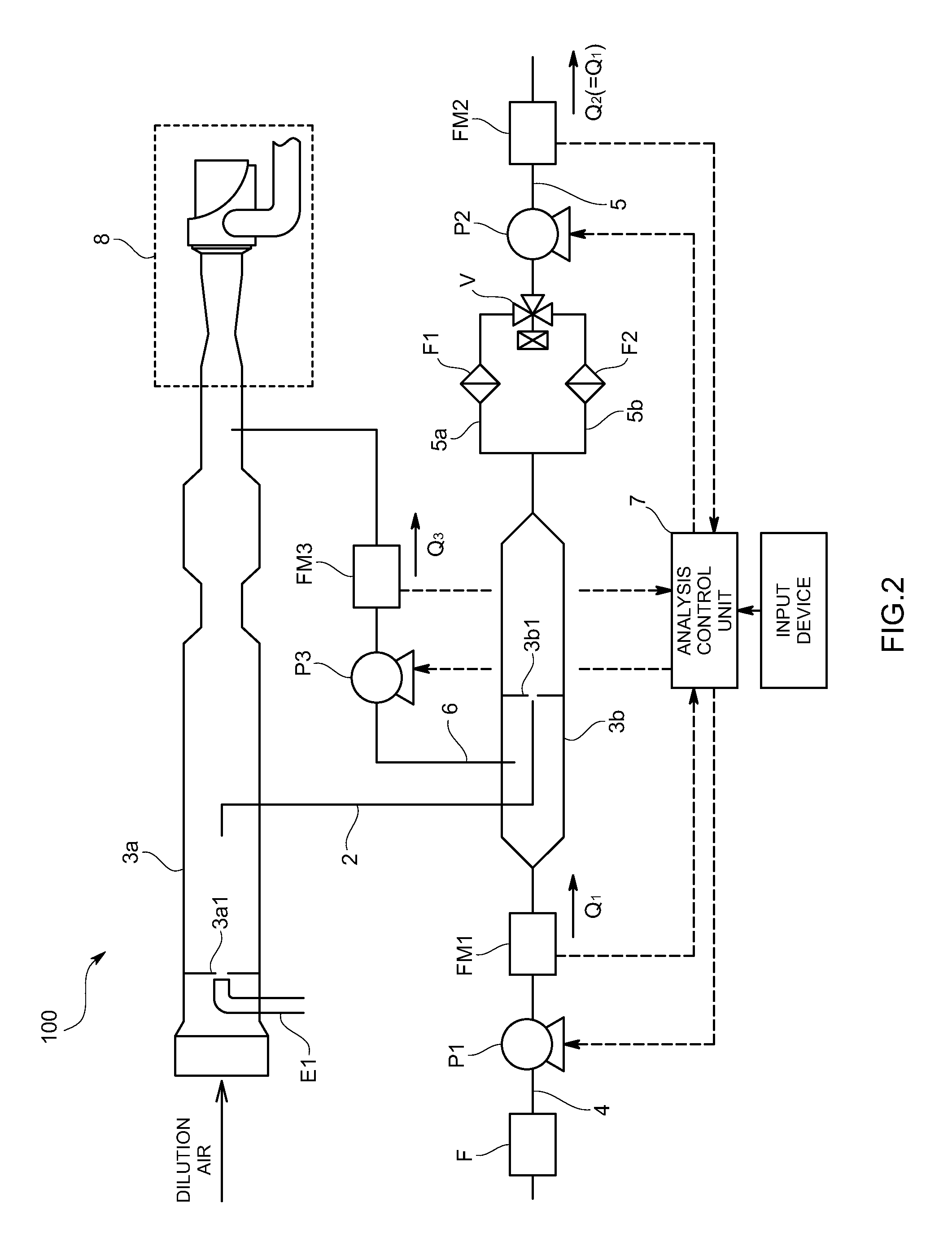

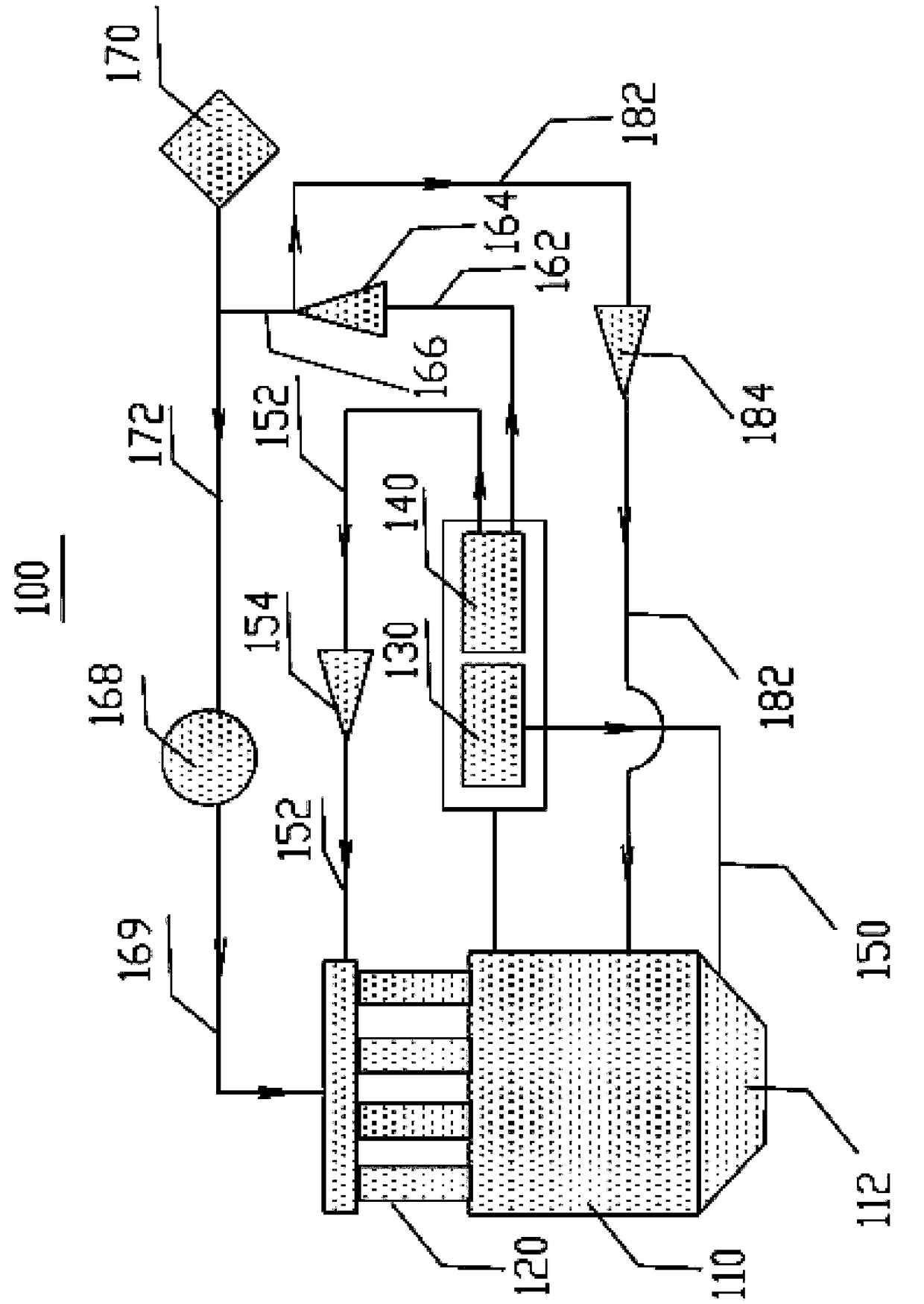

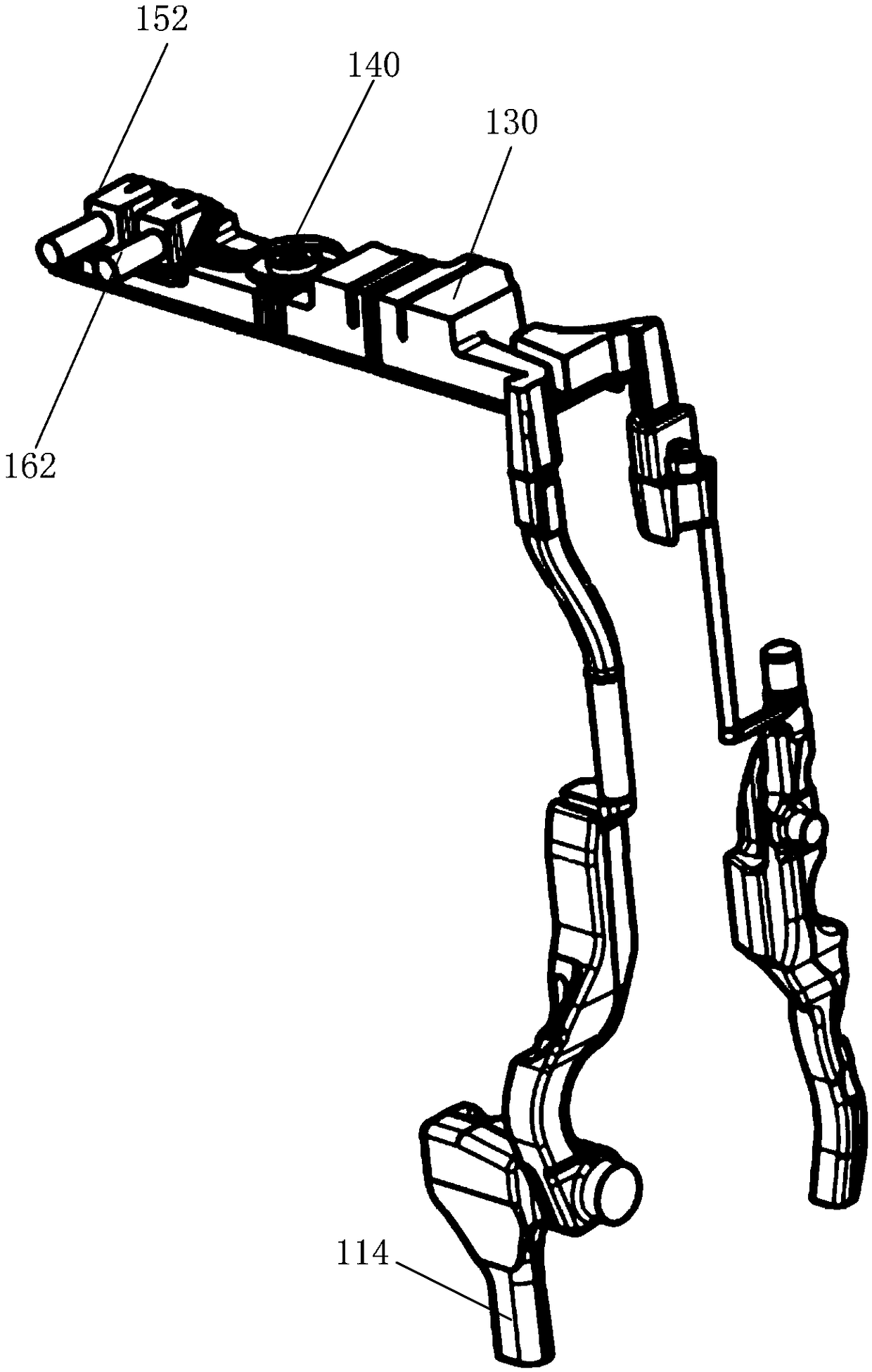

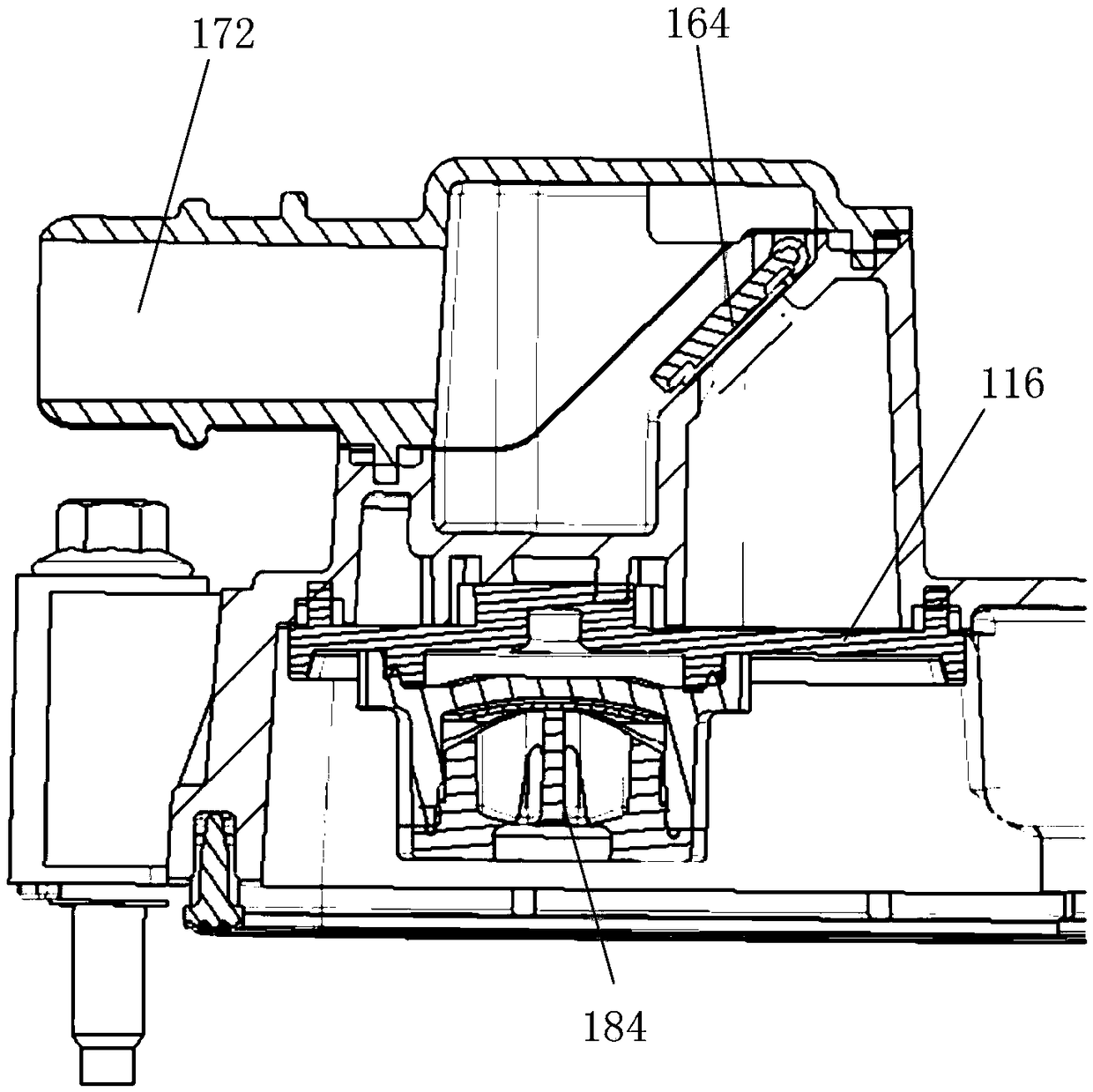

Exhaust gas sampling device

An engine gas sample device which can set a dilution rate of a sample gas without being restricted by warranty flow ranges of first and second flowmeters. The device makes it possible to dilute the sample gas at a low dilution rate, and is provided with a downstream-side dilution tunnel in which a part of exhaust gas flowing through an exhaust pipe is introduced as sample gas into a mixing part. A dilution gas flow path which is connected to an upstream side of the downstream-side dilution tunnel and includes the first flowmeter FM1, a diluted sample gas flow path which is connected to the downstream side of the downstream-side dilution tunnel and includes the second flowmeter FM2. A dilution gas discharge flow path which is connected to an upstream side of the mixing part in the downstream-side dilution tunnel and includes a third flowmeter FM3.

Owner:HORIBA LTD

Method for overlaying glass die by plasma

ActiveCN101913019AImprove welding efficiencyIncrease profitArc welding apparatusPlasma welding apparatusFree coolingWear resistance

The invention discloses a method for overlaying a glass die by plasma. The method comprises the following steps of: (1) reheating; (2) prefabricating a glass die for overlaying; (3) setting an overlaying parameter; (4) arranging the position of an overlaying gun and overlaying; (5) insulating heat; and (6) heating the glass die and naturally cooling. The overlaying efficiency of the glass die is improved, and nickel-base powder overlaid to the glass die is not easy to fall off, thus the utilization ratio of the nickel-base powder is higher. The glass die overlaid by the method has better uniformity and has no pores on the surface. In the overlaying process, the invention solves the problem that the glass die is extremely easy to have an oxidation layer, is beneficial to improving the oxidation resistance and the wear resistance of the glass die and guarantees the quality stability of the glass die.

Owner:CHANGSHU JINGGONG MOLD MFG

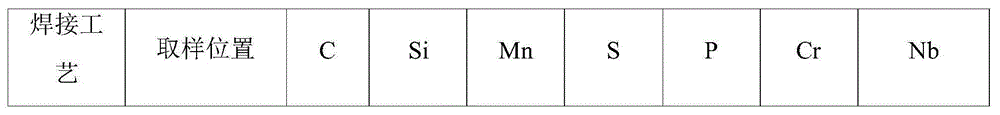

Mn and Nb added NiCrFe alloy surfacing solder strip for nuclear power and welding method

InactiveCN105215571AImprove deposition efficiencyLow dilution rateWelding/cutting media/materialsSoldering mediaCrack resistanceNuclear power

The invention provides a Mn and Nb added NiCrFe alloy surfacing solder strip for nuclear power and a welding method and belongs to NiCrFe nickel base alloy solder strips. The solder strip is composed of, by weight, less than 0.04% of C, less than 0.50% of Si, less than 5.0% of Mn, less than 0.015% of S, less than 0.020% of P, 28.0-31.5% of Cr, 7.0-12.0% of Fe, less than 2.5% of Nb, less than 0.30% of Cu, less than 0.50% of Al, less than 0.50% of Ti, and the balance nickel. The Mn and Nb added NiCrFe alloy surfacing solder strip for nuclear power can be applicable to a submerged arc overlay welding process and an electroslag surfacing process and can also be applicable to manufacturing of key components of a nuclear island of a nuclear power plant by being matched with corresponding soldering flux, the Mn element and the Nb element are added in the solder strip and improve the performance of resistance to high temperature plasticity-losing cracks of surfacing deposited metal, the surfacing deposited metal has high crystallization crack resistance and stress corrosion cracking resistance, the excellent corrosion resistance is achieved and integrated mechanical performance is good. By being matched with the soldering flux for surfacing, a weld pass is attractive in formation, corrugations are compact, deslagging is easy and welding defects are avoided.

Owner:HARBIN WELDING INST LTD +2

Crankcase ventilation system

InactiveCN108894851ASpeed up the flowEasy to diluteMachines/enginesCrankcase ventillationAir filterPressure controlled ventilation

The invention provides a crankcase ventilation system which comprises an engine body, an intake manifold, an oil and gas separating system, a pressure control valve and an oil loop. The intake manifold and the oil and gas separating system are connected with the engine body separately, the pressure control valve is connected with the oil and gas separating system, and the oil and gas separating system is connected with the engine body through an oil loop; the crankcase ventilation system further comprises a first crank ventilation access, a second crank ventilation access and a gas supplementing access, the first crank ventilation access is a gas access under the small-load working condition, and the two ends of the first crank ventilation access are connected with the pressure control valve and the intake manifold respectively; the second crank ventilation access is connected with the first crank ventilation access in parallel and is a gas access under the large-load working condition, and the two ends of the second crank ventilation access are connected with a booster front pipeline and the pressure control valve respectively; the two ends of the gas supplementing access are connected with an air filter rear pipeline and the engine body respectively. The crankcase ventilation system can solve the problems that engine oil is diluted and engine oil is emulsified.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +1

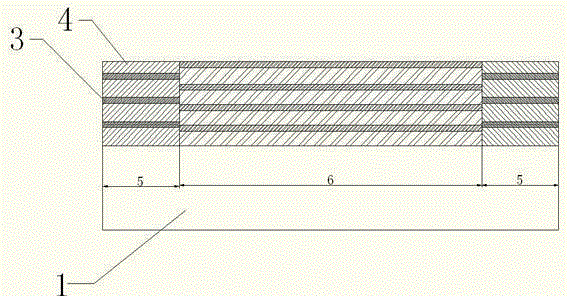

Method for preparing WC (Wolfram Carbide) cemented carbide wearing layer on surface of petroleum drilling tool stabilizer through laser cladding

InactiveCN103484852AUniform coatingExcellent wear resistance and corrosion resistanceMetallic material coating processesCemented carbideAutomatic control

The invention discloses a method for preparing a WC (Wolfram Carbide) cemented carbide wearing layer on a surface of a petroleum drilling tool stabilizer through laser cladding. A tough bottoming transition layer which is in good metallurgical bonding with a matrix is formed on the surface of a shell in a fusion covering manner through rapid laser scanning by using a high-power laser, and mixture alloy powder of spherical WC and Ni-Cr-B-Si, which is wearing-resisting and excellent in corrosion resistance, is prepared on the surface of the bottoming alloy through laser cladding. The power, position, shape and the like of a laser beam of the method can be accurately controlled, selective area or even micro-area fusion covering is easy to realize, the dilution rate of coating components is low, the coating thickness can be accurately controlled, non-contact type treatment is adopted, and automatic control is easy to realize in the whole process; in addition, a laser cladding process is non-pollution on the environment, free of radiation and low in noise, has the characteristics that the productivity is high, the energy consumption is low, the cladding layer machining margin is small, the finished product rate is high, the comprehensive cost is low, and the like, and can be widely applied.

Owner:武汉团结点金激光科技有限公司

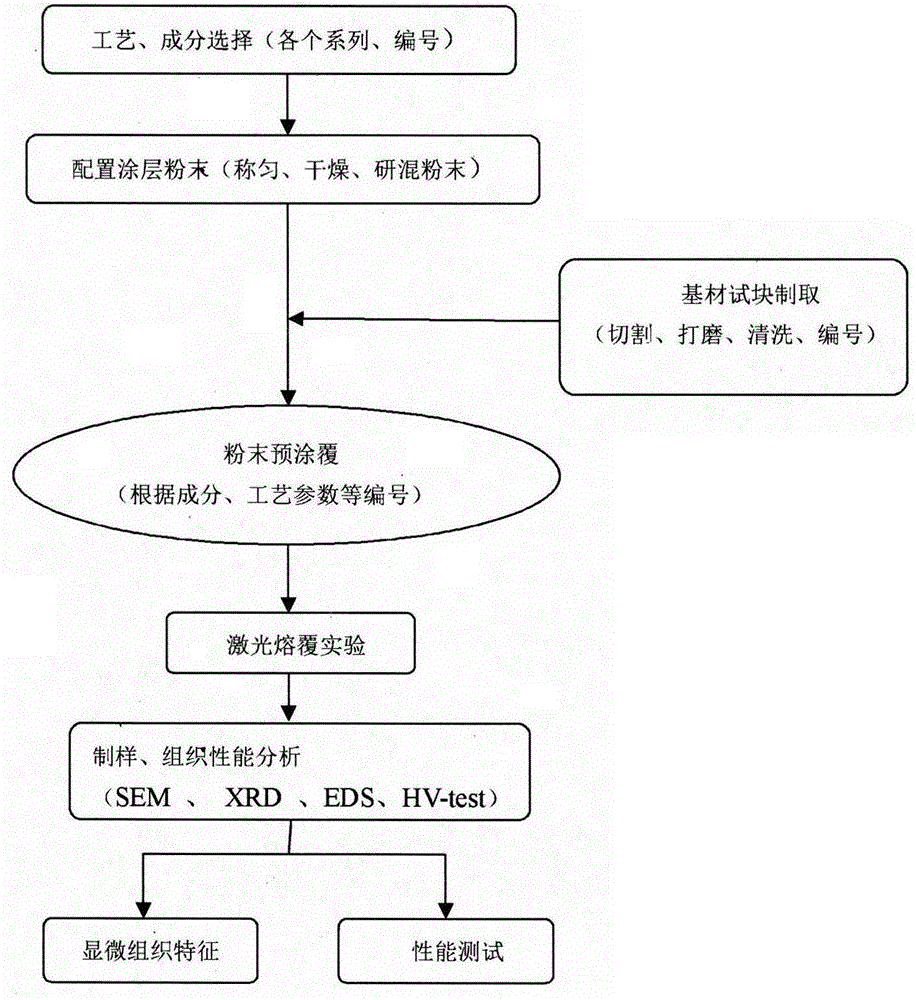

Method for preparing high-content WC (Wolfram Carbide) enhanced alloy powder coating

ActiveCN103290403AImprove corrosion resistanceImprove high temperature performanceMetallic material coating processesSurface engineeringAfter treatment

The invention belongs to the field of material surface engineering and in particular relates to a method for preparing a high-content WC (Wolfram Carbide) enhanced alloy powder coating by employing a laser cladding technology. The composite powder is clad on the surface of a workpiece by employing laser cladding, wherein the composite powder is prepared from WC powder and bonding-phase alloy powder according to a weight ratio, the content of WC powder in the composite powder is 50-70wt%, and the content of bonding-phase alloy powder is 30-50wt%. The WC enhanced alloy powder composite functional coating is prepared by employing the process method, the wear resistance and high-temperature performance of the workpiece are greatly improved after treatment, the service life is prolonged by over 8 times, and the economic benefits are obvious.

Owner:无锡新松机器人自动化有限公司

Metal-based material for preparation of crystallizer or tuyere as well as preparation method of metal-based material

ActiveCN110144582AImprove high temperature wear resistanceLower perfect fitMetallic material coating processesSurface engineeringAlloy

The invention discloses a metal-based material for the preparation of a crystallizer or a tuyere and belongs to the technical field of surface engineering. According to the metal-based material, a transition layer is innovatively arranged between a Cu or Cu alloy matrix and a high-abrasion-resistance working layer by the adoption of a metallurgical bonding method, and made of at least one of pureCo metal, pure Ni metal, pure Cr metal, pure Cu metal, pure Mo metal, pure Ag metal and a NiCr or MCrAlY alloy; through the transition layer, the functions of improving the laser absorption rate, lowering the matrix heat conductivity, and lowering the dilution rate can be achieved; due to the existence of the transition layer, the thickness of the working layer can be adjusted within a range of 0.01-3 mm and the formation of surface cracks can be avoided; furthermore, the ratio of the thickness of the transition layer to that of the high-abrasion-resistance working layer is 1:(1-3), so that the perfect bonding of the transition layer and the high-abrasion-resistance working layer can be guaranteed within the ratio range; the formation of a high-abrasion-resistance coating or coating product which is free of surface cracks and subjected to metallurgical bonding on the Cu or Cu alloy matrix can be improved; the reliability of the crystallizer or the tuyere can be improved; and the service life of the crystallizer or the tuyere can be prolonged.

Owner:XI AN JIAOTONG UNIV

Plasma arc overlaying alloy powder used for heat-working die

ActiveCN105081612AHigh deposition speedImprove productivityPlasma welding apparatusWelding/cutting media/materialsCrack resistanceOxidation resistant

The invention provides plasma arc overlaying alloy powder used for a heat-working die. The overlaying alloy powder is iron-base alloy powder; the raw material comprises, by mass, 1%-2% of nano chromium nitride powder and 2%-5% of yttrium oxide powder. By adding the nano chromium nitride powder into the iron-base alloy powder, fine nitride interstitial phases are formed in overlaying metal, and the overlaying metal is made to be good in toughness and crack resistance; meanwhile, the yttrium oxide is added into the alloy powder, so that the overlaying metal and glomeration inclusion are purified, nitride strengthening phases are promoted to form, and the fatigue resistance of the overlaying metal is improved. The heat-working die is repaired through the alloy power in combination with the plasma arc overlaying technique, the obtained overlaying metal is excellent in high-temperature oxidation resistance, abrasive resistance and cleanliness and is good in fatigue resistance.

Owner:SHANDONG UNIV

Method for reinforcing rail by laser and auxiliary heat source efficient hybrid cladding

PendingUS20200199698A1Reduce cooling rateReduce gradientFurnace typesMetallic material coating processesMartensite transformationHeat-affected zone

The disclosure discloses a method for reinforcing a rail by laser and auxiliary heat source efficient hybrid cladding. The laser and the auxiliary heat source simultaneously apply on a region to be cladded of a rail surface. The laser serves as a main heat source to enable simultaneous and rapid fusion of an added metal powder and partial substrate material in the rail surface to form a molten pool. The auxiliary heat source moves with the laser heat source in the same direction at the same speed, and performs synchronous preheating and / or post-heating on the laser molten pool, the heat-affected zone and the surface layer of the rail substrate to reduce the temperature gradient, thereby reducing the cooling rate, and avoiding martensite transformation and cracking in the heat-affected zone.

Owner:WUHAN HIVALUE INTELASER LTD +2

Laser melting deposition ceramic particle enhanced metal-base composite coating based on tubular powder core wire and machining method

InactiveCN110965060AEvenly distributedLow dilution rateMetallic material coating processesMachiningLaser

The invention discloses a laser melting deposition ceramic particle enhanced metal-base composite coating based on a tubular powder core wire and a machining method. A tubular metal layer serves as ametal base body, a filler serves as a ceramic particle enhancing phase, the advantages of the powder sending type and the advantages of the wire sending type are combined, and under the action of lasers, not only can the stable and smooth globular transfer process in the ceramic particle even distribution process be formed, but also the cladding efficiency, material utilization rate and automationdegree are high; and the continuous stable injection transition process can be realized through the wire. In addition, since the lasers are used as a heat source, heat input is precise and controllable, and the compact no-defect composite coating with low dilution rate and evenly distributed enhancing particles can be prepared.

Owner:TIANJIN UNIV

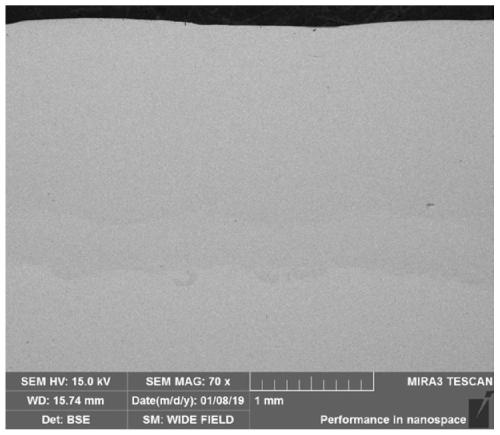

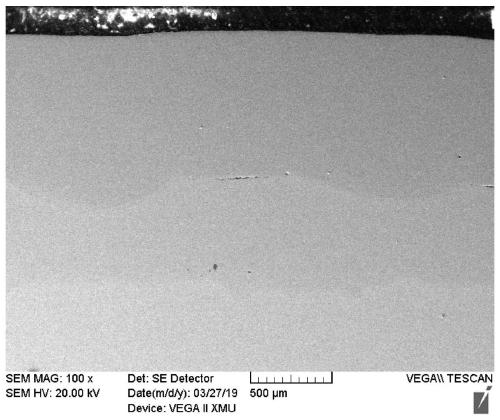

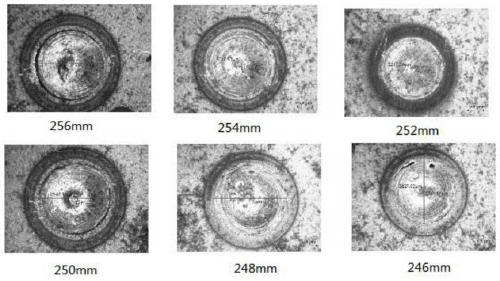

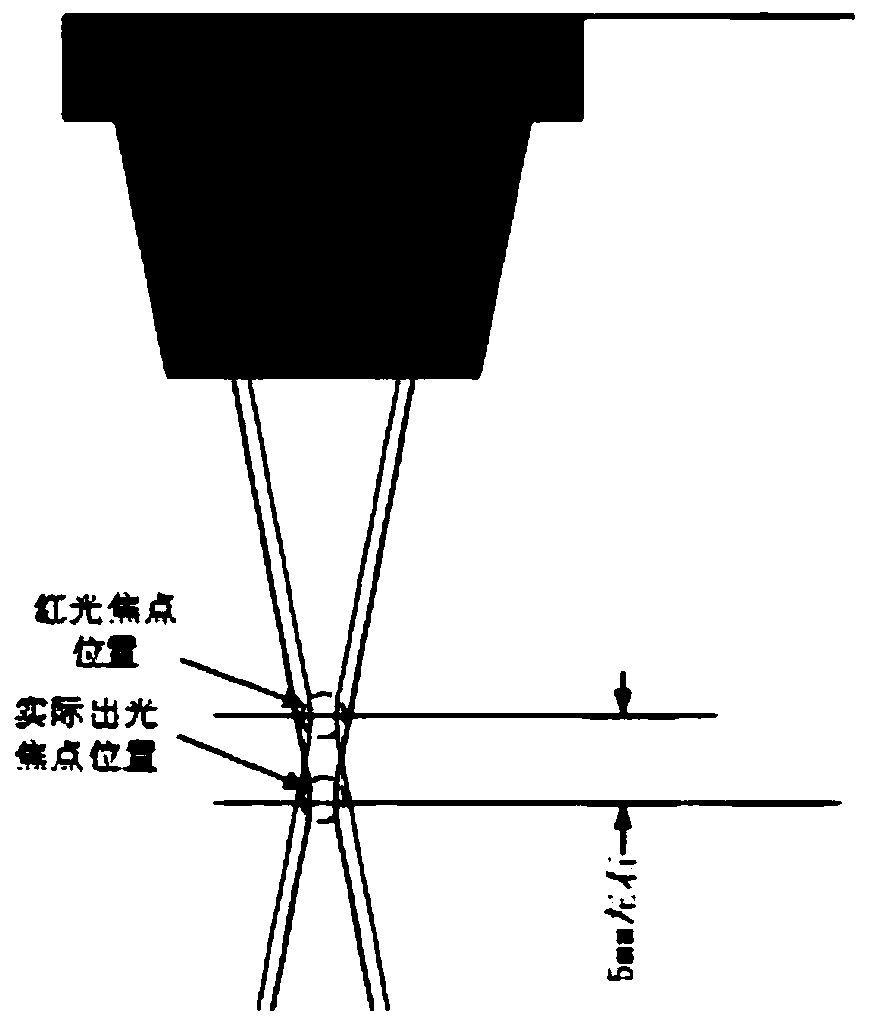

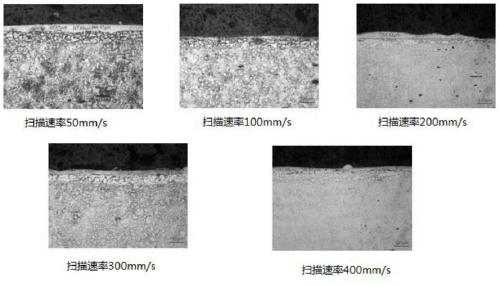

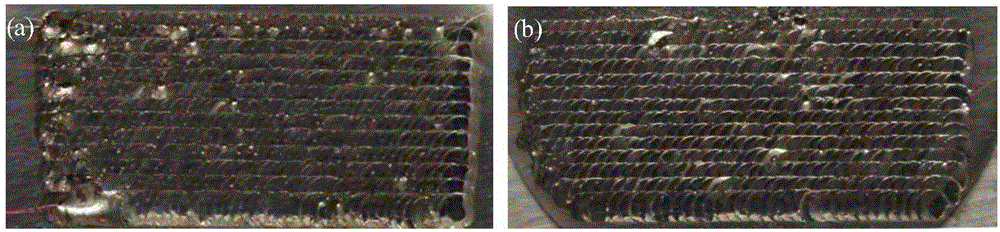

Process for preparing cladding layer on surface of copper base body by utilizing high-speed laser cladding technology

The invention discloses a process for preparing a cladding layer on the surface of a copper base body by utilizing a high-speed laser cladding technology. The process is characterized in that a lasercoaxial powder feeder is used for feeding a cladding alloy material to the surface of the copper base body, meanwhile, layer-by-layer high-speed laser cladding is performed by using an optical fiber laser or an optical fiber coupling semiconductor laser, wherein the process parameters of the laser in the cladding operation process are as follows, the focal length of a focusing lens is 250-300 mm,the cladding power is 2000-8000 W, the diameter of a light spot is 0.3-1.2 mm, the cladding scanning speed is 100-400 mm / s, and the lap joint rate is 65%. According to the preparation process of the obtained cladding layer, by utilizing the laser with the high scanning speed and adopting the specific cladding alloy powder for cooperation, the process parameters of the high-speed laser are determined, on the premise that subsequent other treatment is not needed, the cladding layer with the compact structure, without cracks and air holes and with extremely low dilution rate can be formed the surface of the copper base body, good metallurgical bonding between the cladding layer and the surface of the copper base body can be formed.

Owner:唐山中科量子激光科技有限公司

Iron-based amorphous-nanocrystal composite coating and preparation method thereof

ActiveCN106283039AHigh amorphous contentCompact structureMetallic material coating processesAmorphous metalLaser

The invention provides an iron-based amorphous-nanocrystal composite coating and a preparation method thereof. The preparation method of the iron-based amorphous-nanocrystal composite coating comprises the step that smelted alloy comprising 44-45 wt% of Fe, 8-9 wt% of Co, 10-15 wt% of Cr, 25-27 wt% of Mo, 3-5 wt% of C, 1-2 wt% of B and 1-3 wt% of Y is smeared onto a base material, so that the composite coating is obtained. According to the preparation method provided by the invention, the smelted alloy is adopted in the fusion cladding process, the process of smelting high-purity amorphous self-melting powder of conventional raw materials in a laser way is omitted, holes formed by generation of the amorphous self-melting powder are avoided accordingly, it is ensured that the composite coating of a compact structure is obtained, and the corrosion resistance of the composite coating is improved; and the amorphous forming ability of the adopted smelted alloy is high, and the amorphous content of the coating obtained through fusion cladding is high.

Owner:NANCHANG HANGKONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com