Manufacturing method of large-calibre seamless titanium alloy barrel body

A seamless titanium alloy and manufacturing method technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of short production process, low yield, high yield, etc., to achieve simple method, low manufacturing cost, organization fine uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

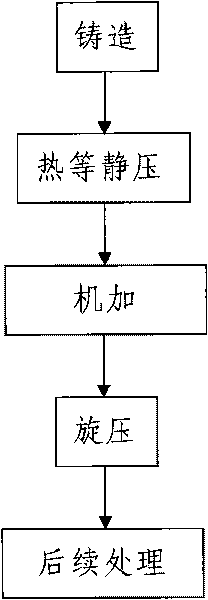

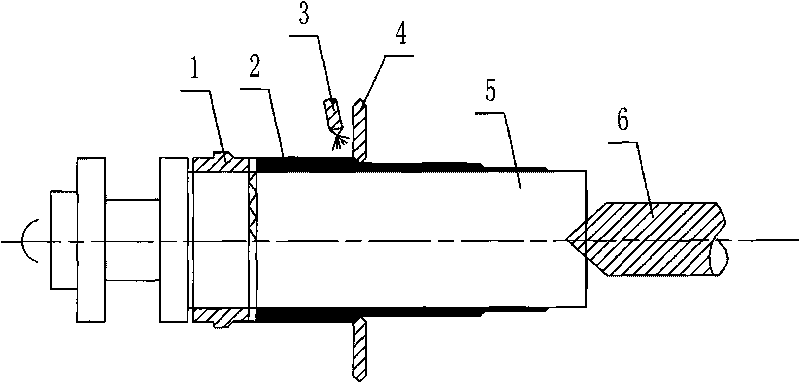

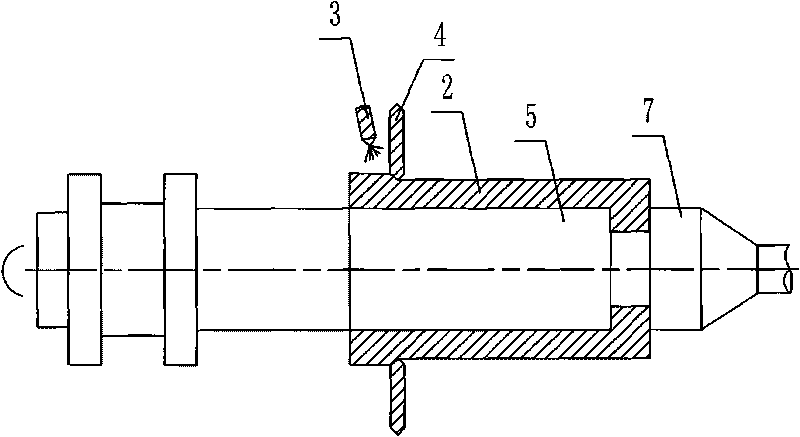

[0044] combine figure 2 , in this embodiment, when manufacturing a large-diameter seamless titanium alloy cylinder, its manufacturing process includes the following steps:

[0045] Step 1. Casting: the titanium alloy raw material is cast into a large-diameter titanium alloy tube billet by using a vacuum melting furnace and a vacuum melting method. The vacuum melting furnace is a vacuum consumable arc shell solidification furnace, and titanium alloy ingots or titanium alloy forging rods are used as consumable electrodes during vacuum melting. In this embodiment, the Φ480mm qualified TA2 titanium alloy ingot (or forged rod) through secondary vacuum consumable arc smelting is used as the smelting consumable electrode, and the vacuum melting is carried out in an 800Kg vacuum consumable arc coagulation furnace and Casting into a straight tube blank with an inner diameter of Φ1000mm, a wall thickness of δ40mm and a length of L500mm. For vacuum melting, titanium alloy ingots or ti...

Embodiment 2

[0054] In this example, the difference from Example 1 is that in step 1, when the titanium alloy raw material is cast into a large-diameter titanium alloy billet by using a vacuum melting furnace through a vacuum melting method, the obtained large-diameter titanium alloy billet is outer The diameter Φ is 100mm, the wall thickness δ is 5mm, and the length L is 150mm. When vacuum melting, titanium alloy ingots or titanium alloy forging rods are used as electrodes, and the vacuum degree of melting and casting is 0.67Pa. When hot isostatic pressing is carried out in step 2, the temperature is 600° C., the applied pressure is 100 MPa, and the hot isostatic pressing time is 1 hour. When multi-pass hot spinning is performed in step 4, the spinning temperature of the initial pass is 550±10°C, the spinning temperature of the intermediate pass is 400±10°C, and the spinning temperature of the final pass is 200±10°C. And when carrying out multi-pass strong hot spinning, the pass thinning ...

Embodiment 3

[0056] In this example, the difference from Example 1 is that in step 1, when the titanium alloy raw material is cast into a large-diameter titanium alloy billet by using a vacuum melting furnace through a vacuum melting method, the obtained large-diameter titanium alloy billet is outer The diameter Φ is 2000mm, the wall thickness δ is 40mm, and the length L is 1000mm. For vacuum melting, titanium alloy ingots or titanium alloy forging rods are used as electrodes, and the vacuum degree of melting and casting is 6.7Pa. When hot isostatic pressing is carried out in step 2, the temperature is 1000° C., the applied pressure is 200 MPa and the pressing time is 2.5 hours. When multi-pass hot spinning is carried out in step 4, the heating temperature gradually decreases with the increase of hot spinning passes. The spinning temperature of the first pass is 900±20°C, and the spinning temperature of the intermediate pass is 700±20°C. The final spinning temperature is 600±20°C. And whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com