Patents

Literature

182results about How to "Address process complexity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

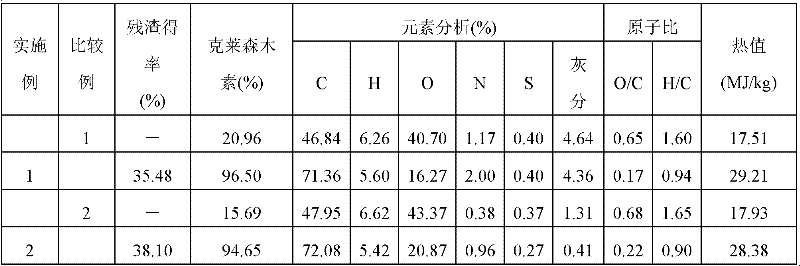

Method for preparing biomass carbon by utilizing agricultural and forestry waste

InactiveCN102583311AImprove protectionRaw materials are easy to getSolid waste disposalCarbon preparation/purificationBiomass carbonSorbent

The invention relates to a method for preparing biomass carbon by utilizing agricultural and forestry waste, belonging to the technical fields of preparation of carbon materials and utilization of biomass resources. The method comprises the following steps of: adopting agricultural and forestry waste as raw materials; under the condition of subcritical water, fully mixing dried biomass materials and deionized water according to the proportion of 1:(10-30); under the protection of inert atmosphere, carbonizing for 2-6 hours at the temperature of 220-250 DEG C; and then carrying out vacuum filtration and hot-water cleaning, and drying to obtain the biomass carbon. The biomass carbon prepared by the invention is coaly carbon material with an aromatic-ring structure, is high in carbon content and calorific value and large in specific surface area, and can be used as a soil conditioner or an absorbent. The method has the advantages that the materials are low in cost and easy to obtain, the process is simple, the operation is convenient, the manufacturing cost is low, the industrial promotion is convenient, and the application range and the application value of biomass resources are further expanded in the aspect of carbon materials.

Owner:BEIJING FORESTRY UNIVERSITY

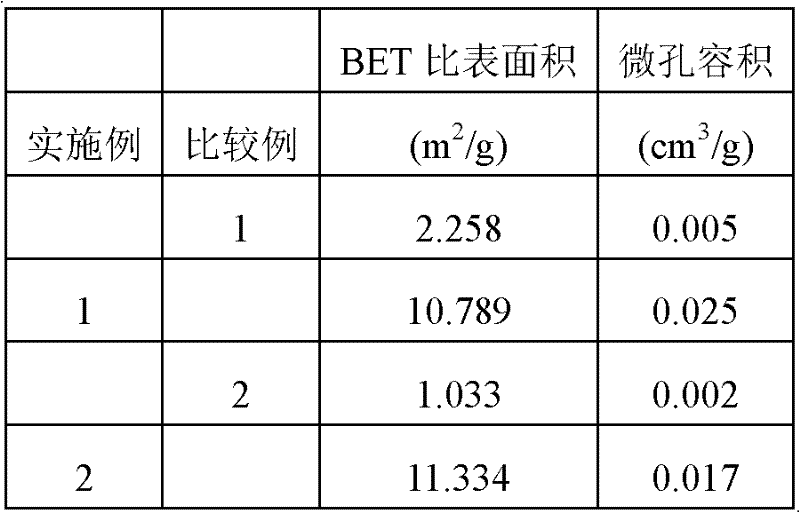

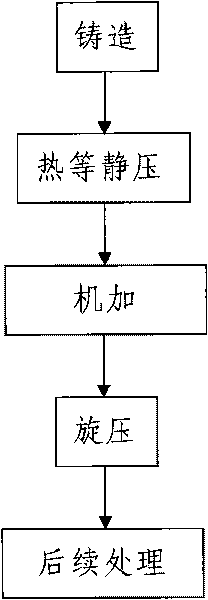

Manufacturing method of large-calibre seamless titanium alloy barrel body

InactiveCN101733641AWide range of sizesEasy to prepareOther manufacturing equipments/toolsTitanium alloyMachining

The invention discloses a manufacturing method of a large-calibre seamless titanium alloy barrel body, which comprises the steps of: 1, casting: casting titanium alloy raw materials into a large-calibre titanium alloy barrel blank by using a vacuum smelting furnace and through a vacuum smelting method; 2, hot isostatic pressing: performing the hot isostatic pressing for the large-bore titanium alloy barrel blank in an inert protective atmosphere by using a hot isostatic pressing device; 3, mechanical machining: processing a chamfer angle for spinning at the head of the large-bore titanium alloy barrel blank after the hot isostatic pressing by using mechanical processing equipment to obtain a spinning barrel blank; 4, spinning: thermally spinning the mechanically processed spinning barrel blank with the total deformation rate not less than 60% for many times by using spinning equipment to obtain a large-bore seamless titanium alloy thin-wall barrel body; and 5, subsequent treatment. The production process has short process flow, high yield, low cost, high utilization rate of materials and easy realization, and the defects of the large-bore seamless titanium alloy barrel body, such as complex process, high cost, low yield and the like of the traditional production process can be effectively solved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

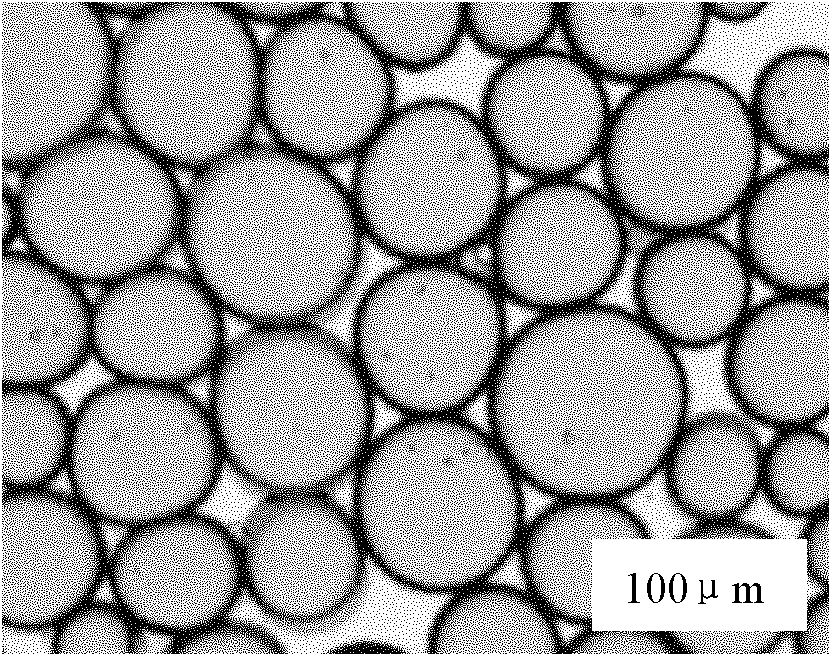

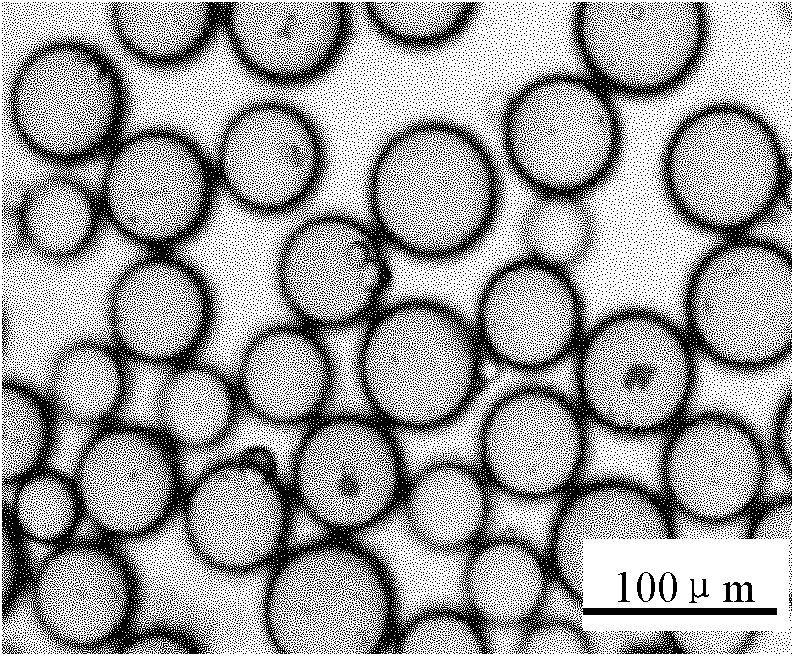

Glaze for fast-fired crystal glaze ceramic tile, and preparation method and applications of ceramic tile

ActiveCN104829268AReduce granularity requirementsSimple manufacturing processManufacturing technologyBrick

The invention provides a glaze for fast-fired crystal glaze ceramic tile and a preparation method and applications of ceramic tile. The glaze comprises basic crystal glaze and a color developing agent, wherein the basic crystal glaze comprises the following raw materials: zinc oxide, titanium dioxide, quartz, cryolite, zinc phosphate, kaolin, and lead frit. A proper amount of zinc phosphate is introduced into the glaze to avoid the raw material frit treatment, which is carried out to ensure the residual amount of nucleating agent, the requirements on the glaze granularity are reduced, the manufacture technologies of crystal glaze and ceramic tiles are simplified, and the technical difficulties that the crystal glaze sintering technology is complicated, the crystal patterns are difficult to control, and the production cost is high are solved. Moreover, the addition amount of quartz and lead frit is precisely controlled to obtain crystal glaze art ceramic tiles which have the advantages of good crystallization effect, strong three-dimensional effect, and good artistic effect. The provided preparation method has the advantages of simpleness, lower sintering temperature, shorter period, and suitability for massive industrial production.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

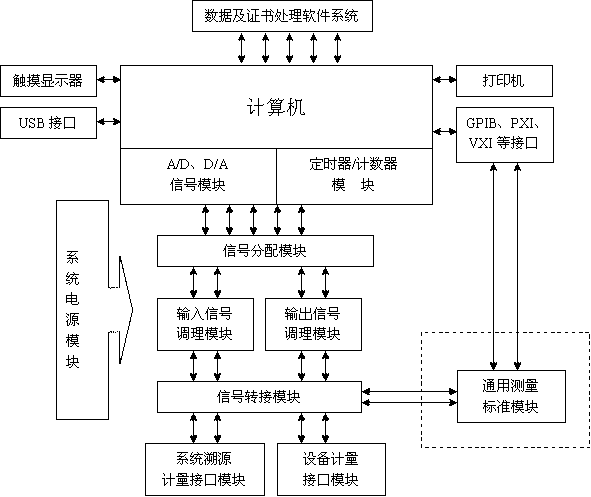

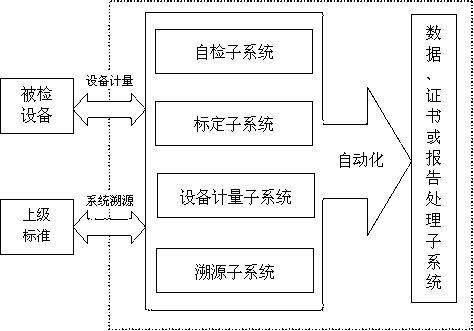

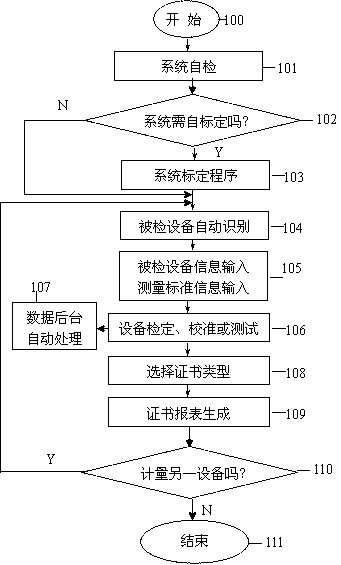

Automatic electric quantity calibrating system and automatic electric quantity calibrating method

ActiveCN103176161ARealize value traceabilityAchieve deliveryElectrical measurementsSignal conditioningComputer module

The invention discloses an automatic electric quantity calibrating system and an automatic electric quantity calibrating method and belongs to the technical field of electromagnetism measuring. An automatic electric quantity calibrating device mainly comprises a computer, an AD / DA (analog to digital / digital to analog) module, a timer / counter module, a signal distribution module, a signal conditioning module, a signal transfer module, a system traceability measuring interface module, an equipment measuring interface module and a system power source module, and the automatic electric quantity calibrating system mainly comprises a self-checking system, a demarcating subsystem, an equipment measuring subsystem, a traceability subsystem and a data, certificate or report processing subsystem. The automatic electric quantity calibrating device has the advantages of small size, light weight, simplicity in operation, functional powerfulness, high accuracy and the like, the calibrating system applies signal-oriented designing technologies such as signal distribution, conditioning, converting and measurement adaption, measuring signal excitation and testing are realized, and requirements of automatized calibration of automatic testing systems under laboratory and carry-out conditions can be met.

Owner:NO 63908 TROOPS PLA

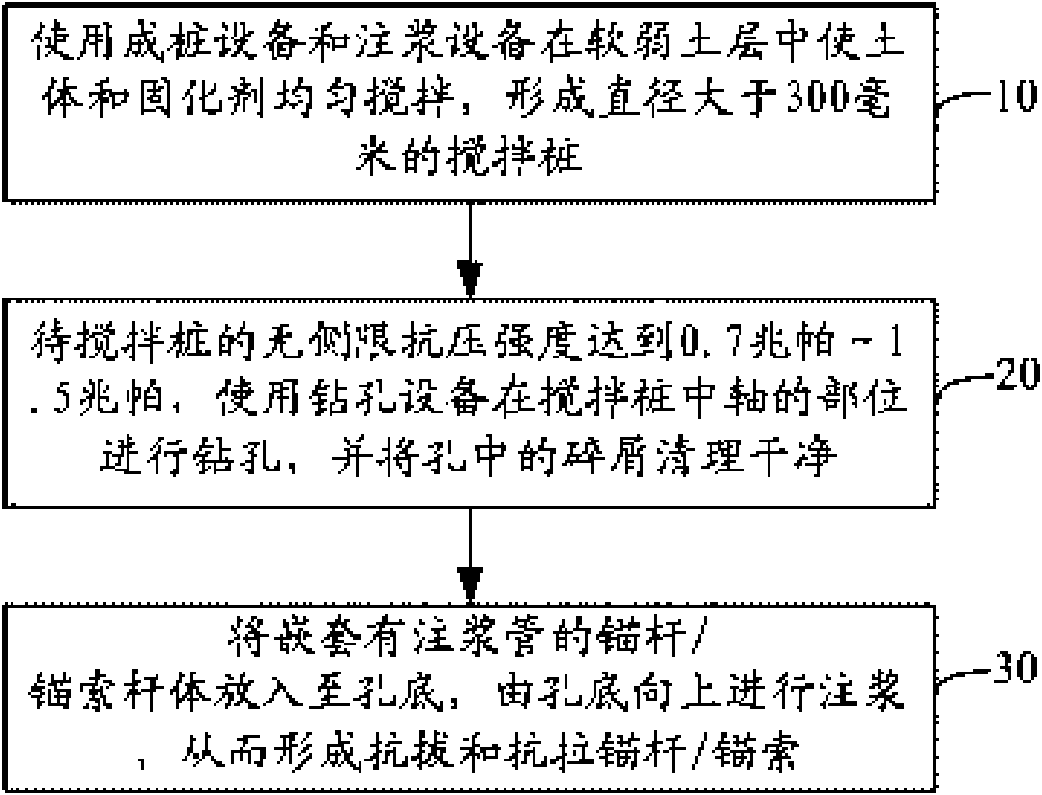

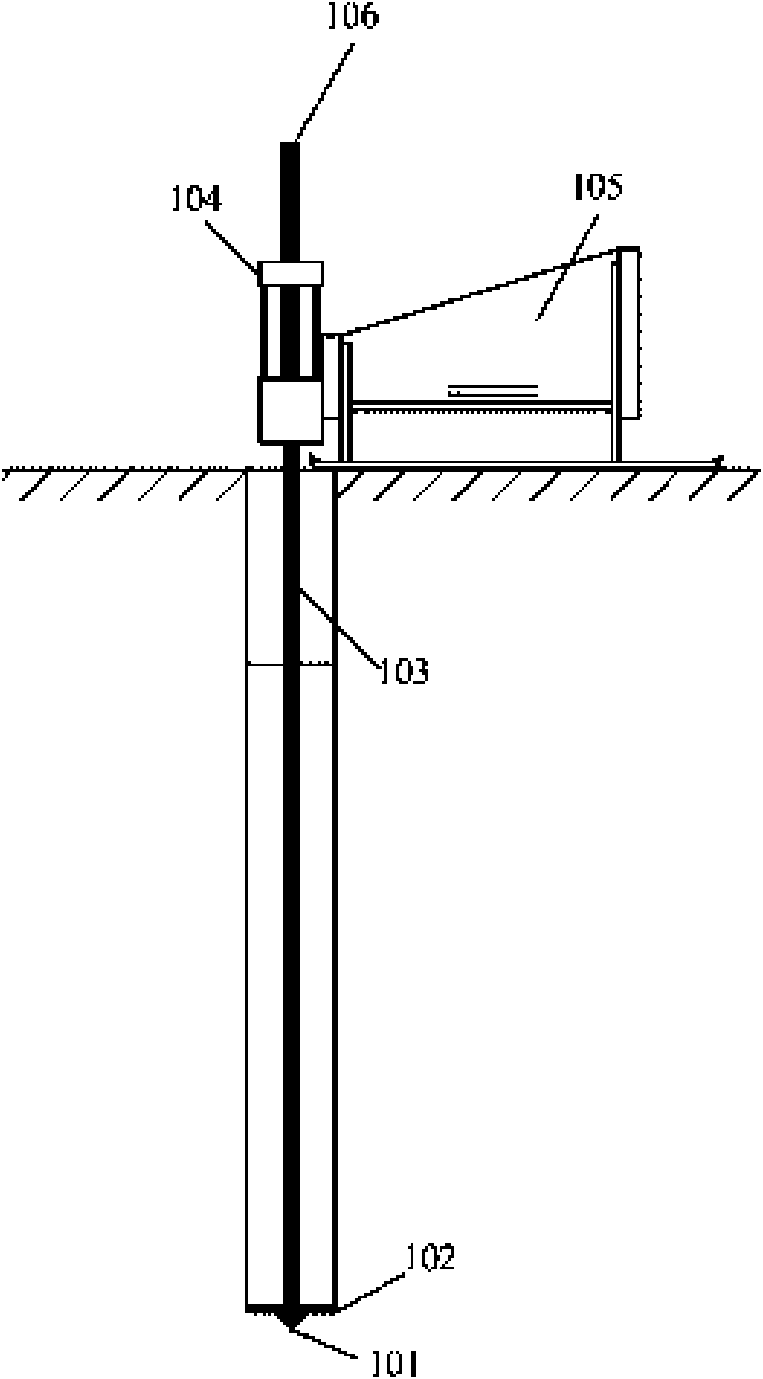

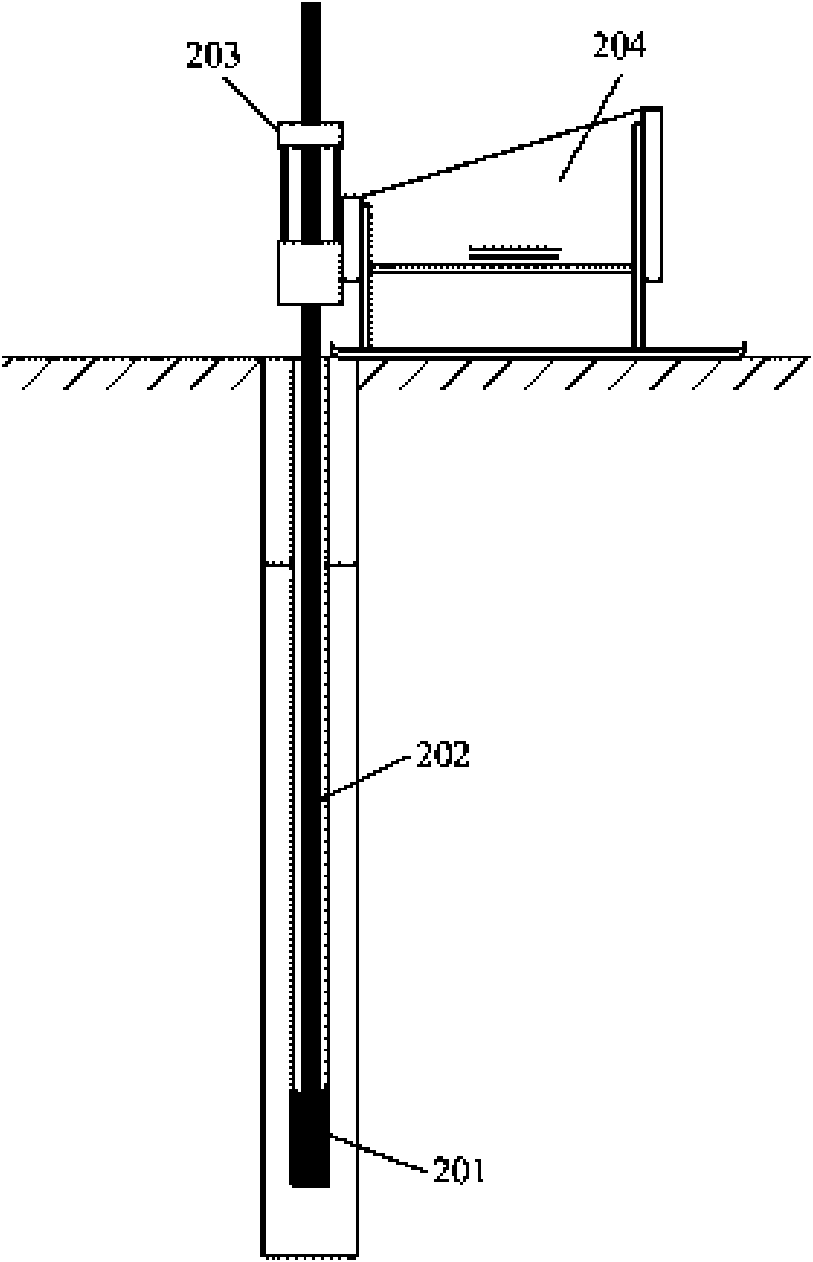

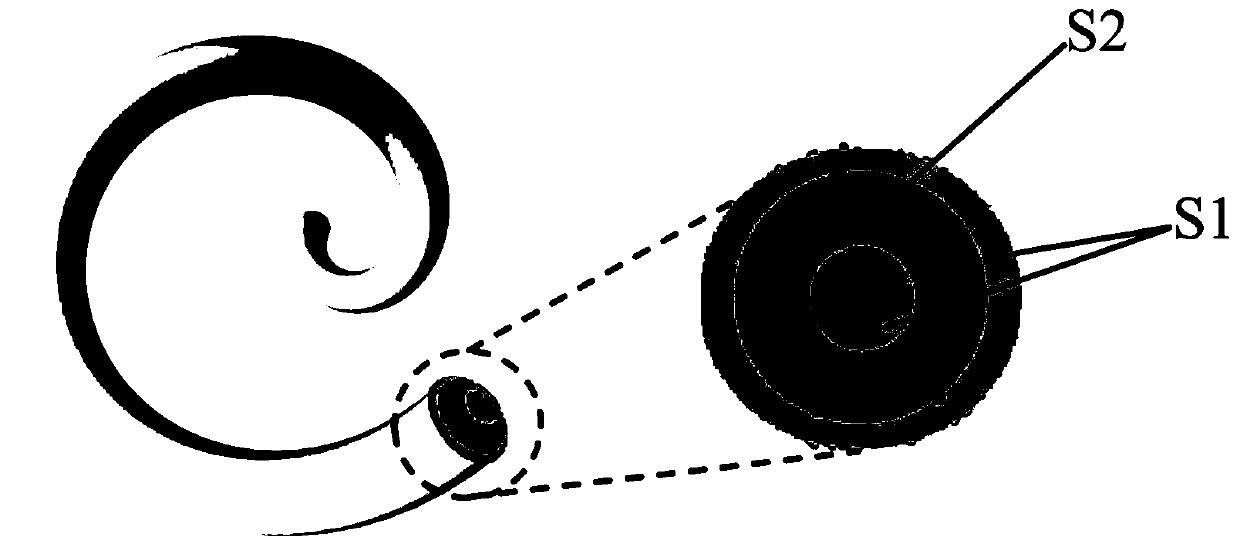

Method for enhancing pulling-resistant and tensile-resistant capability of soft and weak soil layer anchor rod/anchor rope

The invention relates to a method for enhancing pulling-resistant and tensile-resistant capability of a soft and weak soil layer anchor rod / anchor rope. The method comprises the following steps: evenly stirring soil body and a solidifying agent in the soft and weak soil layer by using pile-forming equipment and grout injecting equipment, and forming a stirring pile; drilling holes at the positionof a central shaft in a stirring pile by using drilling equipment when unconfined compressive strength of the stirring pipe reaches 0.7MPa to 1.5MPa, and cleaning detritus in the holes; and placing the anchor rod / anchor rope rod body embedded with a grout injecting pipe into the bottom of the holes, and carrying out grout injection from the hole bottom to top to form the pulling-resistant and tensile-resistant anchor rod / anchor rope. The method solves the problem that the soil layer anchor rod / anchor rope can not be used in soft soil areas, solves a series of problems of slurry pollution, longconstruction period, complex technique, high cost and the like due to pile injecting by the use of the pulling-resistant drilling and solves the problems of easy corrosion and nondurability of a reinforced pile anchor.

Owner:凌光荣 +1

Organic/inorganic composite material for rapidly repairing pit slots of bituminous pavement and preparation method thereof

The invention discloses an organic / inorganic composite material for rapidly repairing pit slots of a bituminous pavement, which is prepared from the following main raw materials of polymethylene polyphenyl polyisocyanates, a polyurethane prepolymer, polyether polyol, petroleum asphalt, a catalyst, sodium silicate powder, carborundum and the like. The composition material comprises components A, B and C, wherein the components A and the component B are blended with the component C after being mixed, and can be quickly solidified after being cast into the pit slots at room temperature, so that the composite material has strong caking property and similar rigidity with an original bituminous pavement, and the travelling stationarity and comfortableness are achieved after restoration. The composite material is simple and convenient to construct, rapid, efficient and environmentally friendly, the setting time is smaller than or equal to 30 minutes, and the bituminous pavement can be opened after 90 minutes, so that the rapid repairing purpose is achieved, and the effect on traffic jam caused by pavement rehabilitation is greatly relieved. The composite material has excellent water tolerance, weather fastness, abrasive resistance and compressive shear resistance, is a novel green material for rapidly repairing pit slots of a pavement, and has positive promotion action and a good application effect on development of a preventive maintenance technology of highways.

Owner:北京中科安途交通科技有限公司

Manganese-containing steel alloying process

The invention provides a manganese-containing steel alloying process. The alloying process includes: 1) a step of baking a steel ladle, wherein manganese ore blocks having a particle size of 10-50 mm and a sulphur content smaller than 0.05% and a phosphorus content smaller than 0.05% are added into the steel ladle, addition and matching are performed according to the middle of the manganese content limit, the baking temperature is higher than 1000 DEG C, the baking time is longer than 2 h, and the steel ladle is covered with a steel ladle cover in a conveying process after baking; 2) a step of converter operation, wherein the tapping temperature is performed according to the middle limit and the upper limit, the temperature of the molten steel is 1685-1705 DEG C, the temperature of the molten steel in the steel ladle is guaranteed to be not less than 1670 DEG C, the carbon content in the end point is more than 0.08%, the slag quantity discharged from the converter is controlled, the thickness of the slag is smaller than 50 mm, and the operation of blowing argon to the bottom of the steel ladle is performed after the tapping step; and 3) a step of refining operation in an LF furnace, wherein strong stirring is adopted, the argon flow rate is not less than 250 NL / min, the temperature is controlled according to the target refining temperature upper limit, and other alloys are added to adjust the component of the molten steel so as to satisfy the requirements of the steel. The process is simple in operation, free of improvement of original equipment, and free of influence on other production working, and can significantly reduce the steelmaking cost. The yield of the manganese in the manganese ore can be higher than 90%.

Owner:ANGANG STEEL CO LTD

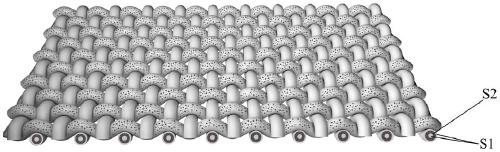

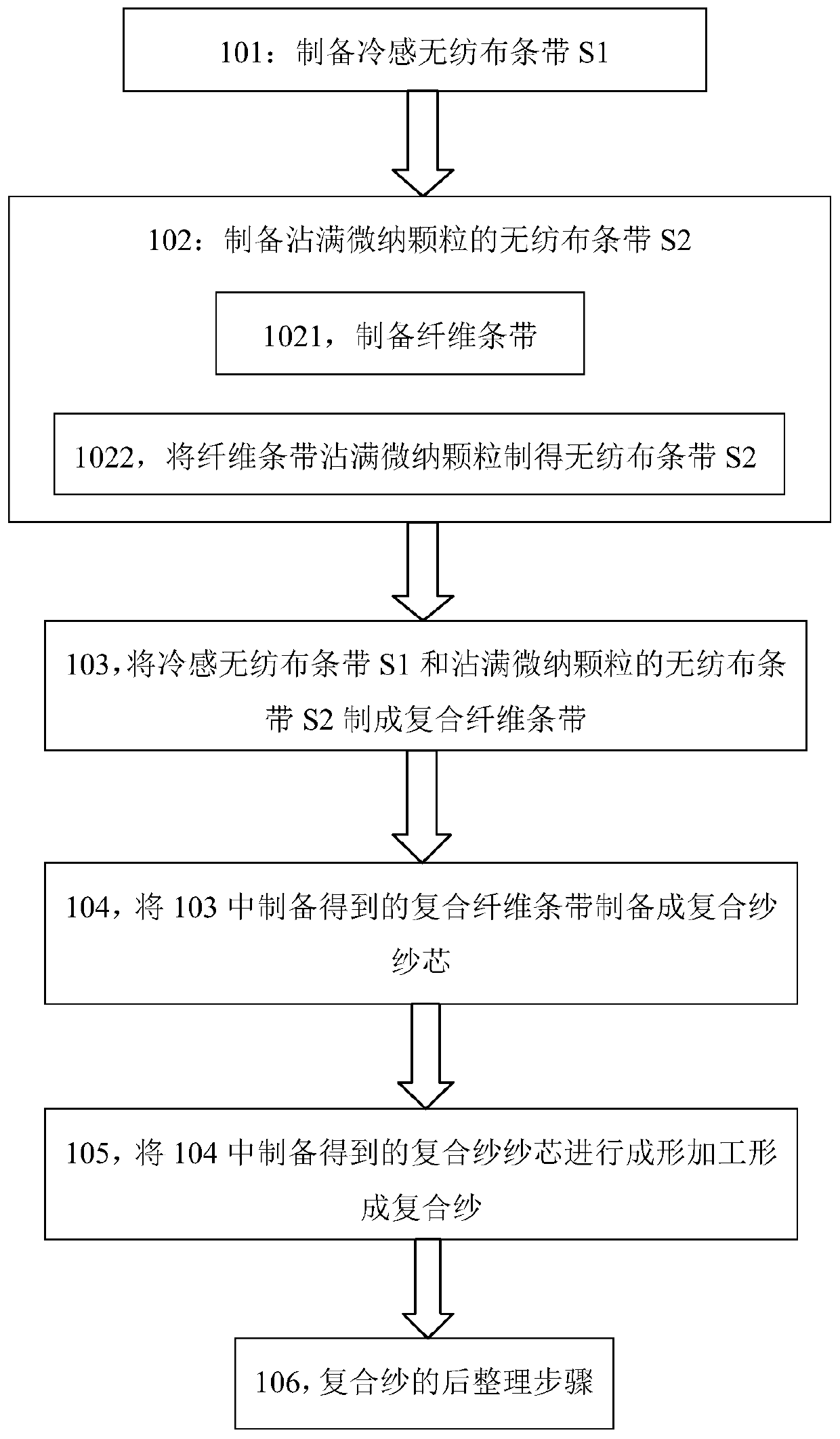

Preparation method for composite yarn with radiation refrigeration function, and fabric

ActiveCN111560672ASolve the cooling effectAddress process complexityWoven fabricsYarnYarnNonwoven fabric

The invention discloses a preparation method for a composite yarn with a radiation refrigeration function, and a fabric. The preparation method for the composite yarn with the radiation refrigerationfunction, and the fabric comprises the following steps: preparing a cold-sense non-woven fabric strip; preparing a non-woven fabric strip fully attached with micro-nano particles; preparing a composite fiber strip from the cold-sense non-woven fabric strip and the non-woven fabric strip fully attached with the micro-nano particles; preparing a composite yarn core from the composite fiber strip; carrying out forming processing on the composite yarn core to form the composite yarn; and preparing the fabric from the composite yarn. According to the preparation method for the composite yarn with the radiation refrigeration function, and the fabric, the inorganic micro-nano particles with a concentration which is adjustable in a large range are introduced outside and inside the yarn by virtue of a padding method and a coating method, and the radiation-refrigeration composite yarn appliable to cooling for human skin, and the fabric are prepared; and the preparation method is simple and shortin flow, and solves the problems of inapplicability to cooling for human skin, complex process, difficulty of being subjected to textile processing, and poor refrigeration effect of an existing radiation-refrigeration material.

Owner:武汉新润兴材料科技有限公司

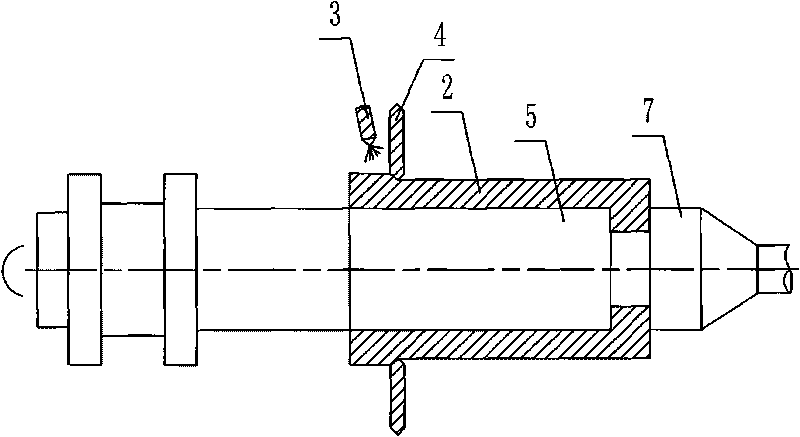

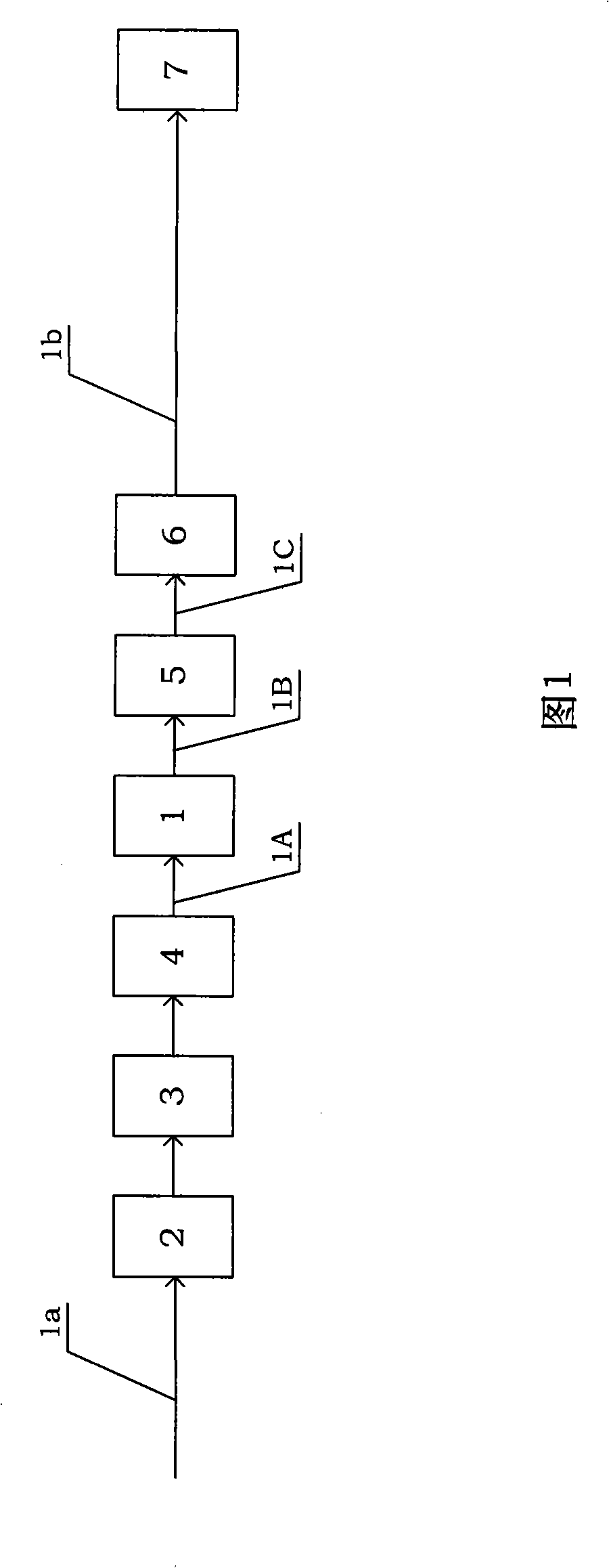

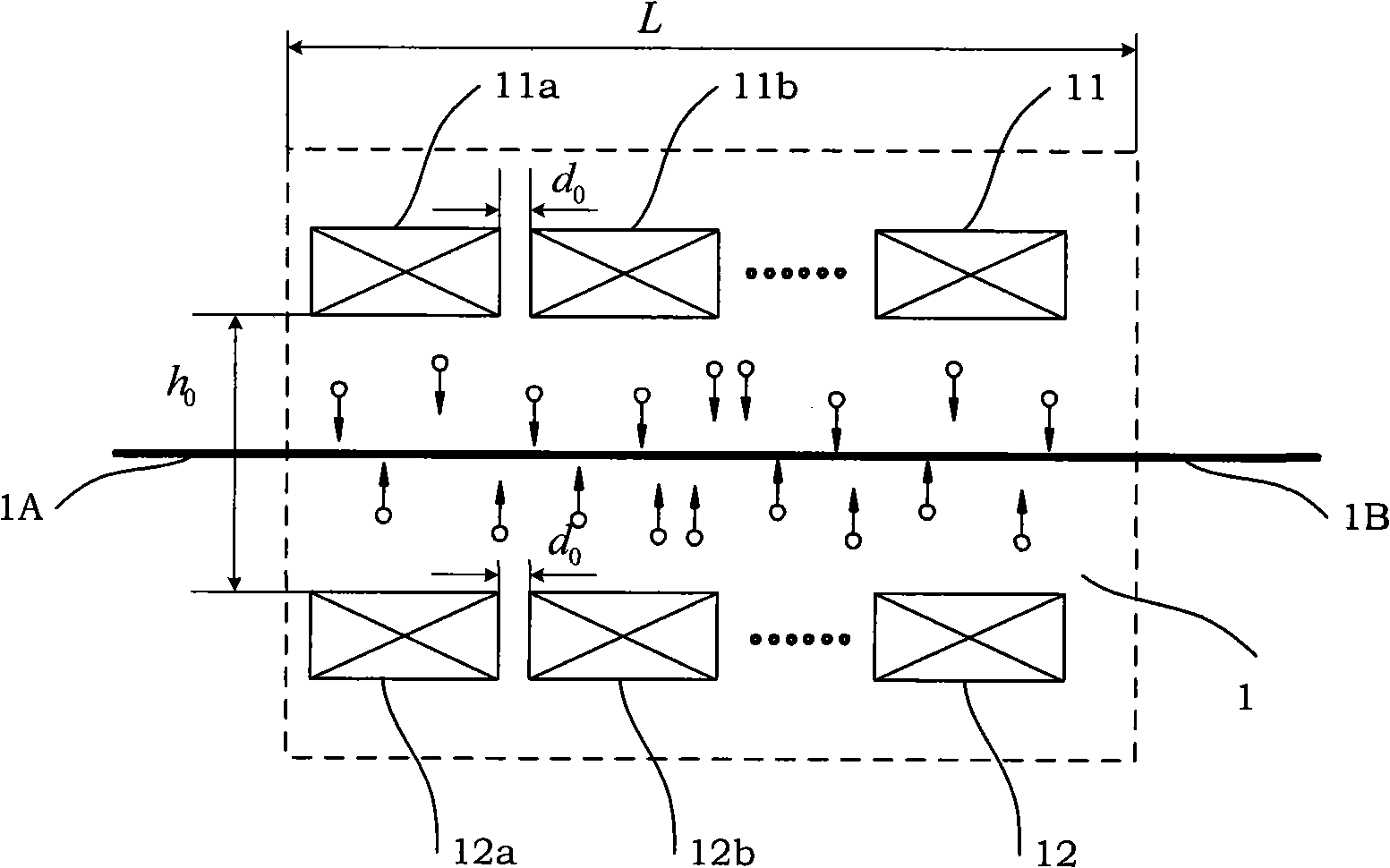

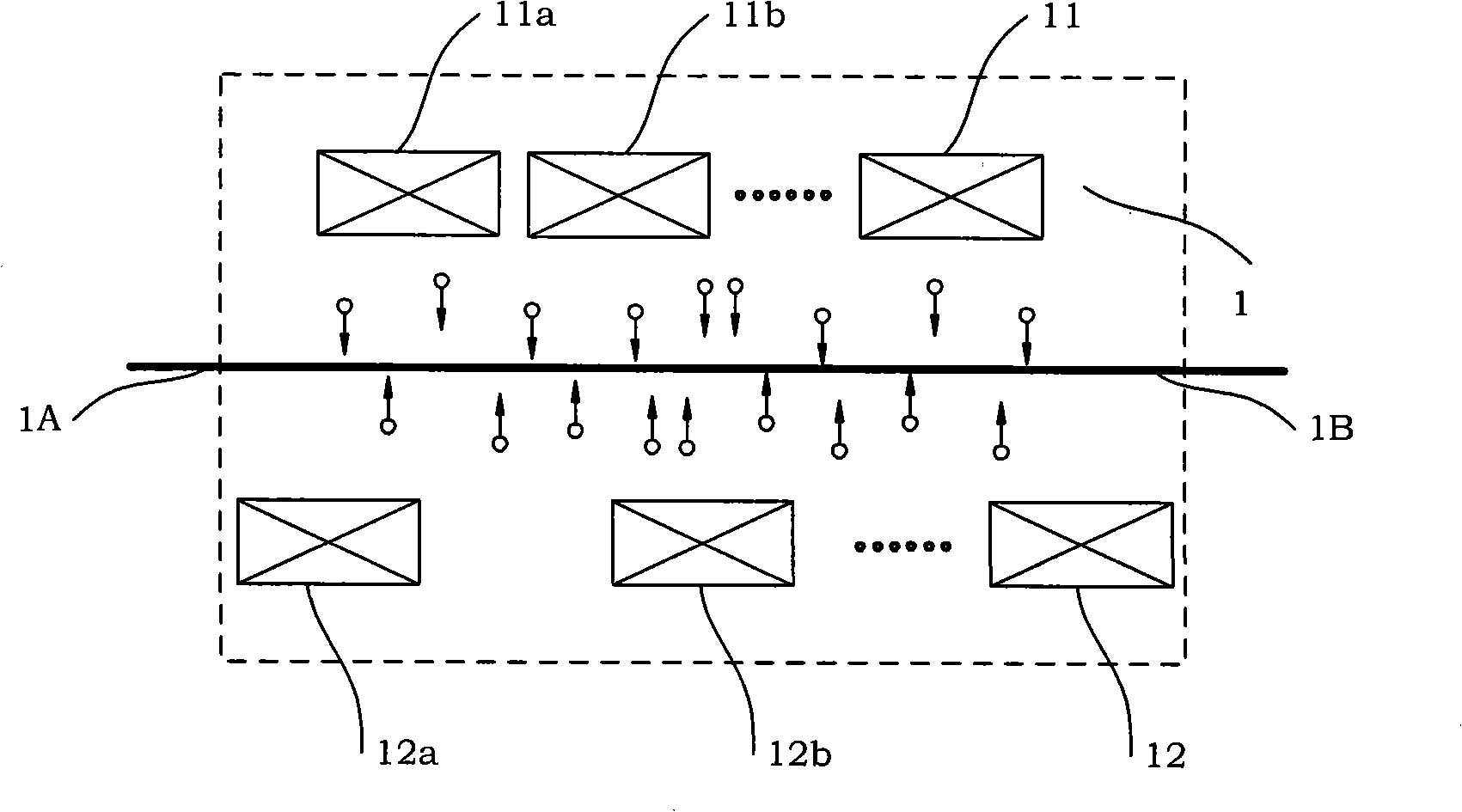

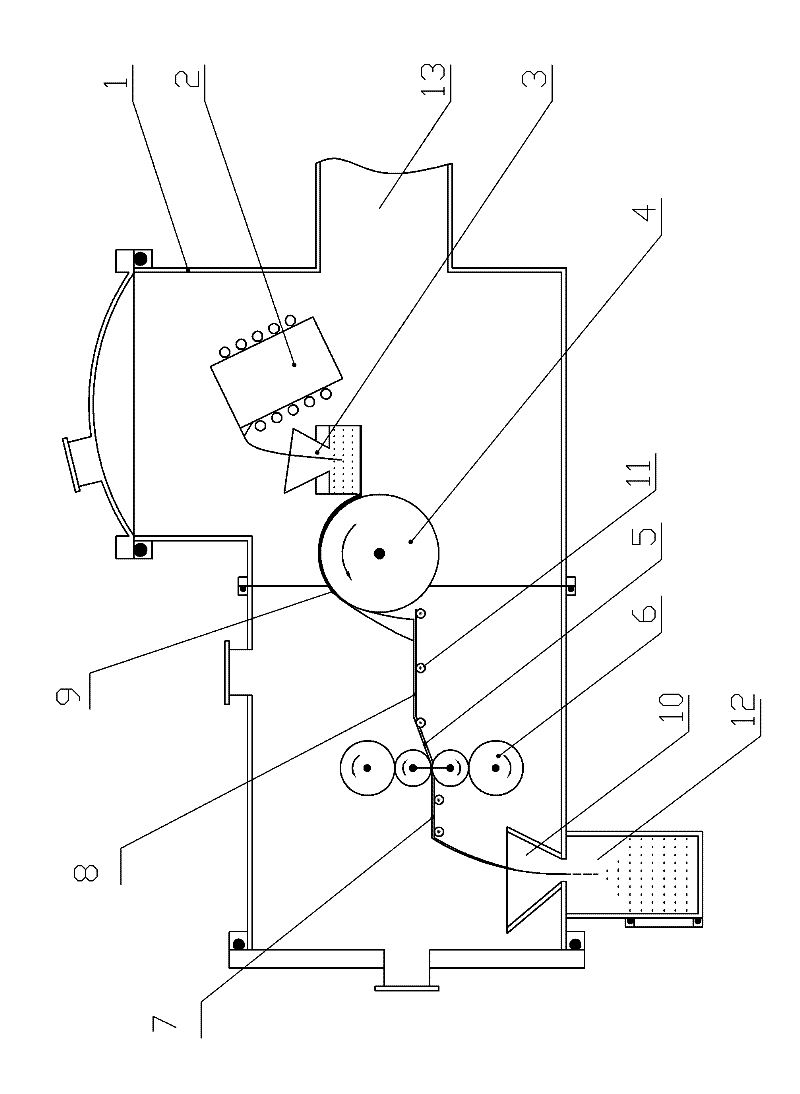

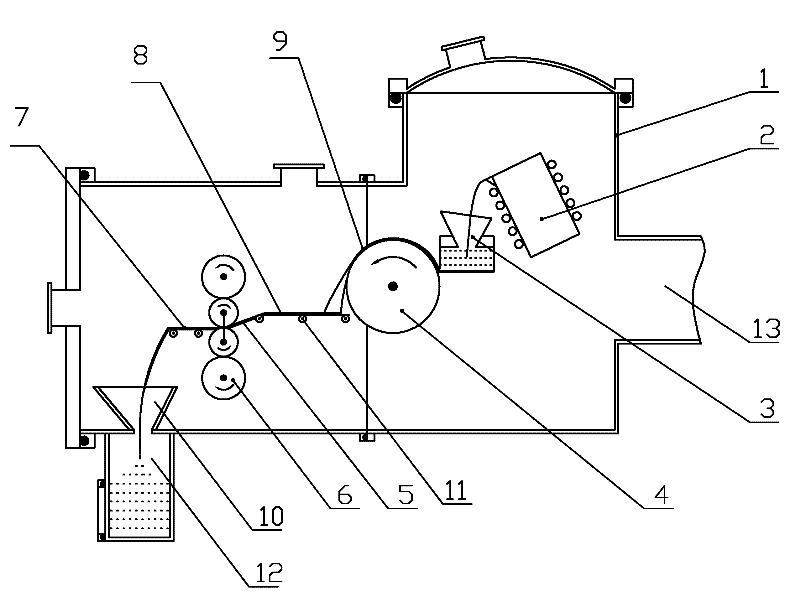

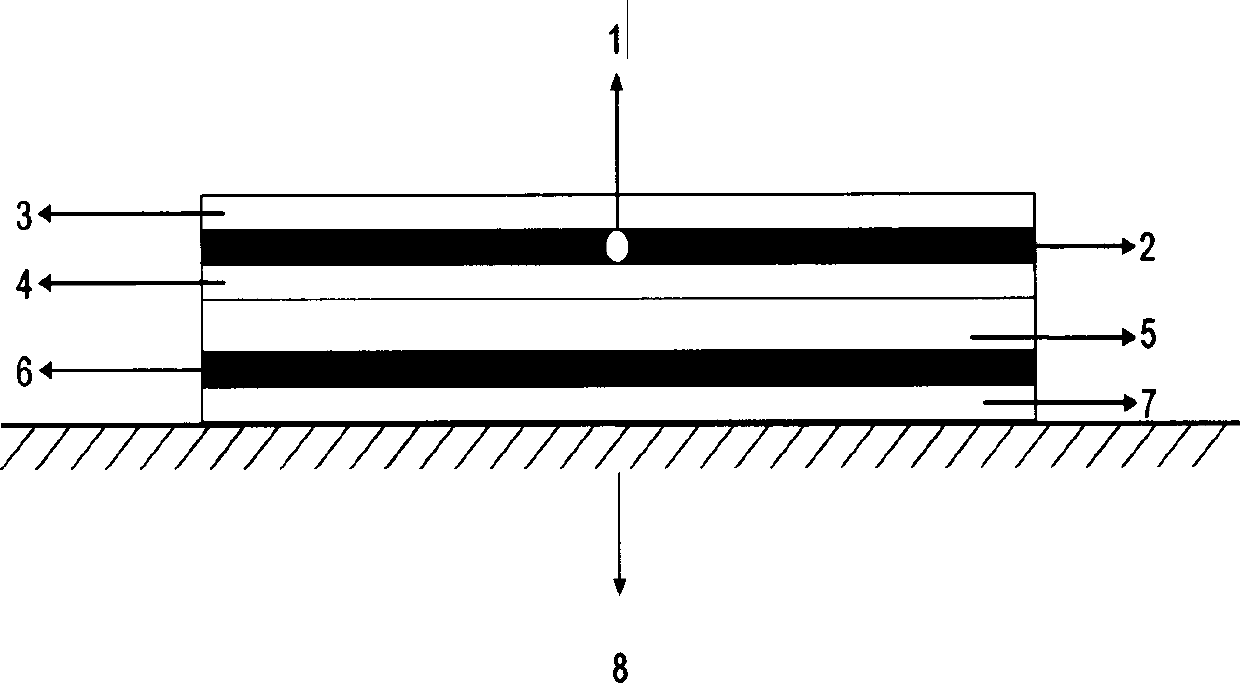

Industrial production system for producing high-silicon strip with magnetron sputtering continuous two-sided codeposition process

InactiveCN101319306ASilicon content adjustmentAdjustable thicknessVacuum evaporation coatingSputtering coatingProduction lineGas phase

The invention discloses an industrialized production system for making a high-silicon steel strip by a process of magnetron sputtering continuous double-sided codeposition. The industrialized production system of a high-silicon silicon plate comprises a welding machine (3), a preheating chamber (4), a magnetron sputtering chamber (1), a diffusion chamber (5), a cooling chamber (6), and a coiler (7), which are sequentially arranged on a production line starting from the deliverty of the low-silicon silicon plate to the production system by an unwinding coiler (2) to the finish of the production of high-silicon silicon plate. The industrialized production system for making the silicon material by the process of the continuous double-sided codeposition, driven by the unwinding coiler (2), is capable of performing deposition on a the low-silicon silicon plate with a thickness of less than 0.35mm with silicon content of between 5 and 8 weight percent to by means of symmetrically disposing a plurality of cathode targets in the magnetron sputtering chamber, thereby achieving the aim of continuous deposition of silicon material with low energy consumption and high production efficiency. The industrialized production system solves the defect that the silicon plate of the commercialized Fe-6.5 weight percentage Si can only be produced by adopting a method of chemical gas-phase deposition.

Owner:BEIHANG UNIV

Porous hydrogel film for extracting uranium from seawater and preparation method of porous hydrogen film

InactiveCN110684233ASimple processShort preparation timeOther chemical processesProcess efficiency improvementFilm materialTweezers

The invention discloses a preparation method of a porous hydrogel film for extracting uranium from seawater. The preparation method comprises the following steps: stirring and mixing hydroxylamine hydrochloride, N-N dimethylformamide, sodium carbonate and polyacrylonitrile according to a certain proportion, and heating the mixture to carry out oximation reaction to obtain amidoximated polyacrylonitrile sol; dropwise adding the amidoximated polyacrylonitrile sol onto a glass substrate by using a dropper, carrying out scraping and coating to enable the amidoximated polyacrylonitrile sol to be uniformly laid on the substrate, then soaking and forming in water, separating the film by using tweezers, cleaning the film by using water for several times, and carrying out vacuum drying to obtain aporous hydrogel film; and soaking the porous hydrogel film material in an alkaline solution to obtain the porous hydrogel film for extracting the uranium from the seawater. The method disclosed by theinvention has the characteristics that the process is simple, the film is formed easily and is high in separation speed, the prepared film material has ultra-high hydrophilicity, large specific surface area and high porosity, the adsorption rate on uranyl ions is high, and the adsorption rate can reach up to 375 mg / g.

Owner:HAINAN UNIVERSITY

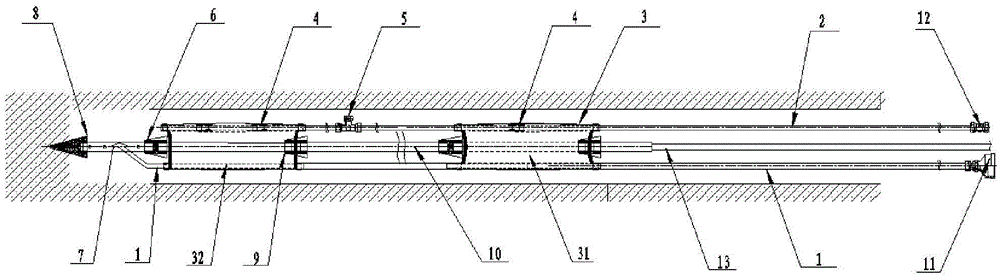

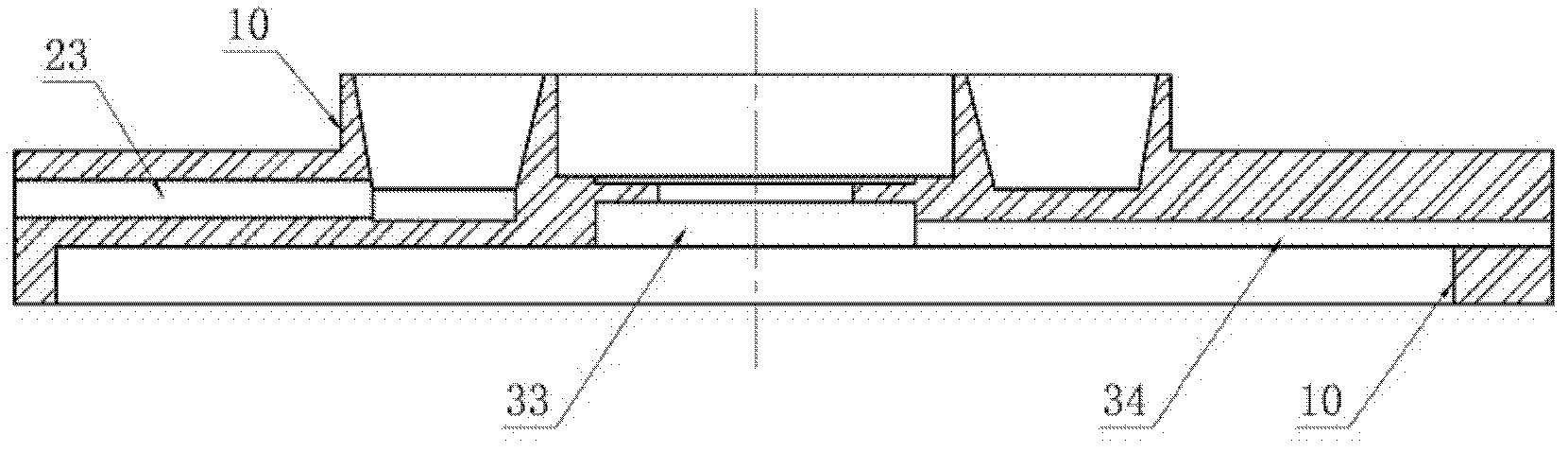

Deep sealing type hole sealing device and hole sealing method

The invention provides a deep sealing type hole sealing device which can solve the technical problem that a traditional hole sealing device is complex in process and cumbersome in operation. The deep sealing type hole sealing device comprises a suction pipe and a grouting pipe, wherein the suction pipe and the grouting pipe are arranged in parallel, two sealed bags are arranged at the two ends of a hole sealing segment of the suction pipe and the grouting pipe respectively, the bag close to a hole opening is a hole opening bag, the bag close to a hole bottom is a hole bottom bag, the bags wrap the suction pipe and the grouting pipe, the tail end of the grouting pipe is sealed and arranged at the bottom of the hole bottom bag, a one-way valve is arranged at the position, in the corresponding bag, of the grouting pipe, and an explosion valve is arranged between the two bags. The deep sealing type hole sealing device further comprises a floral pipe, wherein the floral pipe is provided with a plurality of notches, one end of the floral pipe is fixed to the outer portion of the bottom of the hole bottom bag, a sharp cone is arranged at the other end of the floral pipe, the tail end of the suction pipe stretches out of the bottom of the hole bottom bag to be connected into the notches of the floral pipe, and the end, close to the hole bottom, of the suction pipe is provided with a plurality of holes. According to the deep sealing type hole sealing device, casing installation, hole sealing and drainage are integrated, so that convenience is achieved, and operation procedures are reduced.

Owner:淮南东华欧科矿山支护设备有限责任公司

Method and device for recycling VOC in low-concentration VOC-containing mixed gas

ActiveCN104524918AImprove solubilityImprove adsorption capacityDispersed particle separationRecovery methodRetention time

The invention discloses a method and a device for recycling VOC in low-concentration VOC-containing mixed gas and belongs to the technical fields of energy conservation and environmental protection. The VOC gas is recycled from the low-concentration VOC mixed gas under the conditions of the absolute pressure of 0.08-0.5MPa and the temperature of 20-60 DEG C below zero by adopting a bubble absorption-adsorption and enrichment combined mode, the problems that the traditional low-concentration VOC-containing mixed gas process is complex, the equipment is large and the recycling cost is high are solved, the absorber volume and operation retention time can be reduced, low-cost environment-friendly treatment of the low-concentration VOC-containing mixed gas is realized, the total treatment rate of the VOC is over 90 percent, and the total recovery rate is over 50 percent.

Owner:ZHEJIANG UNIV OF TECH

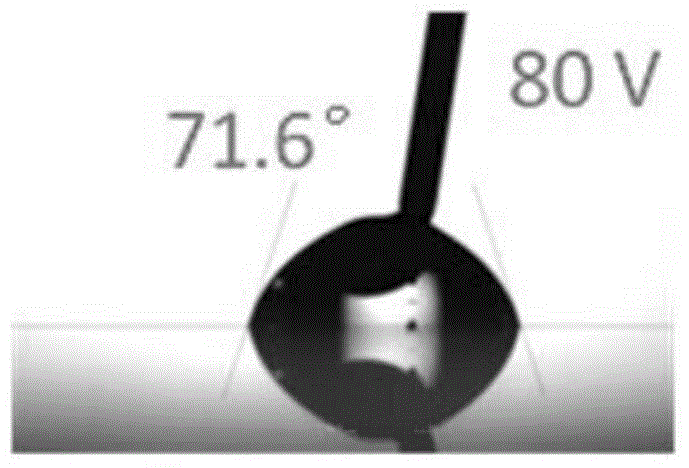

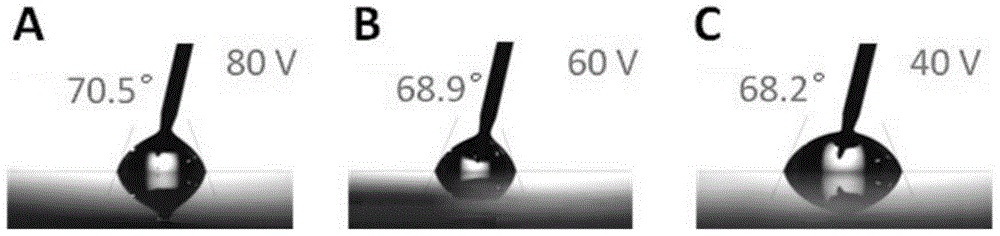

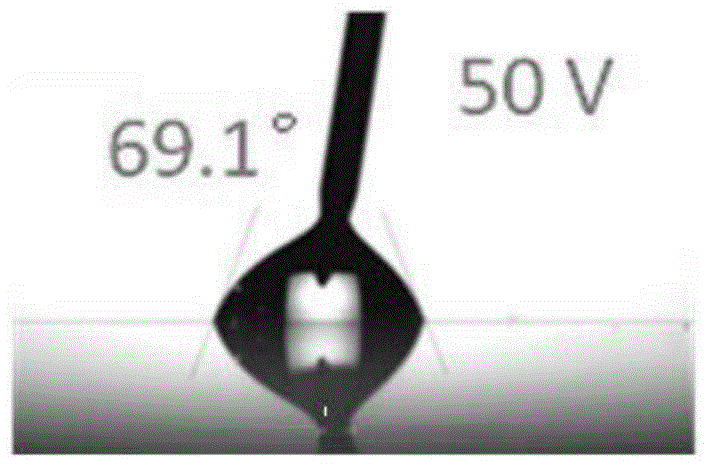

Method for preparing coating on surface of hydrophobic insulating layer

InactiveCN104907238AImprove wettabilitySimple processPretreated surfacesSpecial surfacesCoatingElectrowetting

The invention discloses a method for preparing a coating on the surface of a hydrophobic insulating layer. The method includes the following steps that the hydrophobic insulating layer is prepared on a base material; coating paint is added to the hydrophobic insulating layer; electrowetting processing is conducted, that is, proper voltage is applied on the position between the base material and the coating paint, the electrowetting effect is utilized, and the surface of the hydrophobic insulating layer becomes wettable; coating is conducted. The method can be used for preparing coatings on the surface of various hydrophobic insulating layers, such as, electrowetting display, micro-fluidic chips, electrowetting sensing, electrowetting micro lens and electrowetting micro electro mechanical system and the application range of hydrophobic insulating materials can be greatly expanded.

Owner:SOUTH CHINA NORMAL UNIVERSITY +2

Preparation method of anisotropic rare earth permanent magnet alloy material and magnetic powder

ActiveCN102403078AAddress process complexitySolving expensive equipmentMagnetic materialsRare earthAlloy

A preparation method of anisotropic rare earth permanent magnet alloy material and magnetic powder belongs to the technical field of rare earth iron-based permanent magnet material, wherein the material includes the content of Sm2+X(Fe1-yMy) 17NZ, wherein M is at least one of the Cu, Al, Zn, Sn, Ga, Ni, Zr, Cr, Ti and Nb, y=0-4, z=2.5-3.0. The preparation includes the steps of: preparing a certain content of Sm-Fe alloy raw materials, in the anisotropic rare earth permanent magnet alloy magnetic powder preparing device, under the protective atmosphere of vacuum and Ar, preparing the soft magnetic Sm2+X(Fe1-yMy) 17 rapid-solidified alloy slices mainly containing microcrystallines with obvious processing structure and anisotropism, crushing the slices into fine powders, and thermally penetrating and diffusing the N to obtain the Sm2+X(Fe1-yMy) 17NZ permanent magnet alloy magnetic powder with obvious processing structure and anisotropism. The invention solves the problems of complex process, low magnetic performance and bad anisotropism.

Owner:SHENYANG GENERAL MAGNETIC

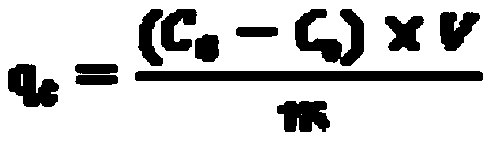

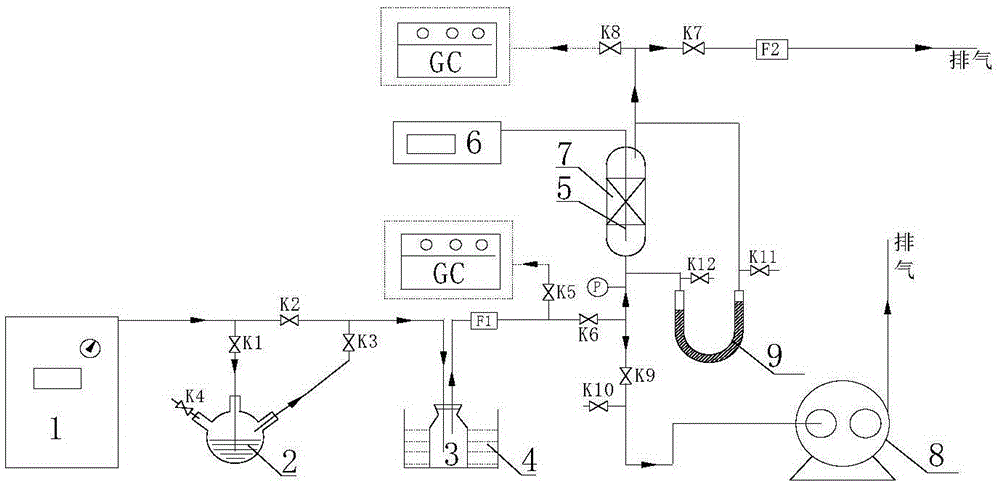

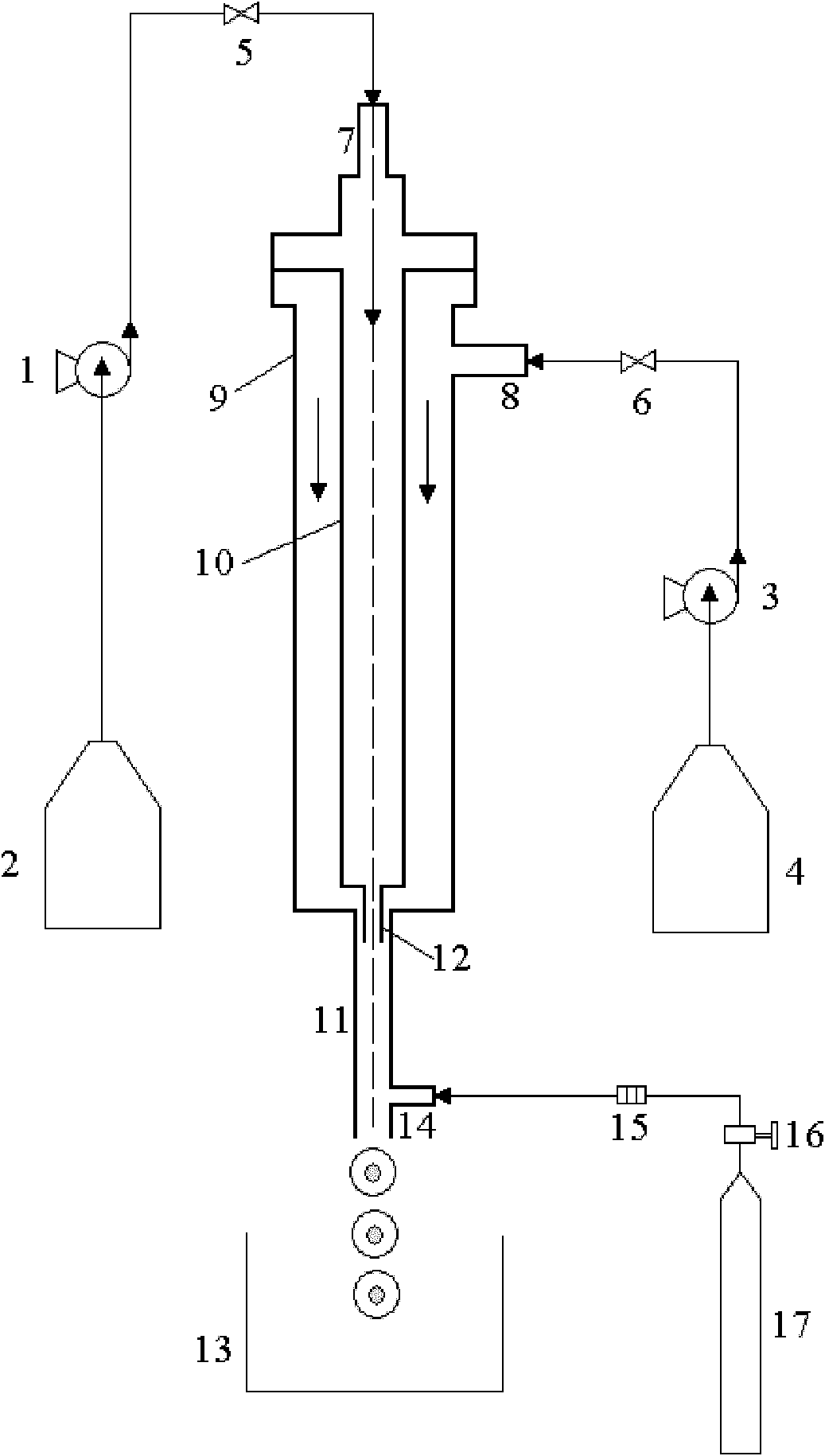

Adsorbent performance dynamic detection device

InactiveCN105136922ASimulated vapor concentration is stableImprove heat transfer performanceComponent separationDesorptionSorbent

The present invention provides an adsorbent performance dynamic detection device. The adsorbent performance dynamic detection device can test the dynamic adsorbent performance of different adsorbents by changes of gas concentration, gas flow rate, adsorption temperature, adsorption layer height and other conditions, heat produced during the adsorbent adsorption and desorption processes can be tested, a laboratory adsorbent dynamic performance testing adsorption and desorption integrated experimental test device is provided, the problems of experimental device complexity, large investment, poor security and the like can be reduced, a simple structure, easy operation, low cost and accurate data device is disclosed, and is more generally used in more experimental tests.

Owner:CHANGZHOU UNIV

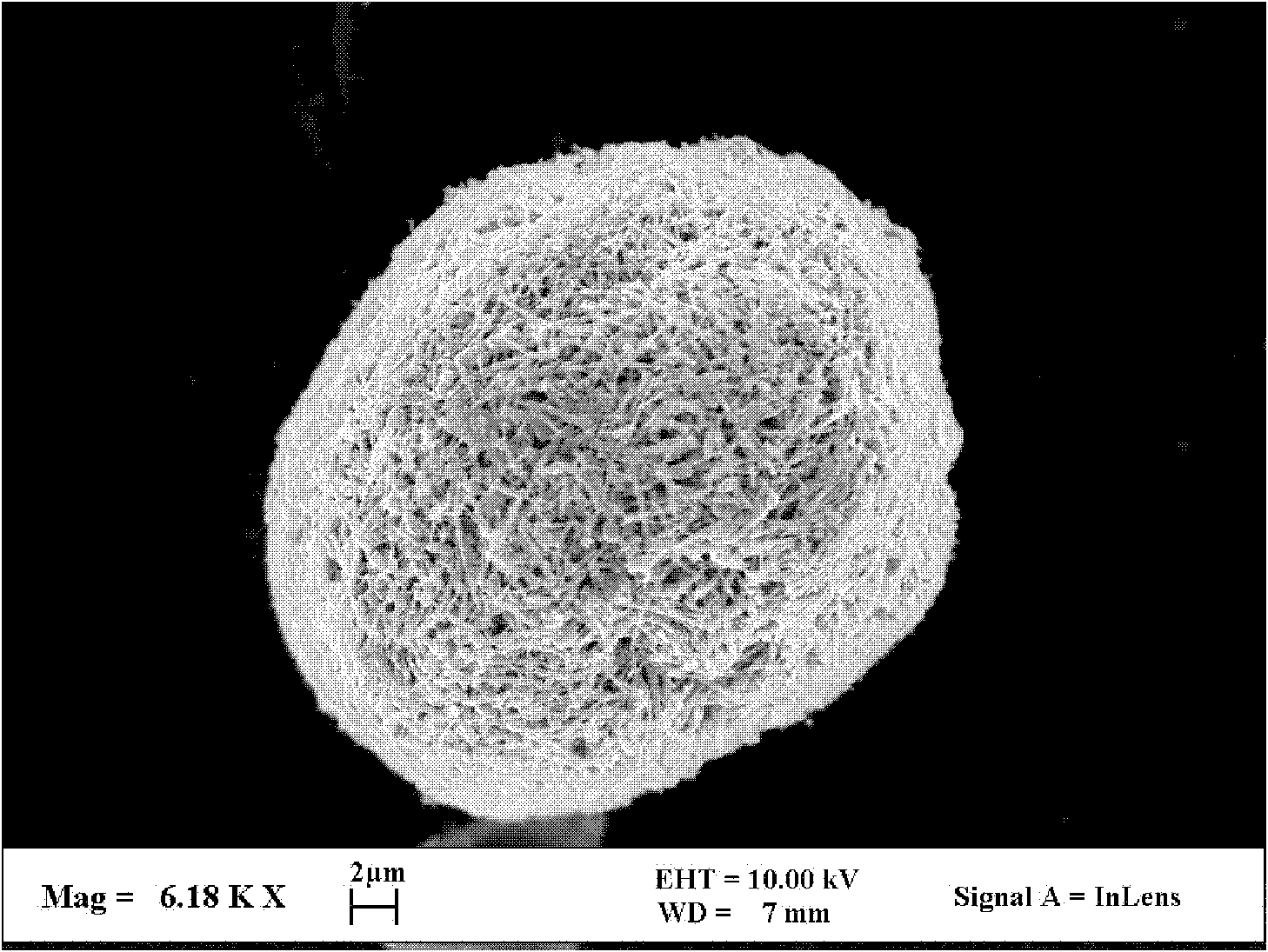

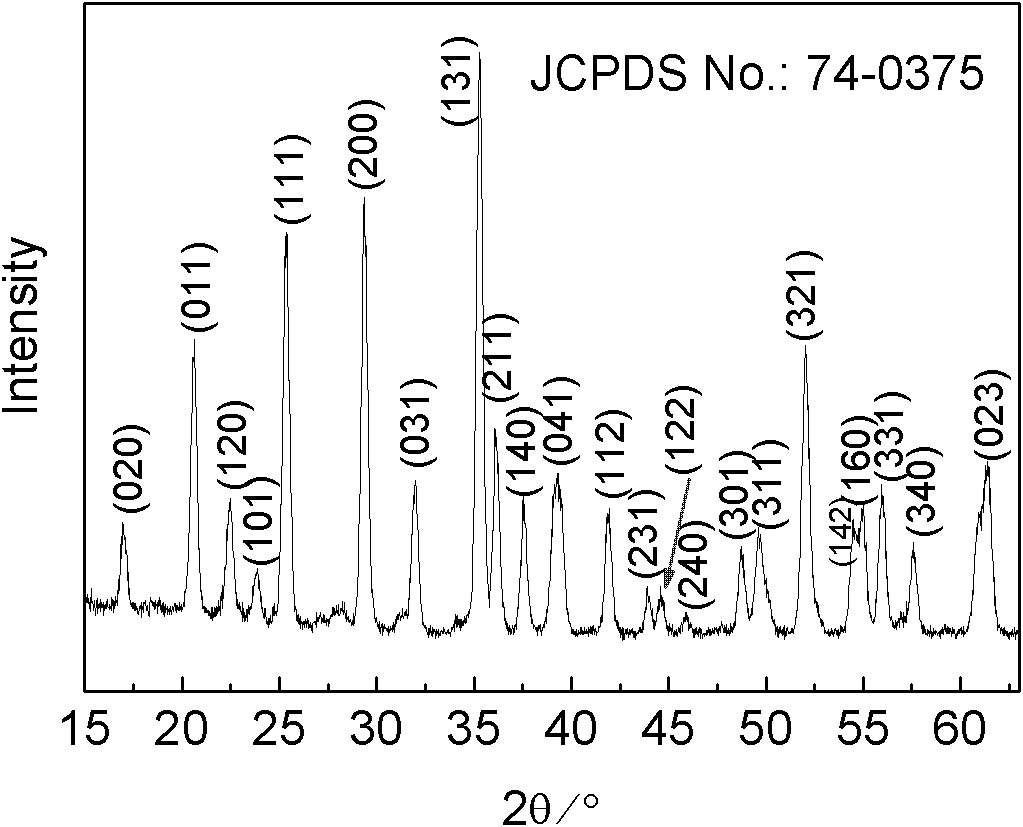

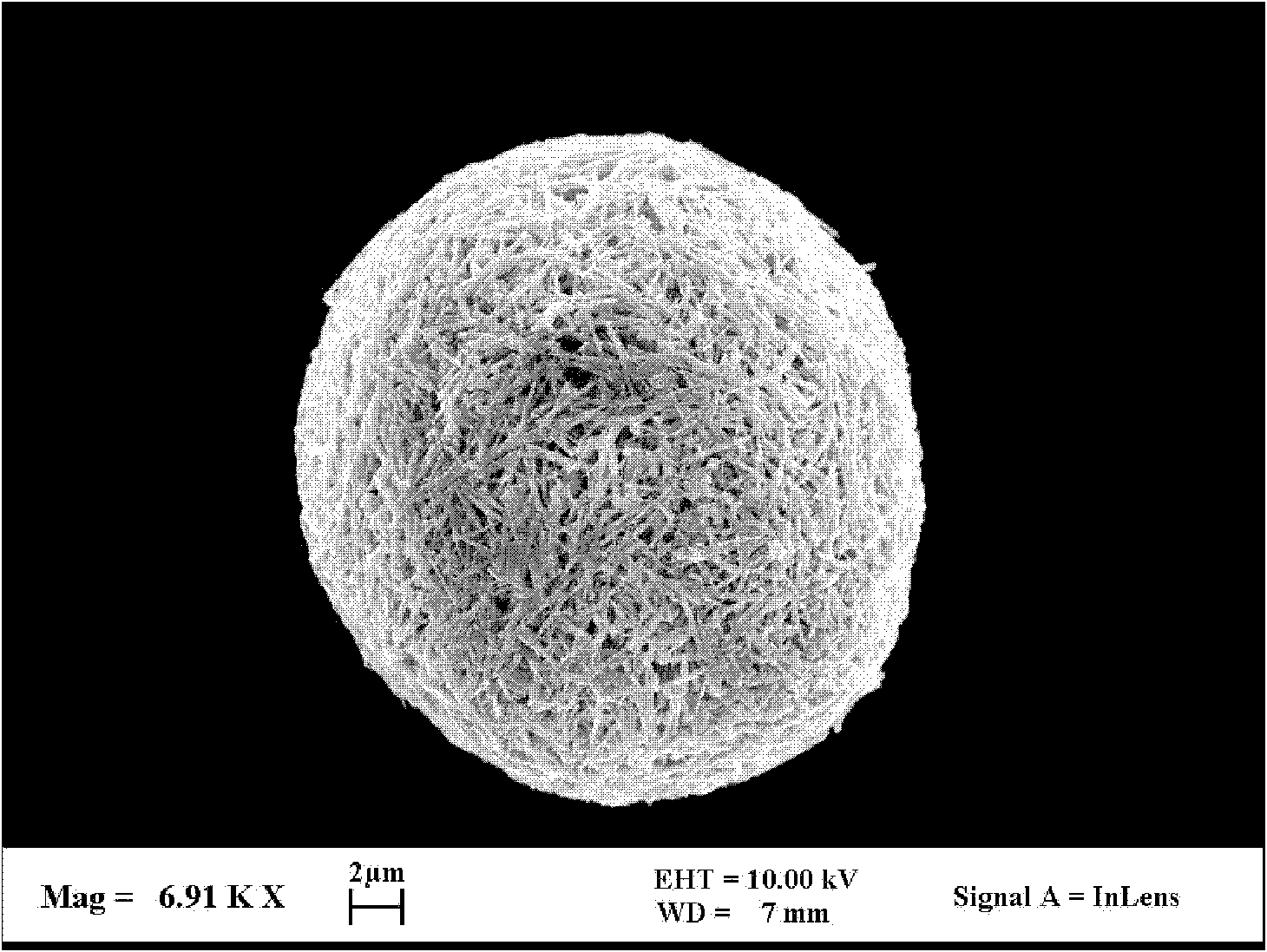

Fiber-ball-shaped lithium manganese phosphate anode material of lithium ion battery and preparation method of fiber-ball-shaped lithium manganese phosphate anode material

ActiveCN102610816AAddress process complexityReduce manufacturing costCell electrodesPhosphorus compoundsFiberSlurry

The invention relates to preparation method for a fiber-ball-shaped lithium manganese phosphate anode material of a lithium ion battery. The preparation method includes particular steps: mixing and ball-milling a lithium source, a manganese source, a phosphorus source, a carbon source and dispersing agent to obtain uniformly mixed slurry; drying the slurry to obtain fiber-ball-shaped precursor; and realizing heat treatment for the precursor in shielding atmosphere to obtain the fiber-ball-shaped lithium manganese phosphate anode material of the lithium ion battery. The preparation method has the advantages of simplicity in process, low cost, environmental protection, convenience in operation and applicability to industrial production. In addition, the lithium manganese phosphate anode material prepared in the method is fiber-ball-shaped, the size of the lithium manganese phosphate anode material ranges from 2 micrometers to 35 micrometers, and the lithium manganese phosphate anode material is fine in crystallinity, high in purity and excellent in circulation performance and can be used as an anode material of the lithium ion battery.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

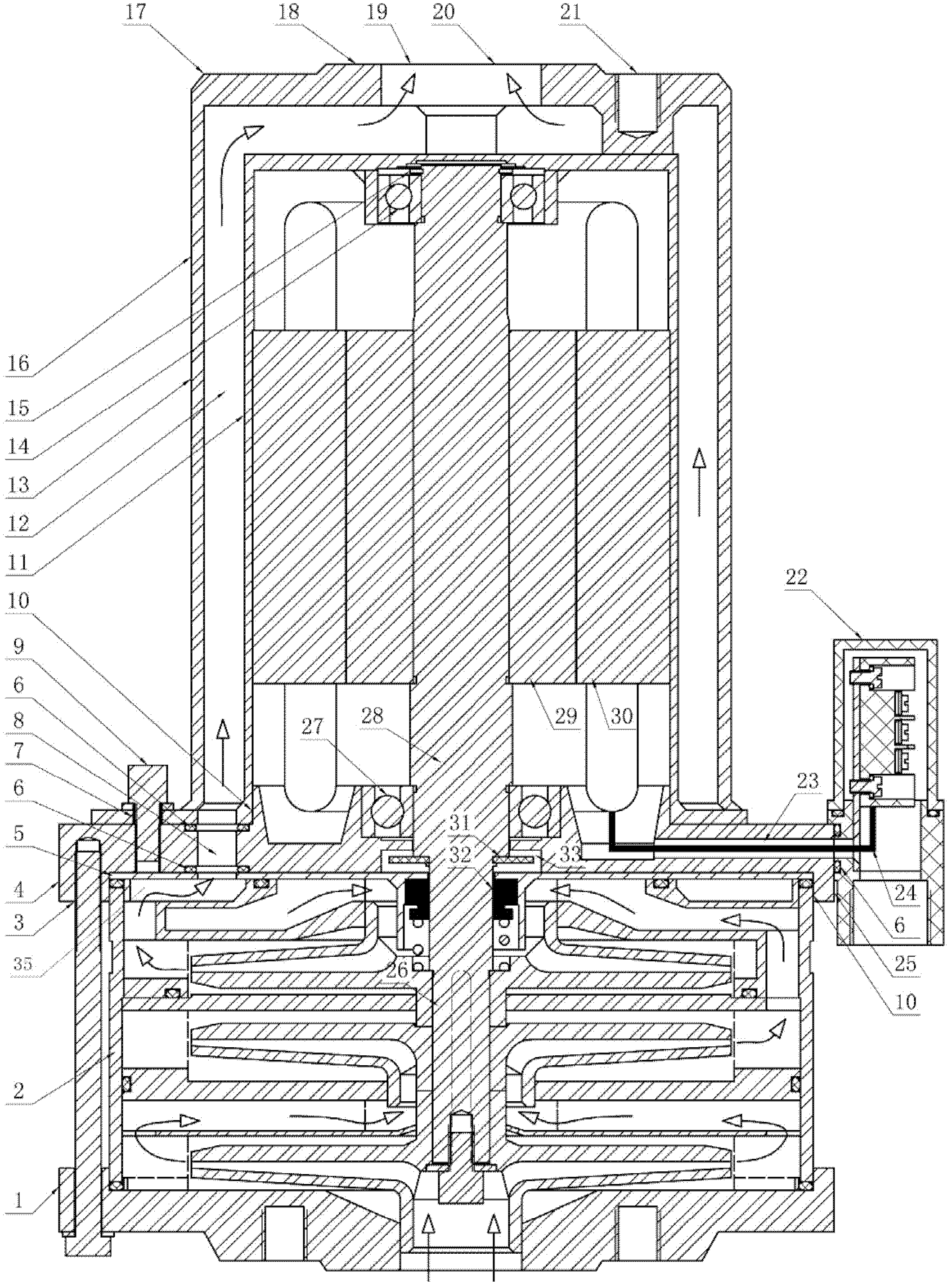

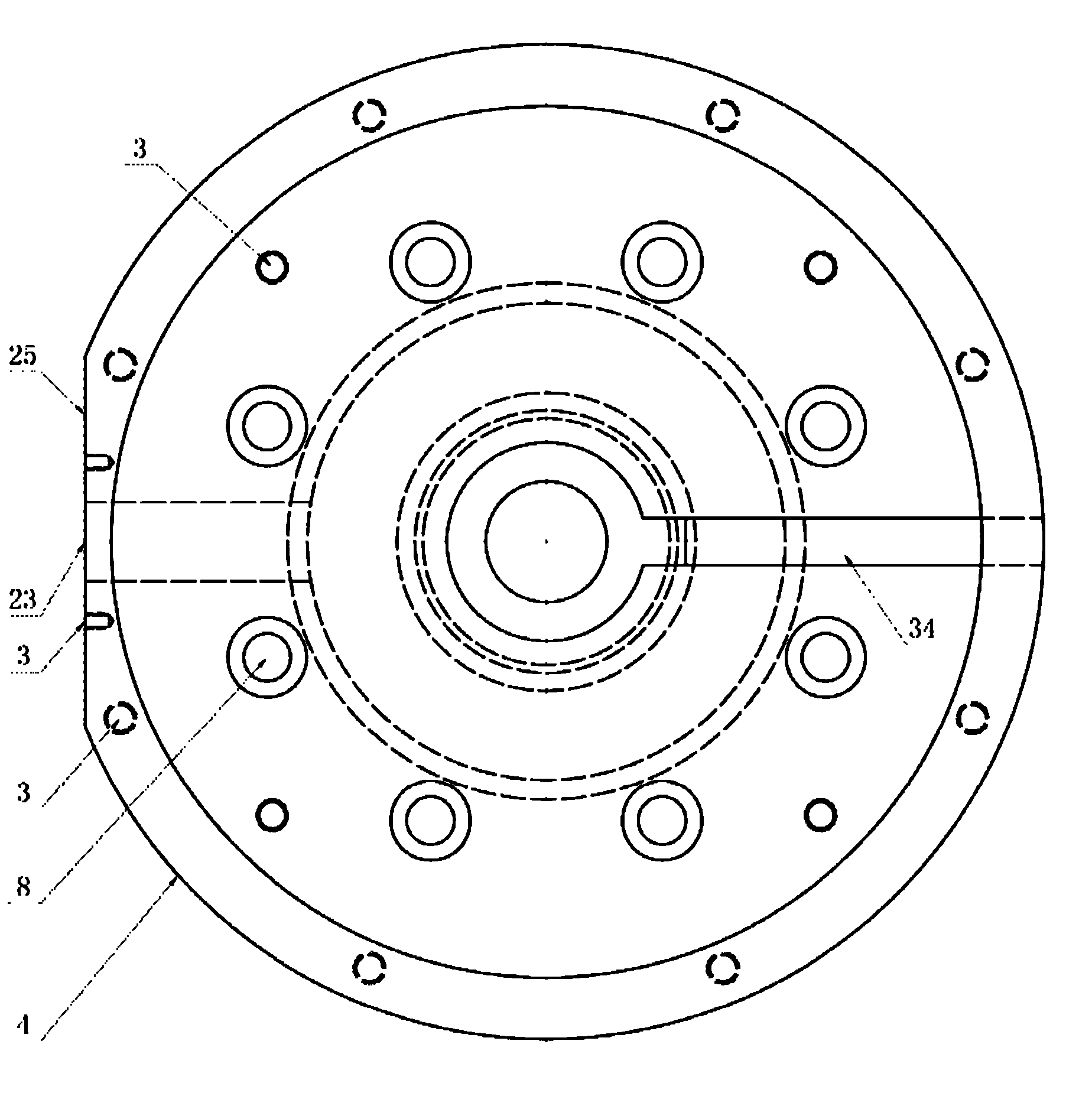

Pump water-cooled motor

InactiveCN102628445ACancel wind noiseRemove wind blade energy consumptionPump componentsPump installationsInsulation layerWater leakage

The invention discloses and relates to a pump water-cooled motor. a motor shellof the motor is provided with a cooling interlayer. The end of the inner shell is closed and the end of the outer shell is provided with a water outlet. The diversion outlets distributed on the ring cooling interlayer of the pump end of the motor shell are opposite to the diversion outlets of the cover end of the motor. Water from the pump passes through the diversion outlets and into the cooling interlayer of the motor shell, and is discharged from the water outlet. A motor shaft is led out from the pump end. If there is water leakage in mechanical seal, the leakage waterflows out of the pump through a draining chamber and a draining tank between the pump and the motor. A motor line is led out from a side hole of the cover end of the motor. The motor provided by the invention is characterized in that firstly the motor solves the problems of wind noiseand fan energy consumption of an air-cooled motor, greatly improves motor overload capacity, and effectively improves the disadvantages of quick motor bearing wear, fast lead insulation layer aging and burnout caused by super-large flow of a centrifugal pump; secondly the motor solves the disadvantages that water-cooled motor has high damage rate, has complex motor lead process, needs external diversion pipe, is not beautiful, has large size, and has high cost; thirdly the motor has characteristics of beautiful appearance, simple structure and easy production.

Owner:朱学斌

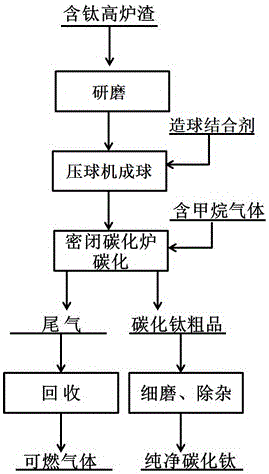

Titanium carbide preparation method based on carbonization titanium extraction treatment of titanium-bearing blast furnace slag

The invention provides a titanium carbide preparation method based on carbonization titanium extraction treatment of titanium-bearing blast furnace slag. The method comprises the steps that the titanium-bearing blast furnace slag serves as the raw material, grinding and balling are conducted, heating is conducted to 1,100 DEG C to 1,300 DEG C, methane is decomposed into hydrogen and carbon black, and a titanium carbide crude product is obtained after reduction and carbonization are conducted; the titanium carbide crude product is subjected to levigating treatment and purifying, and a more pure titanium carbide product can be obtained; the processes of the method are simple and easy to operate, due to the fact that methane is decomposed to obtain hydrogen and carbon black with high activity, hydrogen and the titanium-bearing blast furnace slag are subjected to a gas-solid reaction, and the reduction efficiency is high; meanwhile, by means of the carbon black with the high activity, the carbonization efficiency is greatly improved, the overall reaction efficiency is improved, the carbonization temperature is decreased, tail gas obtained from the reaction is used as gas fuel supply for heating of a closed-type carbide furnace, therefore, energy consumption is effectively reduced, an existing titanium-bearing blast furnace slag resource is better utilized, the added value of the titanium-bearing blast furnace slag is increased, and good industrial application value is achieved.

Owner:CHONGQING UNIV

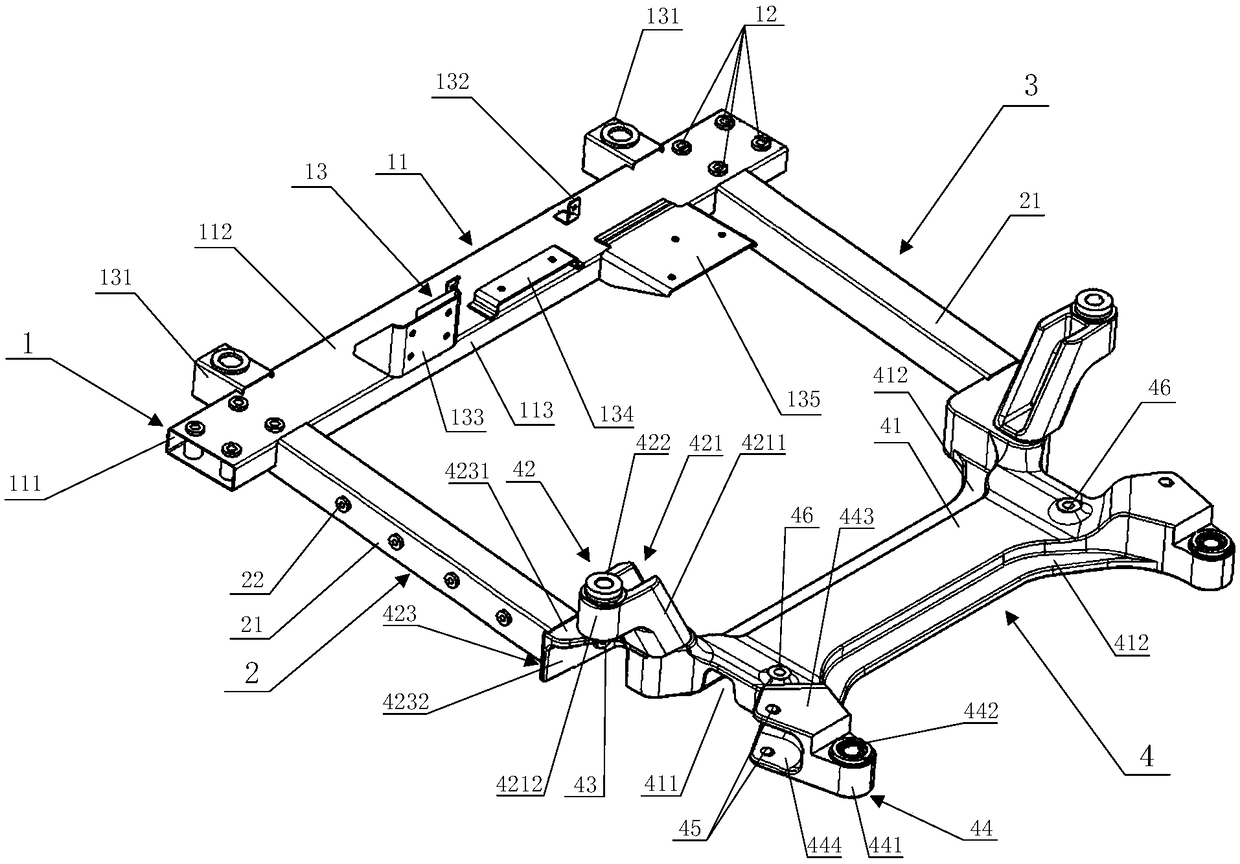

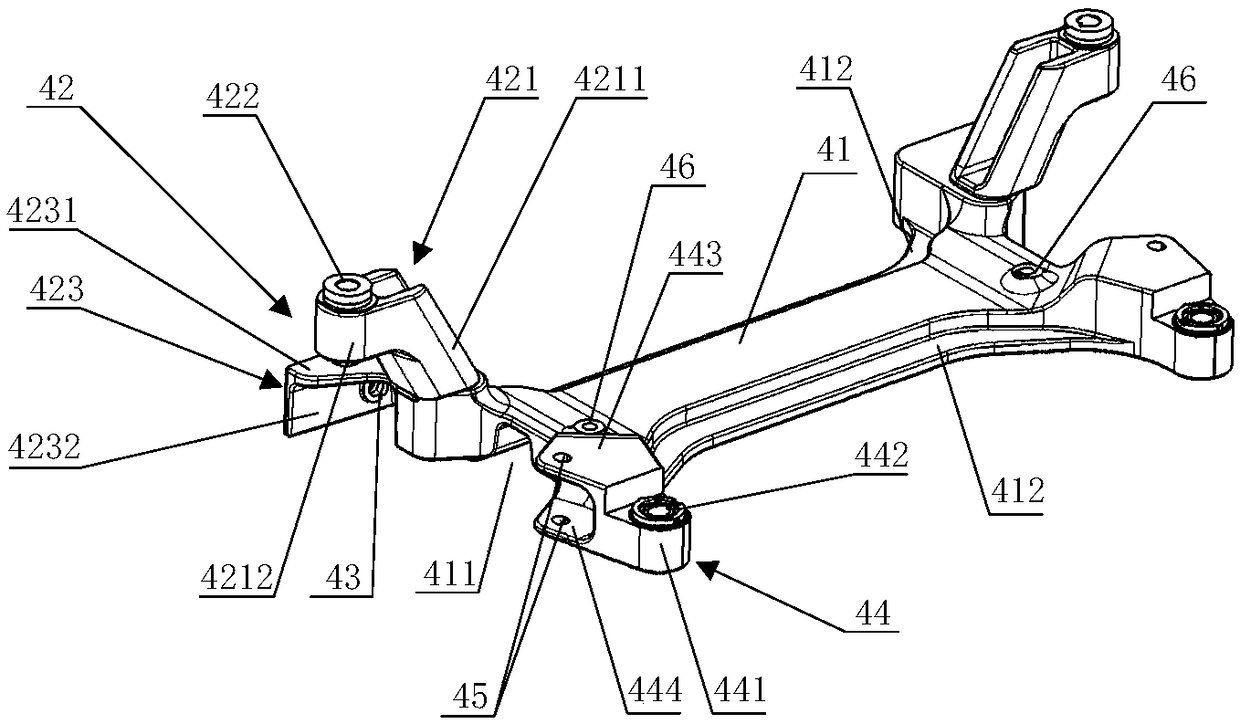

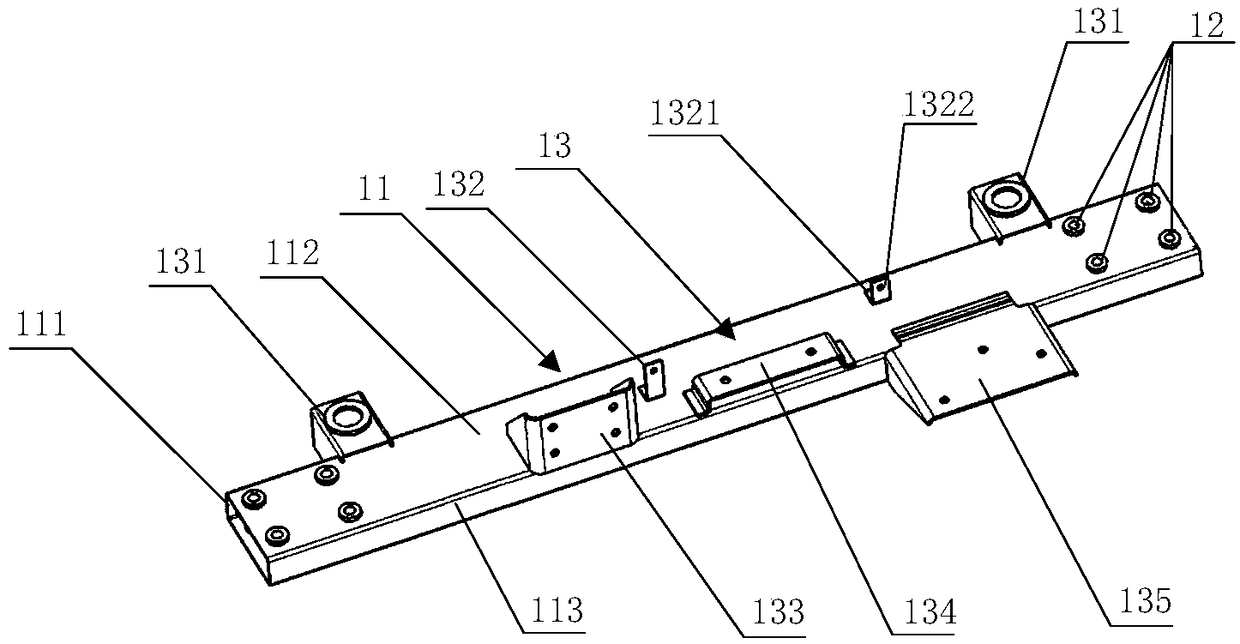

Front auxiliary vehicle frame assembly and vehicle

ActiveCN108657278AReduce weightReduce production processUnderstructuresManufacturing technologyVehicle frame

The invention provides a front auxiliary vehicle frame assembly and a vehicle. The front auxiliary vehicle frame assembly comprise a front transverse beam, a left longitudinal beam, a right longitudinal beam and an auxiliary vehicle frame body assembly; the left longitudinal beam, the front transverse beam, the right longitudinal beam and the auxiliary vehicle frame body assembly are sequentiallyconnected end to end to form a frame body structure; and the left longitudinal beam, the front transverse beam and the right longitudinal beam are each made of a hollow aluminum alloy profile. In thefront auxiliary vehicle frame assembly, the left longitudinal beam, the front transverse beam and the right longitudinal beam are each made of the hollow aluminum alloy profile, the manufacturing technology of the front auxiliary vehicle frame assembly can be reduced while the weight of the front auxiliary vehicle frame assembly can be decreased, thus the weight of the vehicle is decreased, the lightweight effect of the vehicle is achieved, and thus the endurance mileage of the vehicle is increased.

Owner:CH AUTO TECH CORP CO LTD

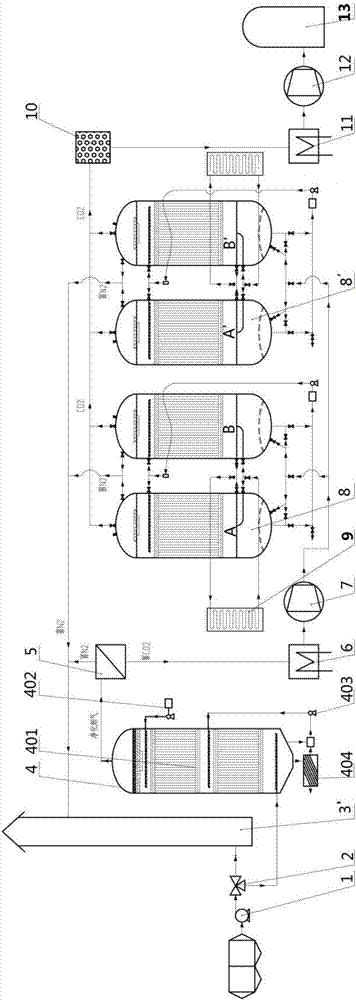

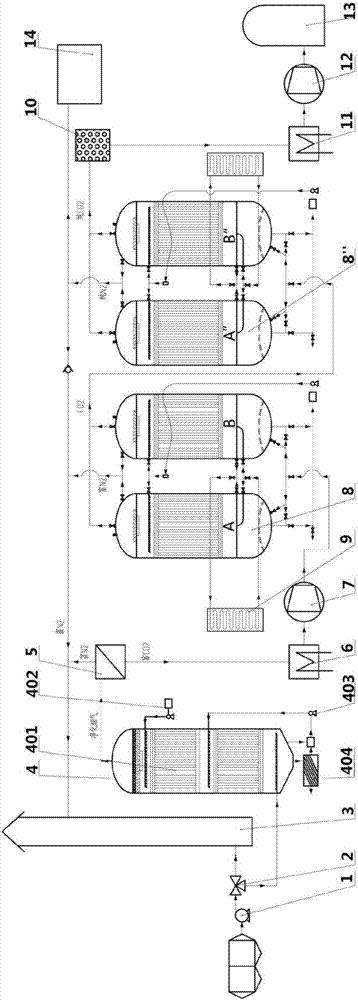

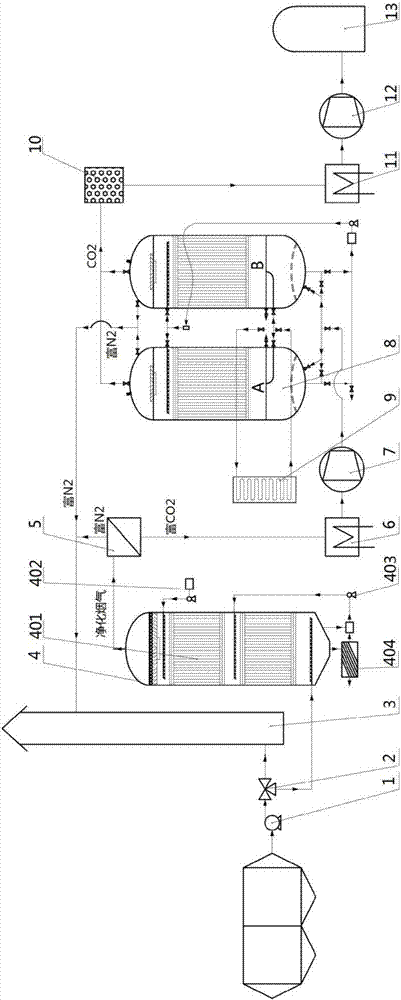

Equipment system applicable to continuous capture of CO2 in flue gas of cement kiln

PendingCN107115776AEffective emission reductionEffective productivityProductsReagentsProduction lineFlue gas

The invention discloses an equipment system applicable to continuous capture of CO2 in flue gas of a cement kiln. The equipment system comprises a kiln end exhaust fan, a chimney, a flue gas oxidization purifier, a N2 / CO2 membrane separation device, a cooler, a flue gas compressor, a CO2 cycle capture tower, a dehydration dryer, a CO2 cooler, a CO2 compressor and a liquefied CO2 storage tank, wherein the kiln end exhaust fan is communicated with a gas inlet of the flue gas oxidization purifier; a purified flue gas outlet of the flue gas oxidization purifier is communicated with a gas inlet of the N2 / CO2 membrane separation device; a N2-rich discharge port of the N2 / CO2 membrane separation device is communicated with the chimney; a CO2-rich discharge port of the N2 / CO2 membrane separation device is sequentially communicated with the CO2 cycle capture tower by the cooler and the flue gas compressor; the CO2 cycle capture tower comprises a CO2 cycle capture releaser A and a CO2 cycle capture releaser B which alternately and continuously perform CO2 capture and CO2 release. The equipment system is simple in structure and low in construction cost, has industrial applicability, realizes clean discharge of the flue gas on a cement production line, realizes effective discharge reduction and low-carbon production of a cement enterprise, and also realizes high-efficiency and continuous CO2 capture and separation.

Owner:长沙紫宸科技开发有限公司

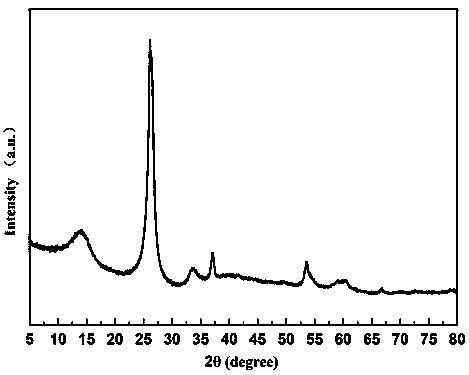

Molybdenum disulfide/graphene composite material and preparation method and application thereof

InactiveCN109256546AImprove conductivityInhibition of agglomerationCell electrodesSecondary cellsNew energySlurry

The invention discloses a molybdenum disulfide / graphene composite material and a preparation method and application thereof, belonging to the field of electrochemistry and new energy material. The preparation method of the invention comprises the following steps: (1) preparing ammonium tetrathiomolybdate; (2) preparation of graphene slurry by electrochemical method; (3) surface modification of graphene; (4) Preparation of molybdenum disulfide / graphene composites. The process of the invention is simple and easy to operate, the condition is mild, the repeatability is high, the yield is high, andthe invention is suitable for batch production. The conductivity of MoS 2 was improved and the aggregation of MoS 2 and graphene was inhibited by the composites. When the composites were used as cathode materials for lithium ion batteries, they showed high specific capacity and excellent cycle stability. The first discharge specific capacity reaches 700-1200 mAh / g at 0.01- 3.0 V and 200 mA / g current density, and the discharge specific capacity maintains at 550 -850 mAh / g after 200 cycles. The results show that the first discharge specific capacity reaches 700-1200 mAh / g at 200 mA / g current density.

Owner:山西焦煤集团科学技术研究院有限公司

Preparation device and preparation method for electronic ink microcapsule

InactiveCN102553502AImprove dispersion stabilityUniform particle sizeInksMicroballoon preparationElectronCore Particle

The invention discloses a preparation device and a preparation method for an electronic ink microcapsule and belongs to the technical field of ink. Capsule core particles and capsule wall solution are simultaneously sprayed from different passages of the device respectively, and a capsule wall collides with the capsule core particles and is absorbed on the surfaces of the capsule core particles to form a layer of uniform and compact coating, so that the microcapsule is obtained. The defects of complex process, long synthetic time, uneven capsule particle size distribution, uneasiness in control, and the like of the traditional preparation method are overcome by the preparation device and the preparation method provided by the invention. The preparation method is simple in technical step, low in pollution and high in yield; and required equipment is convenient to operate simply and low in cost. The particle size of the microcapsule prepared by the method is uniform and is 10 to 100 microns generally. High-quality products are provided for the mass application of a microcapsule display material.

Owner:BEIJING UNIV OF CHEM TECH

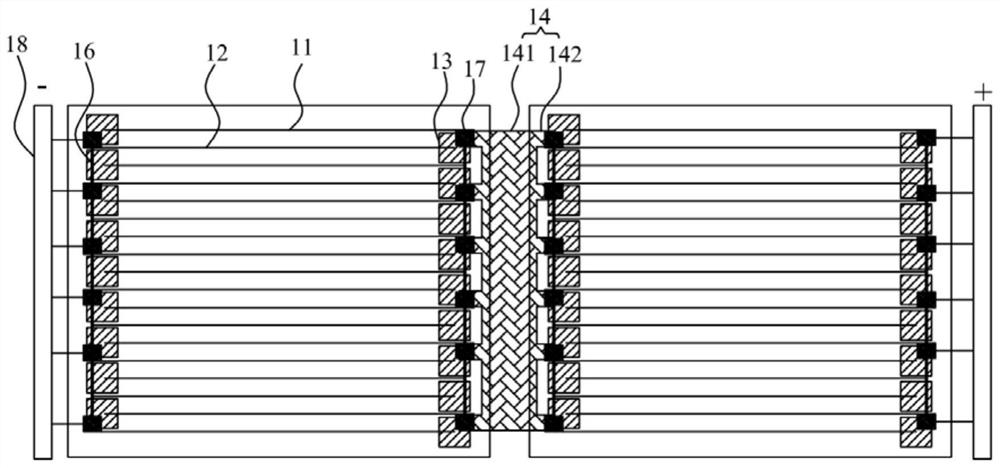

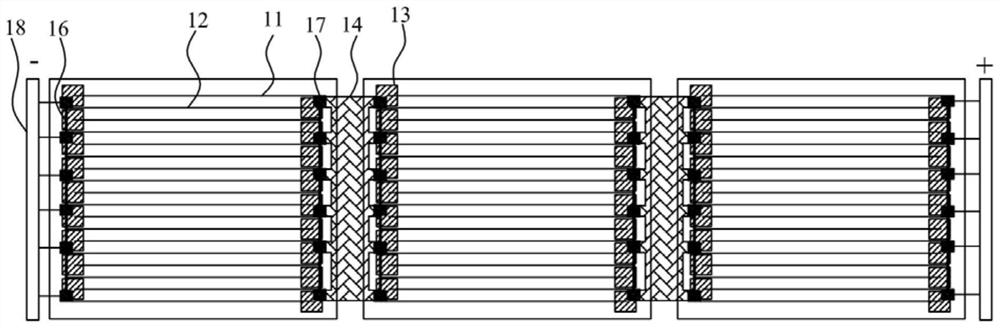

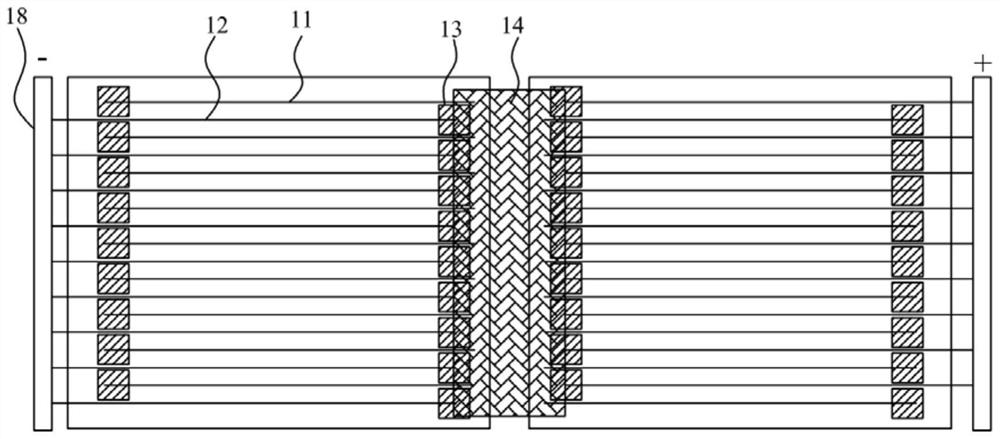

Back contact solar cell string, preparation method, assembly and system

PendingCN113327997AAddress process complexityReduce the requirement for precise alignmentPhotovoltaic energy generationSemiconductor devicesElectrical batteryEngineering

The invention is suitable for the technical field of solar cells, and provides a back contact solar cell string, a preparation method, an assembly and a system. The back contact solar cell string comprises at least two cell pieces, wherein each cell piece comprises positive electrode regions and negative electrode regions which are alternately arranged; an insulating layer covering each positive electrode region on one side of each cell piece and each negative electrode region on the other side of each cell piece; and a first bus bar used for connecting the two adjacent cell pieces, wherein the first bus bar is electrically connected with each positive electrode region and each negative electrode region which are not covered with the insulating layer in the two adjacent cell pieces. According to the back contact solar cell string provided by the invention, the problems that accurate alignment is needed and the process is complex when an existing cell string is manufactured are solved.

Owner:ZHEJIANG AIKO SOLAR ENERGY TECH CO LTD +3

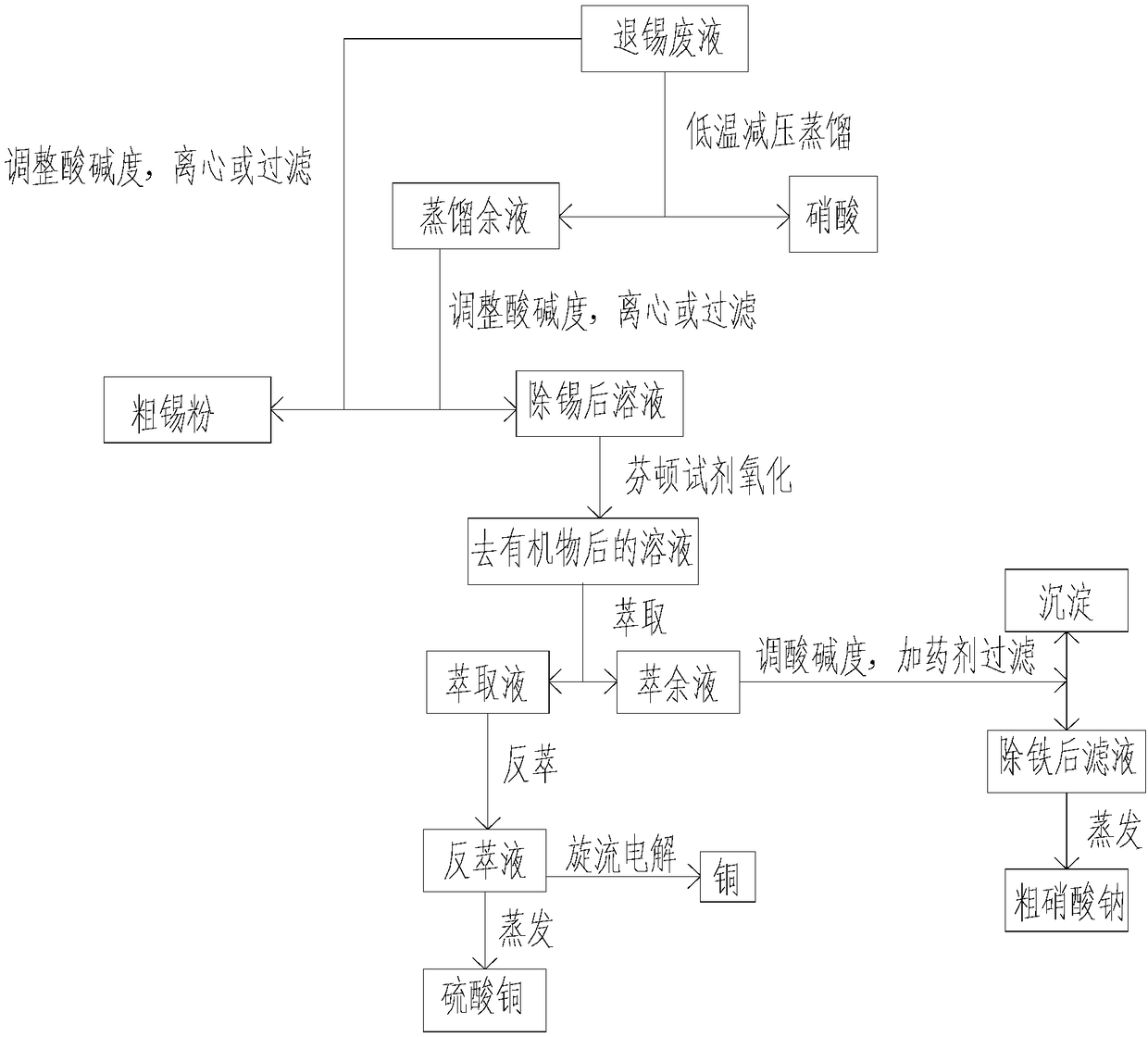

Comprehensive recovery method for tin-stripping waste liquid

ActiveCN108070720AResolve recovery rateAddress process complexityProcess efficiency improvementRecovery methodElectrolysis

The invention discloses a comprehensive recovery method for tin-stripping waste liquid. The method includes the following steps that (1) the tin-stripping waste liquid is subjected to reduced pressuredistillation so that nitric acid in the tin-stripping waste liquid can be recovered, a still residue is obtained, and tin powder is recovered from the still residue; or the pH value of the tin-stripping waste liquid is directly adjusted to recover the tin powder; (2) organic matter in a tin-removed solution is removed by means of oxidation with a Fenton reagent; (3) extraction is performed, and electrolysis or evaporation is conducted to extract copper; (4) iron and lead in the residue are removed; and (5) sodium nitrate is recovered through evaporation. Compared with the prior art, the method mainly solves the problems that the comprehensive recovery rate of the substances like tin and copper in the recovery process of the tin-stripping waste liquid is low, the technology is complicated,secondary pollution is serious, and all the components in the tin-stripping waste liquid cannot be fully recovered. By adoption of the method, various resources like the nitric acid, tin, copper andiron in the tin-stripping waste liquid can be effectively recovered step by step, the recovery rate is high, the technology is simple, secondary pollution is avoided, aero release in tin-stripping waste liquid treatment is realized, and the practical value and comprehensive benefits are good.

Owner:HOHAI UNIV

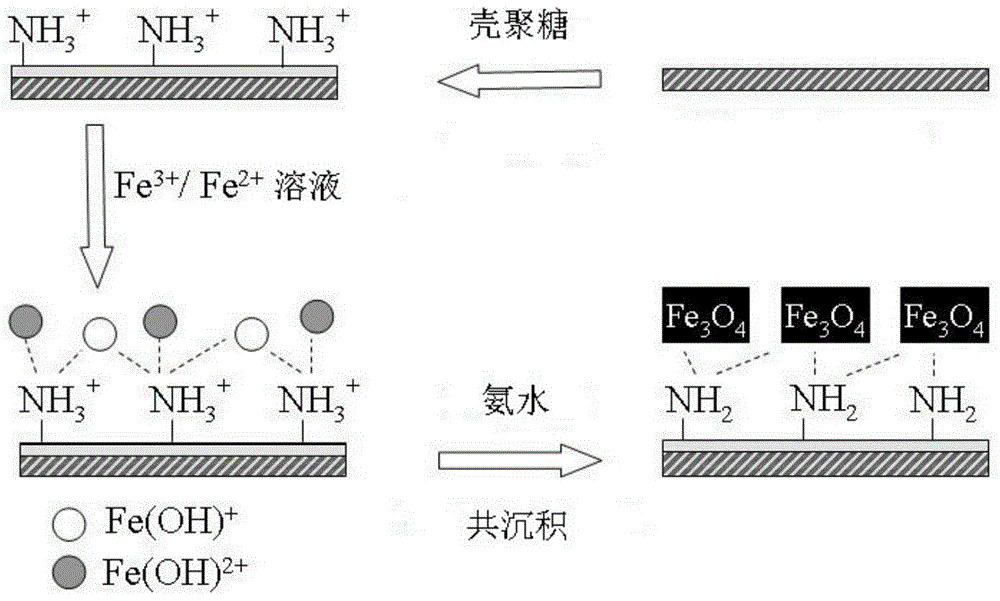

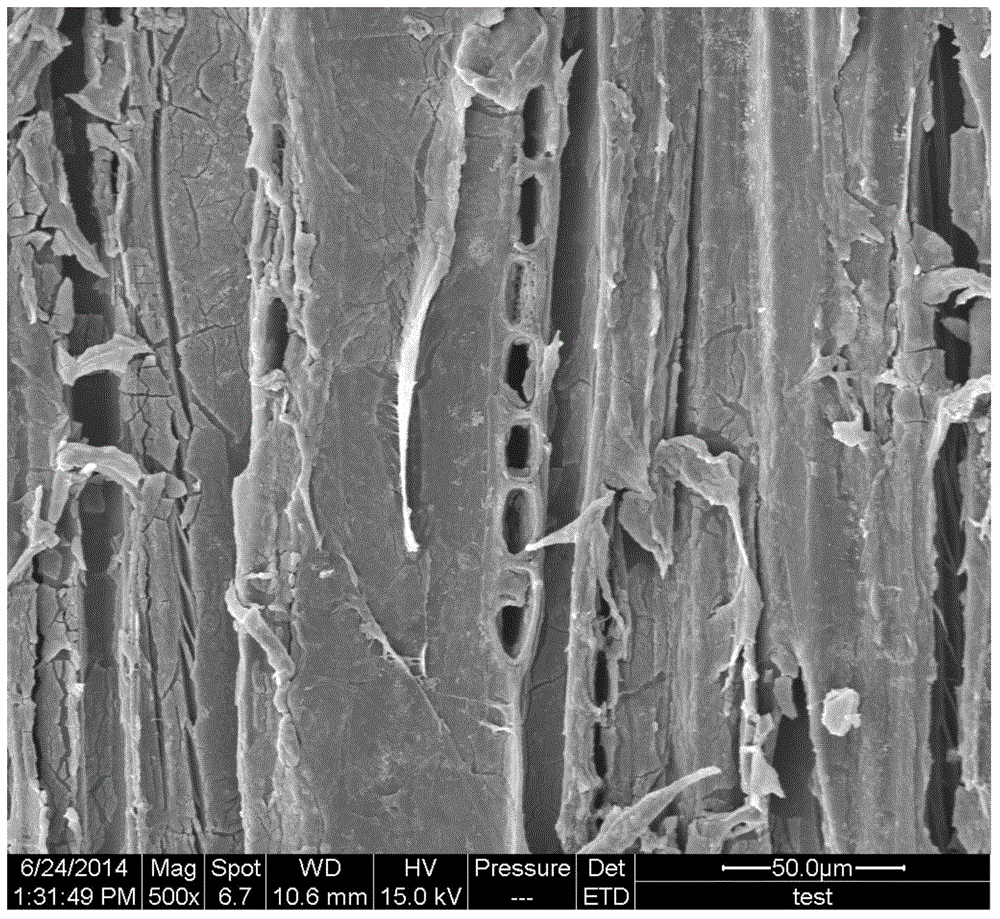

Preparation method of magnetic-response wood/Fe3O4 composite material

InactiveCN104400846AHas a "response" functionEasy to operateWood treatment detailsWood impregnation detailsMagnetic responseAmmonia

The invention discloses a preparation method of a magnetic-response wood / Fe3O4 composite material, and relates to a method for in-situ growth of Fe3O4 on the surface of wood. The invention aims to solve the defects that conventional magnetic-response wood preparation is complicated in process, long in preparation cycle and poor combination of a magnetic material with a wood substrate. The preparation method comprises the steps: one, carrying out ultrasonic treatment; two, carrying out chitosan modification; three, loading with a ferric salt solution; four, dipping into an aqueous solution of ammonia; and five, drying to obtain the magnetic-response wood / Fe3O4 composite material. The obtained magnetic-response wood / Fe3O4 composite material has the magnetic moment of 14.065 memu-57.460 memu; a specific magnetic 'identity' can be endowed to each kind of wood, and an anti-counterfeit label is pasted on the wood. Provided is the preparation method which can obtain the magnetic-response wood / Fe3O4 composite material.

Owner:NORTHEAST FORESTRY UNIVERSITY

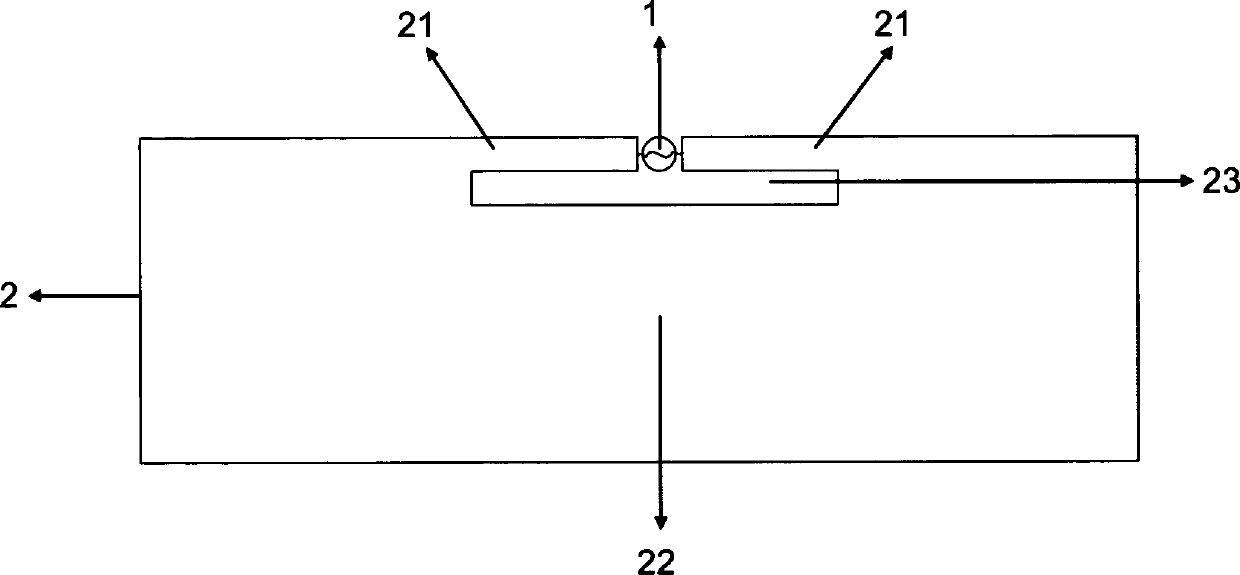

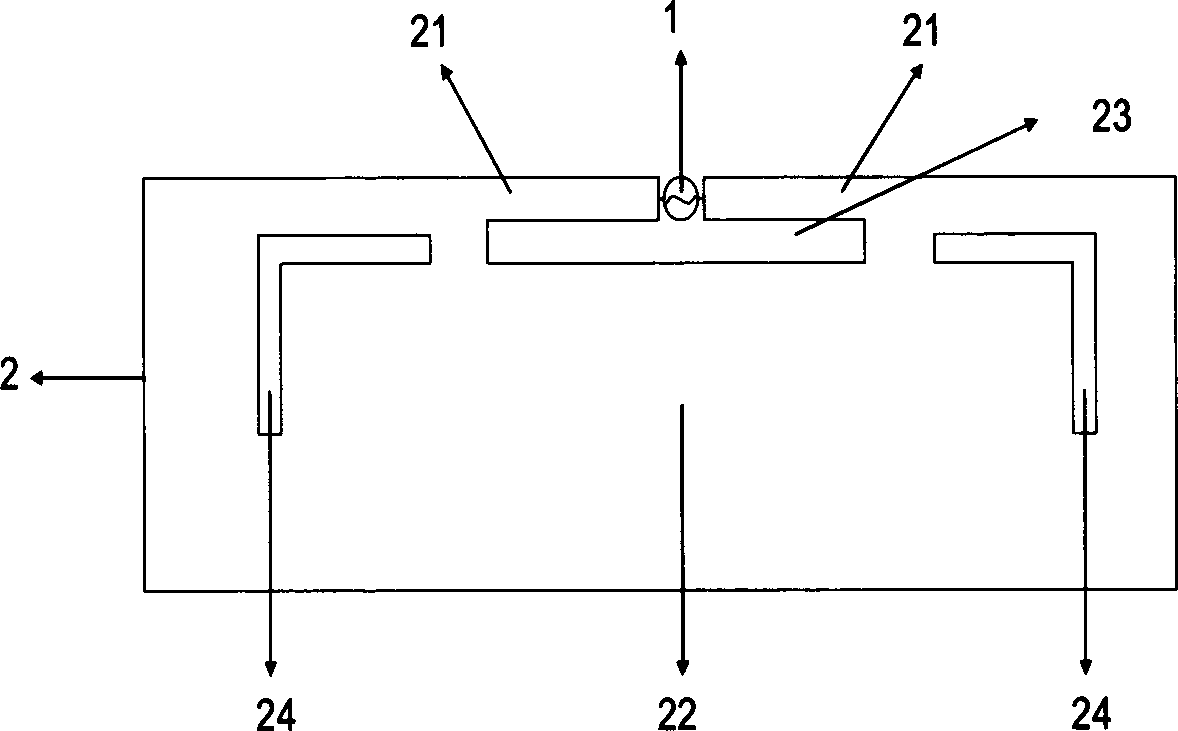

Radio frequency identification (RFID) ultrathin metal-resisting electronic tag based on folded dipole

InactiveCN102982368AAddress process complexitySolve the process priceRecord carriers used with machinesFar distanceManufacturing technology

The invention discloses a radio frequency identification (RFID) ultrathin metal-resisting electronic tag based on folded dipole. Far distance reading can be achieved in a free space and a metal surface. The RFID ultrathin metal-resisting electronic tag based on the folded dipole comprises an ultra-high frequency RFID chip, a radiation body, an ultrathin insulation medium and a metal thin layer. The radiation body is of a folded dipole structure, or a multiple folded dipole structure or a deformed structure. A radiation surface is large in metal area, so that receiving capacity of the electronic tag can be improved, and effect of electromagnetic wave from metal reflection is shielded. The radiation body is not connected with the metal thin layer. A single-layer printing antenna without a through hole and a short circuit structure is adopted, and at the same time a complex structure like electroblepharogram (EBG) does not exist. The thickness of the electronic tag is wholly below 0.5mm. The RFID ultrathin metal-resisting electronic tag based on the folded dipole has high flexibility, can be directly pasted on a metal pipe and a packing bag containing the metal thin layer, and metal articles which have strict requirements for thickness and bending. The RFID ultrathin metal-resisting electronic tag based on the folded dipole is simple in manufacturing technology, and greatly reduces production cost.

Owner:王学祥

Production method of electric contact point

InactiveCN101320642ASolve productivityAddress process complexityElectric switchesElectricityManufacturing technology

The invention discloses a manufacturing method of an electric contact; the electric contact manufactured by the method is made by electroplating the contact material on the outer surface needing to contact power transmission of the shaped conductive substrate; the outermost clad layer of the contact material is added with putty powder in the plating solutions of silver plating to lead the putty powder to deposit the obtained silver tin oxide layer together with the metallic silver. The invention relates to the technical field of manufacturing the electric contact element; the electric contact manufactured in the invention is able to solve the problem of the much production equipment, complicated technique and high producing cost in the existed technology.

Owner:LIUZHOU CITY SEMICON MATERIAL FACTORY

Process of growing self-organized Ge quantum dot by means of ion beam sputtering in low growth beam flux

InactiveCN1974838ASolve the costAddress process complexityVacuum evaporation coatingSputtering coatingHigh densityQuantum dot

The process of ion beam sputtering to grow self-organized Ge quantum dots in low growth beam flux includes vacuum ion beam sputtering and Ar as the work gas, and features that at the conditions of low growth beam flux current of 2mA-10mA, beam flux voltage of 0.2-1.5 KV, sputtering pressure of (1.0-4.0)x10<-2> Pa, growth temperature from room temperature to 400 deg.c, multilayer Ge / Si film with island-like self-organization grown Ge quantum dot structure is sputtering deposited on Si substrate. The present invention can obtain quantum dot material with high density and homogeneous size in a cheap industrial ion beam sputtering equipment and in high production efficiency.

Owner:YUNNAN UNIV

Preparation method of self-cleaning antifogging astronomical telescope lens

InactiveCN110591555ALower contact angleAnti-reflection effectAntifouling/underwater paintsPaints with biocidesNano siliconAstronomical telescopes

The invention relates to a preparation method of a self-cleaning antifogging astronomical telescope lens. According to a preparation method of a self-cleaning antifogging coating, nano silicon dioxideis doped with nano titanium dioxide for the first time, the nano silicon dioxide, the nano titanium dioxide and nano silver are taken as main components to enable the coating to be self-cleaning andantifogging, the coating not only has a good self-cleaning effect, but also has a lasting antifogging effect, and a coating film has excellent antibacterial function. By the prepared self-cleaning antifogging coating film, a thin and transparent protecting film can be formed on the surface of the glass, the adhesive force of the film is high, a lens surface can be rapidly cleaned, rapid volatilization is implemented, and marks do not remain on the lens surface. Meanwhile, the prepared lens also has the characteristics of excellent self-cleaning, antifogging, stabilization and high transmittance properties and the like.

Owner:福建中美友拓科技发展有限公司

Alloying method adding manganese ore in RH refining process

The invention discloses an alloying method adding a manganese ore in an RH refining process, wherein the method comprises the steps: 1) controlling an RH treatment starting molten steel temperature at 1580-1600 DEG C; 2) before RH alloying, dividing into 2-5 batches, adding the manganese ore through an alloy chute, wherein the added manganese ore is required to have the diameter of 10-50 mm, the mass percentage contents of phosphorus and sulfur in the manganese ore are both required to be less than 0.05%, and the addition amount of the manganese ore is not more than 15 kg / t-steel; 3) after adding the manganese ore, controlling the flow quantity of rising gas of an RH rising tube at 130-150 Nm<3> / h; controlling the cycling time in 6-10 min; and controlling the vacuum chamber pressure to be less than 150 Pa; and 4) after cycle operation is finished, carrying out deoxidation alloying, and adjusting the composition of molten steel to a steel type target value. The process has simple operation, does not need to improvement of original equipment, does not affect other production operations, and can significantly reduce the cost of steelmaking.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com