Patents

Literature

336results about How to "Small and uniform tissue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

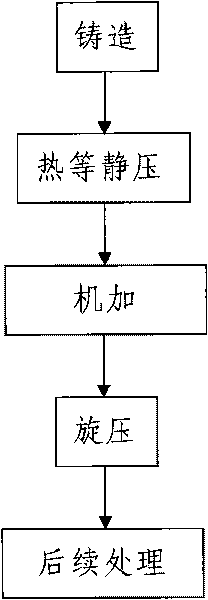

Manufacturing method of large-calibre seamless titanium alloy barrel body

InactiveCN101733641AWide range of sizesEasy to prepareOther manufacturing equipments/toolsTitanium alloyMachining

The invention discloses a manufacturing method of a large-calibre seamless titanium alloy barrel body, which comprises the steps of: 1, casting: casting titanium alloy raw materials into a large-calibre titanium alloy barrel blank by using a vacuum smelting furnace and through a vacuum smelting method; 2, hot isostatic pressing: performing the hot isostatic pressing for the large-bore titanium alloy barrel blank in an inert protective atmosphere by using a hot isostatic pressing device; 3, mechanical machining: processing a chamfer angle for spinning at the head of the large-bore titanium alloy barrel blank after the hot isostatic pressing by using mechanical processing equipment to obtain a spinning barrel blank; 4, spinning: thermally spinning the mechanically processed spinning barrel blank with the total deformation rate not less than 60% for many times by using spinning equipment to obtain a large-bore seamless titanium alloy thin-wall barrel body; and 5, subsequent treatment. The production process has short process flow, high yield, low cost, high utilization rate of materials and easy realization, and the defects of the large-bore seamless titanium alloy barrel body, such as complex process, high cost, low yield and the like of the traditional production process can be effectively solved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method for preparing TiAl alloy plate by argon atomization in powder metallurgy

ActiveCN102513537AThe overall thickness is thinImprove mechanical propertiesMetal rolling arrangementsMechanical propertyImpurity

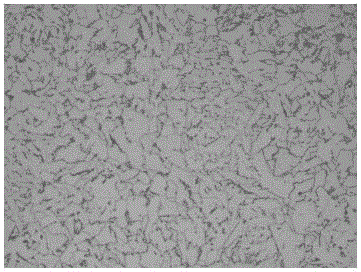

The invention relates to a method for preparing a TiAl alloy plate by argon atomization in powder metallurgy. The method comprises the following steps of: reducing the content of inclusions in TiAl alloy powders by purity smelting in a cold-wall crucible and high-purity argon atomization; performing hot isostatic pressure compaction on the high-purity prealloy powder which is atomized by pure argon under such conditions that the temperature is 1100 to 1300 DEG C, the pressure is 140 to 200 MPa and the compaction time is 2 to 4 hours; removing coatings of the alloy blank after hot isostatic pressure compaction and then performing surface treatment and coating; heating alloy and rolling at a high temperature; and removing coatings to obtain a powder TiAl alloy plate. The plate has the advantages of uniform deformation, good surface quality, fine and uniform texture, low oxide and impurity contents, small thickness, good overall mechanical property and high quality and reliability. The method solves the key problems in development and application of TiAl alloy powder-metallurgy plates, and provides a technical support for innovation and progress of civil industry and aerospace industry.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

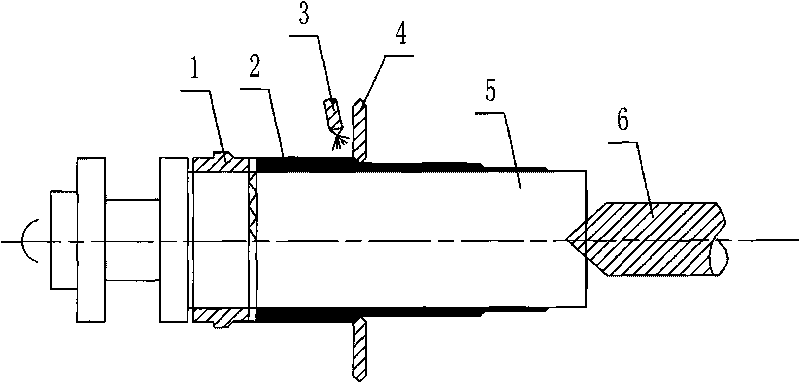

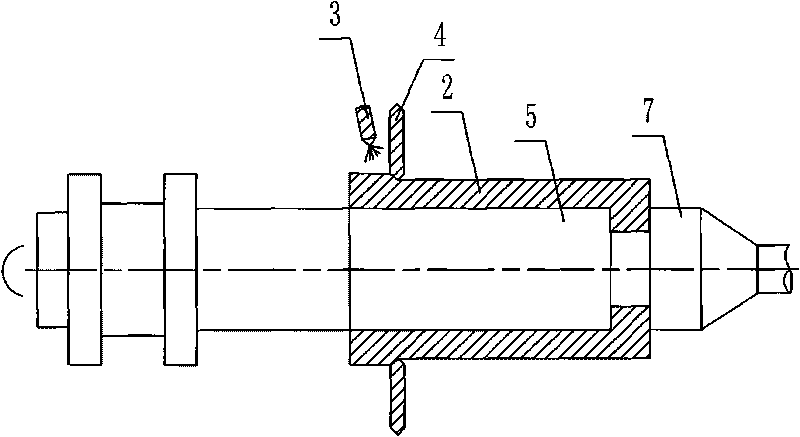

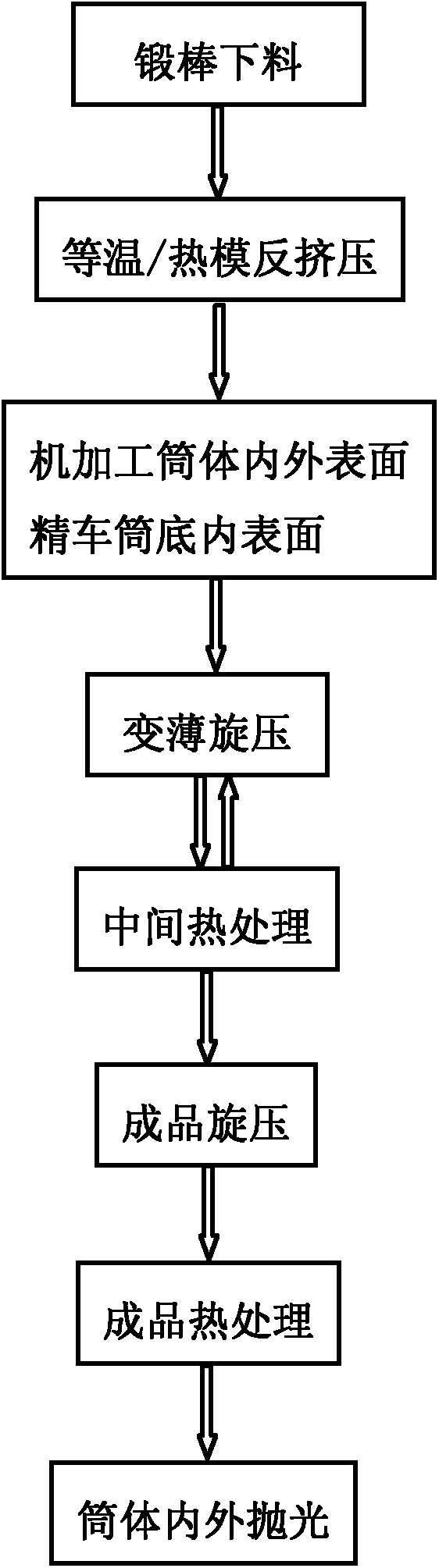

Machining method of high-quality large-diameter thin-wall metal barrel body

The invention relates to a machining method of a high-quality large-diameter thin-wall barrel body. The machining method comprises the following steps. Firstly, isothermy or hot die anti-extrusion technology is utilized, and anti-extrusion is performed on an alloy forging rod. Secondly, machining is performed on the inner and outer surfaces of a spinning barrel billet, and finish turning is performed on the inner surface of the barrel bottom of the barrel billet. Thirdly, multi-pass brute force thinning spinning is performed on the machined spinning barrel billet, and the spinning is hot spinning or cold spinning. Fourthly, intermediate heat treatment is performed on a spinning semi-finished product, and the intermediate heat treatment is annealing or solution treatment. Fifthly, the third step and the fourth step are performed repeatedly and alternatively so that finished product spinning is performed. Sixthly, scouring and cleaning are performed on the barrel body, and finished product heat treatment is performed. Seventhly, polishing of the inner and outer surfaces of the barrel body after heat treatment in the sixth step is performed, and a finished product barrel body is obtained. By adoption of the machining method of the high-quality large-diameter thin-wall barrel body to machine a large-diameter thin-wall metal barrel body without welding lines, organization is even and fine, comprehensive performance is high, the process is short, product additional values are high, and good application and popularizing prospects and certain economic and social benefits are achieved.

Owner:有研金属复材技术有限公司

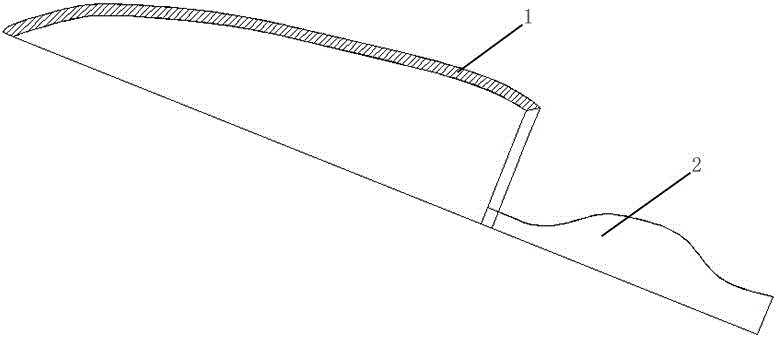

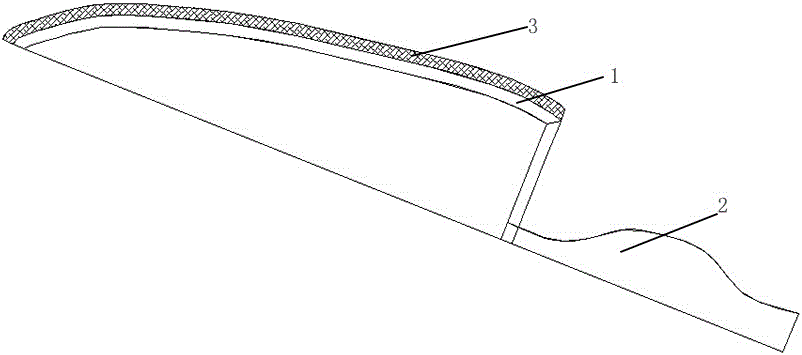

Tool for strengthening blade through laser cladding technology

ActiveCN106119838ASmall and uniform tissueLow dilution rateMetallic material coating processesMetal working apparatusAlloyLaser

The invention discloses a tool for strengthening a blade through the laser cladding technology. The tool comprises a tool body and a handle. The position of a cutting edge line of the tool body is provided with a cladding layer in a cladding manner, wherein the cladding layer is formed by abrasion-resisting hard alloy mixed powder. The hard alloy mixed powder is formed by mixing nickel-base alloy powder and tungsten carbide powder according to the proportion. By mass percent, the nickel-base alloy powder accounts for 40%-70%, and the tungsten carbide powder accounts for 30%-60%. The nickel-base alloy powder comprises, by mass percent, 18%-23% of Cr, 4%-7% of Fe, 2%-4.5% of Nb, 8%-11.5% of Mo, 0.2%-0.4% of Al, 1%-2.5% of Ti, 0.1%-0.6% of C, 0.2%-0.5% of Si, 0.2%-0.6% of Mn, 1.5%-2.5% of V and the balance Ni. The tool has the beneficial effects that the cladding layer and the tool body are in well metallurgy combination, the structure of the cladding layer is fine and uniform, and the dilution rate is low; after the tool body is sharpened, the hardness, sharpness, abrasion resistance and corrosion resistance of a blade part are greatly improved, cost is low, the hardness of the blade part is improved, and meanwhile tenacity cannot be reduced.

Owner:YANGJIANG KNIFESCISSOR HARDWARE RES INSTITUTION OF IND TECH +1

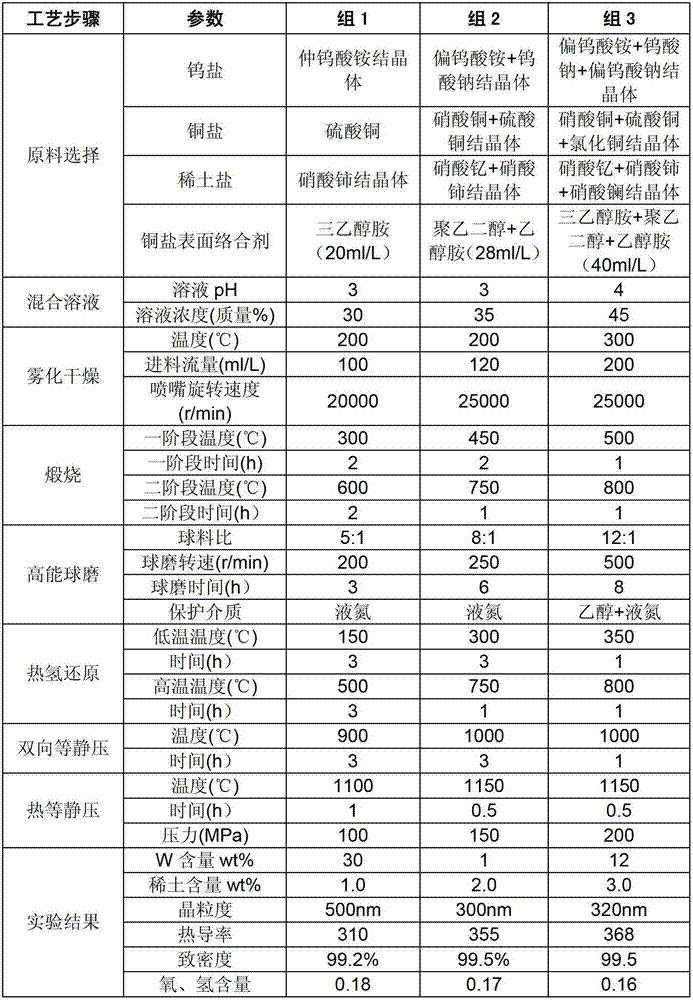

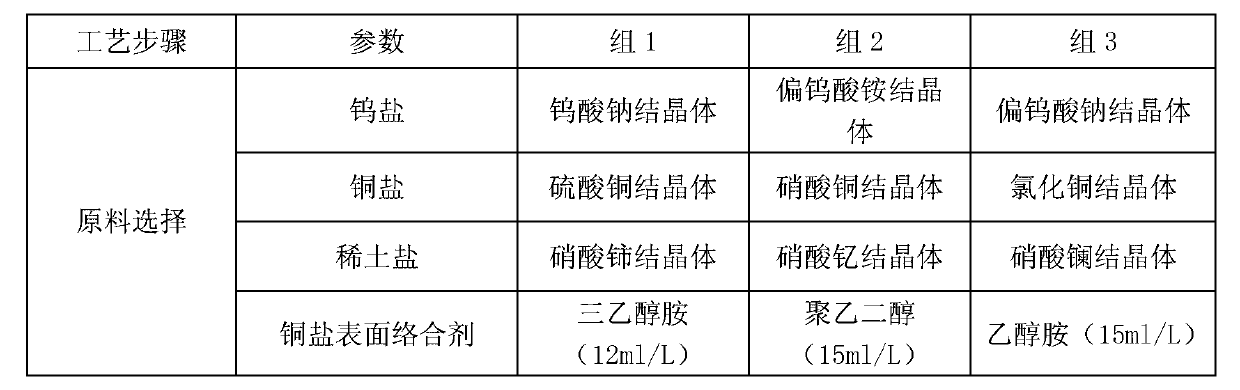

Nanocrystalline tungsten-based alloy block body material and preparation method thereof

The invention relates to a plastic forming technique and a powder metallurgical technique, in particular to a nano crystal tungsten based alloy block material and a method for preparing the same. The block material comprises the following components in weight percentage: 86 to 88 percent of W, 6.5 to 7.5 percent of Ni, 2.5 to 3.5 percent of Fe, 2 to 4 percent of Mo and 1 to 2 percent of Co. The preparation method comprises the following steps: Fe-Co-Ni and W-Mo after dry mixing are ball milled in advance respectively until the Fe, Co and Ni completely form solid solution, and tungsten phase crystal grain is thinned to below 100nm; the Fe-Co-Ni and W-Mo are subjected to high energy ball milling until the Fe-Co-Ni is evenly distributed around the W-Mo crystal grain; and the discharge plasma rapid sintering is adopted. The nano crystal tungsten based alloy block material has the advantages of reasonable formula, even and thin microstructure, nearly full compact, higher hardness and tensile strength and good specific elongation, and the method for preparing the block material effectively improves the mechanical performances of the sintering material.

Owner:SOUTH CHINA UNIV OF TECH

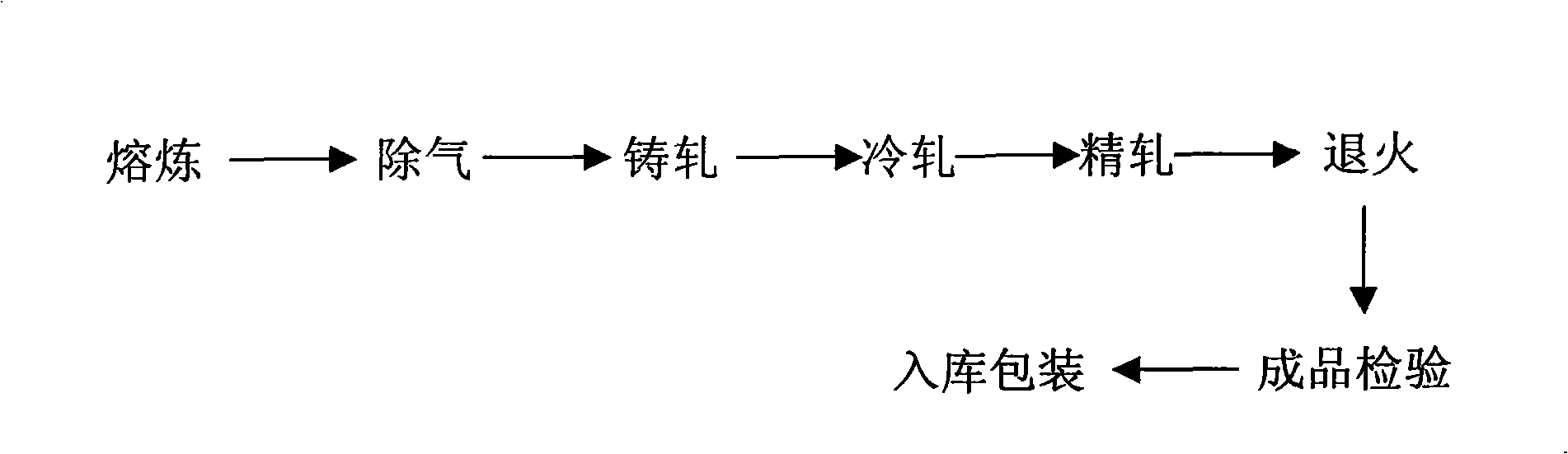

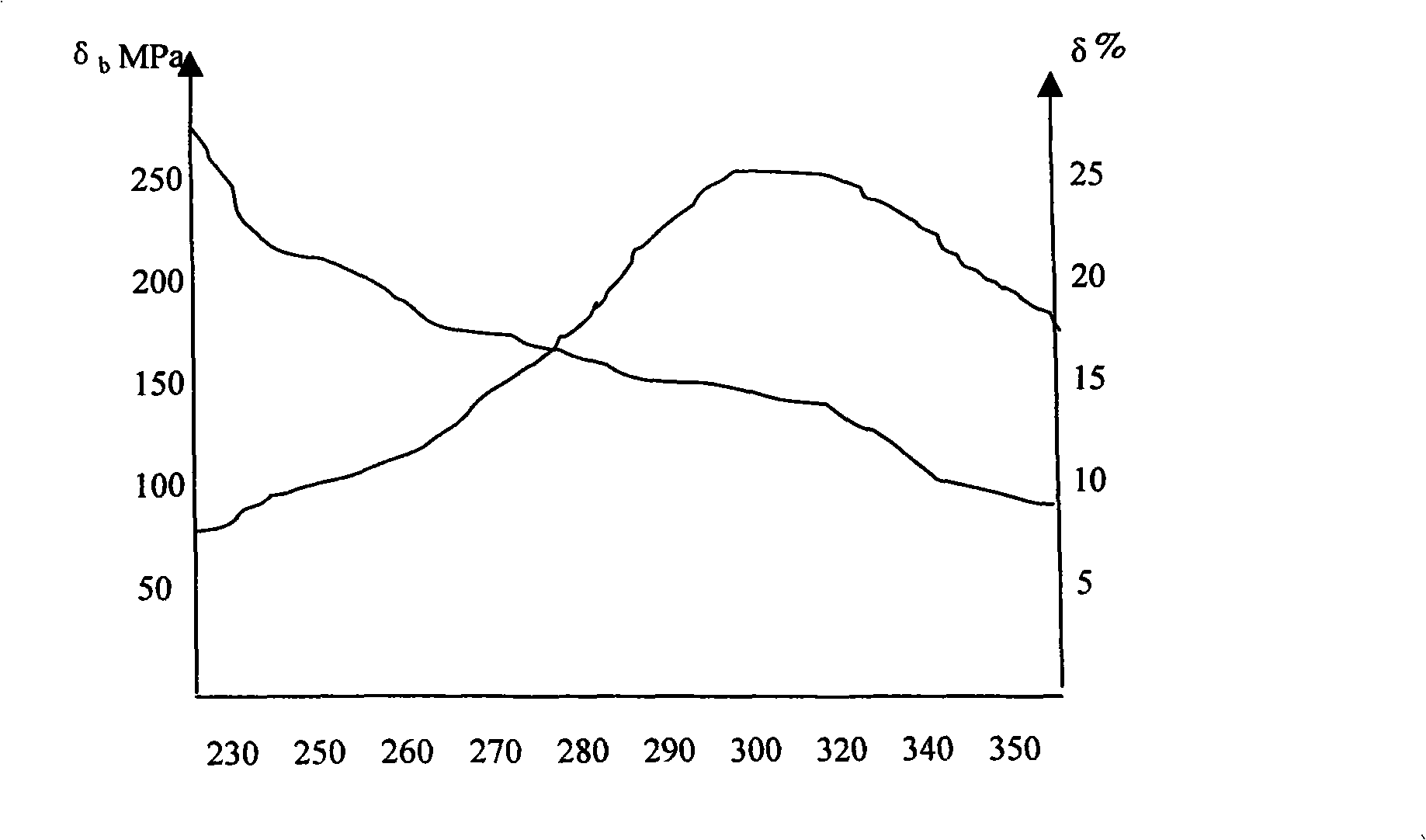

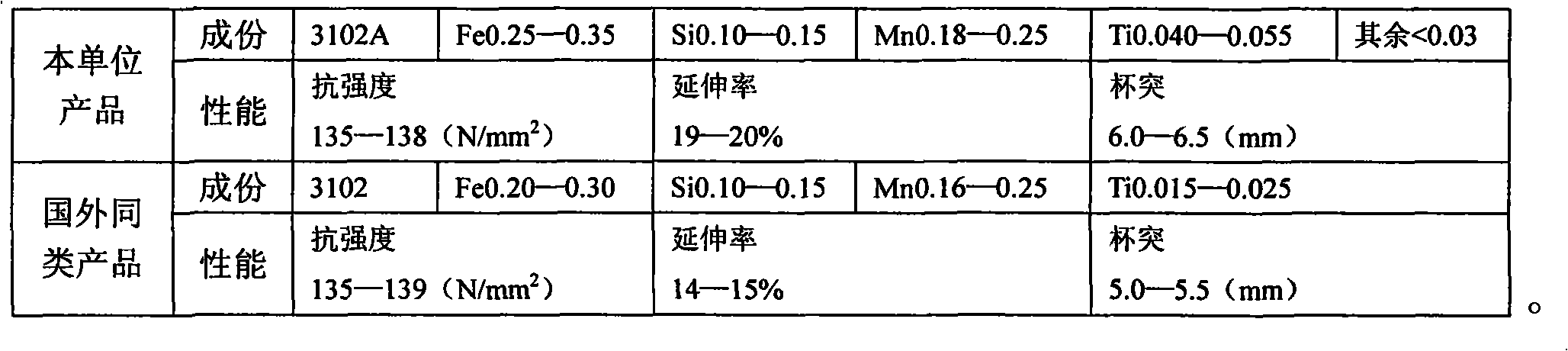

High performance air conditioning aluminum foil and method for preparing same

InactiveCN101307404AHigh strengthImprove plasticityRoll mill control devicesMetal rolling arrangementsFlangingAlloy

The invention relates to a high-performance air conditioner aluminum foil and a method for preparing the same. The aluminum foil mainly consists of the following alloying elements in percentage by weight: 0.28 to 0.33 percent of FeO, 0.1 to 0.15 percent of Si, 0.20 to 0.25 percent of Mn, 0.01 percent of Cu, 0.05 percent of Zn, 0.04 to 0.055 percent of Ti and the balance being Al and inevitable impurities. The preparation method mainly comprises the following: step one, melting, refining and heat preservation; step two, casting and rolling; step three, cold rolling and trimming cut; step four, precision rolling; step five, annealing at an annealing temperature of between 260 and 310 DEG C and heat preservation for 2 to 3 hours; step six, checkup and packaging. The high-performance air conditioner aluminum foil and the method can lessen the thickness of the air conditioner aluminum foil and ensure plasticity, height of the air conditioner aluminum foil and no flanging of longthrust.

Owner:江阴博威合金材料有限公司

Processing method of nickel-titanium memorial alloy tube with thin diameter and thick wall

The invention discloses a processing method of a nickel-titanium memorial alloy tube with a thin diameter and a thick wall and belongs to the field of material processing. The processing method of the nickel-titanium memorial alloy tube with thin diameter and thick wall includes: manufacturing a nickel-titanium memorial alloy tube blank according to actual use requirements and adopting a method of three-roller cold rolling to roll the inner diameter into 3 to 8 millimeters according to a gate working rate of 10% to 25%; and then enabling the inner diameter to nearly reach a final size by conducting rotary swaging, wherein rotary swaging is conducted at a working rate of not more than 30% of gate deformation; processing the outer diameter into a needed size on the premise of guaranteeing that the inner diameter reaches an appropriate size by drawing, wherein the gate deformation is 5% to 15%; and finally obtaining a finished product of the tube with the thick wall and the thin diameter by correcting and cylindrical grinding. According to the processing method of the nickel-titanium memorial alloy tube with thin diameter and thick wall, the nickel-titanium memorial alloy tube with the thin diameter of lower than 3 millimeters and the thick wall of 1millimeter to 3 millimeters can be manufactured. The nickel-titanium memorial alloy tube with the thin diameter and the thick wall has the advantages of possessing an appropriate organization and an axial structure and being particularly suitable for preparing the nickel-titanium memorial alloy thin diameter tube connector with high recoverability.

Owner:GRIMAT ENG INST CO LTD

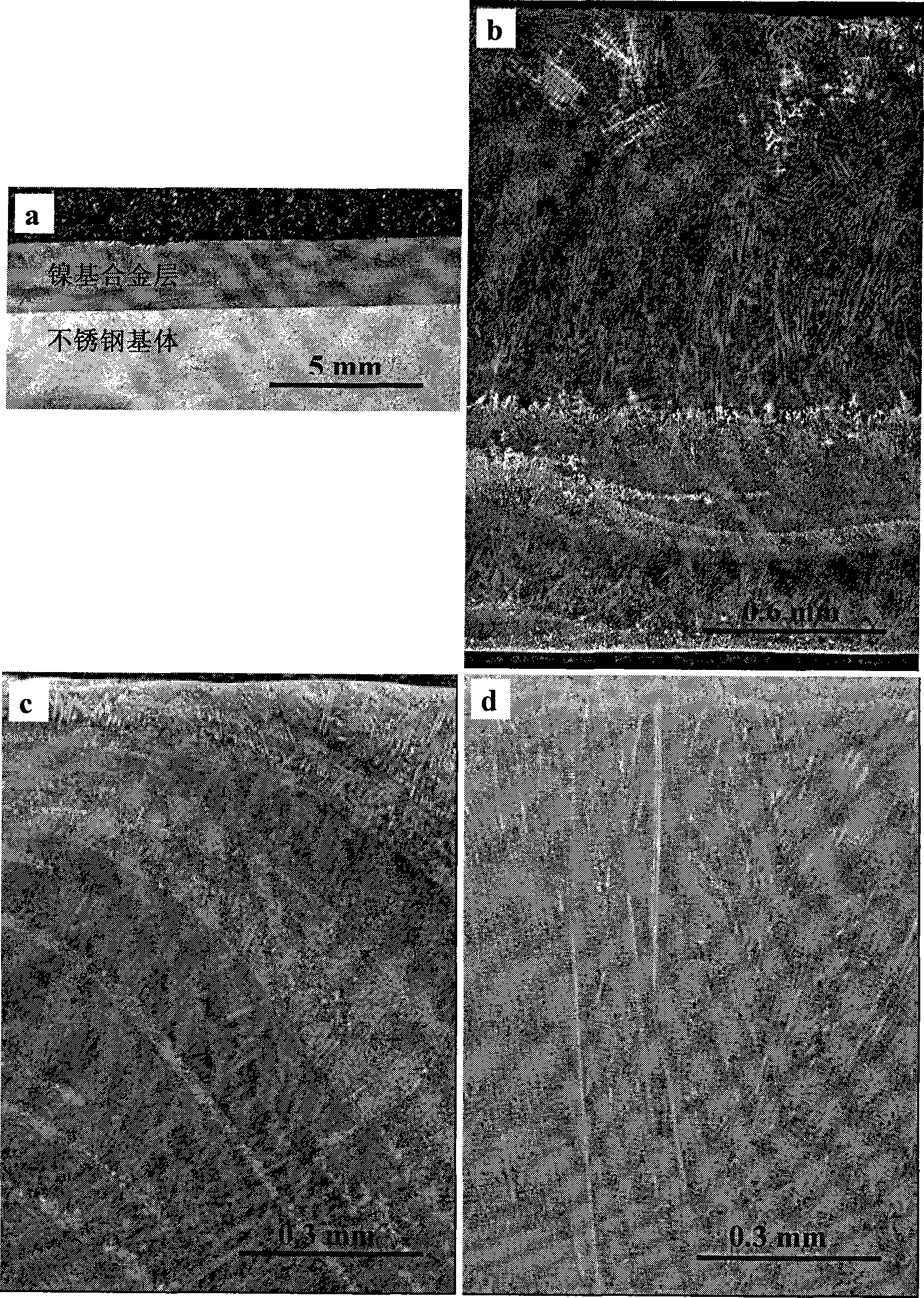

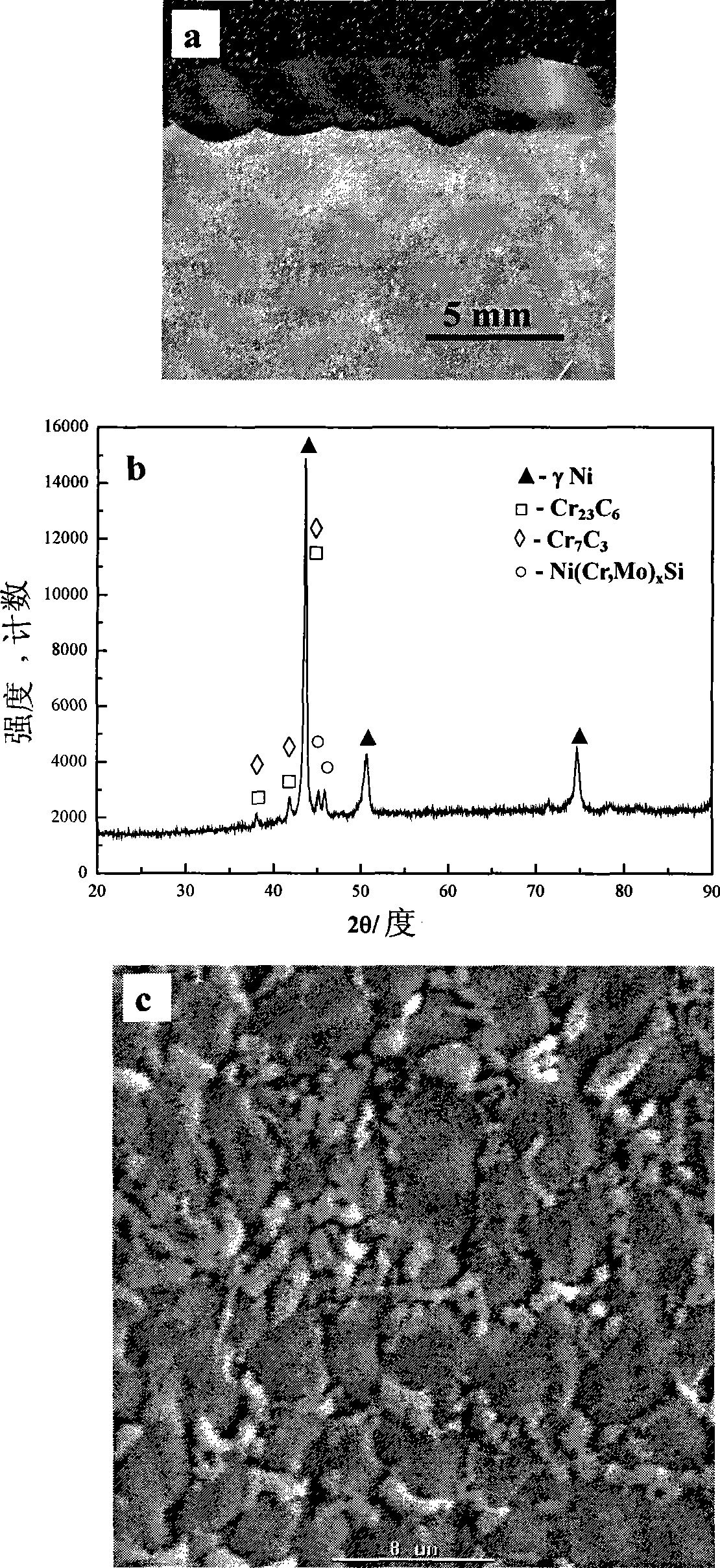

Nickel base alloy and stainless steel valve with nickel base alloy layer sealing surface, and production method thereof

ActiveCN101368239AHigh dilution rateHigh hardnessMetallic material coating processesMetal silicideMetal

The invention relates to a nickel-based alloy, a stainless steel valve provided with a seal surface of a nickel-based alloy layer and a preparation method. The components and the contents of the nickel-based alloy used on the seal surface of the nickel-based alloy layer are respectively: 1.0 to 1.5wt percent of C, 17.5 to 19.5wt percent of Cr 7.0 to 9.0wt percent of Mo, 3.5 to 4.5wt percent of W, 1.5 to 2.5wt percent of Nb, 2.0 to 3.0wt percent of Si and the rest is Ni. The stainless steel valve provided with a seal surface of a nickel-based alloy layer is lead the powder of the nickel-based alloy to form a seal surface nickel-based alloy on the stainless steel valve through a laser plating method. The nickel-based alloy layer and a stainless steel matrix are completely metallurgically bonded without the defects like cracks, air holes, and the like. The alloy layer comprises nickel-based solid solution dendrites, the metallic carbides between the dendrites, the metal silicides, and the like. The reinforced layer of the nickel-based alloy has higher rigidity (HRC43-49) and excellent properties for anti-heat and shock and can be used for preparation the alloy reinforced layer on the seal surface of the stainless steel which has strict demands on the alloy components (B and Co are excluded).

Owner:有研金属复材技术有限公司

TiAl-base composite material enhanced by three-dimensional network Ti2AlC and manufacturing method thereof

The invention relates to the making of TiAl based composite material with reinforced three dimensional net structure Ti2AlC. It solves the poor indoor plasticization and low strength issue of existing material. The newly invented material is made in the following combination based on atomic percentage: Ti powder 45-50at.%, Al powder 40-49at.%, 1-15at.% of one or more of Nb,Cr,Mn,V, Ni,W,Ta,Mo,Zr,Si,B powders, and carbon nanometer tube with the total weight of Ti, Al and element powder 0.05-20%, with two or more of Nb,Cr,Mn,V,Ni,W, Ta,Mo,Zr,Si,B, with all the element powders in random atomic percentages. It is made through ball grinding, mixing powder after feeding carbon nanometer tube, plasma sintering to get the final product.

Owner:HARBIN INST OF TECH

Rolling method of TC4 titanium alloy wide thick plate

ActiveCN103203361AReduce anisotropyUniform tissueTemperature control deviceMeasuring devicesThick plateMetallurgy

The invention provides a rolling method of a TC4 titanium alloy wide thick plate. The method comprises the steps of: 1, heating a TC4 titanium alloy plate blank, of which the thickness is 200mm-400mm and the length and the width are both 800mm-1200mm, for the first time; 2, rolling the TC4 titanium alloy plate blank for the first time to get a semi-finished plate blank; 3, cooling the semi-finished plate blank to be below 400 DEG C with water, shearing and eliminating the surface scale, and then, heating for the second time; and 4, rolling for the second time to get the TC4 titanium alloy wide thick plate of which the thickness is 30mm-100mm and the width is 1000mm-2600mm. The rolling method is simple in technology, and can easily realize industrial large-scale volume production; and the TC4 titanium alloy wide thick plate prepared by the rolling method has uniform and fine tissue, and is excellent in comprehensive performance.

Owner:WESTERN TITANIUM TECH

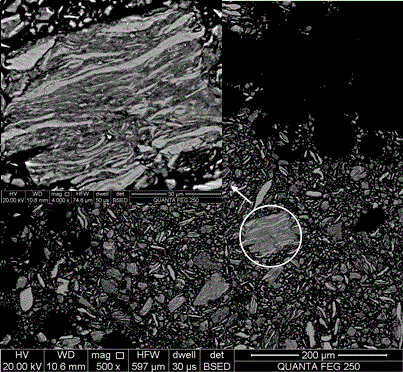

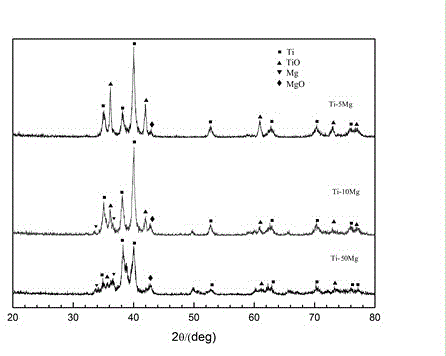

A Ti-Mg alloy material, a preparing method thereof and applications of the alloy material

The invention discloses a Ti-Mg alloy material applied as human tissue bone repair materials and a preparing method thereof. Phase composition of the alloy comprises Ti, Mg, TiO and MgO. The alloy comprises 70-80% of the Ti, 0-10% of the Mg, 8-20% of the TiO and 2-5% of the MgO. The Ti-Mg alloy is prepared by utilization of mechanical alloying and spark plasma sintering. The porosity of the alloy is smaller than 1%, the Vickers hardness of the alloy is HV400-HV500, the compressive strength of the alloy is 1600-1700 MPa, the elasticity modulus of the alloy is 12-13 GPa, the self-corrosion potential of the alloy ranges from -900 mV to -800 mV, the self-corrosion current density is 50-90 [mu]A / cm<2>. The alloy has characteristics of uniform structure, high compactness, good mechanical compatibility, capability of being biodegradable, and good corrosion resistance.

Owner:CENT SOUTH UNIV

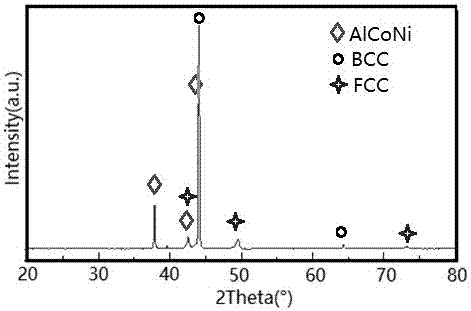

Multi-main-element alloy for cutter and preparation method of multi-main-element alloy

The invention provides a multi-main-element alloy for a cutter. The multi-main-element alloy is manufactured from metal powder, and the chemical formula of the multi-main-element alloy is Al<x>CoCuFe<y>MnNiZn<z>. A preparation method of the multi-main-element alloy comprises the following steps of weighing the metal powder according to the chemical formula, putting the weighed metal powder in a ball milling tank, adding an appropriate number of stainless steel balls in the ball milling tank, and sealing the ball milling tank under inert gases; placing the sealed ball milling tank in a ball milling machine and performing mixing; loading the mixed powder in a graphite mold under the protection of the inert gases, and loading the mold in a discharging plasma sintering furnace; and loading prepressure, performing vacuumizing, performing temperature rise, and performing heat preservation so as to obtain the multi-main-element alloy. According to the multi-main-element alloy disclosed by the invention, a multi-main-element alloy material of which the ingredients are uniform can be obtained, and the formation of intermetallic compounds is effectively restrained; the preparation method is high in temperature rising speed, low in sintering temperature, and high in production efficiency; and the product is tiny and uniform in structure, and the material of high density can be obtained.

Owner:ZHONGYUAN ENGINEERING COLLEGE

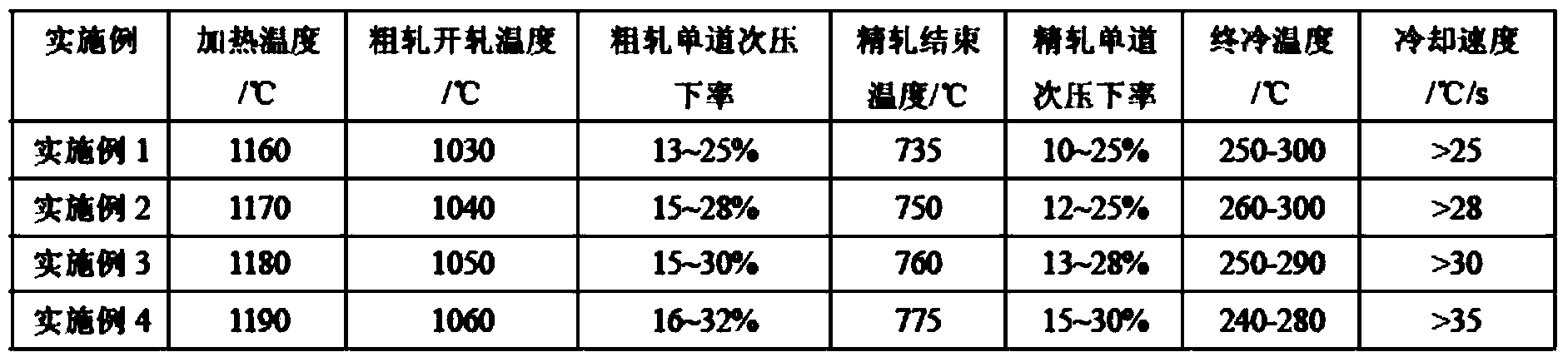

X90 pipeline steel wide and thick plate and production method thereof

ActiveCN103981461AImprove low temperature toughnessGood welding performanceThick plateTear resistance

The invention relates to an X90 pipeline steel wide and thick plate and a production method thereof, belonging to the technical field of low-carbon microalloy steel. The wide and thick plate comprises the following components in percentage by weight: 0.06-0.10% of C, 0.20-0.50% of Si, 1.50-1.80% of Mn, at most 0.010% of P, at most 0.003% of S, 0.04-0.06% of Nb, 0.04-0.06% of V, 0.010-0.020% of Ti, 0.15-0.30% of Ni, 0.15-0.30% of Cr, 0.10-0.30% of Mo, 0.020-0.05% of Als, and the balance of Fe and inevitable impurities. The technique comprises the following steps: predesulfurizing blast furnace molten iron, smelting in a converter, carrying out LF+RH refinement, continuously casting a plate blank, heating the plate blank, rolling by a 4300 rolling mill, carrying out ACC quick cooling, cooling in pile, sampling, inspecting, warehousing and shipping. The steel plate has the advantages of high strength, excellent low-temperature toughness and excellent dynamic tear resistance.

Owner:SHOUGANG CORPORATION

W-Cu composite material with high Cu content and preparation method of W-Cu composite material

The invention relates to a W-Cu composite material with high Cu content and the preparation method of the W-Cu composite material. The W-Cu composite material is characterized in that due to the improvement of raw materials and a technology, the prepared composite material has high Cu content reaching up to more than 70% and has the characteristics of uniform structure and high compactness.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

CSP production process of steel for automobile crossbeam

ActiveCN1974823ALow costEasy stability controlTemperature control deviceWork treatment devicesProduct inspectionChemical composition

The production process of SCP for automobile crossbeam includes the steps of converter smelting, LF refining, continuous casting and rolling, coiling and product inspection. The steel of SCP for automobile crossbeam consists of C 0.16-0.20 wt%, Si 0.3-0.5 wt%, Mn 1.3-1.5 wt%, P not more than 0.015 wt%, S not more than 0.010 wt%, Ti 0.01-0.03 wt%, Als 0.020-0.035 wt%, N not more than 65 PPm. Compared with available technology, the present invention has the advantages of relatively low alloy content in the steel, easy control of the chemical comprise, short production process and low production cost.

Owner:MAANSHAN IRON & STEEL CO LTD

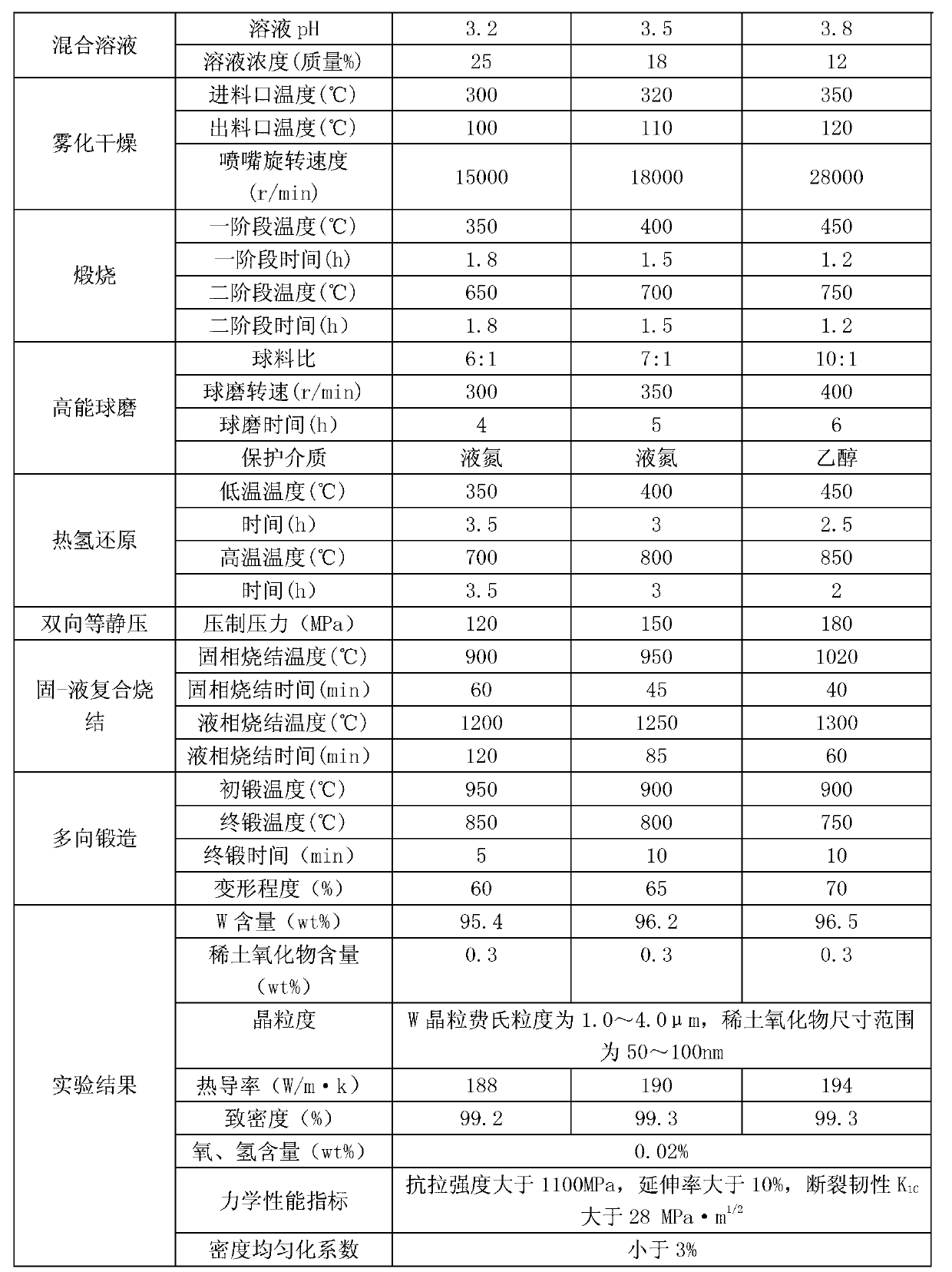

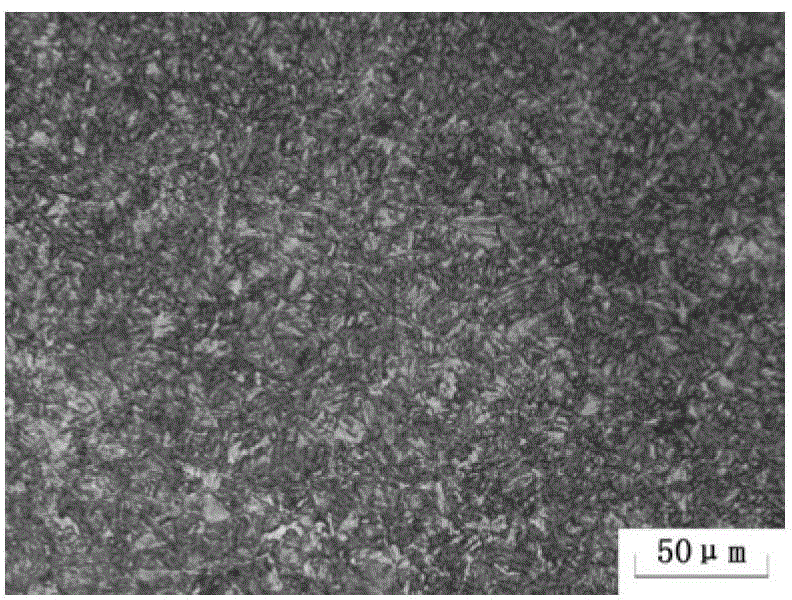

High-strength martensite stainless steel plate and production method thereof

ActiveCN105132820AGuaranteed straightnessImprove surface qualityMartensitic stainless steelSlow cooling

The invention discloses a high-strength martensite stainless steel plate and a production method thereof. The production method comprises a cogging process, a rolling process and a thermal treatment process. The steel plate consists of the following chemical components in percentage by mass: less than or equal to 0.06% of C, less than or equal to 1.00% of Si, less than or equal to 1.00% of Mn, less than or equal to 0.030% of P, less than or equal to 0.015% of S, 15.00%-17.00% of Cr, 4.50%-5.50% of Ni, 0.80%-1.20% of Mo, less than or equal to 0.00025% of H, greater than or equal to 0.020% of N, and the balance of Fe and inevitable impurities. The rolling process adopts whole-process water-avoiding quick rolling without extruding by use of a vertical stick; after being cogged, steel ingot is introduced into a slow cooling pit to carry out slow cooling; the rolling process adopts multi-pass heating quick rolling with small rolling reduction; and the thermal treatment process adopts a quenching and tempering process. The steel plate is good in plate form and stable in performance, good in room-temperature tensile strength and yield strength, good in low-temperature impact toughness at a temperature of (-)40 DEG C and good in ductility.

Owner:WUYANG IRON & STEEL

Low-cost continuous casting billet produced large-thickness steel plate for low-temperature pressure vessel and production method thereof

The invention discloses a low-cost continuous casting billet produced large-thickness steel plate for low-temperature pressure vessel and a production method thereof. The steel plate comprises the following chemical components in percentage by mass: 0.05-0.10% of C, 0.20-0.50% of Si, 1.30-1.60% of Mn, less than or equal to 0.012% of P, less than or equal to 0.005% of S, 0.020-0.050% of Alt, less than or equal to 0.70% of Ni, less than or equal to 0.040% of Nb, and the balance of Fe and inevitable impurities. The production method specifically comprises the procedures of smelting, casting, heating, rolling, and heat treatment. According to the present invention, with reasonable composition design and the production process of controlled rolling and controlled cooling, and heat treatment, and by completely using continuous casting billets for production, the maximum thickness of the steel plate reaches up to 120 mm; the produced steel plate has favorable comprehensive mechanical properties and welding properties, and is low in production cost and high in market competitiveness, thus meeting the increasing market demand.

Owner:WUYANG IRON & STEEL

High-temperature resistant turbine blade and production process thereof

ActiveCN104099516AImprove performanceImprove impact toughnessBlade accessoriesSolid state diffusion coatingChemical compositionSteam turbine blade

The invention discloses a high-temperature resistant turbine blade. The turbine blade comprises the following chemical components in percentage by weight: 0.19-0.21% of C, 0.55-0.57% of Mn, 0.20-0.22% of Si, 0.38-0.40% of Al, 0.30-0.32% of V, 0.40-0.42% of Ti, 0.12-0.14% of Ni, 0.06-0.08% of Sn, 0.25-0.27% of Zr, no more than 0.025% of S, no more than 0.025% of P, no more than 0.20% of Cu, 0.20-0.22% of lanthanide serial rare earth, and the balance Fe. The invention further designs a production process of the turbine blade. The production process has the advantages of simplicity and low cost, helps to largely improve the impact toughness of the blade, enhance the high temperature resistance of the blade and prolong the service life of the blade through the nitridation surface treatment.

Owner:南京赛达科技有限公司

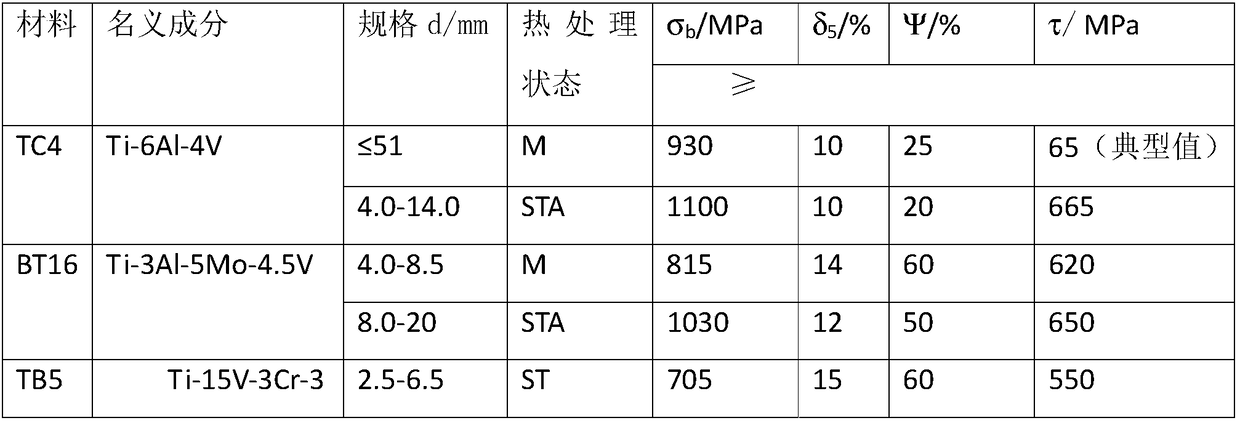

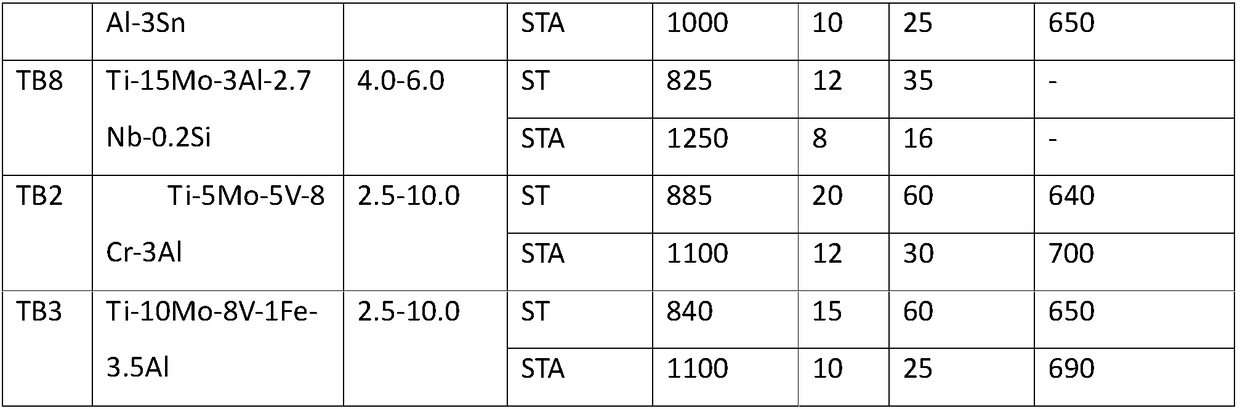

Preparation method of high-strength titanium alloy wire

The invention belongs to the technical field of material science, and relates to a preparation method of a high-strength titanium alloy wire. The adopted titanium alloy is prepared from the followingcomponents in percentage by mass: 6.3 to 7 percent of Al; 3.5 to 4.5 percent of Mo; 5.5 to 6.5 percent of V; 1.5 to 2.5 percent of Nb; 0.5 to 1.5 percent of Fe; less than or equal to 0.05 percent of C; less than or equal to 0.13 percent of O; less than or equal to 0.05 percent of N; less than or equal to 0.015 percent of H; and the balance of Ti. According to the invention, the alloy which keeps higher plasticity and toughness while having higher strength is adopted, temperatures above and below the phase transformation point are alternately used in the process of ingot cogging and rolling, consequently, original grains are sufficiently crushed, the microstructure is more uniform and finer, and a high-performance wire can be more easily obtained. In the whole process of processing, a special annealing process is not used, moreover, continuous rolling or furnace rerolling can be adopted below the phase transformation point, the process is simplified, the period is shortened, and the cost is reduced. In addition, by undergoing specified heat treatment, the processed wire can obtain excellent comprehensive property in which the tensile strength is higher than 1,500MPa, the elongationis higher than 8 percent and the shear property is higher than 950MPa.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

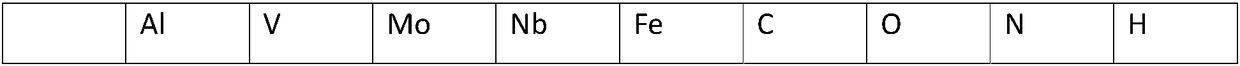

Spark plasma sintering system

The invention discloses a spark plasma sintering system which comprises a sintering furnace and a control system connected with the sintering furnace. The control system comprises a displacement / pressure control system, an atmosphere control system, a vacuum control system and a temperature control system. The sintering furnace comprises a pressurization device and an impulse current generator. The pressurization device comprises an upper pressing head and a lower pressing head which are correspondingly arranged, upper electrodes and lower electrodes which are arranged on the upper sides and the lower sides of both the upper pressing head and the lower pressing head respectively, a sintering die arranged between the upper pressing head and the lower pressing head and a water cooling vacuum chamber arranged on the outer side of the sintering die, and the impulse current generator is connected with the upper electrodes and the lower electrodes. The spark plasma sintering system is good in forming effect, the forming process is controlled accurately, and the product quality is greatly improved.

Owner:浙江晨华科技有限公司

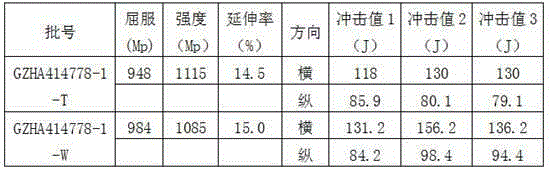

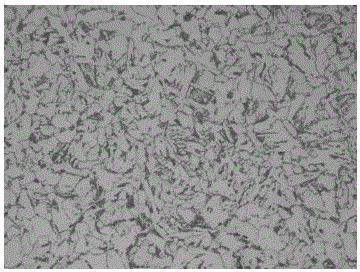

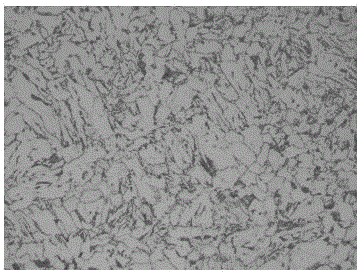

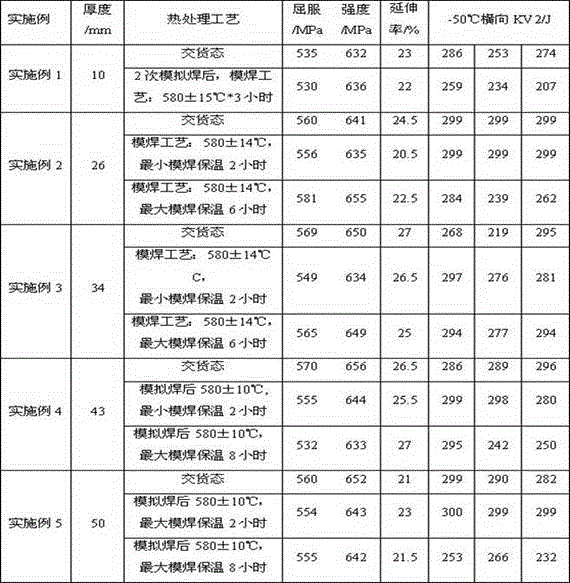

Rare-earth-oxide-doped W-Cu composite material and preparation method thereof

The invention provides a W-Cu composite material which is characterized by comprising the following components in percentage by mass: 5-30 wt% of Cu, 0.5-2 wt% of rare-earth oxide and the balance of W. The invention also provides a preparation method of the W-Cu composite material. The density of the composite material is up to 99.2%, the density uniformized coefficient of different positions is less than 5%, the room temperature tensile strength is greater than 900 MPa, the elongation percentage is greater than 10%, and the fracture toughness K1C is greater than 28 MPa.m<1 / 2>; and thus, the composite material satisfies the performance requirements of electric contact materials and liner materials for complete density, structure uniformity, ablation resistance and the like of the W-Cu alloy.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Tempering type high-strength steel plate for low-temperature container and production method for tempering type high-strength steel plate

The invention discloses a tempering type high-strength steel plate for a low-temperature container and a production method for the tempering type high-strength steel plate. The steel plate is smelted from the following components in percentage by mass: 0.05-0.09% of C, 0.20%-0.50% of Si, 1.50%-1.60% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.020%-0.050% of Alt, 0.30%-0.60% of Ni, 0.15%-0.30% of Mo, 0.015%-0.025% of Nb, and the balance being Fe and inevitable impurities. According to tempering type high-strength steel plate for the low-temperature container and the production method for the tempering type high-strength steel plate disclosed by the invention, a uniform tempered sorbite+ferrite structure is obtained by adopting a production process with a reasonable component design, controlled rolling and controlled cooling as well as tempering thermal treatment, so that the good comprehensive mechanical property and the welding property of the steel plate are guaranteed, the production cost is low, the market competitiveness is strong, and the ever-growing market requirements are met.

Owner:WUYANG IRON & STEEL

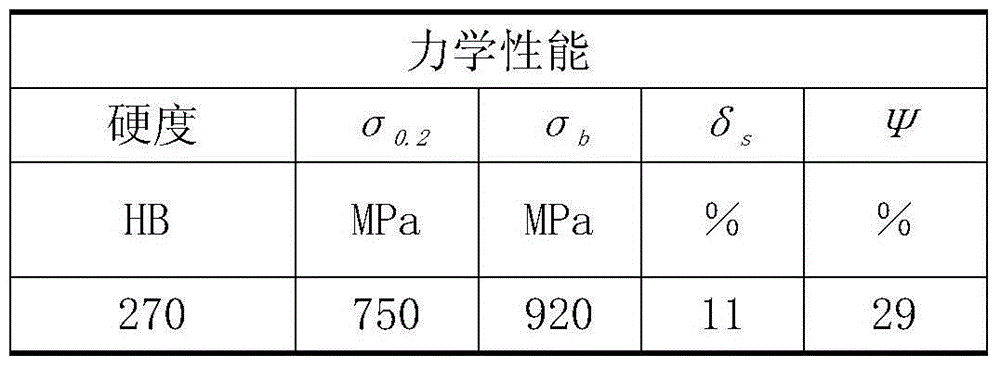

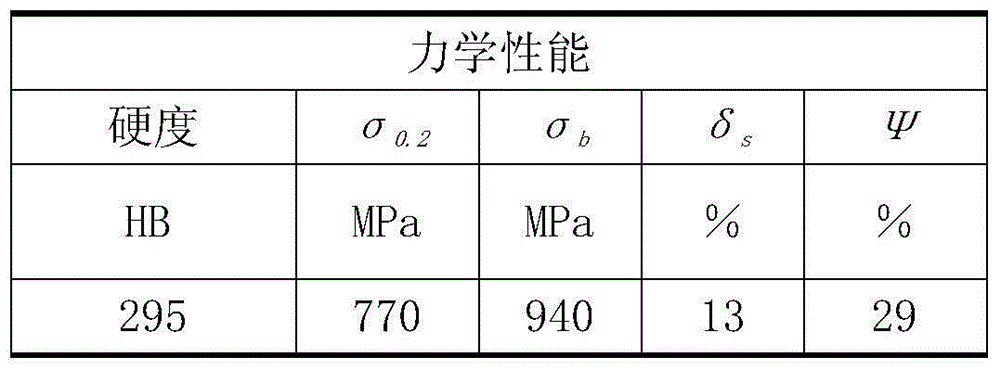

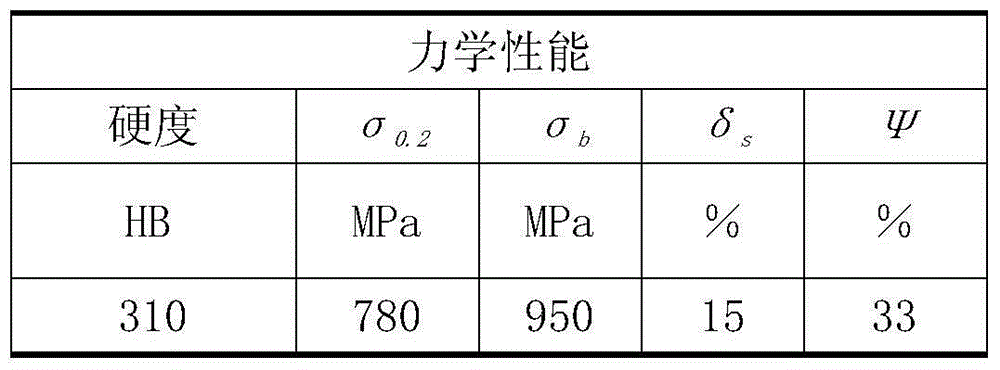

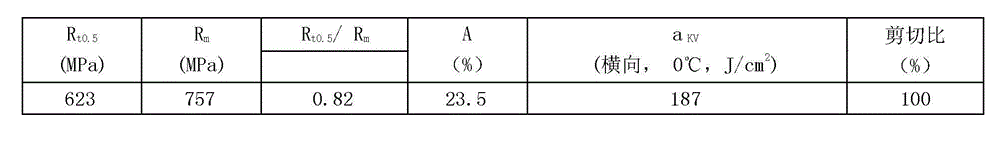

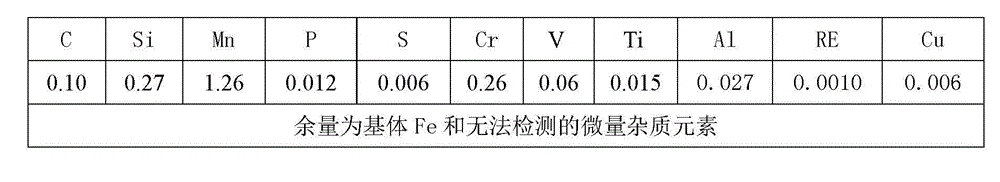

Rare earth containing, high-strength and high-toughness seamless steel pipe for L555Q pipeline and production method thereof

The invention relates to a rare earth containing, high-strength and high-toughness seamless steel pipe for the L555Q pipeline and a production method thereof. The seamless steel pipe is composed of 90 wt% of blast furnace molten iron and 10 wt% of high-quality waste steel in percentage by weight. The pipe blank comprises the following chemical components in percentage by weight: 0.06 to 0.13 wt% of C, 0.15 to 0.35 wt% of Si, 1.10 to 1.40 wt% of Mn, not more than 0.020 wt% of P, not more than 0.010 wt% of S, 0.10 to 0.30 wt% of Cr, 0.03 to 0.09 wt% of V, 0.01 to 0.03 wt% of Ti, 0.01 to 0.04 wt% of Al, 0.0005 to 0.0100 wt% of rare earth (RE), not more than 0.10 wt% of Cu, and the balance being substrate Fe and undetectable trace impurity elements. The mechanical properties of the seamless steel pipe are as follows: the yield strength is 600 to 680 MPa, the residual stress is smaller than or equal to 30 MPa, the impact value is more than or equal to 160 J / cm<2>, and the grain size is more than or equal to 8.5 grade. The technology process can be simplified as the following steps: molten iron pre-treating, smelting in a top-bottom combined blowing converter, refining in a LE furnace, VD vacuum processing, round continuous casting, cutting, heating the pipe blank, perforating, continuous rolling, sizing (stretch reducing), cooling, sawing, heat treating, straightening, flaw detecting, and chamfering. The product has the advantages of low impurity element content, high roughness matching degree, uniform and fine tissue, and good welding performance.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

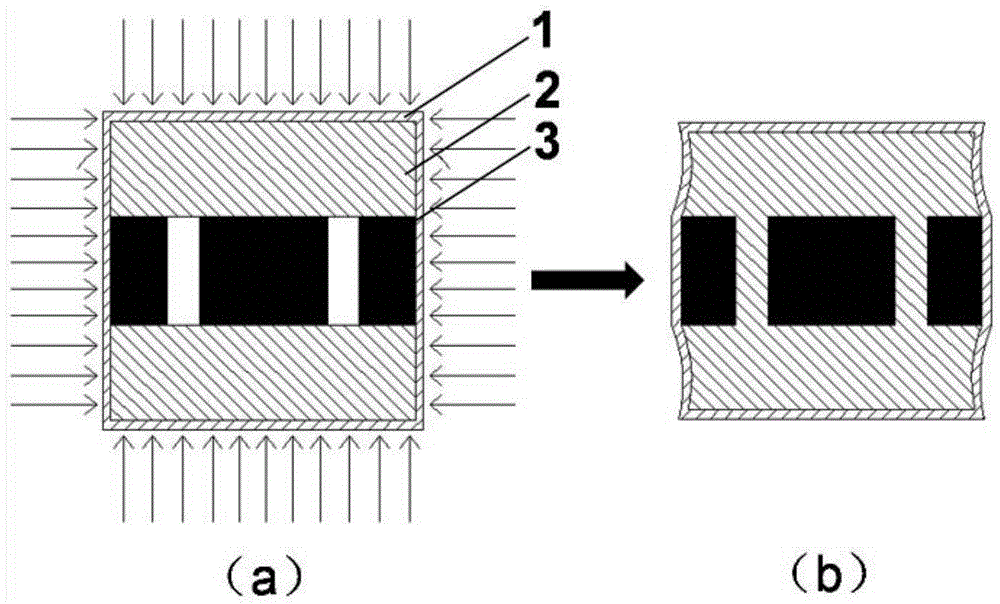

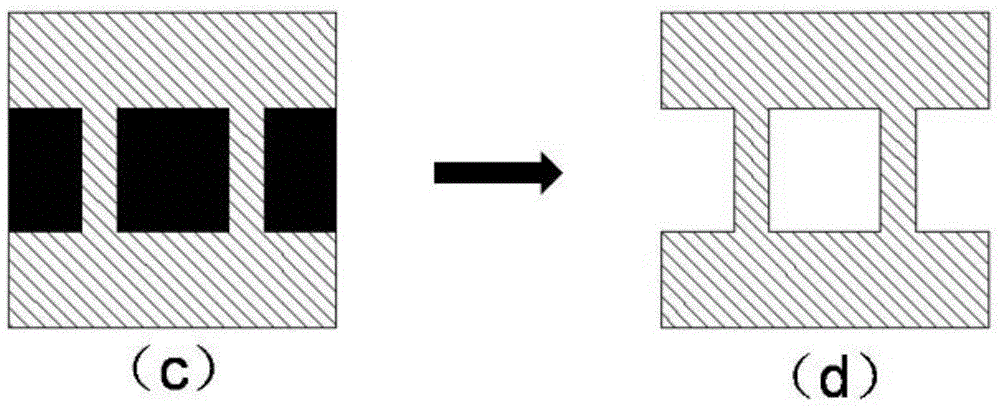

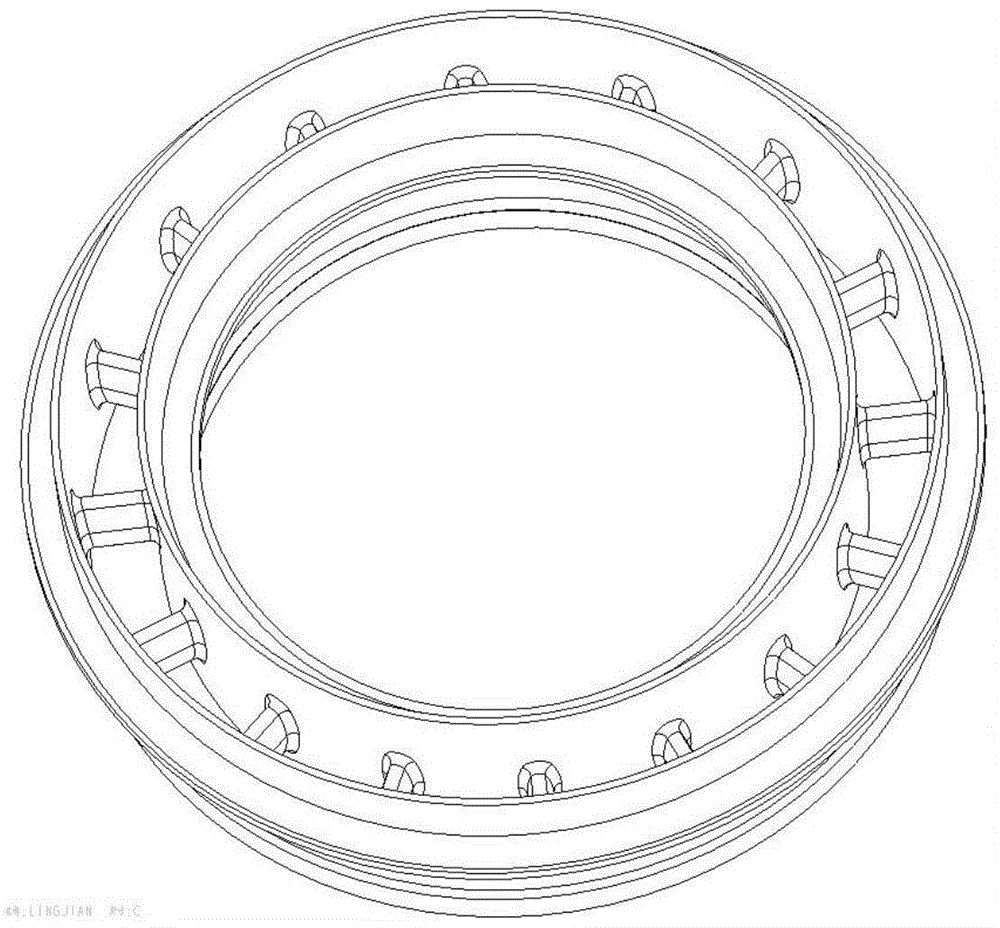

Hot isostatic pressure near-net forming method for semi-solid complex difficult-machining compact piece

InactiveCN105772726ASmall and uniform tissueGuaranteed forming accuracyHigh pressureTemperature and pressure

The invention discloses a hot isostatic pressure near-net forming method for a semi-solid complex difficult-machining compact piece. The hot isostatic pressure near-net forming method comprises the steps that a semi-solid material is used as a forming material, graphite is used as an internal form control core, the hot isostatic pressure temperature is selected as the solid-liquid two-phase interval temperature, and the compact piece in a complex shape is directly formed under coupling of temperature and pressure. According to the hot isostatic pressure near-net forming method for the semi-solid complex difficult-machining compact piece, performance defects caused by powder surface pollutants in traditional methods can be effectively overcome, and the part forming precision can be effectively ensured through high pressure at the high temperature; in addition, the temperature close to the melting point of an alloy material is adopted, and a solid-liquid coexisting phase occurs in a ladle sleeve at the temperature; due to the fact that liquid phase components exist among crystal grains or solid phase particles, the solid phase particles almost have no binding force and are very low in flow deformation resistance, and a complex runner in the form control core is filled with parent metal advantageously; and moreover, the solid phase particles are easy to separate on specification portions, and while, due to the fact that the liquid phase components exist, the separated portions are very easy to connect integrally.

Owner:HUAZHONG UNIV OF SCI & TECH

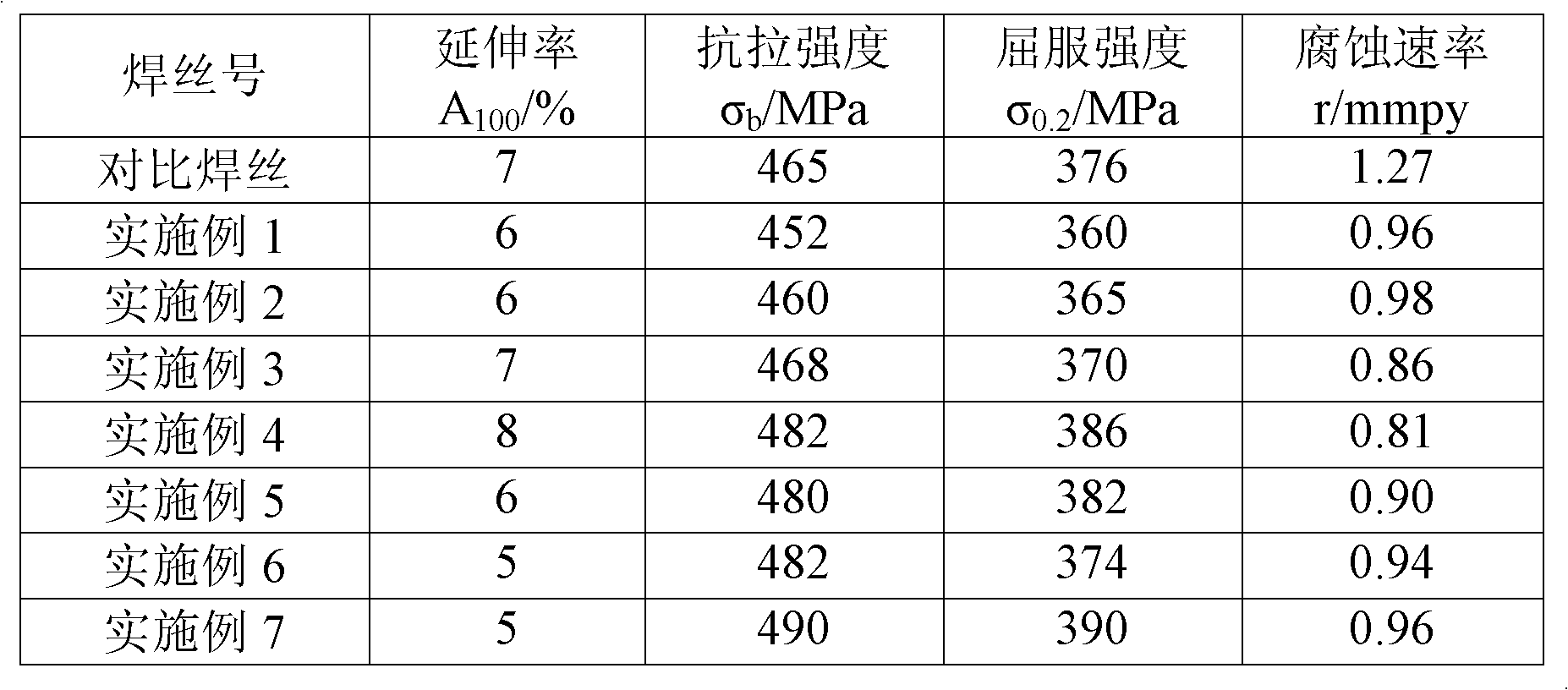

Multi-element compounded micro-alloyed Al-Mg-Sc series welding wire and preparation method thereof

InactiveCN102079019AImprove liquidityWeaken the effect of pouringWelding/cutting media/materialsSoldering mediaCeriumManganese

The invention discloses a multi-element compounded micro-alloyed Al-Mg-Sc series welding wire. The welding wire comprises the following components in percentage by mass: 4.5 to 7.5 percent of magnesium, 0.3 to 0.63 percent of manganese, 0.1 to 0.2 percent of zirconium, 0.18 to 0.4 percent of scandium, 0.25 to 0.4 percent of cerium and lanthanum and the balance of Al. When the Sc and Zr multi-element compounded micro-alloyed Al-Mg-Sc series welding wire is used for the fusion welding of an Al-Zn-Mg (Sc) series alloy and an Al-Mg (Sc) series alloy, the welding seam alloy has fine and uniform textures and the hot cracking tendency of a welded joint is obviously reduced. The alloy welding wire has relatively high fluidity at a welding temperature, can obtain more excellent welding seam textures, reduces the welding hot cracking tendency of the welding seam alloy, obtains relatively high strength of the joint after welding and has relatively strong corrosion resistance.

Owner:ZHEJIANG YINYU WELDING NEW MATERIAL TECH

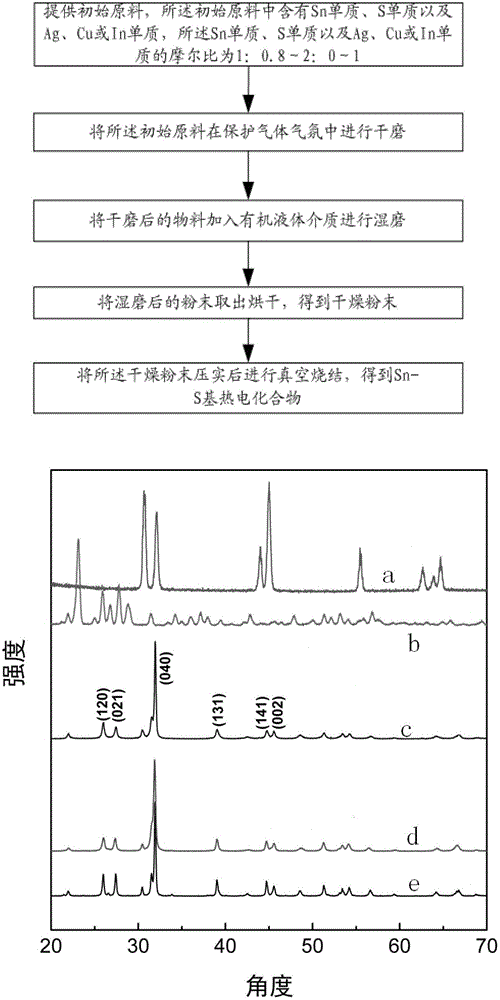

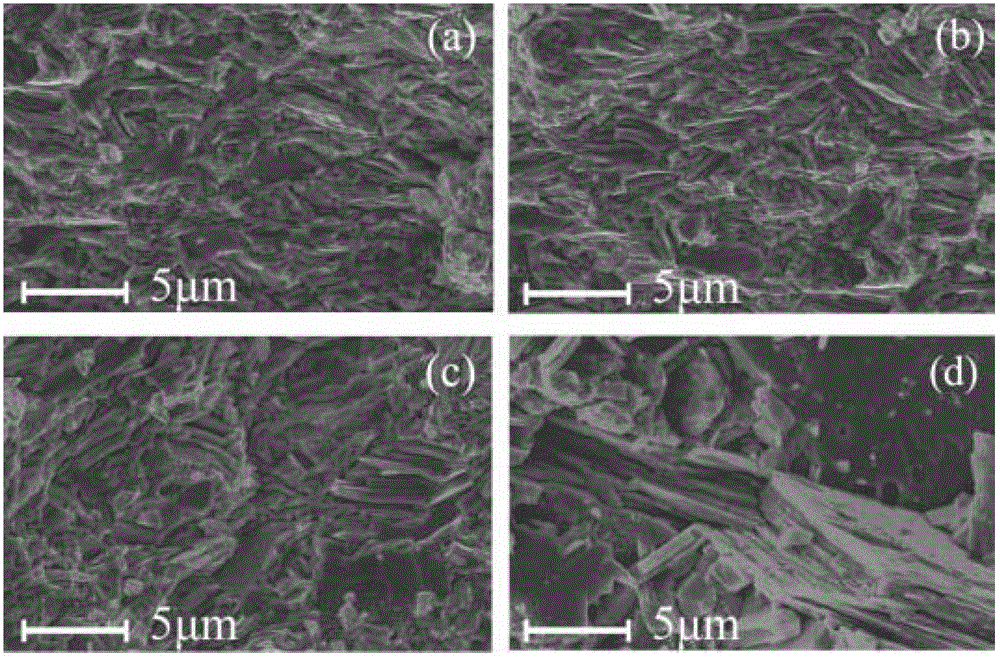

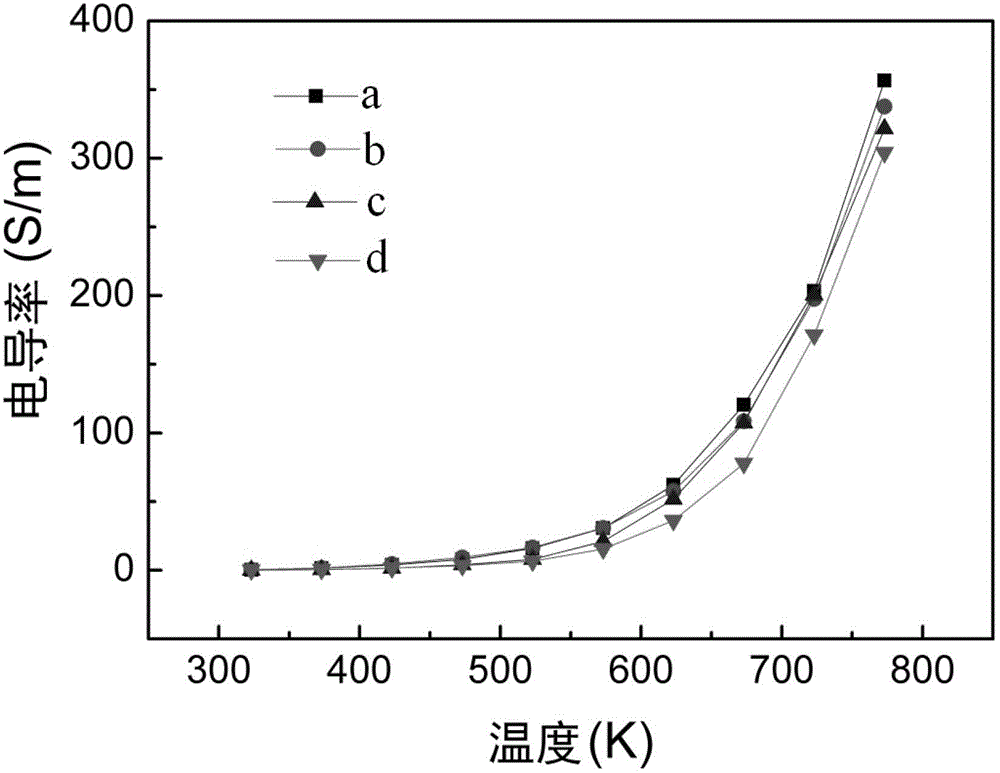

Sn-S-based thermoelectric compound and preparation method thereof

ActiveCN102867905AReduce energy consumptionLow priceThermoelectric device manufacture/treatmentThermoelectric device junction materialsLiquid mediumOrganic fluid

The invention discloses a Sn-S-based thermoelectric compound and a preparation method thereof. The preparation method comprises the following steps of: (a) providing an initial raw material, wherein the initial raw material consists of a Sn elementary substance, an S elementary substance and an Ag, Cu or In elementary substance, and the molar ratio of the Sn elementary substance to the S elementary substance to the Ag, Cu or In elementary substance is 1: (0.8-2): (0-1); (b) carrying out dry grinding on the initial raw material in a protective gas atmosphere; (c) adding the material subjected to dry grinding into an organic liquid medium and carrying out wet grinding; (d) taking the powder subjected to wet grinding and drying the powder to obtain dried powder; and (e) compacting the dried powder and carrying out vacuum sintering on the compacted powder to obtain the Sn-S-based thermoelectric compound. According to the preparation method disclosed by the invention, the adopted initial raw material is a nontoxic pollution-free raw material and is low in cost; the preparation method is short in process flow, little in time consumption, high in efficiency and low in energy consumption; and the obtained Sn-S-based thermoelectric compound is fine and uniform in tissues, good in thermoelectric property and suitable for large-scale industrial production.

Owner:TSINGHUA UNIV

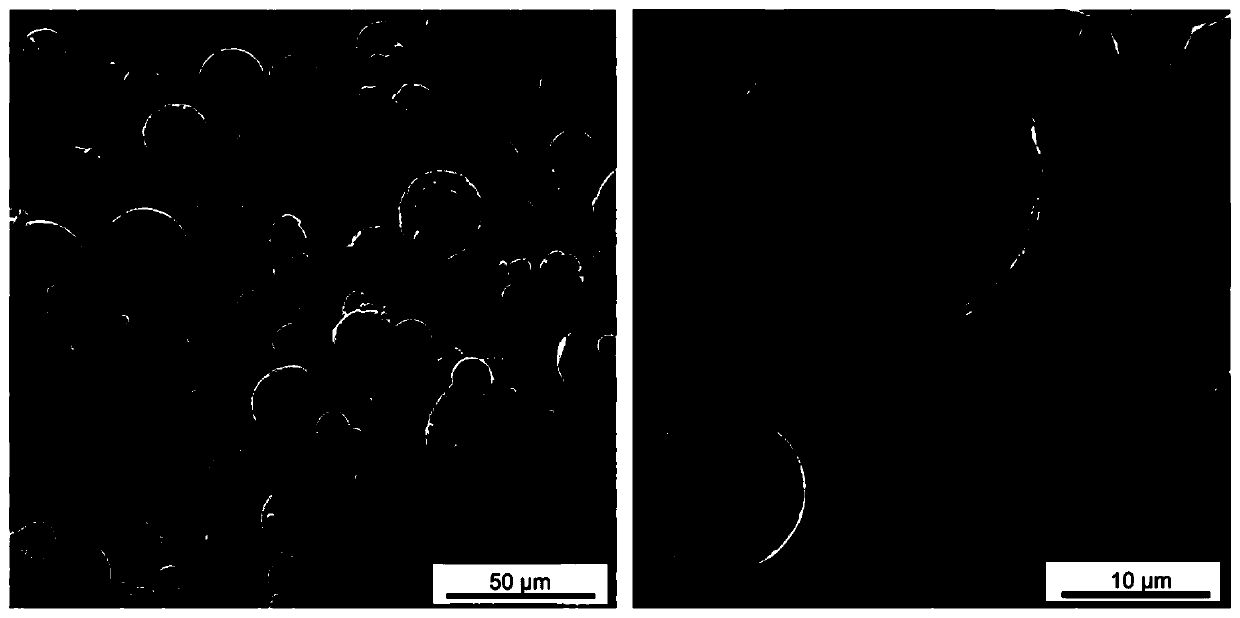

High-strength Al-Cr-SC alloy through 3D printing

ActiveCN111001800AReduce anisotropyEasy to manufactureAdditive manufacturing apparatusIncreasing energy efficiencyHigh densityMetal powder

The invention discloses a high-strength Al-Cr-SC alloy through 3D printing. The metal powder for a high-strength aluminum-chromium alloy through 3D printing comprises the following components, by masspercentage, 2.5-10% of Cr, 0.5-2.5% of Mg, 0.1-0.9% of Sc, 0.2-0.7% of Zr, 0.1-0.3% of Si, 0.2-0.45% of Mn, 0.1-0.35% of Fe, 0.1-0.25% of Ti, 0.05-0.5% of AlCl3 powder, 0.05-0.3% of CaCl2 + NaCl andthe balance Al. The preparation method of the metal powder comprises the following steps that Al, Cr, Mg, Sc, Zr, Si, Mn, Fe, Ti pure metal block raw materials are weighed to be heated and melted, atomized for powder making, sieving and heat preservation for drying are conducted, AlCl3, CaCl2 and NaCl powder are added, and milling and mixing are conducted. According to the high-strength Al-Cr-SC alloy through 3D printing, the printed aluminum alloy part has no cracks and has high density, and the mechanical properties, wear resistance, corrosion resistance and high temperature and oxidation resistance are high.

Owner:CENT SOUTH UNIV +1

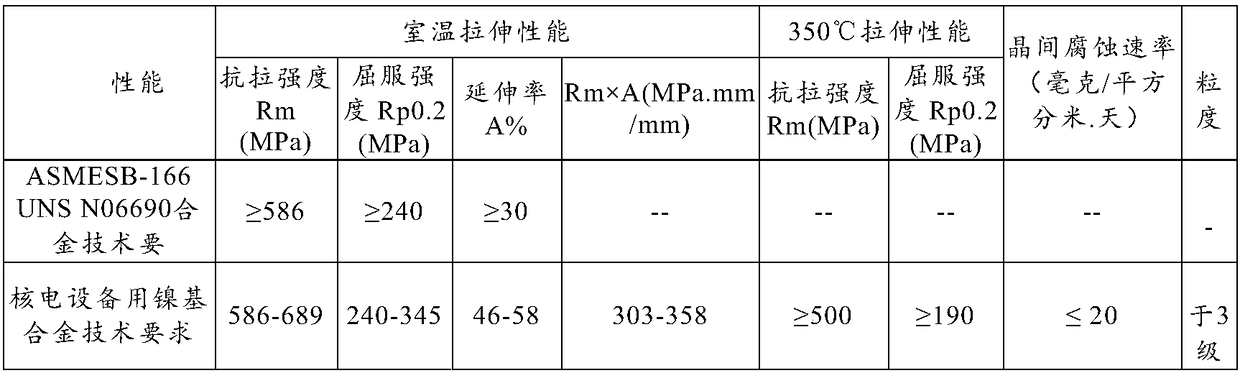

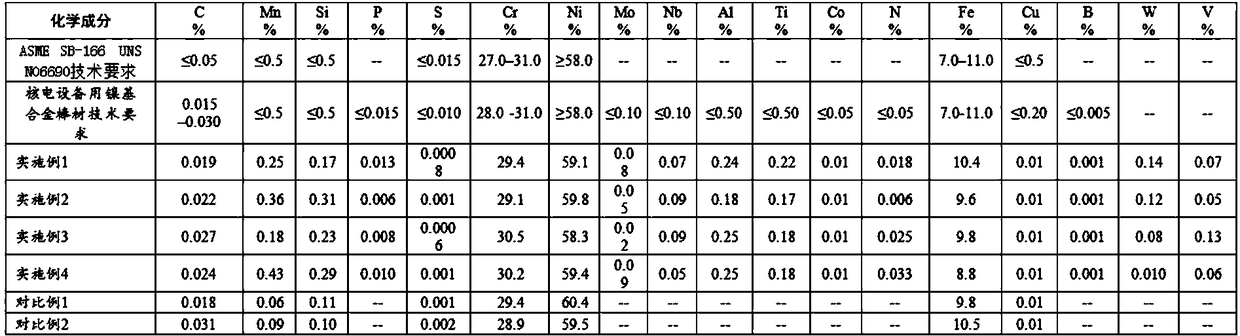

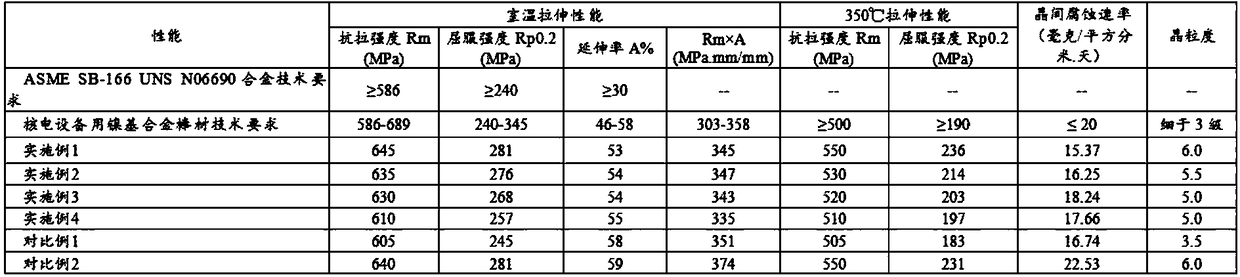

Nickel-based alloy large-section bar used for nuclear power critical equipment and manufacturing method of large-section bar

The invention provides a nickel-based alloy used for nuclear power critical equipment and a manufacturing method of a nickel-based alloy bar. The alloy comprises the following elements: C, Cr, Fe, W and the balance Ni and unavoidable impurities, wherein the content of Ni is not less than 58%. The preparation method of the bar includes the following steps of nickel-based alloy preparation, hot rolling and forming of the bar and heat treatment of the bar. Compared with the prior art, the nickel-based alloy and the manufacturing method has the following advantages that the manufacture process isespecially suitable for manufacturing large-section nickel-based alloy bar of Phi 300 mm to Phi660 mm, and the nickel-based alloy bar is completely applicable to key components of nuclear island equipment in nuclear power plants and of great significance for effectively promoting the independent construction of large nuclear power plants in China.

Owner:宝武特种冶金有限公司

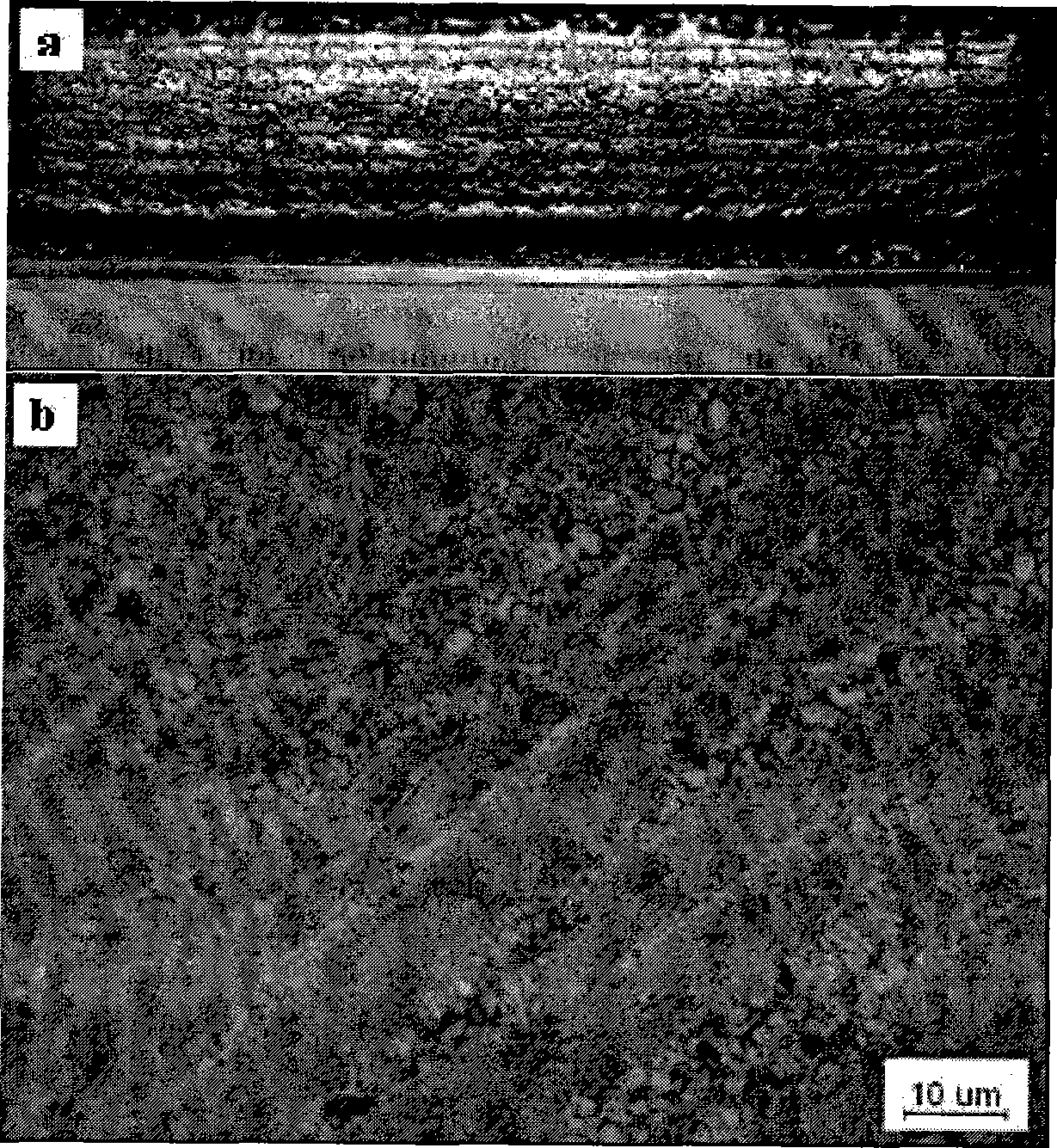

Preparation method and application of graphene copper / steel composite material

ActiveCN108396346ASmall and uniform tissueShorten the timeElectrolytic coatingsCopper platingElectrical conductor

An electroplating solution of a graphene copper / steel composite material comprises 220-280 g / L of copper sulfate, 0.1-3.0 g / L of graphene, 0.1-6.0 g / L of nonionic surfactants and deionized water. In the process of electroplating, sinusoidal pulse is used; and according to the electrical parameter of the sinusoidal pulse, the current density range is 500-3000A / m<2>, the pulse current frequency is 250Hz, the pulse width is 25s, the use time of the electroplating is 0.5-4.0h, the temperature of the electroplating solution is 20-70 DEG C, and the pH is 2.0-5.0. The copper sulfate-grapheme platingsolution is non-toxic and recyclable, the cost is saved, and environmental protection is achieved; the surface of an obtained graphene copper plating is bright and has high bonding strength with a steel core wire; and the volume ratio of graphene copper in the obtained graphene copper / steel composite material is 10-25%, the conductivity of the composite material is obviously higher than that of acopper-clad steel composite material for a conductor in a traditional coaxial-cable, and the graphene copper / steel composite material is suitable for manufacturing conductors in coaxial cables for transmitting high-frequency signals.

Owner:CHANGZHOU UNIV

A magnetic material with high temperature stability and a preparation method thereof

InactiveCN108962528AThree low melting pointsImprove remanenceInorganic material magnetismInductances/transformers/magnets manufactureProper treatmentAlloy

The invention discloses a magnetic material with high temperature stability and a preparation method thereof, which is composed of an alloy material 1, an alloy material 2, an alloy material 3 and aninorganic ceramic material. The weight ratio of the alloy material 1, the alloy material 2, the alloy material 3 and the inorganic ceramic material is 1: 0.03- 0.09:0.003- 0.008:0.011- 0.015. The product obtained by the invention has excellent magnetic properties. In addition, the homogeneity of composition, microstructure and properties of the alloys were ensured by proper treatment, and the quality of the alloys was ensured. The preparation process of the alloy is simple, the cost of raw materials used for preparation is low, the process is simple, and the produced alloy has good properties,which is convenient for industrial production. The permanent magnet material prepared by the invention is suitable for the electric appliance industry.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com